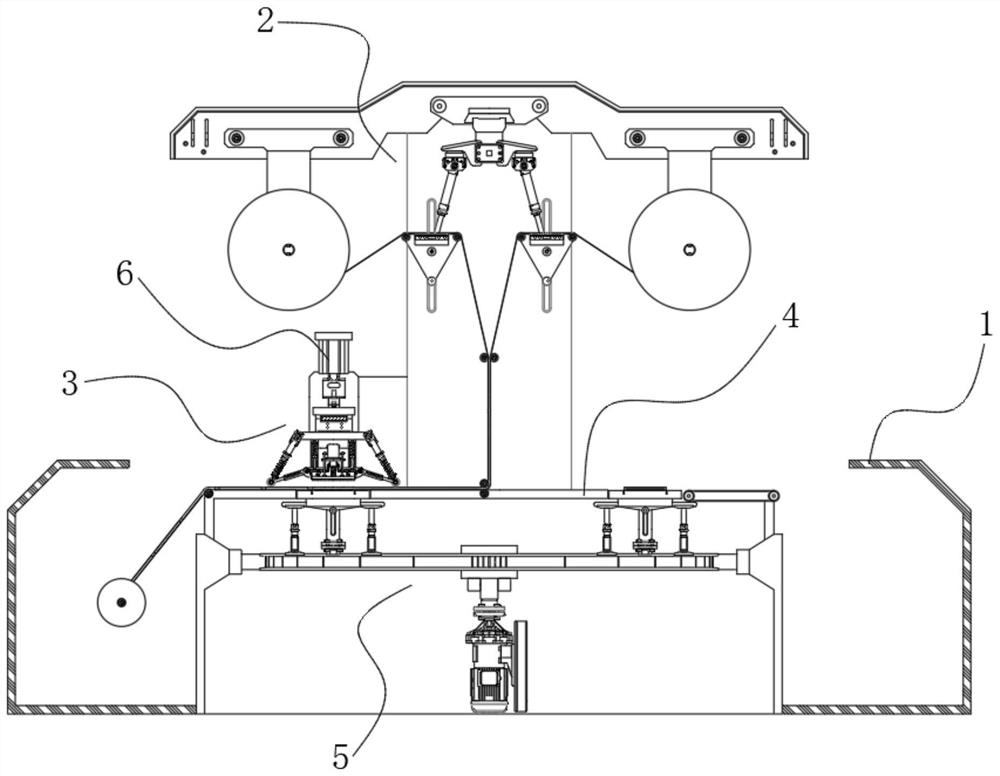

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about How to "Stable cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for splitting news video program, and method and system for cataloging news videos

InactiveCN102547139APromote expansionAccurate segmentationTelevision system detailsColor television detailsCatalogingEngineering

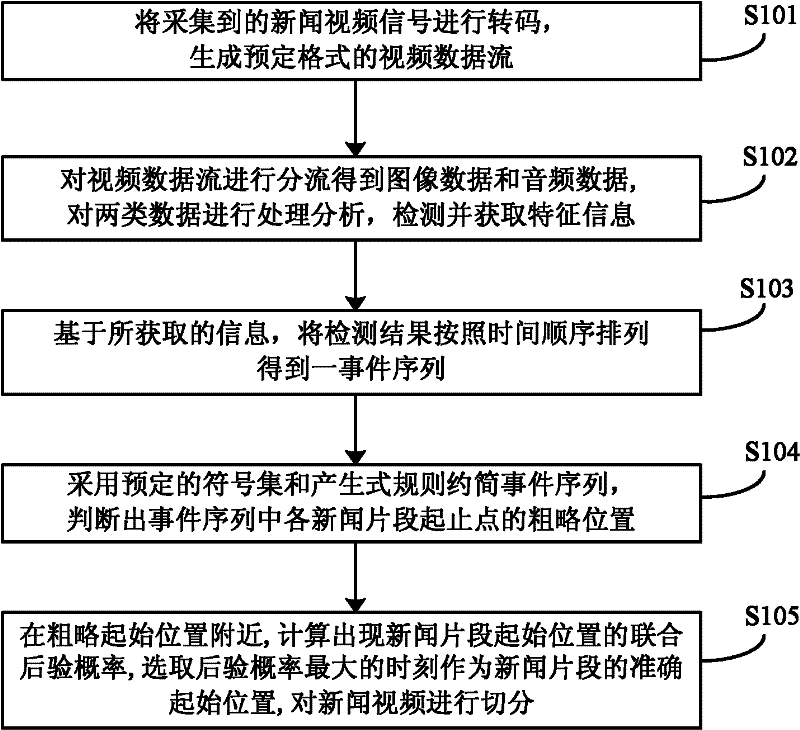

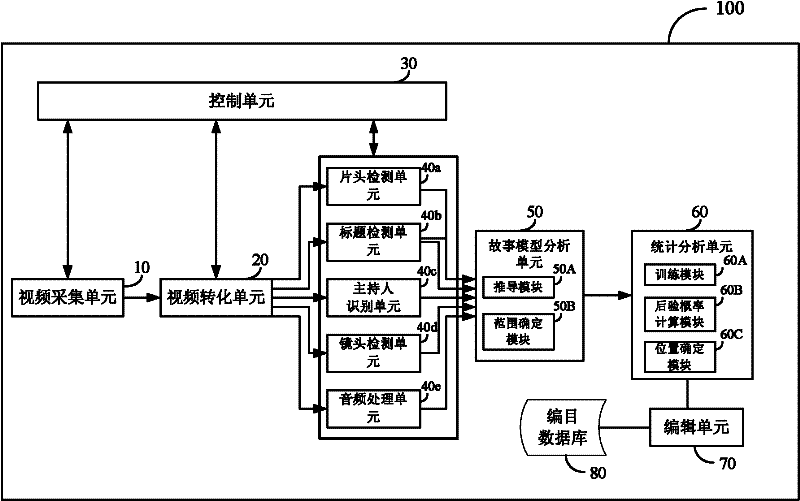

The invention discloses a method for splitting a news video program and a method and a system for cataloging news videos. The method for splitting the news video program comprises the following steps of: sequencing detection results according to a time sequence to obtain an event sequence by detecting characteristic information of titles of the news video, a headline, characteristic information of comperes, lens transformation, a mute point of an audio, a switching point, a keynote period sudden change point and the like; briefing the event sequence by adopting a preset symbol set and a production rule, and judging rough positions of start points and end points of news sections in the event sequence; calculating a union posterior probability of a start position of each news section near the rough start position according to the event sequence, selecting the moment with the maximum posterior probability as the accurate start position of each news section, splitting the news video, and thus obtaining the news video sections. According to the method, the adopted algorithm is stable and effective; the structural information in the news video can be summarized effectively; the accurate positions of splitting points of the news sections can be determined; and the news video can be split stably and accurately.

Owner:北京新岸线网络技术有限公司

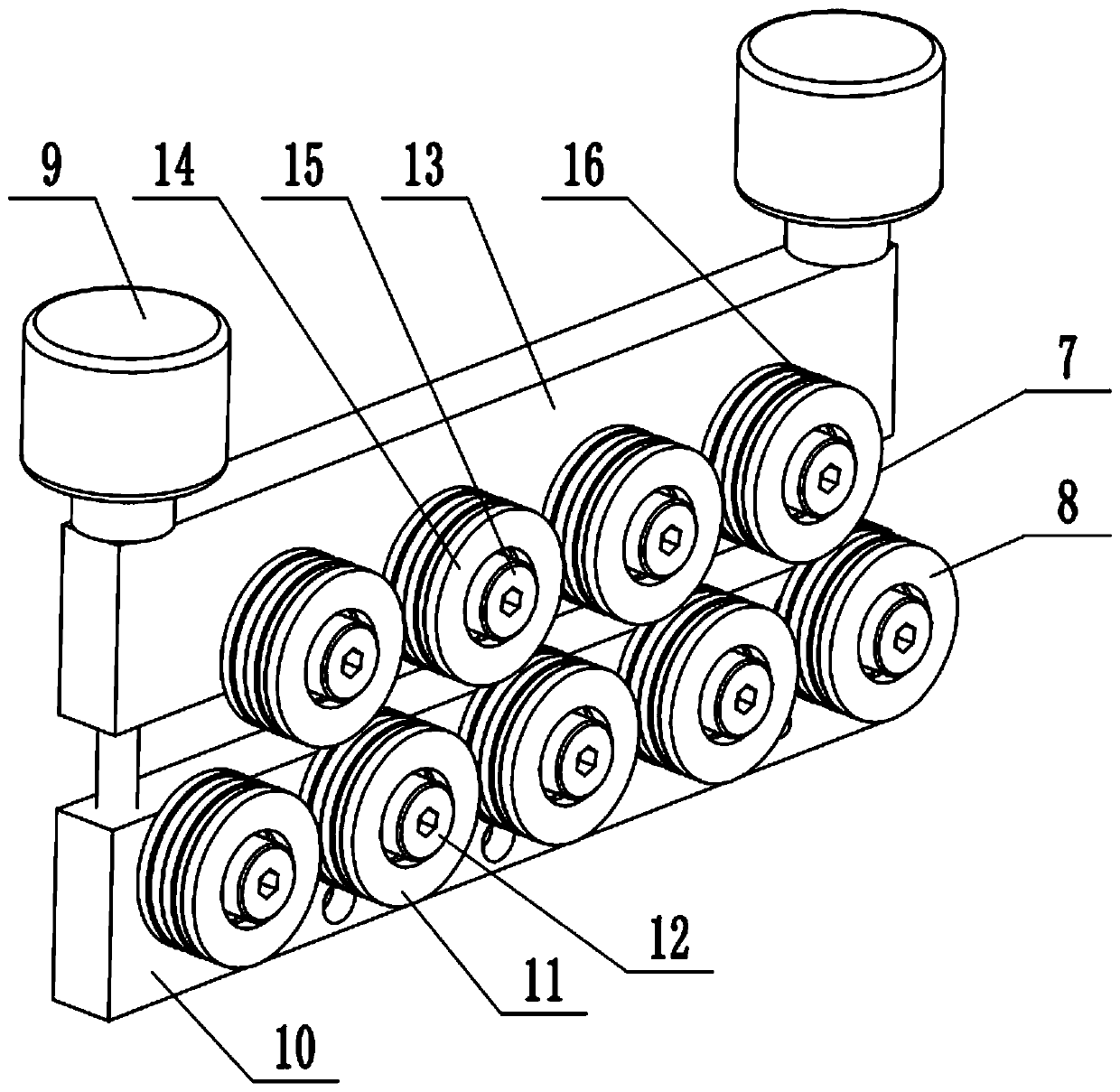

Sheet material processing method and device

ActiveCN101746057AStable processingStable cutting processDomestic articlesBandagesEngineeringThermal treatment

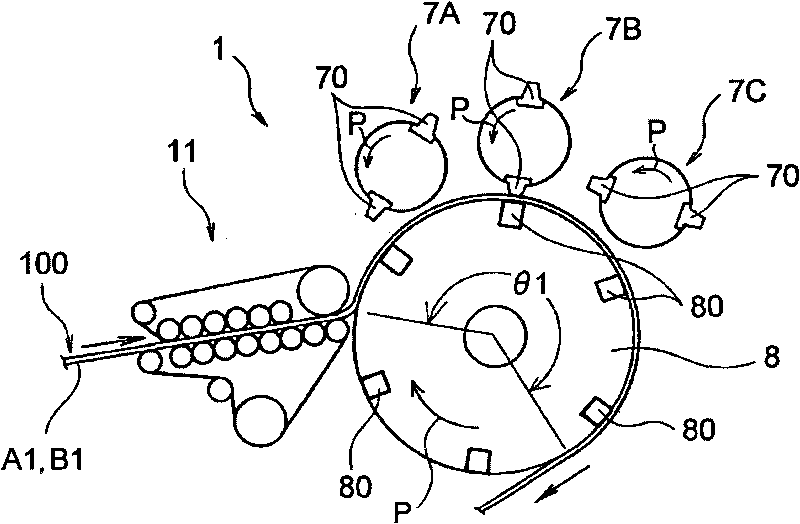

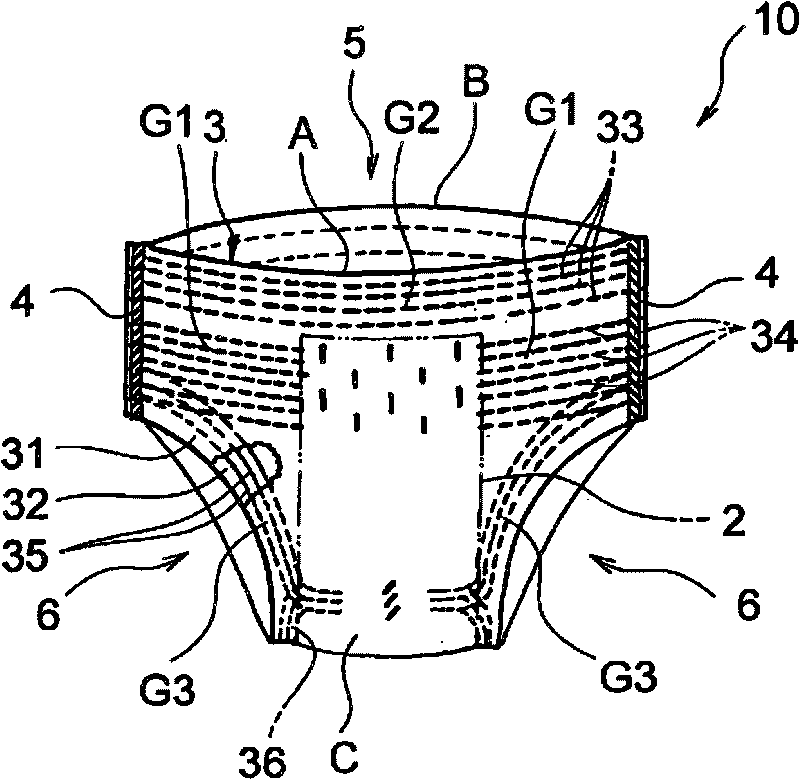

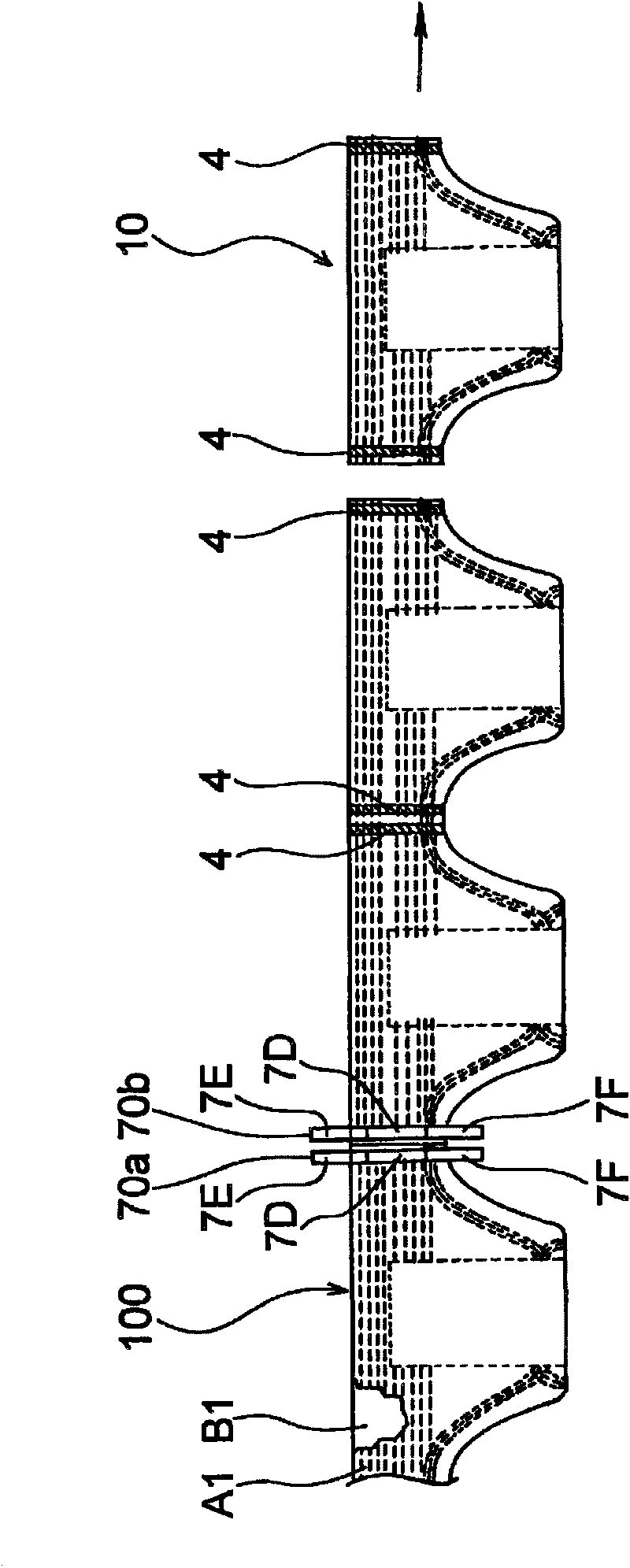

The invention provides a sheet material processing method and device. The sheet material processing method is used for processing the sheet material (100 between two rollers (7A, 8) which are arranged oppositely, wherein, the processing method includes at least one of the compacting of the sheet material, the heat seal of sheet materials and the cut off of an elastomeric element arranged among the sheet materials, in the processing method, the outer periphery temperature of at least one roller (8) is respectively controlled in a plurality of thermal treatment zones arranged in the shaft direction of the roller, while the sheet materials (100) are processed.

Owner:KAO CORP

Diamond abrasive wire cutting fluid for semiconductor precision sheet and preparation method of diamond abrasive wire cutting fluid

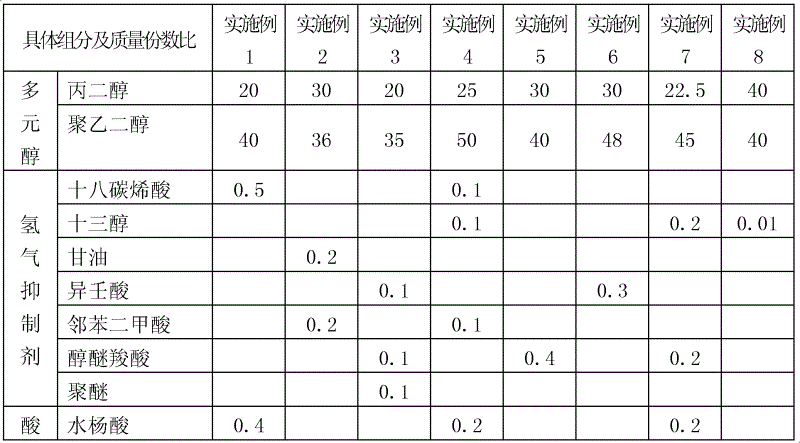

The invention relates to a diamond abrasive wire cutting fluid for a semiconductor precision sheet. The raw materials of the diamond abrasive wire cutting fluid consist of the following compositions in parts by mass: 30-80 parts of polyalcohol, 0.01-0.5 parts of hydrogen inhibitor, 0.01-0.5 parts of acid, 0.1-1.0 part of surfactant, 1.0-10.0 parts of dispersing agent, 0.01-0.5 parts of preservative and 10-35 parts of deionized water, wherein the polyalcohol is mixture of propylene glycol and polyethylene glycol with ratio being 1 to (1:2) and the molecular weight of the polyethylene glycol is between 100 and 600. The diamond abrasive wire cutting fluid for the semiconductor precision sheet has the characteristics that the hydrogen is effectively inhibited from being generated, the lubricating effect is remarkable, the cleaning is easy to conduct, the cost is low and the performance is stable.

Owner:CHANGZHOU JUNHE TECH

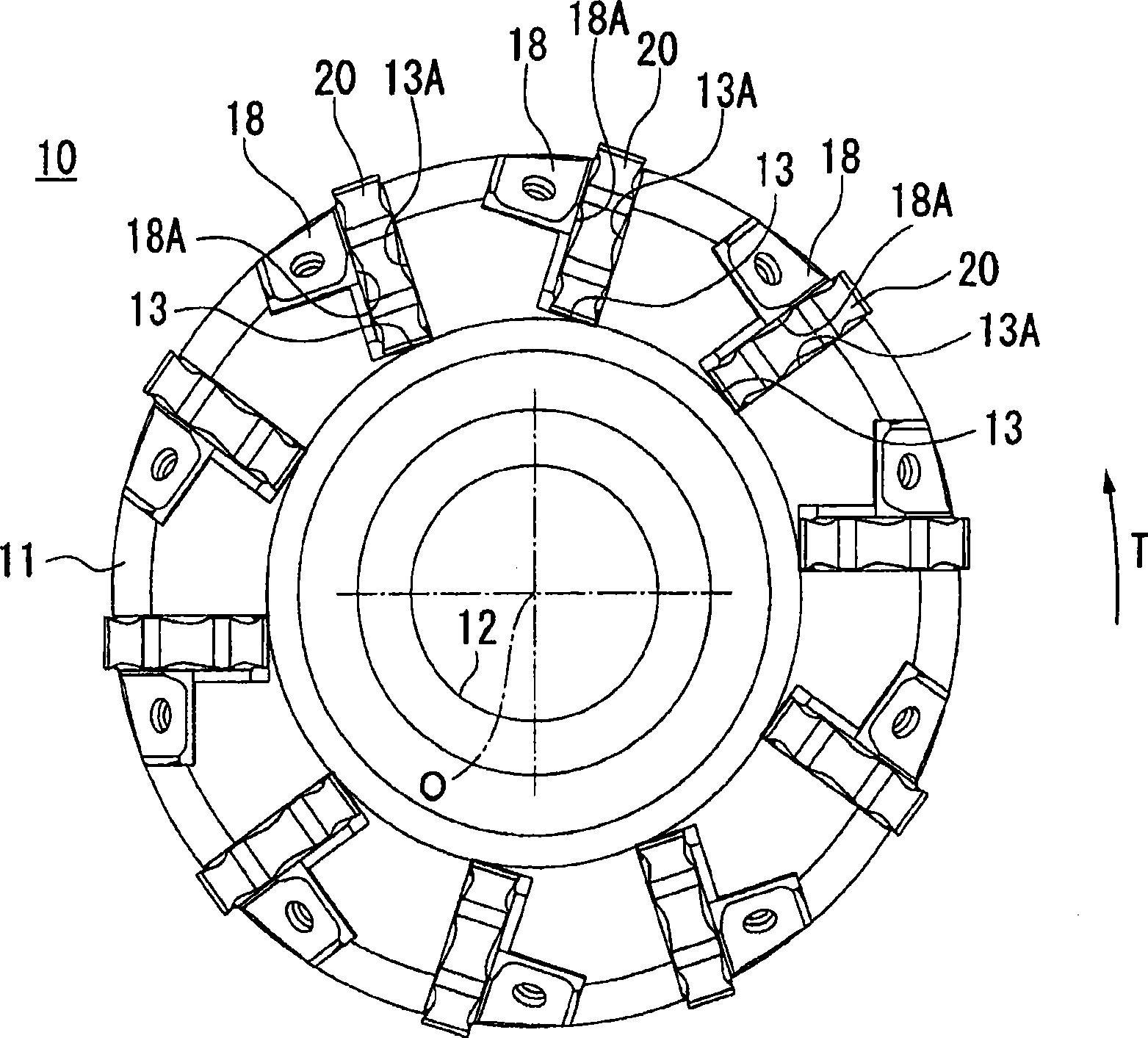

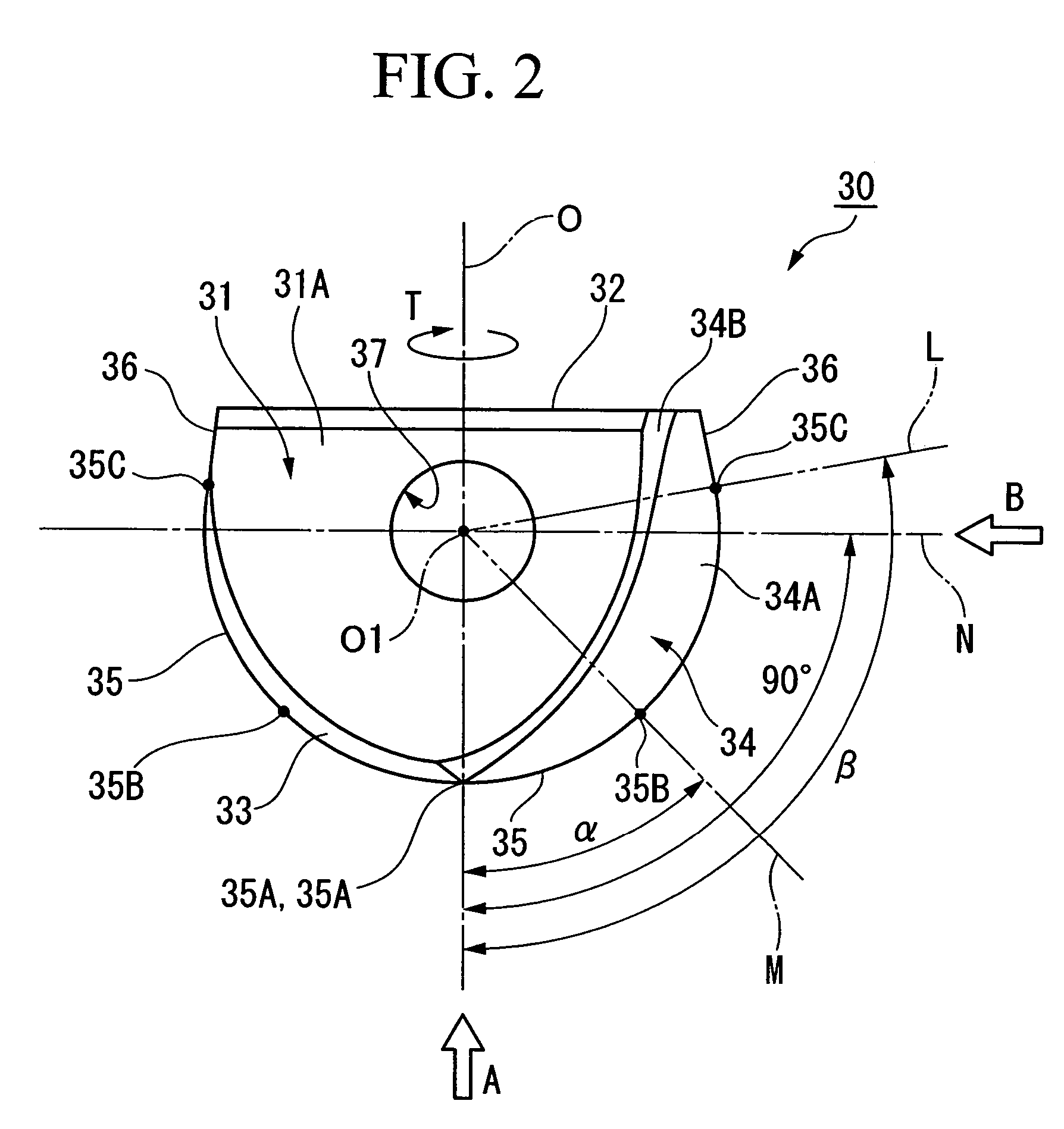

Cutting tool and cutting insert

ActiveCN101460276AStable cutting processMilling cuttersTurning toolsEngineeringMechanical engineering

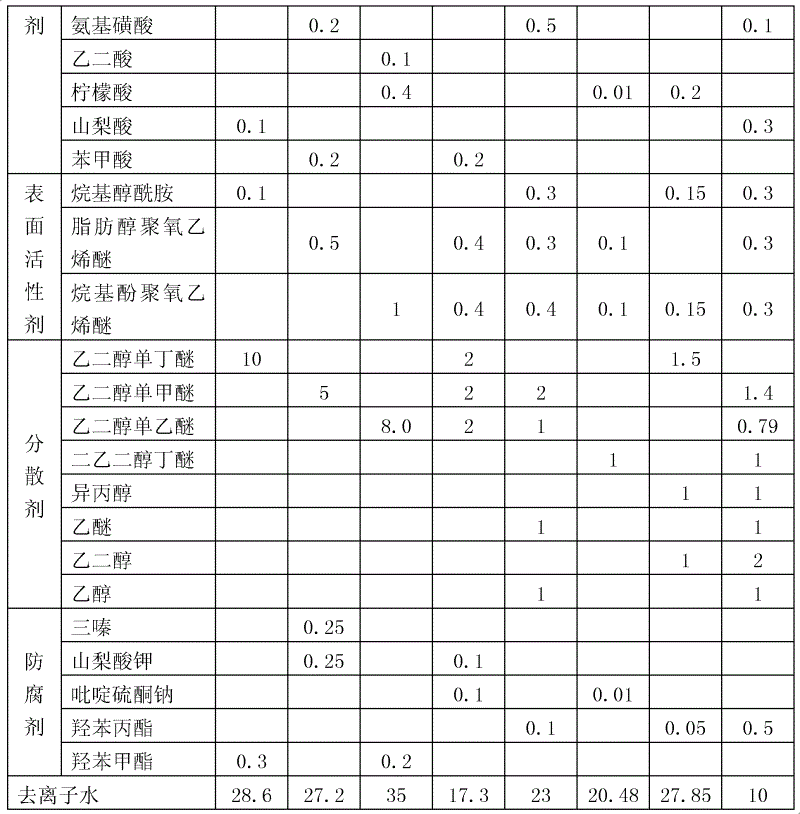

A cutting tool comprising a tool body being turned about the axis, and a cutting insert fixed removably to the outer circumference at the tip of the tool body. The cutting insert has a front / back-reversal symmetric substantially regular heptagonal plane shape having two heptagonal faces parallel with each other, a side face continuous to each heptagonal face at right angle, and a cutting edge provided at each ridge line between the heptagonal face and the side face. The cutting edge includes a main cutting edge projected onto the side of the regular heptagon, and sub-cutting edges extending from the opposite ends of each main cutting edge to incline toward the center of the heptagonal face and connecting the adjoining main cutting edges. The tool body is equipped with a fixing seat for holding the cutting insert such that one main cutting edge is directed toward the tip side of the tool body and in the radial-outer direction in order to allow it to participate in the cutting, and the corner angle a between the main cutting edge and the axis satisfy a relation 40 DEG<=alpha<=44 DEG .

Owner:MITSUBISHI MATERIALS CORP

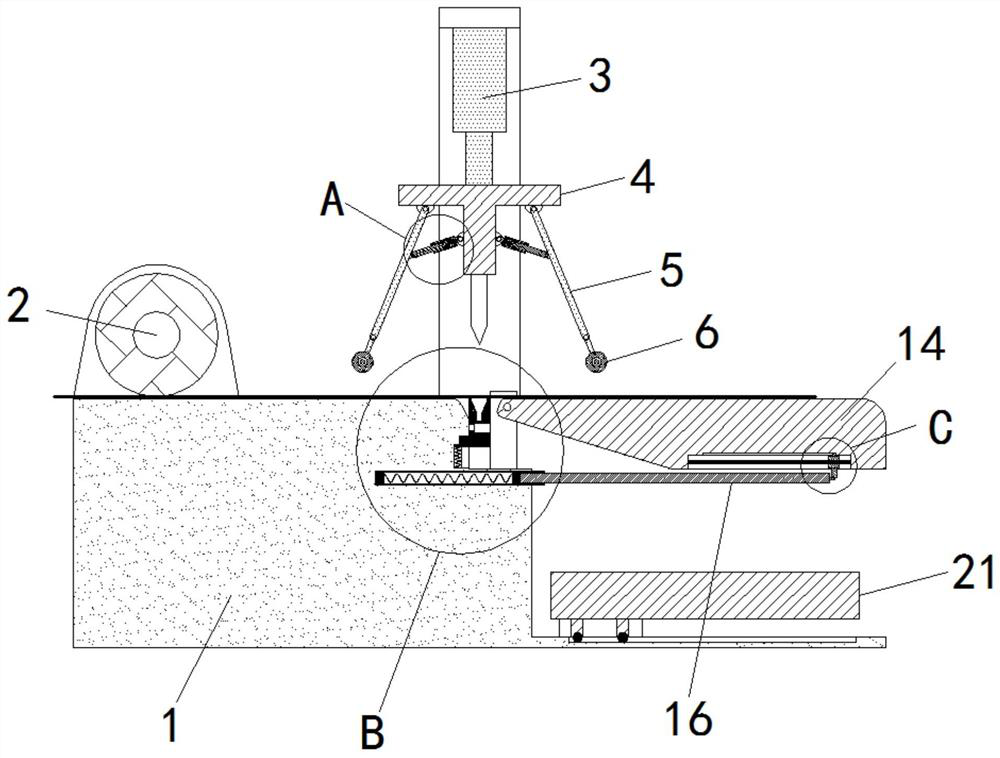

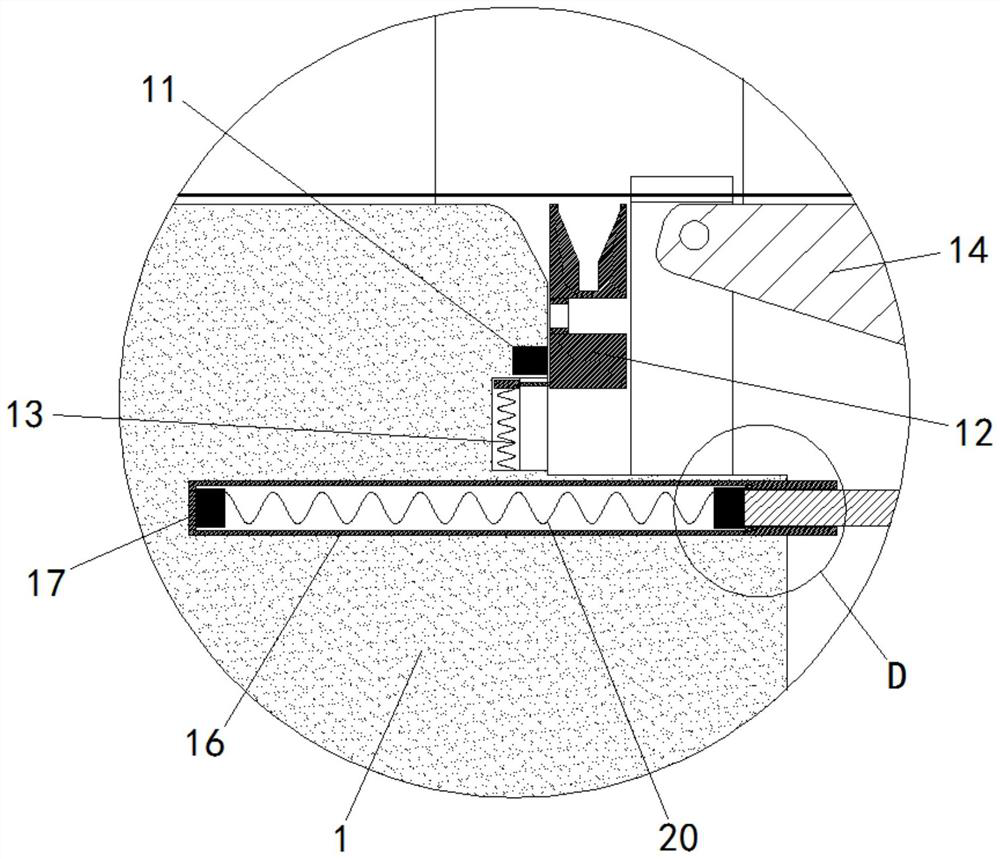

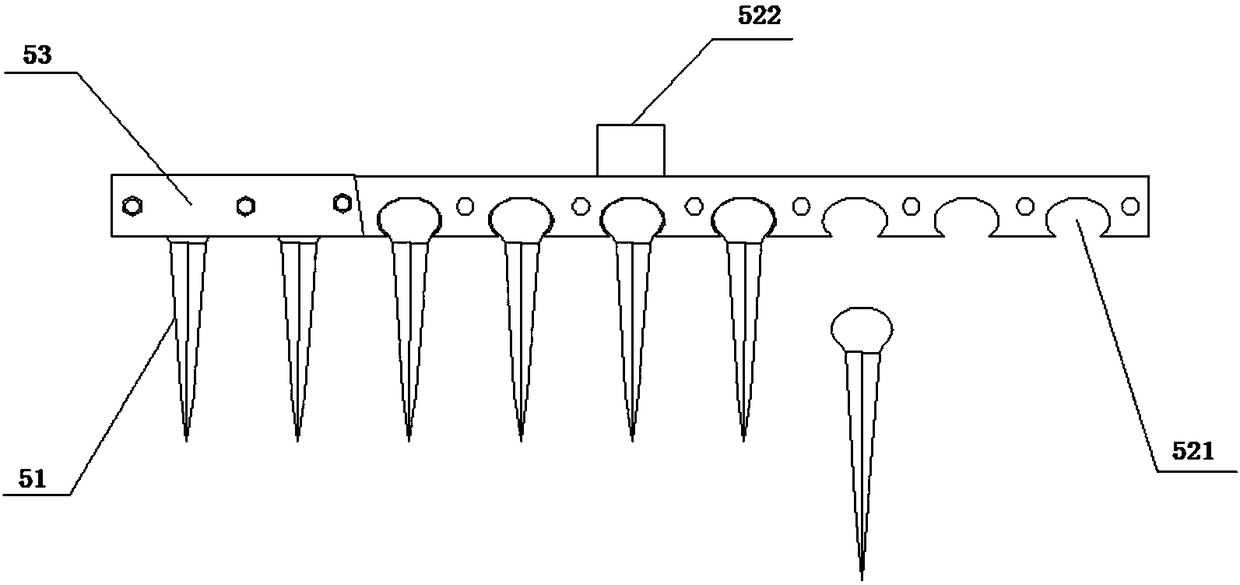

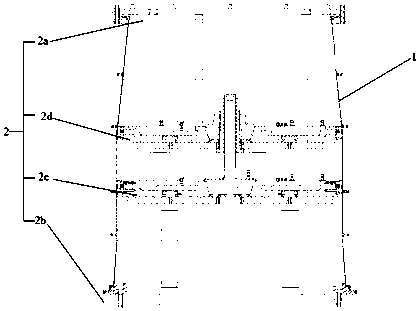

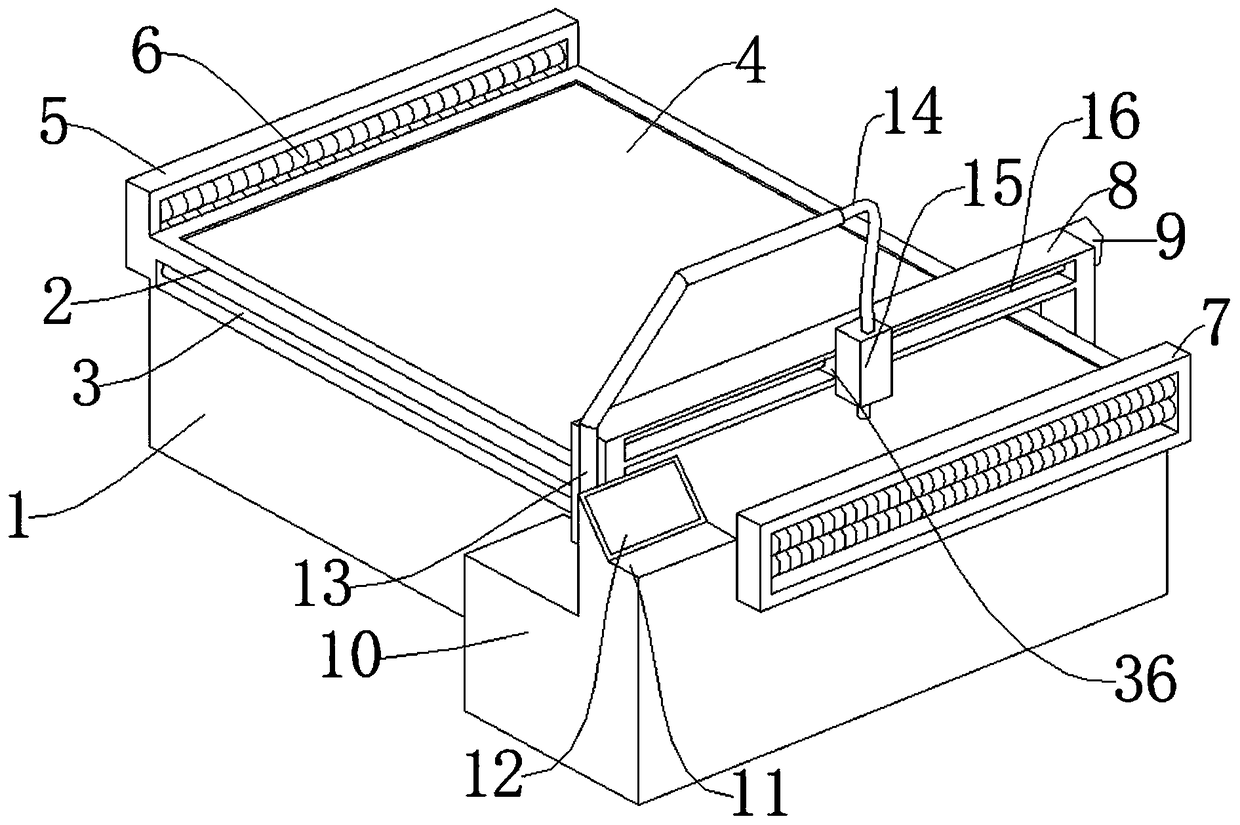

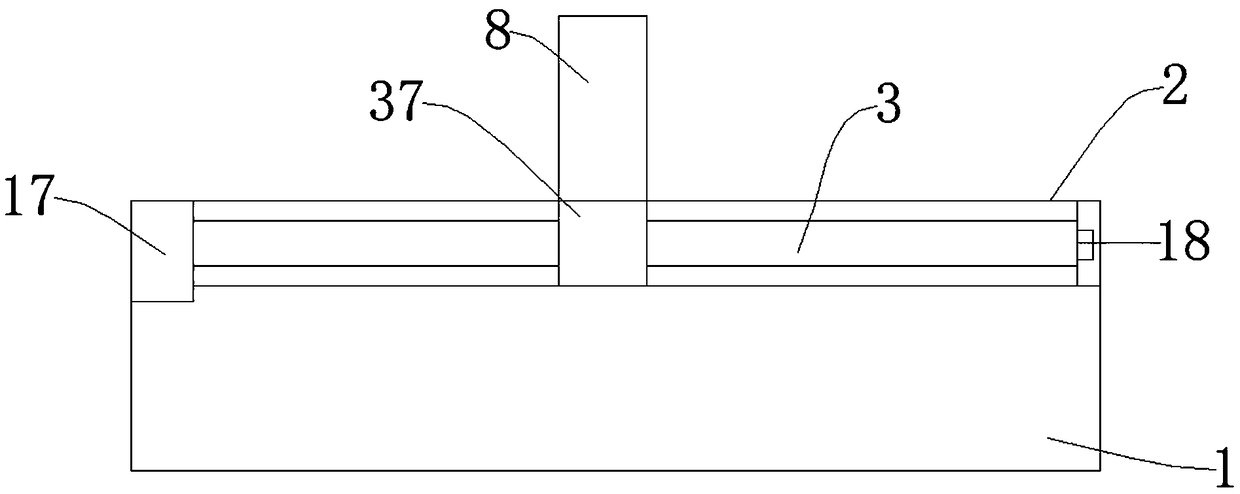

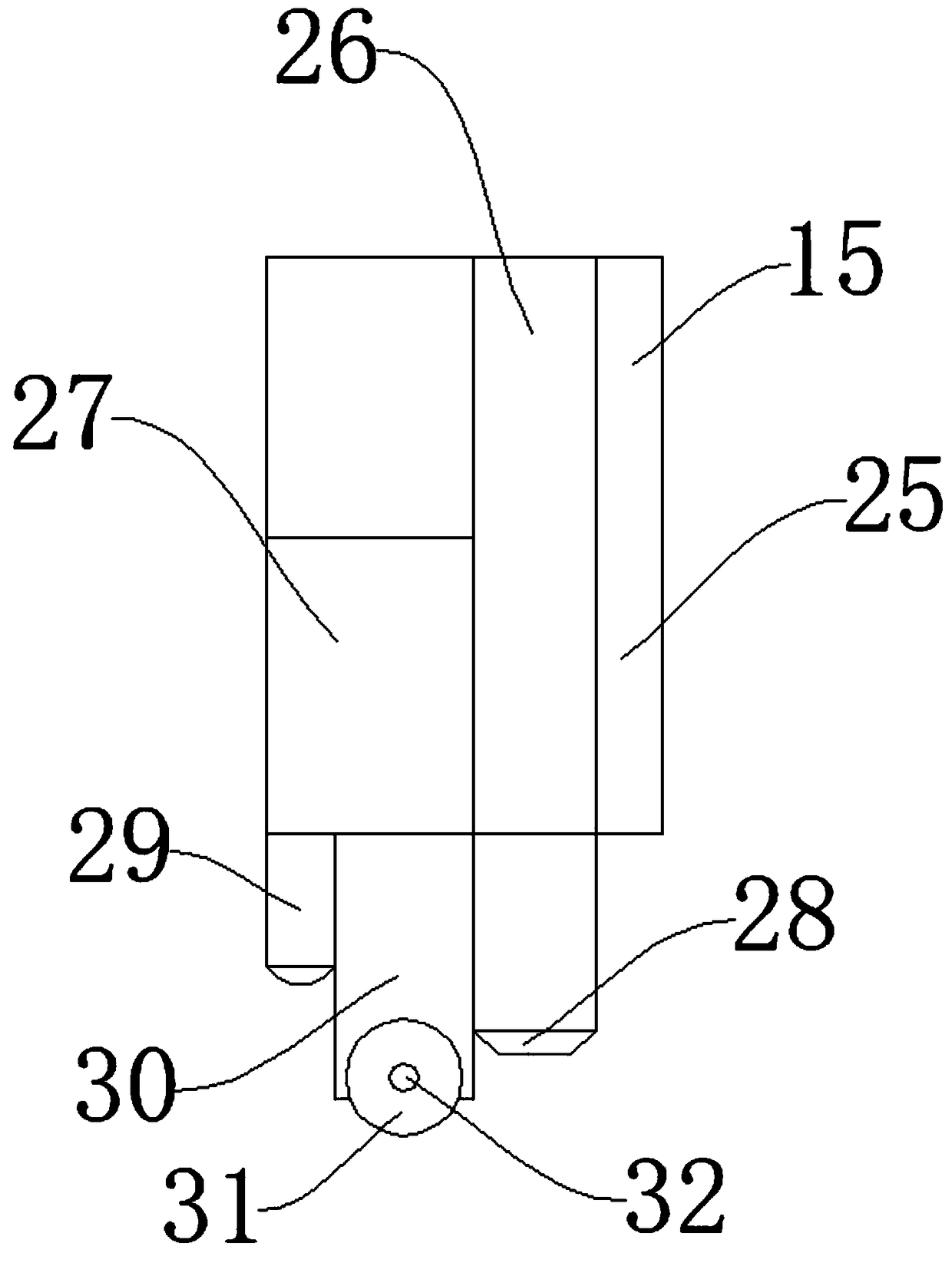

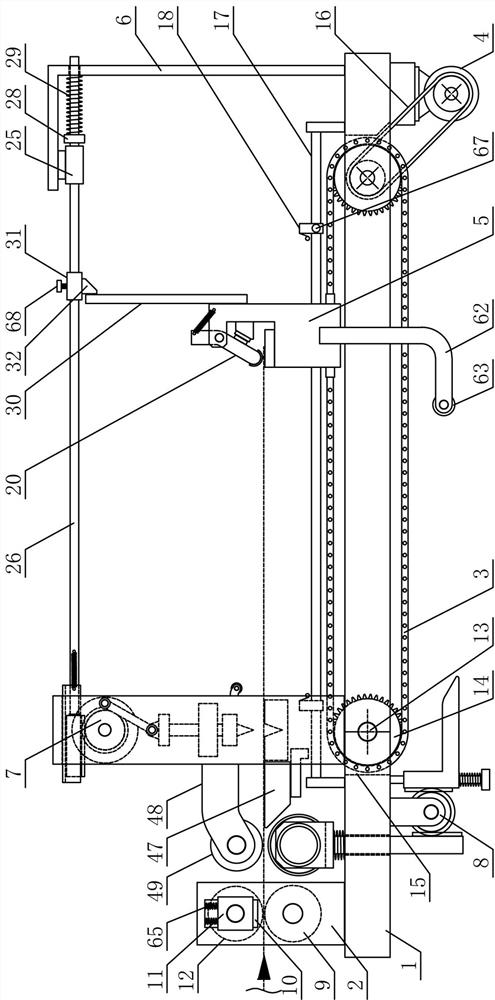

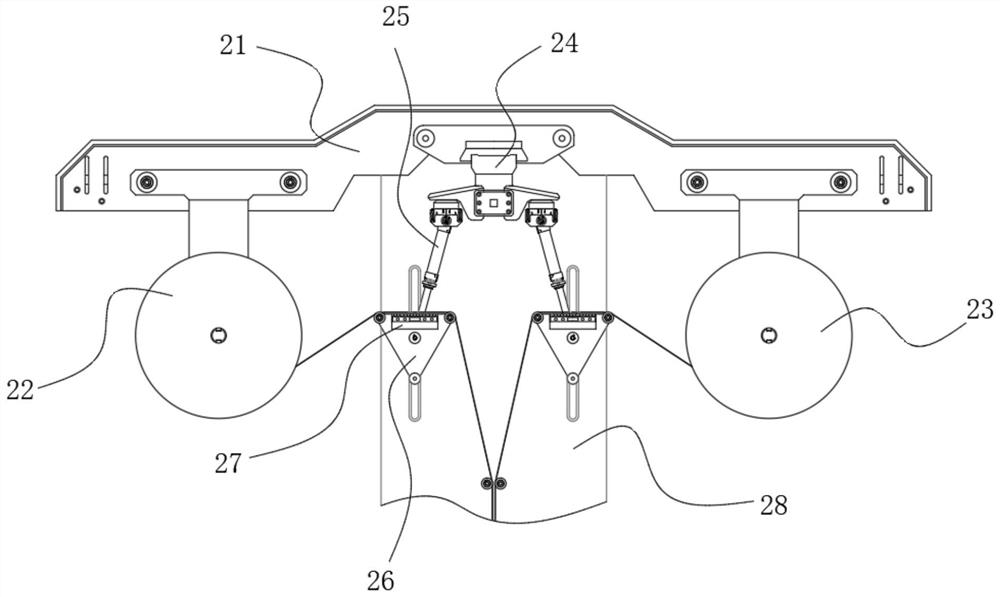

Tailoring device for knitted fabric processing

ActiveCN111636187AGuaranteed smooth cuttingImprove cutting efficiencySevering textilesTextile shapingEngineeringMechanical engineering

The invention relates to the technical field of knitted fabric processing, and discloses a tailoring device for knitted fabric processing. The tailoring device comprises a worktable. A conveying roller is arranged on the left side of the upper portion of the worktable. A telescopic column is fixedly installed at the position, located on the right side of the conveying roller, of the upper portionof the worktable. The lower end of the telescopic column is fixedly connected with a tailoring mechanism. Connecting rods are movably hinged to the left portion and the right portion of the tailoringmechanism correspondingly. A leveling roller is arranged at the lower portion of each connecting rod. A light shielding mechanism is slidingly connected with the right side of the upper portion of theworktable. A turning plate is movably hinged to the right side of the upper portion of the worktable. The tailoring device for knitted fabric processing drives the leveling rollers to fall, the conveying roller to stop and the leveling rollers to stretch a fabric flat, and rotates the turning plate clockwise in cooperation with the light shielding mechanism extruded to fall, thereby realizing theeffects of improving tailoring efficiency and relieving labor intensity of users.

Owner:衣拉拉集团股份有限公司

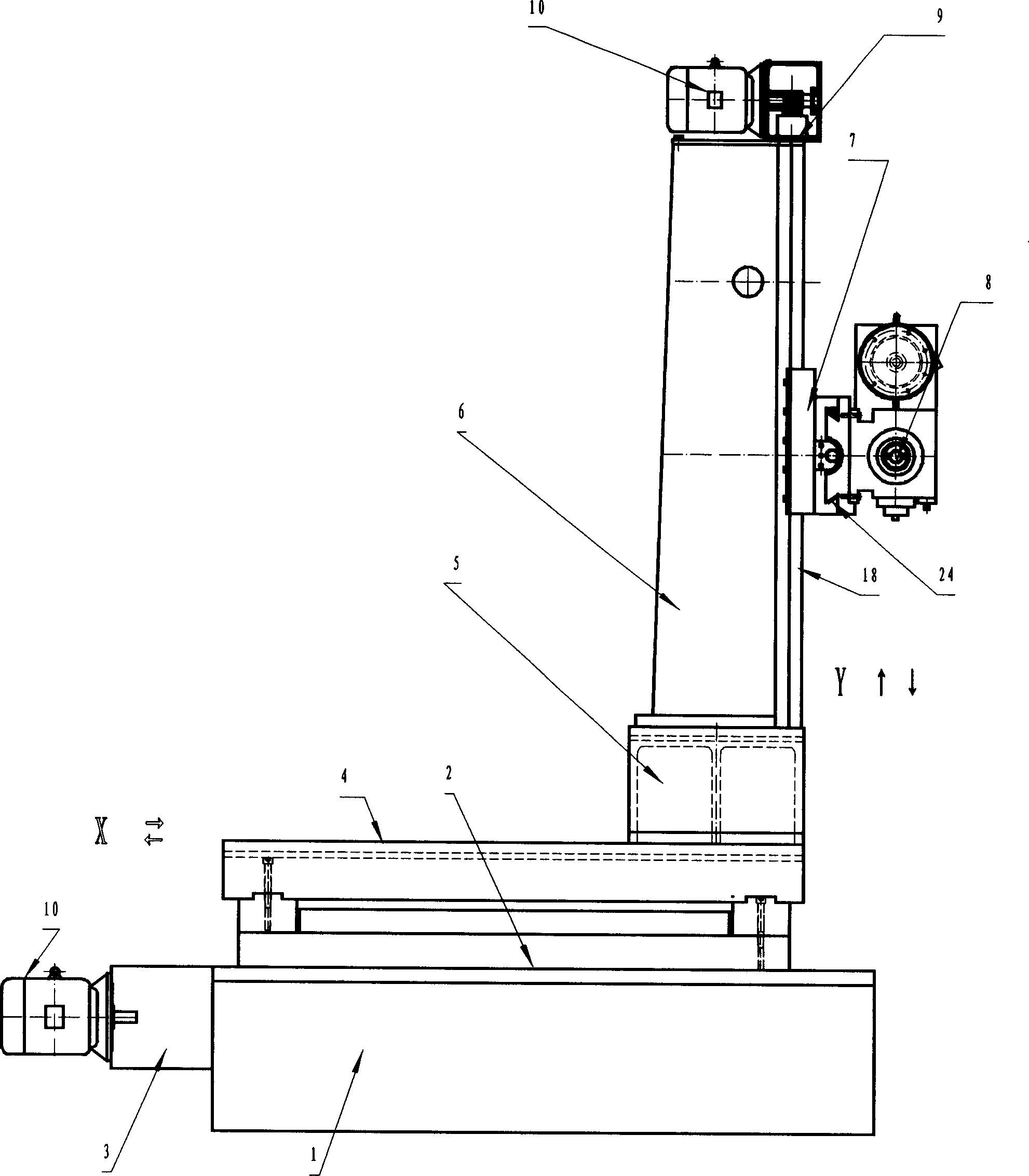

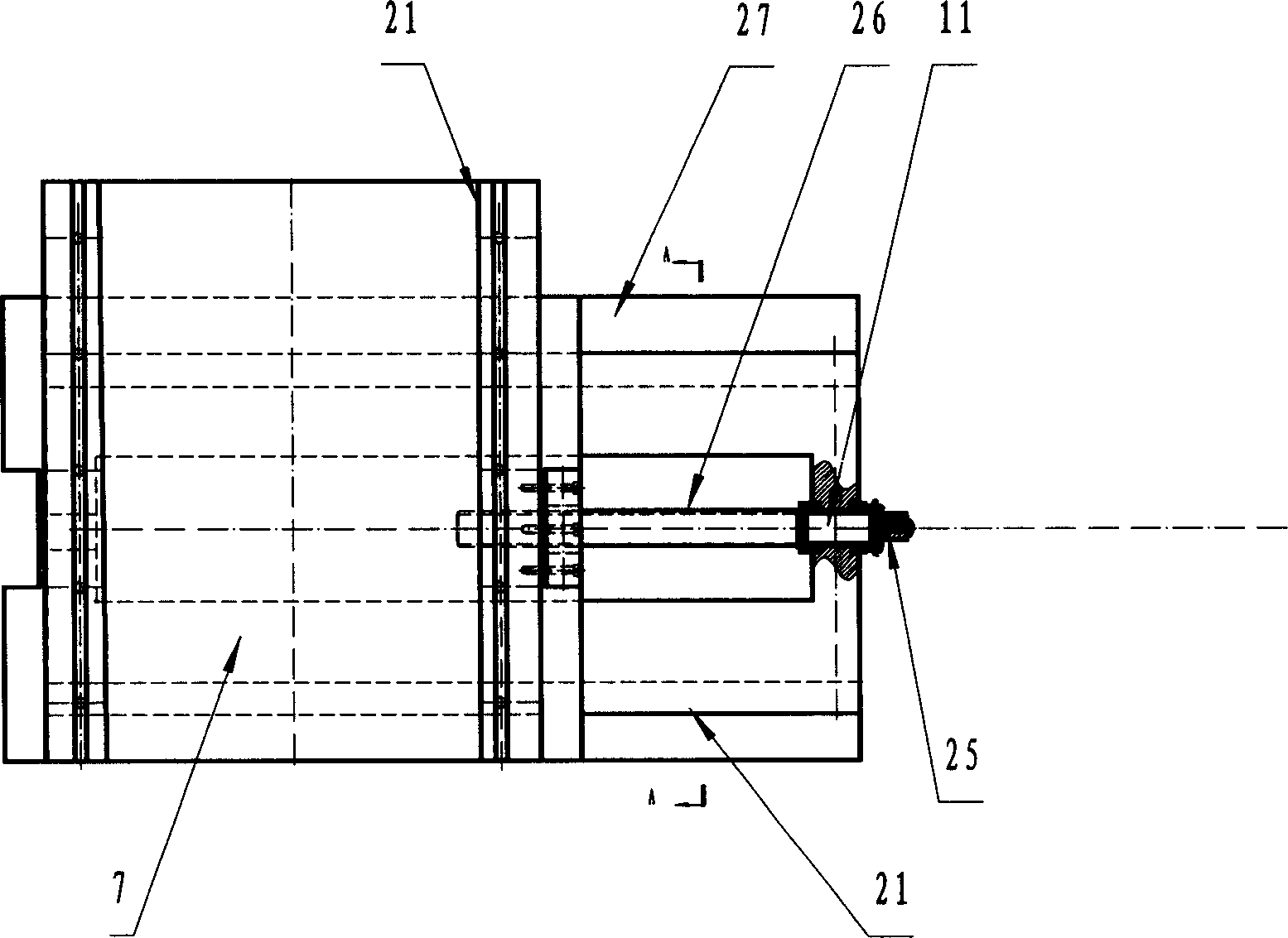

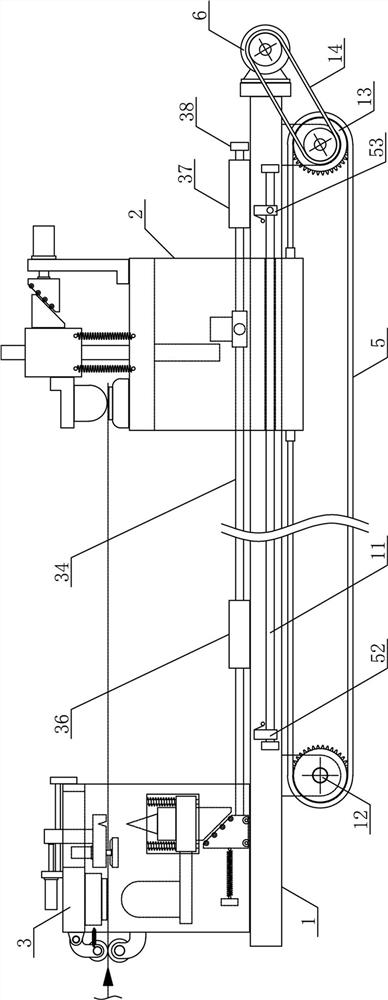

On-line repair method and special combined machine tool thereof

InactiveCN1454744AStable cutting processGuaranteed uptimeOther manufacturing equipments/toolsLarge fixed membersFrequency conversionEngineering

The present invention provides a kind of special combination machine tool repairing the large-scale unmovable overhead device; it possesses all kinds of function such as boring, milling and cutting and belongs to the machining device field. According to different machining object the present invention can assemble and unassemble different machine tool, many functions can be piled up. The machine tool structure adopts floor milling machine frame, and its circuit adopts one-drive-two frequency conversion control technique, to fit milling, boring and cutting device together. The machine tool can quickly move toward three-dimensional direction and lock any direction to make machining steady going. Moreover it has highly precision and simple machine structure.

Owner:NANJING NANGANG IND DEV CO LTD

Ball nose cutting insert and ball end mill thereof

ActiveUS7226249B2Reduce resistanceSatisfactory cuttingMilling cuttersShaping cuttersMilling cutterNose

In this insert, in addition to the insert being formed so that the cutting edge is twisted at a helix angle within the range of 5° to 25° about the axis when the insert is attached to the insert mounting seat, the thickness of the insert body at the flank located on a straight line, which passes through the center of the rough hemisphere formed by the rotational locus of the cutting edge and forms an angle of inclination of 90° relative to the axis, is set to be within the range of 0.5 D to 0.9 D relative to the thickness D of the rough plate that composes the insert body. As a result, since a comparatively gentle but adequately large helix angle is imparted to the cutting edge, cutting resistance decreases. In addition, since the thickness of the insert body at the flank on the rear end side of the insert body is not excessively thin, the rigidity of the insert body is adequately secured.

Owner:MITSUBISHI MATERIALS CORP

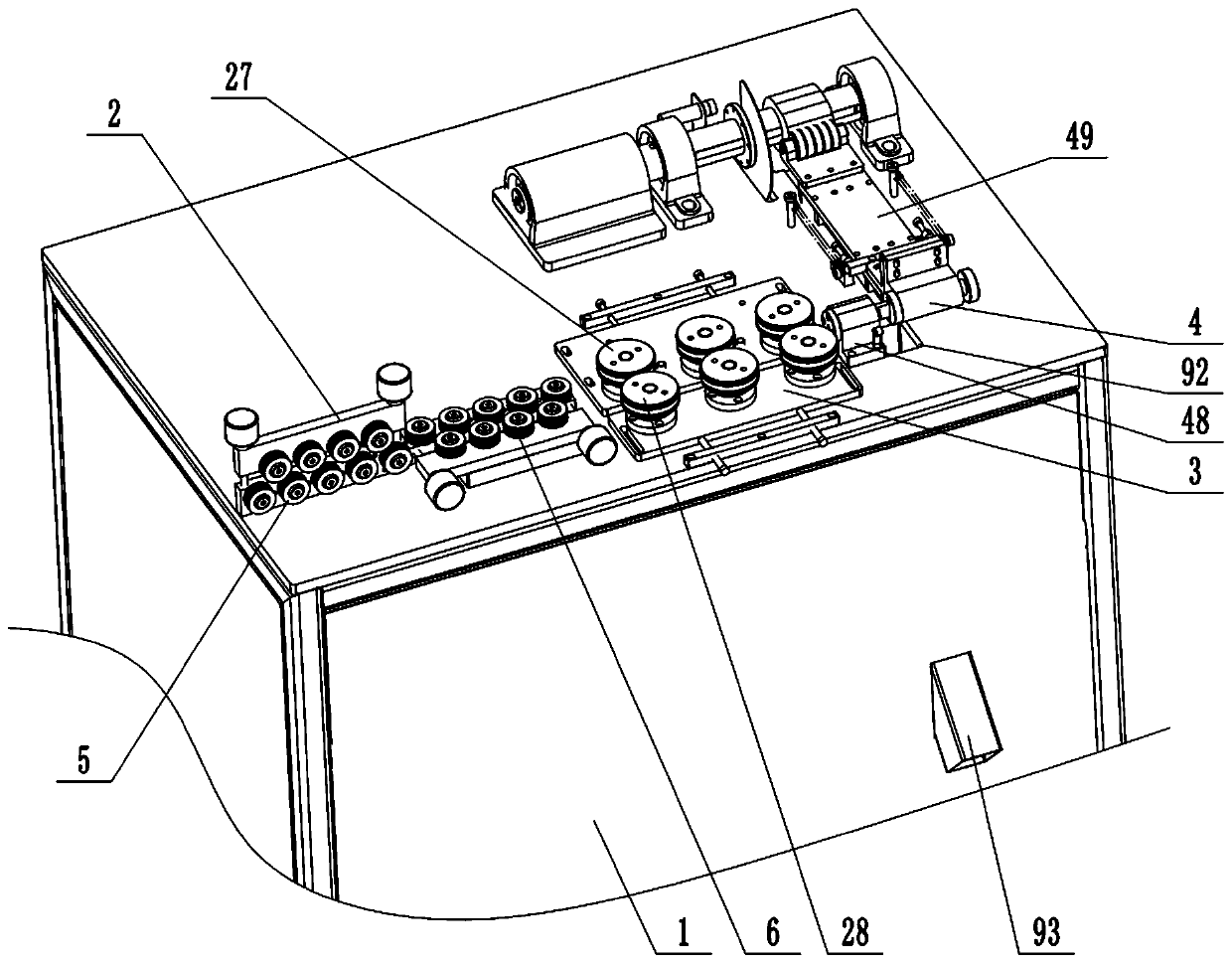

Full-automatic wood cutting equipment

The invention relates to the field of wood processing equipment and particularly discloses full-automatic wood cutting equipment comprising a rack, a platen, a cutting mechanism, a storage mechanism and a feed mechanism. The storage mechanism comprises a frame, a first adjusting plate and a second adjusting plate. Spaces are reserved between the platen and the bottom of the first adjusting plate as well as the bottom of the second adjusting plate. The frame is provided with a support mechanism, a push mechanism and an adjusting mechanism. The platen is provided with a lifting mechanism. The feed mechanism comprises a feed plate, a baffle, a slideway, a sliding groove, a feed assembly and a feed motor. The feed assembly comprises a sliding push block, an L-shaped push plate and a balance plate. The cutting mechanism comprises a guide rail, a driving cylinder, a movable support, a lifting cylinder, a movable seat, a cutting motor, a cutting saw web, a fixed cylinder, a fixed plate, an alignment cylinder, an alignment plate, an inductor and a locating block. The full-automatic wood cutting equipment has the characteristics that labor cost is low, cutting efficiency is high, the automation degree is high, raw wood is not inclined, and potential safety hazards are avoided.

Owner:HUNAN MAOYUAN FORESTRY CO LTD

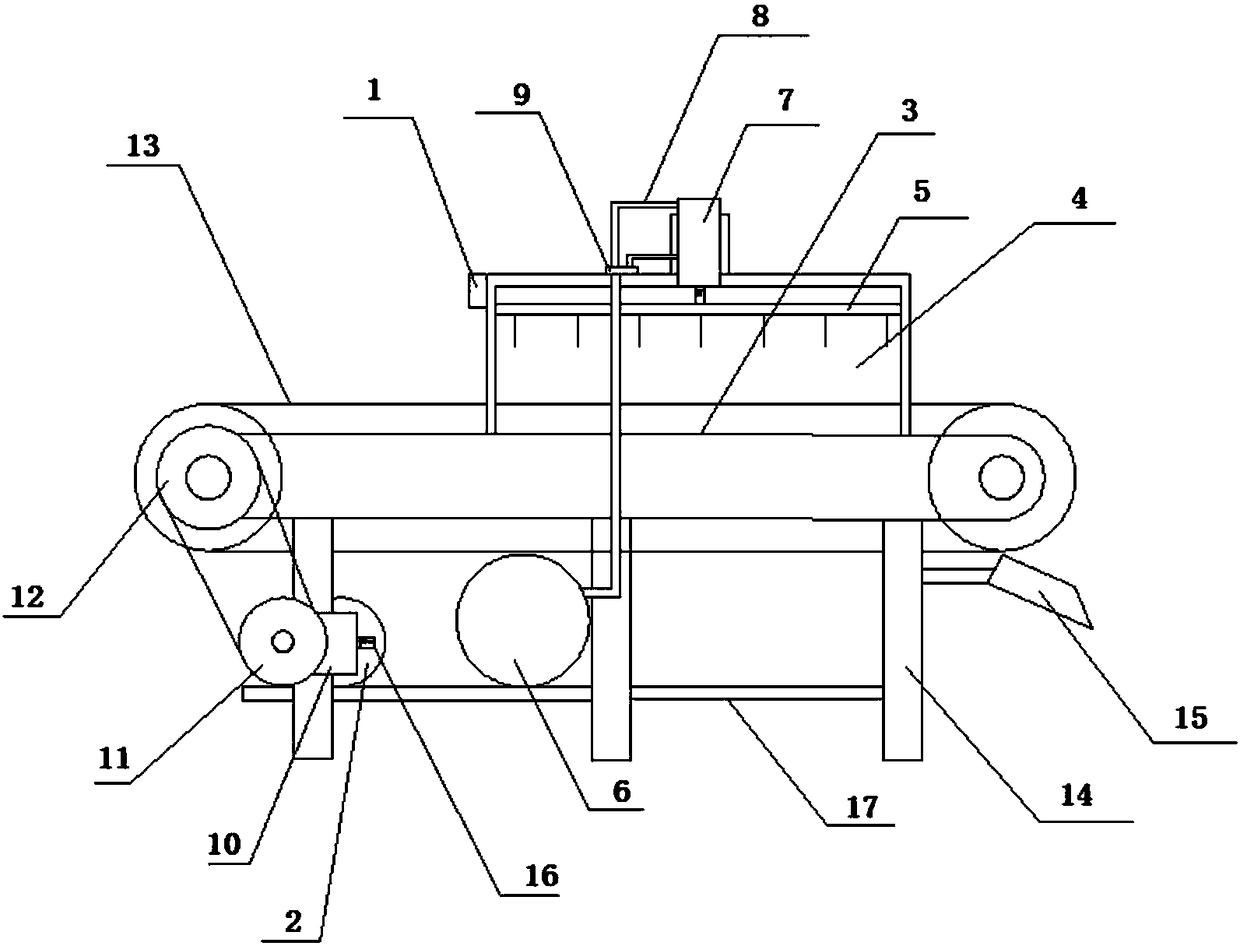

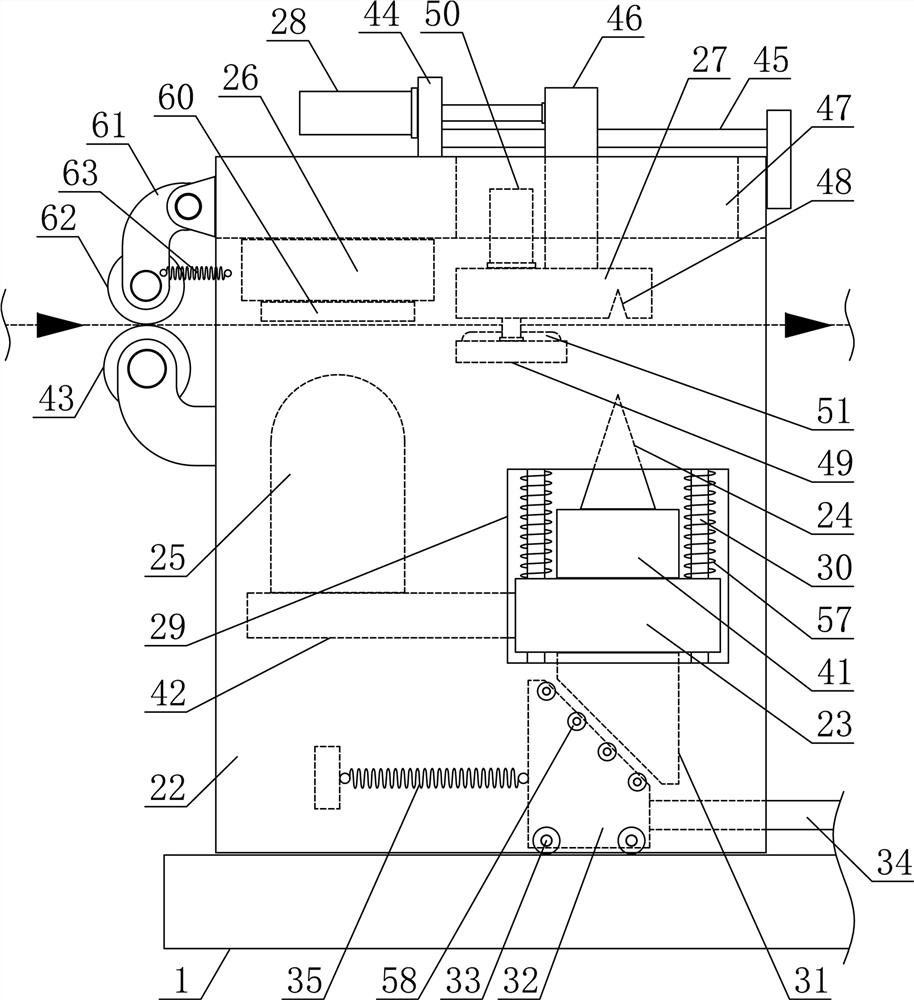

Uncaria cutting equipment

ActiveCN108381622ATo achieve the effect of automatic controlStable cutting processMetal working apparatusDrive wheelEngineering

The invention discloses uncaria cutting equipment which comprises a control panel, a motor, a worktable, a cutting room, a tool, an air compressor, an air cylinder, an air pipe, an electromagnetic valve, a conversion box, a driving wheel, a driven wheel, a conveyor belt, supporting columns, a hopper and a telescopic control block, wherein the cutting room is arranged on the worktable and is internally provided with the tool; the air cylinder is arranged in the top of the cutting room and one end of the air cylinder extends to the cutting room; the control panel is arranged on the cutting room;the driven wheel is arranged on the left side of the worktable; the conveyor belt is arranged on the worktable; the supporting columns are arranged below the worktable; mounting plates are arranged on the supporting columns; the conversion box is arranged on the left side supporting column; the motor is connected to the conversion box; the driving wheel is arranged on the conversion box; the telescopic control block is arranged on the right side of the conversion box; the air compressor is arranged below the cutting room; the air compressor is connected to the air cylinder through the air pipe; the air cylinder is controlled by means of the electromagnetic valve; the hopper is arranged on the right side supporting column; and the motor and the air compressor are electrically connected tothe control panel.

Owner:江苏威扬环境科技有限公司

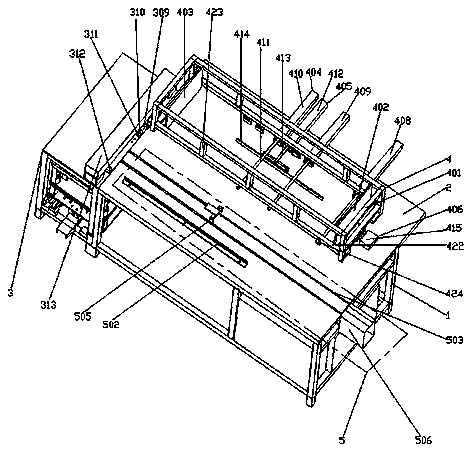

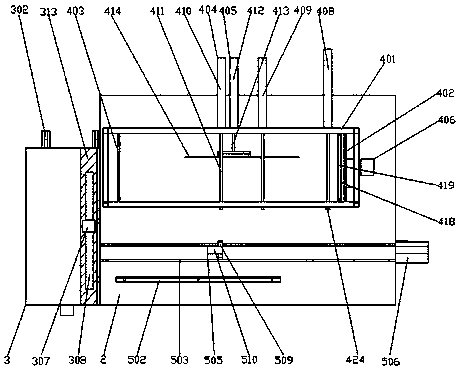

Mass production process suitable for plate welding receivers

ActiveCN110405426AGuaranteed deformationReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention relates to the field of machinery, in particular to a mass production process suitable for plate welding receivers. During welding, a tool I is adopted to expand a receiver main body, sothat the outer surface of the receiver main body is bonded with the inner surface of a flange edge, the welding line quality is guaranteed, and the deformation of the receiver main body is the smallest; the end with the smaller diameter of the receiver main body is downwards; then, a tool II is lifted into the receiver main body from the top; the receiver main body and the tool II are totally heated according to a heat treatment process; the tool II drops to the bottom under the effect of gravity to achieve a shape correcting effect; when the receiver main body is machined, the receiver mainbody is clamped by adopting a tool III; the receiver main body and the flange edge are machined according to a manufacturing process, and a longitudinal mounting edge window is formed in the receivermain body; and the tool III is totally bonded with the inner wall of the receiver main body to prevent vibration of the receiver main body and cutter avoidance, so that the deformation of the receivermain body is reduced, the cutting parameters in the machining process can be doubled or higher, the machining period is shortened, and the mass production is realized.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

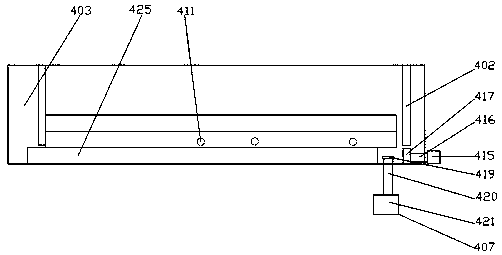

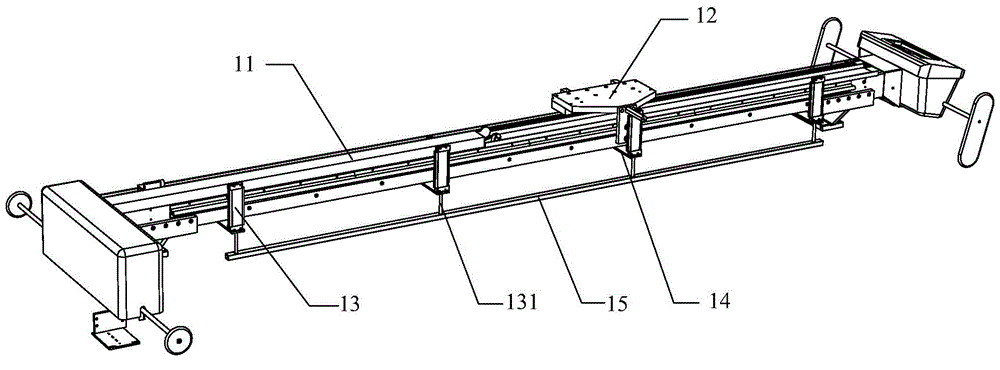

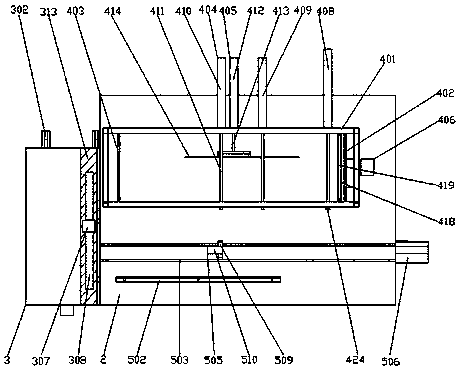

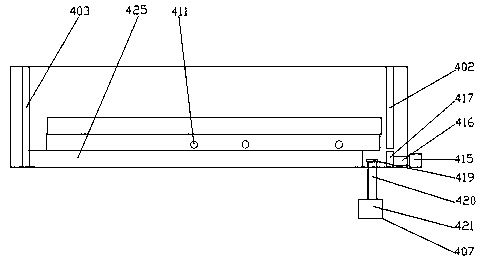

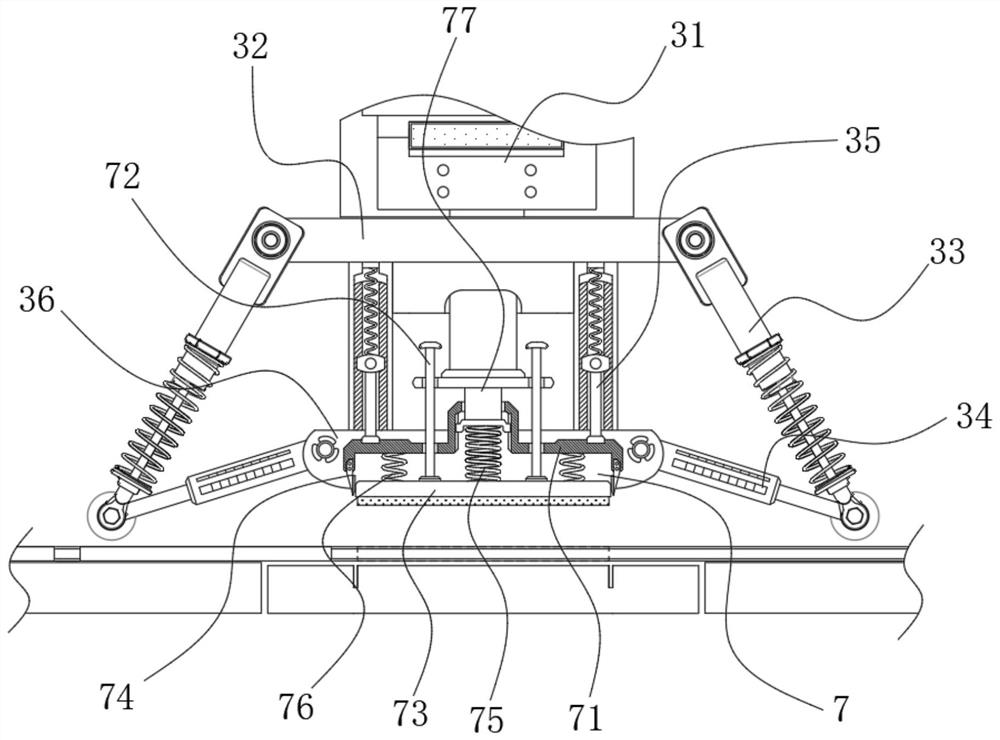

Cloth pressing device and cloth pressing method of automatic cutting bed

ActiveCN104088128AStable cutting processImprove efficiencySevering textilesLimit valuePressure controlled ventilation

The invention discloses a cloth pressing device and cloth pressing method of an automatic cutting bed. The cloth pressing device comprises a cloth pressing unit and a pressure control unit. The cloth pressing unit is mounted on a cutting head beam of a cutting table and comprises at least two cylinders and one cloth pressing rod, and the push rod of each cylinder is fixedly connected to the cloth pressing rod; the pressure control unit comprises an electromagnetic valve communicated with the cylinders, a controller connected to the electromagnetic valve and a pressure relief valve connected between the electromagnetic valve and the air source of the cylinders. The cloth pressing method includes setting a pressure limiting value of the pressure relief valve according to the height of the cloth; after cutting, allowing the controller to send a window passing signal to the cutting table to drive the cutting table to move towards a material collecting table; allowing the window passing signal to trigger the electromagnetic valve to allow the push rods of the cylinders to push the cloth pressing rod to press the cloth to the cutting table so as to allow the cloth to move with the cutting table; after window passing, allowing the electromagnetic valve to drive the cloth pressing rod to lift from the cloth, and finishing the cloth pressing process. Synchronous motion of the cloth and cutting table is guaranteed, and the automatic window pass of the cloth is implemented.

Owner:BULLMER ELECTROMECHANICAL TECH

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

Wavy-patterned monowire for cutting

InactiveCN104108141AEnough containmentImprove performanceSemiconductor/solid-state device manufacturingFine working devicesAlloySemiconductor

Owner:HYOSUNG ADVANCED MATERIALS CORP

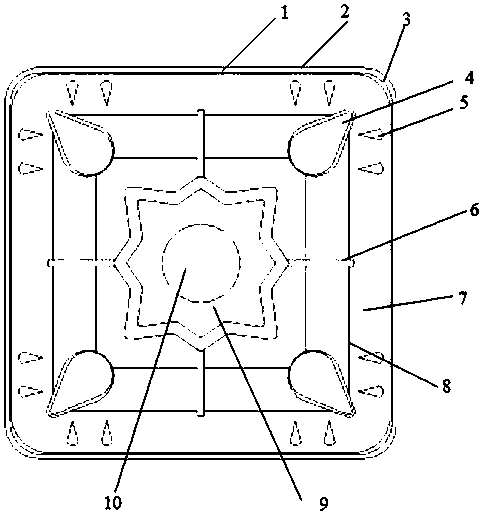

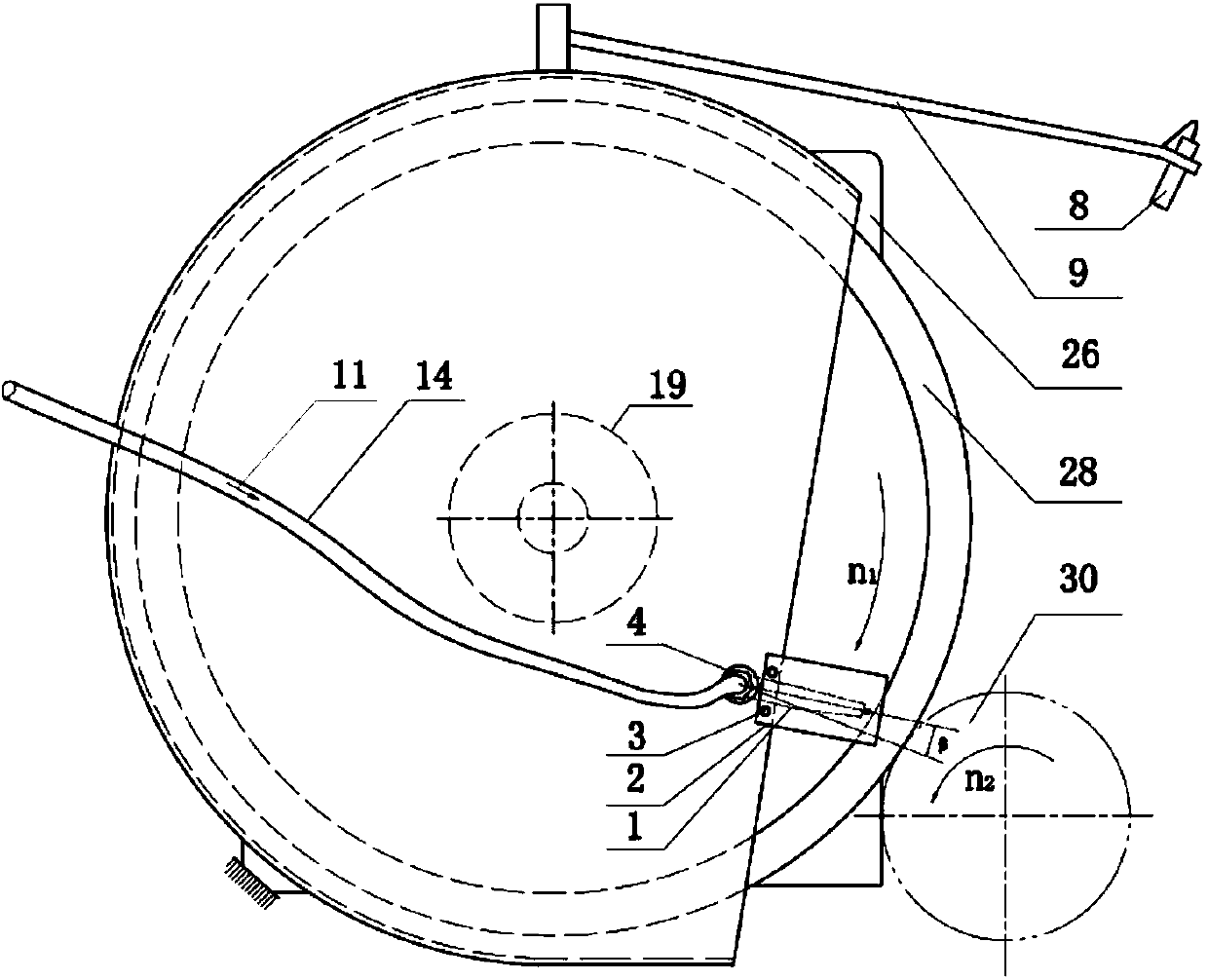

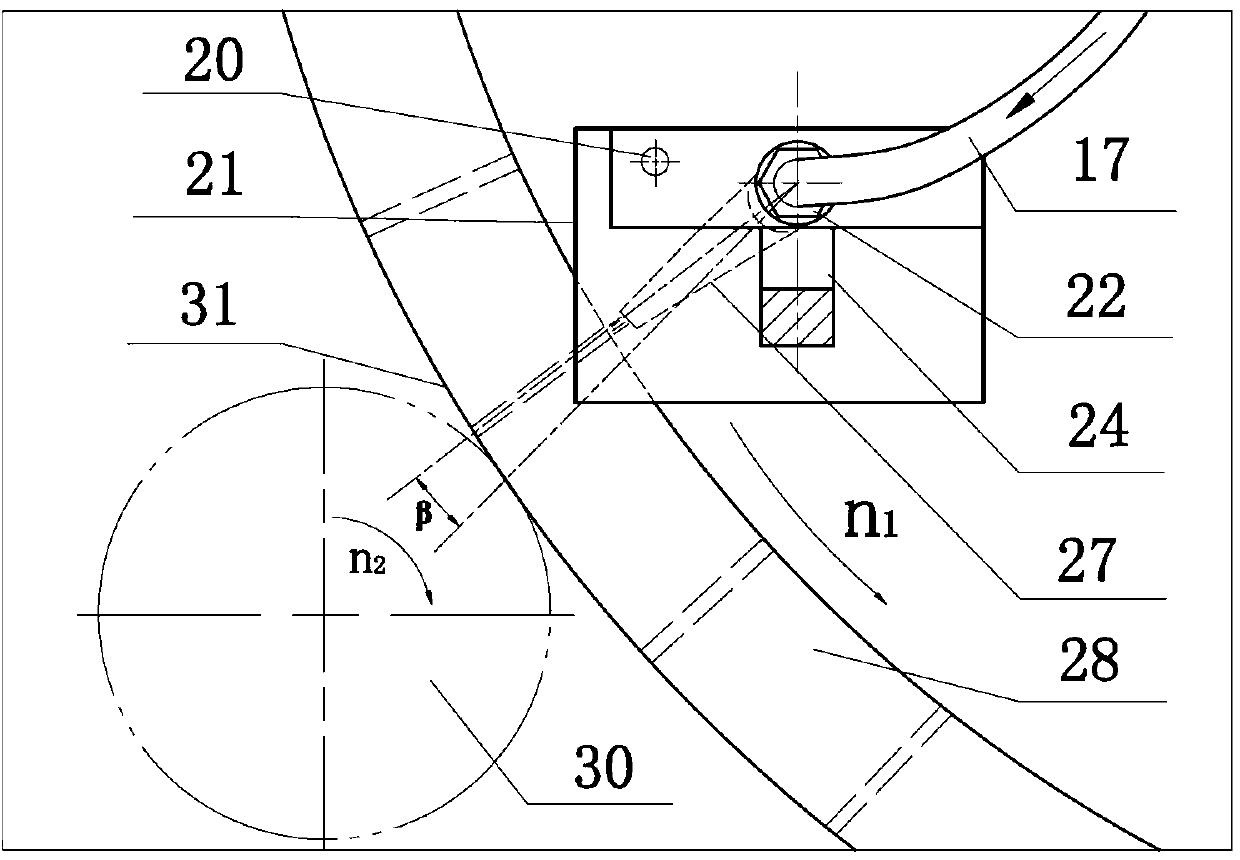

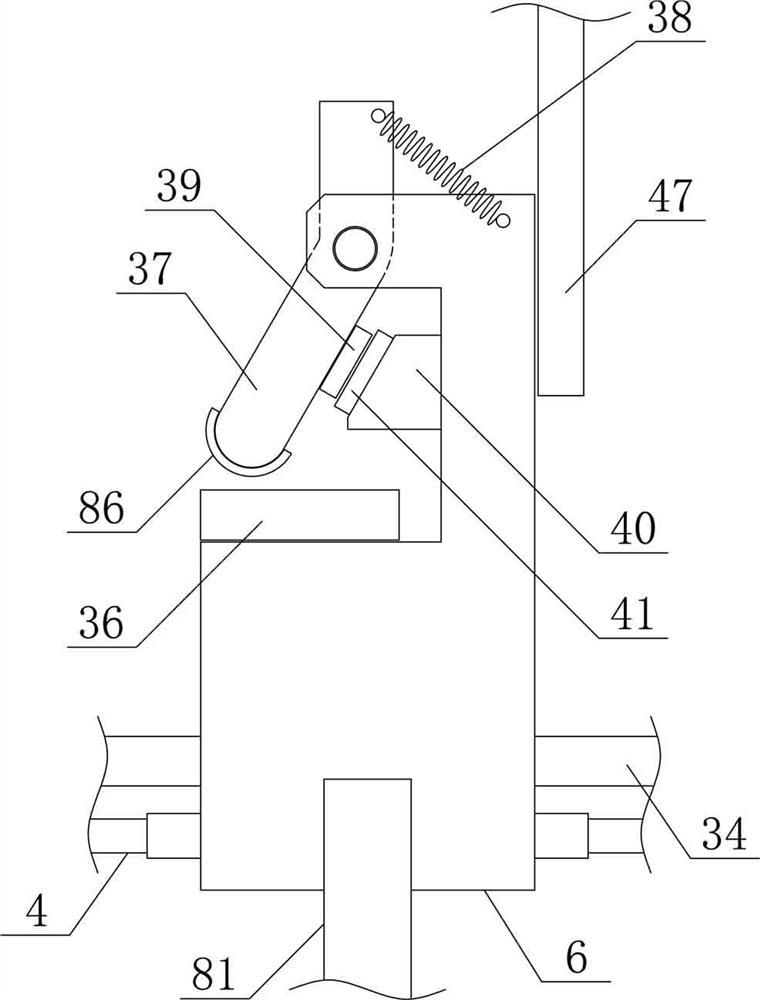

Turning tool capable of achieving rapid clamping and rapid clamping method using same

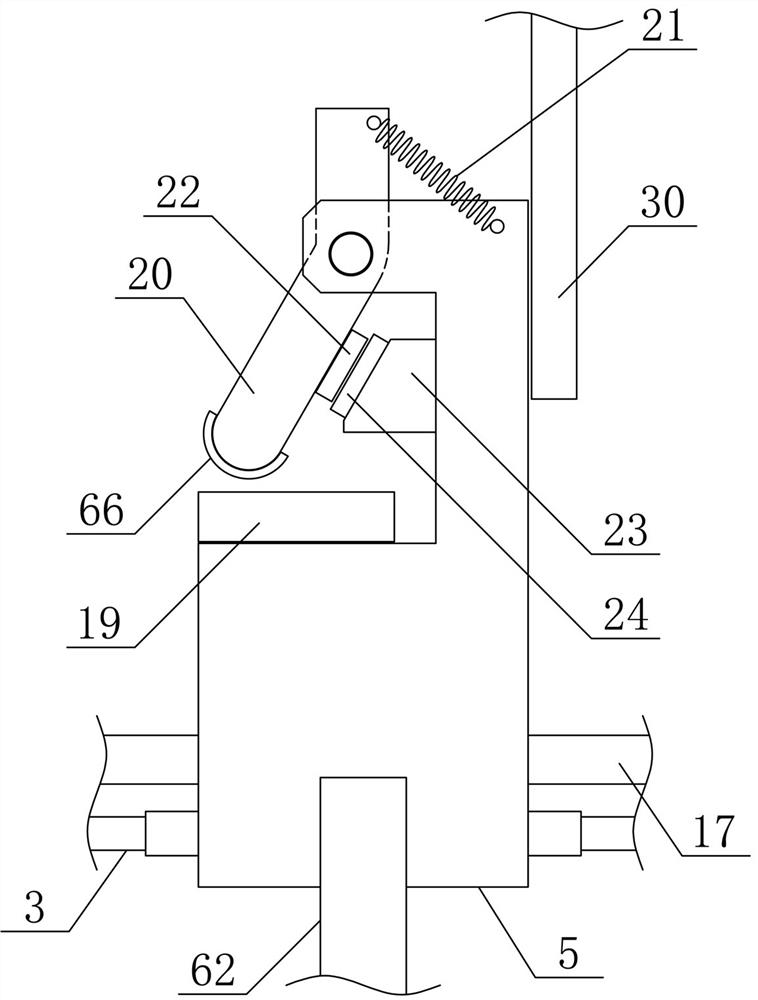

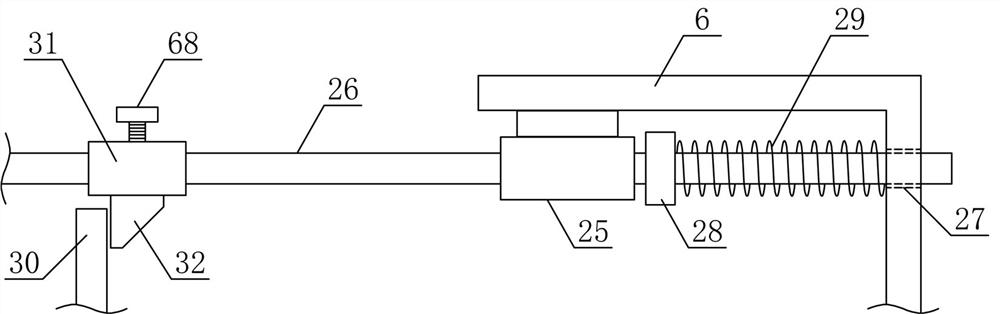

PendingCN109483283AImprove clamping strengthStable cutting processPositioning apparatusMetal-working holdersEngineeringMachining process

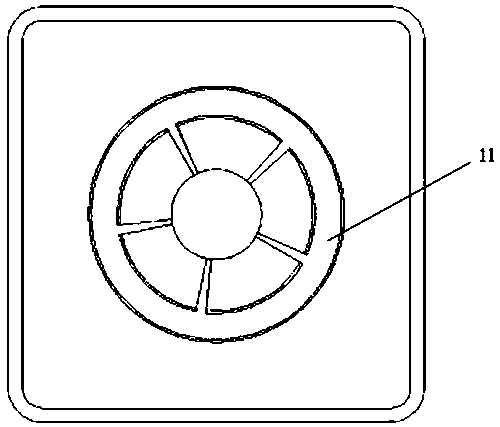

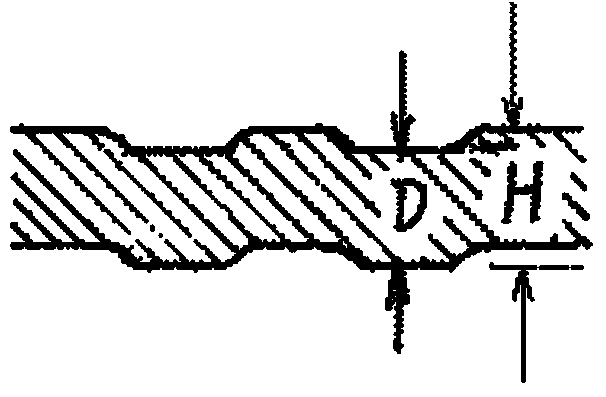

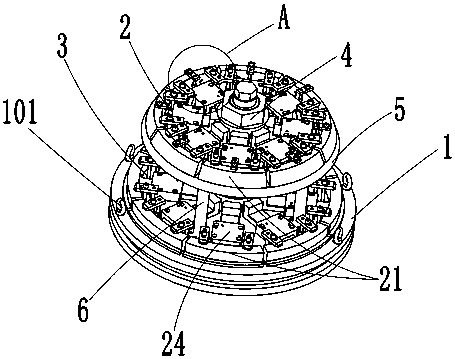

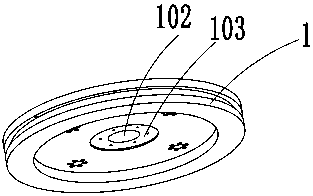

The invention relates to the technical field of machining of thin-walled parts, in particular to a turning tool capable of achieving rapid clamping. The turning tool comprises a base, a lower positioning device and an upper positioning device, wherein the lower positioning device and the upper positioning device are sequentially installed on the base from bottom to top, the turning tool further comprises a driving device, each of the upper positioning device and the lower positioning device is composed of a plurality of supporting blocks, moreover, the plurality of supporting blocks of each ofthe upper positioning device and the lower positioning device are arranged at intervals to form a circular support for the part correspondingly, a fitting surface matched with the inner wall of the part is arranged on the outer wall of each supporting block, the driving device can drive the supporting blocks in the upper positioning device to move synchronously, and can drive the supporting blocks in the lower positioning device to move synchronously. The turning tool achieves positioning through an upper section and a lower section, the circular supports are formed to the part from the innerwall of the part, then the problem that the quality of the part is influenced in the machining process due to insufficient strength of the thin-wall part is solved, the thin-walled part can be quickly clamped, the inner parts are tightly attached, then the cutting parameters can be improved, the production efficiency can be improved, batch machining can be realized, and the mass production chokepoint can be broken through.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Device for cutting carbon fiber cloth used in preparing outer layer of CT bed plate and use method thereof

InactiveCN109322134AReasonable structureEasy to useSevering textilesCleaning using gasesFiberCarbon fibers

The invention discloses a device for cutting carbon fiber cloth used in preparing an outer layer of a CT bed plate and a use method thereof, which includes a device shell, a regulating mechanism, a cutting mechanism and a motor shell, a working table is arranged on the upper end of the device shell, and the working table is connected to the device shell through bolts, longitudinal moving shells are arranged on both sides of the working table, the longitudinal moving shells are integrated with the device shell, and a longitudinal screw rod is arranged inside the longitudinal moving shell, the longitudinal screw rod is rotatably connected with the longitudinal moving shell, the inner part of the device shell is provided with a longitudinal moving motor. The device has the advantages that: the structure is reasonable, the device is integrated with scanning, cutting and dust absorption, the use effect of the device is ensured, the operation is simple, the device adopts automatic scanning and cutting method, the work efficiency is improved, the cutting efficiency is high, the regulating mechanism can be used to adjust the flatness and tenacity of the carbon fiber cloth effectively, which makes the cutting process more smooth.

Owner:鑫材泰克(天津)复合材料有限公司

Fabric cutting device for chemical fiber quilt production

InactiveCN112359579ASmooth and orderly transmission and processingCompact and orderly transfer processingSevering textilesFiberMechanical equipment

The invention discloses a fabric cutting device for chemical fiber quilt production, and belongs to the field of home textile processing mechanical equipment. A feeding conveying support is verticallyand fixedly arranged on one side of the upper portion of a fabric processing support, a feeding conveying pressing roller is horizontally arranged on the upper side of a feeding conveying rotating roller of the feeding conveying support, a translation reciprocating pull plate is horizontally and slidably arranged on a material pulling translation guide rod, a fabric cutting mechanism is arrangedon the fabric processing support on the side of the feeding conveying support, a connecting rod reciprocating support and the fabric cutting mechanism are vertically and fixedly arranged on two sidesof the upper portion of the fabric processing support correspondingly, a cutting translation connecting rod is horizontally arranged in a connecting rod reciprocating sleeve of the connecting rod reciprocating support in a sliding mode, and the fabric guiding and conveying mechanism is arranged on the fabric processing support between the fabric cutting mechanism and the feeding conveying support.The fabric cutting device is reasonable in structural design, capable of efficiently and stably cut chemical fiber quilt fabric in a continuous and smooth mode and high in automation degree of processing, and meets production and use requirements.

Owner:桐乡市康悦时装寝具有限公司

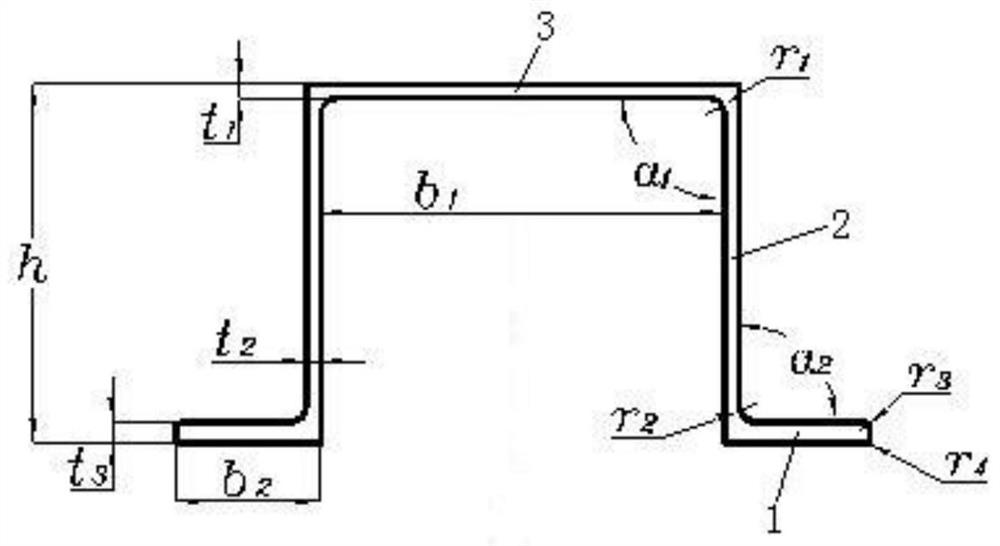

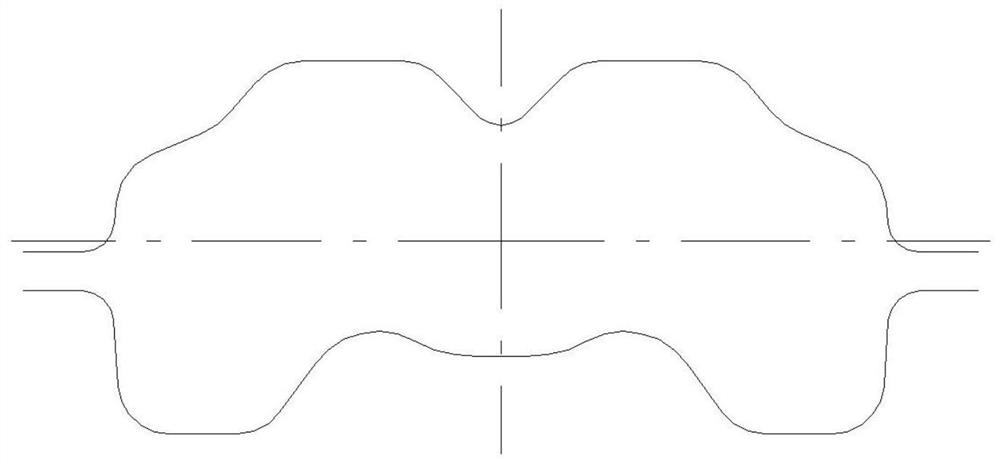

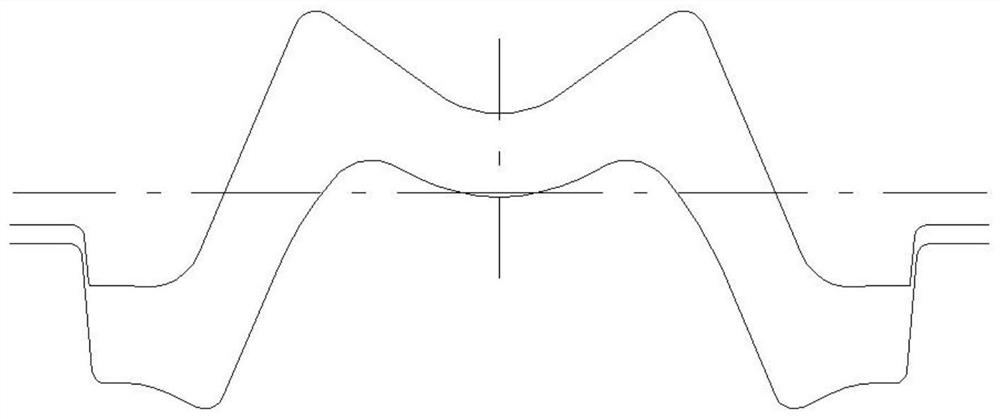

Hat shape steel rolling method and hat shape steel

ActiveCN112474794AReduce lossIncrease productivityTemperature control deviceRolling mill drivesStructural engineeringMechanical engineering

The invention discloses a hat shape steel rolling method and hat shape steel. The technological process of rolling comprises the steps of heating, high-pressure water descaling, cogging rough rolling,reciprocating type continuous rolling, cooling and straightening. A rolling hole pattern comprises a wavy flat arc-shaped pre-segmentation hole, an M-shaped n-type segmentation hole, an n-type finishrolling hole and a hot rolling finished product hole, arc-shaped sections are arranged in the middles of the n-type finish rolling hole and the hot rolling finished product hole, upper leg parts andlower leg parts are symmetrically arranged at the two ends of each arc-shaped section, and the upper ends of the upper leg parts and one ends of the arc-shaped sections intersect to form included angles; the lower leg parts are arranged at the lower ends of the sides, away from the arc-shaped sections, of the upper leg parts and intersect with the upper leg parts to form included angles; and the hat shape steel comprises a horizontal waist, vertical straight legs and horizontal flat legs are symmetrically arranged at the two ends of the waist respectively, and the flat legs are located at thesides, away from the waist, of the straight legs. According to the method, the production efficiency of the hat shape steel can be effectively improved, the rolling stability is improved, the processdesign difficulty is reduced, and the roller equipment loss is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

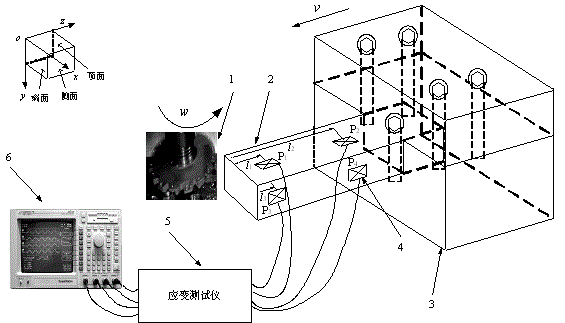

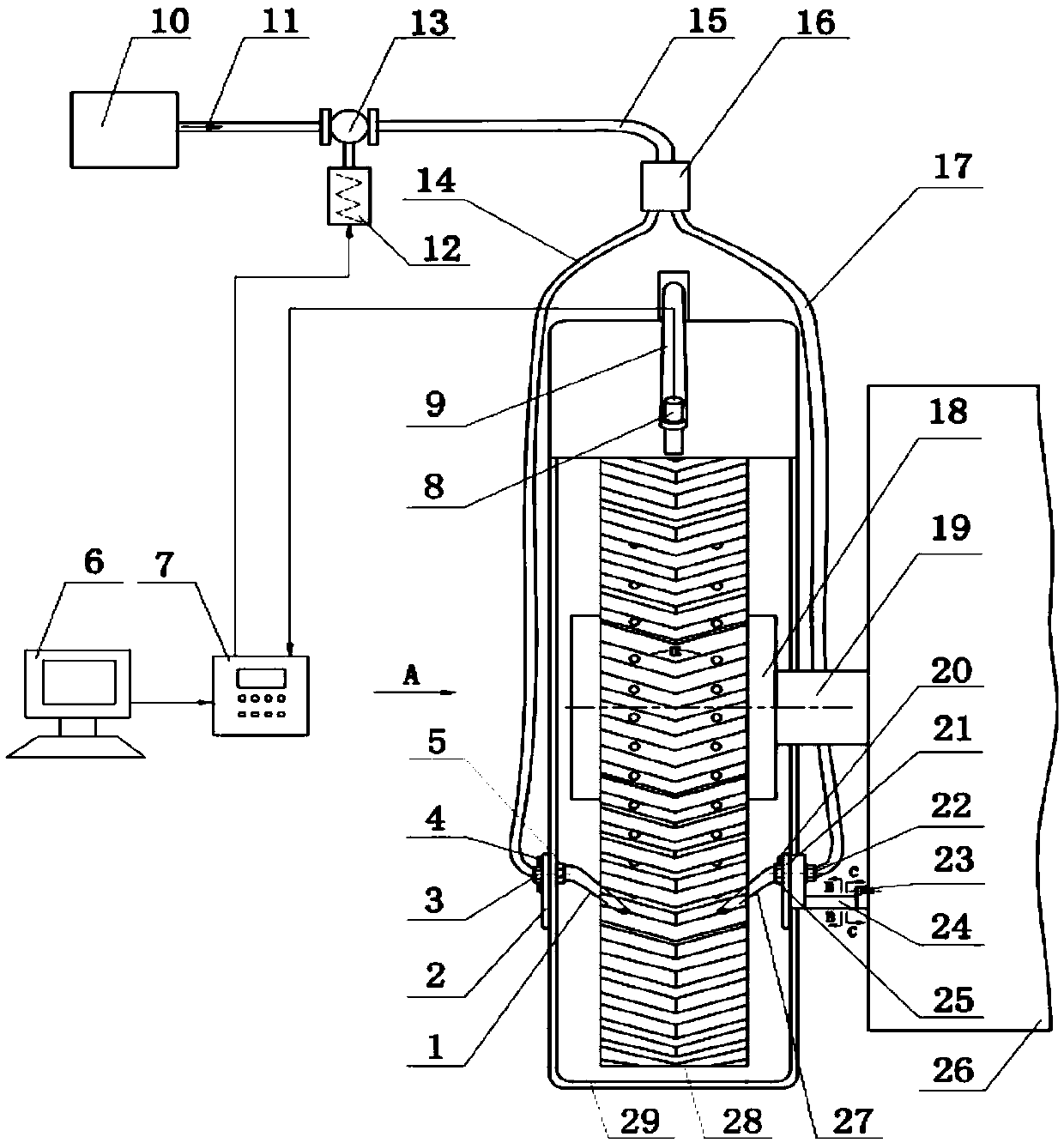

Device and method measuring high rotating speed/superhigh rotating speed three dimensional cutting force

InactiveCN105081881AStable cutting processAvoid distortionMeasurement/indication equipmentsMetal working apparatusEngineeringDynamometer

The invention discloses a device and method using dynamics reverse engineering technology to obtain three dimensional cutting force; the device comprises a cantilever structure and a fixing device suitable for cutting process under a high rotating speed / superhigh rotating speed condition, a resistance foil gauge and strain gauge measuring workpiece surface deformation, and an oscilloscope displaying workpiece surface stress and frequency. The cantilever beam surface stress obtained by the resistance foil gauge can be converted into three dimensional cutting force size and frequency through mechanics of materials and cantilever beam dynamics knowledge. The device and method can use dynamics reverse engineering technology to measure three dimensional cutting force; the device is clear in principle, simple in device, high in measure precision, wide in application scope, can measure cutting force size and frequency under the high rotating speed / superhigh rotating speed processing condition, thus solving the problems that an existing dynamometer under high rotating speed / superhigh rotating speed condition is small in fixed frequency, and distorted in signal.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Fully-automatic wood cutting machine

PendingCN108908489AMeet supply needsMeet alignment requirementsFeeding devicesAdjusting equipmentEngineeringFully automatic

The invention relates to the field of intelligent wood processing, and particularly discloses a fully-automatic wood cutting machine which comprises a frame, a table plate, a cutting mechanism, a storage mechanism and a conveying mechanism. The storage mechanism comprises a shelf, a first adjusting plate and a second adjusting plate, the bottom of the second adjusting plate is fitted with the table plate, a gap is reserved between the bottom of the first adjusting plate and the table plate, a supporting mechanism, a pushing mechanism and an adjusting mechanism are arranged on the shelf, a lifting mechanism is arranged on the table plate, the conveying mechanism comprises a conveying plate, a baffle plate, a sliding way, a sliding groove, a conveying component and a conveying motor, the conveying component comprises a slidable pushing block, an L-shaped pushing plate and a balance plate, and the cutting mechanism comprises a guide rail, a driving cylinder, a movable support, a movable seat, a cutting motor, a cutting saw blade, a fixed cylinder, a fixed plate, an alignment cylinder, an alignment plate, a sensor and a positioning block. The cutting machine has the advantages that thehuman cost is low, cutting efficiency and automation degree are high, an original wood material cannot be inclined, and potential safety hazards are avoided.

Owner:景宁畲族自治县畲山凤民族工艺品开发有限公司

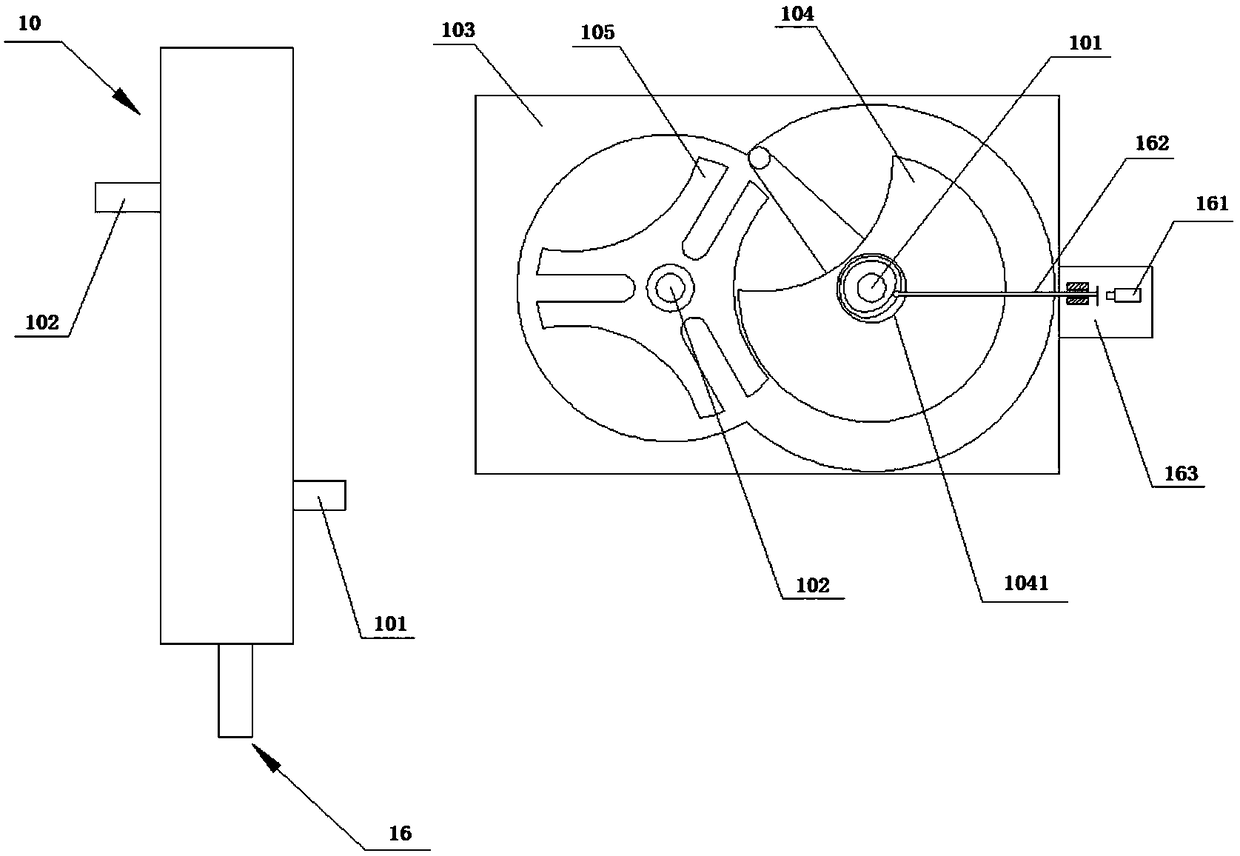

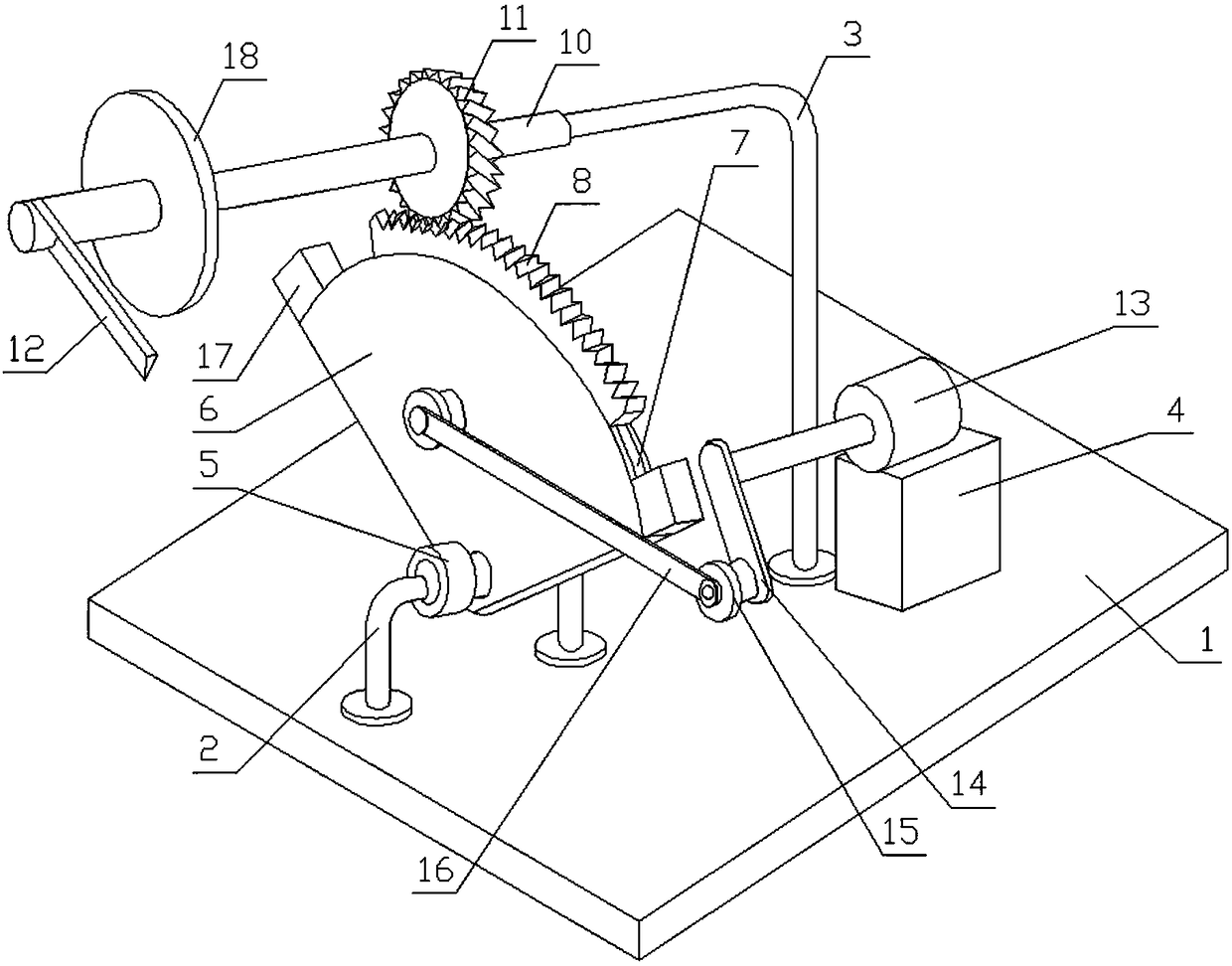

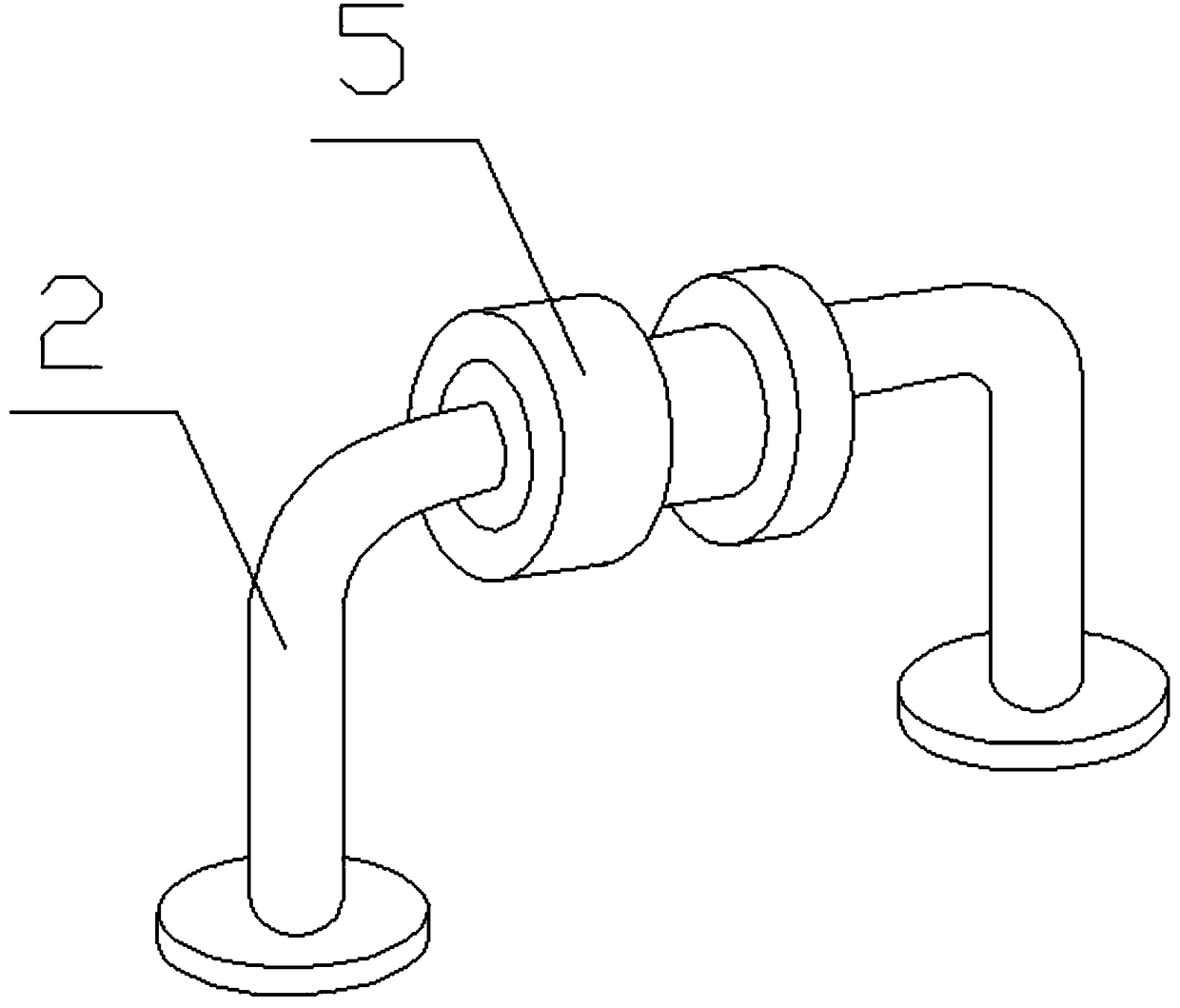

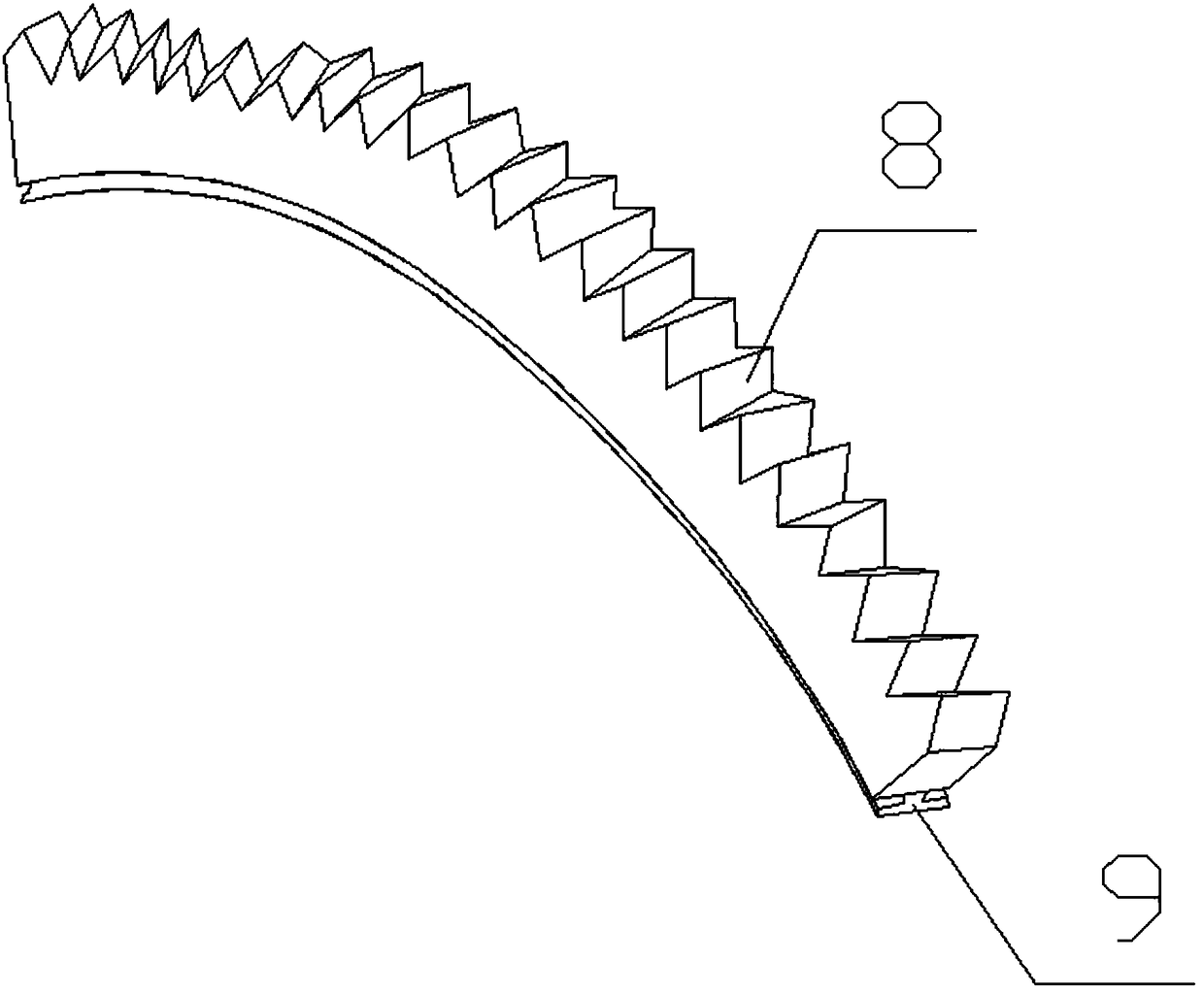

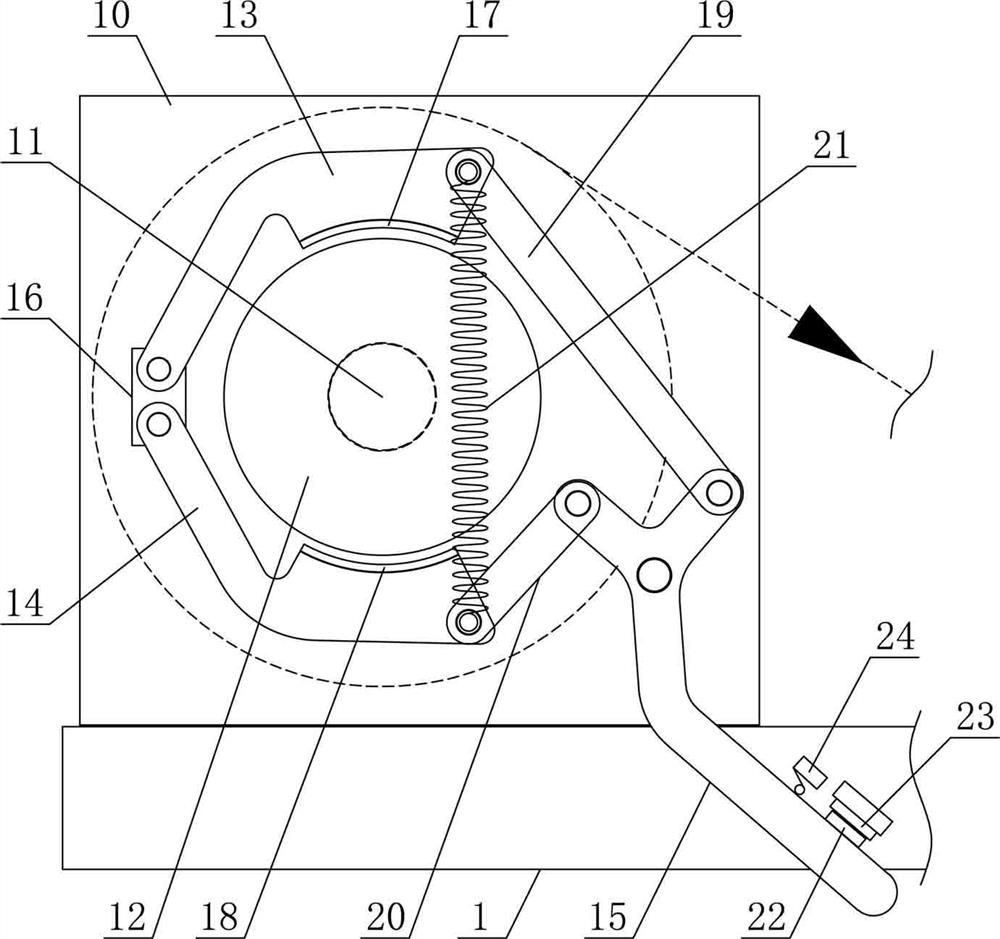

Intermittent material cutting machine

InactiveCN108500386AStable cutting processCutting process safetyDriving apparatusEngineeringRotating disc

The invention discloses an intermittent material cutting machine comprising a bottom plate, a C-shaped bracket, an L-shaped bracket and a mounting seat. The C-shaped bracket, the L-shaped bracket andthe mounting seat are arranged on a base, the C-shaped bracket is provided with an I-shaped rotating seat, the I-shaped rotating seat is rotatably provided with a fan-shaped rotating disc, and a T-shaped sliding groove is formed in the arc surface of the fan-shaped rotating disc; an arc-shaped rack is arranged on the arc surface of the fan-shaped rotating disc, a T-shaped sliding block is arrangedat the bottom of the arc-shaped rack, the T-shaped sliding block is slidably arranged in the T-shaped sliding groove, a hollow rotating shaft is arranged at the front end of the L-shaped bracket in asleeving mode, and a gear and a cutting blade are fixedly arranged on the hollow rotating shaft; a rotating motor is arranged on the mounting seat, an output shaft of the rotating motor is provided with a rotating plate, mounting columns are fixedly arranged at the tail end of the rotating plate and the center of the fan-shaped rotating disc, a long-strip transmission plate is arranged between the two mounting columns, and the two ends of the transmission plate are rotatably connected with the two mounting columns. According to the intermittent material cutting machine, certain stopping timeis left at the conversion interval of driving the cutting blade to rotate in a reciprocating mode, and feeding and discharging once more are convenient.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

Forming structure on packaging bag production device

InactiveCN113184249APrevent looseningNeat edgesWrapper twisting/gatheringSuccessive articlesEngineeringRoll film

The invention discloses a forming structure on a packaging bag production device. The forming structure comprises a shell frame, a tensioning device, a sealing device, a supporting flat plate, a conveying device and a main lifting machine; the tensioning device is arranged above the shell frame and used for fixing a packaging roll film and adjusting the tension degree of the film; the shell frame is arranged at the bottom end; the supporting flat plate is fixed to the upper end face of the shell frame; multiple sets of square holes are formed in the supporting flat plate in a circumferential arrangement manner; the sealing device is arranged over the square hole close to the left side; the main lifting machine drives the sealing device to be integrally pressed downwards and lifted upwards, and the packaging film is subjected to heat sealing and cutting; the conveying device is arranged below the supporting flat plate and used for rotationally conveying packaging bags; and a leftover material collecting chamber and a packaging bag collecting chamber are arranged on the left side and the right side of the shell frame correspondingly.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Industrial production method of Lanzhou hand-pulled beef noodles

InactiveCN105851863AHigh glutenGood flexibilityFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFood additiveRefrigeration

The invention provides an industrial production method of Lanzhou hand-pulled beef noodles. The industrial production method comprises the following steps: (1) preparing materials: preparing the following dough mixing raw materials in parts by weight: 400-600 parts of flour, 80-120 parts of vital wheat gluten, 40-80 parts of rice flour, 40-80 parts of lotus root powder, 2-5 parts of salt and 0.5-2 parts of edible alkali; (2) mixing dough; (3) kneading dough; (4) pressing dough; (5) refrigeration: refrigerating wrappers obtained through pressing dough for 2-5 hours at 0-5 DEG C; and (6) molding: making the refrigerated wrappers into noodles with different thicknesses through a dough kneading machine or artificial stretching. According to the industrial production method, conventional pottasche and hand-pulled noodle additives are effectively replaced, the edible safety of the noodles is improved, meanwhile the noodles are smooth in appearance and high in nutritional values; the industrial production of the Lanzhou hand-pulled beef noodles is realized, the noodle making efficiency is greatly improved, the noodles are not sticky to a knife in the process of cutting and are non-sticky to each other, the cooked noodles are soft and glutinous in mouth feel and tough and chewy, and the edible taste is greatly improved.

Owner:LANZHOU MONITOR NIU FOOD & BEVERAGE MANAGEMENT

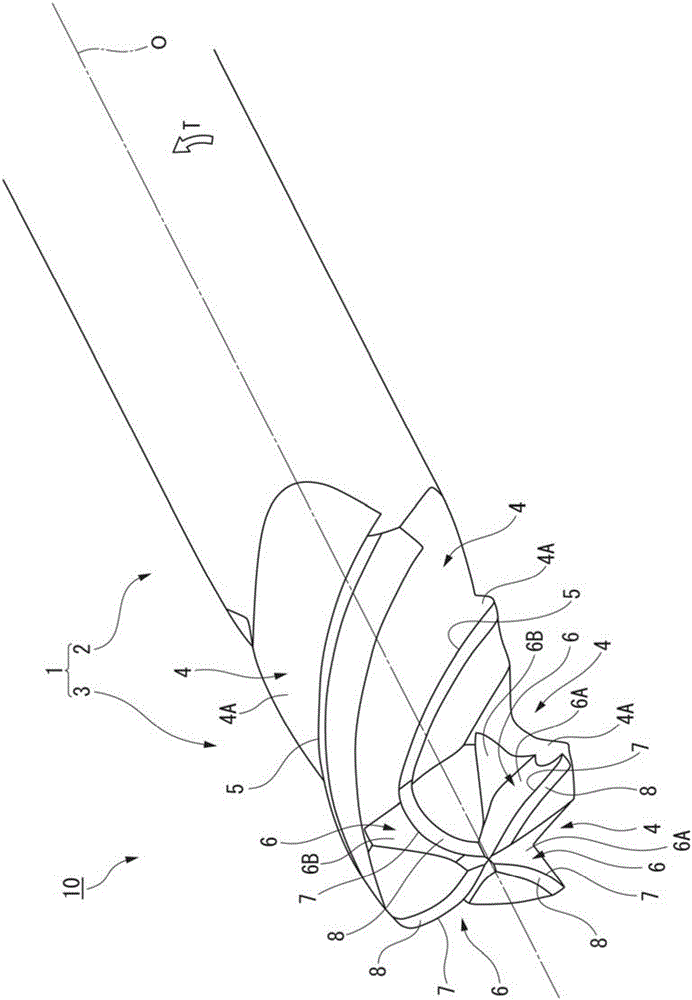

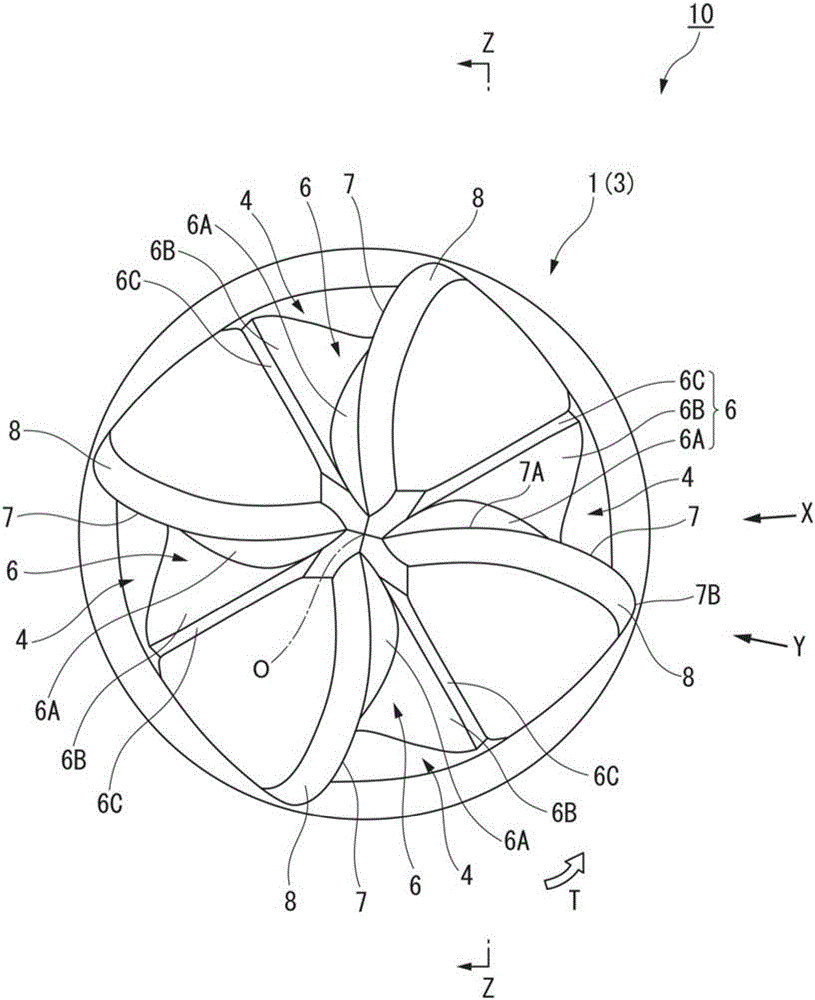

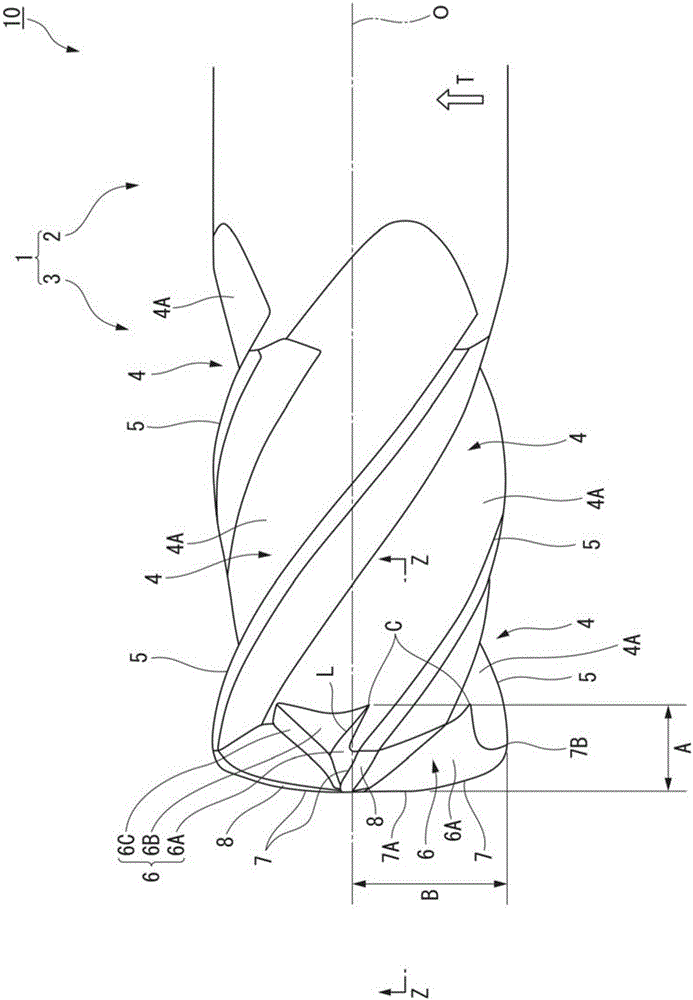

Radius end mill

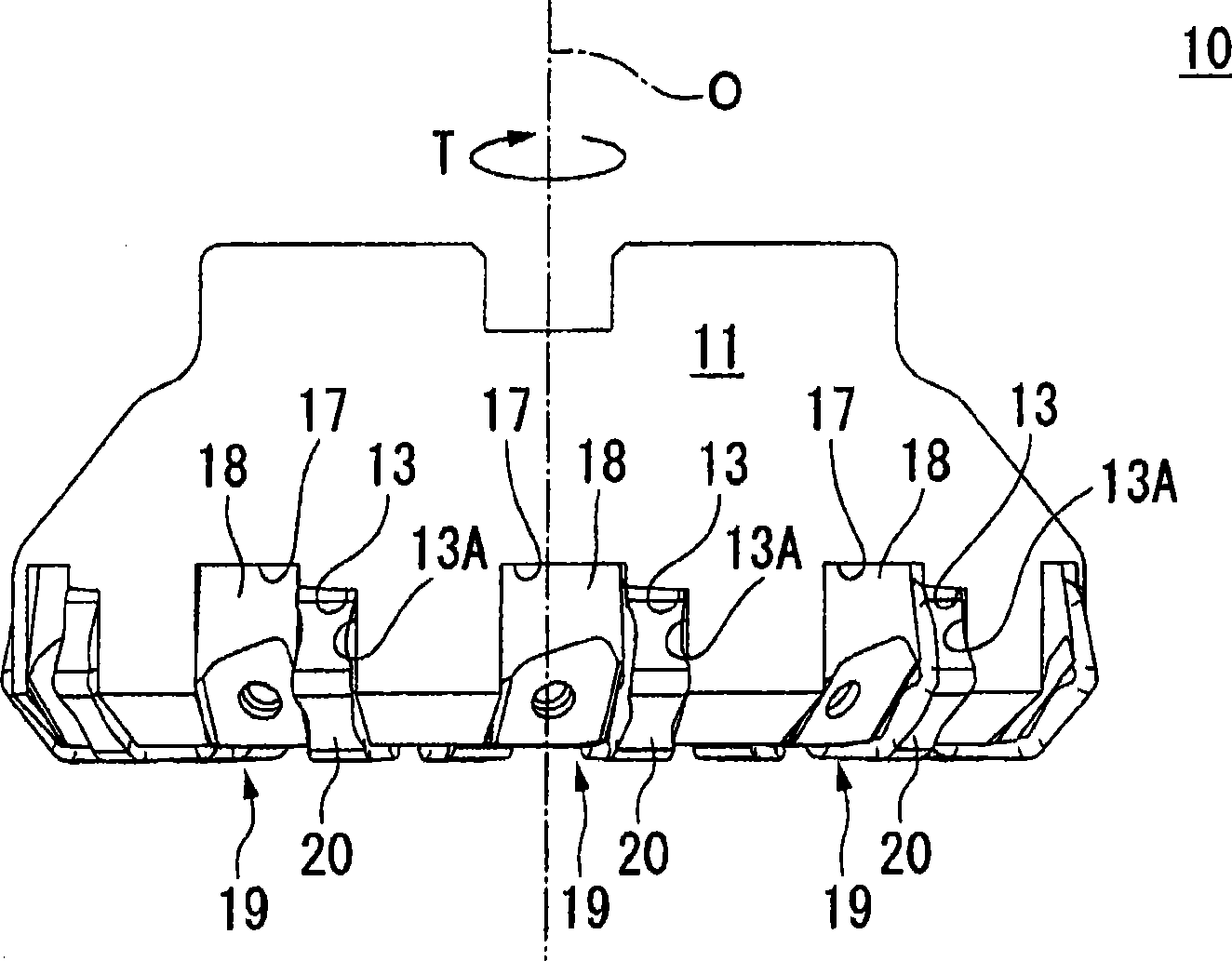

The present invention is a radius end mill (10) equipped with end cutting edges (7) formed so that the rotation tracks thereof around the axial line (O) trace a convex surface. The convex surface is formed so that in cross-sectional view along the axial line, the convex surface has a convex line such that the radius of curvature at the inner portion (7A), which is located closer to the axial line than the tip periphery (7B) of the end mill body (1), is larger than the radius of curvature at the tip periphery. The gash depth angle theta (degree) calculated from theta = tan-1 (A / B) based on the distance A (mm) from the tip (7A) of the end cutting edge to the rearmost edge of a gash (6) in the axial direction and the radius B (mm) from the axial line to the point of contact (7B) between the peripheral cutting edge (5) and the end cutting edge is set to be not more than 50 degrees. The sum (theta (degree) + alpha (degree)) of the gash depth angle alpha 2 (degree) and the axial direction rake angle difference alpha (degree) = (theta (degree) - alpha (degree)) between the axial direction rake angle alpha 2 (degree) of the end cutting edge at the point of contact and the axial direction rake angle alpha 1 (degree) of the end cutting edge at the tip is set to be at least 60 degrees.

Owner:MITSUBISHI MATERIALS CORP

Grinding device with inverted V-shaped slot in grinding wheel and grinding method

ActiveCN104669090AReduce the temperatureReduce processing costsGrinding feed controlGrinding machinesSemi automaticEngineering

The invention provides a grinding device with an inverted V-shaped slot in a grinding wheel and a grinding method, and belongs to the technical field of metal cutting and processing. The grinding device comprises a grinding fluid flow rate control system, a grinding fluid conveying system and a grinding processing system. In order to obtain a high-quality grinding surface, the inverted V-shaped slot is formed in the periphery of a grinding wheel base body, a grinding fluid spray hole is formed in the slot, a grinding fluid is simultaneously sprayed at the two sides of the grinding wheel, the grinding fluid enters a grinding region through spray holes, and the flow rate of the grinding fluid can be automatically regulated. According to the grinding device and the grinding method, the temperature of the grinding region can be effectively reduced, vibration in the grinding process is reduced, the grinding surface quality is remarkably improved, semi-automatic production can be realized, and the grinding device and the grinding method are especially suitable for high-speed precision grinding of a deep trench.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Fabric conveying and processing device for chemical fiber quilt production

InactiveCN112299092AReasonable structural designAvoid slackSevering textilesWebs handlingFiberMechanical equipment

The invention discloses a fabric conveying and processing device for chemical fiber quilt production, and belongs to the field of home textile processing mechanical equipment. An upper damping pressing plate and a lower damping pressing plate are arranged on the upper side and the lower side of a fabric conveying rotary disc at the end of a fabric unwinding rotary roller correspondingly, a feedingand conveying pressing roller is arranged on the upper side of a feeding and conveying rotary roller, and the two ends of a horizontal moving reciprocating pull plate are arranged on material pullinghorizontal moving guide rods correspondingly in a sliding manner. The two ends of the upper side of a fabric pulling and conveying chain are fixedly connected with the two sides of the horizontal moving reciprocating pull plate correspondingly, a fabric cutting mechanism is arranged on a fabric processing support on the side of a feeding and conveying support, and a cutting horizontal moving connecting rod is horizontally arranged in a connecting rod reciprocating sleeve of a connecting rod reciprocating support in a sliding manner. A fabric guiding and conveying rotary roller is rotationallyconnected to a lifting rotary roller support on the lower side of a fabric guiding and conveying bearing roller. The fabric conveying and processing device for chemical fiber quilt production is reasonable in structural design, chemical fiber quilt fabric can be continuously and smoothly unwound, conveyed and cut efficiently and stably, the fabric processing automation degree is high, and the production and use requirements are met.

Owner:桐乡市康悦时装寝具有限公司

Steel wire dissecting machine

The invention provides a steel wire dissecting machine, and belongs to the technical field of metal machining. The steel wire dissecting machine comprises a straightening device, a wire drawing deviceand a dissecting device. The straightening device comprises a longitudinal straightening mechanism and a transverse straightening mechanism. The wire drawing mechanism comprises a driving wire drawing mechanism and a driven wire drawing mechanism. The dissecting device comprises a dissecting standard shaft knife mechanism and a dissecting reciprocating knife mechanism. A steel wire walking groovehole is formed in the axial direction of a dissecting standard shaft knife of the dissecting standard shaft knife mechanism. The dissecting reciprocating shaft knife mechanism comprises a dissectingreciprocating assembly and a dissecting reciprocating drive assembly. A steel wire cutting groove hole is formed in the axial direction of the dissecting reciprocating shaft knife. Steel wires can becontinuously dissected, the dissecting length is accurate, the cutting efficiency is high, the cutting length can be adjusted, and the applicability is high.

Owner:潘萍儿

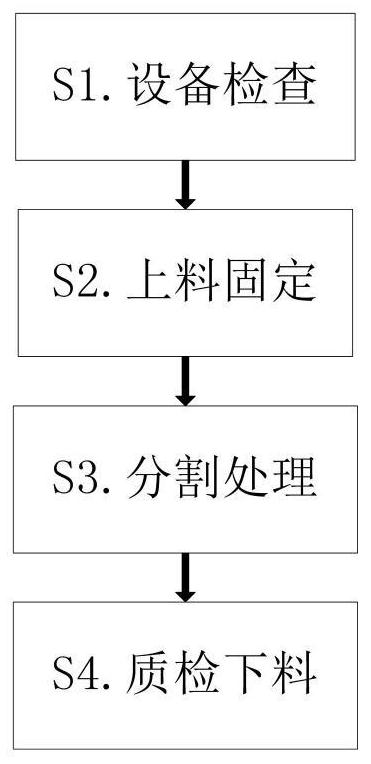

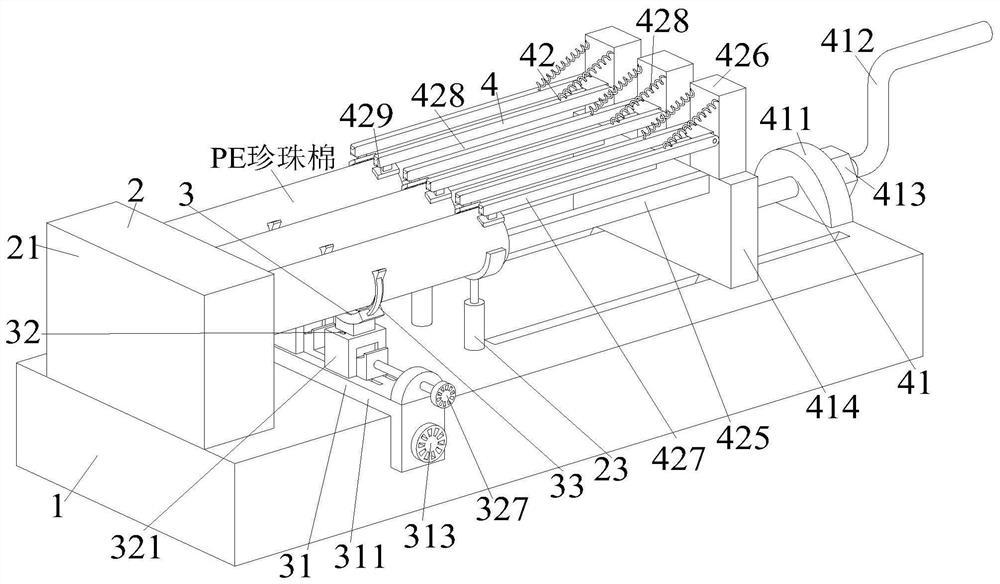

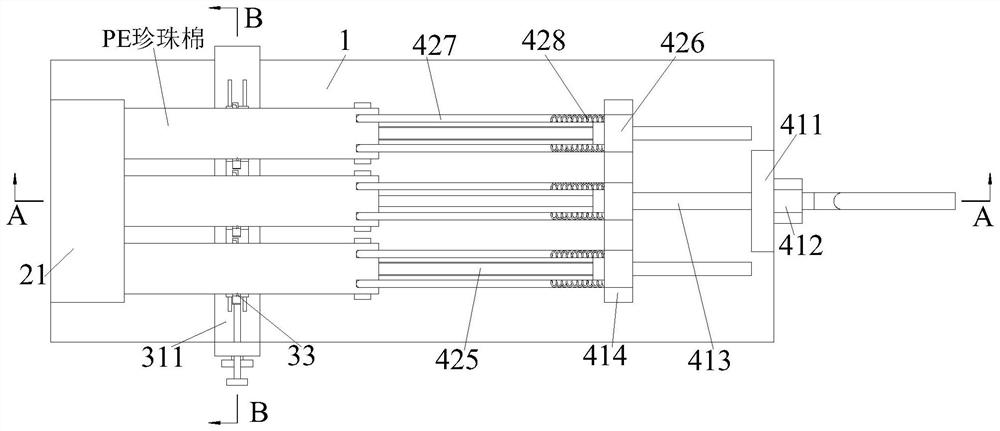

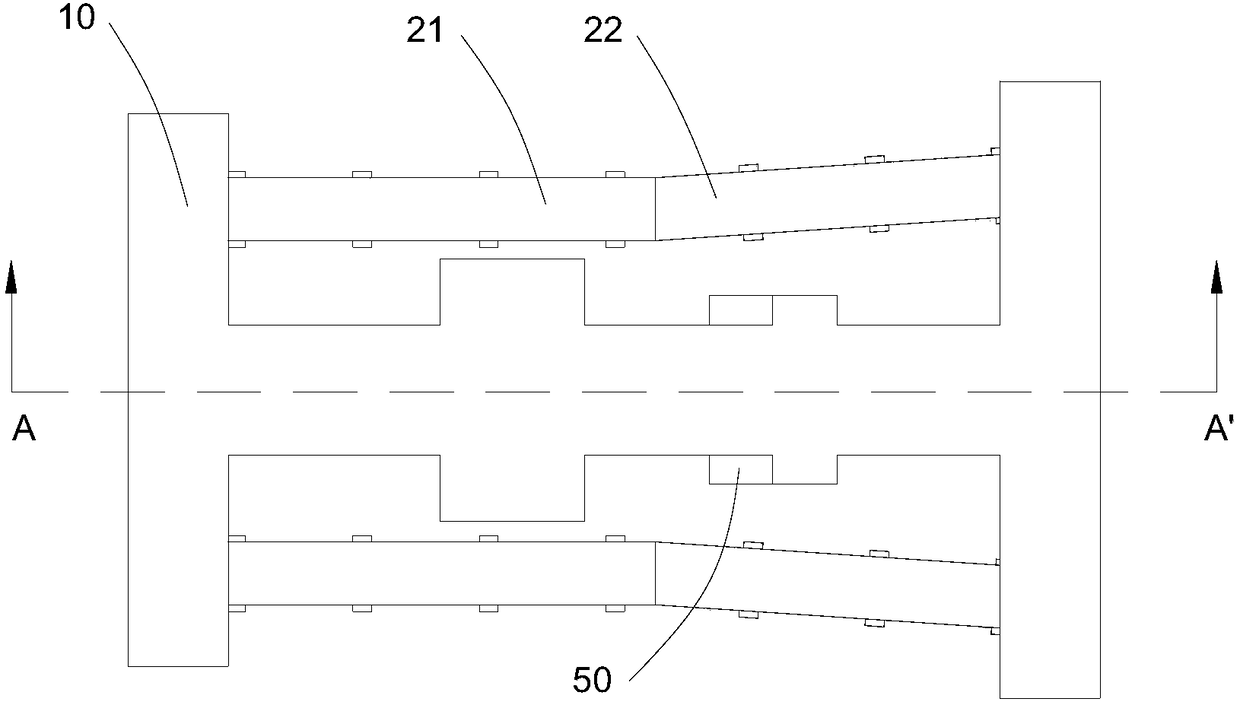

PE pearl wool packaging material structure forming processing technology

InactiveCN111730669AImprove processing efficiencyReduce cumbersomeFlexible coversWrappersMachiningIndustrial engineering

The invention relates to a PE pearl wool packaging material structure forming processing technology which comprises a workbench, a fixing device, a circumferential dividing device and an axial dividing device. The fixing device is installed on the left side of the upper end of the workbench, the circumferential dividing device is arranged on the right side of the fixing device, the circumferentialdividing device is installed at the upper end of the workbench, and the axial dividing device is mounted on the right side of the upper end of the workbench. According to the PE pearl wool packagingmaterial structure forming processing technology, the problems that in the manual processing process, PE pearl wool is locked and fixed firstly, then the PE pearl wool is divided in the circumferential direction and the axial direction, manual cutting easily enables the PE pearl wool dividing position to generate fractures, when existing PE pearl wool manufacturing equipment is used for machining,the PE pearl wool is clamped and fixed firstly and then is divided, the existing PE pearl wool manufacturing equipment can only divide the PE pearl wool in the circumferential direction or the axialdirection, the dividing process is tedious, and consequently, the PE pearl wool dividing and forming efficiency is low are solved.

Owner:黄远明

Household vegetable cutting machine

InactiveCN104029233ASave capital and spaceForget about putting and collectingMetal working apparatusEngineeringCam

The invention belongs to household kitchen appliance and discloses a household vegetable cutting machine comprising a cutter rest, a special cutter, a cam, a motor, a first gear, a base plate, a second gear, a first belt, a first gear drum, a first conveying belt, a conveying handle, a firs drum, a support, a second drum, a second conveying belt and a second gear drum. The vertical moving direction of the special cutter is fixed through the cutter rest, the cam is connected to the motor and contacts with a link of the special cutter, the first gear is connected to the second gear through the first belt, the second gear drives the first gear drum to move, the first gear drum drives the first drum to move through the firs conveying belt, the first gear drum drives the second gear drum to move through the belt, and the second gear drum drives the second drum to move through the conveying belt. The household vegetable cutting machine has the advantages that the motor is used for supplying power, the belt is used for conveying the vegetables, the special cutter is used for cutting the vegetables, and the machine can be used for house daily vegetable cutting conveniently and rapidly.

Owner:陈梦佳

Thick plate corrugated paper cutting device

ActiveCN108453799AStable cutting processAvoid scrappingMetal working apparatusThick platePulp and paper industry

The invention provides a thick plate corrugated paper cutting device which comprises a conveying mechanism. A pre-cutting mechanism and a cutting mechanism are arranged in the conveying direction of the conveying mechanism in sequence; the pre-cutting mechanism comprises two pre-cutting tool aprons arranged coaxially, and the opposite ends of the two pre-cutting tool aprons are fixedly provided with pre-cutting tool heads; and the cutting mechanism comprises a cutting base fixed to a rack, a cutting blade is fixed to the side, close to the pre-cutting mechanism, of the cutting base, and an included angle alpha formed between the cutting blade and the horizontal direction is larger than 0 and smaller than or equal to 90 degrees. According to the thick plate corrugated paper cutting device,the two surfaces of thick plate corrugated paper are scratched and cut to form guide grooves, then final cutting is carried out from the side face of the thick plate corrugated paper, the guide grooves conduct cutting blade guide in the cutting process, the cutting stability can be effectively improved, deflection of the cutting blade is prevented, the cutting blade and the horizontal face are arranged in an inclined manner, the cutting resistance can be effectively reduced, and it is guaranteed that a cutting opening of the thick plate corrugated paper is orderly and meets the requirement.

Owner:东莞市汇驰纸业有限公司

Fabric cutting device for silk quilt production

InactiveCN112850312AStable cutting processEfficient and stable cuttingArticle deliveryStructural engineeringMechanical equipment

The invention discloses a fabric cutting device for silk quilt production, and belongs to the field of home textile processing mechanical equipment. A fabric pressing and cutting mechanism and a fabric pulling and conveying mechanism of the fabric cutting device are arranged on the two sides of a fabric processing support, the two sides of the upper side of a reciprocating pulling chain are fixedly connected with the two sides of the lower side of a fabric pulling and conveying support correspondingly, a pressing plate mounting connecting plate and a lifting fixing wedge plate are horizontally and fixedly arranged on the two sides of the upper side of a lifting reciprocating guide plate correspondingly, a fabric pulling and conveying lower bearing plate is horizontally and fixedly arranged on the fabric pulling and conveying support on the lower side of a fabric pulling and conveying upper pressing plate, a pressing and cutting fixing wedge plate is horizontally and fixedly arranged on the lower side of a pressing and cutting lifting plate, a translation pressing and cutting wedge plate matched with the pressing and cutting fixing wedge plate is horizontally arranged on the fabric processing support on the lower side of the pressing and cutting fixing wedge plate, and a fabric pressing cutter is horizontally and fixedly arranged on the upper side of a cutter mounting base. The fabric cutting device for silk quilt production is reasonable in structural design, silk quilt fabric can be efficiently, stably, continuously and accurately cut in a sectional mode, the processing automation degree is high, and the requirements of production and use are met.

Owner:桐乡市诺创信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com