Horizontal sand mill of combined rotary dispersion disk grinding structure

A horizontal sand mill and dispersing disc technology, applied in the field of grinding machinery, can solve the problems of low efficiency, high energy consumption, long grinding time, etc., and achieve the effects of long service life, high grinding efficiency, and convenient cleaning and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

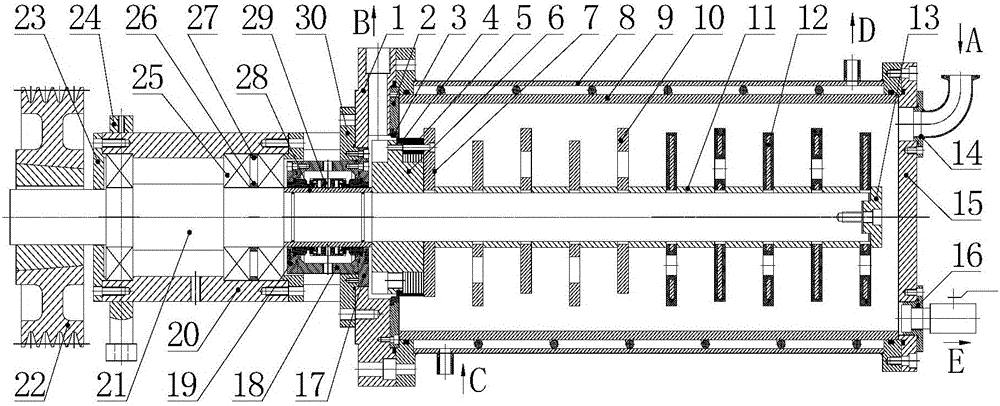

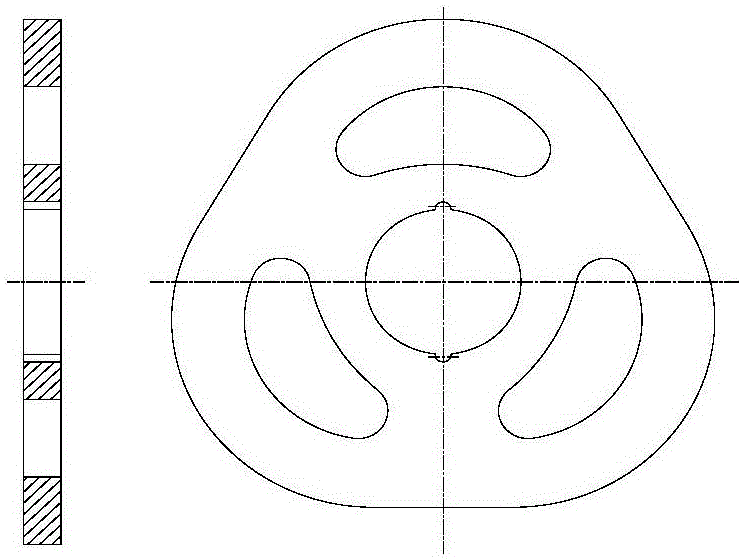

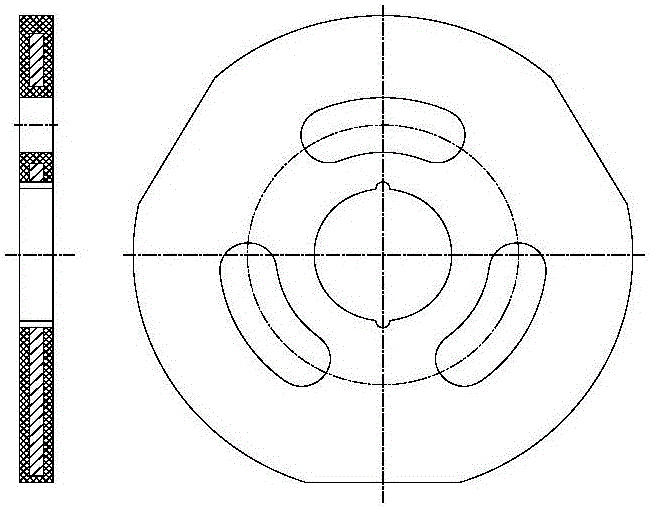

[0012] Such as figure 1 As shown, a horizontal sand mill with a combined rotating dispersing disc grinding structure, the external structure is composed of a frame, a motor, a main shaft, a grinding unit, a material pump, a material inlet and outlet, a pressure gauge, a temperature gauge and an electrical control system; The grinding unit is composed of a grinding outer cylinder 8 with a jacket and cooling water inlet C and outlet D, a grinding chamber inner cylinder 9, a main shaft 21, a discharge separation device 6, and a discharge end cover (flange) 1 , wear-resistant plate 2, feed port A, discharge port B, grinding cylinder end cover plate 15 and ball valve E; the main shaft 21 is equipped with a pulley 22 at one end, and the pulley is driven by a motor through a V-belt. One end stretches in the cylinder body 9 in the grinding chamber; on the described main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com