Wind turbine gearbox and sun gear and planet carrier spline pair connection structure thereof

A connection structure and planet carrier technology, which is applied in wind turbines, wind turbine components, engines, etc., can solve problems such as poor lubrication and cooling effects, insufficient oil intake and storage, inconvenient installation and disassembly, etc., to achieve lubrication and cooling Good effect, low manufacturing difficulty, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

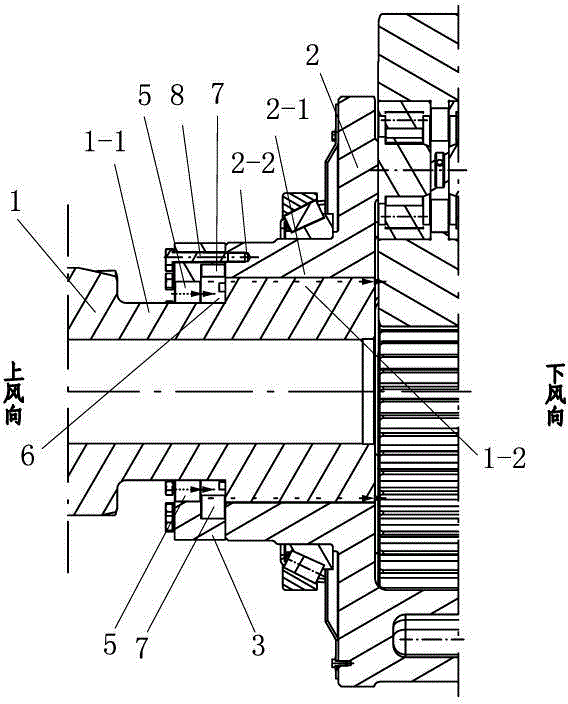

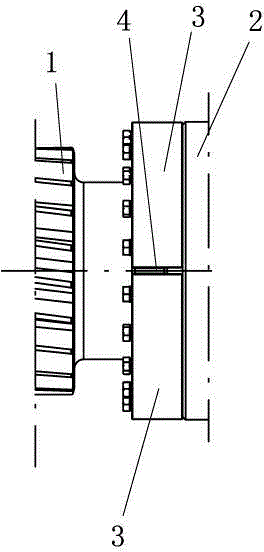

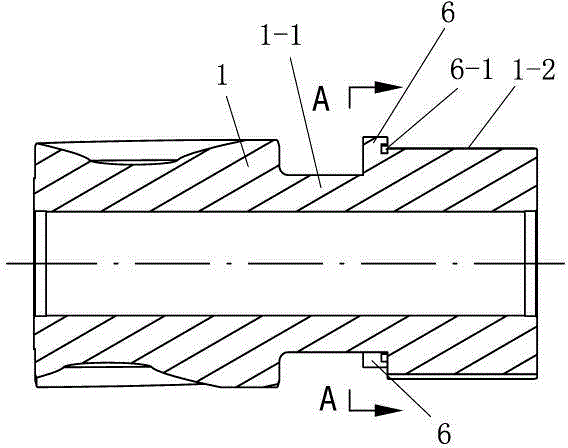

[0040] Such as Figure 1-12As shown, the sun gear and planetary carrier spline coupling structure of the present invention includes a primary sun gear 1, a secondary planetary carrier 2, a convex plate 3 and a rubber gasket 4, and the secondary planetary carrier 2 has an internal spline Section 2-1, the primary sun gear 1 has a shaft body 1-1, an external spline section 1-2 and several bosses 6, and the external spline section 1-2 is connected to the inner surface of the secondary planet carrier 2 The spline sections 2-1 are meshed to form a spline pair. The several bosses 6 are arranged at a certain distance and are all located at the upwind end of the outer spline section 1-2. The end faces of the wind direction are close to each other. The convex plate 3 is a half ring with an L-shaped cross-section and there are two. A rubber gasket 4 is placed between the two half rings to form a complete ring. The ring is connected to the secondary The upwind end surface of the planet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com