Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

245results about How to "Lighten the task" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Haptic feedback for button and scrolling action simulation in touch input devices

ActiveUS20060119586A1Enhanced interactionEnhance manipulationCathode-ray tube indicatorsInput/output processes for data processingGraphicsActuator

Owner:IMMERSION CORPORATION

Haptic feedback for button and scrolling action simulation in touch input devices

ActiveUS20060109256A1Enhanced interactionEnhance manipulationCathode-ray tube indicatorsInput/output processes for data processingGraphicsActuator

A planar touch control is used to provide input to a computer and haptic feedback is provided thereto. A touch control includes a touch input device with a planar touch surface that inputs a position signal to a processor associated with the computer based on a location of user implemented contact on the touch surface. The computer can position or modify a cursor or image in a displayed graphical environment based at least in part on the position signal, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user via the touch surface.

Owner:IMMERSION CORPORATION

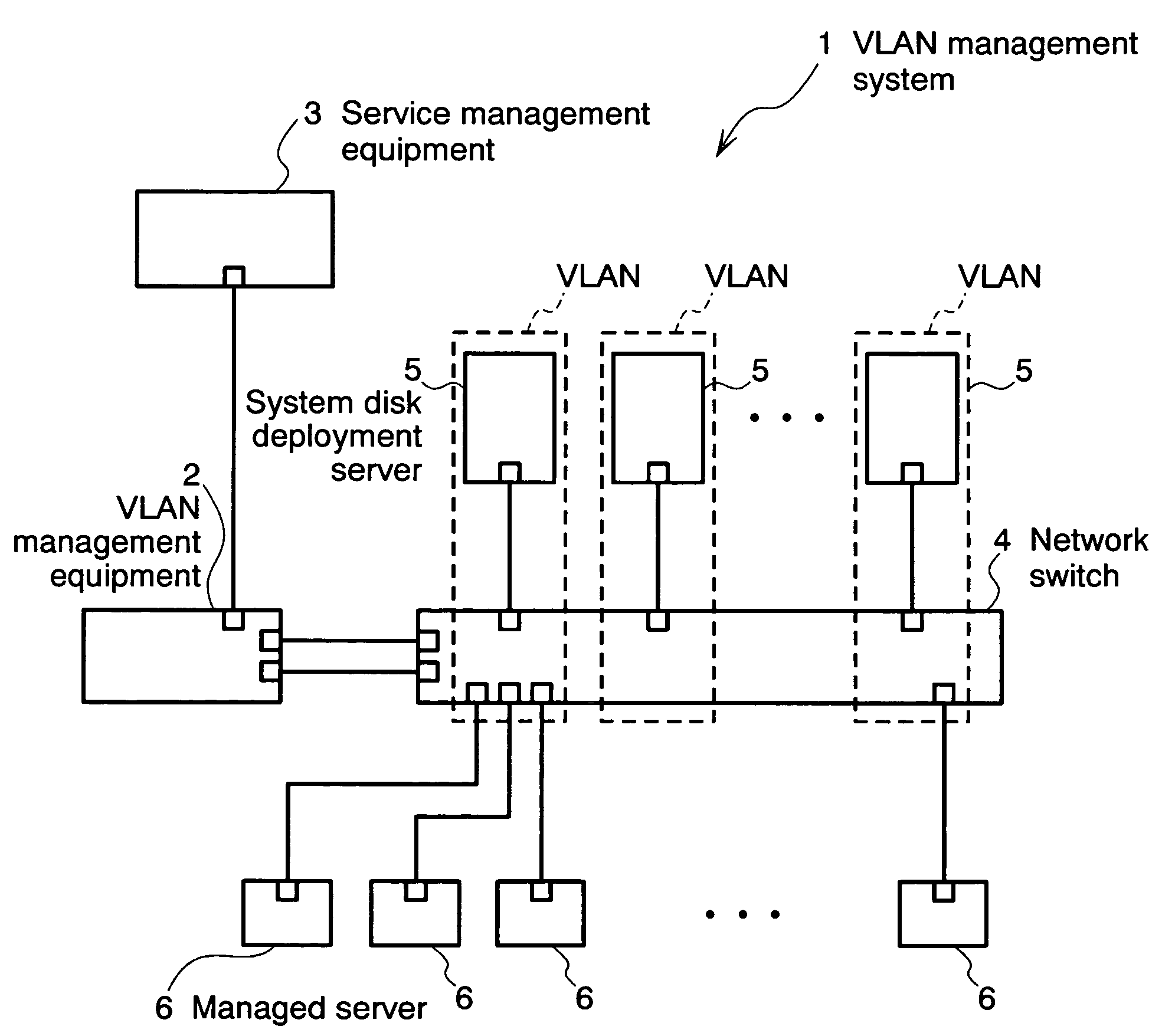

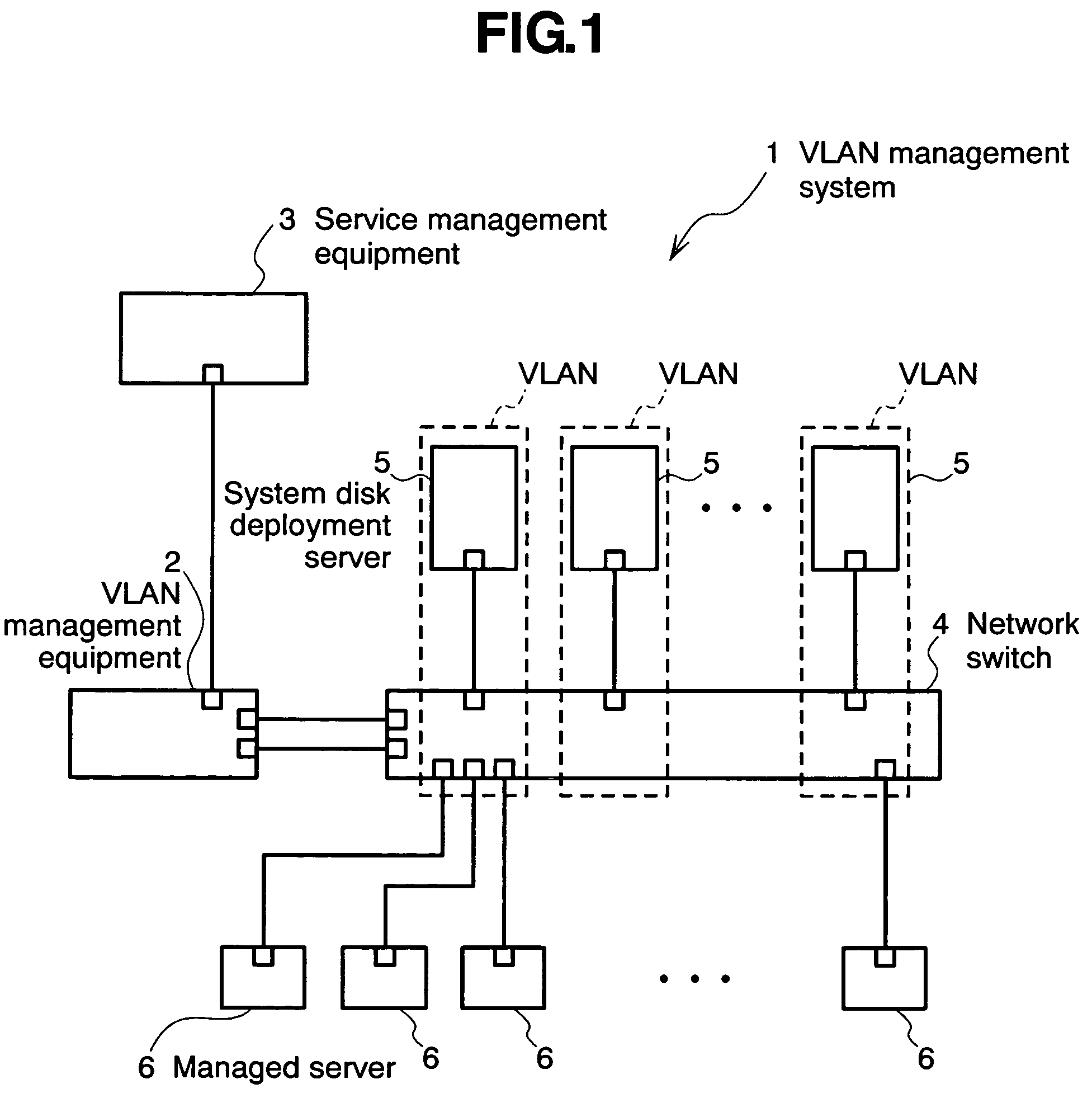

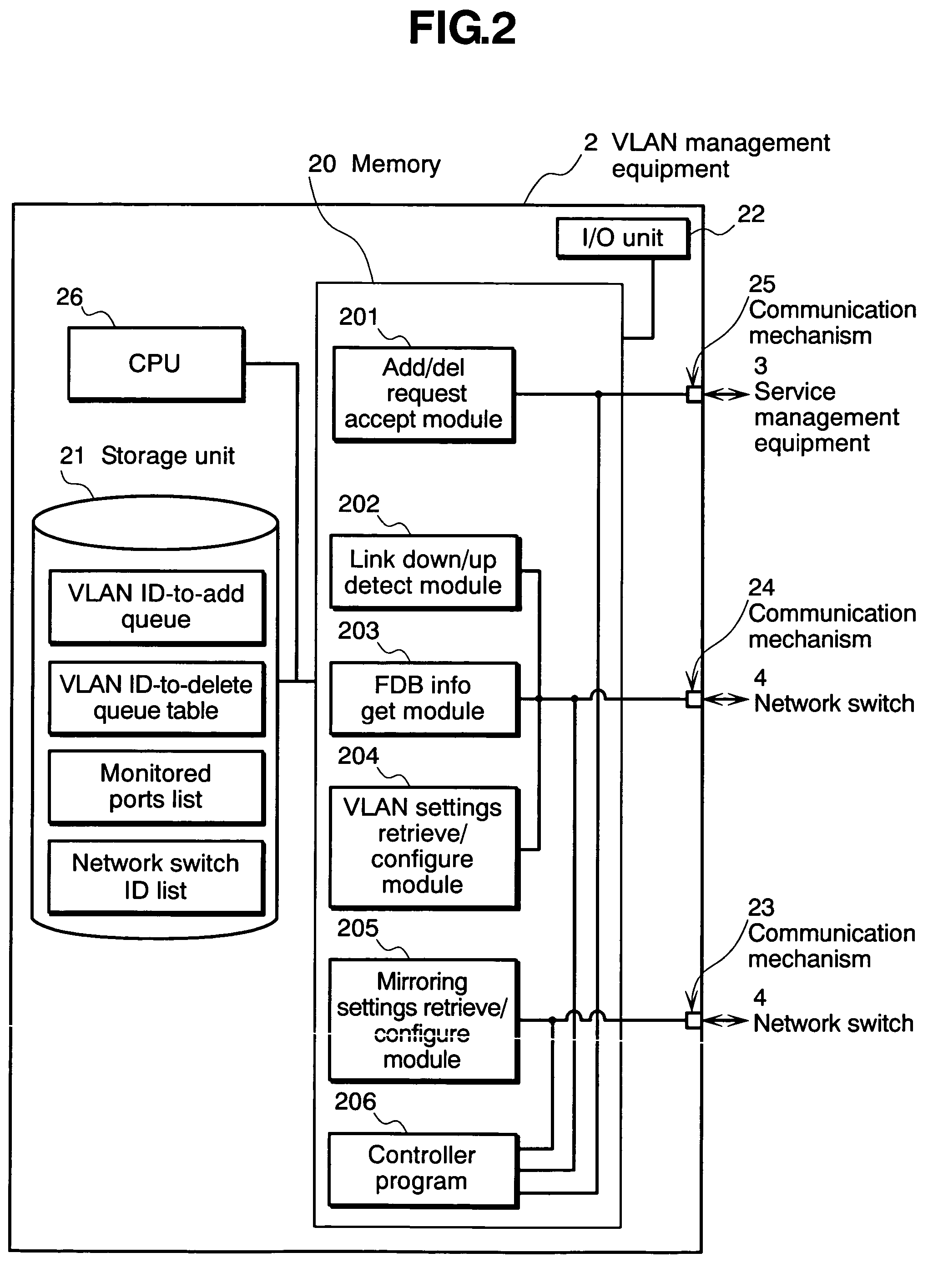

Virtual network management method, virtual network management program, virtual network management system, and virtual network means

InactiveUS7649851B2Lighten the taskDigital computer detailsData switching by path configurationManagement information baseNetwork management

The invention relates to a network management method wherein: a service management equipment holds the mapping of services and virtual networks as management information; a managed server sends an advice to a VLAN management equipment when its status changes; and the VLAN management equipment receives the advice and refers to the information contained in the advice to thereby identify the managed server and the connection port of a network switch, and configures a virtual network belonging to the identified port of the network switch. The method alleviates the task of reconfiguration associated with the adding or deleting of servers.

Owner:HITACHI LTD

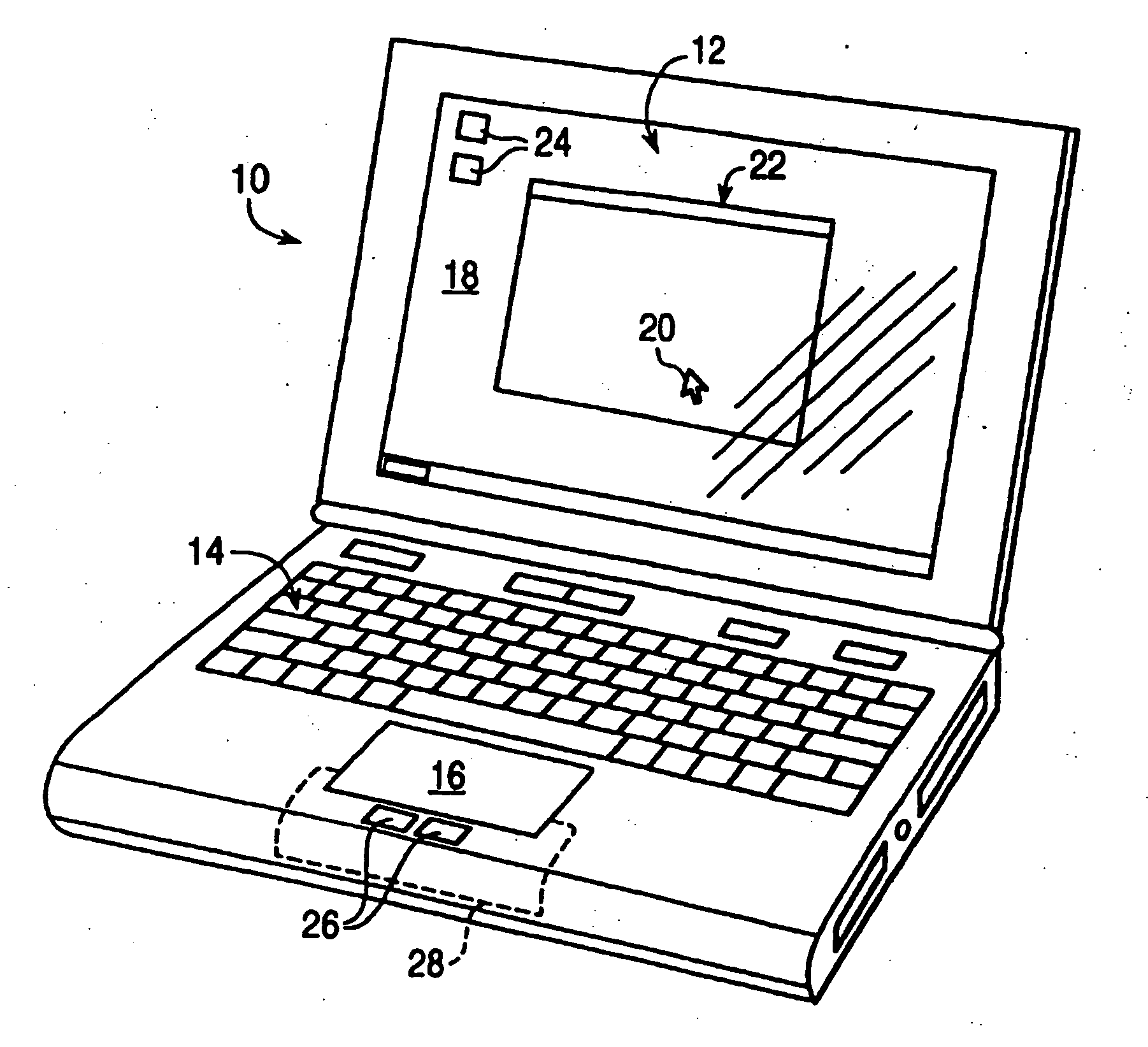

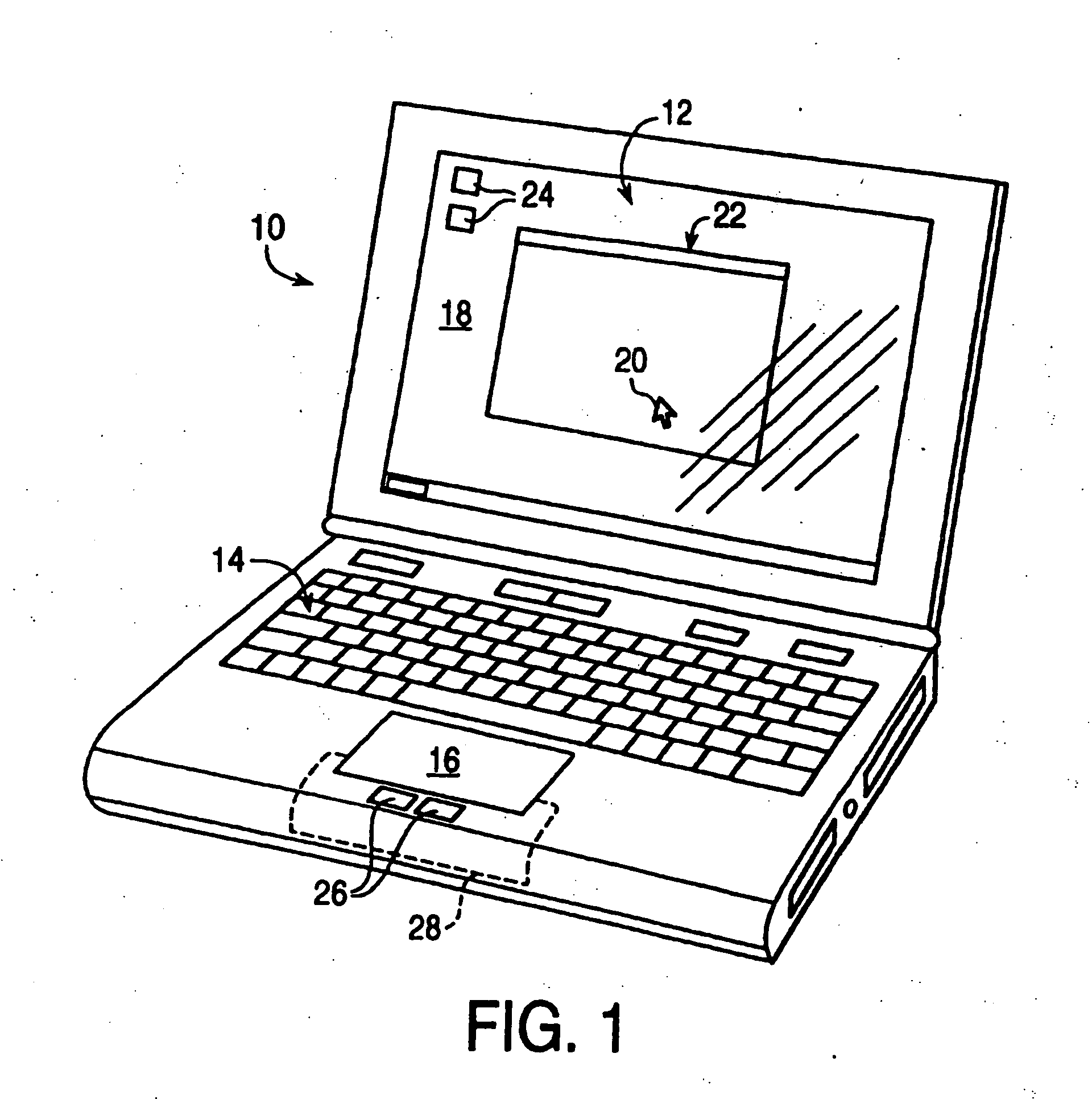

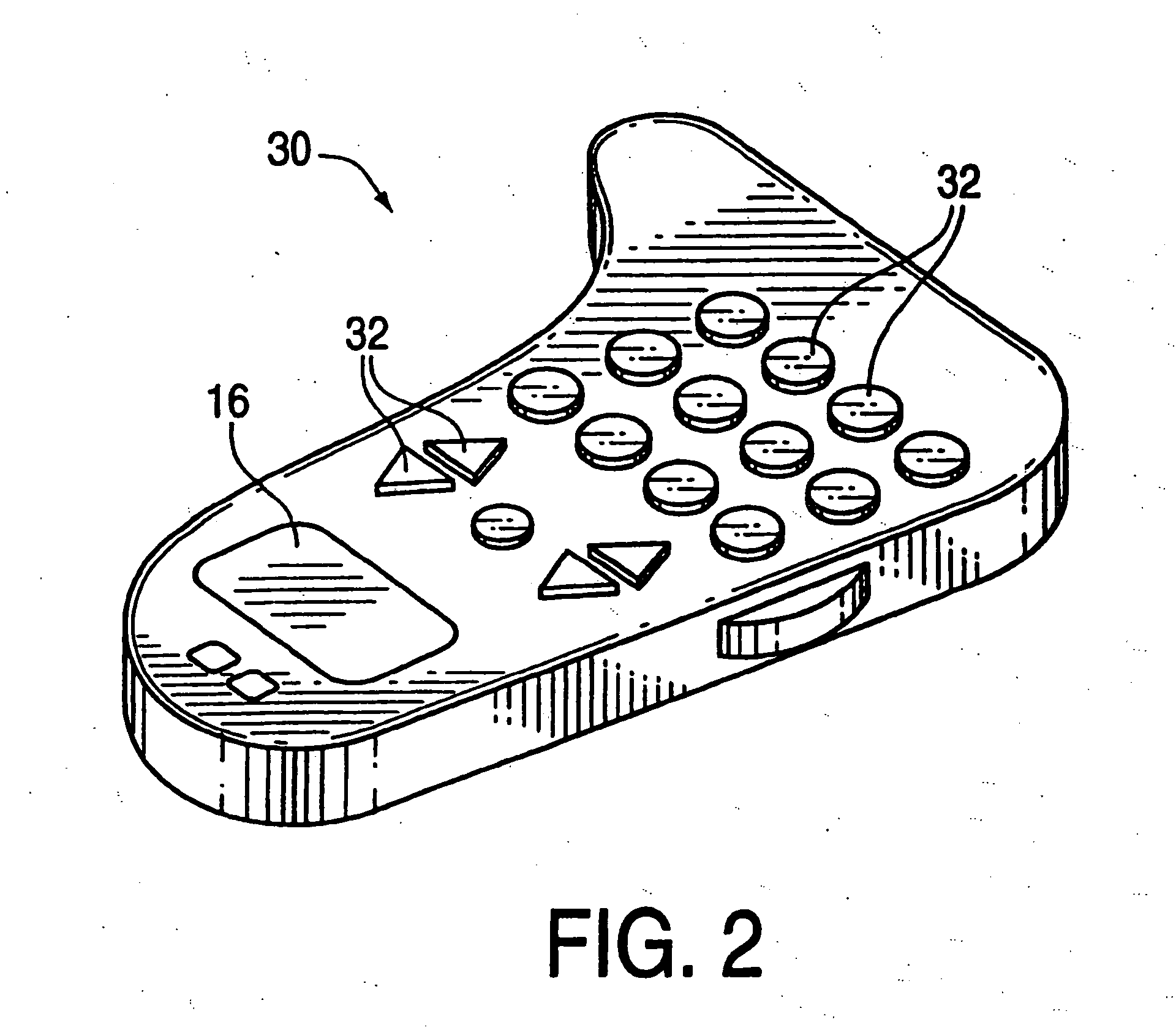

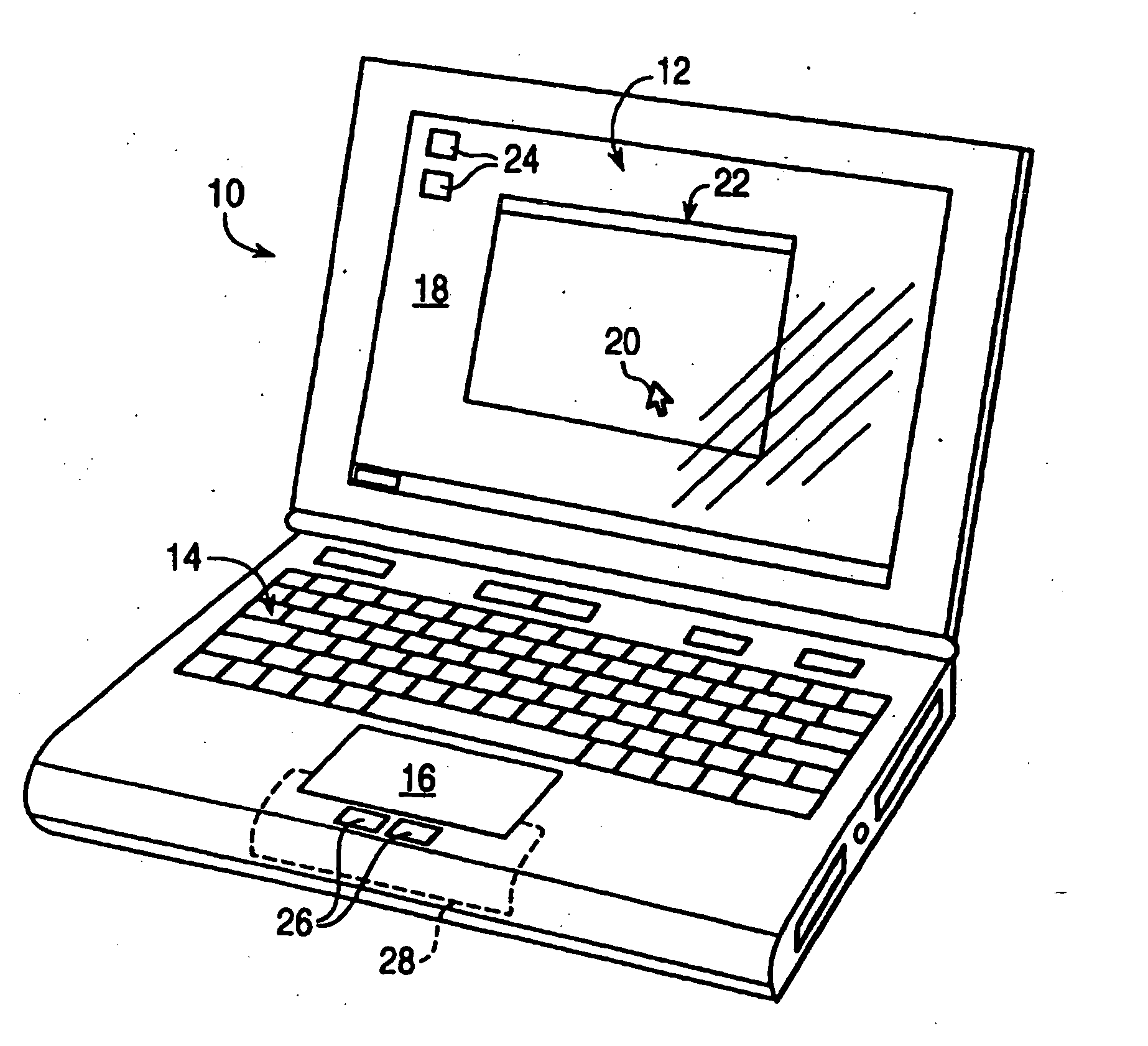

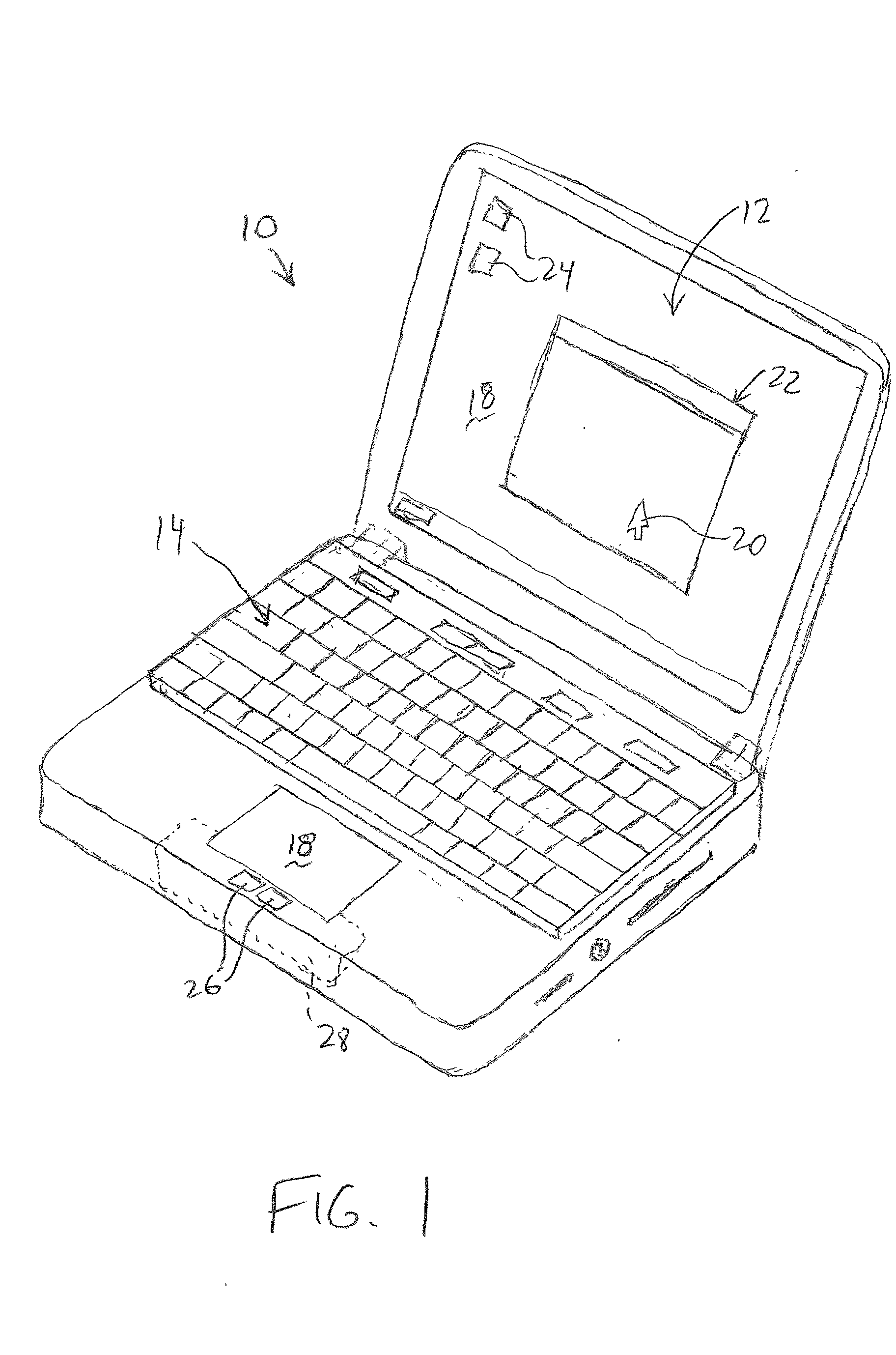

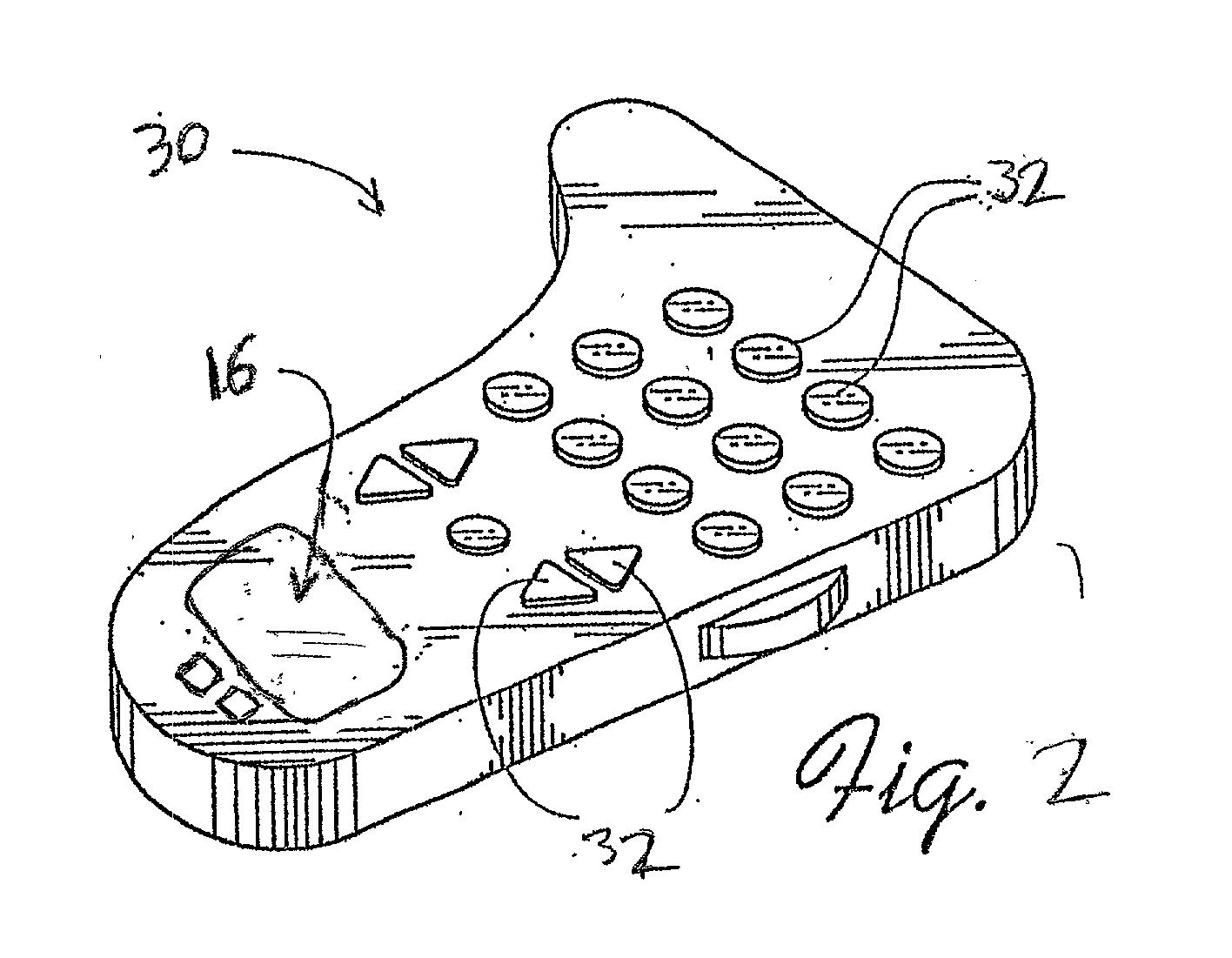

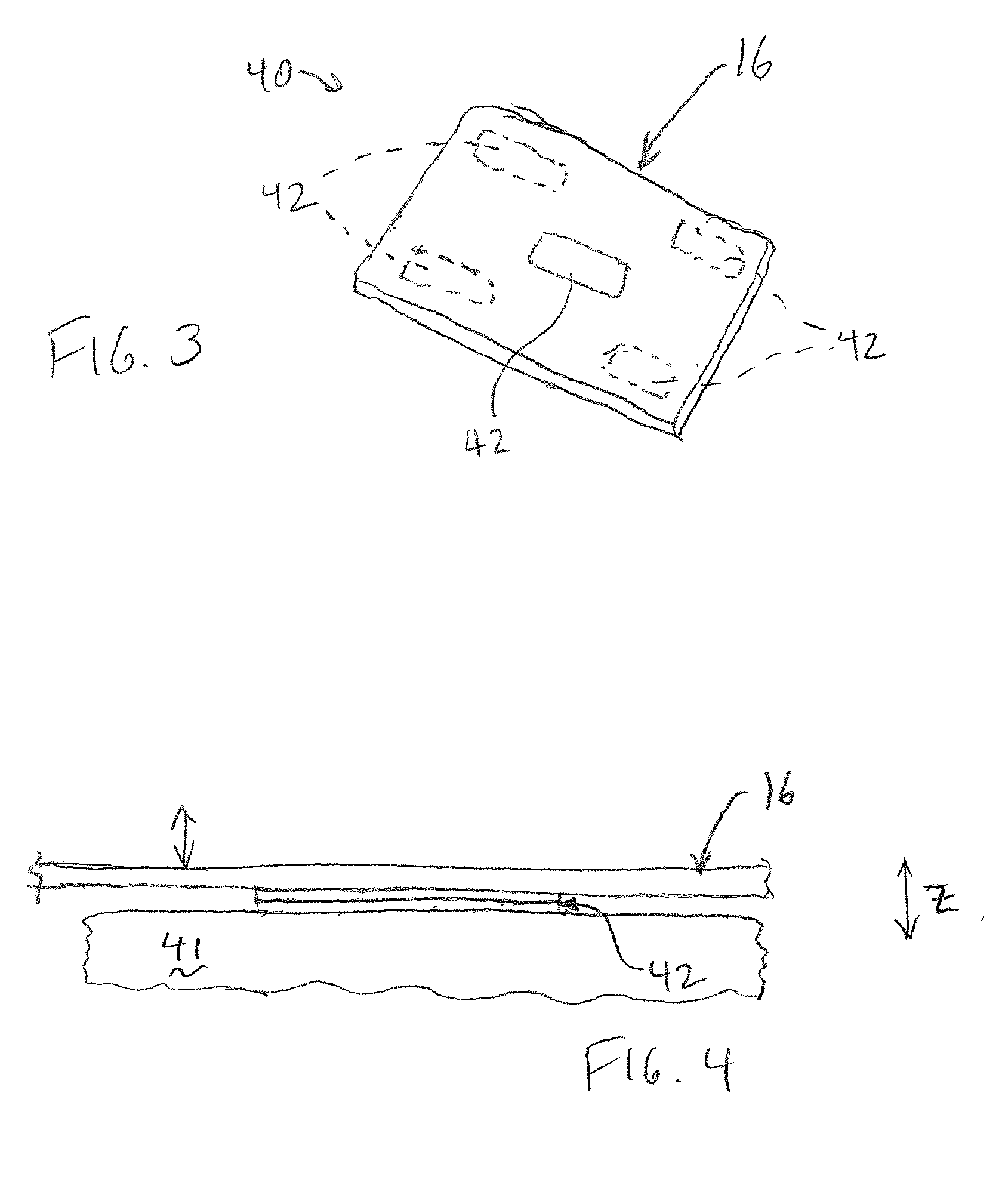

Haptic feedback for touchpads and other touch controls

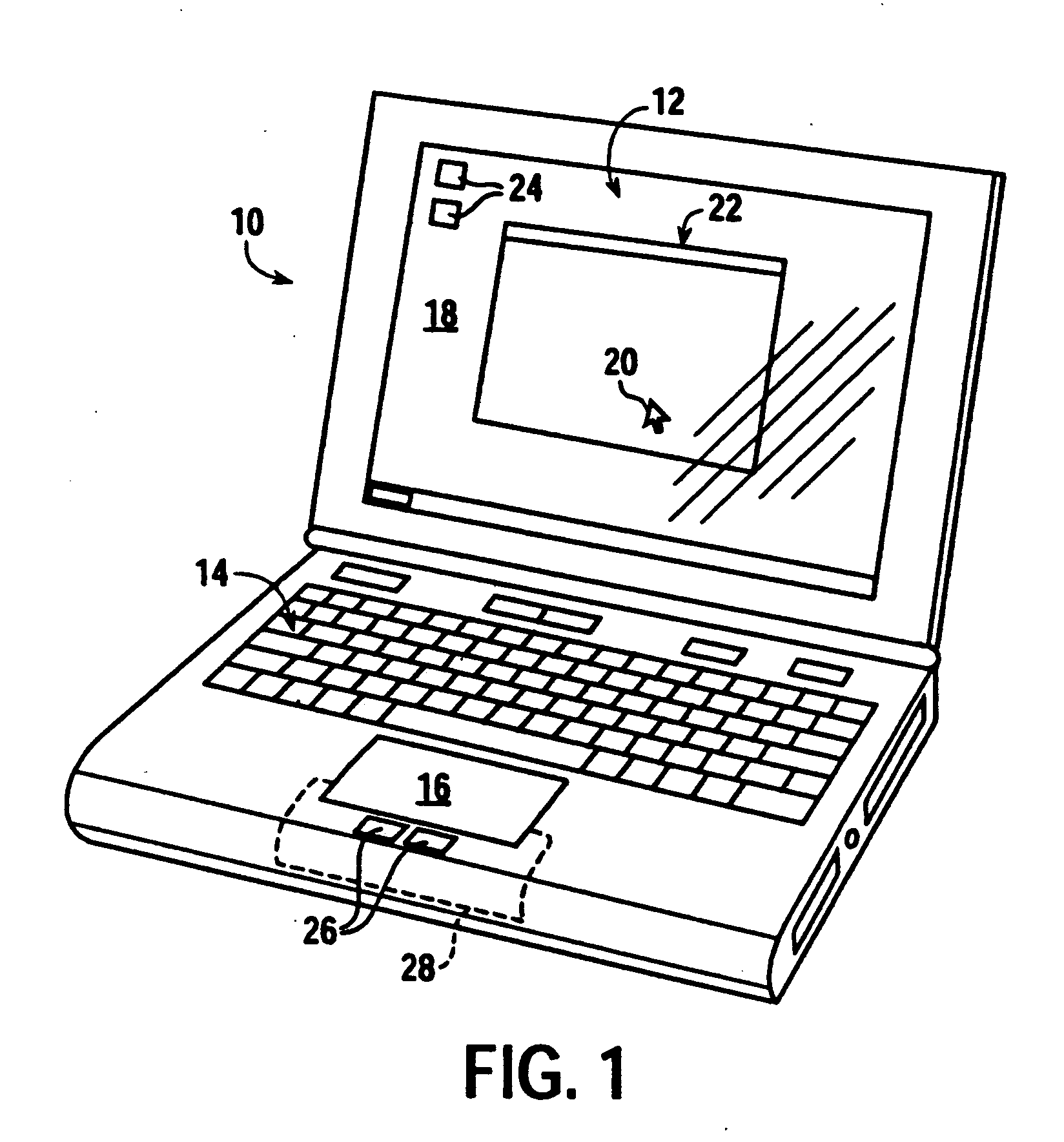

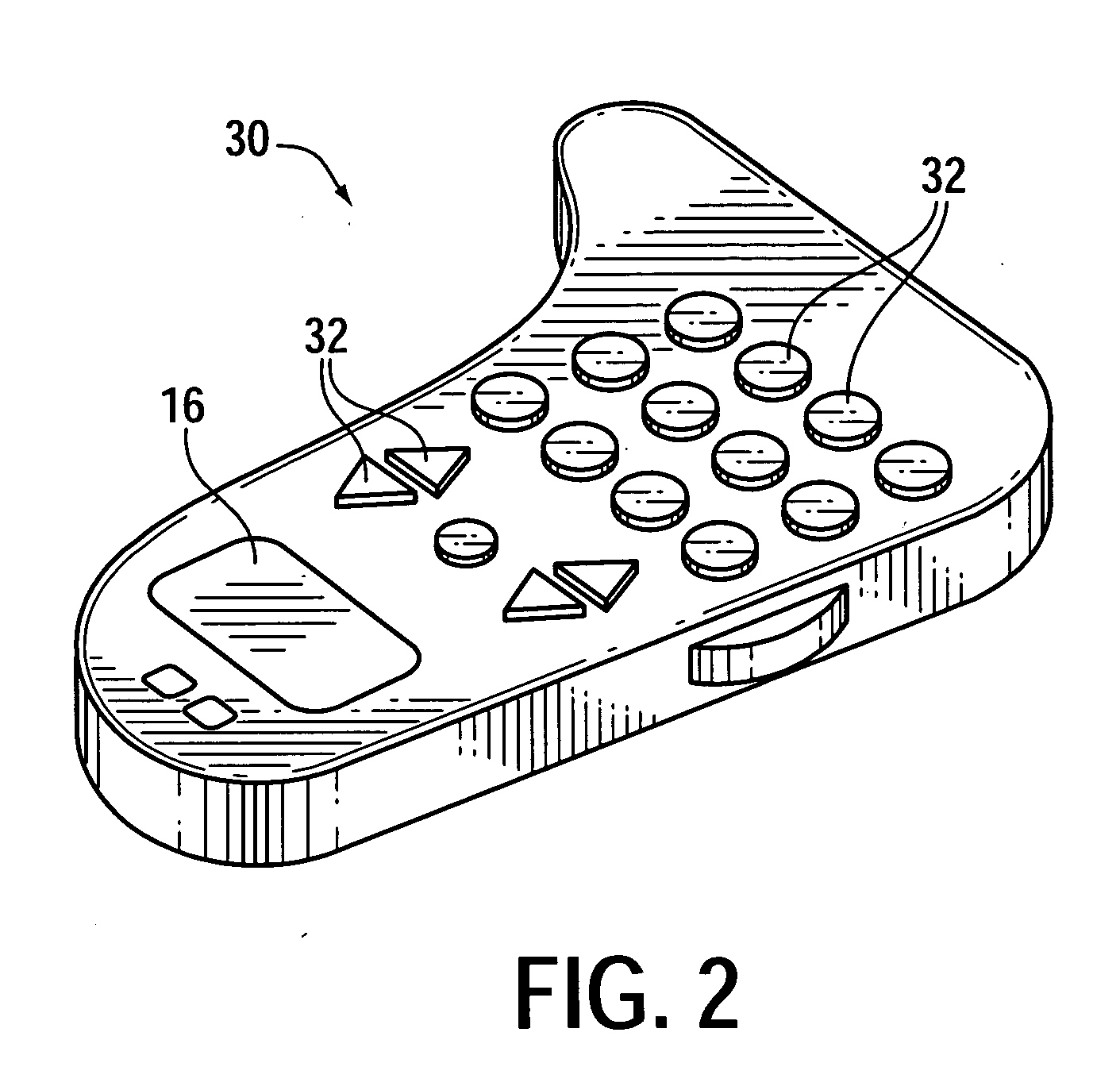

InactiveUS20010035854A1Enhance interaction and manipulationEnhanced interactionInput/output for user-computer interactionCathode-ray tube indicatorsComputer basedTouch Perception

A haptic feedback planar touch control used to provide input to a computer. A touch input device includes a planar touch surface that inputs a position signal to a processor of the computer based on a location of user contact on the touch surface. The computer can position a cursor in a displayed graphical environment based at least in part on the position signal, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user contacting the touch surface. The touch input device can be a touchpad separate from the computer's display screen, or can be a touch screen. Output haptic sensations on the touch input device can include pulses, vibrations, and spatial textures. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

Network appliance for dynamic protection from risky network activities

InactiveUS20160044054A1Efficient solutionLighten the taskMemory loss protectionError detection/correctionNetwork activityDistributed computing

Electronic appliances, computer-implemented systems, non-transitory media, and methods are provided to identify risky network activities using intelligent algorithms. The appliances, systems, media, and methods enable rapid detection of risky activities.

Owner:NORSE NETWORKS INC

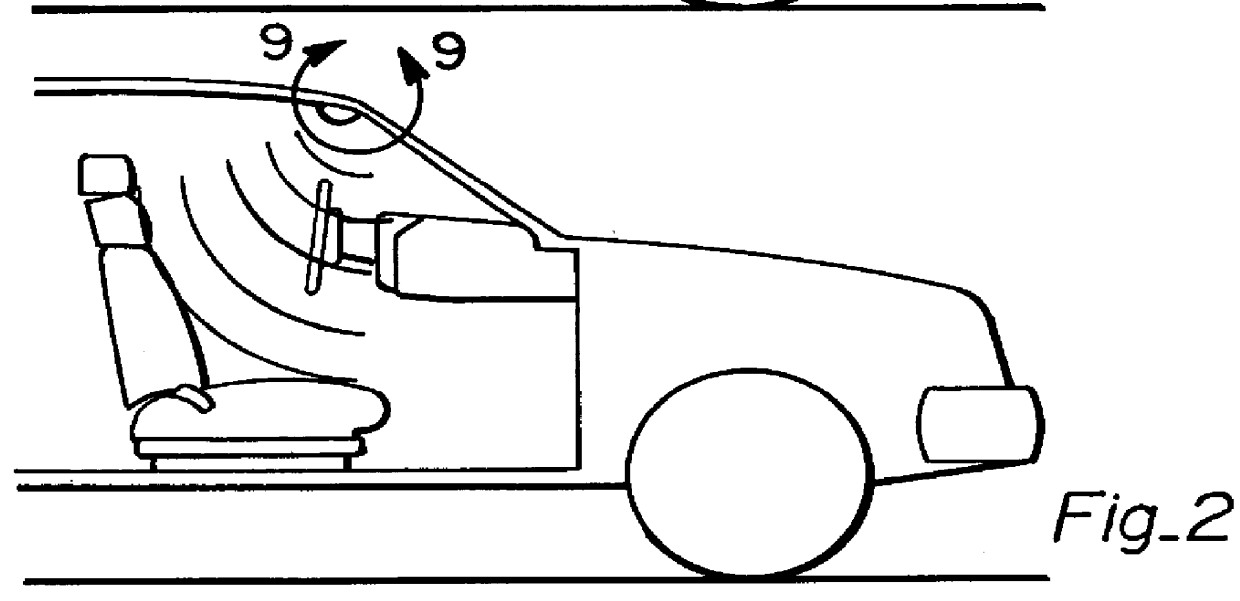

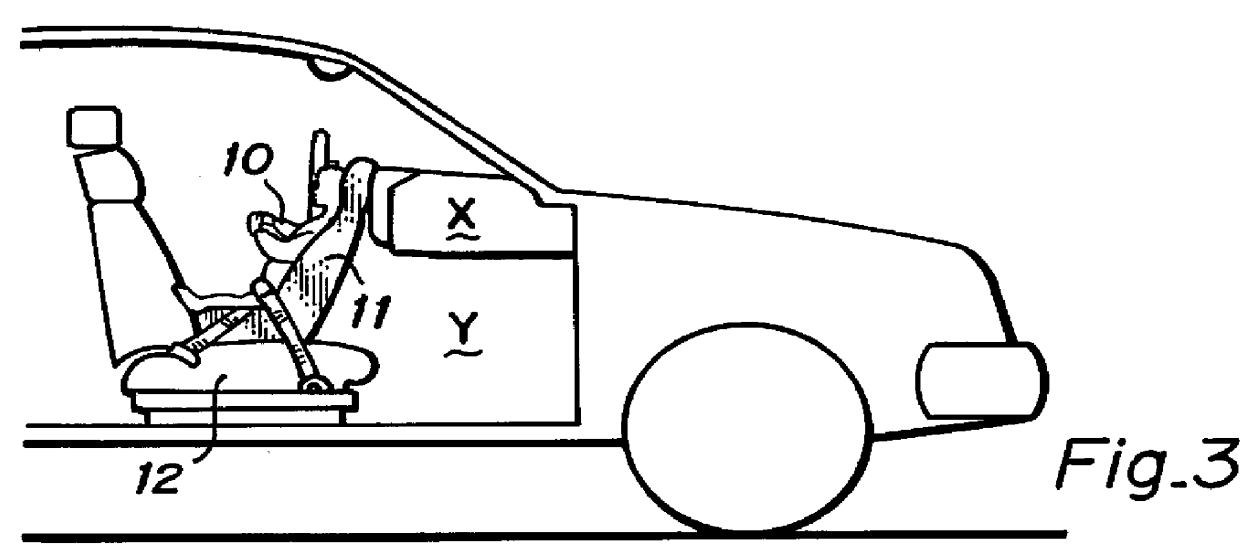

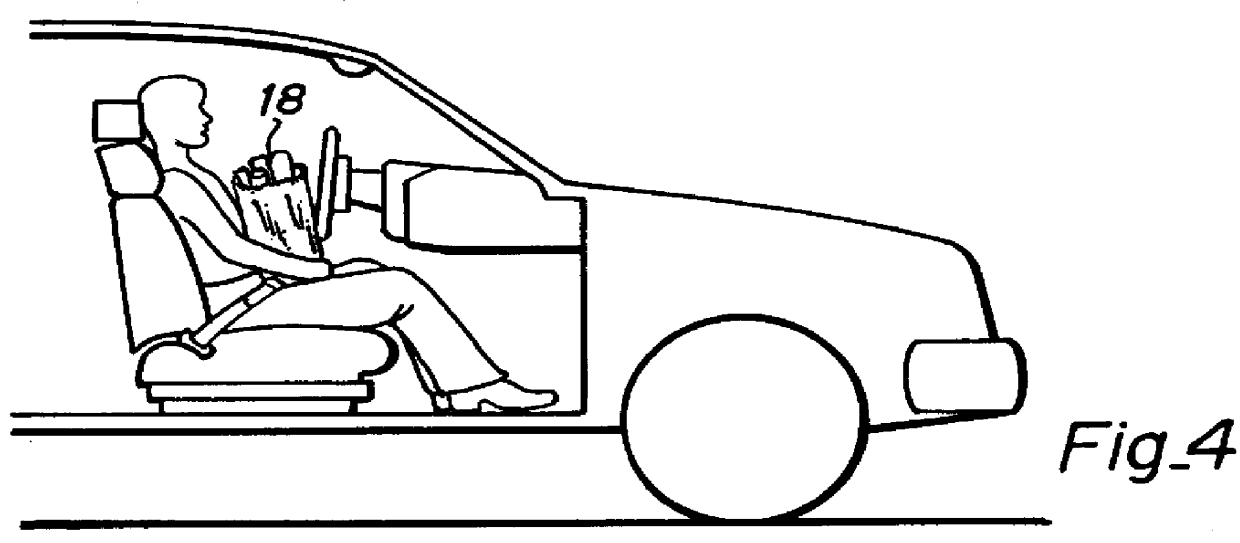

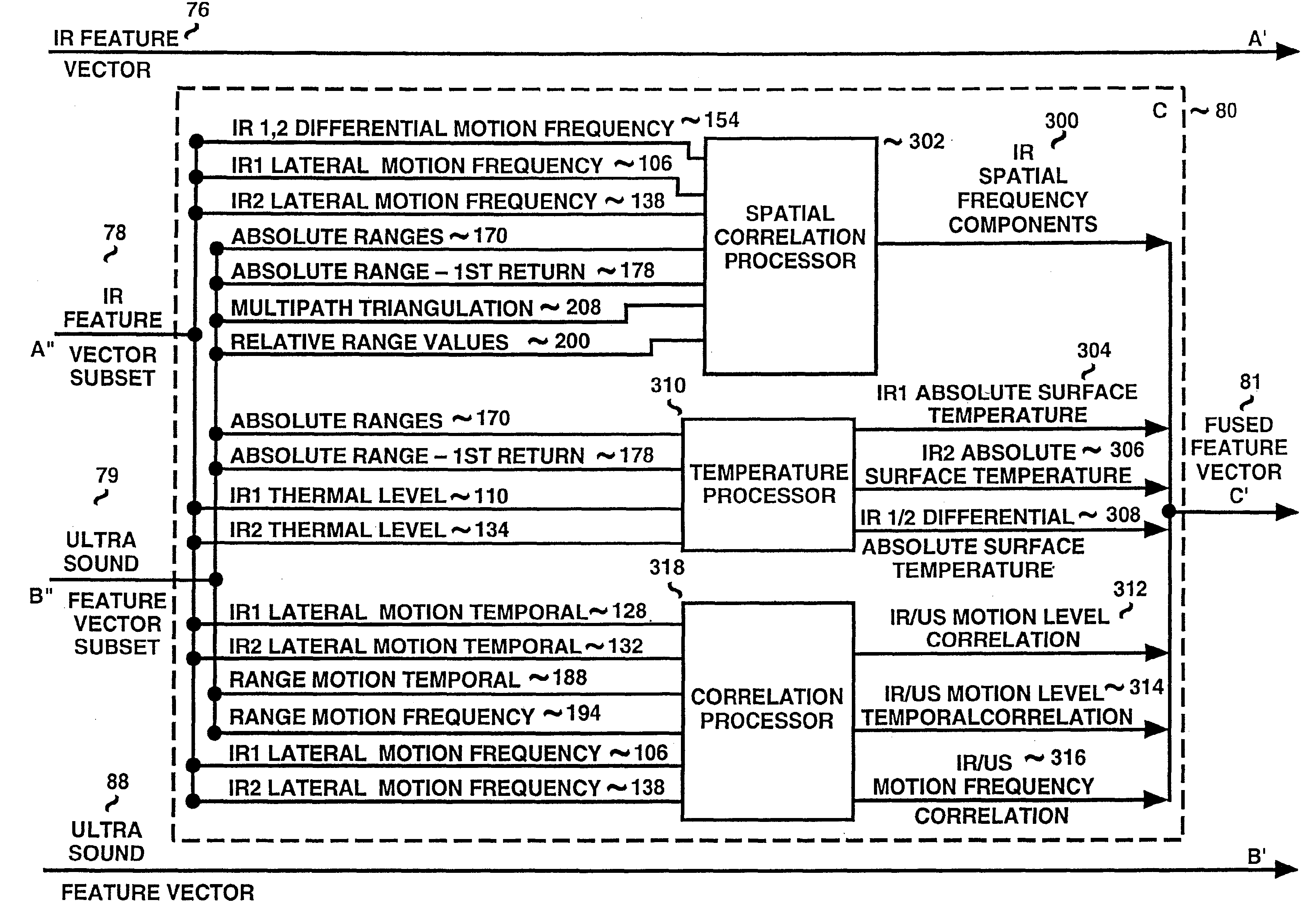

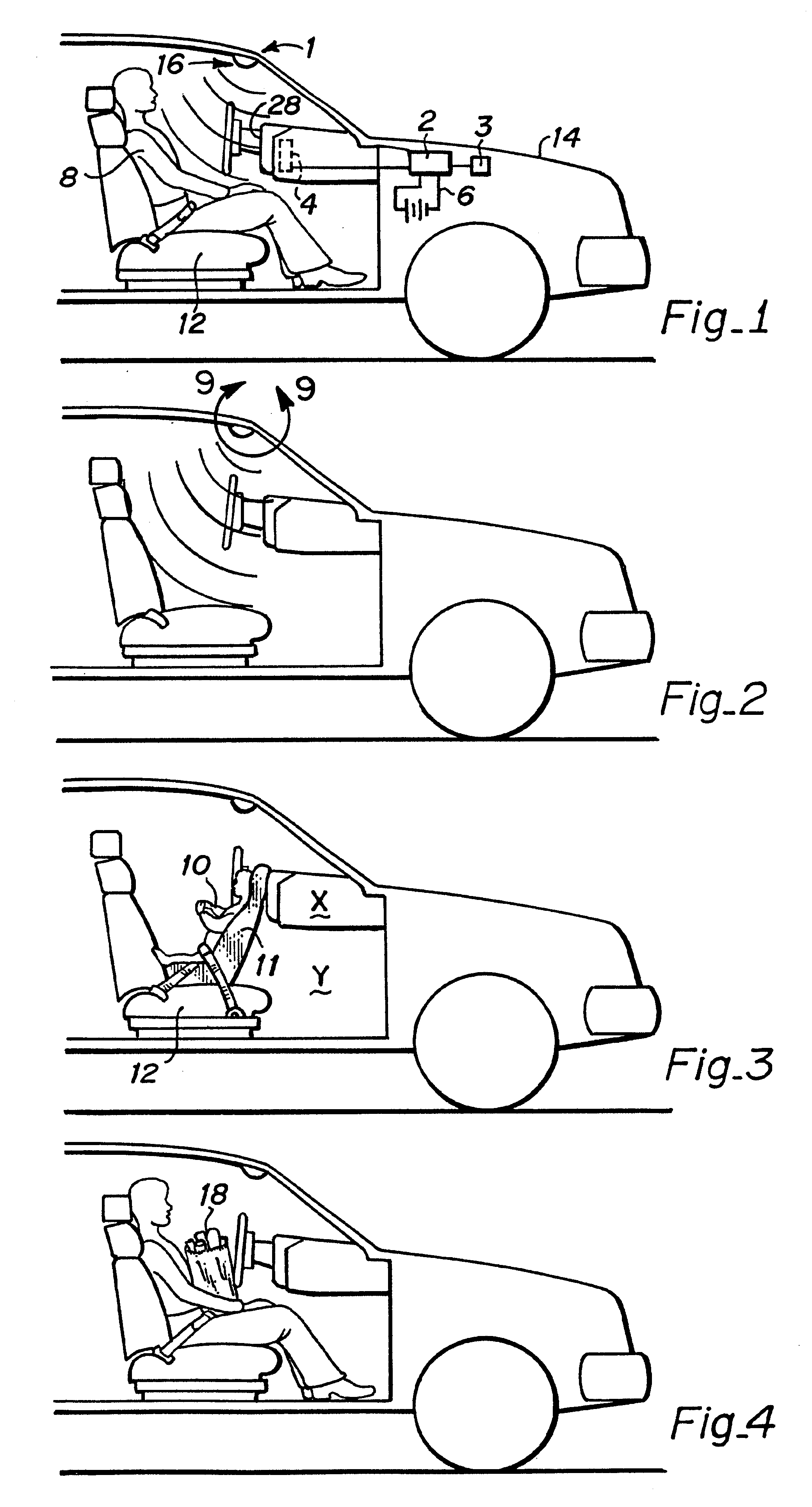

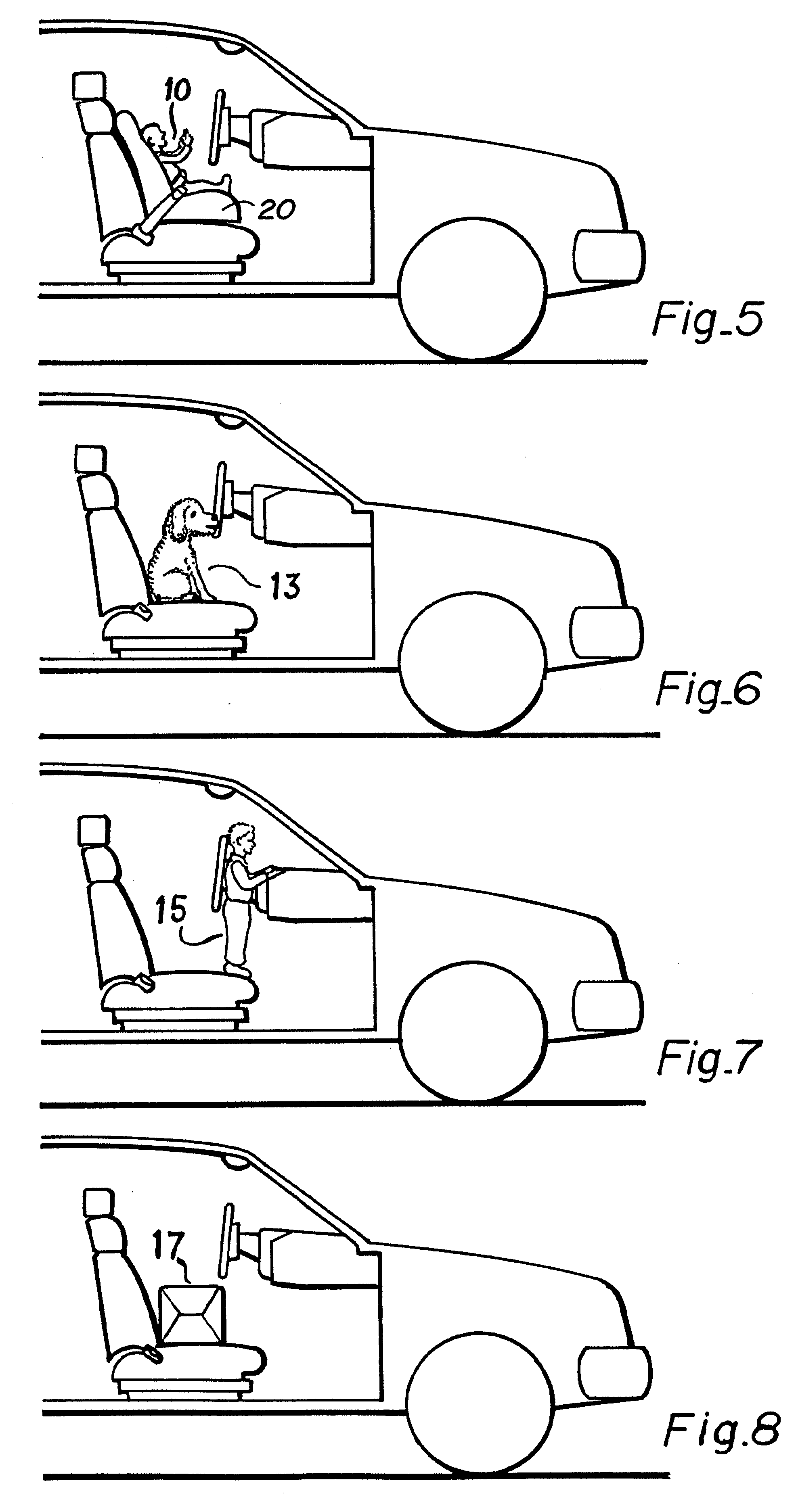

Automotive occupant sensor system and method of operation by sensor fusion

InactiveUS6026340AReliable detectionImprove reliabilityVehicle seatsDigital data processing detailsUltrasonic sensorTyping Classification

A system for sensing the presence, position and type classification of an occupant in a passenger seat of a vehicle, as well as for sensing the presence of a rear-facing child seat therein, for use in controlling a related air bag activator control system to enable, disable or control inflation rate or amount of inflation of an air bag. The sensor system employs sensor fusion, a process of combining information provided by two or more sensors (24, 26), each of which "sees" the world in a unique sense. In a preferred embodiment, infrared sensor inputs (78) and ultrasonic sensor inputs (79) are combined in a microprocessor by a sensor fusion algorithm (80) to produce an occupancy state output signal (85) to the air bag controller.

Owner:ROBERT BOSCH CORP

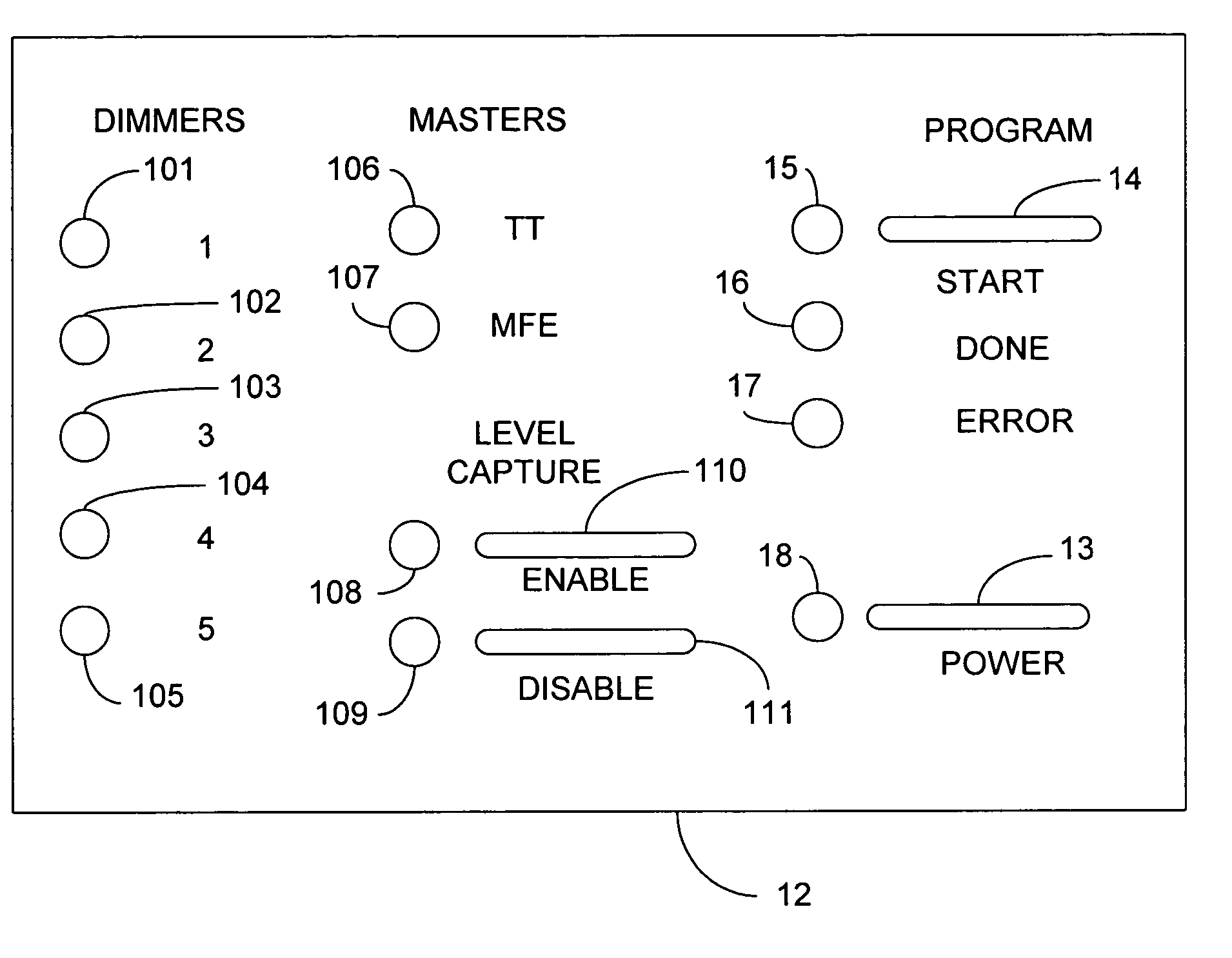

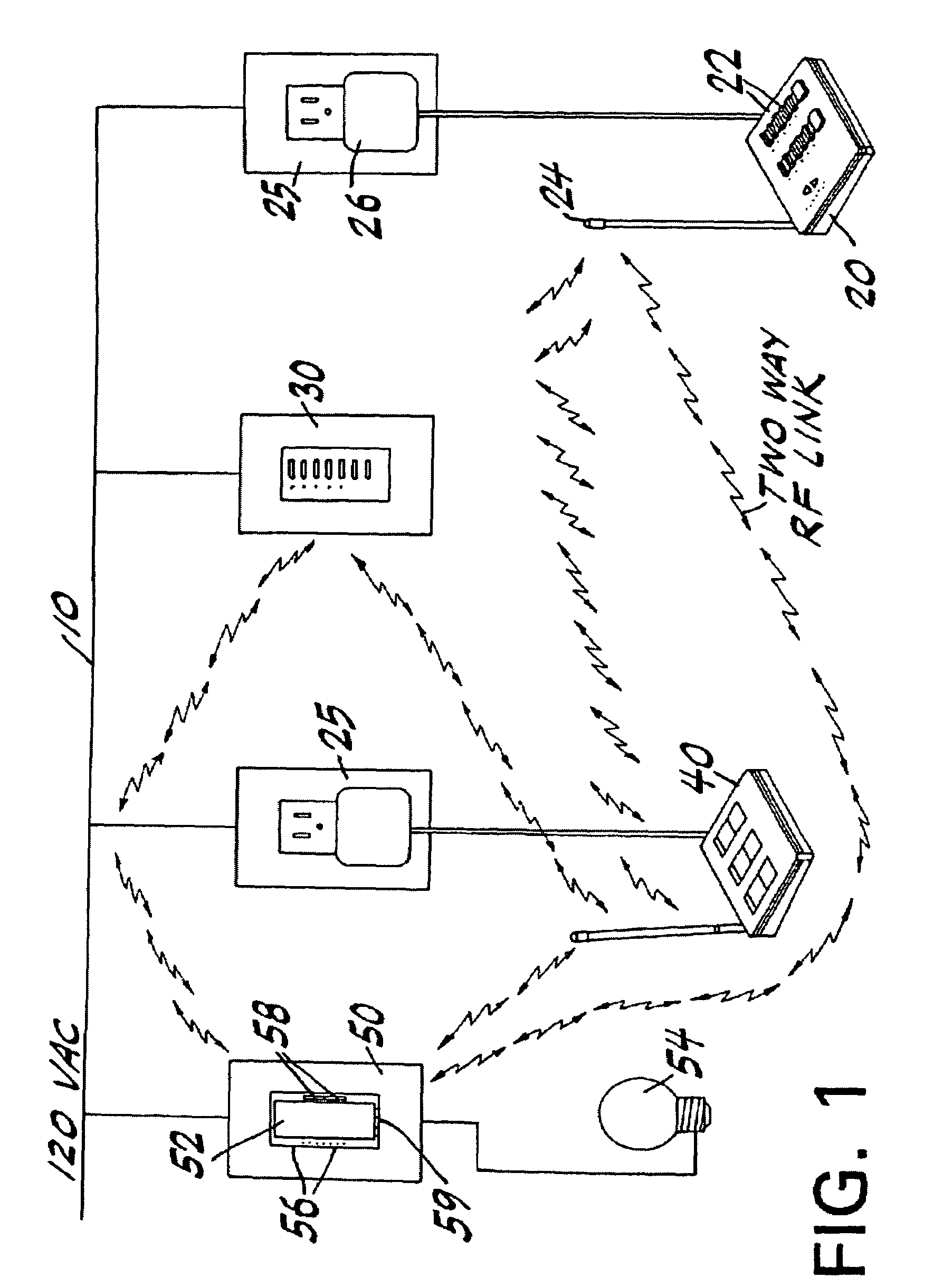

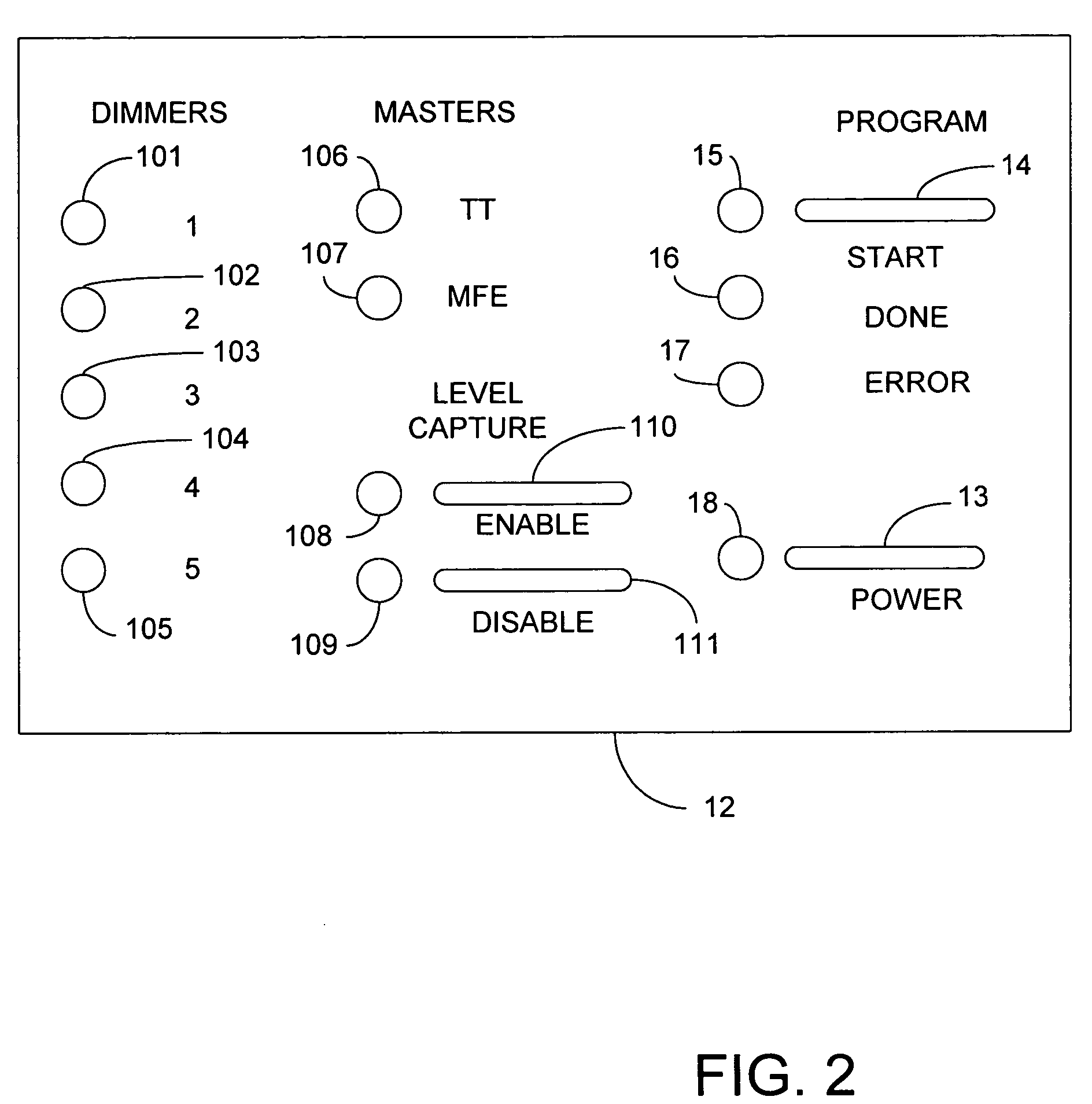

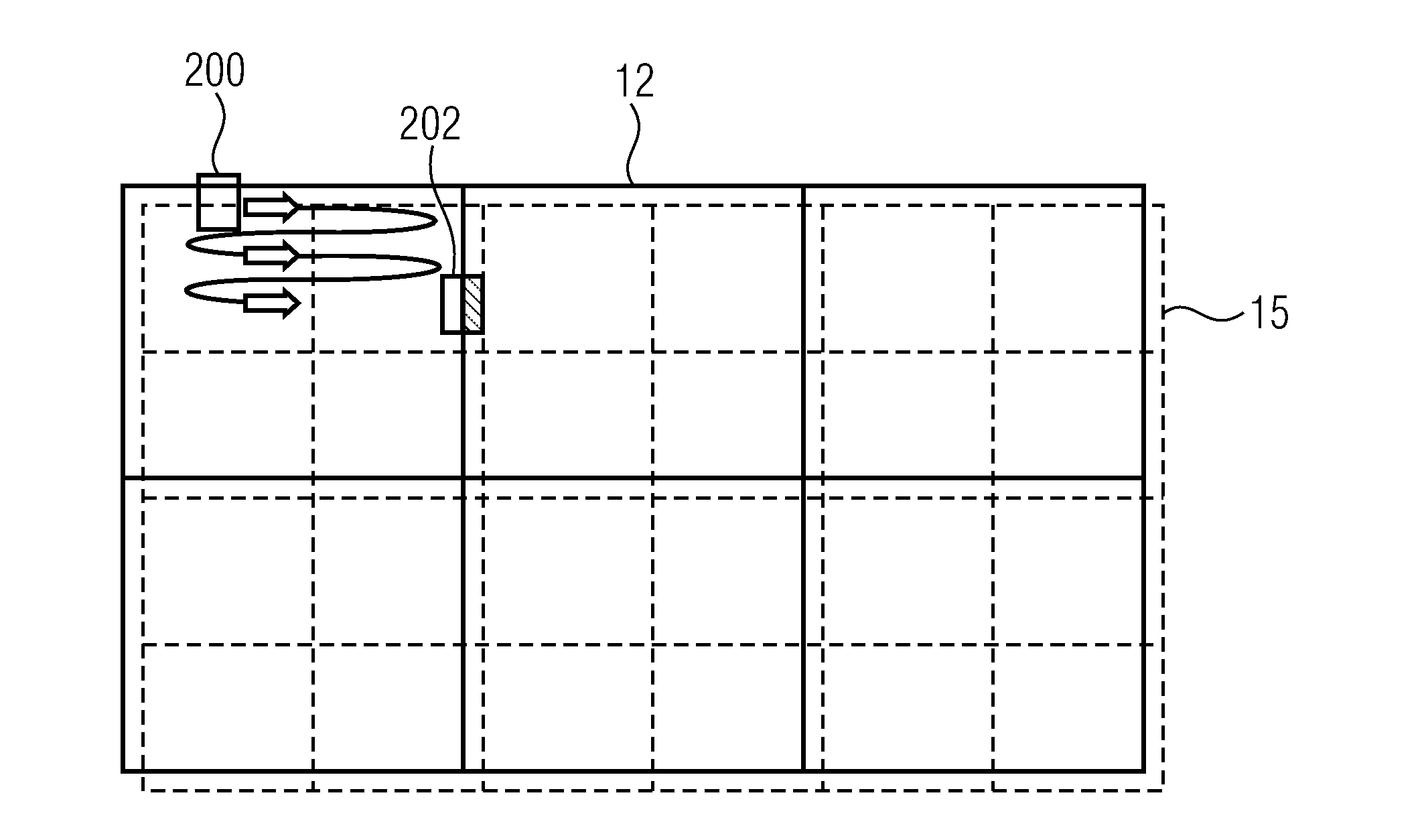

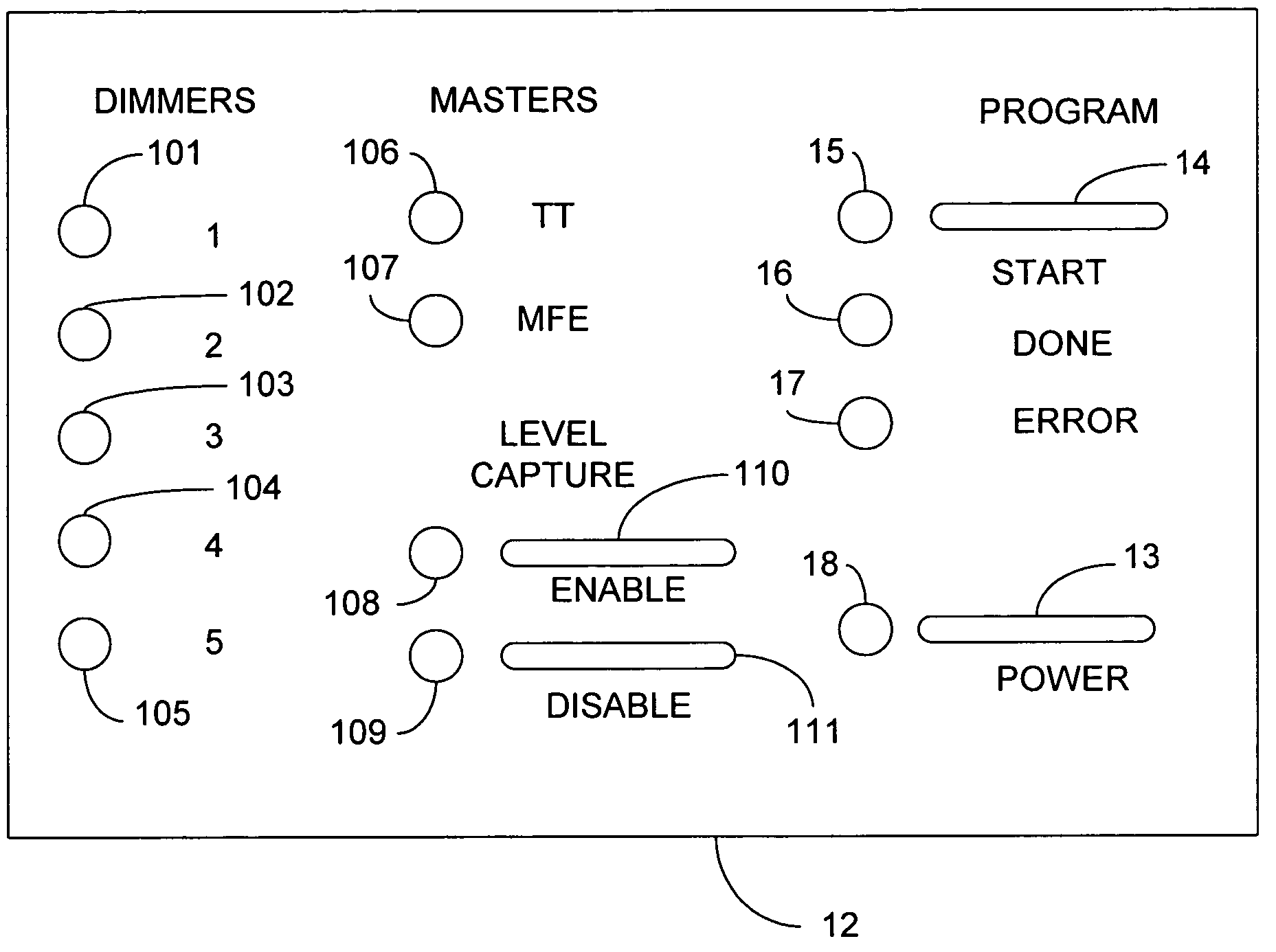

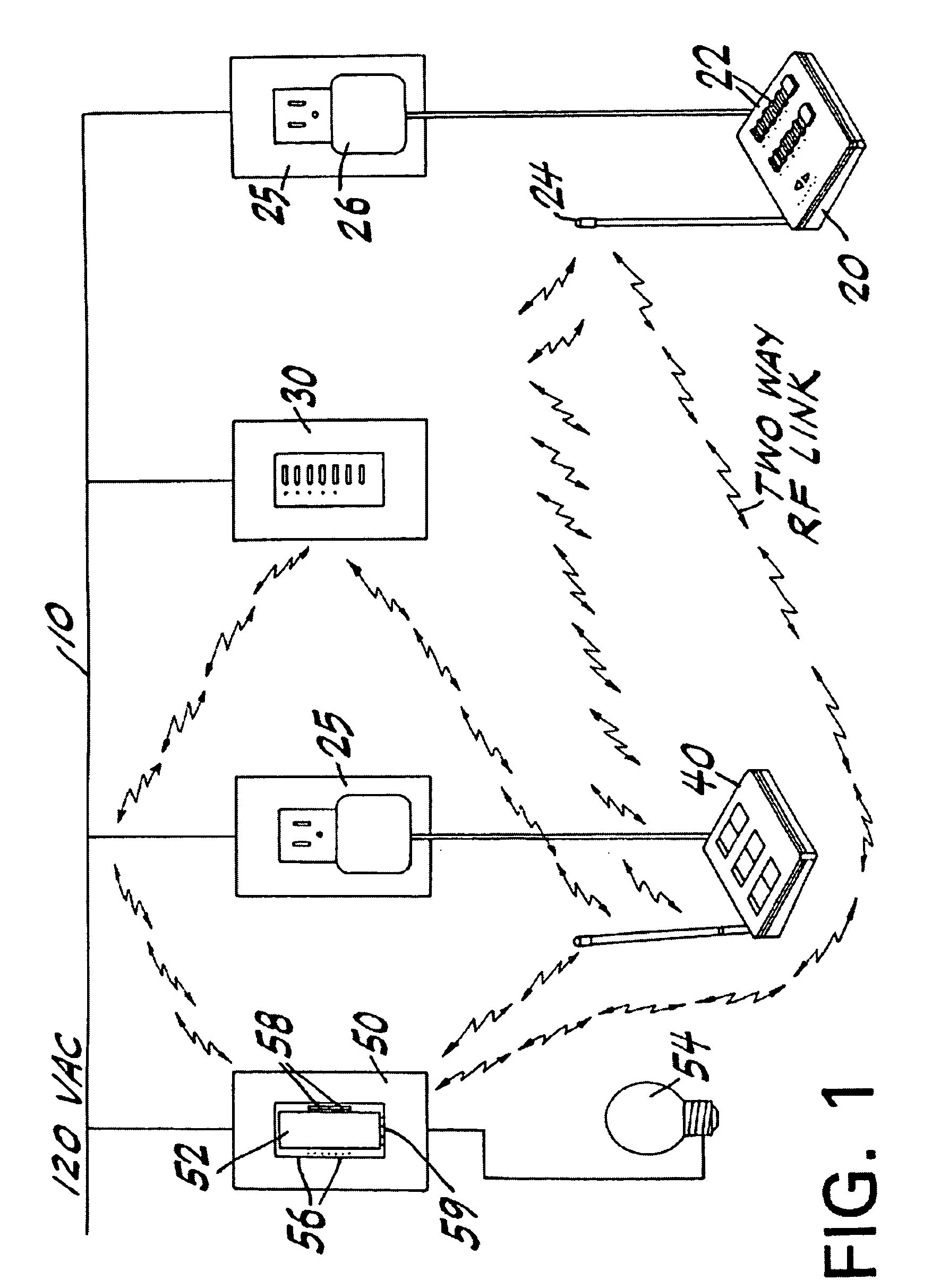

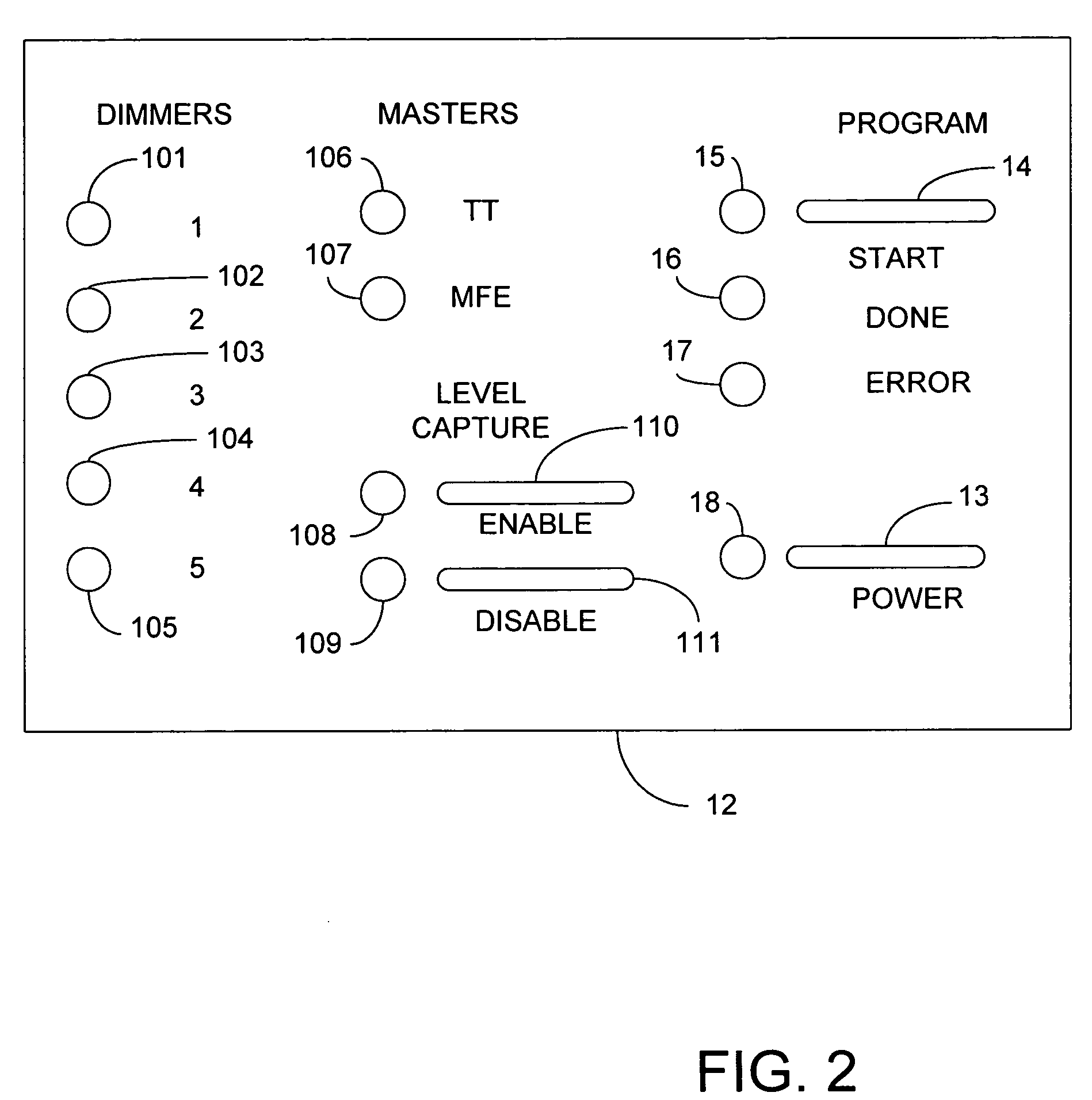

Radio frequency lighting control system programming device and method

ActiveUS7126291B2Lighten the taskSave programming timeElectrical apparatusComputer controlMaster controllerLighting system

An independent radio frequency programming device automates a setup process for a lighting system with lighting control devices and master controls. The programming device intercepts communications between the lighting control devices and the master control during an initial setup phase. A start function permits the programming device to provide automated setup information to the master controls. Once the automated setup process completes, the lighting system is fully programmed with behavior functions for all lighting control devices.

Owner:LUTRON TECH CO LLC

Method of operating a vehicle occupancy state sensor system

InactiveUS6272411B1Reliable detectionImprove reliabilityVehicle seatsDigital data processing detailsUltrasonic sensorControl system

A system for sensing the presence, position and type classification of an occupant in a passenger seat of a vehicle, as well as for sensing the presence of a rear-facing child seat therein, for use in controlling a related air bag activator control system to enable, disable or control inflation rate or amount of inflation of an air bag. The sensor system employs sensor fusion, a process of combining information provided by two or more sensors (24, 26), each of which "sees" the world in a unique sense. In a preferred embodiment, infrared sensor inputs (78) and ultrasonic sensor inputs (79) are combined in a microprocessor by a sensor fusion algorithm (80) to produce an occupancy state output signal (85) to the air bag controller.

Owner:ROBERT BOSCH CORP

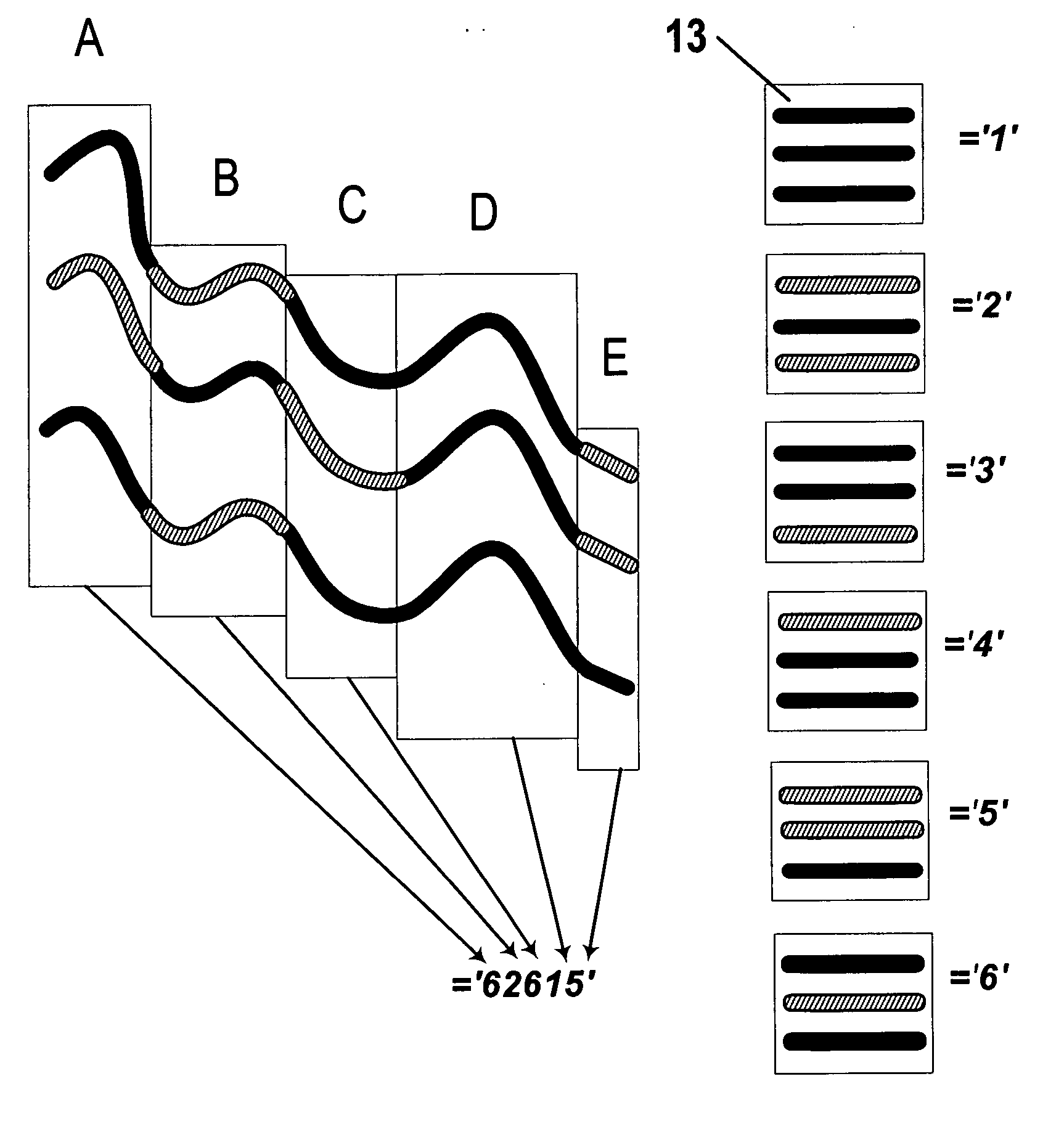

Device and system for calculating 3D seismic classification features and process for geoprospecting material seams

InactiveUS20050171700A1Eliminate needEliminate errorSeismic signal processingSpecial data processing applicationsFeature vectorComputer science

A device for calculating 3D seismic classification features constrained to be tangent to a path in a 3D volume is provided as a “geo-operator”. The method has the capability to associate horizontal (2D), vertical (2D) or arbitrary (3D) classification “feature vectors” with the geo-operator output, to allow determining where the geo-operator has sufficient data for the calculation to form a valid output and where the output of the geo-operator indicates a measure to which alternative feature vector prototypes may be present along the path. The geo-operator has the flexibility of using variable crossline, inline and vertical extent and having a direction able to be designated as it traverses the path, from the start point to the endpoint, aligned to be tangent to the path.

Owner:CHROMA ENERGY

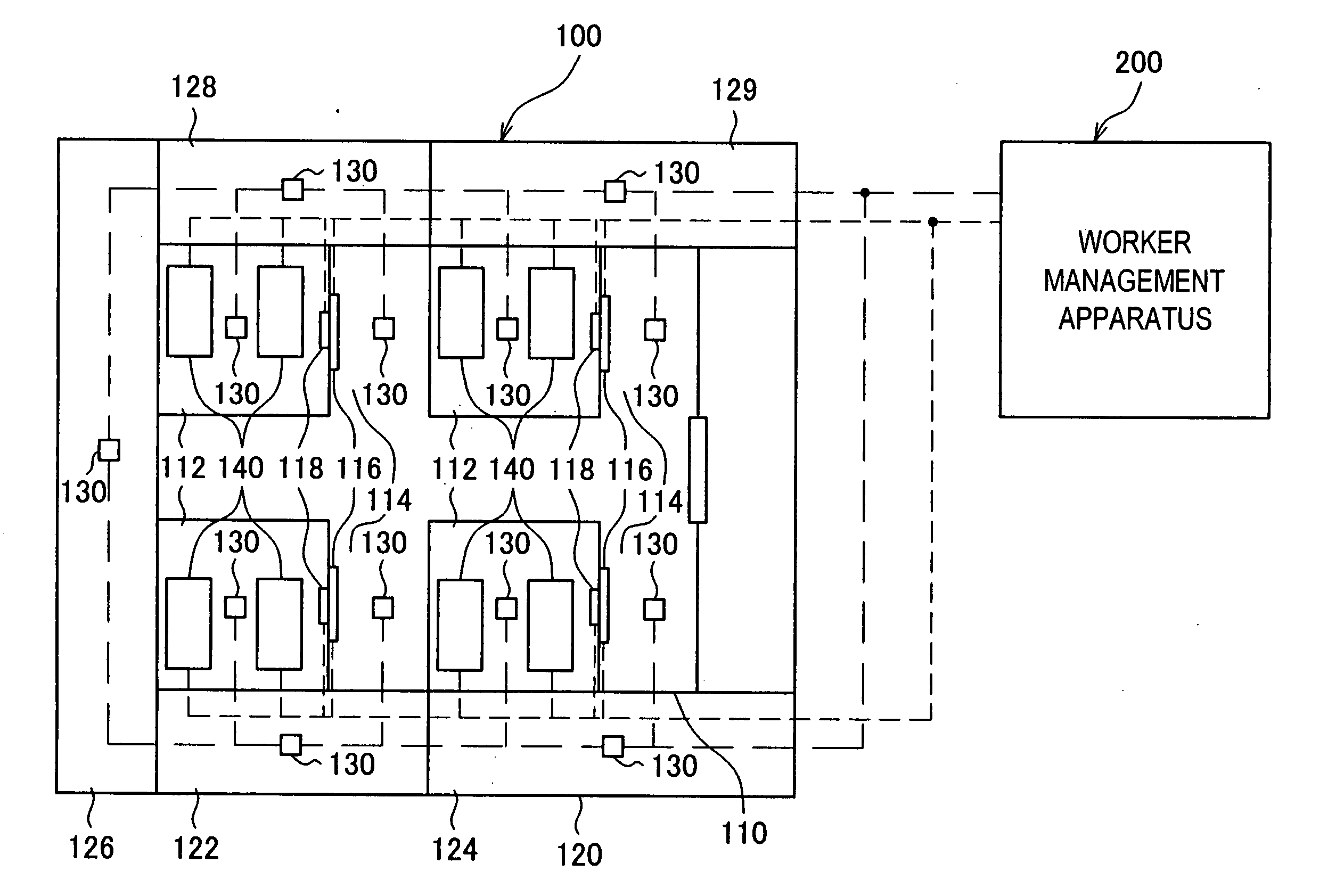

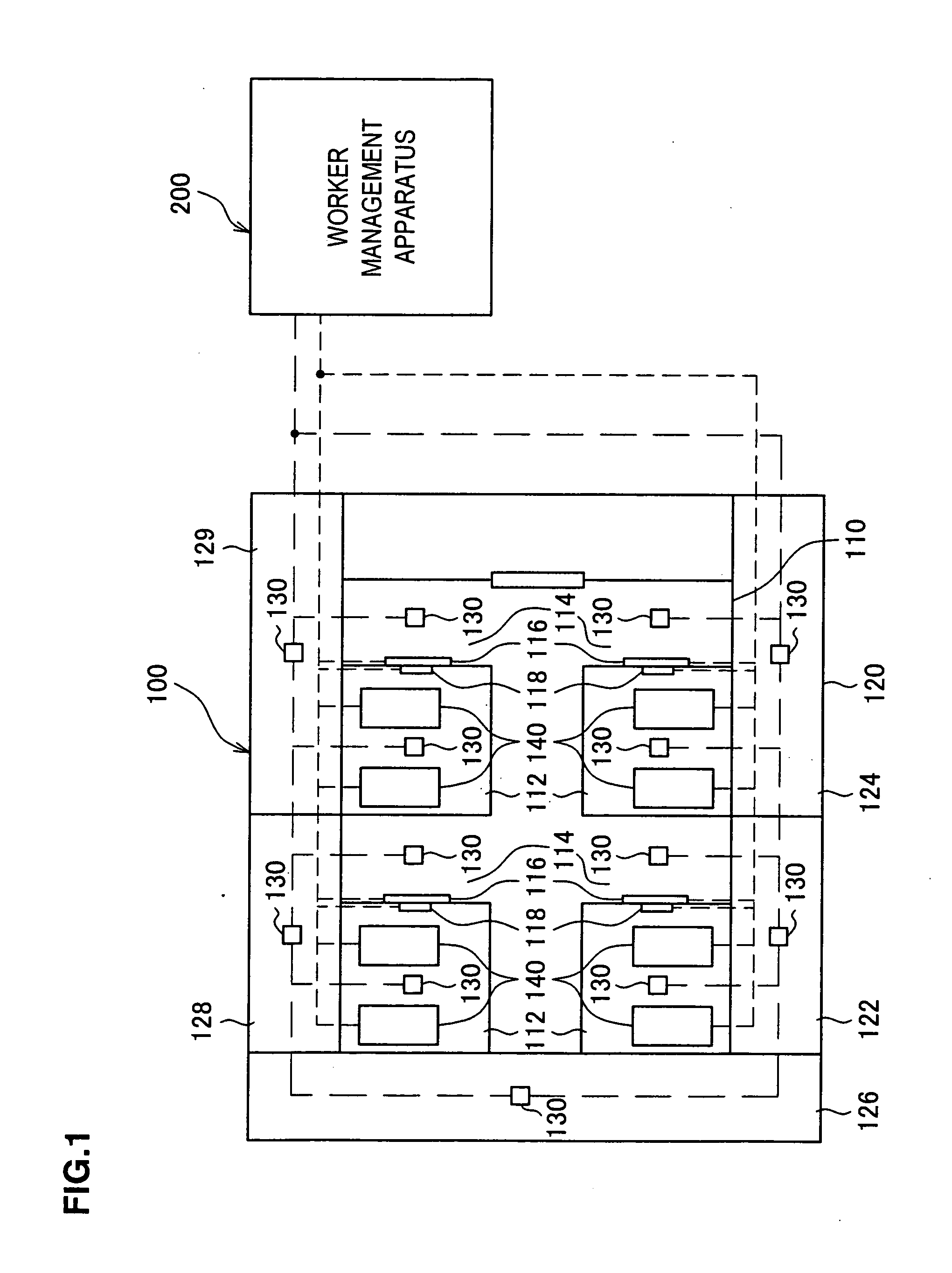

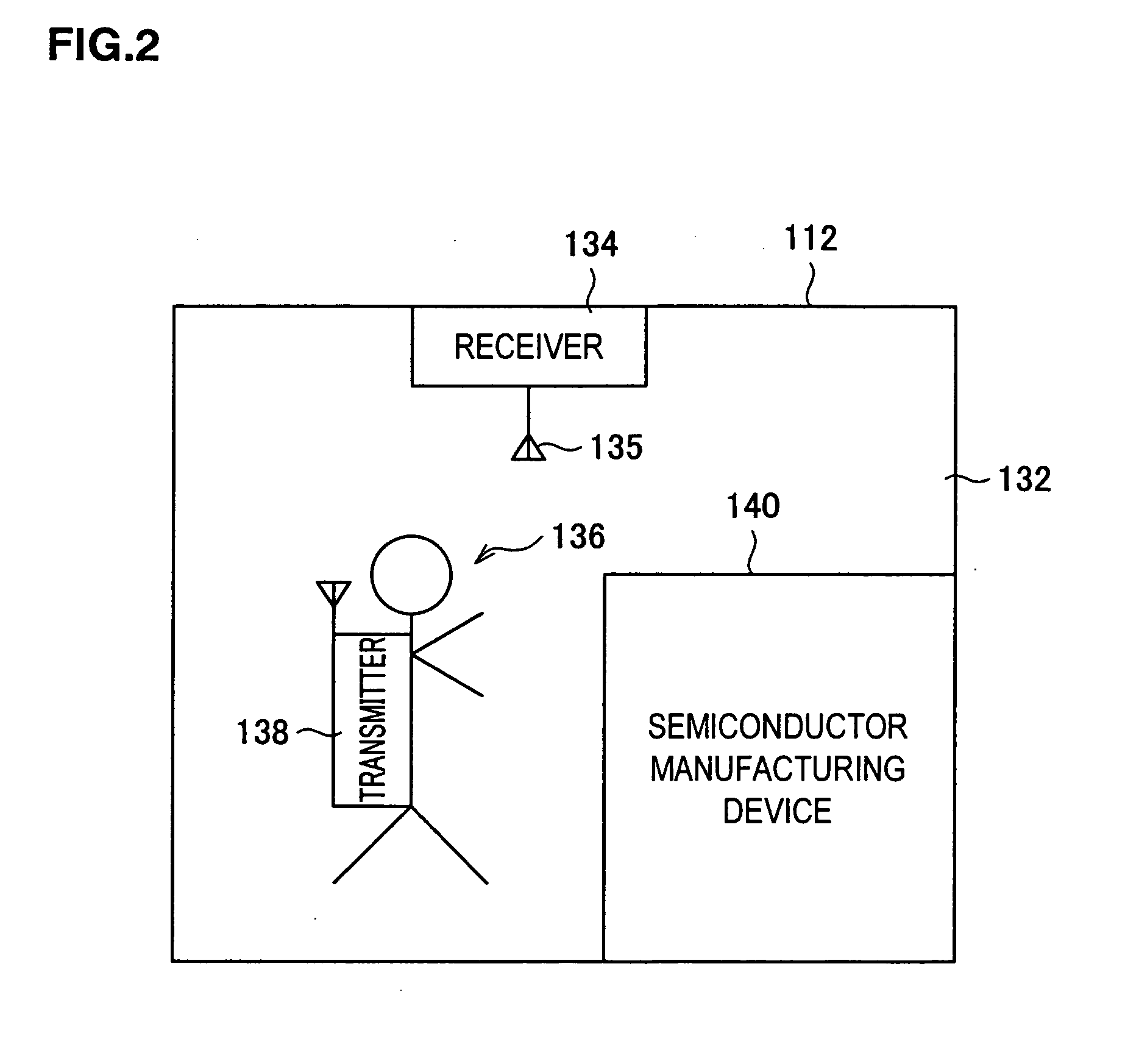

Worker management system, worker management apparatus and worker management method

InactiveUS20050209902A1Easy to detectDelay detectionFrequency-division multiplex detailsTime-division multiplexComputer scienceManagement system

A worker management system, which includes a plant 100 divided into a plurality of work areas each in correspondence to specific task contents, a database 220 having stored therein task identification information correlating each work area 112 with contents of tasks performed therein and worker detection sensors 130 installed in each work area, identifies the specific work area where a worker is currently located based upon outputs from the worker detection means and then identifies the task currently performed by the worker based upon the task identification information. Based upon the current task thus identified, a decision is made as to whether the worker should continue the current task or be assigned a new task and an instruction for task execution is issued to the worker. Therefore the identification of current tasks, the assignment of a new task and the task reassignment are facilitated to improve the work efficiency.

Owner:TOKYO ELECTRON LTD

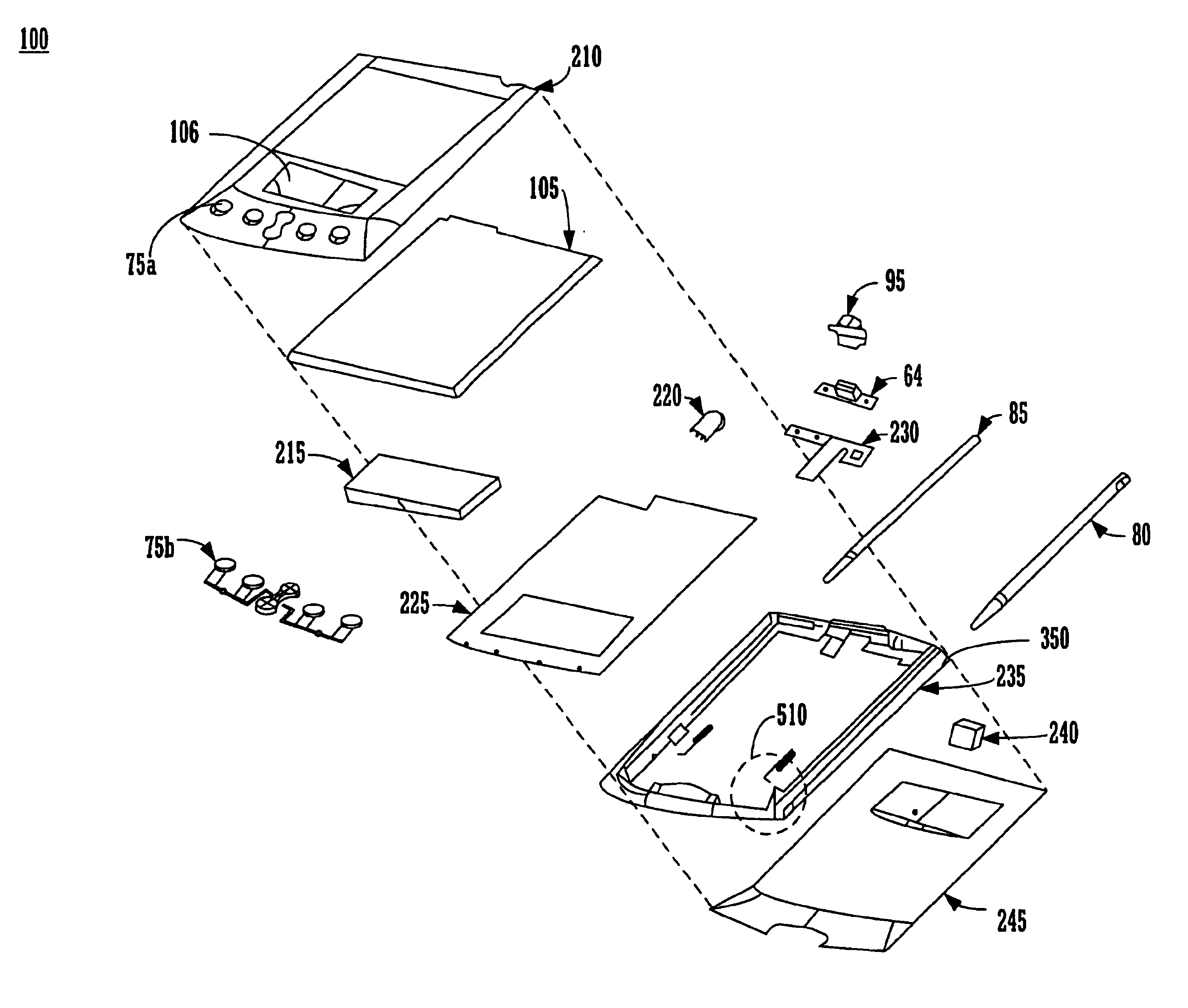

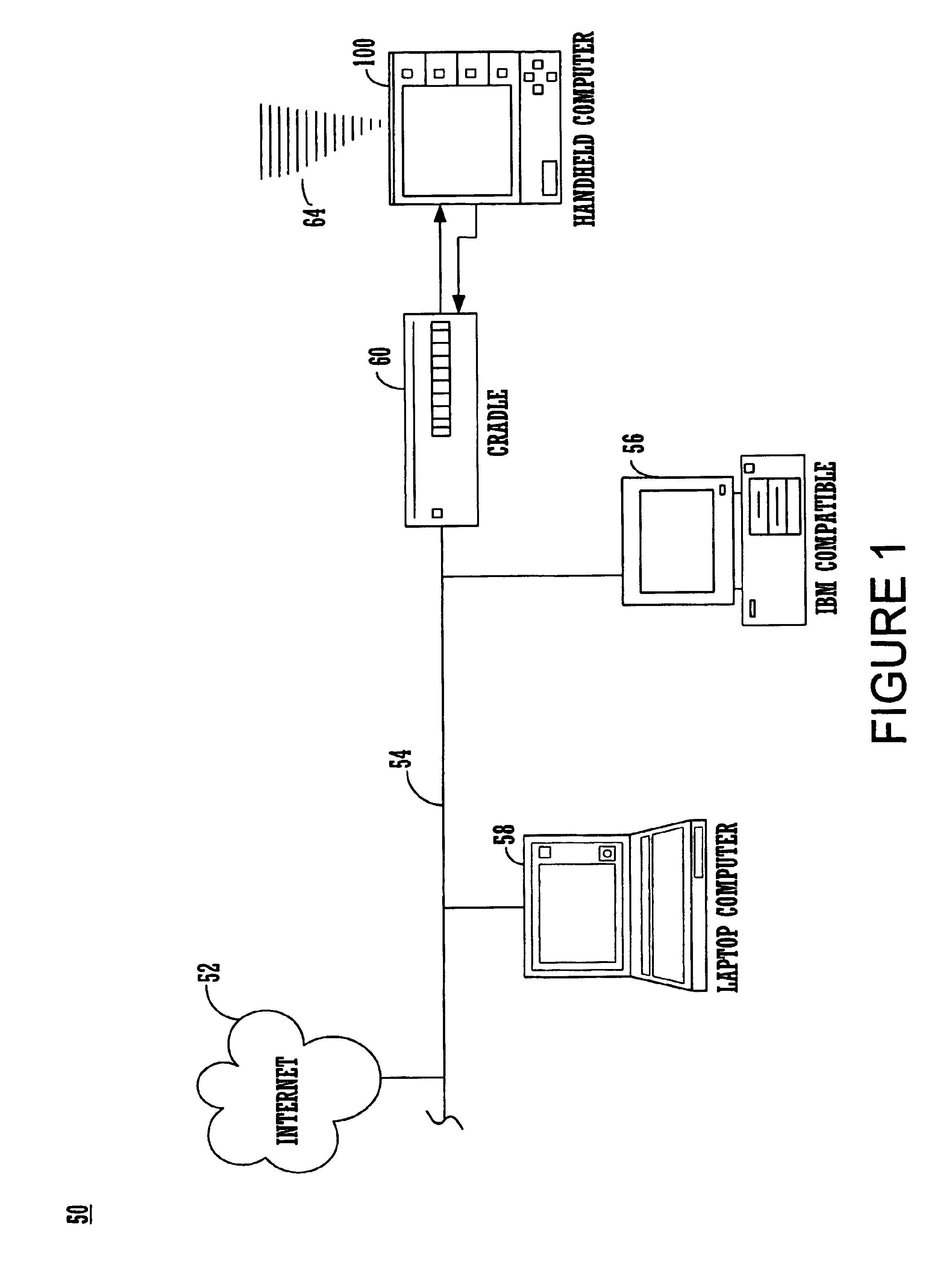

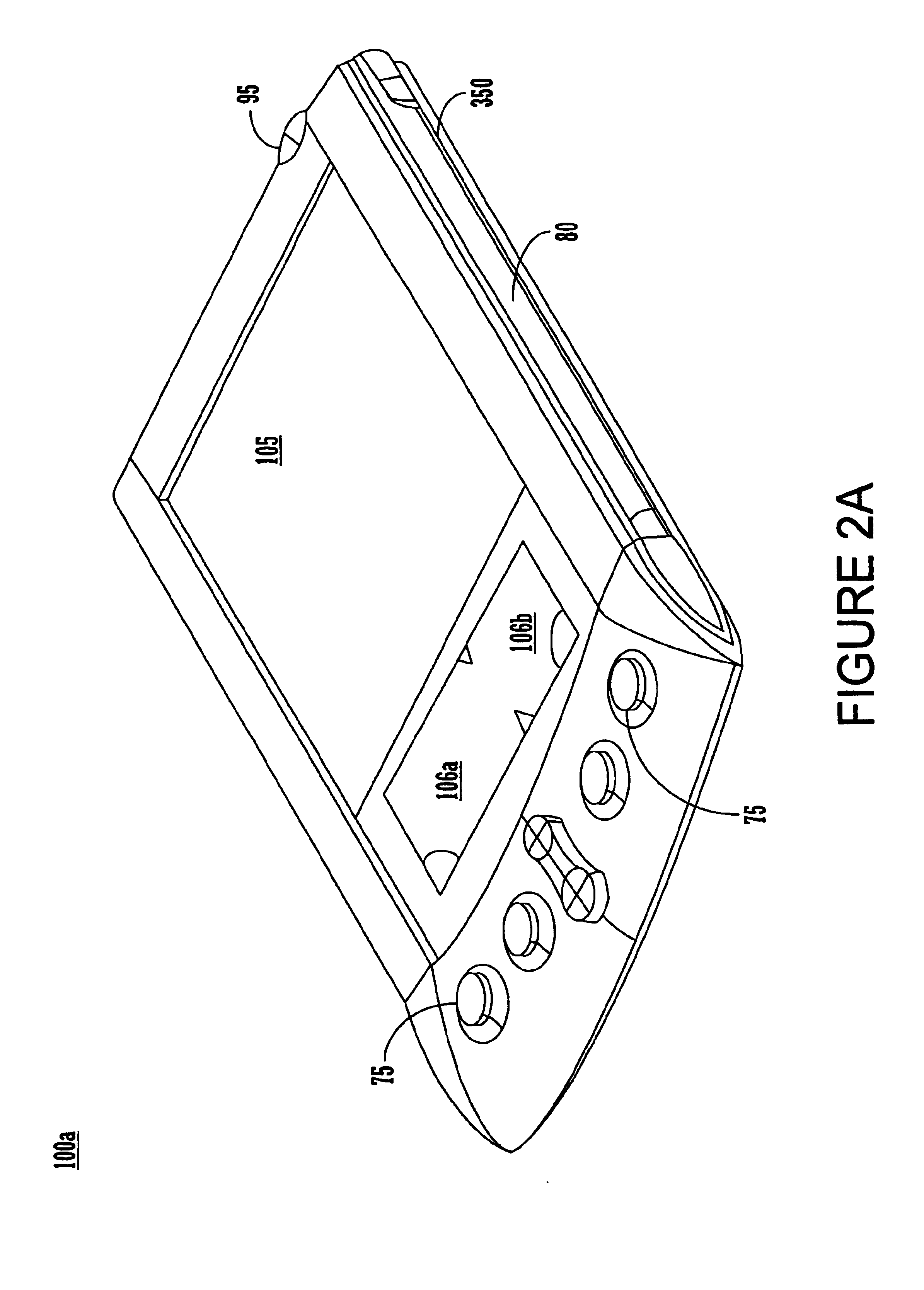

Method and apparatus for automatic power-up and power-down of a computer system based on the positions of an associated stylus and/or hinge

InactiveUS6924791B1Reduce in quantityLighten the taskTransmission systemsVolume/mass flow measurementElectricityComputerized system

A method and system for automatic power-up and automatic power-down of a computer system based on the position and / or rotation of an associated stylus and / or hinge. In one embodiment, the computer system is a portable computer having a logic board, a display screen, a digitizer and a receiving slot for an associated stylus. When the stylus is removed from the receiving slot, a switch automatically turns full power onto the computer system thereby allowing a user full use of the computer without requiring an on / off button to be pressed. When the stylus is inserted back into the receiving slot, the switch automatically returns the computer to a power reduction mode where one or all of the components of the computer are powered down. Again, the power reduction mode is entered without requiring the user to press the on / off button. The switch can be made of a single detector or a dual detector combination and can be of a mechanical, electromagnetic, optical or electrical nature. In another embodiment, the stylus-based automatic power-up and power-down features work in concert with other power-up and power-down mechanisms of the computer, such power-on interrupts, the on / off button, and time-out power off modes. In another embodiment, the stylus is a hinge attached to a cover that can be rotated to protect the computer or rotated away to use the computer. When rotated to cover, the switch automatically powers down the computer. When rotated out for computer use, the switch automatically powers up the computer.

Owner:QUALCOMM INC

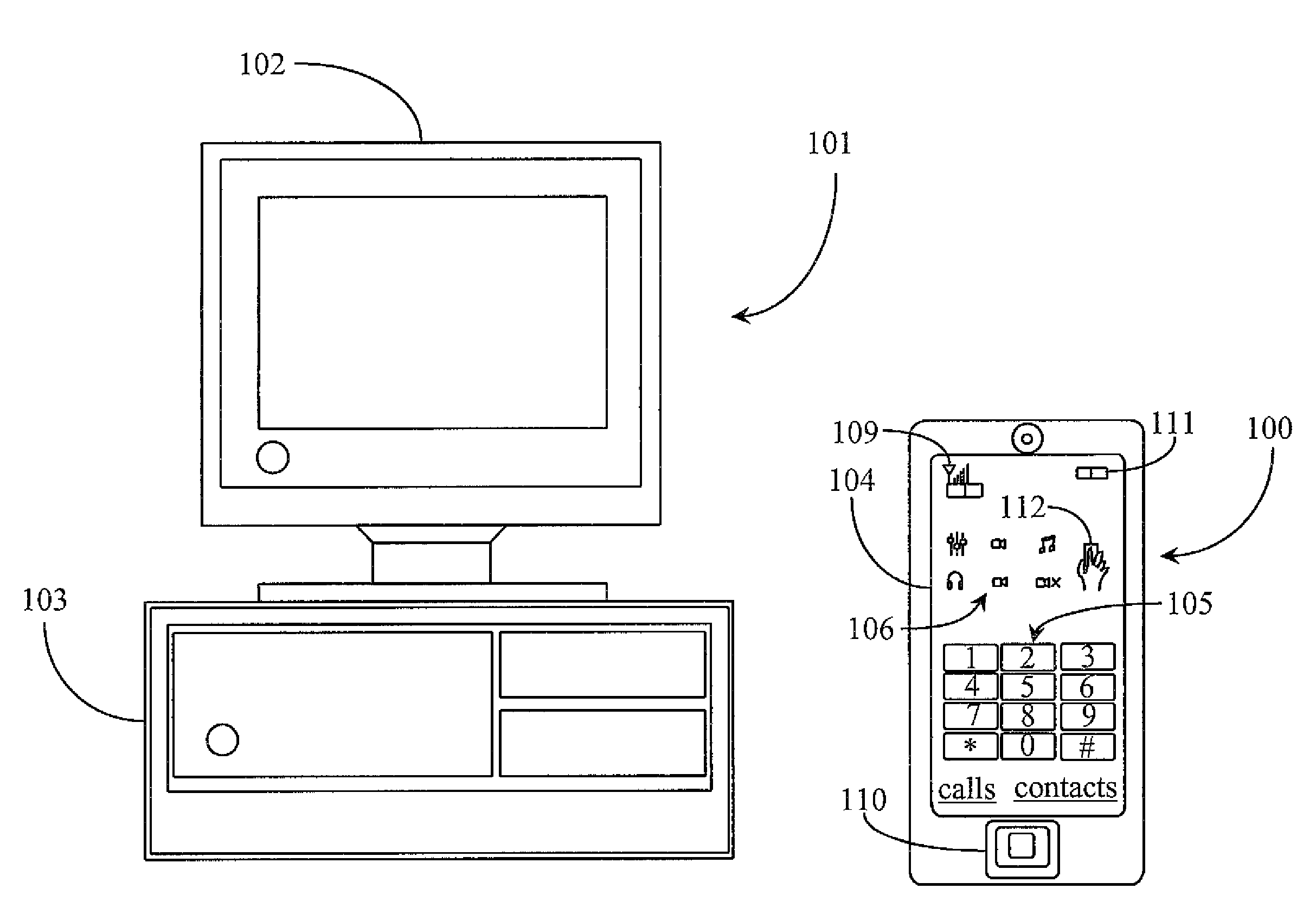

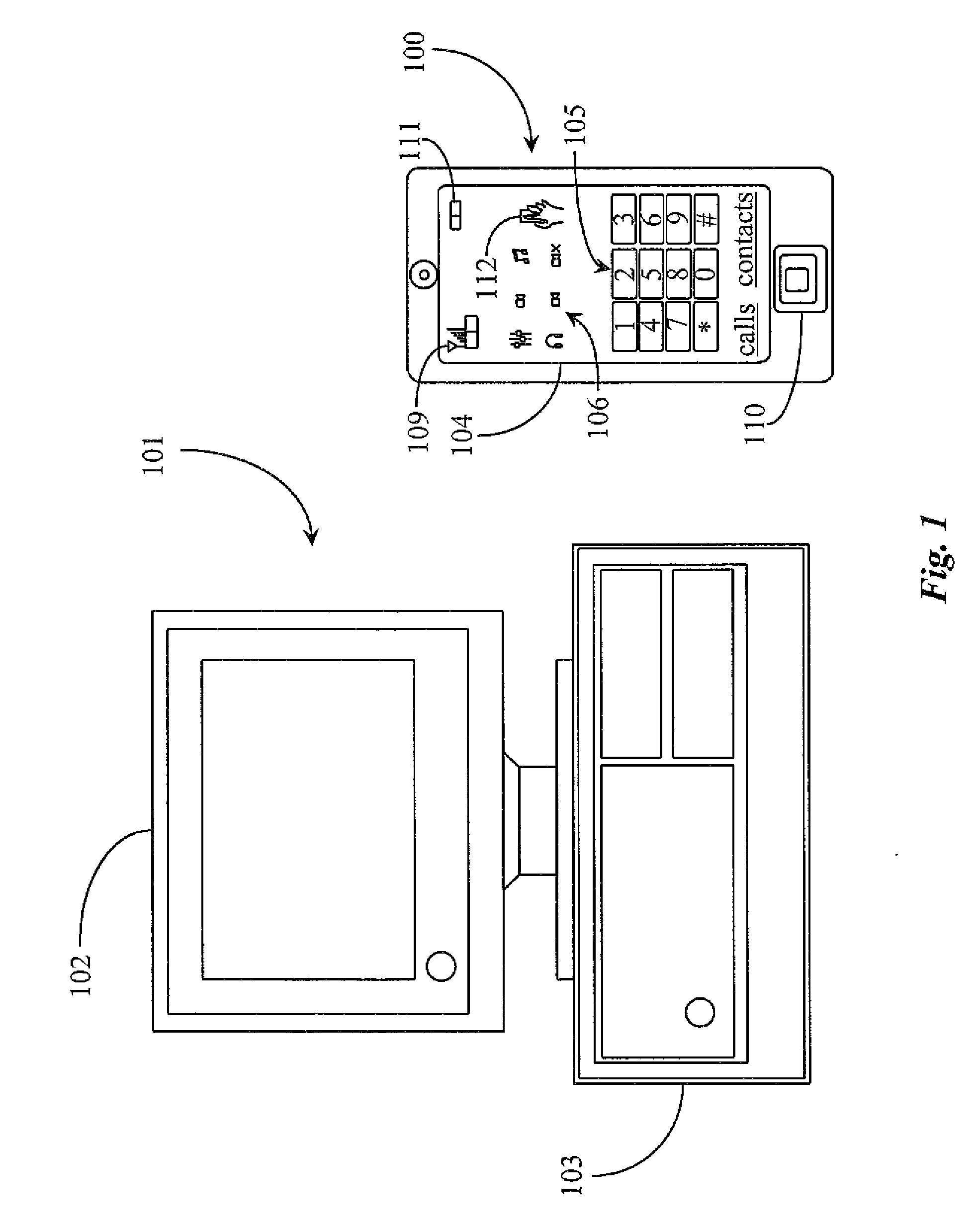

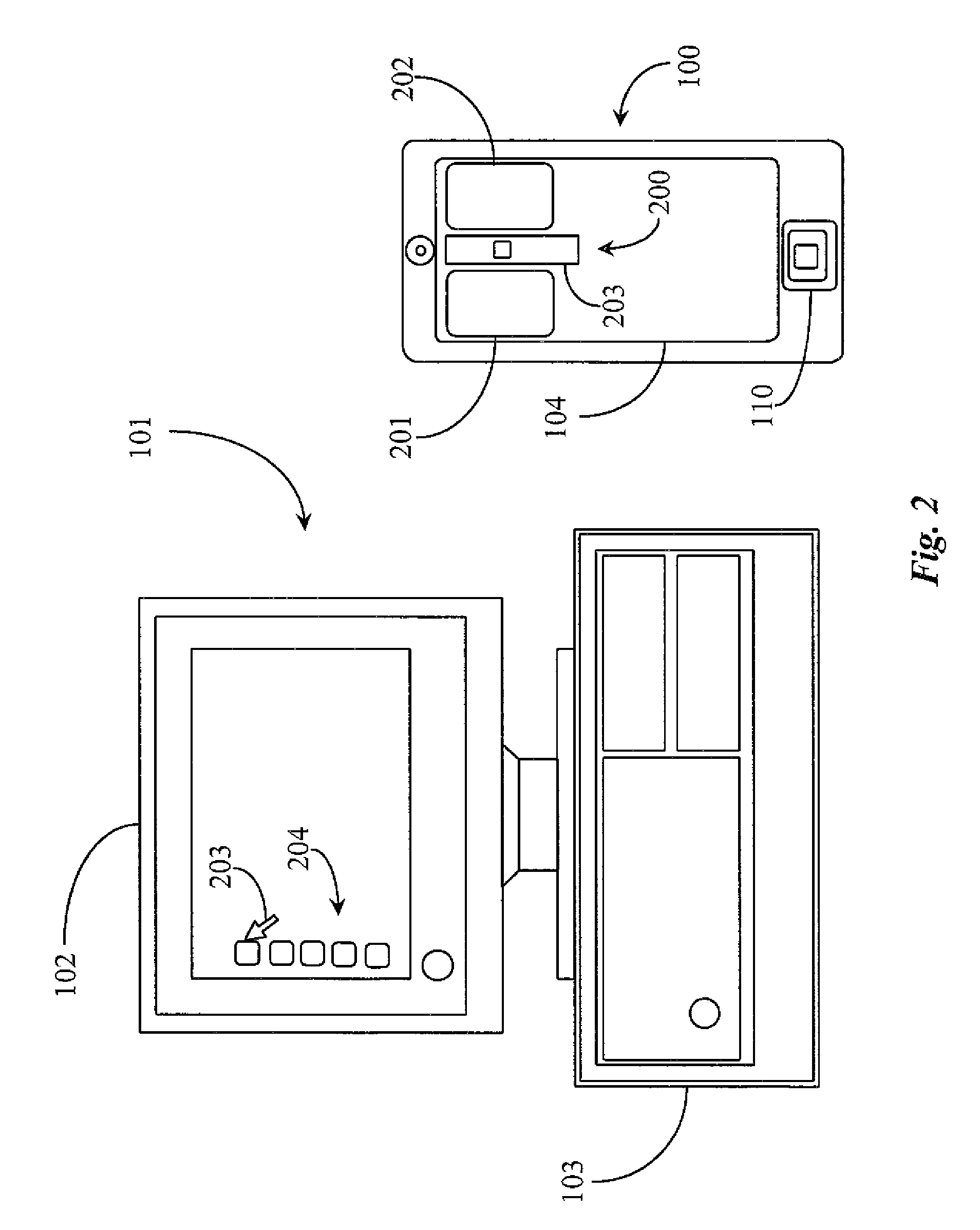

Computer Peripheral Device Used for Communication and as a Pointing Device

InactiveUS20100066677A1Lighten the taskShorten the timeTelevision system detailsDevices with sensorWireless transceiverTransceiver

A computer peripheral device used for communication and computing input is provided comprising a digital medium for storing data and software, a processor for controlling computing functions, a power source, a motion detection sensor, communication software residing on and executable from the digital medium, computing input device software residing on and executable from the digital medium, a user interface for enabling user control and task performance, and a wireless transceiver for enabling wireless communication.

Owner:EDGE MOBILE PAYMENTS LLC

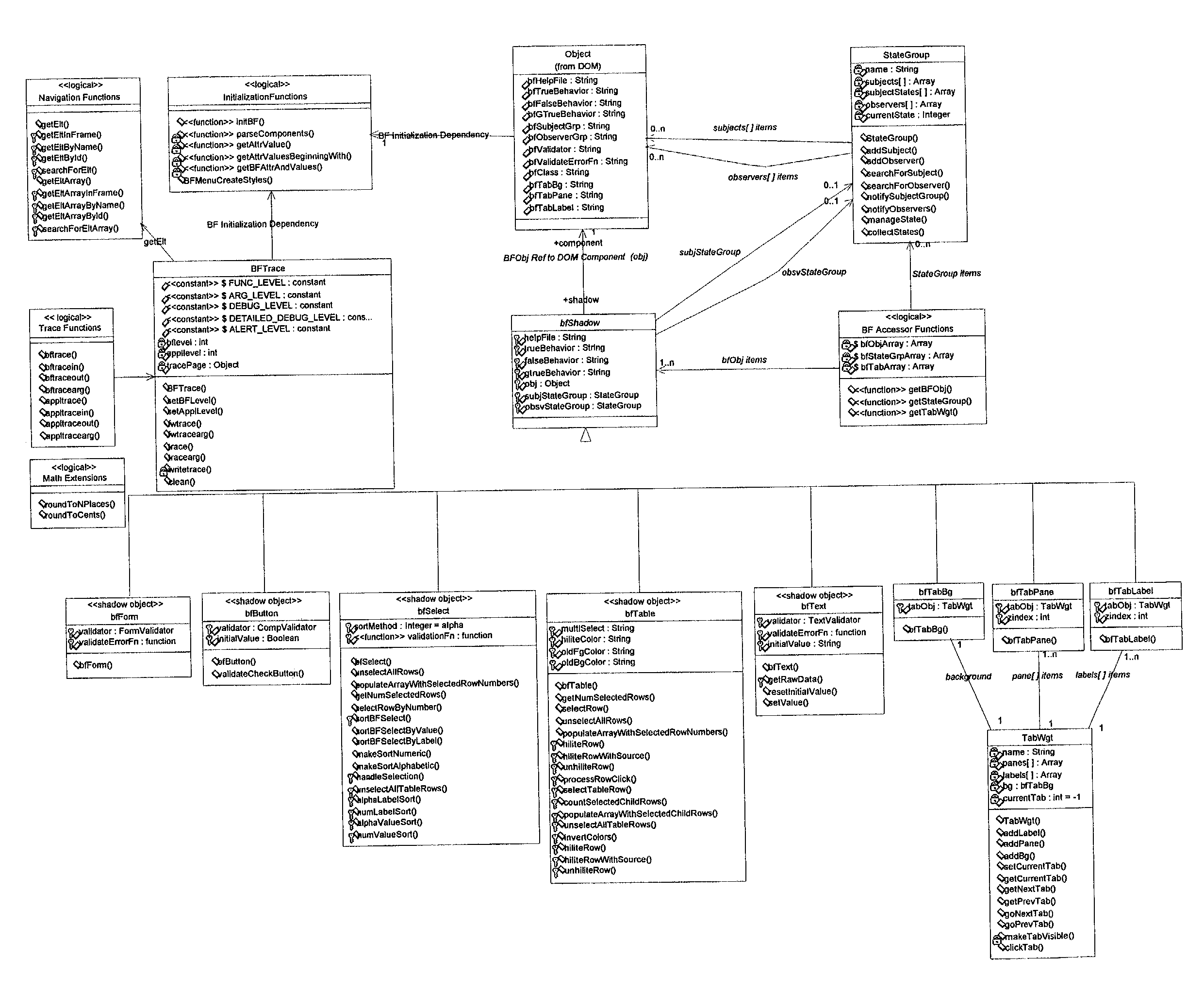

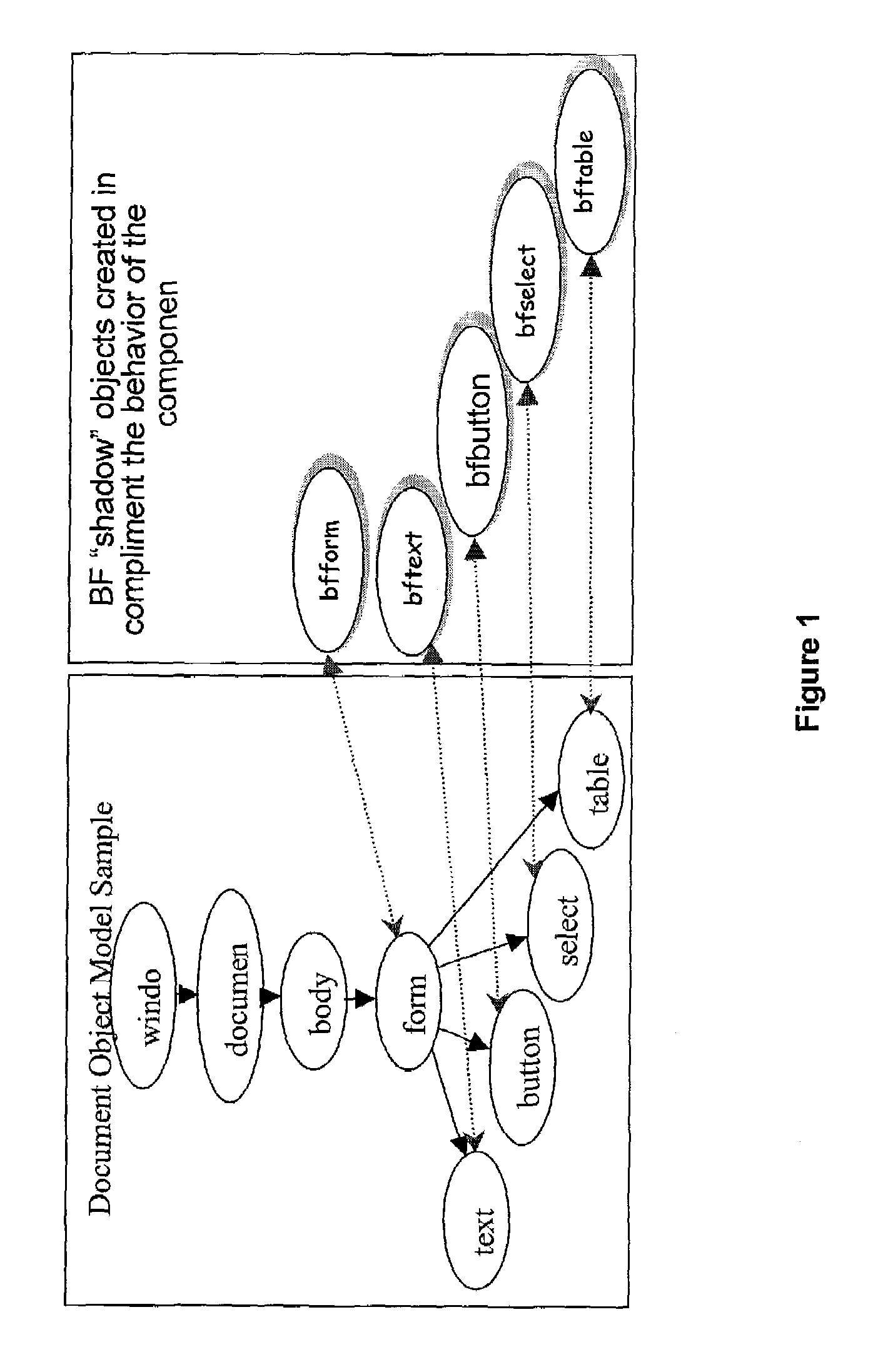

Method for creating browser-based user interface applications using a framework

ActiveUS6973625B1Promotes great code reuseImprove stabilitySoftware engineeringSpecific program execution arrangementsClient-sideApplication software

A framework and method of programming web-based interfaces using management classes for the management of behavior regarding specific web elements wherein said code relating to said management classes is loaded into a user's browser and primarily executed within the client-side browser environment.

Owner:NETCRACKER TECH SOLUTIONS

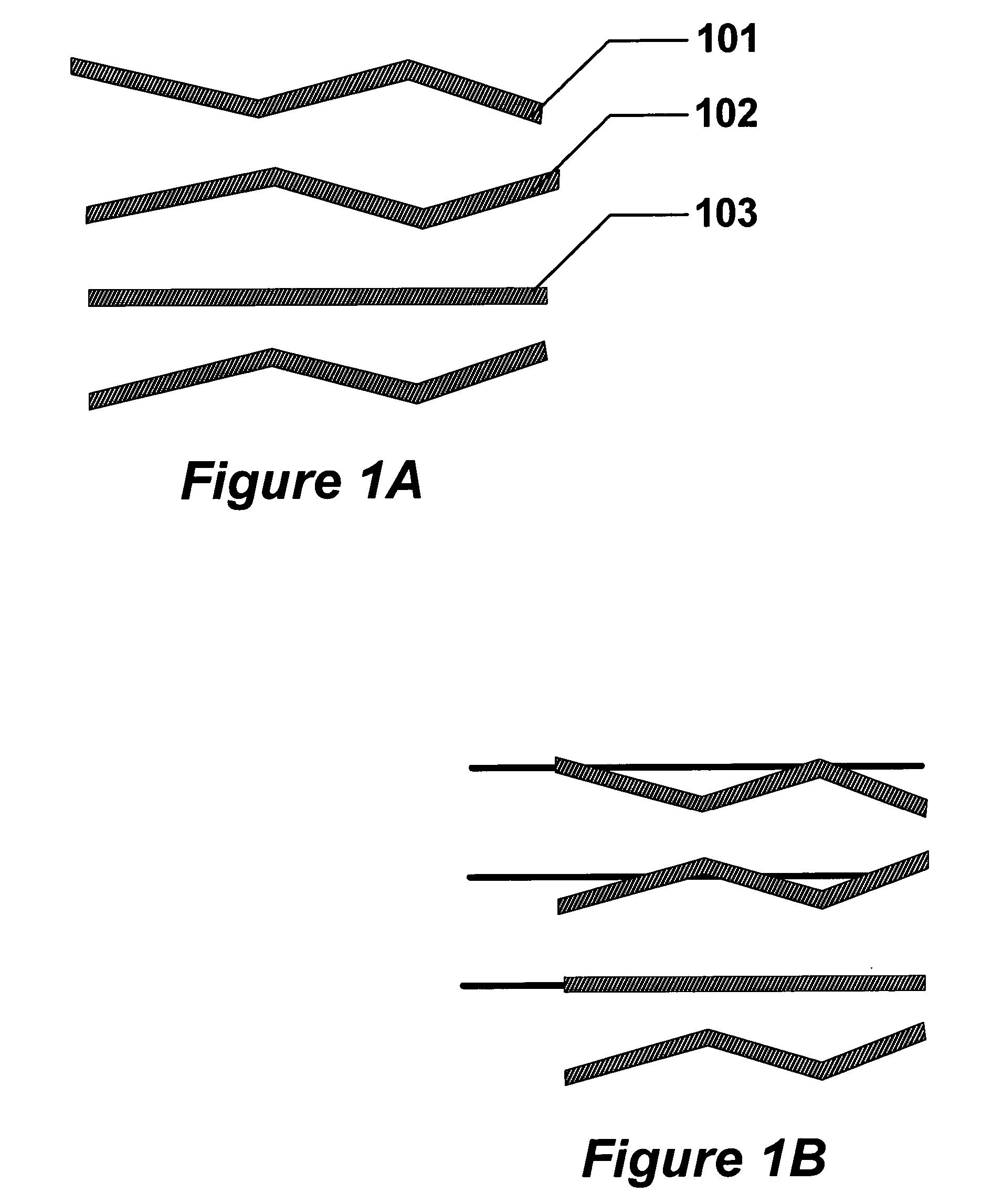

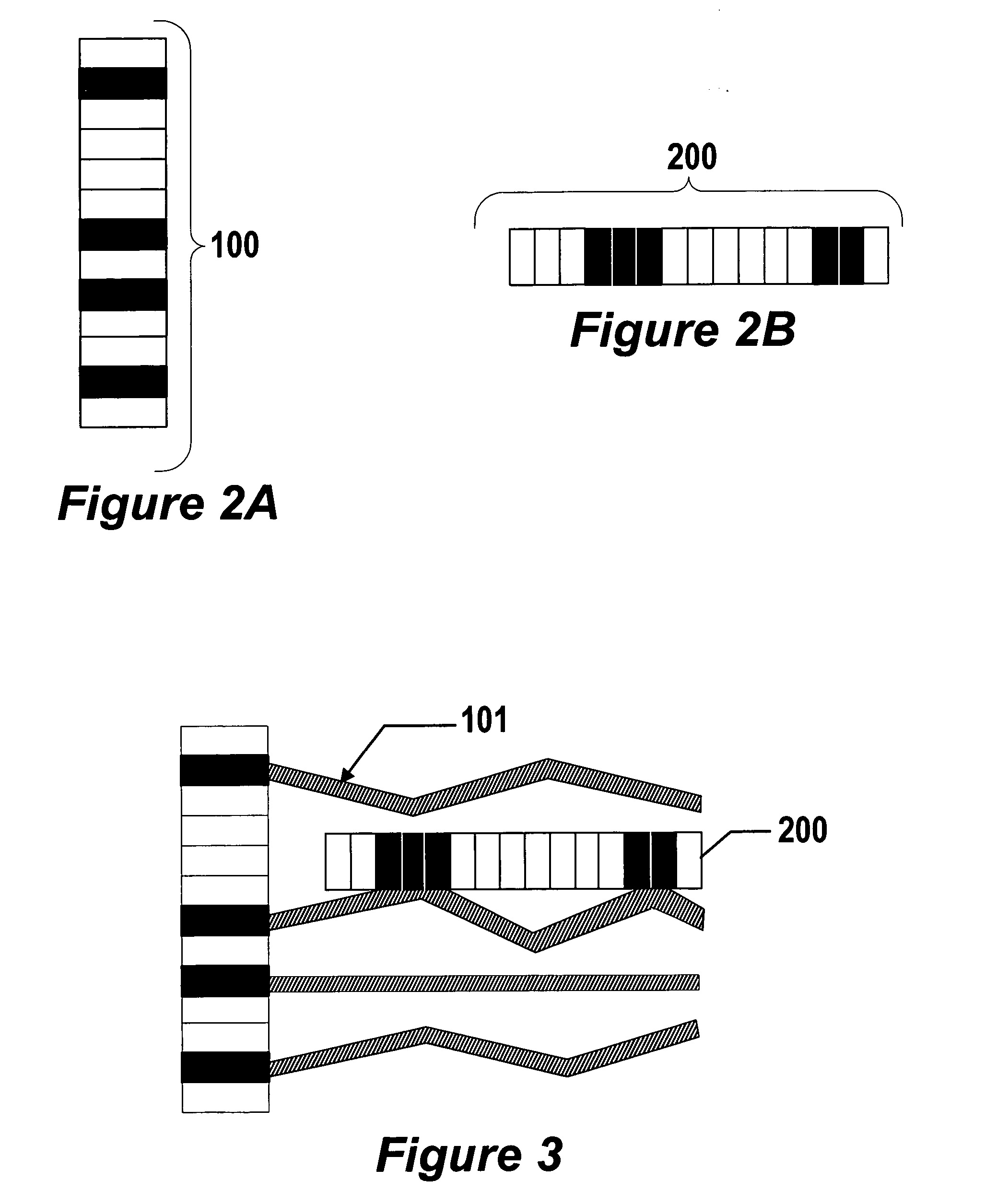

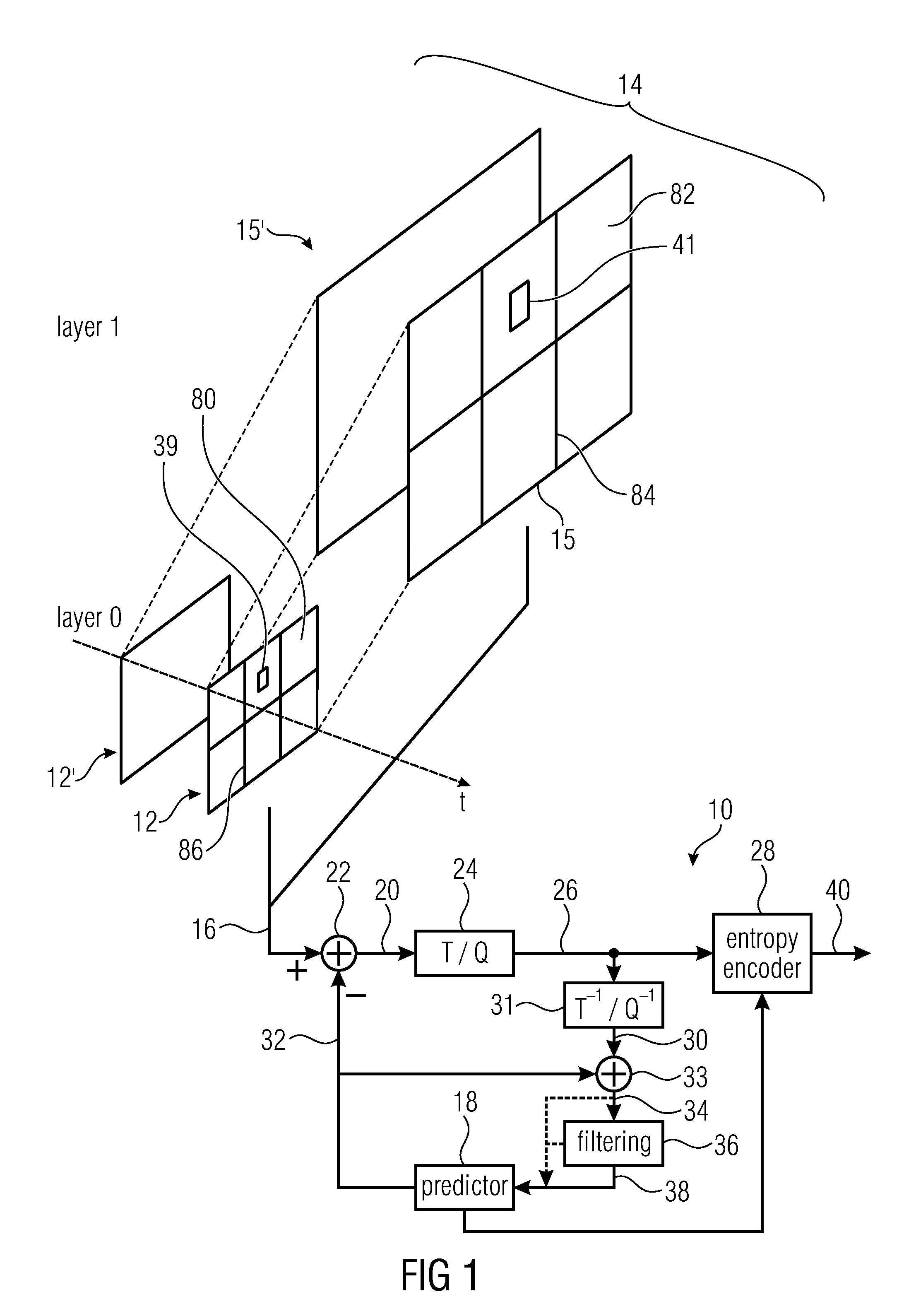

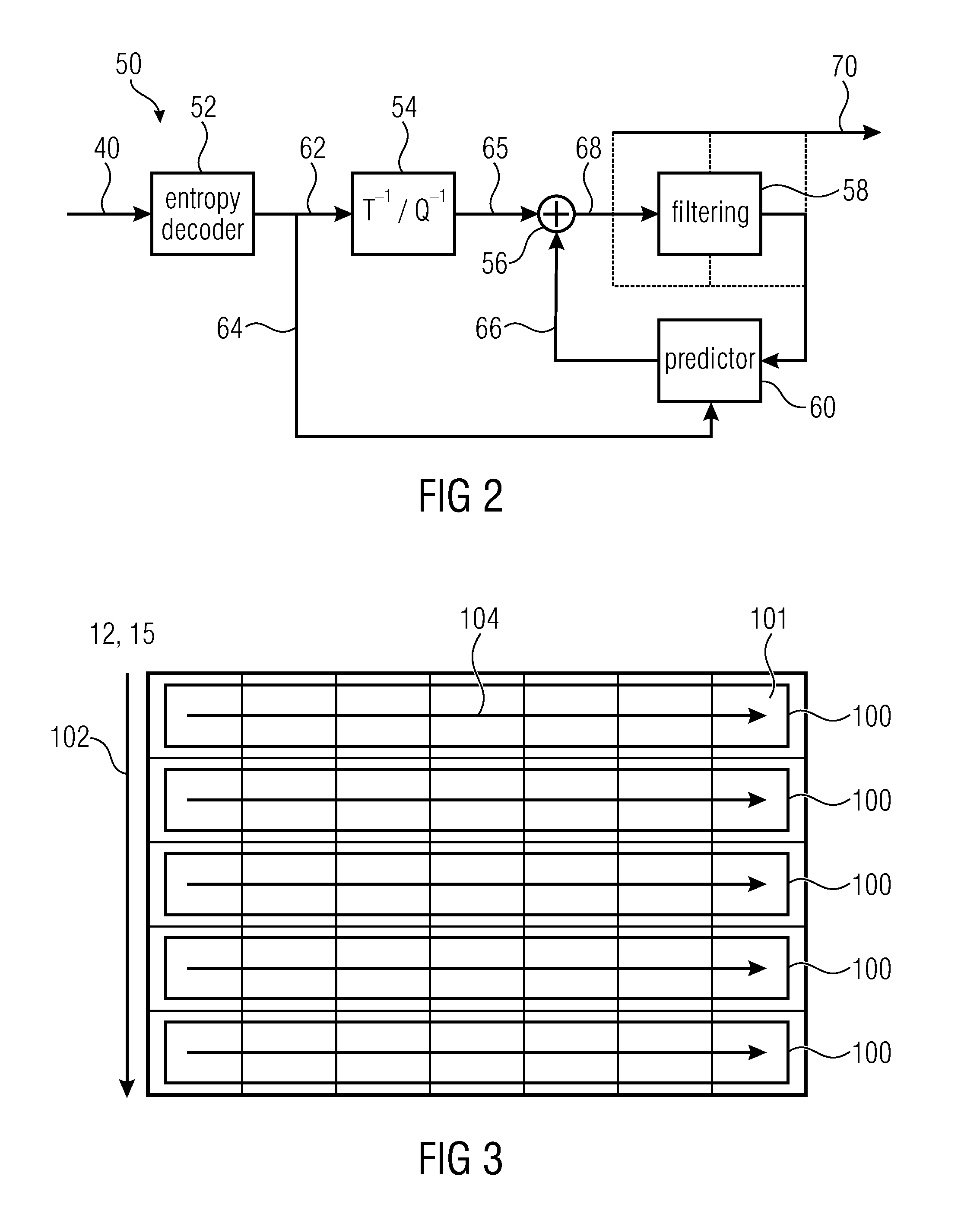

Efficient scalable coding concept

ActiveUS20150304667A1Alleviate decoder 's burdenReduce the numberColor television with pulse code modulationColor television with bandwidth reductionOverlayData stream

Scalable coding concepts are described. One aspect improves parallel decoding of inter-dependent layers of a multi-layer video data stream by introducing a long-term syntax element structure for guaranteeing that during a predetermined time period the pictures of the dependent layer are subdivided so that borders of the spatial segments of the pictures of the second layer and the spatial segments of the first layer overlay. Another aspect concerns upsampling from base layer to enhancement layer. Another aspect introduces a long-term syntax element structure allowing the decoder to determine the inter-layer offset for a predetermined time period. Another aspect introduces a type indicator field changing a way a layer indicator field within the NAL unit headers is to be interpreted. Another aspect allows different codecs / standards to be used for the different layers. Another aspect concerns a syntax element structure which indicates the inter-layer offset in units of the base layer blocks.

Owner:GE VIDEO COMPRESSION LLC

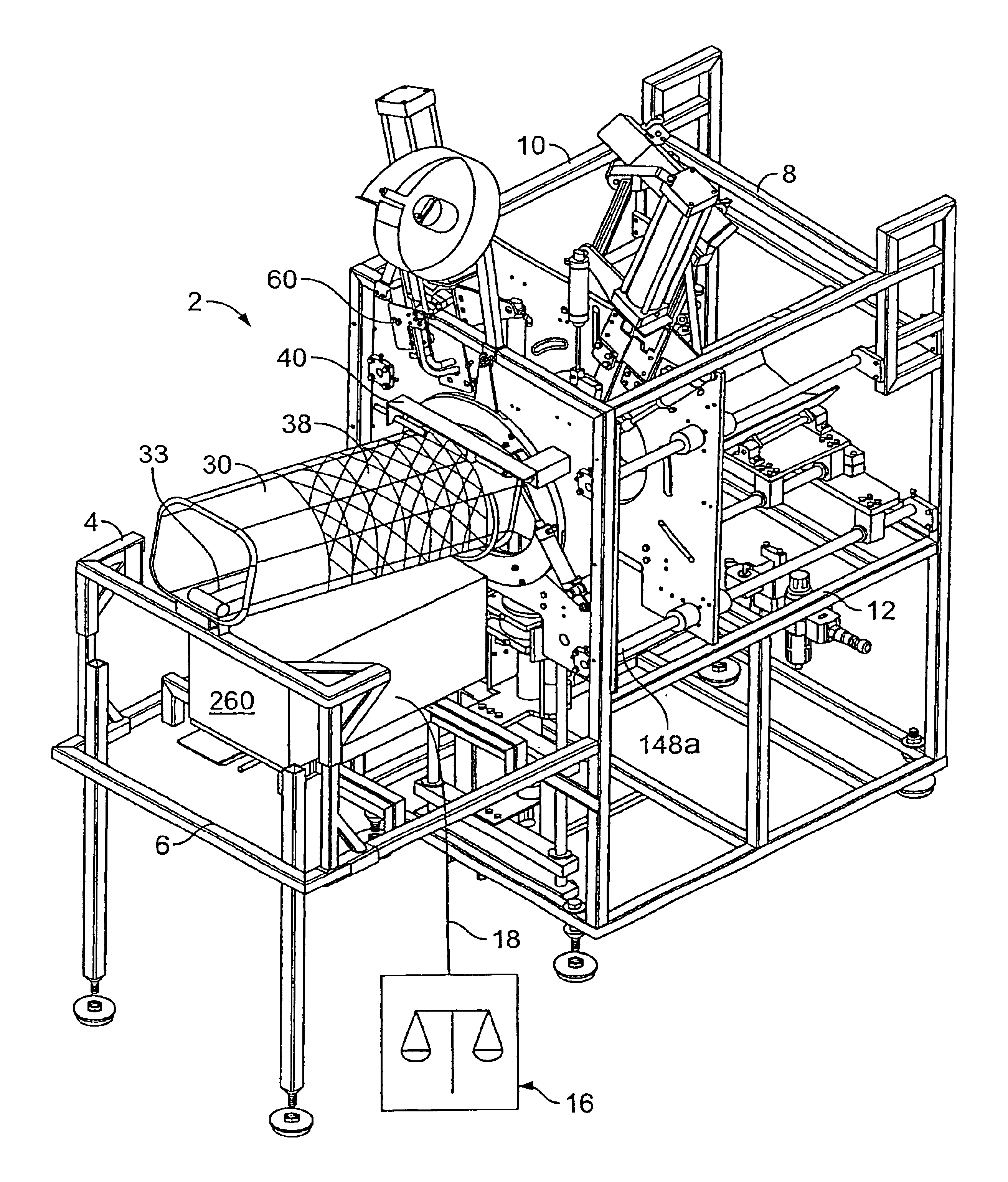

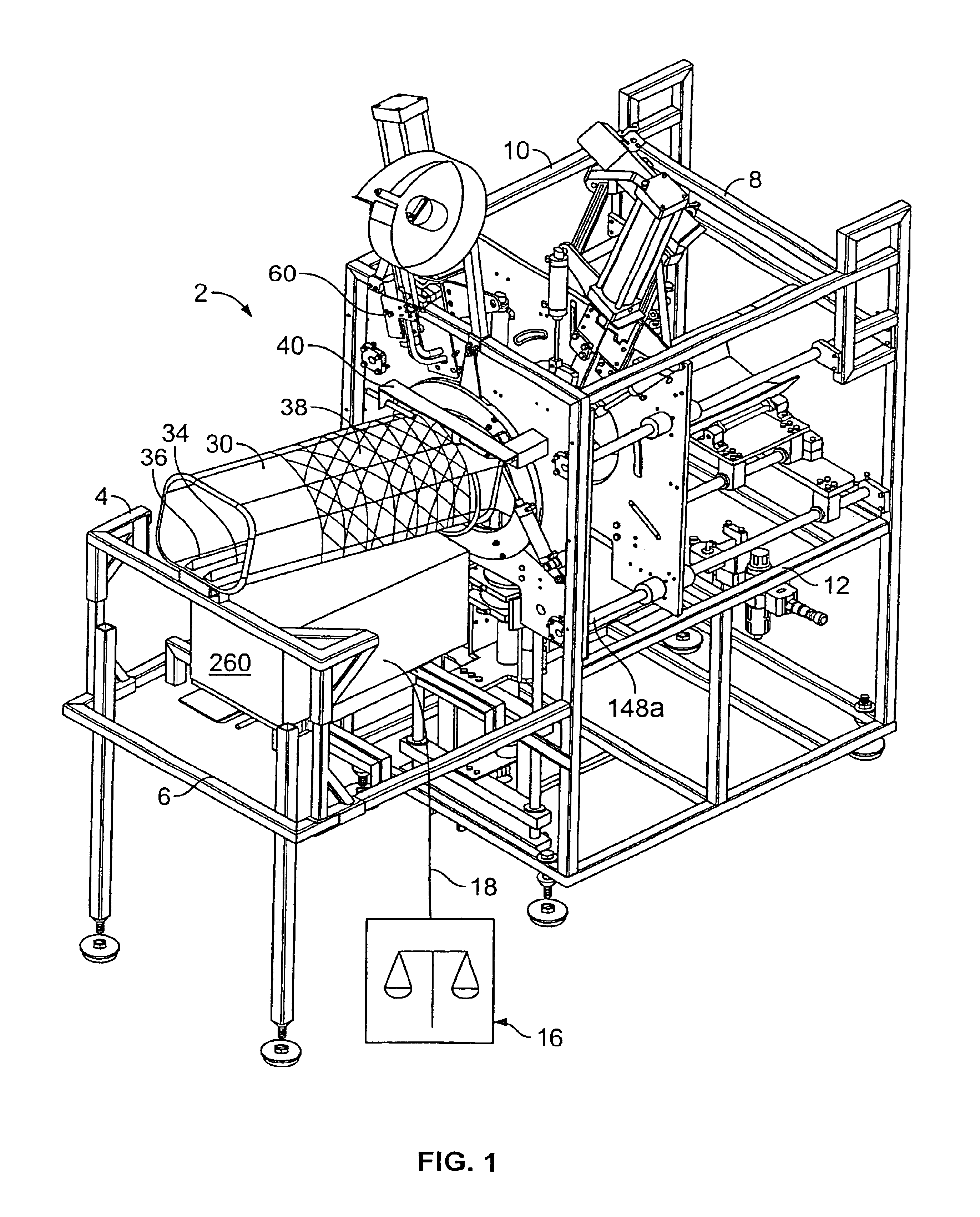

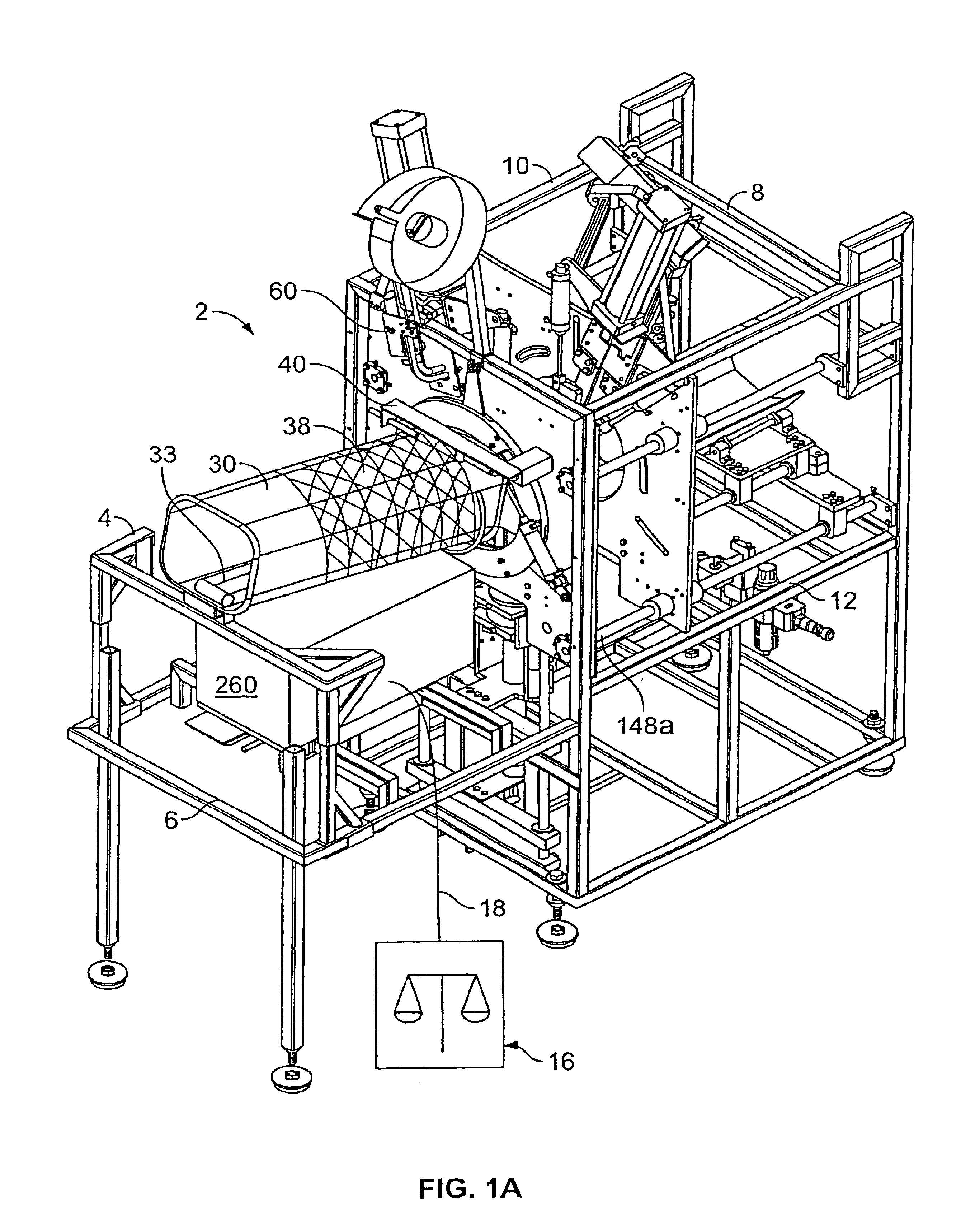

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

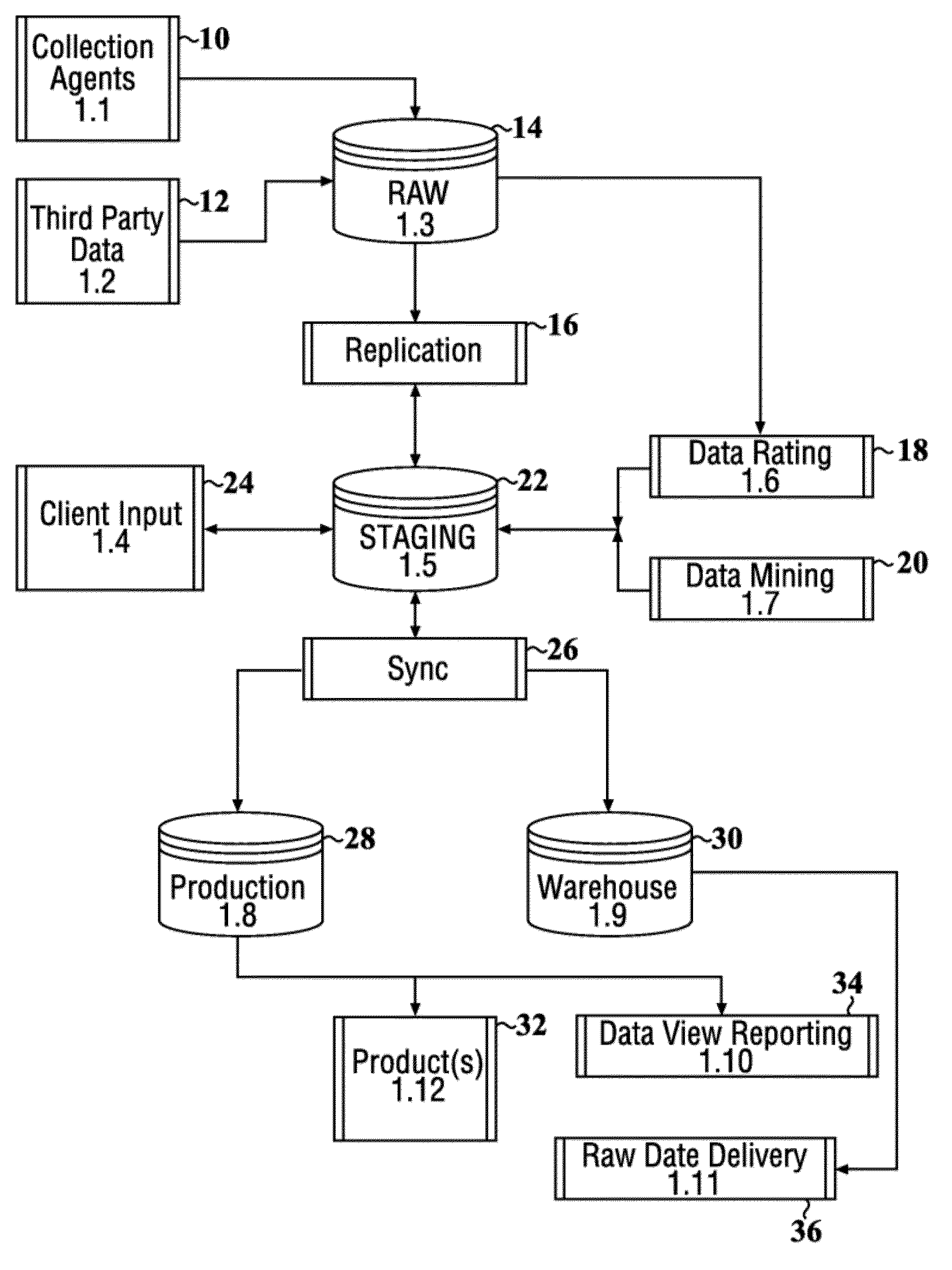

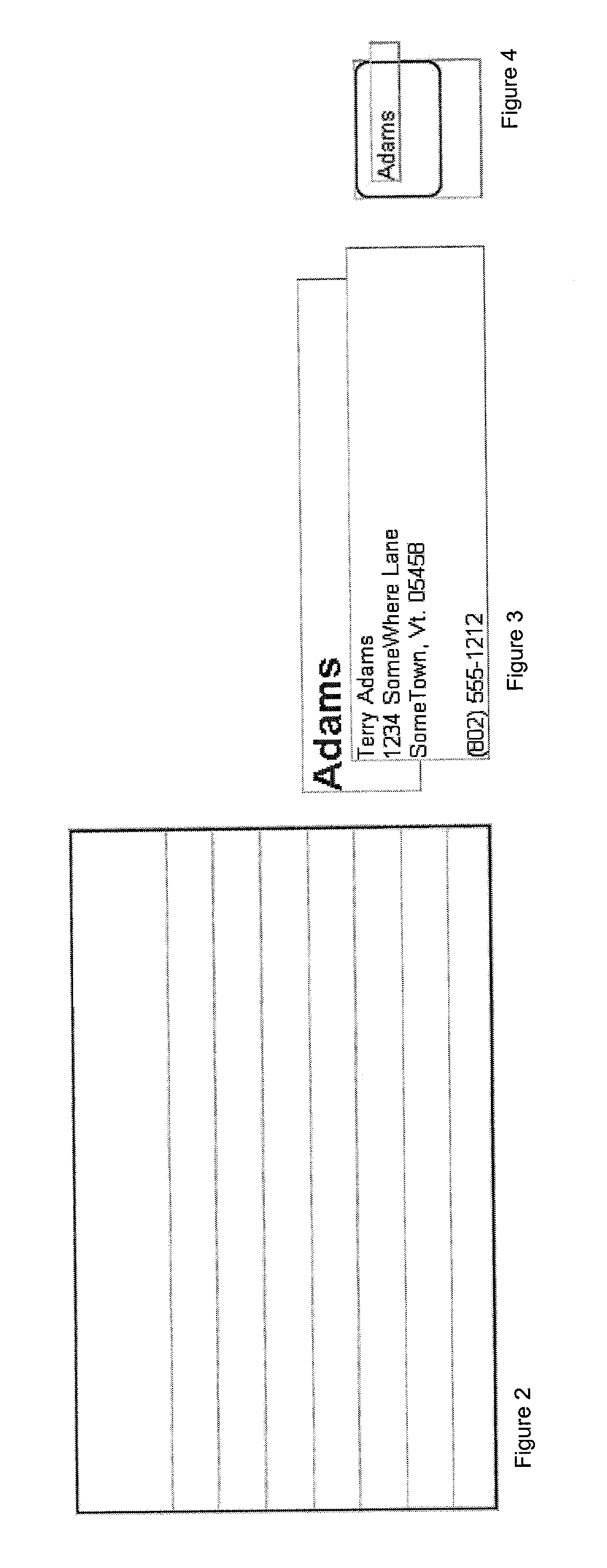

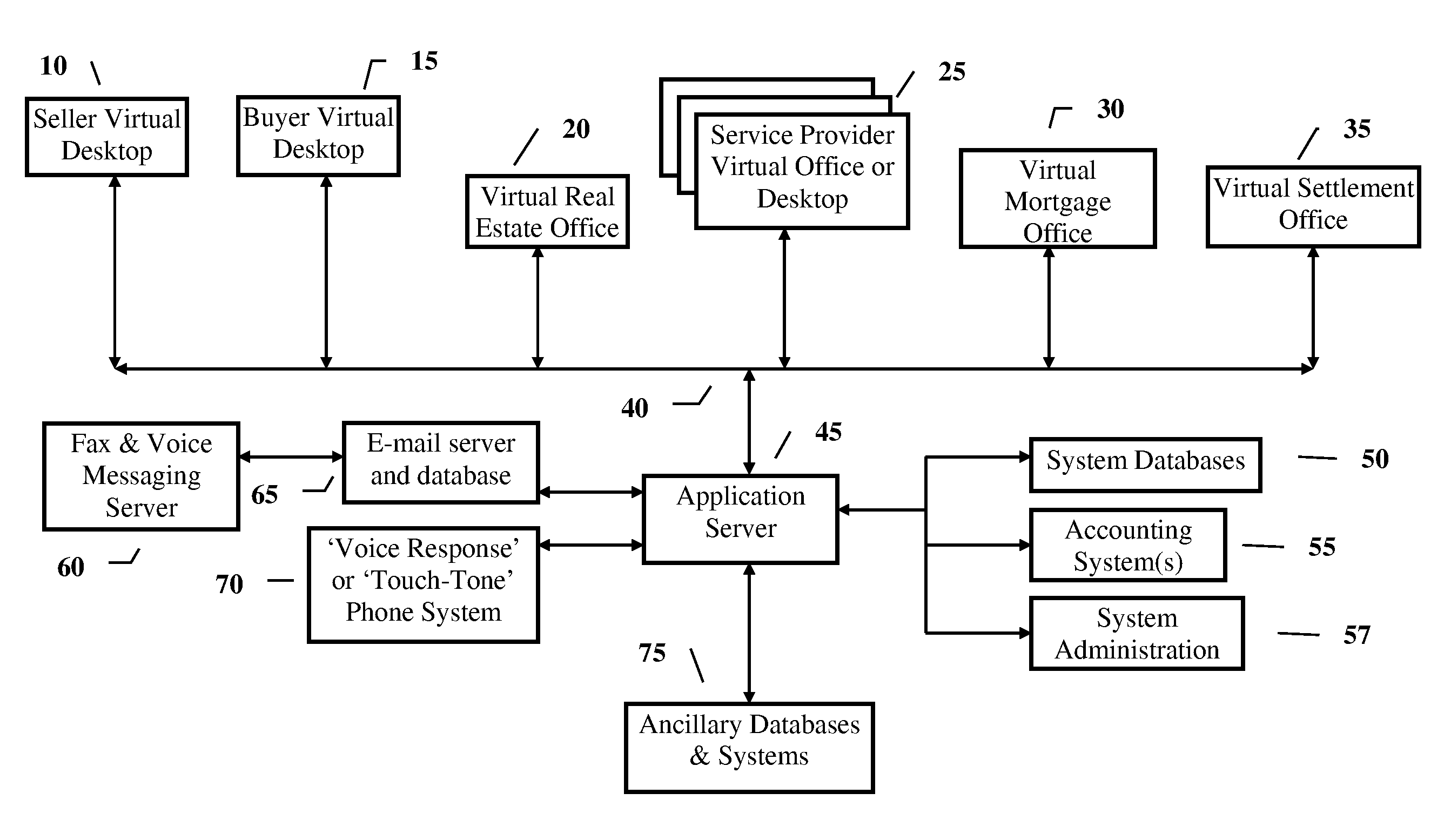

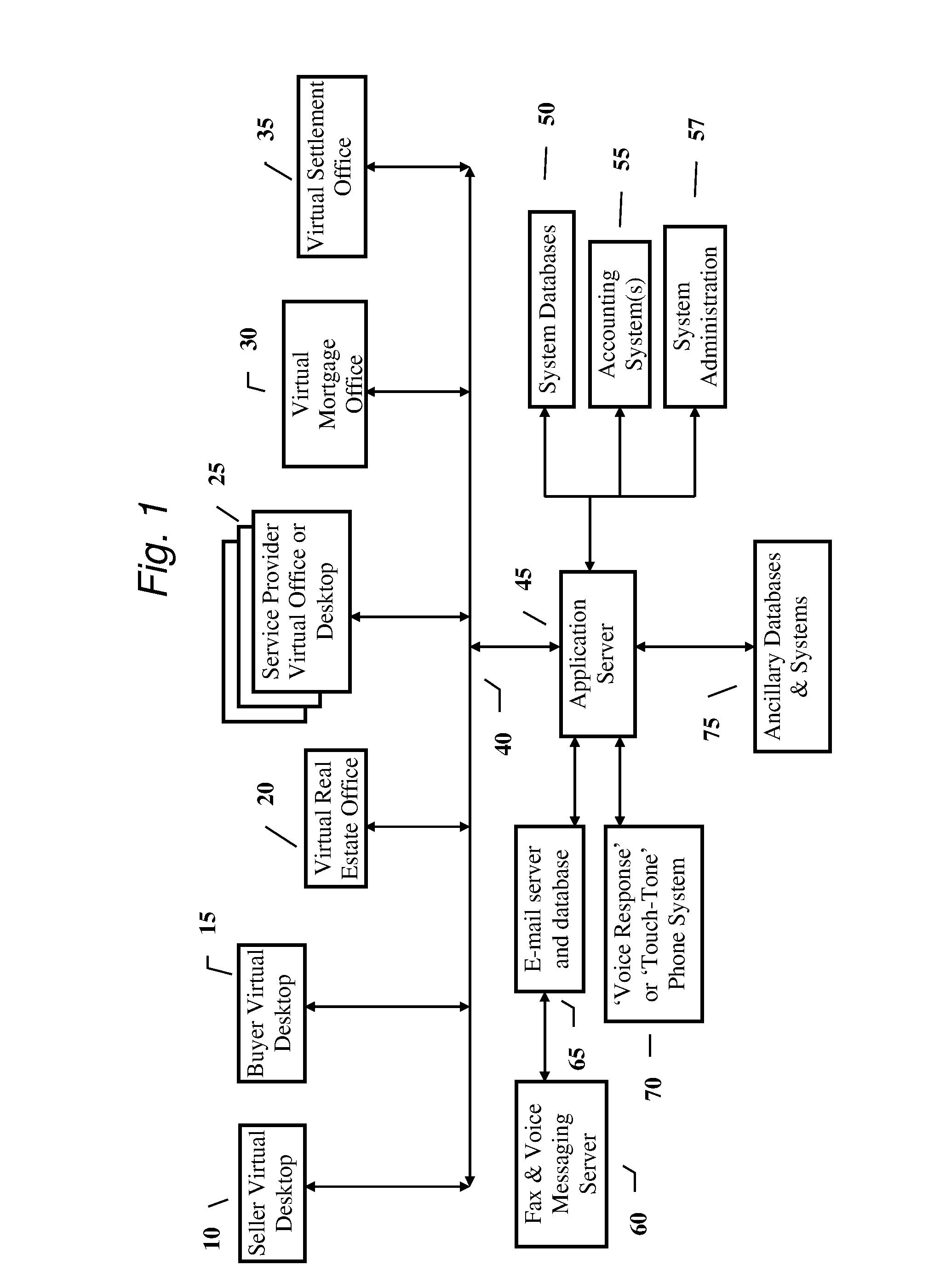

Computerized process to, for example, automate the home sale, mortgage loan financing and settlement process, and the home mortgage loan refinancing and settlement processes

ActiveUS7548884B1Saving expenseShorten the timeFinanceCommerceInformation deliveryInformation transfer

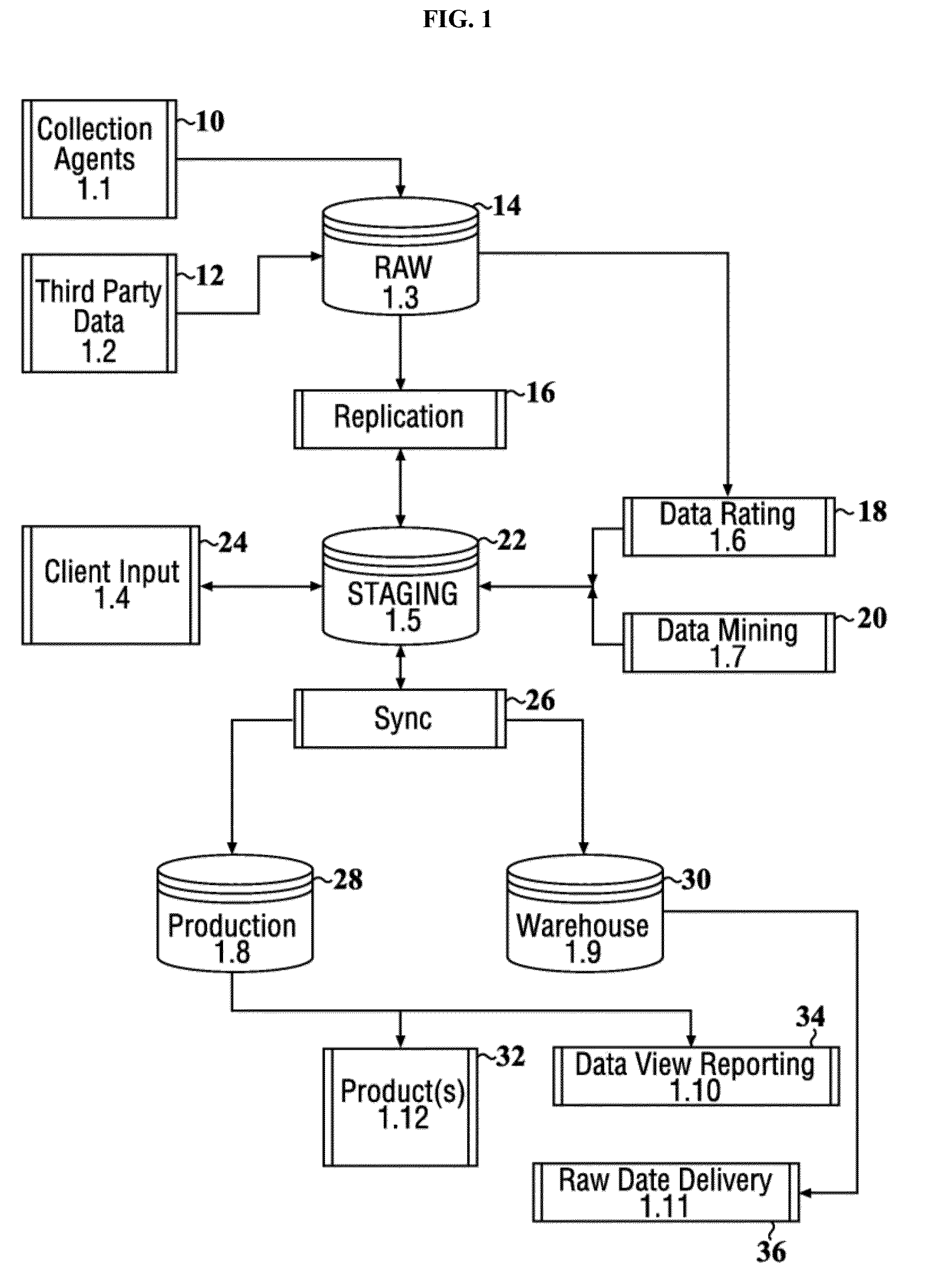

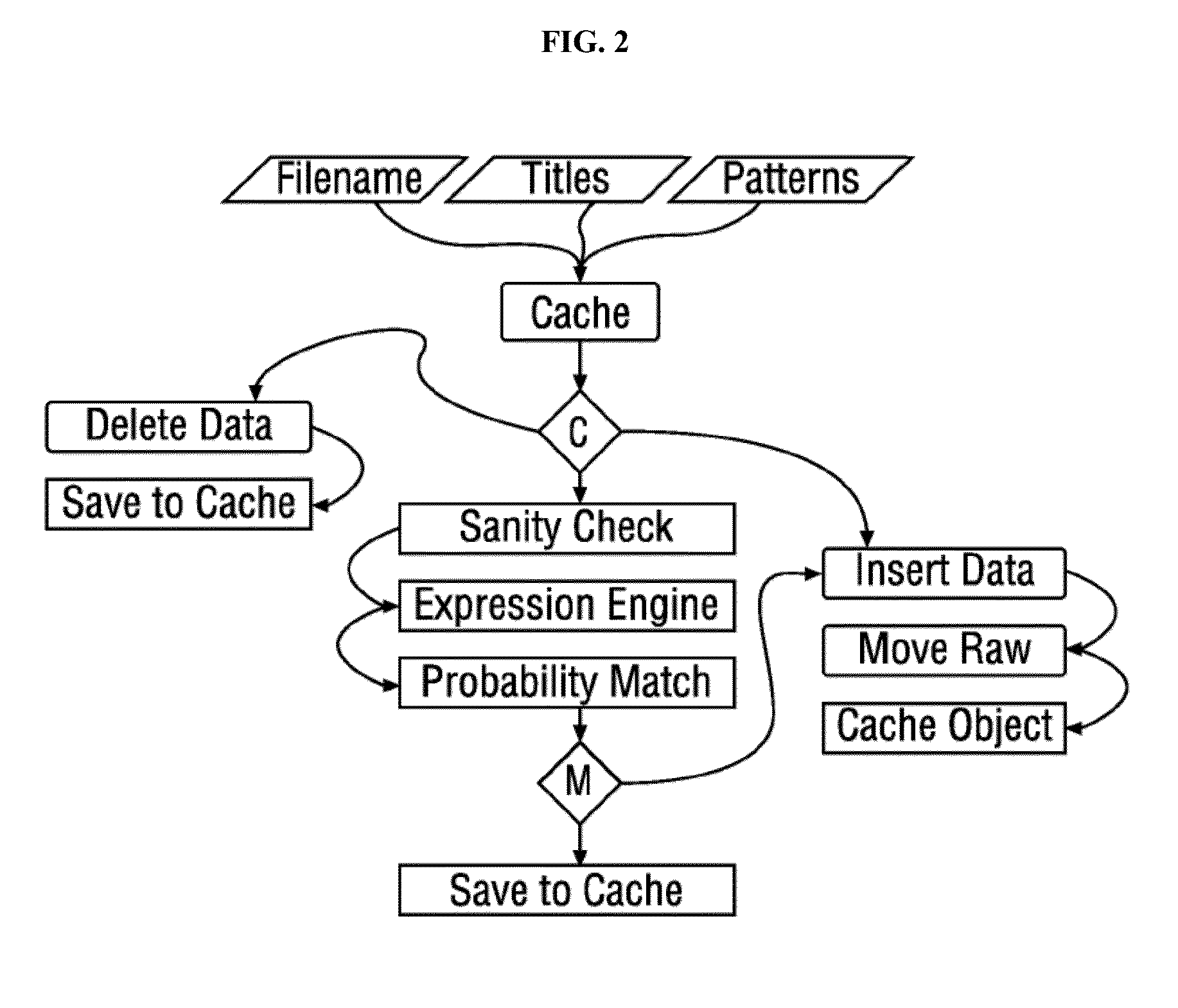

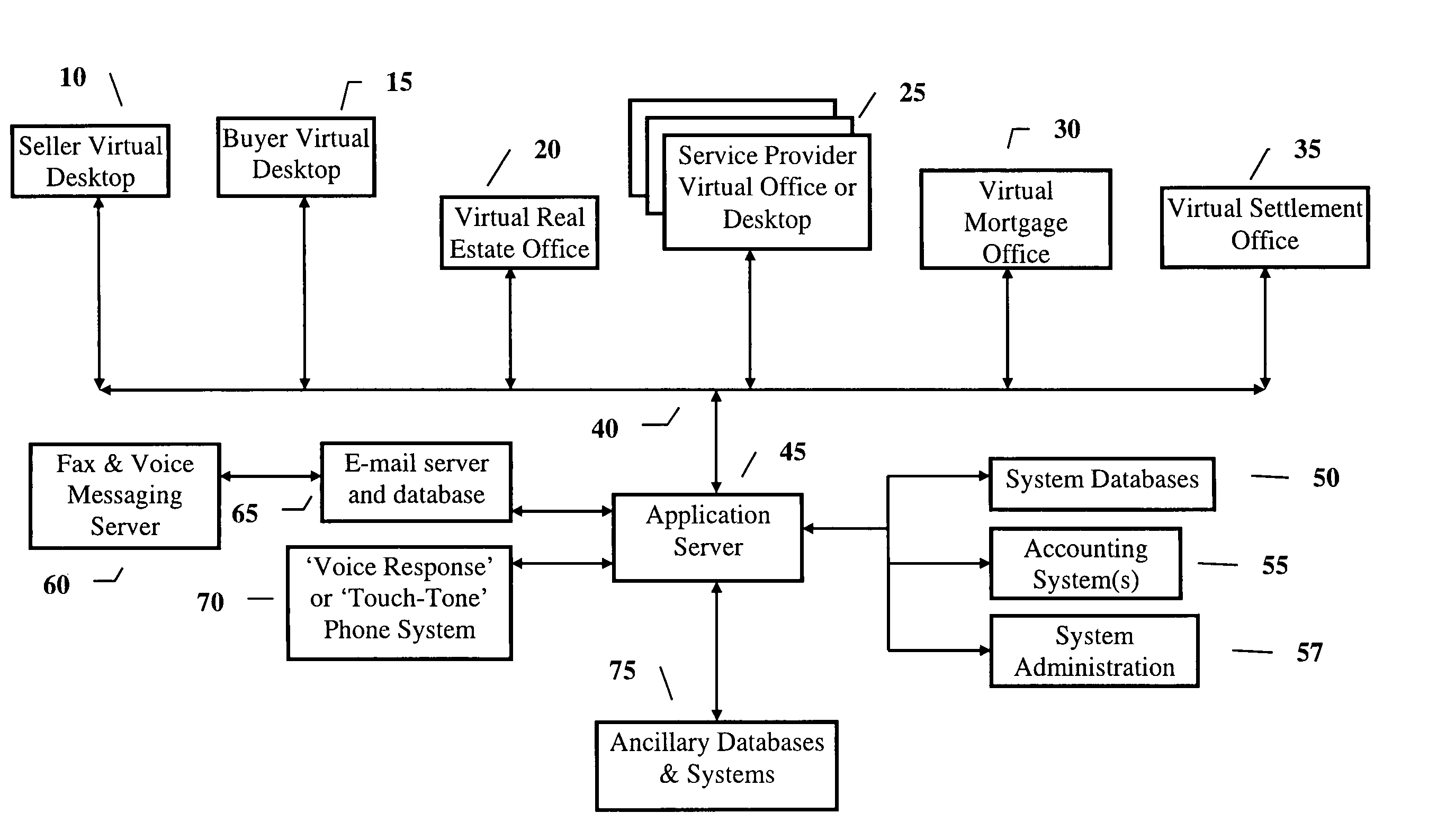

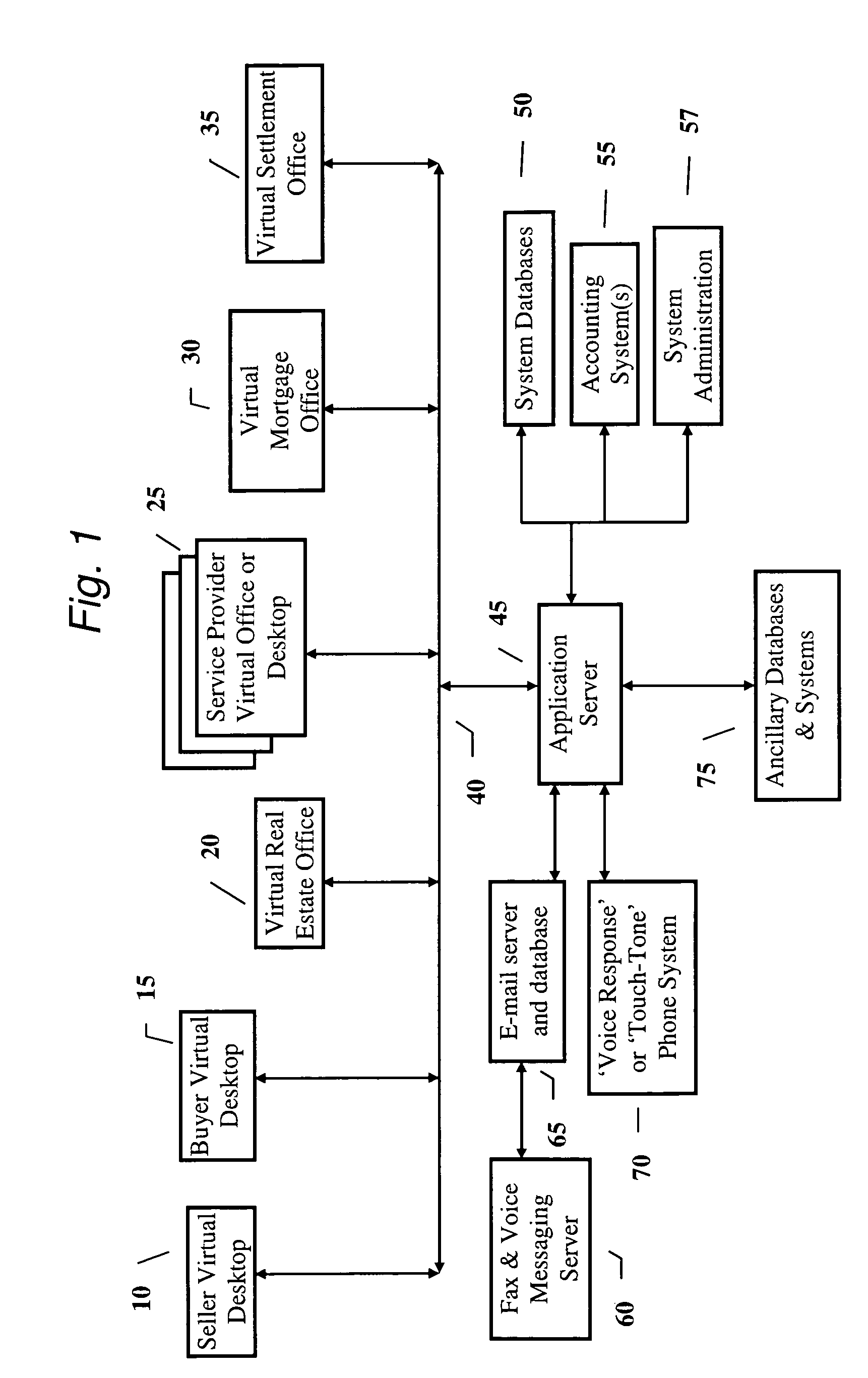

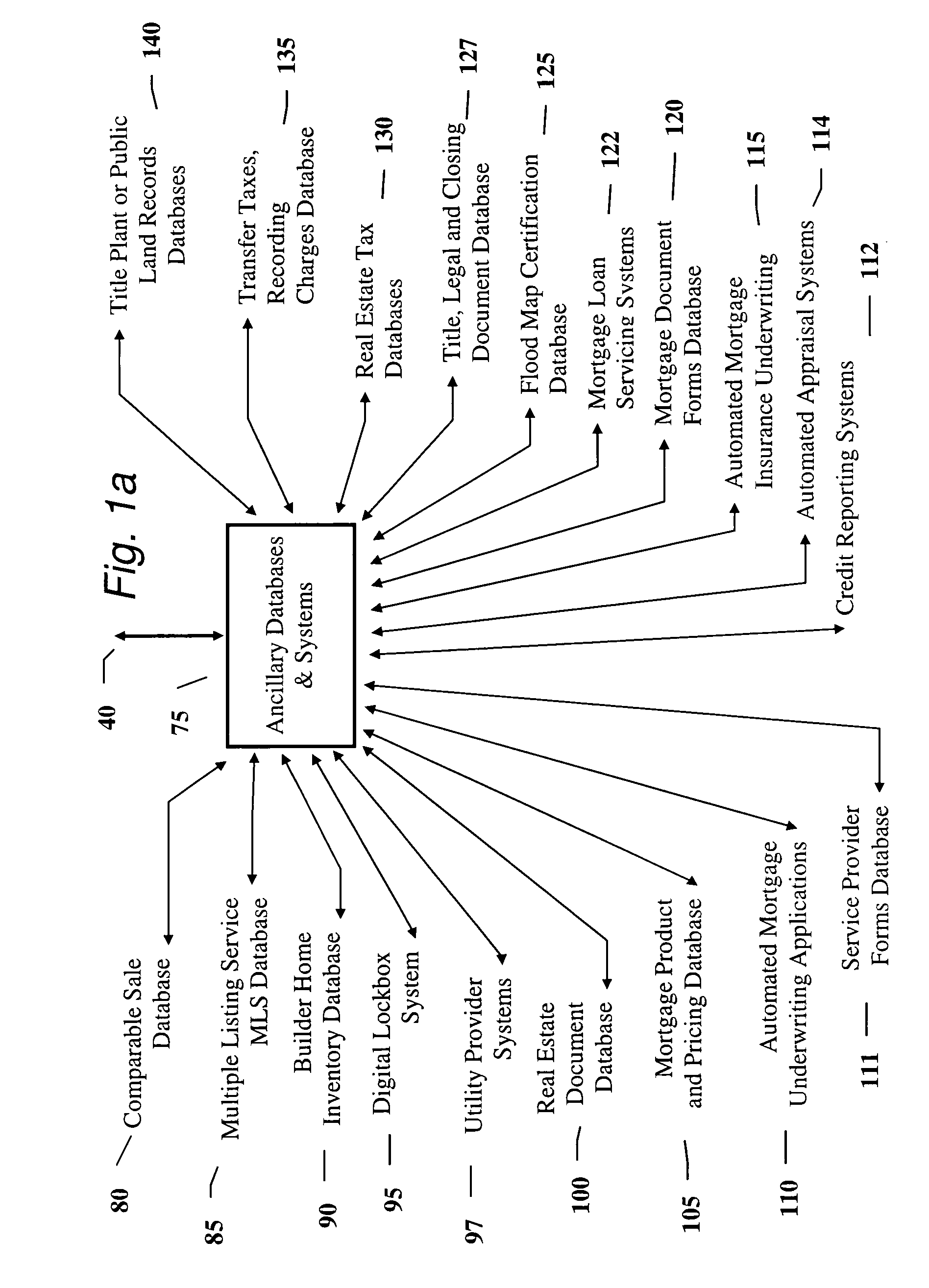

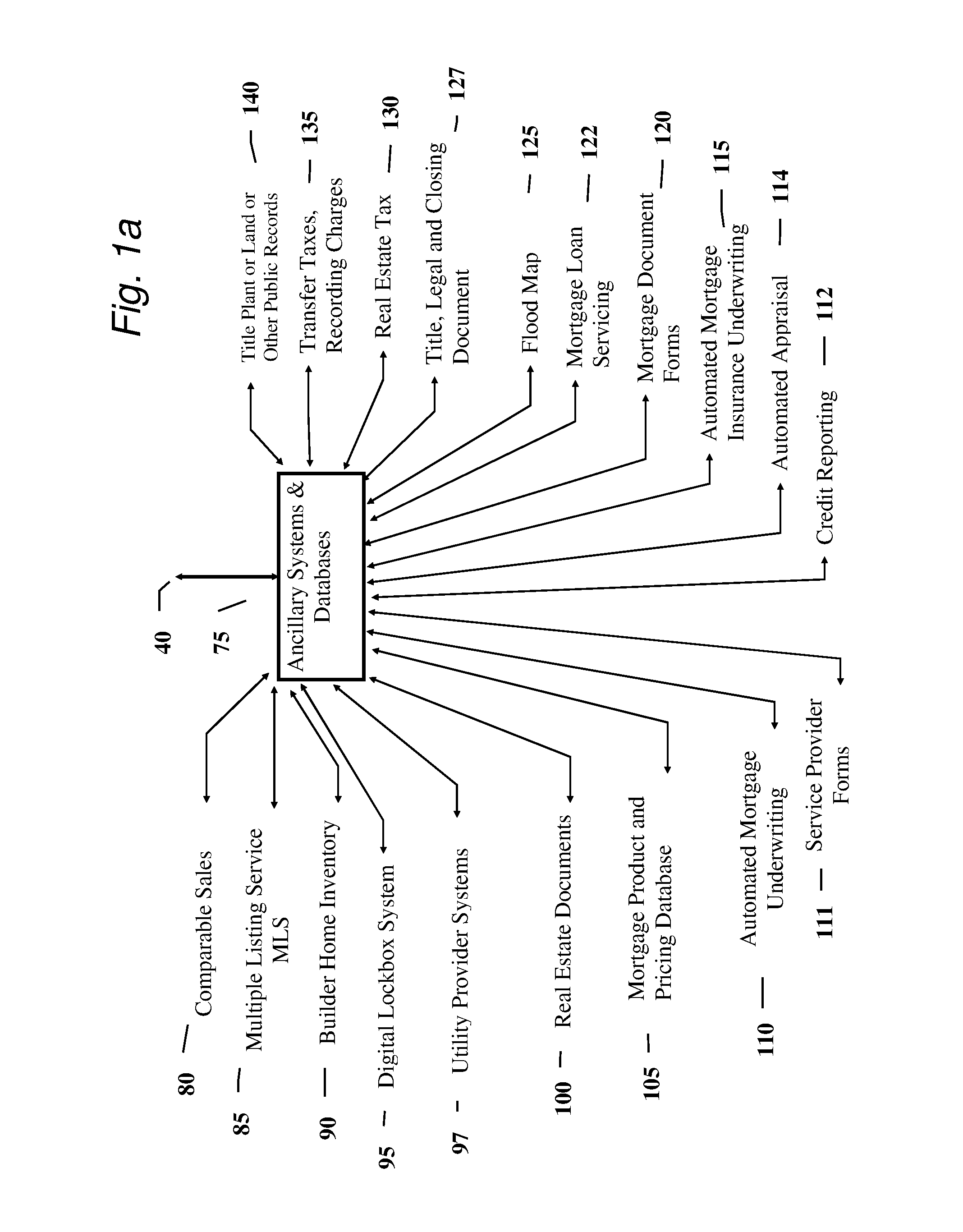

In some embodiments, a comprehensive computer system and method (See FIGS. 1, 1a, 2) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the home sale (See FIG. 3a), mortgage origination (See FIG. 3b), and settlement process (See FIG. 3c), and the home mortgage refinancing origination and settlement process (See FIGS. 1b, 1c, 2a) (or performing other business processes), over a distributed computing network are disclosed.

Owner:THOMAS NEIL

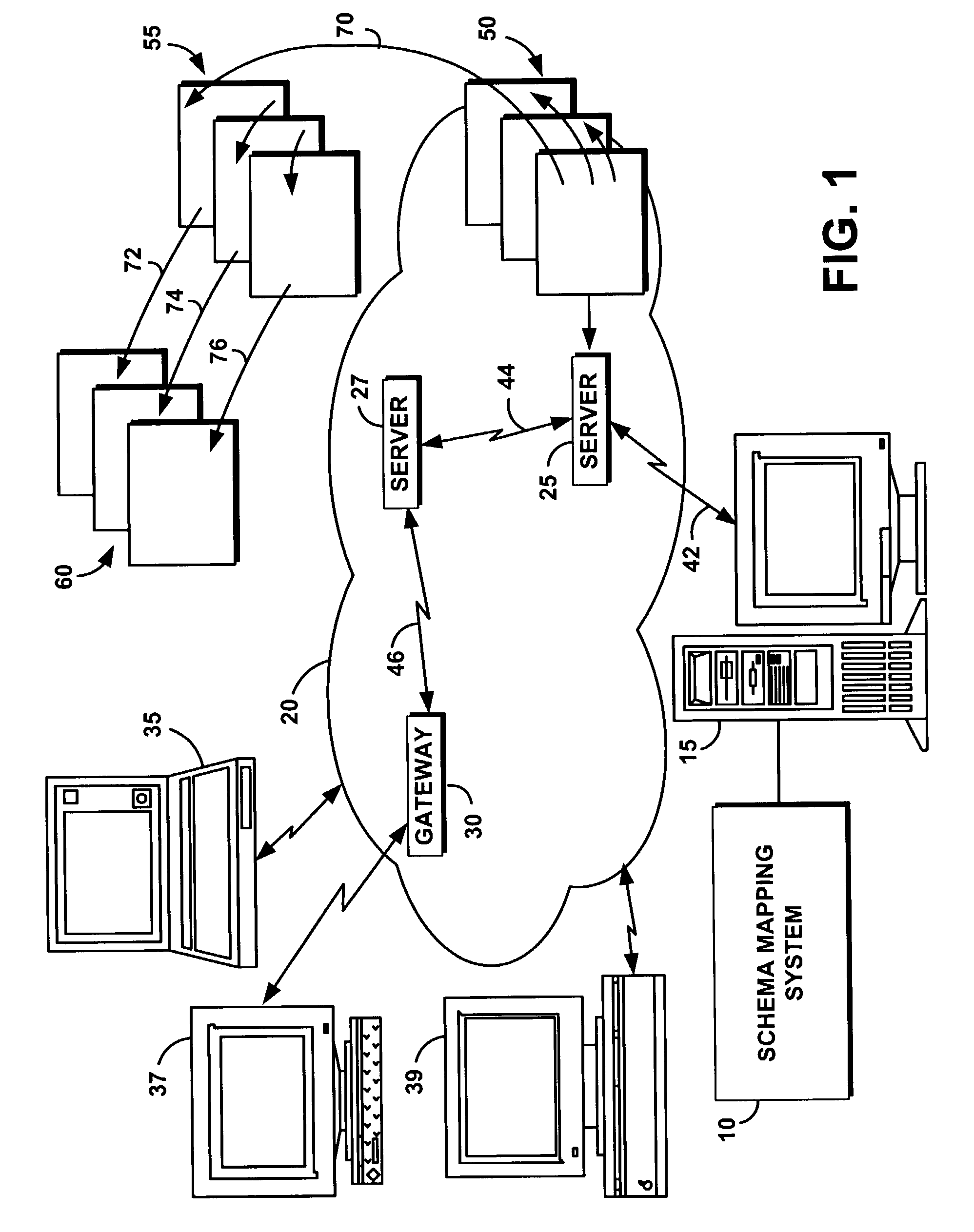

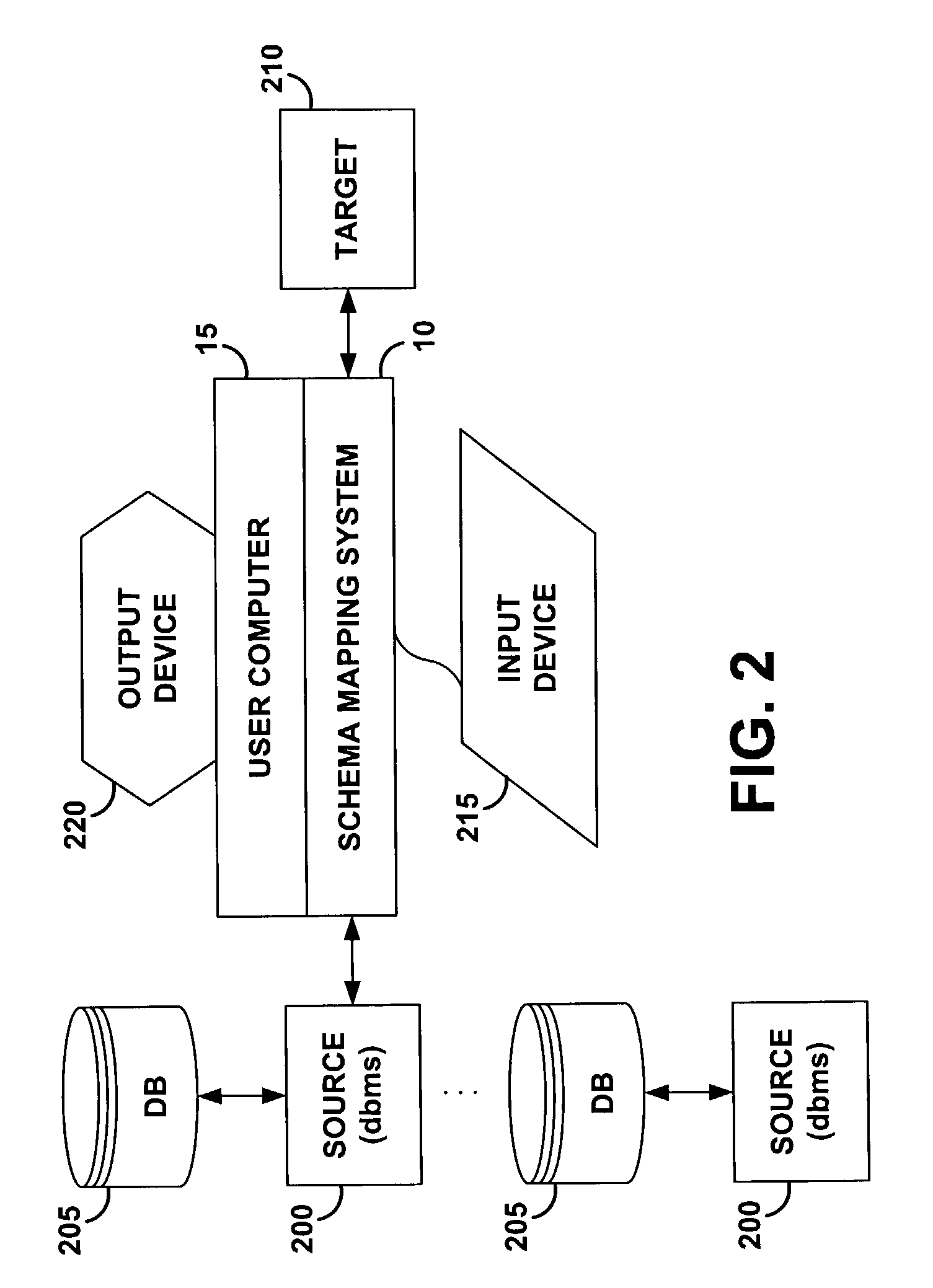

Method for schema mapping and data transformation

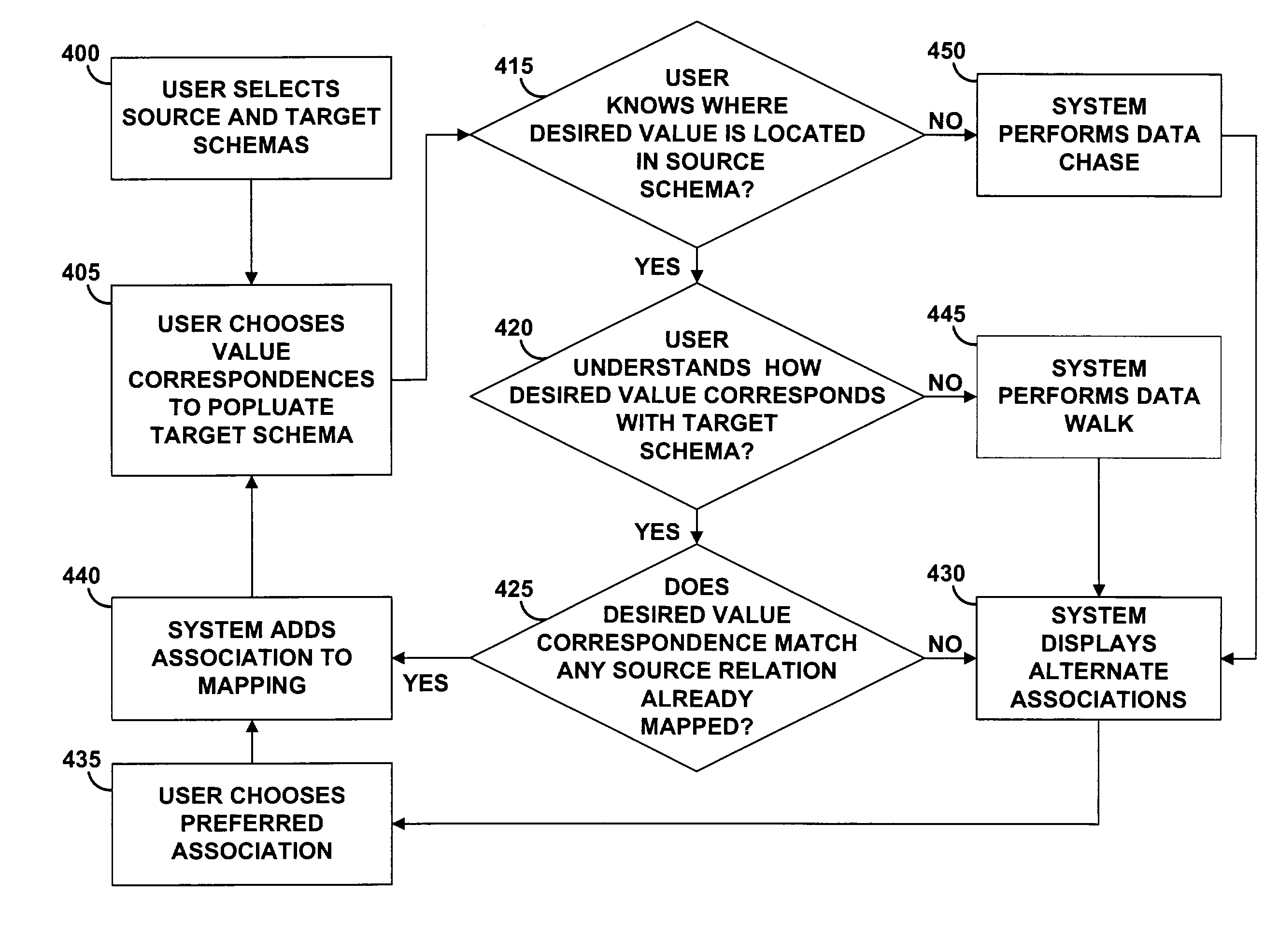

InactiveUS7149746B2A large amountLighten the taskData processing applicationsDigital data information retrievalSchema mappingData transformation

A computer program product is provided that uses data examples as a basis for understanding and refining declarative schema mappings. The system of the present invention identifies a set of intuitive operators for manipulating examples including establishing value correspondences, data linking, data trimming, data walking, and data chasing. These operators allow a user to follow and refine an example by walking through a data source. In addition, these operators can identify a large class of schema mappings and distinguish effectively between alternative schema mappings. With these operators, a user is able to quickly and intuitively build and refine complex data transformation queries that map one data source into another while continuously verifying that the mapping is accurate and appropriate.

Owner:IBM CORP

Computerized process to, for example, automate the home sale, mortgage loan financing and settlement process, and the home mortgage loan refinancing and settlement processes

In some embodiments, a comprehensive computer system and method (See FIGS. 1, 1a, 2) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the home sale (See FIG. 3a), mortgage origination (See FIG. 3b), and settlement process (See FIG. 3c), and the home mortgage refinancing origination and settlement process (See FIGS. 1b, 1c, 2a) (or performing other business processes), over a distributed computing network are disclosed.

Owner:THOMAS NEIL

Haptic feedback for touchpads and other touch controls

InactiveUS20060119589A1Enhanced interactionEnhance manipulationInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsTouchpad

A haptic feedback planar touch control used to provide input to a computer. A touch input device includes a planar touch surface that inputs a position signal to a processor of the computer based on a location of user contact on the touch surface. The computer can position a cursor in a displayed graphical environment based at least in part on the position signal, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user contacting the touch surface. The touch input device can be a touchpad separate from the computer's display screen, or can be a touch screen. Output haptic sensations on the touch input device can include pulses, vibrations, and spatial textures. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

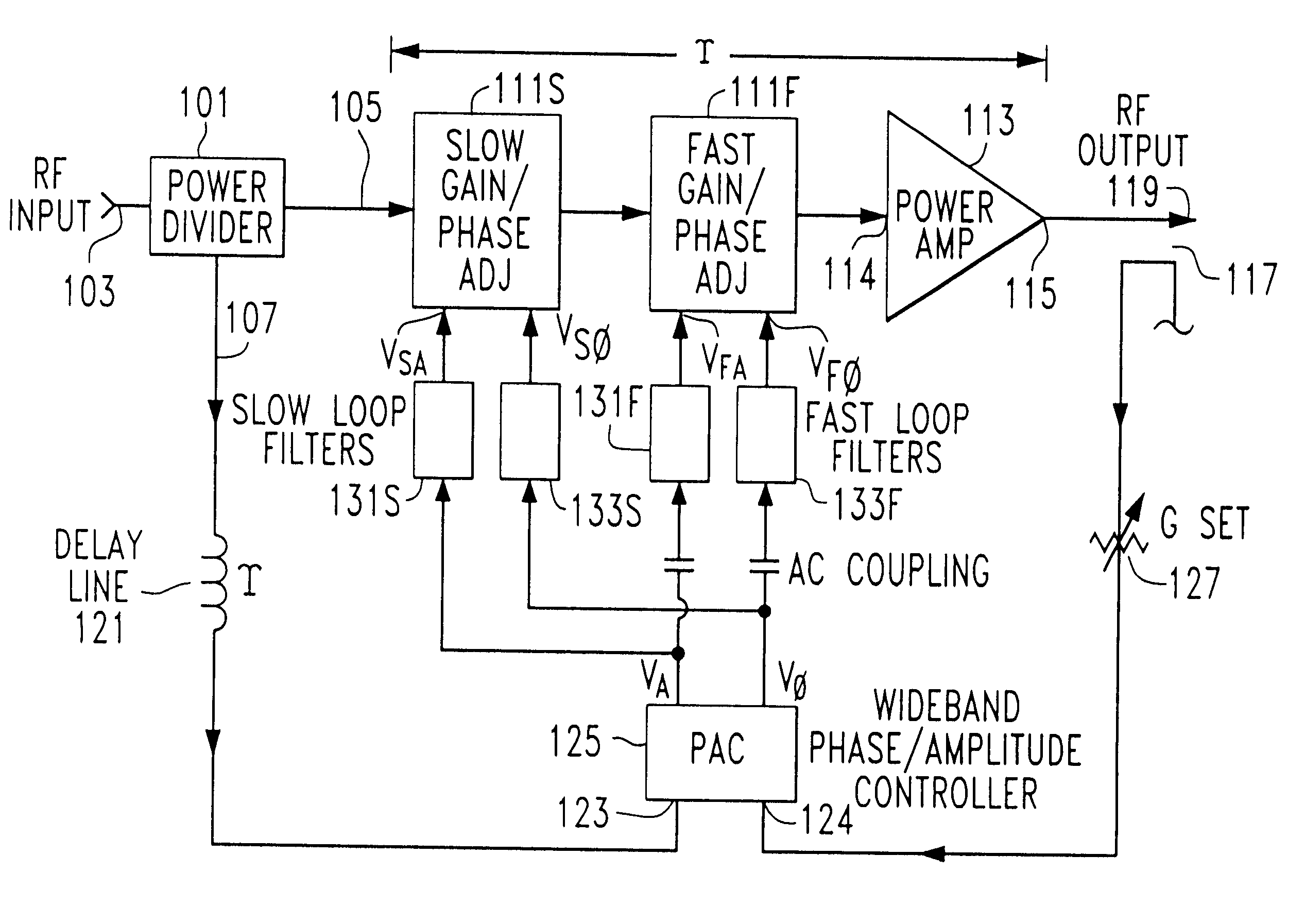

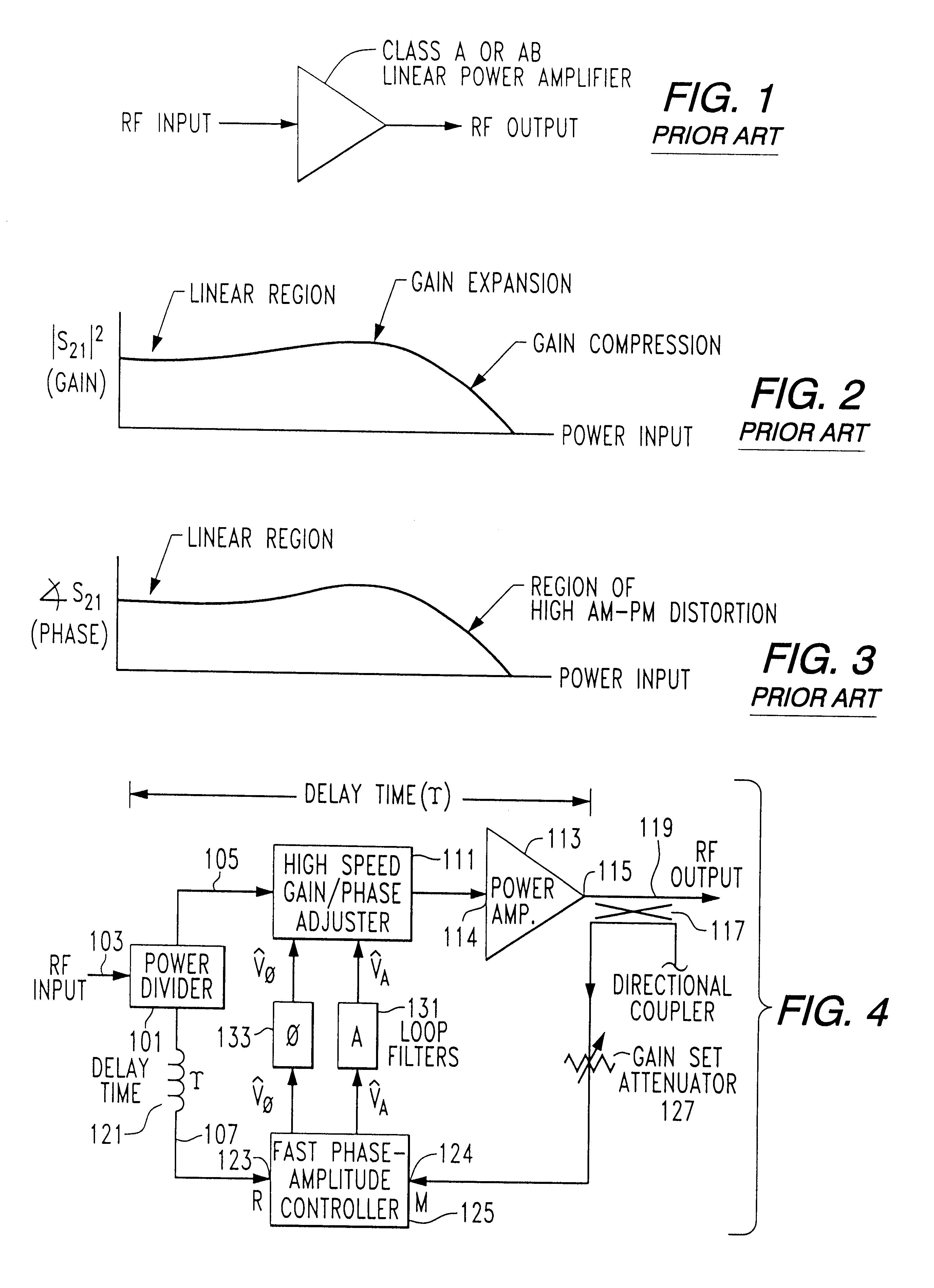

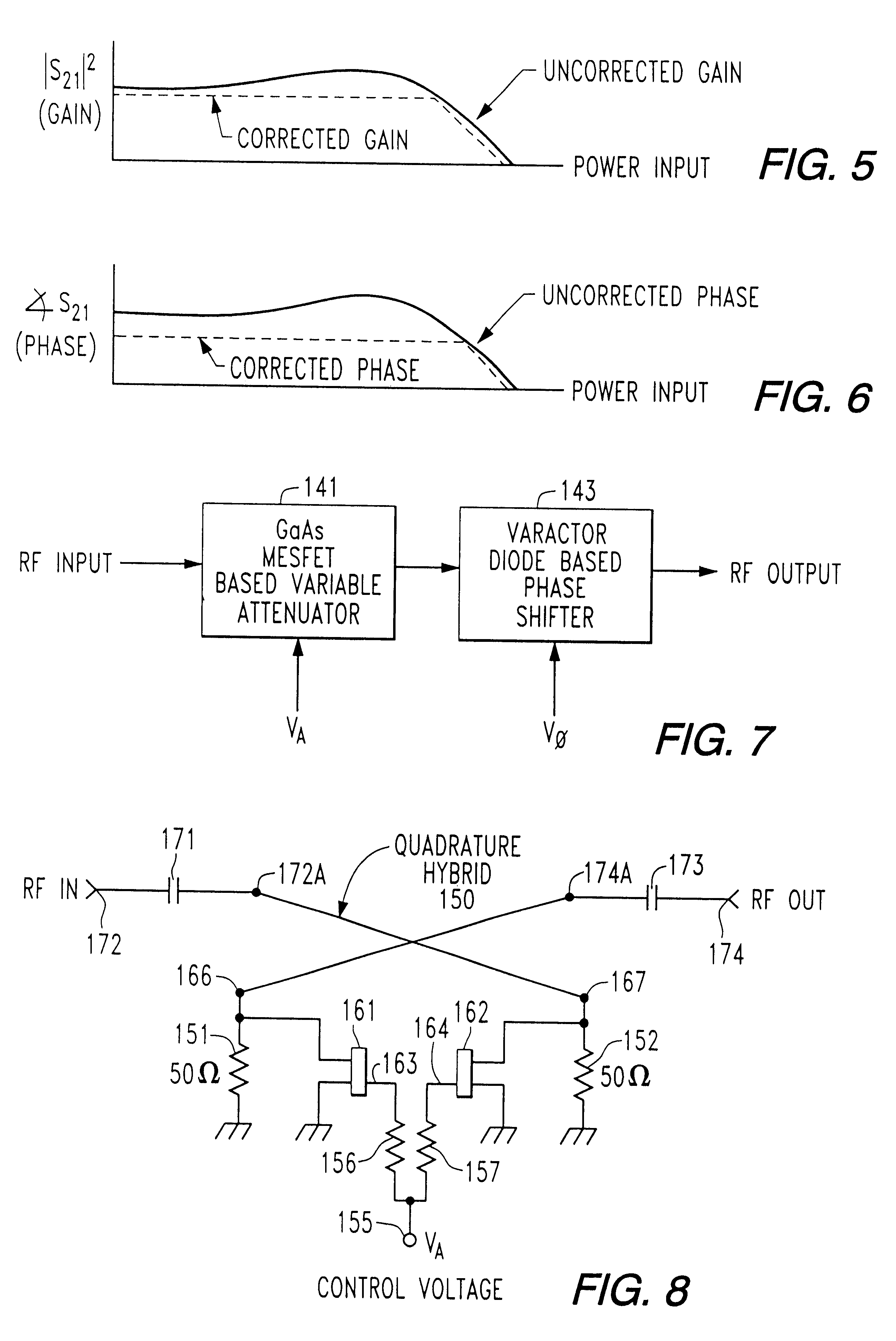

Polar envelope correction mechanism for enhancing linearity of RF/microwave power amplifier

InactiveUSRE37407E1Modest bandwidthImprove linearityAmplifier modifications to reduce non-linear distortionElectric devicesPhase distortionAudio power amplifier

Linearity of an RF / microwave power amplifier is enhanced by an amplitude and phase distortion correction mechanism based upon signal envelope feedback, that operates directly on the RF signal passing through the power amplifier. A phase-amplitude controller responds to changes in gain and phase through the RF / microwave power amplifier signal path caused by changes in RF input power, DC power supply voltages, time, temperature and other variables, and controls the operation of a gain and phase adjustment circuit, so as to maintain constant gain and transmission phase through the RF / microwave power amplifier.

Owner:INTEL CORP

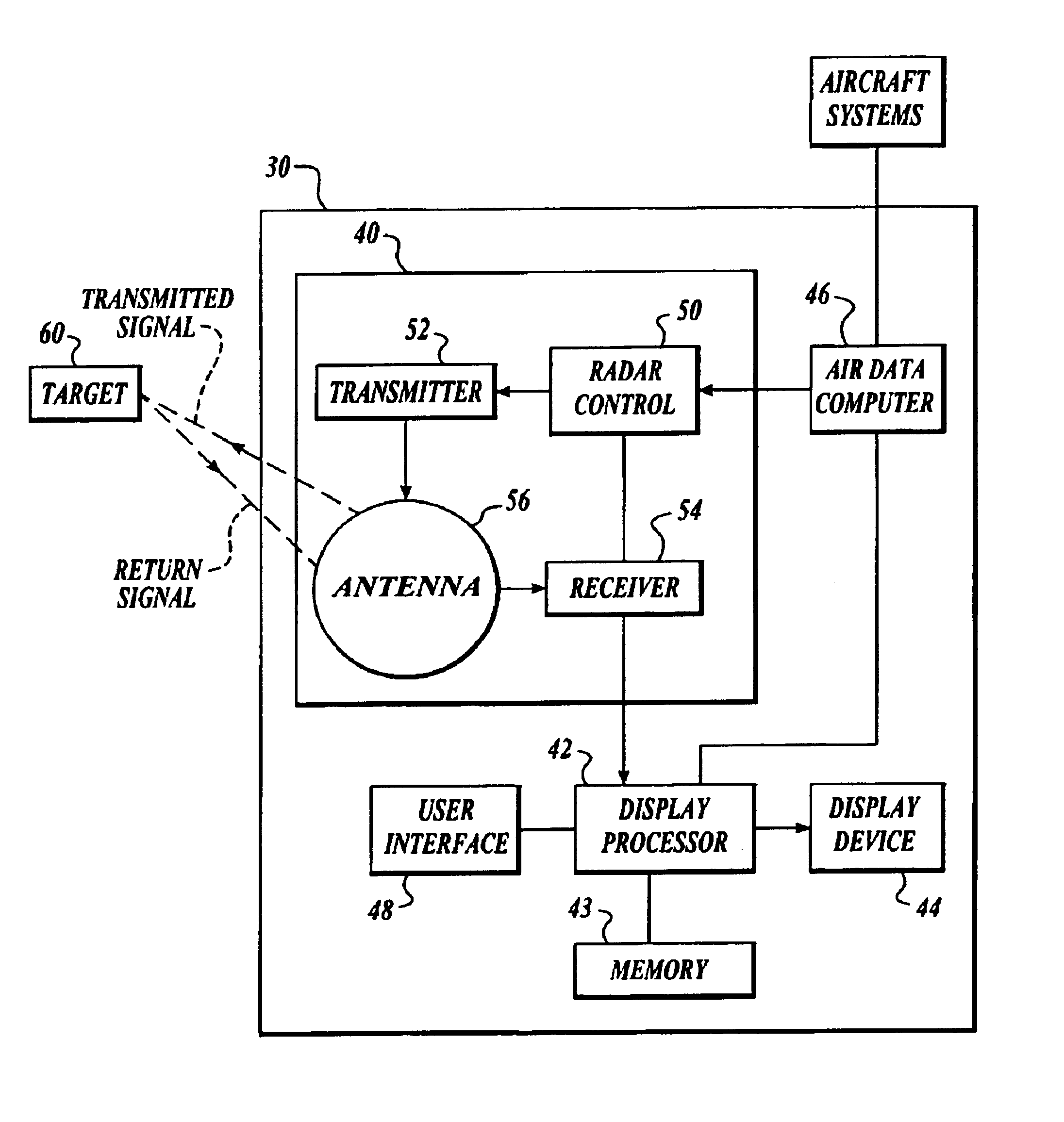

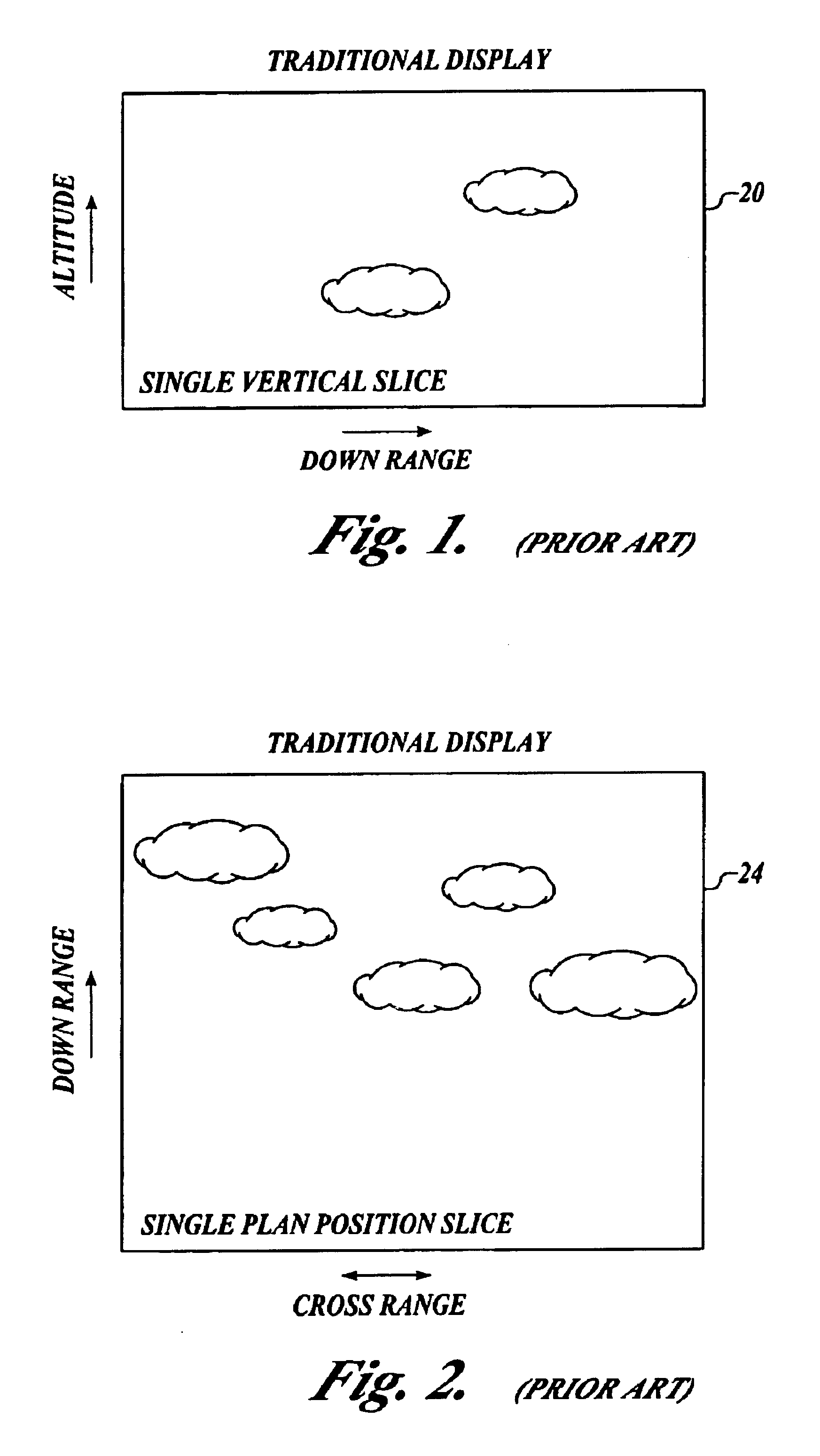

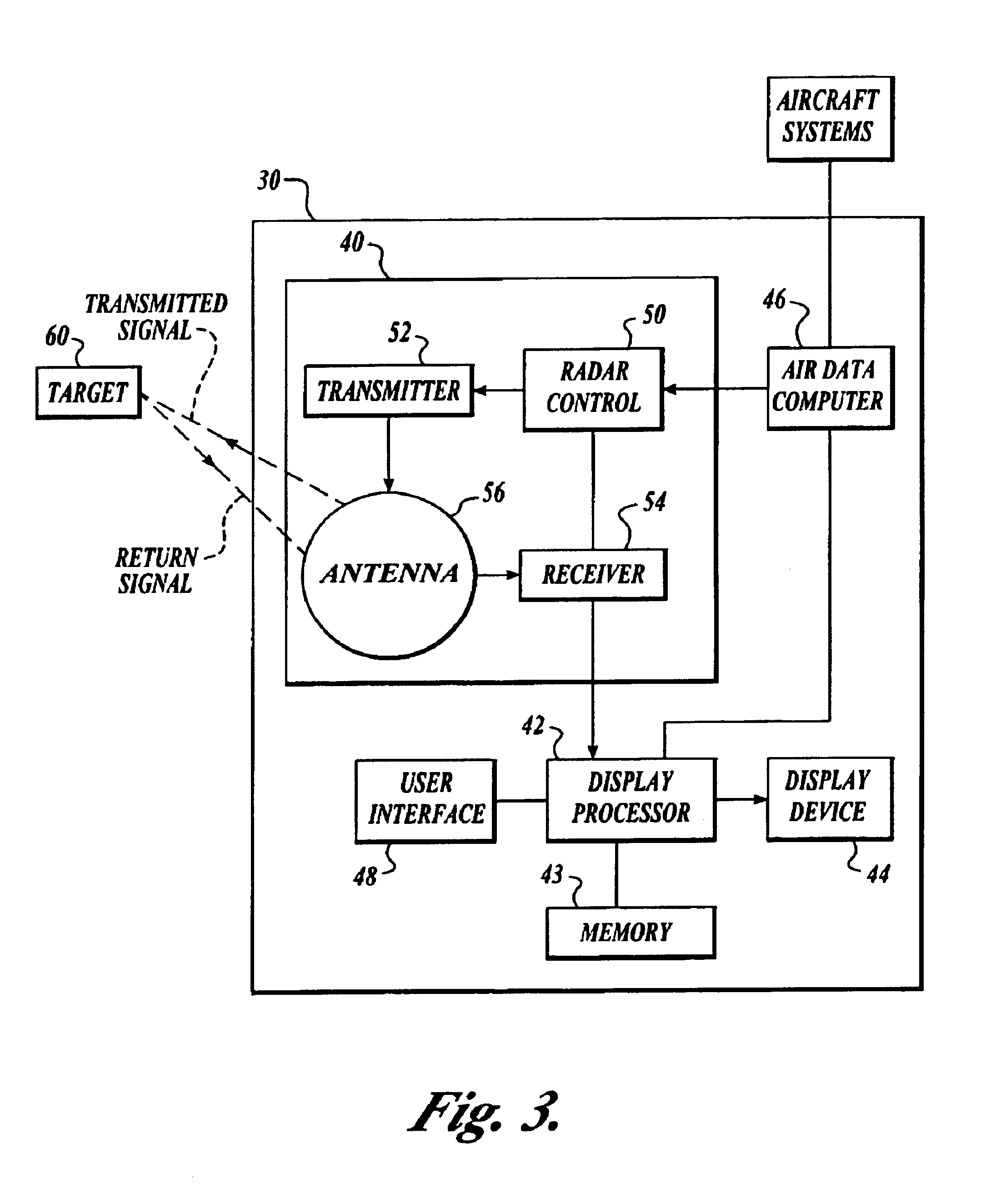

Vertical profile display with arbitrary plane

InactiveUS6839018B2Reducing pilot taskQuick fixRadio wave reradiation/reflectionICT adaptationWeather radarVoxel

A system for allowing pilots to quickly determine weather hazard-free flight paths and weather hazards that exist along the aircraft flight plan. The system includes a memory, a processor, and a display device. The memory stores weather radar return information in a three-dimensional buffer. The processor is coupled to the memory. The processor receives a display distance value signal, retrieves weather radar return information stored in a plane of voxels in the three-dimensional buffer based on the selected display distance value and aircraft position information, and generates an image based on the retrieved weather radar return information. The display device is coupled to the processor for displaying the generated image.

Owner:HONEYWELL INT INC

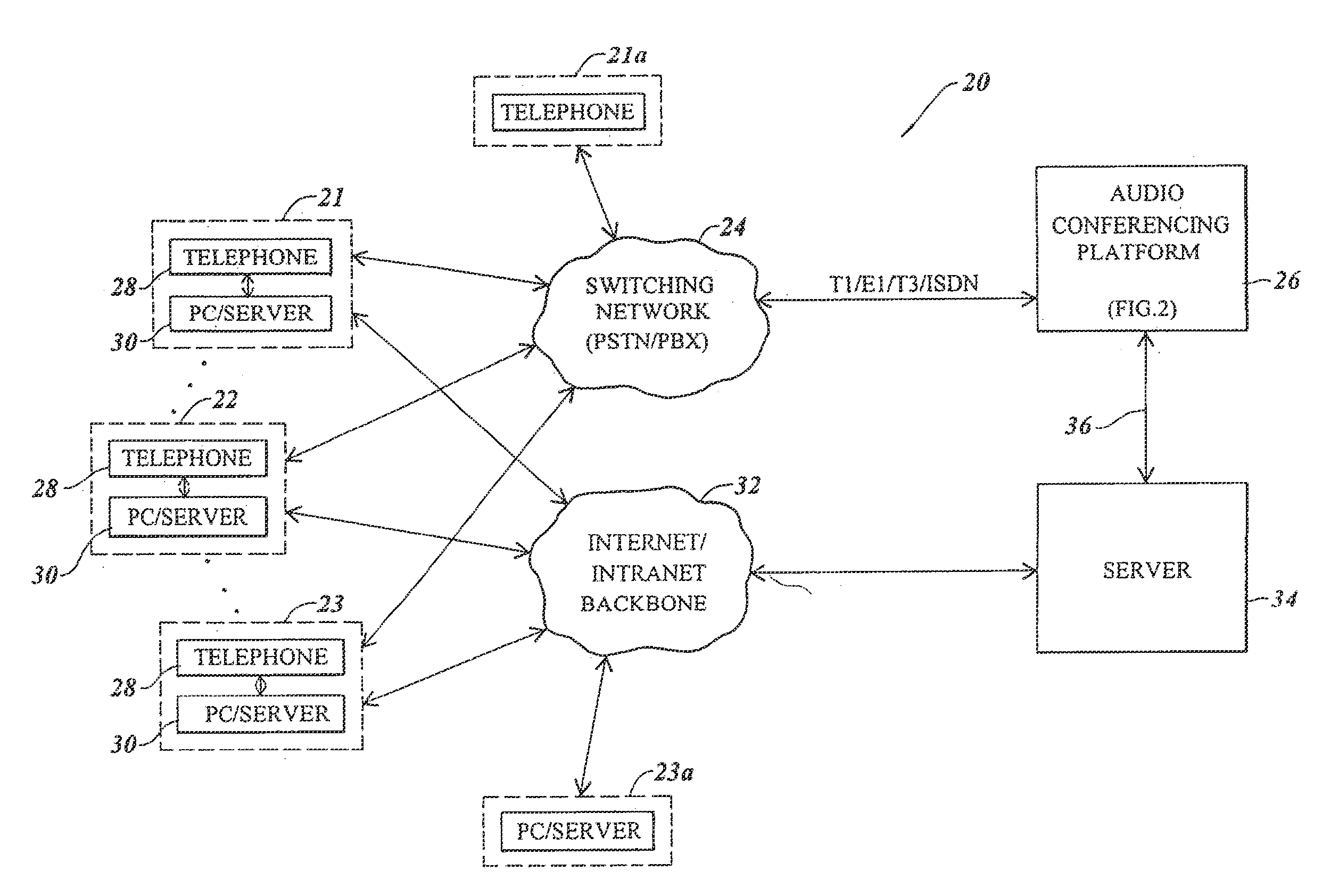

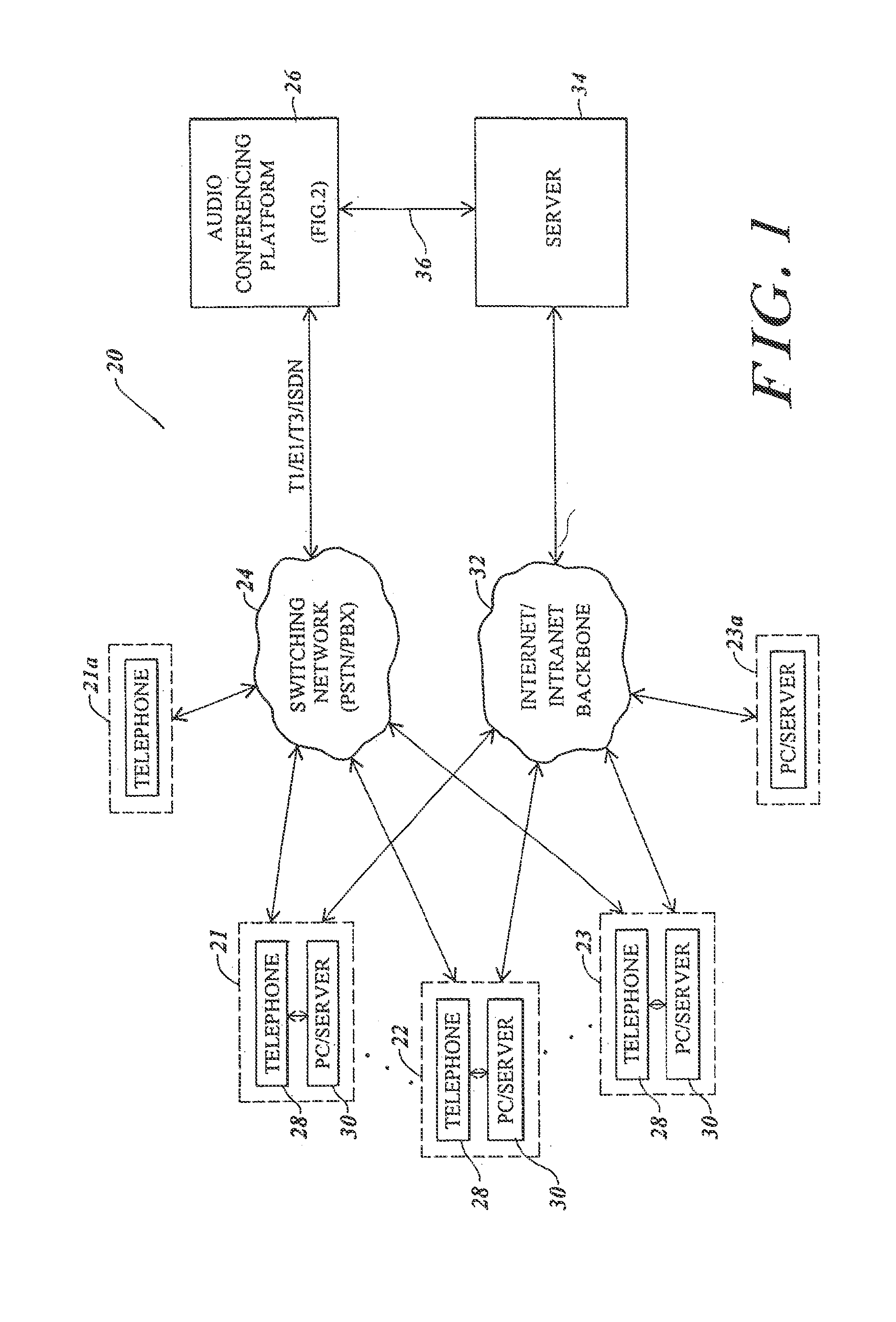

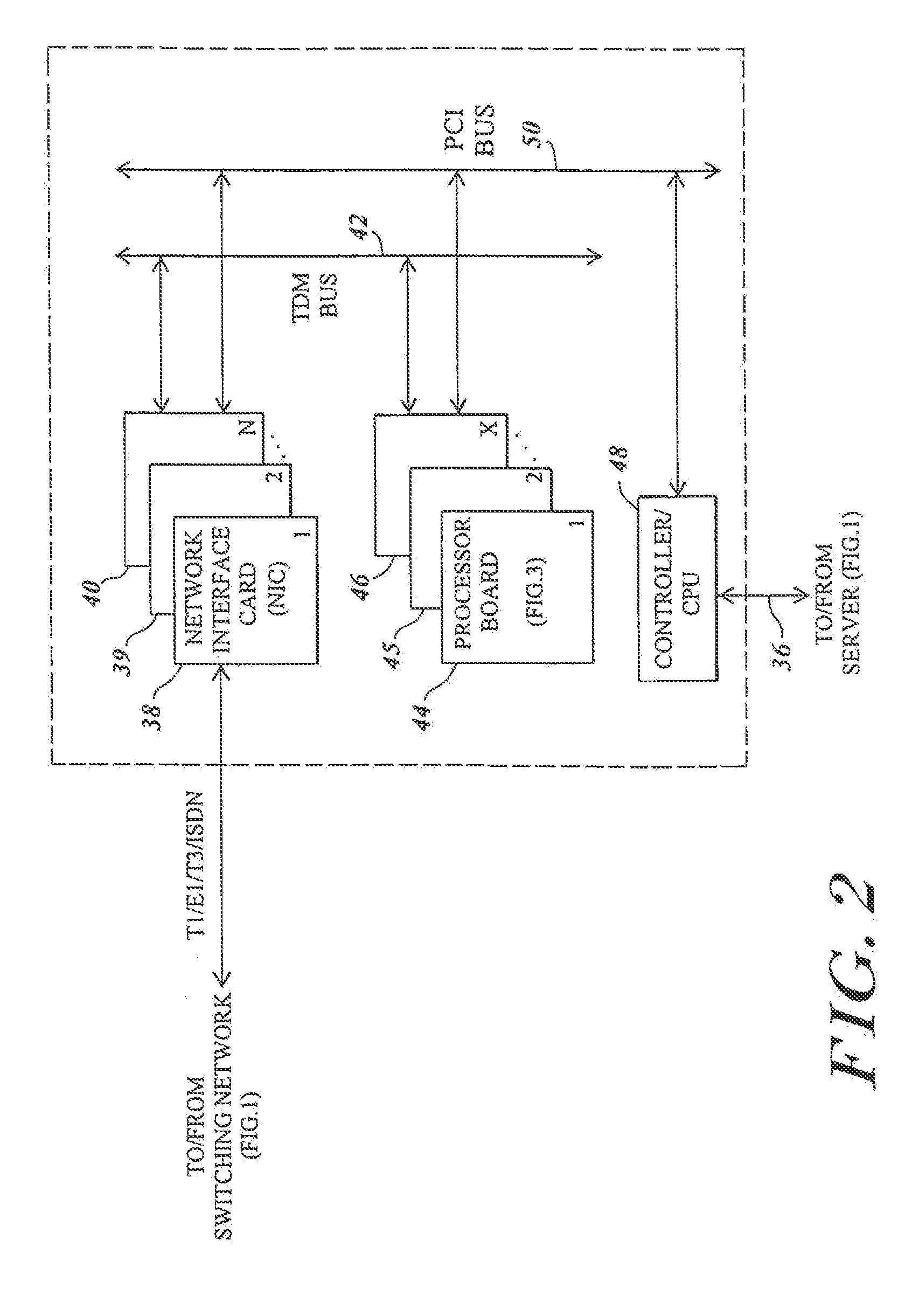

Audio conference platform with dynamic speech detection threshold

InactiveUS20130028404A1Improve conferencingReduce echoSpecial service provision for substationTwo-way loud-speaking telephone systemsEngineeringSpeech sound

The present invention comprises a method for audio / video conferencing. In a preferred embodiment, the method comprises using a dynamic threshold value to determine whether there is speech on a line. One aspect, the method comprises determining a dynamic threshold value based on one or more characteristics of signals received on a port, associating that dynamic threshold value with the port; and comparing one or more characteristics of signals subsequently received on the port to the dynamic threshold value. Signals received over a plurality of ports are summed, but for ports whose signal characteristics have a specified relationship to the dynamic threshold value associated with that port, signals are not contained in the sum.

Owner:HEWLETT PACKARD DEV CO LP

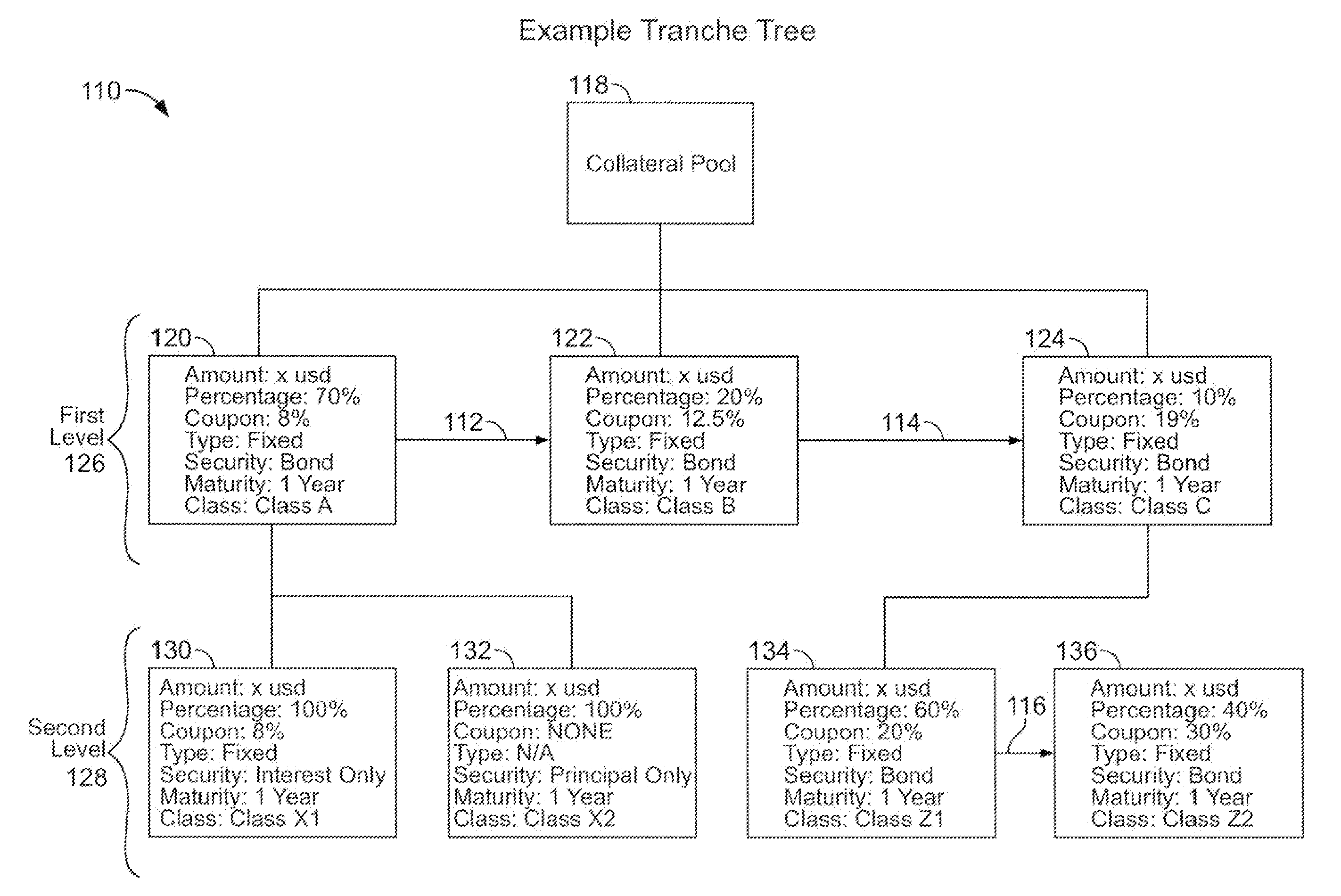

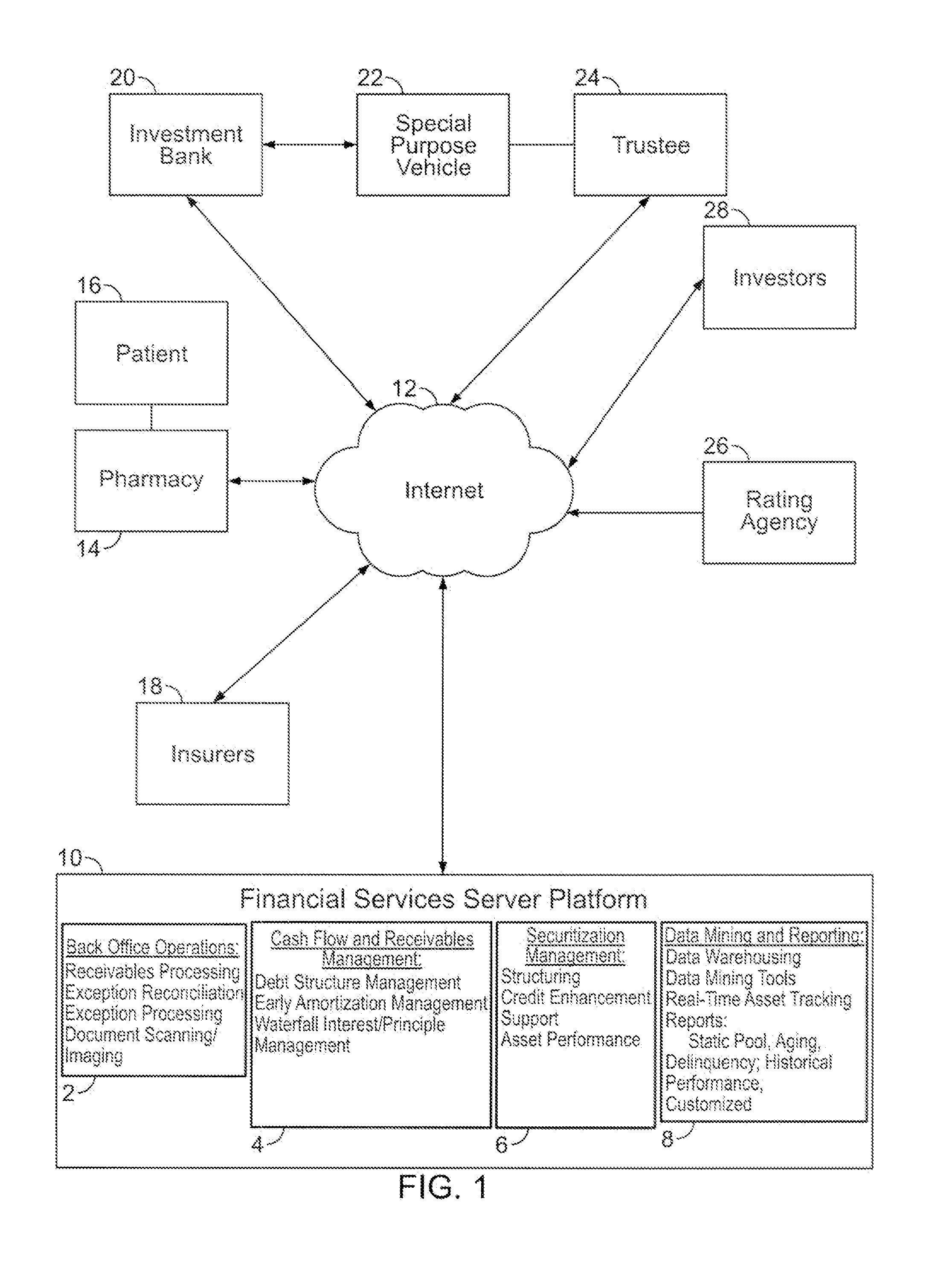

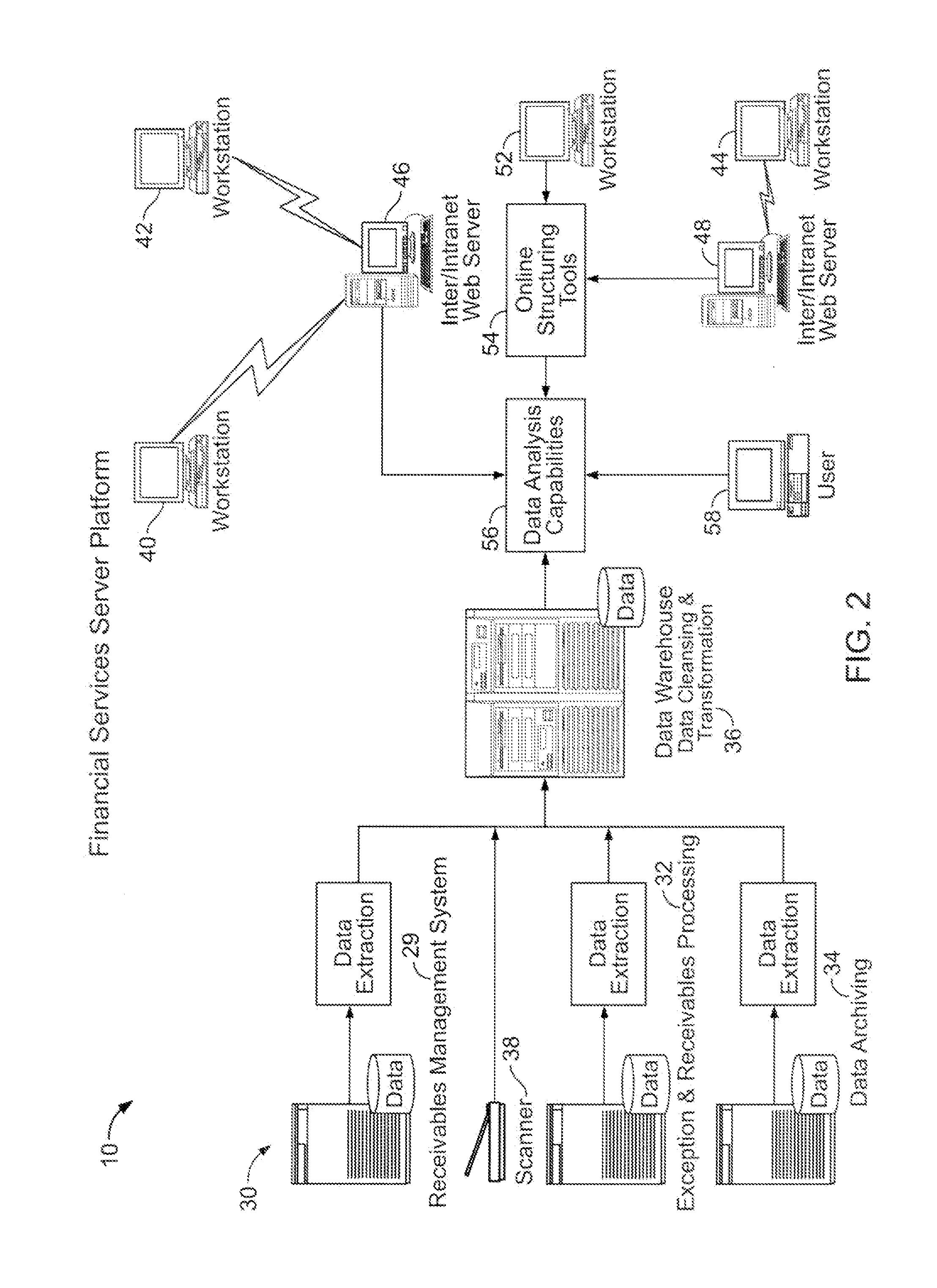

Segregation and management of financial assets by rules

The invention supports the management of financial assets such as accounts receivable or mortgages. The invention provides a facility for a user to define rules to segregate assets into pools, define purchasing rules, capture real time information regarding transactions, reconcile payments and produce exception reports, define access rules for individual users to see information relating to pools of assets and individual assets within a pool, and provide customized reports and access to asset details over a network. Abstract representations of financial assets are used to obtain instances of defined financial-asset object classes to define pools of financial assets with common abstract characteristics. The invention uses a tree structured representation of asset classes for allocation of transactions to tranches and sub-tranches of assets within a pool. A user may define custom tranches and sub-tranches, as well as design pools of assets to an investment rating specification in advance.

Owner:TRANQUILMONEY

Radio frequency lighting control system programming device and method

ActiveUS20050102040A1Lighting controlEasy resetElectrical apparatusComputer controlMaster controllerLighting system

An independent radio frequency programming device automates a setup process for a lighting system with lighting control devices and master controls. The programming device intercepts communications between the lighting control devices and the master control during an initial setup phase. A start function permits the programming device to provide automated setup information to the master controls. Once the automated setup process completes, the lighting system is fully programmed with behavior functions for all lighting control devices.

Owner:LUTRON TECH CO LLC

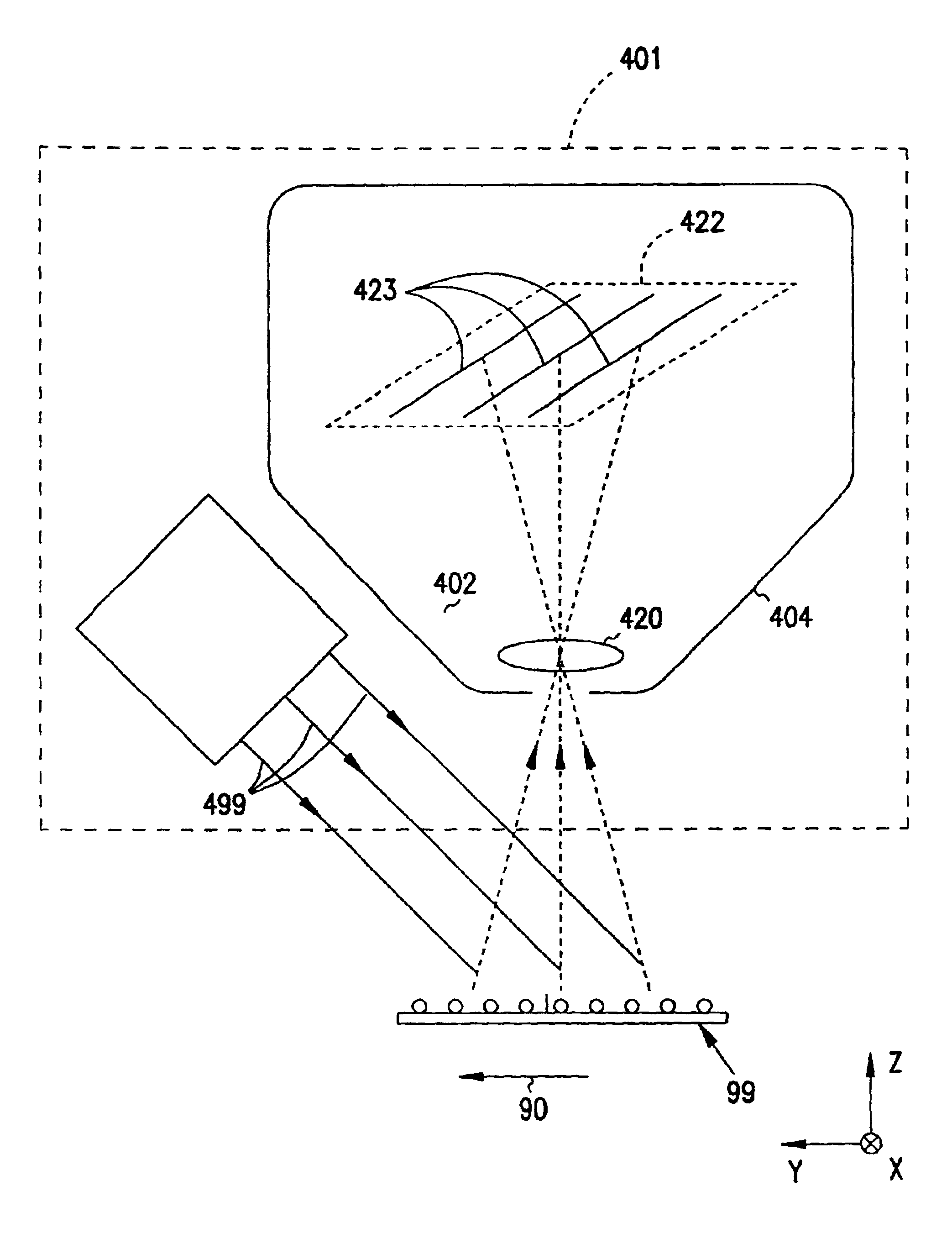

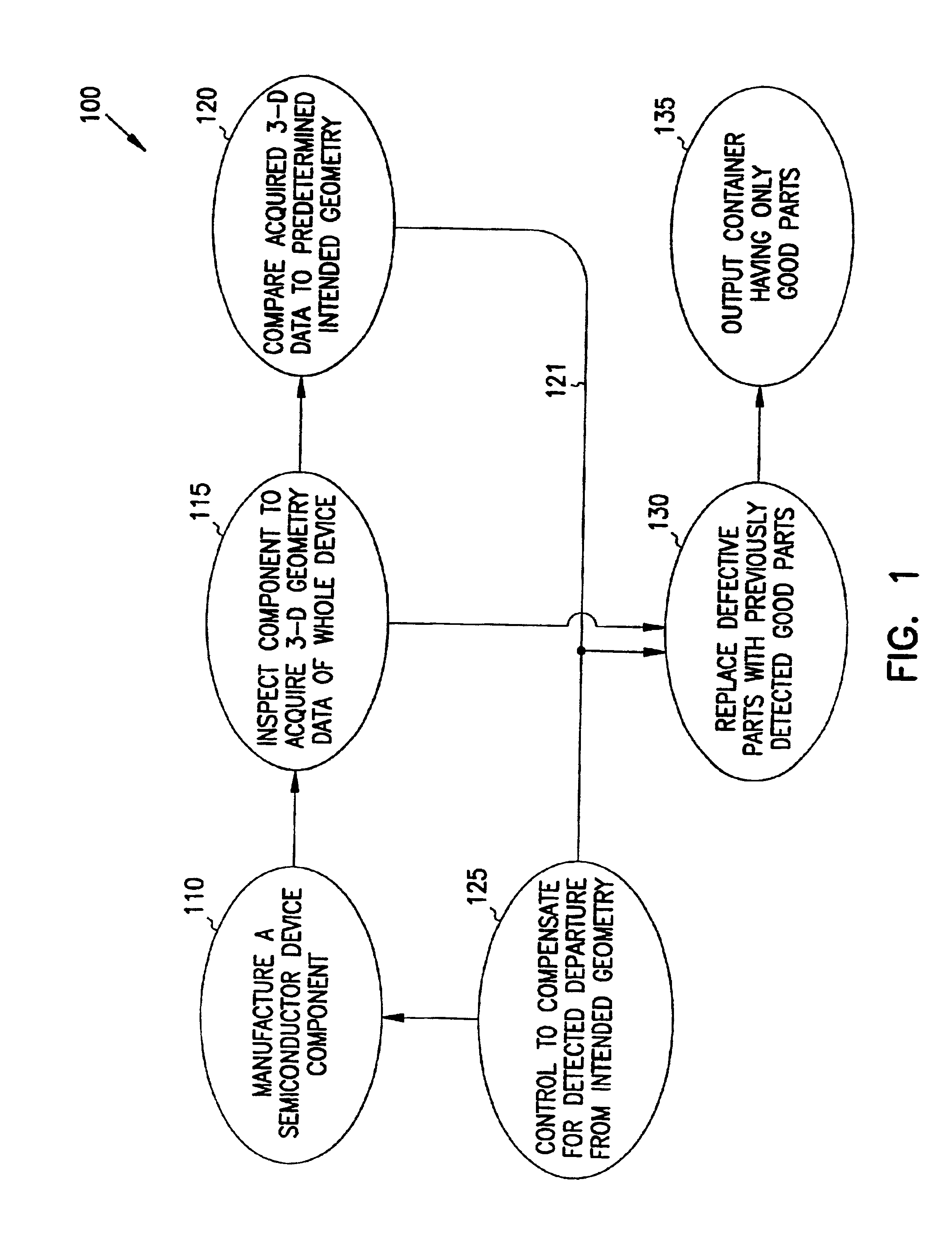

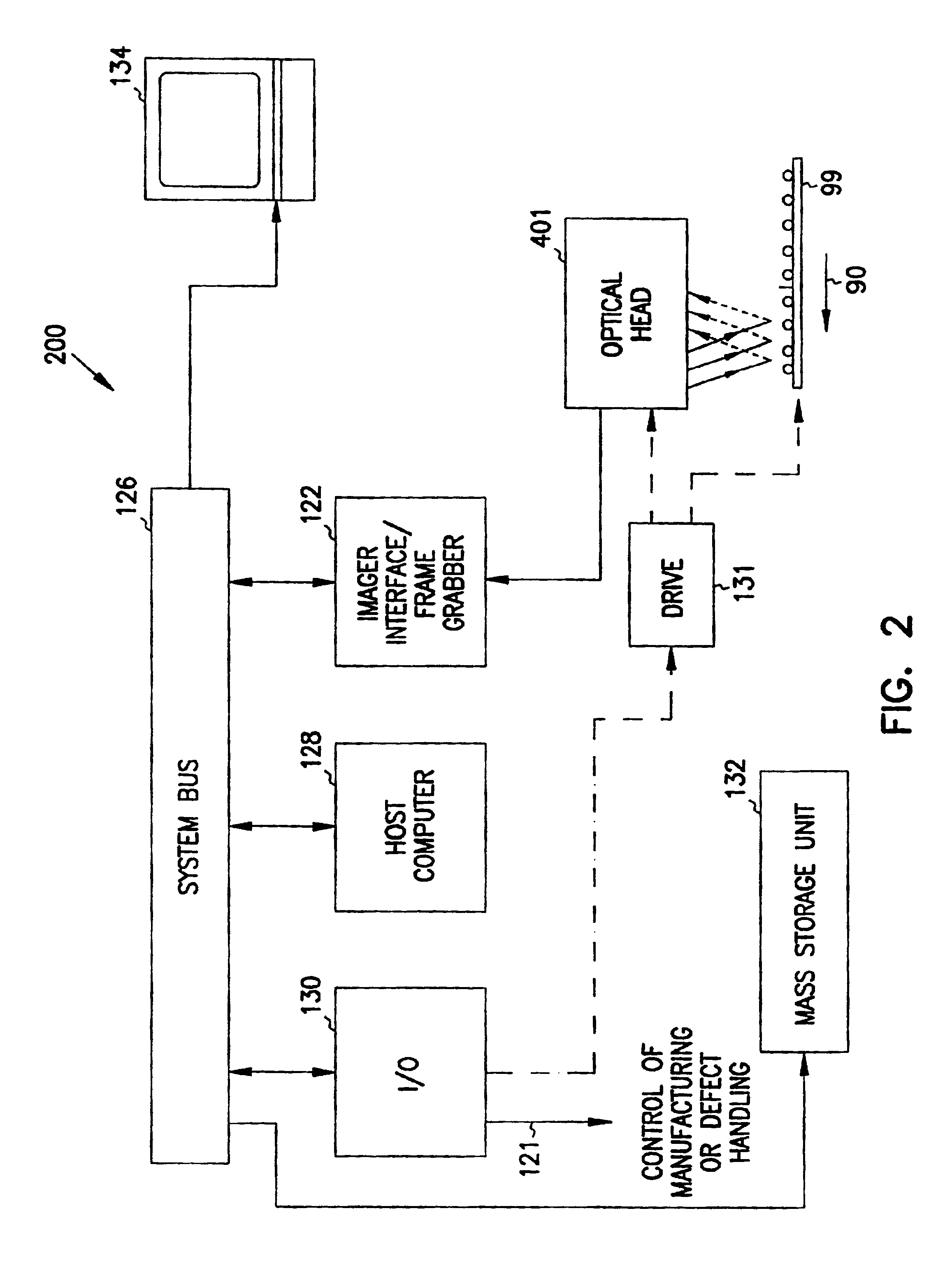

Imaging for a machine-vision system

InactiveUS6956963B2Prevents thermal driftLow variabilityImage analysisSemiconductor/solid-state device manufacturingImage detectionSemiconductor fab

Manufacturing lines include inspection systems for monitoring the quality of parts produced. Manufacturing lines for making semiconductor devices generally inspect each fabricated part. The information obtained is used to fix manufacturing problems in the semiconductor fab plant. A machine-vision system for inspecting devices includes a light source for propagating light to the device and an image detector that receives light from the device. Also included is a light sensor assembly for receiving a portion of the light from the light source. The light sensor assembly produces an output signal responsive to the intensity of the light received at the light sensor assembly. A controller controls the amount of light received by the image detector to a desired intensity range in response to the output from the light sensor. The image detector may include an array of imaging pixels. The imaging system may also include a memory device which stores correction values for at least one of the pixels in the array of imaging pixels. To minimize or control thermal drift of signals output from an array of imaging pixels, the machine-vision system may also include a cooling element attached to the imaging device. The light source for propagating light to the device may be strobed. The image detector that receives light from the device remains in a fixed position with respect to the strobed light source. A translation element moves the strobed light source and image detector with respect to the device. The strobed light may be alternated between a first and second level.

Owner:ISMECA SEMICONDUCTOR HOLDING SA

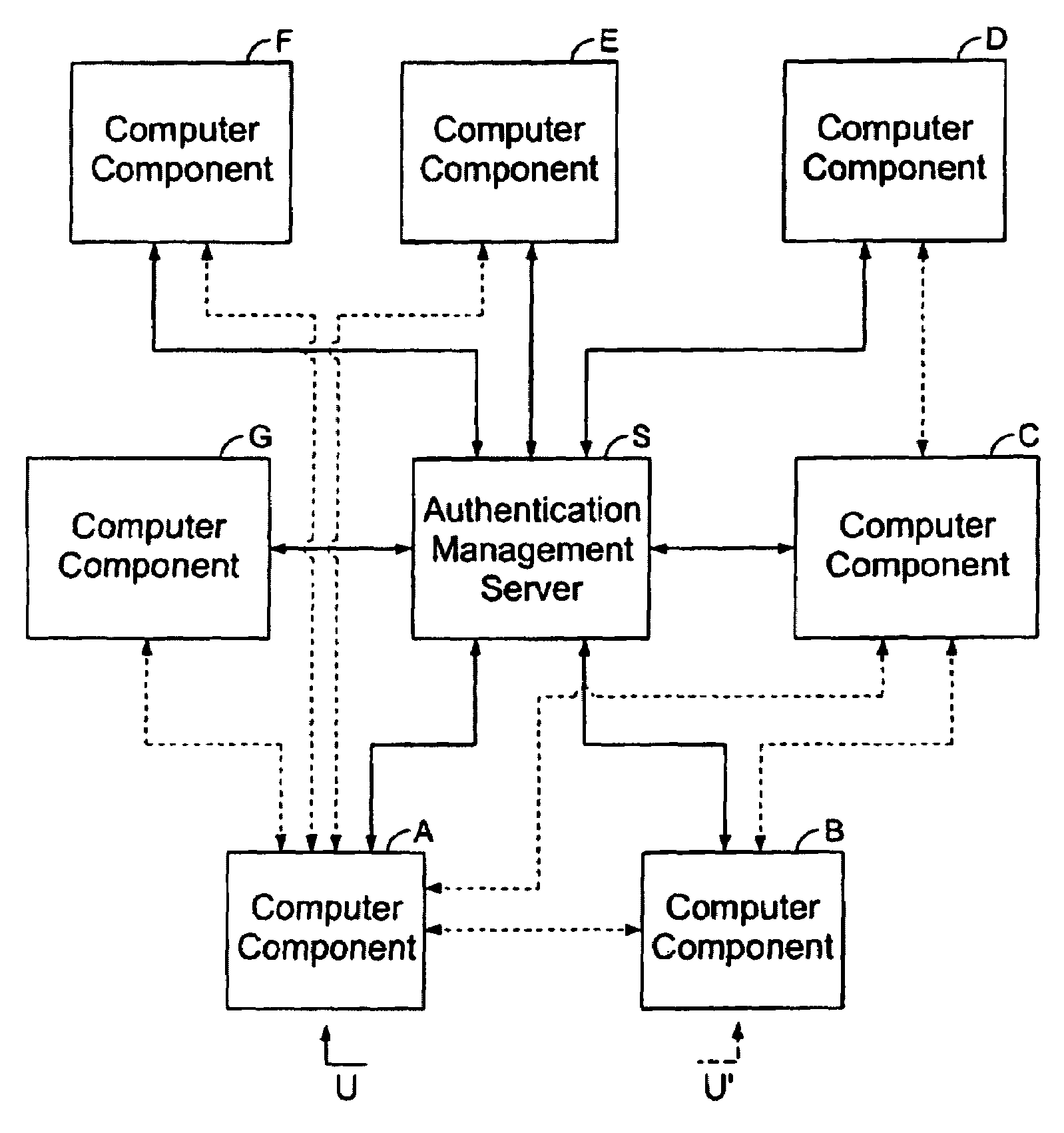

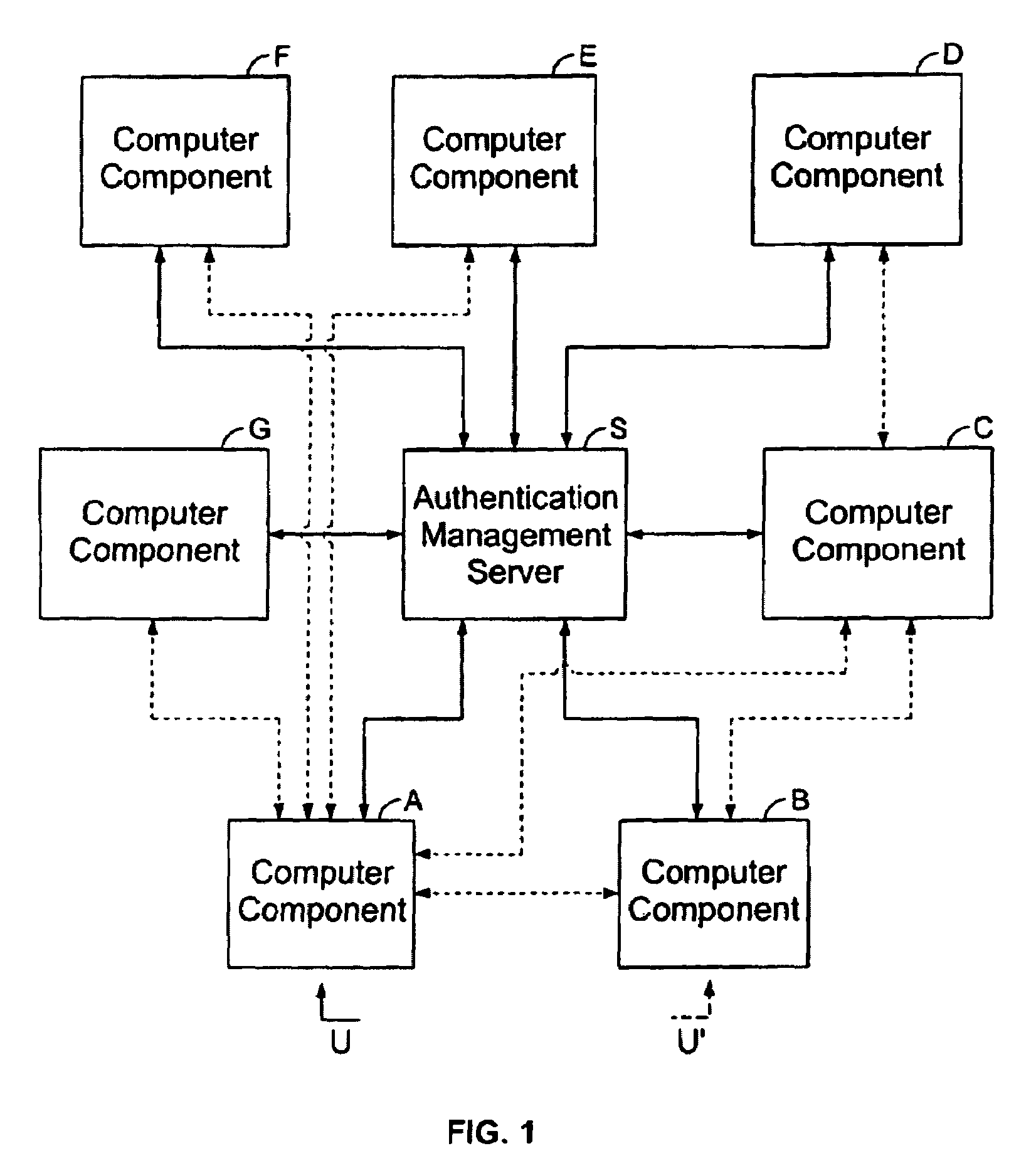

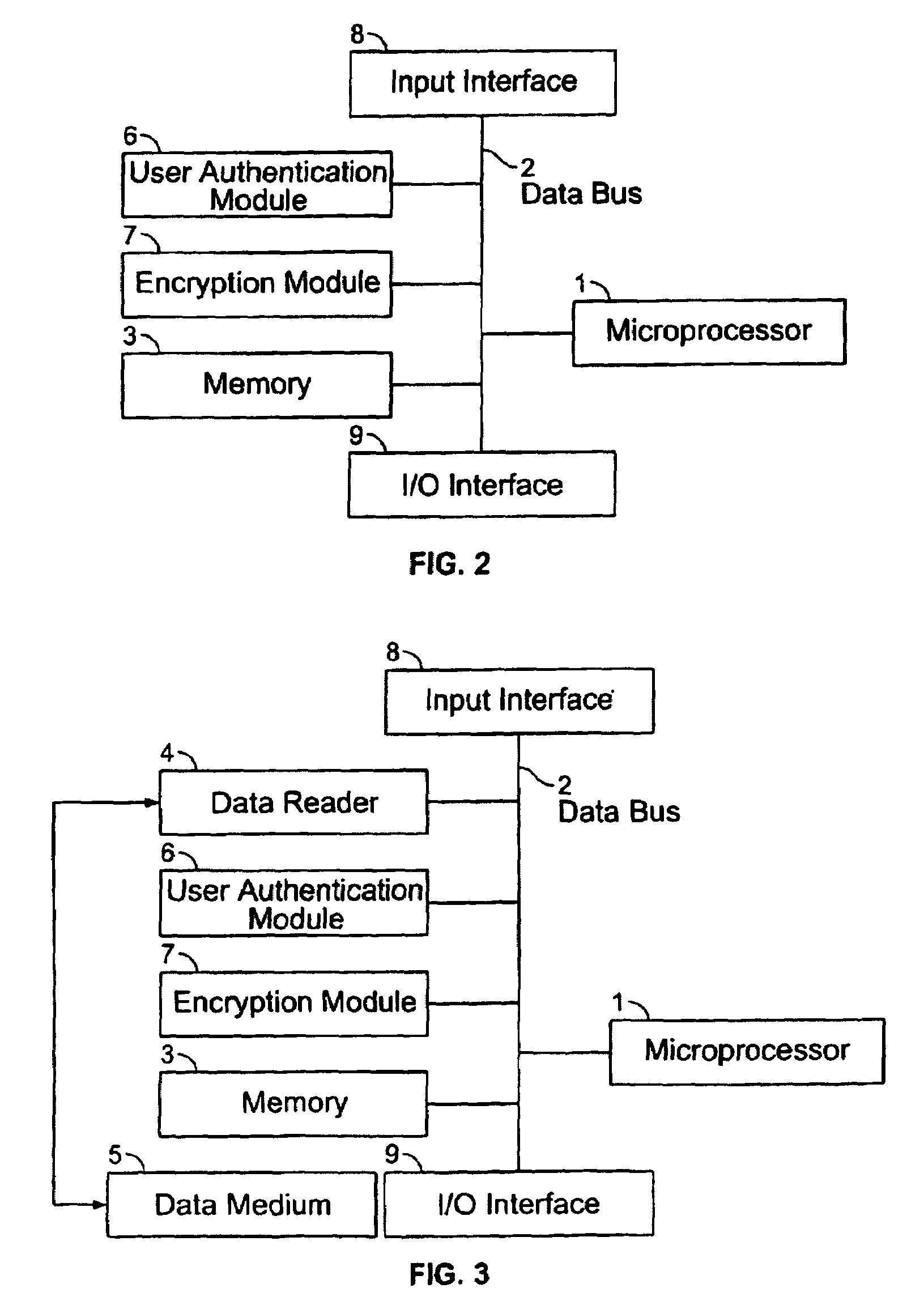

Method, server system and device for making safe a communication network

InactiveUS6981156B1Easy to changeFlexible management of networkKey distribution for secure communicationData taking preventionSecurity parameterSecurity level

The invention concerns a server for management of authentication (S) and devices interconnected between each computer equipment needing to be made secure and the communication network. It enables to make secure said network in a distributed and dynamic manner. The device intercepts communications between a computer equipment (A) whereto it is connected and the network and enables to obtain, by means of an authenticating module, data concerning a user (U) and to define a security level for said device. The authentication management server (S), connected to the network, processes said data and said security level and authenticates the user (U). The server (S) manages the authentication and transmits to the network devices security parameters. Said parameters are stored and processed by the network devices.

Owner:EVERBEE NETWORKS

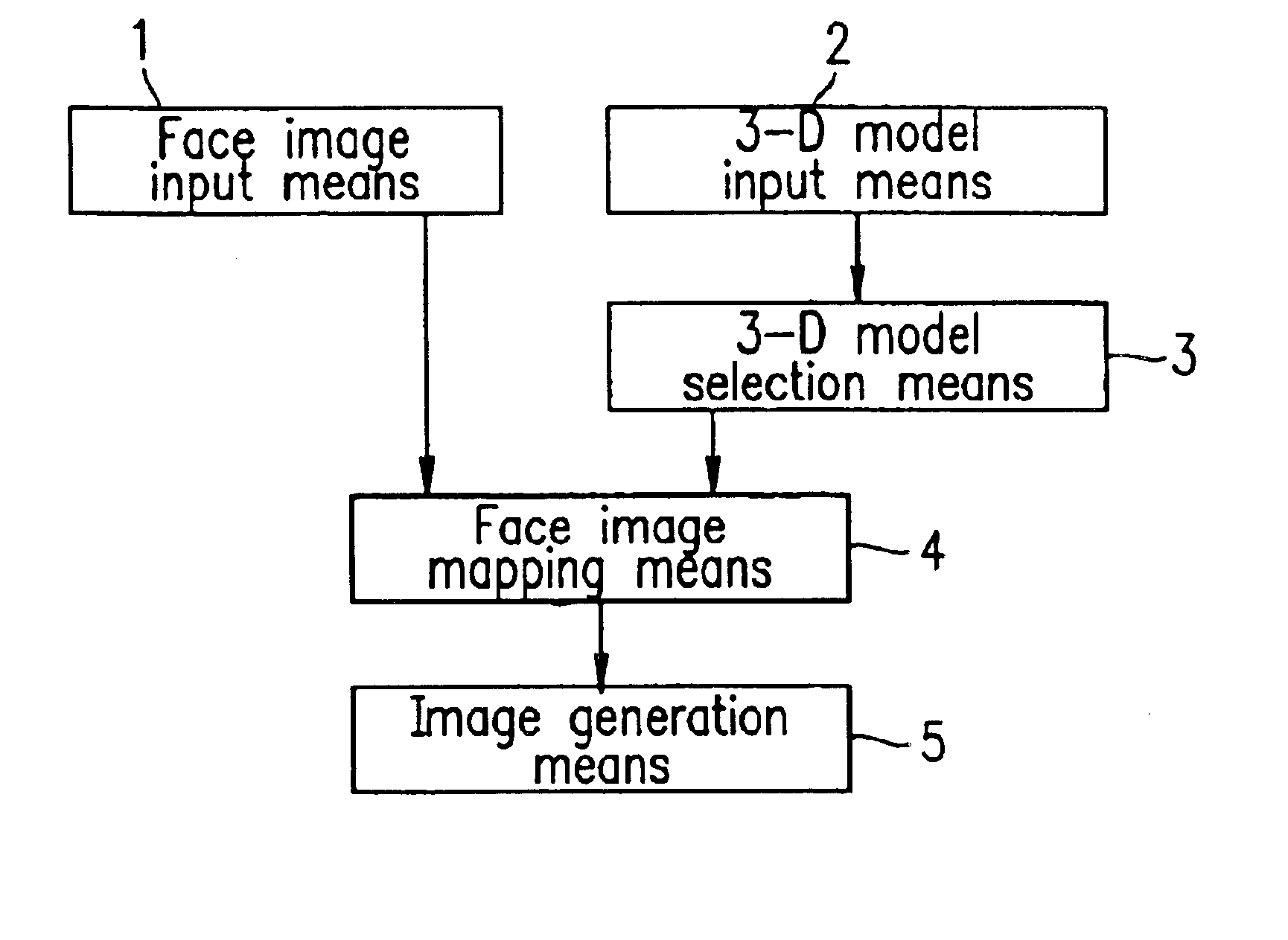

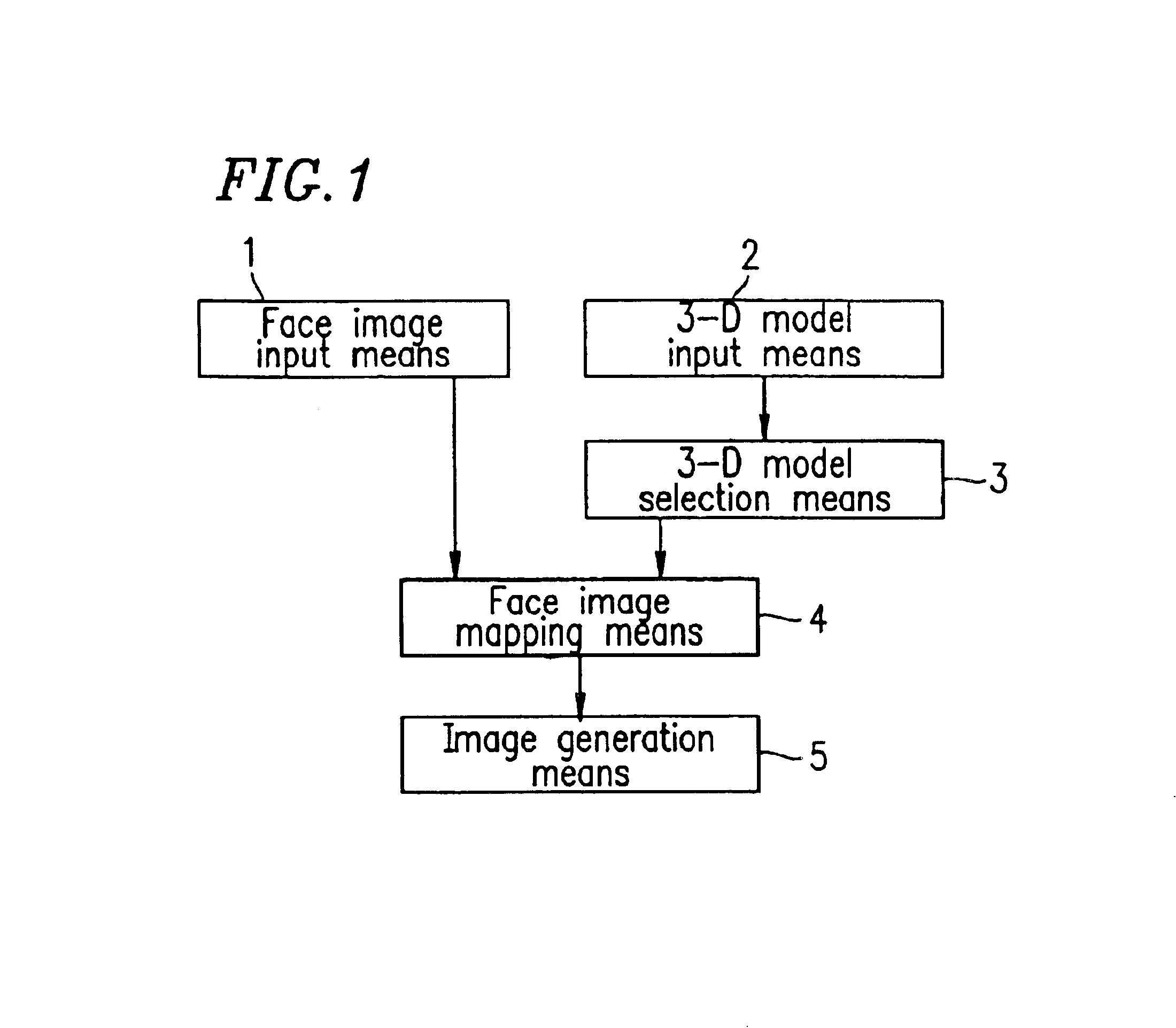

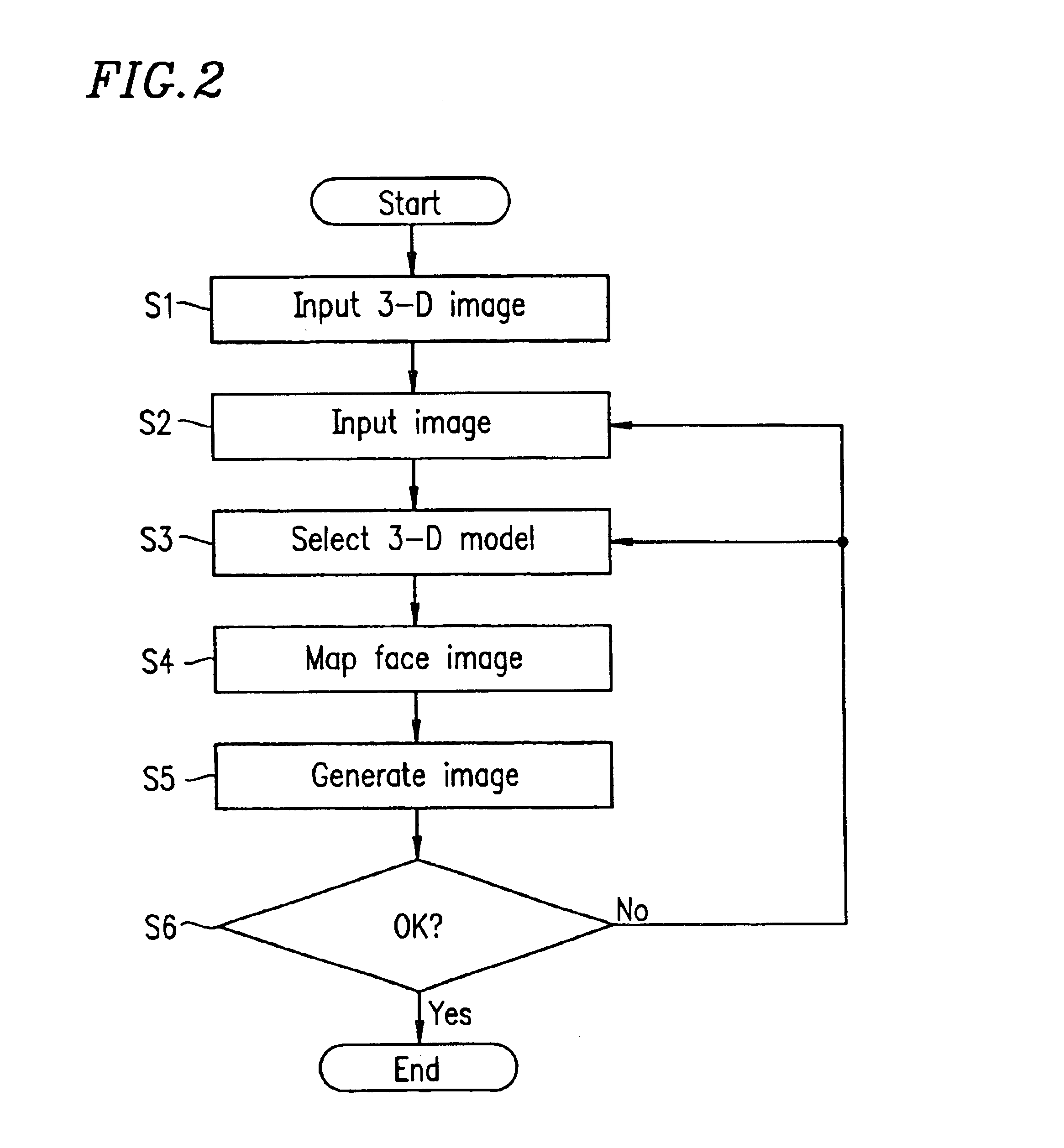

Image processing device, image processing method, and recording medium storing the image processing method

InactiveUS6862374B1Lighten the taskColor signal processing circuitsCharacter and pattern recognitionImaging processingComputer graphics (images)

An image processing device for generating a 3-D model image of a target object included in an input image, comprises a face image input means for inputting a face image; a 3-D model input means for inputting one or a plurality of 3-D models for each of a plurality of parts; a 3-D model selection means for selecting a 3-D model for an arbitrary part of the plurality of parts based on an instruction input by an operator; a face image mapping means for mapping the face image input via the face image input means to the 3-D model selected by the 3-D model selection means and for displaying the mapped 3-D model; and an image generation means for generating a 3-D still image using the 3-D model selected by the 3-D model selection means and the face image input by the face image input means.

Owner:SHARP KK

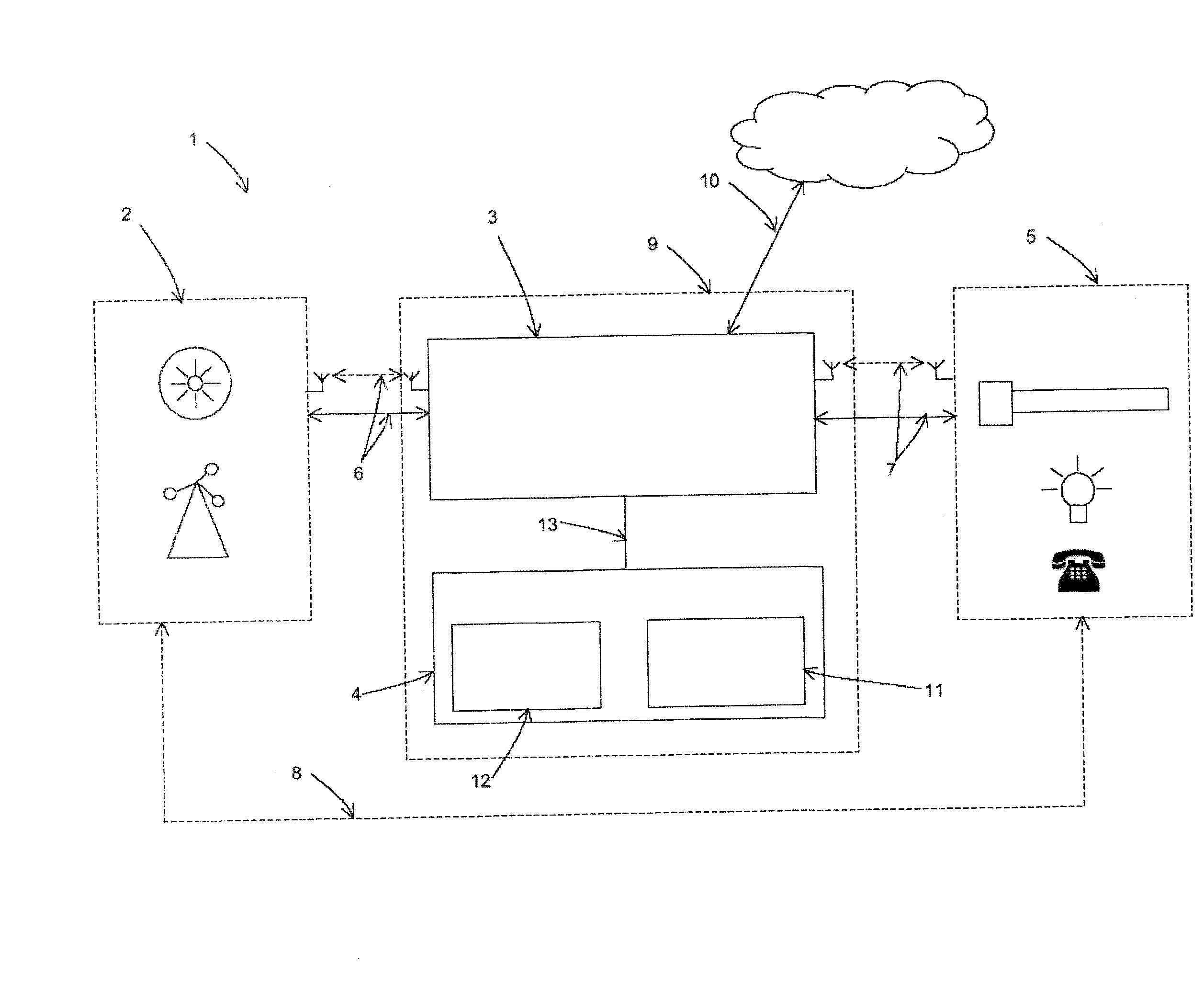

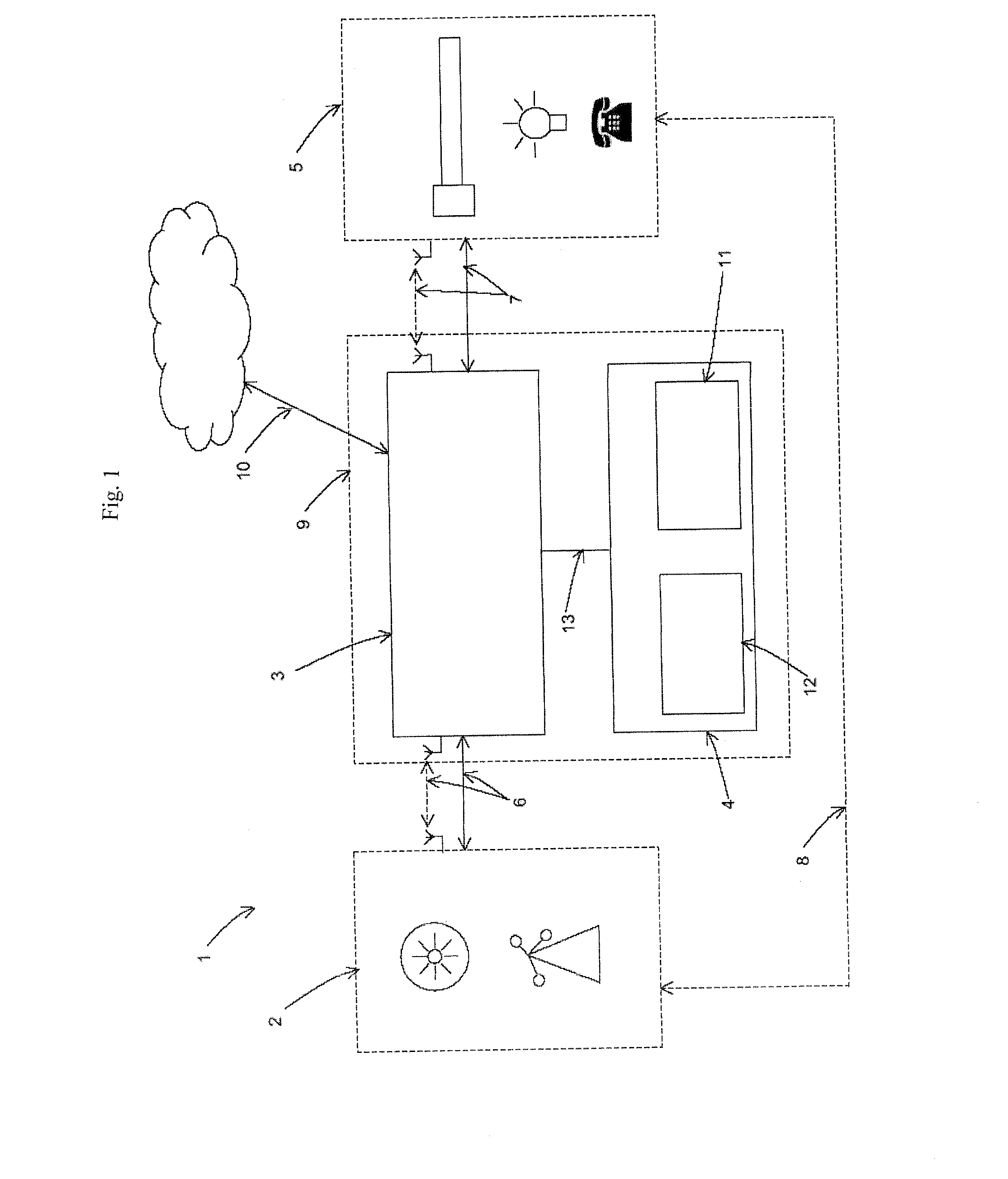

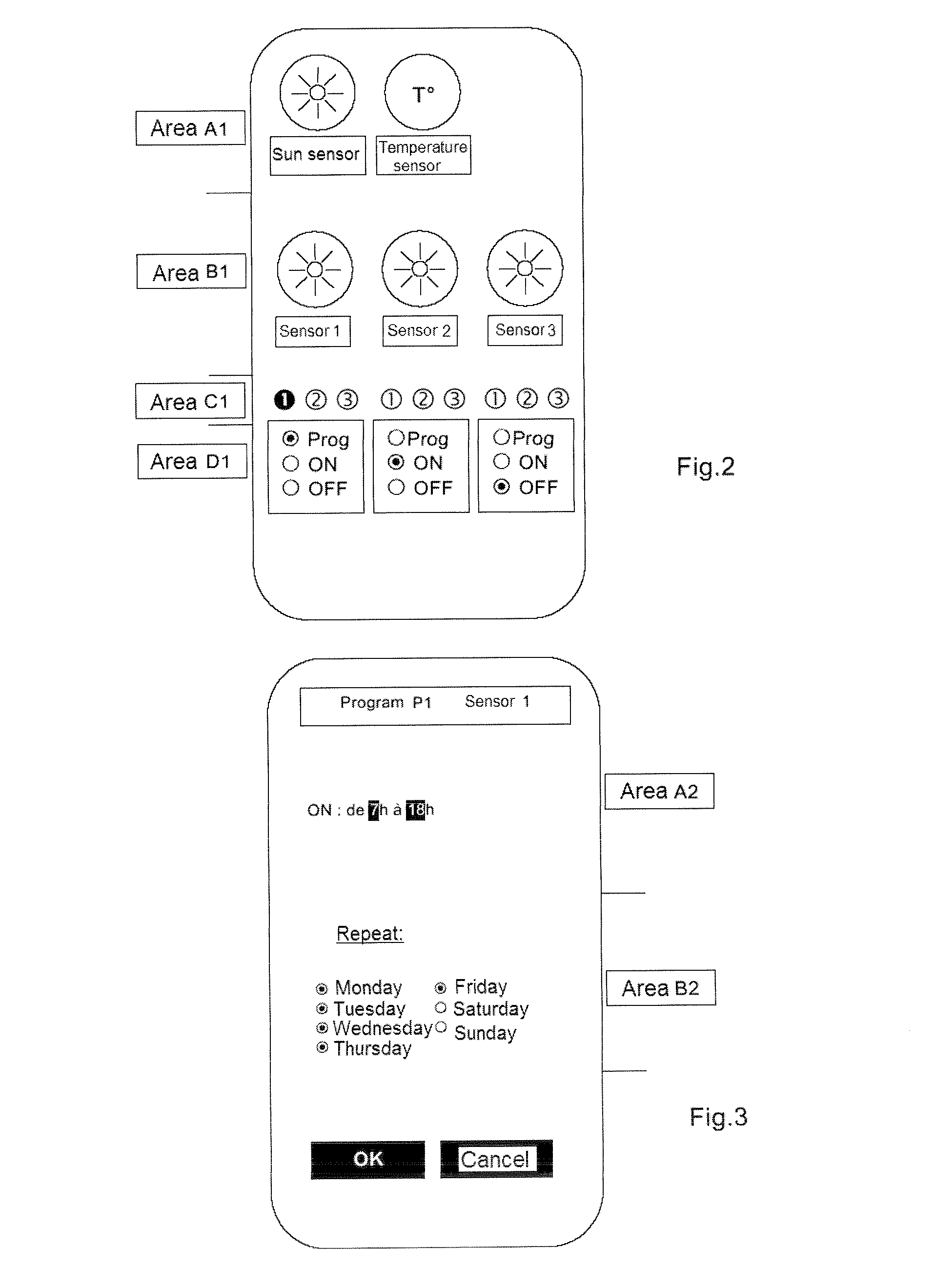

Methods for Controlling and Parameterizing a Home Automation Installation and Home Automation Installation Implementing Said Methods

A home automation installation includes several sensors, several pieces of controlled home automation equipment, and a control unit communicating with the sensors and the controlled home automation equipment. To control this installation, it is provided to select a control scenario by the control unit for at least one parameterized sensor from among the sensors, at a current moment belonging to a periodic time range from among one or more time ranges associated with the parameterized sensor, and as a function of at least one current value of the signal coming from the parameterized sensor, then to send, by the control unit to at least one of the pieces of controlled home automation equipment, at least one order depending on the selected control scenario. To parameterize the control unit, a procedure is provided consisting of choosing a sensor to be parameterized from among at least one periodic activation time range and / or at least one periodic inhibition time range and associating at least one control scenario with at least one state or a change of state of the signal from the sensor to be parameterized.

Owner:SOMFY ACTIVITES SA

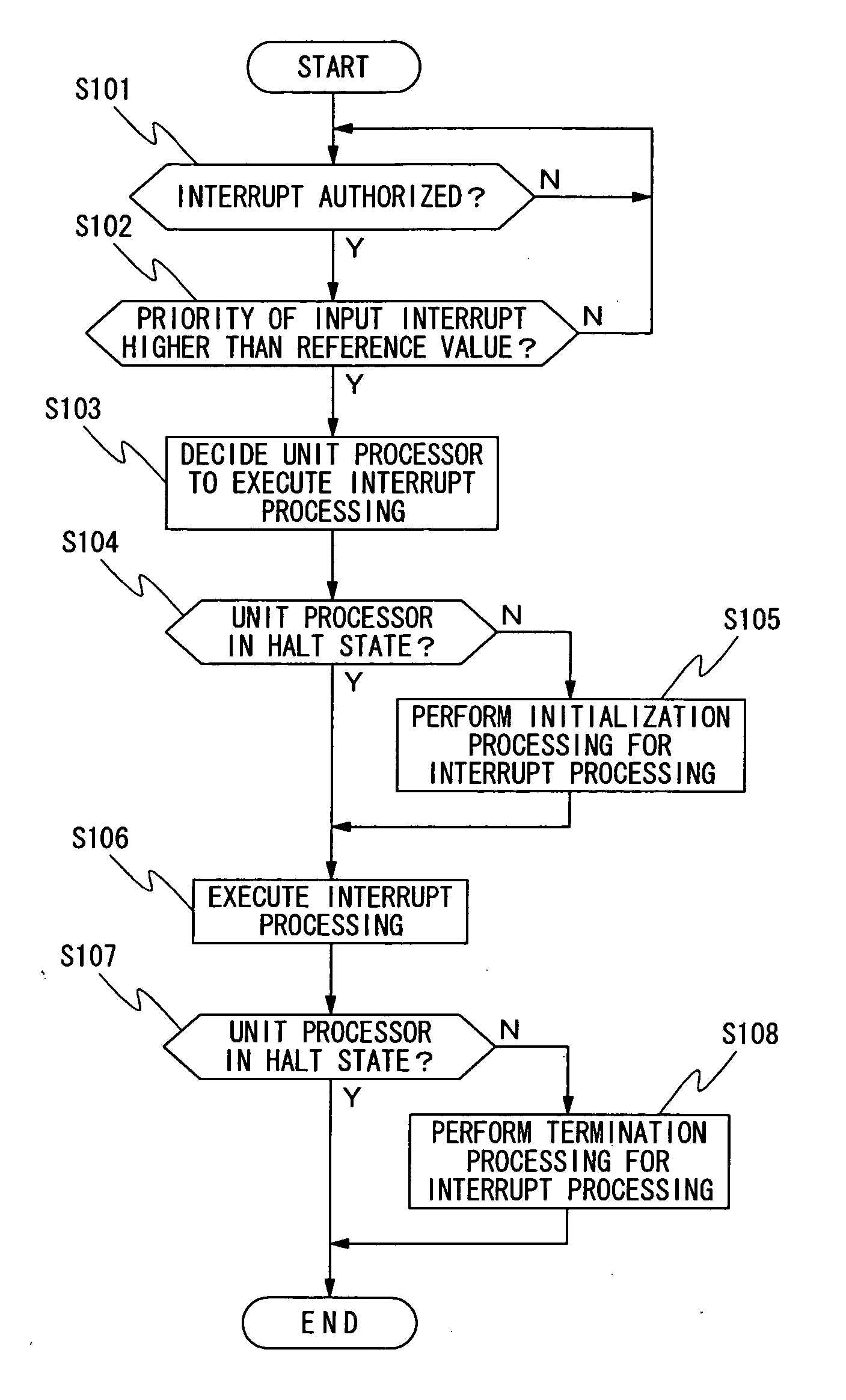

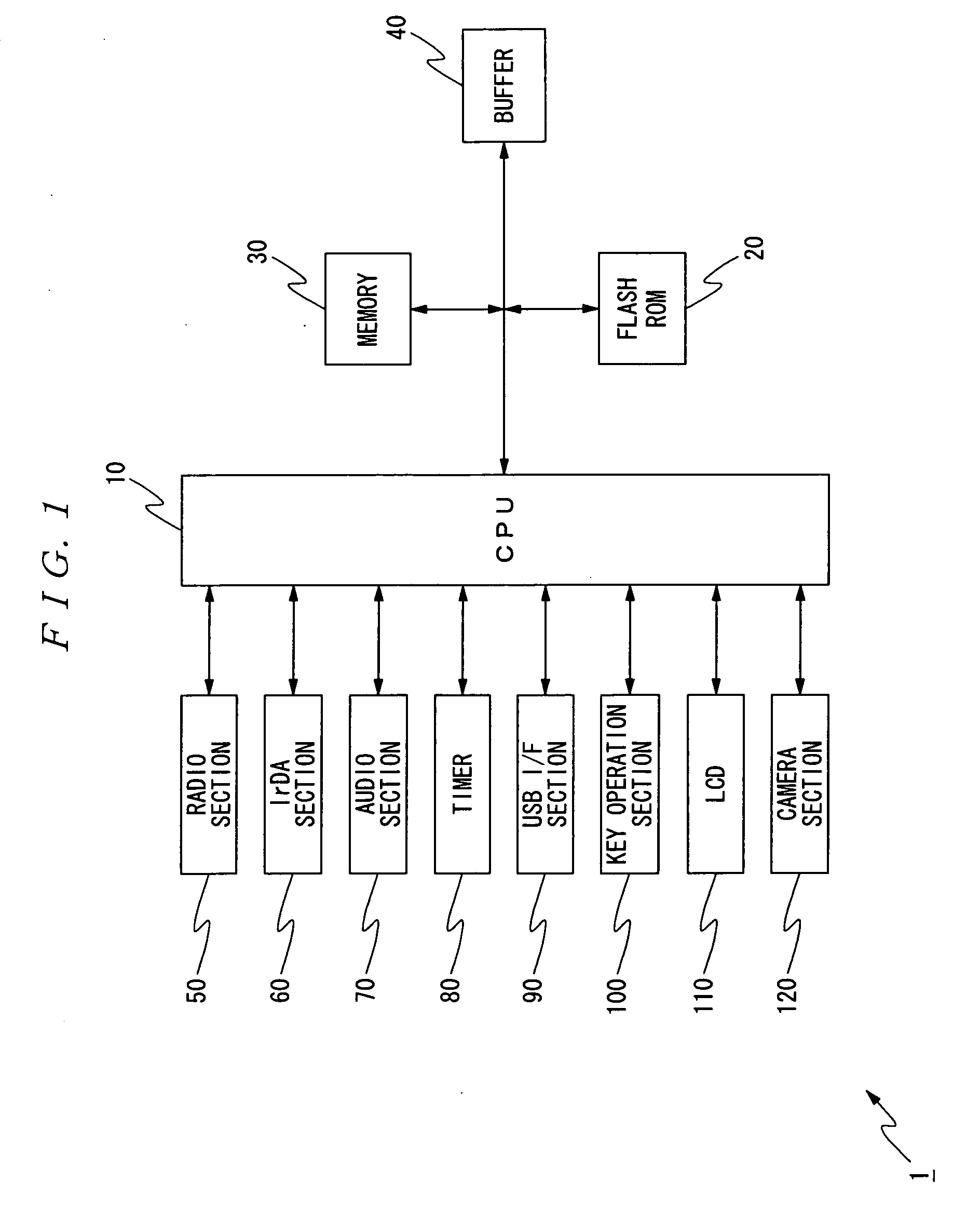

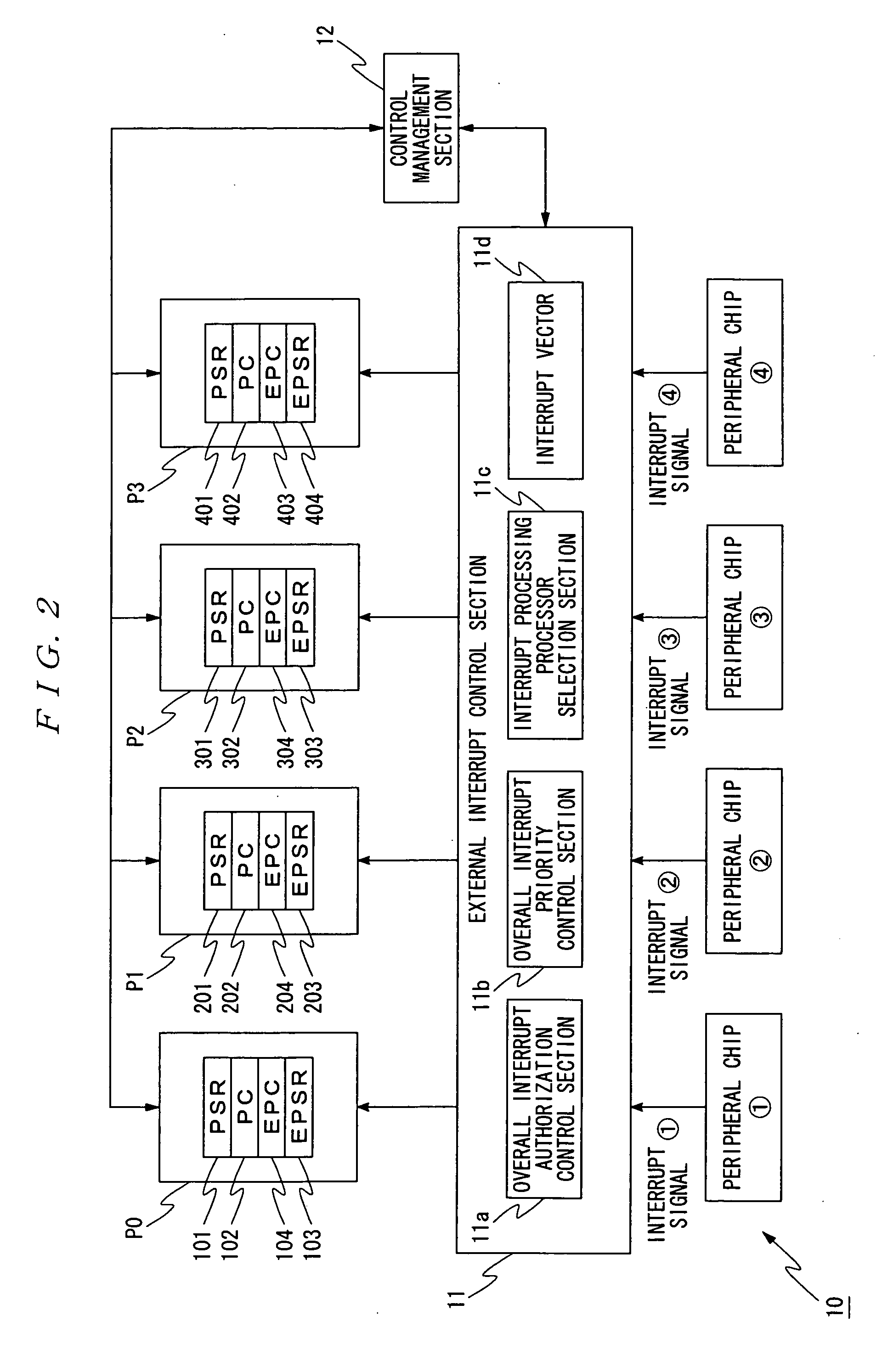

Processor and information processing method

InactiveUS20060200826A1Efficient processingLighten the taskMultiprogramming arrangementsMultiple digital computer combinationsInformation processingParallel computing

A processor includes a plurality of processor sections that process a task or a thread and a high priority processing control section that controls execution of a high priority processing that was input, wherein the high priority processing control section causes a processor section that is not executing processing of a task or a thread or a processor section that is executing processing of a task or a thread of the lowest priority among the plurality of processor sections to execute the high priority processing that was input.

Owner:SEIKO EPSON CORP

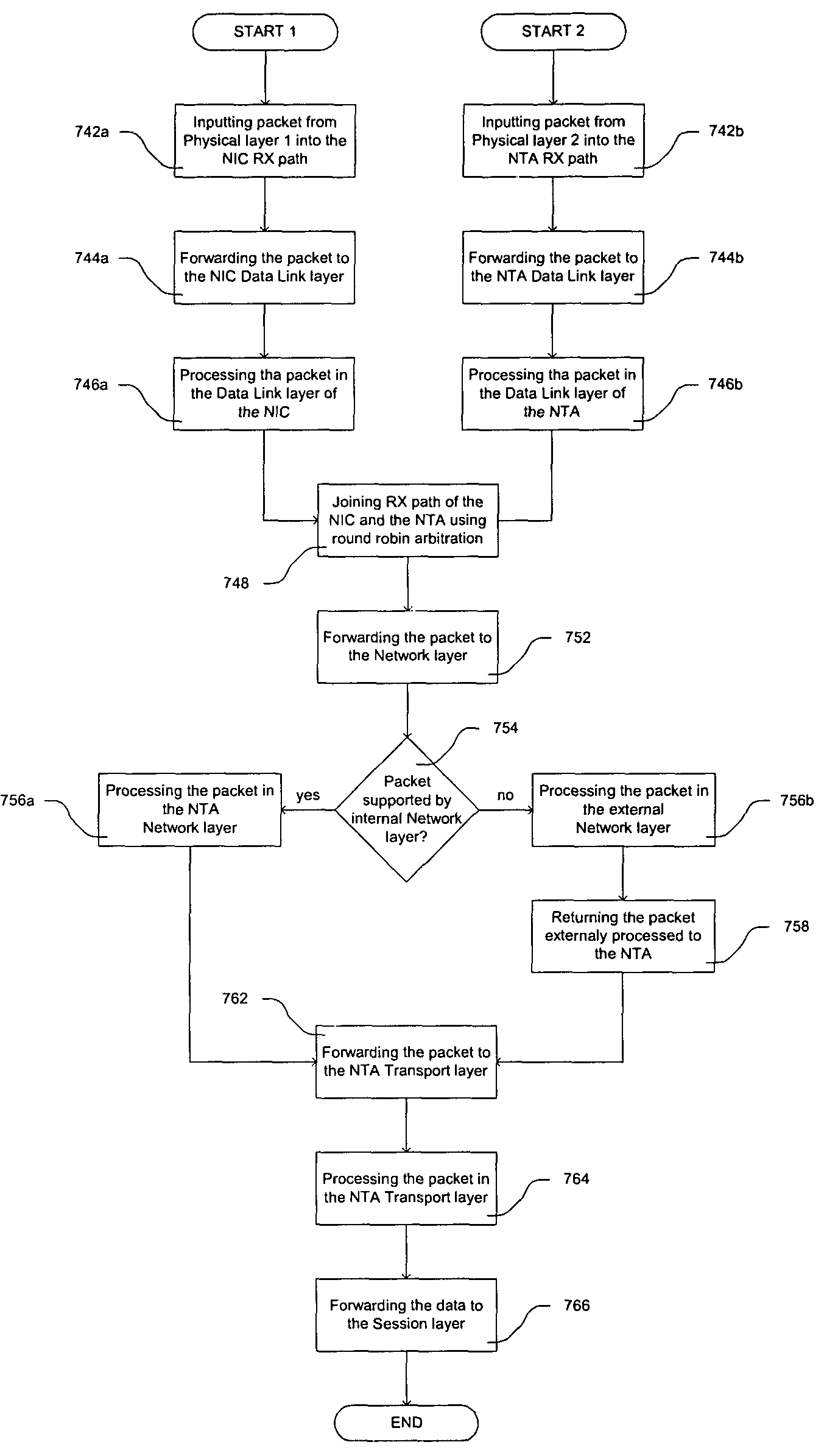

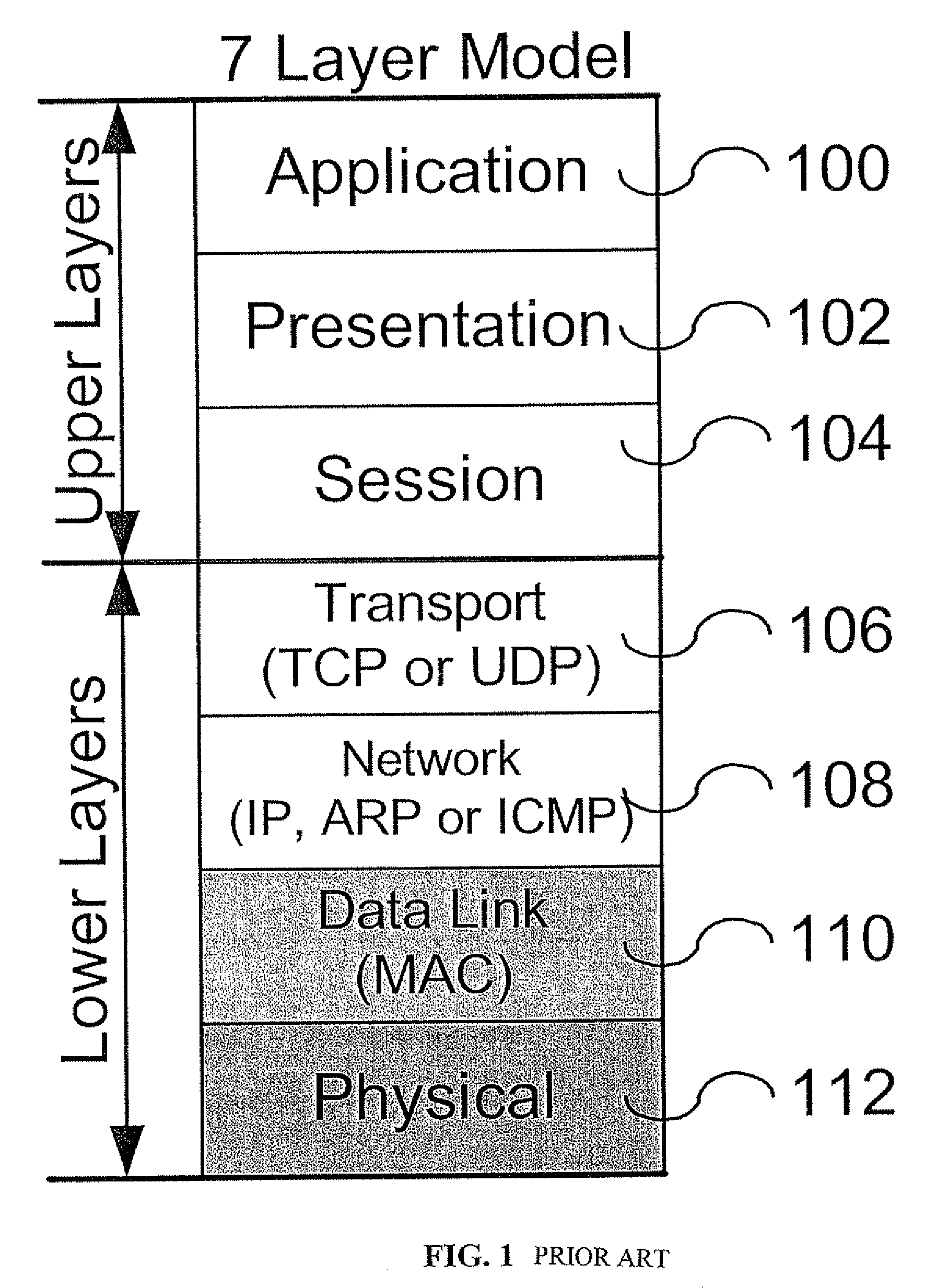

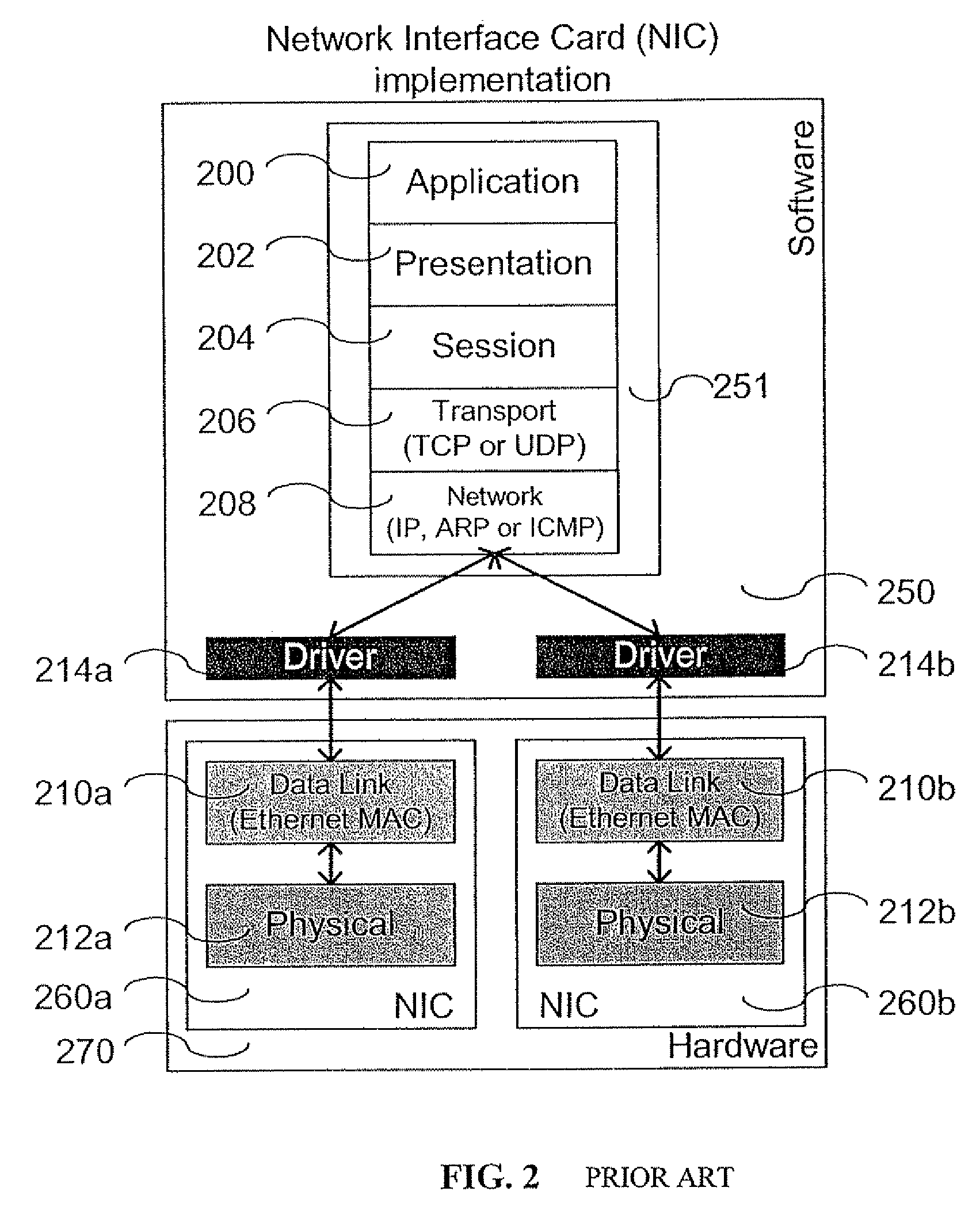

Network traffic accelerator system and method

InactiveUS7480312B2Reduce and offload CPU taskIncreasing available CPU processing powerTime-division multiplexMultiple digital computer combinationsTraffic capacityTransport layer

A network traffic accelerator (NTA) in a TCP / IP communication network comprises a hardware implemented internal network layer, transport layer and data link layer, and is configured to process protocol-supported or protocol-unsupported packets. Both protocol-supported and protocol-unsupported packets may originate from internal or external layers. The NTA includes means to merge such internally and externally originated packages into an internal receive or an internal transmit path, means to split transmit packets between two paths through two data link layers, and means to direct protocol-unsupported packets for external processing.

Owner:TEHUTI NETWORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com