V-block-positioning pneumatic clamping machining center fixture

A machining center and pneumatic clamping technology, applied in positioning devices, clamping devices, manufacturing tools, etc., can solve the problems of low processing efficiency, difficult to guarantee workpiece processing accuracy, long time for workpiece alignment, etc., to achieve stable processing, structure Simple, novel, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

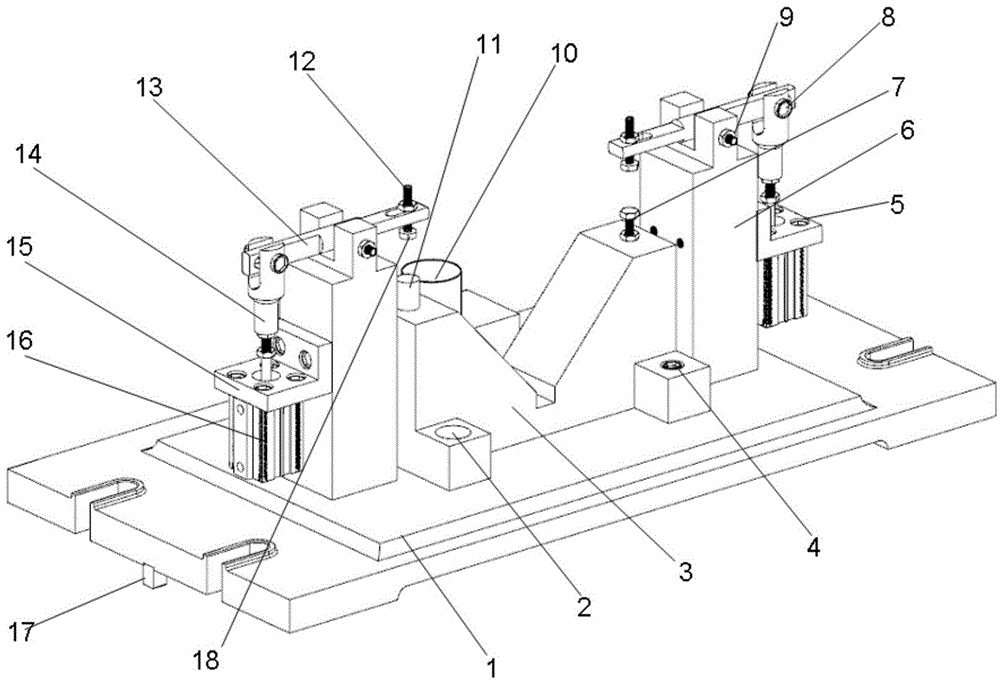

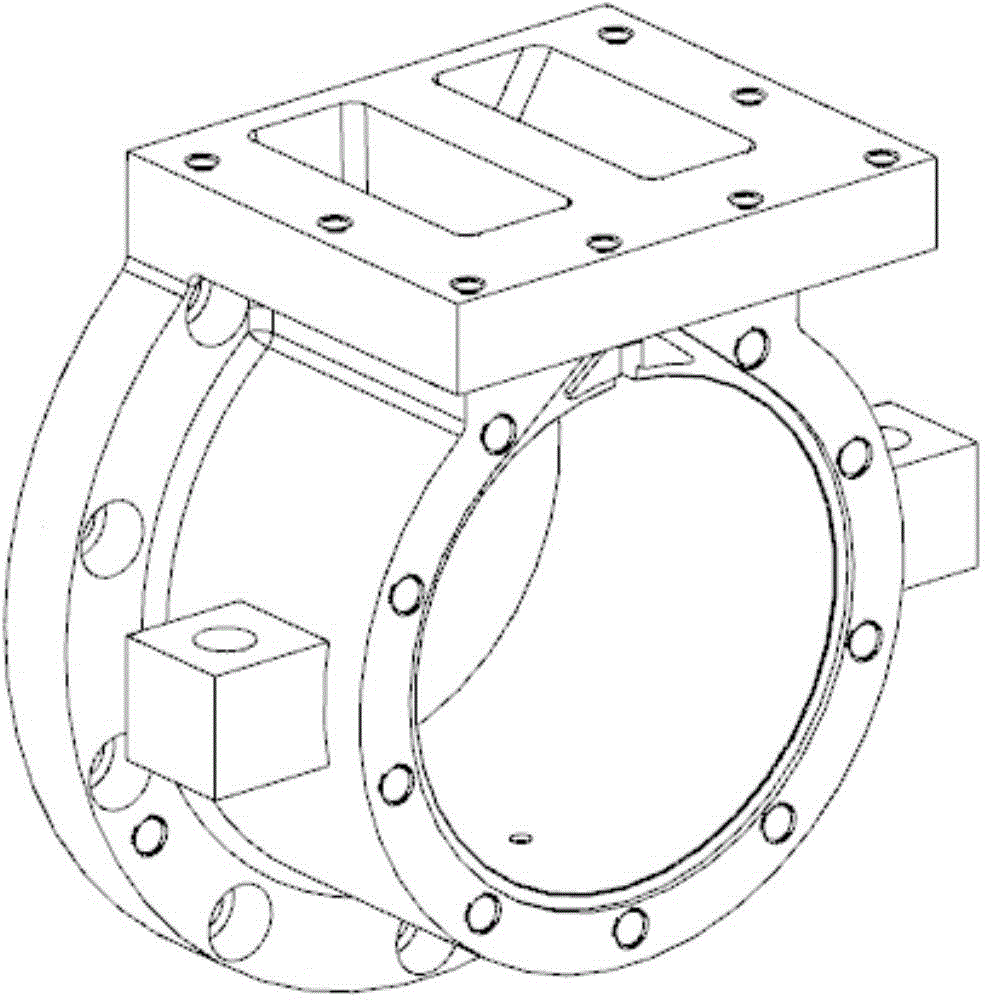

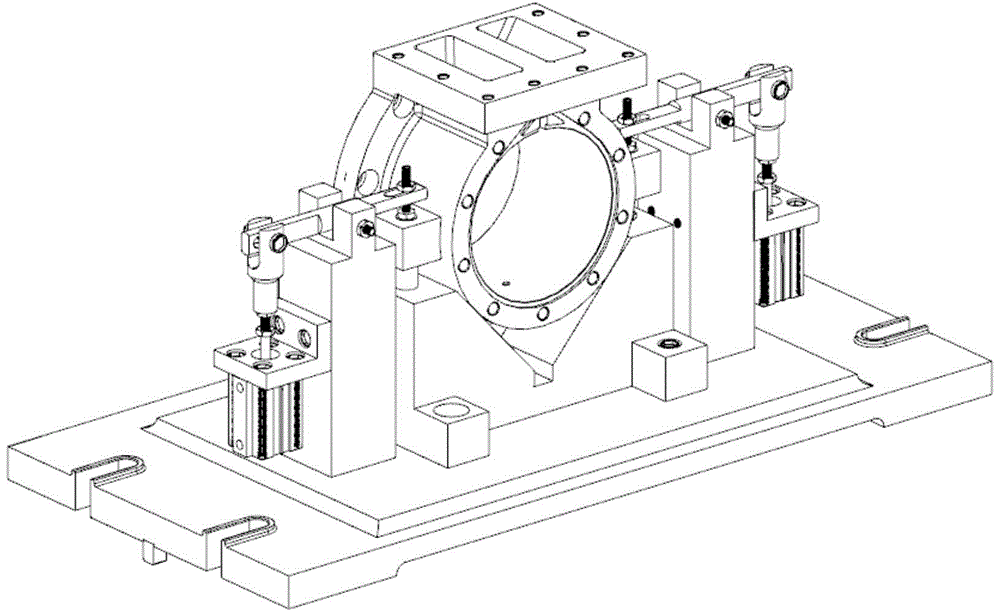

[0023] Such as Figure 1~Figure 5 As shown, a pneumatic clamping machining center fixture with V-shaped block positioning includes a clamp body 1, a positioning mechanism and a clamping mechanism. The positioning mechanism includes a V-shaped block 3, which is fixed on the clamp body 1, and the V-shaped block 3 is fixed on the clamp body 1. A fixed support 11 and an auxiliary support 7 are respectively fixed on the upper end surfaces of both ends of the block 3, and a cylindrical stop pin 10 is provided on the side corresponding to the center of the V port of the V-shaped block 3; Cylinders 16 on both sides of the block 3, a column 6 is respectively arranged between the two cylinders 16 and the V-shaped block 3, and the bottoms of the two columns 6 are fixed on the clamp body 1, and the ejector rods 14 of the two cylinders 16 are vertically arranged, and the ejector rods The top of 14 is horizontally rotated to be equipped with lever 13, and the middle part of lever 13 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com