Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "Increase the probability of collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

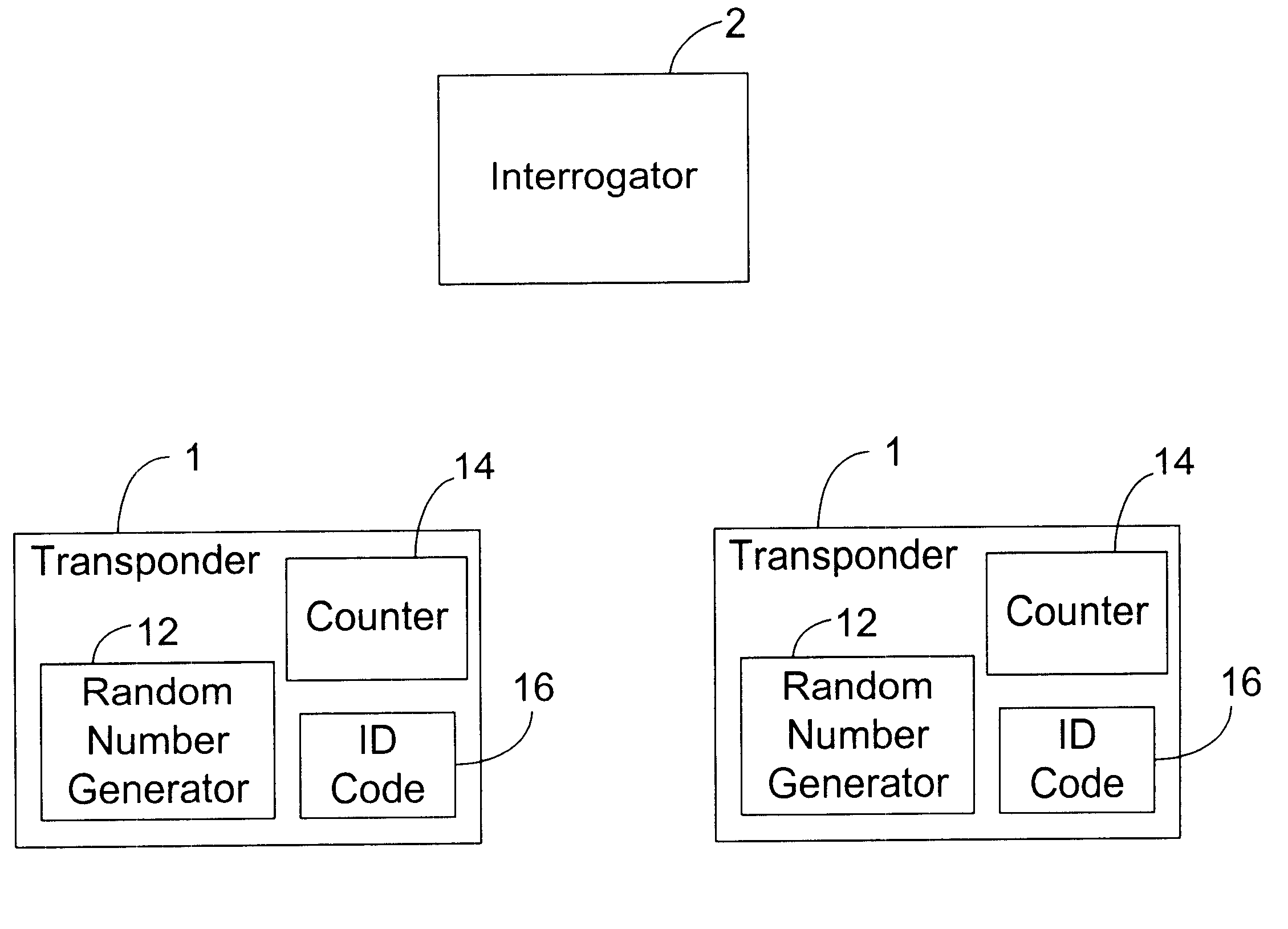

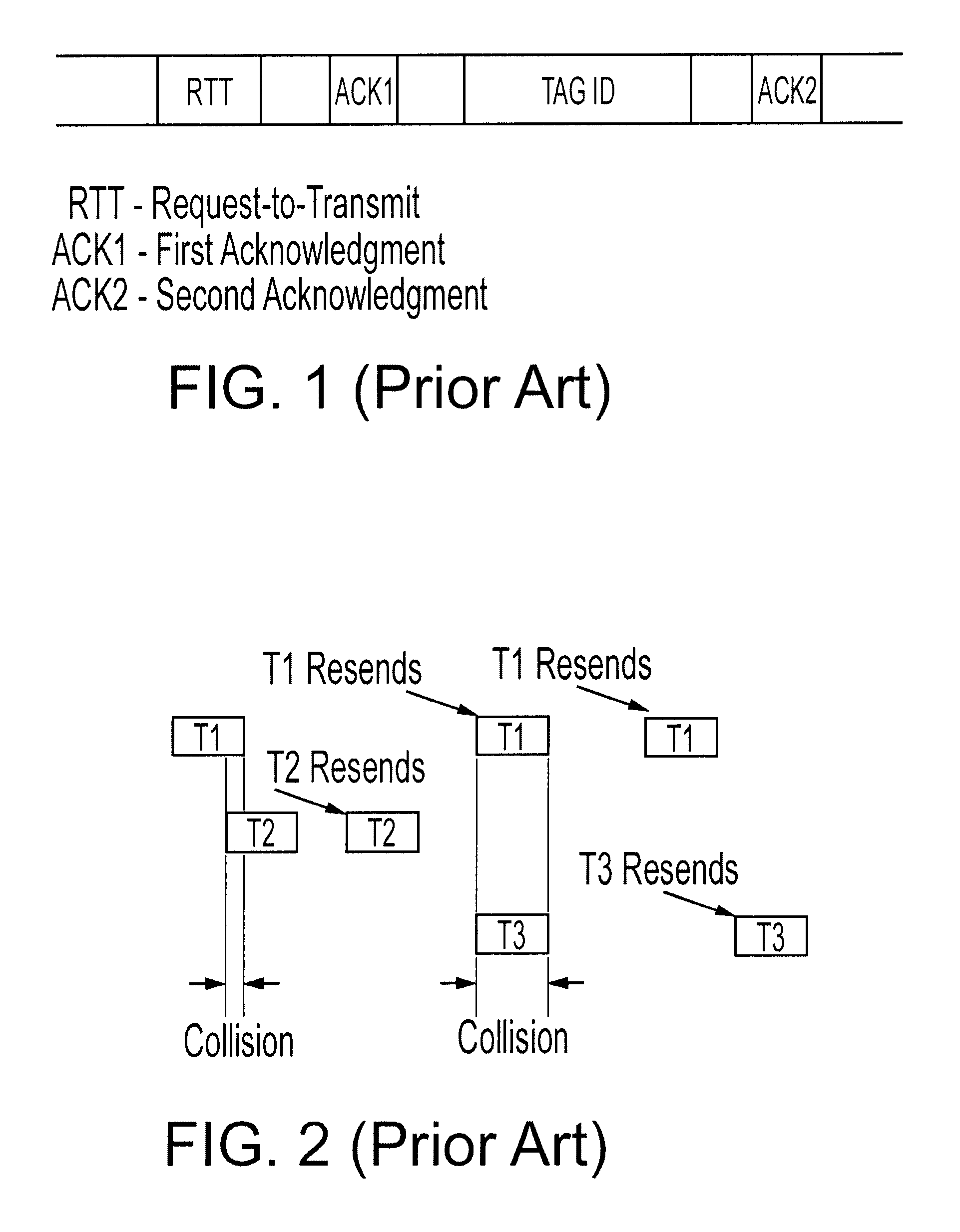

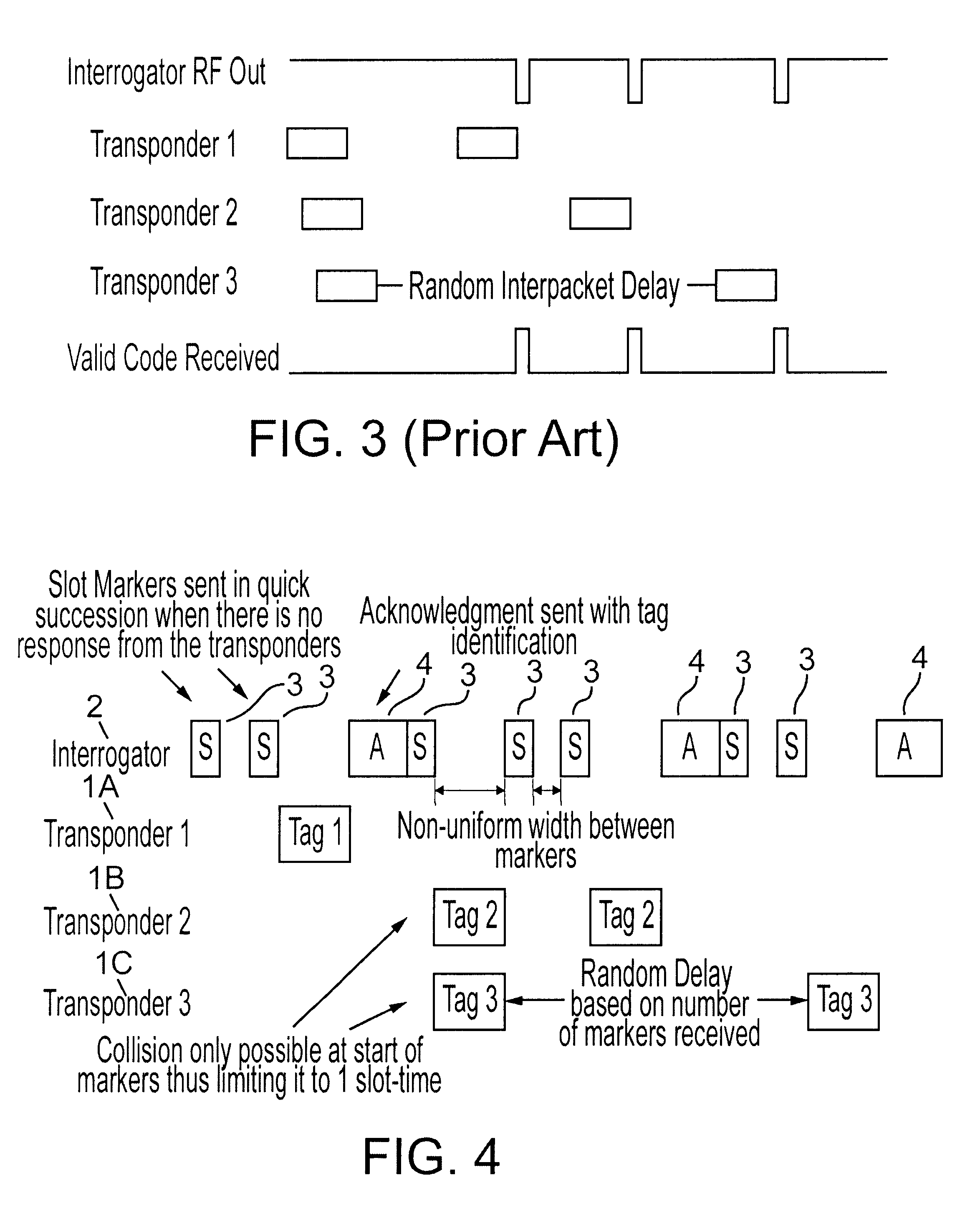

RF transponder identification system and protocol

InactiveUS6538563B1Increase the probability of collisionImprove system performanceMemory record carrier reading problemsSubscribers indirect connectionIdentification systemElectrical and Electronics engineering

An RF transponder identification system with an interrogator operable to transmit a plurality of marker signals and a plurality of transponder. Each transponder has a random number associated therewith, a counter counting the number of marker signals received from the interrogator and transmission means to transmit an identification code when the number of marker signals received by the transponder equals the random number associated with the transponder.

Owner:NAT UNIV OF SINGAPORE

Bounding box and space partitioning-based virtual object collision detection method

ActiveCN105469406AImprove accuracyEfficiencyImage enhancementImage analysisSpatial correlationCollision detection

The invention provides a bounding box and space partitioning-based virtual object collision detection method. The method includes the following steps that: virtual object collision pre-detection is performed on two irregular virtual objects; region segmentation is performed on a region to be detected; intersection testing is performed in the sub regions segmented from the region to be detected; virtual object collision detection is performed by using a point vector set representing a moving virtual object and a triangular surface representing a virtual object which does not require assembly at present; and if the virtual objects intersect with each other, the virtual objects collide with each other, otherwise, the virtual objects do not collide with each other. According to the bounding box and space partitioning-based virtual object collision detection method of the invention, a collision detection range of a space is narrowed through using the spatial correlation of the virtual objects, so that time consumption can be reduced, and at the same time, the detection efficiency of the method and the geometric accuracy of collision detection are greatly improved; a bounding box is reduced into the triangular surface and the points, so that the misjudgment of the collision detection can be decreased; and a collision detection process is refined to the interference between the triangular surface and the points, and separate detection is carried out, and therefore, detection efficiency can be greatly improved.

Owner:NORTHEASTERN UNIV

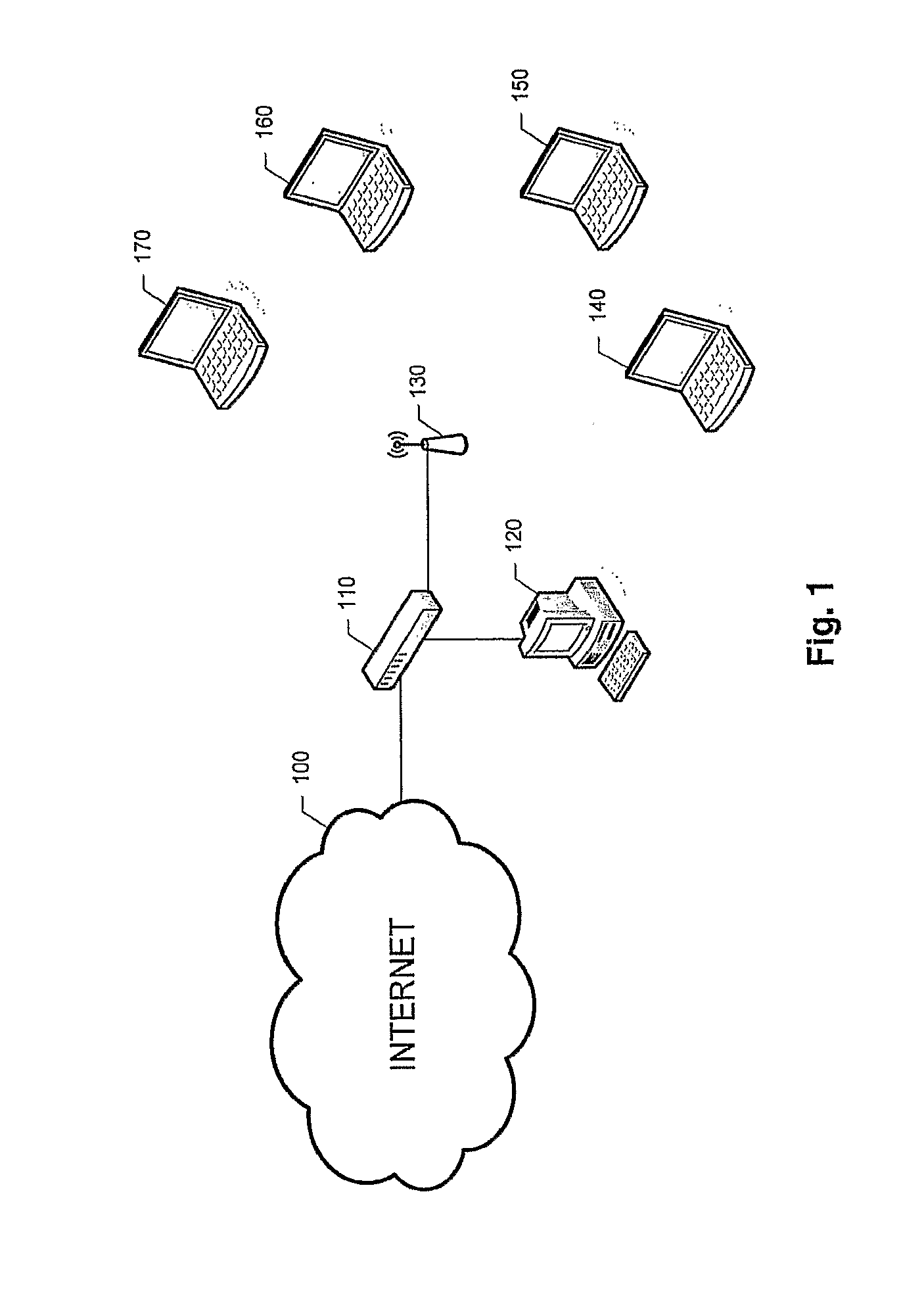

Optimization Procedure for Wireless Networks Operating in Infrastructure Mode with Standard Protocol IEEE 802.11

InactiveUS20090225682A1Improving global throughputShorten the timeNetwork topologiesData switching by path configurationTraffic characteristicWireless mesh network

The present invention is a procedure that allows configuring a random access IEEE 802.11 wireless network, operating in infrastructure mode (all terminals communicate exclusively with an AP (Access Point)), in such a way that throughput is optimized when the network is saturated, satisfying traffic characteristics, in presence or absence of the hidden terminal phenomenon and the number of terminals that communicate with the AP. It may be applied to networks that run a specific application or to those that have devices that run different applications. This procedure can be translated into a program that is operated by a wireless network administrator for network configuration. This program may also be incorporated into the configuration program of an AP and devices conforming to these standards. This invention can be applied to devices that act as AP's, such as a bridge, switch or router and the configuration can be manual or automatic, static or dynamic.

Owner:GROTE LOPEZ ALEX PETER +3

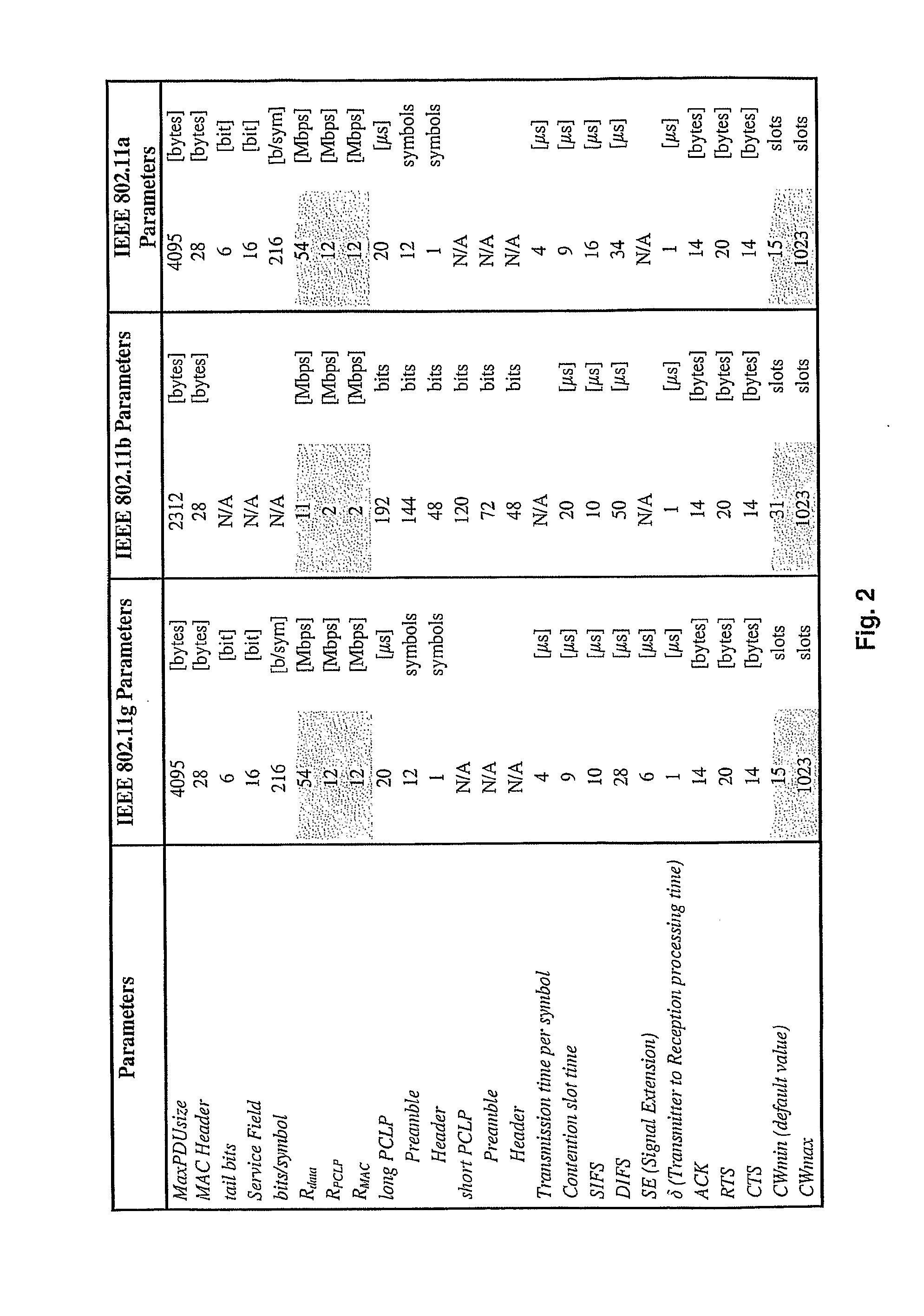

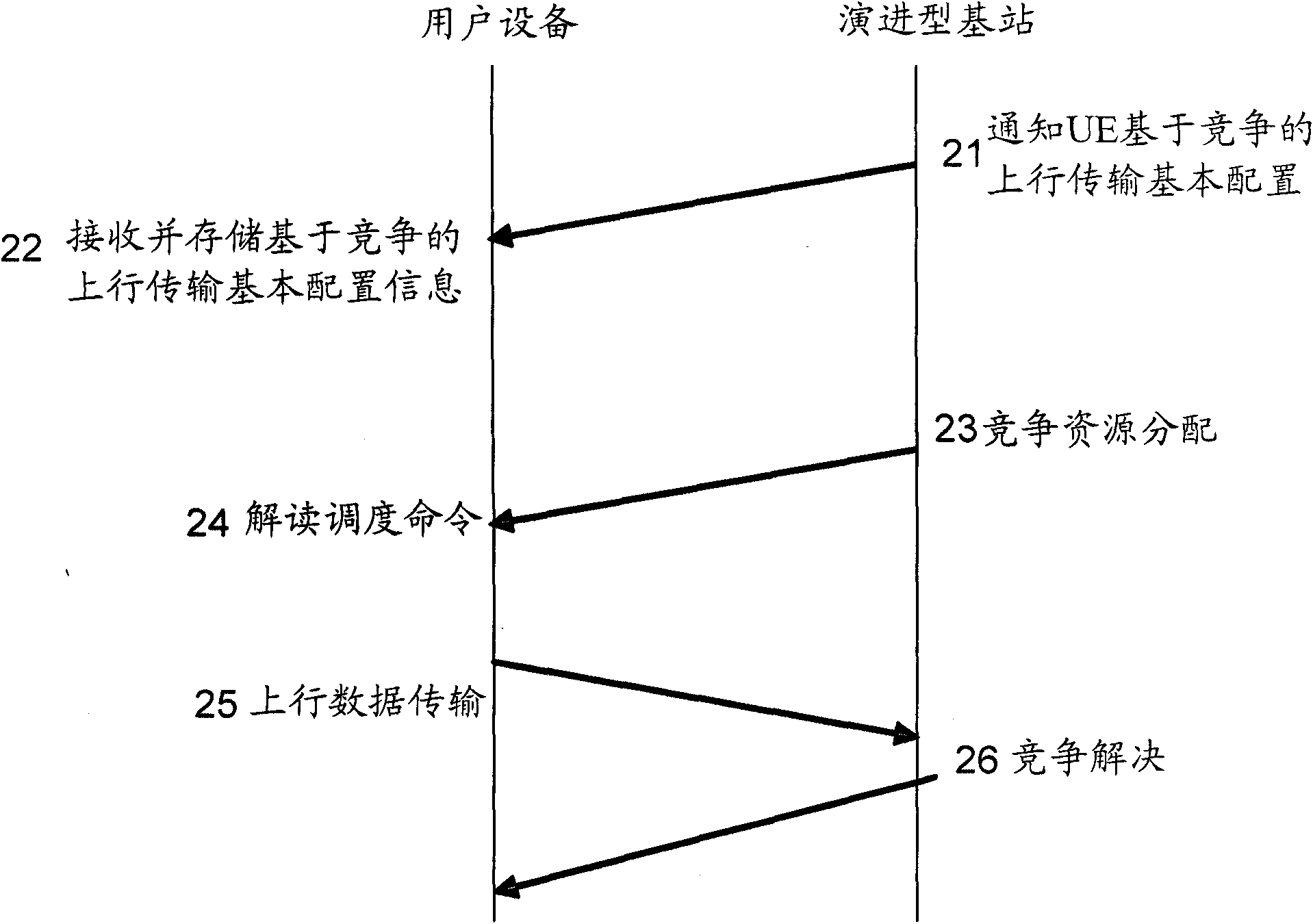

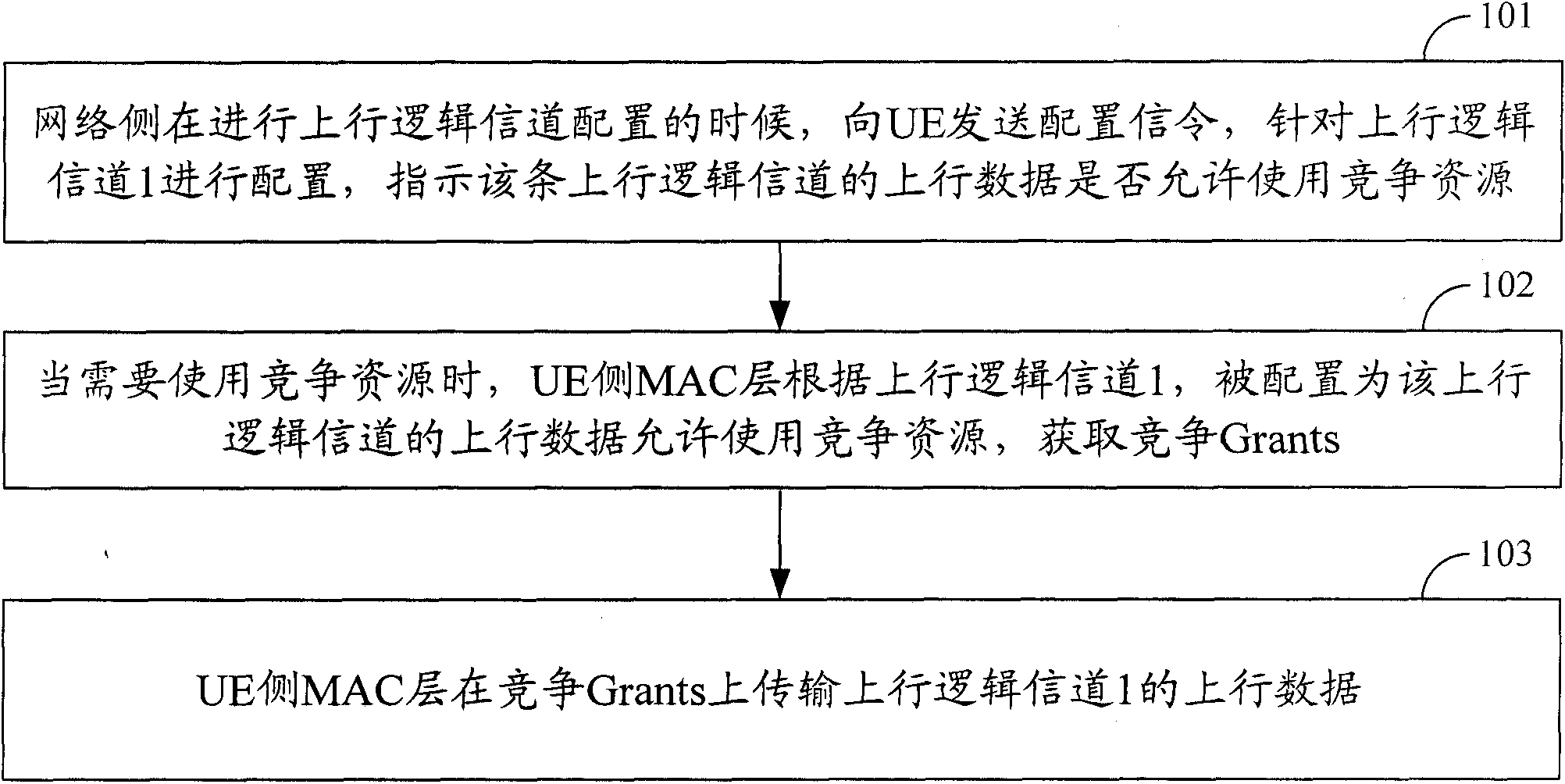

Contention-based uplink data transmission method and device

ActiveCN102083224AImprove efficiency and successIncreased chance of avoiding collisionsError prevention/detection by using return channelWireless communicationData transmissionMedia access control

The invention discloses a contention-based uplink data transmission method and a contention-based uplink data transmission device, which aim to solve the problem that the overall performance of uplink data transmission cannot be ensured well at the same time of shortening the switching time of a status switching process. The method comprises that: a user equipment medium access control (UE MAC) layer acquires configuration information which is used for indicating whether the uplink data of each uplink logic channel allows the utilization of contention resources or not, and if the contention resources are required to be utilized, transmits the uplink data allowing the utilization of the contention resources on contention grants and forbids the transmission of the uplink data not allowing the utilization of the contention resources on the contention grants. Processing is performed according to whether to allow the utilization of the contention resources or not respectively, the method and the device improve the efficiency and success rate of the utilization of the contention resources for the data capable of obtaining relatively higher gain by shortening a time delay, avoid the increasing of probability of collision of other data on the contention resources, ensure the transmission success rate of the other data and improve the overall performance of the uplink data transmission.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Method for increasing stability of cooling fluid for engine

InactiveUS20060017044A1Small diameterMore opportunity for separationOther chemical processesHeat-exchange elementsChemistryCorrosion

The present invention relates to a method for increasing the stability of the cooling fluid for engine. This invention selects the most preferred conditions, e.g. the composition of the solution, pH value, means and amount of addition, and proportion of silicate added, so that the products thereof has excellent property for inhibiting corrosion for many kinds of metals, being with low costs and good storage stability. Moreover, since this method is simple, it is easy to be put into practice and popularization.

Owner:GREAT WALL LUBRICATING OIL APPL RES CENT

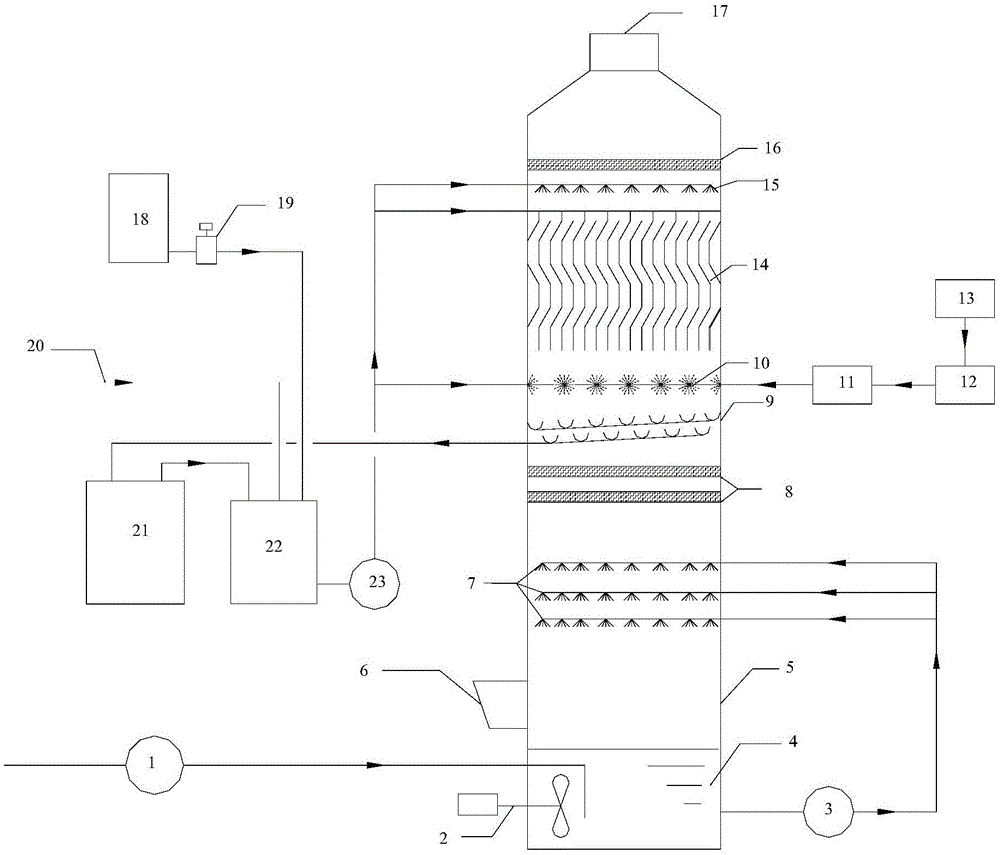

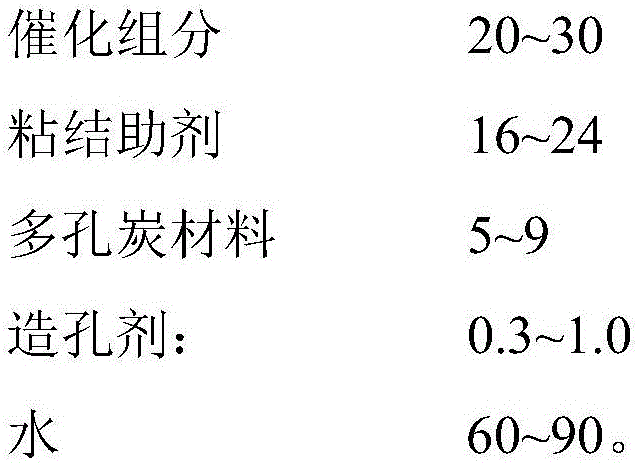

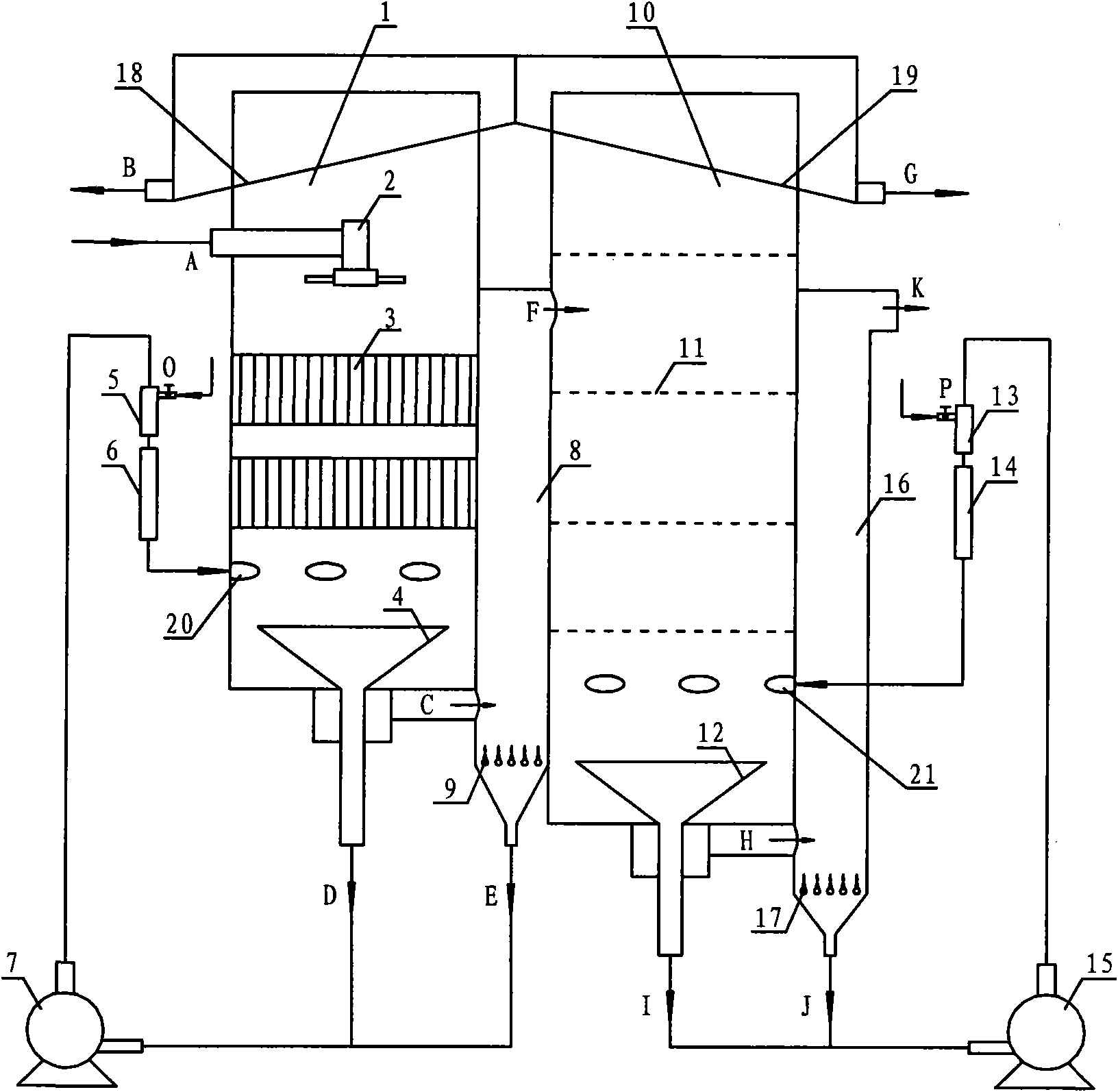

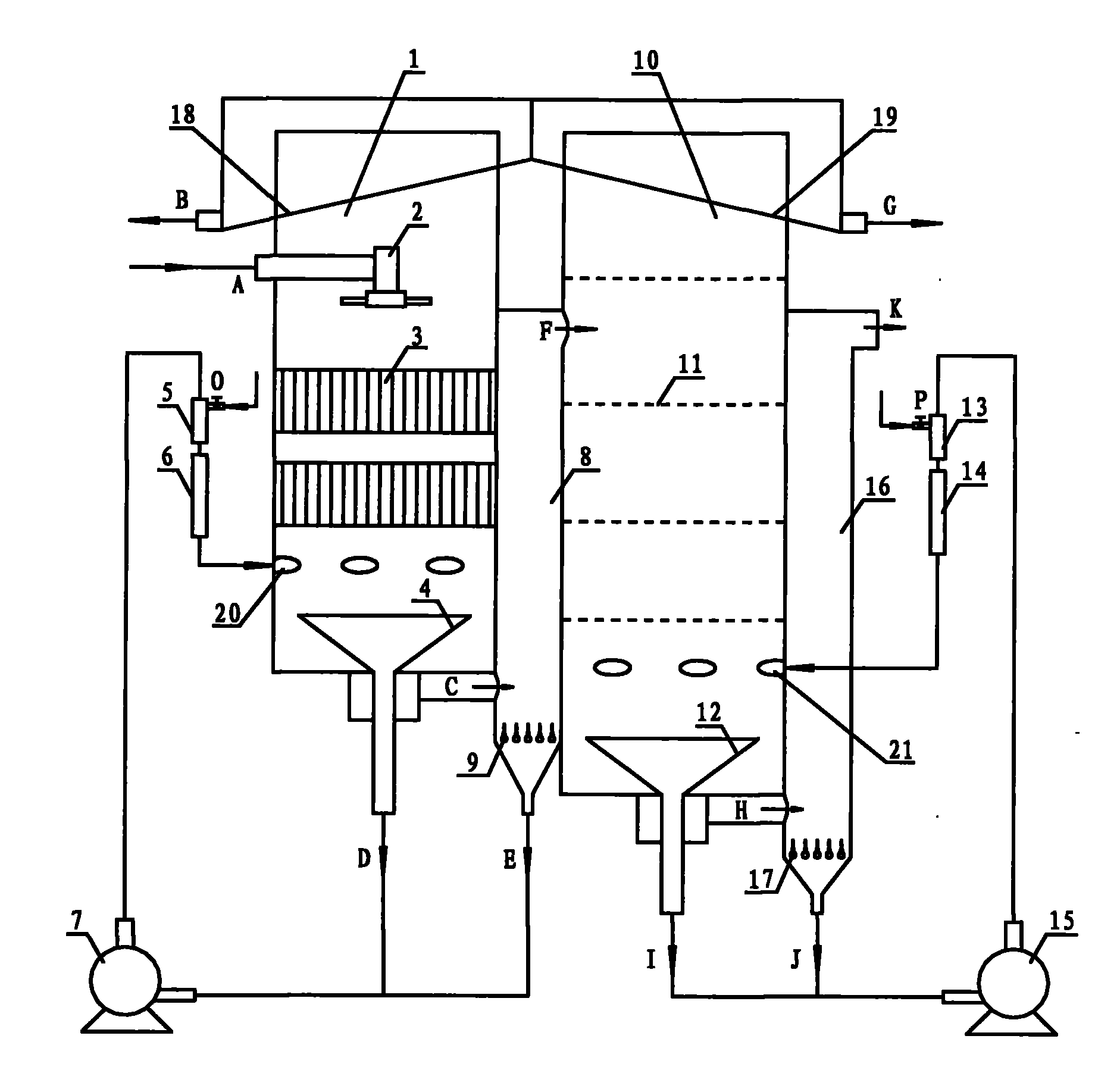

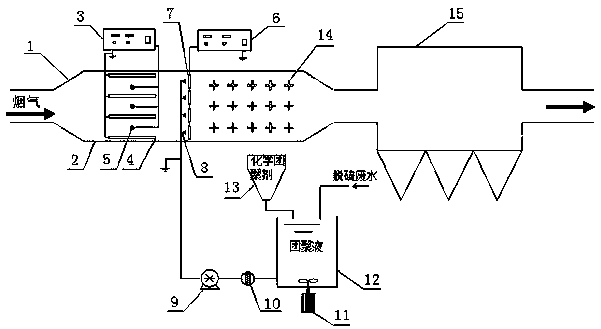

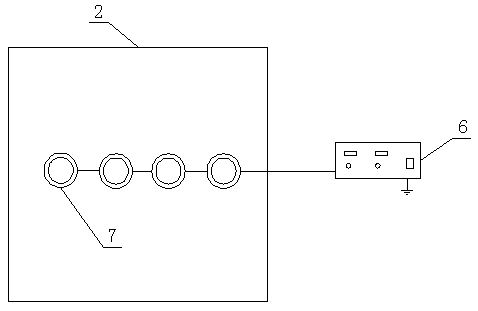

Super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas

ActiveCN105080311AWell mixedIncrease profitCombination devicesExternal electric electrostatic seperatorElectricitySlurry

The invention discloses a super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas. The treating technology includes the steps that the exhaust gas is fed into an absorption tower through an exhaust gas inlet of the absorption tower and upwards flows, desulfurization spraying and primary demisting are sequentially carried out, ozone oxidation, alkali liquor atomization mixing denitration and wet-type electric precipitation are carried out at the same time, secondary demisting is finally carried out, and then the exhaust gas is exhausted through an exhaust gas outlet in the top of the absorption tower; ozone and denitration absorption liquor are fed into an oxidation and denitration section through an air way and a liquor way respectively and mixed through double-fluid denitration spraying guns to be atomized and sprayed into the exhaust gas; slurry generated by desulfurization spraying falls into a slurry pond, and air is introduced into the slurry pond for oxidation; atomization alkaline liquor is captured through wet-type electric precipitation, and washing water generated in the wet-type electric precipitation process and washing water generated after wet-type electric precipitation are collected through a liquid collecting tank and temporarily stored and filtered outside the absorption tower to be reused as washing water. By means of the super-clean exhausting integral tower and treating technology, the desulfurization efficiency of the absorption tower is improved; meanwhile, denitration, dust removing and demisting can be achieved, and therefore the coal-fired exhaust gas can meet the stricter exhausting standard.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

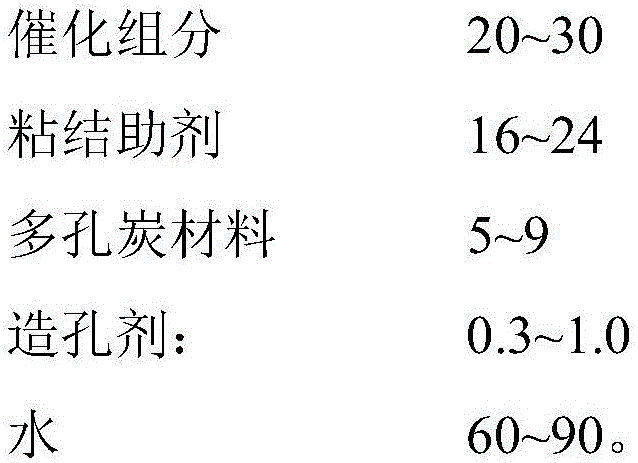

Porous composite material for purifying formaldehyde and TVOCs and preparation method of porous composite material

ActiveCN106334549ASimple molding processEasy to operateGas treatmentPhysical/chemical process catalystsPorous carbonCore shell

The invention relates to a porous composite material for purifying formaldehyde and TVOCs and a preparation method of the porous composite material, and belongs to the field of air purification materials. The porous composite material for purifying formaldehyde and TVOCs is characterized by comprising a core-shell structure, wherein the core-shell structure consists of a core material with a porous carbon material, and a shell material containing a catalytic component; pore channels for air circulation are formed in both the core material and the shell material. By adopting the porous composite material provided by the invention, a material formation process can be simple and easy to operate, the purification capacity for formaldehyde can be up to 6.05mg / g, and the purification capacity for methylbenzene can be as high as 299.41mg / g.

Owner:PANJIN SHENGSHIKANG ENVIRONMENTAL PROTECTION TECH

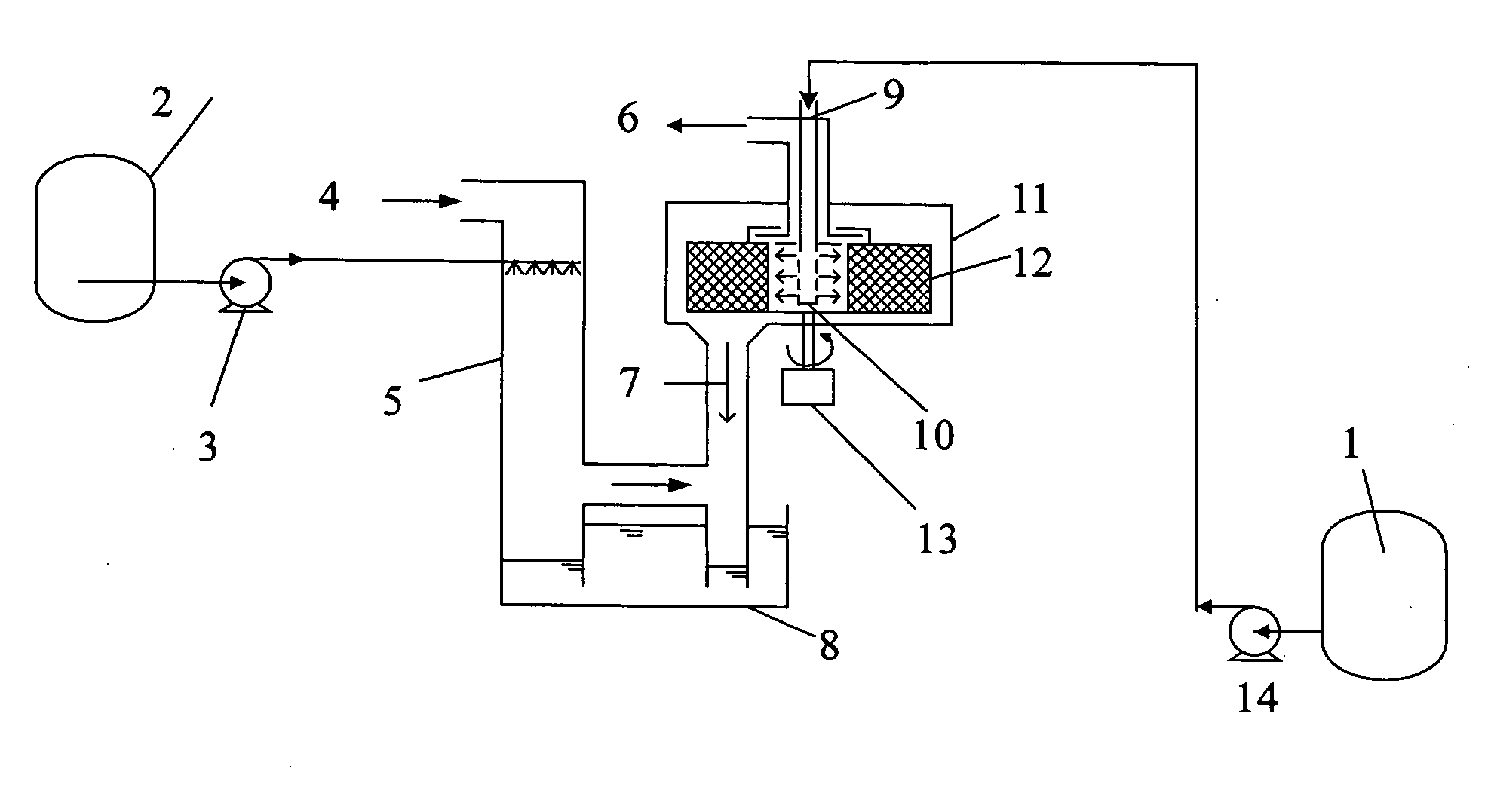

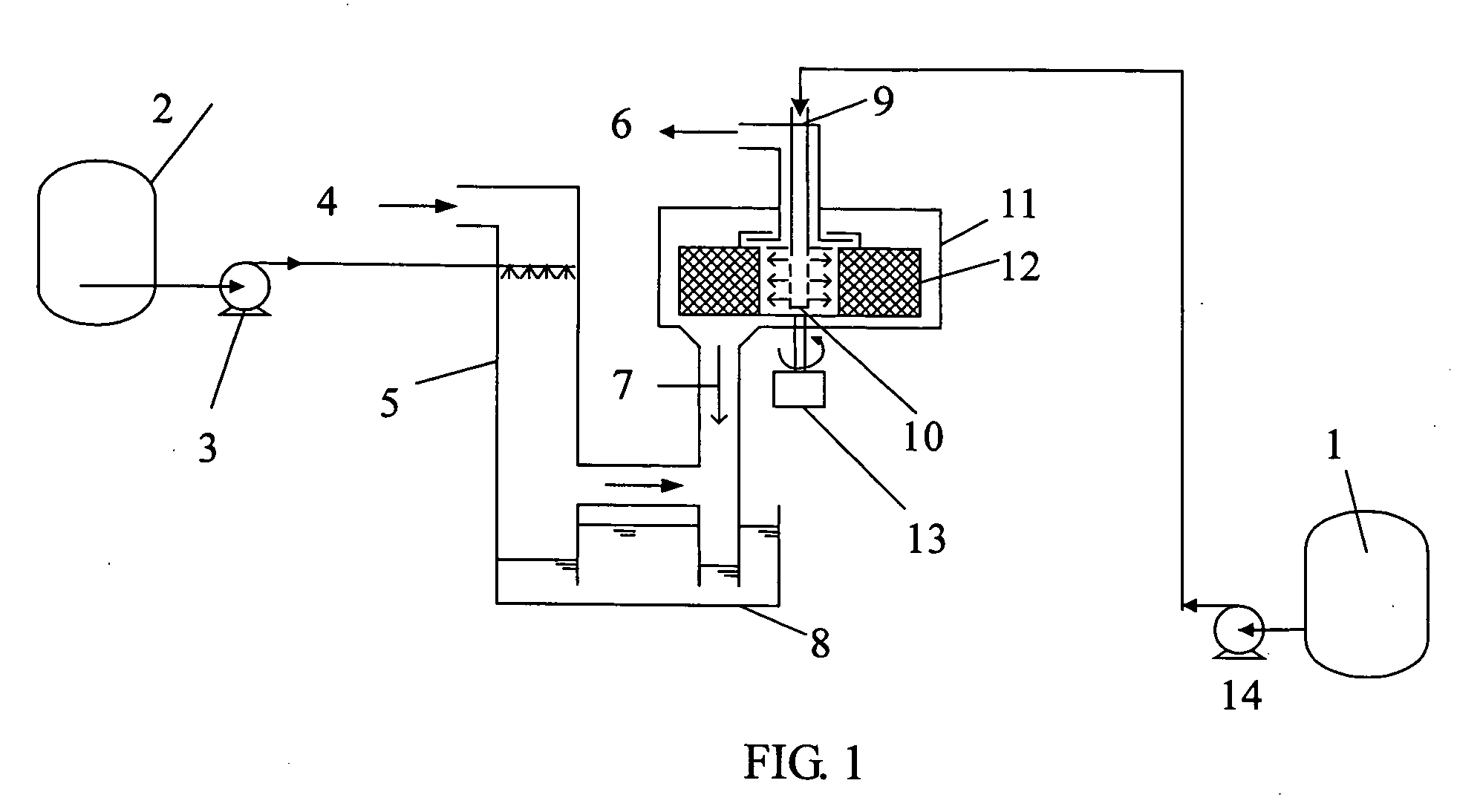

Slime separation method and equipment

InactiveCN101773873AImprove recycling effectSurface as soon as possibleFlotationEconomic benefitsEngineering

The invention relates to a slime separation method and equipment. The slime separation method adopts a one-piece double-flotation-column to carry out circulating flotation and classification for slime, and a flow stabilizer is arranged in a first flotation column; the flow stabilizer can eliminate large vortex, support a foam layer and increase the probability of collision between particles and bubbles, so that the slime easy to float can be floated out as soon as possible so as so reduce mix and pollution and play the role of flow stabilization; the material floated out through sedimentation is classified by a first sedimentation box and then enters a second floatation column to be floated again, and then enters a second sedimentation box to be classified again; and the number of the circulating separation of pulp is increased, and the recovery capabilities of coarse-fraction slime and difficultly floated fine-fraction slime are improved. The equipment has compact structure, large treating capacity, low production operation cost, and convenient installation and operation, improves the number and quality of fine coal products on the whole, and has marketable economic benefits.

Owner:CHINA UNIV OF MINING & TECH

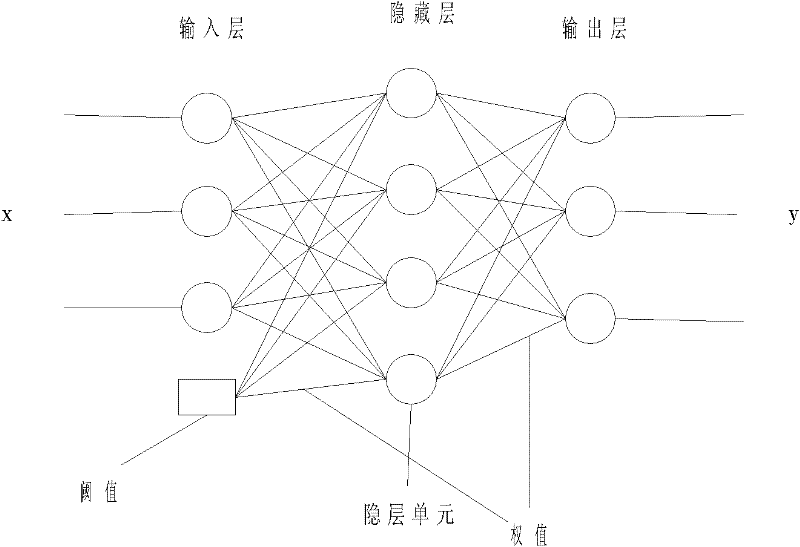

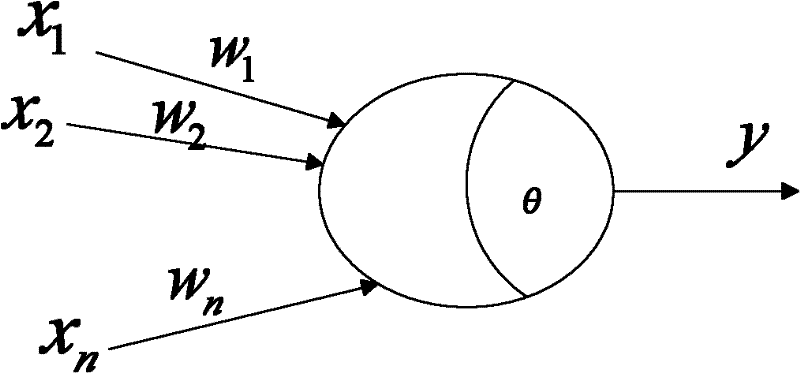

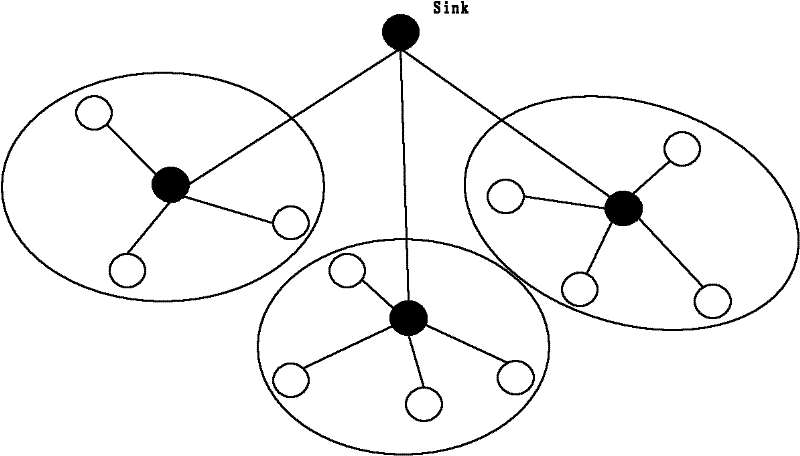

Wireless sensor network topology control method based on artificial neural network (ANN)

ActiveCN102238705AProlong survival timeReduce energy consumptionPower managementEnergy efficient ICTInformation processingTransmitted power

The invention provides a wireless sensor network topology control method based on an artificial neural network (ANN). The method is characterized in that the aim of saving energy is achieved by simulating an information processing system of a biological neutral network; when the total vector of the signals input by senor nodes is more than the threshold of a neurone, the neurone is activated and gives out pulses, thus outputting the signals; the nodes are selected to become the cluster heads according to the output signals and the dump energy to primarily form a network topology map; other nodes select the nearest cluster heads and join in the clusters and transfer own information to the cluster heads; the network topology map is optimized in combination with power control; and the transmitting power of the cluster heads is controlled so as to balance the number of the sensor nodes covered by the network, thus reducing collision during communication and improving the communication efficiency. The method has the following beneficial effects: under the condition of ensuring the network connectivity and coverage, the network energy is reasonably and efficiently used as far as possible, the life time of the whole network is lengthened and the nodes in each cluster are balanced to reduce communication interference among the nodes and improve the network communication efficiency.

Owner:NANJING UNIV OF POSTS & TELECOMM

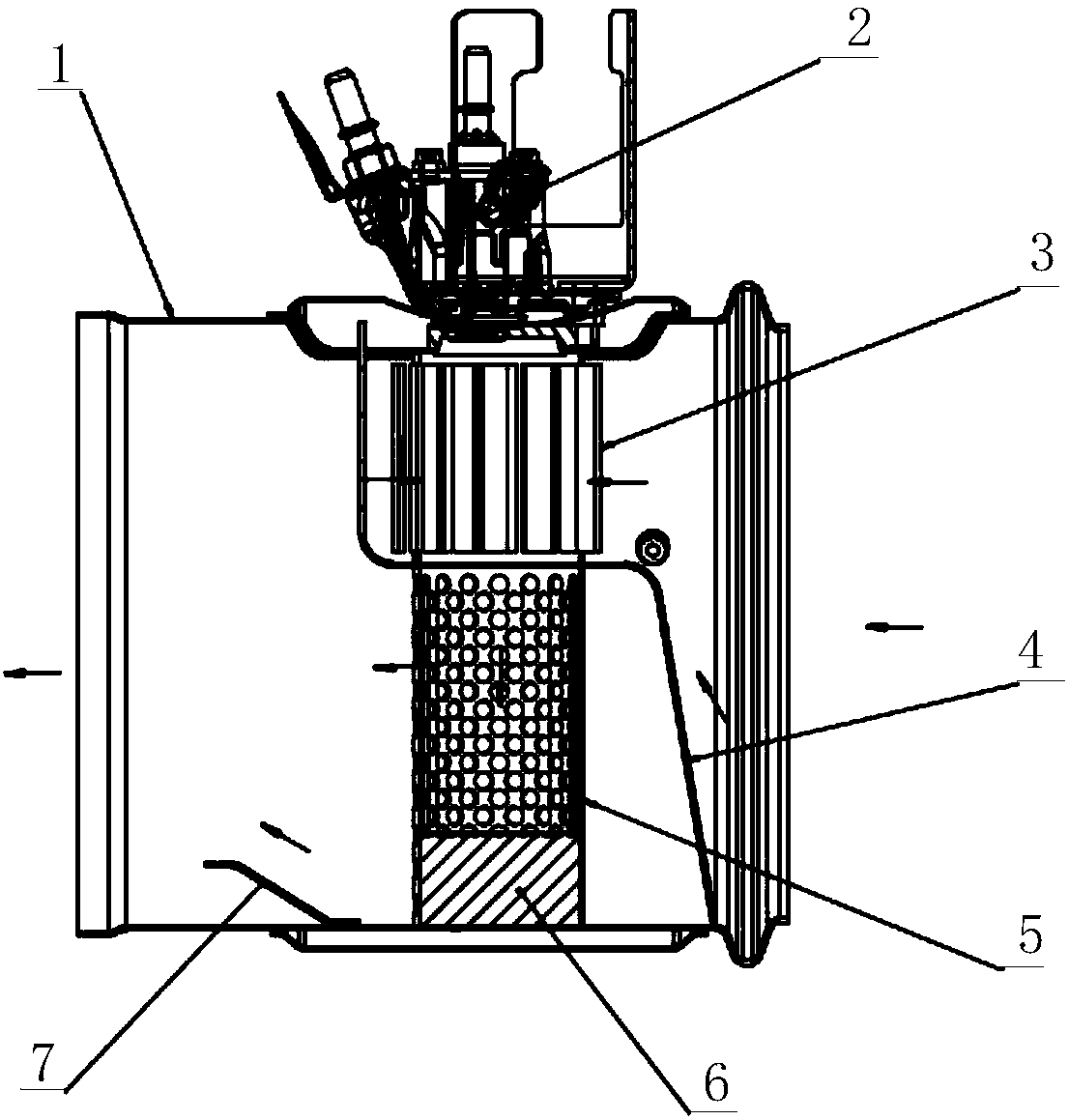

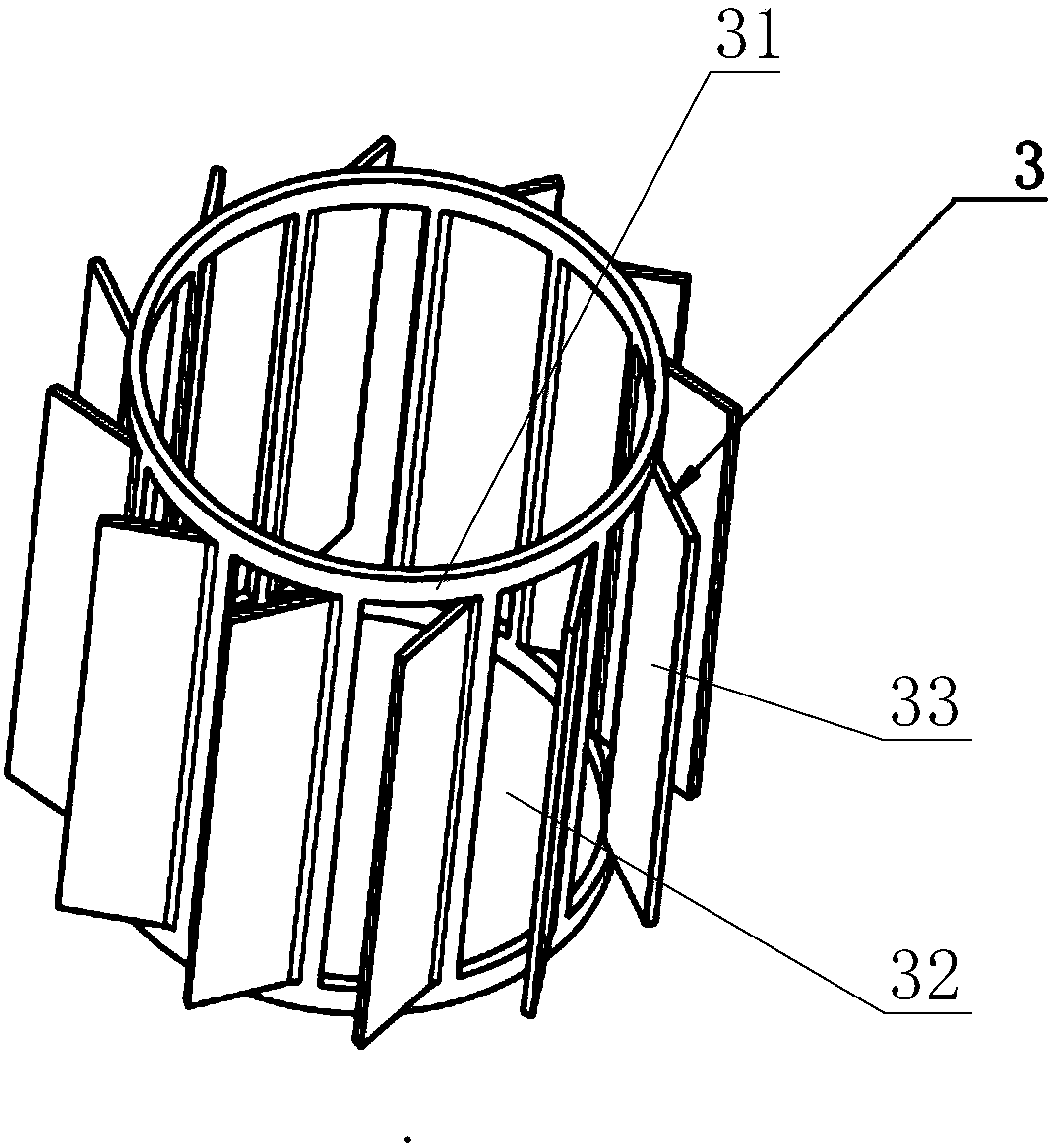

After-treatment intake mixing device

InactiveCN108194179AIncrease the probability of collisionWell mixedInternal combustion piston enginesExhaust apparatusNitrogen oxidesAfter treatment

The invention discloses an after-treatment intake mixing device. The after-treatment intake mixing device comprises a bucket body, a urea injection device, an intake swirl sheet and an intake mixing pipe, wherein the intake sheet blade comprises a barrel body; a first through hole is formed in the barrel wall of the barrel body; an inclined sheet is arranged on the first through hole; a urea nozzle of the urea injection device is aligned with the inner ring of the intake swirl sheet; the intake swirl sheet is butted with the intake mixing pipe; and a plurality of second through holes are formed in the intake mixing pipe. Tail gas enters from an intake port of the bucket body, and swirl mixing is carried out on the tail gas and an aqueous urea solution injected through the urea nozzle in the intake swirl sheet; the swirl sheet is beneficial to adequate mixing for the tail gas and mist urea liquid drops; and the mixed gas flow enters the intake mixing pipe, directly flows out through thesecond through holes in the intake mixing pipe, and contacts with a carrier with an SCR catalyst to carry out a catalytic reduction reaction. The intake swirl sheet enables the gas flow to form effective vortex, so that the collision probability of the tail gas and the aqueous urea solution is increased, and then the conversion efficiency of nitrogen oxides is increased.

Owner:WEICHAI POWER CO LTD +1

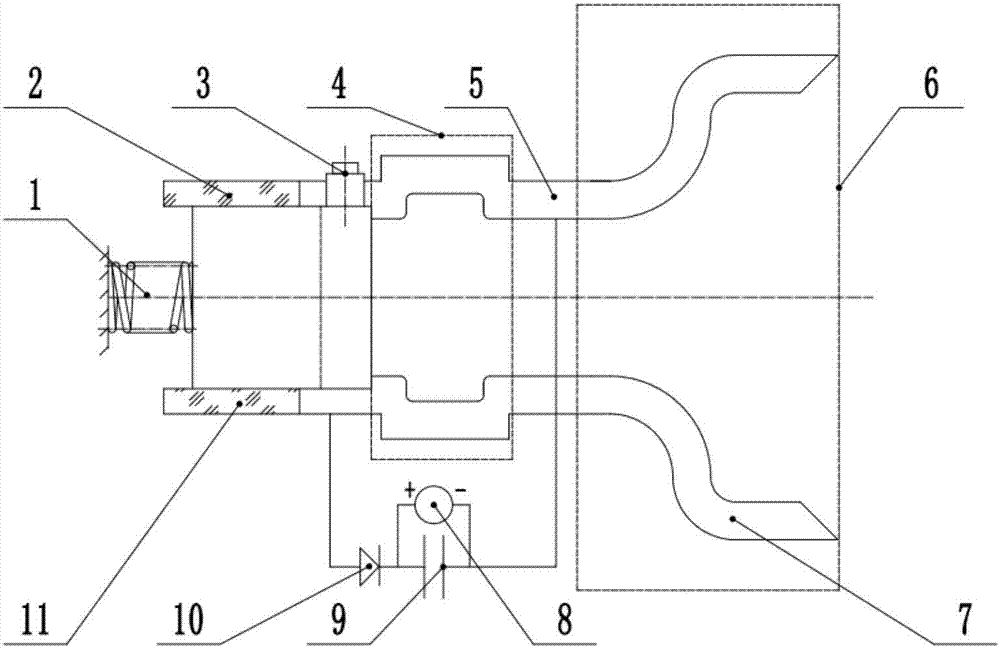

Solid pulse plasma thruster with high propellant utilization rate and working method

InactiveCN107178479AIncrease profitIncrease the probability of collisionMachines/enginesUsing plasmaMicro nanoHigh pressure

The invention discloses a solid pulse plasma thruster with high propellant utilization rate and a working method, and belongs to the technical field of aerospace propulsion of micro-satellites. The solid pulse plasma thruster with high propellant utilization rate comprises a constant-force spring, an upper insulating plate for fixing a propellant, a semiconductor spark plug, a permanent magnet for increasing impulse bit, a cathode plate, a permanent magnet for increasing specific impulse, an anode plate, a high-voltage power supply, a main spark-gap capacitor, a diode, a lower insulating plate for fixing the propellant and a solid propellant; gas storage cavities for reducing the forward movement speed of neutral gas are respectively formed in the cathode plate and the anode plate; the distance between the cathode plate and the anode plate is increased on the rear sides of the gas storage cavities; tail ends, which are close to a nozzle, of the cathode plate and the anode plate are parallel to each other; the permanent magnet for increasing the impulse bit is added in the direction which is opposite to the direction of a self-inductance magnetic field; and the permanent magnet for increasing the specific impulse is added in the direction which is the same as the direction of the self-inductance magnetic field. The propellant utilization rate of the solid pulse plasma thruster can be increased. The solid pulse plasma thruster has the advantage of low cost, and is suitable for being used as a main thruster of a micro-nano satellite or an adjusting device of various large satellites.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

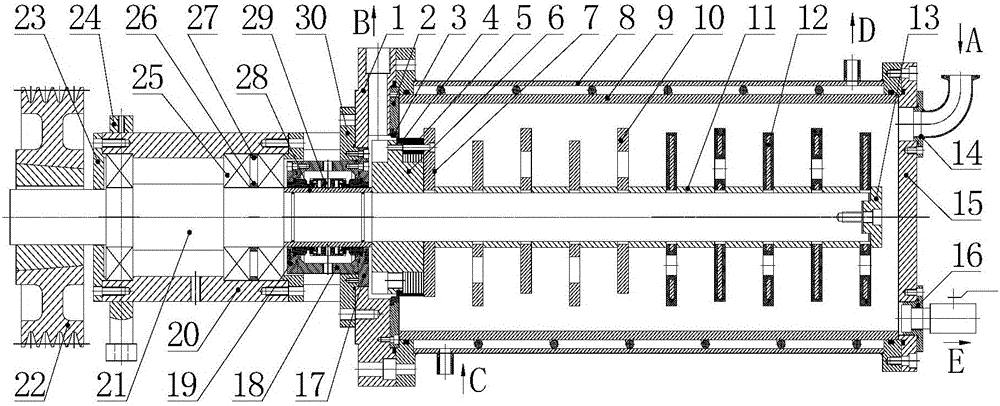

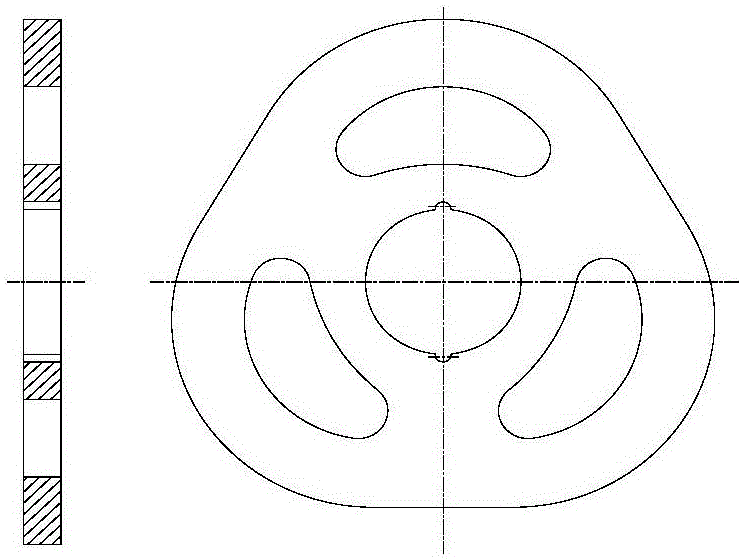

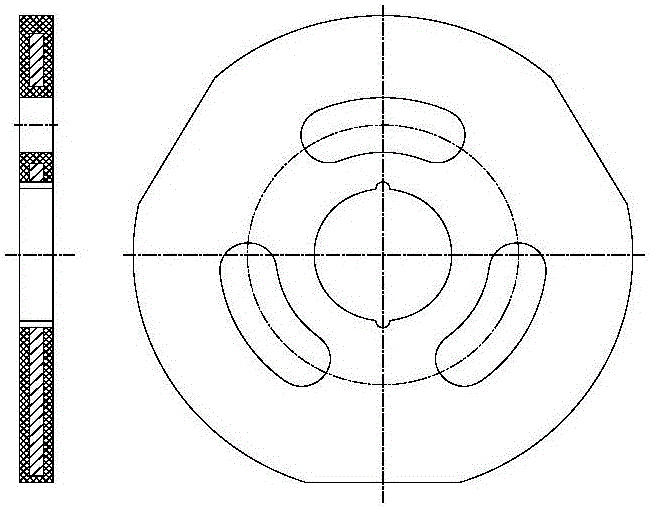

Horizontal sand mill of combined rotary dispersion disk grinding structure

The invention provides a horizontal sand mill of a combined rotary dispersion disk grinding structure. The horizontal sand mill of the combined rotary dispersion disk grinding structure is composed of a machine frame, a motor, a main shaft, a grinding unit, a material pump and an electric system. The grinding unit is of the rotary dispersion disk grinding structure combining a crescent round dispersion disk and an eccentric dispersion disk, and is composed of an outer grinding cavity barrel body, an inner grinding cavity barrel body, the main shaft, a discharge separation device, a discharging end sealing cover, an abrasion-resistant plate, a barrel end sealing cover plate and a ball discharging valve. The horizontal sand mill of the combined rotary dispersion disk grinding structure has two different shearing forces and can change the movement mode of balls and materials in the barrel bodies, thereby increasing the relative movement speed and impact probability of balls and material particles, obtaining higher relative movement speed and impact force compared with a single round disk or eccentric disk, enabling materials to reach the ideal fineness as soon as possible, and obtaining higher grinding efficiency. The horizontal sand mill of the combined rotary dispersion disk grinding structure further has abrasion resistance and corrosion resistance, is long in service life, is convenient to clean and replace, and is widely applied to processing and production of paints, ink, pigment and other fields.

Owner:东莞市利腾达智能装备有限公司 +1

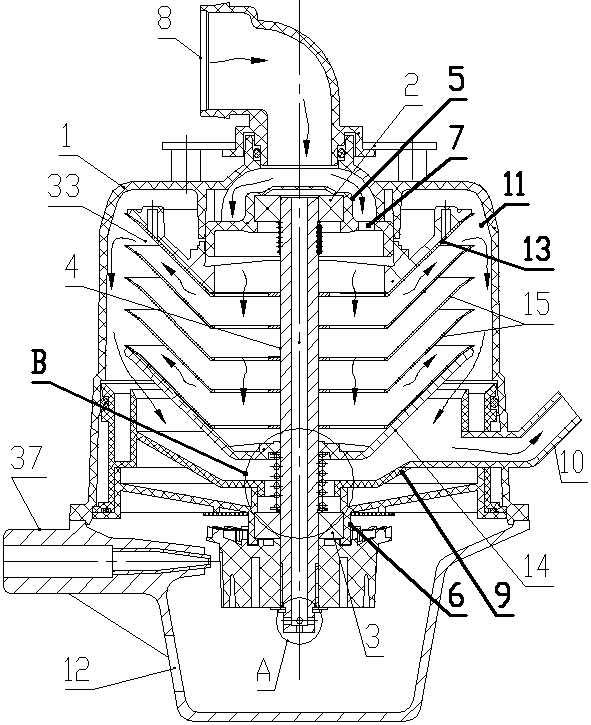

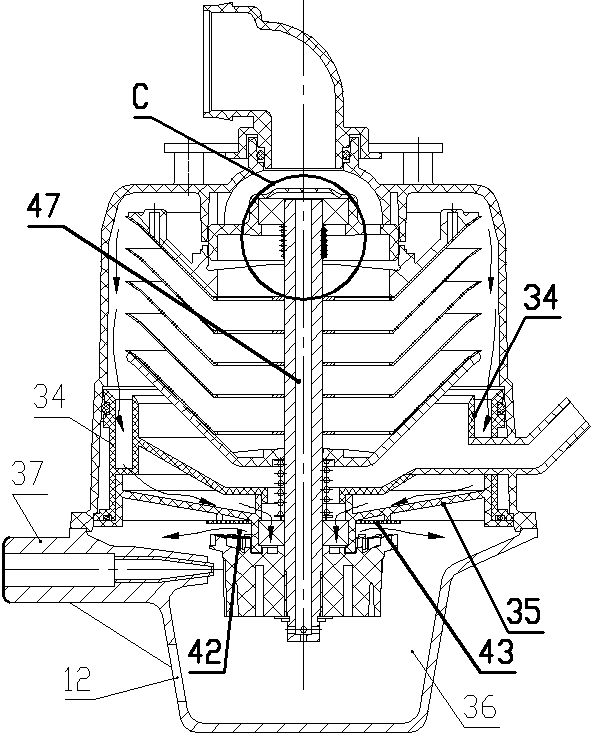

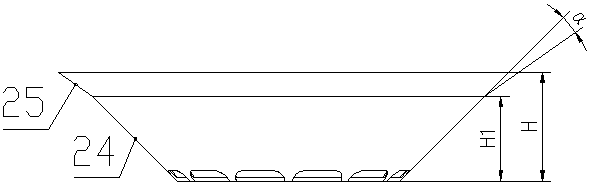

Active oil-gas separator

PendingCN110500159AEfficient separationEasy to separateMachines/enginesCrankcase ventillationStopped workEngineering

The invention discloses an active oil-gas separator which comprises a shell. An oil-gas separation mechanism is arranged between the upper middle portion of a center shaft in the shell and the shell,and a driving mechanism used for driving the center shaft to rotate is arranged between the bottom of the center shaft and the shell. An air inlet used for introducing fleeing gas of an internal combustion engine is formed in the top of the shell, a pure gas outlet is formed in the position, at the bottom of the oil-gas separation mechanism, of the side wall of the shell, and an oil return openingused for lubricating oil to flow out is formed in the position, below the driving mechanism, of the side wall of the shell. The oil-gas separation mechanism comprises a separation disc upper end cover, a separation disc lower end cover and all middle separation discs which are connected between the separation disc upper end cover and the separation disc lower end cover and are arranged on the center shaft. The active oil-gas separator begins to work automatically after a motor vehicle is ignited and stops working automatically after the flameout, electric control is not needed in the work process, efficient oil-gas separation can be conducted on engine fleeing gas, losses of lubricating oil are reduced, long-term stable running can be achieved without maintenance, and very high market value is achieved.

Owner:PINGYUAN FILTER

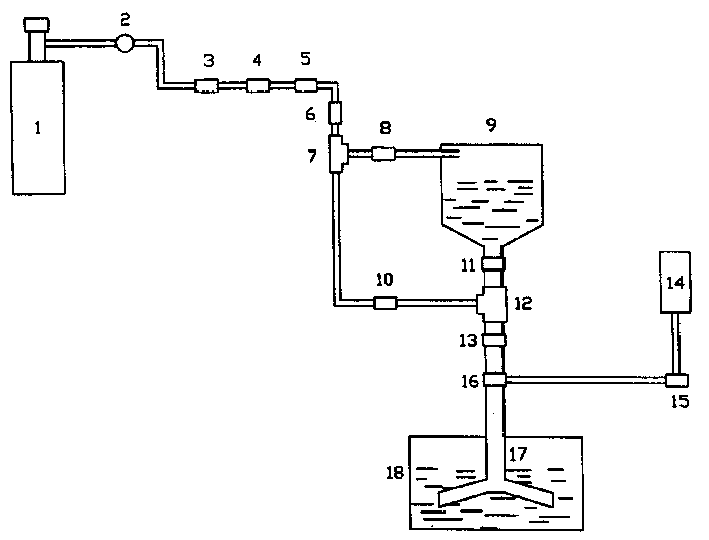

Cleaning method and equipment of spinneret plate for polyacrylonitrile fiber

InactiveCN104775167AImprove dissolution efficiencyIncrease the probability of collisionSpinnerette packsNon-surface-active detergent solventsBiochemical engineeringUltrasonic vibration

The invention relates to a cleaning method of a spinneret plate, in particular to a cleaning method and cleaning equipment of the spinneret plate for polyacrylonitrile fiber. In the vacuum cleaning environment, an alkaline spinneret plate cleaning solution is heated, circulating dissolved cleaning is performed on polyacrylonitrile (PAN) on the spinneret plate, auxiliary cleaning of ultrasonic vibration wave oscillation is performed in the whole cleaning process, and the cleaning solution is filtered by an external circulating system, so that no impurity in the cleaning solution in the vacuum environment is guaranteed. The cleaning method has the advantages of short process flow, simple equipment and good cleaning effect, and the cleaning solution can be reused.

Owner:ZHONGFU SHENYING CARBON FIBER

System and method for synergistically treating desulfurization waste water and enhancing agglomeration and removal of fine particles

ActiveCN109759233AFully dispersed atomizationHigh quantity densityElectrostatic separationHigh-voltage direct currentEngineering

The present invention discloses a system and a method for synergistically treating desulfurization waste water and enhancing agglomeration and removal of fine particles. The system comprises a condensational growth system. The fine particles in flue gas are negatively charged under the action of a negative high voltage direct current electric field; agglomeration liquid prepared by the desulfurization waste water and a chemical agglomeration agent is sprayed through a two-fluid atomizing nozzle and charging and electrostatic atomization effects are generated under the action of a high voltageannular electrode so that atomization and dispersion of droplets are more fully and droplets are positively charged. Then eddy current at different scales is generated by a cross-shaped insulating turbolator in a turbulent agglomeration area so that the fine particles with different charges and the agglomeration liquid droplets collide and agglomerate in a turbulent flow field and an attractive action is generated by a coulomb force between the two; meanwhile, adsorption and adhesion are generated among the fine particles by the chemical agglomeration agent in the droplets, thereby the condensational growth among the fine particles is enhanced; finally the fine particles are removed by an electrostatic dust collector, and then evaporation treatment of the desulfurization waste water and enhanced removal of the fine particles are realized.

Owner:SOUTHEAST UNIV

Technological process for removing fine occluded foreignsubstance in molten steel

ActiveCN101323893AImprove purityEfficient removalProcess efficiency improvementSlagNon-metallic inclusions

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel. The technology of the invention comprises the steps as follows: a. the adjustment of an RH work position: the positions of a down pipe and a feed pipe of the RH are adjusted to ensure that the down pipe is positioned at the opposite side of the feed pipe; b. refining: after being transported to the RH work position, ladles are done with temperature measurement, sampling, vacuumizing, ingredient adjustment and clean circulation; c. input of compound spheres: after the refining, the compound spheres are put into the molten steel at the work position; d. continuous casting: after the compound spheres are put into the molten steel, the molten steel is then directly cast on a machine and the continuous casting adopts a whole-process protection casting. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5micron to 9micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

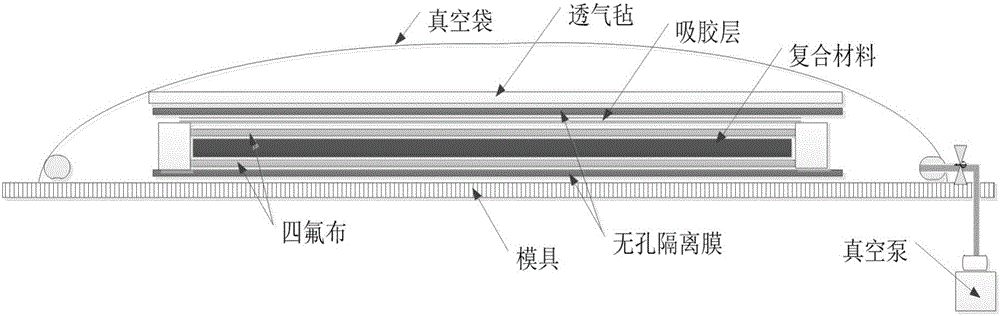

Anti-ionizing radiation fiber-reinforced resin matrix composite and preparation method thereof

In the invention, basalt fiber has relatively high content of heavy-nucleus elements such as iron and manganese, and the heavy-nucleus elements enhance the adsorbing and scattering effects of the basalt fiber on high-energy ionizing radiation; and compared with other reinforcing fiber, the basalt fiber has better ray shielding performance. The elements including tungsten and lead realize perfect weakening and shielding effects on the ionizing radiation with relatively high energy; and by adding the heavy metals tungsten and lead and other compound fillers, the energy of high-energy ray can be effectively reduced so that the high-energy ray is converted into low-energy radiation and further absorbed by the basalt fiber. In the invention, the heavy metals and compounds thereof, the resin matrix and the basalt fiber cooperate with each other and interact, and the obtained anti-ionizing radiation composite obtains good anti-radiation property and mechanical property.

Owner:BEIHANG UNIV

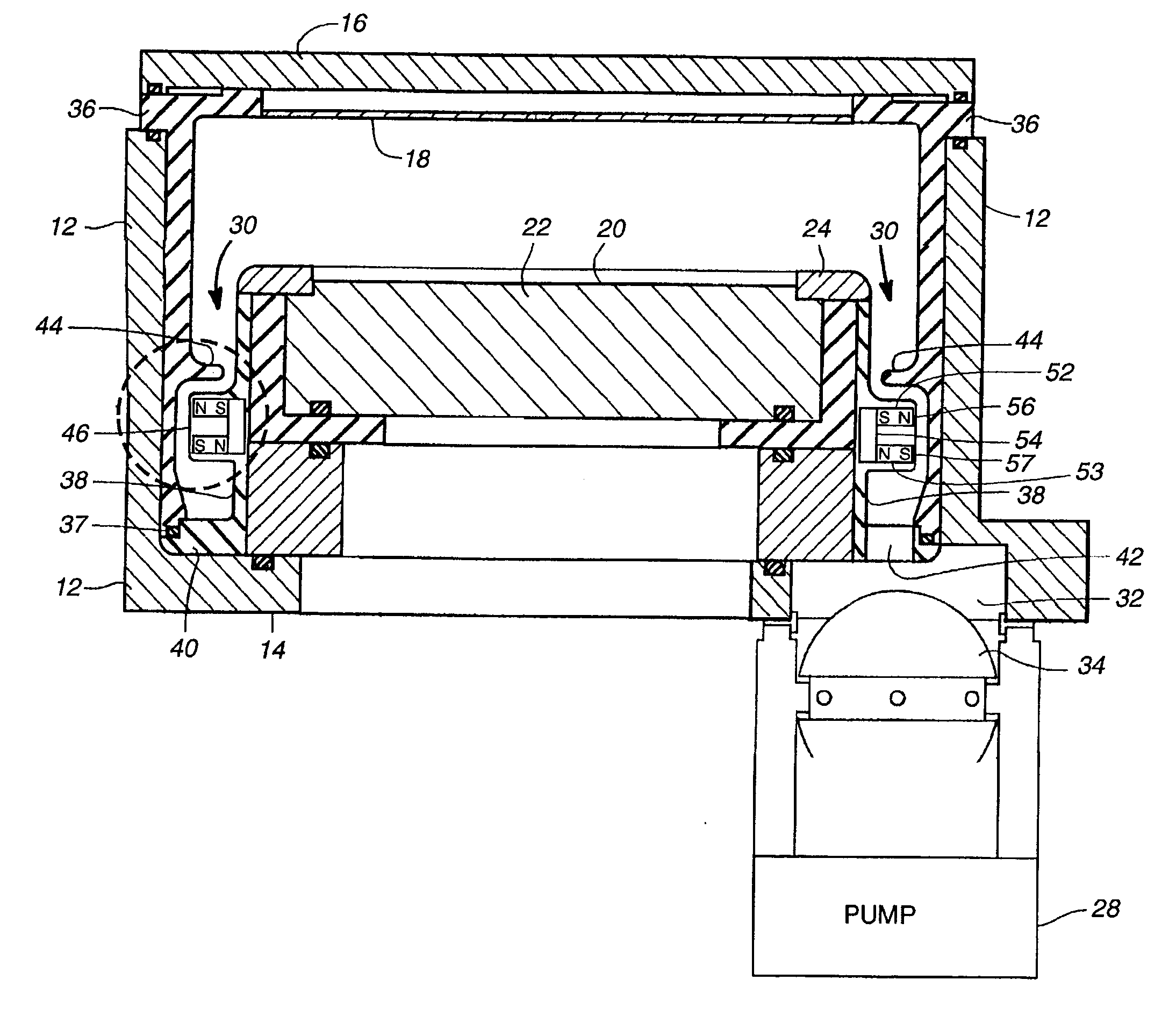

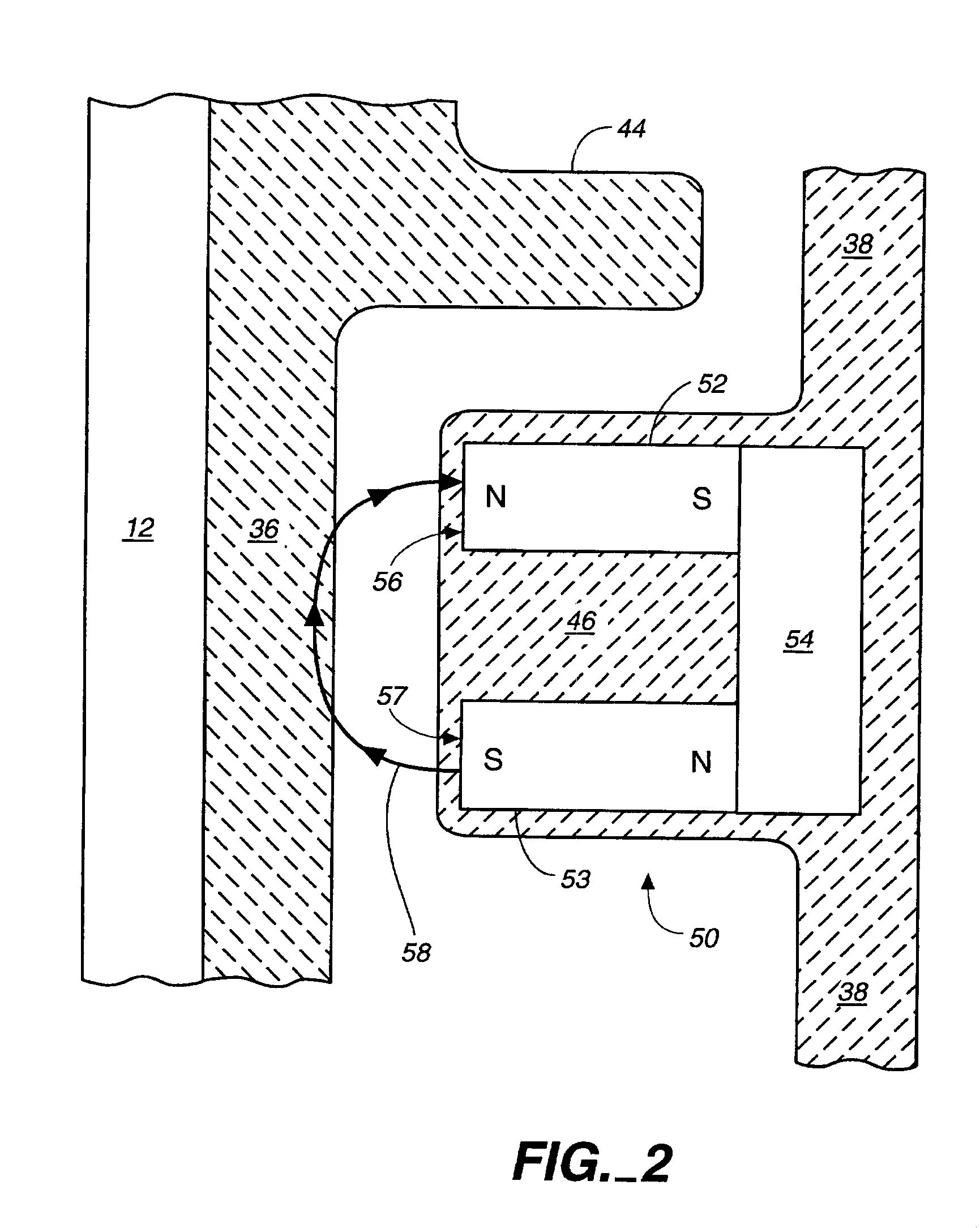

Magnetic barrier for plasma in chamber exhaust

InactiveUS6863835B1Efficient designEffective blockingElectric discharge tubesDecorative surface effectsMagnetic barrierPlasma confinement

A plasma chamber apparatus and method employing a magnet system to block the plasma within the chamber interior from reaching the exhaust pump. An exhaust channel between the chamber interior and the pump includes a magnet and at least one deflector that creates turbulence in the flow of exhaust gases. The magnetic field and the turbulence produced by the deflector both increase the rate of recombination of charged particles in the gases, thereby reducing the concentration of charged particles sufficiently to quench the plasma downstream of the magnet and deflector, thereby preventing the plasma body within the chamber from reaching the exhaust pump. The plasma confinement effect of the magnetic field permits the use of a wider and / or less sinuous exhaust channel than would be required to block the plasma without the magnetic field. Therefore, the pressure drop across the exhaust channel can be reduced in comparison with prior art designs that rely entirely on the sinuousness of the exhaust channel to block the plasma. Alternatively, if the magnetic field is strong enough, the magnetic field alone can block the plasma from reaching the exhaust pump without the need for any deflector in the exhaust channel.

Owner:APPLIED MATERIALS INC

Purifying method for casting-smelting mag nesium alloy and air blowing apparatus thereof

The present invention relates to a method for cleaning impurity in the course of casting and smelting magnesium alloy and its air-blowing equipment. It is characterized by that the impurity-removing solvent using pressure inert gas as carrier is blown into the molten alloy, its gas pressure is 0.05MPa-0.5 MPa, flow rate is 5Lmin-100 L / min, and the flow rate of solvent carrier by gas is 100g / min-500g / min. Said invention also provides its cleaning operation steps, it not only raises alloy purity and property, but also raises its production efficiency.

Owner:JILIN UNIV

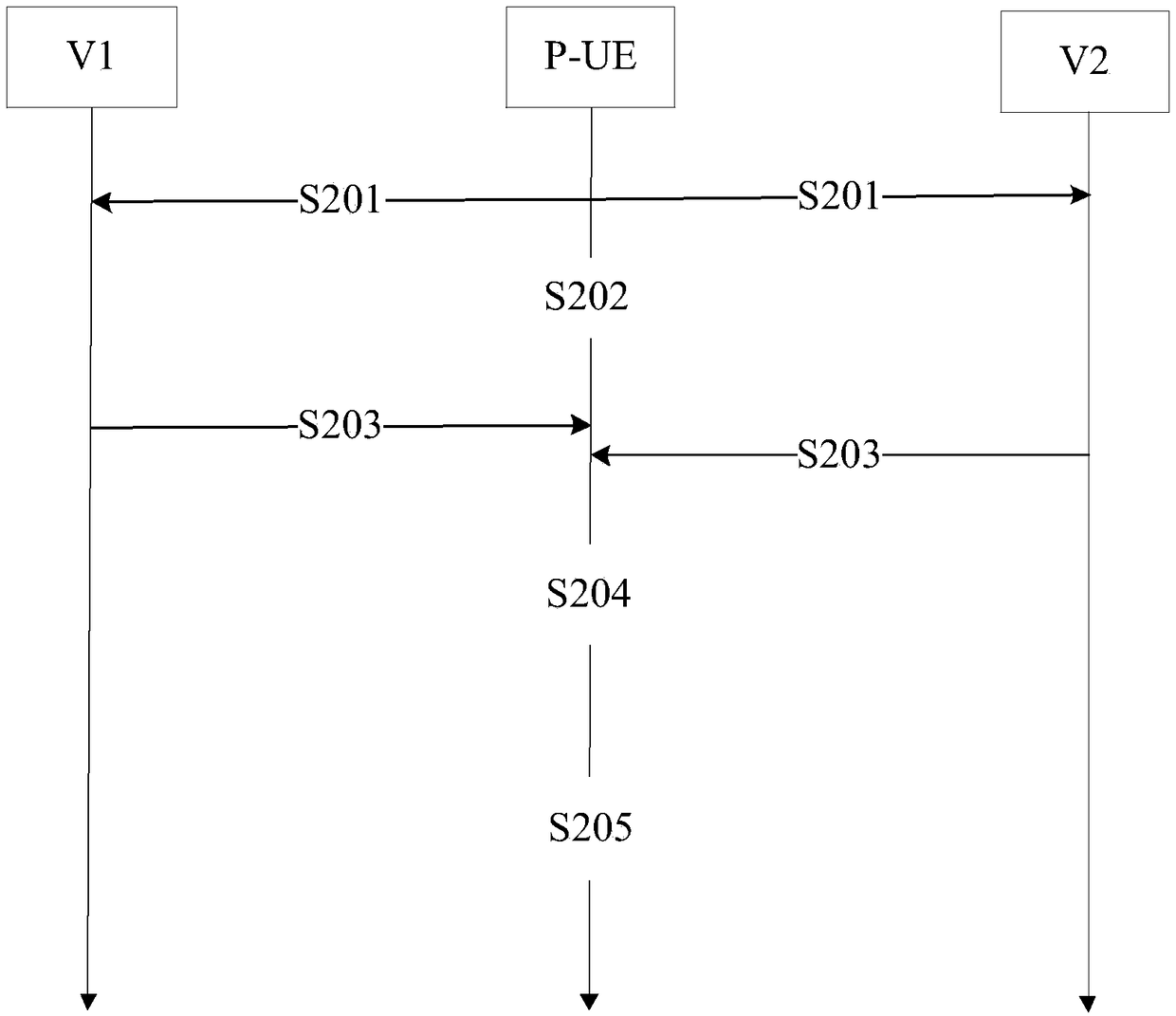

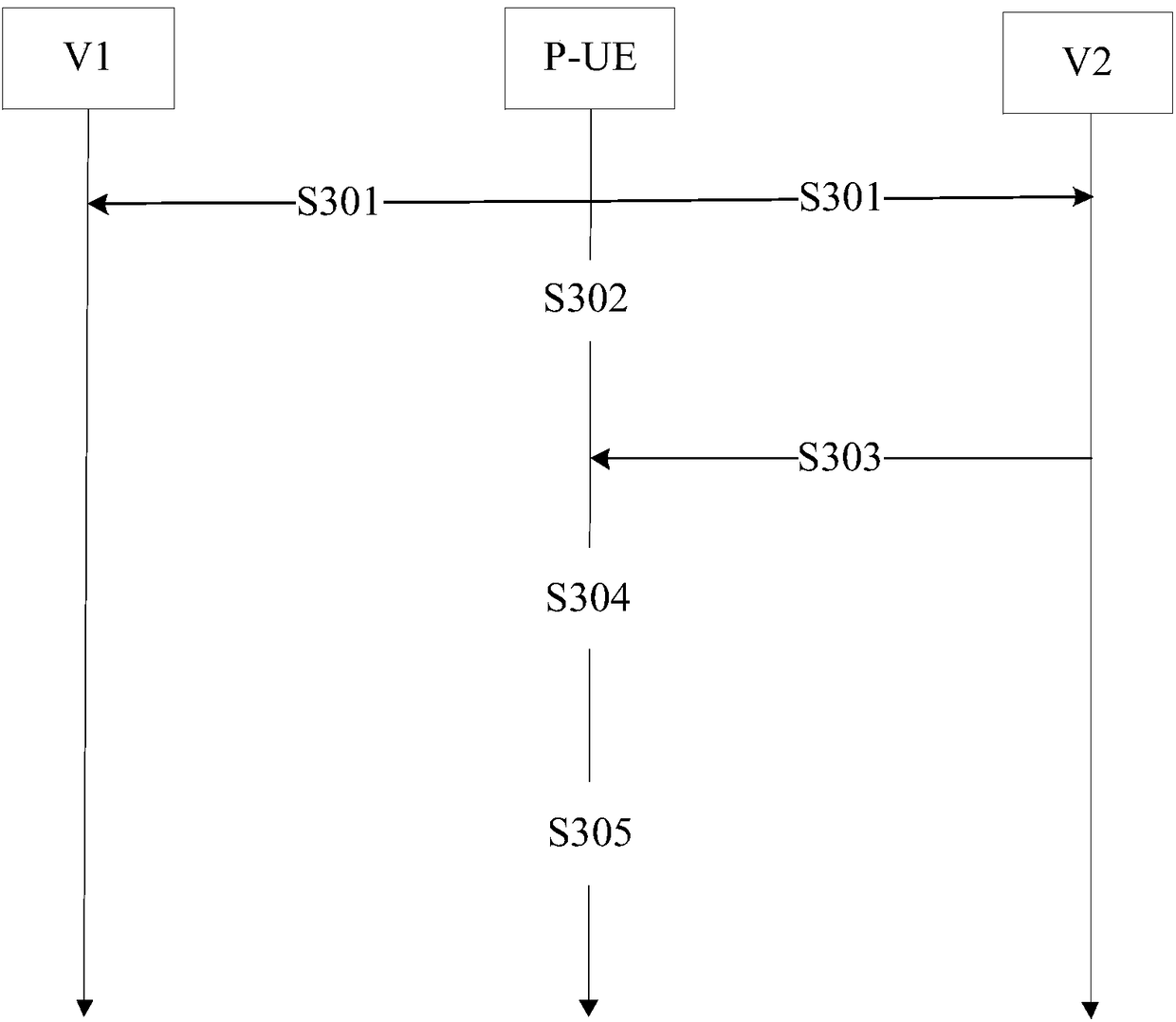

Method for selecting transmission resources, method for transmitting shared information, terminal and external device

InactiveCN108616839AIncrease the probability of collisionImprove performanceParticular environment based servicesInter user/terminal allocationResource poolComputer terminal

The present invention provides a method for selecting transmission resources, a method for transmitting shared information, a terminal and an external device. According to the method, the terminal andthe external device of the invention, the terminal judges whether at last one of N sensing results is received within a first preset time period, wherein the N sensing results are sent by M externaldevices and are used for characterizing the resource use condition of a transmission resource pool, M is an integer greater than or equal to 1, and N is an integer greater than or equal to 1; and if at last one of the N sensing results is received within the first preset time period, the terminal selects transmission resources on the basis of the received at least one sensing result. With the method of the invention adopted, the terminal can receive the sensing results which are sent by the external devices and are used for characterizing the resource usage condition of the transmission resource pool, and technical problems that cannot be solved in the prior art can be solved.

Owner:CHINA ACAD OF TELECOMM TECH

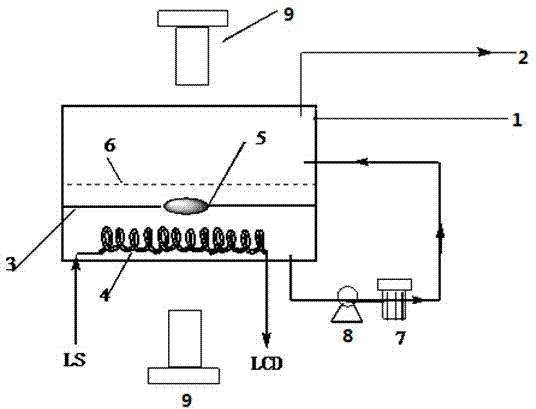

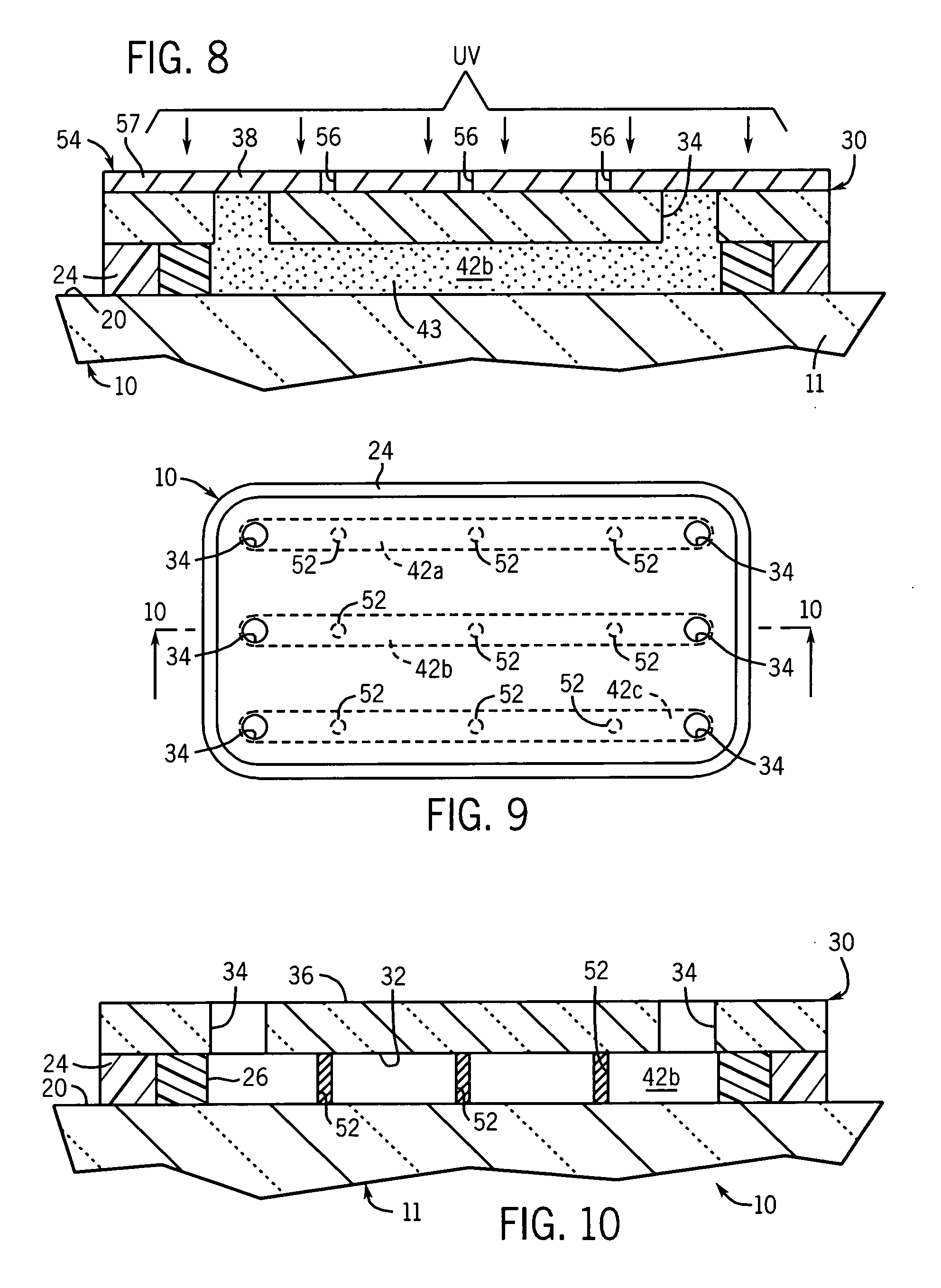

Cell mimic platform and method

ActiveUS20060110722A1Easy to catchAccurate predictionBioreactor/fermenter combinationsBiological substance pretreatmentsChemistry

A platform and method for mimicking the environment within a cell is provided. The platform includes a microfluidic device defining a chamber. At least one hydrogel post is positioned within the chamber of the microfluidic device. Each hydrogel post defines a corresponding pore for receiving a first molecule therein. Second molecules are introduced into the pores of the hydrogel posts and the interactions between the first and second molecules are observed.

Owner:WISCONSIN ALUMNI RES FOUND

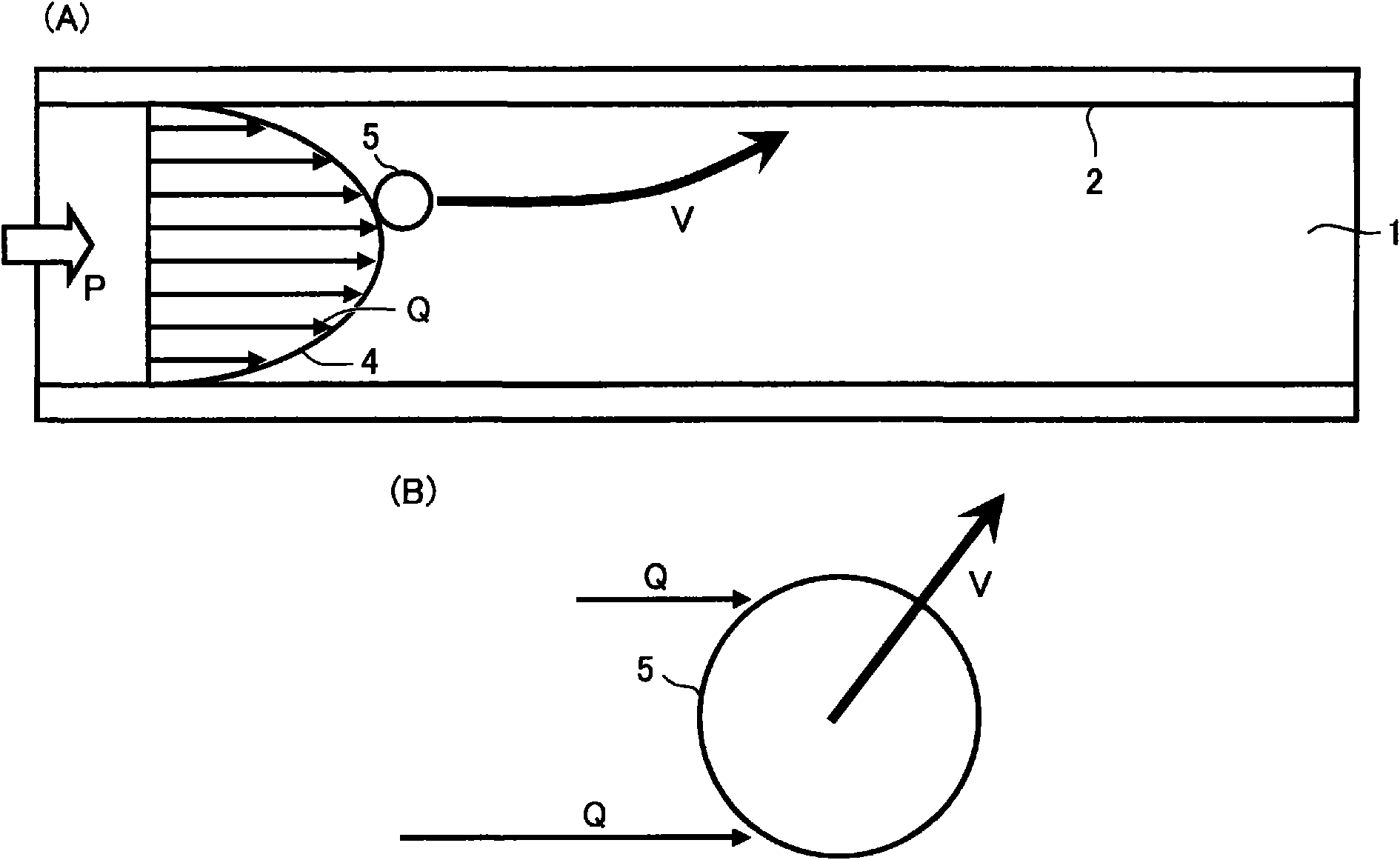

Dust flocculating passage, dust flocculating method, and vacuum cleaner

InactiveCN101528102AIncrease the probability of collisionShort intervalAuxillary pretreatmentSuction filtersFlocculationParticle collision

The present invention provides a dust flocculating passage, which is enabled with a simple structure to promote the flocculation of particles in dust by increasing the number of particle collisions, thereby to reduce the particle number and to enlarge the apparent particle diameter, and a dust flocculating method and a vacuum cleaner. The dust flocculating passage (10) comprises a passage (11) for a gas to pass therethrough, a wall (12) for forming the passage (11), and vortex generating means for generating vortexes in the gas flowing in the passage (11). The vortex generating means is so arranged on the inner face of the wall (12) as to give a heterogeneous velocity distribution to the gas flow near the wall (12). The vortex generating means includes either a turning portion (13) having a wall portion protruding from the inner face of the wall (12) into the passage (11) so as to turn the gas flow in the passage (11), or protrusions from the inner face of the wall (12) so as to make heterogeneous the velocity of the passing gas.

Owner:SHARP KK

Technological process for removing small inclusions in secondary refining

ActiveCN101323894AScientific and reasonable preparationIncrease the probability of collisionProcess efficiency improvementCollision probabilitySlag

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel by the external refining technology. The technology of the invention comprises the steps as follows: a. molten steel is refined at LF, RH, VD or CAS-OB work position; b. a wire feeding technology is adopted to feed cored wires into the molten steel at the work positions; c. the molten steel is then directly cast on a machine after the wire feeding and the continuous casting adopts a whole-process protection casting. As the added cored wires have a scientific and reasonable prescription, when micro-air bubbles occur in the molten steel, the bubbles have high collision probability with the slag inclusions and fine slag drops have the function of wash heat and can also effectively remove the slag inclusions in the molten steel. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount can be controlled to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5 micron to 9 micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

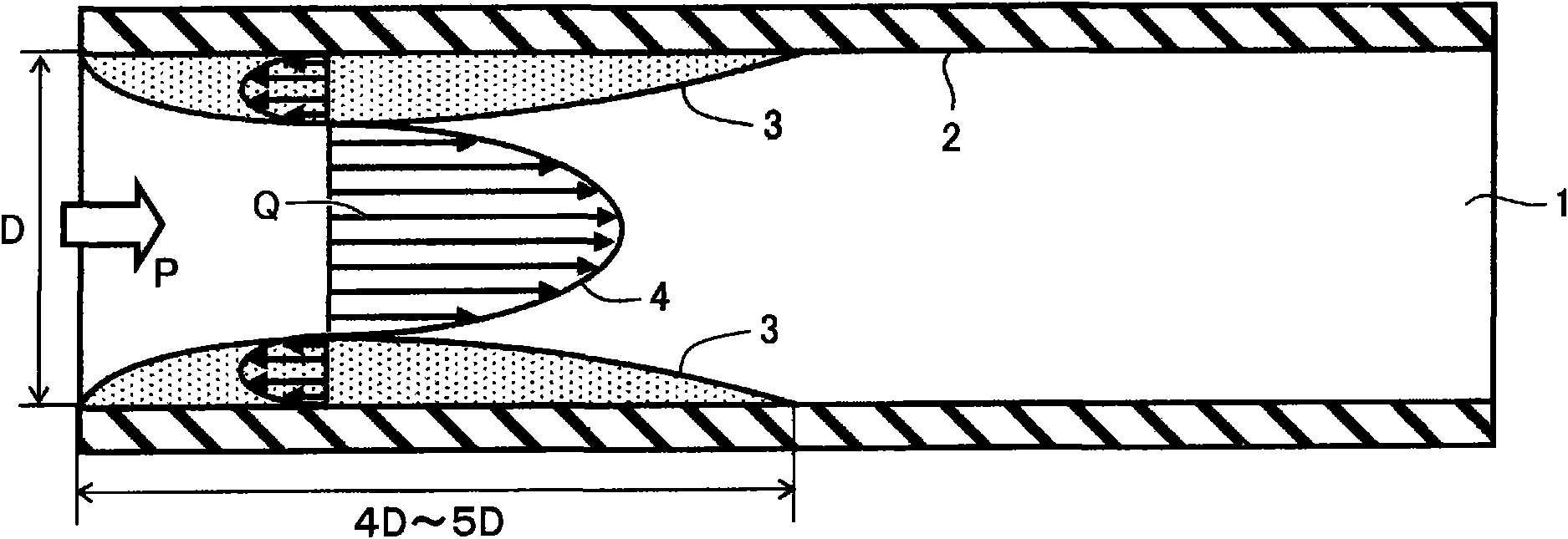

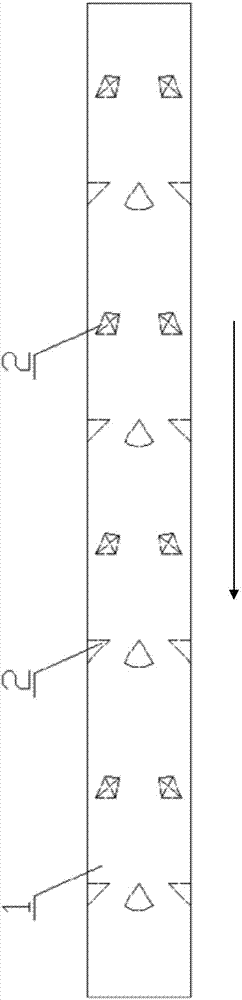

Pipe flow section device applicable to mineralized fine grain minerals

ActiveCN104511374AIncreased turbulence intensityIncrease the probability of collisionVortex flow apparatusFlotationEngineeringMaceral

The invention discloses a pipe flow section device applicable to mineralized fine grain minerals. The device comprises a pipeline (1) between the downstream of a bubble generator of a flotation column and an inlet end of a rotating flow inlet end, wherein the inner pipe wall of the pipeline (1) along the inner pipe wall of a pipeline axis is provided with at least a row of vortex generators (2), and the vortex generators are a plurality of protuberances (21) surrounding the inner pipe wall. The vortex generator in the pipe can be changed by the vortex generator set in the pipeline, therefore the collision probability between mineral grains and bubbles can be improved, the turbulence intensity in the pipe can be gradually enhanced, the mineral effect can be enhanced, and the recovery ratio of the fine minerals can be improved.

Owner:CHINA UNIV OF MINING & TECH

Method of catching nano-particles

InactiveUS20060090647A1Efficient collectionContamination problemDispersed particle filtrationUsing liquid separation agentCombustionWater vapor

The present invention discloses a method for catching particles having diameters size down to the nanometer level including a first step of increasing particle diameters of particles contained in an outlet gas from a fabrication process of nano-particles or an exhaust from a combustion; and a second step of introducing the resulting effluent from the first step into a rotating packed bed. The first step involves contacting the gas / exhaust with droplets or water vapor, creating collision of the nano-particles with the droplets or condensation of water vapor using the nano-particles as condensation nuclei, so that the size of the nano-particles increases to the micro level. The second step uses the minute water drops generated from and the hindrance of the rotating packed bed to catch the micro-particles in the gas / exhaust under a relatively high centrifugal force. The first step can occur in the rotating packed bed if the gas / exhaust is introduced directly into the rotating packed bed and has a sufficient long residence time in the rotating packed bed.

Owner:IND TECH RES INST

Powder preparation additive for outside-stove refining dephosphorization, removing fine foreign matter and its manufacturing method

The invention relates to an external refining method for microalloy steel and special steel, in particular to a powder additive for external refining desulphurization and fine inclusion removal and a preparation method thereof. The powder additive is the preferred powder additive for refining desulphurization and fine inclusion removal of various microalloy steel or special steel. The powder additive is prepared by mixing raw materials of low melting point premelting slag powder, calcium fluoride, calcium carbonate or magnesium carbonate or a mixture of the calcium carbonate and the magnesium carbonate, calcium oxide or magnesium oxide or a mixture of the calcium oxide and the magnesium oxide, and adhesive according to a formula. The method has scientific formula and simple and reasonable process, can effectively remove inclusions in molten steel, can realize the quick refining desulphurization of the molten steel until the content of sulfur is lower than 0.0030 percent proven by application, is high in efficiency, steady and short in time, can meet the requirements of different molten steel on the content of the sulfur, greatly improves the quality of refining steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

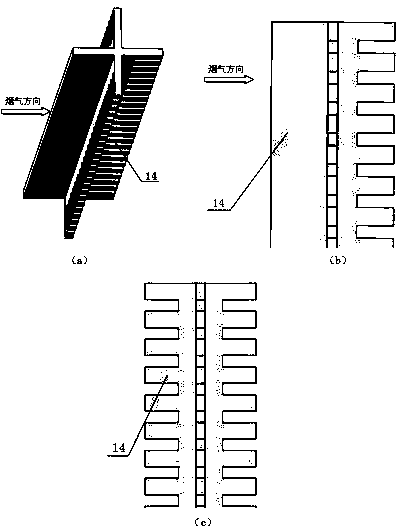

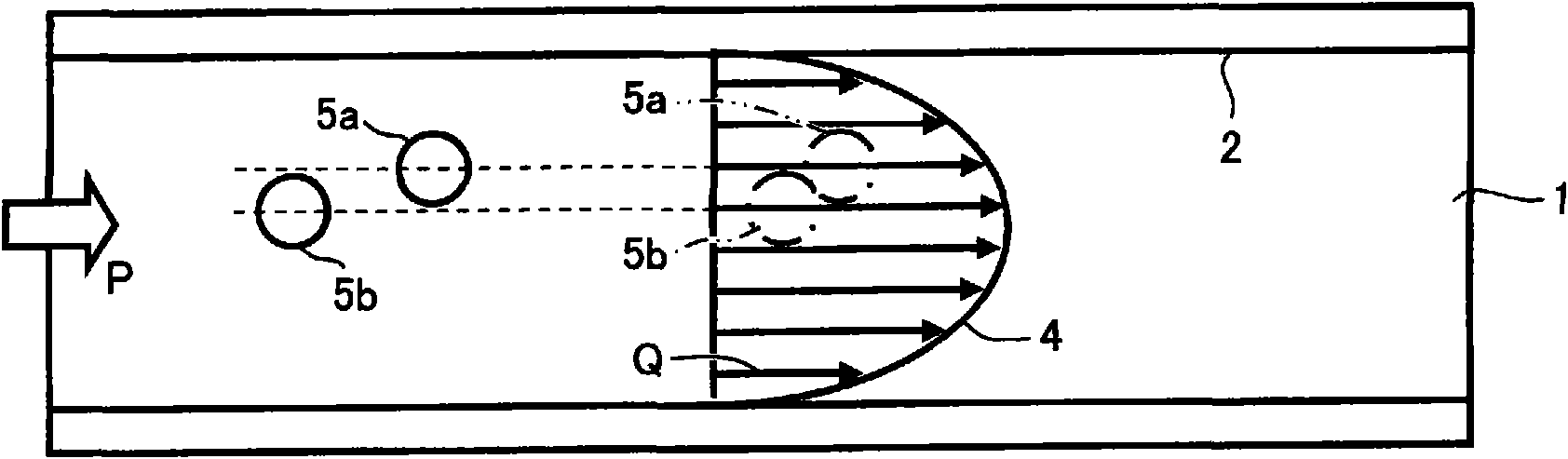

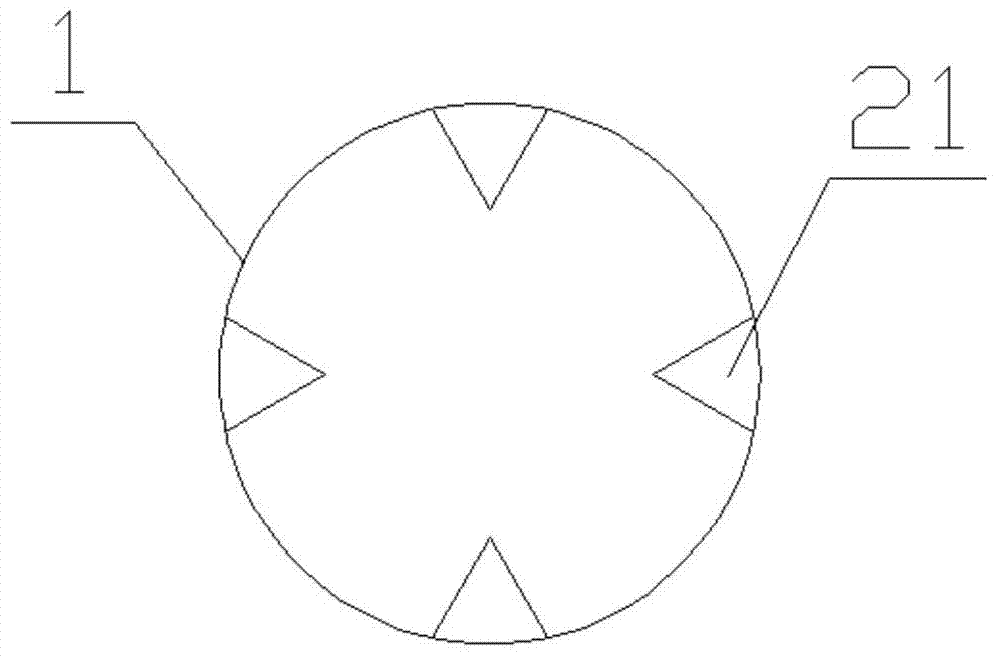

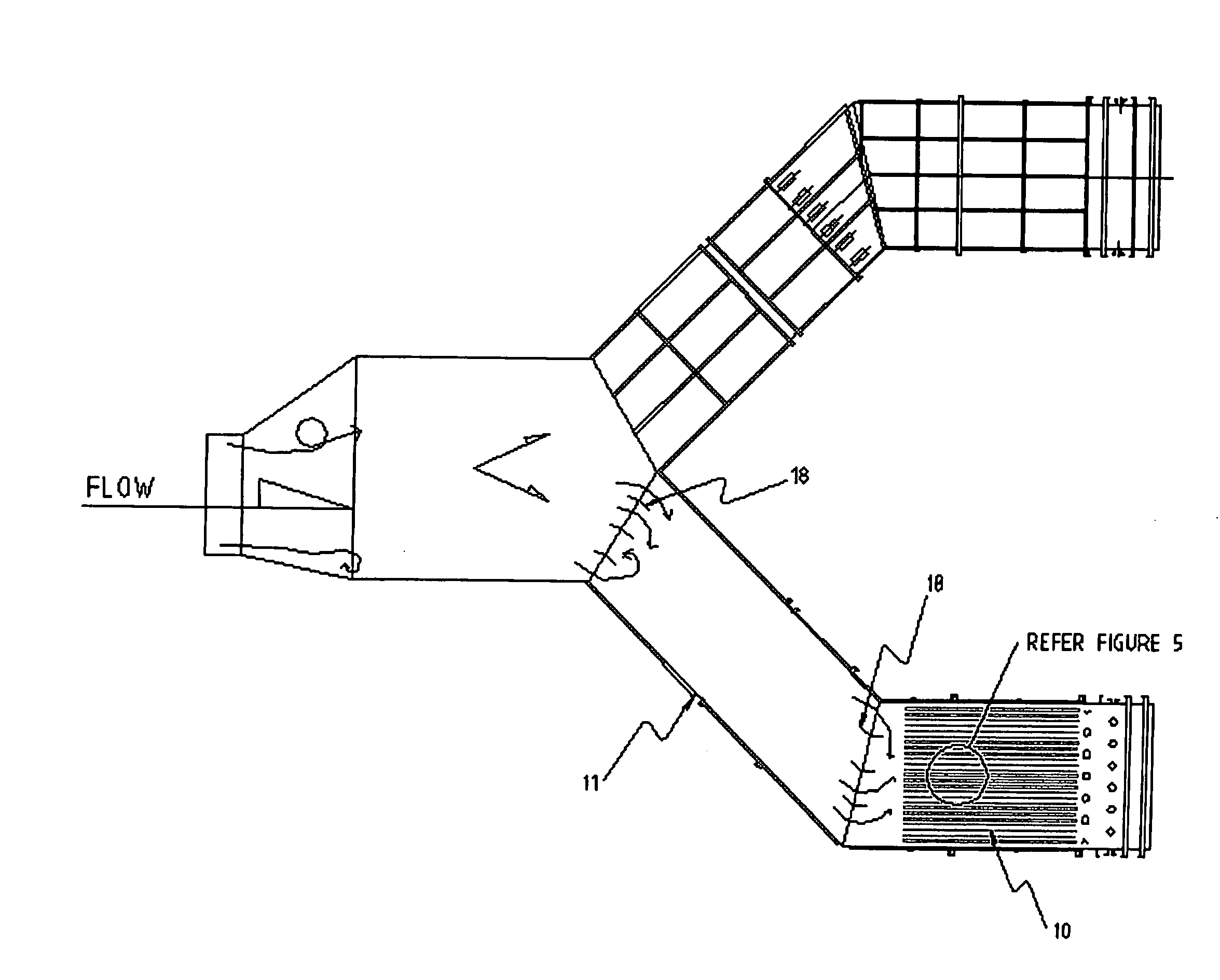

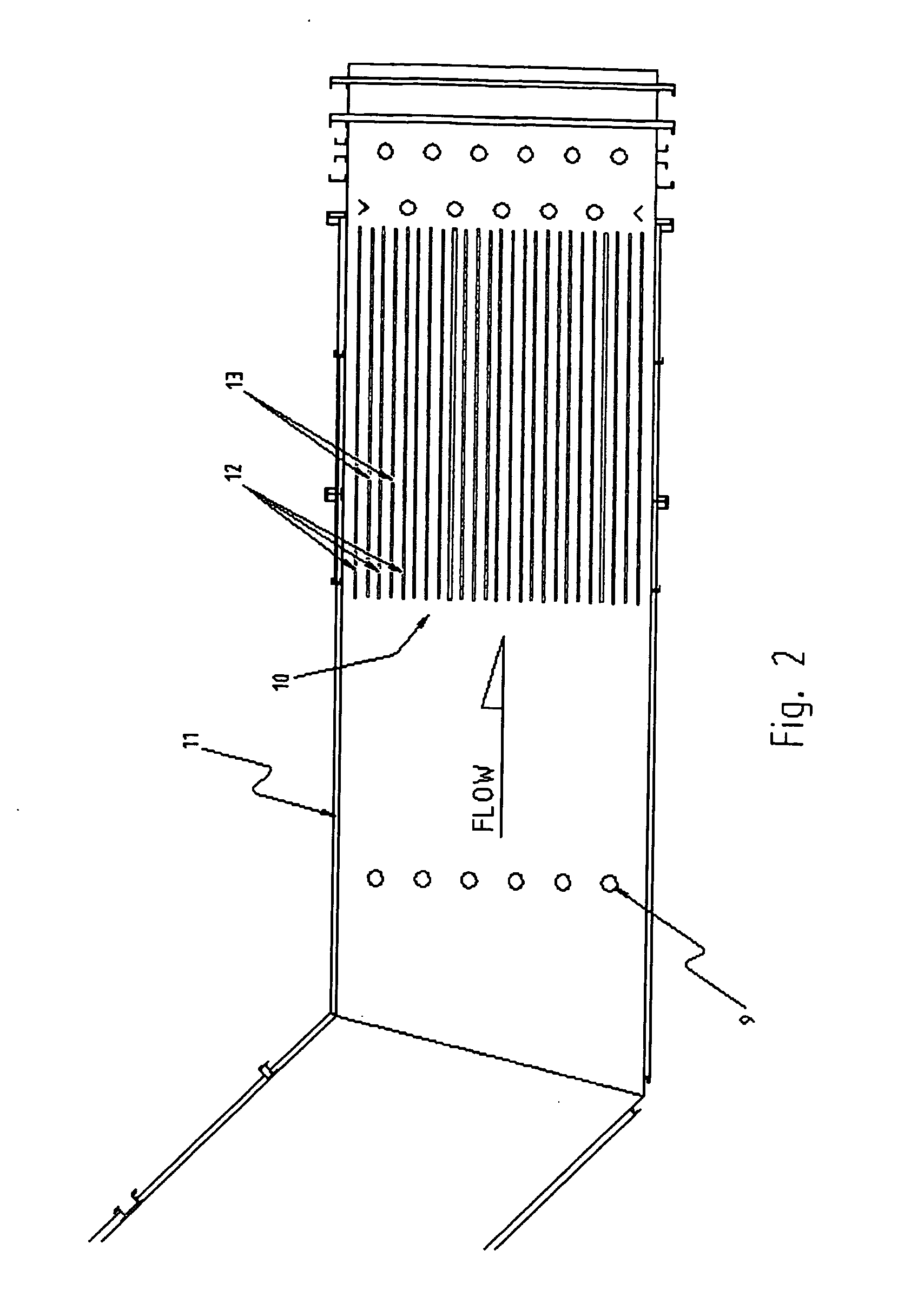

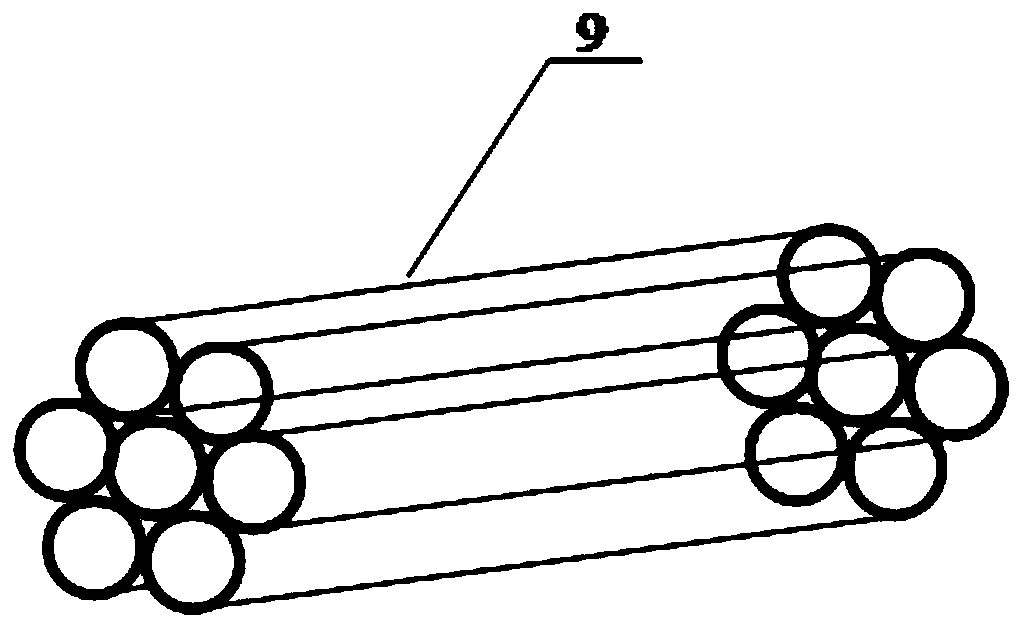

Method and apparatus for mixing fluids for particle agglomeration

InactiveUS20060256649A1Minimized pressure lossWell mixedAuxillary pretreatmentFlow mixersParallel plateStream flow

An aerodynamic agglomerator (10) promotes mixing and agglomeration of pollutant particles in a gas stream, to facilitate the subsequent removal of the particles from the gas stream. The agglomerator (10) is mounted in a duct (11) through which the gas stream flows. The agglomerator (10) comprises a plurality of parallel plates (12) which extend in the overall direction of flow of the gas stream, and are spaced transversely across the width of the duct (11) to divide the duct into multiple parallel passages. The duct (11) is configured and / or has formations therein for creating large scale turbulence in the gas stream upstream of the passages. A vane assembly (13) is provided in each passage for generating a zone of small scale turbulence of such size and / or intensity that the pollutant particles are entrained in the turbulence. Each vane assembly (13) is located centrally relative to its respective passage and comprises a plurality of sharp-edged vanes (15) spaced successively in the overall direction of flow of the gas stream. The large scale turbulence in the substreams causes each substream to pass through the zone of small scale turbulence in its respective passage so that particles therein are subjected to the small scale turbulence.

Owner:INDIGO TECH GRP PTY LTD

Mineralization-flotation separation column sorting device and method

ActiveCN109759243AImprove recycling effectIncrease the probability of collisionFlotationFlocculationSlurry

The invention provides a mineralization-flotation separation column sorting device and method, which are applicable to ore processing. The mineralization-flotation separation column sorting device comprises a stirring barrel, a pump, a bubble generator, a mineralization chamber, a flocculation elimination pipe, a flotation column and an air compressor; after flotation ore slurry is mixed through slurry blending equipment and passes through the bubble generator, the ore slurry enters the cyclone mineralization chamber; the ore slurry which is rotated at a high speed and bubbles are subjected tohigh-strength turbulent flow collision and mineralized bubbles are formed; a large vortex of the mineralized bubbles are eliminated through the flocculation elimination pipe and then the mineralizedbubbles enter a flotation column static sorting region to finish static separation; a flotation assisting baffle plate is arranged at the bottom of the flotation column static separation region and the ore slurry is prevented from entering tailings due to short circuiting; ore grains which are not mineralized and desorbed are subjected to intensive recovery; low-ash clean coal is recycled and high-ash ores are discharged from a tailing opening. According to the mineralization-flotation separation column sorting device, the flotation and falling probability of low-ash coarse grains is effectively reduced and the equipment processing capability is great; the device has strong adaptability on different coal properties, low production and operation cost and is convenient to mount and operate;the quantity and quality of clean coal products are wholly improved.

Owner:CHINA UNIV OF MINING & TECH +2

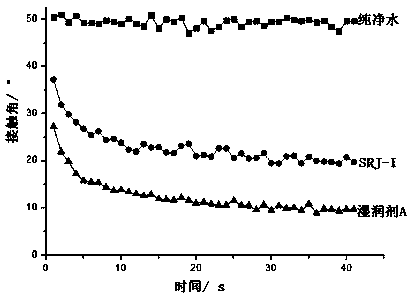

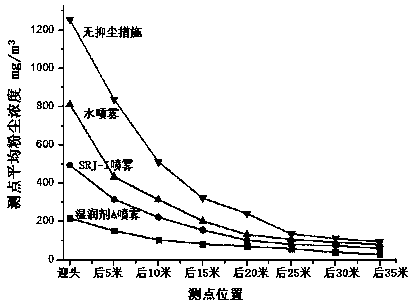

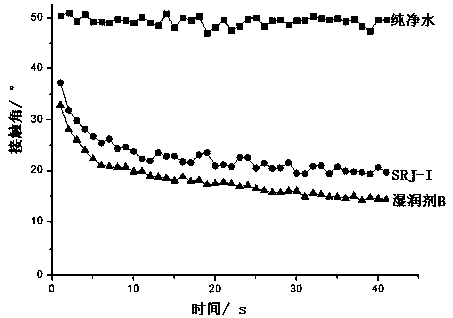

Polynary ionic wetting agent for inhibiting mine dust and preparation method thereof

InactiveCN108059948AImprove performanceImprove wettabilityOther chemical processesTransportation and packagingInorganic saltsChemical reaction

The invention discloses a polynary ionic wetting agent for inhibiting mine dust and a preparation method thereof, which are applied to the inhibition of a lot of dust produced during the production ofa mining working face of a mine. A variety of anionic, cationic, nonionic and neutral ionic surfactants are first isotropically combined and compounded, then anisotropically cross-compounded, added with water, put into a chemical reaction kettle and agitated under 120 DEG C for 2 hours while pressure is kept at 0.8MPa; inorganic salt is added to improve the ionized characteristic of the mixture,and agitation is carried out for 1 hour; adhesive is added to improve the capturing capability of mixture droplets, curing and reinforcing agent is added to increase the suspension period of the droplets in the air, and agitation is carried out for 2 hours; imidazole ionic liquid is added as an additive, agitation is carried out for 1 hour, the mixture is depressurized, cooled and taken out of thekettle, and thereby the polynary ionic wetting agent is formed. The wetting agent can greatly improve wetting capability and capturing capability on respirable dust and prolong the suspension life ofdroplets; the mine dust suppression cost is low, skin cannot be injured, machine corrosion is little, and the polynary ionic wetting agent has good applicability and environment-friendliness.

Owner:CHINA UNIV OF MINING & TECH

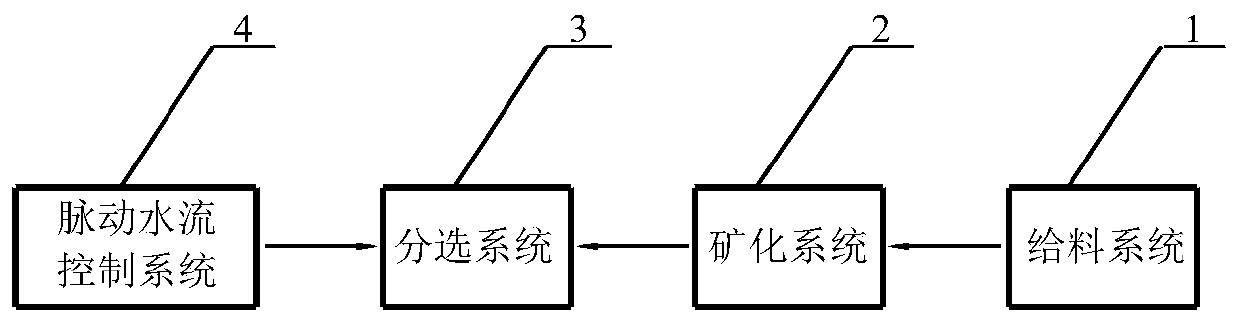

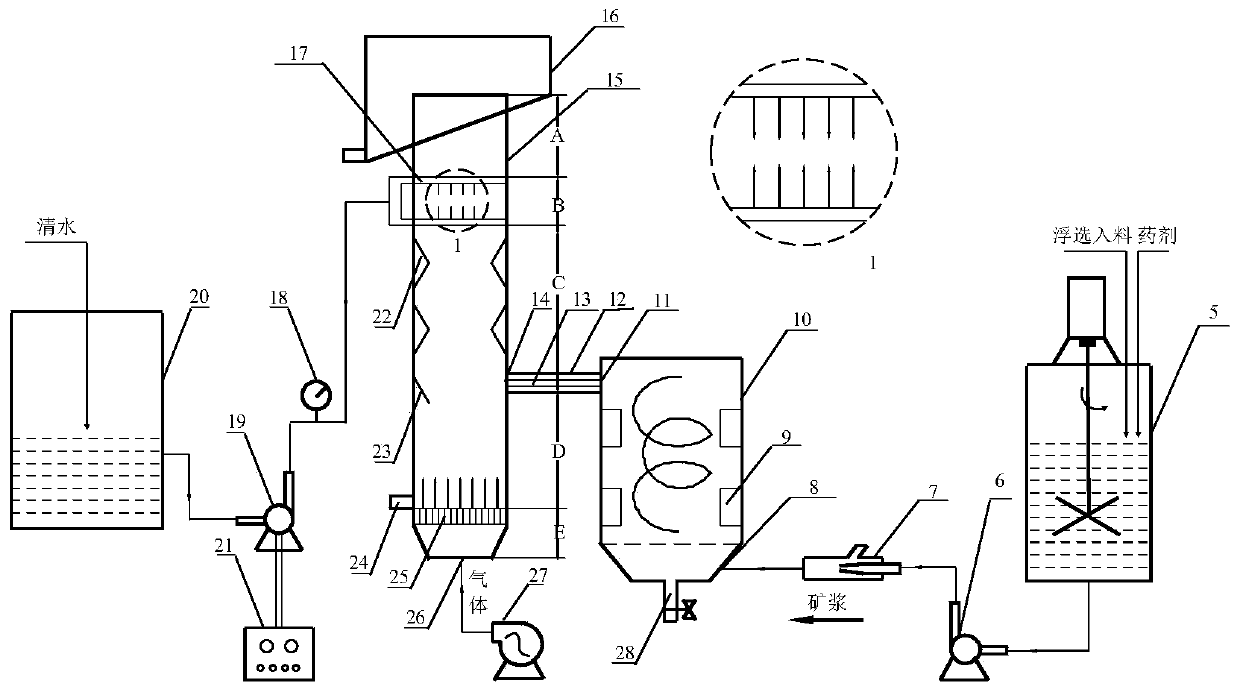

High ash fine grain coal slurry separation equipment and method

ActiveCN109759242AImprove recycling effectIncrease the probability of collisionSeparation devicesFlotationControl systemWater flow

The invention provides a high ash fine grain coal slurry separation equipment and method which areapplicable to the field of coal washing. The separation equipment comprises four parts, specifically afeeding system, a mineralization system, a separation system and a pulse water flow control system. The equipment is characterized in that a coal slurry mineralization area is separated from a separation area, and the ore separation system is internally provided with a damping block and a pulse water flow device. Flotation materials are fed into the feeding system, the size mixing operation is completed, coal slurry subjected to size mixing enters the mineralization system to be subjected to turbulent collision, mineralized bubbles are formed, the mineralized bubbles enter the separation system after passing through a disorder eliminating pipe, meanwhile the pulse water flow control system supplies the separation system with pulse water flows with certain frequency and waveform, the finecoal ash content is lowered, and the coal slurry separation selectivity is improved. Recycling of low ash coarse particles is effectively improved, high ash thin slurry carried by water flow and the thin slurry covering the surface of the particles are beneficially reduced by means of the damping block and the pulse water flow effect, and the separation selectivity is improved. The equipment has high coal slurry adaptability on different coal qualities, the separation effect is good, the separation efficiency is high, the production operation cost is low, and the economical benefit is outstanding.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com