Supporting structure for large-section weak surrounding rock tunnel construction and construction method thereof

A technology for weak surrounding rock and tunnel construction, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of inability to use large-scale mechanical operations, high construction costs, and high risk of dismantling braces. The effect of construction efficiency and process connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

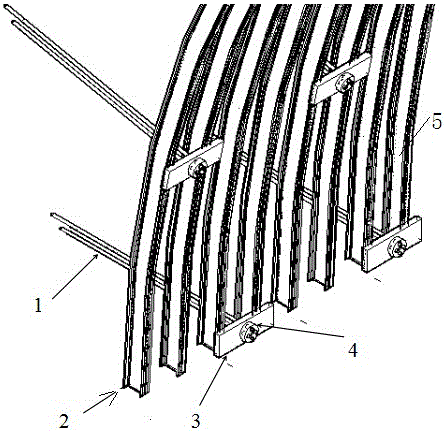

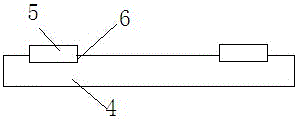

[0023] Embodiment 1: as Figure 1-Figure 2 As shown, a support structure for the construction of tunnels with large cross-sections and weak surrounding rocks, including steel arches 2, steel arches 2 are formed by a plurality of arc-shaped I-shaped steels 5 arranged at intervals along the direction of the tunnel, and the I-shaped steels 5 The groove of the groove faces the direction of the tunnel, and a strip-shaped anchor plate 3 is arranged between the adjacent I-beams 5. The anchor plate 3 is fastened to the arc-shaped inner surface of the I-beam 5, and the inner surface is provided with an anchor. 4. A prestressed anchor cable 1 is connected to the anchorage 4, and the prestressed anchor cable 1 extends radially outward toward the I-beam 5 into the side wall of the tunnel.

[0024] Preferably, the two ends of the above-mentioned anchor backing plate 3 are fixedly connected on the I-beam 5 by welding, and the set anchor backing plate 3 can form the steel arch 2 as a whole a...

Embodiment 2

[0027] Embodiment 2: A construction method for the construction support structure of a large-section weak surrounding rock tunnel. The method is to use the existing pilot pit and formed steel arch initial support of the tunnel, and set temporary vertical supports and temporary elevations. Prestressed anchor cables are applied to the positions of the arch cross braces, and the original temporary vertical braces and cross braces are replaced by anchor cables, and the prestress is adjusted according to the tunnel load to meet the requirements of cable replacement braces. The specific implementation steps are as follows:

[0028] Step 1. Drill holes and install prestressed anchor cables at the middle position of the two steel arches of the initial support that have been formed. The anchor cables are provided with anchor sections and free sections. 6, 2 on the vault, staggered up and down by 1.5~2m, 2 on the left and right arches, staggered up and down by 1.5~2m; vertically set acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com