Porous composite material for purifying formaldehyde and TVOCs and preparation method of porous composite material

A porous composite material and composite material technology, applied in the field of air purification materials, can solve the problem that the purification ability and particle strength are easily affected by the temperature and humidity of the application environment, reduce the contact probability of gas pollutants and active components inside the material, and the internal pore structure Problems such as limited quantity, to achieve the effect of rich channels, easy operation, and increased polar functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Activated carbon pretreatment: configure 300mL nitric acid solution (1mol / L), accurately weigh 100g activated carbon particles (150 mesh) into the nitric acid solution, stir and impregnate at a constant temperature of 50°C for 12h; then fully wash with deionized water until the pH of the washing solution It was 6.5, and then dried at a constant temperature of 85°C for 24h. The ratio of activated carbon particles to nitric acid solution was 1 g: 3 mL.

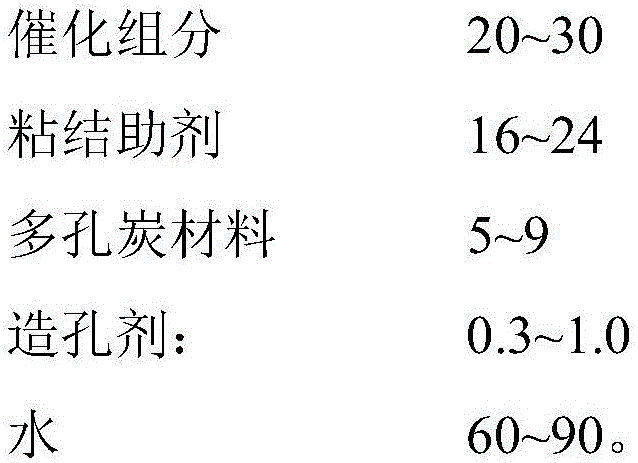

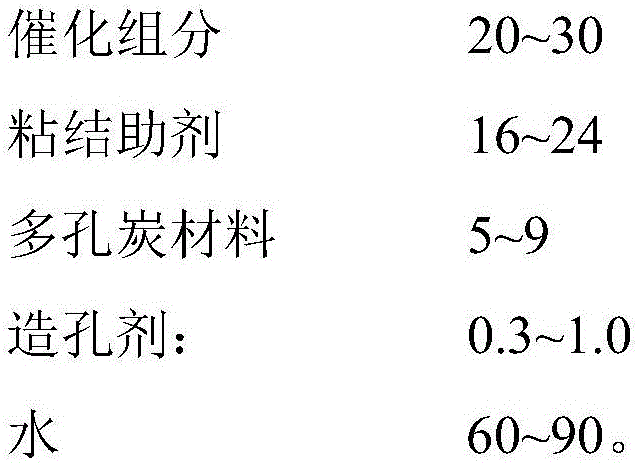

[0044] 2, the preparation of nuclear material: the pore-forming agent sodium bicarbonate is dissolved in water in advance, is prepared into the aqueous solution that concentration is 0.6%; The active carbon particle after step (1) modification treatment, binding aid (200 mesh attapulgite Rod clay), catalytic components (nano-scale manganese dioxide), and powder raw materials are mixed evenly, and the pre-prepared sodium bicarbonate aqueous solution is added as needed, fully kneaded, and extruded to obtain a cylindrical...

Embodiment 2

[0050] 1. Activated carbon pretreatment: configure 300mL nitric acid solution (1mol / L), accurately weigh 100g activated carbon particles (200 mesh) into the nitric acid solution, stir and impregnate at a constant temperature of 50°C for 12h; then fully wash with deionized water until the pH of the washing solution 7.5, and then dried at a constant temperature of 85°C for 24h. The ratio of activated carbon particles to nitric acid solution was 1 g: 3 mL.

[0051] 2. Preparation of nuclear material: Dissolve the pore-forming agent sodium bicarbonate in water in advance to prepare an aqueous solution with a concentration of 0.6%; the modified activated carbon particles and bonding aid (200 mesh kaolin) in step (1) , Catalyst component (nano-level manganese dioxide), powder raw materials are mixed evenly, add the sodium bicarbonate aqueous solution prepared in advance as required, knead fully, extrude molding, obtain the cylindrical particle of diameter 2mm, particle length 2~4mm....

Embodiment 3

[0057] 1. Activated carbon pretreatment: prepare 300mL nitric acid solution (1mol / L), accurately weigh 100g activated carbon particles﹝m (150 mesh):m (200 mesh)=4:1﹞put into the nitric acid solution, stir and impregnate at 50℃ 12h; and then fully washed with deionized water until the pH of the washing solution is 7.0, and then dried at a constant temperature of 85°C for 24h. The ratio of activated carbon particles to nitric acid solution was 1 g:5 mL.

[0058] 2, the preparation of nuclear material: the pore-forming agent sodium bicarbonate is dissolved in water in advance, is prepared into the aqueous solution that concentration is 0.6%; The active carbon particle after step (1) modification treatment, binding aid (200 mesh attapulgite Rod clay), catalytic components (nano-scale manganese dioxide), and powder raw materials are mixed evenly, and the pre-prepared sodium bicarbonate aqueous solution is added as needed, fully kneaded, and extruded to obtain a cylindrical shape wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com