Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Good lubricating and cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

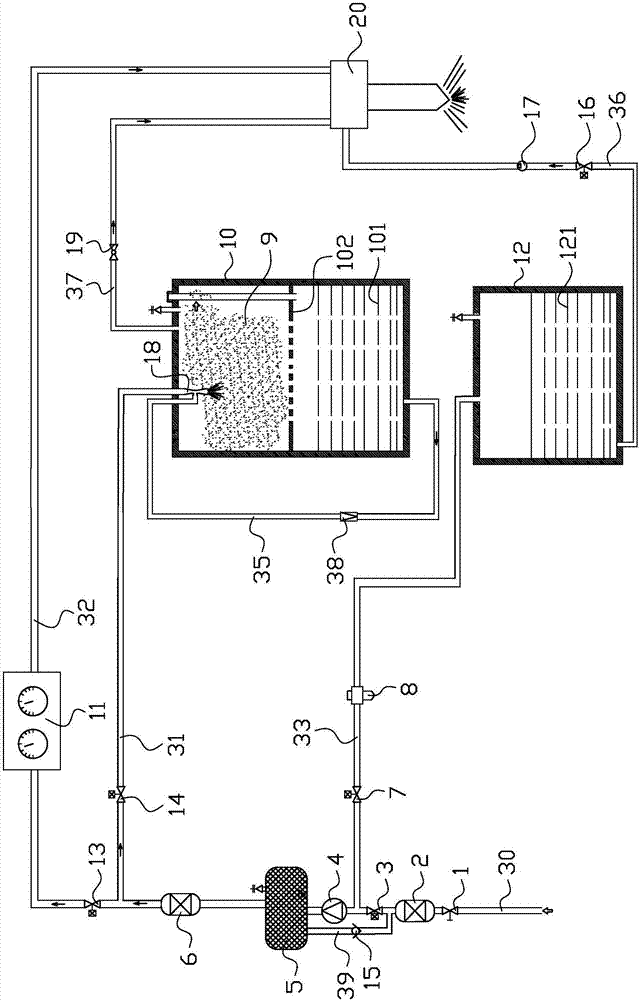

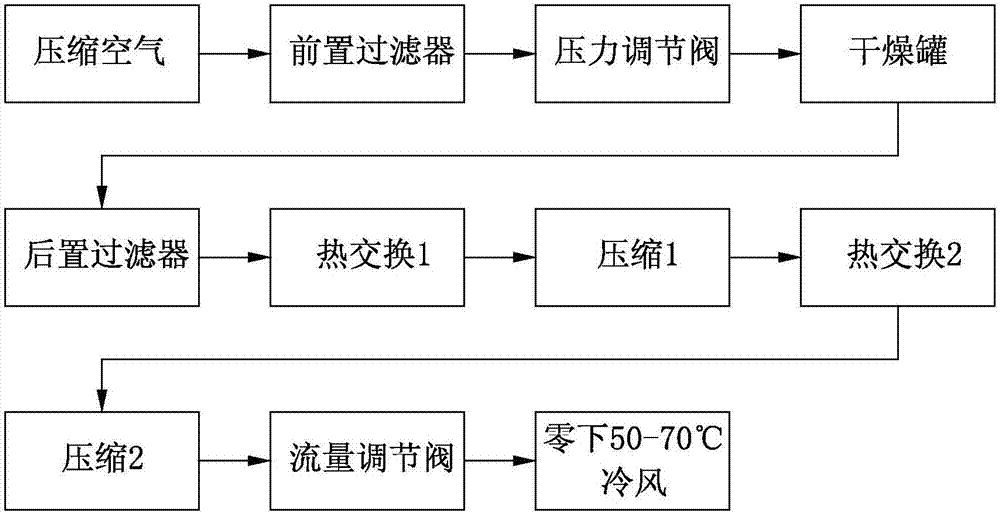

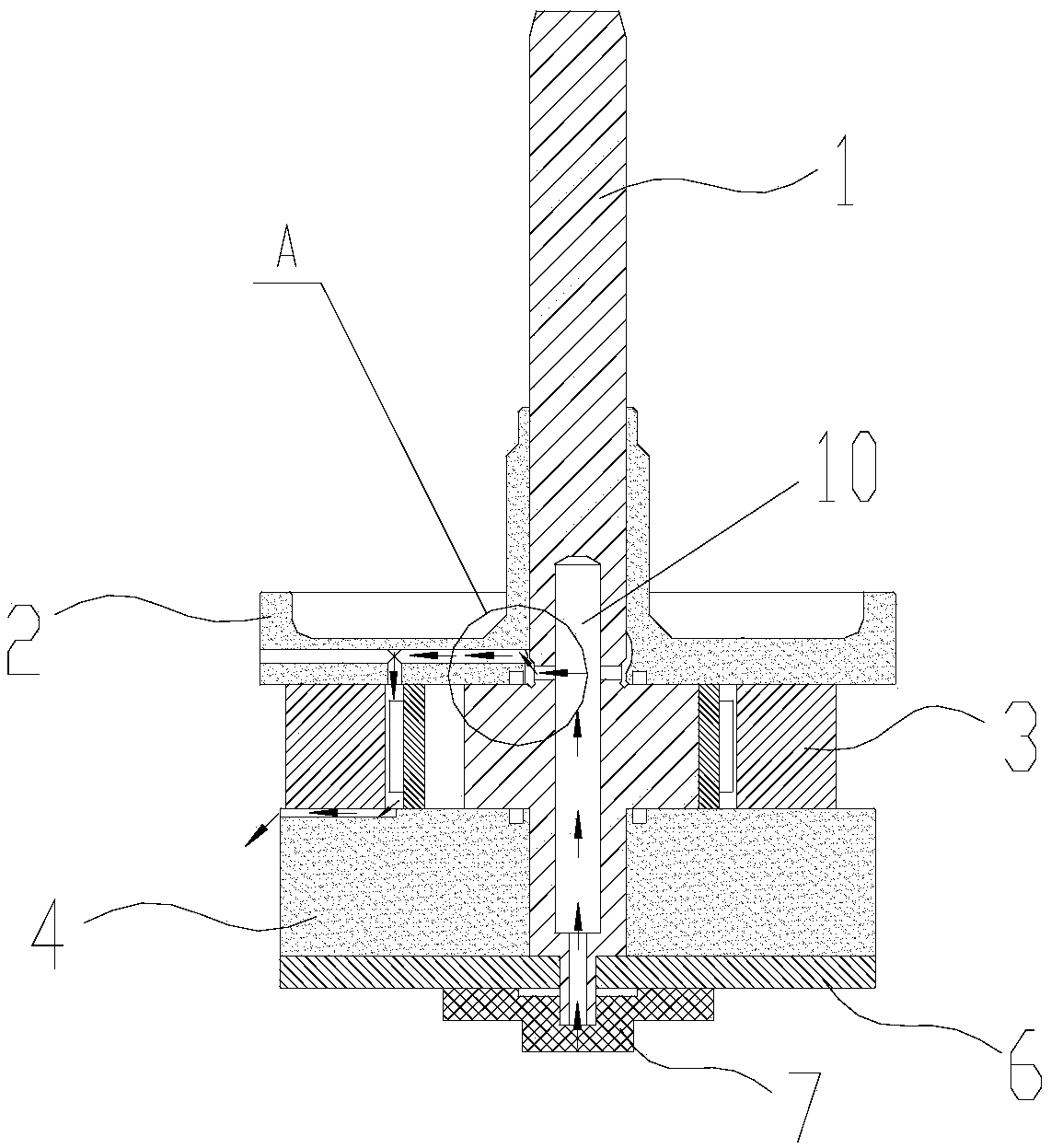

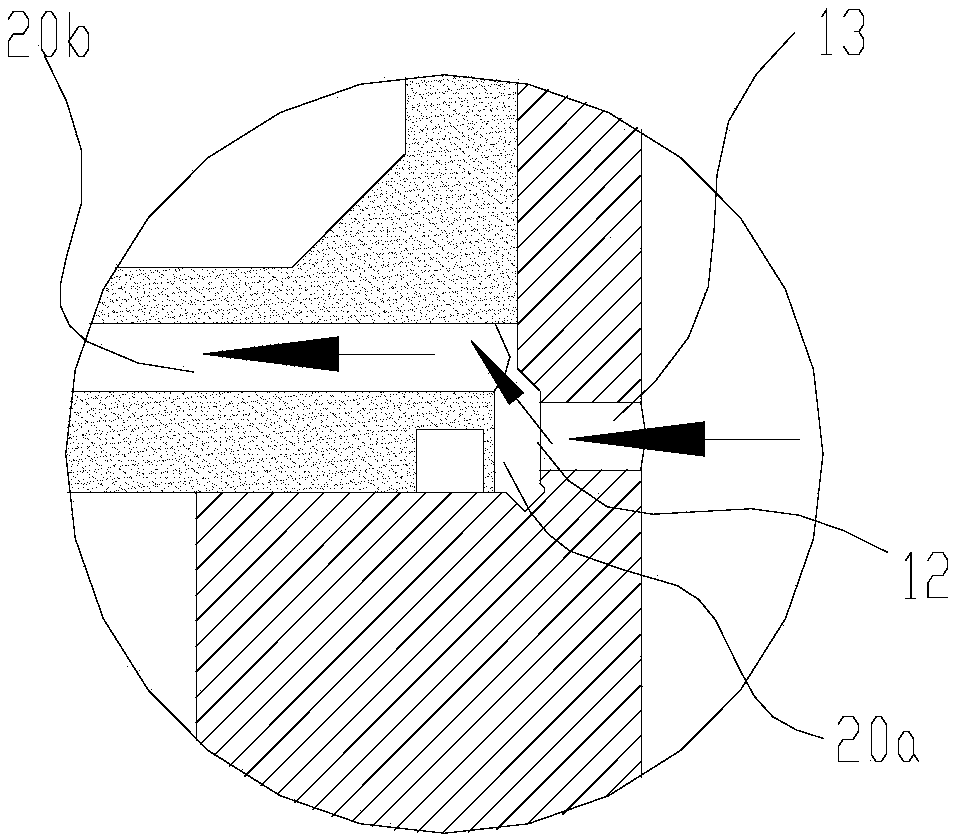

Low temperature water mist and oil mist cutting cooling lubrication supply system

ActiveCN106863002AImprove permeabilityExtend your lifeMaintainance and safety accessoriesAviationSprayer

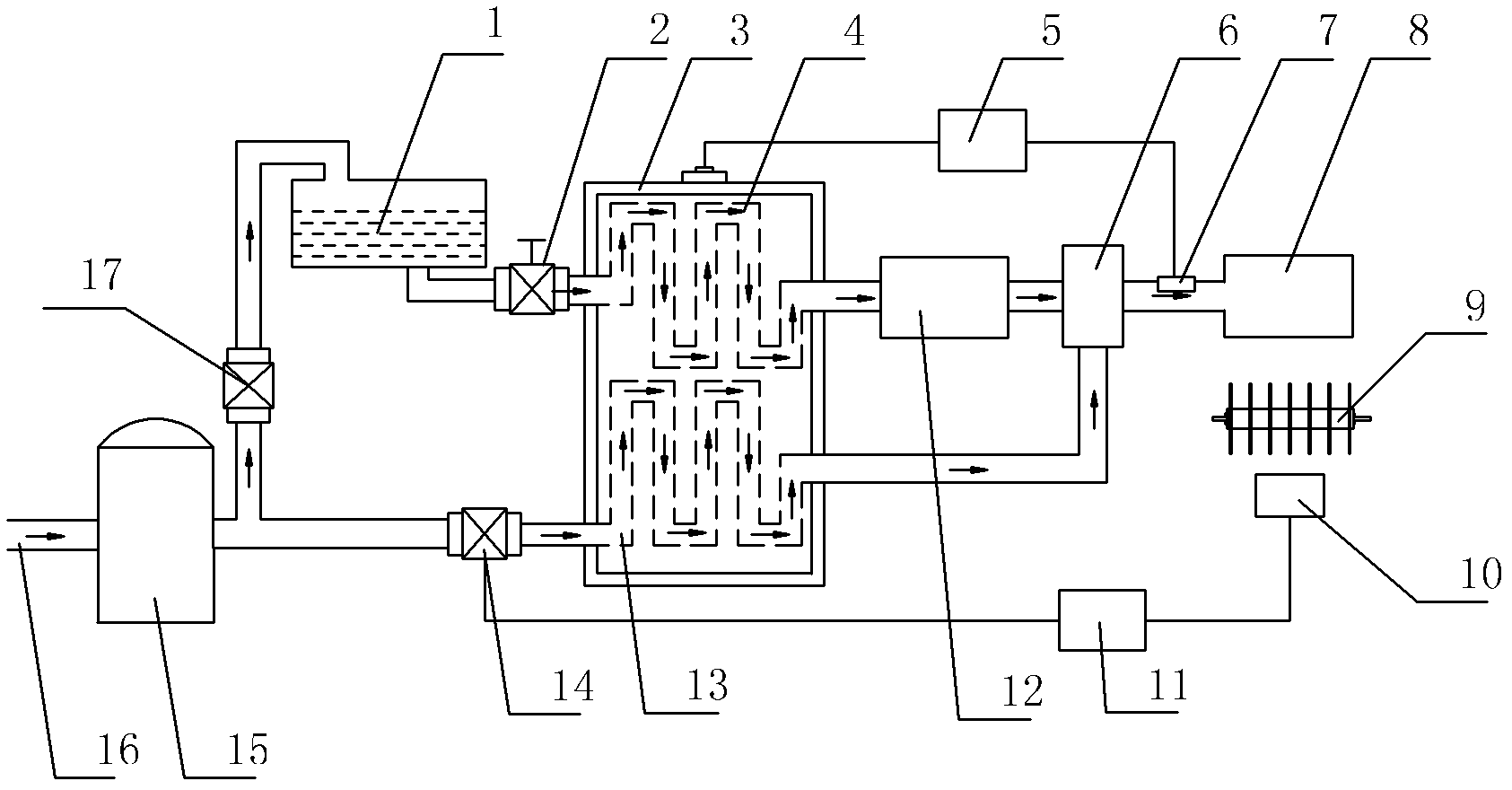

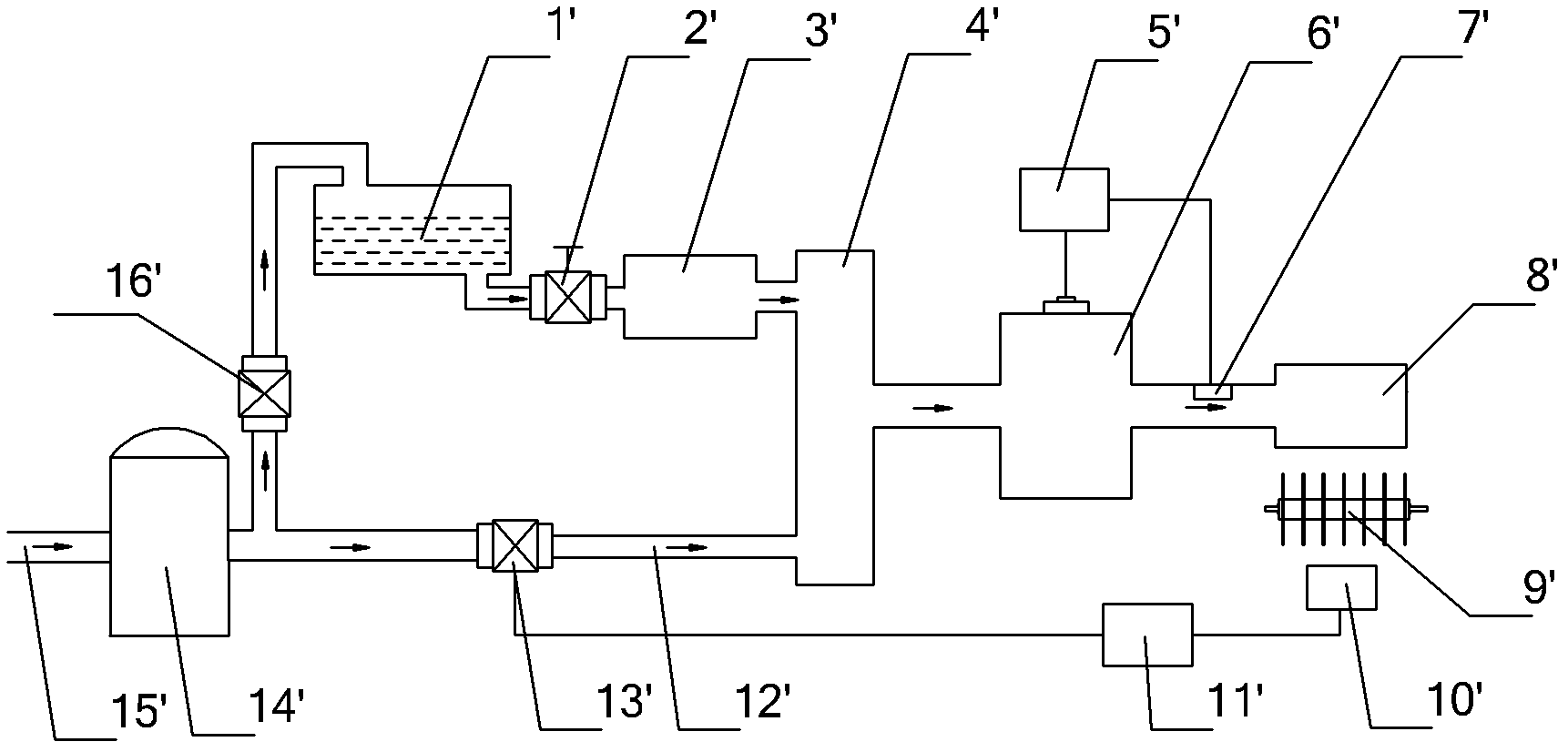

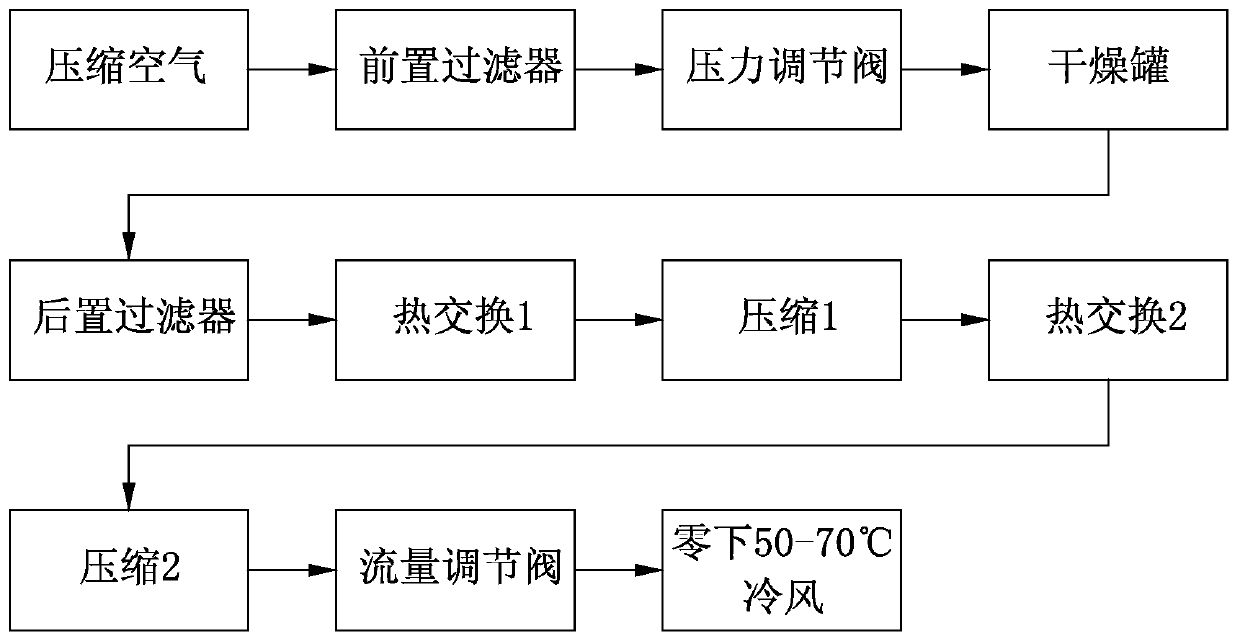

The invention discloses a low temperature water mist and oil mist cutting cooling lubrication supply system. A Venturi atomization sprayer is arranged at the upper portion of an inner cavity of an atomization chamber, an air inlet of the Venturi atomization sprayer is connected to the outlet end of an air tank through a first air conveying pipe, an eddy atomization sprayer comprises an eddy pipe and an oil-water mixing sprayer, the eddy pipe is connected to the outlet end of the air tank through a second air conveying pipe, and a compression refrigerator is arranged on the second air conveying pipe; the oil-water mixing sprayer is connected with the water tank through a water pipe, and is connected with the atomization chamber through an oil mist conveying pipe; and cold air refrigerated through the compression refrigerator and the eddy pipe is mixed with oil mist coming from the atomization chamber and water coming from the water tank at the position of the oil-water mixing sprayer. By means of the system, advantages of low-temperature cold air and composite spraying mist are combined, and therefore when a cutter is used for machining difficultly-machined materials such as the titanium alloy, the high-temperature alloy and the aviation composite material, the cutting temperature is rapidly decreased, the machining process is more efficient, and the service life of the cutter is prolonged.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

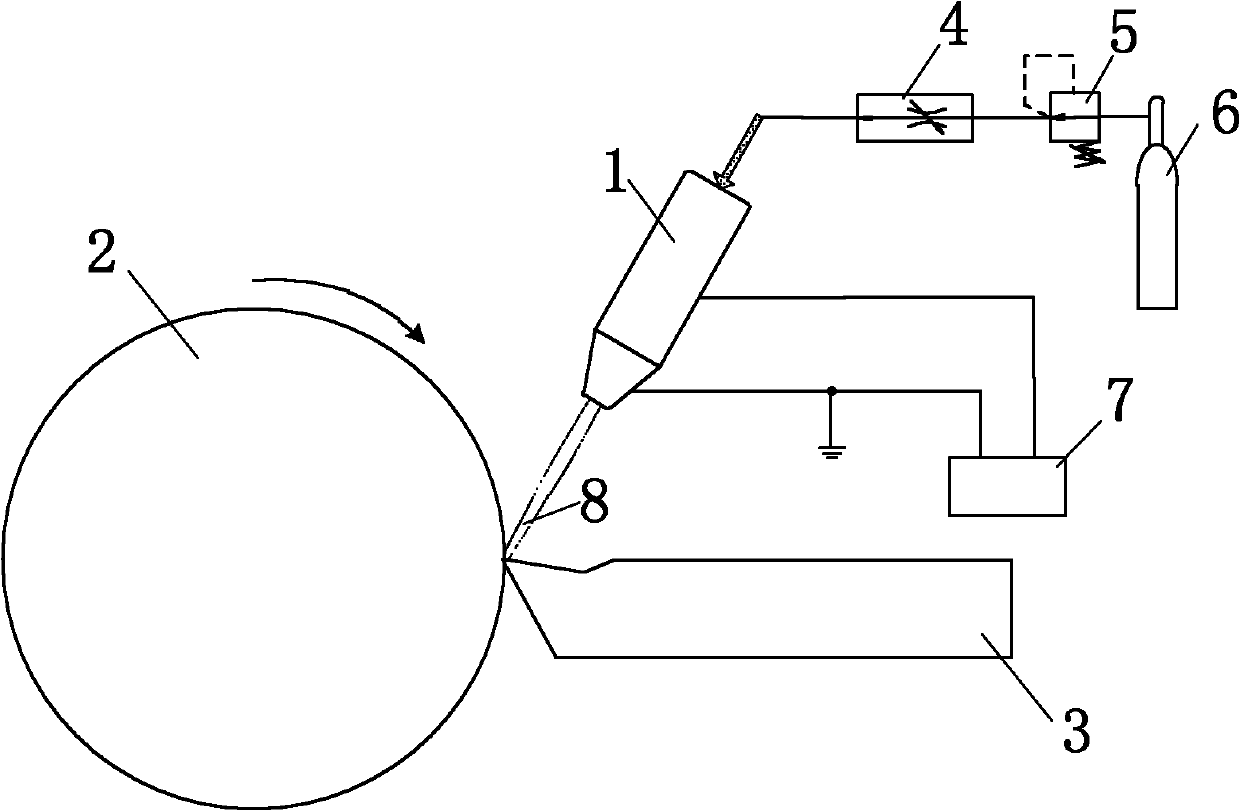

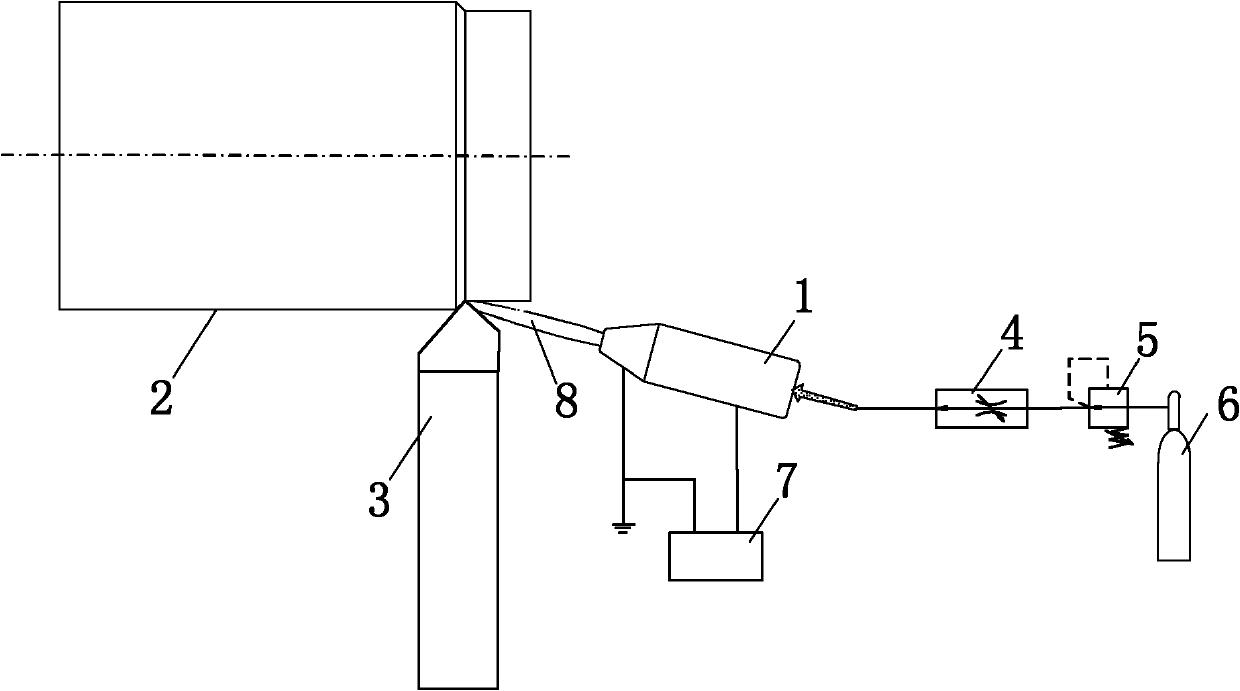

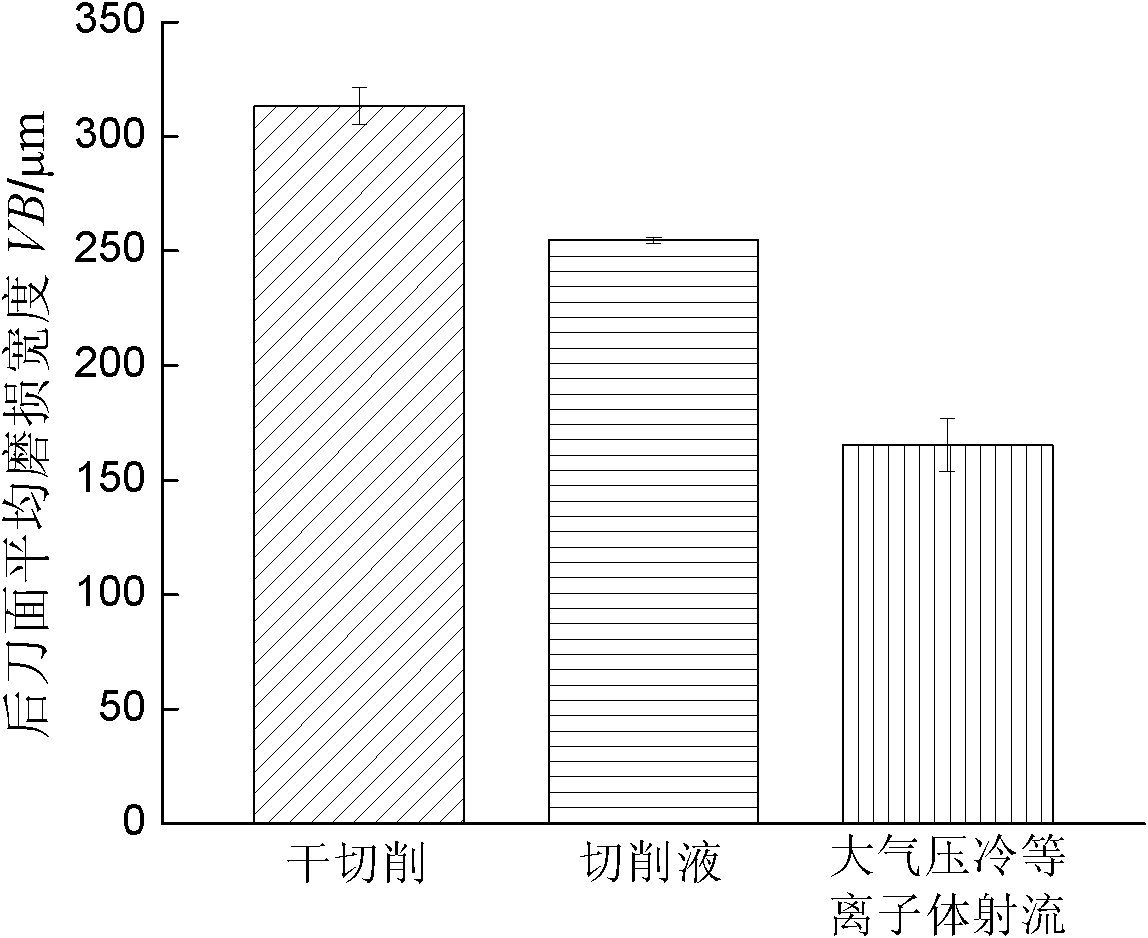

Atmospheric cold plasma jet auxiliary cutting method

ActiveCN102601677AReduce plastic deformation resistanceExtend your lifeMaintainance and safety accessoriesPlasma jetCooling effect

The invention provides an atmospheric cold plasma jet auxiliary cutting method. Cold plasma jet generated under atmospheric pressure is used as a lubricating cooling medium during material cutting. Working gas enters a cold plasma jet generator from a working gas source via a pressure reducing valve and an adjustable flow meter, the flow of the working gas and output voltage of a high-voltage power source are adjusted so that uniform cold plasma jet is sprayed out from a nozzle outlet of the cold plasma jet generator, the temperature of the jet is the room temperature or is slightly higher than the room temperature, and a tool and workpiece interface and a tool and chip interface are always soak in the cold plasma jet during cutting by means of adjusting a spraying angle. Plasma can be generated in a dielectric barrier discharge mode, a suspension electrode discharge mode or a bare electrode discharge mode. The atmospheric cold plasma jet auxiliary cutting method is an environment-friendly cutting method, an excellent lubricating and cooling effects for various metal and nonmetal materials can be realized during cutting, accordingly, cutting force is reduced, the service life of a tool is prolonged, and the quality of the surface of a workpiece is enhanced.

Owner:DALIAN UNIV OF TECH

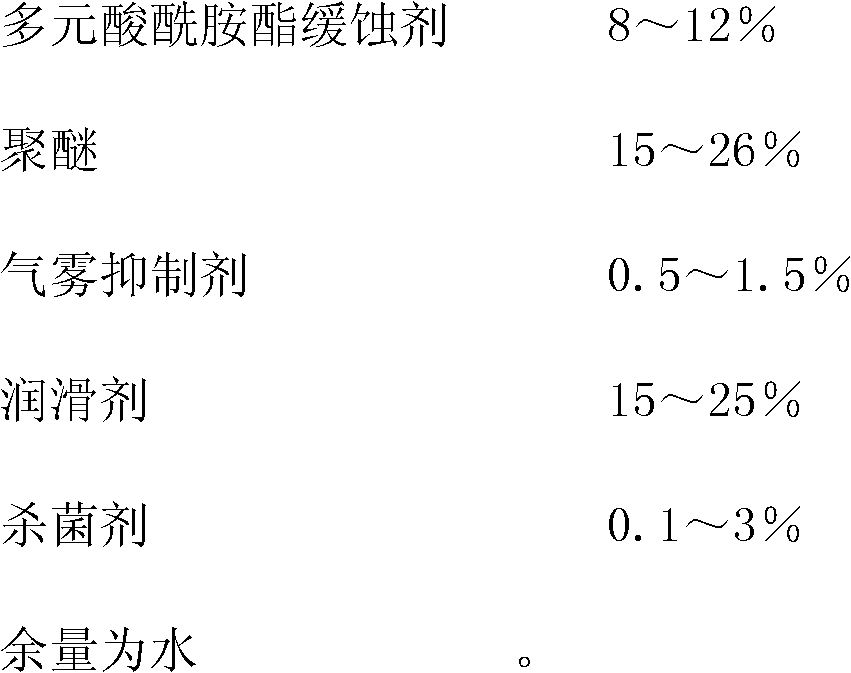

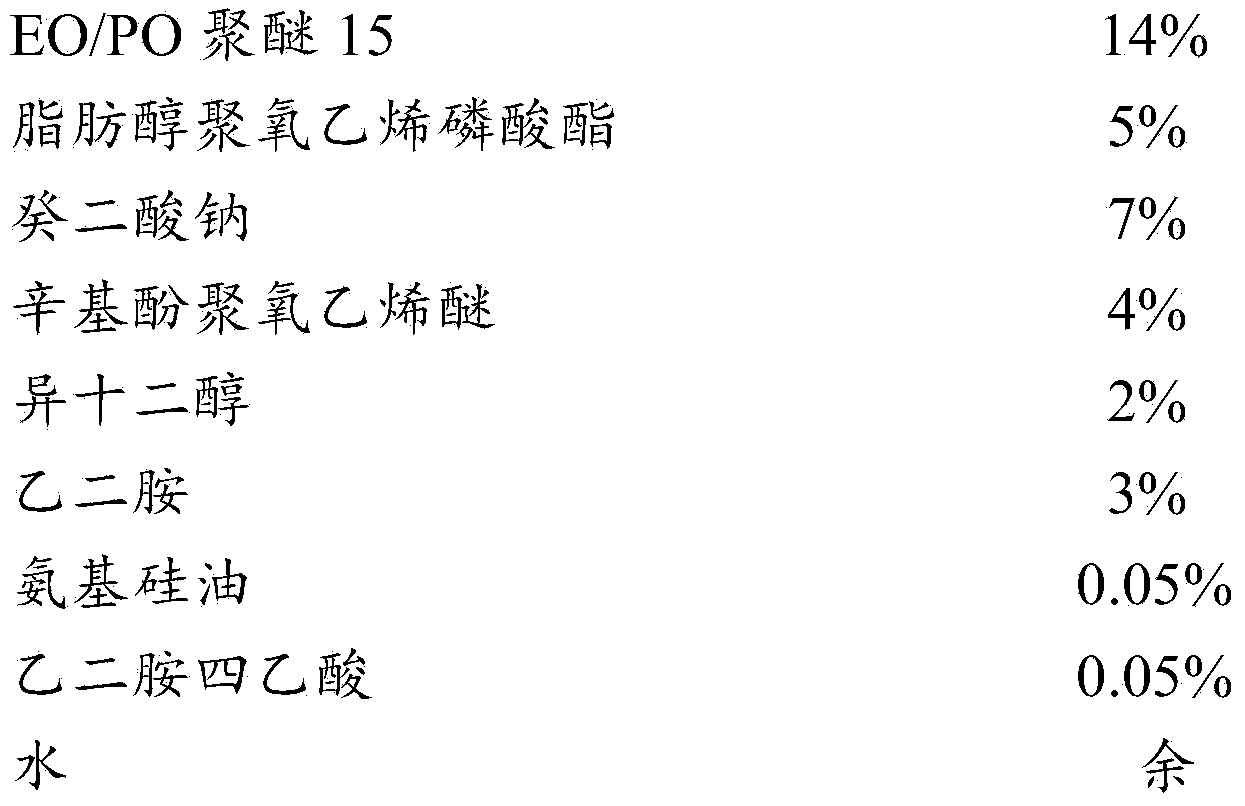

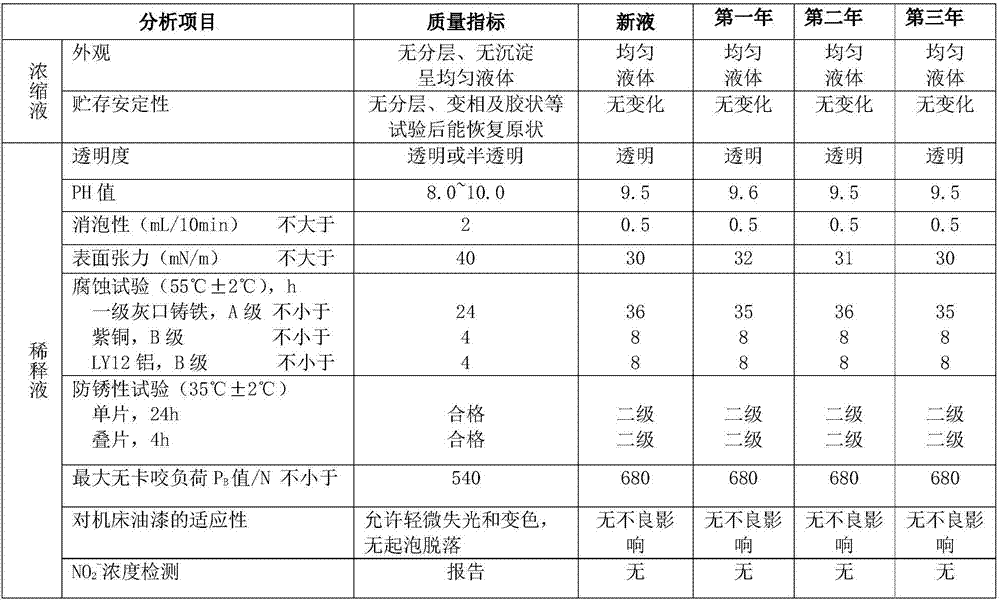

Novel total-synthesis water-soluble magnesium alloy cutting solution and preparation method thereof

The invention relates to a novel total-synthesis water-soluble magnesium alloy cutting solution. The novel total-synthesis water-soluble magnesium alloy cutting solution comprises the following components by weight percent: 8-12% of polybasic amide ester corrosion inhibitor, 15-26% of polyether, 0.5-1.5% of aerial fog inhibitor, 15-25% of lubricant, 0.1-3% of sterilizing agent and water. According to the novel total-synthesis water-soluble magnesium alloy cutting solution, the polyether is used for improving the magnesium hard water resistance of a product, a polybasic amide ester is used as a magnesium alloy corrosion inhibitor, and the lubricant, the sterilizing agent and the aerial fog inhibitor are compounded, so that the cutting solution has excellent lubricating and cooling effect, but also has the excellent magnesium hard water resistance, excellent magnesium collision resistance and work safety performance; and therefore, the novel total-synthesis water-soluble magnesium alloy cutting solution is the best substitute product of the current full-emulsion type magnesium alloy cutting solution.

Owner:泰伦特生物工程股份有限公司

Fully synthetic stainless steel cold rolling mill compound and application thereof

InactiveCN104342274AExtended service lifeGood lubricating and cooling effectLubricant compositionWater solubleCleansing Agents

The invention relates to a fully synthetic stainless steel cold rolling mill compound and application thereof and mainly aims to solve the problems of poor lubricating extreme pressure property and short service life. The fully synthetic stainless steel cold rolling mill compound comprises the following components in parts by weight: a) 5-30 parts of water-soluble polyether; b) 1-10 parts of a water-soluble extreme pressure agent; c) 3-10 parts of a water-soluble antirust agent; d) 1-10 parts of a cleaning agent; e) 1-5 parts of a coupling agent; f) 0.01-0.5 part of a chelating agent; and g) 35-65 parts of water. With application of the technical scheme, the problems in the prior art are solved very well; and the fully synthetic stainless steel cold rolling mill compound can be applied to the stainless steel cold rolling process.

Owner:CHINA PETROLEUM & CHEM CORP

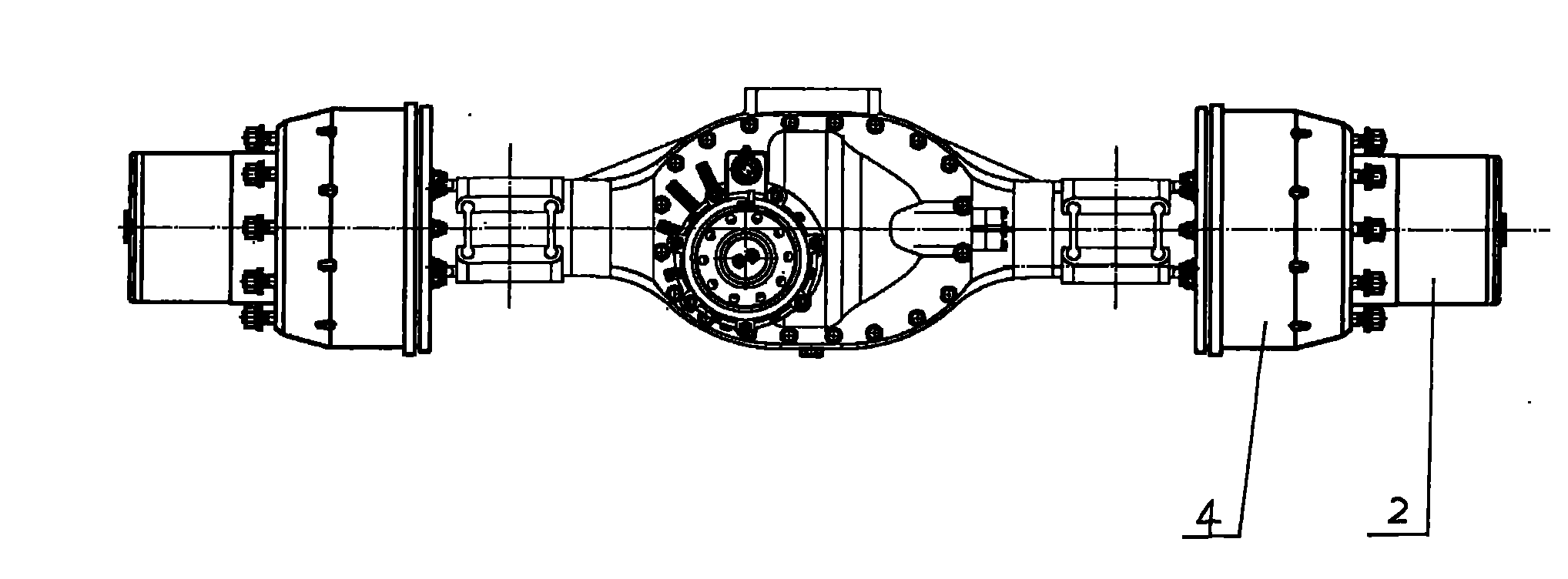

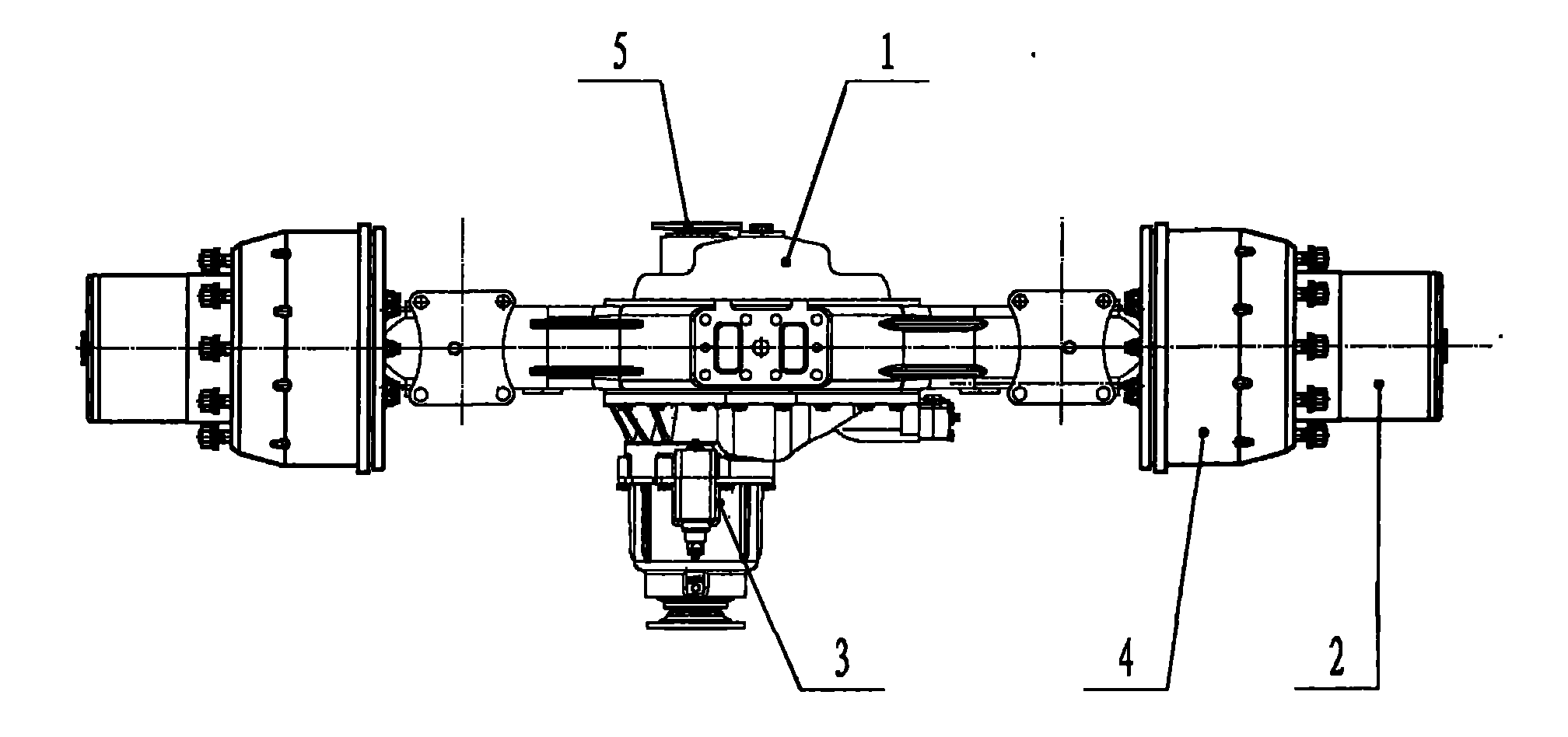

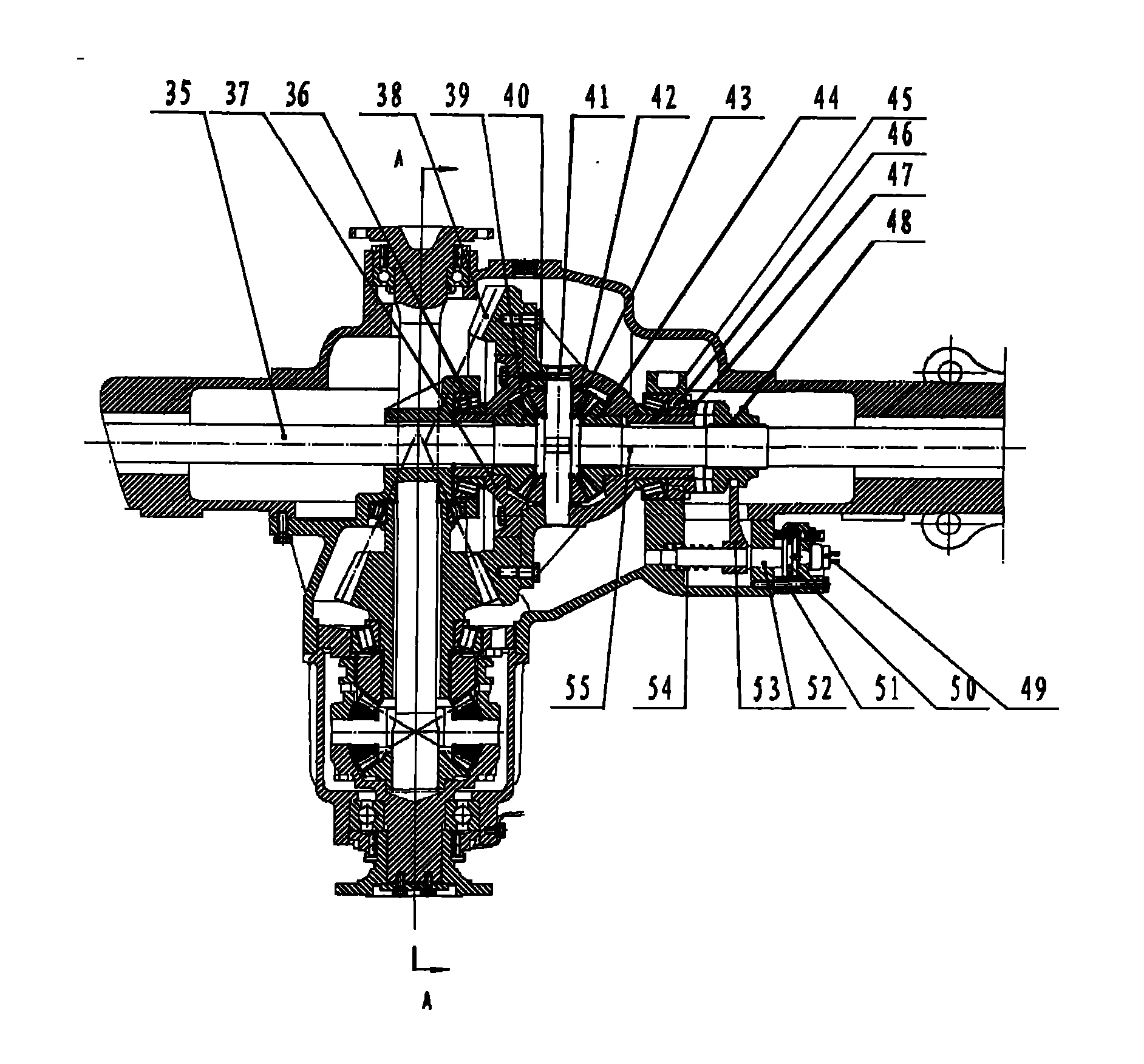

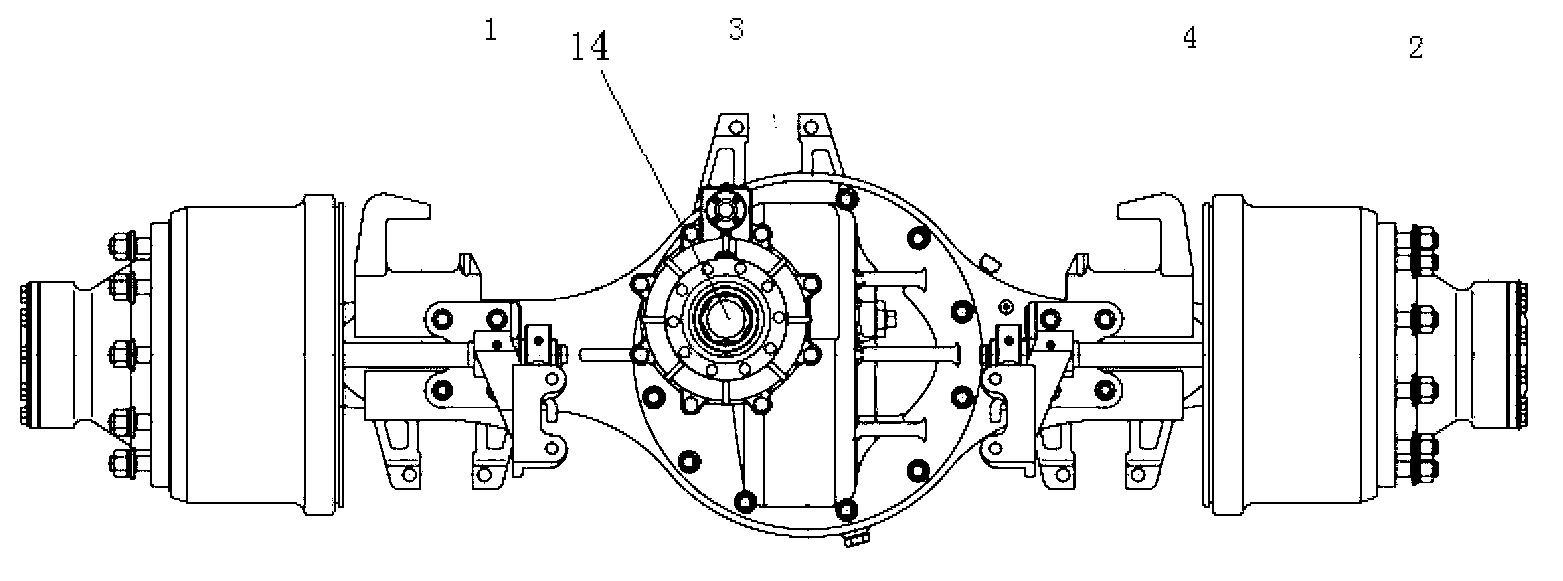

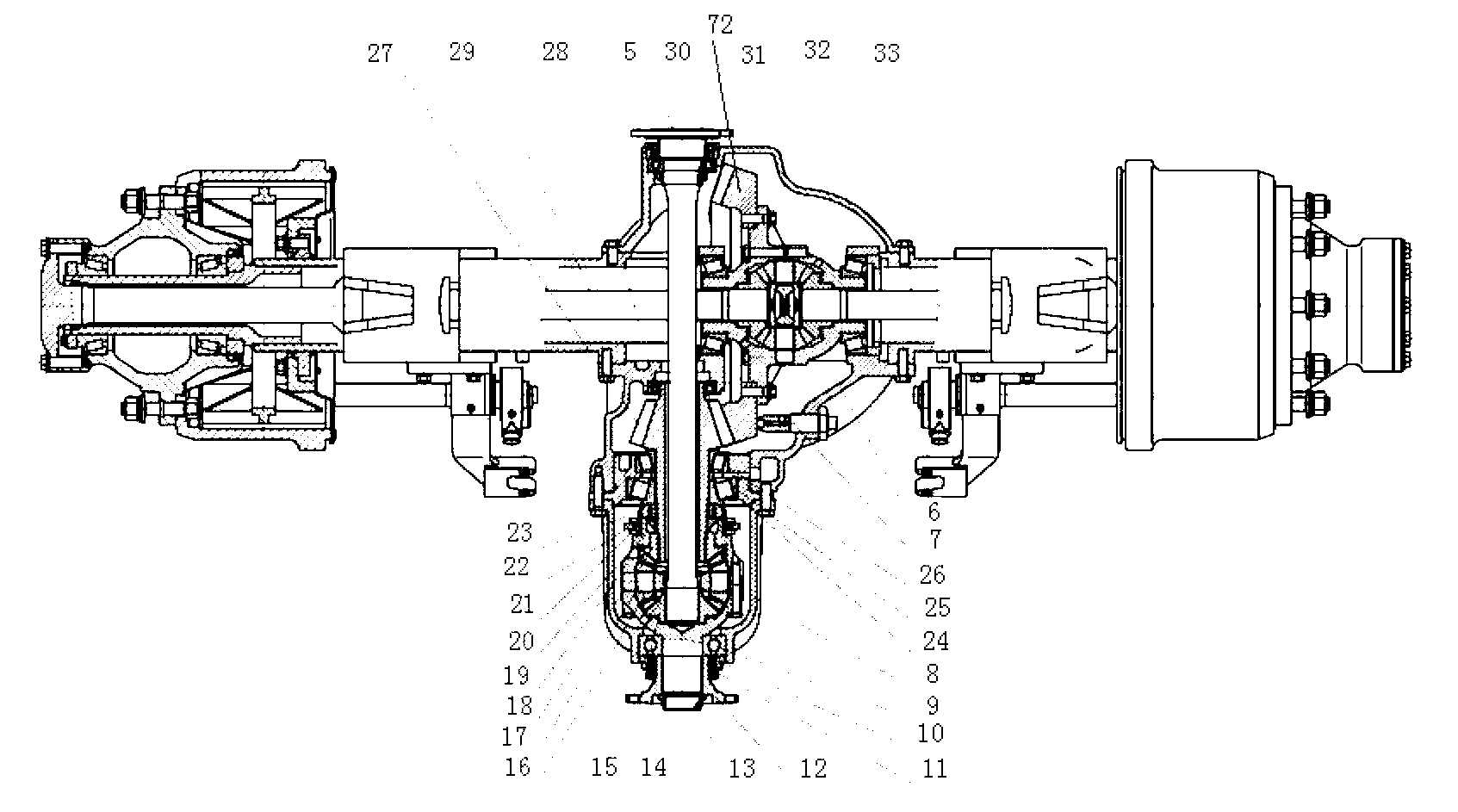

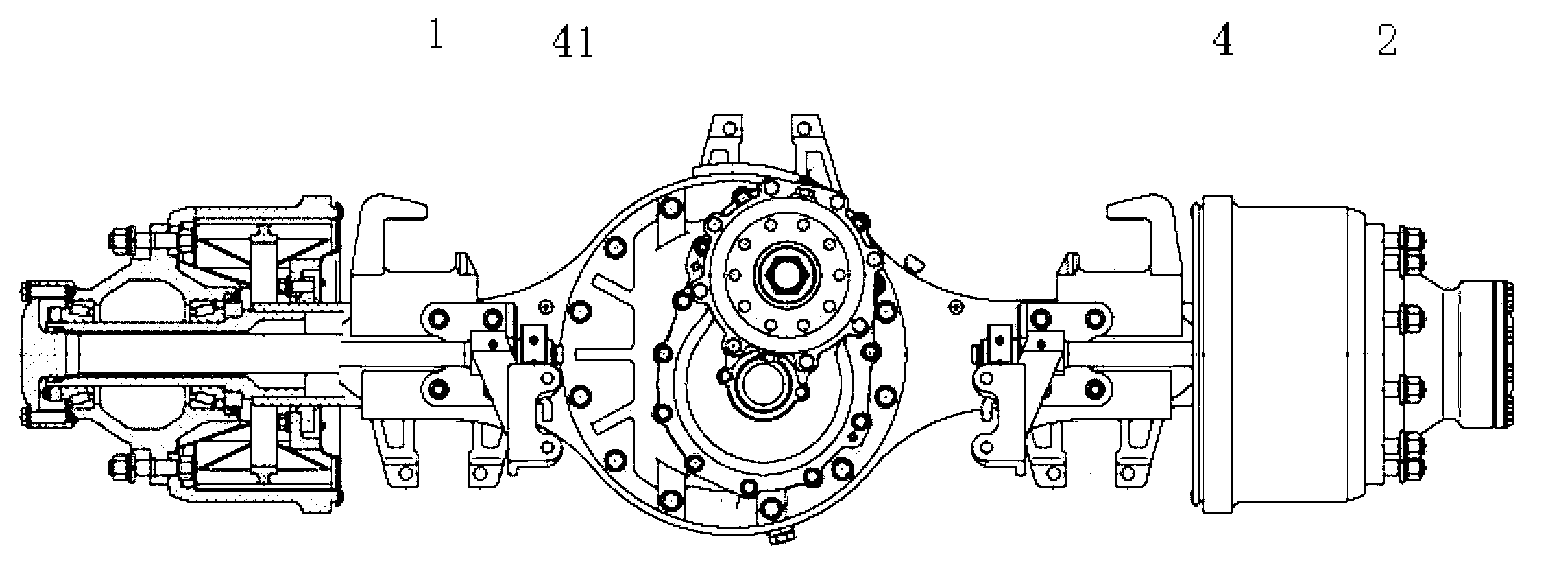

Through drive axle with hyperboloid bevel gear

ActiveCN101774334ASimple transmissionImprove use reliabilityToothed gearingsAxle unitsManufacturing cost reductionHyperboloid

The invention provides a through drive axle with a hyperboloid bevel gear and relates to the technical field of vehicle transmission. A through main speed reducer of the through drive axle adopts a through main speed reducer with the hyperboloid bevel gear. The through drive axle comprises an inter-axle differential lock, an input shaft, an input flange, a spline housing, a through drive axle bevel gear, an active bevel gear, a spider, a planet gear, a through shaft, an active hyperboloid bevel gear, a passive hyperboloid bevel gear, an inter-gear differential and an inter-gear differential lock. The through drive axle uses the characteristics that axial leads of a gear wheel and a pinion of a hyperboloid bevel gear pair are vertical but not intersected and have a certain offset. The through shaft passes through the active hyperboloid bevel gear to coaxially rotate and passes through from the upside or the downside of a half axle so that the transmission mode of the through drive axle is simplified, the manufacturing cost is reduced, the transmission efficiency is improved, the noise is effectively reduced, the problems of poor cooling and lubricating and the like are solved, and light weight of a drive axle assembly is realized. Therefore, the through drive axle is suitable for popularization and application.

Owner:重庆大江车桥有限责任公司

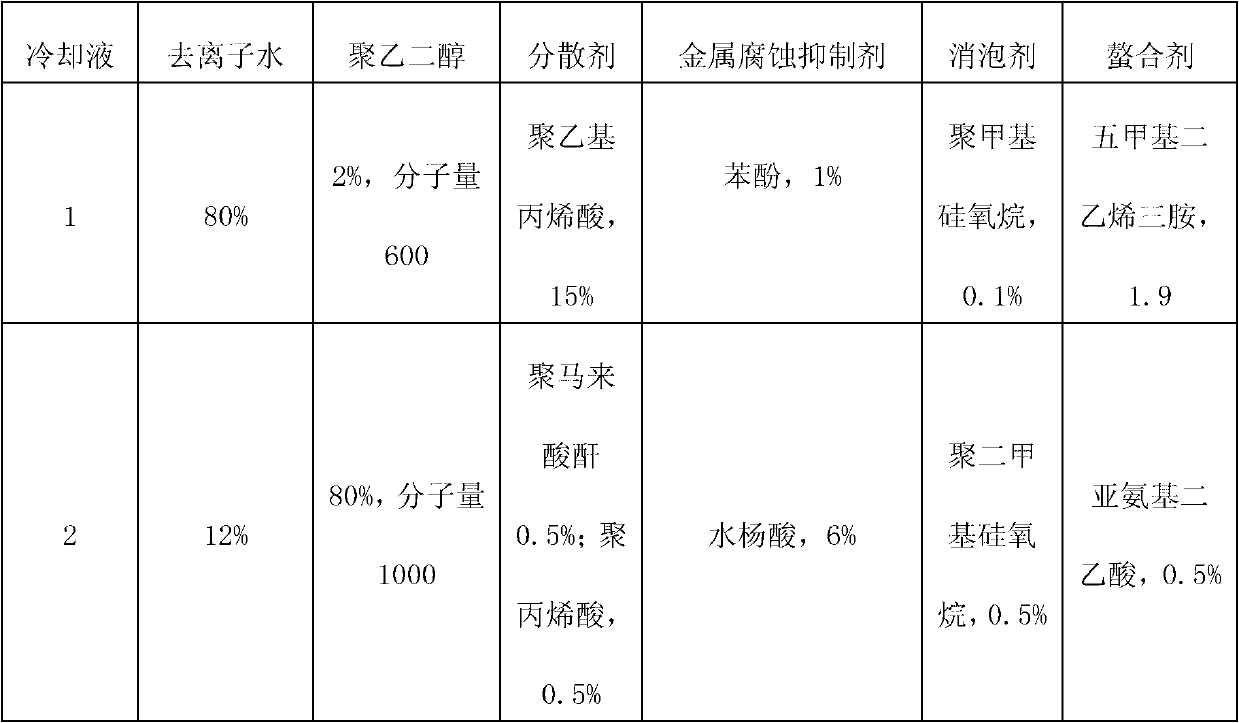

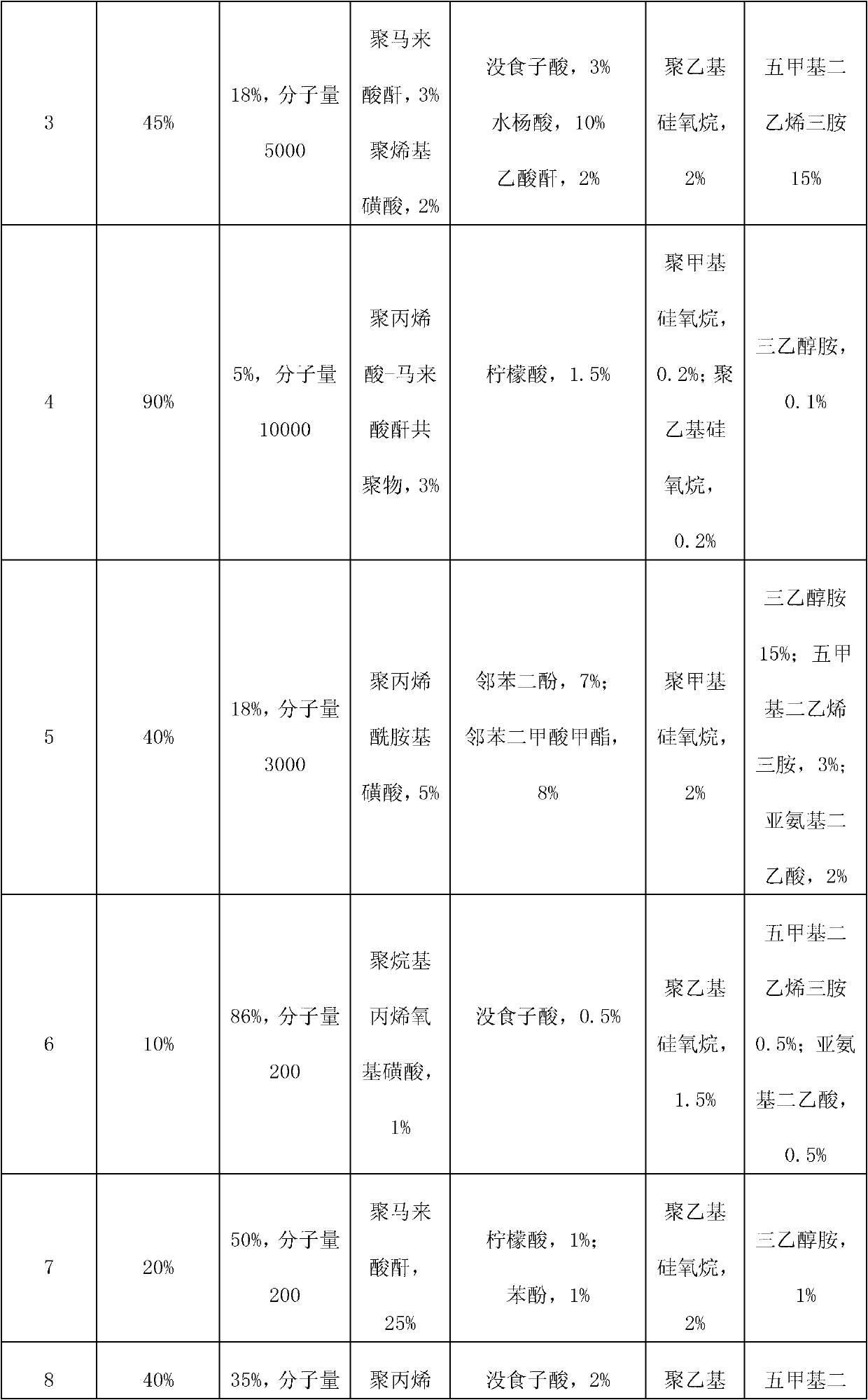

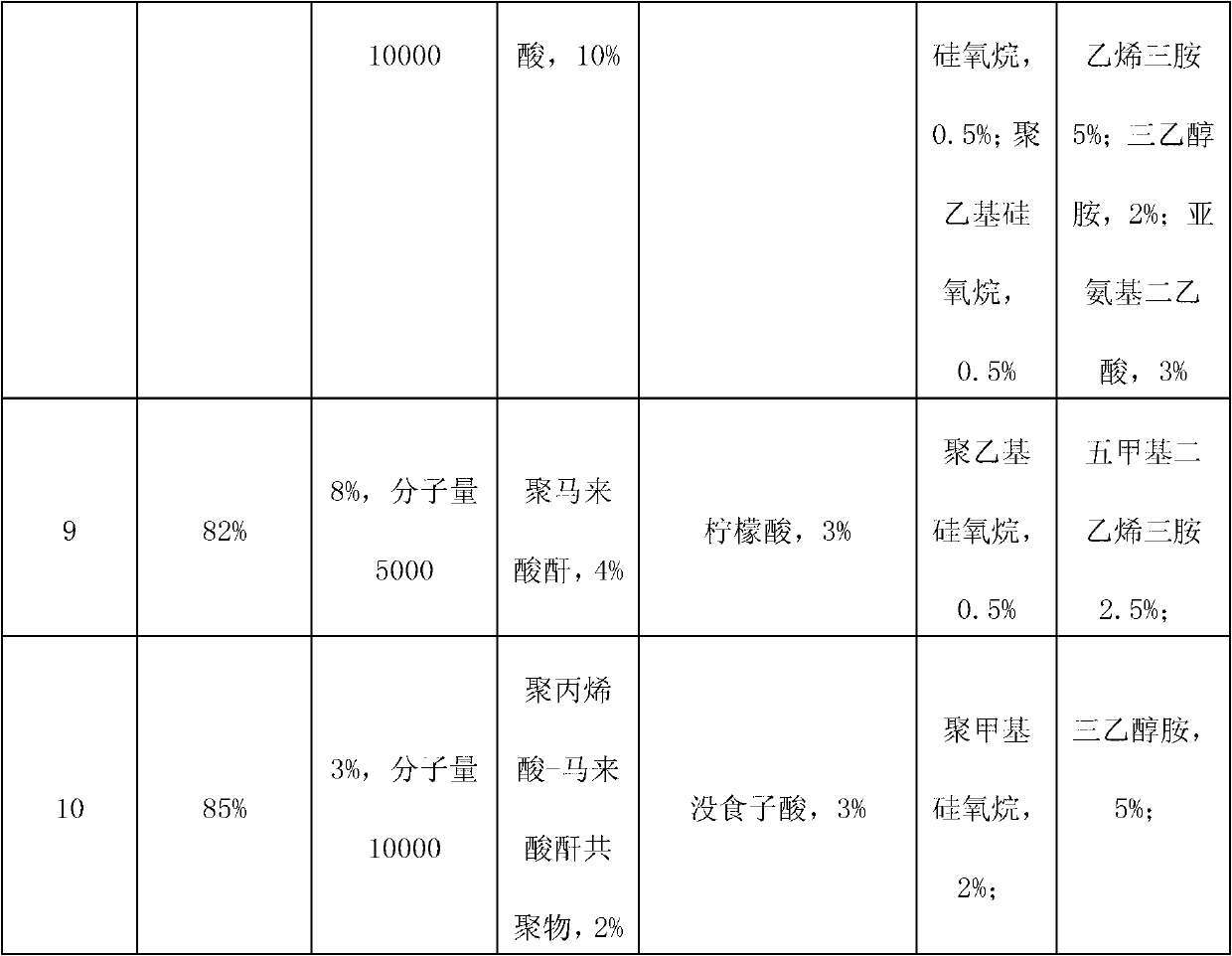

Cooling liquid for diamond cutting line to cut solar silicon chips

ActiveCN102851109AGuaranteed Surface PropertiesLow costLubricant compositionDiamond cuttingPolyethylene glycol

The invention provides a cooling liquid for a diamond cutting line to cut solar silicon chips, which comprises the following components by mass percent: 10 to 90 percent of water, 2 to 86 percent of polyethylene glycol, 1 to 25 percent of dispersing agent, 0.1 to 20 percent of chelate, 0.5 to 15 percent of metal corrosion inhibitor and 0.1 to 2 percent of defoamer. The cooling liquid can be matched with the diamond cutting line for cutting, has good lubricating and cooling effects, effectively reduces the line breaking rate, has a good dispersant effect on silicon powder and iron tramp produced during the cutting process, guarantees the surface performance of the silicon chips, is low in cost and is pollution-free and environmentally friendly.

Owner:FUNDANT CHANGZHOU ADVANCED METAL TECH

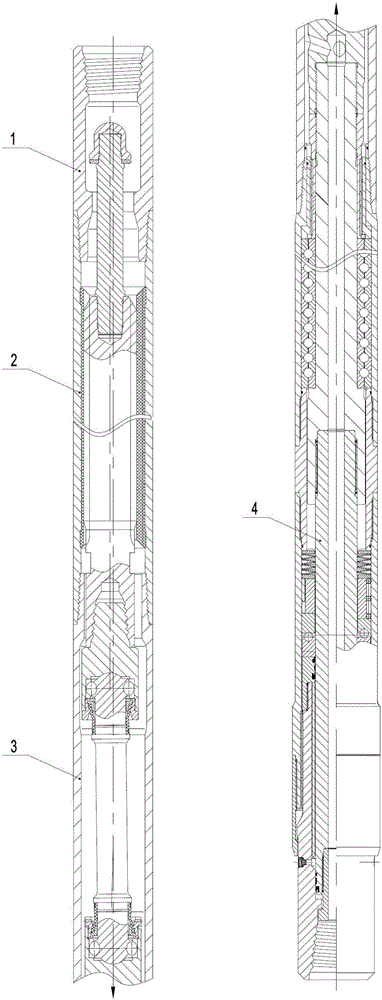

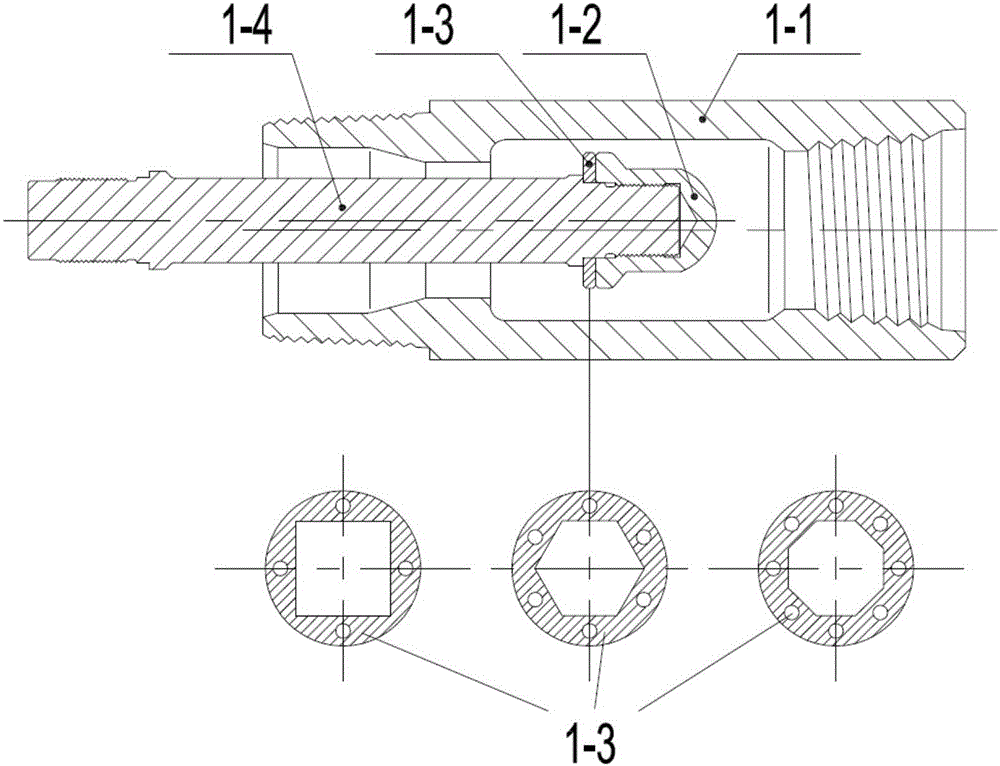

Novel rotary percussion drilling tool

InactiveCN106639866AImprove reliabilityRealize rotary drillingDrilling drivesWell drillingDrive shaft

The invention discloses a novel rotary percussion drilling tool. The tool comprises an anti-dropping switching assembly, a motor assembly, a universal shaft assembly and a driving impact assembly. The interior of the anti-dropping switching assembly is provided with anti-dropping discs. An anti-dropping connecting rod is fixed by a spare fastening nut. An upper spherical joint and a lower spherical joint of the universal shaft assembly are connected to two ends of a spherically-hinged connecting rod through a movably articulated manner. Driving balls are utilized for transferring torque. The upper spherical joint is connected with a rotor of the motor assembly. The lower spherical joint is connected with a driving shaft of the driving impact assembly. One end of the driving shaft is connected with the lower spherical joint and the other end of the driving shaft is connected with a spline mandrel. The bottom of the spline mandrel stretches into a spline housing. The novel rotary percussion drilling tool has following beneficial effects: an impact generator is arranged in an open-type lubricating driving shaft assembly; the drilling tool is simple in structure; functions of rotary drilling and directional drilling for a bent housing of a common screw drill tool and a turbine drill can be fulfilled; and meanwhile, the function of an impact drill is also fulfilled so that drilling speed is effectively increased.

Owner:成都海猛石油机械有限公司

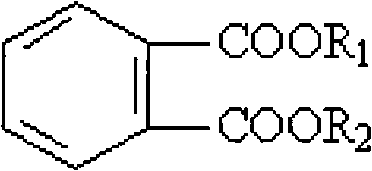

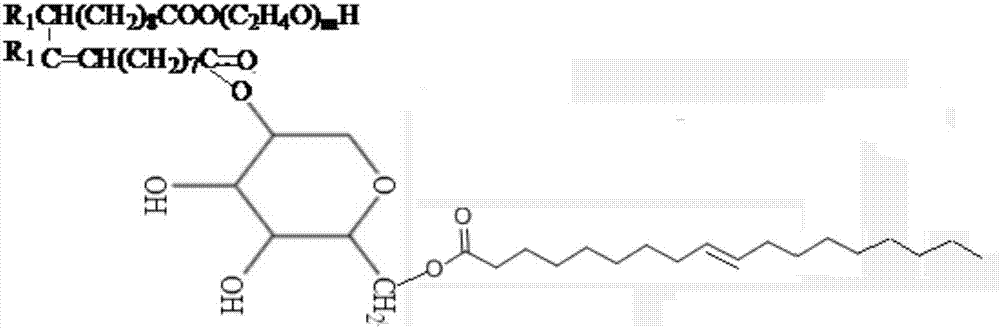

Cold rolling oil composition and use thereof

The invention relates to a cold rolling oil composition and use thereof, which is mainly used for solving the problems of heavy oil mist in a workshop after rolling as well as poor surface cleanness and poor annealing cleanness after rolling in the prior art. The cold rolling oil composition comprises the following components in parts by weight: a) 1-20 parts of aromatic acid diester, b) 1-25 parts of fatty acid monoester, c) 0.01-5 parts of a fog resistant agent and d) 50-97.99 parts of base oil; and the structural formula of the aromatic acid diester is shown in the specification, wherein R1 and R2 are chosen from alkyl groups with 3-8 carbon atoms. By means of the technical scheme, the problems are better solved; and the cold rolling oil composition can be applied to industrial production of stainless steel thin plates with 2B and BA high-precision grades.

Owner:CHINA PETROLEUM & CHEM CORP

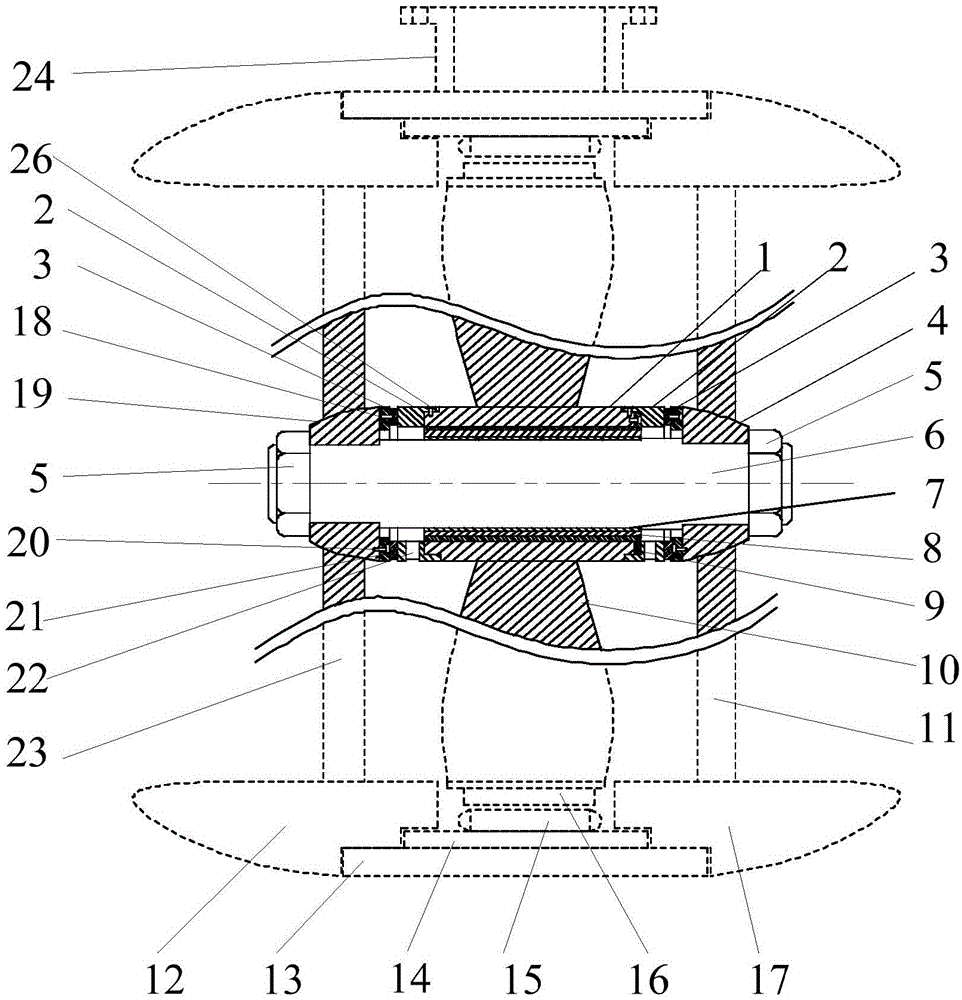

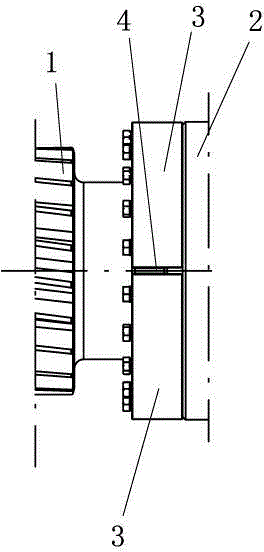

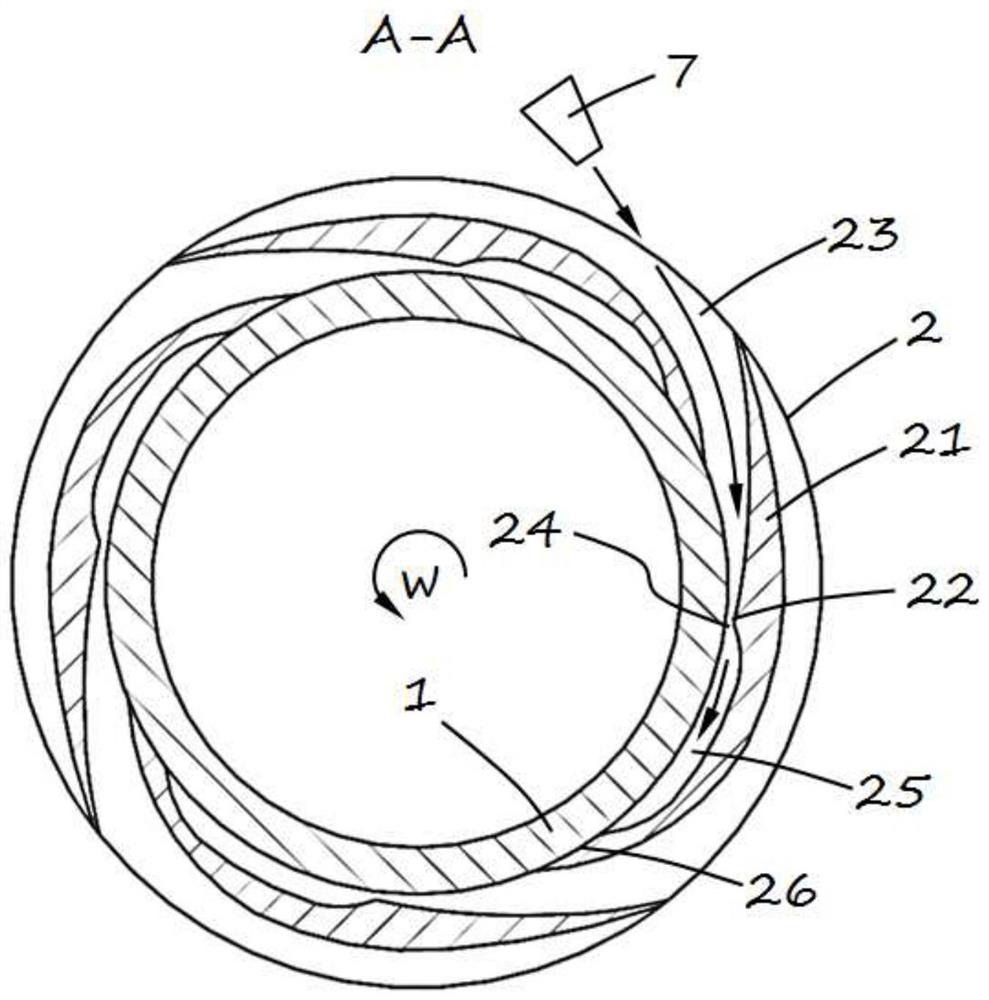

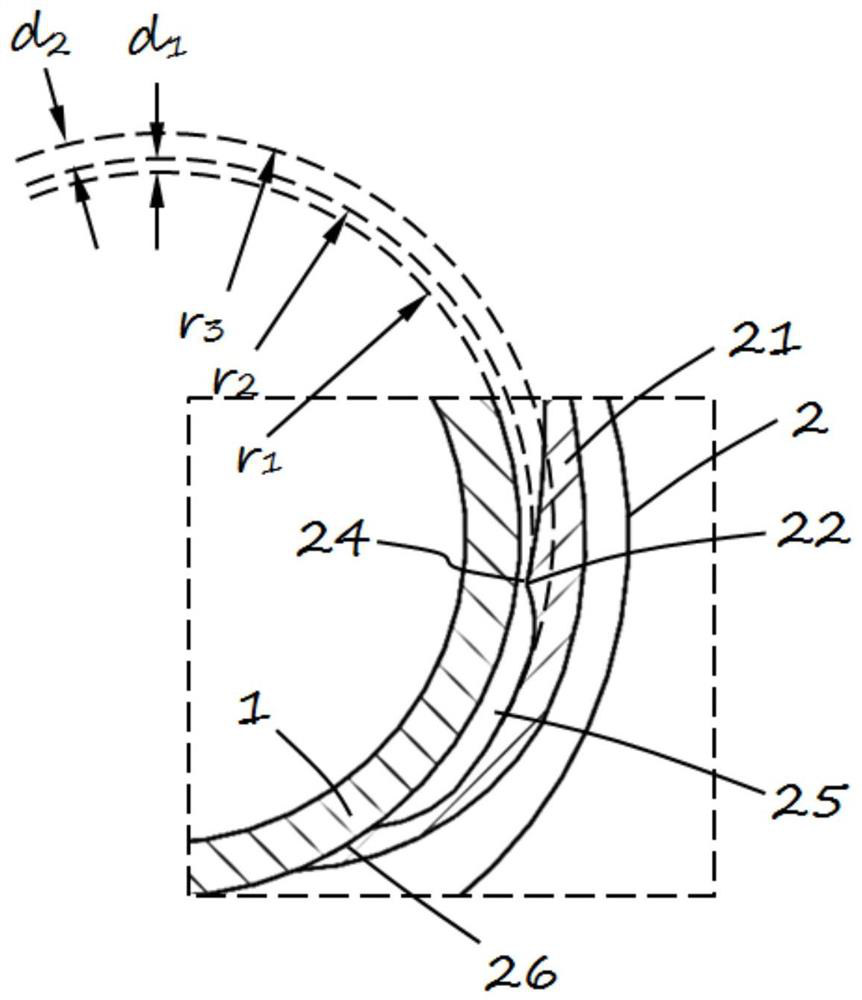

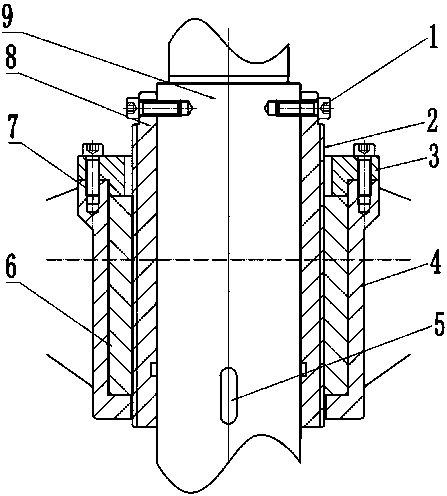

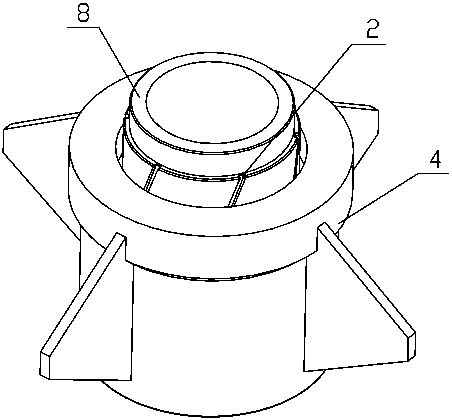

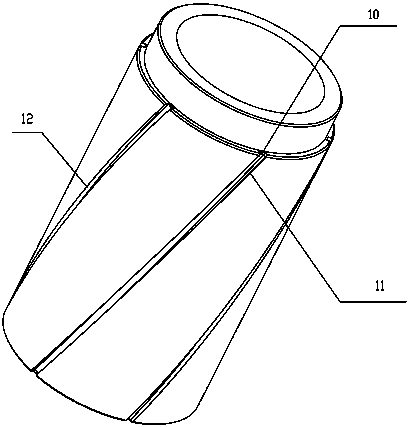

Integrated water lubrication bearing for thruster with hub flange

ActiveCN105129060AImprove cooling effectImprove carrying capacityRotary propellersPropulsive transmissionThrust bearingCooling effect

The invention discloses an integrated water lubrication bearing for a thruster with a hub flange. The integrated water lubrication bearing is mainly composed of thrust discs (2), supporting rings (3), a shaft sleeve (7), a rubber batten (8), a propeller hub copper sleeve (9) and thrust pads (21). The propeller hub copper sleeve is arranged in a propeller hub (1), the two thrust discs are installed at the two ends of the propeller hub respectively, spiral flow channels (22) are machined in the thrust discs, the two supporting rings are arranged on a front guide vane hub (4) and a rear guide vane hub (19) connected with a propeller shaft (6) respectively, and the thrust pads are assembled in fan-shaped grooves (33) in the supporting rings. The thrust pads (21), the thrust discs (2) and the supporting rings (3) form a thrust bearing. The rubber batten is vulcanized on the outer cylindrical surface of the shaft sleeve. The shaft sleeve (7), the rubber batten (8) and the propeller hub copper sleeve (9) form a combined radial bearing. The integrated water lubrication bearing has the advantages that the structure is simple and compact, the cooling effect of the radial bearing and the thrust bearing is improved, the bearing capacity of the radial bearing is improved, and the service life is prolonged.

Owner:WUHAN UNIV OF TECH +1

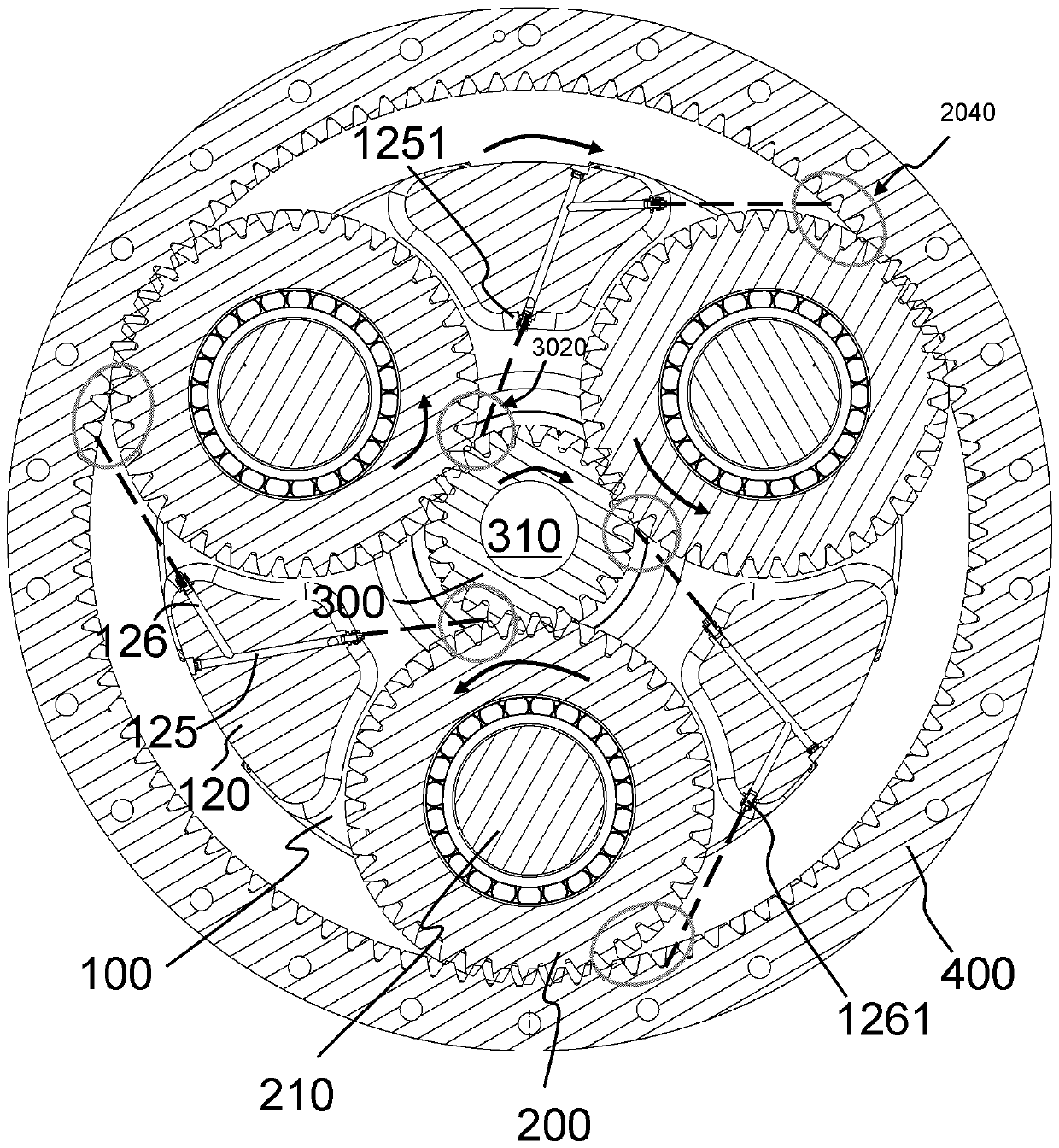

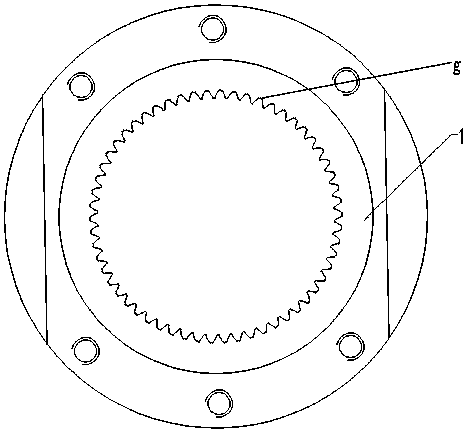

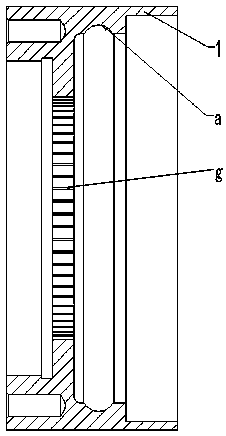

Planet carrier and planet gear case with planet carrier

The invention provides a planet carrier and a planet gear case with the planet carrier and belongs to the technical field of lubrication of the planet gear case. The planet carrier is used for assembling a planet gear between a sun wheel and an inner gear ring to form a planet gear-sun wheel gear pair and a planet gear-inner gear ring gear pair, the planet carrier and the planet gear synchronouslyrotate around the sun wheel, and the planet carrier comprises a first radial plate, a second radial plate and a connection column which is fixedly connected with the first radial plate and the secondradial plate; at least a first oil channel is formed in the connection column; the axis of the first oil channel is arranged to face the planet gear-inner gear ring engaging-out region of the planetgear-inner gear ring gear pair, and the first oil channel is used for jetting lubricating oil to the planet gear-inner gear ring engaging-out region. The planet gear case with the planet carrier can achieve the effect that the planet gear-inner gear ring engaging-out region is cooled along with the lubrication oil, and the lubrication and cooling effects are achieved.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

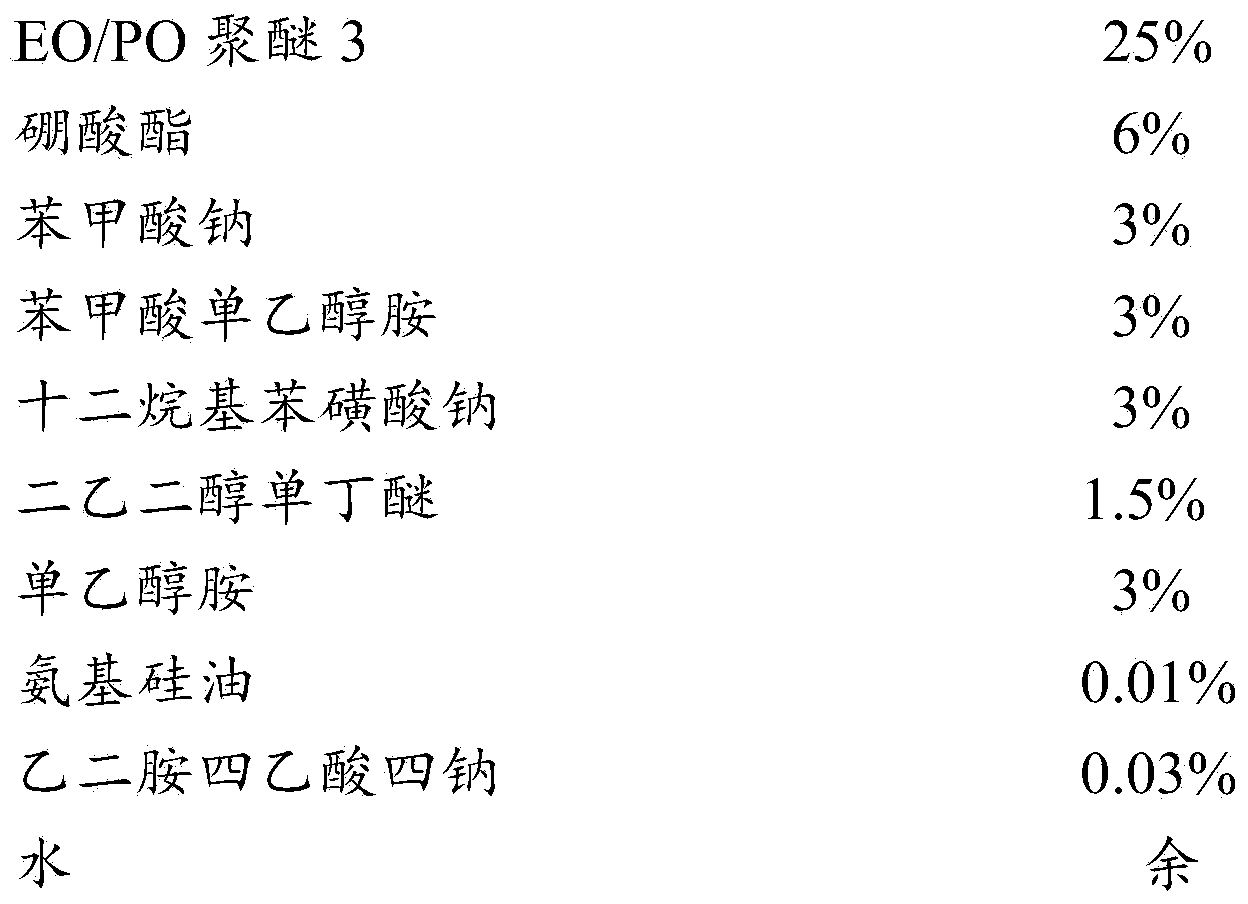

Emission-free reusable waterborne cutting fluid and preparation method thereof

The invention discloses emission-free reusable waterborne cutting fluid. The cutting fluid is characterized by being prepared from the following ingredients in weight percentage: 5 to 15% of high-viscosity water-soluble polyether SDN-20, 0.1 to 10% of graphene, 5 to 25% of polyether SDR-40, 2 to 20% of wetting agent, 0.2 to 1.5% of glacial acetic acid, 0.1 to 10% of complexing agent, 4 to 15% of anti-wear agent, 5 to 15% of triethanolamine, 1 to 2% of Grotan OK and 20 to 77.6% of water. The emission-free reusable waterborne cutting fluid has the advantages of no emission, reusability, no replacement, excellent lubrication cooling performance, anti-wear extreme pressure property, rust and corrosion resistance, high inverse solubility, biological stability, corruptibility resistance, stability in all the items of performance, greenness, environmental friendliness, excellent processability, simple production technology, easily obtained raw materials and good product universality.

Owner:HUBEI CHENGXIANG TECH

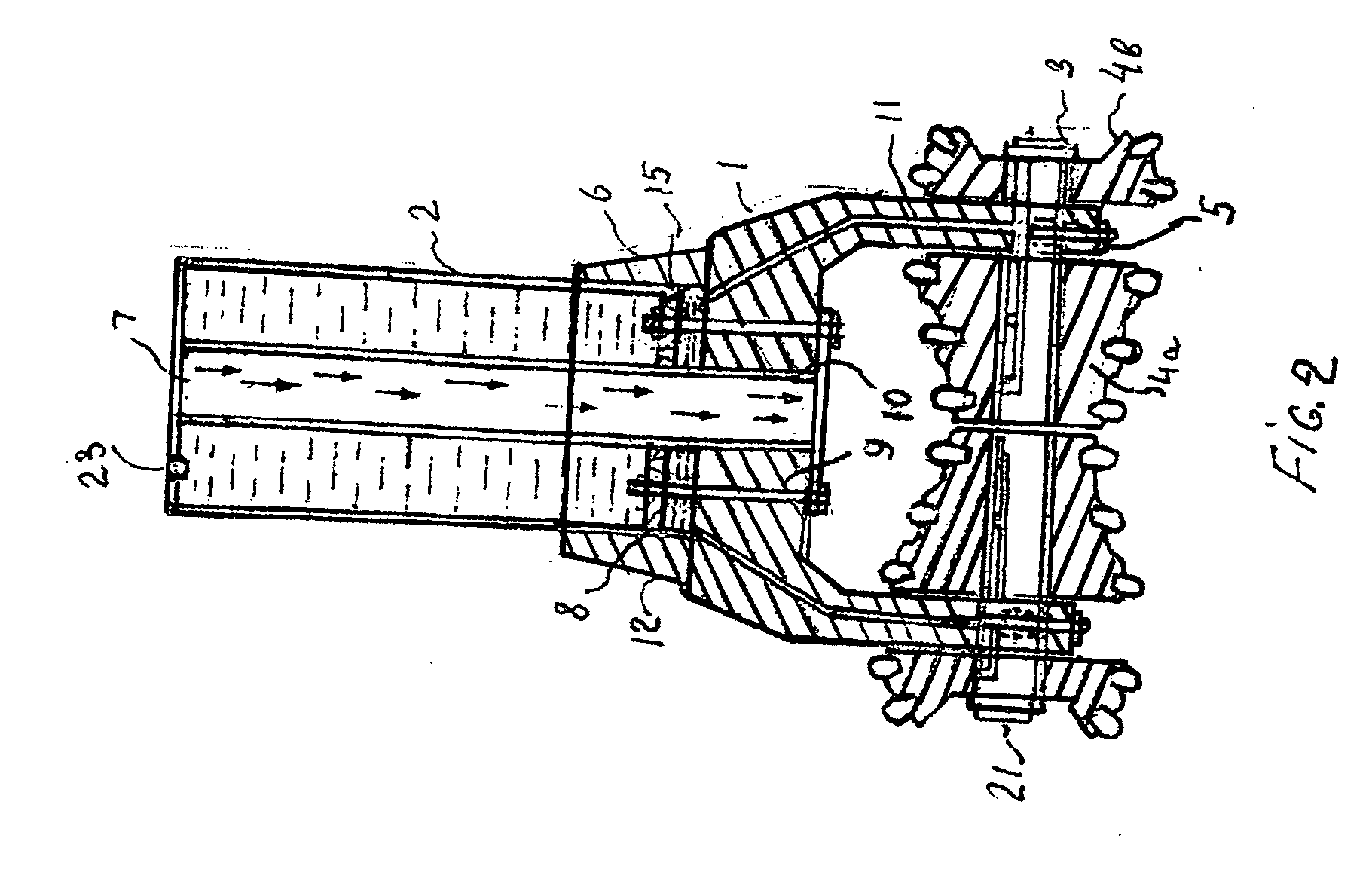

Multi-saw blade sawing and cooling system of woods and bamboos

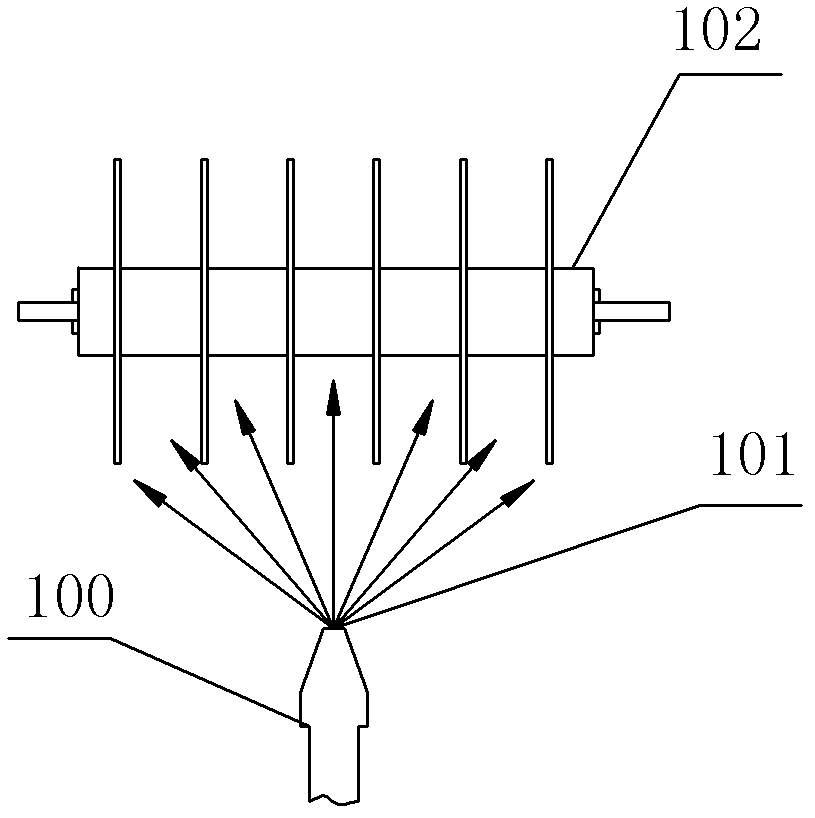

InactiveCN102528855AIncrease flow rateReduce the temperatureCircular sawsCooling effectLiquid storage tank

The invention discloses a multi-saw blade sawing and cooling system of woods and bamboos. The multi-saw blade sawing and cooling system comprises an air storage tank, a liquid storage tank, a cooling device, an ultrasonic atomization device, a mixing chamber and a spray head, wherein the air storage tank is provided with two output pipelines for outputting compressed gas; cooling liquid is stored in the liquid storage tank; the liquid storage tank is connected with one output pipeline of the air storage tank; the cooling device is used for cooling compressed air output by the other output pipeline of the air storage tank and the cooling liquid output by the liquid storage tank to pre-determined temperature; the ultrasonic atomization device is used for ultrasonically atomizing the cooled cooling liquid to form cooling gas; the mixing chamber is used for mixing the atomized cooling air and the cooled compressed air to form mixed gas; and the spray head is used for spraying the mixed air to a cutting region of the woods or the bamboos to cool a saw blade set in the cutting region. The multi-saw blade sawing and cooling system disclosed by the invention is capable of cooling the compressed air and the cooling liquid at the same time and sufficiently atomizing the cooling liquid through the ultrasonic atomization device and finally forming low-temperature atomization steam, thus, the lubrication cooling effect is good.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

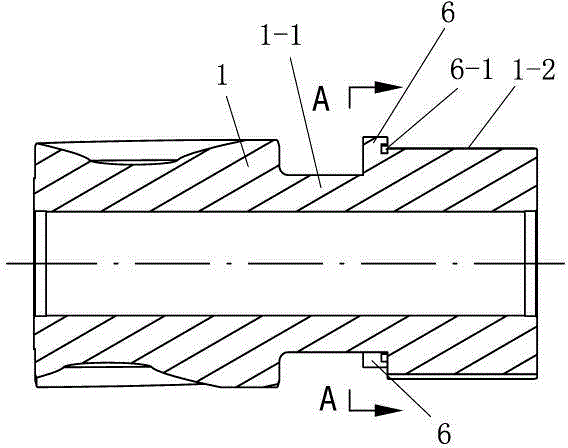

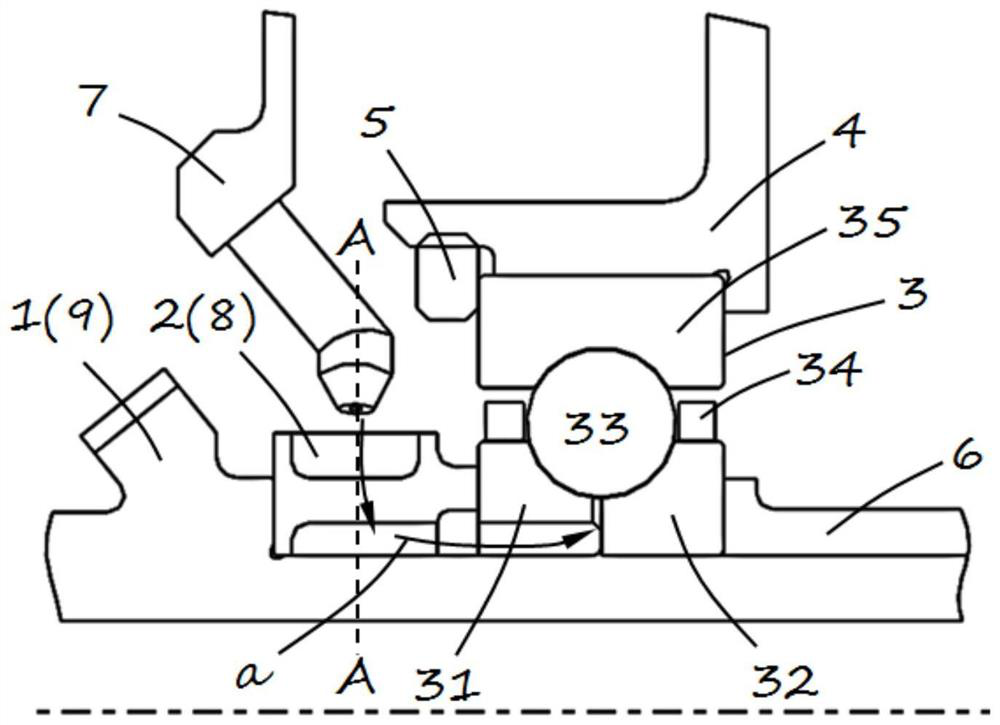

Oil channel structure of compressor and compressor

ActiveCN107701447AIncrease temperatureImprove energy efficiencyRotary piston pumpsRotary piston liquid enginesRolling-element bearingEngineering

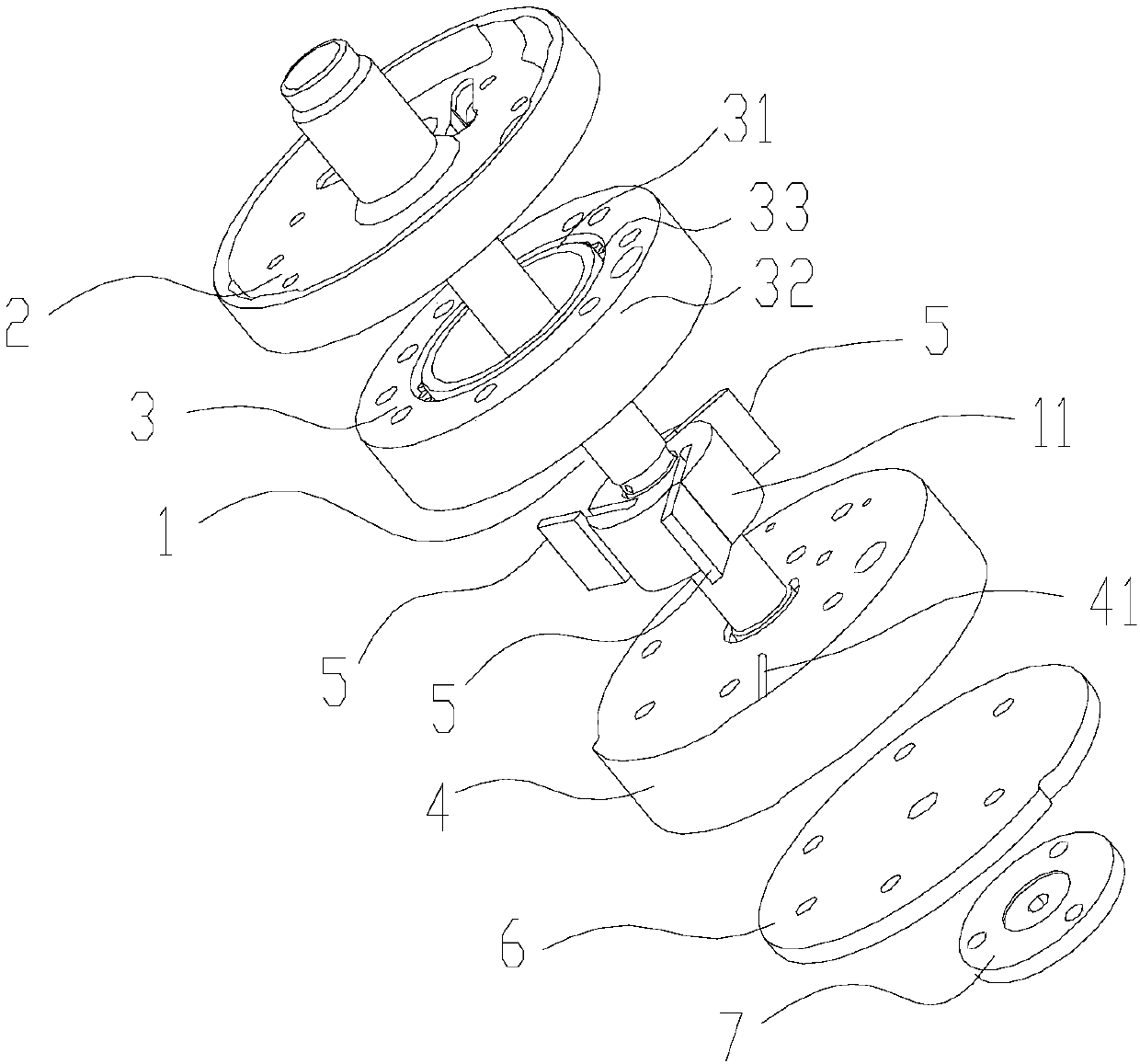

The invention provides an oil channel structure of a compressor and the compressor. The oil channel structure comprises a main shaft (1), an upper flange (2) and a rolling bearing (3). An air cylindercavity for compression is defined in the rolling bearing (3). The rolling bearing (3) comprises a rolling body (33). The inner portion of the main shaft (1) is provided with a main shaft oil hole (10). An upper oil groove (20) is formed in the upper flange (2). The upper oil groove (20) communicates with the main shaft oil hole (10) and can guide oil into the rolling body (33) so as to lubricatethe rolling body (33). By the adoption of the oil channel structure of the compressor, oil in the main shaft oil hole of the compressor can be effectively guided into the rolling body part of the rolling bearing through the upper flange, the rolling body is lubricated and cooled, so that heat generated due to friction of the rolling body can be dissipated out in time, the temperature of the bearing is prevented from rising, and wear is reduced; and in this way, the energy efficiency value of the compressor is improved, and normal operation of the compressor is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

Direct through type single-stage reduction drive axle

InactiveCN103057406ASimple transmission structureImprove transmission efficiencyAxle unitsControl devicesLeft halfSingle stage

The invention relates to a direct through type single-stage reduction drive axle. The direct through type single-stage reduction drive axle comprises an axle housing, wheel hubs, a brake and a direct through type main reducer. A wheel differential mechanism is arranged in the direct through type main reducer, one end of a left-half shaft and one end of a right-half shaft which are arranged in the axle housing are respectively matched and connected with a left-half shaft gear and a right-half shaft gear in the wheel differential mechanism, the other end of the left-half shaft and the other end of the right-half shaft are matched and connected with wheel hubs arranged at the left end and the right end of the axle housing, and the wheel differential mechanism is connected with a passive double curved surface gear. The wheel differential mechanism is arranged in the direct through type main reducer, a through shaft is arranged above and perpendicular to the left-half shaft, one end of the through shaft is matched and connected with the axle housing, the other end of the through shaft is matched and connected with a first bevel gear, one end of a shaft barrel integrated with an active double curved surface gear is matched and connected with a second bevel gear arranged in the wheel differential mechanism, and the active double curved surface gear is a right-handed rotation gear and meshed with the passive double curved surface gear arranged on the wheel differential mechanism. The direct through type single-stage reduction drive axle is high in transmission efficiency and good in economical efficiency and passing ability.

Owner:CHONGQING DAJIANG IND

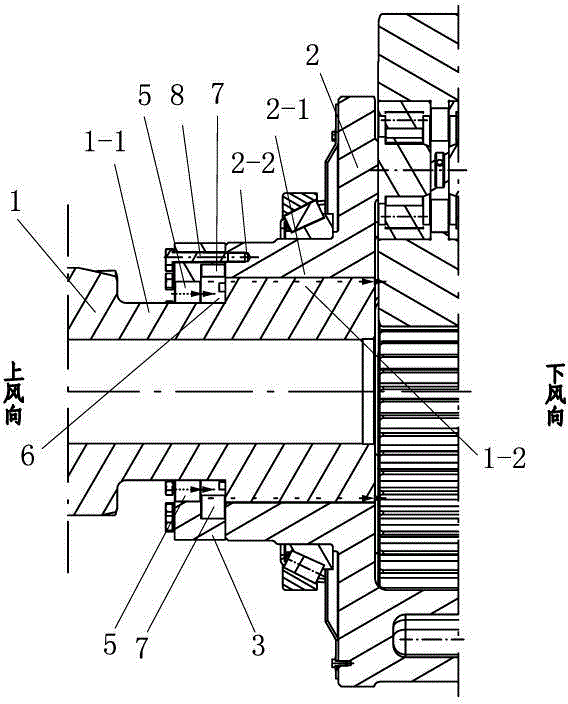

Wind turbine gearbox and sun gear and planet carrier spline pair connection structure thereof

ActiveCN104930165AImprove reliabilityAxial space savingGear lubrication/coolingWind energy generationSpur gearPlanet

The present invention discloses a wind turbine gearbox and a sun gear and planet carrier spline pair connection structure thereof. The connection structure comprises a first stage sun gear, a second stage planet carrier, protruding plates and a rubber gasket; the second stage planet carrier has an internal spline segment; the first stage sun gear has an external spline segment; the external spline segment and the internal spline segment are engaged to form a spline pair; a plurality of bosses are arranged with certain intervals and are all positioned at an upwind direction end of the external spline segment; the bosses are also attached to an upwind direction end surface of the second stage planet carrier; the rubber gasket is disposed between the two half rings and a complete circular ring is formed; a first oil inlet circular groove is formed between the circular ring and a shaft body of the first stage sun gear; a second oil inlet circular groove is formed between the circular ring and the shaft body, the upwind direction end surface of the external spline segment, and the upwind direction end surface of the second stage planet carrier; the bosses of the first stage sun gear are positioned in the second oil inlet circular groove; and the wind turbine gearbox comprises a box body, a first stage planetary gear train and a second stage planetary gear train. Lubricating and cooling effects are good, axial space is effectively shortened, and strength is guaranteed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

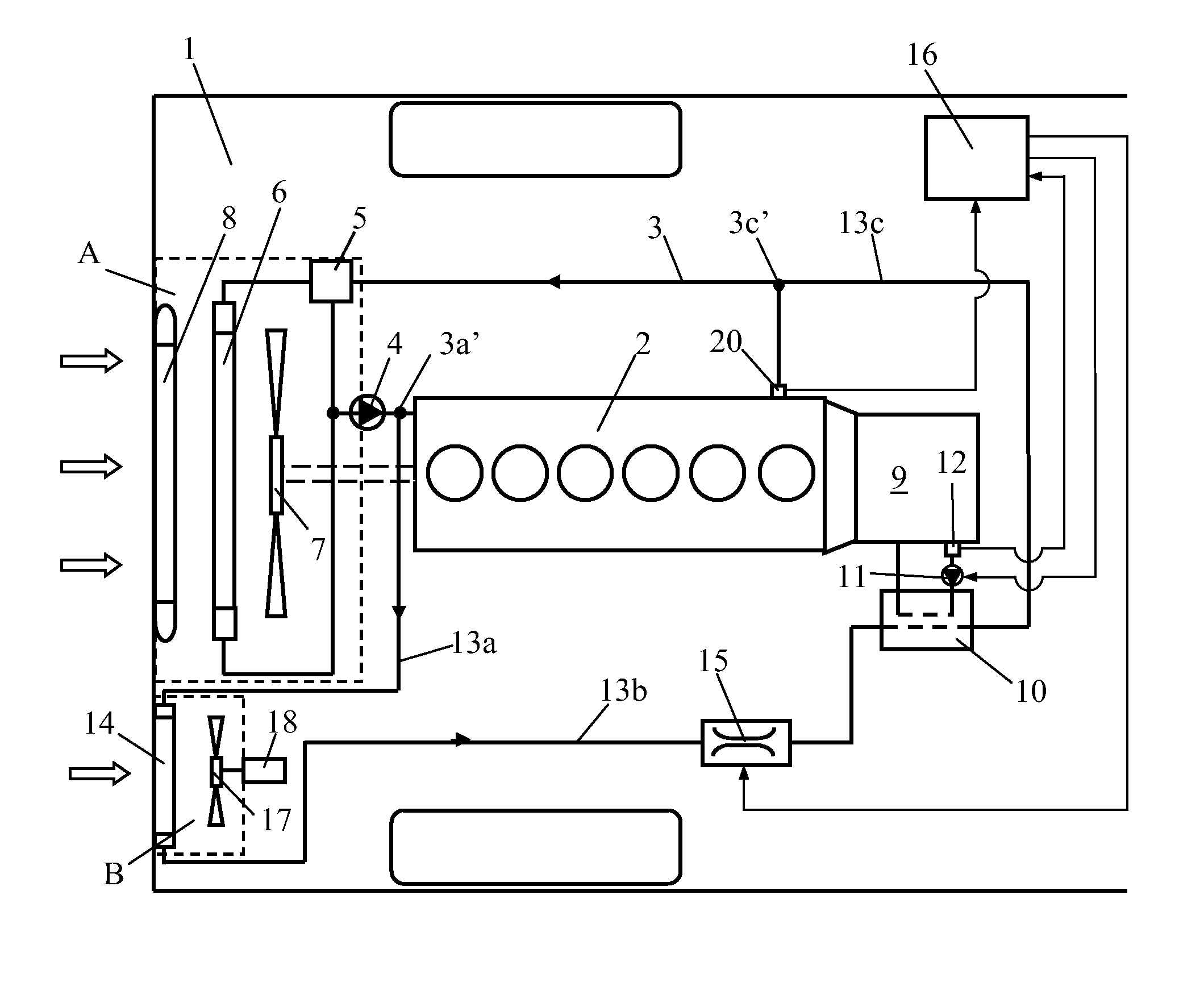

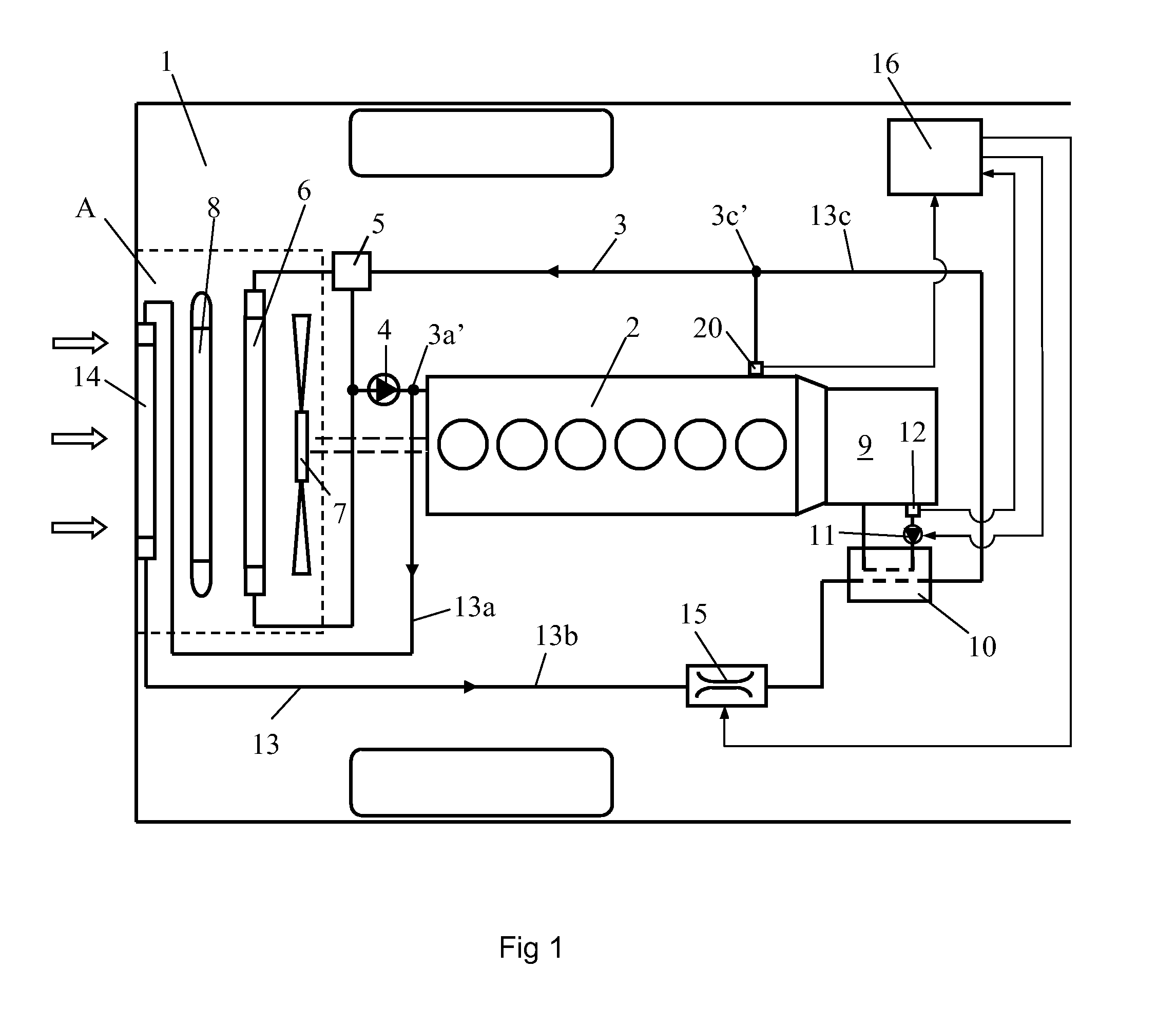

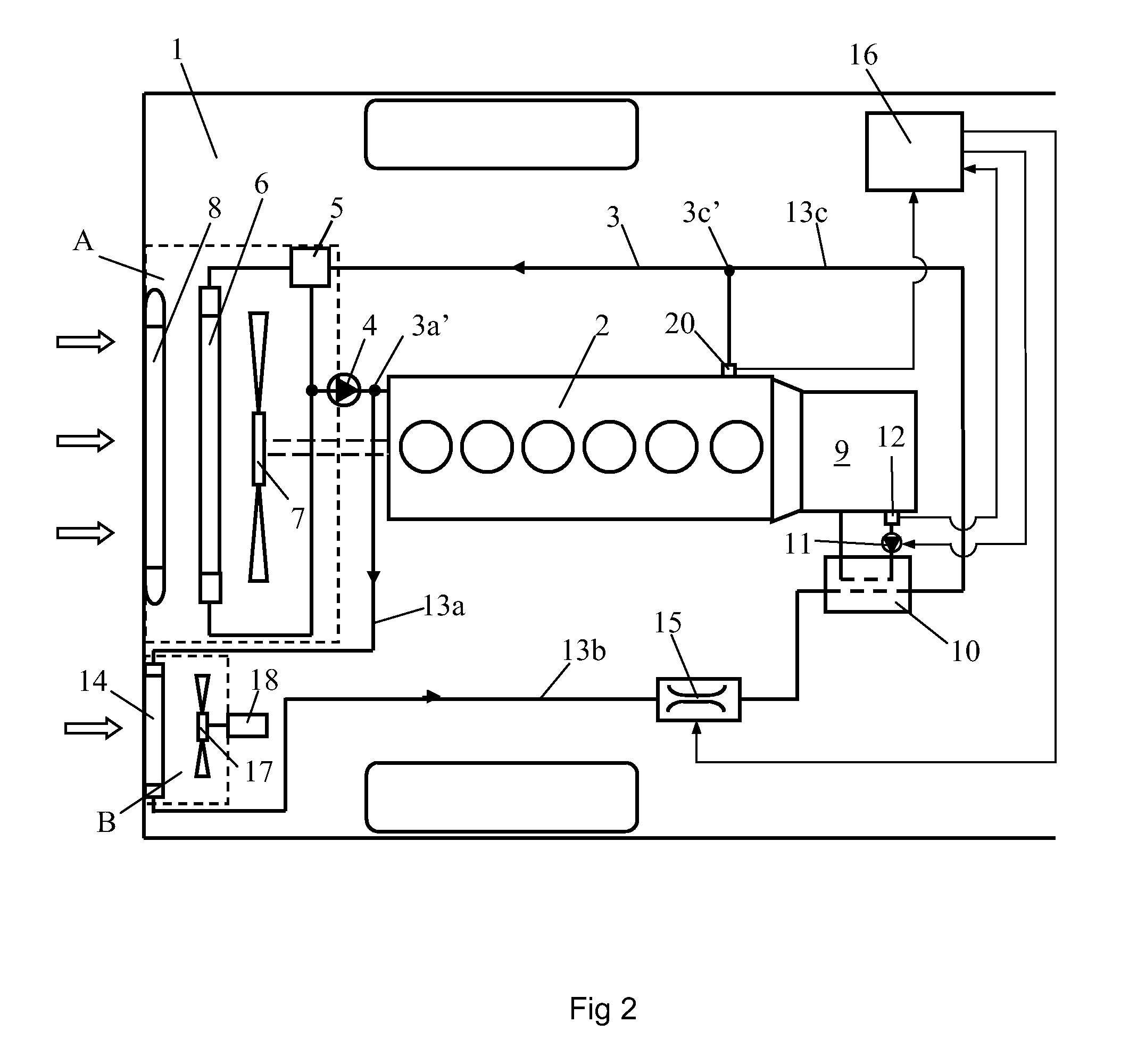

Arrangement for cooling of oil in a gearbox for a vehicle

ActiveUS8316806B2Extended service lifeGood lubricating and cooling effectLiquid coolingCoolant flow controlCombustionInternal combustion engine

An arrangement for cooling oil in a gearbox in a vehicle which is powered by a combustion engine, the arrangement including an oil cooler, an oil system configured to circulate oil between the gearbox and the oil cooler, and a coolant circuit configured and operable to lead coolant to the oil cooler. The coolant circuit includes a radiator element for cooling the coolant and a line to lead the cooled coolant from the radiator element to the oil cooler. The coolant circuit has a flow-regulator to regulate the coolant flow through the radiator element for imparting to the coolant a temperature which makes possible a desired cooling of the oil in the oil cooler.

Owner:SCANIA CV AB

Process for producing lubricating cooling liquid

InactiveCN1624089ANo pollution in the processIncreased durabilityBase-materialsOctanoic AcidsGrinding wheel

A process for preparing lubricating-cooling liquid is prepared from borax, biethanolamine or triethanolamine, silica oil, sodium petrosulfonate, boric acid, decanedioic acid, heptanoic acid or octanoic acid, phenyltriazole, and oleic acid. Its advantages are high performance and no pollution.

Owner:HAIYING CHEM IND TRADE SHANGHAI

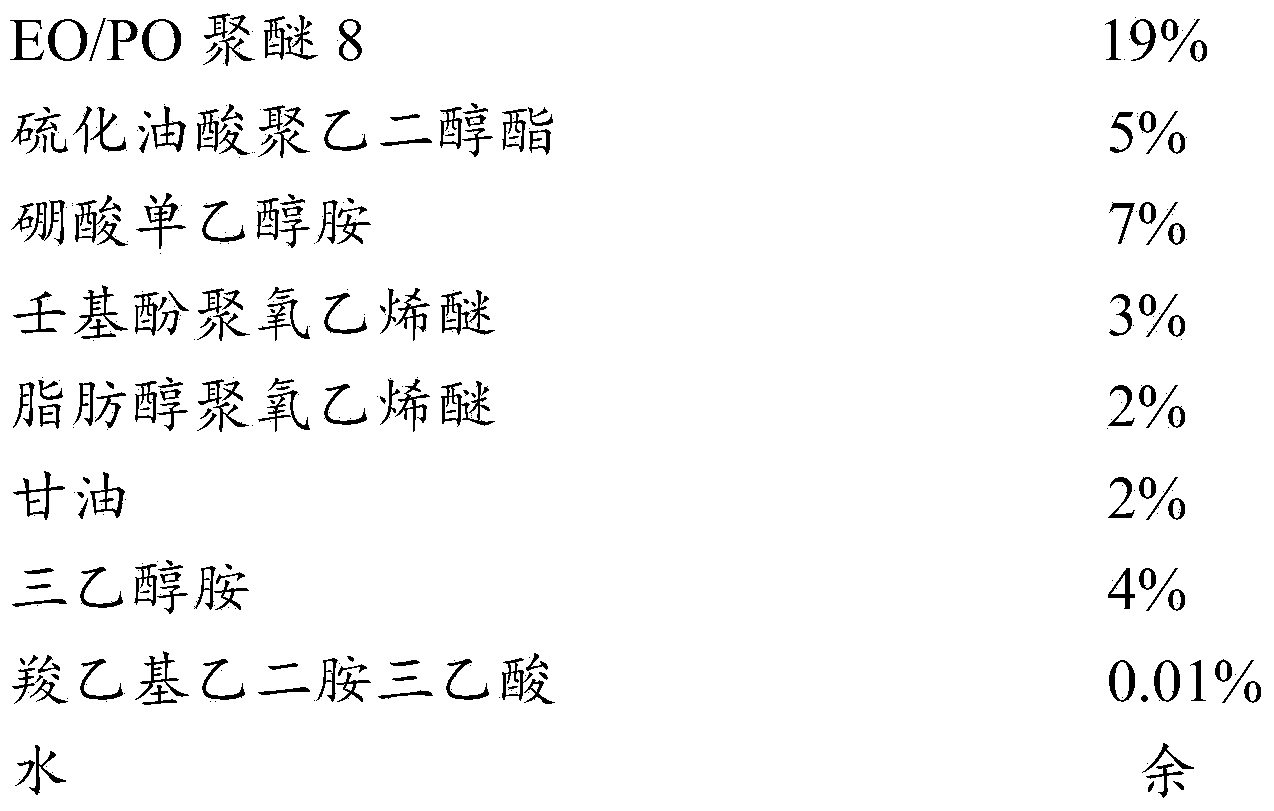

Cooling liquid for cutting solar silicon wafer through diamond wire

InactiveCN104087406AGuaranteed Surface PropertiesGood dispersionLubricant compositionEthylenediaminePolyethylene glycol

The invention discloses a cooling liquid for cutting a solar silicon wafer through a diamond wire. The cooling liquid consists of the following raw materials in parts by weight: 2-3 parts of triethanolamine, 2-4 parts of glycerin, 2-3 parts of methoxy polyethylene glycol, 3-5 parts of hydroxyethyl acrylate, 2-3 parts of fatty alcohol-polyoxyethylene ether, 3-4 parts of p-toluenesulfonic acid, 2-5 parts of fumaric acid, 1-2 parts of phthalic anhydride, 2-4 parts of maleinimide, 1-3 parts of cis-butenedioic acid, 2-4 parts of diisopropanolamine, 2-3 parts of n-butylamine, 1-2 parts of tri-isopropanolamine, 2-3 parts of potassium sorbate, 1-3 parts of phenoxyethanol, 2-3 parts of methylparaben, 2-3 parts of ethylenediamine tetraacetic acid, 2-5 parts of titanium dioxide, 2-4 parts of methyl methacrylate, 3-5 parts of acetone, and 50-70 parts of deionized water. The cooling liquid for cutting the solar silicon wafer through the diamond wire can be well applied to cutting with the diamond wire, is good in lubrication and cooling effects, low in cost and free of pollution, can effectively reduce the breakage rate, has a good dispersion function on silicon powder and iron impurities generated in the cutting process, and ensures the surface property of the silicon wafer.

Owner:梁胜光

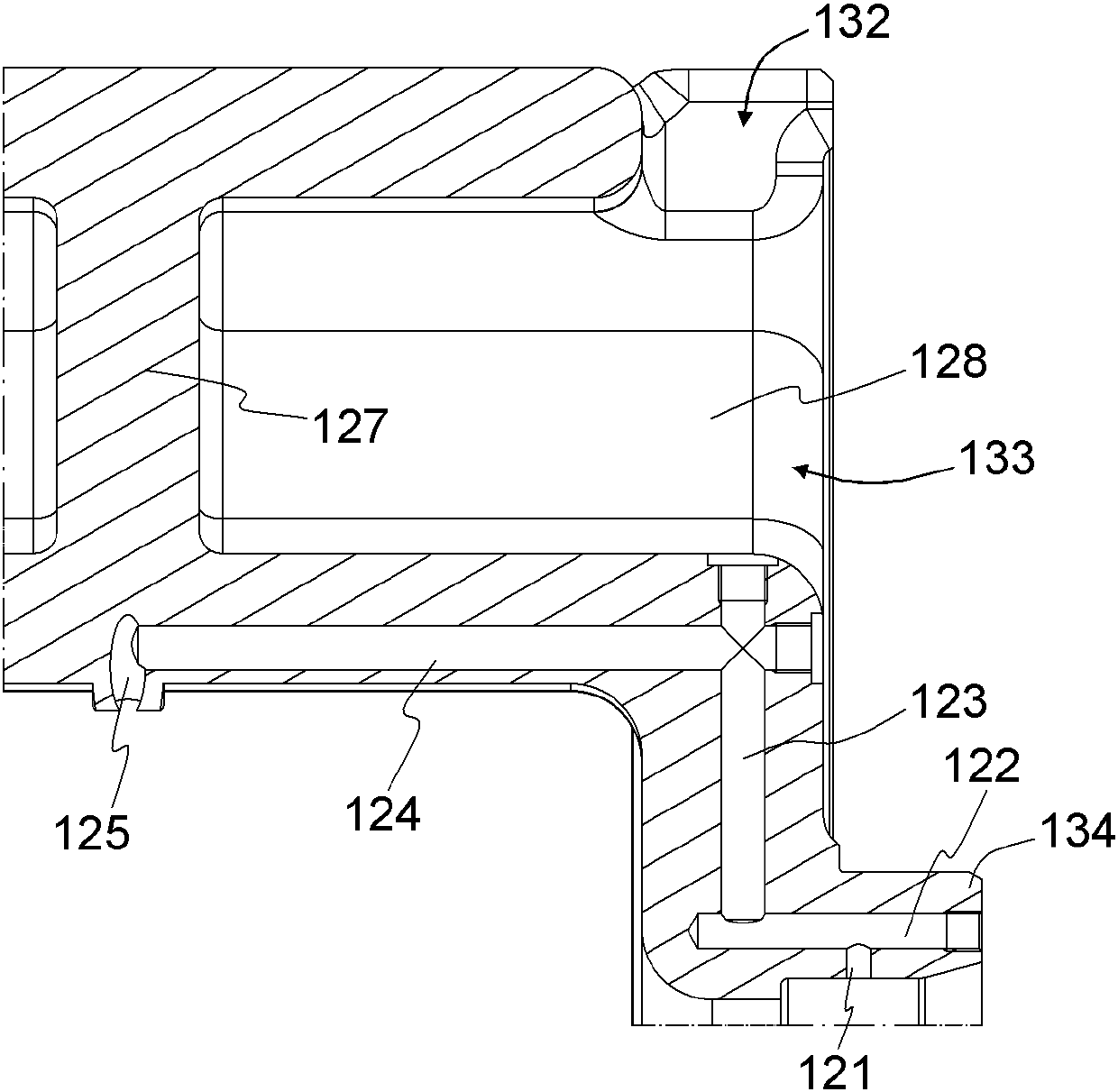

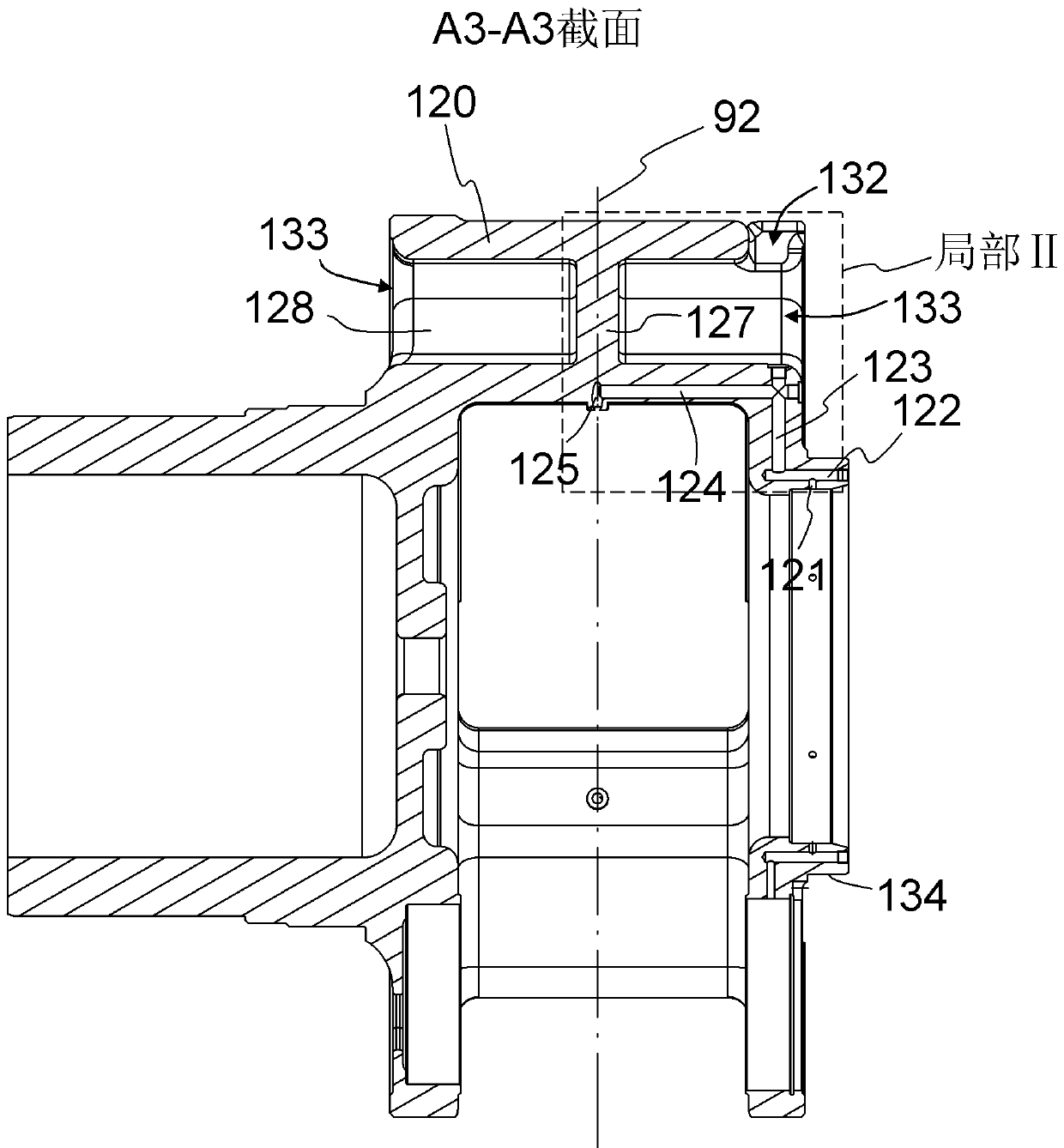

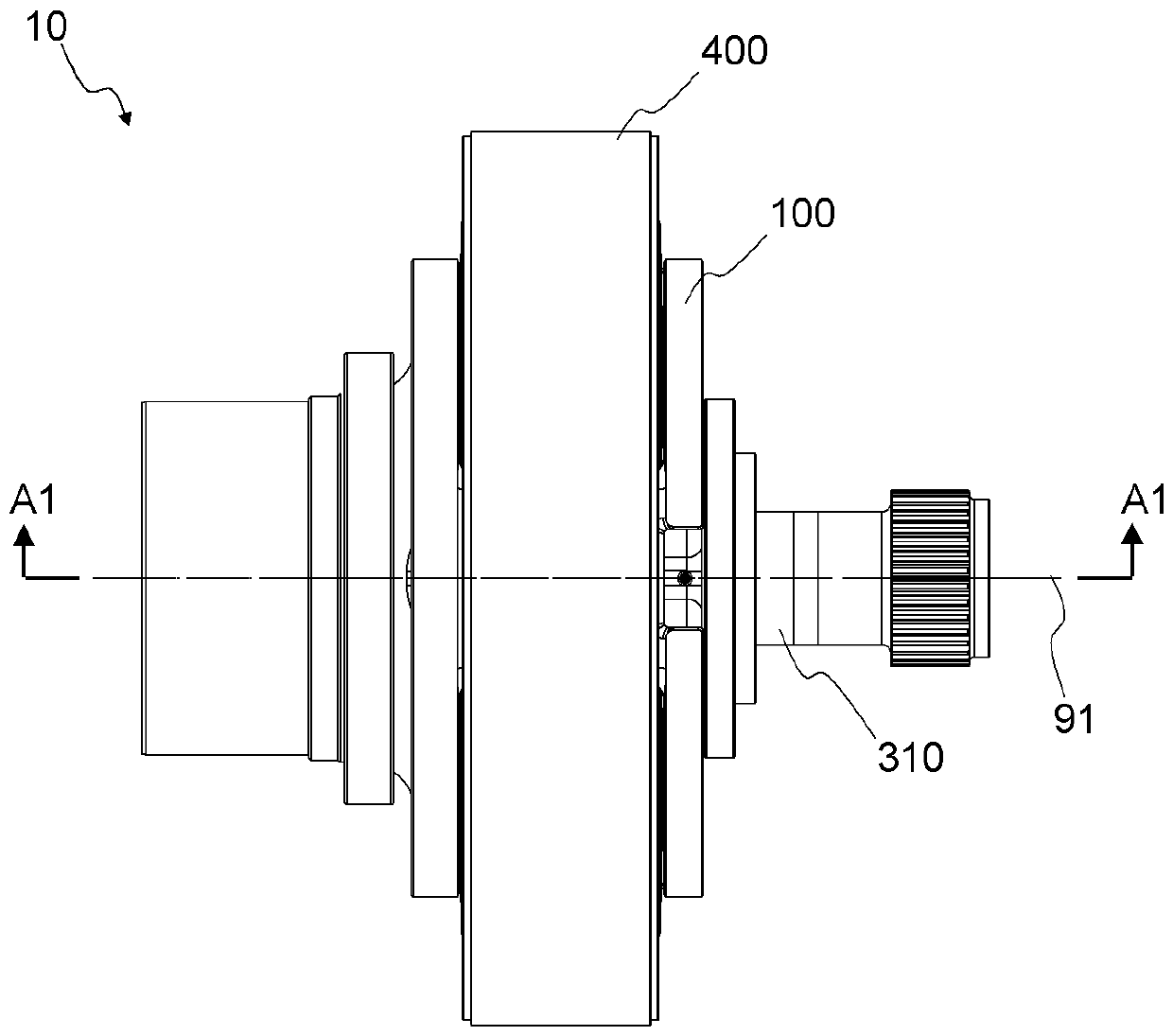

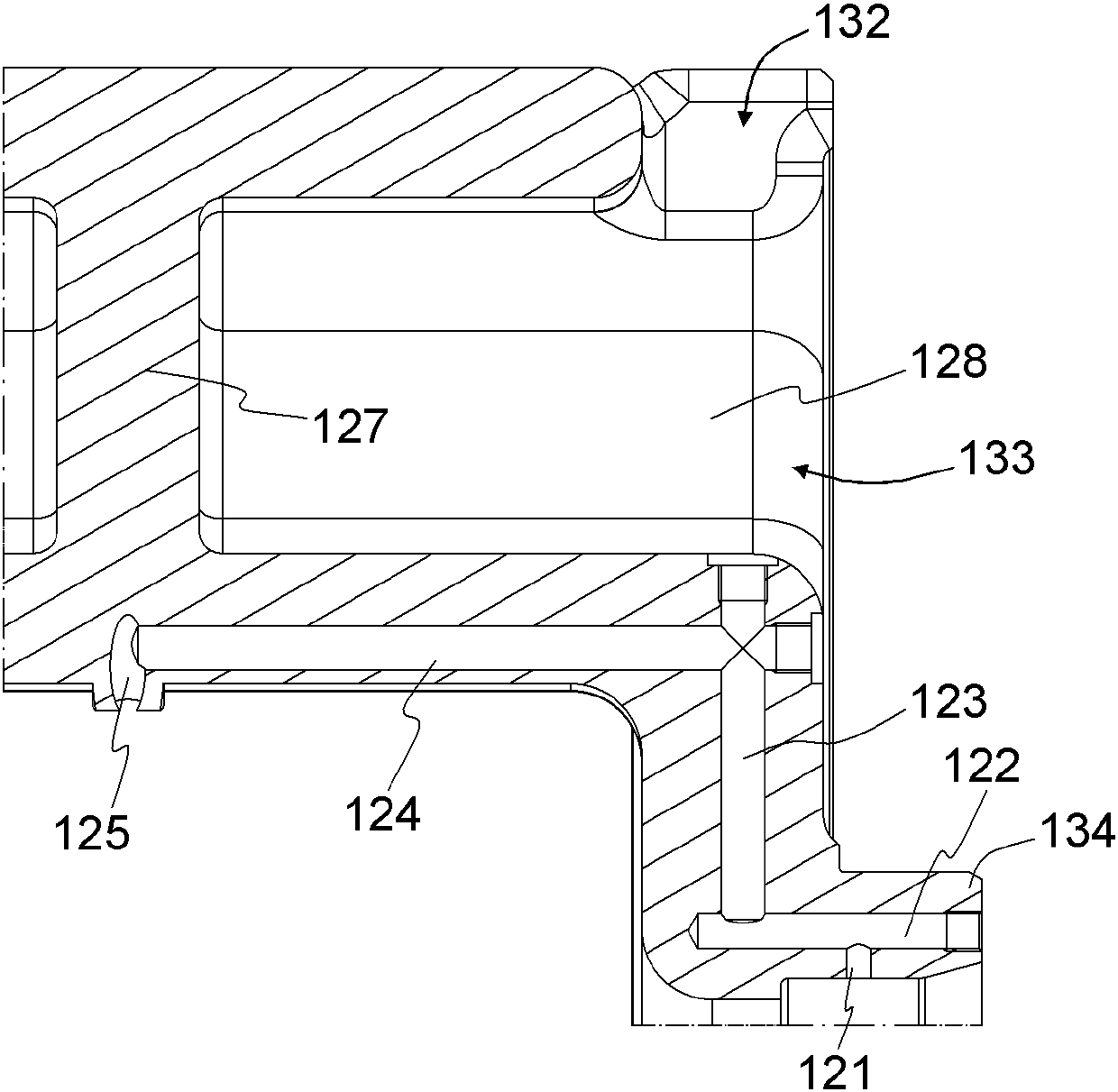

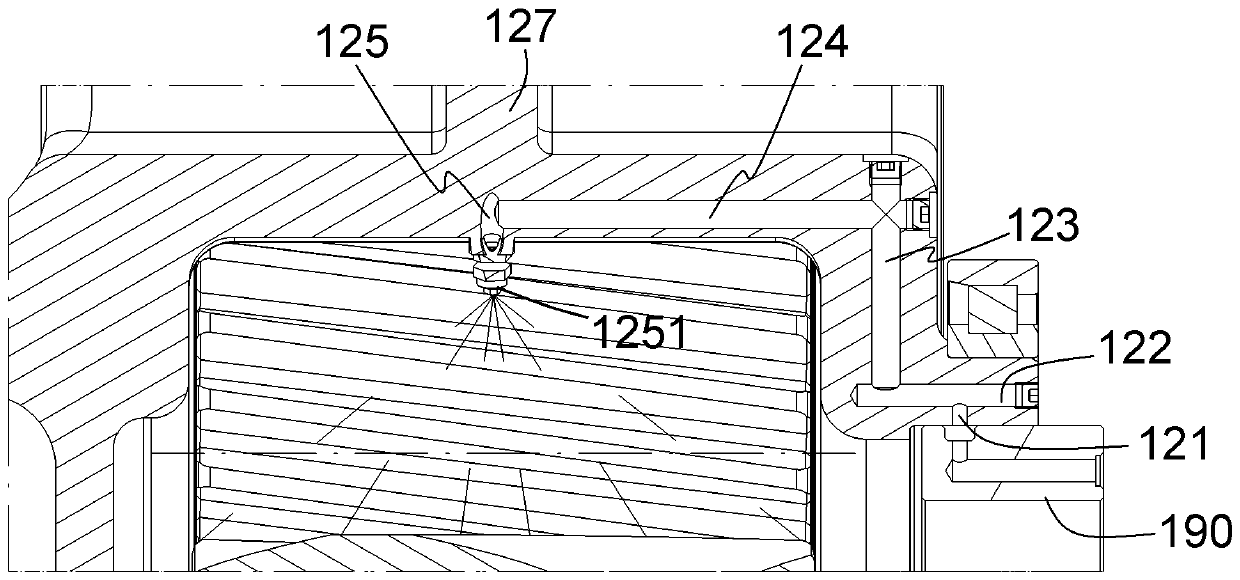

Bearing assembly of aero-engine and aero-engine

ActiveCN112648295ALow efficiencyMiniaturizationEfficient propulsion technologiesBearing componentsMechanicsAero engine

The invention relates to a bearing assembly of an aero-engine, which is supported between a main shaft and a bearing seat, and comprises: a bearing, having a split type bearing inner ring; an oil collecting ring, attached to one side of the bearing in the axial direction; and a nozzle, spraying right towards the oil collecting ring and used for spraying lubricating oil for lubricating the bearing, wherein the main shaft is provided with a groove body, the groove body is located in a sleeving area of the main shaft and the oil collecting ring, the groove body and the oil collecting ring jointly form a lubricating oil channel, and the lubricating oil channel can receive lubricating oil sprayed from the nozzle and convey the lubricating oil to the split type bearing inner ring. According to the embodiment, efficient radial oil collection and under-ring oil supply of the aero-engine bearing can be achieved, it is ensured that the performance of a bearing oil supply device is stable and efficient at all state points of an engine, especially at large state points with severe conditions, the bearing is well lubricated and cooled, and the light weight of the oil supply device is facilitated to a certain extent.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Planet carrier and planetary gearbox including same

ActiveCN107781402BExtend your lifeImprove reliabilityGear lubrication/coolingGear wheelCooling effect

The invention provides a planet carrier and a planet gear case with the planet carrier and belongs to the technical field of lubrication of the planet gear case. The planet carrier is used for assembling a planet gear between a sun wheel and an inner gear ring to form a planet gear-sun wheel gear pair and a planet gear-inner gear ring gear pair, the planet carrier and the planet gear synchronouslyrotate around the sun wheel, and the planet carrier comprises a first radial plate, a second radial plate and a connection column which is fixedly connected with the first radial plate and the secondradial plate; at least a first oil channel is formed in the connection column; the axis of the first oil channel is arranged to face the planet gear-inner gear ring engaging-out region of the planetgear-inner gear ring gear pair, and the first oil channel is used for jetting lubricating oil to the planet gear-inner gear ring engaging-out region. The planet gear case with the planet carrier can achieve the effect that the planet gear-inner gear ring engaging-out region is cooled along with the lubrication oil, and the lubrication and cooling effects are achieved.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Die polishing method

The invention discloses a die polishing method. The die polishing method comprises the following operation steps that (1) a molded die is subjected to coarse polishing through oilstone, and a lubrication coolant and the oilstone cooperate to achieve coarse polishing; (2) abrasive paper is attached to a batten to conduct polishing, and the angle formed between the batten and the surface of the dieis 50 degrees to 60 degrees; and (3) cloth finishing mop mixed grinding paste is used for conducting elaborate polishing. The die polishing method is simple in operation, the polished die is high in gloss finish, the surface is free of scratch, and the finished product rate is high.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

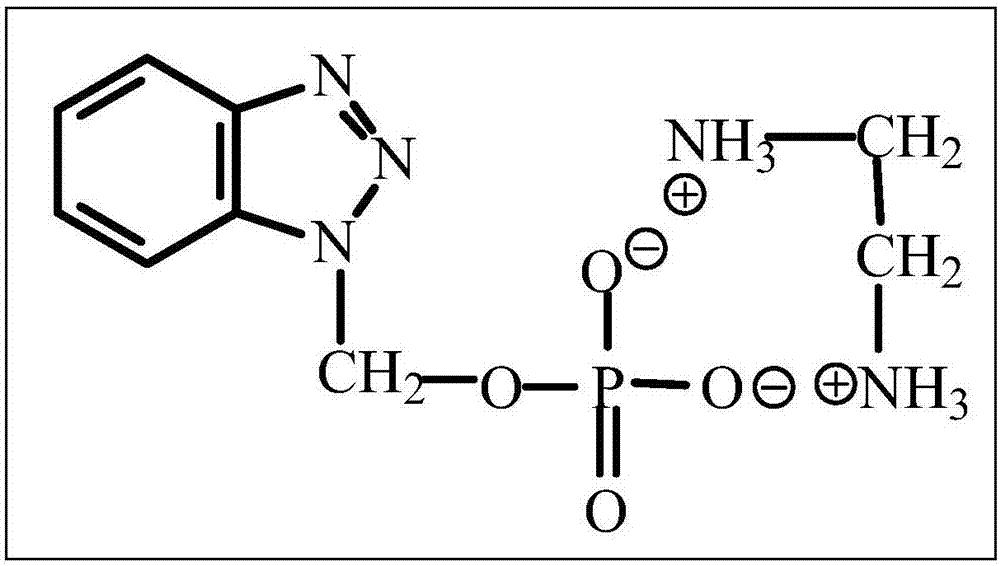

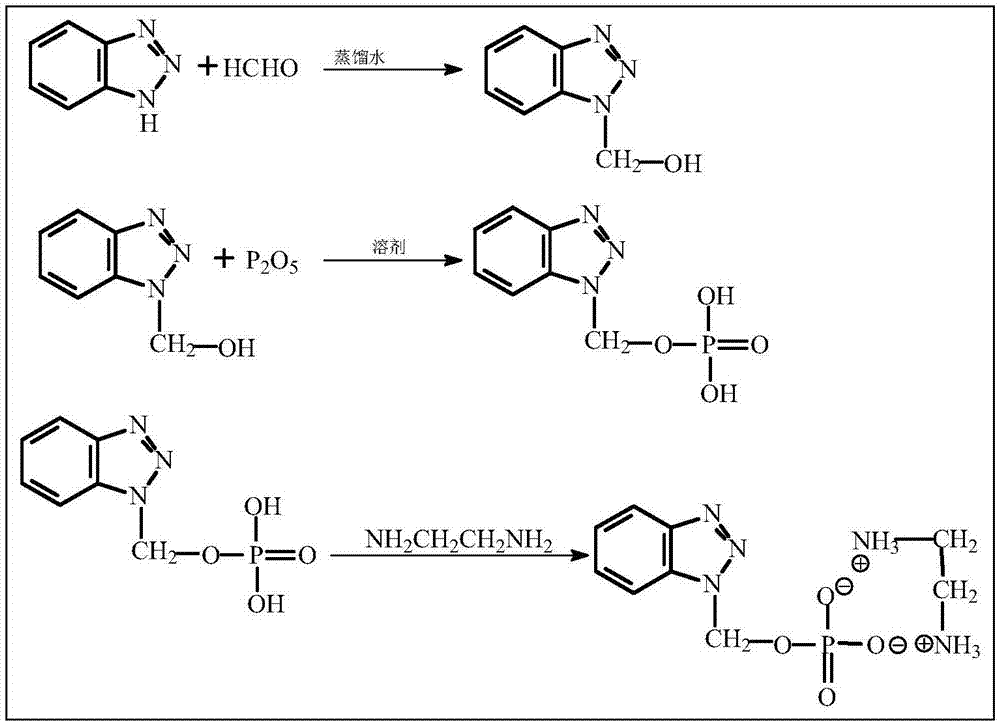

Tire steel wire cord antioxidant thickener as well as synthesis method and application thereof

ActiveCN107445993AImprove adhesionPromote degradationOrganic compound preparationGroup 5/15 element organic compoundsWater basedEthylenediamine

The invention provides a tire steel wire cord antioxidant thickener as well as a synthesis method and application thereof. The antioxidant thickener is 1-hydroxymethyl triazole phosphate ethylenediamine salt; first, 1-hydroxymethyl benzotriazole is synthesized by taking benzotriazole and formaldehyde as raw materials, and then the 1-hydroxymethyl triazole phosphate ethylenediamine salt is synthesized by the 1-hydroxymethyl benzotriazole together with P2O5 and ethylenediamine; after that, the the 1-hydroxymethyl triazole phosphate ethylenediamine salt is used as a thickener and compounded with phosphate, a lubricating grease oiliness agent, a surfactant, a corrosion inhibitor, 100# white oil, animal oil, oleic acid, triethanolamine, phosphate ammonium salt, triethylene glycol, sodium silicate, salicylic acid and sodium hydroxide to form a water-based wire drawing lubricant. The antioxidant thickener provided by the invention can remarkably enhance the adhesive force of the coppered steel wire of a radial tire; the water-based wire drawing lubricant added with a brass antioxidant thickener can improve the adhesive force; the adhesive force of a steel cord with the same structure is 20N or more higher than that of an imported product on average.

Owner:余宪虎

Low temperature water mist oil mist cutting cooling lubrication supply system

ActiveCN106863002BImprove permeabilityExtend your lifeMaintainance and safety accessoriesAviationSprayer

The invention discloses a low temperature water mist and oil mist cutting cooling lubrication supply system. A Venturi atomization sprayer is arranged at the upper portion of an inner cavity of an atomization chamber, an air inlet of the Venturi atomization sprayer is connected to the outlet end of an air tank through a first air conveying pipe, an eddy atomization sprayer comprises an eddy pipe and an oil-water mixing sprayer, the eddy pipe is connected to the outlet end of the air tank through a second air conveying pipe, and a compression refrigerator is arranged on the second air conveying pipe; the oil-water mixing sprayer is connected with the water tank through a water pipe, and is connected with the atomization chamber through an oil mist conveying pipe; and cold air refrigerated through the compression refrigerator and the eddy pipe is mixed with oil mist coming from the atomization chamber and water coming from the water tank at the position of the oil-water mixing sprayer. By means of the system, advantages of low-temperature cold air and composite spraying mist are combined, and therefore when a cutter is used for machining difficultly-machined materials such as the titanium alloy, the high-temperature alloy and the aviation composite material, the cutting temperature is rapidly decreased, the machining process is more efficient, and the service life of the cutter is prolonged.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Phytic acid silane protection type emulsive cutting fluid added with modified chitosan oligosaccharide surface active agent

InactiveCN106635366AImprove adsorption capacityExcellent anti-rustAdditivesTectorial membranePyrrolidinones

The invention discloses phytic acid silane protection type emulsive cutting fluid added with modified chitosan oligosaccharide surface active agent. The emulsive cutting fluid is prepared from, by weight, 50-54 parts of polyol ester, 18-19 parts of lauryl diethanol amide, 3-3.3 parts of boric acid, 0.7-0.8 part of p-toluenesulfonic acid, an appropriate amount of petroleum ether, 0.4-0.5 part of methyl triethoxysilane, 5-5.5 parts of phytic acid, an appropriate amount of deionized water, an appropriate amount of absolute ethyl alcohol, 0.2-0.25 part of sodium bromate, 30-34 parts of castor oil polyoxyethylene aliphatate, 8-8.5 parts of petroleum sodium sulfonate, 3-4 parts of sorbitan monooleate, 1-1.5 parts of sodium oleate, 10-11.5 parts of dehydroabietic acid glycidyl ester, 2-2.2 parts of chitosan oligosaccharide, 10-11 parts of 1-Methyl-2-pyrrolidinone and an appropriate amount of acetone. The phytic acid silane protection type emulsive cutting fluid added with the modified chitosan oligosaccharide surface active agent is a waterborne formula, and the lubricating cooling performance is good; meanwhile, in the metal cutting machining process, a layer of protective film can be formed at the surface of metal, and the corrosion inhibition efficiency is high.

Owner:江海涛

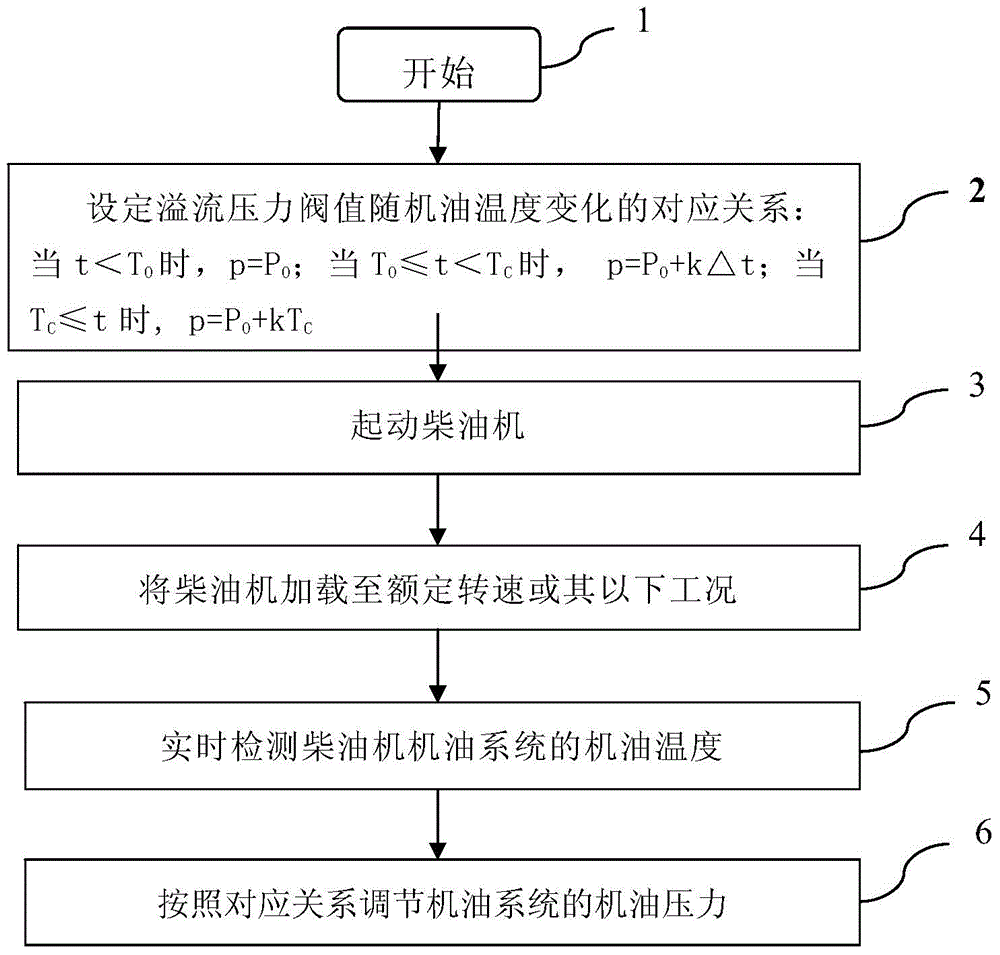

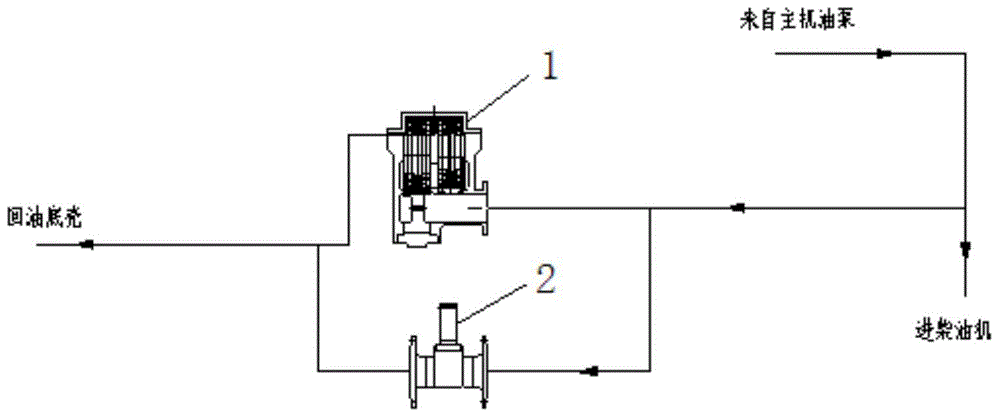

Method and device for controlling engine oil pressure of diesel engine and generator set

ActiveCN104533566AGood lubricating and cooling effectSimple and compact structureLubrication pressure controlForced inductionPressure threshold

The invention relates to a method and device for controlling the engine oil pressure of a diesel engine and a generator set. The corresponding relation of the overflow pressure threshold, changing along with the temperature of engine oil, of an engine oil system is set, wherein when t is smaller than TO, p is equal to PO, when t is larger than or equal to TO but smaller than TC, p is equal to PO+kdeltat, and when t is larger than or equal to TC, p is equal to PO+kTC; after the diesel engine is started, the diesel engine can be loaded to reach the working condition with the rated rotating speed or the rotating speed smaller than the rated rotating speed, meanwhile, the real-time overflow pressure threshold is obtained according to the corresponding relation, and the engine oil pressure of the engine oil system is regulated. According to the control device for achieving the method, a temperature control valve can be connected with an overflow pressure reducing valve in parallel, and the temperature control valve is initially in a starting state and is gradually closed along with the gradual rising of the engine oil temperature. The structure is simple and compact, and cost is low. The initial pressure of the engine oil system after engine starting is regulated continuously along with the change of the engine oil temperature, parts such as a supercharger and an oil injection pump cannot be damaged, meanwhile, the lubricating and cooling effects are reliably ensured, the time for warming-up is saved, and the light oil saving effect of a heavy oil unit is especially obvious.

Owner:CRRC DALIAN CO LTD

Machining process of steel wheel of robot reducer

The invention discloses a machining process of a steel wheel of a robot reducer. The machining process of the steel wheel of the robot reducer comprises the following steps of precision casting or forging of a blank of a first steel wheel; rough machining of the blank of the first steel wheel; heat treatment on the rough machined first steel wheel; finish machining of the first steel wheel; heat treatment on the finished first steel wheel; superfinish machining of the first steel wheel by adopting one-time clamping; and detecting various indexes of the superfinished first steel wheel until therequirements of a finished product are met.

Owner:SHANDONG SHKE MACHINERY MFG +1

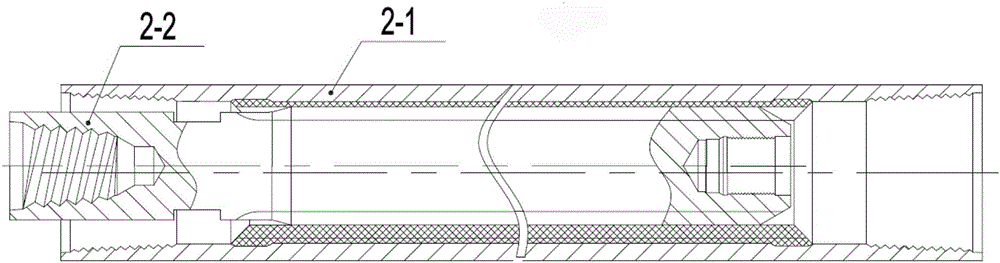

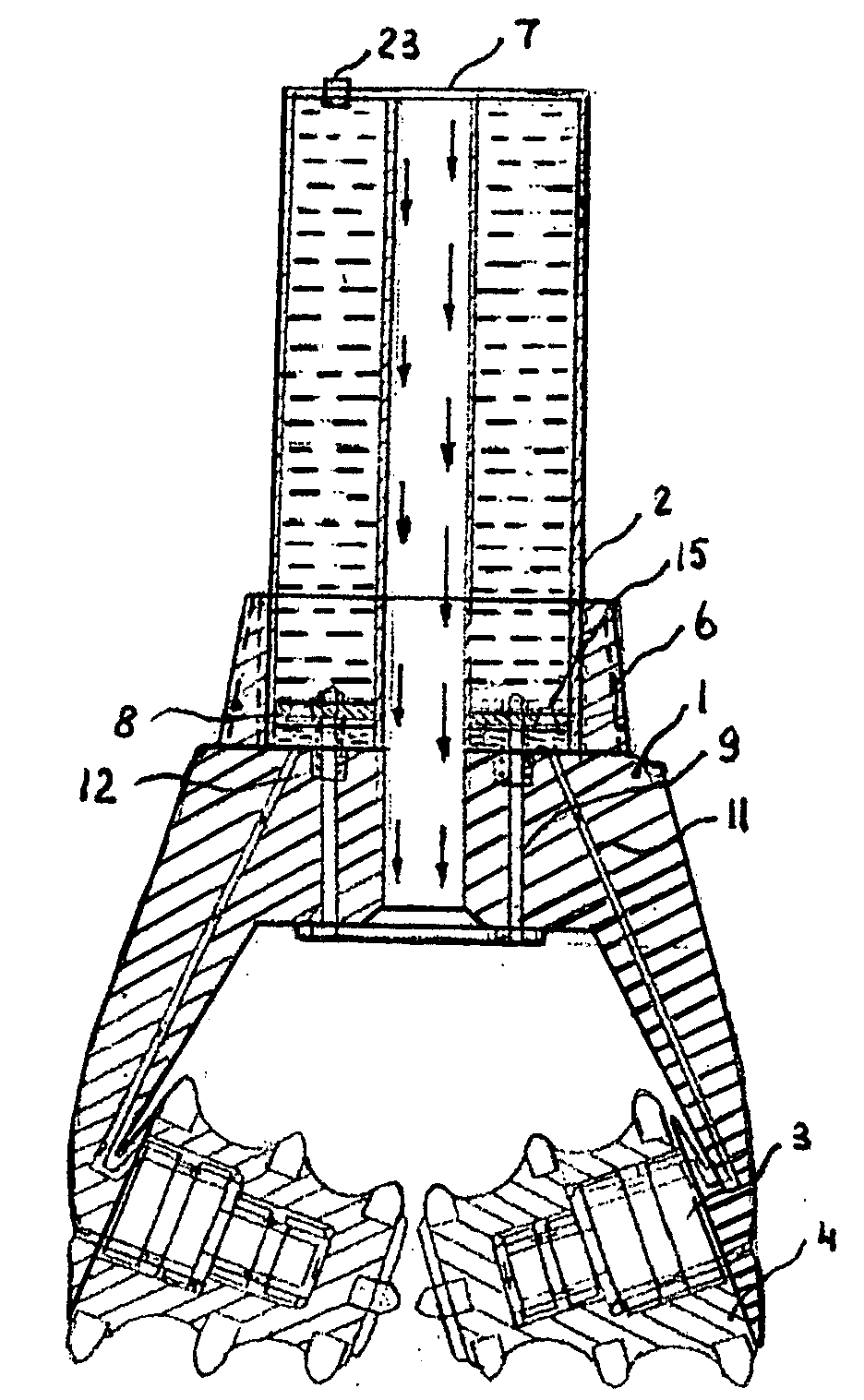

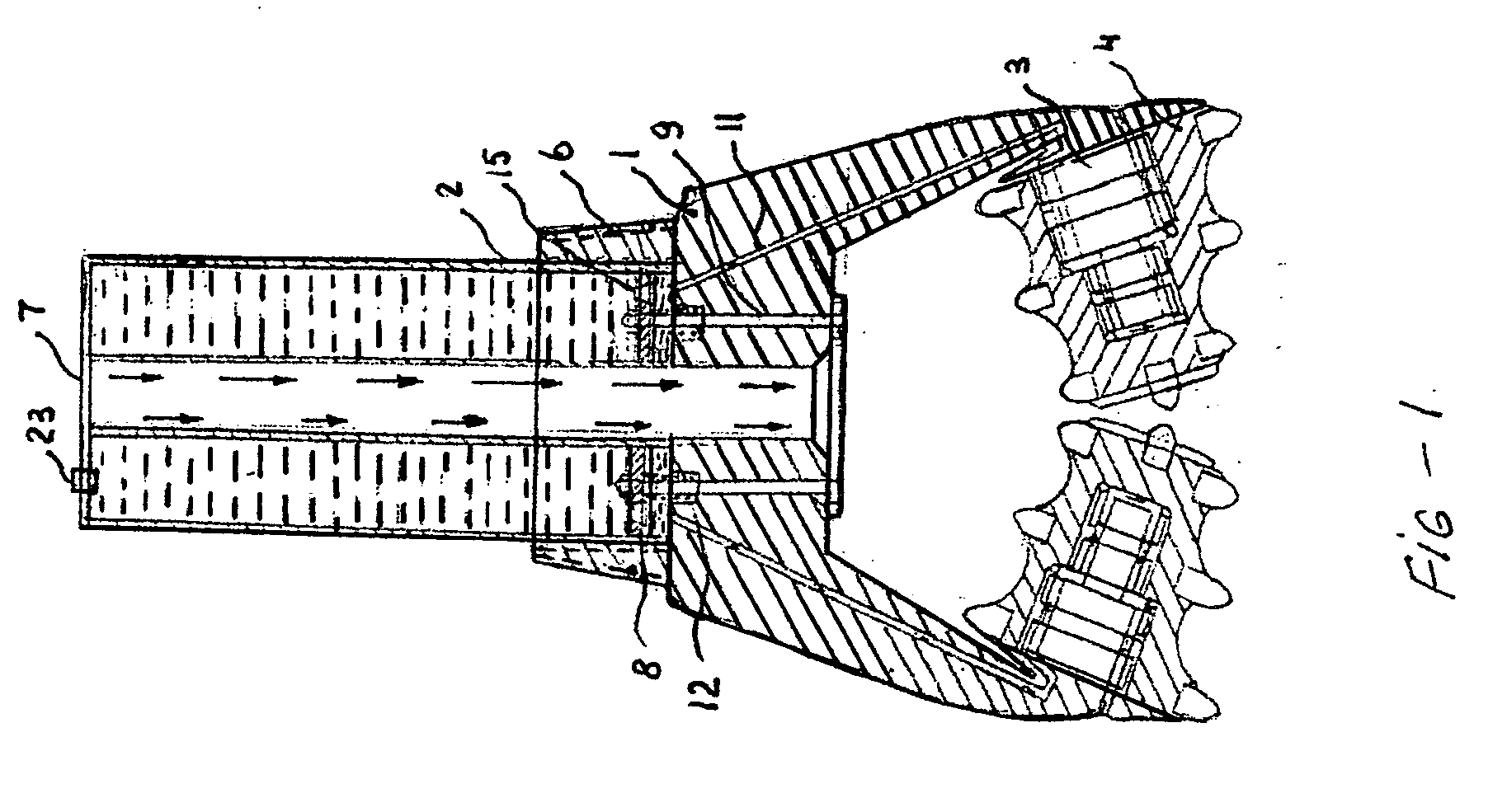

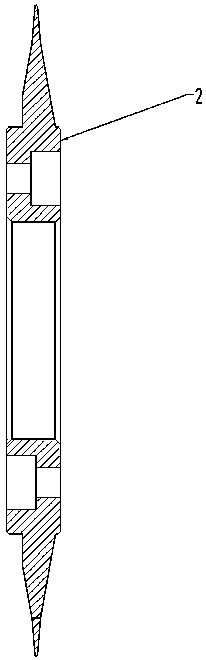

Drill bits for drilling wells

InactiveUS20100300762A1Improve the lubrication effectImproved cooling meanDrill bitsWell drillingEngineering

A device including a drill bit is disclosed. The bit preferably comprises lug members, joined by a support member, each lug member includes a through hole, bearings rotatably mounted on the lug members which bearings support cutter members, a sleeve with lubricant mounted upon the support member, a central channel within the sleeve whose lower end can be closed or opened with a reciprocating valve-plate, an annular piston snug-fitting between the sidewalls of sleeve and central channel, which piston has a discharge valve outletting the lubricant through the piston, a spring disposed in the sleeve, rods mounted in the sleeve and inserted through the holes, lubrication channels arranged in the lug members and communicating the lower portion of sleeve with the bearings for lubrication thereof. The rods are coupled to the piston and the valve-plate. Embodiments include shafts supporting the bearings. Some shafts are hollow and have a coolant system.

Owner:YATSENKO YURIY +2

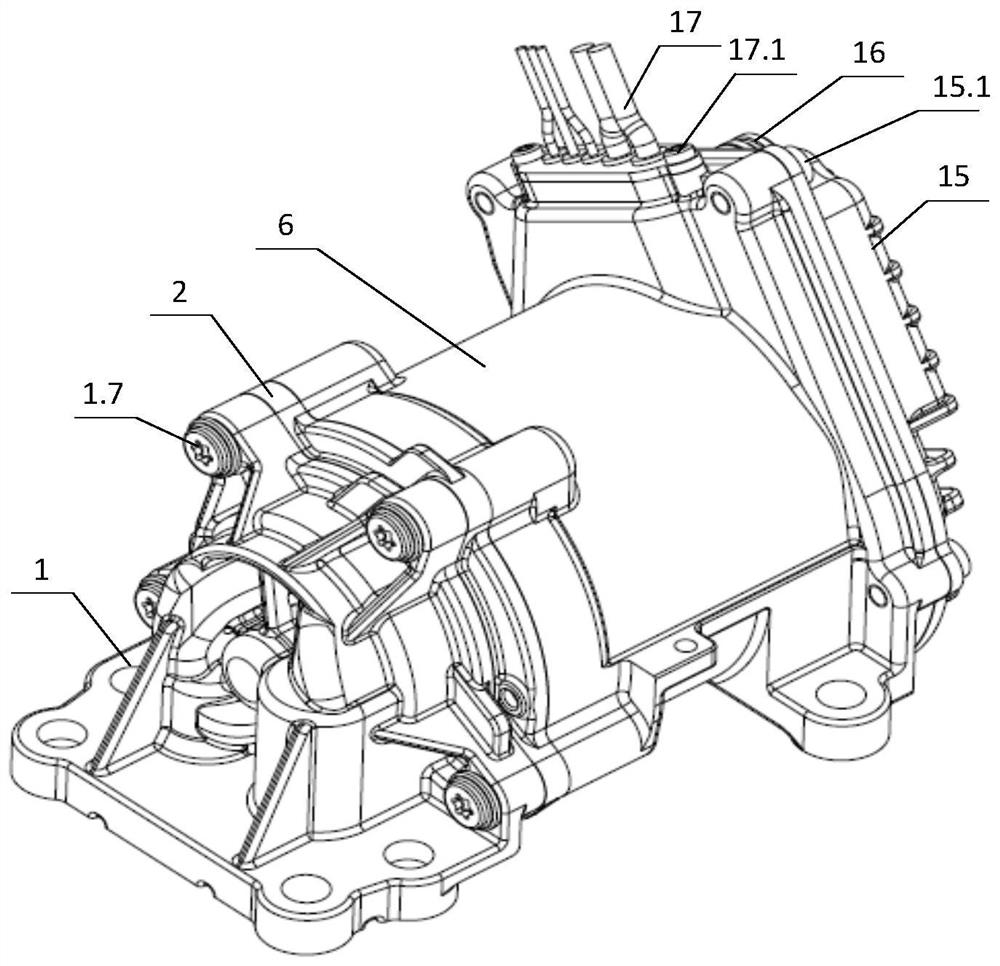

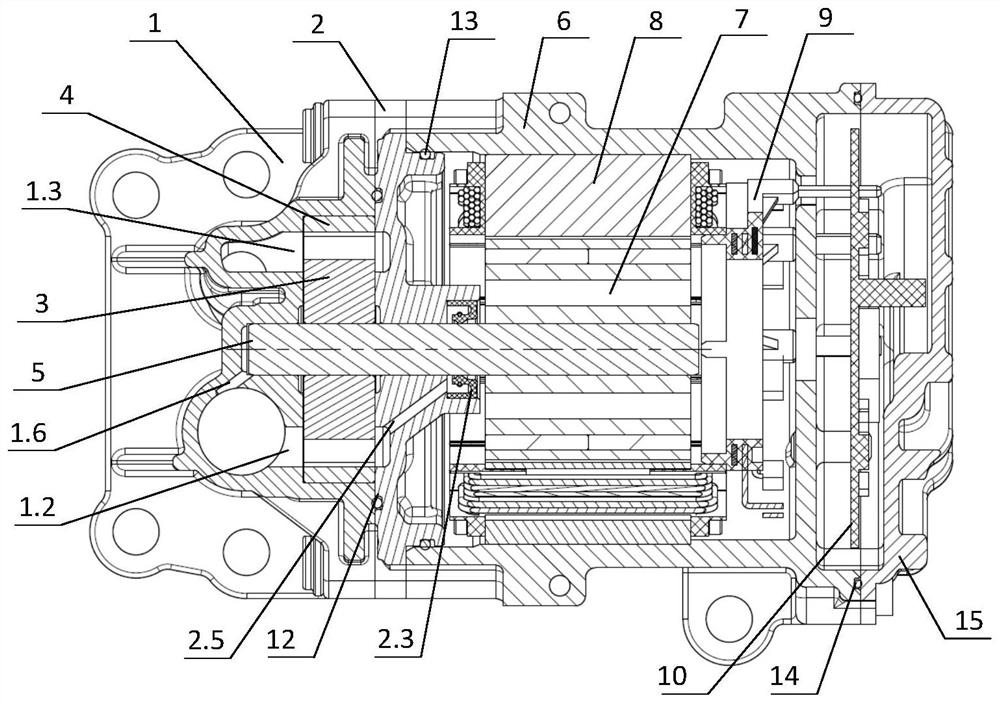

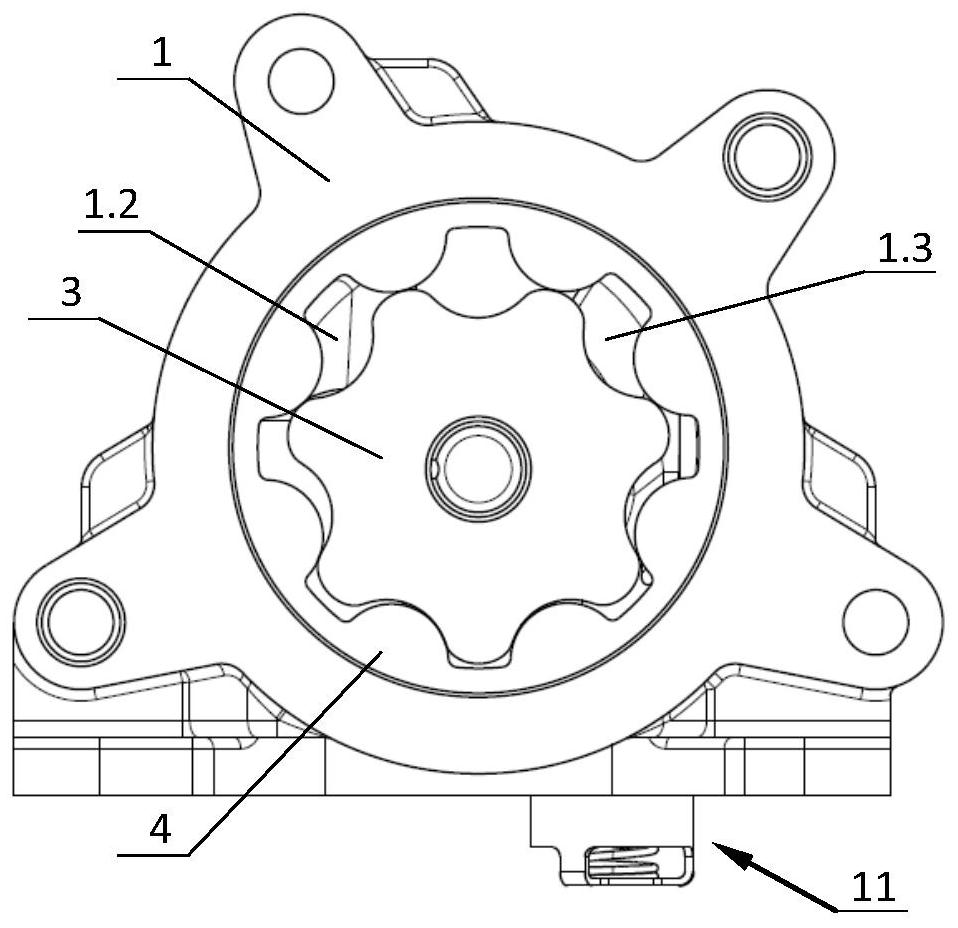

Electronic oil pump

PendingCN111664089AEffective lubricationImprove the lubrication effectRotary piston pumpsRotary/oscillating piston combinationsBodies oilElectric machine

The invention discloses an electronic oil pump. The electronic oil pump comprises a pump body, a pump cover, an inner rotor, an outer rotor, a driving shaft, a motor shell, a motor rotor, a motor stator, a confluence disc and a controller, wherein the inner rotor and the outer rotor are installed in a cavity of the pump body, the motor rotor and the motor stator are installed in the motor shell, the motor rotor and the inner rotor are separated by the pump cover and are connected by a driving shaft, the controller is installed on the motor shell, the controller is connected with the motor stator through the confluence disc, a pump body shaft hole is formed in the pump body, a pump body lubricating oil groove is formed in the pump body shaft hole, a pump body oil drainage pipeline is arranged at the bottom of the pump body shaft hole, a pump cover shaft hole is formed in the pump cover, a pump cover lubricating oil groove is formed in the pump cover shaft hole, and a pump cover oil drainage pipeline is arranged at the bottom of the pump cover shaft hole. The device is simple and compact in structure, low in cost, simple and reliable in supporting structure of the driving shaft and excellent in lubricating and cooling performance.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Self-lubricating bearing device for high-temperature molten salt pump

The invention discloses a self-lubricating bearing device for a high-temperature molten salt pump. The self-lubricating bearing device for the high-temperature molten salt pump comprises a shaft, a shaft sleeve, a bushing and a bearing block, wherein the shaft sleeve is fixedly arranged on the outside of the shaft in a sleeving manner; the shaft sleeve is mounted in the bearing block; the bushingis arranged between the bearing block and the shaft sleeve, is mounted on the outside of the shaft sleeve and is mounted in the bearing block; the lower end of the bearing block is inwards bent to form a baffle which stops the bushing; a bushing gland for covering the bushing is fixed at the upper end of the bearing block; two ends of the shaft sleeve extend out of the bushing; two ends of the shaft extend out of the shaft sleeve; a plurality of spiral channels are uniformly formed in the outer wall of the shaft sleeve; a lubricating medium inlet flow channel is formed in the lower end of theshaft sleeve; and a lubricating medium outlet flow channel is formed in the upper end of the shaft sleeve. The self-lubricating bearing device for the high-temperature molten salt pump has the beneficial effects that the spiral channels are formed in the sliding bearing shaft sleeve of the high-temperature molten salt pump, thus, the flow channels are filled with a lubricating medium which flows rapidly, the lubricating and cooling effect is good, excessive abrasion of a sliding bearing is avoided effectively, and the service life of the sliding bearing is prolonged.

Owner:CHANGZHOU SOLAR MOLTEN SALT PUMP VALVE TECH CO LTD

Processing technology of rigid flexible wheels of robot speed reducer

The invention discloses a processing technology of rigid flexible wheels of a robot speed reducer. The processing technology includes the steps of manufacturing blanks of the rigid flexible wheels byprecise casting or forging casting, subjecting the blanks of the rigid flexible wheels to rough processing, subjecting the rough-processed blanks of the rigid flexible wheels to heat treatment, subjecting external gears and internal races of the rigid flexible wheels to super-finishing, and detecting various index of the super-finished rigid flexible wheels until reaching requirements of finishedproducts.

Owner:SHANDONG SHKE MACHINERY MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com