High oxidation resistance nanocrystalline-amorphous structured superhard composite film cutting tool and deposition method therefor

An amorphous structure and nanocrystalline technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of difficult adhesion, unfavorable tool coating wear resistance, large surface friction coefficient, etc. problem, to achieve the effect of improving service life, reducing cutting force and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] 1. Description of several important technical issues

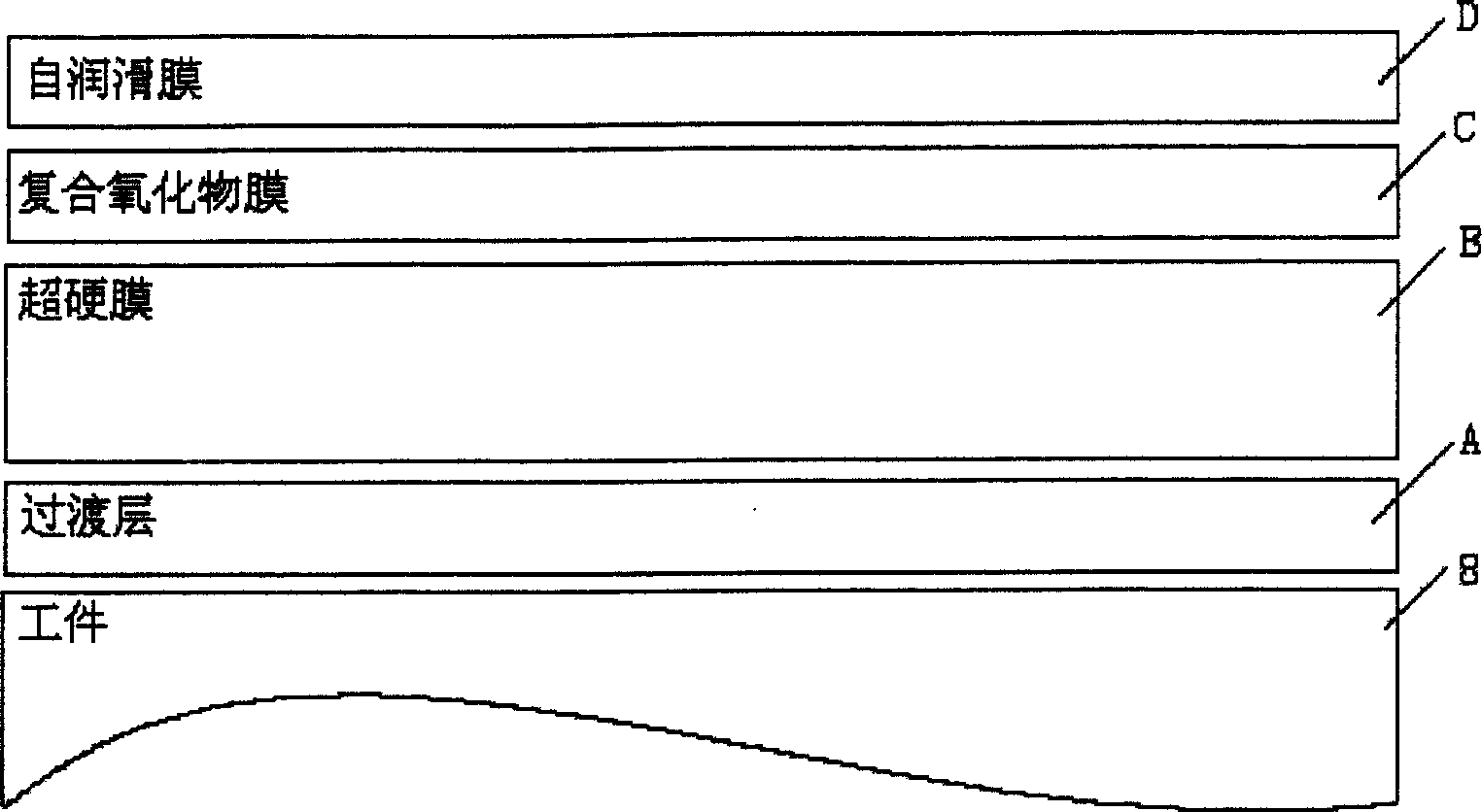

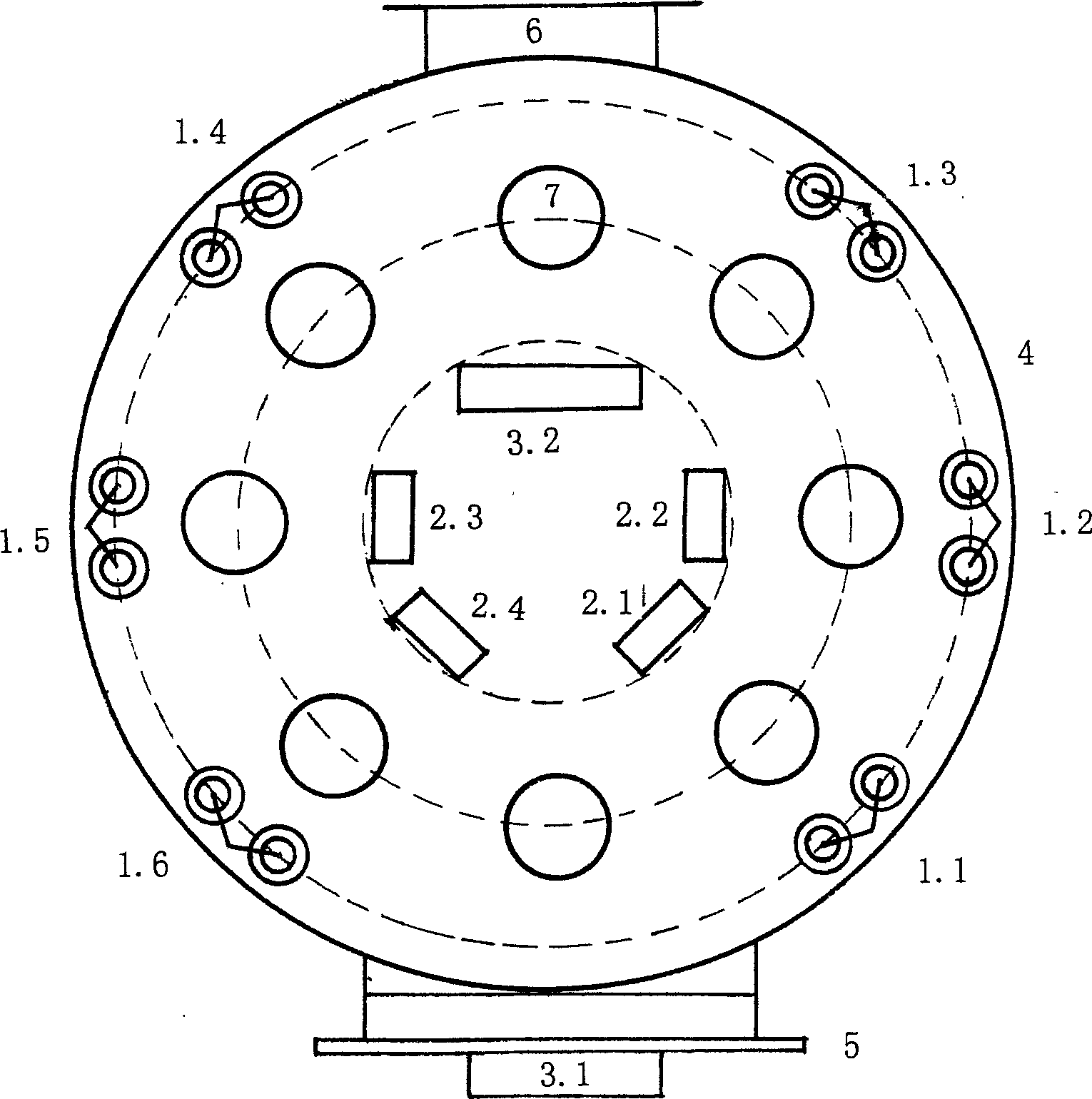

[0080] ①Application of cylindrical magnetron sputtering target 1

[0081] Nanocrystalline-amorphous structure (nc-TiAlN / a-Si) of two types of functional film materials involved in the present invention 3 N 4 ) superhard film (referred to as superhard film) and aluminum oxide (Al 2 o 3 ), zirconium dioxide (ZrO 2 ) composed of superlattice structure composite oxide films, all of which are insulating films with high resistivity, the sputtering products often adhere to the non-sputtering area of the target surface during deposition, and gradually expand to the sputtering area, causing the target surface to be "poisoned". "Phenomenon, the positive charges are enriched on the insulating film, which will cause arc discharge on the target surface to a certain extent. The light ones will cause the target power supply to work unstable, and the severe ones will even burn the sputtering power supply. The best way to solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com