Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1396results about How to "Simple molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-organic framework material for methane adsorption separation and preparation method thereof

InactiveCN102962037AStrong structural controllabilityExcellent dynamic separation adsorption capacityOther chemical processesDispersed particle separationHigh concentrationMetal-organic framework

The invention relates to a metal-organic framework material for methane adsorption separation and a preparation method thereof. The metal organic framework material is prepared by reaction of at least a metal compound and at least one organic ligand, wherein the metal is one or more selected from Li, Mg, Al, Fe, Co, Ni, Cu, Zn, Mn, Zr, La and Sm, and the organic ligand is one or more selected from single or multidentate organic compounds containing nitrogen, oxygen or sulfur atom. The material has advantages of simple preparation process, high yield, easily available raw materials, mild reaction conditions; besides, the material has stable self properties and porous structure, and is especially suitable for separation of low-quality methane and purification process of high-concentration methane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

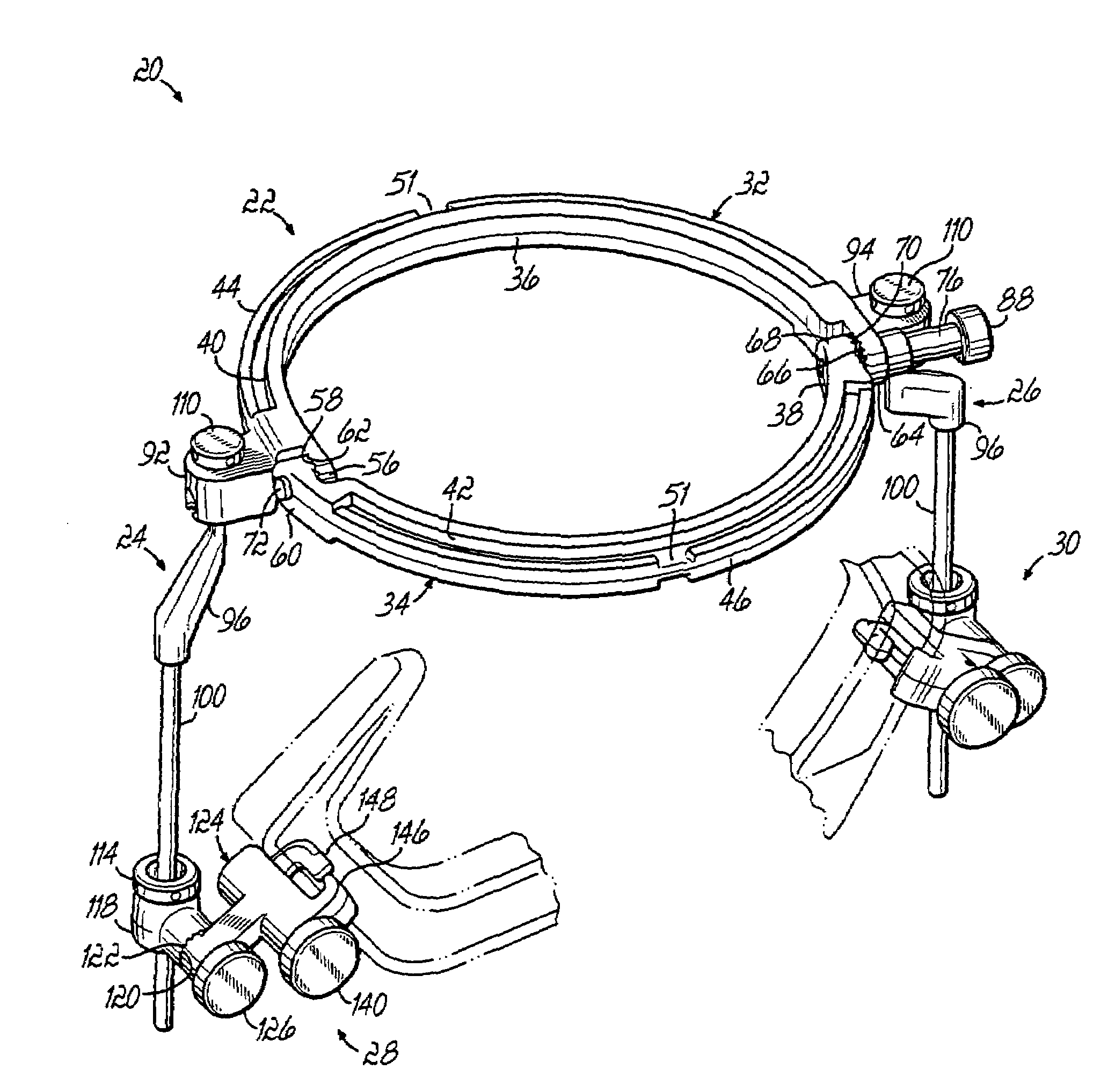

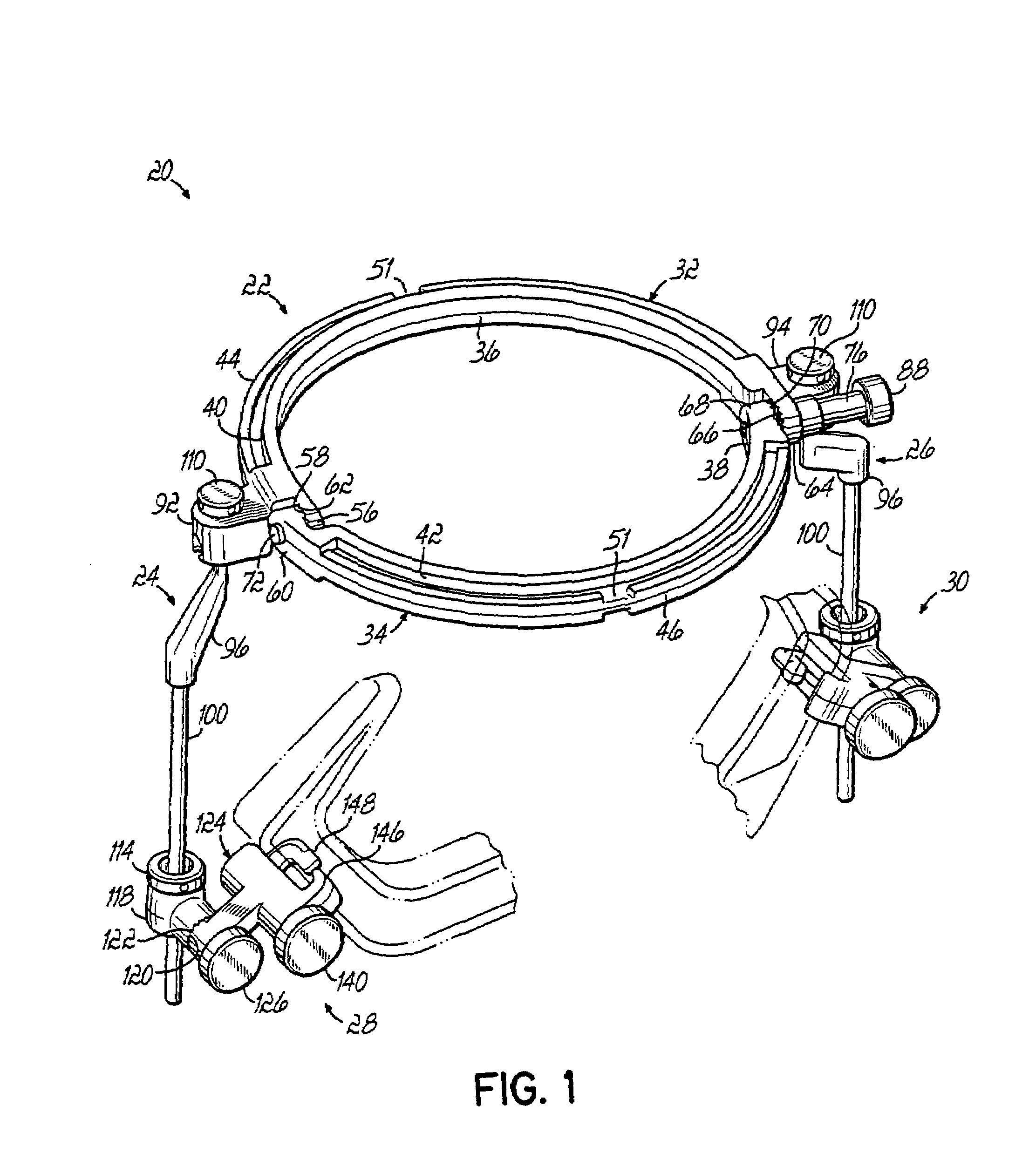

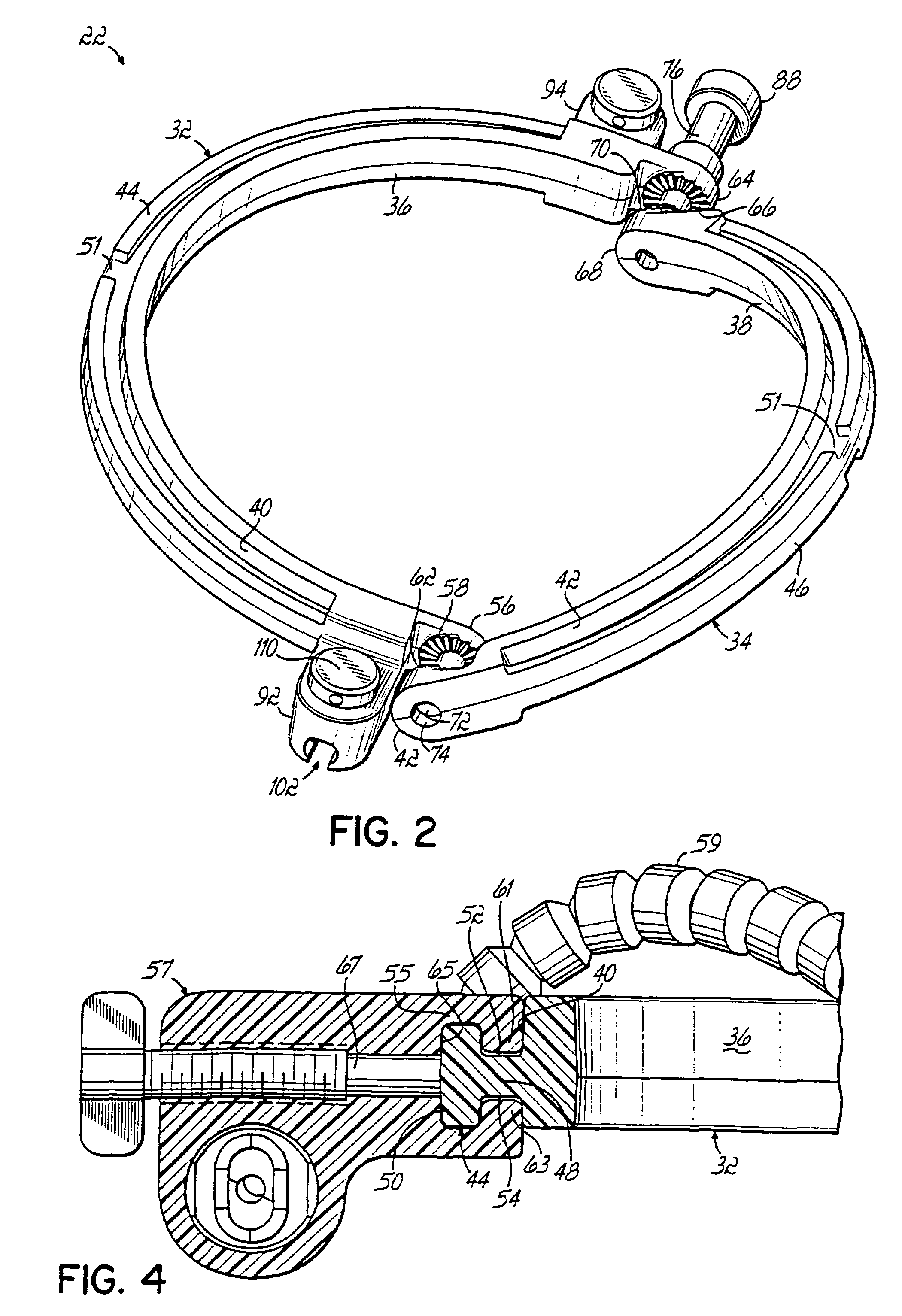

Radiolucent retractor and related components

InactiveUS20050080319A1Easy to useReduce manufacturing costDiagnosticsInstruments for stereotaxic surgeryCouplingAngular orientation

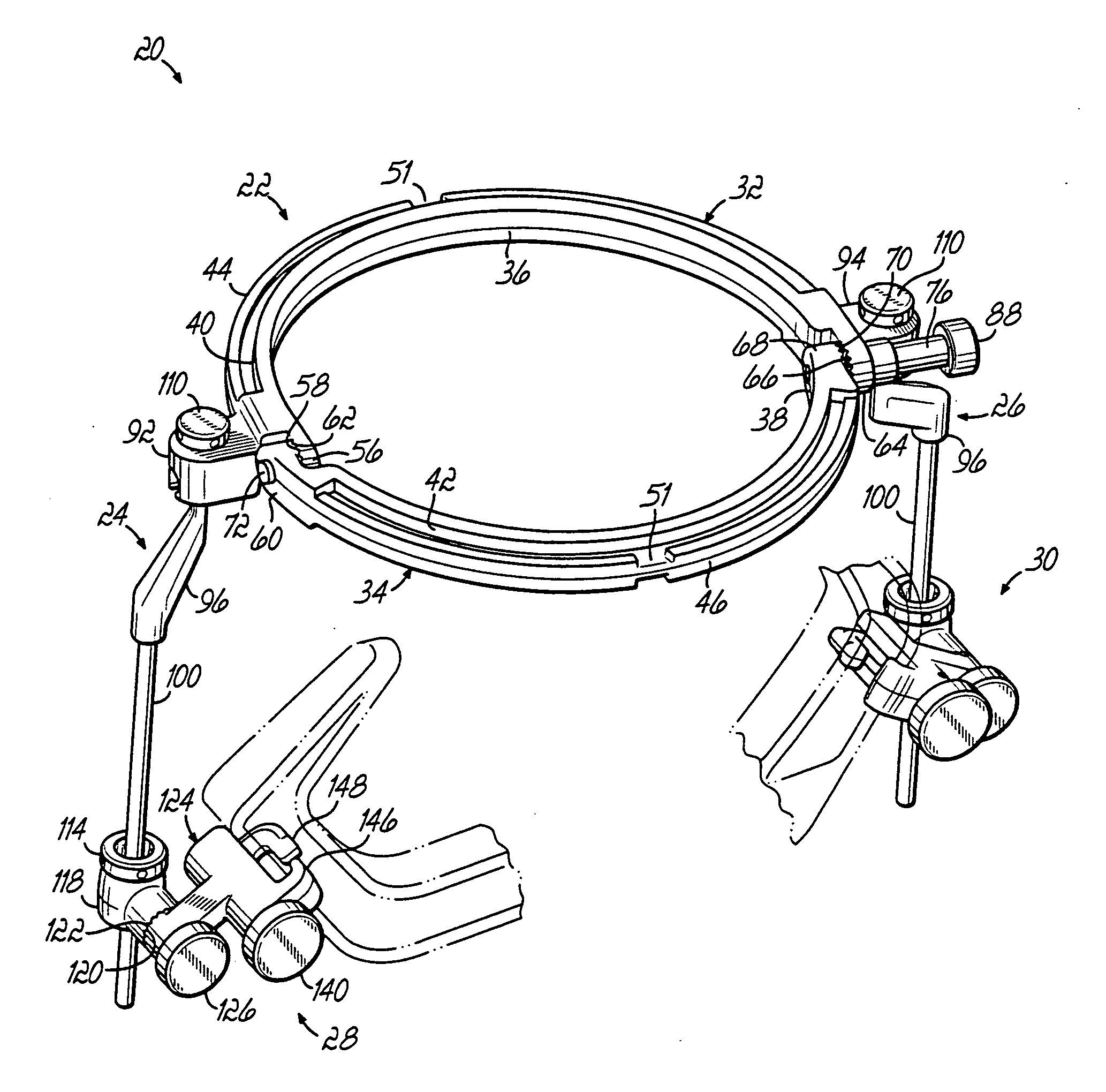

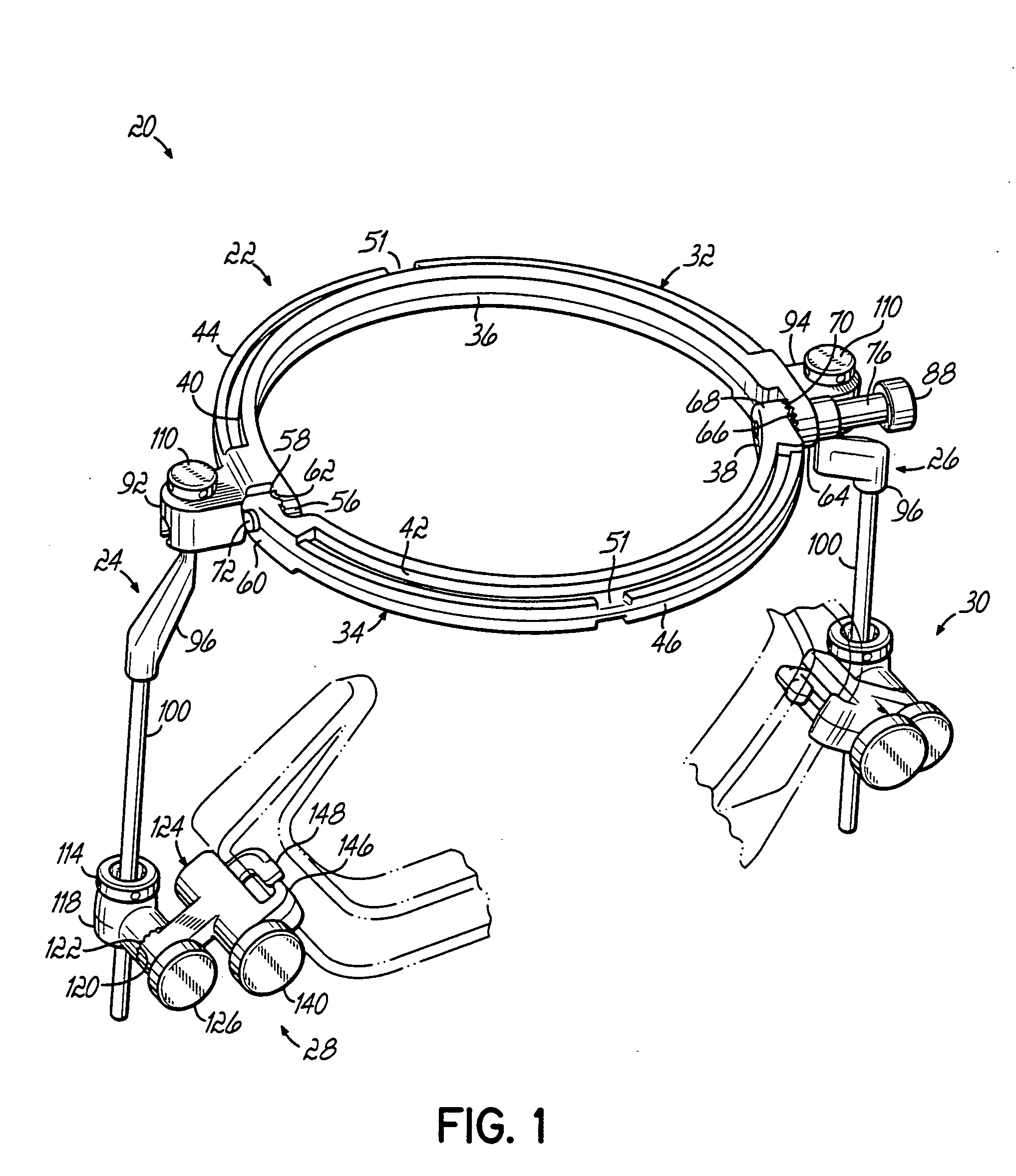

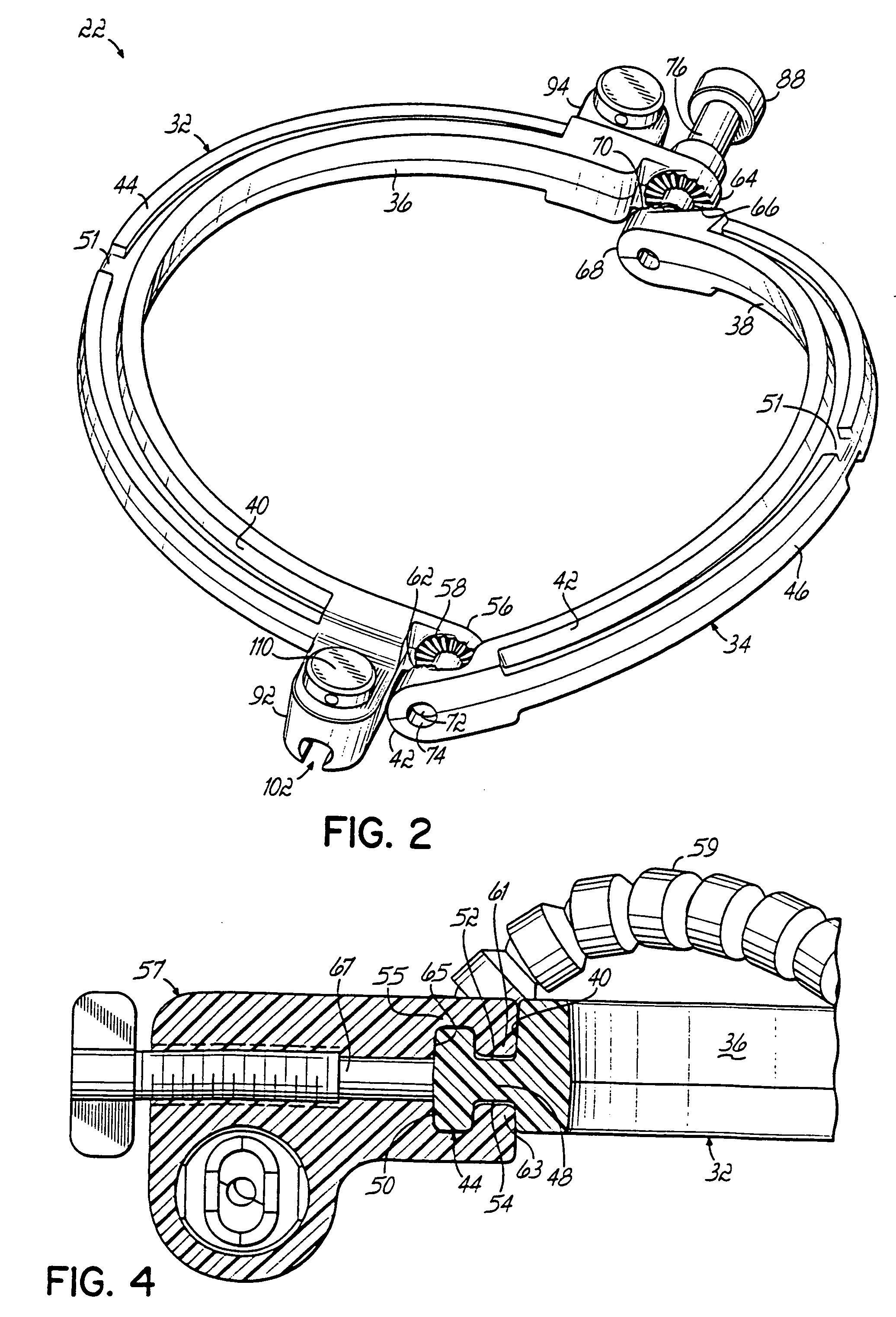

A radiolucent halo-type retractor (20) having a radiolucent curvilinear fixed member (32) connected to a radiolucent curvilinear movable member (34). Each of the fixed and movable members has a radiolucent male coupling (44, 46) projecting outward from a convex surface (40, 42) to receive a female coupling of a retractor arm. The ends (60, 68) of the movable member are separated by a distance less than a distance separating the ends (56, 64) of the fixed member. Radiolucent starburst connectors (58, 62) are disposed on first ends of the fixed and movable members to secure the fixed and movable members at a desired angular orientation. Radiolucent starburst connectors (66, 70) are also disposed on second ends of the fixed and movable members to secure the fixed and movable members at a desired angular orientation. A pin (72) rotatably connects the first ends. A locking shaft (76) rotatably connects the second ends and is operable to lock the fixed and movable members in a desired orientation.

Owner:INTEGRA LIFESCI

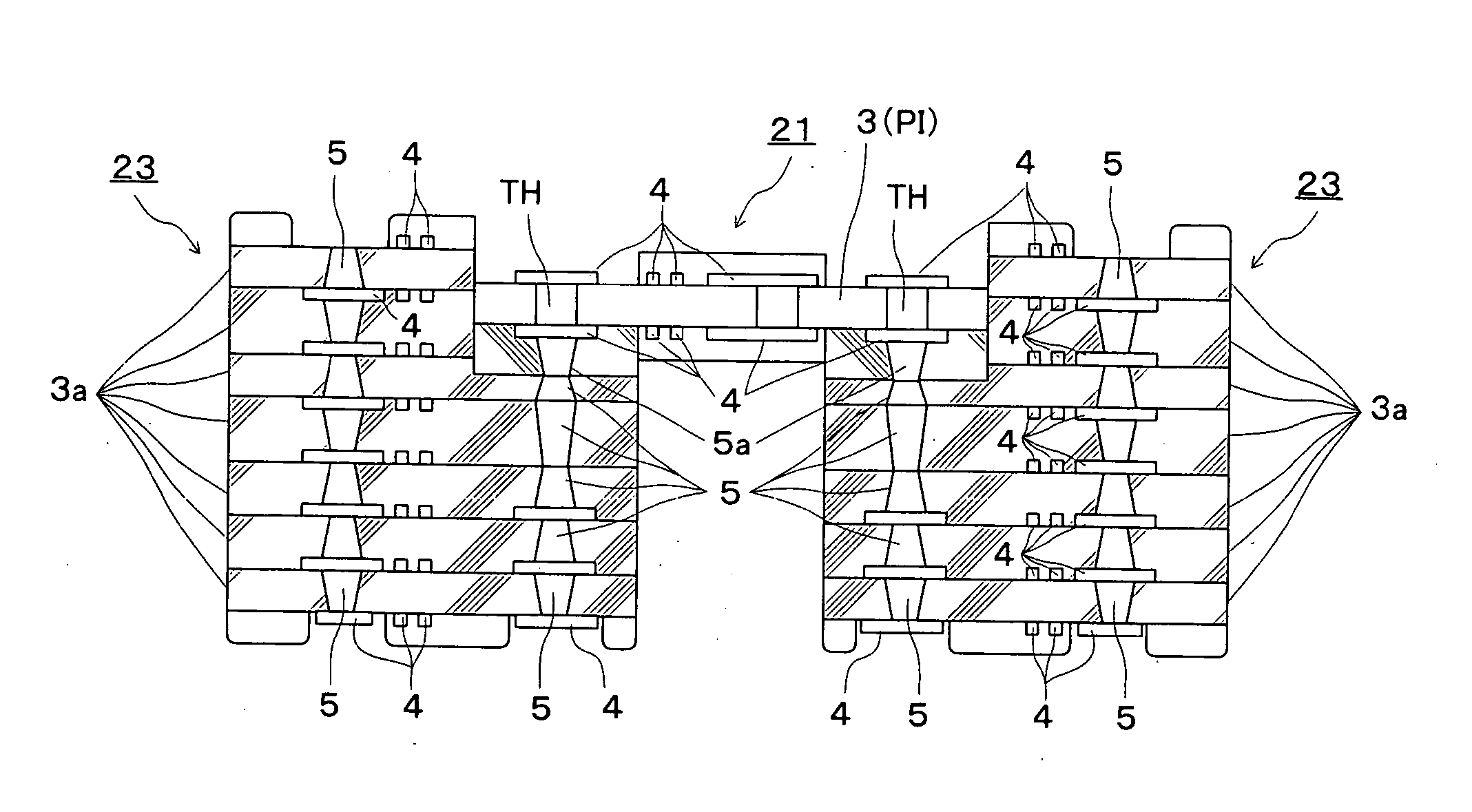

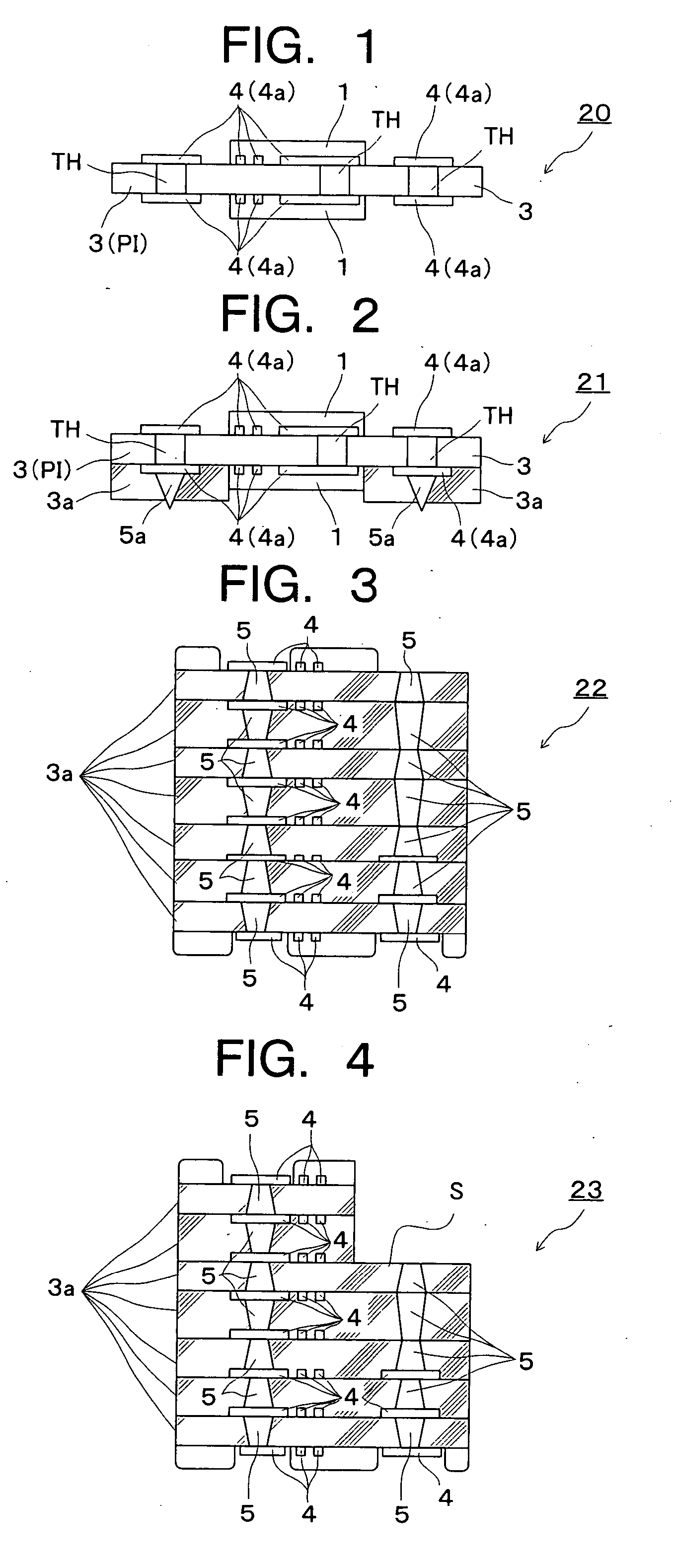

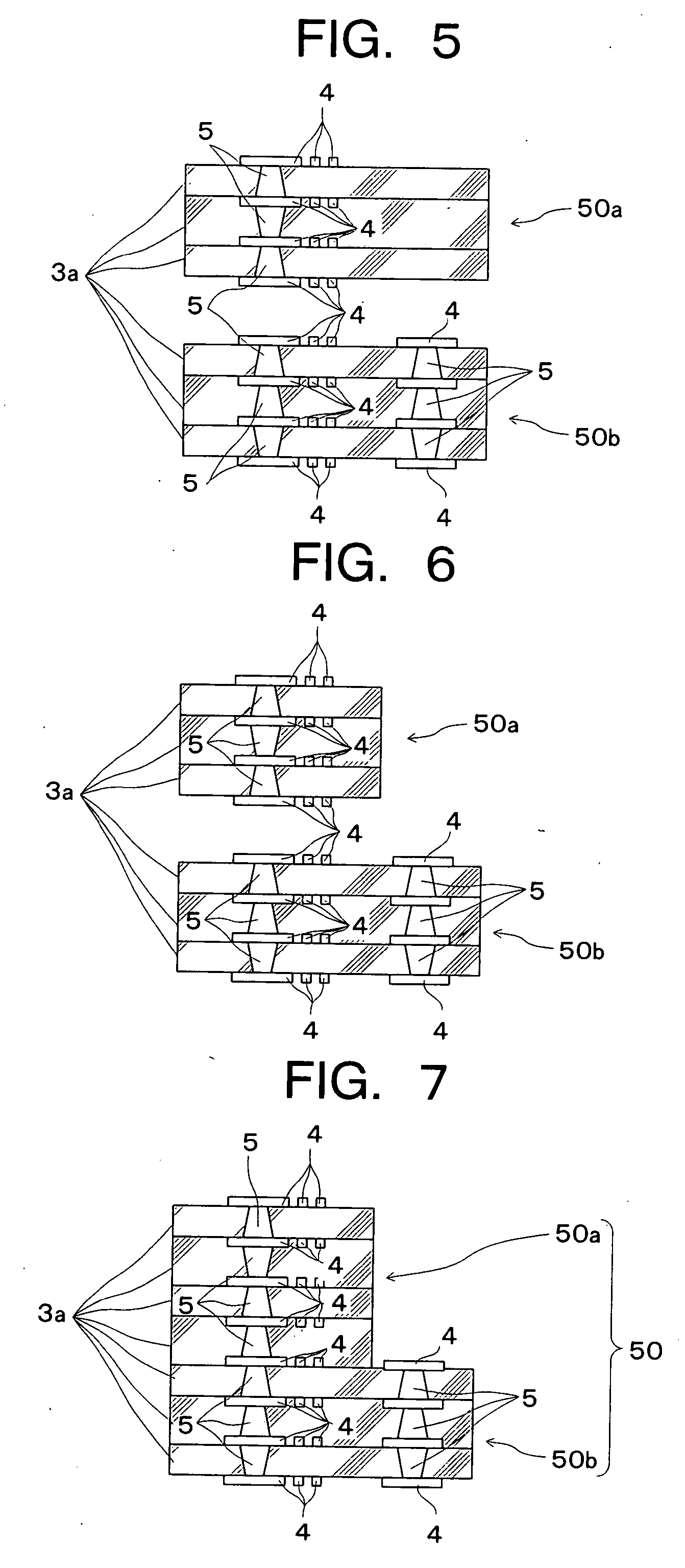

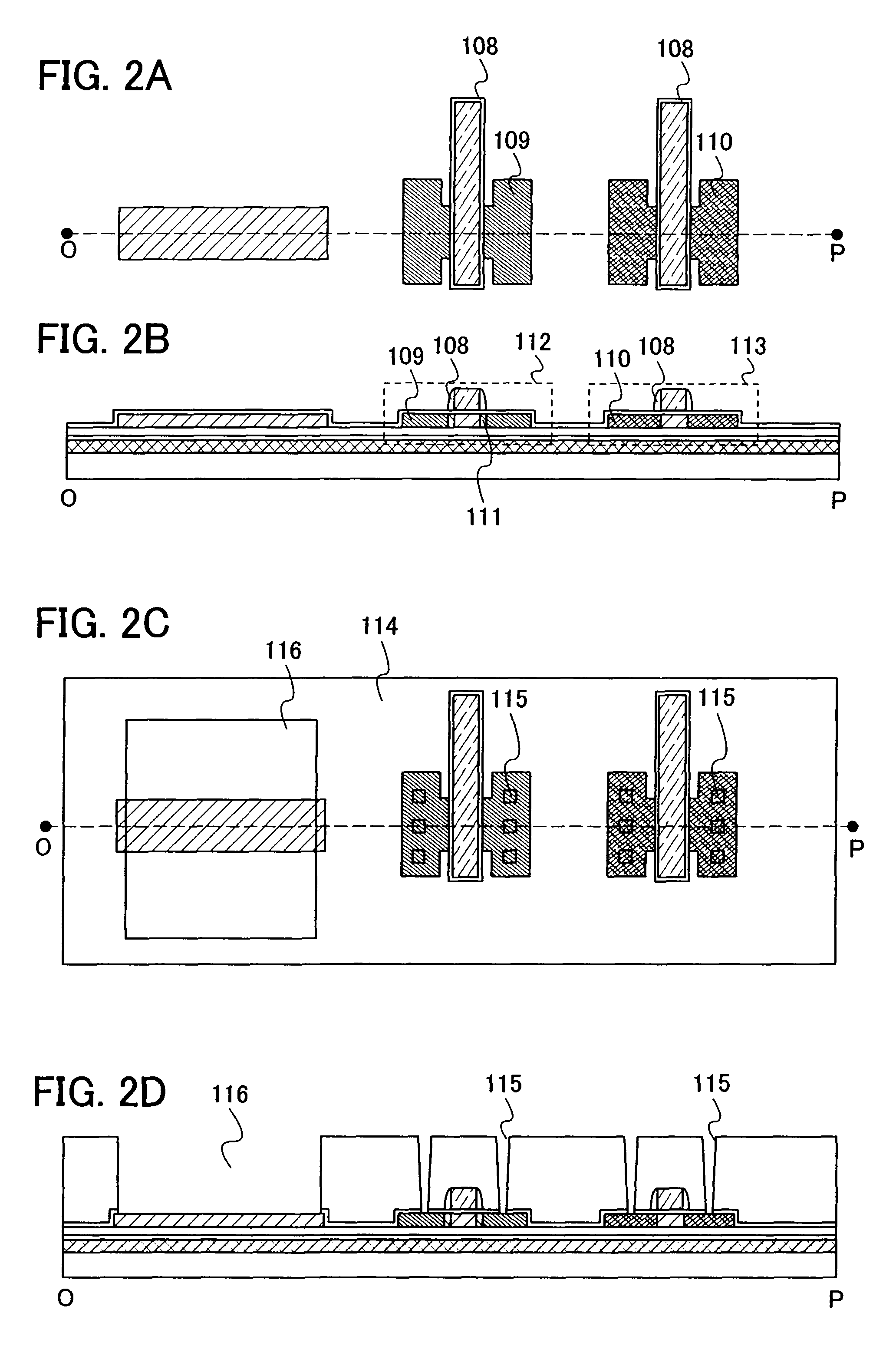

Rigid-Flexible Board and Method for Manufacturing the Same

InactiveUS20070281505A1High aspect ratioSimple molding processPrinted circuit assemblingLamination ancillary operationsEngineeringYield ratio

A rigid-flexible board and a method for manufacturing the same can be provided, whereby the material yield ratio can be enhanced and the productive yield can be also enhanced. A rigid board with a step for connection and a flexible board with a connector at the edge thereof are formed independently. Then, the connecting area is spot facing processed so that the depth of the thus obtained depressed portion is equal to or lower than the thickness of the flexible board. The connector of the flexible board is electrically connected to the vertical wiring area of the depressed portion.

Owner:DAI NIPPON PRINTING CO LTD

Method Of Molding A Microneedle

InactiveUS20080088066A1Simple molding processReliably producedMicroneedlesMedical devicesReciprocating motionMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

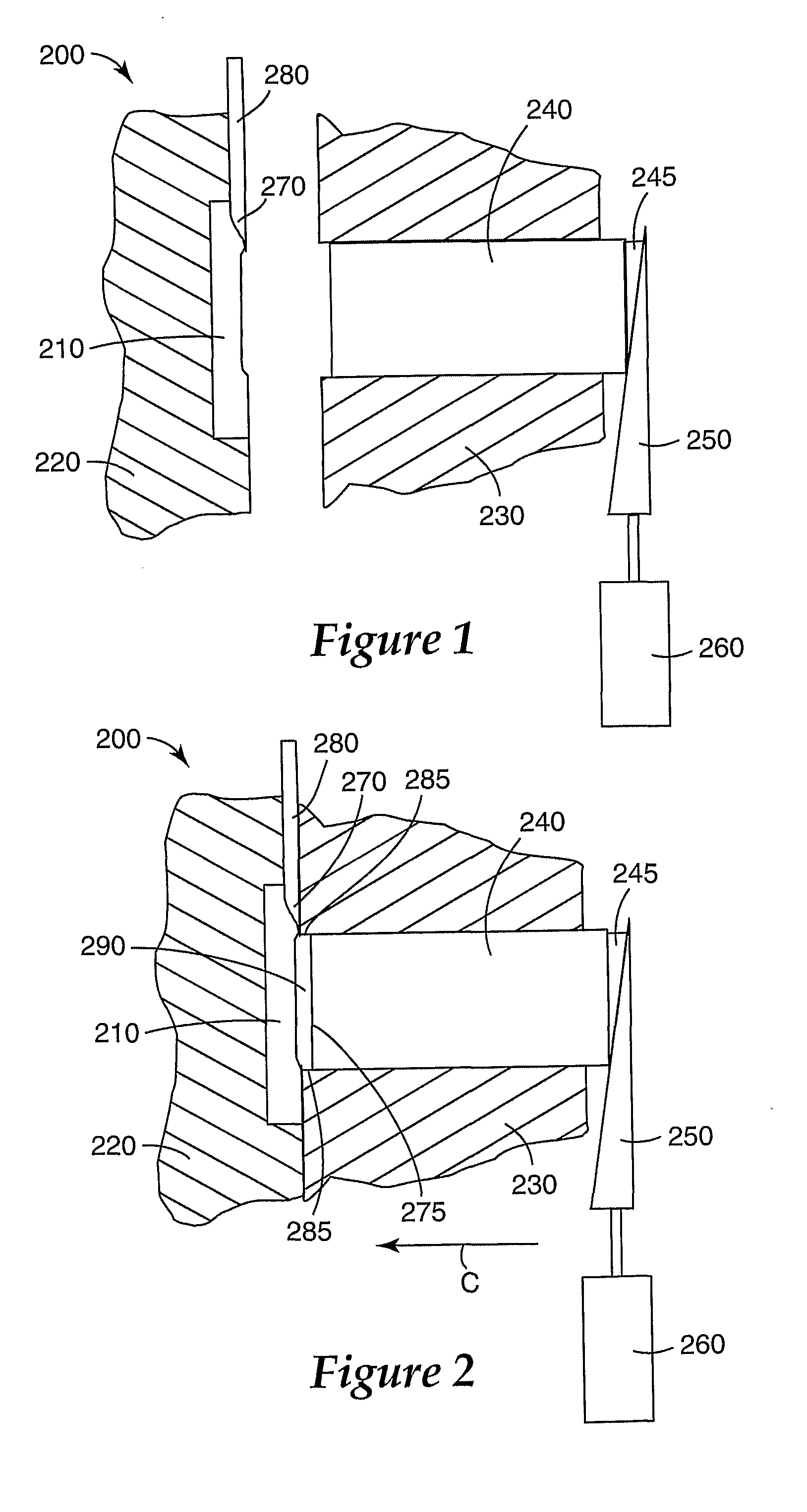

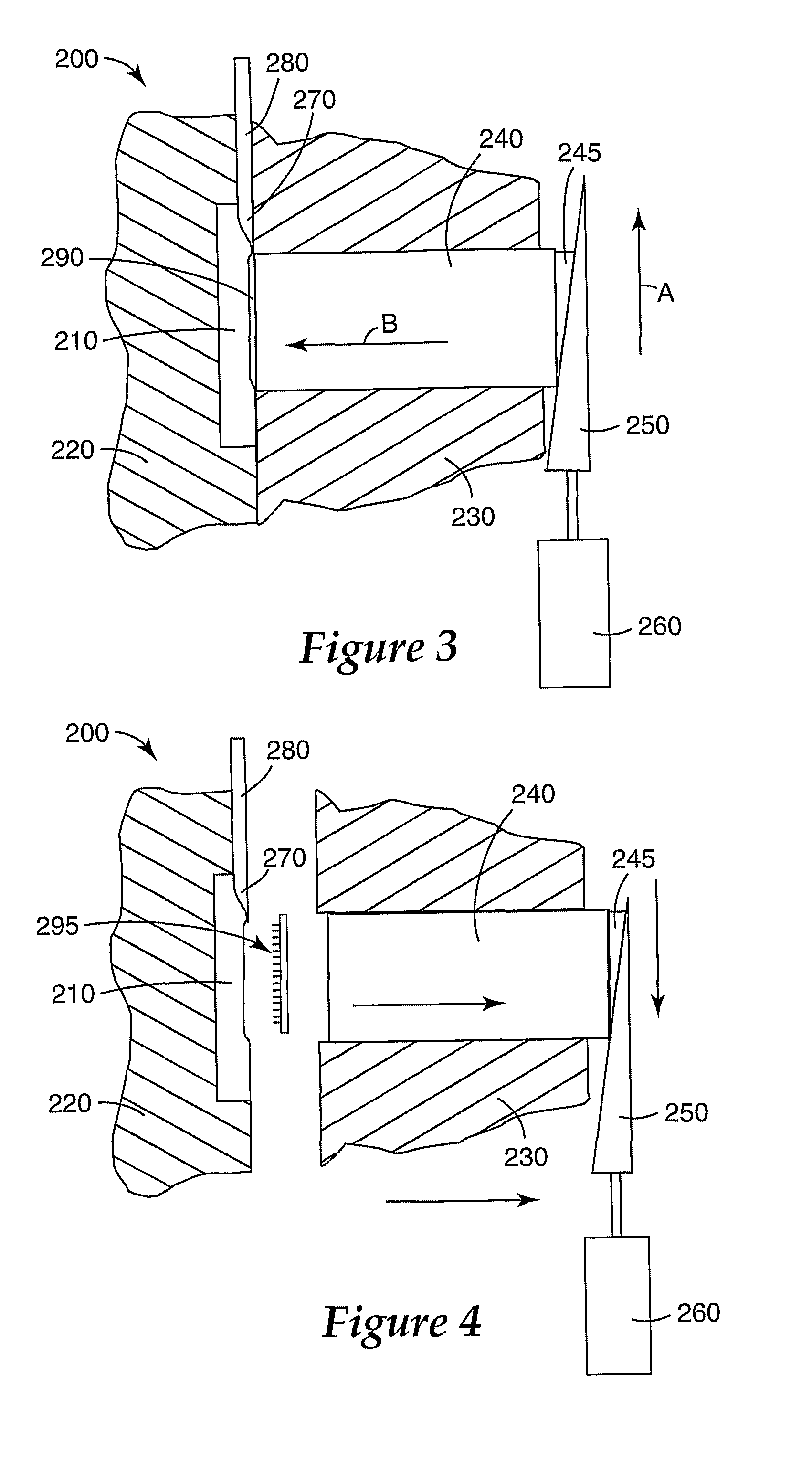

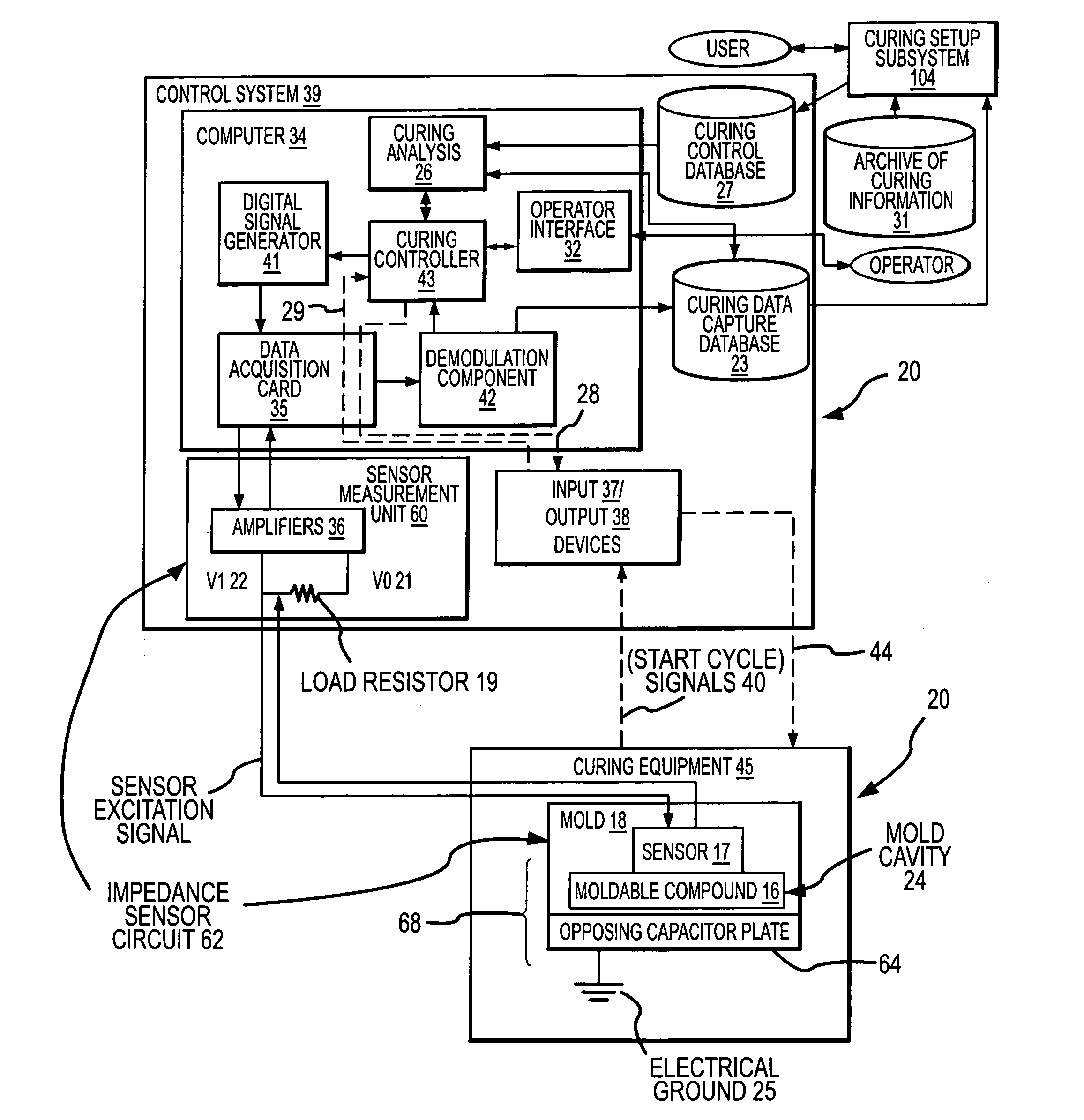

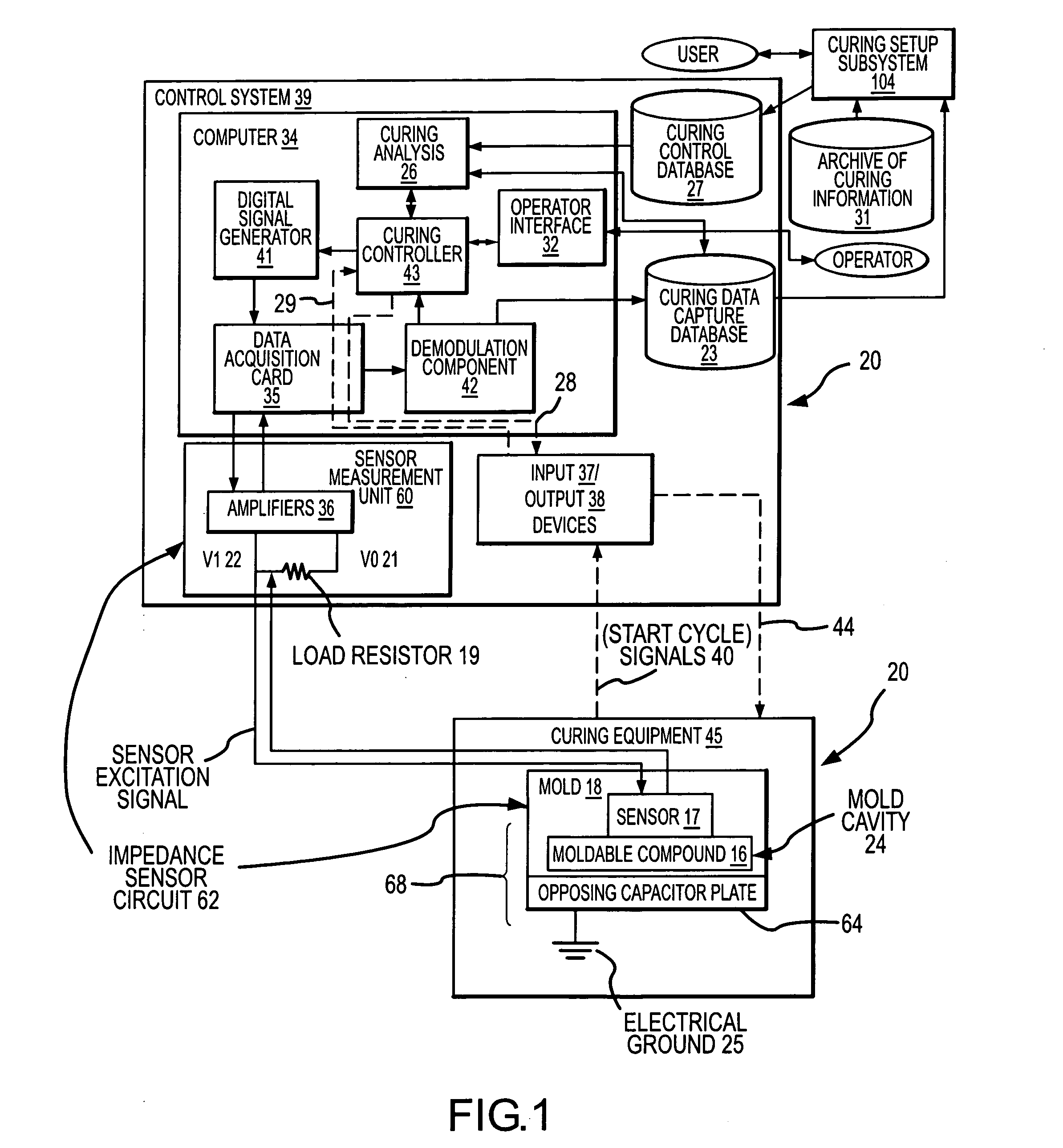

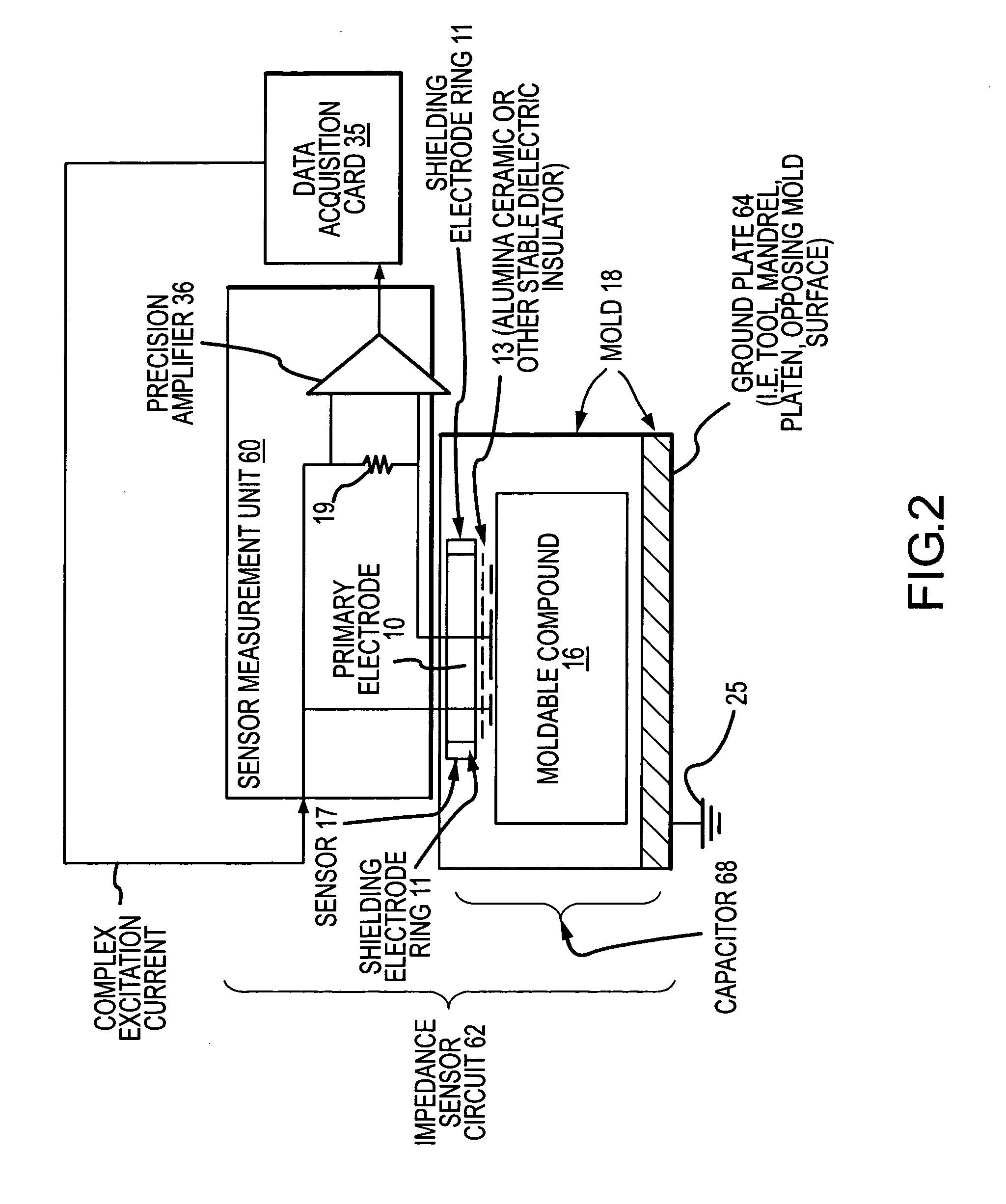

Process and apparatus for improving and controlling the curing of natural and synthetic moldable compounds

InactiveUS20050173820A1Robust and repeatableEfficient changeFlow propertiesVolume/mass flow measurementCompound aMedicine

A process for curing a moldable compound under a plurality of curing conditions by: (1) obtaining time dependent data streams of dielectric or impedance values from a plurality of sensors distributed within a curing mold, wherein the moldable compound is a dialectric for each of the sensors; (2) determining impedance related measurements from the data streams for the plurality of sensors; (3) determining predictive and / or corrective curing actions for enhancing the curing process using the impedance related measurements for the plurality of sensors; and (4) controlling the mass production curing of parts to obtain cured parts having one or more desired properties.

Owner:SIGNATURE CONTROL ENG LLC

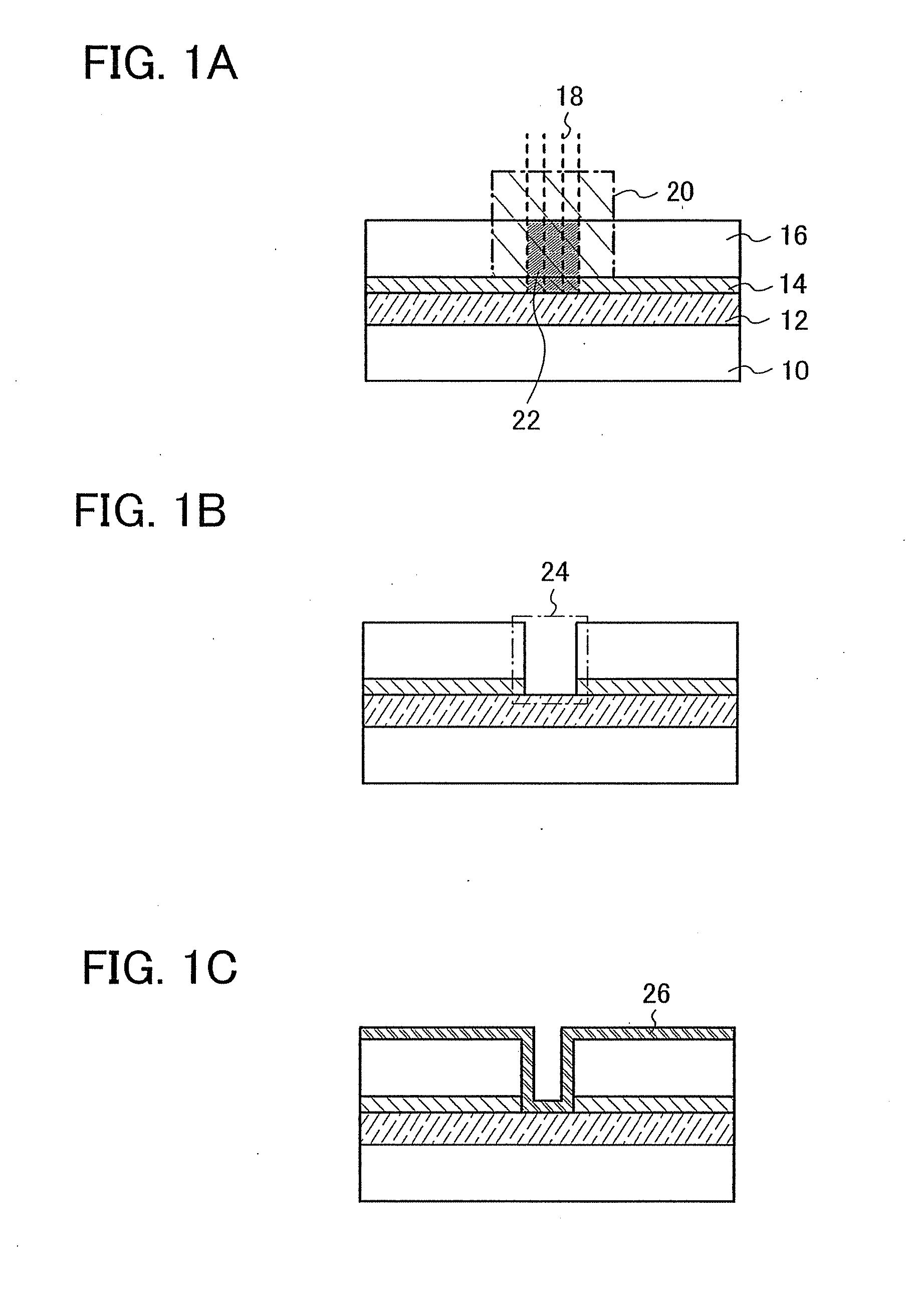

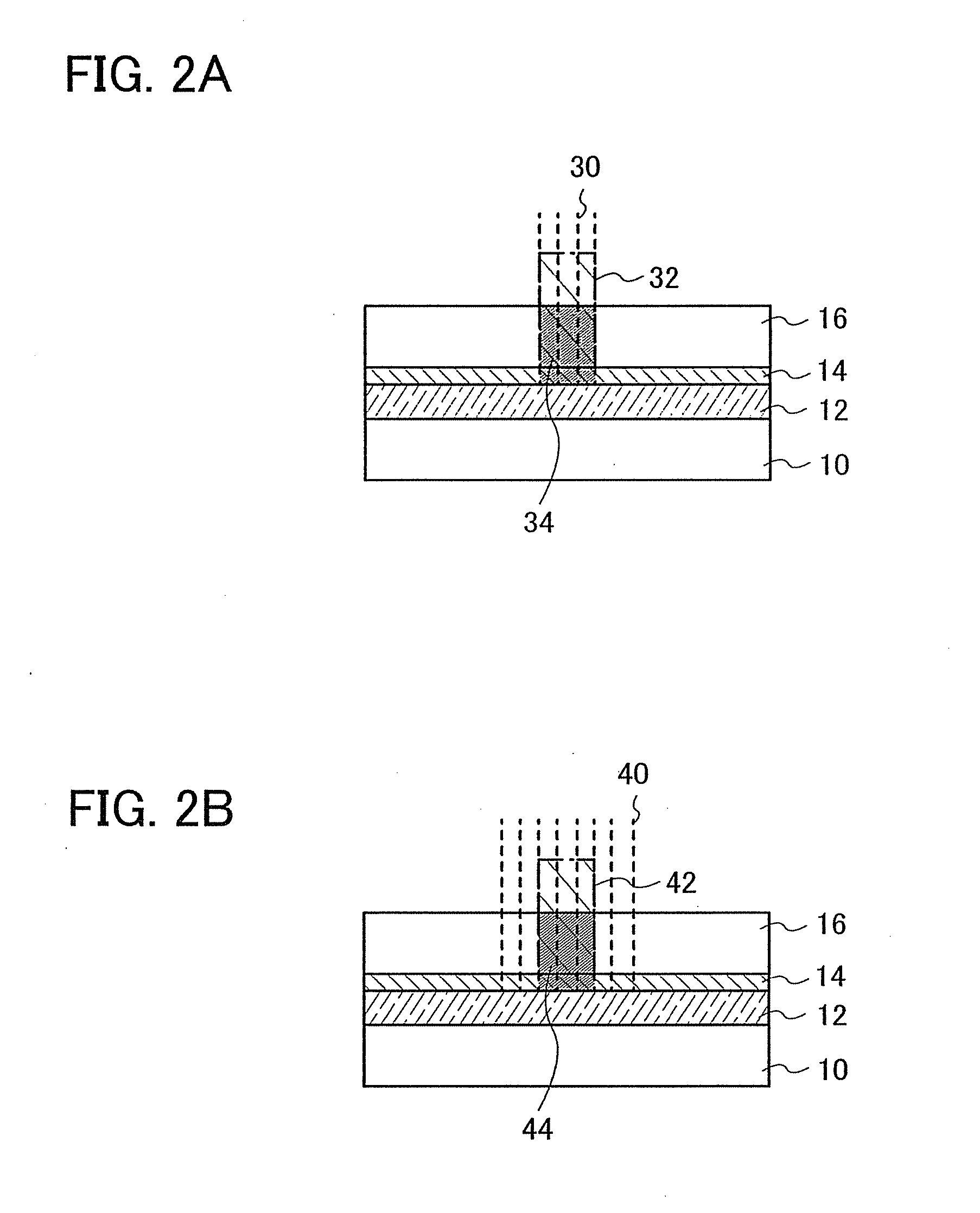

Manufacturing Method of Semiconductor Device

InactiveUS20080108229A1Reduce manufacturing costImprove throughputSolid-state devicesPhotomechanical apparatusManufacturing cost reductionLithographic artist

In a manufacturing process of a semiconductor device, a manufacturing technique of a semiconductor device by which a lithography step that uses a photoresist is simplified is provided. A manufacturing cost is reduced and throughput is improved. An irradiation object is formed over a substrate by sequentially stacking a first material layer and a second material layer. The irradiation object is irradiated with a first laser beam that is absorbed by the first material layer and a second laser beam that is absorbed by the second material layer so that the laser beams overlap. A part or all of the region irradiated with an overlap part of the laser beams is ablated to form an opening.

Owner:SEMICON ENERGY LAB CO LTD

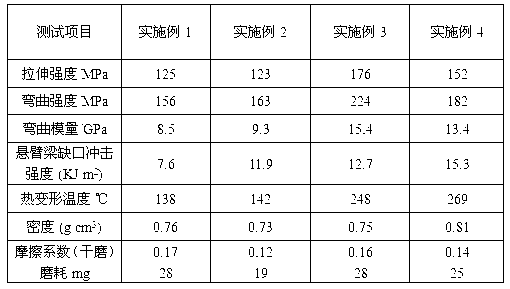

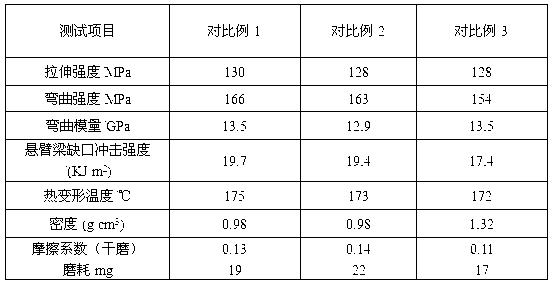

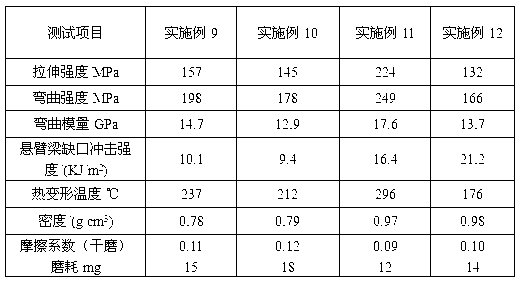

Novel plastic-base enhanced foaming composite material as well as preparation method and application thereof

The invention relates to a novel plastic-base enhanced foaming composite material which is prepared from the following raw materials in parts by weight: 100 parts of thermoplastic resin, 20-50 parts of continuous fiber, 5-10 parts of filling, 2-8 parts of foaming agent, 2-8 parts of compatilizer, and 0.1-1 parts of processing aid. The invention also discloses a preparation method of the novel plastic-base enhanced foaming composite material, and applications of the material in the preparation of a cue and a table tennis bat. Compared with the prior art, the novel plastic-base enhanced foaming composite material provided by the invention can be directly injection-molded, and the obtained product has the advantages of pretty high strength, pretty high modulus, good toughness, good wear resistance, simple molding and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Titanium silicon molecular sieve catalyst as well as preparation method and use thereof

ActiveCN101371989ALarge particle sizeHigh mechanical strengthOrganic chemistryMolecular sieve catalystsMolecular sieveNano al2o3

The invention relates to a titanium silicate molecular sieve catalyst and the preparation method and the application thereof. The catalyst comprises 25-65 percent of titanium silicate molecular sieve and 20-65 percent of nanometer alumina. The mechanical strength is 20-30N / cm<2>. Prepared by an extruded moulding method, the catalyst has the characteristics of high mechanical strength, high catalytic activity and selectivity, and the like, and is especially applied to catalyzing 3-chloropropene oxidation reaction to prepare epichlorohydrin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Radiolucent retractor and related components

InactiveUS7232411B2Minimal artifactCost-effective manufacturingDiagnosticsInstruments for stereotaxic surgeryCouplingEngineering

Owner:INTEGRA LIFESCI

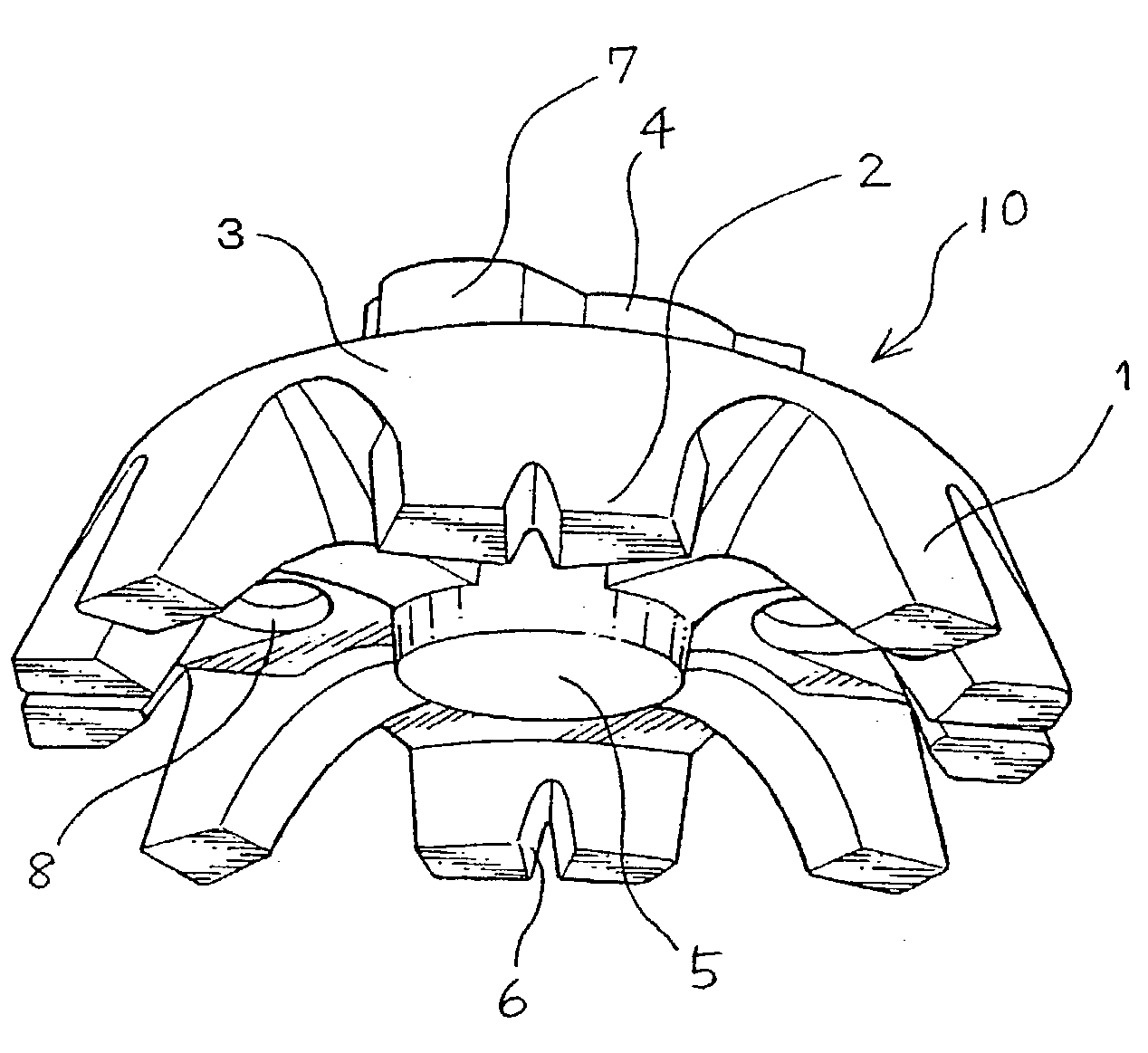

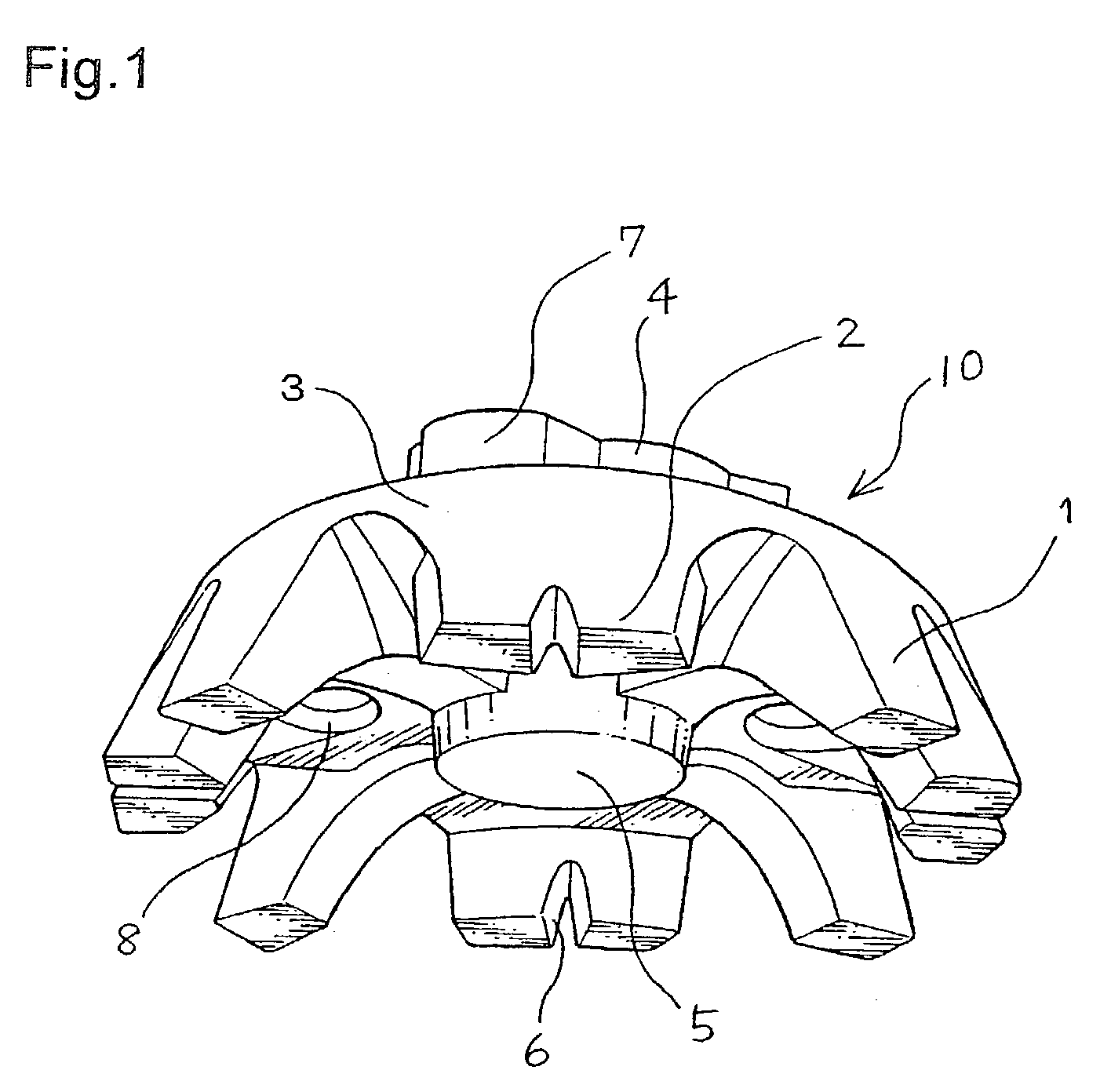

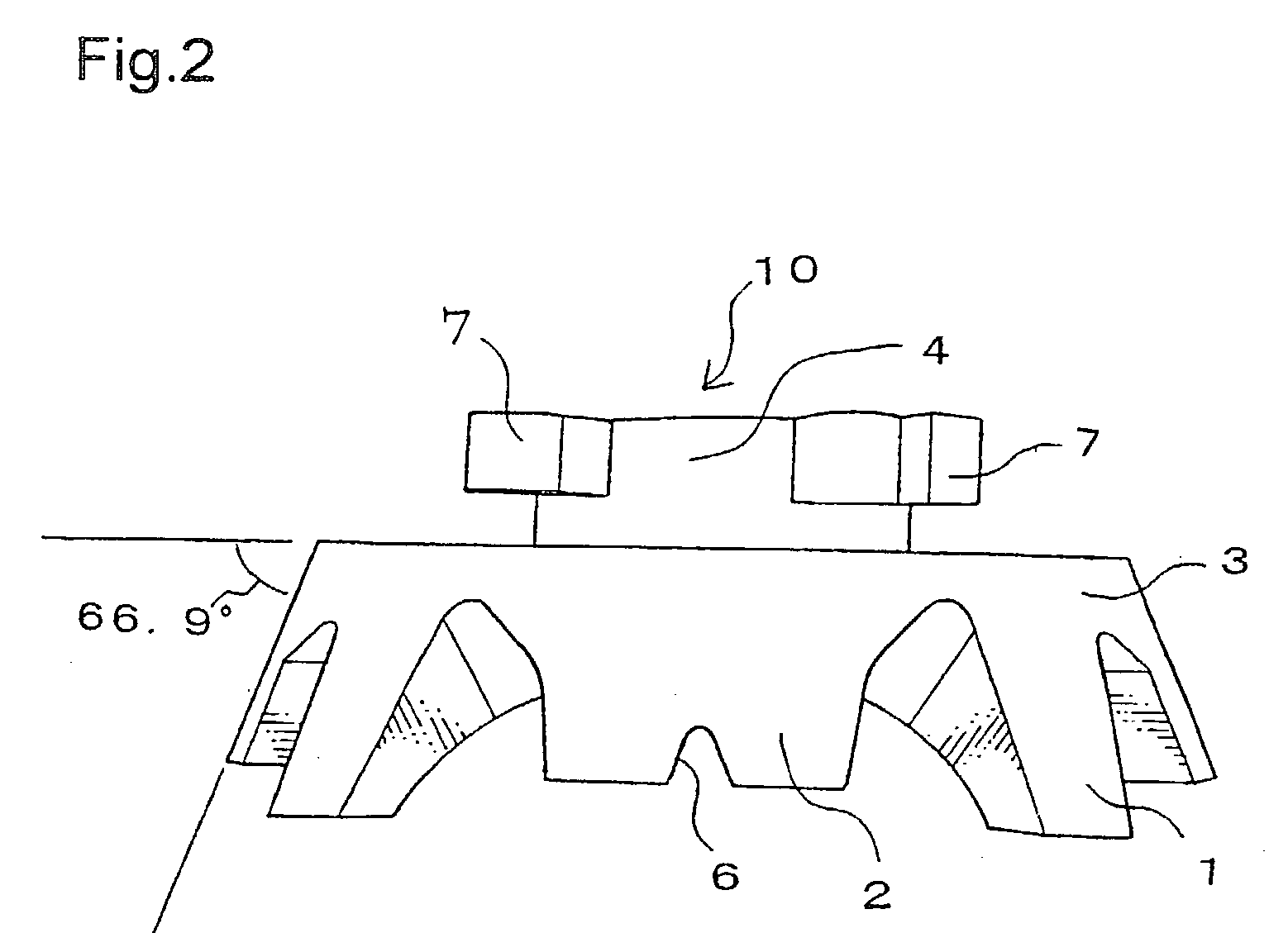

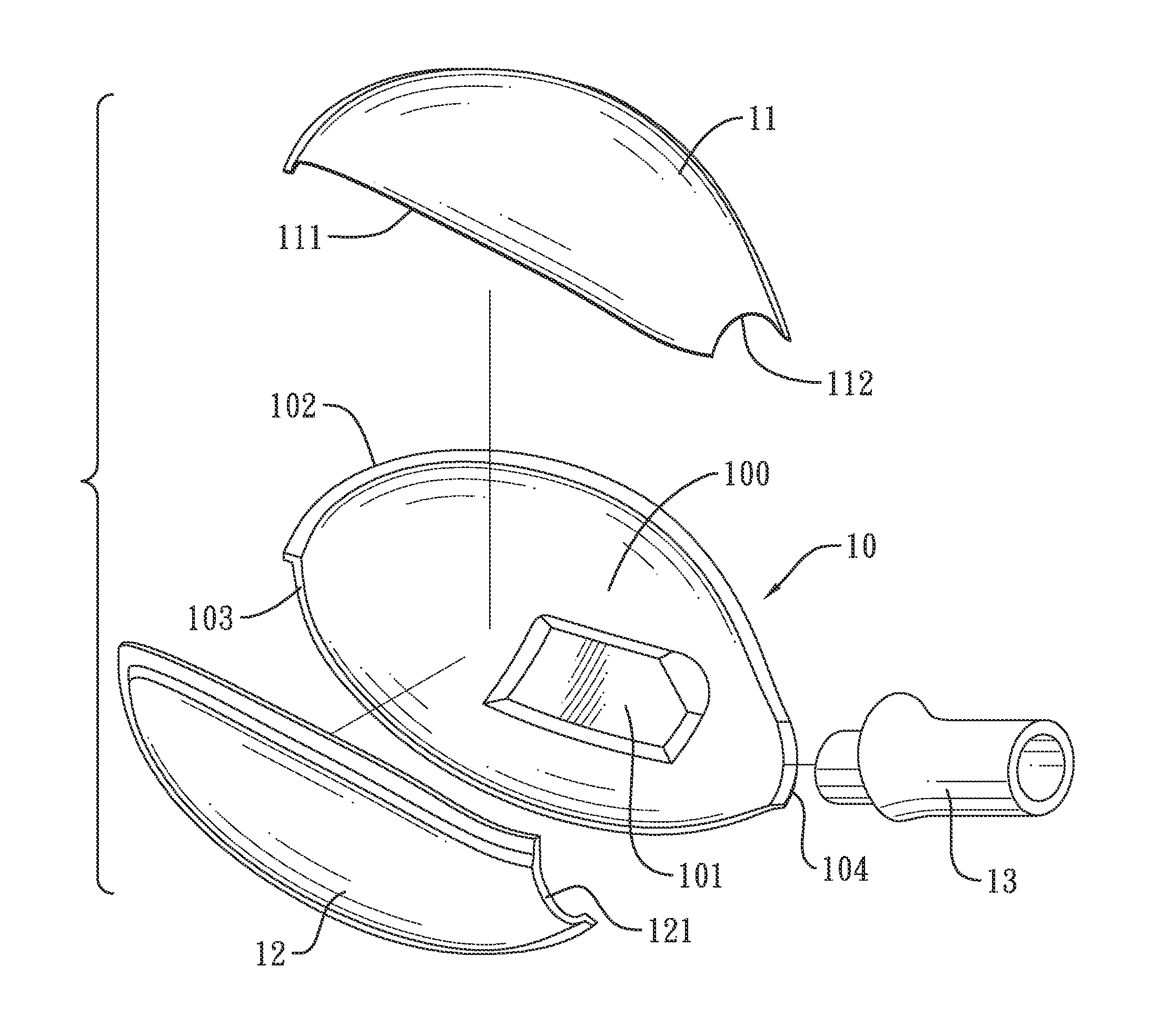

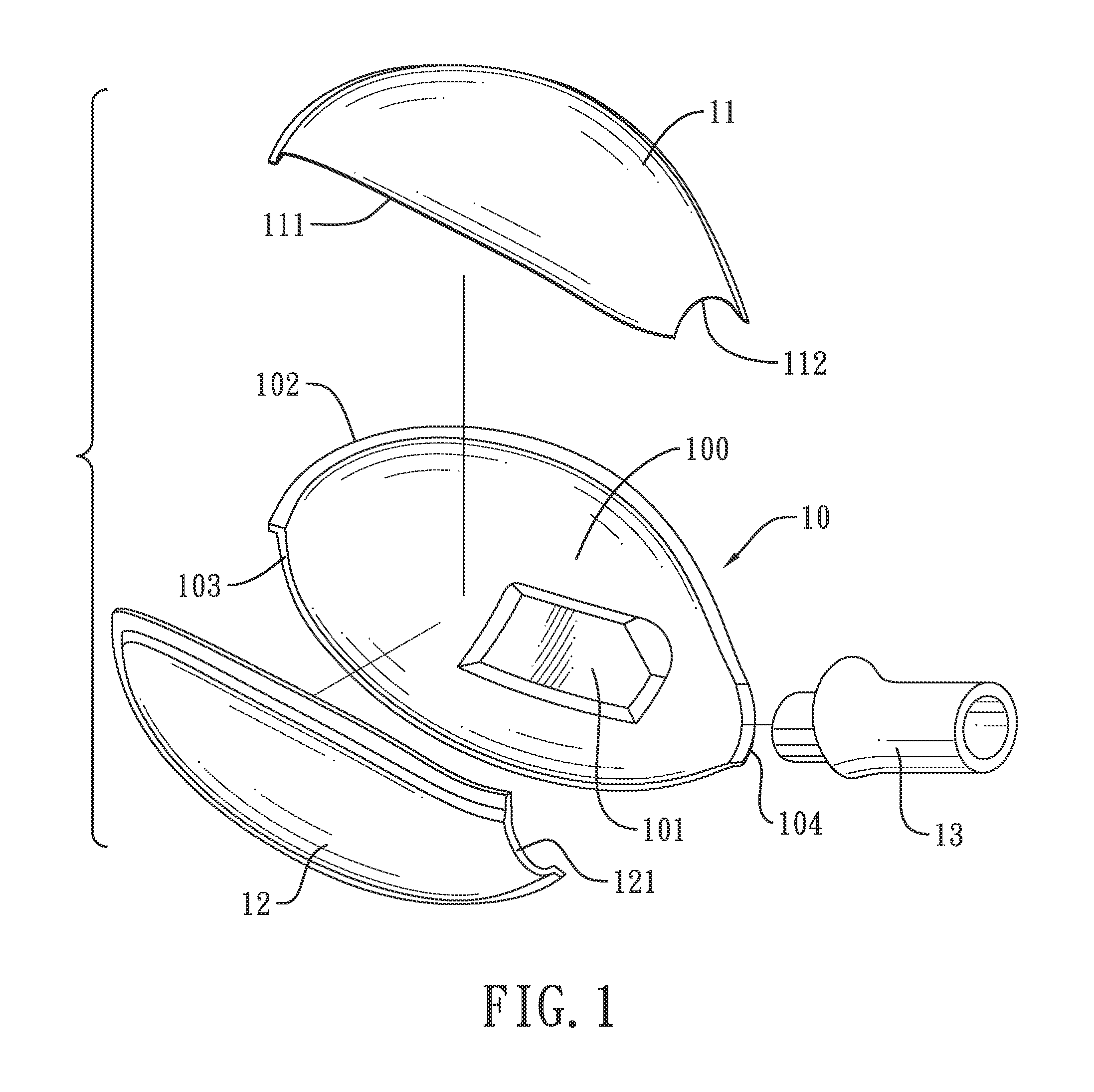

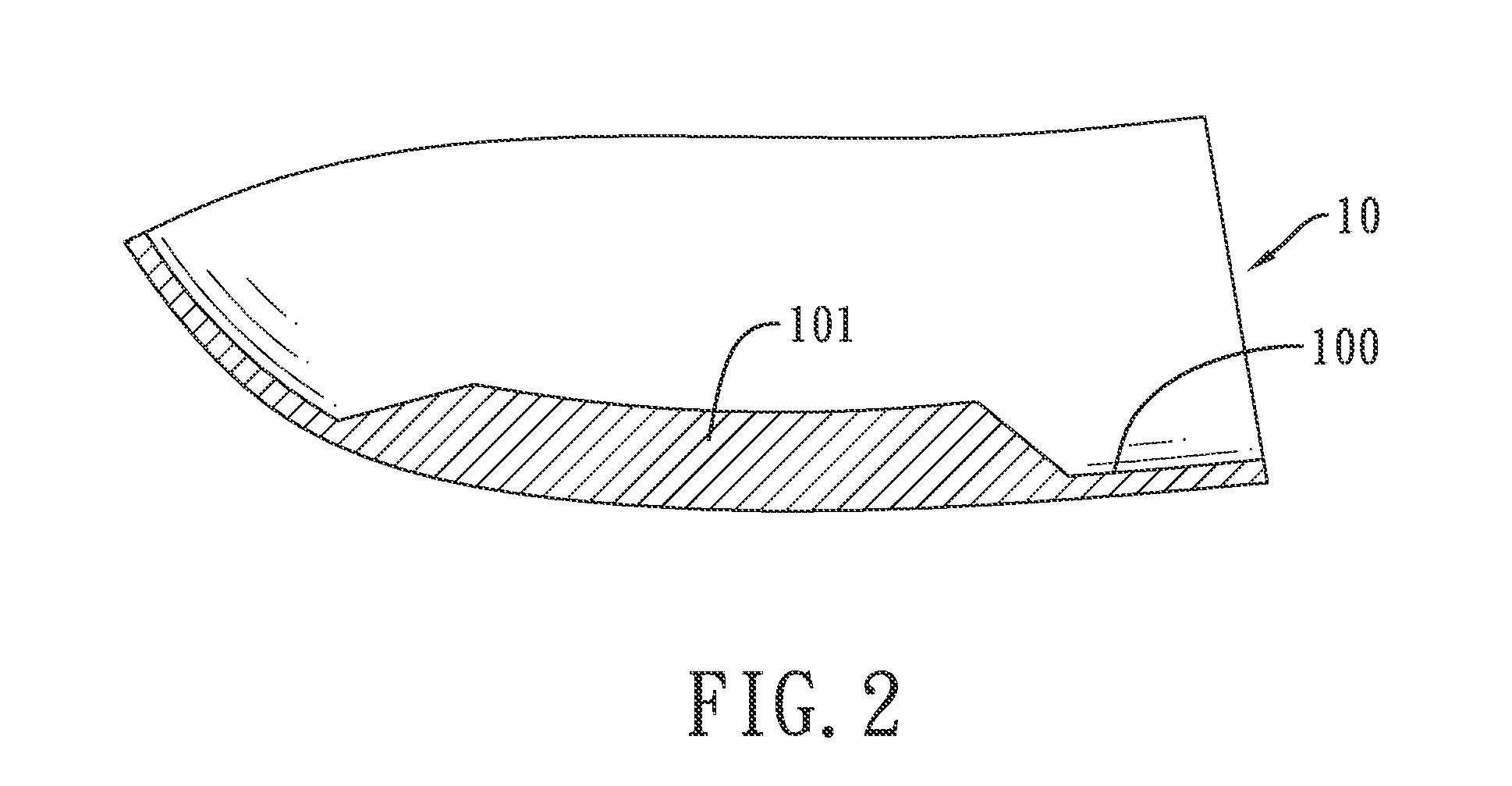

Golf Shoe Cleat

A plastic cleat (10) for a golf shoe is disclosed, including a cleat body (3), a plurality of flexible protrusions (1) and rigid protrusions (2) extending from the cleat body (3). The flexible protrusions (1) and rigid protrusions (2) provide good grips on grass without damaging the grass. The flexible protrusions (1) bend outwardly on a hard surface, when the rigid protrusions (2) chiefly support weight. The cleat (10) can be economically manufactured by "forced extraction molding" utilizing the shape rebounding nature of half hardened plastic materials.

Owner:JAPANA CO LTD

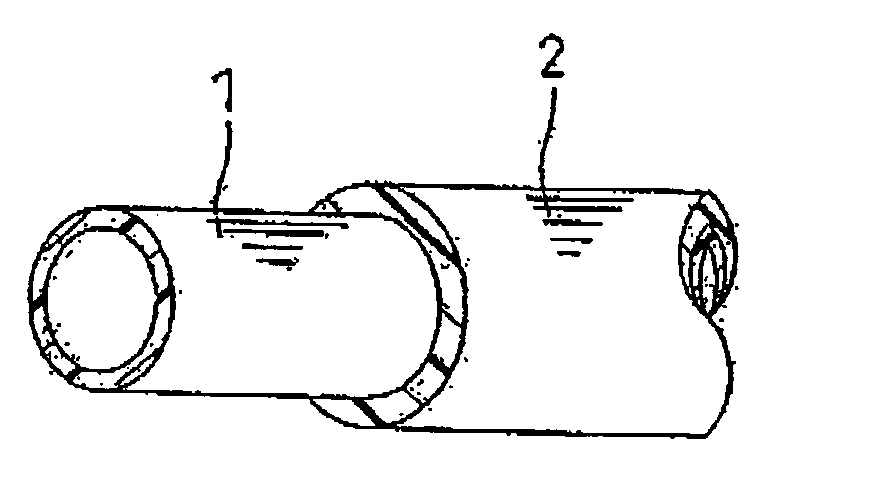

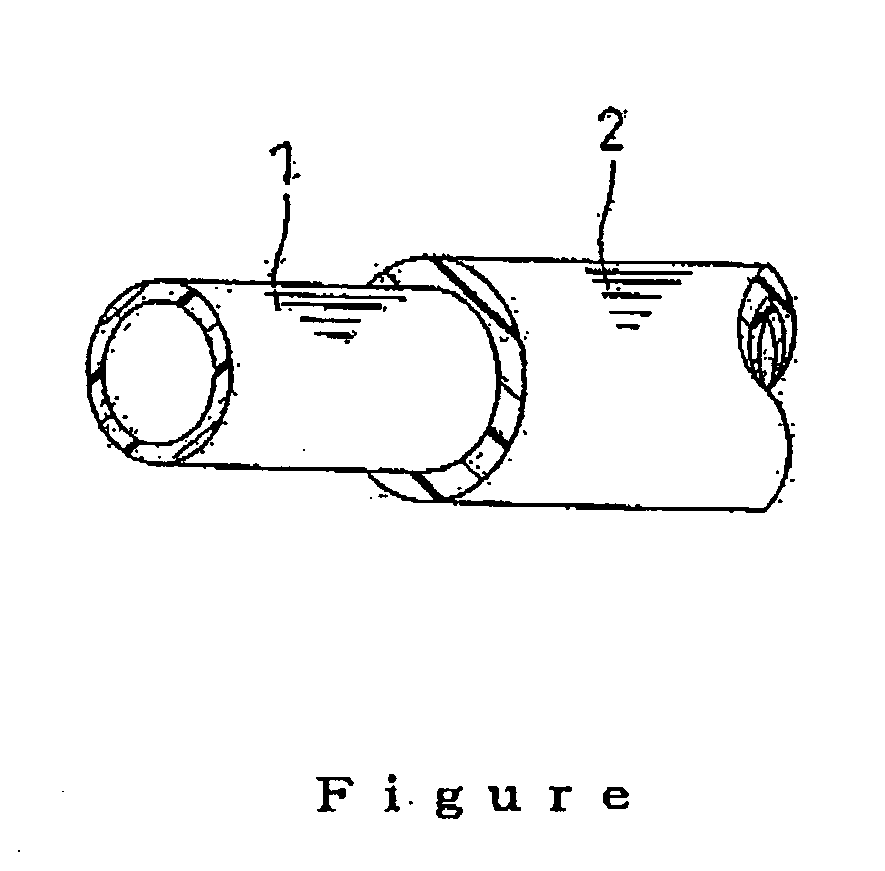

Automotive fuel hose and method for producing the same

InactiveUS20050208248A1Low layerSimple molding processSynthetic resin layered productsLaminationEngineeringAutomotive fuel

An automotive fuel hose excellent in interlaminar adhesion between a low permeability resin layer and a rubber layer, wherein the low permeability resin layer and the rubber layer are directly adhered to each other without forming an adhesive layer at the interface between both layers. The automotive fuel hose has a laminated structure of a low permeability resin layer and a rubber layer, the low permeability resin layer is formed by the following (A) and the rubber layer is formed by the following (B). (A) a polyphenylene sulfide resin containing a softening component, or a modified fluororesin. (B) a rubber composition composed of at least one of an amine additive and an amine vulcanizing agent as an essential component.

Owner:SUMITOMO RIKO CO LTD

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

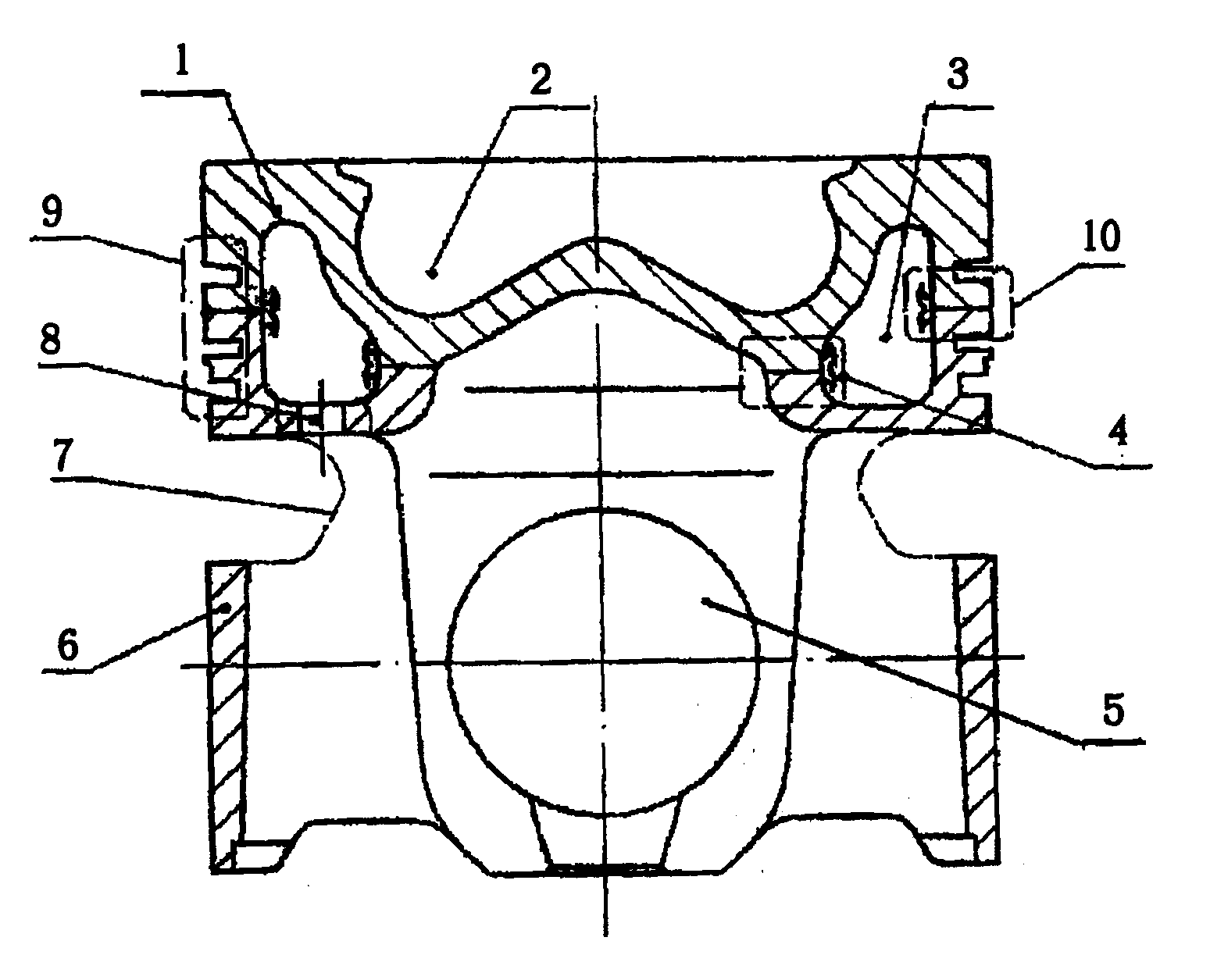

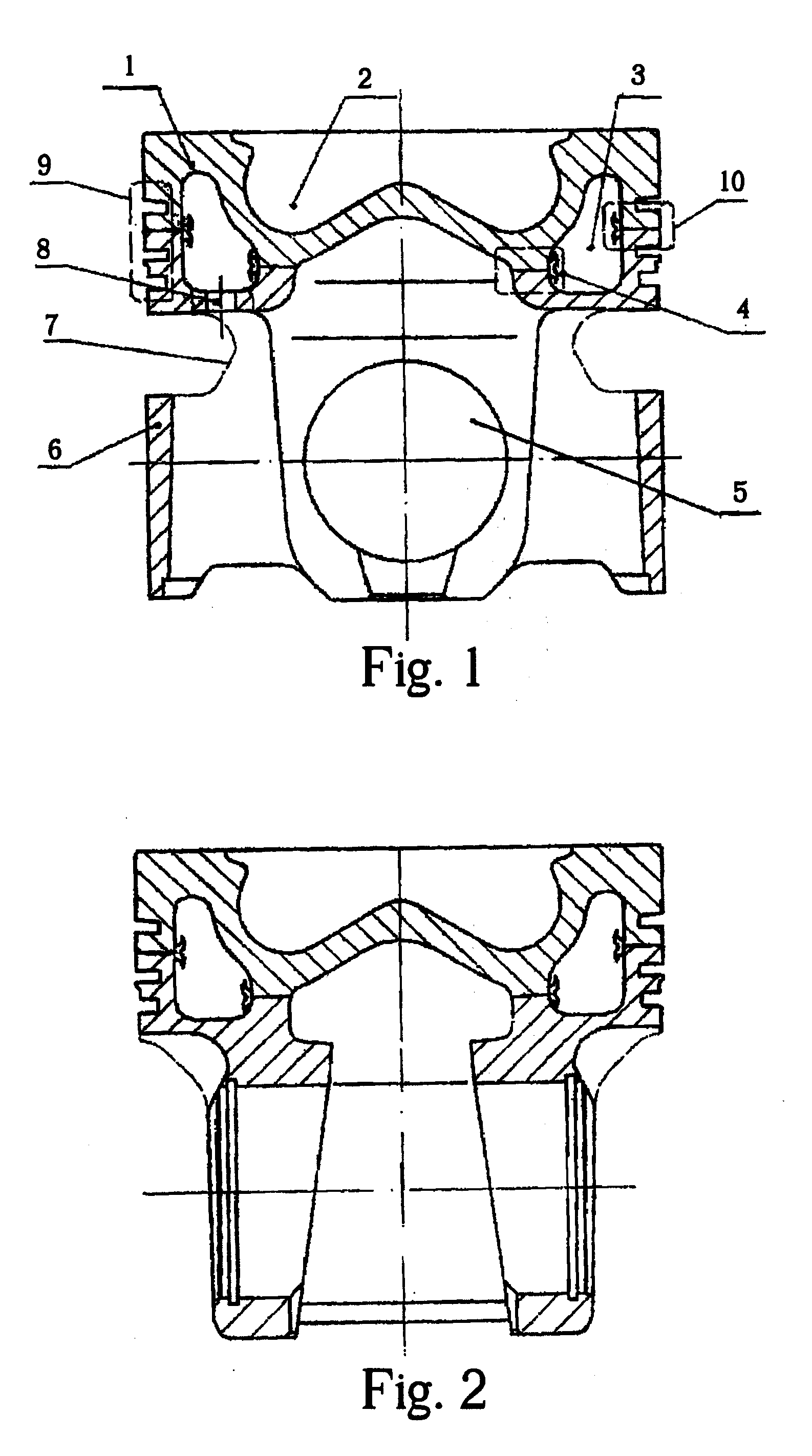

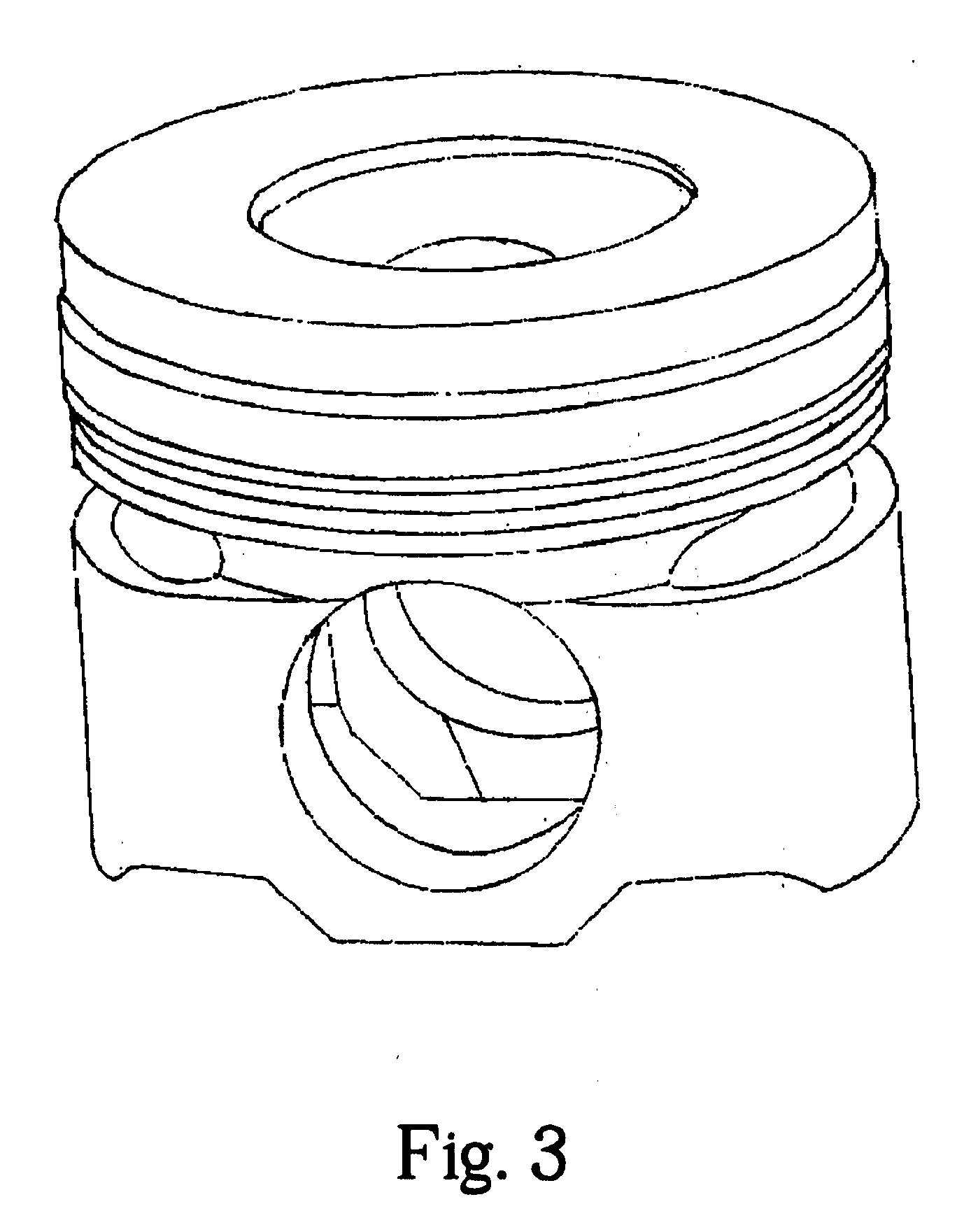

Welding Forged Steel Single Piece Piston and Its Manufacturing Methods

InactiveUS20070079775A1Simple manufacturing processImprove structural strengthAir coolingMachines/enginesFriction weldingCombustion chamber

The present invention has provided a welding forged steel single piece piston and its manufacturing methods. A semi-finished head and a semi-finished skirt are forged respectively; the semi-finished head and semi-finished skirt are heat-treated respectively; rough machining is carried out respectively to the semi-finished head and the semi-finished skirt, and a face of weld between the two adjacent ring grooves is higher than the one under the combustion chamber; the head and the skirt are welded together through friction welding; an annular groove, a combustion chamber, a ring groove, a pinhole, an outer annulus and oil inlet / outlet holes are manufactured respectively; and the surface of the piston is phosphorized and graphitized. Compared with one-piece forged piston, it has better processing technology, because the head and skirt are forged respectively and then welded together. Over-all structural rigidity of the piston has been increased, and distortion of the ring groove in high temperature is slight because the cooling oil recess is sealed through welding. As the annular groove is located on the upper part of skirt, the weight of body of the piston is lowered and this kind of structure can accelerate engine oil returning on, decrease the clearance between the piston and the cylinder and reduce the engine oil consumption.

Owner:SHANDONG BINZHOU BOHAI PISTON

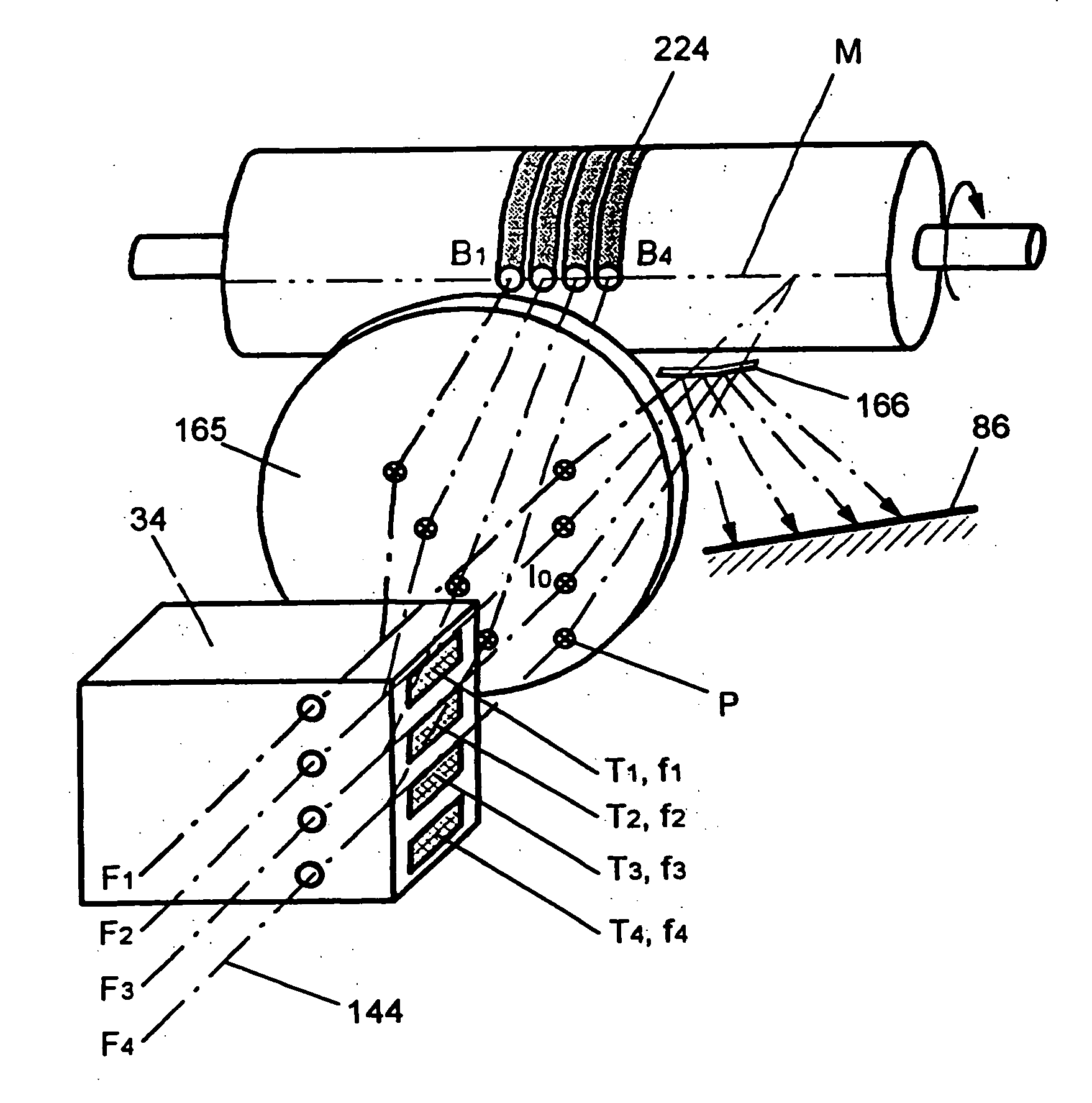

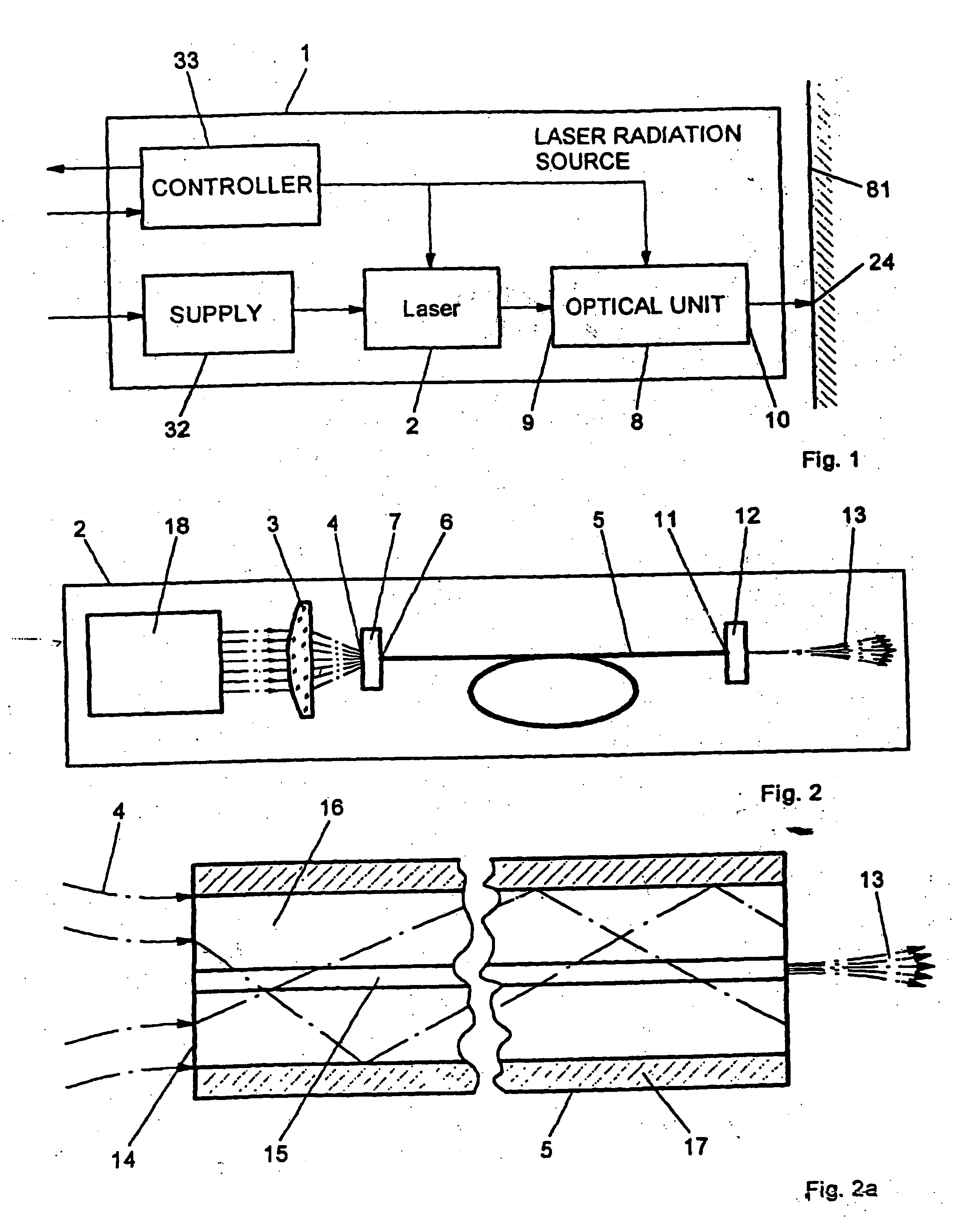

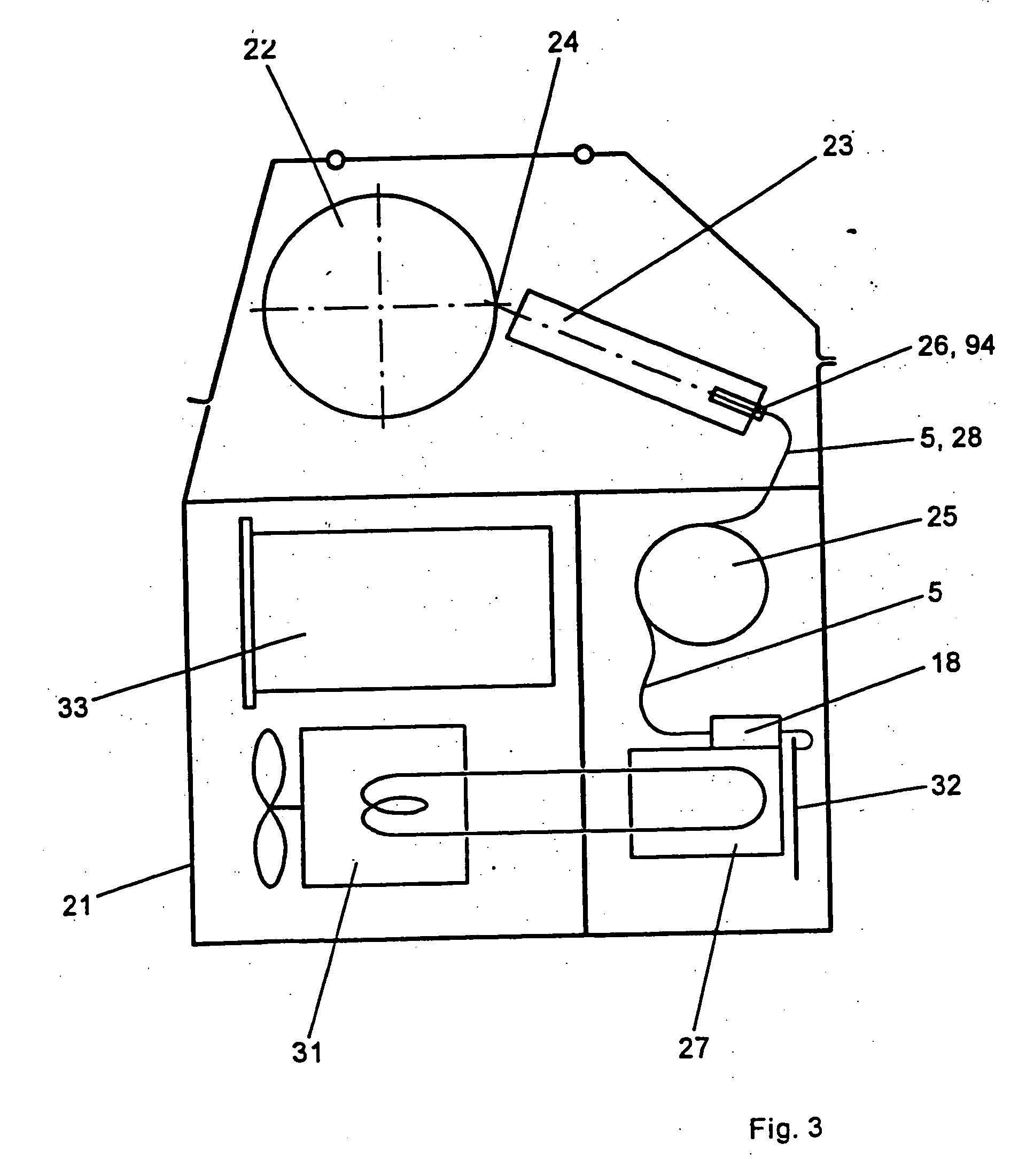

Laser radiation source

InactiveUS20060249491A1Simple molding processAvoid radiationLaser beam welding apparatusForme preparationOptoelectronicsLaser beams

In a method or system for forming ink holding indicia at a processing surface of a printing form associated with a printing cylinder, a laser beam is provided. The laser beam is modulated to control whether or not at least a portion of the laser beam strikes the processing surface. A focusing optics focuses the laser beam to create a processing spot on the processing surface to create the ink holding indicia. At least a portion of the laser beam not intended to reach the processing surface is directed to a sump. A cover is provided over the sump substantially preventing radiation of the laser beam away from the sump. Alternatively, the processing surface may serve as the sump.

Owner:HELL GRAVURE SYST

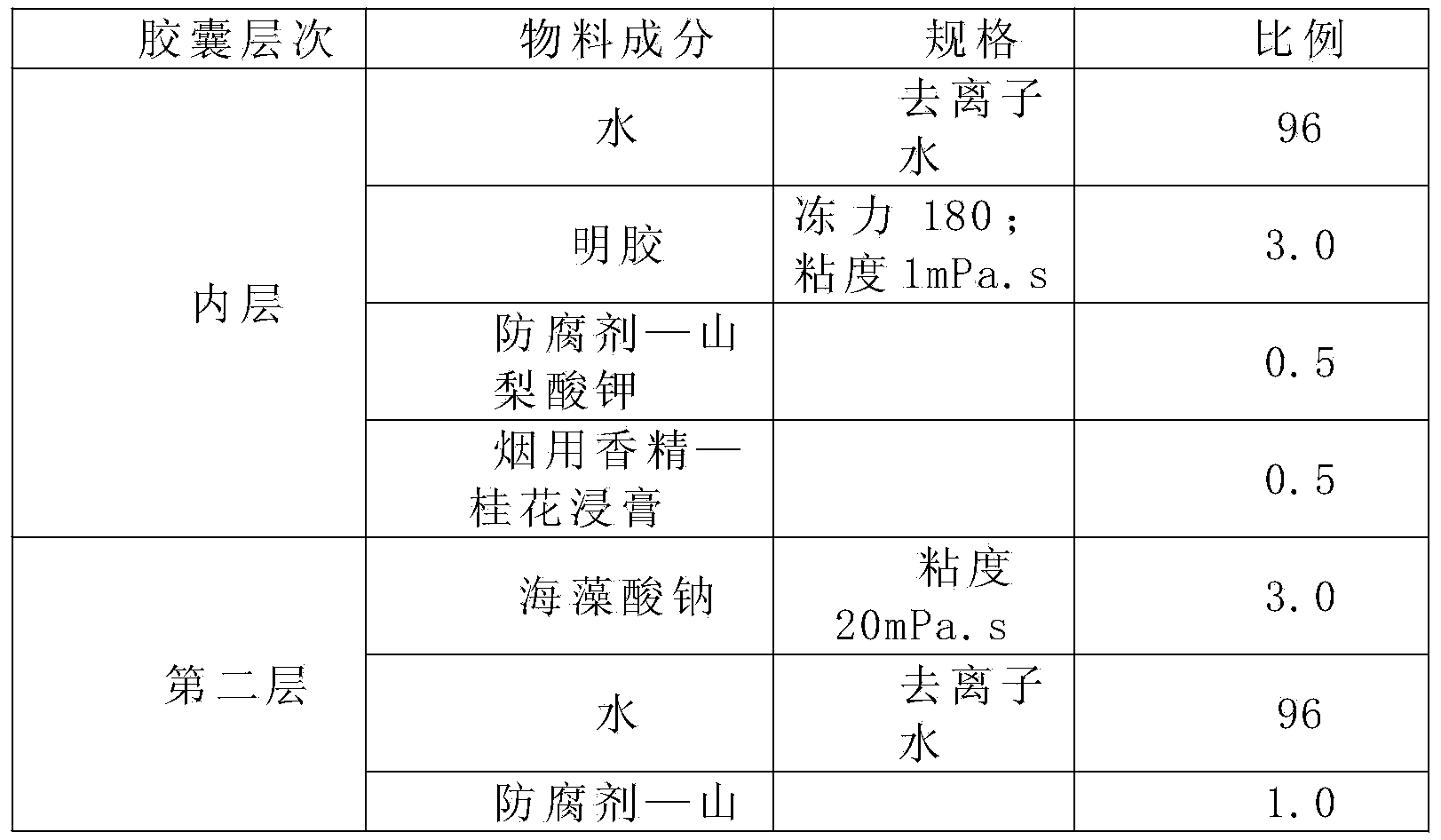

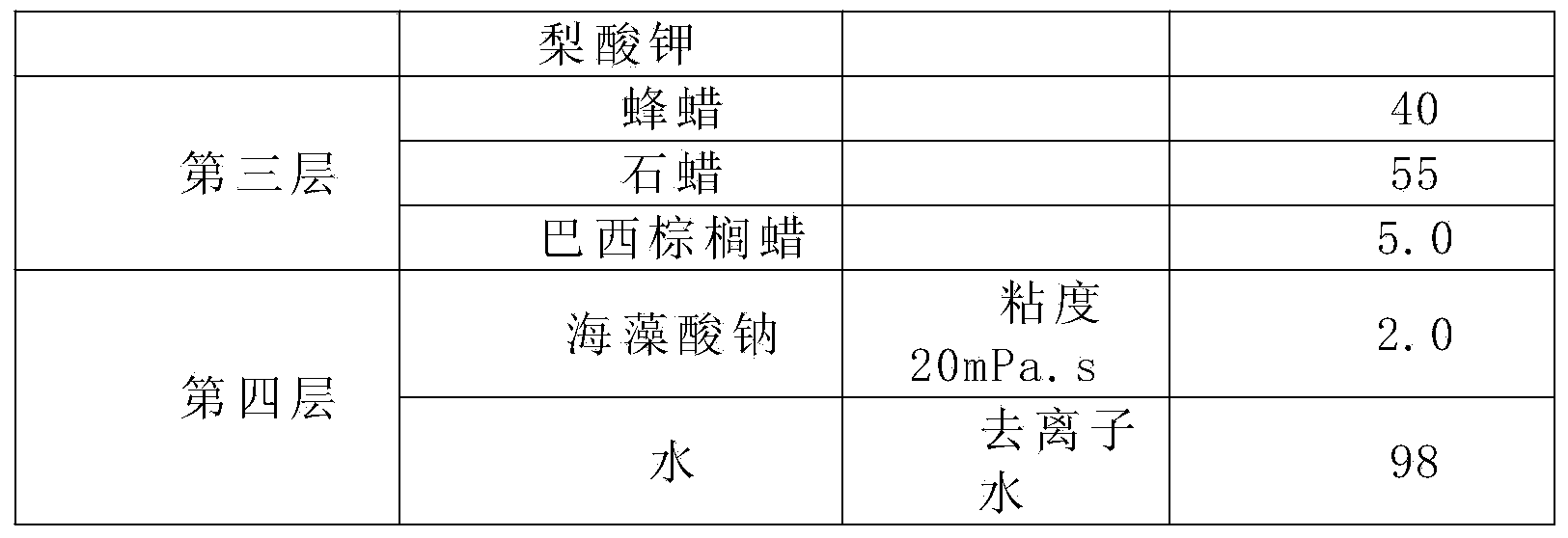

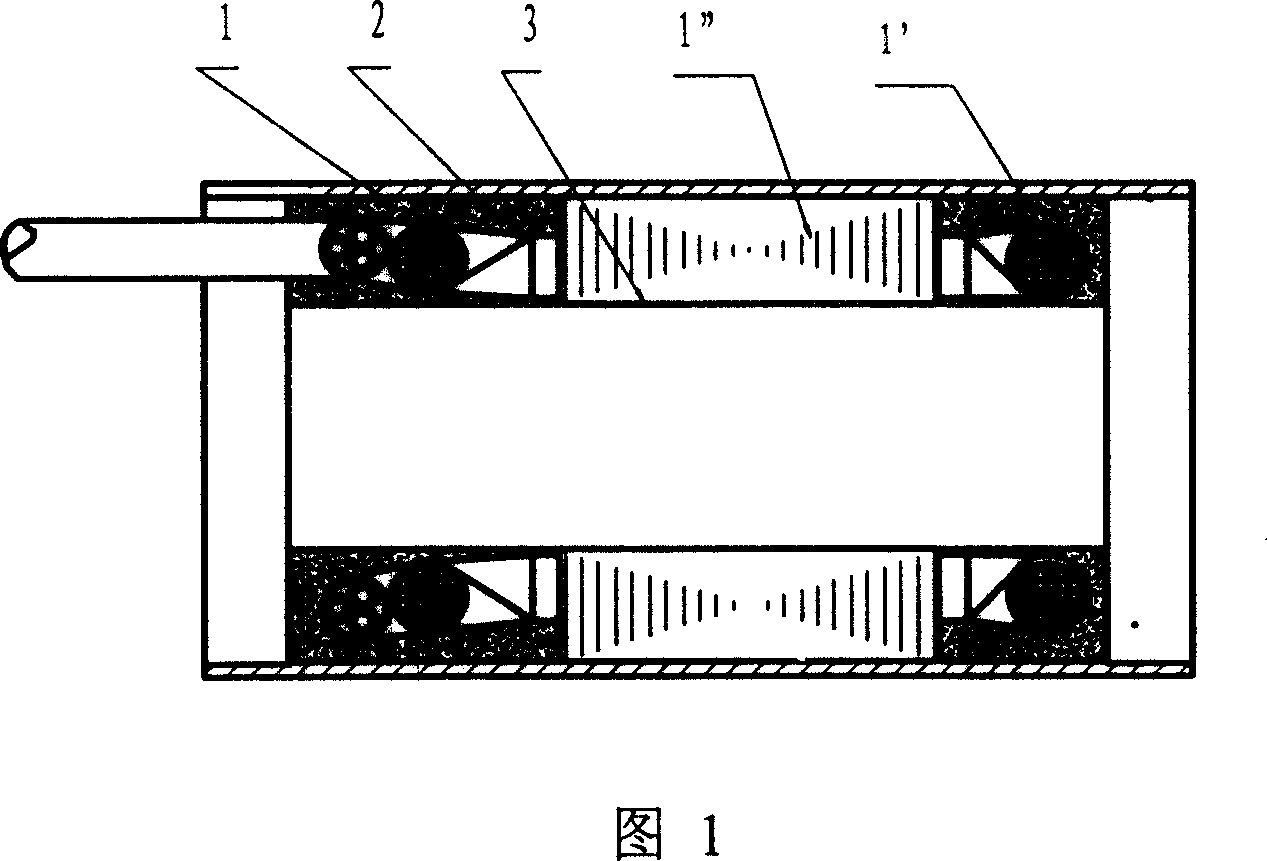

Four-layer water capsule used for cigarettes and manufacturing method of four-layer water capsule

ActiveCN103815542AImproved scrollabilityImprove pressure resistanceTobacco preparationTobacco treatmentWater solubleSolvent

The invention discloses a four-layer water capsule used for cigarettes and a manufacturing method of the four-layer water capsule. According to the four-layer water capsule used for cigarettes, water-soluble essence serves as an inner layer in the capsule, water serves as a solvent to dilute the essence, sodium alga acid complex compounds serve as the middle layer to wrap the water and the essence, waxy material serves as the third layer to prevent possible permeation of the water in the capsule, and sodium alga acid also serves as raw materials for the outermost layer to form a protection film so that cracking of the waxy layer can be reduced and the efficiency of adding the capsule to cigarettes can be improved. The manufacturing method of the four-layer water capsule includes the steps of wrapping a cigarette additive in a special rubber sheet and manufacturing the capsule through a dropping method. Dropping pills of the cigarette additive are manufactured through a dropping mechanism, used for filter tips and wrapped in tobacco bundles, and the additive or the essence is exposed when the four-layer water capsule is used and pinched broken by hand. The method is simple and practicable in process, simple in device, capable of being directly used for cigarette machining and convenient to popularize and apply. Raw materials are wide in source and low in cost.

Owner:HUBEI CHINA TOBACCO IND +1

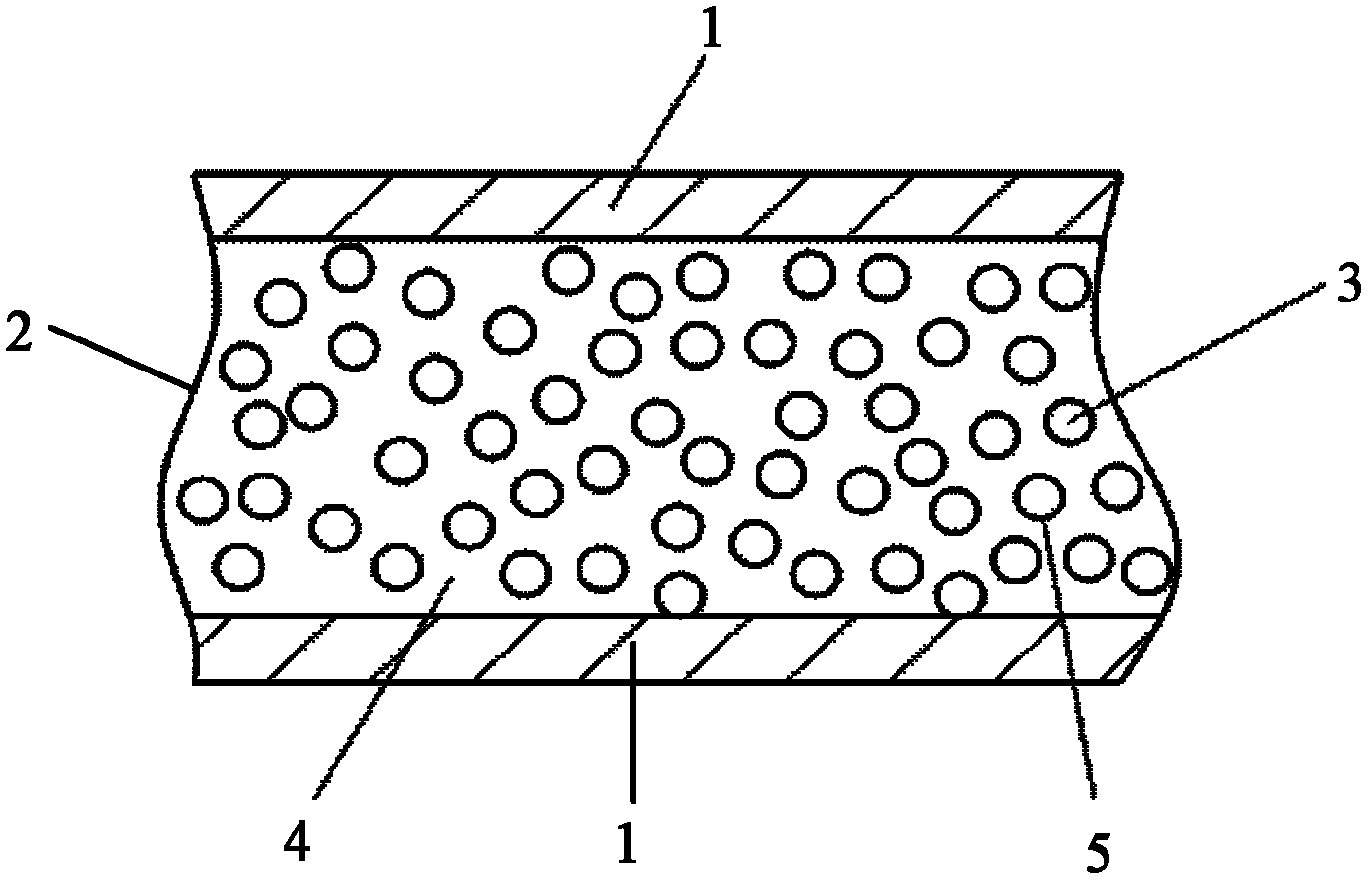

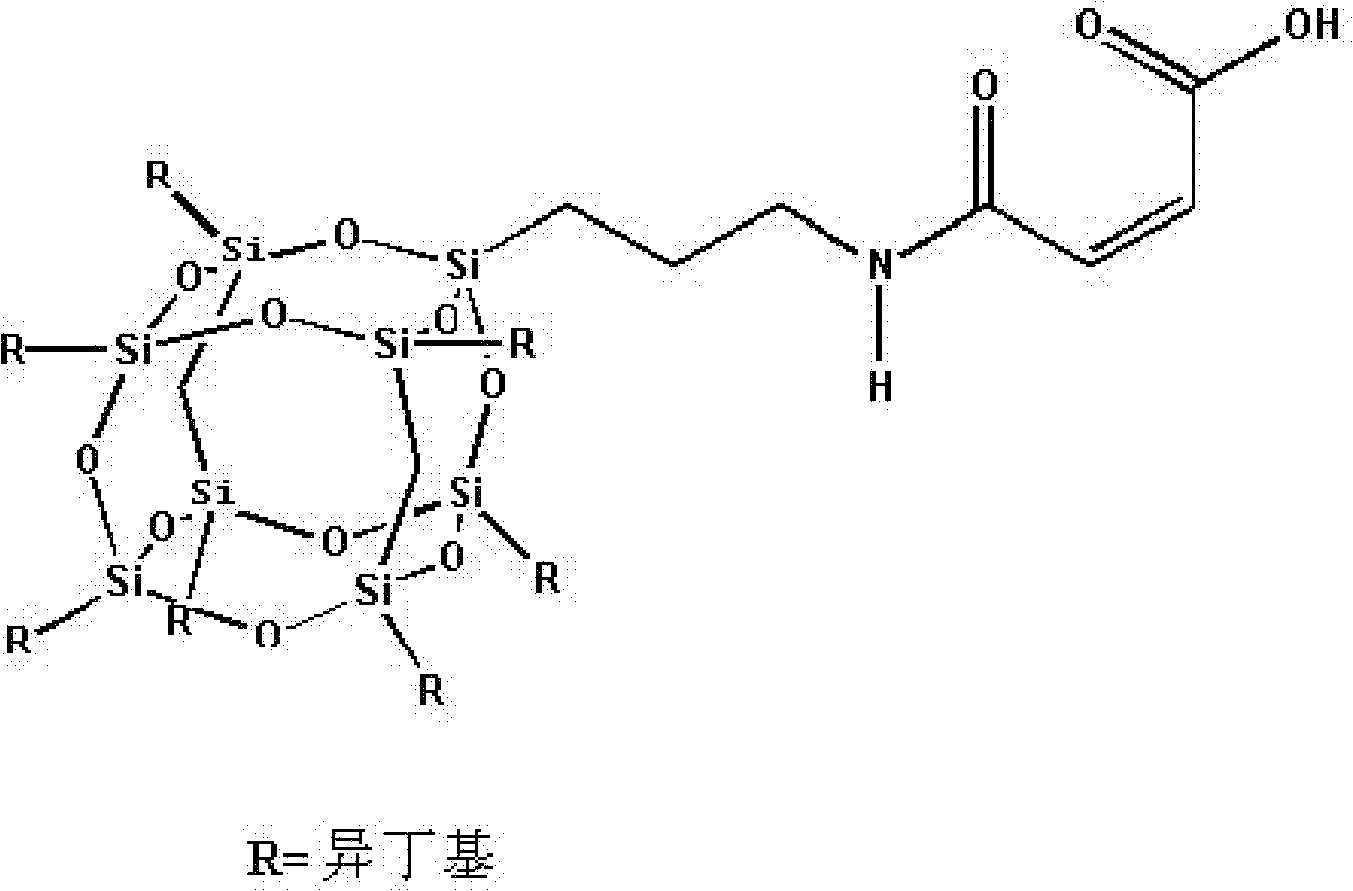

Composite heat-insulating wallboard and preparation method thereof

InactiveCN102505798AImprove interface compatibilityImprove physical and mechanical propertiesClimate change adaptationCeramic shaping apparatusCalcium silicateEmulsion

The invention discloses a composite heat-insulating wallboard and a preparation method thereof and relates to a heat-insulating wallboard. The heat-insulating wallboard is provided with two layers of calcium silicate plates, wherein a heat-insulating core material is clamped between the two layers of calcium silicate plates and is prepared from cement, coal ash, gypsum, expandable polystyrene (EPS), Maleamic Acid-Isobutyl Polyhedral Oligomeric Silsesquioxane (POSS), emulsion powder, a water reducing agent, a foaming agent and an early strength agent. Dry POSS powder is dissolved in normal hexane and then the solution is sprayed onto the surface of EPS particles to obtain substance A; the cement, the coal ash, the gypsum and the emulsion powder are drily stirred, water is added into the mixture, the mixture is stirred into paste, the substance A is added into the paste to form a slurry B; the foaming agent solution is stirred through a stirrer to form foam C; the slurry B and the foam C are mixed to obtain a heat-insulating core material slurry; the surfaces of the calcium silicate plates are brushed and washed, the calcium silicate plates are placed on the two sides of a fixed mold, the heat-insulating core material slurry is poured into the middle of the two calcium silicate plates, and the mold is vibrated to mold the slurry; and the mold is de-molded, and after watering to maintain, the wallboard is obtained.

Owner:XIAMEN UNIV +1

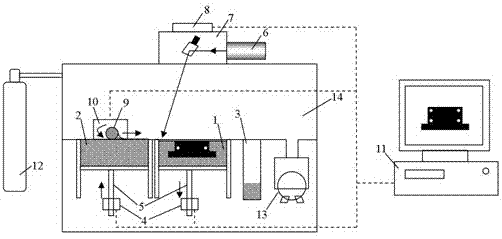

Forming device and method of aluminum-based silicon carbide particle reinforced composite material and member thereof

ActiveCN103695681ASimple molding processDense and uniform internal tissueCarbide siliconControl system

The invention provides a forming device and method of an aluminum-based silicon carbide particle reinforced composite material and a member thereof. The forming device comprises a laser system, a powder spreading system, an inert atmosphere system and a control system. By using the forming device, quick formation of the aluminum-based silicon carbide particle reinforced composite material and the member thereof can be realized. The forming method provided by the invention is simple, and adopts digitized manufacturing. The formed product is compact and uniform in texture, and any complicated members can be directly manufactured without being secondarily processed.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

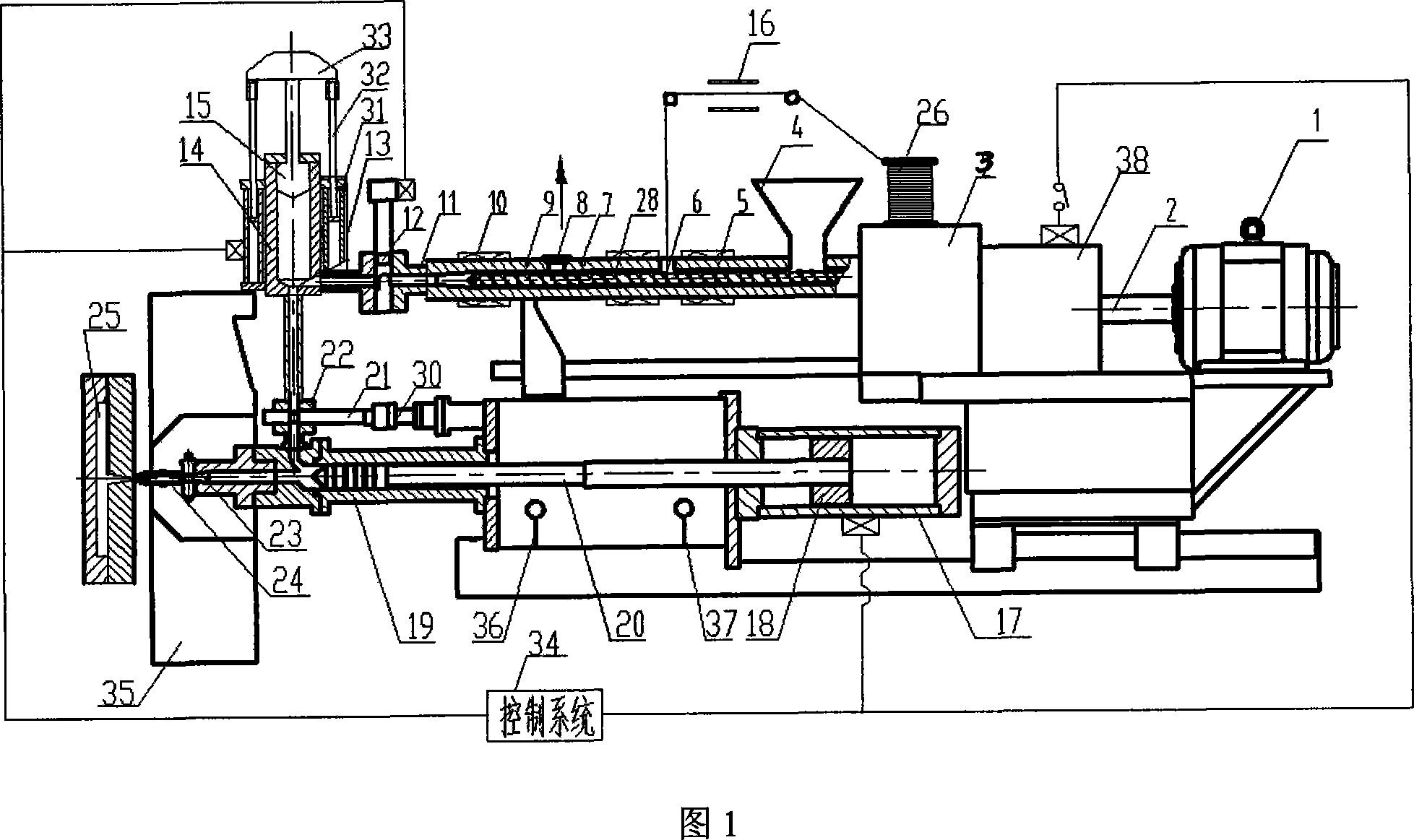

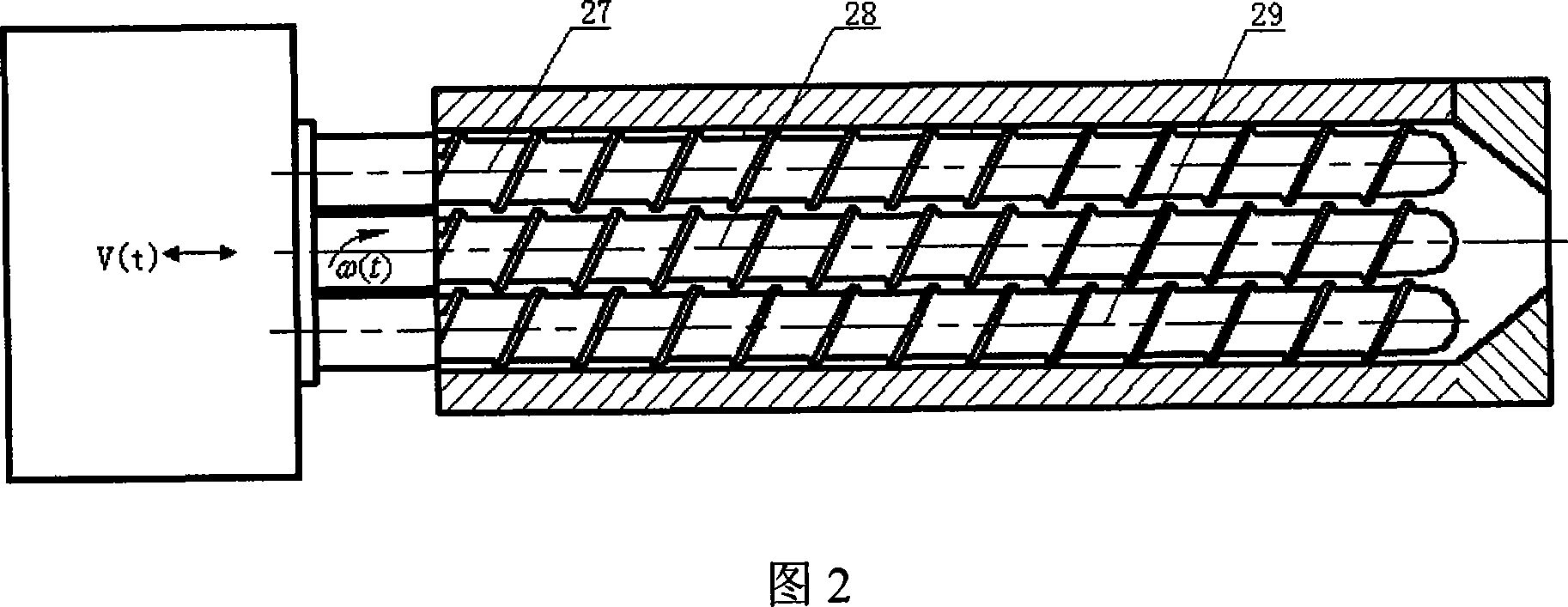

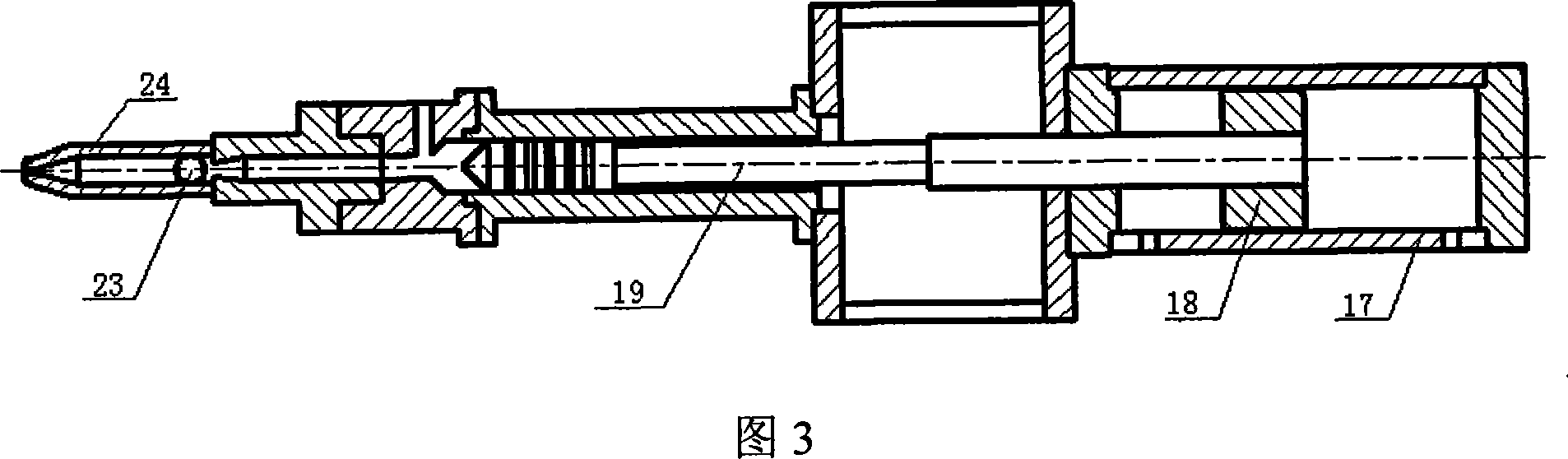

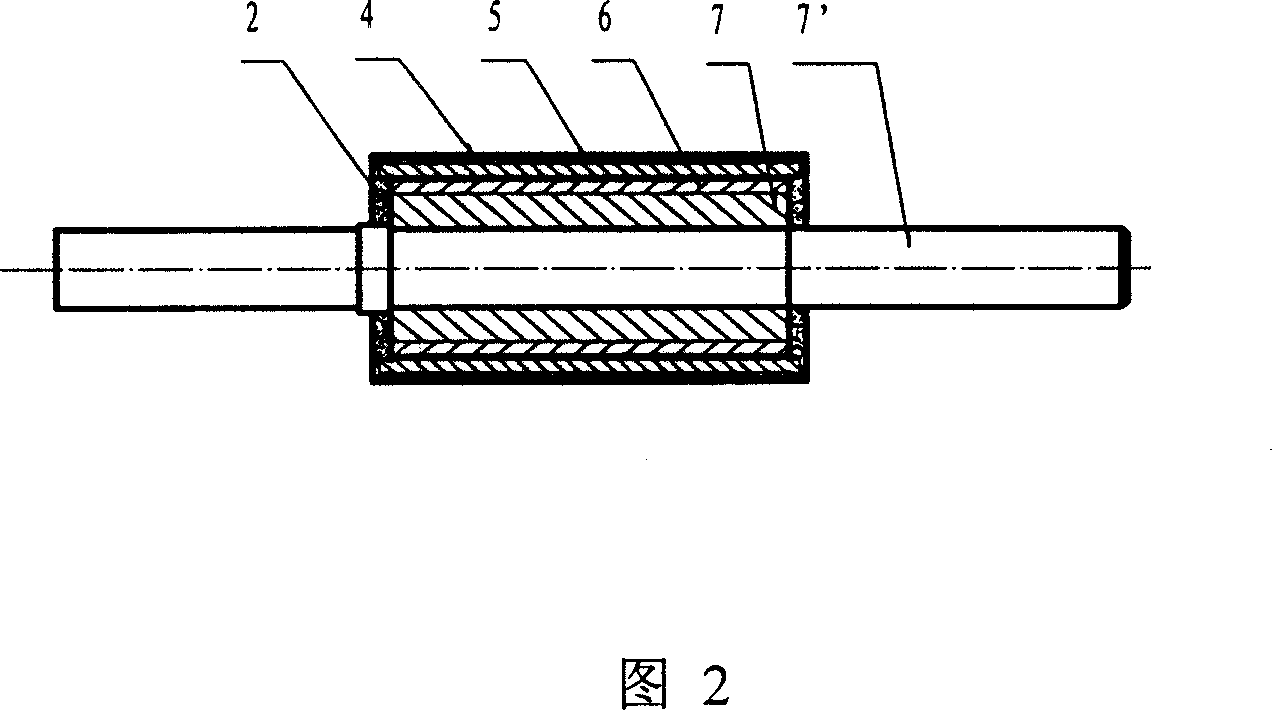

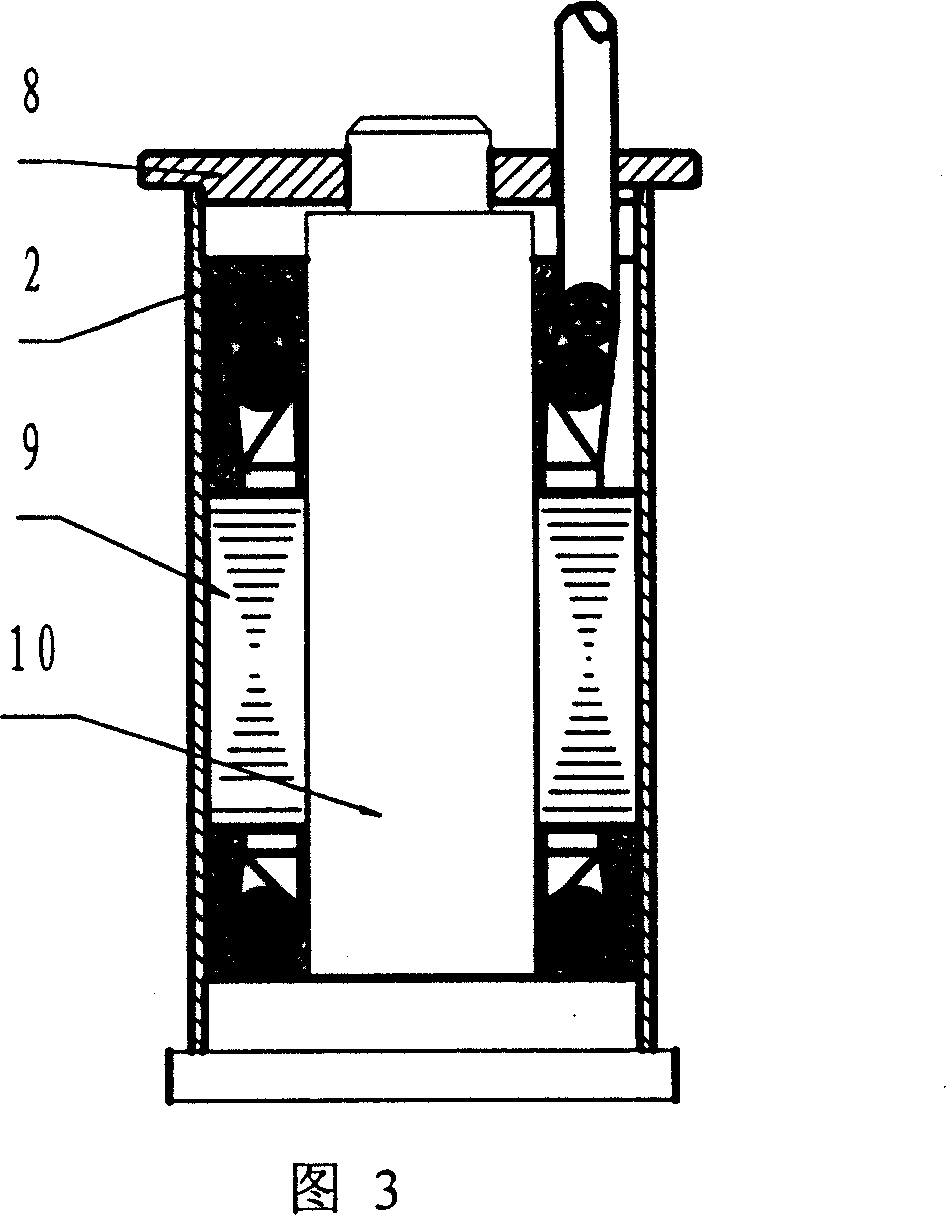

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

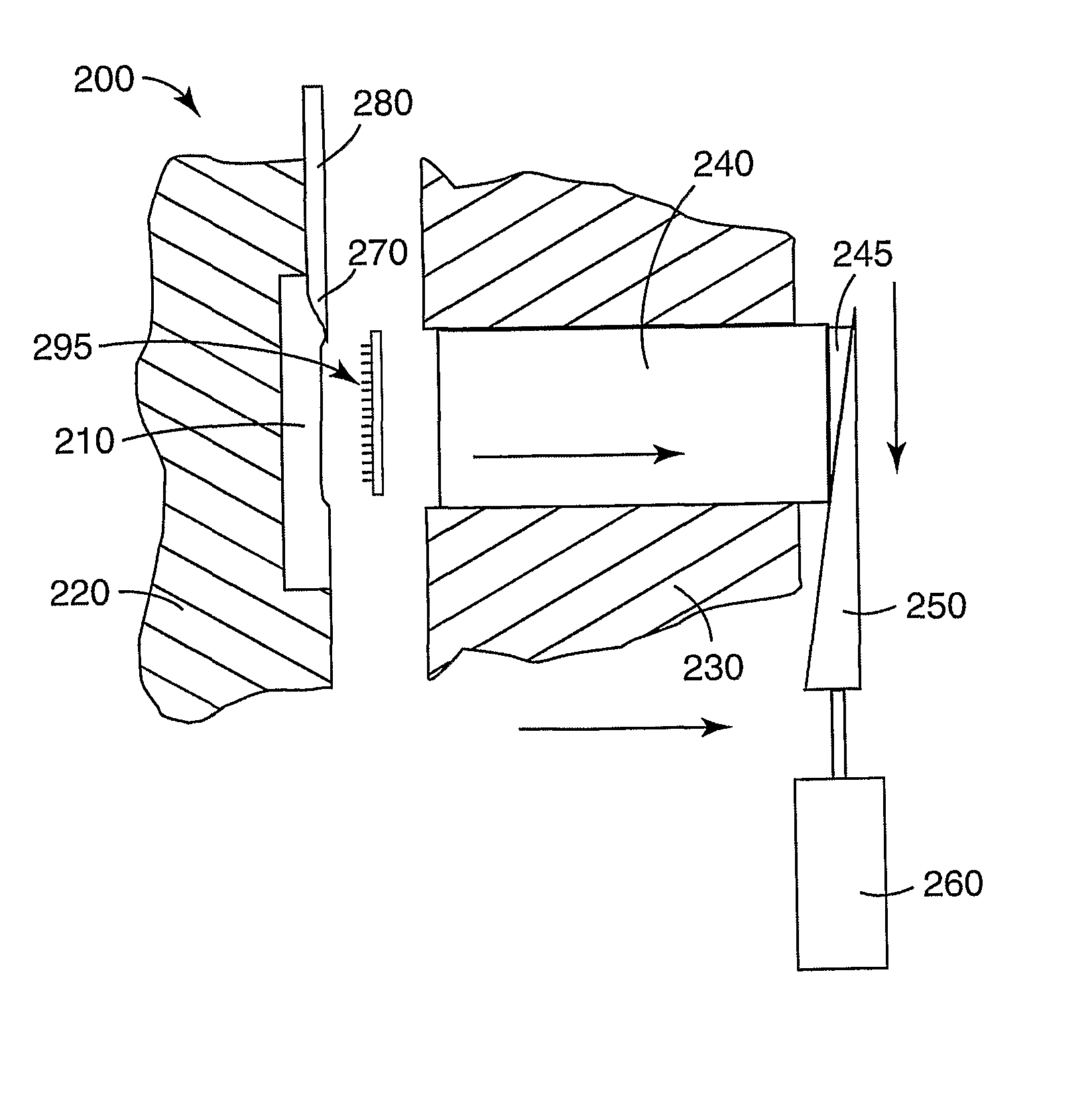

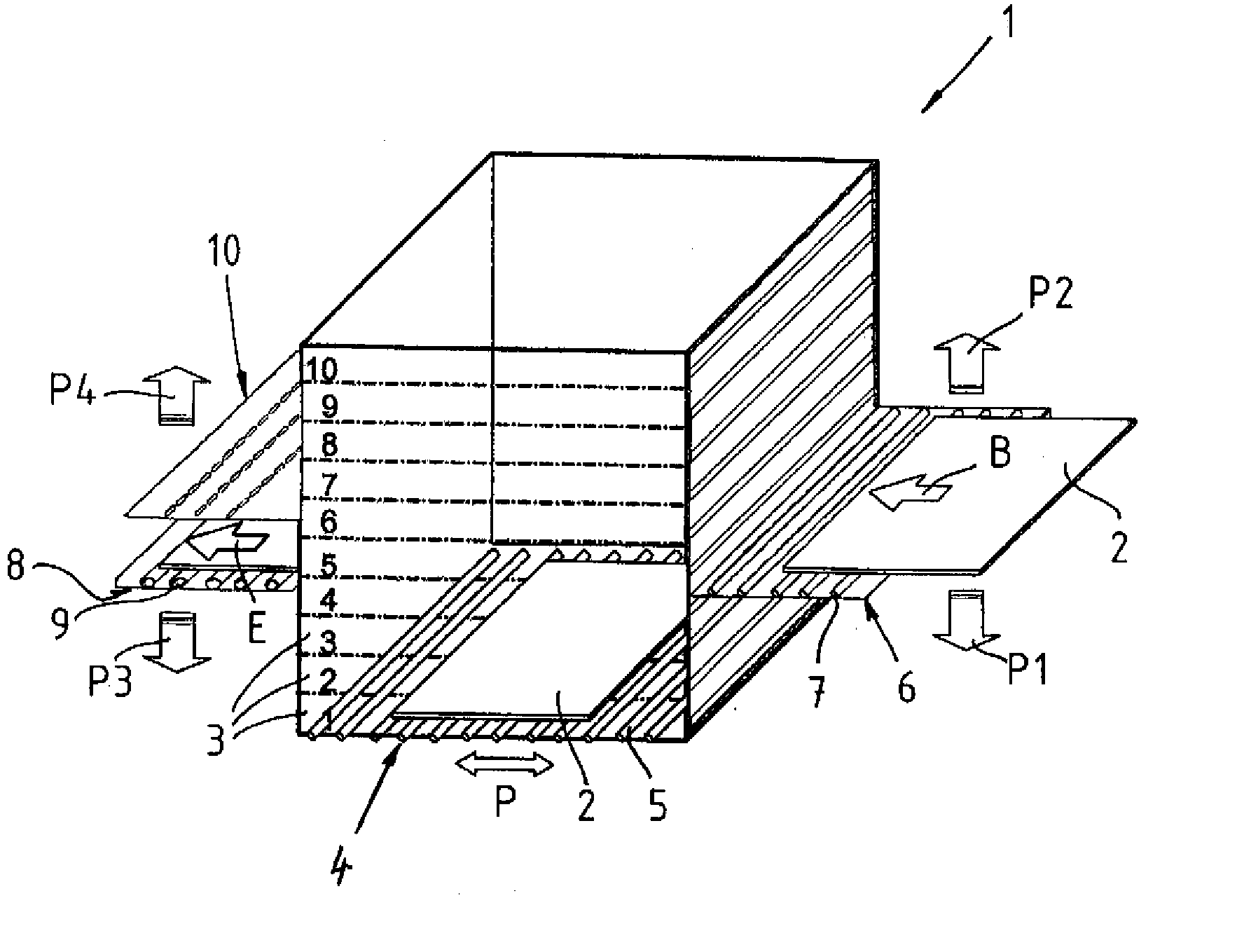

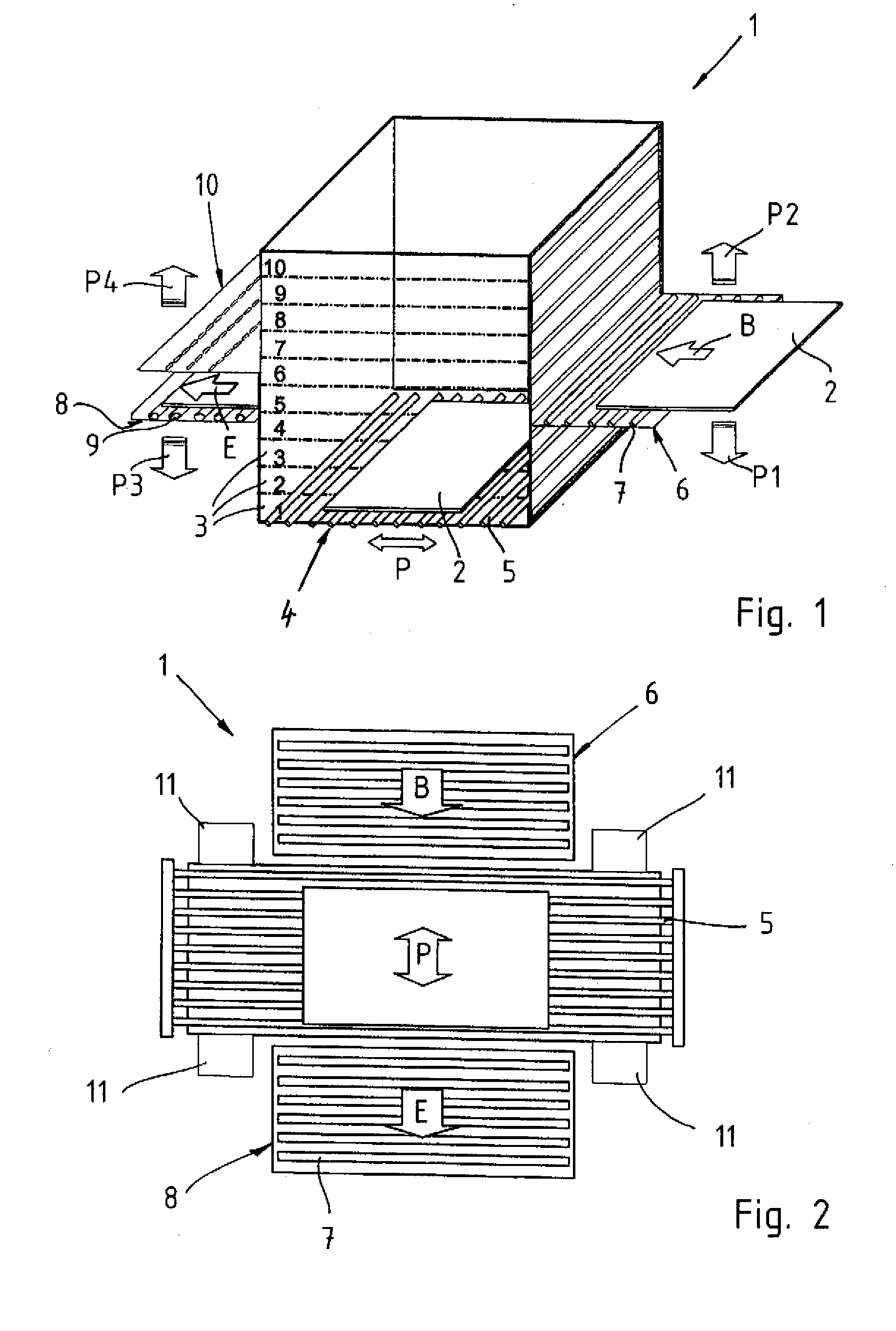

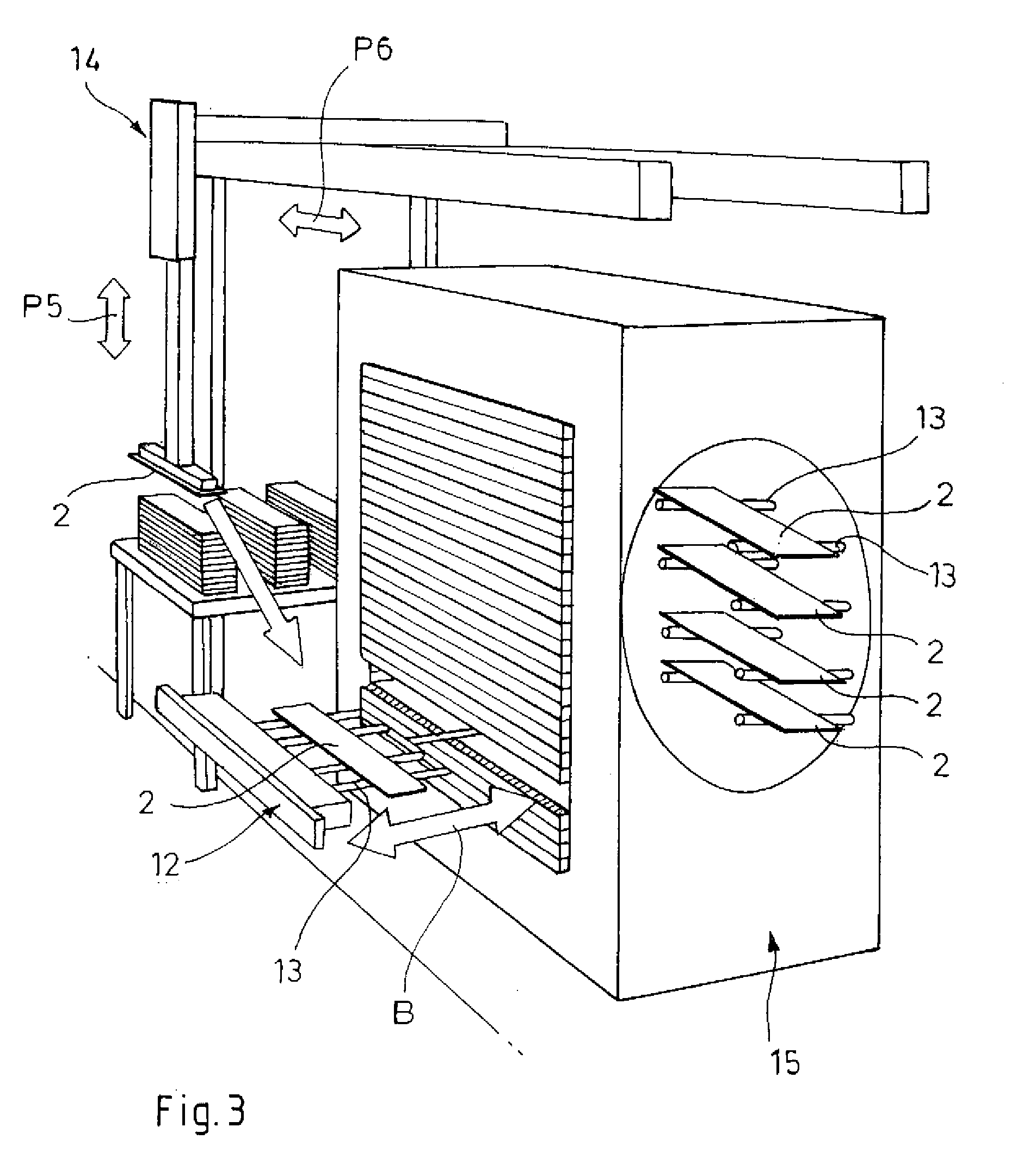

Multi-deck furnace

InactiveUS20070257407A1Raise the ratioEvenly heatedCharge manipulationFurnace typesMetallurgySteel plates

A furnace for heating steel plates includes a plurality of horizontal furnace levels in superimposed disposition. Each furnace level is constructed for acceptance of at least one steel plate and includes a transport mechanism for moving the at least one steel plate during a heating process.

Owner:BENTELER AUTOMOBILTECHNIK GMBH +1

Carbon-based polymer composite material capable of being ceramized and preparation method thereof

The invention relates to a carbon-based polymer composite material capable of being ceramized and a preparation method thereof. The carbon-based polymer composite material is formed by mixing and pressing carbon-based resin, a fiber-reinforced material, a high temperature-resistant coupling agent, aluminium silicate mineral powder and non-oxide ceramic powder, and the carbon-based polymer composite material specifically comprises the following components in parts by weight: 20-50 parts of the carbon-based resin, 10-40 parts of the fiber-reinforced material, 0.5-2 parts of the high temperature-resistant coupling agent, 10-50 parts of the aluminium silicate mineral powder and 1-10 parts of the non-oxide ceramic powder. Compared with the prior art, the composite material disclosed by the invention has the advantages of good thermal protection performance and anti-scour performance; a forming process of the composite material is simple, and aerobic thermal protection and ceramic formationare integrated; the ceramization temperature is lower and the ceramic conversion rate is higher; and the polymer composite material further has the advantages of capability of being formed by the polymer composite material process, strong designability, good mechanical properties at medium and low temperature, high ceramic conversion rate, low thermal weight loss rate, high retention rate of high-temperature strength and the like.

Owner:WUHAN UNIV OF TECH

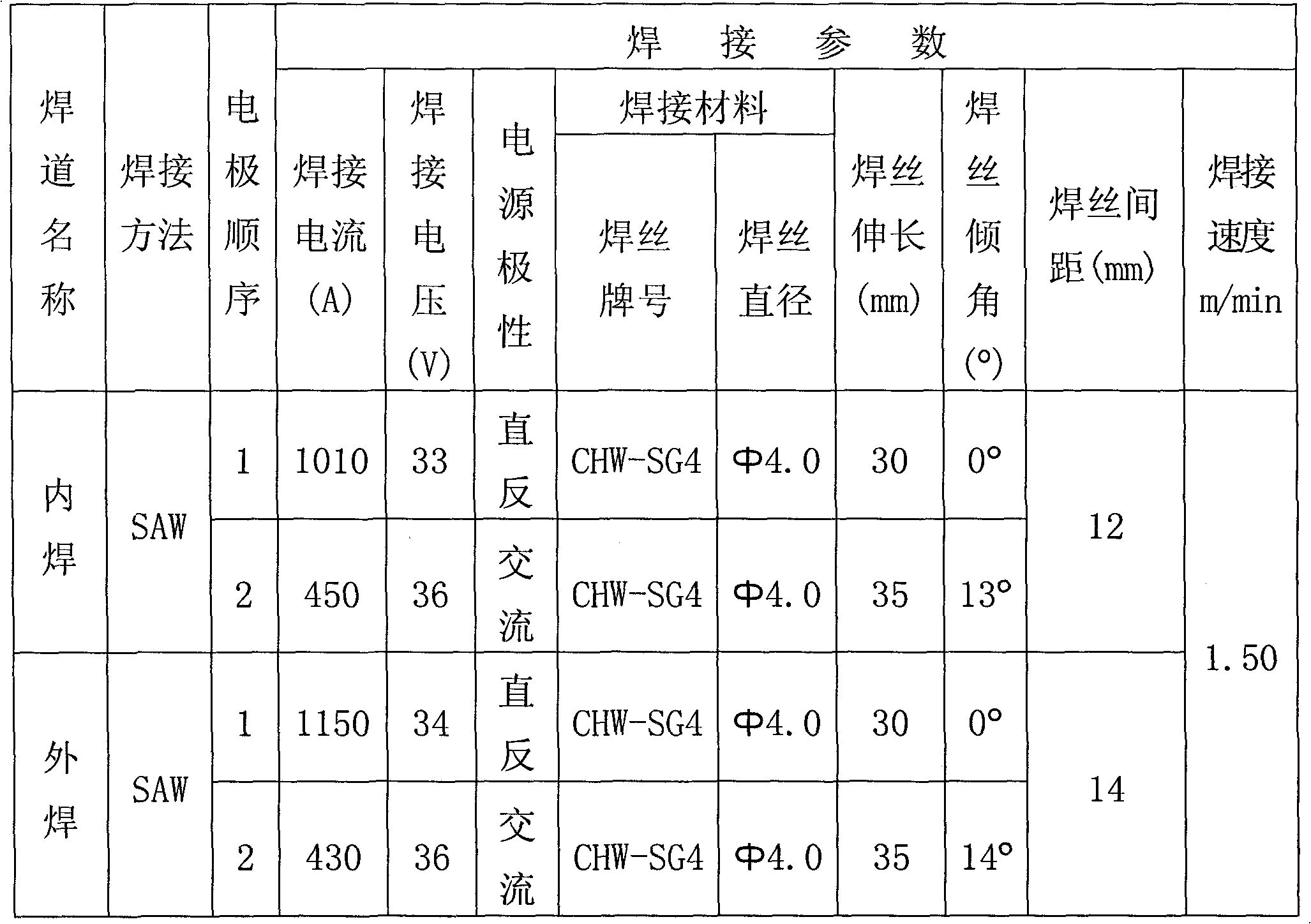

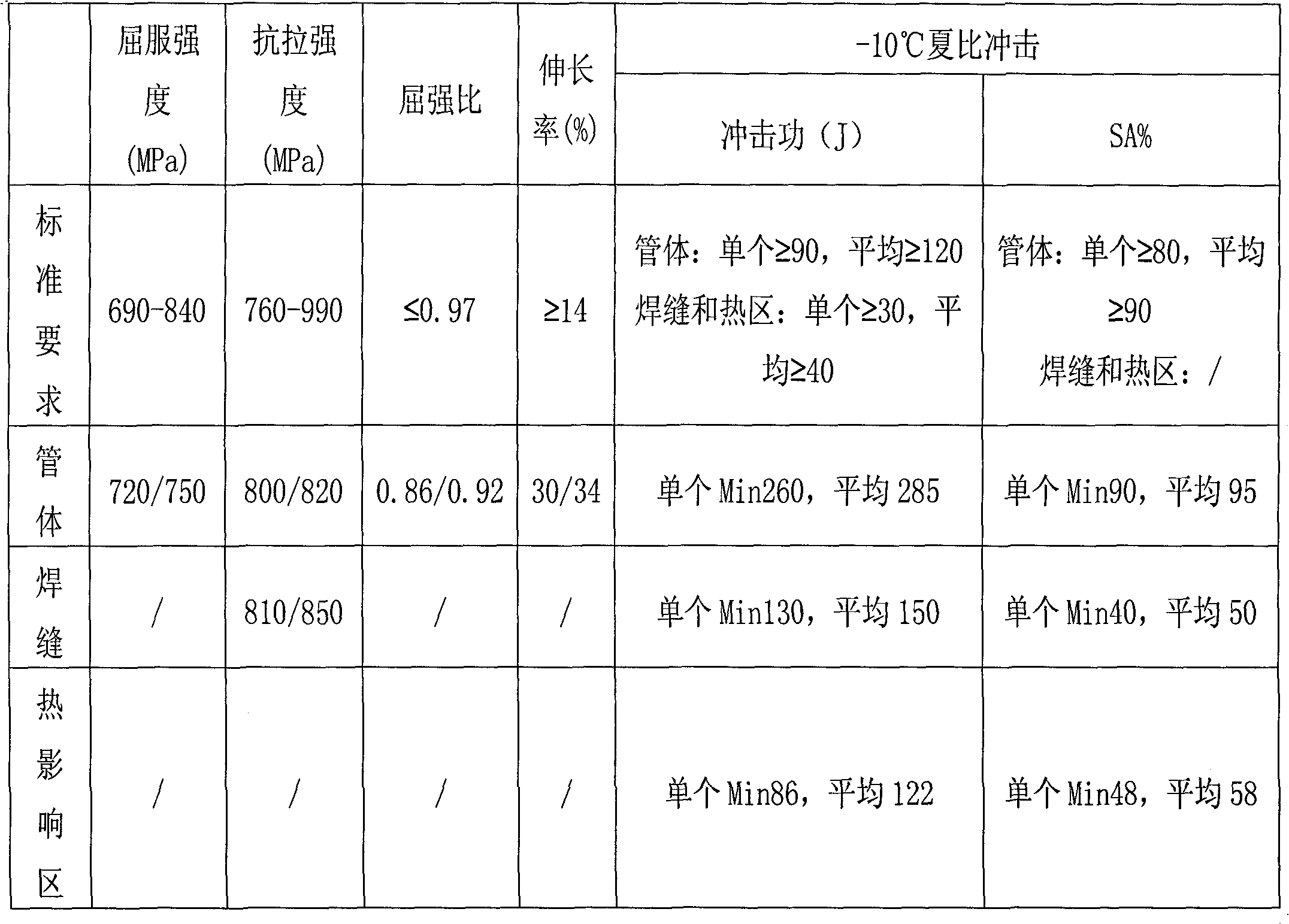

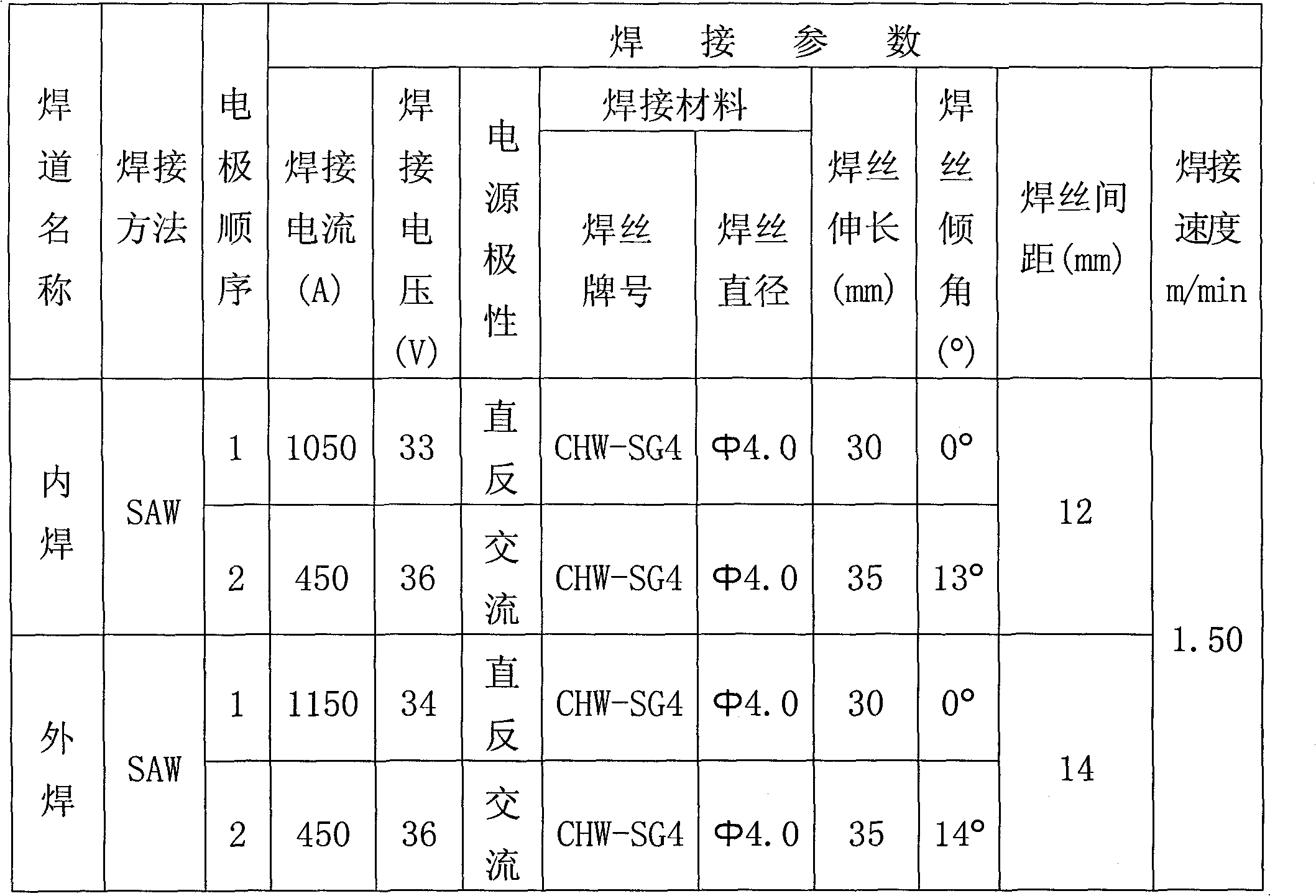

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

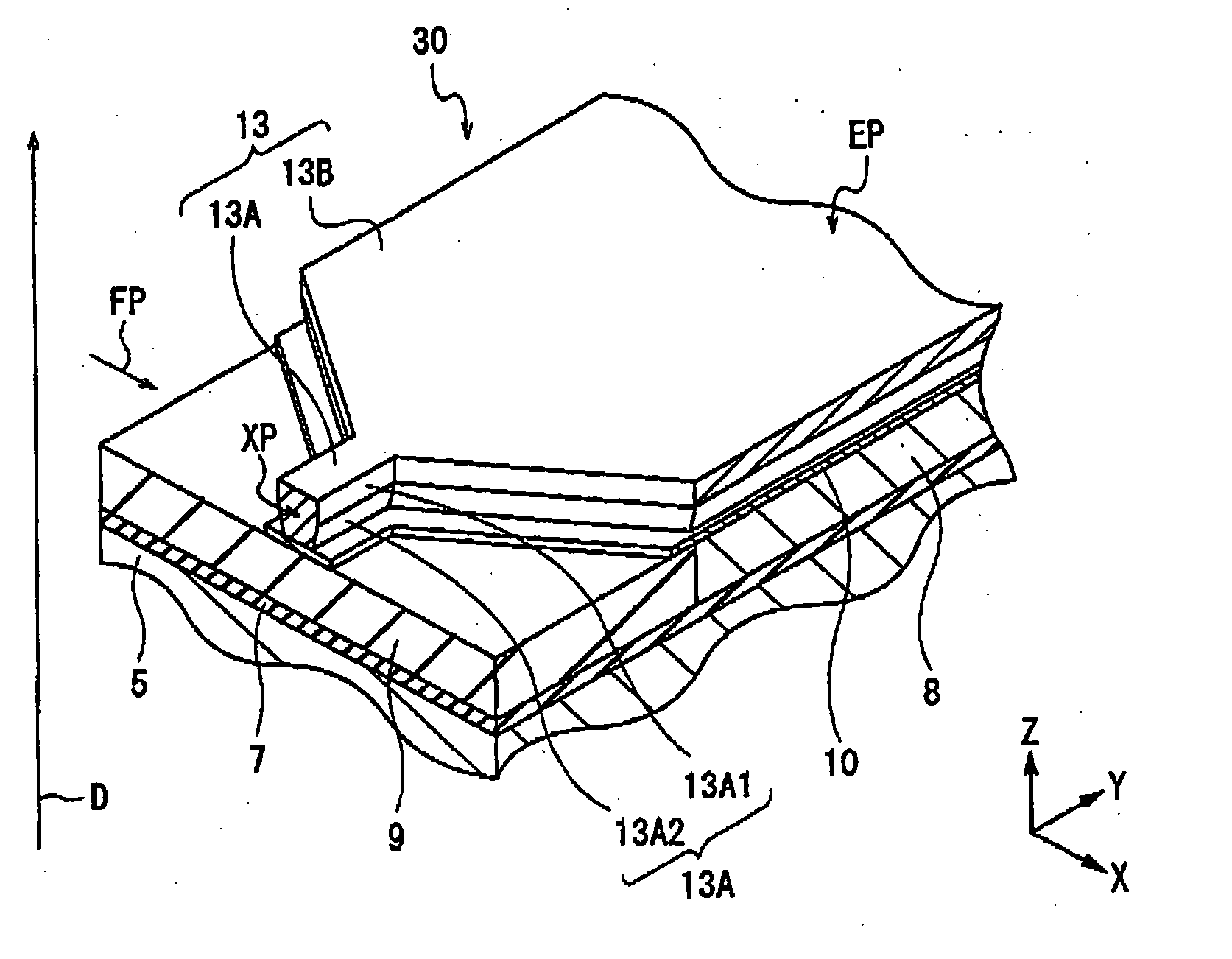

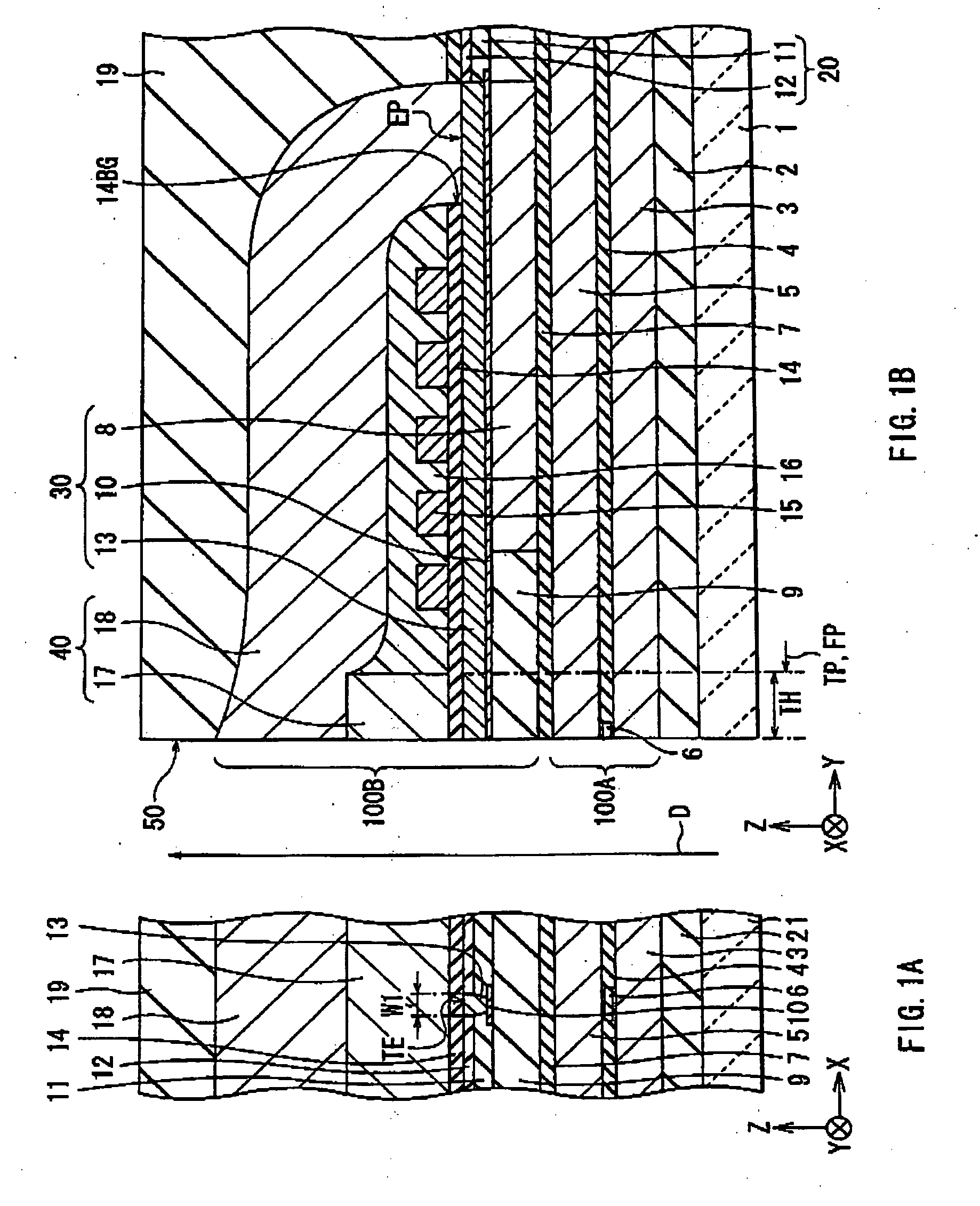

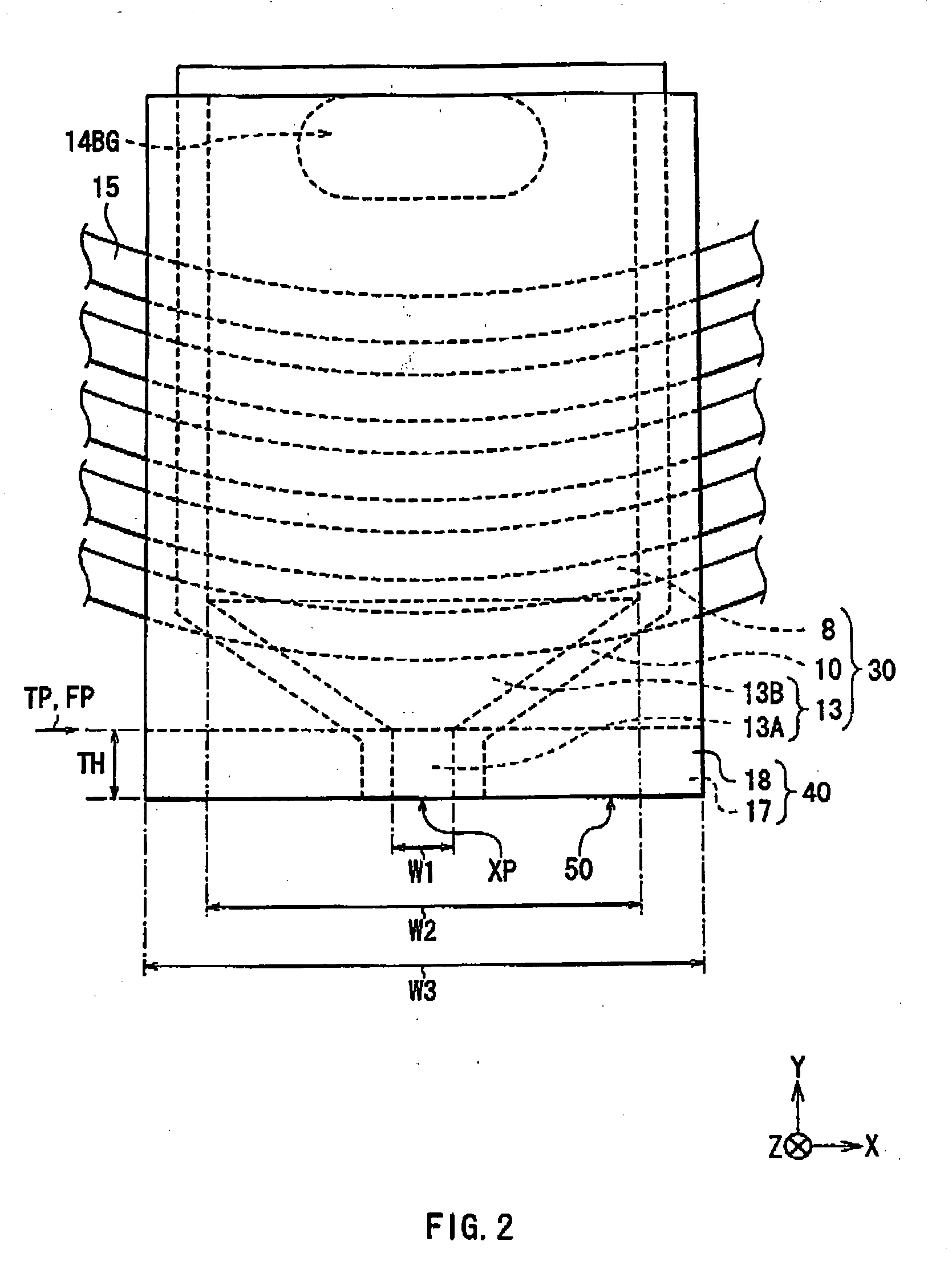

Thin film magnetic head, method of manufacturing the same, and magnetic recording apparatus

InactiveUS20050117251A1Well formedUniform widthManufacture head surfaceElectrical transducersMagnetic polesEngineering

The present invention provides a method of manufacturing a thin film magnetic head, capable of forming a magnetic pole layer as easily as possible. By etching a lower insulating layer and the upper insulating layer by RIE using a fluorine-based gas (CF4 or CHF3) or chlorine-based gas (Cl2 or BCl3), a magnetic pole formation space R1 is formed so as to have a uniform width in an upper insulating layer by and a magnetic pole formation space R2 is formed in the lower insulating layer so as to have a width gradually narrowed from width W1 to width W4 with distance from the magnetic pole formation space R1. After that, a plating film is grown in the magnetic pole formation spaces R1 and R2, thereby forming a main magnetic pole layer. Since the main magnetic pole layer is formed in one process by using the structural characteristics of the magnetic pole formation spaces R1 and R2, the process of forming the main magnetic pole layer is simplified and the number of processes required to form the main magnetic pole layer is reduced.

Owner:TDK CORPARATION +1

Molding of Thermoplastic Polyesters

InactiveUS20070224377A1Improve clarityIncrease flexibilityLayered productsBottlesPolyesterPolymer science

Disclosed are processes for rotational molding of thermoplastic polyesters and for hollow articles produced therefrom. The thermoplastic polyesters have a crystallization half time of at least 10 minutes and an inherent viscosity of 0.55 to 0.70 dL / g. Additional thermoplastic polymers may be used to produce multilayered articles.

Owner:EASTMAN CHEM CO

Wood golf club head

A wood golf club head has a sole plate, a crown, a strike face and a hosel that are all made of metal and are welded together. The sole plate is formed by forging to have different thicknesses at different parts and has a weight formed as a thicker part of the sole plate. Therefore, when the wood golf club head is manufactured, the shape, the size and the position of the weight is precisely set based on the design of the wood golf club head. Then the gravity center of the wood golf club head is accurately determined. Moreover, since the weight is directly formed on the sole plate without any gaps and the shape of the weight is simple and smooth, the wood golf club head performs a clear and pleasing striking sound while it strikes.

Owner:SU CHI HUNG

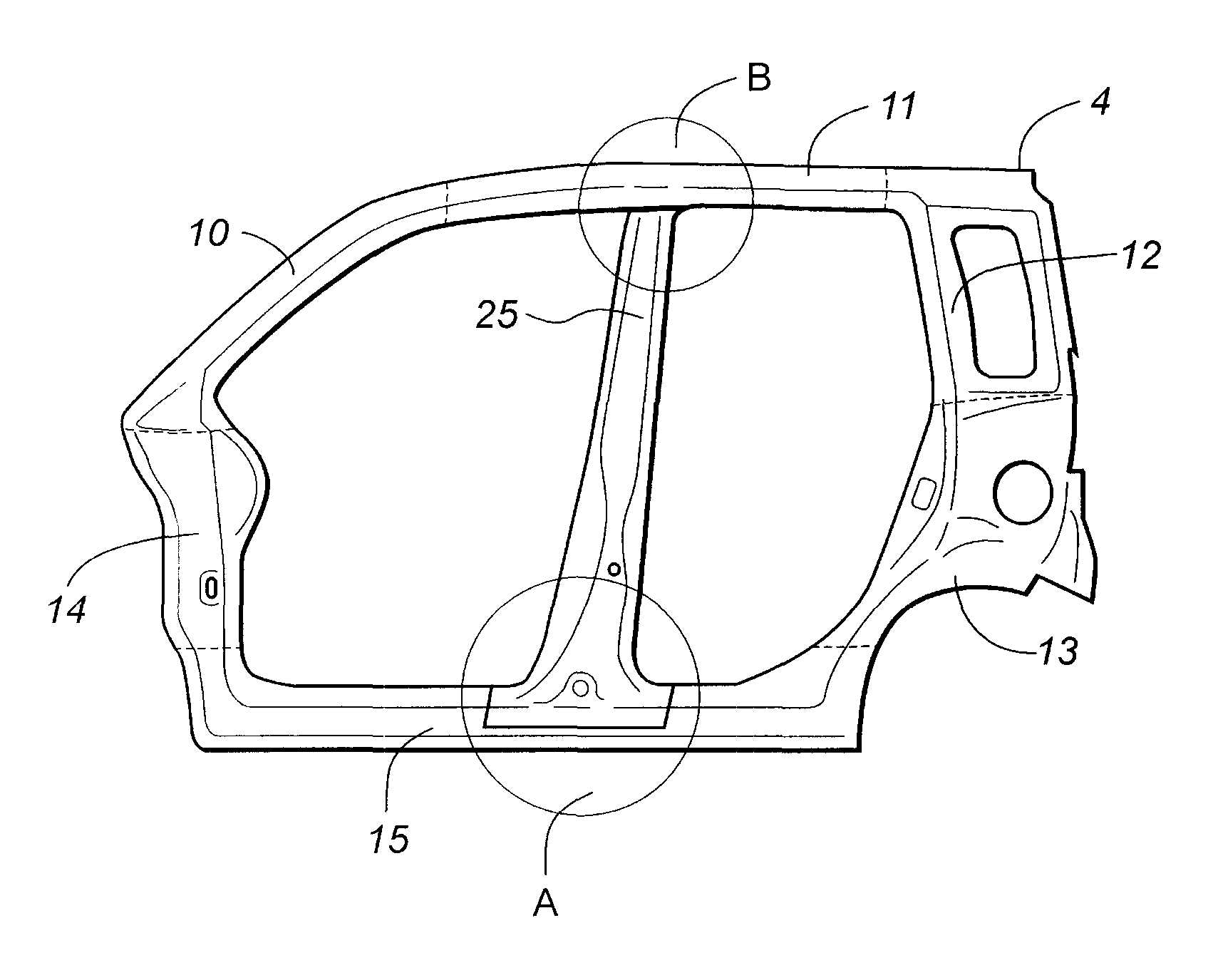

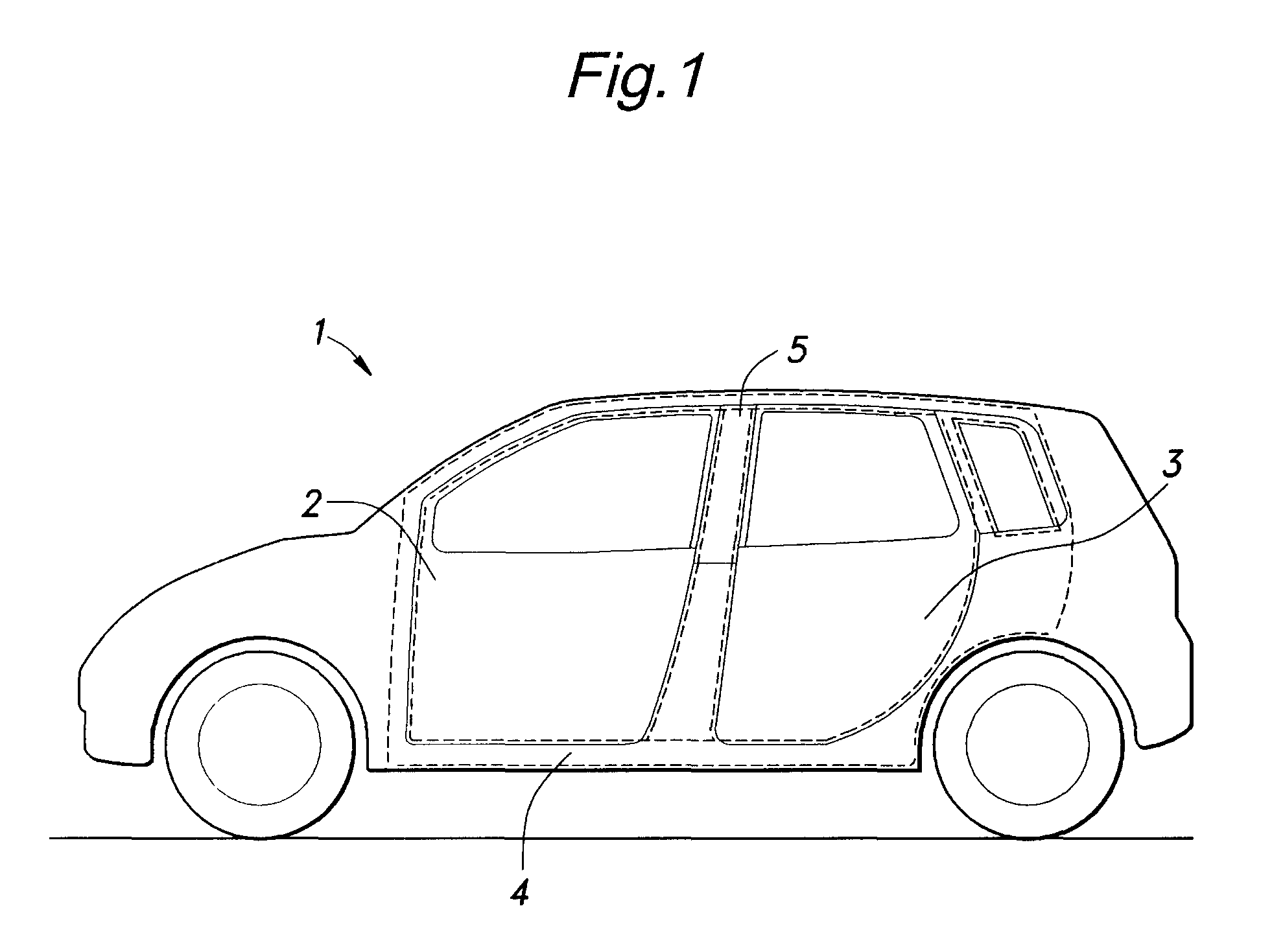

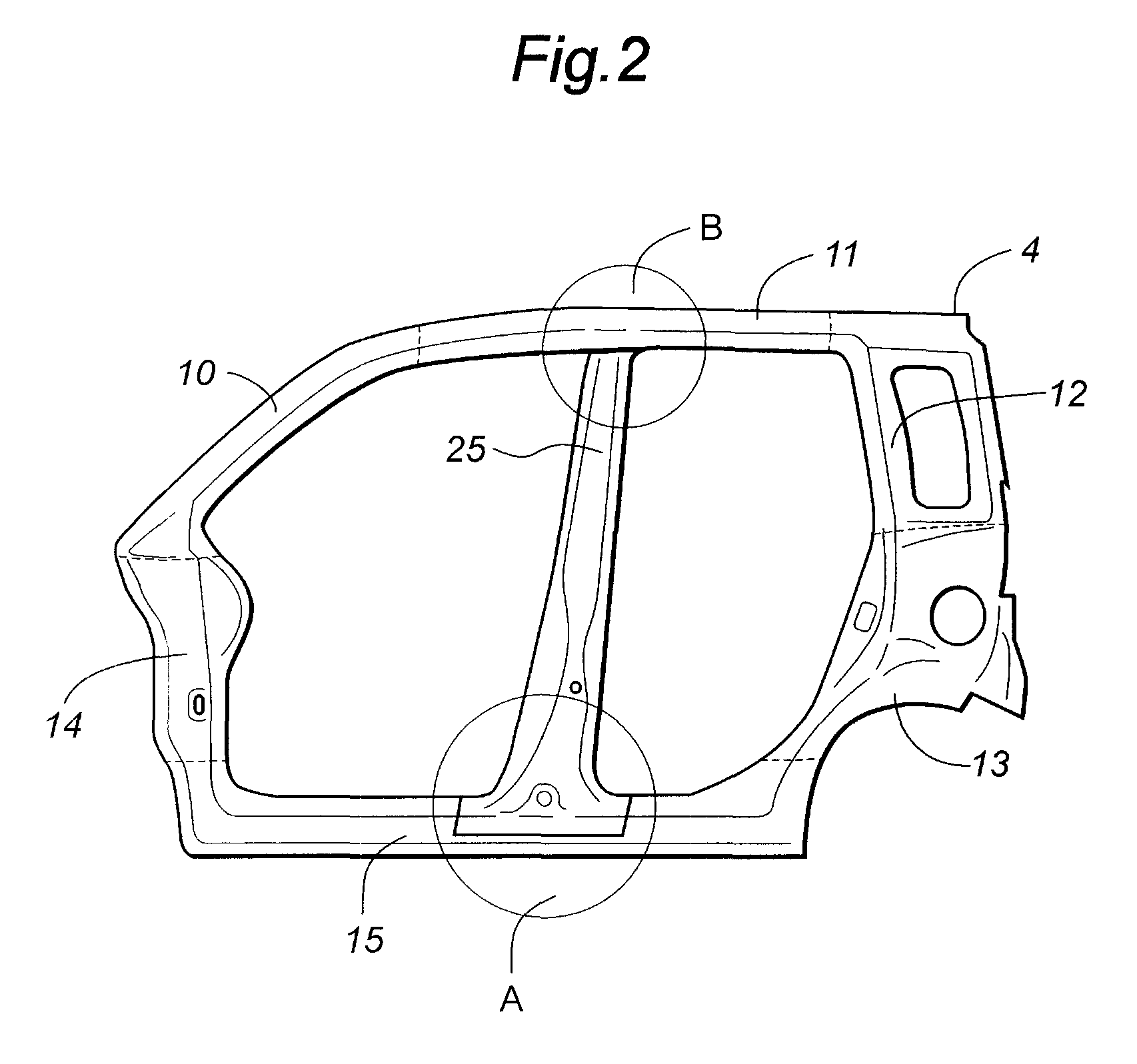

Vehicle body side structure

ActiveUS7914068B2High mechanical strengthImprove rigidityVehicle seatsSuperstructure subunitsEngineeringUltimate tensile strength

In a vehicle body side structure, a tailor welded blank is used for forming an outer panel assembly consisting of a frame structure, and a center pillar assembly is connected vertically between a roof side rail and a side sill outer of the outer panel assembly. The center pillar assembly is made of a material having a higher mechanical strength than most of the outer panel assembly. Thereby, the stamp forming process can be simplified, and a required mechanical strength can be ensured in a favorable manner. In particular, the center pillar assembly may include a center pillar outer made of material having a higher mechanical strength than at least a part of the outer panel assembly, the center pillar outer being attached to an outboard side of the side sill outer at a lower end thereof and to an inboard side of the roof side rail at an upper end thereof.

Owner:HONDA MOTOR CO LTD

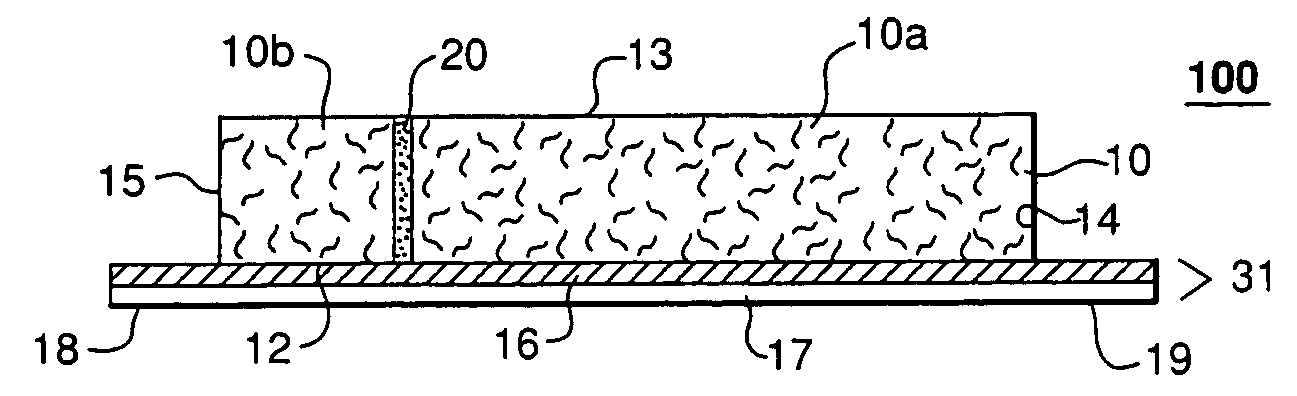

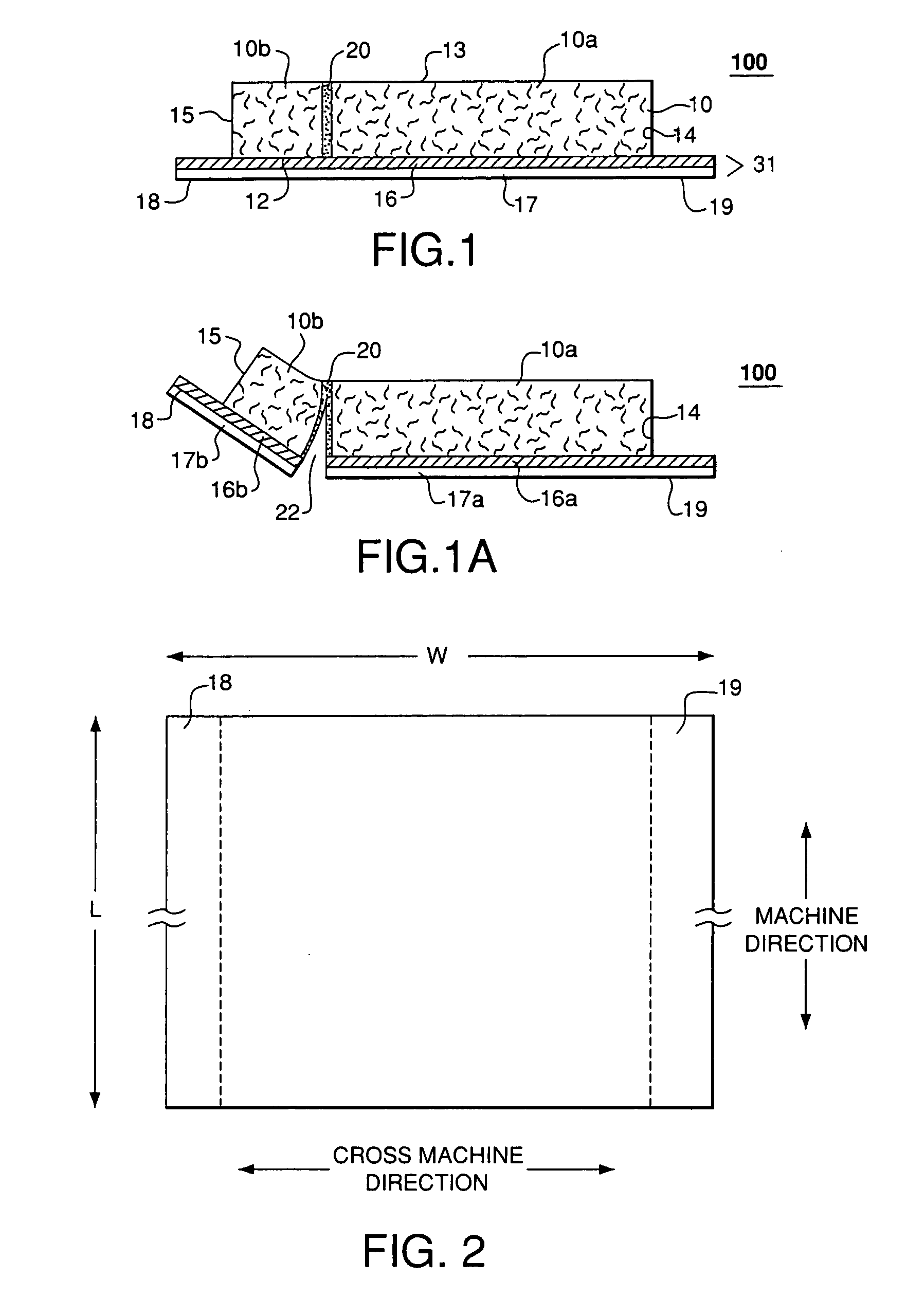

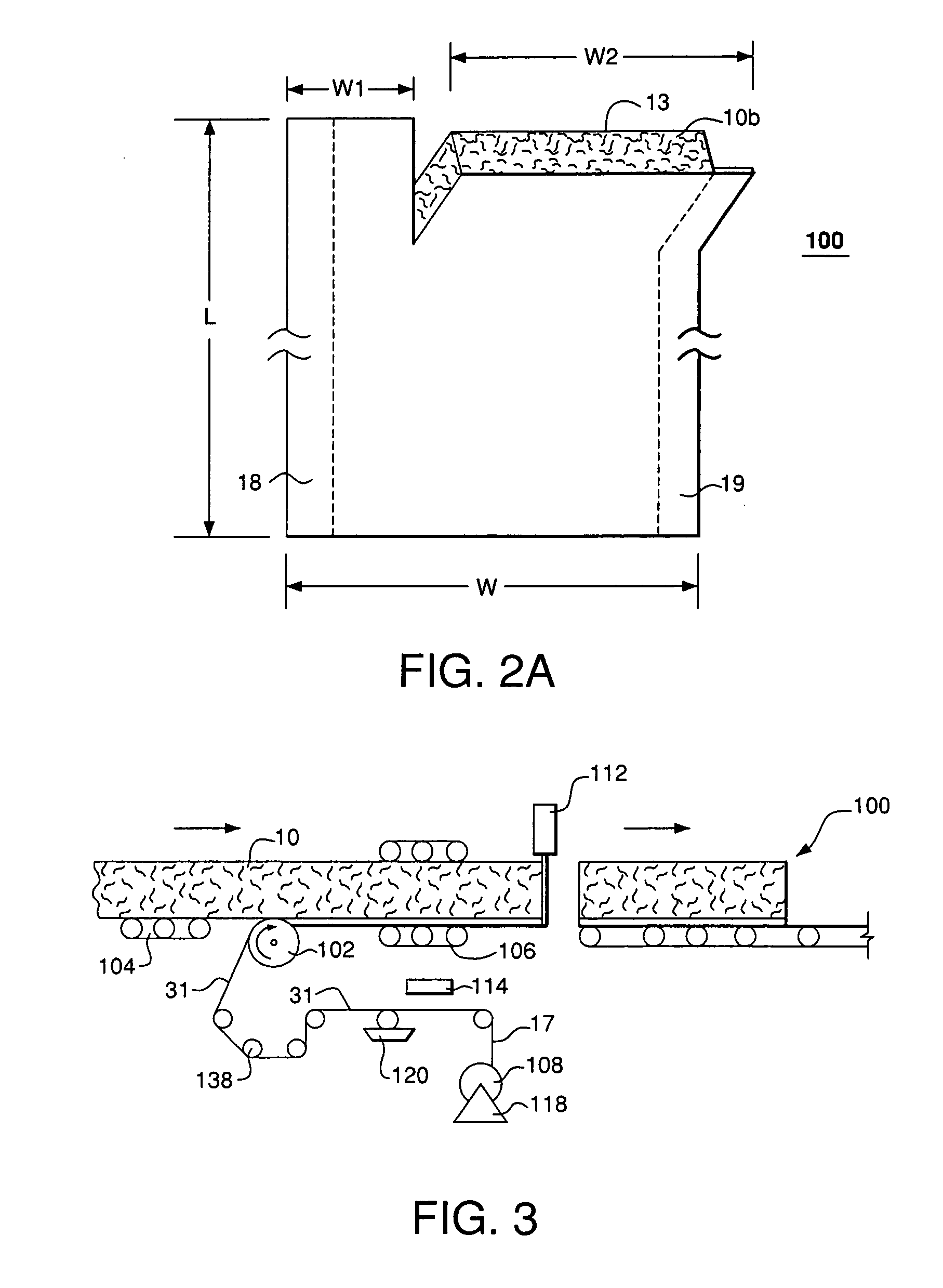

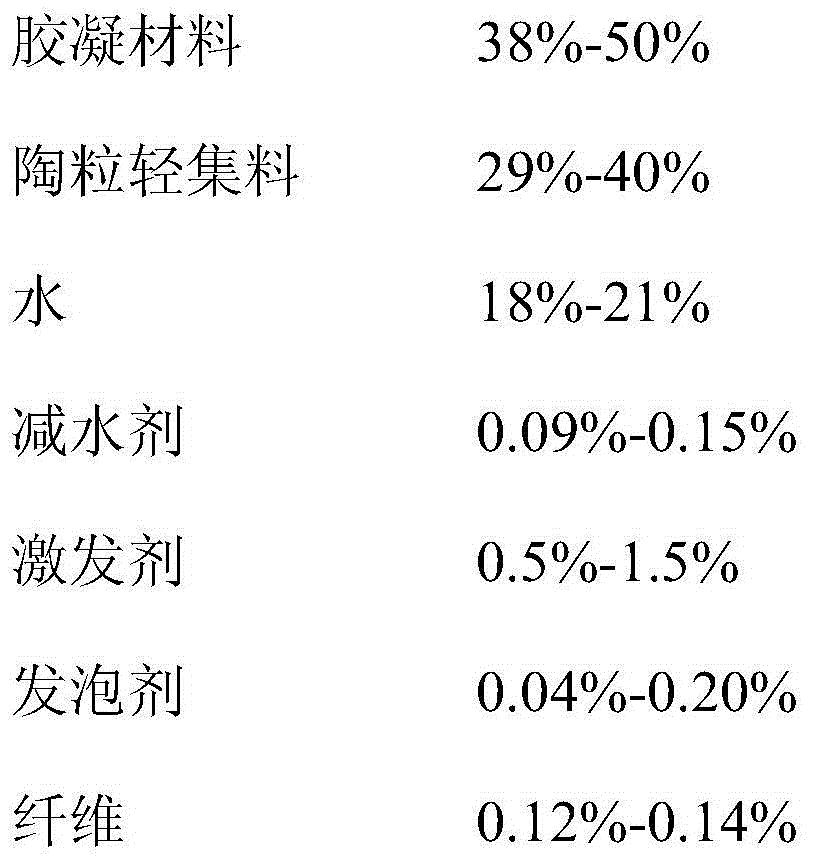

Insulation product having directional facing layer thereon and method of making the same

InactiveUS20050081482A1Reduce widthReduced width and paper weightLayered productsHeat proofingEngineeringFiber orientation

An insulation product is provided comprising an insulation mat comprising randomly oriented fibers. The mat has first and second major surfaces and a pair of side portions. A vapor retardant facing layer is bonded to at least one of the major surfaces of the mat. The facing layer has a fiber orientation such that the facing layer has a ratio of machine direction tensile strength to cross machine direction tensile strength which permits the facing layer to be separated by hand along a substantially straight line selected in the machine direction.

Owner:CERTAINTEED CORP

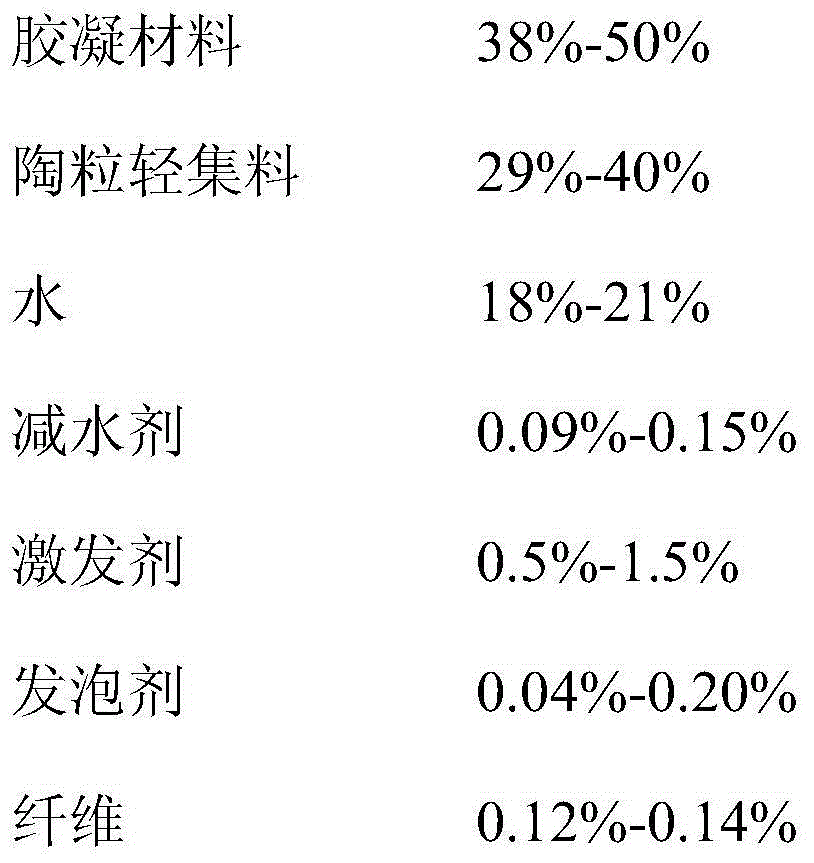

High-volume coal ash ceramsite foam concrete and preparation method thereof

The invention provides a preparation method of high-volume coal ash ceramsite foam concrete. The preparation method of the ceramsite foam concrete comprises the following steps: putting 38%-50% of a binding material, 29%-40% of ceramsite lightweight aggregates, 0.5%-1.5% of an excitant and 0.12%-0.14% of a fiber into a stirrer, and stirring evenly; simultaneously adding 0.04%-0.20% of a foaming agent and foam which is formed by a part of water in a foaming machine and has the particle sizes of 50-1,000mu m, the residual water and 0.09%-0.15% of a water reducer into the stirrer, and stirring with powder evenly to form slurry; adding the foam into the slurry, stirring evenly, and then pouring into a mold to mold; and demolding to prepare the ceramsite foam concrete of which the density is 300-800kg / m<3>. According to the formula provided by the invention, low-cost coal ashes are taken as a main raw material, and the material cost is reduced; meanwhile, the volume-weight of the concrete is reduced by adding the ceramsite lightweight aggregates with different particle sizes; and the mechanical strength and the stability of the concrete are effectively improved.

Owner:中冶武汉冶金建筑研究院有限公司

Plastic package material of AC permanent magnet submersible motor, plastic package technique and application

InactiveCN1958706AImprove plastic sealing efficiencyMolding time shortenedOther chemical processesManufacturing dynamo-electric machinesEpoxyTransformer

This invention provides a plastic sealant for AC permanent magnetic submersible motor, its sealing process and application. The plastic sealant is composed of: epoxy resin, diluent, curing agent, and silicon micropowder. The process comprises: (1) preparing the plastic sealant; (2) placing the motor stator in the stator sealing mold, locating, and placing the rotor in the rotor sealing mold; (3) sealing; (4) curing. This invention can be used for sealing AC permanent magnetic submersible motor, permanent magnetic wind power generator, electrical appliance, capacitor, transformer and inducer. This invention can largely shorten the sealing time, and can improve the sealing efficiency of diving motor. The plastic sealant has such advantages as low viscosity, smooth pouring, simple process, high product smoothness, good heat conductivity, good insulation, good waterproof property, no pollution during production and usage, and no toxicity to human bodies, thus is suitable for mass production.

Owner:SUN YAT SEN UNIV

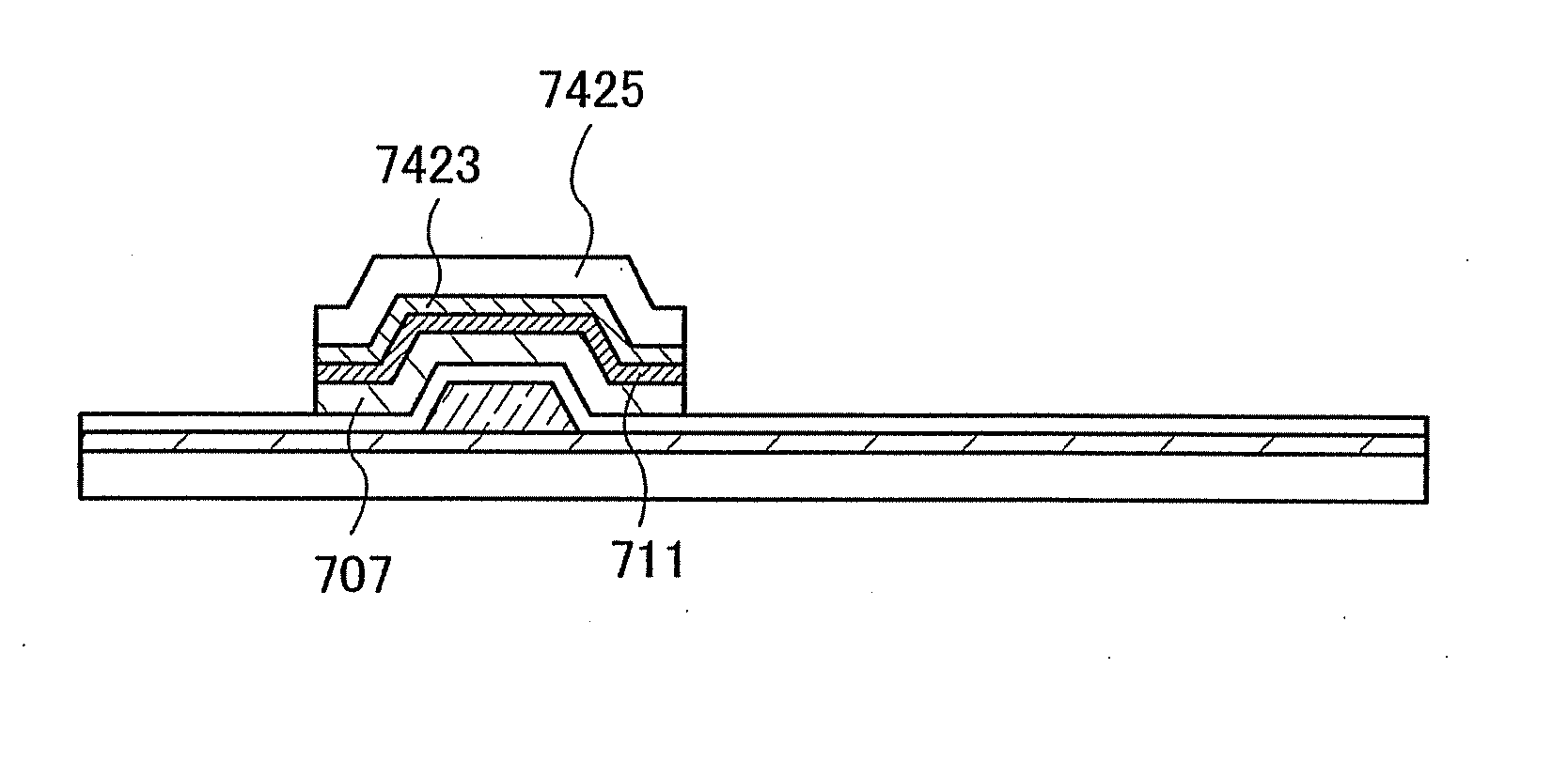

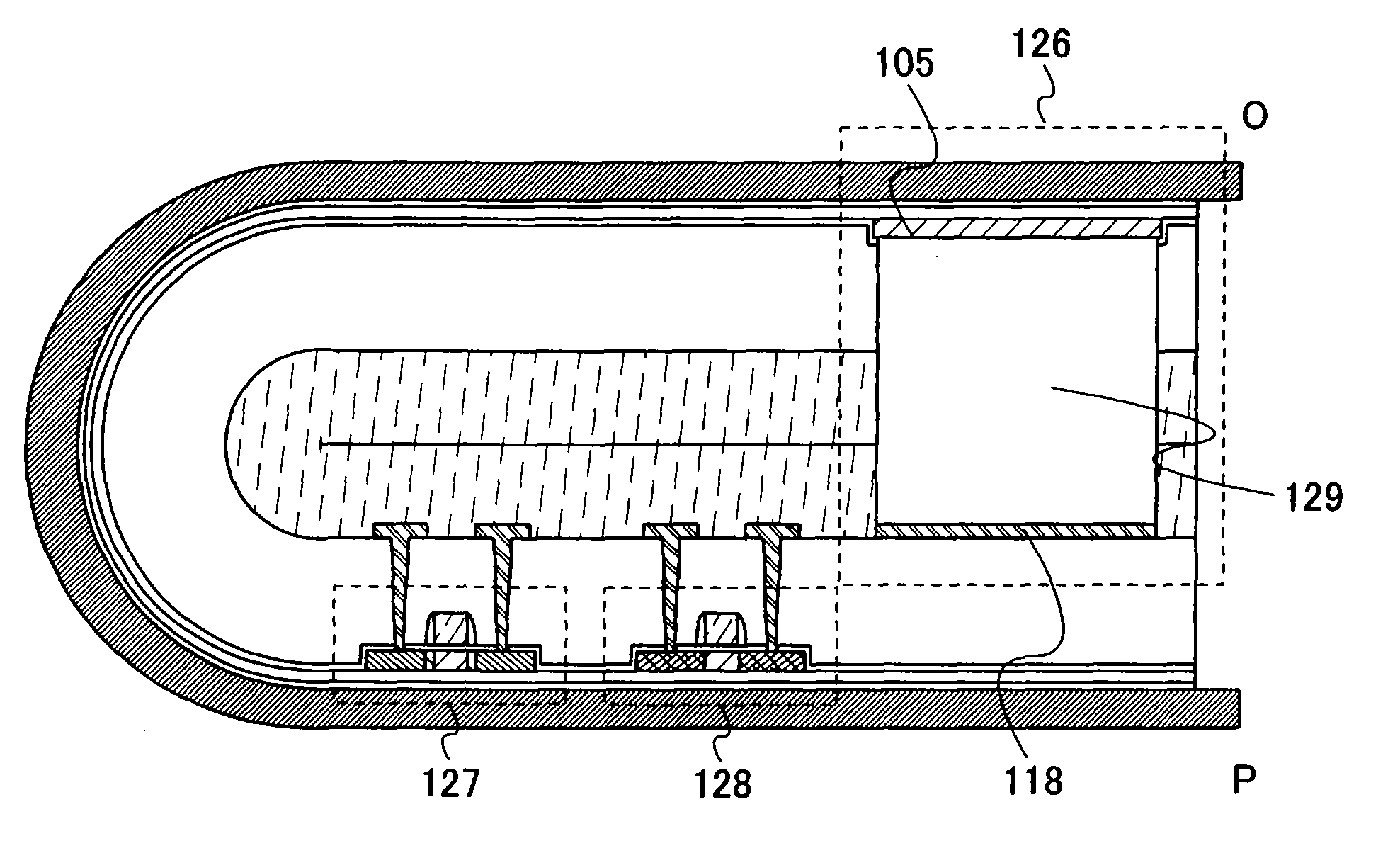

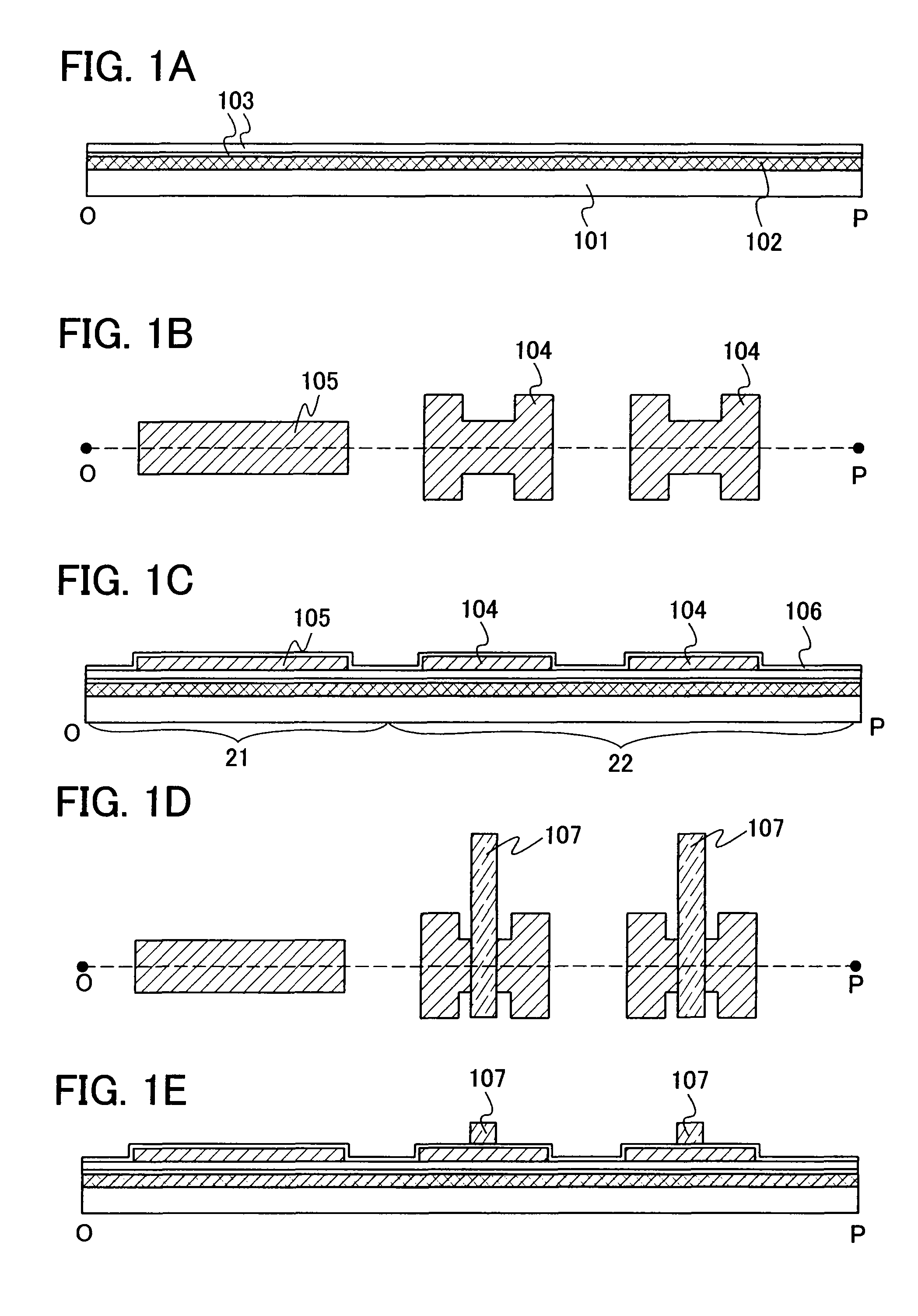

Method for manufacturing a micro-electro-mechanical device with a folded substrate

InactiveUS7767543B2Simple molding processSimple manufacturing processSolid-state devicesPharmaceutical product form changeEngineeringMicrostructure

It is an object of the present invention to provide a micro-electro-mechanical-device having a microstructure and a semiconductor element over one surface. In particular, it is an object of the present invention to provide a method for simplifying the process of forming the microstructure and the semiconductor element over one surface. A space in which the microstructure is moved, that is, a movable space for the microstructure is formed by processing an insulating layer which is formed in a process of forming the semiconductor element. The movable space can be formed by forming the insulating layer having a plurality of openings and making the openings face each other to be overlapped each other.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com