Method for preparing pseudo-boehmite and method for preparing microcrystalline fused alumina abrasive

A pseudo-boehmite and microcrystalline corundum technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, other chemical processes, etc., can solve the problems of low purity, reduced product strength, poor quality controllability, etc. Achieve the effect of high purity and strength, improved compatibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of pseudoboehmite

[0034] Add 250 grams of deionized water into a polytetrafluoroethylene reactor with a volume of 500 ml, and then add 25 grams of anhydrous aluminum trichloride while stirring. After the aluminum trichloride is completely dissolved, heat to 80°C while stirring, and then continue heating to keep the temperature constant. Then close the reaction kettle, slowly add 50 grams of ammonia water to the closed reaction kettle under stirring for hydrolysis (the hydrolysis is completed within 1 minute). After the hydrolysis is complete, the generated Al(OH) 3 The precipitate formed a suspension with stirring.

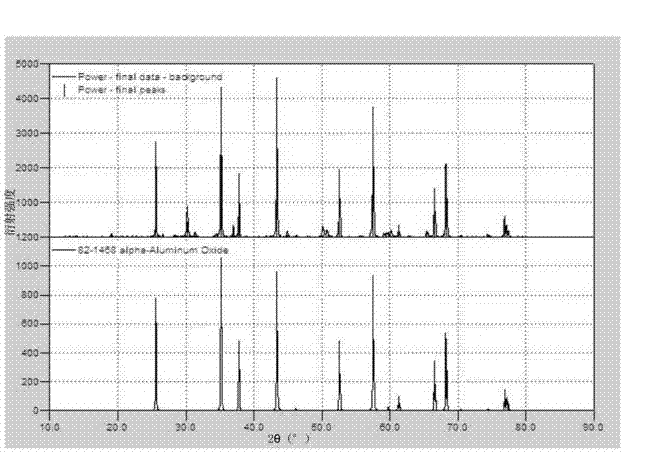

[0035] The resulting suspension was stirred and heated in a closed polytetrafluoroethylene reactor at 90°C for 3 hours to make the Al(OH) 3 It is completely hydrolyzed to pseudo-boehmite (Al 2 o 3 ·nH 2 O, where n=0.08~0.62).

[0036] Centrifuge the white reaction product while it is hot, then add 80°C deionized water to wash the so...

Embodiment 2

[0047] 1. Preparation of pseudoboehmite

[0048] Method is the same as embodiment 1, and difference is that the consumption of anhydrous aluminum trichloride is brought up to 50 grams, and the add-on of ammoniacal liquor is brought up to 100 grams.

[0049] 2. Preparation of Microcrystalline Corundum Abrasives

[0050] Method is with embodiment 1.

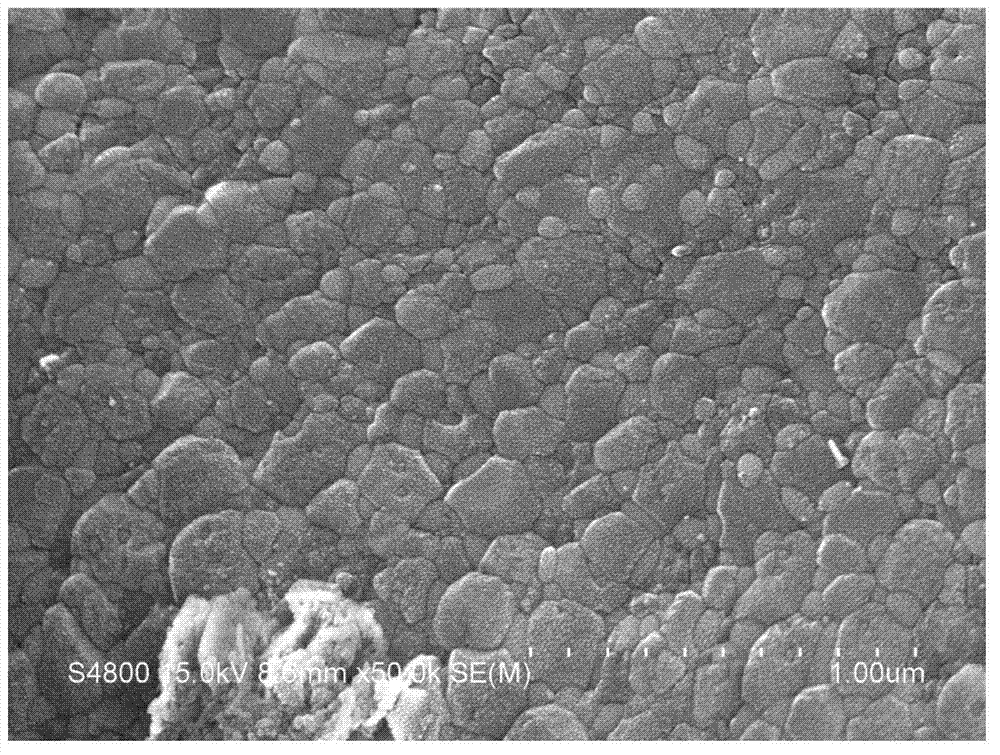

[0051] The crystal grain diameter of the obtained microcrystalline corundum abrasive is 100-300nm, and the particle density is 3.88g / cm 3 , the average hardness is 19.8Gpa, and the single particle strength is 40.8N.

Embodiment 3

[0053] 1. Preparation of pseudoboehmite

[0054] The method is the same as in Example 1, except that 70 grams of aluminum nitrate nonahydrate is used instead of 25 grams of anhydrous aluminum trichloride.

[0055] 2. Preparation of Microcrystalline Corundum Abrasives

[0056] Method is with embodiment 1.

[0057] The crystal grain diameter of the obtained microcrystalline corundum abrasive is 100-300nm, and the particle density is 3.87g / cm 3 , the average hardness is 20.3Gpa, and the single particle strength is 40.3N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com