Iron carbide catalyst coated by high-iron-content graphite layer as well as synthetic method and application thereof

A technology of catalyst and graphite layer, which is applied in the field of new high iron content Fe-based Fischer-Tropsch synthesis catalyst and its synthesis, can solve the problems of loss of activity specific surface, reduction of catalyst activity, reduction of mechanical strength, etc., to prevent agglomeration and uniform particle dispersion , the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] [Example 1] Preparation of a high iron content graphite layer wrapped iron carbide catalyst

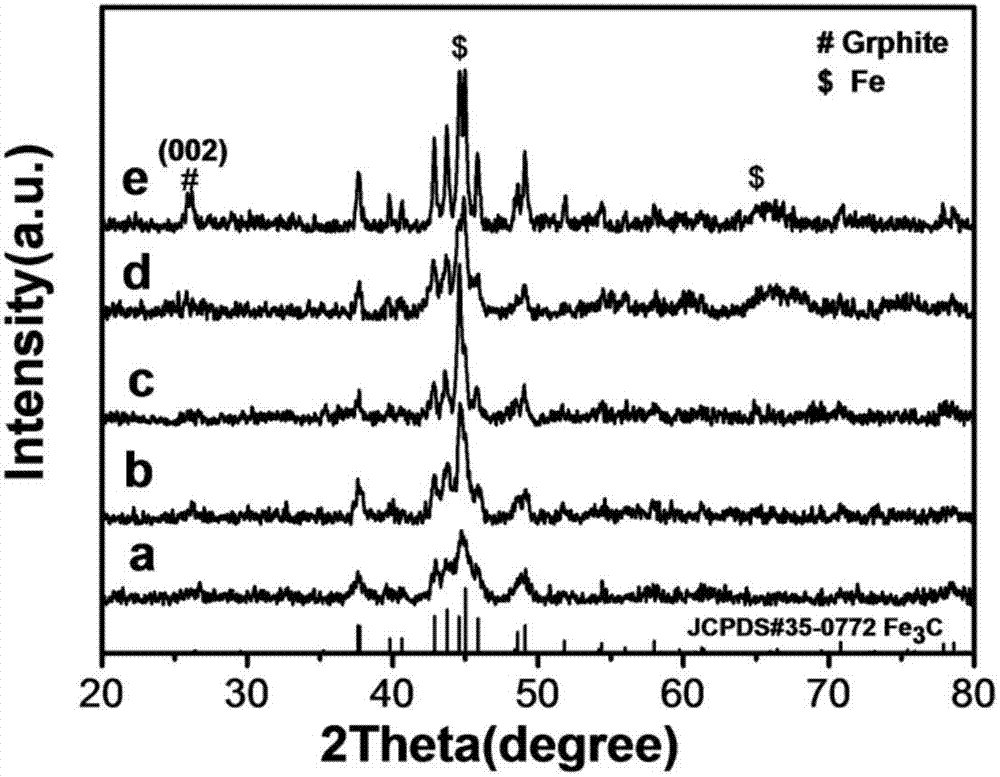

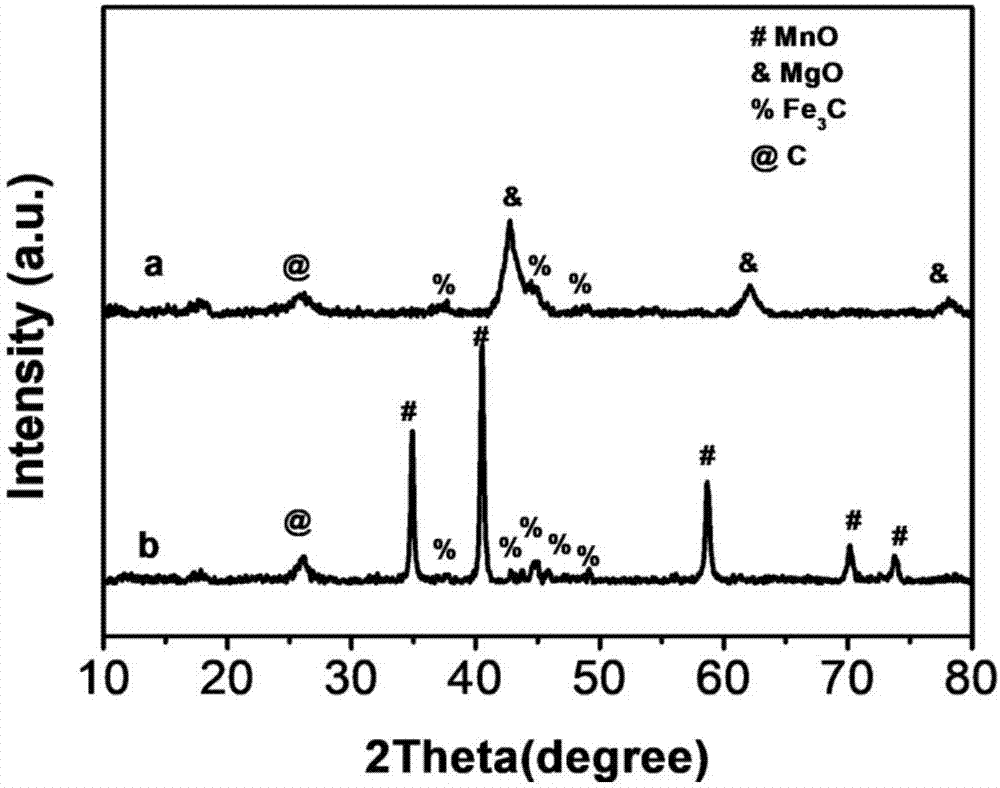

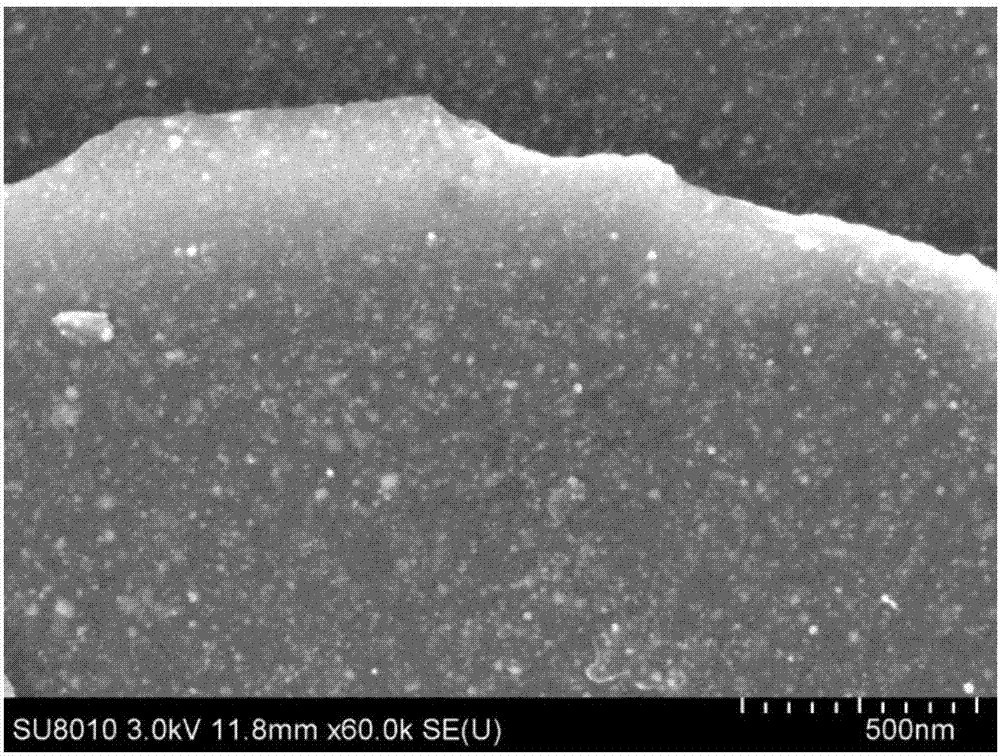

[0056] Put 3g of glucose and 8g of urea in a 100ml beaker, stir it mechanically to make it evenly mixed, then place it in a heating mantle at 165°C and continue to stir for 10 minutes until the two are completely melted, add 2g of ferric nitrate nonahydrate, and continue to stir vigorously for 5 minutes until completely mixed The beaker was quickly transferred to an oven at 180°C, kept for 20 hours, then the product was taken out and ground to powder, and the ground powder was roasted in a tube furnace at 750°C for 2 hours in a nitrogen atmosphere to obtain a catalyst, and its BET specific surface area was measured to be 304.3m 2 / g, its X-ray powder diffraction pattern, scanning electron microscope pattern, Fe in the catalyst 3 The particle size distribution diagram of C particles and the high-resolution transmission electron microscope diagram of the catalyst are shown in f...

Embodiment 2

[0057] [Example 2] Preparation of a high iron content graphite layer wrapped iron carbide catalyst

[0058] Put 4g of sucrose and 8g of urea in a 100ml beaker, mechanically stir to mix evenly, then place in a heating mantle at 165°C and continue to stir for 10 minutes until the two are completely melted, add 3g of ferric nitrate nonahydrate, and continue to stir vigorously for 5 minutes until completely mixed The beaker was quickly transferred to an oven at 180°C, kept for 20 hours, then the product was taken out and ground to powder, and the ground powder was roasted in a tube furnace at 750°C for 2 hours in a nitrogen atmosphere to obtain a catalyst, and its BET specific surface area was measured to be 232.0m 2 / g, its X-ray powder diffraction pattern, scanning electron microscope pattern, Fe in the catalyst 3 The particle size distribution diagram of C particles and the high-resolution transmission electron microscope diagram of the catalyst are shown in figure 1 and Fi...

Embodiment 3

[0059] [Example 3] Preparation of a high iron content graphite layer wrapped iron carbide catalyst

[0060] Put 6g of fructose and 8g of triethylamine in a 100ml beaker, mechanically stir to mix evenly, then place in a heating mantle at 165°C and continue to stir for 10 minutes until the two are completely melted, add 4g of ferric nitrate nonahydrate, and continue to stir vigorously for 5 minutes to Completely miscible, quickly transfer the beaker to an oven at 180°C, keep it for 20 hours, take out the product and grind it to powder, roast the ground powder in a tube furnace at 750°C for 2 hours in a nitrogen atmosphere to obtain a catalyst, and test its BET ratio Surface area is 179.9m 2 / g, its X-ray powder diffraction pattern, scanning electron microscope pattern, Fe in the catalyst 3 The particle size distribution diagram of C particles and the high-resolution transmission electron microscope diagram of the catalyst are shown in figure 1 and Figure 9-11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com