Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve water fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent fixation of dyes to surface-modified inorganic particulate-coated media

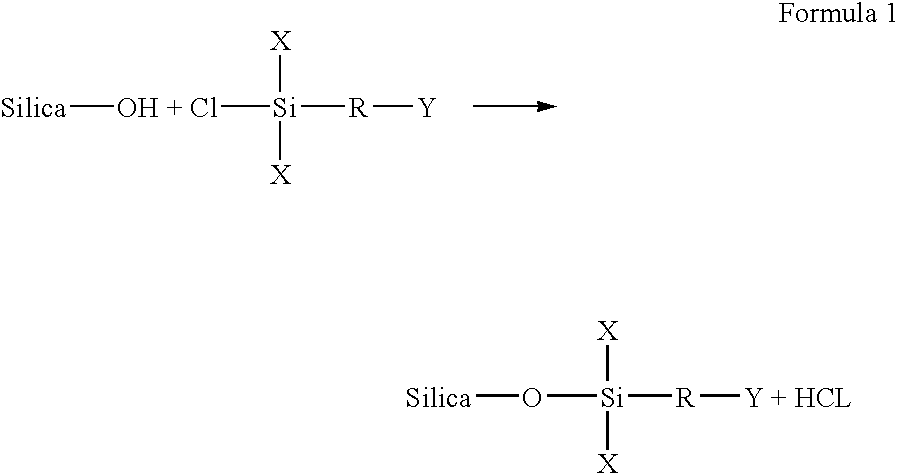

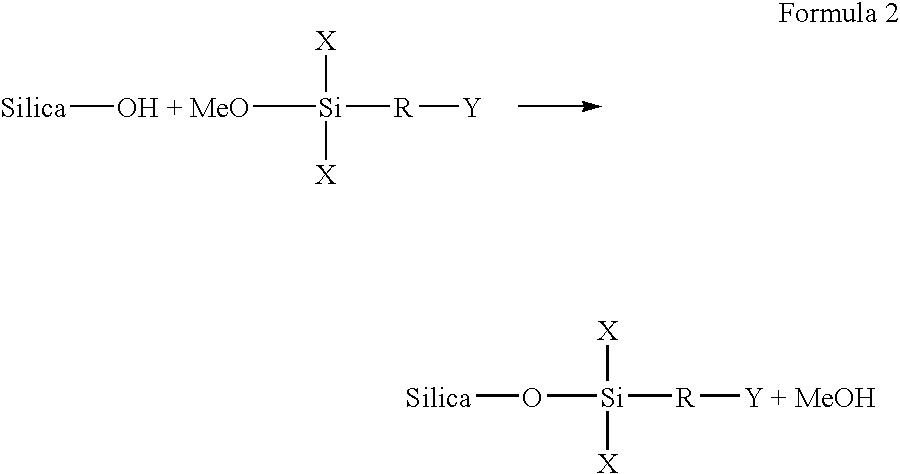

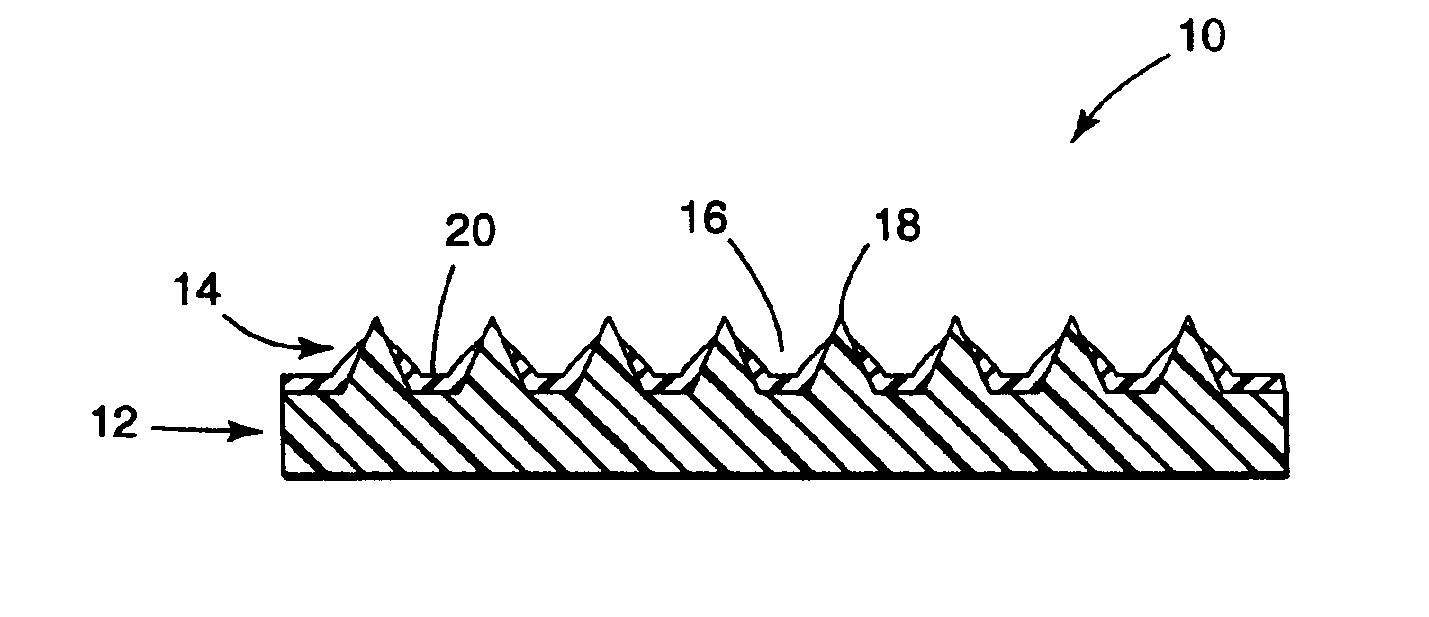

Systems and methods for producing permanent ink-jet images are provided. In one embodiment, a system comprises a media substrate coated with a porous media coating, wherein the porous media coating comprises inorganic porous particulates, and wherein at least a portion of the inorganic porous particulates have a first reactive group covalently attached thereto. The system further includes an ink-jet ink containing a dye, wherein the dye comprises a second reactive group, and wherein the first reactive group and the second reactive group are configured to react with one another upon contact to form a covalent bond. In an alternative embodiment, a method of producing permanent ink-jet images can comprise the steps of covalently bonding a first reactive group to an inorganic porous particulate; coating the inorganic porous particulate onto a media substrate to form a coated media substrate; ink-jetting a dye-containing ink-jet ink composition onto the coated media substrate, wherein the dye includes a second reactive group. The first reactive group and the second reactive group, upon contact, can interact to form a covalent bond.

Owner:HEWLETT PACKARD DEV CO LP

Inkjet inks containing crosslinked polyurethanes

InactiveUS20050215663A1Improve water fastnessDuplicating/marking methodsInksPolymer chemistryPolyurethane

Inkjet inks are described that have, as a principal component, a crosslinked polyurethane dispersoid binder additive. These inks can be used for printing on different media, and are particularly suitable for printing on paper.

Owner:EI DU PONT DE NEMOURS & CO

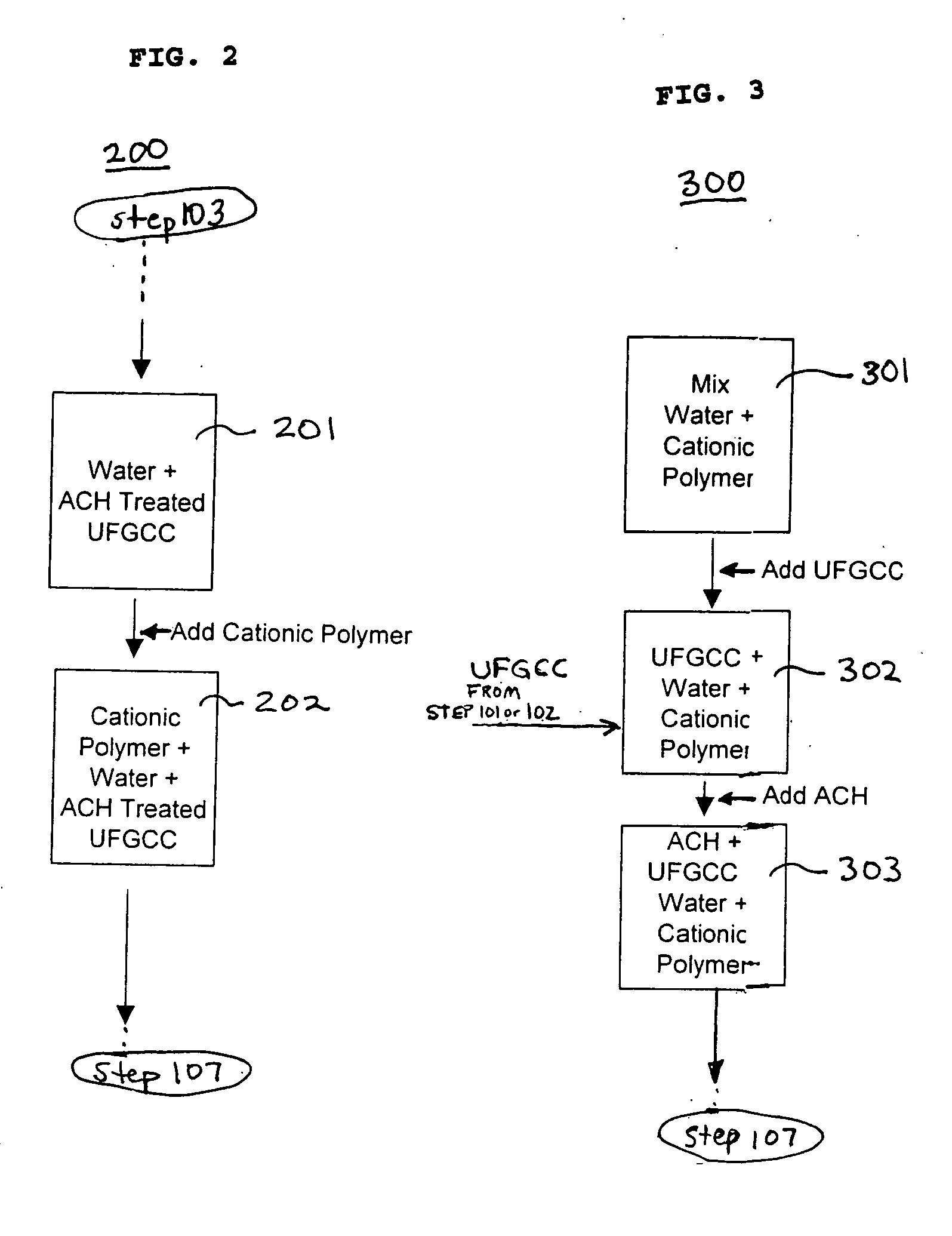

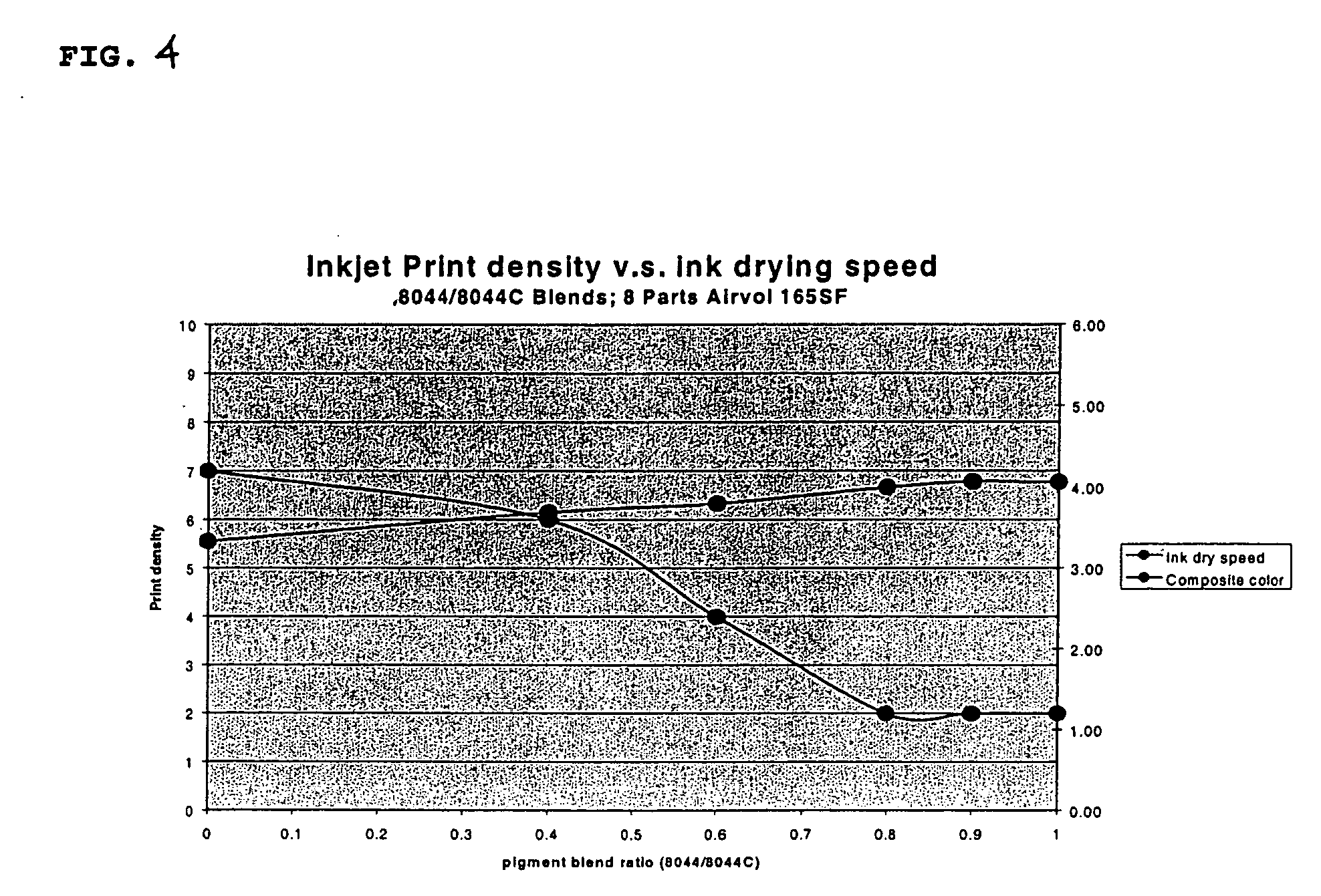

Pigment treatment in paper coating compositions for improving ink-jet printing performance

InactiveUS20030048346A1High densityImprove resolutionSpecial paperInksImage resolutionPulp and paper industry

Paper coating compositions are provided for use with thermal ink-jet color printers, such as Hewlett-Packard Company's DeskJet(R) printer. The organic pigment present in the paper is modified by the addition of a metal-charge complex which causes anionic colorants in the ink to be precipitated on the surface of the paper. Printing any of the ink-jet ink sets onto the specially-prepared paper improves resolution, color retention, waterfastness, smear-fastness, image retention and image density while decreasing image bleed in ink-jet printing.

Owner:RENESAS TECH CORP +1

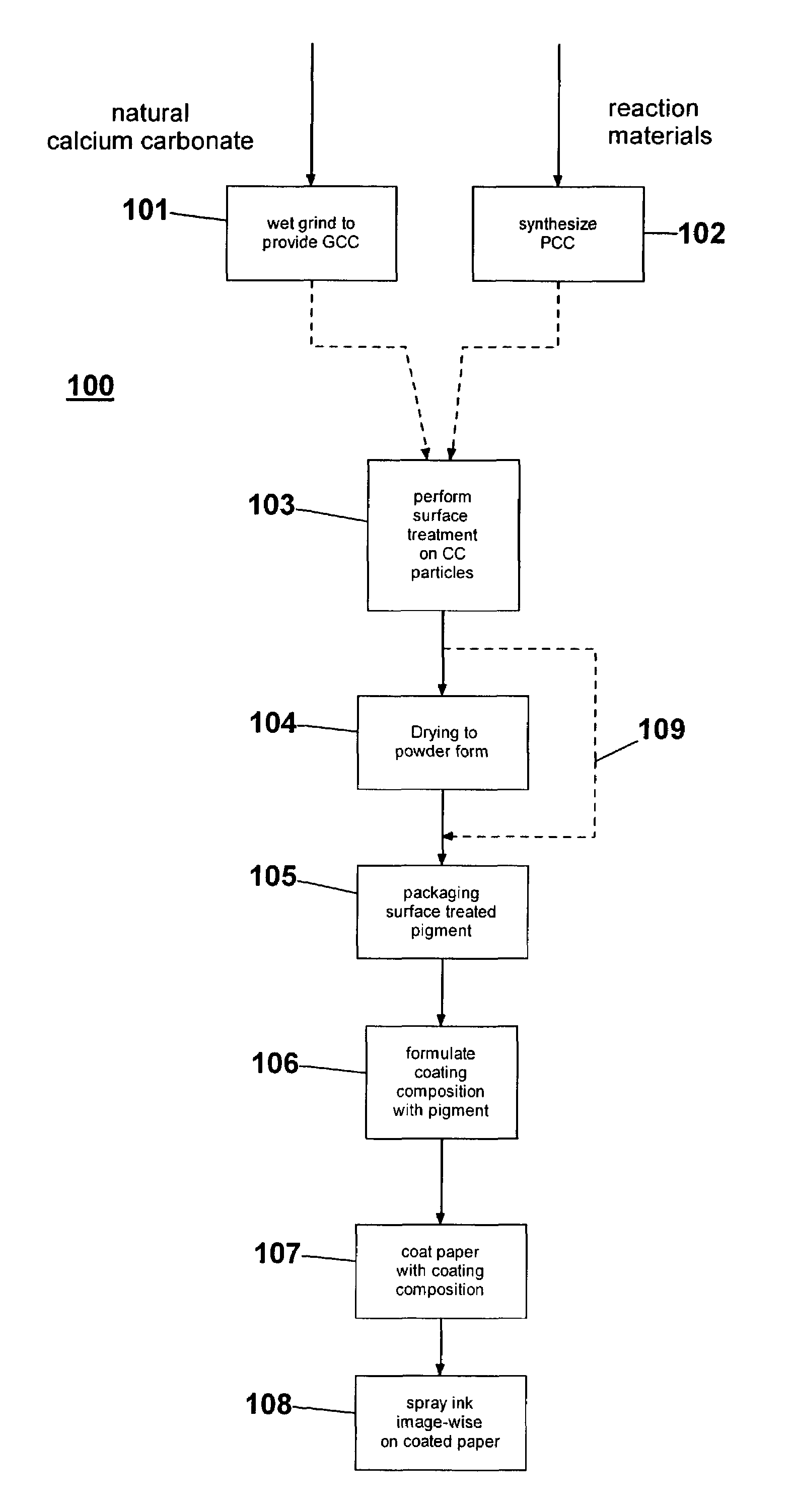

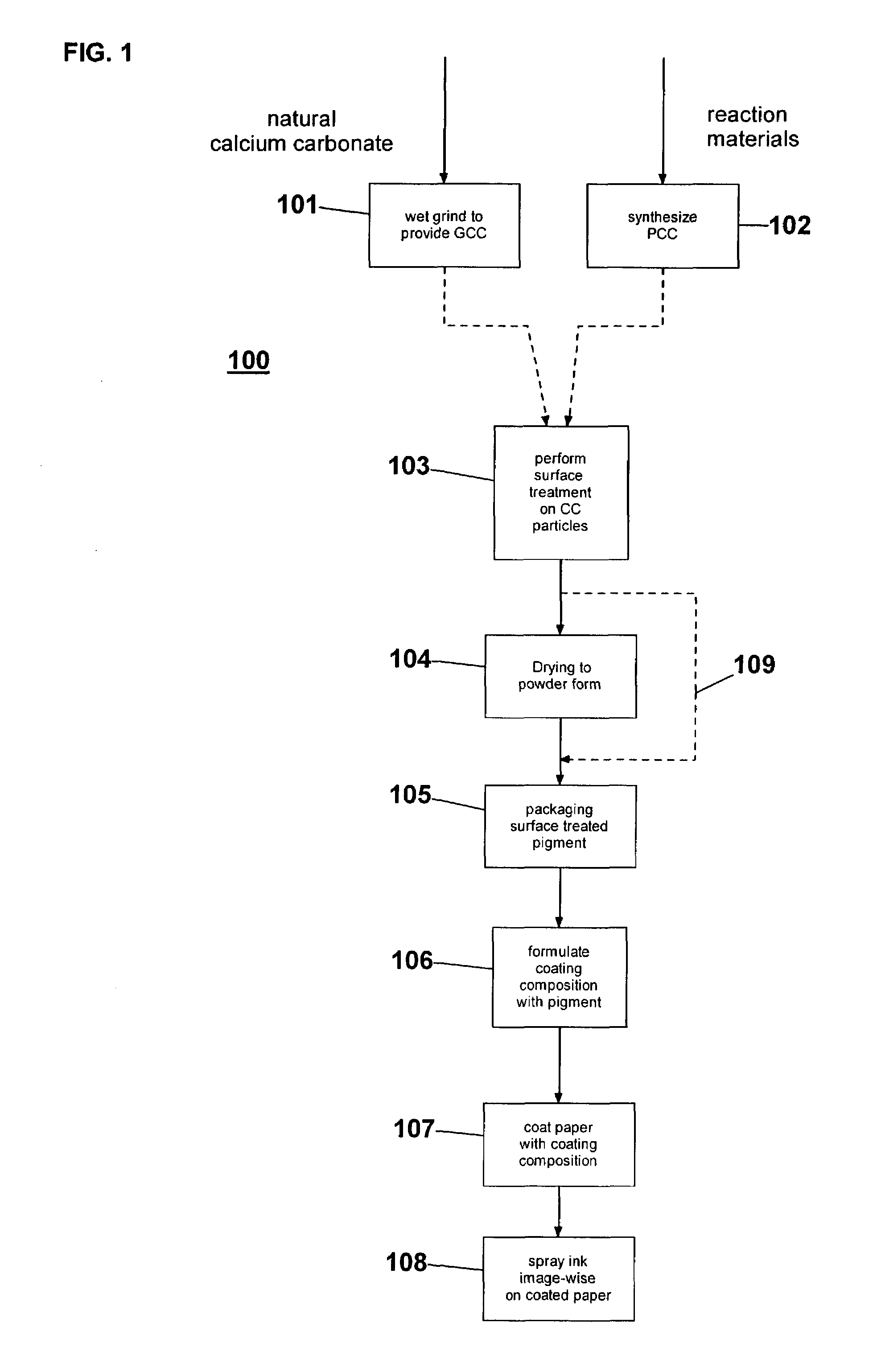

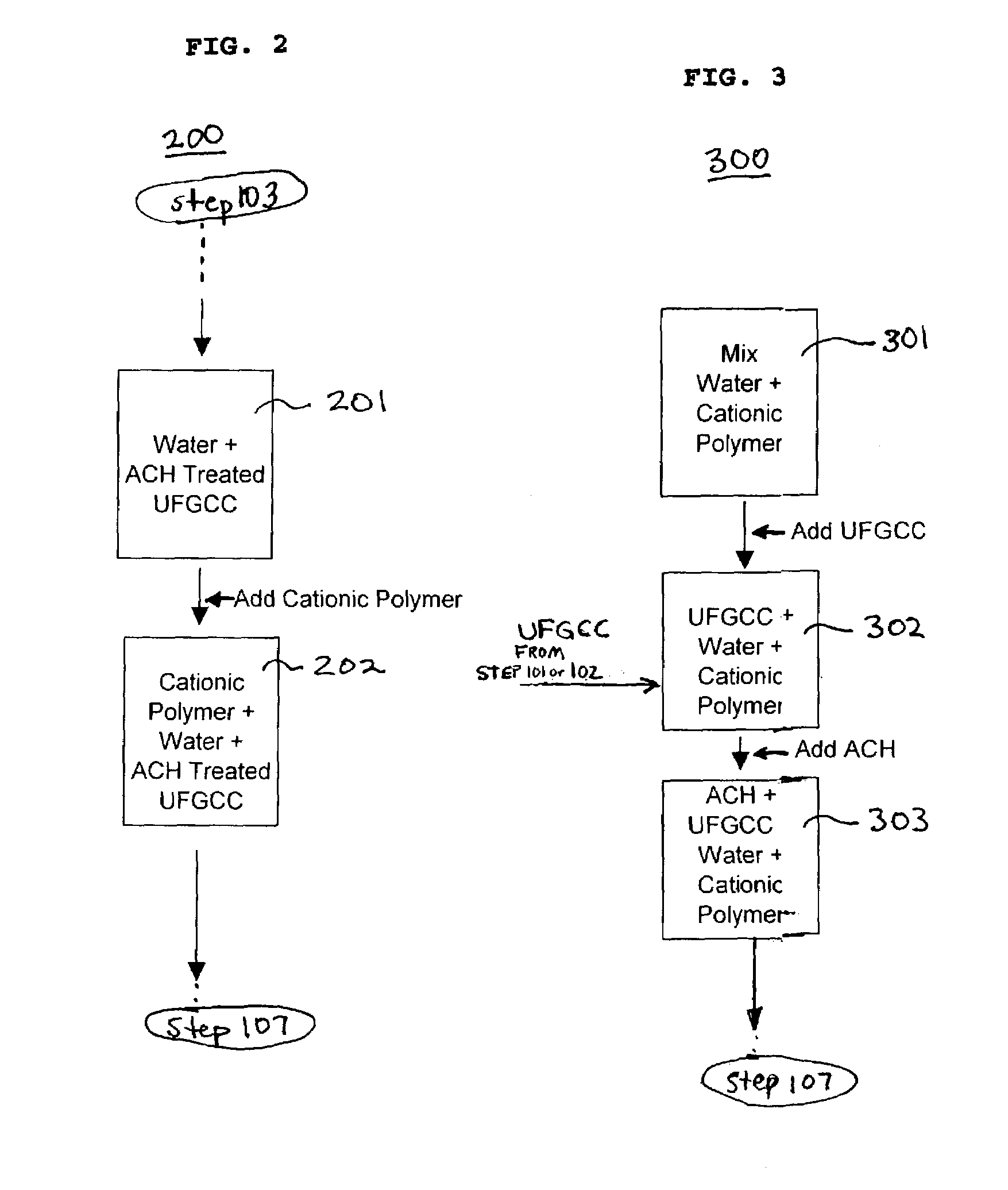

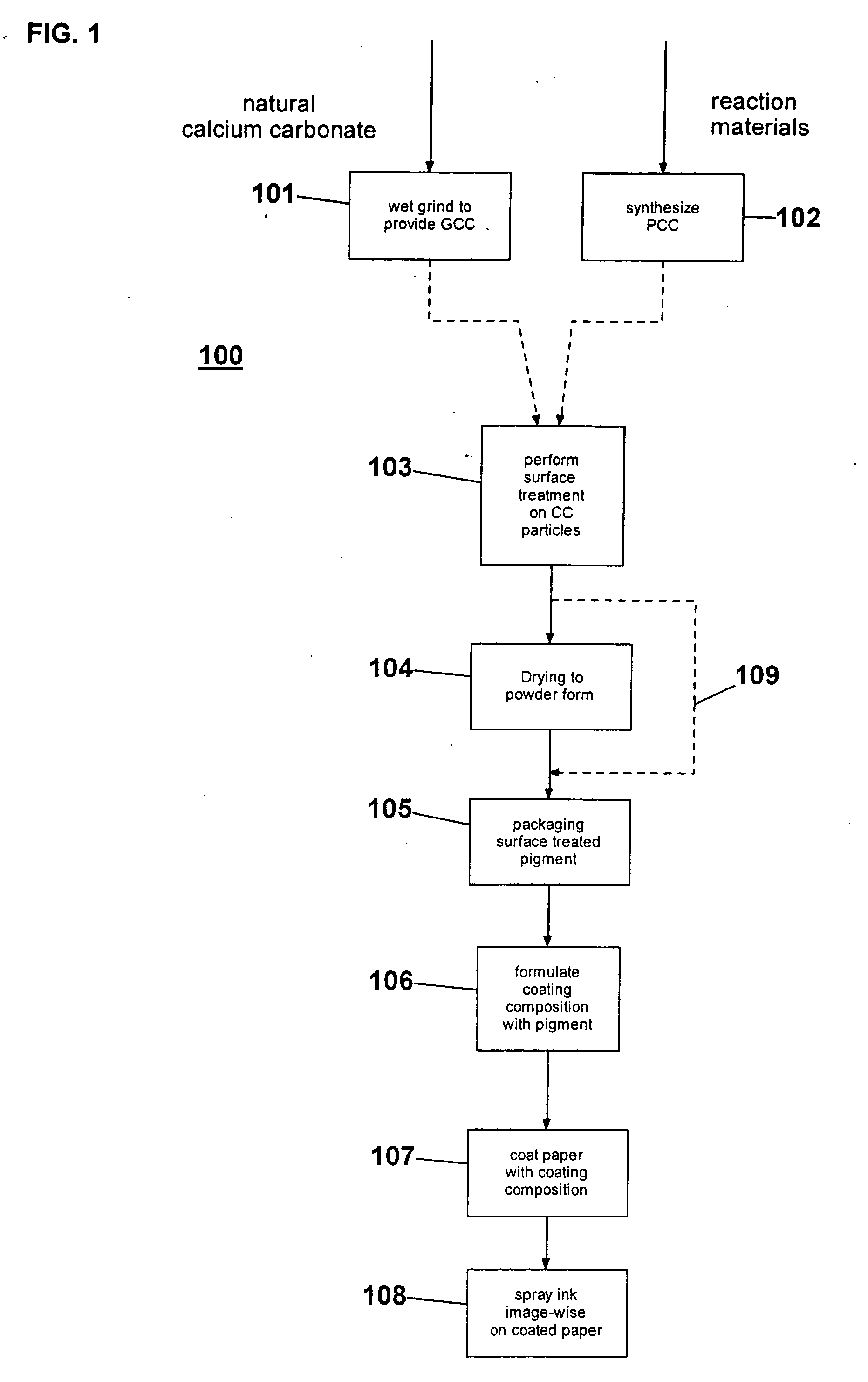

Pigment for use in inkjet recording medium coatings and methods

InactiveUS7172651B2Effective functional replacementHigh solidsPigmenting treatmentSpecial tyresParticulatesSilicon dioxide

Pigment suitable for use in coating compositions for inkjet recording media. Surfaces of an inorganic particulate are interacted with a water-soluble polyvalent metal salt in an aqueous medium. The treated particle surfaces have a significant cationic surface charge imparted to them. The salt is a salt of a metal of Group II or Group III of the Periodic Table. Inkjet recording media treated with a coating composition containing the above pigment provide high density, fast-drying, and non-feathering ink images with suitable water fastness, while the coating compositions also offer cost advantages and improved rheology at higher pigment levels over coatings based on silica pigments.

Owner:KAMIN

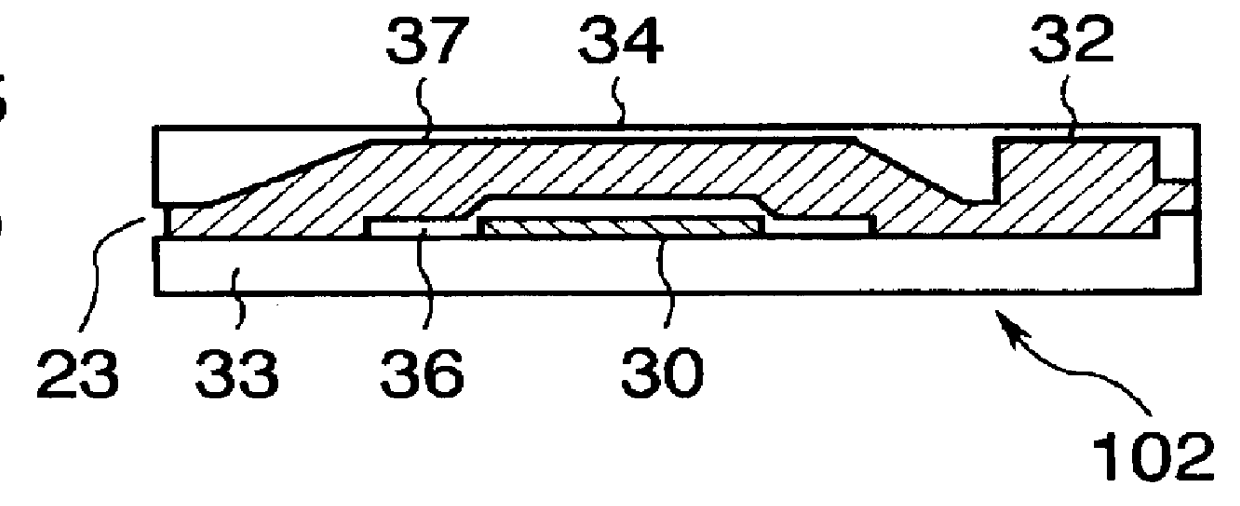

Ink-jet recording process, ink-jet recording apparatus and image formed article

InactiveUS6158856AAvoid it happening againImprove evennessMeasurement apparatus componentsPrintingEngineeringMechanical engineering

Disclosed herein is an ink-jet recording process for forming an image by applying an ink to a recording medium in accordance with an ink-jet recording system, comprising the steps of: (A) applying an ink containing a coloring material to the recording medium in accordance with the ink-jet recording system; and (B) applying a liquid composition different from the ink to an ink-applying region of the recording medium in accordance with the ink-jet recording system, wherein the liquid composition is applied in an amount less than 50% by volume of the amount of the ink to be applied to the ink-applying area.

Owner:CANON KK

Ink jet recording element

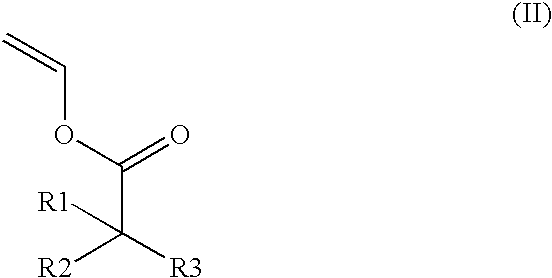

InactiveUS20020094421A1Maintain good propertiesImprove water fastnessCoatingsThermographyPolymer scienceVinyl ester

An improved medium for ink jet recording is disclosed. Apart from a pigment and an optional binder, the ink receiving layer contains a film-forming latex being a polymer containing repeating units derived from a particular monomer type. Preferred monomers are vinyl ester monomers most preferably derived from versatic acid. The medium is particularly suited for outdoor use.

Owner:AGFA GEVAERT AG

Pigment treatment in paper coating compositions for improving ink-jet printing performance

InactiveUS6505929B1High densityImprove resolutionSpecial paperDuplicating/marking methodsImage resolutionPulp and paper industry

Paper coating compositions are provided for use with thermal ink-jet color printers, such as Hewlett-Packard Company's DeskJet(R) printer. The organic pigment present in the paper is modified by the addition of a metal-charge complex which causes anionic colorants in the ink to be precipitated on the surface of the paper. Printing any of the ink-jet ink sets onto the specially-prepared paper improves resolution, color retention, waterfastness, smear-fastness, image retention and image density while decreasing image bleed in ink-jet printing.

Owner:HEWLETT PACKARD DEV CO LP

Pigment for use in inkjet recording medium coatings and methods

InactiveUS20070014941A1Absorb evenlyMore color reproductionPigmenting treatmentSpecial tyresParticulatesSilicon dioxide

Pigment suitable for use in coating compositions for inkjet recording media. Surfaces of an inorganic particulate are interacted with a water-soluble polyvalent metal salt in an aqueous medium. The treated particle surfaces have a significant cationic surface charge imparted to them. The salt is a salt of a metal of Group II or Group III of the Periodic Table. Inkjet recording media treated with a coating composition containing the above pigment provide high density, fast-drying, and non-feathering ink images with suitable water fastness, while the coating compositions also offer cost advantages and improved rheology at higher pigment levels over coatings based on silica pigments.

Owner:J M HUBER CORP

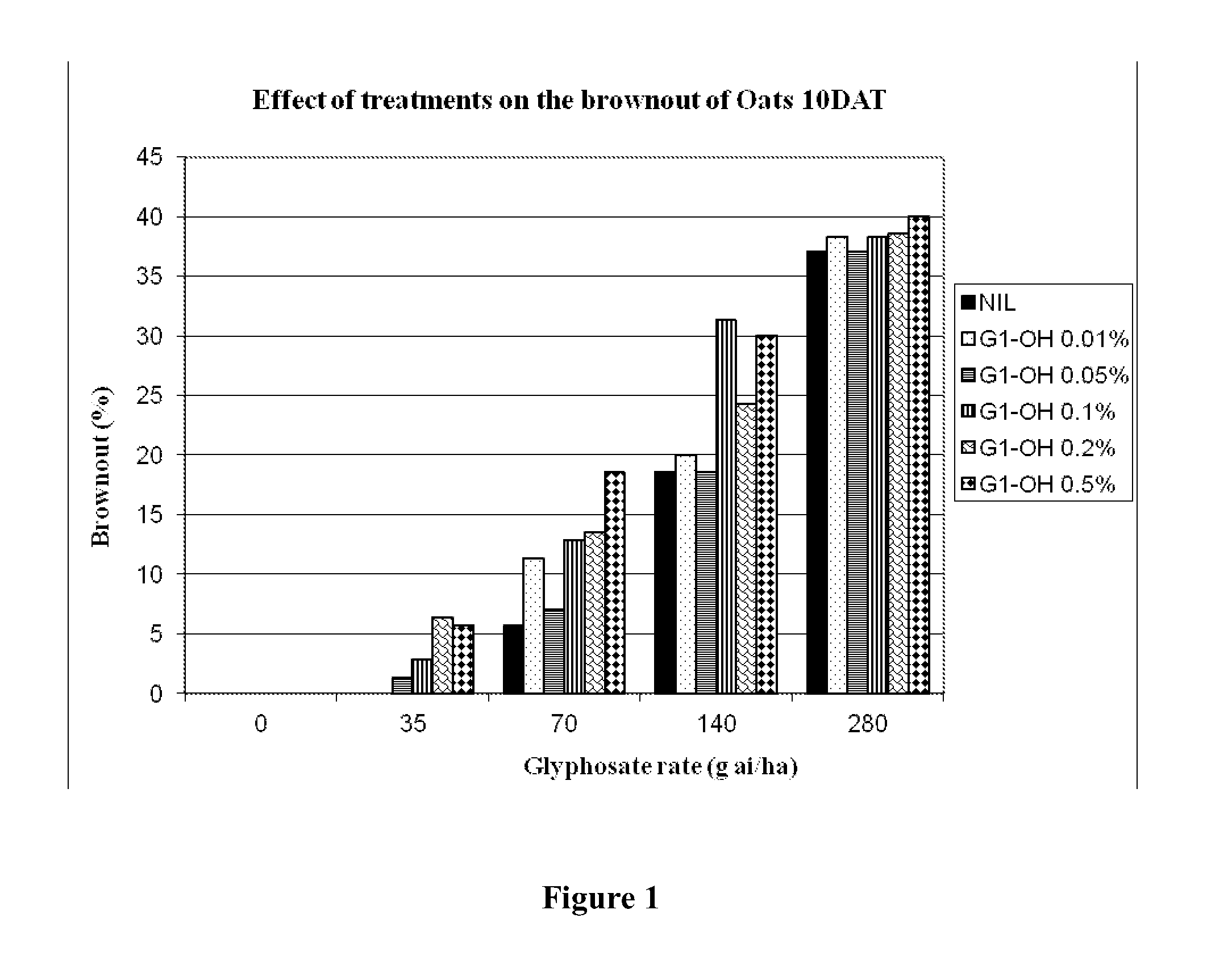

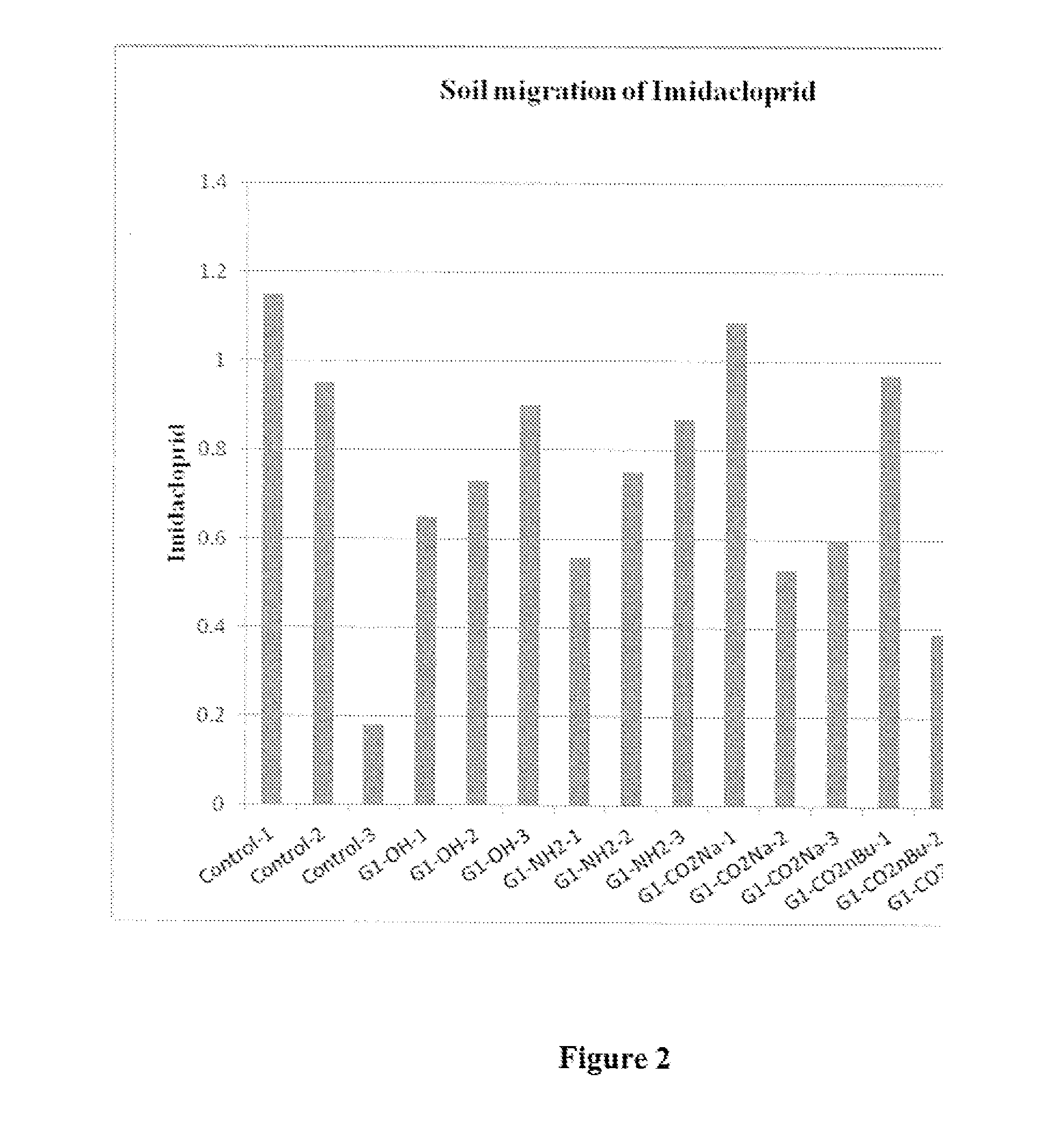

PEHAM Dendrimers for Use in Agriculture

Specific PEHAM dendrimers are used in a formulation with an active agent for agricultural purposes, particularly for increasing the efficacy of the active agent in various ways, such as by improving solubility of the active agent in the formulation, by improving adhesion and penetration of the active agent to plant surfaces, by improving the water-fastness of the active agent to the plant or seed, by increasing soil penetration of the active agent to reach the plant roots or under soil parts, or by reducing soil adhesion of the active agent to reach the plant roots or under soil parts, or reducing enzymatic degradation of the active agent by the plant or seed or microorganisms in the soil.

Owner:DENDRITIC NANO TECH INC +1

Recording material with an extrusion coated PVA layer

InactiveUS6403202B2High glossKeep dryDuplicating/marking methodsSynthetic resin layered productsPolyvinyl alcoholAqueous dispersion

A recording material for the ink-jet printing method comprises a raw base paper, an extrudable polyvinyl alcohol containing layer which is extruded on the raw base paper, and an ink-receiving layer which is applied as an aqueous dispersion or solution.

Owner:FELIX SCHOELLER TECHN PAPERS

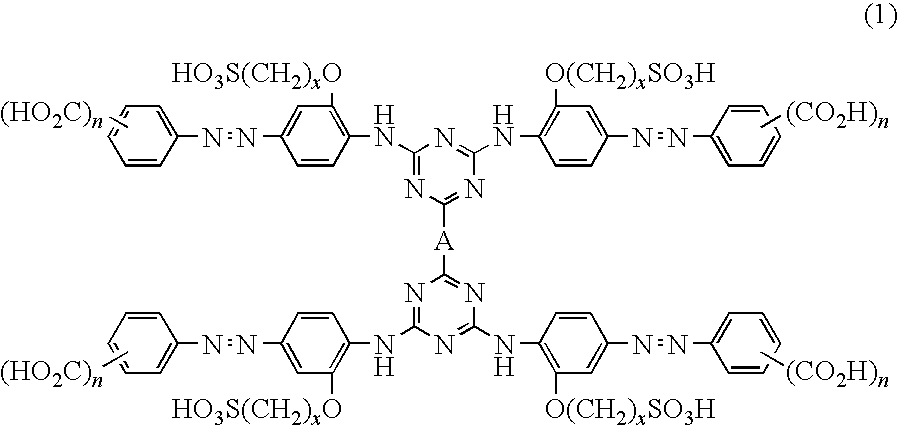

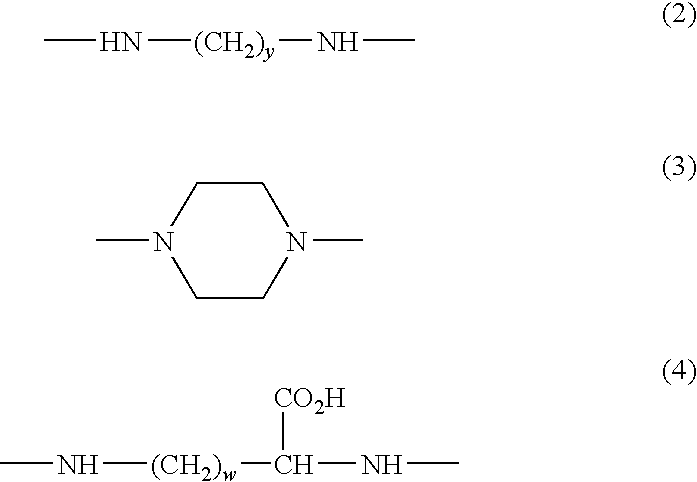

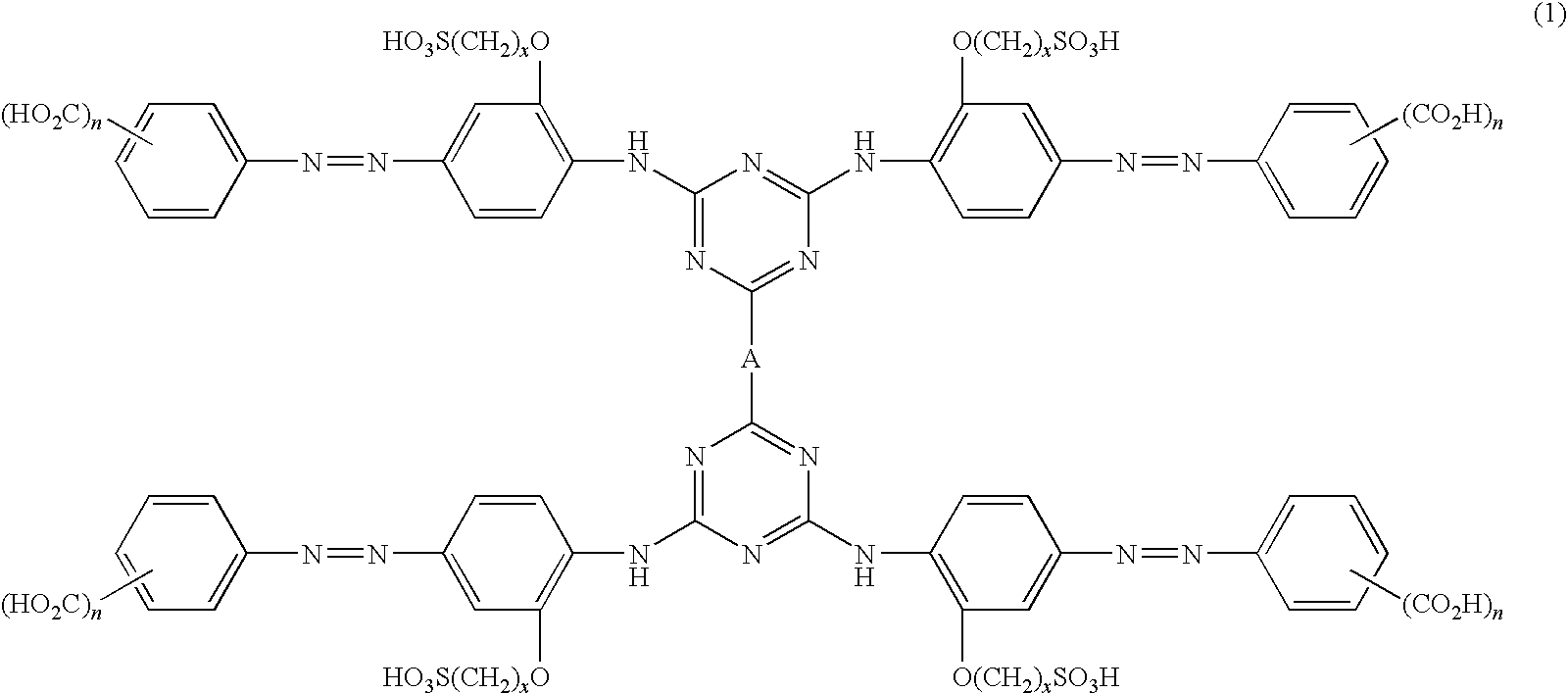

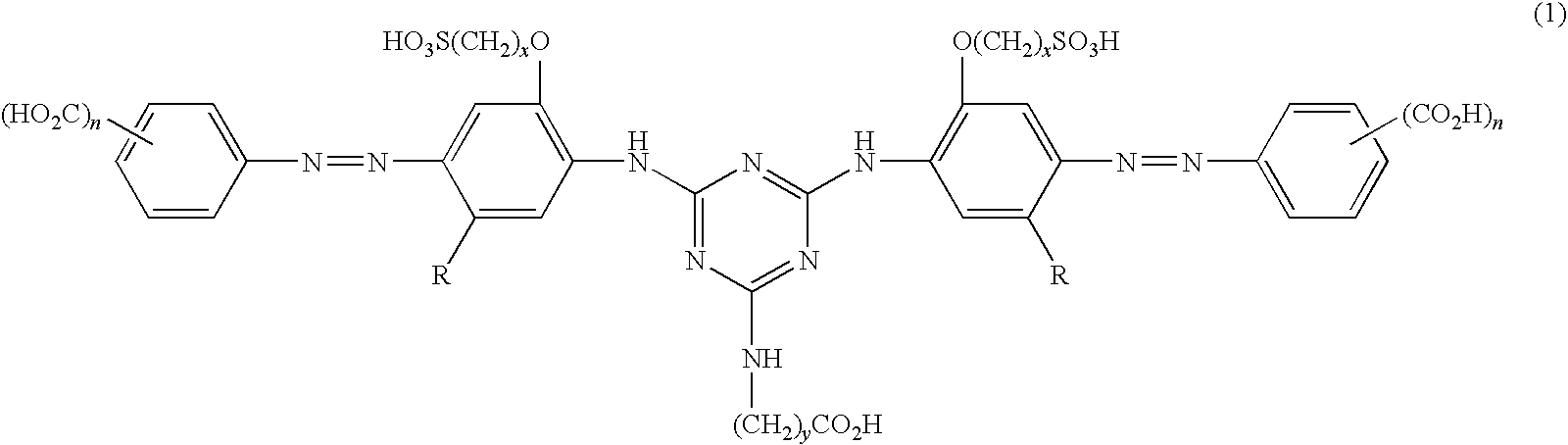

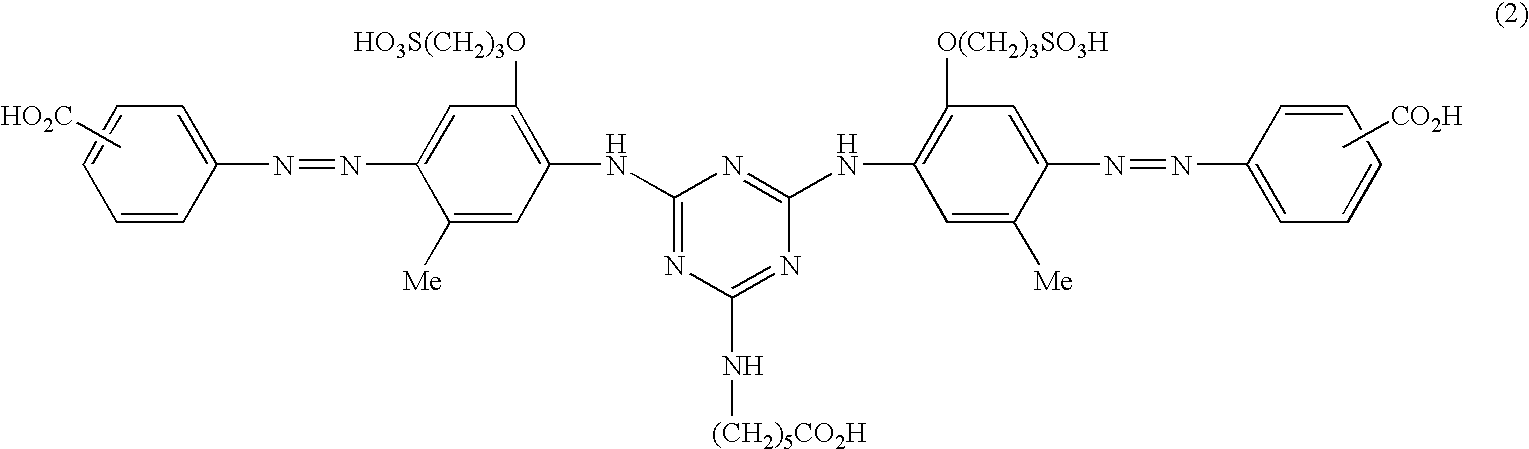

Water-soluble azo compound or salt thereof, ink composition and colored product

InactiveUS20100118067A1Improve solubilityImprove filtering effectOrganic chemistryMeasurement apparatus componentsHueWater soluble

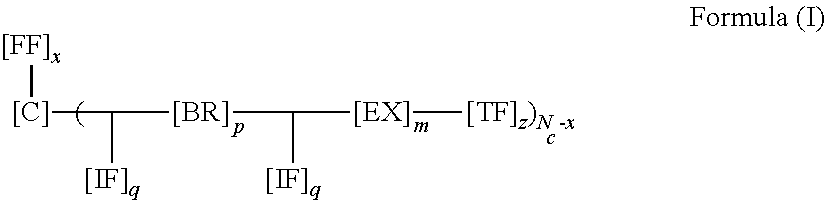

The present invention relates to a water-soluble azo compound represented by the following formula (1):[wherein, n denotes 1 or 2, x denotes 2 to 4 and A denotes a divalent bonding group represented by one of the following general formulas (2) to (4):(Wherein, y denotes an integer number of 2 to 6 and w denotes an integer number of 1 to 4)]or a salt thereof, and an ink composition containing it; it shows a hue having high vividness suitable for inkjet recording and provides a recorded matter having high water fastness, and the ink composition prepared using it is excellent in storage stability.

Owner:NIPPON KAYAKU CO LTD

Anisotropic colorants for inkjet printing

InactiveUS6572226B2Change the surface energy of the printed substrateImprove water fastnessMeasurement apparatus componentsDuplicating/marking methodsColoring agentsAnisotropy

Owner:HEWLETT PACKARD DEV CO LP

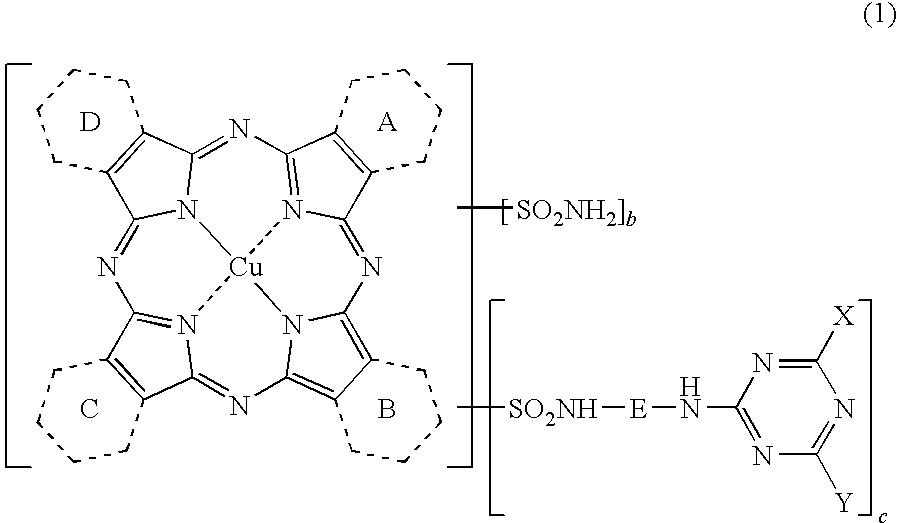

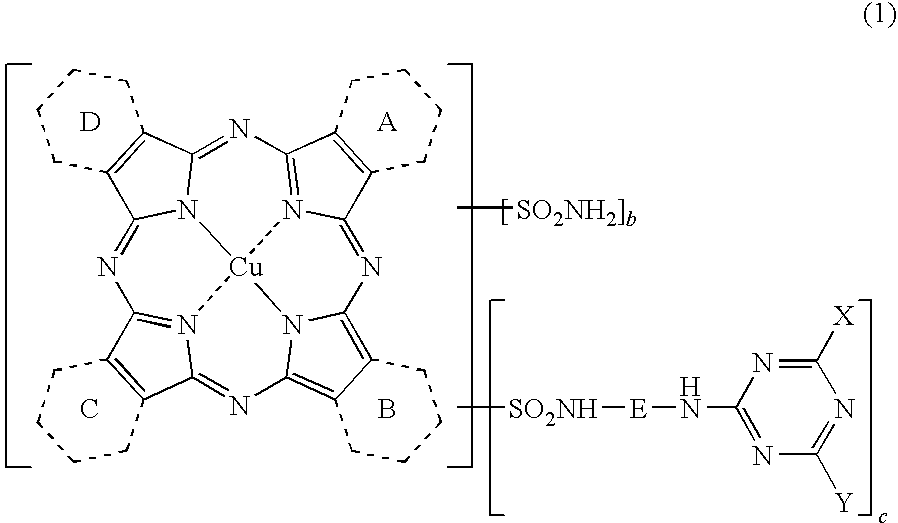

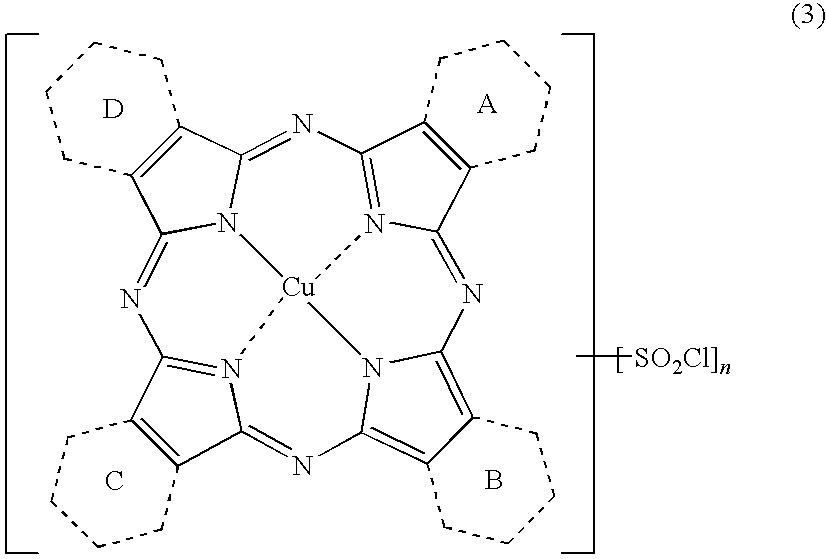

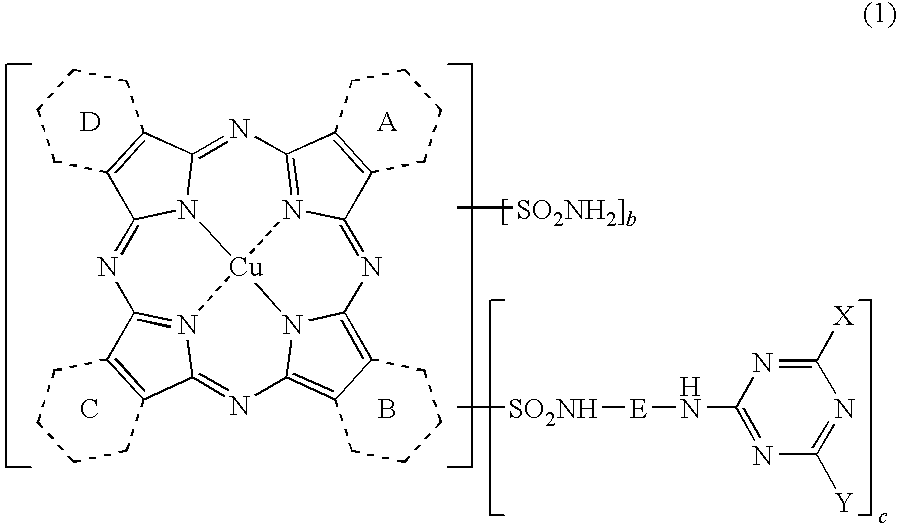

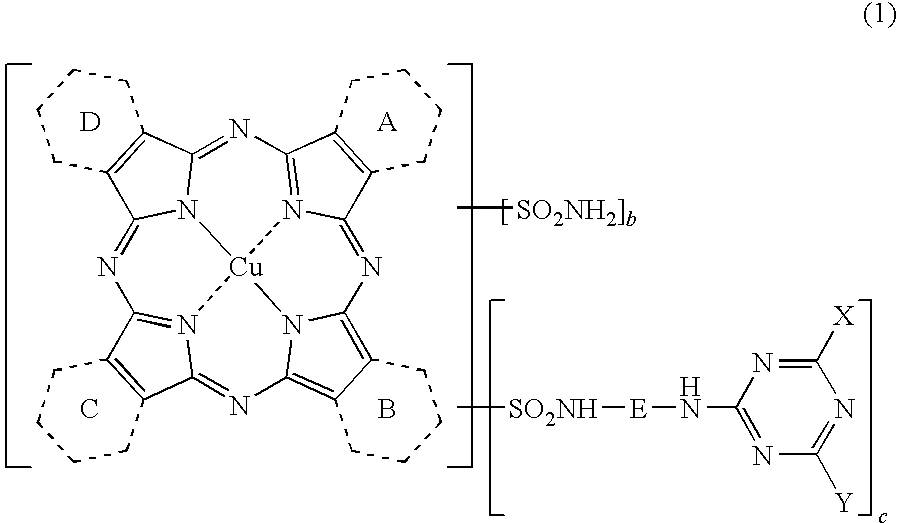

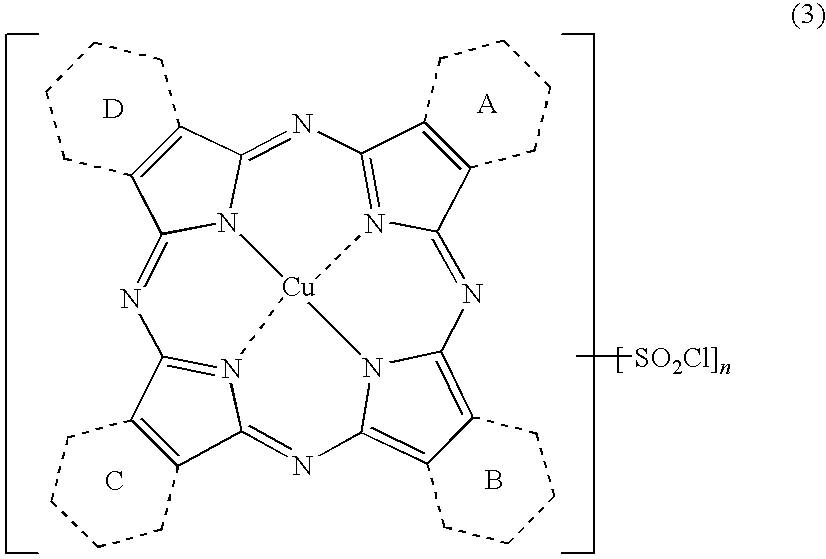

Porphyrazine Coloring Matter And Ink Composition Containing The Same

InactiveUS20100279082A1Improve solubilityVivid hueOrganic chemistryMeasurement apparatus componentsSolubilityOrganic solvent

The present invention relates to a porphyrazine coloring matter represented by the following formula (1) or a salt thereof[wherein, the rings A, B, C and D shown by broken lines each independently represent a 6-membered ring having aromaticity, at least 1.0 of said rings A to D is a benzene ring and at least 0.5 of them is a nitrogen-containing heteroaromatic ring, when shown as an average value; E represents an alkylene group; X and Y are each independently an anilino group having 1 to 3 carboxy groups; and b is 0 to 3.4, c is 0.1 to 3.5, and the sum of b and c is 1.0 to 3.5, when shown as an average value]. The present invention can provide a porphyrazine coloring matter suitable for inkjet recording, which has characteristics of having a good hue as cyan ink, excellent fastnesses, in particular, extremely excellent water fastness when printed on plain paper, and high solubility in water or a water-soluble organic solvent.

Owner:NIPPON KAYAKU CO LTD

Anisotropic colorants for inkjet printing

InactiveUS20020158951A1Increased waterfastnessIncreased gloss gloss uniformityMeasurement apparatus componentsDuplicating/marking methodsChromismColoring agents

Owner:HEWLETT PACKARD DEV CO LP

Jet ink composition

Owner:EASTMAN KODAK CO

Porphyrazine coloring matter and ink composition containing the same

InactiveUS7981204B2Improve solubilityVivid hueOrganic chemistryMeasurement apparatus componentsSolubilityOrganic solvent

The present invention relates to a porphyrazine coloring matter represented by the following formula (1) or a salt thereof:wherein, the rings A, B, C and D shown by broken lines each independently represent a 6-membered ring having aromaticity, at least 1.0 of said rings A to D is a benzene ring and at least 0.5 of them is a nitrogen-containing heteroaromatic ring, when shown as an average value; E represents an alkylene group; X and Y are each independently an anilino group having 1 to 3 carboxy groups; and b is 0 to 3.4, c is 0.1 to 3.5, and the sum of b and c is 1.0 to 3.5, when shown as an average value. The present invention can provide a porphyrazine coloring matter suitable for inkjet recording, which has characteristics of having a good hue as cyan ink, excellent fastnesses, in particular, extremely excellent water fastness when printed on plain paper, and high solubility in water or a water-soluble organic solvent.

Owner:NIPPON KAYAKU CO LTD

Ink jet printing method

InactiveUS6224202B1Improve water fastnessMeasurement apparatus componentsDuplicating/marking methodsImage recordingWater soluble

An ink jet printing process for improving the water-fastness of an ink jet image comprising the steps of:A) providing an ink jet printer that is responsive to digital data signals;B) loading the printer with an image-recording element comprising a support having thereon an ink-receptive layer comprising a cross-linkable polymer;C) loading the printer with an ink jet ink composition comprising water, an anionic, water-soluble dye and from about 0.1 to about 5% by weight of a hardener; andD) printing on the image-recording element using the ink jet ink composition in response to the digital data signals.

Owner:EASTMAN KODAK CO

Ink jet printing process

InactiveUS6142621AImprove water fastnessEnhance the imageDuplicating/marking methodsPretreated surfacesCross-linkPolyvinyl alcohol

An ink jet printing process for improving the water-fastness of an ink jet image comprising: a) providing an ink jet recording element comprising a support having thereon an image-recording layer comprising a cross-linkable polymer of acetoacetylated poly(vinyl alcohol) and a mordant, b) applying liquid ink droplets of an anionic, water-soluble dye on the image-recording layer in an image-wise manner, and c) submerging the element in an aqueous solution of a hardener to cross-link the binder.

Owner:EASTMAN KODAK CO

Ink jet printing process

An ink jet printing process for improving the water-fastness of an ink jet image comprising: providing an ink jet recording element having a support having thereon an image-recording layer comprising a cross-linkable polymer of gelatin or acetoacetylated poly(vinyl alcohol) and a mordant; applying liquid ink droplets of an anionic, water-soluble dye on the image-recording layer in an image-wise manner; and applying an aqueous solution of a hardener to the image to cross-link the binder.

Owner:EASTMAN KODAK CO

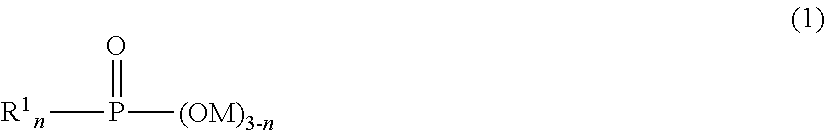

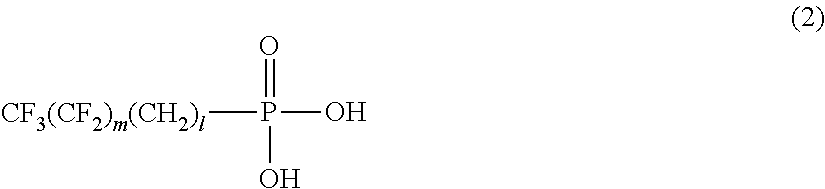

Aqueous pigment dispersion and aqueous ink composition containing the same

ActiveUS20150096466A1Excellent metallic glossinessGood water dispersibilityInksPigment pastesX-rayPigment dispersion

Disclosed is an aqueous pigment dispersion including water and a base metal pigment, in which the base metal pigment is a base metal pigment which is surface-treated with a fluorine-based compound, and when performing an X-ray Photoelectron Spectroscopy analysis of a base metal pigment surface, a concentration of a fluorine element is 21 atm % to 35 atm %.

Owner:SEIKO EPSON CORP

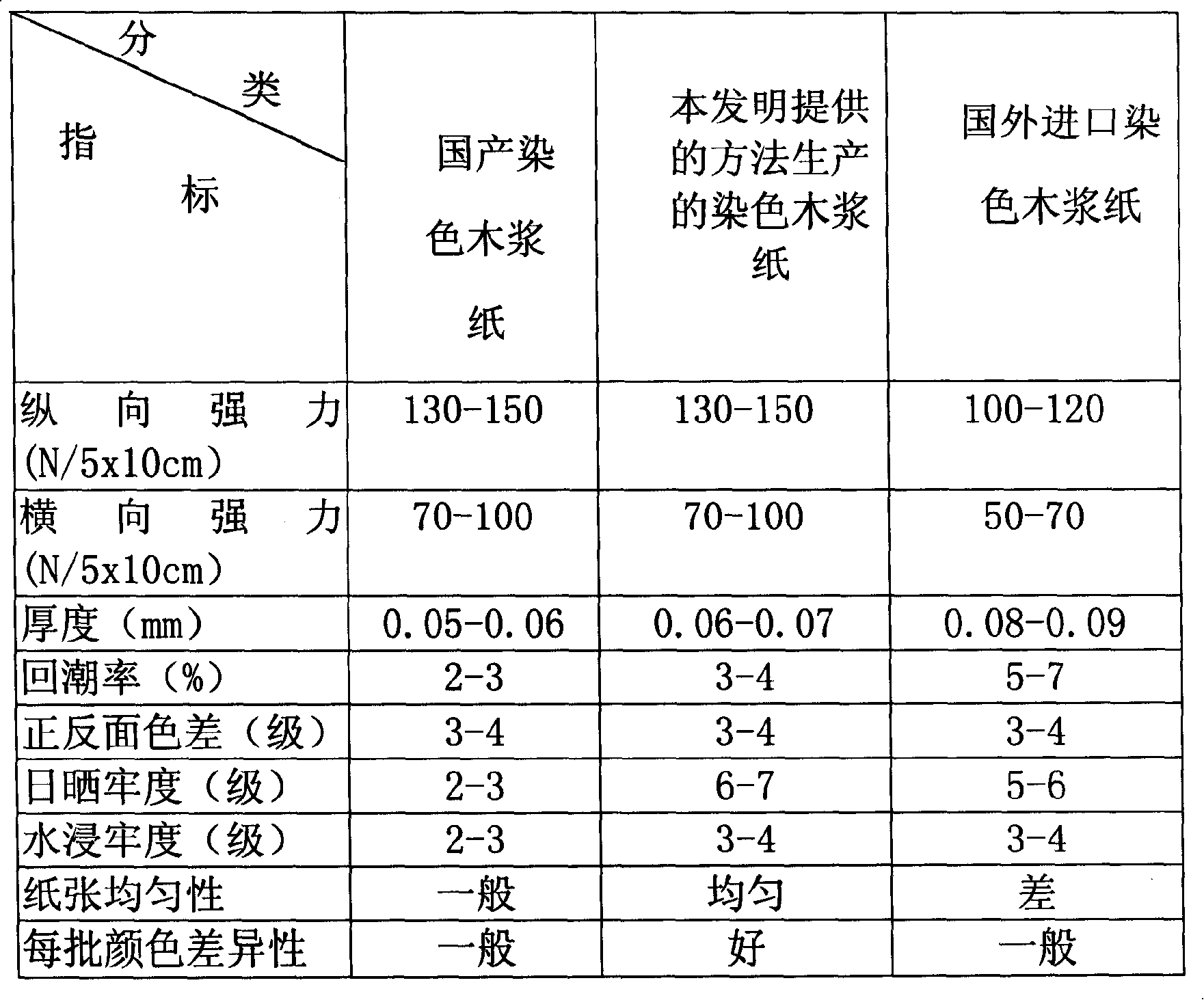

Dyeing technique of coloring wood-pulp paper used for non-woven material

InactiveCN101148845AImprovement of front and back chromatic aberrationGood light fastnessSpecial paperPaper/cardboardPaperboardPulp and paper industry

The present invention belongs to the field of paper making technology, and is especially technological process of dyeing wood pulp paper for making non-woven material. The technological process includes the steps of pulping, dyeing, fixing color, feeding, squeezing, stoving, etc. The dyeing step adopts the dye of DF turquoise blue, GDFN blue, RF bright blue, 3GSFN yellow or their mixture; and the color fixing agent is TF232 color fixing agent. The dyed product has homogeneous color, high color fastness, stable quality, low cost and other advantages.

Owner:XINLONG HLDG GROUP

Recording sheets for ink jet printing

InactiveUS7235284B1Good light fastnessImprove water fastnessSynthetic resin layered productsCoatingsEngineeringPaper sheet

There is described a recording sheet for ink jet printing comprising a polyethylene coated paper support having coated onto the front side of said support one ink receiving layer comprising a mixture of gelatin and rice starch.

Owner:WIFAG POLYTPE HLDG AG

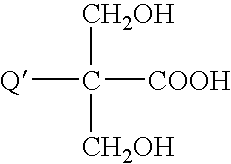

Water soluble colorants for ink jet printing

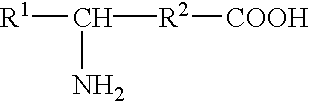

In accordance with one embodiment of the present invention, a colorant in an ink jet ink formulation is disclosed. The colorant comprises an organic dye chromophore with at least one functional group Y containing one or more primary, secondary or tertiary amino groups, which in the presence of an acid provides a water soluble, cationic ink jet ink colorant with increased water fastness when applied to paper.

Owner:PITNEY BOWES INC

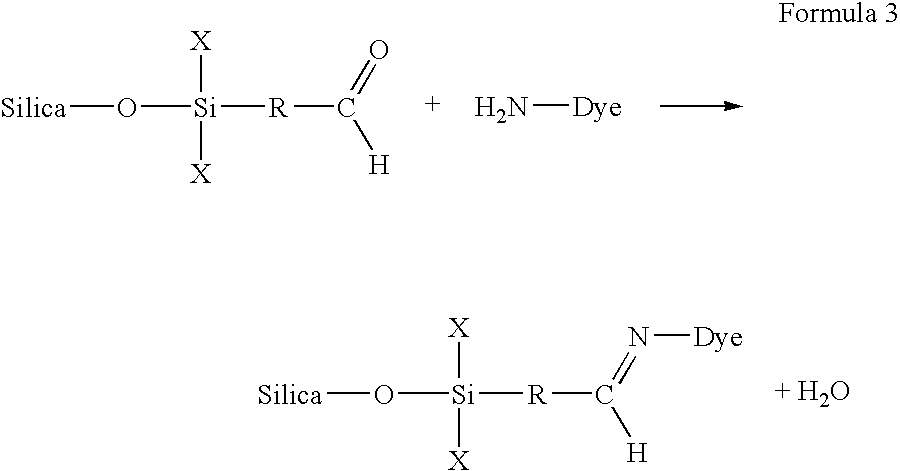

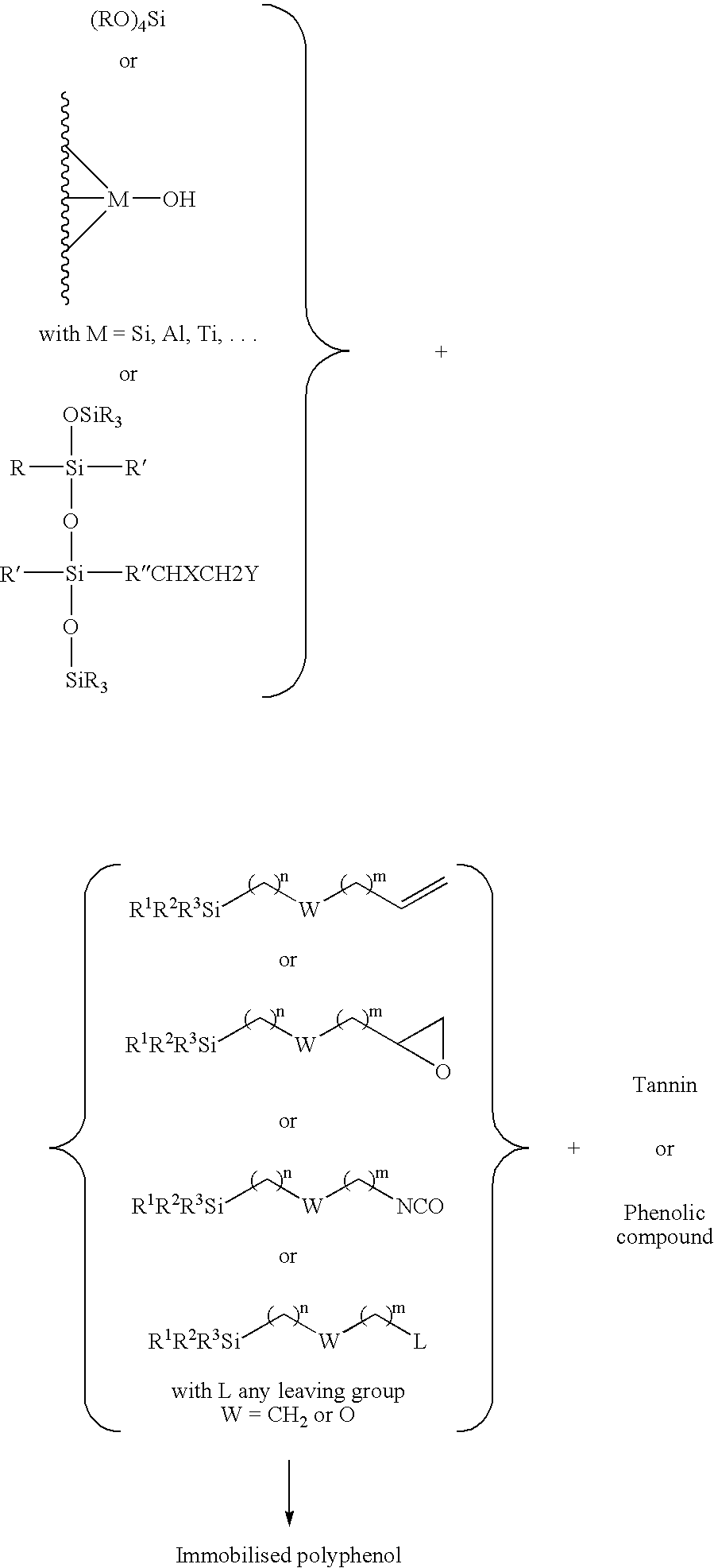

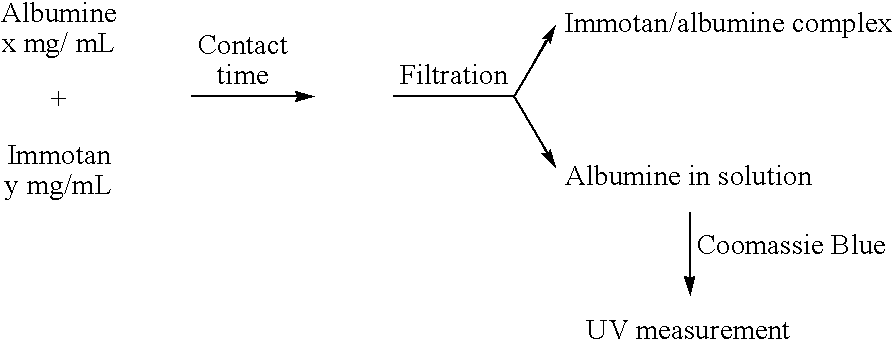

Complexating systems, intermediates for their production and method for obtaining and using the same

InactiveUS20040248975A1Improve crust formationAvoid infectionBiocideOrganic active ingredientsScavengerAntioxidant

The present invention is related to a complexating system comprising a tannin immobilised on a solid support by means of a bifunctional spacer which is covalently bound from one hand to said solid support by a first function and from the other hand to said tannin by a second function, wherein the tannin is a naturally occurring tannin and exhibits at least six hydroxyl groups. Said complexating system can be used in particular for chelating metals and proteins, as an antioxidant, as a radical scavenger or as an antibacterial. More specifically, applications can be found in the clarification and stabilisation of beverages, the treatment of textiles, or the separation and / or purification of proteins and / or metals.

Owner:OMNICHEM

Ink jet recording element

Owner:AGFA GEVAERT AG

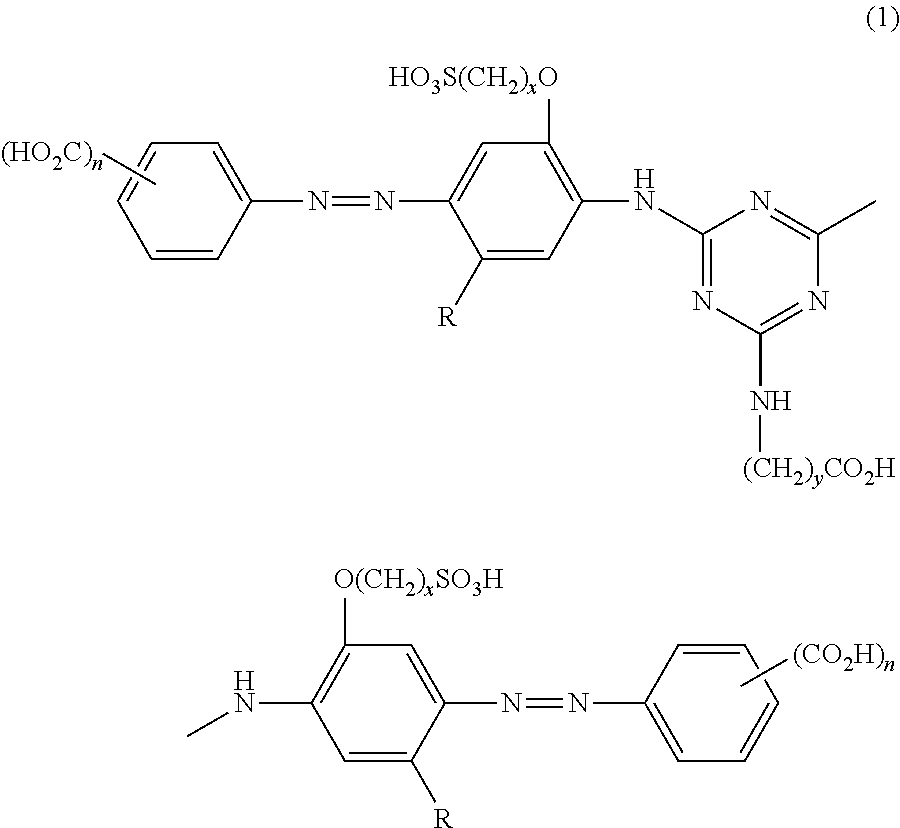

Water-soluble azo compound or salt thereof, ink composition and colored product

The present invention relates to a water-soluble azo compound represented by the following formula (1) or a salt thereof:wherein, R represents an alkyl group having 1 to 4 carbon atoms, n represents an integer number of 1 or 2, x represents an integer number of 2 to 4 and y represents an integer number of 2 to 11, respectively and an ink composition containing this; and provides a yellow coloring matter which has a highly vivid hue suitable for inkjet recording, gives various high fastnesses to recorded matter and is excellent in storage stability when prepared as an ink composition, and an ink composition containing this.

Owner:NIPPON KAYAKU CO LTD

Methods of fixing ink

InactiveUS7005162B2Improve image qualityImprove waterproof performanceAdditive manufacturing apparatusDecorative surface effectsImaging qualityEngineering

The invention provides methods for providing improved image quality and water resistance of dye based ink images on substrates using aqueous dispersed mordants and dispersed hydrophobic materials.

Owner:3M INNOVATIVE PROPERTIES CO

Open-width continuous washing system

InactiveCN106958102AMeet the requirements of washing processReduce processing stepsSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersWater savingElectricity

The invention belongs to the technical field of production and application of fabric and particularly discloses an open-width continuous washing system. The system comprises a cloth feeding assembly, a water washing machine, a first wash water box, a second wash water box, a first single-drum wash water box, a second single-drum wash water box and a cloth discharging assembly. The open-width continuous washing system has the beneficial effects as follows: by means of the system, continuous washing can be realized for fabric printing and dyeing, washing processing technique requirements of high-grade knitted fabric are met, the defect that the conventional knitted fabric washing processing process is required to be performed in batches and in different vats is overcome, the production efficiency is improved, and the production time is saved; besides, consumption of water, electricity and steam is reduced, the purposes of high efficiency, low energy consumption, low emission and environmental protection are achieved, and water fastness, dry / wet rub fastness and six-fiber test performance are improved to 0.5-1 level; practice proves that compared with a conventional dyeing vat process, the system has the advantages that during continuous washing on the basis of the yield of 15 tons every day, about 28 tons of water is saved for each ton of cloth by use of the equipment, about 126,000 tons of water can be saved every year, and the water saving and emission reduction effects are very remarkable.

Owner:江苏川徽科技有限公司

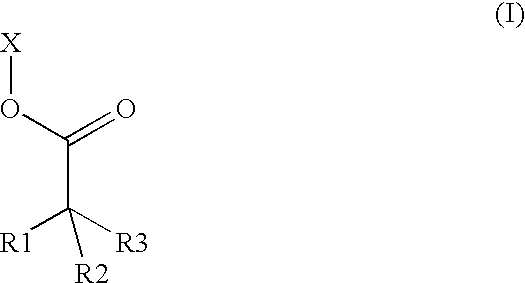

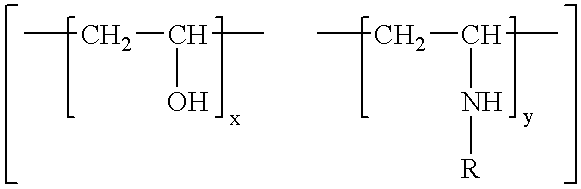

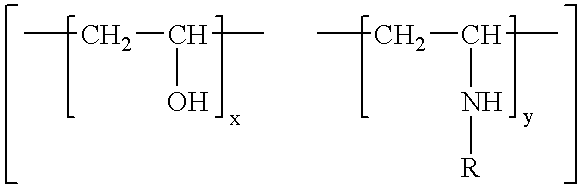

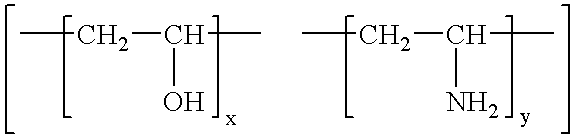

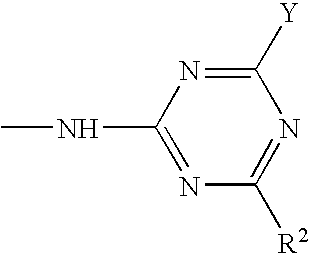

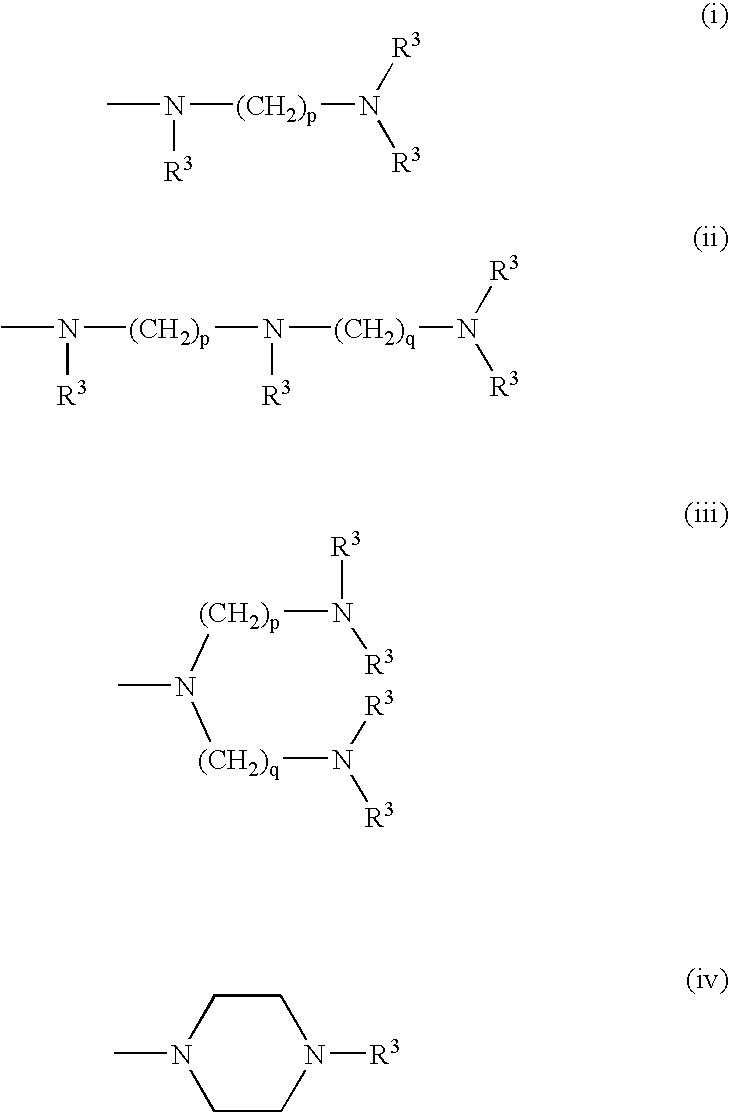

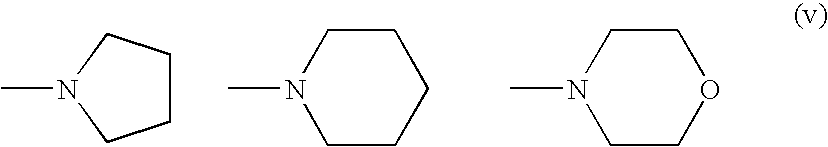

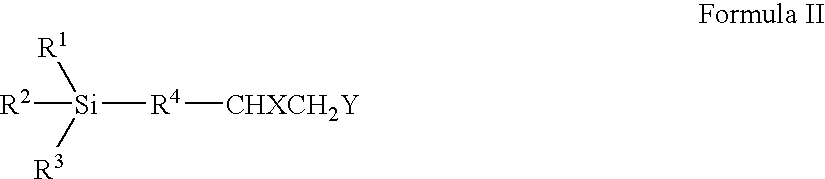

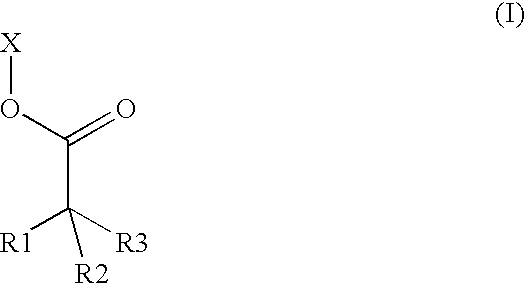

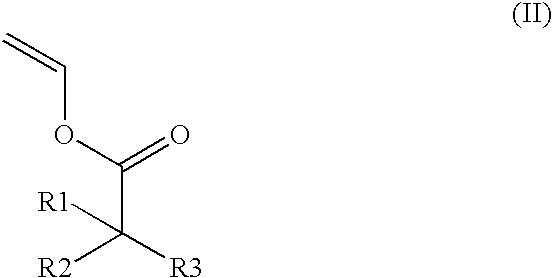

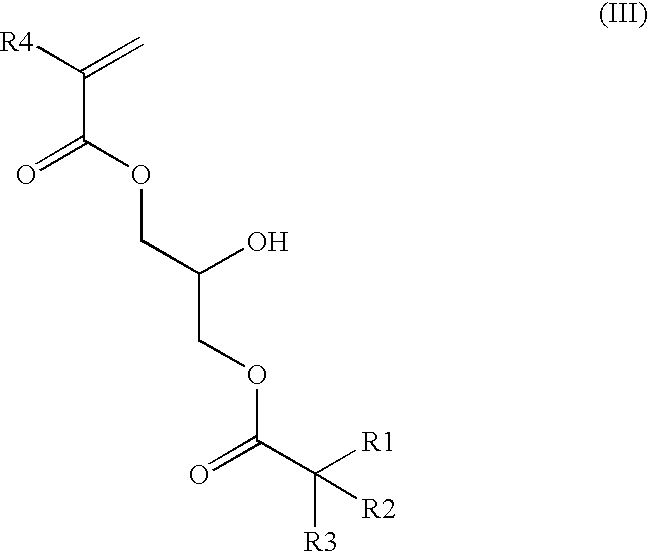

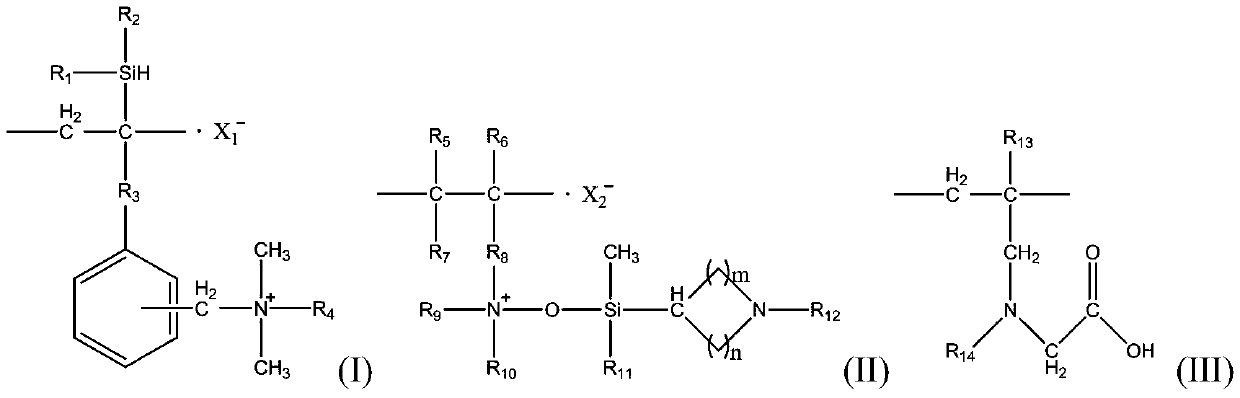

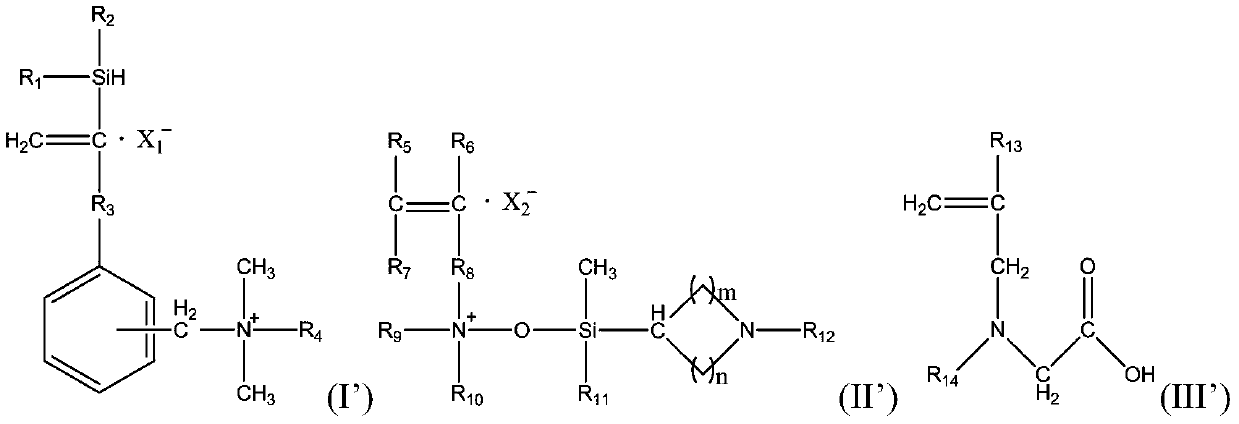

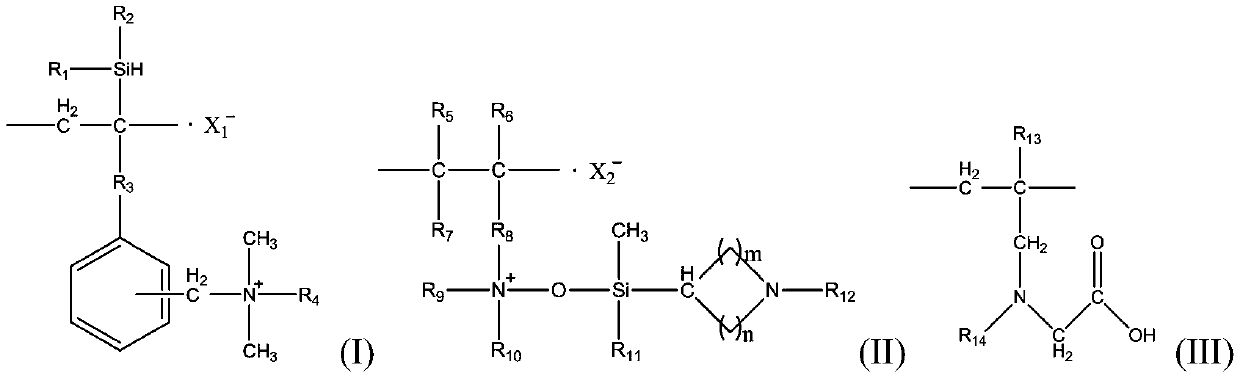

Textile dye fixing agent and application thereof

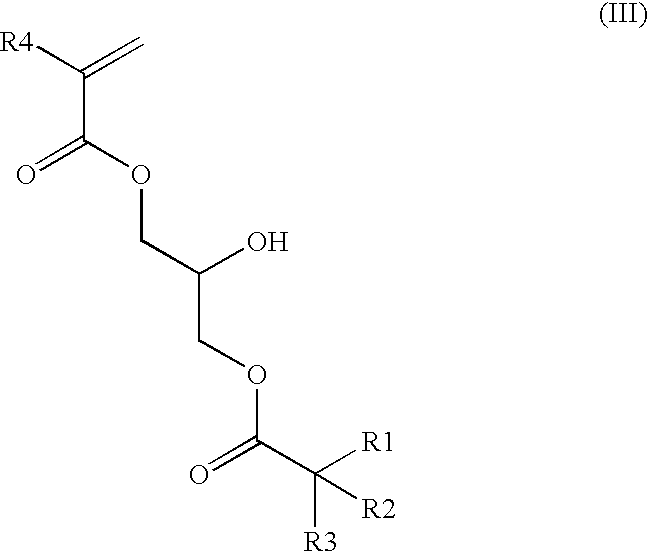

The invention provides a textile dye fixing agent and application thereof, and belongs to the technical field of textile printing and dyeing assistants. Specifically, the textile dye fixing agent comprises a mole of at least one copolymerized unit shown as formula (I), b mole of at least one copolymerized unit shown as formula (II) and c mole of at least one copolymerized unit shown as formula (III); the beneficial effects are that: the textile dye fixing agent disclosed by the invention is a polymer; the preparation method is simple, the reaction is mild, the phenomena of implosion, gelling and the like are avoided, a new branched structure containing silicon-carbon chains, nitrogen-carbon chains, particularly silicon-oxygen chains is introduced, and sulfydryl is introduced and condensedinto disulfide bonds, so that the crosslinking density of the textile dye fixing agent is further increased, and the resistances such as wear resistance, water soaking resistance and the like are greatly improved.

Owner:浙江新海天生物科技有限公司

Environment-friendly type synthetic tannin color fixing agent as well as preparation method and application thereof

The invention discloses an environment-friendly type synthetic tannin color fixing agent as well as a preparation method and application thereof. The color fixing agent is a synthetic tannin color fixing agent prepared from the following raw materials in percentage by mass: 15-30% of a phenol compound, 10-30% of an aromatic sulfonic acid compound, 1-5% of a catalyst, 5-15% of a formaldehyde solution, 0.5-2% of a chelating agent, 0.5-3% of a modifier, 1-4% of a dispersant and the balance of water. When being applied to color fixation of chinlon and blended fabrics, the synthetic tannin color fixing agent disclosed by the invention has the advantages of being good in acid resistance stability, small in color change, good in color fastness, and the like.

Owner:东莞市中纺化工有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com