Automatic pipe discharging and feeding device

A technology of feeding device and automatic discharging, applied in the direction of automatic in/out of workpieces, metal processing machinery parts, metal processing, etc., can solve the problems of low work efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

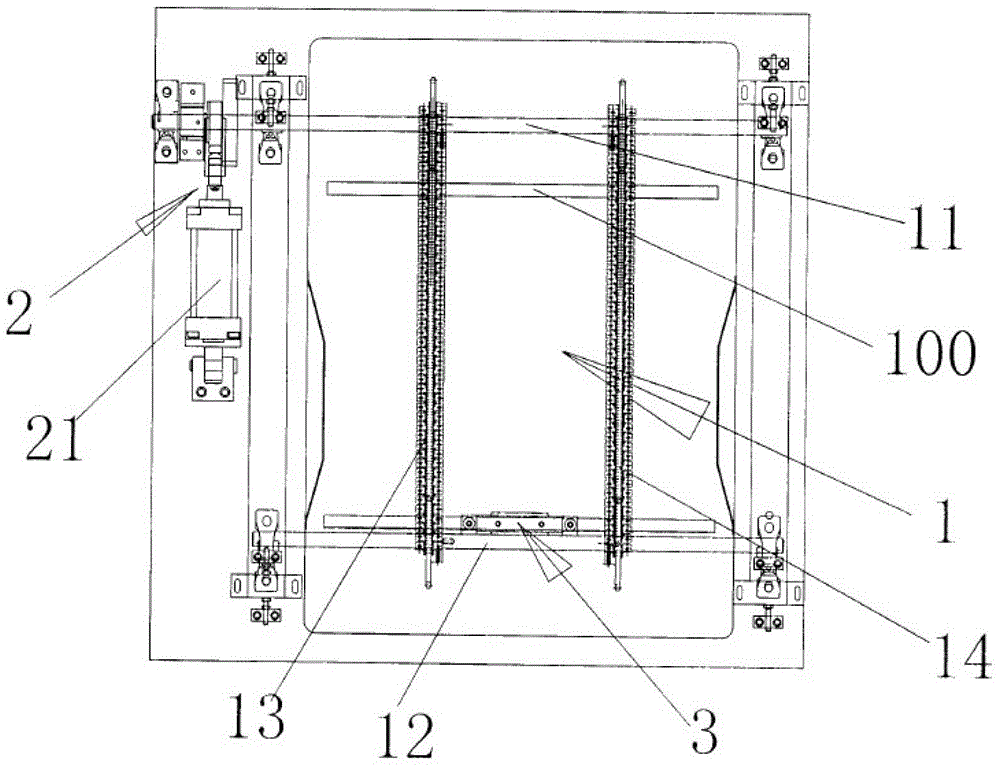

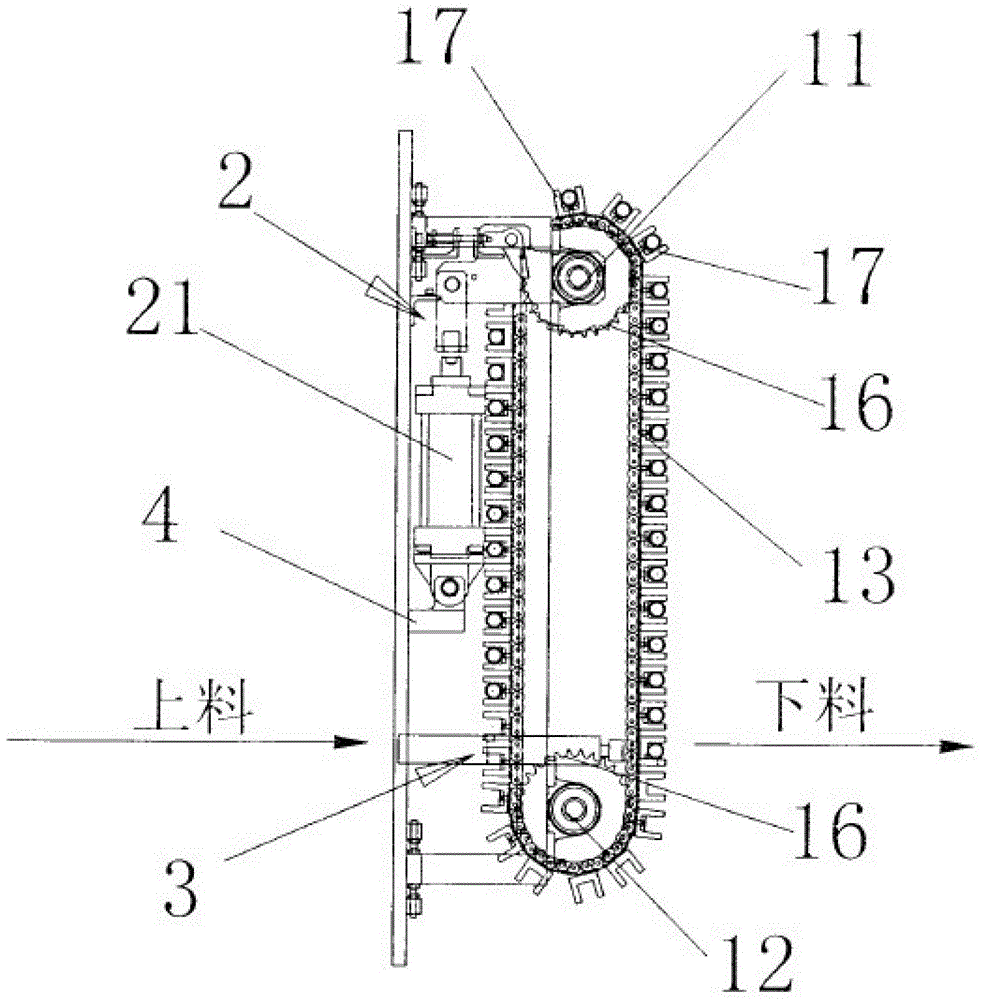

[0026] like figure 1 , figure 2 , image 3 and Figure 4 As shown, an automatic discharge and feeding device for pipe fittings includes a discharge mechanism 1 that can be embedded in a pipe fitting 100, a drive mechanism 2 that can drive the displacement of the pipe fittings on the discharge mechanism, and a device that can grab and transport the pipe fittings on the discharge mechanism. Feeding mechanism 3, wherein:

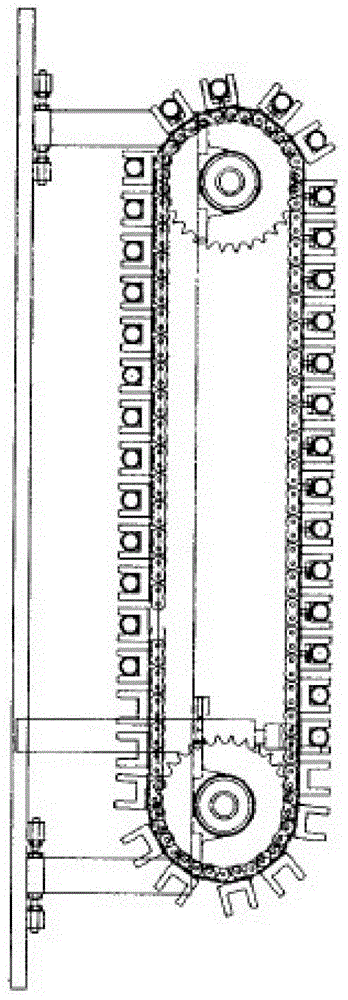

[0027] 1) The discharge mechanism 1 has two side-by-side chain rings 13, 14, and the two chain rings 13, 14 are jointly installed on two main shafts 11, 12 arranged side by side through a set of sprockets 16, and the two main shafts 11, 12 are vertically vertical Set, these two chain rings 13,14 respectively fix many pairs of pipe fitting clamping dies 17 that can be embedded in the same pipe fitting, and the multiple pairs of pipe fitting clamping dies 17 are evenly distributed on the two chain rings 13,14. The embedded notch, in order to facilitate the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com