Disassembling device for waste motor casing

A motor casing and waste technology, which is applied in the field of dismantling devices for waste motor casings, can solve the problems of personal safety risks of dismantling personnel, dust and flammables in the dismantling environment, and harsh working environment of manual dismantling, etc. The effect of dismantling loss, simple structure and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

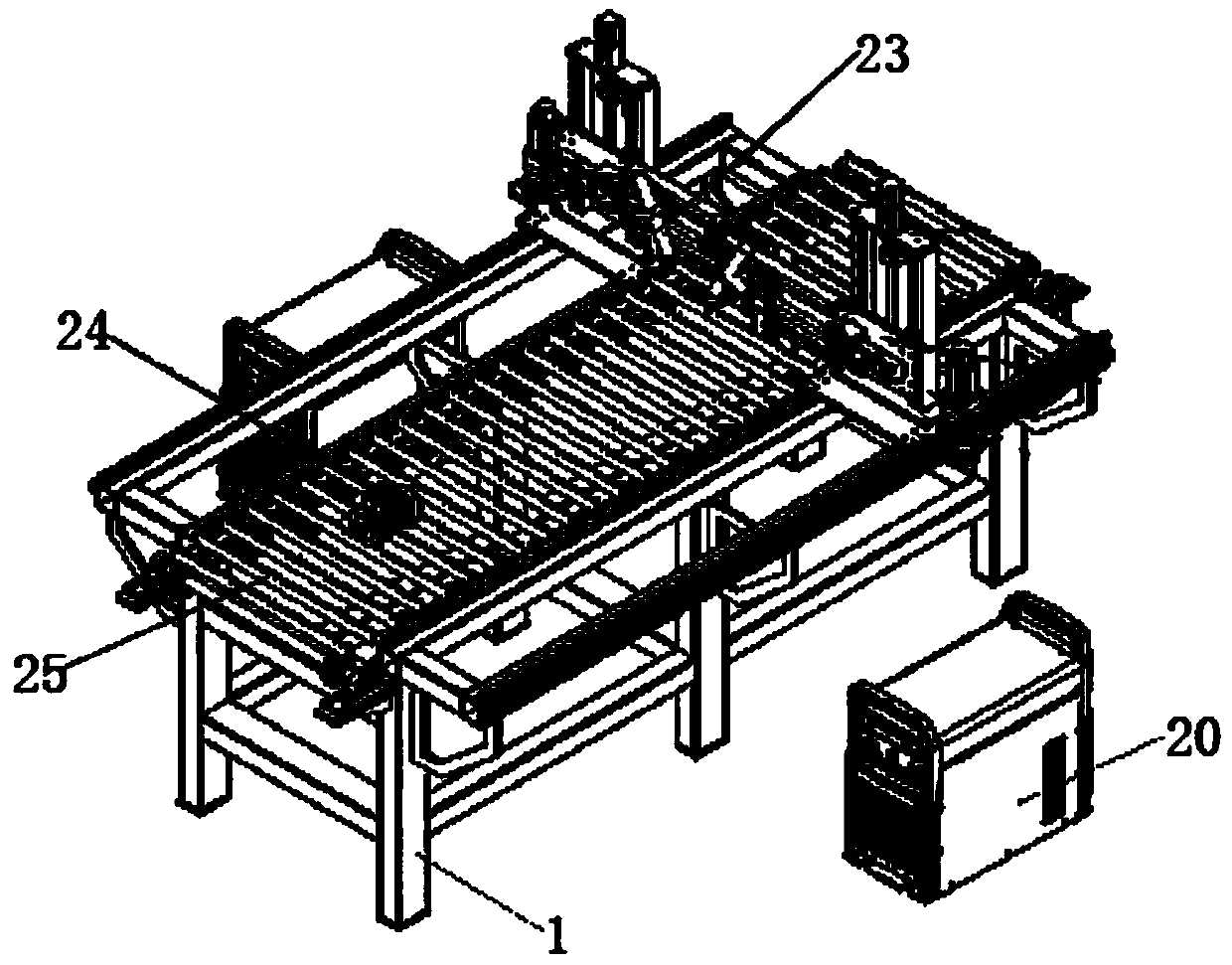

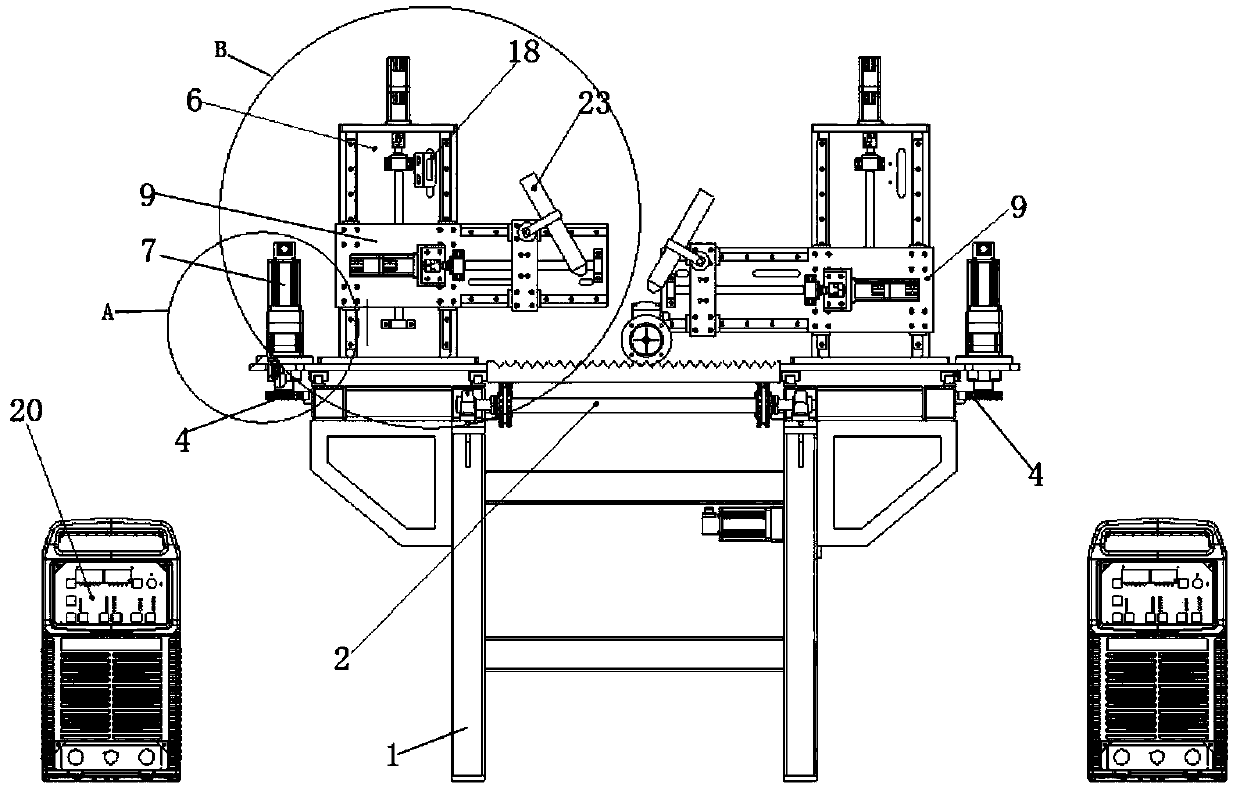

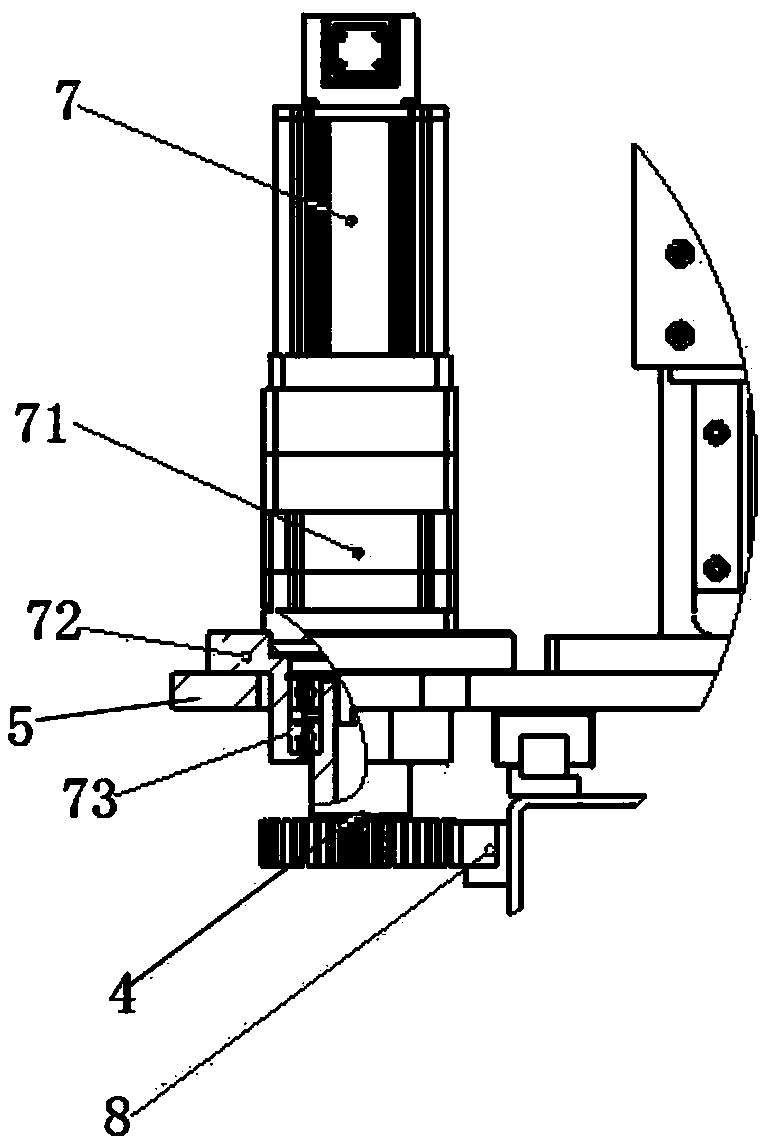

[0020] Figure 1 to Figure 7 The various structural schematic diagrams of the present invention are shown. Such as Figure 1 to Figure 7 As shown, the present invention provides a device for disassembling the casing of a waste motor 24. It includes a frame 1, a conveying device, a cutting system, a control system, and an image recognition device set above the frame 1. The conveying device, cutting system, and image recognition device are respectively connected to the control system, and the image recognition device (not shown in the figure) Out) is located above the conveying device. The image recognition device includes an image recognition lens, which is used to automatically recognize the external appearance of the used motor 24, determine the model of the used motor 24, determine the position of the ribs on the casing of the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com