Bending characteristic measurement device for high-temperature superconducting tape

A technology of high-temperature superconducting strips and measuring devices, which is applied in the directions of measuring devices, analyzing materials, and material analysis through electromagnetic means, and can solve the problem of not being able to obtain the bending characteristic curve data of high-temperature superconducting strips and not being able to obtain high-temperature superconducting strips. Bending characteristics measurement, affecting measurement accuracy and other issues, to achieve the effect of ensuring accuracy, small cone angle, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

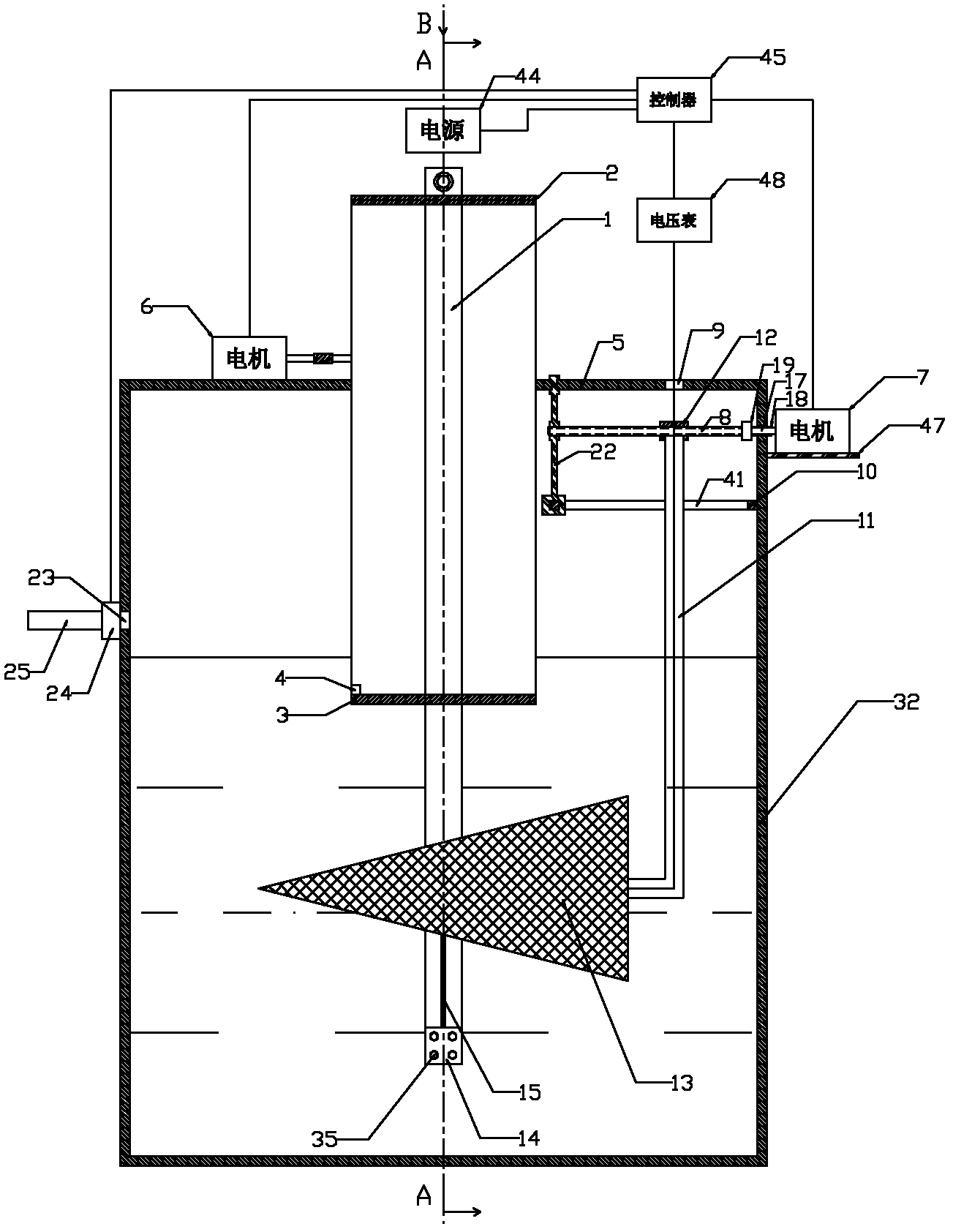

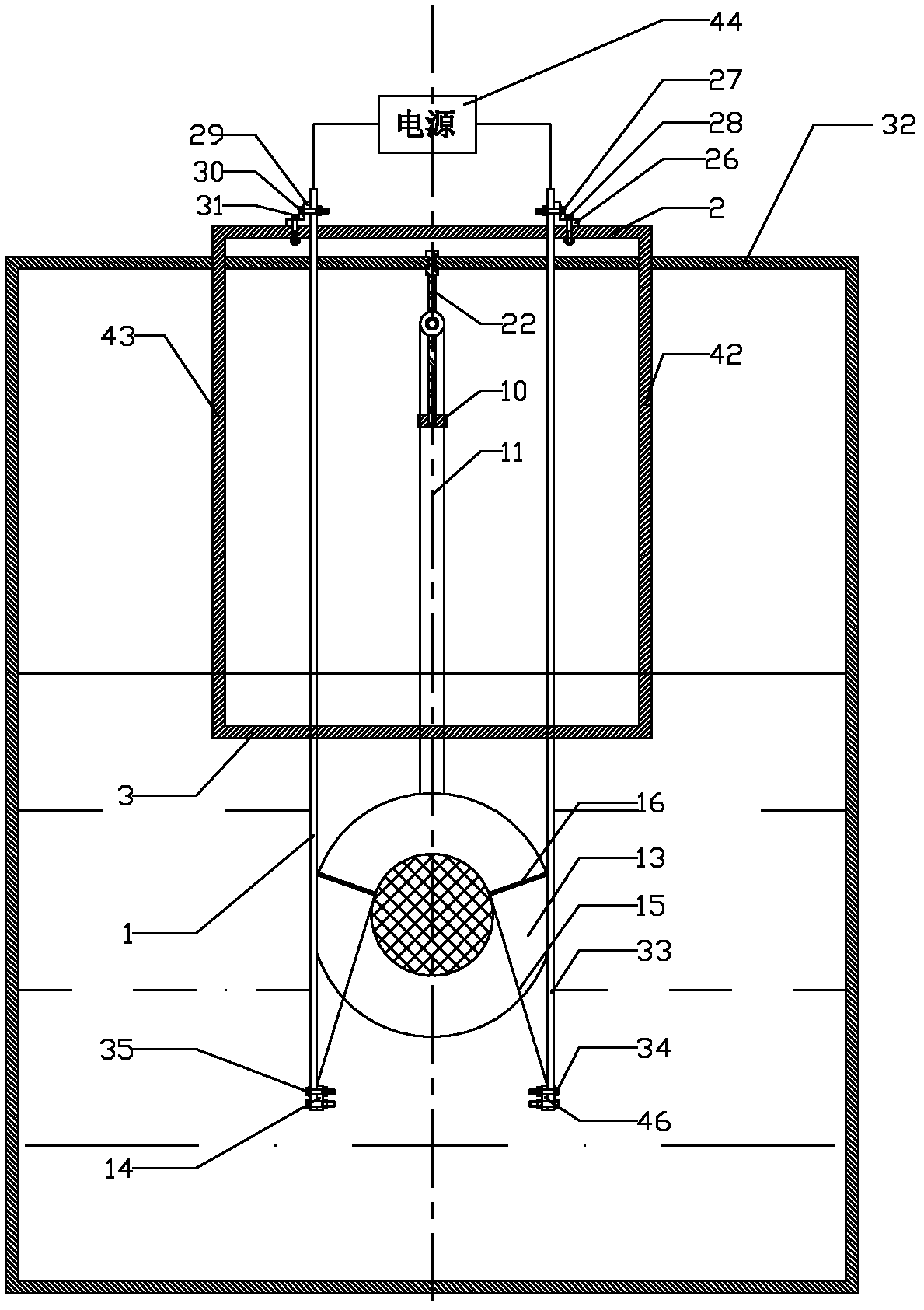

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] figure 1 It is a front view of the high-temperature superconducting strip bending characteristic measuring device of the present invention, which is a cross-sectional view cut from the center of the high-temperature superconducting strip bending characteristic measuring device of the present invention and viewed from the front of the device. figure 2 is along figure 1 The side view of the high-temperature superconducting strip bending characteristic measuring device of the present invention obtained by observing line A-A in . image 3 is along figure 1 The top view of the high-temperature superconducting strip bending characteristic measuring device of the present invention observed by arrow B in , that is, observed from above.

[0055] from Figure 1-3 It can be seen that the high-temperature superconducting strip bending characteristic measuring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com