Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255 results about "Finings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finings are substances that are usually added at or near the completion of the processing of brewing wine, beer, and various nonalcoholic juice beverages. They are used to remove organic compounds, either to improve clarity or adjust flavor or aroma. The removed compounds may be sulfides, proteins, polyphenols, benzenoids, or copper ions. Unless they form a stable sediment in the final container, the spent finings are usually discarded from the beverage along with the target compounds that they capture.

Water-soluble resin composition

InactiveUS6555607B1Improved coating propertiesEasy to diffuseFilm/foil adhesivesSemiconductor/solid-state device manufacturingResistAlcohol

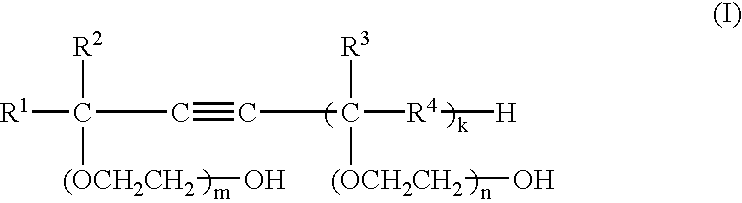

A water-soluble resin composition comprising (1) a water-soluble resin, (2) a water-soluble crosslinking agent, (3) at least one of surface active agents selected from acetylene alcohols, acetylene glycols, polyethoxylates of acetylene alcohols and polyethoxylates of acetylene glycols, and (4) a solvent consisting of water or a mixture of water and a water-soluble solvent. This water-soluble resin composition is applied onto a resist pattern, then heated to crosslink by an acid supplied from the resist, followed by development to remove the non-crosslinked water-soluble resin coating layer. This water-soluble resin composition is excellent in coating characteristics on steps of resist patterns and in dimensional regulation upon fining of patterns so that resist patterns such as trench patterns and hole patterns can effectively be fined.

Owner:MERCK PATENT GMBH

Ultra pure electroslag remelting method for high-performance corrosion resistant alloy

ActiveCN102912151AImprove performanceImprove organizationIncreasing energy efficiencyCorrosion resistant alloySolution treatment

The invention relates to an ultra pure electroslag remelting method for a high-performance corrosion resistant alloy, and the method comprises the following steps of: preparing the following ingredient components of a self-fluxing electrode bar in parts by weight: 25-34 parts of Ni, 25-29 parts of Cr, 2.5-4.5 parts of Mo and 30-45 parts of Fe, and carrying out vacuum induction melting, so as to obtain the self-fluxing electrode bar; slowly melting the self-fluxing electrode bar in melted electroslag remelting slag charge comprising the following components in parts by weight: 55-80 parts of CaF2, 5-25 parts of CaO, 5-15 parts of Al2O3 and 5-10 parts of MgO, purifying, and recrystallizing in a crystallizer, so as to obtain an electroslag ingot; and forging the electroslag ingot into a bar material at the temperature of 1130+ / -5 DEG C, and carrying out solution treatment, so that the high-performance corrosion resistant alloy is obtained. By utilizing the ultra pure electroslag remelting method provided by the invention, the content of harmful elements such as sulphur and phosphorus in the alloy can be reduced, the impurity distribution of the alloy is improved, fining of structure can be facilitated, and the hot workability and yield of the alloy can be improved.

Owner:CHONGQING MATERIALS RES INST

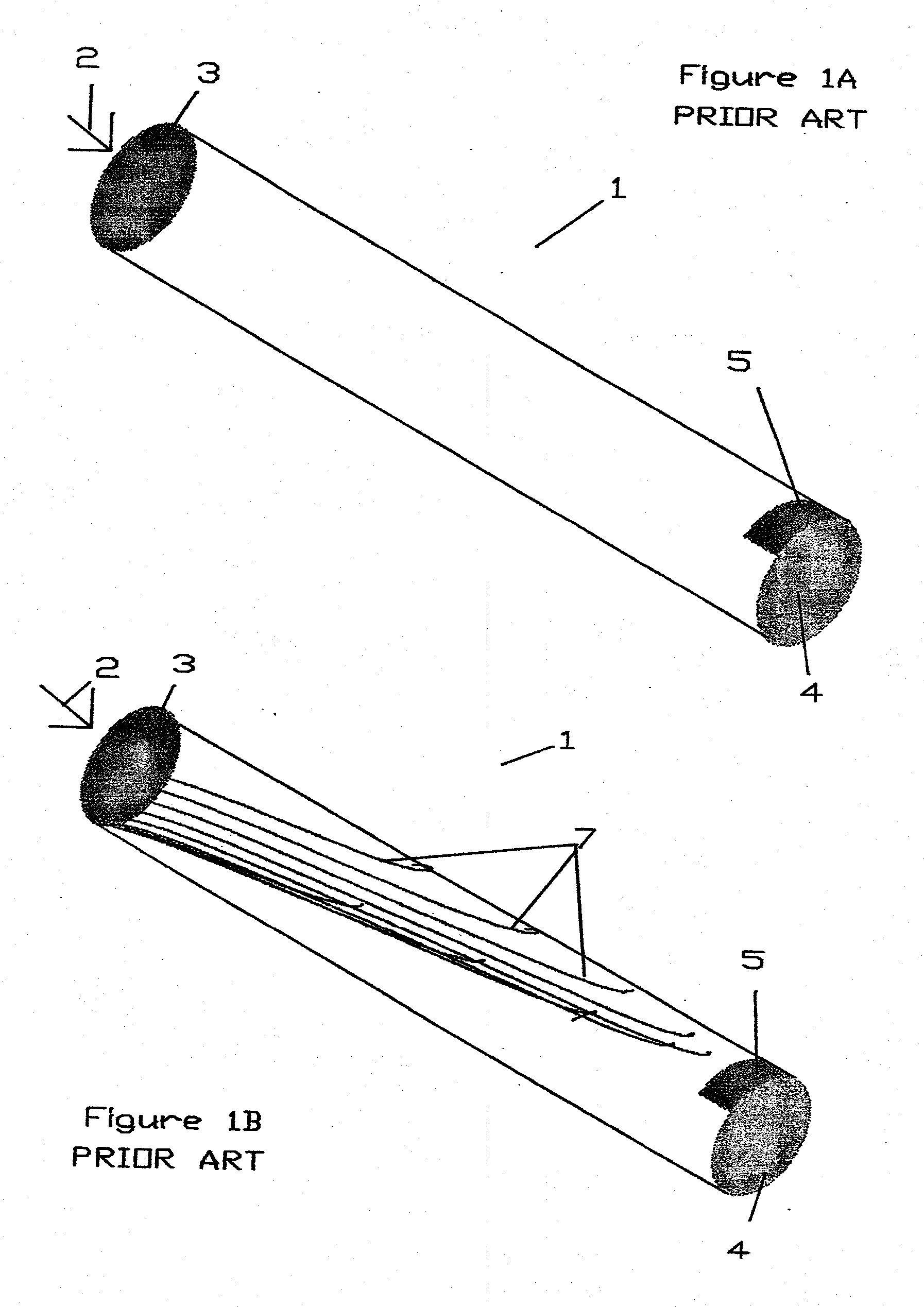

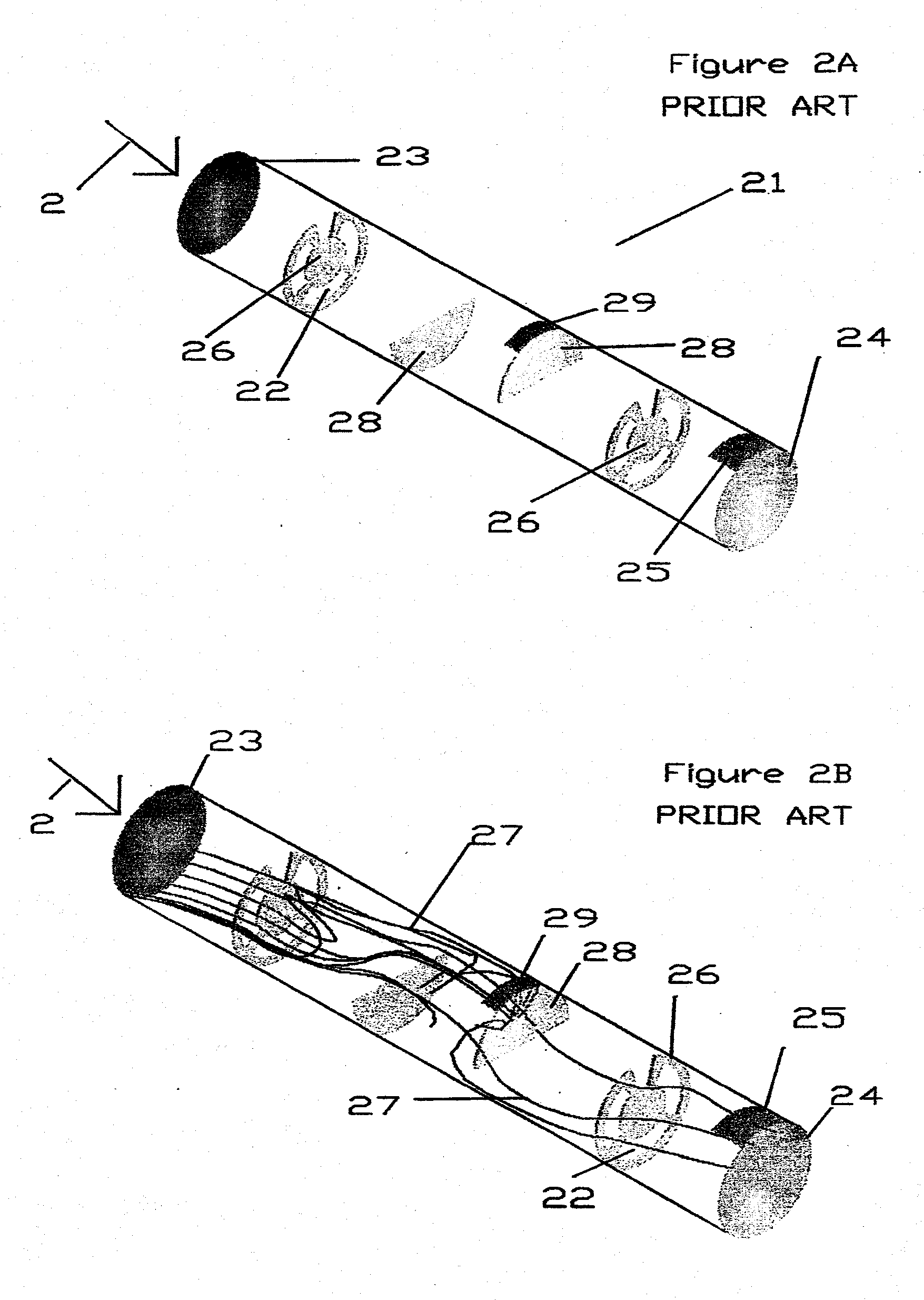

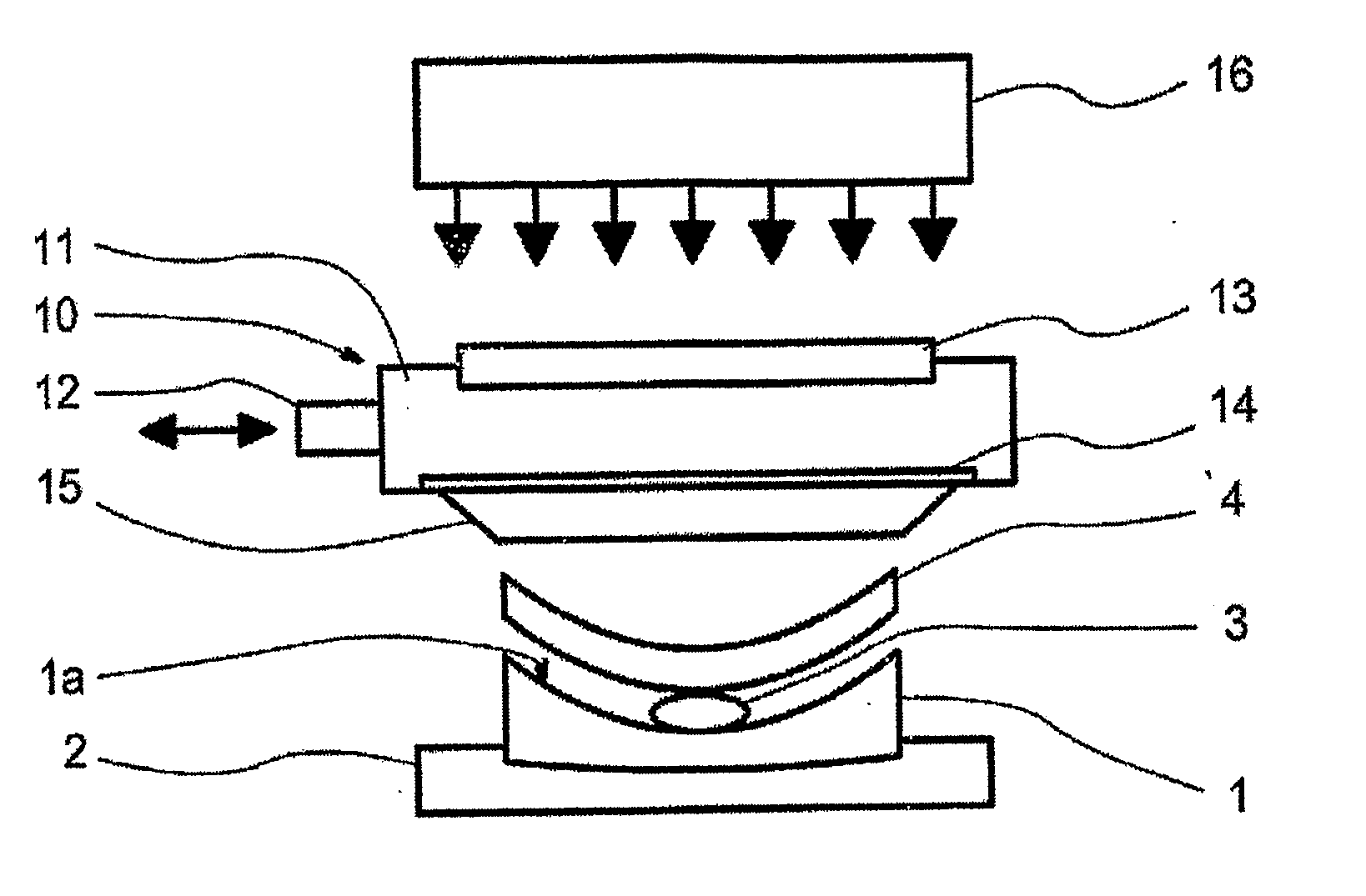

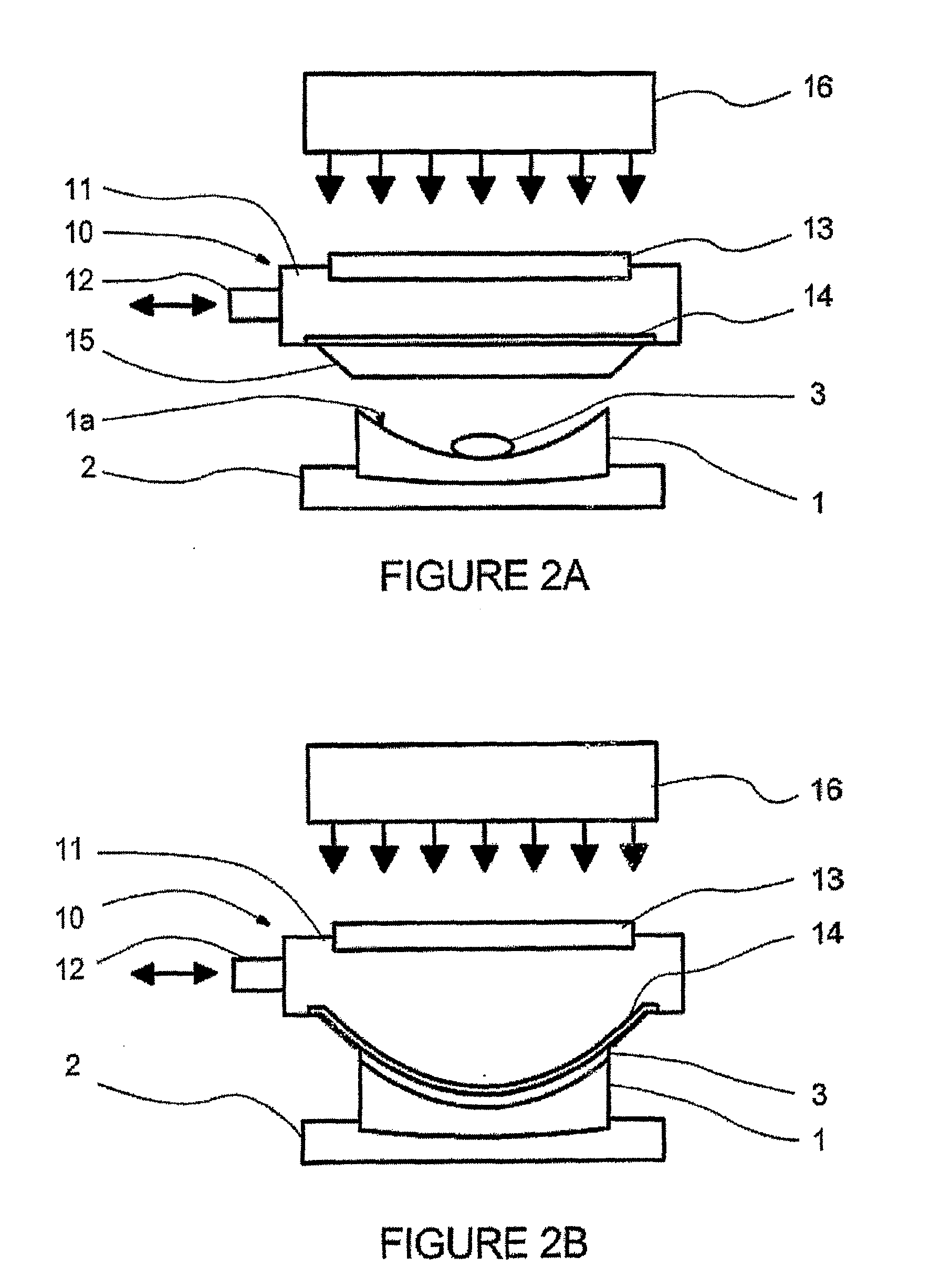

Process for making a coated optical article free of visible fining lines

InactiveUS20050140033A1Fine surfaceImprove optical qualityMouldsOptical articlesLiquid stateEngineering

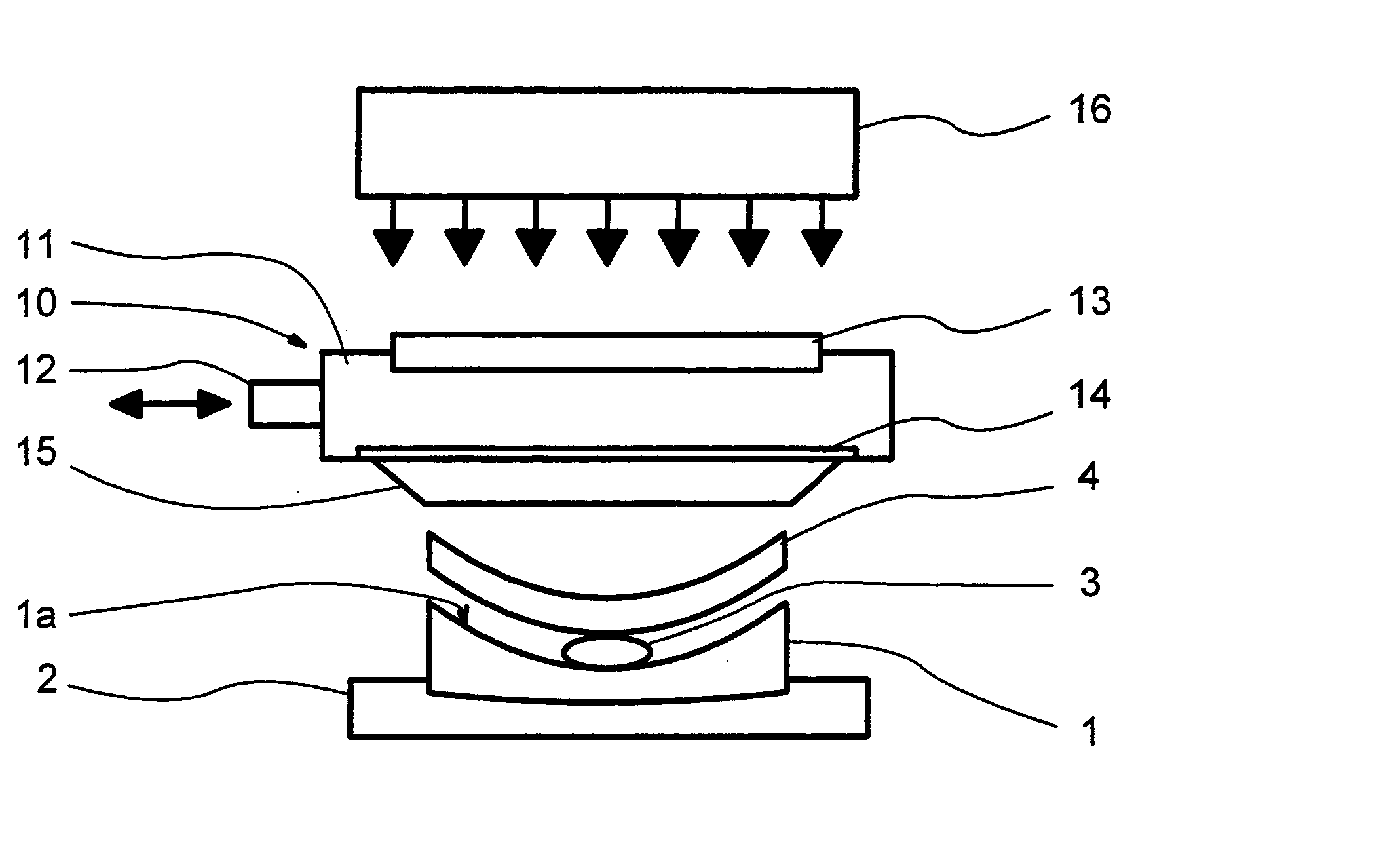

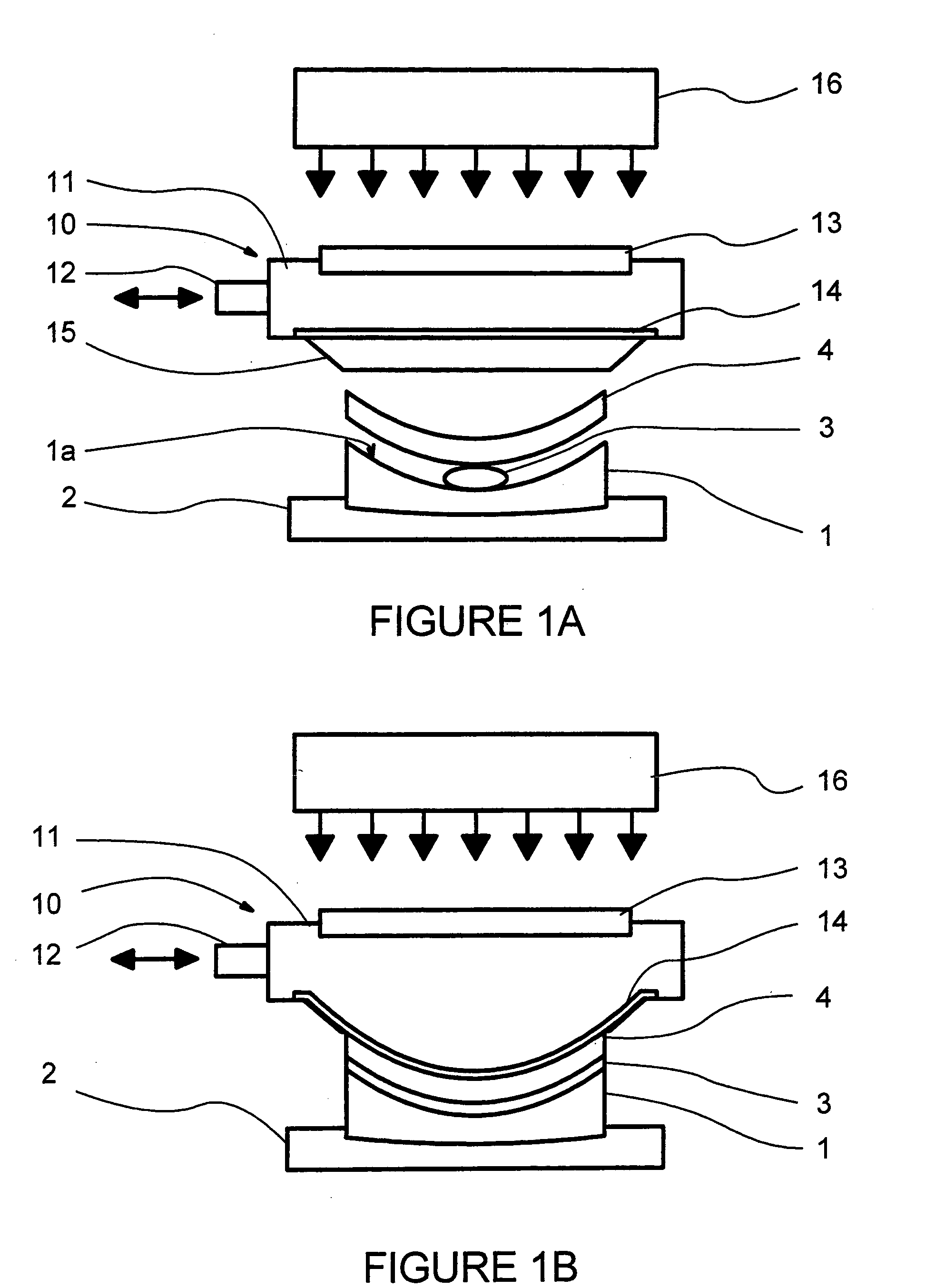

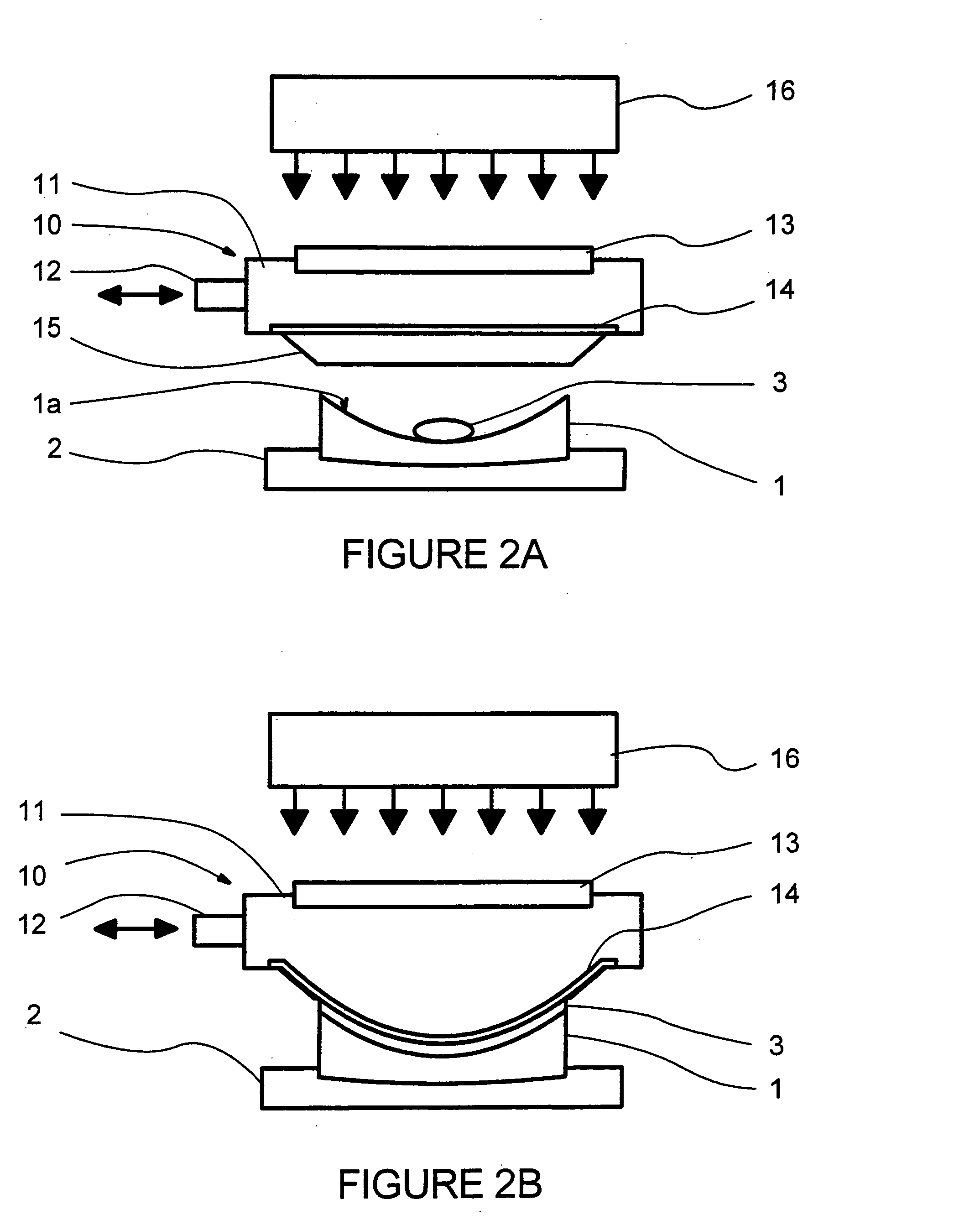

The invention concerns a process for making a coated optical lens blank free of visible fining lines which comprises: (i) providing an optical article having at least one fined but unpolished geometrically defined main face; (ii) providing a mold part having an internal and external surface; (iii) depositing on said main face of said optical article or on the internal surface of the mold part a requisite amount of a liquid curable coating composition; (iv) moving relatively to each other the optical article and the mold part to either bring the coating composition into contact with the main face of the optical article or into contact with the internal face of the mold part; (v) applying pressure to the mold part to spread the liquid curable coating composition on said main face and form a uniform liquid coating composition layer onto the main face; (vi) curing the liquid coating composition layer; (vii) withdrawing the mold part; and (viii) recovering the free of visible fining lines coated optical article.

Owner:ESSILOR INT CIE GEN DOPTIQUE

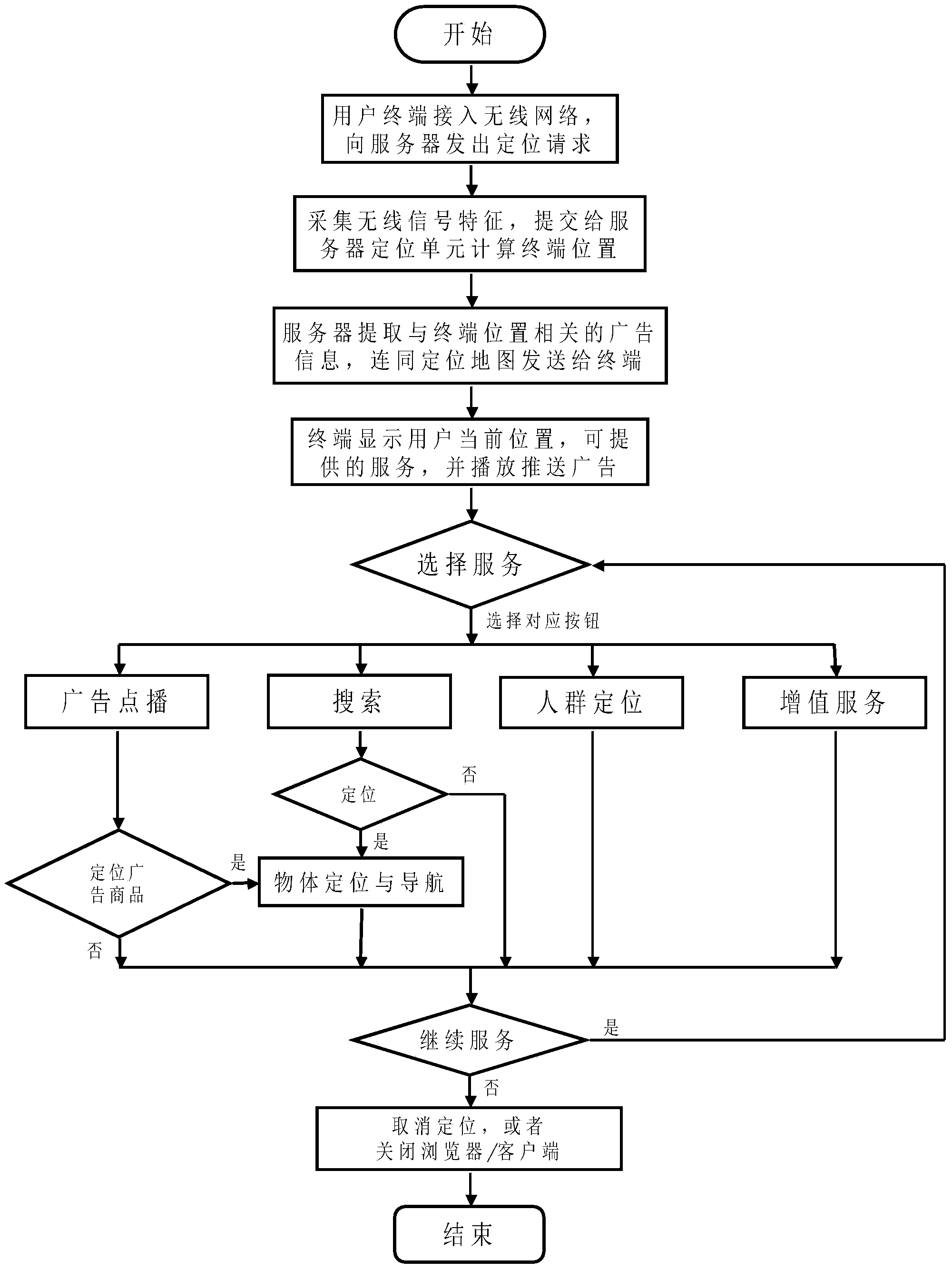

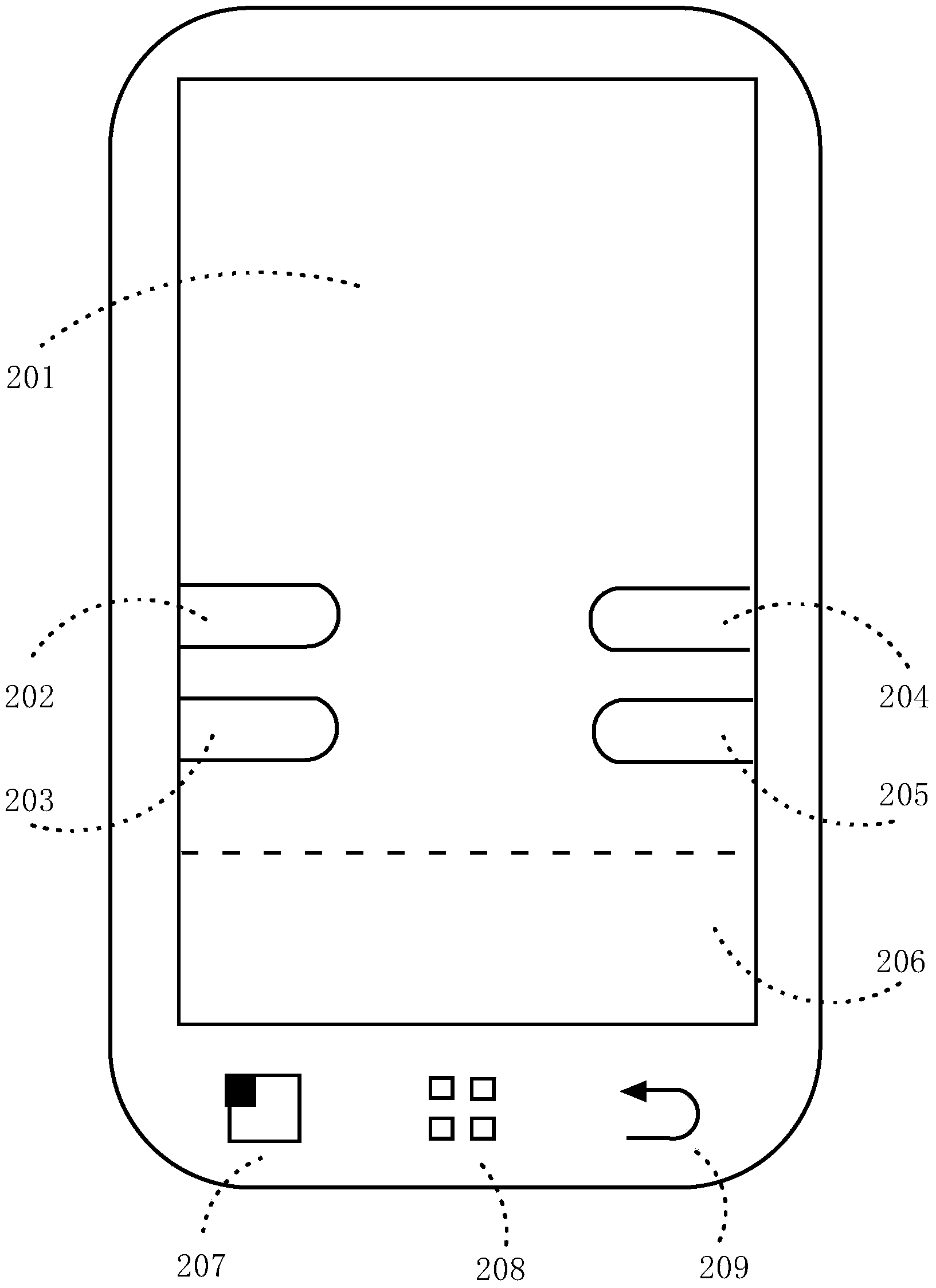

Mobile terminal push service method based on Wi-Fi positioning

InactiveCN103458366AHigh precisionReduce construction costsLocation information based serviceWi-FiPublic place

The invention discloses a mobile terminal push service method based on Wi-Fi positioning. According to the mobile terminal push service method based on the Wi-Fi positioning, a user has access to a Wi-Fi network at first through a terminal, and after the selection and positioning are conducted, a wireless access point (AP) or the terminal transmits the wireless signal features needed by the positioning to a server; the server determines the position of the terminal according to existing models and algorithms, then mobile services related to positioning are provided for the user, the mobile services comprise advertisement pushing and broadcasting (particularly related to the position of the user), area searching, positioning and navigation of the target object, crowd positioning, derived services and the like. The mobile terminal push service method based on Wi-Fi positioning can be applied to large public places such as a market and an exhibition hall, and specific, real-time, fining, convenient and fast area mobile service is provided for the user.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

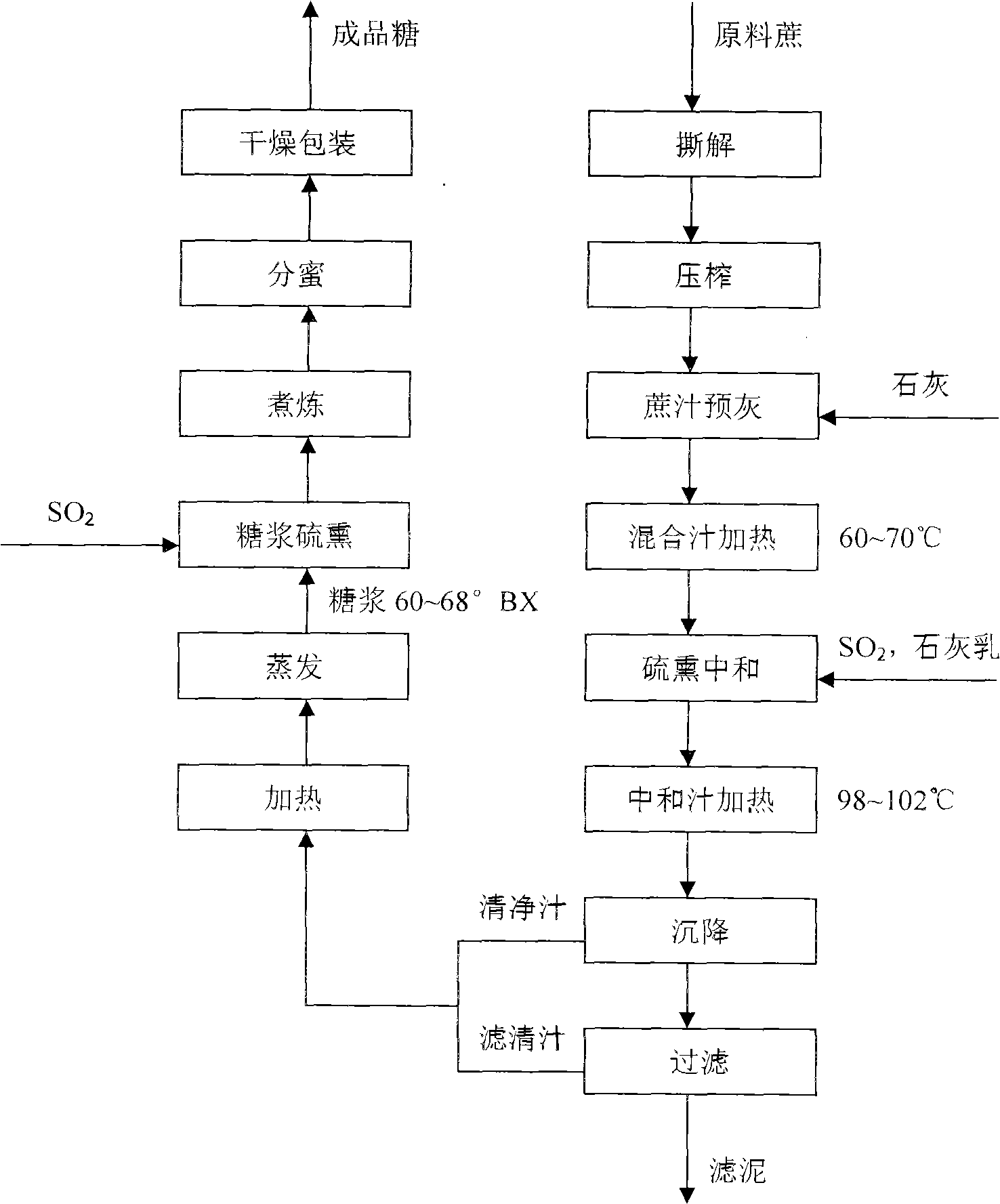

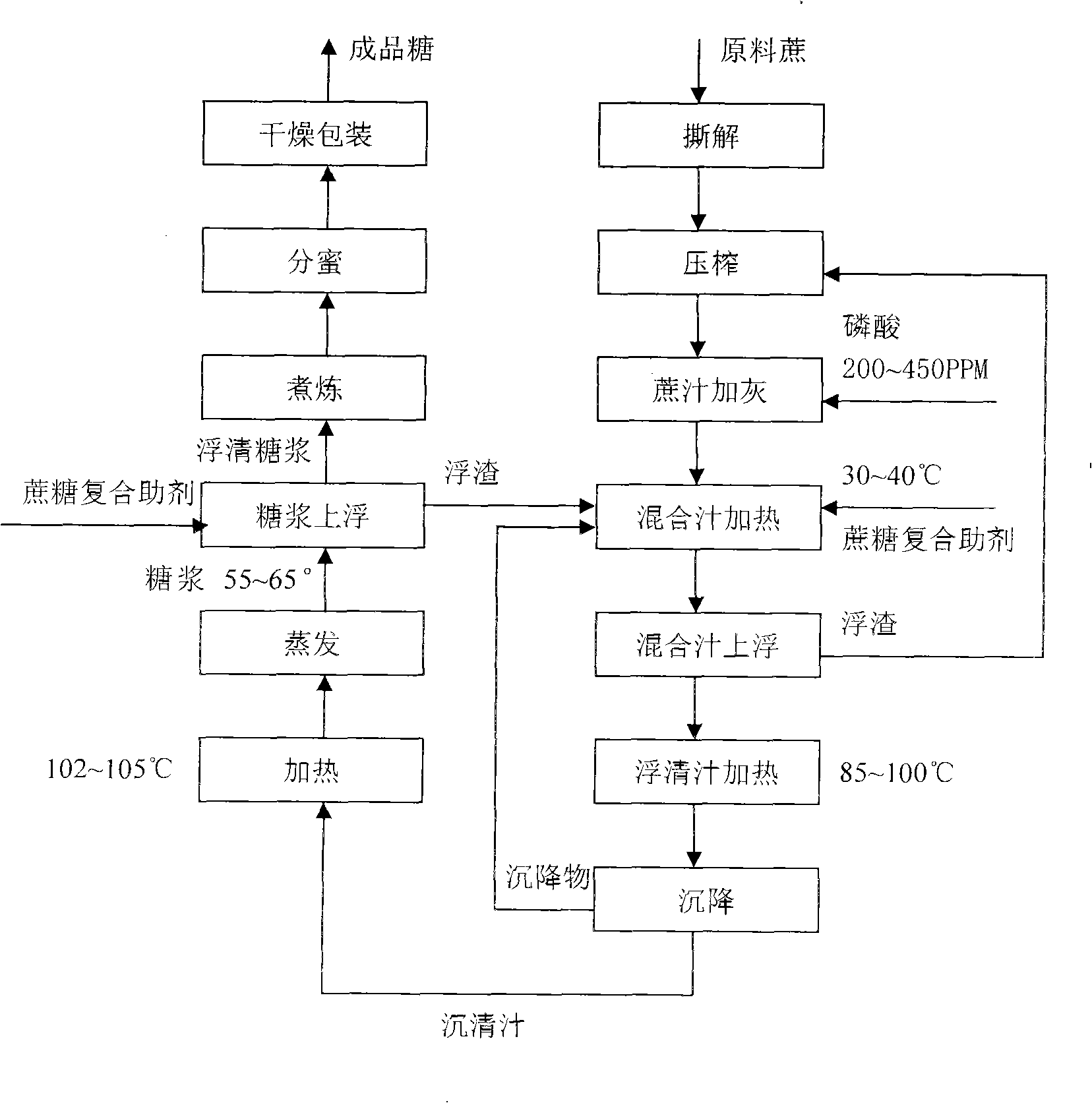

Production method of sulfurless superior saccharose

InactiveCN101323885AHigh purityPurity is higher than mixed puritySugar crystallisationSugar juice purificationRetention timeFiltration

The invention relates to a production method of high-quality sugar, specifically to an improvement of a technology of sugar refinement and purification. High-quality white granulated sugar products are obtained after sugar canes are torn, pressed, cane juice is defecated, mixed juice is heated, a cane sugar complex auxiliary agent is added, the mixed juice is stirred up, floating juice is heated, sedimentated and vaporized, phosphoric acid and the cane sugar complex auxiliary agent are added, syrup is stirred up, the process of honey separation is carried out, the mixture is boiled, refined, crystallized, dried and packed. As the method of the invention adopts a low-temperature technology and a floating treatment method of adding the phosphoric acid, lime and the cane sugar auxiliary agent to lead the floating juice to reach or exceed the effect of the floating juice by original traditional technology, and utilizes a syrup floating principle and a scruff repressing method to substitute the sediment, filtration and stoving technology in the prior art, and cancels such technologies and equipment thereof as filtration, neutralization and sulfur dioxide gas system, retention time in cane juice production process is shortened, sulfur is used as a clarifier during the whole technical process, and sugar without sulfur is produced, thus improving product quality as well as reducing cost.

Owner:高晓军 +1

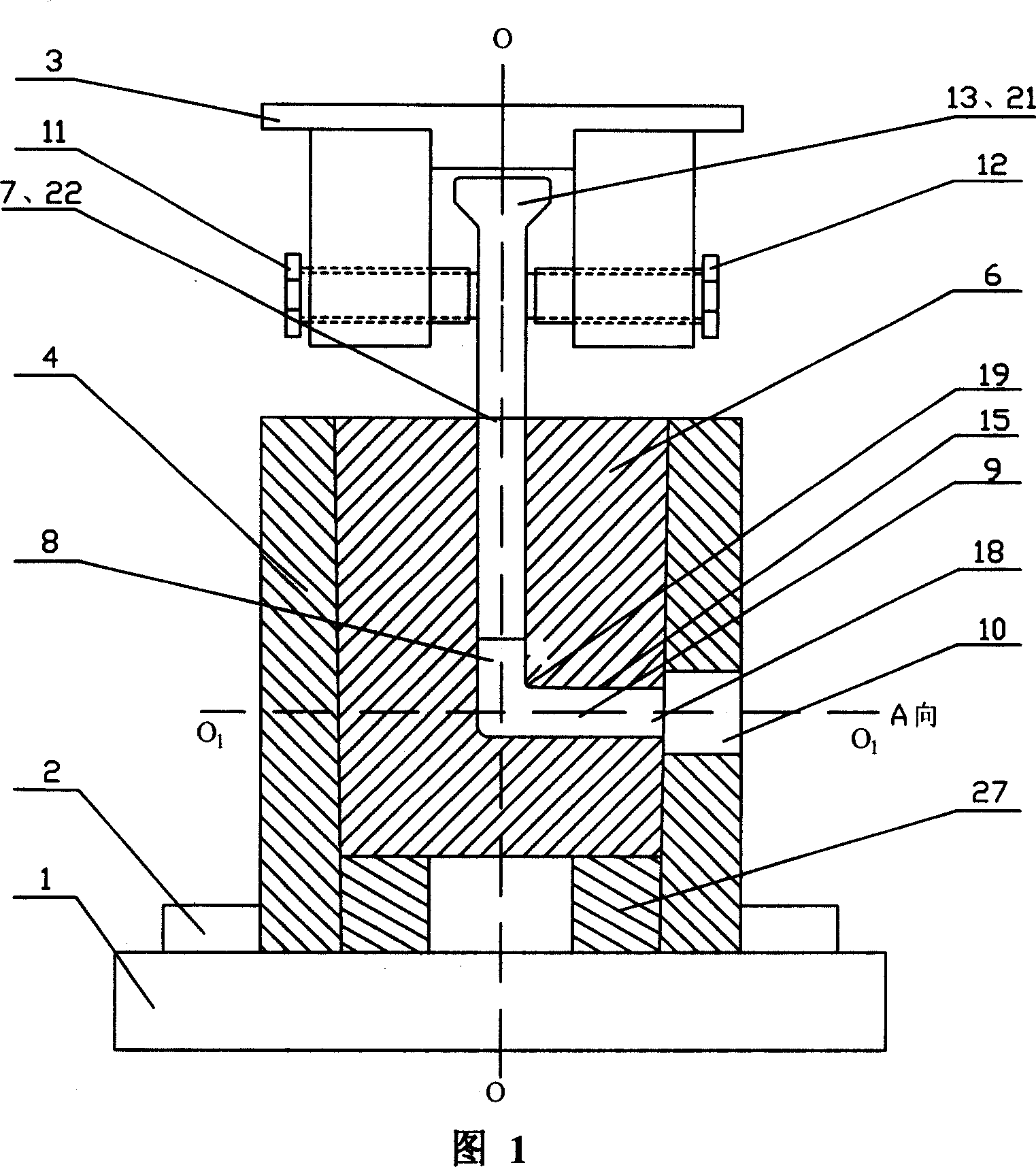

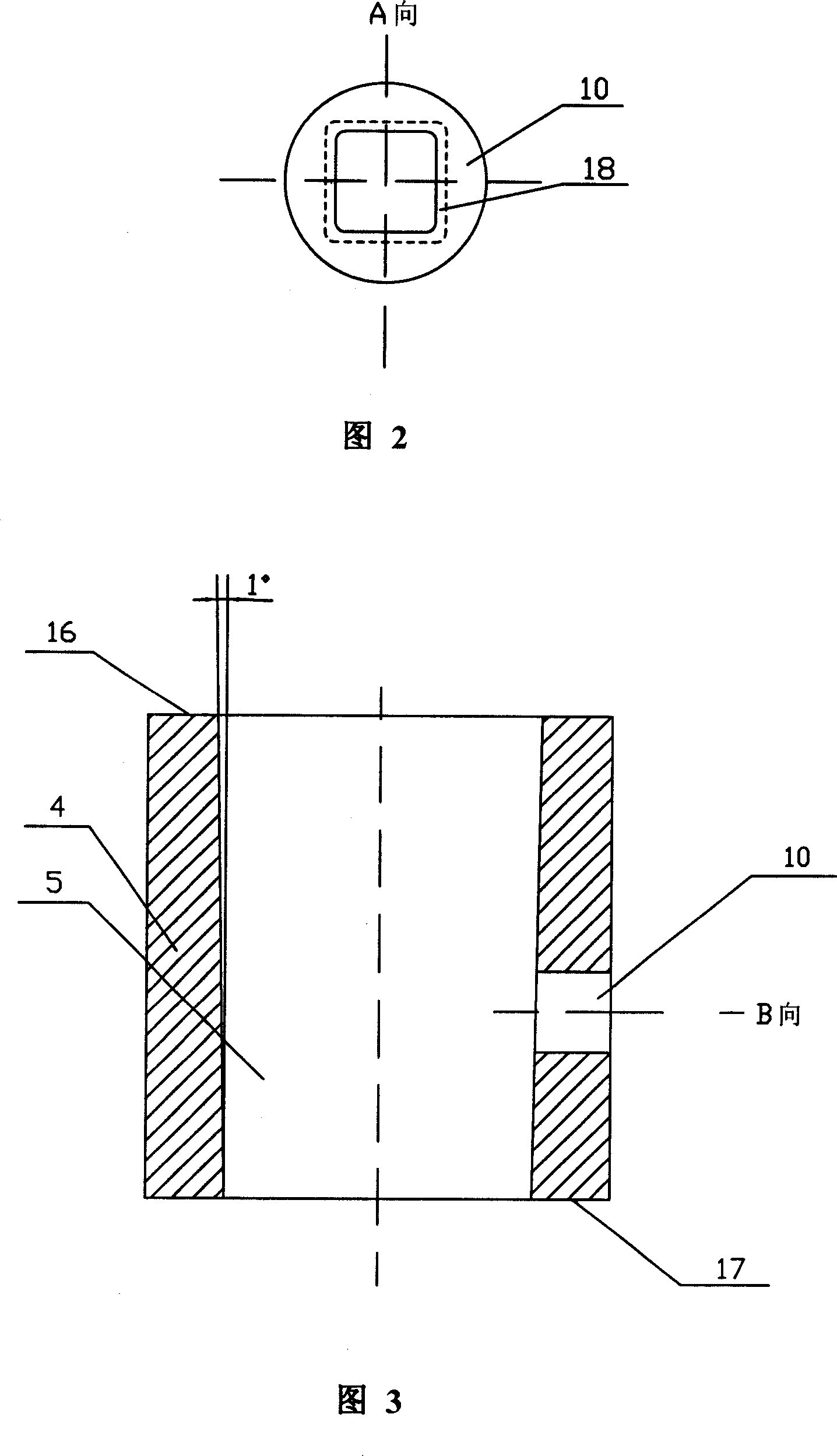

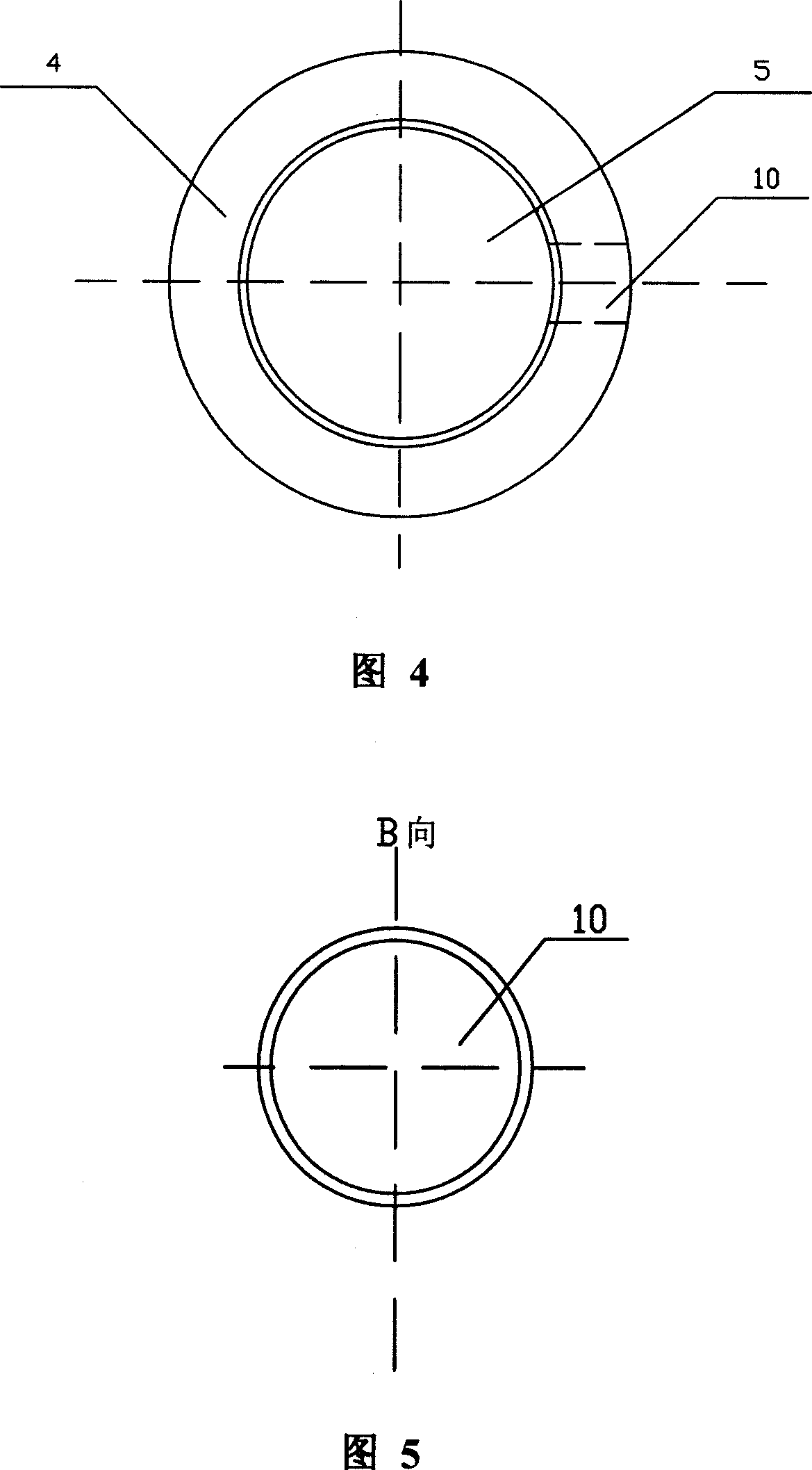

L-shaped extrusion device for producing ultra-fine crystal block body material

The extrusion apparatus for preparing superfine crystal block material has one structure comprising a die holder, a connecting seat, a conic die case, a conic die core, a wedged extruding rod with reduced extrusion force to avoid cracking of the block, a turning unit, a square vertical channel, a square horizontal channel and a product outlet. The product has high crystal grain fining and smooth surface, and the extrusion apparatus has simple structure, excellent mechanical performance, easy installation and use, and no pollution.

Owner:TAIYUAN UNIV OF TECH

Molten Optical Glass Fining Apparatus

ActiveUS20070084247A1Avoid excessive distanceGood clarificationGlass furnace apparatusEngineeringAdemetionine

Owner:CORNING INC

Process for Making a Coated Optical Lens Free of Visible Fining Lines

The invention concerns a process for making a coated optical lens blank free of visible fining lines which comprises: (ix) providing an optical article having at least one fined but unpolished geometrically defined main face; (x) providing a mold part having an internal and external surface; (xi) depositing on said main face of said optical article or on the internal surface of the mold part a requisit amount of a liquid curable coating composition; (xii) moving relatively to each other the optical article and the mold part to either bring the coating composition into contact with the main face of the optical article or into contact with the internal face of the mold part; (xiii) applying pressure to the mold part to spread the liquid curable coating composition on said main face and form a uniform liquid coating composition layer onto the main face; (xiv) curing the liquid coating composition layer; (xv) withdrawing the mold part; and recovering the free of visible fining lines coated optical article.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Tea wine and preparation method thereof

InactiveCN103305371AHigh alcohol contentSweet and mellow tasteAlcoholic beverage preparationFlavorAlcohol

The invention provides a tea wine and a preparation method thereof. The tea wine is prepared by mixing a tea extraction solution and a grain saccharification solution and fermenting. The preparation method provided by the invention comprises the following steps of: firstly leaching tea to prepare the tea extraction solution; secondly mixing Chinese sorghum, rice and corn according to a certain proportion, crushing, steaming, boiling and saccharifying to obtain the saccharification solution, mixing with the tea extraction solution, adding koji, and forming a tea fermentation solution by liquid-state fermentation; and finally performing sterilization, blending, fining, filtering, aging and secondary filtration to obtain the tea wine. The tea wine is characterized in that a product provided by the invention has the characteristics of heavy tea fragrance, sweet and mellow taste, coordination of various flavors, long after-taste and the like; and furthermore, compared with the traditional tea wine, the tea extraction solution is adopted for performing fermentation together with the Chinese sorghum, the rice and the corn, the functional active ingredients in the tea can be retained to the greatest extent, the blending of a base wine is simultaneously performed after fermentation, the shortcomings of low alcohol degree of the fermented wine and complex process and pungent smell of the distilled wine can be overcome, the softness of the tea and the rigidity of the wine can be perfectly combined, and the species of tea and wine products are enriched.

Owner:四川省广汉市常乐春酒厂(普通合伙)

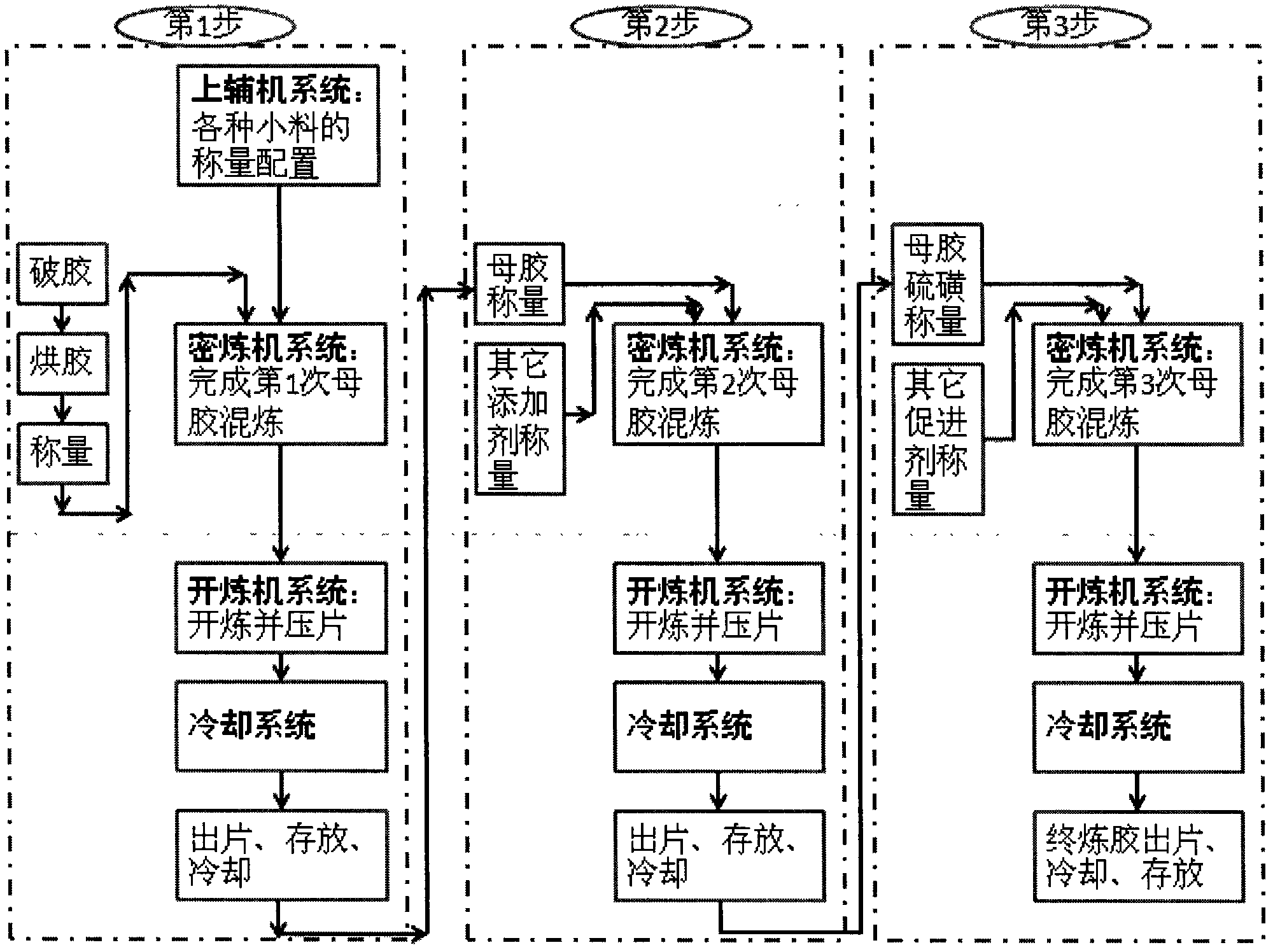

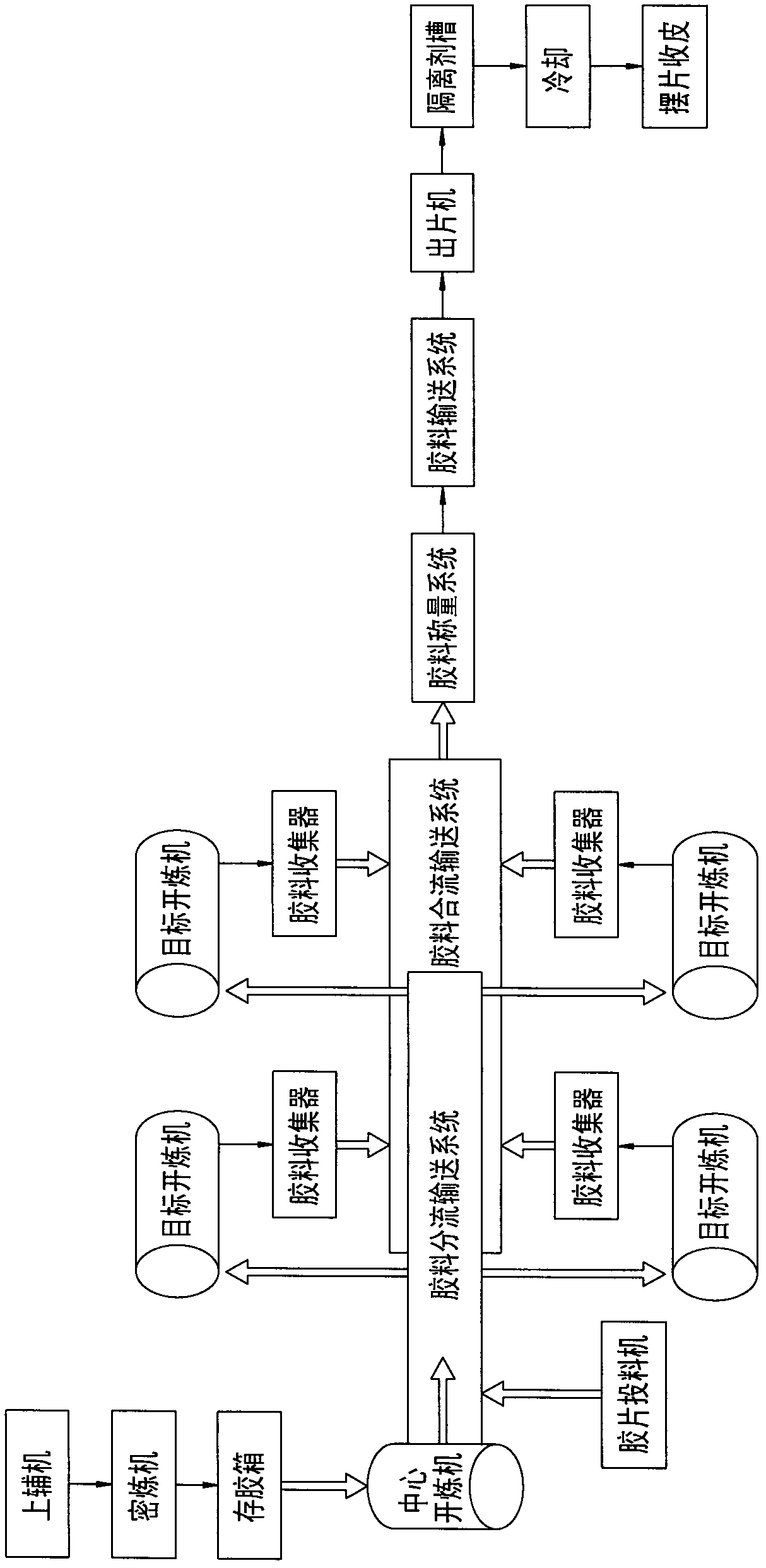

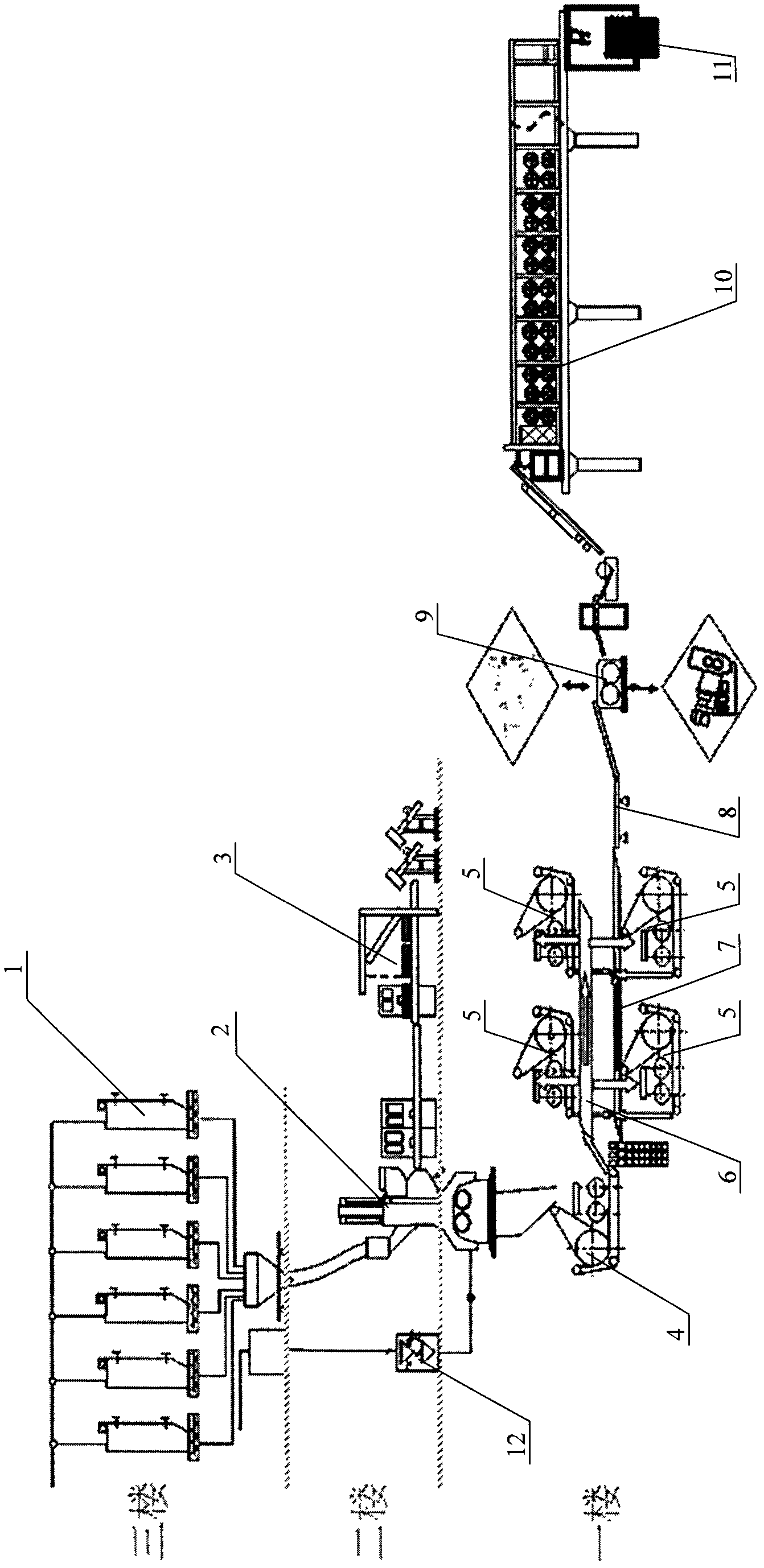

Central flow dividing type one-step rubber fining process and system

The invention discloses a central flow dividing type one-step rubber fining process and system. In the invention, a rubber fining process with an internal mixer, a central open mill and a plurality of parallel open mills is adopted; after rubber materials are mixed and discharged, the rubber materials enter the central open mill and cooled by the central open mill, and then the master batch of a vulcanizing agent is added; then, the rubber materials enter a rubber material dividing and delivery system and assigned to a plurality of surrounding target open mills for further rubber fining, wherein the rubber fining time of each target open mill can be four times as long as the mixing time so as to guarantee the effect of uniform rubber fining; after four open mills discharge rubber, the discharged rubber materials enter a rubber material convergence and delivery system through a rubber material collecting system; and then a rubber slice cooling system is used for cooling and dischargingrubber slices so as to finish the whole rubber fining process. The process benefits the reduction of the floor area of a plant, the occupation area of equipment and the number of worker and the greatimprovement of the rubber fining quality and the rubber fining productivity so as to achieve the purposes of high quality, high efficiency, energy saving, low carbon and low cost of rubber fining.

Owner:特拓(青岛)轮胎技术有限公司 +2

Method for producing micro crystal glass by combined using of yellow phosphorus slag and exhaust

The invention discloses a method for a multipurpose utilization of yellow phosphorus clinker and offgas to produce glass-ceramic which belongs to the manufacture field of building materials. The invention is with a simple technics and a low cost, stable, and can do an industry production including following steps: melting the yellow phosphorus into slag in the melting furnace in a temperature of 1450-1500 DEG C, meanwhile, doing a speedy bath analysis; making the material composition accord with SiO2 50-60, Al2O3 6-7, CaO 22-30, K2O+Na2O 3-9, than adding the material containing Si, Al, Na into the melting furnace; burning the clean and dried yellow phosphorus offgas by the arranged ejecting mouths on the top melting furnace after mixing with the oxygen and maintaining the temperature of 1450 DEG C in the furnace; controlling the temperature of 1450 DEG C in the furnace and keeping warm for 2 hours to make all of the material mold after melting, equalization and fining, then coring and crystallizing, getting finished products after anneal and cutting-abrading.

Owner:WENGFU (GRP) CO LTD

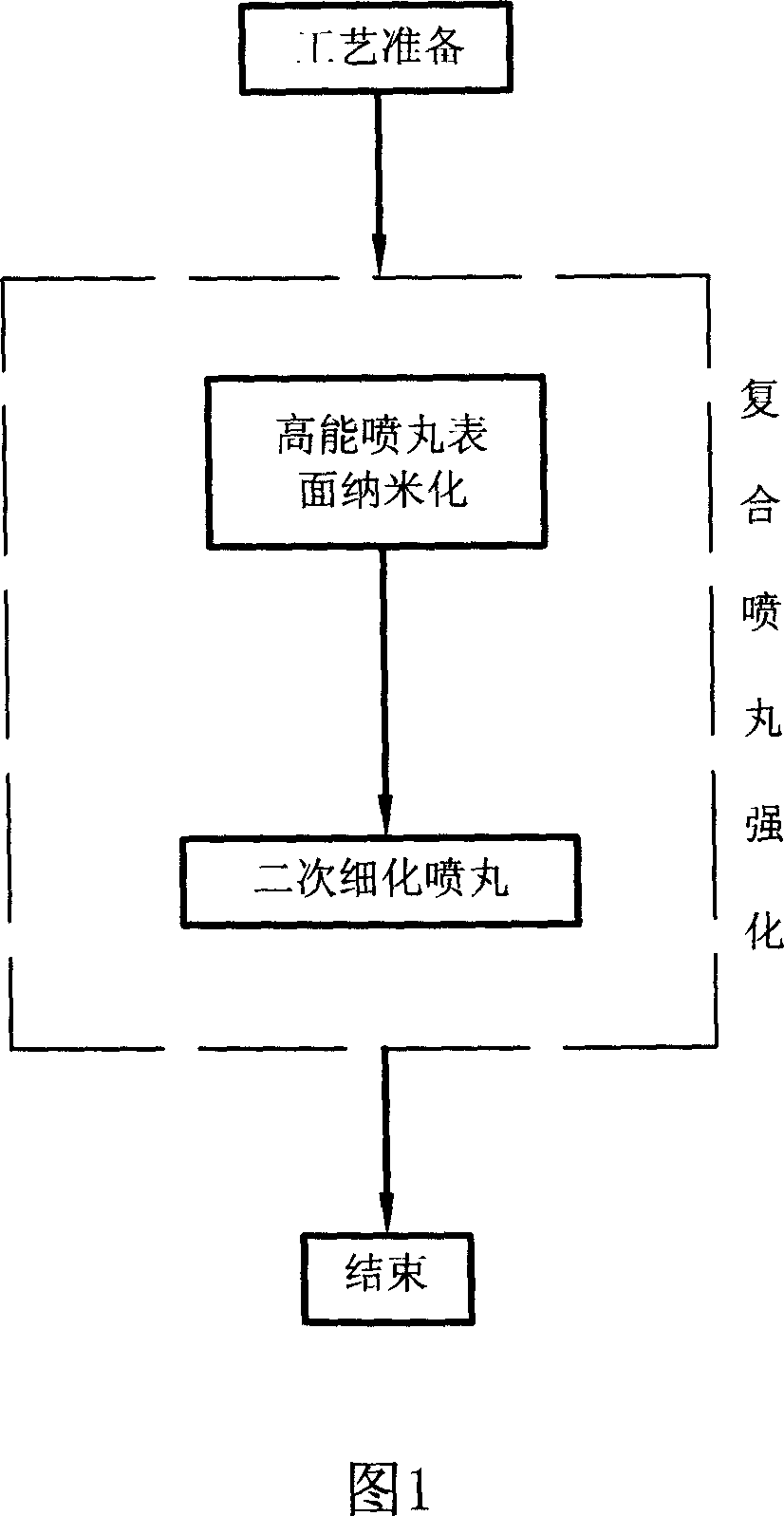

Composite shot blasting reinforcement process to raise fatigue strength of titanium metal

The composite shot blasting reinforcement process to raise the fatigue strength of titanium metal includes one step of eliminating surface attachment and dirt, and one high-energy shot blasting step for surface nanometer treatment and secondary fining treatment. The process can obtain one nanometer surface layer in certain depth and one very deep residual compressive stress field and raise the fatigue strength of the material.

Owner:DALIAN JIAOTONG UNIVERSITY

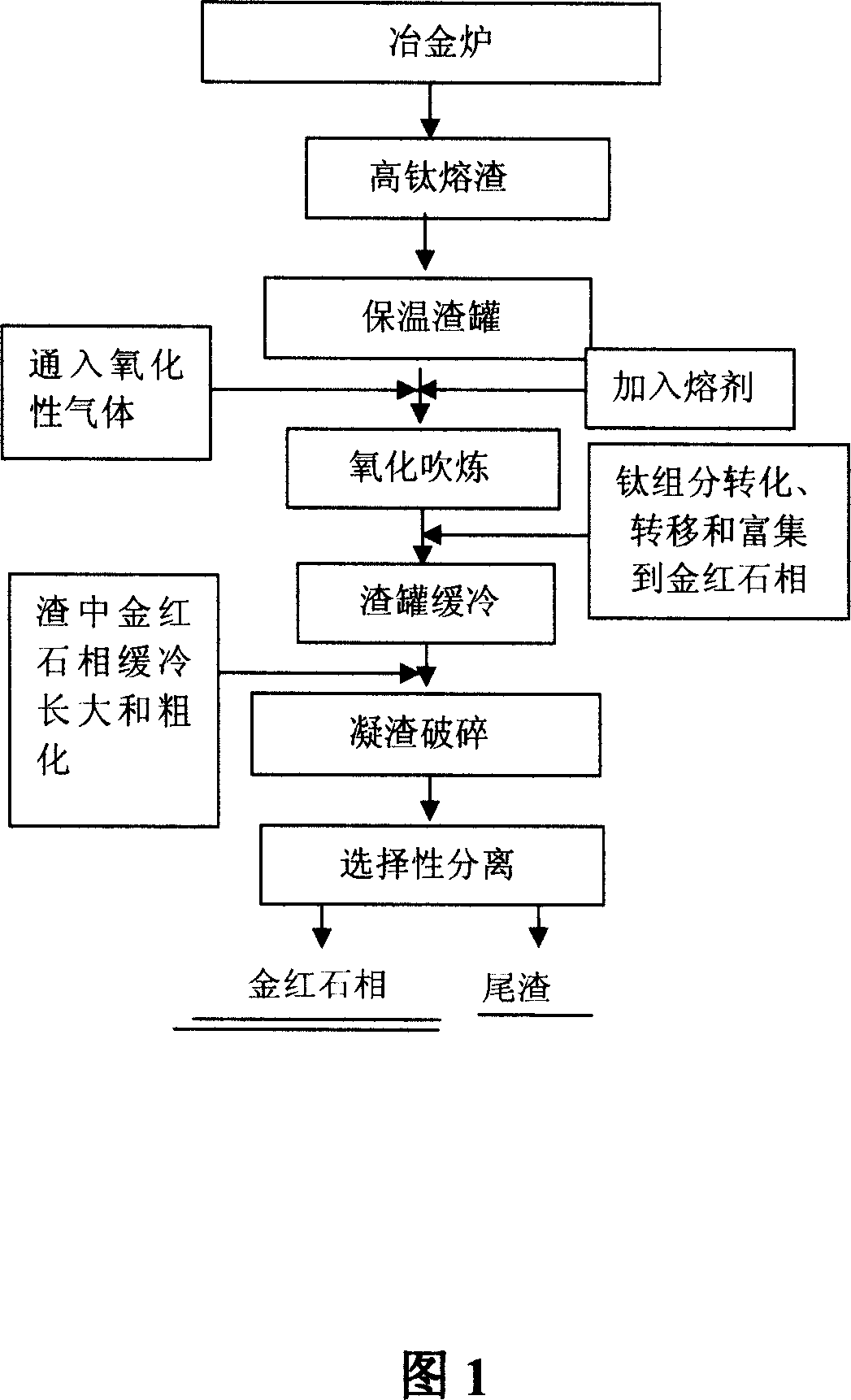

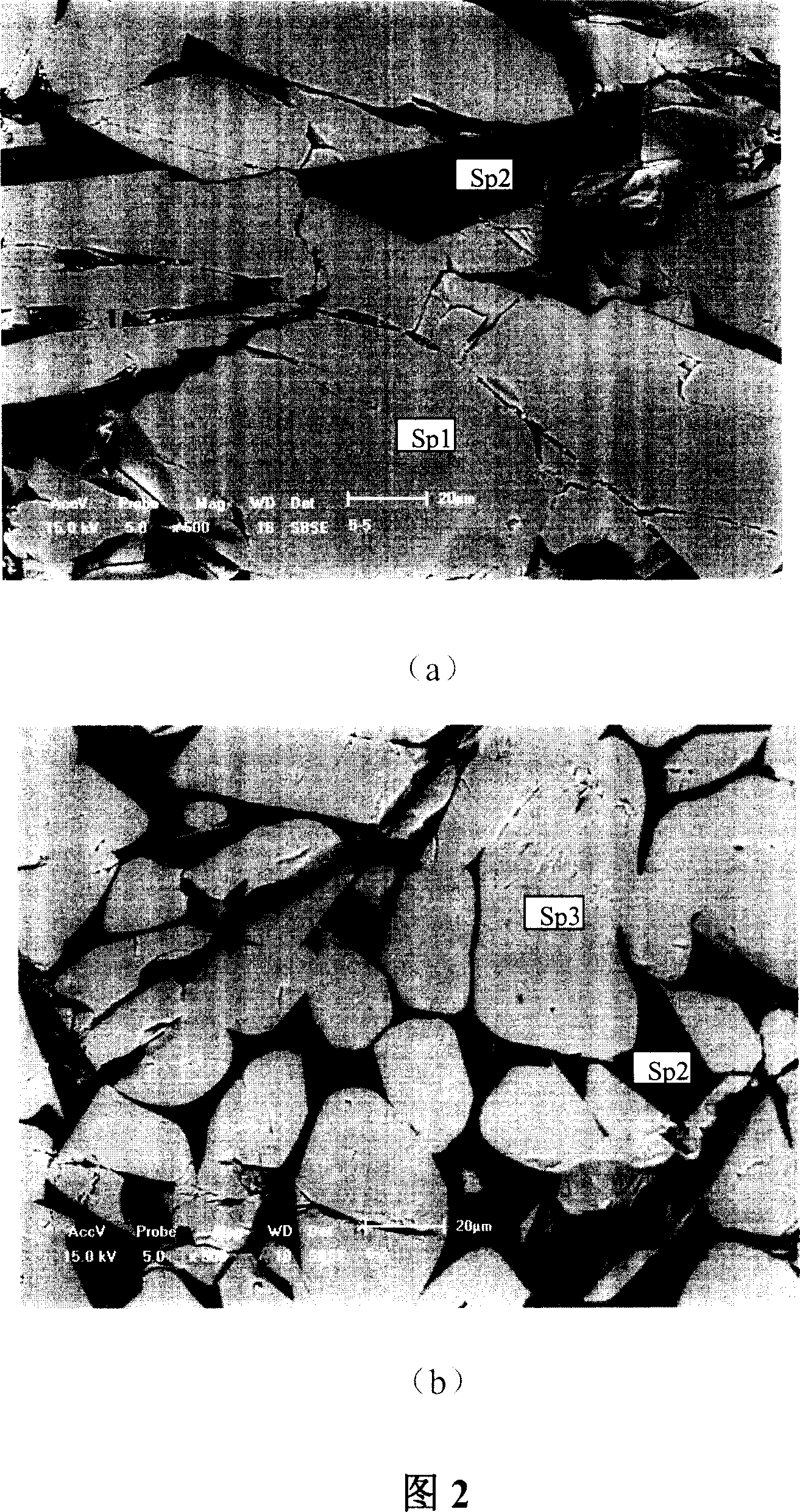

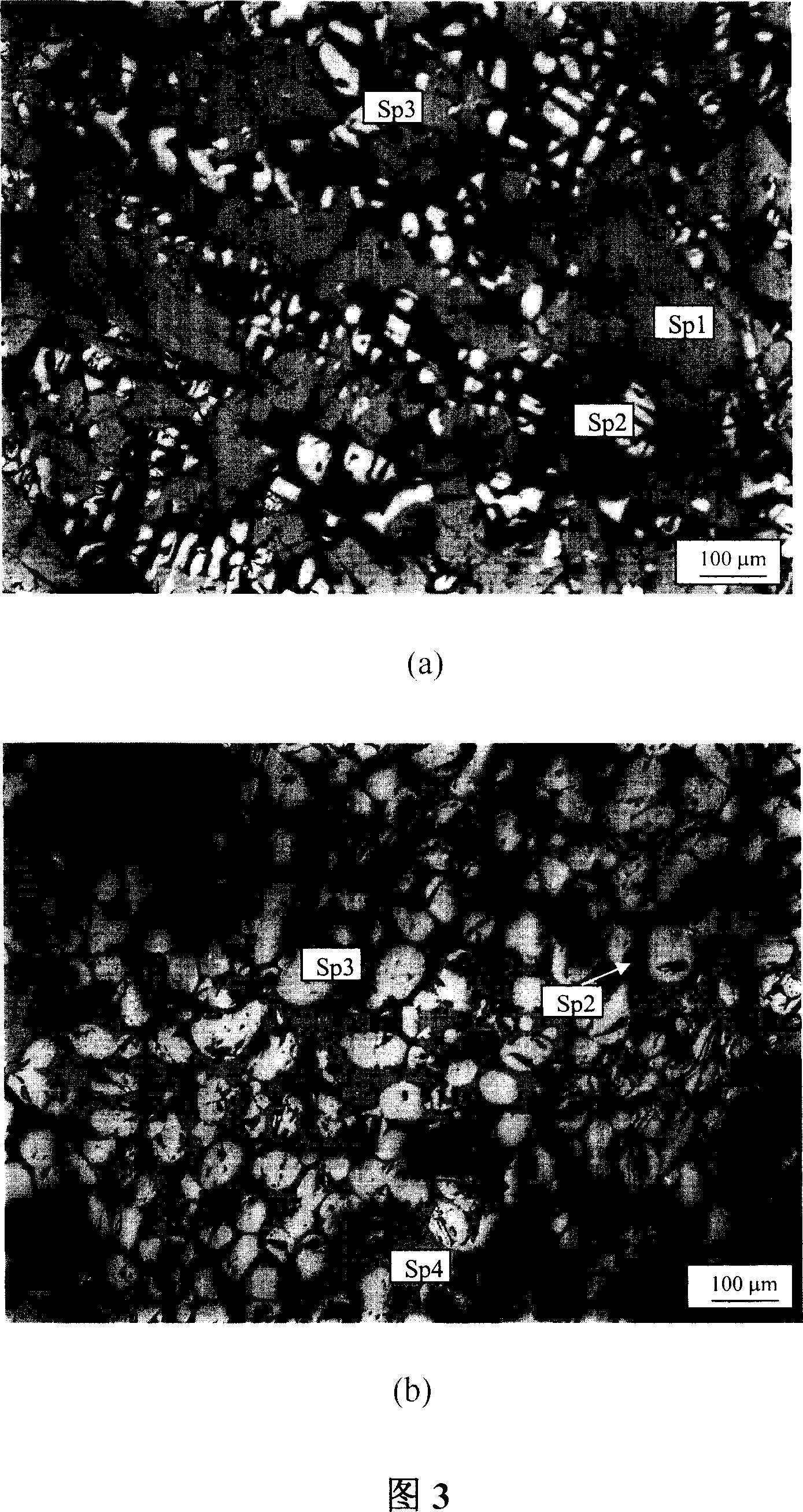

Method of producing synthetic rutile utilizing high-titanium slag

InactiveCN1919740AFacilitate chemical reactionsReasonable process designSolid waste disposalTitanium dioxideHydrometallurgyRutile

The invention discloses a manufacturing method of artificial rutile through high-titanium slag, which comprises the following steps: heating to fuse titanium slag in the slag container; adding addictive in the slag tank; blowing oxidized gas in the slag; making titanium component enriched in the rutile selectively; controlling the cooling velocity to cool slag to indoor temperature; growing rutile phase selectively; grinding the cooled condensed slag; fining; adopting wet metallurgical separating method or ore dressing separating method to separate rutile from condensed slag; obtaining artificial rutile with high-grade TiO2.

Owner:隋智通 +1

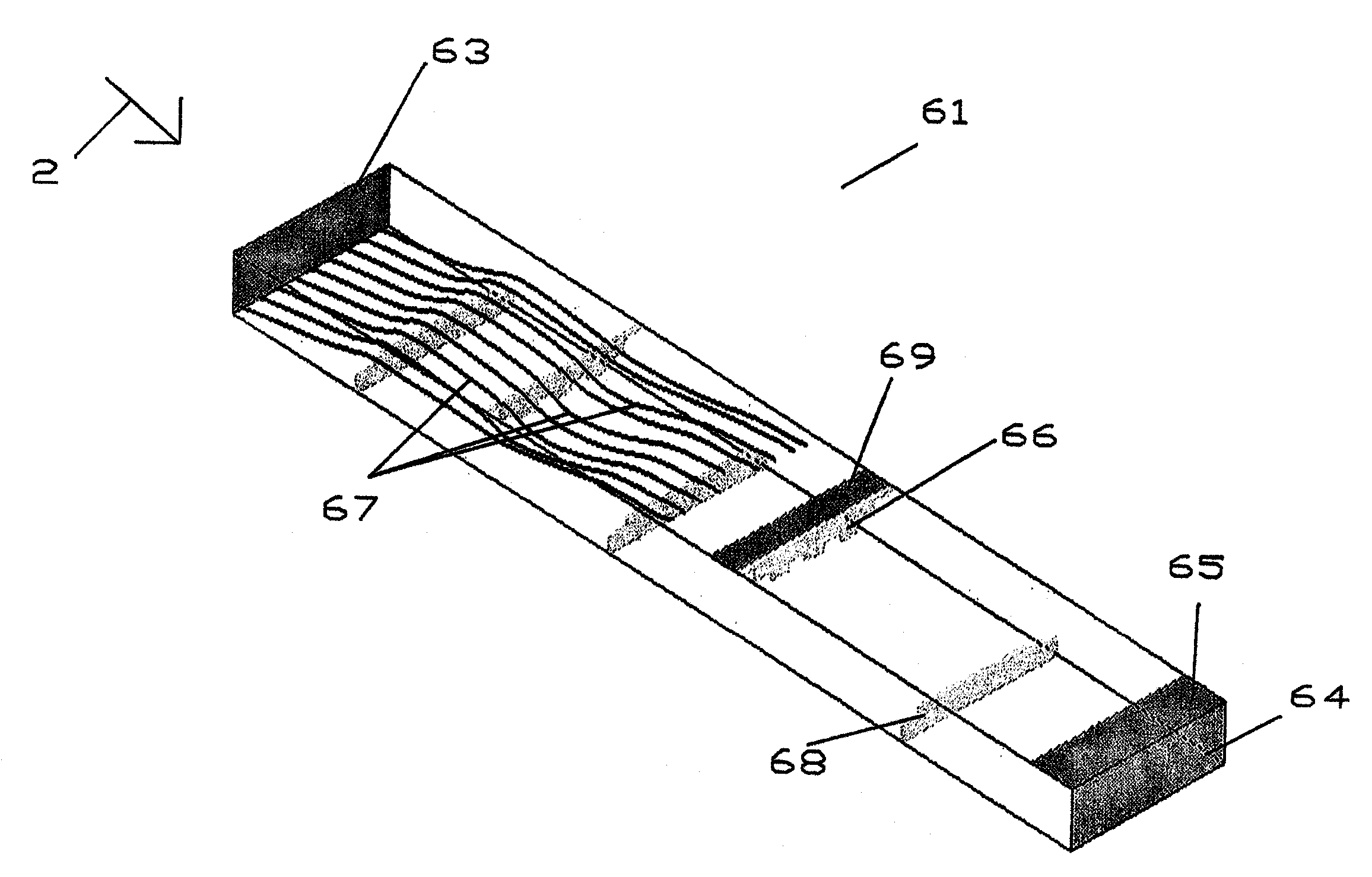

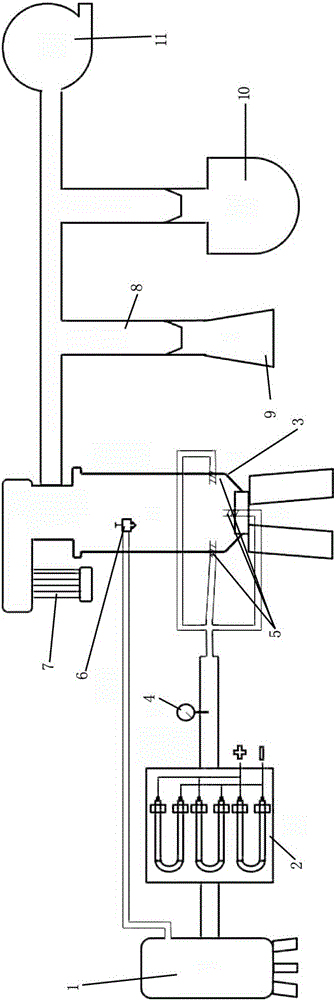

Fluidized bed type jet milling and modifying system and application thereof

ActiveCN105107595AIncrease productivityReduce labor costsMaterial granulationChemical/physical/physico-chemical processesFluidized bedSpray nozzle

The invention discloses a fluidized bed type jet milling and modifying system and application thereof. The fluidized bed type jet milling and modifying system comprises an air compressor, a heater, a jet milling and grading device, a cyclone separator, a bag collector, an induced draft fan and an atomizing nozzle. The jet milling of powder material carried by hot air is conducted; the atomizing nozzle is used for atomizing a surfactant solution and then injecting the surfactant solution into a milling cavity; the hot air is used for drying the material continuously and simultaneously providing a certain environment temperature for the coating reaction of surfactants on the surface of the material, so that the surfactants are relatively liable to crosslink and form films on the surfaces of powder particles, thereby achieving the effect of milling and modifying simultaneously. An integrated process for milling and modifying ultrafine powder is provided; the fluidized bed type jet milling and modifying system is mainly used for solving the agglomeration phenomenon caused by increase of surface energy of the powder in the ultra-fining process; the fluidity of the powder is improved, so that the high operational performance of the powder can be retained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

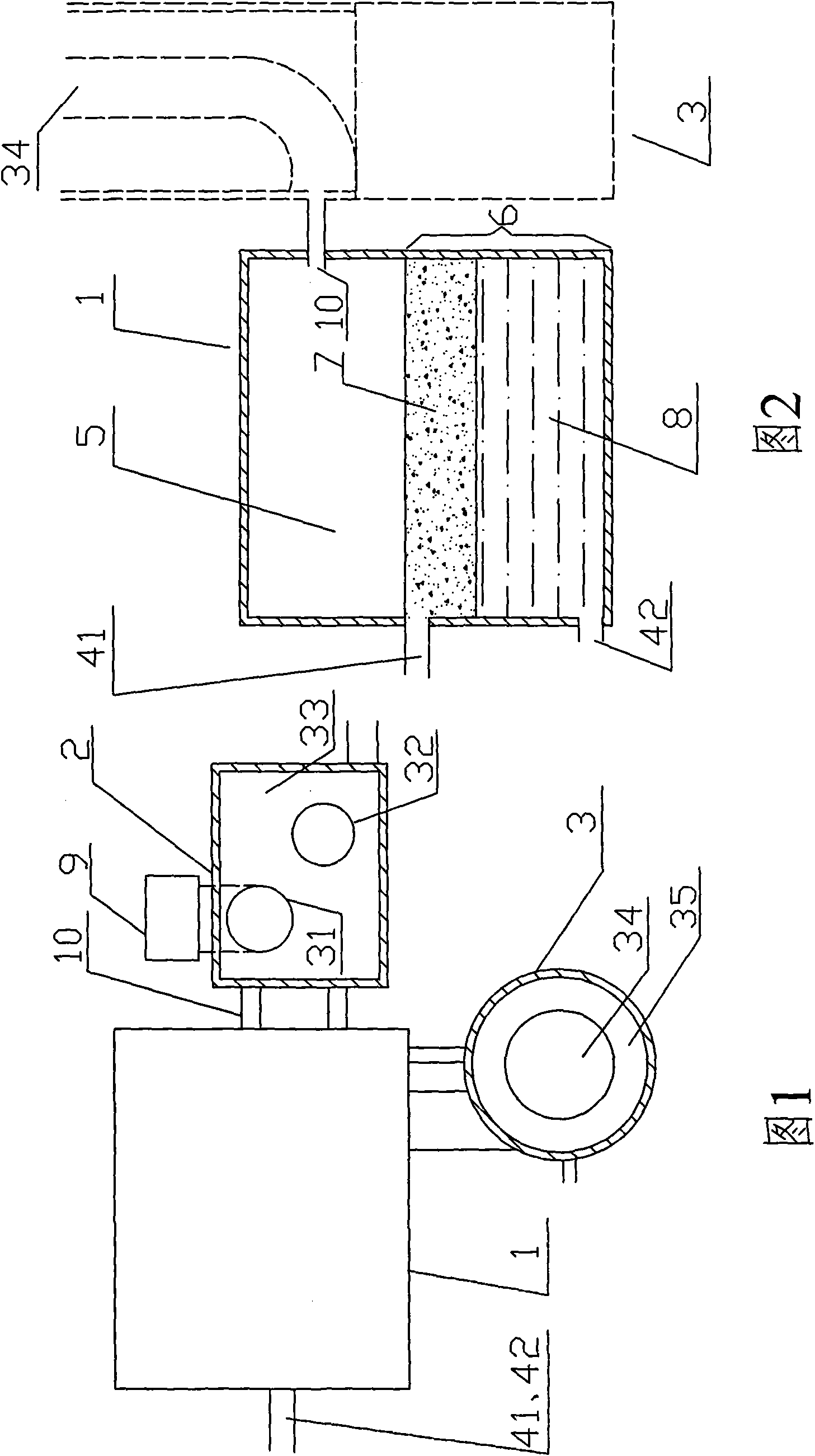

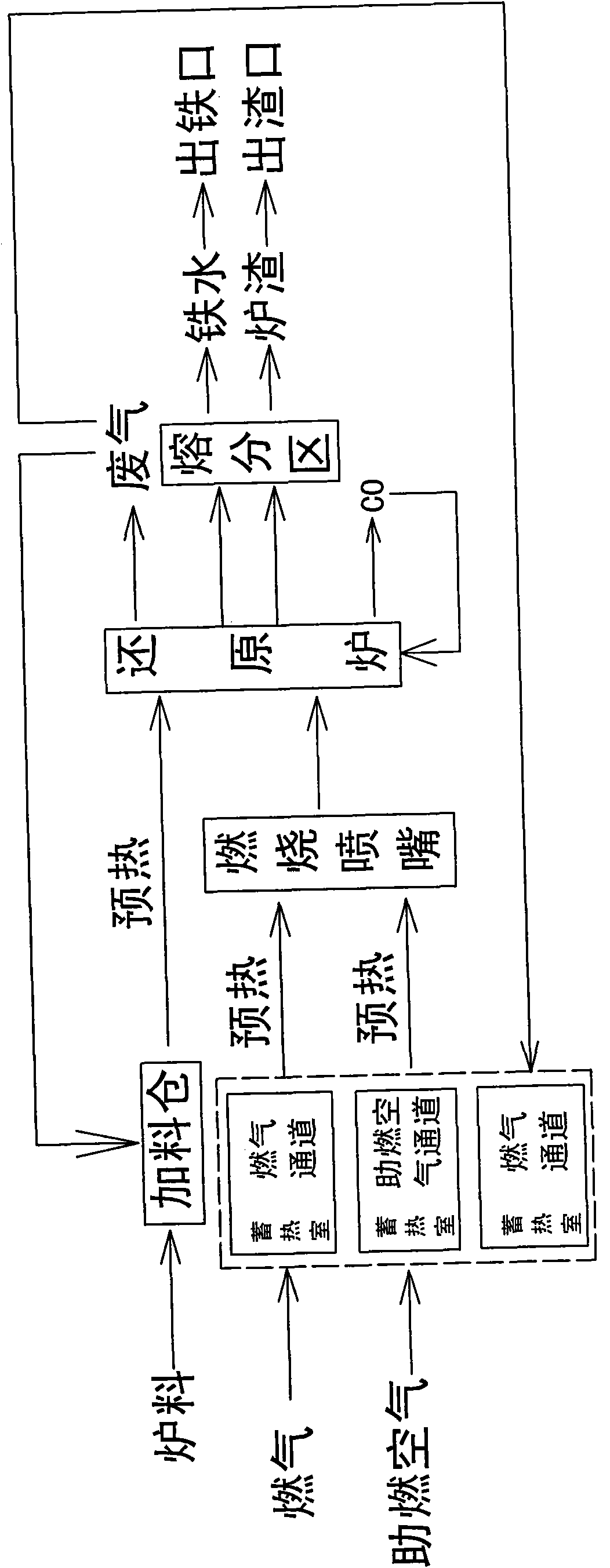

Gas-burning reducing iron-fining furnace and one-step reducing iron-fining method thereof

The invention discloses a gas-burning reducing iron-fining furnace and a one-step reducing iron-fining method thereof. The gas-burning reducing iron-fining furnace comprises a reducing furnace, a heat accumulation chamber and a feed bin, wherein the heat accumulation chamber and the feed bin are respectively used for preheating gas and furnace charges and delivering the gas and the furnace charges to the reducing furnace, and the furnace charges inside the reducing furnace are melted to be reduced into iron and realize slag-iron separation. The gas-burning reducing iron-fining furnace has simple structure, small investment and small occupying area and is used for the one-step reducing method to fine the iron. In the one-step reducing iron-fining method, raw materials, gas fuel and combustion air are preheated by the waste gas of the reducing furnace before entering the reducing furnace, therefore, the furnace charges can be melted by being supplied with lower heat energy in a reducing area so as to achieve the purpose of sufficiently utilizing the heat energy and reducing environment pollution, energy consumption and operation cost. The one-step reducing iron-fining method utilizes non-coke fuel, thereby further reducing the cost, having cleanness, environmental protection, emission reduction and high heat efficiency and being used for one-step iron-fining.

Owner:杜辉

Health-care wine and preparation method thereof

InactiveCN101948730AImprove immunityRelieve fatigueAlcoholic beverage preparationBifidus factorRhizome

The invention is comprehensive heath-care wine. Based on the mixture of fermented grape juice distilled wine and millet vinegar, Chinese herbal medicines including hawthorn, burdock root, cassia seed, cynomorium songaricum, Chinese angelica, eucommia bark, medicinal cyathula root, codonopsis pilosula, dried longan pulp, liquoric root, astragalus, cinnamon, south dodder seed, common curculigo rhizome, Chinese wolfberry, mint safflower, Chinese date, desertliving cistanche, raspberry, epimedium herb, rehmanniae vaporata and prepared tuber of multiflower knotweed are added with water and decocted by the conventional decocting method to prepare decoction; bifidus factor, zinc gluconate, citric acid and cooked white sugar are added into the dectoction; and the finished product is obtained by settling, clarifying, coarsely filtering, fining, finely filtering, stabilizing by freezing and filtering by a membrane. The product has overall health-care functions, excellent taste and high stability and adopts a simple and easy-to-implement process.

Owner:QINGDAO JINNAN DRINK

Dendrobium officinale wine brewing technology

The invention discloses a dendrobium officinale wine brewing technology which comprises the following steps that dendrobium officinale stalks are soaked for 15min by 0.5PPM ozone water; grapes are subjected to sorting, impurity removal and peduncle removal or squeezing treatment; the stalks are cut into sheets with the length less than 2mm; the sheets and pure water are squeezed into homogenate at a weight ratio of 1:1; the grapes or grape juice is put into a fermentation tank; SO2 and pectinase are sequentially added for treatment; then yeast is added for activation and fermentation; the homogenate is added to a fermentation liquid at a weight ratio of the stalks to the grapes or the grape juice of 1:(10-200); suction filtration is performed after mixed fermentation; SO2 is added for stopping the fermentation when residual sugar is less than 4g / L; natural settlement, fining, freezing, filtration and encapsulation are performed; and a finished product is prepared. The technology can ensure that active ingredients of dendrobium officinale are absorbed by a human body more easily, and are within an absorbable range of the human body; the finished product prepared by the brewing technology has effects of nourishing a stomach, promoting secretion of a body fluid, resisting a cancer, maintaining beauty, keeping young, improving immunity, protecting a blood vessel and the like; and a drinking group of wine is expanded.

Owner:ZHEJIANG XINYUANJING AGRI SCI & TECH

Refining degumming method for silk fiber and its fabrics

InactiveCN1570258AAccelerates and enhances penetrationSpeed up and enhanceUltrasonic/sonic fibre treatmentTextile fiberEngineering

This invention discloses one kind of silk textile fiber and its fabric fining come unglued method. Front it uses the low temperature plasma technology carries on to the raw silk textile fiber and its the fabric processes, substitutes the conventional fining come unglued center's pretreatment, initially practices working procedure, then the direct process duplicate practices, achieves to the silk textile fiber and its the fabric concise come unglued's goal. Because the low temperature plasma physical ability sericin the macro-molecule carries on to the raw silk textile fiber and its fabric surface shells and splatters sculpture, causes its stopped chain or sculpture dehiscence, loose, duplicate causes to practice the fining medicinal preparation to be able fast to seep, bulked, degrades (hydrolisis or enzymolysis) sericin, therefore, has the craft simply, the energy conservation is highly effective, is advantageous to the clean production and the environmental protection merit.

Owner:SUZHOU UNIV

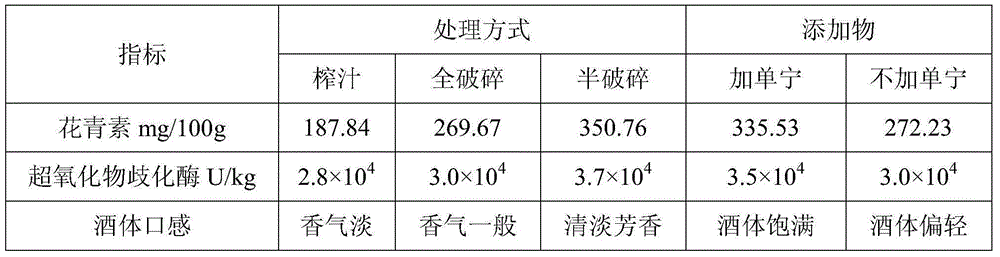

Brewing method of fermented blueberry wine

InactiveCN105087277AKeep the flavorElegant and soft aromaAlcoholic beverage preparationPectinaseGrape wine

The invention discloses a brewing method of fermented blueberry wine. The brewing method comprises the following steps: selecting Bluecrop blueberries and Duke blueberries; crushing moderately till the blueberries are in half-grain state; adding potassium metabisulfite and tannin into the half-grain blueberries, and mixing the potassium metabisulfite and tannin with the half-grain blueberries uniformly; adjusting the temperature to 20-30 DEG C, and adding pectinase into the mixture; inoculating by adopting wine brewer's yeast; fermenting under stirring every two hours till the content of residual sugar is not larger than 4g / L wherein the fermentation temperature is not higher than 30 DEG C; carrying out mechanical extruding after fermentation is finished for separating skin dregs from wine liquid; carrying out fining and clarification; carrying out stability analysis; regulating the concentration of free sulfur dioxide and the alcoholic strength; and filtering and storing. According to the brewing method, the proper blueberry variety is selected for producing the blueberry wine, thus the taste of a product is guaranteed; through the half-broken and half-grain fermentation method, the prepared blueberry wine is soft and elegant in aroma; and through color protection of tannin, the colour and luster, the taste and the nutrition of the product are guaranteed, and the wine body is relatively mature and plump.

Owner:WOLIN QINGDAO FOOD CO LTD

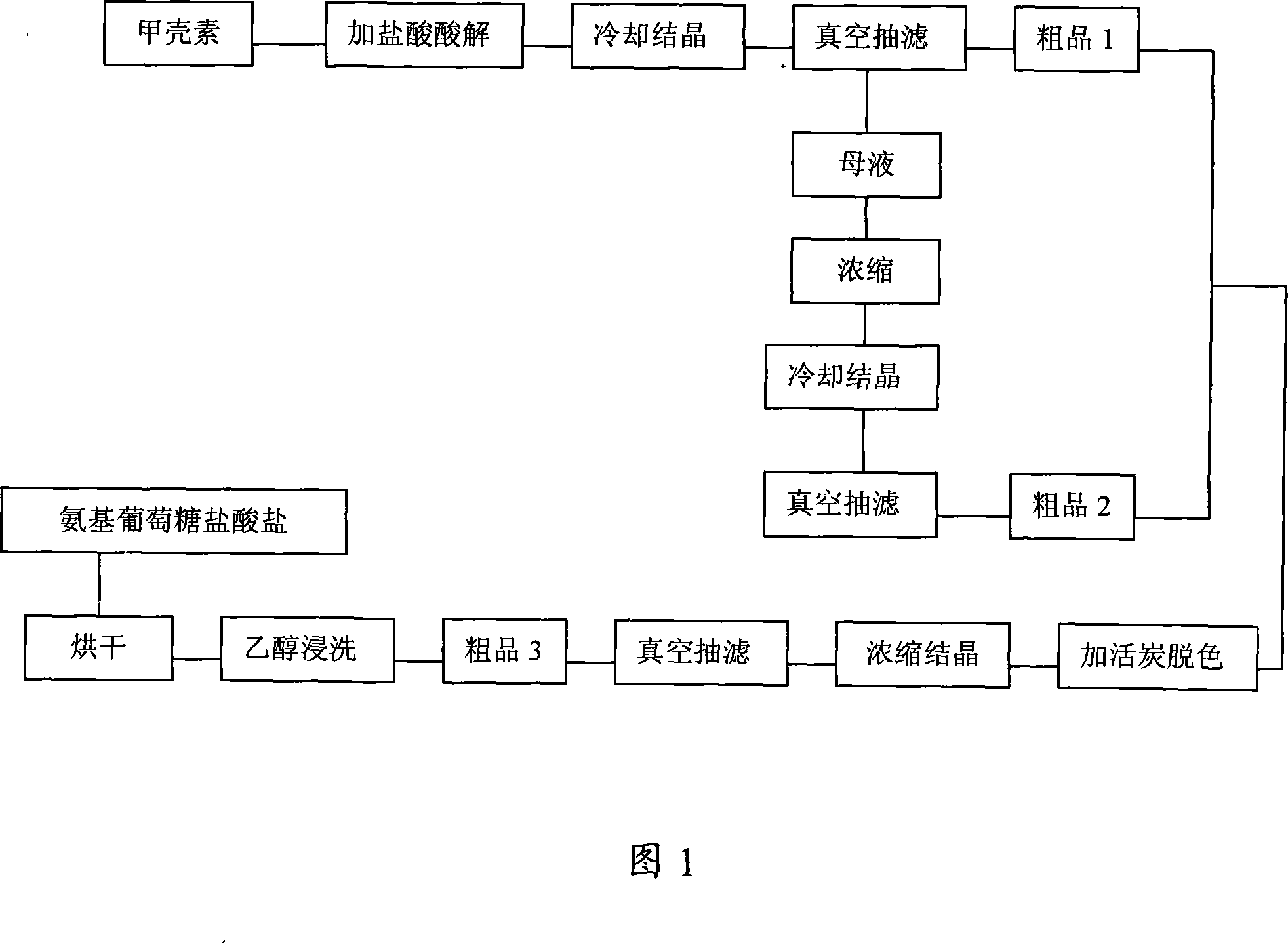

Method for preparing aminoglucose hydrochloride

The invention provides a new method that prepares glucosamine hydrochloride by adopting chitosan, which comprises the steps of the hydrolysis of hydrochloric acid, the cooling crystallization of mother liquid, the concentration of filter liquid, the cooling crystallization of concentrated solution, decolorization, the crystallization of decolorized liquid, fining, etc. The preparation method of the invention adopts the cooling crystallization firstly after the hydrolysis and the concentration of filter liquid to cause the glucosamine hydrochloride to be separated from the liquid that contains relatively high impurity content and also cause grease and impurities to be separated and suspended at the top layer of crystalline solids, thus being beneficial for removing the grease and the impurities. The preparation method of the invention can obtain the glucosamine hydrochloride with high purity and high yield in the condition that hydrochloric acid concentration is 30-32 percent and reaction temperature is 85-88 DEG C and greatly reduces the dosage of activated carbon, thus greatly saving manufacturing cost.

Owner:谢锐权

Method for making dry white wine through red grape varieties

The invention discloses a method for making dry white wine through red grape varieties. The method is characterized by comprising the process steps of determining of the grape picking period, harvesting of grapes, ear-by-ear selection, peduncle removal, grain-by-grain selection, crushing, low-temperature juice taking, low-temperature clarification, juice separation and temperature increasing, low-temperature alcohol fermentation, tank transferring, ageing or storage, fining, freezing, sterilization, filling and the like. In this way, the produced dry white wine is pale yellow or straw yellow in color, clarified, transparent and glossy. The dry white wine has the pure, active, elegant, fresh and rich fruit aroma; the wine after ageing also has complicated and rich ageing fragrance, and is soft in mouthfeel, fresh, tasty and refreshing.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Method for preparing jujube and seabuckthorn ice wine

The invention discloses a method for preparing jujube and seabuckthorn ice wine, and relates to functional ice wine. The method comprises the following steps of: crushing and pulping fresh jujube, performing color protection and enzymolysis, performing alcoholic fermentation by using active dry yeast as distiller's yeast, ageing, picking seabuckthorn at the temperature of below minus 7 DEG C, squeezing to obtain seabuckthorn juice, adding the juice into the jujube wine in a certain volume ratio, and performing low-temperature fermentation, thus obtaining the ice wine with unique flavor and health-care effect. The process flow comprises picking, cleaning, crushing, color protection, enzymolysis, juicing, inoculation, fermentation, wine pouring, fining, filtration, ageing, blending, cold and heat treatment, filtration, fine filtration, storage, sterilization and filling. According to the method, pure juice is used for complete raw juice fermentation, the alcoholic strength of the produced jujube and seabuckthorn ice wine is about 10 degrees, and the sugar degree reaches 100g / L; the health-care wine has rich nutrition, and does not contain any artificially synthesized pigment, essence or sweetening agent; the adopted raw materials are special fruits with rich resources, wide distribution and high nutrition; and the method can be used for realizing large-scale industrialized production.

Owner:JIANPING XINSHENG SEABUCKTHORN

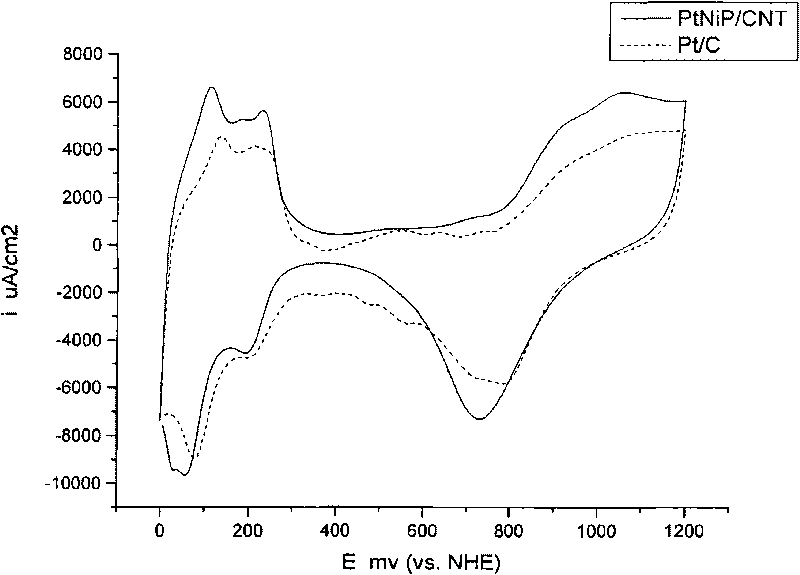

Preparation method of fuel-cell catalyst

InactiveCN101733134AAvoid corrosionReduced oxygen reduction currentCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlloyDirect development

The invention relates to a preparation method of a fuel-cell catalyst, belonging to the field of catalysts. The preparation method of the fuel-cell catalyst comprises the following steps of: using a CNT as a vector; adding sodium phosphite to a nickel sulfate and chloroplatinic acid solution; controlling the pH value and the temperature of the solution; hydrolyzing the sodium phosphite to release P; forming an alloy solid solution by the P generated through the self reduction of the sodium phosphite and reduced Pt and Ni, wherein the addition of Ni stops the remove of platinum particles of the fuel-cell catalyst, the addition of P inhibits the corrosion of non-noble metal, the formation of the alloy realizes the fining and the decentralization of the Pt particles, and the particle diameters of the fuel-cell catalyst are uniformly distributed. A test result shows that the fuel-cell catalyst has excellent property. The method is convenient and easy to operate, reduces the cost by doping Ni to noble metal, also effectively inhibits the corrosion of the non-noble metal and meets the requirements of the direct development and the utilization of the field of direct methanol fuel cells and the like.

Owner:BEIJING UNIV OF TECH

Method for fermenting waxberry wine by full fruits

InactiveCN103361216AReduce process stepsSimple processMicroorganism based processesAlcoholic beverage preparationCold treatmentYeast

The invention relates to a method for fermenting waxberry wine by full fruits and belongs to the field of fruit processing. The method is characterized in that the full fruits of waxberries are used as raw material and do not need to be pulped and squeezed (previous researches take waxberry normal juice as a fermentation raw material); white sugar is added to adjust components; after the juice of the waxberries is squeezed, an active dry yeast is added to ferment for 2-3 days; an aroma increasing yeast is added to ferment for 7-8 days; and then the full fruit fermented waxberry wine is prepared by the steps of fermenting, separating wine dregs, classifying by a classifying agent, ageing, carrying out cold treatment, finely filtering and the like. The method disclosed by the invention adopts the full fruits of waxberries to ferment; compared with traditional juice fermentation, a process step of squeezing the juice is saved and a process is simplified; the equipment investment of an enterprise is saved; and volatilized aroma components, free amino acids and a color of the waxberry wine obtained by fermenting the full fruits are better than those of the waxberry wine obtained by juice fermentation. The method disclosed by the invention is suitable for middle-size and small-size waxberry processing enterprises and has great significance for improving the consumption amount of waxberry processing raw materials, pulling the price of the waxberries and accelerating the sustainable development of a waxberry processing industry.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

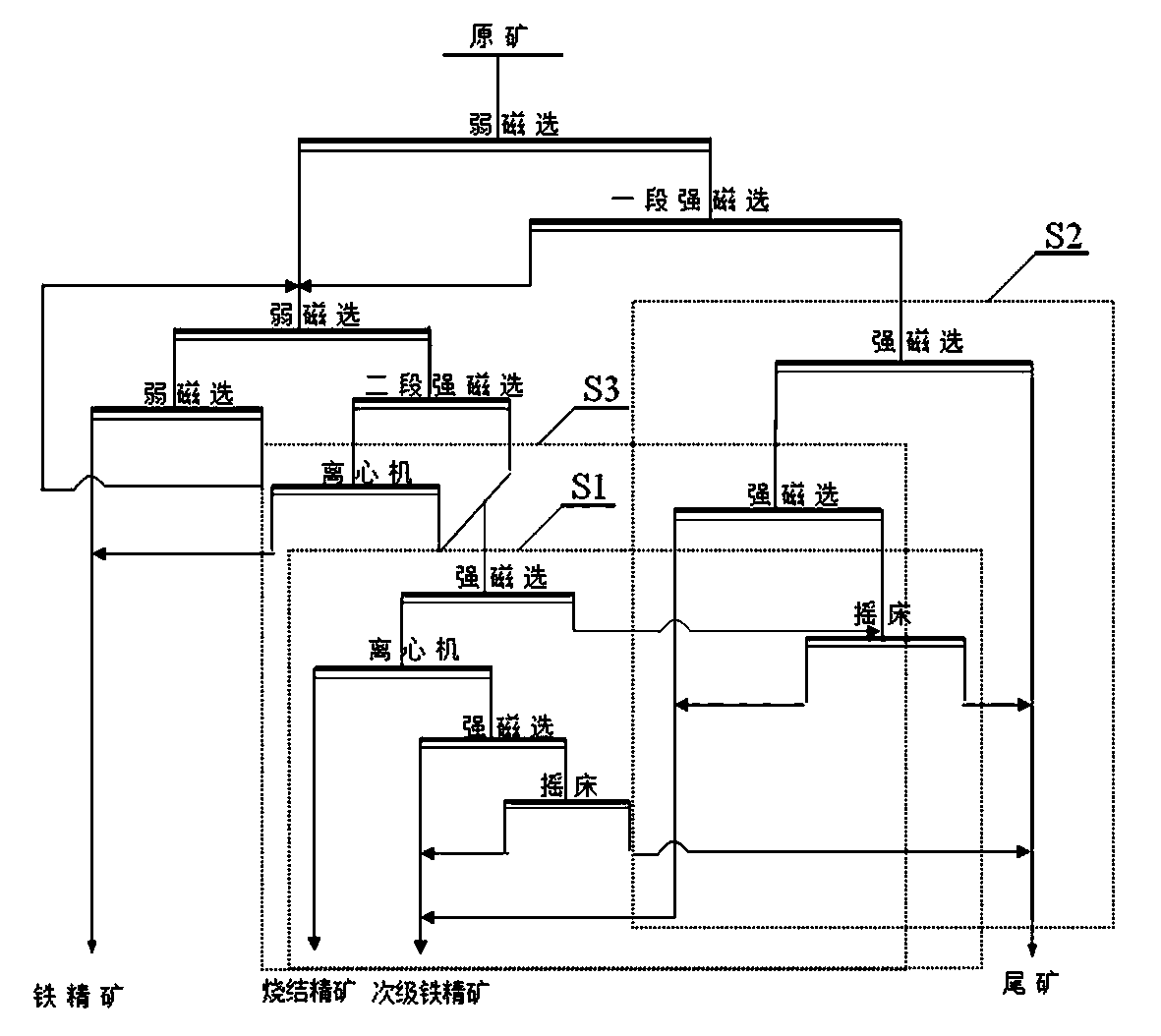

Separation process of ferrous high silicate type iron ore

ActiveCN103894283AOvercome the disadvantages of independent processingReduce secondary selectionWet separationResource utilizationFinings

The invention discloses a separation process of ferrous high silicate type iron ore. The process includes classifying, degrading tailings and upgrading. Tailing degrading includes S1 tailing degrading and S2 tailing degrading. The separation process has the advantages that the process is free of calcination and reverse floatation, short is process flow, low in process management requirement, low in operation cost, low in environmental pollution and suitable for industrial production; the iron grade of fine ferrous silicate type iron concentrate is increased, silicon content is lowered, the grade of fine high silicate type iron tailings is lowered, the grade of the iron concentrate is increased by about 10%, and the silicon content is lowered by about 10%; the iron ore in the tailings can be recycled effectively, the comprehensive grade of total tailings is lowered from 16.2% to about 10.53%; the separation process is environmental friendly, low in energy consumption, low in cost, high in fining and concentration degree, and capable of effectively increasing comprehensive resource utilization rate, increasing benefits, saving energy and reducing emission.

Owner:KUNMING UNIV OF SCI & TECH +1

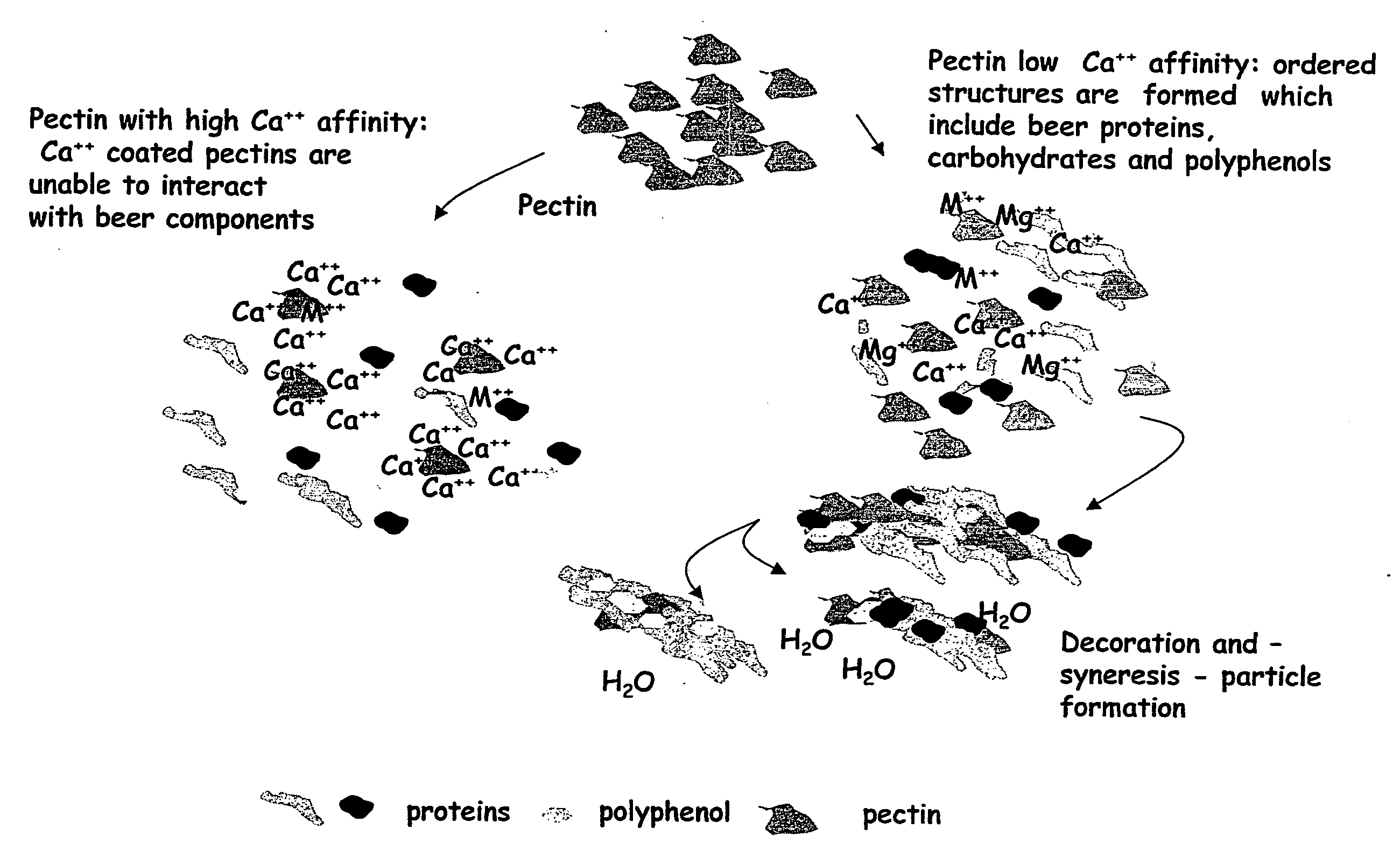

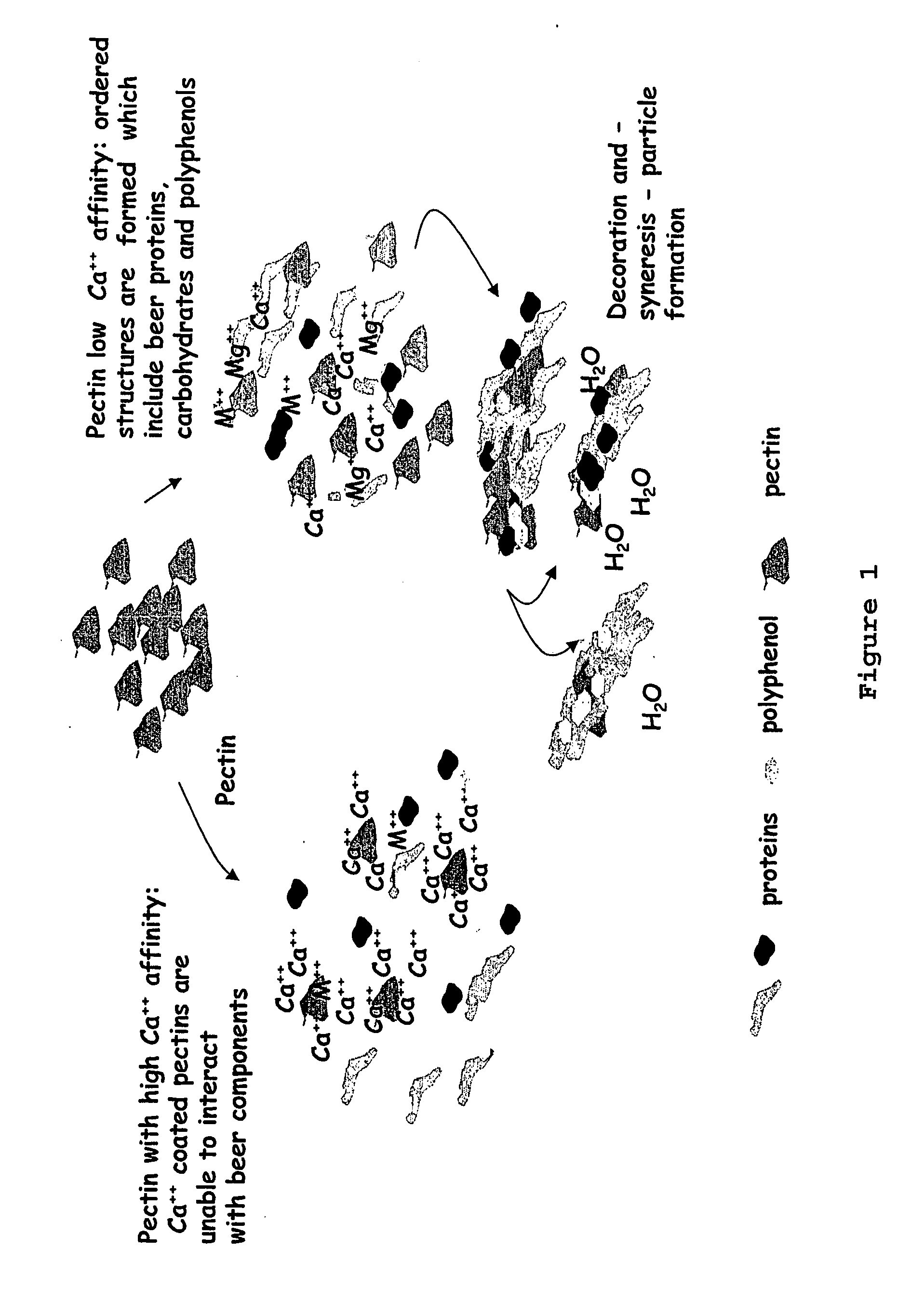

Methods and Compositions for Fining Beverages

ActiveUS20090169691A1Effective fining activityEnhanced finings effectBeer fermentationAnimal feeding stuffFiningsChemistry

Owner:DANSTAR FERMENT AG

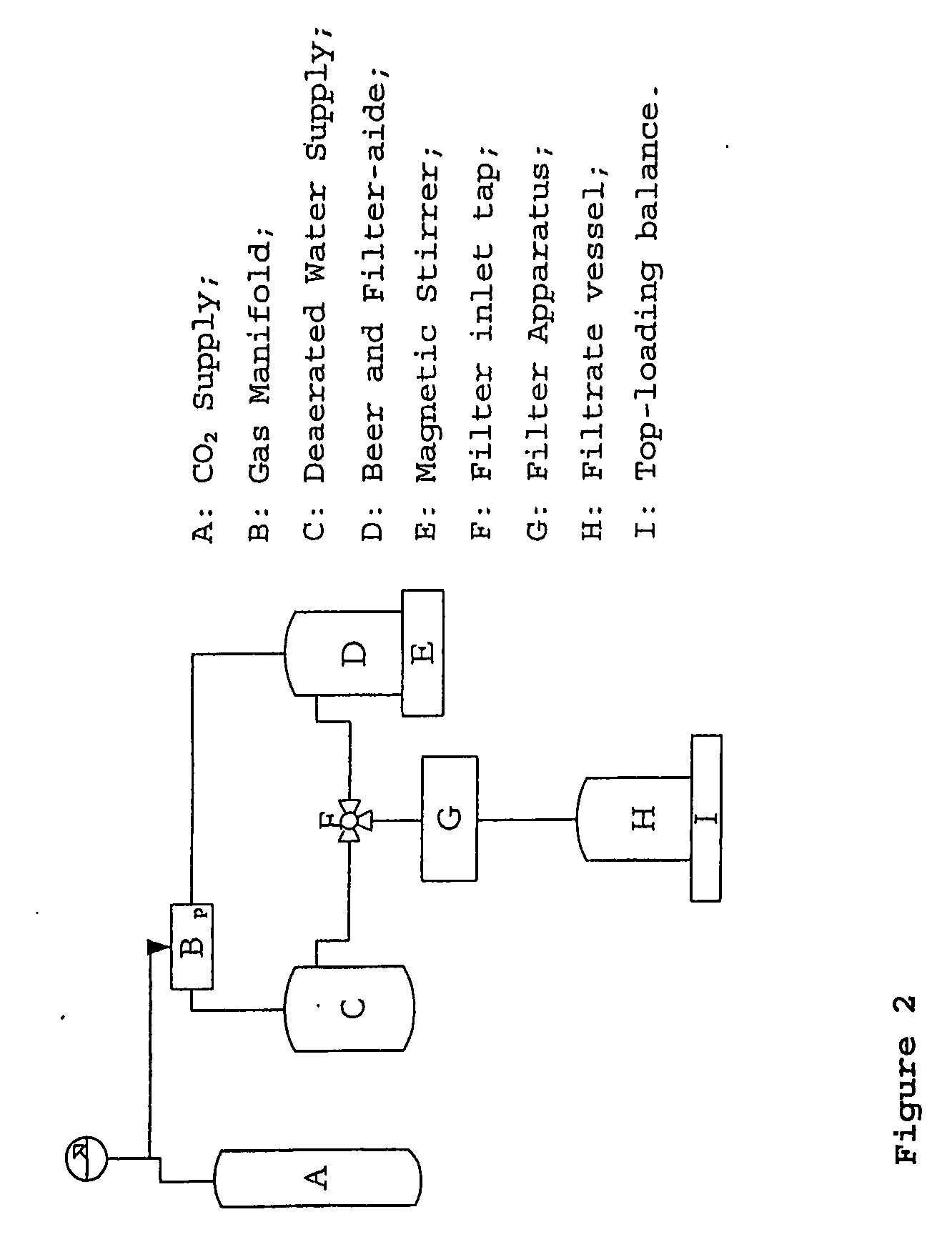

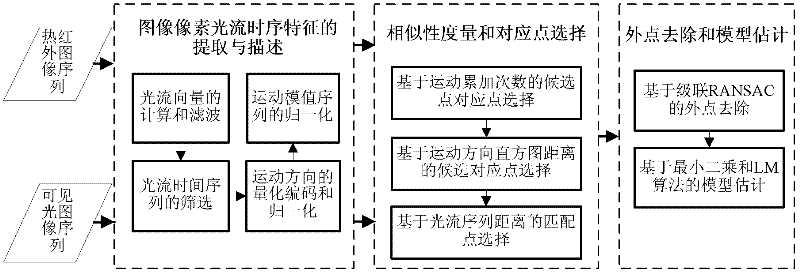

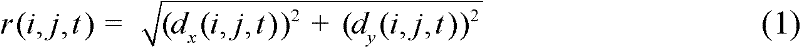

Automatic registration method of visible light and thermal infrared image sequences

ActiveCN102609945AHigh precisionTroubleshoot auto-registration issuesImage analysisPoint pairSimilarity measure

The invention discloses an automatic registration method of visible light and thermal infrared image sequences, which solves the technical problem that the existing registration method of the visible light and thermal infrared image sequences has bad registration accuracy. A technical scheme is as follows: using the normalization light stream timing characteristic and a three-layer gradual fining similarity measurement method of an image pixel to select a candidate homologous point pair among visible light and thermal infrared image sequences; and using the movement timing characteristic of the image pixel to replace the whole characteristic of a movement target. The method effectively overcomes the problem caused by inaccurate movement detection, improves the arithmetic robustness, can be used for registration of image sequences under a crowded monitoring condition with frequency movement, improves the registration accuracy of the image sequences, and reduces an average pixel error relative to reference data to be within a range of 2 pixels from [2.03, 6.9] pixels in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Brewing method of fresh mulberry fruit wine

InactiveCN108949443AGuaranteed contentGuaranteed qualityAlcoholic beverage preparationFruit wineFruit juice

The invention provides a brewing method of fresh mulberry fruit wine. The brewing method comprises the following steps: (1) selecting raw materials; (2) carrying out low-temperature crushing; (3) carrying out low-temperature fermentation; (4) separating fruit juice from pulp; (5) fermenting the fruit juice again; and (6) removing wine lees, and carrying out fining and clarification. The alcoholicstrength of the wine reaches 12%, the residual sugar is less than 3.0g / L, and the volatile acid is less than 0.5g / L. The brewing method has the advantages that the volatile acid in the mulberry wine is controlled by virtue of a key technique in multiple process links, the increase of volatile acid in the mulberry wine is controlled by virtue of multiple links, and the problems that the mulberry wine is difficult to brew, and the brewing of the mulberry wine fails because volatile acid is easily increased are solved. The fresh mulberry fruit wine is attractive purple red and clear and has typical fragrance of mulberries, elegant fragrances of red fruits, pure wine fragrance, balanced, coordinated, smooth and active taste and durable aftertaste.

Owner:TIANJIN AGRICULTURE COLLEGE

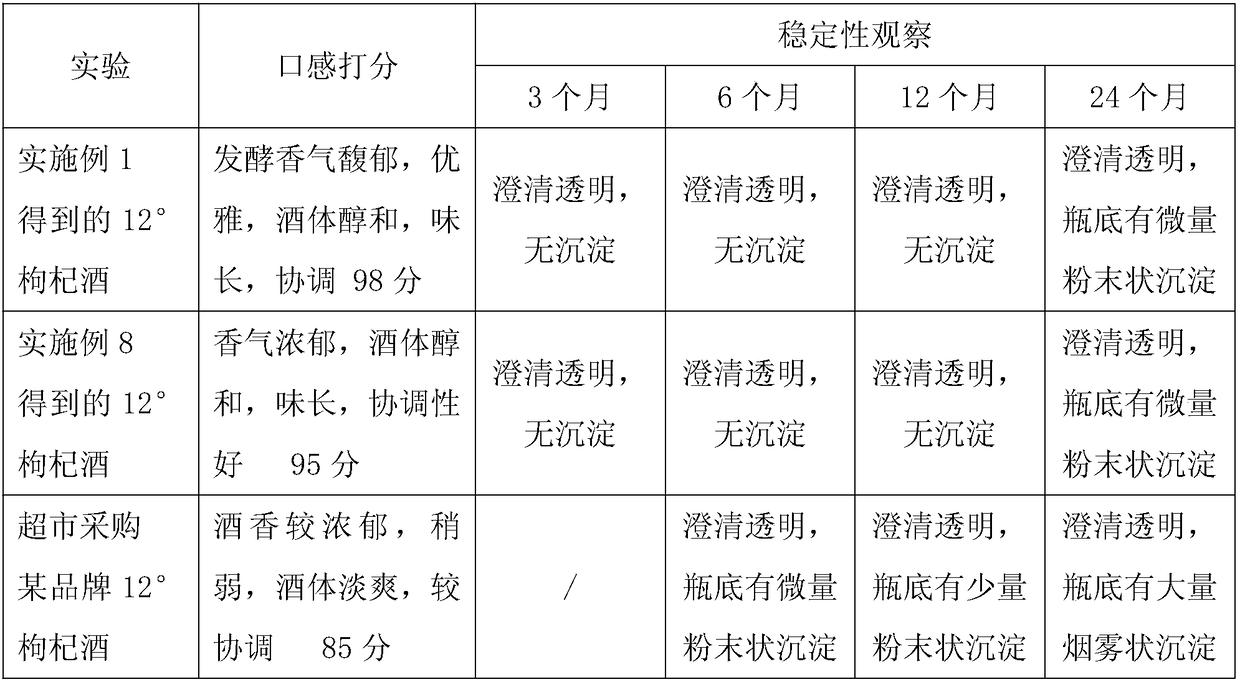

Production method of fructus lycii wine

PendingCN108251253AIncrease aromaHigh nutritional valueAlcoholic beverage preparationFiningsChemistry

The invention discloses a production method of fructus lycii wine. The production method comprises the following steps: preparing fructus lycii juice; carrying out step fermentation; carrying out intermediate treatment and heat treatment; carrying out alcoholic fermentation, aging, stabilized fining or carrying out ultrafiltration treatment and filtering to obtain mature fructus lycii wine; then blending and filling to obtain the fructus lycii wine. The mature fructus lycii wine can be used for preparing fructus lycii wine with high alcohol content and sparkling the fructus lycii wine. The production method of the fructus lycii wine, disclosed by the invention, has the advantages that the aroma and nutritional value of the fructus lycii wine are improved and the stability of the fructus lycii wine is improved.

Owner:周子云

Double temperature quenching and strong toughening treatment method for cold forging die

The present invention relates to cold forging die toughening method and is especially one double temperature cold forging die-toughening quenching process. The double temperature cold forging die-toughening quenching process includes high temperature quenching and crystal fining quenching at relatively low temperature. In the high temperature quenching, the cold forging die is first vacuum heated, then oil quenched for 10-20 min while air is filled and tempered at 250-550 deg.c. In the subsequent crystal fining quenching at relatively low temperature, the cold forging die is first vacuum heated slowly to 850 deg.c, maintained for 20-60 min, further heated to 970-1160 deg.c and maintained, then oil quenched for 10-20 min while air is filled, and finally tempered at 450-550 deg.c for three or four times. The said process can raise the toughness and increase the service life of cold forging die obviously.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com