Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1744results about How to "Stable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

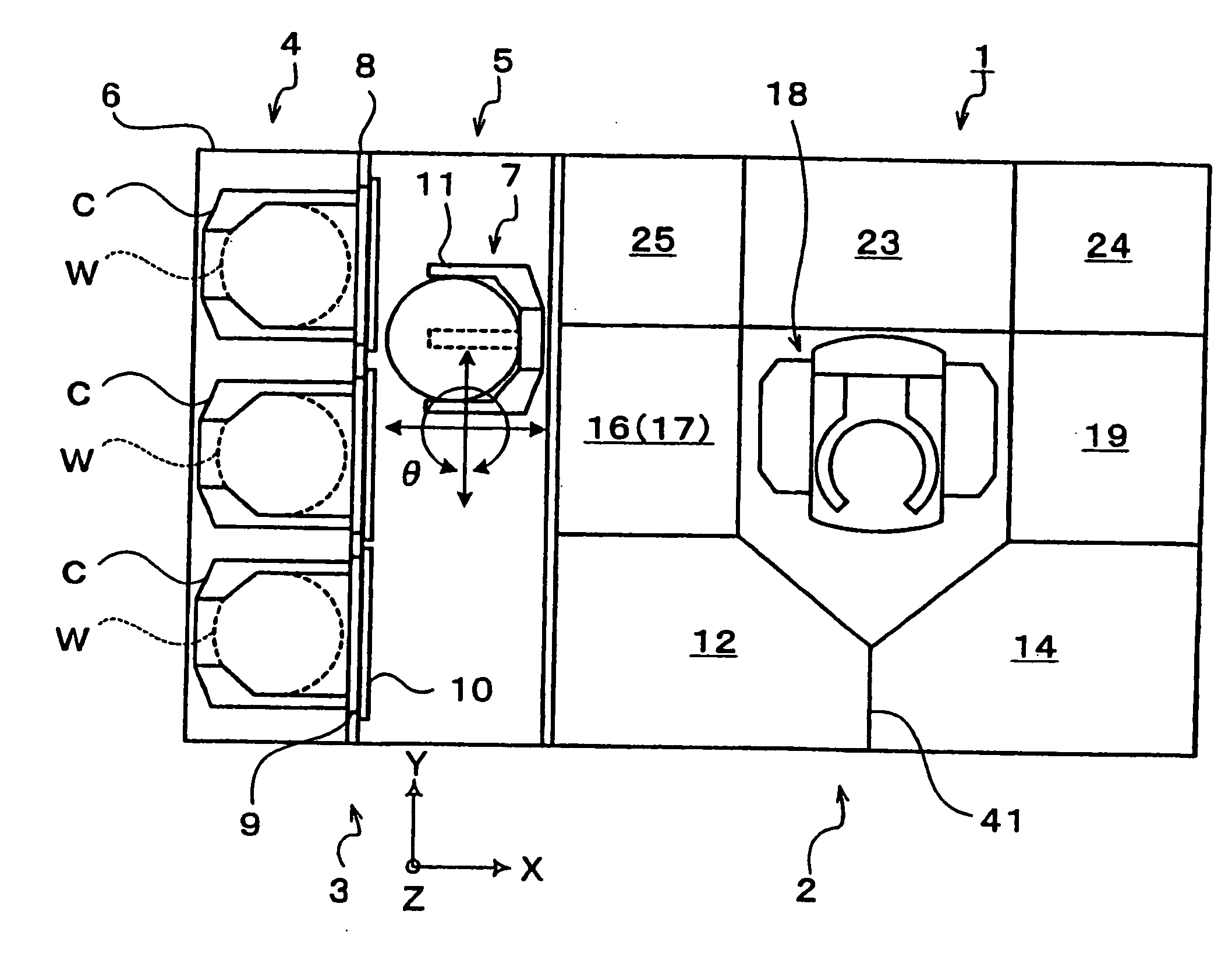

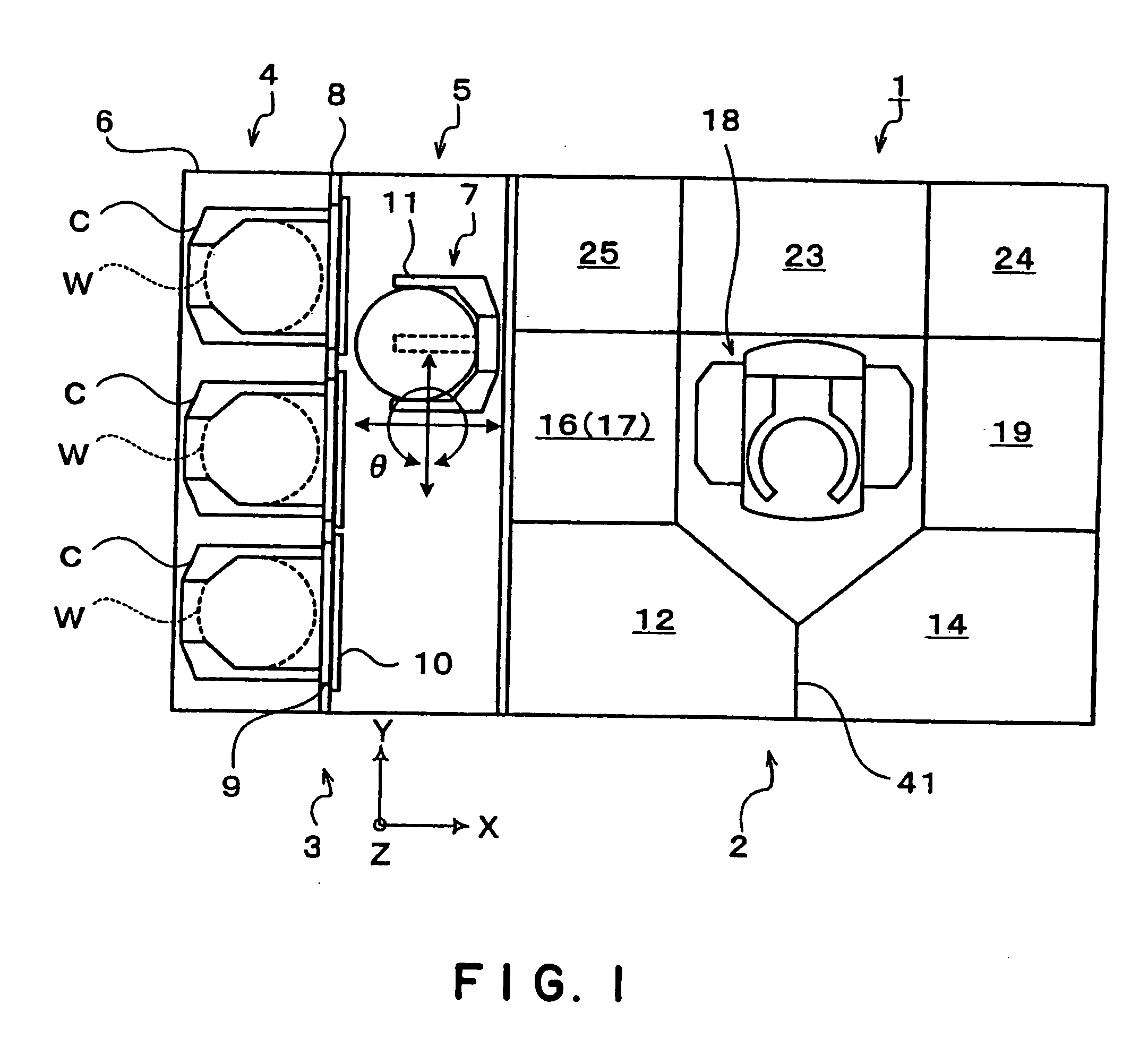

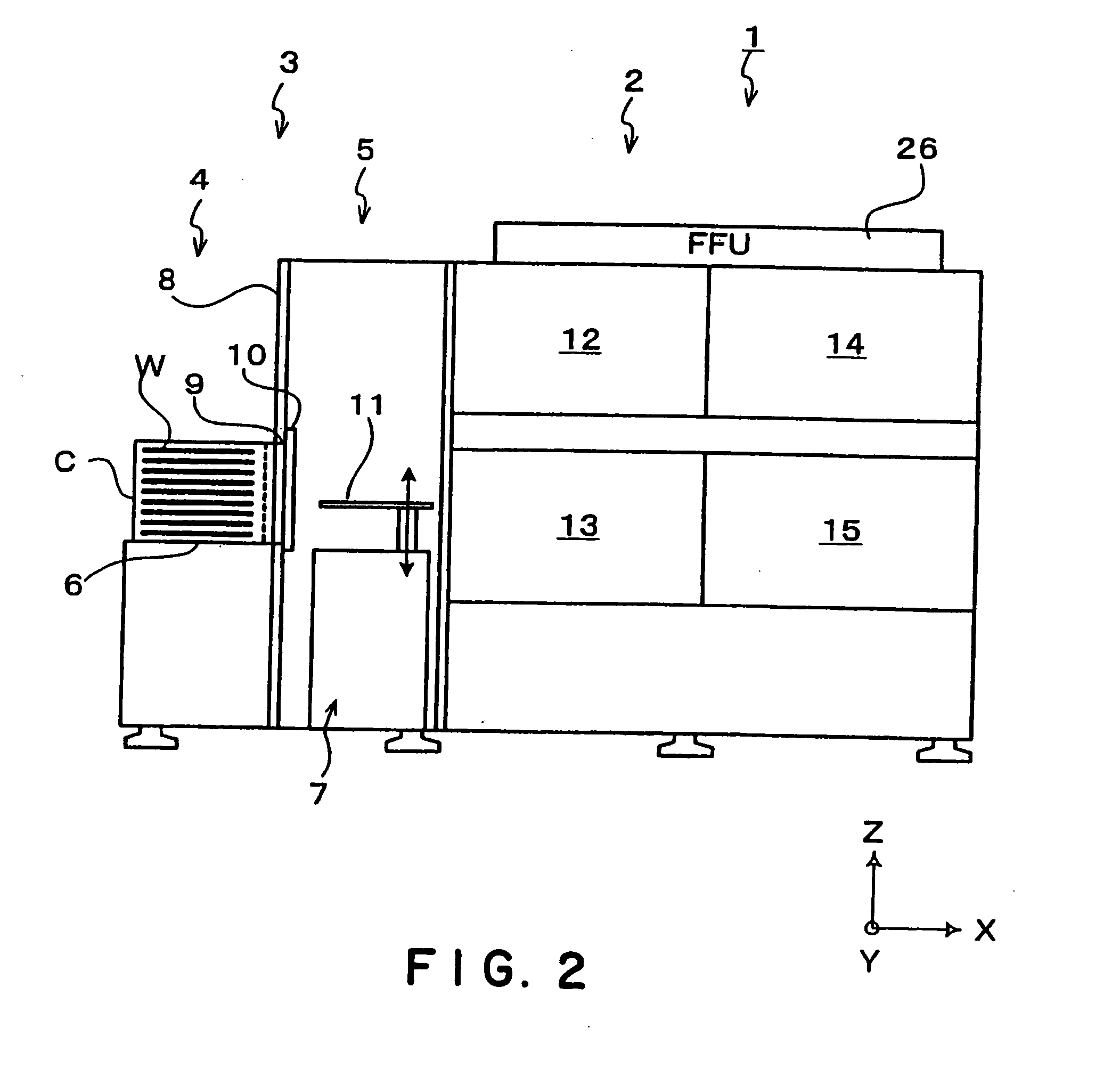

Substrate processing apparatus

InactiveUS20080210278A1Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

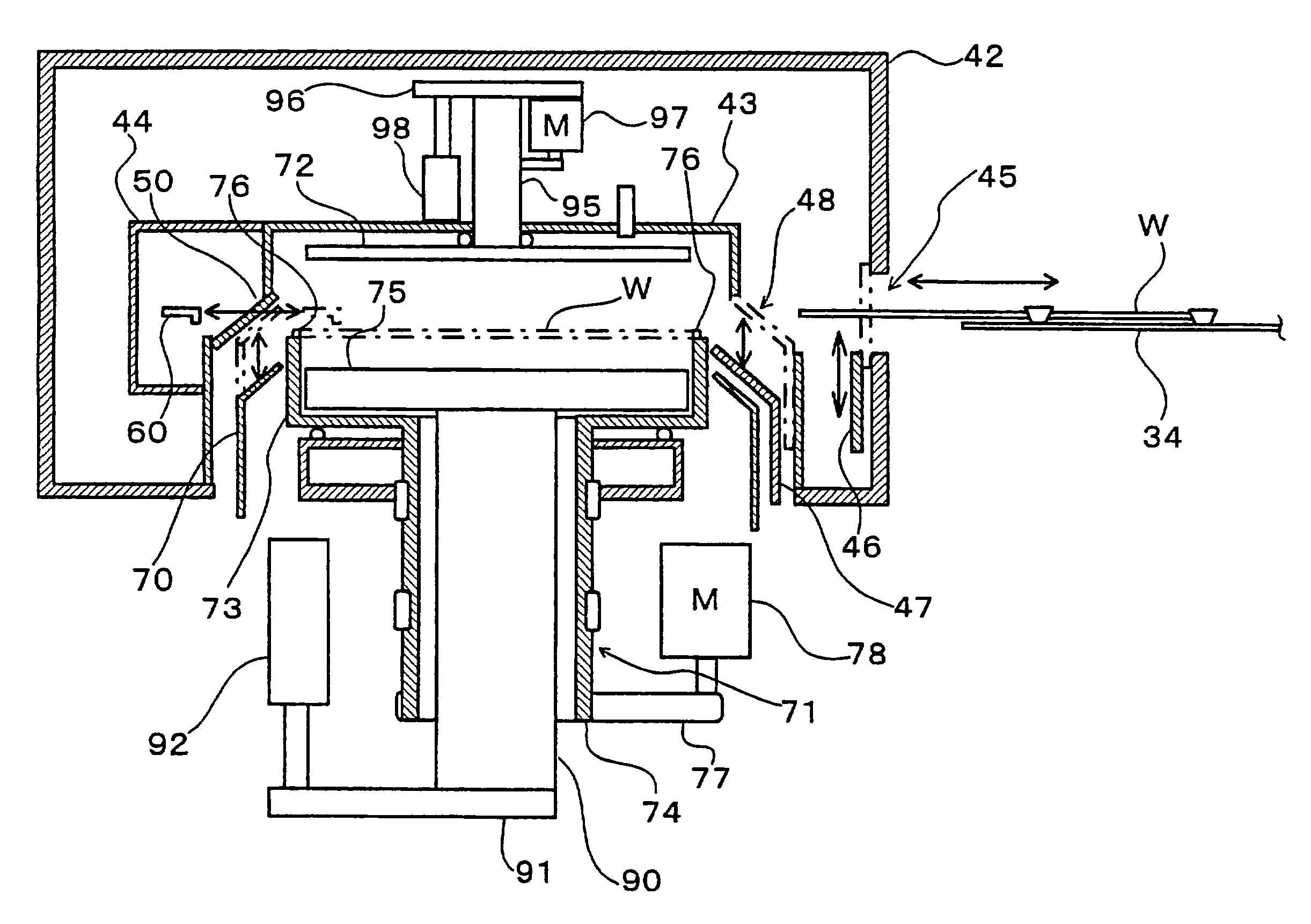

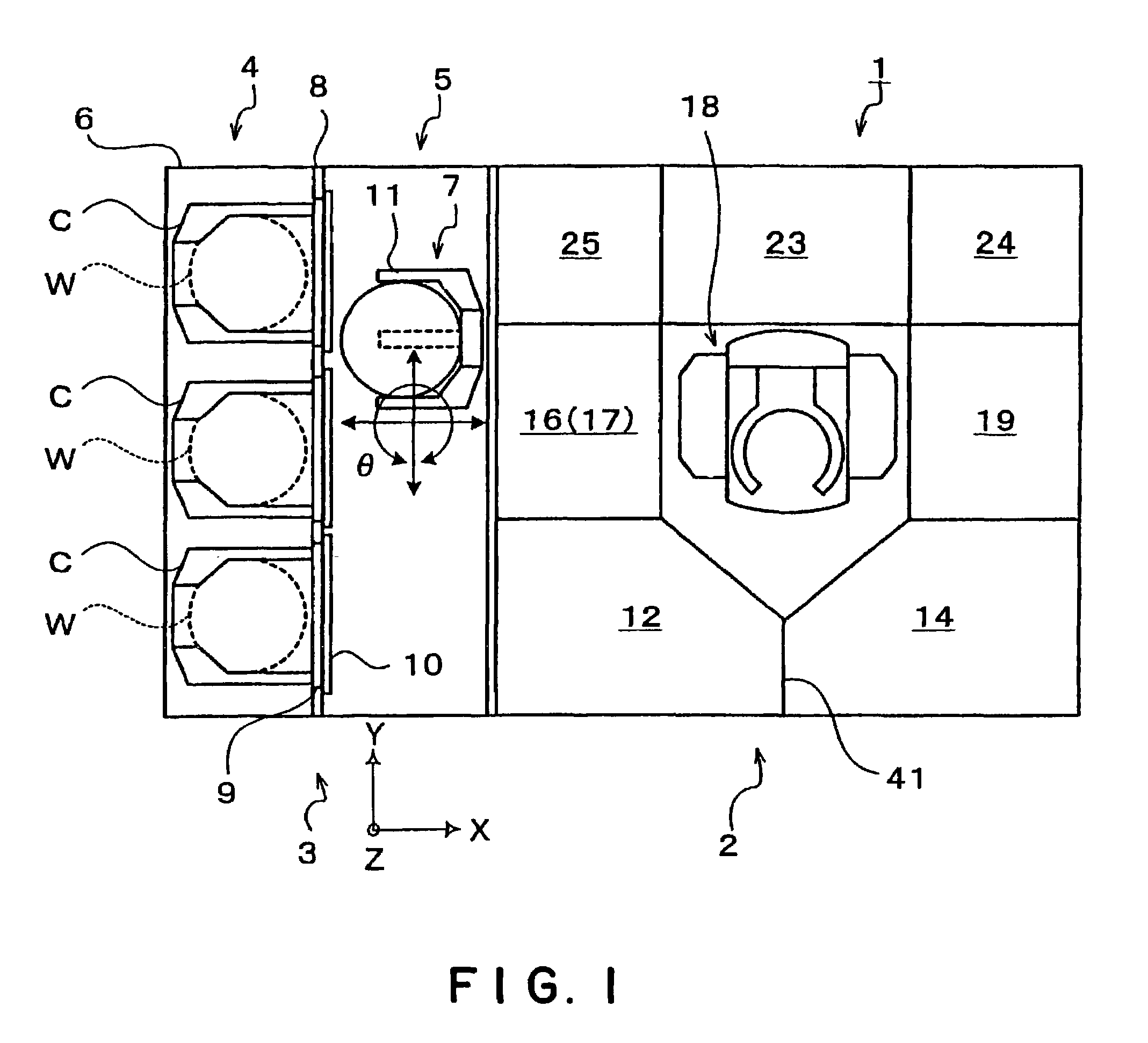

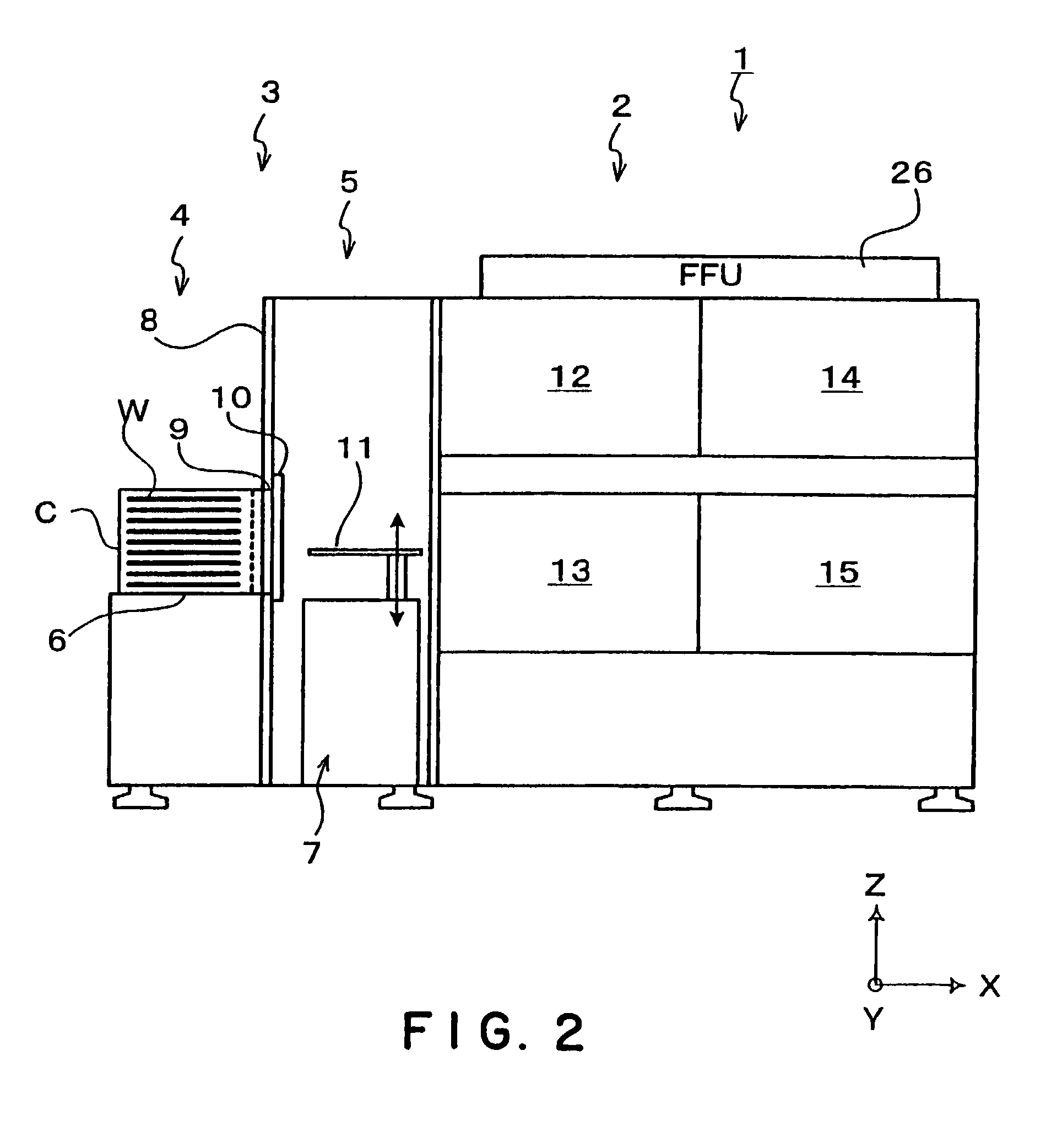

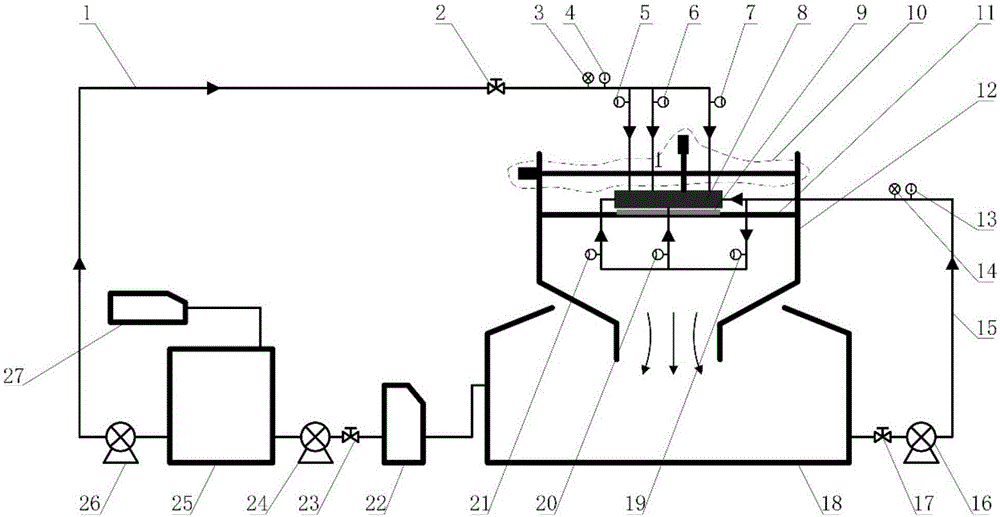

A substrate processing apparatus is provided. The apparatus includes a plurality of fluid suppliers 61, 61, 63 for supplying different processing fluids. In processing a wafer W, the substrate processing apparatus moves the fluid suppliers 61, 62, 63 along the peripheral part of the wafer W relatively. The fluid suppliers 61, 62, 63 are arranged in a direction extending from the circumference of the wafer W to its inside. With the arrangement, the apparatus is capable of stable processing of the wafer W in spite of rotating the wafer W at a low speed. Further, it is possible to improve a throughput of the apparatus in resist processing.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus

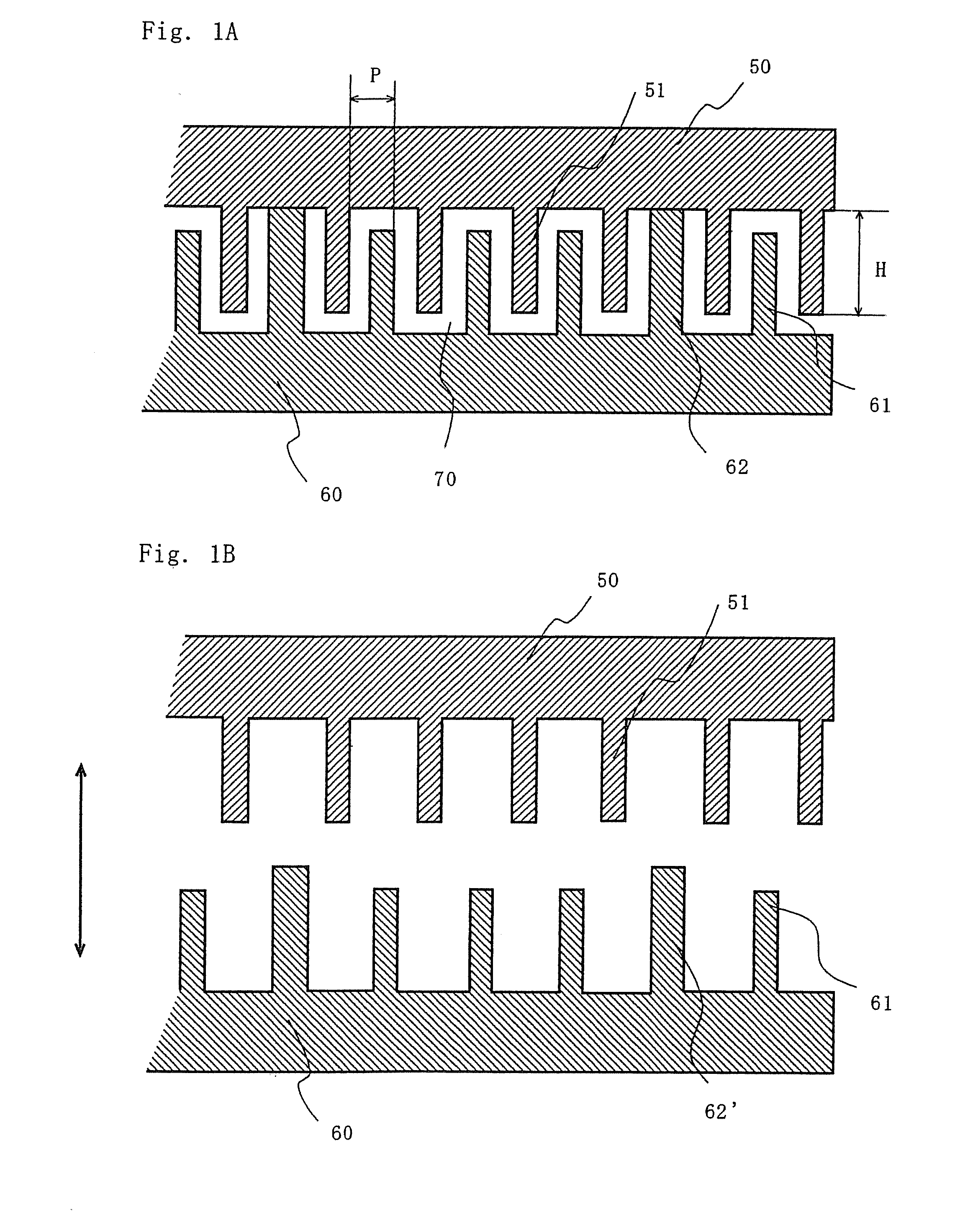

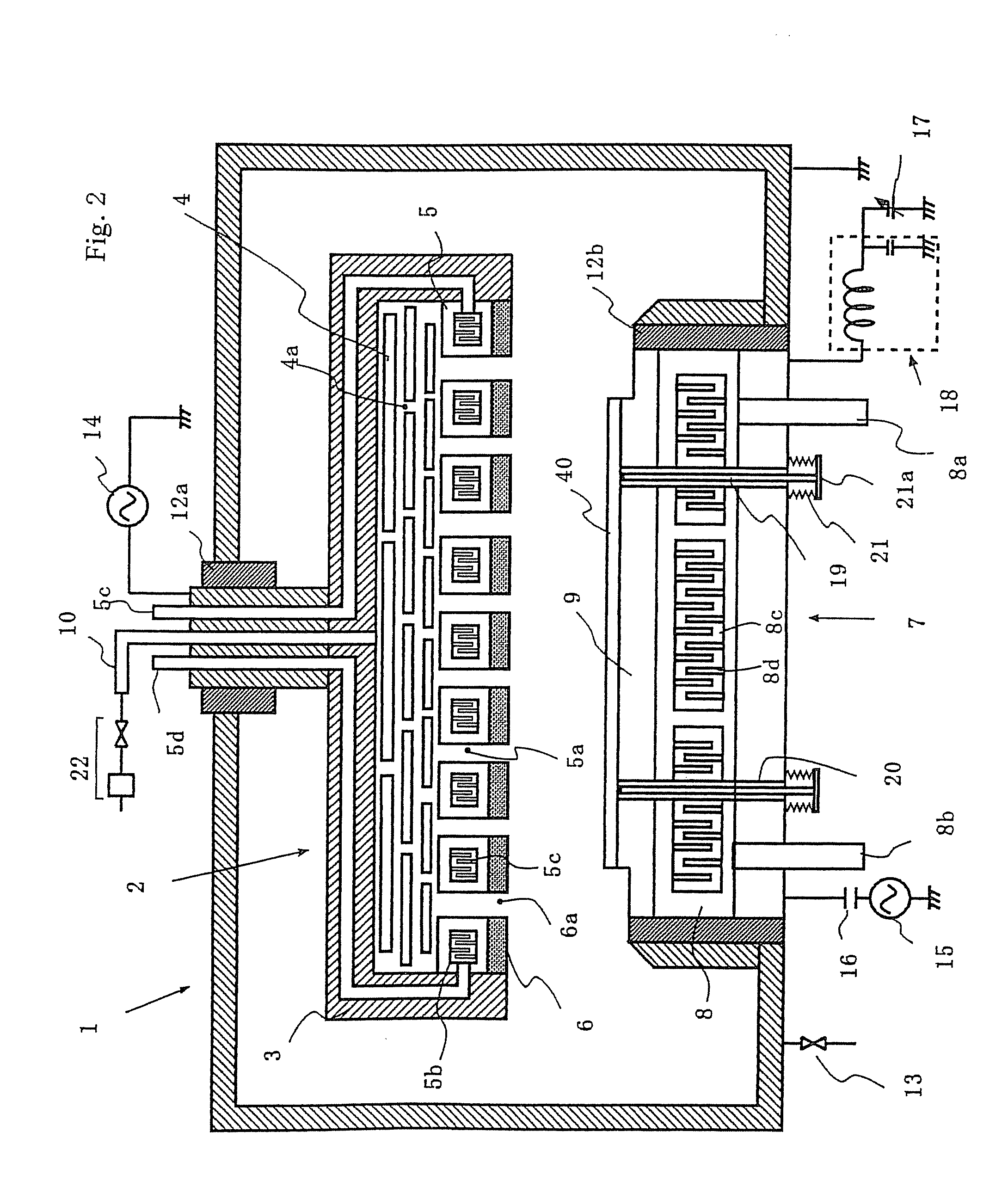

ActiveUS20090197418A1Efficiently and uniformly cool and heat portionStable processingDomestic cooling apparatusDecorative surface effectsPlate heat exchangerEngineering

A method of using a heat exchanger efficiently and uniformly to cool or heats portions to be controlled to a prescribed temperature, and then continuously carry out stable processing. The heat exchanger is constructed by arranging partition walls between two plates to form a fluid channel and a fin parallel with the channel or inclined by a prescribed angle on each of the two plates insides the channel so that the plate or a member in contact with the plate is cooled or heated with the fluid flowing through the channel.

Owner:CANON ANELVA CORP

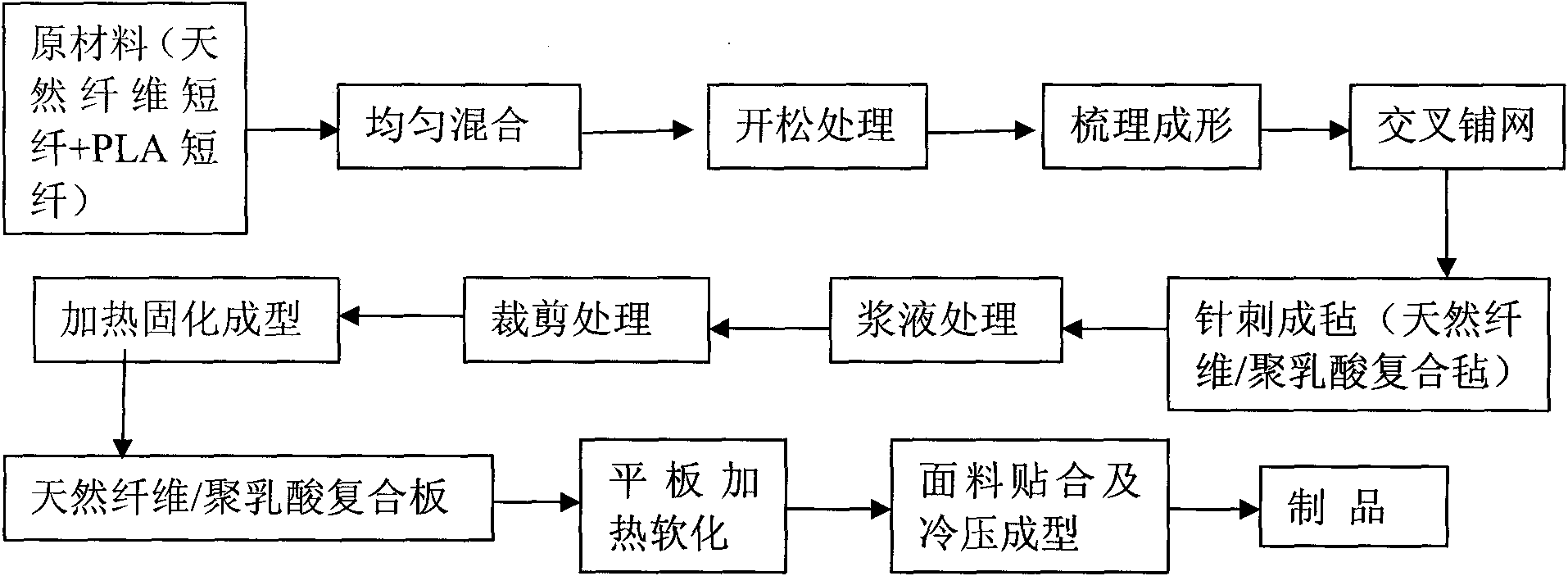

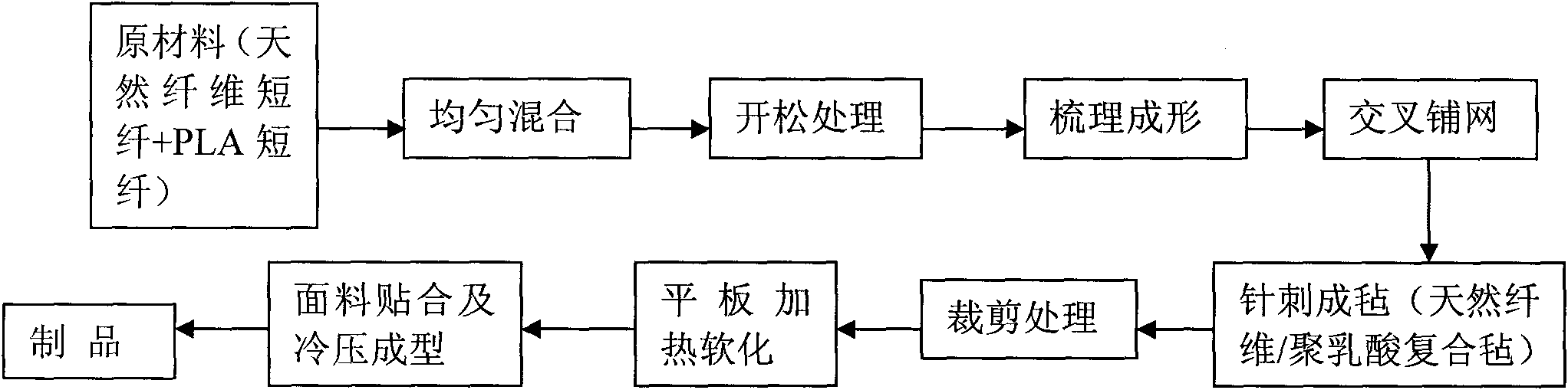

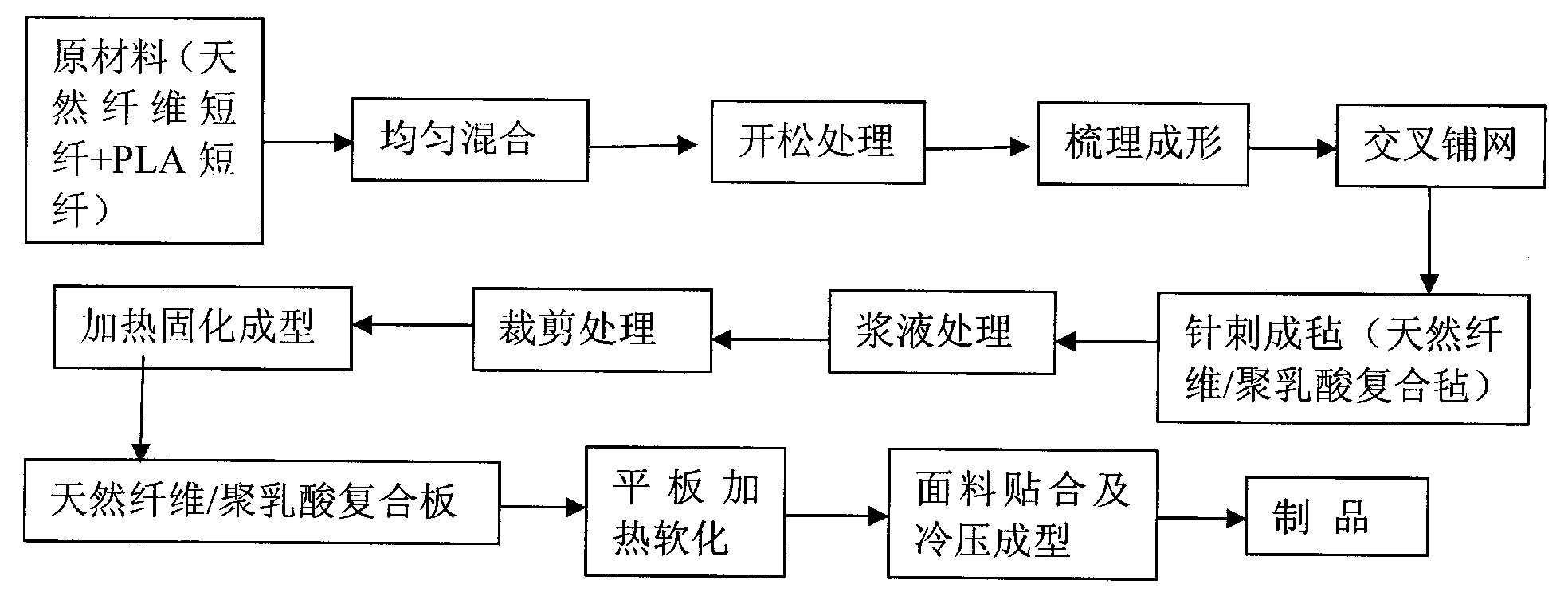

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

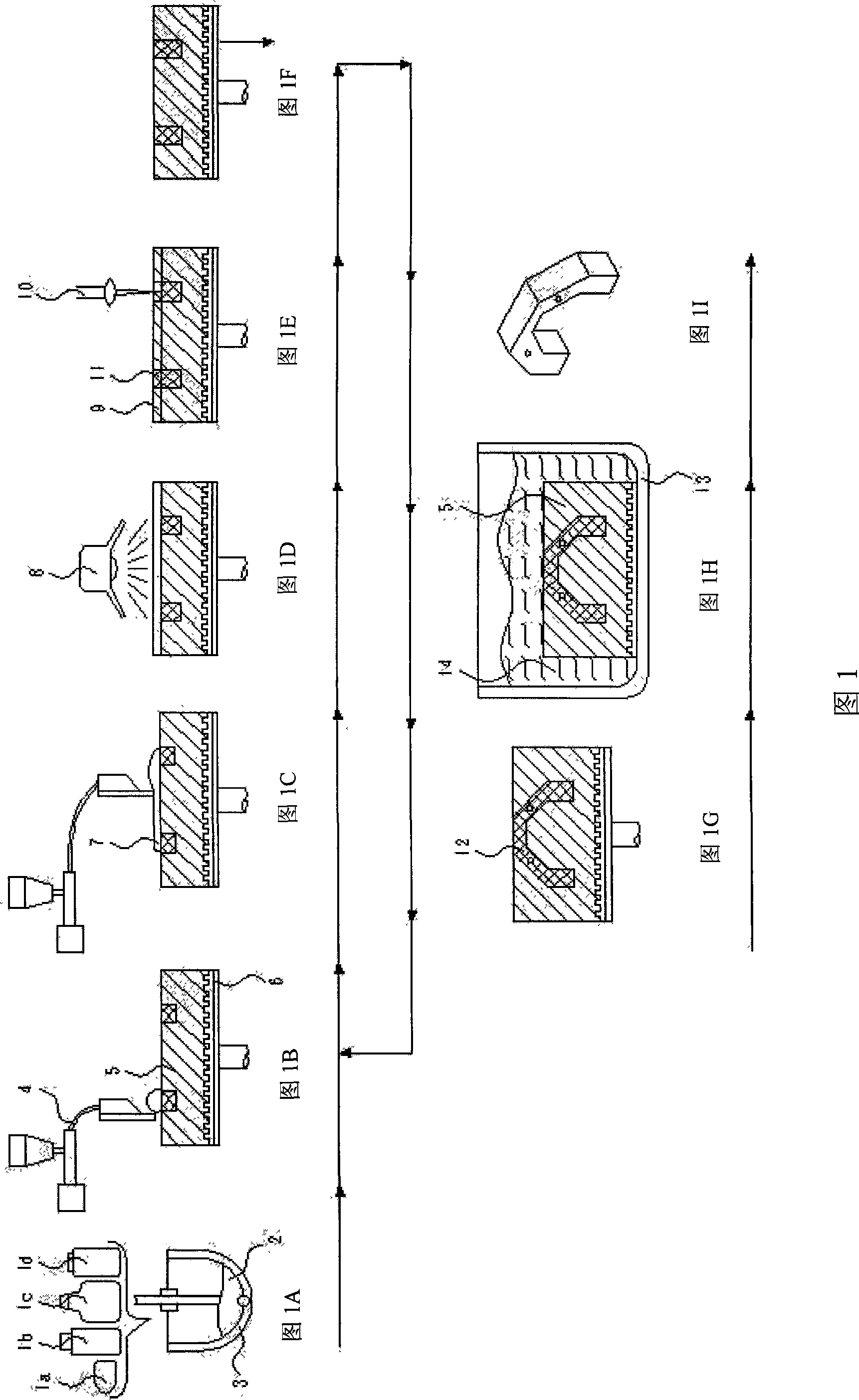

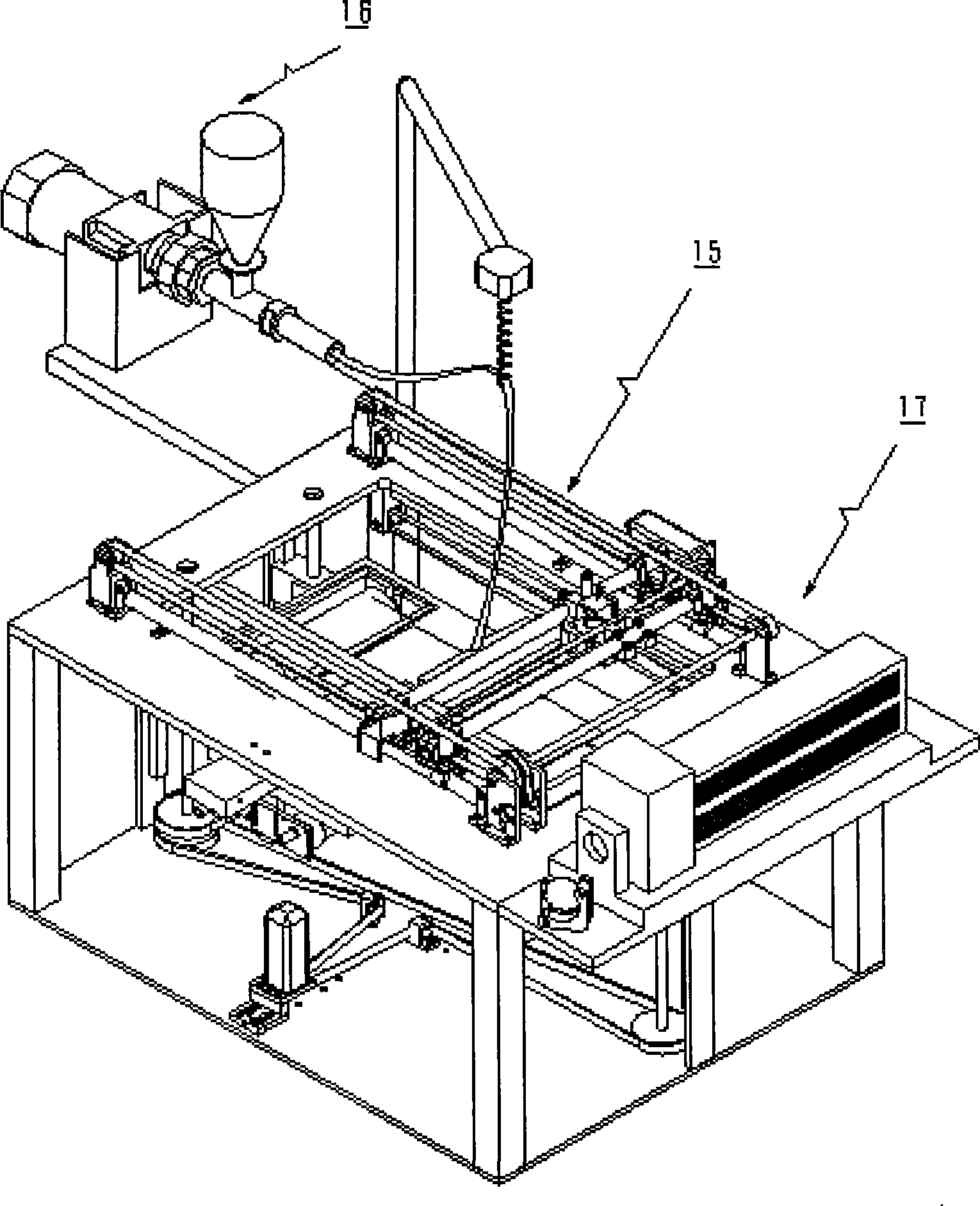

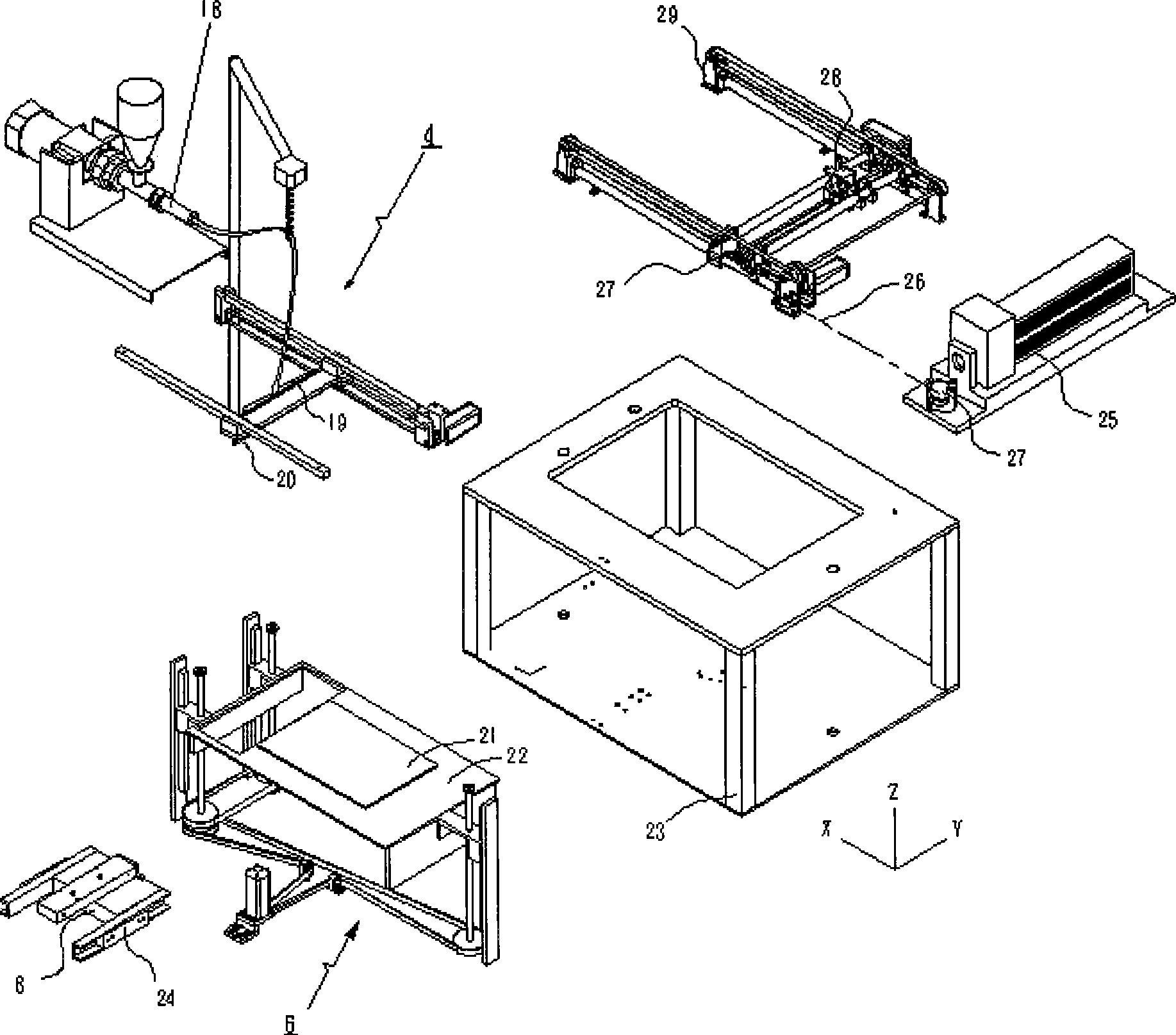

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

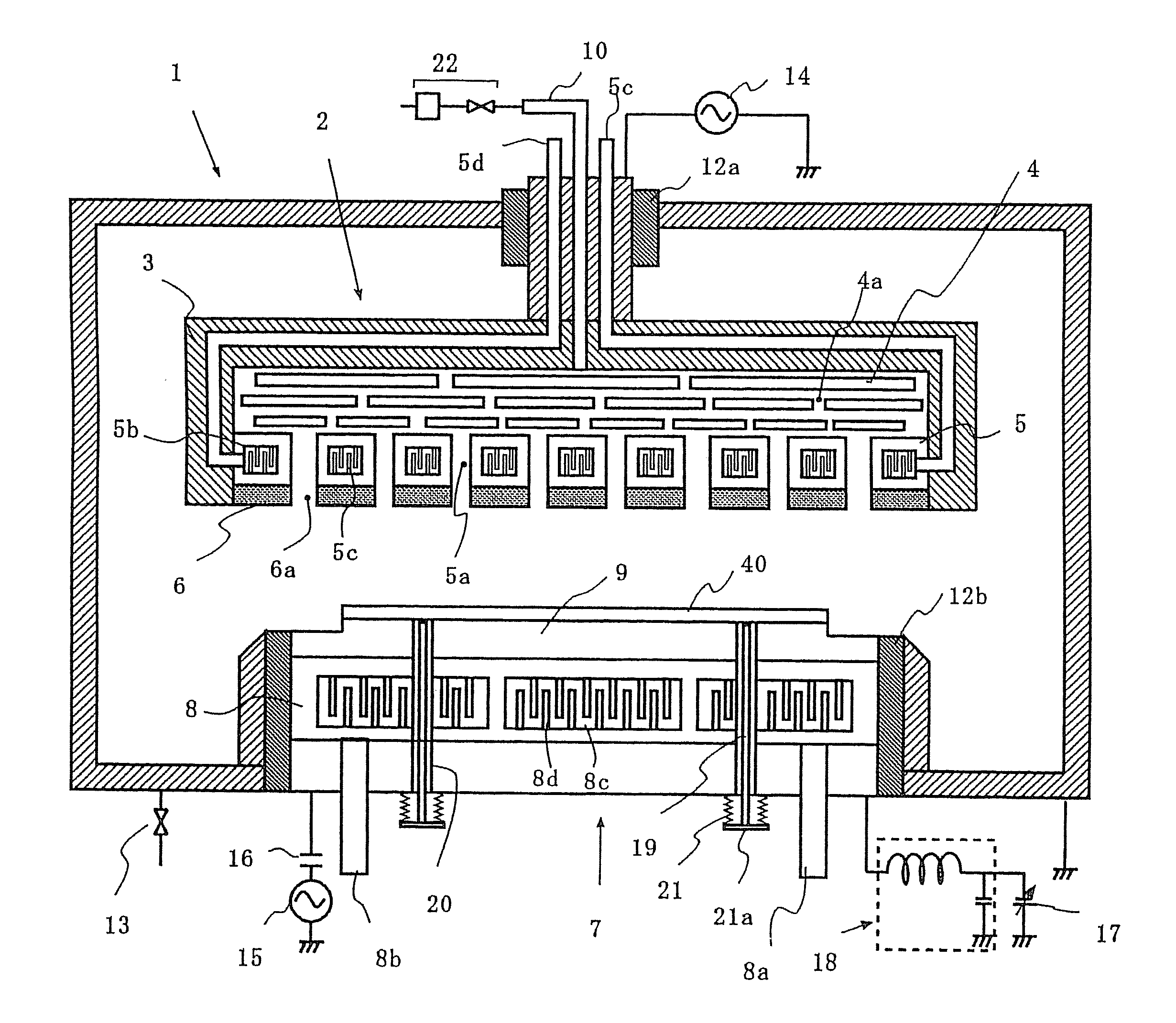

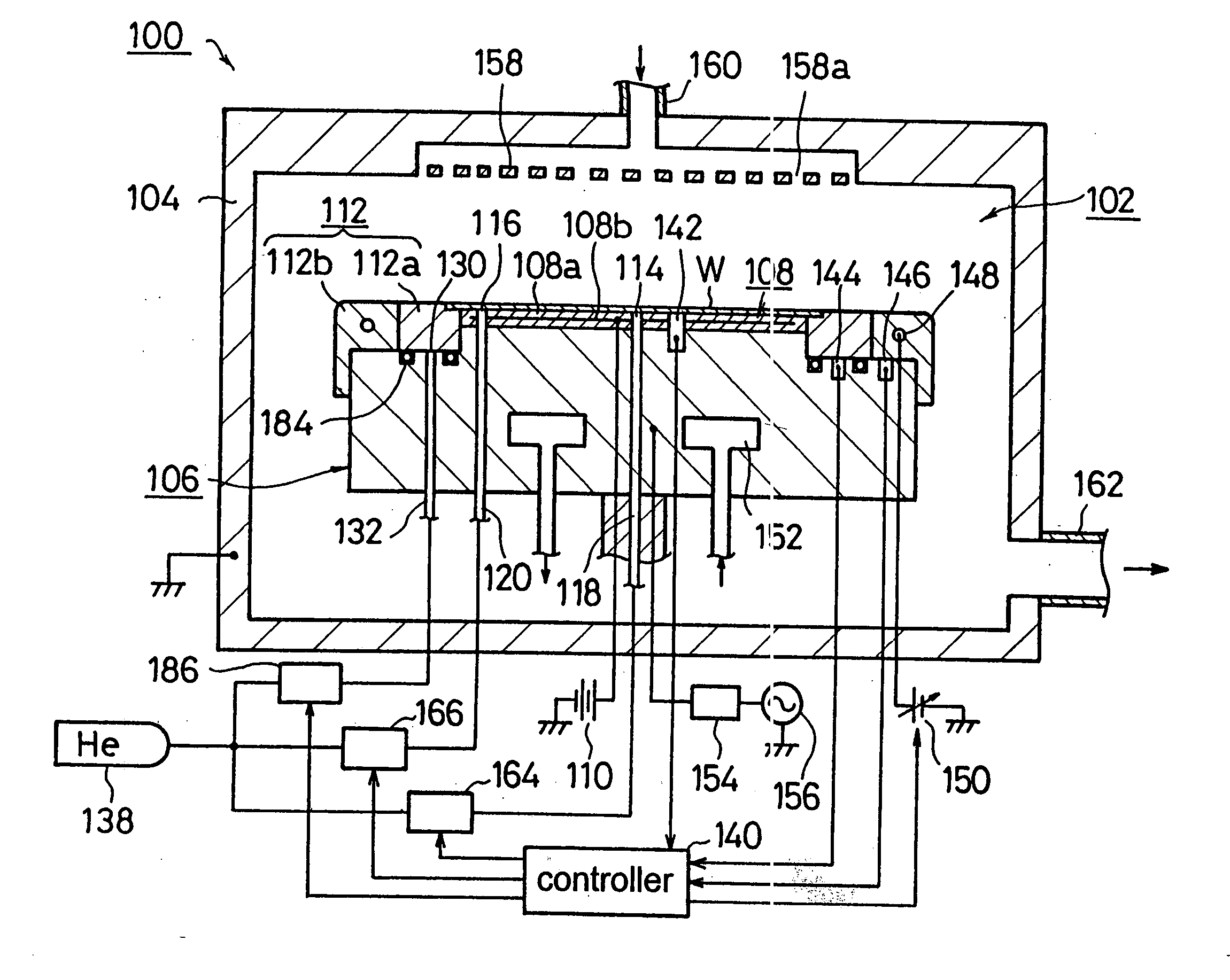

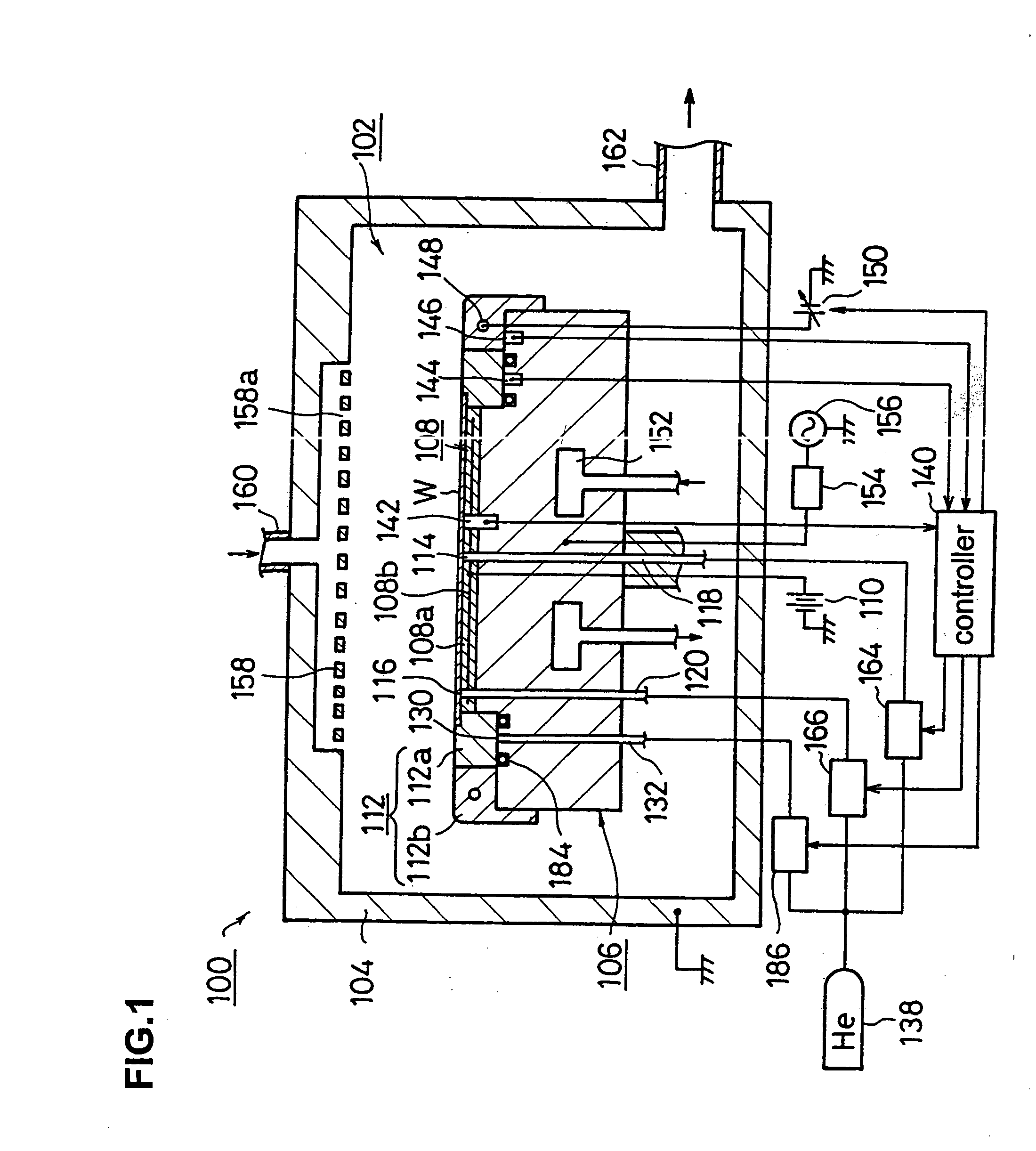

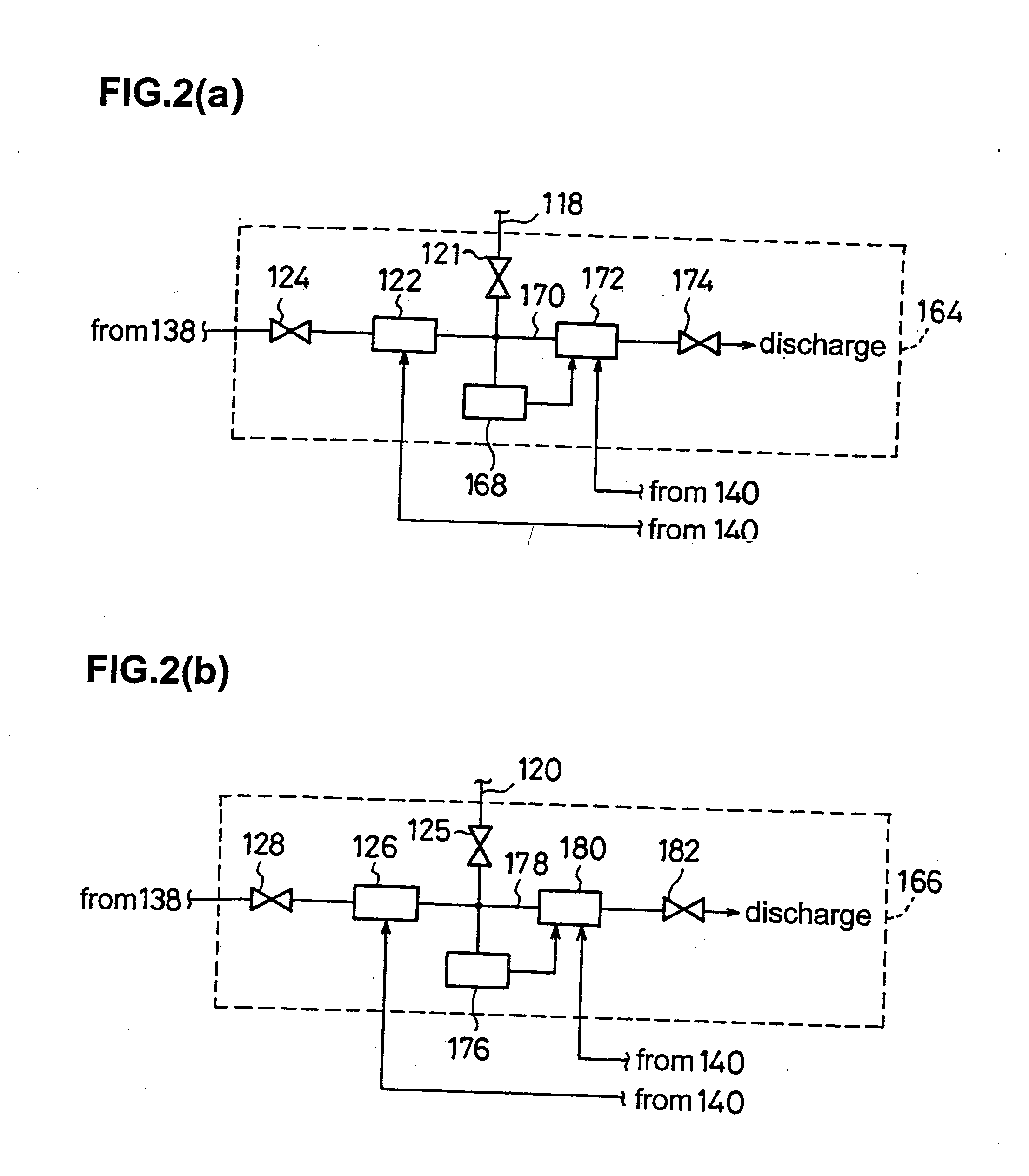

Plasma processing apparatus and plasma processing method

InactiveUS20050172904A1Improve consistencyThermal conductivityElectric discharge tubesVacuum evaporation coatingEngineeringPlasma processing

An electrostatic chuck 108 is provided on a lower electrode 106 provided inside a processing chamber 102 of an etching apparatus 100, and a conductive inner ring body 112a and an insulating outer ring body 112b are encompassing the outer edges of a wafer W mounted on the chuck surface. The temperatures of the wafer W and the inner and outer ring bodies 112a and 112b are detected by first third temperature sensors 142, 144 and 146. A controller 140 controls the pressure levels of He supplied to the space between the center of the wafer W and the electrostatic chuck 108 via first gas outlet ducts 114 and to the space between the outer edges of the wafer W and the electrostatic chuck 108 via second gas outlet ducts 116 and the quantity of heat generated by a heater 148 inside the outer ring body 112b based upon the information on the temperatures thus detected so that the temperatures of the wafer W and the inner ring body 112a are set roughly equal to each other.

Owner:TOKYO ELECTRON AT +1

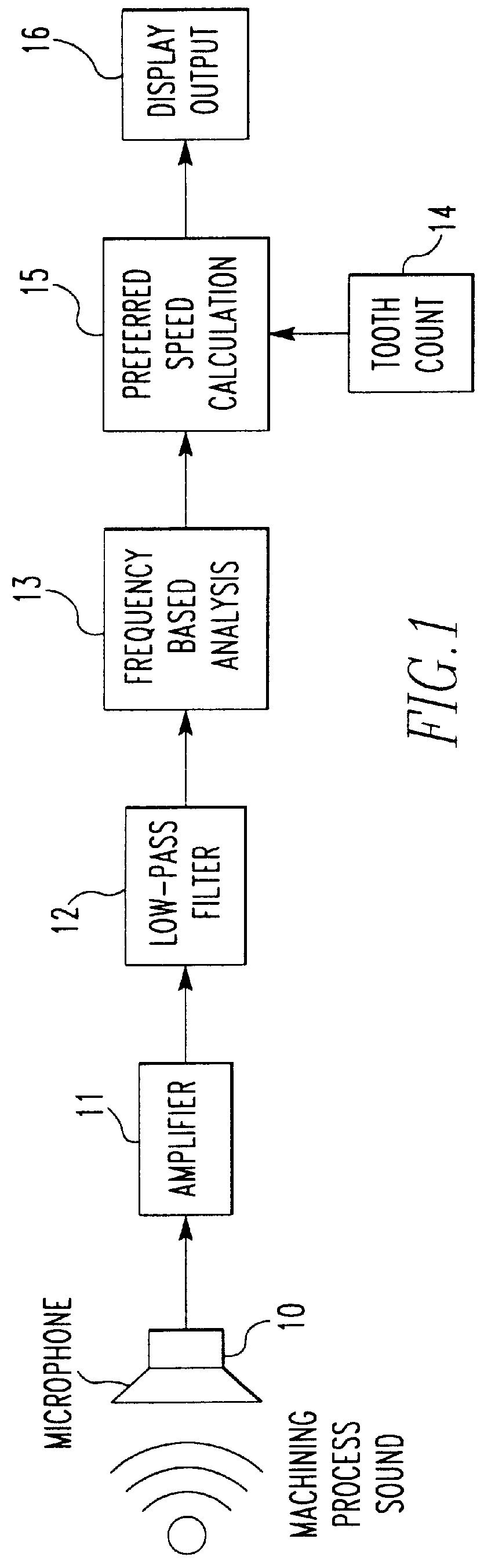

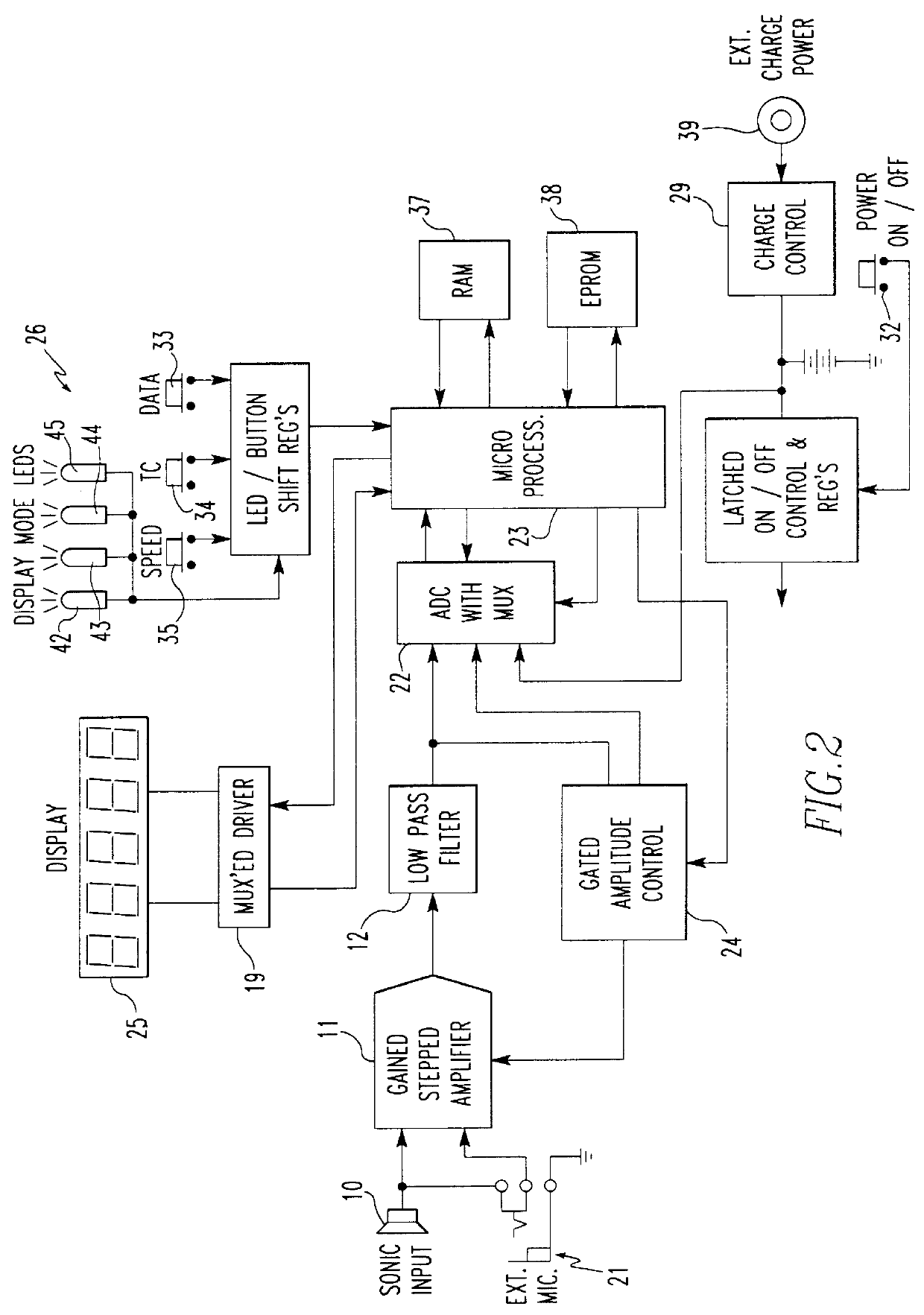

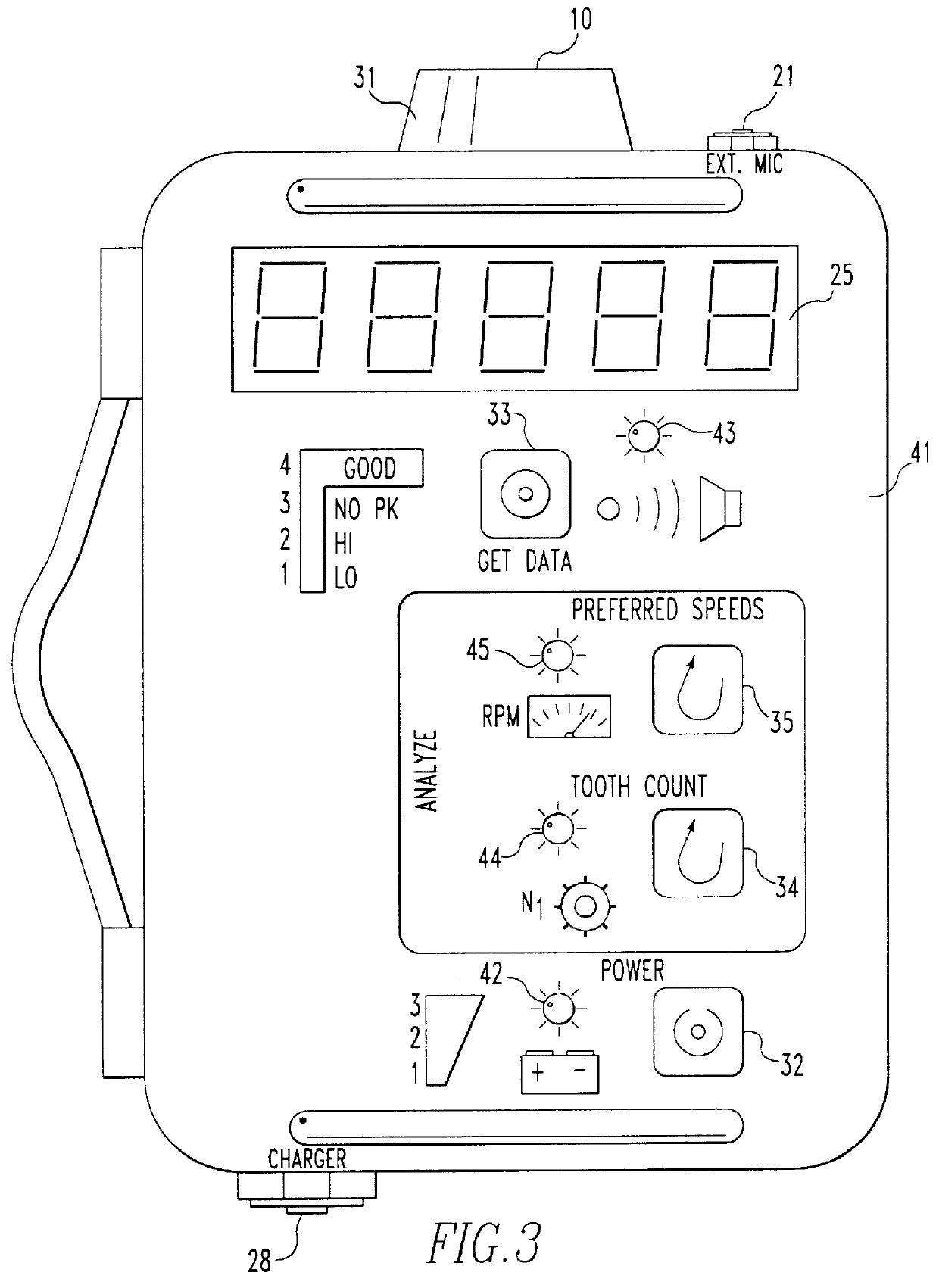

Device and method for recommending dynamically preferred speeds for machining

InactiveUS6085121AStable processingEfficient use ofAutomatic control devicesMeasurement/indication equipmentsRotation velocityHand held

A hand-held, portable device recommends dynamically preferred speeds for stabilizing or reducing undesirable vibration such as chatter in a machining process. The device may be applied to machining processes such as turning, boring, milling and drilling which exhibit a relative rotational motion between the cutting tool and workpiece. The device measures in a safe, non-contact manner via a microphone the dominant audio signal component of the sound pressure emanating from the machining processes. Without prior knowledge of the machining process parameters or the dynamic characteristics of the machine tool or workpiece, the audio signal is conditioned and processed to determine the frequency component levels. The rotational speeds which are more likely to lead to a stable machining process are calculated based on the number of teeth on the cutting tool and the identified dominant frequency of vibration. The dynamically preferred speeds are displayed as recommendations to the process operator or machinist.

Owner:BLUESWARF

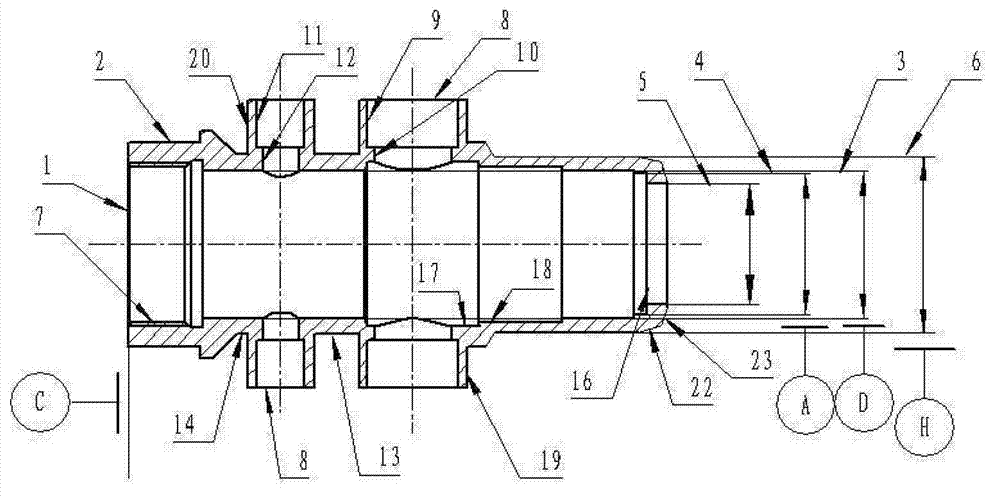

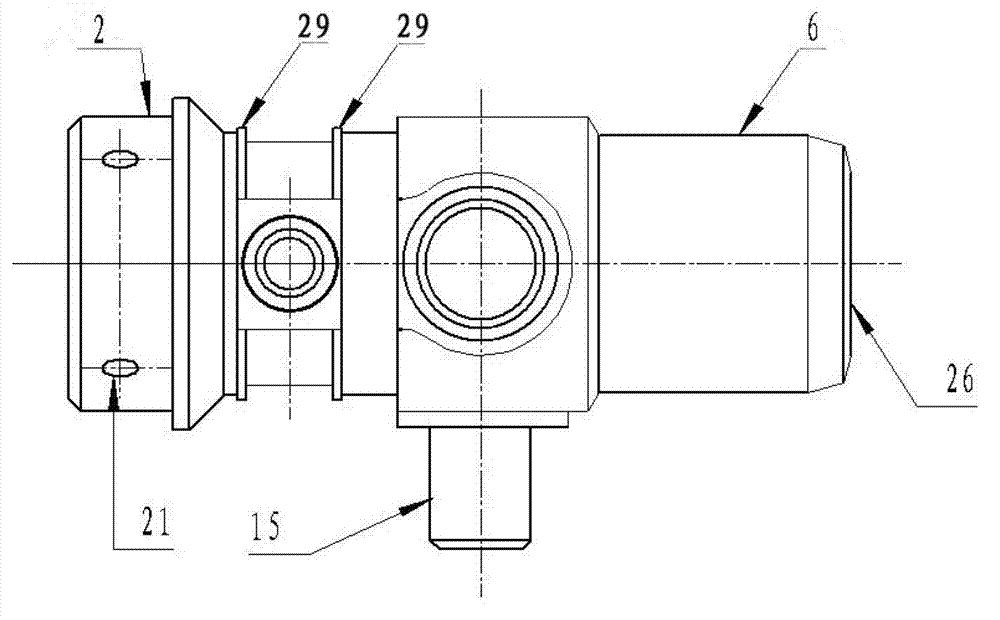

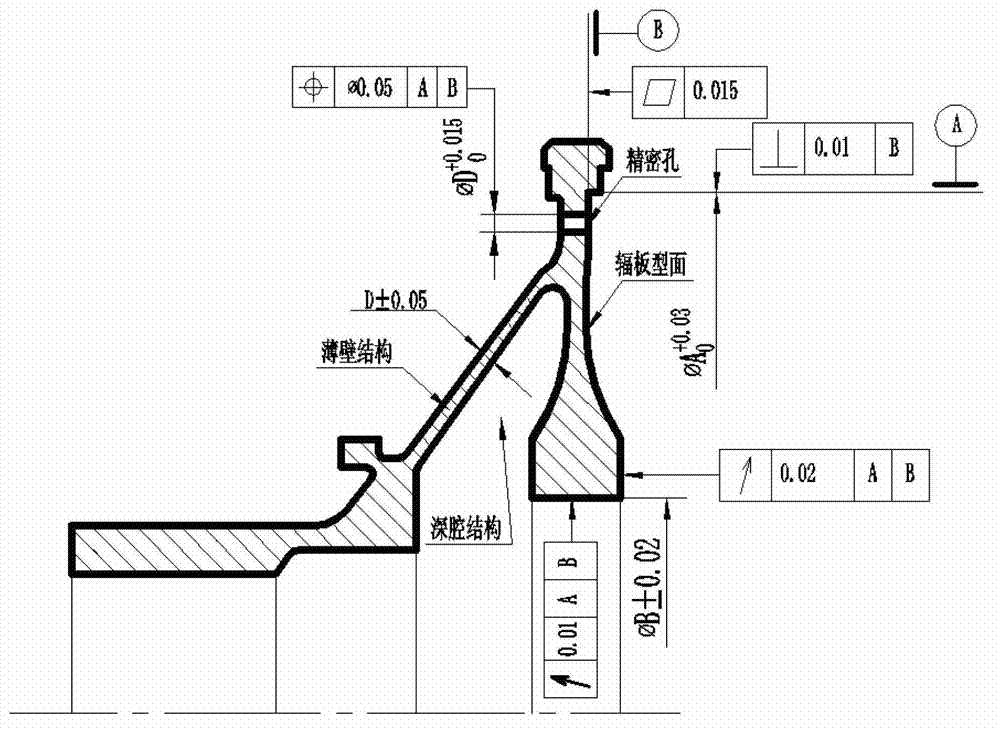

Numerically-controlled processing method of nozzle housing piece

The invention discloses a numerically-controlled processing method of a nozzle housing piece. According to the method, a numerically-controlled machining / milling combined processing center is adopted and comprises two main shafts and an on-line measurement device; the workblank of the nozzle housing piece is a die-forged part, and the die-forged part is made of a nickel-based high-temperature alloy. The method comprises the following steps: designing a nozzle housing processing path; performing polishing treatment on the die-forged part to remove burrs from the die-parting face and end-face die-drawing taper; coarsely machining the tail part of the work piece; performing numerically-controlled machining / milling on the whole work piece; performing numerically-controlled fine machining of the head part of the work piece; cleaning and marking the work piece; and inspecting. The method provides the reasonable designs of processing path and processing method of the work piece as well as the processing positioning reference of the work piece, and completes the processing of the inner cavity, the outer circle, the lateral adapter, the positioning pin and other parts of the nozzle housing piece within one-step loading process. The method solves the problem that the die-forged part has a complex structure and a thin wall and has strict requirements for dimensional precision and positional precision; and overcomes the defects of long processing period, low production efficiency and poor dimensional precision and positional precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

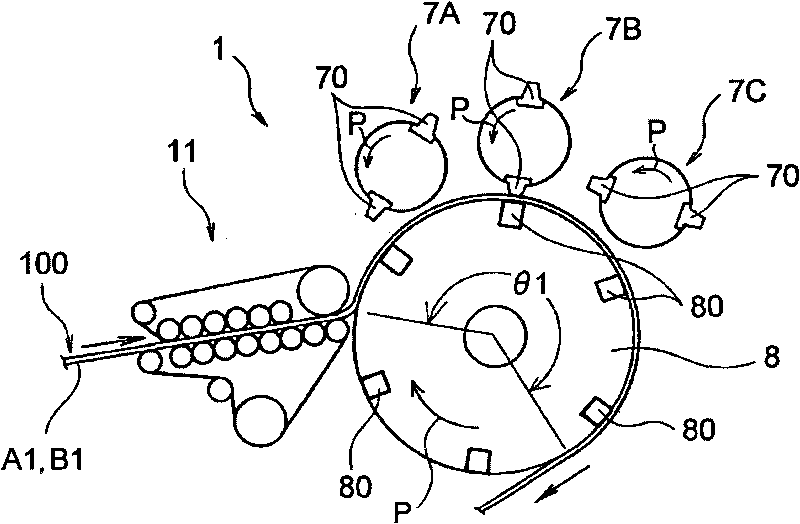

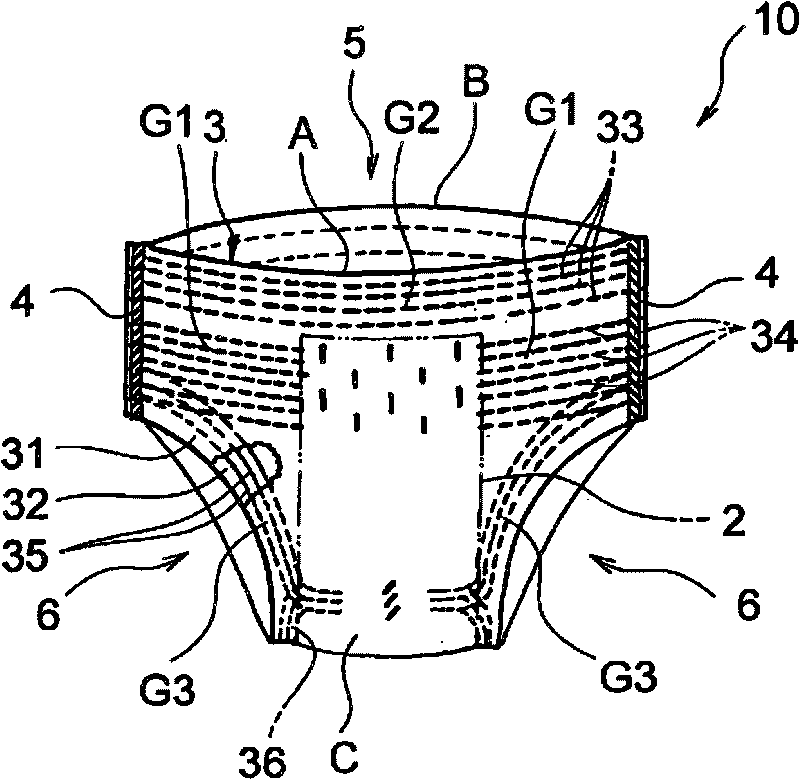

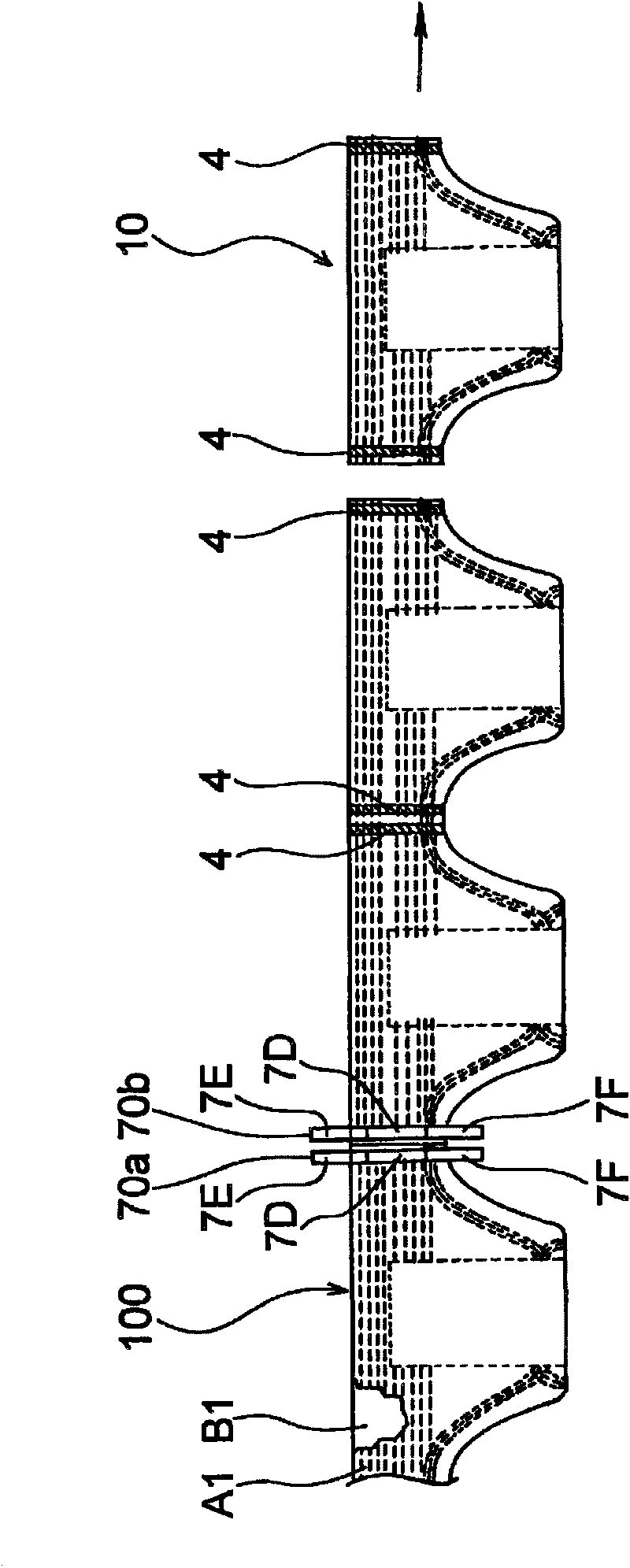

Sheet material processing method and device

ActiveCN101746057AStable processingStable cutting processDomestic articlesBandagesEngineeringThermal treatment

The invention provides a sheet material processing method and device. The sheet material processing method is used for processing the sheet material (100 between two rollers (7A, 8) which are arranged oppositely, wherein, the processing method includes at least one of the compacting of the sheet material, the heat seal of sheet materials and the cut off of an elastomeric element arranged among the sheet materials, in the processing method, the outer periphery temperature of at least one roller (8) is respectively controlled in a plurality of thermal treatment zones arranged in the shaft direction of the roller, while the sheet materials (100) are processed.

Owner:KAO CORP

Substrate processing apparatus

InactiveUS7332055B2Stable processingImprove throughputPretreated surfacesSemiconductor/solid-state device manufacturingResistLow speed

Owner:TOKYO ELECTRON LTD

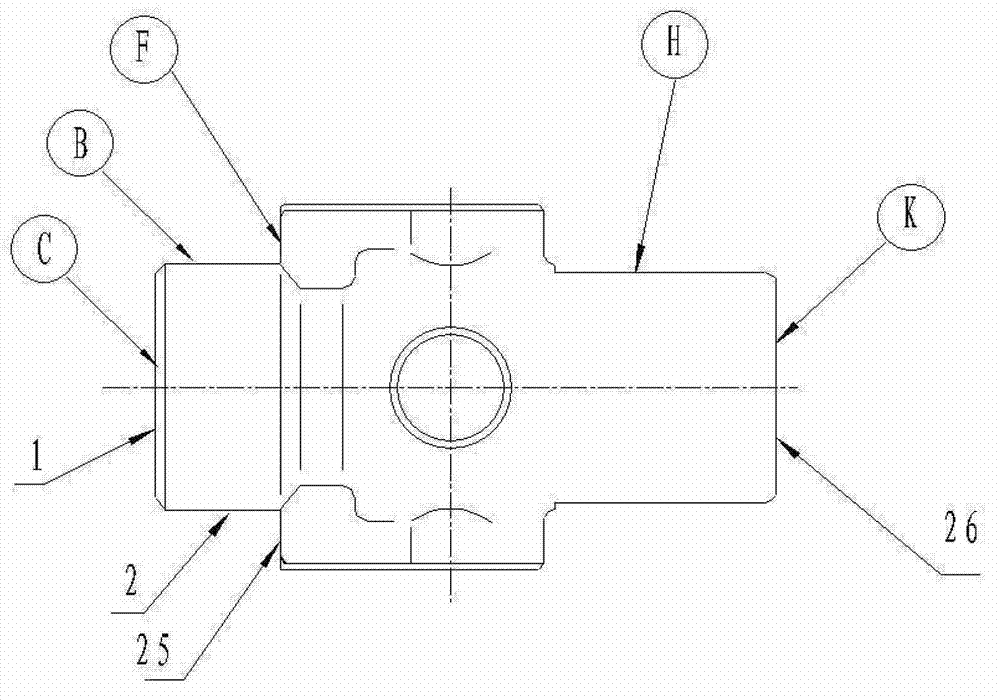

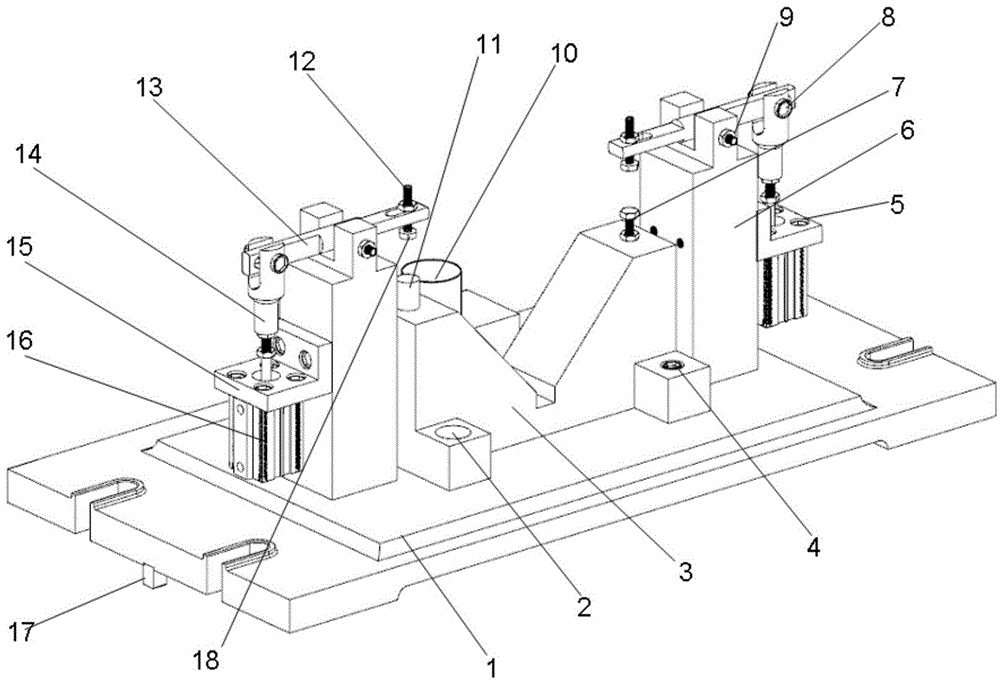

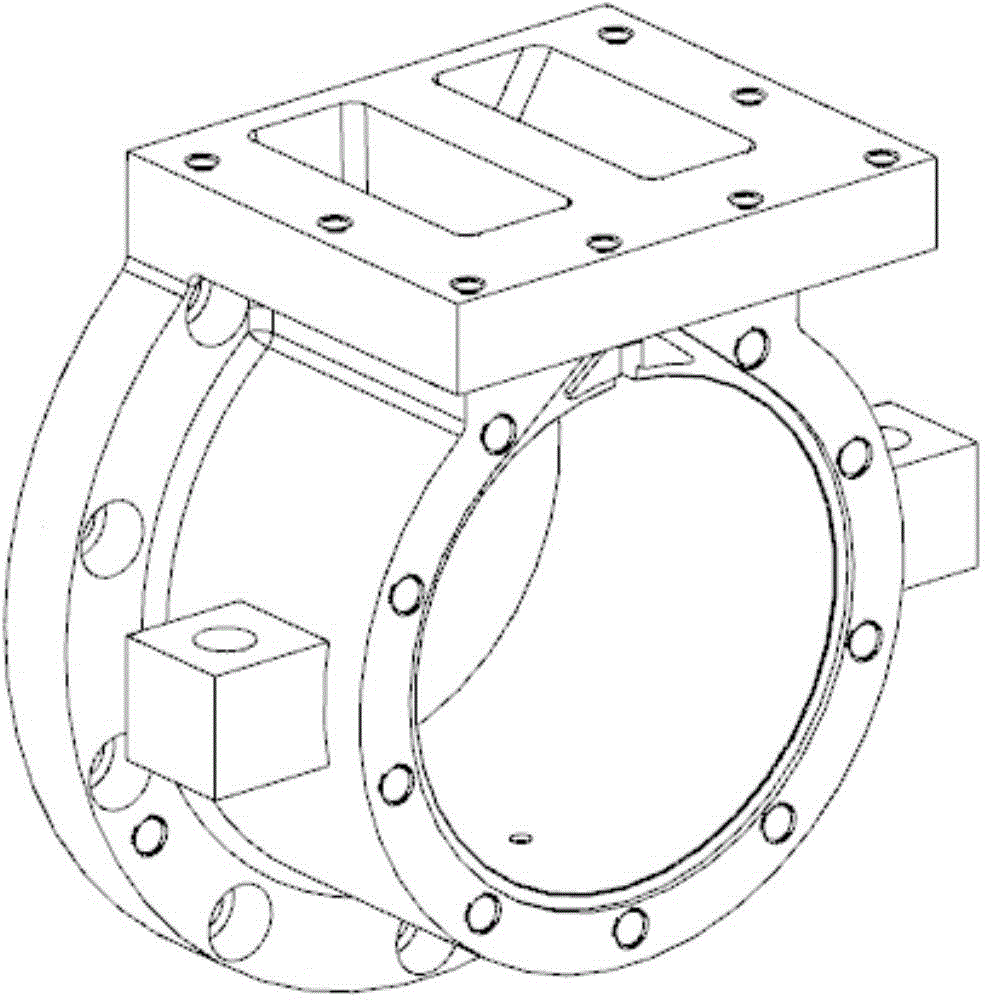

V-block-positioning pneumatic clamping machining center fixture

InactiveCN104128829ANovel structureEasy to operateWork clamping meansPositioning apparatusClassical mechanicsEngineering

The invention discloses a V-block-positioning pneumatic clamping machining center fixture comprising a fixture body, a positioning mechanism and a clamping mechanism. The positioning mechanism comprises a V-block fixed on the fixture body, a fixed support and an auxiliary support are fixed on the upper end faces of two ends of the V-block respectively, and a cylindrical stop pin is arranged on one side corresponding to the center of a V-opening of the V-block. The clamping mechanism comprises two cylinders respectively located on two sides of the V-block, a column is arranged between each cylinder and the V-block, the bottoms of the two columns are fixed on the fixture body, push rods of the cylinders are arranged vertically, a lever is mounted on the top of each push rod transversely and rotationally, the middle of each lever is rotationally mounted at the top of the corresponding column, the other end of each lever is fixed with a pressing block, and each pressing block is located on the lower end face of the corresponding lever and located over the fixing support or the auxiliary support. The V-block-positioning pneumatic clamping machining center fixture is quick and accurate in positioning, quick, controllable and reliable in clamping, and capable of guaranteeing machining stability.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

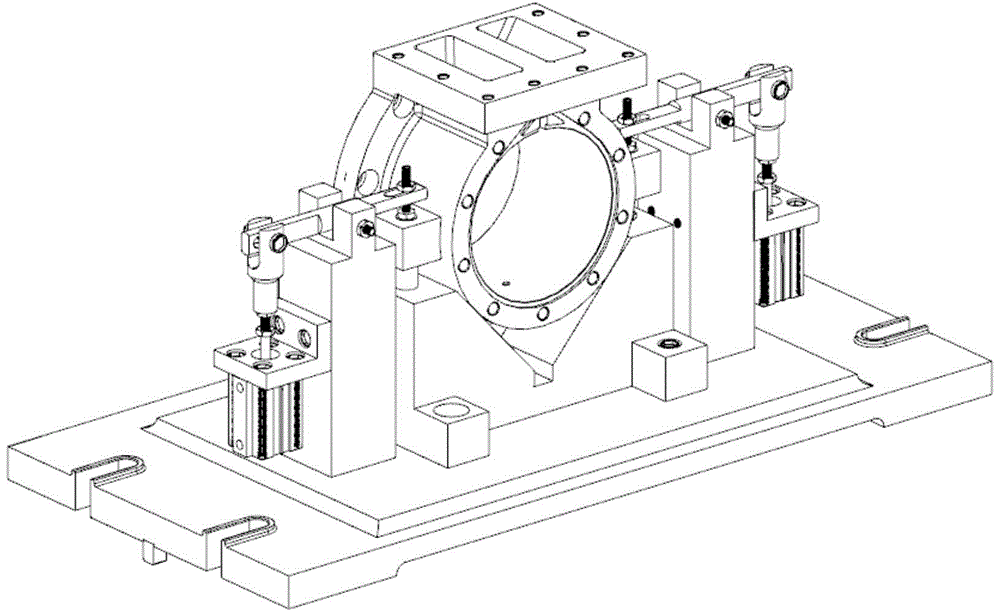

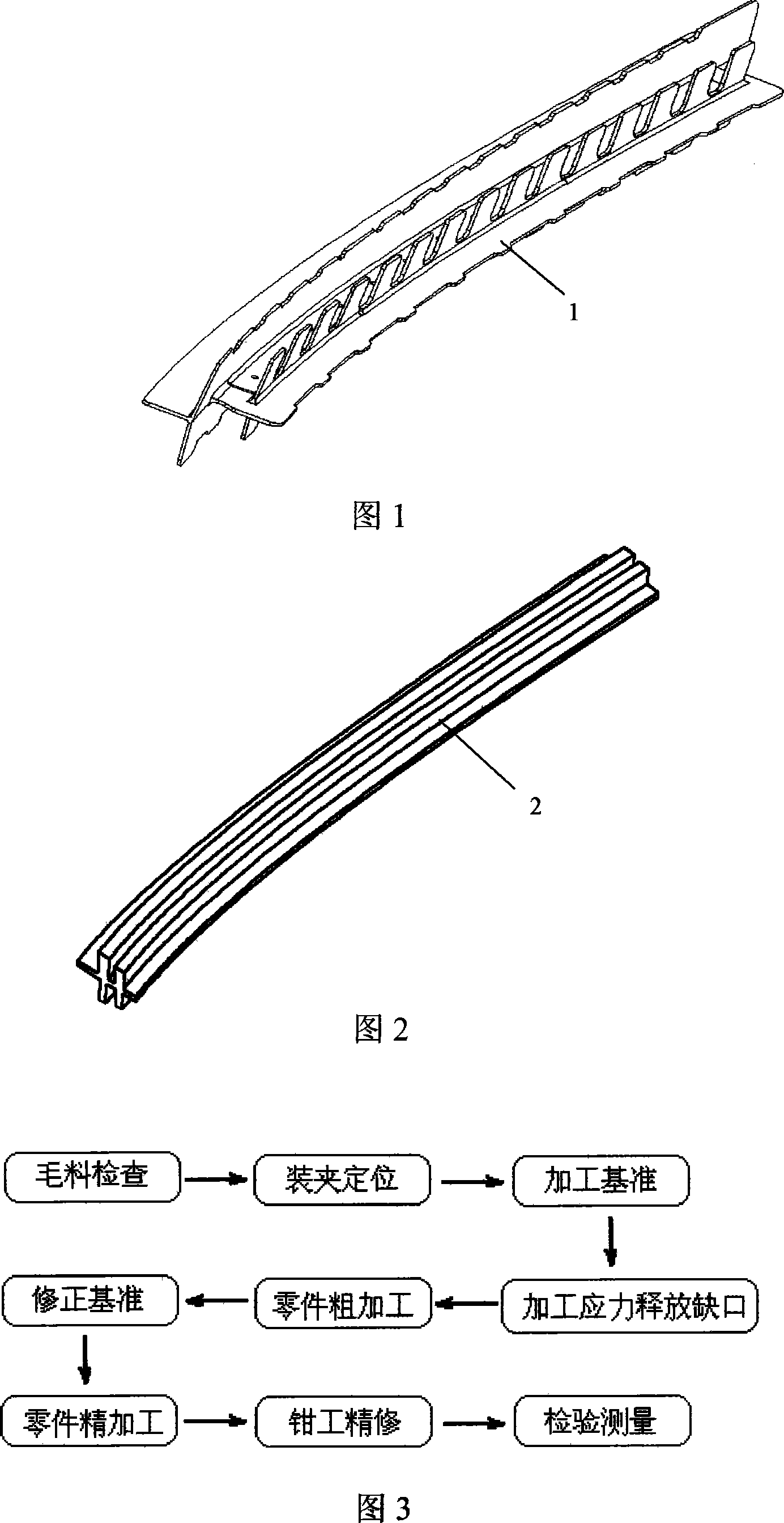

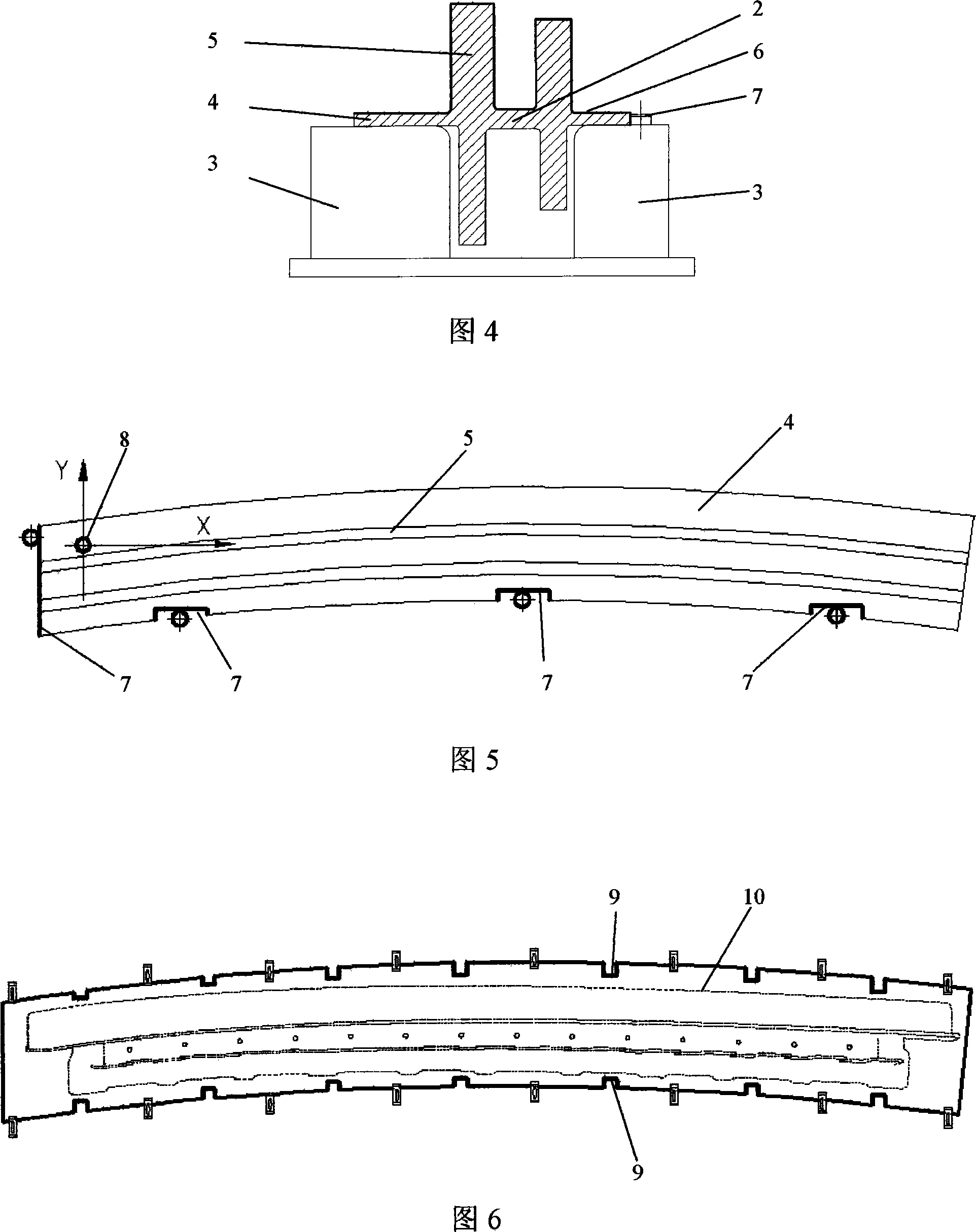

Numerically controlled processing method for plane wing rib beam part

ActiveCN101104242AEffective control of processing deformationReliable clamping and positioning during processingAutomatic control devicesFeeding apparatusDigital controlSurface structure

The invention discloses a digital control processing method for a rib boom part of the aircraft wing, comprising a rough lumber profile with processing margin and a positioning clamp. The rough lumber profile is a multi-surface structure which is provided with a long-striped web plate and a rim plate, and the web plate and the rim plate are drawn bent and molded and form a certain angle. The positioning clamp is provided with a supporting plane and a positioning pin. The particular processing method is that a stress releasing gap is arranged on the web plate, and processing positioning reference is firstly set up before the extensive processing and intensive processing.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

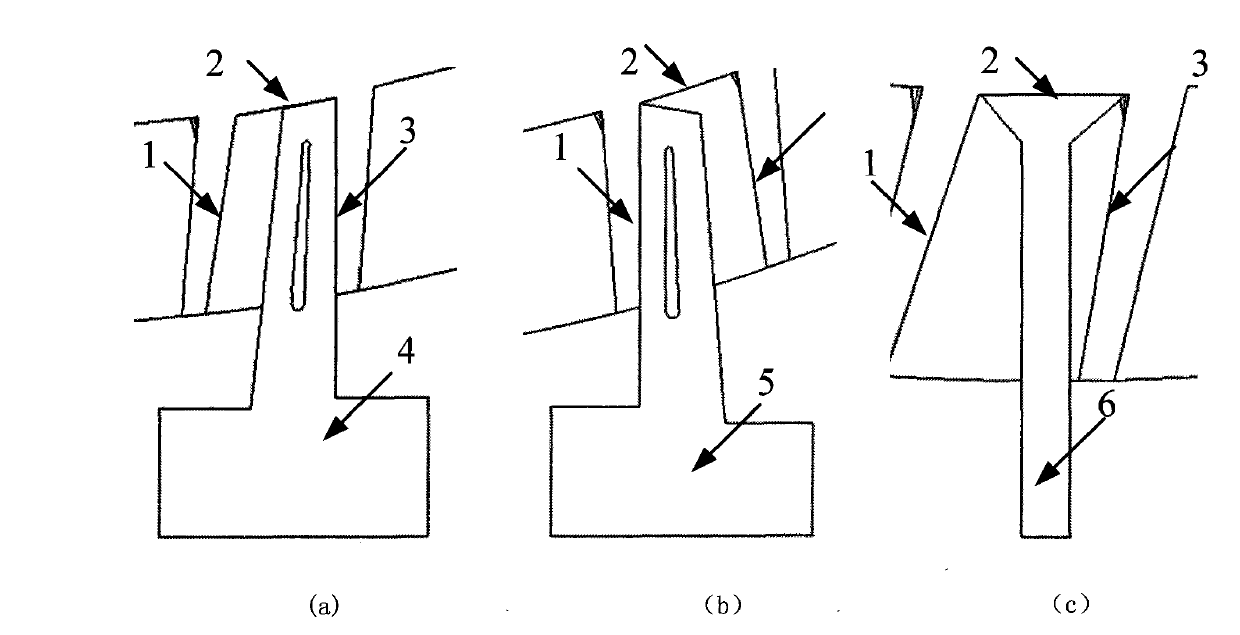

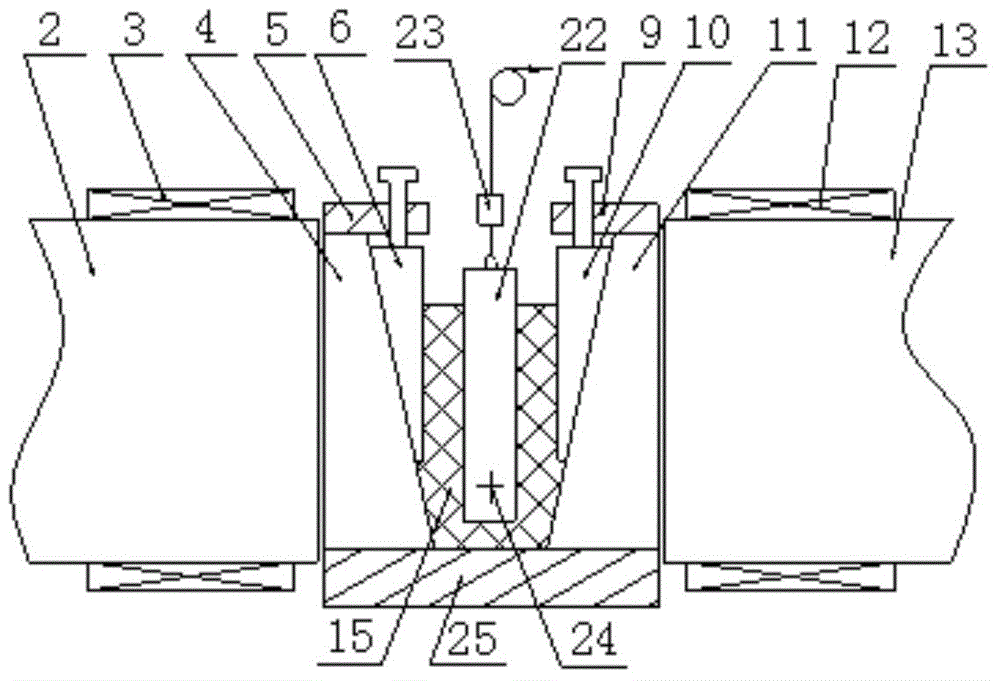

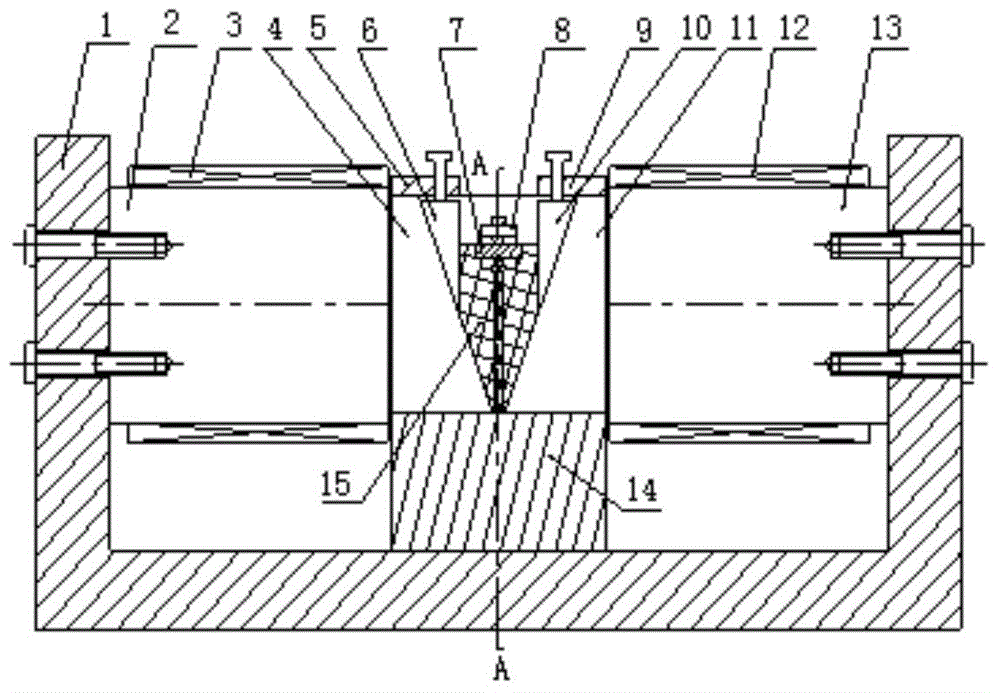

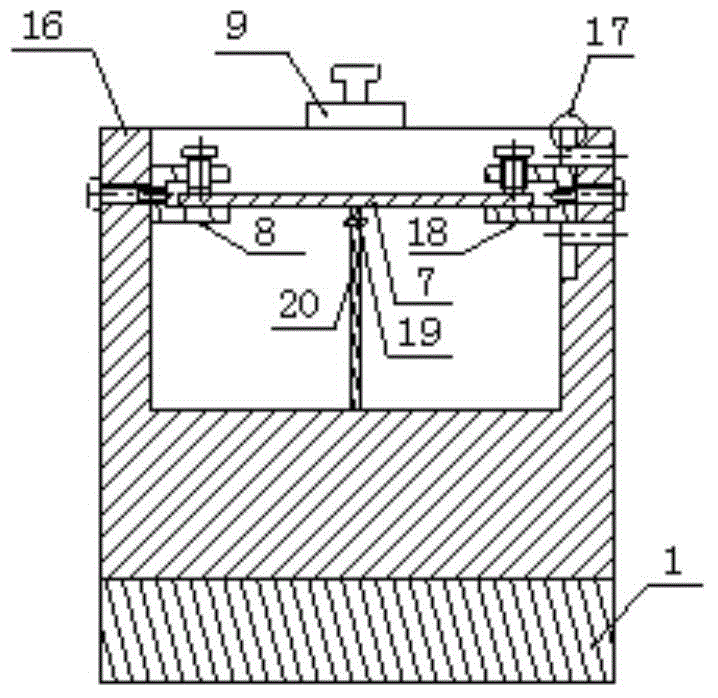

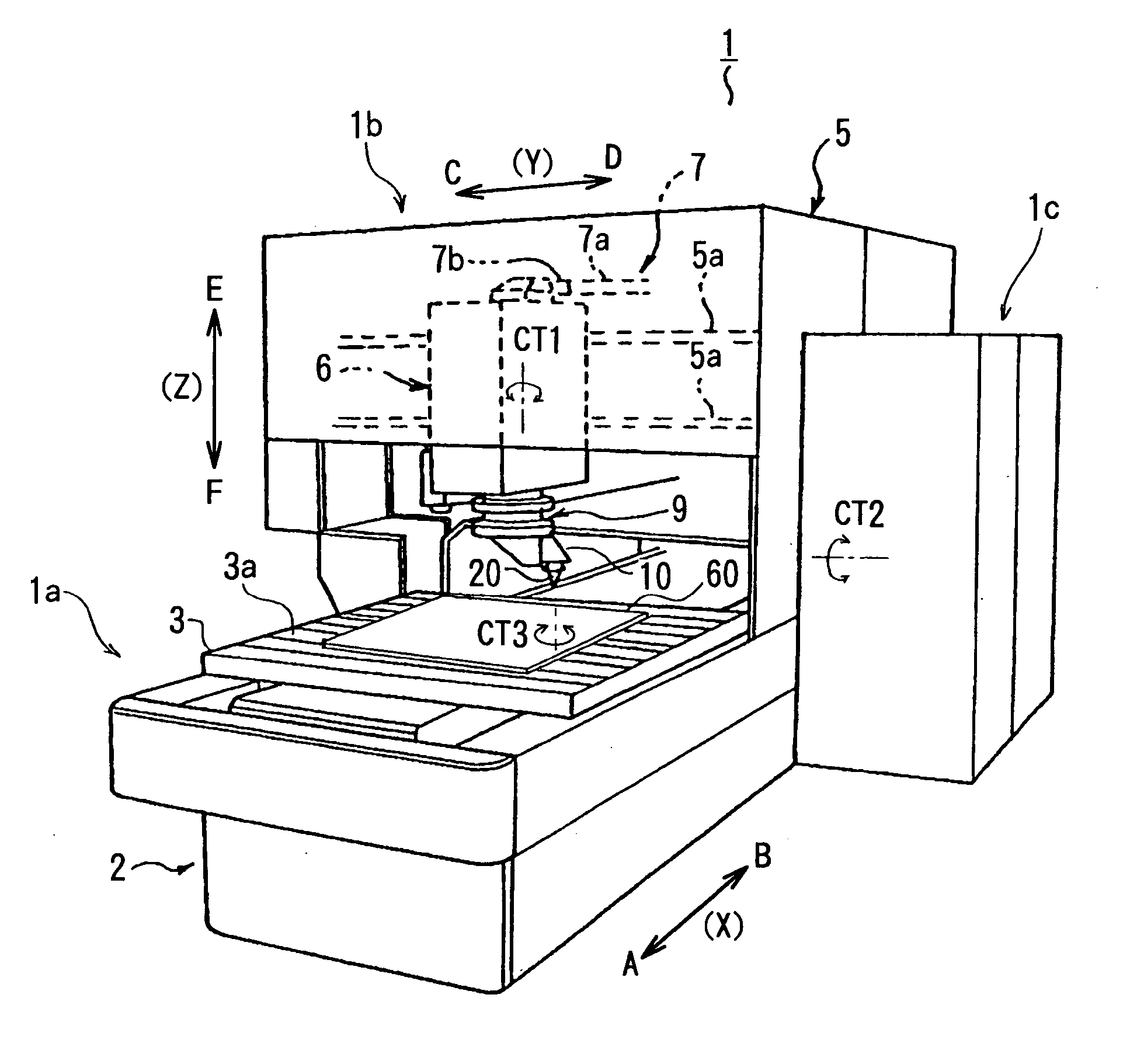

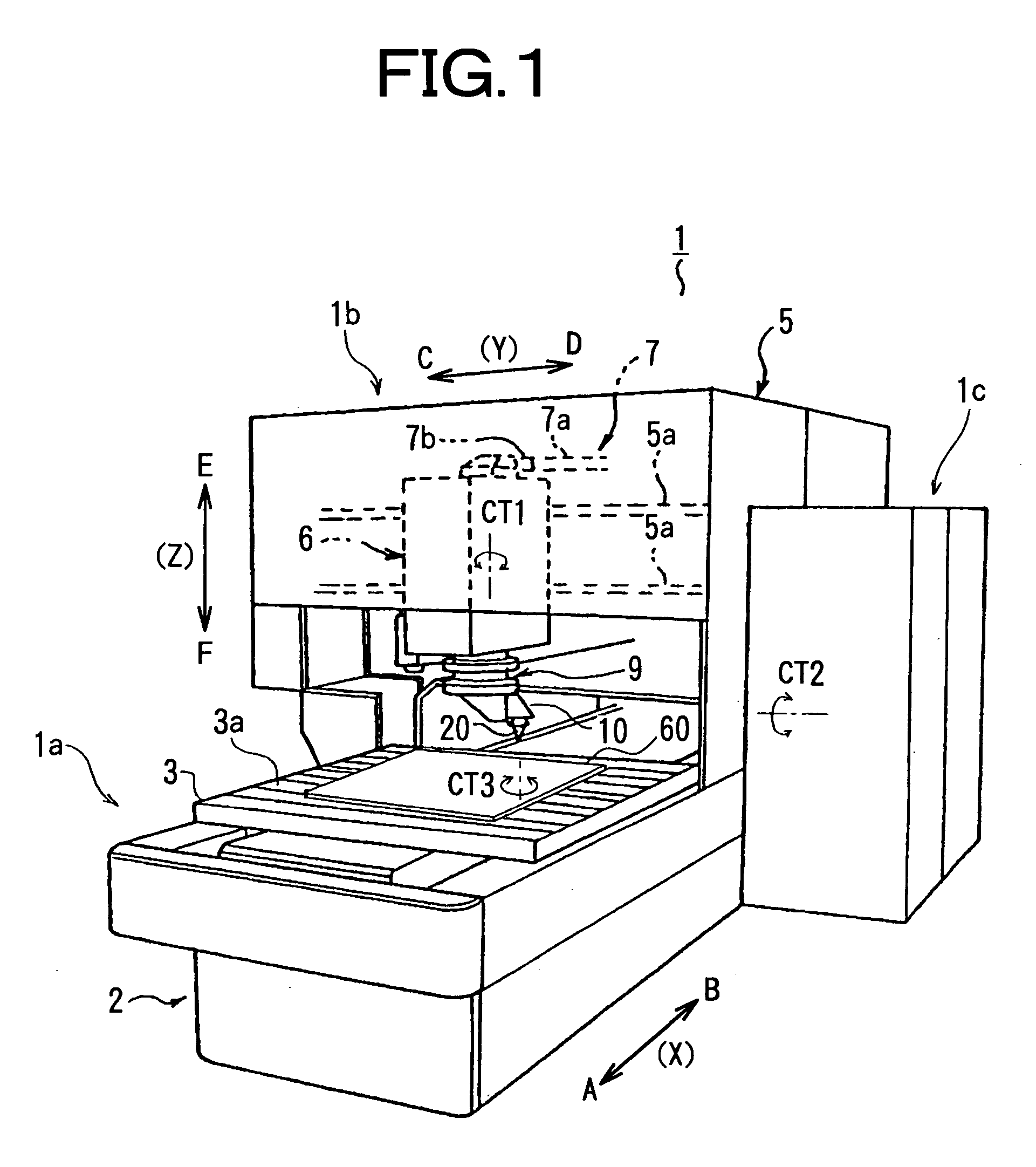

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for radially rolling and forming ring piece with three steps and complicated section

InactiveCN102873511ASave raw materialsIncrease productivityMetal rollingRoom temperatureMechanical property

The invention relates to a method for radially rolling and forming a ring piece with three steps and a complicated section. The method includes sawing a cylindrical bar into a material section with a proper size, uniformly heating the material section so that the temperature of the material section is increased from the room temperature to the austenite temperature, keeping the austenite temperature of the material section for a certain period, performing rounding, heading and die forging for the material section to obtain a pre-forged piece with concave holes at two ends, finally piecing the middle of the pre-forged piece and punching a slug of the pre-forged piece to obtain an annular blank for rolling; feeding the blank into a furnace to heat the blank, taking out the blank from the furnace after the temperature of the blank reaches the target temperature and the target temperature of the blank is kept for a certain period, placing the blank into a closed hole pattern of a radial ring rolling mill to perform rolling and forming for the blank and repeatedly rotationally rolling the blank to enable to the blank to deform so as to obtain an annular forged piece with the specified shape, the specified size, three steps and a complicated section; and performing normalizing and tempering heat treatment for the forged piece to guarantee the mechanical property of the forged piece and finally cutting and processing the forged piece to form the finished ring piece. A near-net-shape precise forming mode is adopted, follow-up machining allowance is small, utilization rate of materials is high, forging heating number is reduced, energy consumption is saved, and the method has the advantages of high production efficiency and low cost.

Owner:SHANDONG JIANZHU UNIV

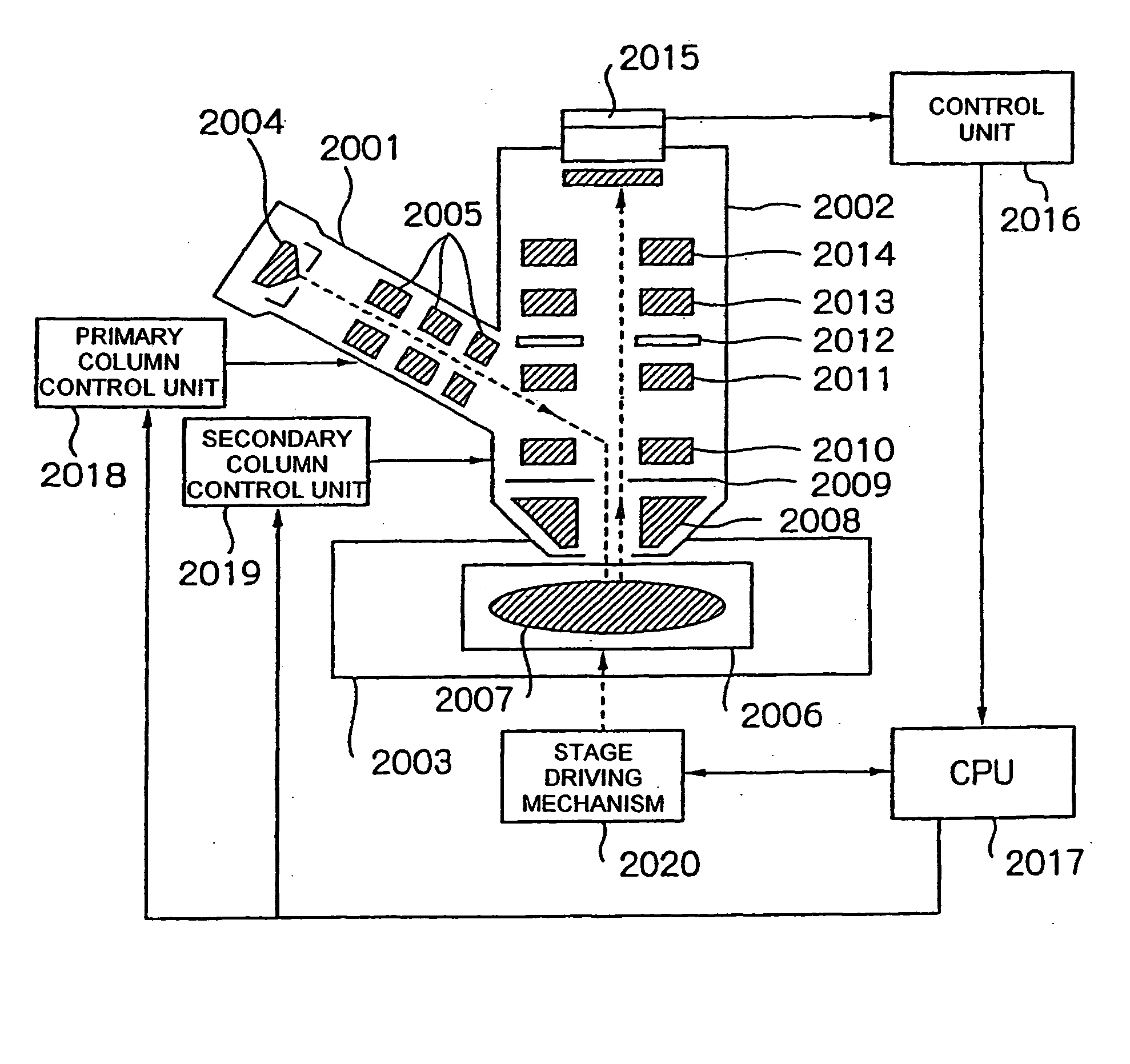

Sheet beam-type inspection apparatus

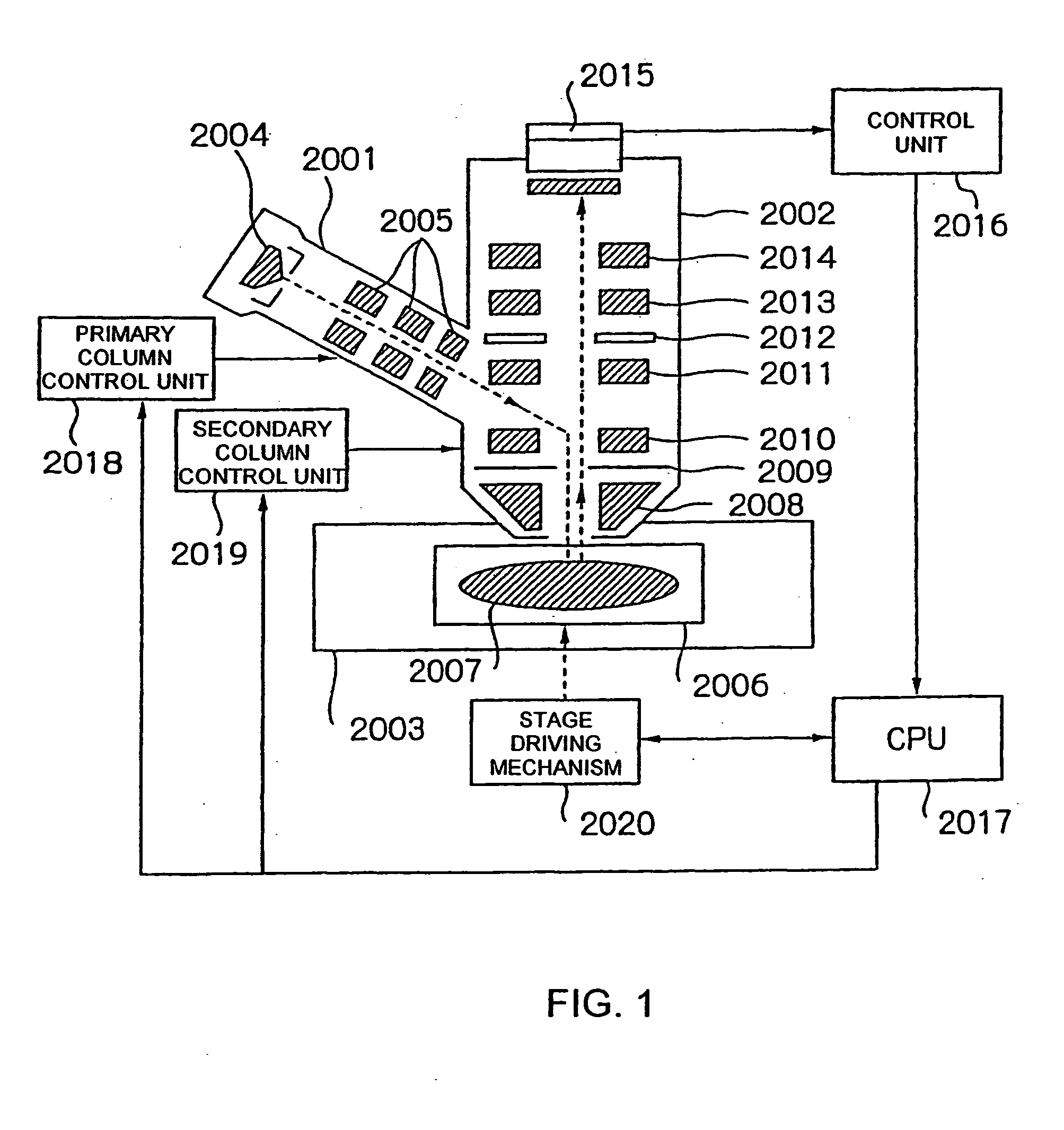

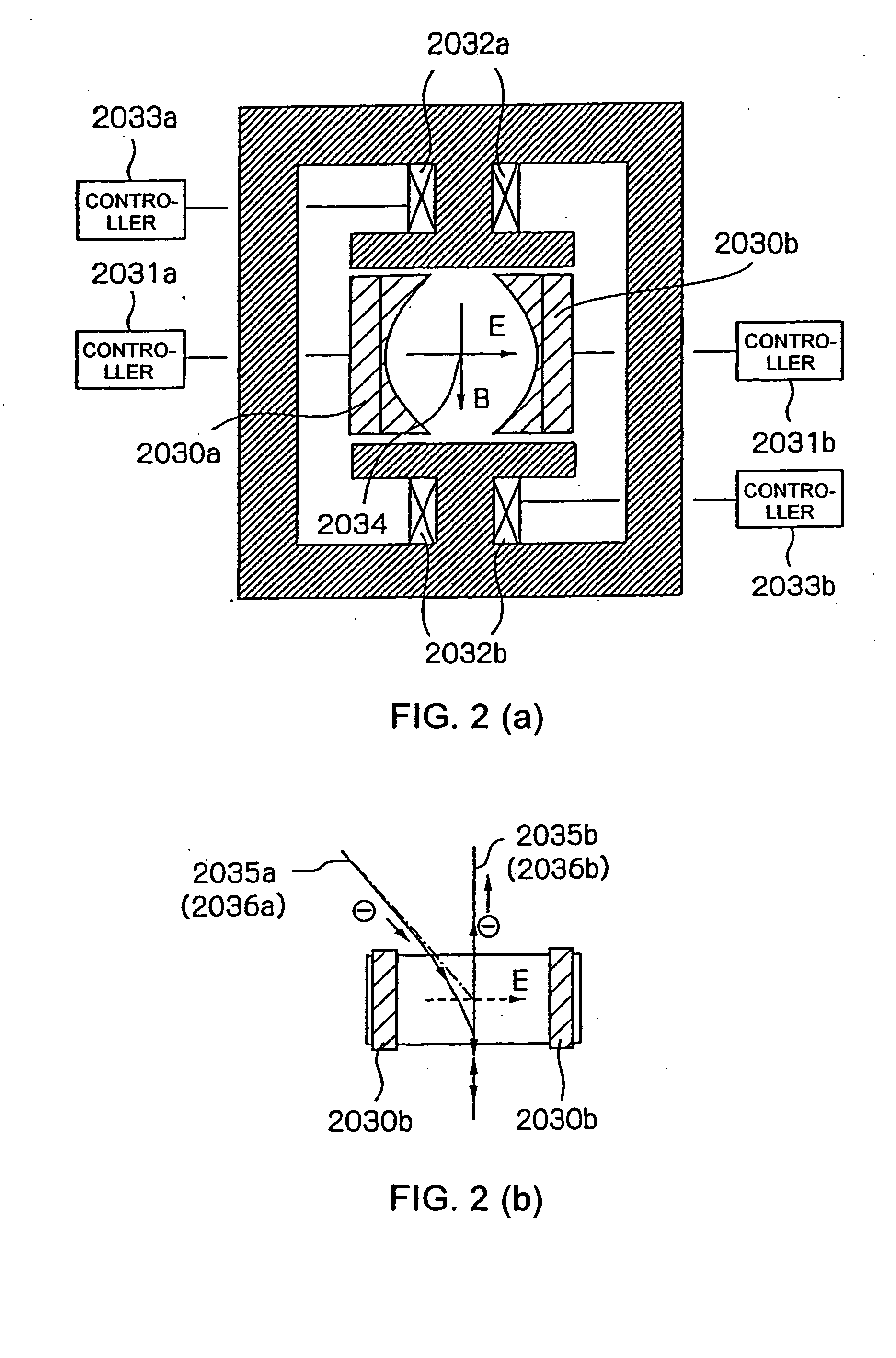

InactiveUS20050092921A1Minimize impactStable processingMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingBeam source

An electron beam apparatus such as a sheet beam based testing apparatus has an electron-optical system for irradiating an object under testing with a primary electron beam from an electron beam source, and projecting an image of a secondary electron beam emitted by the irradiation of the primary electron beam, and a detector for detecting the secondary electron beam image projected by the electron-optical system. Specifically, the electron beam apparatus comprises beam generating means 2004 for irradiating an electron beam having a particular width, a primary electron-optical system 2001 for leading the beam to reach the surface of a substrate 2006 under testing, a secondary electron-optical system 2002 for trapping secondary electrons generated from the substrate 2006 and introducing them into an image processing system 2015, a stage 2003 for transportably holding the substrate 2006 with a continuous degree of freedom equal to at least one, a testing chamber for the substrate 2006, a substrate transport mechanism for transporting the substrate 2006 into and out of the testing chamber, an image processing analyzer 2015 for detecting defects on the substrate 2006, a vibration isolating mechanism for the testing chamber, a vacuum system for holding the testing chamber at a vacuum, and a control system 2017 for displaying or storing positions of defects on the substrate 2006.

Owner:EBARA CORP

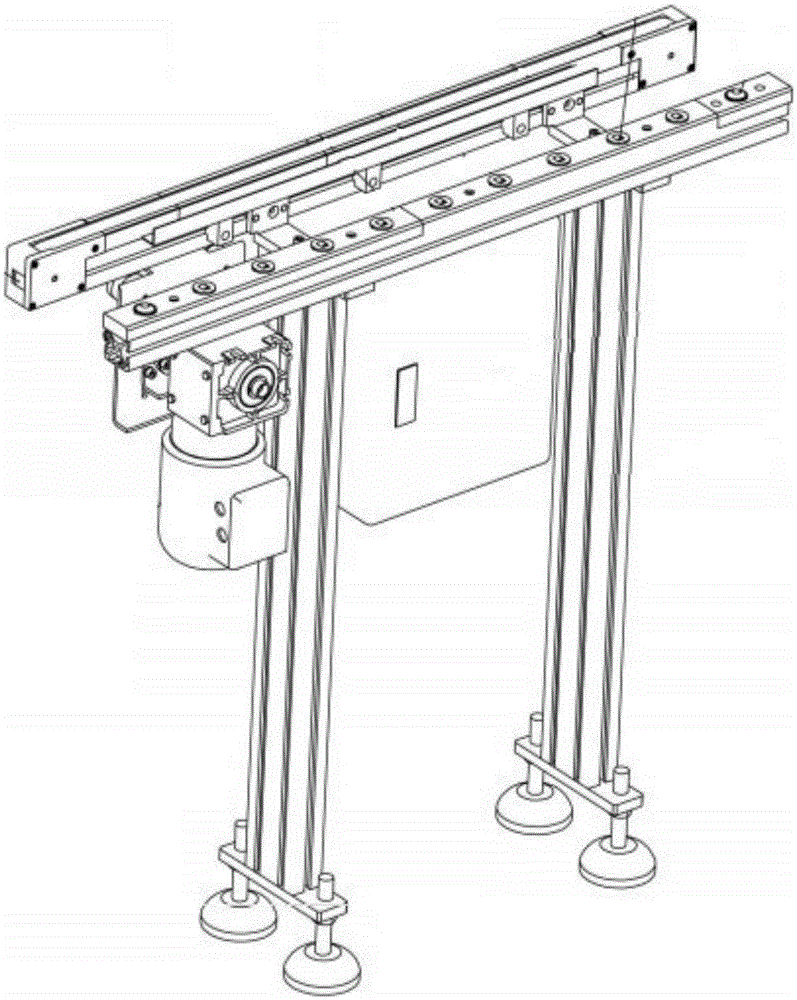

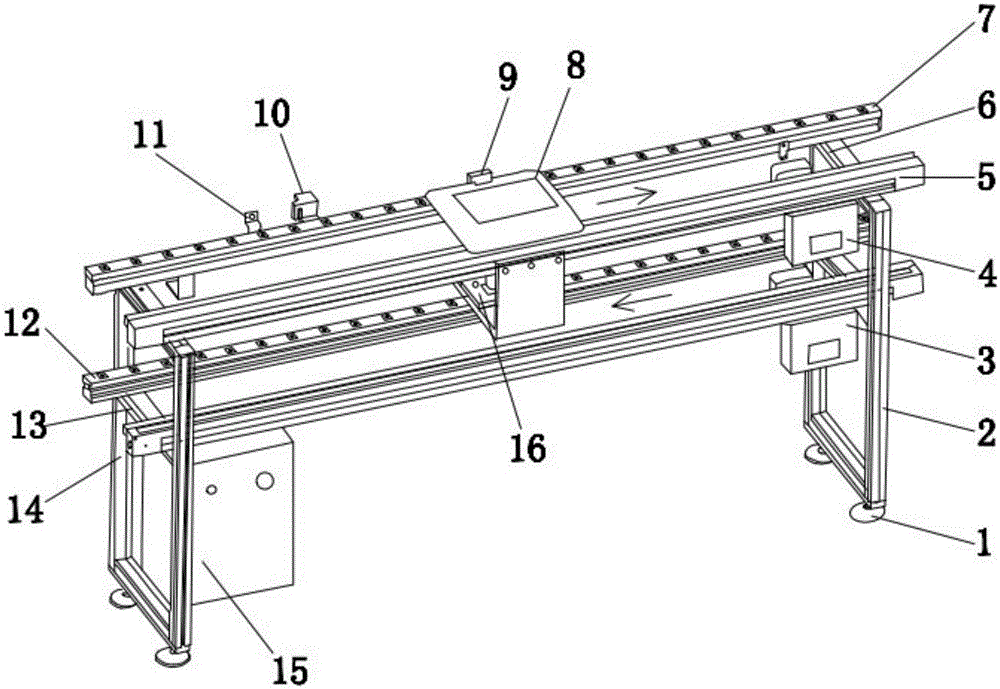

Double-layer belt line provided with jacking module and operating method thereof

InactiveCN105129358AReduced backflow spaceAchieve positioningMechanical conveyorsChinese charactersComputer module

The invention discloses a double-layer belt line provided with jacking module and an operating method thereof. A support in a shape of a Chinese character 'ri' is arranged at two ends of the belt line respectively, the two supports in the shapes of the Chinese characters 'ri' are placed oppositely, and belt line bodies are erected at the positions of two cross beams connected with the upper portions of the supports in the shapes of the Chinese characters 'ri' to form a double-layer belt line structure. The double-layer belt line comprises an upper-layer belt conveying line and a lower-layer belt conveying line, wherein the upper-layer belt conveying line is used for conveying trays loaded with products and enabling the trays loaded with the products to be moved to the tail portion of the line, and the lower-layer belt conveying line is used for conveying the empty trays back to the head portion of the line. The jacking module connected with the trays is arranged under the trays, and an extensible device is arranged on the jacking module, and the trays can be upwards jacked up or put down. Two sensors and two stoppers are arranged on the upper-layer belt conveying line of the double-layer belt line, and the phenomenon that mutual bump of the trays influences product processing can be avoided. Intelligent belt line design is adopted, so that product processing is smooth, and the working efficiency of the whole belt line is improved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

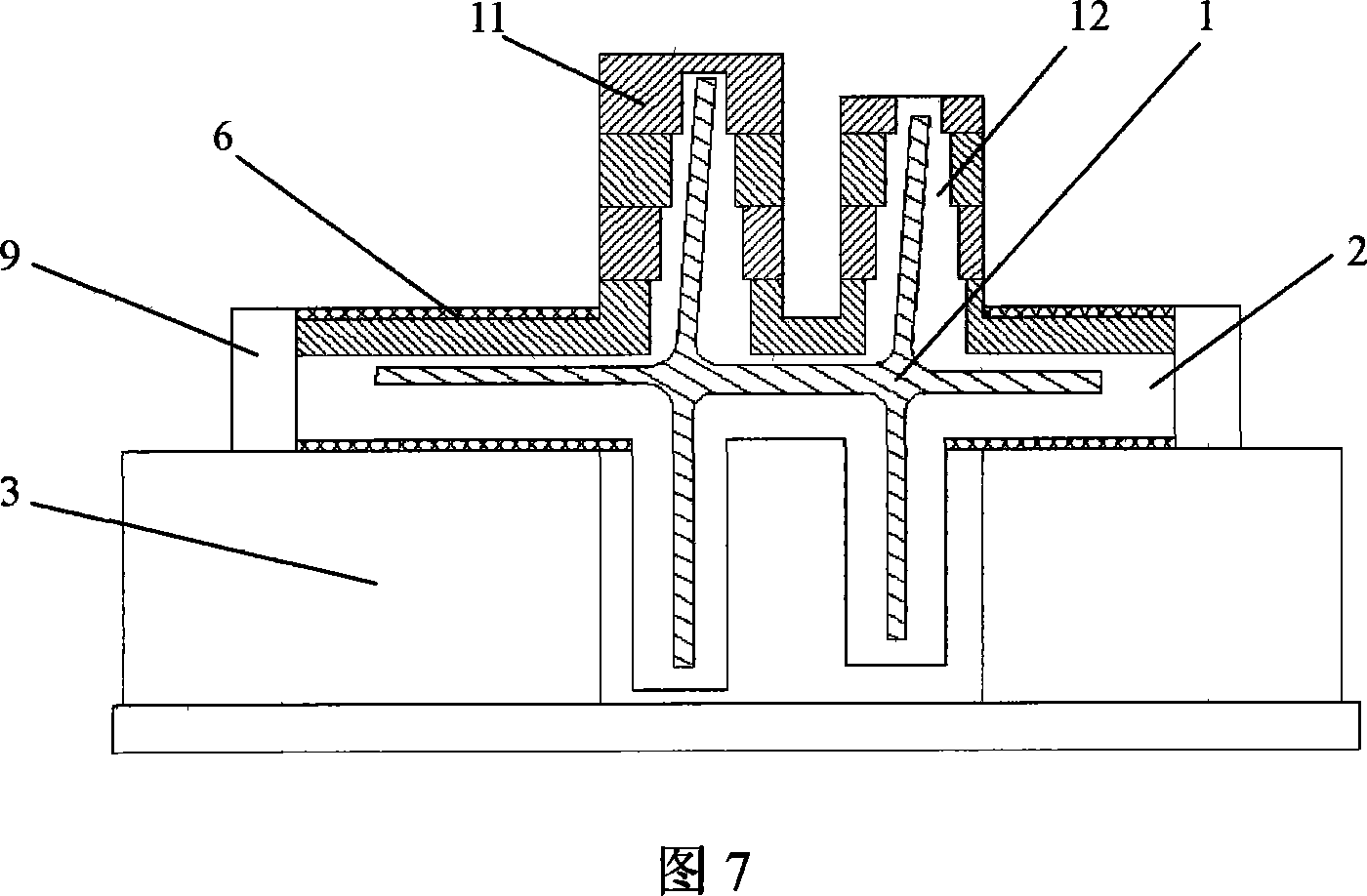

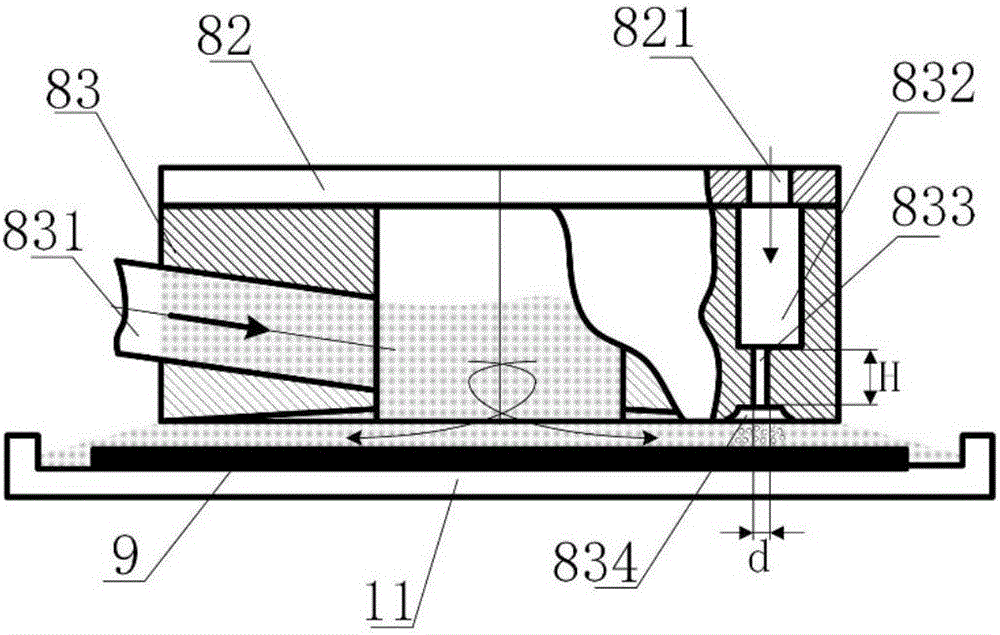

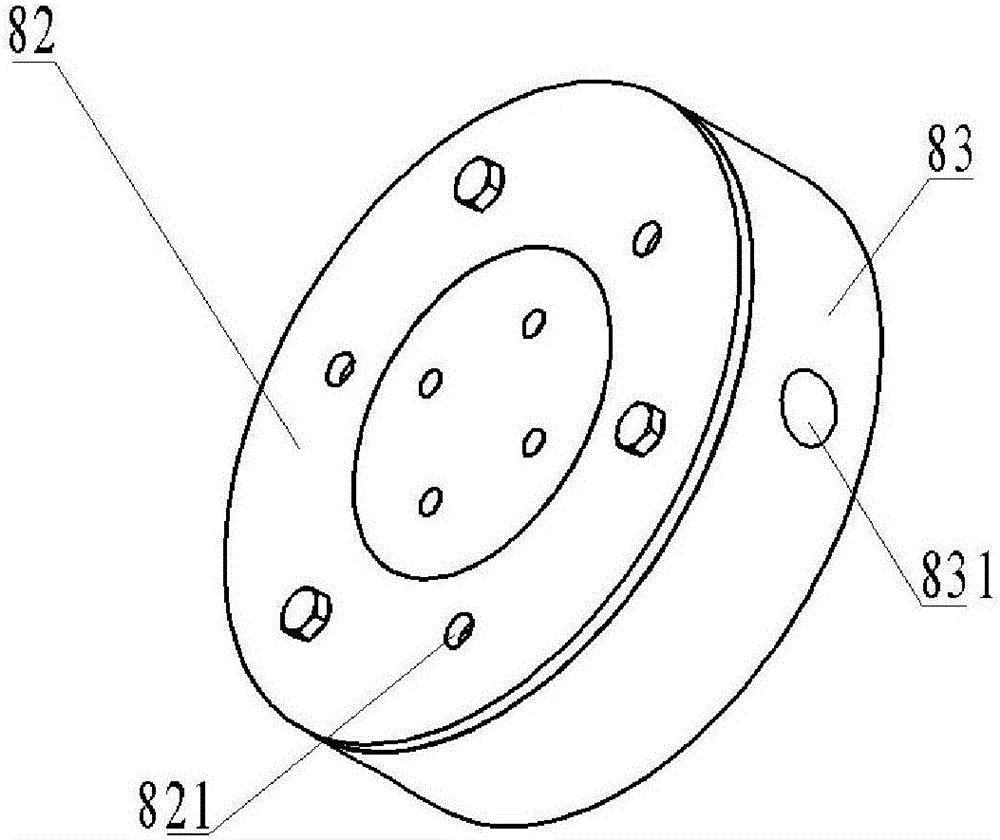

Efficient fluid finishing method and device based on structure cavitation effect

ActiveCN106392863ACollapse drive effect is obviousSimple structureEdge grinding machinesPolishing machinesBubble cavitationWear particle

The invention discloses an efficient fluid finishing method based on the structure cavitation effect. According to the efficient fluid finishing method, the Venturi tube cavitation effect is introduced to fluid finishing, strong bubble cavitation action is formed in the effective polishing area formed between a processing tool and a workpiece to be processed by arranging a Venturi tube structure on the processing tool, and the bubble cavitation action is utilized to drive a liquid-solid abrasive flow in the formed effective polishing area to move in a high-speed turbulent vortex mode to achieve processing on the surface of the workpiece to be processed through abrasive particles. According to the efficient fluid finishing method based on the structure cavitation effect, the Venturi tube structure is utilized to achieve growth and collapse of bubbles in the microspur gap between the processing tool and the workpiece to be processed so as to achieve unordered and high-speed turbulent flow of the abrasive particles; compared with processing equipment adopting ultrasonic waves, the structure is simpler and the cost is lower; and compared with normal bubble-free-collapse processing equipment, the controllability is better, and the bubble collapse driving effect is more obvious.

Owner:ZHEJIANG UNIV OF TECH

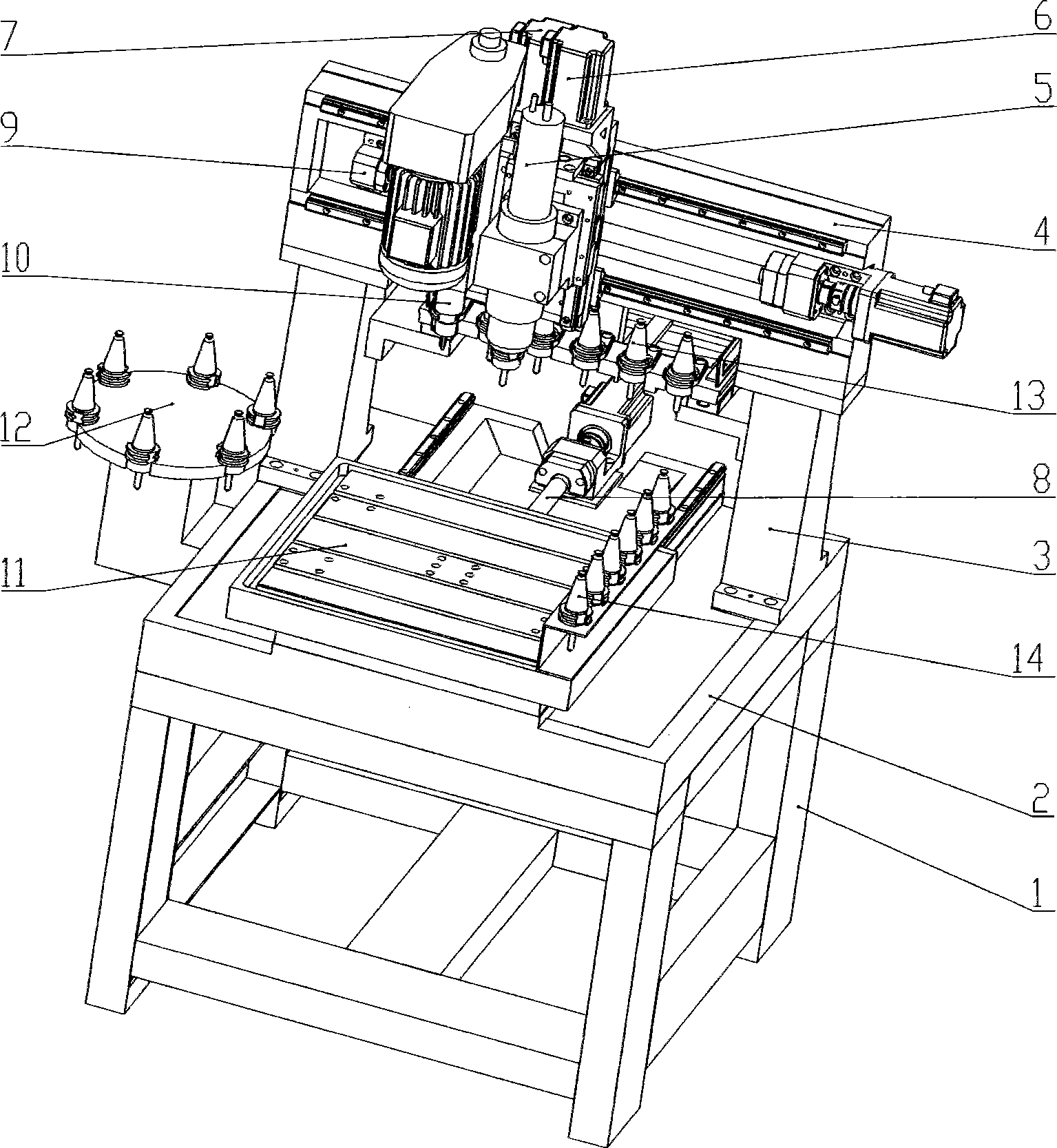

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

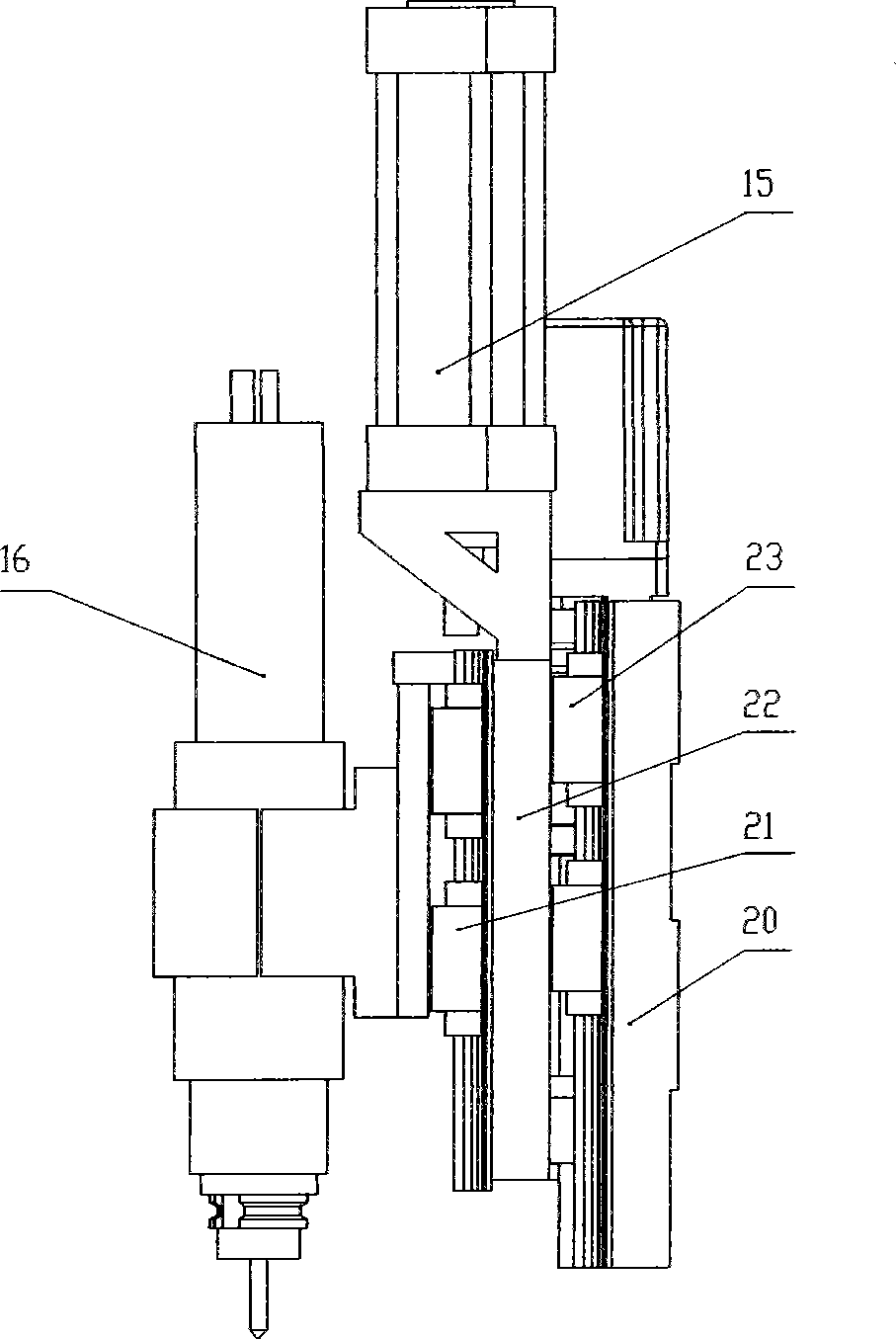

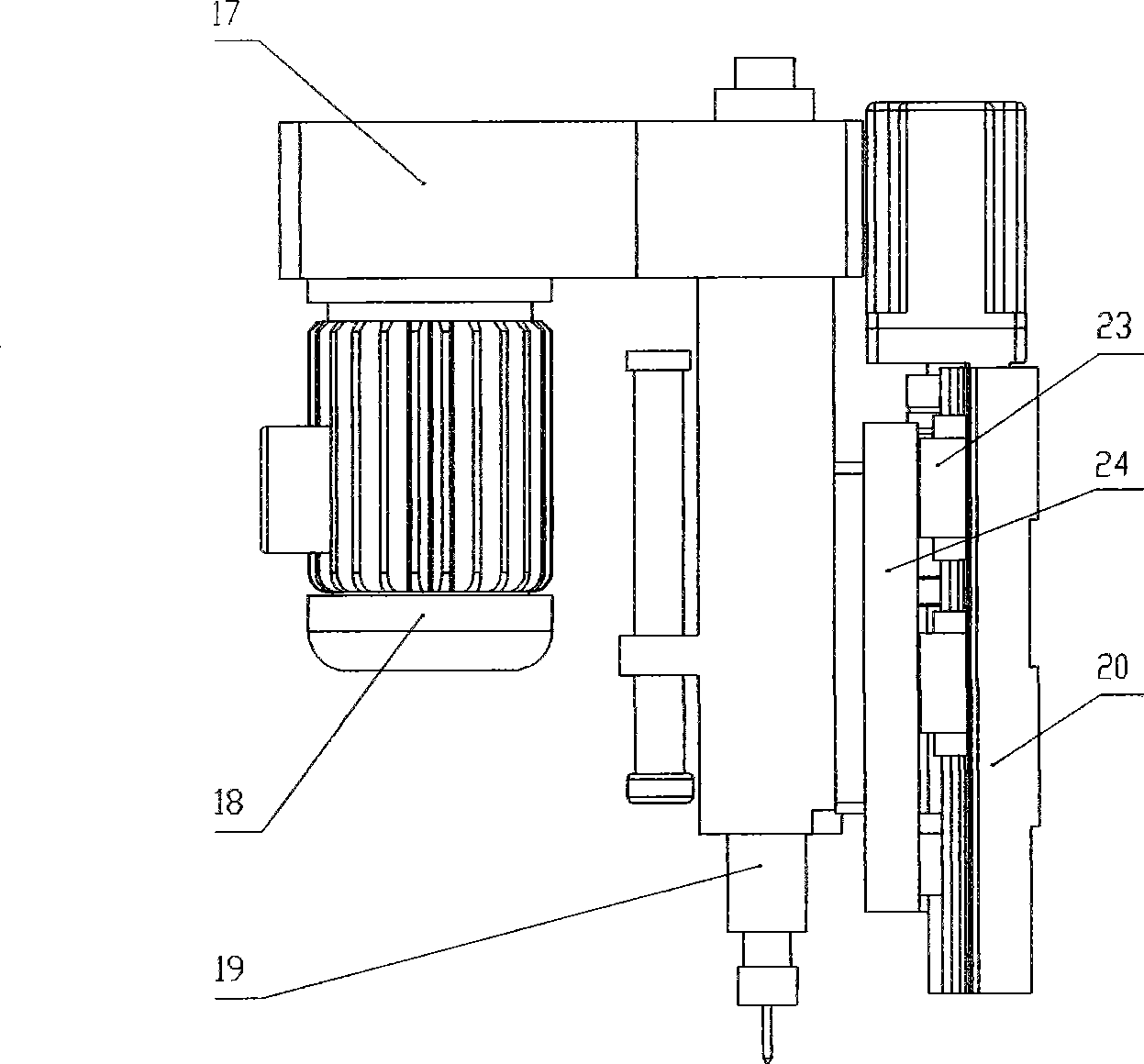

Numerical control machining method of aero-engine disc-shaft integrated structure part

InactiveCN103111814AOne-time submission pass rate increasedStable processingAviationNumerical control

Disclosed is a numerical control machining method of an aero-engine disc-shaft integrated structure part. Main machining processes of the part are four procedures of die forging, rough machining of a big end, rough machining of a small end, vacuum stress relief heat treatment, finish machining of a molded surface of the big end, and finish machining of a molded surface of the small end, and two sets of special clamps are needed. A turn-milling composite machining center with double main shafts is adopted to replace an original ordinary lathe, a numerical control lathe, a five-coordinate machining center and other devices to machine the part, when finish turning machining is carried out, an online measuring function of the turn-milling composite machining center is adopted to carry out part size measurement and automatic compensation of cutter compensation of a cutter, a cutter compensation deviation value is automatically calculated by the numerical control lathe and input into a lathe cutter wear value, the automatic compensation is carried out, and finished size machining of the part is finished. The numerical control machining method of the aero-engine disc-shaft integrated structure part has the advantages that a machining process is stable, quality is improved, once submit qualified rate of the part is obviously improved, single-set machining cycle is reduced by more than 100 hours, production efficiency is improved by 35%, and a solid foundation is laid for machining a part with a homogeneous structure on the turn-milling composite machining center.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Flexible supporting device

ActiveCN104625822AChange the curing strengthStable processingWork clamping meansPositioning apparatusThin walledMagnet

The invention discloses a flexible supporting device which is used for solving the technical problem that as an existing supporting device is low in positioning accuracy, the part machining accuracy is low. According to the technical scheme, the flexible supporting device comprises a left iron core, a left magnet exciting coil, a left wedge-shaped guide container wall, a left supporting plate, a left wedge-shaped block, a right supporting plate, a right wedge-shaped block, a right wedge-shaped guide container wall, a right magnet exciting coil, a right iron core and magnetorheological fluid, and further comprises a machine frame, a left primary positioning device, a right primary positioning device, a displacement sensor, a supporting rod and a direct current voltage stabilizing power source; blades are fixed to the left primary positioning device and the right primary positioning device through a bolt, and the left primary positioning device and the right primary positioning device are fixed to the container walls parallel to the direction of a magnetic field through bolts. The blades are immersed in the magnetorheological fluid, receding deformation, caused by insufficient rigidity of the blades, of the blades in the cutting process is avoided, the positioning accuracy of a complex thin wall part is improved, the rigidity of the complex thin wall part is accordingly improved, and the high-speed and efficient machining accuracy and the machining quality of the complex thin wall part are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

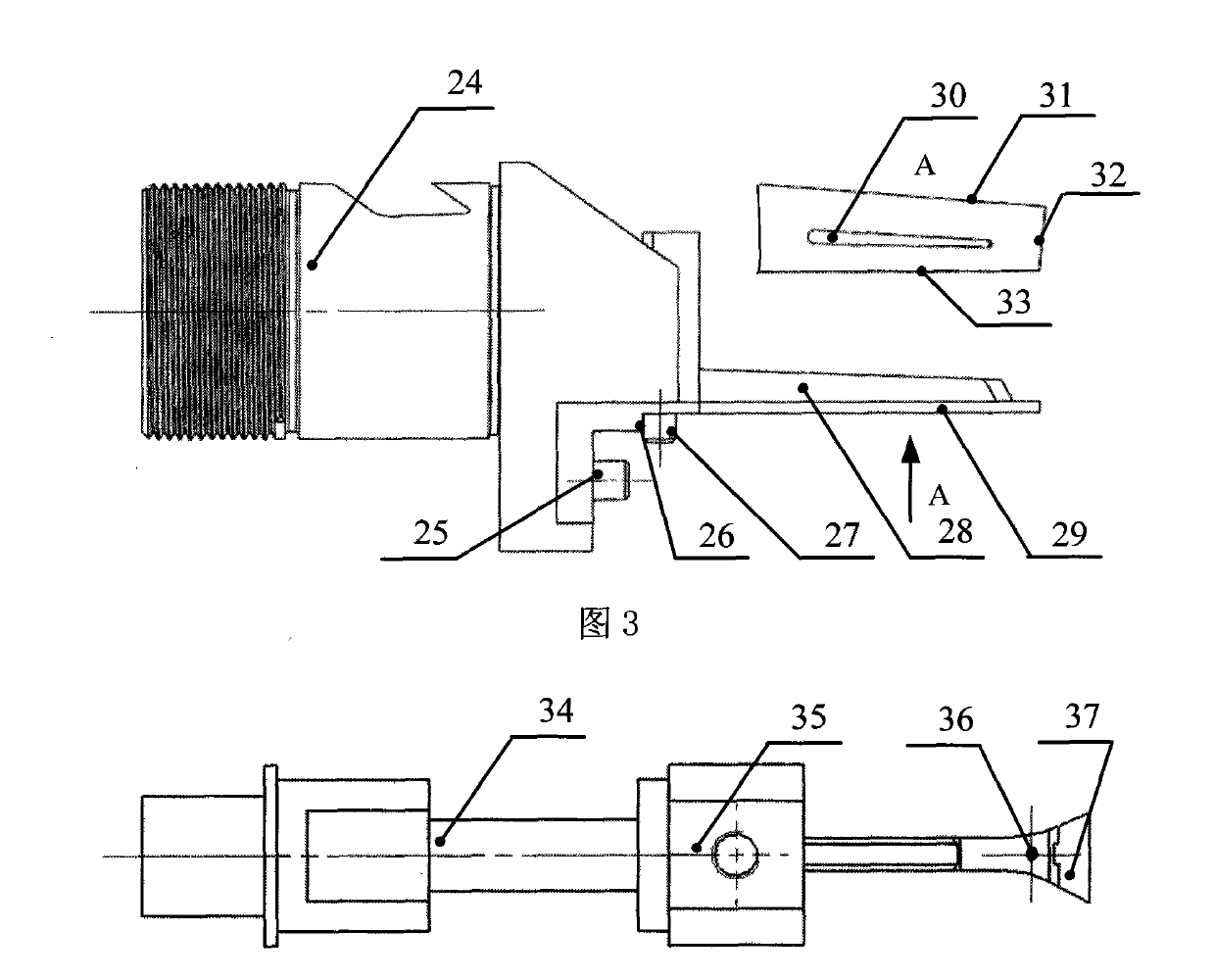

Method for efficient discharge milling with hollow long electrode

InactiveCN1397399AComprehensive effect of efficient processingComprehensive effect of accurate processingMachining electrodesElectrical-based machining electrodesTitanium alloyMachining

A discharge mill technology using simple hollow long electrode is based on the numeral control technique and features use of simple hollow long electrode plus guider. The said electrode features simple cross-section, hollow structure for delivering liquid and high length-radium ratio (more than 3:1). Its advantages are high productivity to Ti-alloy, refrectory alloy and stainless steel.

Owner:苏州中特机电科技有限公司

Polyester drawn textured yarn and production process thereof

The invention discloses a polyester drawn textured yarn, which is continuously produced by polyester. The polyester drawn textured yarn is characterized in that the specification is 75D / 288F, and a product has excellent performance. The invention also discloses production process thereof, which comprises the following steps of: performing esterification reaction on pure terephthalic acid and glycol serving as raw materials; then performing pre-polycondensation and final polycondensation to prepare polyester melt for direct spinning; and adopting a POY-DTY circular blast cooling process route, wherein the viscosity of the prepared polyester melt is 0.650. The production process has the advantages of reasonable process, good fiber spinnability, excellent physical indexes, few broken filaments and broken ends, high switching success ratio, 95 percent of full-package rate, smooth subsequent processing, light and soft texture and good style of woven fabrics, and application in fabrics and linings of high-grade down jackets and fabrics of sportswear and casual wear.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

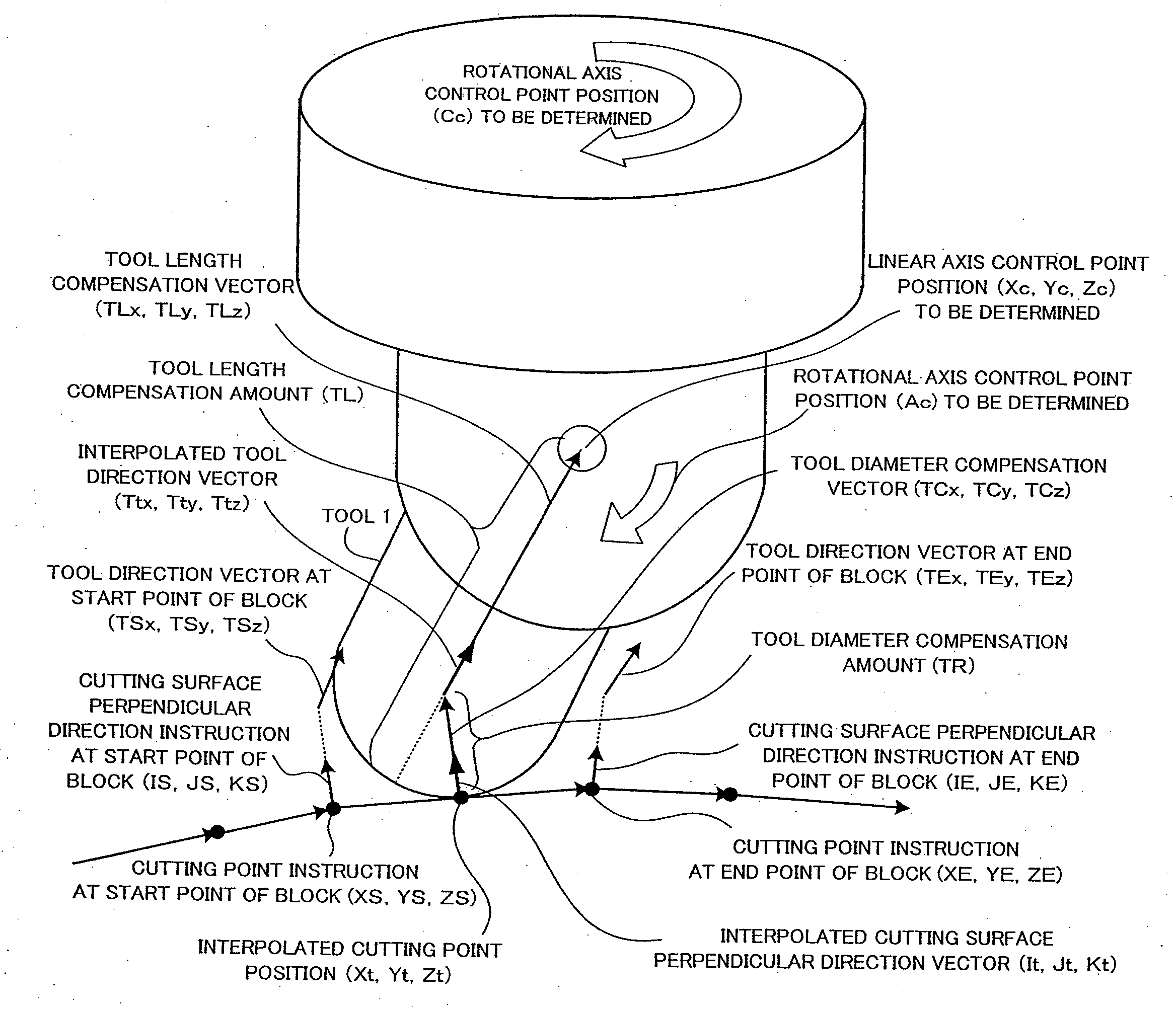

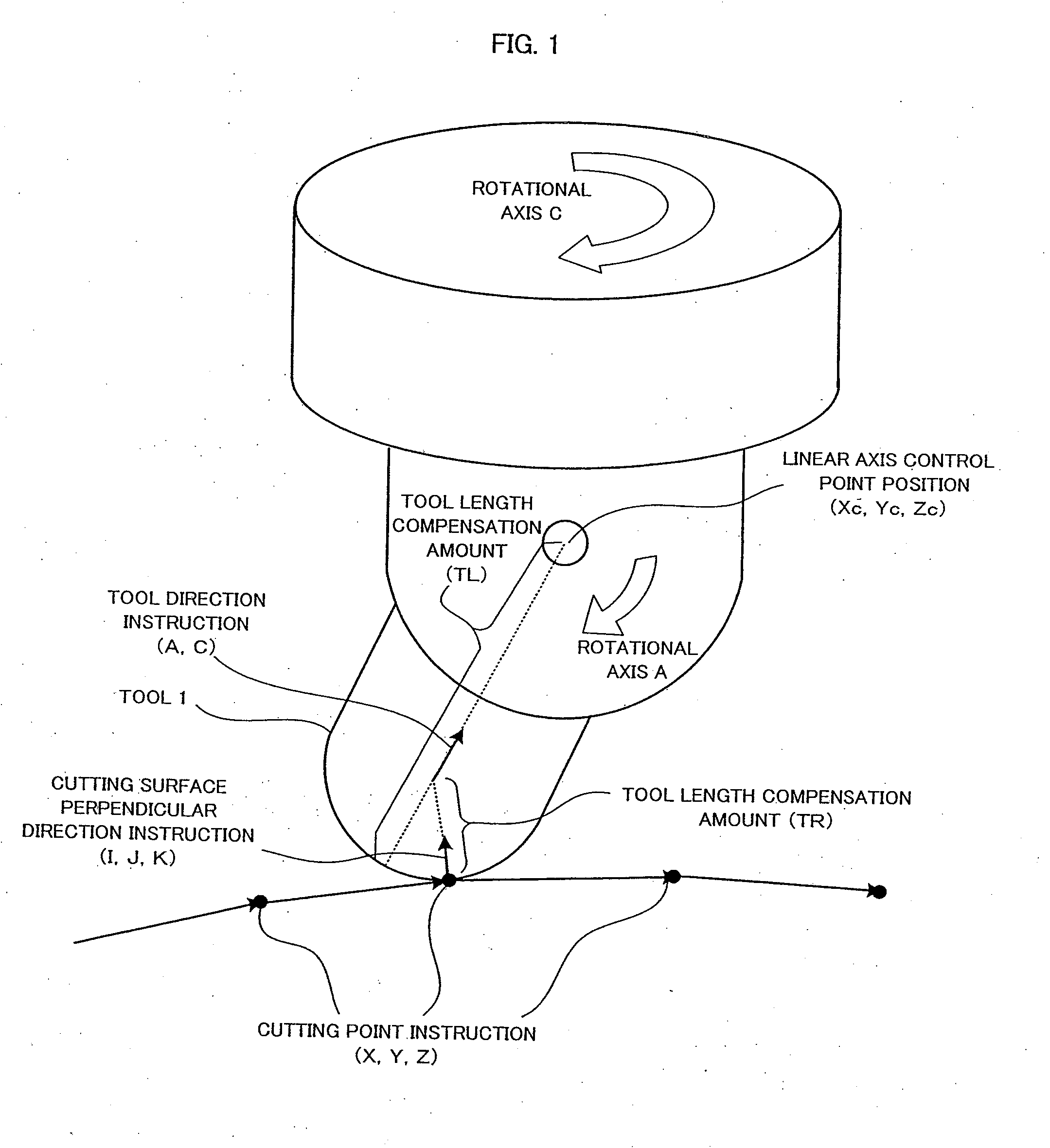

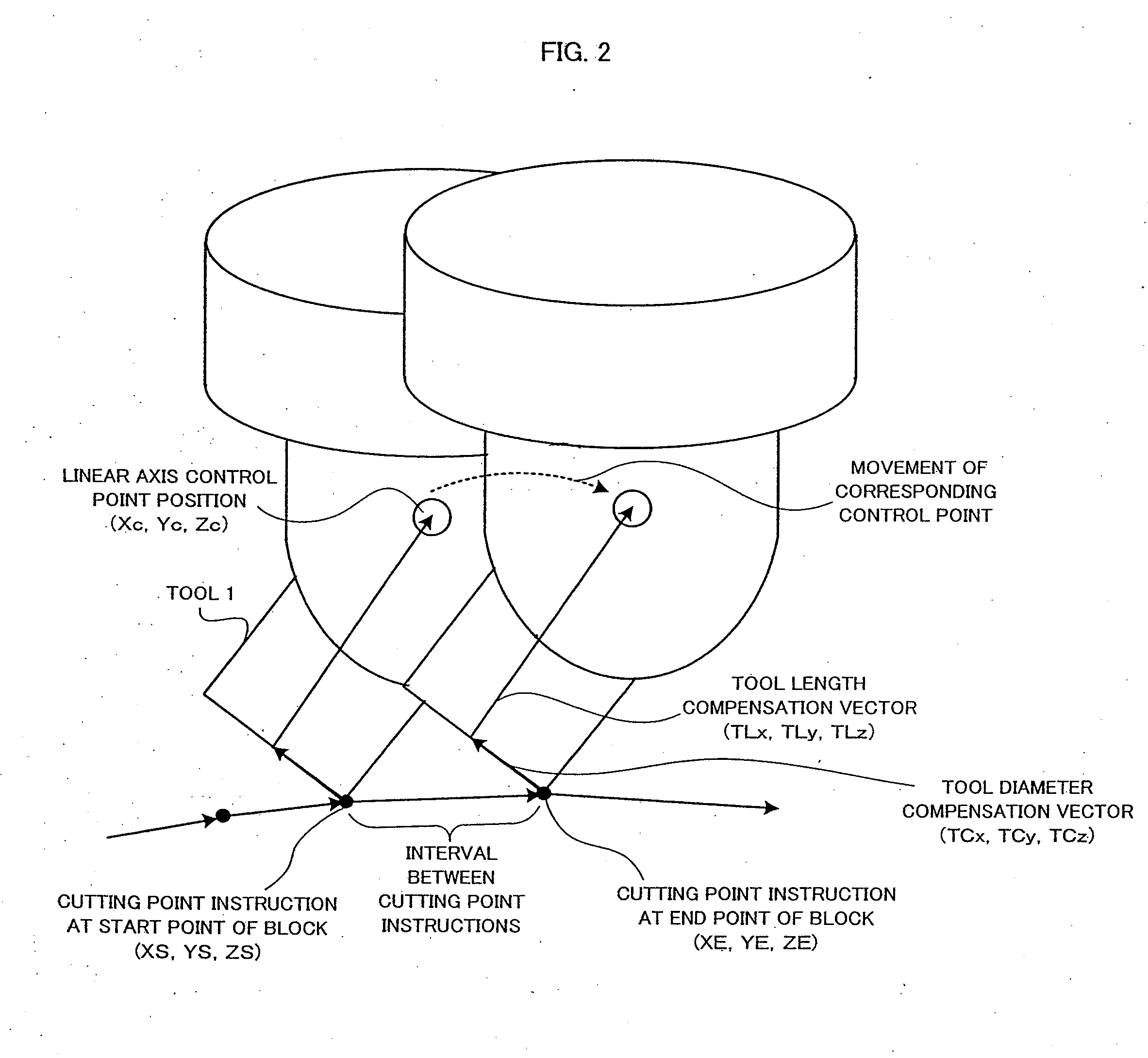

Numerical control method for five-axis processing machine

ActiveUS20080288103A1Avoid erratic movementMore processedSpecial data processing applicationsNumerical controlNumerical controlEngineering

If the angle α formed between the interpolated cutting surface perpendicular direction vector (It, Jt, Kt) and the interpolated tool direction vector (Ttx, Tty, Ttz) becomes smaller, movement of a tool becomes unstable. In this case, the tool diameter compensation vector (TCx, TCy, TCz) is set to the tool diameter compensation vector calculated in the immediately previous interpolation cycle, thereby preventing unstable movement. Further, in case of a block instruction where a distance between positions in cutting point instructions is large whereas distance of movement of linear axis control point is small, an excessive cutting may occur. To deal with this problem, movement of linear axis control point in a current block is stopped or converted into linear movement so as to prevent a loop-shaped movement of the linear axis control point.

Owner:FANUC LTD

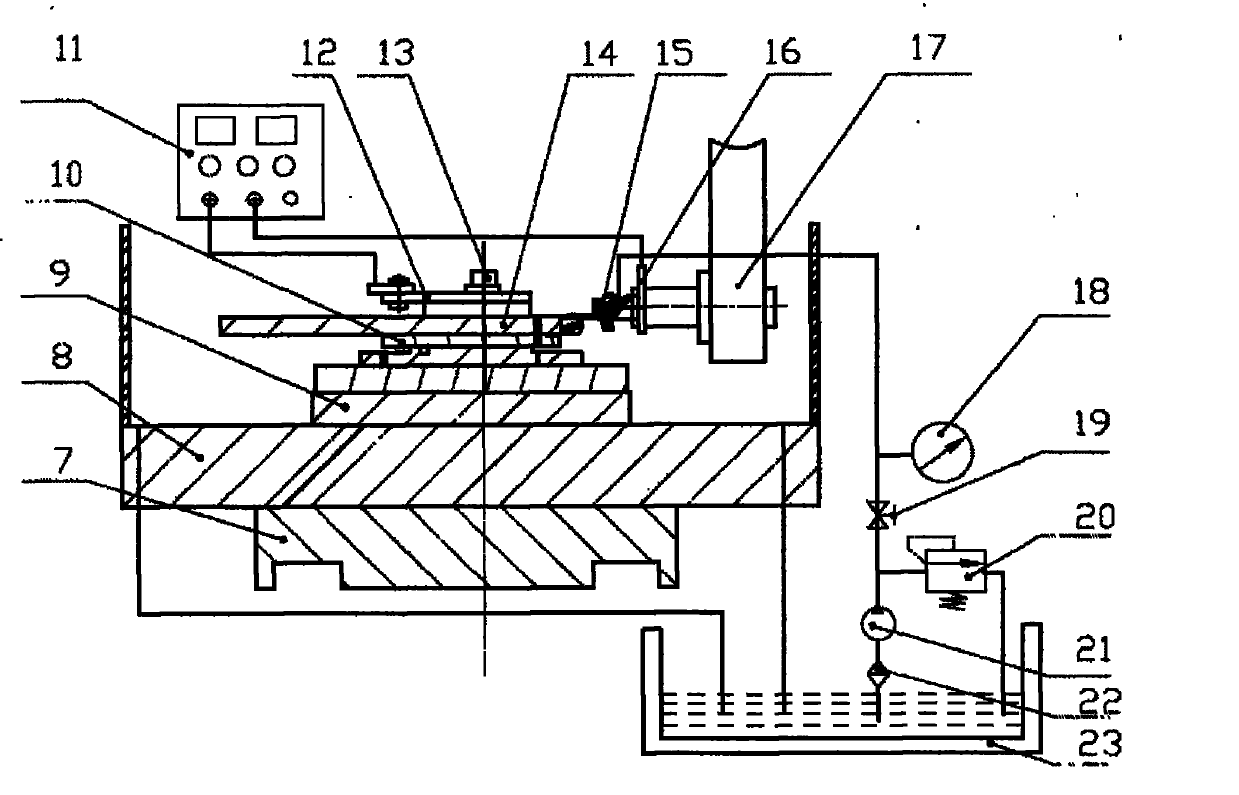

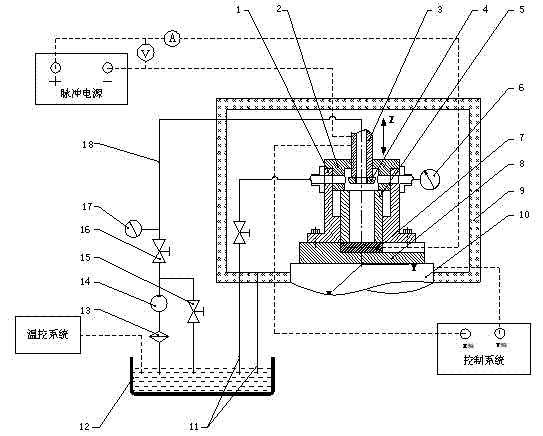

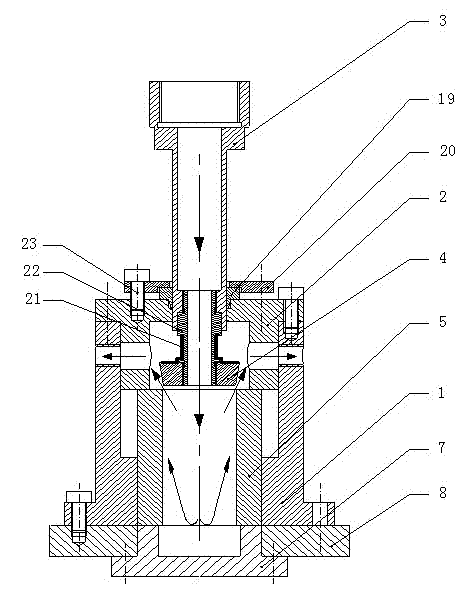

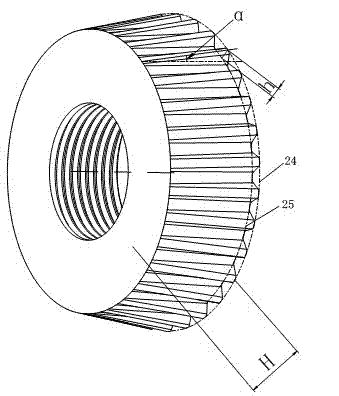

Electrolytic machining method of difficult-to-cut material, fine-module internal gear and device

InactiveCN102896383AIncrease feed rateImprove processing efficiencyMachining electrodesElectrical-based machining electrodesElectrolytic agentEngineering

The invention discloses an electrolytic machining method of a difficult-to-cut material, a fine-module internal gear and a device. The method comprises the following steps that a tool cathode with a top-bottom different shape structure is adopted; the surface of the small end of the tool cathode is circular, and a gap between the tool cathode and a work piece pre-hole is served as an initial machining gap which can ensure that a flow field is stable; the large end of the tool cathode is served as a cathode tooth; a part from the small end to the large end of the tool cathode is smoothly transited to a cathode tooth shape from a circular; a forward flow and backpressure electrolyte flowing mode is adopted; and electrolyte flows into a hollow channel of a cathode system, further an organic glass cavity with organic pieces is filled with the electrolyte, and then the electrolyte flows out off the gap between the tool cathode and the work piece. The tool cathode adopts a top-bottom different shape structure, can realize three-dimensional feeding, a pre-hole is arranged in a work piece blank, so that a feeding speed of the tool cathode is improved by 5 to 10 times relative to the feeding speed of an end surface during electrolytic machining, a machining process is stable, and the method is beneficial to improvement of machining efficiency and forming accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

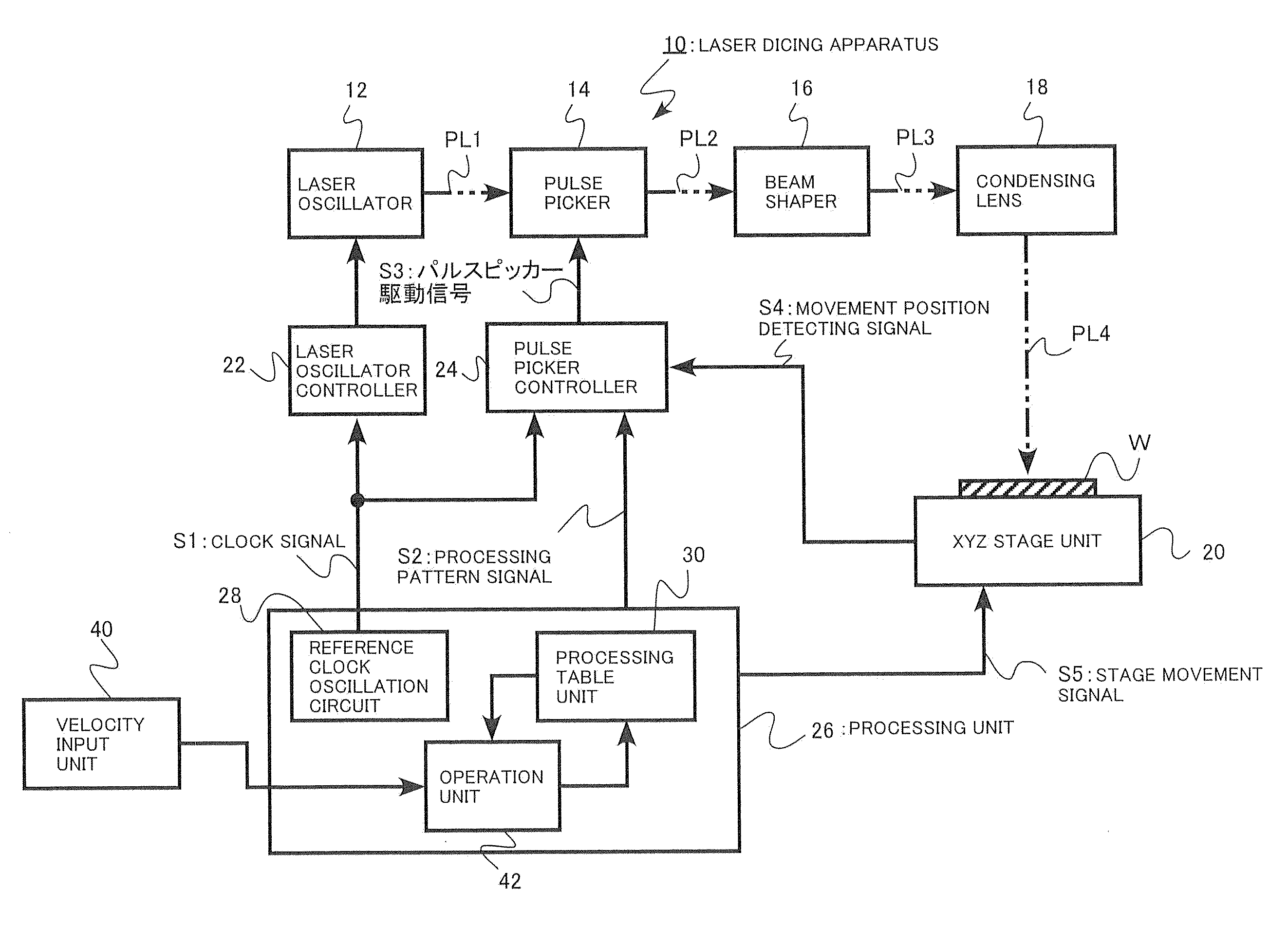

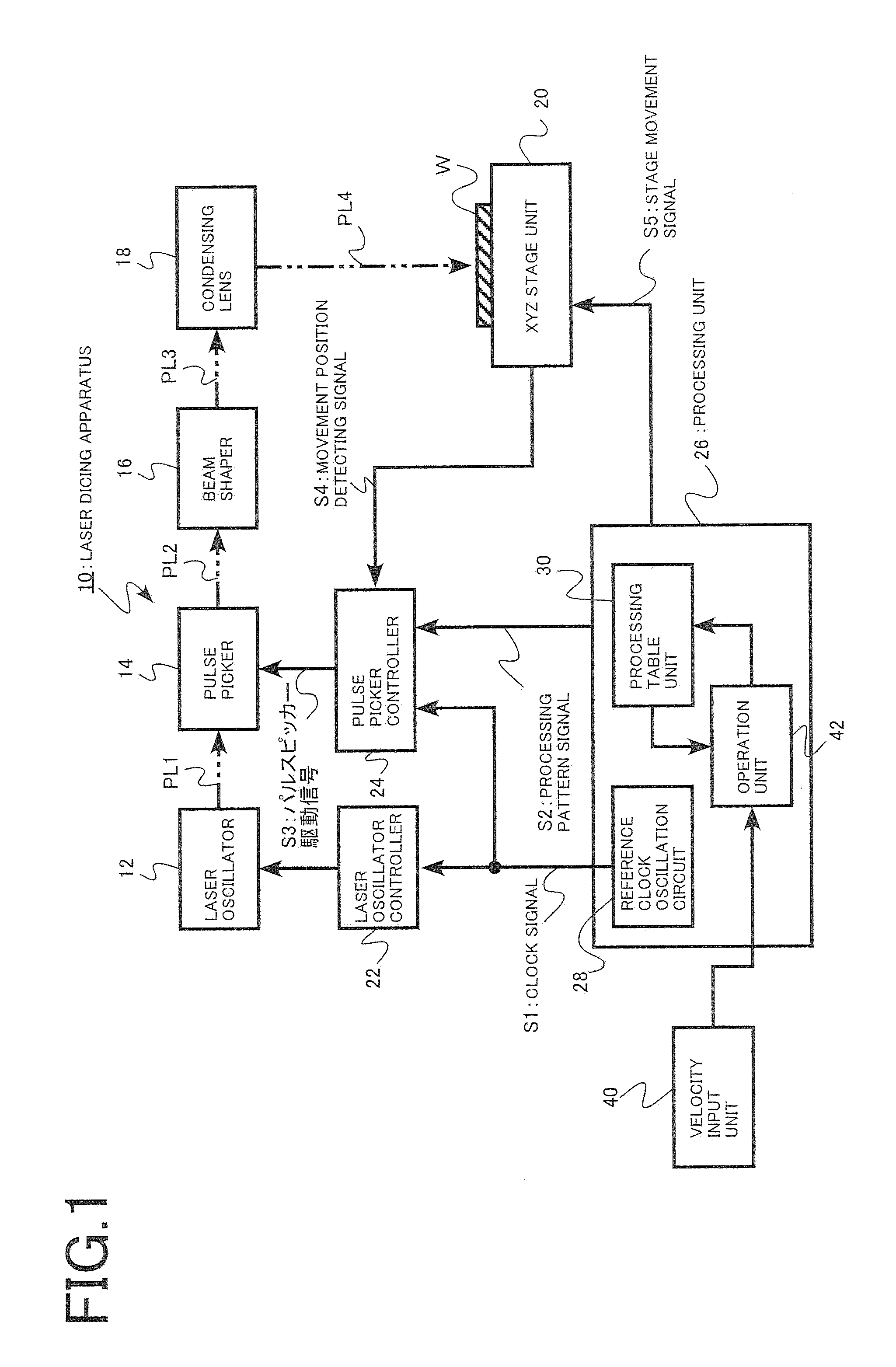

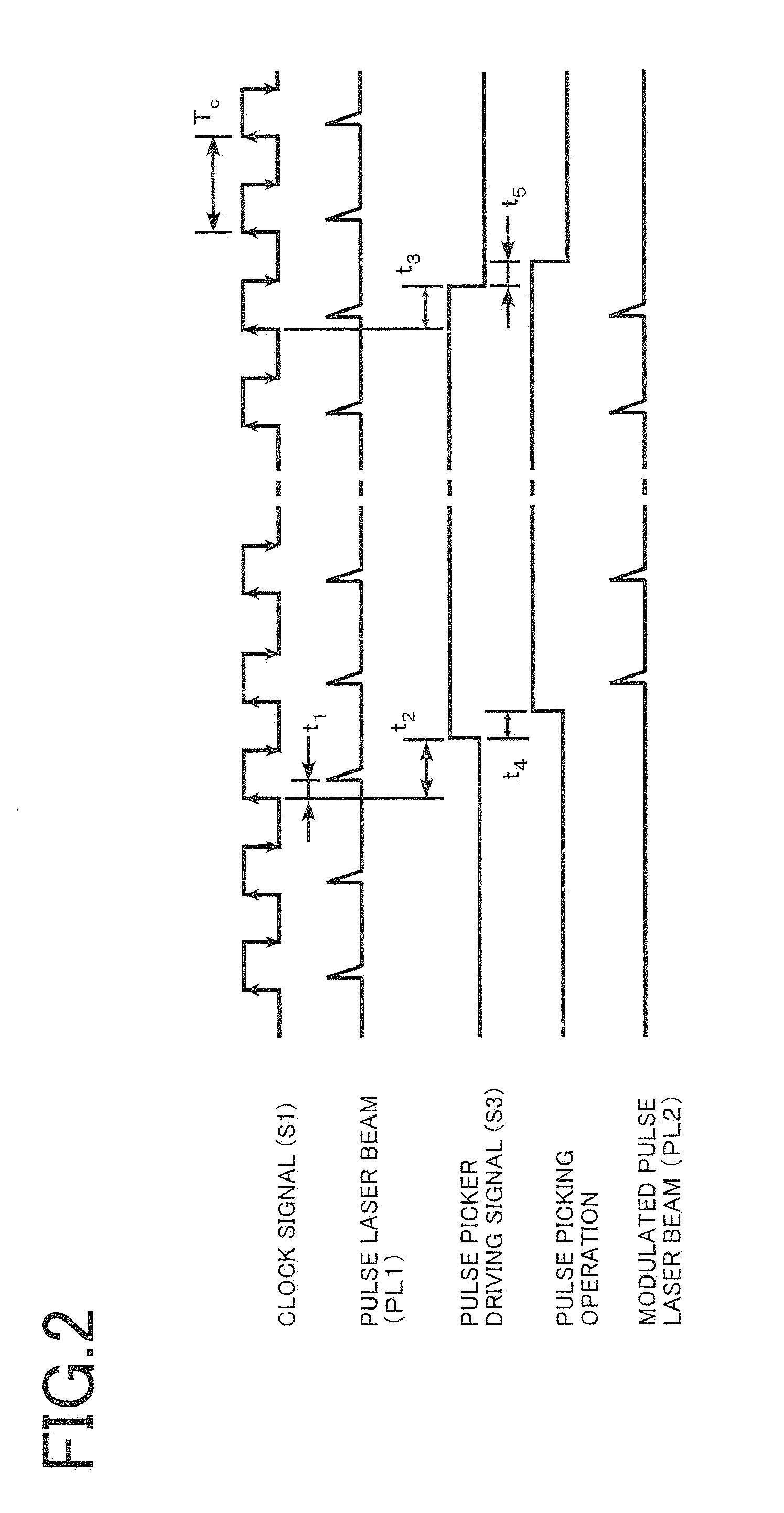

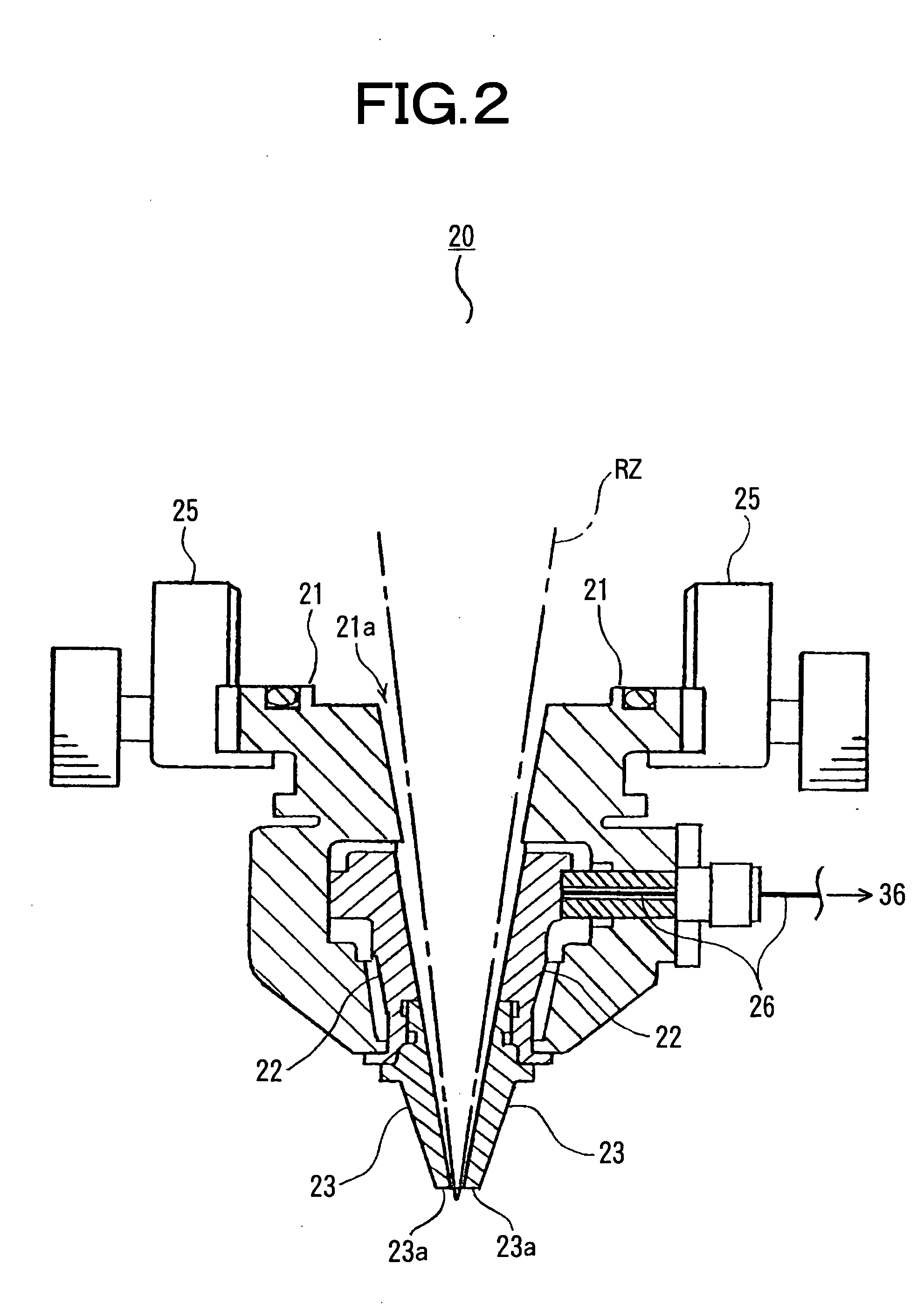

Laser dicing apparatus

InactiveUS20110174787A1Improve cutting performanceStable processingFine working devicesWelding/soldering/cutting articlesLight beamOptoelectronics

A laser dicing device is provided to perform dicing processing that has excellent cutting properties and is stable even when the dicing speed is changed. The laser dicing apparatus includes: a stage; a reference clock oscillation circuit; a laser oscillator that emits a pulse laser beam; a laser oscillator controller that synchronizes the pulse laser beam with the clock signal; a pulse picker that switches irradiation and non-irradiation of the pulse laser beam onto the substrate to be processed; a pulse picker controller that controls pass and interception of the pulse laser beam for each light pulse in synchronization with the clock signal; a processing table unit that stores a processing table in which dicing processing data with respect to a standard relative velocity between the substrate to be processed and the pulse laser beam is written; a velocity input unit that inputs a new set value of a relative velocity; and an operation unit that calculates a new processing table and stores the new processing table into the processing table unit. Based on the new processing table, the pulse picker controller controls pass and interception of the pulse laser beam.

Owner:TOSHIBA MASCH CO LTD

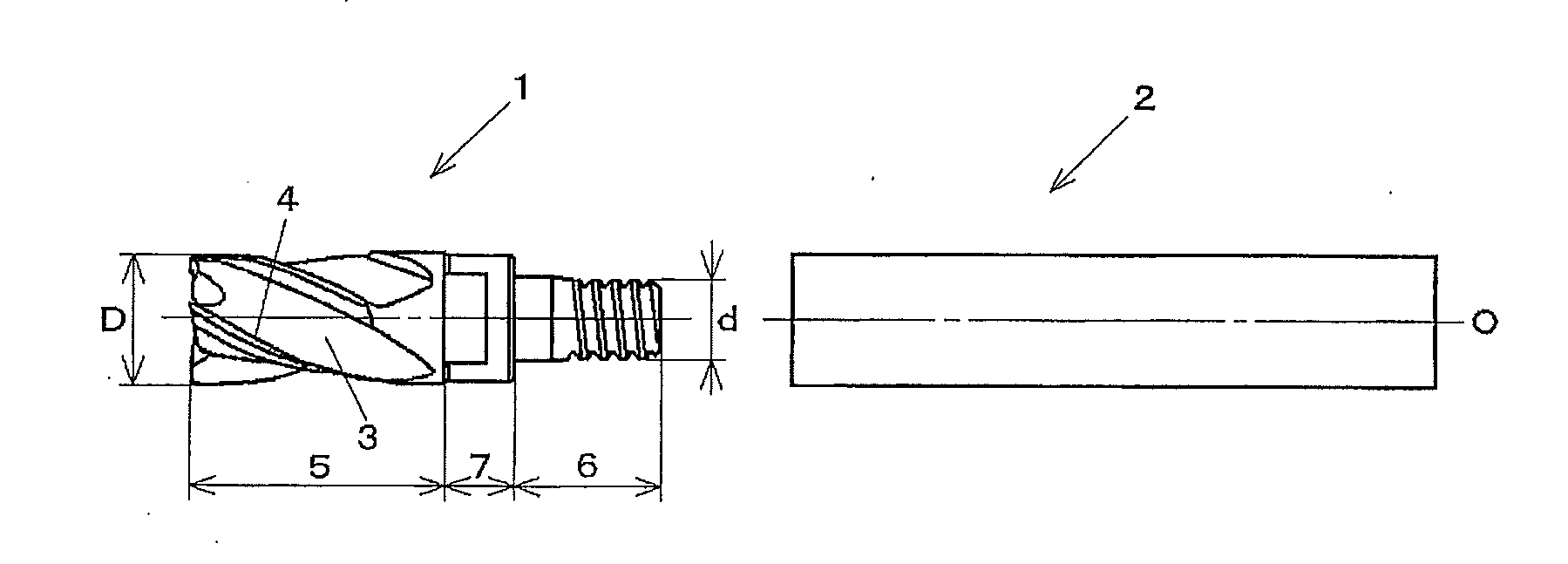

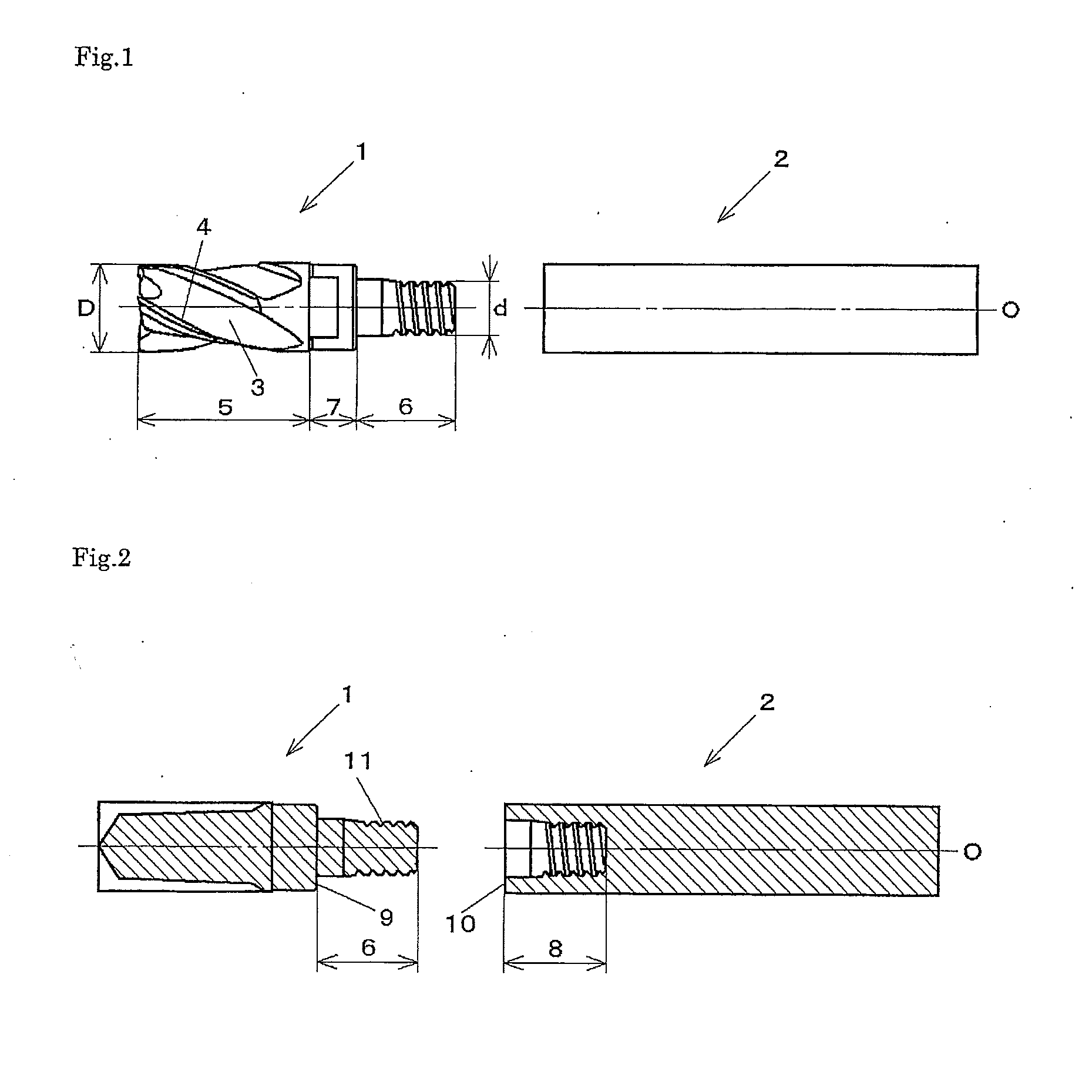

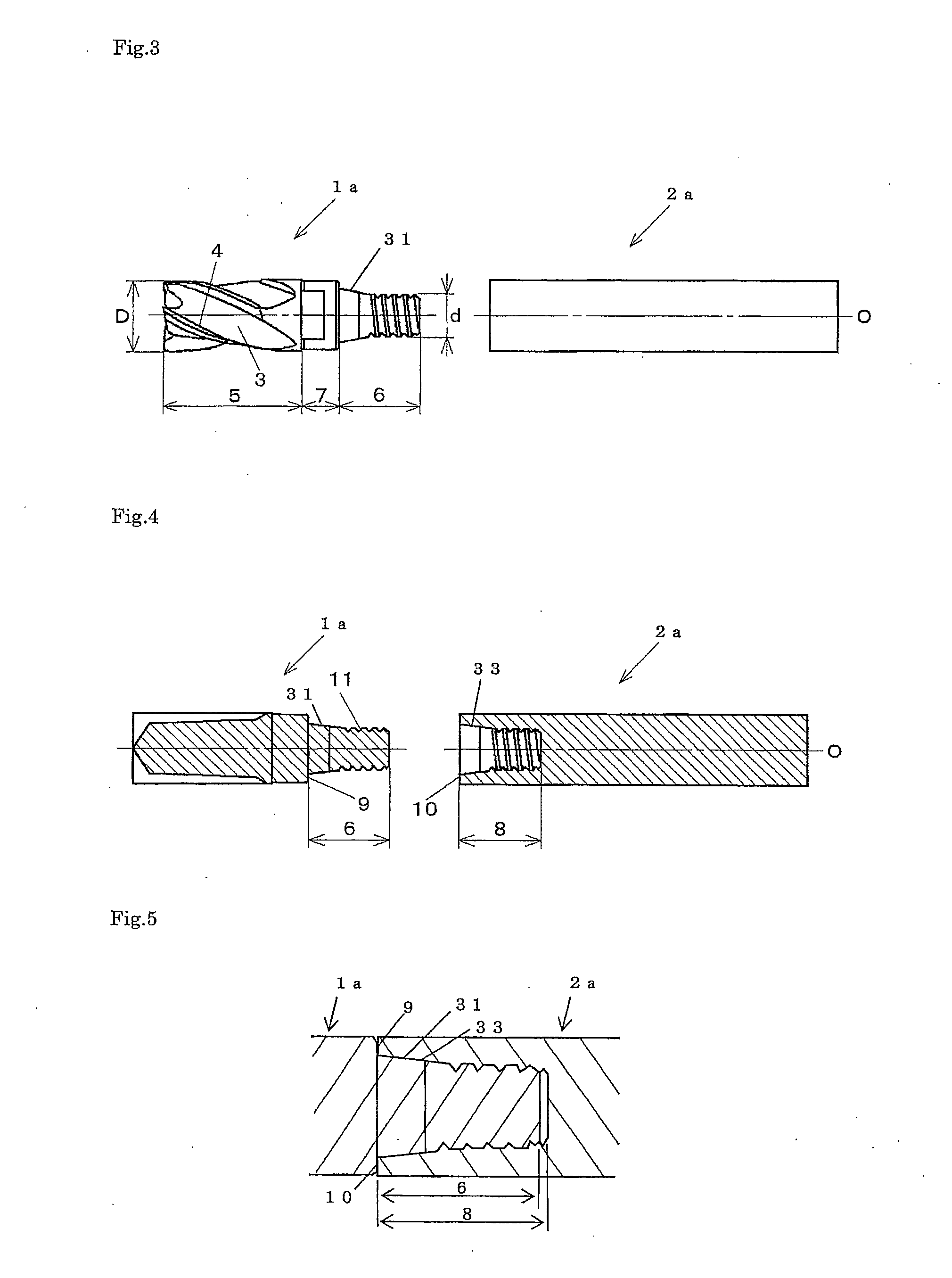

Machining head, holder and exchangeable tip cutting tool

InactiveUS20150063928A1Efficient cuttingDamage suppressionTool workpiece connectionMilling cuttersTool bitEngineering

Provided are: an exchangeable tip cutting tool in which breakage of the threaded section and breakage of the thread ridges during installation of the machining head and under increased cutting load during cutting are limited and which is capable of performing machining with high efficiency; and a machining head and a holder to be used in the exchangeable tip cutting tool. The flank angle (α) of the pressure flank (11) is set to be larger than the flank angle (β) of the clearance flank (12); and a holder (2, 2a) having a female threaded fastening section (8) wherein the angle of the screwing surface of the pressure flank is set to be larger than the angle of the screwing surface of the clearance flank.

Owner:HITACHI TOOL ENG LTD

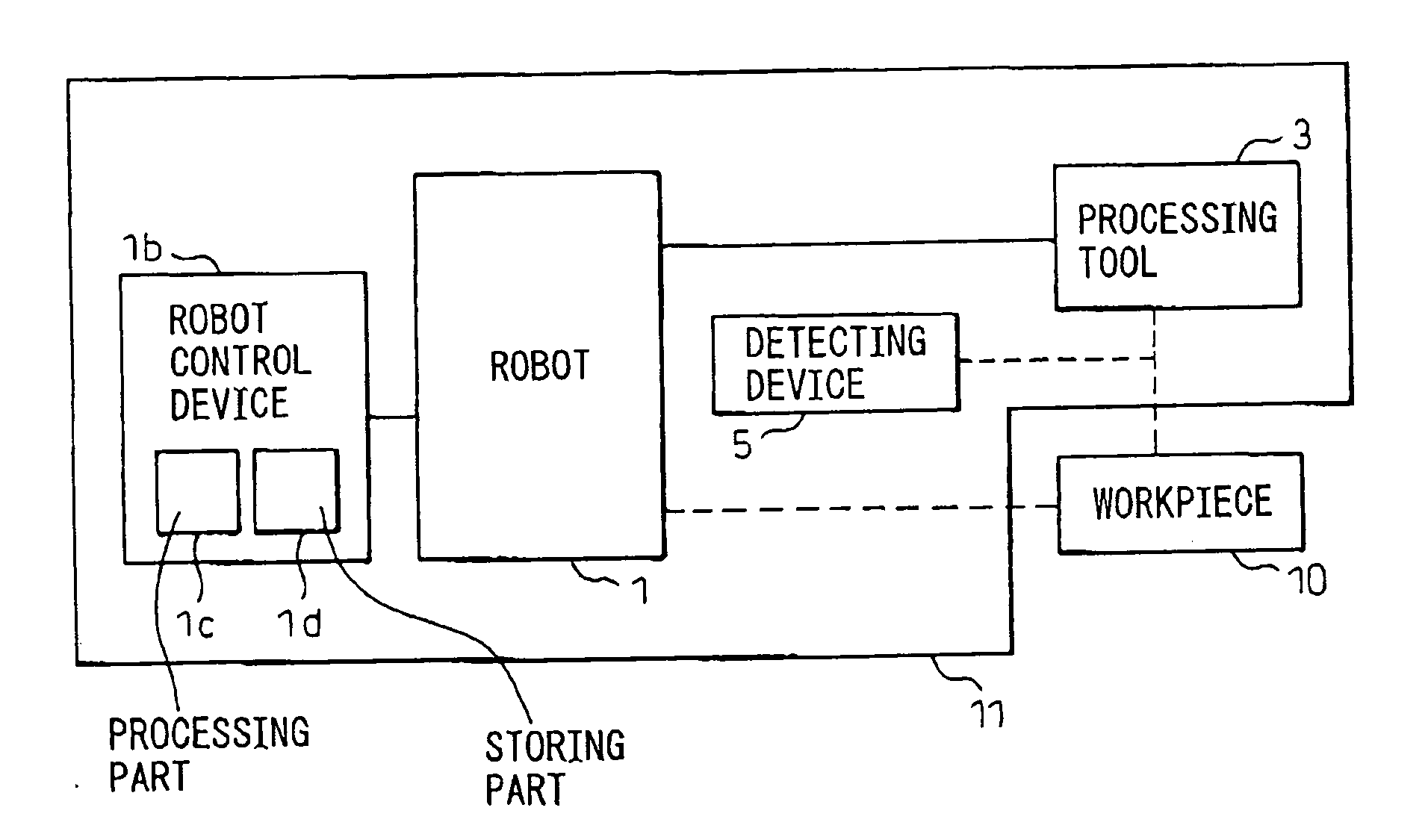

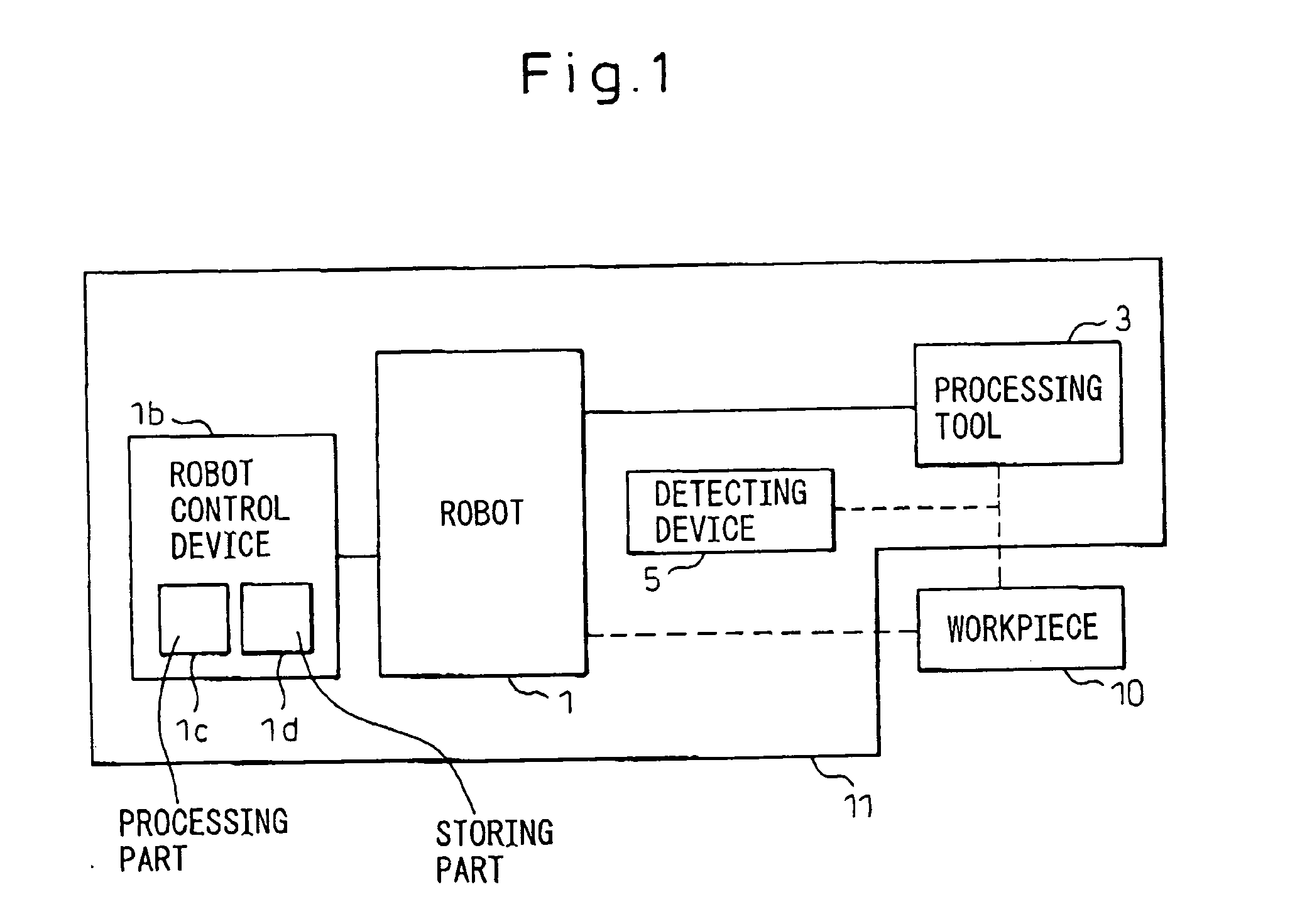

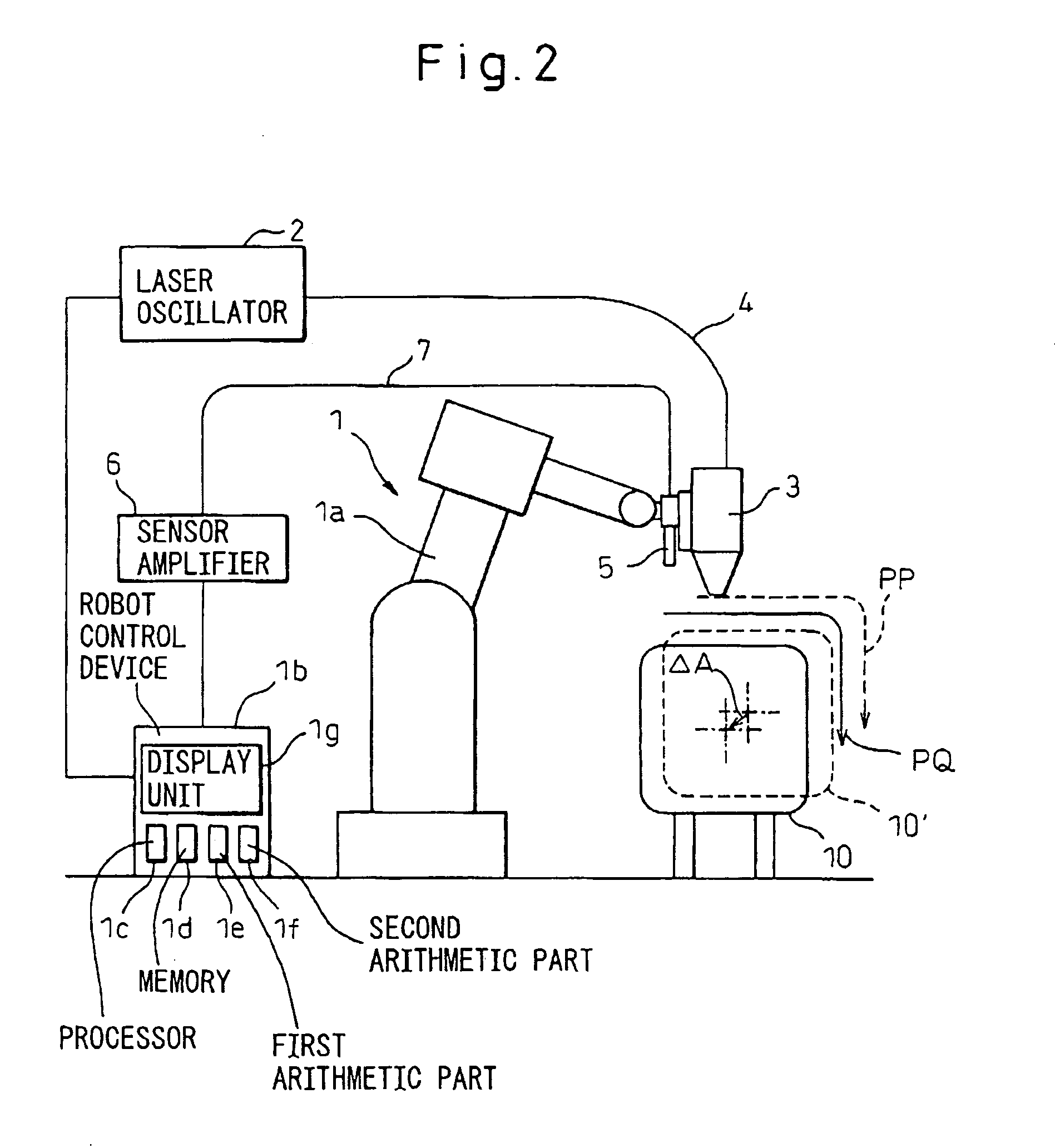

Processing system

InactiveUS20050143861A1Stable processStable processingProgramme-controlled manipulatorComputer controlDistance sensorsHead parts

A processing system for stably processing a workpiece even if the shape of the workpiece changes every production lot of the workpiece, or by a change of the workpiece. The distance between the workpiece and an end of a nozzle of a laser machining head is measured by a distance sensor. A data correcting value ΔZ′mn is calculated using a measured distance ΔZrn at each teaching point and a set gap value ΔZs (step S6-S15). By using ΔZ′mn, the data of the teaching points are corrected to new data of the teaching points of the program (step S16-S19). The distance between the workpiece and the end of the nozzle of the laser machining head does not become larger because the teaching points of the processing program are corrected every time when the workpiece is processed. The interference between the workpiece and the head may be prevented and the processing may be stably implemented because the amount of correction becomes smaller when the position of the head is corrected during the processing.

Owner:FANUC LTD

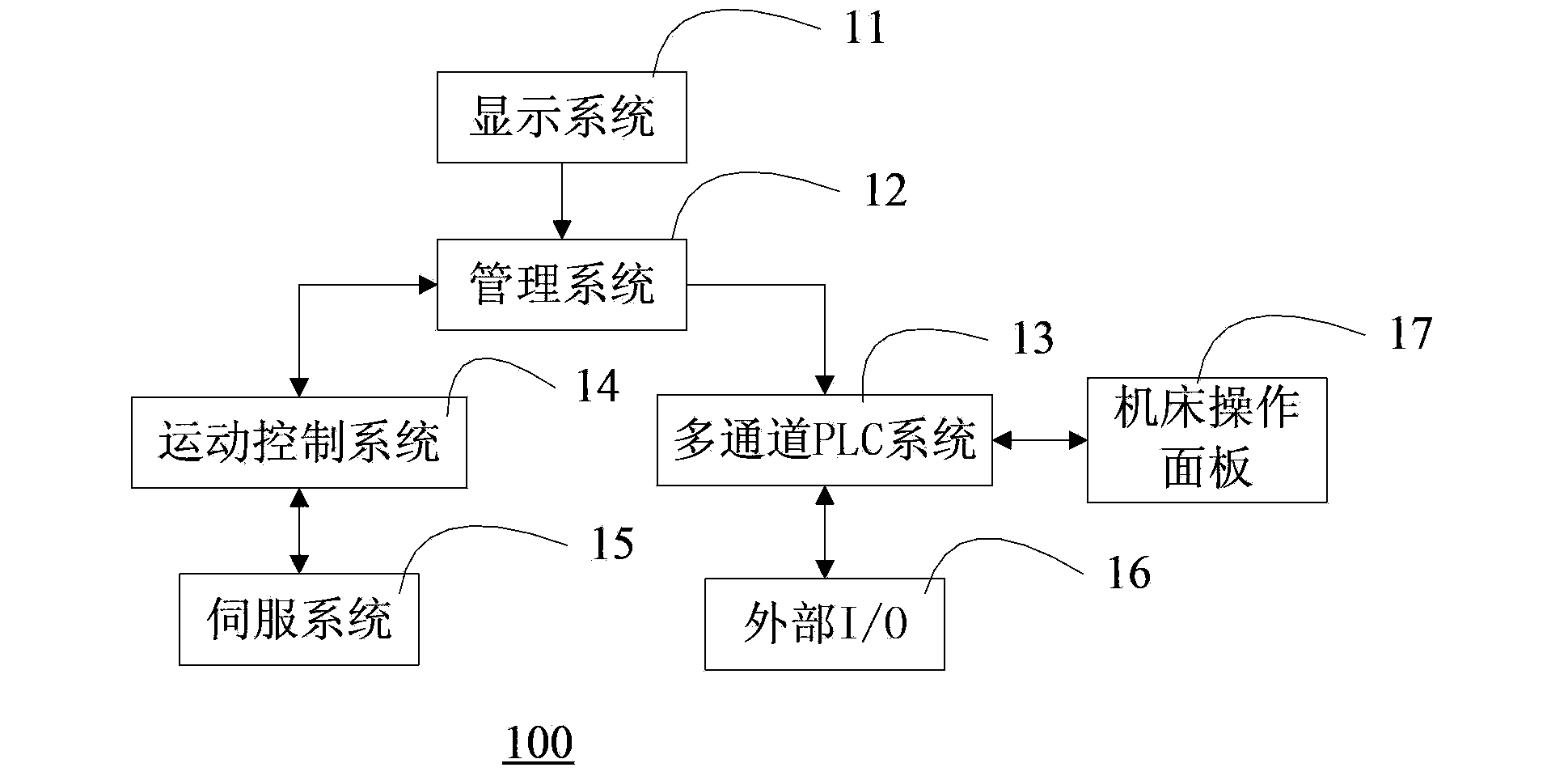

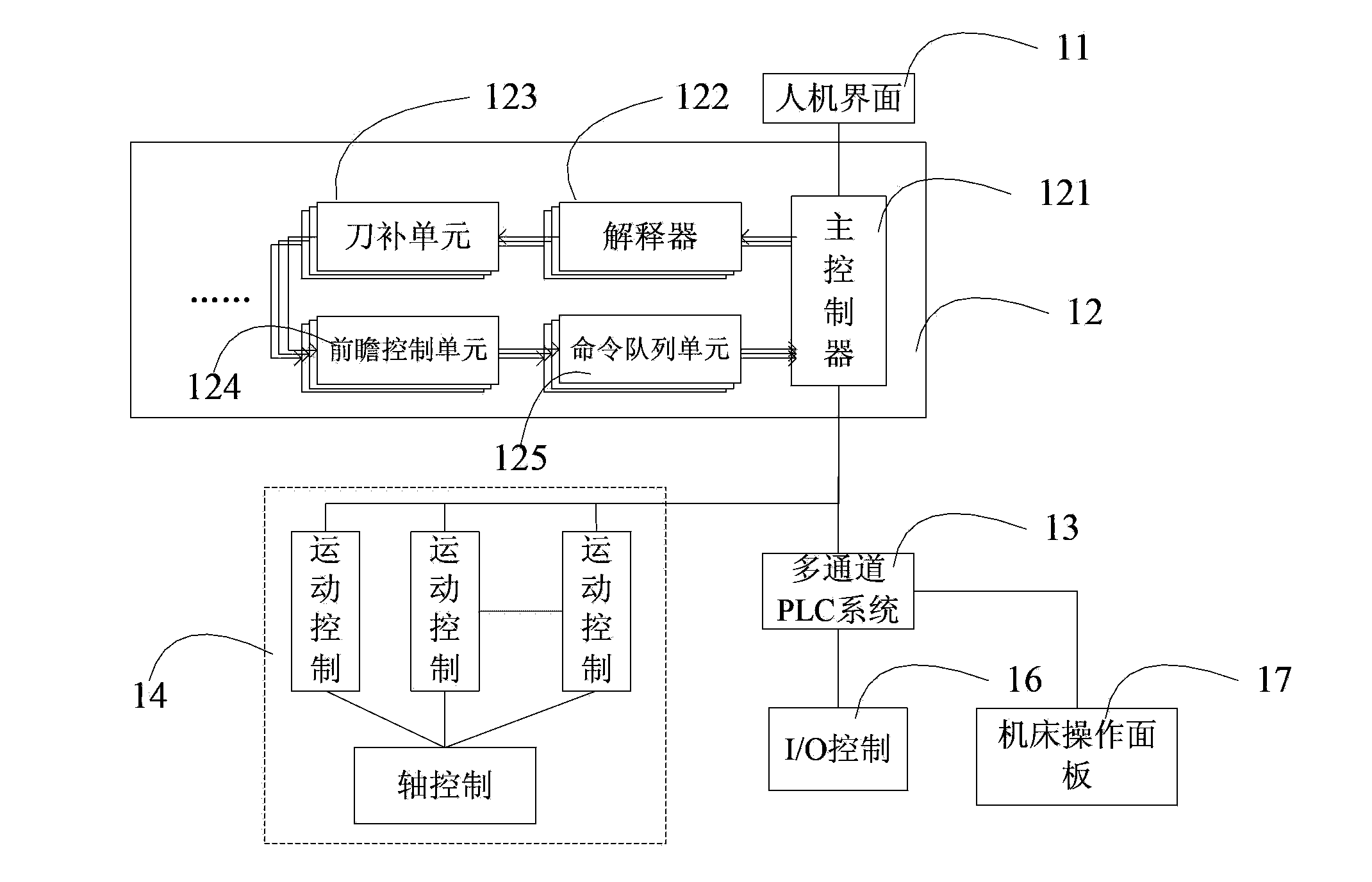

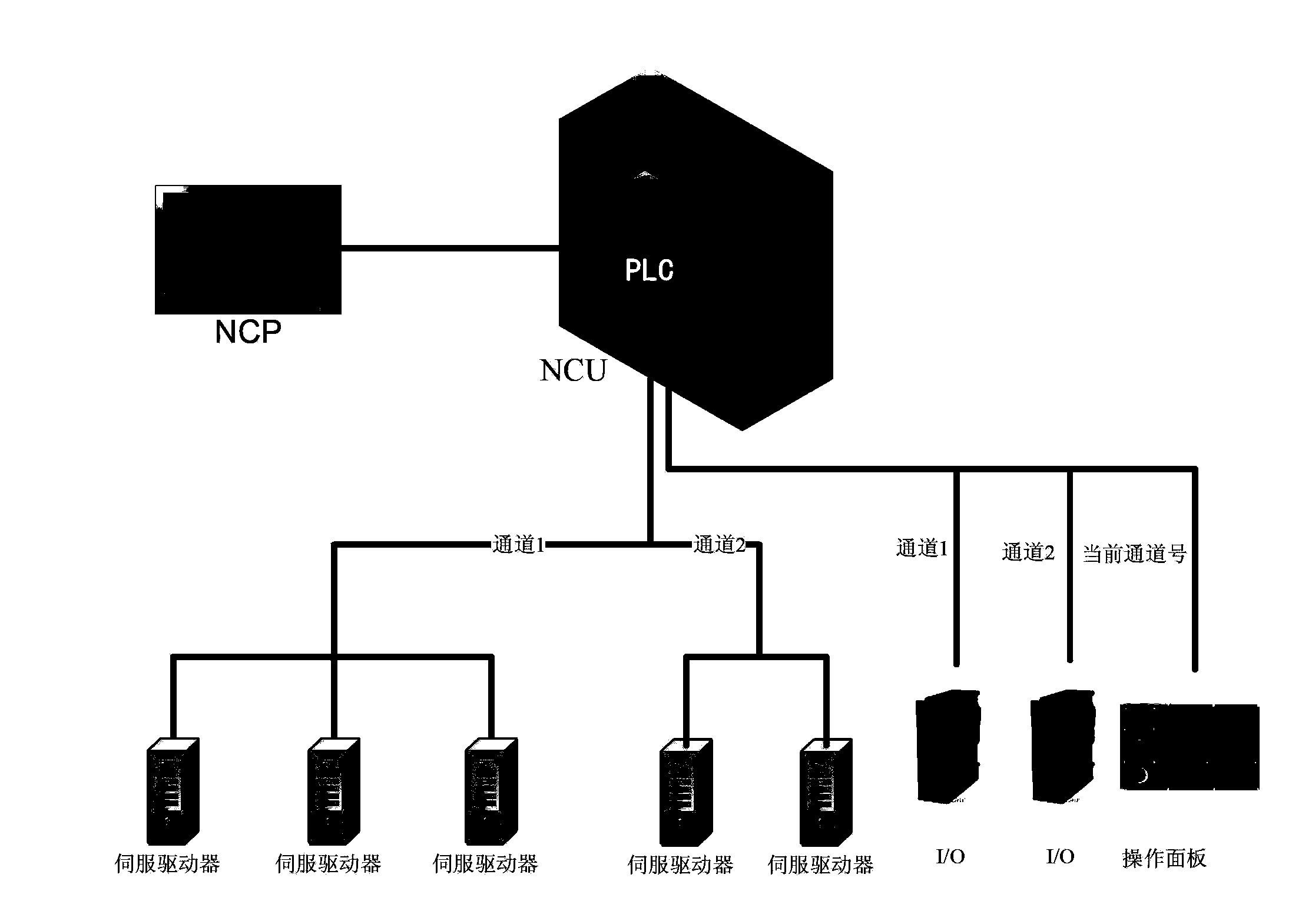

Multi-channel numerical control system and multi-channel control method thereof

InactiveCN103809523AImprove data securityAvoid mutual interferenceComputer controlSimulator controlNumerical control systemManagement system

The invention discloses a multi-channel numerical control system and a multi-channel control method thereof. The method comprises the following steps that: step one, a plurality of PLC logic control modules are stored in a numerical control system and a data mapping zone is arranged respectively for each PLC logic control module; step 2, a display system is used to obtain a channel configuration parameter including the activation channel number and a management system invokes the PLC logic control modules with the number corresponding to the activation channel number so as to activate a plurality of channels; and step 3, the management system sends control data of each channel to the data mapping zone of the channel in real time, so that the multi-channel PLC system carries out execution. According to the invention, multi-channel logic processing mutual interference can be avoided and the design difficulty of the PLC logic control module can be simplified. Moreover, invoking and synchronization between channels can be realized and the processing process can be ensured to be carried out successfully.

Owner:BEIJING INST OF COMP TECH & APPL +1

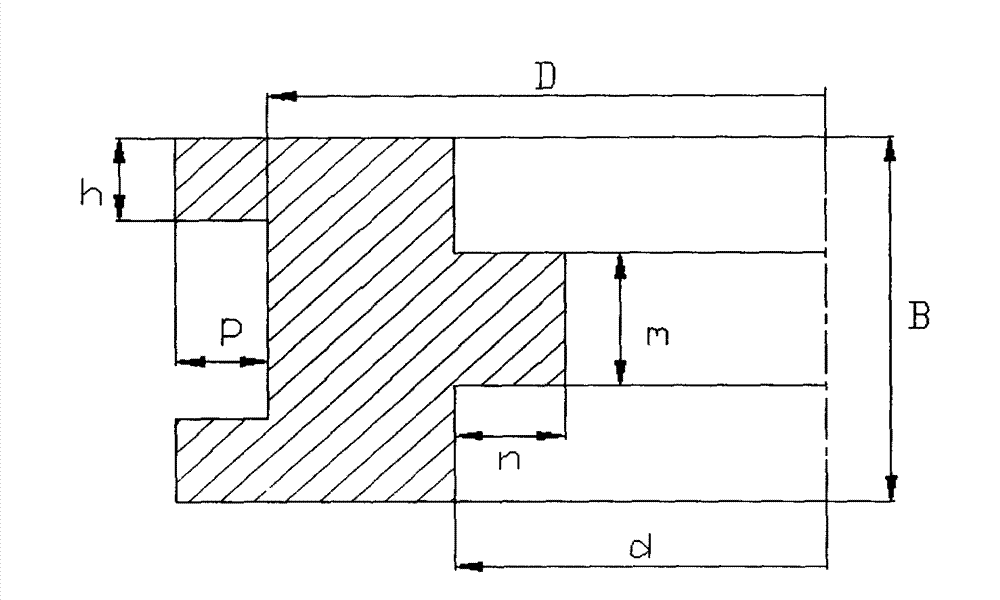

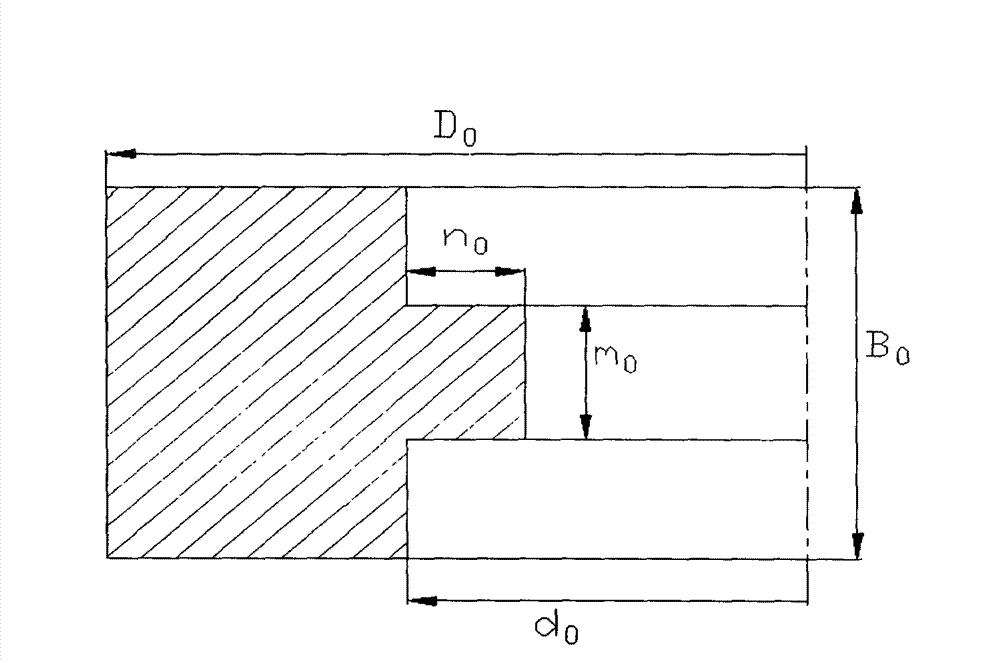

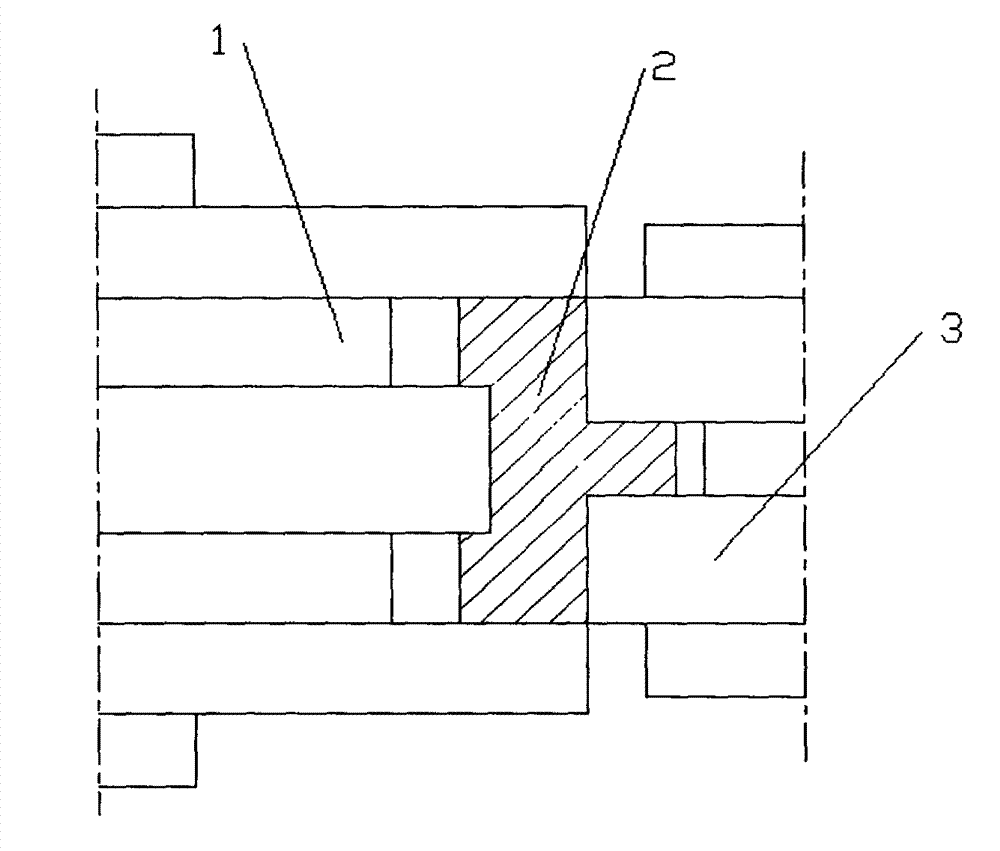

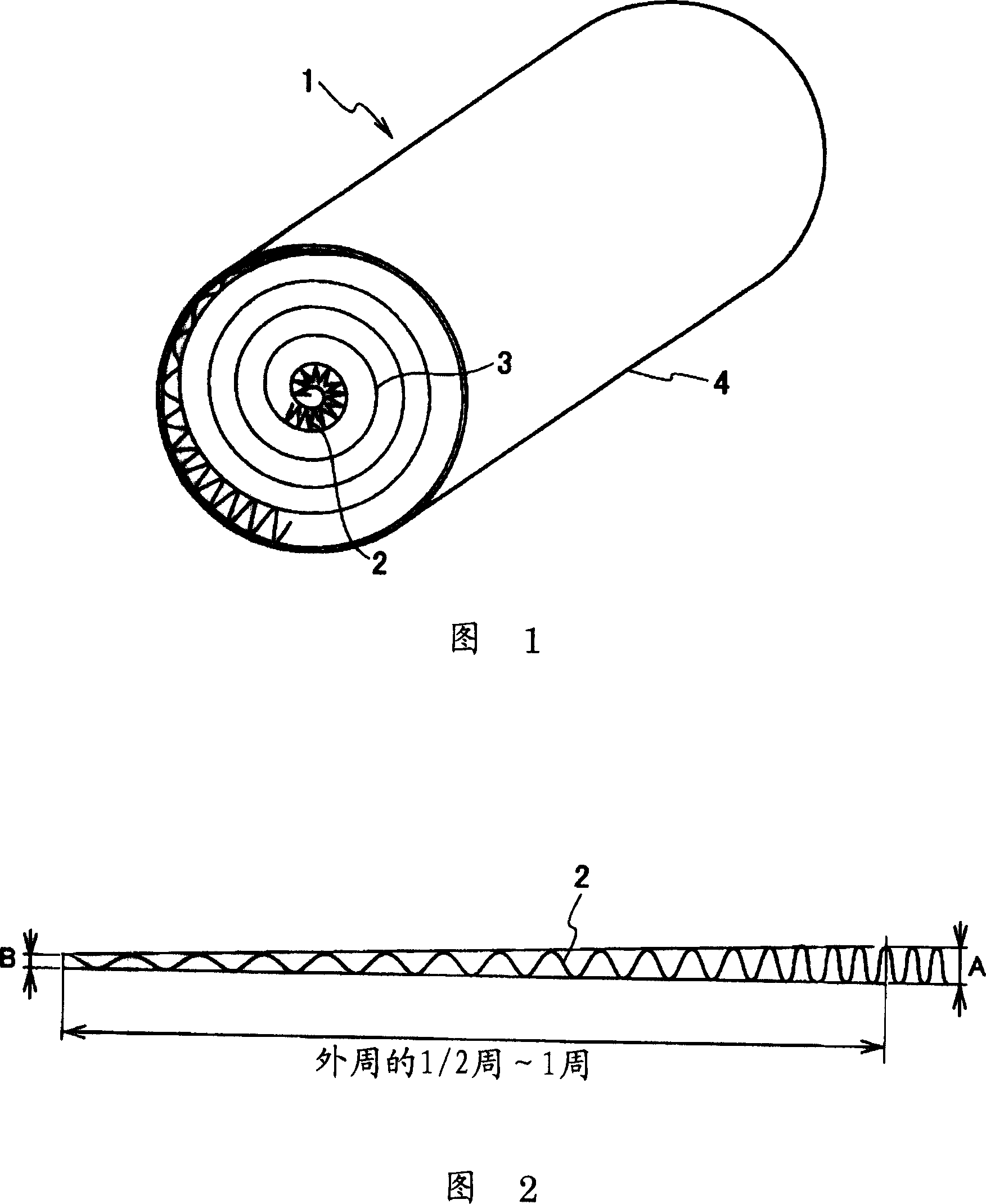

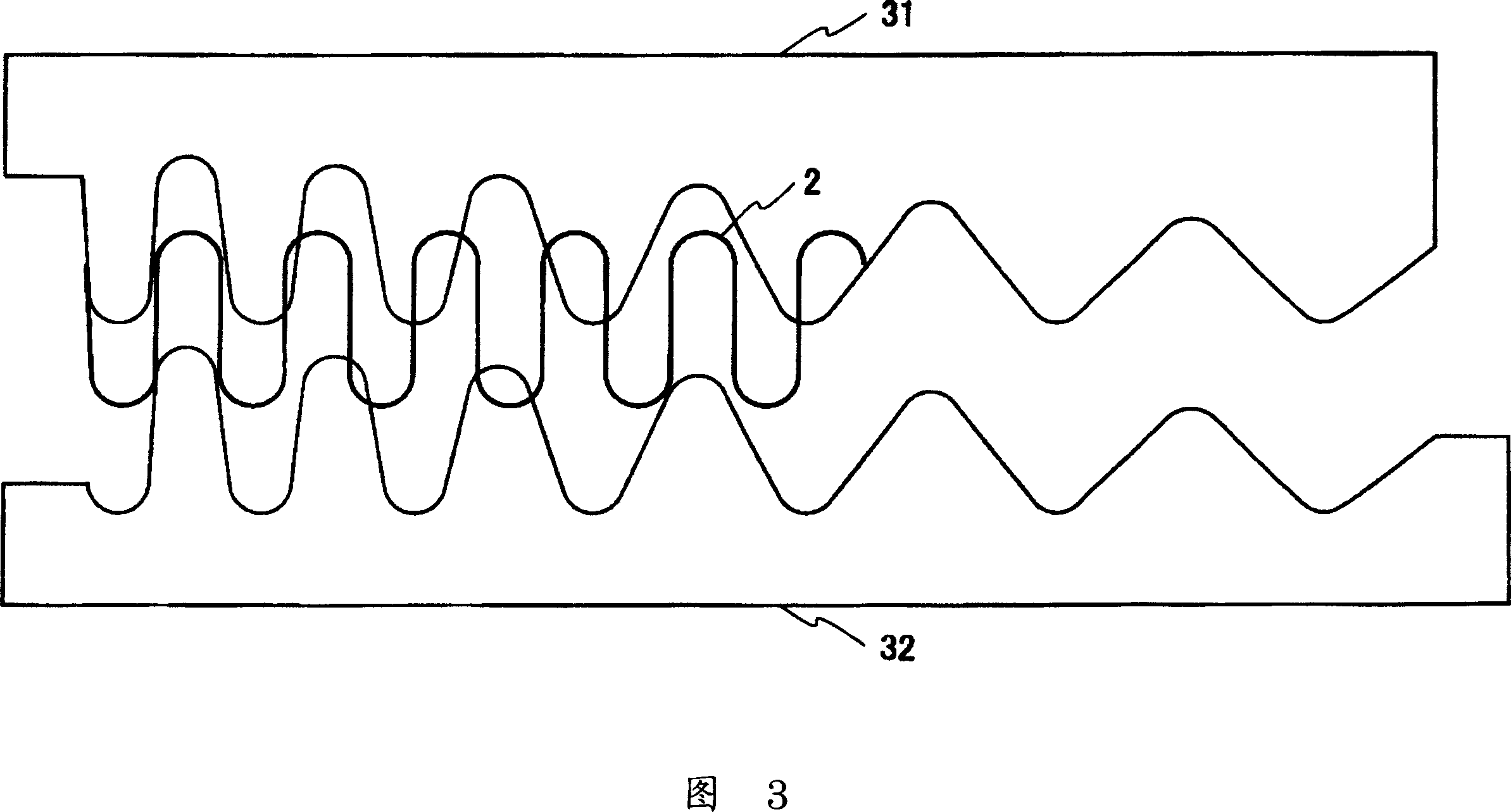

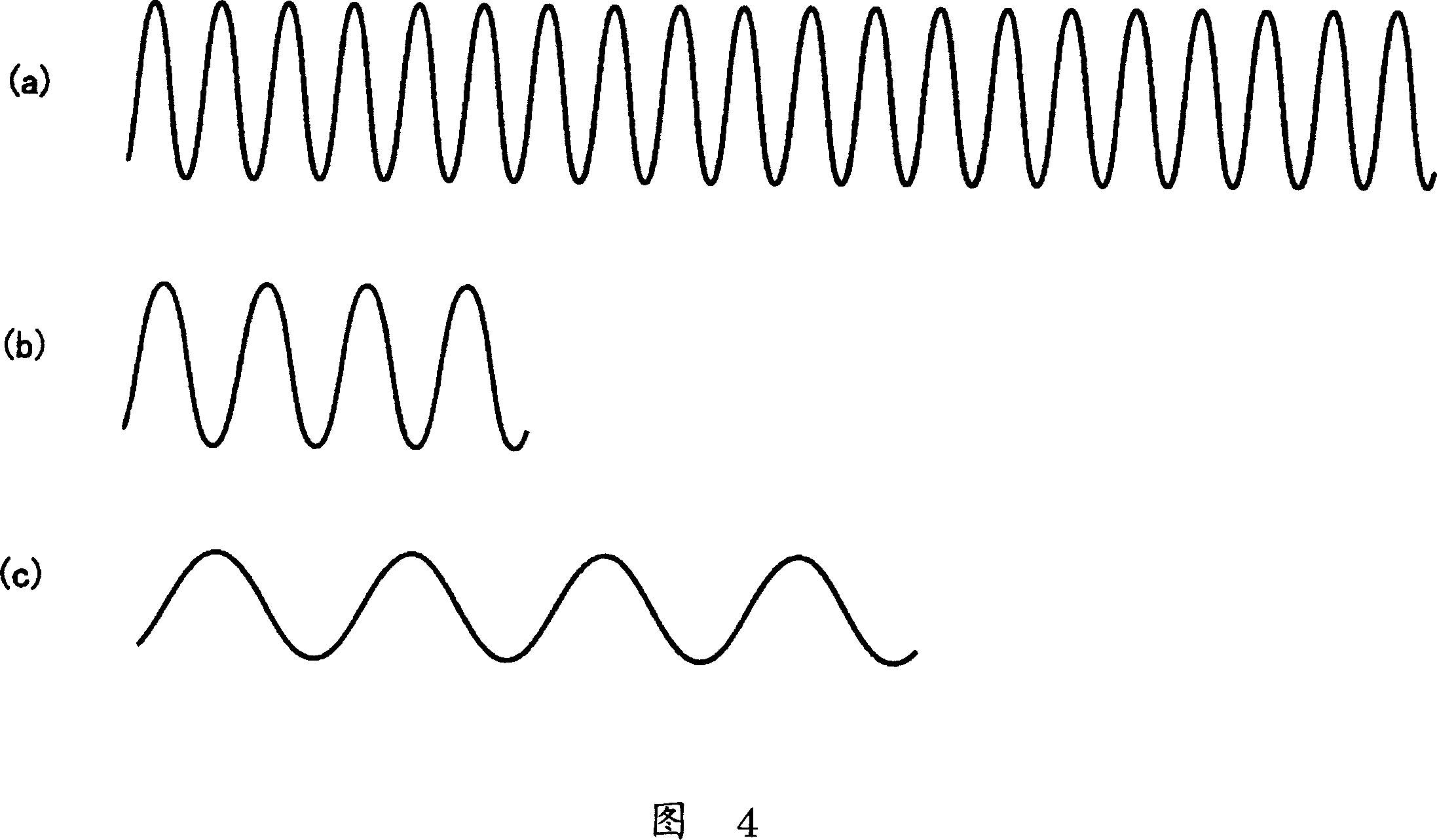

Metal carrier and manufacturing method of metal carrier

InactiveCN101007288APrevents degradation of purification performanceEliminate stepsCatalyst carriersMechanical working/deformationMetal sheetBiomedical engineering

The invention provides a metal carrier, wherein, the wound final end of the metal carrier is provided with stairs and the metal carrier has no small-chamber shaped local deformation even being pressed into a shell. The metal carrier (1) is produced by superposing a metal flat sheet (3) and a metal corrugated sheet (2) on each other and winding them. The invention is characterized in that at the wound end when the corrugated sheet (2) and the flat sheet (3) are wound, the corrugation height of the corrugated sheet (2) is gradually lowered.

Owner:CALSONIC KANSEI CORP

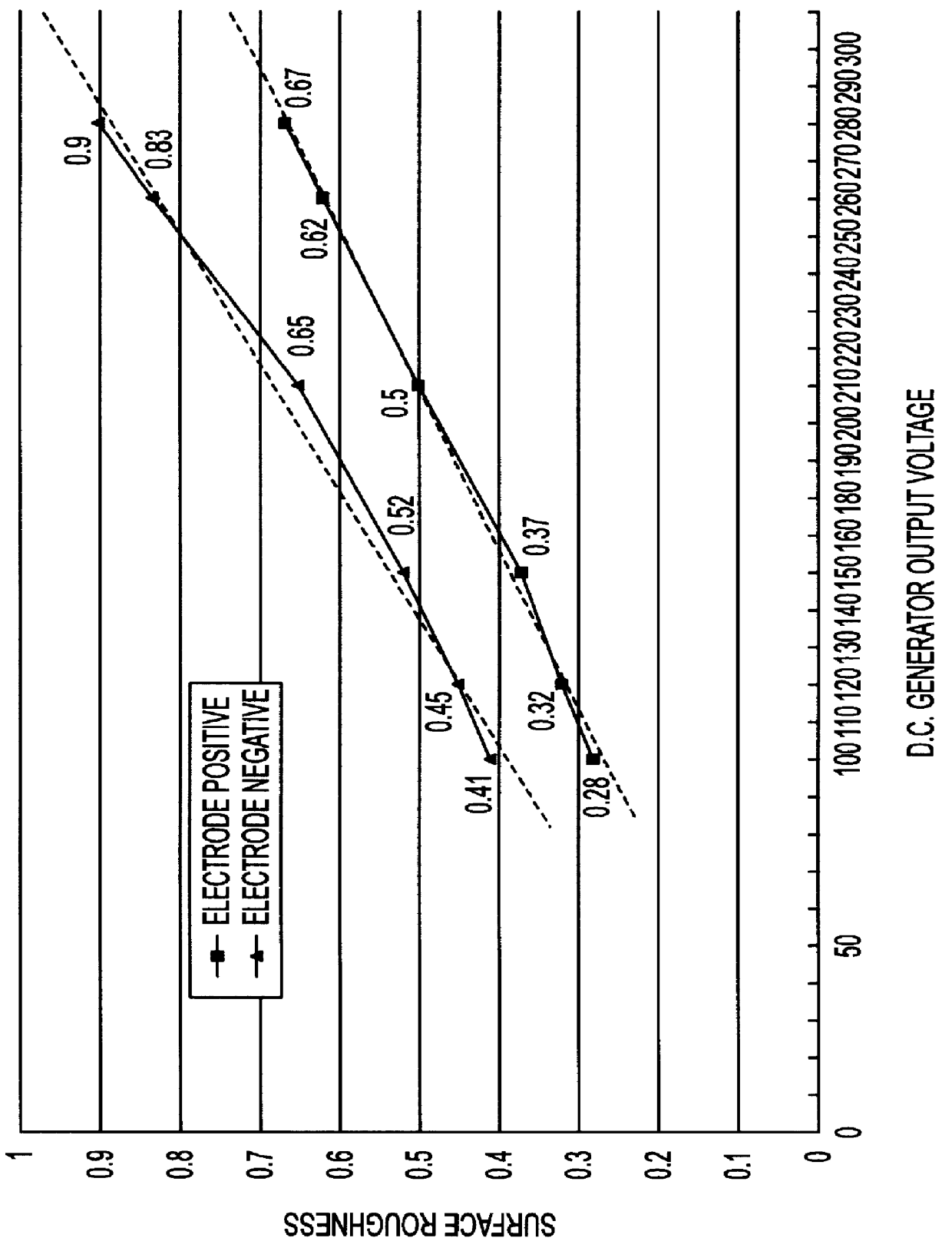

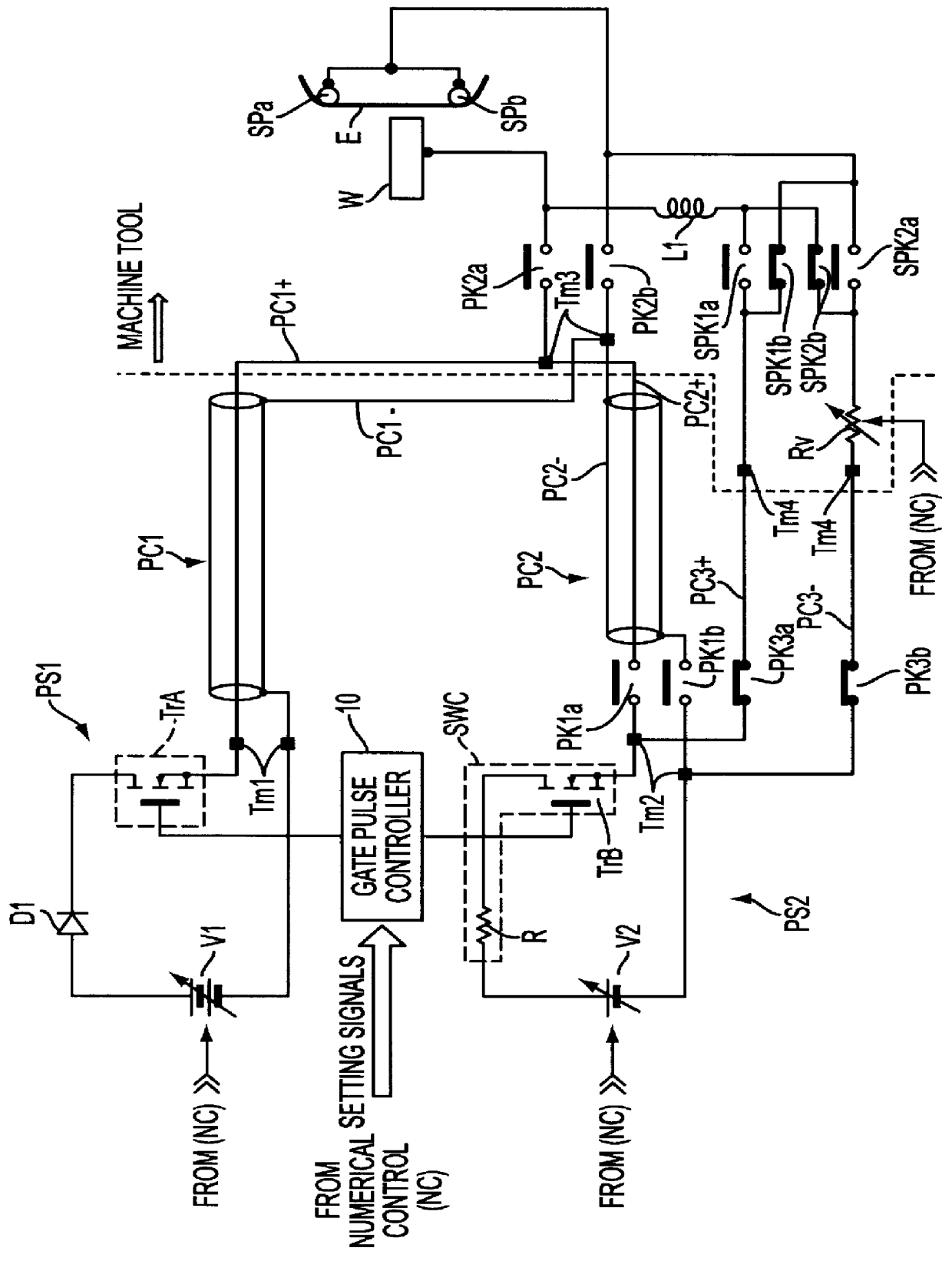

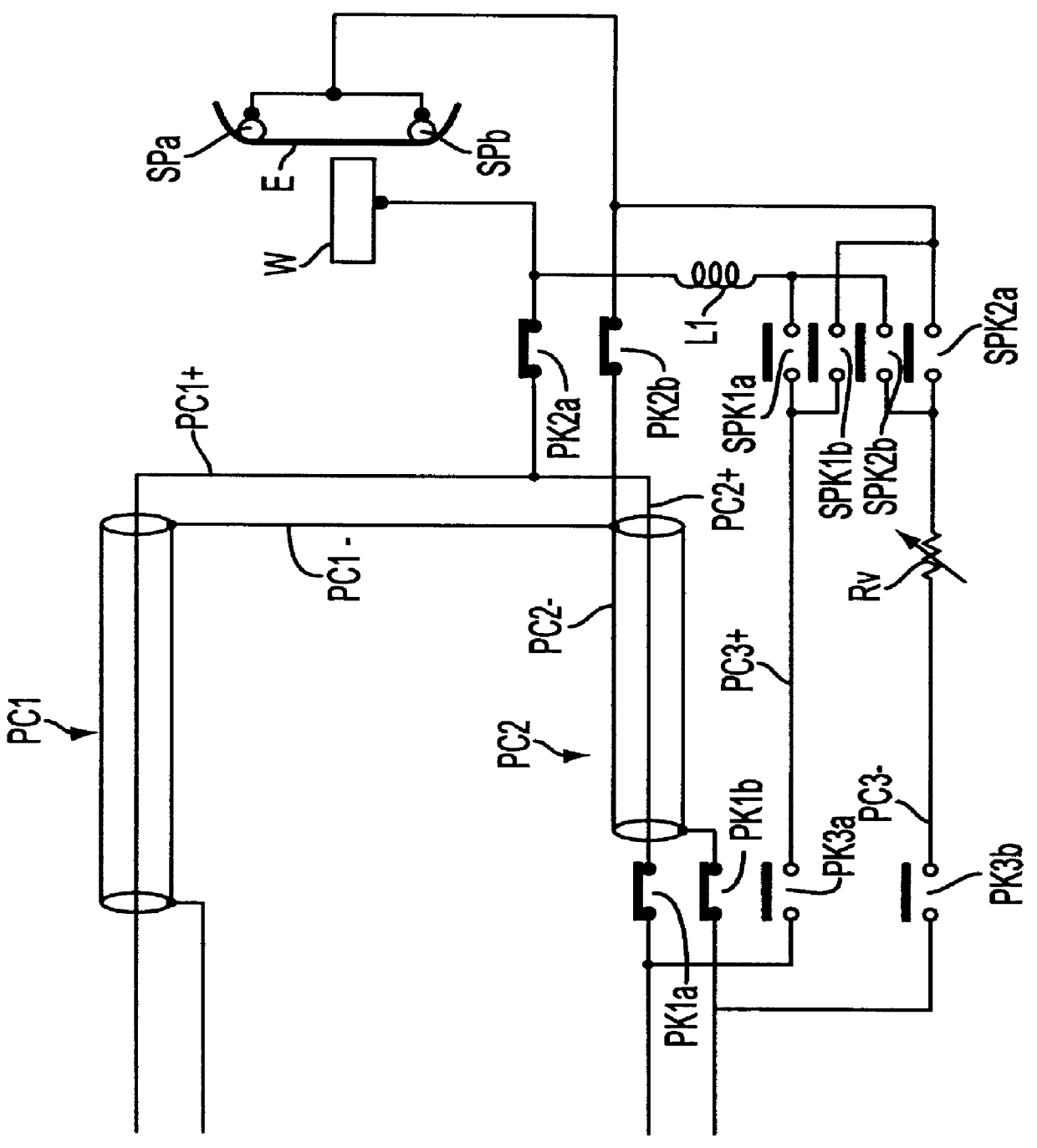

Method and apparatus for achieving a fine surface finish in wire-cut EDM

InactiveUS6130395AImprove surface roughnessStable processingArc welding apparatusElectric circuitsSurface finishRough surface

A wire-cut EDM method and apparatus for machining to a fine surface roughness of 1 mu m Rmax or less. Two power supplies and a electrode polarity switching system are used. A first high energy power source is used for initial profile cutting and may also be used for one or more later cuts while the machining pulse parameters, and feed rate and offset are adjusted for increasing less rough surface finishes. The wire electrode is held at negative machining potential. A second power supply and smaller offset values are used for later cuts to create lower values of surface roughness, while still maintaining the wire electrode at a negative machining potential. Finally, in order to create a fine finished surface (Rmax

Owner:SODICK CO LTD

Plasma detector and laser beam machine with plasma detector

ActiveUS20050178749A1Improve processing efficiencyEasy to detectLaser beam welding apparatusElectrical resistance and conductancePhase detector

Voltage fluctuating time integrating means integrates voltage fluctuating time when voltage of a sensor electrode fluctuates as a voltage fluctuation integrated time, and voltage fluctuation occurrence rate computing means computes a rate of occurrence of voltage fluctuation for time on the basis of the voltage fluctuation integrated time integrated. By doing so, quantity of generated plasma can be taken as the rate of occurrence of voltage fluctuation, and plasma detection judging means can easily detect large volume of generated plasma on the basis of the computed voltage fluctuation occurrence rate. Then, it is not necessary to provide a circuit for measuring electric resistance between the sensor electrode and a workpiece as a conventional way, thereby avoiding complexly structured plasma detector.

Owner:YAMAZAKI MAZAK KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com