Atmospheric cold plasma jet auxiliary cutting method

A technology of cold plasma and cutting method, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems that have not been reported, and achieve the effect of simple equipment, good lubrication and cooling effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

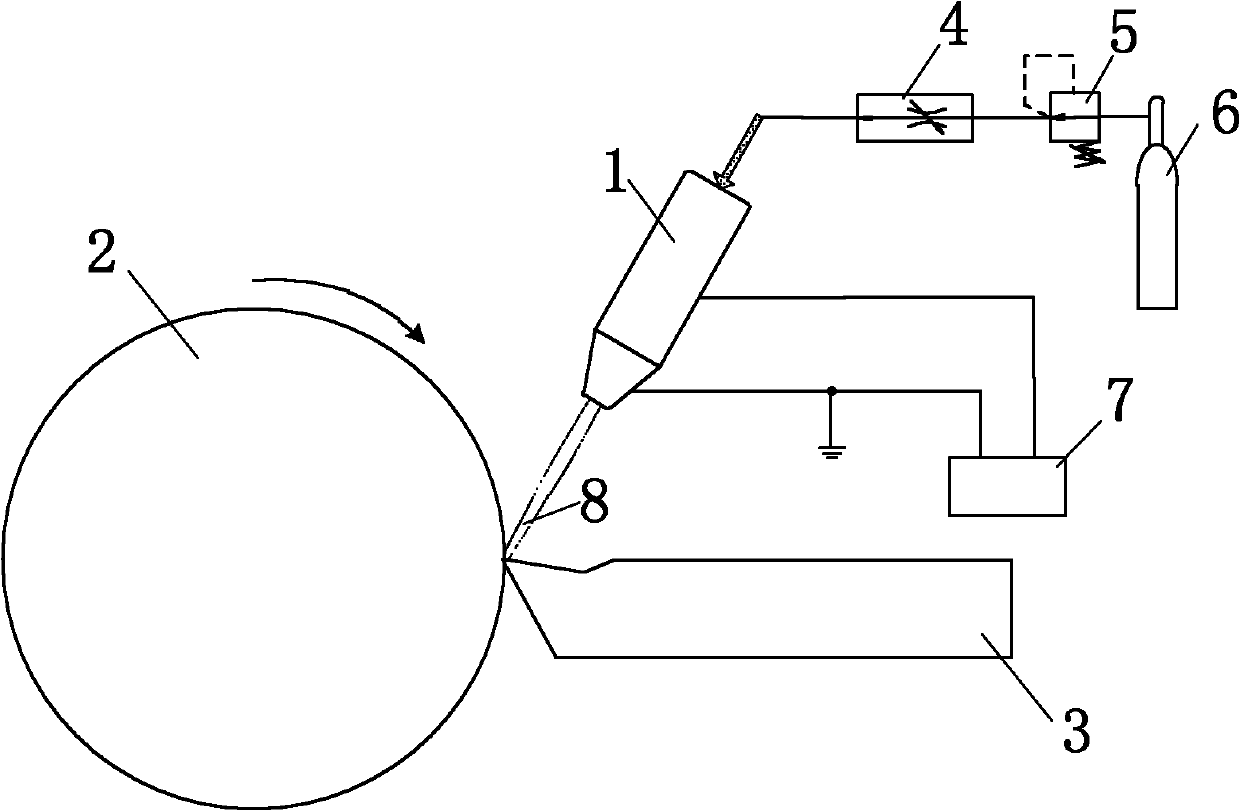

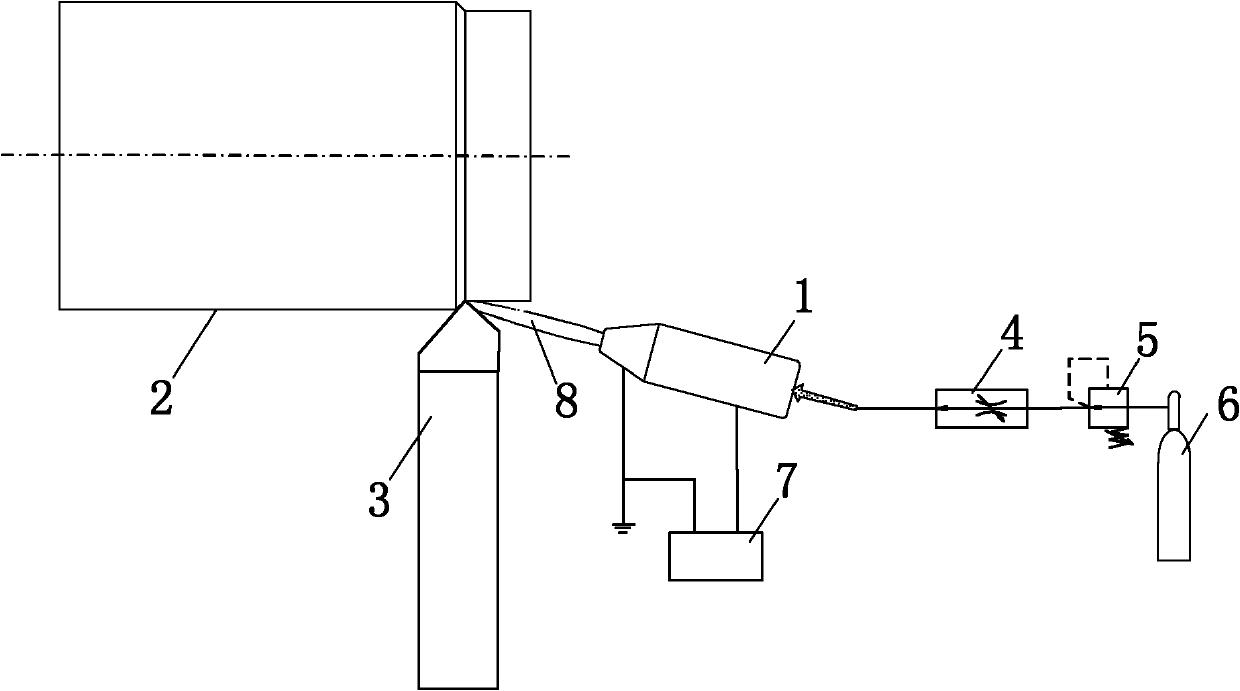

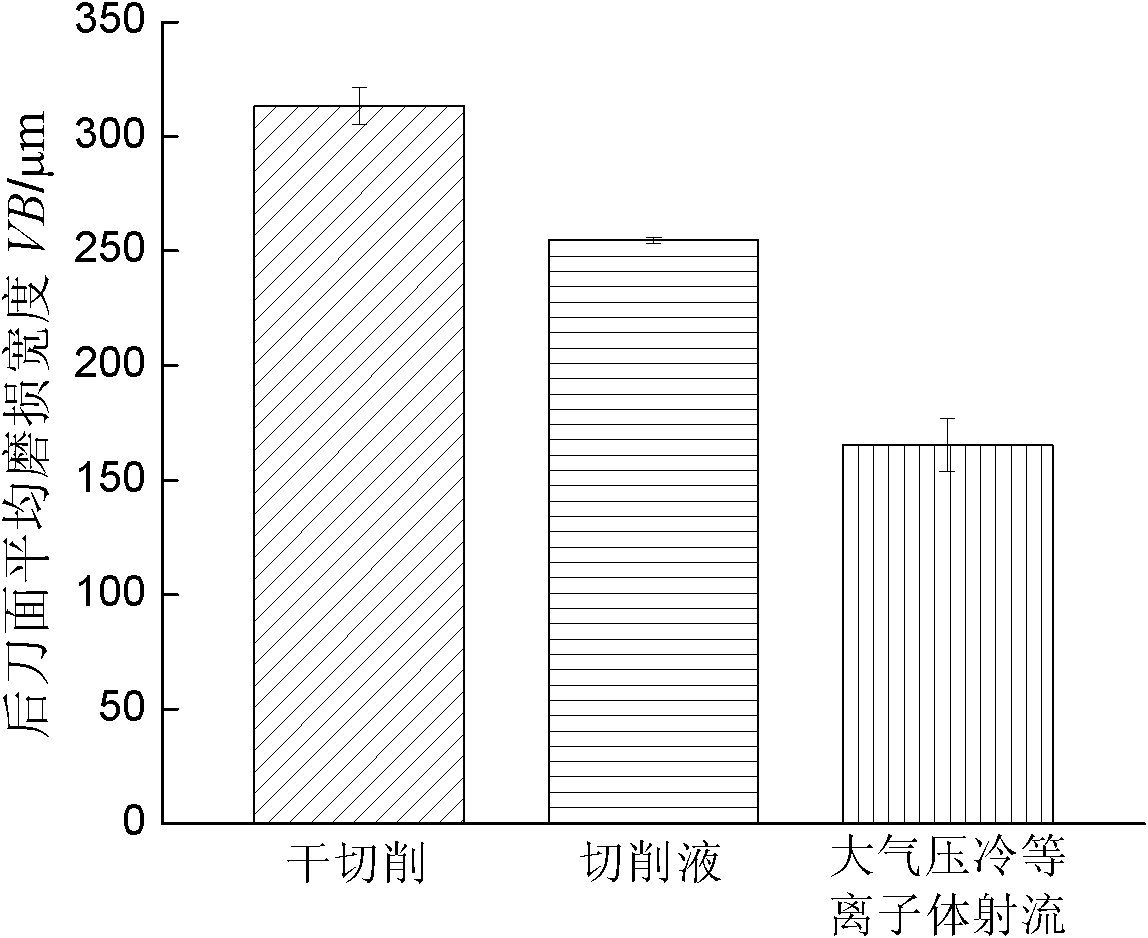

[0028] Taking the turning of titanium alloy with cemented carbide tool as an example, using cold plasma jet as cooling and lubricating medium can reduce tool wear and improve the quality of machined surface.

[0029] Tool 2 is titanium alloy Ti6Al4V bar stock, tool 3 is grade K05 (YG3X), cutting amount is: cutting speed 80m / min, cutting depth 0.5mm, feed speed 0.1mm / r.

[0030] The cold plasma jet generator 1 uses a bare electrode discharge form, and the cold plasma jet generated by such electrodes will not cause arc breakdown discharge between the metal and the metal. The two electrodes are a nozzle electrode made of brass and a needle electrode made of tungsten carbide, and the vertical distance between the two electrodes is 2.5mm.

[0031] The high-voltage power supply 7 adopts an intermediate frequency sine wave AC power supply, with an output frequency of 50k-120kHz, an output voltage of 0-10kV, and a maximum power of 150W; the high-voltage output end of the high-voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com