Full-automatic intelligent processing lathe of cross-axle universal joint

A cross-axis universal, intelligent processing technology, applied in the direction of automatic entry/exit of workpieces, metal processing, metal processing equipment, etc., can solve the problems of high labor intensity and human physical injury, achieve convenient debugging and reduce manual labor Intensive, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

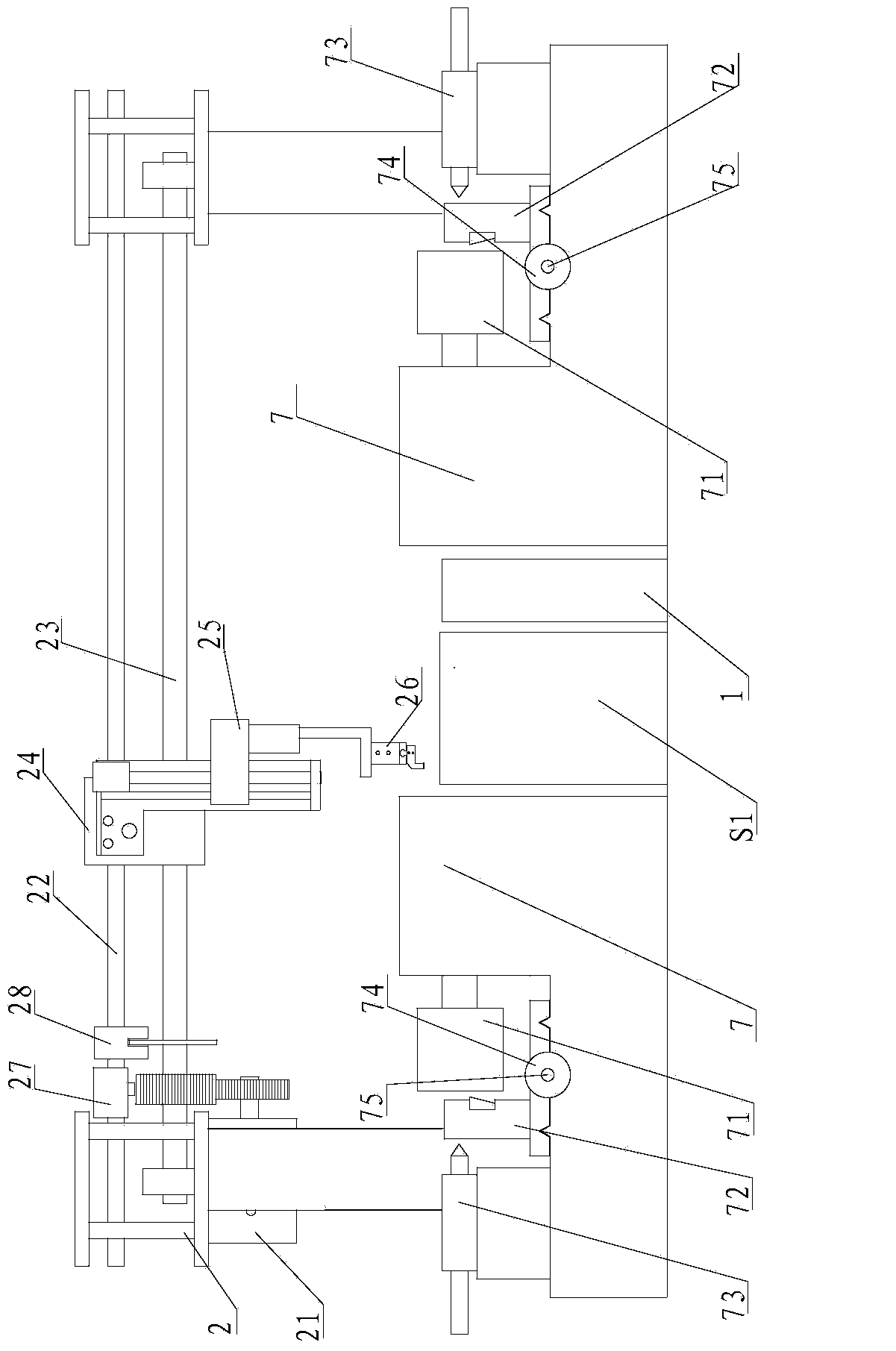

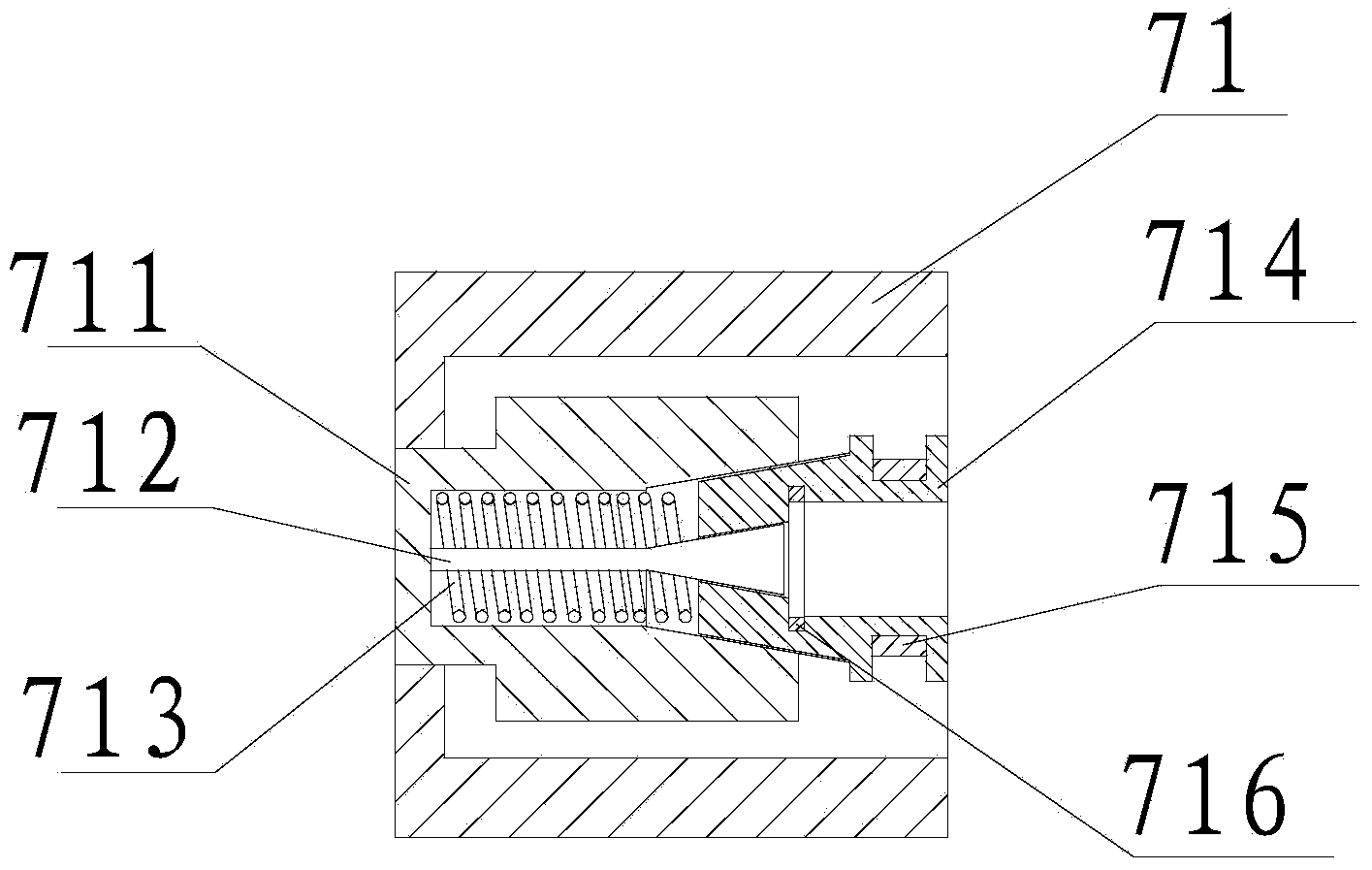

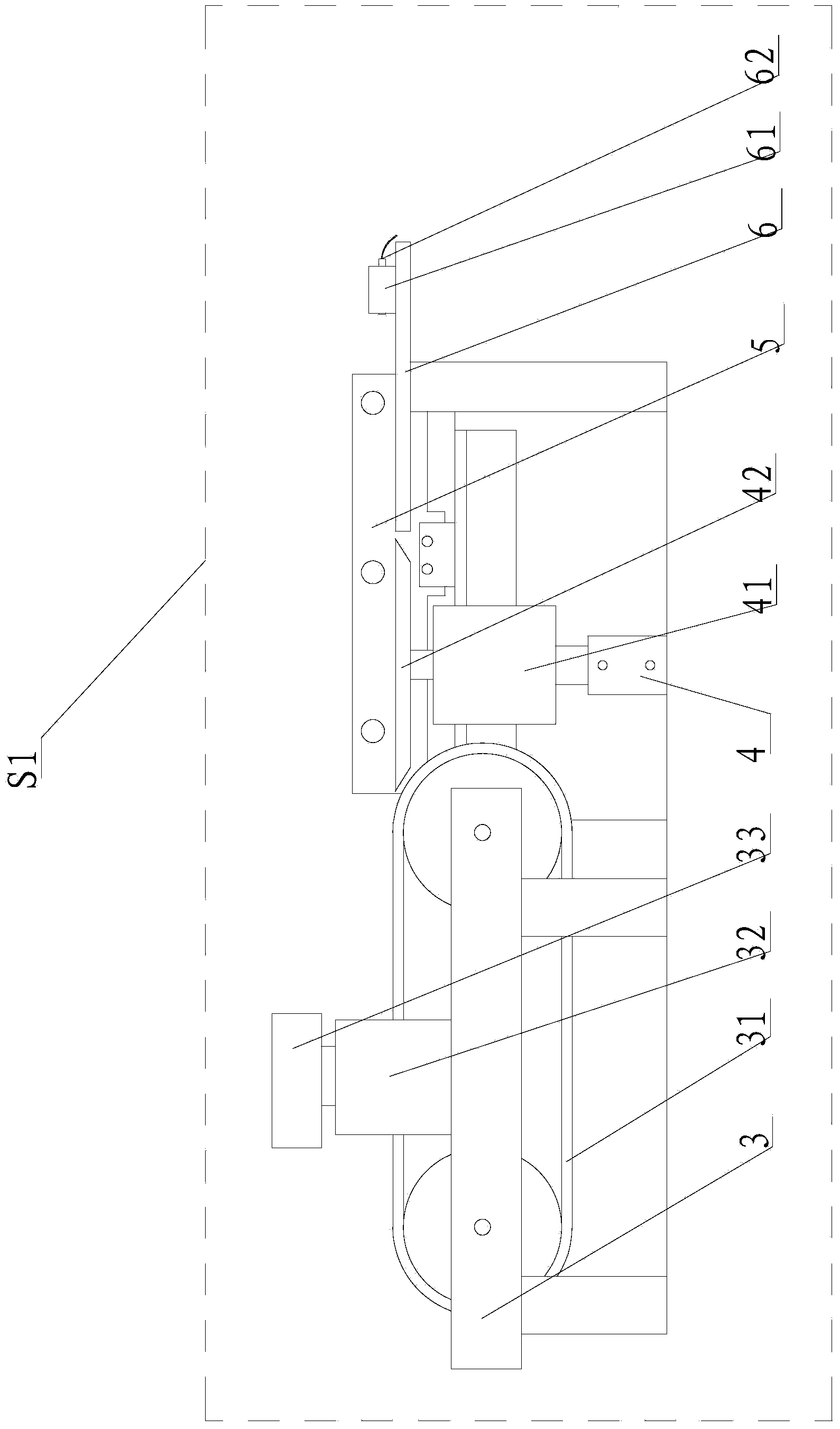

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , a fully automatic cross-axis universal joint intelligent processing lathe of the present invention, the processing of parts can be completed by advanced automation equipment, and the equipment includes a conveying and detecting mechanism S1, a manipulator bracket 2 and a lathe 7, and the conveying and detecting mechanism S1 includes Drive belt support 3, push mechanism 5 and manipulator clamping table 6, air motor 21 is installed on the bottom of described manipulator support 2, manipulator guide rail 22 and manipulator screw mandrel 23 are installed on manipulator support 2, described manipulator screw mandrel 23 and air motor 21 Connected by gears, a transmission belt 31 and an industrial camera support 32 are installed on the transmission belt support 3, an industrial camera 33 is installed on the industrial camera support 32, a turntable 42 is installed on the right side of the transmission bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com