Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208results about How to "Reduce silicon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

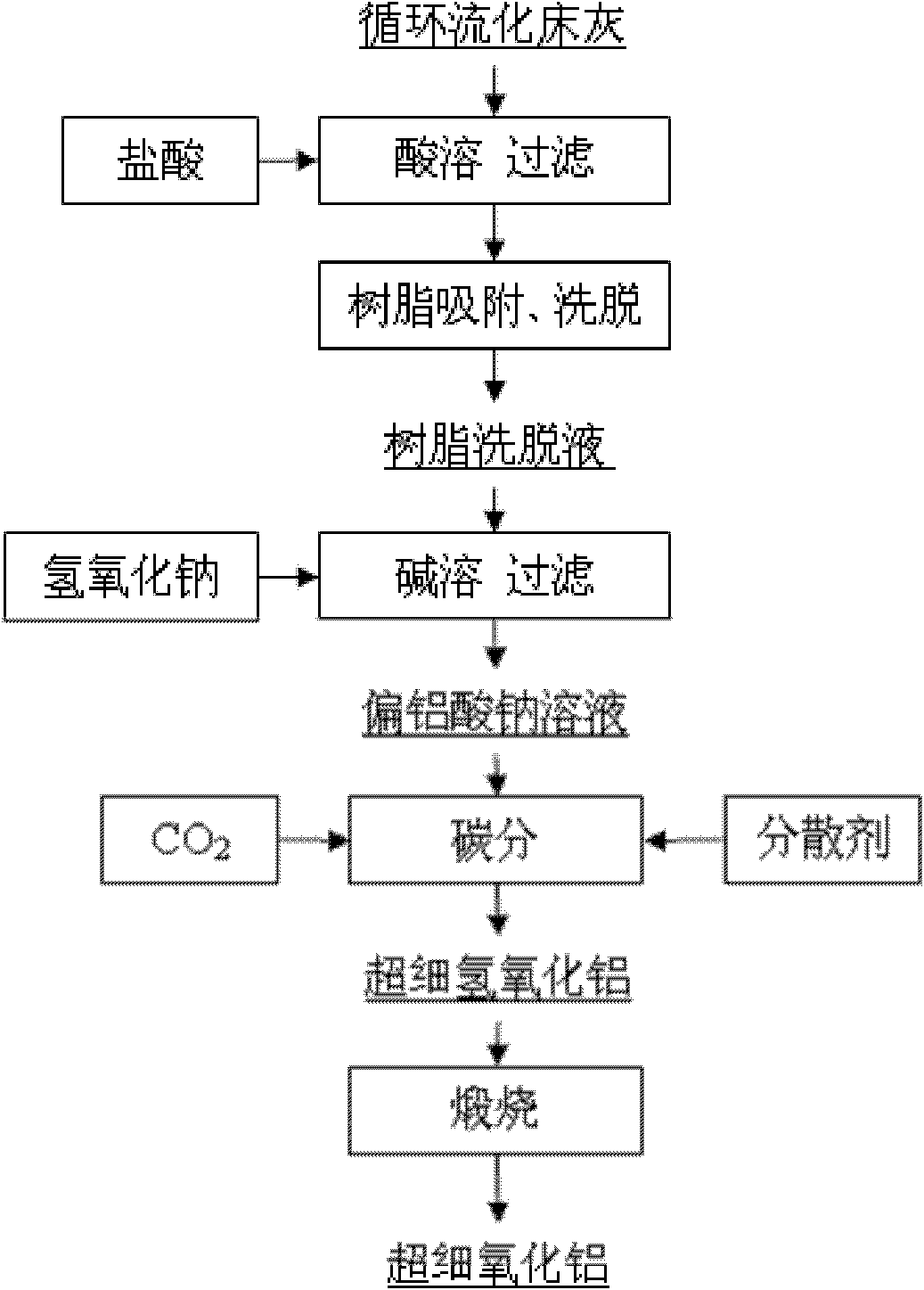

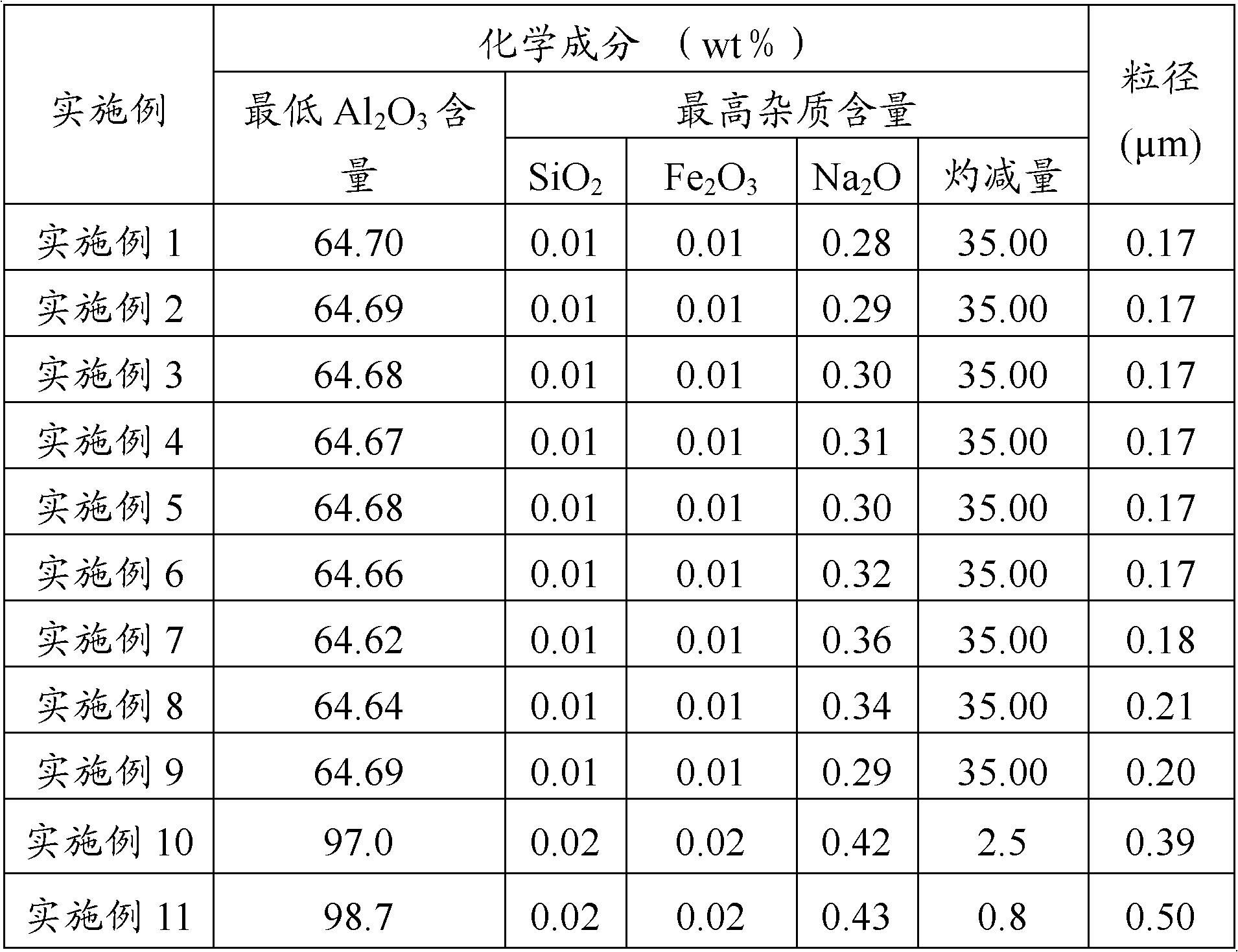

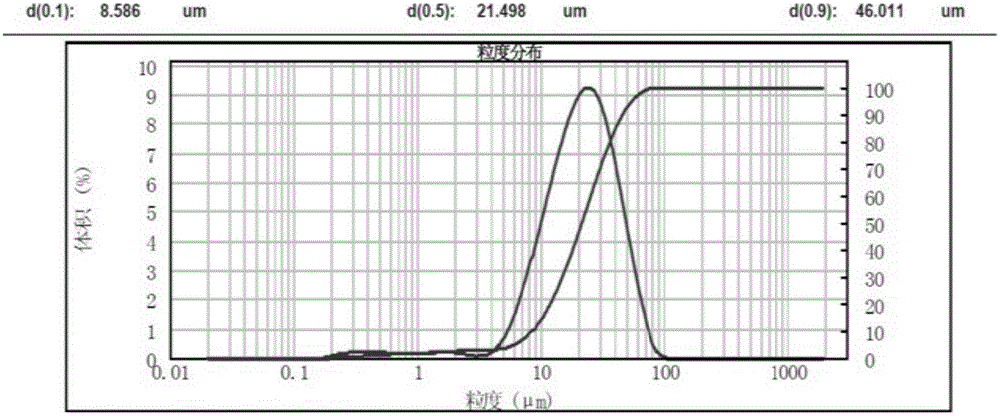

Method for producing superfine aluminium hydroxide and aluminium oxide by using flyash

InactiveCN101870489AHigh purityEliminate high temperature calcination activation stepsProductsReagentsAluminium chlorideDecomposition

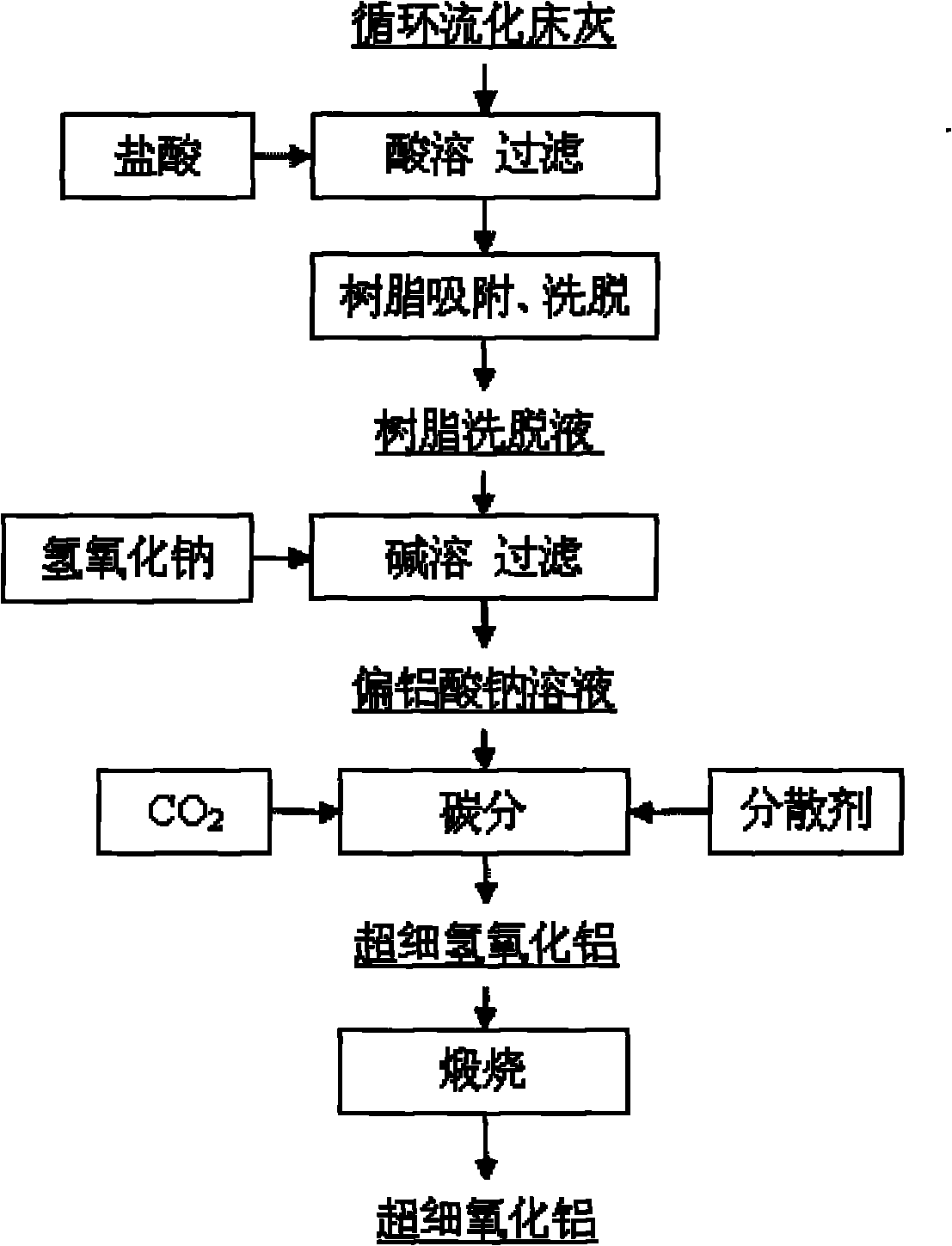

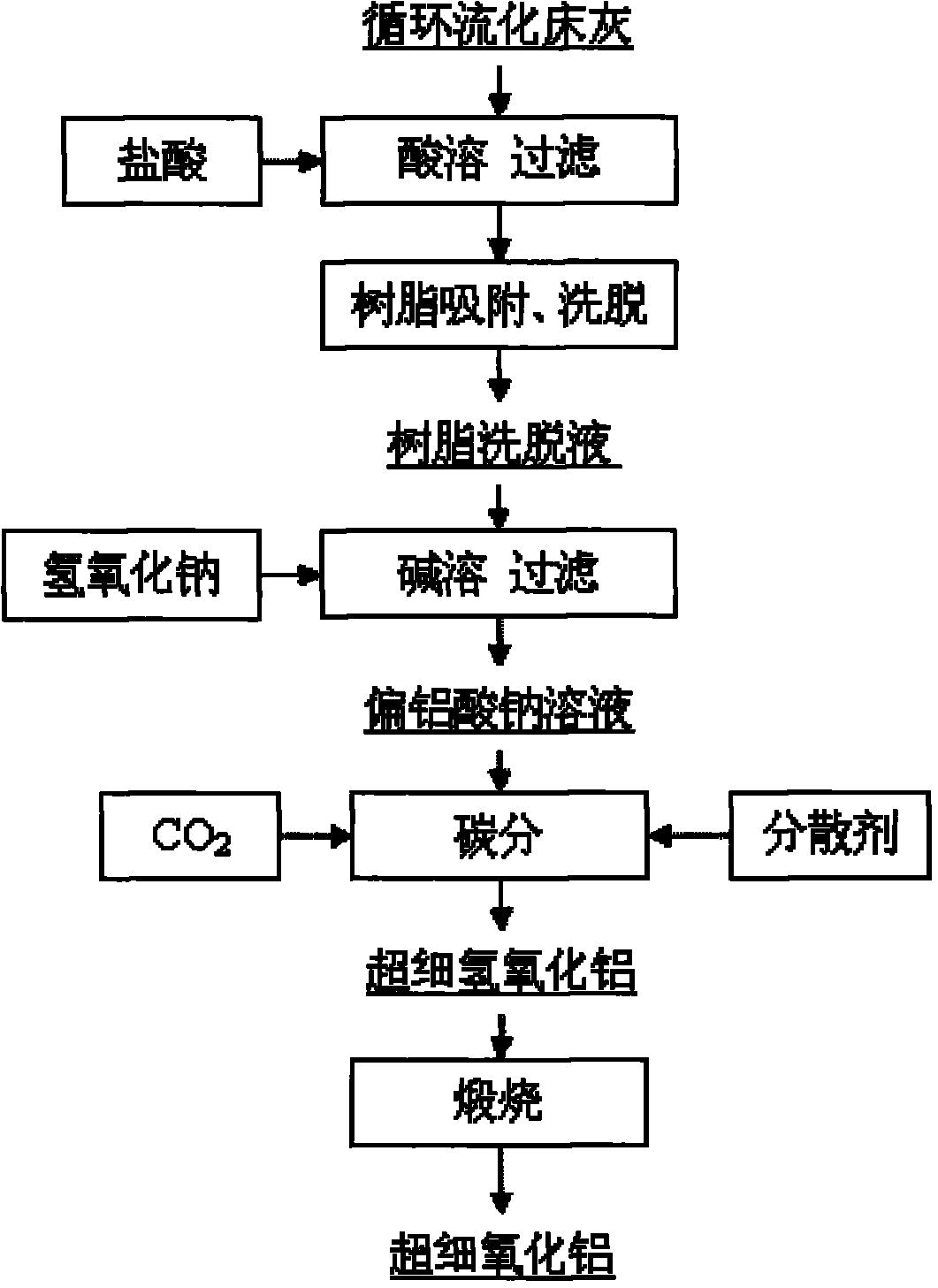

The invention discloses a method for producing superfine aluminium hydroxide and aluminium oxide by taking flyash of a recirculating fluidized bed as a raw material. The method comprises the following steps of: a) grinding the flyash, performing wet magnetic separation and deironization, and reacting with hydrochloric acid to obtain hydrochloric acid extract; b) introducing the hydrochloric acid extract into a macroporous cationic resin column for adsorption, after adsorptive saturation of the resin, eluting by using an eluant to obtain eluent containing aluminium chloride and iron chloride; c) removing iron from the eluent by using alkaline solution to obtain solution of sodium metaaluminate; d) adding a dispersing agent into the solution of sodium metaaluminate, and mixing uniformly to obtain dispersion; and e) performing carbon decomposition on the dispersion to obtain the superfine aluminium hydroxide. The superfine aluminium hydroxide is calcined at different temperatures to form gamma-aluminium oxide and alpha-aluminium oxide respectively. Compared with other methods, the method has the advantages of wide sources of raw materials, simple production process and high purity of the products.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Manganese steel strip having an increased phosphorous content and process for producing the same

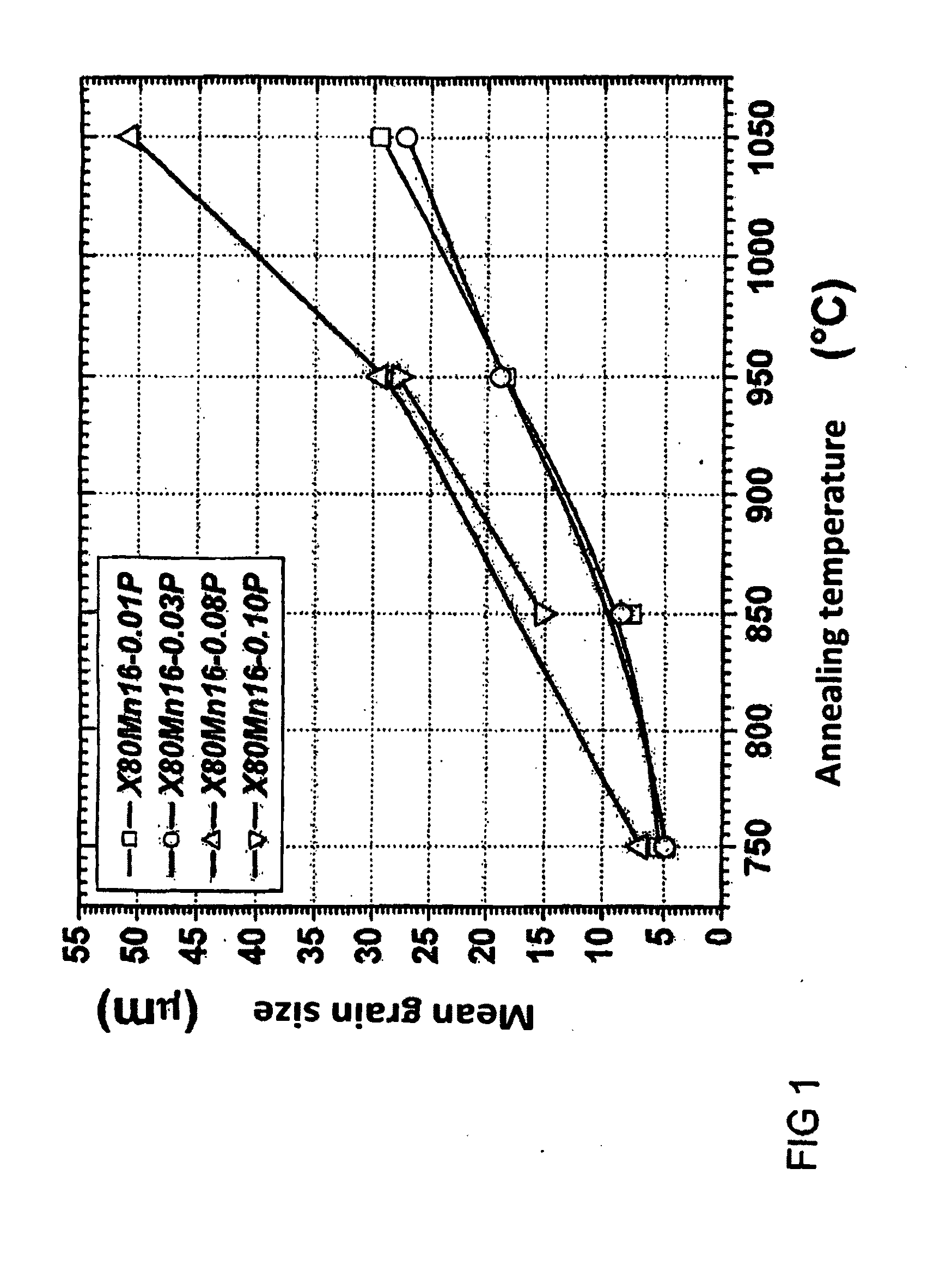

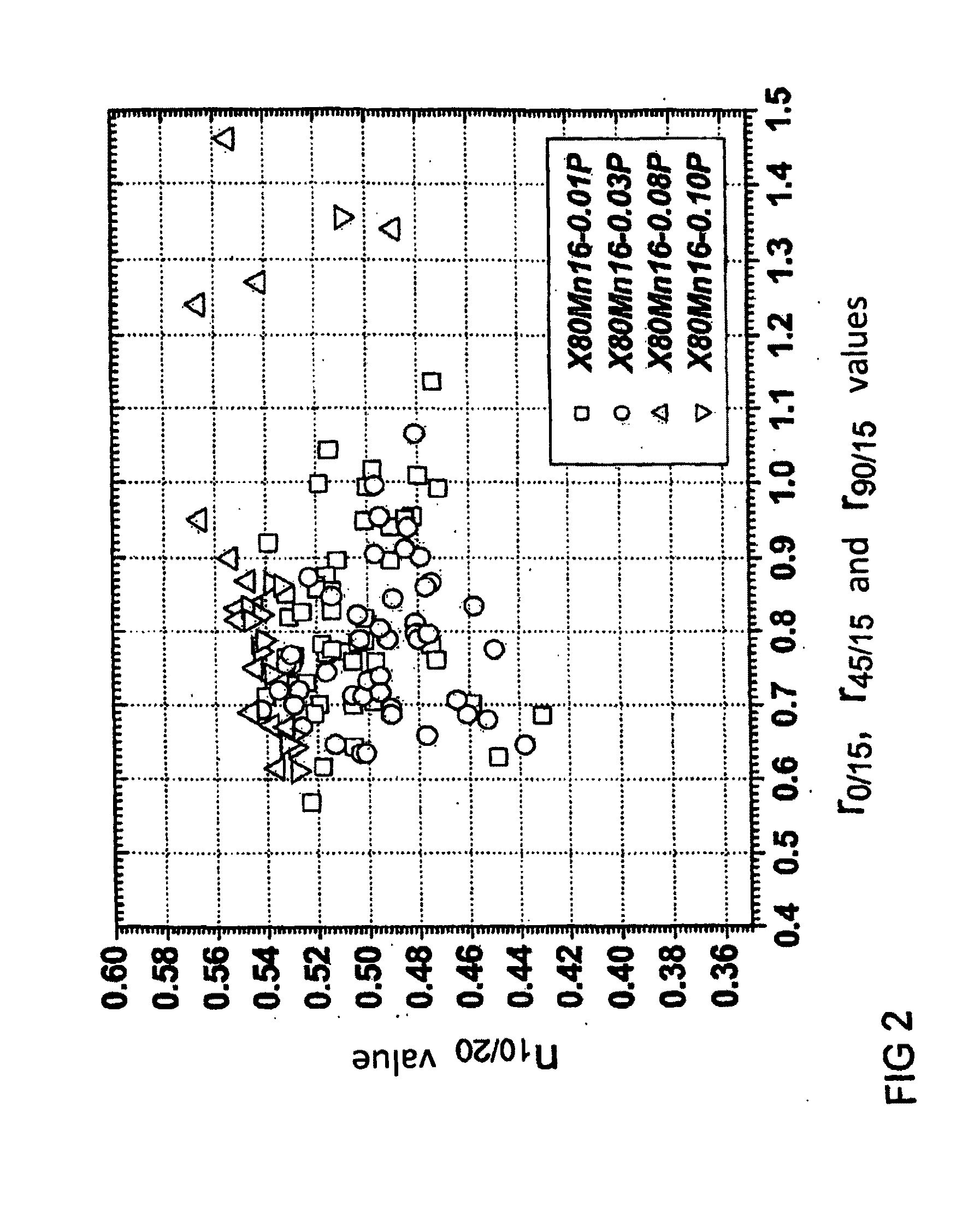

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

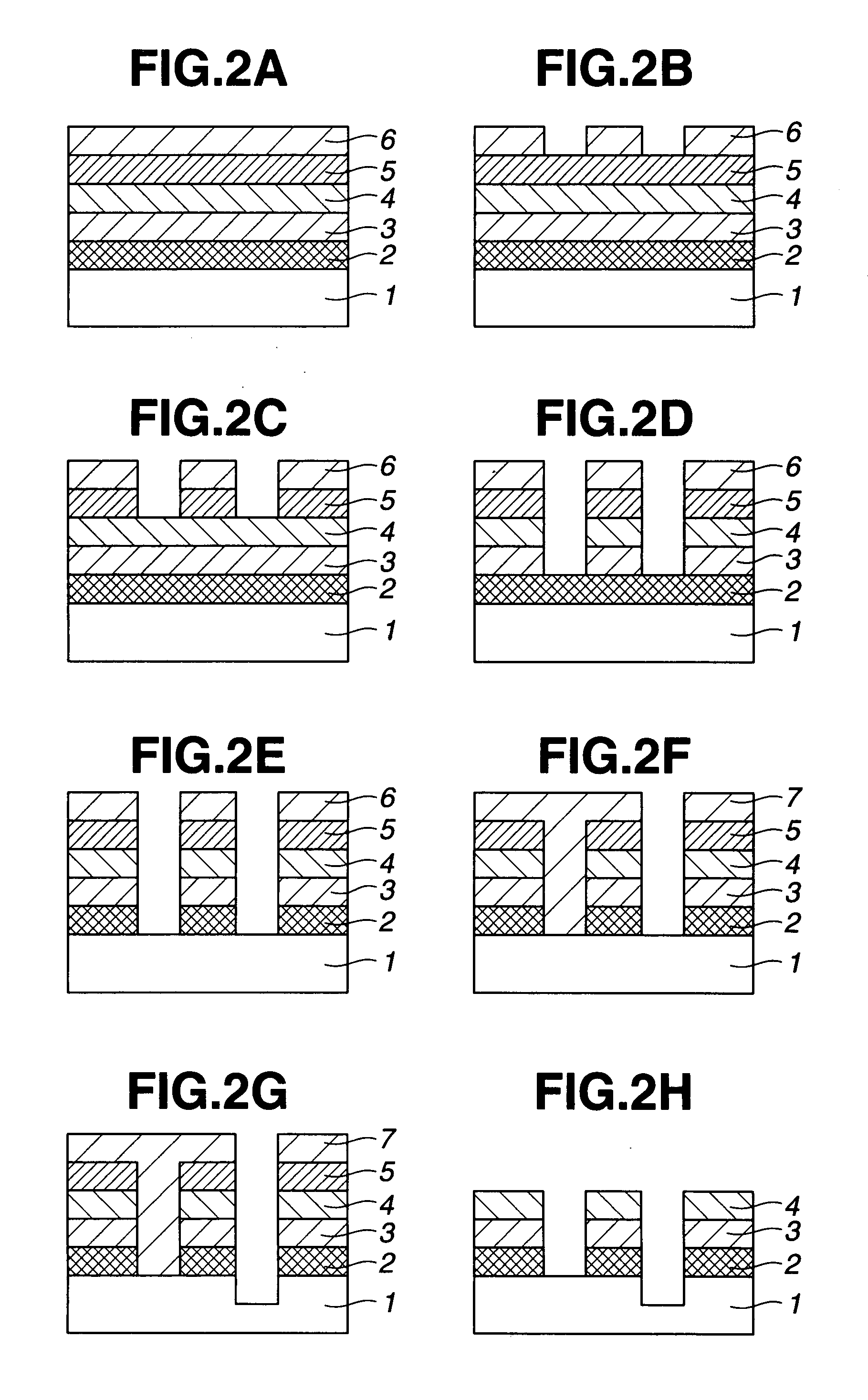

Photomask blank

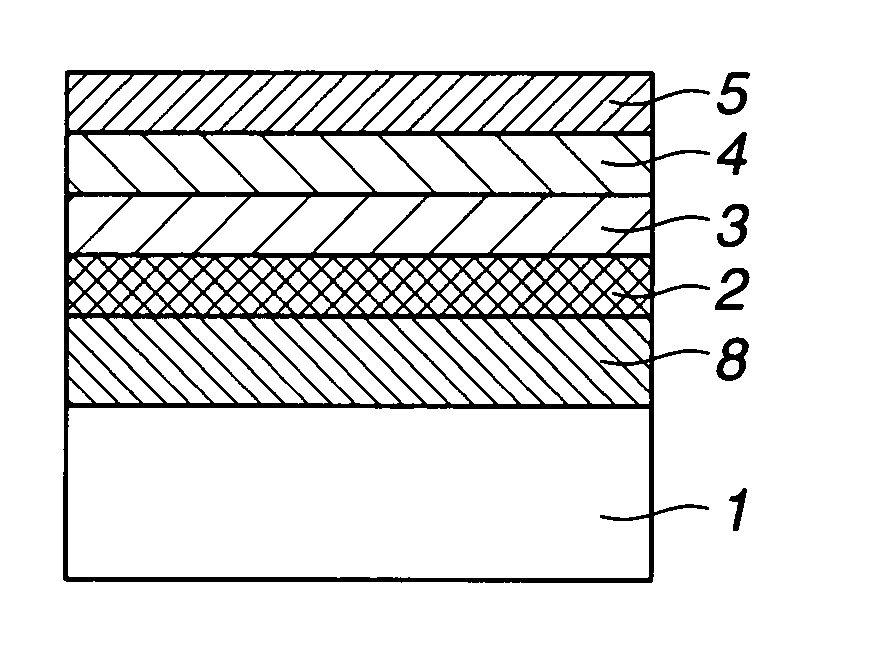

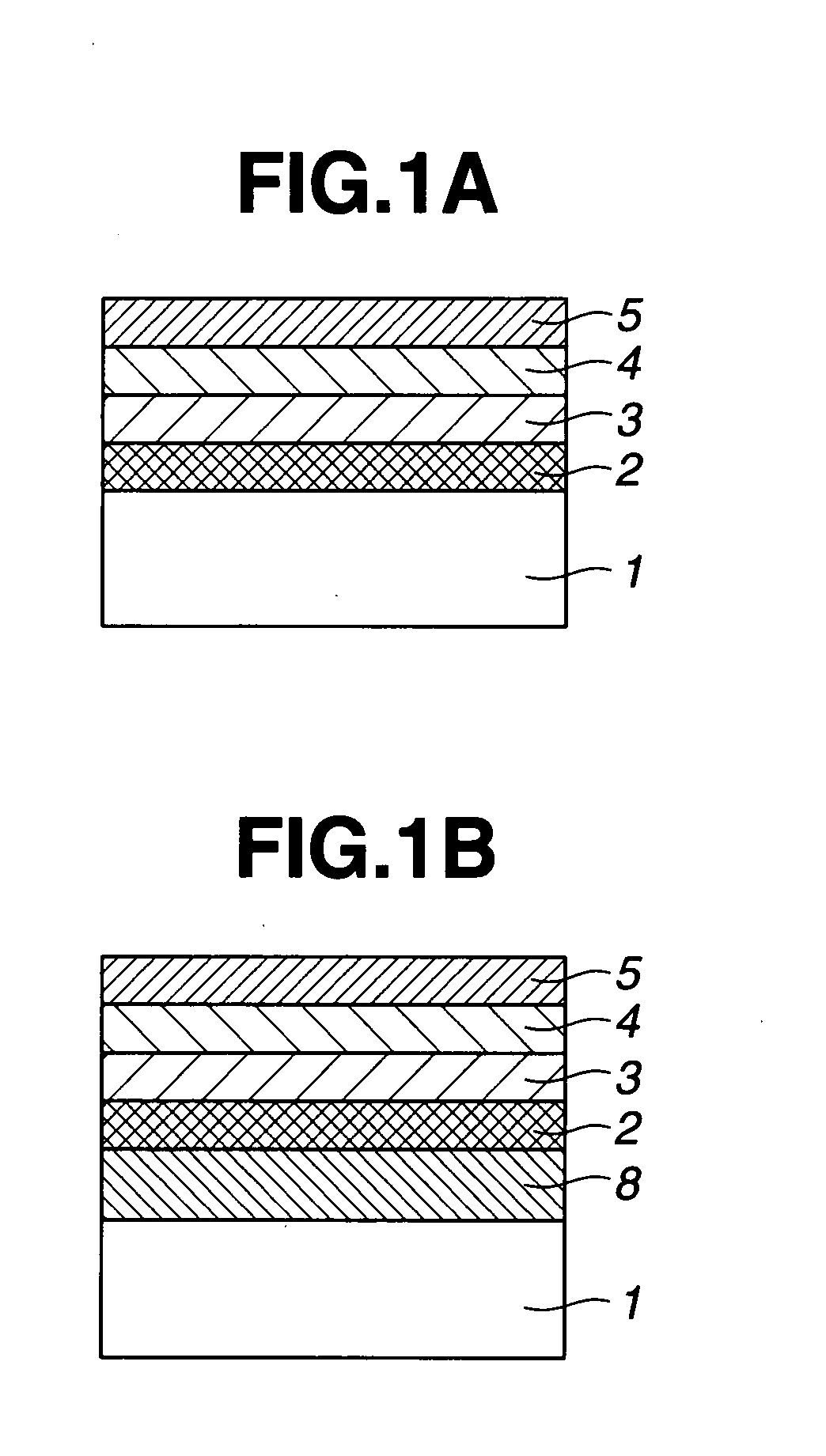

ActiveUS20070248897A1Improve conductivityEnsure stabilityVacuum evaporation coatingSputtering coatingNitrogenOxygen

A photomask blank has a light-shielding film composed of a single layer of a material containing a transition metal, silicon and nitrogen or a plurality of layers that include at least one layer made of a material containing a transition metal, silicon and nitrogen, and has one or more chrome-based material film. The high transition metal content ensures electrical conductivity, preventing charge-up in the photomask production process, and also provides sufficient chemical stability to cleaning in photomask production. The light-shielding film has a good resistance to dry etching of the chrome-based material film in the presence of chlorine and oxygen, thus ensuring a high processing accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

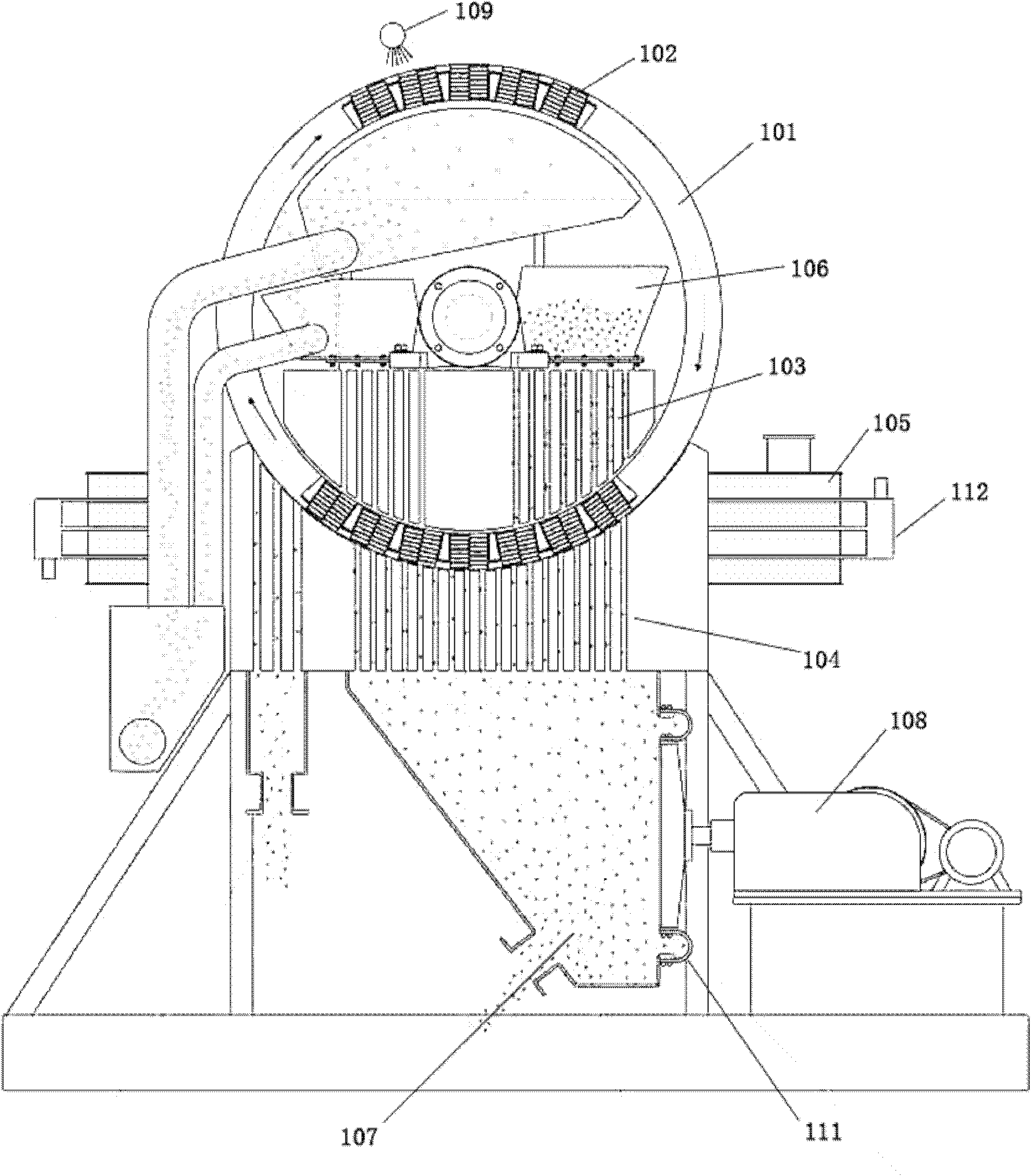

Method for preparing super-fine aluminum hydroxide and alumina from fly ash

ActiveCN102153117AHigh purityEliminate high temperature calcination activation stepsProductsReagentsAluminium chlorideAluminate

The invention discloses a method for preparing super-fine aluminum hydroxide and super-fine alumina by using fly ash of a circulating fluidized bed as a raw material. The method comprises the following steps of: 1, after grinding the fly ash, carrying out wet magnetic separation on the ground fly ash to remove iron and then performing a reaction of the obtained product and hydrochloric acid to obtain immersion liquid of hydrochloric acid; 2, adsorbing the immersion liquid of hydrochloric acid by filling a macroreticular cation resin column and after a resin is adsorbed and saturated, the resin is eluted by eluent to obtain the eluent containing aluminium chloride and ferric chloride; 3, carrying out alkali dissolution iron removal on the eluent to obtain sodium meta-aluminate solution; 4, adding a dispersant into the sodium meta-aluminate solution and uniformly mixing the mixture to obtain dispersion liquid; and 5, carrying out carbon dioxide decomposition on the dispersion liquid to obtain the super-fine aluminum hydroxide. Gamma-alumina and alpha-alumina can be respectively obtained by calcining the super-fine aluminum hydroxide at different temperatures. Compared with other methods, the method has the advantages of wide raw material sources, simple production process and high product purity.

Owner:CHINA SHENHUA ENERGY CO LTD

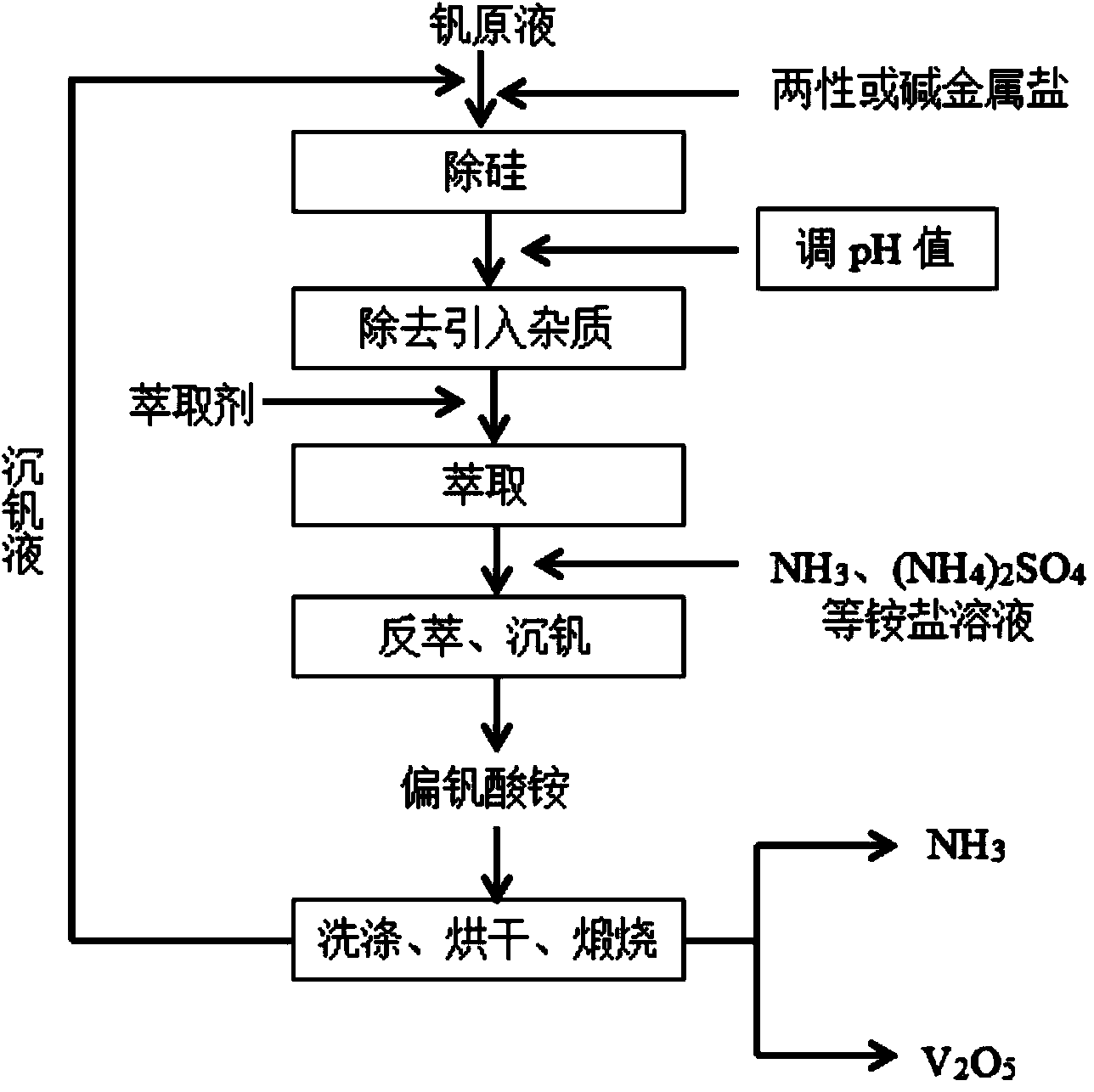

Method for preparing low-silicon vanadium pentoxide from solution containing vanadium, chromium and silicon

ActiveCN103937998AImprove removal efficiencyReduce silicon contentVanadium oxidesProcess efficiency improvementBrickPhase ratio

The invention discloses a method for preparing high-purity low-silicon vanadium pentoxide (V2O5) from a mixed solution containing vanadium, chromium and silicon. The method mainly comprises the following steps: firstly removing the silicon from the solution containing the vanadium, the chromium and the silicon by utilizing amphoteric metal salt and / or alkali metal salt, then also removing other introduced impurities by regulating the pH value of the solution and performing solid and liquid separation; afterwards, selectively extracting most of the vanadium into an organic phase according to a certain phase ratio by use of a primary amine extraction system, then also reversely extracting the vanadium in the organic phase rich in the vanadium by use of an alkaline solution containing ammonium salt, precipitating ammonium metavanadate, filtering or centrifuging the reversely-extracted water phase to obtain a high-purity ammonium metavanadate solid, washing, drying and calcining under a certain temperature to obtain a brick-red substance V2O5, wherein the purity of the V2O5 is above 99.9%, the content of silicon is smaller than 0.007% and no interlayer is formed during the extraction-reverse extraction process. The method disclosed by the invention is used for preparing the high-purity low-silicon V2O5 through processes of intensified silicon removal, extraction, reverse extraction and vanadium precipitation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

Iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings

ActiveCN102909124AAchieve recyclingAchieve quality improvement and silicon reductionSolid separationMechanical material recoveryIron increasedRisk stroke

The invention discloses an iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings, comprising the following steps of: strong magnetic roughing: putting mixed-type lean iron ore tailings through a strong magnetic separator with the magnetic field intensity of [U1] Oersteds to obtain roughed concentrate and roughed tailings; strong magnetic cleaning: selecting the roughed concentrate in the strong magnetic separator with the magnetic field intensity of 10000-20000 Oersteds to obtain magnetic concentrate and magnetic tailings; centrifugal selecting: putting the magnetic concentrate in a centrifugal concentrating machine with the rotating speed of 150-250r / min to obtain centrifugal concentrate and centrifugal tailings; and table selecting: selecting the centrifugal tailings through a table with the stroke of 8-10mm and the frequency of stroke of 250-300 times / min to obtain table concentrate and table tailings. According to the iron-increasing and silicon-reducing reselection technique, a great quantity of tailings is dropped through rough and concentrate double magnetic selection; the magnetic concentrate is selected by using the centrifugal machine so that irons are increased and silicon is reduced; and then the centrifugal tailings are selected by using the table so that the productivity is increased. The iron-increasing and silicon-reducing reselection technique has the effects of realizing iron increment and silicon reduction of the mixed-type lean iron ore tailings, incrasing the productivity of the iron ore to a great extent at the same time and providing an effective approach to iron increment and silicon reduction of the reselected concentrate for the mixed-type lean iron ore tailings.

Owner:YUXI DAHONGSHAN MINING

Method for processing motorcycle hub

The invention provides a processing method for a motorcycle hub. When the hub is processed by the method of the invention, the processing cost is low and the performance is stable. The processing method is characterized in that the processing method comprises the steps as follows: aluminium solution melting, casting blank, riser cutting, bottom pore drilling, air nozzle drilling, grinding, T6 heat disposal, shot blasting, single-board computer, cleaning, coating, numerical control processing, finished product detecting, cleaning, packaging, and warehousing. The processing method is characterized in that the contents of all components in the aluminium solution are 6.5 to7.5 percent of Si, less than 0.25 percent of Fe, less than 0.25 percent of Mg, and 0.2 percent of Zn, 92.5 percent of Al; the melting temperature of the aluminium solution is ranging from 705 DEG C to 735 DEG C; and the casting blank is cast by gravity.

Owner:WUXI WANXUAN METAL PROD

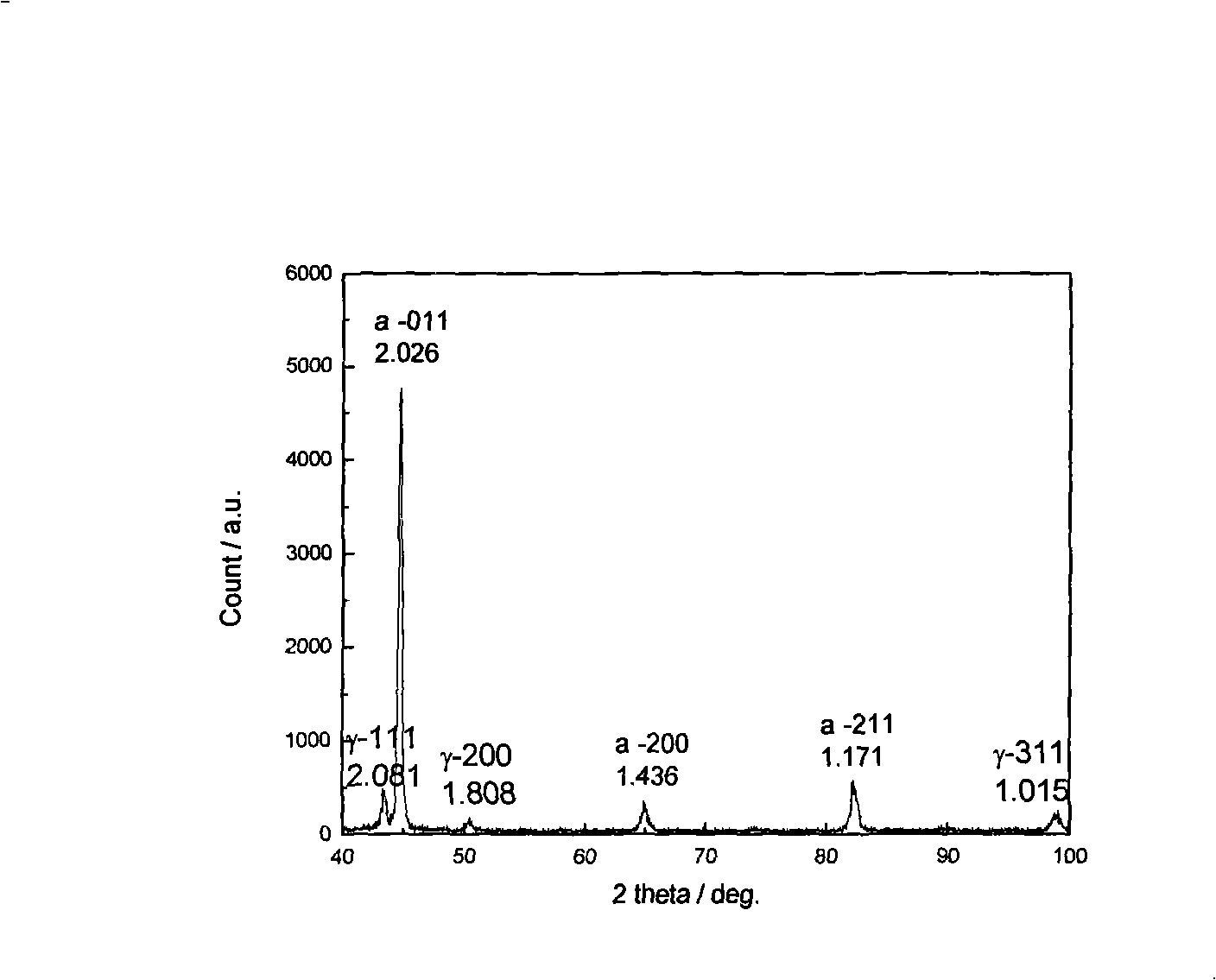

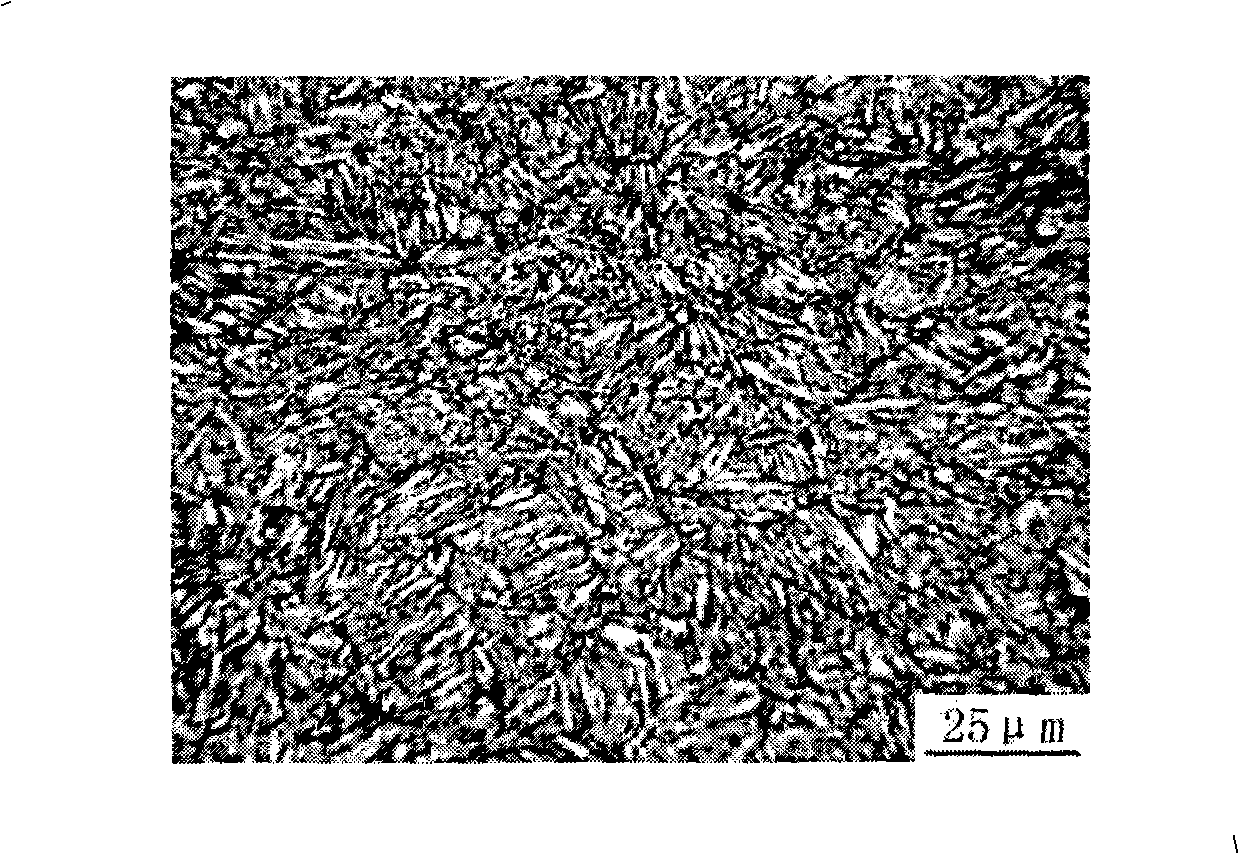

Carbides-free bainite wear resistant steel plate and production process thereof

ActiveCN101338399AImprove hardenabilityHigh strengthTemperature control deviceProduction lineWear resistant

The invention relates to a steel and a production technique thereof, in particular to a non-carbide bainite wear-resistant steel plate and a production technique thereof; the component weight percentages are: 0.15 to 0.25 percent of C, 1.50 to 2.00 percent of Mn, 0 to 0.015 percent of P, 0 to 0.006 percent of S, 1.30 to 2.00 percent of Si, 0.20 to 0.60 percent of Al, 0.60 to 1.00 percent of Cr, 0.25 to 0.50 percent of Mo, 0.010 to 0.035 percent of Nb and the rest is Fe. The production technique is carried out according to the following working procedures: (1) feeding a continuous casting plate to a heating furnace for heating; (2) feeding the continuous casting plate after being heated into a hot rolling production line to carry out the rolling of controlled rolling and controlled cooling; (3) carrying out middle-low temperature drawing temper on a rolling steel plate after the rolling is finished. The non-carbide bainite wear-resistant steel plate can be produced by the working procedures without carrying out online or offline hardening and tempering thermal processing which not only can simplify the working procedures of production, but also can improve the performance and the quality of a product as well as obtain the bainite wear-resistant steel with high intensity and high toughness.

Owner:NANJING IRON & STEEL CO LTD

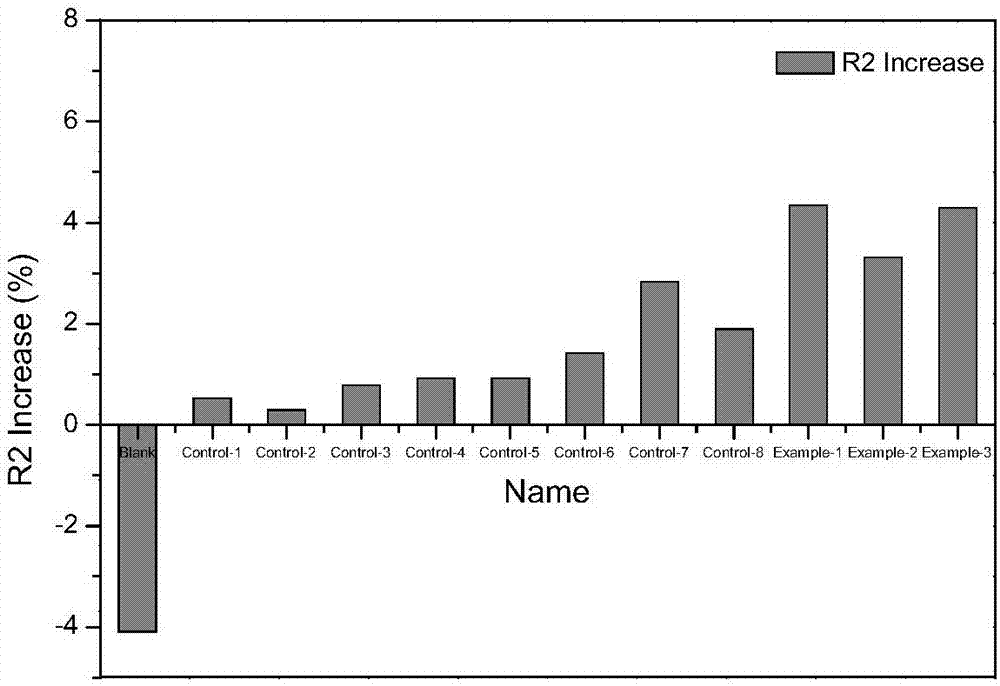

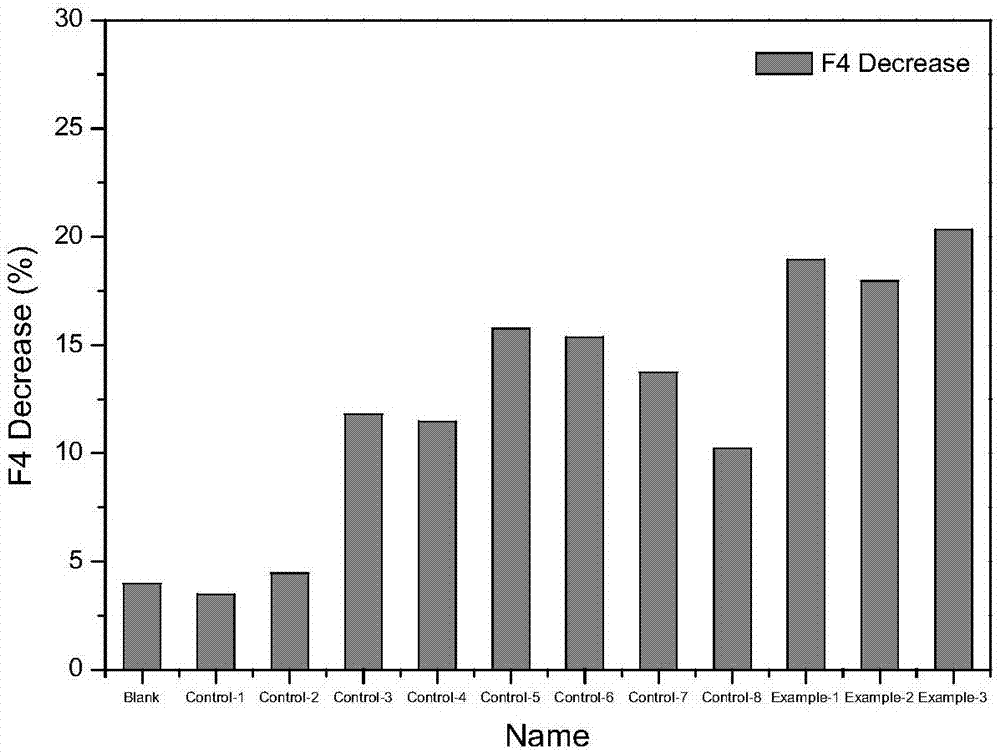

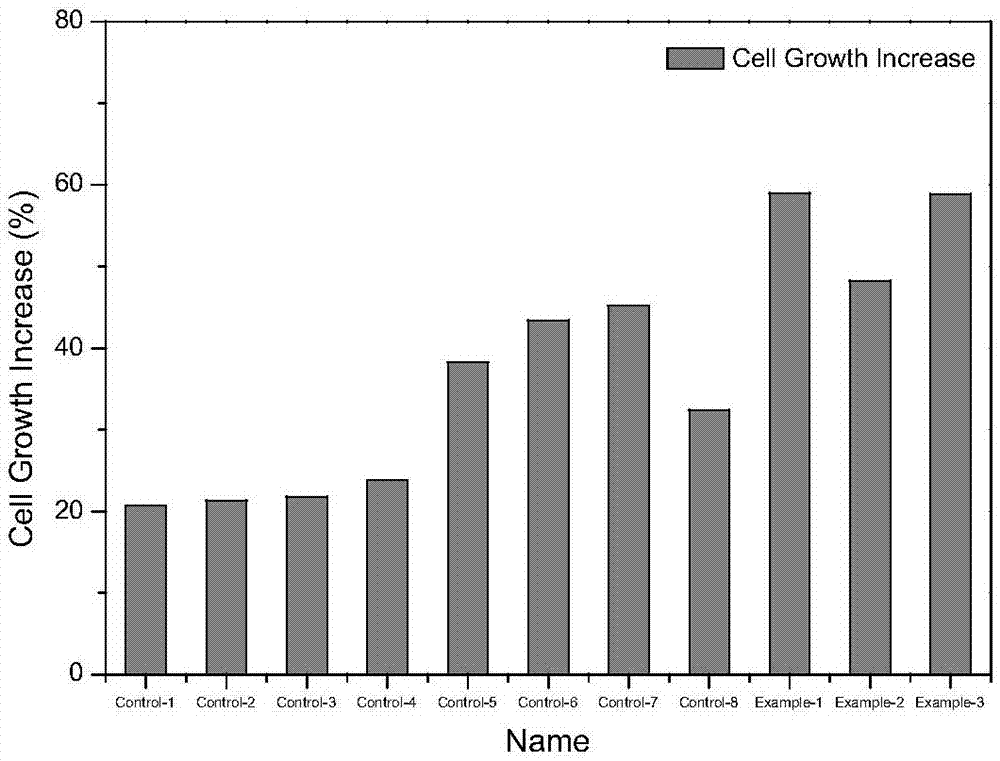

Skin tightening composition and application thereof

ActiveCN107875067AStrengthens Antioxidant Defense SystemImprove firmnessCosmetic preparationsToilet preparationsAdditive ingredientSilanol

The invention relates to a skin tightening composition and application thereof. The skin tightening composition is prepared from the following ingredients: skin restoration compositions, low-molecular-weight hyaluronic acid silanol, skin tightening compositions, carnosine, anti-wrinkle peptide composition, conopeptide, anti-wrinkle compositions and plant extract compositions. The skin tightening composition has the advantages that the obvious advantages are realized in the aspects of timely improving the skin compactness and resisting fatigue; after the skin tightening composition sample is smeared for 30min, the skin elasticity can be improved by 3.3 to 4.34 percent; the skin fatigue resistant degree is reduced by 17.95 percent to 20.33 percent.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

Cold extruding die steel and heat treatment technique thereof

InactiveCN1824818AReduce silicon contentReduce manufacturing costHeat treatment process controlQuenching agentsManganeseMaterials science

This invention relates to a new style alloy tool steel, especially relates to a new style cold extrusion die steal and its heat treatment technique. The weight percentage of the elements is that carbon 0.75-10.5%, chrome 7.3-8.5%, molybdenum 1.2-2.0%, vanadium 0.3-0.9%, nickel 0.3-0.9%, tungsten 1.2-2.0%, silicon 0.1-1.0%, manganese 0.1-0.4%, sulfur not more than 0.015%, phosphor not more than 0.02%, the rest is iron. Compared to home made die steel, the carbon and silicon content is reduced, and the molybdenum content is also reduced, the toughness and wear resistance of the alloy steel in this invention is increased, and the hardenability and synthetic mechanicalness is greatly improved, especially the low temperature impact toughness is great high. It can make fine die, and its using life is long, and the cost is reduced. This product in this invention is the most ideal material used for more than 300 tons cold extrusion die, and it can be widely used as cold extrusion die for stainless steel furnace butt and automobile door. This invention also provides the heat treating technique of the die steel.

Owner:周向儒

Technological method for reducing block masses containing carbon, iron, zinc, etc. into molten iron, zinc, etc. in blast furnace molten iron trough

ActiveCN105296694AReduce consumption costIncrease productionBlast furnace detailsSteelmakingSocial benefits

Te invention discloses a production technological method for reducing oxide block masses (pellets) containing carbon, iron and / or zinc, etc. into molten iron and / or zinc, etc. in a blast furnace molten iron trough (containing a swing flow spout in front of a furnace) and belongs to the field of steel metallurgy. The production technological method is characterized in that the oxide block masses containing the carbon, iron and / or zinc, etc. are added into the blast furnace molten iron trough before blast-furnace tapping and / or during tapping, so that the iron and / or zinc, etc. in the block masses are obtained in a reduction mode through the carbon. The production technological method has the advantages that one kind or several kinds of industrial powder material of cheap blast furnace gas dust (or gas mud), gravitational dust collection dust, sintering machine dust collection dust, converter dust collection dust (or mud), steelmaking steel slag powder, oxidized iron scales, reduced iron powder, etc. and reductants of carbon-containing coal powder, coke powder, etc. are mixed and made into the block masses, the block masses are added into the blast furnace molten iron trough, and the zinc is recovered through increased iron and / or dezincification; the industrial powder material difficult to treat is treated well, so that good economic and social benefits are achieved. Meanwhile, the effect of molten iron desilicication is further achieved.

Owner:廖辉明

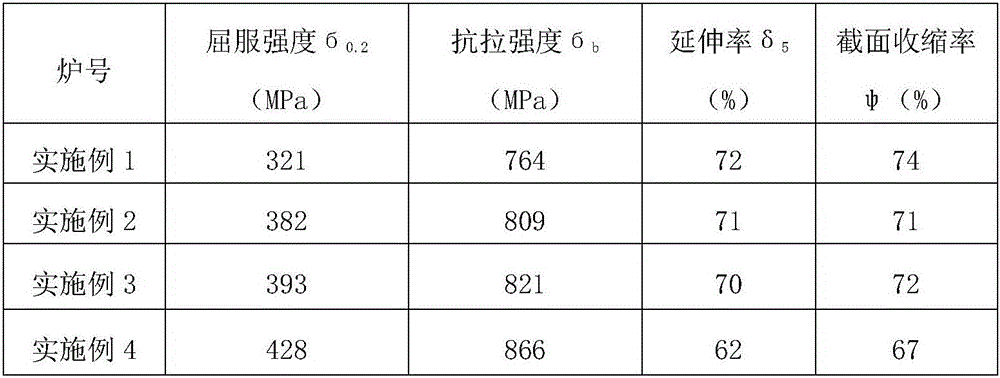

Ultralow-temperature welded alloy steel and production method thereof

Owner:JIANGSU TIANYE ALLOY MATERIAL

Method for preparing low-grade non-oriented electrical steel processed by rare earth

The invention relates to a method for preparing low-grade non-oriented electrical steel processed by rare earth and belongs to the field of electrical sheet. The low-grade non-oriented electrical steel with excellent magnetic properties is finally obtained by using short-process continuously cast blooms as raw materials through the steps of hot rolling, cold rolling and annealing. The design requirement of 0.001 to 0.005 percent of C, 0.5 to 1.0 percent of Si, 0.25 to 0.50 percent of Mn, less than or equal to 0.080 percent of P, less than or equal to 0.005 percent of S, 0.25 to 0.50 percent of Al, 0.0014 to 0.020 percent of RE (Ce) and the balances of iron and unavoidable impurities on ingredients of the hot rolling raw materials is met. The product has the final magnetic properties that when the thickness of a steel plate is 5mm, P15 / 50 is in the range of 3.45 to 5.02W / Kg and B5000 is in the range of 1.67 to 1.75T. The low-grade non-oriented electrical steel processed by the rare earth has the advantages that compared with the prior art, the low-grade non-oriented electrical steel has low silicon content and low O content and N content and excellent magnetic properties; and the production cost is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

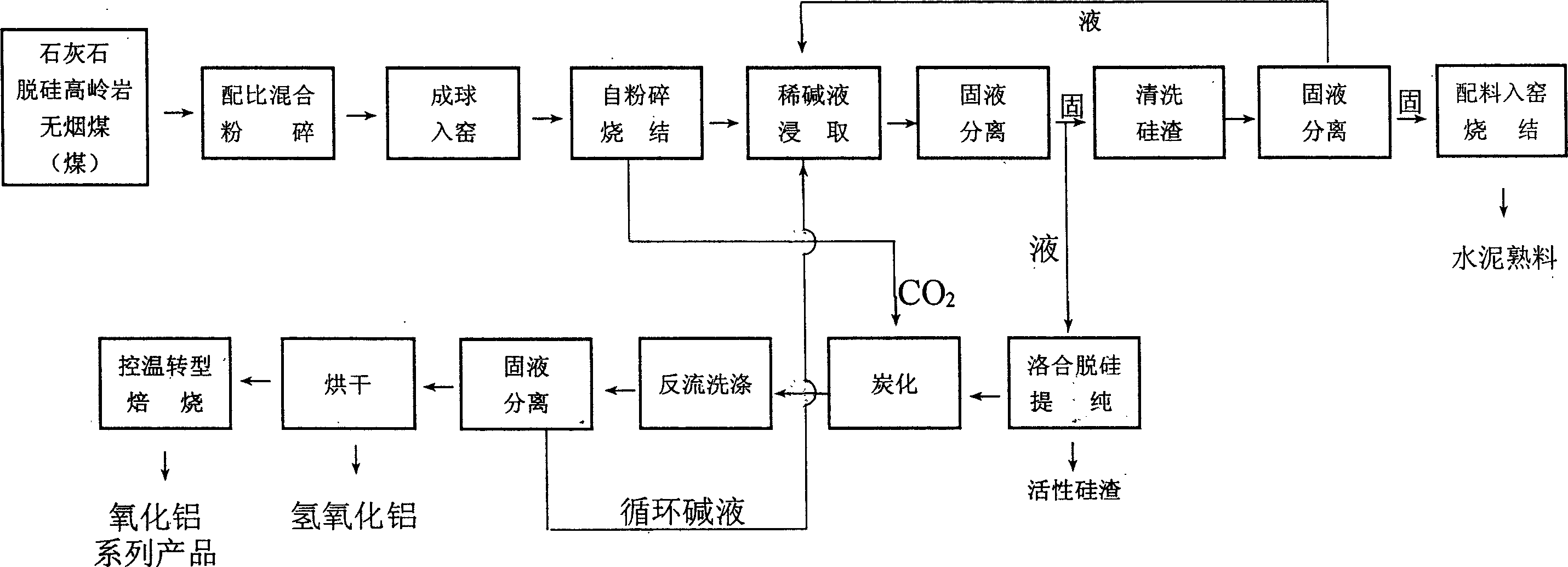

Technology for producing aluminium oxide

InactiveCN1623901AAddress resource shortagesHigh purityAluminium oxide/hydroxide preparationKaoliniteAluminium hydroxide

A process for preparing aluminium oxide features that the kaolinite and powdered coal ash are predesiliconized to make the Al-Si ratio is greater than 4, the self-breaking sinter method is used, the diluted solution of sodium carbonate is used for extracting, and the complex reaction is used for purifying. The pure CO2 gas generated by sintering and NaAl2O3 solution take part in carbonizing reaction to generate aluminium hydroxide. Changing the crystalline structure of aluminium hydroxide can obtain aluminium oxide.

Owner:郭长征 +1

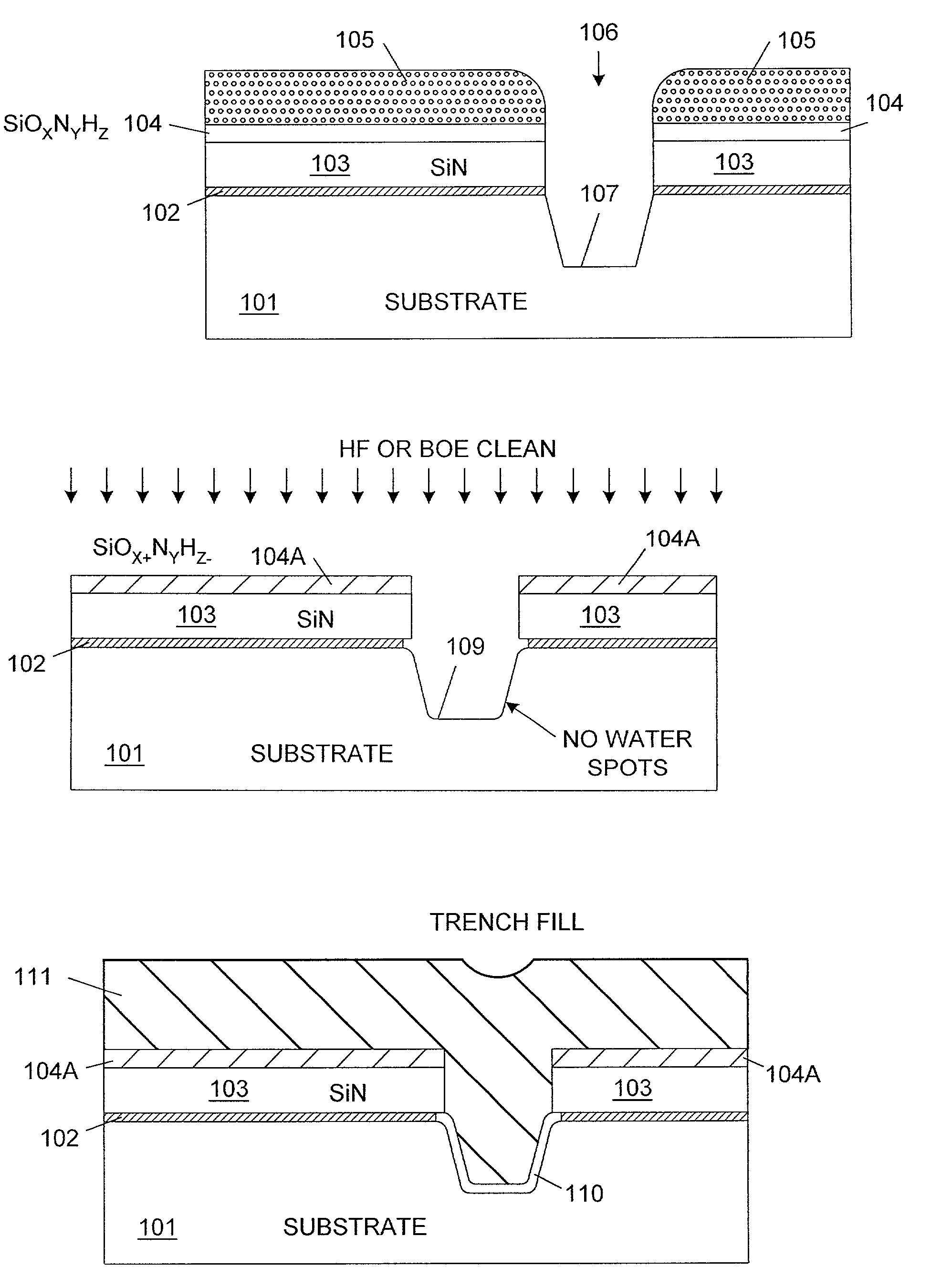

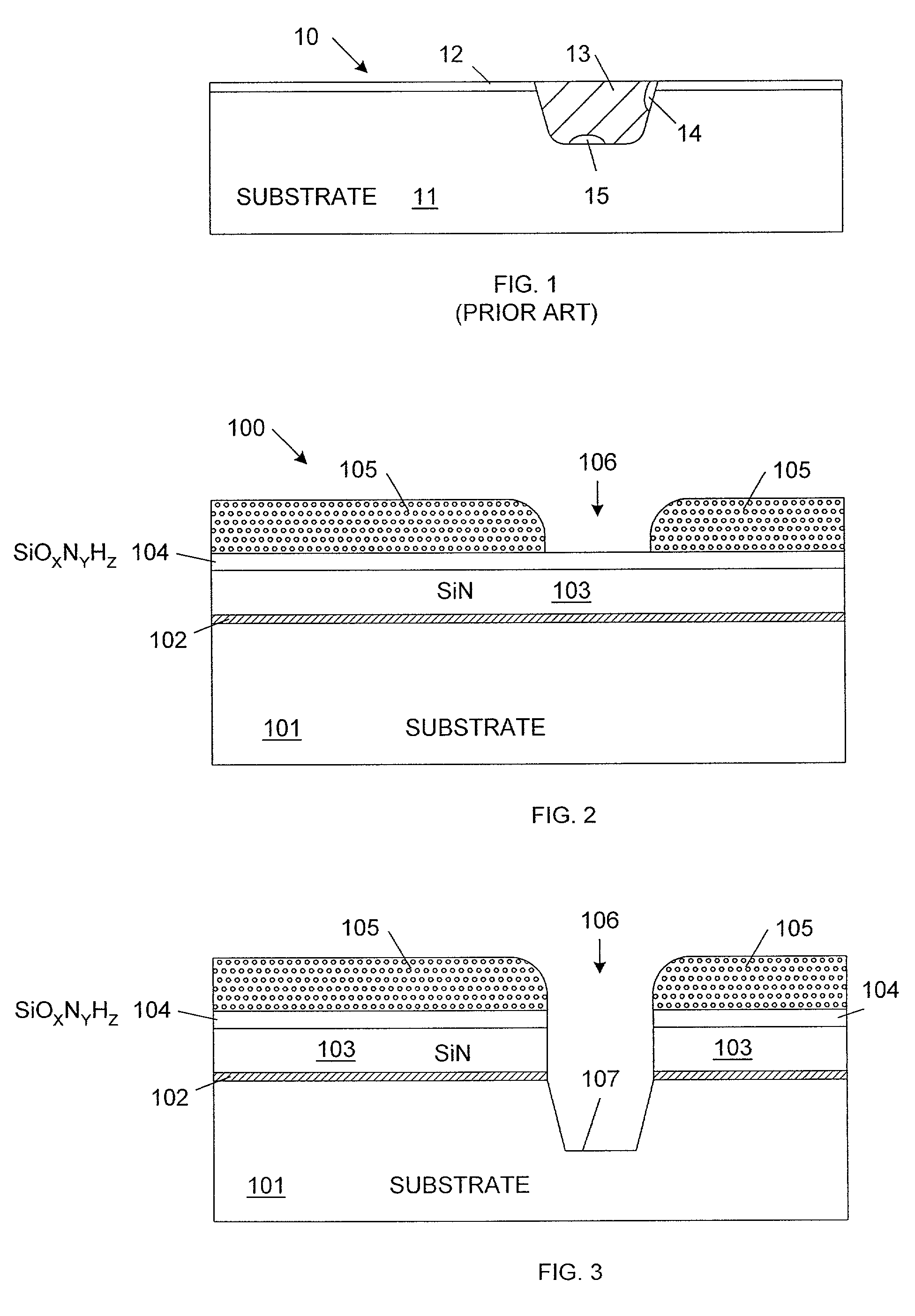

Dielectric anti-reflective coating surface treatment to prevent defect generation in associated wet clean

InactiveUS7125783B2Prevents formationReduce silicon contentSemiconductor/solid-state device manufacturingSemiconductor devicesResistNitrogen gas

A method for preventing the formation of watermark defects includes the steps of forming a pad oxide, a silicon nitride layer and a silicon oxynitride layer over a semiconductor substrate. A photoresist mask is formed over the resulting structure, with the silicon oxynitride layer being used as an anti-reflective coating during exposure of the photoresist material. An etch is performed through the photoresist mask, thereby forming a trench in the substrate. The photoresist mask is stripped, and the silicon oxynitride layer is conditioned. For example, the silicon oxynitride layer may be conditioned by a rapid thermal anneal in the presence of oxygen or nitrogen. A wet clean step is subsequently performed to remove a native oxide layer in the trench. The conditioned silicon oxynitride layer prevents the formation of watermarks during the wet clean process.

Owner:INTEGRATED DEVICE TECH INC

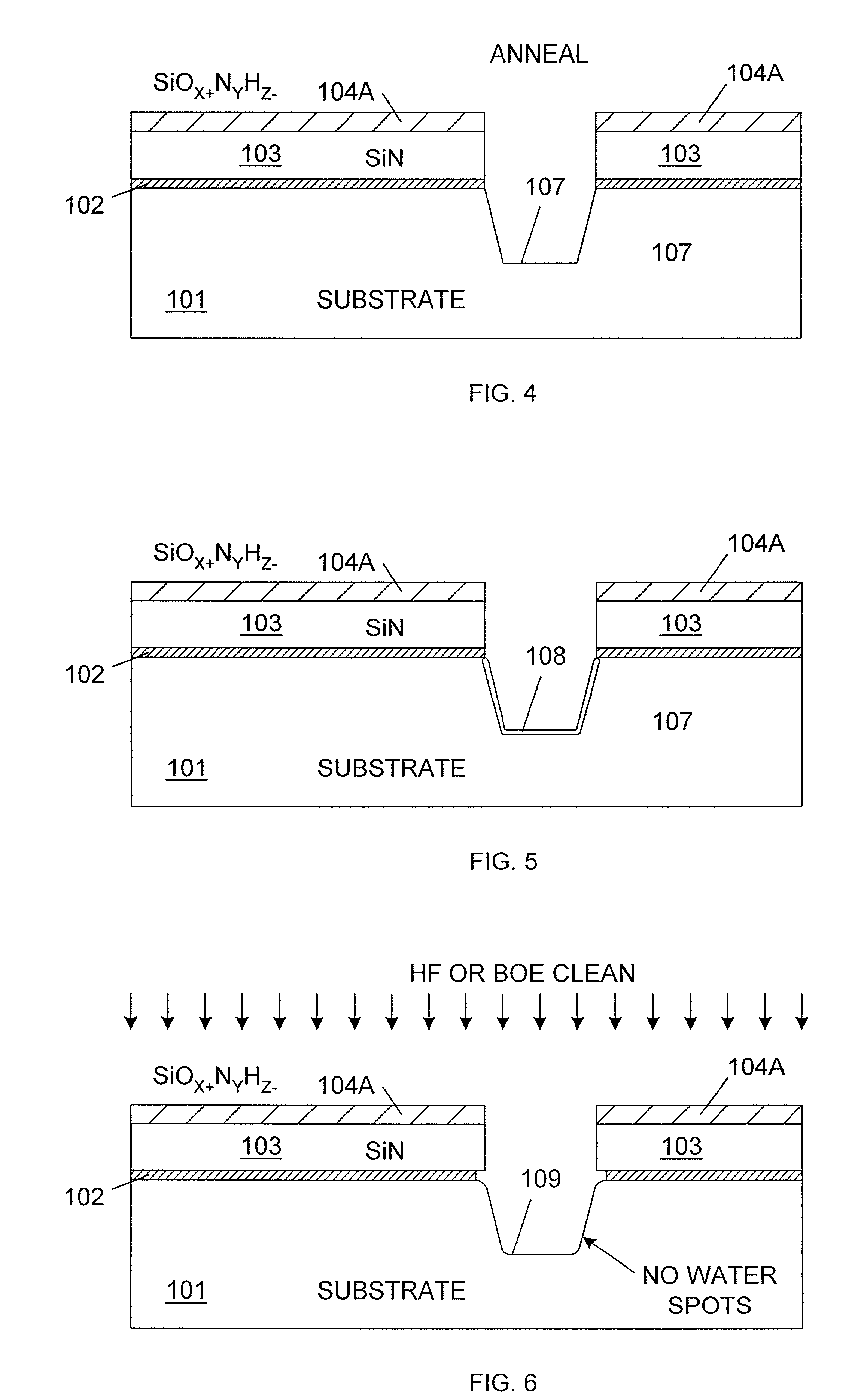

Separation process of ferrous high silicate type iron ore

ActiveCN103894283AOvercome the disadvantages of independent processingReduce secondary selectionWet separationResource utilizationFinings

The invention discloses a separation process of ferrous high silicate type iron ore. The process includes classifying, degrading tailings and upgrading. Tailing degrading includes S1 tailing degrading and S2 tailing degrading. The separation process has the advantages that the process is free of calcination and reverse floatation, short is process flow, low in process management requirement, low in operation cost, low in environmental pollution and suitable for industrial production; the iron grade of fine ferrous silicate type iron concentrate is increased, silicon content is lowered, the grade of fine high silicate type iron tailings is lowered, the grade of the iron concentrate is increased by about 10%, and the silicon content is lowered by about 10%; the iron ore in the tailings can be recycled effectively, the comprehensive grade of total tailings is lowered from 16.2% to about 10.53%; the separation process is environmental friendly, low in energy consumption, low in cost, high in fining and concentration degree, and capable of effectively increasing comprehensive resource utilization rate, increasing benefits, saving energy and reducing emission.

Owner:KUNMING UNIV OF SCI & TECH +1

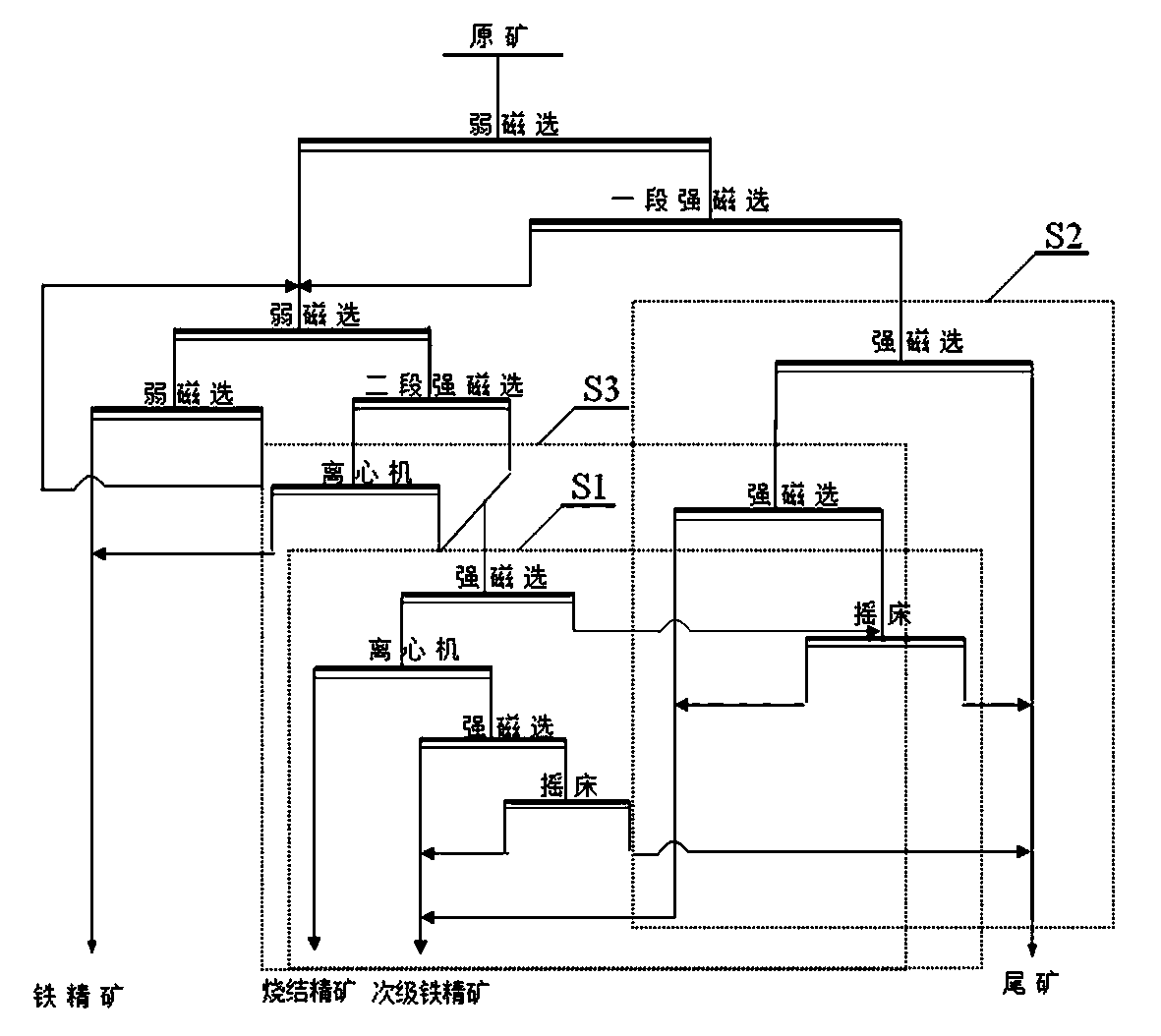

Clean process method for efficiently extracting chromium in extracted vanadium tailings

ActiveCN104195346AFor subsequent useImprove resource utilizationProcess efficiency improvementSiliconMaterials science

The invention discloses a clean process method for efficiently extracting chromium in extracted vanadium tailings. For the extracted vanadium tailings, a silicon fixing agent is added while silicon is leached with low-concentration sodium hydroxide; the silicon is converted into an inert compound in the alkaline leaching and chromium extracting process; the inert compound is subjected to alkaline leaching and chromium extracting to obtain sodium chromate alkali solution with lower silicon content and iron-enriched tailings, so that high-efficiency extraction of the chromium in the extracted vanadium tailings and comprehensive utilization of valuable components are realized. According to the clean process method disclosed by the invention, the high-efficiency extraction of the chromium in the extracted vanadium tailings can be realized, the extraction rate of the chromium is larger than 85 percent, and the content of the silicon in the obtained sodium chromate alkali solution is lower.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-silicon nitrogen-contained austenitic stainless steel and preparing method thereof

InactiveCN106756628AExcellent resistance to high temperature concentrated sulfuric acid corrosionImprove corrosion resistanceRare-earth elementChemical composition

The invention provides high-silicon nitrogen-contained austenitic stainless steel. The high-silicon nitrogen-contained austenitic stainless steel is characterized by comprising chemical compositions including, by mass percent, 15%-20% of Cr, 15%-20% of Ni, 2%-5% of Mn, 4.5%-6.0% of Si, 1%-3% of Mo, 0.5%-1.5% of Cu, 0.1%-0.3% of N, not larger than 1.0% of Al, 0.05%-0.5% of RE, not larger than 0.03% of C, not larger than 0.010% of S, not larger than 0.02% of P and the balance Fe. The invention further provides a preparing method of the above high-silicon nitrogen-contained austenitic stainless steel. The high-silicon nitrogen-contained austenitic stainless steel is mainly used for in the field of chemical engineering, in particular to the sulfuric acid industry; the high-silicon nitrogen-contained austenitic stainless steel can be further used in the fields of food catering instruments, ornaments, environmental protection and the like; and according to the high-silicon nitrogen-contained austenitic stainless steel, by optimizing the silicon content and adding the nitrogen, the copper, the aluminum and the rare earth elements, the corrosion resistance of the stainless steel is improved, and the stainless steel has the excellent cold and heat machining performance and corrosion resistance.

Owner:JIANGSU XIHU SPECIAL STEEL

Ddelay coking defoaming agent composition and preparation method thereof

ActiveCN103768832AImprove defoaming abilityReduce the amount addedThermal non-catalytic crackingFoam dispersion/preventionAlcoholSolvent

The invention relates to a delay coking defoaming agent composition and a preparation method thereof, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, glycerin type dendritic polyether, high carbon alcohol and a solvent. The preparation method of the defoaming agent is as follows: dispersing the fluorine-containing polysiloxane in the high carbon alcohol, stirring for 1 to 2 hours at 10-30 DEG C, then adding the glycerin type dendritic polyether and the solvent, stirring for 1 to 5 hours at 100-150 DEG C, and cooling to obtain a defoaming agent product. The delay coking defoaming agent has excellent defoaming antifoaming performances at 400-500 DEG C, in a high temperature delay coking process, the delay coking defoaming agent can still maintain good defoaming antifoaming performances and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

Coal gangue ceramsite proppant and preparation method thereof

InactiveCN109626960AHigh silicon contentReduce silicon contentFluid removalDrilling compositionExpanded clay aggregateComponents of crude oil

The invention relates to a coal gangue ceramsite proppant and a preparation method thereof. The proppant comprises, by weight, 30%-70% of coal gangue, 20%-65% of flint clay, 5%-10% of a sintering aidand 1-3% of a forming agent. The coal gangue is solid wastes which are discharged in coal collecting process and coal washing process, the silica content is higher, the aluminum content is lower, thecalorific value of the solid waste coal gangue is fully utilized in the preparation process, meta components of the coal gangue are completely utilized again to reduce the volume density of sintered ceramsite to better adapt to the technical demands of oil well fracturing construction, fracturing cost is reduced, and the use of high-grade bauxite resources is reduced to help to protect the environment.

Owner:攀枝花秉扬科技股份有限公司

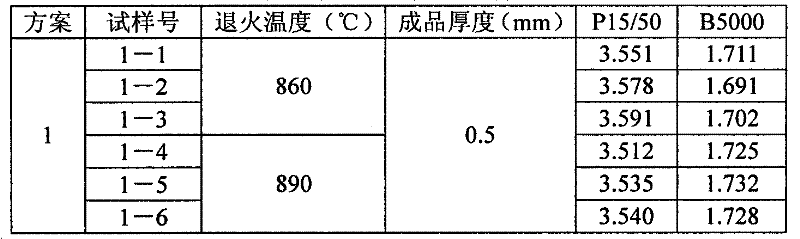

Method for preparing batch annealing low-grade non-oriented electrical steel

The invention relates to a method for preparing batch annealing low-grade non-oriented electrical steel. The method is characterized in that a low-carbon continuously cast sheet billet is used as a hot rolling raw material, wherein the thickness of a casting blank is 2.5-3.5mm, and the hot rolling raw material comprises the following elements by mass fraction; 0.004-0.008% of C, 0.60-0.80% of Si, 0.23-0.45% of Mn, less than or equal to 0.08% of P, less than or equal to 0.008% of S, less than or equal to 0.007% of N, less than or equal to 0.005% of O, 0.20-0.35% of Al and the balance of iron and unavoidable impurities; and seven-rack hot continuous rolling, five-rack cold continuous rolling and batch annealing are carried out so as to finally obtain the non-oriented electrical steel with excellent magnetic characteristics. The method has the advantages that the steel is low in silicon content and O and N contents, a cold rolling rate of 3.6-36% is adopted, and the low-grade non-oriented electrical steel with excellent magnetic characteristics and low cost is produced after batch annealing; and a final product has the specification of 0.65mm and magnetic characteristics of P15 / 50 equaling to 6.57-9.82W / Kg and B5000 equaling to 1.69-1.74T.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low Si-Mg ratio and low RE-Mg nodularizer

The invention provides a low Si-Mg ratio and low RE-Mg nodularizer. The nodularizer comprises the following components by mass percent: 5 to 10 percent of Mg, 20 to 30 percent of Si, 0 to 2 percent of Ca, 0 to 0.5 percent of Al, 0 to 0.2 percent of Bi, 0 to 0.1 percent of Ba, 0 to 0.1 percent of Zr, less than 0.1 percent of Ce, less than 0.1 percent of La and Fe in balancing amount. The nodularizer provided by the invention has the advantages that the Si content and the RE content in the nodularizer are considerably reduced on the premise that smooth iron liquid nodulizing is guaranteed, so that not only the range of control of the Si content of original iron liquid is widened, but also beneficial technological conditions are created for enhancing modification, and the carbonide of thin-walled parts and the fragmental graphite of thick-walled parts can also be effectively eliminated; the nodulizing effect is excellent; and the nodularizer is especially suitable for production of high-quality high-ductility ductile iron castings and high-Ni austenite ductile iron castings.

Owner:盐城市大丰区生产力促进中心

A heat-resistant forged aluminum alloy

A heat-resistant wrought aluminum alloy is characterized by containing the following metal elements: silicon 0.05-0.10%, iron 0.8-1.5%, copper 1.5-3.0%, manganese 0.2-0.5%, magnesium 1-2%, nickel 1-2% %, zinc 0.1-0.5%, titanium 0.05-0.15%, molybdenum 0.01-1% and the balance aluminum. The alloy obtained by the invention is a heat-resistant wrought aluminum alloy with less silicon content and high thermal strength; after adding titanium element, the structure is fine; after adding silicon, molybdenum, nickel, copper, iron and other elements, it can form thermal stability with aluminum The better excess phases Al2CuMg, Al6Cu3Ni, Al2FeSi, Al3Ti, Al2Cu4Mg5Si4, etc., improve the thermal strength of the aluminum alloy, can be strengthened by heat treatment, and have high plasticity in the hot state; do not contain manganese, chromium, so there is no extrusion effect, resistance Good welding, spot welding and seam welding performance, good corrosion resistance and machinability. It can be used to manufacture pistons of internal combustion engines and complex forgings that work at high temperatures, such as compressor impellers, blower impellers, etc.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

Purification method for deep silica removal of ammonium metavanadate

ActiveCN106044853AIncrease productivitySimple methodVanadium compoundsPurification methodsWastewater

The invention discloses a purification method for deep silica removal of ammonium metavanadate. The method comprises the following steps: (1) pouring ammonium metavanadate into water; (2) adding acid for acidification; (3) carrying out solid-liquid separation; (4) adjusting pH to 7-9 by adding ammonia water; and (5) filtering to obtain ammonium metavanadate. According to the method, caustic soda flakes are not used, wastewater is not generated, and the product is high-purity ammonium metavanadate and ammonium sulfate solution and can be recycled.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

Method for preparing silicon nitride crystal whisker

InactiveCN104499053AReduce silicon contentImprove conversion ratePolycrystalline material growthFrom solid stateNitrogen gasMaterials science

The invention relates to a method for preparing silicon nitride crystal whisker. The method comprises the following step of nitriding silicon nitride powder and silicon powder in a nitrogen furnace filled with nitrogen and hydrogen at high temperature. On the basis of the scheme, before high-temperature nitridation, thesilicon nitride powder and the silicon powder are mixed in a weight ratio of (10-50):(90-50). The method has the beneficial effects that ammonium chloride and hydrogen are added, the nitride crystal whisker is prepared by virtue of the direct nitridation process of silicon powder, the content of silicon in a product is very low, and the conversion rate is high. As silicon nitride powder is adopted as a diluent, the nitridation process of silicon powder is effectively controlled, and the method has the advantages of high conversion rate, in-batch production and high product purity, and is particularly applicable to in-batch production of silicon nitride crystal whisker.

Owner:青岛桥海陶瓷新材料科技有限公司

Pretreatment leaching process of flotation zinc oxide concentrates

A pretreatment leaching process of flotation zinc oxide concentrates includes the following steps that a small amount of concentrated sulfuric acid is added into the flotation zinc oxide concentrates and stirred evenly; heat-preservation curing is carried out on obtained mineral powder at a low temperature to partially decompose flotation chemicals on the surface of the flotation zinc oxide concentrates; the obtained clinkers are leached out with waste electrolytes, filtered and separated; and finally, a small amount of active carbon is added into the zinc sulfate solution obtained after filtering and separation for adsorption, filtering and separation are carried out again, and zinc oxide concentrate leachate is obtained. The pretreatment leaching process of flotation zinc oxide concentrates has the advantages of being simple, environmentally friendly and the like, can optimize the leaching conditions of the concentrates, and resolves the problems of residual floatation chemicals and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for removing silicon in green liquid through cooperation of calcium oxide and aluminum salt

InactiveCN102337696AReduce silicon contentPlay a role in removing siliconRegeneration of alkali lyeLime productionFiberFiltration

The invention relates to a method for reducing the silicon content in a green liquid of a non-wood fiber material pulping causticization section through the cooperation of calcium oxide and aluminum salt. In the method, calcium oxide and aluminum sulfate, aluminum oxide, aluminum hydroxide or sodium metaaluminate are sequentially added into the green liquid of the causticization section, the temperature is 90-100 DEG C in the reaction process, a stirrer is used for continuous stirring in the reaction process, the reaction time is 25-30 minutes, and insoluble precipitate is removed by filtration after the reaction is completed. The method is provided for the green liquid produced during non-wood fiber material pulping, and comprises the following steps: adding calcium oxide and aluminum salt into the green liquid of the pulping causticization section to react with silicate in the green liquid so as to generate insoluble precipitate, then filtering to remove the generated insoluble precipitate from the green liquid. The method can achieve a silicon removal rate higher than 87%, and ensures that white slime can be used for calcining and recycling lime after causticization.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com