Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

919 results about "Ethoxylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethoxylation is a chemical reaction in which ethylene oxide adds to a substrate. It is the most widely practiced alkoxylation, which involves the addition of epoxides to substrates. In the usual application, alcohols and phenols are converted into R(OC₂H₄)ₙOH where n ranges from 1 to 10. Such compounds are called alcohol ethoxylates. Alcohol ethoxylates are often converted to related species called ethoxysulfates. Alcohol ethoxylates and ethoxysulfates are surfactants, used widely in cosmetic and other commercial products. The process is of great industrial significance with more than 2,000,000 metric tons of various ethoxylates produced worldwide in 1994.

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

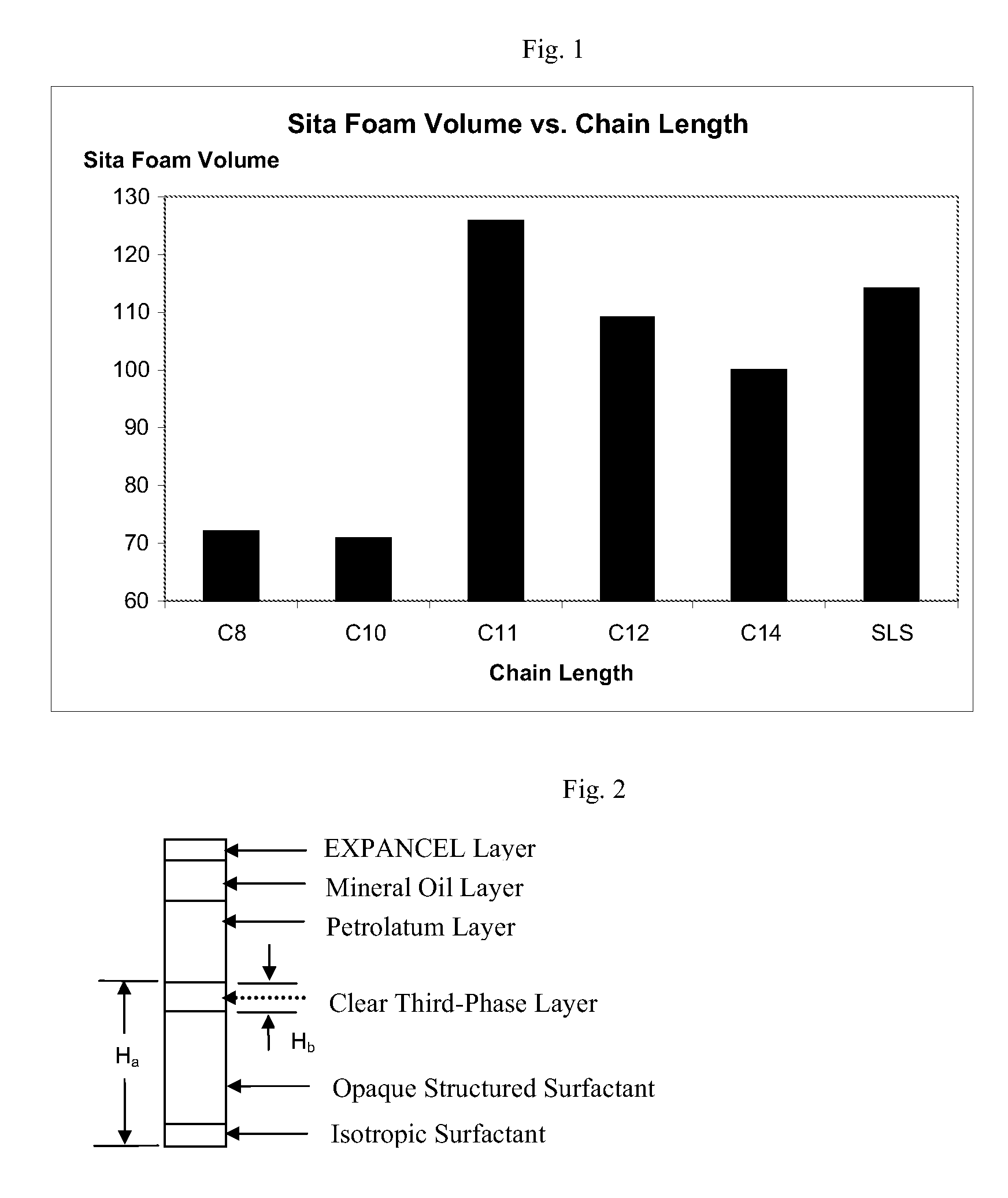

Personal Care Compositions Comprising Undecyl Sulfates

A personal care composition utilizing undecyl sulfates and / or ethoxylated undecyl sulfates (undeceth sulfates).

Owner:THE PROCTER & GAMBLE COMPANY

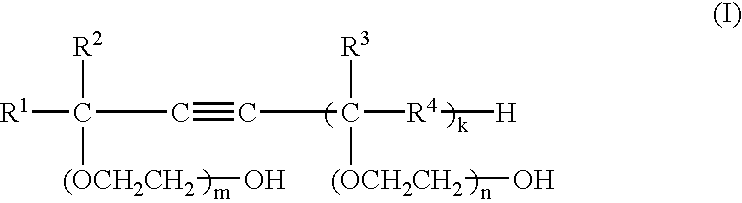

Water-soluble resin composition

InactiveUS6555607B1Improved coating propertiesEasy to diffuseFilm/foil adhesivesSemiconductor/solid-state device manufacturingResistAlcohol

A water-soluble resin composition comprising (1) a water-soluble resin, (2) a water-soluble crosslinking agent, (3) at least one of surface active agents selected from acetylene alcohols, acetylene glycols, polyethoxylates of acetylene alcohols and polyethoxylates of acetylene glycols, and (4) a solvent consisting of water or a mixture of water and a water-soluble solvent. This water-soluble resin composition is applied onto a resist pattern, then heated to crosslink by an acid supplied from the resist, followed by development to remove the non-crosslinked water-soluble resin coating layer. This water-soluble resin composition is excellent in coating characteristics on steps of resist patterns and in dimensional regulation upon fining of patterns so that resist patterns such as trench patterns and hole patterns can effectively be fined.

Owner:MERCK PATENT GMBH

Liquid dispersion comprising dibenzylidene sorbital acetals and ethoxylated nonionic surfactants

InactiveUS6102999ALow viscosityInexpensive fluid dispersionOrganic chemistryTransportation and packagingPeristaltic pumpPolyolefin

This invention relates to a fluid dispersion of at least one dibenzylidene sorbitol acetal derivative. The sorbitol acetal derivative is useful as a clarifying agent for polyolefins and the inventive fluid dispersion permits improvements in the handling and processing of and mixing within the polyolefin composition. The inventive dispersion must be shelf stable, retain its nucleating effects, be compatible with polypropylene (and other polyolefins), and possess both short-term and long-term viscosities which permit acceptable transport through a standard polyolefin-manufacturing peristaltic pump. The preferred inventive dispersion thus comprises 3,4-DMDBS and at least one ethoxylated nonionic surfactant having an HLB of greater than about 8.5. Preferred surfactants include those selected from the group consisting essentially of ethoxylated sorbitan (C8-C22) monoesters and ethoxylated nonyl-phenol ethers. The inventive dispersion may be introduced within any polyolefin composition, preferably polypropylene, which may then be molded into any shape or form. A method of producing a polyolefin plastic utilizing the inventive dispersion is also provided.

Owner:MILLIKEN & CO

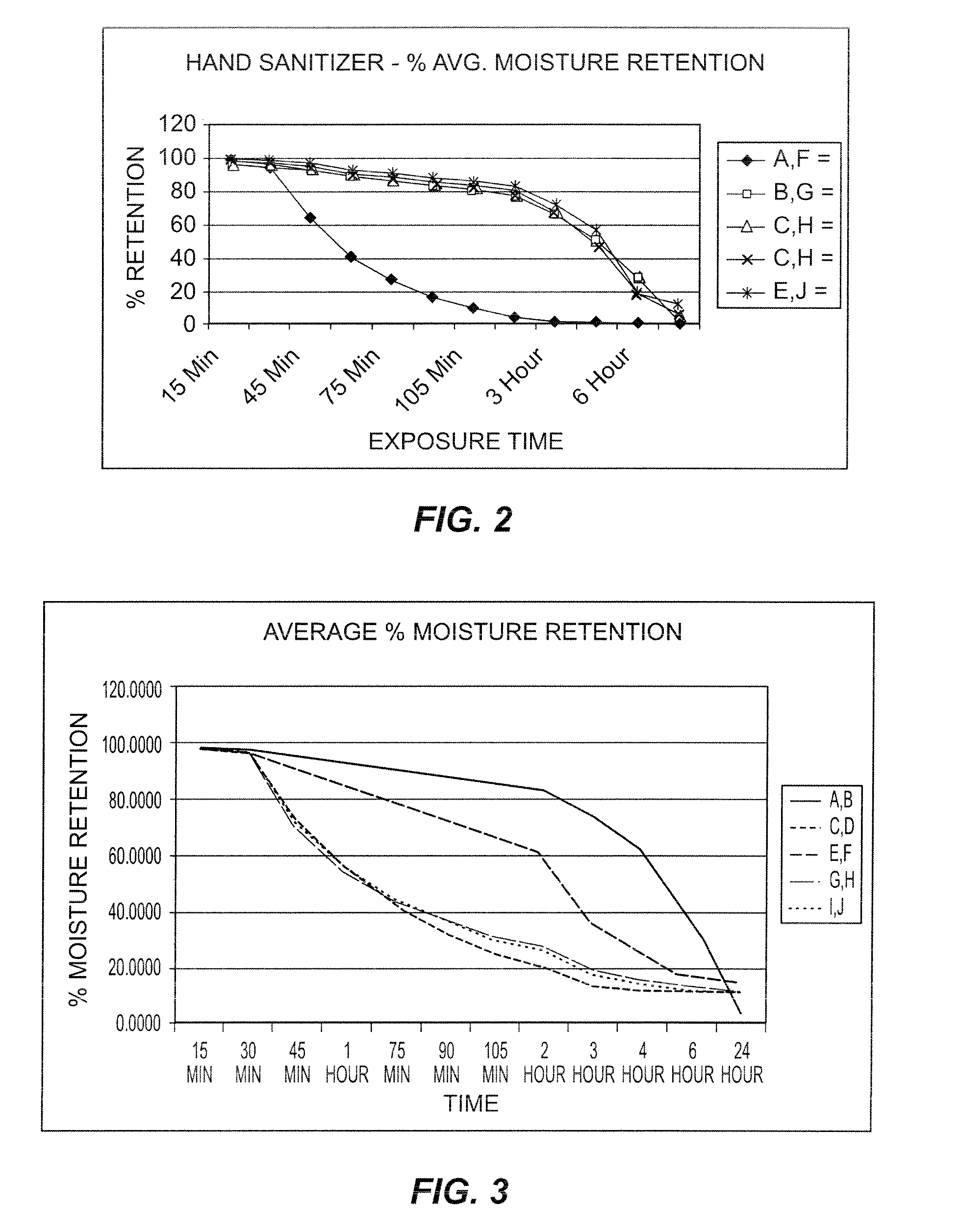

Alcohol-containing antimicrobial compositions having improved efficacy

InactiveUS20070281999A1Improve efficacyReduce skin irritationSalicyclic acid active ingredientsBiocideOrganic acidAlcohol

Antimicrobial compositions having a rapid antiviral and antibacterial effectiveness, and a persistent antiviral effectiveness, are disclosed. The antimicrobial compositions contain (a) a disinfecting alcohol, (b) a blend containing a C12 to C22 alcohol and an ethoxylated C12 to C22 alcohol, such as a cetearyl alcohol and cetereth-20 blend, a cetearyl alcohol, steareth-20, and steareth-10 blend, or a mixture thereof, (c) an optional organic acid, and (c) water.

Owner:DIAL CORPORATION

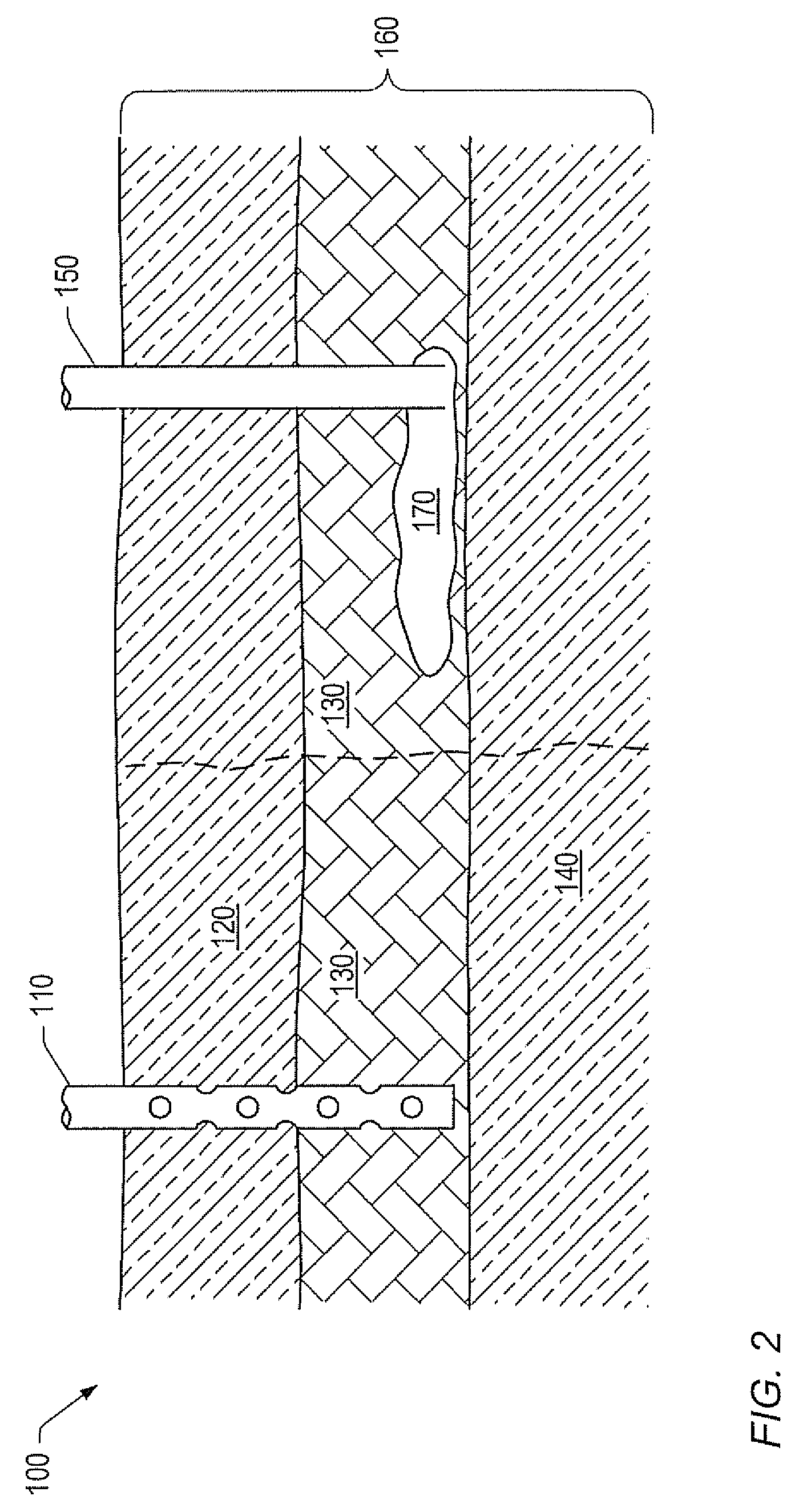

Non-wood fiber plastic composites

This invention is directed to an extrudable compound, an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol and sorbitan, and ethylene bisamides made from fatty acids containing 6-10 carbons and composites manufactured through such processes which simulate conventional wood products. Another embodiment of the invention is directed to a composition containing polymer, a cellulosic fiber from an agricultural waste product and a lubricant containing a mixture of an alkylene bisamide derived from a C10-C18 is fatty acid and an alkaline earth salt of a fatty acid.

Owner:ARXADA LLC

Laundry pre-treatment or pre-spotting compositions used to improve aqueous laundry processing

InactiveUS6204233B1Good water solubilitySubstantial thickening capacityOrganic detergent compounding agentsSurface-active detergent compositionsEthylene oxidePre treatment

The ability of aqueous laundry compositions to remove organic hydrophobic soils, such as oily, greasy or particulate soils, from a laundry item is substantially improved by pre-spotting or pre-treating such a soiled item with a treatment composition having a surfactant comprising a unique hydrophillic ethoxylate surfactant with less than two moles of ethylene oxide or a or blend of at least two surfactant compositions with a blended HLB value of about 7-12. The blend of surfactants with this HLB value penetrates soils and renders the soil more easily removed from the item using aqueous laundry detergent. The treatment composition can be used in a liquid or solid form and can be applied to individual laundry items in the form of a solid stick or liquid spray prior to introduction to the laundry machine. Laundry items can also be contacted in the laundry machine with the pre-spot or pre-treatment composition in the form of an aqueous presoak, preflush, prewash, or other step prior to the cleaning step. A preferred laundry machine comprises an institutional tunnel washer.

Owner:ECOLAB USA INC

Hydrocolloid adhesive mass useful for medical purposes

The present invention relates to a novel hydrocolloid adhesive mass useful for medical purposes, characterized in that said hydrocolloid adhesive mass comprises:a) 0.2 to 5 parts by weight of an ethoxylated sorbitan fatty acid ester;b) 20 to 50 parts by weight of a hydrocolloid;c) 32 to 120 to parts by weight of an adhesive matrix made up of one or more polymers selected from poly(styrene / olefin / styrene) block copolymers, low-molecular polyisobutylenes and high-molecular polyisobutylenes, and one or more compounds selected from sticky resins, or tackifying resins, plasticizers, polybutenes, antioxidants, ethylene / vinyl acetate copolymers, butyl rubbers and ethylene / propylene block copolymers; andd) 0 to 15 parts by weight of an acrylate copolymer with a glass transition temperature below -20° C. It further relates to the use of this hydrocolloid adhesive mass for the production of dressings, especially for the treatment of superficial, deep, chronic or acute dermo-epidermal lesions, exudative wounds and bums.

Owner:LABORATOIRE URGO

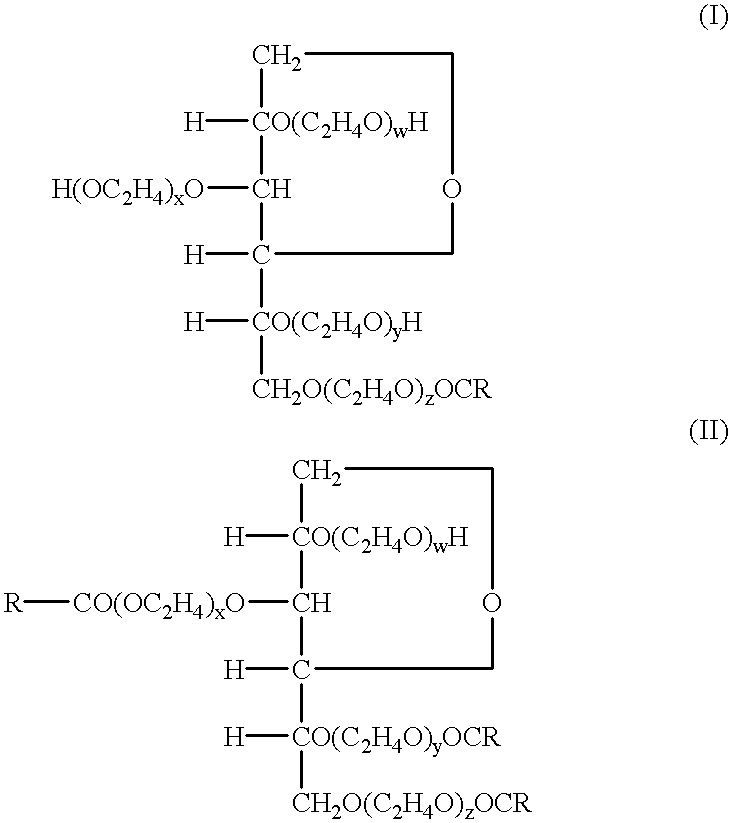

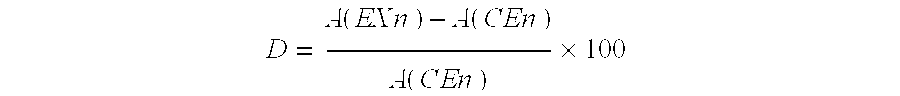

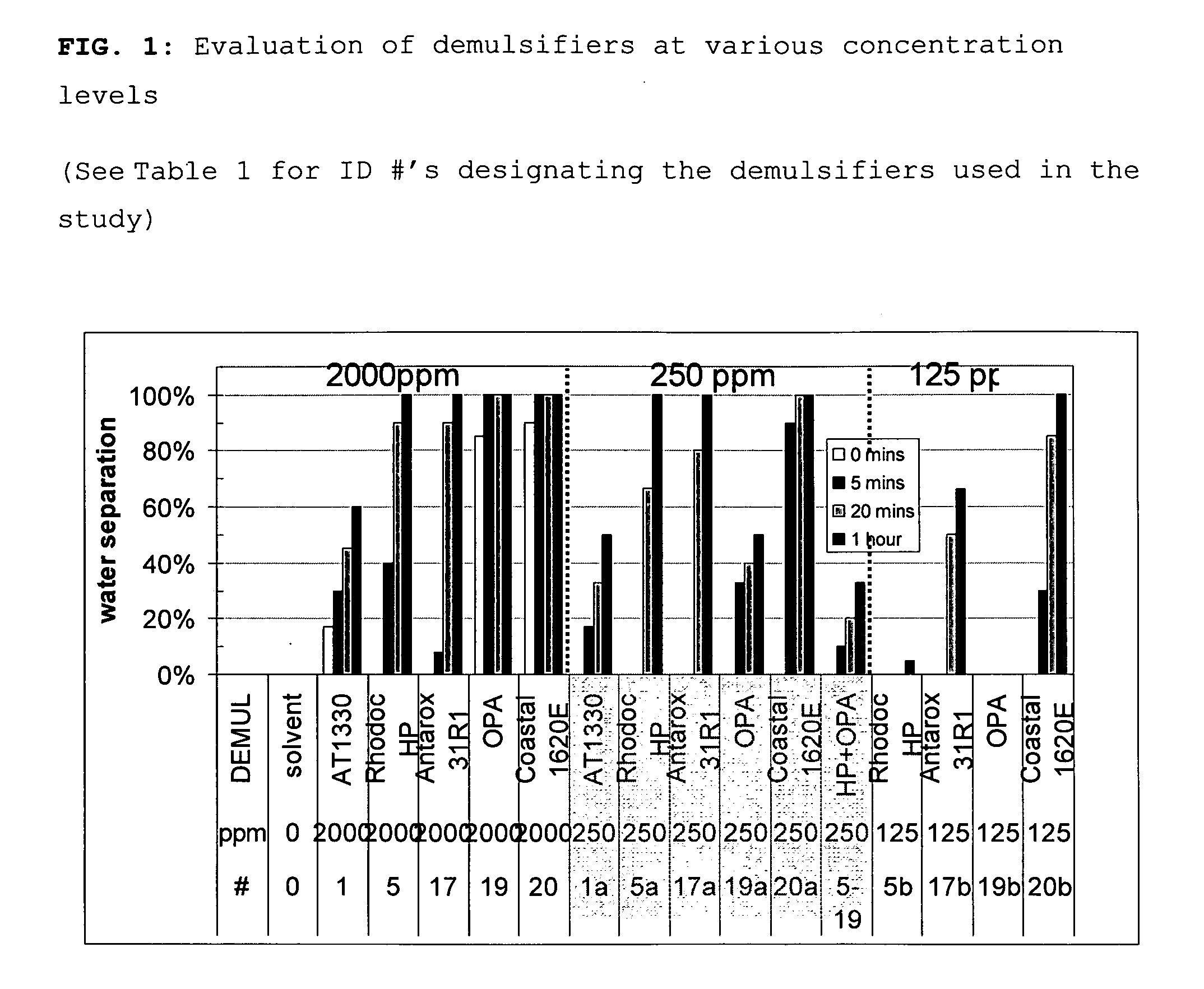

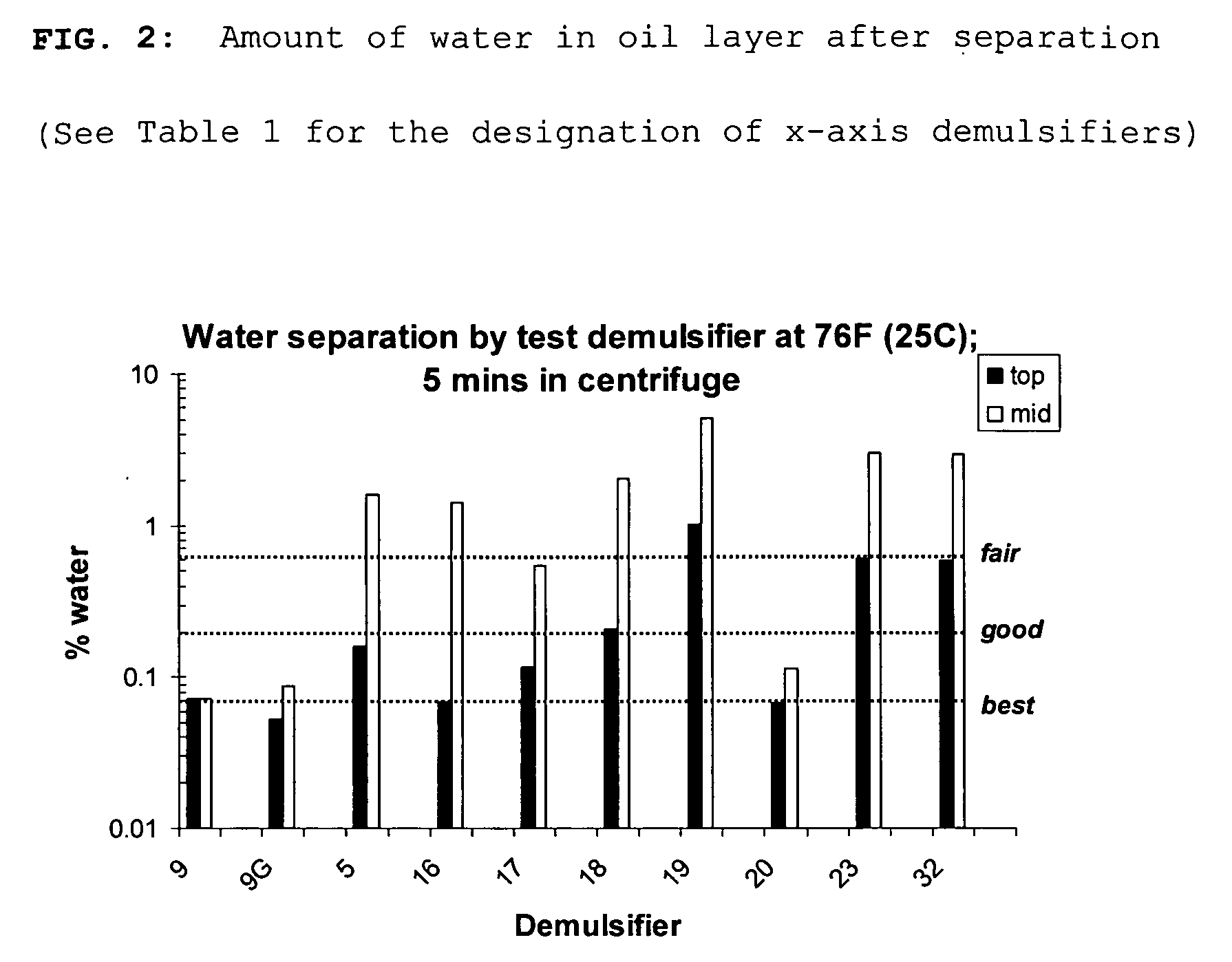

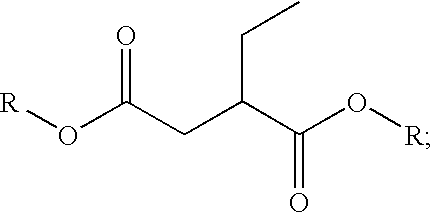

Demulsifiers in solvent base for separating emulsions and methods of use

InactiveUS20090149557A1Improve performanceGuaranteed to workOther chemical processesNon-miscible liquid separationPolymer scienceActive agent

Demulsifiers containing an anionic surfactant selected from alkylsulfosuccinates, alkylphosphonic acids, and their salts; a nonionic surfactant selected from ethylene oxide / propylene oxide copolymers, ethoxylated fatty acids of polyethylene glycol, terpene alkoxylates, and modified alkanolamides; and solvent bases comprising blends of dibasic esters. Methods for breaking emulsions using such demulsifiers and solvent bases are also disclosed.

Owner:RHODIA OPERATIONS SAS

Tuned conductive coatings and blends from intrinisically conductive polymers and processes for making same

InactiveUS6099757AProcess environmental protectionEasy to controlConductive materialNon-conductive material with dispersed conductive materialPolyesterMethacrylate

A composition comprises a) from about 80 to 99.5 percent by weight of a functionalized film-forming polymer matrix; b) from about 0.5 to 20 percent by weight of an intrinsically conductive polymer dispersed in the matrix; wherein the functionalized film-forming matrix controls the electrical conductivity in the composition, within a range of less than 5 orders of magnitude from about 105 to about 1010 ohm / square, and is selected from the group consisting of acyclic organic hydroxyl compounds, and acrylates and methacrylates, containing at least one functionality selected from the group consisting of urethanes, epoxies, glycols, hydroxyls, polyesters, ethoxylates and propoxylates. The present invention also provides processes for making a conductive coating or blend compositions.

Owner:AMERICHEM INC

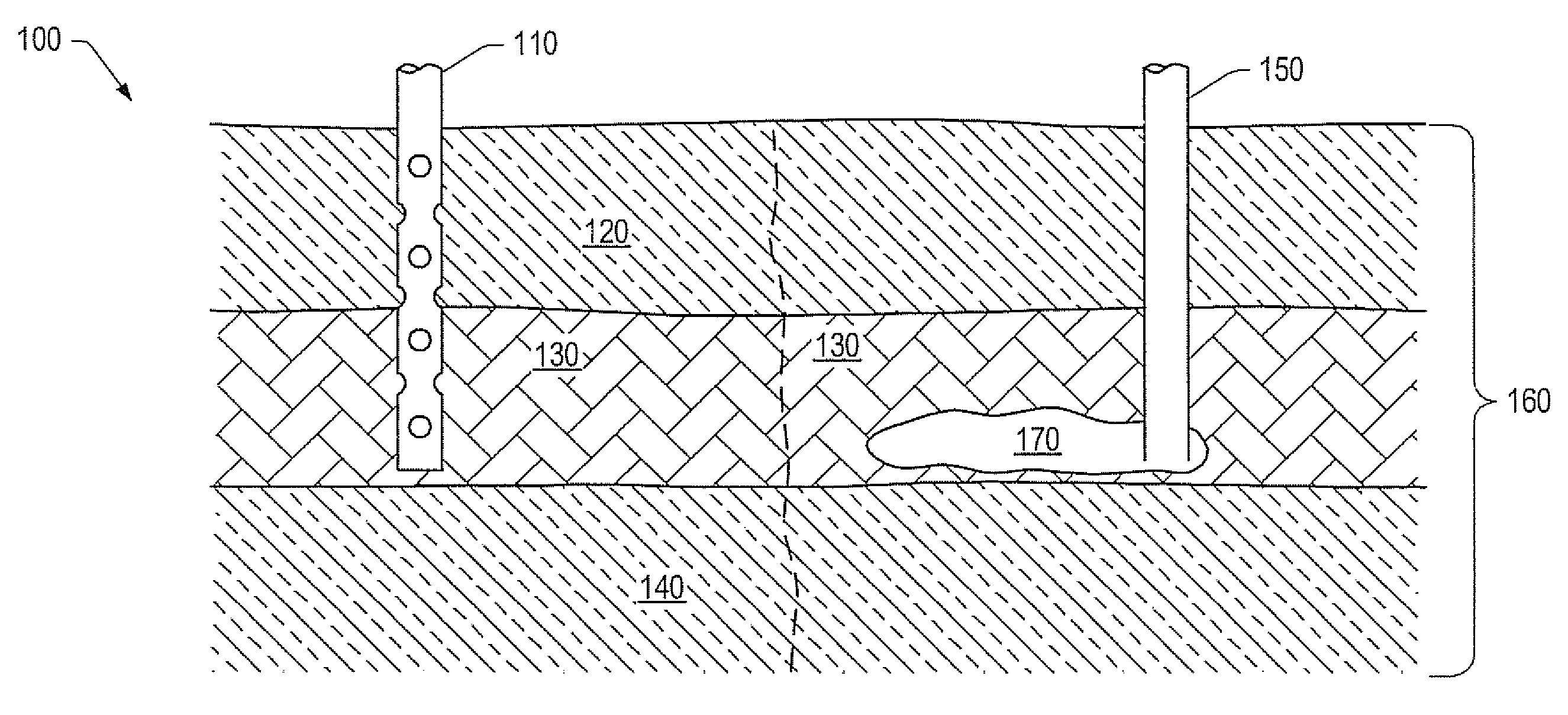

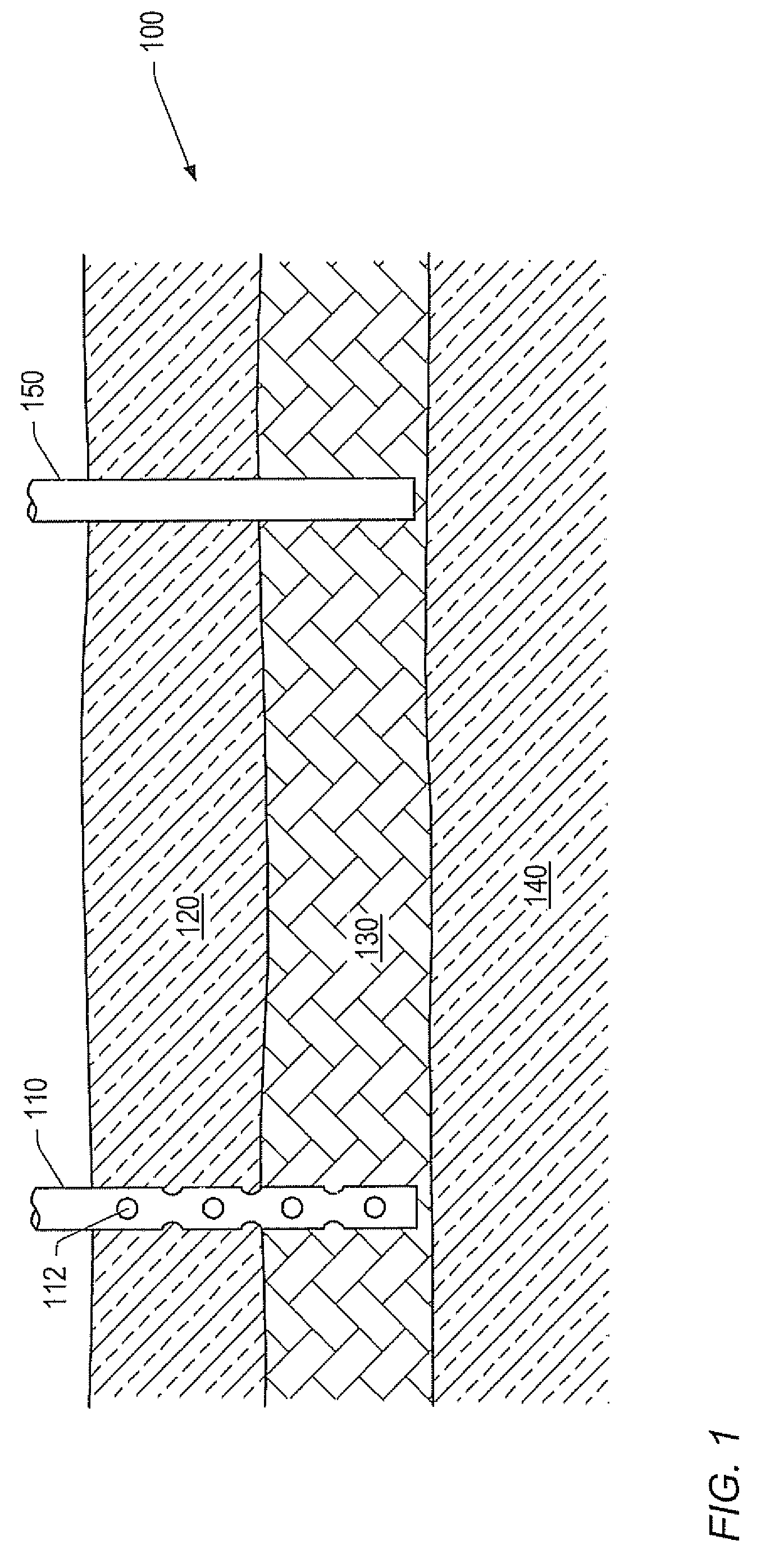

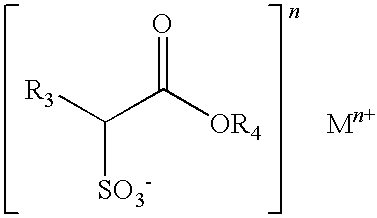

Method and composition for enhanced hydrocarbons recovery

InactiveUS20090203557A1High hardnessHigh salinityTransportation and packagingMixingAlcoholEthoxylation

The present invention provides a method of treating a hydrocarbon containing formation comprising (a) providing a hydrocarbon recovery composition to at least a portion of the hydrocarbon containing formation, wherein the composition comprises one or more internal olefin sulfonates having 17 or more carbon atoms, (b) adding water and / or brine from the hydrocarbon formation to the composition, (c) adding a solubilizer which comprises an ethoxylated alcohol wherein the alcohol before ethoxylation had an average molecular weight of at least about 220 and (d) allowing the composition to interact with hydrocarbons in the hydrocarbon containing formation. The solubilizer may comprise less than about 0.1 wt %, preferably from about 0.02 to about 0.05 wt %, of the total composition and it may have from about 5 to about 9 moles of ethylene oxide per mole of alcohol.

Owner:SHELL OIL CO

Vaccine formulations

ActiveUS7691368B2Improve stabilityStable and safe and easily administrableAntibacterial agentsBiocideAdjuvantNon ionic

The present invention relates to oil-in-water emulsions, their use as adjuvants, and pharmaceutical, immunologic, or vaccine compositions that may comprise the same. In one embodiment, the oil-in-water (O / W) emulsion may comprise an aqueous solution containing an immunogen, a mineral oil, a non-ionic lipophilic ethoxylated fatty alcohol and a non-ionic hydrophilic surfactant. In another embodiment, the oil-in-water (O / W) emulsion may comprise an aqueous solution containing an immunogen, a non-ionic lipophilic surfactant, a mineral oil and a non-ionic hydrophilic ethoxylated fatty alcohol. The present invention also encompasses a method of making a vaccine composition using the adjuvant of the instant invention, the vaccine composition so obtained and methods of use.

Owner:MERIAL INC

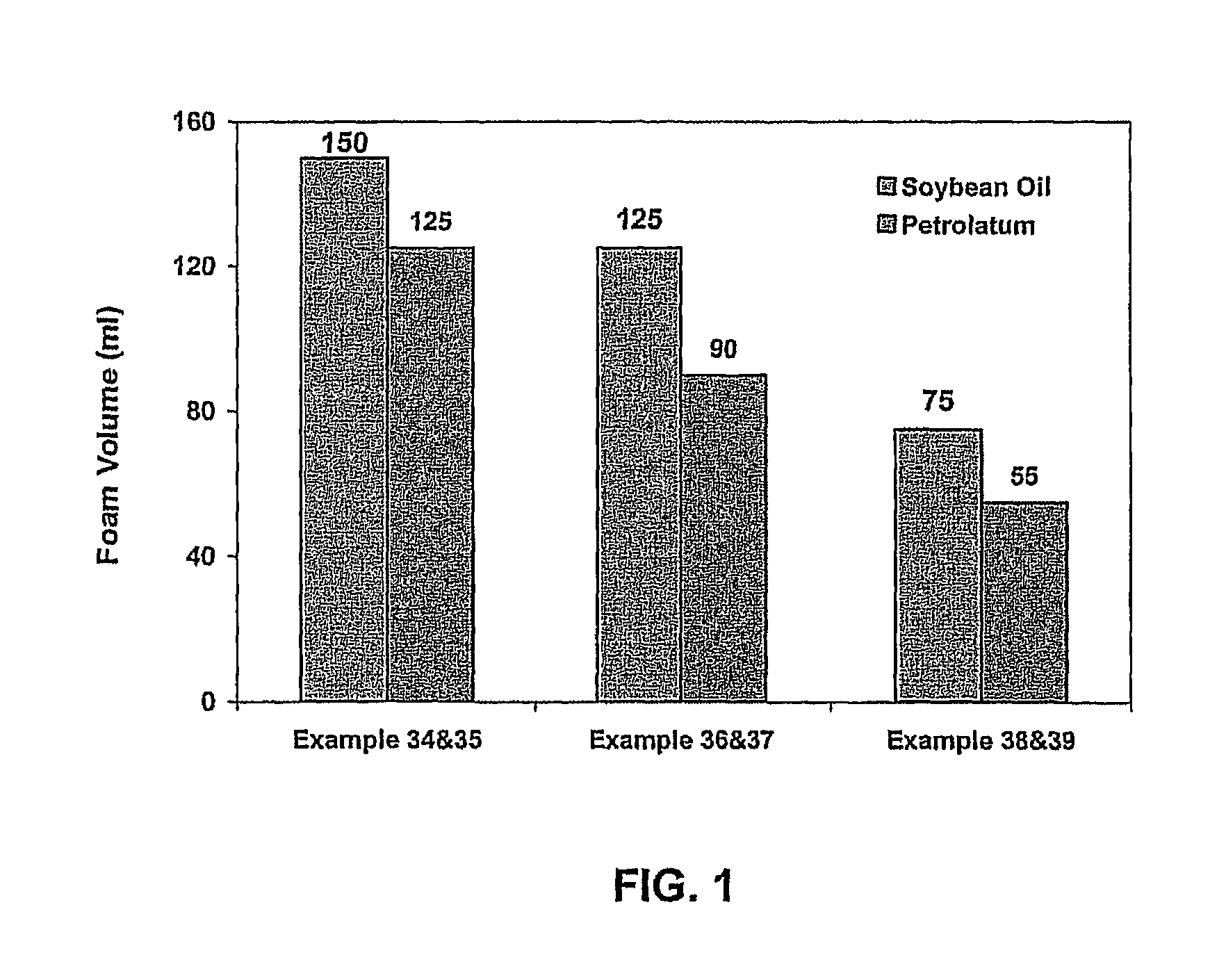

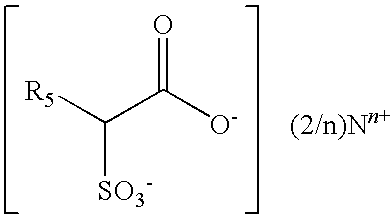

Liquid cleansing composition

A personal cleansing composition exhibiting enhanced skin feel (i.e., enhanced skin softness, reduced skin irritation, reduced residue, and reduced greasy, tacky, or tight skin feel), enhanced foaming and lather, and good cleansing, more specifically, a personal cleansing composition comprising a mixture of alpha sulfonated alkyl esters or sulfonated fatty acids, or salts thereof, with an alkyl sulfoacetate or ethoxylated alkyl sulfoacetate, or salts thereof, secondary surfactants, and optional additives.

Owner:STEPAN COMPANY

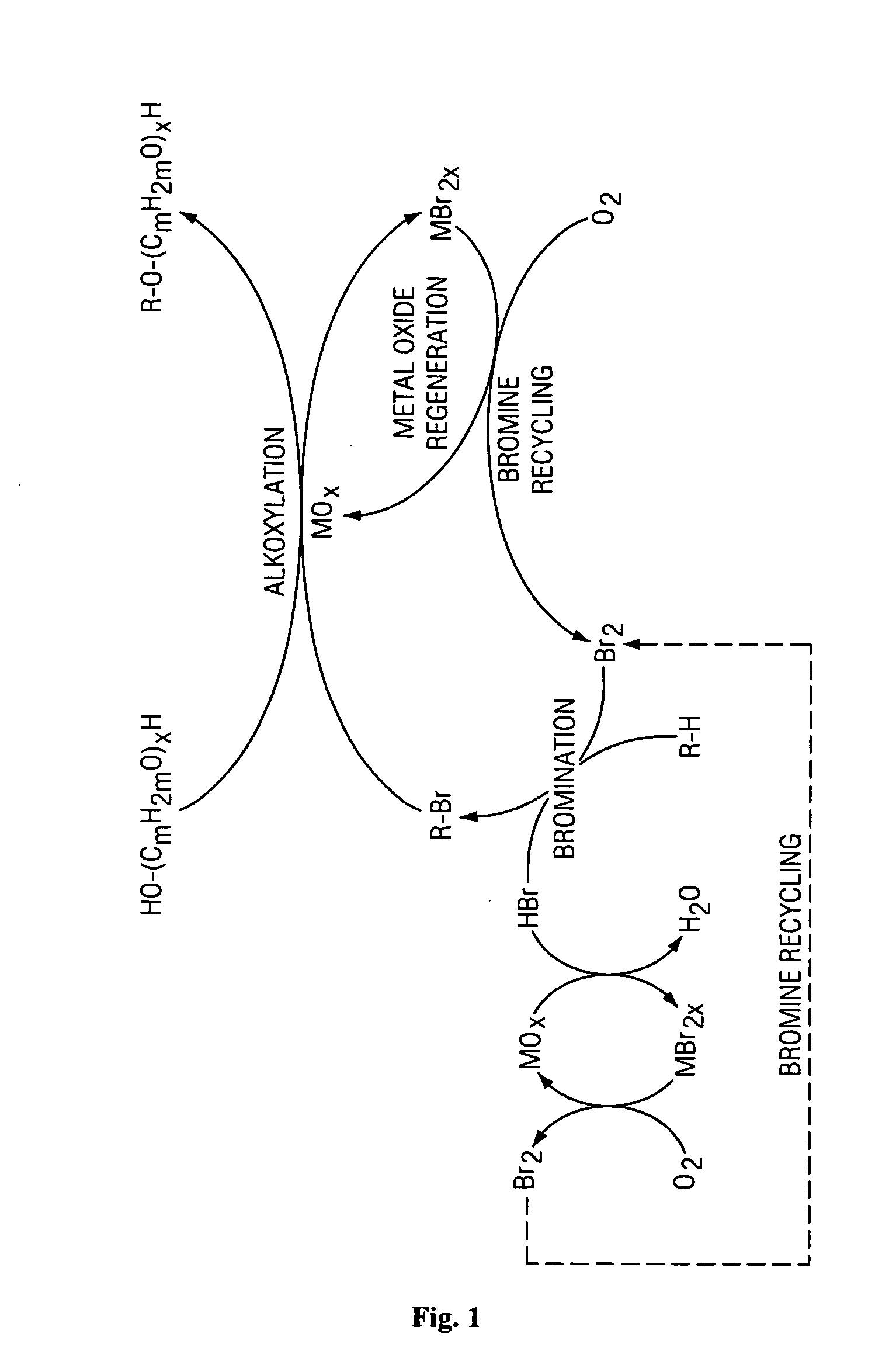

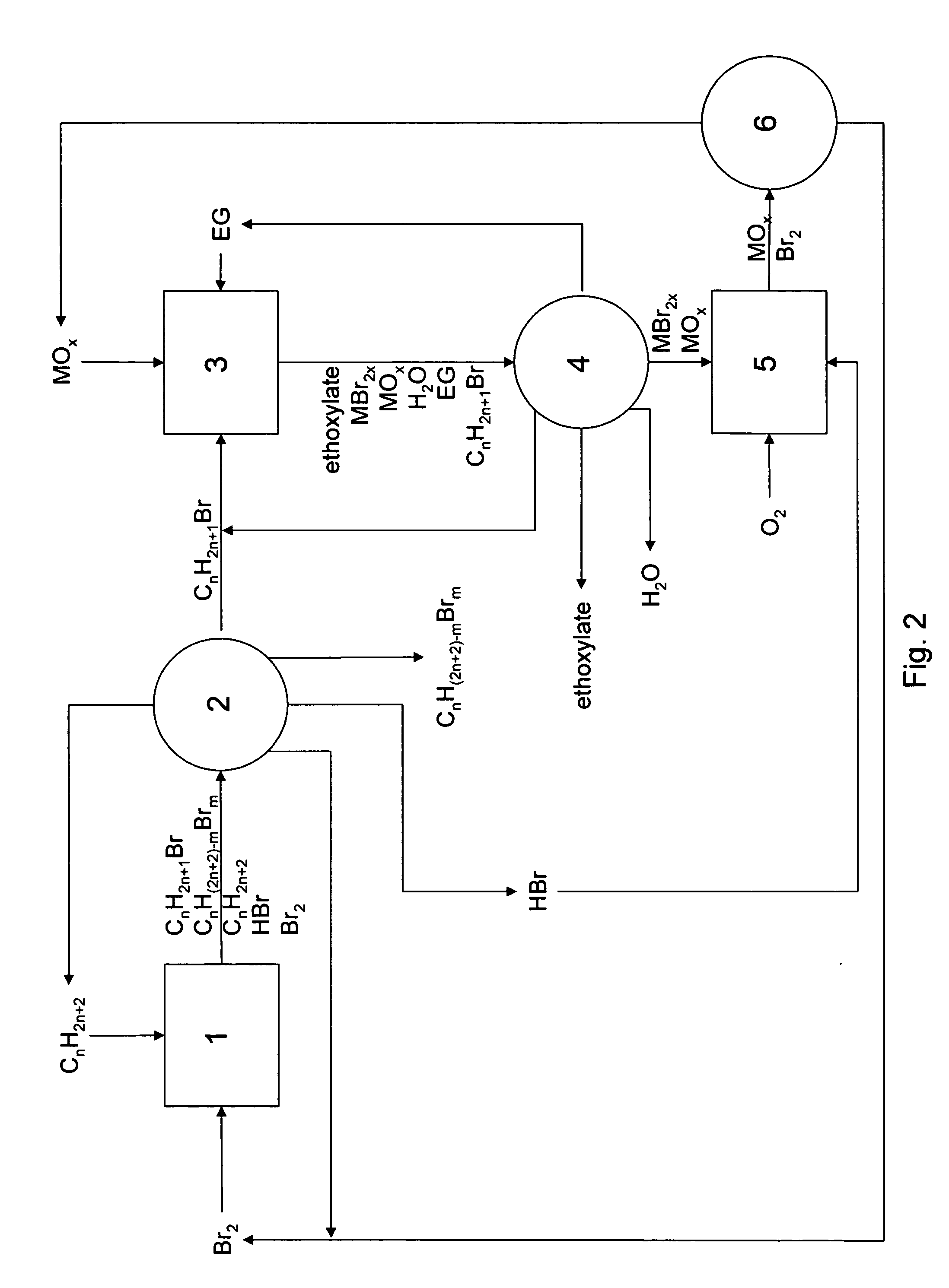

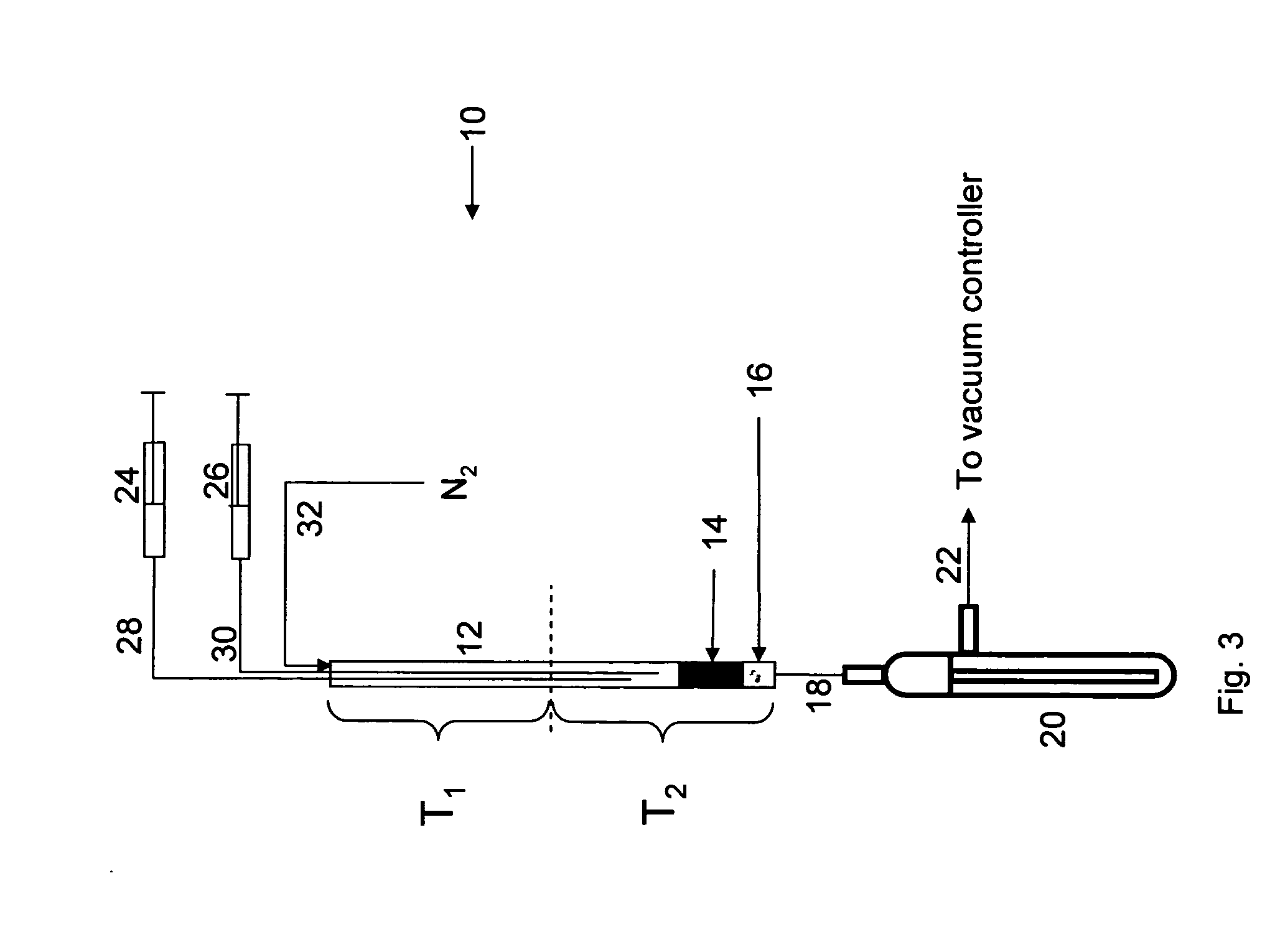

Method of making alkoxylates

InactiveUS20060229228A1More controlledLow costChemical industryEther preparation by ester reactionsBromineOxide

Owner:REACTION 35 LLC

Thickener for hair care products

InactiveUS20040234471A1Easy to processEasy to incorporateCosmetic preparationsHair removalIsostearic acidEthoxylation

A cosmetic and / or pharmaceutical composition comprising a thickening concentrate, said concentrate containing: (a) an isostearic acid; (b) a fatty alcohol; and (c) an ethoxylated fatty alcohol.

Owner:COGNIS DEUT GMBH & CO KG

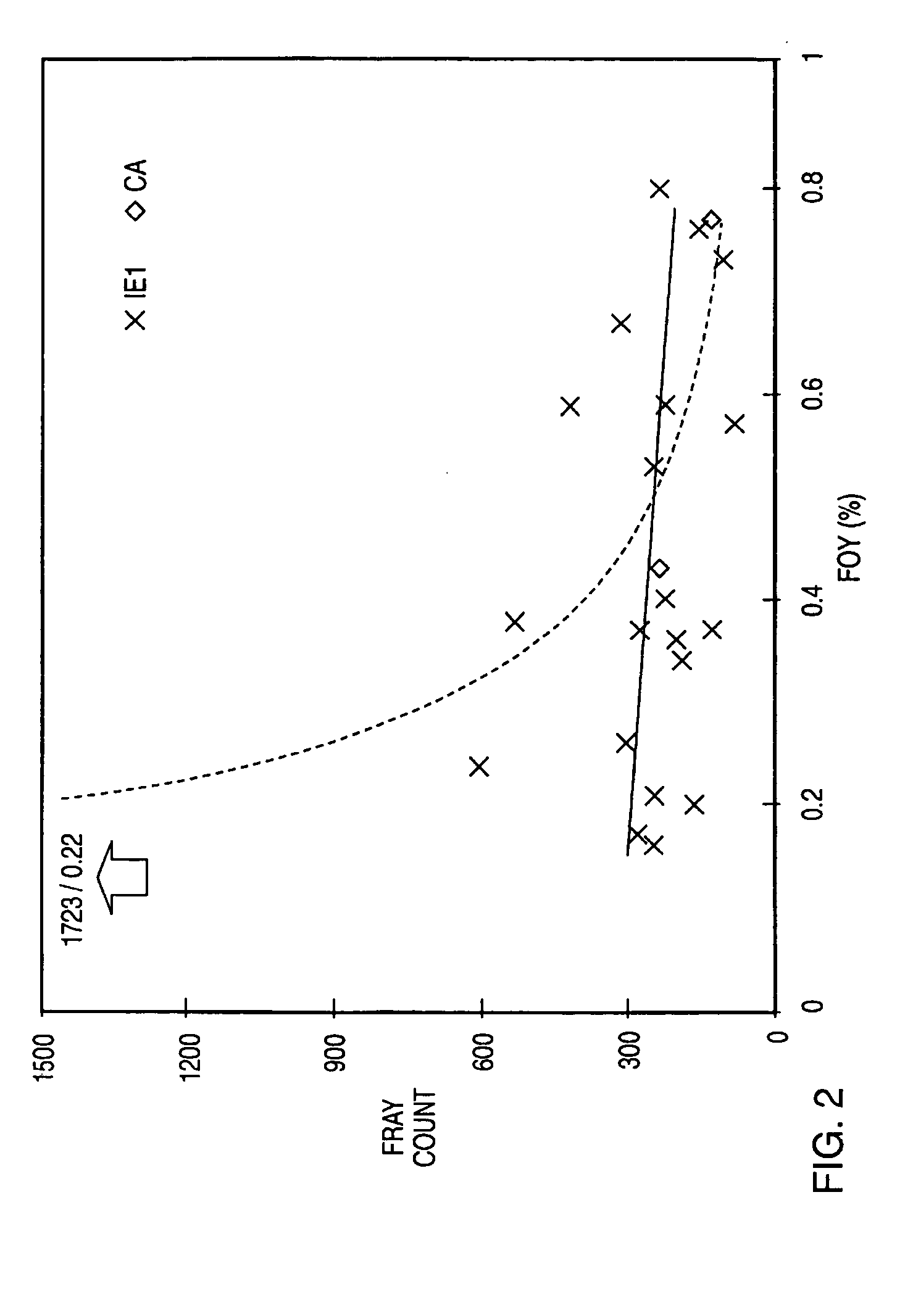

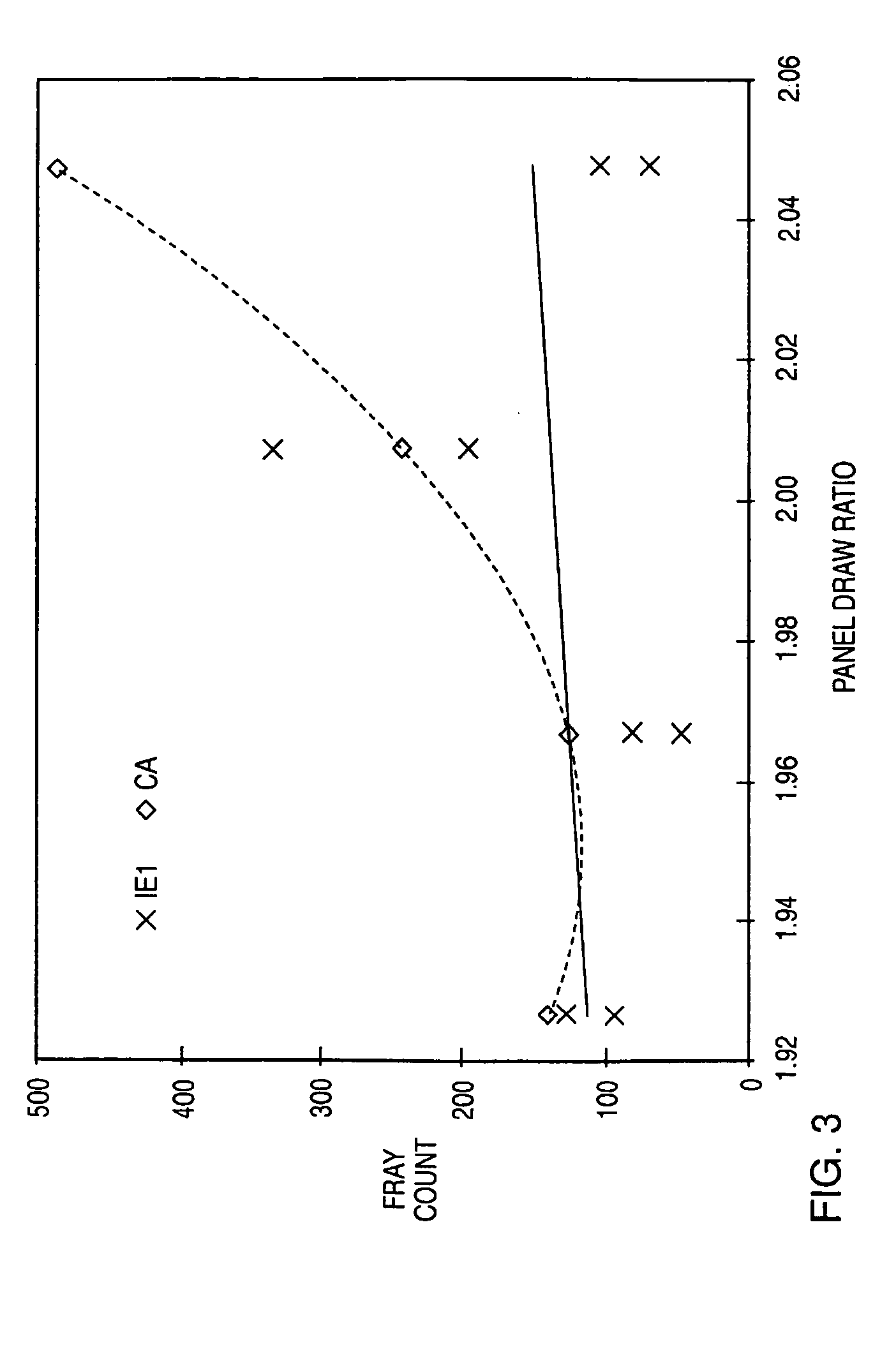

Spin finish

InactiveUS20050142360A1Easy to processLow fumingFibre typesSynthetic resin layered productsHydrogenHydroxy group

The present spin finish composition comprises at least about 10 percent by weight based on the spin finish composition of components (a) and (b) having the formula R1—(CO)x—O—(CH(R2)—CH2—O)y—(CO)z—R3 wherein each of R1 and R3 is selected from the group consisting of hydrogen or an alkyl group having from one to 22 carbon atoms or an alkylene hydroxy group having from one to 22 carbon atoms, x is zero or one, R2 may vary within component (a) or component (b) and is selected from the group consisting of hydrogen or an alkyl group having from one to four carbon atoms, y is zero, or from one to 25, and z is zero or one, in component (a), x and z are equal to zero and the average molecular weight of component (a) is less than or equal to 1,900 and if R2 varies, component (a) is a random copolymer; and in component (b), at least x or z is equal to one or component (b) is a complex polyoxyethylene glyceride-containing compound having greater than 10 polyoxyethylene units; up to about five percent by weight based on the spin finish composition of component (c) of an ethoxylated silicone; and at least about one percent by weight based on the spin finish composition of component (d) having the formula R4(CH2O(CO)aR5)b wherein R4 is —C— or —COC—; a is 0 or 1; R5 is —H; from —CH3 to —C18H37; or —CH(R6)—CH2O; b is 4 or 6; and R6 is —H or —CH3 or —H and —CH3 in a ratio of 10:90 to 90:10. The present spin finish composition may be used on industrial yarn.

Owner:PERFORMANCE FIBERS

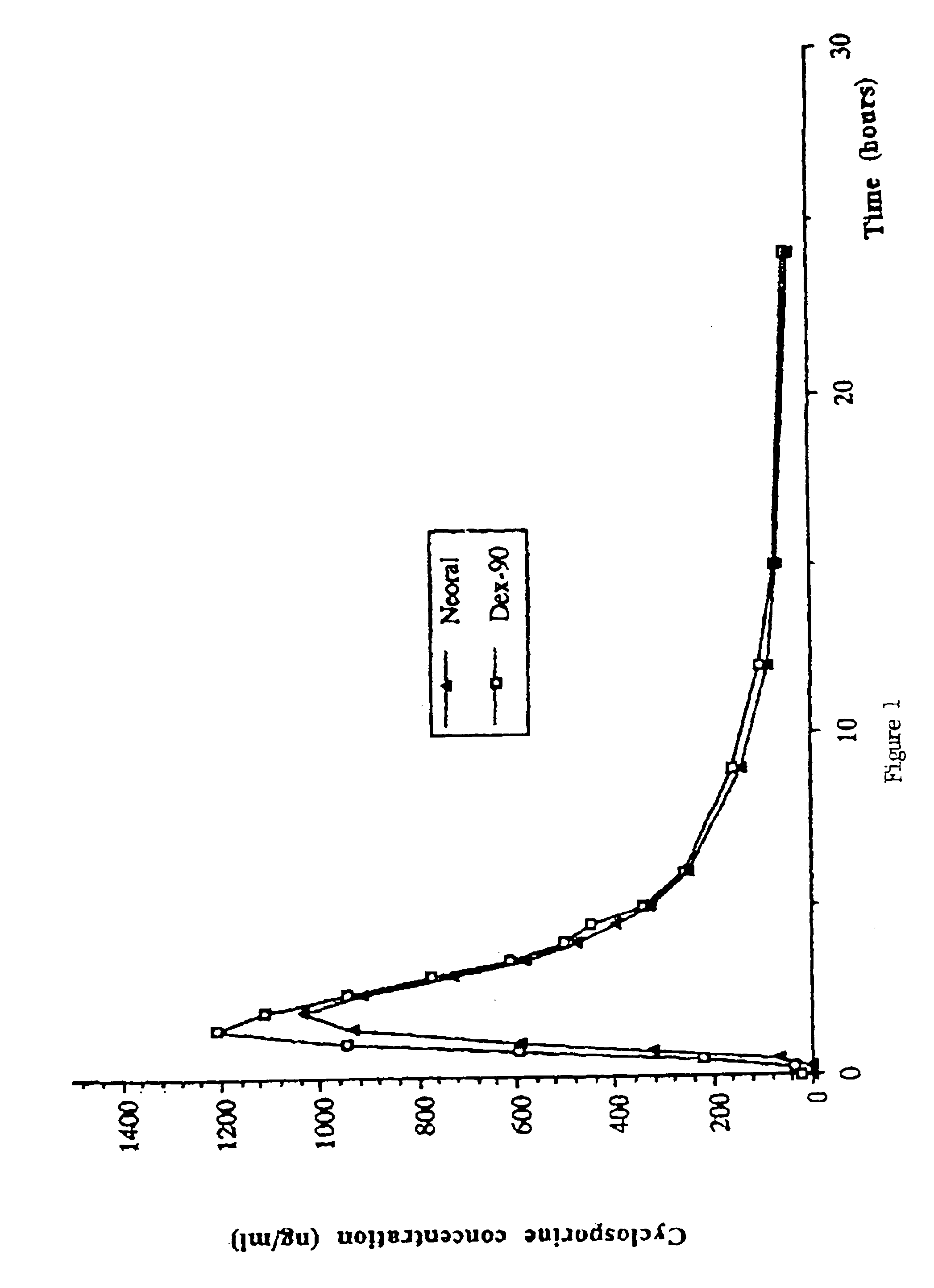

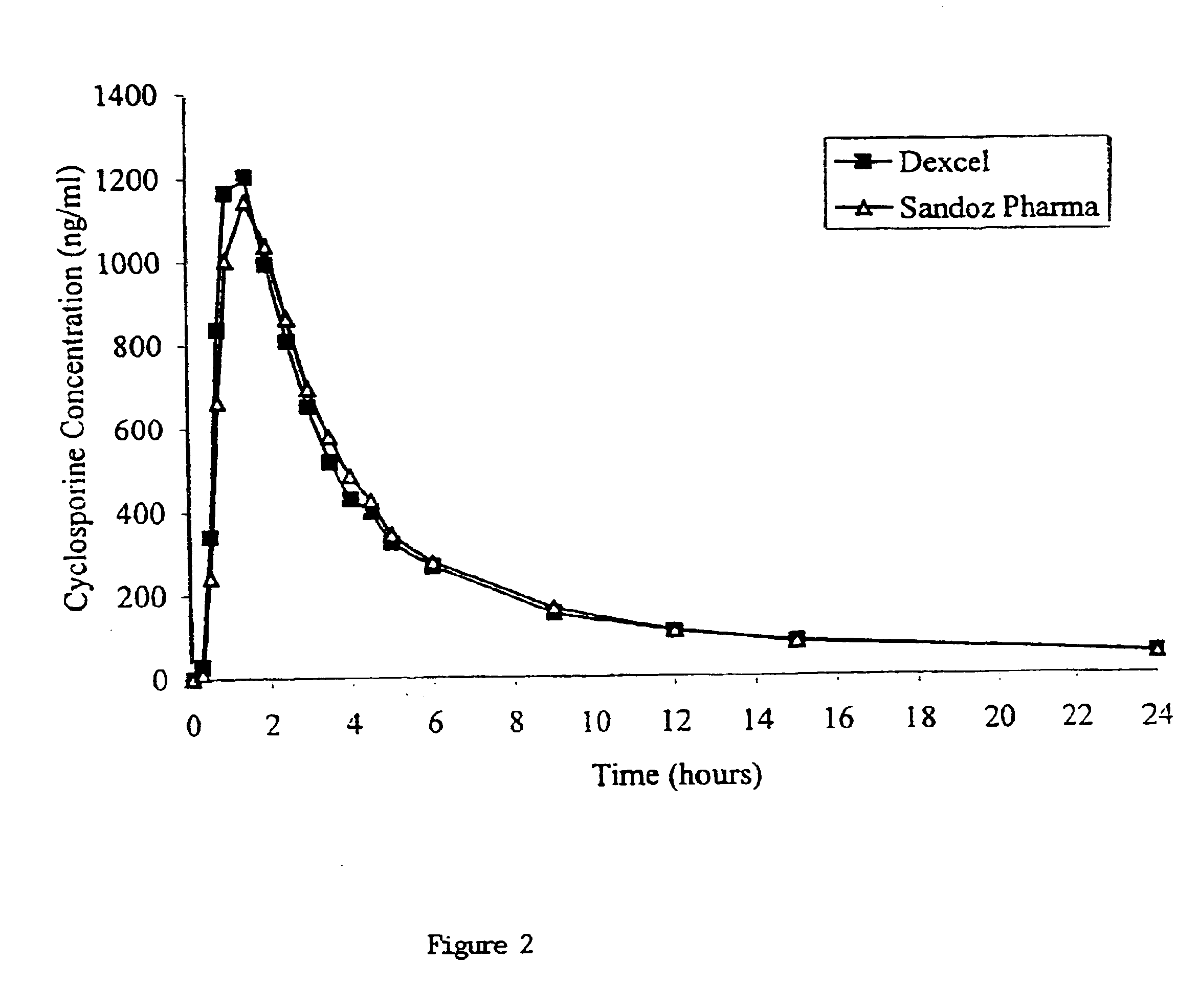

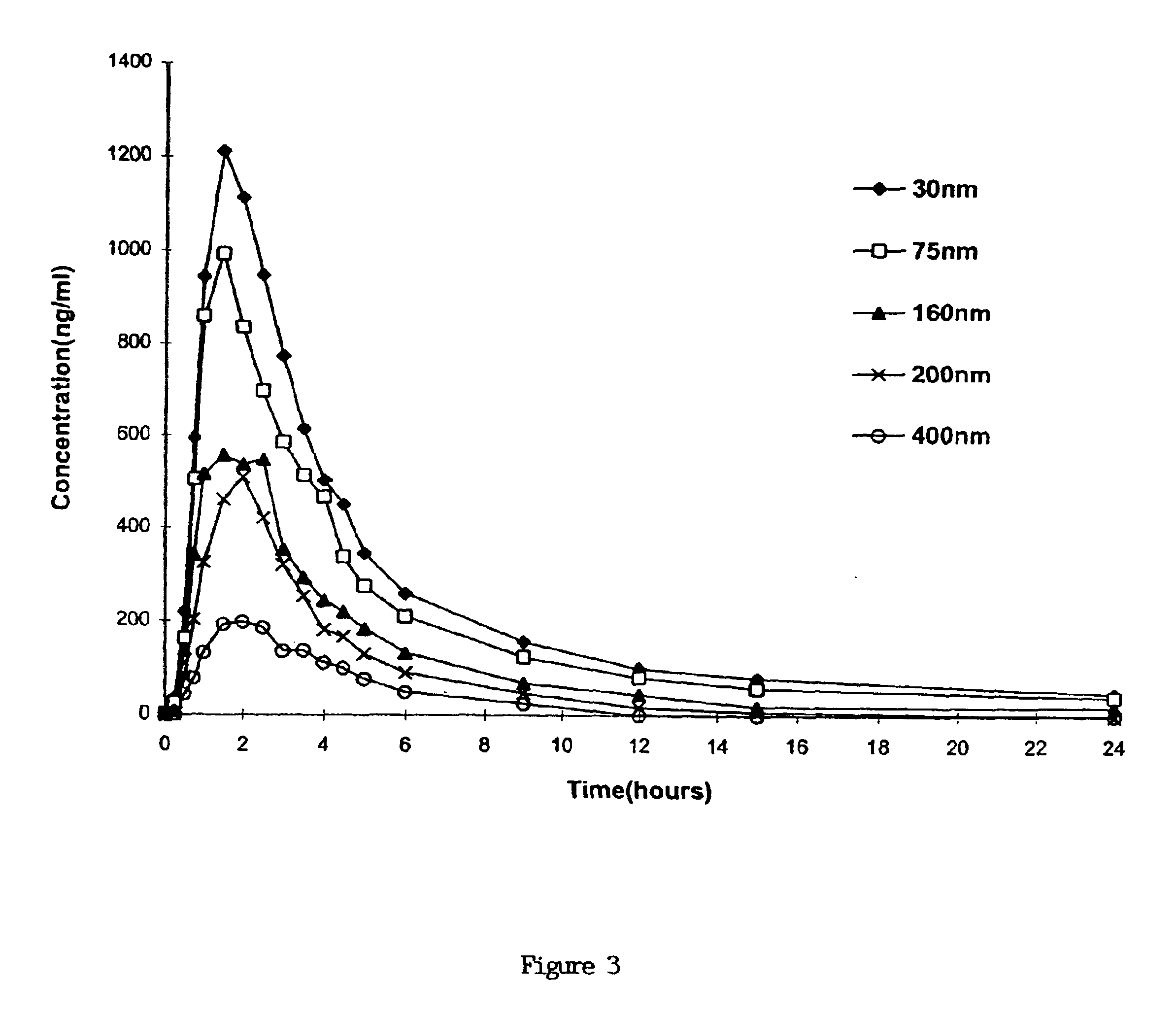

Dispersible concentrate for the delivery of cyclosprin

InactiveUS7026290B1Suitable for useImprove bioavailabilityPowder deliveryAntipyreticCyclosporinsAdditive ingredient

A formulation for the administration of a cyclosporin. This formulation features a hydrophilic solvent which is characterized by being a lower alkyl ester of hydroxyalkanoic acid; and a surfactant, preferably a combination of a surfactant with a high HLB (hydrophilic / lipophilic balance) of at least about 8 and a surfactant with a low HLB of less than about 5. Other ingredients are optional, such as a fatty acid ester such as tricaprin, a phospholipid, and an ethoxylated fat such as Cremophor or another similar substance. Optionally, the ethoxylated fat is substituted for the surfactant. The preferred particle size of the resultant formulation is less than about 100 nm, more preferably less than about 60 nm, and most preferably from about 5 nm to about 50 nm. The formulation of the present invention is characterized by having high bioavailability.

Owner:DEXCEL

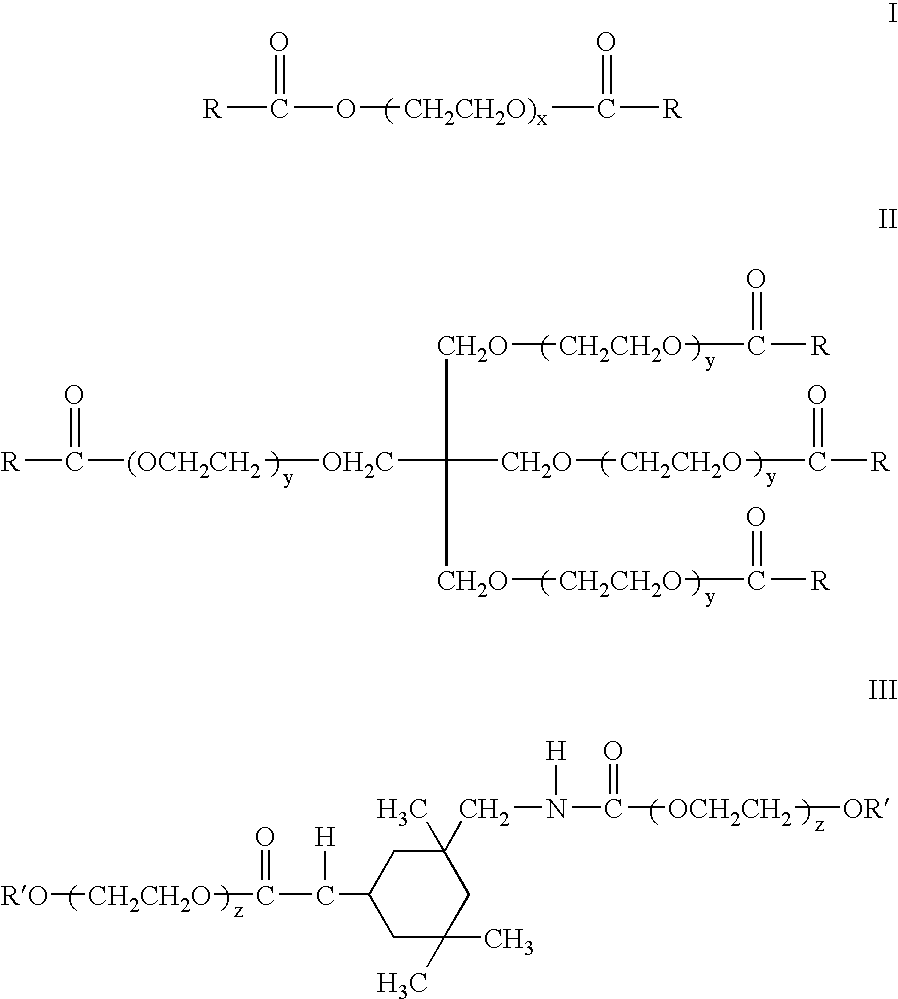

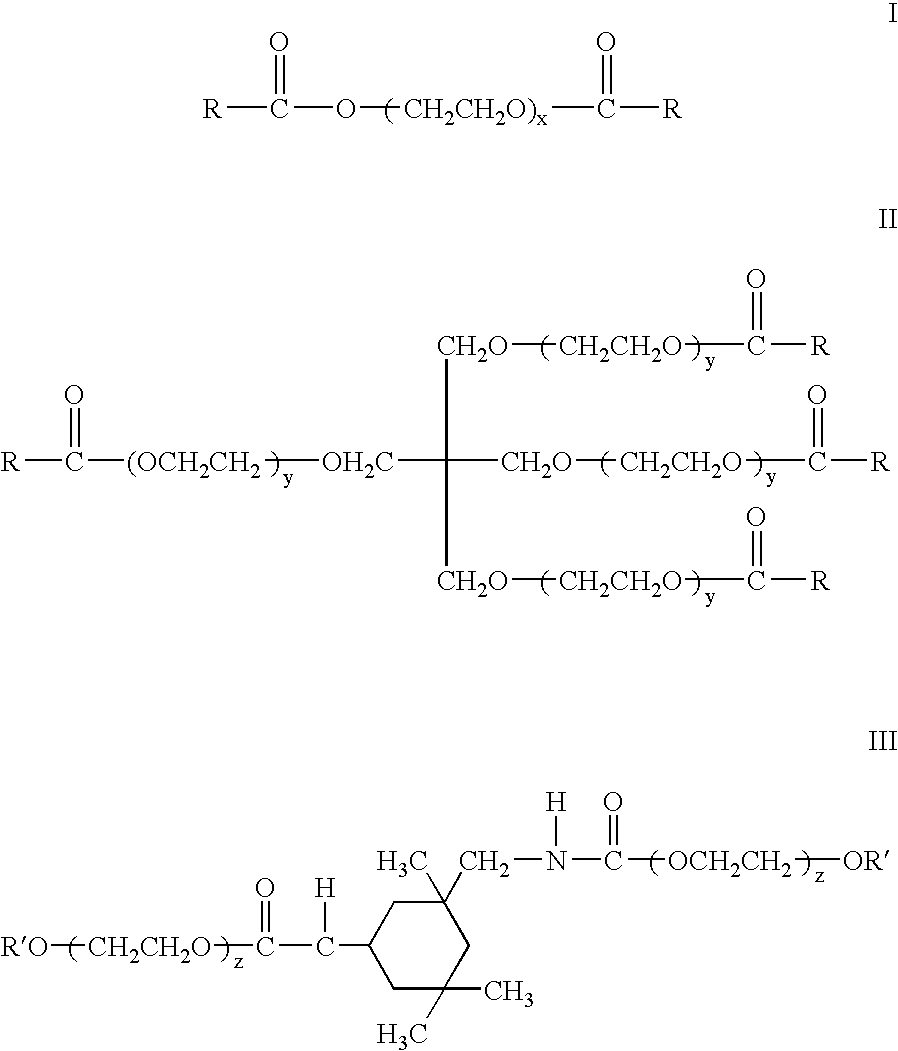

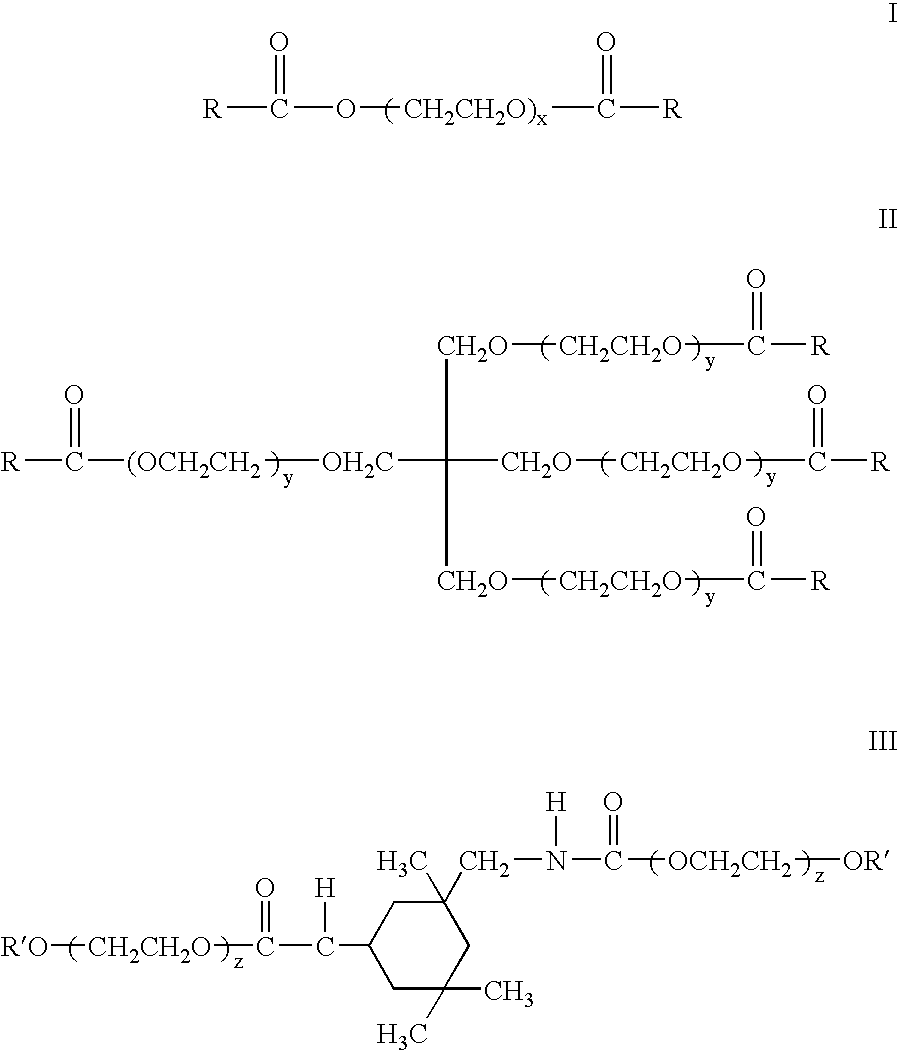

Novel cosmetic emulsions and emulsifiers exhibiting dilatant rheological properties

InactiveUS20060127344A1Simple structureUnexpected dilatancy propertyCosmetic preparationsHair cosmeticsPolyolDilatant

The use of novel nonionic polymeric thickeners that produce cosmetically useful emulsions of an oil phase and a water phase is described. The thickeners of choice are the urethane dimers of ethoxylated fatty alcohols. These materials were not anticipated to have emulsifying properties. Also, it has been found that the esters of ethoxylated polyols show similar emulsifying behavior, although their uses are limited by their inherent susceptibility towards hydrolysis. Further, many of the emulsions produced with these emulsifiers have a dilatant or shear thickening rheology that is unusual and has unique cosmetic applications. In addition, it is possible to produce high internal phase oil-in-water emulsions, with oil phase concentrations greater than 70%, using these emulsifiers. Finally, many of the emulsions, especially the high internal phase ones, have a characteristic “ring” or vibration that is apparent when their container is tapped. This is a characteristic of so called “microemulsions” that has not been observed in conventional appearing, white (albeit dilatant) emulsions.

Owner:ALZO INTTERNAT

Natural deodorant composition

The present invention relates to a natural deodorant system and a natural system for topical and systemic delivery of active ingredients, both systems being primarily free of, preferably substantially free of, more preferably essentially free of, and most preferably completely free of ethoxylates or other petrochemical derivatives, and comprising: (a) at least one of (1) glycerine (preferably of plant origin), (2) a polyol selected from the group consisting of galactitol, erythritol, inositol, ribitol, dithioerythritol, dithiothreitol, (3) a sugar alcohol, selected from the group consisting of mannitol, sorbitol, xylitol and maltitol, (4) a hydrogenated starch hydrosylates of at least one of berries, apples or plums, and (5) mixtures thereof; (b) water or a lower monohydric alcohol, selected from the group of methanol, ethanol, propanol and isoproponal, or mixtures thereof, present at a combined concentration of at least 20%; (c) one or more carrageenans (preferably of plant origin) or alginates, or mixtures thereof, present in combined concentrations of less than about 2%; and (d) optionally, one or more thickeners or gums selected from the group consisting of tara, guar, xanthan, Arabic, tragacanth, agar, locust bean gum, ghatti and microcrystalline celluloses.

Owner:TERRA FA NATUALS

Compositions and methods for enhancement of production of liquid and gaseous hydrocarbons

Owner:PNC BANK NAT ASSOC

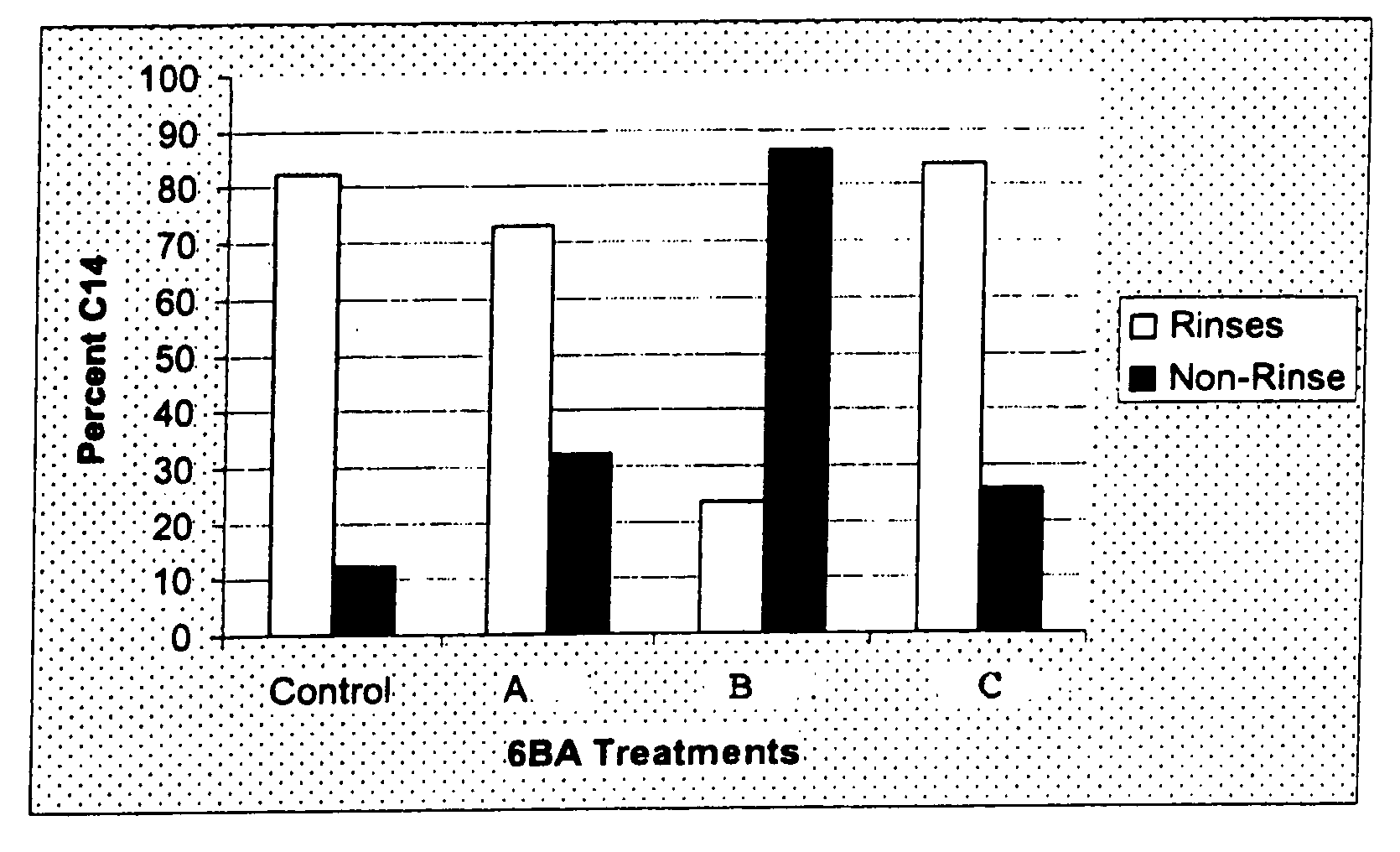

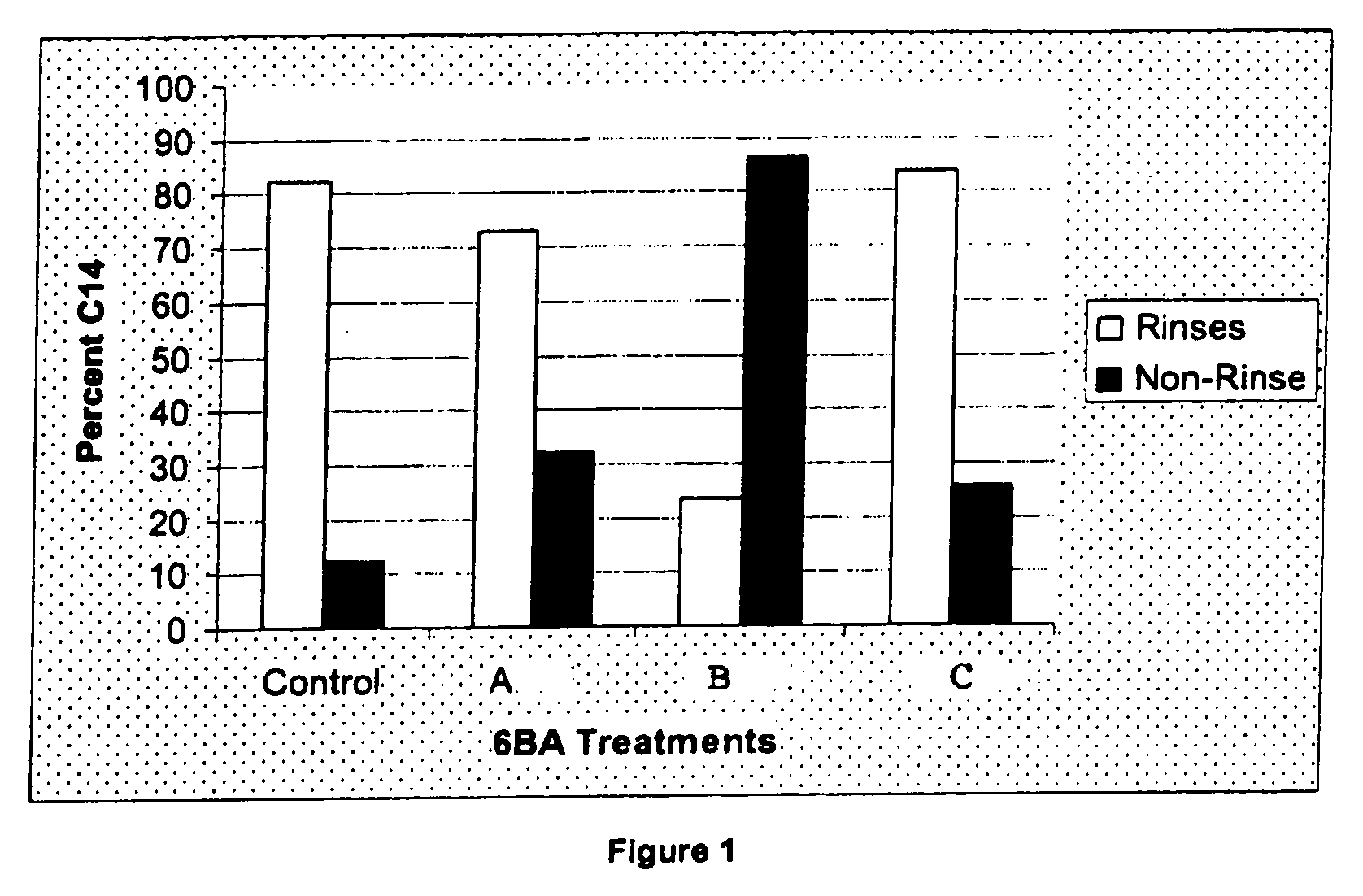

Stable and Water-Soluble Plant Growth Regulator Liquid Compositions and Methods for Use of Same

InactiveUS20080039322A1Effective amountAccurate measurementBiocidePlant growth regulatorsSolubilityAntioxidant

Soluble and stable liquid compositions containing a plant growth regulator selected from the group consisting of cytokinin and a gibberellin, an acid solubilizer such as citric acid, tartaric acid or glycolic acid and a solvent; as well as methods for making and using the composition are disclosed. The compositions improve solubility, handling, stability, safety, as well as activity improvements such as improved plant growth, yield, fruit thinning or sizing and quality. The compositions are soluble and stable by adding an ethoxylated alkyl alcohol wherein the growth regulator is 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) and the ethoxylated alcohol surfactant is C12-15 alkyl alcohol in propylene glycol. The compositions may also contain a cytokinin such as 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) that is increased in solubility and activity and by synergistically combined with GA3 or GA4A7 as well as in storage stability by adding an antioxidant. The compositions are formulated in a ready-to-mix formulation.

Owner:WANG YUEH +6

Cleaning composition having high self-adhesion and providing residual benefits

ActiveUS20100093586A1Improve stabilityFine surfaceOrganic detergent compounding agentsSurface-active detergent compositionsAlcoholCarbon chain

A composition for treating a hard surface. The composition has: (a) at least one adhesion promoter; (b) at least one surfactant selected from the group consisting of: anionic, non-ionic, cationic, amphoteric, zwitterionic, and combinations thereof; (c) mineral oil; (d) a blend of linear primary alcohols, wherein each alcohol of said blend includes a carbon chain containing 9 to 17 carbons or an ethoxylated blend thereof; (e) water; (f) optionally, at least one solvent; and wherein the composition is self-adhering upon application to a surface to be treated, and wherein the composition provides a wet film to said surface when water passes over said composition and surface.

Owner:SC JOHNSON & SON INC

Polymers containing quaternized nitrogen

The invention provides polymers, methods of preparing polymers, and compositions that include polymers, wherein said polymers include a plurality of two-carbon repeating units in a polymer chain, wherein one or more of the two-carbon repeating units of the polymer chain have tertiary amine or pyridine-containing substituents; and at least about 10% of the nitrogen atoms of the tertiary amine or pyridine-containing substituents are quaternized with alkyl groups or with an alkyl group that contains one or more ethylene glycol groups. The alkyl or ethoxylated alkyl groups can also be at least partially fluorinated. The polymers can be used to provide antimicrobial surfaces and antifouling coatings.

Owner:RGT UNIV OF CALIFORNIA +1

Method for enhancing the solderability of a surface

InactiveUS6905587B2Improve solderabilityResistant to electromigrationPretreated surfacesLiquid/solution decomposition chemical coatingSilver plateSolderability

A method for enhancing the solderability of a metallic surface is disclosed where the metallic surface is plated with an immersion silver plate prior to soldering, which immersion silver plate is treated with an additive selected from the group consisting of fatty amines, fatty amides, quaternary salts, amphateric salts, resinous amines, resinous amides, fatty acids, resinous acids, ethoxylated derivatives of any of the foregoing, and mixtures of any of the foregoing. The immersion silver deposits created are resistant to electromigration.

Owner:MACDERMID INC

Ethoxylated alcohol intercalated smectite materials and method

InactiveUS6841226B2Good dispersionGood physical propertiesDiffusion transfer processesPhotography auxillary processesWaxAlcohol

The invention relates to an article comprising ethoxylated alcohol wax intercalated in smectite clay. Embodiments of the invention comprise a sheet or an imaging member comprising an image layer and at least one layer comprising ethoxylated alcohol wax intercalated in smectite clay. The invention comprises a method of forming intercalated clay by providing smectite clay and combining the clay with ethoxylated alcohol wax and heating the mixture to above the softening point of the wax. The method further includes combining the intercalated clay with a polymer.

Owner:EASTMAN KODAK CO

Super-concentration fabric cleaning agent formula and preparing method thereof

InactiveCN104479899AStrong decontaminationImprove decontamination abilityOrganic detergent compounding agentsNon-ionic surface-active compoundsLinear alkylbenzeneSurface-active agents

The invention relates to a super-concentration fabric cleaning agent which is composed of, by weight, 25-99 parts of surface active agents, 0-21 parts of addition agents and 1-75 parts of water. The surface active agent is at least one of ethoxylated lauryl alcohol sulfates (AES), fat polyoxyethylene ether (AEO), fat alcohol sodium sulfate (K12), fatty acid methyl ester ethoxylate (MEE), lauramidopropyl betaine (CAB), fatty alcohol diethanolamide (6501), linear alkylbenzene sulphonic acid (LAS) and alky glycoside (APG). The super-concentration fabric cleaning agent is free of organic solvents, no solubilization is needed, and the active matter content can reach 99%. Through the characteristic that the surface active agent fatty acid methyl ester ethoxylate (MEE) is free of cloud points, the complex formulation is conducted on the fatty acid methyl ester ethoxylate (MEE) and other surface active agents, and the functions of solubilization, complex formulation and surface activation are achieved.

Owner:WALCH GUANGZHOU COMMODITY

Surfactant compositions, cleaning compositions containing same, and methods for using

ActiveUS20080039357A1Non-ionic surface-active compoundsNon-surface-active detergent compositionsAlcoholAlkyl polyglycoside

A surfactant composition including an alkyl polyglycoside, an ethoxylated alcohol with an average of about 1 to about 30 moles of ethylene oxide per mole of alcohol, and an alkoxylated alcohol with an average of about 1 to about 30 moles of ethylene oxide and about 2 to about 60 moles of propylene oxide per mole of alcohol, with a ratio of moles of ethylene oxide to moles of propylene oxide of about 1:2 is provided.The surfactant composition including about 1% to about 50% by weight of an alkyl polyglycoside, about 1% to about 50% by weight of an ethoxylated alcohol, and, about 1% to about 50% by weight of an alkoxylated alcohol is also provided. A cleaning composition including the surfactant compositions described above is also provided. A method for cleaning hard surfaces includes applying to a hard surface the surfactant and cleaning compositions described above is also provided.

Owner:COGNIS IP MANAGEMENT GMBH

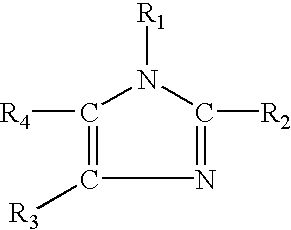

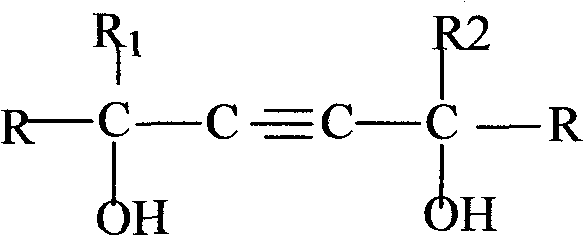

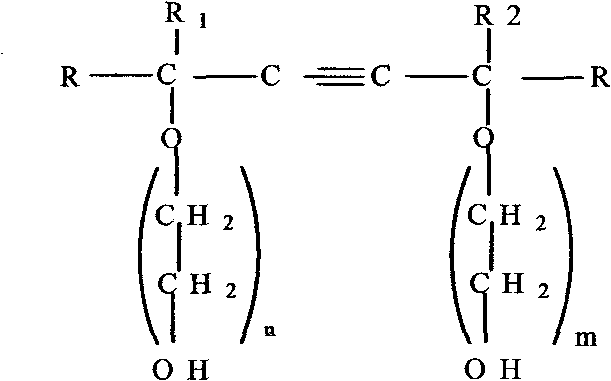

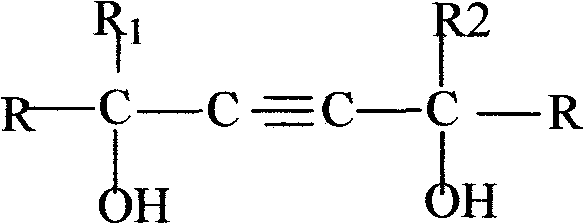

Multifunctional surfactant composition for water-based system and preparation method thereof

InactiveCN102145267ALow dynamic surface tensionNon-macromolecular adhesive additivesTransportation and packagingWater basedAlkane

The invention provides a multifunctional surfactant composition for a water-based system and a preparation method thereof. The surfactant composition used in formulas of a water-based coating, ink, adhesive and a digital material has low foaming effect and has the effect of effectively reducing the dynamic surface tension of the water-based system. The composition is formed by compounding and modifying based on alkynyl diol or alkynyl diol ethoxylate. The key component structure of the composition is an alkane structure in which R, R1 and R2 are straight-chained or branch-chained, and the number of carbons is 1 to 15; R, R1 and R2 can be the same or different groups; the carbon number of the alkane structure in which R, R1 and R2 are straight-chained or branch-chained is 1 to 15; R, R1 and R2 can be the same or different groups; and the sum of m and n is 1 to 30. The invention simultaneously provides the preparation method for the composition.

Owner:TIANJIN SURFYCHEM T&D

Catalyst for ethoxylation and use thereof

InactiveCN1451476ALess reactionImprove conversion rateOrganic chemistryOrganic compound preparationEpoxyHydrogen

A catalyst for the ethoxylation of feedstock without reactive hydrogen in its terminal group with epoxy ethane contains the oxide of alkali-earth metal (30-90 wt.%), the ions of group III metal (1-40wt.%), and carrier (1-30 wt.%). Its advantages are less consumption of catalyst, high reaction speed, high conversion of methylester, and high yield of product.

Owner:中轻日化科技有限公司

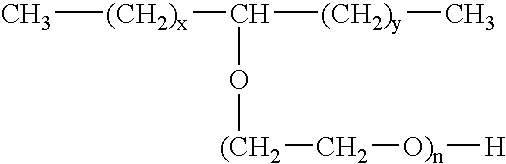

Ethoxylate and propoxylated higher alcohol surfactant in high concentrations in an aqueous composition

InactiveUS6140297AStrong penetrating powerImprove detergencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHigh concentrationEthoxylation

PCT No. PCT / JP97 / 04394 Sec. 371 Date Jul. 29, 1998 Sec. 102(e) Date Jul. 29, 1998 PCT Filed Dec. 2, 1997 PCT Pub. No. WO98 / 24867 PCT Pub. Date Jun. 11, 1998A surfactant composition exhibiting excellent wetting properties and a high penetrating power for the object to be cleansed even in a relatively high surfactant content and being excellent in detergency is provided, which comprises a compound (1) having an average molecular weight of 1,200 or less and water with the proportion of the compound(1) to the sum total of the compound (1) and water being 5 wt. % or above but below 50 wt. %:RO-(EO)x-(PO)y-(EO)x'-H(1)wherein R represents C12-C15 alkyl or the like; EO represents oxyethylene; PO represents oxypropylene; x and x' are each 1 or above; and y ranges from 0.5 to 6.0, provided (EO)x, (PO)y and (EO)x' are bonded to each other in block in this order.

Owner:KAO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com