Device for producing regenerative polyester bottle chips by using waste plastics and production process thereof

A technology of polyester bottle flakes and production technology, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of messy packaging of finished products, uneven product quality, rough production equipment, etc., achieve compact installation structure, improve cleanliness, The effect of systematization of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A device for producing recycled polyester bottle flakes from waste plastics, including a crushing and cleaning system, an electrical transmission control system, a paper dust separation system, a semi-finished product collection system, a finished product metering and sewing system, a polyester bottle flake quality inspection system, and a sewage treatment system ;

[0059] The crushing and cleaning system is used for crushing and cleaning polyester bottle flakes;

[0060] The electric transmission control system adopts frequency-adjustable and variable-speed motor transmission, which is used to control the motor speed of the whole device, and can adjust the production speed and production capacity according to the production process requirements;

[0061] The paper dust separation system is used to separate the paper dust for PET bottle flakes twice;

[0062] The semi-finished product collection system is used to store the crushed semi-finished product;

[0063] The ...

Embodiment 2

[0067] The second embodiment of the present invention proposes a device for producing recycled polyester bottle flakes from waste plastics, which is a more preferred device for the first embodiment, namely:

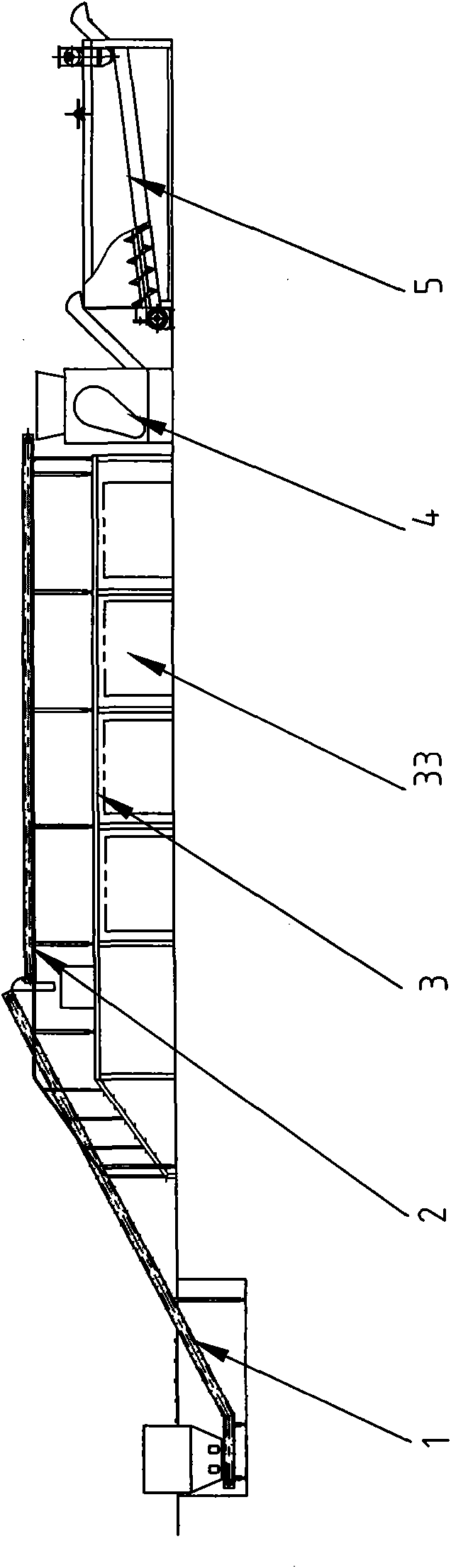

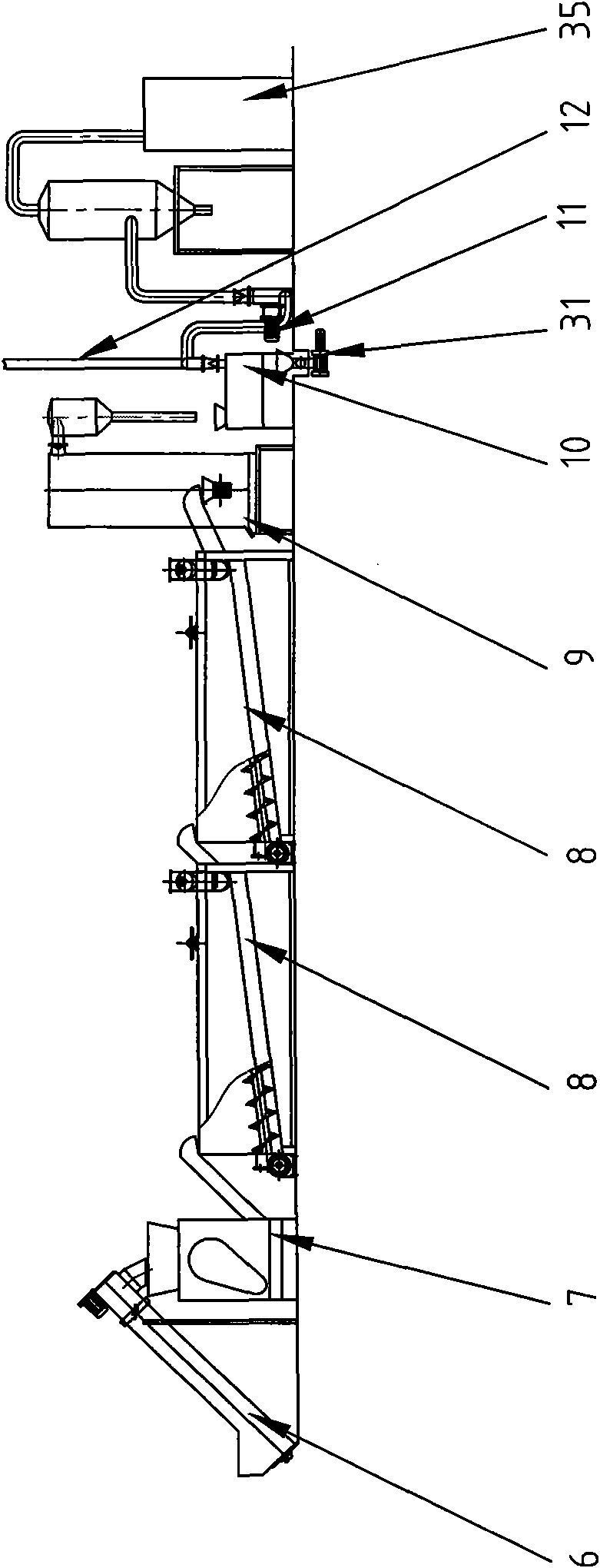

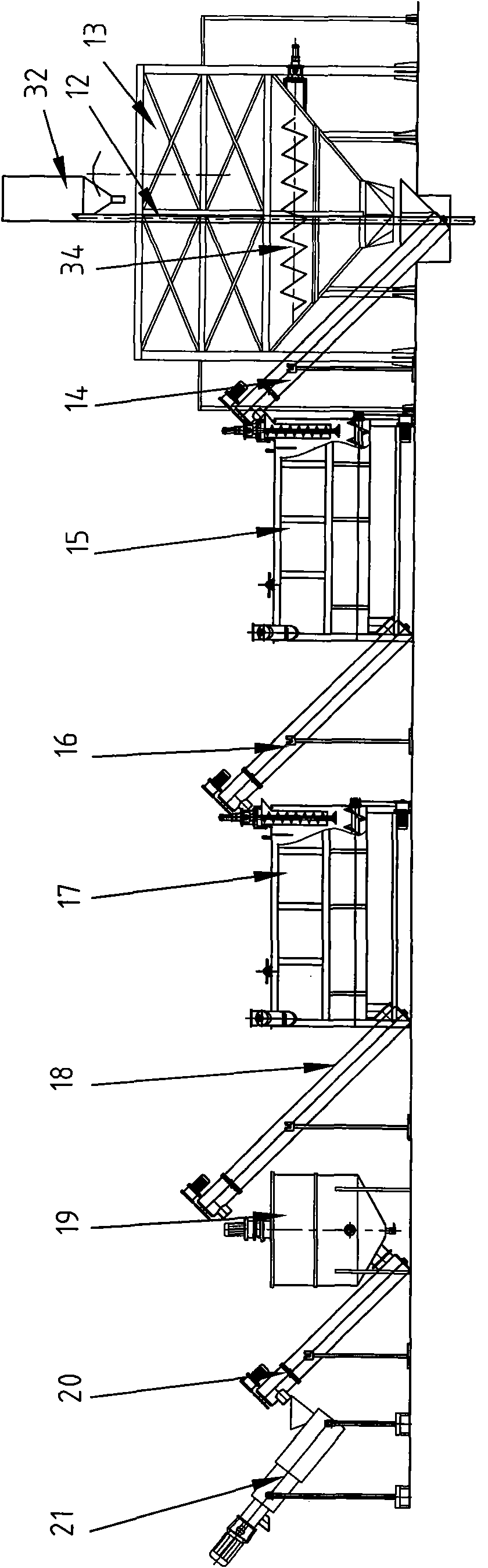

[0068] A device for producing recycled polyester bottle flakes from waste plastics, such as figure 1 and figure 2 As shown, it includes belt lifting conveyor 1, belt plane conveyor 2, selection platform 3, one pulverizer 4, one floating washing tank 5, single screw conveyor 1 6, two pulverizers 7, two Float wash tank 8, centrifugal dehydration separator I9, paper dust separation system I 10, Roots blower 11, air delivery pipeline 12, storage bin 13, single screw conveyor II 14, three float wash tanks 15, single Screw conveyor III 16, four floating washing tanks 17, single screw conveyor IV 18, hot washing tank 19, single screw conveyor V 20, friction separator 21, warm washing tank 22, single screw conveyor VI 23, rinse Tank I 24, single screw conveyor VII 25, rinsing ...

Embodiment 3

[0070] A production process for waste plastics to produce recycled polyester bottle flakes, comprising the following steps,

[0071] (1) Selection unit: Manual sorting, picking out the non-colored bottles and non-polyester bottles from the waste plastic polyester bottles on the workbench;

[0072] (2) Crushing unit: send the polyester plastic sent by the selection unit to the pulverizer, perform pulverization and floating washing twice, and separate the paper scraps;

[0073] (3) Conveying unit: convey the crushed and pretreated polyester bottle flakes to the storage bin of the washing unit through the rotary valve, Roots blower and air delivery pipeline;

[0074] (4) Washing unit: carry out secondary floating washing and hot soaking treatment on the crushed polyester bottle flakes;

[0075] (5) Rinsing unit: friction stripping and secondary rinsing are carried out on the heat-soaked polyester bottle flakes to obtain semi-finished products;

[0076] (6) Drying unit: dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com