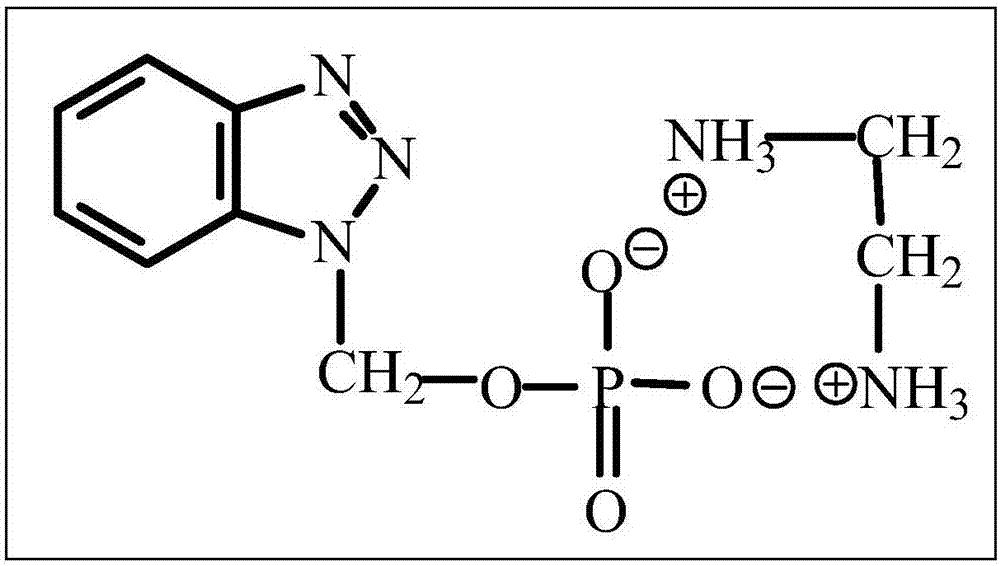

Tire steel wire cord antioxidant thickener as well as synthesis method and application thereof

A technology of steel cords and synthesis methods, applied in the direction of chemical instruments and methods, additives, lubricating compositions, etc., to achieve the effects of improving adhesion, increasing adhesion, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

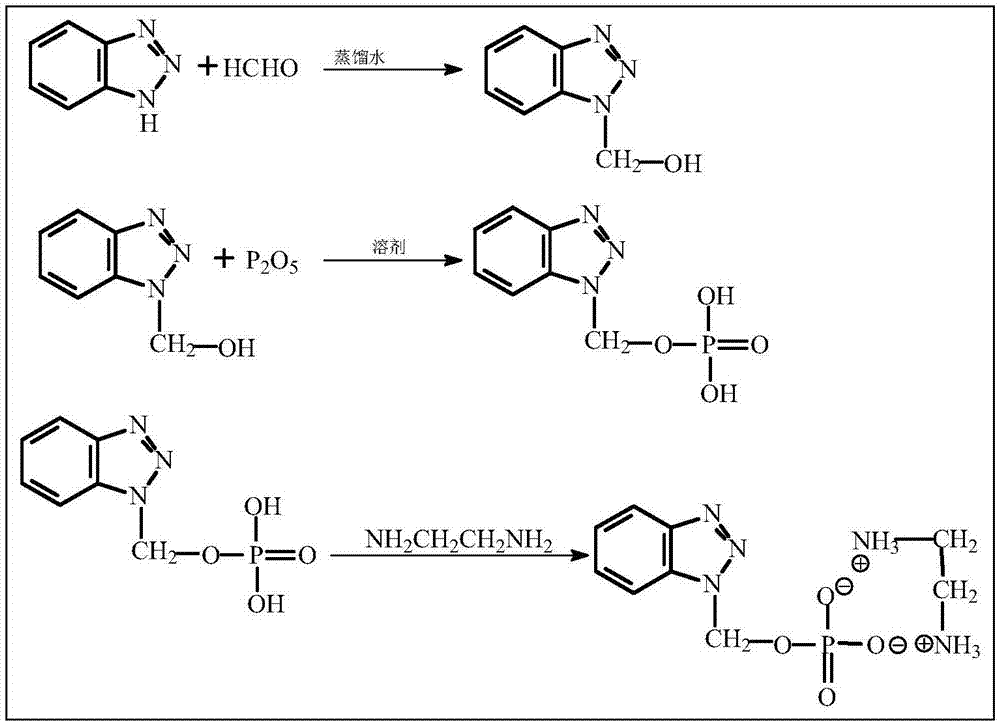

Method used

Image

Examples

Embodiment 1

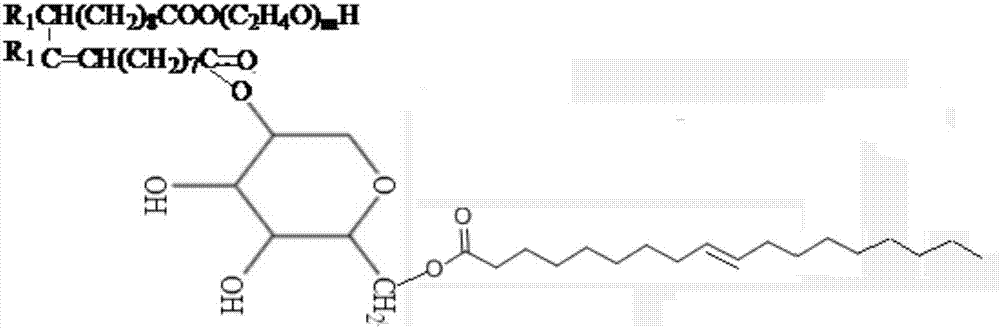

[0043] The anti-oxidant tackifier is used to prepare a lubricant, and the lubricant is configured according to the mass fraction of the following raw materials: lubricating oily agent 16%, MOA-4P phosphate ester 7%, surfactant 3.2%, anti-oxidant Oxygen tackifier 0.55%, B-VCI rust inhibitor 1.5%, No. 100 white oil 7%, animal oil 4.5%, oleic acid 2.5%, triethanolamine 1.5%, phosphate amine salt 4%, triethylene glycol 1%, sodium silicate 0.6%, salicylic acid 0.3%, sodium hydroxide 0.1%, the balance is water, and the sum of the mass fractions of each component is 100%.

Embodiment 2

[0045] The anti-oxidant tackifier is used to prepare a lubricant, and the lubricant is configured according to the mass fraction of the following raw materials: lubricating oily agent 15%, MOA-4P phosphate ester 6%, surfactant 3%, anti-oxidant Oxygen tackifier 0.6%, B-VCI rust inhibitor 2%, No. 100 white oil 6%, animal oil 5%, oleic acid 3%, triethanolamine 2%, phosphate amine salt 5%, triethylene glycol 1.5%, sodium silicate 0.5%, salicylic acid 0.5%, sodium hydroxide 0.2%, the balance is water, and the sum of the mass fractions of each component is 100%.

Embodiment 3

[0047] The anti-oxidant tackifier is used to prepare a lubricant, and the lubricant is configured according to the mass fraction of the following raw materials: 17% lubricating oily agent, 8% MOA-4P phosphate, 3.5% surfactant, anti-oxidant Oxygen tackifier 0.5%, B-VCI rust inhibitor 1%, No. 100 white oil 5%, animal oil 4%, oleic acid 2%, triethanolamine 1%, phosphate amine salt 3.5%, triethylene glycol 2%, sodium silicate 0.3%, salicylic acid 0.4%, sodium hydroxide 0.5%, the balance is water, and the sum of the mass fractions of each component is 100%.

[0048] Described lubricant preparation method: according to the component ratio of above-mentioned embodiment, lubricating oily agent, MOA-4P, surfactant, tackifier, No. 100 white oil, animal oil, oleic acid, triethanolamine, phosphate ester amine Add salt and triethylene glycol into the emulsification reaction tank, stir and mix at 80°C for 30 minutes, add measured deionized water at 80°C, emulsify and stir for about 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com