Technique for coproducing nickel pig iron and rock wool product from lateritic nickel ores

A technology for laterite nickel ore and cotton products, which is applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of different slag phase structure, large changes in slag composition, and failure to meet the requirements of rock wool composition, so as to reduce production costs. , reduce smelting energy consumption, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

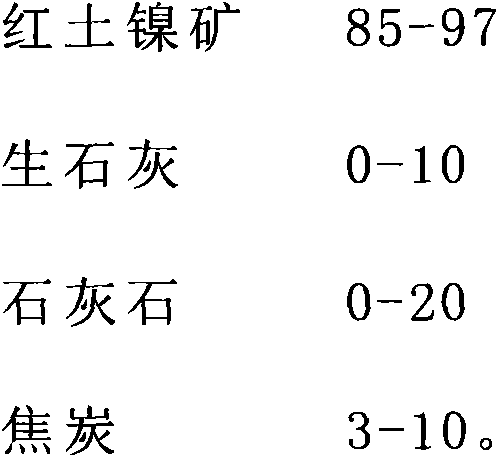

[0038] A process for co-producing nickel pig iron and rock wool products using laterite nickel ore, the rock wool products being rock wool boards, the process includes the following steps:

[0039] a. Use laterite nickel ore calcined sand as the main raw material, add a mixture of quicklime and limestone before sintering, add coke in front of the submerged arc furnace, and smelt through the submerged arc furnace, the ratio of parts by weight of laterite nickel ore, quicklime, limestone and coke 90:5:10:5, 60 tons of nickel pig iron were produced, and 330 tons of hot melt were produced at the same time;

[0040] b. Screen out a hot melt with a temperature of 1550°C and an acidity coefficient of 1.7, about 130 tons;

[0041] c. Inject the hot melt screened in step b into the heat preservation tank and then inject it into the heat preservation furnace, and keep the temperature in the heat preservation furnace at 1500°C;

[0042] d. Guide the hot melt in the holding furnace to th...

Embodiment 2

[0049] A process for co-producing nickel pig iron and rock wool products using laterite nickel ore, the rock wool product being granular cotton, the process comprises the following steps:

[0050] a. Use laterite nickel ore sinter as the main raw material, add quicklime before sintering, add coke in front of the submerged arc furnace, and smelt through the submerged arc furnace. The weight-number ratio of laterite nickel ore, quicklime and coke is 93:2:5 , produced 100 tons of nickel pig iron, and produced 600 tons of hot melt at the same time;

[0051] b. Screen out a hot melt with a temperature of 1530°C and an acidity coefficient of 1.7, about 310 tons;

[0052] c. Inject the hot melt screened out in step b into the heat preservation tank and then pull it into the heat preservation furnace. The temperature in the heat preservation furnace is kept at 1450 ° C. Both the heat preservation tank and the heat preservation furnace are filled with heat preservation agent;

[0053]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com