Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

764 results about "Double edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

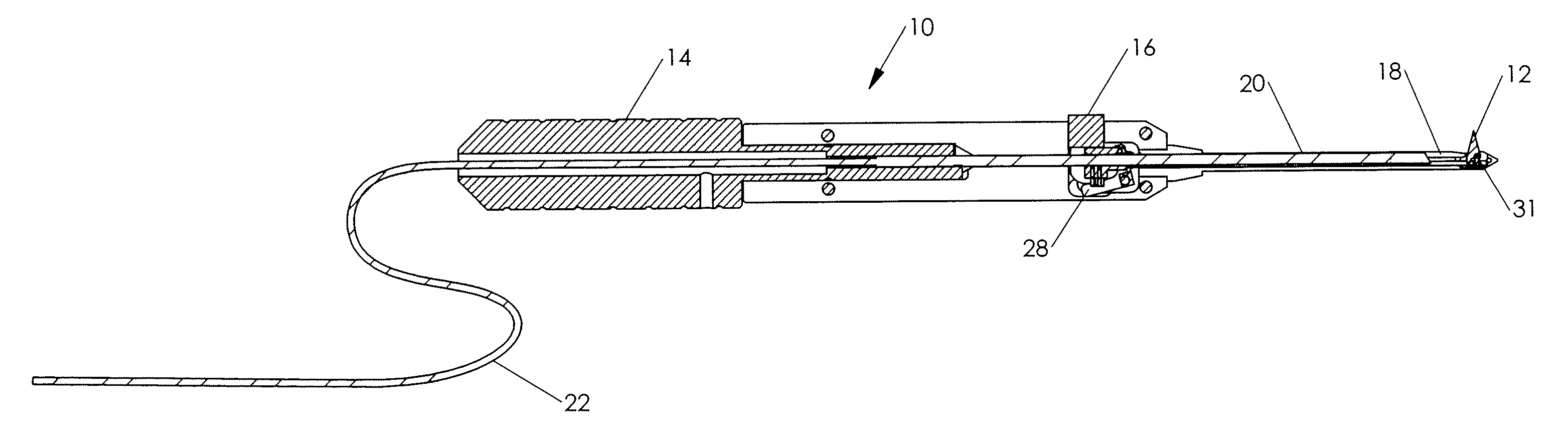

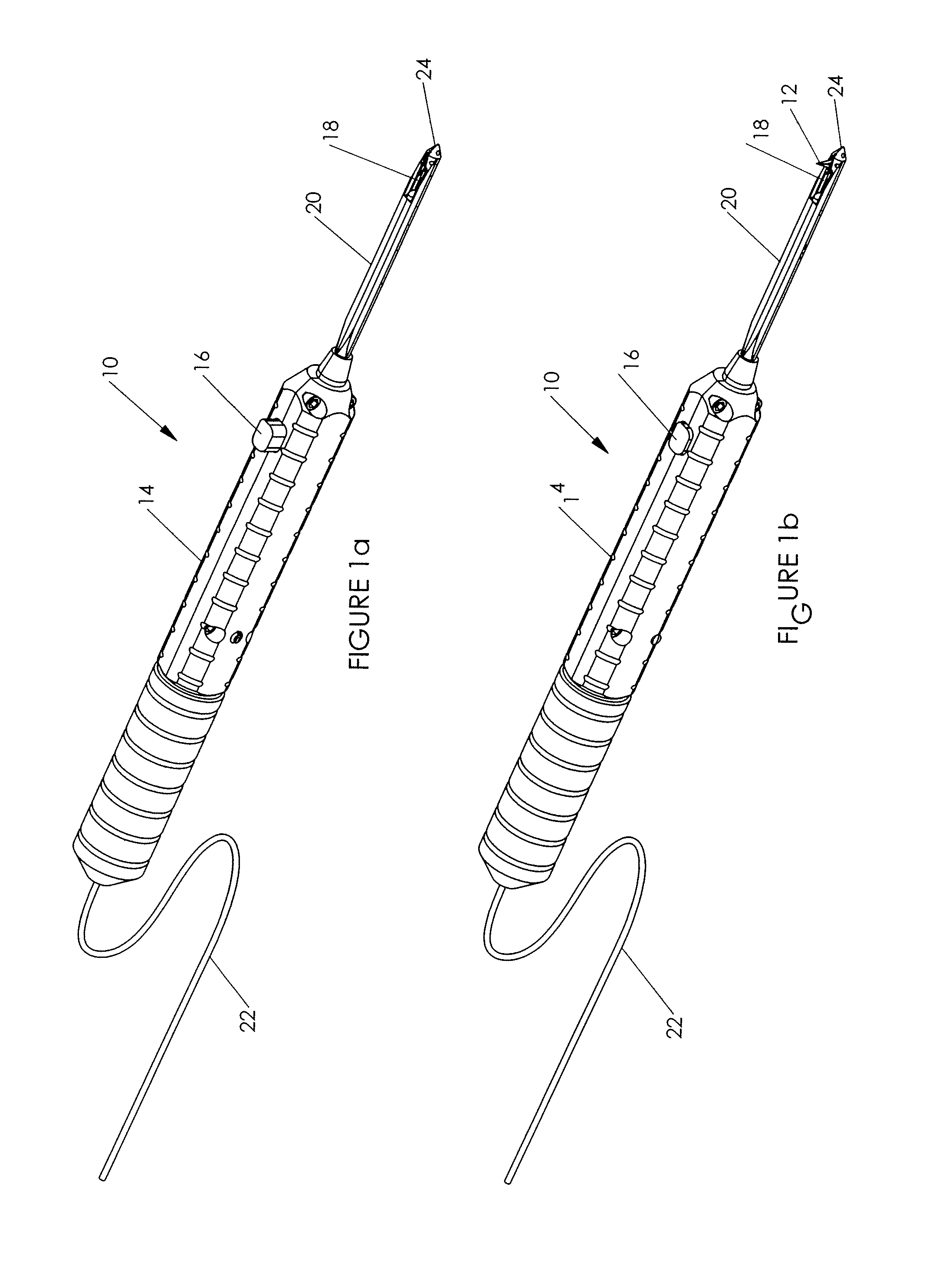

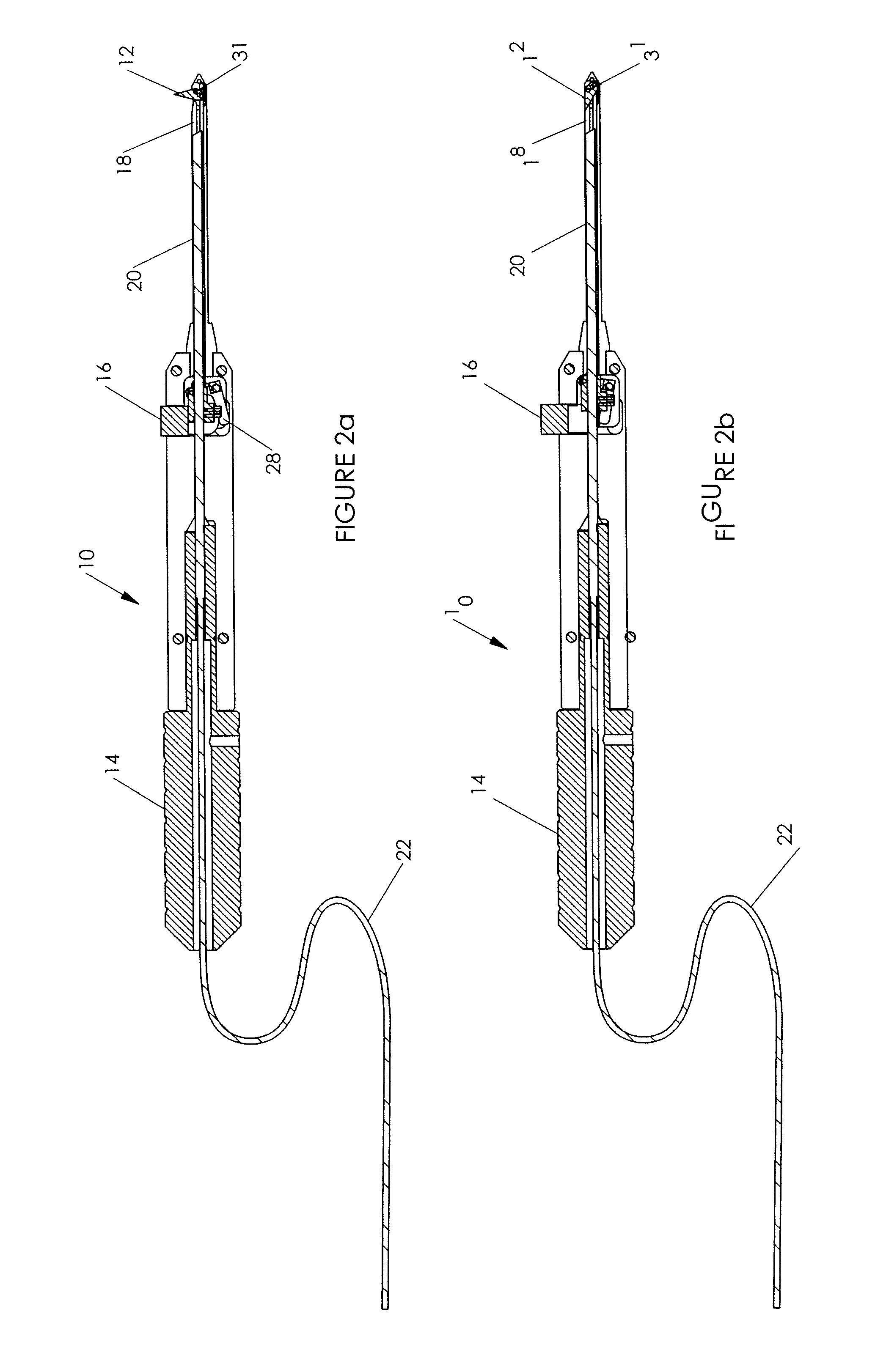

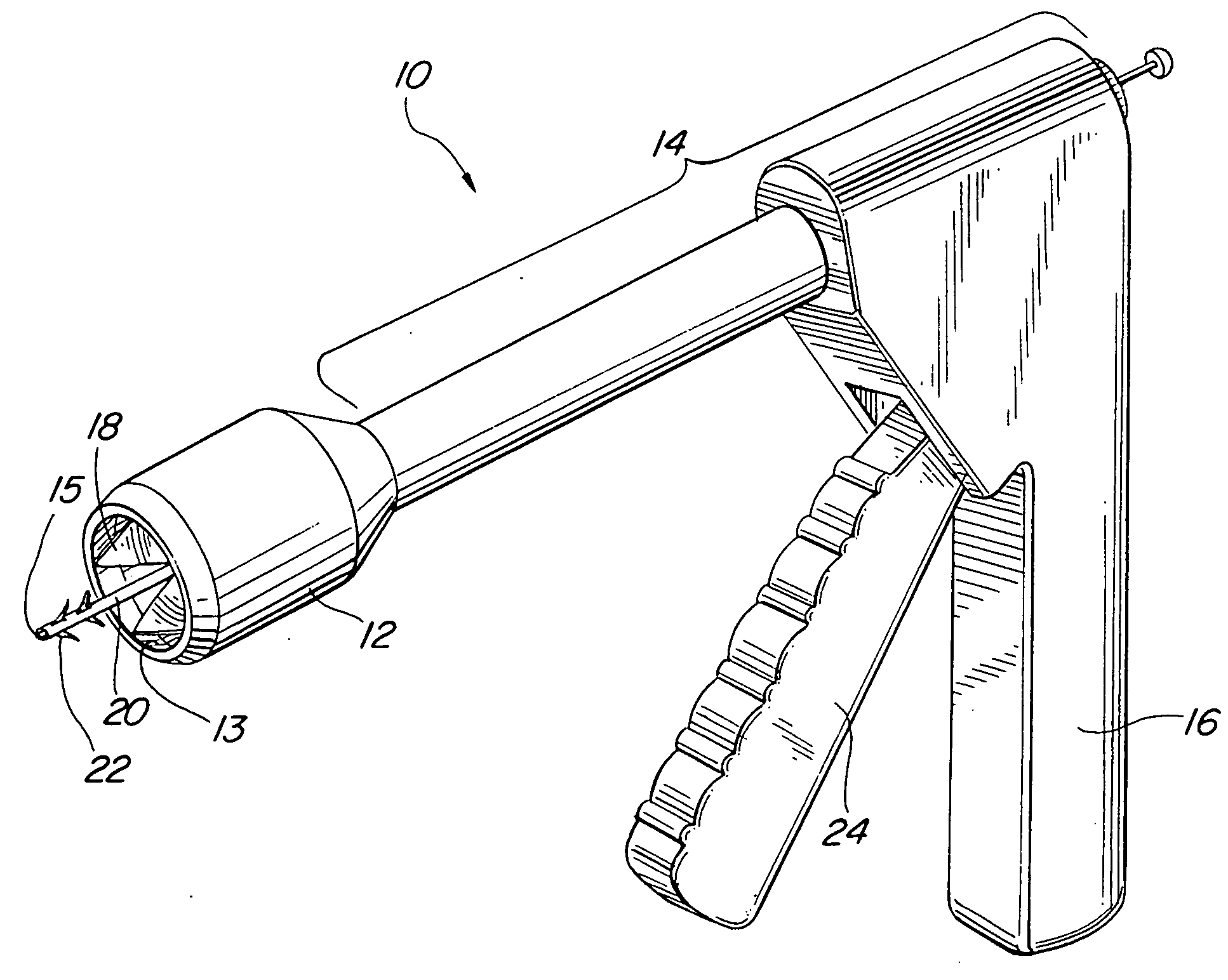

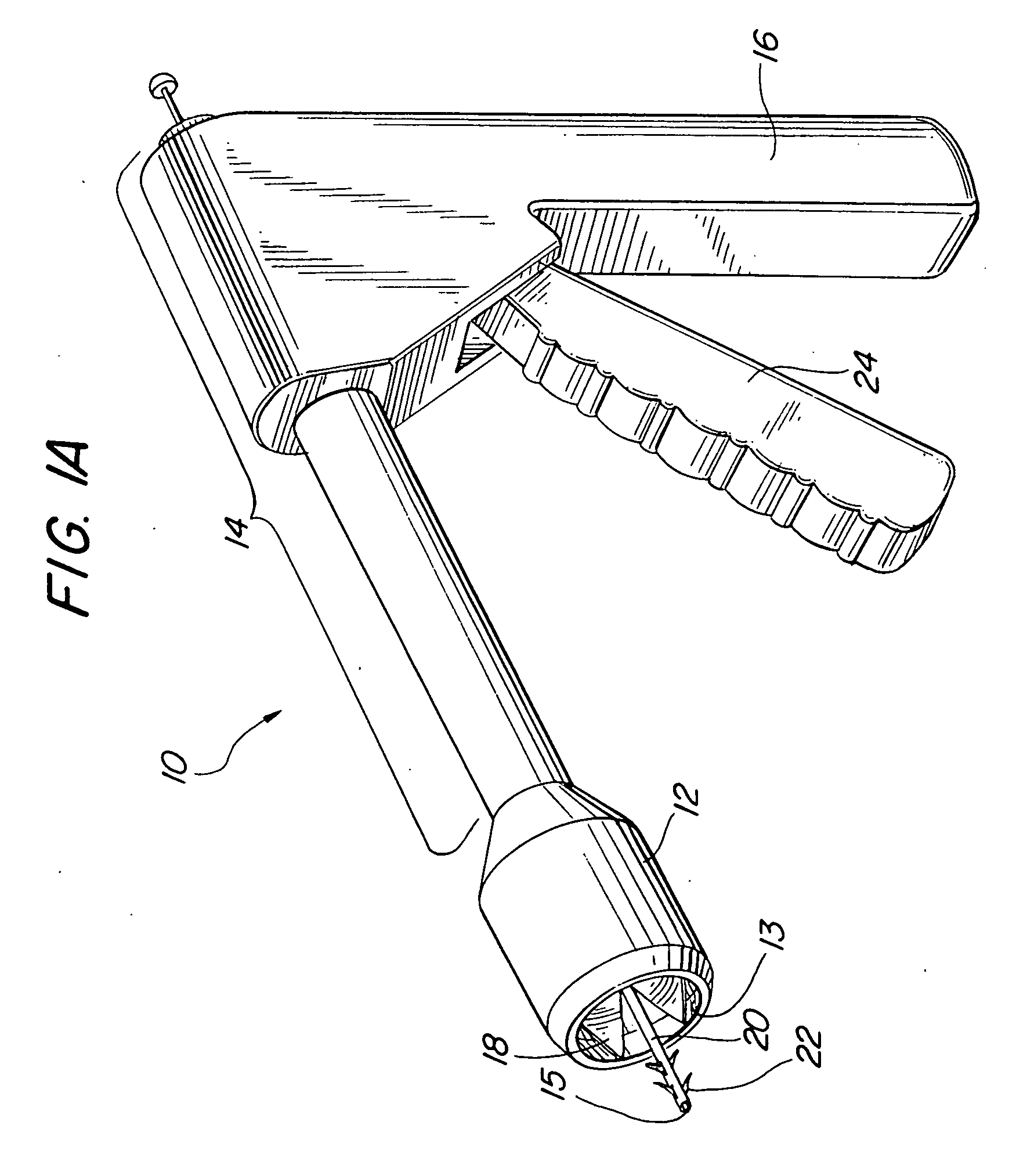

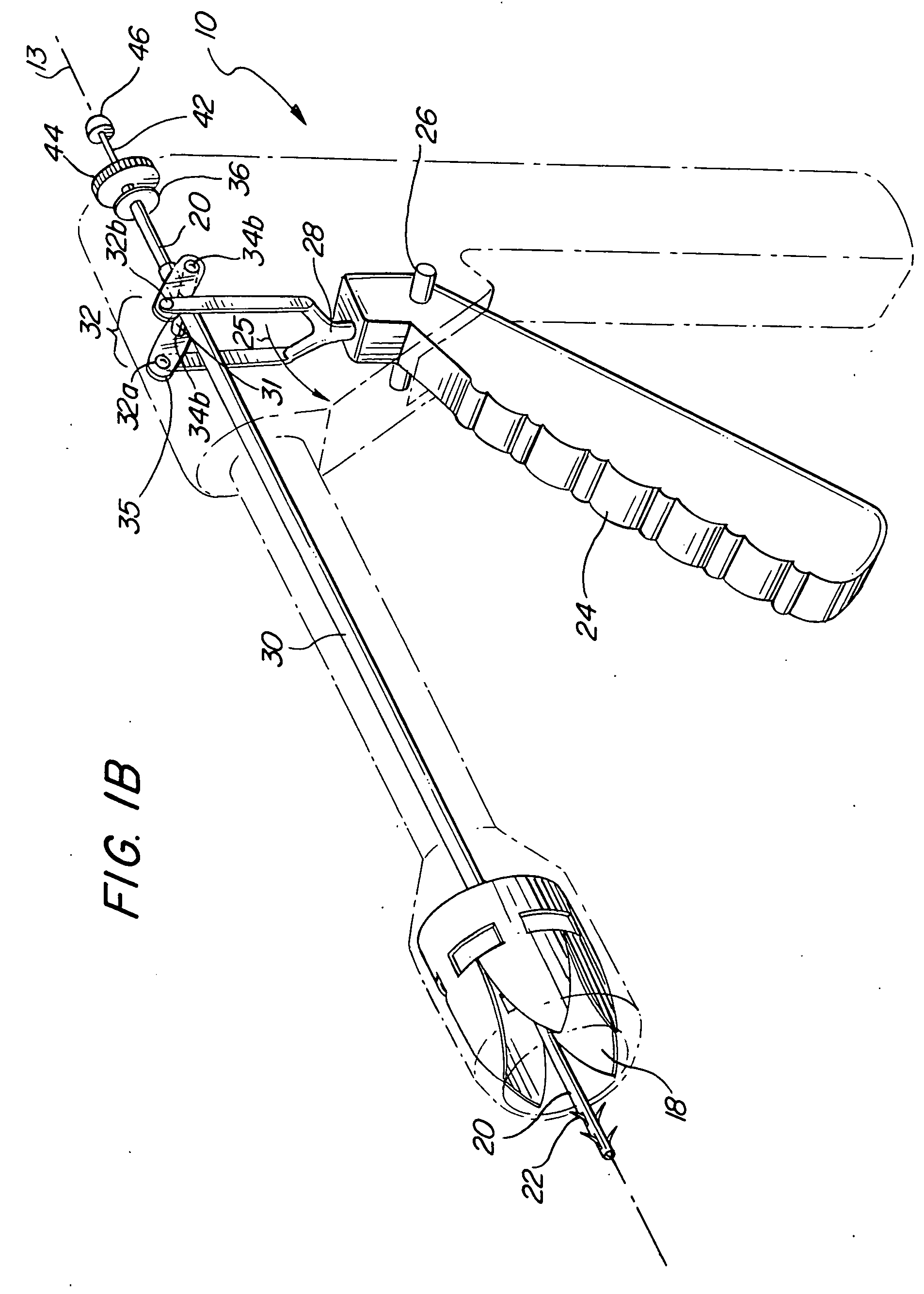

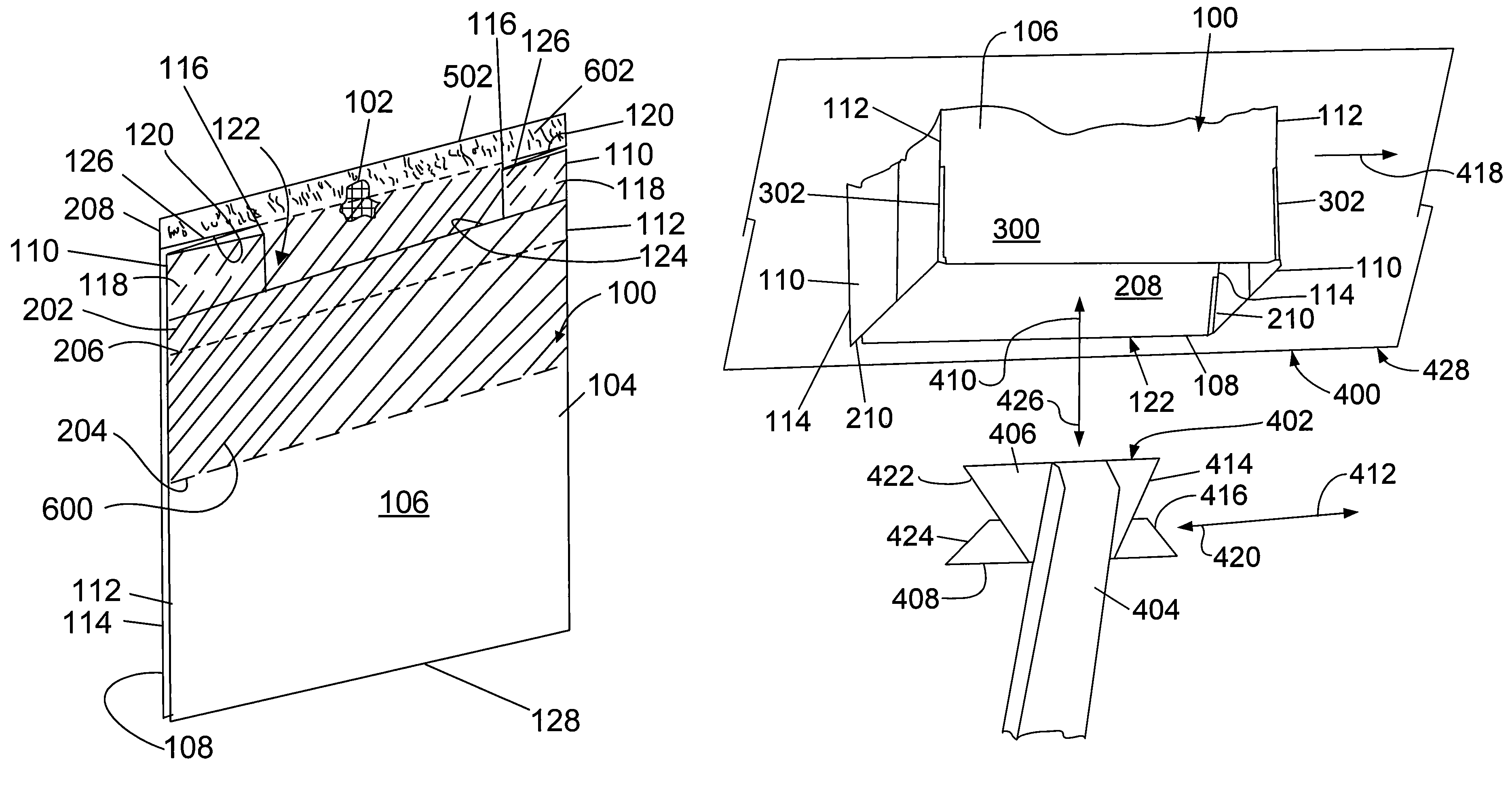

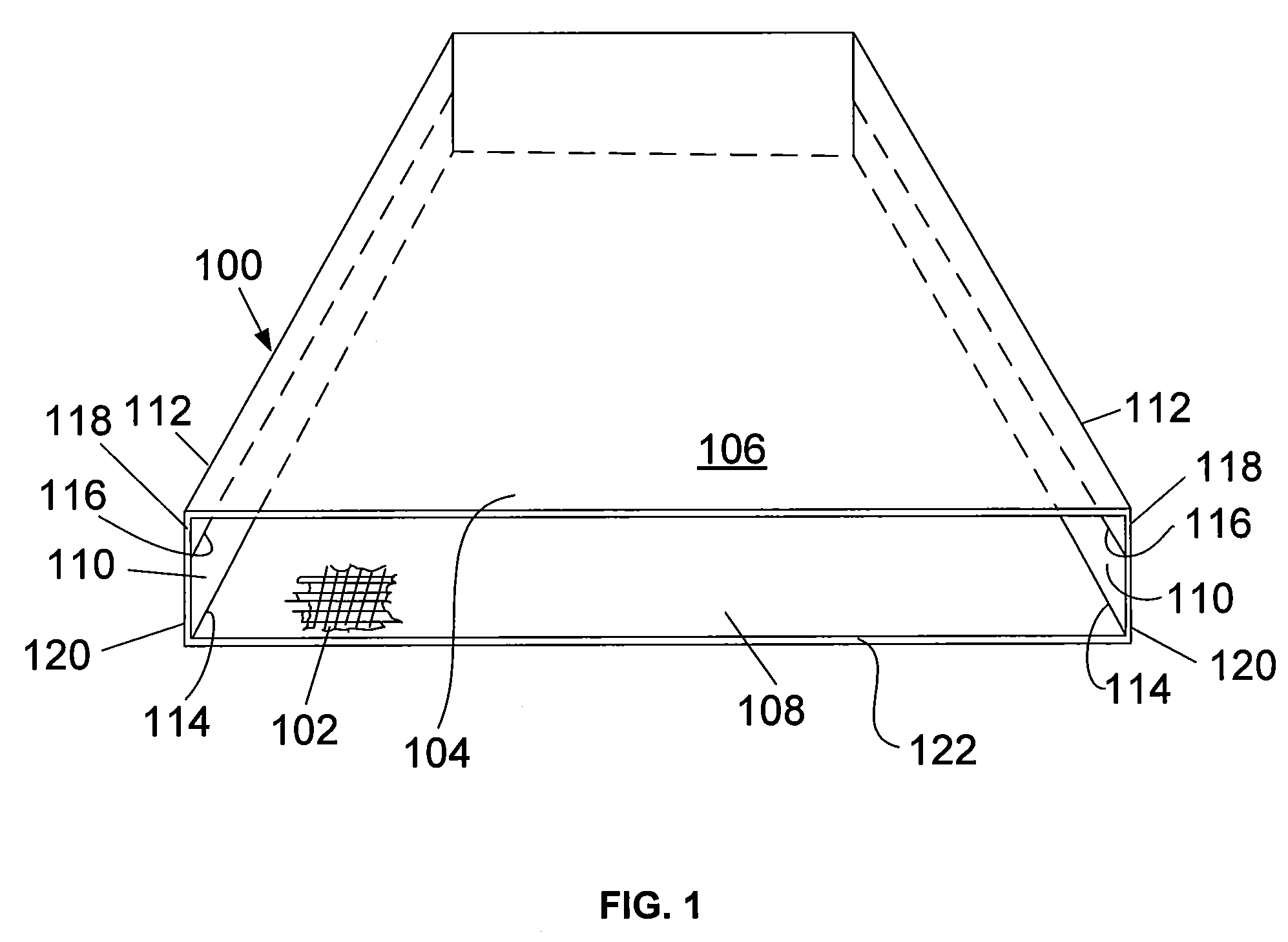

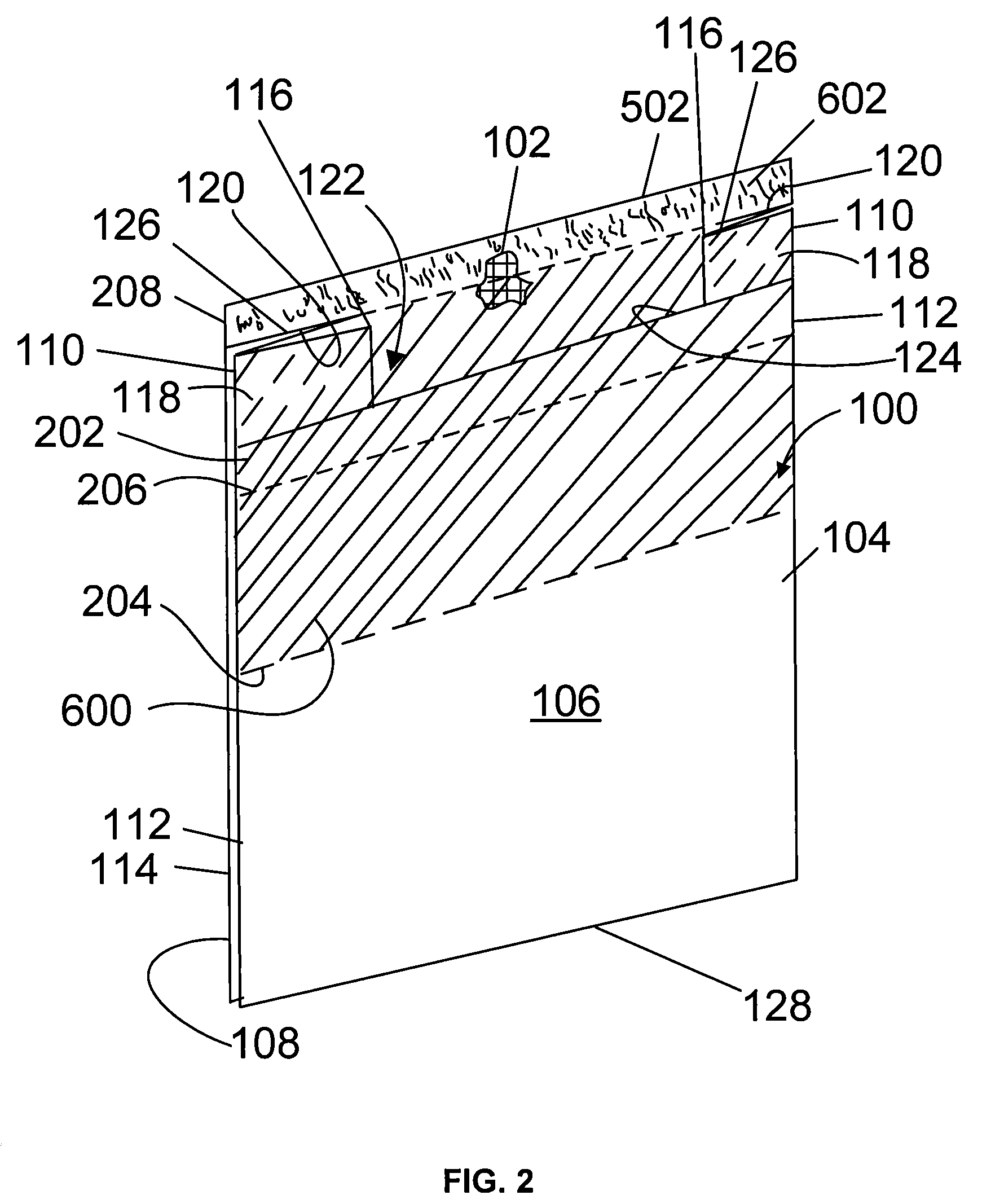

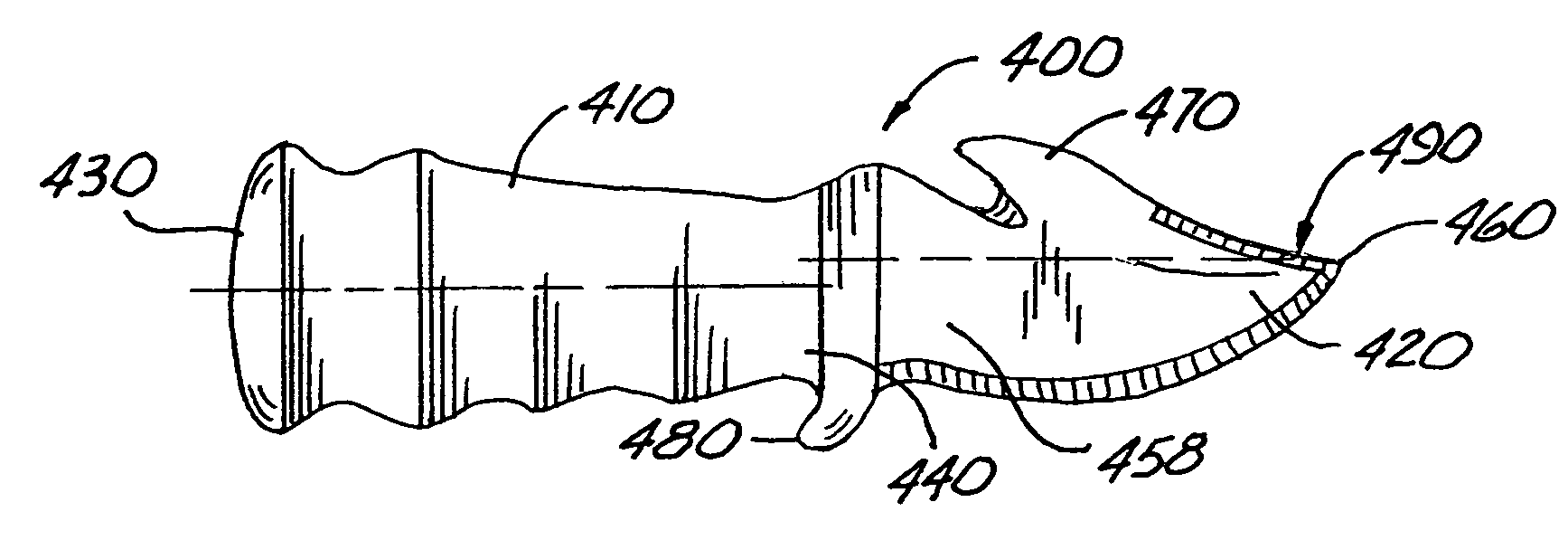

Endoscopic surgical tool

ActiveUS20080045989A1Precise processIncreased durabilityDiagnosticsSurgeryLigament structureActuator

An endoscopic tool utilizes a fiber optic system for illuminating and imaging ligaments or other tissue which are to be cut. Illumination and imaging is performed above a lateral opening at the distal end of a probe that is inserted into an incision point. Preferably, a two edged blade which can be moved in both the distal to proximal direction and the proximal to distal direction is selectively deployable from of the lateral opening at the distal end of the probe. The endoscopic tool is small in size, and preferably includes a pencil grip with a button actuator for deploying the two edged cutting blade. A wire actuator that fits into a slot in the bottom of the deployable blade, can be nested with the fiber optic cable such that the cross sectional area of the probe is reduced. Alternatively, a tube concentric with the fiber optic cable can be used as the mechanism for actuating the blade or other device. The surgeon can observe cutting of the ligament or other tissue as he moves the endoscopic tool in either or both the forward or reverse direction on a display screen which is operatively connected to the fiber optic system. A retractor can be used in conjunction with the endoscopic tool to lift tissue where dissection is desired, and to function as a guide for the blade.

Owner:MICROAIRE SURGICAL INSTR

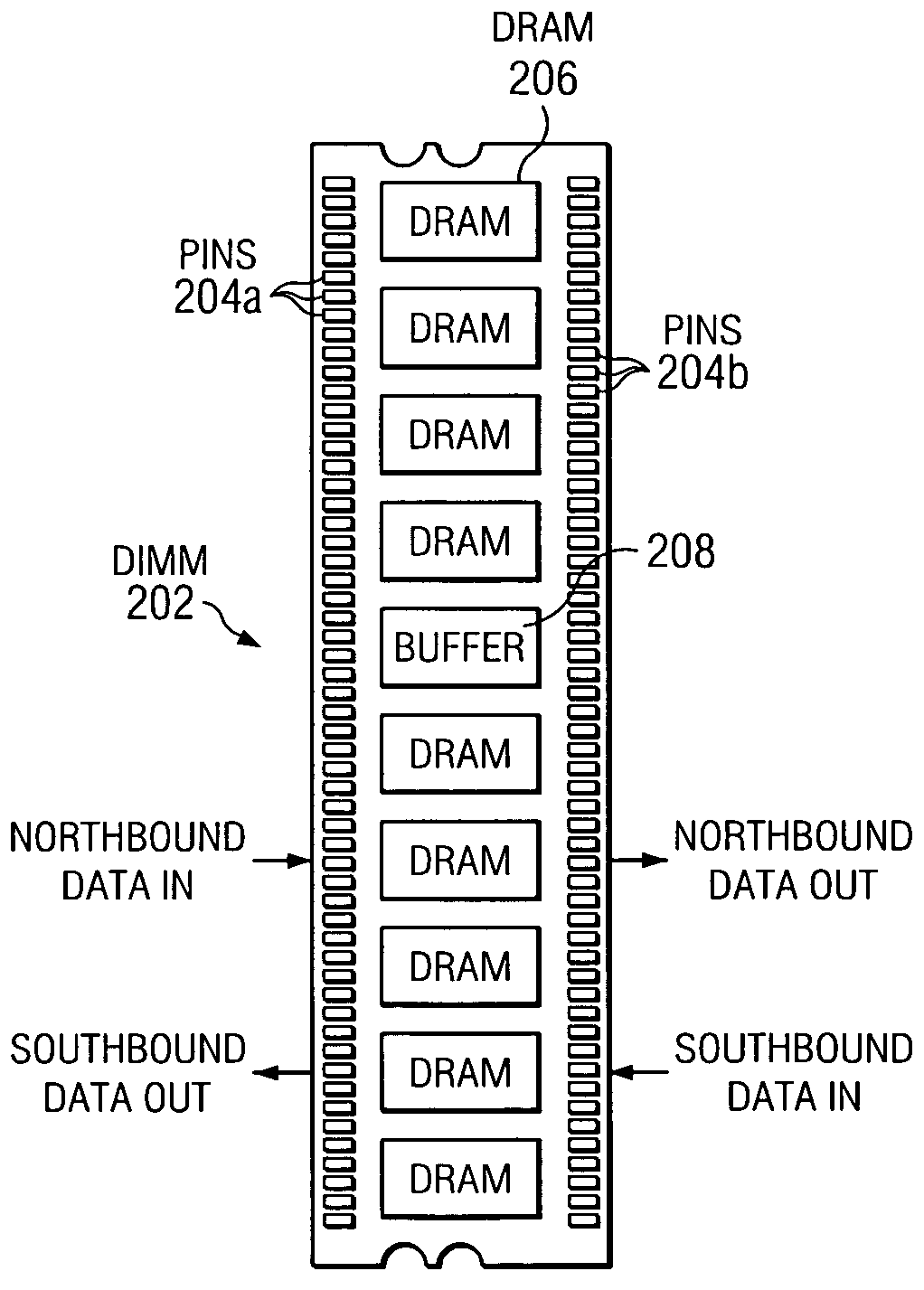

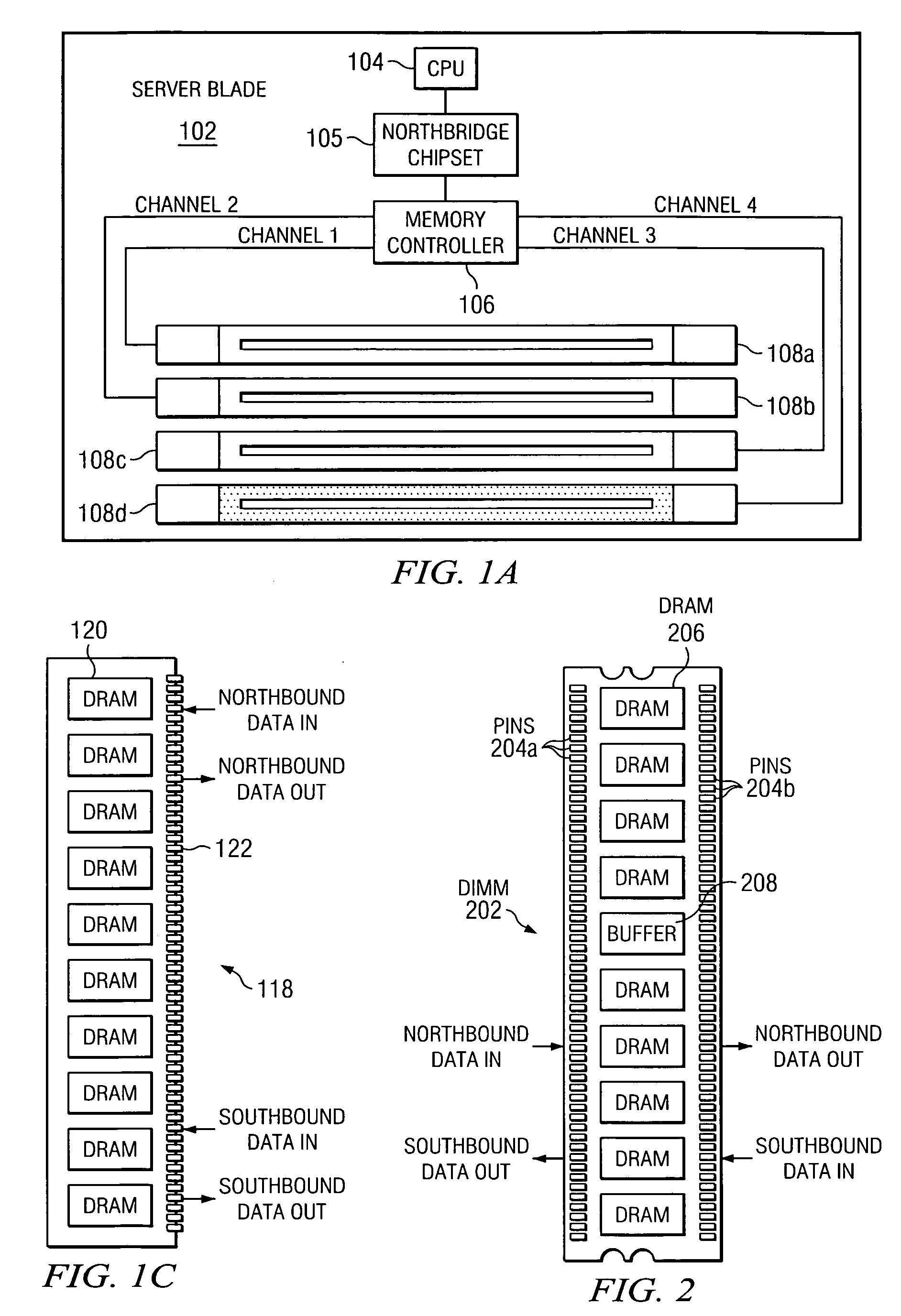

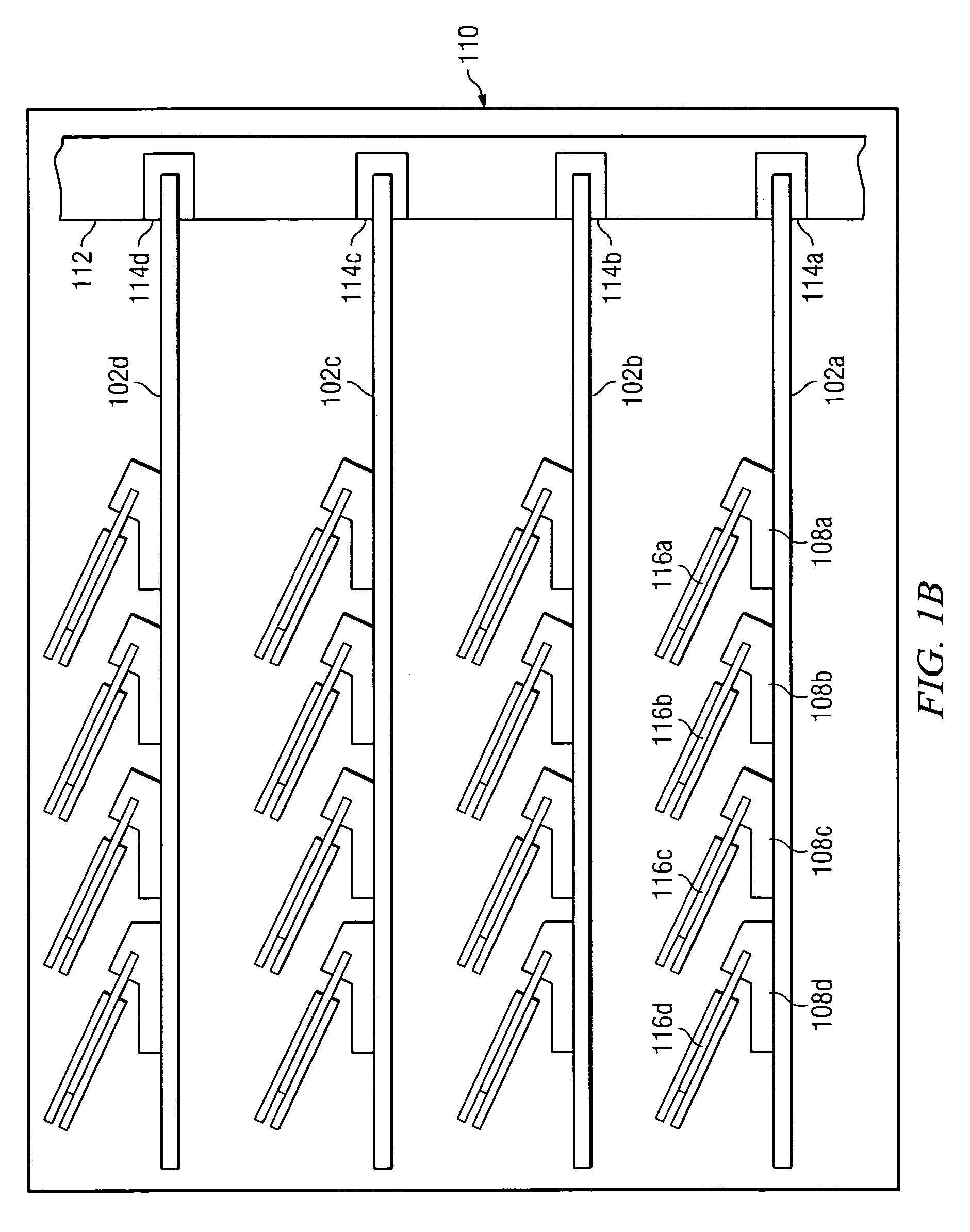

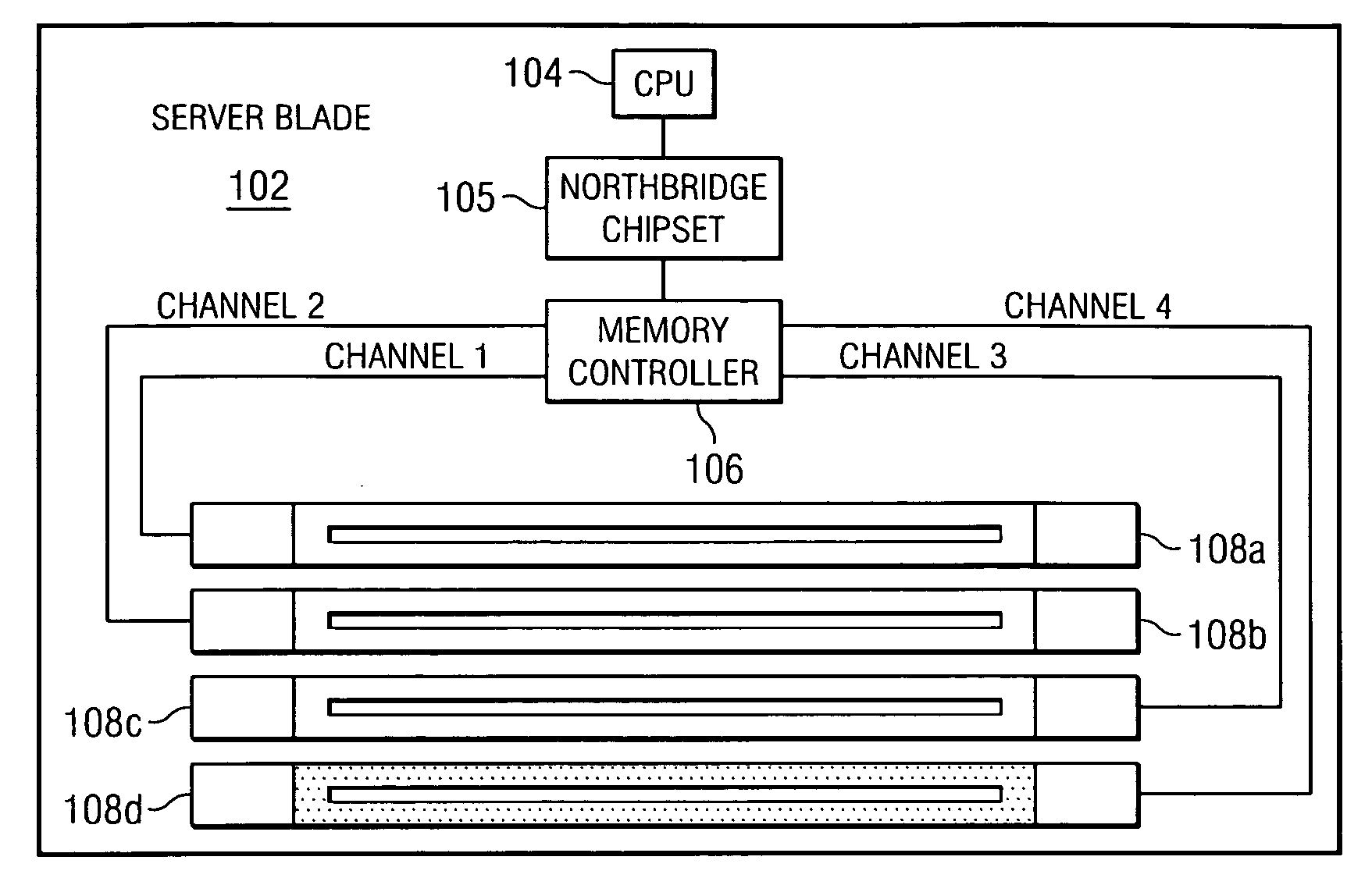

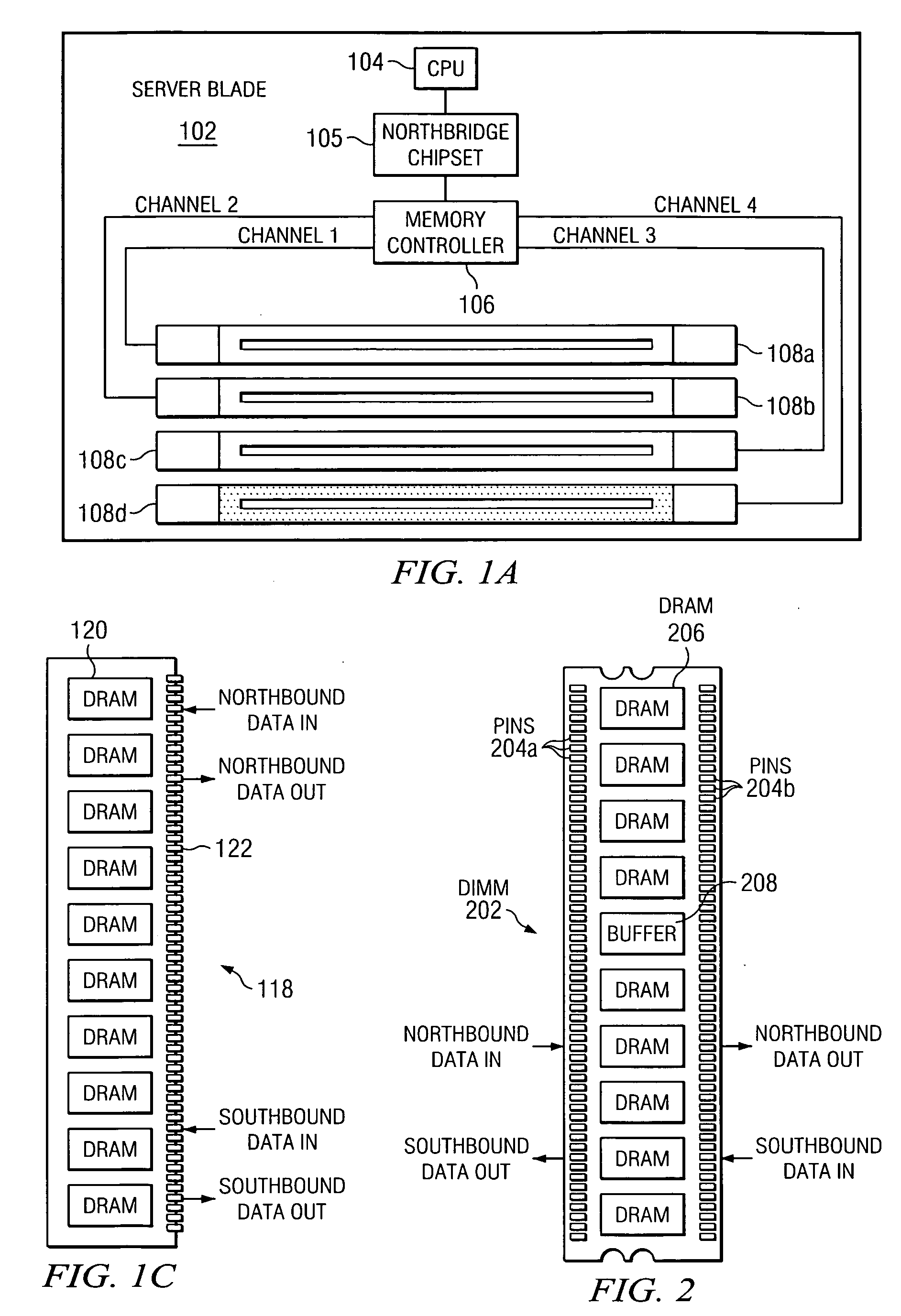

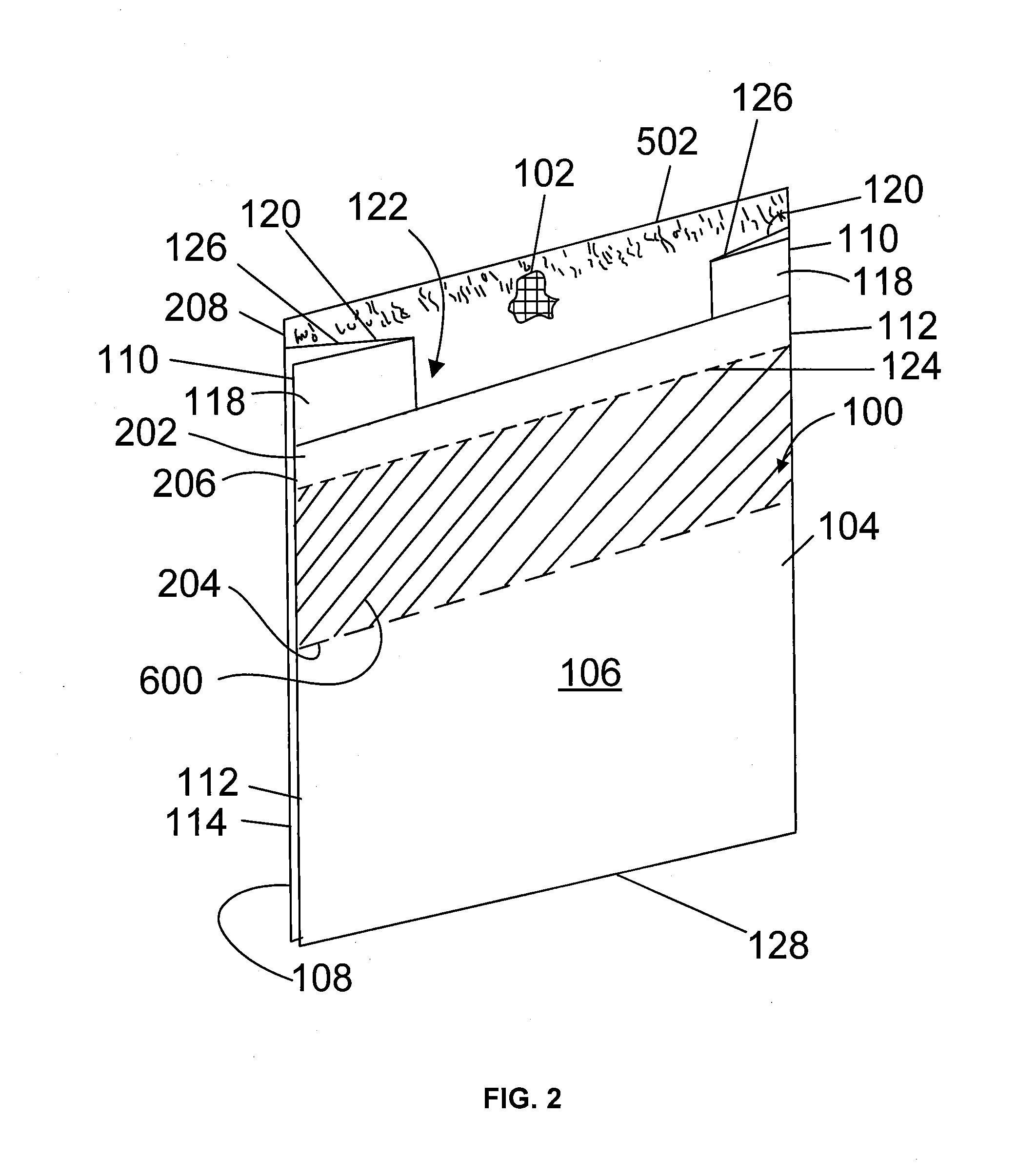

Dual-edged DIMM to support memory expansion

A method and system for expanding the number of memory modules that can be coupled to a motherboard such as a server blade is presented. A stack of multiple Dual In-line Memory Modules (DIMMs) is formed using novel double-connector-edge DIMMs, which each have connector pins on their opposite edges. Alternatively, the double-connector-edge DIMM is used to couple the motherboard to a memory expansion card that has multiple single-edge pinned DIMMs coupled in a “daisy-chain.”

Owner:INT BUSINESS MASCH CORP

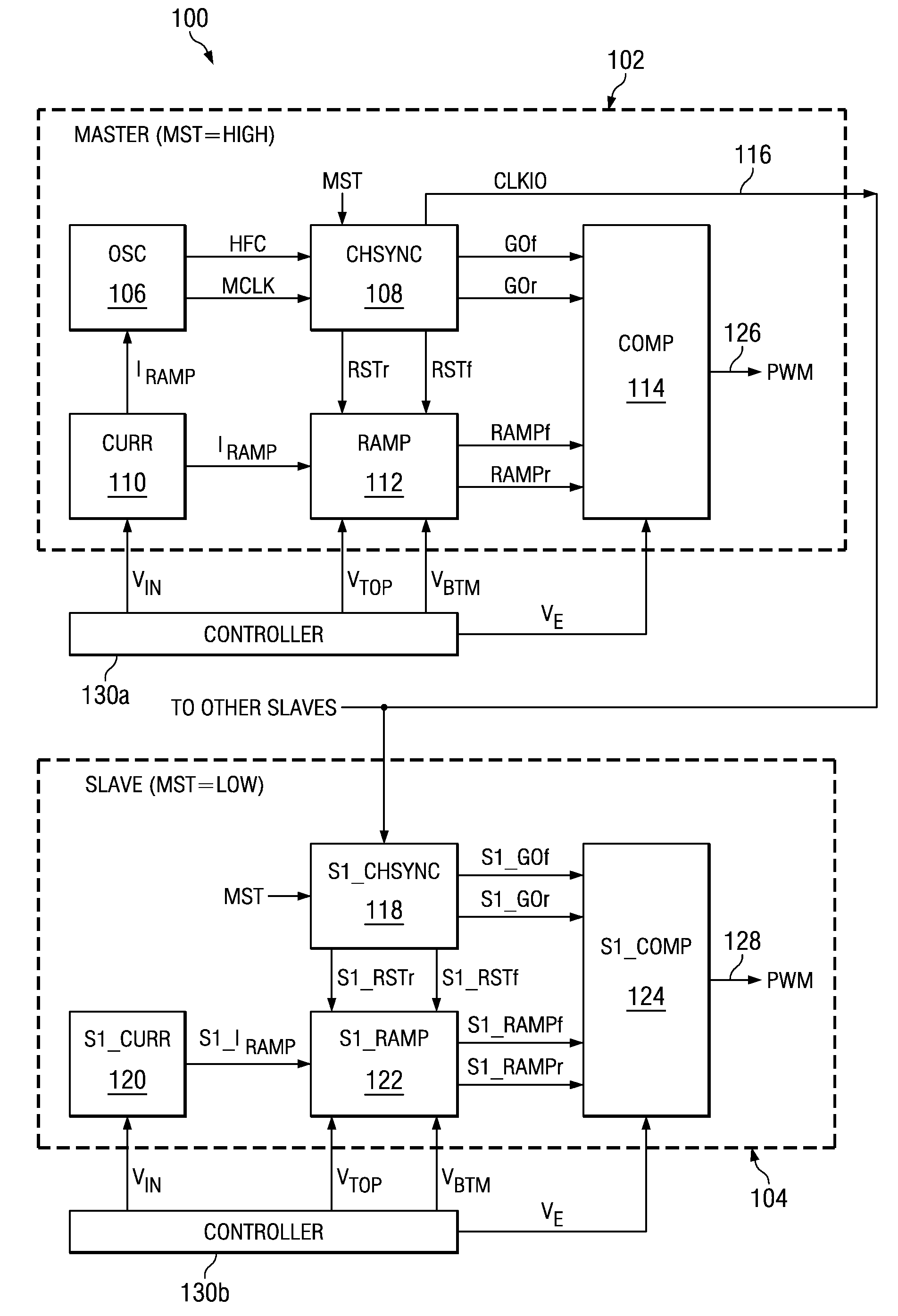

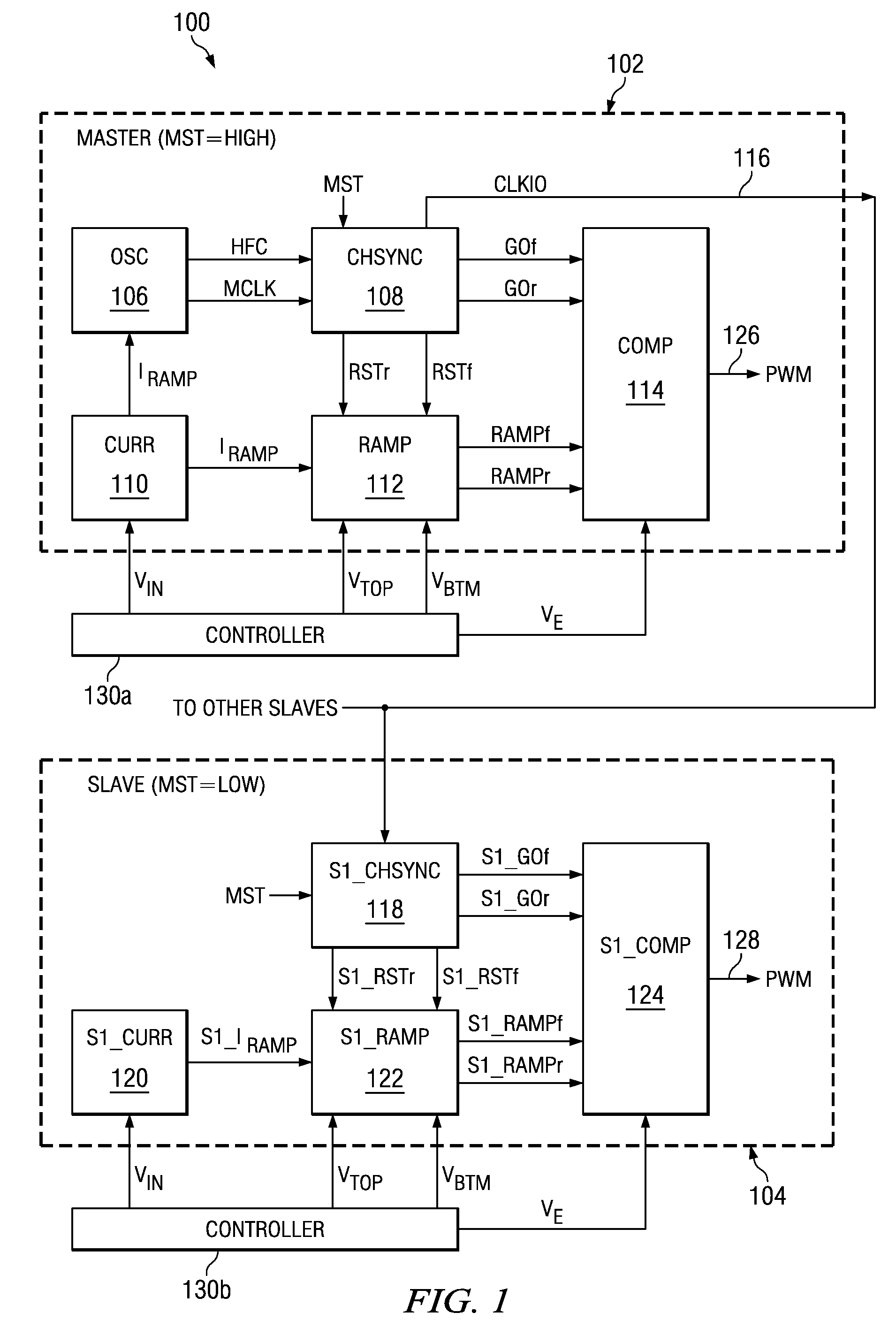

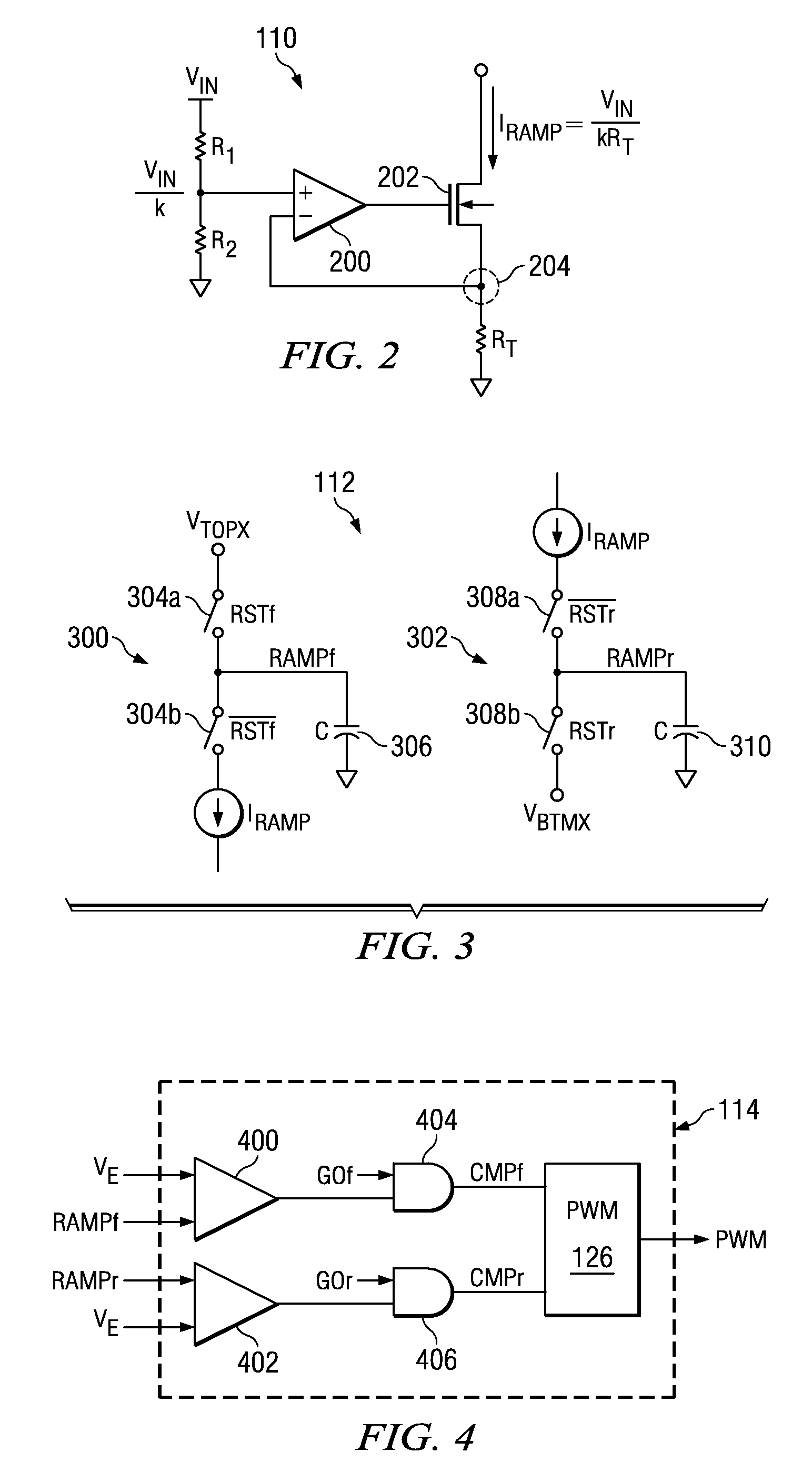

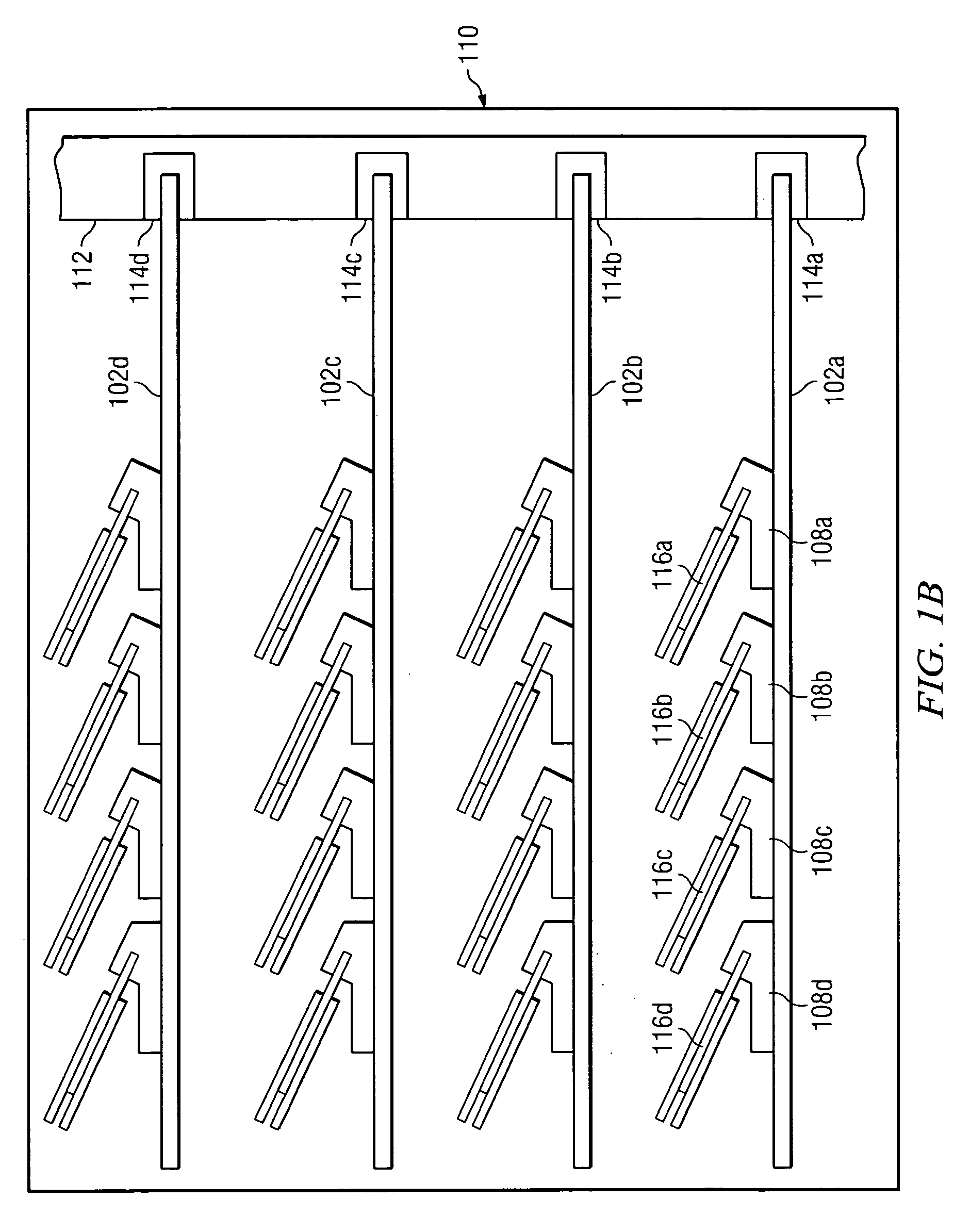

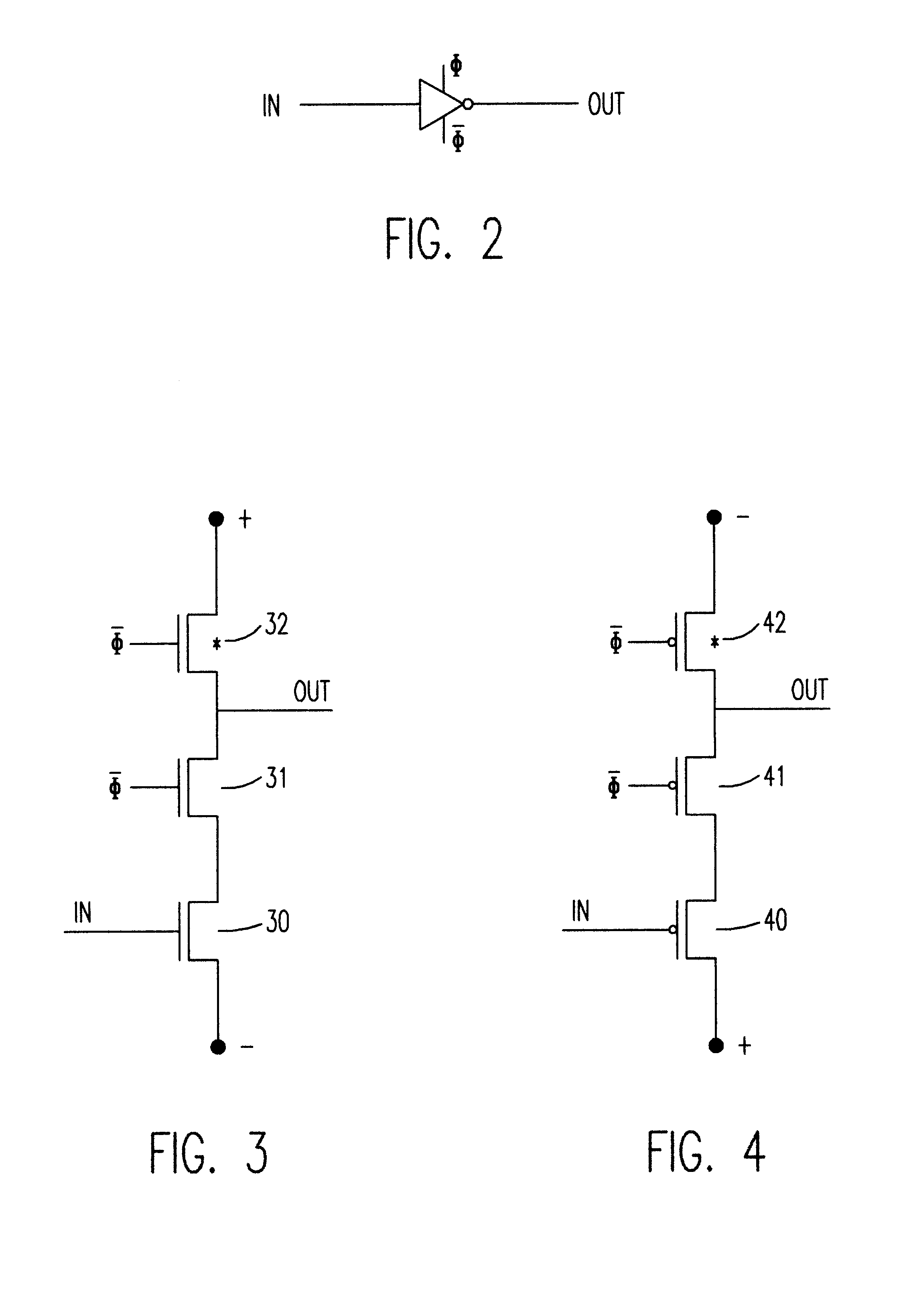

Synchronously stackable double-edge modulated pulse width modulation generators

Synchronously stackable double-edge modulated pulse width modulation generators are disclosed. An example pulse width modulation generator includes a ramp generator to generate first and second ramp signals that interact to form a virtual ramp signal; and a comparator module coupled to the ramp generator configured to produce a pulse width modulated signal based on a comparison between the virtual ramp signal and an input signal.

Owner:TEXAS INSTR INC

Dual-edged DIMM to support memory expansion

A method and system for expanding the number of memory modules that can be coupled to a motherboard such as a server blade is presented. A stack of multiple Dual In-line Memory Modules (DIMMs) is formed using novel double-connector-edge DIMMs, which each have connector pins on their opposite edges. Alternatively, the double-connector-edge DIMM is used to couple the motherboard to a memory expansion card that has multiple single-edge pinned DIMMs coupled in a “daisy-chain.”

Owner:IBM CORP

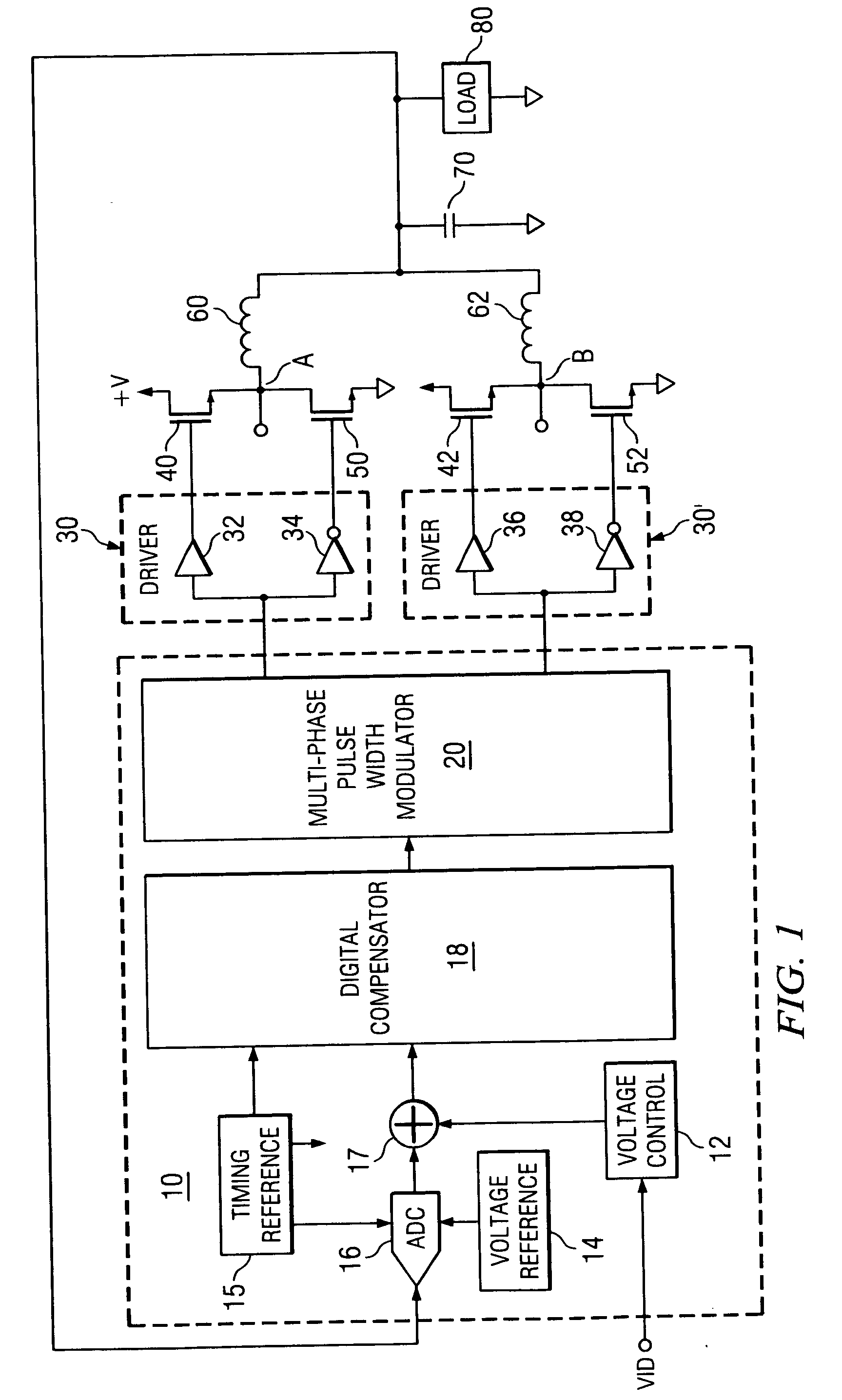

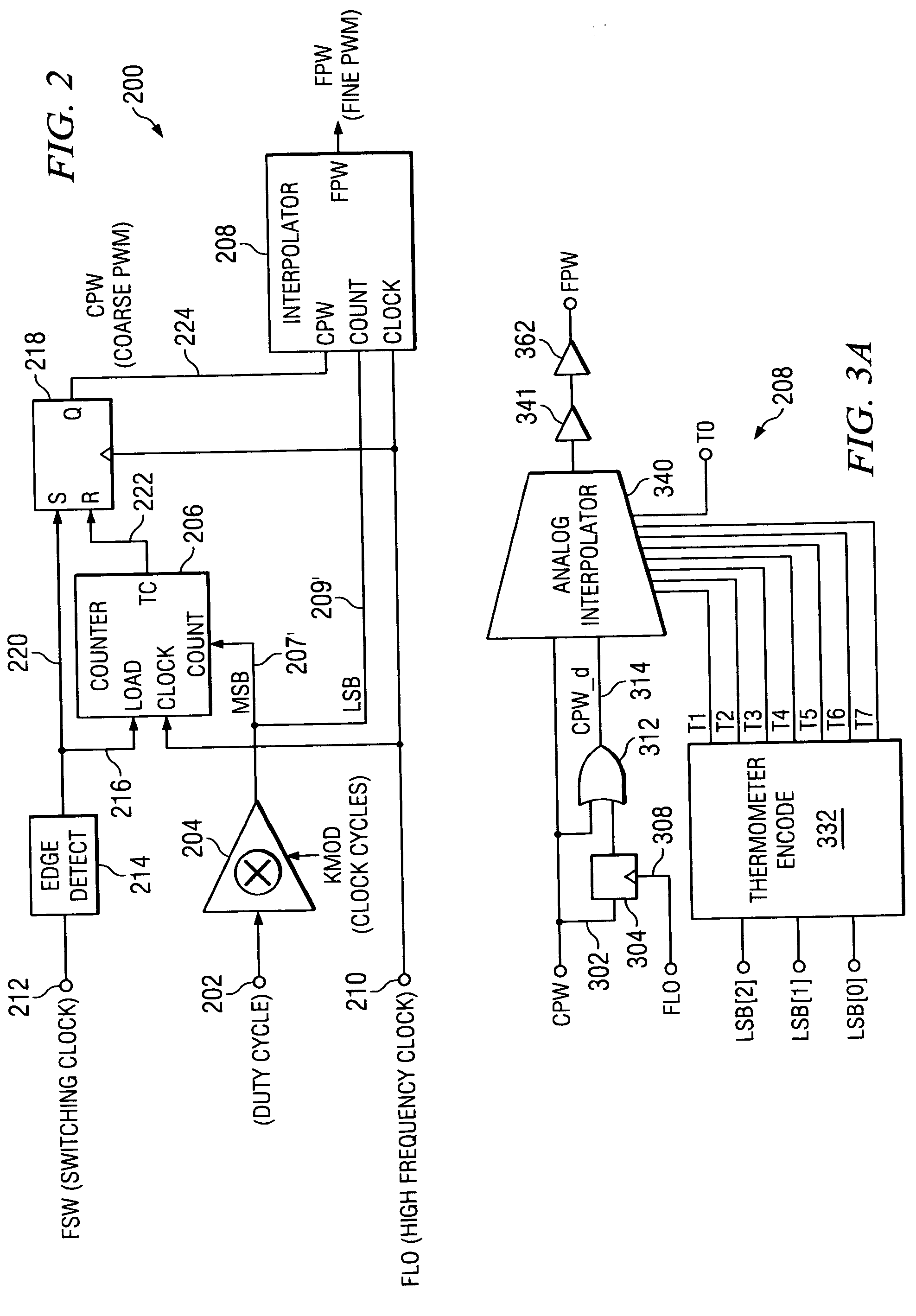

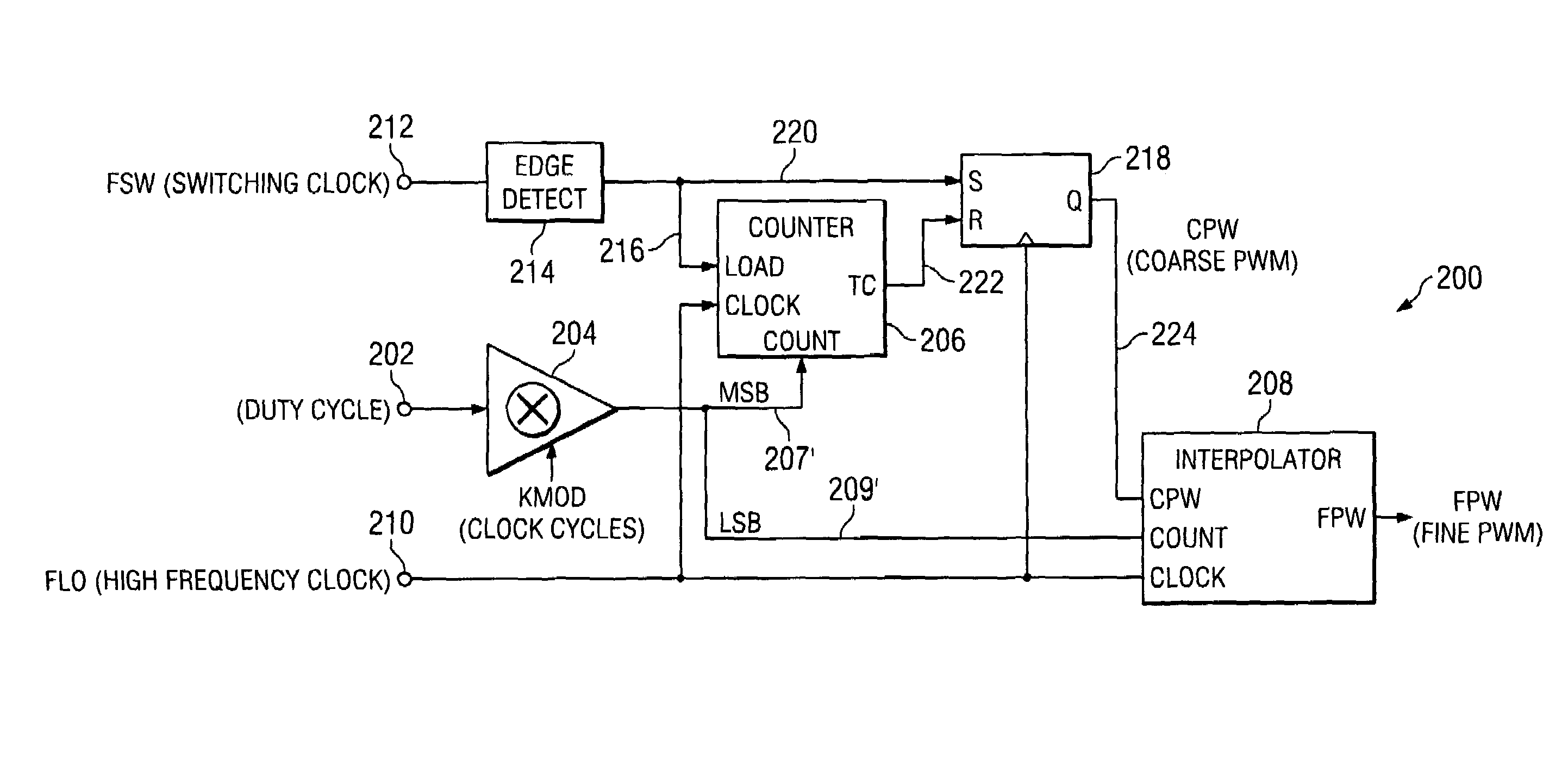

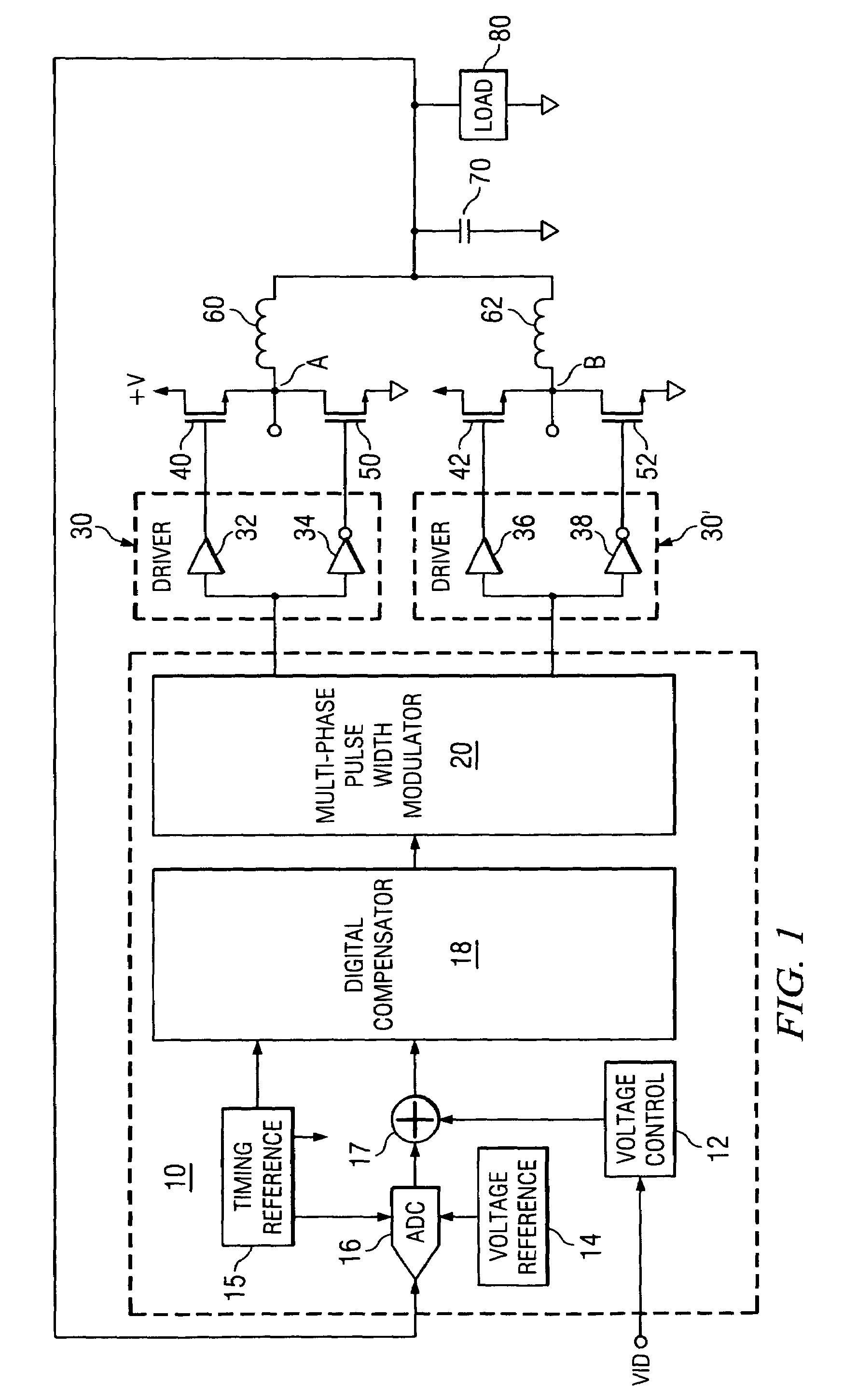

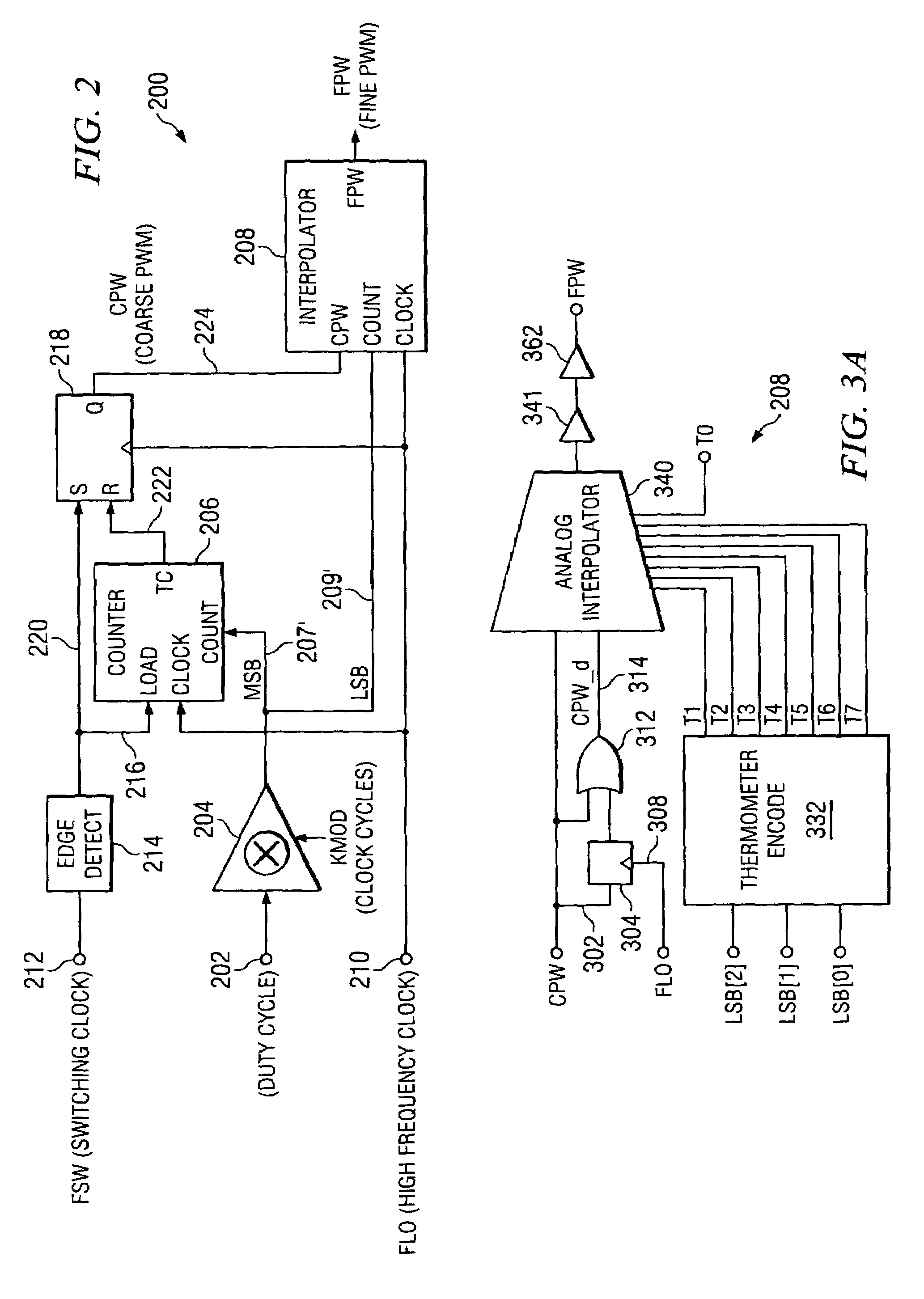

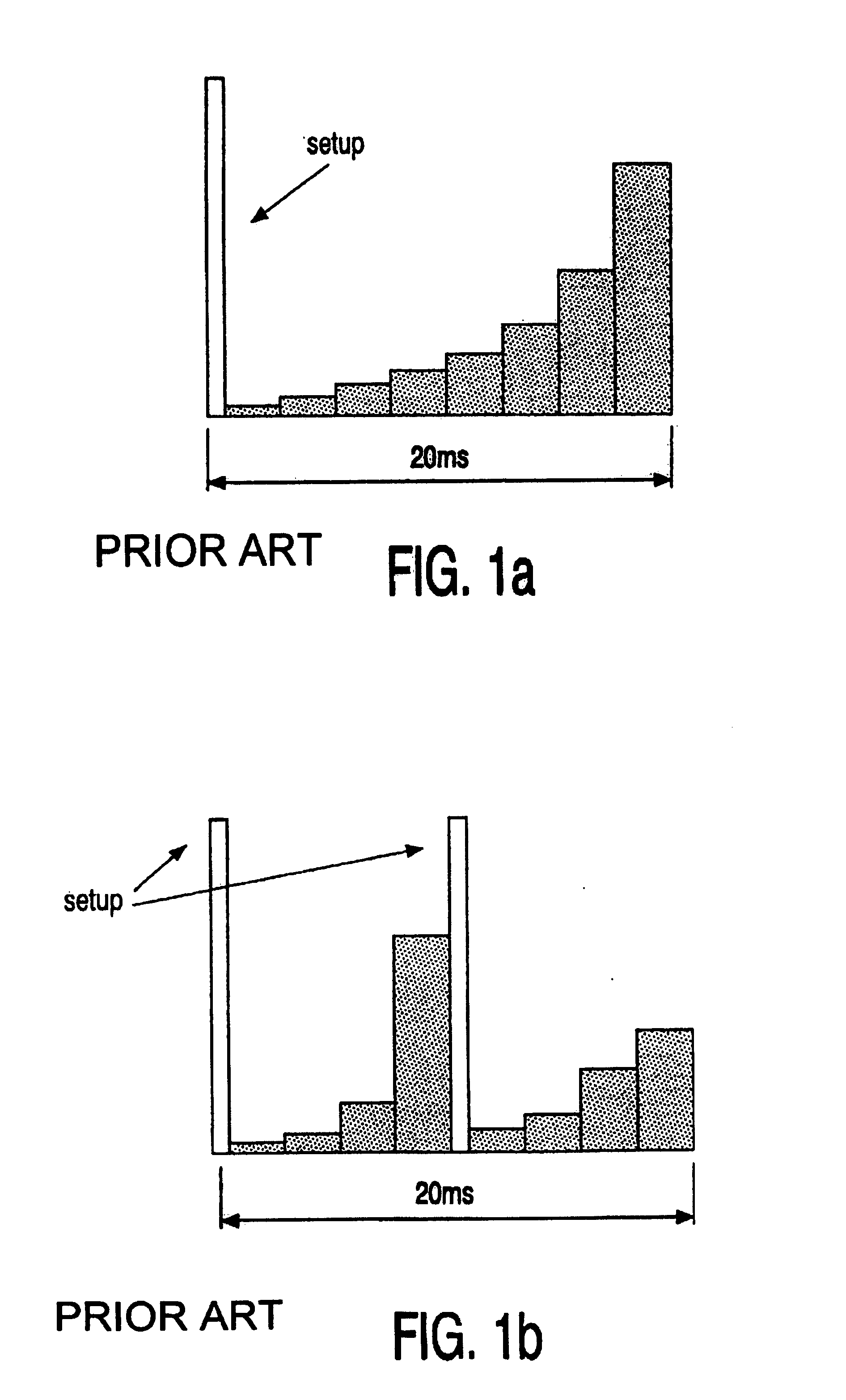

Fine resolution pulse width modulation pulse generator for use in a multiphase pulse width modulated voltage regulator

ActiveUS20060132110A1High resolutionEasy to controlDc-dc conversionElectronic switchingImage resolutionTrailing edge

Disclosed is a fine resolution pulse width generator for use in a multiphase pulse width modulated voltage regulator. The fine pulse width is generated by first generating a pulse with a coarse pulse width and one or more delayed replicas thereof. Then, digitally controlled analog interpolators are used to generate the fine resolution pulse width pulse by interpolating among the coarse pulse width pulses. Both single edge and double edge modulation embodiments are disclosed providing interpolation of just the trailing edges of the coarse pulses or both the leading and trailing edges, respectively. The disclosed fine resolution pulse generator uses counters, thermometer encoders and analog interpolators to achieve interpolation accurately by insuring that each interpolation step corresponds to an equal weight. Accuracy of the interpolation is defined by the linearity (i.e. how well the interpolation fits a best fit straight line) and monotonicity (i.e. how each step contributes a positive weight to the total).

Owner:INFINEON TECH AUSTRIA AG

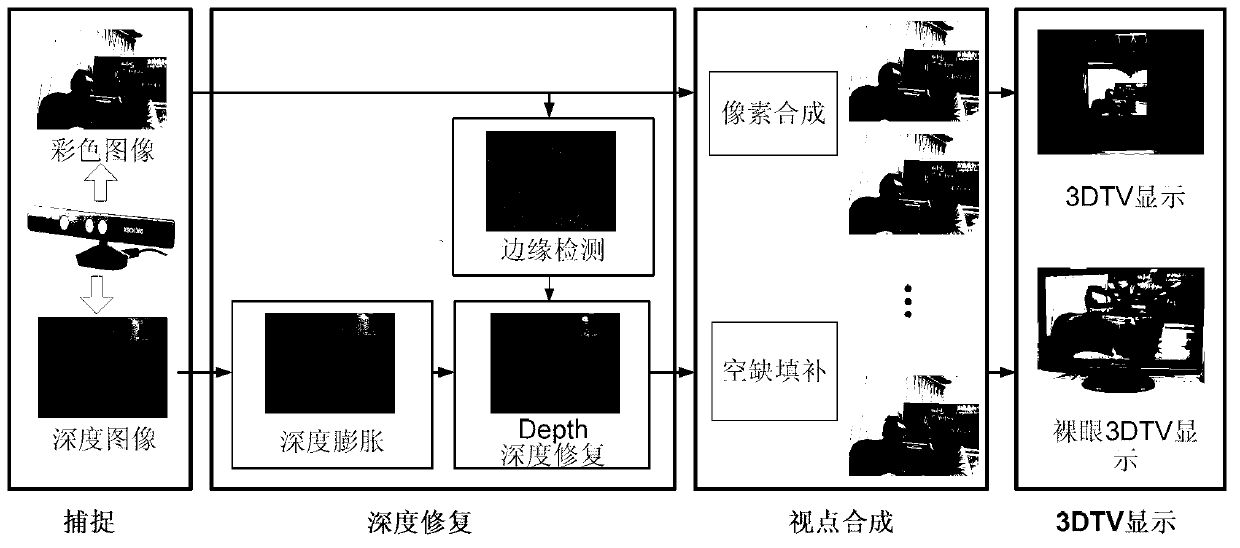

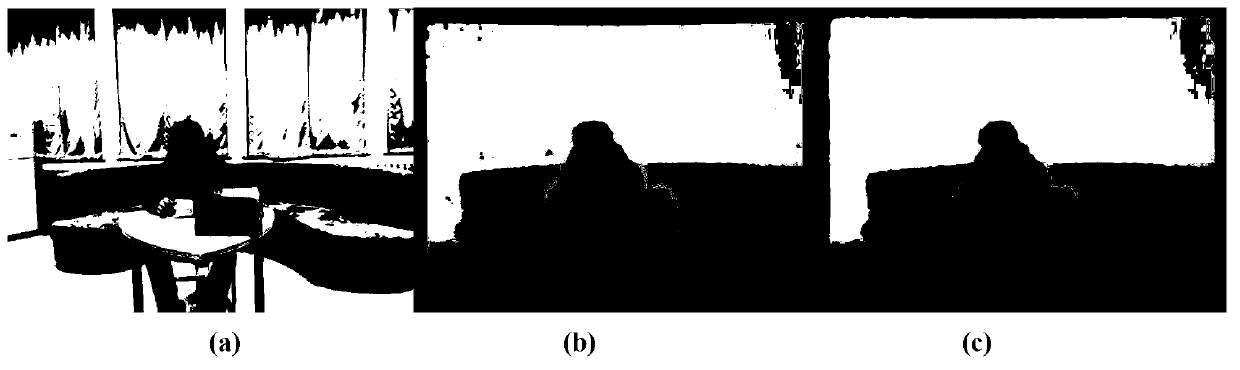

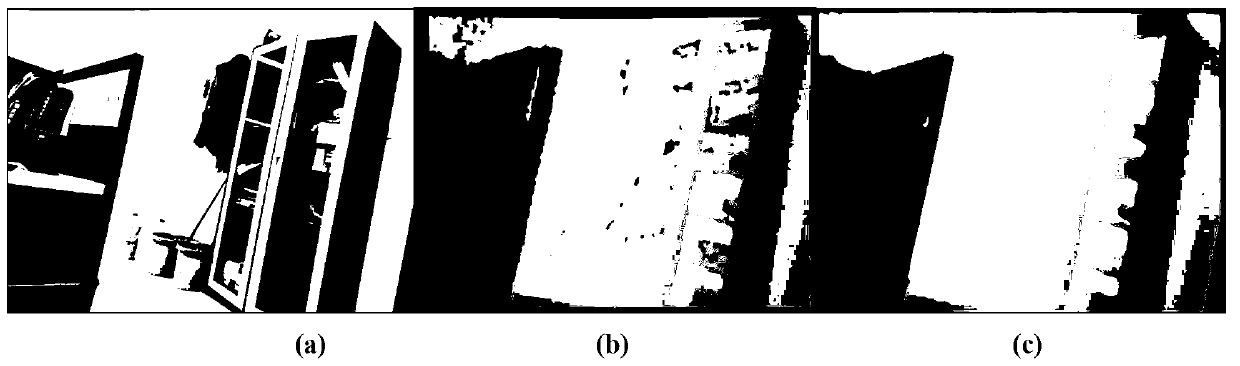

Multi-view-point computing and imaging method based on speckle-structure optical depth camera

The invention belongs to the technical field of image processing, provides a multi-view-point computing and imaging method, and aims to acquire accurate and high-precision depth information. According to the technical scheme, the multi-view-point computing and imaging method based on a speckle-structure optical depth camera comprises the following steps of: acquiring a depth map and a color map from human-machine interaction equipment Kinect of Microsoft; detecting the edge of the color map, and expanding gap information until the expanded gap covers the edge, which corresponds to the color map, near the conventional depth map; then performing double-edge filtration estimation on points on the edge of the gap according to depth information and color information; limiting the estimation process by virtue of edge information of the color map; and after the color map and the restored depth map are acquired, converting the depth map into a disparity map, and synthesizing any number of virtual viewpoint maps by a disparity map synthesis method combining a depth image and a color image. The multi-view-point computing and imaging method is mainly applied to image processing.

Owner:TIANJIN UNIV

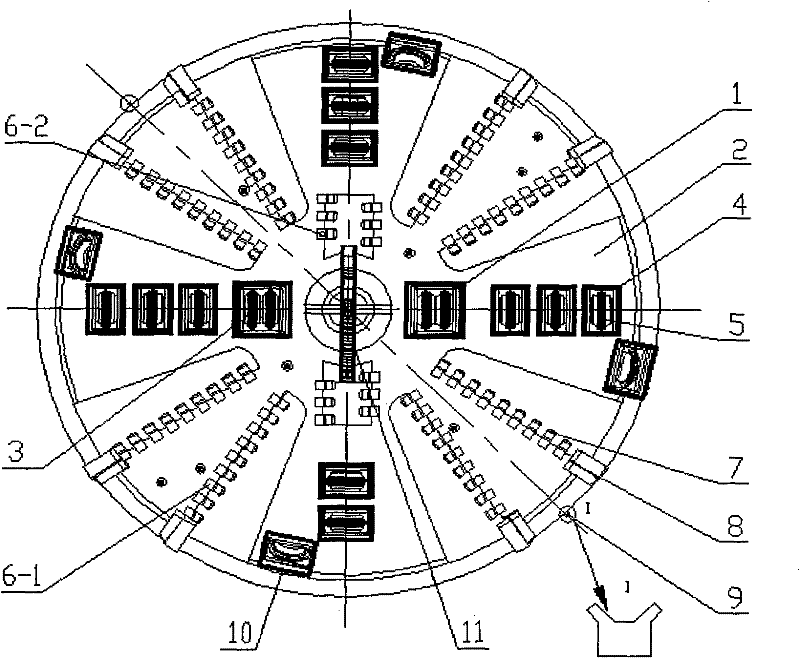

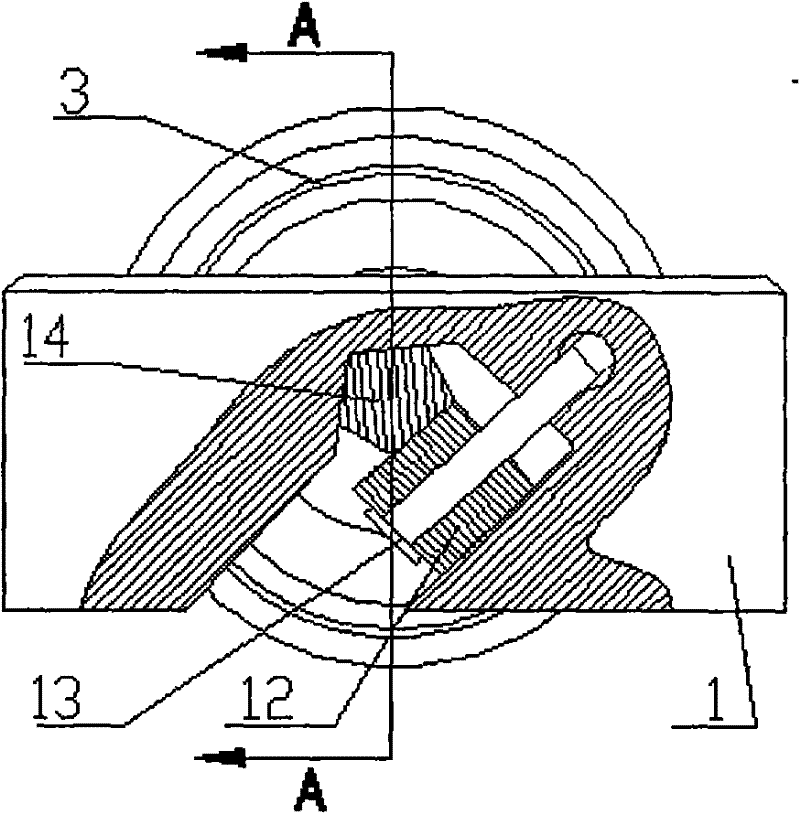

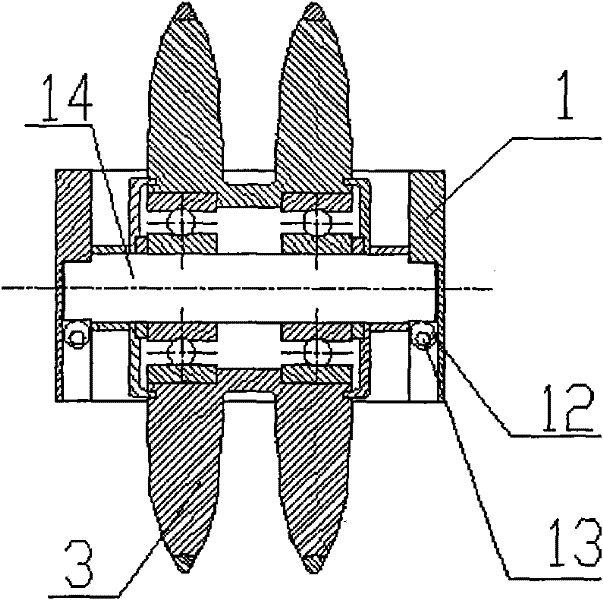

Multi-adaptive cutter head for shield machine

The invention discloses a multi-adaptive cutter head for a shield machine. The cutter head is provided with four cutter seats, three cutters directly fixed with the cutter head and movable cutters. Each cutter seat comprises a central double-edge hob seat, an exchangeable cutter seat, an inner and outer ring side-mounted cutter seat and a peripheral hob seat. The cutters include a peripheral scraper, an over cutter and a fishtail cutter. A main cutting surface of the cutter head is composed of a single-edge hob inlaid in the peripheral hob seat, a cutting blade in the inner and outer ring side-mounted cutter seat and the fishtail cutter; and a full section cutting cutter assembly is composed of a double-edge hob, a single-edge hob, a cutting blade, a peripheral scraper, an over cutter and a fishtail cutter. The multi-adaptive cutter head solves the problem that cutter replacement wastes time and labor, changes the traditional mounting mode to effectively prolong the service life of the cutter because the whole cutter works under a relatively smaller force, and can properly adjust the kind and the number of the cutters according to different geological conditions to effectively improve the adaptability of the cutter head of the shield machine and increase the efficiency and the quality of the tunnel shield.

Owner:TIANJIN UNIV

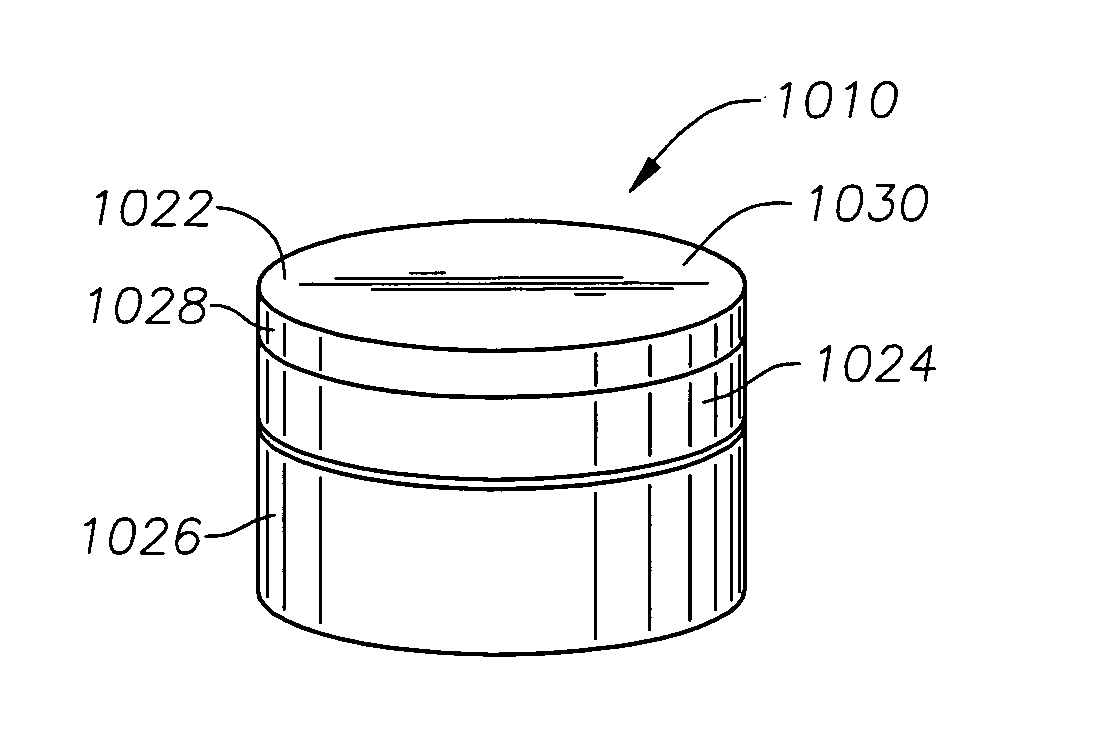

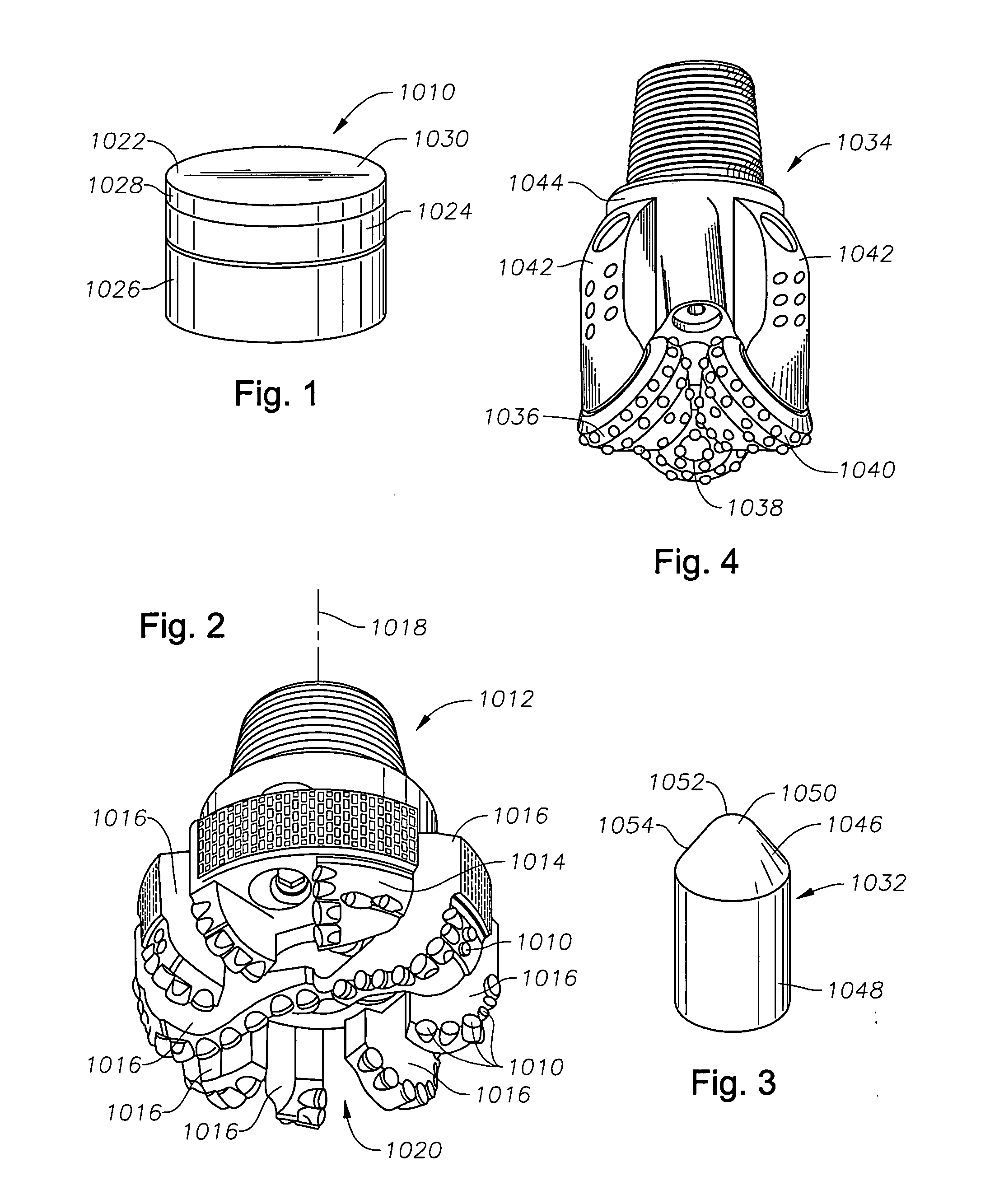

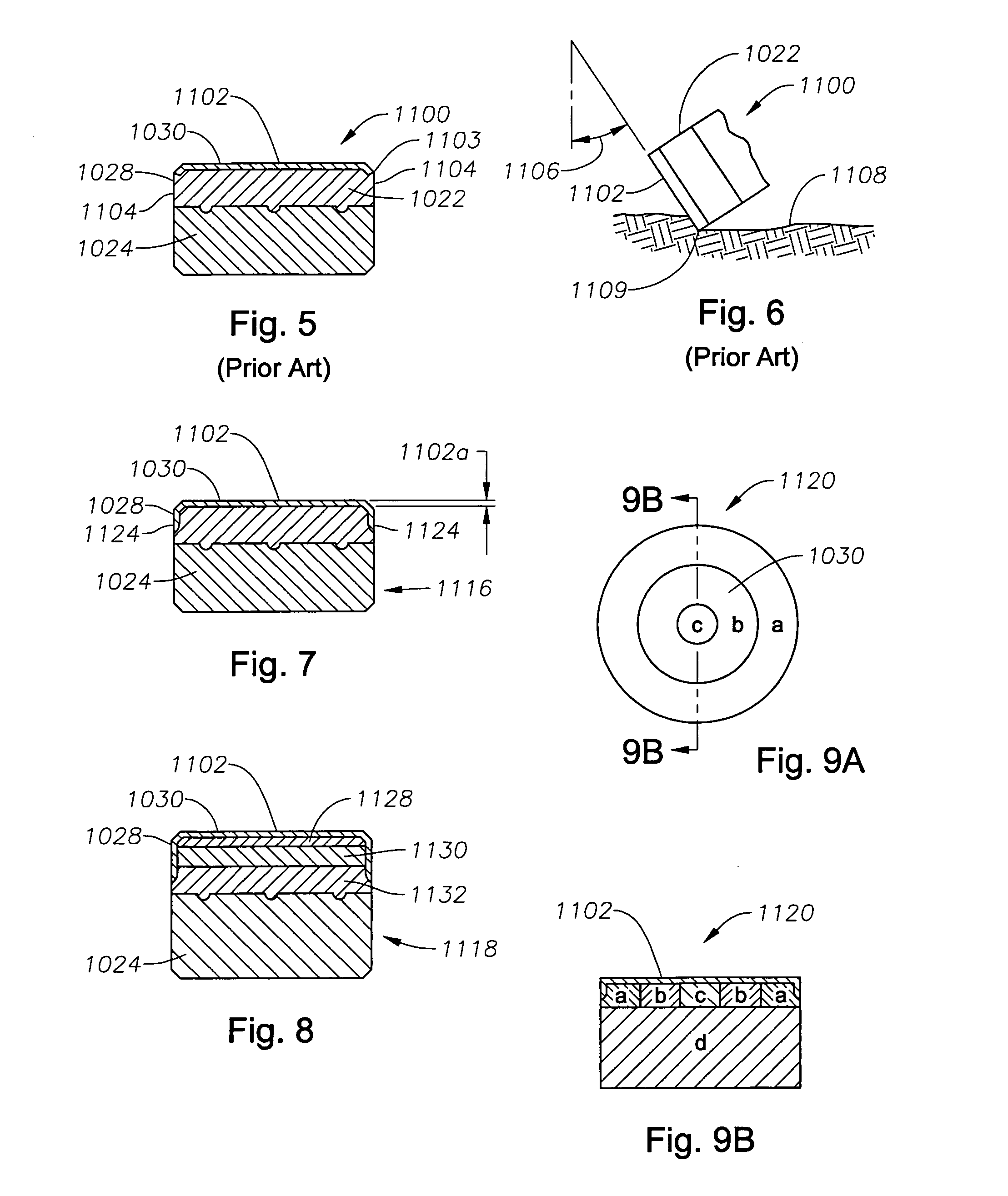

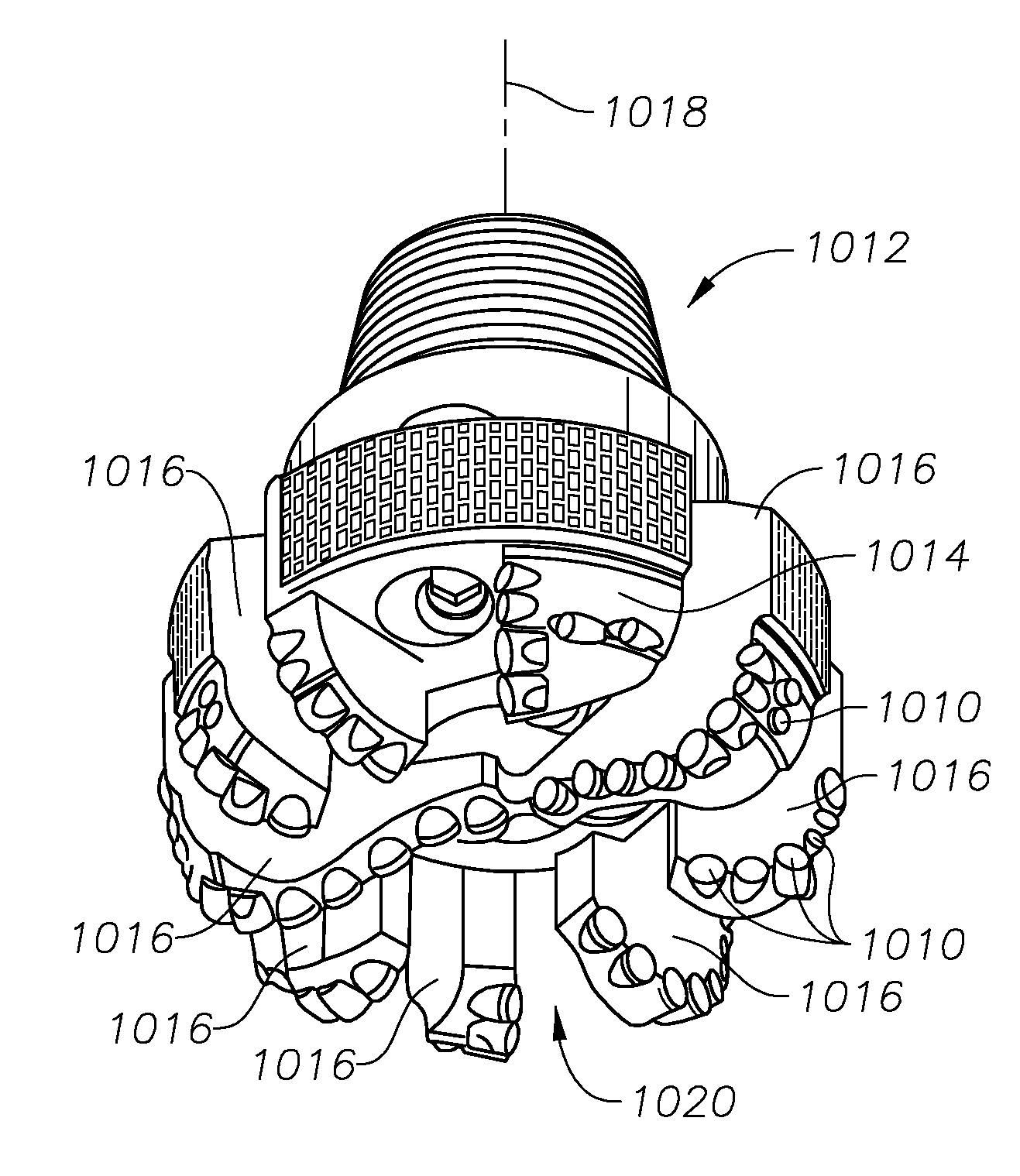

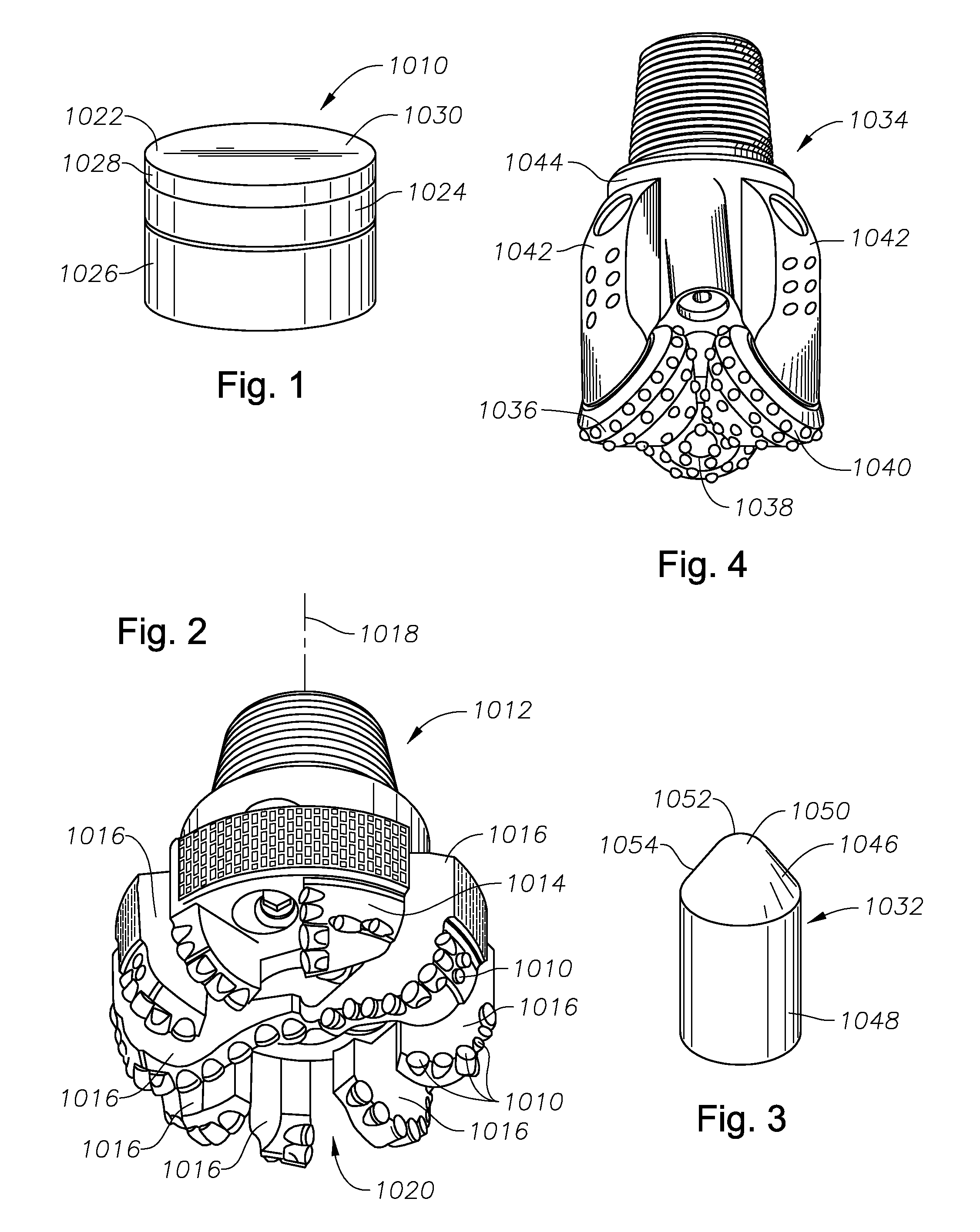

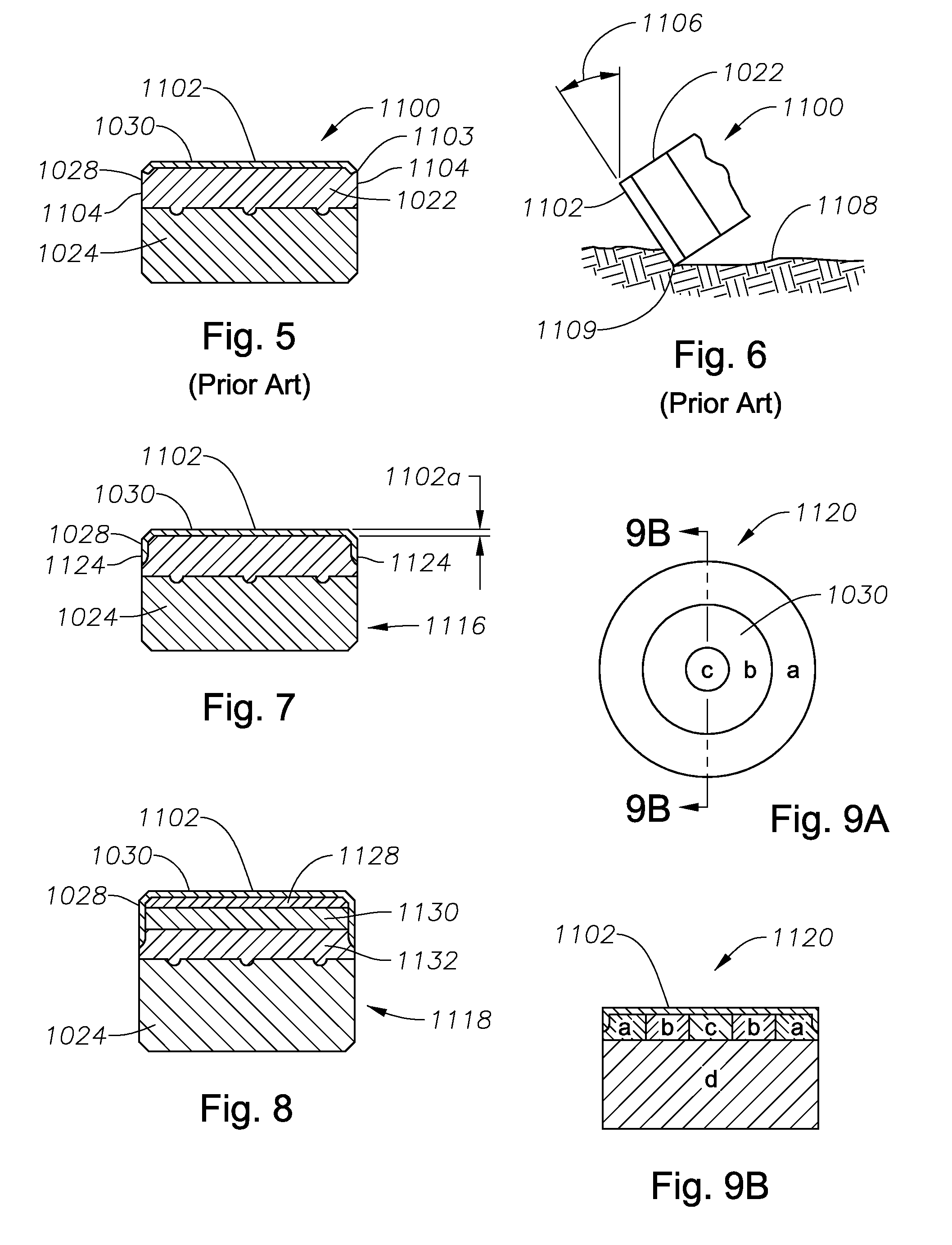

Dual-Edge Working Surfaces for Polycrystalline Diamond Cutting Elements

A polycrystalline diamond cutting element for earth boring drill bits presents regions of different abrasion resistance to the earthen formation when in operation. The cutting element has an end working surface and a region which is substantially free of catalyzing material, forming a layer. In operation, this layer wears at a different rate than the underlying material causing a pair of protruding lips to form. The end working surface may be substantially planar or frusto-conical in form.

Owner:REEDHYCALOG UK

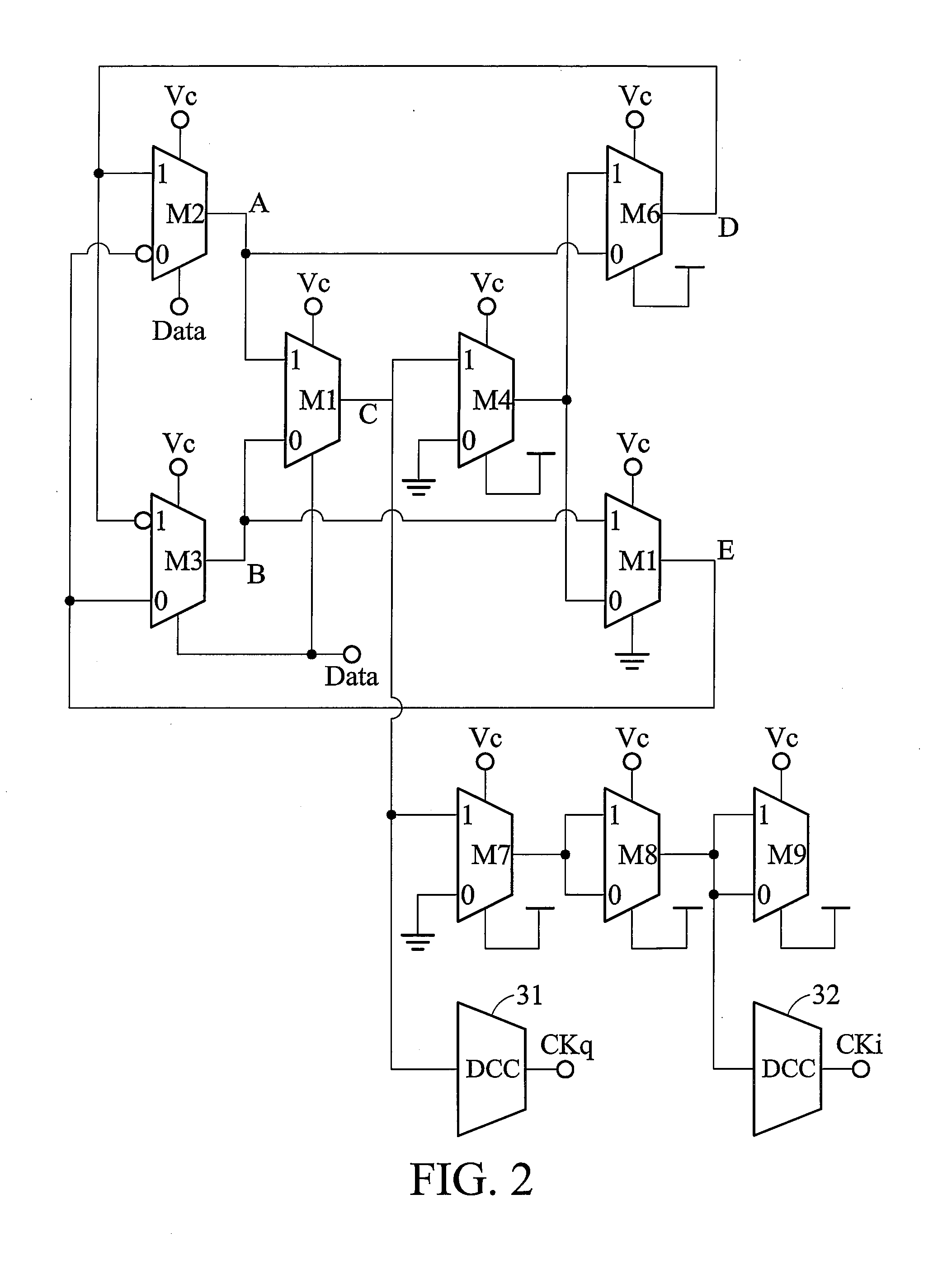

Multi-band burst-mode clock and data recovery circuit

ActiveUS20080260087A1Pulse automatic controlPulse generation by logic circuitsMulti bandVoltage reference

A clock and data recovery circuit is disclosed and comprises a first gated voltage-controlled oscillator, a PLL unit, a phase-controlled frequency divider, a multiplexer, a matching circuit and a double-edge-triggered D flip-flop. The first GVCO receives a data signal and a reference voltage to generate a first clock signal and a second clock signal based on the data signal. The PLL unit receives a reference clock signal and generates the reference voltage to adjust the frequency of the first clock signal and the second clock signal at the vicinity of the predetermined frequency. The phase-controlled frequency divider receives and divides the first clock signal by N to output a third clock signal. The multiplexer controlled by a selection signal receives and outputs the second clock signal or the third clock signal. The matching circuit receives the data signal and the selection signal to match the delays therebetween. The double-edge-triggered D flip-flop comprises a data input terminal receiving the output signal from the matching circuit, a clock input terminal receiving the output signal from the multiplexer, and an output terminal outputting a recovered data signal.

Owner:MEDIATEK INC +1

Fine resolution pulse width modulation pulse generator for use in a multiphase pulse width modulated voltage regulator

ActiveUS7239116B2Improve performanceHigh resolutionDc-dc conversionElectronic switchingTrailing edgeLinearity

Disclosed is a fine resolution pulse width generator for use in a multiphase pulse width modulated voltage regulator. The fine pulse width is generated by first generating a pulse with a coarse pulse width and one or more delayed replicas thereof. Then, digitally controlled analog interpolators are used to generate the fine resolution pulse width pulse by interpolating among the coarse pulse width pulses. Both single edge and double edge modulation embodiments are disclosed providing interpolation of just the trailing edges of the coarse pulses or both the leading and trailing edges, respectively. The disclosed fine resolution pulse generator uses counters, thermometer encoders and analog interpolators to achieve interpolation accurately by insuring that each interpolation step corresponds to an equal weight. Accuracy of the interpolation is defined by the linearity (i.e. how well the interpolation fits a best fit straight line) and monotonicity (i.e. how each step contributes a positive weight to the total).

Owner:INFINEON TECH AUSTRIA AG

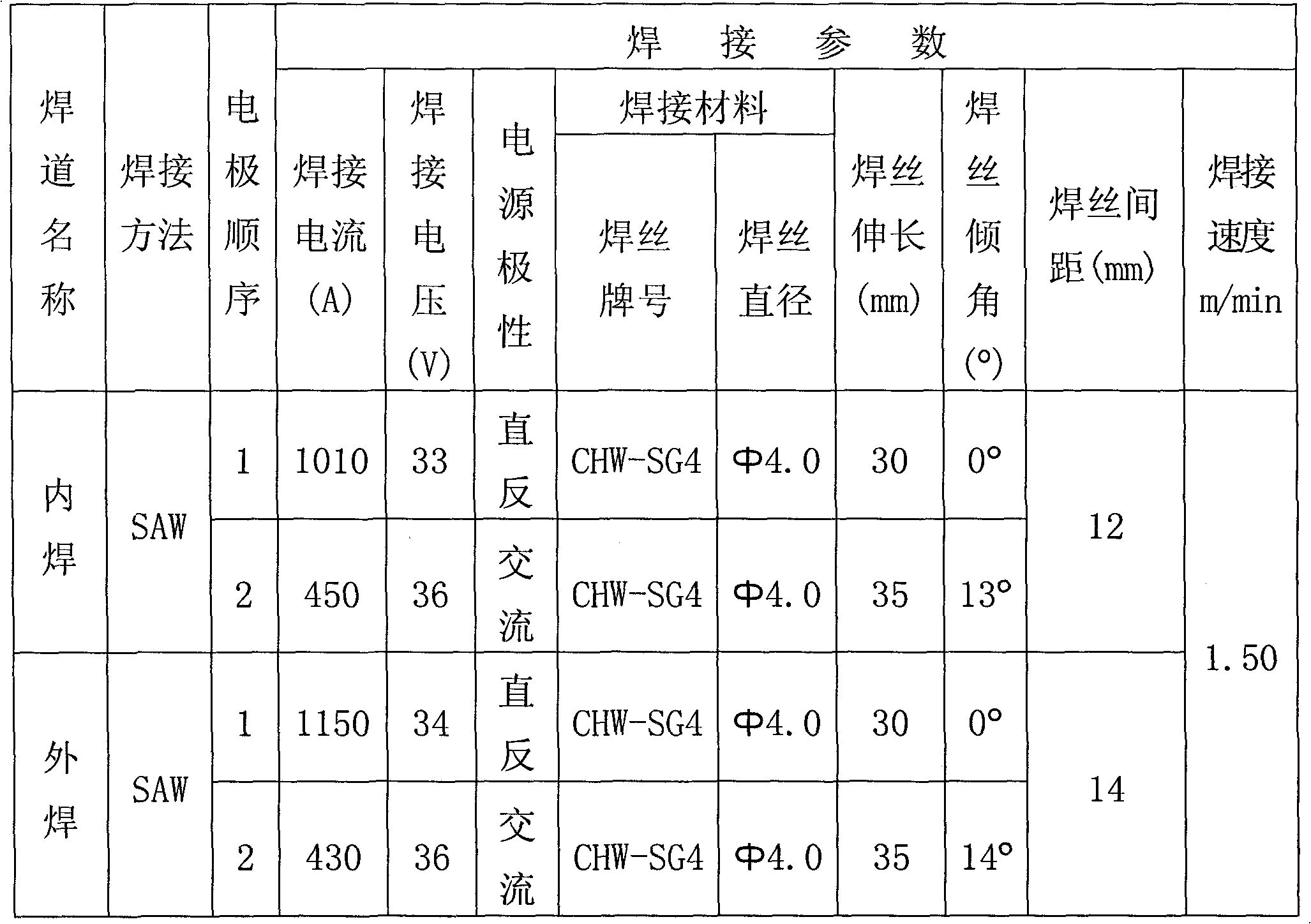

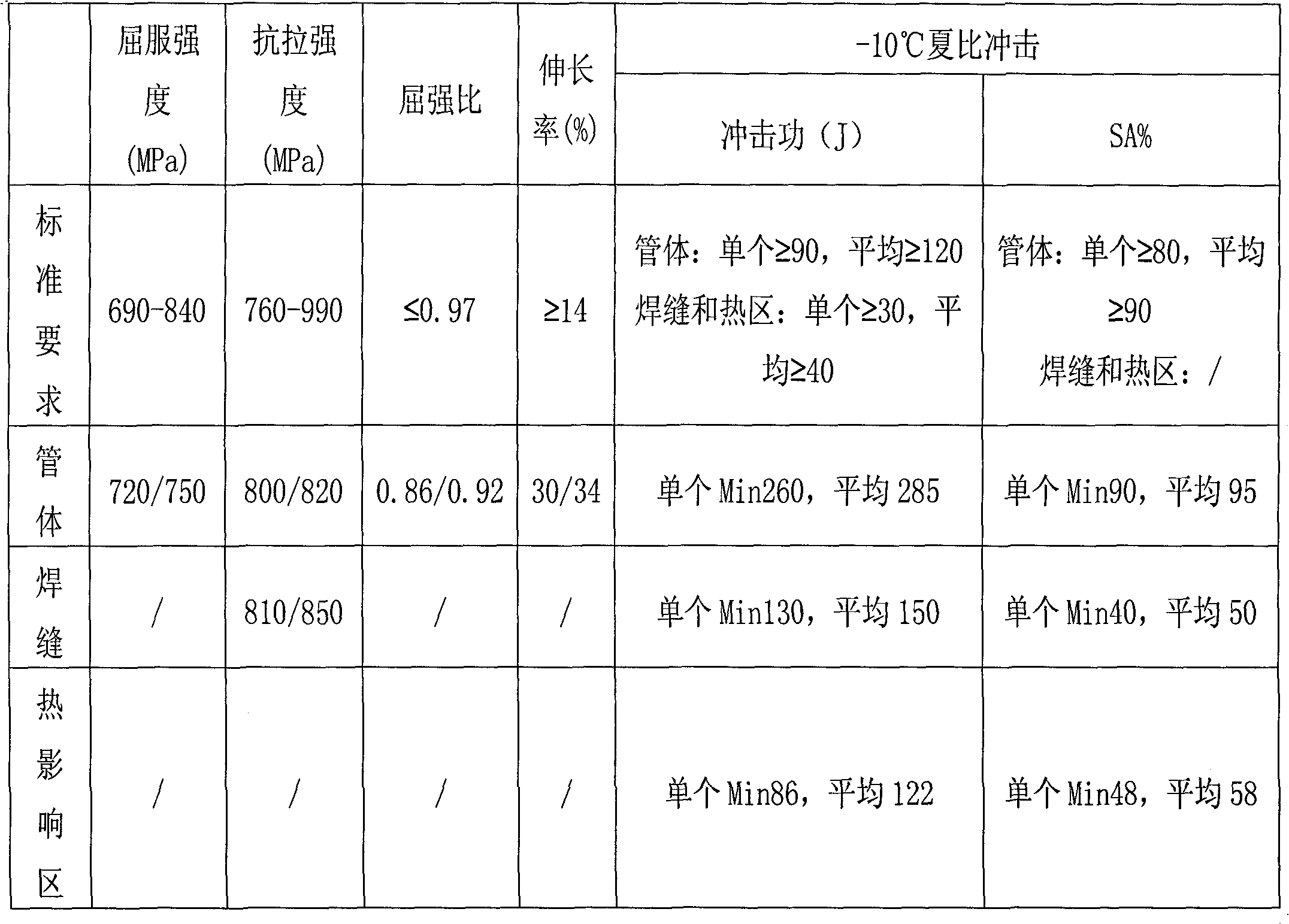

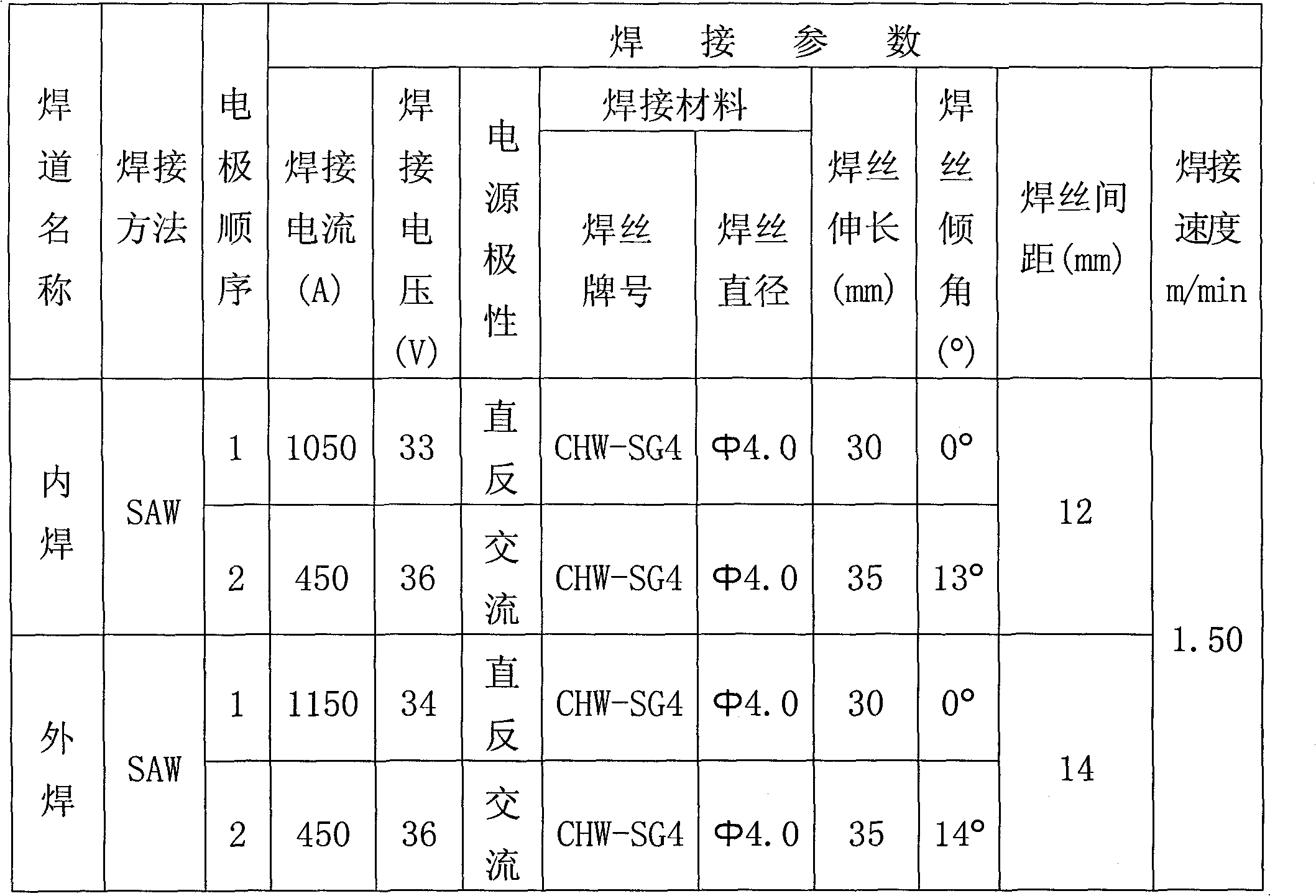

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

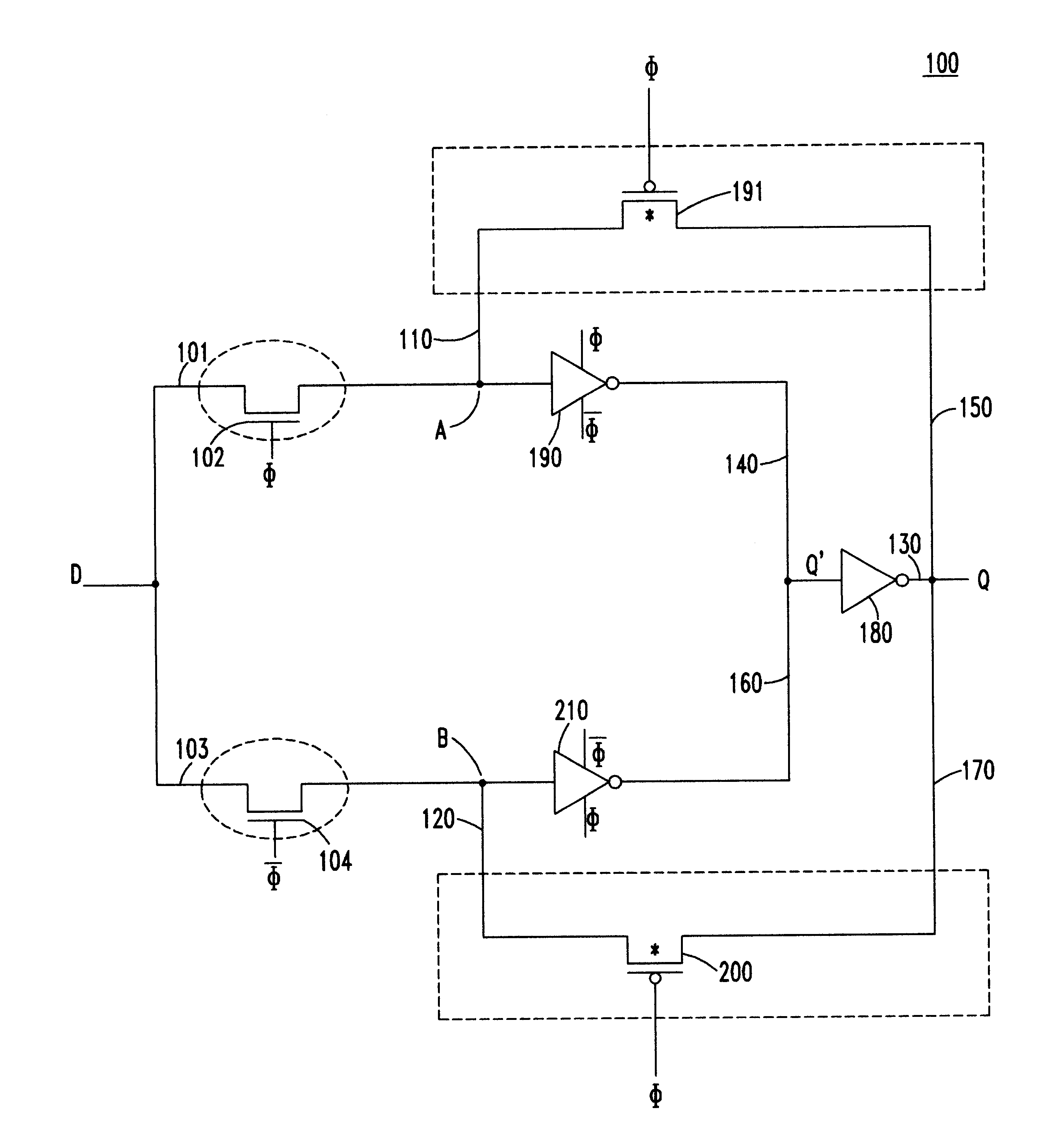

Reduced-transistor, double-edged-triggered, static flip flop

A static, double-edge-triggered flip-flop has an upper data path and a lower data path connected between a data input node and an output terminal. The upper path includes a switch connected to a first data loop, and the lower path includes a switch connected to a second data loop. The first and second data loops share a forward path having a data-inverting circuit. In addition, each loop has a feedback path which contains only one element in the form of a switch. However, no data-inverting circuit is included in either of the feedback paths. Advantageously, all the elements of the flip-flop may be constructed using MOSFET transistors implemented according to any one of a variety of semiconductor technologies. In more than one particularly advantageous embodiments, the flip-flop is constructed using a total of twelve transistors. Through this simplified two-loop design, operational efficiency is improved, low metastability is achieved and costs of manufacture are lowered, all while maintaining low power requirements.

Owner:IBM CORP

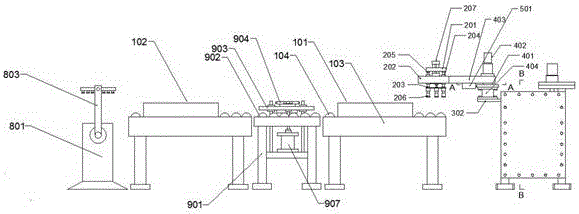

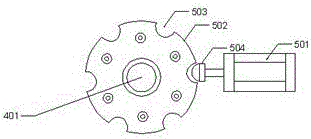

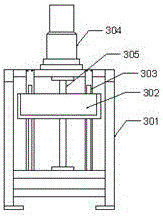

Automatic double-edge glass edge grinding production line

InactiveCN106334984AEasy to operateImprove work efficiencyEdge grinding machinesGrinding feedersProduction lineEngineering

The invention discloses an automatic double-edge glass edge grinding production line. The automatic double-edge glass edge grinding production line comprises a first edge grinding machine, a second edge grinding machine, a reversing system arranged between the first edge grinding machine and the second edge grinding machine, a feeding system conducting automatic feeding of glass and a discharging system discharging the glass after edge grinding is completed. The first edge grinding machine and the second edge grinding machine are identical in structure and each comprise a base, a conveyer belt which is arranged on the base and supports and conveys the glass, an edge grinding system conducting double-sided edge grinding on the glass and a locating system conducting position correction on the glass before edge grinding. The automatic double-edge glass edge grinding production line has the beneficial effects that the control action is precise and stable, the glass is conveyed precisely in place, production operation is facilitated, the production efficiency is improved, the labor cost is reduced, the operation automation degree of the whole automatic double-edge glass edge grinding production line is high, operation is easy and convenient, the glass is aligned before edge grinding, automatic feeding and discharging can be achieved, the automatic double-edge glass edge grinding production line can continuously grind the glass through the coordination of automatic edge grinding machines, and the automatic double-edge glass edge grinding production line is high in practicability and can improve the work efficiency of glass edge grinding.

Owner:宿州市天艺玻璃股份有限公司

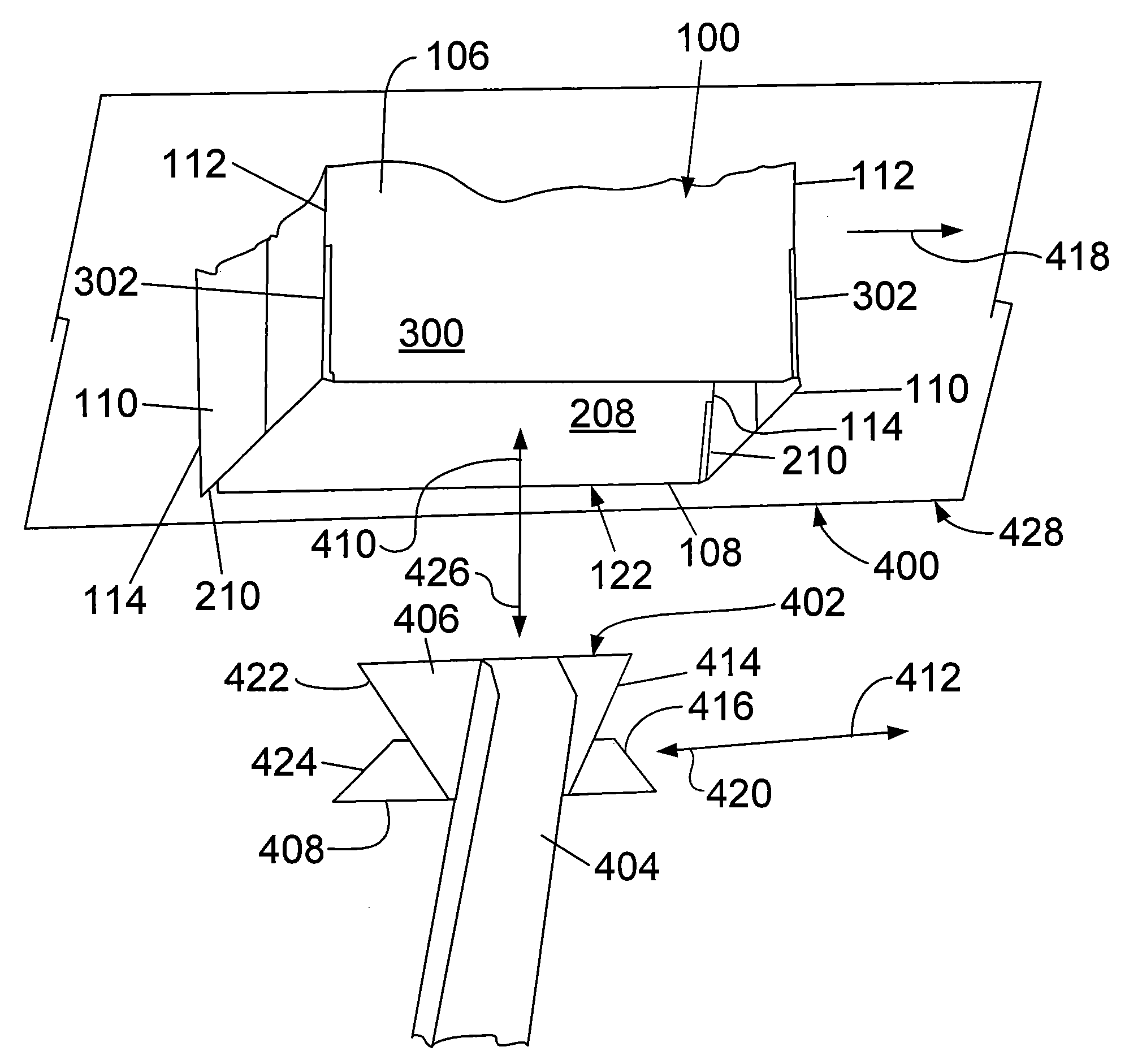

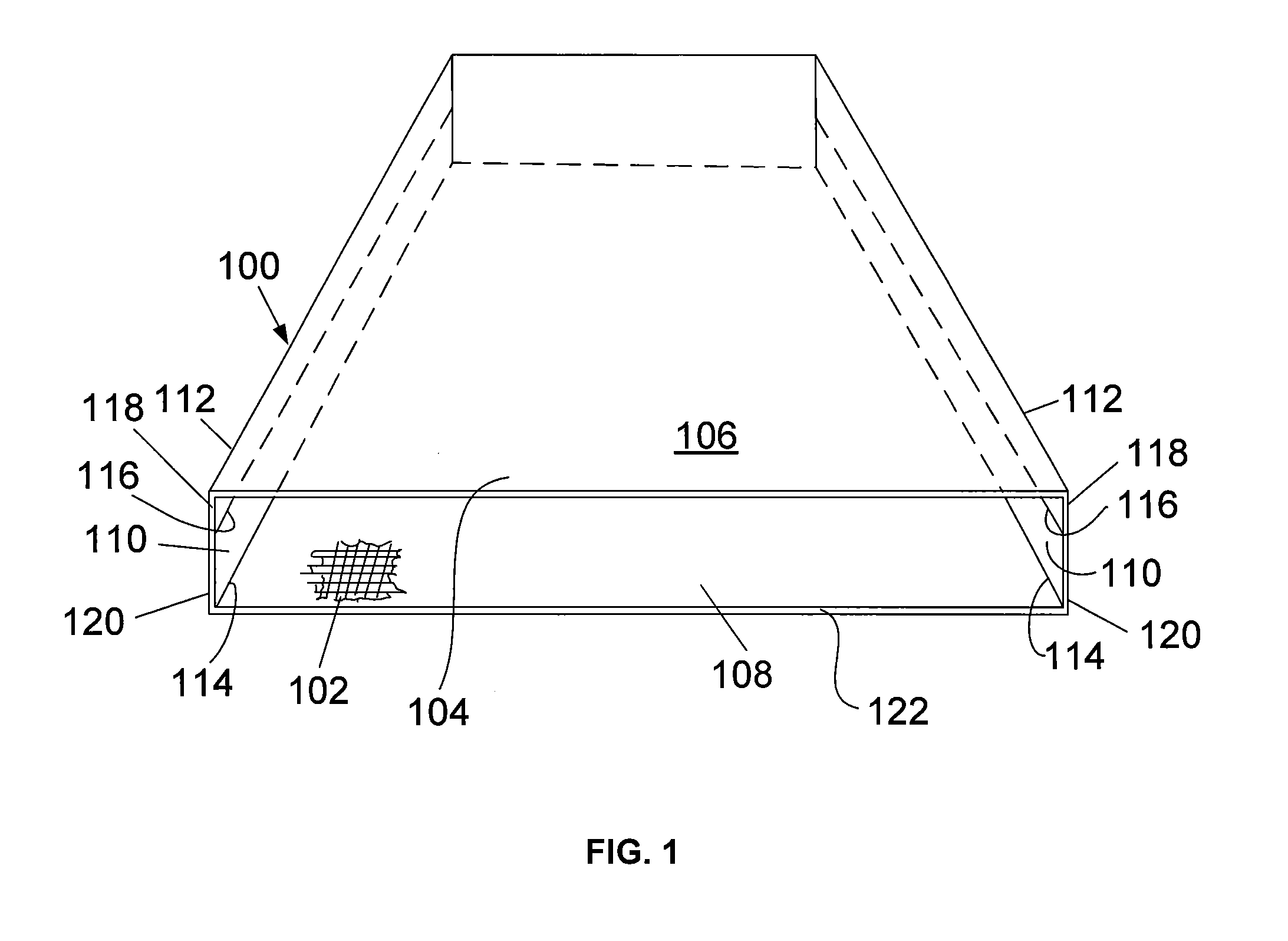

Method and system for making a stepped end

ActiveUS20110263400A1Envelopes/bags making machineryBag making operationsEngineeringAdhesive materials

A method and apparatus for making a stepped end on a tube of flexible material includes a tube slitting station having a slitting tool with double edge slitting blades penetrating through the tube to provide respective slits beside a first panel and beside a second panel, respectively; a first trimming station trimming a first panel of the tube to a first shortened length, a second trimming station trimming the side gussets to a second length, wherein the second length is longer than the first shortened length of the first panel; and an adhesive applying station applying adhesive on the tube above and below a fold line across the tube, wherein the tube is adapted to be folded along the fold line, and the adhesive material is adapted to form an adhesive to adhesive seal above and below the fold line while the tube is folded to provide a closed stepped end for a bag.

Owner:COATING EXCELLENCE INT

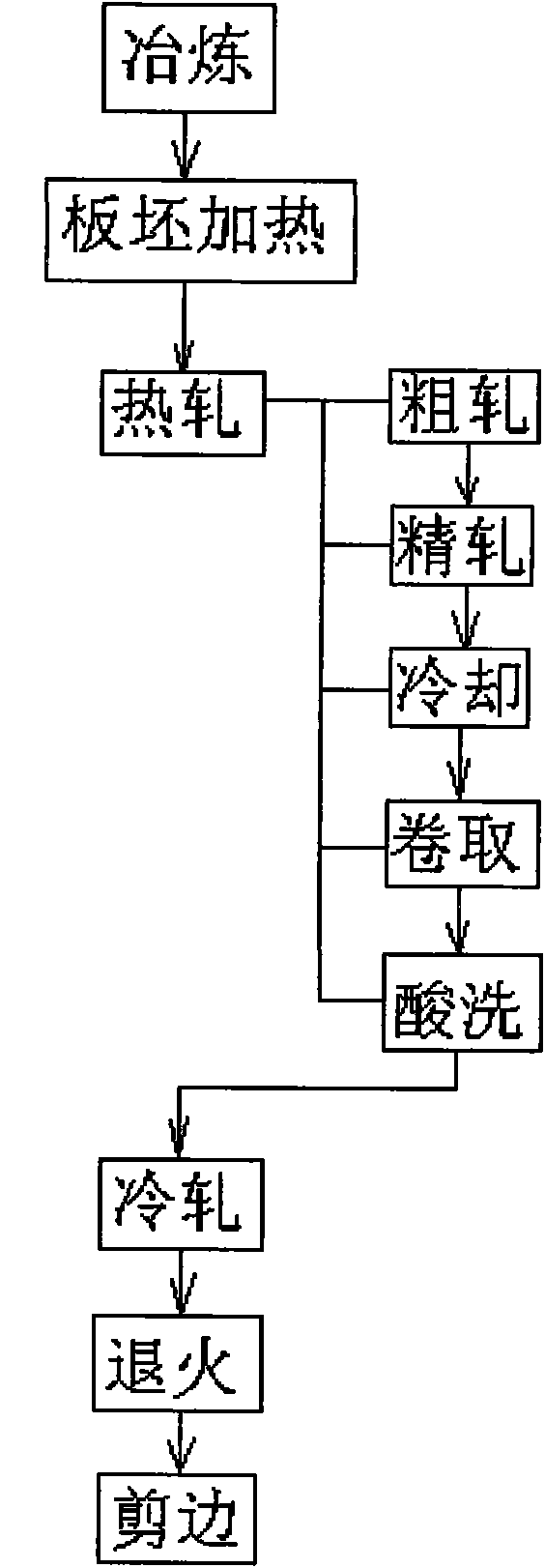

Manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel

InactiveCN101811134AThe chemical composition is simple and easy to controlSimple designTemperature control deviceMetal rolling arrangementsAcid washingStrip steel

The invention relates to a manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel, which sequentially comprises the steps: melting, plate blank heating, coarse milling, fine milling, cooling, coiling, acid washing, cold rolling, annealing and finishing and edge cutting, wherein the edge is not cut during steel coil acid washing, and the circular arc-shaped edge is maintained when the steel enters the cold rolling work procedure after the acid washing. The same plate temperature different in the plate blanking heating is lower than or equal to 40 DEG C, and the side pressure amount of the coarse milling is smaller than or equal to 50 mm. The final rolling temperature of the fine rolling is between 880 and 920 DEG C, an auxiliary vertical roller F1E of a machine frame F1 has the side pressure amount of 3 to 10 mm. The cooling is the laminar cooling of fast front section cooling with the cooling speed between 15 and 30 DEG C / s. The coiling temperature is between 650 and 710 DEG C. The single-edge cutting amount during the edge cutting is controlled between 5 and 7 mm, and the double-edge cutting amount is controlled between 10 and 14 mm. The thickness of cold rolling finished products of strip steel is between 0.15 and 0.45 mm, and the pressing rate is between 87.1 and 95 percent. The invention can solve the problem of edge crack of the paper-thin strip steel in the prior art.

Owner:NINGBO IRON & STEEL

Image restoration method based on double-edge wave filter and margin deconvolution

InactiveCN101639938AQuality improvementRich image detailImage enhancementImage restorationComputer vision

The invention discloses an image restoration method based on a double-edge wave filter and margin deconvolution, comprising the following steps: (1) obtaining a restoration image with rings by adopting a standard RL algorithm to carry out higher iteration according to an image to be restored and a known fuzzy core; (2) adopting a double-edge wave filter to carry out filtering operation of the restoration image with rings to obtain the restoration image without rings; (3) carrying out the deconvolution on the restoration image without rings by the known fuzzy core to obtain a re-fuzzy image; (4) obtaining a restoration image detail by adopting the margin deconvolution by the re-fuzzy image obtained by the step (3) and the image to be restored, and adding the restoration image detail with the restoration image after eliminating ring to obtain a new restoration image containing ring; and (5) repeating the steps (2)-(4) for many times to obtain a final restoration image. The image restoration method can effectively inhibit middle and high frequency rings in the restoration image of the iterative algorithm, remain rich image details and obtain high-quality restoration images.

Owner:ZHEJIANG UNIV

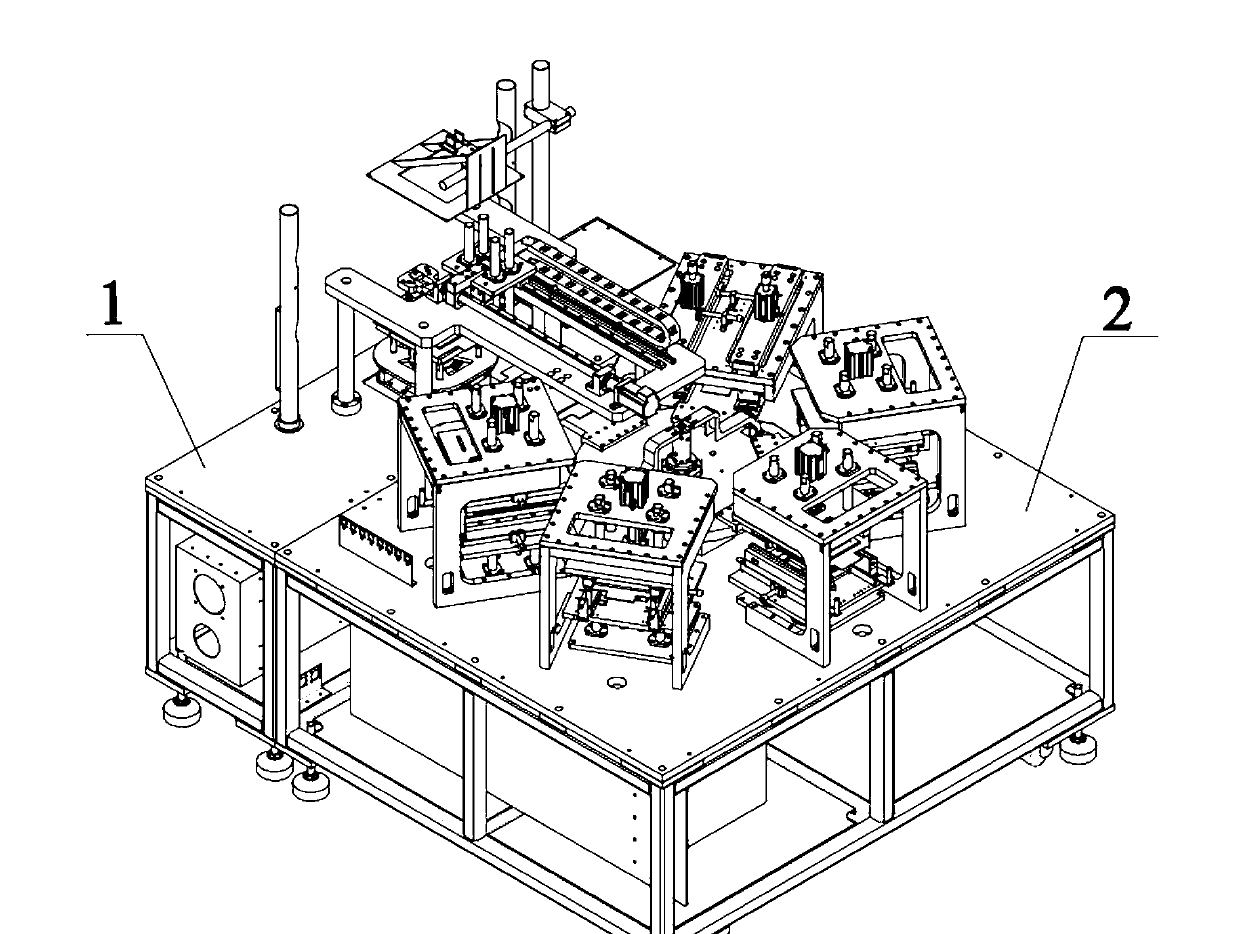

Battery core automatic forming device

ActiveCN103219539AControl positionImprove yieldFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

The invention relates to the field of machinery manufacturing, and specifically relates to a forming device used in soft-package lithium battery automatic edge cutting, edge folding, and edge burning. The device comprises a loading and unloading device, and a plate loading, cutting, folding, and burning device. The loading and unloading device comprises a CCD visual positioning mechanism which is connected with an X, C axis correction mechanism. A turntable loading and unloading manipulator is arranged above the X, C axis correction mechanism. The plate loading, cutting, folding, and burning device comprises a turntable mechanism. The loading and unloading device, a double edge-cutting mechanism, a preheating mechanism, a 90 DEG C edge folding mechanism, a 150 DEG edge folding mechanism, and a 180 DEG edge trimming mechanism are sequentially arranged on the periphery of the turntable mechanism. With the device, battery packaging forming is sequentially completed. Therefore, edge cutting accuracy and high efficiency are ensured, soft package corner breakage during edge folding can be effectively prevented, and same high-precision edge folding effects on the two ends of the battery core can be maintained.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

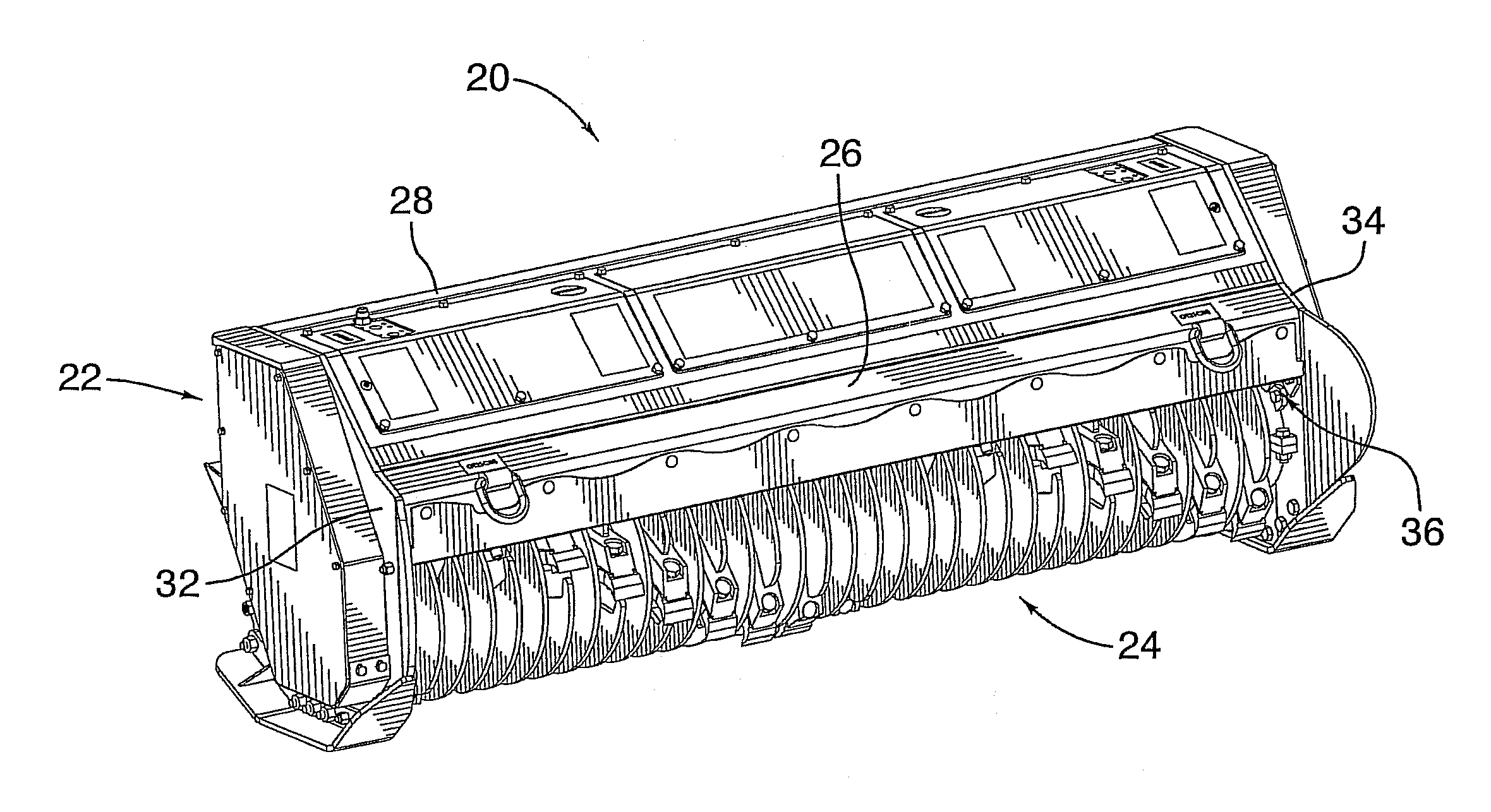

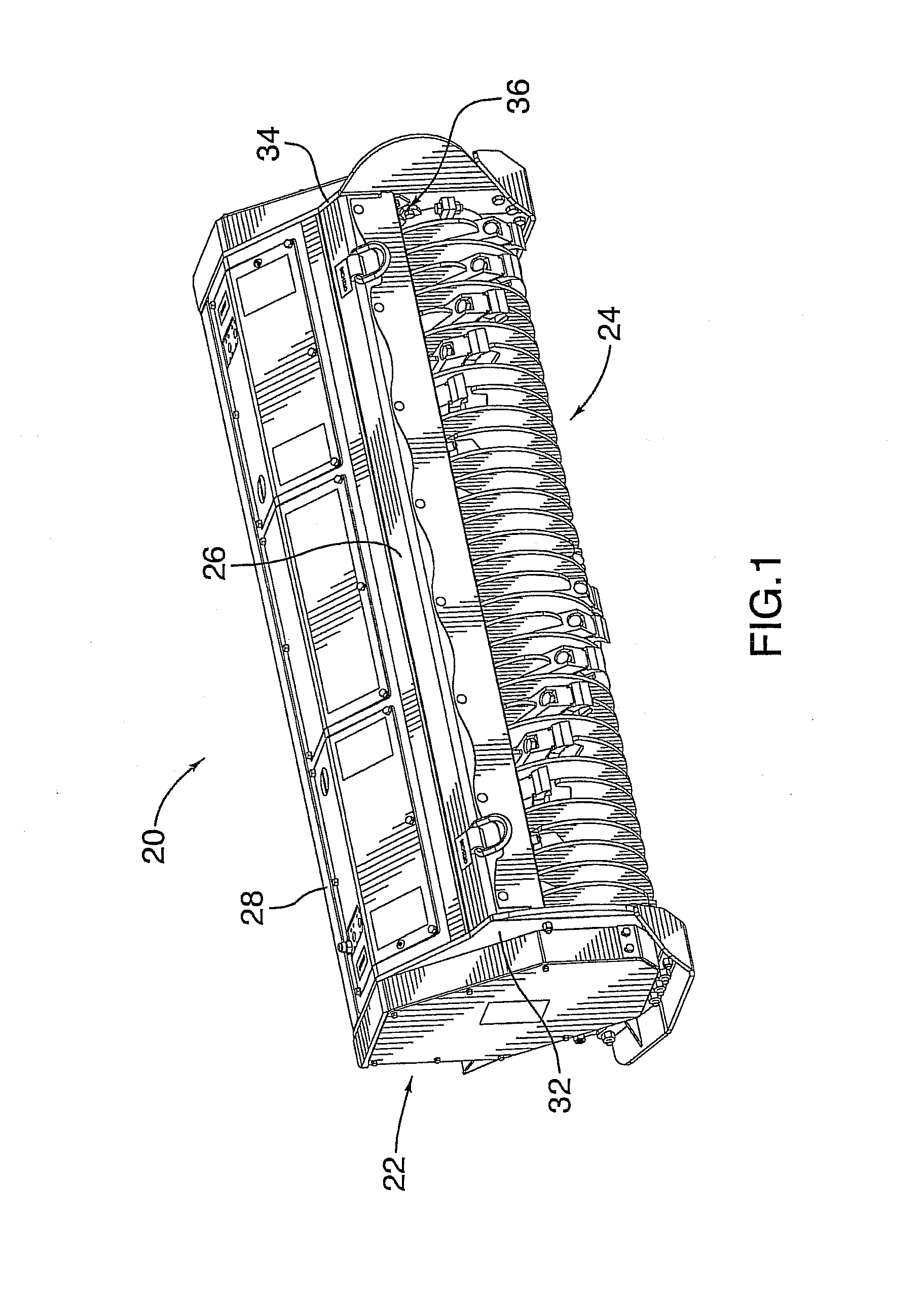

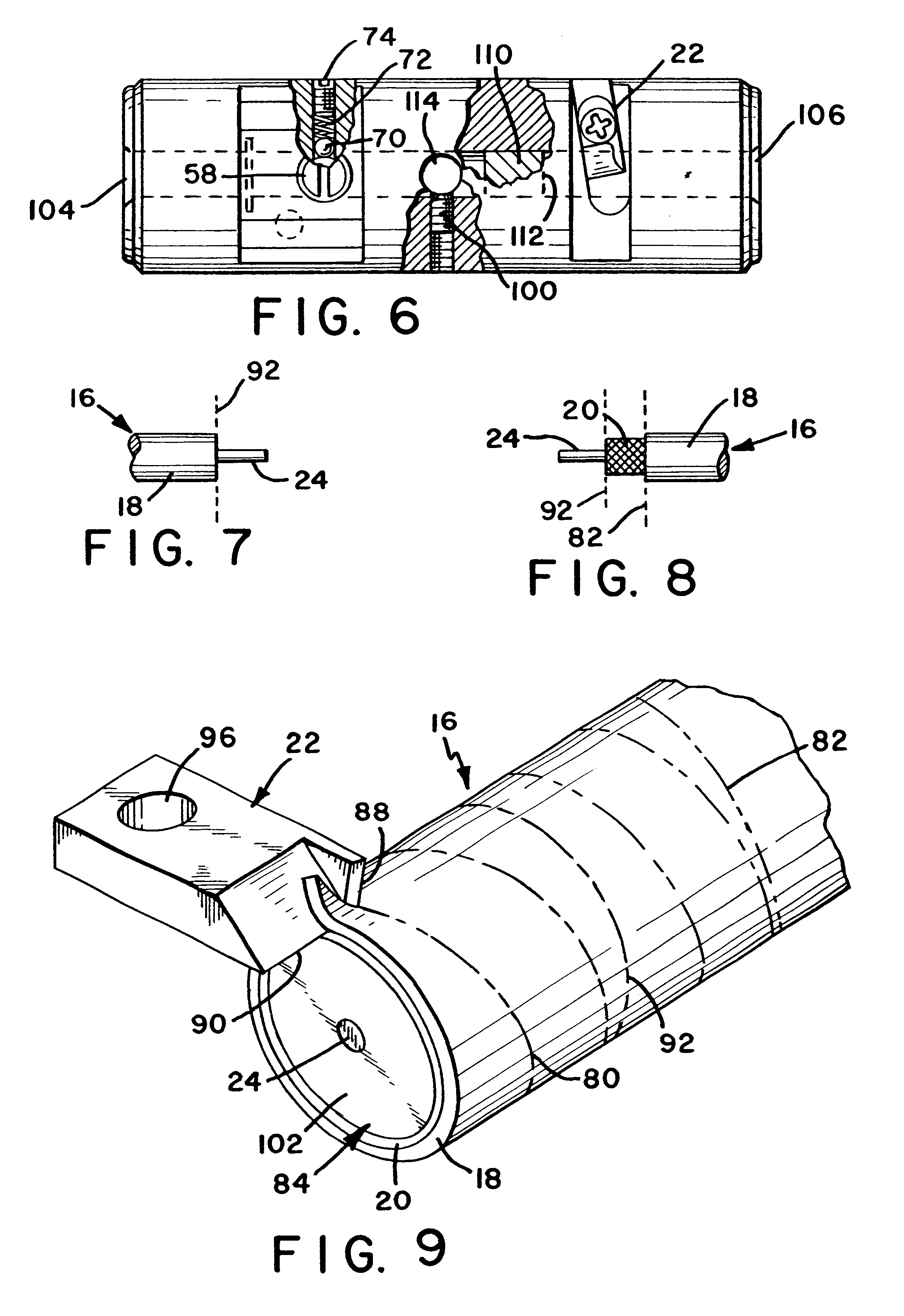

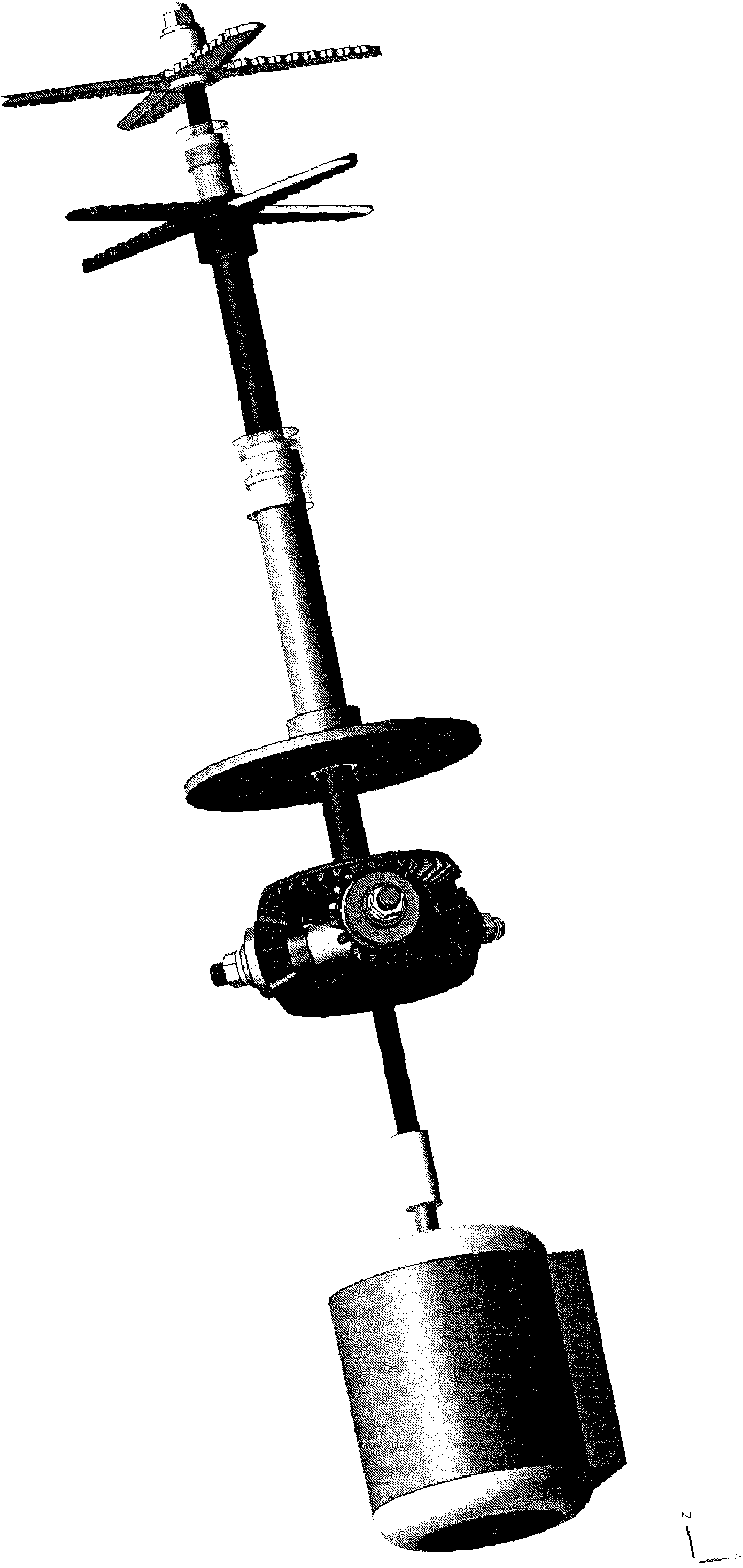

Cutting tooth with dual cutting edges for a brush cutting head

InactiveUS20130099039A1Prevent rotationGrinding machine componentsWood working apparatusEngineeringScrew thread

The present invention relates to a cutting tooth for attachment to a mounting block. The cutting tooth includes a longitudinal body provided with leading and trailing faces, and opposed, first and second cutting portions. The leading face has a projection disposed thereon to reinforce the longitudinal body. The trailing face has defined therein at least one threaded, blind bore. The at least one blind bore extends substantially into the projection but stops short of a leading projection face. It is configured to receive therein a threaded bolt for securing the cutting tooth to the mounting block. The first cutting portion terminates in a first cutting edge having an angle of attack of between 20 and 75 degrees. The second cutting portion terminates in a second cutting edge having an angle of attack between 20 and 75 degrees.

Owner:GYRO TRAC

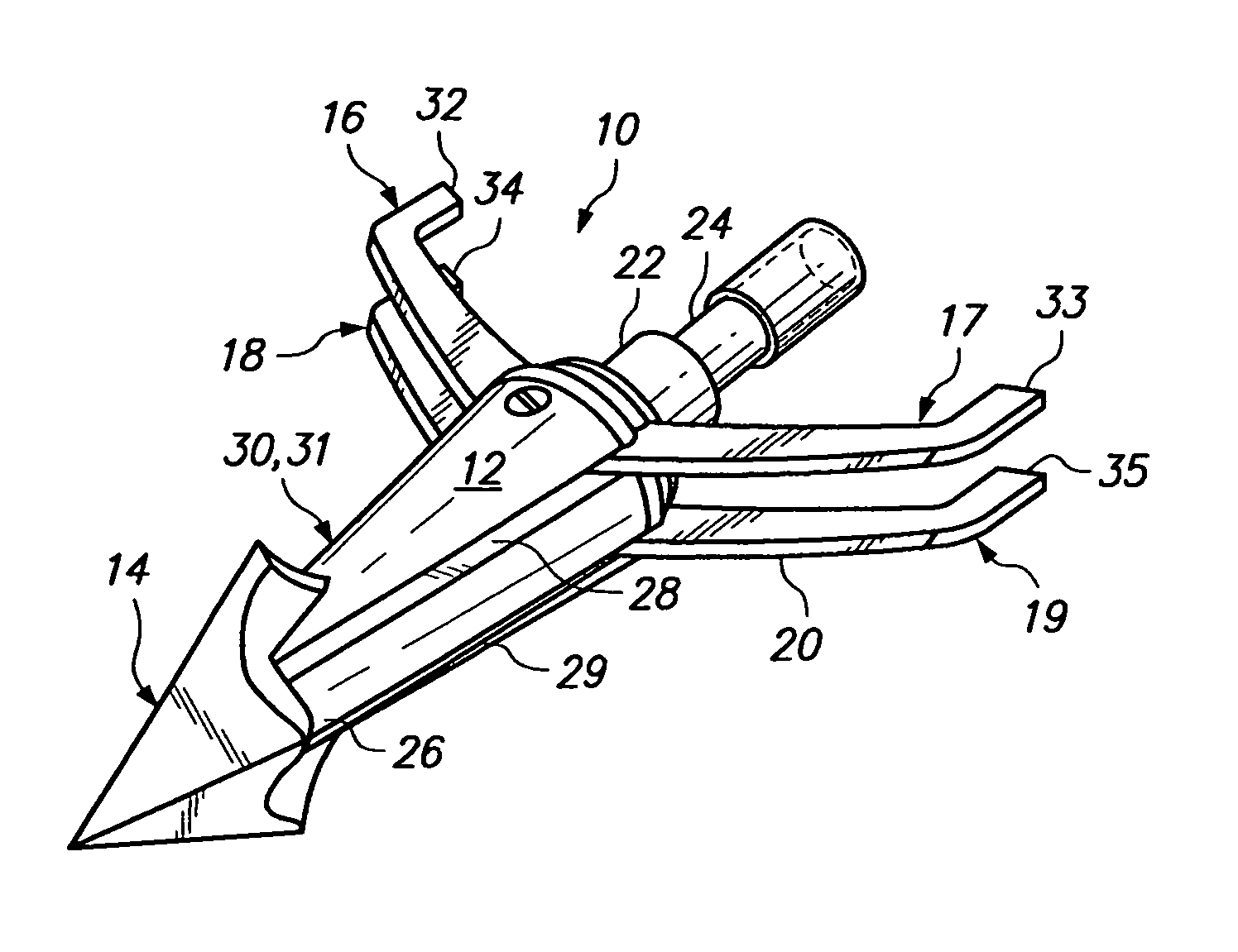

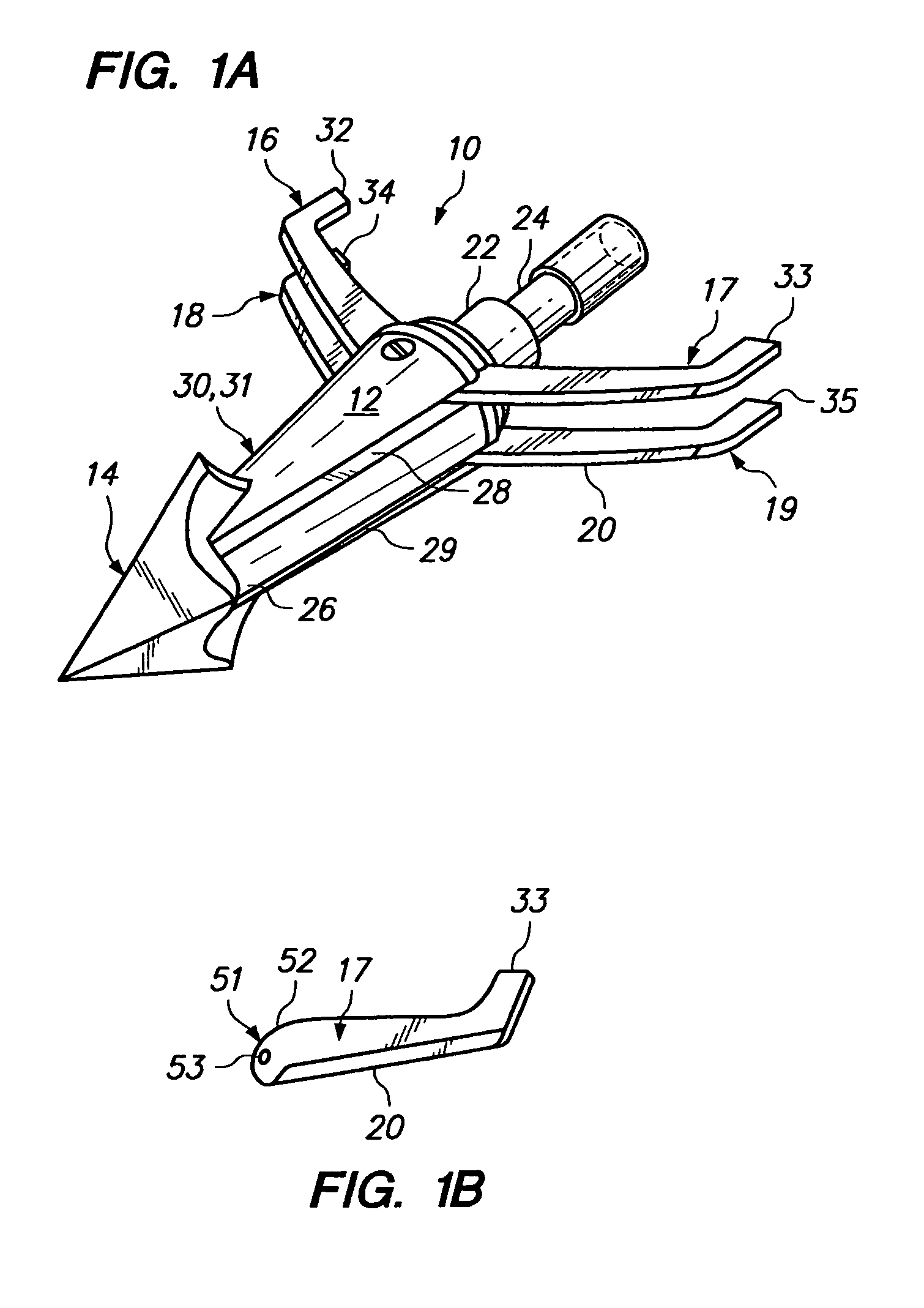

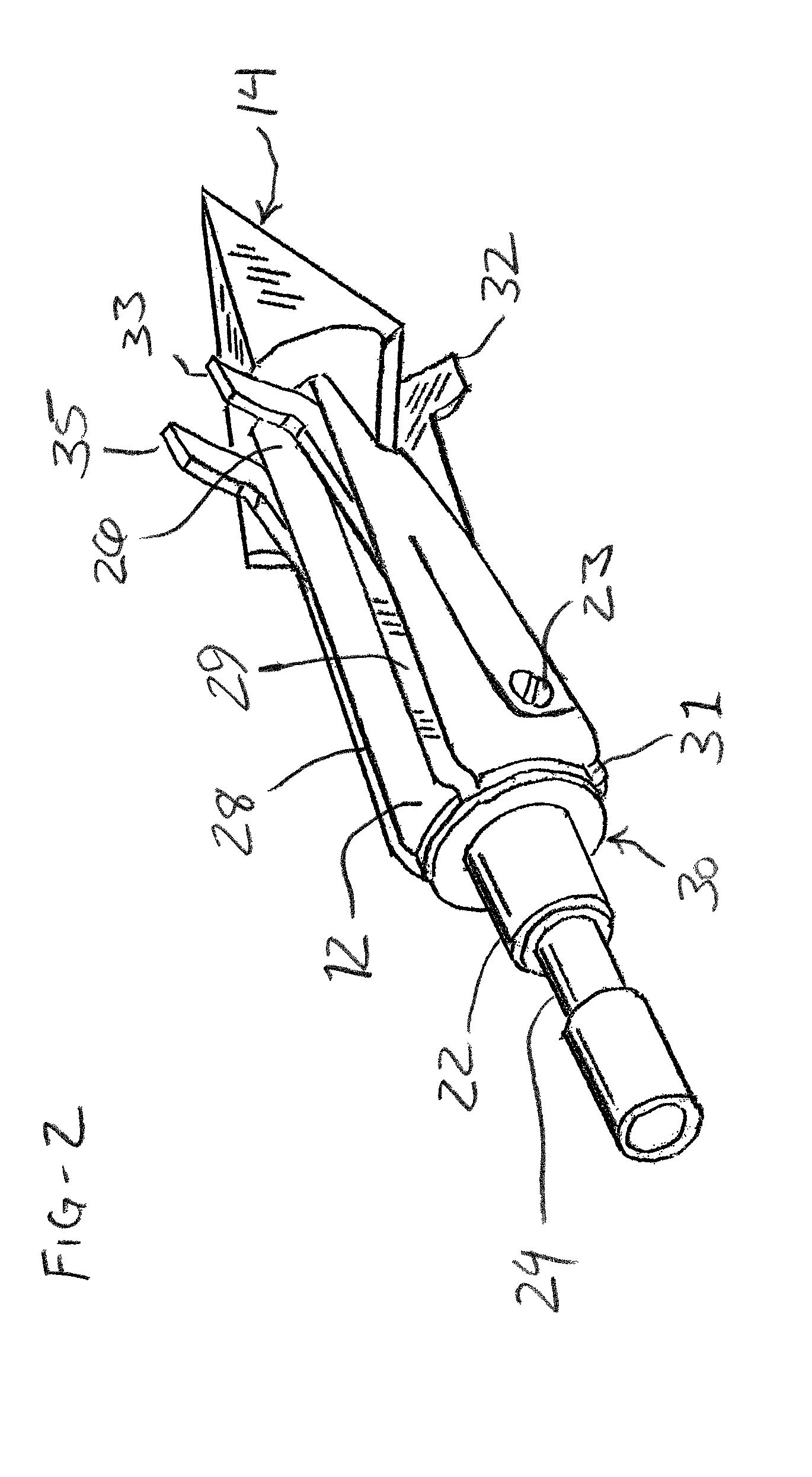

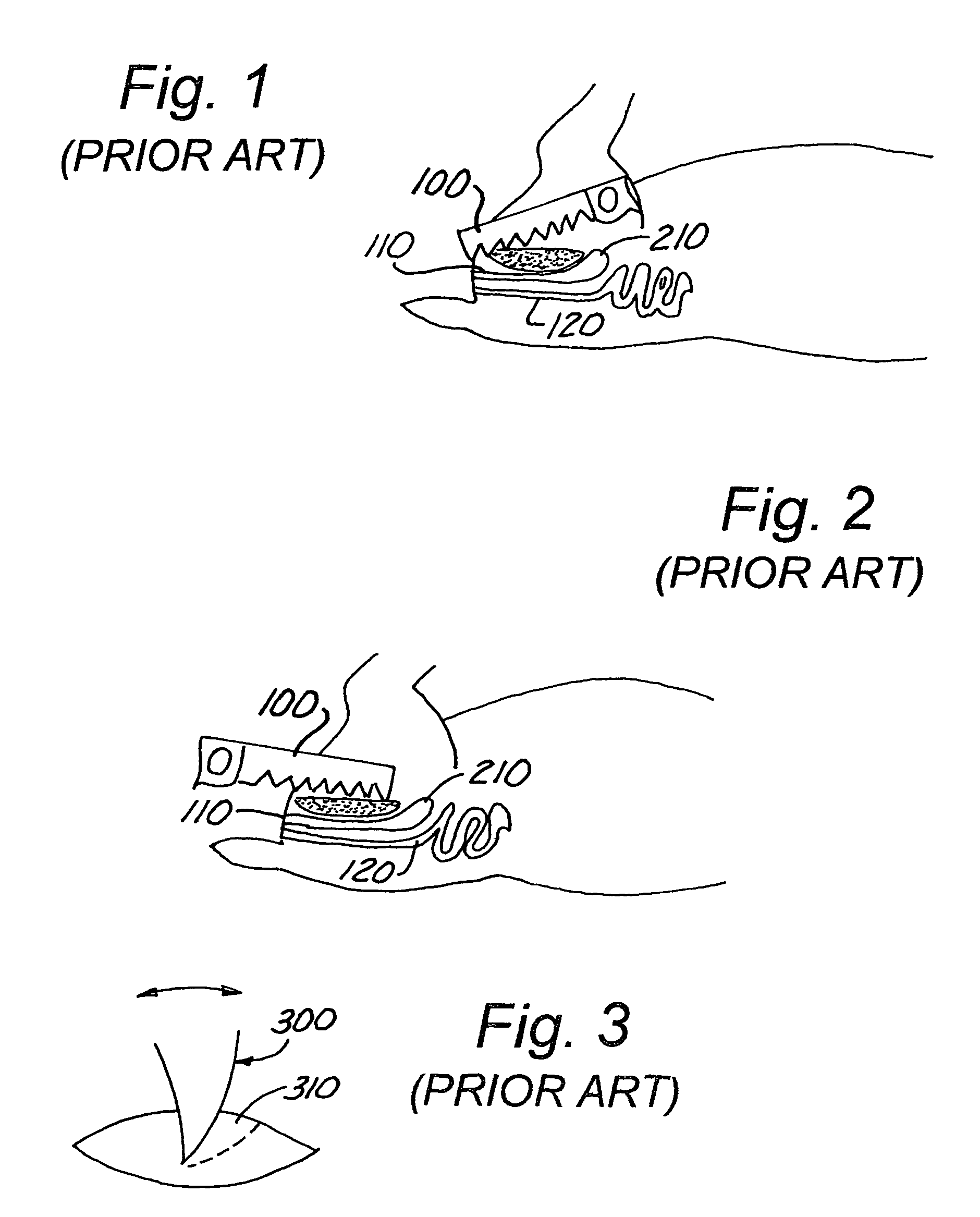

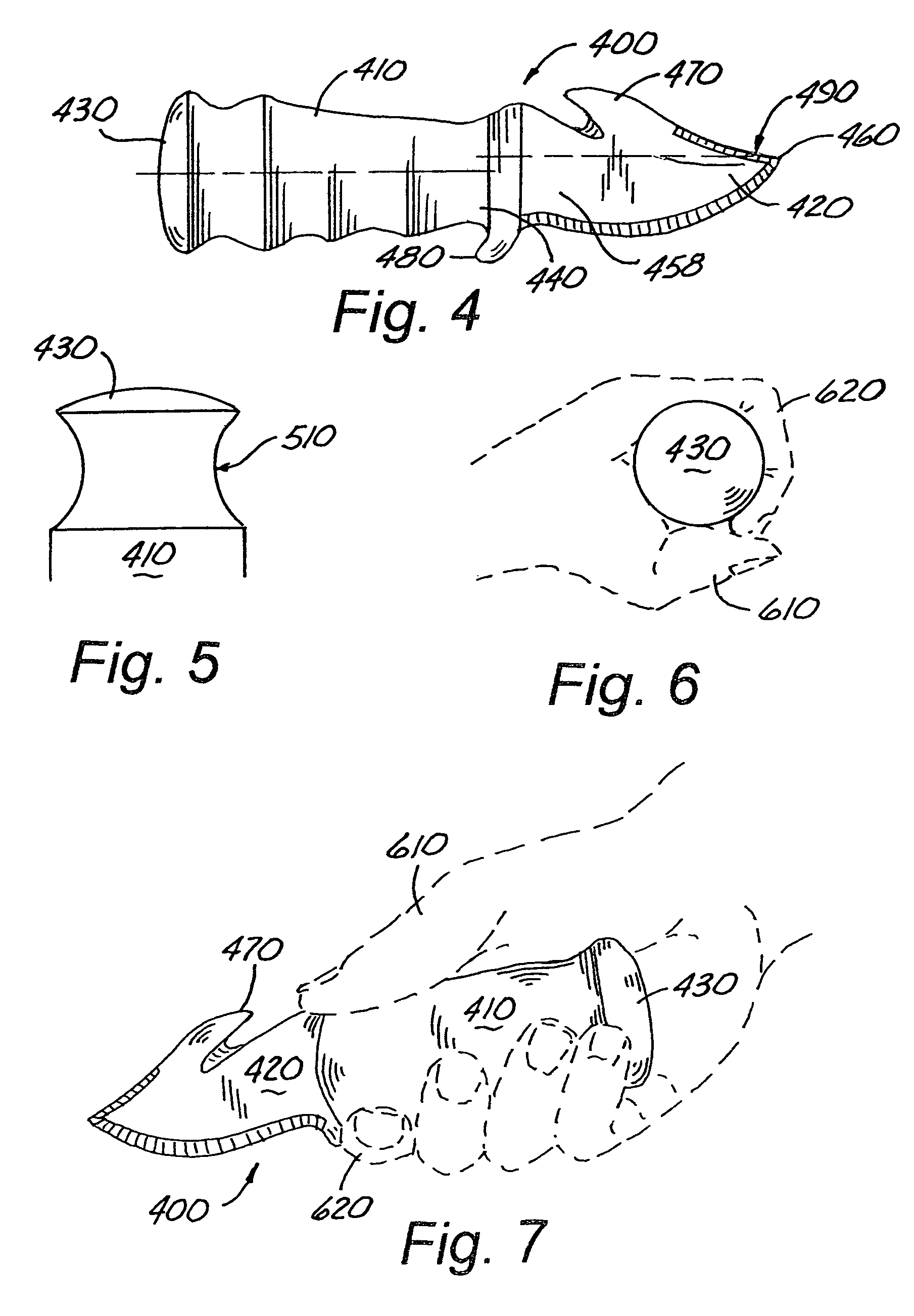

Arrowhead having both fixed and mechanically expandable blades

Owner:FERADYNE OUTDOORS LLC

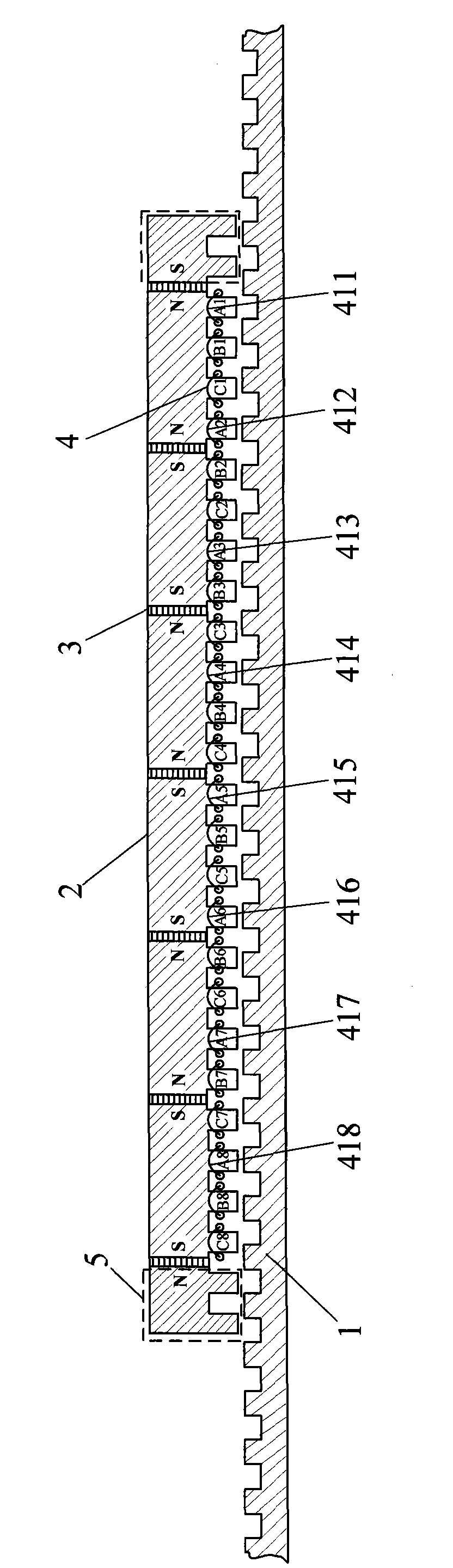

Multiphase long-stator primary permanent magnet linear motor

ActiveCN101783573AImprove cooling conditionsCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsPrimary permanentElectric machine

The invention relates to a multiphase long-stator primary permanent magnet linear motor which has the advantages of simple structure, firmness, stronger output thrust, higher power density and smaller thrust fluctuation. The motor comprises a stator (1), an air gap and rotors (2), wherein each rotor (2) comprises permanent magnets (3), a concentrated winding (4) and additional teeth (5); both the stator and the rotors are double-salient pole single-edges or double-edge flat-panel structures, and all concentrated winding coils of any phase are positioned in a rotor iron core slot; adjacent permanent magnets (3) form a serial magnetic circuit; the number of the permanent magnets (3) is NPM=2k*m+2, wherein k is a positive integer, and the number m of motor phases is not smaller than 3; both end parts of each rotor (2) are respectively provided with a permanent magnet which is an additional permanent magnet of each motor; the number of windings of the rotors is Nmt=(NPM-2)(m+1); and the central distance of adjacent teeth of the rotors is tau p.

Owner:SOUTHEAST UNIV

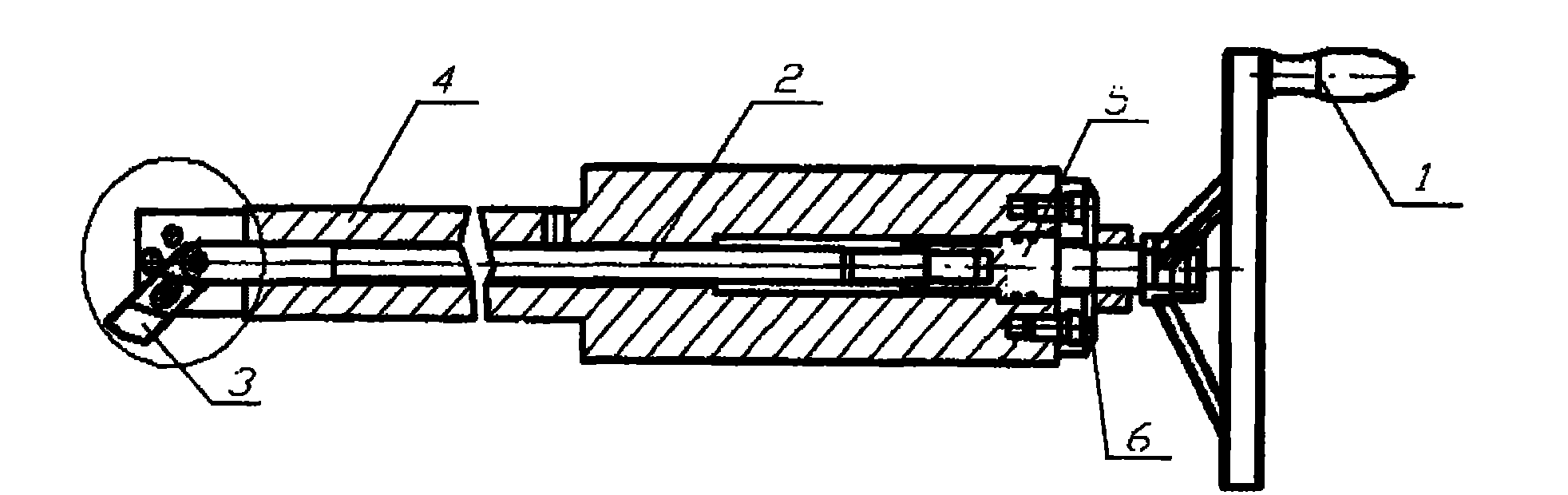

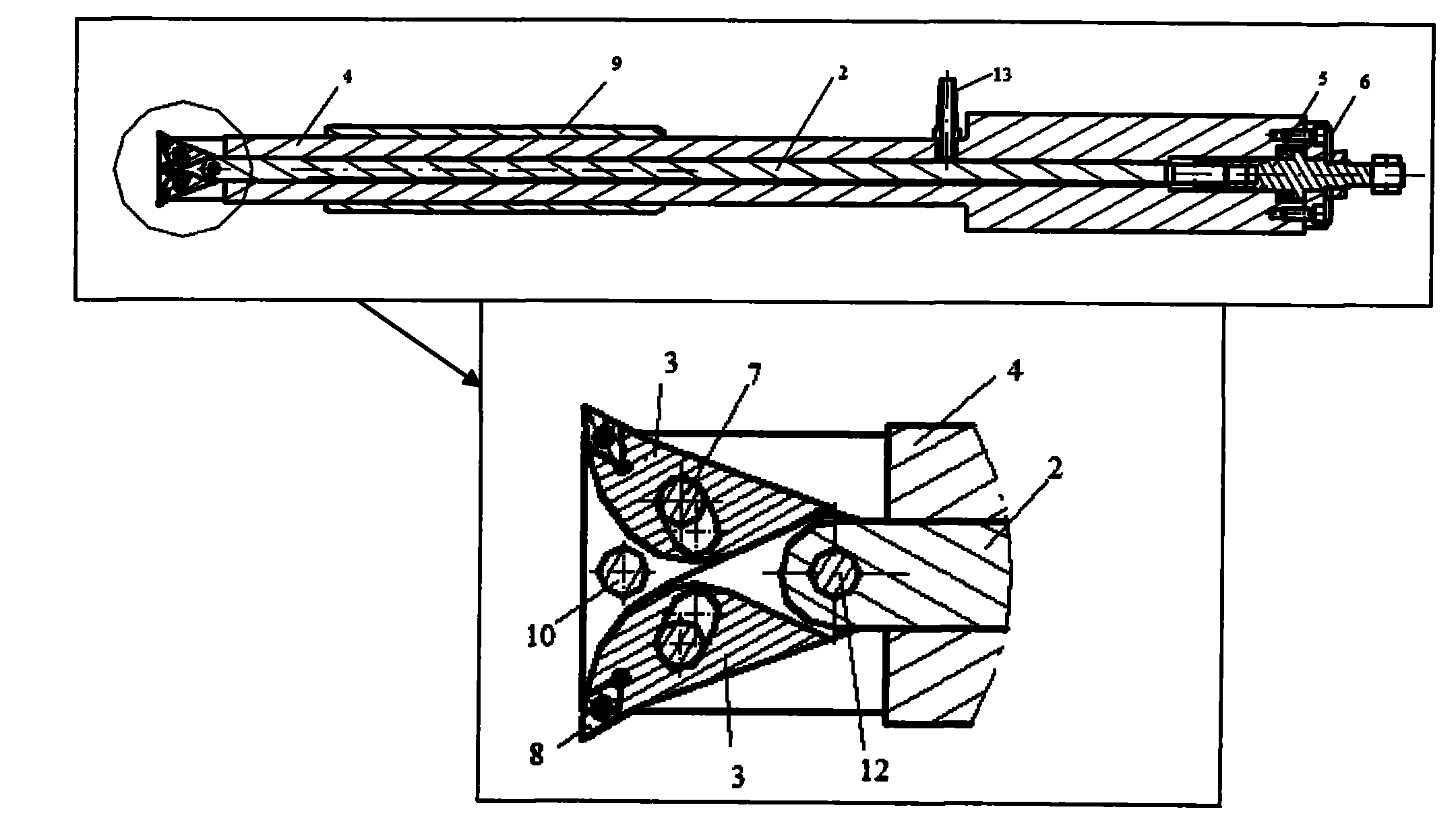

Telescopic double-edged deep-hole boring cutter

The invention provides a telescopic double-edged deep-hole boring cutter, aims to provide a deep-hole drilling boring cutter which has large length-diameter ratio, small self-excited vibration of a boring bar, reliable and stable feeding operation, no radial motion of a cutter arbor, and radial feeding of a cutting edge in a cutting process, and solves the problem that the deep-hole bottle cavity with large length-diameter ratio has large processing difficulty. The boring cutter comprises the boring bar which can extend to the deep-hole bottle cavity, wherein the central axis of the boring bar is provided with a through hole which runs through the central axis; a push rod (2) which is connected with a radial feeding device of the head of the boring bar is arranged in the through hole; the rear end of the push rod (2) is provided with a rotating handle; the rotating handle rotates a screw (5) and pushes the push rod (2) to do radial telescopic motion in the through hole of the boring bar; and the push rod (2) moves by way of pushing or pulling to drive the radial feeding device connected with the push rod and adjust the cutting edge of the double-edged boring cutter on a cutter block (3) to radically feed in the deep-hole bottle cavity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Cervical conization device

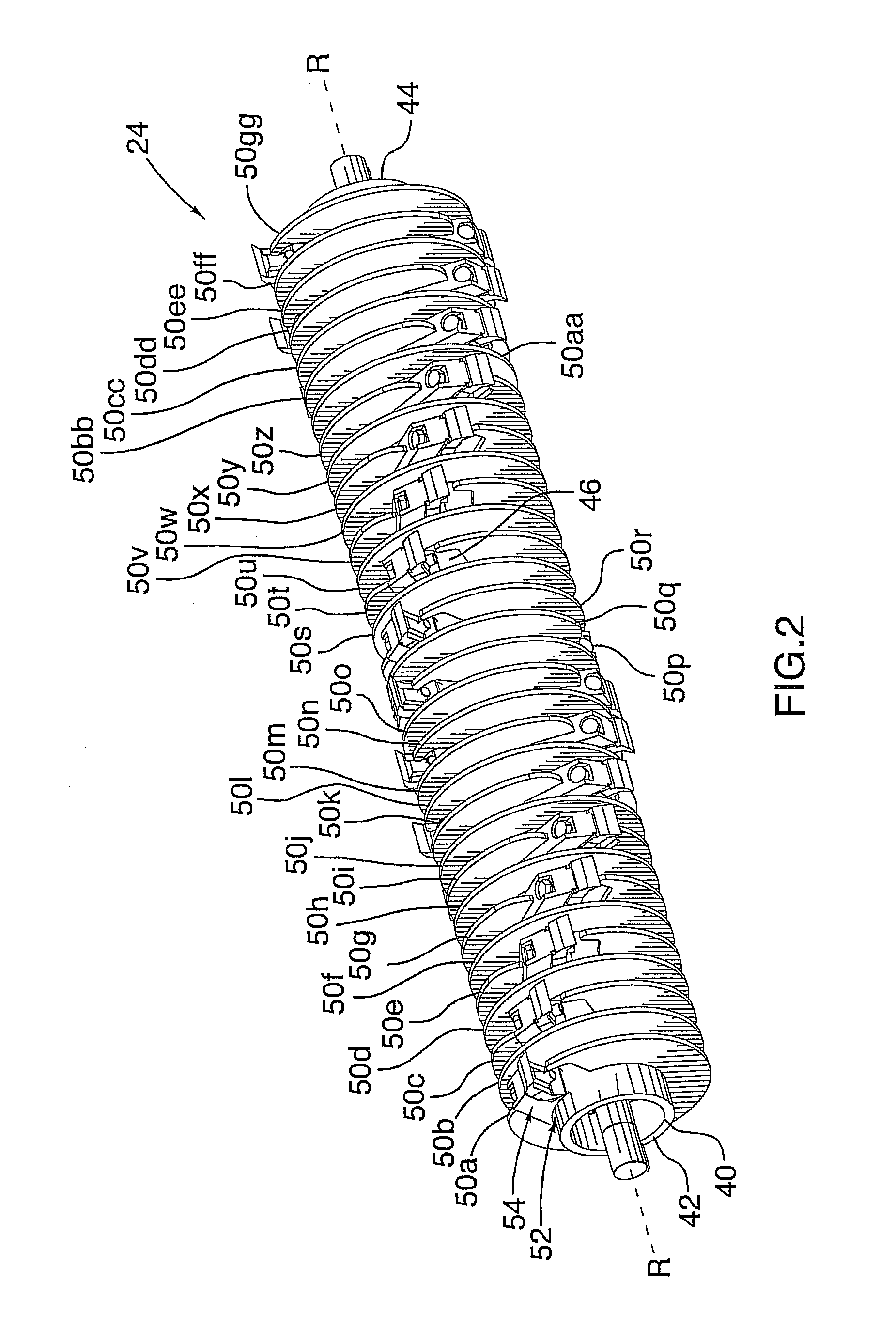

A surgical instrument for removal of a conical section the cervix for pathological examination is disclosed. The device includes a circular knife having a plurality of double-edged blades, the edges of adjacent blades enclosing against one another when the device is operated from unengaged to engaged positions. A hollow plunger is further disclosed used to actuate the circular knife. Novel pivot devices are additionally included to provide translational movement of the hollow plunger bar. A pronged stabilization rod is disclosed to prevent the circular knife from moving away from the target tissue during a cutting stroke. The device is an improvement over prior devices and procedures in that it provides a precision conical tissue sample ideal for analysis with minimal resulting bleeding.

Owner:UCKELE JOHN E

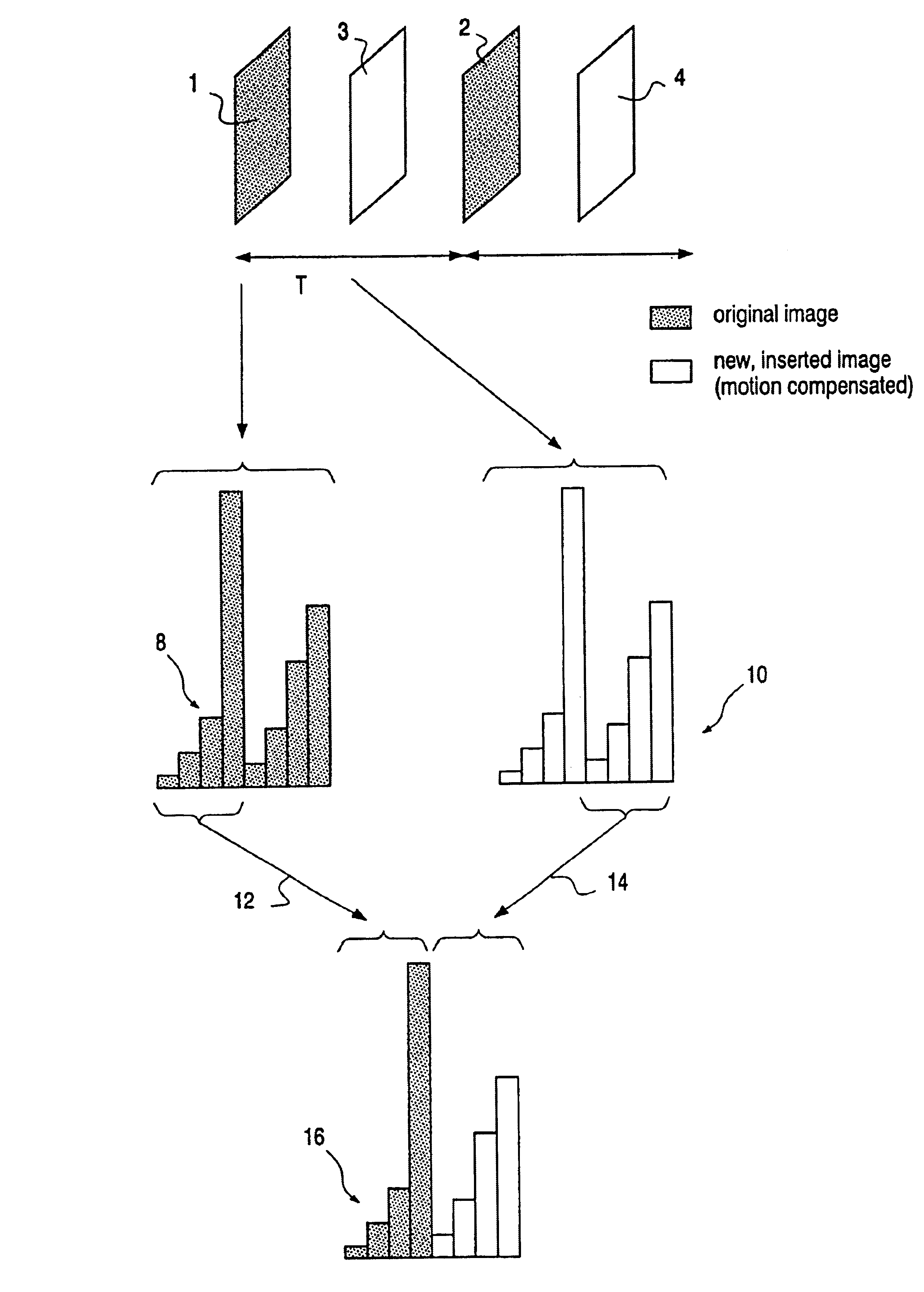

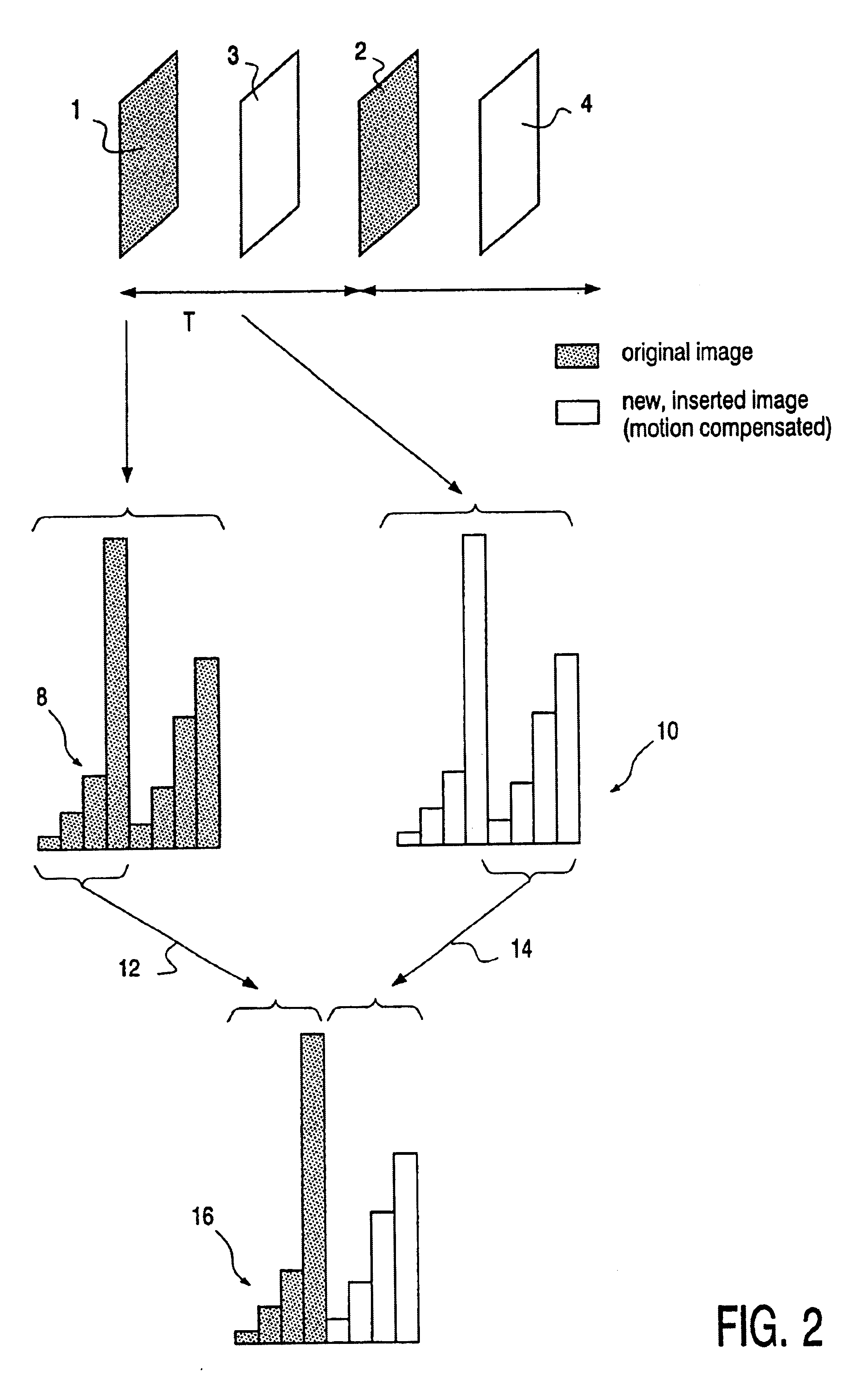

Motion compensated upconversion for plasma displays

InactiveUS6985126B2Simple systemLittle motion artifactTelevision system detailsStatic indicating devicesUp conversionMotion artifacts

Owner:SAMSUNG SDI CO LTD

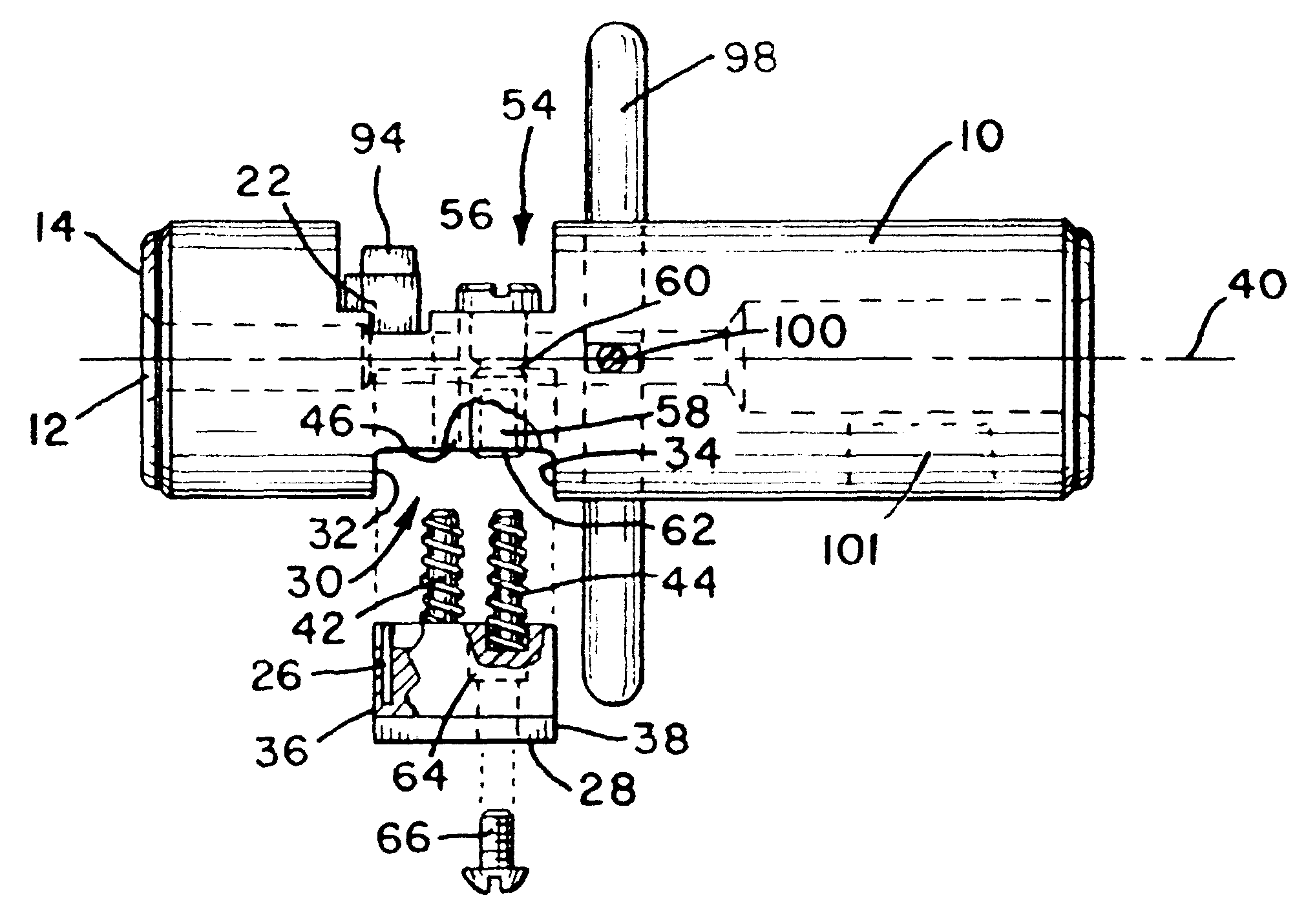

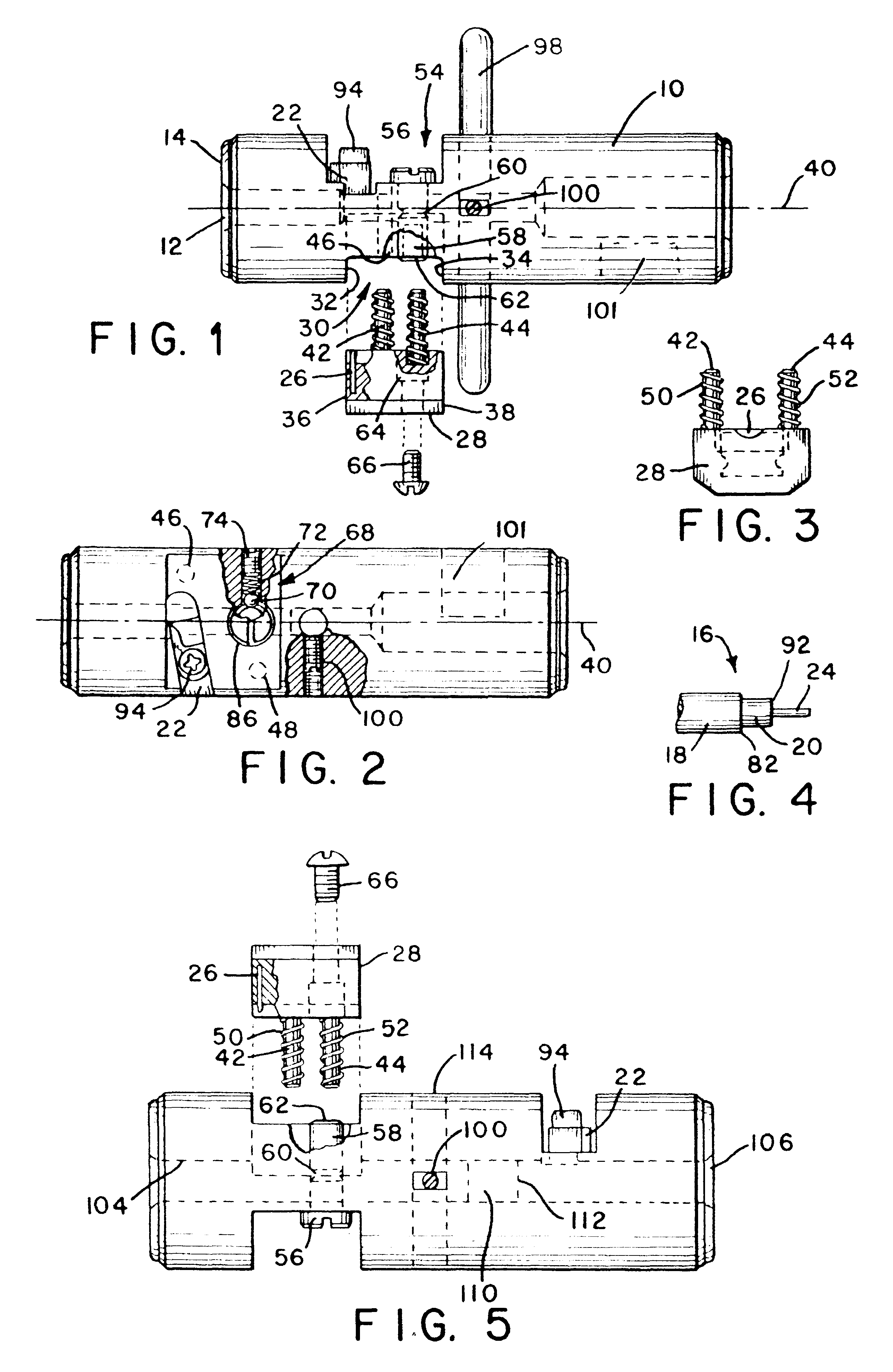

Compound coaxial cable stripping tool

InactiveUS6467171B2Accurately heldMetal working apparatusApparatus for removing/armouring cablesCoaxial cableEngineering

A tool for removing insulation from coaxial cable includes a fixed double-edged cutting blade mounted on the tool body and a planar cutting blade that is mounted on a cassette to move perpendicular to the axis of the cable between a cutting position and a non-cutting position. The double-edged cutting blade includes a transverse cutting edge and a longitudinal cutting edge, the transverse cutting edge lying in a plane substantially perpendicular to an axis of the cable and the longitudinal cutting edge lying in a plane substantially parallel to the axis of the cable. The planar cutting blade has a cutting edge lying in a plane substantially perpendicular to the axis of the cable. The blades may be mounted on the same end of the tool, requiring that the coaxial cable be inserted only once into the tool, or on opposite ends of the tool.

Owner:RIPLEY TOOLS

Method and system for making a stepped end

A method and apparatus for making a stepped end on a tube of flexible material includes a tube slitting station having a slitting tool with double edge slitting blades penetrating through the tube to provide respective slits beside a first panel and beside a second panel, respectively; a first trimming station trimming a first panel of the tube to a first shortened length, a second trimming station trimming the side gussets to a second length, wherein the second length is longer than the first shortened length of the first panel; and an adhesive applying station applying adhesive on the tube above and below a fold line across the tube, wherein the tube is adapted to be folded along the fold line, and the adhesive material is adapted to form an adhesive to adhesive seal above and below the fold line while the tube is folded to provide a closed stepped end for a bag.

Owner:COATING EXCELLENCE INT

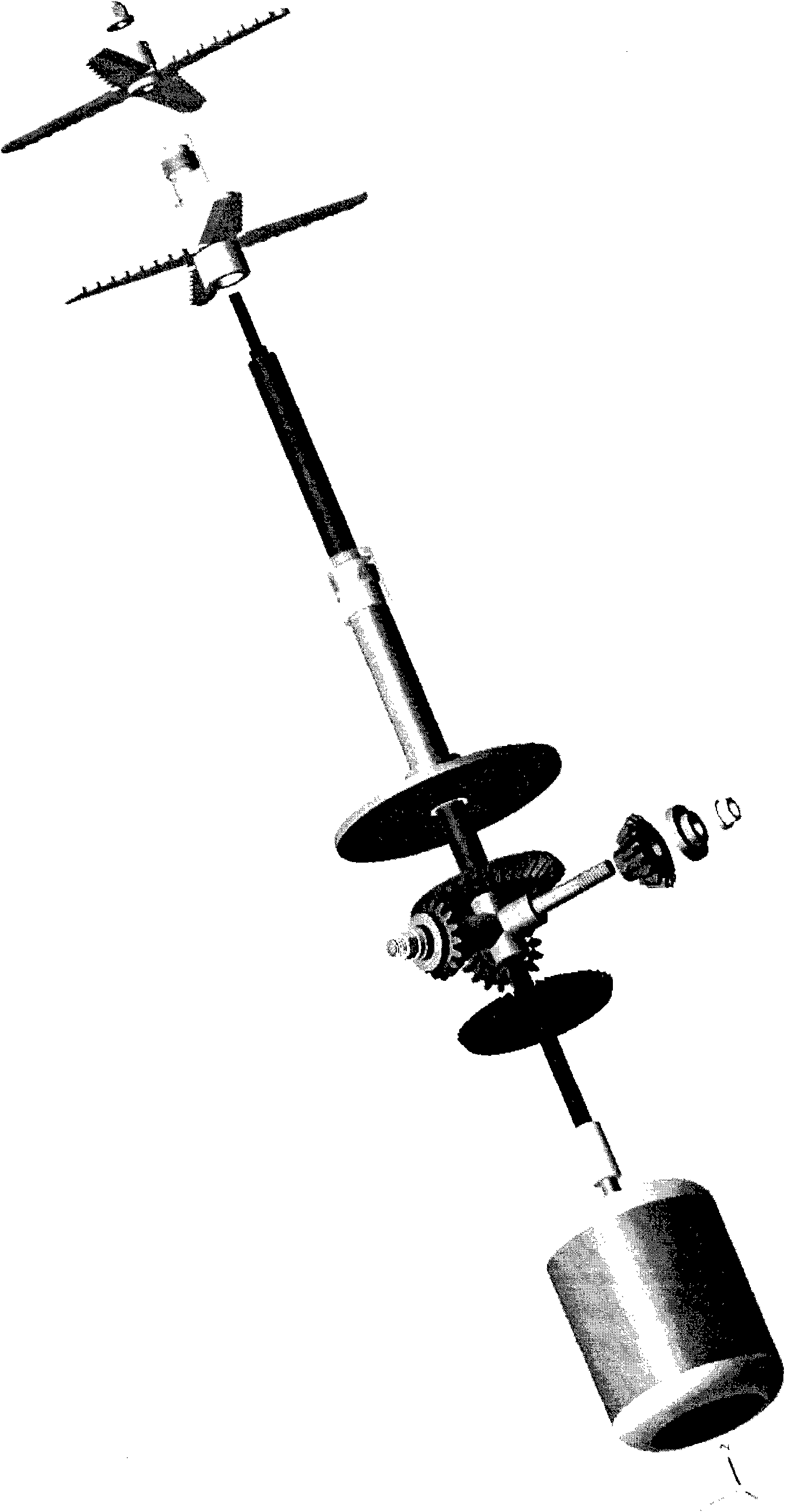

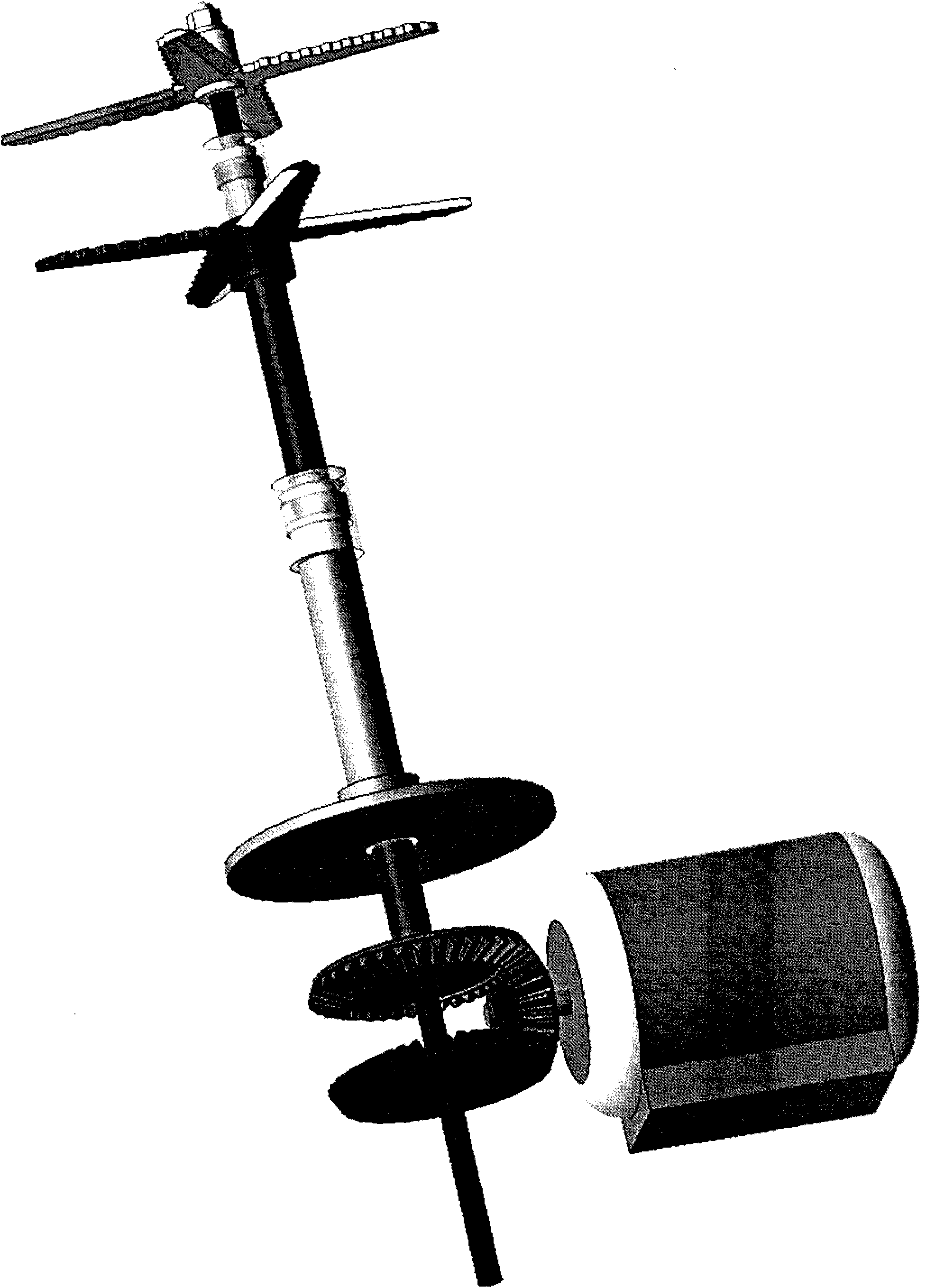

Reciprocal rotary knife type material processor

The invention relates to a reciprocal rotary knife type material processor which is an improvement on a machining unit of kitchen appliances that make food of slurry, juice and paste and the like. The reciprocal rotary knife type material processor has universal working principle and can be arranged on various food processor at current to work or can be used similarly in other fields. The primary working part of the processor uses two concentrically reversed cutter shafts which are fixed with rotary cutters for machining. The machining rotary cutters can rotate at high speed positively and reversely under drive of a motor and transmission machinery, thereby overcoming the deficiency that the materials generate eddy to reduce the machining efficiency when the unidirectional rotary cutter works at high speed. The double-edged cutters have better machining effect in two rotary directions. The layered cutters and curved cutters can increase the working space. The invention solves the problems of the driving mode of dual-cutter shafts, the shape of the rotary cutters and improves the grinding effect and the like.

Owner:管云天

Method and system for making a stepped end

A method and apparatus for making a stepped end on a tube of flexible material includes a tube slitting station having a slitting tool with double edge slitting to provide respective slits beside a first panel and beside a second panel, respectively; a first trimming station trimming a first panel of the tube to a first shortened length, a second trimming station trimming the side gussets to a second length, wherein the second length is longer than the first shortened length; and an adhesive applying station applying adhesive on the tube above and below a fold line across the tube, wherein the tube is adapted to be folded along the fold line, and the adhesive material is adapted to form an adhesive to adhesive seal above and below the fold line.

Owner:COATING EXCELLENCE INT

Field dressing knife

ActiveUS7578731B1Conveniently efficiently splittingSufficient lightingFish washing/descalingPoultry plucking mechanismsEngineeringElectrical and Electronics engineering

A field dressing knife suitable for all aspects of field dressing small and large game is disclosed. Various novel aspects of the knife include: a large butt-end of the handle and a groove near the butt-end of the handle, both to spread the normal stress over a larger surface area when striking the butt-end of the handle with a free hand for splitting pelvis and brisket bones; and a configurable handle, permitting the double-edged field dressing knife to be used in knife mode or in a hatchet mode.

Owner:MOORE HAROLD J

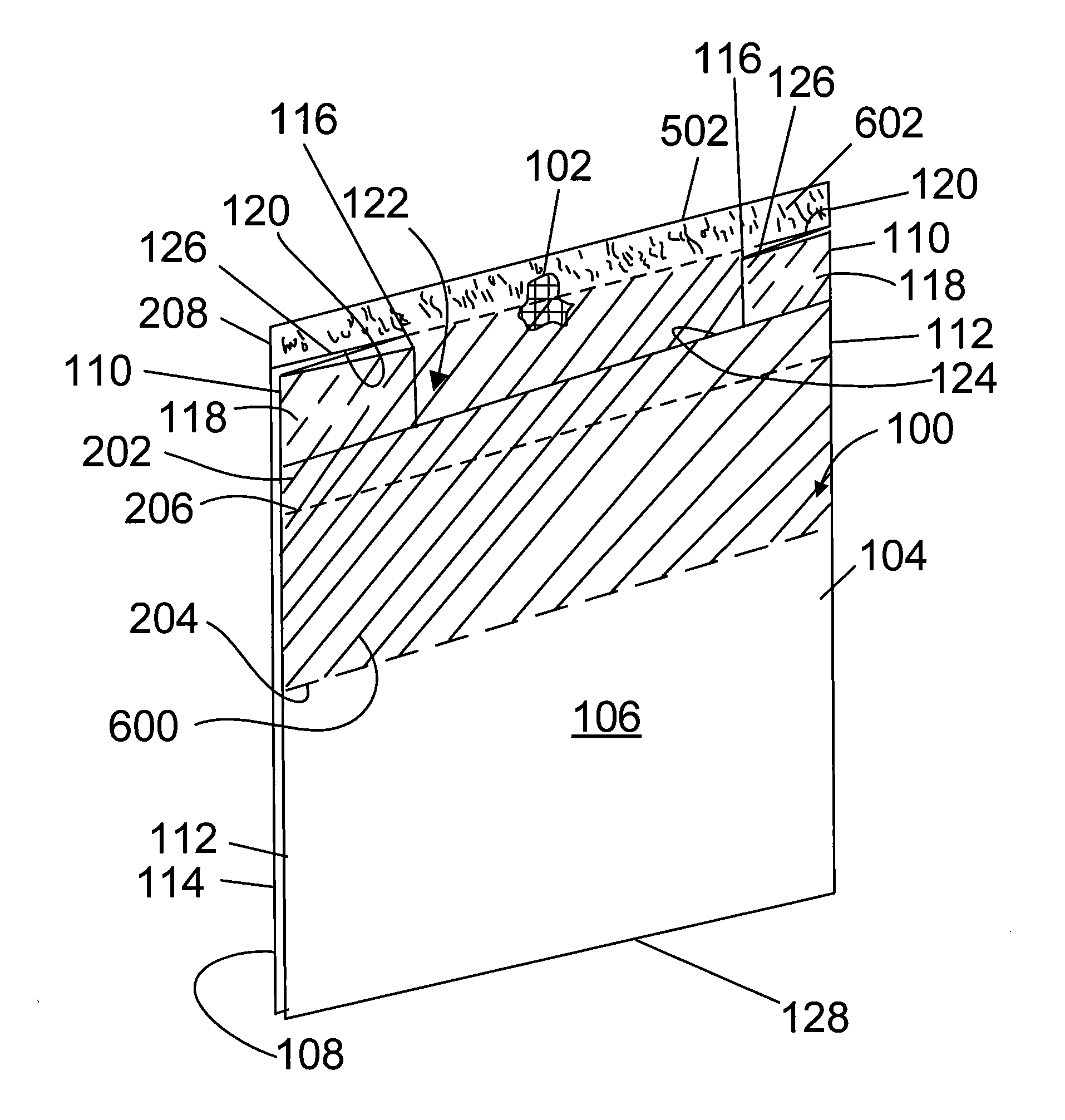

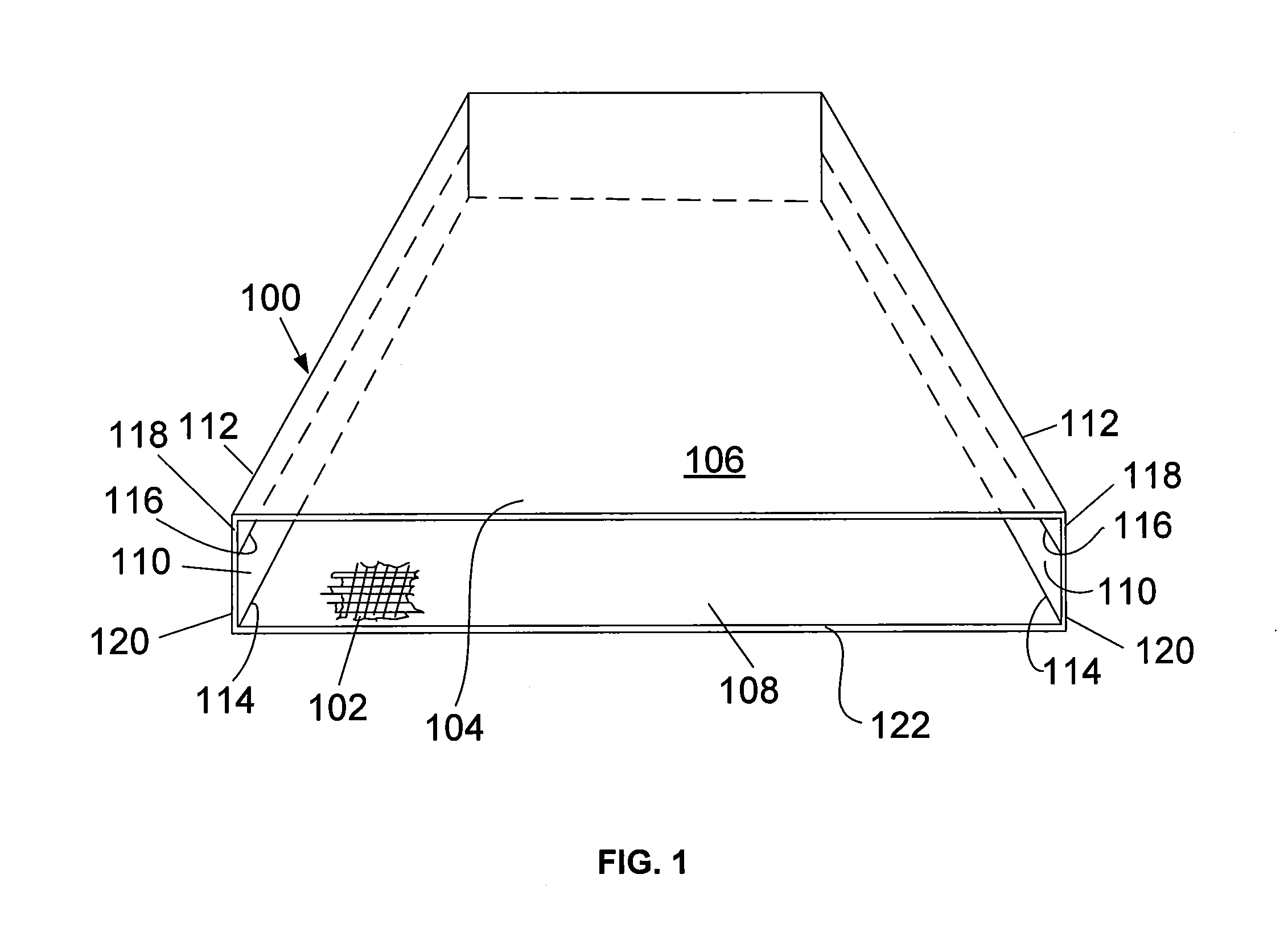

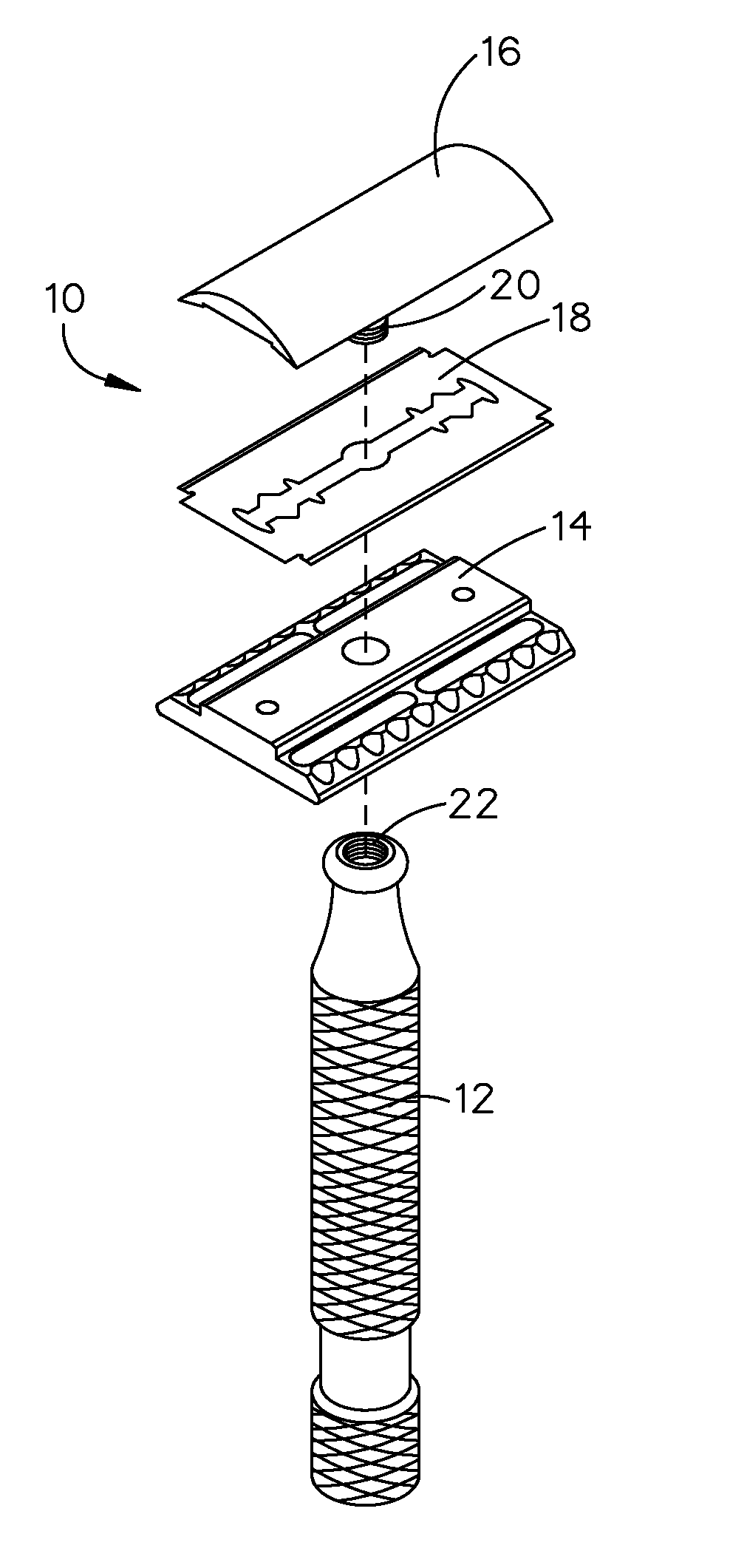

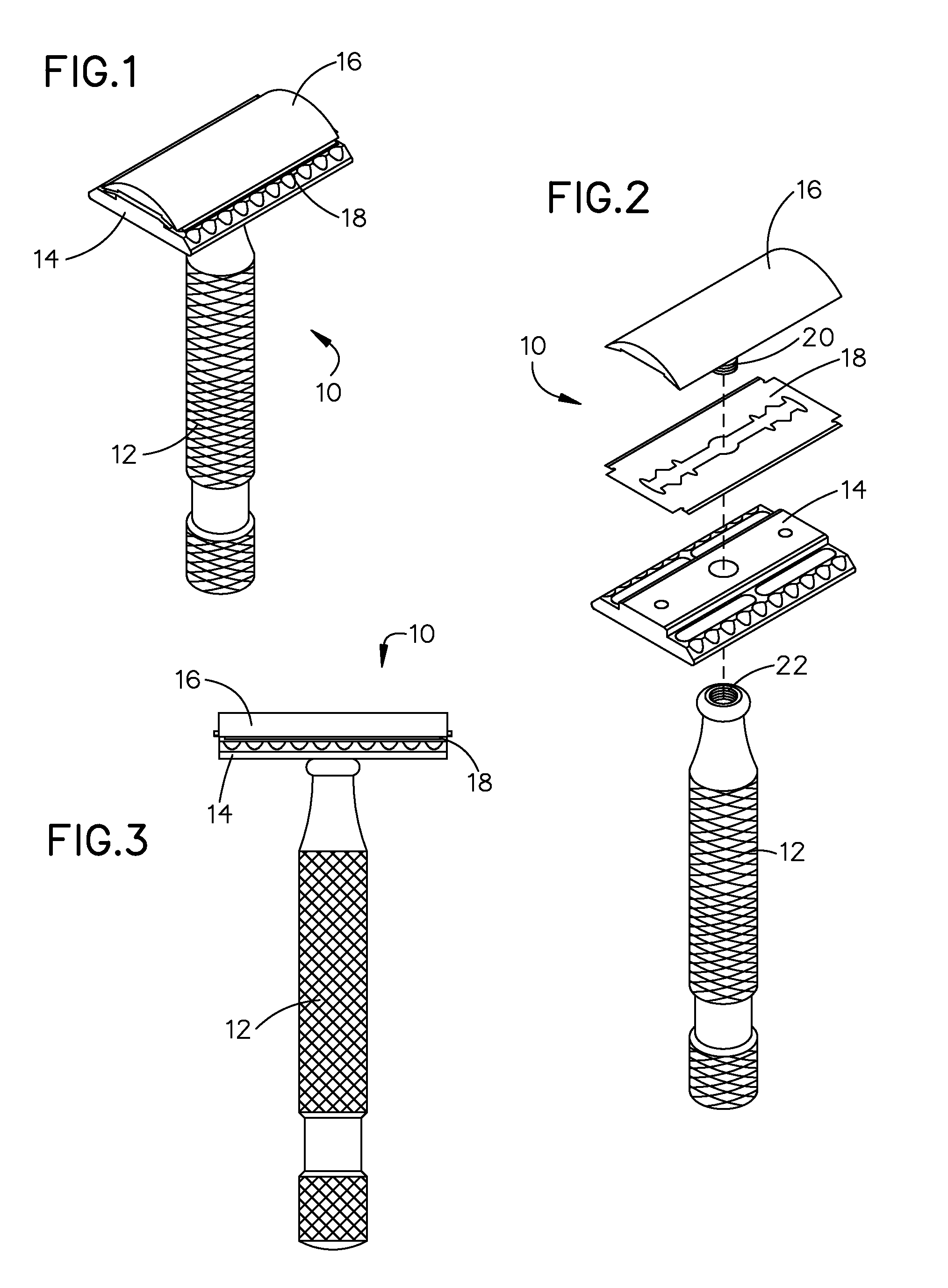

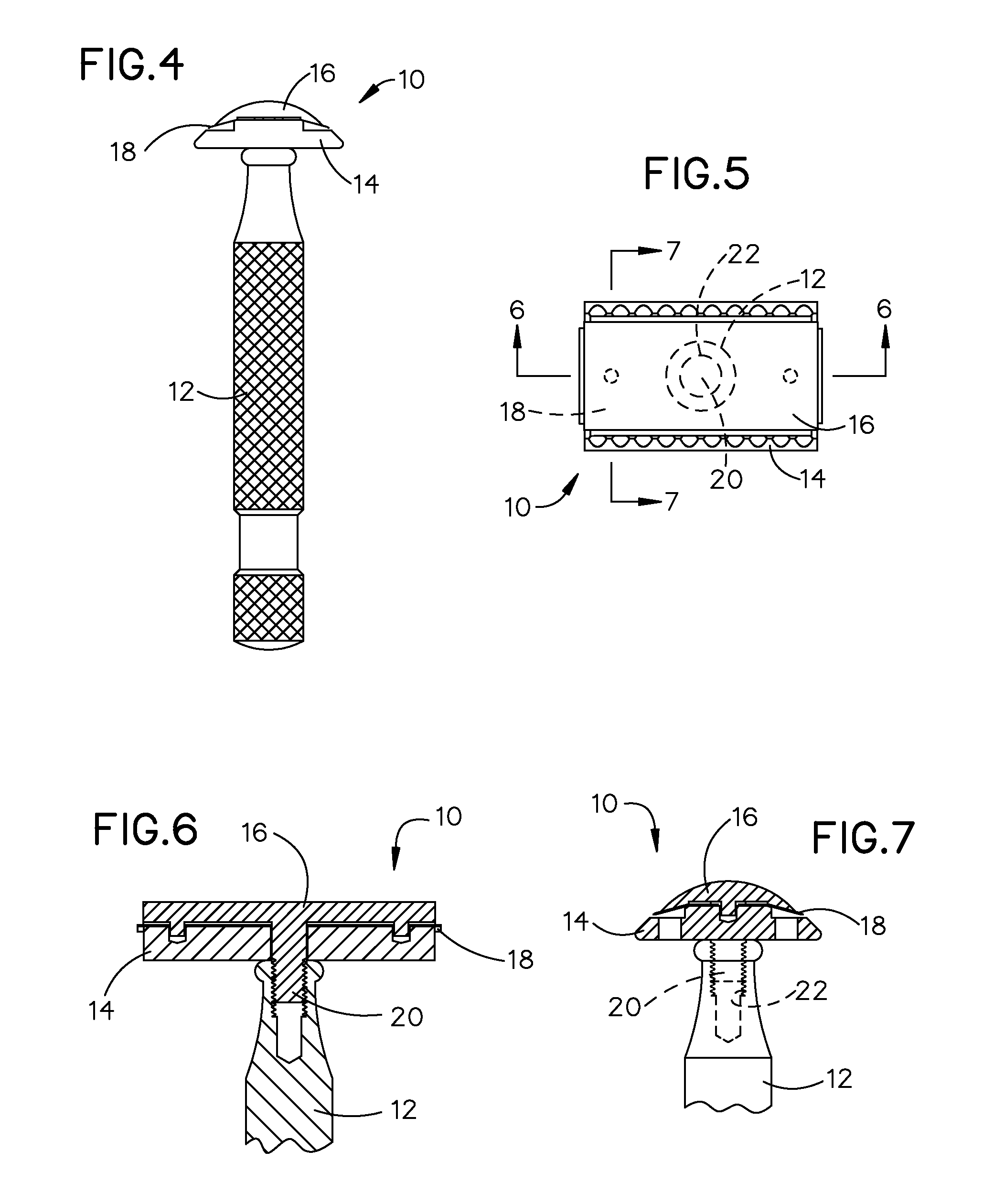

Double edge safety razor with razor blade alignment

A double edge razor assembly with a razor blade alignment is provided. The double edge razor includes a head with a cap and a base. A post and at least one pin may protrude for the inner surface of the cap. The post and the at least one pin may snuggly fit within a channel through the razor. The post may fit through an aperture in the base, and the pin may fit within a pin hole in the base. The pin may align the razor in between the cap and the base, and prevent the razor from spinning out of alignment. The post may then attach to a handle to complete the double edge razor assembly.

Owner:HICKAM STANLEY LEE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com