Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

821 results about "Paper dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

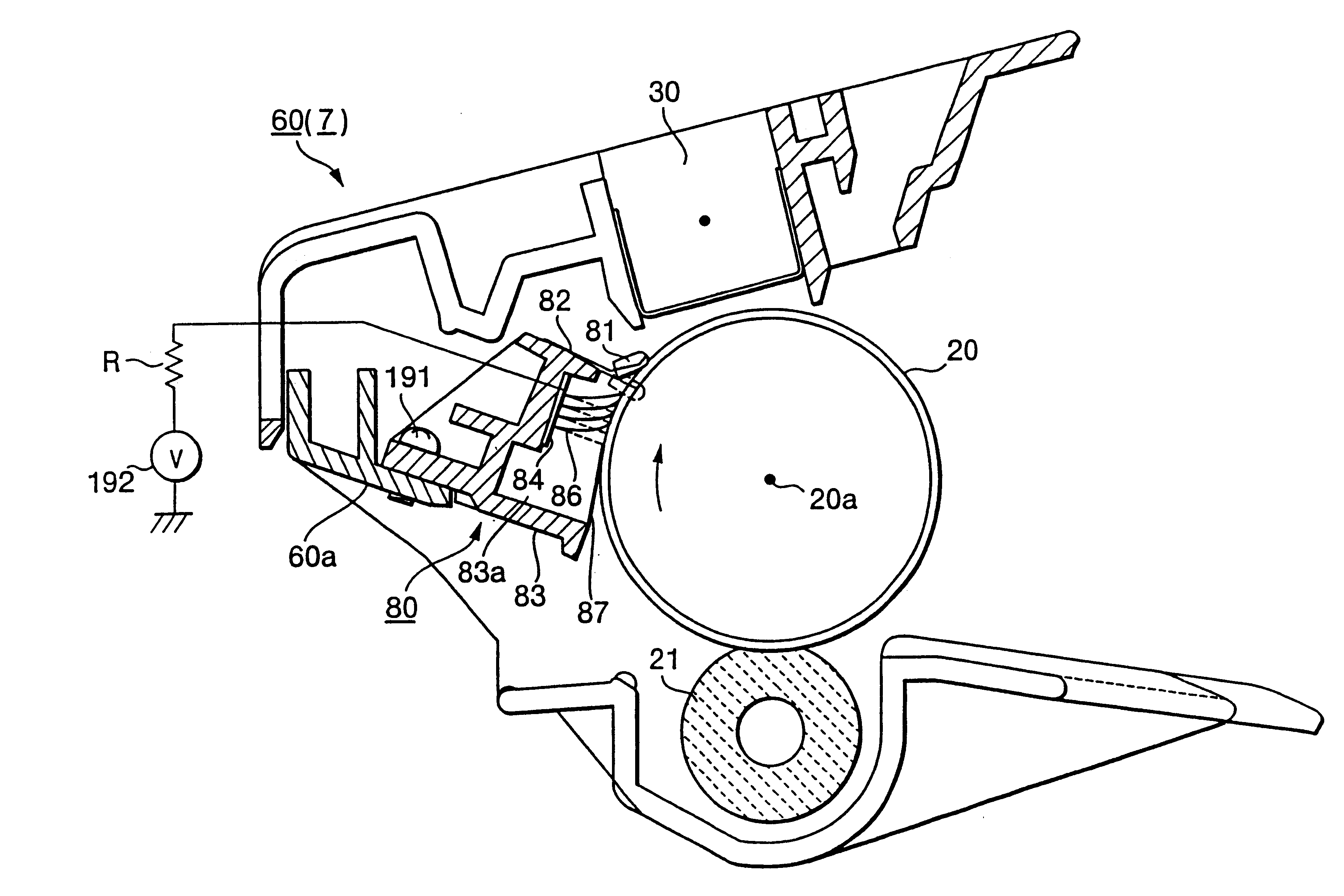

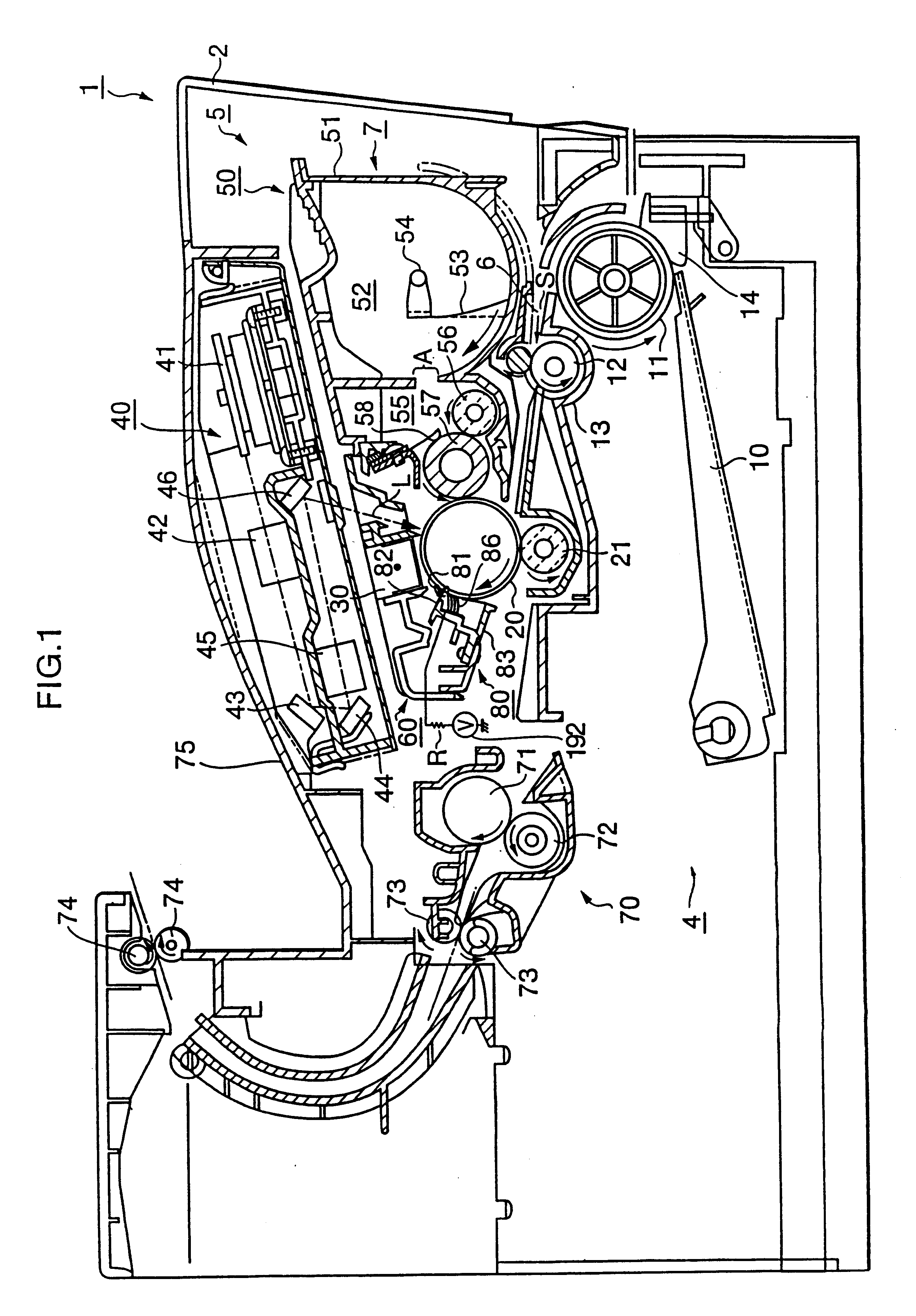

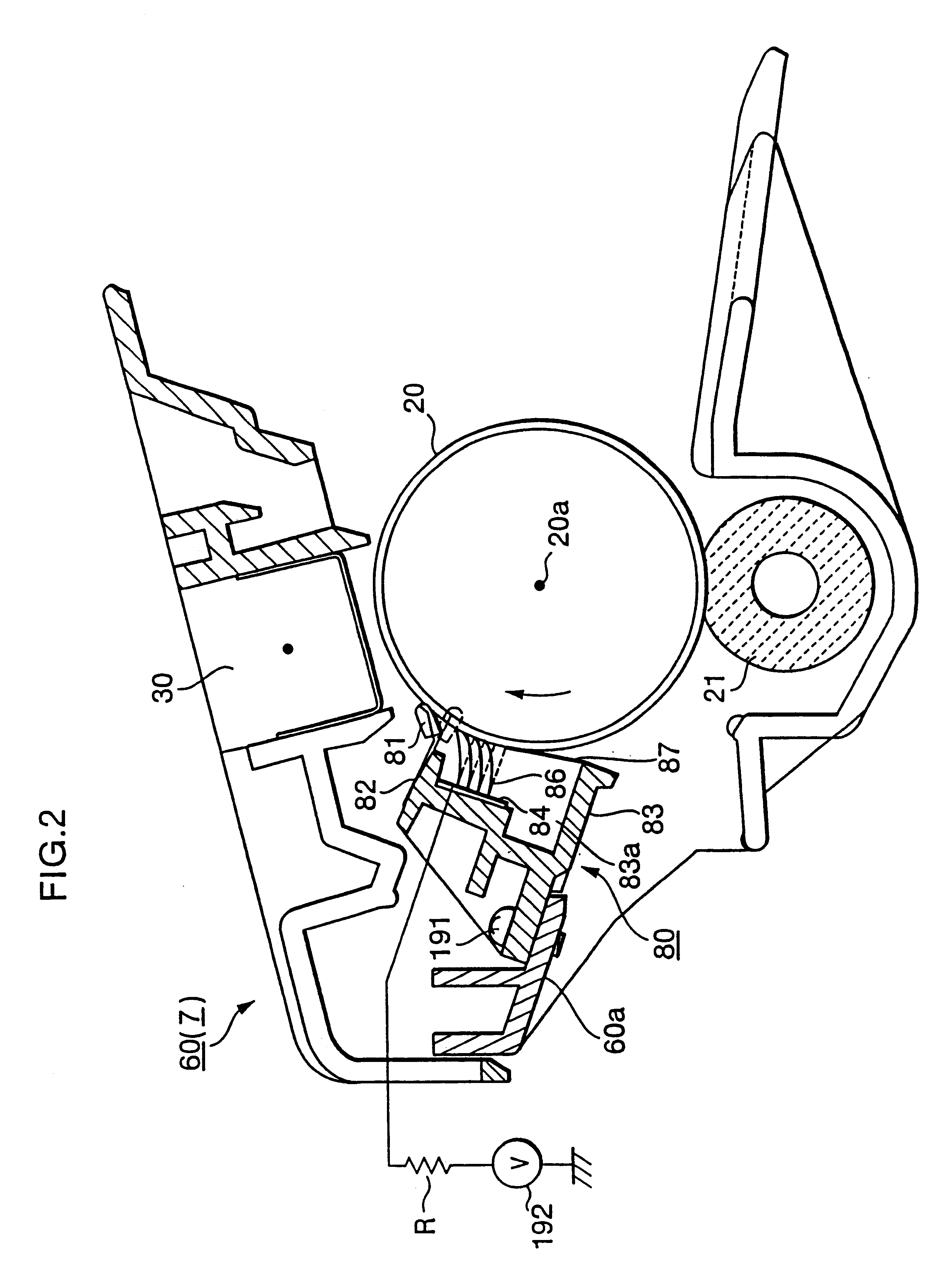

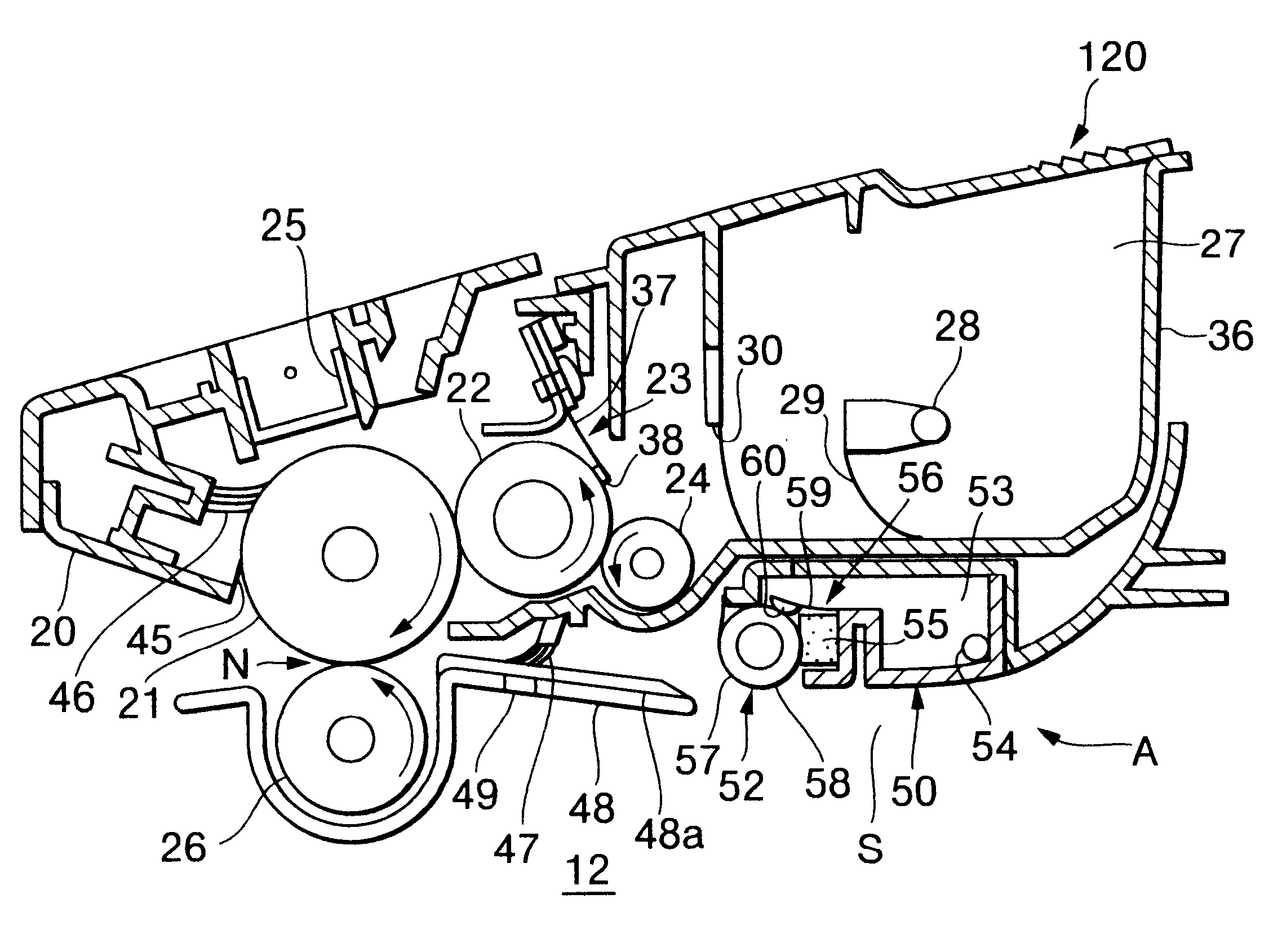

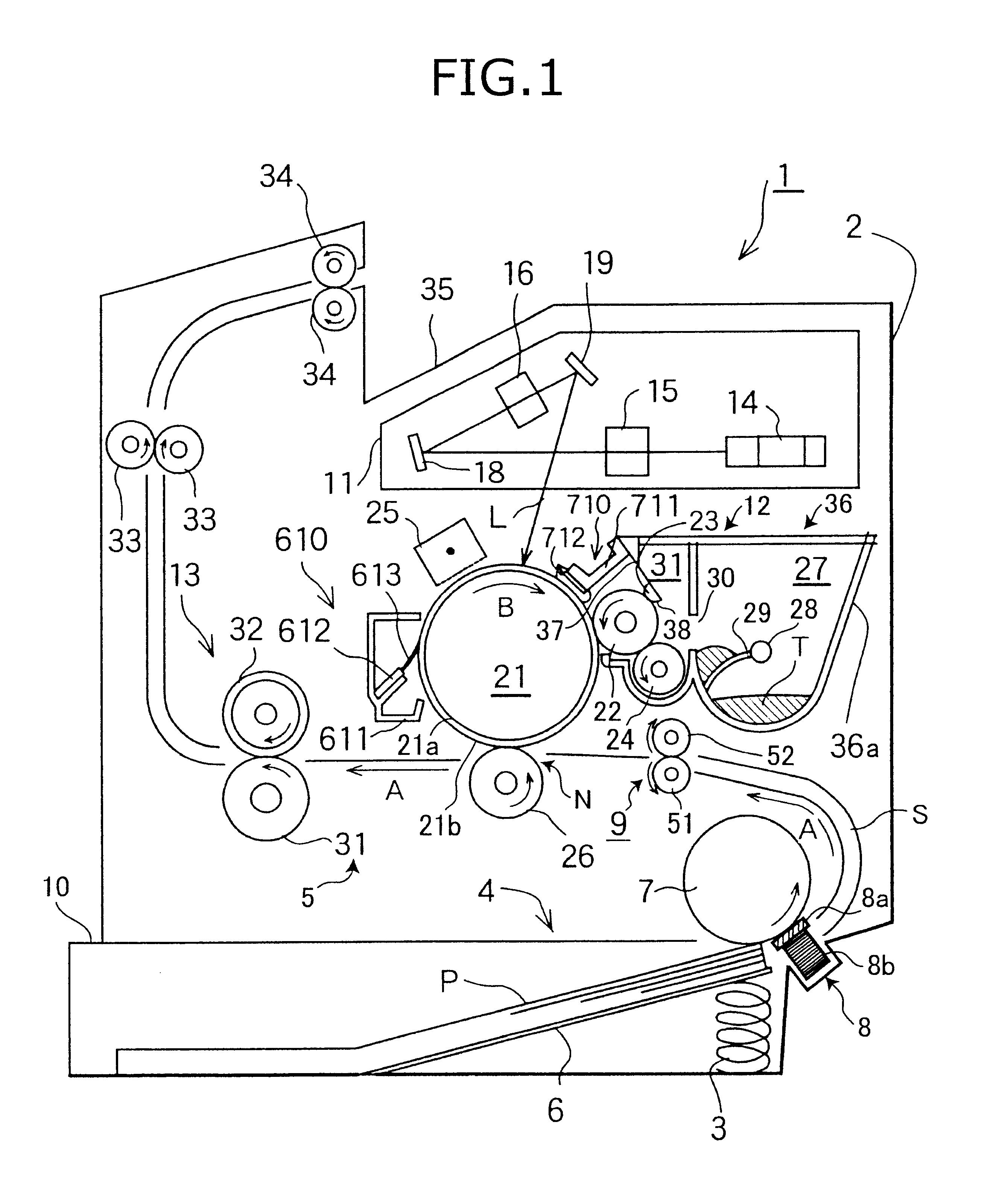

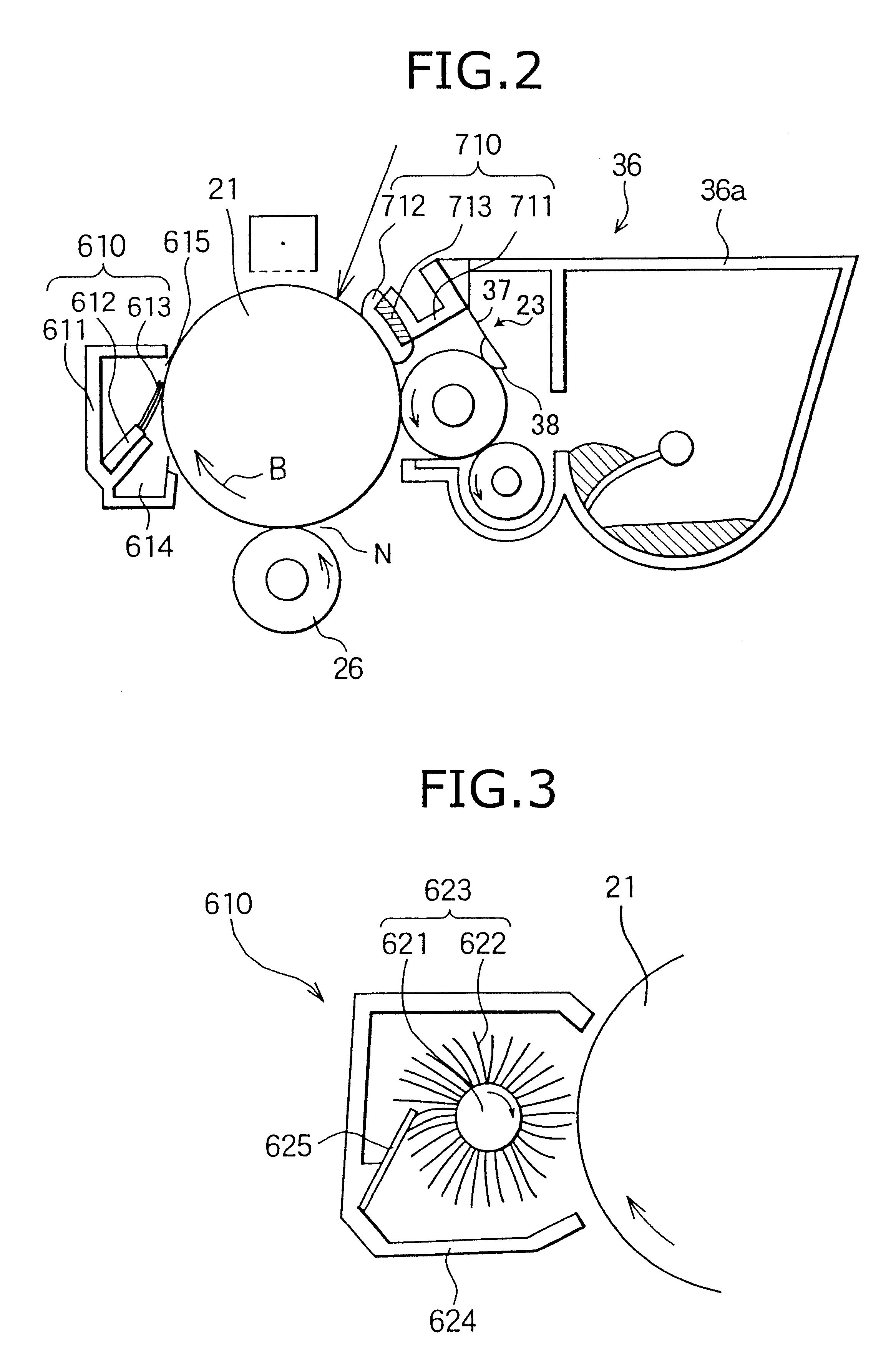

Image forming apparatus having an electrically charged paper dust removing brush

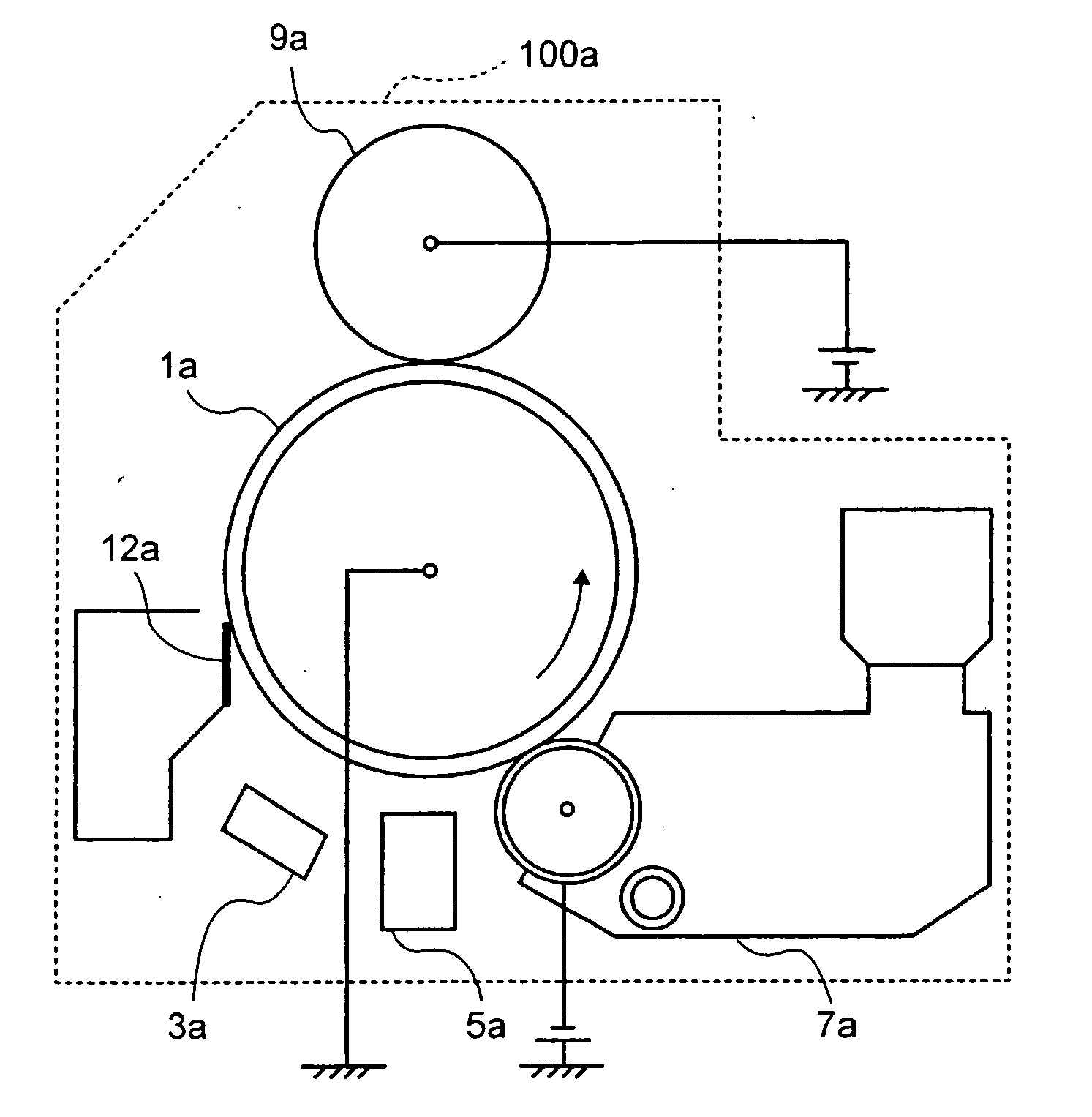

In an image forming apparatus, a brush member is formed from a brush made from acrylic resin that has not been subjected to conductivity-enhancing processes. The brush member is attached to a conductive plate. A resistor is provided in series with the conductive plate and a fixed power source. The fixed power source applies a predetermined high voltage to the conductive plate.

Owner:BROTHER KOGYO KK

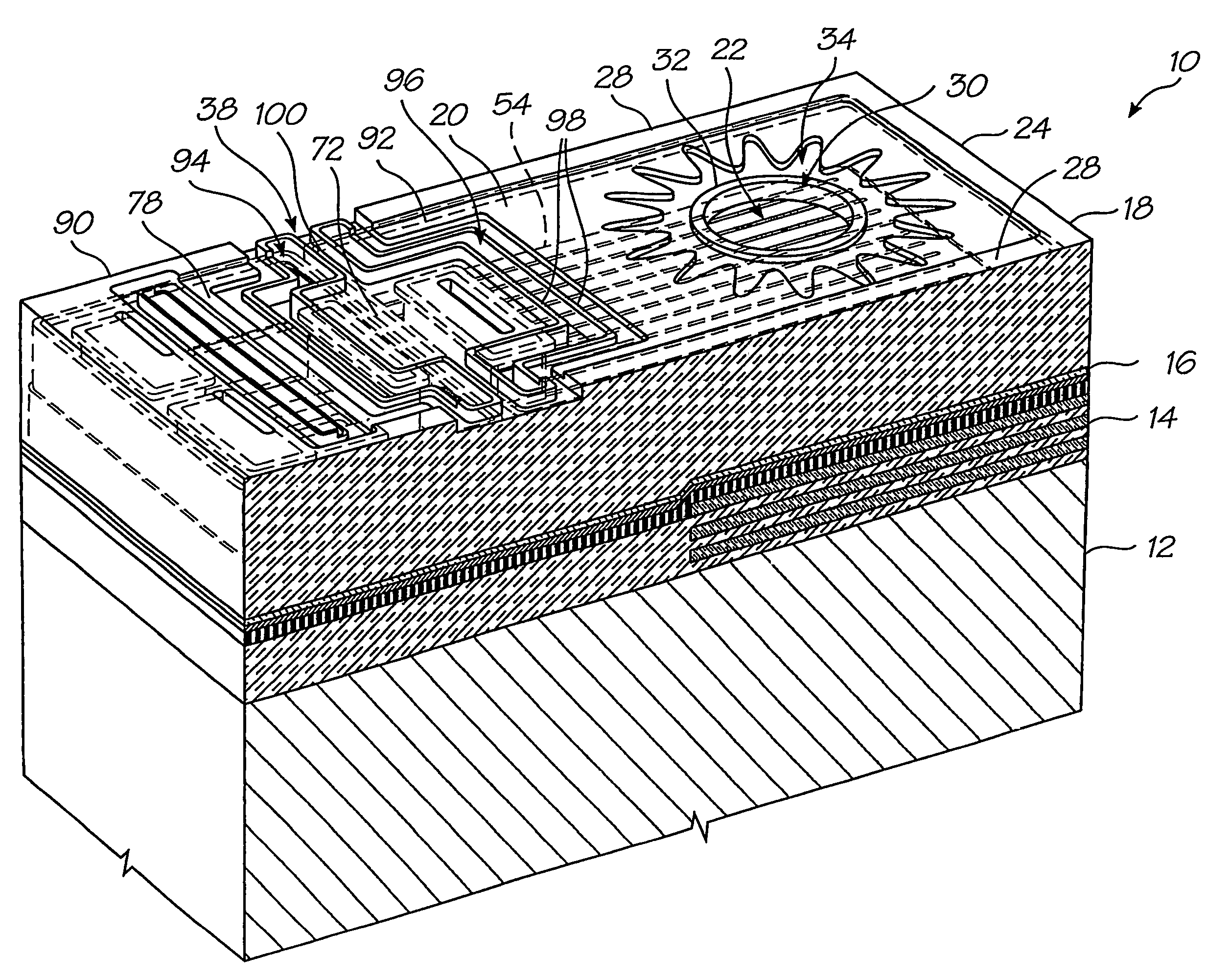

Cartridge unit having negatively pressurized ink storage

InactiveUS20050157040A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusOther printing apparatusPaper dustInk printer

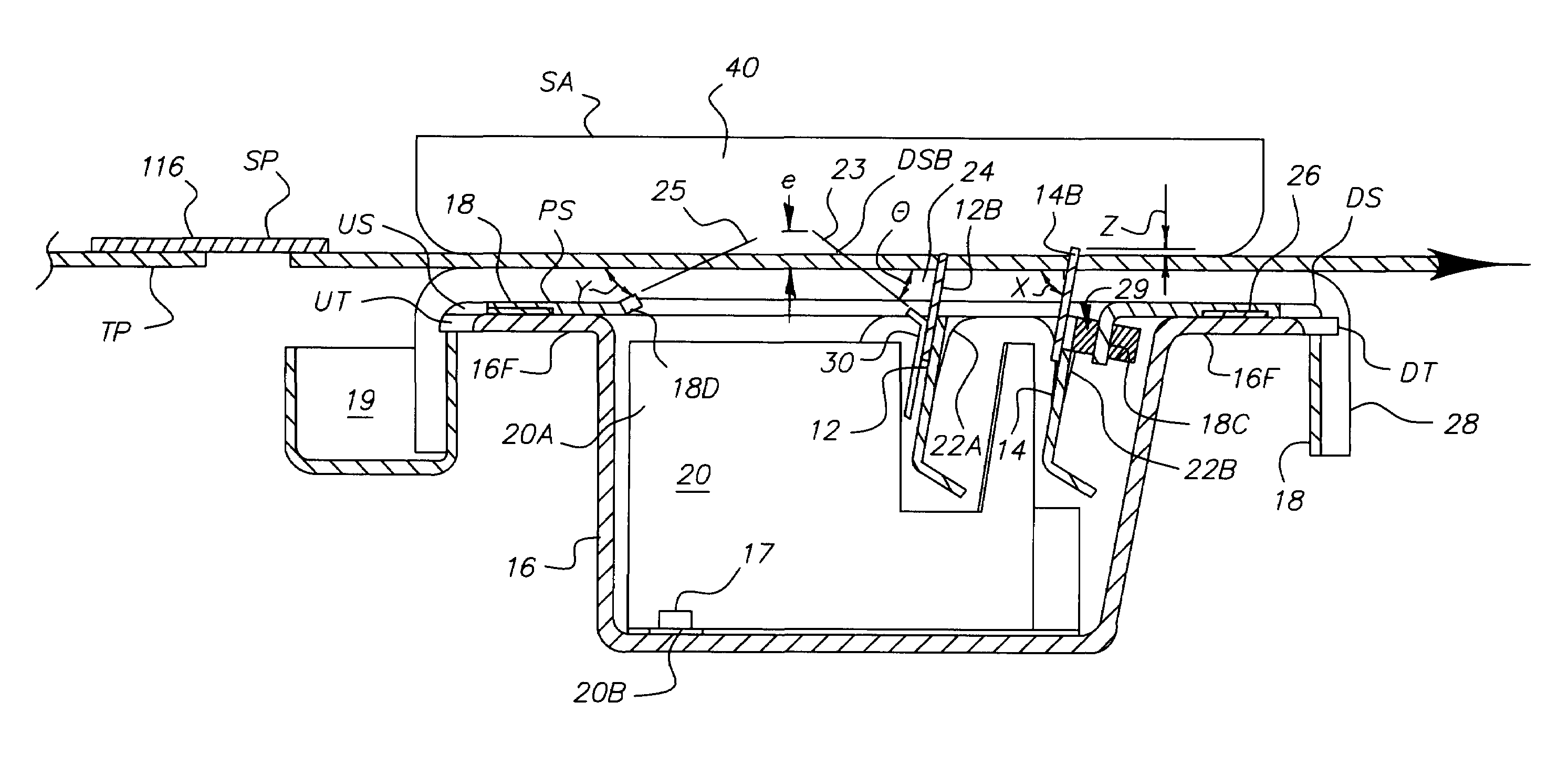

A cartridge unit 10 for an inkjet printer, with an ink storage compartment 46 and an ink feed system 30 for connection to a printhead 22. The ink storage compartment has a displaceable wall section 48 so that its variable storage volume 46 is variable. The displaceable wall 48 is biased 54 toward expanding the variable storage volume 46 so that there is a negative pressure in the ink storage volume 46, such that ink does not inadvertently leak from the ink ejection nozzles. Without negative pressure, an ink meniscus can bulge from the nozzles. The meniscus will ‘pin’ itself to the edge of the nozzle aperture and may be strong enough to stop ink leakage. However, paper dust or other contaminants will eventually stop the bulging meniscus from pinning itself on the nozzle rim and leakage occurs. A negative pressure in the ink storage volume makes the meniscus invert back into the nozzle aperture. As the meniscus does not bulge out of the nozzle, paper dust on the nozzle surface does not break the surface tension to cause leakage.

Owner:SILVERBROOK RES PTY LTD +1

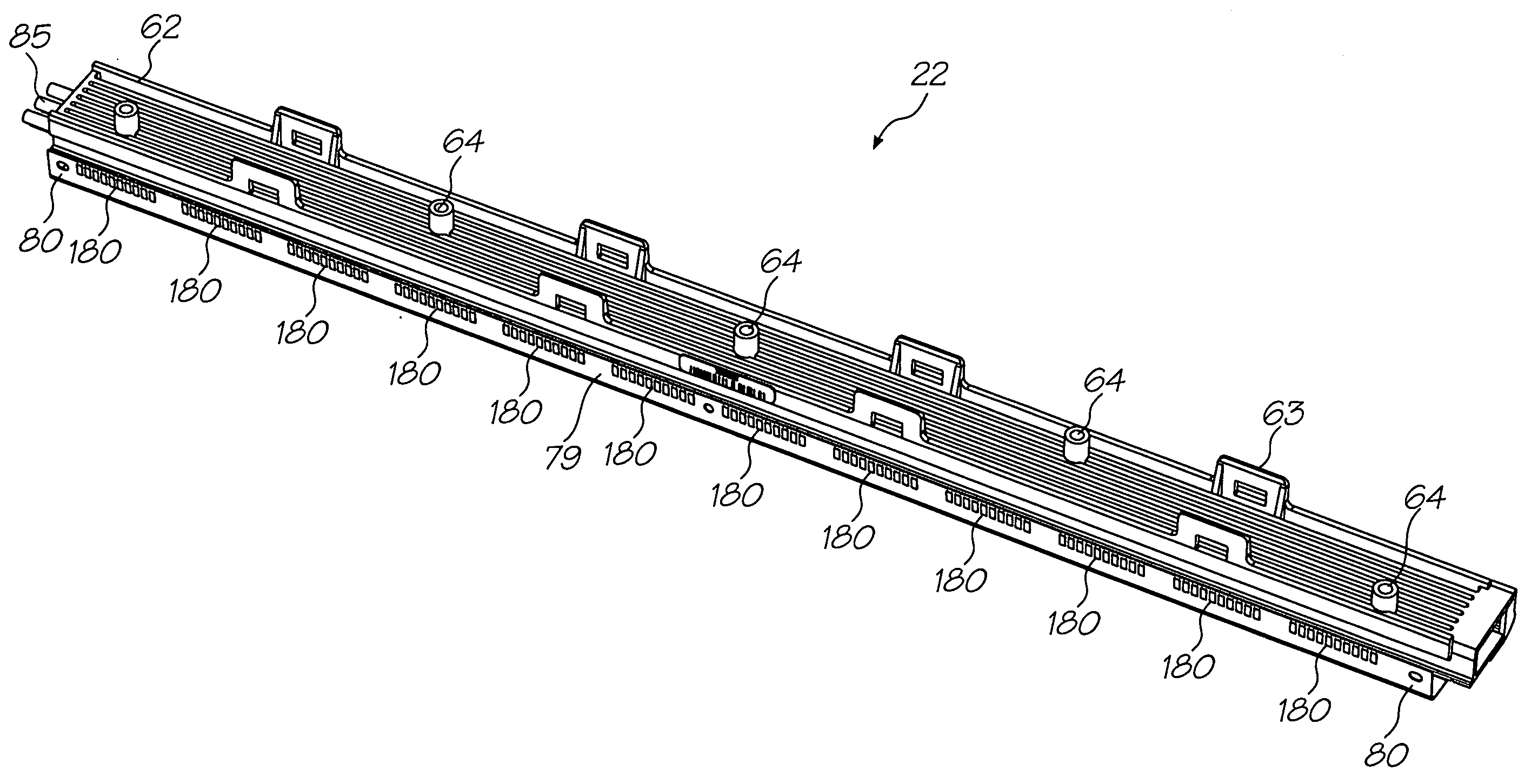

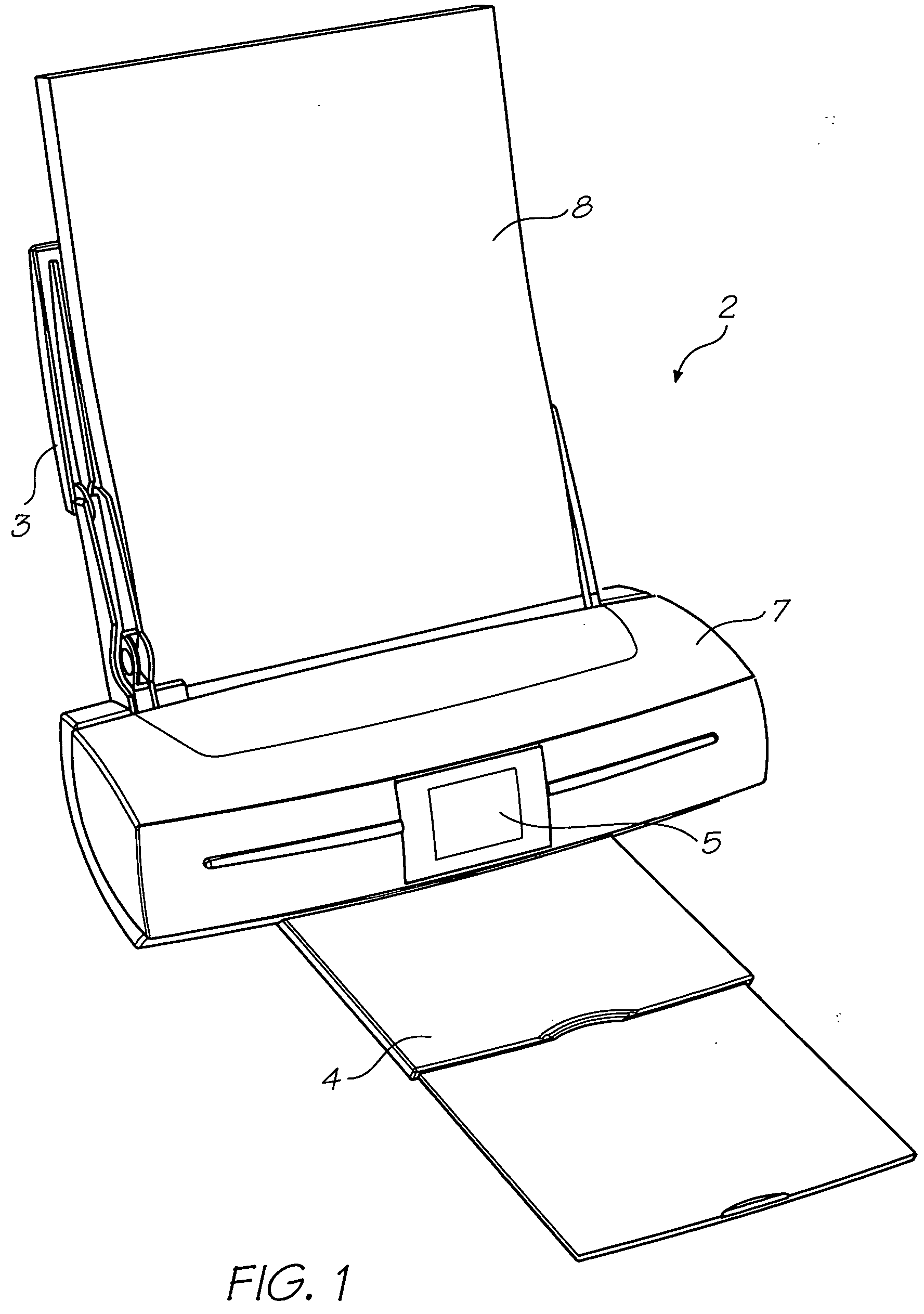

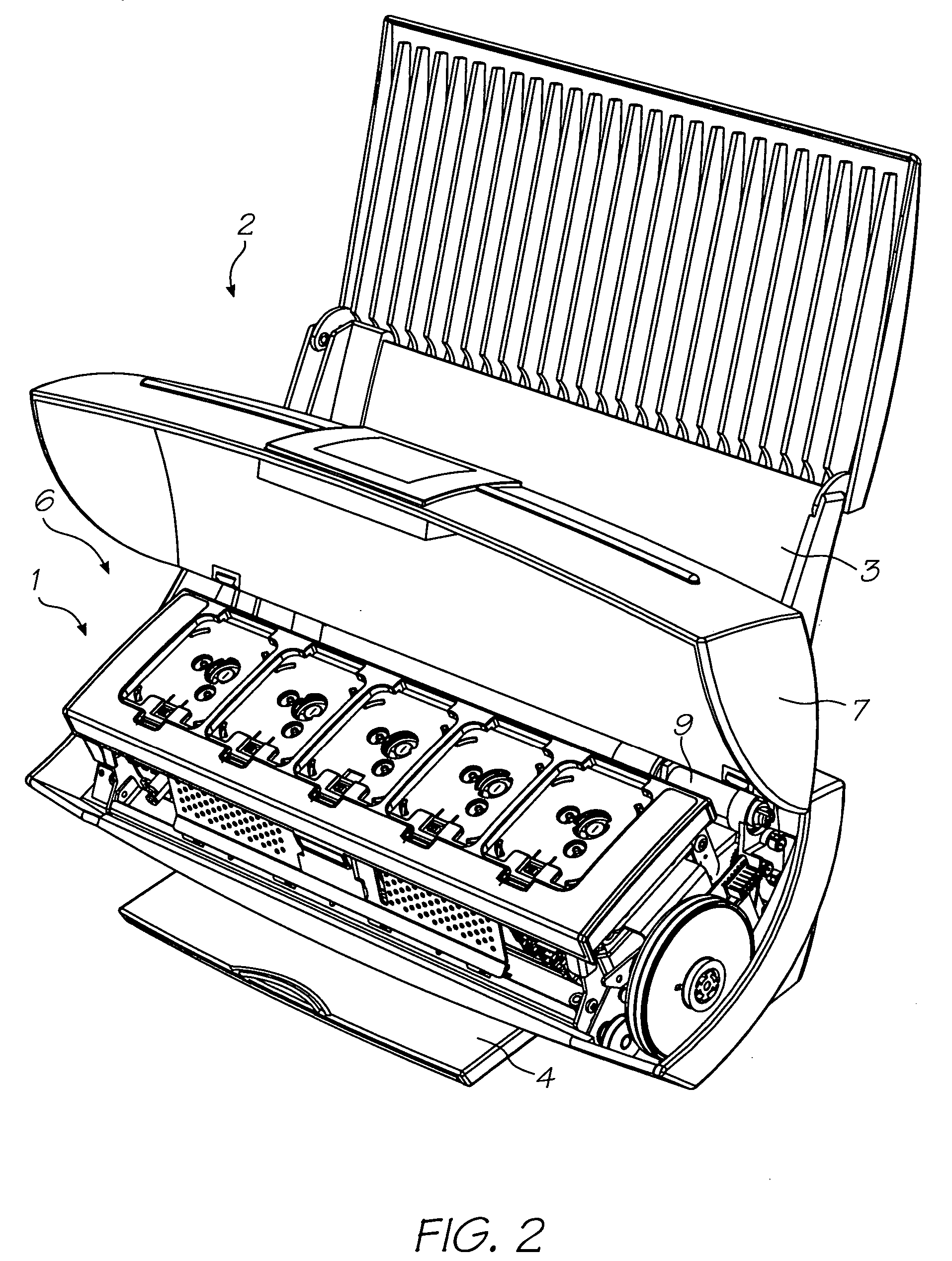

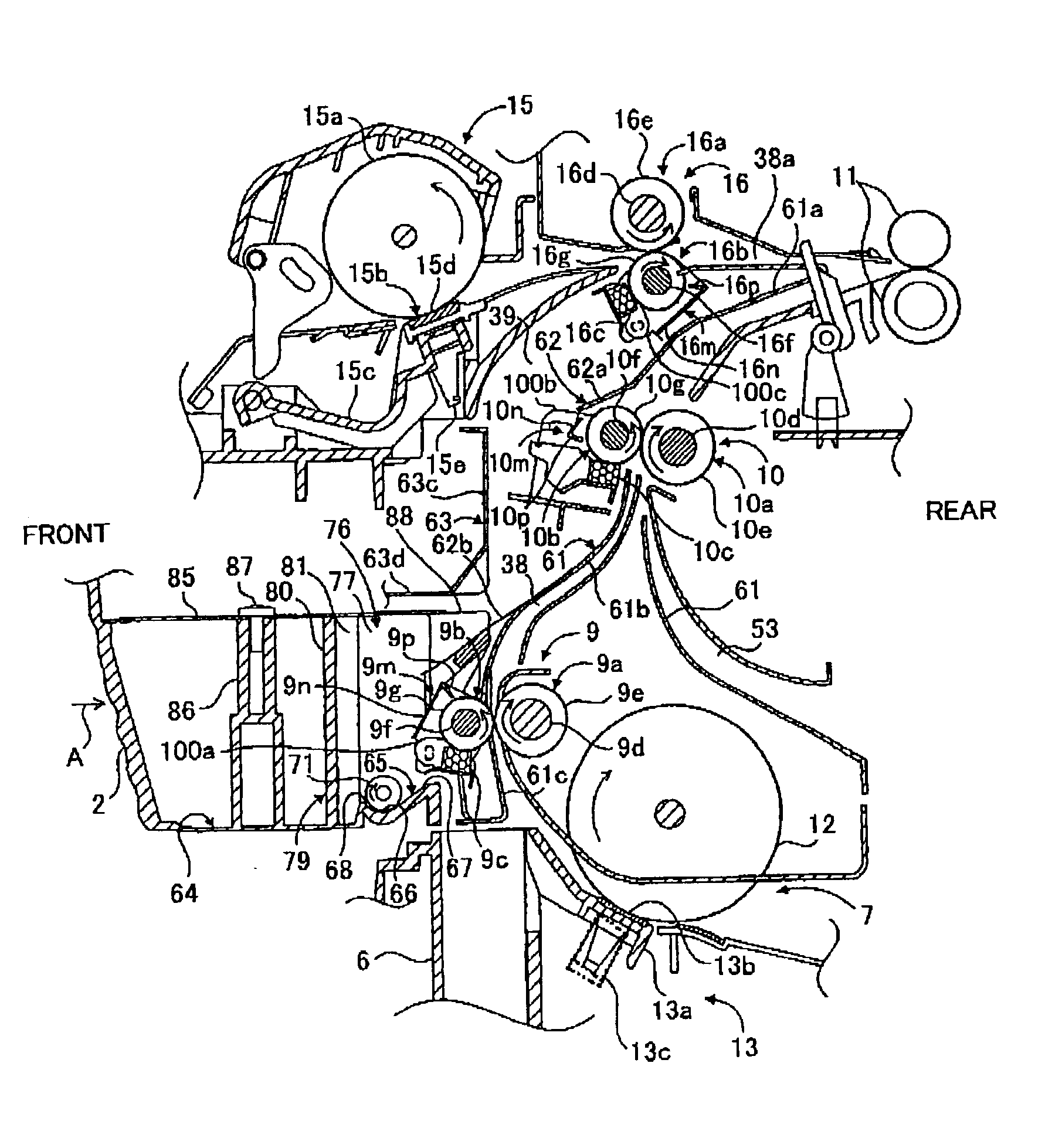

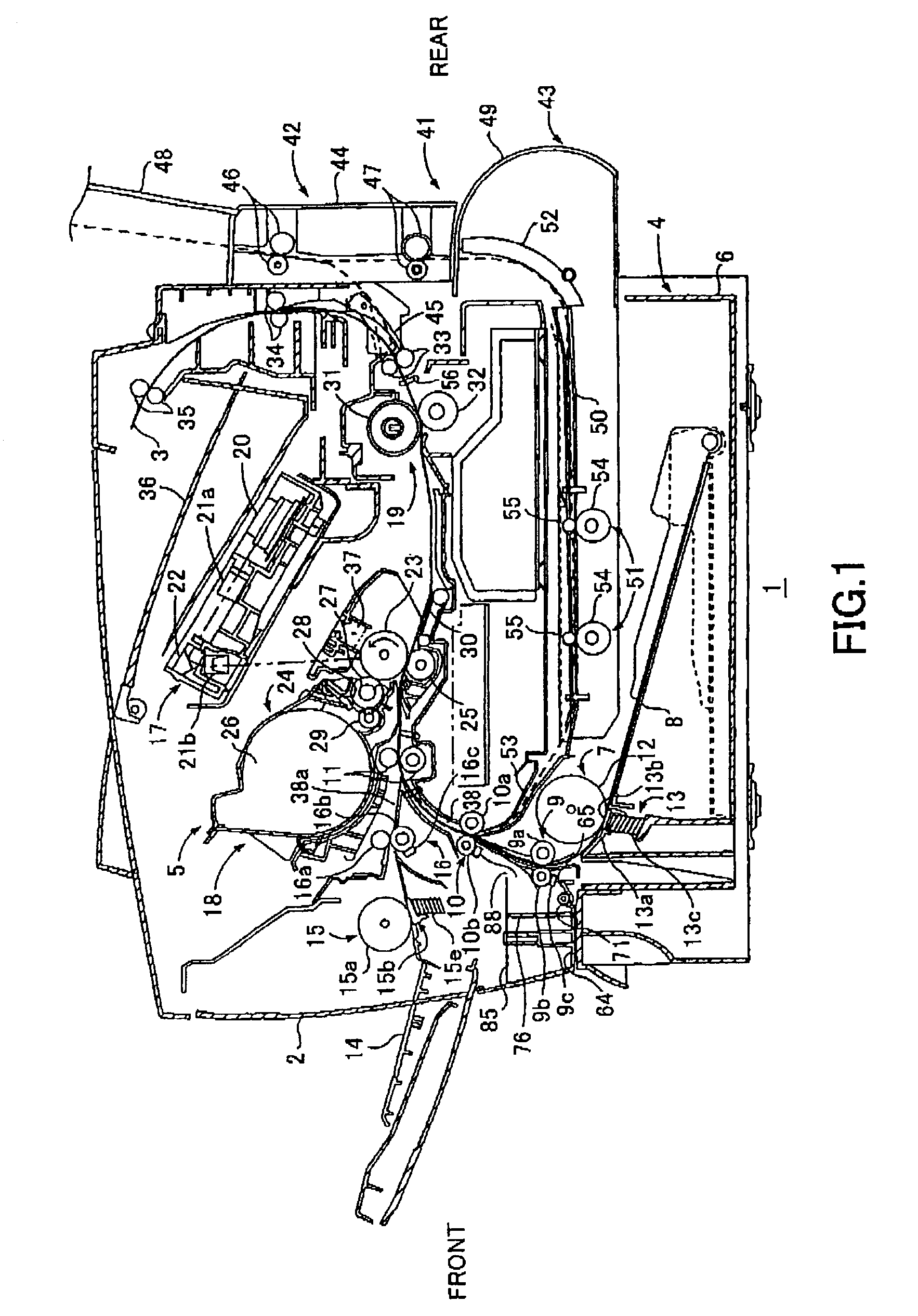

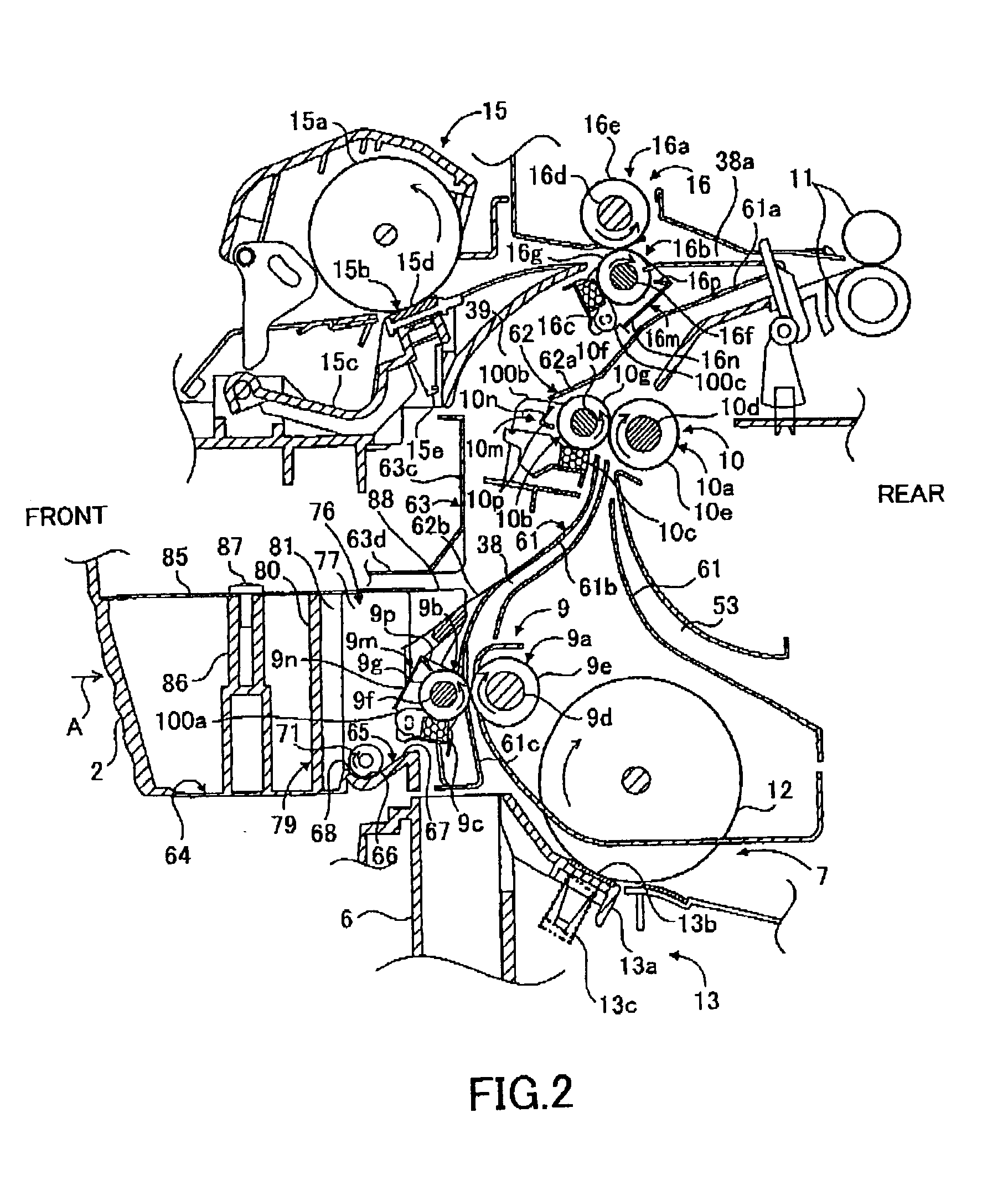

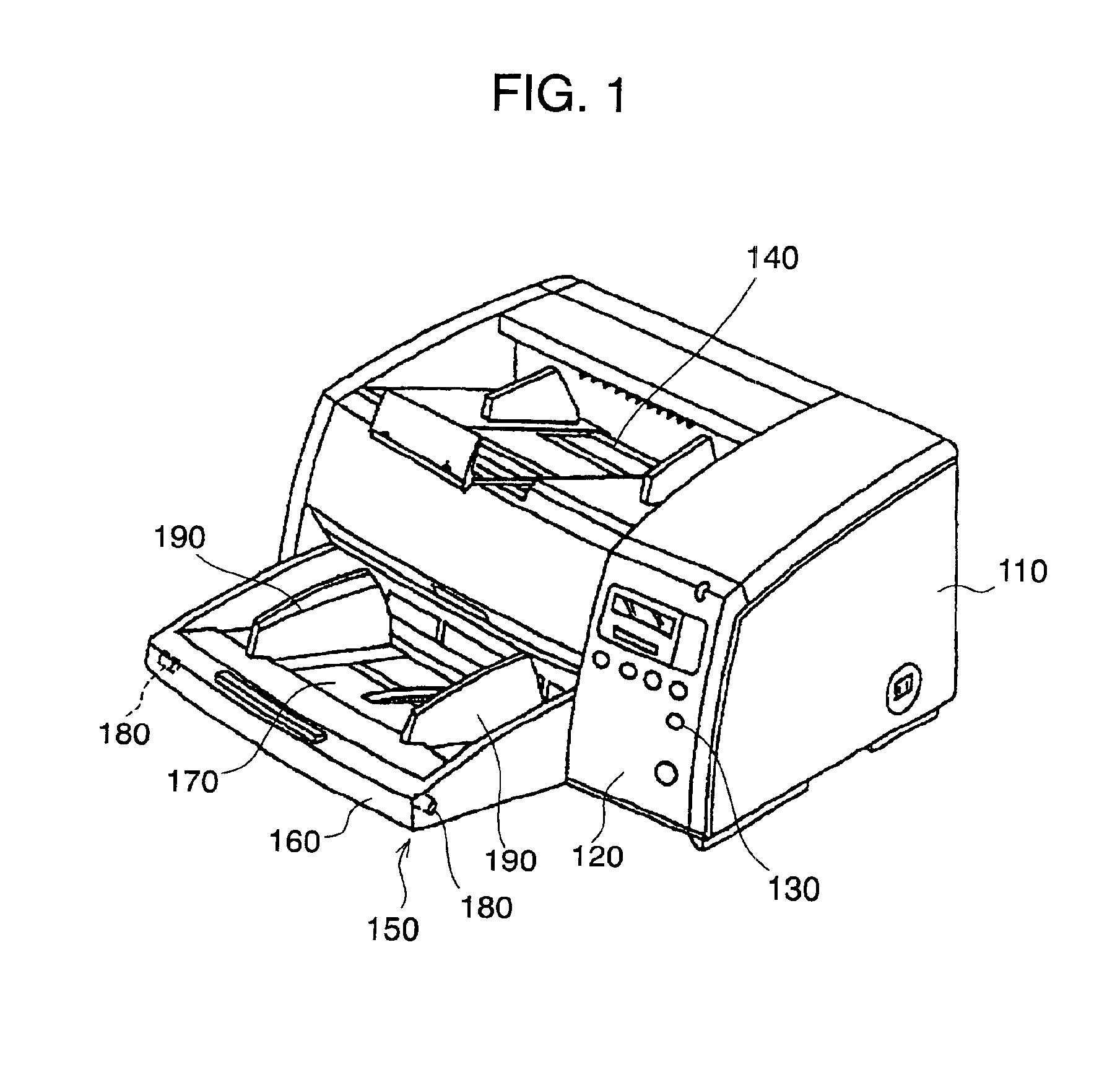

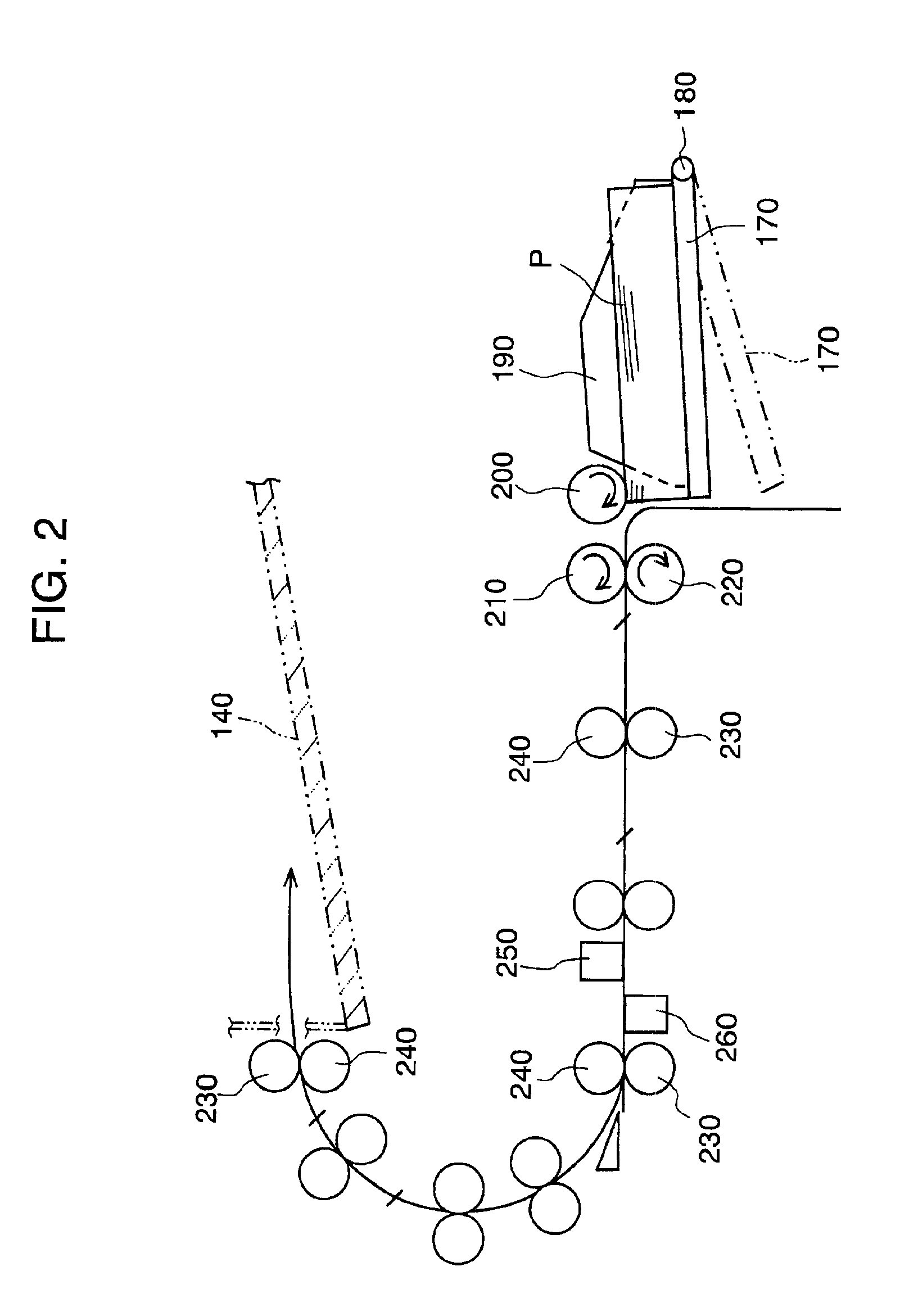

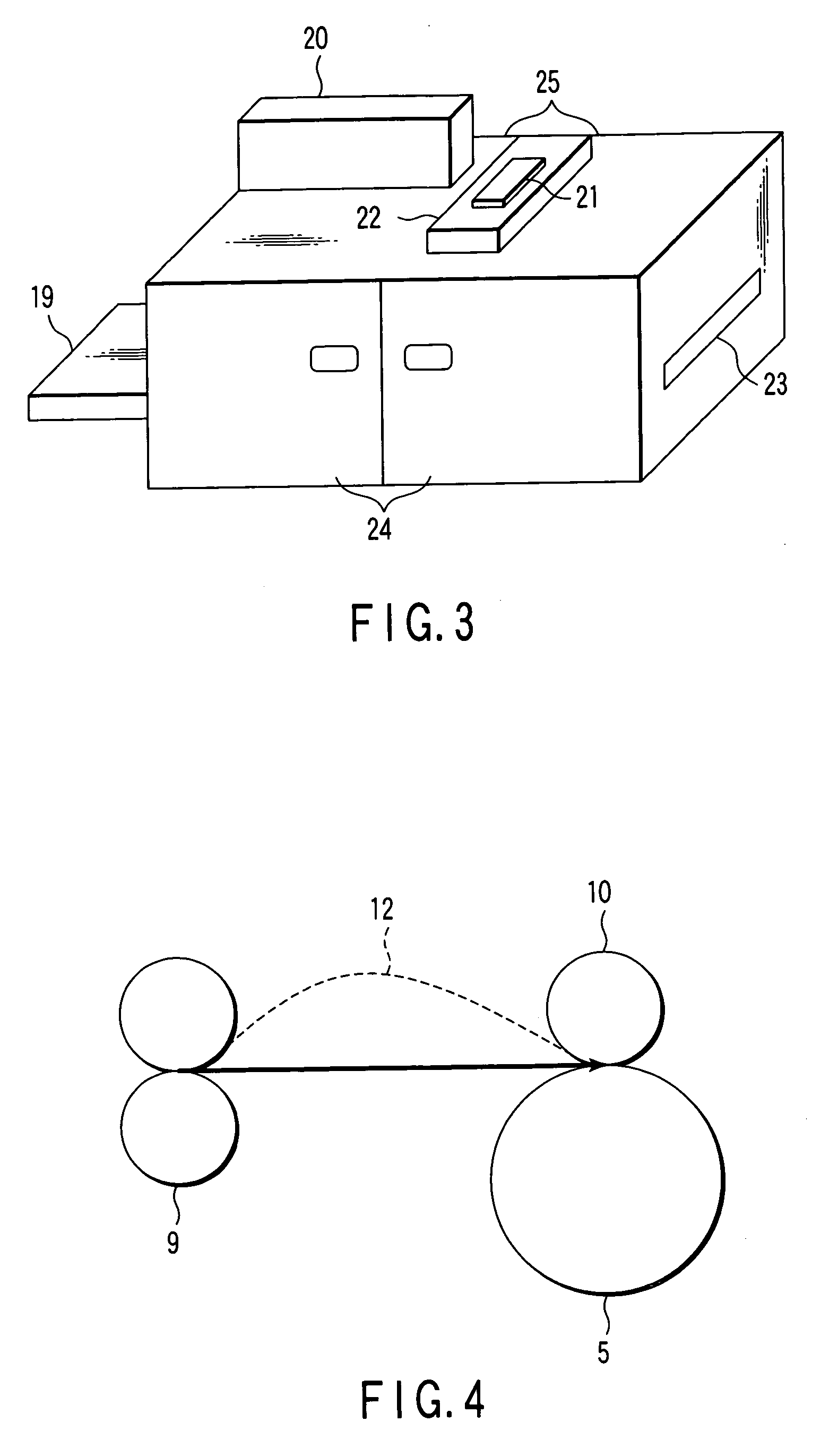

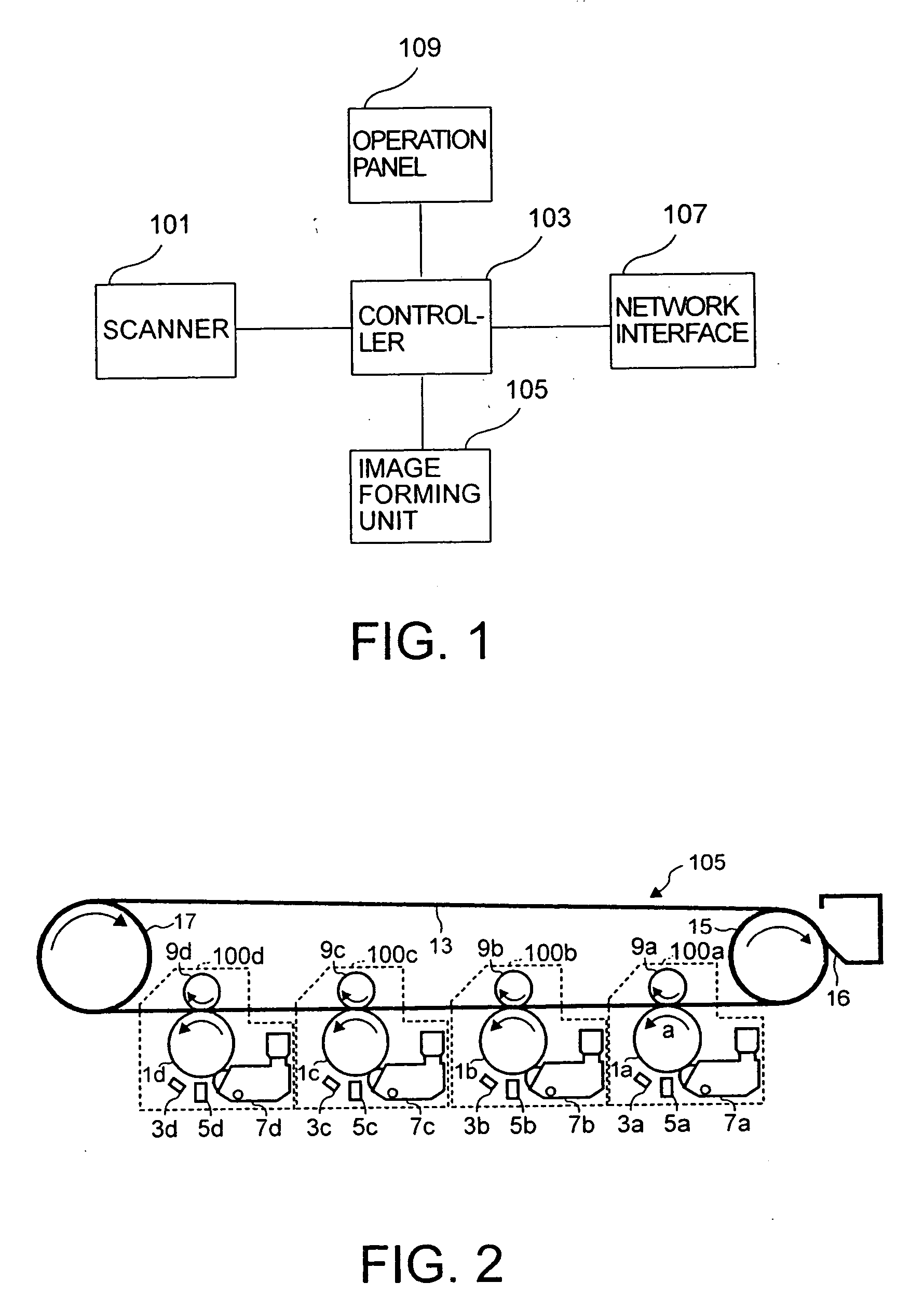

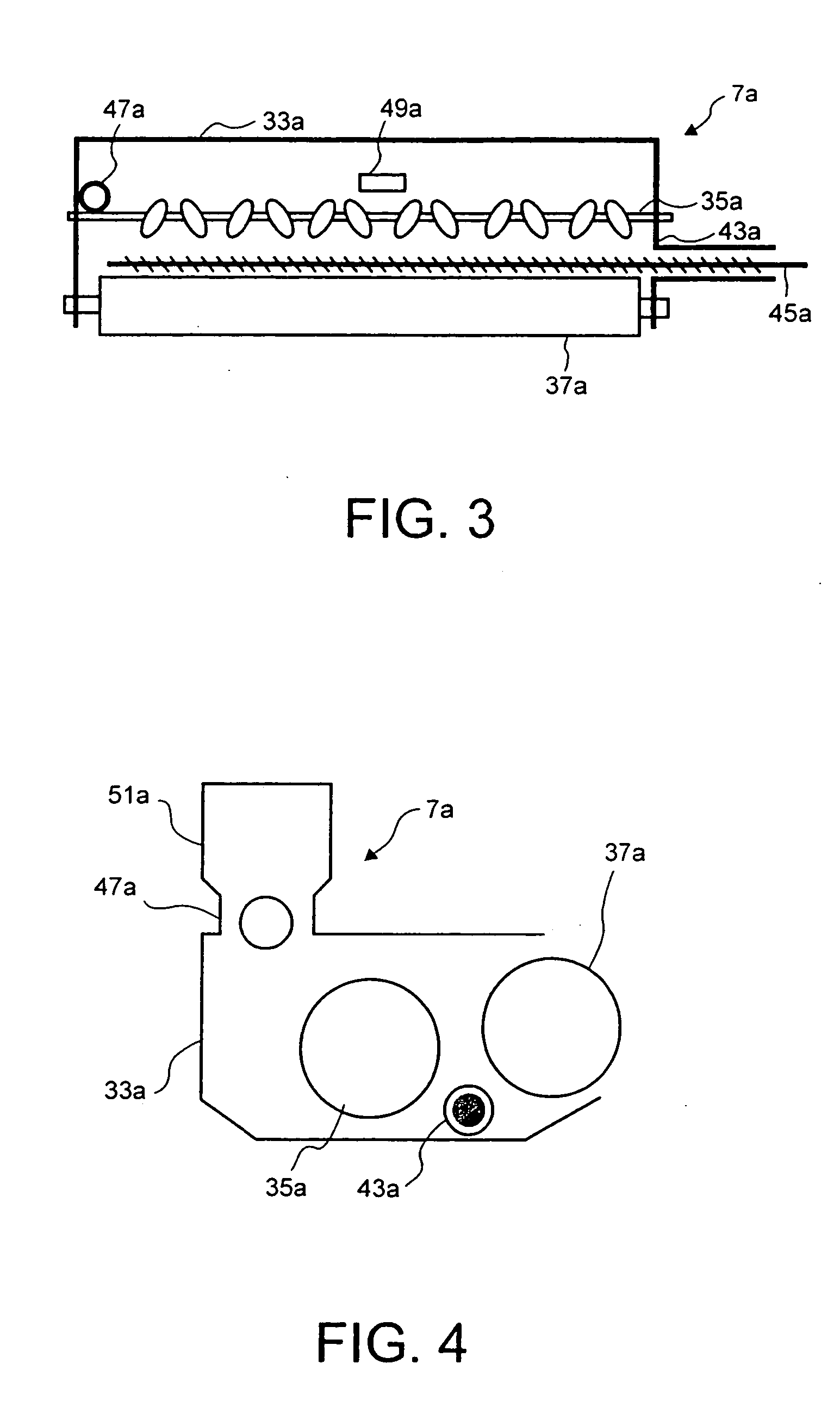

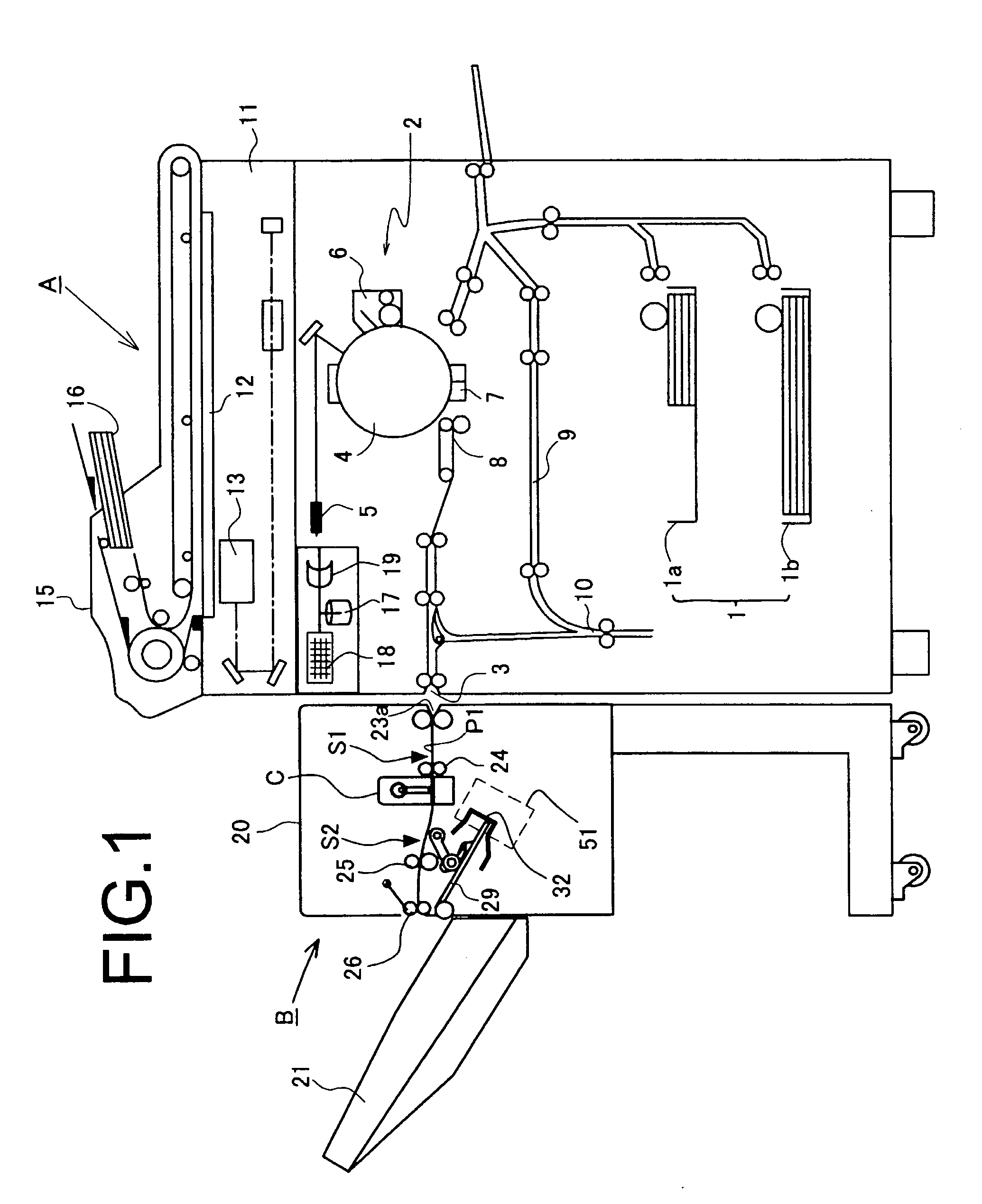

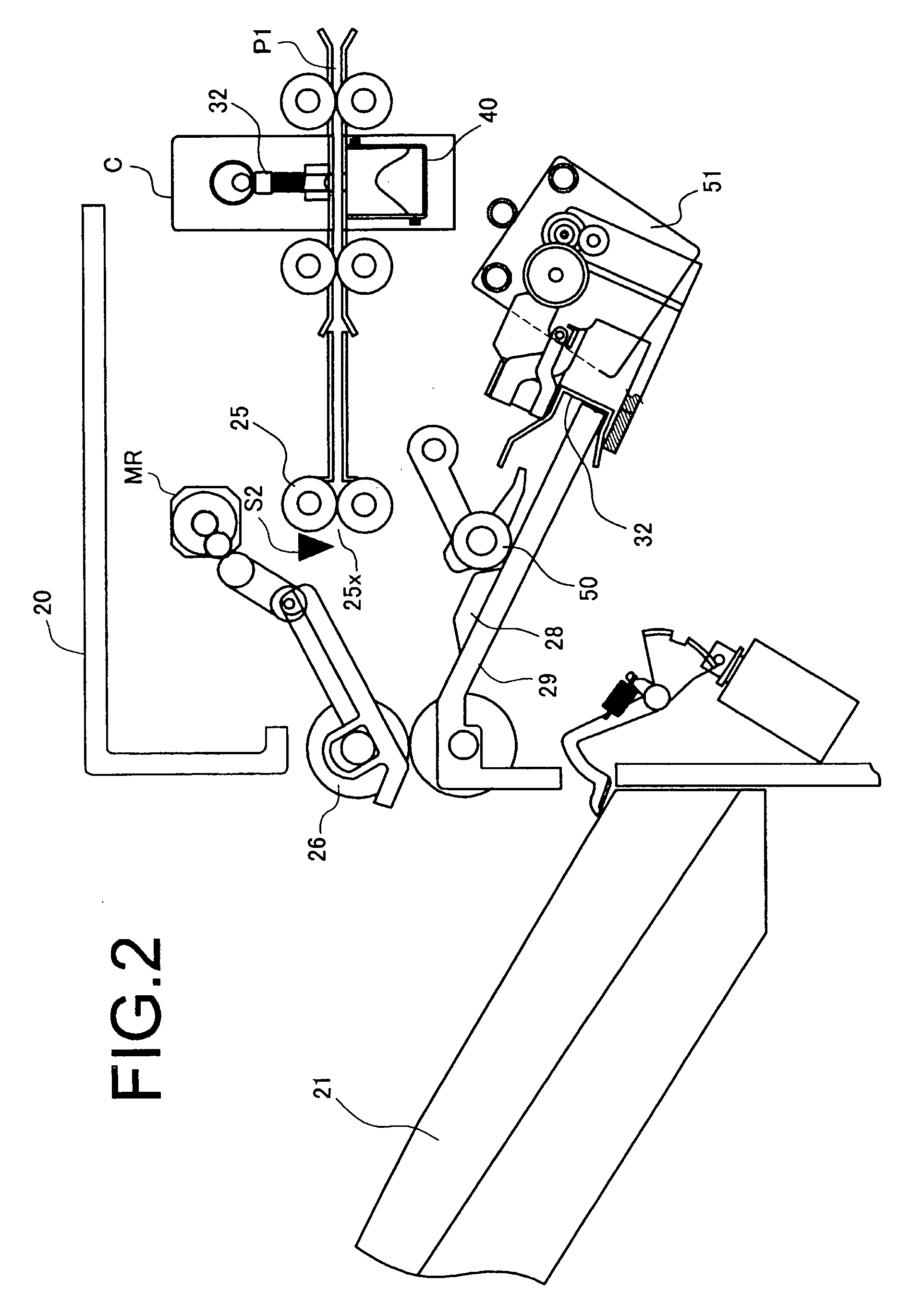

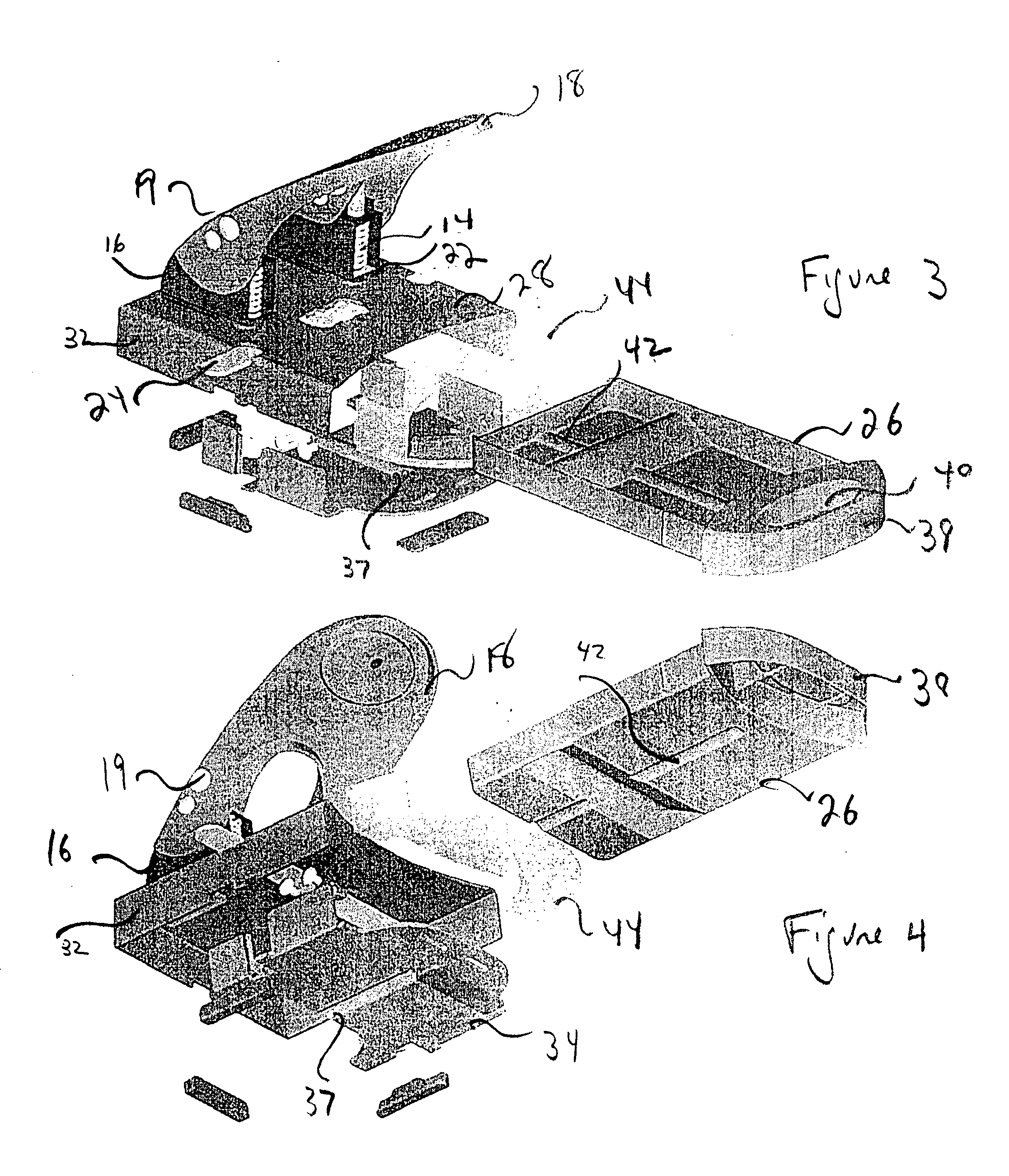

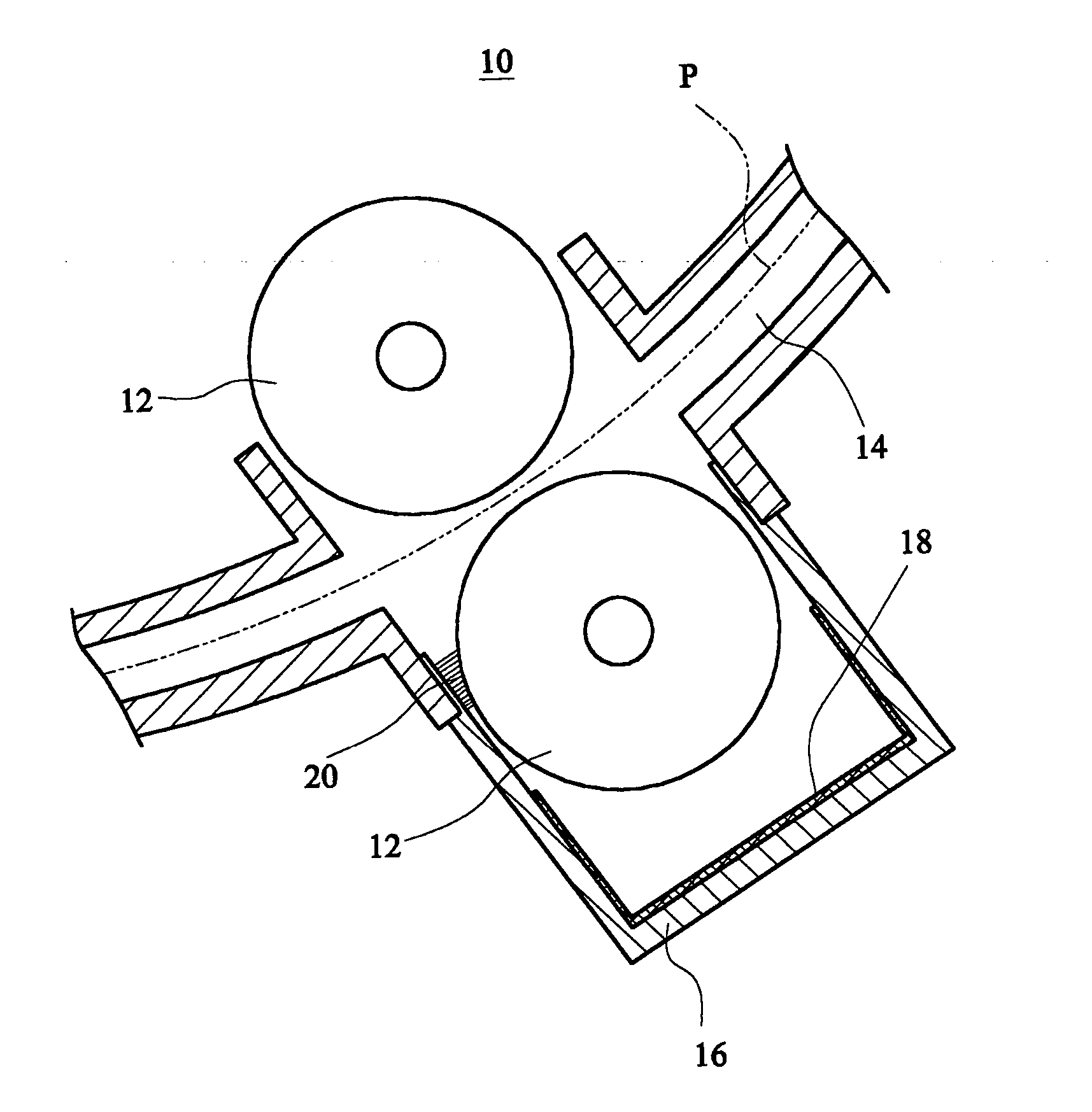

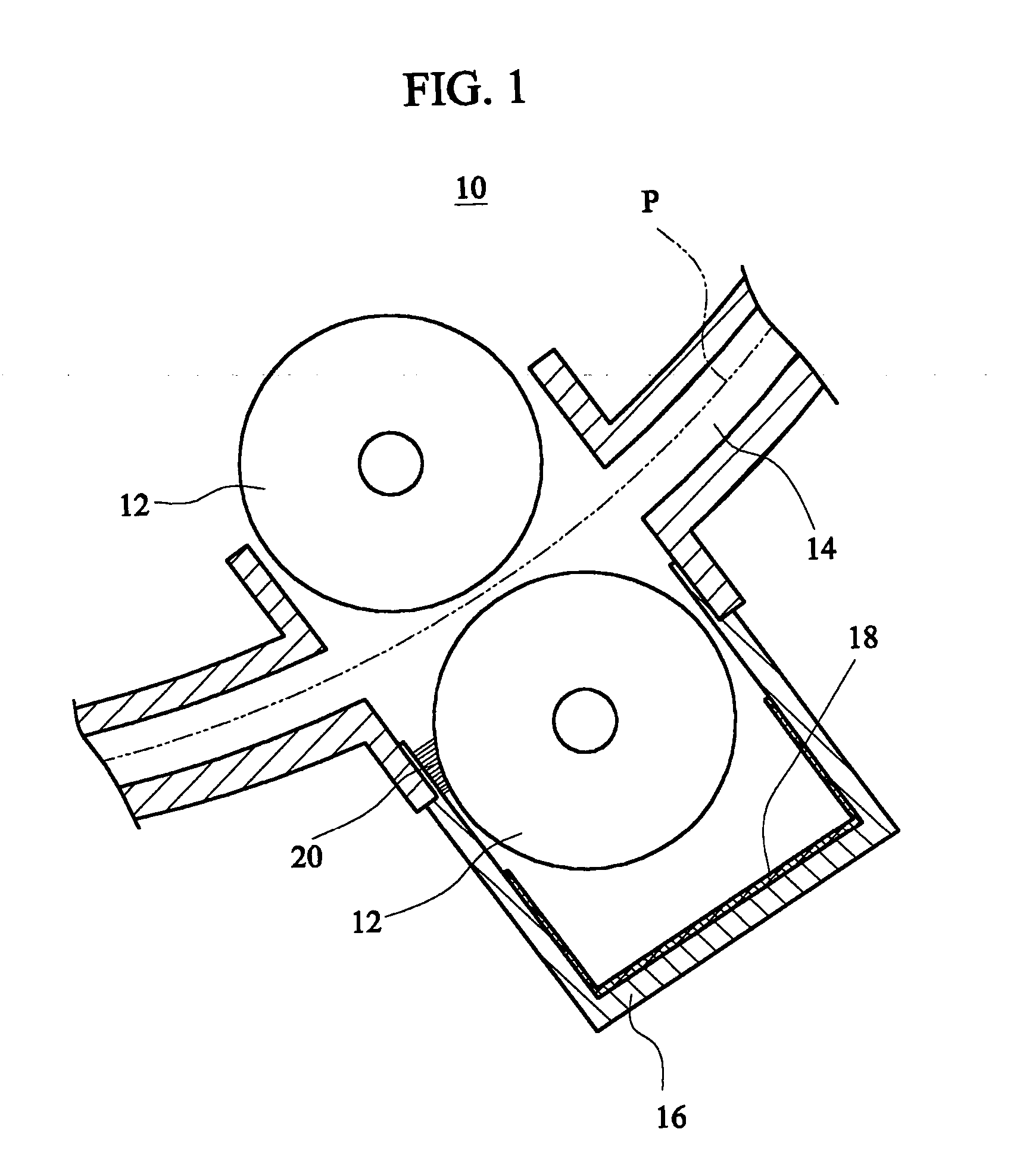

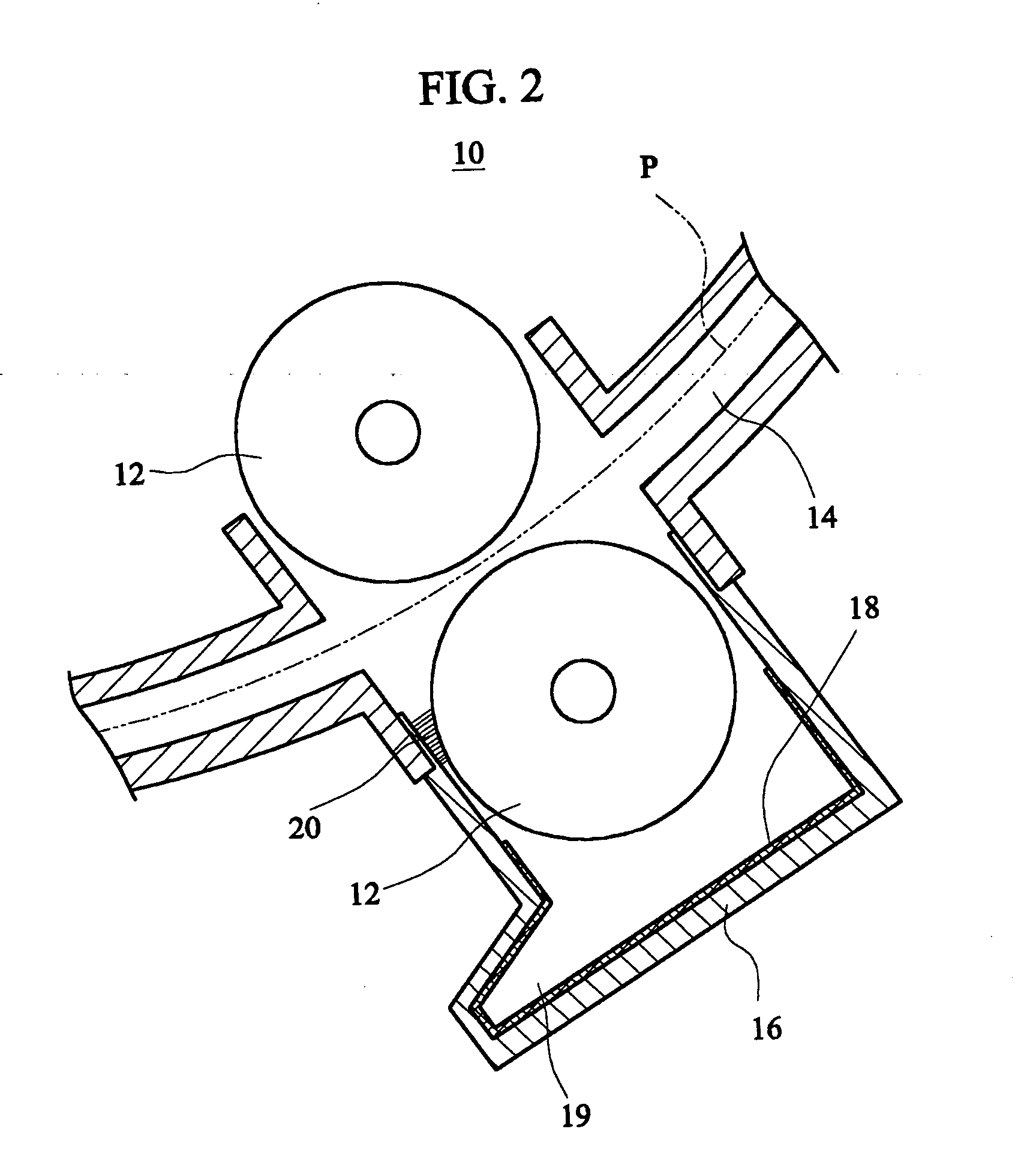

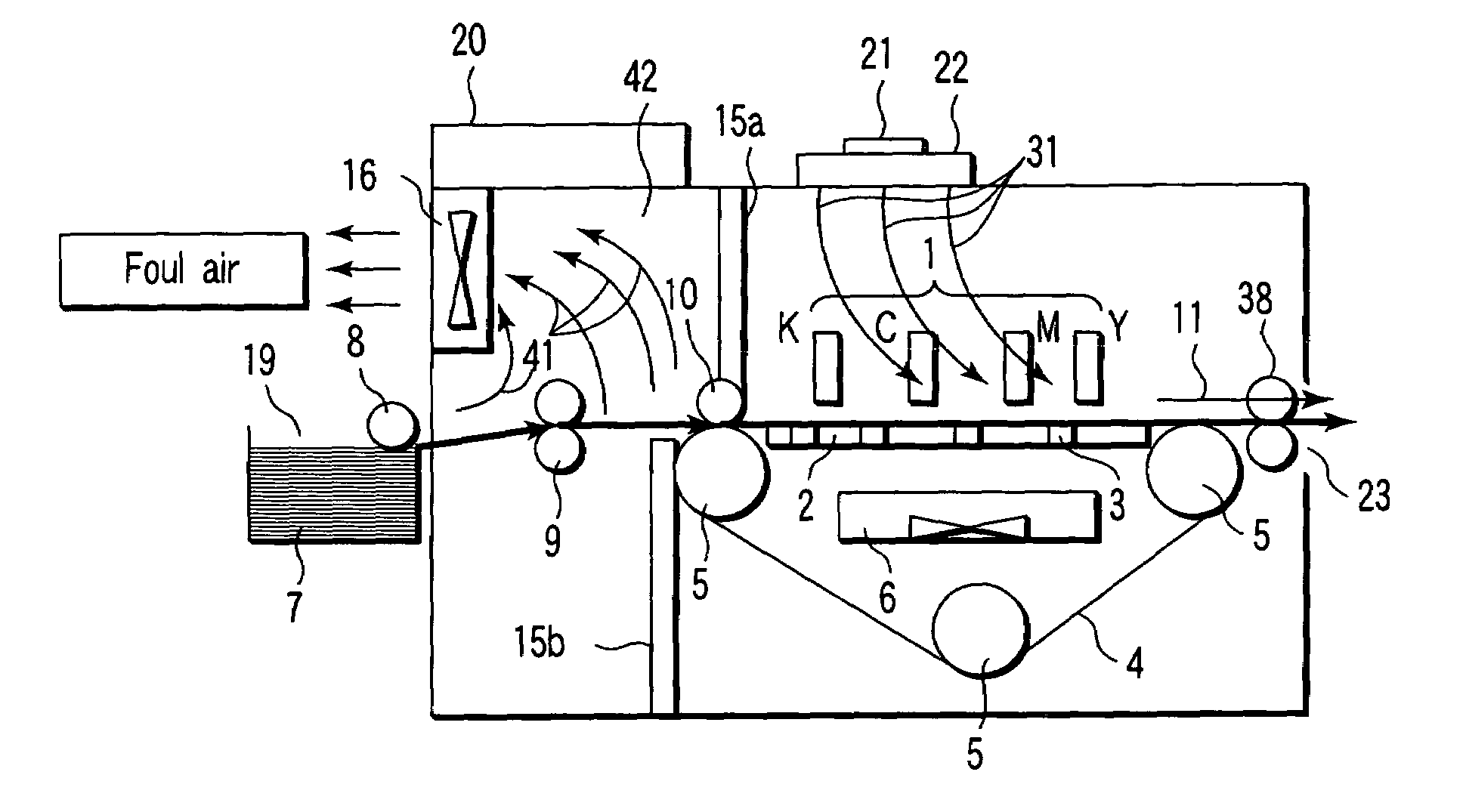

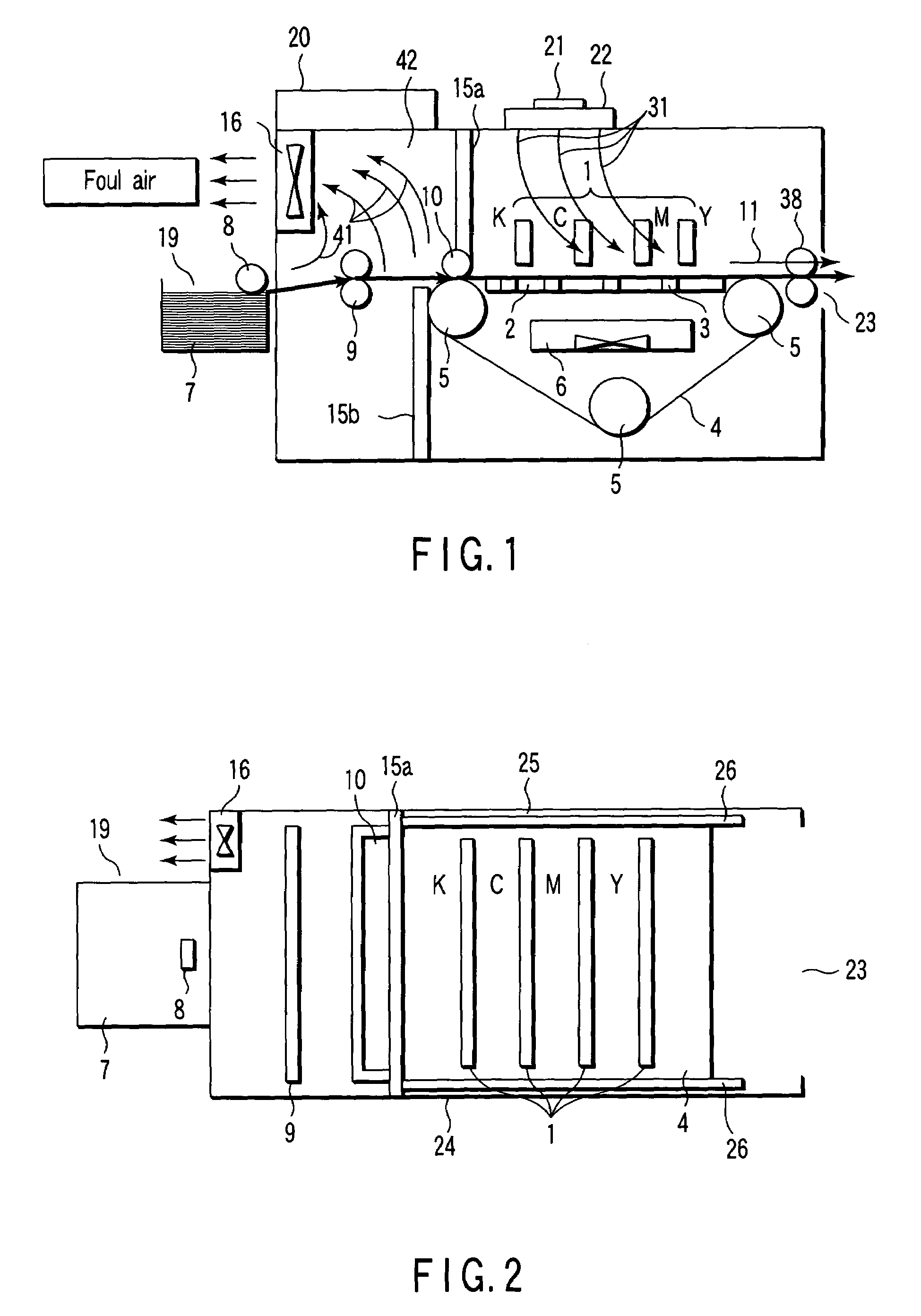

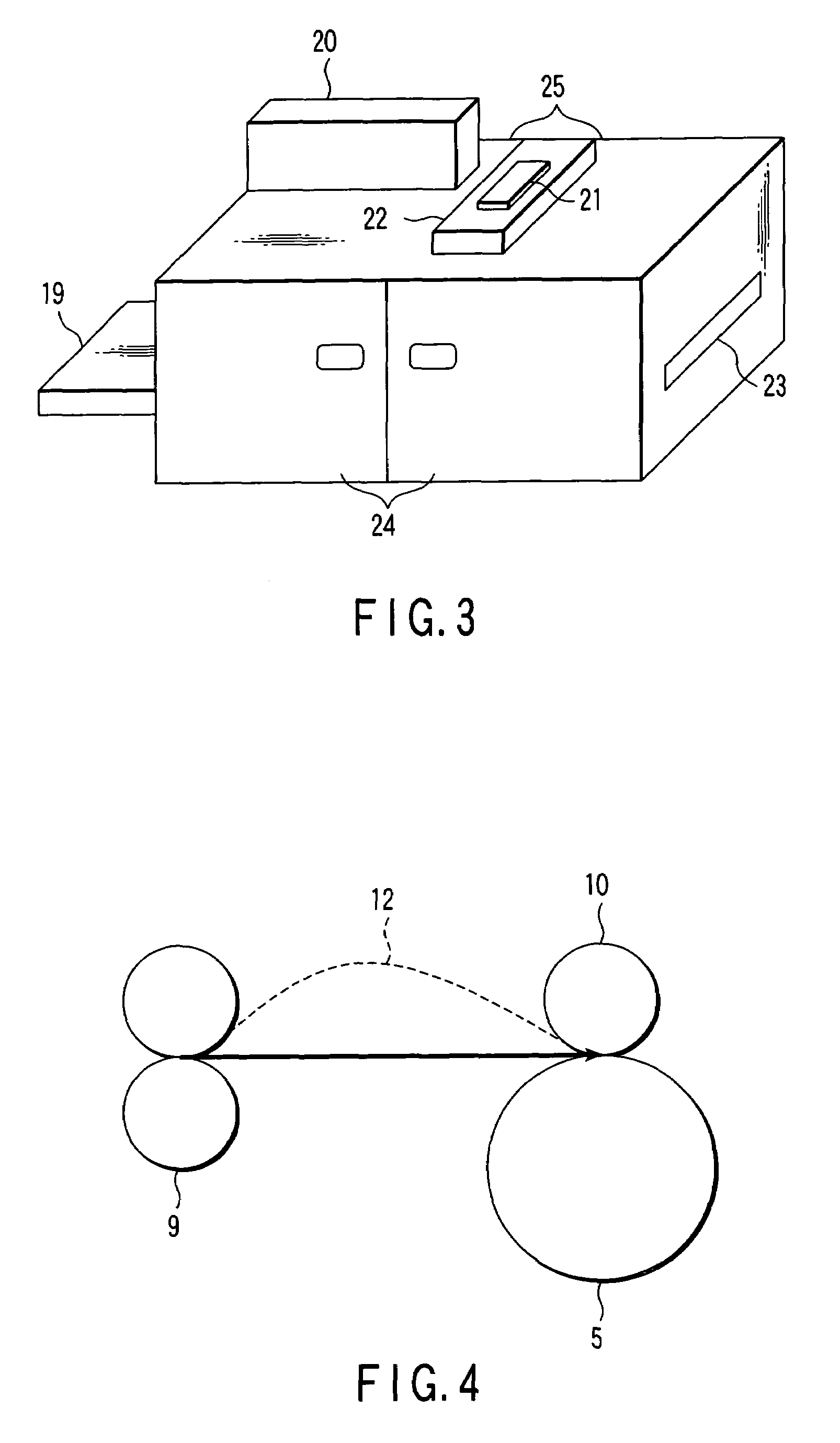

Image forming device having paper dust removing units

InactiveUS20030049043A1Efficient removalHigh quality imagingBrushesWork treatment devicesPaper dustImage formation

An image forming device capable of sufficiently removing paper dusts on a sheet thereby providing high quality image. A sheet transport path 38 is defined between a sheet supply section 7 provided with a separation pad 13 and a sheet supply roller 12 and an image forming section 5. Along the sheet supply section 7, at least a first paper dust removing roller 9b having a width slightly greater than the width of the separation pad 13 and a second paper dust removing roller 10b having a width slightly greater than the sheet width are disposed. Paper dusts generated upon friction against the separation pad 13 are removed by the first paper dust removing roller 9b, and paper dusts spreading over entire surface of the sheet are removed by the second paper dust removing roller 10b.

Owner:BROTHER KOGYO KK

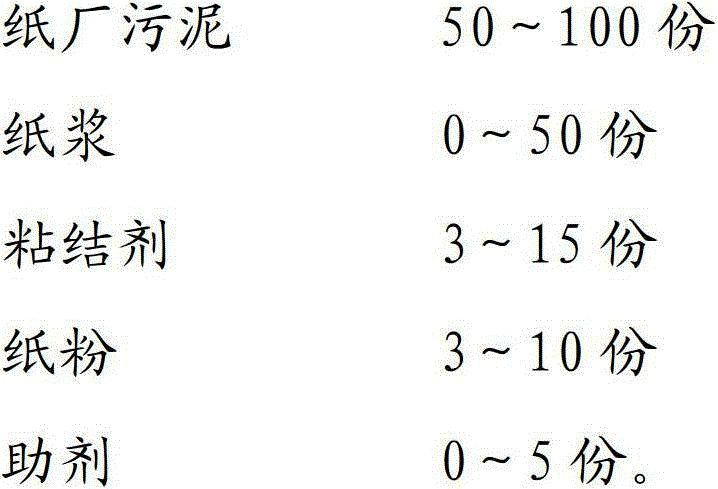

Cat litter for pets and preparation method of cat litter

The invention relates to the technical field of articles for pet garbage cleaning, in particular to cat litter for pets and a preparation method of the cat litter. The cat litter for pets comprises the following ingredients in parts by weight: 50 to 100 parts of paper plant sludge, 0 to 50 parts of paper pulp, 3 to 10 parts of bonding agents, 3 to 5 parts of paper dust and 0 to 5 parts of auxiliary agents, wherein the paper fiber length in the paper pulp is 1.5 to 3mm, and the paper fiber length in the paper dust is 0.5 to 1.5mm. The cat litter for pets has the advantages that the specific gravity is light, the adsorption capacity is high, the caking effect is good, the processing is easy, the environment protection is excellent, and in addition, the cost is low. The flow process of the preparation process of the cat litter is continuous, the time is saved, during the raw material stirring homogenization and granulation, the process is mild, and the operation is easy.

Owner:朱群

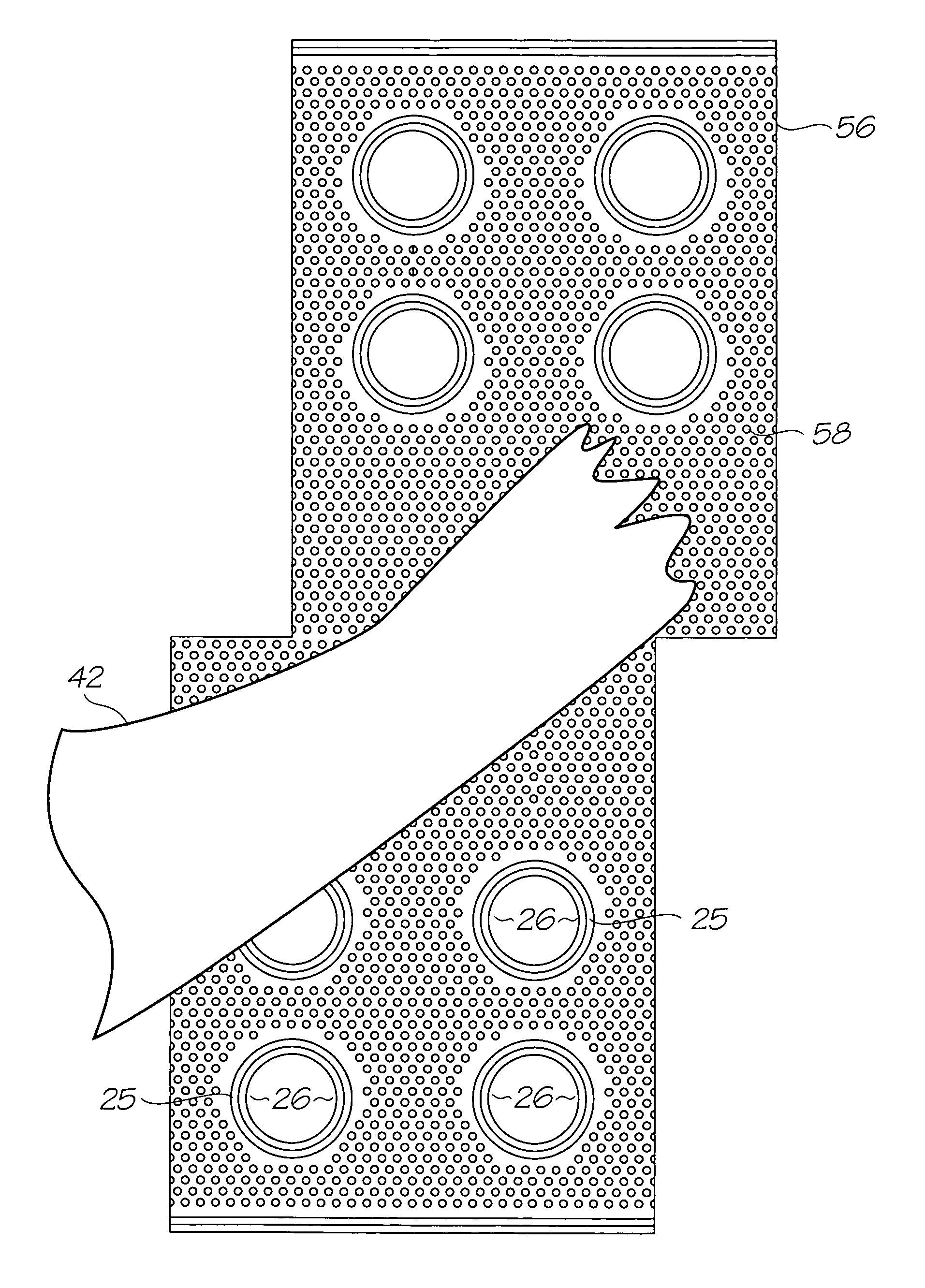

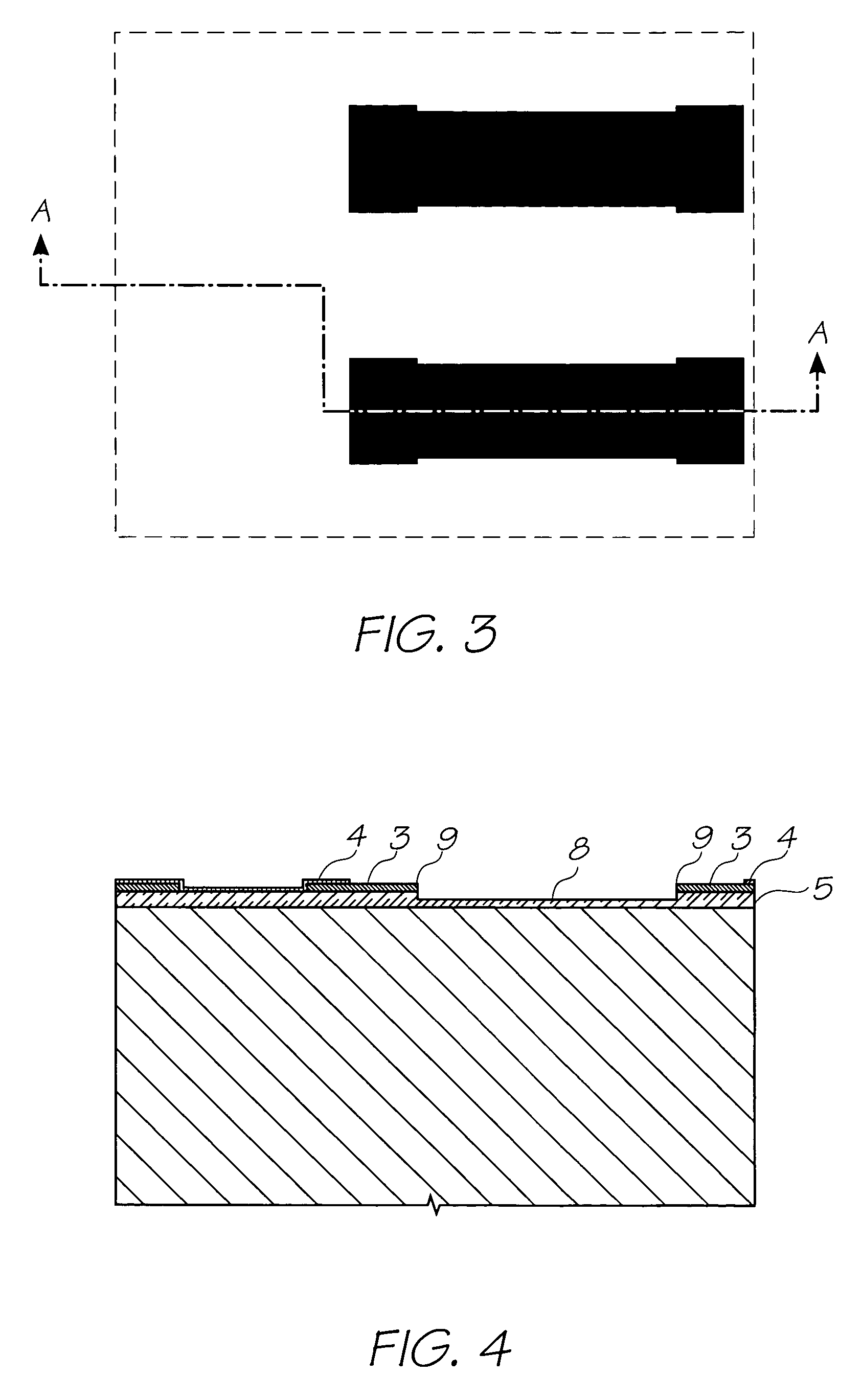

Reduced stiction printhead surface

ActiveUS7510267B2Reduction factorPrintingFlexible microstructural devicesStatic friction coefficientPaper dust

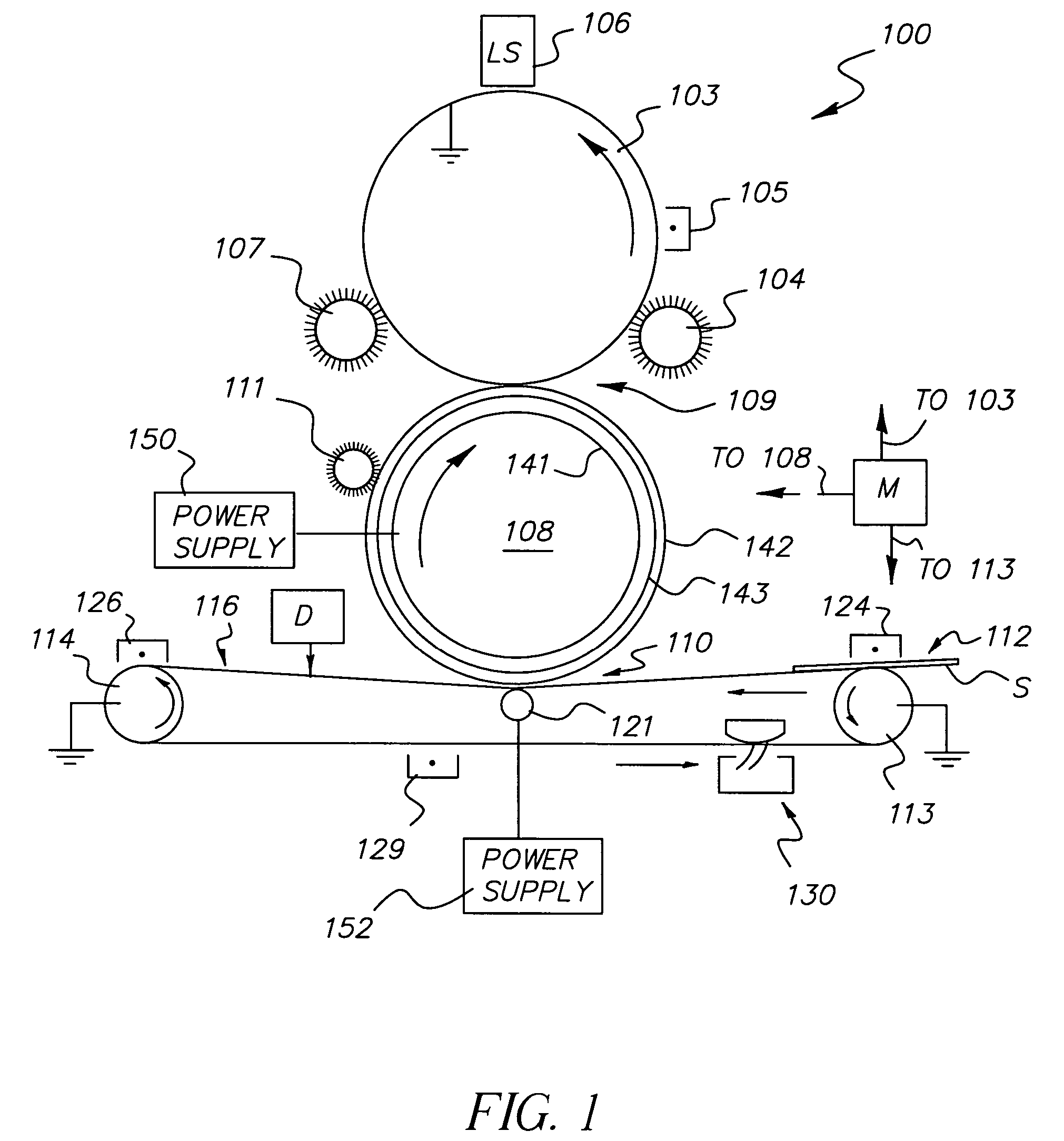

An inkjet printhead with a nozzle plate that has an exterior surface with formations for reducing its co-efficient of static friction. By reducing the co-efficient of static friction, there is less likelihood that paper dust or other contaminants will clog the nozzles in the nozzle plate. Static friction, or “stiction” as it has become known, allows dust particles to “stick” to nozzle plates and thereby clog nozzles. By patterning the exterior of the nozzle plate with raised formations, dust particles can only contact the outer extremities of each formation. This reduces friction between the particles and the nozzle plate so that any particles that contact the plate are less likely to attach, and if they do attach, they are more likely to be removed by printhead maintenance cleaning cycles.

Owner:SILVERBROOK RES PTY LTD +1

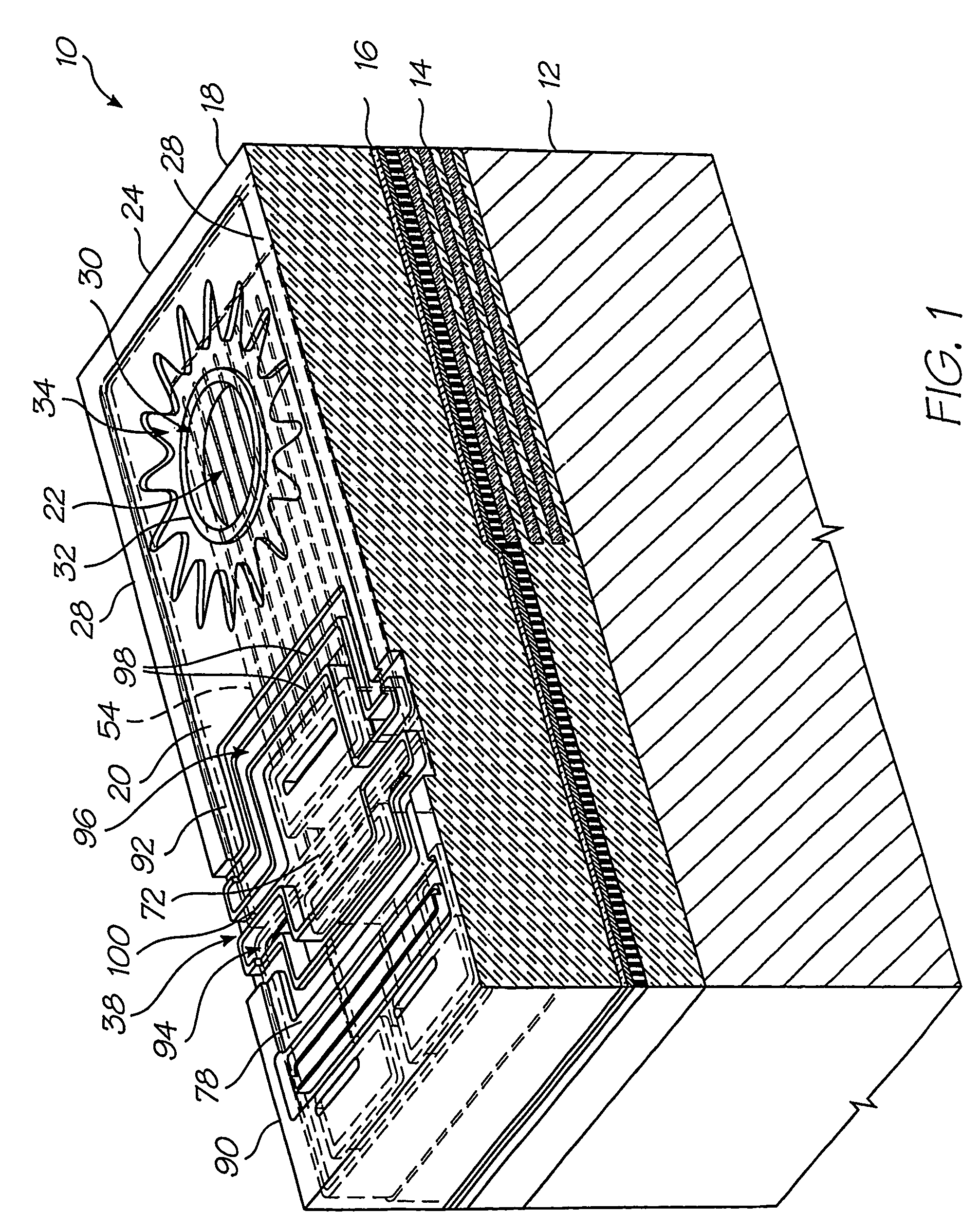

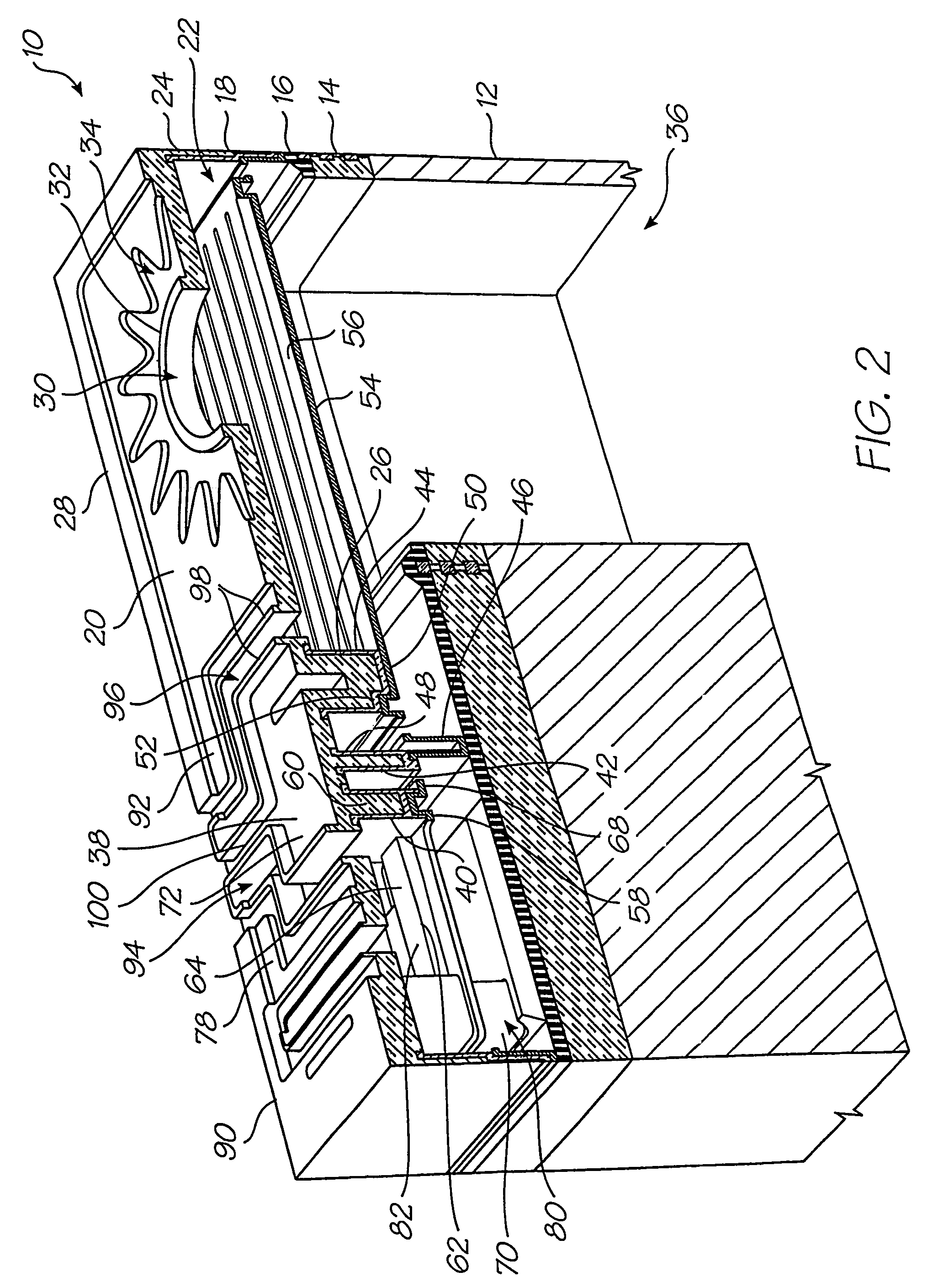

Discrete air and nozzle chambers in a printhead chip for an inkjet printhead

A printhead chip for an inkjet printhead includes a plurality of nozzle arrangements on a substrate. Each nozzle arrangement includes nozzle chamber walls and a roof that define a nozzle chamber with the roof defining an ink ejection port in fluid communication with the nozzle chamber. An ink-ejecting member or paddle is positioned in the nozzle chamber and displaceable towards and away from the ink ejection port so that a resultant fluctuation in ink pressure within the nozzle chamber results in an ejection of ink from the ink ejection port. At least one work transmitting structure of a lever mechanism is displaceable with respect to the substrate results in displacement of the ink-ejecting member. A thermal bend actuator is capable of displacing the structure upon receipt of an electrical drive signal. An air chamber defined by walls and a covering formation are positioned over the actuator to protect the component from ingress of microscopic detritus such as paper dust.

Owner:MEMJET TECH LTD +1

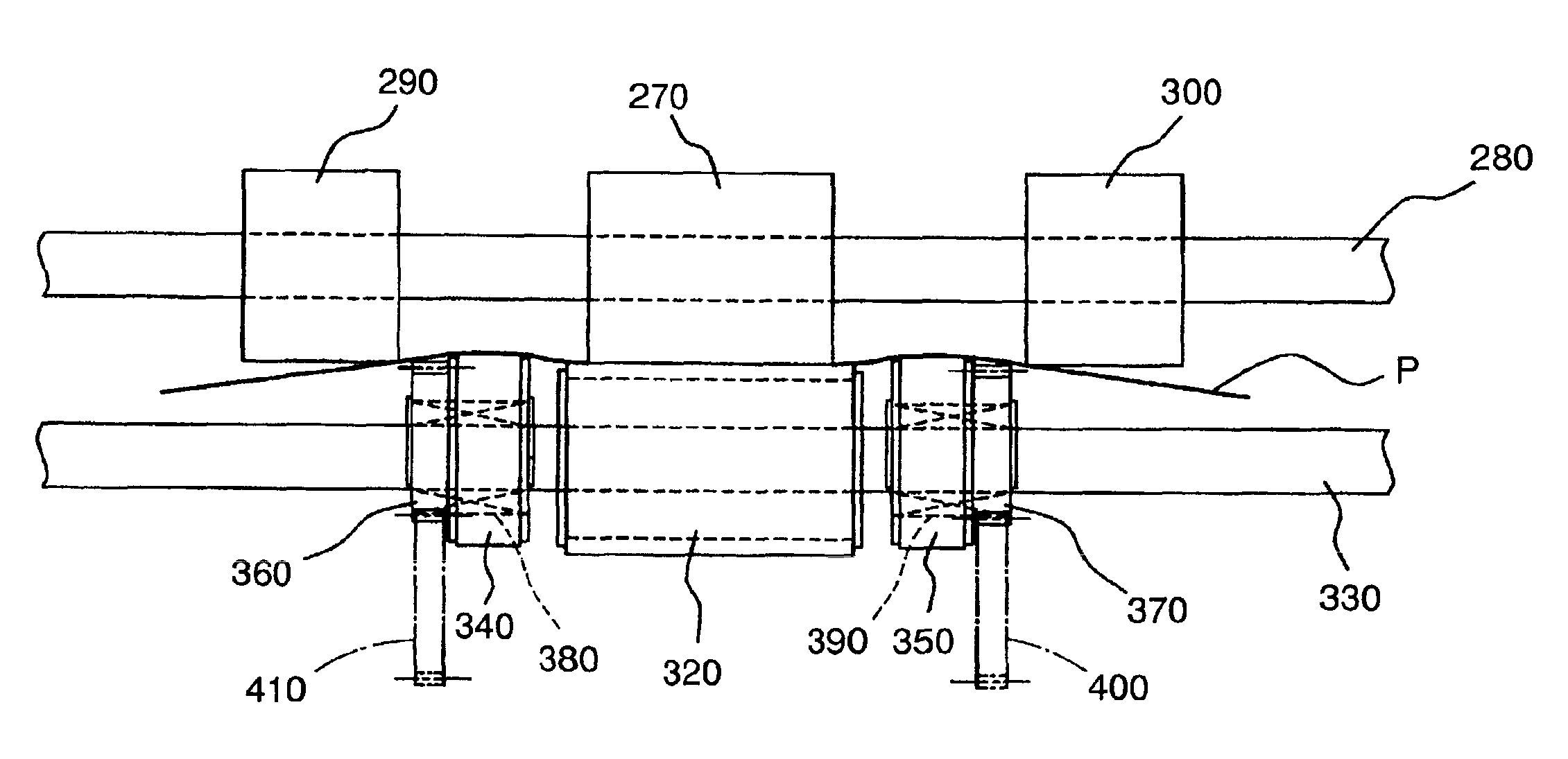

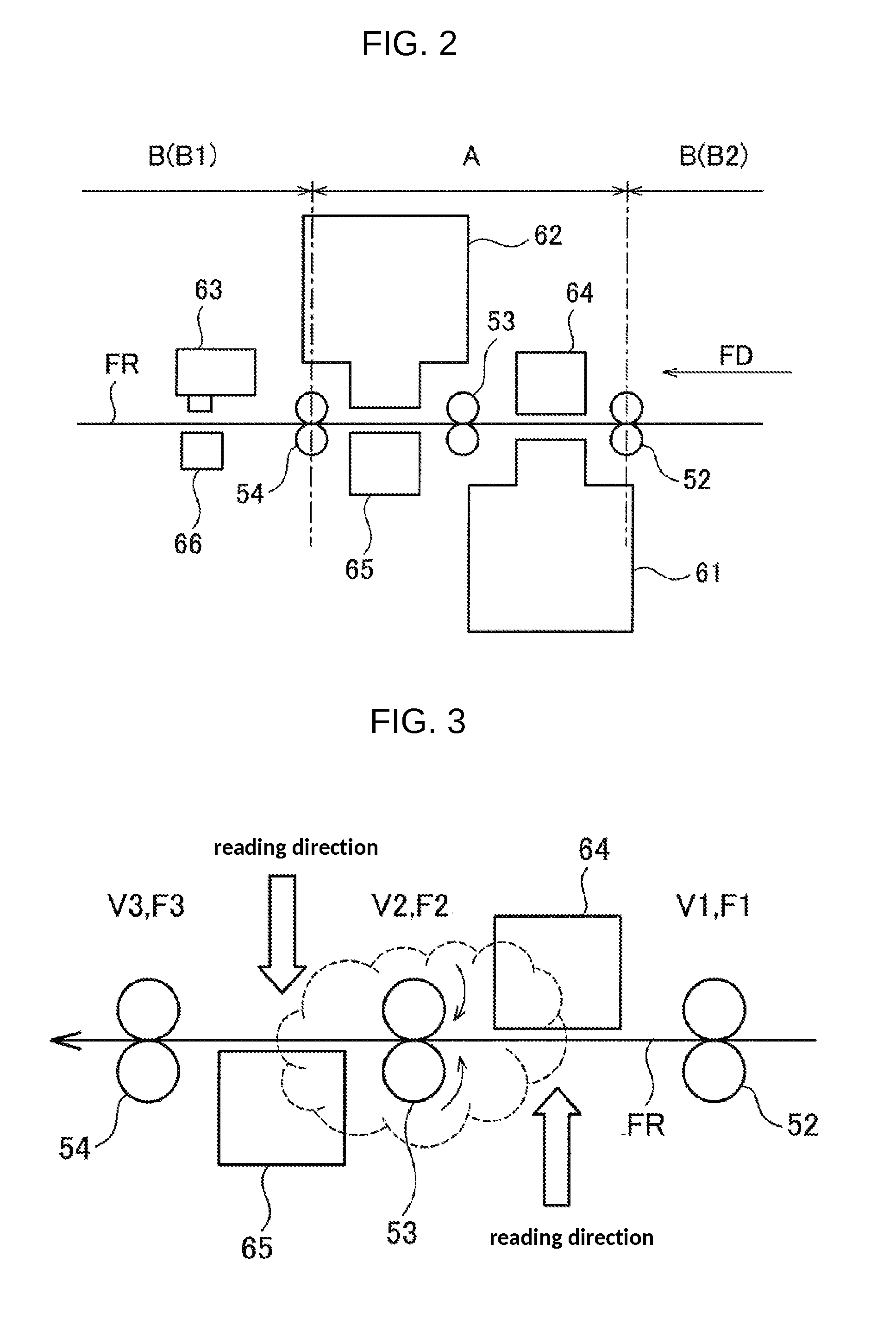

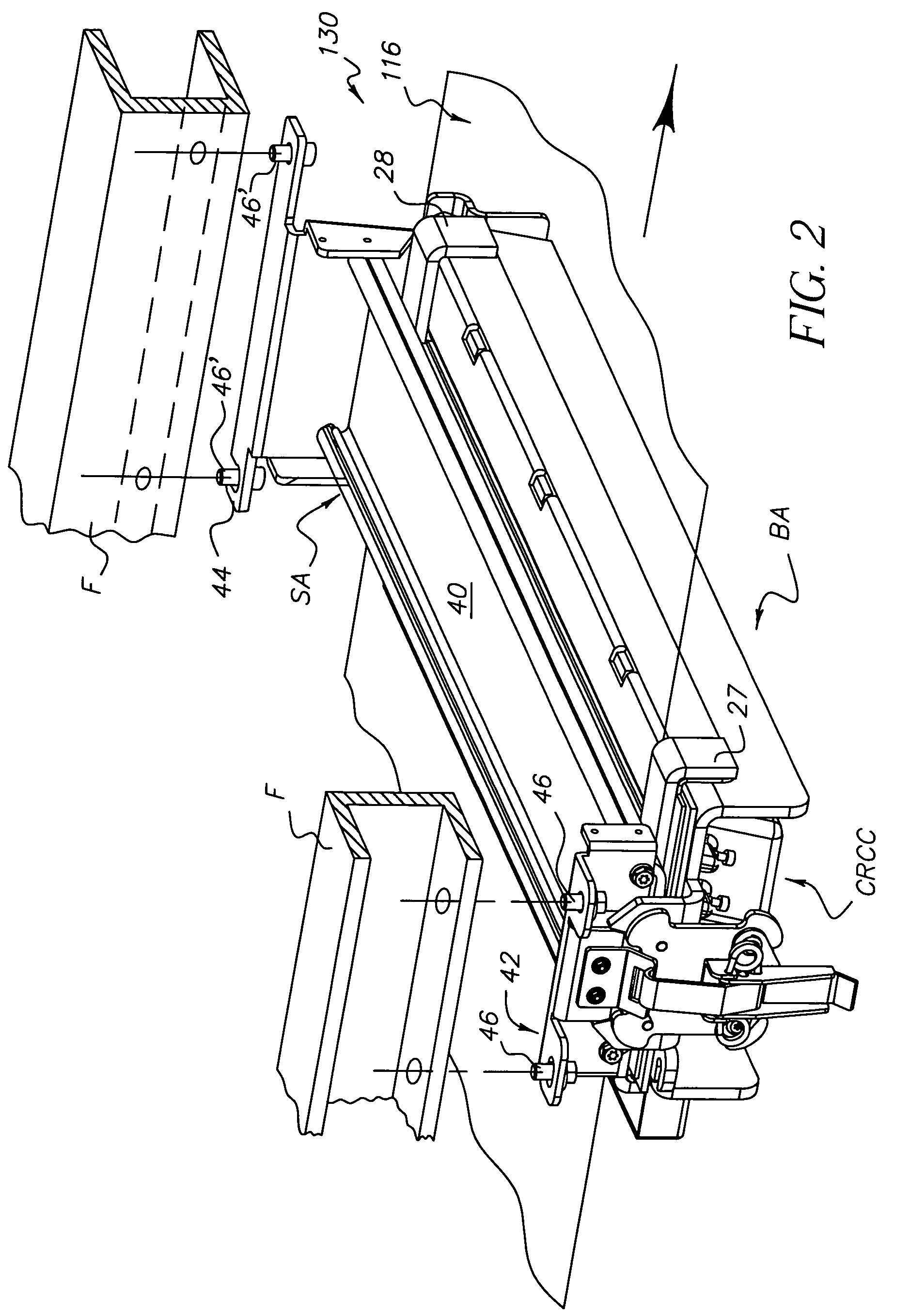

Sheet separation roller configuration

InactiveUS6913257B2Prevention of overlaid sheet transferImprove reliabilityArticle feedersPictoral communicationPaper dustEngineering

An image reader comprising a reading glass plate facing an optical scanning system and a platen roller provided opposite to the reading glass plate; both being grounded. It is combined with an automatic sheet feeder, which comprises a retardation roller containing torque limiters and corrugation rollers. An optimized combination of these rollers provides an ideal sheet transfer and avoids overlaid sheet transfer. Generation of paper dust and toner particles is minimized in the optimized sheet transfer. Furthermore, sticking of such dust and particles on the reading glass plate and the platen roller is prevented in an image reader of the present invention. Thus the image reader reads out high quality images without being affected by dispersed paper dust or toner particles, while overlaid transfer of mother document sheets is prevented in the sheet feeder.

Owner:PANASONIC CORP

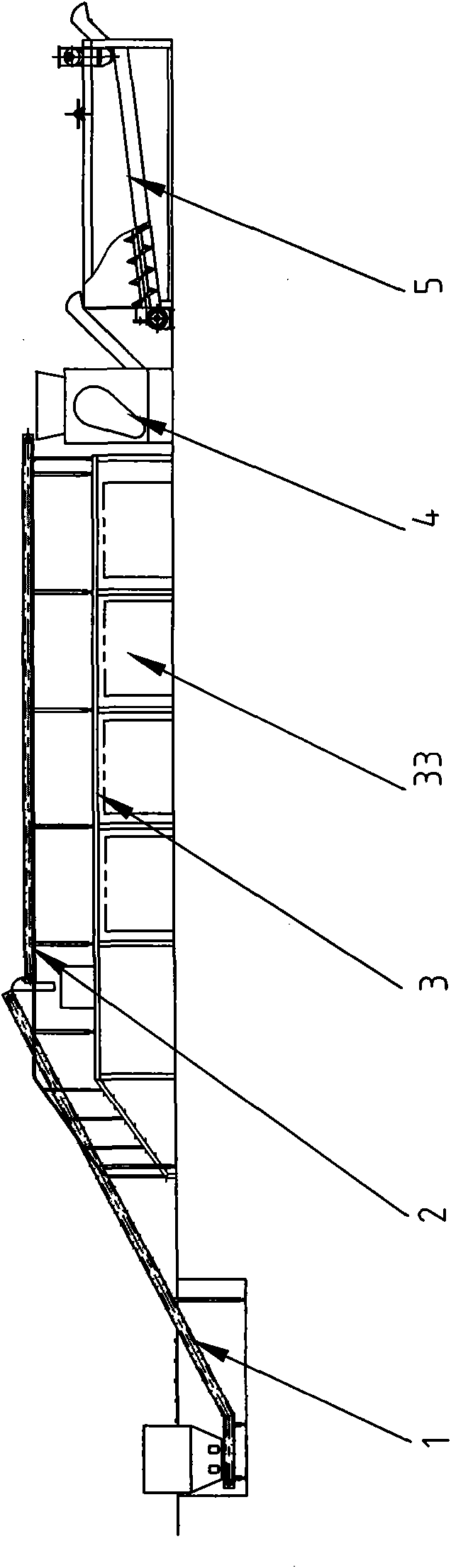

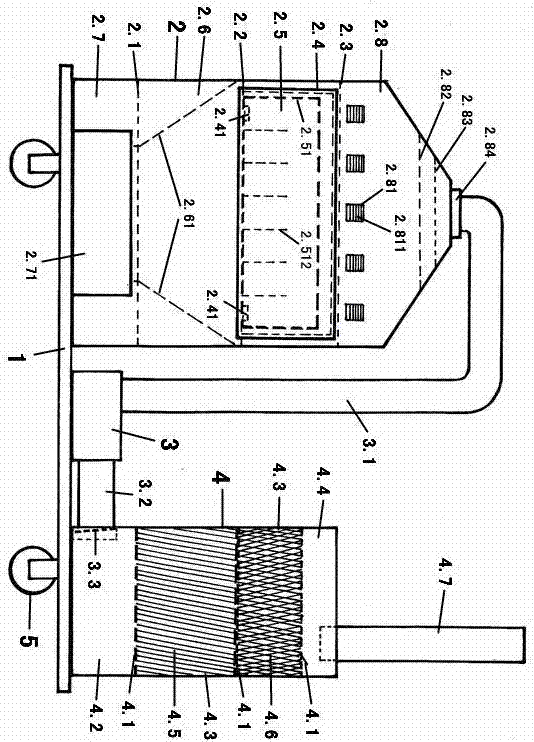

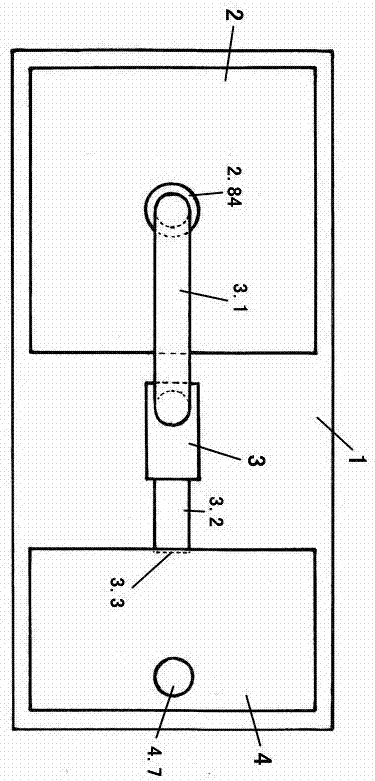

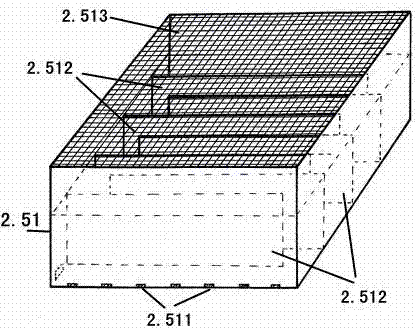

Device for producing regenerative polyester bottle chips by using waste plastics and production process thereof

InactiveCN101844379ASystematization of production processGuaranteed stabilityPlastic recyclingPolyesterWater treatment system

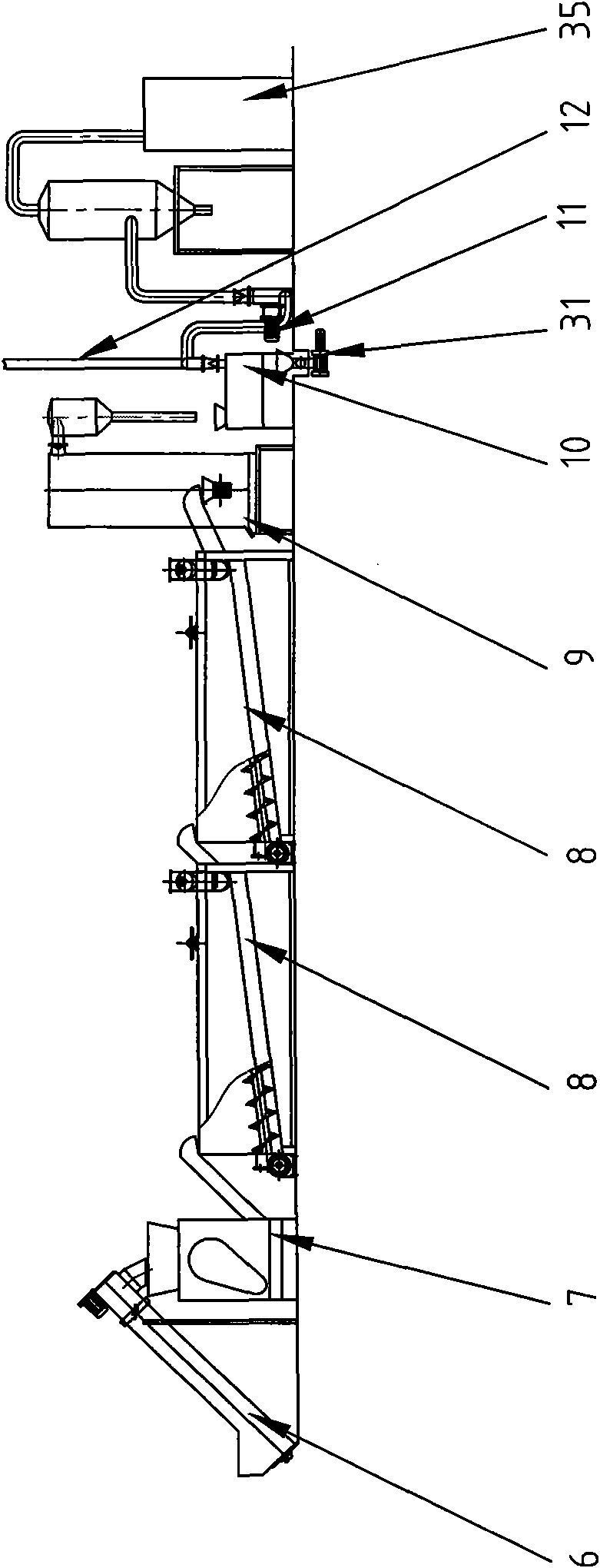

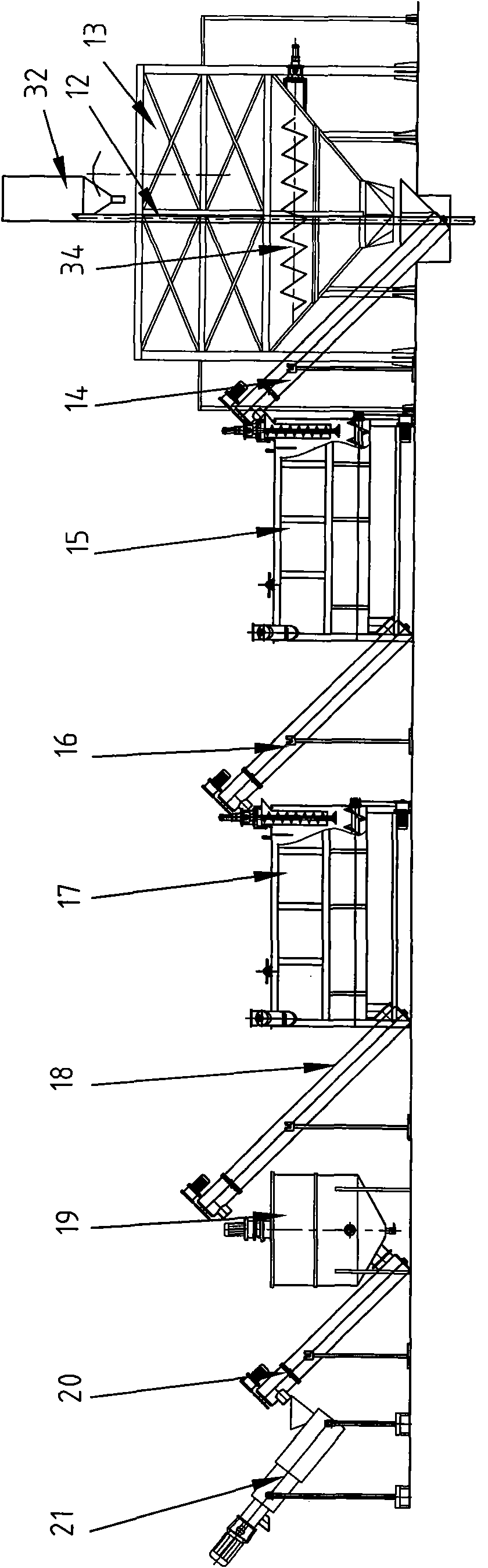

The invention discloses a device for producing regenerative polyester bottle chips by using waste plastics and a production process thereof. The device comprises a crush cleaning system, an electric conveying control system, a paper scrap separation system, a semi-finished collecting system, a finished metering sack sewing system, a polyester bottle chip quality detecting system and a sewage treatment system. The production process for producing the regenerative polyester bottle chips by using the waste plastics comprises sequentially passing the waste plastics through the following units: a selection unit, a crush unit, a conveying unit, a washing unit, a rinsing unit, a drying unit and a storage unit. The system of the embodiment of the invention can realize the recycling of waste plastic resources, solve the problem of white pollution caused by the waste plastics, make wastes profitable, and maximize economic and environmental-protection benefits. The device and the production process are continuous in production, so that the quality of regenerative products is stable, safe and reliable and downstream customers can use the regenerative products safely.

Owner:北京德通化纤工业有限公司

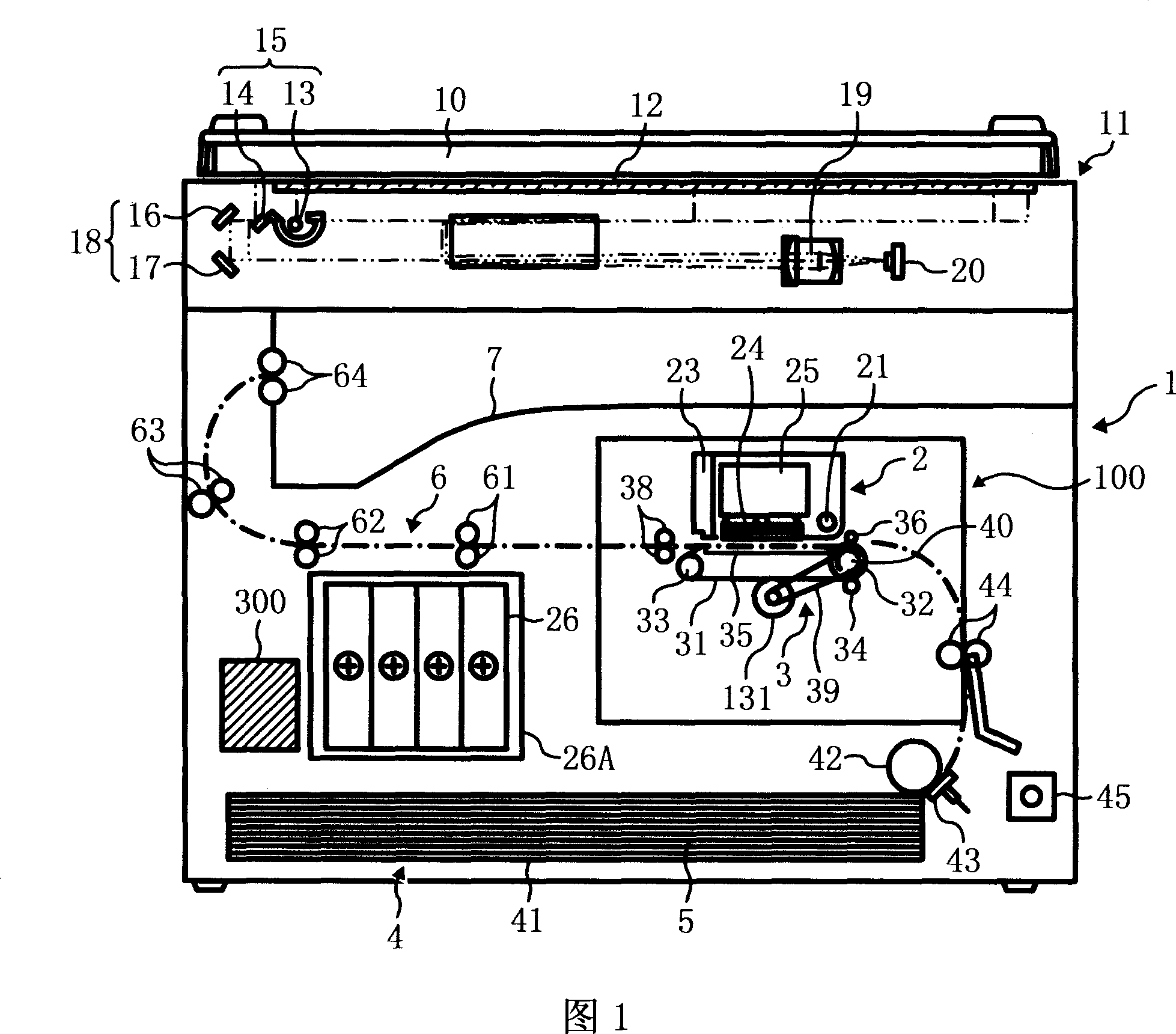

Image recording apparatus

ActiveUS20060023021A1Improve reliabilityHigh quality imagingOther printing apparatusPaper dustImage recording

An image recording apparatus includes an ink jet head which ejects ink toward a recording medium to record an image thereon, a paper feed unit which feeds the recording medium, a recording medium conveyance unit which conveys the recording medium, an intake fan provided at the recording medium conveyance unit to adsorb the recording medium by negative pressure, and an exhaust fan to remove dust from between the paper feed unit and the recording medium conveyance unit. The image recording apparatus prevents the ink jet head from not discharging ink drops and discharging ink drops curvedly because of paper dust and dust in the air, and prevents ink drops from failing to land in a proper position because of an airflow to form a new flow path in the apparatus, thereby recording a high-quality image with high reliability.

Owner:RISO KAGAKU CORP

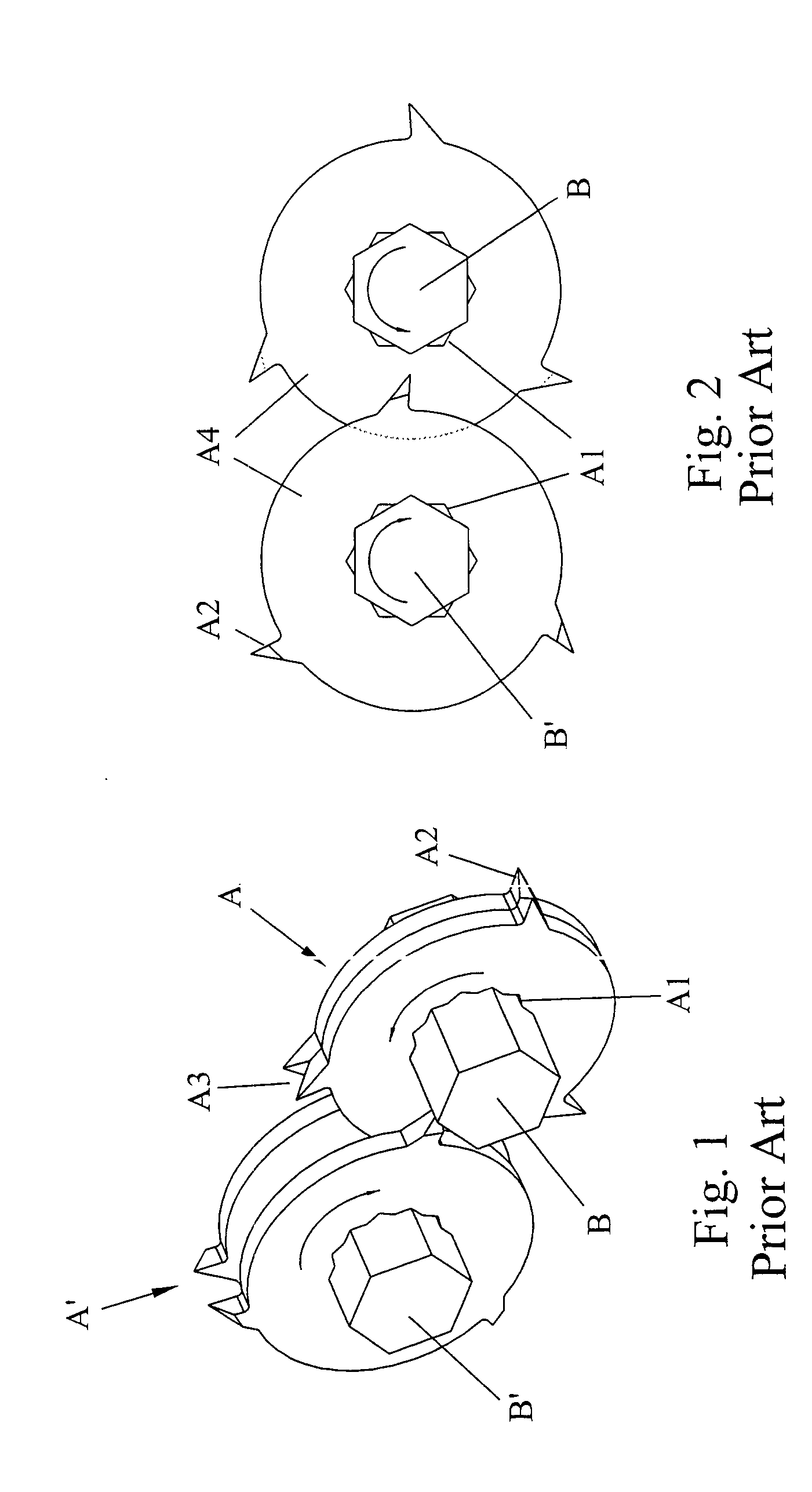

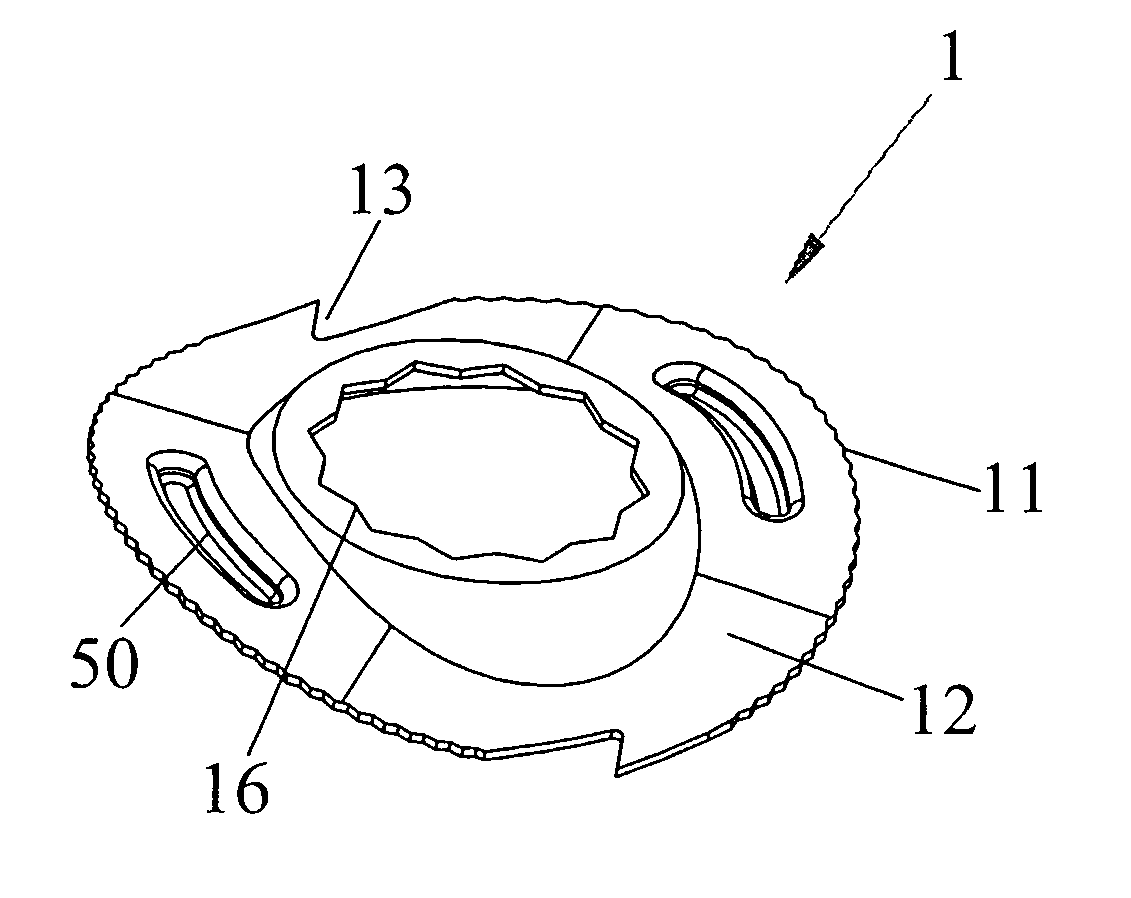

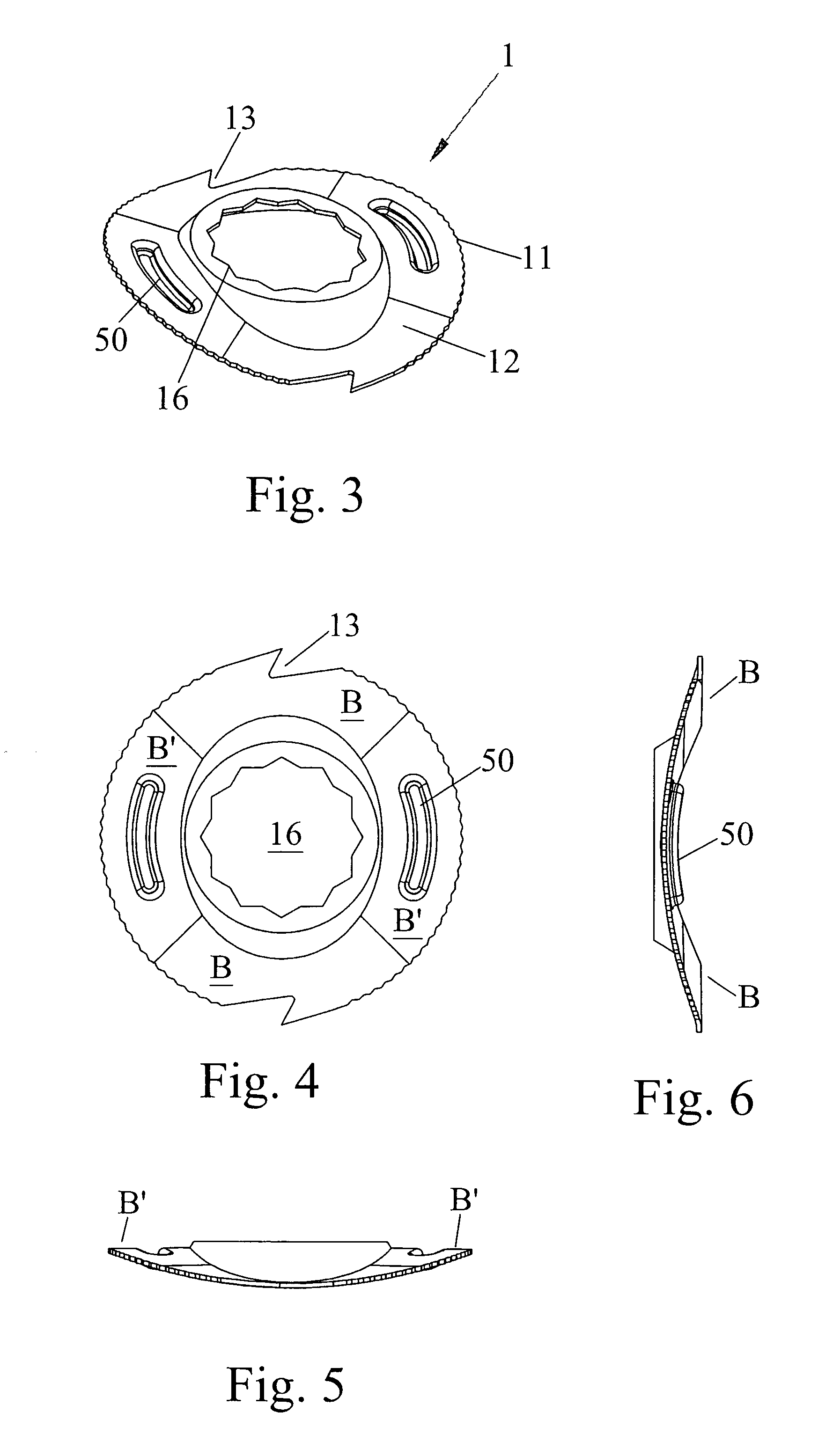

Elliptical acetabuliform blade for shredder

InactiveUS6981667B2Reduce material costsReduce power consumptionCocoaGrain treatmentsManufacturing cost reductionEllipse

Owner:MICHILIN PROSPERITY

Image forming apparatus and image forming method

ActiveUS20050069355A1Continuously forming clear imageSufficiently and efficiently eliminating tonersElectrographic process apparatusPaper dustImage formation

In an image forming apparatus using the cleaner-less processing, a developer vent is provided to a developing device so as to discharge paper dust mixing in the developing device together with developer comprising carrier and toner or carrier only through the developer vent, when removing residual toner.

Owner:KK TOSHIBA +1

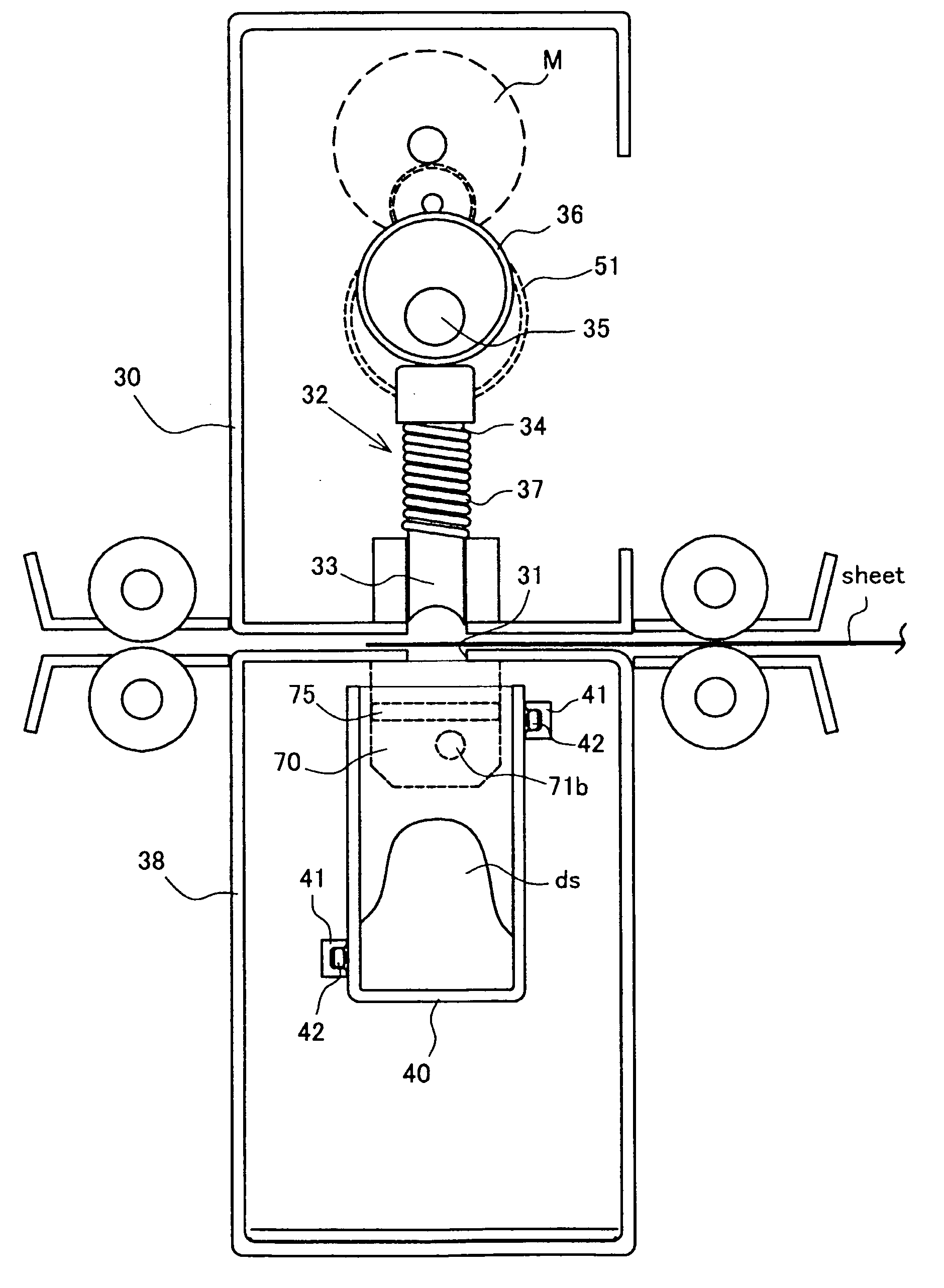

Sheet processing apparatus and image formation system provided with the same

InactiveUS20100143015A1Optimization mechanismEnhance apparatus production efficiencyElectrographic process apparatusRotary pressesPunchingPaper dust

The invention is to provide a sheet processing apparatus enabling a piled amount of debris paper scraps in a debris storage box to be detected accurately in a simplified mechanism in performing cutting processing on sheets, and the sheet processing apparatus is provided with an apparatus frame, sheet processing means disposed in the apparatus frame to perform cutting such as punching and trimming on a transported sheet, debris storage box for storing paper debris generated in the sheet processing means, and debris amount detecting means for detecting a debris amount inside the debris storage box, where the debris storage box is supported by the apparatus frame to be able to move to positions between an installation position for storing the paper debris and a non-installation position for removing stored paper debris in an orthogonal direction to a transport direction of the transported sheet, and the debris amount detecting means is formed of a pair of sensors arranged to oppose each other in positions for enabling the sensors to detect a debris amount piled inside the debris storage box present in the installation position in the orthogonal direction to the transport direction of the transported sheet.

Owner:NISCA KK

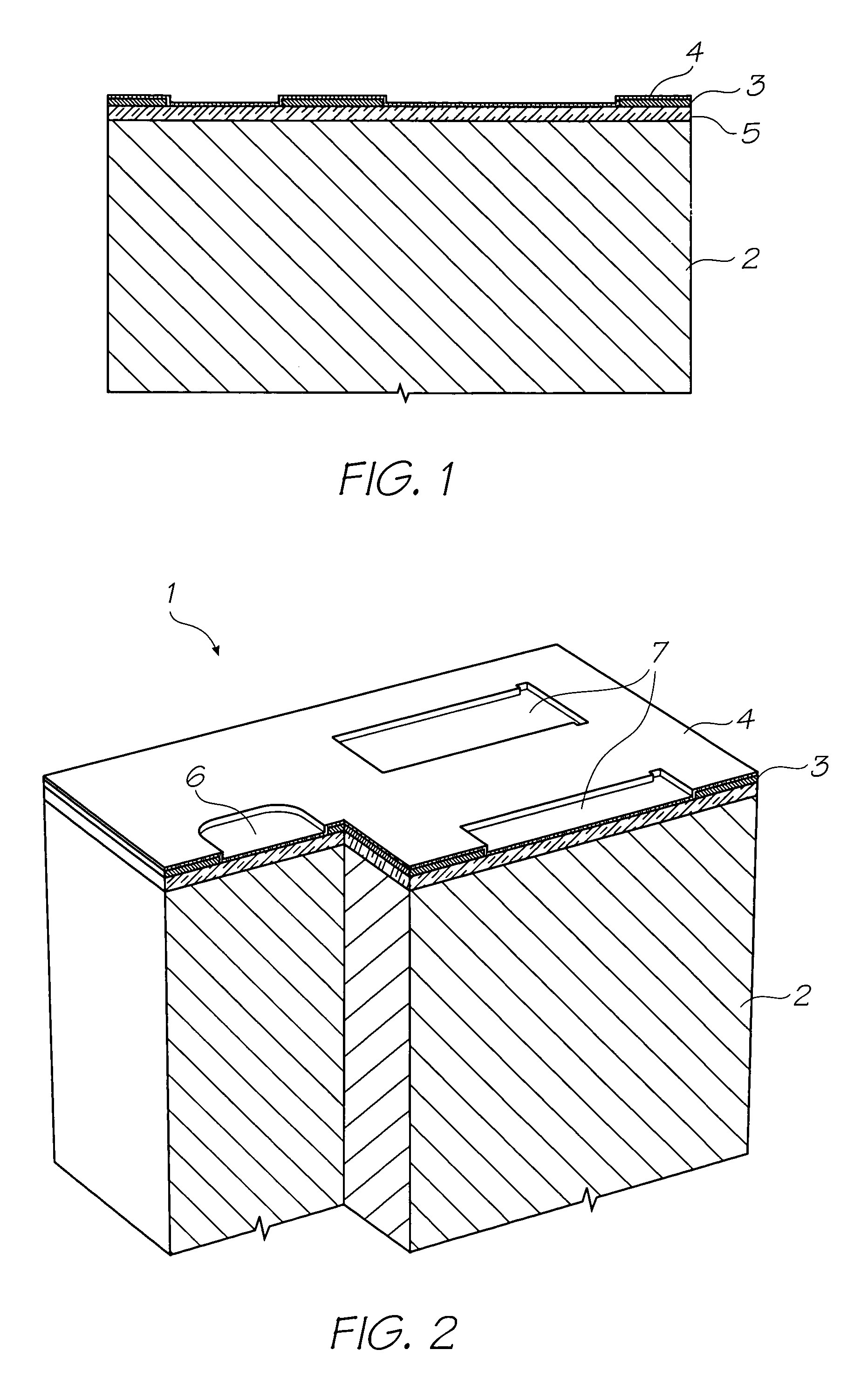

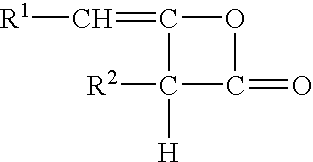

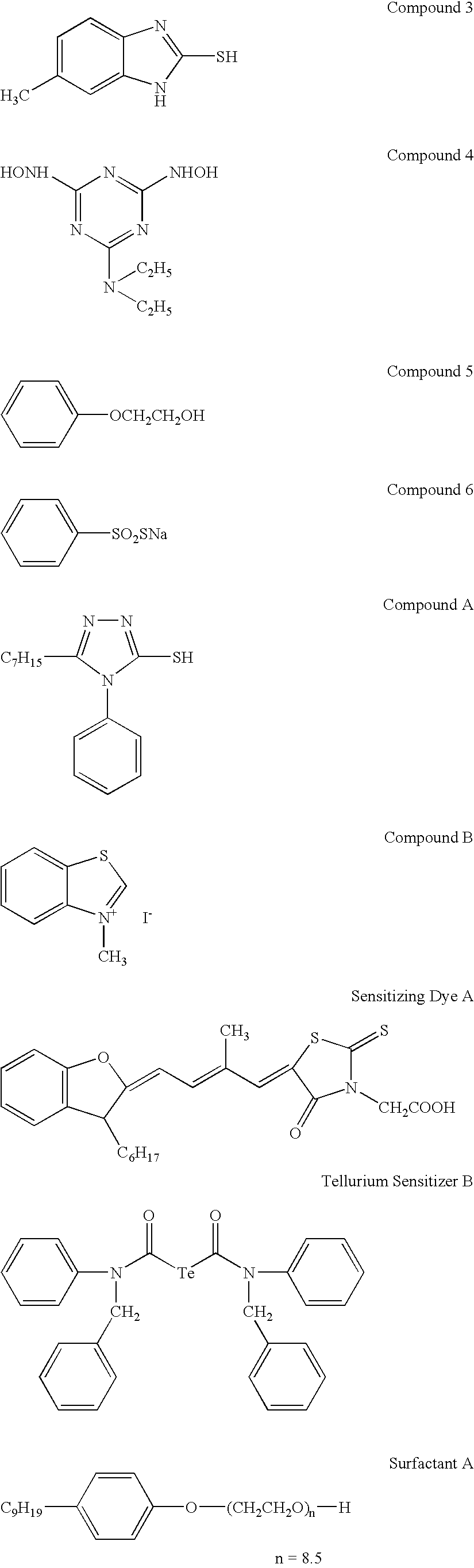

Packing material for sheet recording materials and package employing same

Disclosed is a packing material for a sheet recording material, which contains a paper material comprising an alkyl ketene dimer and cationic starch, the extraction pH of the paper material being within the range of 6.5 to 9.0. The packing material of the present invention suppresses generation of paper dust and prevents occurrence of white spot defect in recorded images on a sheet recording material even when the packing material is not subjected to surface treatment.

Owner:FUJIFILM CORP +1

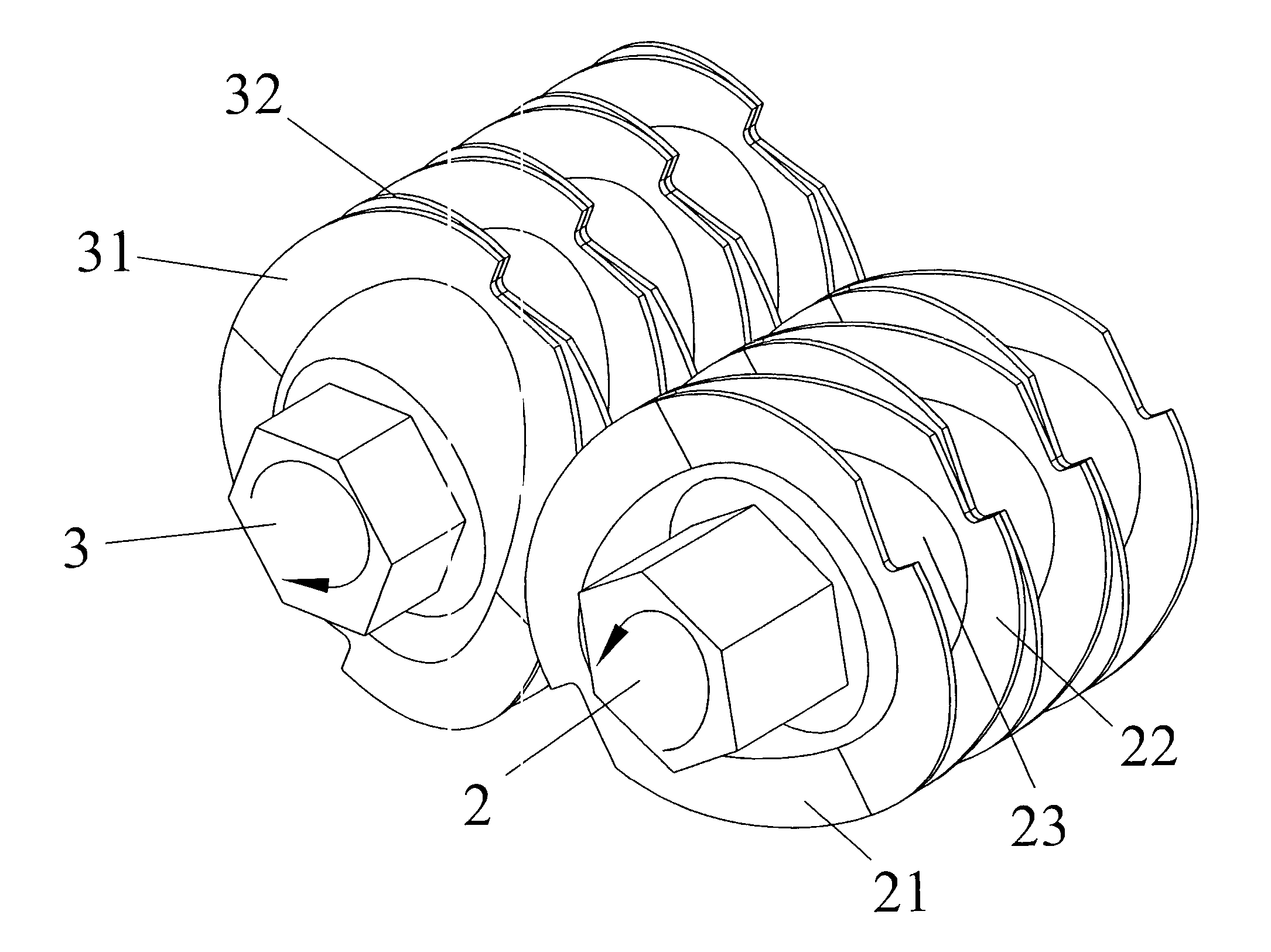

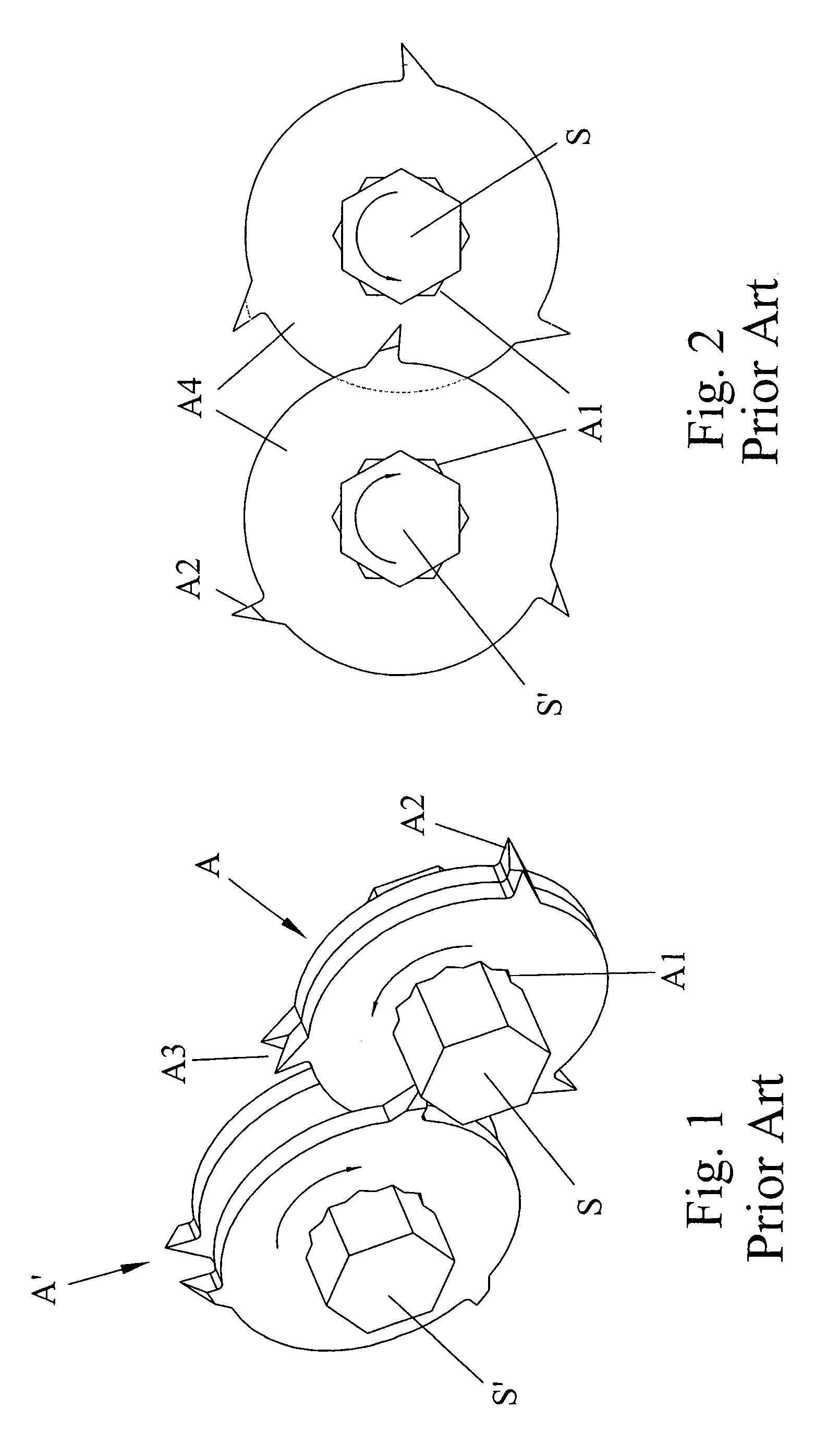

Round undulating blade and blade module for shredder

InactiveUS7044410B2Reduce material costsReduce power consumptionCocoaGrain treatmentsManufacturing cost reductionPaper dust

The present invention relates to a round undulating blade for shredder, where a sheet metal is integrally formed into a round undulating blade to serve as the blades for constructing a blade module. The blade includes: a periphery; an undulating blade flank including at least two cambers having a first curvature and at least two cambers having a second curvature alternatively arranged with respect to the cambers having the first curvature; and hooked edges formed on the periphery of the cambers having the first curvature, wherein the undulating blade flank of the blade serves to cut paper along a longitudinal direction to form paper strips having double-tapering end, and the hooked edges serve to cut the strips along a horizontal direction into paper chips. These characteristics help to reduce the manufacturing cost, reduce the motor load and power consumption, to thereby enhance the market competitiveness.

Owner:MICHILIN PROSPERITY

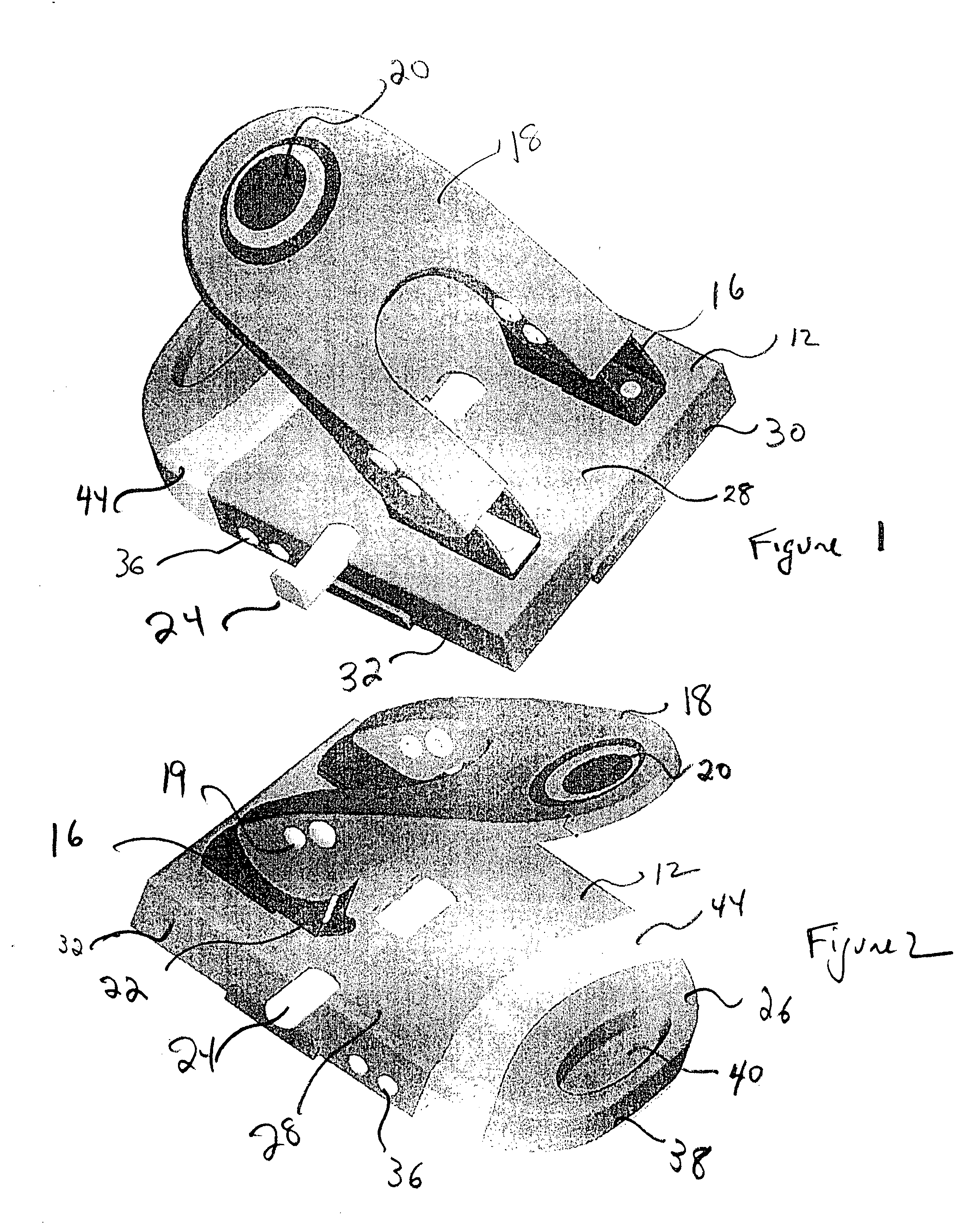

Paper punch

A desk-top paper punch includes a drawer for removable insertion into the base of the paper punch, the drawer serving as a collection receptacle for paper punches to be discarded. Once the drawer is near its capacity, the drawer is pulled out of the base for emptying. Means for viewing the contents of the drawer is provided. In one implementation, the view means is a transparent window which allows the viewer to know when the drawer in nearing its capacity for paper chips. In a second embodiment, the viewing means is at least one viewing aperture that perforates the top surface of the base of the paper punch that allows the user to view the drawer's contents.

Owner:OFFICEMATE INT

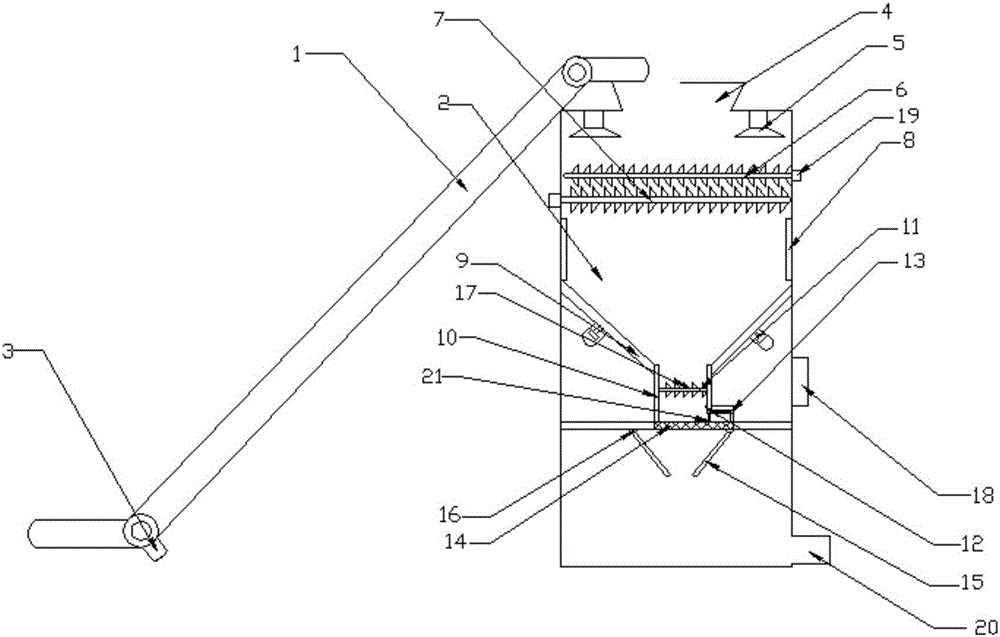

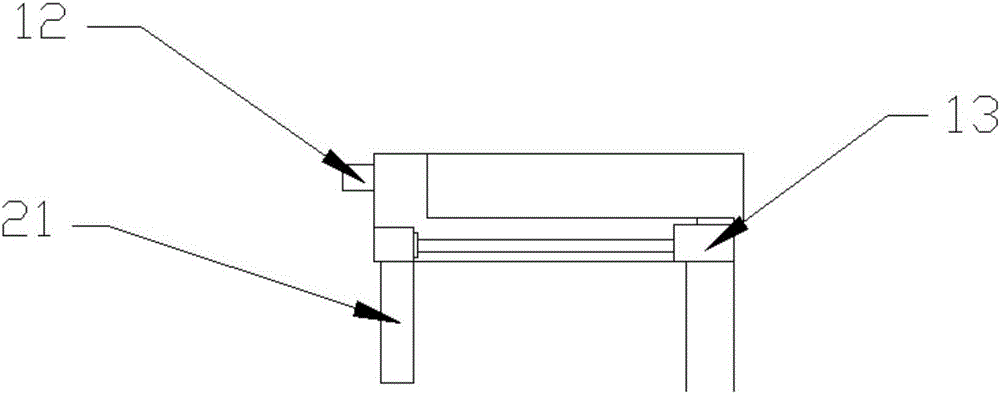

Wheel type paper cutting machine with follow-up tiny paper scrap adsorbing device

The invention relates to the field of paper cutting equipment, in particular to a wheel type paper cutting machine with a follow-up tiny paper scrap adsorbing device. The wheel type paper cutting machine with the follow-up tiny paper scrap adsorbing device comprises a support arranged on a working table top, wherein a sliding rail is arranged on the upper portion of the support, a sliding wheel is arranged in the sliding rail, the sliding wheel is arranged on a belt in a sleeved mode, and the belt is driven by a motor arranged on the upper portion of the right side of the support. The sliding wheel is connected with a connecting rod, the upper end of the connecting rod is a U-type end, the connecting rod is connected to convex shafts on the two sides of the sliding wheel through the U-type end, a cutter motor is connected to the bottom of the connecting rod, and a wheel-type cutting blade is arranged on the spindle head of the cutter motor in a sleeved mode. A lower frame is arranged on the middle portion of the connecting rod, and the two ends of the lower frame are connected with a left adsorbing head and a right adsorbing heat respectively. The wheel type paper cutting machine with the follow-up tiny paper scrap adsorbing device can move along with the moving of the wheel-type cutter blade, cleanly adsorbs the paper scrap dust raised by the wheel-type cutter blade, also cleanly adsorbs the paper scrap dust on paper on the working table top, protects the environment of a workshop, and also ensures the physical health of operating personnel.

Owner:TAICANG XINHE PRINTING & PACKAGING

Image forming apparatus having paper dust removing means

A first paper-dust removing device is provided to mainly remove pulp fibers of the paper dust. The first paper-dust removing device is located downstream from a transfer position in the photosensitive drum rotating direction. A second paper-dust removing device is provided to mainly remove talc in the paper dust. The second paper-dust removing device may be located downstream from the first paper dust removing device in the photosensitive drum rotating direction or upstream from the transfer position in the sheet conveying direction along the sheet transport path. An additional first paper-dust removing device may be located upstream from the transfer position in the sheet conveying direction along the sheet transport path.

Owner:BROTHER KOGYO KK

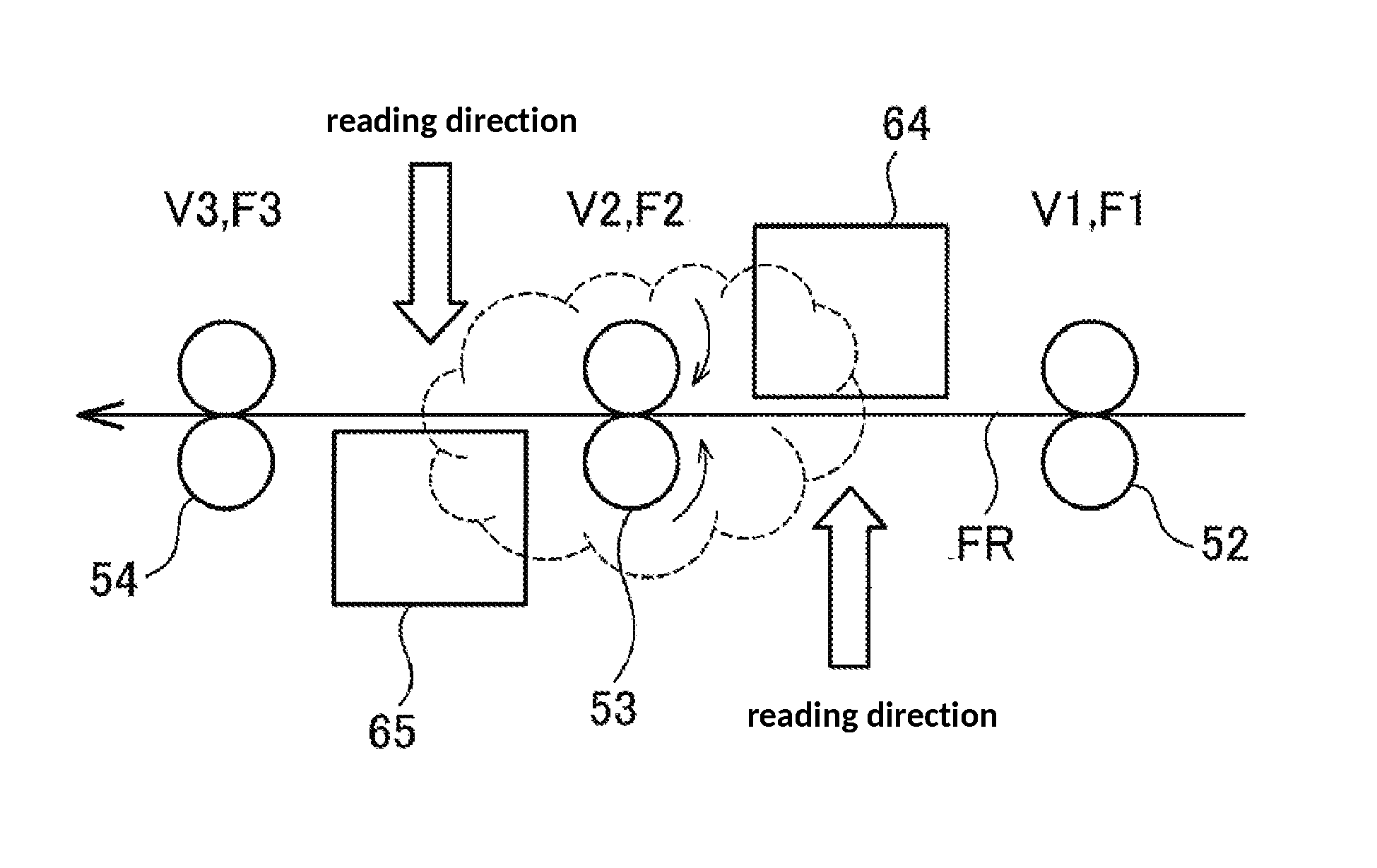

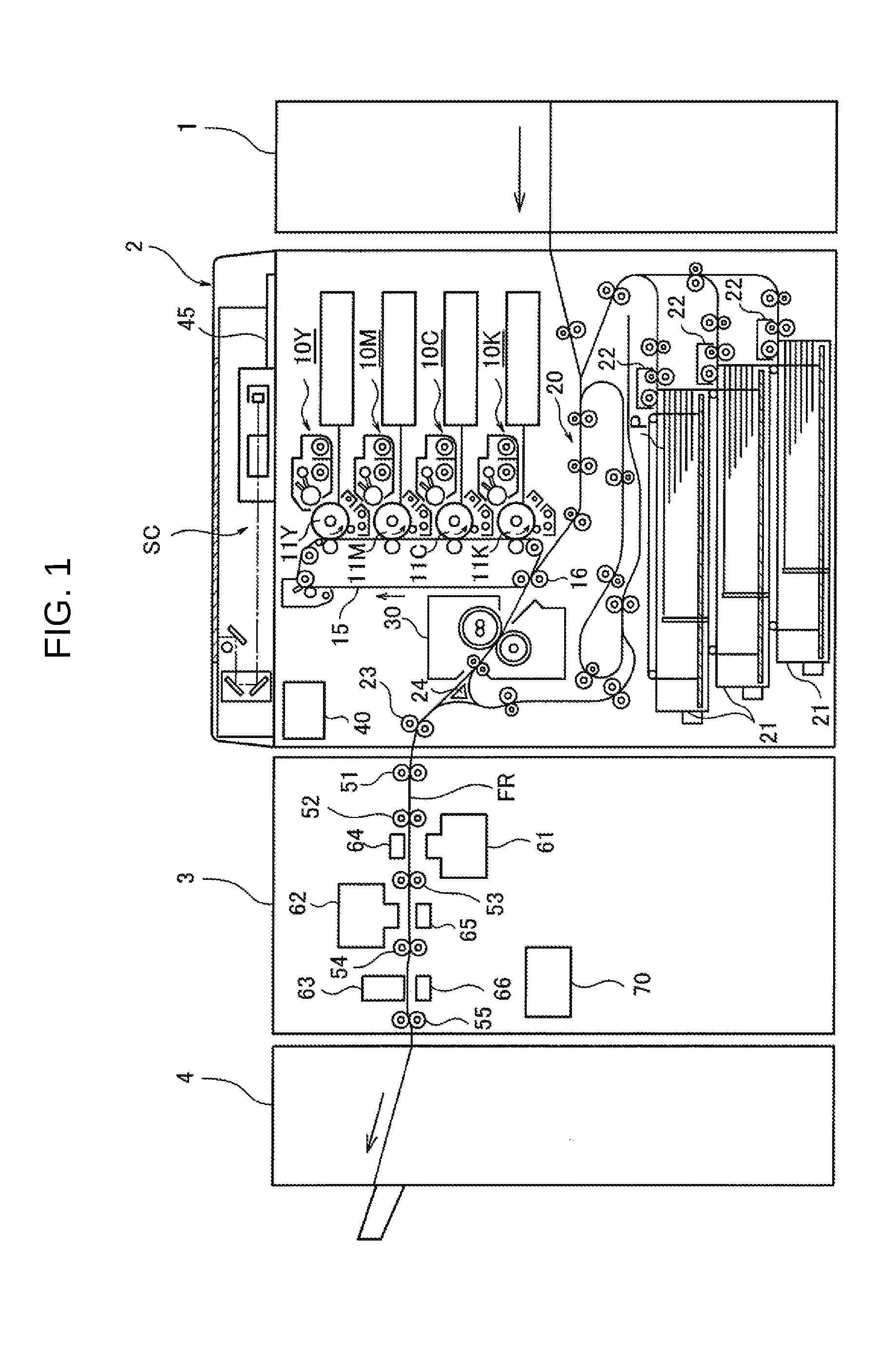

Image reading apparatus and image forming system

ActiveUS20160366296A1PowerfulElectrographic process apparatusPictoral communicationPaper dustComputer science

An image reading apparatus and an image forming system which are hardly affected by noise due to paper dust or the like is provided. An image reading apparatus includes a back side image reading unit and a front side image reading unit which are continuously arranged in a sheet conveying direction. Also, an upstream side conveyance member and an intermediate conveyance member are arranged adjacent to each other in the upstream and downstream sides of the back side image reading unit. The intermediate conveyance member and the downstream side conveyance member are arranged adjacent to each other in the upstream and downstream sides of the front side image reading unit. The colorimetric unit is arranged outside an area from the upstream side conveyance member to the downstream side conveyance member in the sheet conveying direction.

Owner:KONICA MINOLTA INC

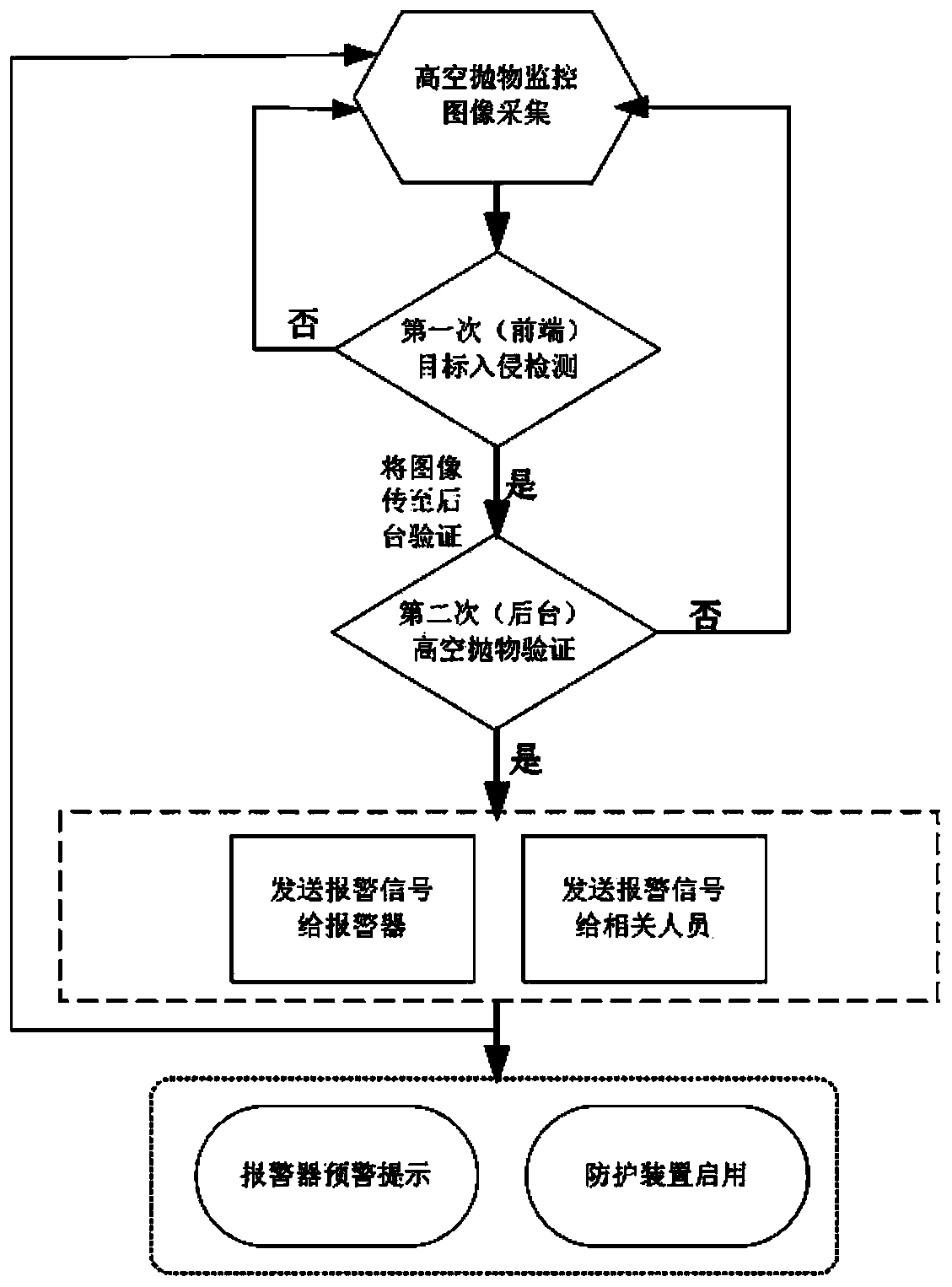

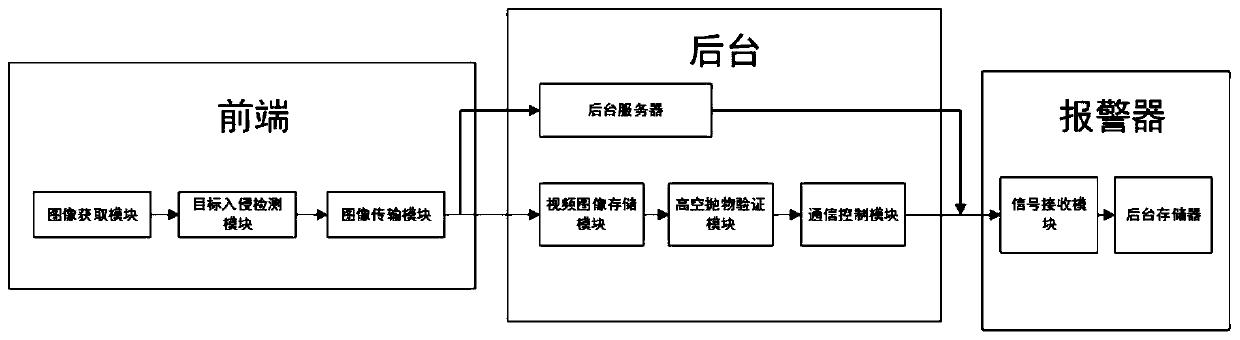

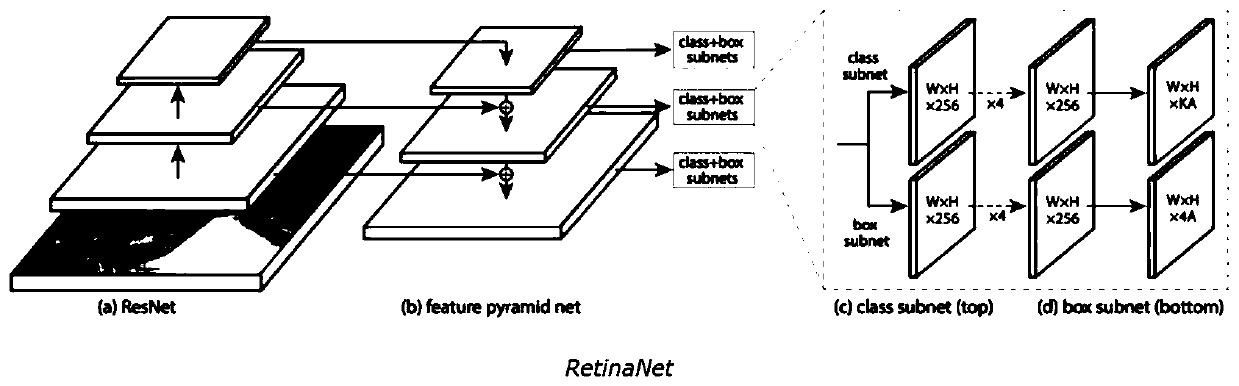

Early-warning method and device of building thrown-off object

InactiveCN110853295AGuaranteed speedGuaranteed accuracyCharacter and pattern recognitionAlarmsPaper dustCigarette butt

The invention relates to the field of community security monitoring and discloses an early-warning method of a building thrown-off object. The method comprises the steps of S1, camera installation andmonitoring image selection; S2, target intrusion detection; S3, verification of the building thrown-off object; and S4, early warning on the building thrown-off object. The invention further discloses an early-warning device of the building thrown-off object. The early-warning device comprises a front end, a background and an alarm device, wherein the front end comprises an image acquisition module, a target intrusion detection module and an image transmission module; the background comprises a building thrown-off object verification module, a video image storage module and a communication control module; and the alarm device comprises a signal receiving module and a voice-controlled alarm module. Through the early-warning method and device, the functions of advanced prevention and earlywarning are achieved, and a building thrown-off object detection technology is truly used for people; computing performance and hardware support problems brought by real-time and uninterrupted accurate discrimination of the building thrown-off object are avoided, and meanwhile a guarantee is provided for speed; and detection of garbage paper scraps, mineral water bottles, cigarette ends and othersmall targets among building thrown-off objects is well realized.

Owner:江西赣鄱云新型智慧城市技术研究有限公司

Medical crepe wrapping paper and production process thereof

InactiveCN102400410AHas tensile strengthProper air permeabilityFlexible coversWrappersFiberPaper dust

The invention relates to medical crepe wrapping paper. The preparation process for the medical crepe wrapping paper comprises: mainly adopting bleached softwood pulp, bleached hardwood pulp and HPZ special fiber according to a certain ratio; carrying out treatments of repulping and beating for the materials, wherein the repulping treatment is performed by a hydrapulper, the beating treatment is performed by a disc attrition mill; then adding assistant materials of a wet strength agent, a sizing agent, a softening agent, a water repellent agent and the like; carrying out forming and pressing dewatering at the mesh part of a long mesh multi-cylinder paper machine or an inclined mesh multi-cylinder paper machine; carrying out wet creping in the one cylinder when the dryness of the wet paper sheet is 30-45%, wherein the angle formed by a creping scraper and the tangent line of the cylinder surface is 30-45 DEG, the blade angle of the creping scraper close to the cylinder surface is 35-90 DEG, a speed ratio of a creping drying cylinder to a heating drying unit cylinder is 1.1-1.15:1; transferring the creped wet paper to the drying unit cylinder to carry out drying; carrying out reeling by a reeler; carrying out rewinding cutting to obtain the medical crepe wrapping paper product. According to the present invention, the wet creping treatment is performed when the dryness of the paper sheet is 30-45%, such that the hydrogen bond combination force between the fibers, and the chemical bond combination force of the wet strength agent and other thermosetting resins are not formed, meanwhile, the strength of the wet paper sheet is low, the crepe formed by collision with the creping scraper is uniform, such that bad phenomena such as paper scraps, paper powder and the like can not be generated.

Owner:ZHEJIANG XINFENG SPECIAL PAPER

Safe and environmentally-friendly firecracker firing device

Owner:芜湖启博知识产权运营有限公司

Holding resuming device for recording head and image forming device

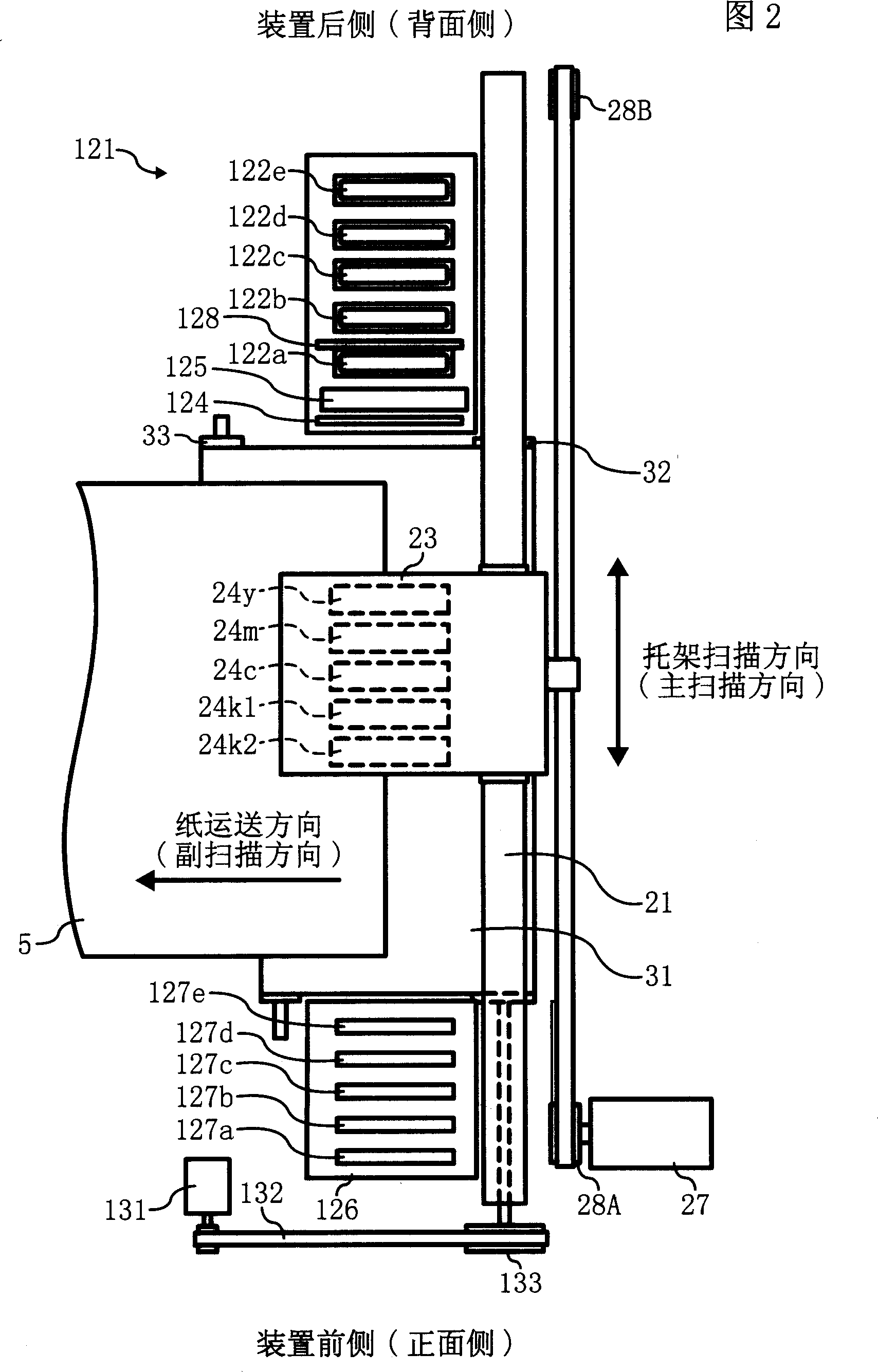

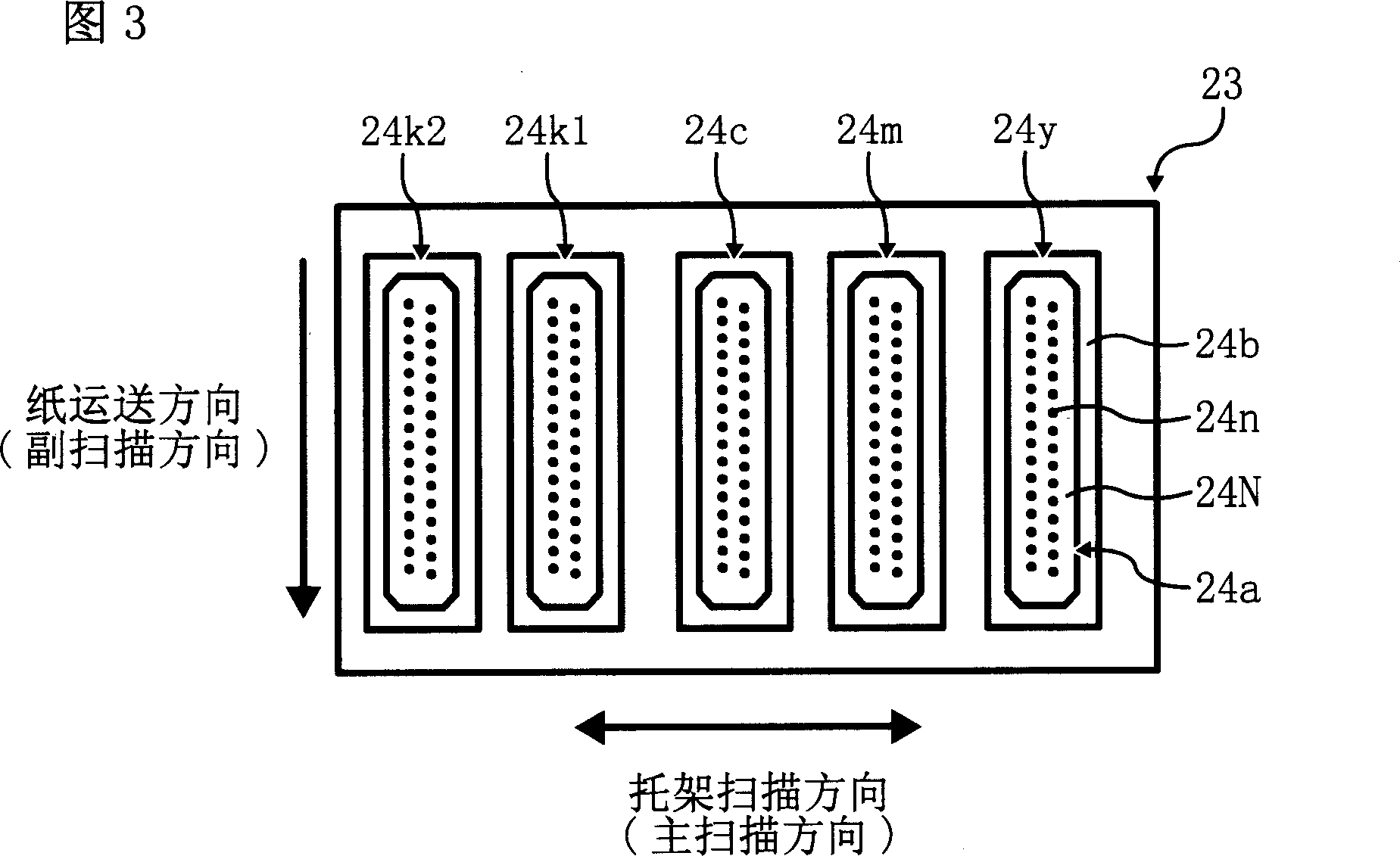

A recording head maintenance recovery mechanism and image forming apparatus, the maintenance recovery mechanism (121) has: caps 122a-122e for sealing the nozzle surface (24a) of the recording head (24), and a wiping sheet for wiping the nozzle surface (124), have simultaneously the nozzle surface (24a) that is arranged along the lengthwise direction of wiping sheet (124), the nozzle surface (24a) of the recording head (24) of relative stop moves up and down and will remain on the nozzle surface (24a) of recording head (24) A removal member (128) for removing residual recording liquid at the end portion on the downstream side in the wiping direction. Therefore, it is possible to prevent image disturbance and contamination inside the device due to residual recording liquid at the end of the nozzle surface after the wiping of paper dust or the like adhering to the wiping of the recording head.

Owner:RICOH KK

Blade cleaner cartridge with dust and lint seal blade

InactiveUS7031634B2Easily mounted into cleaning bladeReduce internal dustingElectrographic process apparatusFiberParticulates

In an apparatus for cleaning particulates from a moving web, a dust seal blade assembly which is easily mounted to a cleaning blade to reduce internal dusting in a cleaner apparatus and for trapping of lint, paper dust, or fibrous material and which might also reduce the effects of oil contamination. The arrangement provides a low-cost, operator-replaceable cartridge having one or more wiper blades with at least one of them having the dust seal blade assembly and enclosed within a particle sump assembly that is easily removed from association with the web being cleaned.

Owner:EASTMAN KODAK CO

Method for producing paper towel by wet corrugating method

InactiveCN101694077AGuaranteed stabilityGuaranteed not to slidePaper-making machinesFiberState of art

The invention relates to a method for producing a paper towel by a wet corrugating method, which comprises the following steps: when the dry degree of a wet paper page is ranged form 30% to 45% after system moulding, dehydration and squeezing of a Harper fourdrinier, corrugating by a corrugating scraper, wherein an angle formed by the corrugating scraper and a tangent of a drying cylinder is 15-35 DEG, a cutting edge angle of the scraper on the cylinder attaching surface is 55-90 DEG, and the speed ratio of the corrugation drying cylinder and the heating and drying cylinder is 1.1-1.2:1; then delivering the paper to the surface of the heating cylinder by an independent power transfer device; drying and collecting the paper and then obtaining the finished product. Compared with the prior art, the invention adopts a wet corrugating process; because the corrugation is carried out when the dry degree of a paper web is 30-45 percent, the hydrogen bond bonding force among fibers and the chemical bond bonding force of thermosetting resin, for example a wet strength agent, and the like are not formed, and the strength of the wet paper page is lower, wrinkles formed after collision by the corrugating scraper is uniform and consistent and can not generate the poor phenomena of paper scraps, paper powder, and the like.

Owner:ZHEJIANG XINFENG SPECIAL PAPER

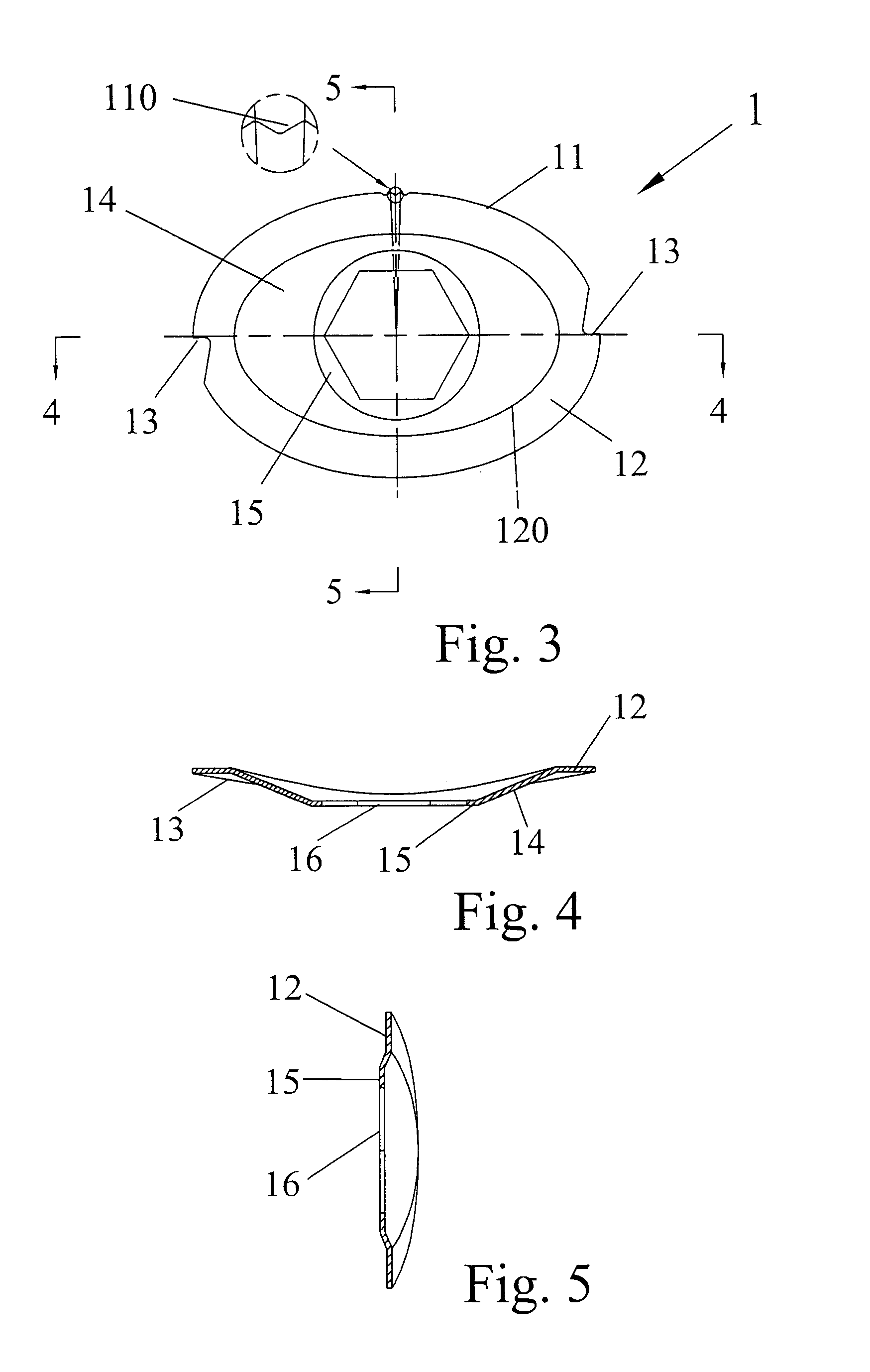

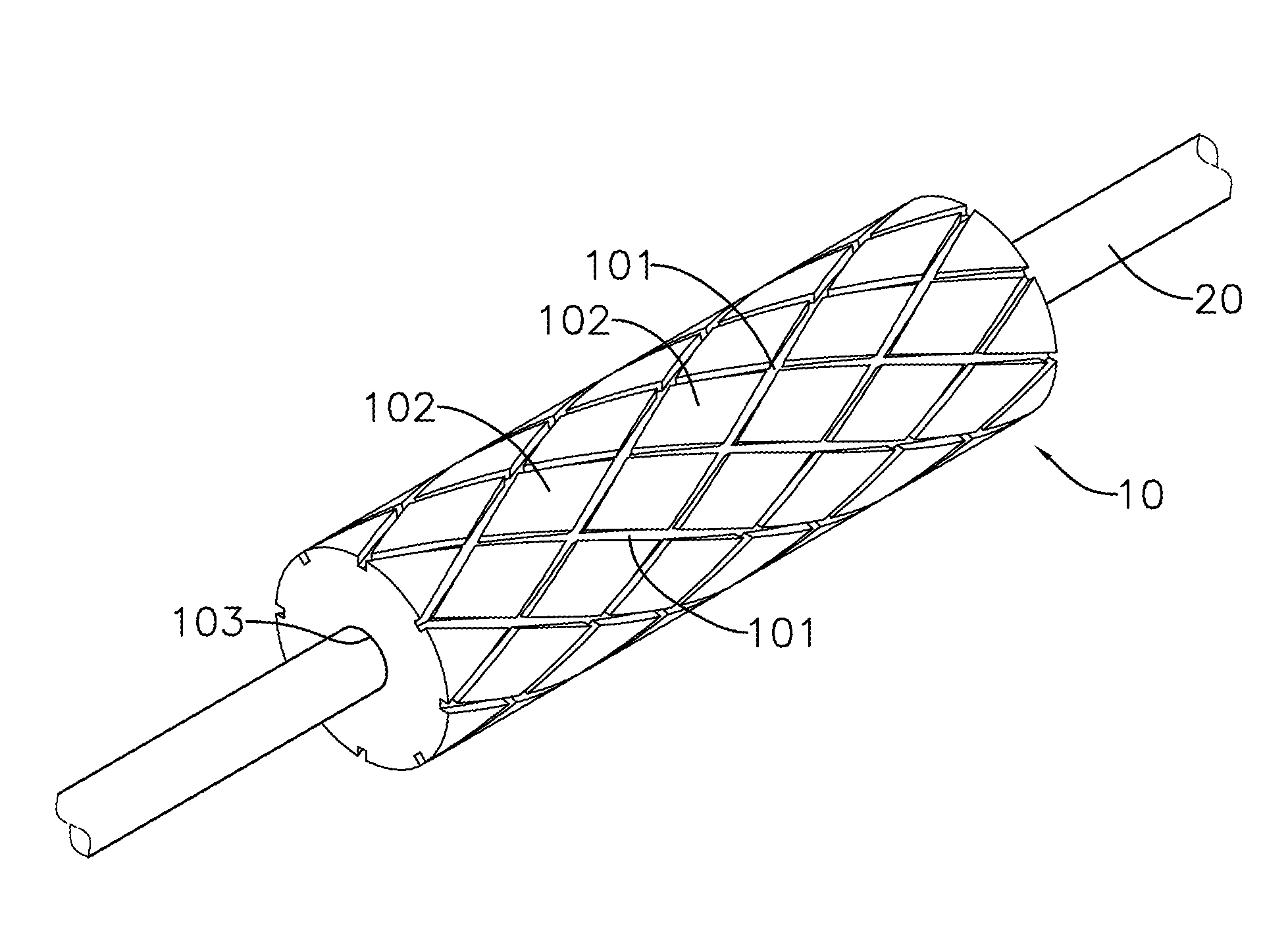

Roller structure of a business machine

InactiveUS20110039671A1Reduce the inconvenience of operationKeep for a long timeAgricultural rollersElectrographic process apparatusPaper dustEngineering

This present invention relates to a roller structure of a business machine, including a roller and a shaft, by which a plurality of intersecting grooves are provided on the friction surface of the roller so as to form a plurality of contact areas simultaneously on the outer surface in the lateral direction along the roller during the whole rotating process, and the shaft, driving the roller, is correspondingly installed through the insertion passage located at the center of its cylindrical structure of the roller, so as to enable feeding and aligning the paper more silently and stably with a better friction force, to accommodate the dirt or paper dust generated, and thus enhancing the life expectancy of the roller parts.

Owner:CHOU CHIH HUANG

Sheet feeder capable of removing dust

InactiveUS20060029446A1Improve dust collection effectLow costElectrographic process apparatusPaper dustEngineering

A sheet feeder capable of removing dust includes a sheet-feeding roller, a dust collecting box and a brush. The sheet-feeding roller transports a sheet along a sheet passageway. The dust collecting box is disposed at a side of the sheet-feeding roller. The dust collecting box has an adhesive layer for collecting and retaining paper flakes and dust coming from the sheet-feeding roller so as to prevent the paper flakes and the dust from being blown back to the sheet passageway. The brush in contact with the sheet-feeding roller brushes the paper flakes and the dust away from the sheet-feeding roller and into the dust collecting box.

Owner:AVISION

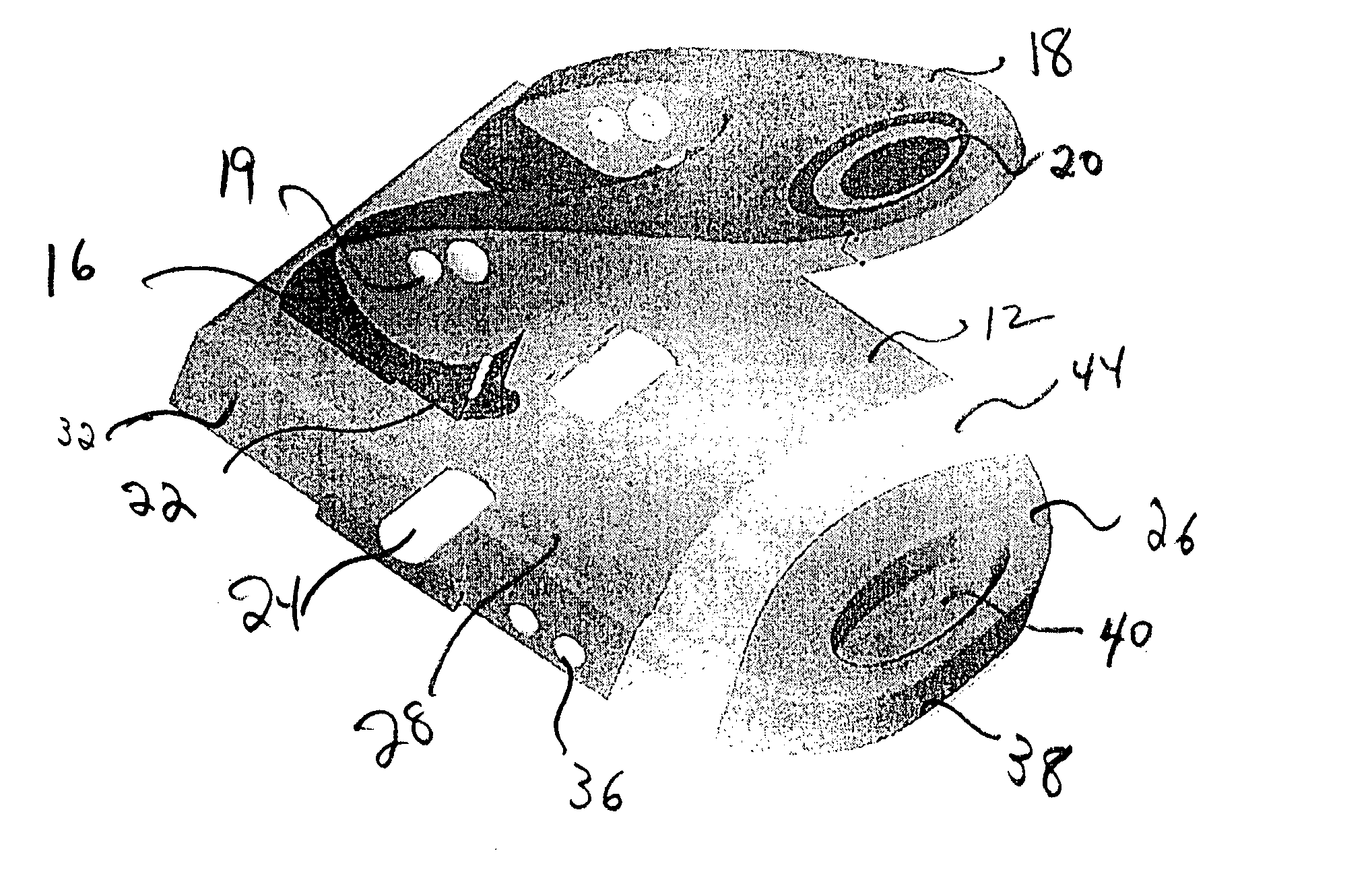

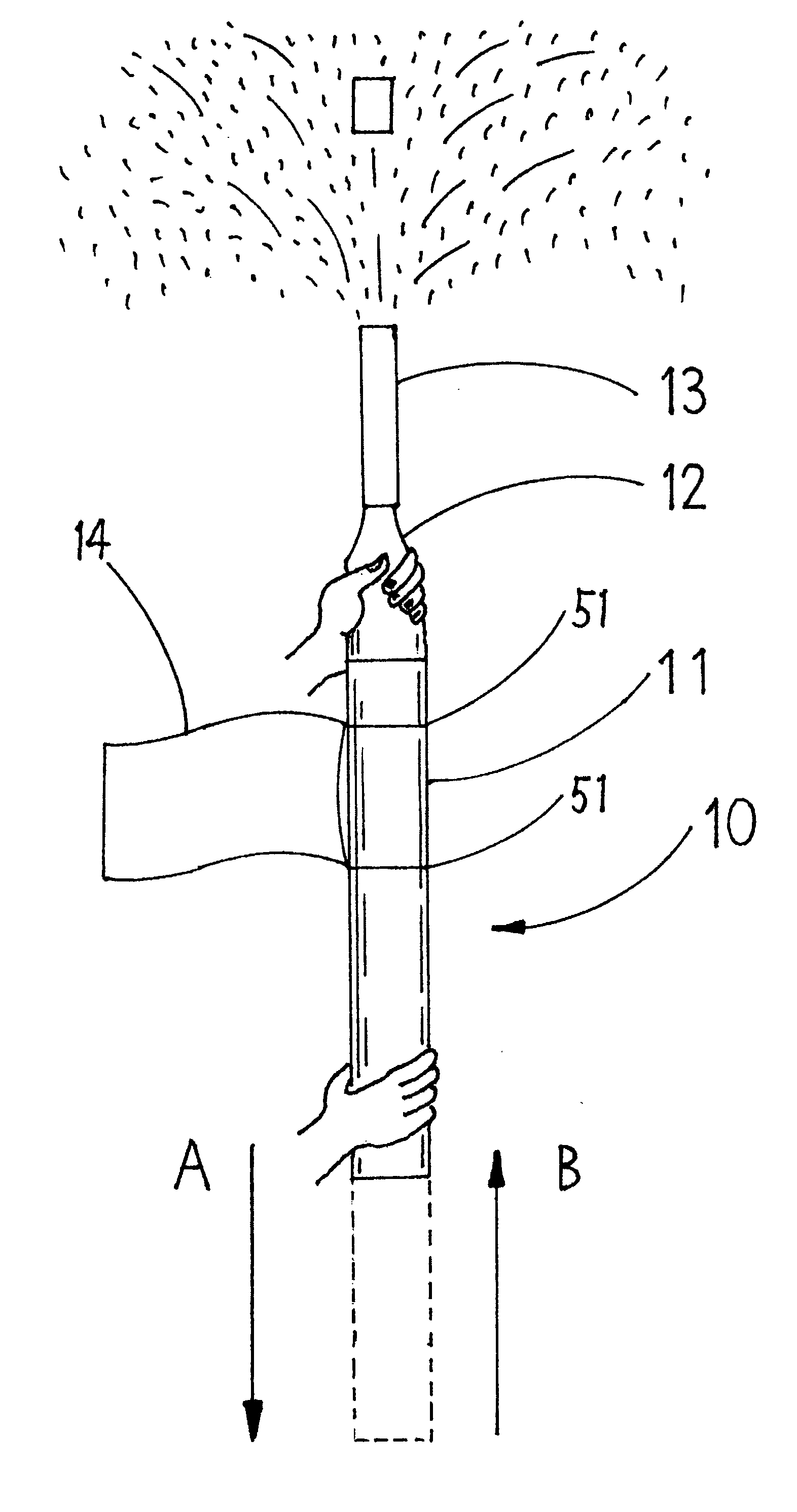

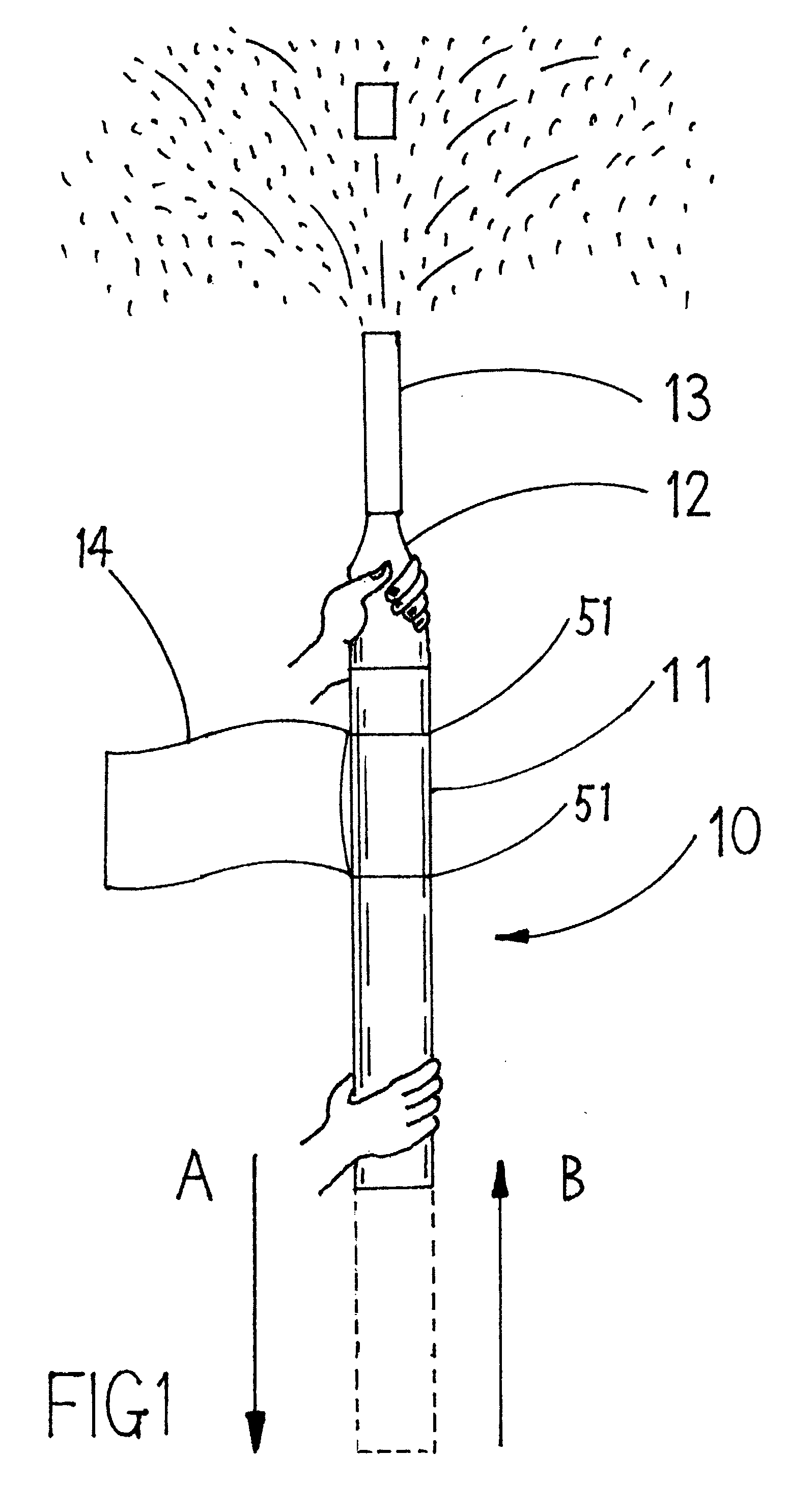

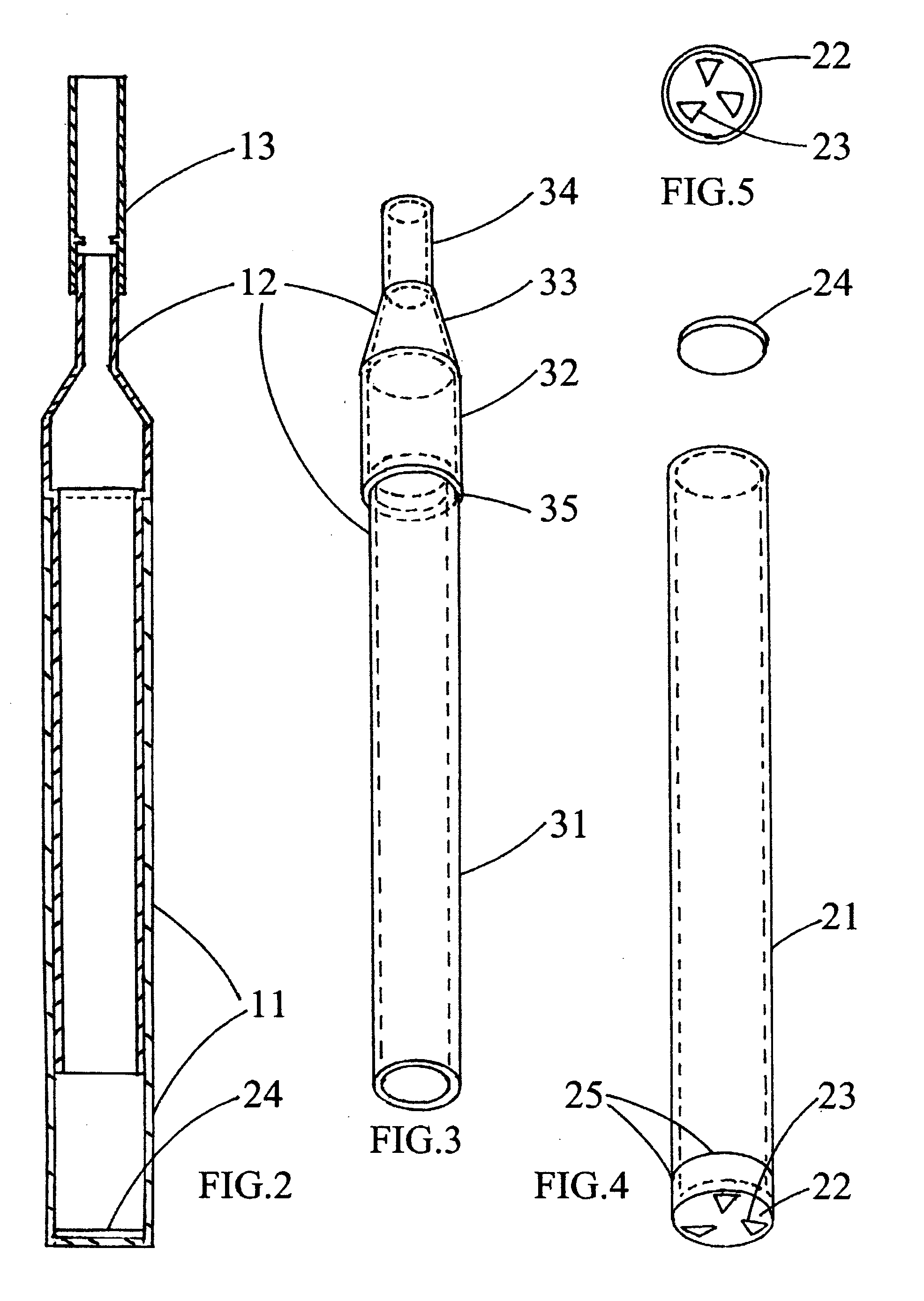

Launching device and disposable cartridge containing confetti, paper discs or fluid

A multi-purpose launching device for propelling and disseminating confetti, paper disks or fluid contained in a disposable cartridge. Contents of the cartridge as well as the outside surface of the launching tube may be covered with a fluorescent material. The top part of the launching tube may serve as a flagpole to supplement its primary function at large social gatherings such as sporting or music events, wedding ceremonies, holiday celebrations, presidential campaigns, etc. The device consists of a cylindrical launching apparatus and a cylindrical cartridge that may contain confetti, paper disks, fluid, or other soft materials such as fiber, string, fabric, etc. The bottom end of the upper section of the launching tube inserts into the lower section of the launching tube. After the cartridge is loaded on the top of the launcher, the lower section of the launching tube is pulled down at first, then pushed up by the user's hands, compress air within the tube, propelling contents of the cartridge to be ejected. A disabled cartridge is used for each shot. The cartridge is economical, its contents are flexible, and it is convenient and fast to change cartridges after each shot. The cartridge's top end has a foam cover, which may be made in various interesting or funny shapes, including rocket, fruit, or even men's sexual organ.

Owner:DU JOHN AKA XIAOQIANG

Variable frequency paper shredder

ActiveCN106269118AHigh recovery rateSimple structureCleaning using gasesGrain treatmentsPaper dustElectric machinery

The invention discloses a variable frequency paper shredder. The variable frequency paper shredder comprises a conveying belt; a pulverizer device is arranged at the bottom of the conveying belt; a variable frequency motor is arranged at the bottom of the conveying belt; a hot air blower is arranged in the pulverizer; an inductor is arranged on the inner wall of a paper outlet; a hydraulic expansion device is arranged on one side of the inductor; a moving rod is arranged at one end of the telescopic expansion device; a screening plate is arranged at the bottom of the moving rod; a rotating rod is arranged at the bottom of the screening plate; a fixing button is arranged on one side of the rotating rod; the rotating rod is connected with the screening plate through the fixing button; a control panel is arranged on one side of the pulverizer device; the variable frequency motor can control the paper scrap cutting frequency of the paper shredder; the hot air blower can clean paper scraps which are adsorbed on a cutting blade and the inner wall of the paper shredder; lager paper scraps which are not pulverized completely can be pulverized secondarily; the paper scrap falling frequency can be controlled by the size of the opening of the rotating plate; the overall device is simple in structure, and the paper scrap recovery rate is high.

Owner:林海青

Image recording apparatus

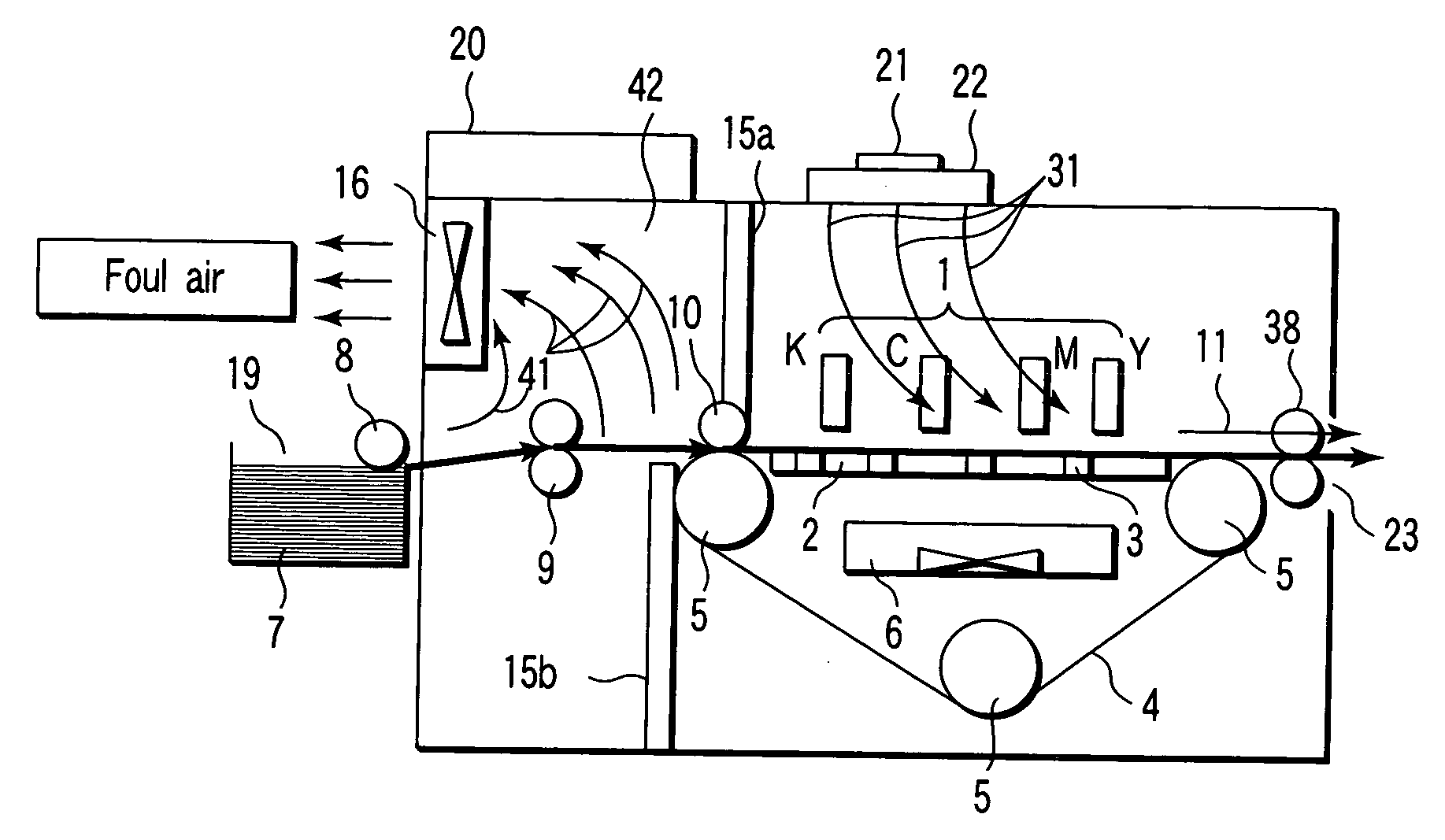

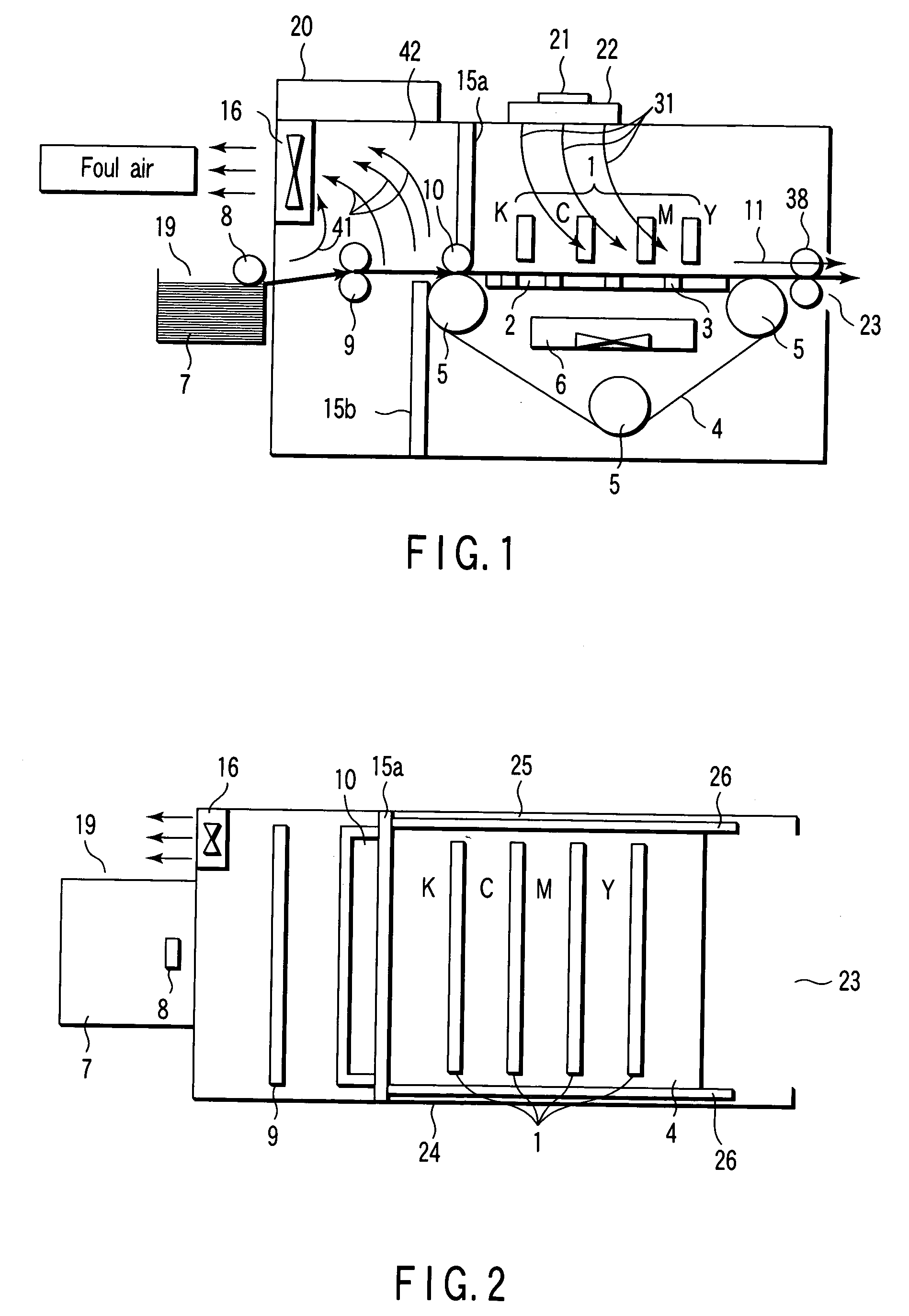

ActiveUS7384122B2High quality imagingImprove reliabilityOther printing apparatusPaper dustImage recording

An image recording apparatus includes an ink jet head which ejects ink toward a recording medium to record an image thereon, a paper feed unit which feeds the recording medium, a recording medium conveyance unit which conveys the recording medium, an intake fan provided at the recording medium conveyance unit to adsorb the recording medium by negative pressure, and an exhaust fan to remove dust from between the paper feed unit and the recording medium conveyance unit. The image recording apparatus prevents the ink jet head from not discharging ink drops and discharging ink drops curvedly because of paper dust and dust in the air, and prevents ink drops from failing to land in a proper position because of an airflow to form a new flow path in the apparatus, thereby recording a high-quality image with high reliability.

Owner:RISO KAGAKU CORP

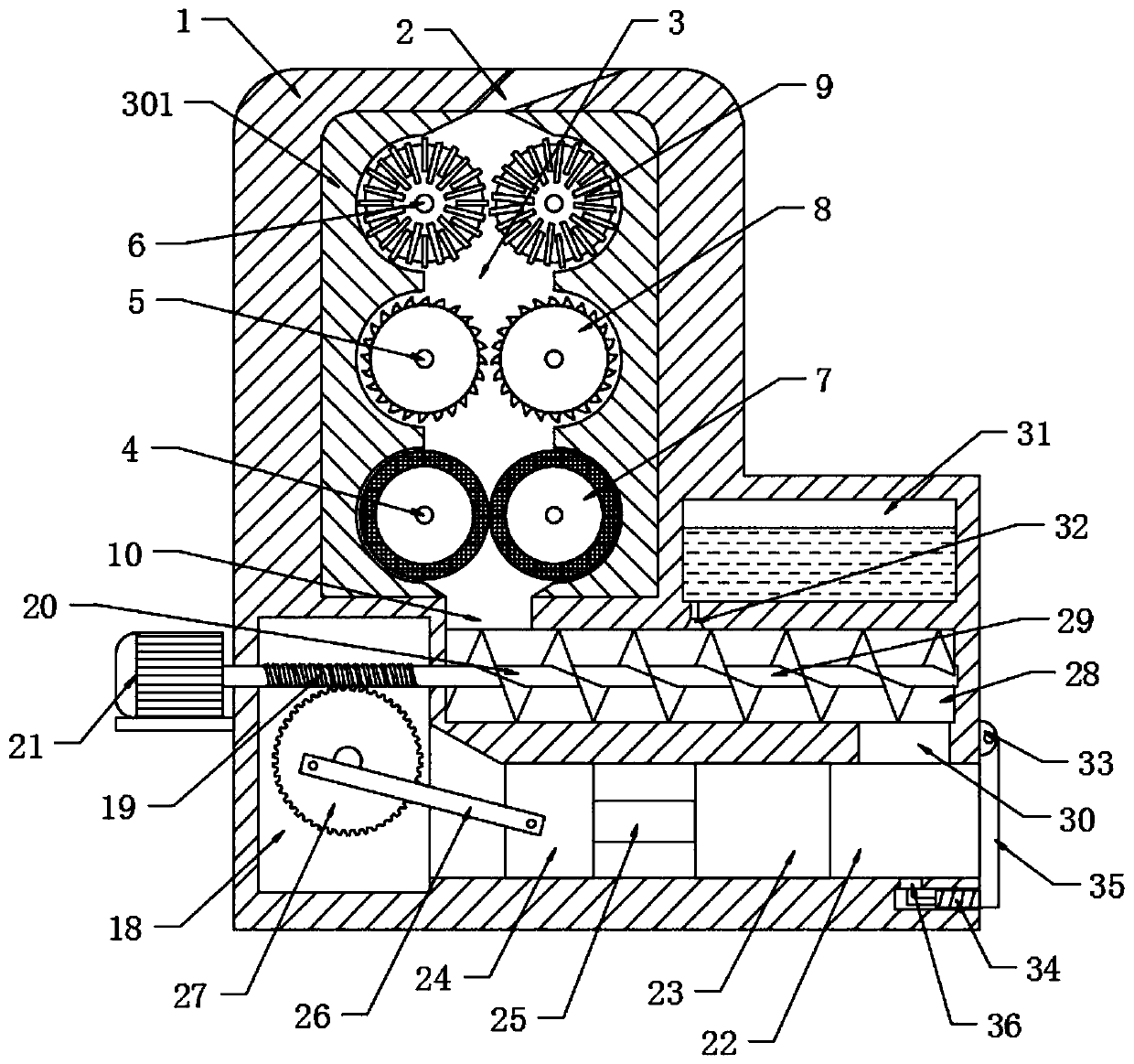

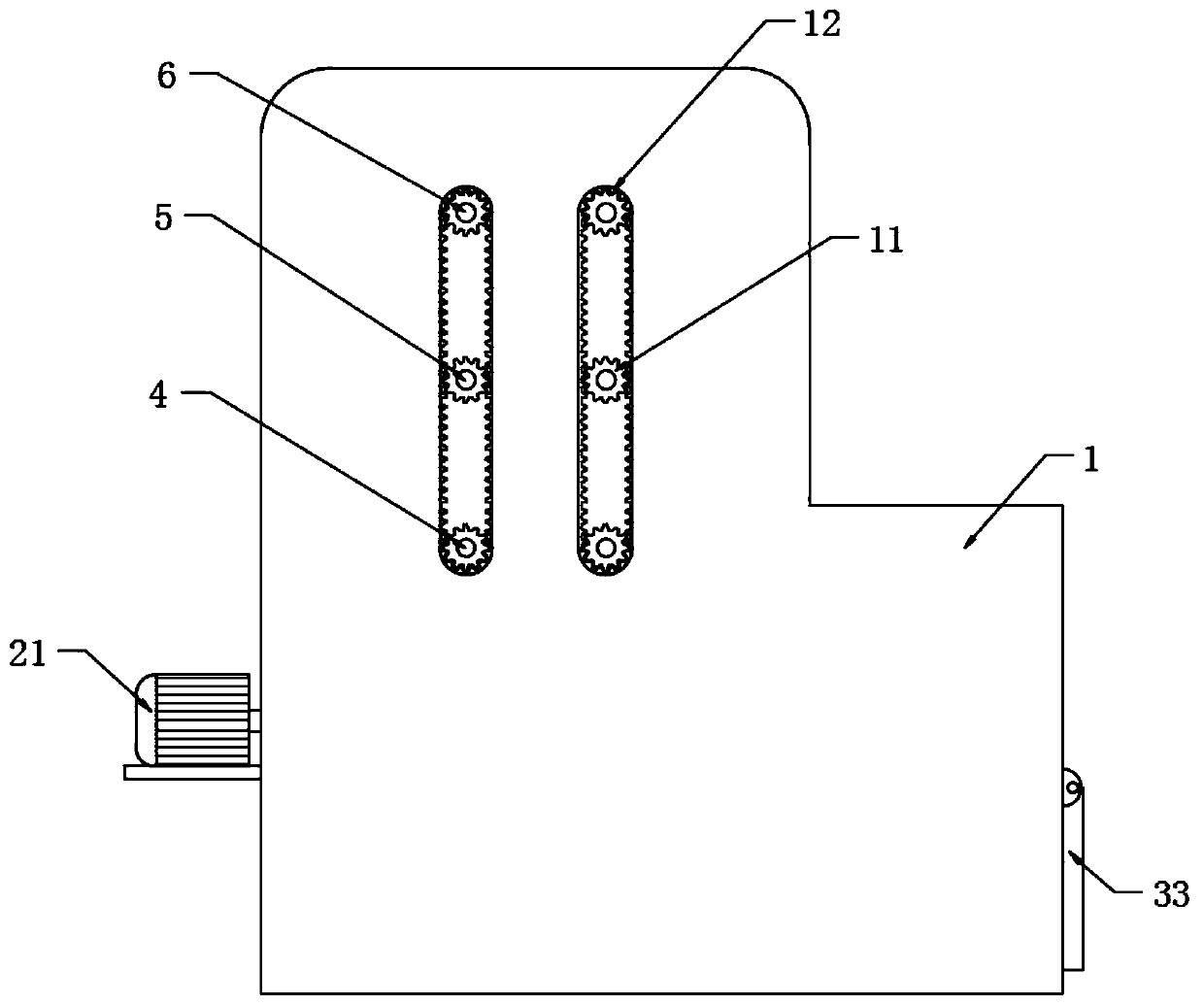

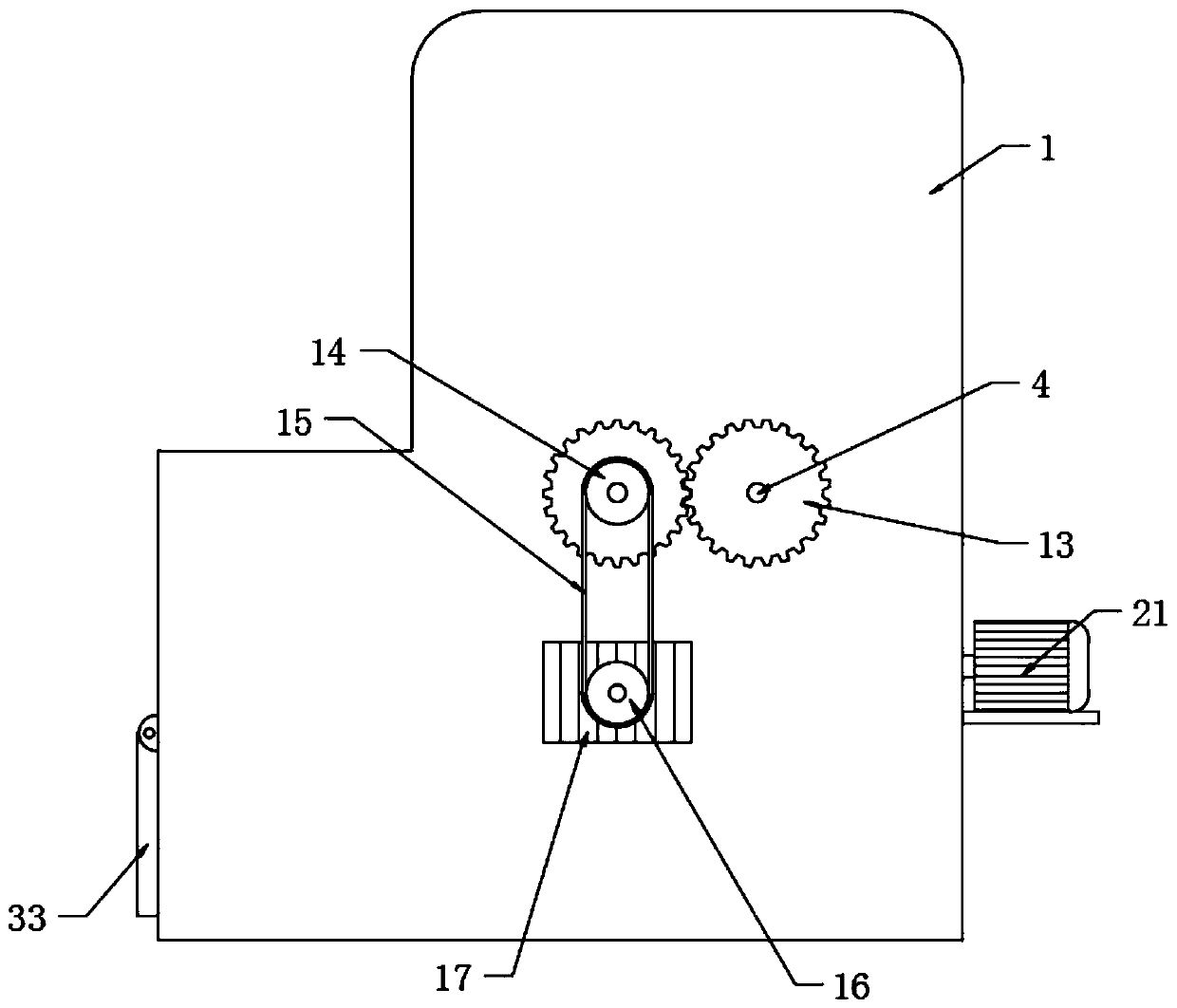

Confidential file integrated destruction and recovery equipment

InactiveCN111330704AImprove destruction securityPromote sheddingSolid waste disposalGrain treatmentsWater storagePaper dust

The present invention discloses confidential file integrated destruction and recovery equipment. The equipment comprises a machine box; the machine box is internally provided with a paper breaking cavity, a power cavity, a sliding cavity, a conveying cavity and a water storage cavity; the box top of the machine box is provided with a paper inlet hopper communicating with the paper breaking cavity;the bottom cavity wall of the paper breaking cavity is provided with a paper outlet; one end of the sliding cavity communicates with the power cavity; the side, far away from the power cavity, of thesliding cavity runs through the box wall of the machine box; the sliding cavity is located below the conveying cavity; the water storage cavity is located above the conveying cavity; and the cavity wall of the end, far away from the power cavity, of the sliding cavity is provided with a connecting hole which communicates with the conveying cavity. The equipment has the advantages that the paper breaking cavity is internally provided with three-stage paper breaking mechanisms including a fine-tooth paper breaking wheel, a rough-tooth paper breaking wheel and a sliver paper breaking wheel, andconfidential files are broken into paper slips and paper scraps, so that the confidential files are difficult to recover, and the destruction security of the confidential files is greatly improved.

Owner:北京融诚信达科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com