Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

529 results about "Linear alkylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear alkylbenzenes (sometimes also known as LABs) are a family of organic compounds with the formula C₆H₅CₙH₂ₙ₊₁. Typically, n lies between 10 and 16, although generally supplied as a tighter cut, such as C₁₂-C₁₅, C₁₂-C₁₃ and C₁₀-C₁₃, for detergent use. The CₙH₂ₙ₊₁ chain is unbranched. They are mainly produced as intermediate in the production of surfactants, for use in detergent. Since the 1960s, LABs have emerged as the dominant precursor of biodegradable detergents.

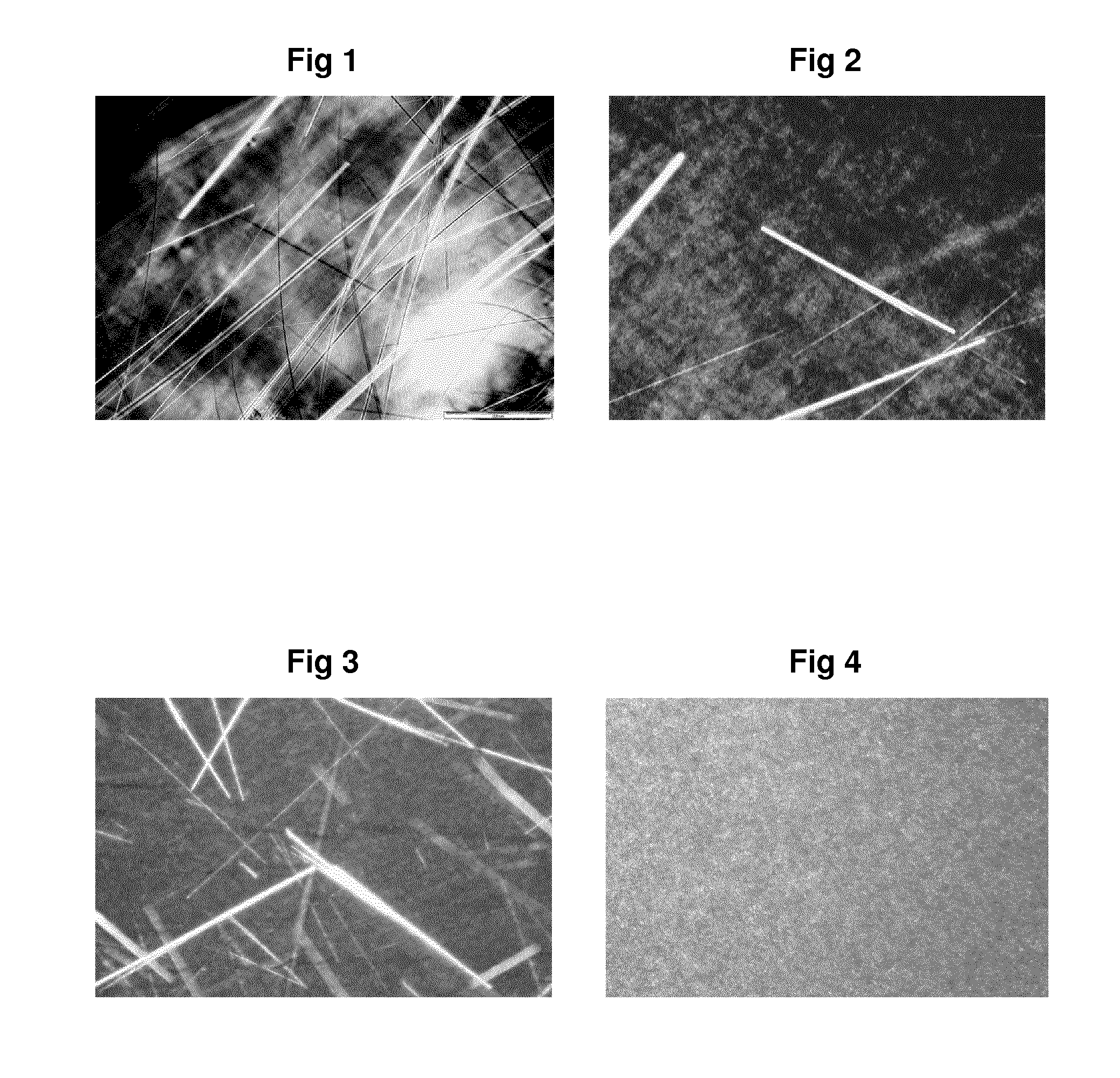

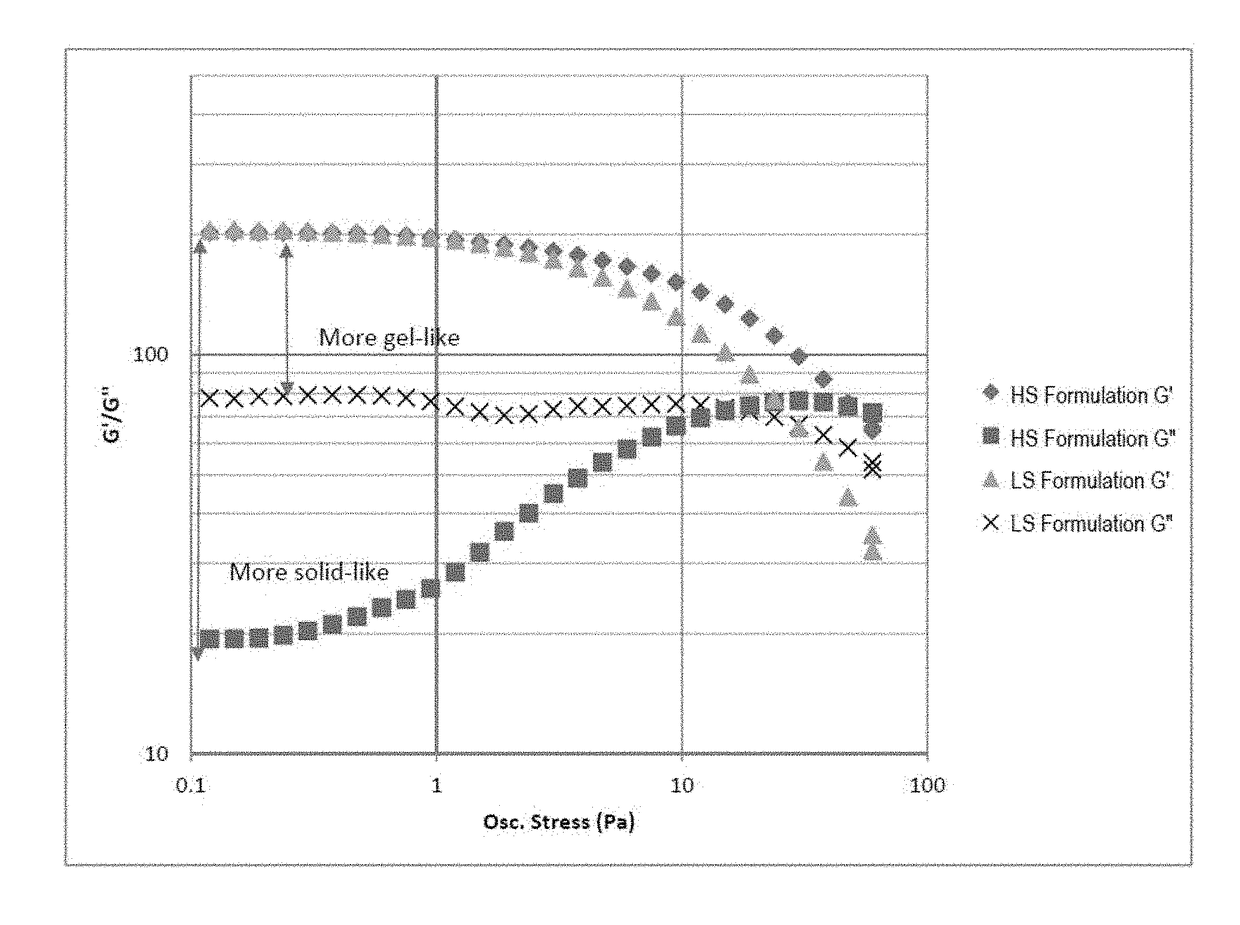

Structured liquids made using LAB sulfonates of varied 2-isomer content

InactiveUS6849588B2High olefin conversionLong life-timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSulfonateLinear alkylbenzene sulfonate

Provided herein are structured liquid surfactants produced using a linear alkylbenzene sulfonate having various levels of 2-isomer content.

Owner:HUNTSMAN PETROCHEMICAL LLC

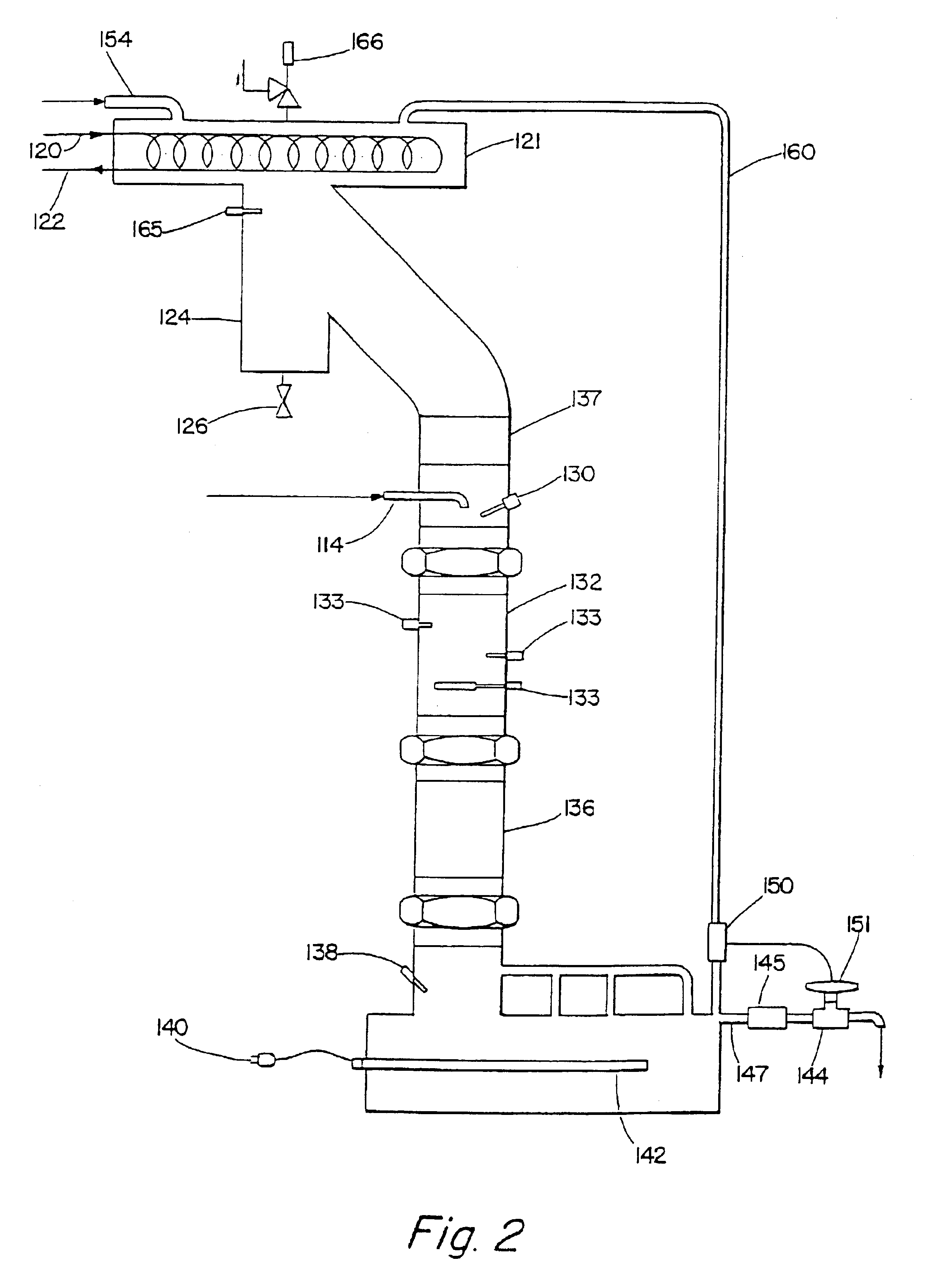

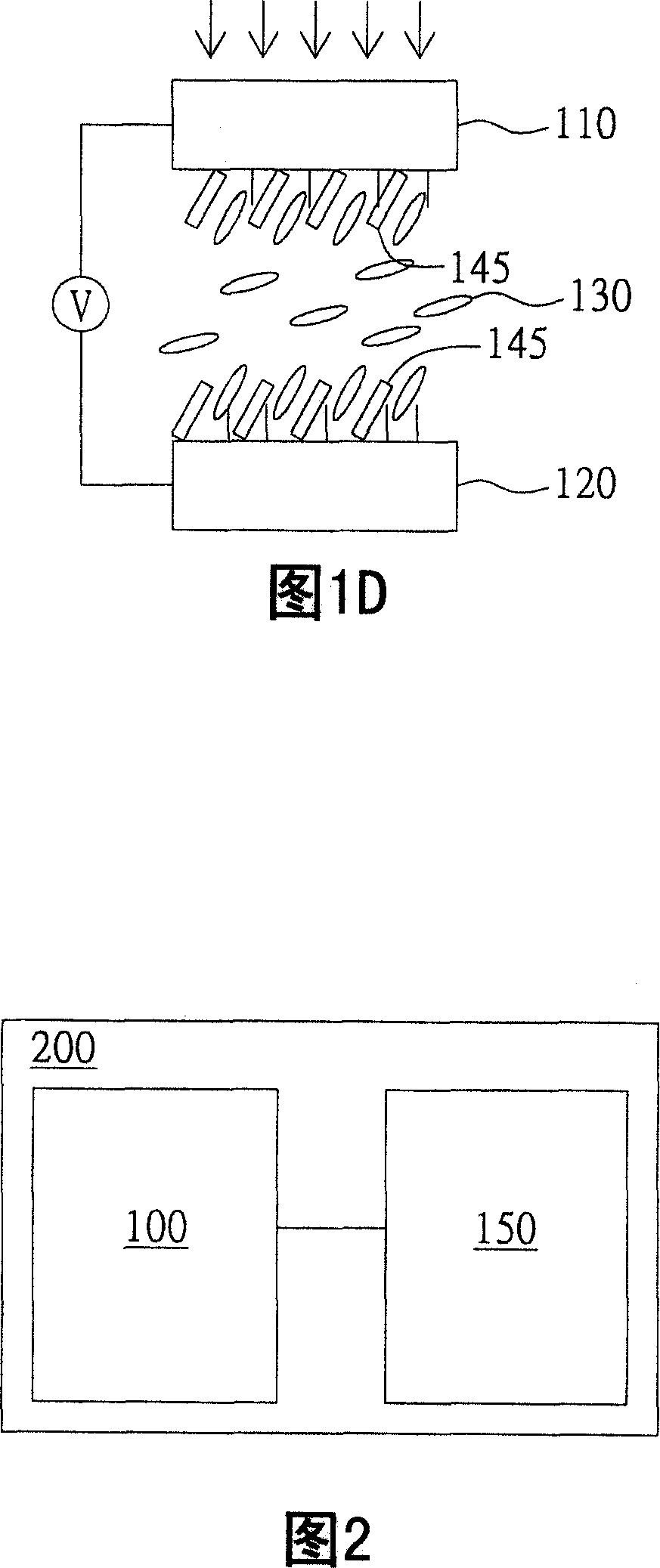

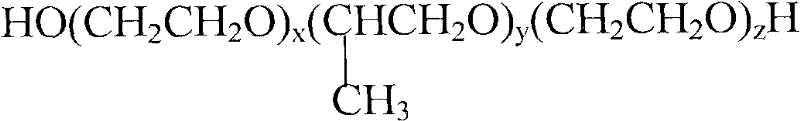

Photosensitive monomer, liquid crystal material, liquid crystal panel and photoelectric equipment and manufacture method thereof

InactiveCN101008784ALiquid crystal compositionsPhotosensitive materials for photomechanical apparatusAlkaneLinear alkylbenzene

This invention relates to one light sensitive monomer, which comprises the following compounds with following chemical formula: R for A-Sp-P; R1, R2, R3, R4, R5 and R6 with at least two A-Sp-P; A from oxygen atom, sulfur atom, methoxy, carbonyl, carboxy group, formamido, methylmercapto group, ethoxycarbonyl group, ethoxycarbonyl group and single key; Sp from isolation base, linear alkylbenzene, branched chain alkane and singly-bound; P for polymerisable group; Z from oxygen atom, sulfur atom, methoxy, carbonyl, carboxy group, formamido, methylmercapto group, ethoxycarbonyl group, ethoxycarbonyl group and single key.

Owner:AU OPTRONICS CORP

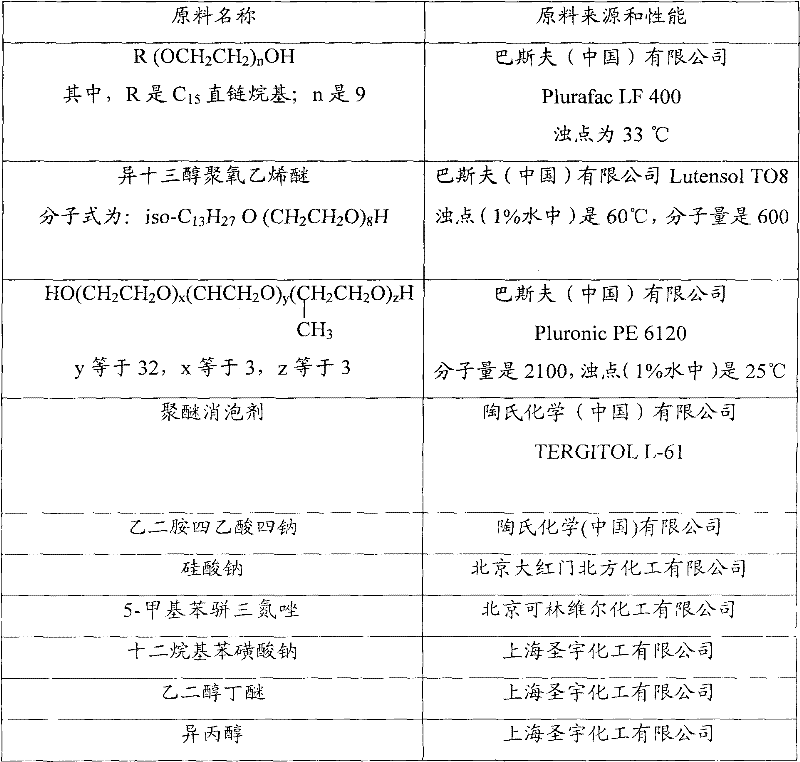

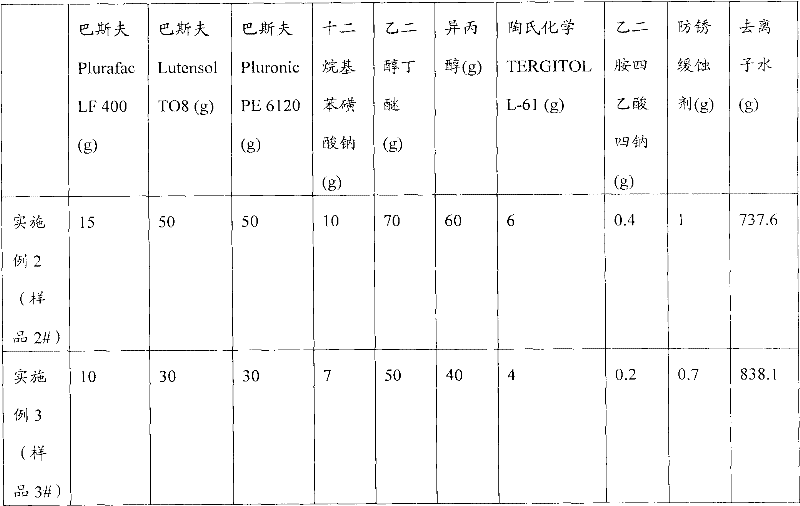

Neutral cleaning agent and preparation method thereof

InactiveCN102399642AReduce surface tensionBest damage-free cleaningOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedLinear alkylbenzene

The invention provides a neutral water-based cleaning agent and a preparation method thereof. The neutral water-based cleaning agent comprises the following components in percentage by mass: 0.5-1.5%, preferably 1%, of aliphatic alcohol alkoxy surfactant, 1-5%, preferably 3%, of aliphatic alcohol polyoxyethylene ether surfactant, 1-5%, preferably 3%, of ployether surfactant, and 0.5-1%, preferably 0.7%, of linear alkyl benzene sodium sulfonate. In the invention, as nonionic surfactants are compounded with anionic surfactants, surface tension of the cleaning agent is reduced, and pH of the cleaning agent is kept neutral; the neutral water-based cleaning agent disclosed by the invention has a good cleaning effect on polar and nonpolar pollutants, and can achieve an unexpected beneficial effect in cleaning slits by adopting physical cleaning means such as ultrasonic cleaning, high-pressure spraying, brushing and the like.

Owner:英泰沃斯(苏州)新材料有限公司

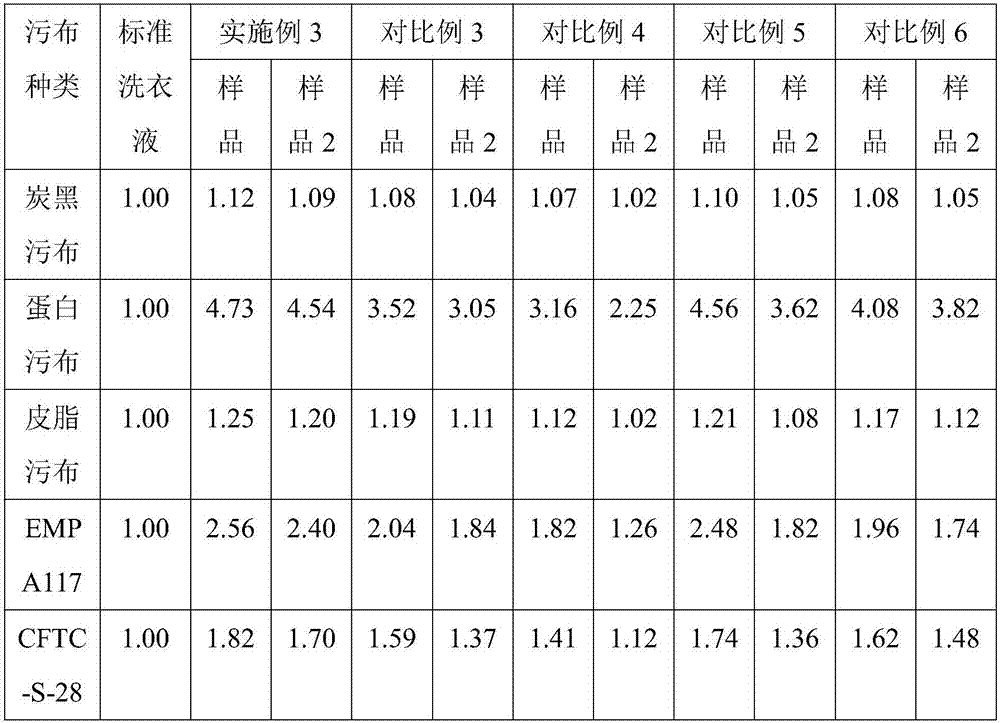

Detergent compositions with unique builder system for enhanced stain removal

ActiveUS20080064619A1Good decontamination effectImproves stain removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholBleach

A unique liquid laundry detergent with enhanced stain removal capacity on bleachable stains is described that comprises linear alkyl benzene sulfonate, alkyl ether sulfate, alcohol ethoxylate, alkali metal silicate, polyacrylate, and optionally carbonate. The composition is remarkably effective at stain removal although the composition is entirely devoid of enzymes and the wash conditions devoid of any bleach additives.

Owner:HENKEL KGAA

Efficient laundry detergent and preparation method thereof

ActiveCN107955743AKeep activeEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPotassiumLinear alkylbenzene

The invention belongs to the field of daily chemical products, and particularly relates to an efficient laundry detergent and a preparation method thereof. The efficient laundry detergent comprises, in weight percent, 5-20% of sodium ethoxylated alkyl sulfate with the mass concentration of 70%, 3-15% of linear alkyl benzene sulfonic acid, 3-6% of fatty alcohol-polyoxyethylene ether, 3-8% of cocamidopropyl betaine with the mass concentration of 35%, 3-10% of potassium laurate water solution with the mass concentration of 17%, 3-10% of potassium oleate water solution with the mass concentrationof 5%, 1-10% of sodium hydroxide, 0.1-2% of compound enzyme, 0.05-0.2% of preservative, 0.1-0.5% of ethylene diamine tetraacetic acid, 0.05-0.5% of citric acid, 0.5-3% of sodium chloride, 0.15-0.5% ofessence and the balance deionized water. The efficient laundry detergent is high in antibacterial and stain removal ability and environmentally friendly and has fewer bubbles, and energy, time and water are saved.

Owner:WALCH GUANGZHOU COMMODITY

Super-concentration fabric cleaning agent formula and preparing method thereof

InactiveCN104479899AStrong decontaminationImprove decontamination abilityOrganic detergent compounding agentsNon-ionic surface-active compoundsLinear alkylbenzeneSurface-active agents

The invention relates to a super-concentration fabric cleaning agent which is composed of, by weight, 25-99 parts of surface active agents, 0-21 parts of addition agents and 1-75 parts of water. The surface active agent is at least one of ethoxylated lauryl alcohol sulfates (AES), fat polyoxyethylene ether (AEO), fat alcohol sodium sulfate (K12), fatty acid methyl ester ethoxylate (MEE), lauramidopropyl betaine (CAB), fatty alcohol diethanolamide (6501), linear alkylbenzene sulphonic acid (LAS) and alky glycoside (APG). The super-concentration fabric cleaning agent is free of organic solvents, no solubilization is needed, and the active matter content can reach 99%. Through the characteristic that the surface active agent fatty acid methyl ester ethoxylate (MEE) is free of cloud points, the complex formulation is conducted on the fatty acid methyl ester ethoxylate (MEE) and other surface active agents, and the functions of solubilization, complex formulation and surface activation are achieved.

Owner:WALCH GUANGZHOU COMMODITY

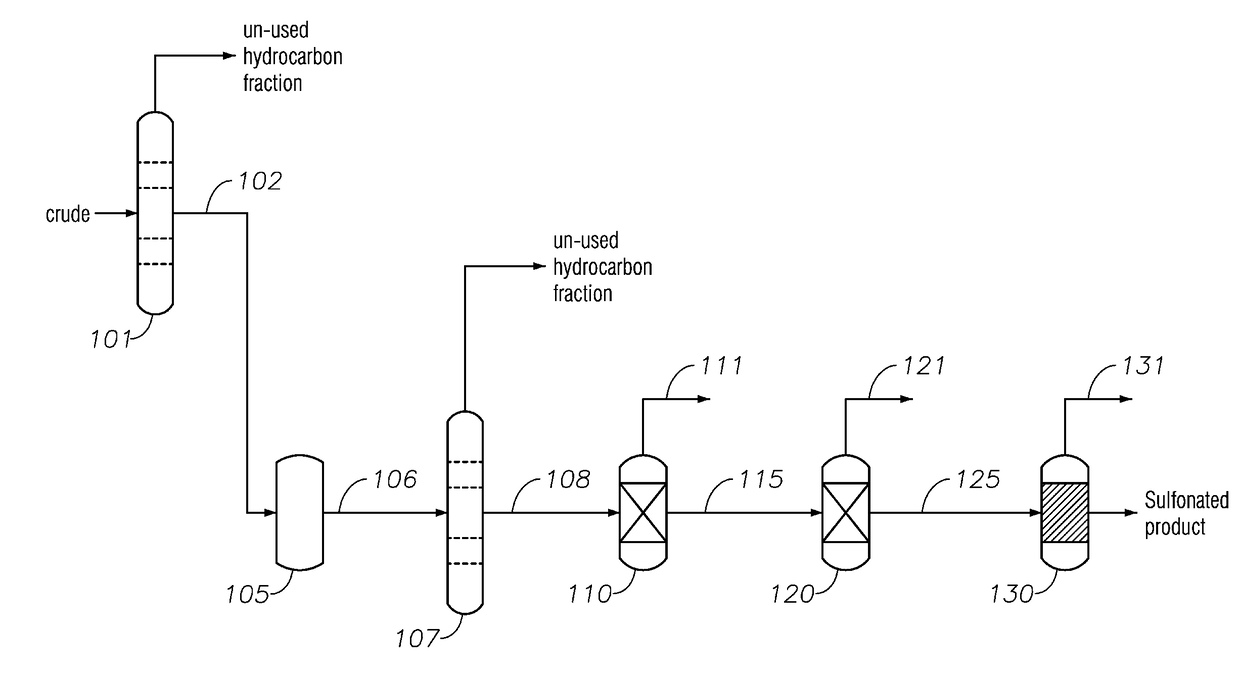

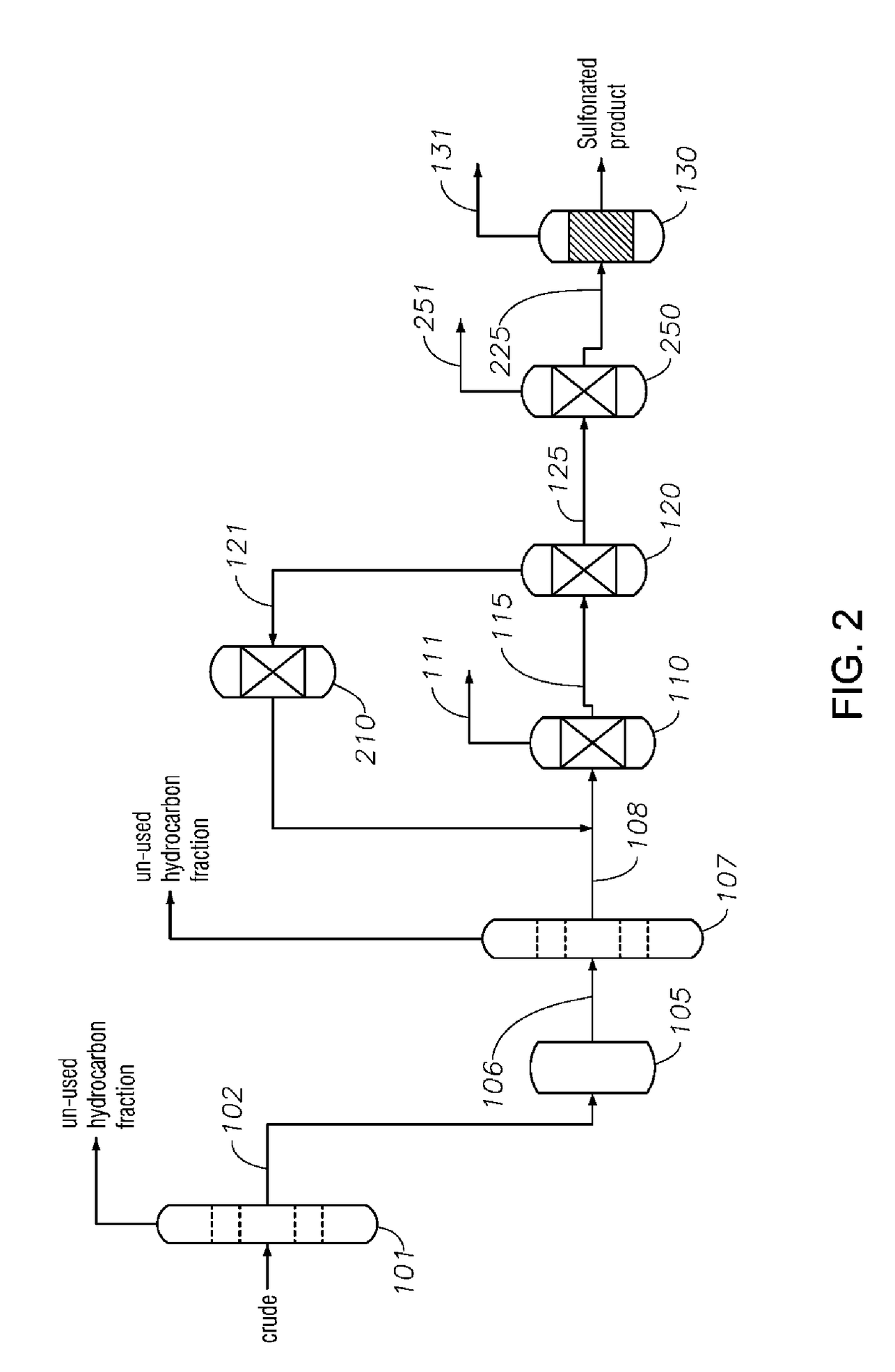

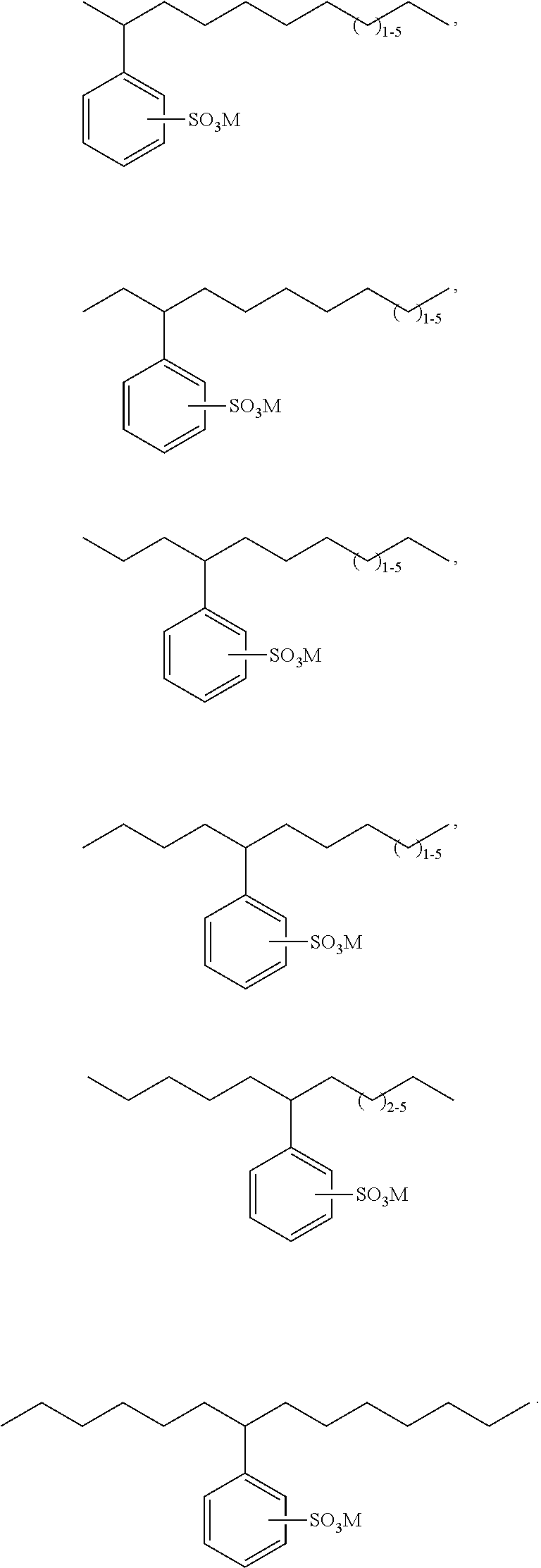

Alkylaromatic Sulfonate Compositions From Mixed Hydrocarbons

ActiveUS20180057451A1Impact performanceCheap productionOrganic compound preparationSulfonic acids salts preparationArylSulfonate

Provided herein are various methods for forming alkylaromatic sulfonate compositions and blended alkylaromatic sulfonate compositions, and such compositions themselves. The methods of various embodiments include obtaining a C8-C30 hydrocarbon mixture, optionally treating the mixture to concentrate the mixture in sulfonatable aromatics, and sulfonating the mixture to form the alkylaromatic sulfonates. The mixture or treated mixture may be blended with linear alkyl benzene (LAB) compositions and sulfonated, and / or the alkylaryl sulfonates may be blended with linear alkylbenzene sulfonate (LAS) compositions, to form the blended alkylaromatic sulfonates of some embodiments. These compositions and processes for making them may be tailored to serve a variety of end uses, such as detergents in cleaning solutions or for enhanced oil recovery operations, and / or as low foaming and / or hydrotropic additives in detergent formulations, and the like.

Owner:EXXONMOBIL CHEM PAT INC

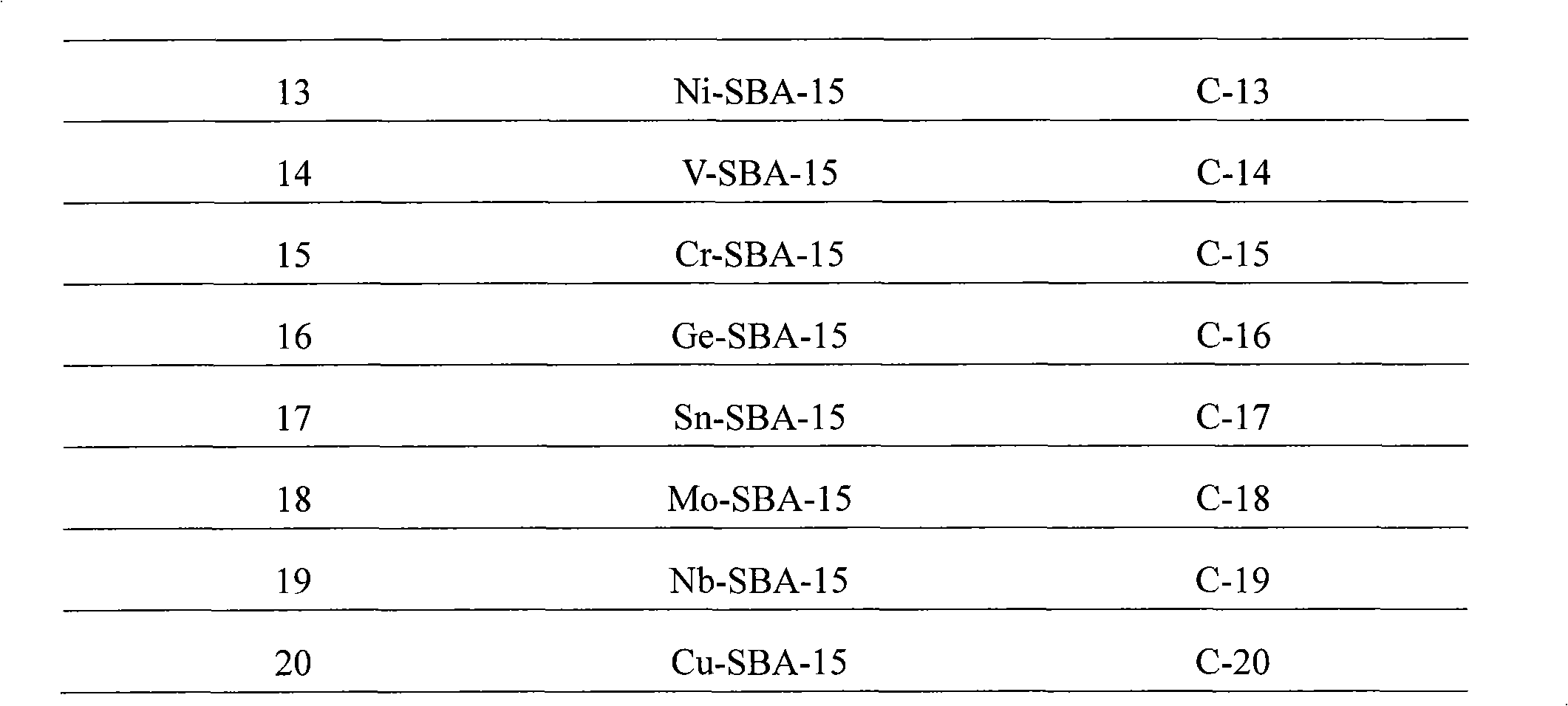

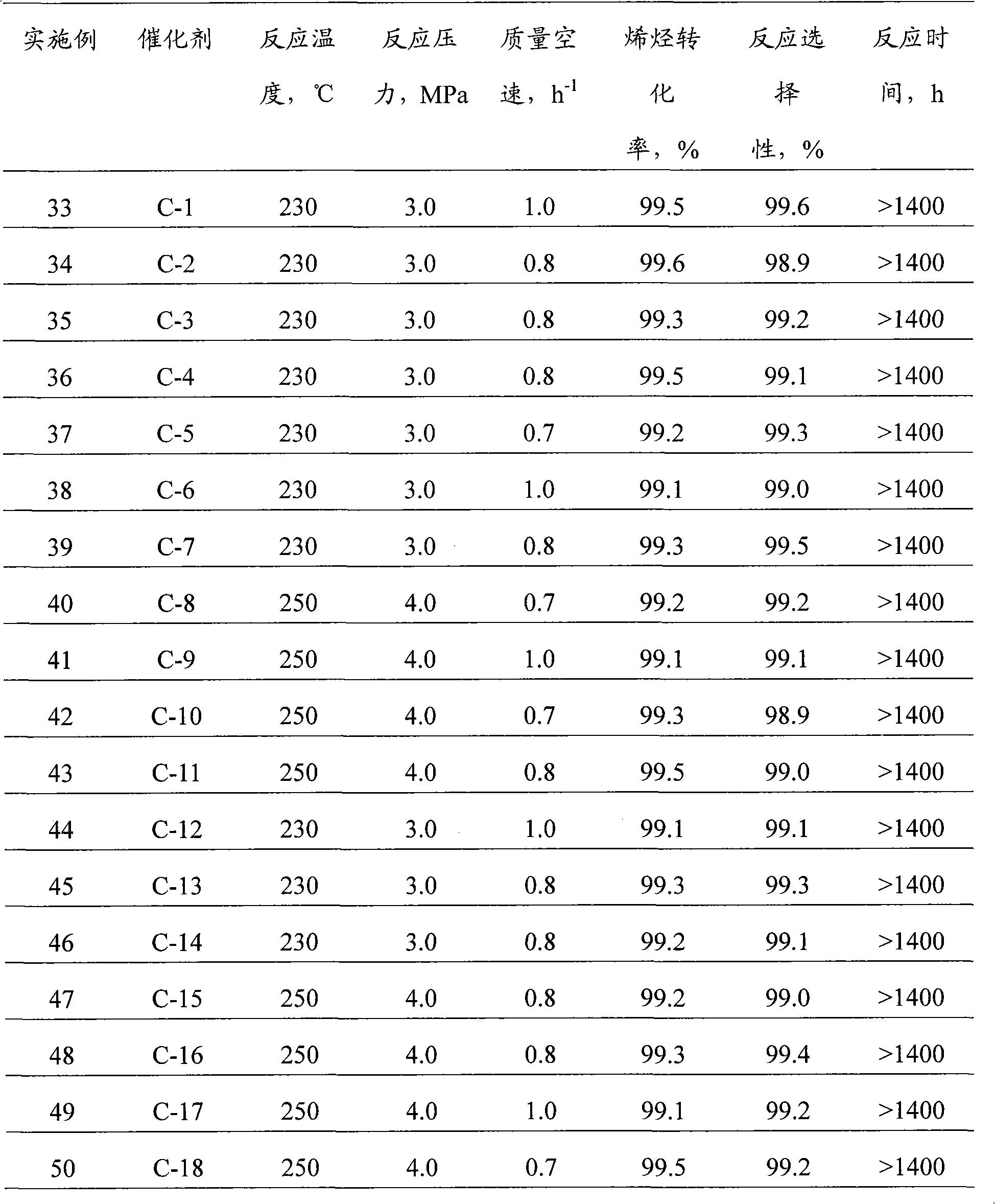

Method for synthesizing linear alkylbenzene

ActiveCN101289358AGood activity and stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsSolid acidLinear alkylbenzene

The invention provides a synthetic method for linear alkylbenzene. By taking linear olefin containing 2 to 20 carbon atoms and benzene as raw materials under the reaction condition of a temperature being 10 to 450 DEG C, a pressure being 0.1 to 15MPa, the ratio of the amount of substances of benzene and the olefin is 2 to 100:1 and the airspeed of a feeding total mass is 0.1 to 20 h<-1>, and an alkylation reaction is carried out by catalyzing by a solid acid catalyst, the linear alkylbenzene is obtained. The solid acid catalyst is M-SBA-15 typed mesopore molecular sieve catalyst or compound solid acid catalyst which is obtained by modifying the M-SBA-15 typed mesopore molecular sieve catalyst. The catalyst adopted by the invention has no corrosion, is friendly to environment and has good activity stability; therefore, higher olefin conversion and reaction selectivity can also be obtained even under comparatively lower temperature. Furthermore, the device is stable and has long operation time; therefore, frequent switching operation on the reaction and regeneration of the reactor can be avoided.

Owner:ZHEJIANG UNIV OF TECH

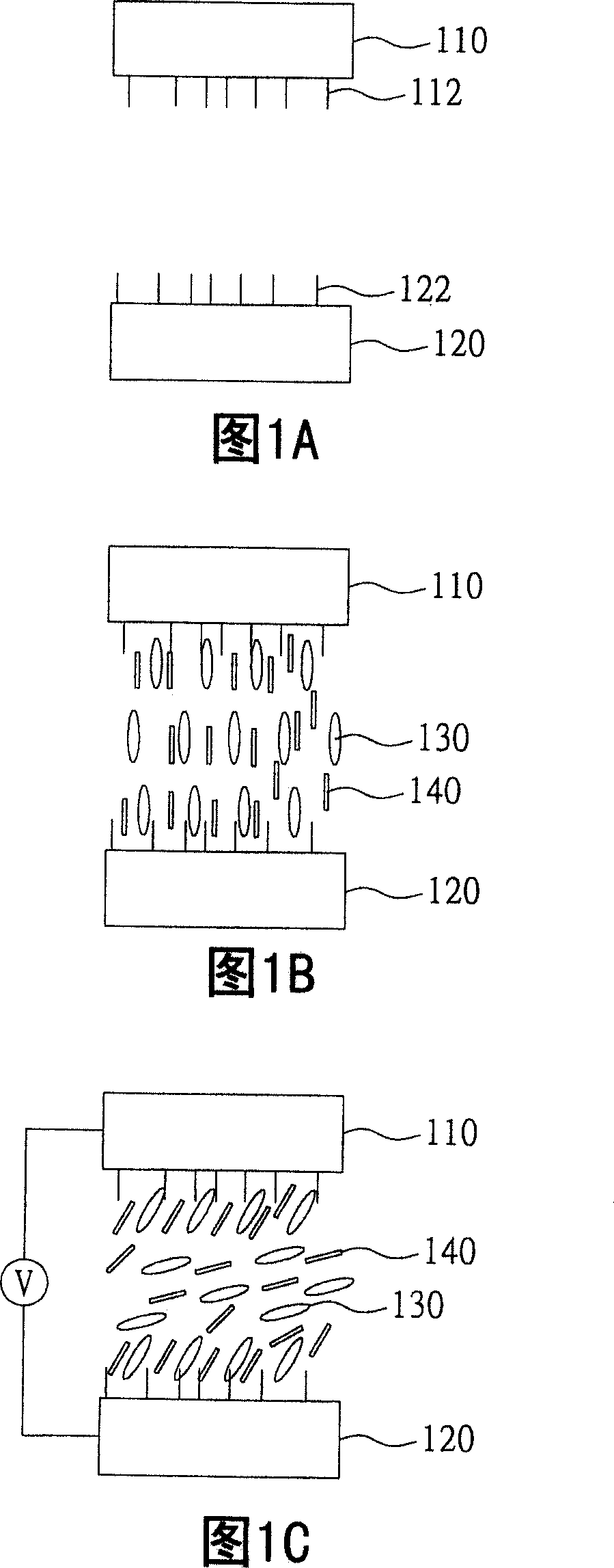

Manufacture of high active detergent particles

ActiveUS20120058266A1Nice appearanceImprove coating qualityNon-ionic surface-active compoundsLiquid surface applicatorsLinear alkylbenzene sulfonateLinear alkylbenzene

A process for manufacturing detergent particles comprising the steps of: a) forming a liquid surfactant blend comprising a major amount of surfactant and a minor amount of water, the surfactant part consisting of at least 51 wt % linear alkylbenzene sulfonate and at least one co-surfactant, the surfactant blend consisting of at most 20 wt % nonionic surfactant; b) drying the liquid surfactant blend of step (a) in an evaporator or drier to a moisture content of at most 2 wt % and cooling the output from the evaporator or dryer; c) feeding the cooled material, which output comprises at least 93 wt % surfactant blend with a major part of LAS, to an extruder, optionally along with less than 10 wt % of other materials such as perfume, fluorescer, and extruding the surfactant blend to form an extrudate while periodically cutting the extrudate to form hard detergent particles with a diameter across the extruder of greater than 2 mm and a thickness along the axis of the extruder of greater than 0.2 mm, provided that the diameter is greater than the thickness; d) optionally, coating the extruded hard detergent particles with up to 30 wt % coating material selected from powdered inorganic material and mixtures of such material and nonionic material with a melting point in the range 40 to 90° C.

Owner:CONOPCO INC D B A UNILEVER

Heavy grease stain environment-friendly type water base cleaning compound

InactiveCN103834487AGood decontamination effectGood compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsWater basedTriclosan

The invention discloses a heavy grease stain environment-friendly type water base cleaning compound comprising 10-15% of surfactant, 1-3% of additive, 1-5% of antiseptic, 3-5% of organic amine and remaining tap water; the ingredient of the surfactant comprises 4-5% of aliphatic acid methyl esters ethoxylate, 2-3.5% of APG, 1-3% of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5-1% of straight chain sodium alkyl benzene sulfonate (LAS) and 0.5-2% of aliphatic acid methyl esters ethoxylate; the additive is one or more from a group formed by sodium citrate, citric acid, lactic acid and DL-malic acid; the organic amine is one or more from a group formed by triethanolamine, n-butylamine, diethanolamine and N-methyl diethanolamine; the antiseptic at least is triclosan or tetrachloro isophthalonitrile; through the said method, the heavy grease stain environment-friendly type water base cleaning compound has anti bacterium, heavy grease stain cleaning and environmental protection performances.

Owner:SUZHOU LOTTE CHEM TECH

Mite-removing laundry liquid

ActiveCN102051279AImprove securityPrevent mildewOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsAlcoholActive component

The invention relates to a mite-removing laundry liquid which comprises the following main active components in parts by mass: 5-10 parts of dodecyl dimethyl lycine, 7-12 parts of sodium alcohol ether sulfate, 6-10 parts of fatty alcohol polyoxyethylene ether, 4-8 parts of sodium linear alkyl benzene sulfonate, 0.5-1 part of antibiotic mildewproof miticide (MGU-350), 0.2-0.5 part of chelator and 1-5 parts of thickening agent. The mite-removing laundry liquid has the advantage of strong detergency, does not damage the surface and has the effect of removing mites.

Owner:BEIJING REWARD HOME CARE CHEM

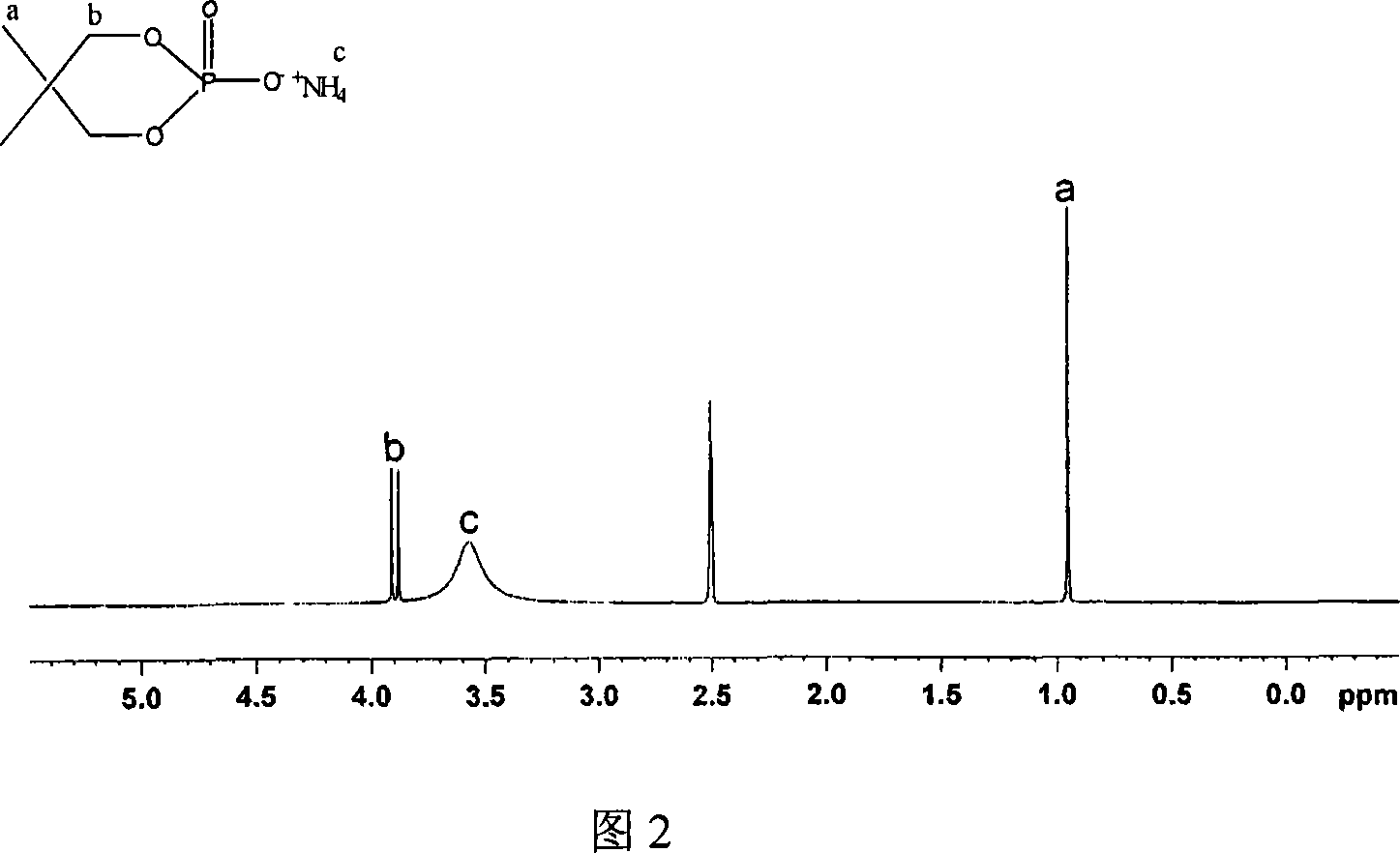

Phosphorus-nitrogen type halogen-free ionic fire retardant, preparation method thereof and fire retarding polyvinyl alcohol material prepared from the same

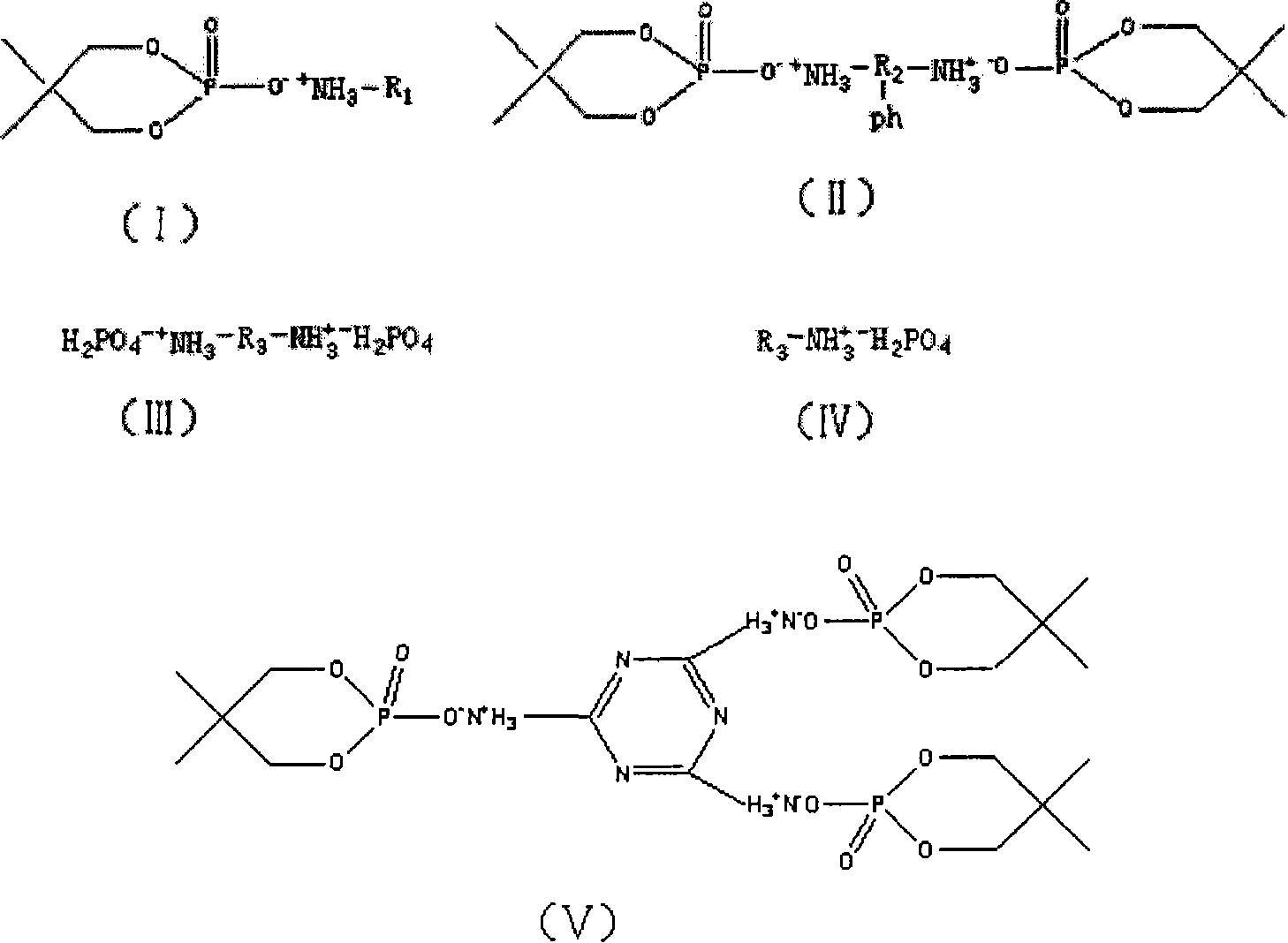

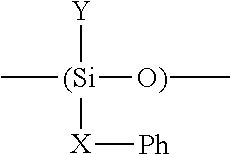

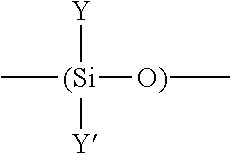

The invention discloses a phosphonitryl no halide ion fire retardant which comprises the following structures: regarding R1 as linear alkyl or linear alkylbenzene; regarding R2 as linear alkylbenzene; regarding R3 as linear alkyl or acyl or linear alkylbenzene (the carbon atomicity on the straight chain of R1, R2, R3 is 0-6). The invention also discloses a method for the fire retardant and a fire retardant polyvinyl alcohol material with a compounded fire retardant made up by the fire retardant and the other composition. The invention provides no halide ion and a good water-solubility, which reduces the adding content; provides a good force property, a low cost, a simple technique.

Owner:SICHUAN UNIV

Liquid detergent composition

InactiveUS20060111266A1Easy to cleanLower levelCationic surface-active compoundsNon-ionic surface-active compoundsLinear alkylbenzene sulfonateLinear alkylbenzene

Owner:CONOPCO INC D B A UNILEVER

Wax removing water for cleaning wax scale on surface of polished workpiece and preparation method thereof

The invention discloses wax removing water for cleaning wax scale on the surface of a polished workpiece and a preparation method thereof. The wax removing water comprises the following components: 3 to 5 g / L of linear alkylbenzene sodium sulfonate, 5 to 10 g / L of secondary alkyl sulfate, 5 to 10 g / L of alkanolamide, 30 to 40 g / L of fatty alcohol polyoxyethylene ether sulfate, 100 to 150 g / L of sodium tripolyphosphate, and 3 to 5 g / L of ethylene diamine tetraacetic acid (EDTA). The wax removing water has good emulsifying effect and very strong solubilizing and dispersion effects, and can thoroughly clean the wax scale on the surface of the polished workpiece.

Owner:HUBEI DE MEI TECH

Bio-based linear alkylphenyl sulfonates

InactiveUS20120213726A1Inorganic/elemental detergent compounding agentsCosmetic preparationsSulfonateHard-surface cleaner

The invention is directed to mixtures comprising C10-C14 linear alkylphenyl sulfonates with alkyl groups having a biobased content of at least 50%. These C10-C14 linear alkylphenyl sulfonates are used in consumer product cleaning and personal care compositions (e.g., dishcare, laundry, hard surface cleaners, shampoos, conditioners, and soaps). The invention is further directed to a method of making a mixture of partially or wholly bio-based C10-C14 linear alkylphenyl sulfonates with alkyl groups having a particular bio-based content.

Owner:THE PROCTER & GAMBLE COMPANY

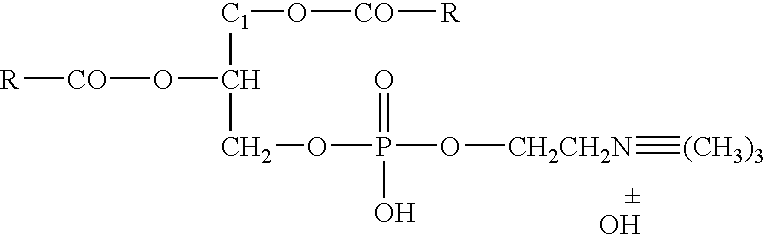

Biodegradable lubricants

InactiveUS7517837B2Improve anti-wear propertiesImprove performanceGroup 5/15 element organic compoundsAdditivesHydroxystearic AcidLinear alkylbenzene

Lubricant compositions based on a biodegradable base oil, such as a polyol ester or polyalkylene glycol, a calcium sulfonate based thickener and a naturally occurring phospholipid as an anti-wear additive, such as lecithin for environmentally sensitive applications and when having a specific gravity greater than 1.0 at 60° F. (15.6° C.) for marine applications are provided. The thickener may include a linear alkybenzene sulfonic acid, acetic acid and 12 hydroxystearic acid and a calcium carbonate solid film lubricant. The lubricant submerges when dispensed on water avoiding formations of a surface sheen and biodegrades when submerged resulting in a water ecology friendly lubricant.

Owner:CHEMTURA CORP

Antimicrobial moldproof finishing agent for silk fabrics

The invention discloses an antimicrobial moldproof finishing agent for silk fabrics, which is prepared from the following components in parts by weight: 7-12 parts of linear alkyl benzenesulfonic acid, 8-13 parts of ethylene glycol, 6-11 parts of zinc acetate, 4-8 parts of cocoyl monoethanolamine, 3-9 parts of ethoxylated straight-chain primary alcohol, 4-11 parts of nickel N,N-di-n-butyldithiocarbamate, 6-15 parts of alkyl glycoside, 3-7 parts of polyvinylpyrrolidone, 2-4 parts of potassium xylenesulfonate and 5-7 parts of pyrethrin. The finishing agent for silk fabrics has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:WUJIANG DALONG JET WEAVING

Stable unit dose compositions with high water content

ActiveUS20180216033A1Increase moisture contentHigh activityNon-ionic surface-active compoundsDetergent solventsWater dispersibleLinear alkylbenzene sulfonate

Stable unit dose compositions with high water content are provided. Such unit dose compositions include an aqueous composition having a water activity of from about 0.65 to about 0.95 and a water-soluble container formed from a water-soluble or water-dispersible film material. In one embodiment, the aqueous composition includes water in an amount of 25% to 70% by weight, a surfactant system, and a water binding agent. The surfactant system may include: (1) a linear alkylbenzene sulfonate (LAS) and / or an alcohol ethoxylsulfate (AES), (2) a non-ionic surfactant, and (3) a fatty acid. The unit dose compositions can prevent the enclosed liquid detergent composition with a high level of water content from dissolving or pre-maturely dispersing the water-soluble container.

Owner:HENKEL KGAA

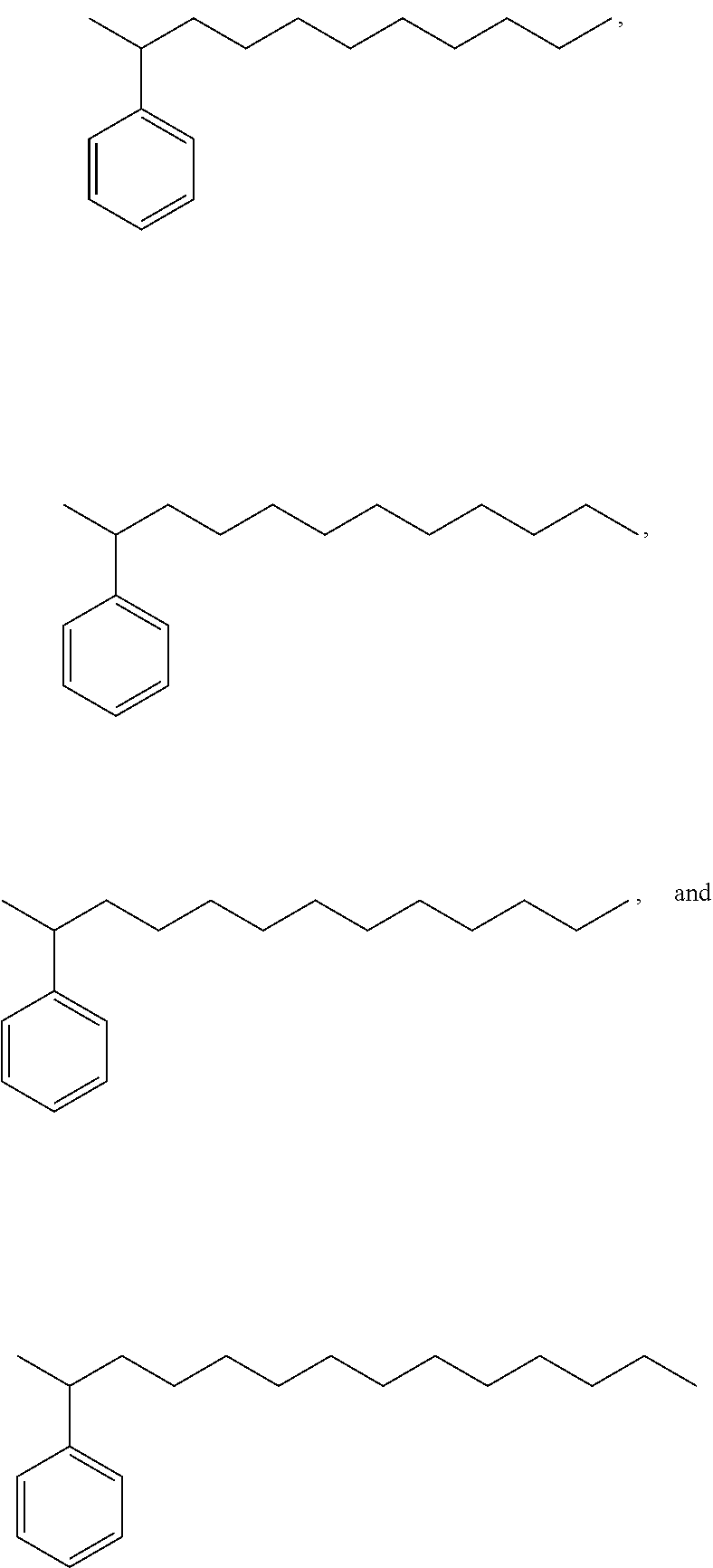

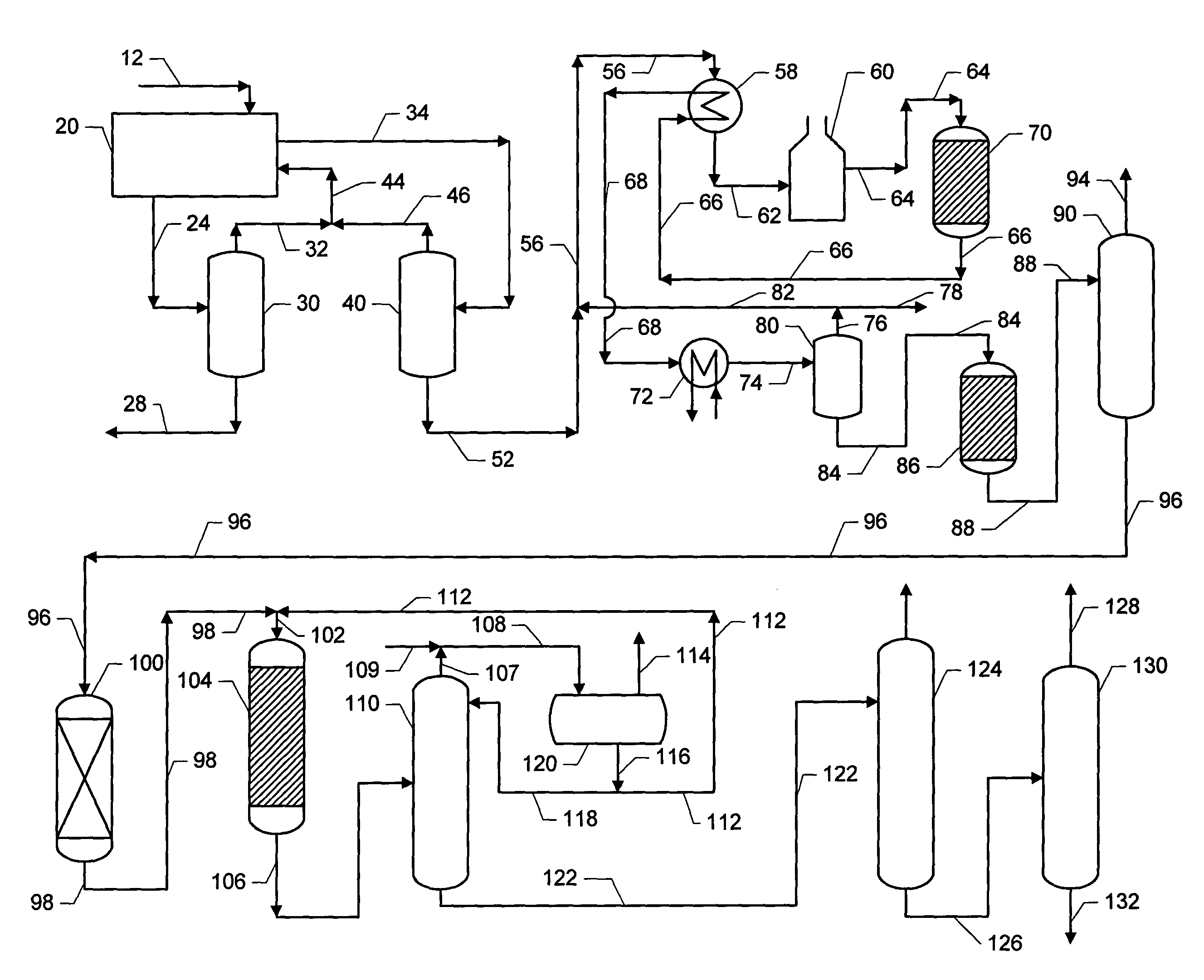

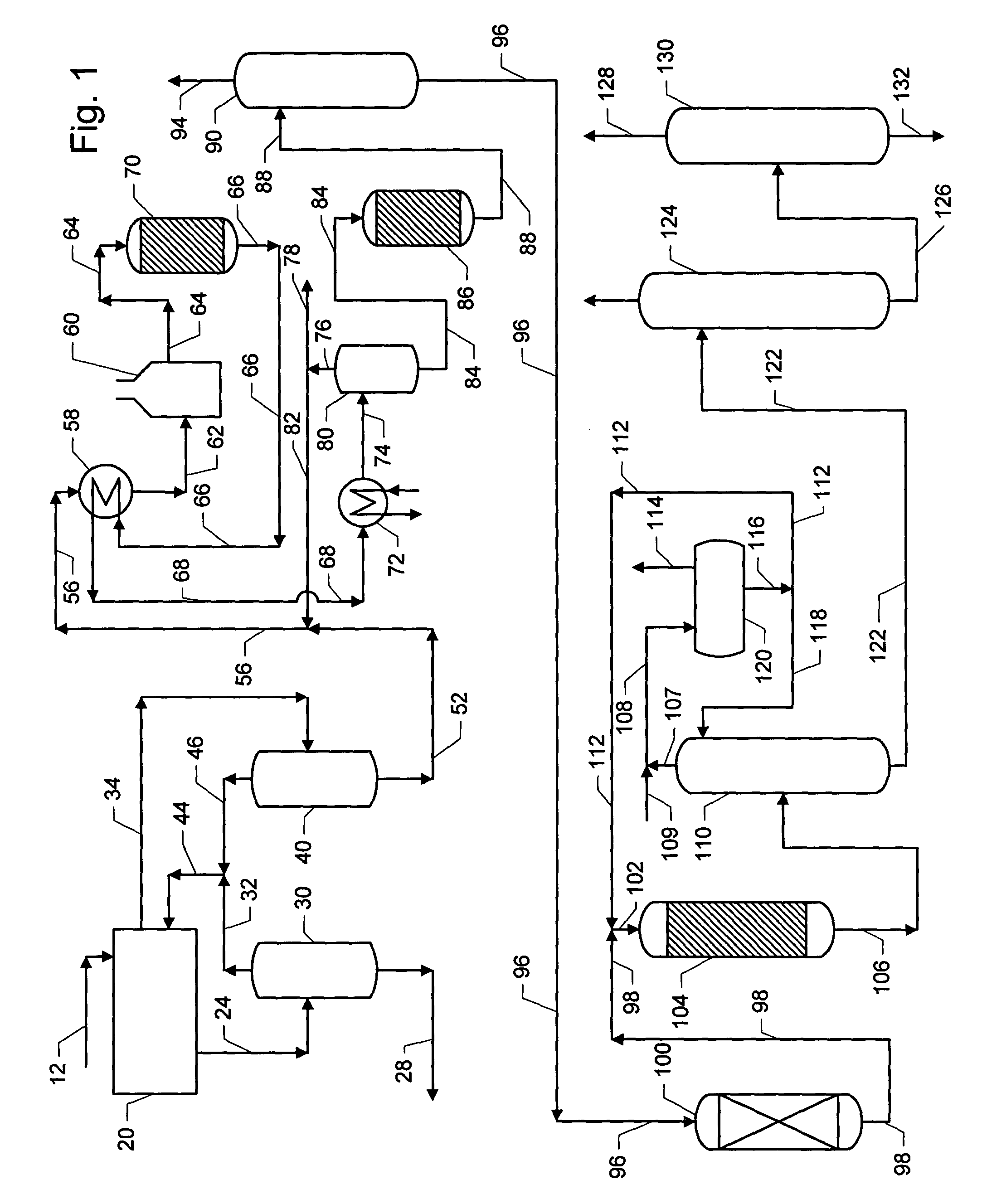

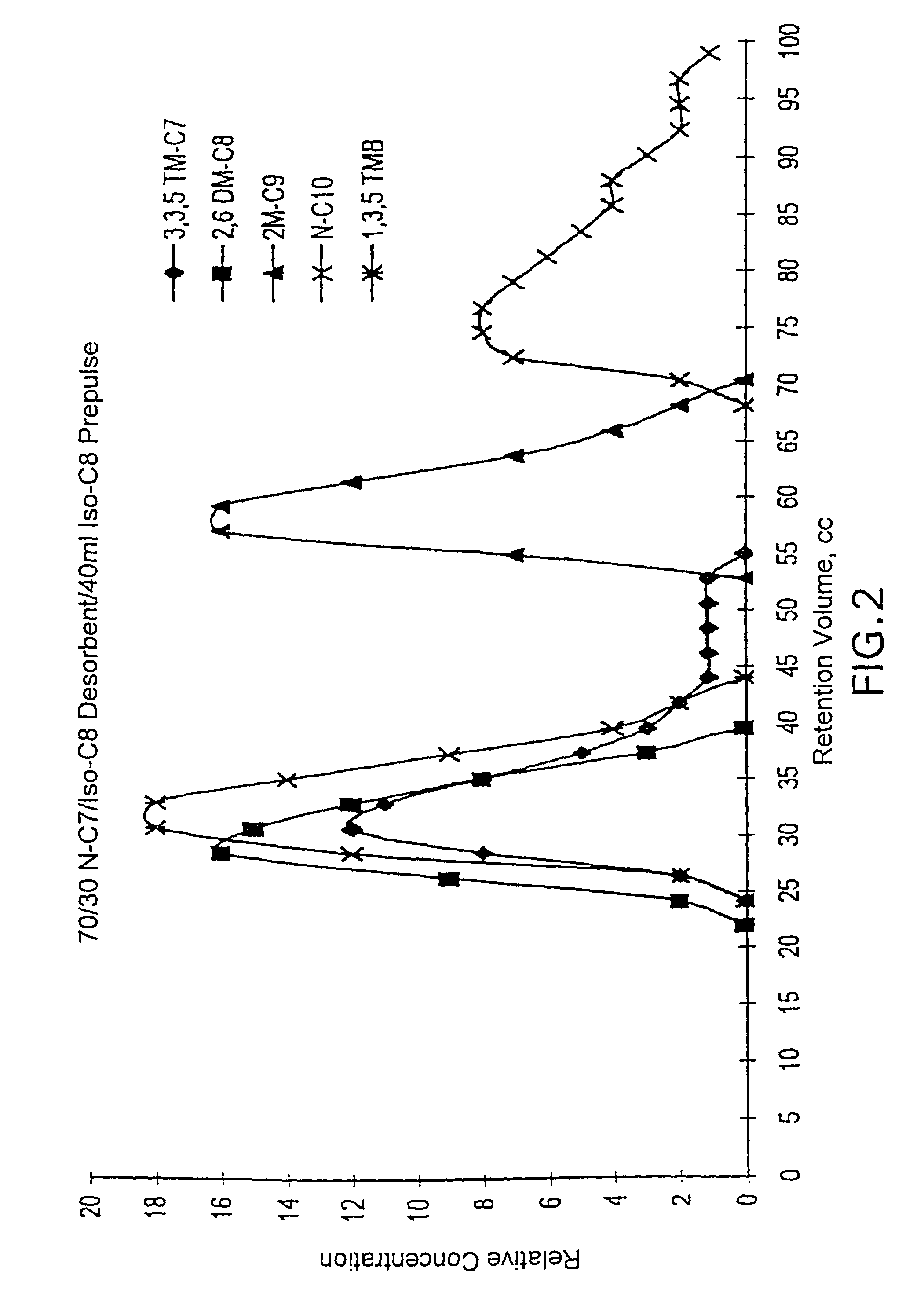

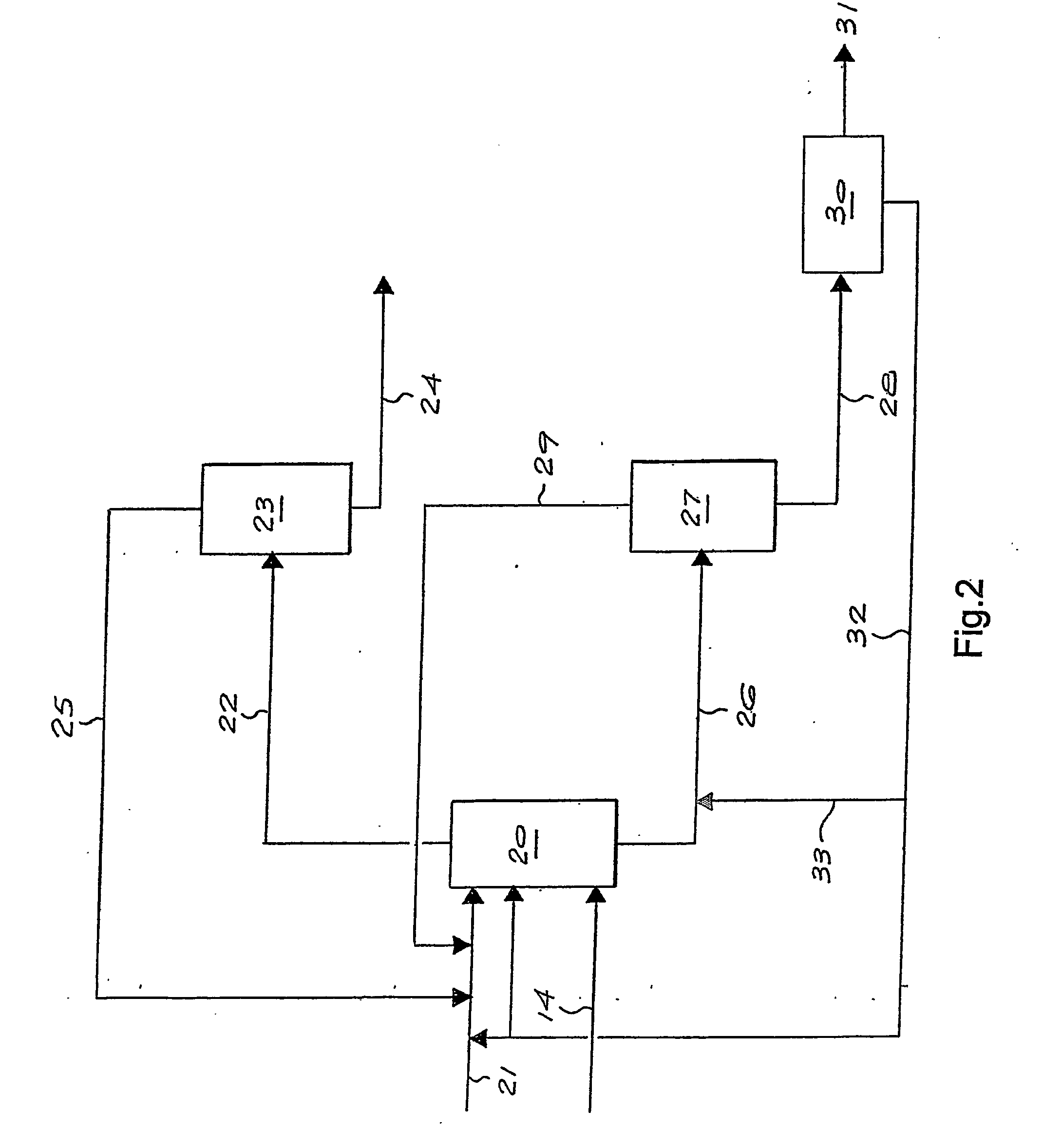

Phenyl-alkane compositions produced using an adsorptive separation section

The present invention is a process for producing phenyl-alkanes by paraffin adsorptive separation followed by paraffin dehydrogenation and then by alkylation of a phenyl compound by a lightly branched olefin. The adsorptive separation step employs a silicalite adsorbent and, as the desorbent, a C5-C8 linear paraffin, a C5-C8 cycloparaffin, a branched paraffin such as isooctane, or mixtures thereof. The effluent of the alkylation zone comprises paraffins that are recycled to the adsorptive separation step or to the dehydrogenation step. This invention is also a process that that sulfonates phenyl-alkanes having lightly branched aliphatic alkyl groups that to produce modified alkylbenzene sulfonates. In addition, this invention is the compositions produced by these processes, which can be used as detergents having improved cleaning effectiveness in hard and / or cold water while also having biodegradability comparable to that of linear alkylbenzene sulfonates, as lubricants, and as lubricant additives. This invention is moreover the use of compositions produced by these processes as lubricants and lubricant additives.

Owner:UOP LLC

Free flowing aqueous lamellar gel laundry detergent liquid comprising epei

InactiveUS20160312152A1Improve performanceReduce crystallinityOrganic detergent compounding agentsNon-ionic surface-active compoundsPolyesterPotassium

A free flowing aqueous lamellar gel laundry detergent liquid comprising, in addition to water: a) 20 to 35 wt % of a surfactant system in the form of vesicles comprising potassium neutralised linear alky benzene sulfonate anionic surfactant (LAS), alkyl ether sulphate anionic surfactant (AES) and nonionic surfactants, b) at least 3 wt % of a first nonionic polymeric material (EPEI) which is a water-soluble fabric cleaning polymer; c) from 0.1 to 1 wt % of a second nonionic polymeric material (Pluronic) which is a tri-block polymer with a hydrophobic midblock and two hydrophilic end-blocks with an HLB of at least 20 d) optionally, a polyester soil release polymer and e) optionally, at least 2 wt % 1-hydroxyethane 1,1-diphosphonic acid (HEDP).

Owner:CONOPCO INC D B A UNILEVER

Stable unit dose compositions with high water content and structured surfactants

ActiveUS20180216034A1Increase moisture contentHigh activityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater dispersibleLinear alkylbenzene sulfonate

Stable unit dose compositions with high water content are provided. Such unit dose compositions include an aqueous composition having a water activity of from about 0.60 to about 0.95 and a water-soluble container formed from a water-soluble or water-dispersible film material. In one embodiment, the aqueous composition includes water in an amount of 20% to 70% by weight, a structured surfactant system which is in the form of a lamellar structure, and a salt which promotes the formation of the lamellar structure. The surfactant system may include: (1) a linear alkylbenzene sulfonate (LAS) and / or an alcohol ethoxylsulfate (AES), (2) a non-ionic surfactant, and (3) a fatty acid. The unit dose compositions can prevent the enclosed liquid detergent composition with a high level of water content from dissolving or pre-maturely dispersing the water-soluble container due to the lamellar structure of the composition.

Owner:HENKEL KGAA

Efficient low-foam normal-temperature phosphorous-free oil removing liquid

InactiveCN105483726AEasy to handleGood degreasing effectSodium metasilicateLinear alkylbenzene sulfonate

The invention discloses efficient low-foam normal-temperature phosphorous-free oil removing liquid. The oil removing liquid consists of the following components in percentage by weight: 3.0-7.0 wt% of alkylphenol polyoxyethylene ether, 1.0-5.0 wt% of fatty alcohol polyoxyethylene ether, 1.0-5.0 wt% of fatty acid methyl ester polyoxyethylene ether sulfonate, 0.5-4.0 wt% of linear alkylbenzene sulfonate, 10.0-30.0 wt% of carbonate, 4.0-15.0 wt% of sodium metasilicate pentahydrate, 5.0-15.0 wt% of sodium hydroxide, 4.0-12.0 wt% of sodium citrate, 0.5-1.0 wt% of redeposition resisting agent, 2.0-5.0 wt% of complexing agent, 0.1-0.3 wt% of defoaming agent, 1.0-3.0 wt% of corrosion inhibitor, 0.01-0.1 wt% of flocculating settling agent, and the balance of water. The oil removing liquid has the characteristics of cost saving, improvement of oil removing efficiency and economic benefit.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

Normal-temperature nonphosphorus degreasing agent for metal surface processing and preparation method thereof

The invention discloses a normal-temperature nonphosphorus degreasing agent for metal surface processing and a preparation method thereof. The normal-temperature nonphosphorus degreasing agent comprises the raw material percentages by weight: 10-20% of sodium hydroxide, 5-10% of sodium metasilicate, 3-5% of sodium carbonate, 6-8% of alkylphenol polyoxyethylene, 2-4% of linear alkyl benzene sulphonate, 1-2% of 2-butoxyethanol, 0.5-1% of polyether and the balance of water. Compared with the prior art, the normal-temperature nonphosphorus degreasing agent has the characteristics of normal temperature, environmental protection (non phosphorus), high efficiency, safety, low foam, solubilization, good decontaminability and the like, and does not corrode steel plates, aluminum, copper, plastics, rubber and the like.

Owner:合肥华清高科表面技术股份有限公司

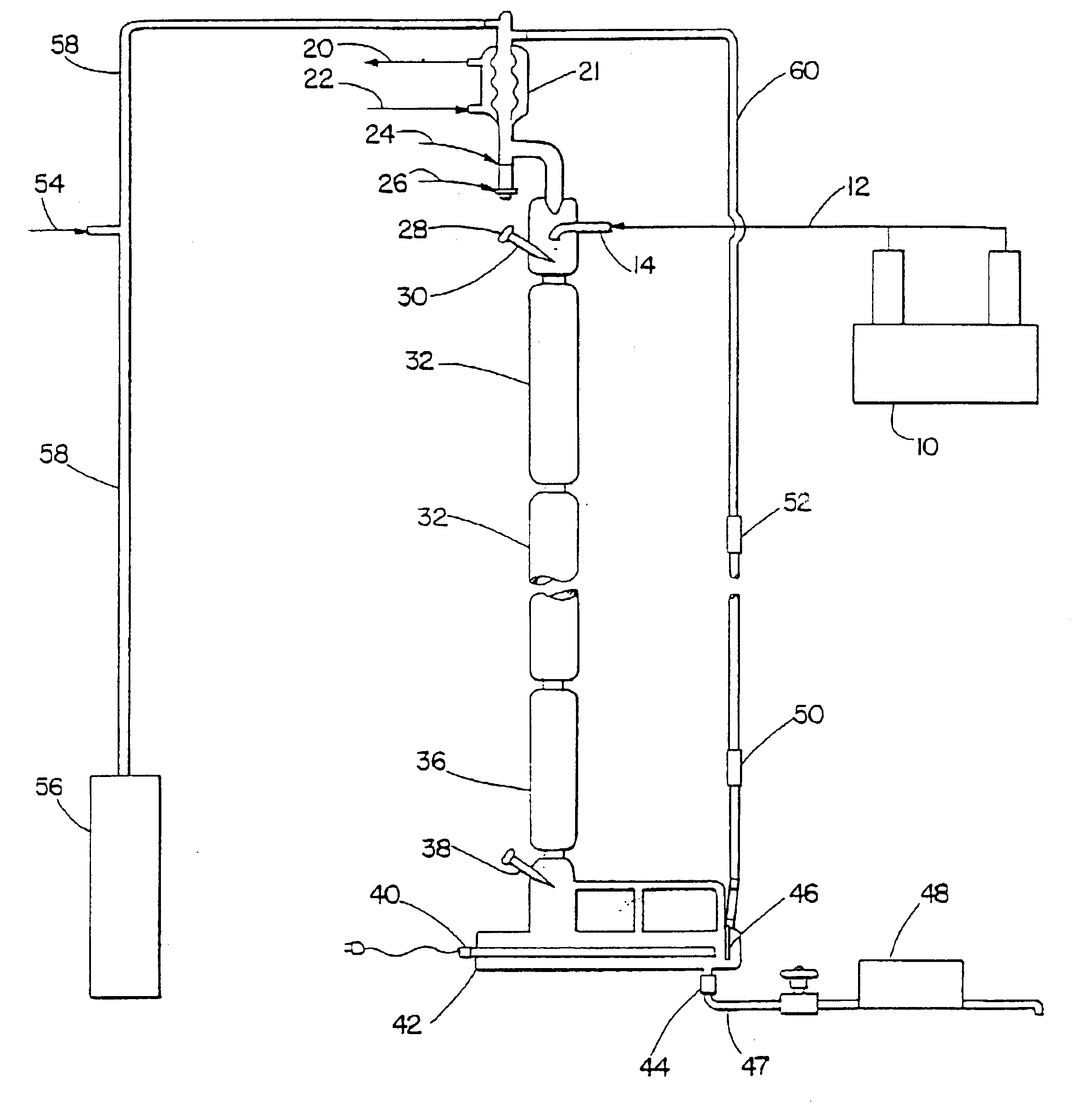

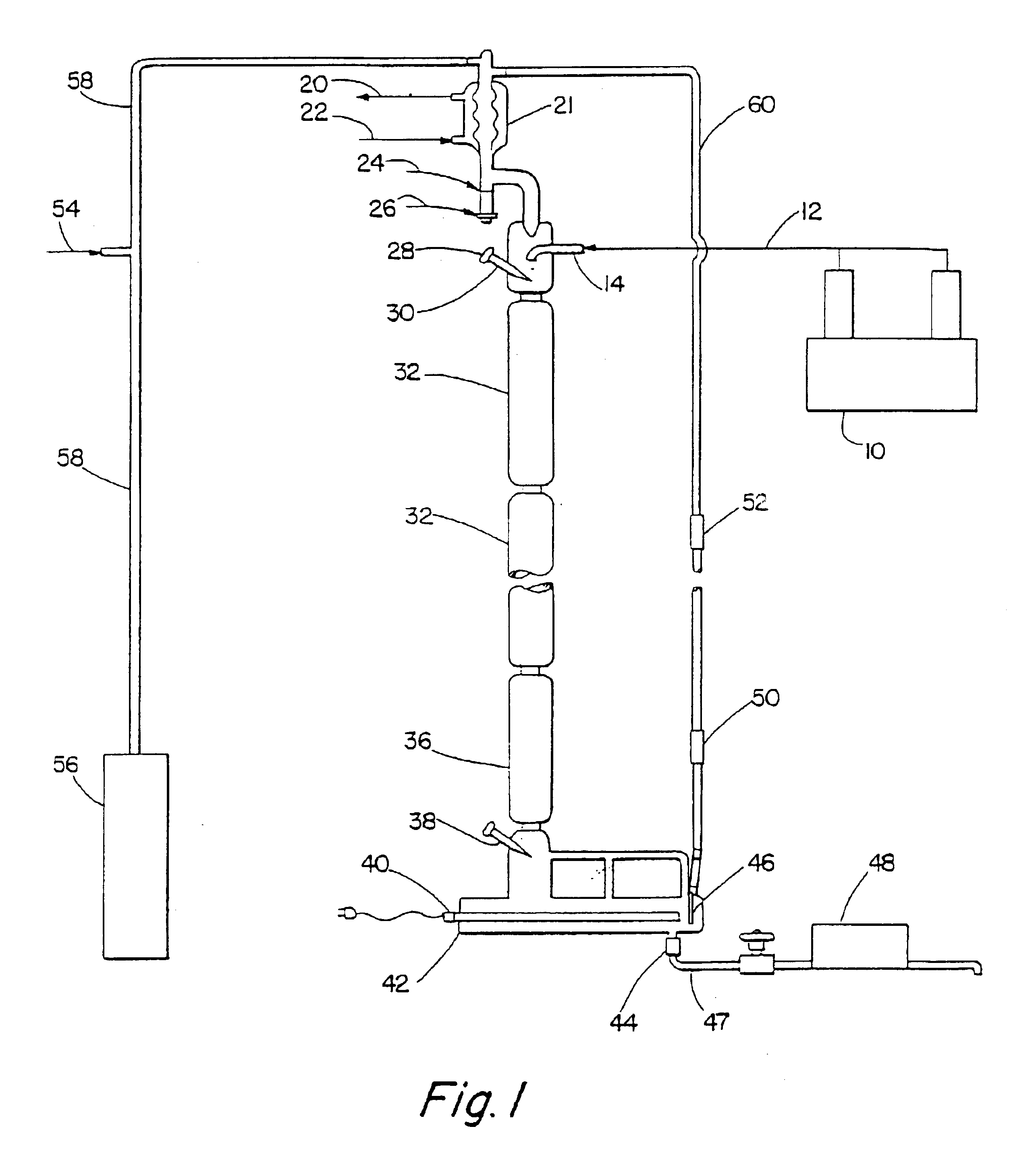

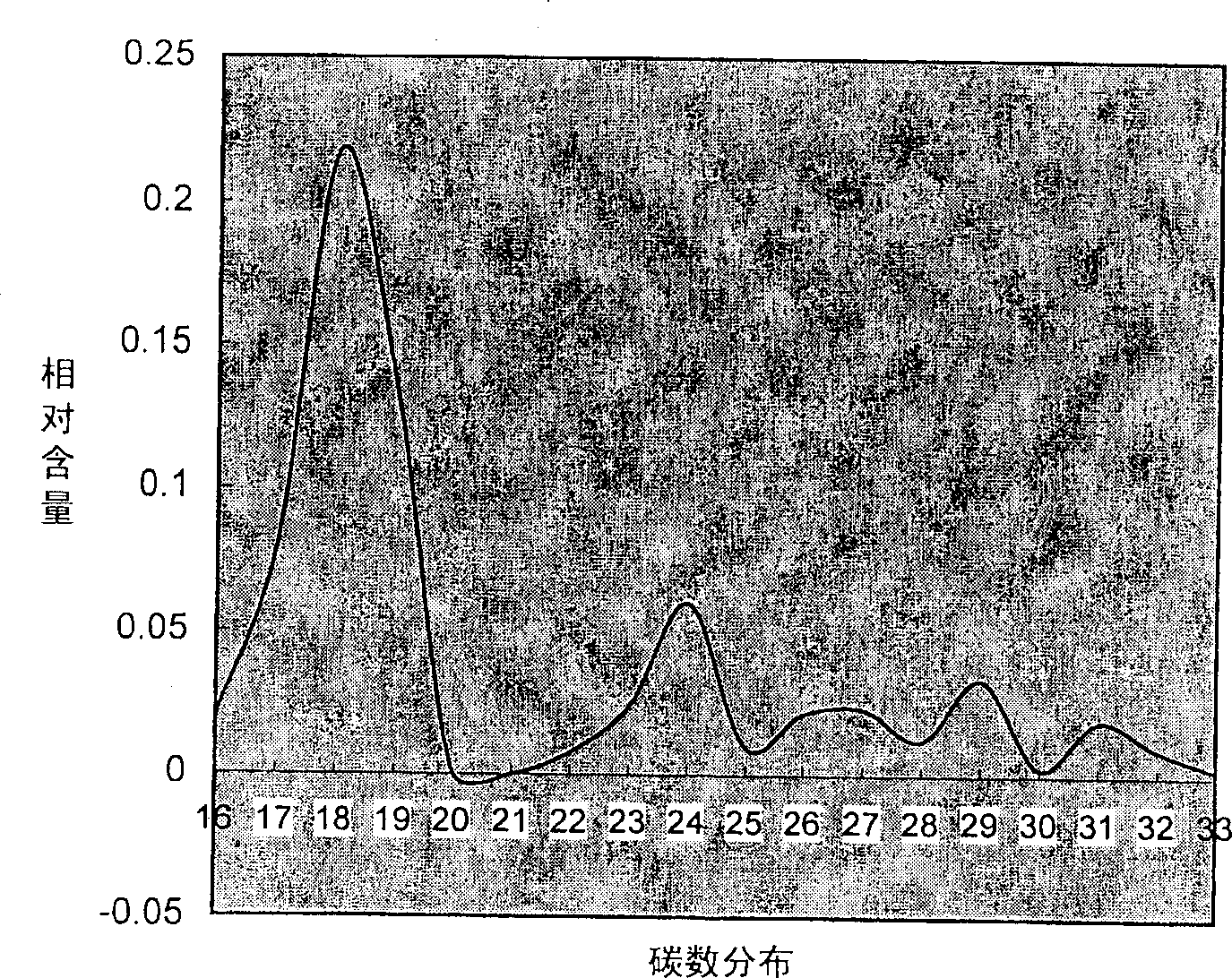

Production of linear alkyl benzene

InactiveUS20070038007A1Promote recoveryTreatment with plural serial cracking stages onlyCoke ovensAlkaneCarbon number

This invention relates to a process for producing linear alkyl benzene, the process including the steps of obtaining a hydrocarbon condensate containing olefins, paraffins and oxygenates from a low temperature Fischer-Tropsch reaction; a) fractionating a desired carbon number distribution from the hydrocarbon condensate to form a fractionated hydrocarbon condensate stream; b) extracting oxygenates from the fractionated hydrocarbon condensate stream from step (a) to form a stream containing olefins and paraffins; c) combining the stream containing olefins and paraffins from step (b) with the feed stream from step (g) to form a combined stream; d) alkylating olefins in the combined stream from step (c) with benzene in the presence of a suitable alkylation catalyst in an alkylation reactor, e) recovering linear alkyl benzene from the alkylation reactor; f) recovering unreacted paraffins from the alkylation reactor; g) dehydrogenating the unreacted paraffins in the presence of a suitable dehydrogenation catalyst to form a feed stream containing olefins and paraffins; and h) sending the feed stream containing olefins and paraffins from step (g) to step (c).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Sulphuric acid plant liquid and liquid heat exchanger on-line cleaning method

ActiveCN101871745ARaw materials are easy to getSimple and fast operationOrganic detergent compounding agentsSurface-active detergent compositionsLinear alkylbenzeneSurface-active agents

The invention discloses a sulphuric acid plant liquid and liquid heat exchanger on-line cleaning method, which relates to the sulphuric acid production. The invention is characterized in that sulfamic acid, surface active agents and corrosion and scale inhibitors are selected as cleaning scale removing liquid according to ingredients of water side scale of a heat exchanger. A concrete recipe comprises 5 to 10 percent of sulfamic acid, 0.1 to 0.3 percent of surface active agents, 0.1 to 0.4 percent of corrosion inhibitors Lan-826 and the balance water. The method comprises the following steps: filling clean water in a scale removal preparation tank; placing the reagents into water to be prepared into scale removal cleaning liquid with the pH between 1.5 and 2.5; then, circularly injecting the scale removal liquid into the water side of the exchanger by a cleaning pump under the condition without a stop; and controlling the pH value of the cleaning scale removal liquid until a structure is cleanly cleaned. The sulfamic acid in the cleaning scale removal liquid is a high-grade product with the mass percent higher than or equal to 99.8 percent, the surface active agents are sodium n-alkylbenzenesulfonate, and the corrosion inhibitors (Lan-826) have major ingredients of organic nitrogenous compounds. The method of the invention has the advantages of easy acquisition of raw materials, simple and convenient operation and high scale removal efficiency, and is applicable to sulphuric acid production enterprises.

Owner:WENGFU (GRP) CO LTD

Low surfactant, high carbonate liquid laundry detergent compositions with improved suds profile

InactiveUS20150337236A1Broad representationInorganic/elemental detergent compounding agentsCationic surface-active compoundsBenzeneLiquid laundry detergent

The present invention relates to a stable liquid laundry detergent composition containing low levels of a C10-C20 linear alkyl benzene sulphonate surfactant in combination with high levels of a water-soluble alkali metal carbonate for achieving improved suds profile.

Owner:THE PROCTER & GAMBLE COMPANY

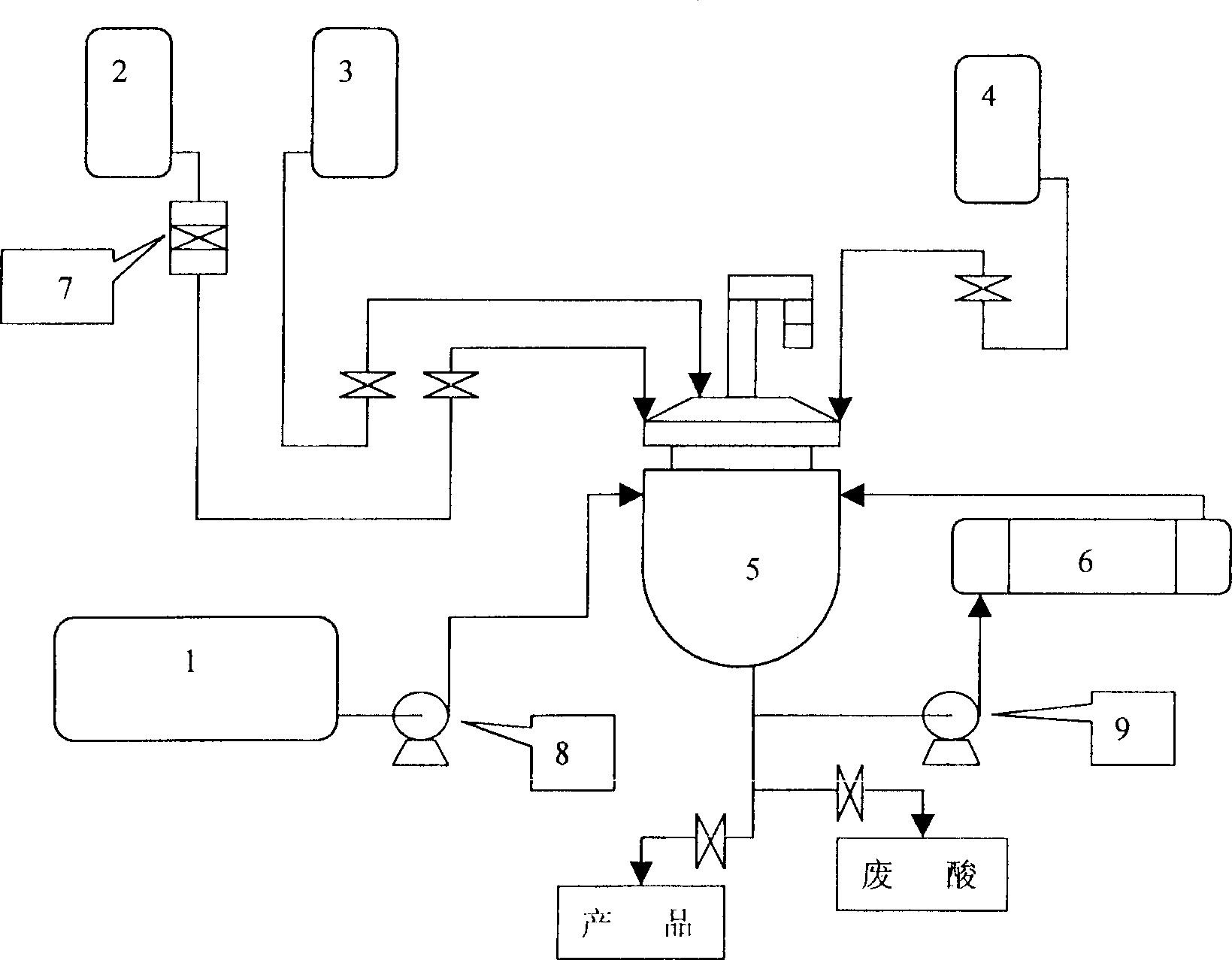

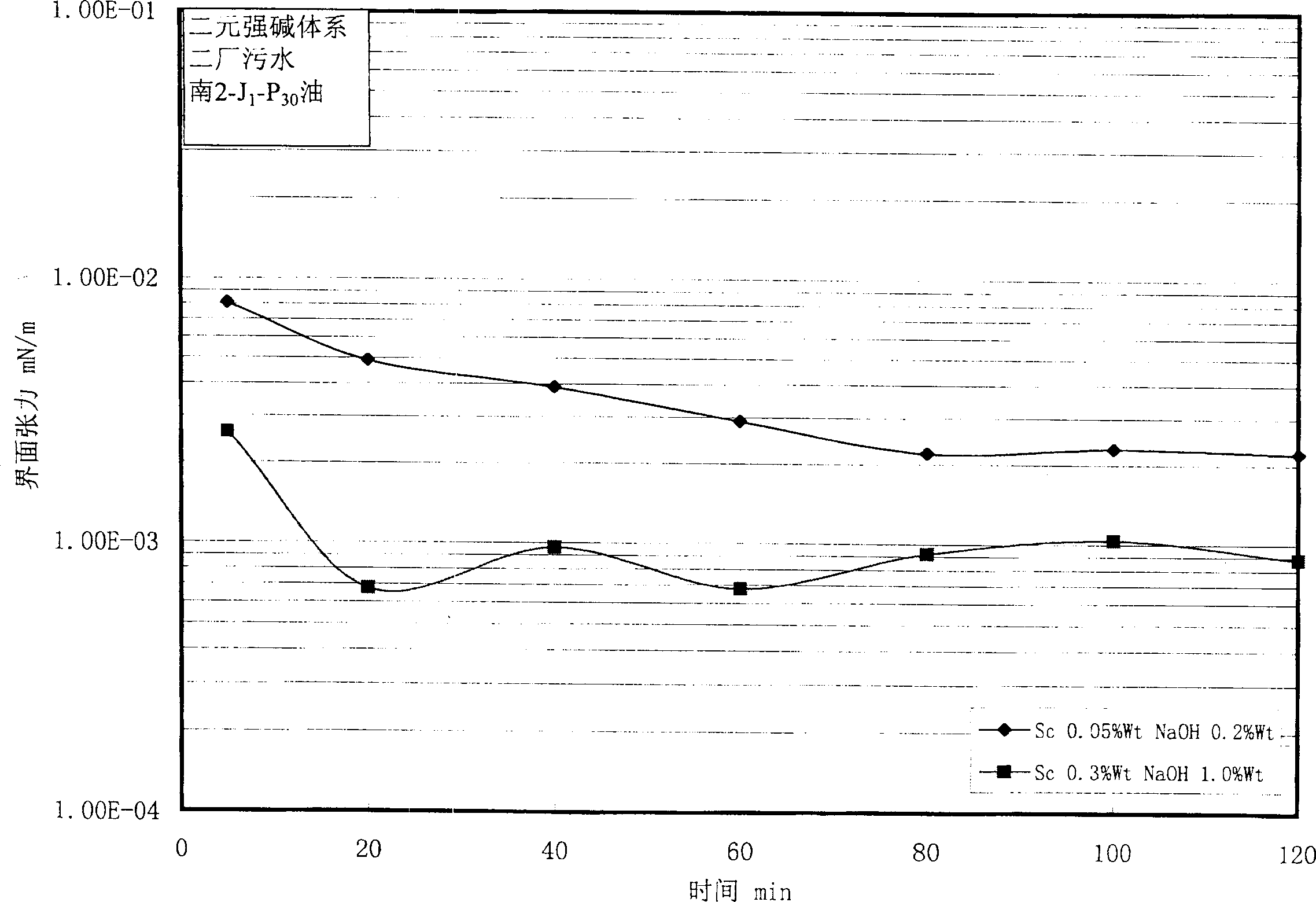

Prepn and application of alkyl aryl sulfonate

InactiveCN1486976AEasy to operateGood application effectSulfonic acids salts preparationArylSulfonate

The preparation process of alkyl aryl sulfonate includes the following main steps: adding C8-C26 straight chain alkylbenzene in 0-50 wt% to heavy alkylbenzene of average molecular weight of 310-370; sulfonation reaction of mixed alkylbenzene and fuming sulfuric acid in the weight ratio of 1 to 0.3-3 inside a sulfonation reactor, with the adding speed of fuming sulfuric acid being controlled to result in reaction temperature of 40-55 deg.c adding water in the amount of 5-25 % of total material weight through stirring at 30-80 deg.c; for 0.2-3 hr and stagnation to balance for 0.5-5 hr; and neutralizing the ractant mixture to pH 8-9 with 10-40% concentration NaOH solution. The alkyl aryl sulfonate is applied in tertiary oil extraction to compound oil displacing agent and may form stable superlow interface tension area in relatively low and wide alkali concentration range and relatively side surfactant concentration range.

Owner:大庆油田有限责任公司勘探开发研究院 +1

Solid laundry detergent composition

InactiveUS20060183659A1Improve performanceEnhance the imageNon-ionic surface-active compoundsDetergent compounding agentsBenzeneAlcohol

The present invention relates to a solid laundry detergent composition comprising: (a) a linear alkyl benzene sulphonate surfactant; (b) an alkoxylated alkyl sulphate surfactant; (c) from 0.1 wt % to 10 wt % alkoxylated alkyl alcohol having an average degree of alkoxylation of from 50 to 100; and (d) from 0.001 wt % to 0.5 wt % polyethylene glycol; (e) from 0 wt % to 5 wt % zeolite builder; (f) from 0 wt % to 5 wt % phosphate builder; and (g) optionally, one or more adjunct components; wherein the weight ratio of the alkoxylated alkyl alcohol and the polyethylene glycol is in the range of from 9:1 to 1,000:1.

Owner:THE PROCTER & GAMBLE COMPANY

Compacted liquid laundry detergent composition

InactiveUS20160355755A1Organic detergent compounding agentsNon-ionic surface-active compoundsAlcoholSuppressor

A liquid laundry detergent composition that includes: a non-amine neutralized linear alkylbenzene sulphonate; a non-ionic surfactant; a fatty acid; an alcohol; less than 5% by weight of the composition of a hydroxyl-containing amine; water; and a siloxane-based polymer suds suppressor.

Owner:THE PROCTER & GAMBLE COMPANY

Environmental-protection range hood detergent and preparation method thereof

InactiveCN105255597AEfficient removalEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLinear alkylbenzeneFatty alcohol

The invention discloses environmental-protection range hood detergent and a preparation method thereof. The environmental-protection range hood detergent is prepared from, by mass, 1-3 parts of sodium dodecyl benzene sulfonate, 1-2 parts of fatty alcohol polyoxylethylene ether sodium sulphate, 2-5 parts of linear alkylbenzene sulphonic acid, 0.5-1.5 parts of hydroxyethyl dodecyl alcohol, 0.1-0.8 part of triethanolamine, 3-8 parts of polyatomic alcohol, 2-6 parts of sodium carbonate, 1-5 parts of potassium sorbate, 0.5-1.3 parts of triethanolamine oleate, 0.8-1.6 parts of EDTA-disodium, 0.6-1.5 parts of emulgator, 0.5-1.2 parts of stabilizers and 50-70 parts of distilled water. According to the obtained environmental-protection range hood detergent, the safety to the human body is achieved, the toxicity to the human body does not exist, skins are not stimulated in the cleaning process, the greasy stains on a range hood and various cooking utensils can be cleaned away rapidly, simply and conveniently, and the detergent and the cleaning method do not damage the utensils.

Owner:李康

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com