Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1124results about How to "Improve coating quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

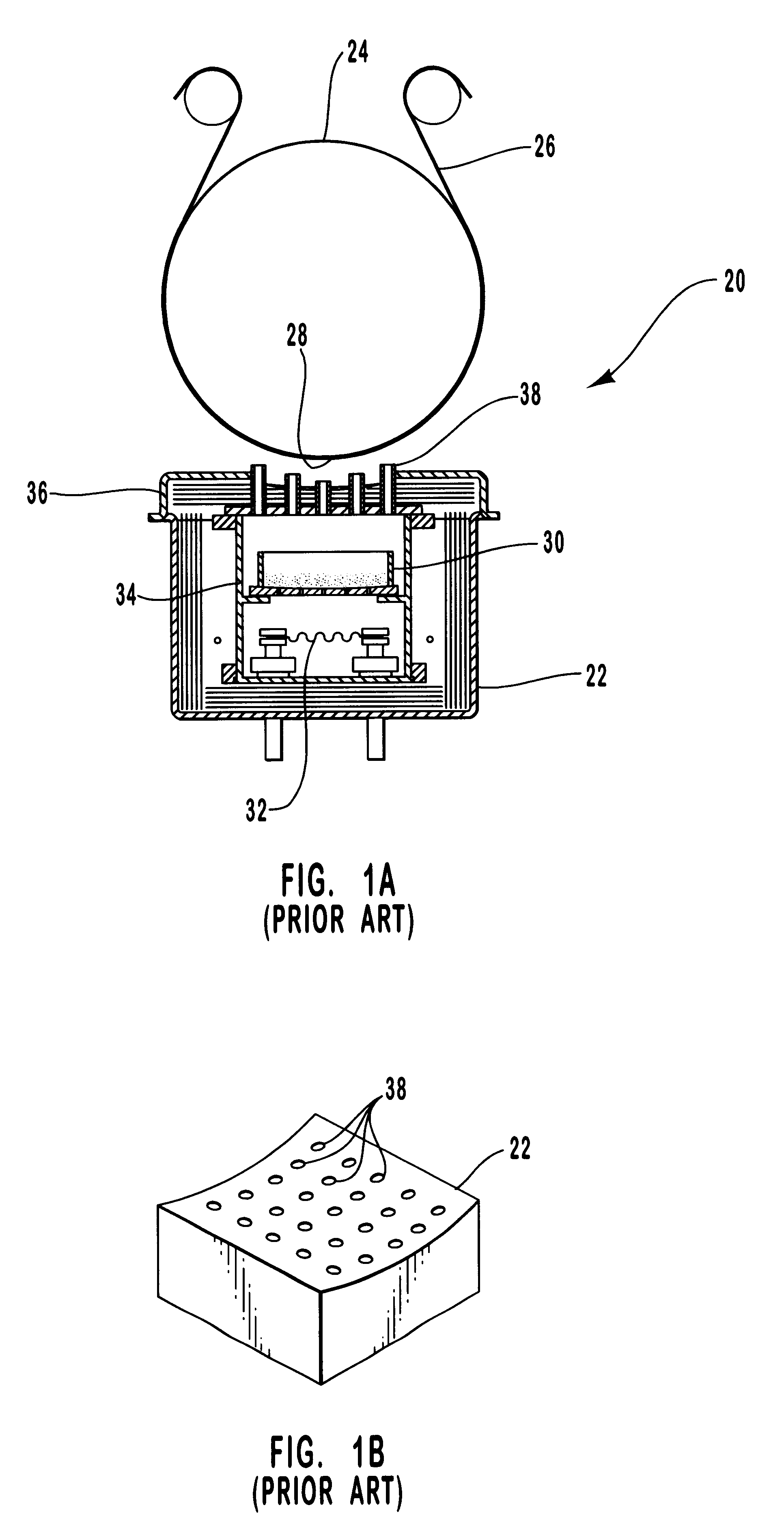

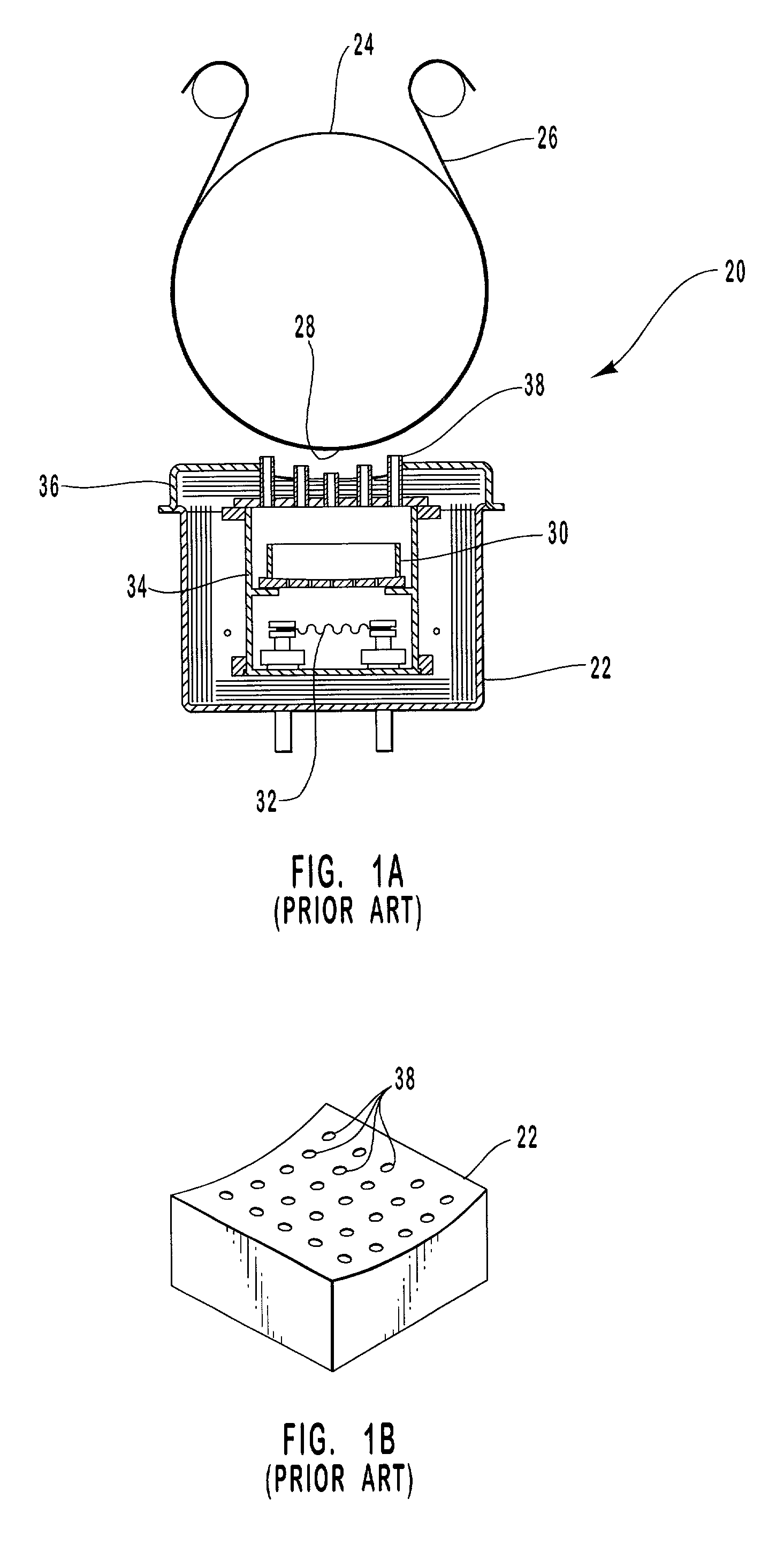

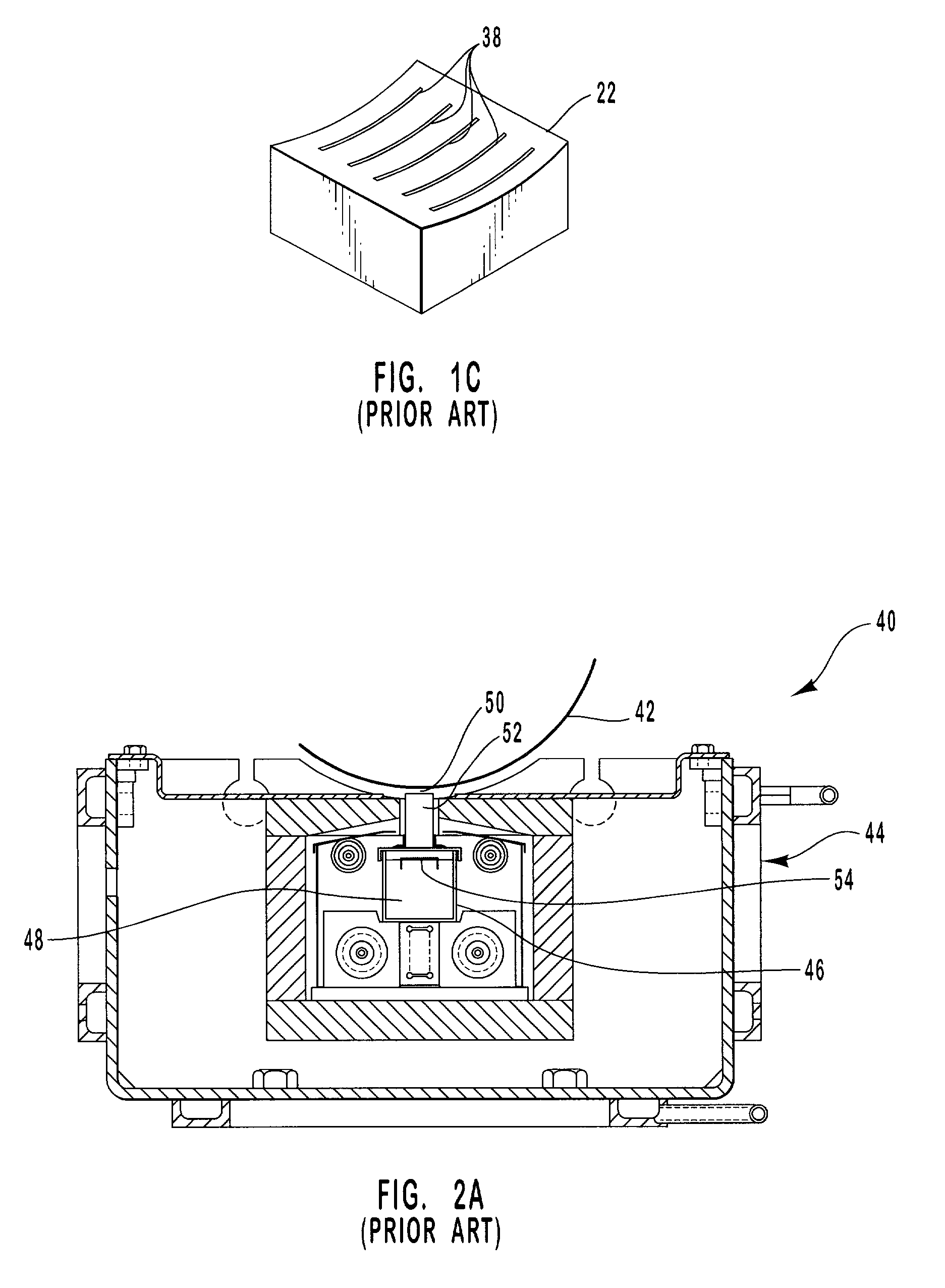

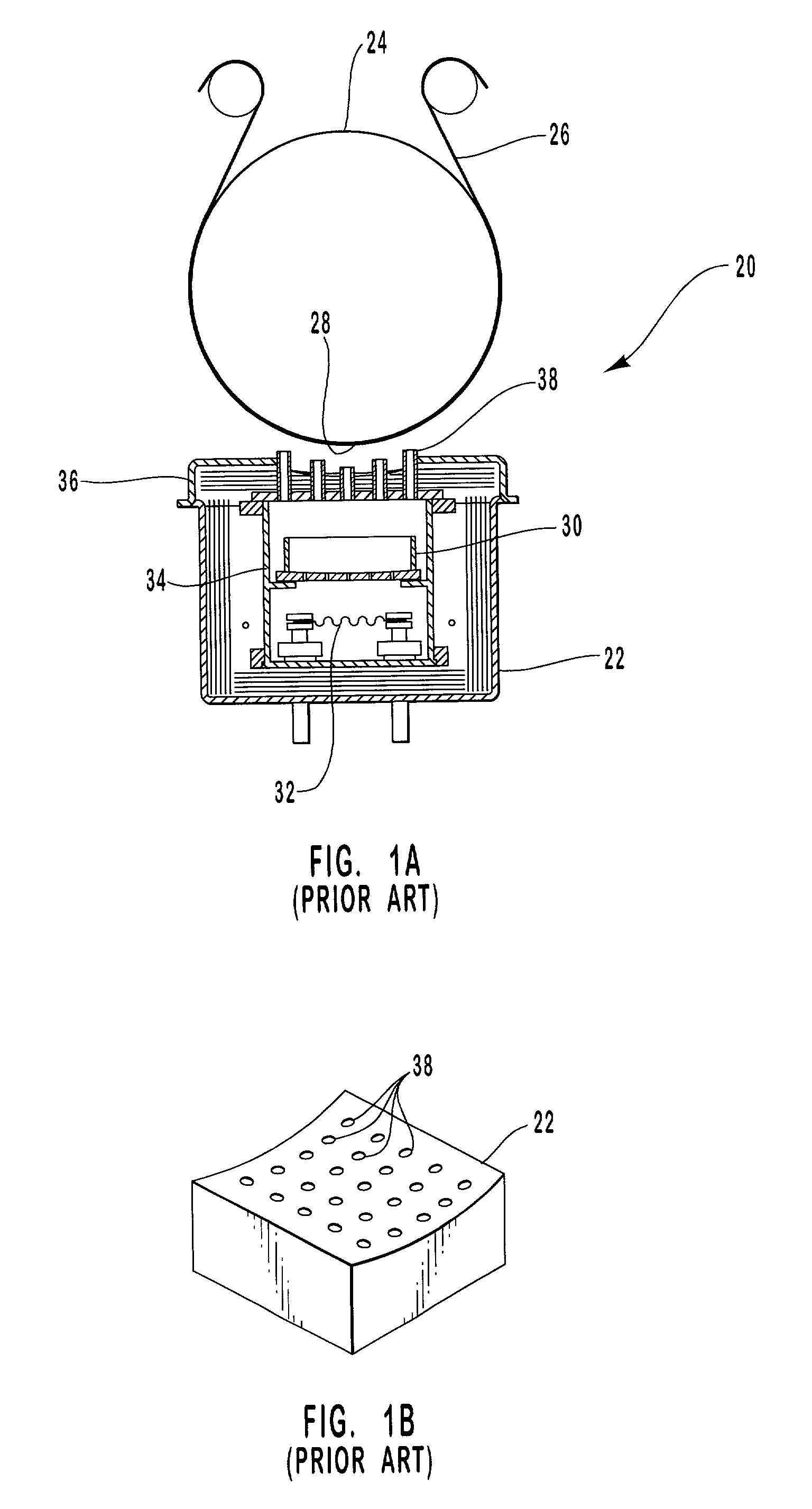

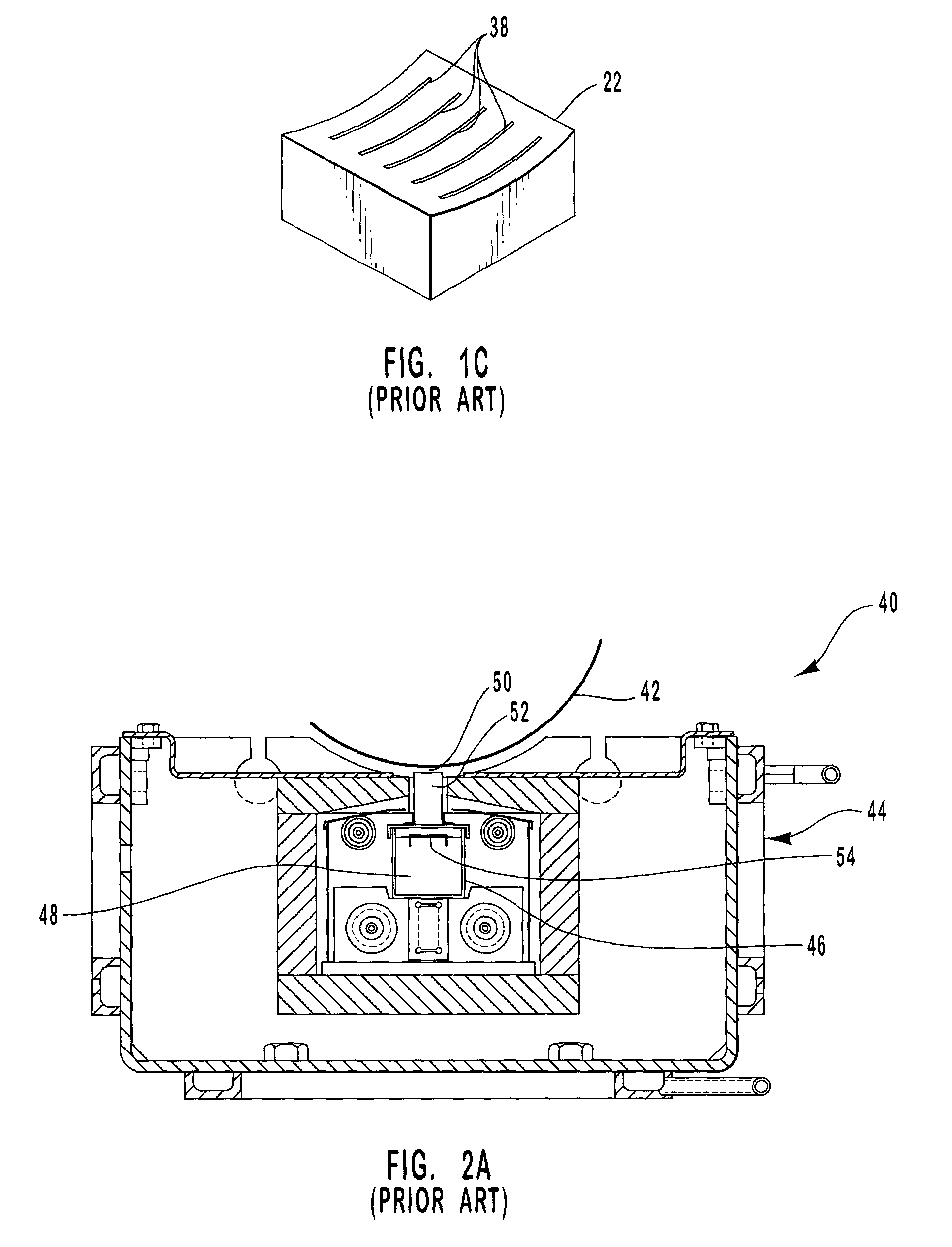

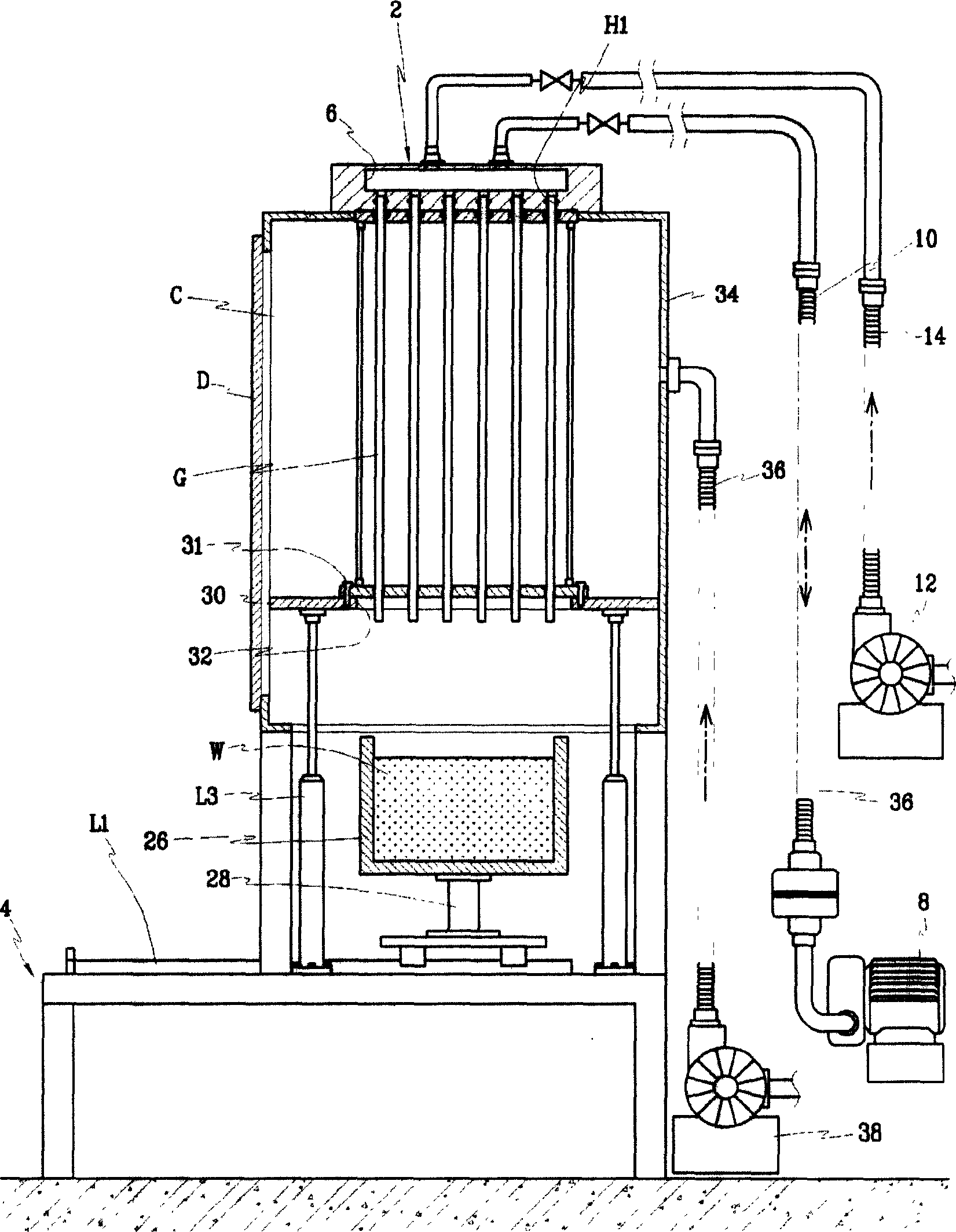

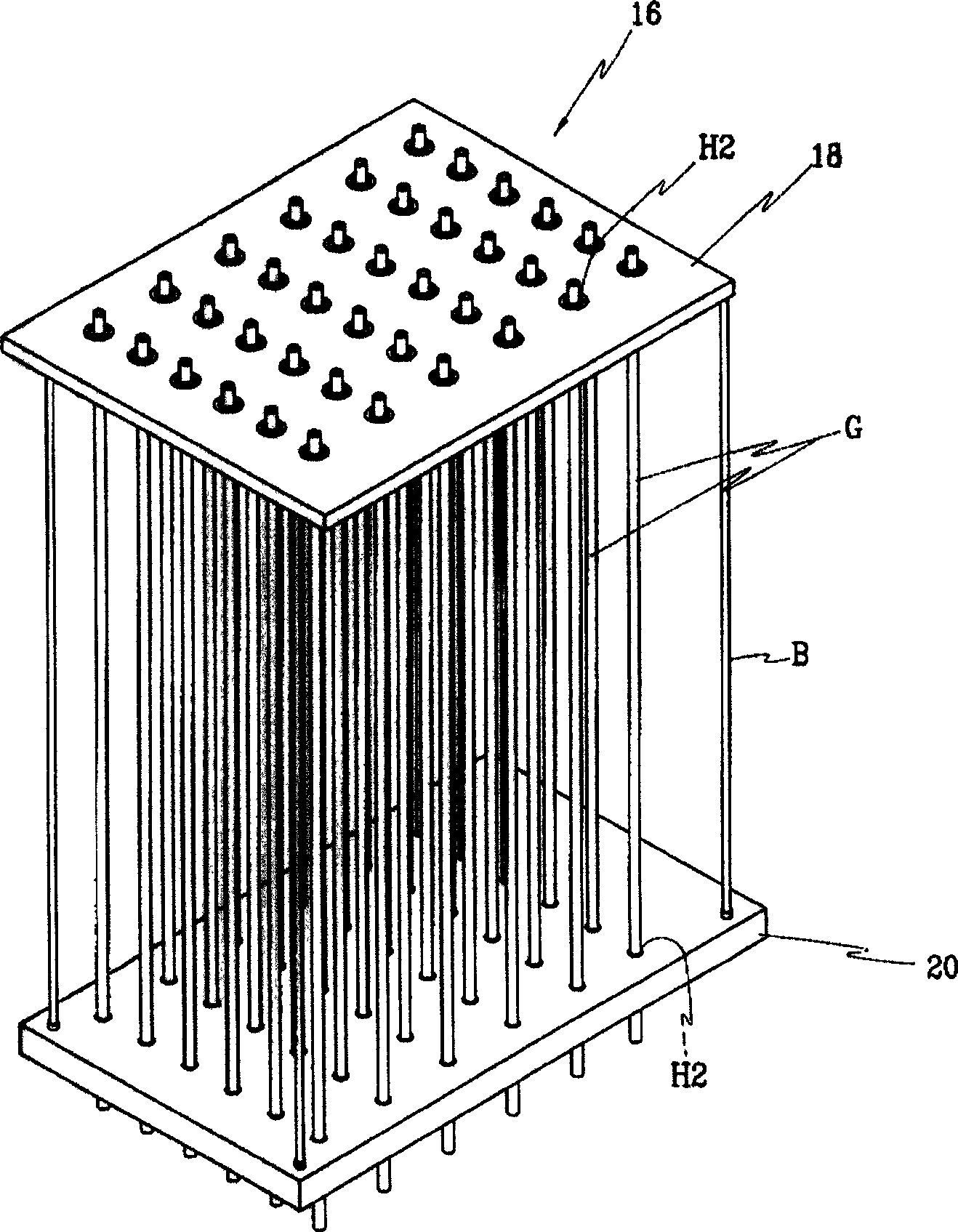

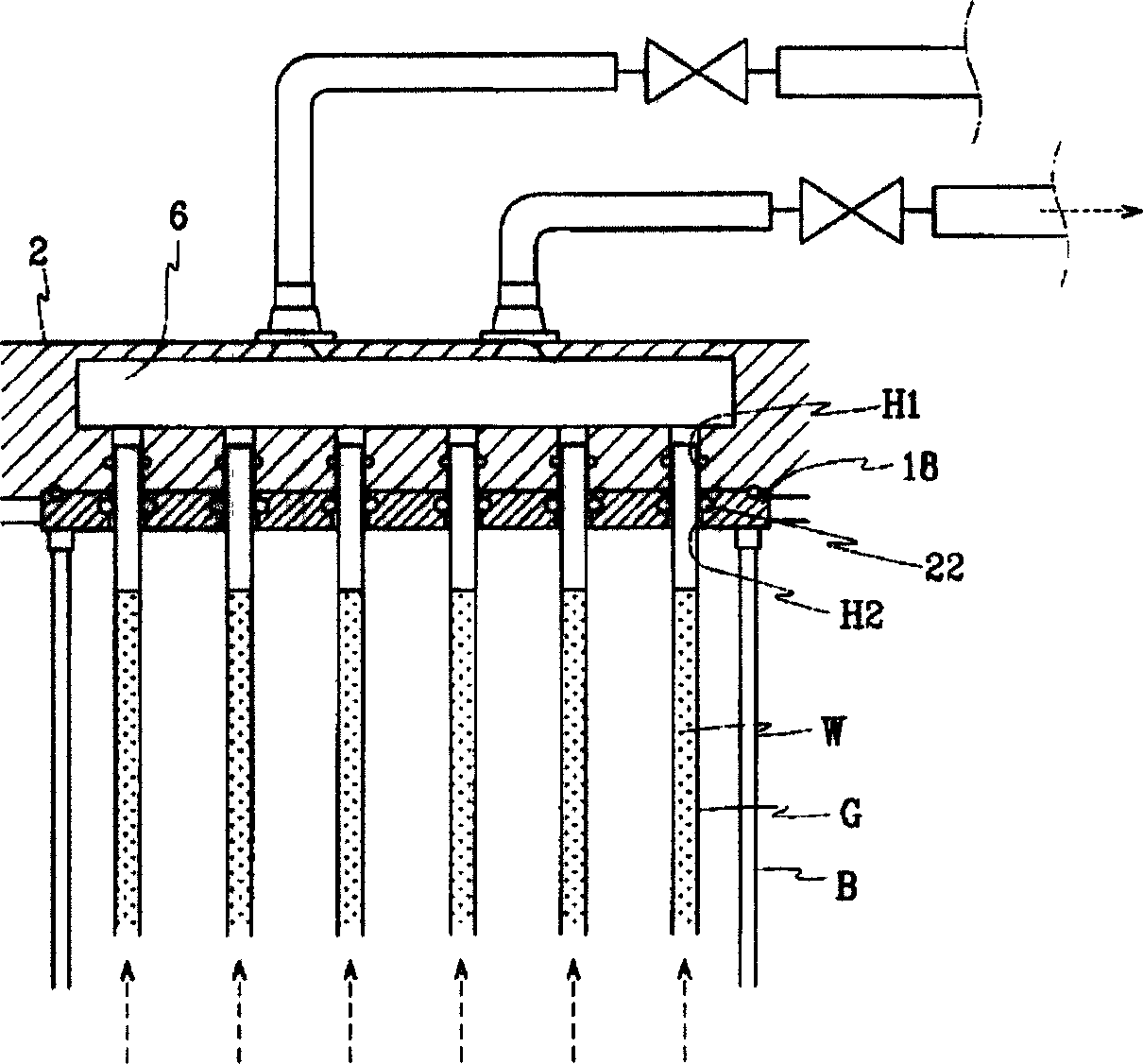

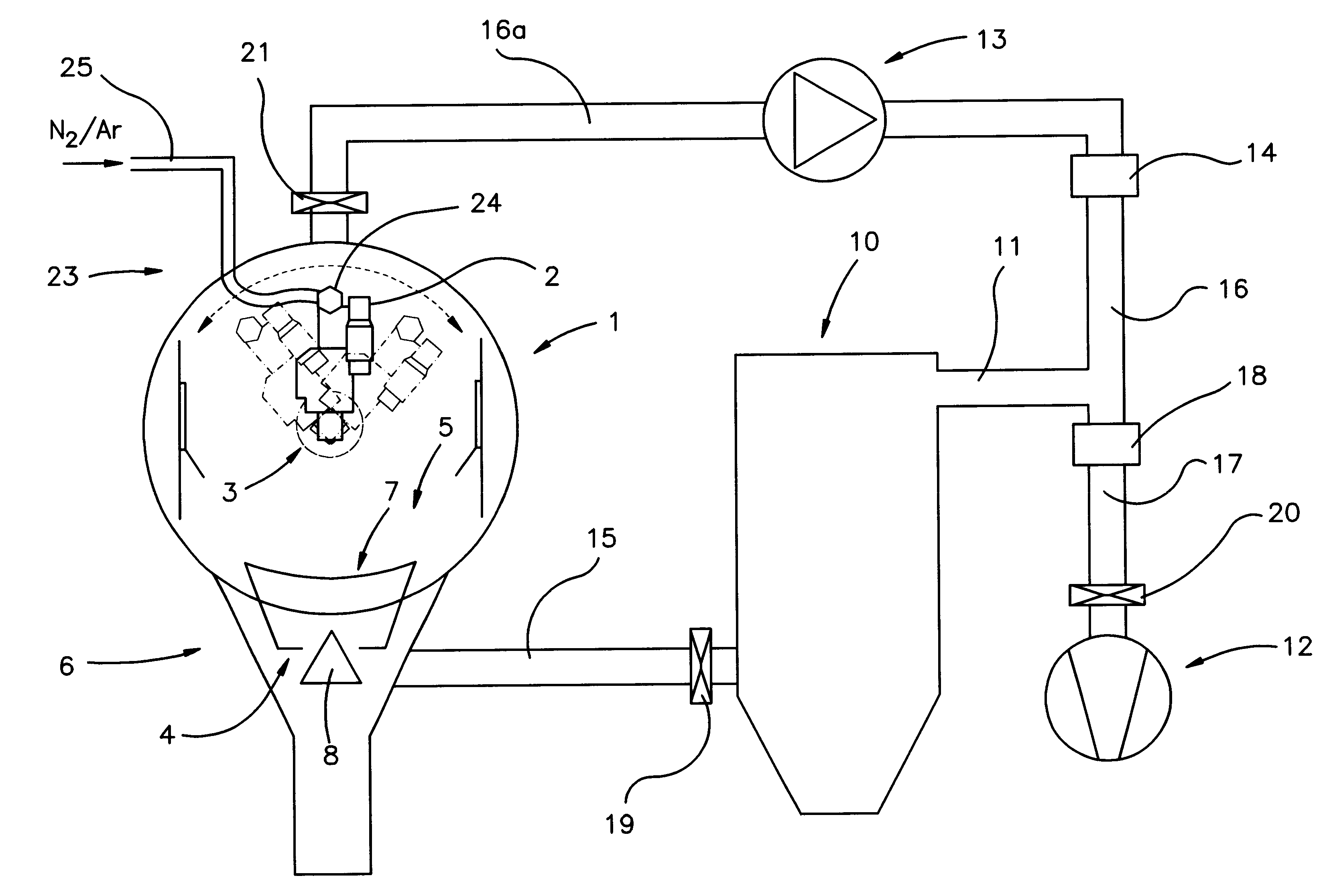

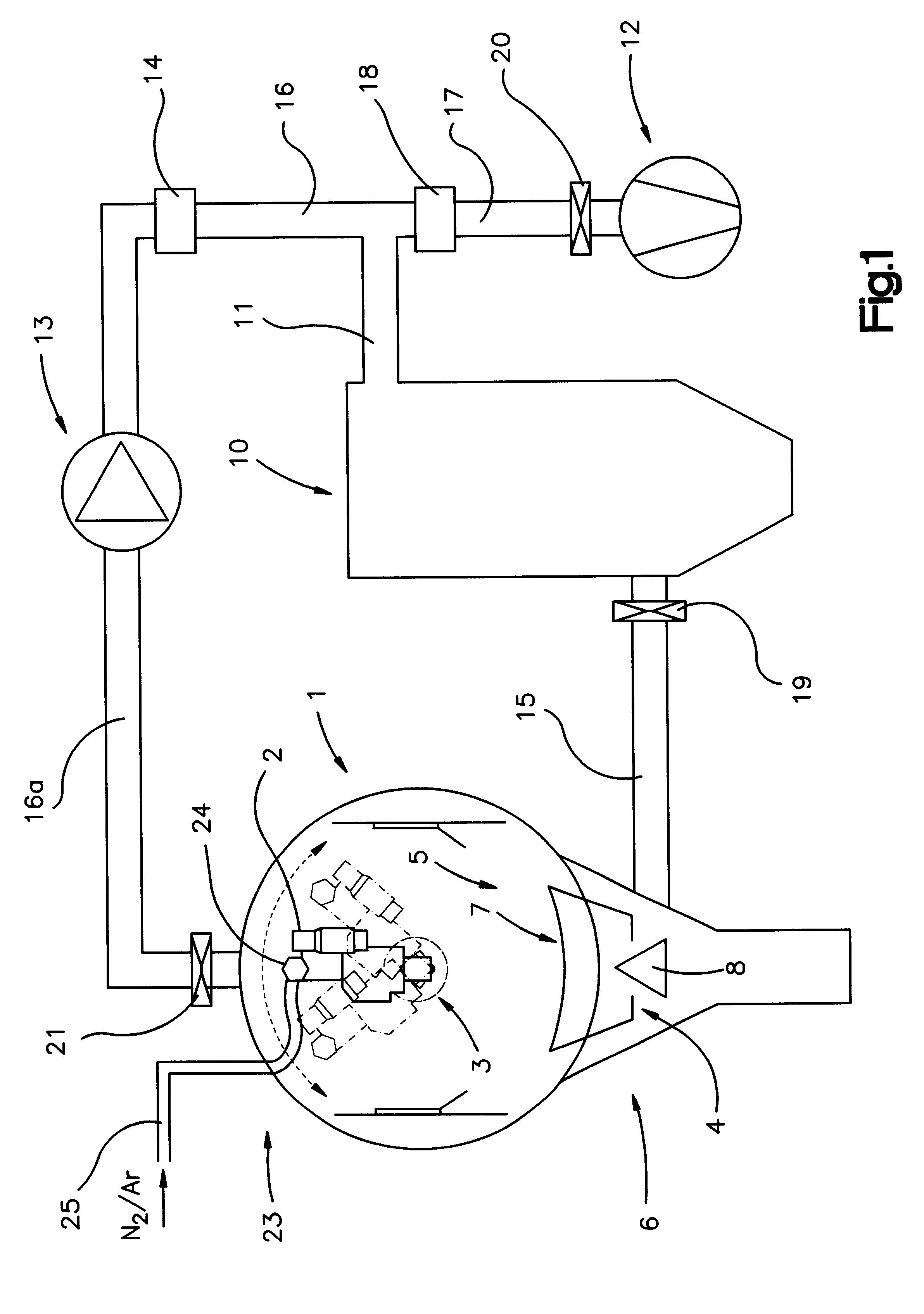

Linear aperture deposition apparatus and coating process

InactiveUS6202591B1High and stable rateEasy to useVacuum evaporation coatingSputtering coatingParticulatesSource material

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:JDS UNIPHASE CORP

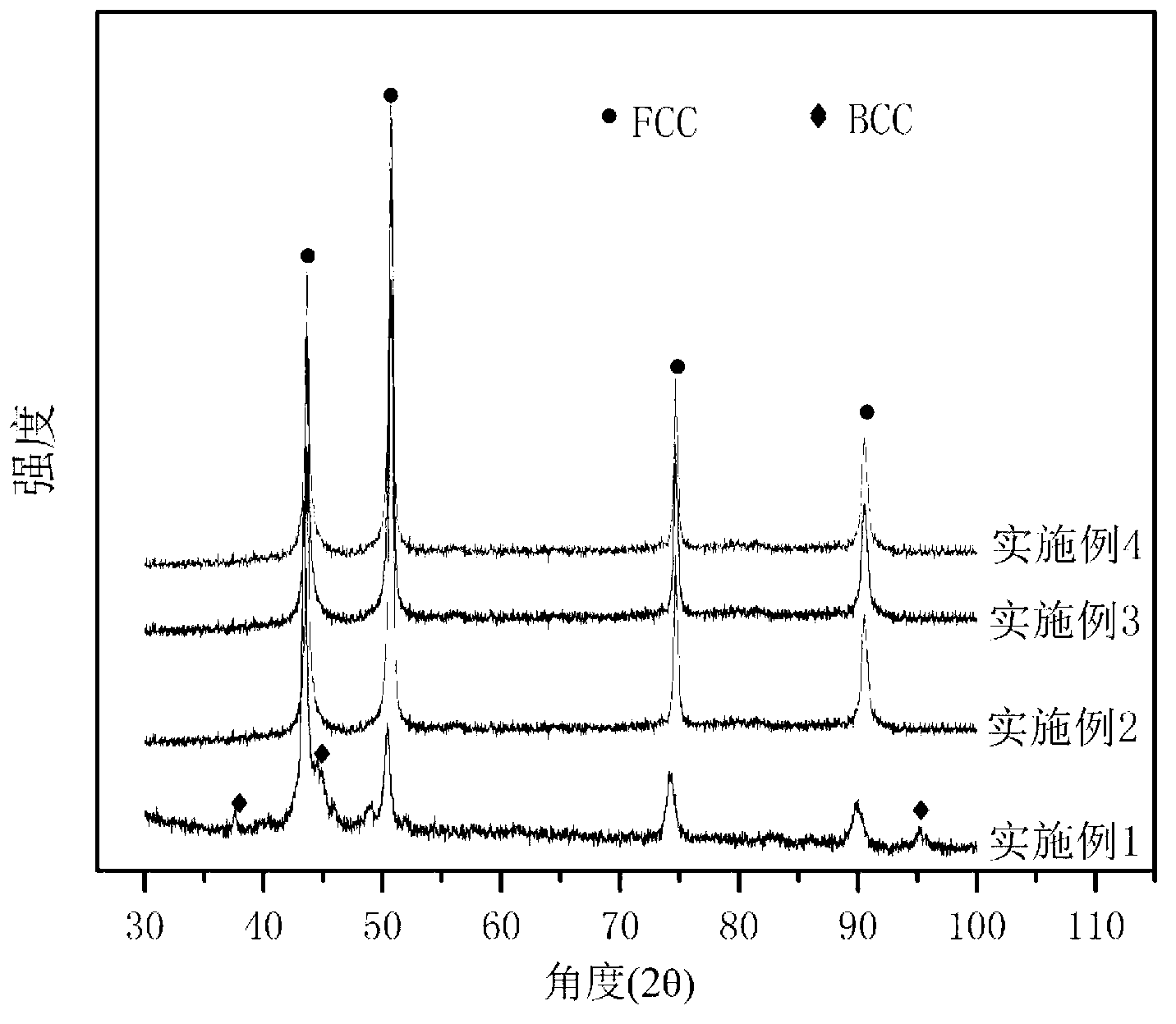

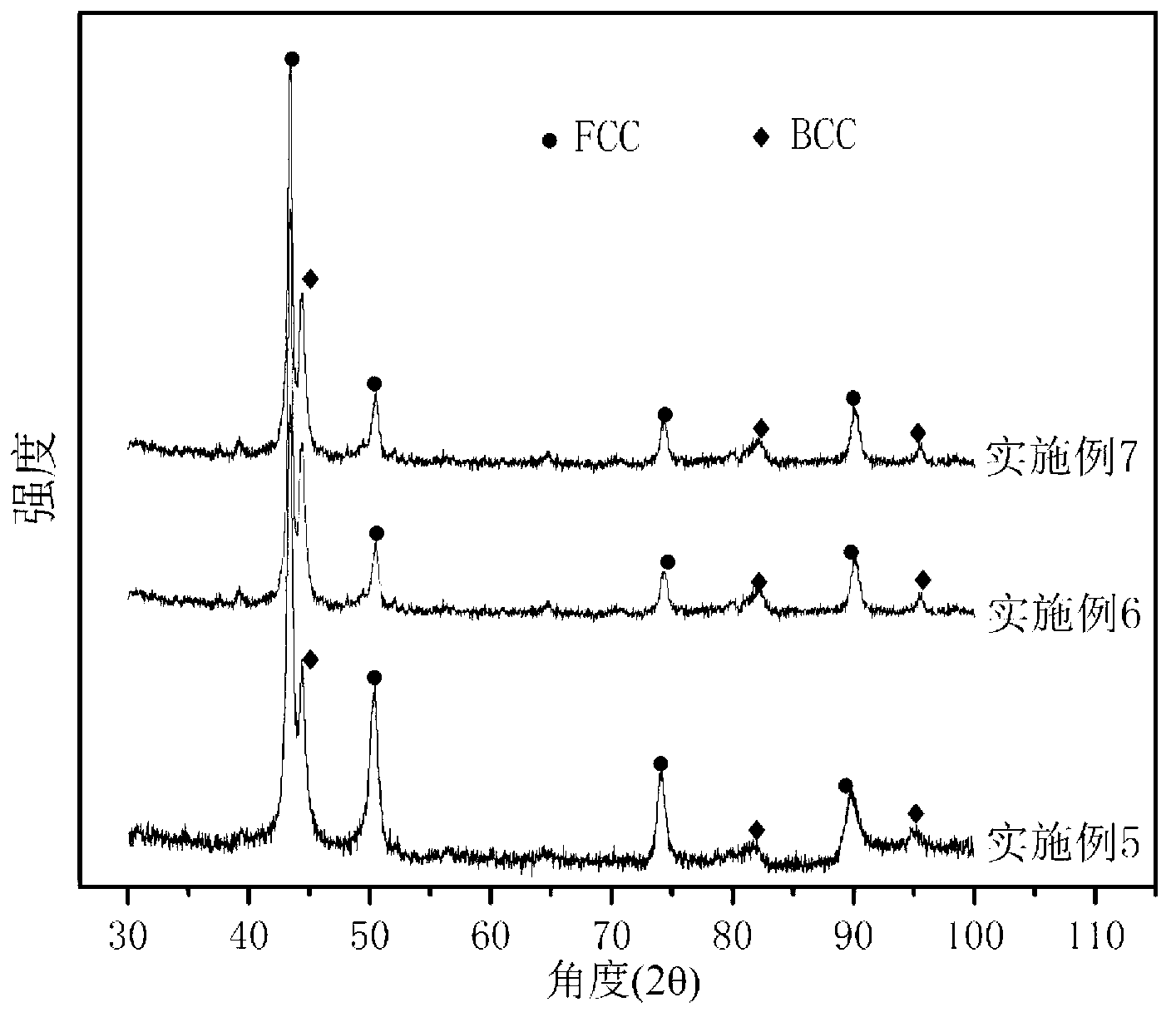

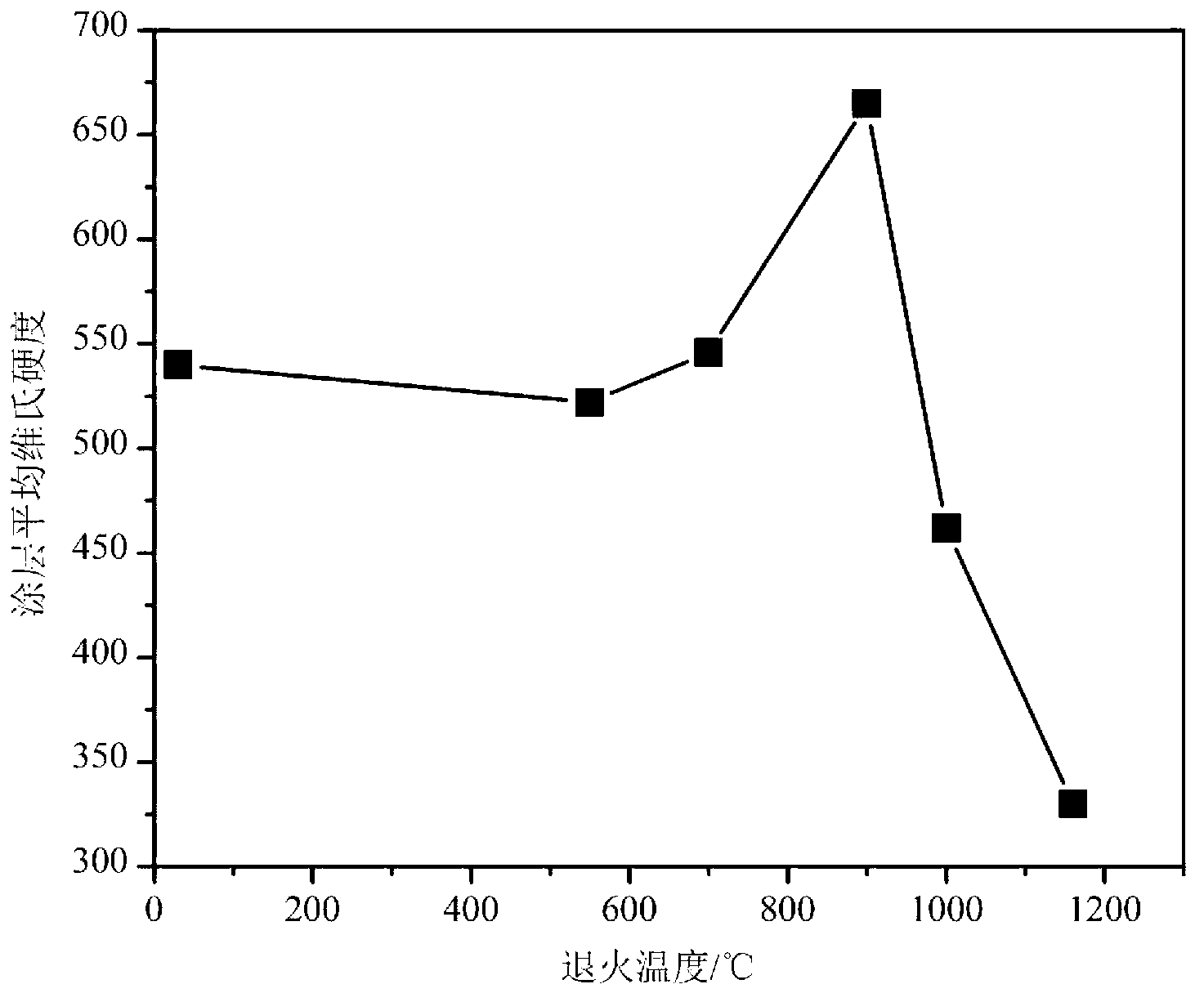

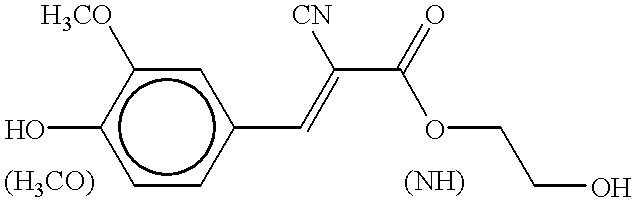

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

Recording sheet for ink jet printing

InactiveUS20060078696A1Improve image qualityImprove water fastnessMaterial nanotechnologyPigmenting treatmentCompound (substance)Silicon dioxide

A method for the preparation of silicon dioxide dispersions is described, wherein the surface of the silicon dioxide is modified by a treatment with the reaction products of a compound of trivalent aluminum with least one aminoorganosilane. These reaction products are formed in a separate reaction step. The present invention also relates to recording sheets for ink jet printing having such a dispersion incorporated in an ink-receiving layer.

Owner:WIFAG POLYTPE HLDG AG

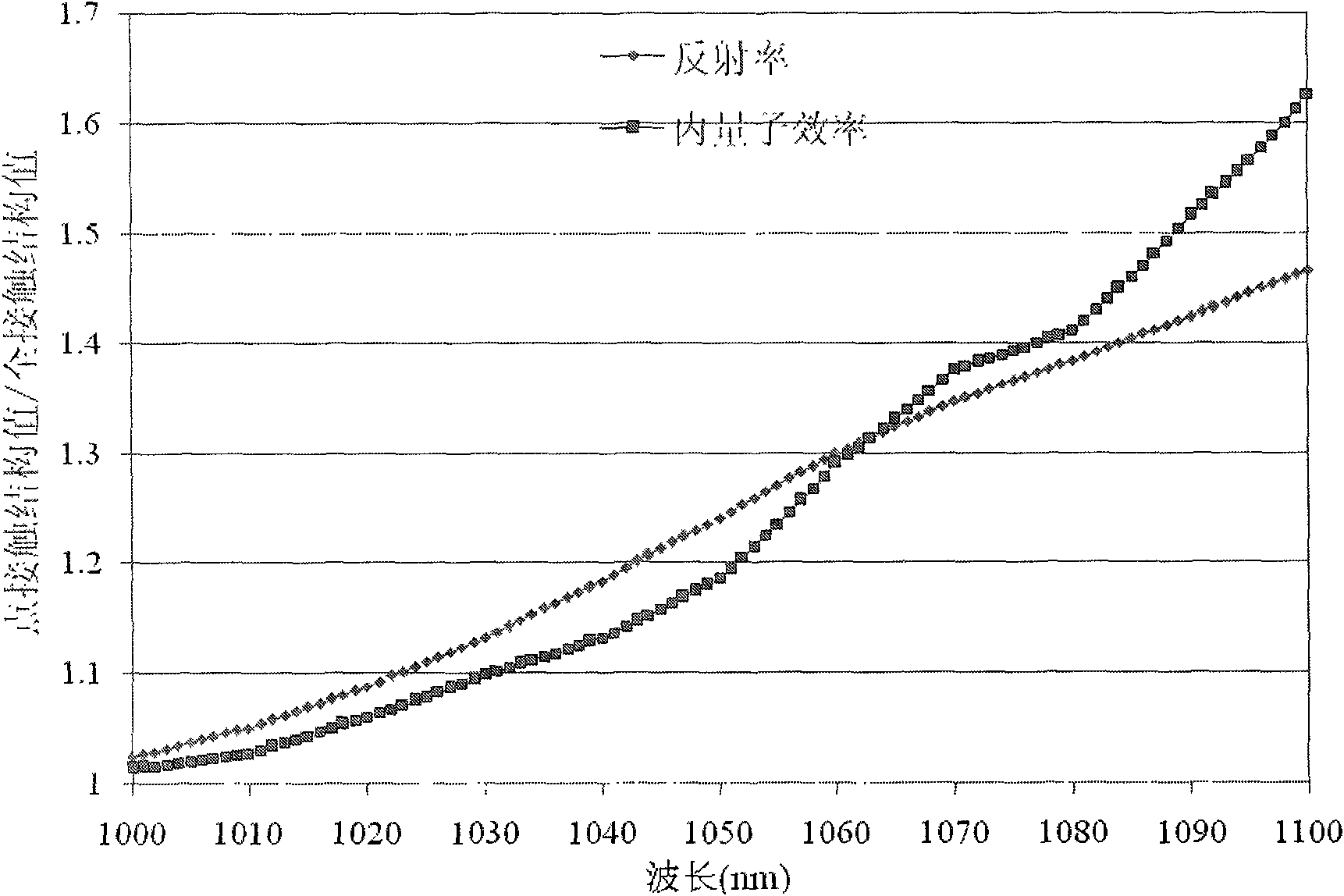

Method for preparing N-type crystalline silicon solar cell with aluminum-based local emitters on back side

InactiveCN101853897AAvoid damageAvoid Edge Leakage SituationsFinal product manufactureSemiconductor devicesP–n junctionMaterials science

The invention provides a method for preparing an N-type crystalline silicon solar cell with aluminum-based local emitters on the back side. The method comprises the following steps: firstly, selecting N-type silicon wafers to carry out the surface-textured etching process; further forming a front surface field through phosphorous diffusion; depositing a passivating film on the front surface after the phosphorosilicate glass is formed during the removal of diffused phosphorous; carrying out the back-side chemical polishing process on the silicon wafers to remove the N+ layer formed on the back side during the phosphorous diffusion; then, sequentially printing an aluminum layer or a silver-aluminum layer through the passivating film deposited on the back side, local holes or grooves on the back side and screens on the back side; then, printing silver paste on the front surface; and finally, carrying out the one-step sintering process to form a local P+ layer on the back side and allowing the P+ layer to coming into ohmic contact with the electrodes on the front and back surfaces. By using the N-type substrate, forming local aluminum-based P-N junctions on the back side and further using the back-side chemical polishing process to remove the edge junctions, the invention can substitute for the conventional stacking-type plasma etching process, simplify the technological procedures and further bring a series of performance improvement to cells.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

Linear aperture deposition apparatus and coating process

InactiveUS20010011524A1High and stable rateEasy to useVacuum evaporation coatingSputtering coatingParticulatesSource material

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:JDS UNIPHASE CORP

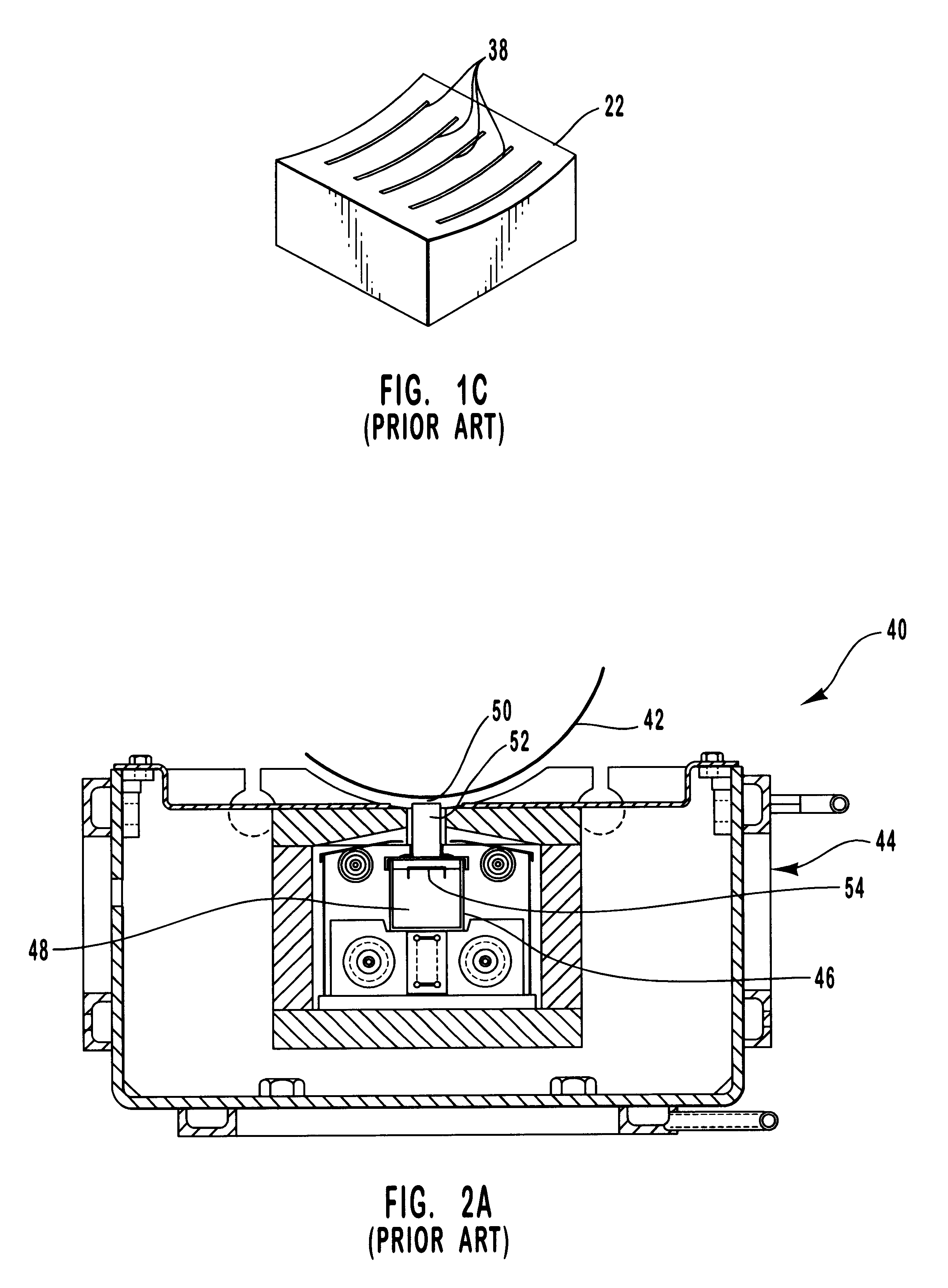

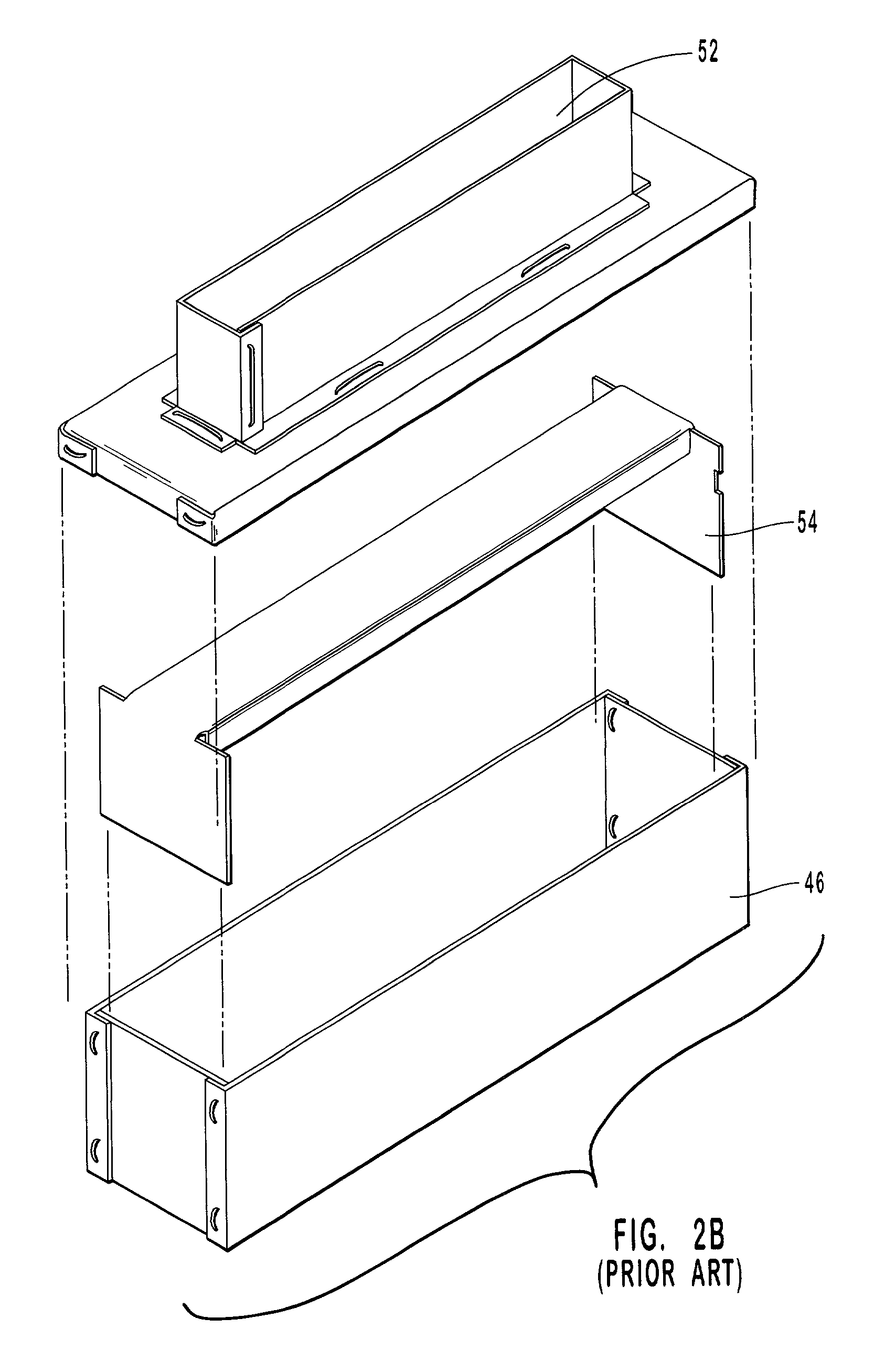

Linear aperture deposition apparatus and coating process

InactiveUS20010005553A1Increase temperatureShorten the lengthSynthetic resin layered productsVacuum evaporation coatingParticulatesSource material

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:WITZMAN MATTHEW R +3

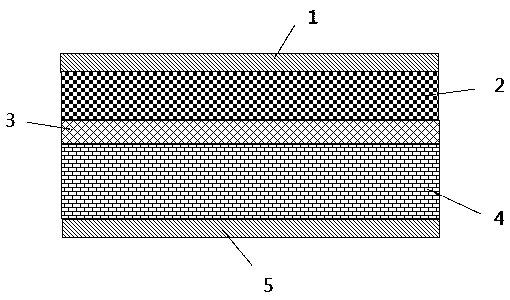

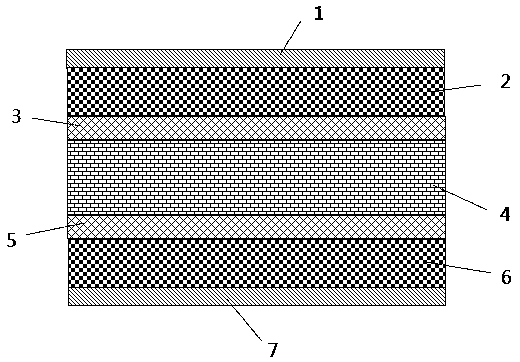

A preparation method of a ceramic coated separator for lithium ion batteries

The invention discloses a preparation method of a ceramic coating separator for lithium ion batteries and belongs to the technical field of lithium ion battery separator production. The method involves a polymer porous base film, a polymer glue applied on one or both sides of the base film surface, a ceramic coating applied on the surface of the polymer glue, and a PVDF and its copolymer glue applied on the other side of the ceramic coating surface and the base film surface, wherein the PVDF and its copolymer glue are coated on the other side of the ceramic coating surface and the base film surface. The inorganic ceramic particles adopted by the invention are non-spherical and multi-particle, which can greatly improve the porosity of the ceramic coating, increase the lithium ion transit property, improve the liquid absorption rate of the diaphragm, and improve the rate performance and cycle life of the lithium ion battery. As the structure design of the ceramic coat diaphragm of the invention can increase the adhesive force of the ceramic coating and the polymer porous base membrane, the adhesive strength of the diaphragm and the positive and negative electrode sheets is improved,the problems of powder dropping and coating peeling off are effectively improved, the high-efficient automatic assembly of the lithium battery is realized, and the heat resistance and electrochemicalstability of the diaphragm are greatly improved.

Owner:HENAN FUSEN NEW ENERGY TECH

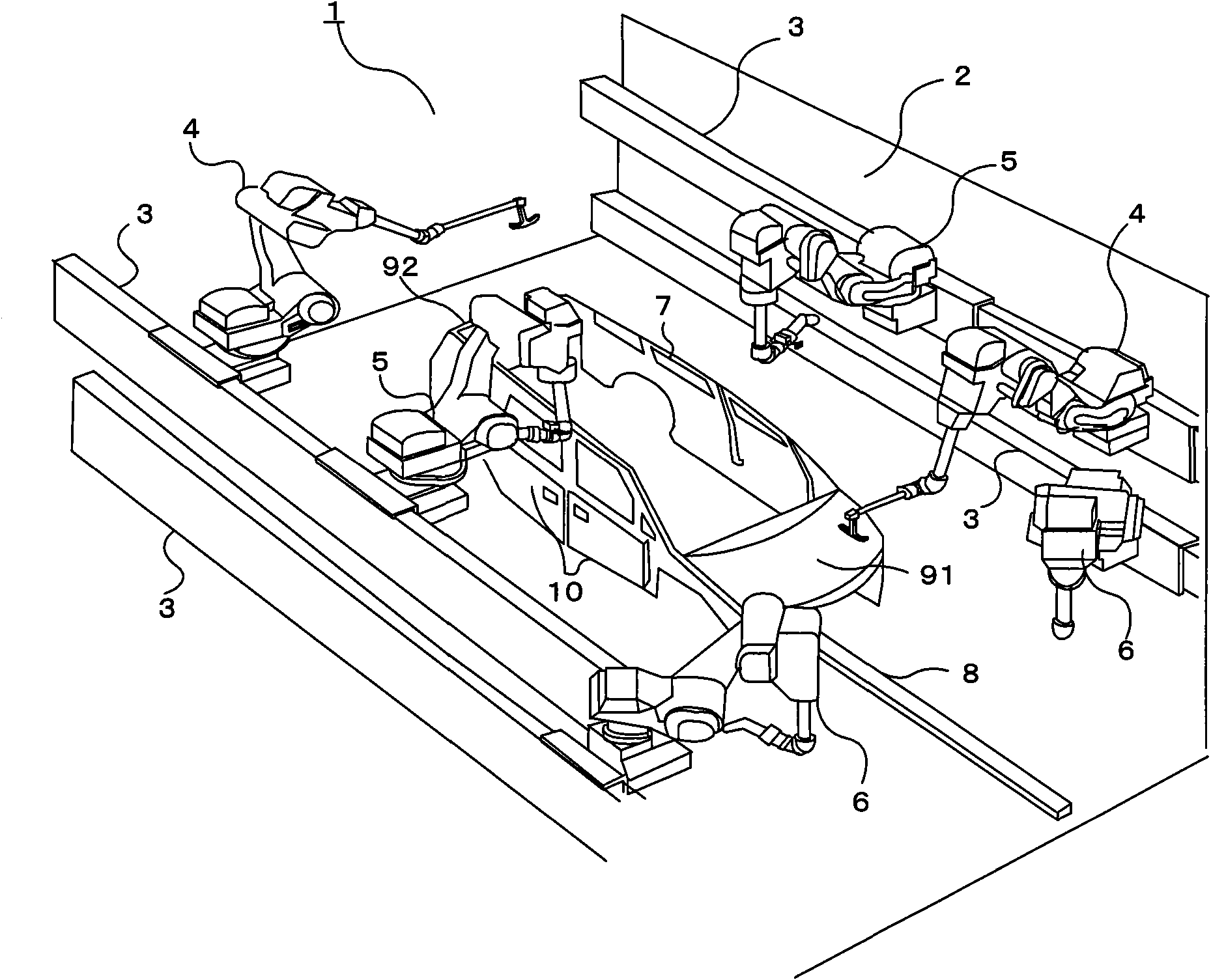

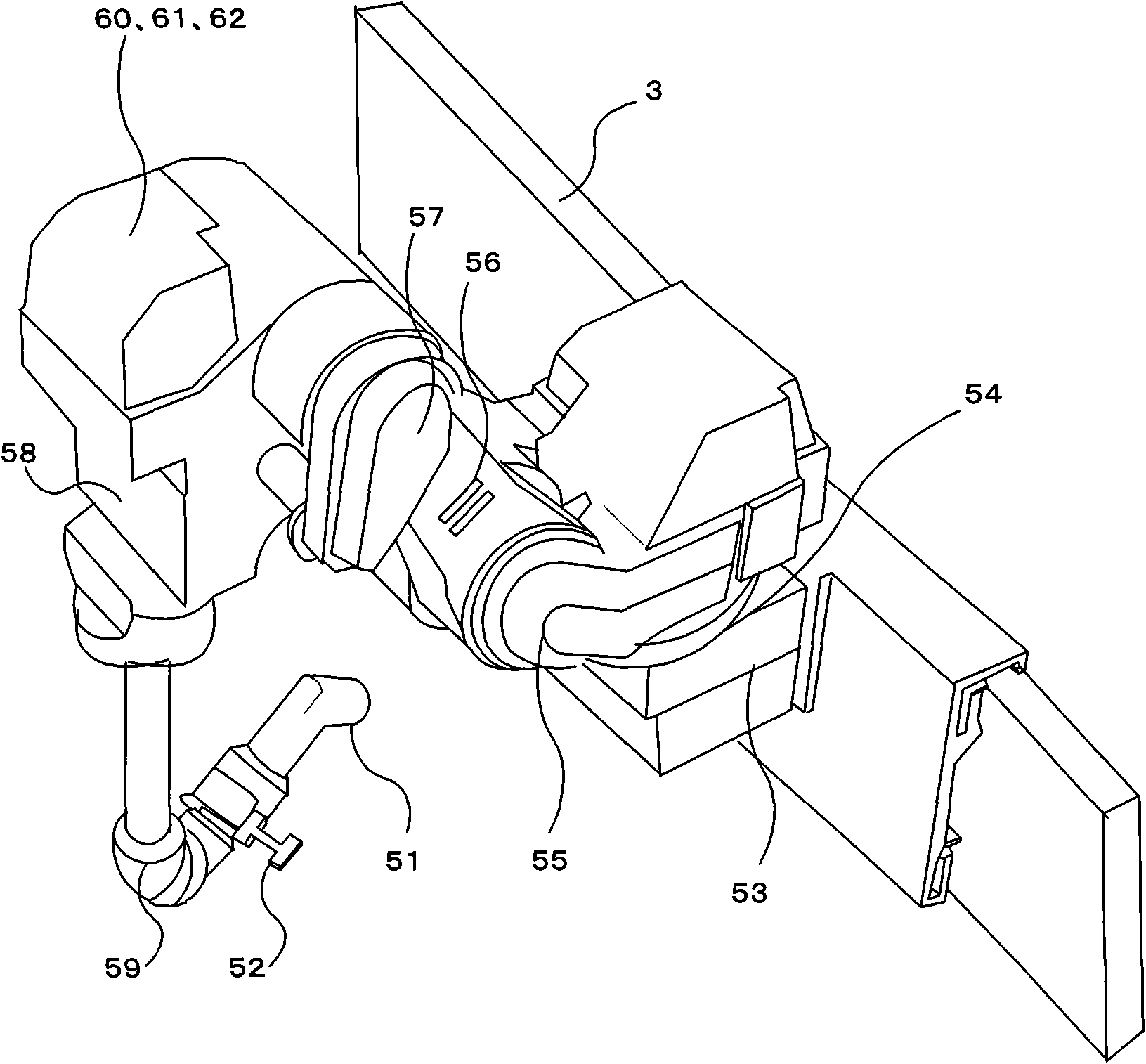

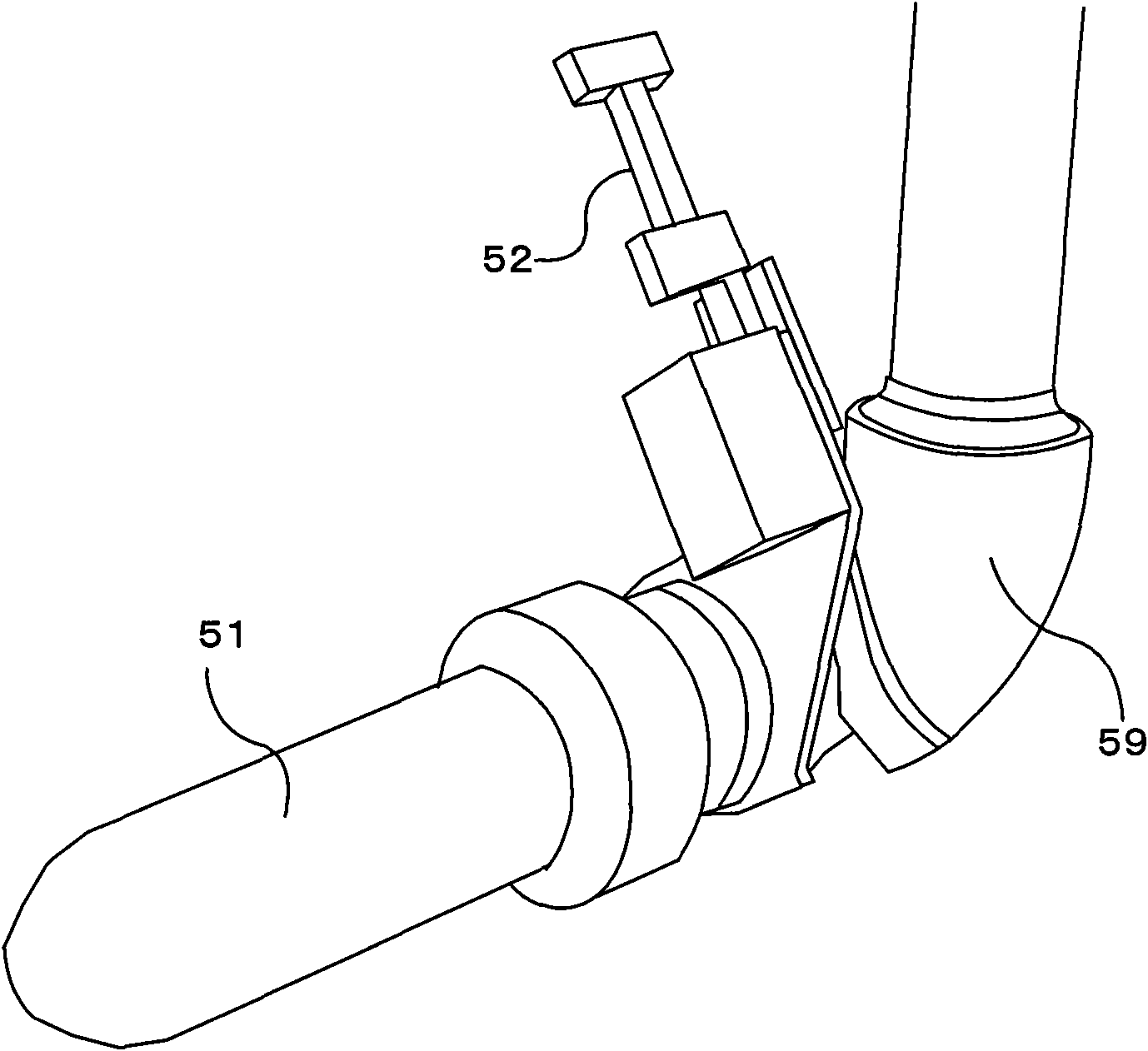

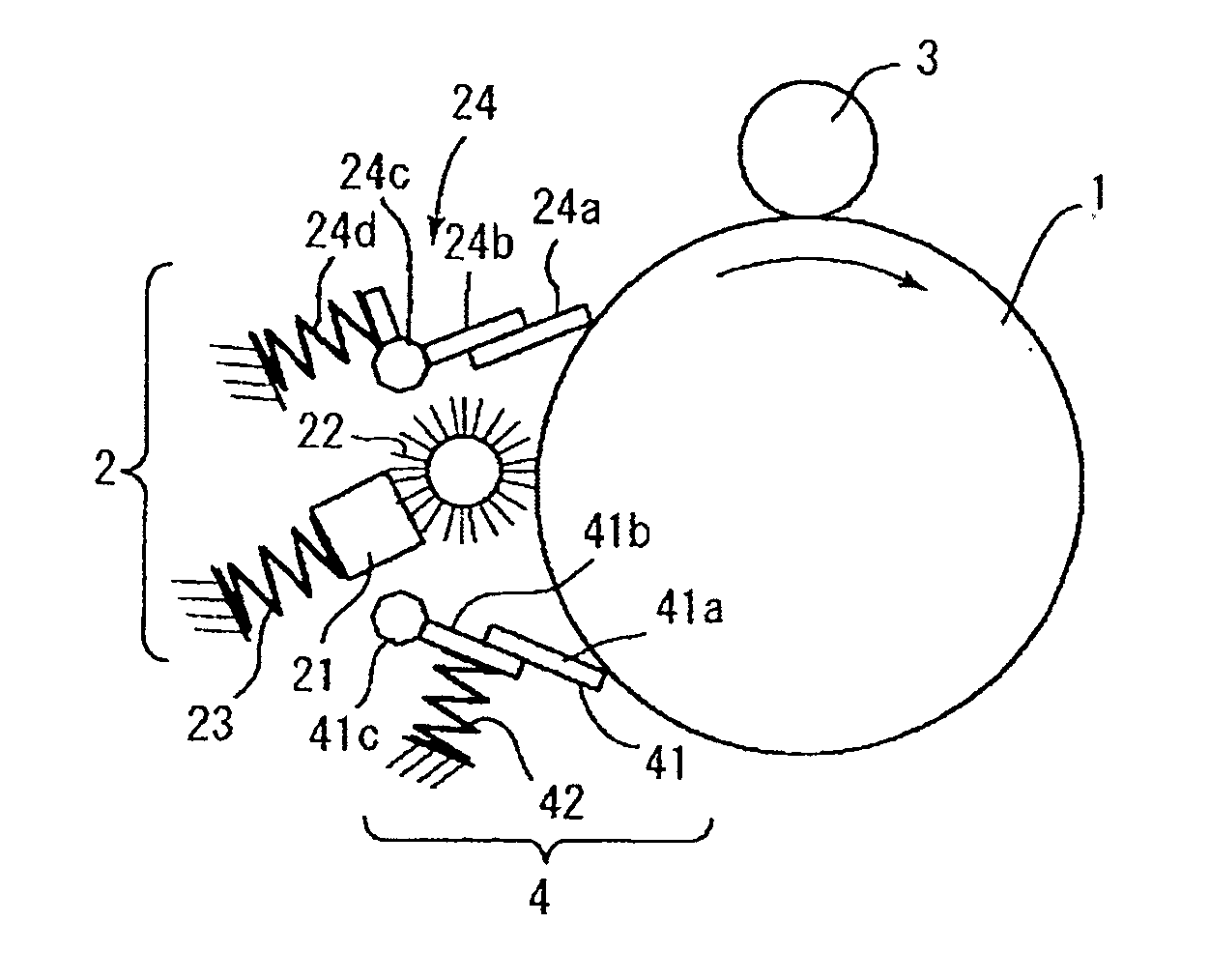

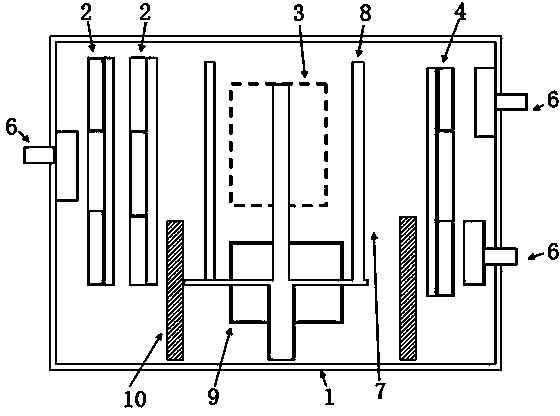

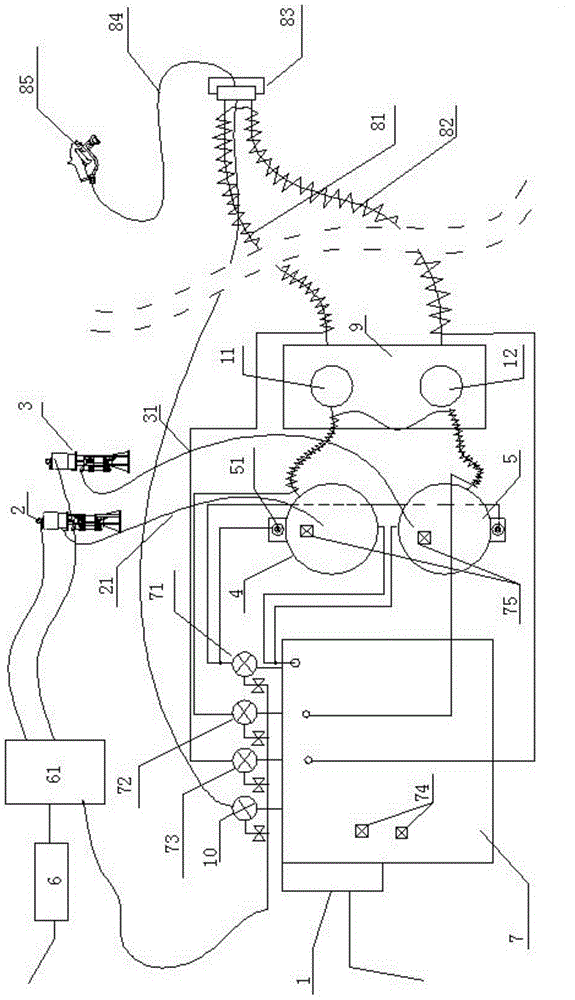

Painting system

ActiveCN101657264AAbnormal color does not occurRealize continuous coatingProgramme-controlled manipulatorSpray boothsControl theoryRobot

The present invention relates to a painting system having improved productivity achieved by optimizing the number and arrangement of robots in a painting booth. A painting system (1) in which a painting robot (6) and an opener robot (4) can pass each other without interference on a first travel guide rail (3) and a second travel guide rail (3). The first travel guide rail (3) is placed at a lower position than the second travel guide rail (3). The painting robot (6) is placed on the first travel guide rail (3), and the opener robot (4) is placed on the second travel guide rail (3).

Owner:YASKAWA DENKI KK +1

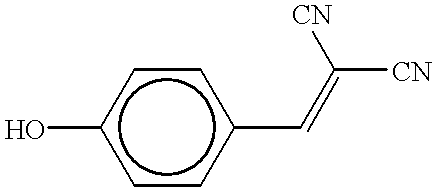

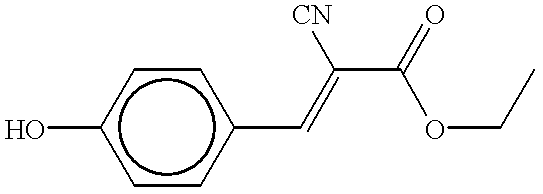

Spin-on graded k silicon antireflective coating

InactiveUS20090274974A1Good image transferGood characteristicPhotosensitive materialsPhotoprinting processesSilicon basedAnti-reflective coating

Owner:AZ ELECTRONICS MATERIALS USA CORP

Double-component polyurethane coating and production method and construction method

InactiveCN101457120AShorten the coating production cycleHigh fullnessPretreated surfacesPolyurea/polyurethane coatingsLacquerPolyurethane coating

The present invention discloses a bicomponent polyurethane paint and preparation method and execution method thereof, wherein the bicomponent polyurethane paint includes primer, primer fluidifying agent and bicomponent polyurethane PU varnish lacquer that matched with the primer. The bicomponent polyurethane PU paint can be used on HIPS plastic rubber case with complicated structure, and can improve productivity effect and save energy sources, have appearance with high lustrousness and high fullness; the preparation method provides simple producing process and the execution method provides convenient painting.

Owner:DONGGUAN JIAZHUOCHENG CHEM TECH

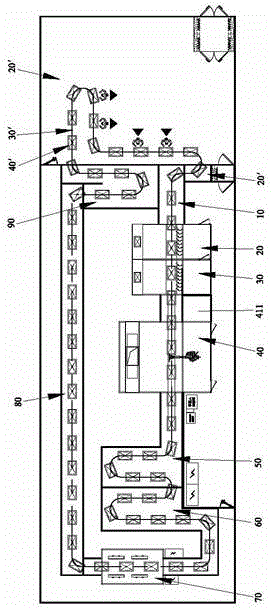

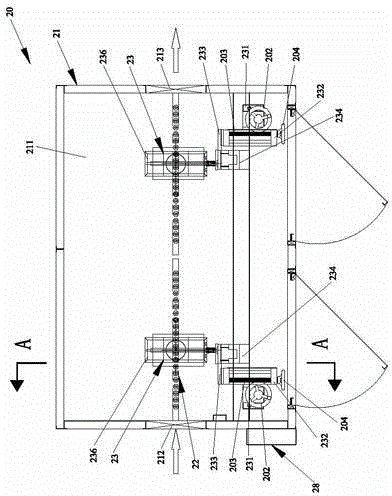

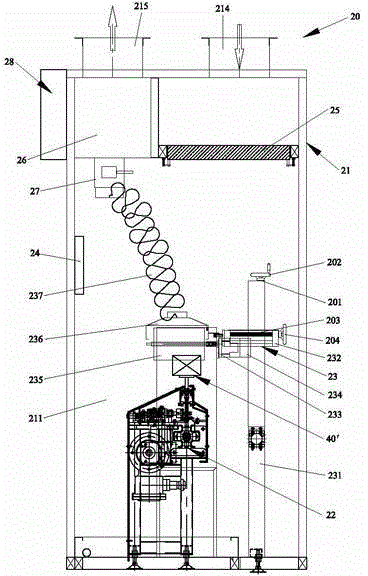

Fully-automatic dust-free painting line of plastic component

ActiveCN104588247AHigh degree of automationReduce manpower consumptionLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses a fully-automatic dust-free painting line of a plastic component. The painting line comprises a preheating furnace, a first dust-removing cabinet, a second dust-removing cabinet, a spraying room, a leveling device, an IR (infrared) furnace, a UV (ultraviolet) light curing machine, a PU (polyurethane) curing oven, a cooling device and a component loading and unloading area, wherein the preheating furnace, the first dust-removing cabinet, the second dust-removing cabinet, the spraying room, the leveling device, the IR furnace and the UV light curing machine are sequentially and transversely connected and are positioned on the front side of the PU curing oven. Operation procedures, such as continuous dust removal, paint spraying, baking, drying and cooling, are sequentially finished by matching and using each device, the automation degree is high, labor consumption is reduced, the production efficiency is effectively improved, and meanwhile, the painting quality is improved; intelligent control is realized, and the aims of energy conservation, emission reduction, waste removal, production cost reduction and the like are fulfilled by arranging each electric sensor; the painting line is reasonable in structural layout, can be used for painting a UV paint and a PU paint to a workpiece, and is strong in function and wide in application range.

Owner:东莞市慧江平成机械有限公司

Fast-etching, thermosetting anti-reflective coatings derived from cellulosic binders

InactiveUS6316160B1Improve compatibilityGood stability at room temperatureSemiconductor/solid-state device manufacturingCellulose derivative coatingsCelluloseAnti-reflective coating

Owner:BREWER SCI

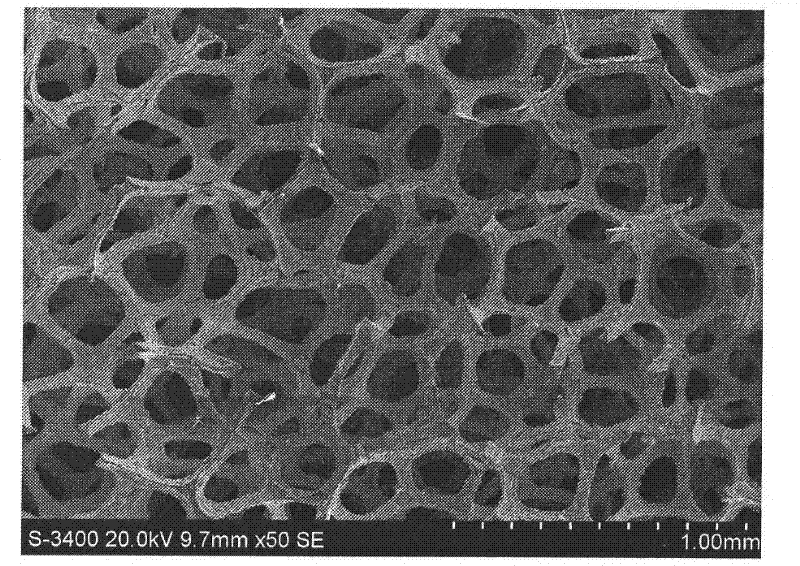

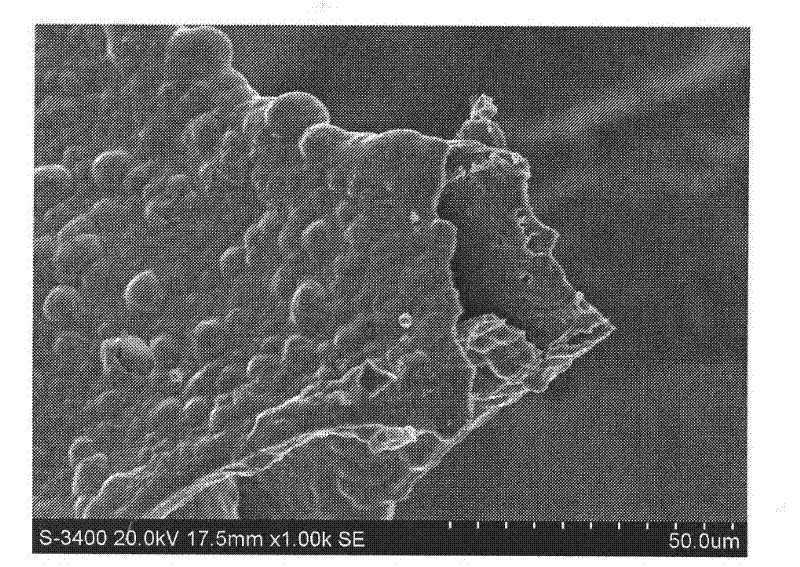

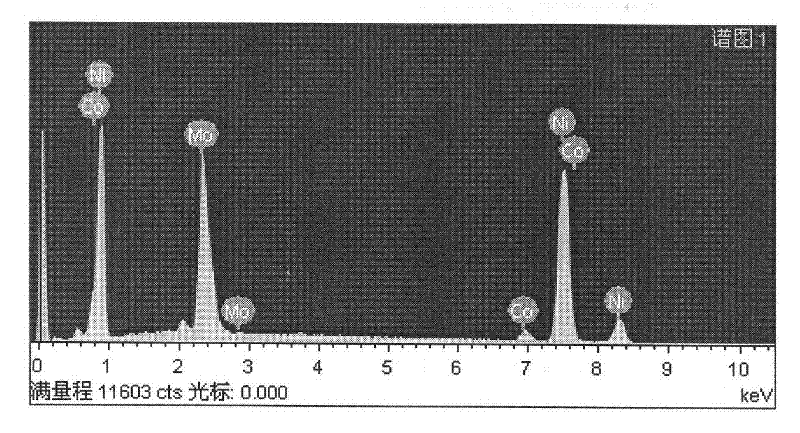

Multi-element alloy foam material and preparation method thereof

The invention discloses a multi-element alloy foam material and a preparation method thereof. The multi-element alloy foam material is a porous alloy material, and consists of two, three or more elements of metallic nickel, molybdenum, cobalt, zinc, ferrum, tungsten, copper and zirconium. In the preparation method, an organic foam material is used as a precursor; and the preparation method comprises the following steps of: performing conductive treatment on the organic foam material; electroplating the organic foam material which is subjected to conductive treatment; taking out the organic foam material from the electroplated organic foam material; and performing heat treatment to prepare the multi-element alloy foam material. The multi-element alloy foam material has a large specific surface area and high hydrogen-evolution catalytic activity, so the multi-element alloy foam material has multiple purposes in functional fields, such as electrolysis hydrogen production industry, battery industry and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Bituminous products, the mixture thereof with aggregates and the use thereof

ActiveUS20090088499A1Bituminous mix production temperatureMaintain managementIn situ pavingsTransportation and packagingRoad surfaceCore temperature

The invention relates to anhydrous bituminous products containing one or several specific additives which make it possible to substantially reduce a temperature for producing aggregate and bituminous product mixtures in such a way that it ranges from 20 to 40° C., wherein the temperature of the aggregate and the bituminous product mixture during spreading ranges from 10 to 40° C. and the temperature in the core of the aggregate and bituminous product mixtures during compacting can be raised to 50° C. without degrading the standardized properties of the bituminous product and the bituminous product and aggregate mixture and ensuring the process continuity from transport to compacting according to the state of the art. The inventive aggregate and bituminous product mixtures are particularly suitable for tightening, building and servicing road surfaces, pavements and airfield runways.

Owner:ARKEMA FRANCE SA

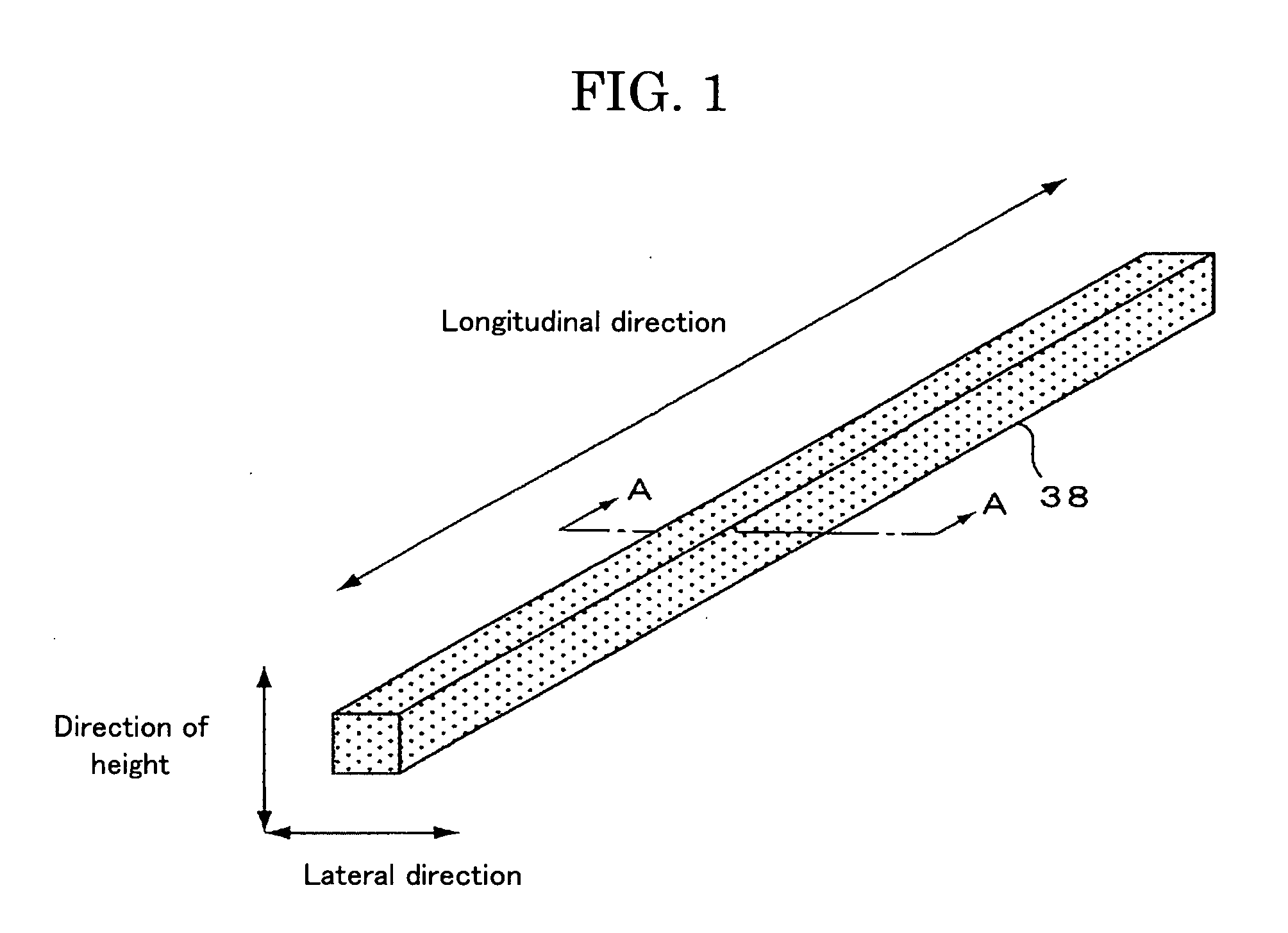

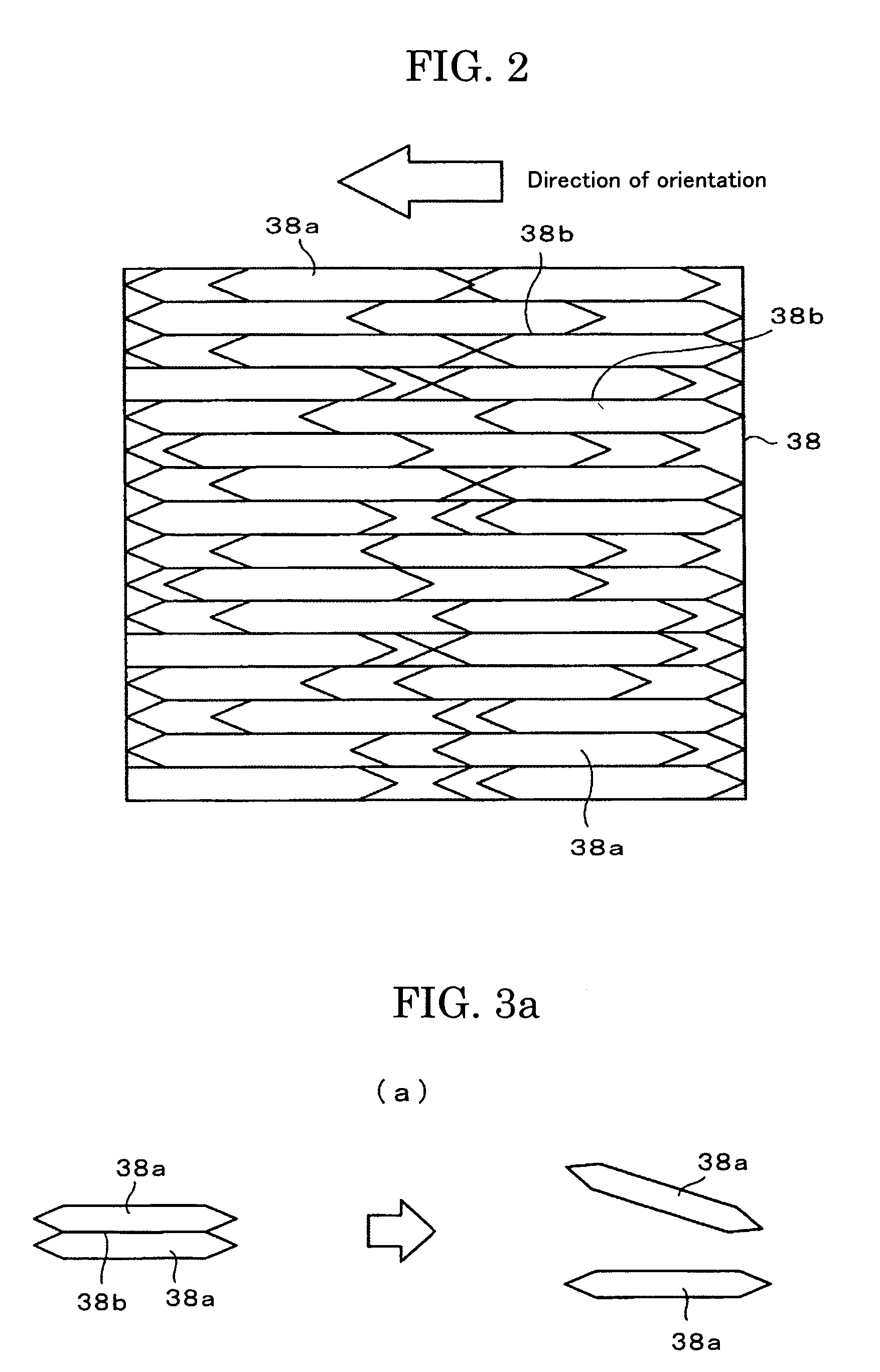

Image-bearing member protecting agent, method of applying an image-bearing member protecting agent, protective layer forming device, image forming method, process cartridge, and image forming apparatus

ActiveUS20100310291A1Improve application qualityQuality improvementElectrography/magnetographyImage formationEngineering

The present invention provides an image-bearing member protecting agent, which has a block shape and is used in an image forming process where the image-bearing member protecting agent is applied or attached to a surface of an image bearing member while being scraped off with a roll-shaped brush, the image-bearing member protecting agent including: a fatty acid metal salt, wherein the image-bearing member protecting agent includes a plurality of small blocks and has such an orientation that one or more of the small blocks are easily separated from other small blocks, and a plurality of oriented surfaces of the plurality of small blocks are arranged in a laminated state in a substantially same direction.

Owner:RICOH KK

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

Alumina coats pulp and preparation method thereof

ActiveCN101491776AHigh bonding strengthHigh hydrothermal stabilityCatalyst carriersDispersed particle separationThin shellsAdhesive

The invention relates to alumina coat slurry and a preparation method thereof, and mainly solves the problems of the prior art of poor stability of a prepared laminar composite carrier and short service life of a prepared thin-shelled noble metal catalyst. The alumina coat slurry comprises the following components: aluminum sol with an average granularity of less than 20 micrometres, active alumina, an organic adhesive, an inorganic adhesive, a surfactant, a pH modifying agent and the balance being water, wherein the average granularity of the slurry is less than 10 micrometres. The preparation method comprises the following steps: dissolving the aluminum sol, the organic adhesive, the surfactant and the pH modifying agent in water; mixing the mixture evenly with stirring at a high speed; then adding the inorganic adhesive and active alumina powder for high-speed dispersion; and regrinding the obtained alumina coat slurry to prepare the alumina coat slurry. Thus, the preparation method better solves the problems by adopting the technical proposal, and can be used in the industrial production of laminar composite carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

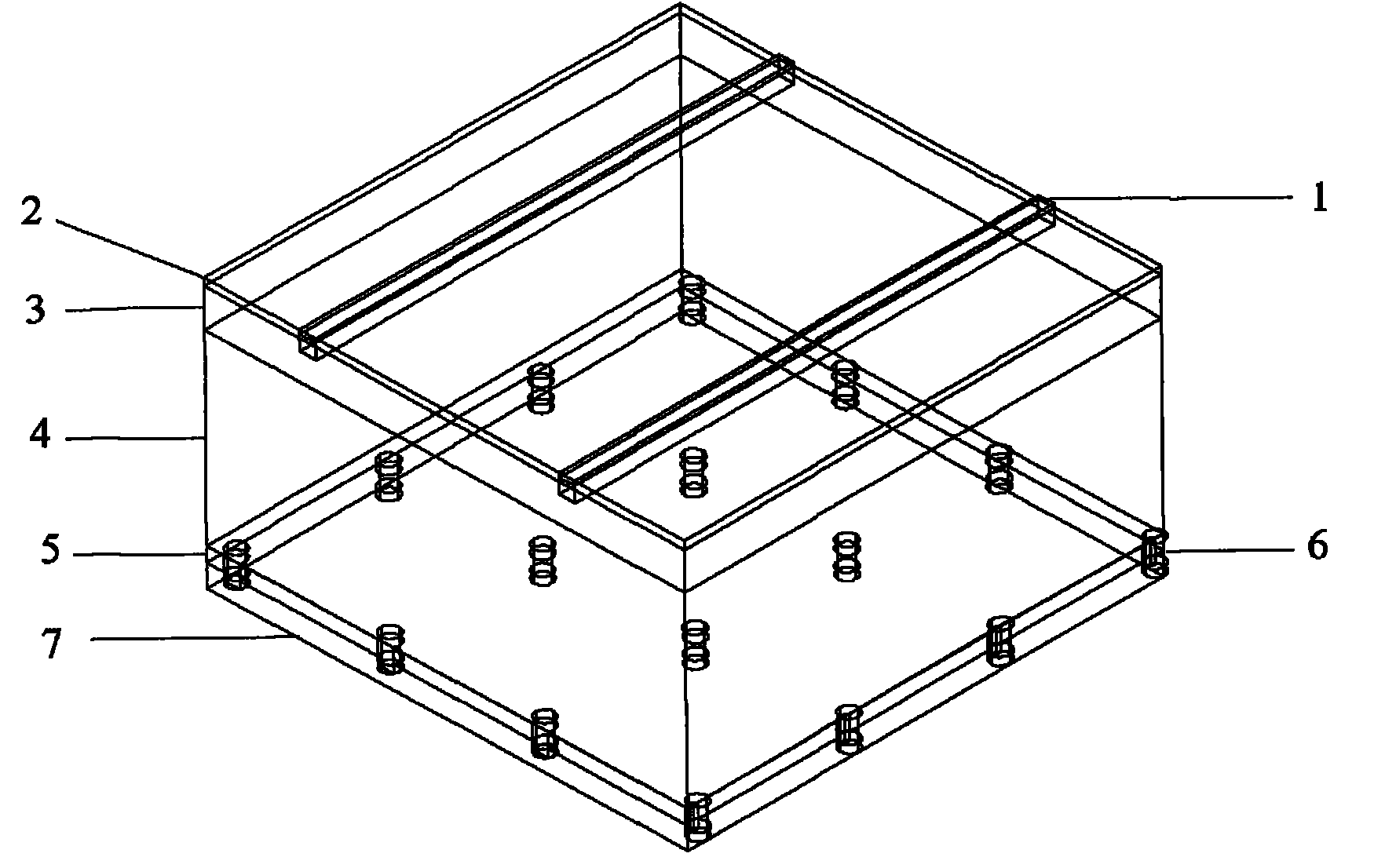

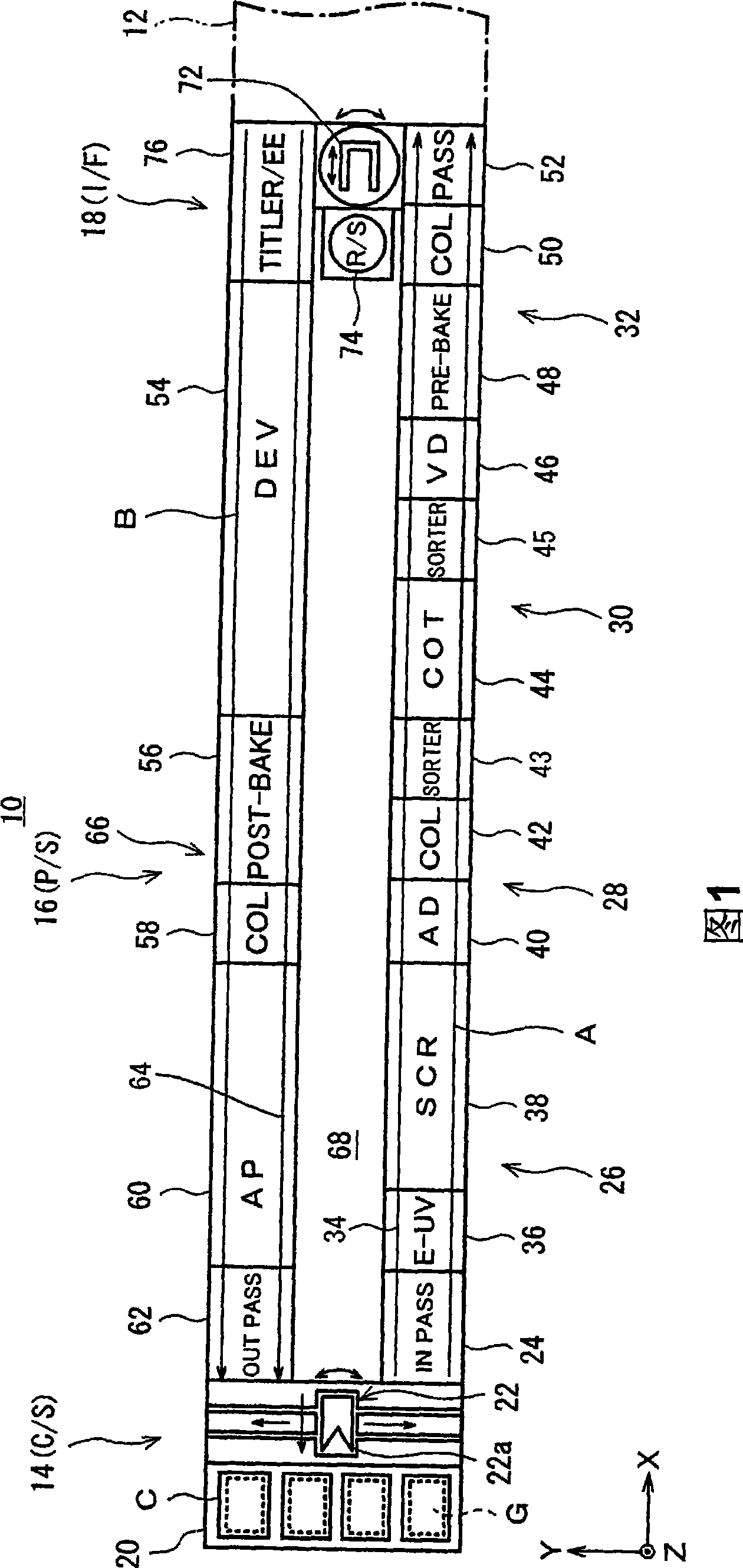

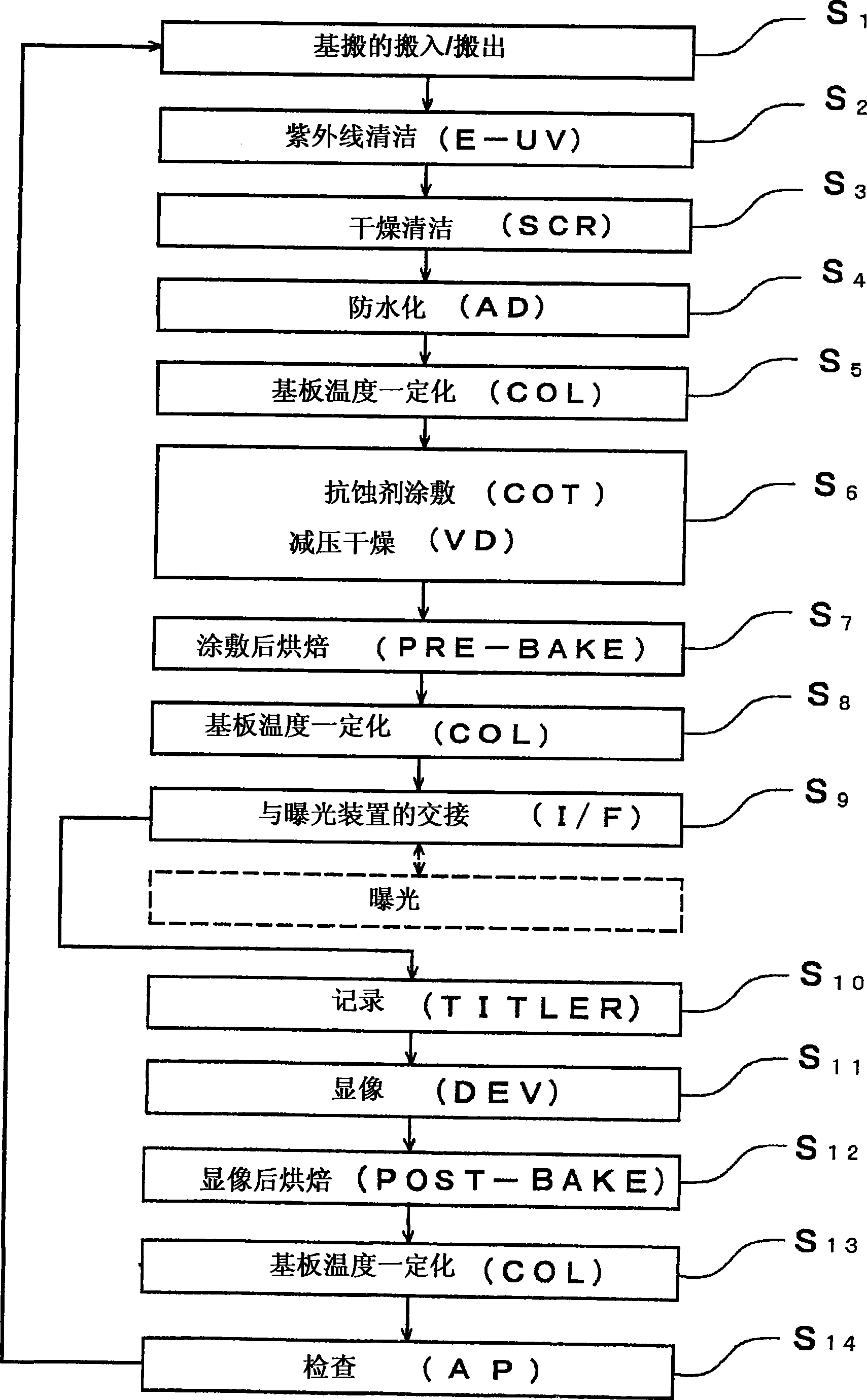

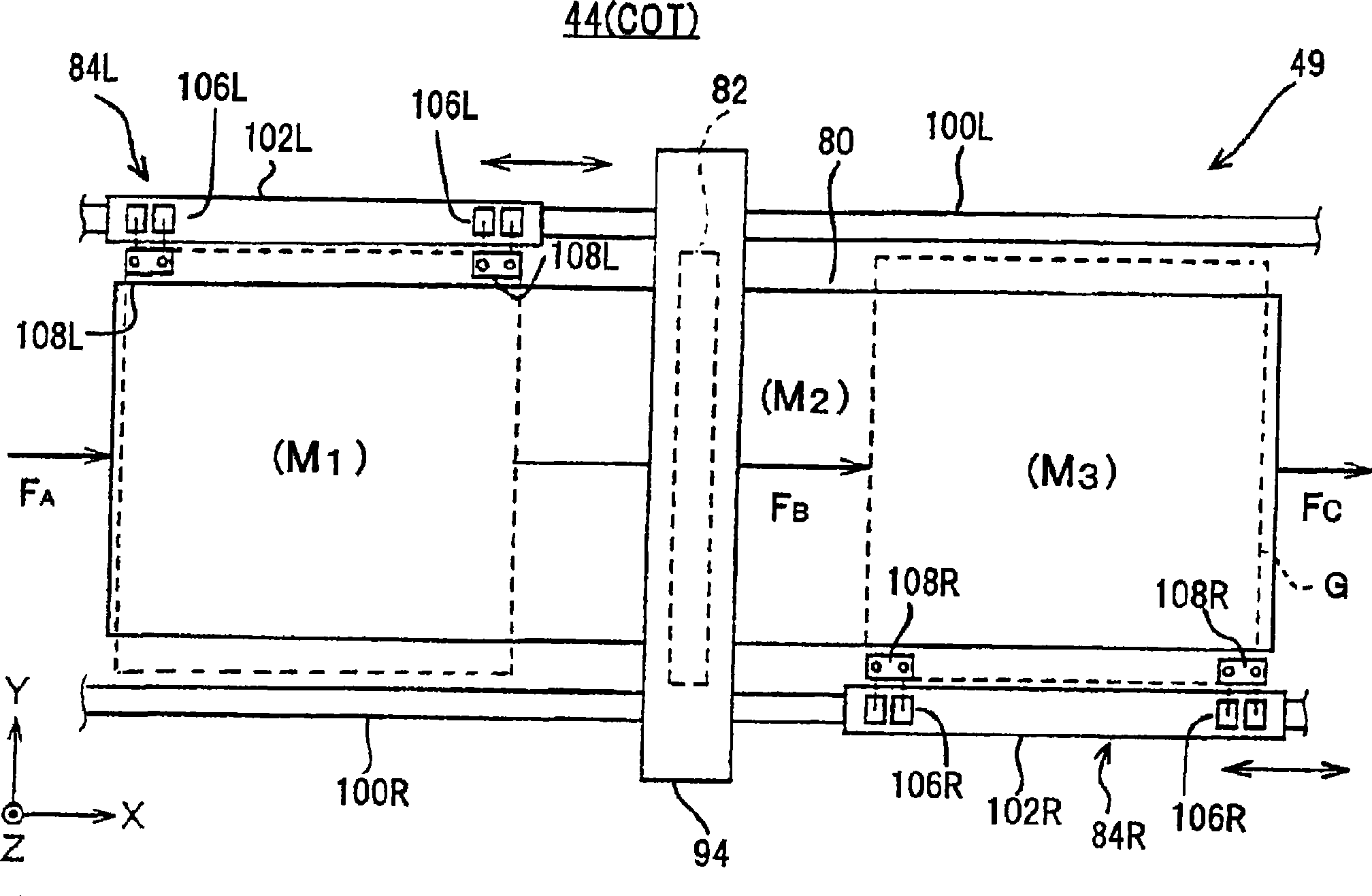

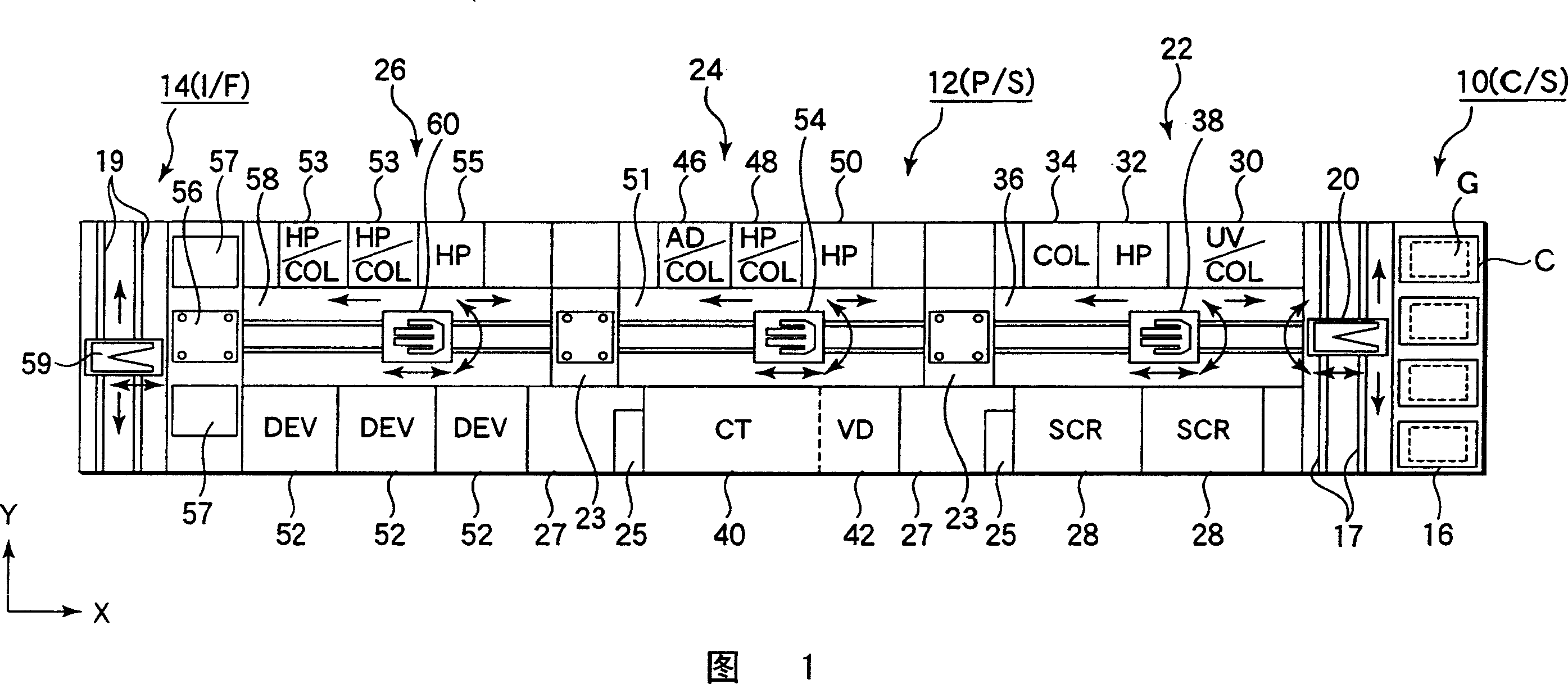

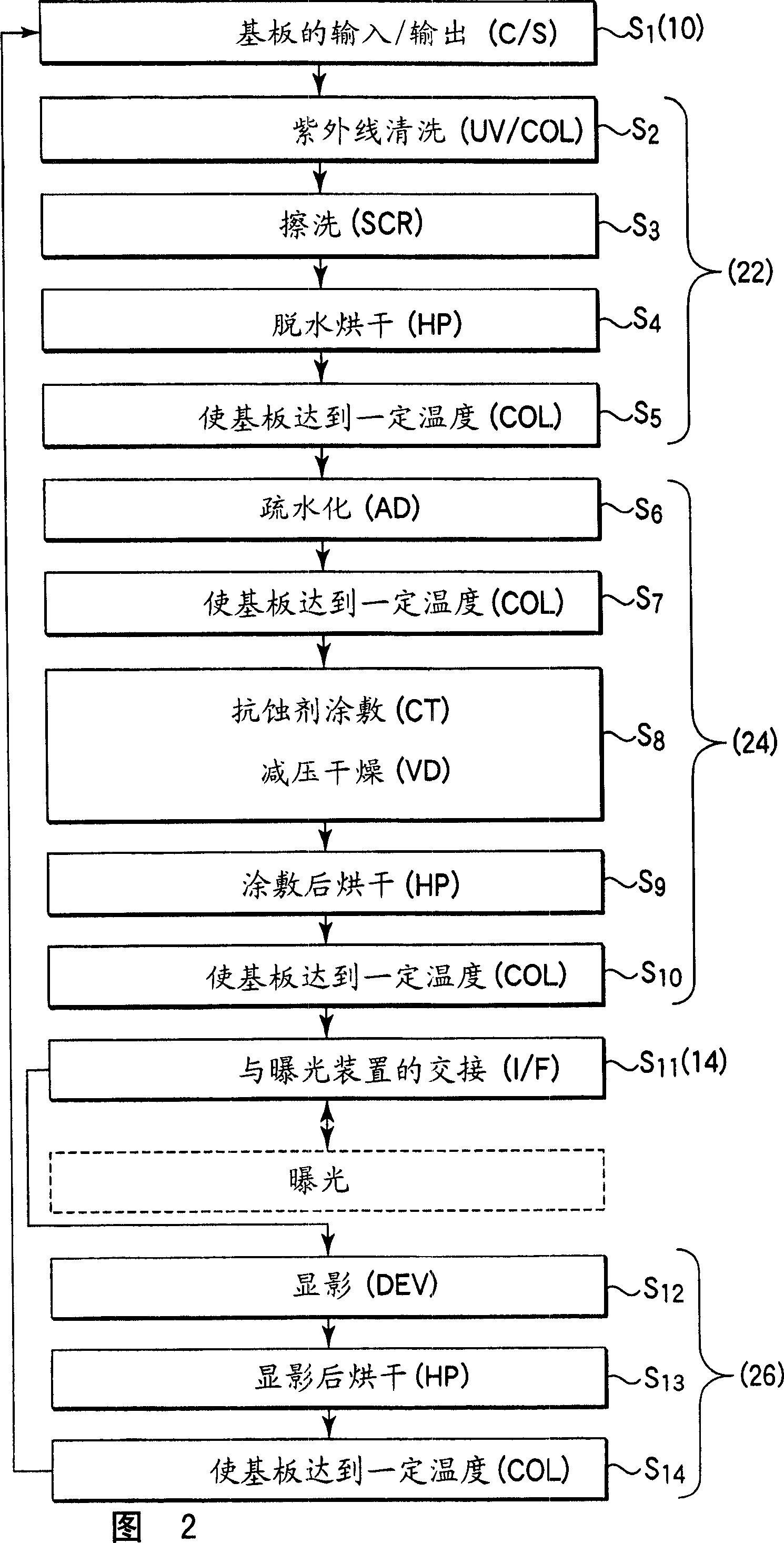

Substrate treatment device, coating device and coating method

ActiveCN101431008AStable Suspension TransportImprove coating qualityLiquid surface applicatorsSemiconductor/solid-state device manufacturingDown shiftingEngineering

The invention provides a substrate processing apparatus and a coating apparatus and a coating method characterized in that a rectangular processed substrate is kept a fitting processed posture as a simple structure for stably suspending moving on a suspension loading station. A first and a second holding parts (106L, 106R) in a first (left side) and a second (right side) moving parts (84L, 84R) comprise two adsorption pads (108L, 108R) combined at the reverse (low surface) of the two corners at left side and right side of the substrate G through a vacuum adsorption force; a pair of pad support parts (110L, 110R) for inhibiting the displacement in perpendicular direction of each adsorption pad (108L, 108R) in two positions which are separated by a prescriptive space along the moving direction (X direction); and a pair of pad actuators (112L, 112R) enabling the pad support parts (110L, 110R) to respectively independently up-down moving or up-down shifting.

Owner:TOKYO ELECTRON LTD

Fluorescent material coating apparatus and method of coating fluorescent substance using the same

InactiveCN1828804AUniform viscosityEnsure coating uniformityLuminescent coatings applicationShoresSubstance useEngineering

There is provided a fluorescent material coating apparatus for a fluorescent lamp. The fluorescent material coating apparatus includes a cassette on which a plurality of glass tubes are detachably mounted, a delivery member having a delivery chamber communicating with first ends of the glass tubes, a negative pressure generating unit for allowing fluorescent solution to be drawn into the glass tubes by generating a negative pressure in the glass tubes communicating with the delivery chamber by lowering the pressure of the delivery chamber, a dry air supplying unit for supplying dry air to the delivery chamber to dry the fluorescent solution applied on inner surfaces of the glass tubes, a solution tank containing the fluorescent solution and disposed below the glass tubes mounted on the cassette, and a moving unit for allowing lower end portions of the glass tubes mounted in the delivery chamber to be dipped into the fluorescent solution contained in the solution tank.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

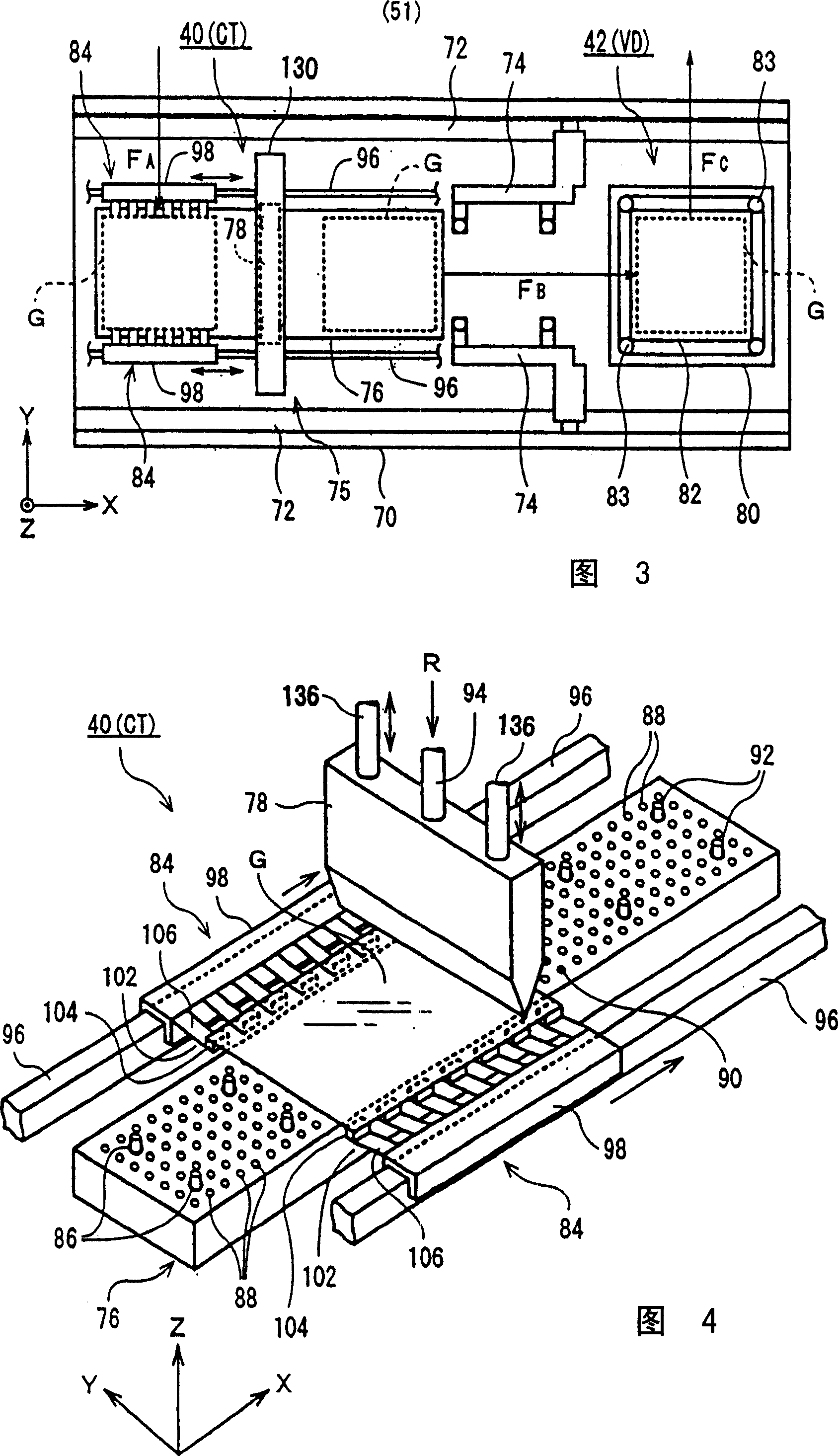

Application method, applicator and processing procedure

ActiveCN101003041AImproved film thickness controlImprove coating qualityLiquid surface applicatorsSpraying apparatusEtchingEngineering

In the last stage of the coating scanning procedure, etching resist agent / liquid apophysis RQ, which formerly clings to or follows the lower side face 78b of the etching resist agent nozzle, will be separated form the etching resist agent nozzle 78 by instantly rising scanning speed (rapid acceleration), preferably is left adjacent to guarantee region boundary (LX). Further, as soon as the scanning is finished, the etching resist agent nozzle 78 executes inverse suction on a substrate G so as to eliminate superfluous etching resist agent on coating scanning terminal section, at this time, the influence of inverse suction can be counteracted by the left etching resist agent / liquid apophysis RQ so as to prevent the etching resist agent membrane thickness in a guarantee region (ES) declining under the predetermine value or allowable range.

Owner:TOKYO ELECTRON LTD

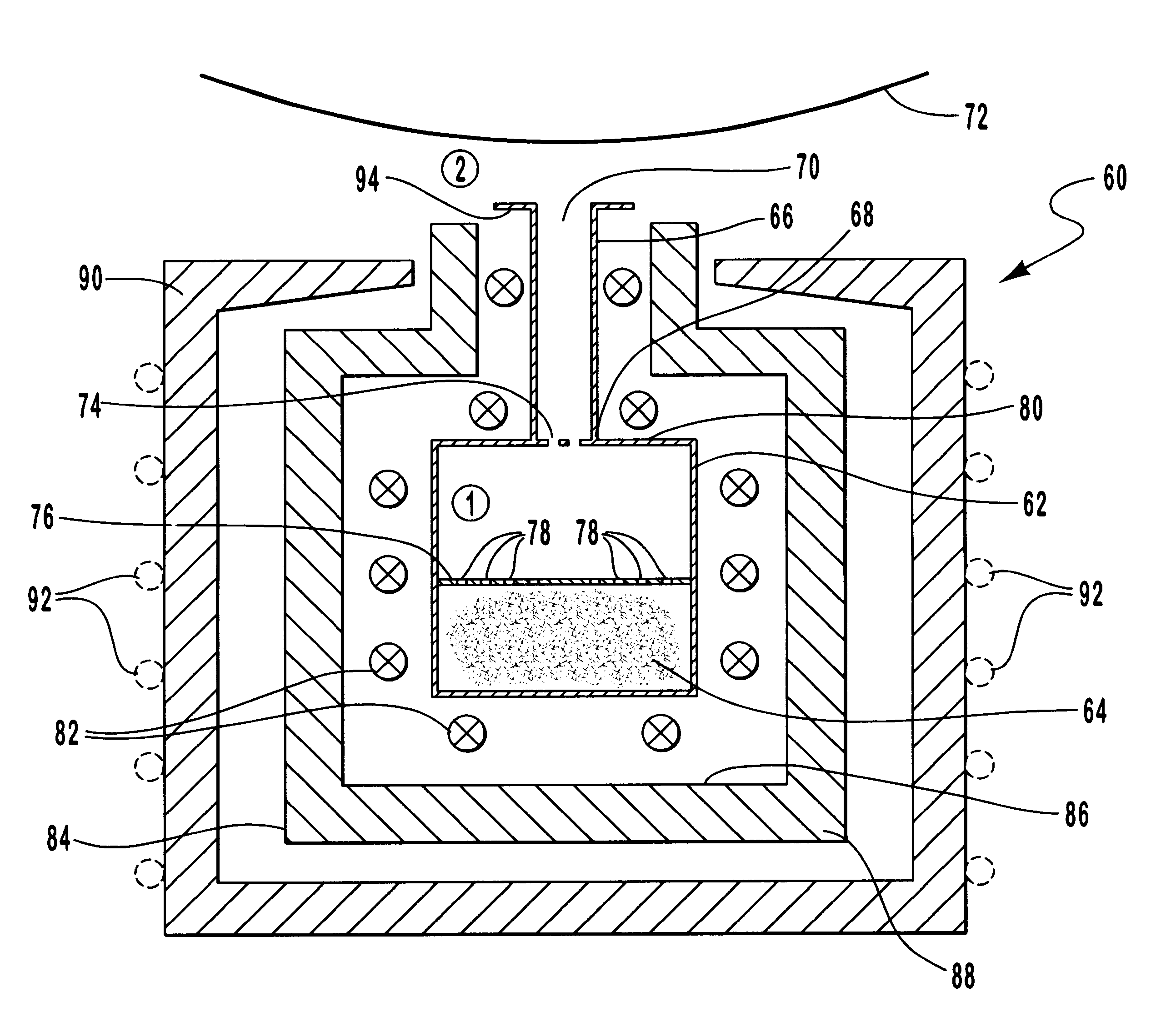

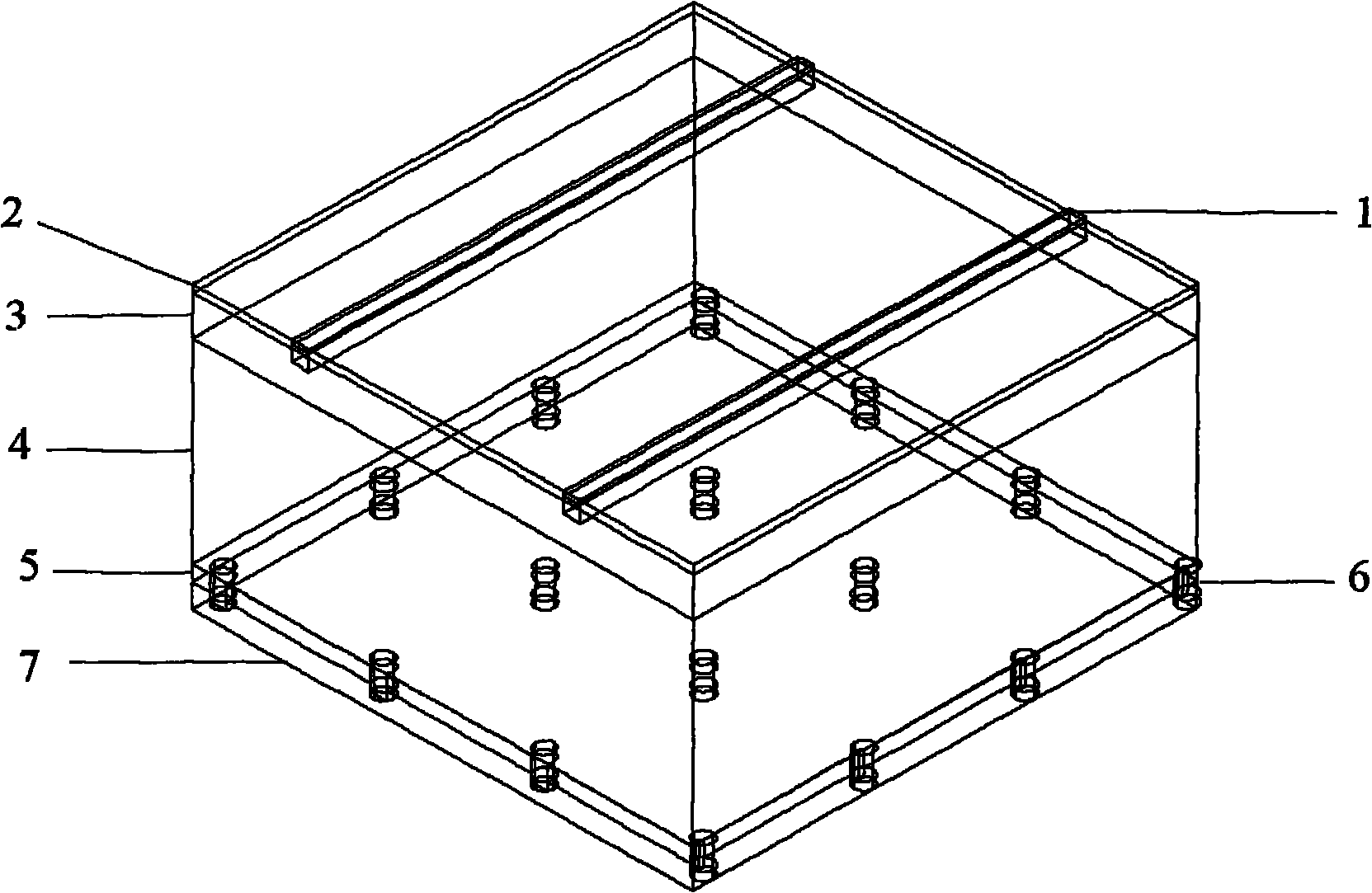

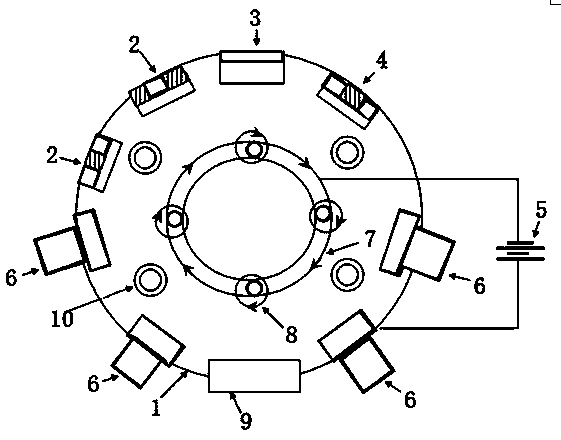

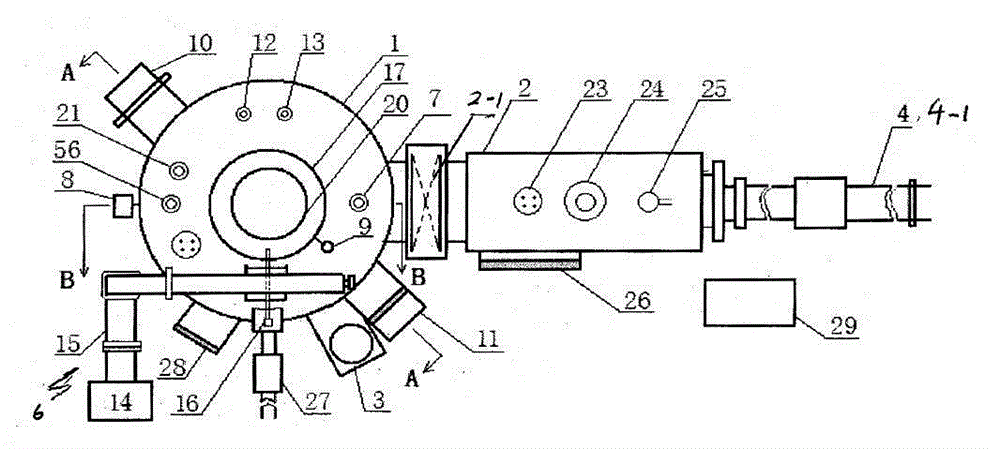

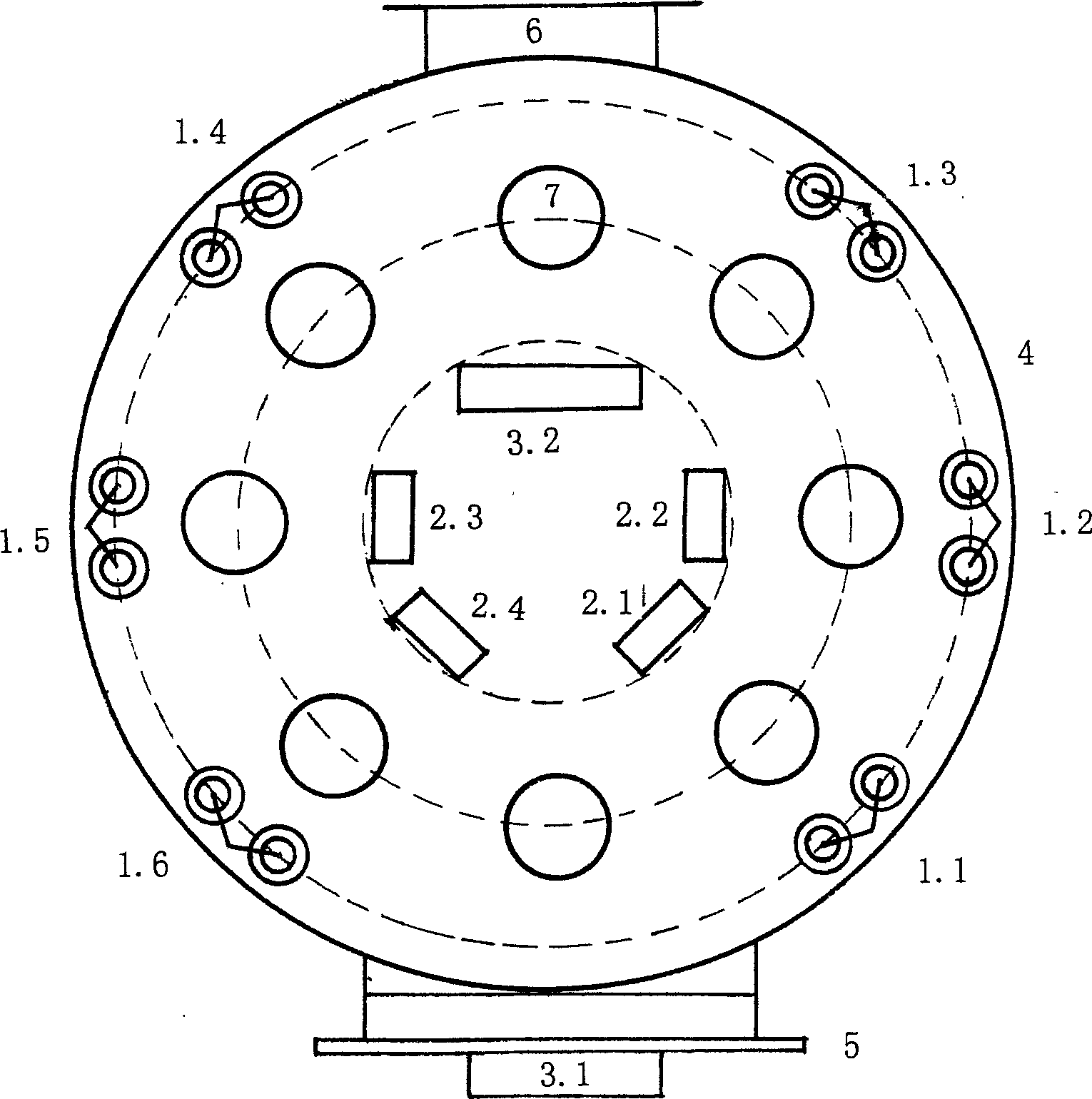

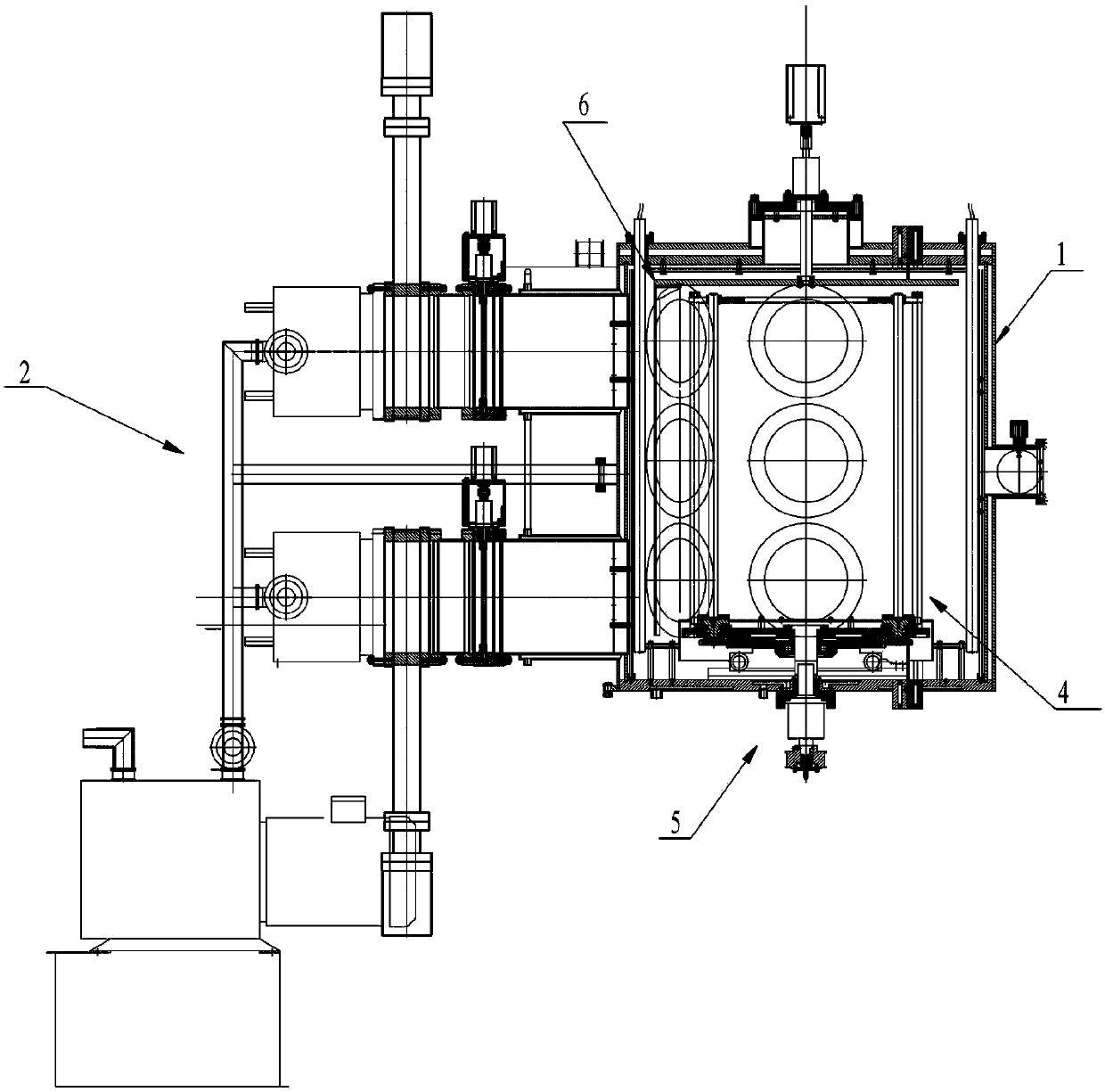

Multifunctional fully-automatic ion-plating machine for deposition of cutting tool coating and using method of multifunctional fully-automatic ion-plating machine

ActiveCN103695858AIncrease profitIncrease gas ionization rateVacuum evaporation coatingSputtering coatingAlloyOxygen

The invention relates to the technical field of thin film materials, in particular to a multifunctional fully-automatic ion-plating machine for the deposition of a cutting tool coating. The machine comprises a vacuum chamber, bipolar pulse magnetron sputtering targets, a rectangular anode layer gas ion source, a high-power pulse magnetron sputtering source, a bias power supply, cathode arc sources, a workpiece rack and a support, wherein the bipolar pulse magnetron sputtering targets, the anode layer gas ion source, the high-power pulse magnetron sputtering source, the bias power supply and the cathode arc sources are controlled through five groups of independent switches respectively. Due to the adoption of the structure, pure metal, alloy and reaction film layers can be prepared, and multi-element and multilayer nanometer composite coatings and oxygen-containing coatings can also be prepared to meet the requirements of metal cutting tools with different shapes and sizes on high-speed machining.

Owner:GUANGDONG UNIV OF TECH

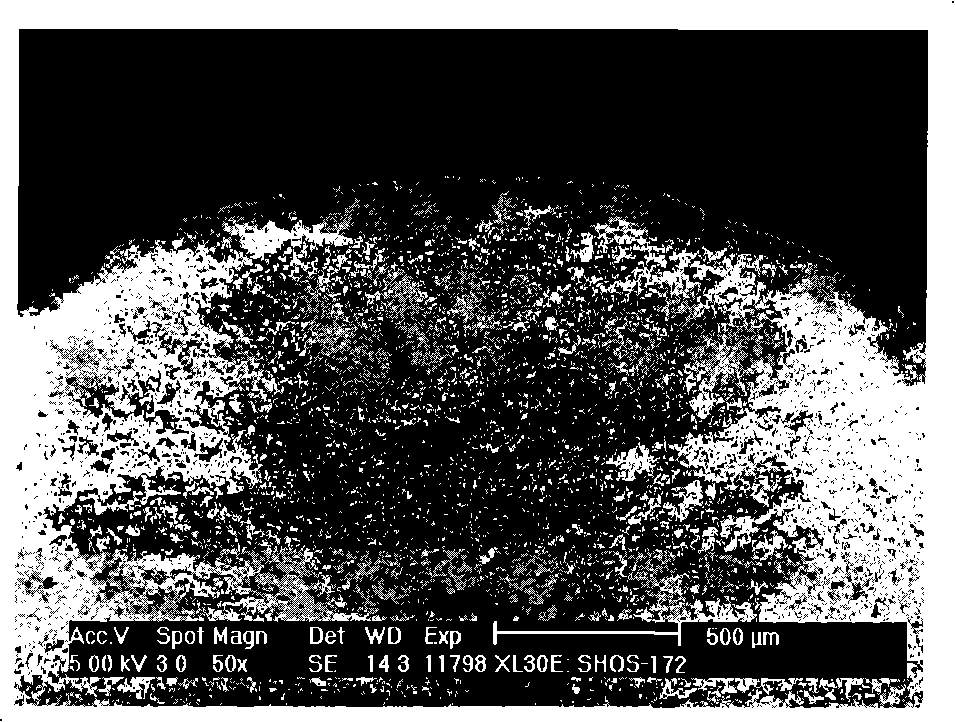

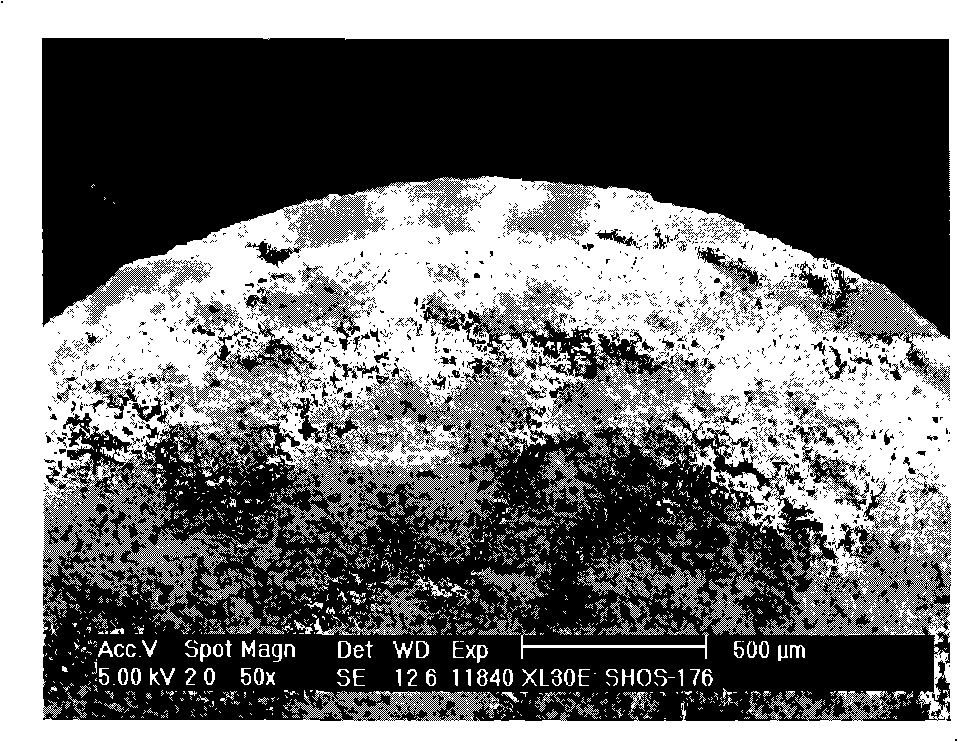

Manufacture of high active detergent particles

ActiveUS20120058266A1Nice appearanceImprove coating qualityNon-ionic surface-active compoundsLiquid surface applicatorsLinear alkylbenzene sulfonateLinear alkylbenzene

A process for manufacturing detergent particles comprising the steps of: a) forming a liquid surfactant blend comprising a major amount of surfactant and a minor amount of water, the surfactant part consisting of at least 51 wt % linear alkylbenzene sulfonate and at least one co-surfactant, the surfactant blend consisting of at most 20 wt % nonionic surfactant; b) drying the liquid surfactant blend of step (a) in an evaporator or drier to a moisture content of at most 2 wt % and cooling the output from the evaporator or dryer; c) feeding the cooled material, which output comprises at least 93 wt % surfactant blend with a major part of LAS, to an extruder, optionally along with less than 10 wt % of other materials such as perfume, fluorescer, and extruding the surfactant blend to form an extrudate while periodically cutting the extrudate to form hard detergent particles with a diameter across the extruder of greater than 2 mm and a thickness along the axis of the extruder of greater than 0.2 mm, provided that the diameter is greater than the thickness; d) optionally, coating the extruded hard detergent particles with up to 30 wt % coating material selected from powdered inorganic material and mixtures of such material and nonionic material with a melting point in the range 40 to 90° C.

Owner:CONOPCO INC D B A UNILEVER

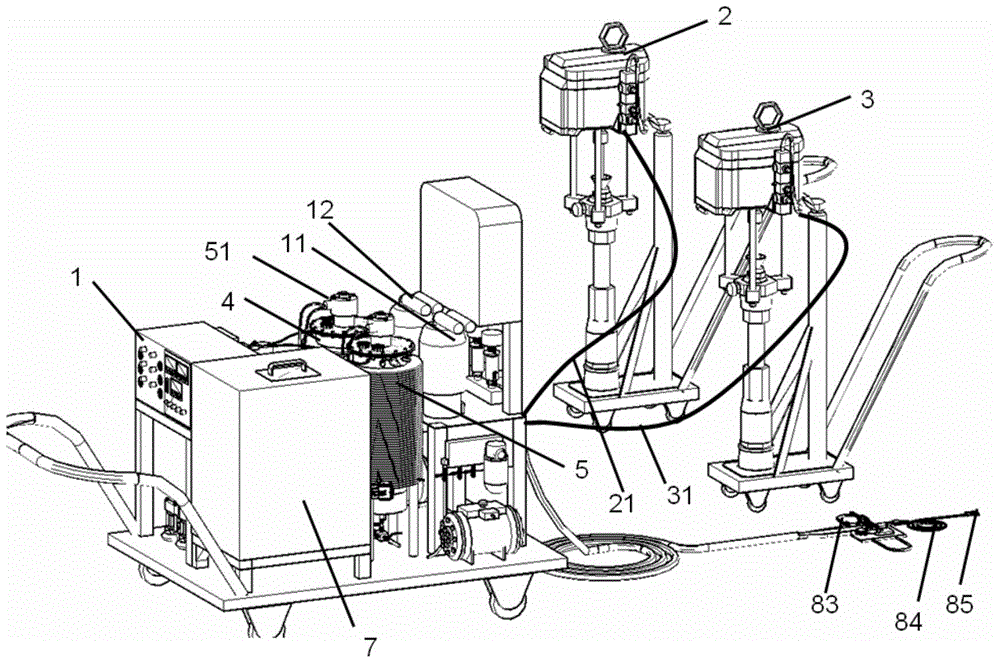

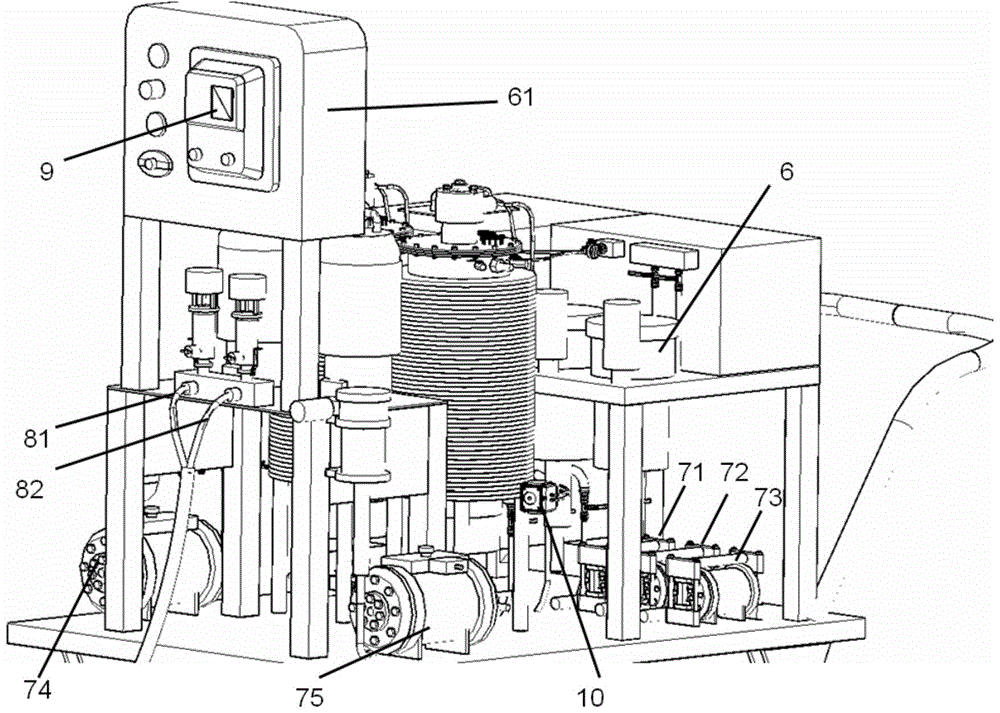

Dual-component high-pressure proportion-adjustable fire retardant coating spraying device and method

ActiveCN104084331ASmall atomization effectPromote atomizationLiquid spraying apparatusElectronic controllerAgricultural engineering

The invention provides a dual-component high-pressure proportion-adjustable fire retardant coating spraying device and method. The dual-component high-pressure proportion-adjustable fire retardant coating spraying device comprises a control mechanism, a main air feed pump, a feeding mechanism, a heating mechanism, a proportioning mechanism, a spraying mechanism and a cleaning mechanism. The control mechanism is a digital electronic controller, the input end of the main air feed pump is connected with an external air source, the output end of the main air feed pump is connected with the feeding mechanism, the heating mechanism, the proportioning mechanism, the spraying mechanism and the cleaning mechanism through an air pressure adjusting device, and a switch of the main air feed pump is connected with a main air switch of the digital electronic controller. The dual-component high-pressure proportion-adjustable fire retardant coating spraying method includes the steps of adding A-component coatings and B-component coatings into an A-component coating bucket and a B-component coating bucket; heating the A-component coatings, the B-component coatings and coating pipes; when the temperature of the A-component coatings and the temperature of the B-component coatings reach the set temperature, adjusting the proportion of the A-component coatings to the B-component coatings, and carrying out proportion testing; mixing the A-component coatings and the B-component coatings through a far end mixer; adding the A-component coatings and the B-component coatings which are completely mixed into a mixed coating pipe; carrying out spraying; cleaning the device after spraying is completed; stopping the device. The spraying efficiency is high, and the coating quality is good.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Facility for manufacturing vertical GaN-based LED chips by metal substrates

ActiveCN102751399AHigh densityImprove uniformityElectric discharge tubesChemical vapor deposition coatingElectron probe microanalysisGas phase

The invention discloses a facility for manufacturing vertical GaN-based LED chips by metal substrates. The facility comprises a computer information acquisition controller, a reaction room, a metal substrate feeding room, a gaseous-phase metal organism supply device, a nitrogen and / or hydrogen and / or ammonia supply device, an ECR (electron cyclotron resonance) plasma resource supply device, a vacuum degree meter and an imaging display formed relatively by a reflection high-energy electron diffractometer and a fluorescent screen, and is mainly characterized by further comprising a magnetic field coil support cylinder, a photoelectric alarm, a Faraday cylinder, an electronic probe and a direct-current bias voltage. The facility is reasonable in structure, high in film-coating quality and working efficiency, low in chip manufacture cost and the like.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Efficient paint mist coagulating agent and preparation thereof

InactiveCN101407353AImprove working environmentExtended service lifeWater/sewage treatment by flocculation/precipitationIron saltsWastewater

The invention relates to a highly-efficient paint mist coagulant and an application method thereof. The paint mist coagulant includes an A reagent and a B reagent, the A reagent is a water solution mainly prepared by a modified macromolecule polymerization metal salt, the macromolecule polymerization metal salt is aluminium salt or iron salt; the B reagent is a water solution mainly prepared by a polymerization amide-type substance with molecular weight of 9 millions to 12 millions. When in application, the paint waste water is blended with the A reagent and the B reagent according to volume ratio of 500:2:1, thus leading the paint in the paint waste water to cake and float, the paint and the water are separated, clear water is obtained to reuse. The usage is firstly adding the A reagent, and adding the B reagent after even blending. The processed paint waste water is fat-soluble paint waster water and water-soluble paint waste water. The highly-efficient paint mist coagulant has a wide reagent source, effectively overcomes the disadvantages of the trivial preparation process, many and complex additional reagents and high price of the traditional paint mist coagulant, can reduce common paint waste water treatment cost to 0.25 yuan / ton and can be widely used in circulating water treatment in a wet-typed paint mist removing system.

Owner:WUHAN UNIV OF TECH

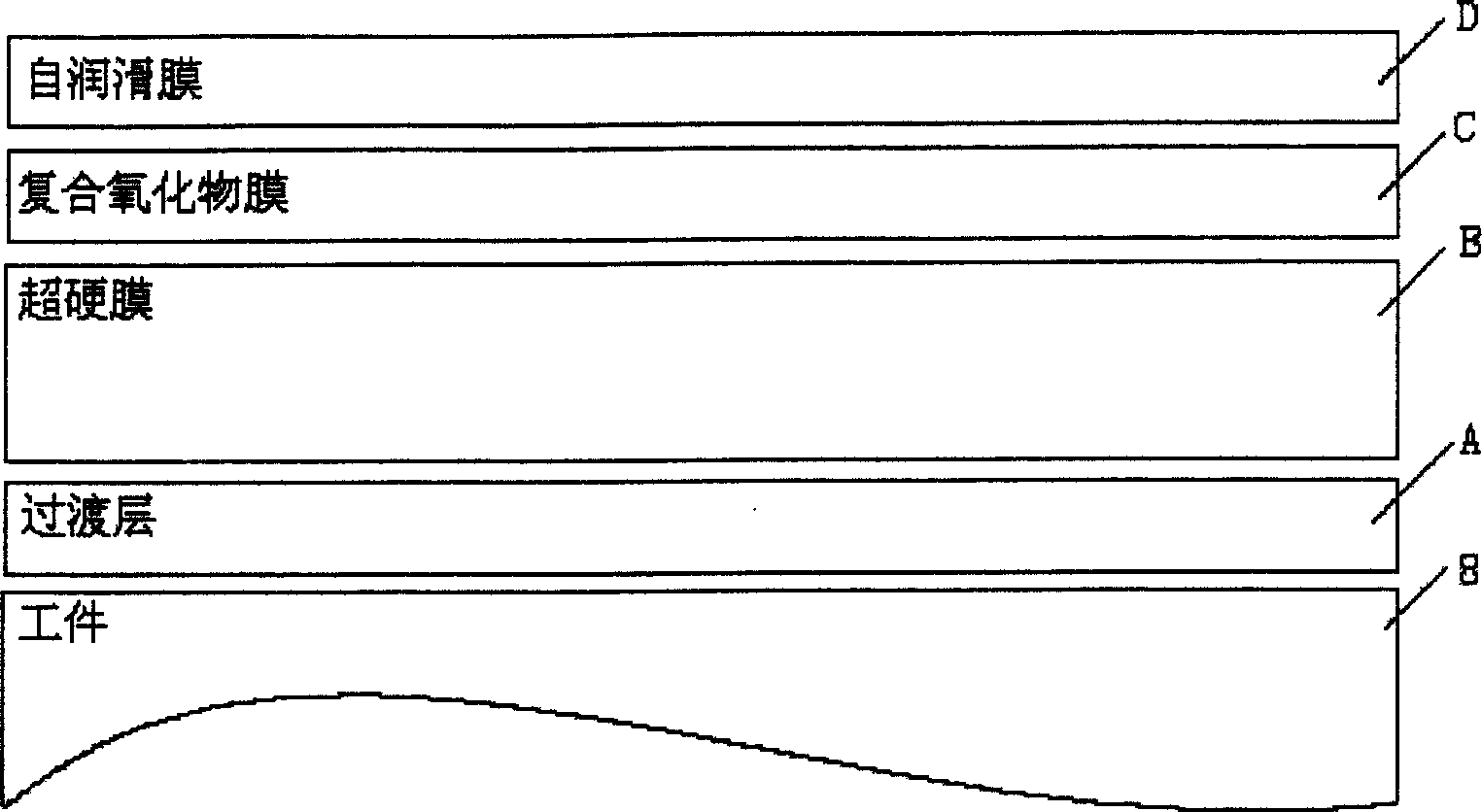

High oxidation resistance nanocrystalline-amorphous structured superhard composite film cutting tool and deposition method therefor

InactiveCN1654702AReduce cutting forceReduce wearVacuum evaporation coatingSputtering coatingComposite filmAlloy

The present invention is super hard composite antioxidant film in nanometer crystal-amorphous structure for cutter and its depositing process, and especially relates to super hard film in nanometer crystal-amorphous structure and composite oxide film. The composite film on cutter includes successively the adhering transition layer, super hard nanometer crystal-amorphous structure TiAlN / alpha-Si3N4 film, composite oxide film for raising antioxidant performance and self-lubricating film with low friction coefficient. The present invention provides a vacuum chamber with outer target, inner target and ion source and industrial filming process with high production efficiency, high coating quality and low production cost. The present invention is suitable for various kinds of cutters of high speed steel, hard alloy and ceramic and various kinds of molds.

Owner:吴大维

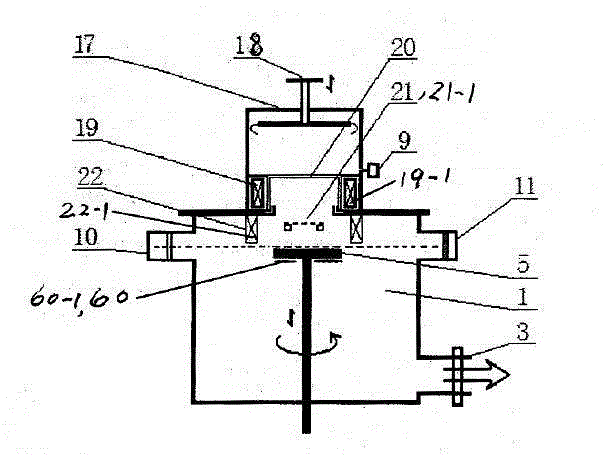

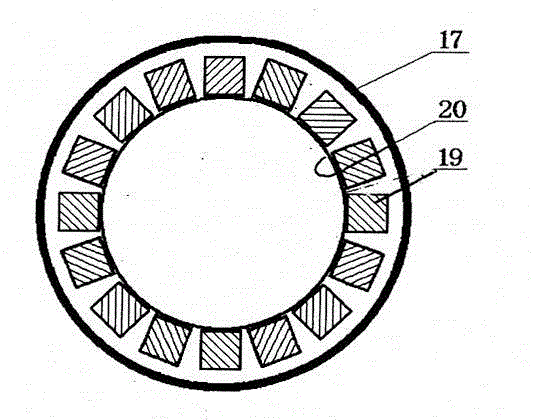

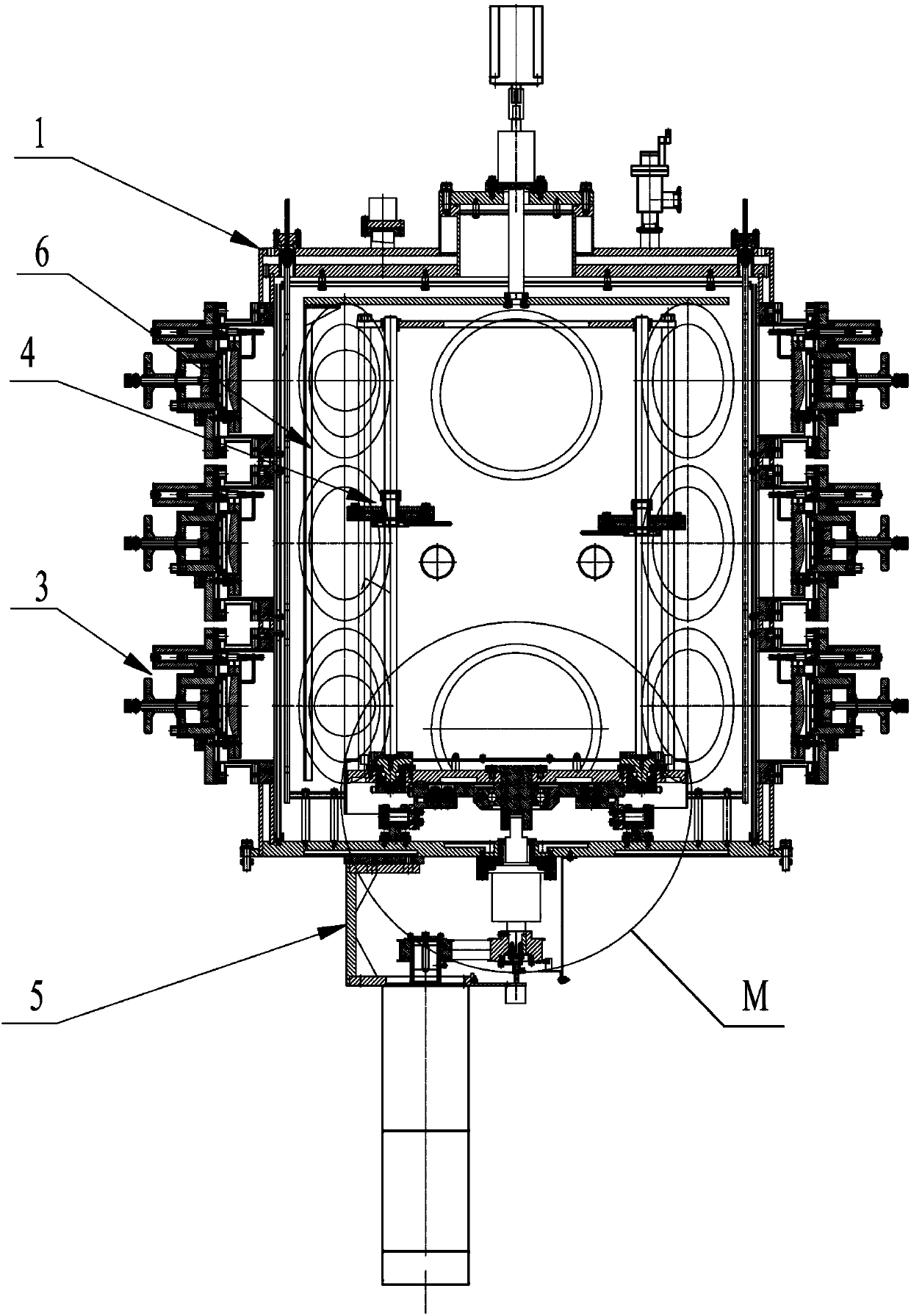

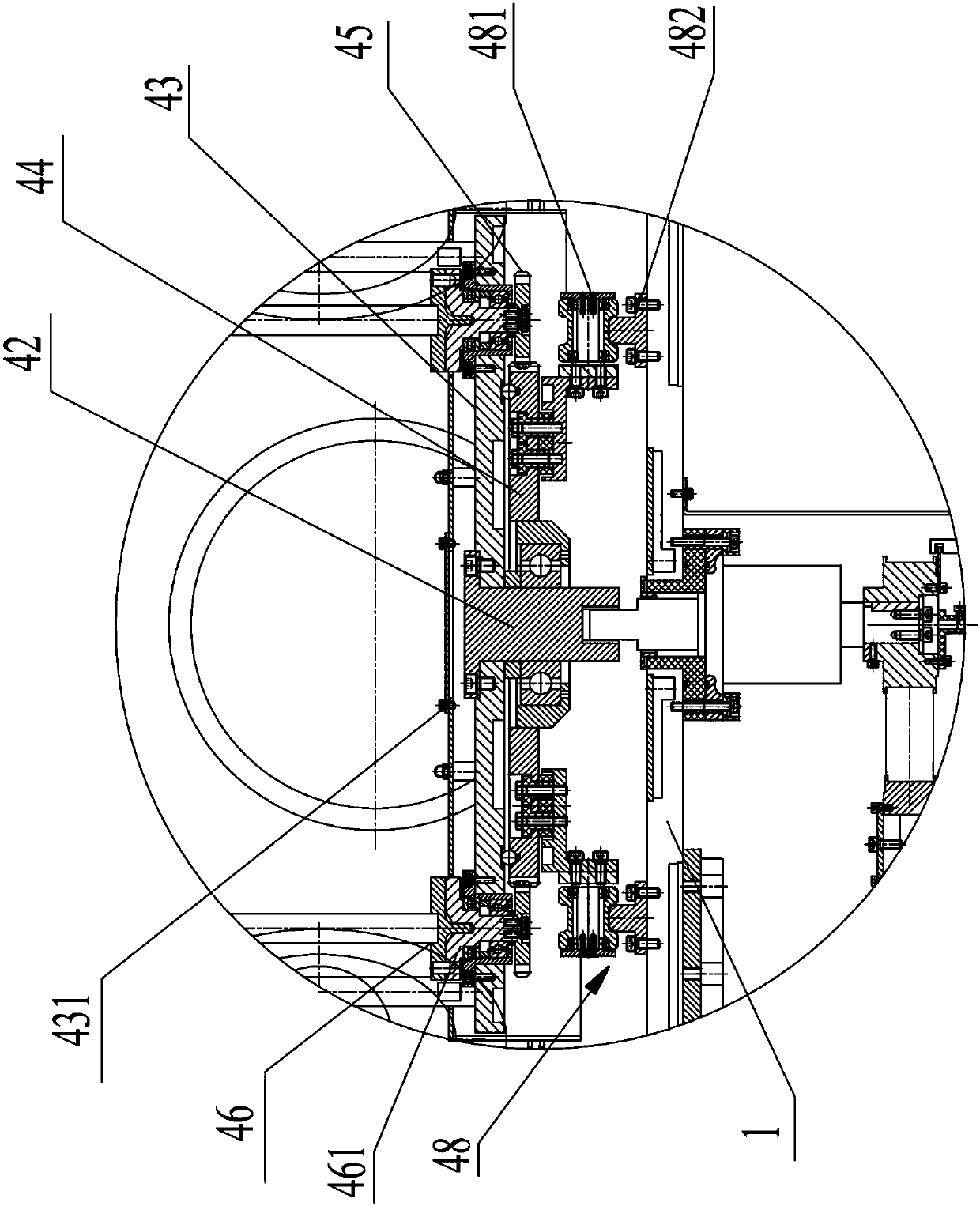

Multi-arc-ion vacuum coating machine

PendingCN107805786AHigh hardnessReduce frictionVacuum evaporation coatingSputtering coatingStraight tubeEngineering

The invention discloses a multi-arc-ion vacuum coating machine which comprises a cavity, a vacuum-pumping system and a multi-arc target assembly. A rotary frame assembly is arranged in the cavity, a worktable is installed on the rotary frame assembly, the rotary frame assembly is used for driving the worktable to rotate in the cavity, and the worktable is used for installing workpieces. The vacuum-pumping system is connected with the cavity. The multi-arc target assembly comprises a plurality of cathode multi-arc target seats, a permanent magnet is arranged on each cathode multi-arc target seat, the inner end of each cathode multi-arc target seat is in sealed connection with the cavity through a straight tube magnetic field superposition device, the inner ends of the cathode multi-arc target seats are connected with target material seats sleeved with the straight tube magnetic field superposition devices, the target material seats are used for installing target materials, the cathode multi-arc target seat is provided with an arc introducing device, the arc introducing pins of the arc introducing devices can be in contact with the target materials, and the straight tube magnetic field superposition devices can produce changing magnetic fields in the space where the target materials are located. The multi-arc-ion vacuum coating machine can effectively filter large particles in acoating and make the coating dense and polish and is excellent in performance.

Owner:BEIJING TECHNOL SCI

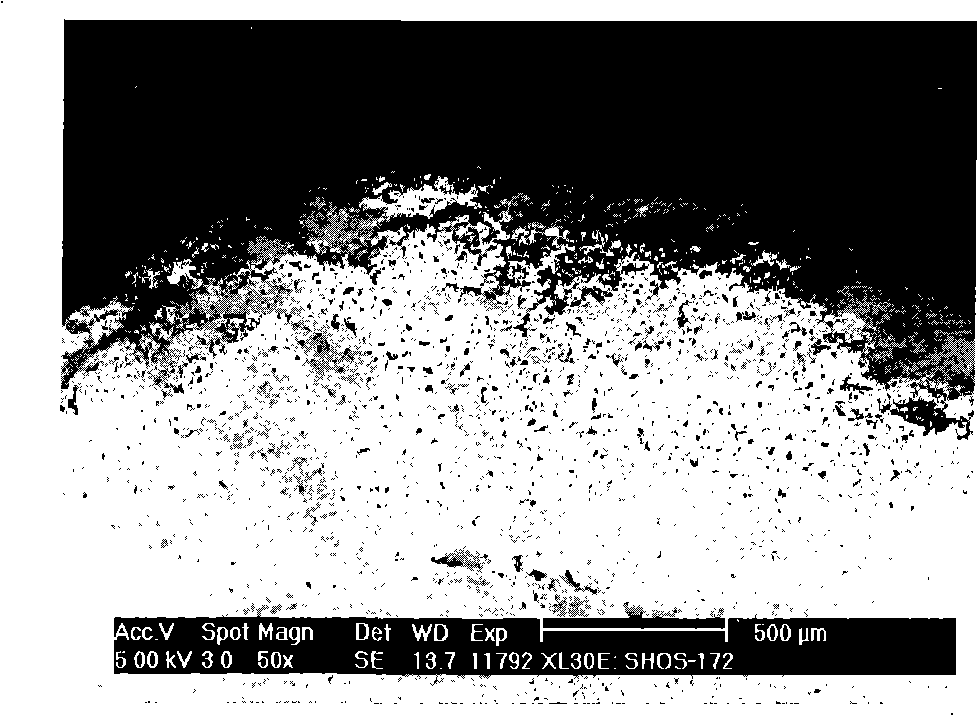

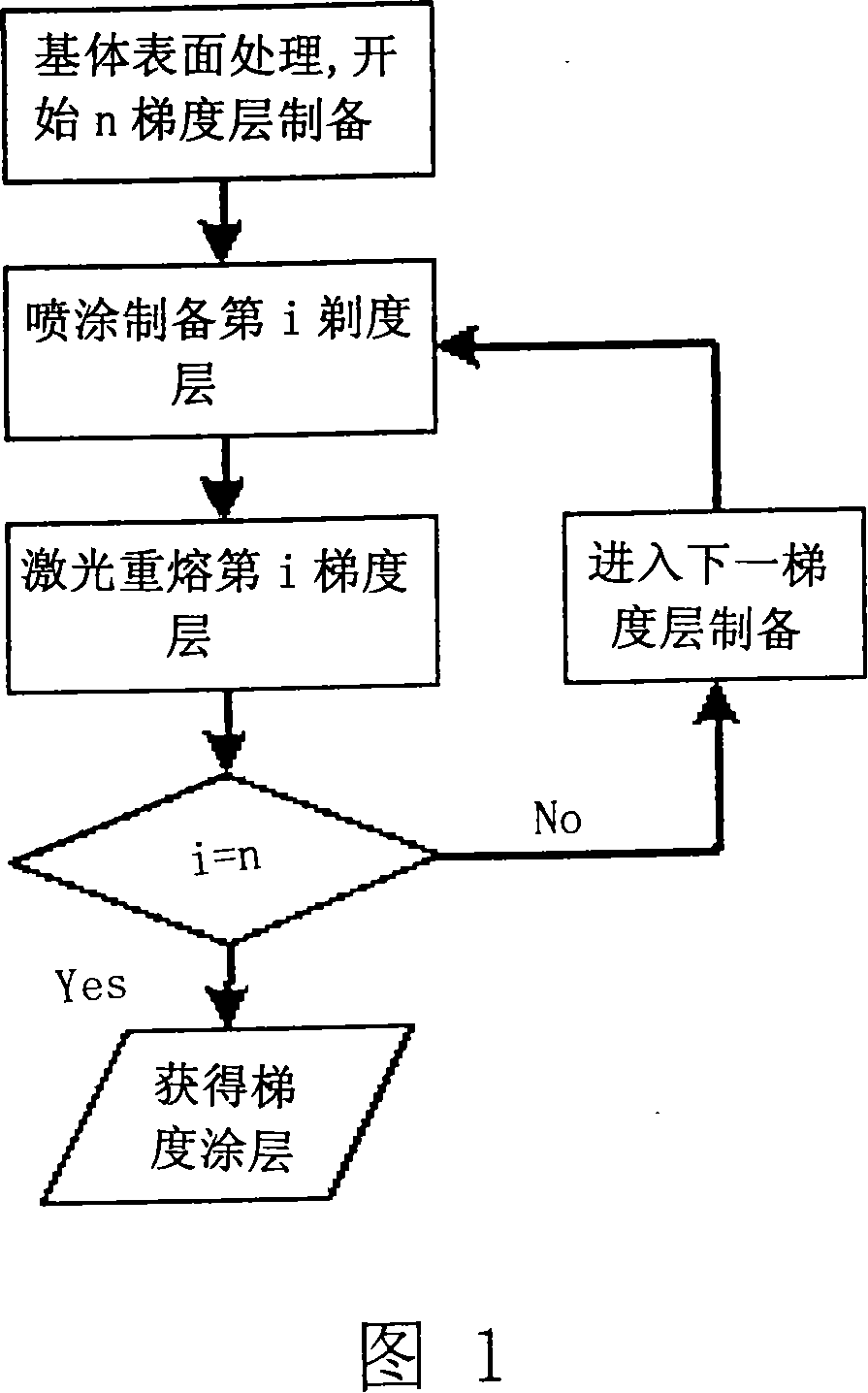

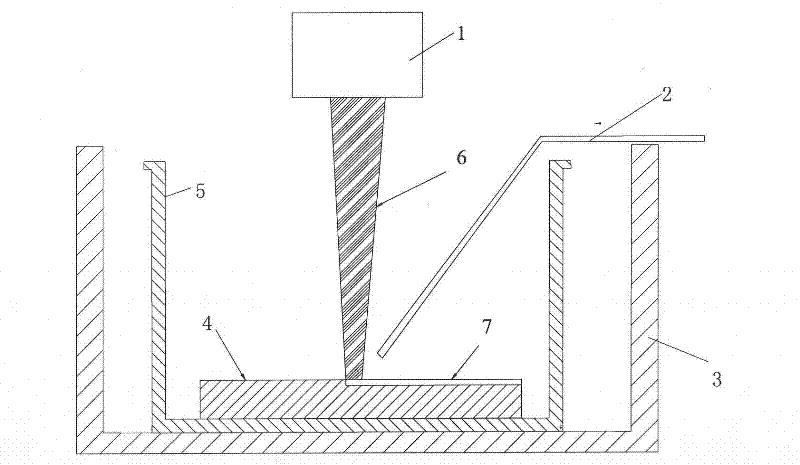

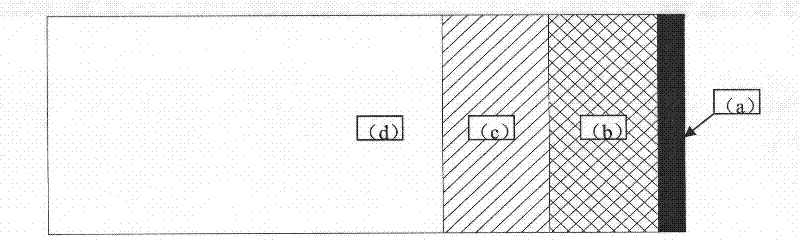

Processing method of hot sprayed gradient coatings based on time after time laser refusing

InactiveCN101112701AImprove bindingGood metallurgical bondPretreated surfacesCoatingsThermal sprayingOptoelectronics

A hot spray grads coat processing method based on multi-time laser remelting belongs to a novel material processing method. The method has a main innovative point that the multi-time laser remelting method is adopted for the composite process of the hot spraying grads coats, and the defects that not all sub-coat reaches the metallurgy combination, the grads structure in the coats is damaged and the hot spraying laminated organization can not be eliminated, etc. on the conditions of remelting without laser or one-time laser remelting are overcome. The detailed process is that the purification and activation disposal are firstly disposed to the base metal material, the first grads material is sprayed on the surface of the base and one-time laser remelting is sequentially carried out for the first grads layer, causing the first grads layer to form the metallurgy combination with the base; after that, the second grads material is sprayed on the surface of the first grads layer after remelting of laser and the secondary laser remelting is carried out, causing the metallurgy combination to be formed between the two grads oats; sequentially adopting the method, the hot spraying and laser remelting process are respectively carried out to all grads coats. The invention has the advantages of simple and reliable processing method and meeting the comprehensive performance requirements of coats.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

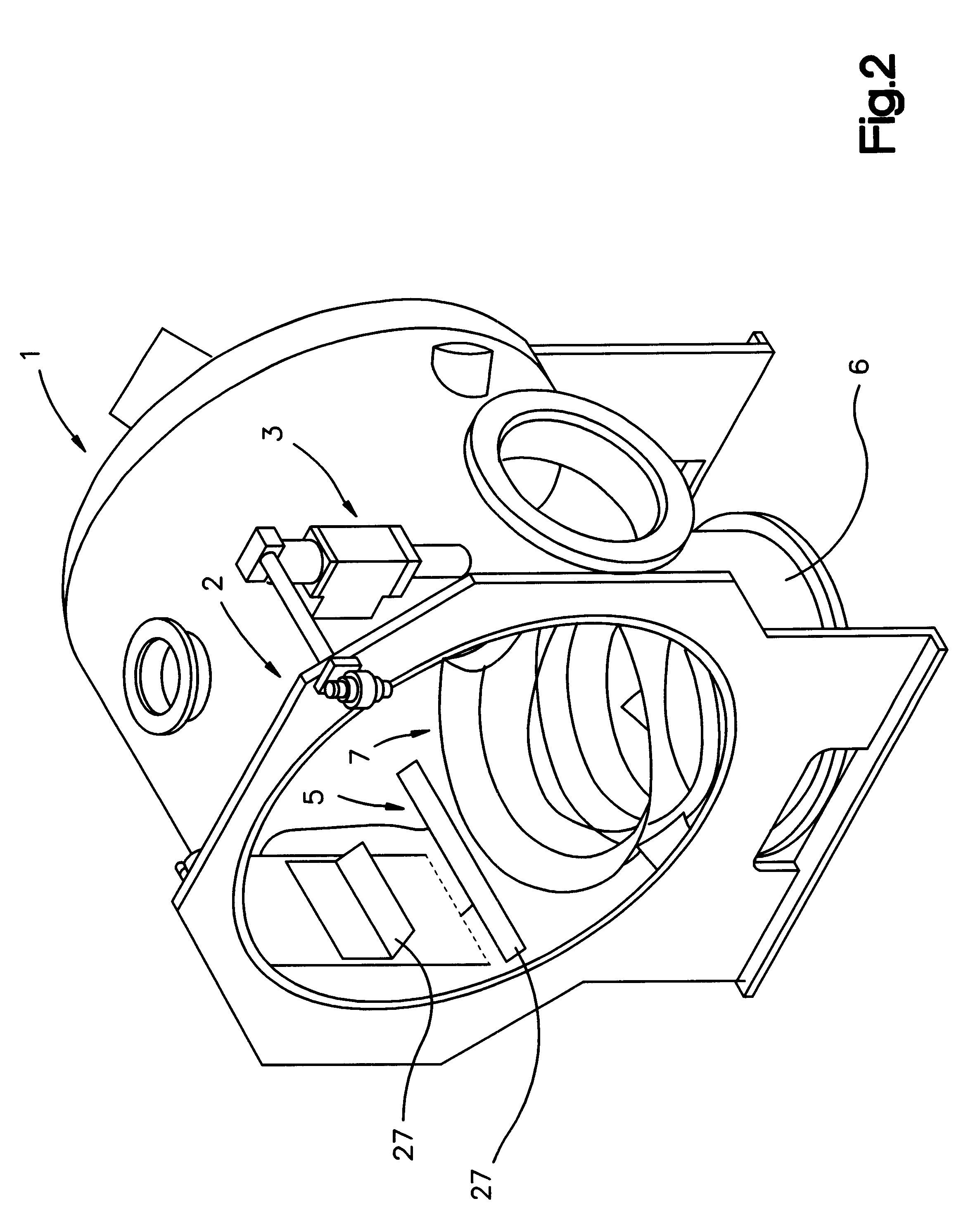

Assembly for controlling the gas flow in a plasma spraying apparatus

InactiveUS6357386B1Improve coating qualityLiquid surface applicatorsMolten spray coatingEngineeringPlasma sprayed

A plasma spraying assembly comprising a treatment chamber and a plasma spraying device located in the interior thereof is disclosed that further comprises an assembly for controlling the gas flow in the interior of the treatment chamber. In order to prevent a gas flow in the interior of the treatment chamber that whirls deposits to be created, a deflection device is provided that is located at least partially in the interior of the treatment chamber. Vertically below the treatment chamber, a collecting shaft is located. In the region between the treatment chamber and the collecting shaft, there is provided a basic element comprising baffle members, but leaving open a passage between the treatment chamber and the collecting shaft. In the interior of the collecting shaft, a deflection element is located having essentially conical shape and towering into the passage of the basic element. The collecting shaft is in operative connection with the suction side of a blower and with a vacuum pump.

Owner:SULZER METRO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com