Disassembly reclamation system for scrapped motor vehicle

A recycling system and motor vehicle technology, applied in the field of scrapped motor vehicle dismantling and recycling systems, can solve problems such as high-efficiency dismantling of scrapped cars, resource waste environment, and classified recycling, and achieve favorable resource recycling, environmental protection, and dismantling efficiency High, large-scale production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

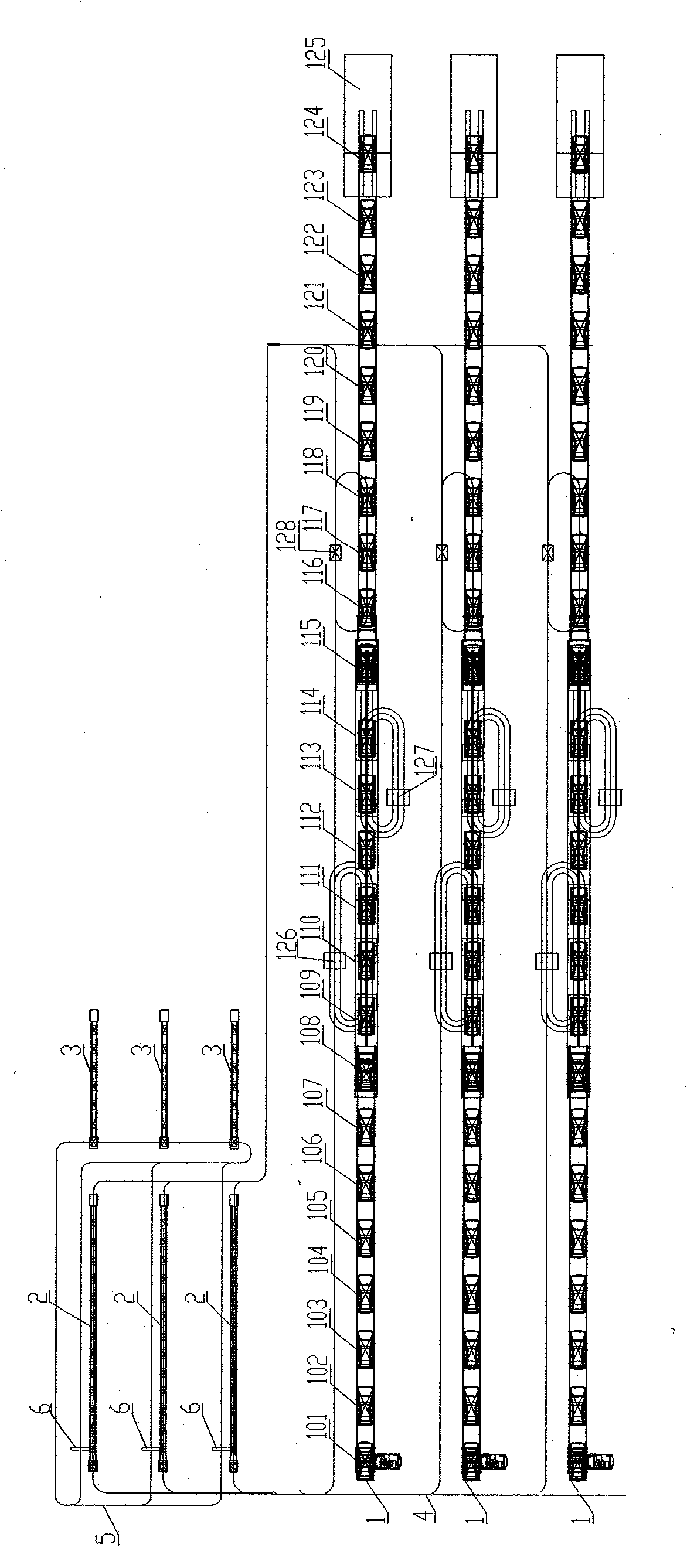

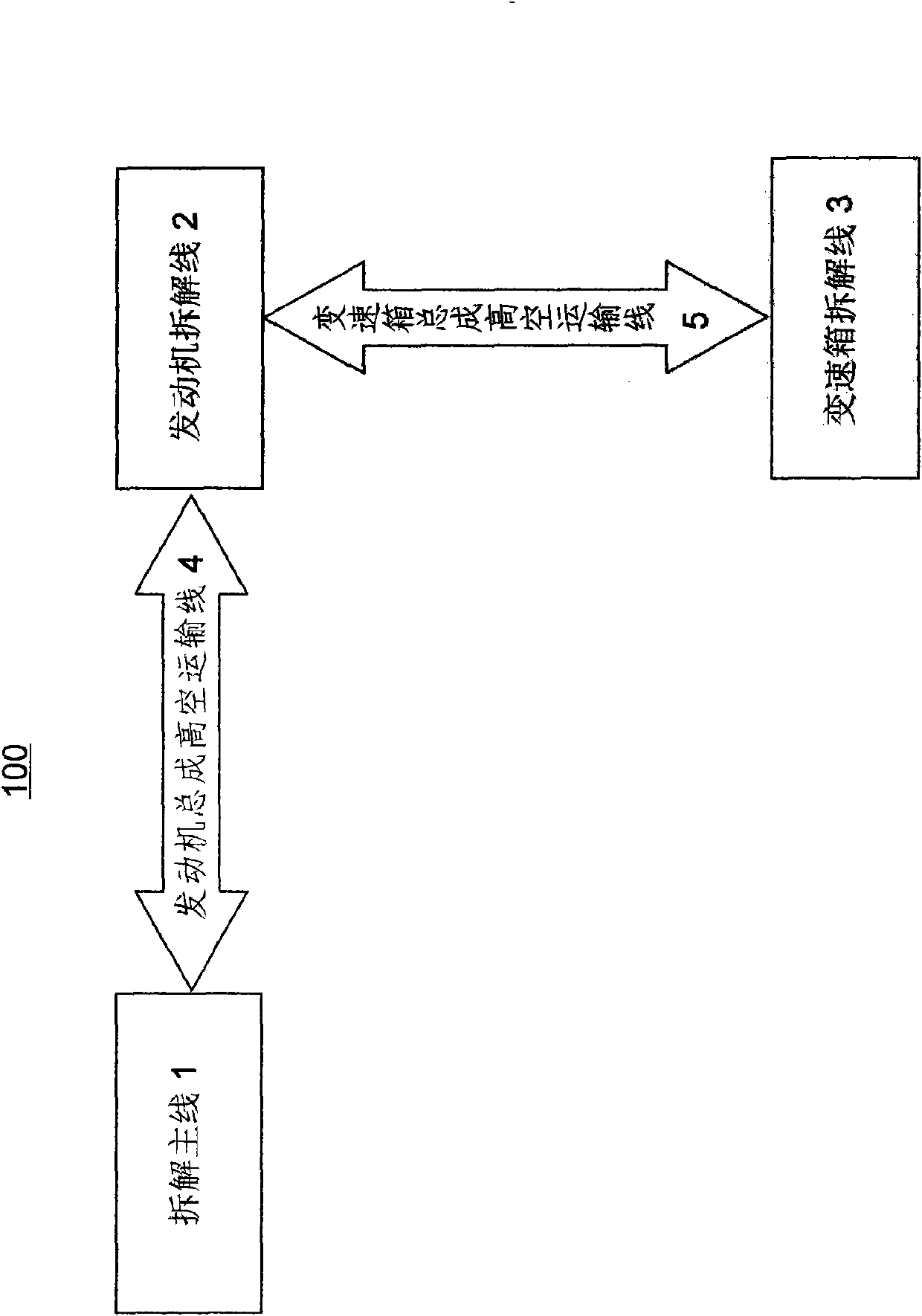

[0065] seefigure 1 , figure 1 An end-of-life vehicle dismantling recovery system 100 is shown, comprising:

[0066] The dismantling main line 1 is used for launching and dismantling the scrapped motor vehicle, and among the dismantled parts, at least the engine assembly of the vehicle is transferred to the next process.

[0067] The engine assembly high-altitude transportation line 4, whose input end is connected to the dismantling main line 1, is used to receive the engine assembly transferred by the dismantling main line 1, and transfer the engine assembly to its output end.

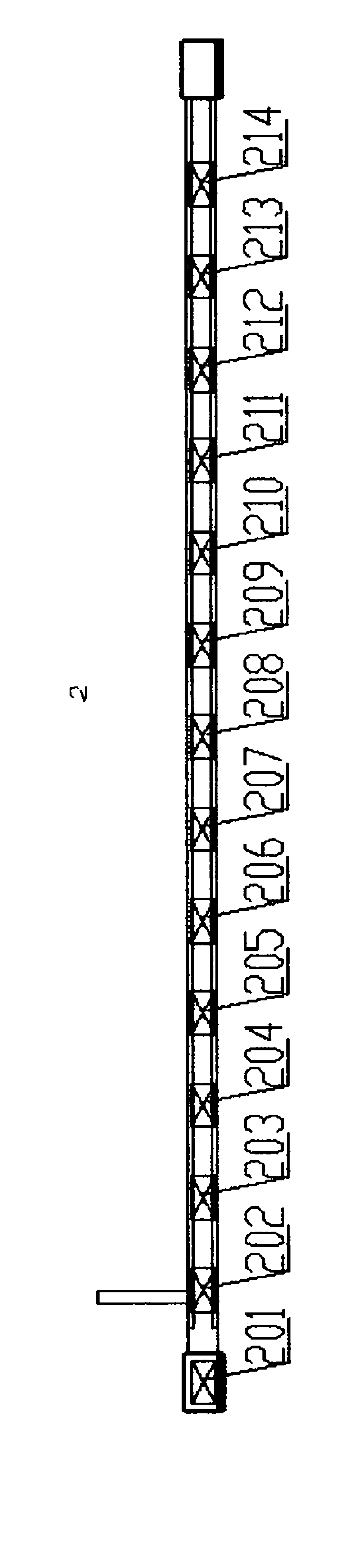

[0068] The engine dismantling line 2 is connected to the output end of the high-altitude transportation line 4 of the engine assembly to receive the engine assembly and further dismantle it. Among the disassembled parts, at least transfer the engine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com