Alumina coats pulp and preparation method thereof

A technology of alumina coating and activated alumina, which is applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of short service life of thin-shell precious metal catalysts and poor stability of layered composite carriers, etc. Achieve the effects of high hydrothermal stability, excellent performance and high coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

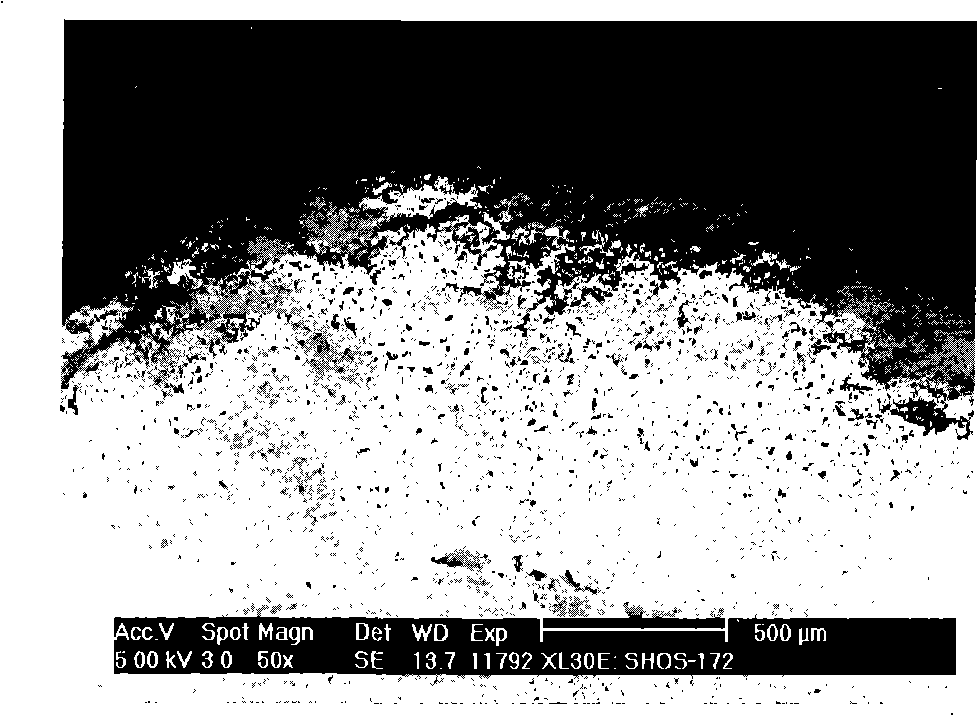

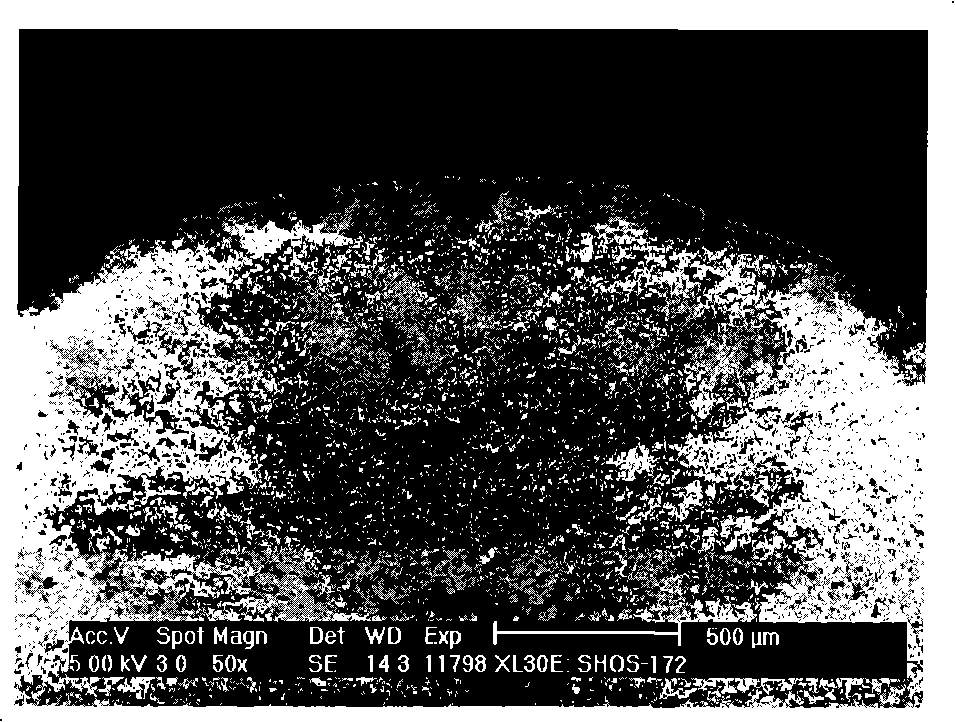

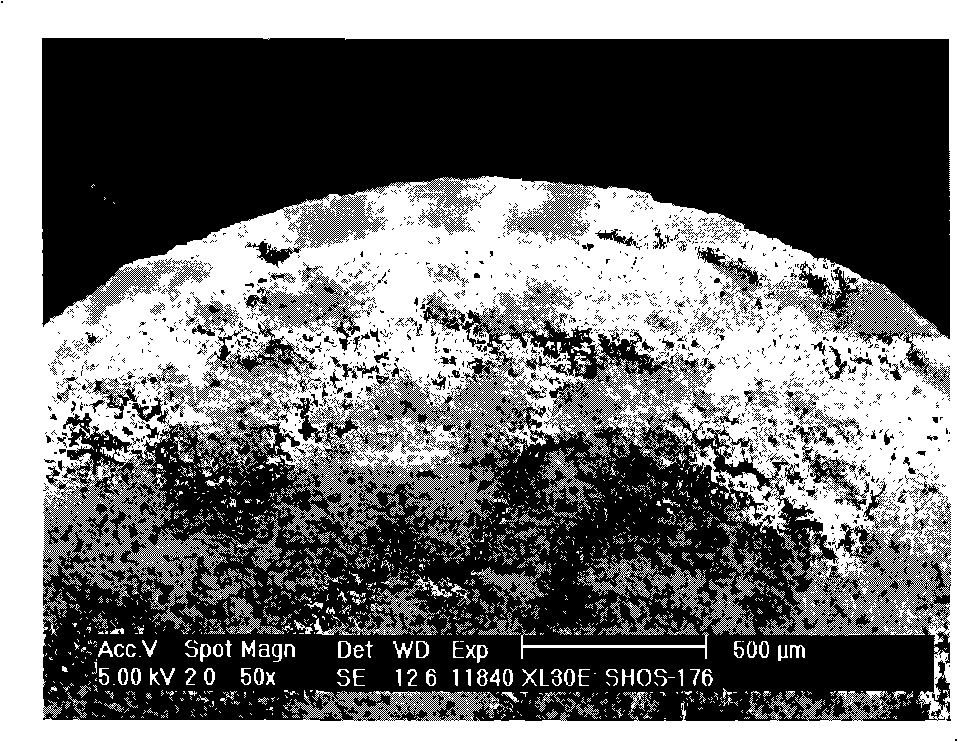

Image

Examples

Embodiment 1

[0035] 40 grams of concentration are 10% aluminum sol, 20 grams of 2% polyvinyl alcohol, 30 grams of 1% hydroxymethyl cellulose solution, 1.2 grams of Span 80 and 0.1 milliliters of concentration are 8% nitric acid to make slurry, adjust When the pH value reaches 1.5, stir at a high speed of 2000 rpm for 30 minutes. Then add 1.5 gram of potassium feldspar, 0.8 gram of diatomaceous earth, 40 gram of gamma-alumina powder (specific surface area 230 meters) below 10 microns 2 / g), and continued to stir for 60 minutes, and then the slurry was ball milled at room temperature for 4 hours, thereby making an alumina coating slurry. Detected by laser particle size analyzer, the average particle size of the slurry is below 8 microns.

Embodiment 2

[0037] 36 grams of 5% polyethylene glycol (molecular weight is 20000), 5 grams of 2% carboxyethyl cellulose, 0.4 gram of Tween, 2 milliliters of concentration are 20% aluminum chloride, 2 grams of concentration are 40% silica sol, 30 milliliters of ammonia water with a concentration of 6%, 160 grams of alumina sol with a concentration of 30%, adjust the pH value to 6.5, stir at a high speed of 1000 rpm for 20 minutes, and then add 15 grams of θ-Al with a particle size below 15 microns 2 o 3 (Specific surface area 180 meters 2 / gram), 10 gram inorganic clays add, stir 20 minutes with 5000 rev / min high speeds. The slurry was then subjected to colloid milling at room temperature for 1 hour to produce an alumina coating slurry. Detected by laser particle size analyzer, the average particle size of the slurry is below 9.5 microns.

Embodiment 3

[0039] 35 grams of alumina sol with a concentration of 25%, 30 grams of 4% cyclodextrin solution, 10 grams of hydroxymethyl cellulose, 10 grams of hydroxypropyl cellulose solution, 1.0 grams of hexadecyl trimethyl Ammonium bromide and 1 ml of 1% hydrochloric acid were used to make a slurry, the pH value was adjusted to 4, and the mixture was stirred at a high speed of 2000 rpm for 30 minutes. Then add 0.4 grams of diatomaceous earth, 0.3 grams of potassium feldspar and 36 grams of δ-Al with a particle size of less than 1 micron to this mixed solution. 2 o 3 powder (specific surface area 160 m 2 / gram), with 2000 rpm high-speed stirring for 150 minutes, and then the slurry was colloidally milled at room temperature for 2 hours to make an alumina coating slurry. Detected by laser particle size analyzer, the average particle size of the slurry is below 8.2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com