Cannonball dismantling line

A projectile and projectile technology, applied in the field of dismantling and destroying dangerous goods, can solve the problems of casualties, low dismantling efficiency, high labor intensity, etc., and achieve the effect of high dismantling efficiency, low dismantling cost and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

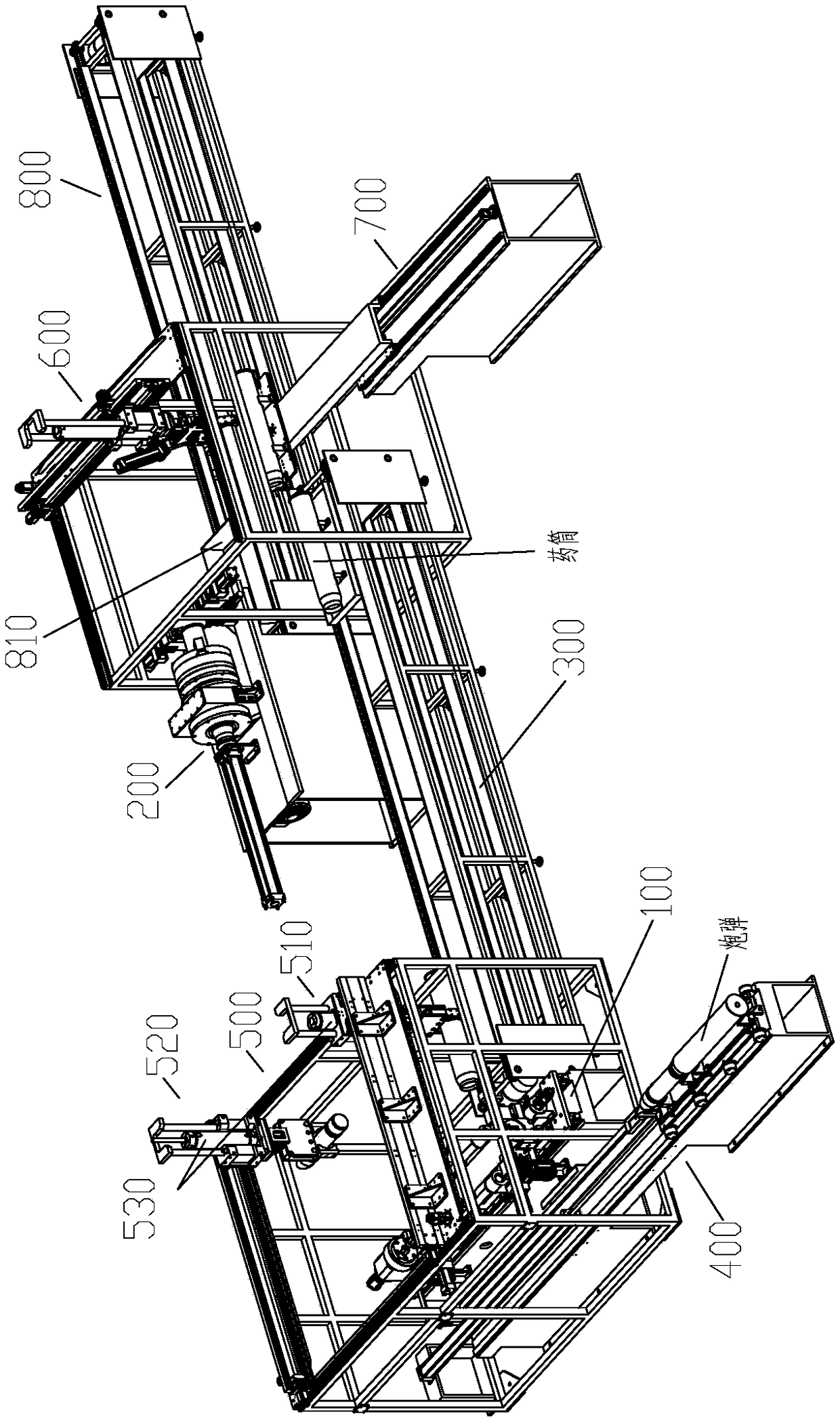

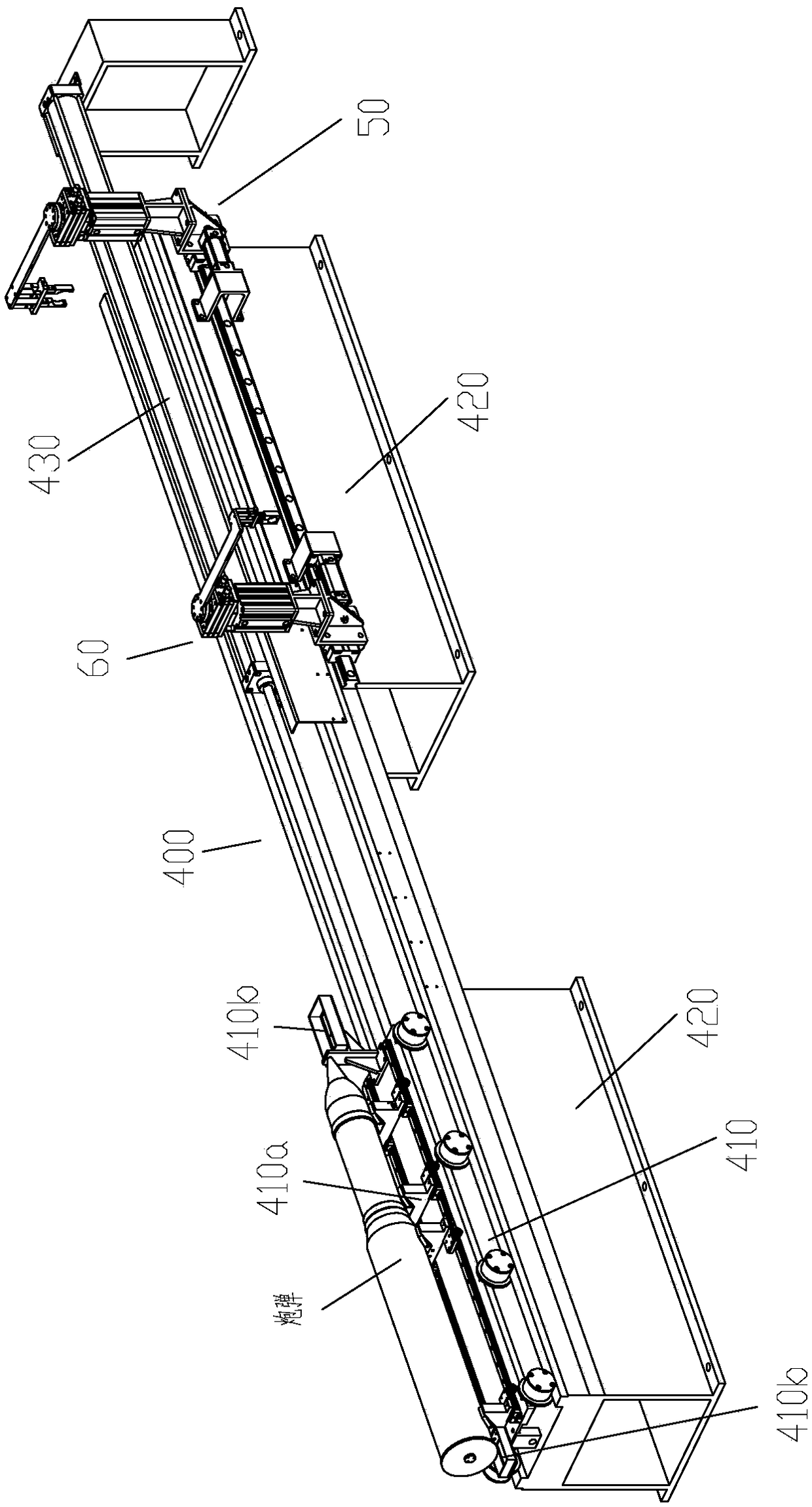

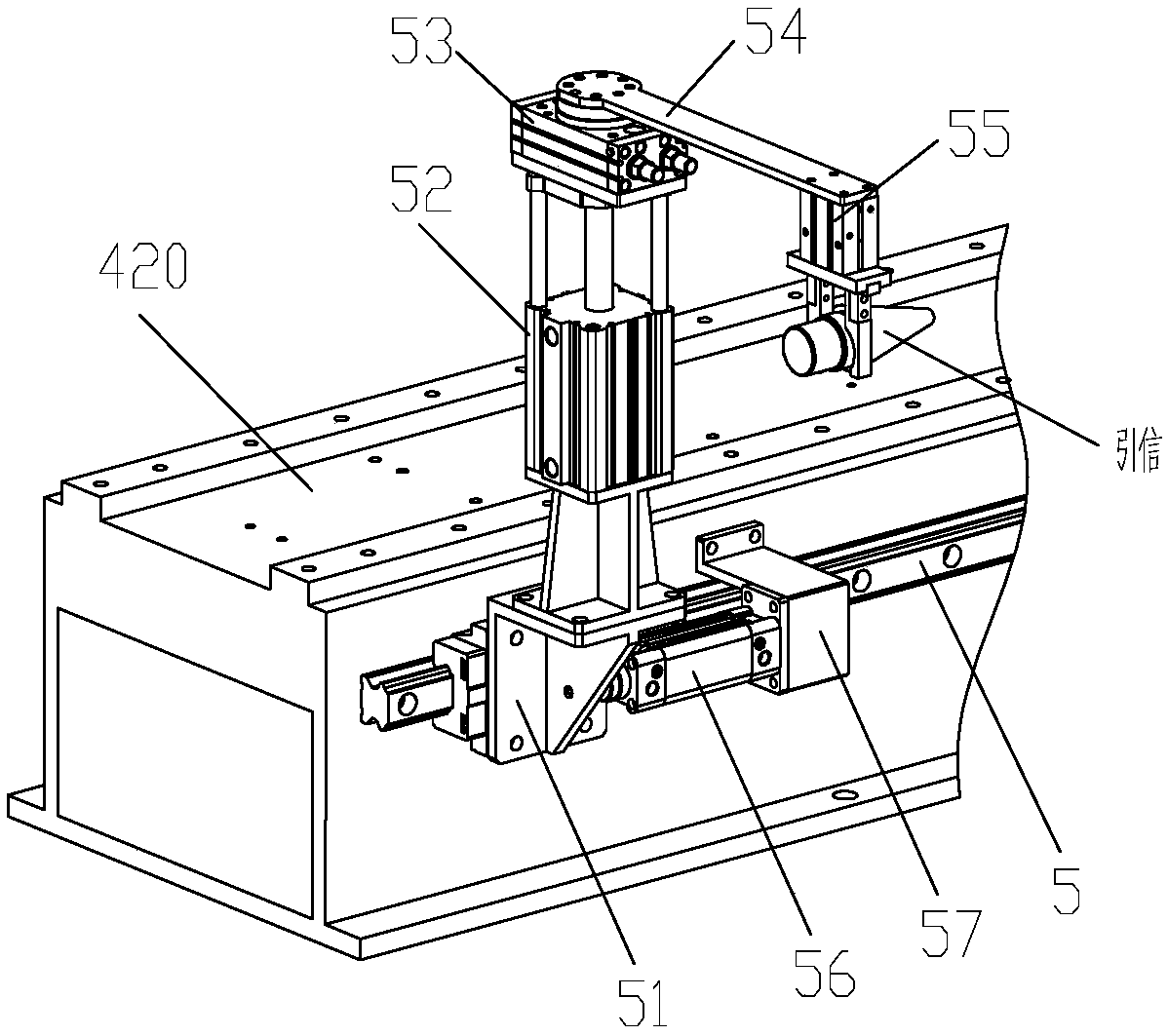

[0035] see figure 1 , a shell dismantling line, comprising a spin-off separator 100 and a cartridge turning separator 200, the spin-off separator 100 is used to disassemble the shell into fuzes, projectiles, cartridges and primers; the cartridge turning separator 200 is used To cut off the bottom of the cartridge and separate the explosive from the cartridge; the cartridge is conveyed through the cartridge conveying line 300 between the spin-off separator 100 and the cartridge turning separator 200, and the front end of the spin-off separator 100 is provided with a shell delivery machine 400, a first truss manipulator 500 is provided above the junction of the spinner separator 100, the shell conveyor 400 and the cartridge conveying line 300; the cartridge turning and separating machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com