Planet carrier and planet gear case with planet carrier

A planetary carrier and planetary gear technology, applied in gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem that the cooling effect of the gear pair is not obvious, and it is impossible to directly spray lubricating oil on the planetary gear-sun gear meshing Problems such as out-of-zone and planetary-inner, poor lubrication and cooling effects, etc., to achieve obvious lubrication and cooling effects, good follow-up lubrication and cooling effects, and improve life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this invention will be thorough and complete, and will fully convey the concept of the invention to those skilled in the art.

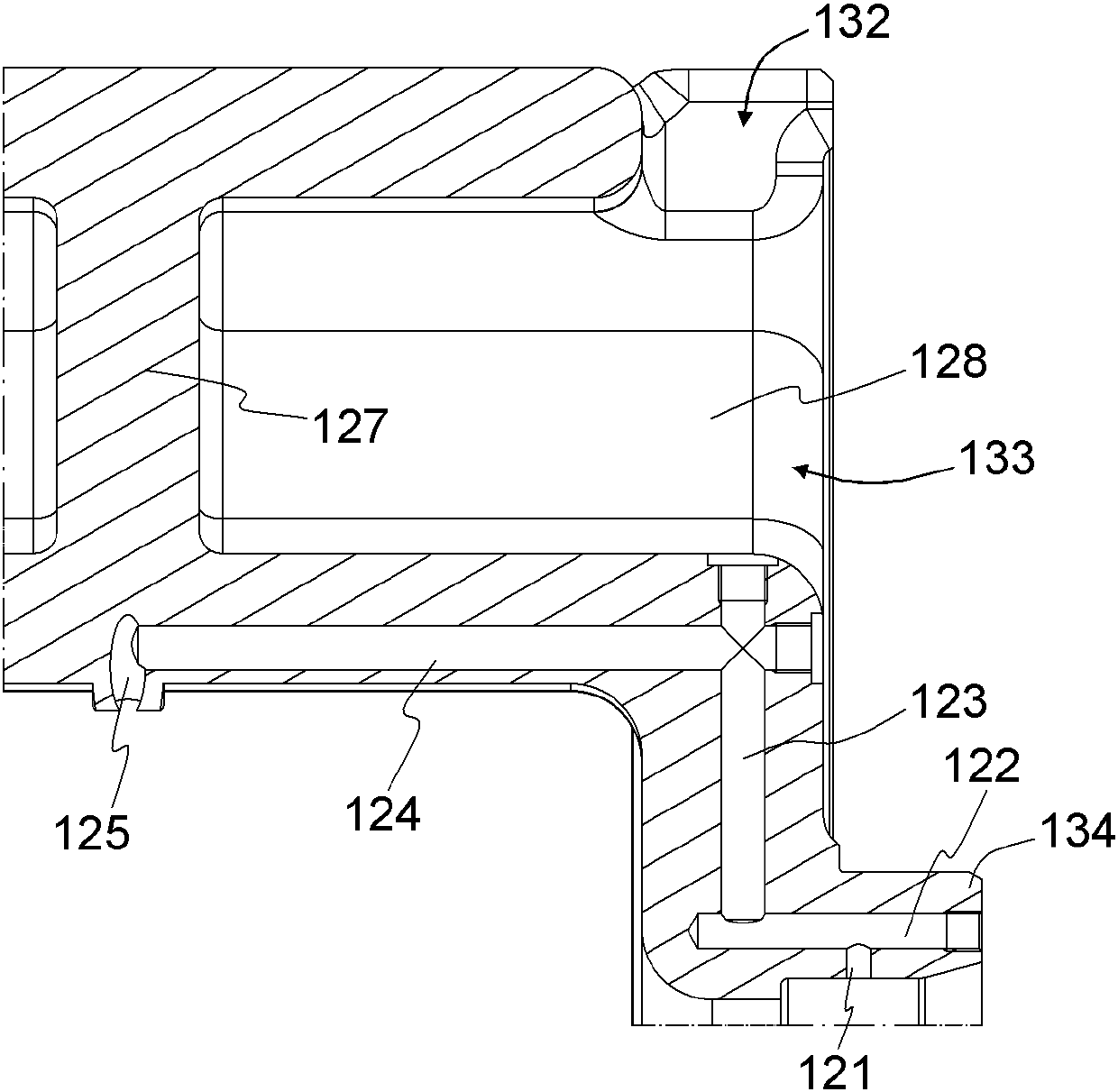

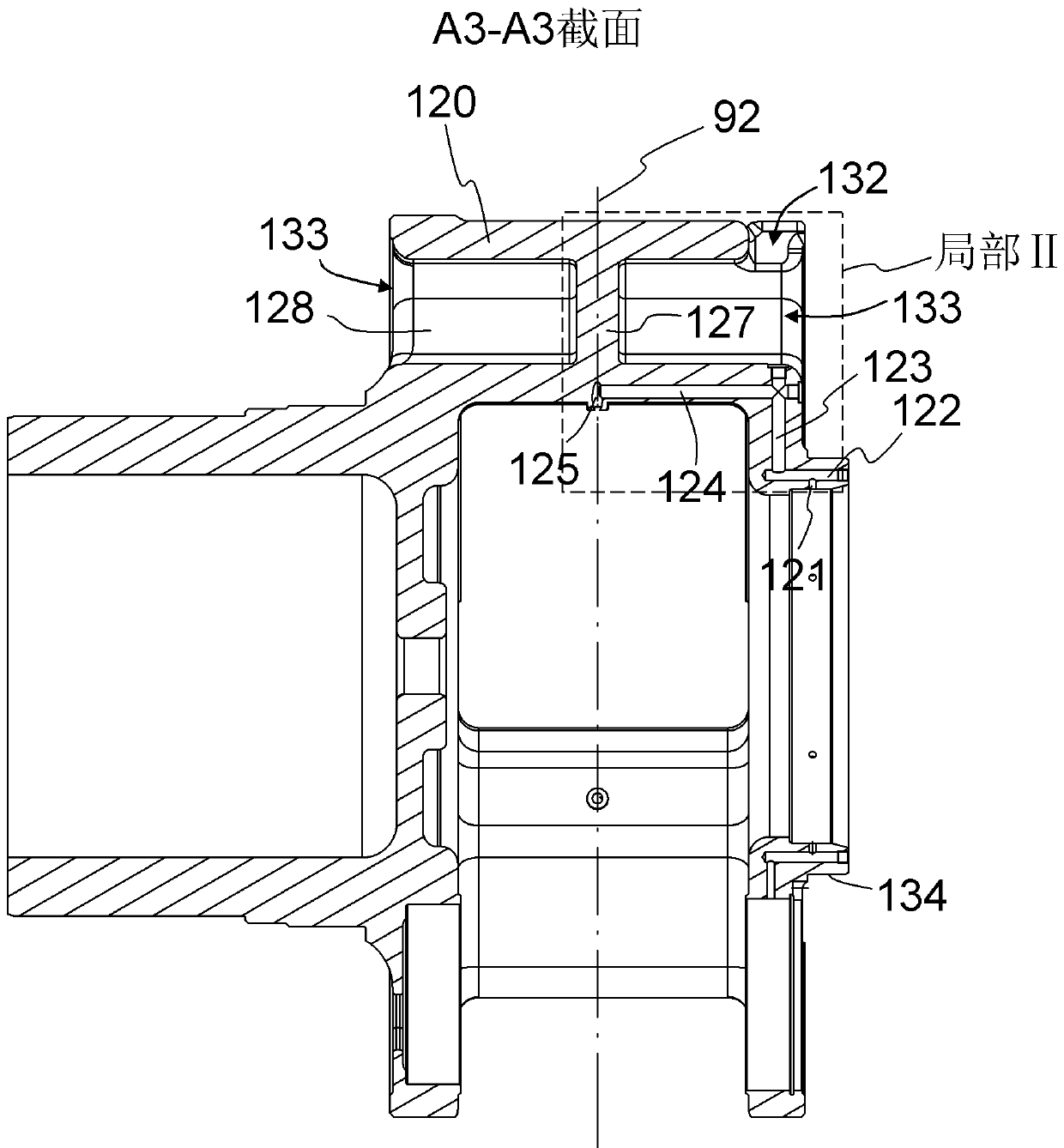

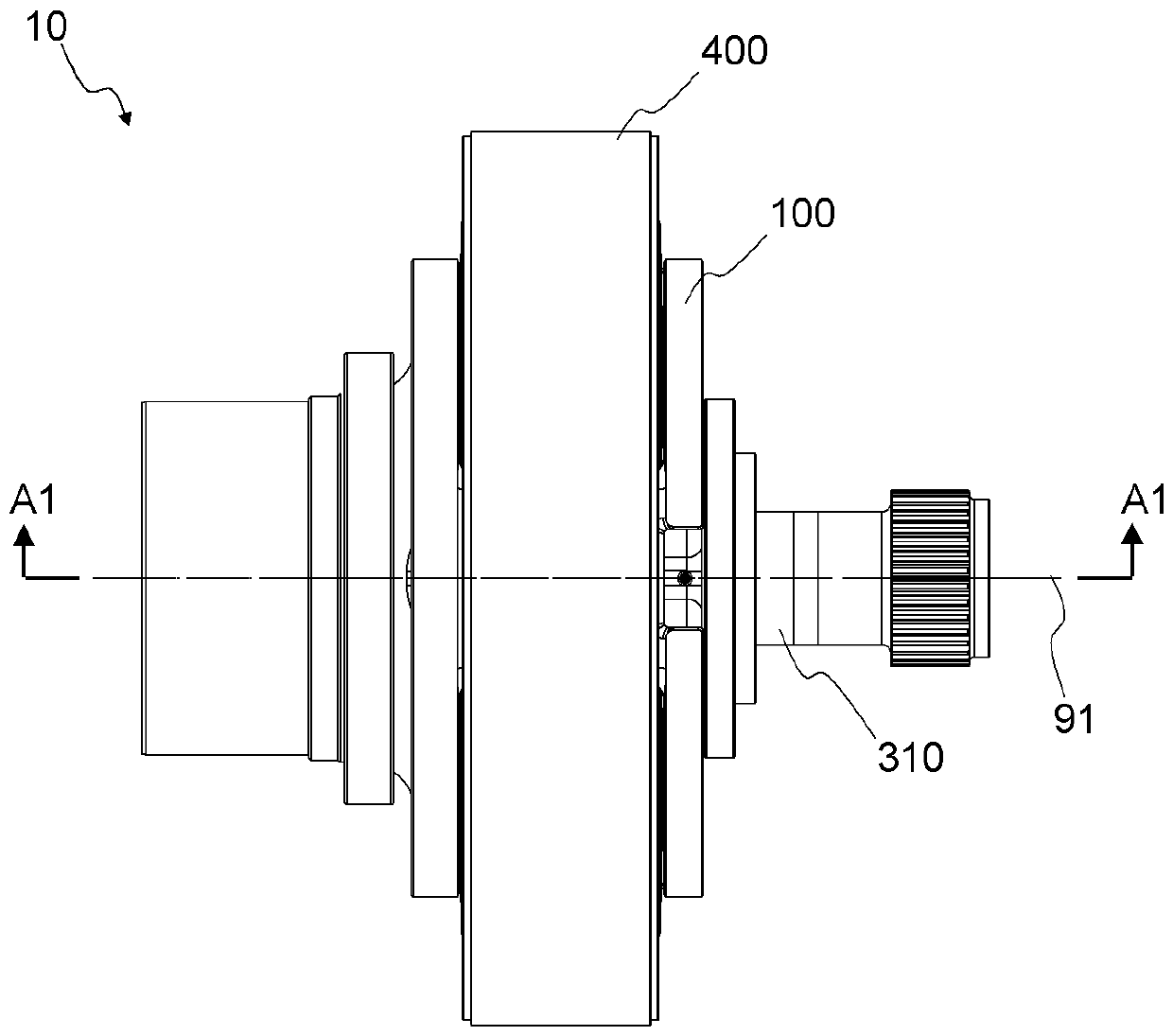

[0054] Refer to the following Figure 1 to Figure 10 The planetary carrier 100 and the planetary gearbox 10 of the embodiment of the present invention are illustrated, wherein, Figure 1 to Figure 4 The planetary gearbox 10 of the illustrated embodiment is used as Figure 5 to Figure 10 The planet carrier 100 of the illustrated embodiment. The improvement of the embodiment of the present invention mainly lies in the lubricating system in the planetary gearbox 10. Therefore, in the following description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com