Lead-acid battery compound additive production device

A compound additive and lead-acid battery technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as high labor intensity, low work efficiency, and physical injury to workers, so as to improve product quality, improve work efficiency, reduce labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

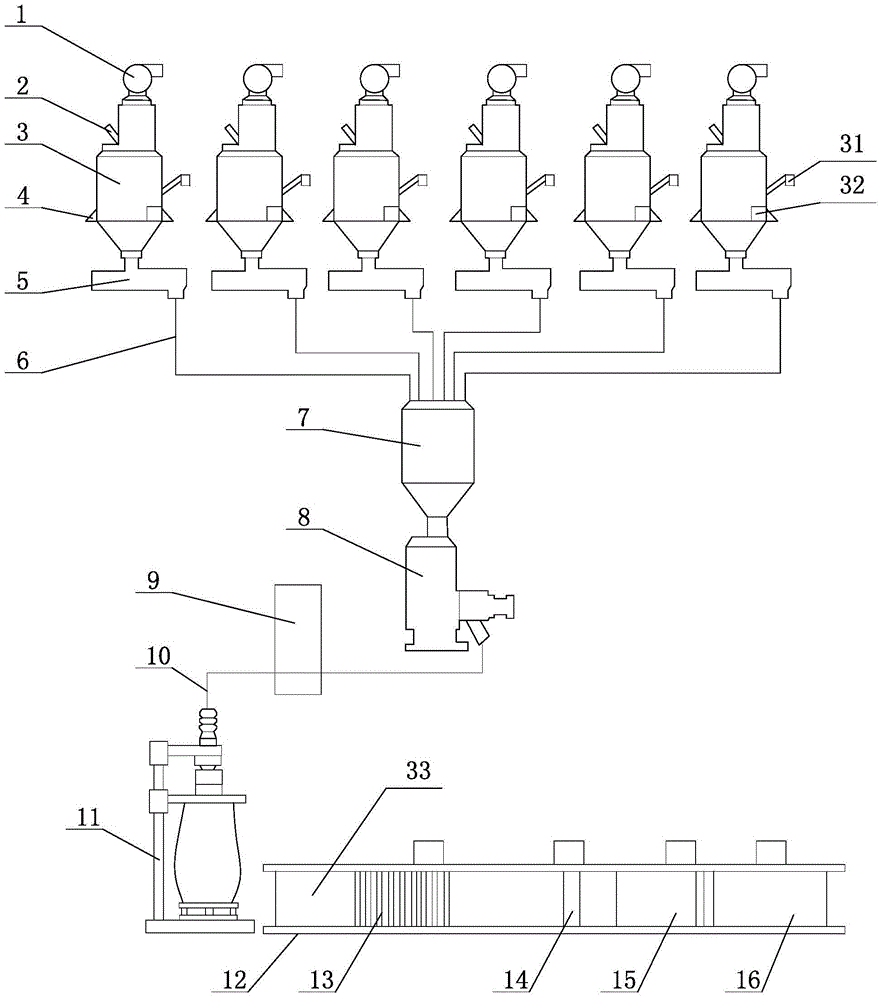

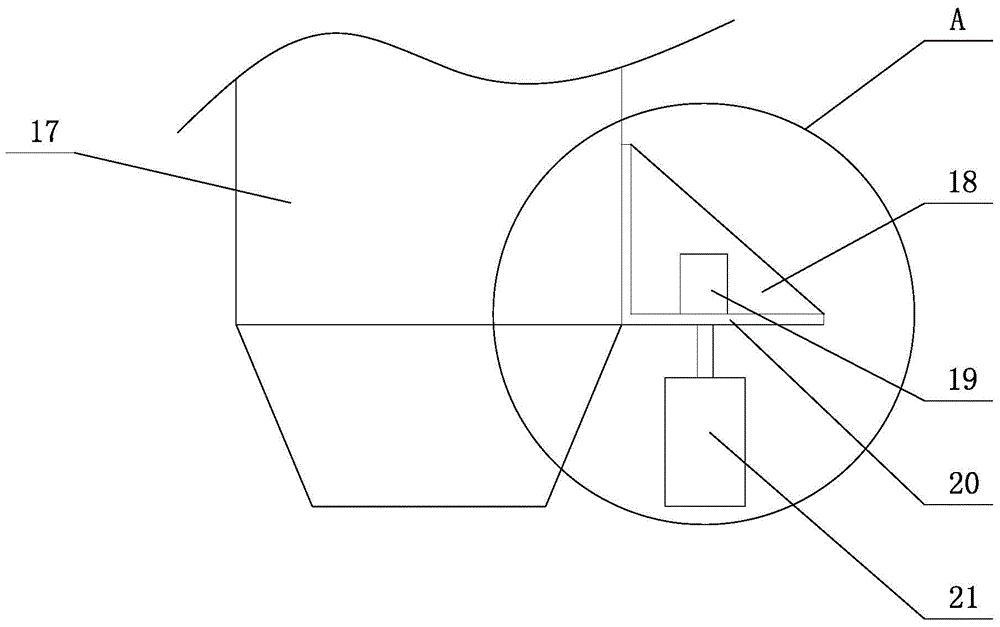

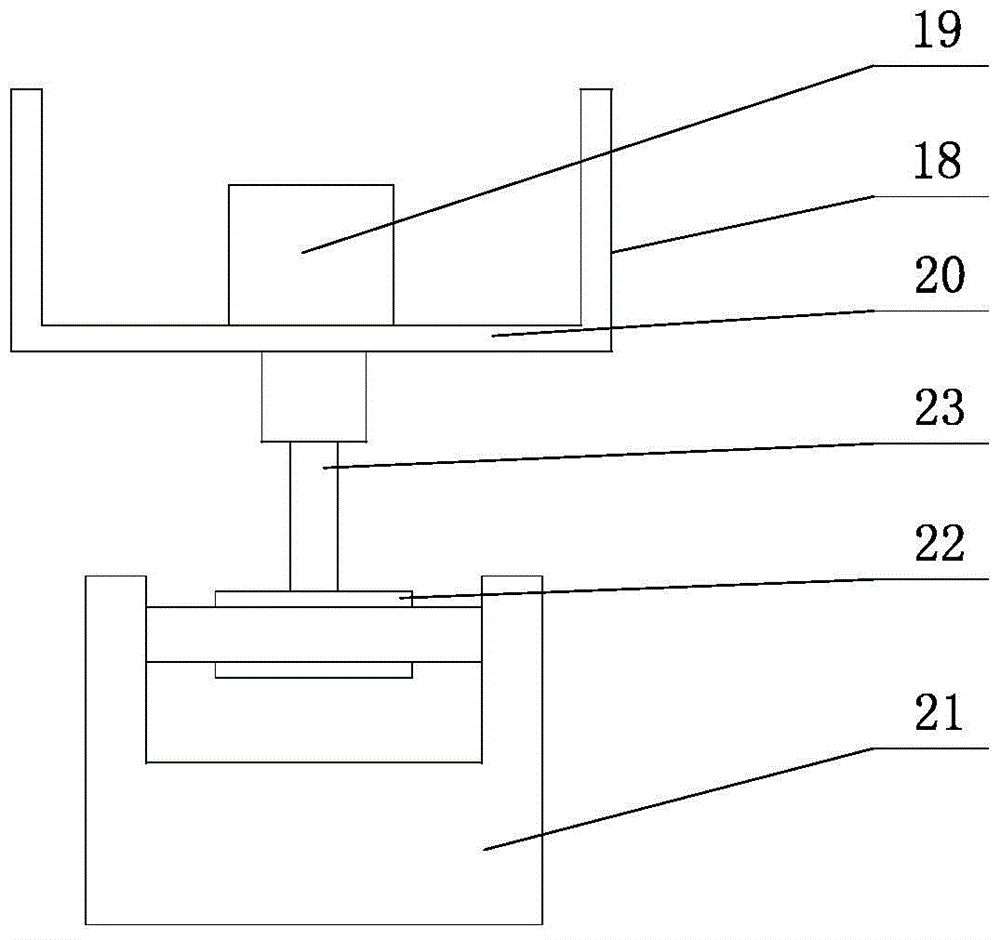

[0024] Such as Figure 1 to Figure 5 As shown, the lead-acid storage battery composite additive production device of the present invention includes a storage tank 3, a feeding mechanism 5 is arranged at the bottom of the storage tank 3, and the feeding mechanism 5 is connected to the batching bin 7 through the delivery pipe 6, and the bottom of the batching bin 7 is connected to the mixing bin. The feed bin 8, the mixing bin 8 and the vibrating screen 9 are communicated through the feeding pipe 10, and the vibrating screen 9 is communicated with the weighing and packaging device 11. The side of the weighing and packaging device 11 is provided with a packaging bag conveying device 12, and the packaging bag conveying device 12 is configured according to In the conveying direction, a leveling mechanism 13, a magnetic detection device 14, a secondary check weighing device 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com