Pretreatment method of marine placer

A sea sand ore pretreatment technology, applied in the field of metallurgy, to achieve the effects of improving smelting reaction efficiency, increasing contact area, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

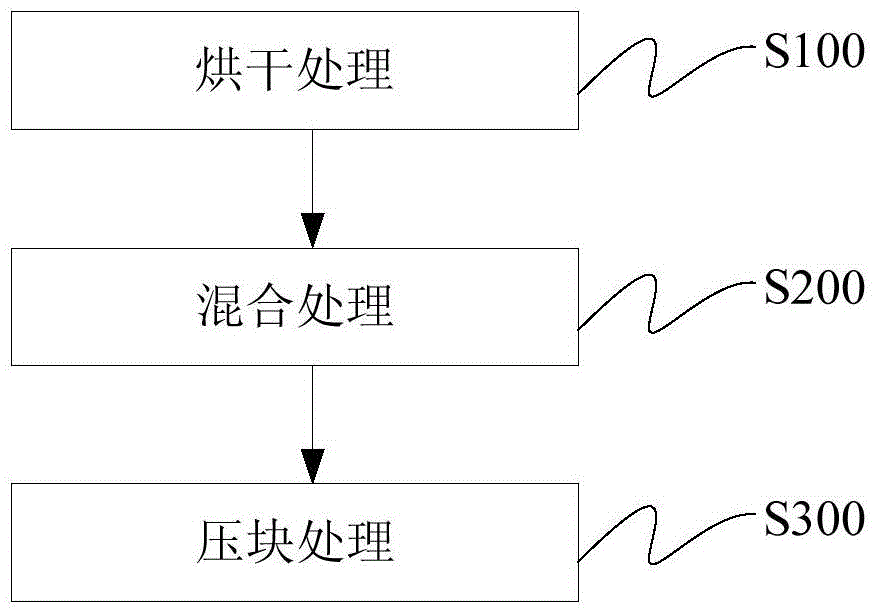

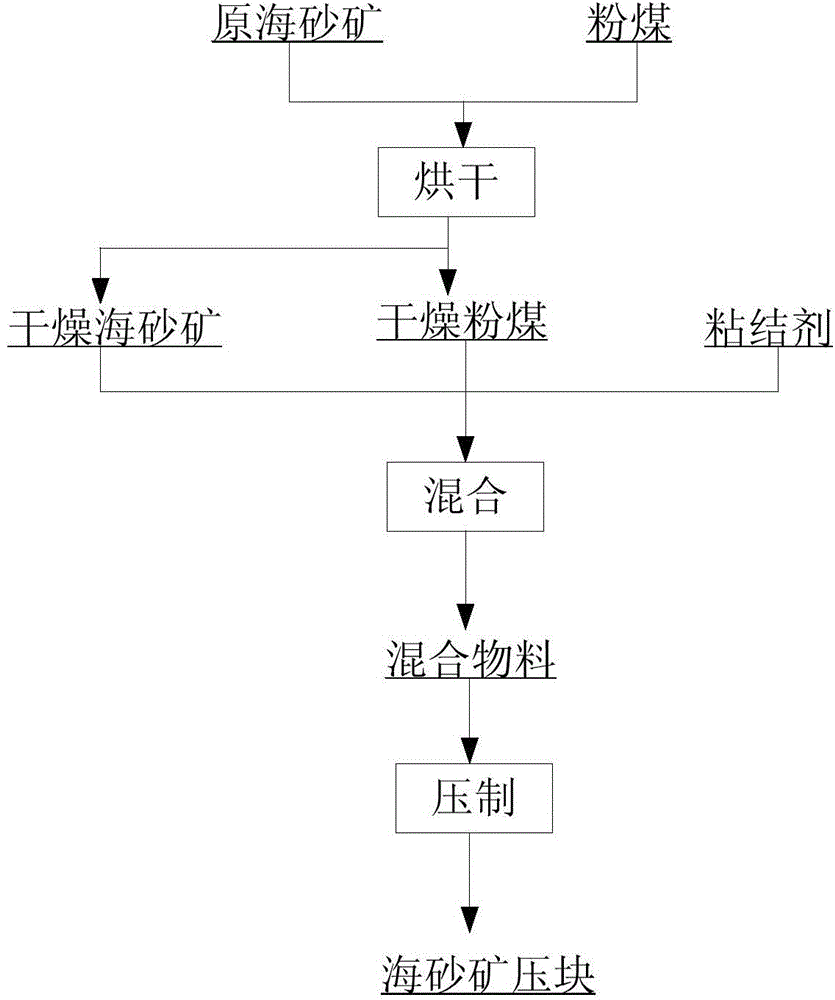

Method used

Image

Examples

Embodiment 1

[0058] The vanadium-titanium magnetite sea placer is dried to make the moisture content in the range of 1 to 2% by weight; the anthracite is crushed to obtain coal powder with a particle size of not more than 1 mm. 225Kg of dried vanadium-titanium magnetite sea placer, 55Kg of anthracite coal powder and 1Kg of carboxymethyl cellulose and corn starch are mixed uniformly using a combination of rotating chassis and multi-axis slurry, and the uniformity reaches 90%. A pair of roller briquetting machine is used to compress the mixture material to obtain a rectangular sea sand ore briquette with length, width and height of 40*22*13.

[0059] The cloth in the rotary hearth furnace of the sea placer briquette is controlled, the temperature in the rotary hearth furnace is controlled to be 1300-1400 degrees Celsius, and the smelting process is performed for 15-30 minutes to obtain reduced iron. By preparing vanadium-titanium magnetite sea placer into sea placer briquette and then smelting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com