Thermoplastic elastomer sealing strip material and preparation method thereof

A thermoplastic elastomer and sealing strip technology, applied in the field of sealing strip materials and its preparation, can solve the problems of limited durability and repeated fatigue resistance, limited heat resistance of TPE, and limited use range, etc., to improve processing performance, Reduce surface friction and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

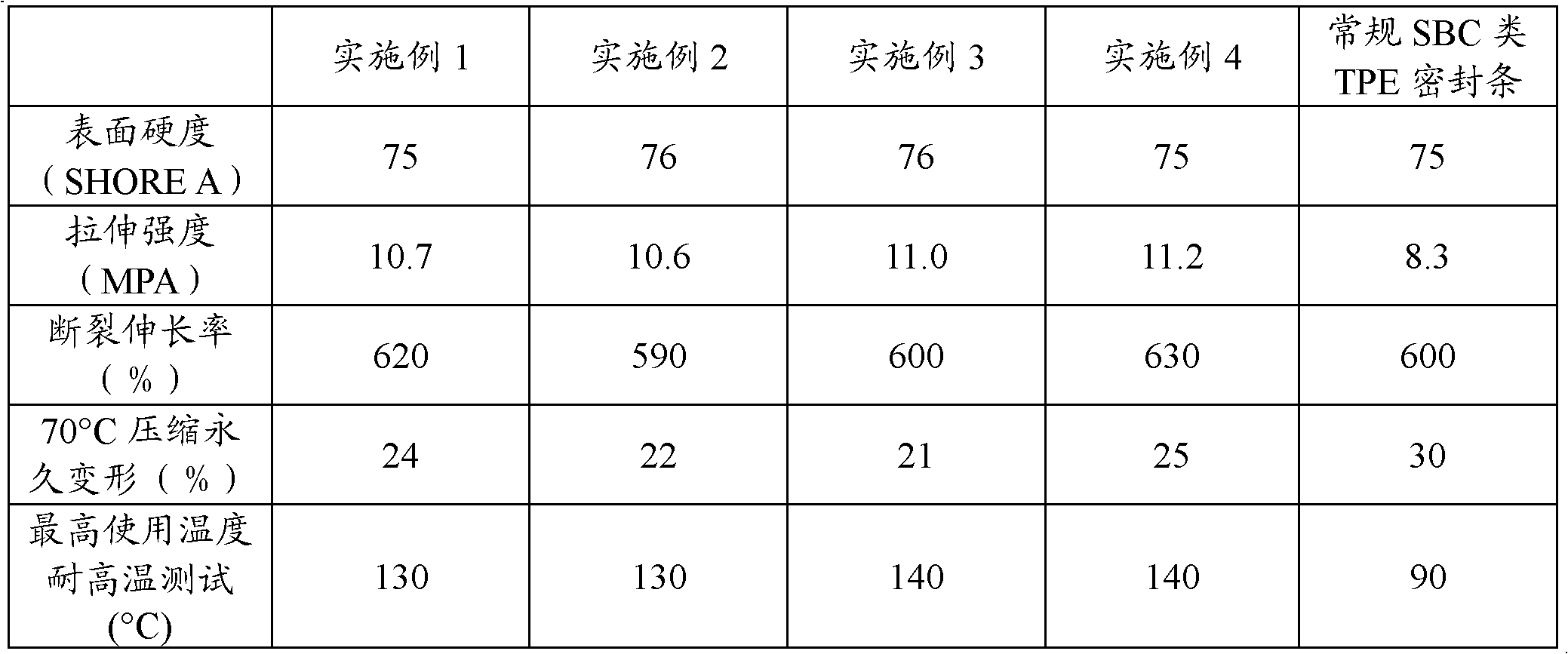

Examples

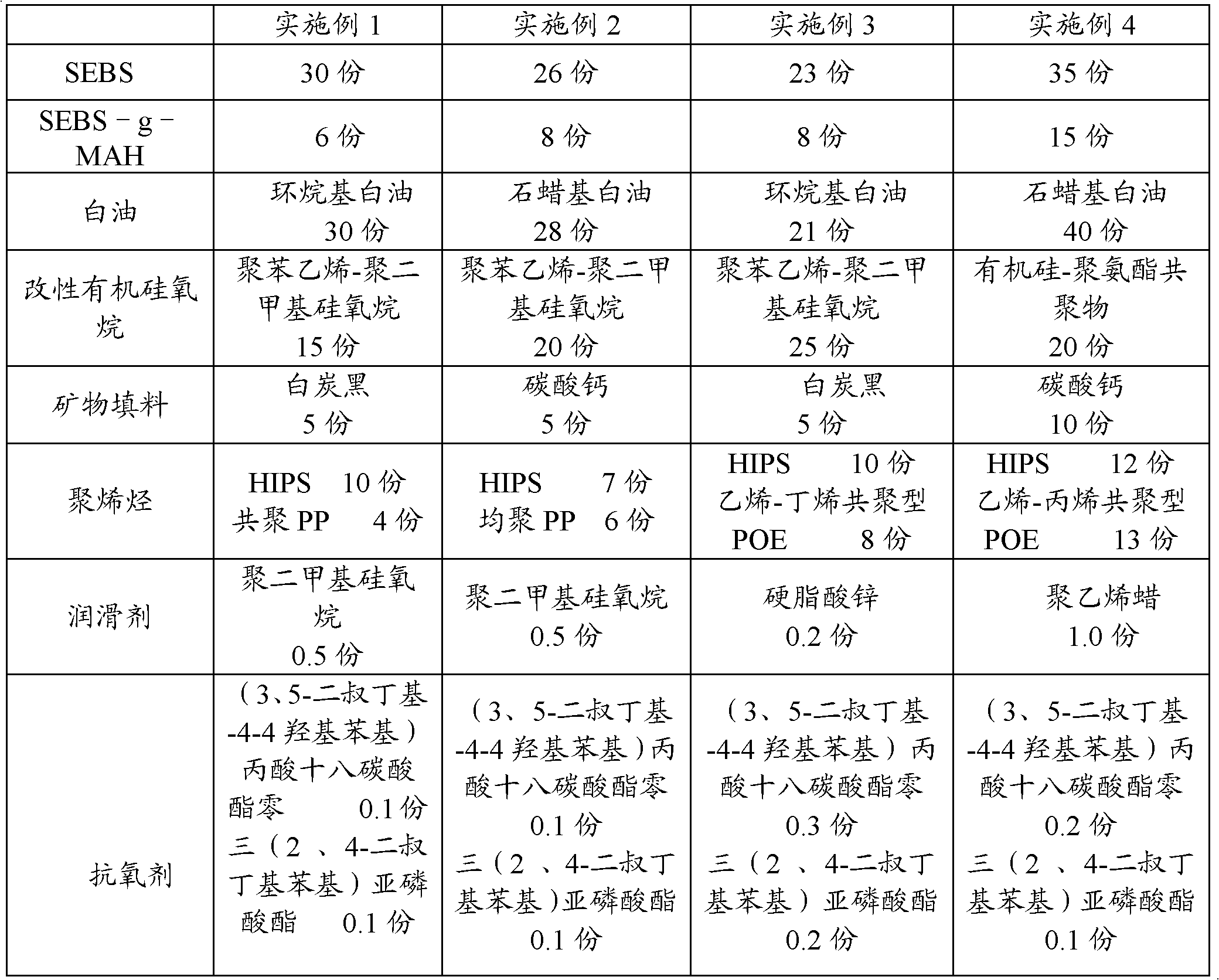

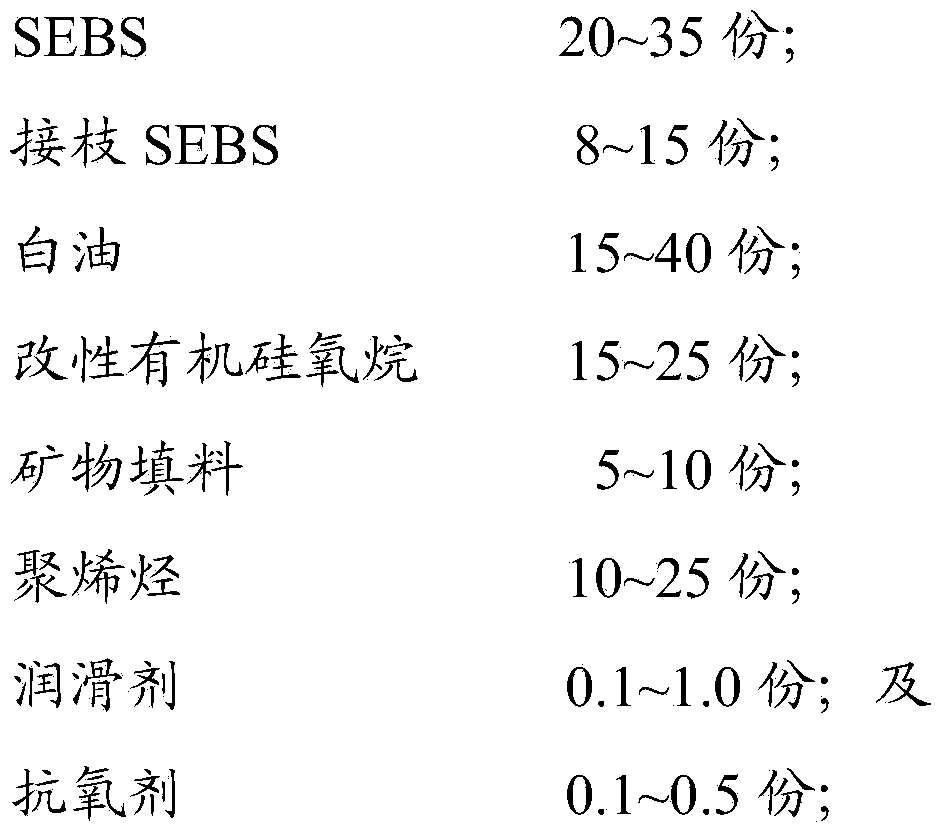

preparation example Construction

[0049] The preparation method of above-mentioned thermoplastic elastomer sealing strip material, comprises the steps:

[0050] Step 1. Weigh 15-40 parts of white oil and 0.1-1.0 parts of lubricant according to parts by weight, mix the two, and stir evenly;

[0051] Step 2: Weigh 20-35 parts of SEBS according to parts by weight and add them into the mixture obtained in Step 1 and stir evenly until SEBS completely absorbs the white oil;

[0052] Step 3. Weigh 8-15 parts of grafted SEBS, 15-25 parts of modified organosiloxane, 5-10 parts of mineral filler, 10-25 parts of mineral filler, 0.1-0.5 parts of antioxidant according to the weight fraction, and add The mixed solution obtained in step 2 is stirred evenly; and

[0053] The fourth step is to use a twin-screw extruder to plasticize, extrude, cool, and granulate to obtain the thermoplastic elastomer sealing strip material.

[0054] The modified organosiloxane is introduced into the above-mentioned thermoplastic elastomer sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com