Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

317results about How to "Easy to incorporate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

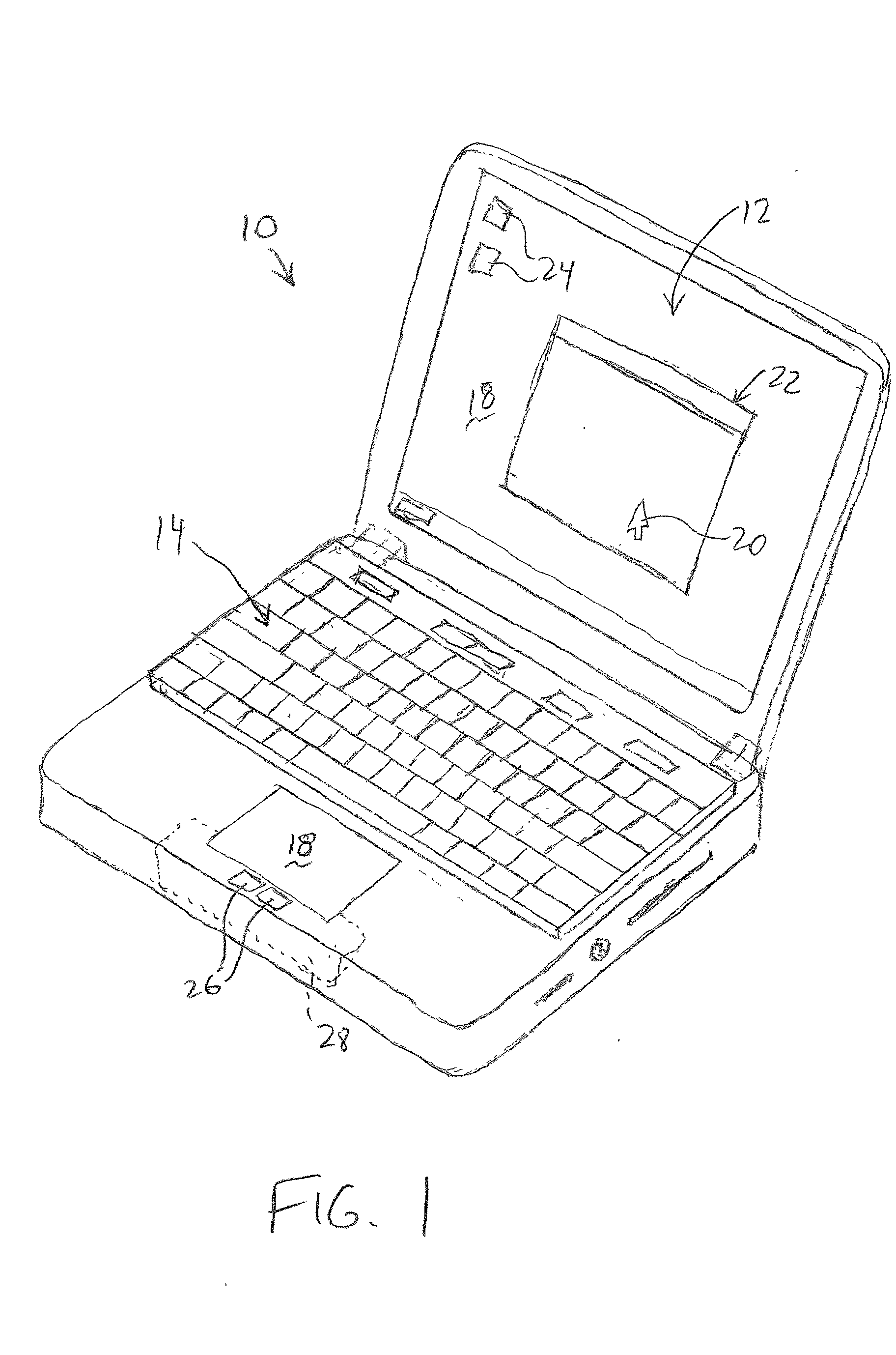

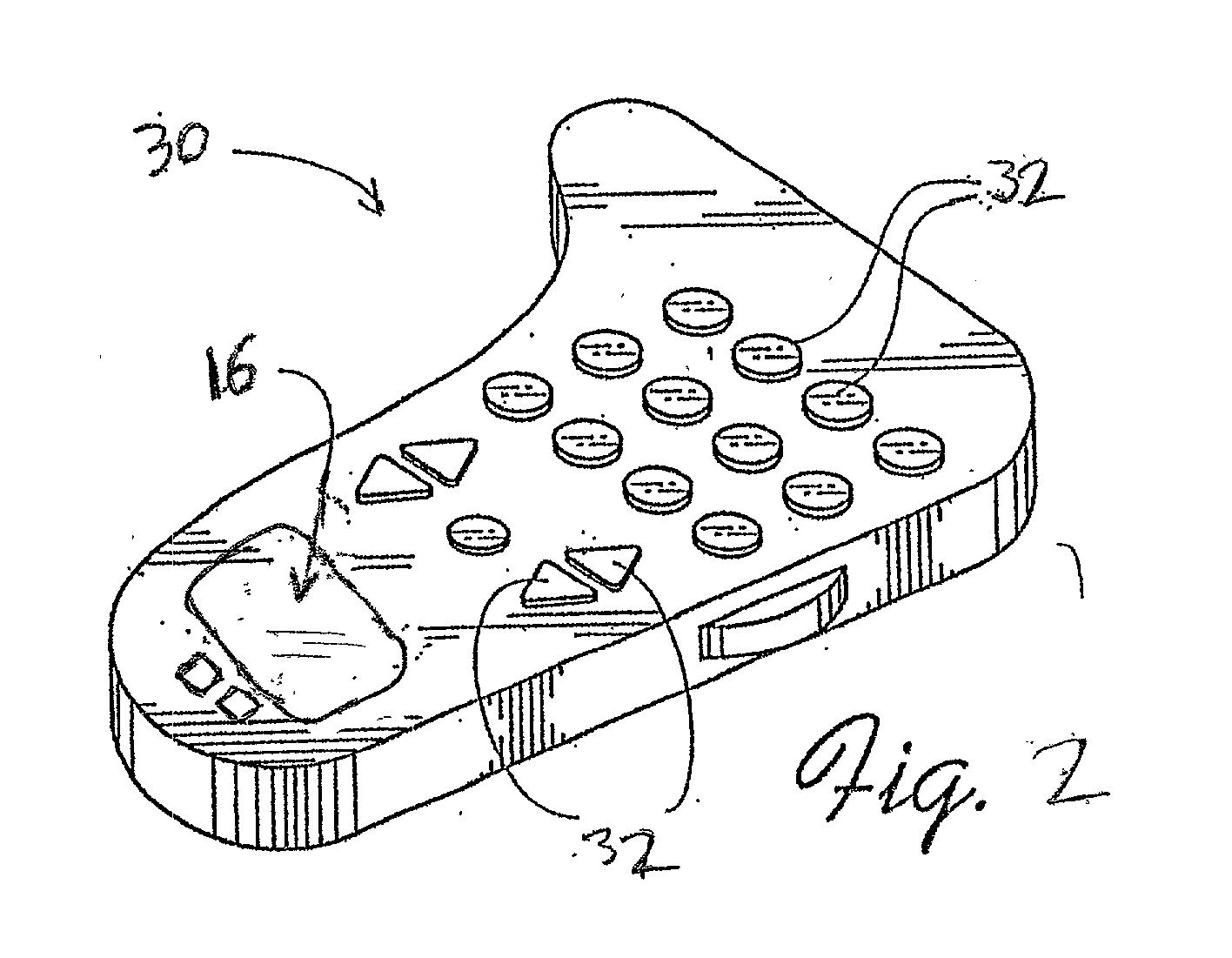

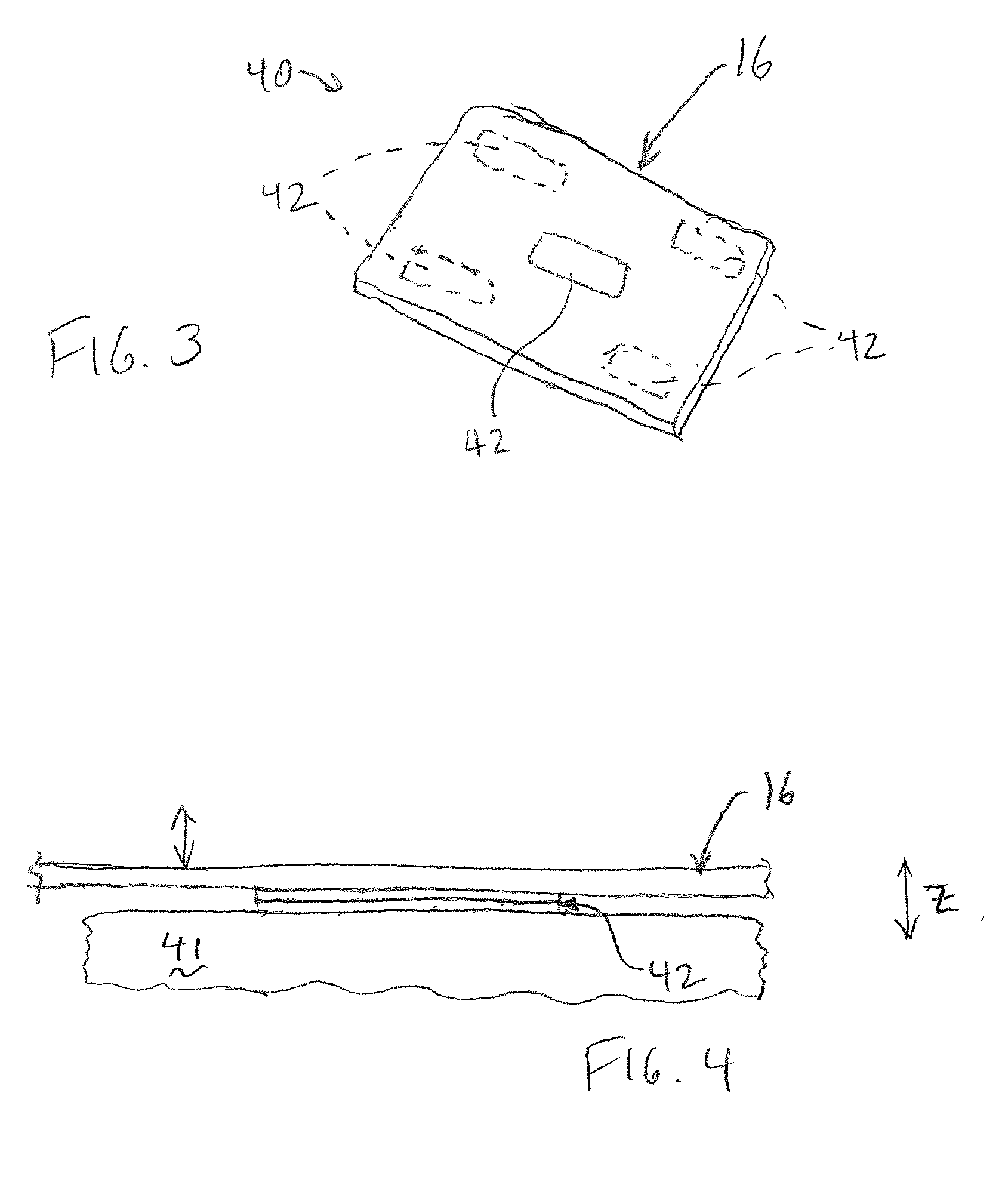

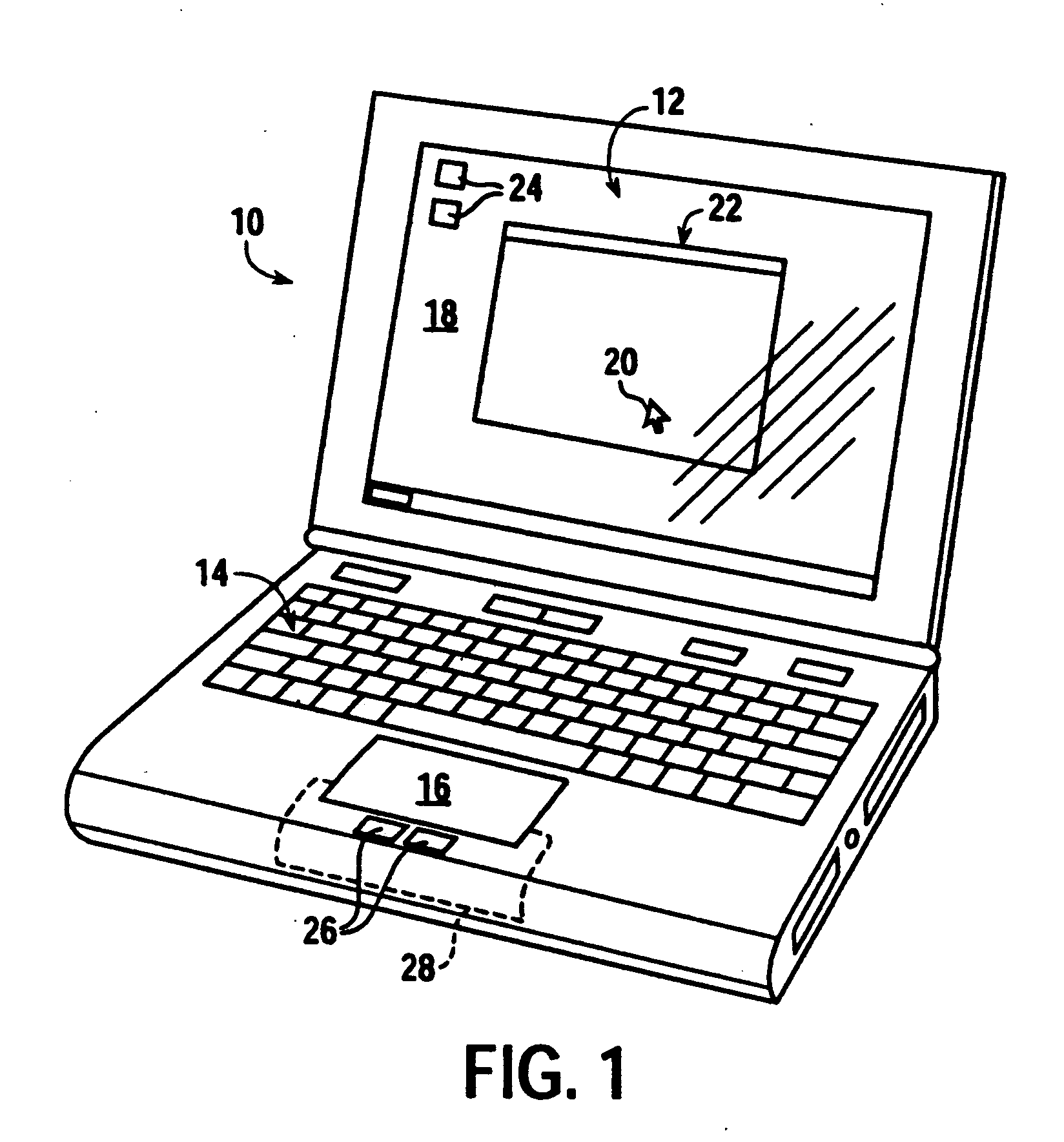

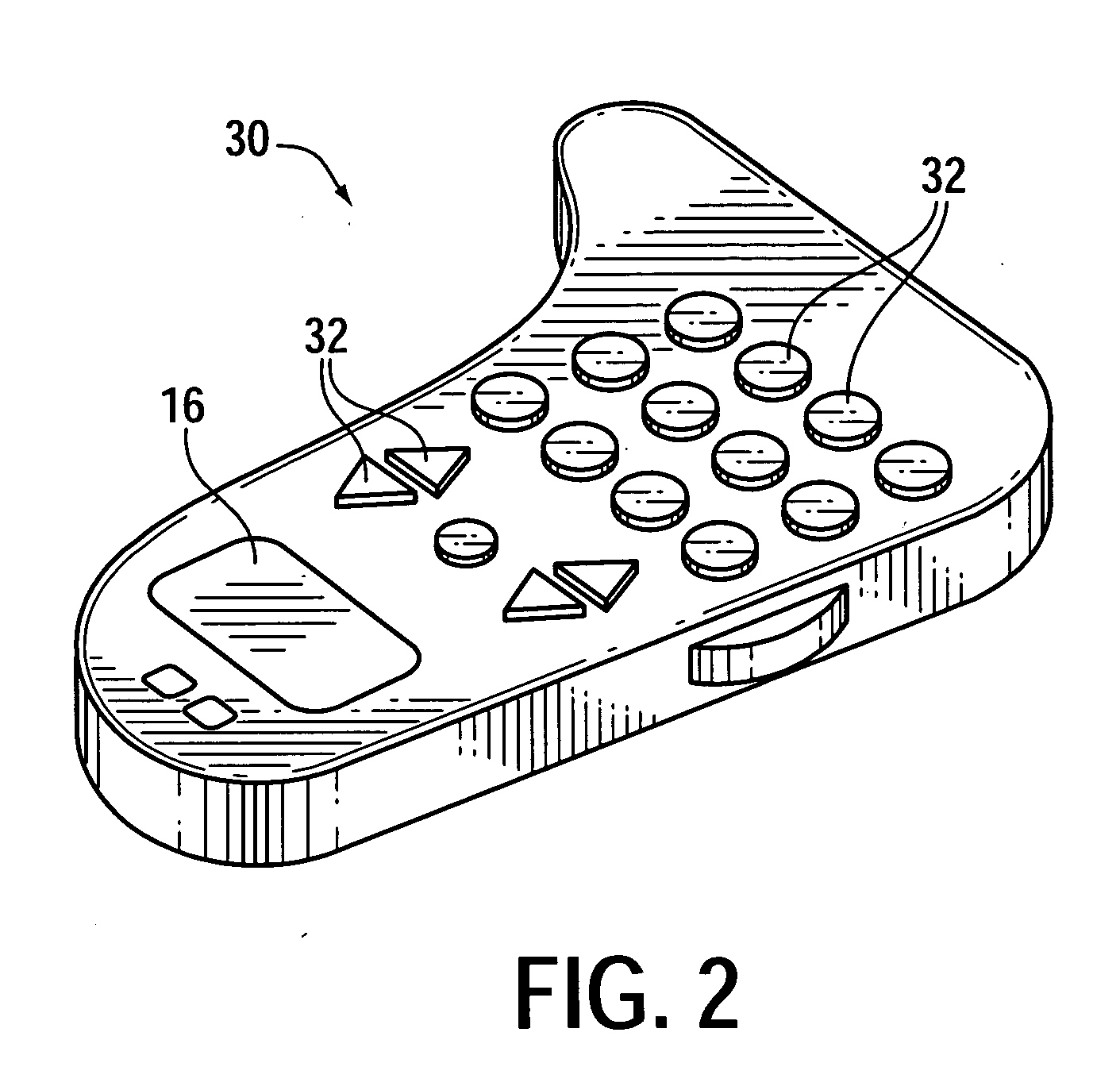

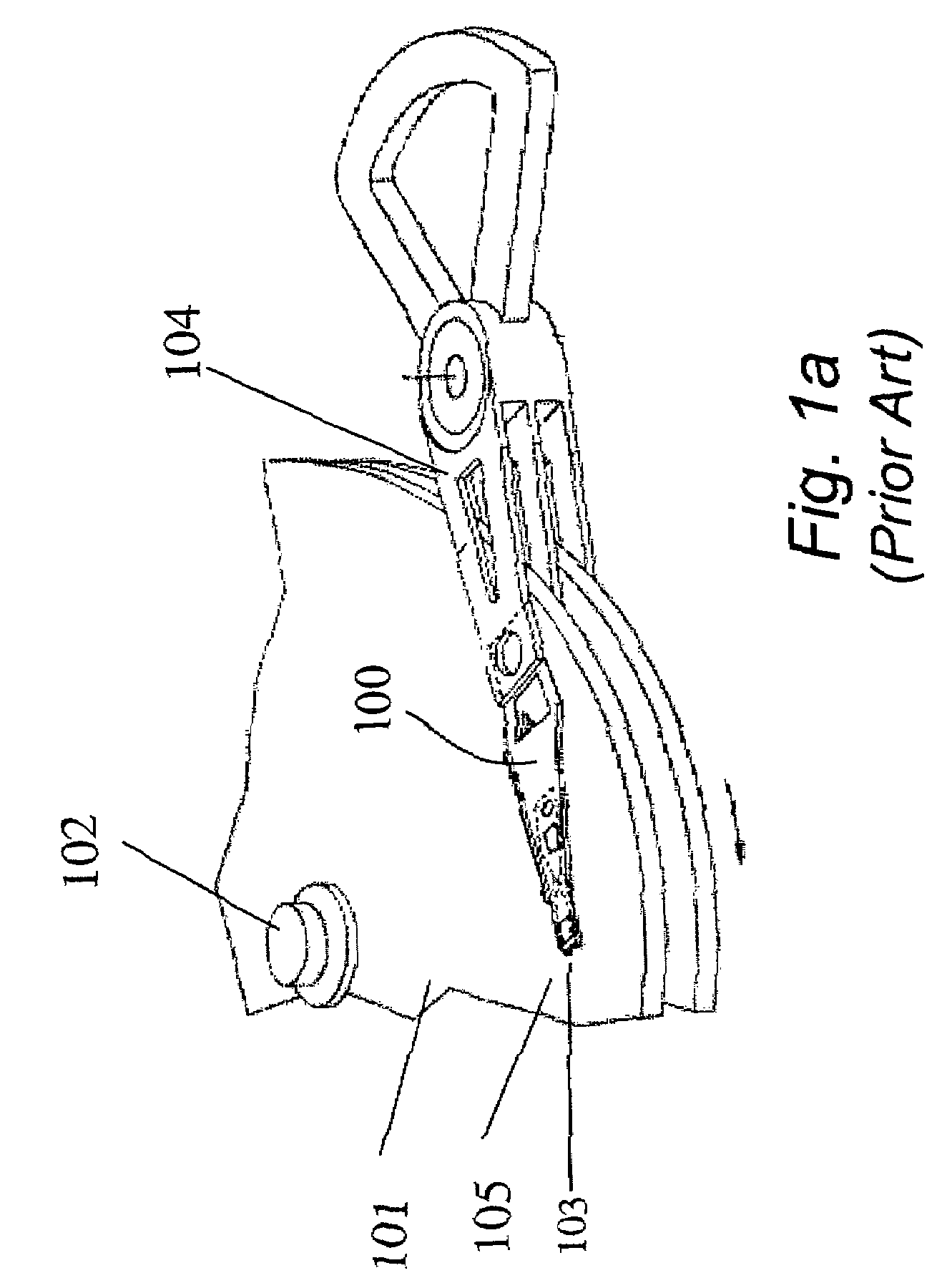

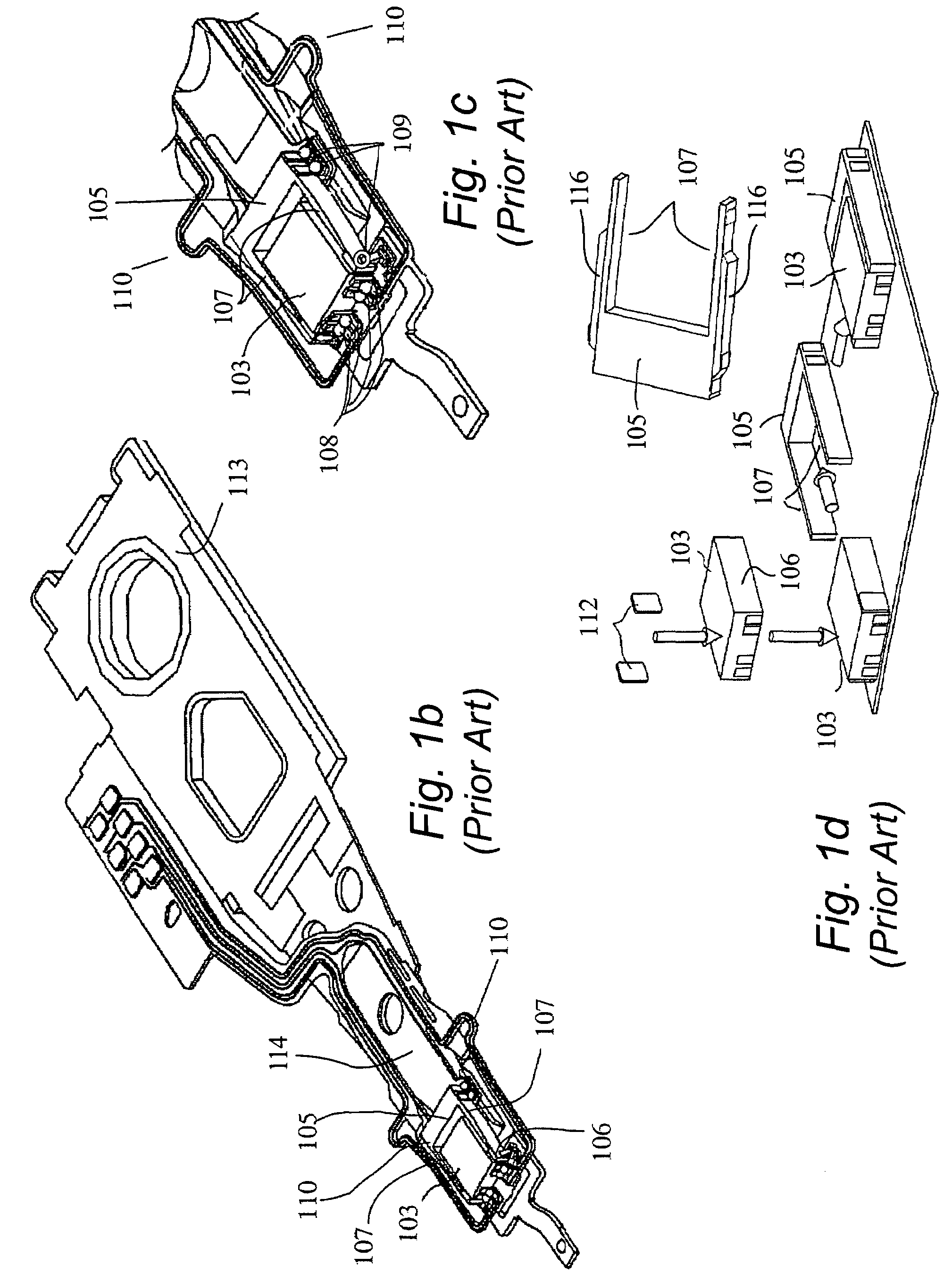

Haptic feedback for touchpads and other touch controls

InactiveUS20010035854A1Enhance interaction and manipulationEnhanced interactionInput/output for user-computer interactionCathode-ray tube indicatorsComputer basedTouch Perception

A haptic feedback planar touch control used to provide input to a computer. A touch input device includes a planar touch surface that inputs a position signal to a processor of the computer based on a location of user contact on the touch surface. The computer can position a cursor in a displayed graphical environment based at least in part on the position signal, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user contacting the touch surface. The touch input device can be a touchpad separate from the computer's display screen, or can be a touch screen. Output haptic sensations on the touch input device can include pulses, vibrations, and spatial textures. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

Tunnel effect transistors based on silicon nanowires

InactiveUS20080067495A1Optimize architectureReduce power consumptionTransistorNanoinformaticsMOSFETLattice mismatch

Tunnel field-effect transistors (TFETs) are regarded as successors of metal-oxide semiconductor field-effect transistors (MOSFETs), but silicon-based TFETs typically suffer from low on-currents, a drawback related to the large resistance of the tunnel barrier. To achieve higher on-currents a nanowire-based TFET with a germanium (Ge) tunnel barrier in an otherwise silicon (Si) channel is used. A nanowire is introduced such that the lattice mismatch between silicon and germanium does not result in a highly defective interface. A dynamic power reduction as well as a static power reduction can result, compared to conventional MOSFET configurations. Multiple layers of logic can therefore be envisioned with these nanowire Si / Ge TFETs resulting in ultra-high on-chip transistor densities.

Owner:KATHOLIEKE UNIV LEUVEN

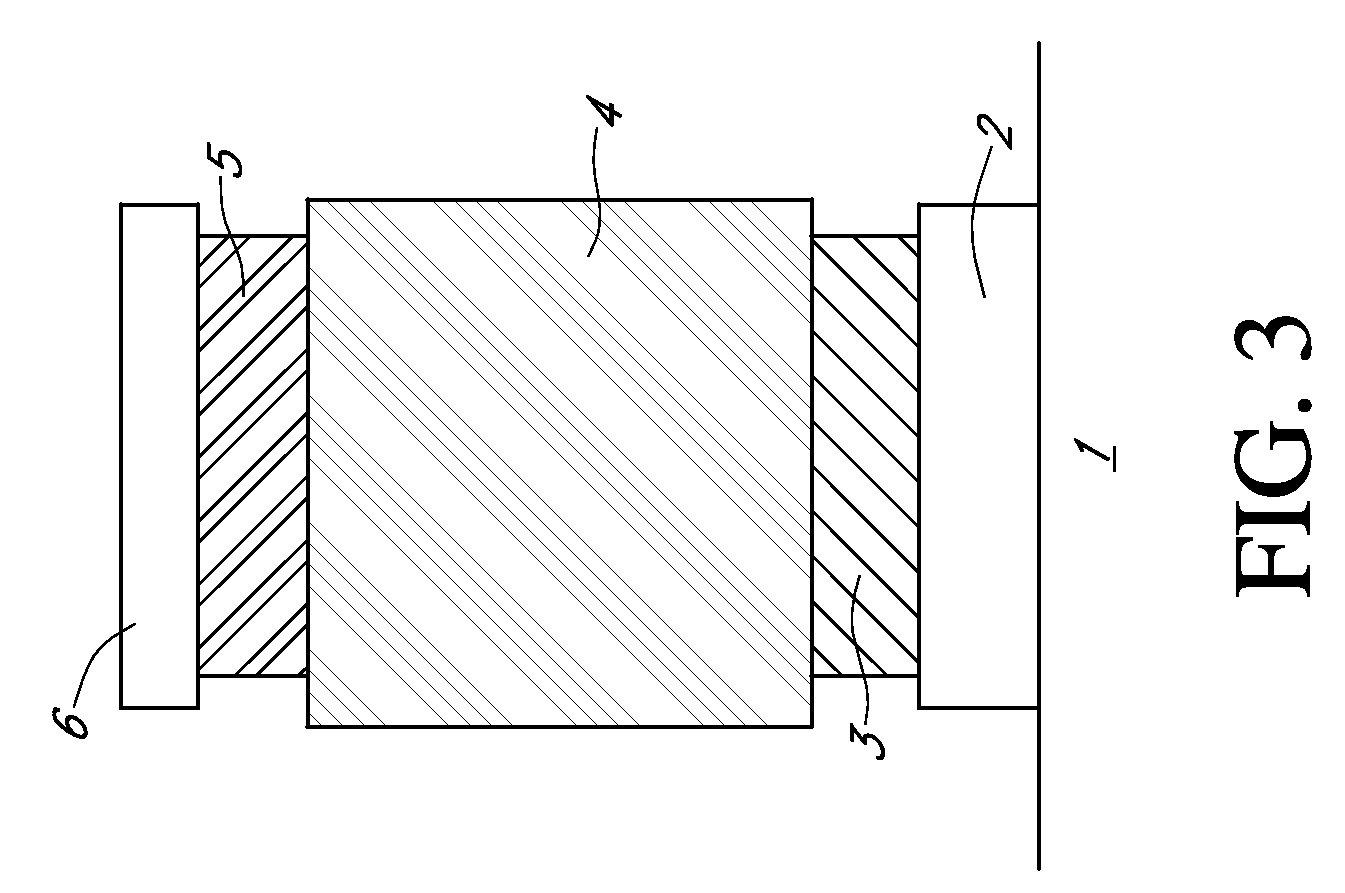

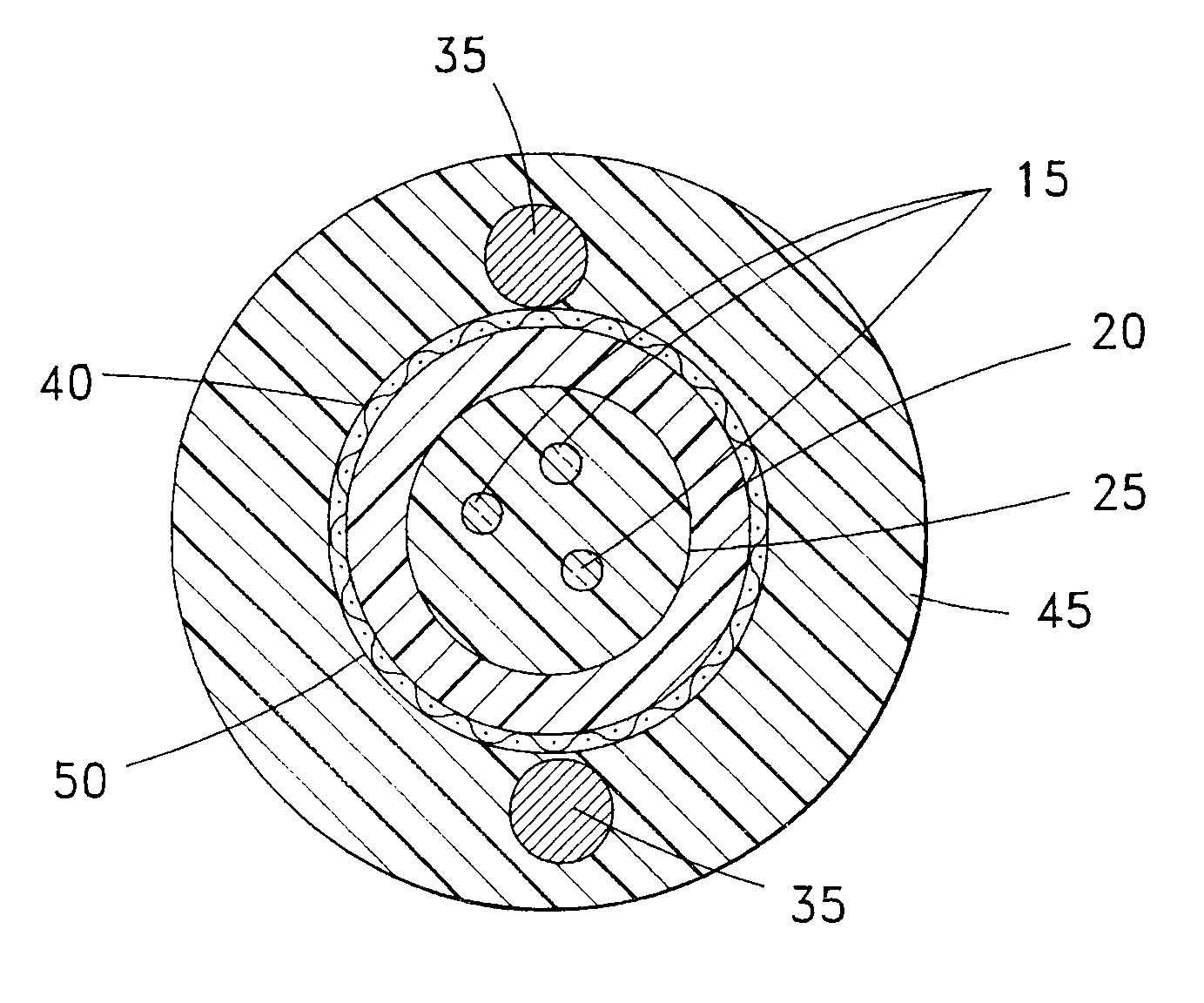

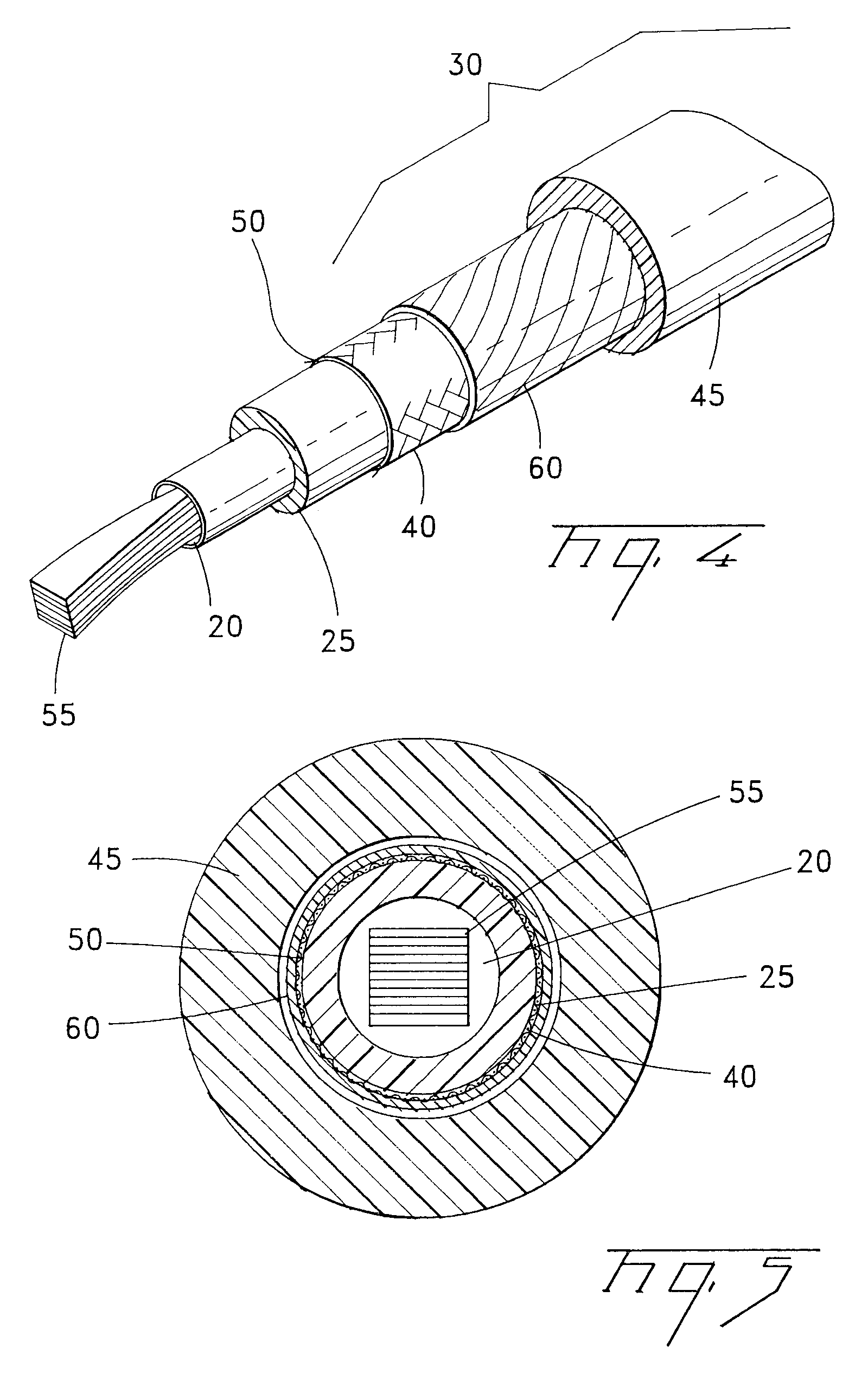

Communication cable containing novel filling material in buffer tube

InactiveUS6374023B1Minimizes strainAvoid drippingCable fittingsFibre mechanical structuresFilling materialsEngineering

A cable containing at least one optical fiber within a tube, a space between the optical fiber and the tube and a filling material at least partially filling the space. The filling material contains thermoplastic polymeric molecules which have bonded to form a three-dimensional network substantially throughout said filling material.

Owner:CORNING OPTICAL COMM LLC

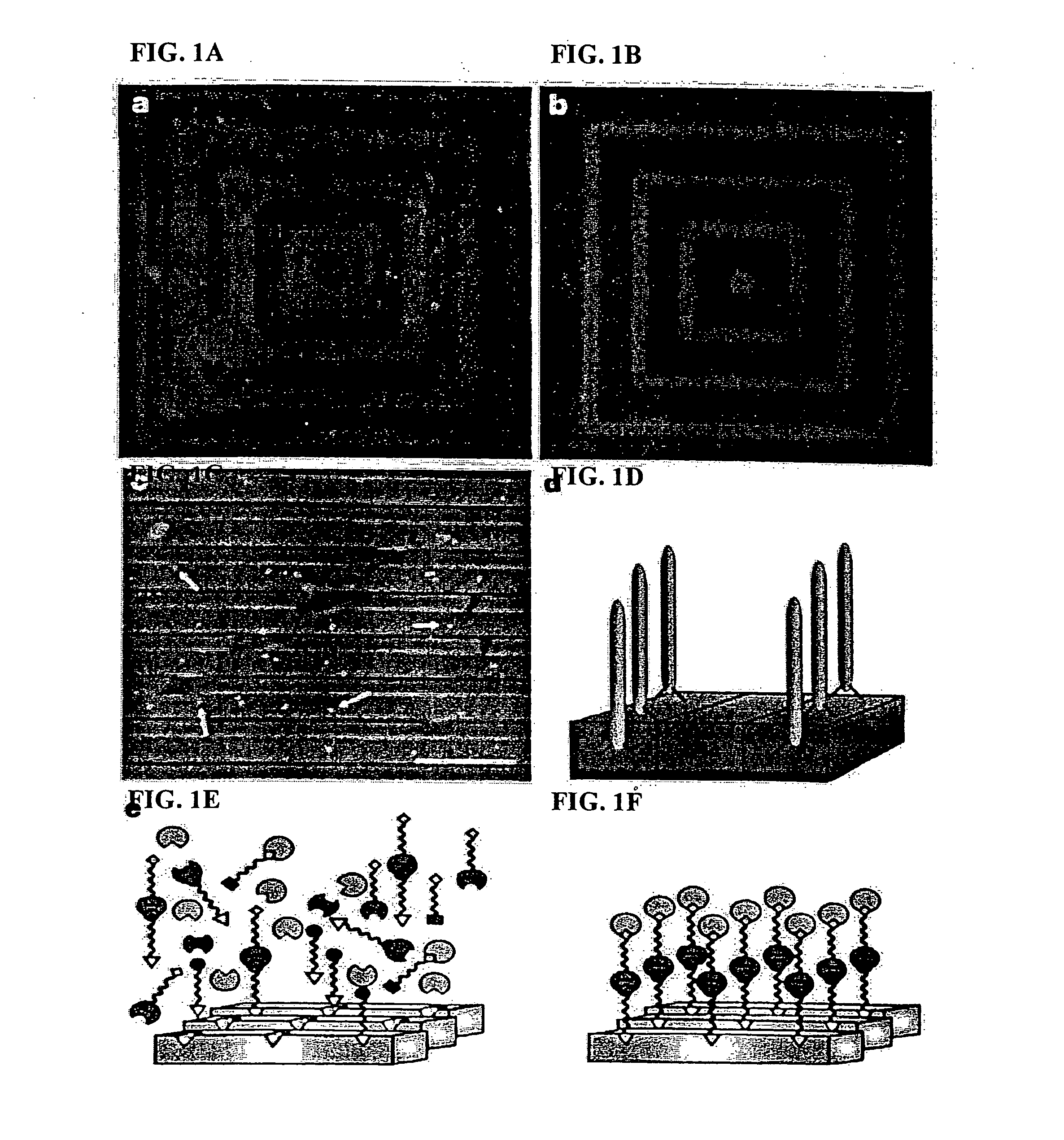

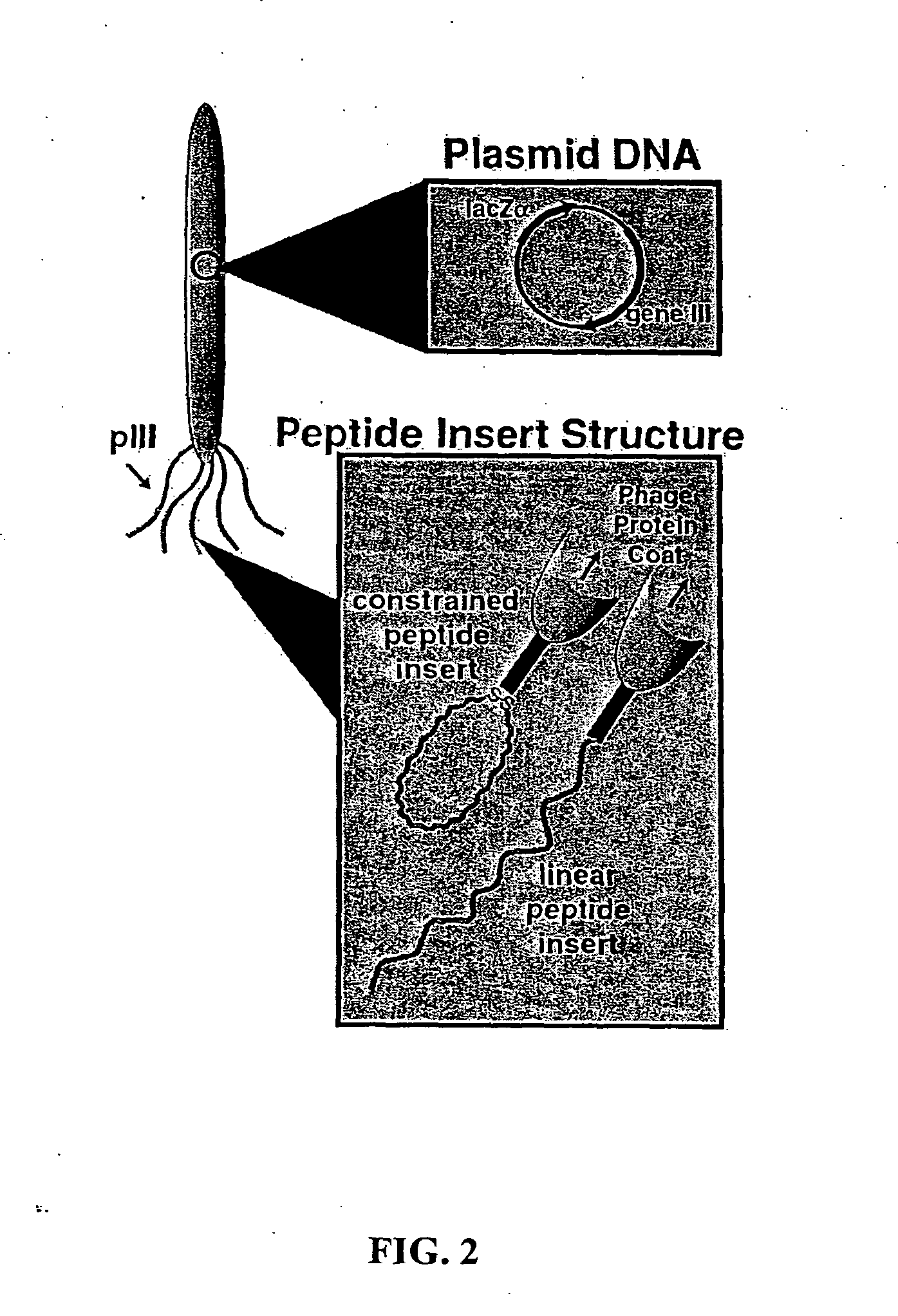

Peptide mediated synthesis of metallic and magnetic materials

InactiveUS20050064508A1Small sizeEasy to controlMaterial nanotechnologyLibrary screeningOligomerNanocrystal

The present invention includes methods for producing magnetic nanocrystals by using a biological molecule that has been modified to possess an amino acid oligomer that is capable of specific binding to a magnetic material.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Tunnel effect transistors based on elongate monocrystalline nanostructures having a heterostructure

ActiveUS20080067607A1Optimize architectureReduce power consumptionTransistorNanoinformaticsMOSFETSemiconductor materials

Tunnel field-effect transistors (TFETs) are regarded as successors of metal-oxide semiconductor field-effect transistors (MOSFETs), but silicon-based TFETs typically suffer from low on-currents, a drawback related to the large resistance of the tunnel barrier. To achieve higher on-currents an elongate monocrystalline nanostructure-based TFET with a heterostructure made of a different semiconducting material (e.g. germanium (Ge)) is used. An elongate monocrystalline nanostructure made of a different semiconducting material is introduced which acts as source (or alternatively drain) region of the TFET. The introduction of the heterosection is such that the lattice mismatch between silicon and germanium does not result in a highly defective interface. A dynamic power reduction as well as a static power reduction can result, compared to conventional MOSFET configurations. Multiple layers of logic can therefore be envisioned with these elongate monocrystalline nanostructure Si / Ge TFETs resulting in ultra-high on-chip transistor densities.

Owner:KATHOLIEKE UNIV LEUVEN +1

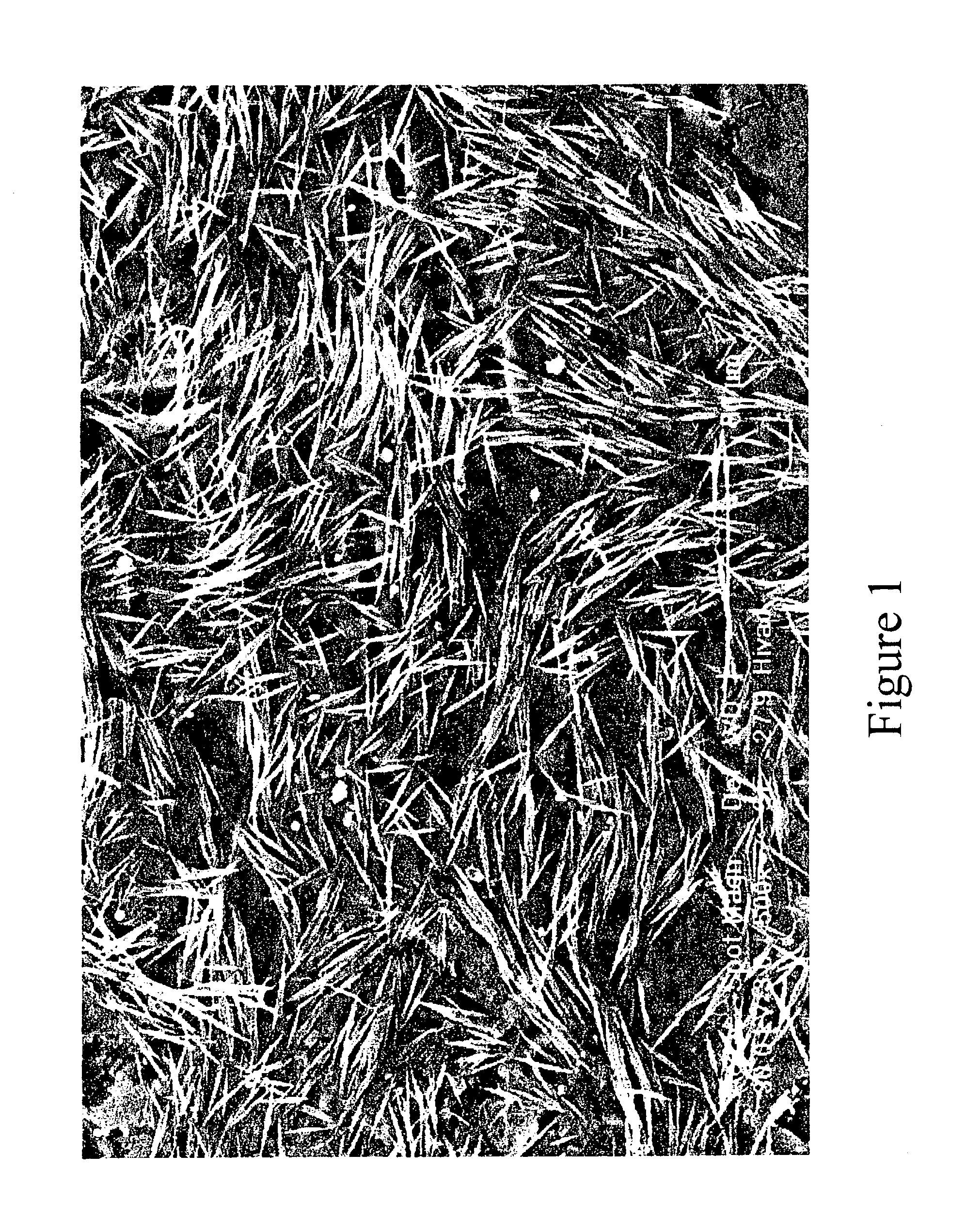

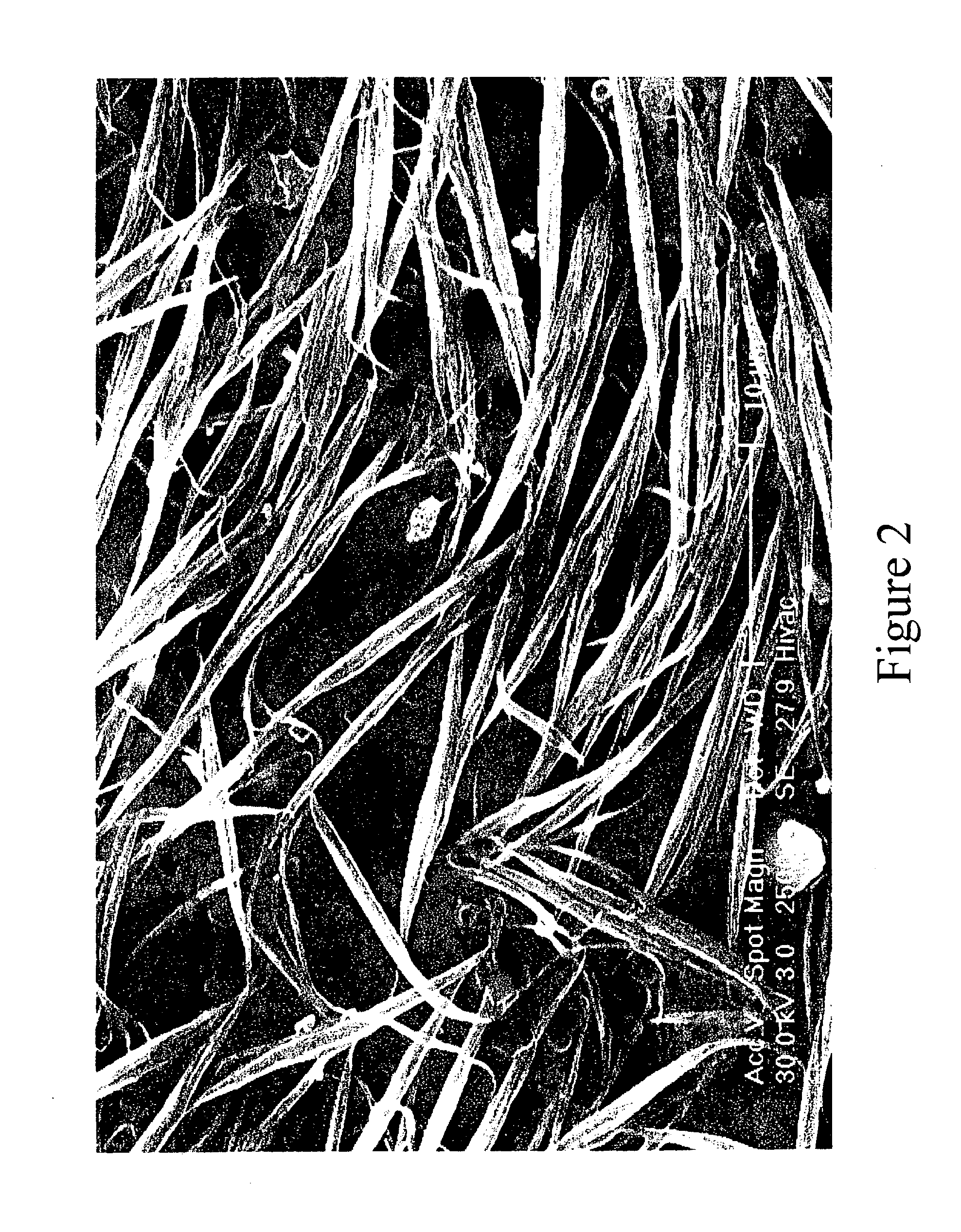

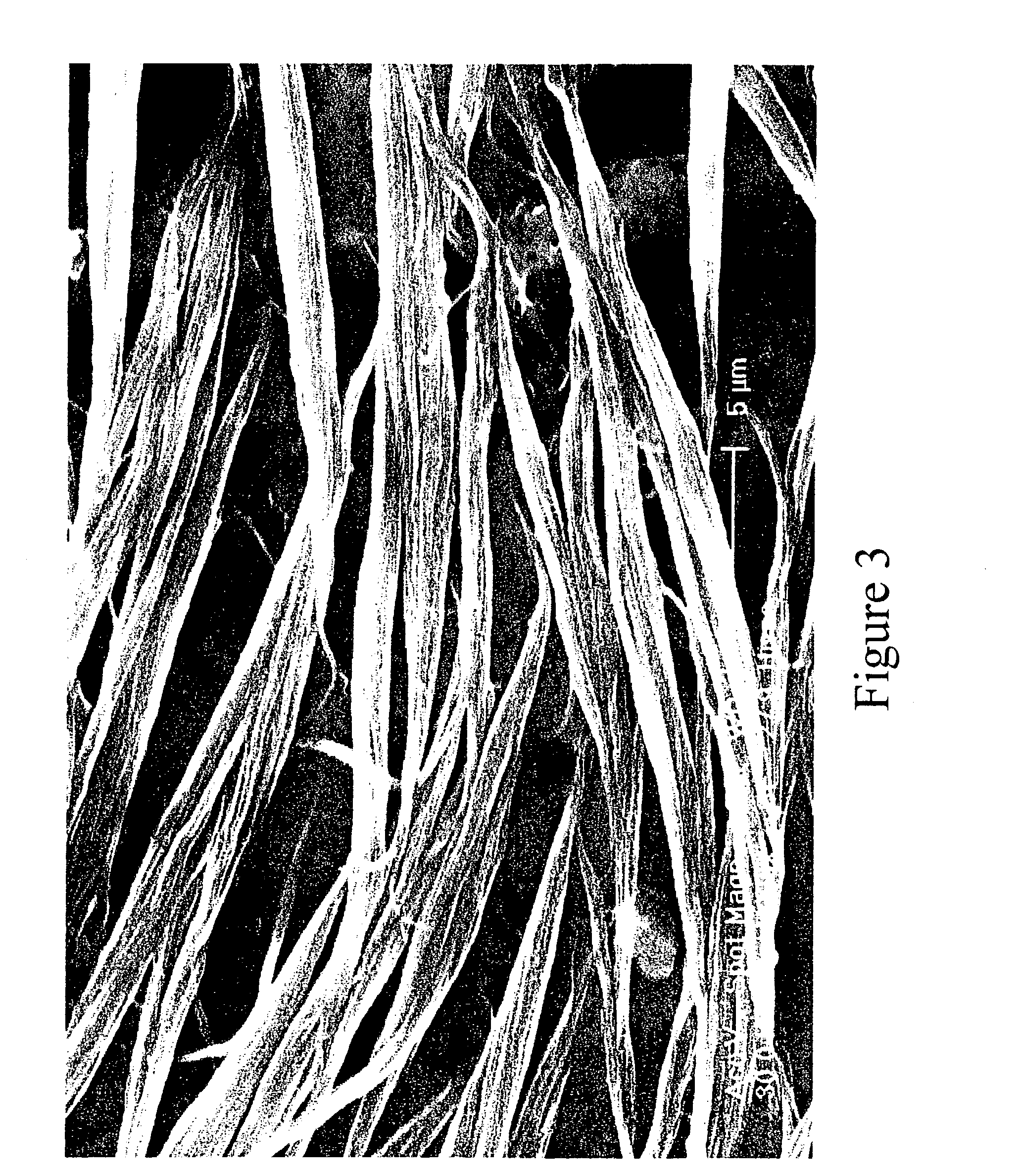

Fibers of aligned single-wall carbon nanotubes and process for making the same

ActiveUS7125502B2Good dispersionEasy to incorporatePigmenting treatmentNanosensorsFiberCarbon nanotube

The present invention involves fibers of highly aligned single-wall carbon nanotubes and a process for making the same. The present invention provides a method for effectively dispersing single-wall carbon nanotubes. The process for dispersing the single-wall carbon nanotubes comprises mixing single-wall carbon nanotubes with 100% sulfuric acid or a superacid, heating and stirring under an inert, oxygen-free environment. The single-wall carbon nanotube / acid mixture is wet spun into a coagulant to form the single-wall carbon nanotube fibers. The fibers are recovered, washed and dried. The single-wall carbon nanotubes were highly aligned in the fibers, as determined by Raman spectroscopy analysis.

Owner:DEXMAT INC

Haptic feedback for touchpads and other touch controls

InactiveUS20060119589A1Enhanced interactionEnhance manipulationInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsTouchpad

A haptic feedback planar touch control used to provide input to a computer. A touch input device includes a planar touch surface that inputs a position signal to a processor of the computer based on a location of user contact on the touch surface. The computer can position a cursor in a displayed graphical environment based at least in part on the position signal, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user contacting the touch surface. The touch input device can be a touchpad separate from the computer's display screen, or can be a touch screen. Output haptic sensations on the touch input device can include pulses, vibrations, and spatial textures. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

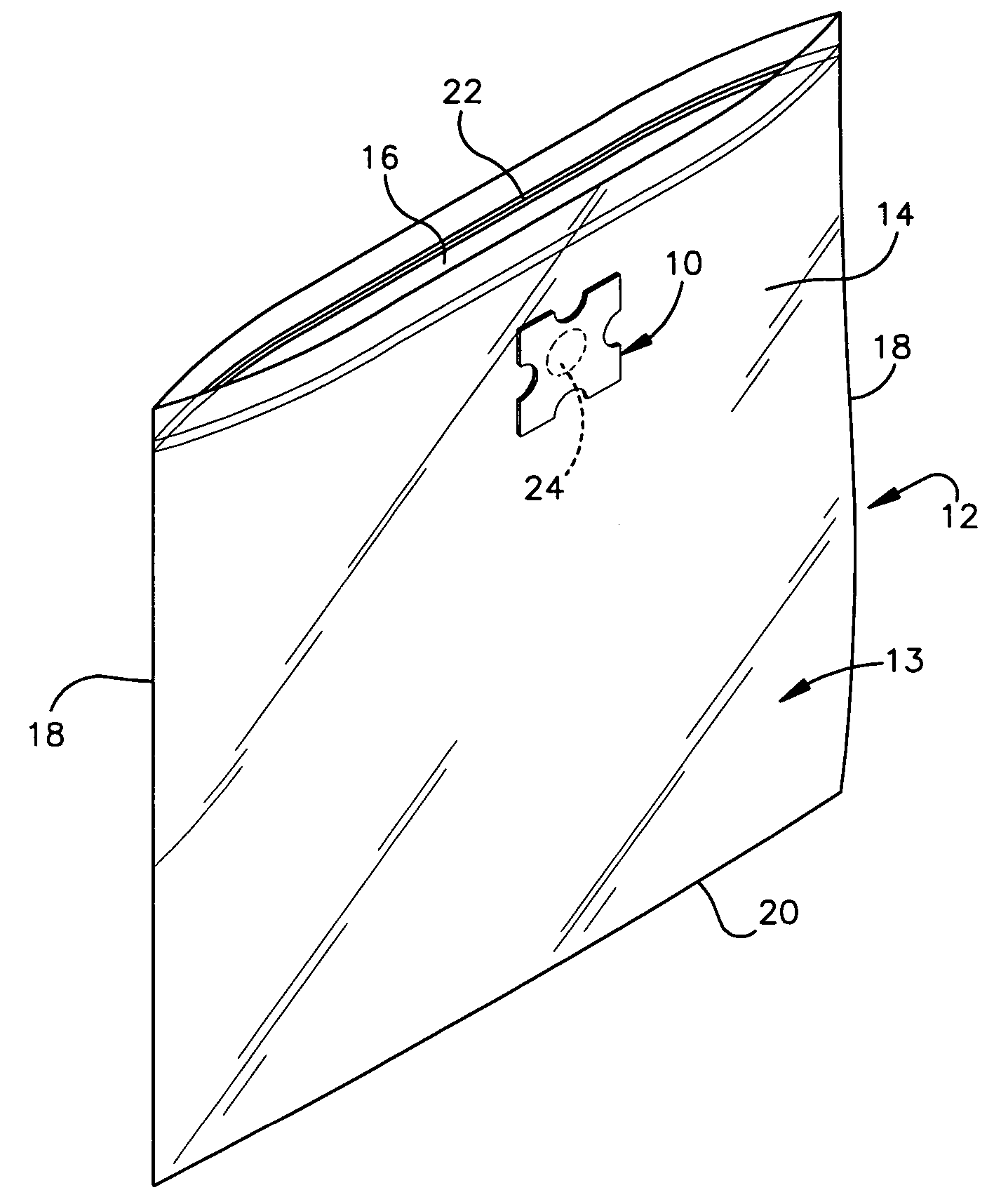

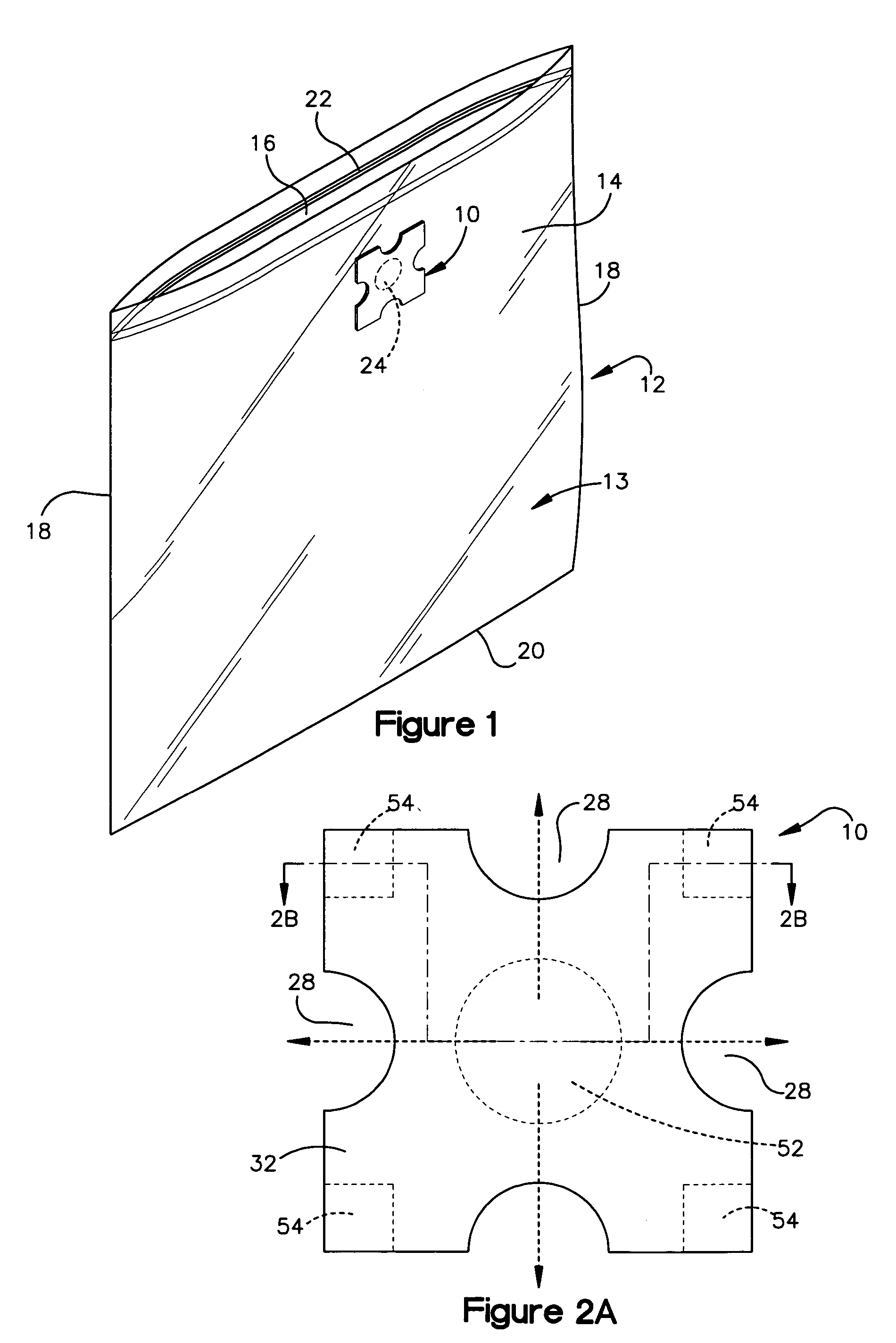

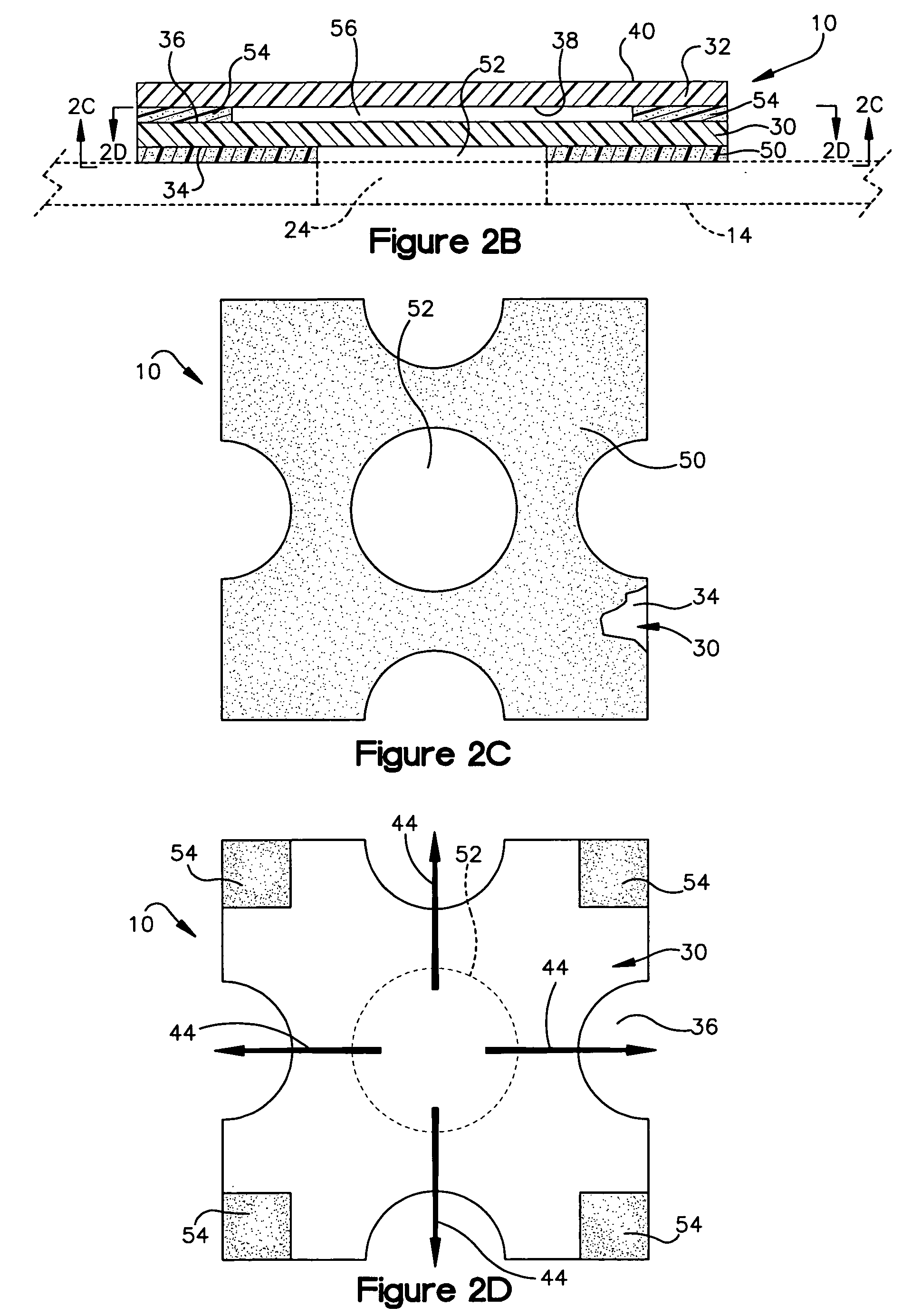

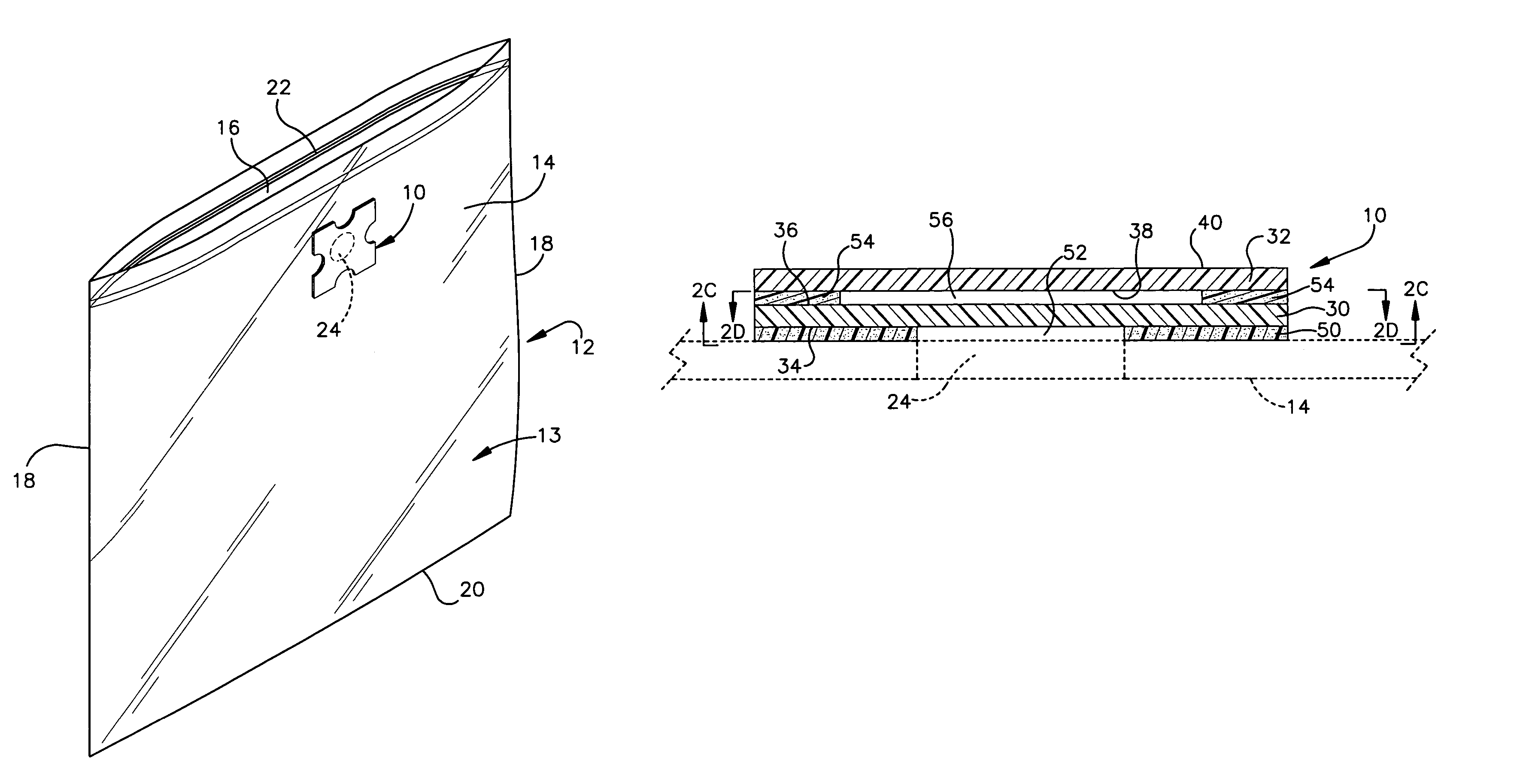

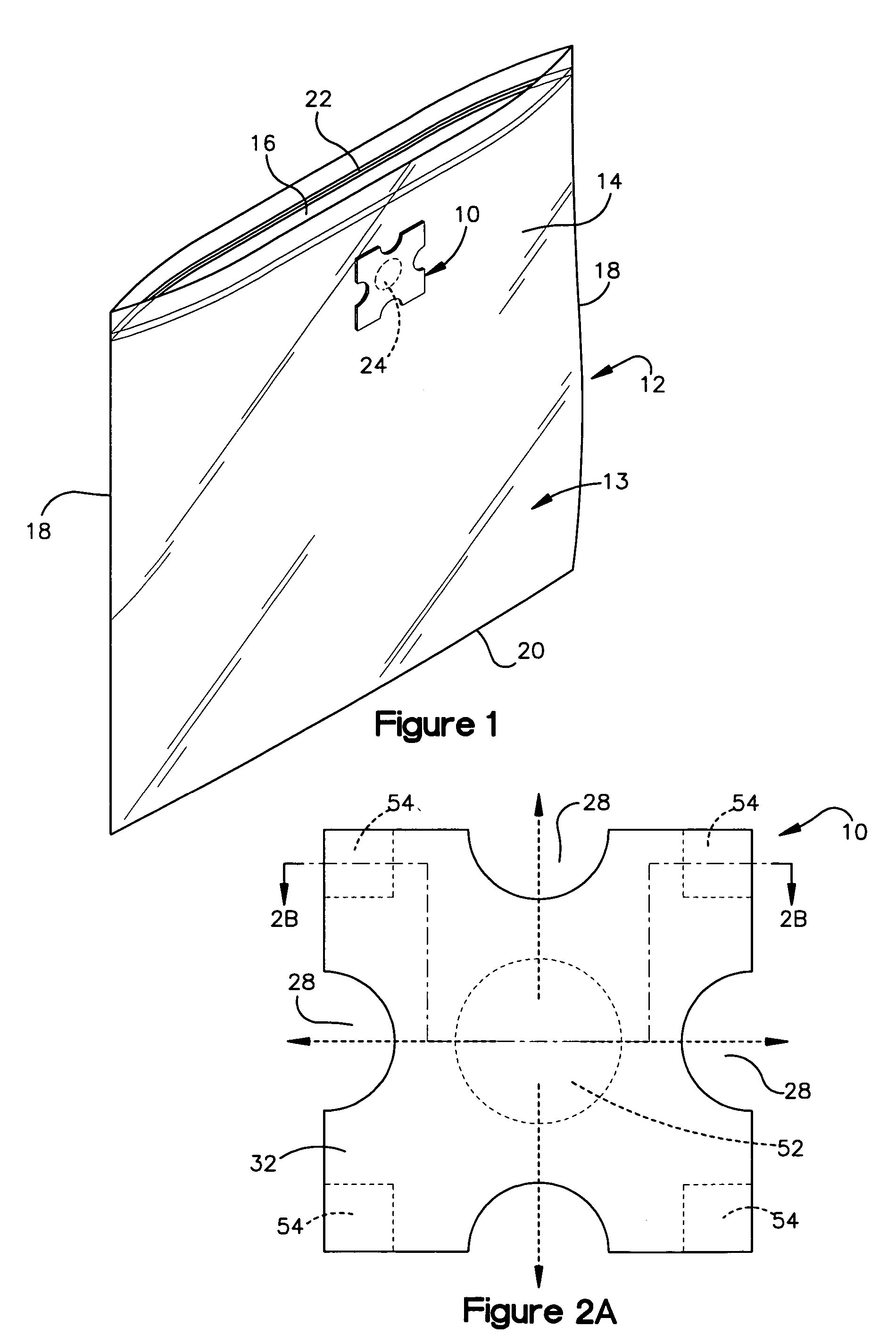

Food bag release valve

ActiveUS20060030472A1Decrease freezer burnComplicated processEnvelopes/bags making machineryBag making operationsIngested foodVALVE PORT

Owner:CCL LABEL INC

Food bag release valve

ActiveUS7244223B2Sufficient protectionNot compromise current (and quick) bag-making speedEnvelopes/bags making machineryBag making operationsBiomedical engineering

Owner:CCL LABEL INC

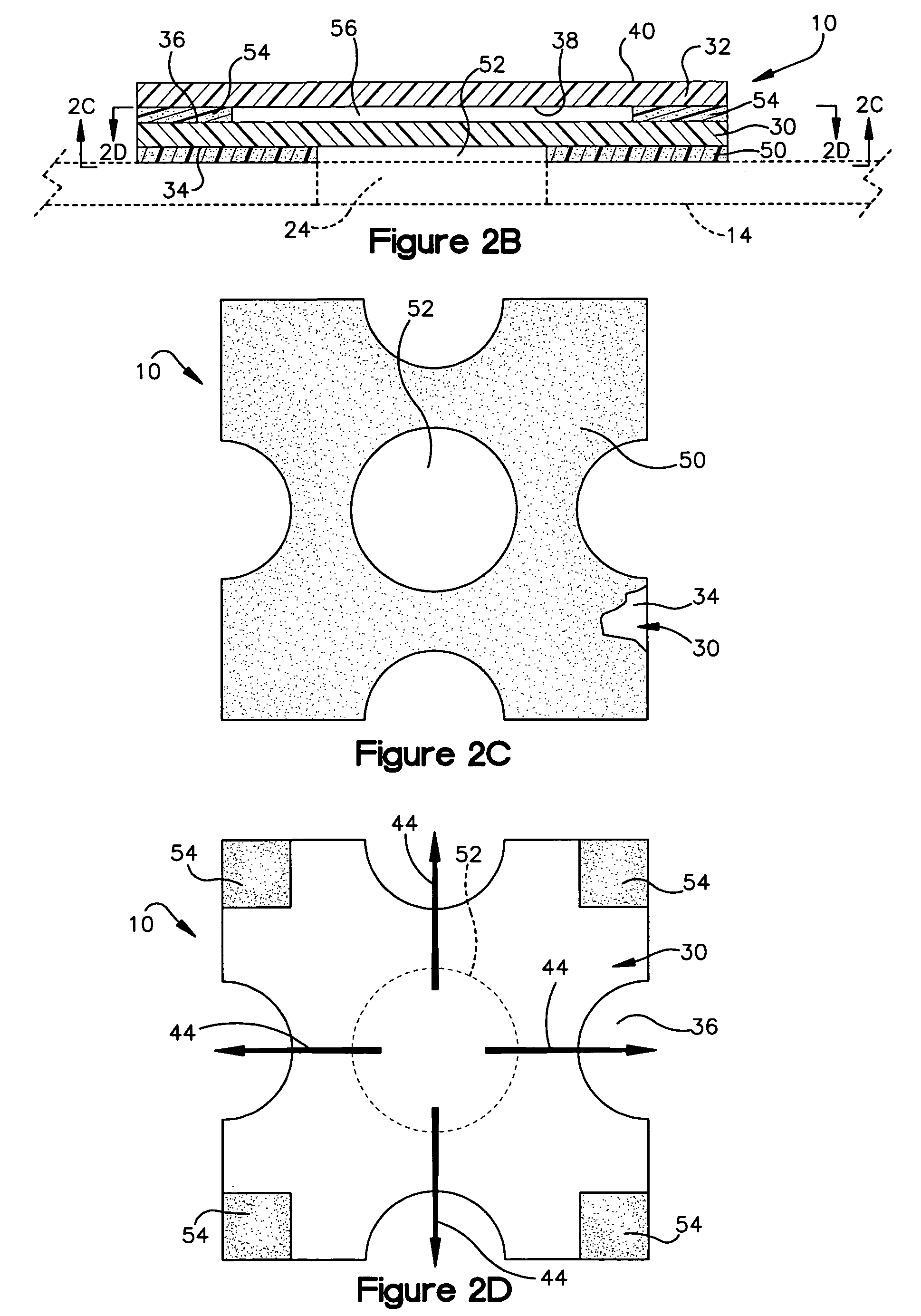

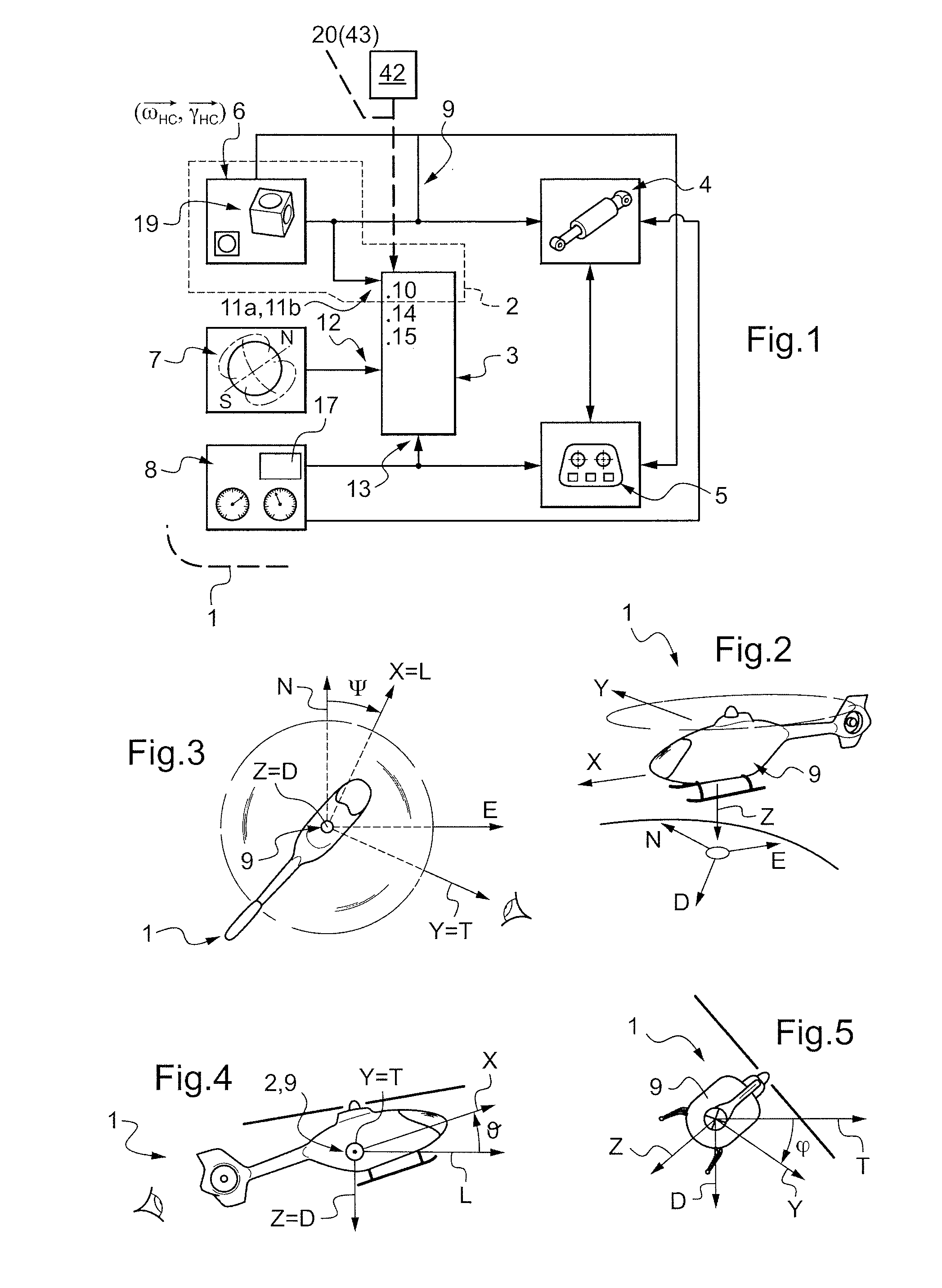

Turning-stabilized estimation of the attitude angles of an aircraft

ActiveUS20110190964A1Easy to mergeSystem stabilityDigital data processing detailsNavigation by speed/acceleration measurementsGyroscopeHorizontal axis

The present invention relates to estimating the attitude angles of an aircraft (1). The estimated attitude angles are generated by a device (9) that performs algorithmic integration on inertial measurements indicative of an angular velocity and of a linear acceleration. Horizontal components (34-39) of desired corrections are obtained by a linear combination of two horizontal components (32-33), with cross coefficients between said horizontal axes being continuous variable over time and dependent on the estimated rate of turn. As a result, the estimated attitude angles are stable, and the biases of the gyros continue to be estimated, including during stages during which the aircraft (1) is turning.

Owner:EUROCOPTER

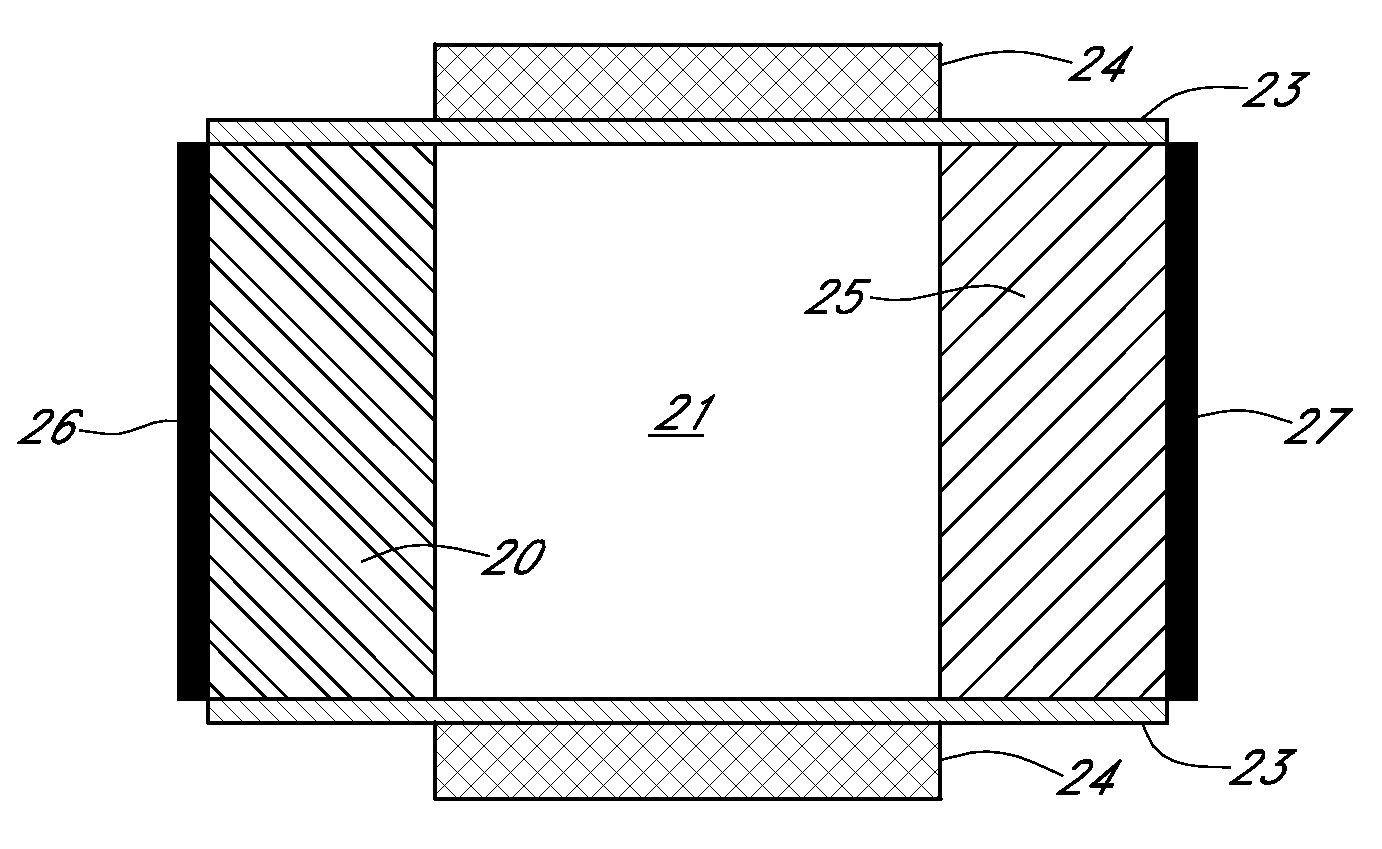

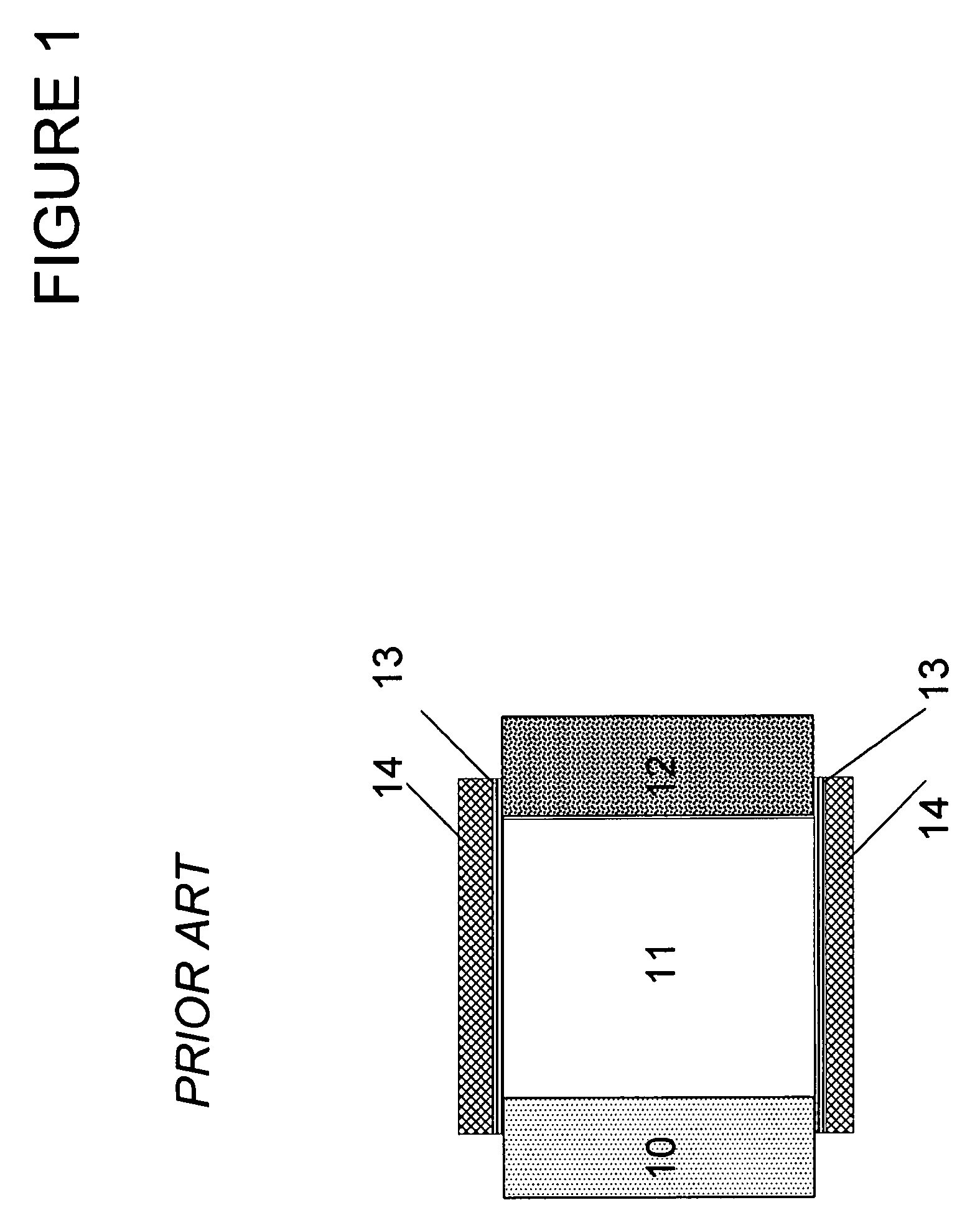

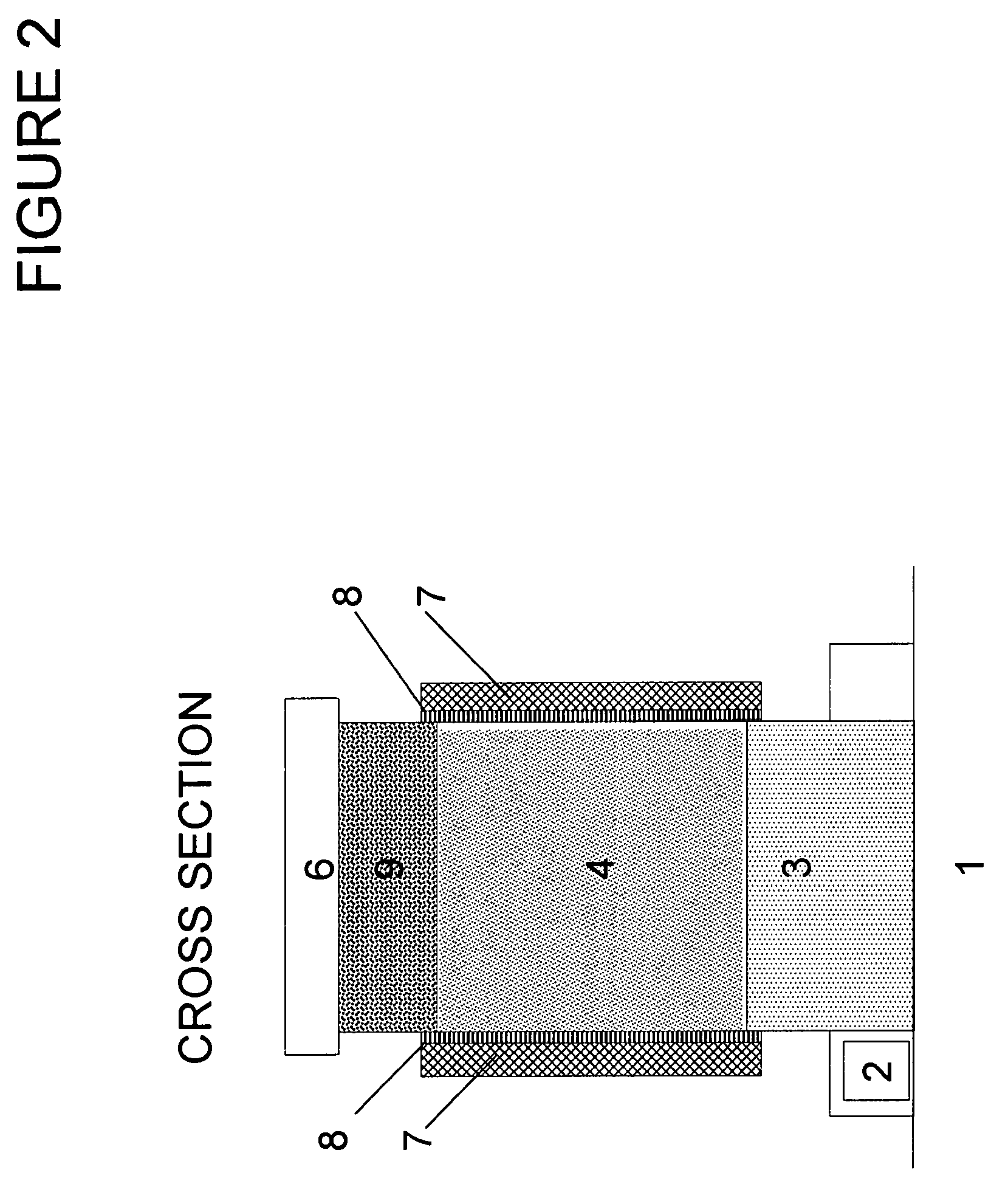

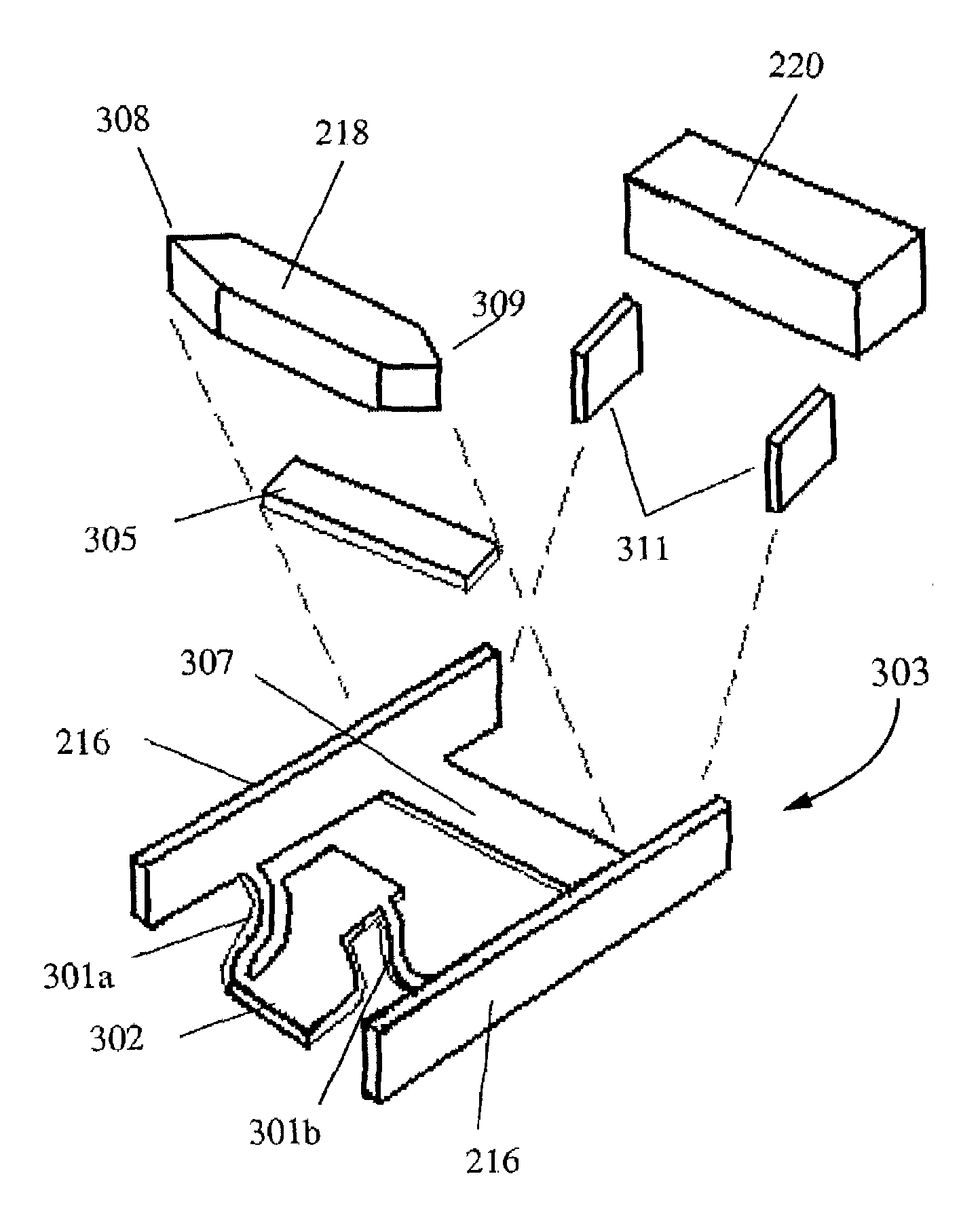

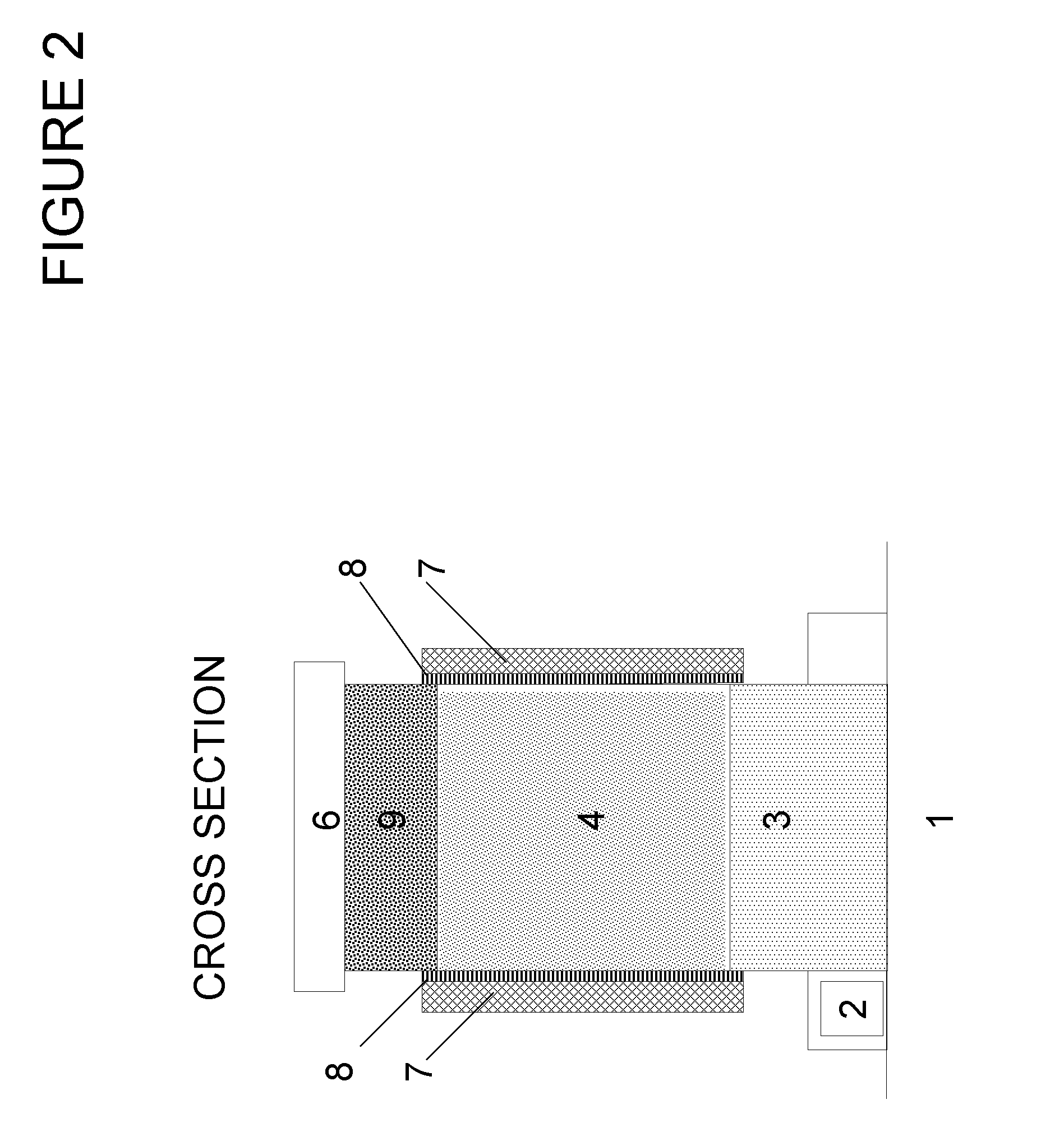

Rotational PZT micro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS7379274B2Precise positioningImprove featuresArm with actuatorsRecord information storageMicro actuatorControl theory

A head gimbal assembly (HGA) for a disk drive unit that includes a micro-actuator, a slider and a suspension to load the slider and the micro-actuator. The micro-actuator includes a pair of actuator side arms, a PZT element extending between and connecting the actuator side arms; a rotatable plate positioned between the actuator side arms, wherein the slider is mounted on the rotatable plate; and a pair of connection elements that connect the rotatable plate to the actuator side arms, respectively. The rotatable plate rotates in a first direction when the PZT element contracts and a second direction when the PZT element expands.

Owner:SAE MAGNETICS (HK) LTD

Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

The invention discloses a method for a preparing low density polypropylene foam section or beads by two-step extrusion molding, which comprises the following steps that: expandable master batch is prepared from 30 to 80 portions of polypropylene, 10 to 40 portions of foaming agent, 0 to 15 portions of foaming accelerant, 0 to15 portions of dispersant and 0 to 10 portions of nucleating agent at a temperature below the decomposition temperature of the foaming agent and above a viscous flow temperature of the polypropylene; 20 to 99 portions of polypropylene with high melt strength, 0 to 70 portions of common polypropylene and 1 to 10 portions of expandable master batch are plasticizated and extruded together; supercritical gas is added to perform the blending of the plasticizated and extruded mixture; and the product obtained is made to generate foamcores in a foaming nucleation apparatus to form the section or beads finally. A chemical foaming agent is partially decomposed and foamed during the plasticization and extrusion, so that the viscosity of fused mass is reduced, the dissolution and dispersion of the supercritical gas are facilitated, and a problem that a foam imploding is likely to happen in a secondary forming process so as to influence the quality and appearance of secondarily formed product is solved as the chemical foaming agent retained in molding beads can be decomposed and foamed again during the secondary processing.

Owner:SICHUAN UNIV

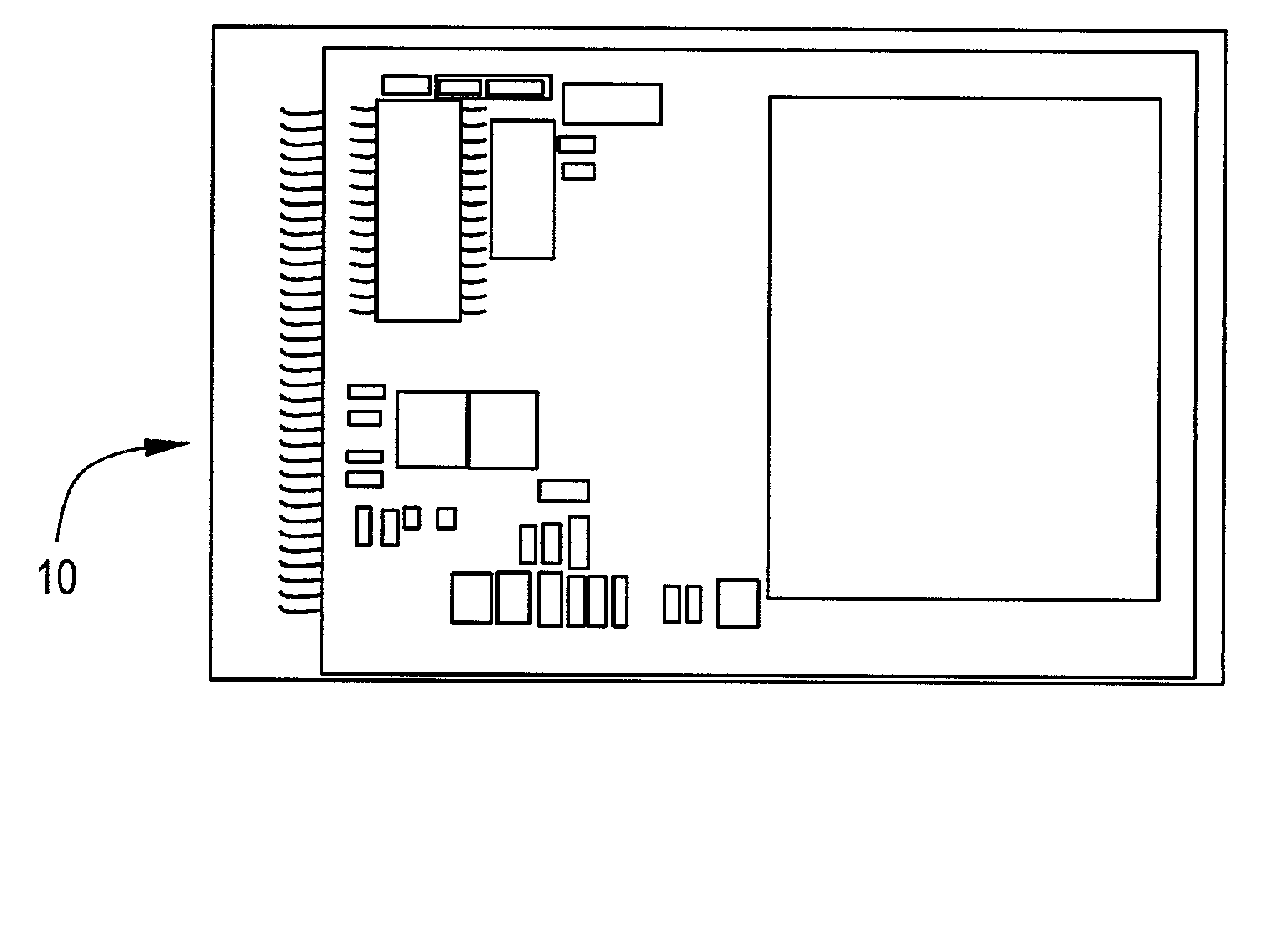

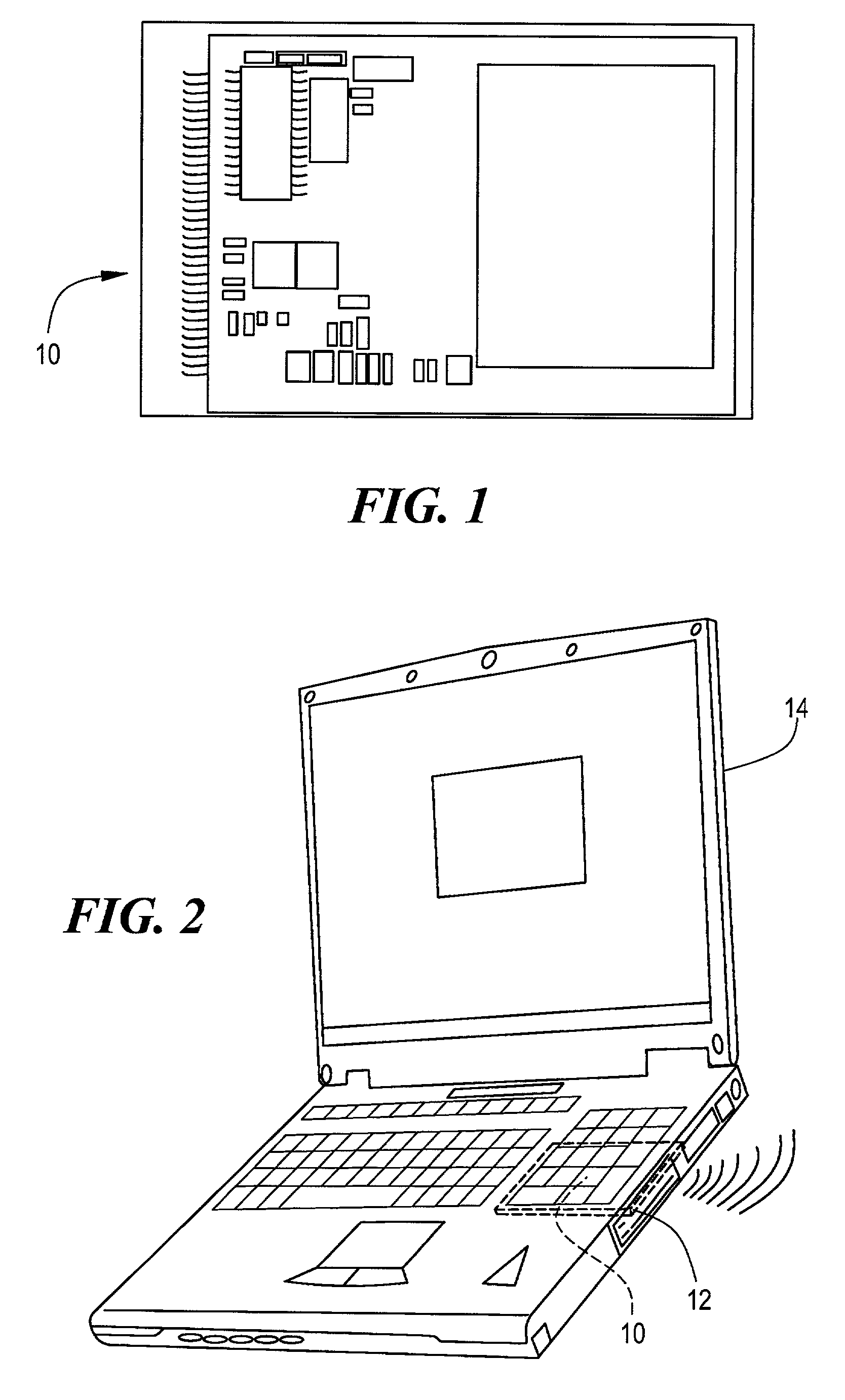

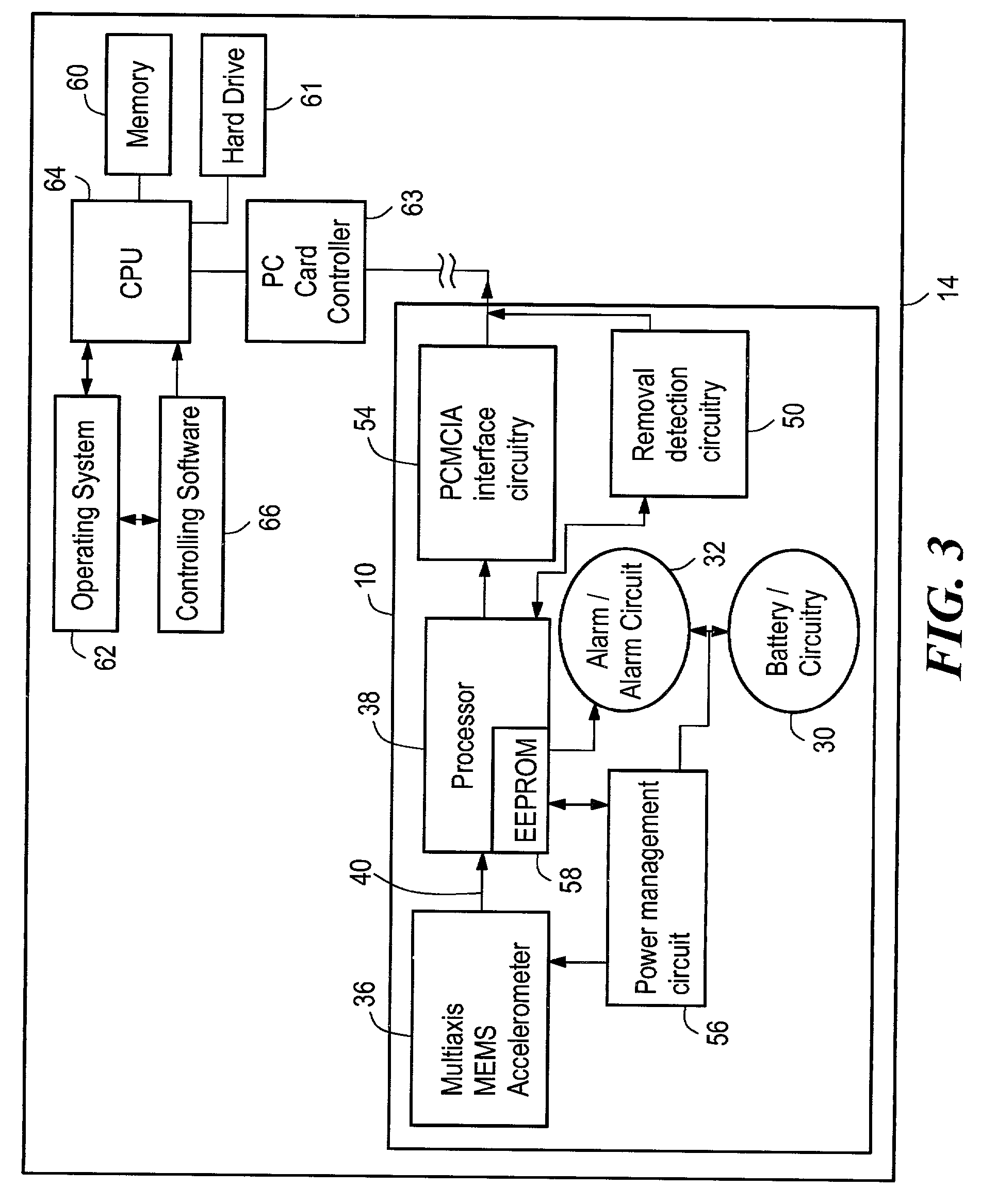

PC card security system

InactiveUS20030014660A1Easy to incorporateEasy to useError detection/correctionVolume/mass flow measurementPC CardSafe system

A security system including a removable circuit card having an unauthorized movement detection subsystem including a motion sensor, a processor responsive to the motion sensor for detecting whether motion sensed thereby is indicative of unauthorized movement and a response circuit activated by the processor in response to unauthorized movement. The security system also includes a power source integrated with the circuit card for powering the unauthorized movement detection subsystem in the event of a lack of available external power including removal of the circuit card.

Owner:CAVEO TECH

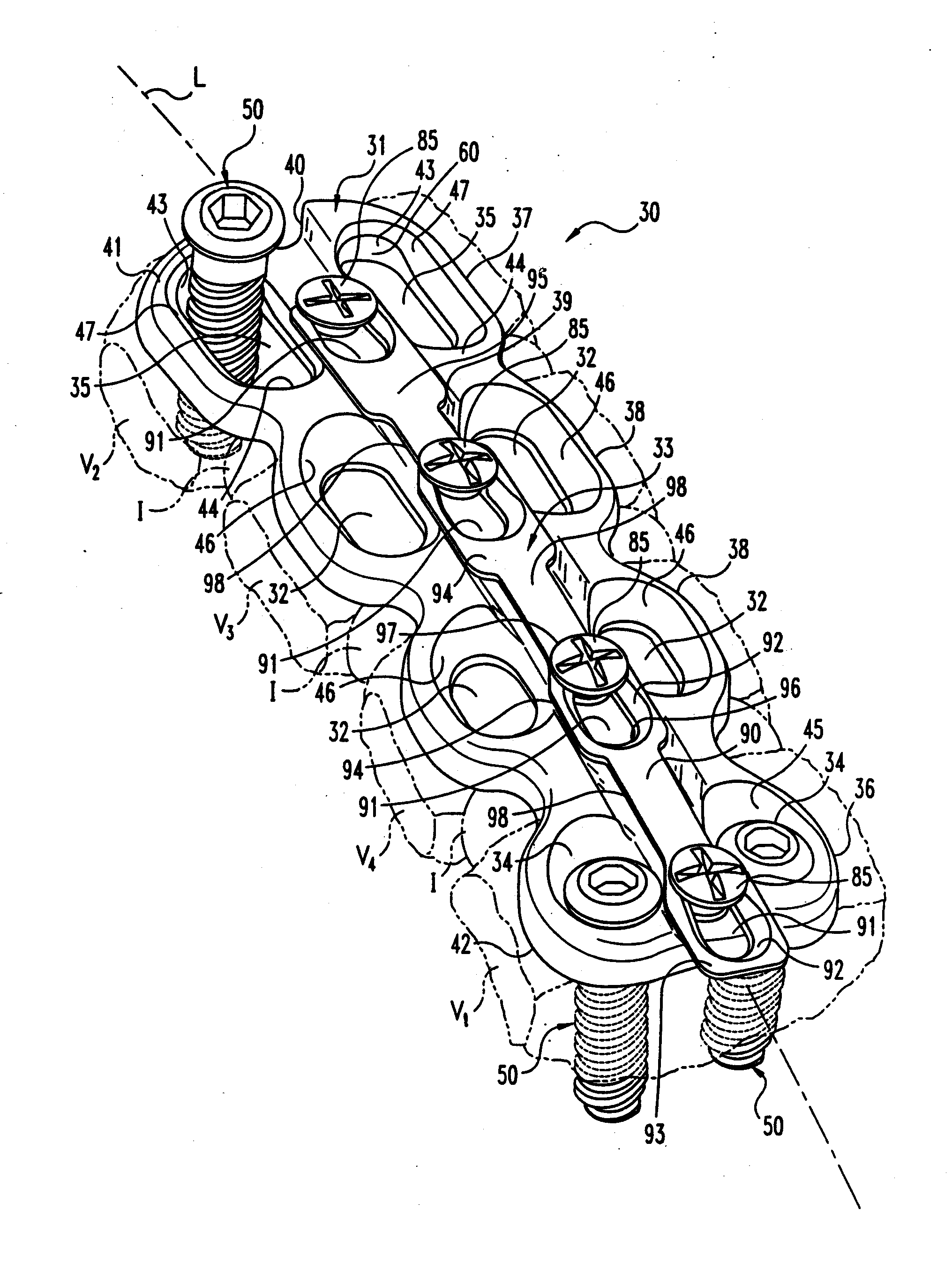

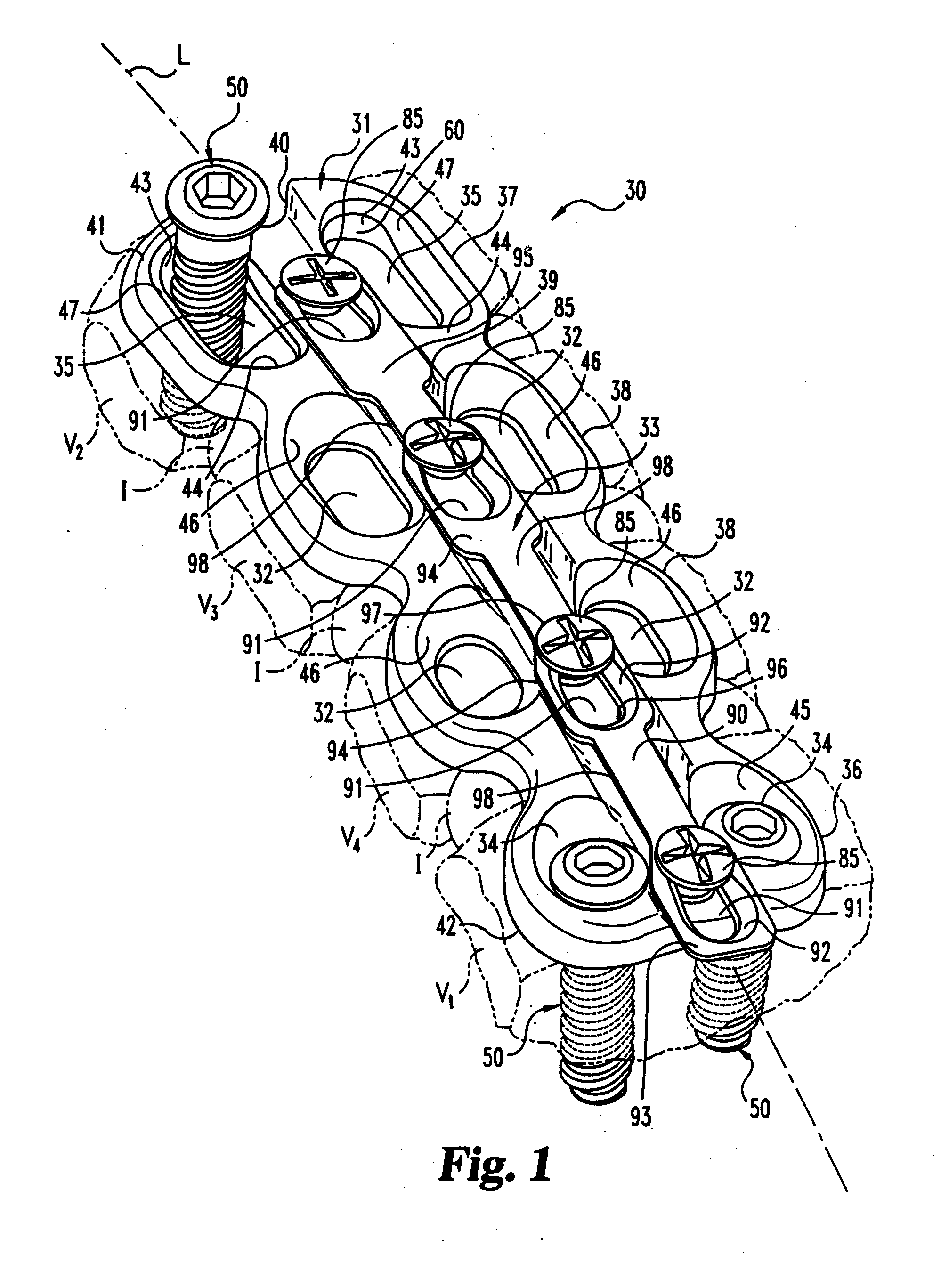

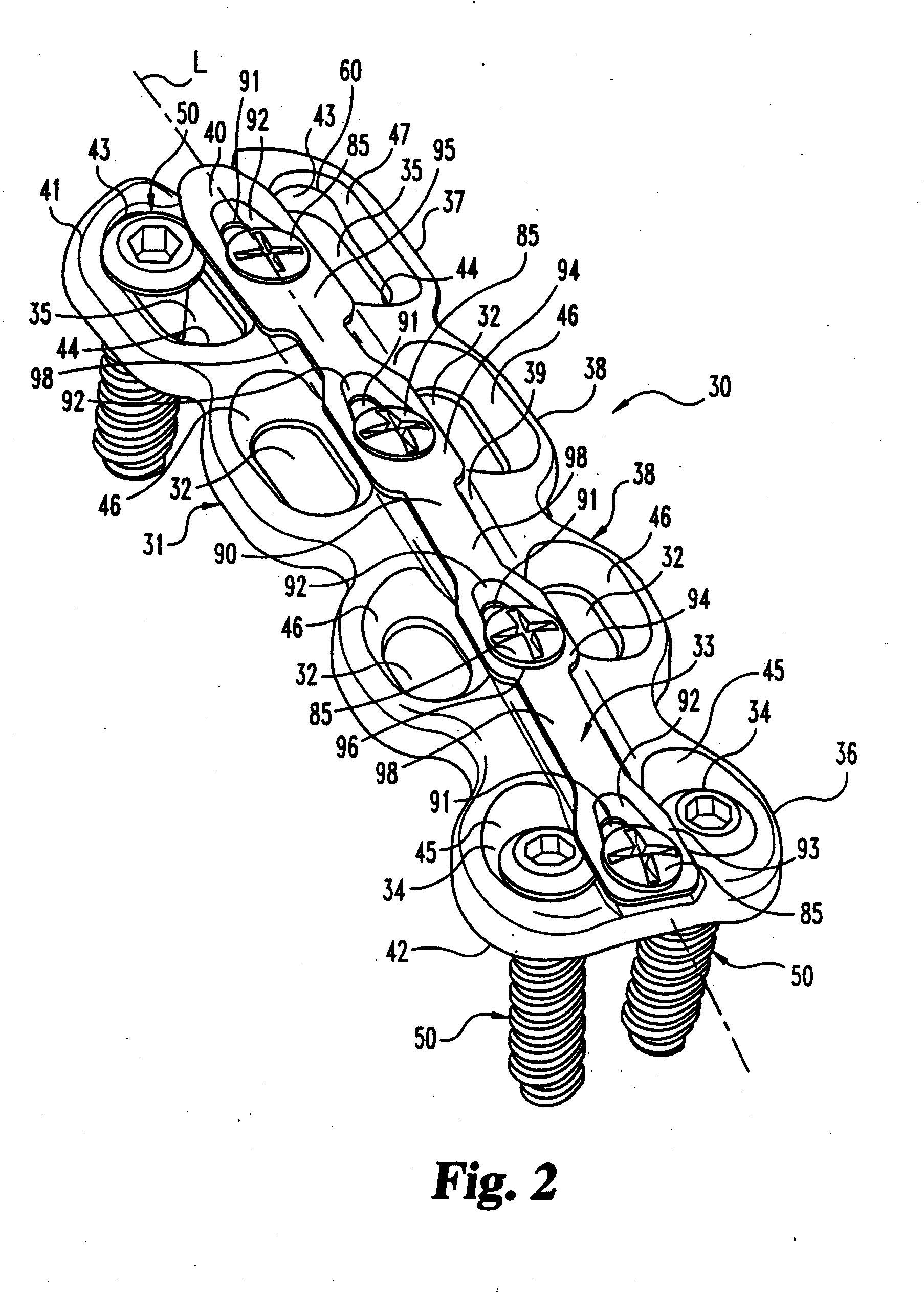

Anterior cervical plating system and method

InactiveUS20070203492A1Easy to fuseEasy to incorporateInternal osteosythesisBone platesSpinal columnAnterior approach

The present invention is directed to a system for anterior fixation of the spine that utilizes an elongated fixation plate. The plating system stabilizes the spine and promotes fusion and incorporation of a graft or implant in a portion of the spinal column. In one aspect of the invention, the fixation plate has a first end with a pair of holes. Bone screws extend through the holes to rigidly secure the plate to a first vertebra. The second end of the plate is provided with a pair of slots through which bone screws extend for engagement with a second vertebra. The screws extending through the slots are translatable in the slot to maintain compression of the spinal column portion. The plating system includes a retainer assembly that prevents screw back out. Methods and instruments relating to the plating system are also described.

Owner:WARSAW ORTHOPEDIC INC

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

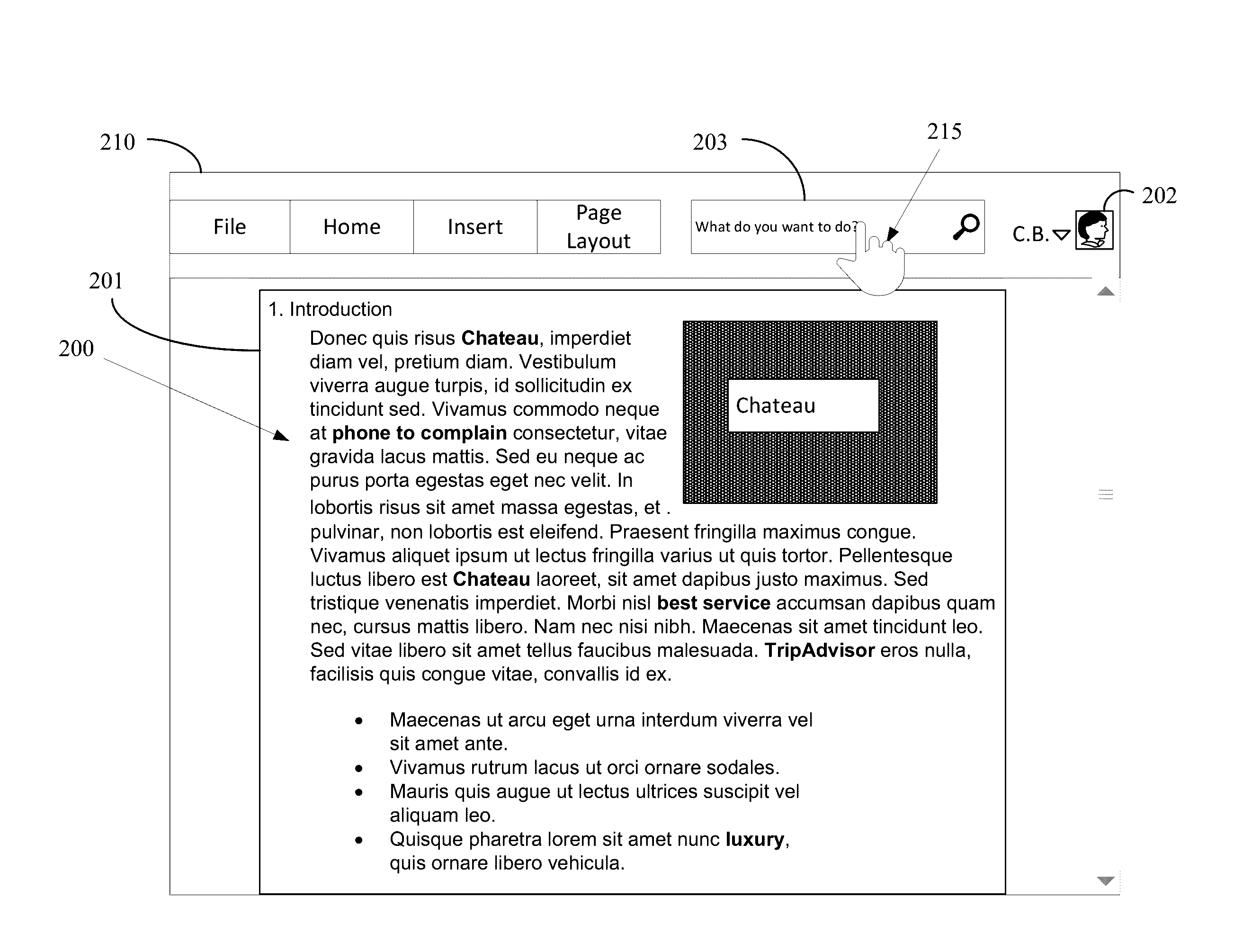

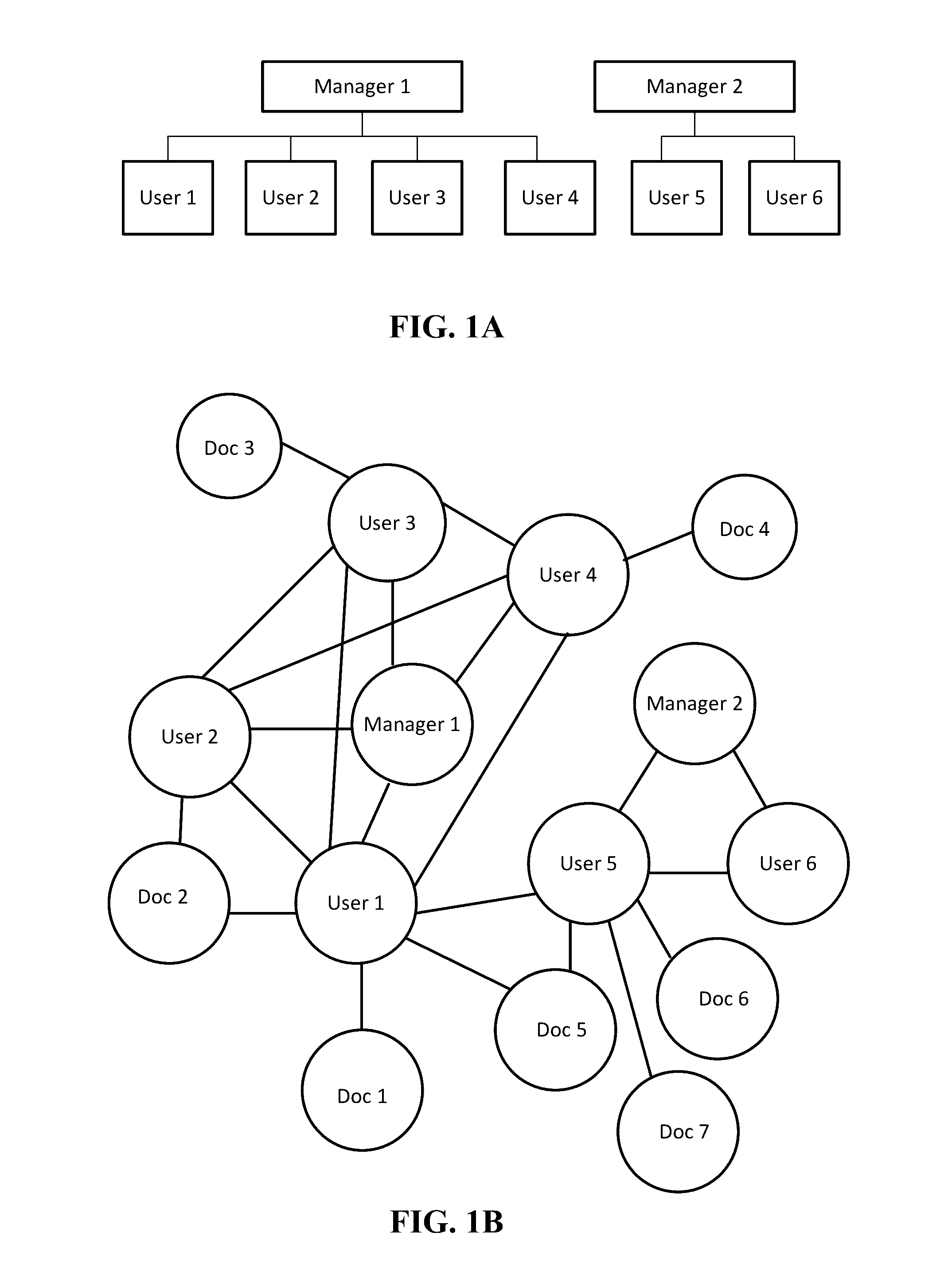

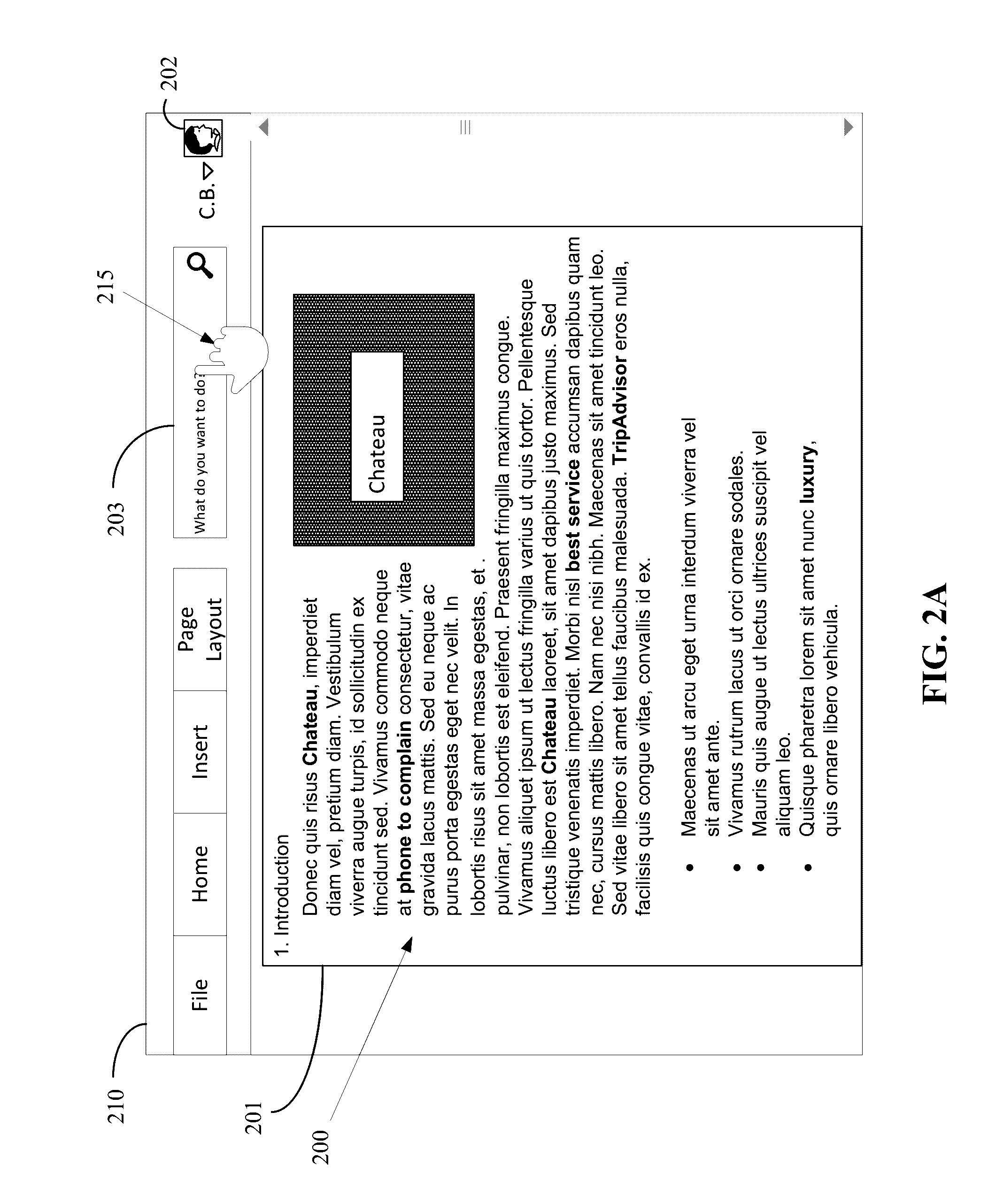

Graph-driven authoring in productivity tools

ActiveUS20160357842A1Easy to incorporateEasy to reuseDrawing from basic elementsRelational databasesGraphicsDocumentation

Owner:MICROSOFT TECH LICENSING LLC

Thickener for hair care products

InactiveUS20040234471A1Easy to processEasy to incorporateCosmetic preparationsHair removalIsostearic acidEthoxylation

A cosmetic and / or pharmaceutical composition comprising a thickening concentrate, said concentrate containing: (a) an isostearic acid; (b) a fatty alcohol; and (c) an ethoxylated fatty alcohol.

Owner:COGNIS DEUT GMBH & CO KG

Rare earth mixed transparent oxyfluoride glass ceramic and preparation process thereof

A transparent glass ceramics of RE-doped oxyfluoride is proportionally prepared from SiO2, Al2O3, EnF2, MF2 and ReF3, where M is 2-valence alkali-earth metal ion chosen from Mg, Ca, Sr, and Ba and Re is 3-valence RE ion chosen from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, through high fusing and heat treating. It can be extensive used in laser, luminous and optical communication field.

Owner:ZHEJIANG UNIV

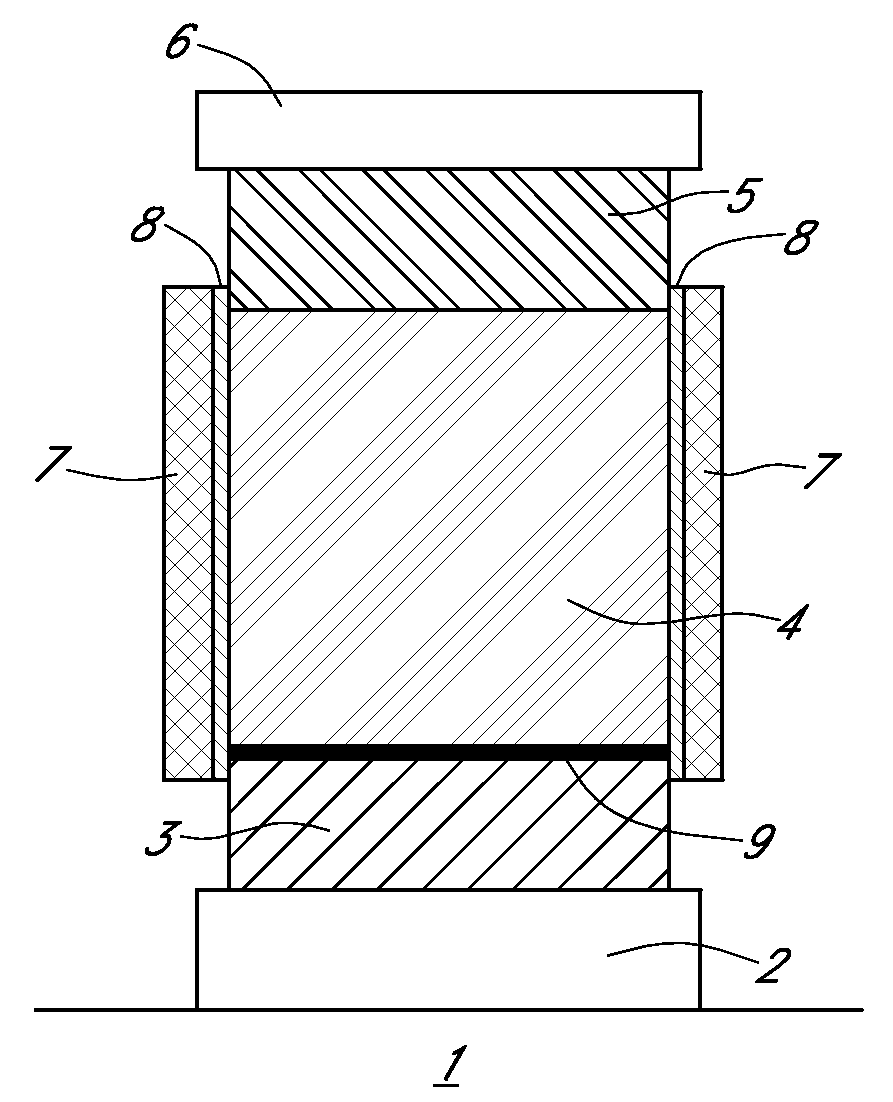

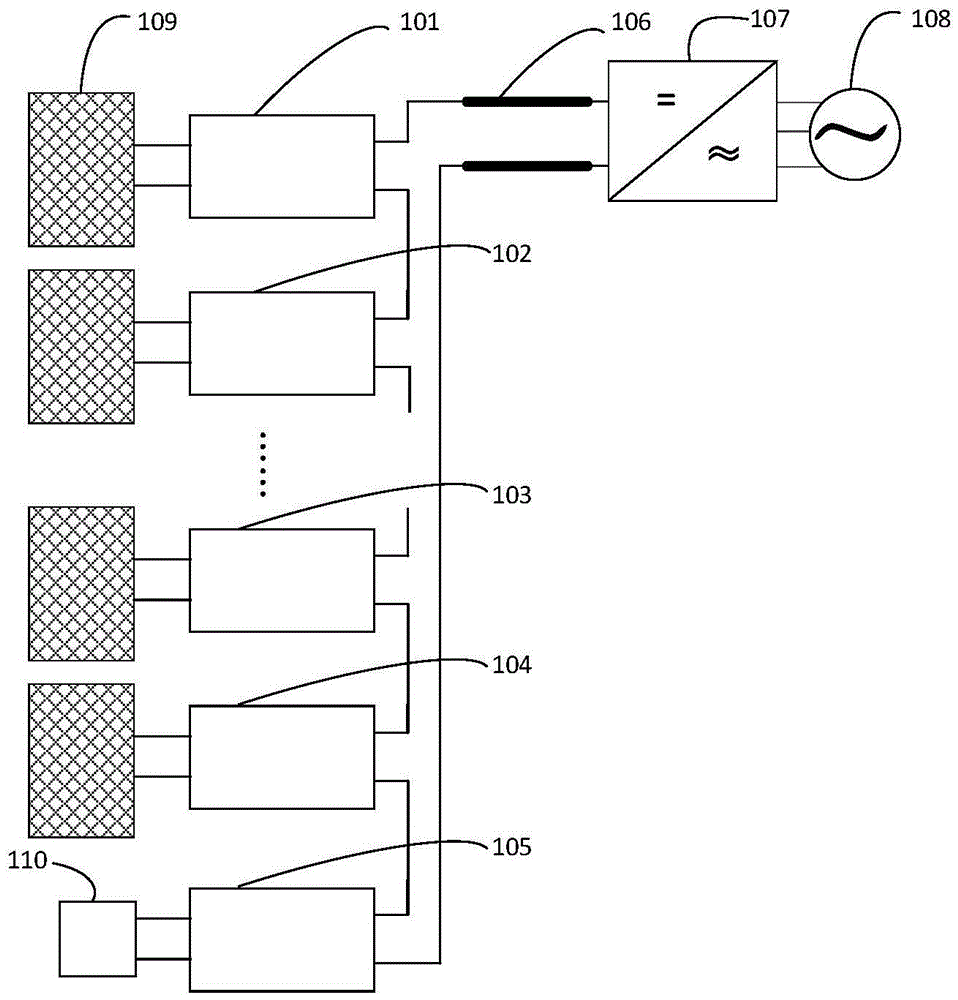

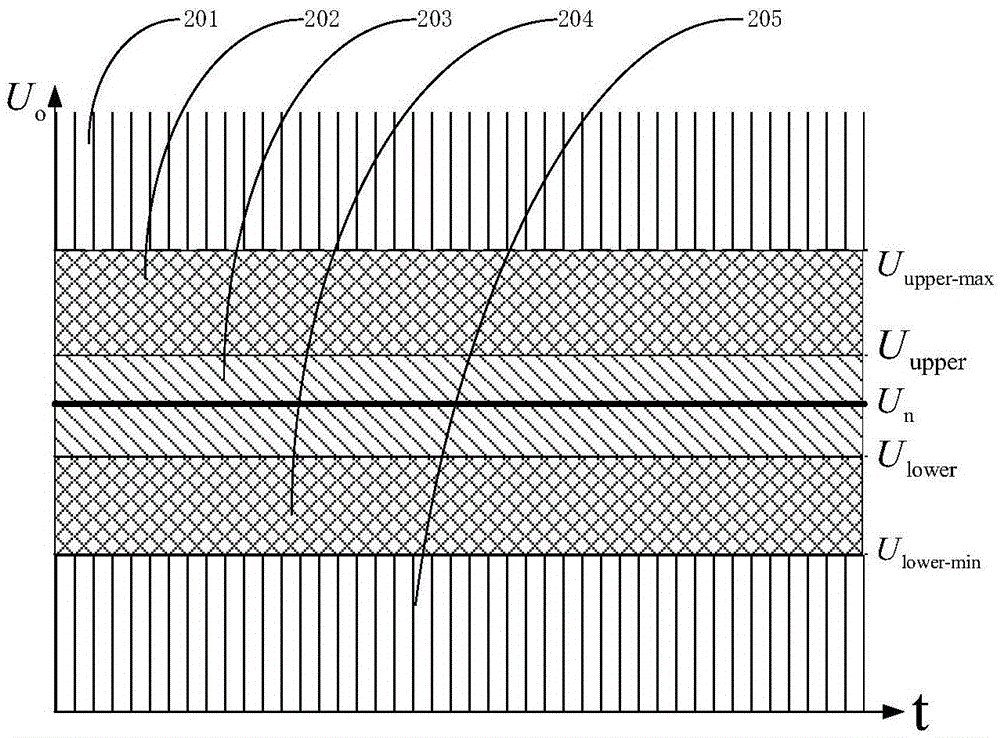

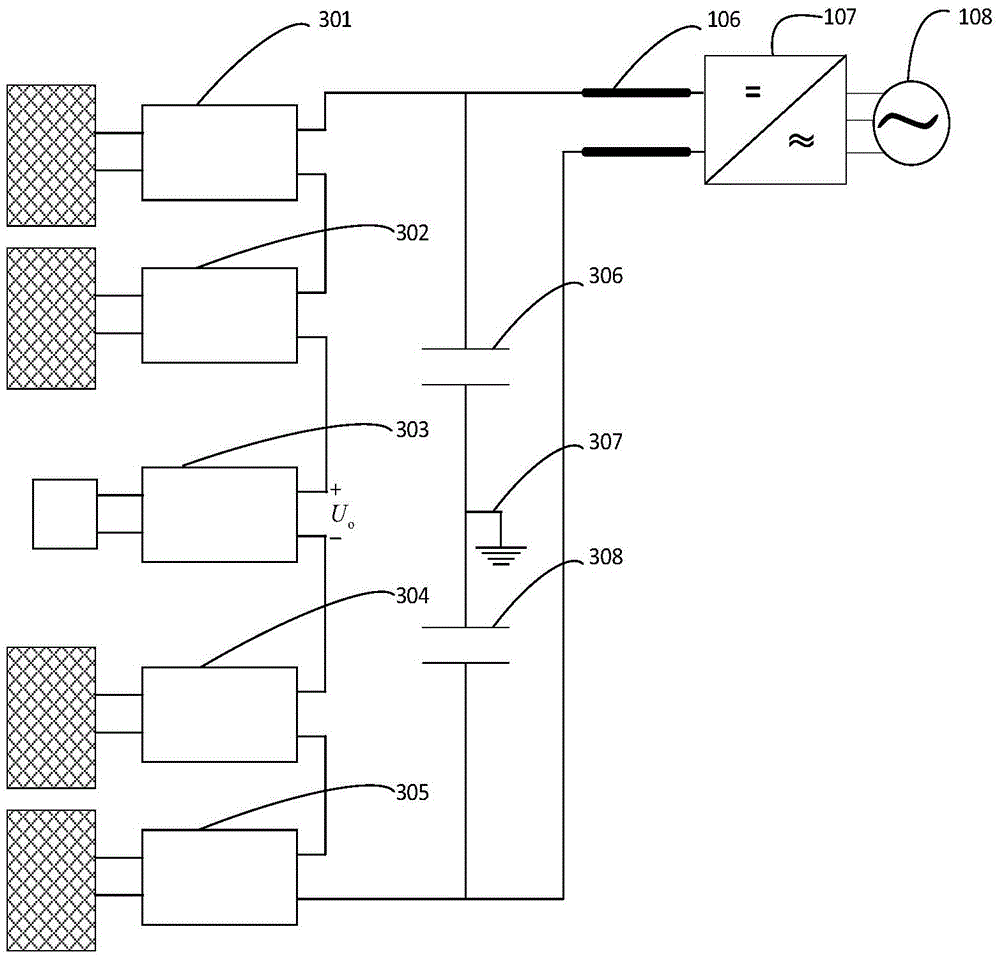

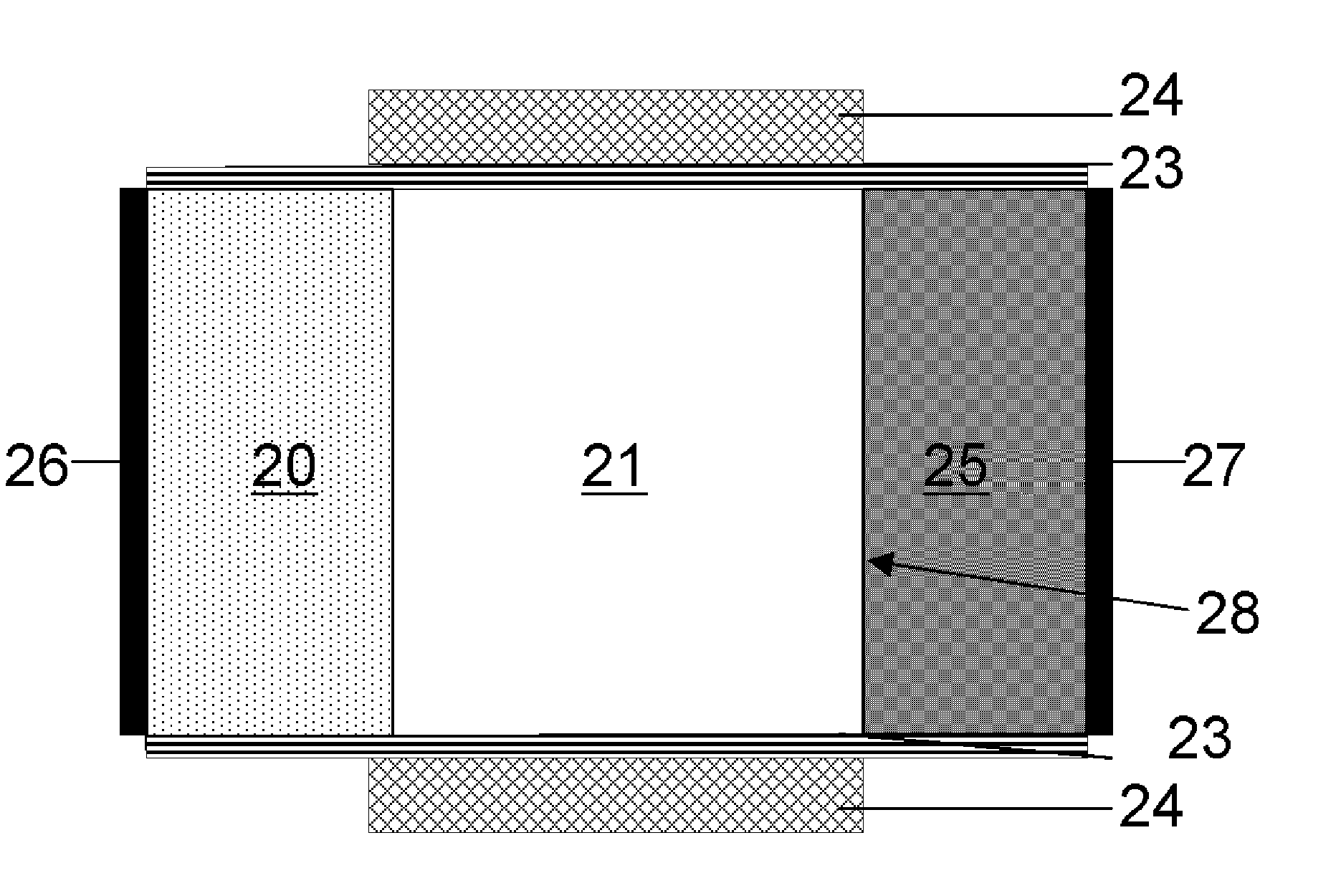

Photovoltaic high-voltage and direct-current series grid-connected system comprising dynamic voltage compensator

ActiveCN105490298AAvoid frequent switchingAvoid instabilitySingle network parallel feeding arrangementsAc network voltage adjustmentGrid connected inverterPower limits

The invention provides a photovoltaic high-voltage and direct-current series grid-connected system comprising a dynamic voltage compensator. The photovoltaic high-voltage and direct-current series grid-connected system comprises a plurality of photovoltaic direct-current grid-connected inverters and at least one dynamic voltage compensator, wherein input ends of the plurality of photovoltaic direct-current grid-connected inverters are independent and output ends are connected in series; the input ends of the plurality of photovoltaic direct-current grid-connected inverters are connected with a photovoltaic module respectively; and the output ends of the plurality of photovoltaic direct-current grid-connected inverters are connected in series and are connected with the input end of the dynamic voltage compensator in series. Through coordination and cooperation of the dynamic voltage compensator and the photovoltaic direct-current grid-connected inverters, the probability that the photovoltaic direct-current grid-connected inverters enter a power limiting mode; the generating capacity of the photovoltaic system is improved; and output voltage exceeding of the photovoltaic direct-current grid-connected inverters caused by power fluctuation of the photovoltaic module is overcome.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for preparing active carbon from rice husk

InactiveCN101993070AReduce pollutionReduce manufacturing costSolid waste disposalActivated carbonChloride

The invention discloses a method for preparing active carbon from rice husk, which uses rice husk, zinc chloride, diluted hydrochloric acid, sodium hydroxide and water as raw materials and prepares the active carbon by a series of reactions.

Owner:南通新景华企业管理服务有限公司

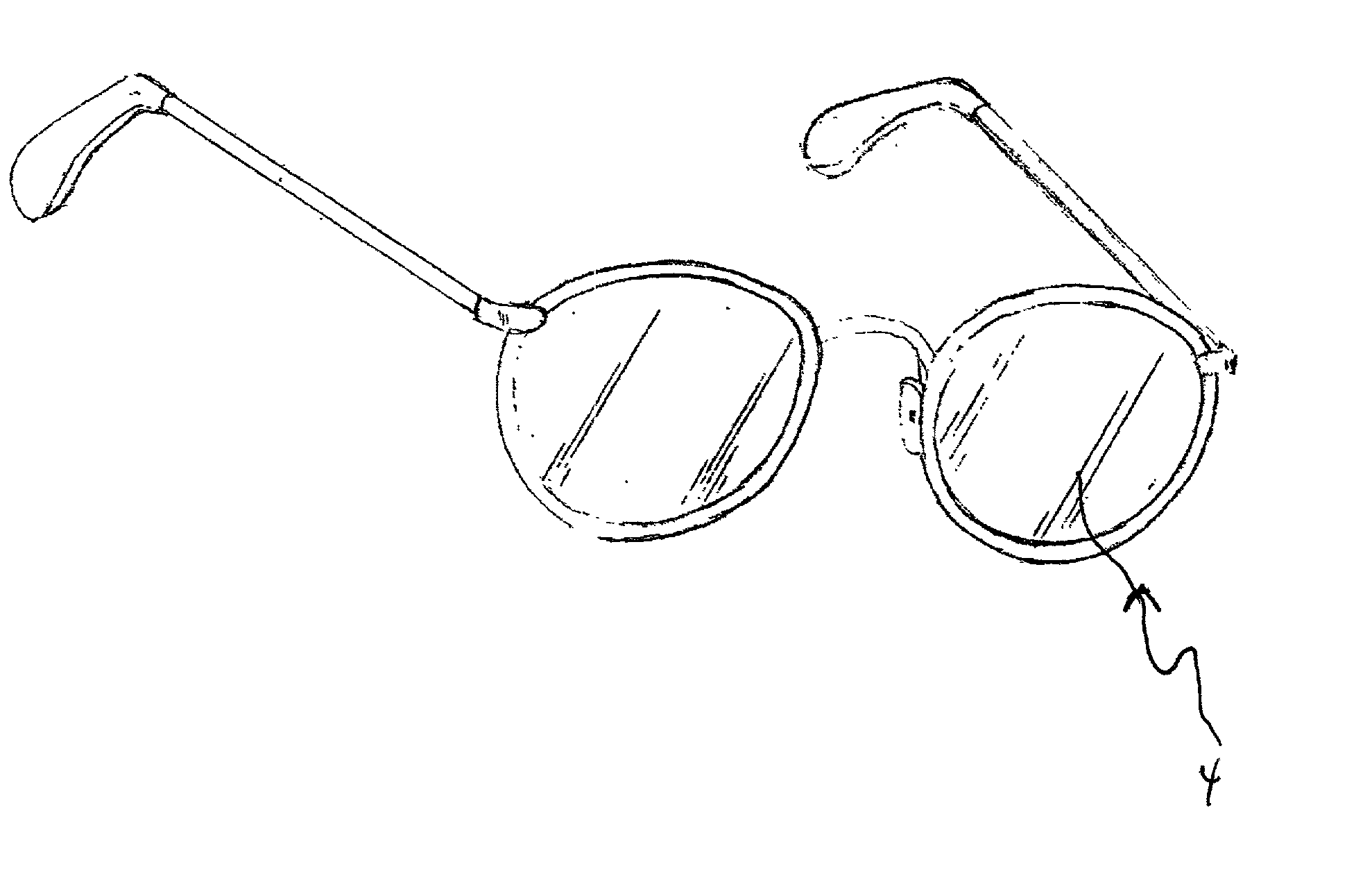

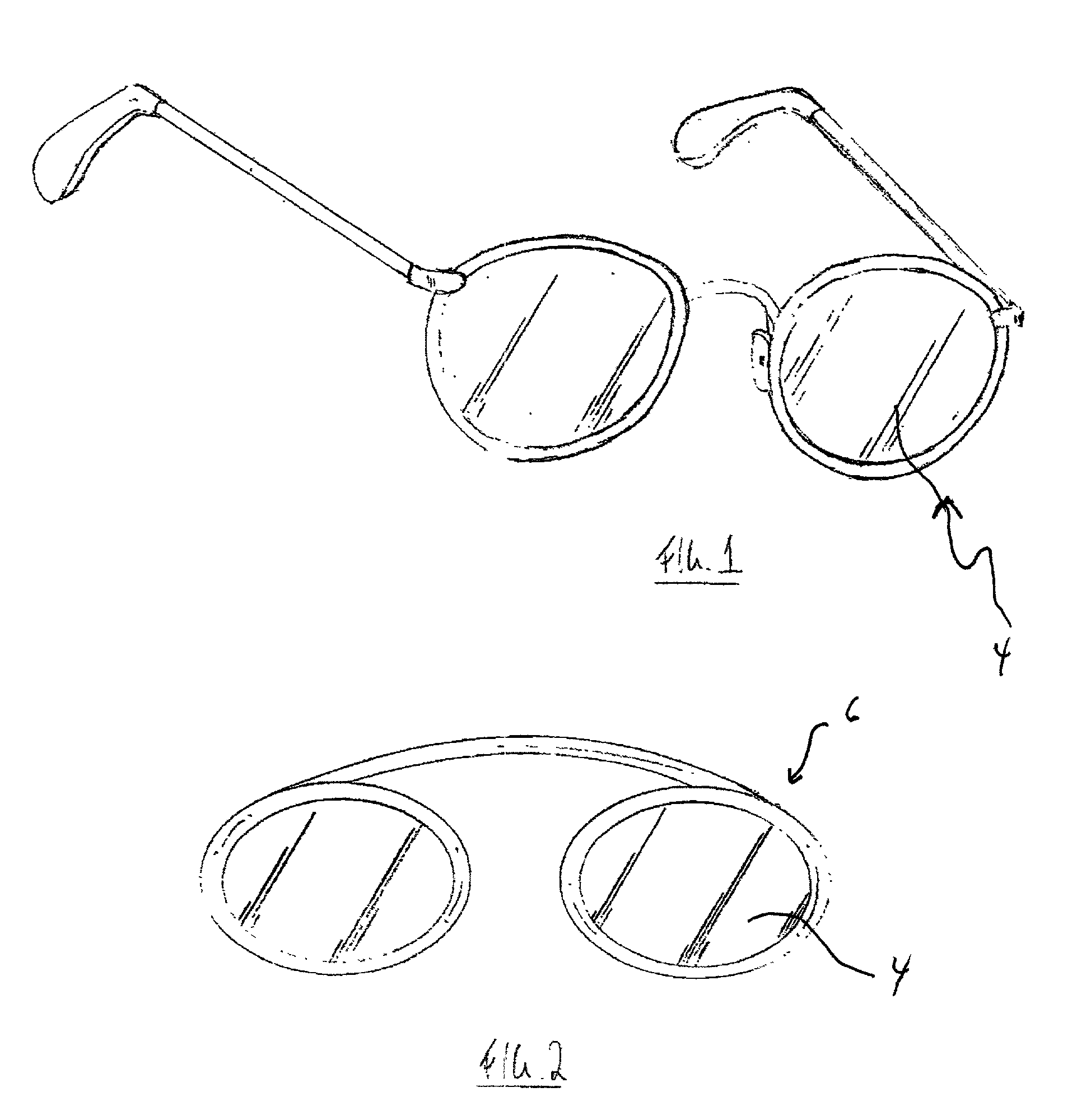

Optical lens for improved vision under conditions of low or poor illumination

InactiveUS20030020988A1Easy to useEasy to incorporateElectromagnetic transmissionOptical partsEngineeringLens plate

An eyeglass lens having a power of from about a minus 0.12 to about minus 1.00 diopters (and preferably minus 0.50 diopters) that is particularly beneficial and improves vision of a user under night or other low-light conditions. The lens may be incorporated in a pair of eyeglass frames and may be used by users without corrective eyewear or in a pair of clip-on" frames for use by a user already requiring corrective eyewear.

Owner:STONE ROBERT F

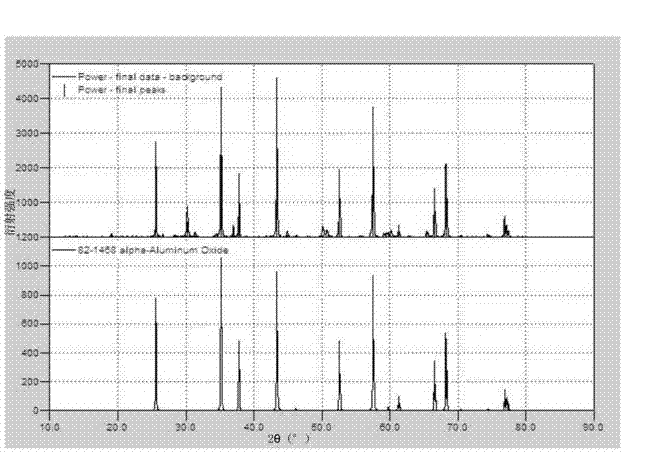

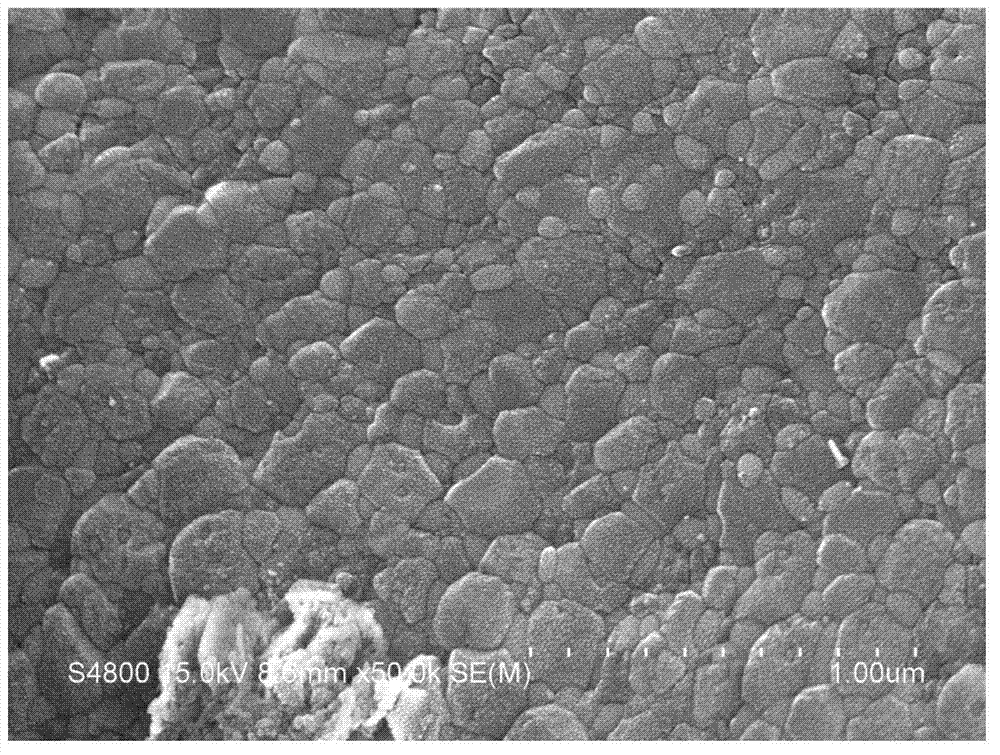

Method for preparing pseudo-boehmite and method for preparing microcrystalline fused alumina abrasive

InactiveCN102807240ARaw materials are readily availableLow costOther chemical processesAluminium oxides/hydroxidesWater solubleCalcination

The invention discloses a method for preparing pseudo-boehmite. The method includes preparing water-soluble salt of aluminum into pseudo-boehmite by a hydrothermal method. The invention further discloses a method for preparing microcrystalline fused alumina abrasive. The method for preparing microcrystalline fused alumina abrasive includes by the sol-gel process, performing ball milling, drying, breaking and granulating, calcination and firing to the prepared pseudo-boehmite to prepare the microcrystalline fused alumina abrasive. The methods are convenient to implement, low in cost and suitable for large-scale production, and purity and particle strength of the prepared microcrystalline fused alumina abrasive are high.

Owner:SHANGHAI SHANGMO ABRASIVES & GRINDING TOOL

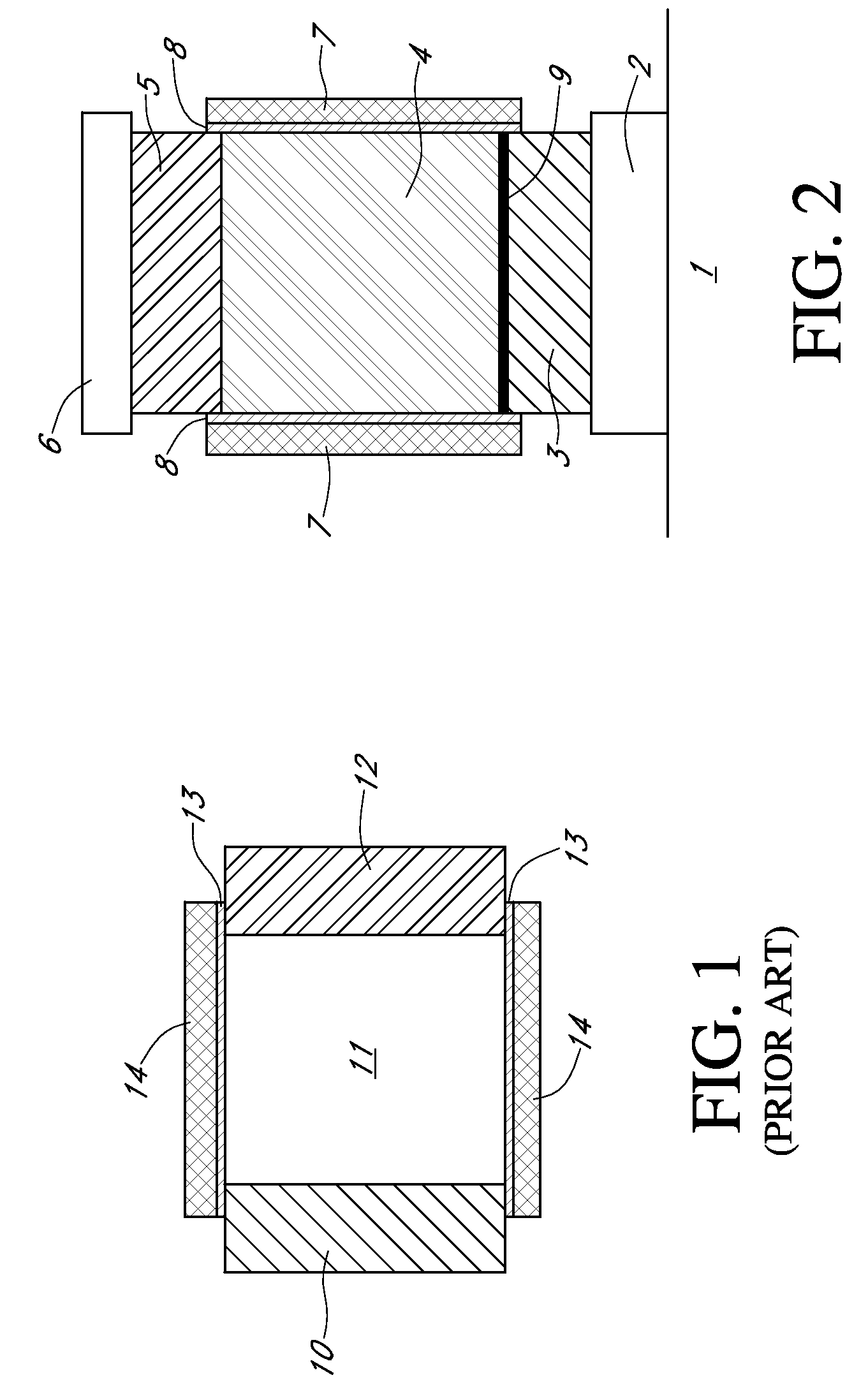

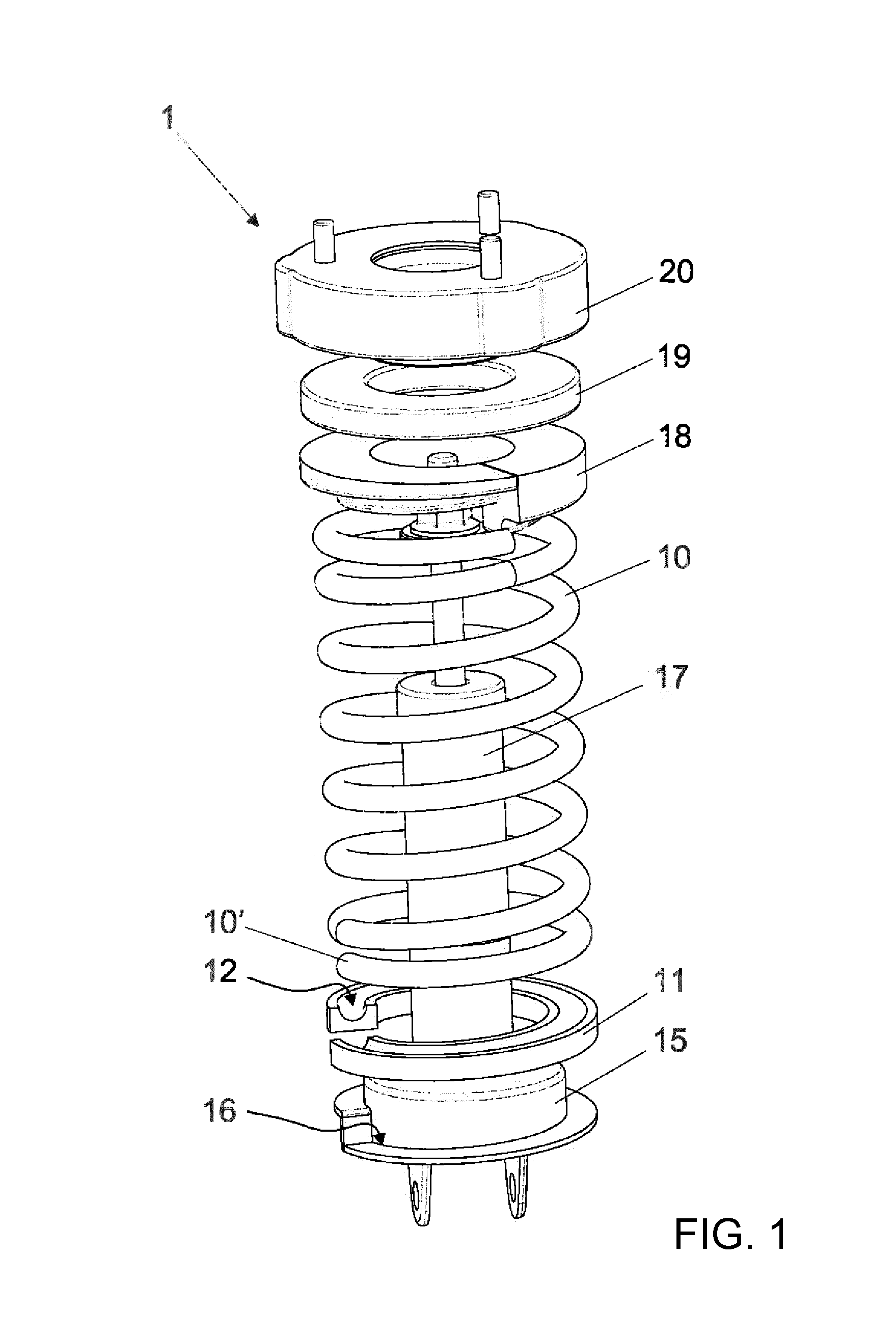

Bearing arrangement for a spring of a vehicle chassis

ActiveUS20140225319A1Easy to incorporateEasy to manufactureLaminationLamination apparatusElastomerAdhesive

A bearing arrangement and a method for forming a bearing arrangement for a spring, in particular for a spring of a vehicle chassis, having at least one spring insert in which at least part of a spring coil of the spring is accommodated. The spring insert is an elastomer and is flexible. The spring insert is configured to be movable with a moving of the spring coil. An adhesive is introduced between the spring and the spring insert, with the result that the connection of the spring insert to the spring has a bonded connection.

Owner:THYSSENKRUPP FEDERN & STABILISATOREN

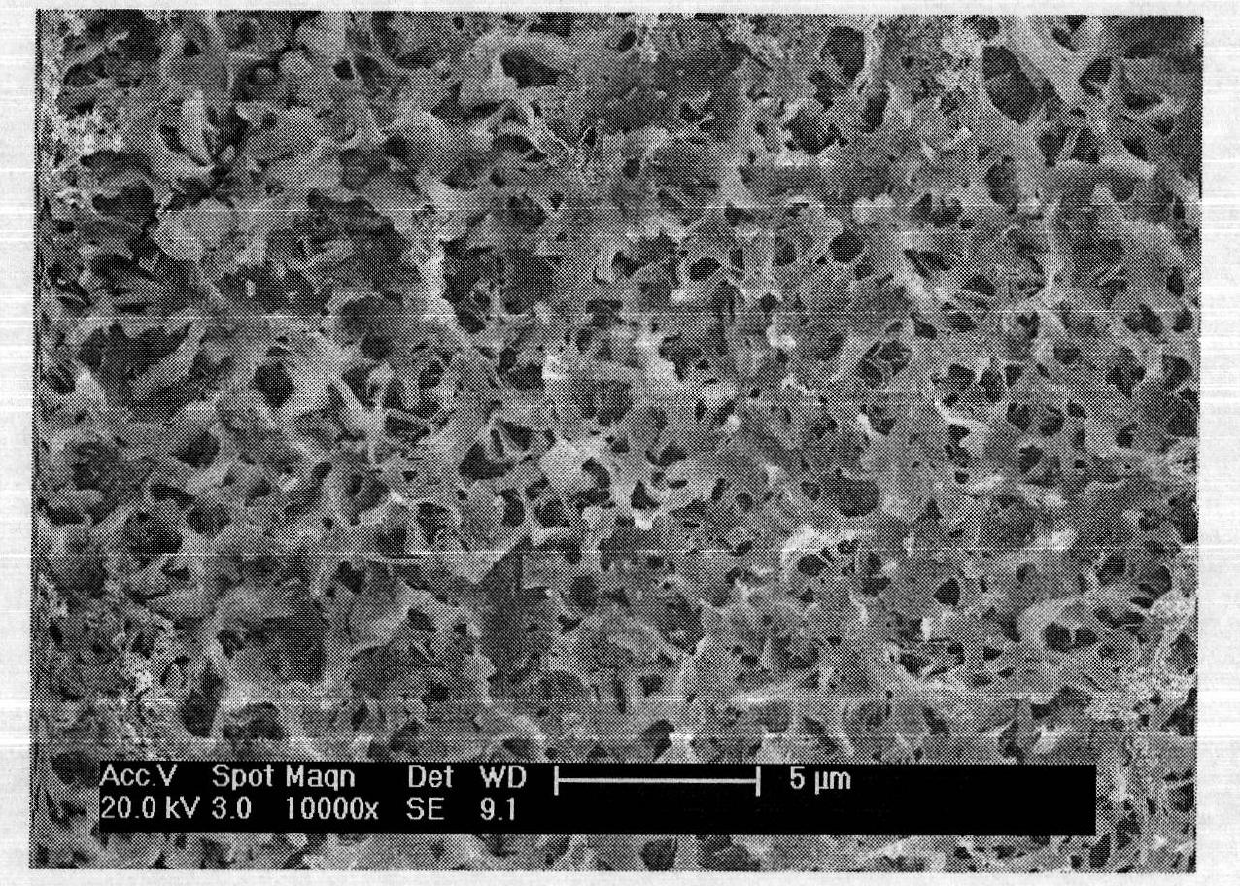

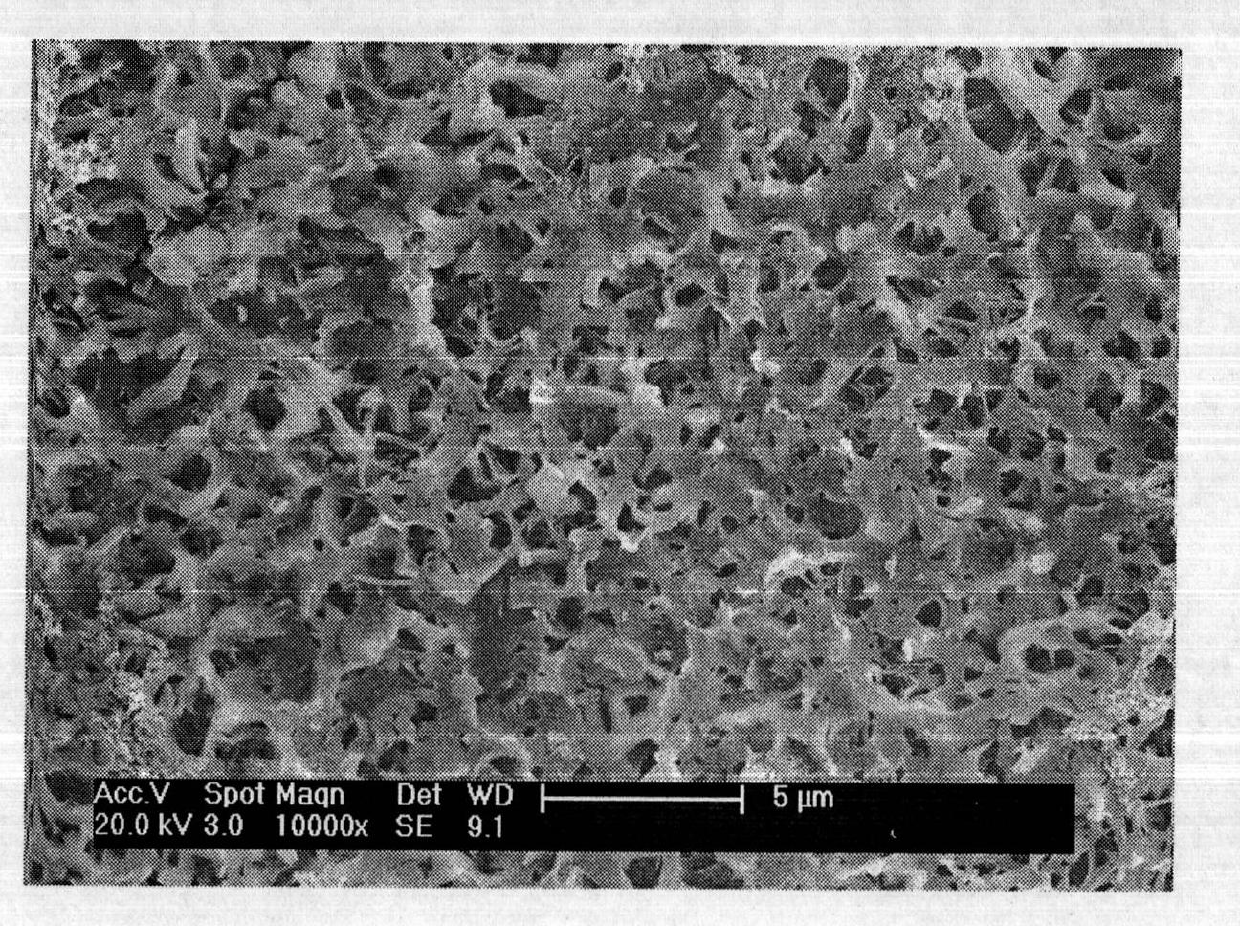

Silver-loaded antibacterial artificial joint and preparation method thereof

InactiveCN101766839ABroad-spectrum antibacterialImprove sterilization efficiencyTitanium compoundsCoatingsSodium titanateTitanium alloy

Owner:江苏广达医材集团有限公司 +1

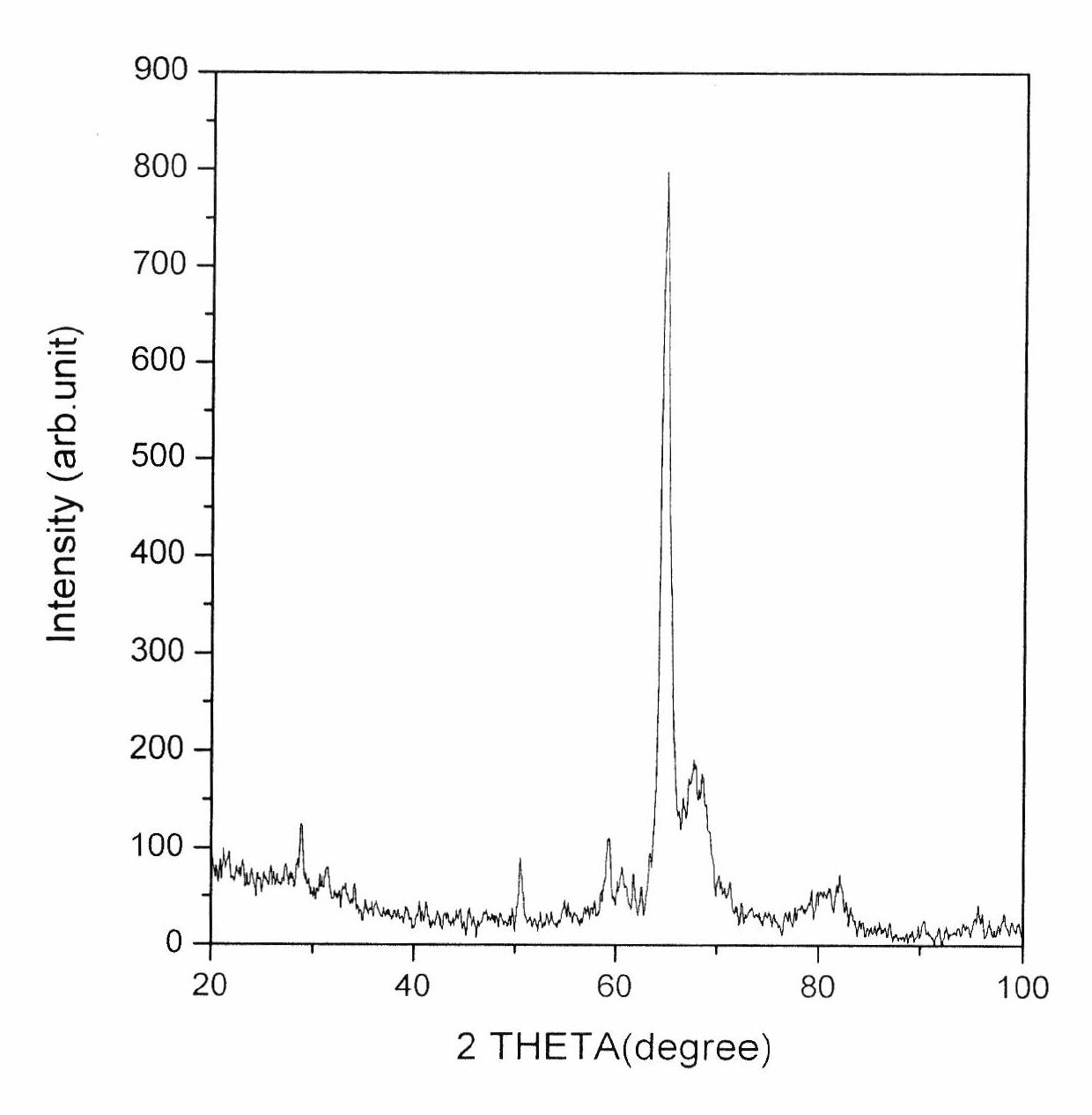

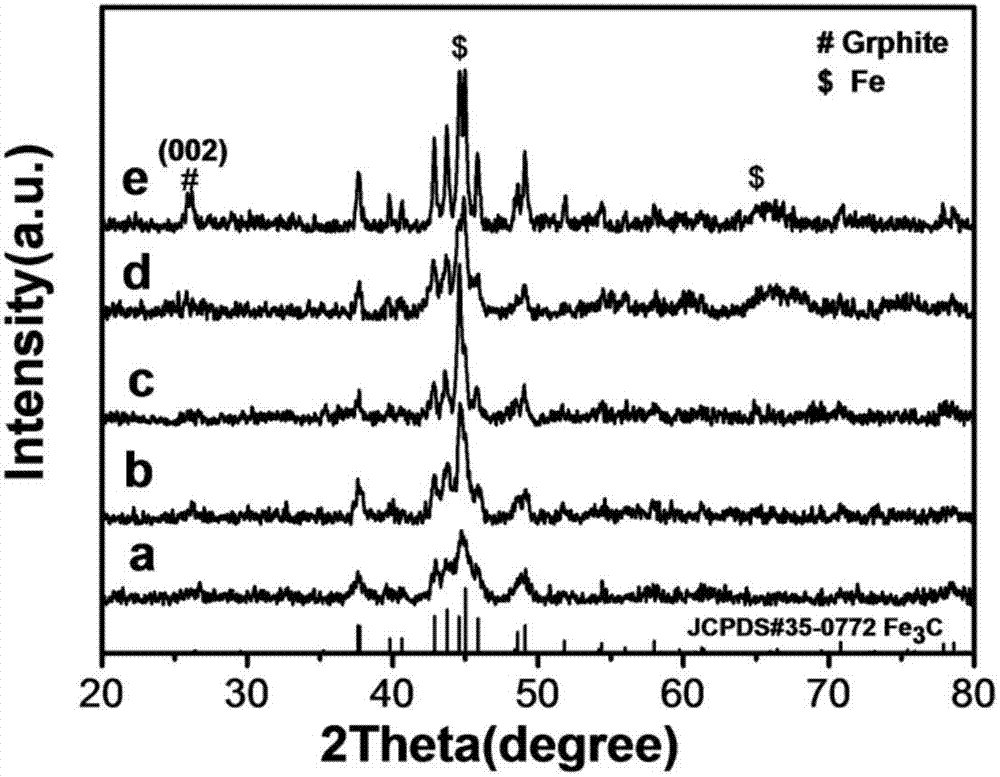

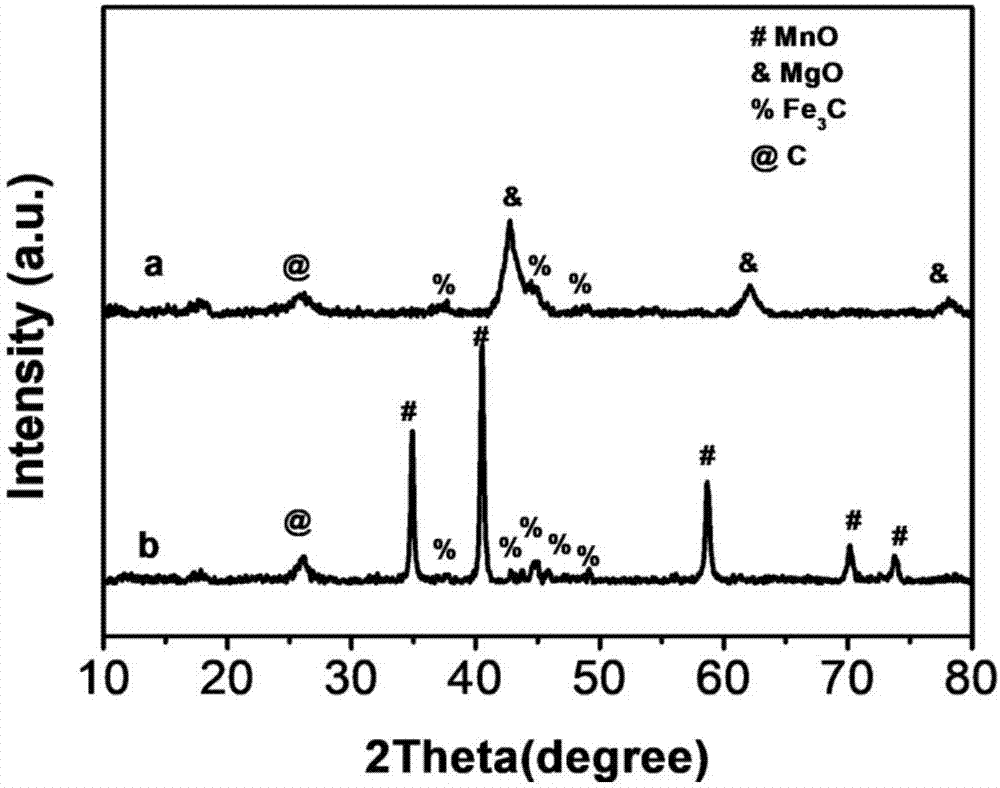

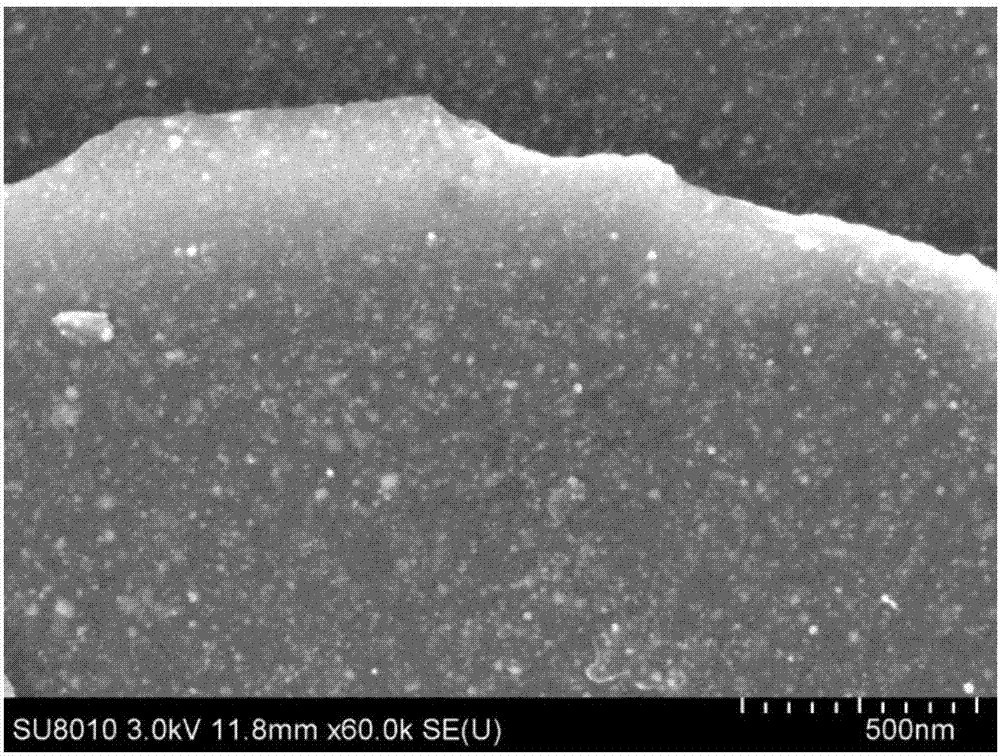

Iron carbide catalyst coated by high-iron-content graphite layer as well as synthetic method and application thereof

ActiveCN107442147ARich pore structureEvenly dispersed particlesHydrocarbon from carbon oxidesPhysical/chemical process catalystsNitrogenIron content

The invention belongs to the technical field of designed synthesis of Fischer-Tropsch synthesis catalysts and specifically discloses a graphite layer coated iron carbide catalyst as well as a preparation method and application thereof in Fischer-Tropsch synthesis. The catalyst prepared in the invention comprises Fe3C particles with uniform size and is uniformly inlaid in a graphite carbon layer, the surface of the catalyst is enriched in oxygen / nitrogen-containing functional groups, and the specific surface area of the catalyst is 80-350m<2> / g. Under the high-iron-content condition, the CO conversion frequency FTY value of the catalyst under unit iron content reaches 1130umol COgFe<-1>s<-1>, and the catalyst has ultrahigh catalytic activity; and meanwhile, an electron promoter can be conveniently doped in the preparation process for regulating the selectivity of the Fischer-Tropsch synthesis product, and a specific Fischer-Tropsch synthesis product can be obtained.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

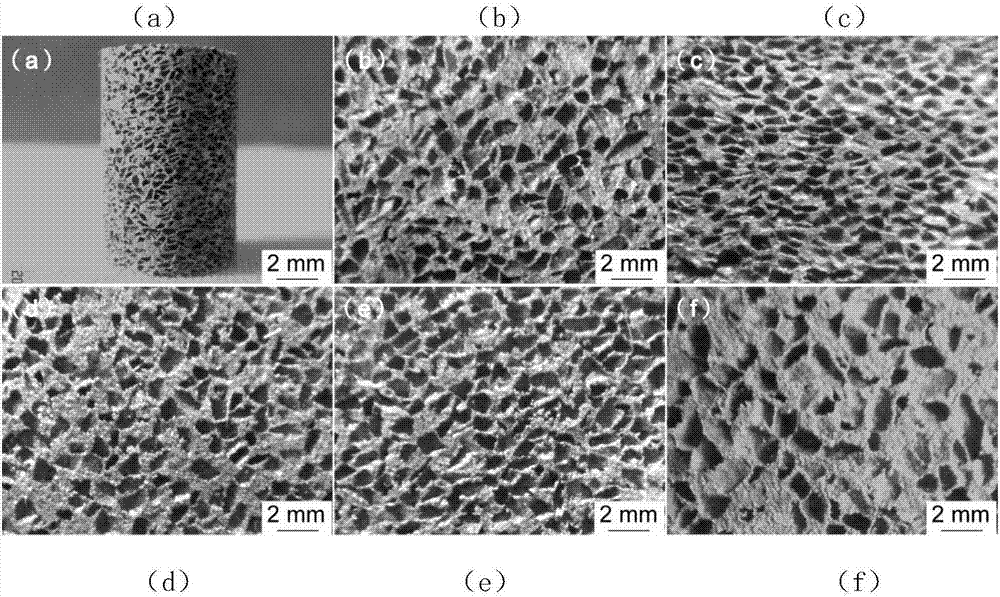

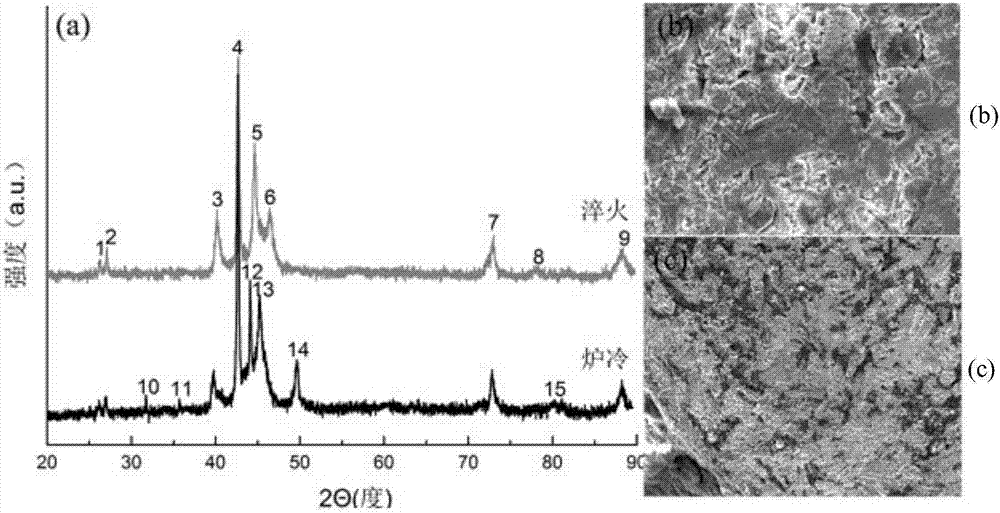

Preparation method of porous copper-based shape memory alloy

The invention discloses a preparation method of a porous copper-based shape memory alloy and relates to manufacturing of the porous shape memory alloy. Cu-Al-Mn prealloying powder prepared by compounding of original metal pure Cu powder, pure Al powder and pure Mn powder serves as a base material; the base material is uniformly mixed with absolute ethyl alcohol and then uniformly mixed with decrystallization water NaCl particles, and pressing is conducted to obtain a green body; and the green body is subjected to sinter molding, then placed in boiling water of 100 DEG C to thoroughly removing the residual NaCl particles in holes in a boiling mode and finally placed in a dryer of 60 DEG C to be subjected to heat preservation for 20-30 minutes, and the porous copper-based shape memory alloy with a through hole structure, the average porosity being 50-80% and the average pore diameter being 0.2-1.5 mm is prepared. The defects that in the prior art, the preparation cost of a product is high, and production safety is low are overcome.

Owner:HEBEI UNIV OF TECH

Anionic latex as a carrier for bioactive ingredients and methods for making and using the same

InactiveUS20080171804A1Antimicrobial properties of the latex can be enhanced and controlledEasy to mergeDental implantsAntifouling/underwater paintsAntifungalPolymer science

This invention relates to latex compositions that incorporate at least one bioactive component such as an antibacterial or an antifungal agent, and methods for making and using such latex compositions. The latex compositions disclosed herein can be prepared by the emulsion polymerization of the latex component monomers in the presence of the at least one bioactive component.

Owner:MALLARD CREEK POLYMERS

Lead-free composite glass adhesive solar battery positive silver paste

ActiveCN104979035AMeet the protection requirementsImprove conversion efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesElectrical batterySolar battery

The invention relates to the formulation and the preparation method of a lead-free composite glass adhesive solar battery positive silver paste. A lead-free glass adhesive is designed. The positive silver paste made of the lead-free glass adhesive is an environment-friendly material. A crystalline silicon solar battery made of the positive silver paste has the advantages of high conversion efficiency and strong electrode adhesion. According to the lead-free glass adhesive, a silicon (Si)-tellurium (Te)-germanium (Ge) composite glass material is used; Bi2O3, Al2O3, ZnO, a transition metal oxide, an rare earth metal oxide, an alkaline earth metal oxide and the like are added; the composite glass adhesive can quickly dissolve and precipitate silver grains in a battery sintering process; a good conductive path is formed between a silver thick film electrode and an emitting area n-Si; Ag-Si ohmic contact is formed; the series resistance of the battery is reduced; the conversion efficiency of the battery is improved; and through the composite glass adhesive, firm adhesion of a silver electrode and a silicon substrate is generated, and a positive silver electrode has strong adhesion.

Owner:武汉硕美特电子材料有限公司

Tunnel effect transistors based on elongate monocrystalline nanostructures having a heterostructure

ActiveUS20120045879A1Optimize architectureReduce power consumptionNanoinformaticsSemiconductor/solid-state device manufacturingMOSFETSemiconductor materials

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Products comprising nano-precision engineered electronic components

InactiveUS7306822B2Low costEasy to incorporateNitrogen compoundsSelenium/tellurium compundsFuel cellsElectrical battery

Electronic devices prepared from nanoscale powders are described. Methods for utilizing nanoscale powders and related nanotechnology to prepare capacitors, inductors, resistors, thermistors, varistors, filters, arrays, interconnects, optical components, batteries, fuel cells, sensors and other products are discussed.

Owner:PPG IND OHIO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com