Battery core automatic forming device

A technology of forming equipment and battery cells, which is applied in the field of forming equipment for ironing, folding, and automatic edge trimming of soft-packed lithium batteries. It can solve problems such as low work efficiency, cracked battery shells, and poor performance to ensure accuracy. and uniformity, the degree of automation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, the present invention will be further described:

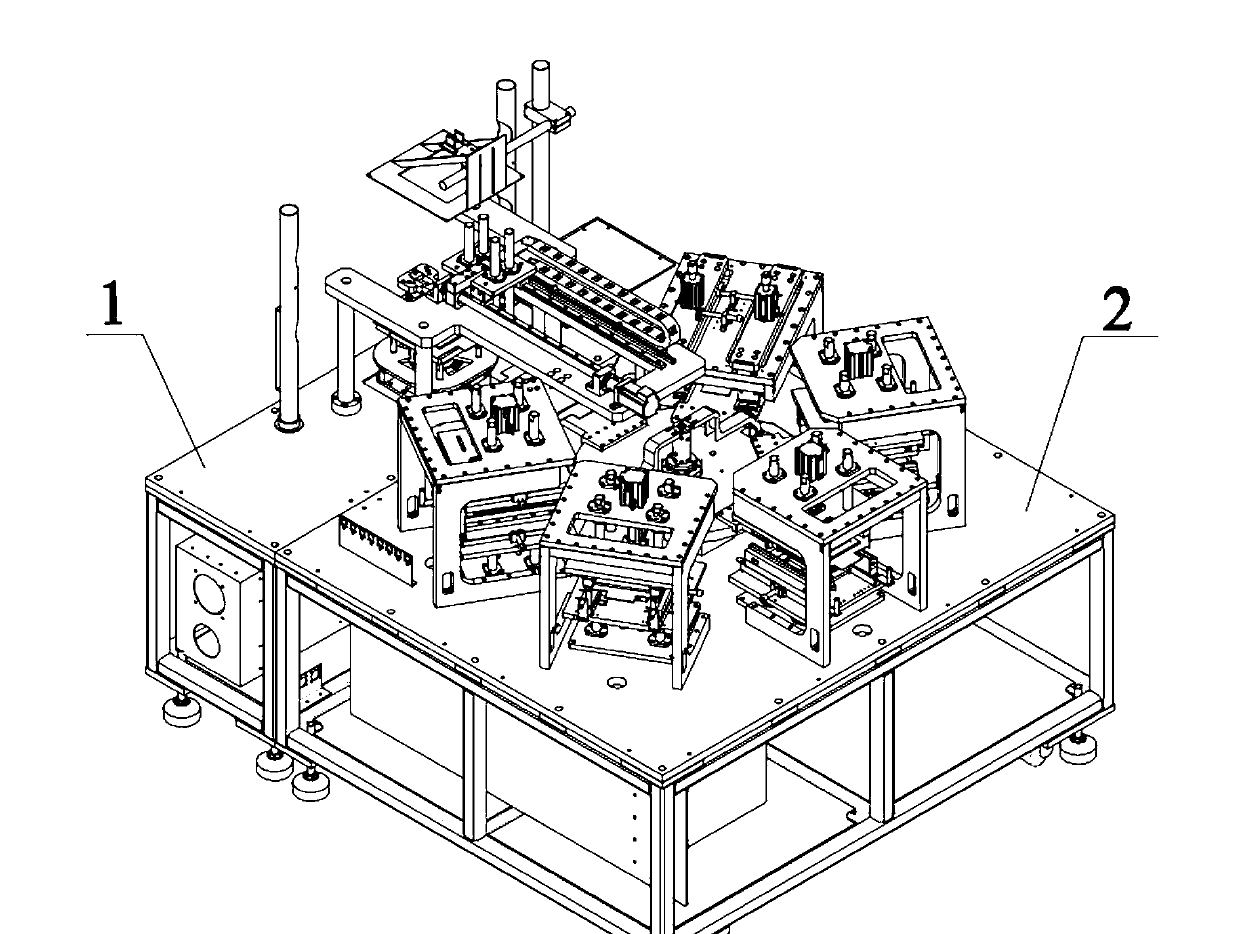

[0028] According to Fig. 1, Fig. 2 and Fig. 5, the battery automatic packaging and forming equipment includes a loading and unloading device 1 and a tray cutting, folding and ironing device 2, wherein the loading and unloading device includes a CCD vision positioning mechanism 130, and the CCD vision positioning mechanism 130 is connected to an X , C-axis correction mechanism 120, above the X-axis and C-axis correction mechanism 120, there is a turntable loading and unloading manipulator 110; the CCD vision positioning device 130 is controlled by an industrial computer, and the visual system screen is adjusted, and the battery is placed in the X- and C-axis correction machine 120 mechanism After loading, the CCD visual positioning mechanism 130 is compared with a certain reference line to adjust the position of the battery so that the position of the battery on the correctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com