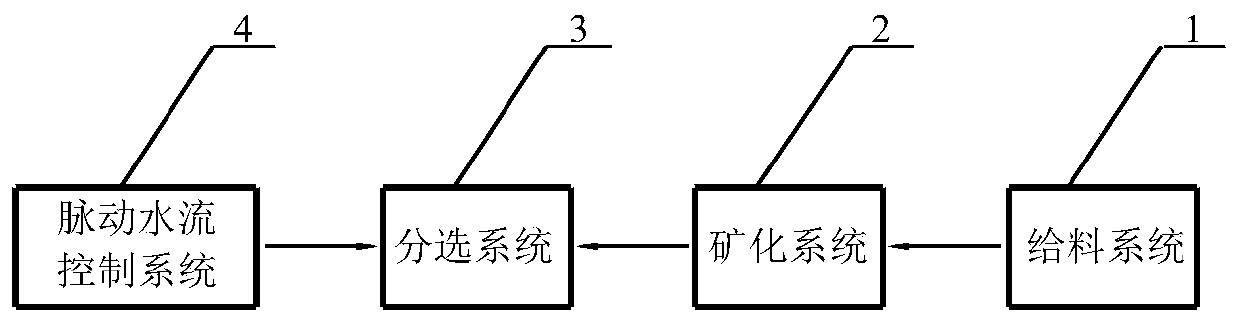

High ash fine grain coal slurry separation equipment and method

A fine-grained coal separation technology, applied in chemical instruments and methods, flotation, solid separation, etc., can solve the problems of high ash content of clean coal, high content of entrained ash and fine mud, shallow flotation tank, etc., to achieve The effect of increasing the ash content of tailing coal, increasing the yield of clean coal, and increasing the intensity of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

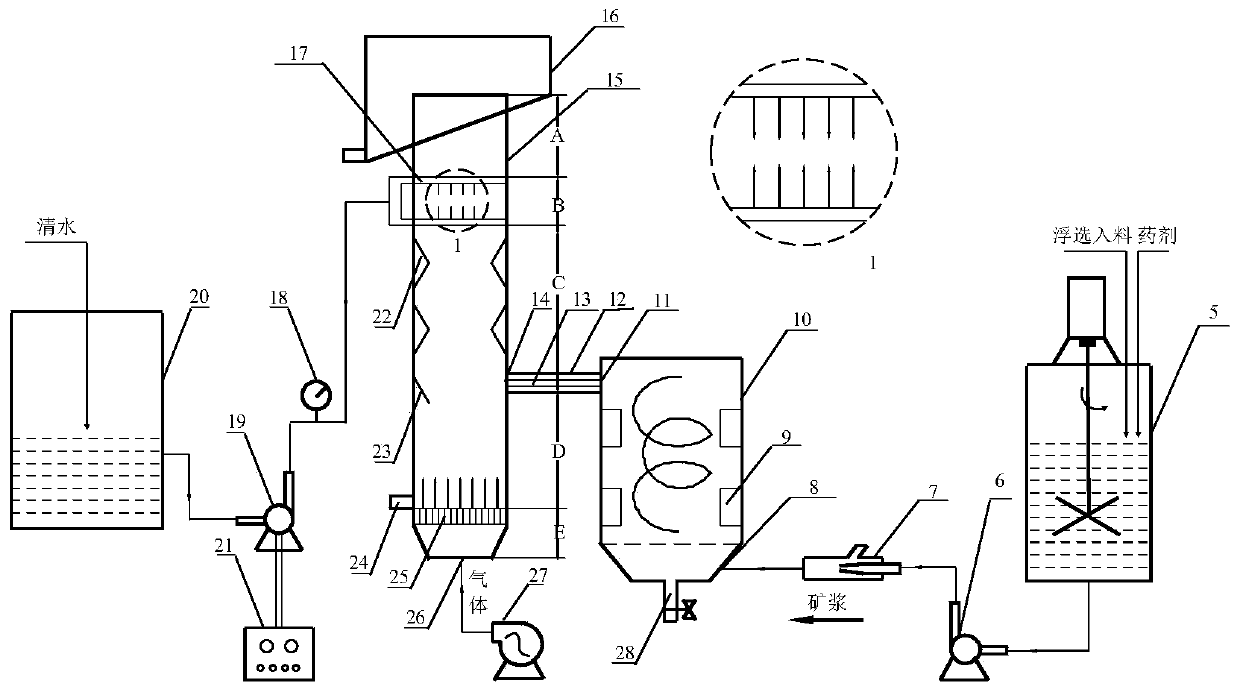

[0047] a, start the air compressor 27 to inflate the damping pulsating water flow type flotation column 15 through the microporous ceramic plate 25; start the frequency conversion pump 19, adjust the frequency of the frequency conversion pump 19 through the PID control cabinet 21, thereby adjusting the frequency and amplitude of the pulsating water flow; close Mineralization chamber 10 accident discharge pipe 28;

[0048] b. After the floating coal slime and medicament are fed into the mixing tank 5 and mixed evenly, the pump 6 feeds the air bubble generator 7, and the mixture sucks air under the negative pressure generated by the jet flow, and crushes the air into tiny air bubbles;

[0049] c. The jet slurry containing air bubbles, water and mineral particles continues to descend to the mineralization chamber 10, and under the action of the centrifugal force field of the mineralization chamber 10 and the damping plate 9, a strong turbulent flow is generated to realize efficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com