Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1844 results about "Forced induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

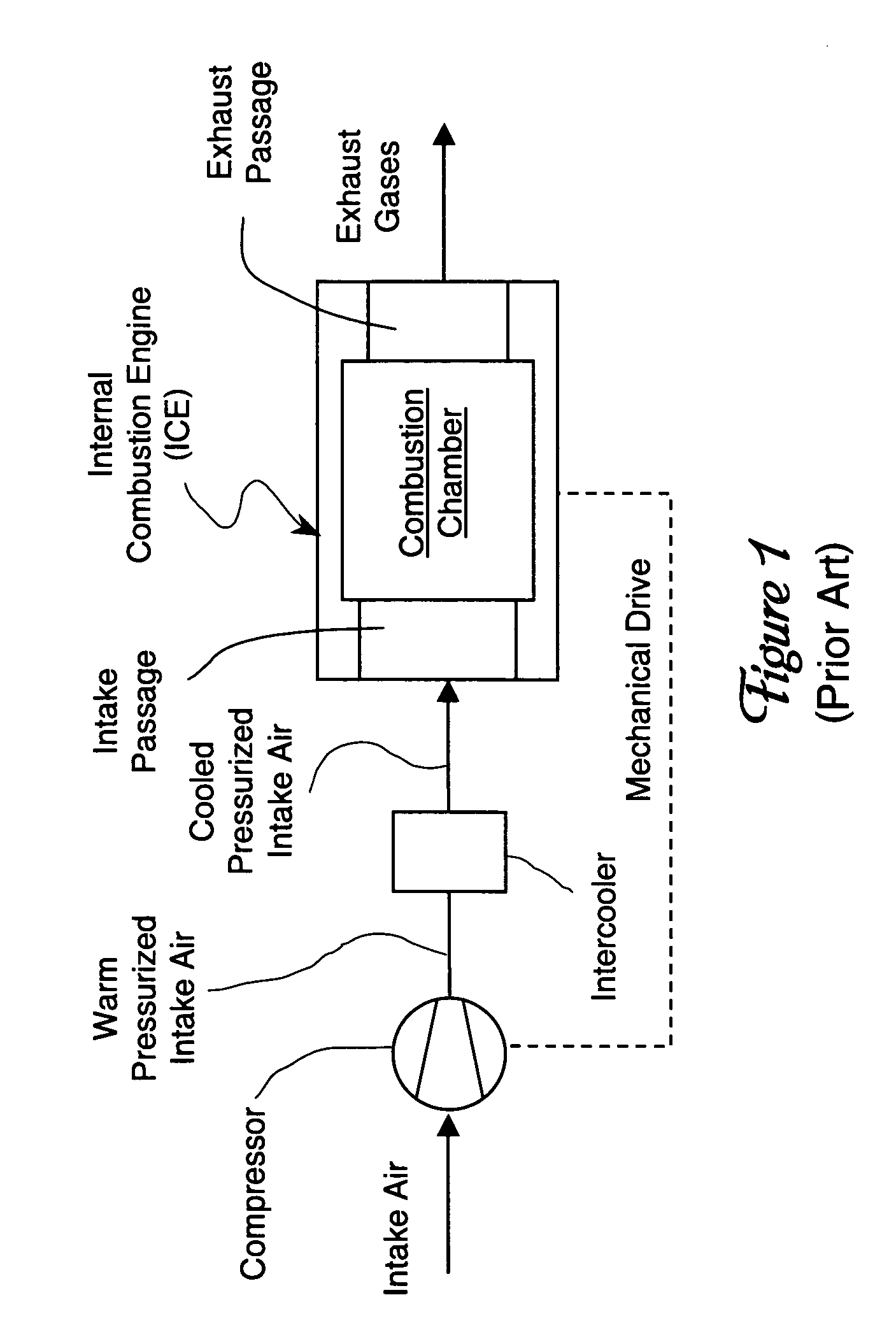

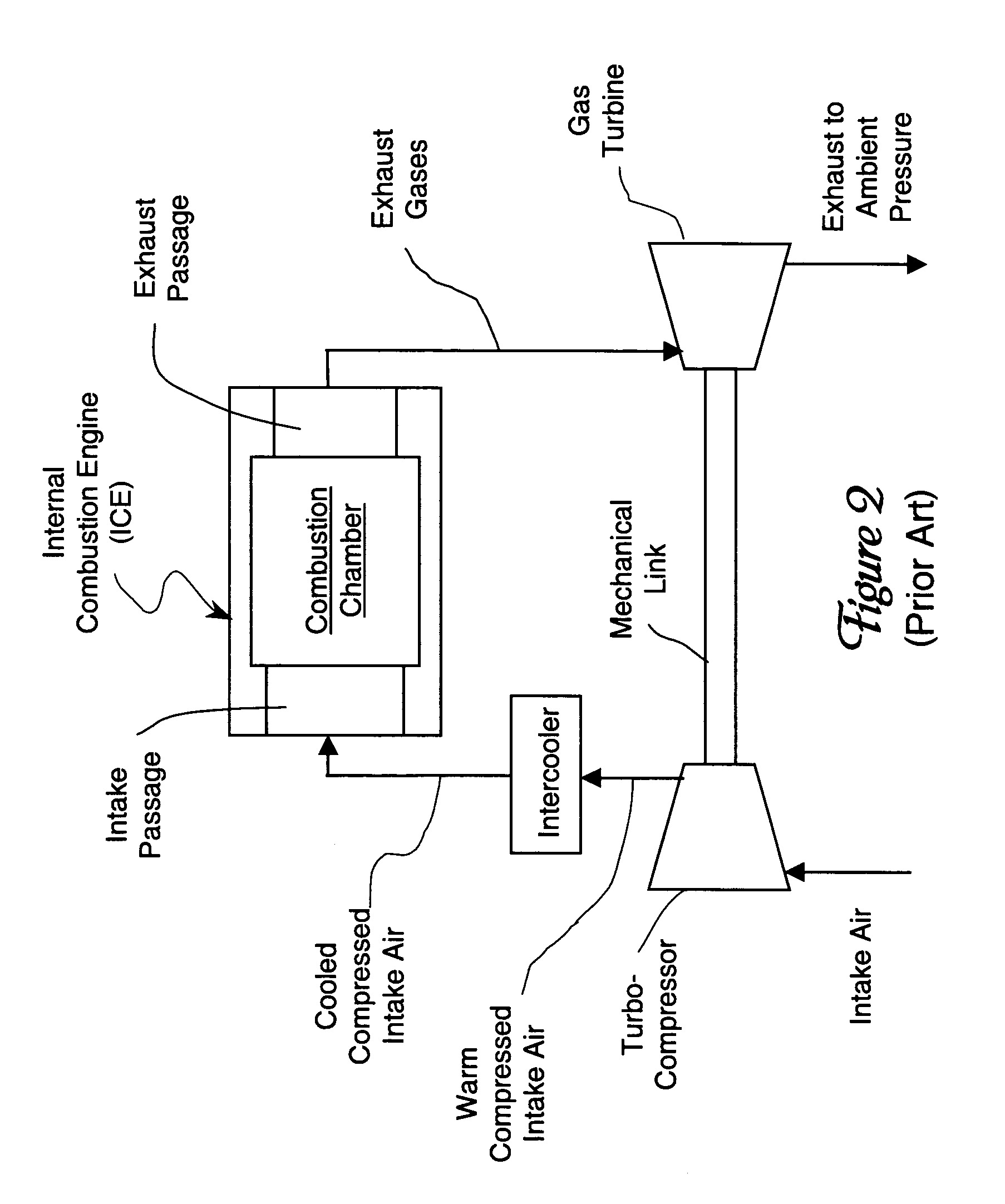

Forced induction is the process of delivering compressed air to the intake of an internal combustion engine. A forced induction engine uses a gas compressor to increase the pressure, temperature and density of the air. An engine without forced induction is considered a naturally aspirated engine.

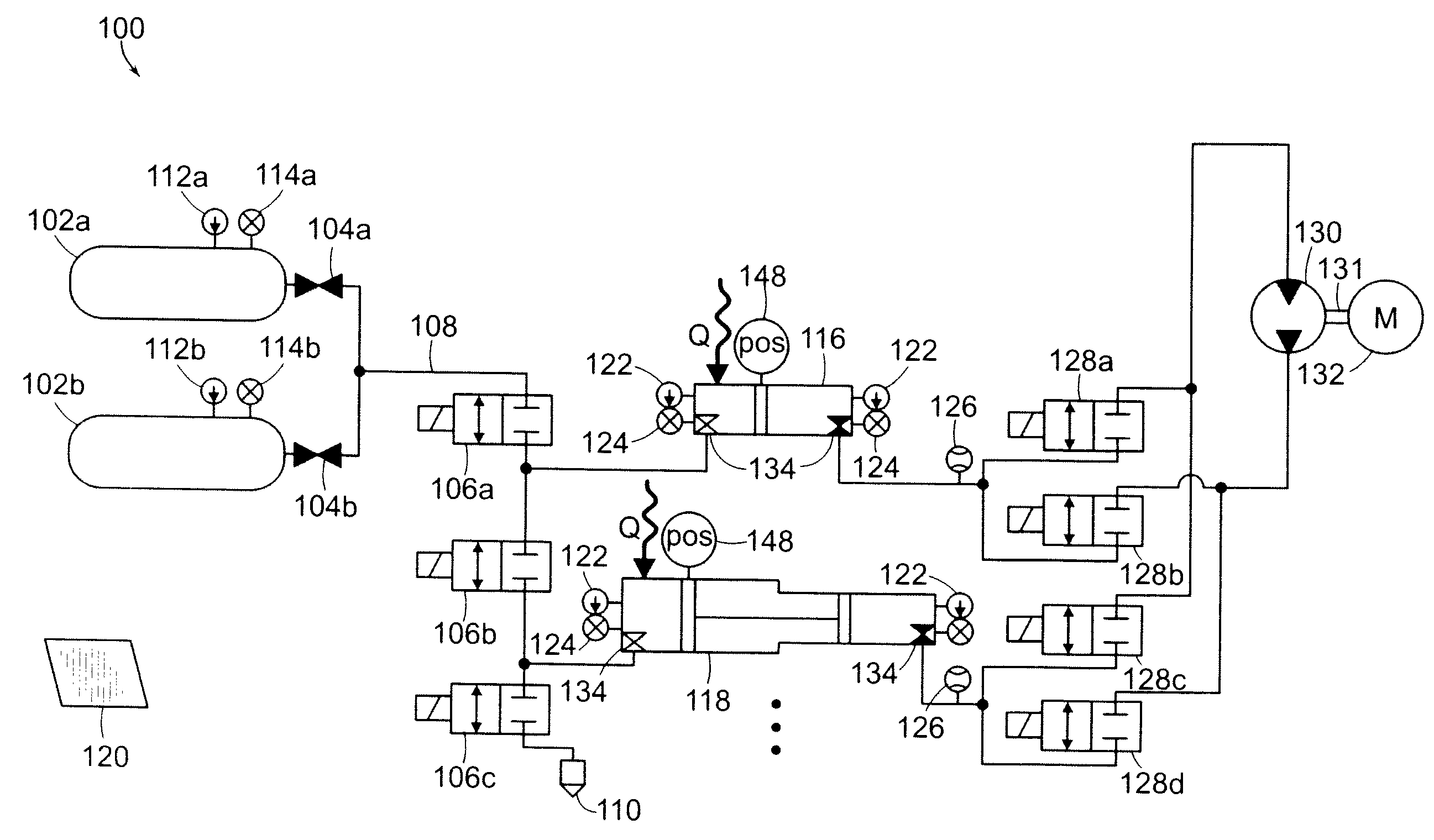

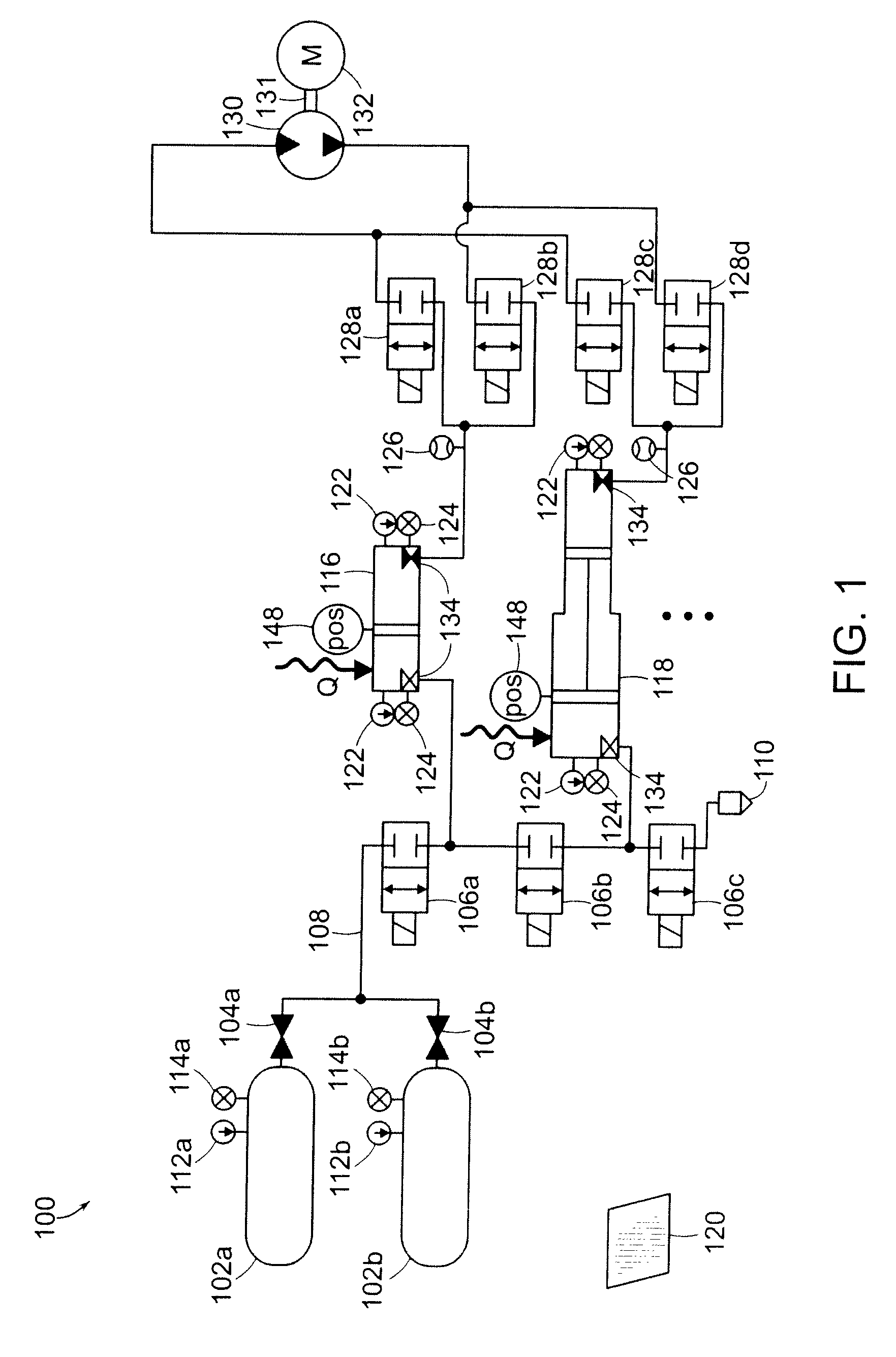

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

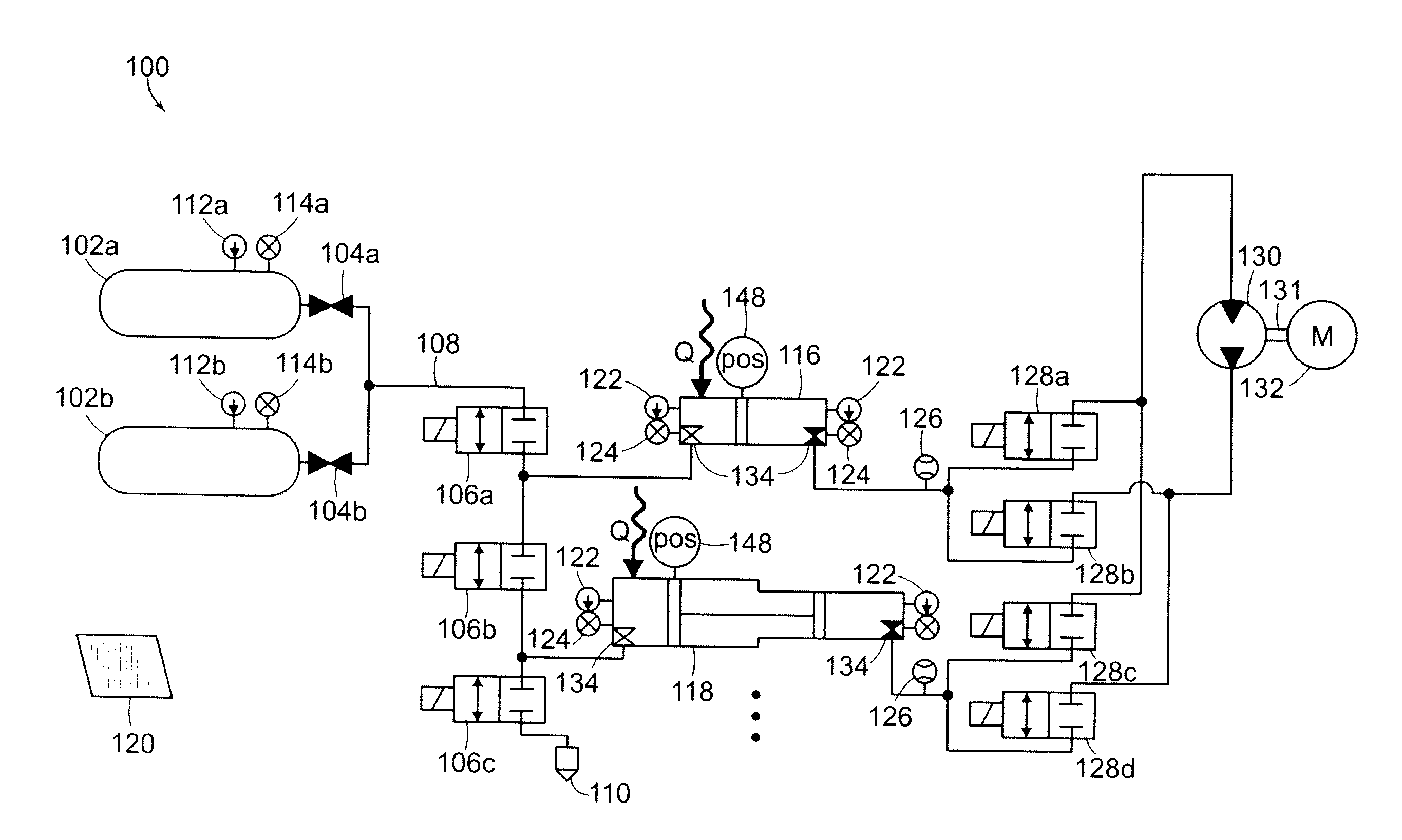

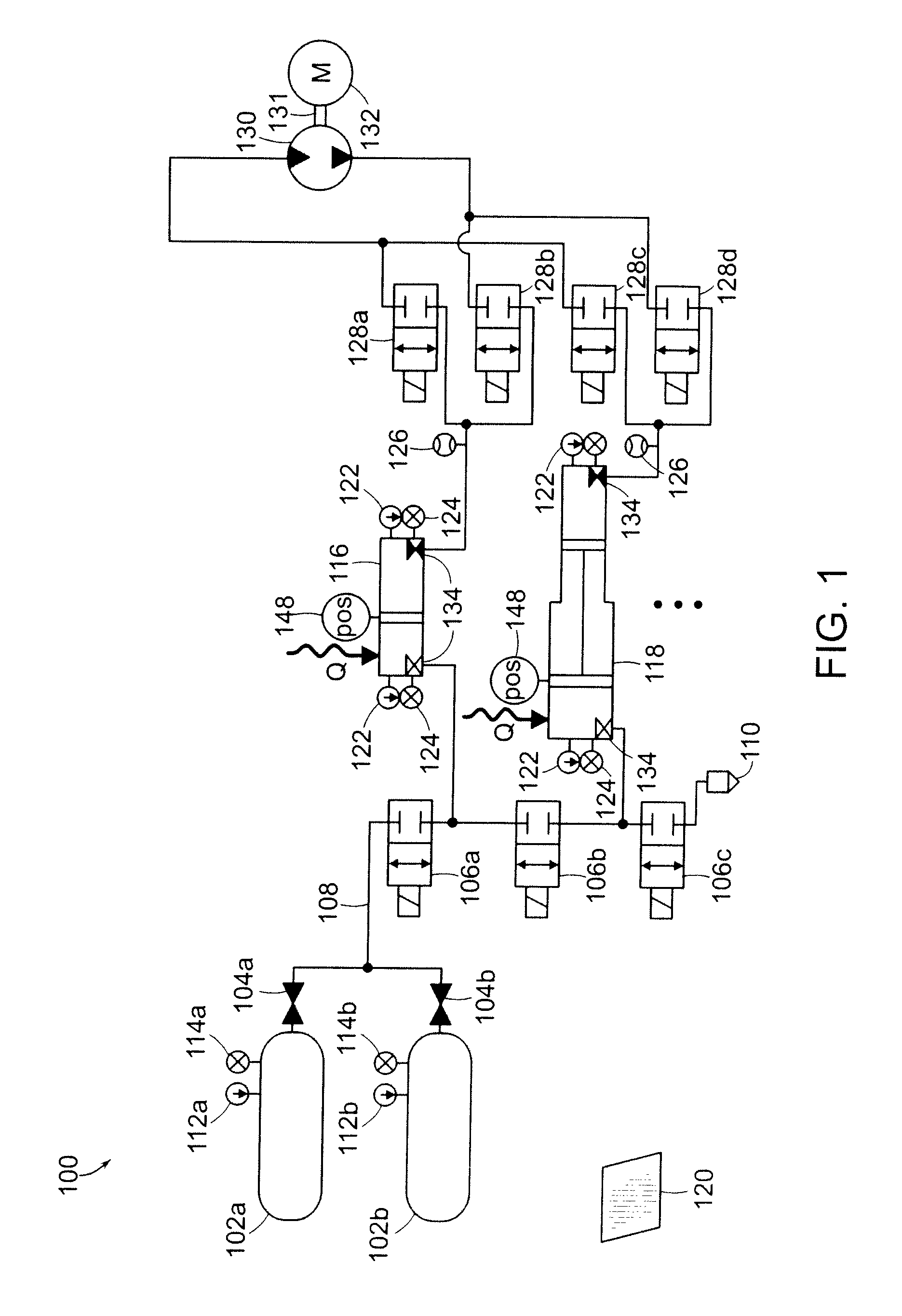

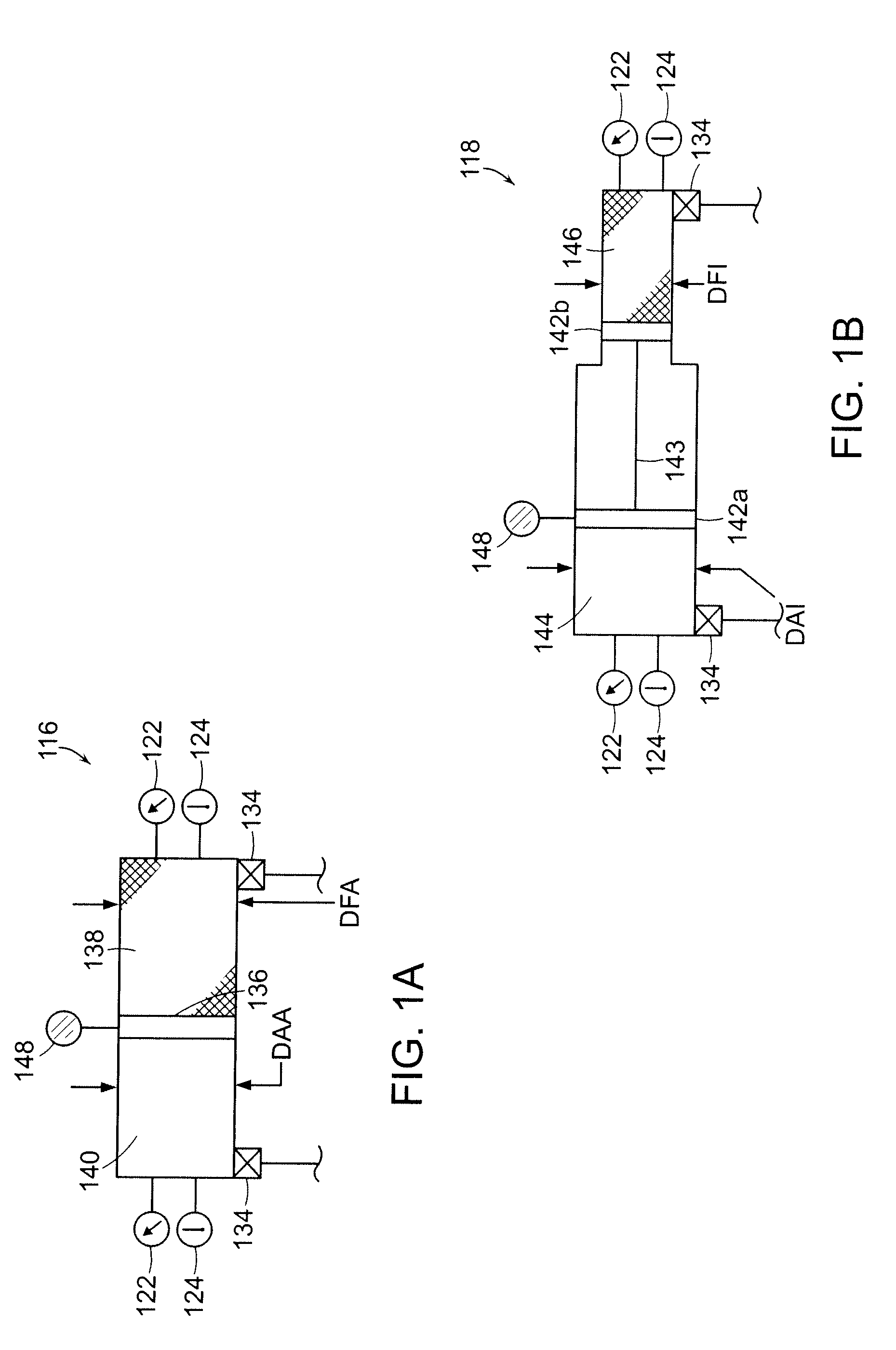

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

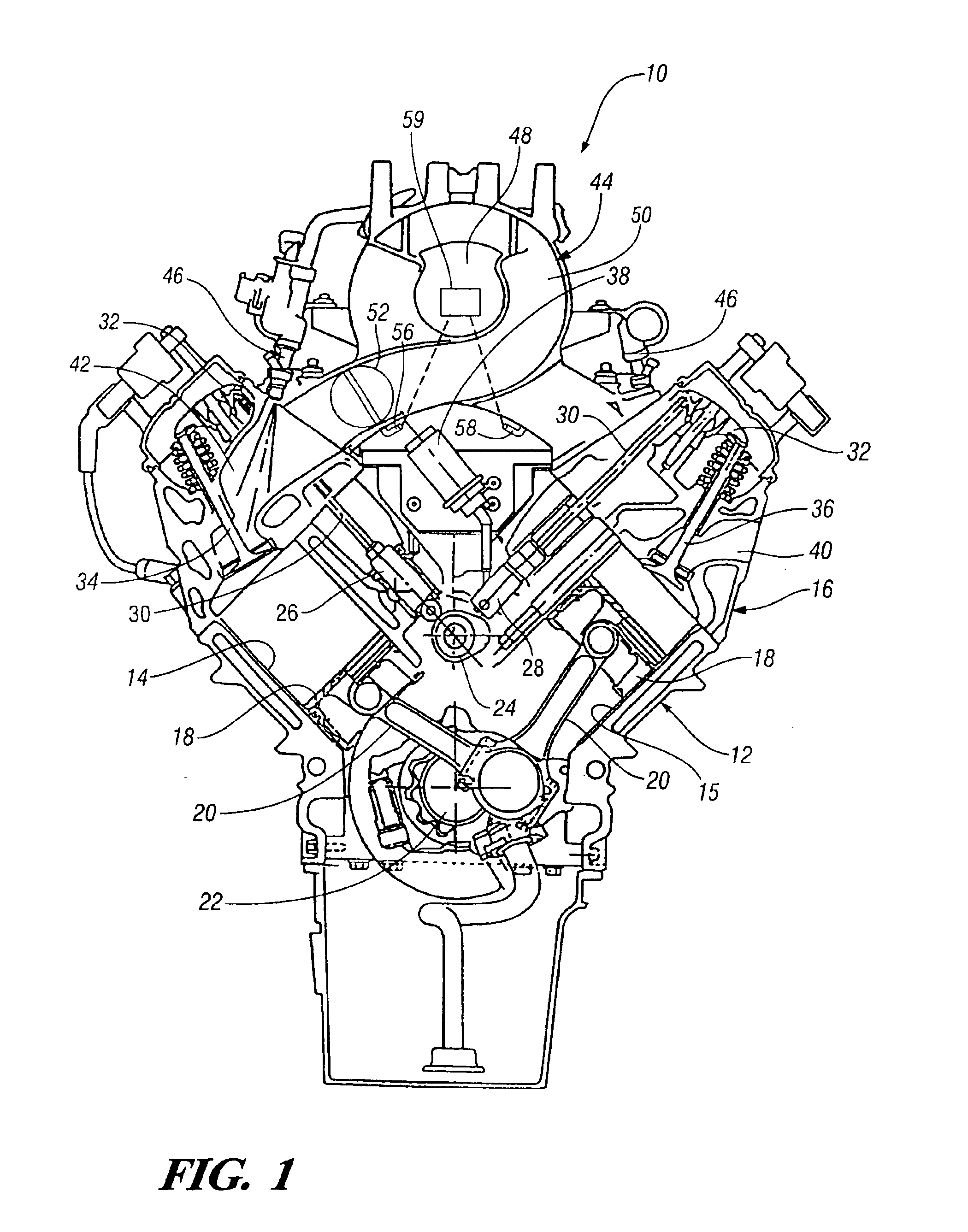

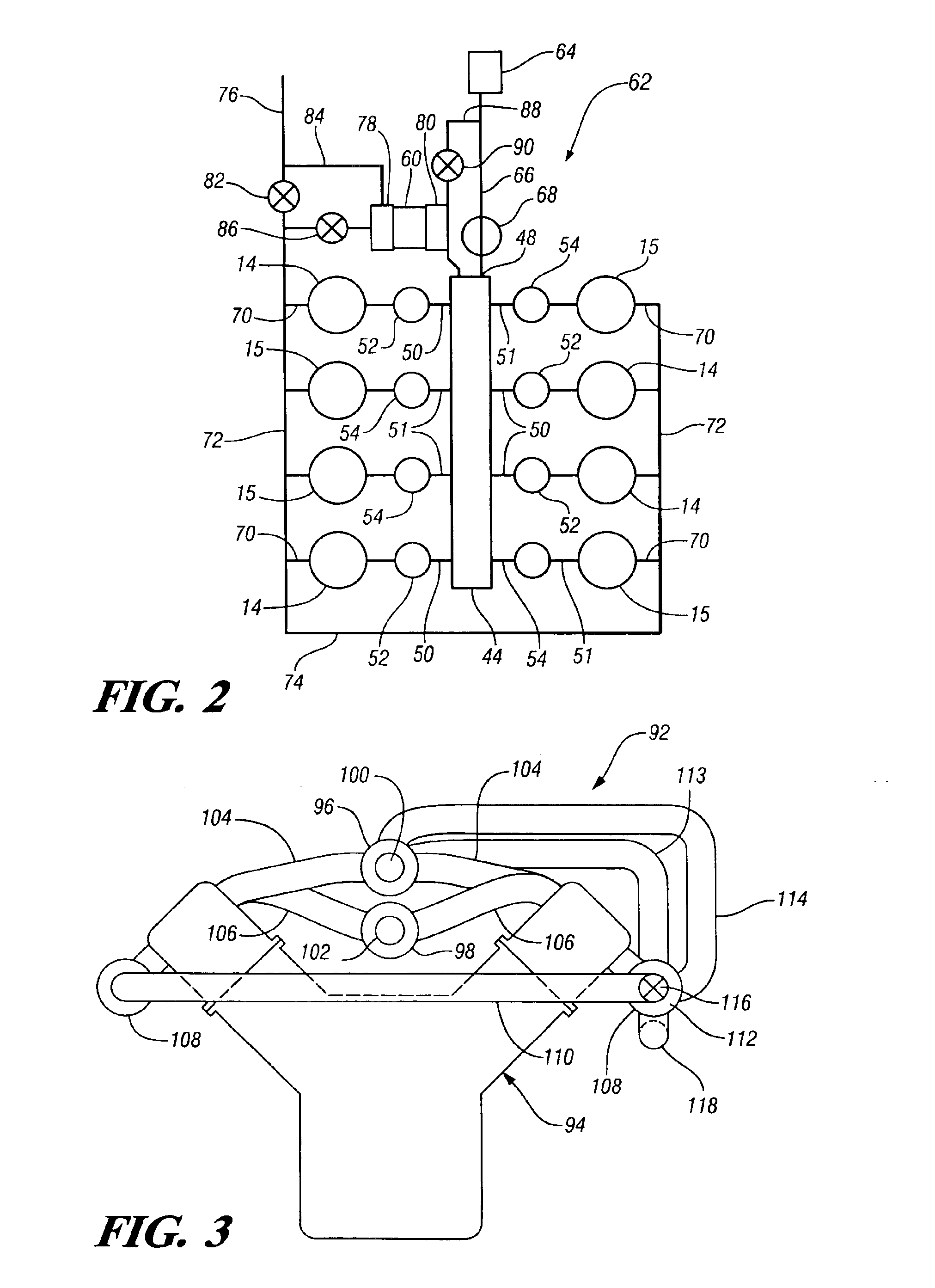

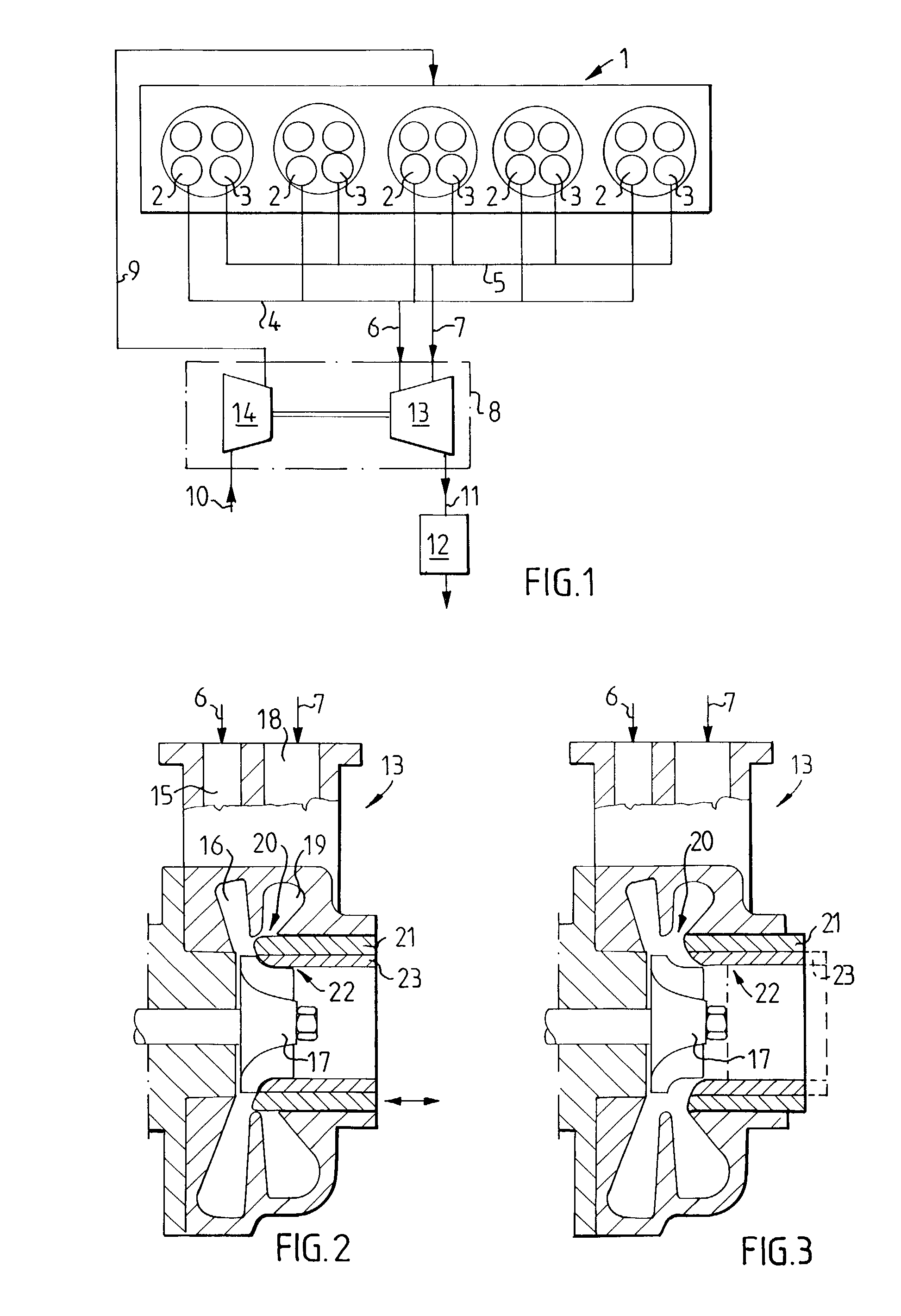

Engine and method of operation with cylinder deactivation

ActiveUS6874463B1Improvement in DOD operationEasy to operateElectrical controlInternal combustion piston enginesExhaust valveCylinder Valve

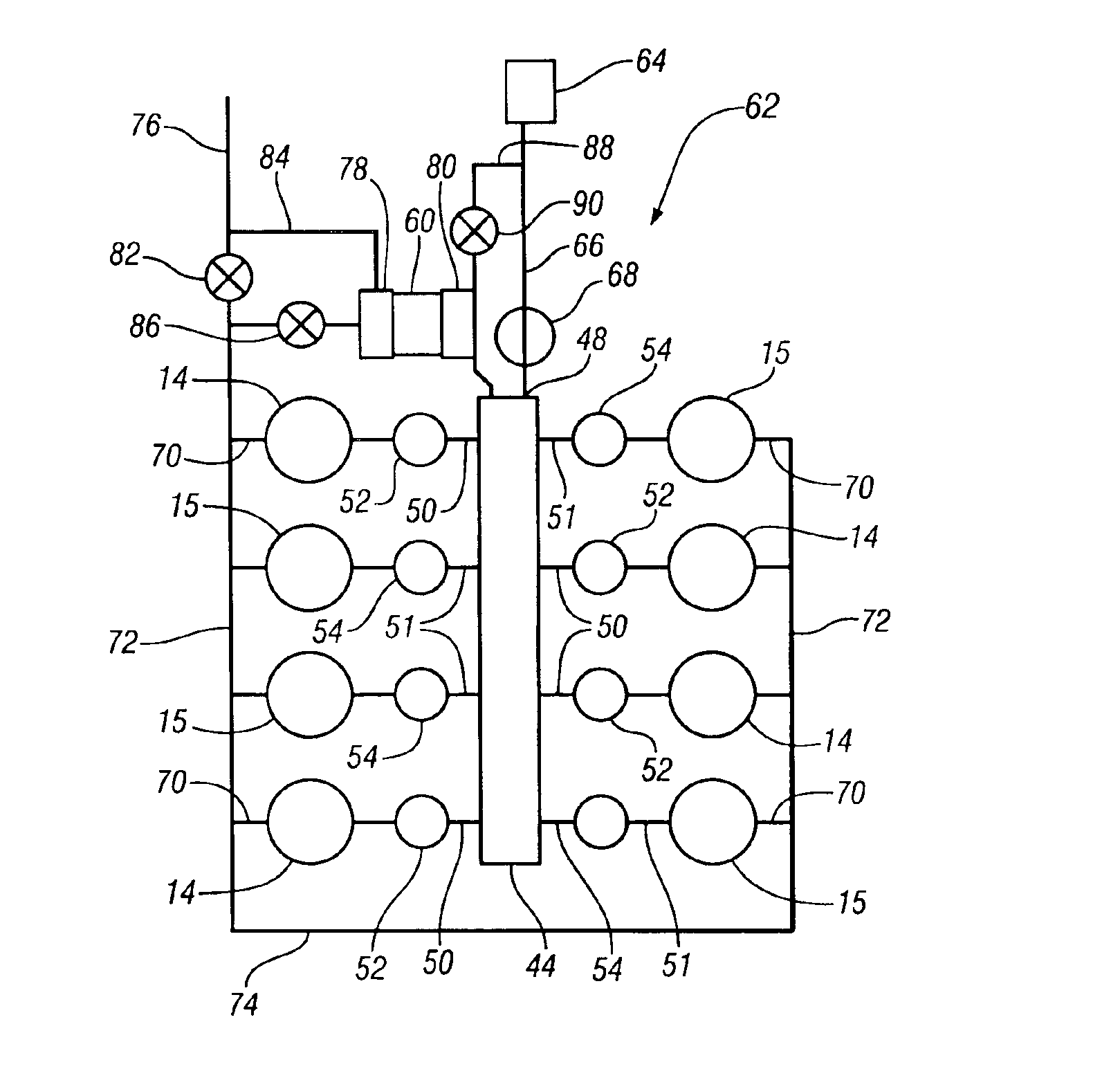

An engine with cylinder deactivation (Displacement on Demand or DOD™) includes standard (STD) cylinders which are not deactivated and DOD cylinders which can be deactivated by closing their intake and exhaust valves and shutting off their fuel supply. To provide smooth transitions, the STD and DOD cylinders form separate groups each supplied with charge air through one or more separate throttles. When switching to DOD operation, the throttles are oppositely actuated to cut out the DOD cylinders and maintain torque in the active cylinders prior to deactivation of the cylinder valves. When returning to STD operation, the valves are reactivated before oppositely actuating the throttles to enable full cylinder operation. In DOD operation, a small supercharger may be operated to boost torque of the operating STD cylinders and thus increase the DOD operating range.

Owner:GM GLOBAL TECH OPERATIONS LLC

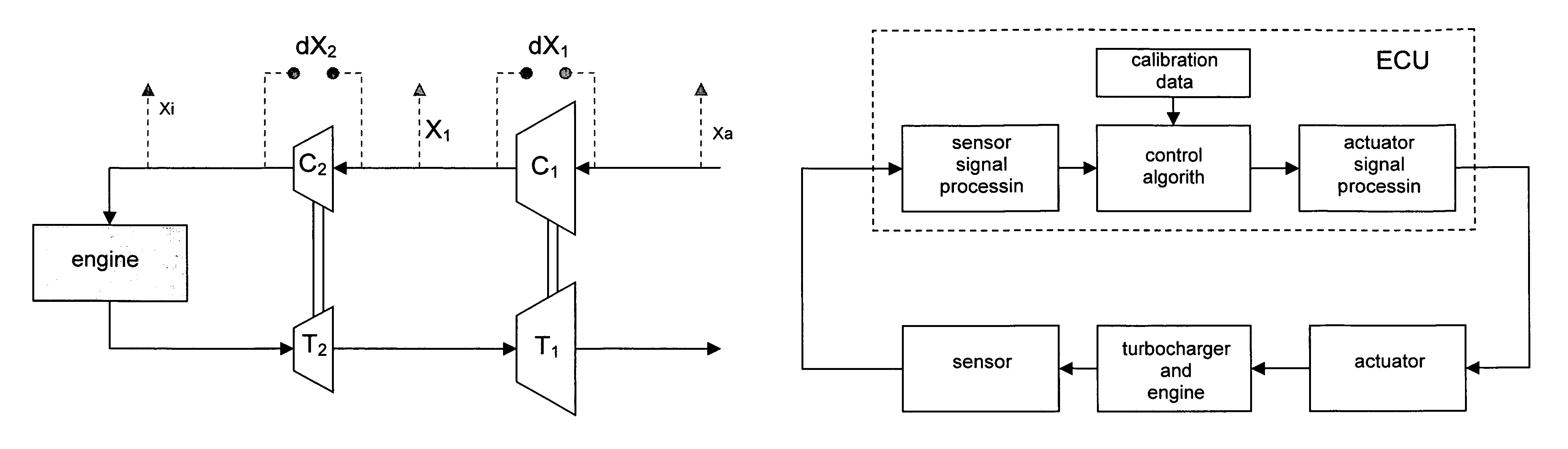

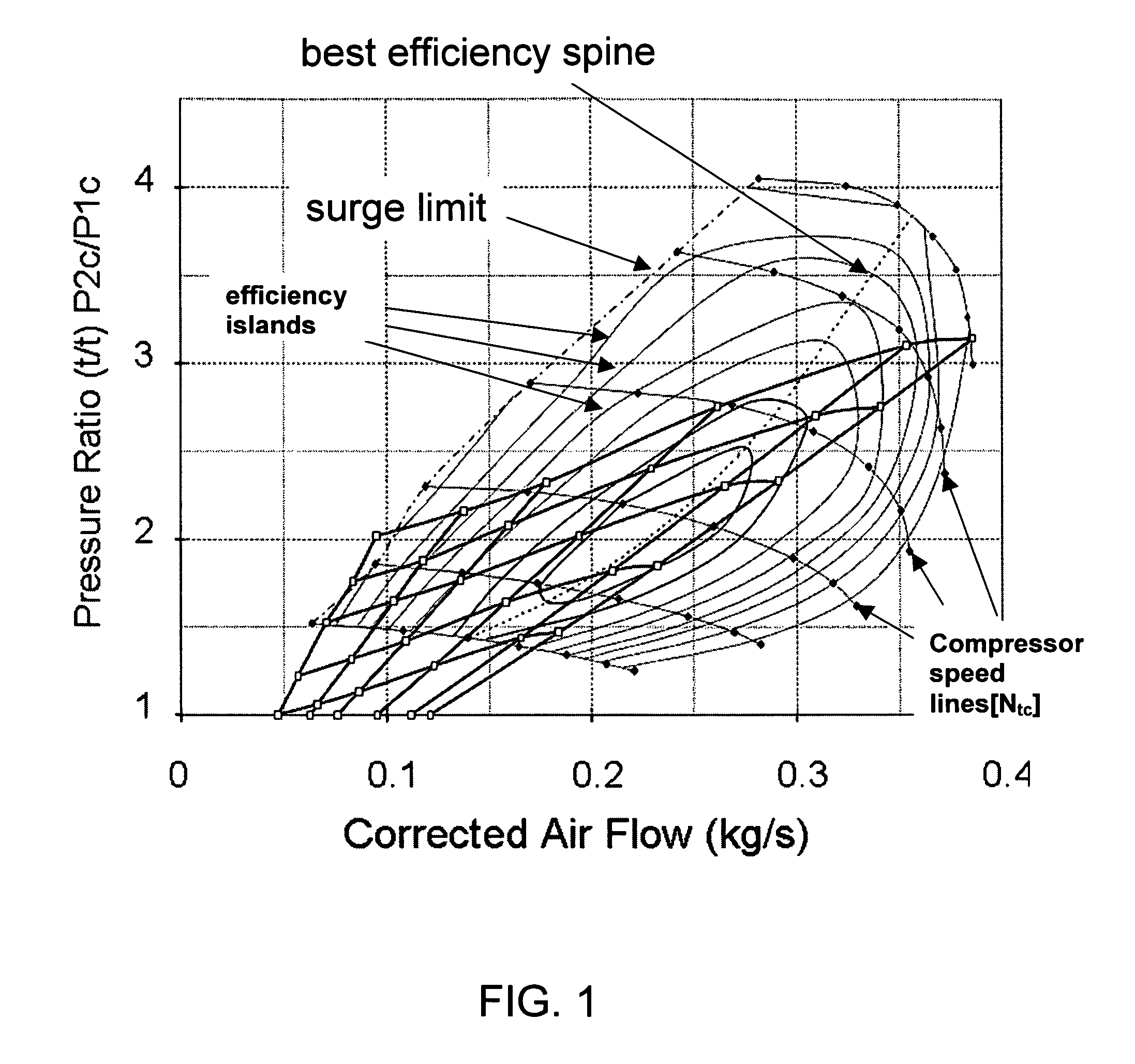

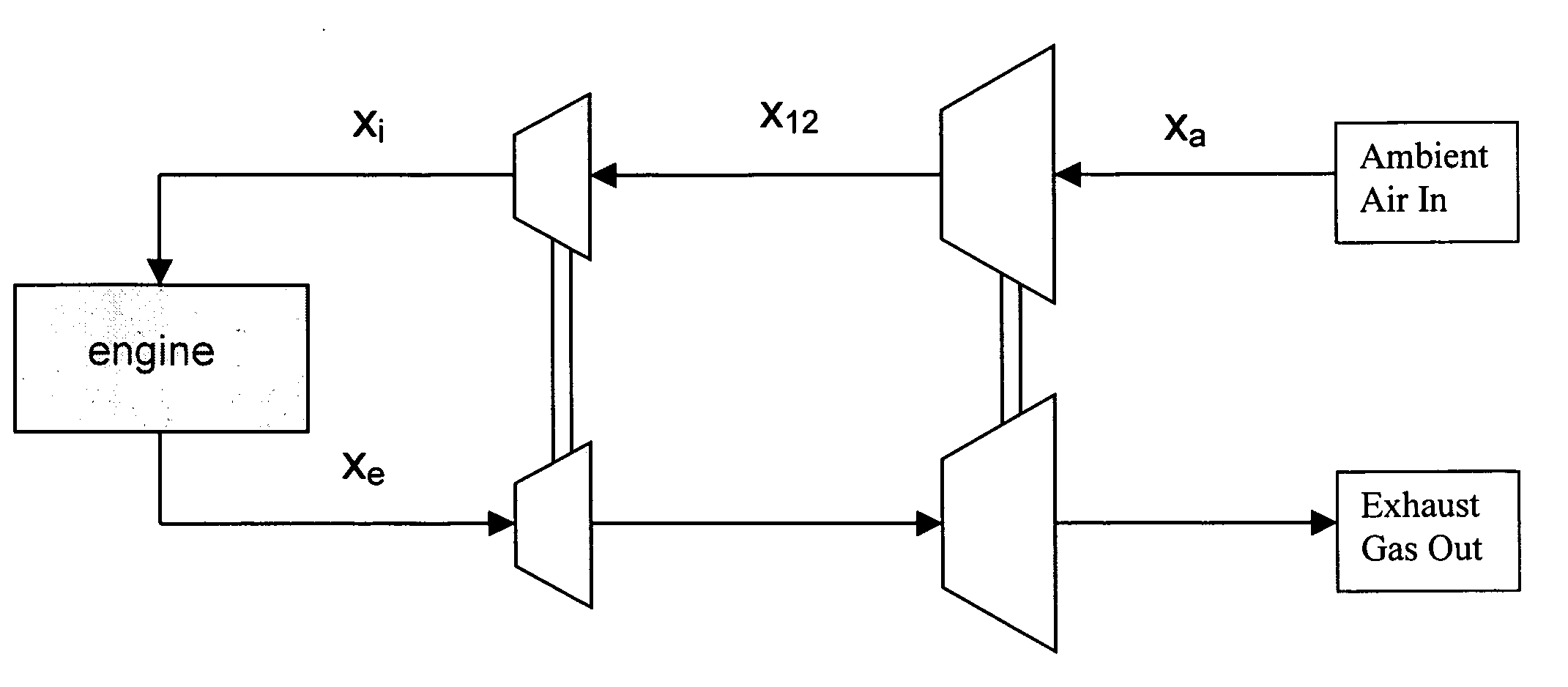

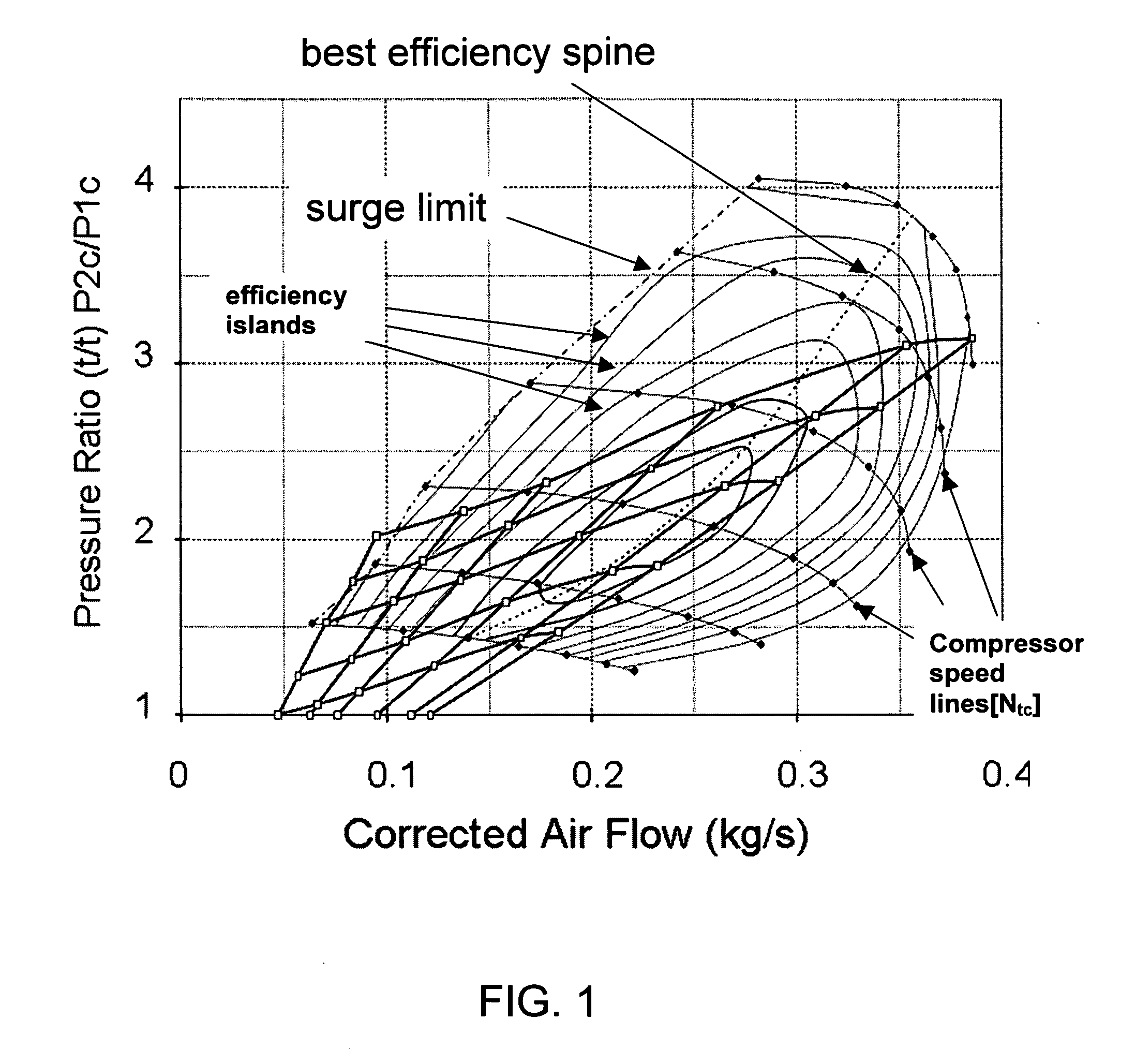

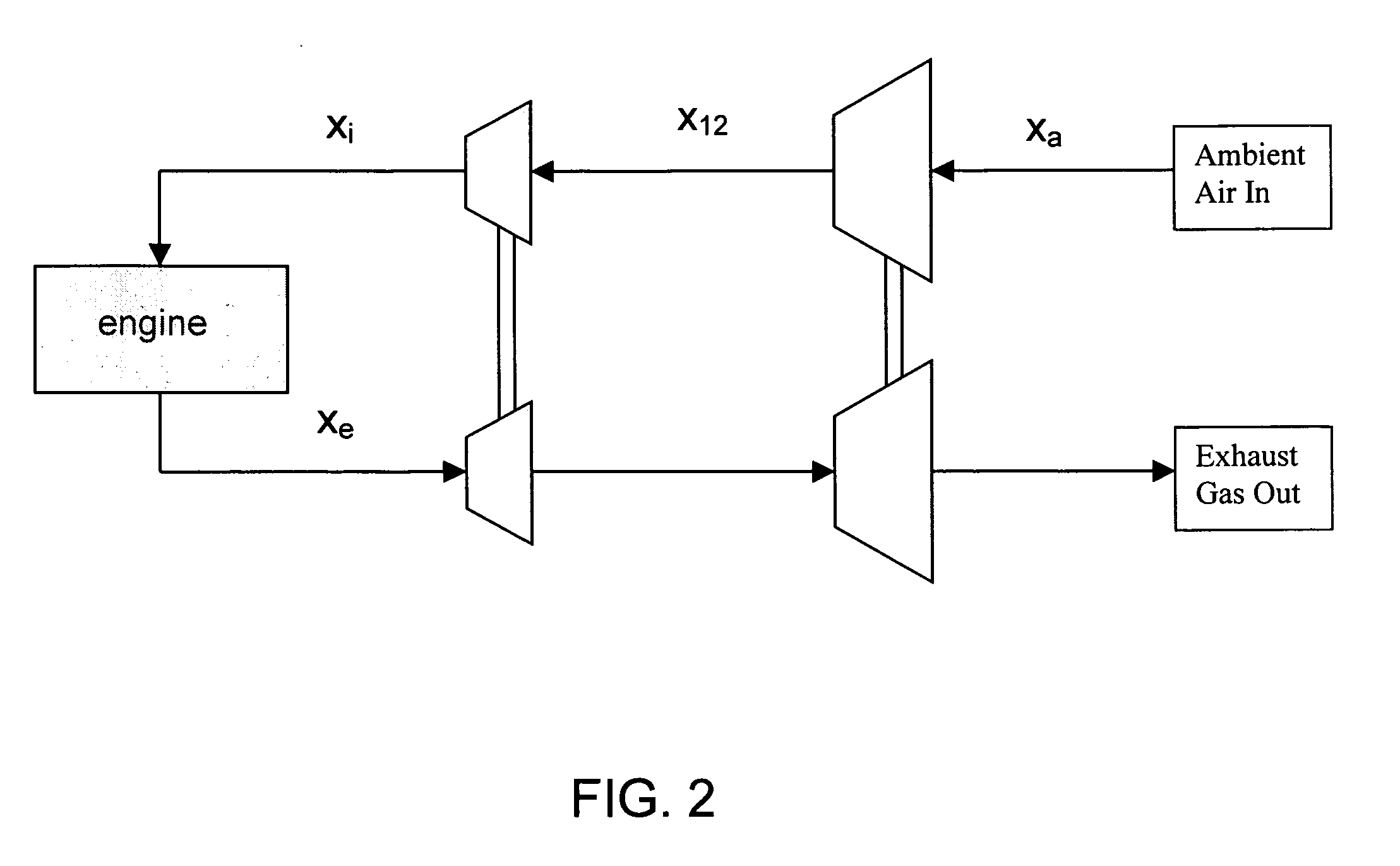

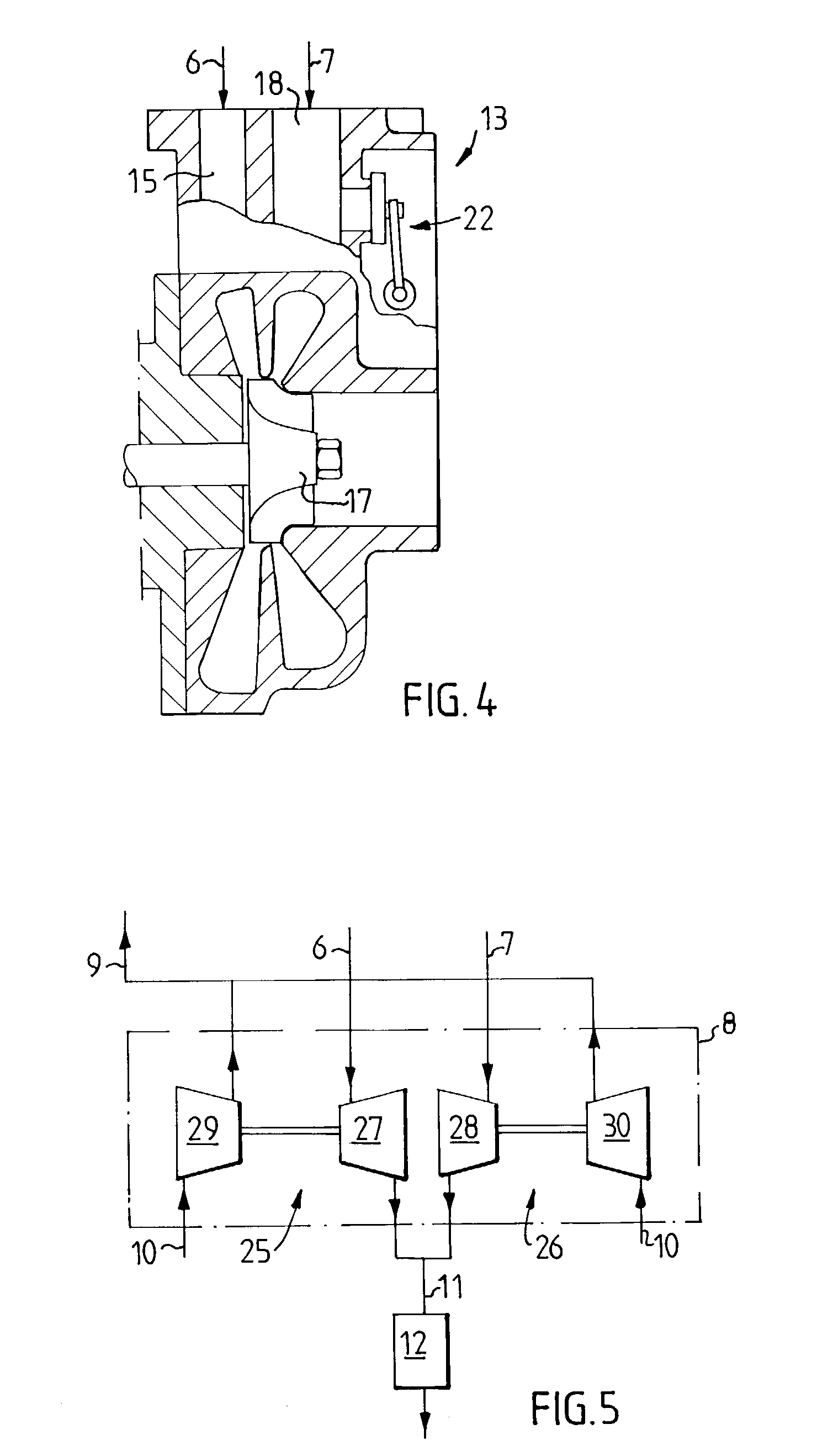

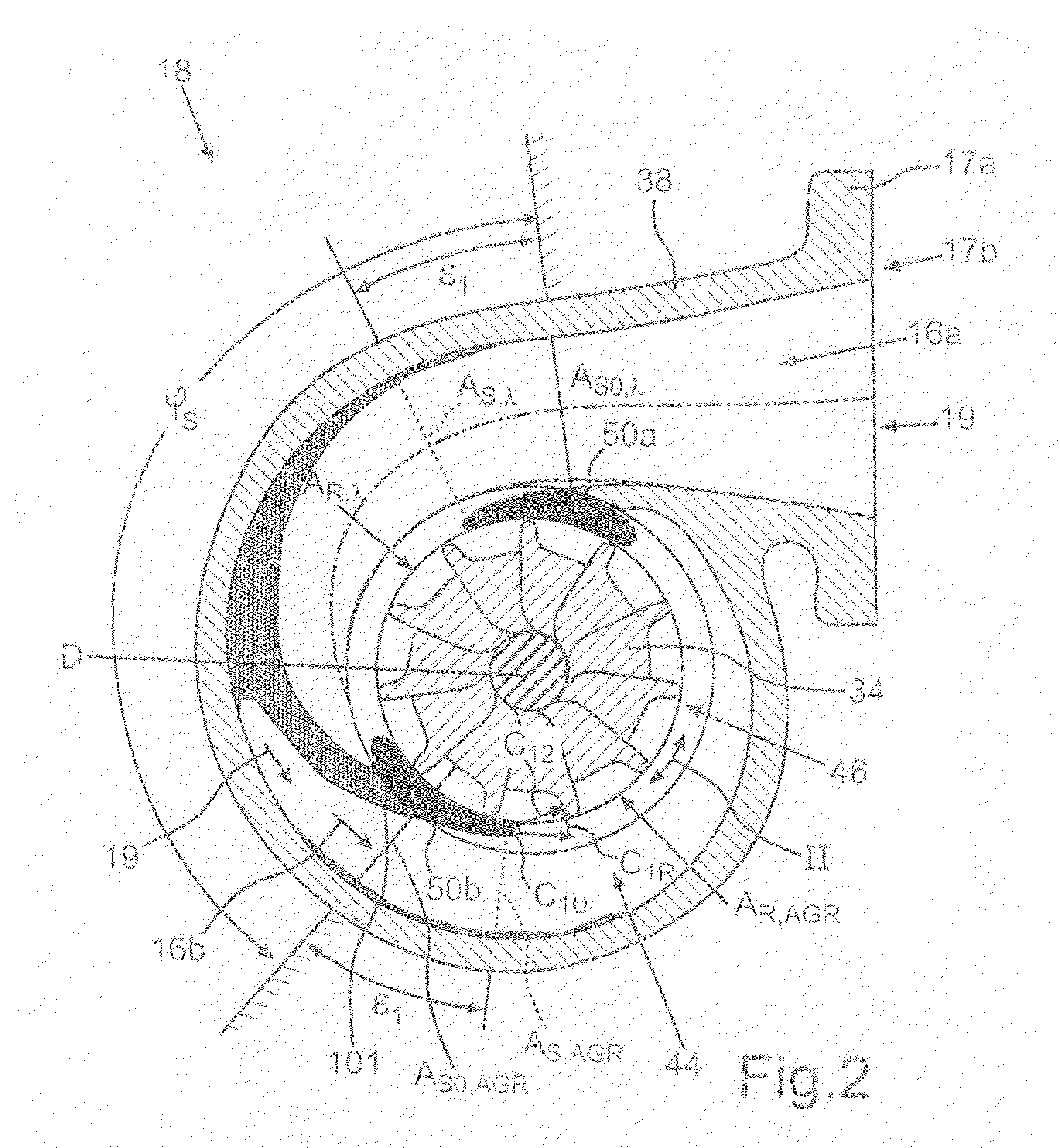

Control of dual stage turbocharging

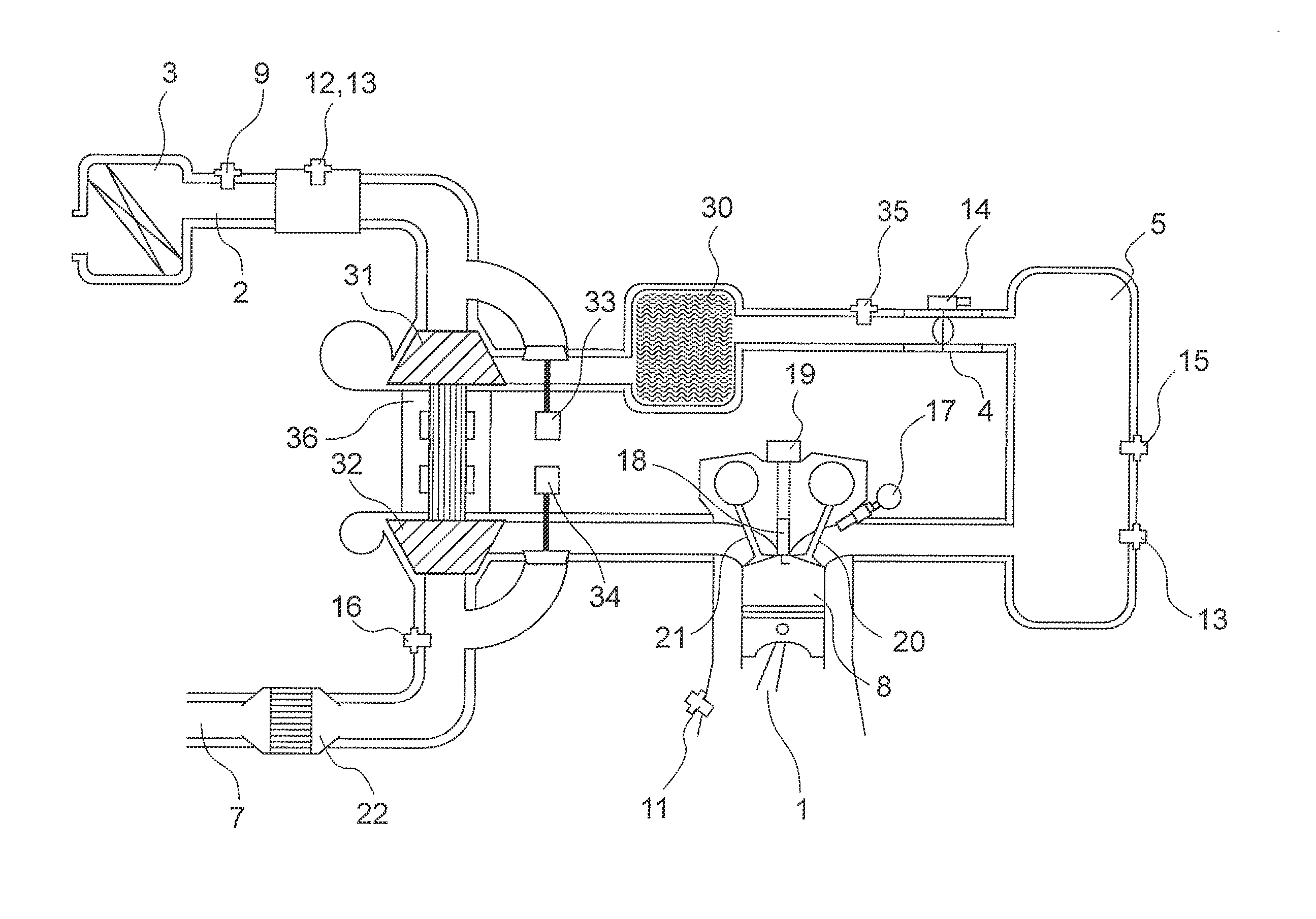

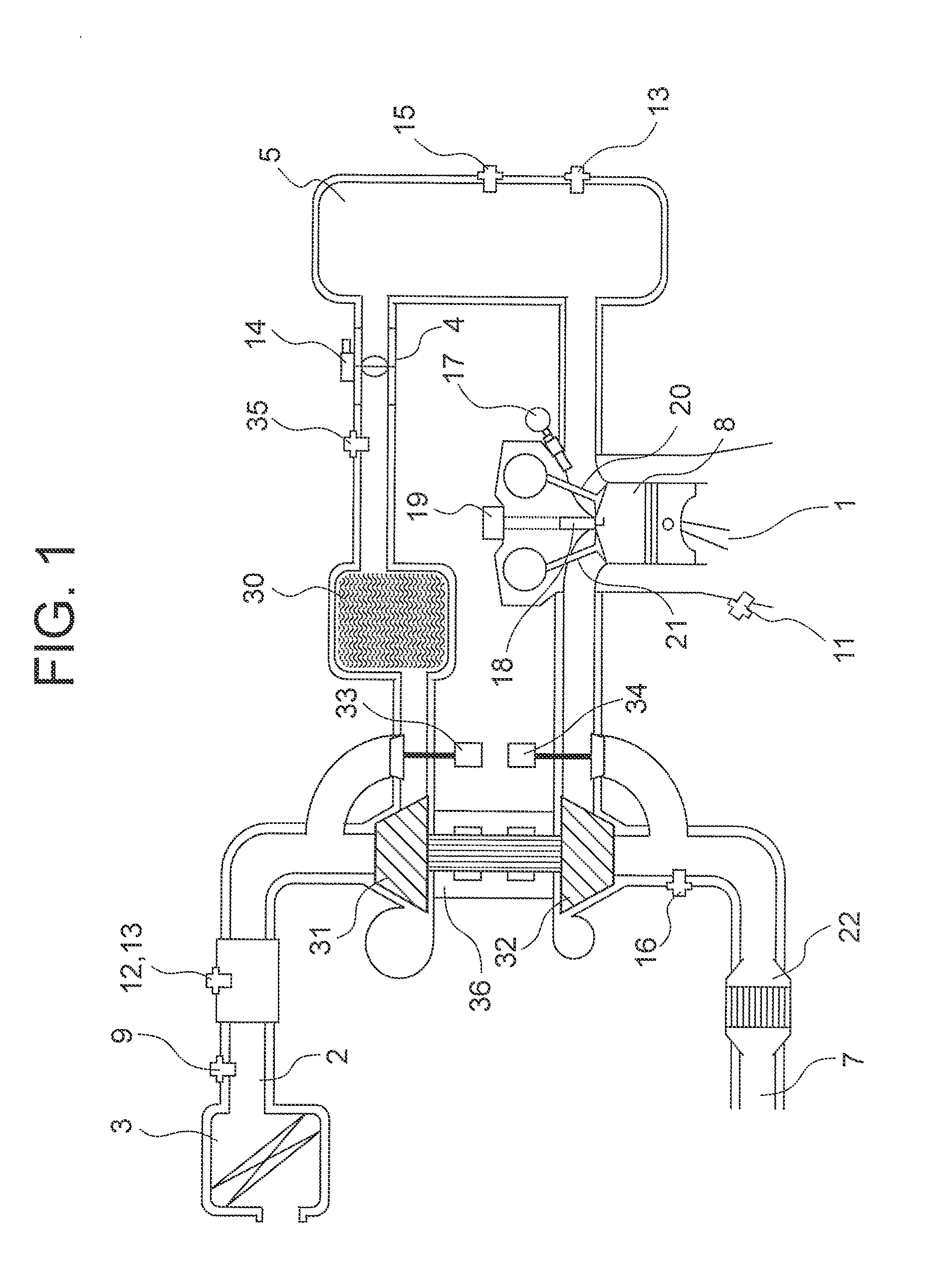

The invention concerns turbochargers, or more particularly to multivariable dual stage series turbochargers having two degrees of freedom. A multistage series turbocharger apparatus has a low pressure turbocharger comprising a low pressure compressor and a low pressure turbine; a high pressure turbocharger comprising a high pressure compressor and a high pressure turbine, and a exhaust gas recirculation device. A controller controls the operation of at least two of the low pressure compressor, high pressure compressor, low pressure turbine, high pressure turbine, and exhaust gas recirculation device such that at least one operating parameter is maintained at about a selected value.

Owner:GARRETT TRANSPORATION I INC

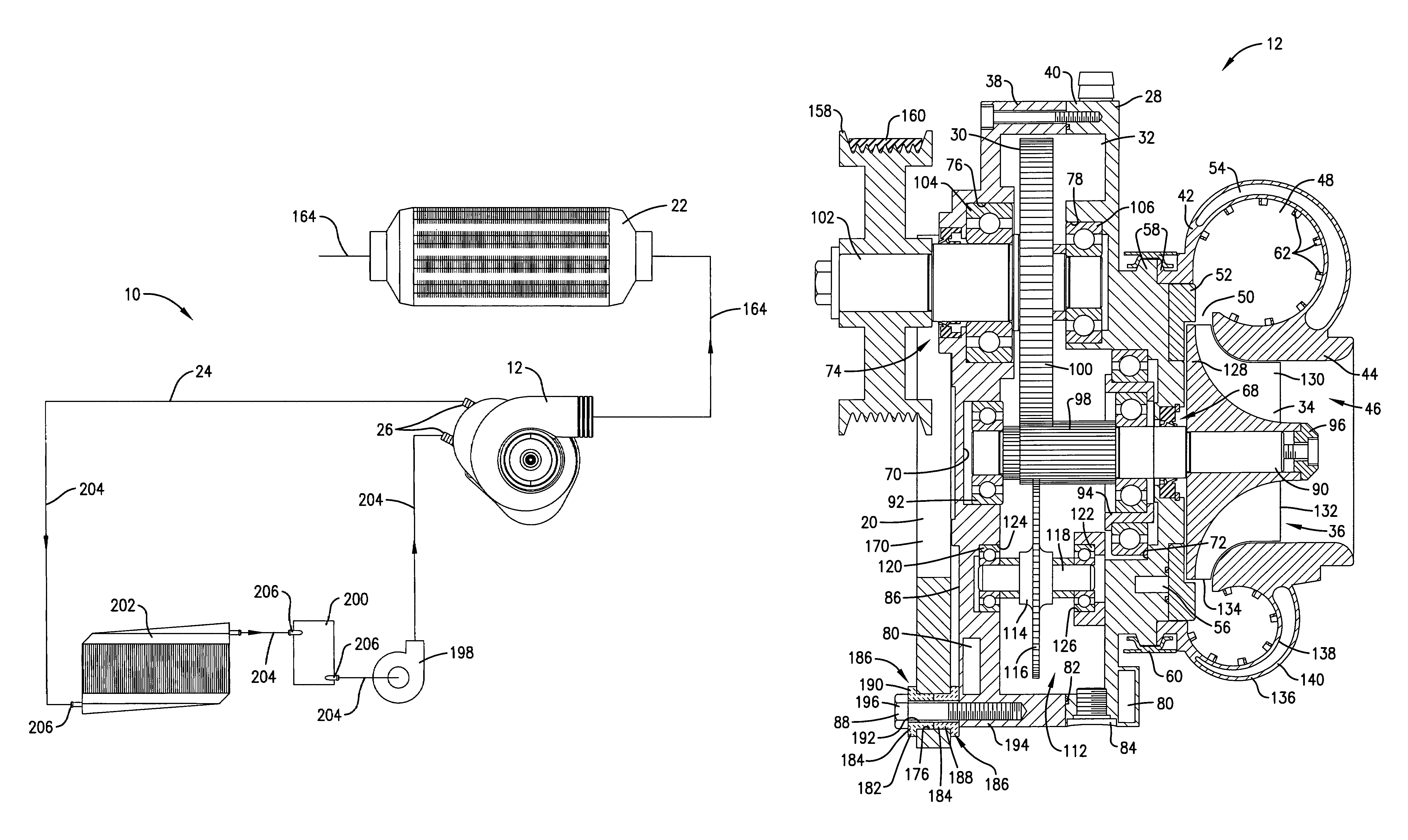

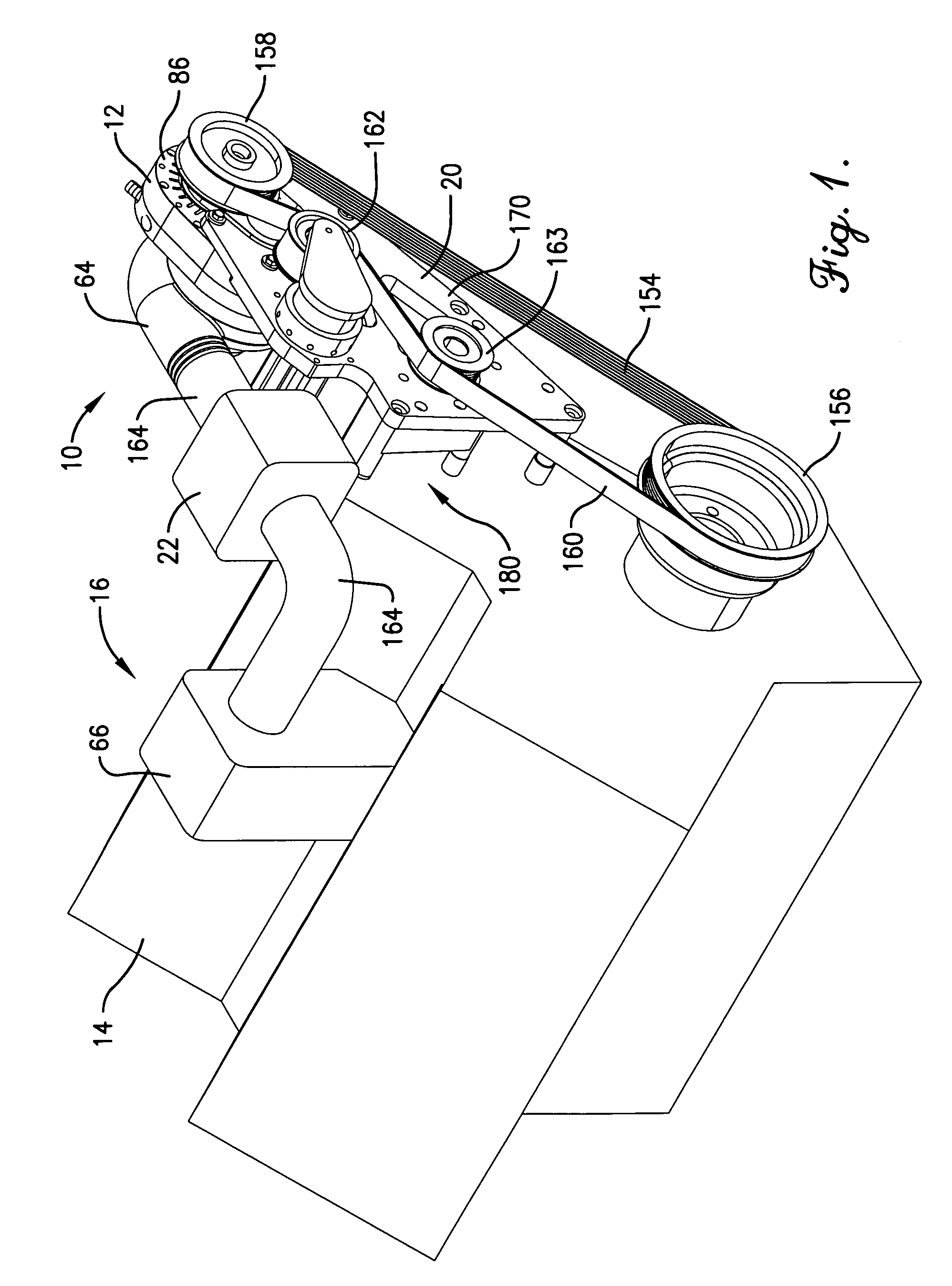

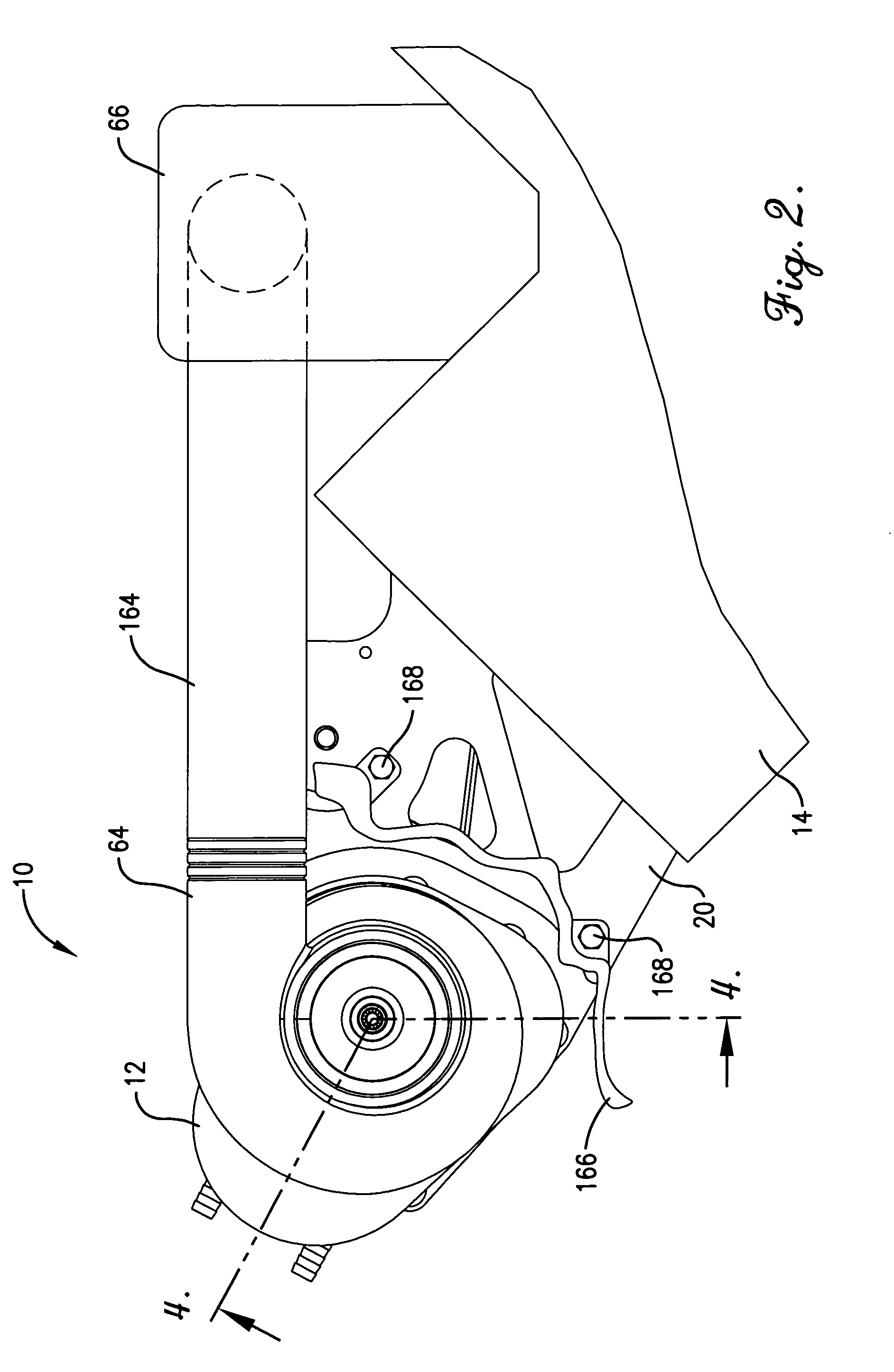

Fluid cooled supercharger

InactiveUS7469689B1Promotes an increase in inductionRaise transfer toPump componentsCombustion enginesForced-airIntercooler

A forced air induction system for use with a powered vehicle is disclosed as including a centrifugal supercharger supported by the vehicle's engine and a recirculating induction coolant system that cools the supercharger and the compressed induction fluid provided by the supercharger. The induction coolant system operates by providing coolant to the supercharger and to an intercooler of the forced air induction system. The supercharger case includes internal passageways for cooling the transmission and compressor. The forced air induction system further includes spacers and radiant heat shields for rejecting heat transferred conductively and radiantly from the engine.

Owner:ACCESSIBLE TECHONOLOGIES

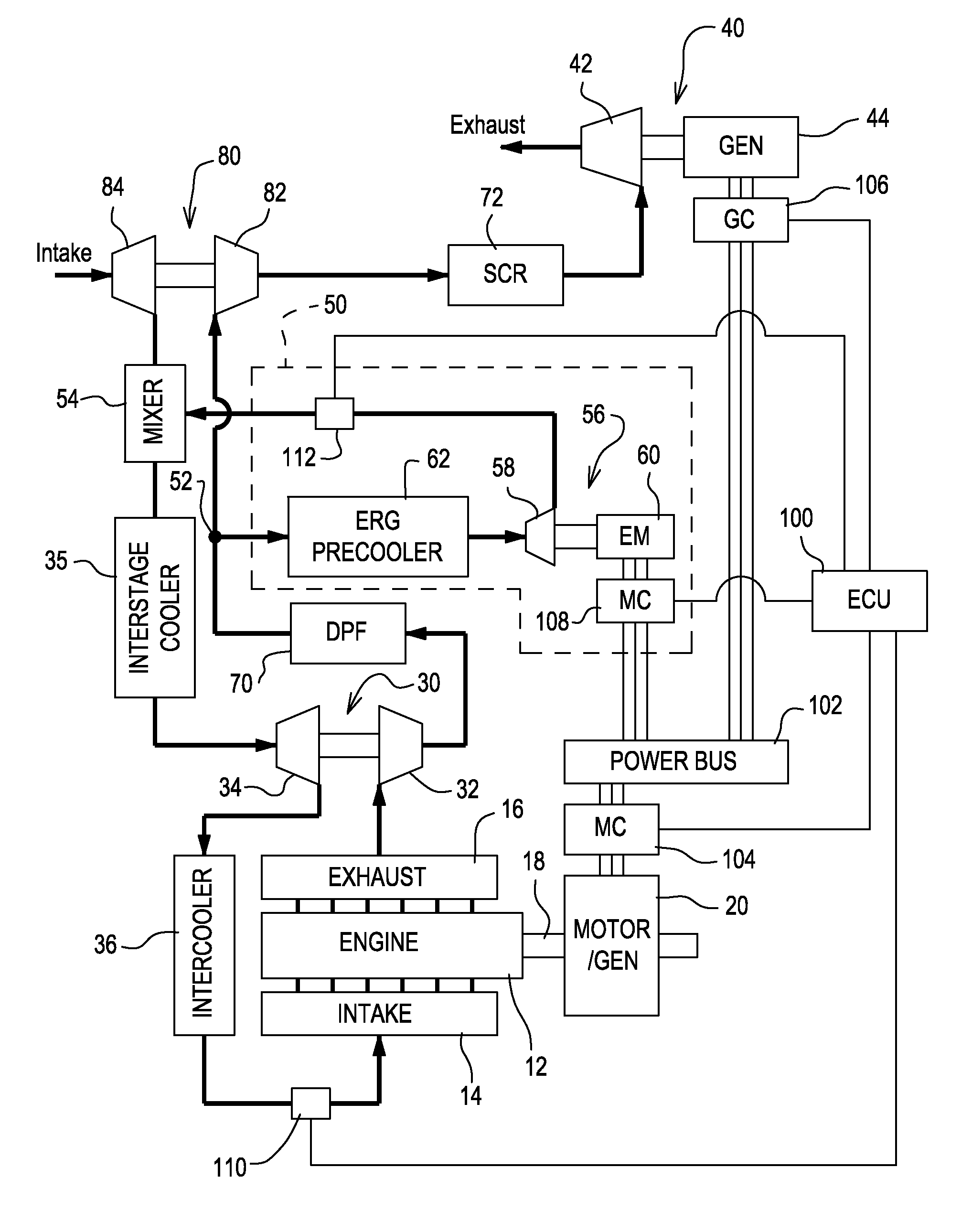

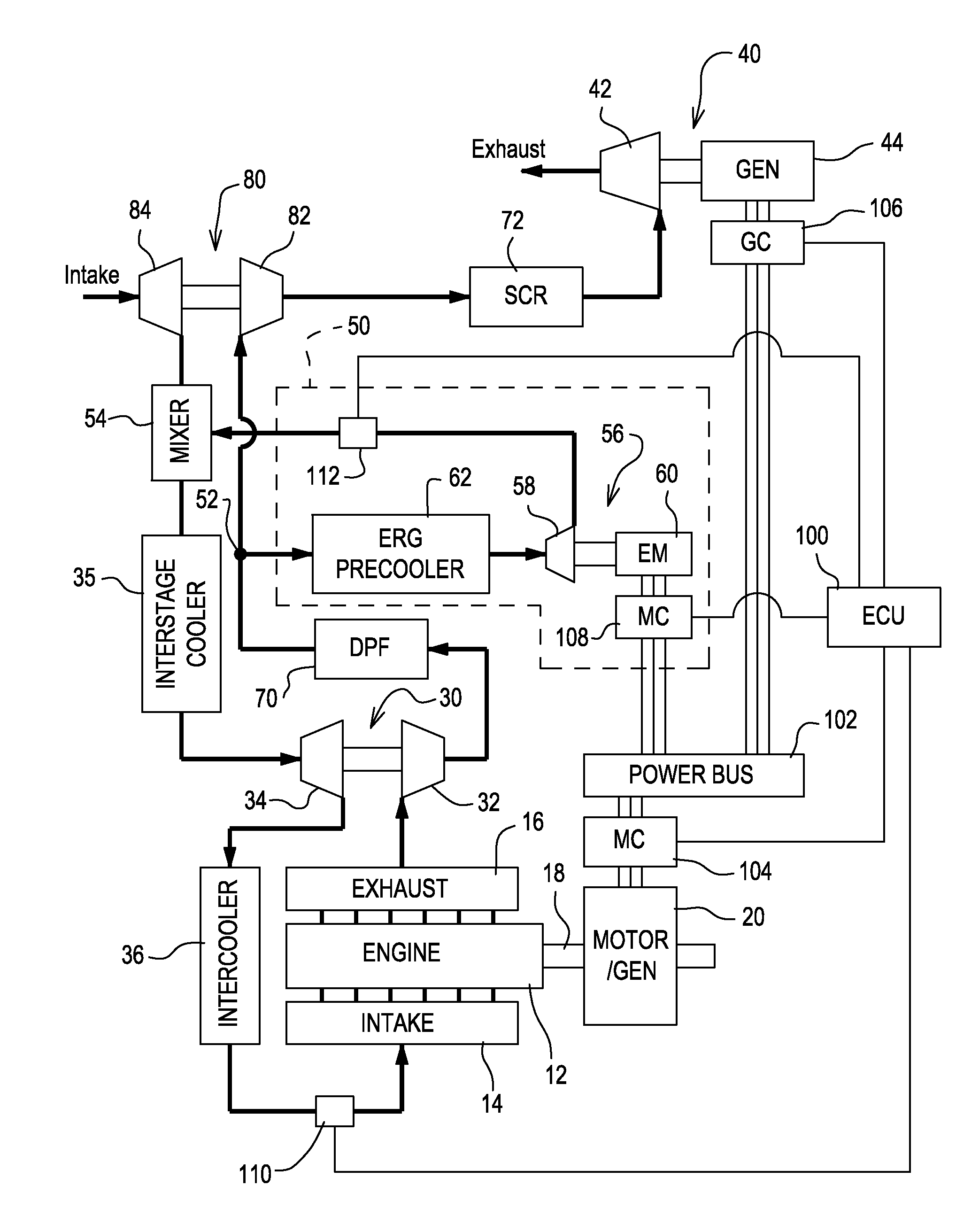

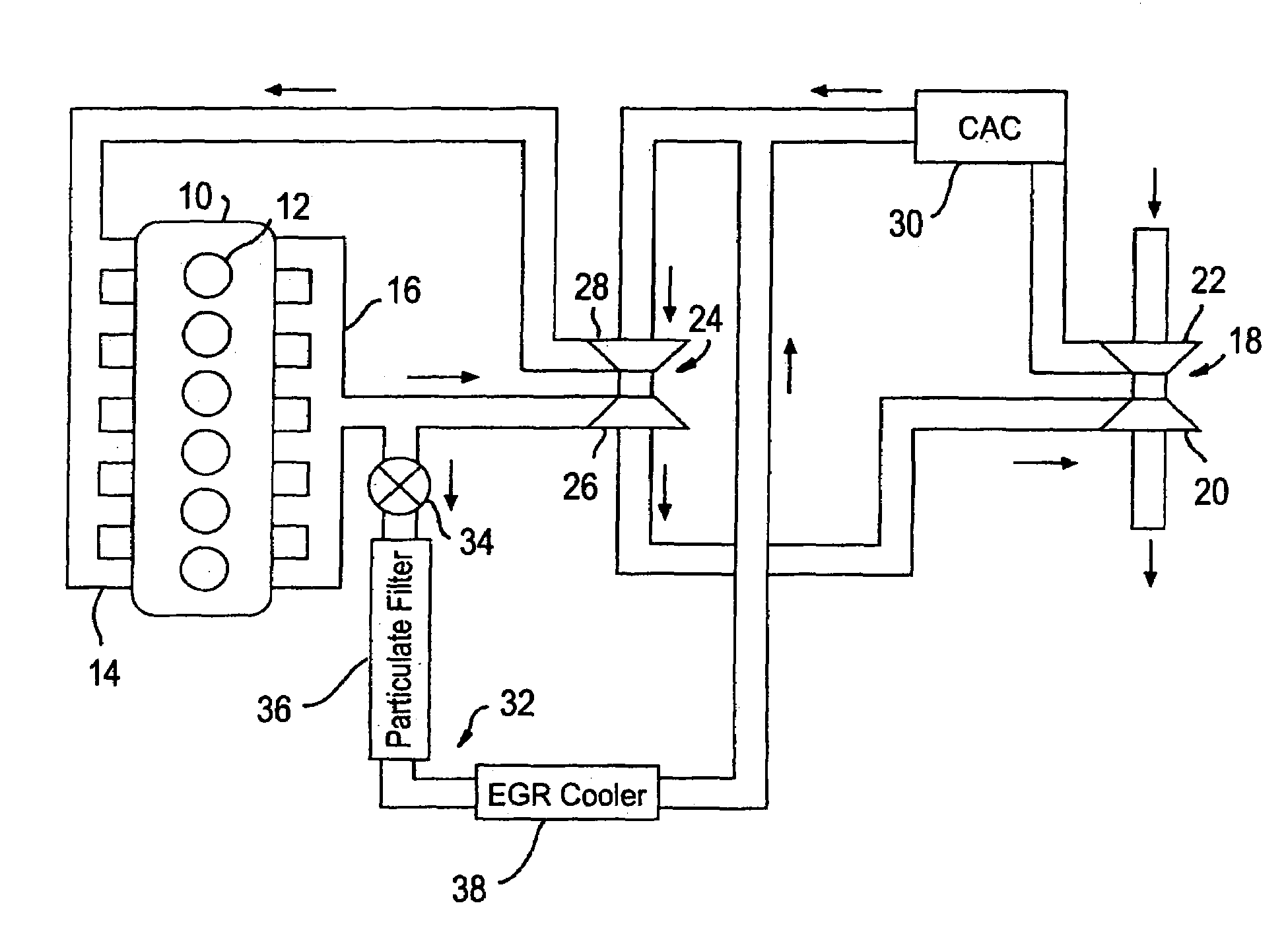

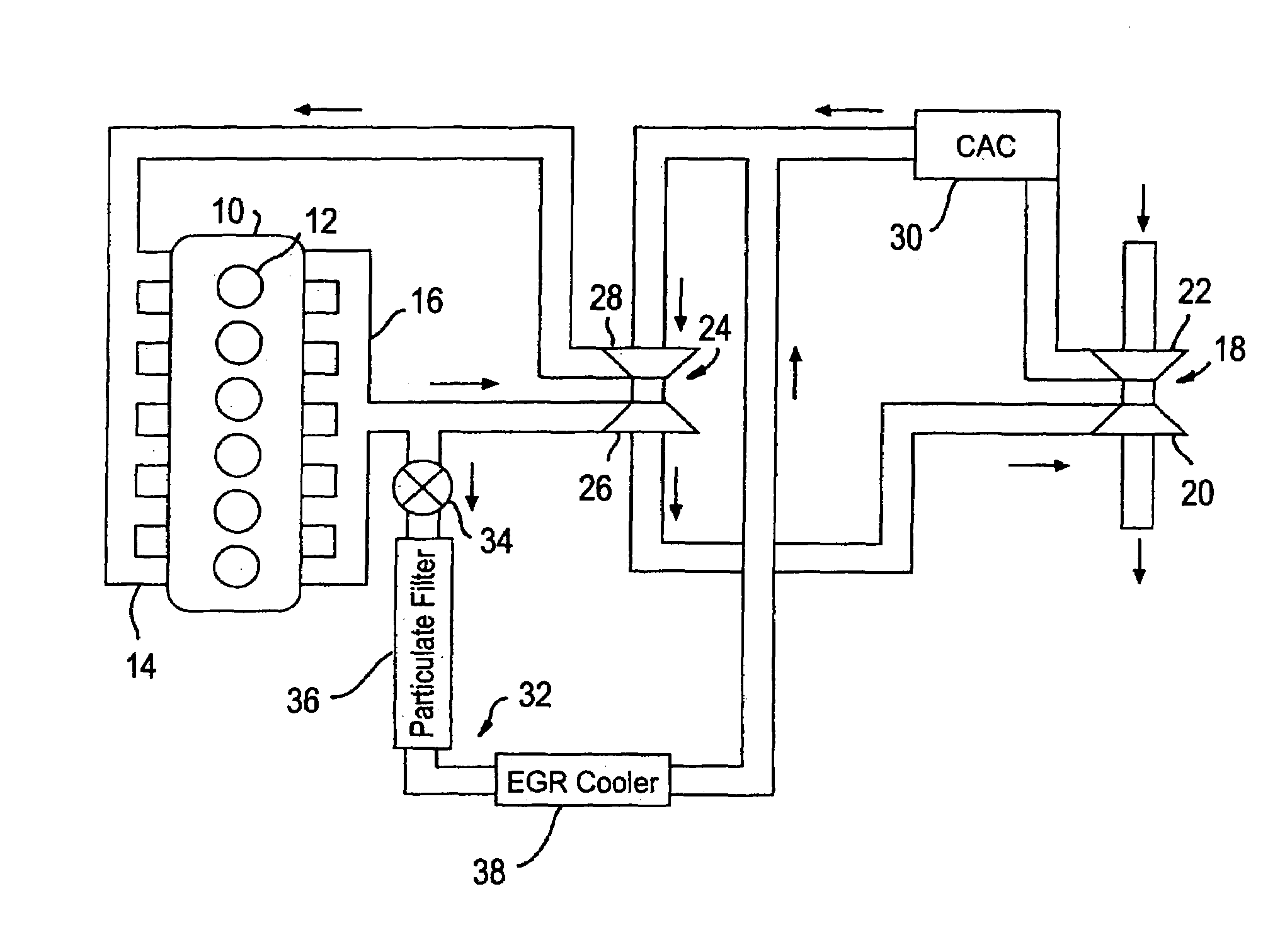

Interstage exhaust gas recirculation system for a dual turbocharged engine having a turbogenerator system

InactiveUS20110094485A1Improve performanceLow costInternal combustion piston enginesExhaust apparatusLoop controlTurbocharger

An internal combustion engine defined as having an engine block for internal combustion, a high-pressure turbocharger for delivering pressurized intake air to the engine block, a low-pressure turbocharger for delivering pressurized intake air to the high-pressure turbocharger, a turbogenerator for recovering heat energy from the exhaust gas downstream of the low-pressure turbocharger to generate electricity, and an exhaust gas recirculation (EGR) system comprising an EGR-pump drawing exhaust gas from an EGR inlet located between the low-pressure and high-pressure turbocharger turbines, wherein the EGR-pump controllably delivers exhaust gas to an EGR mixer in the pressurized intake air stream at a location between the low-pressure and high-pressure turbocharger compressors. An electronic control unit (ECU) is adapted to command the EGR-pump to deliver a desired EGR flow-rate to the engine block based on look-up tables and either open-loop and / or closed-loop control algorithms.

Owner:DEERE & CO

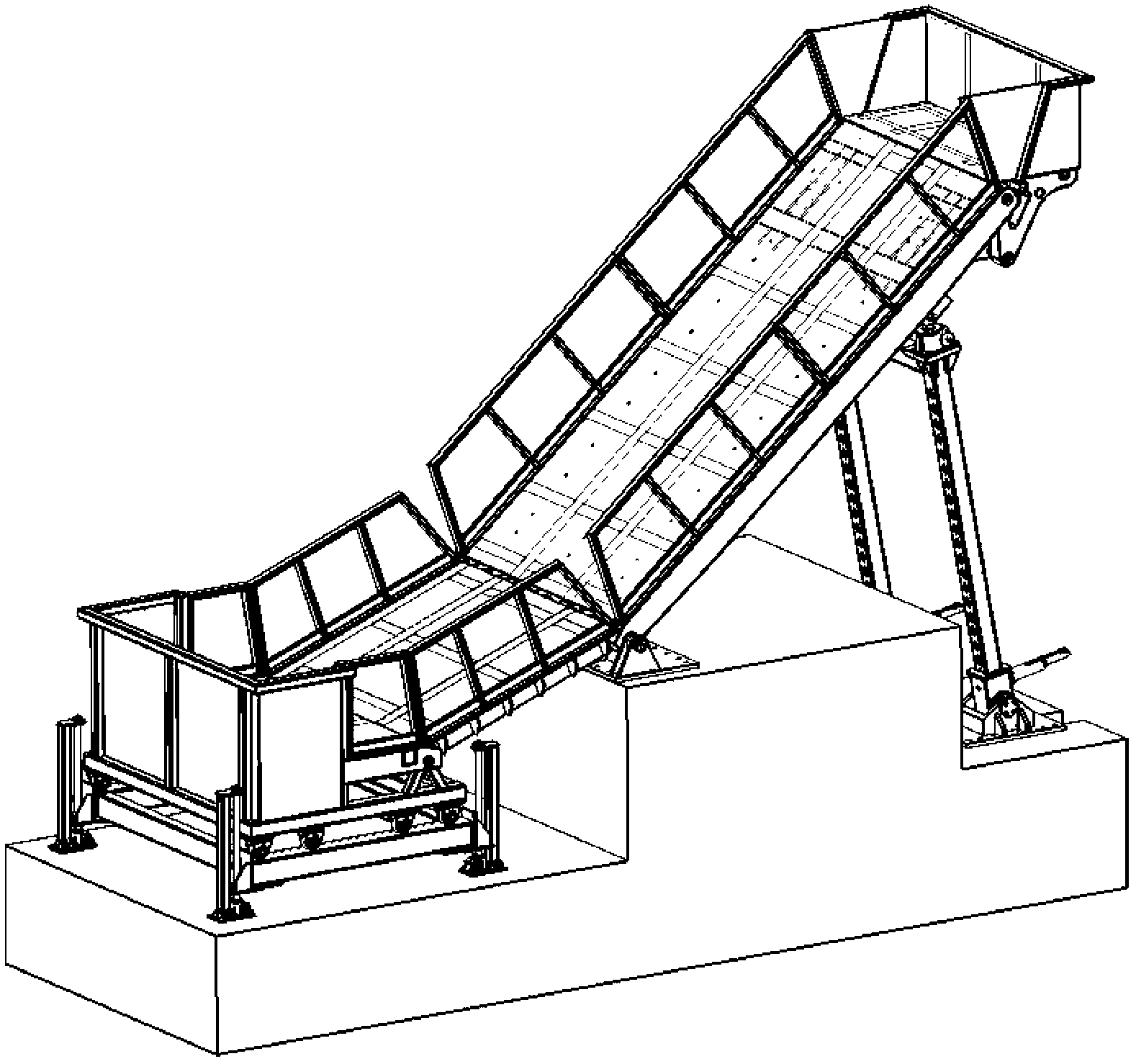

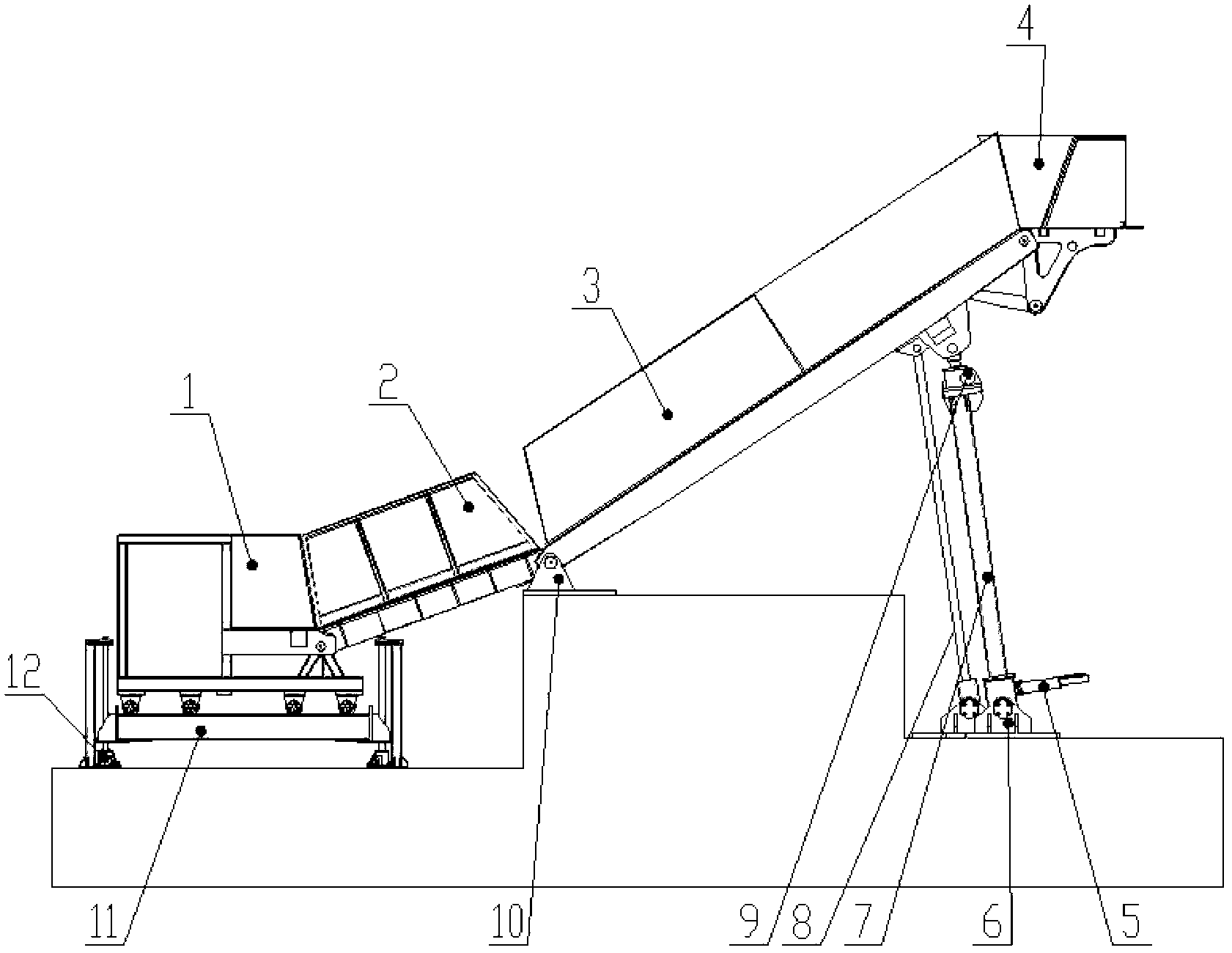

Experimental device with physical landslide model

The invention discloses an experimental device with a physical landslide model. The experimental device comprises a landslide experiment tank which comprises a base and four segments of platforms, wherein the first segment of platform is located above the base, the first segment of platform, the second segment of platform, the third segment of platform and the fourth segment of platform are connected in sequence, the first segment of platform is horizontal, and the inclination angles of the second segment of platform, the third segment of platform and the fourth segment of platform are adjustable. The experimental device with the physical landslide model disclosed by the invention has the characteristics of large scale, sectional type, multi-factor and overall process, and can truly simulate the overall damage evolution process of a landslide disaster chain under hydrodynamic force induction factors.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

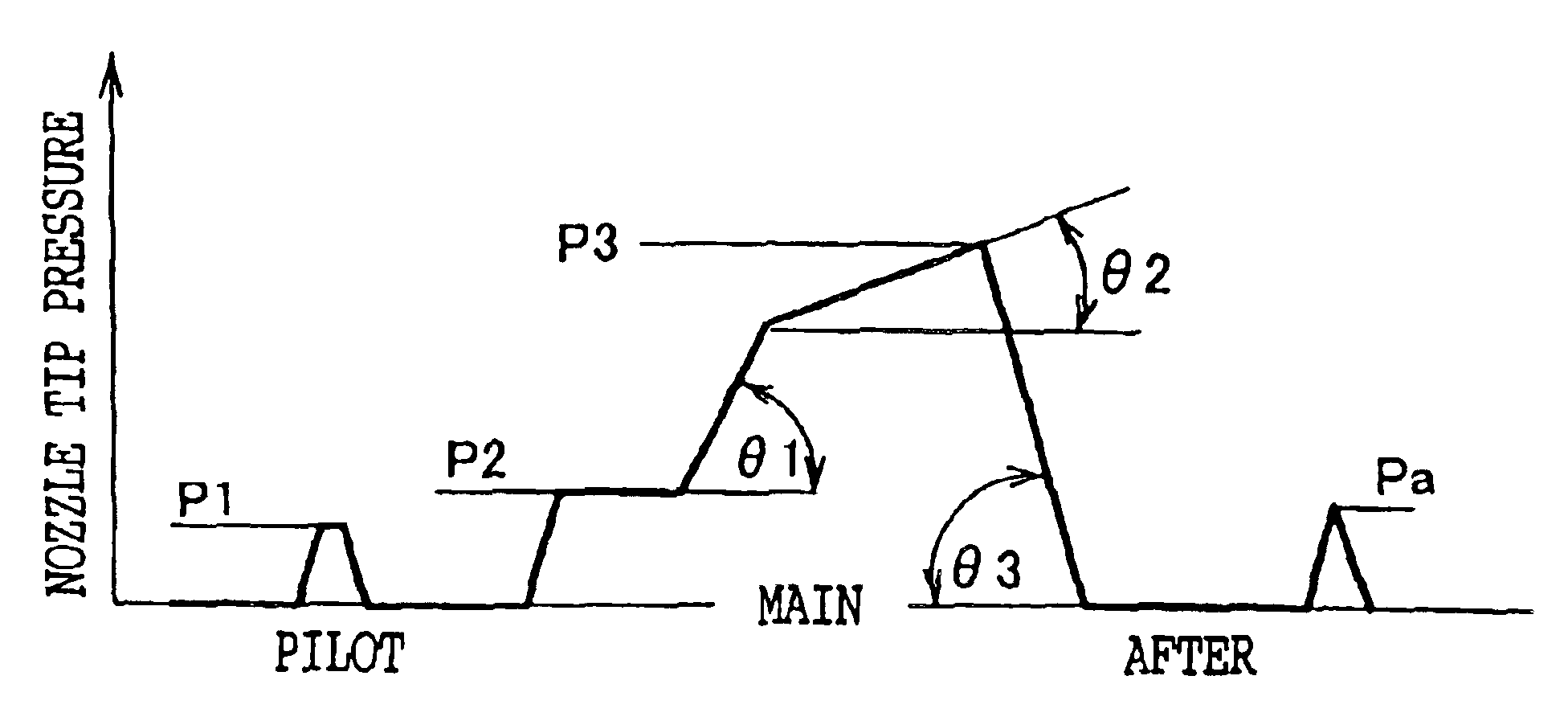

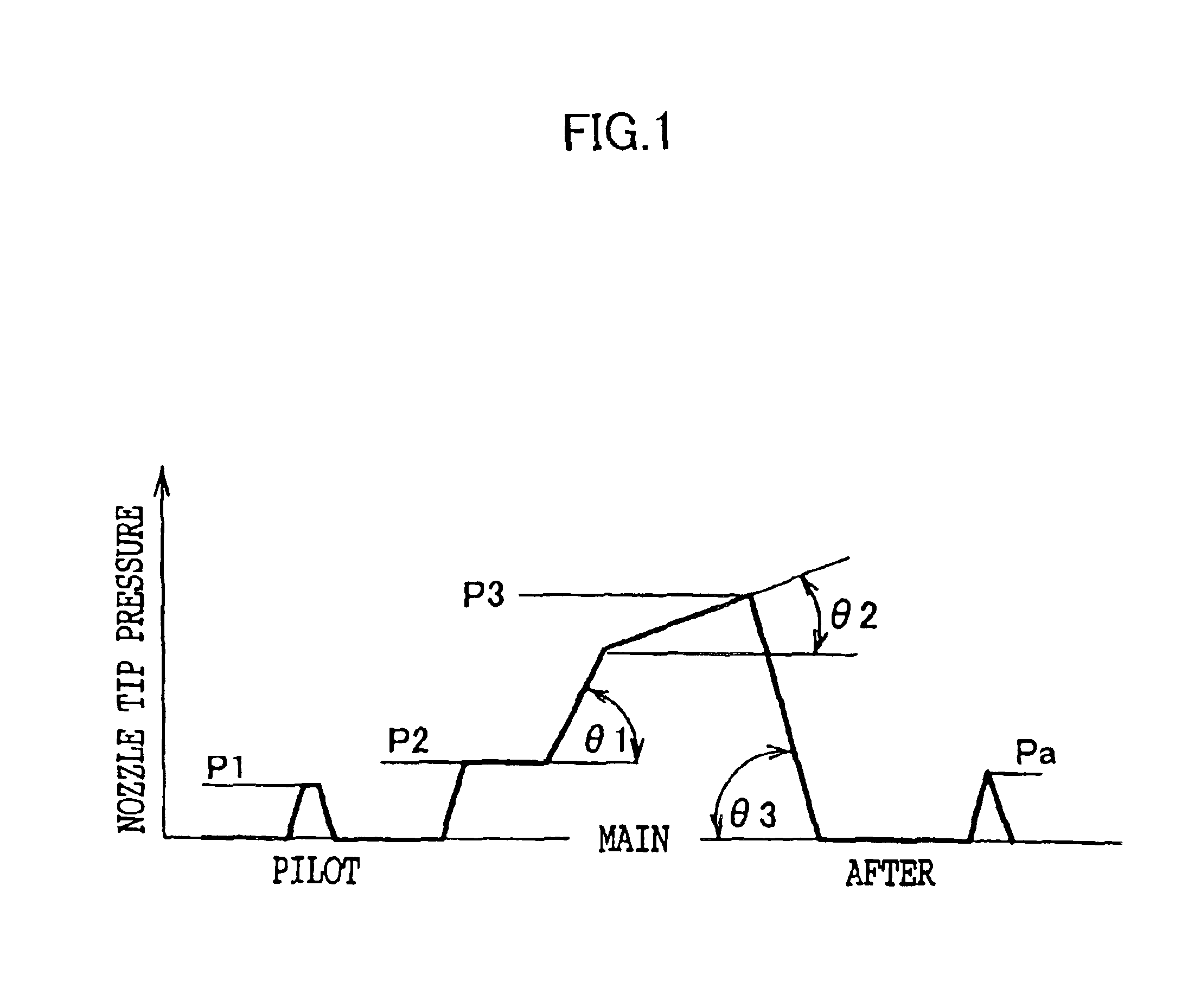

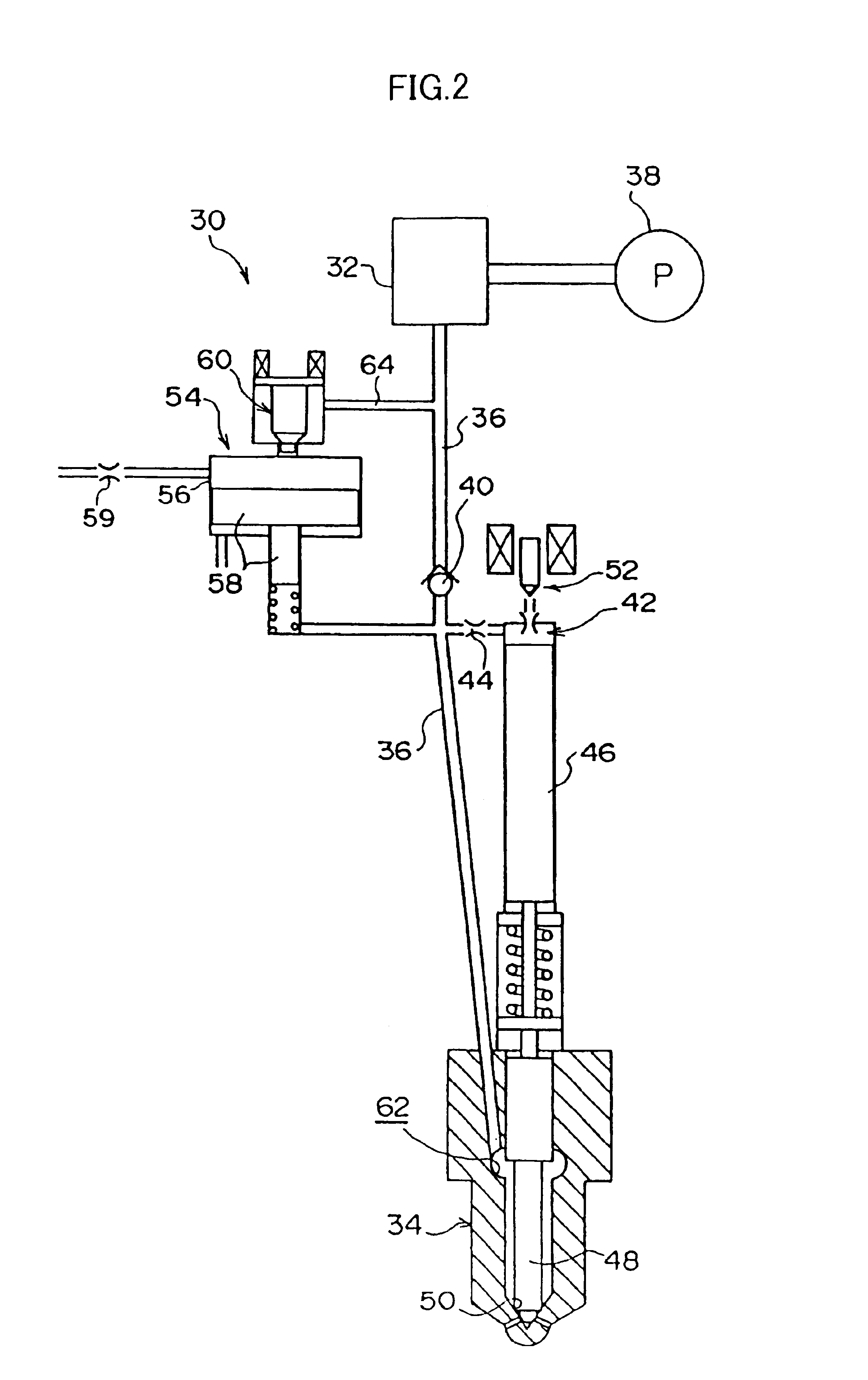

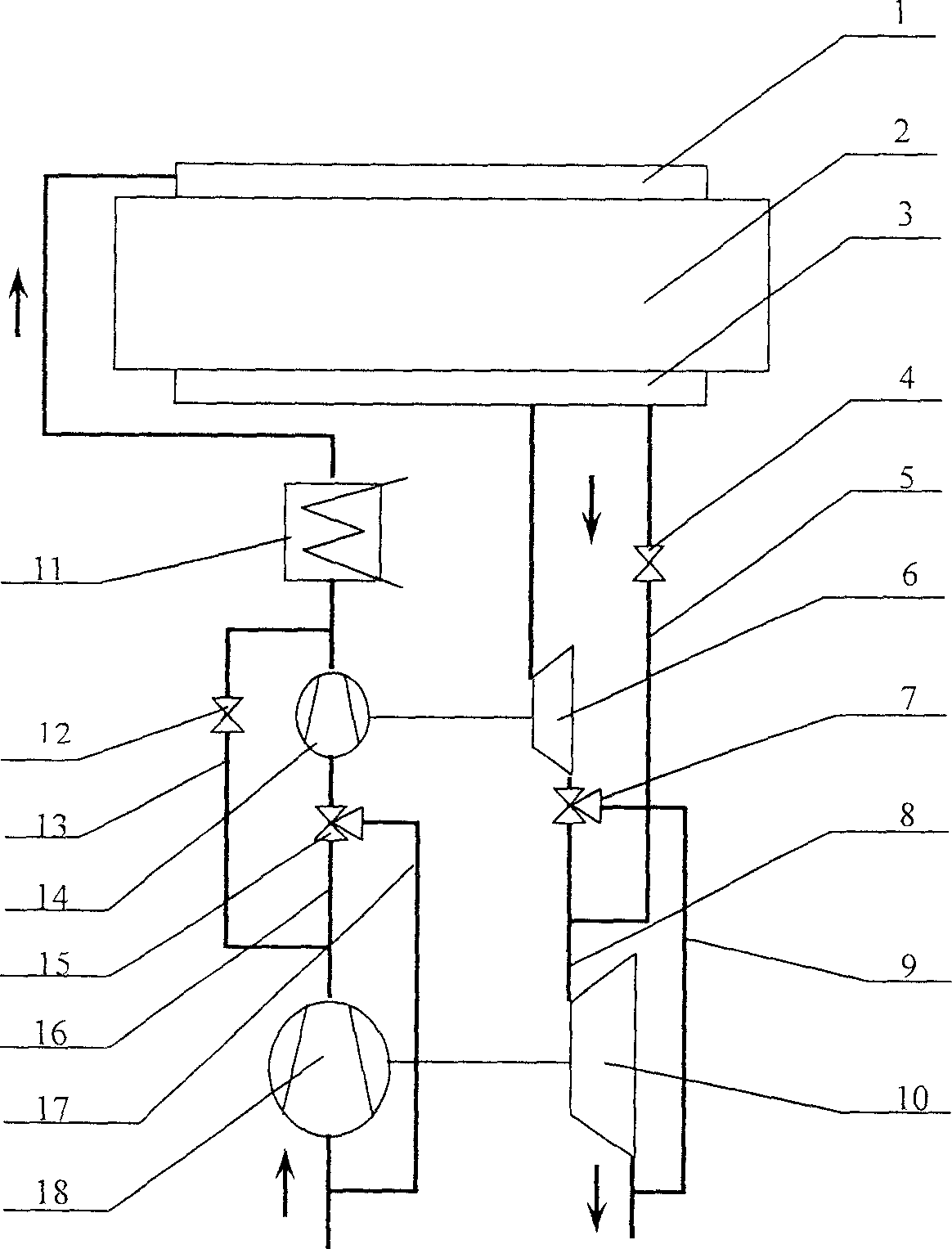

Fuel injection method in fuel injector

InactiveUS6904893B2Increase freedomRealize the structureElectrical controlInternal combustion piston enginesPhase differenceEngineering

In fuel injector including an accumulator and an intensifier, fuel is injected such that an injection control valve and a piston control valve are individually controlled, an operational phase difference therebetween is regulated, and at least one of a maximum injection pressure, a rate of increase of an injection pressure at the start of an increase of pressure, a rate of decrease of the injection pressure at the completion of injection, a pilot injection pressure, and an after injection pressure of fuel injected from a fuel injection nozzle is arbitrarily changed. Namely, a pressure during a movement from a base common rail pressure of the accumulator to a static maximum pressure statically determined by an operation of the intensifier is positively used as a control factor of injection, whereby a fuel injection pattern can be implemented with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

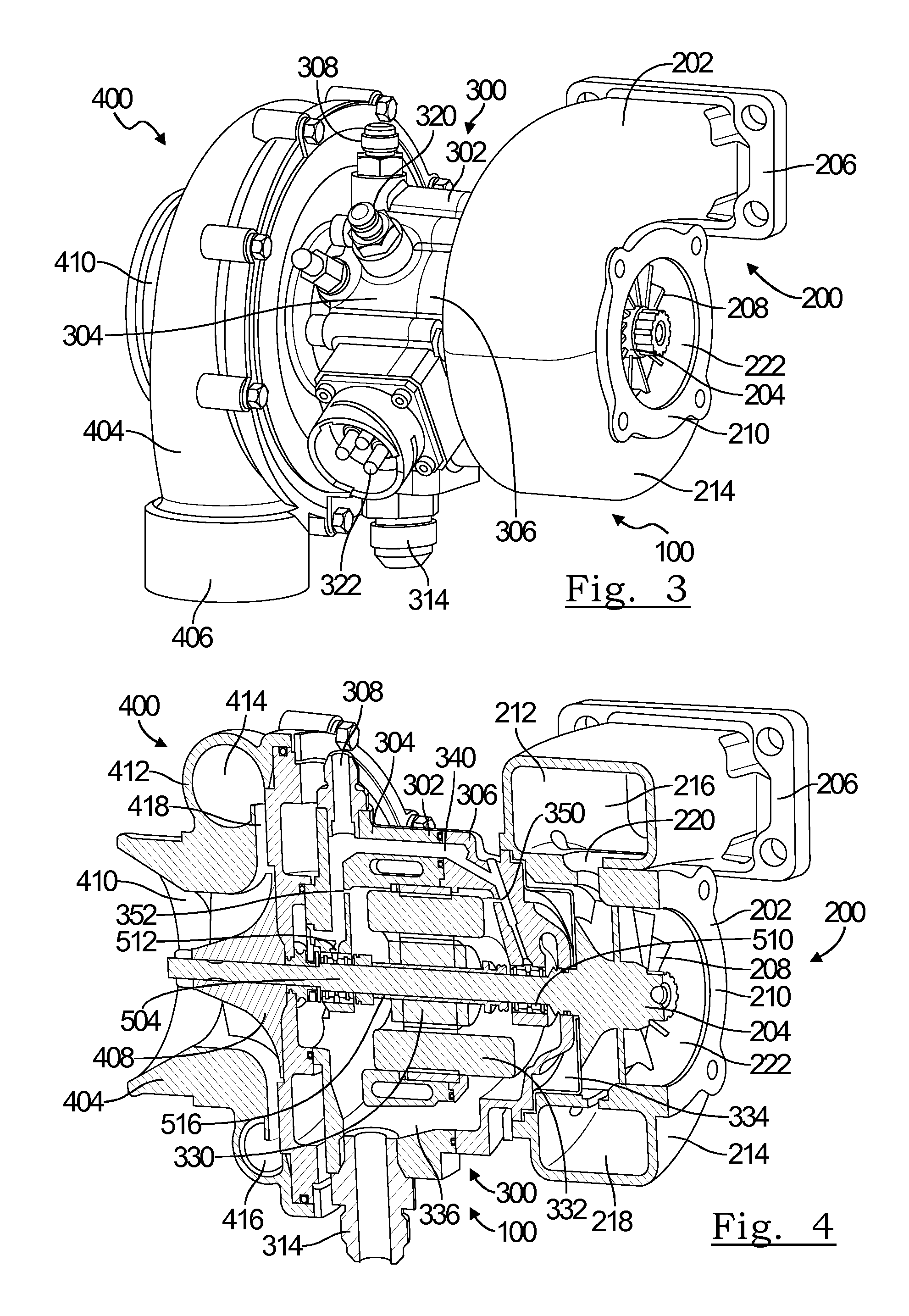

Supercharger for an engine

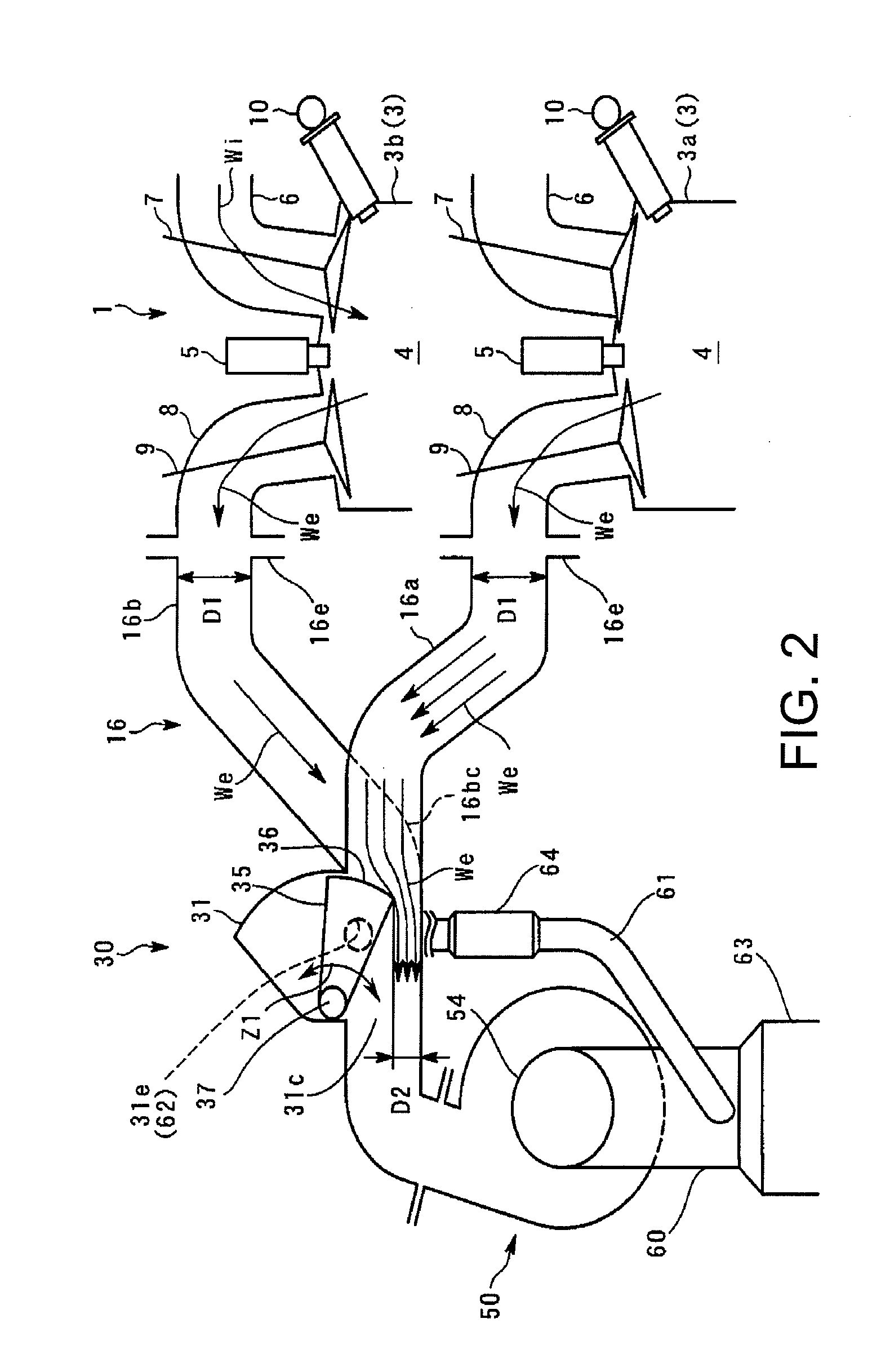

ActiveUS20090094978A1Improve performanceImprove charging effectInternal combustion piston enginesExhaust apparatusThrottle controlExhaust valve

An engine system with a turbocharger is provided. The system may include an exhaust manifold having plural independent exhaust passages, each of the exhaust passages being connected to an exhaust port of a corresponding engine cylinder. The system may further include a collective part formed by gathering said independent exhaust passages in said exhaust manifold or on a downstream side of said exhaust manifold. The system may further include an exhaust turbocharger connected to a downstream side of said collective part. The system may further include a variable exhaust valve for changing each passage cross-sectional area of said independent exhaust passage at an upstream side of said collective part. The system may further include a controller for controlling said variable exhaust valve, wherein said controller is configured to perform independent exhaust throttle control for reducing a passage cross-sectional area of at least one of said independent exhaust passages.

Owner:MAZDA MOTOR CORP

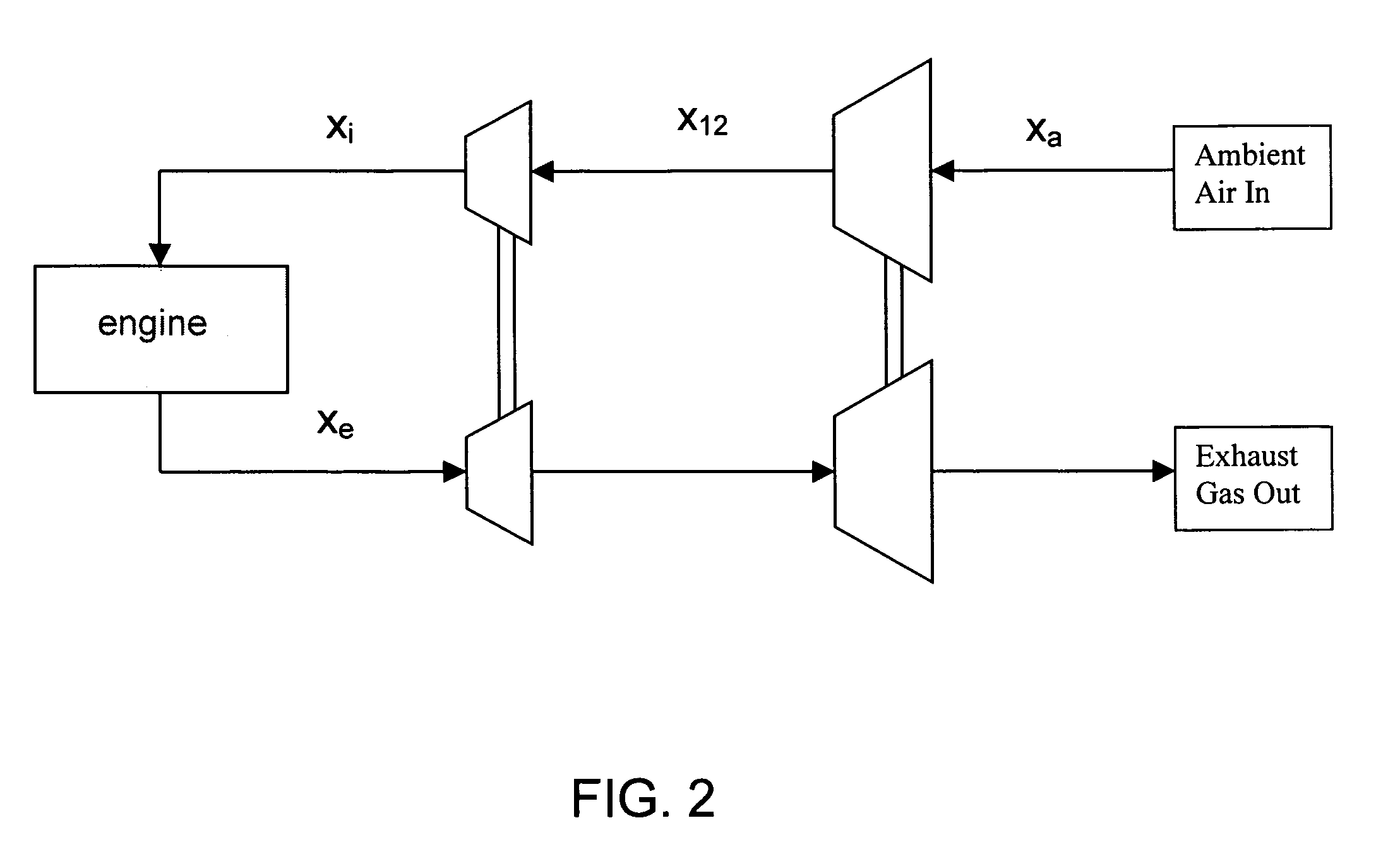

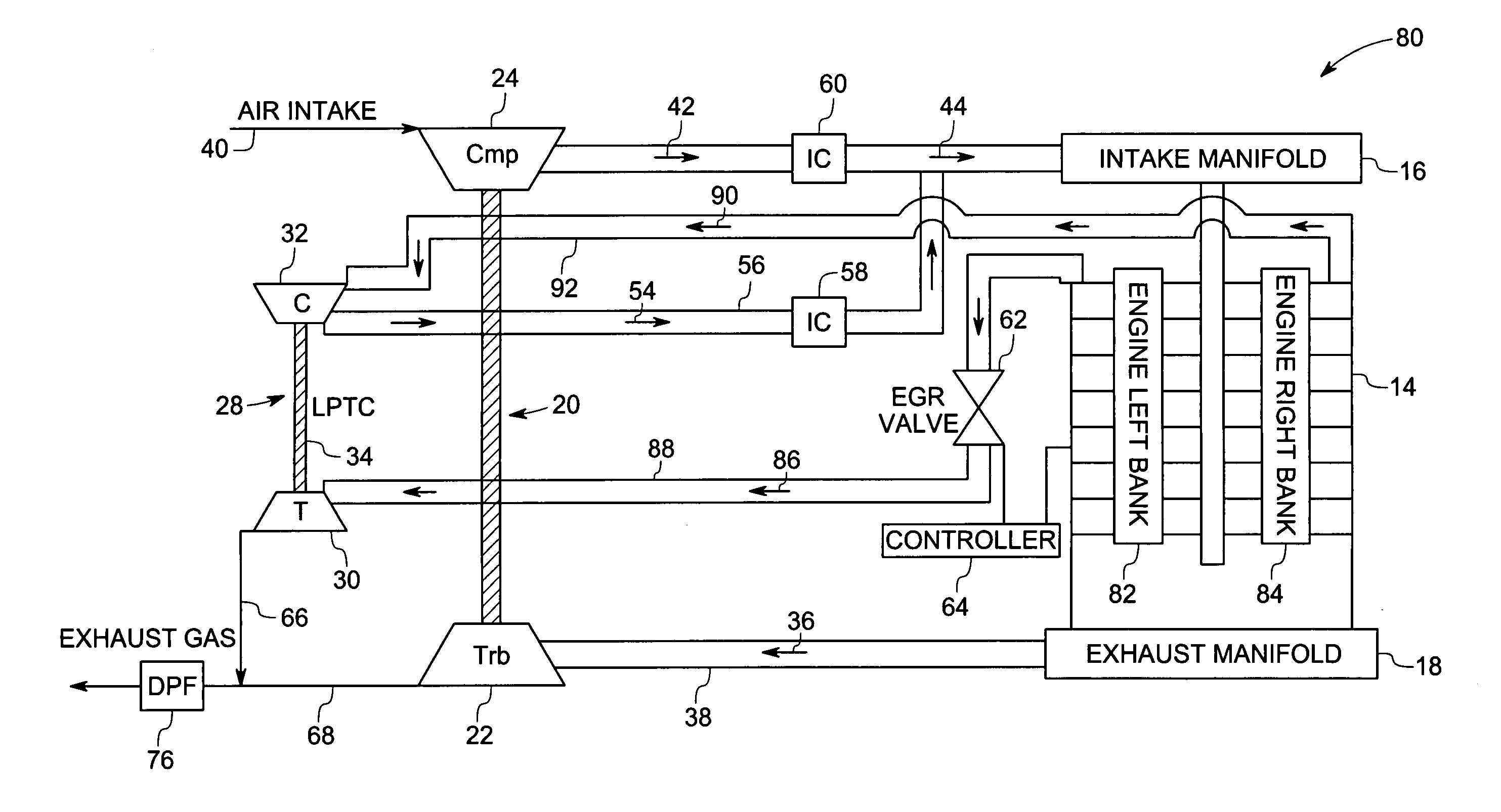

Control of dual stage turbocharging

The invention concerns turbochargers, or more particularly to multivariable dual stage series turbochargers having two degrees of freedom. A multistage series turbocharger apparatus has a low pressure turbocharger comprising a low pressure compressor and a low pressure turbine; a high pressure turbocharger comprising a high pressure compressor and a high pressure turbine, and a exhaust gas recirculation device. A controller controls the operation of at least two of the low pressure compressor, high pressure compressor, low pressure turbine, high pressure turbine, and exhaust gas recirculation device such that at least one operating parameter is maintained at about a selected value.

Owner:GARRETT TRANSPORATION I INC

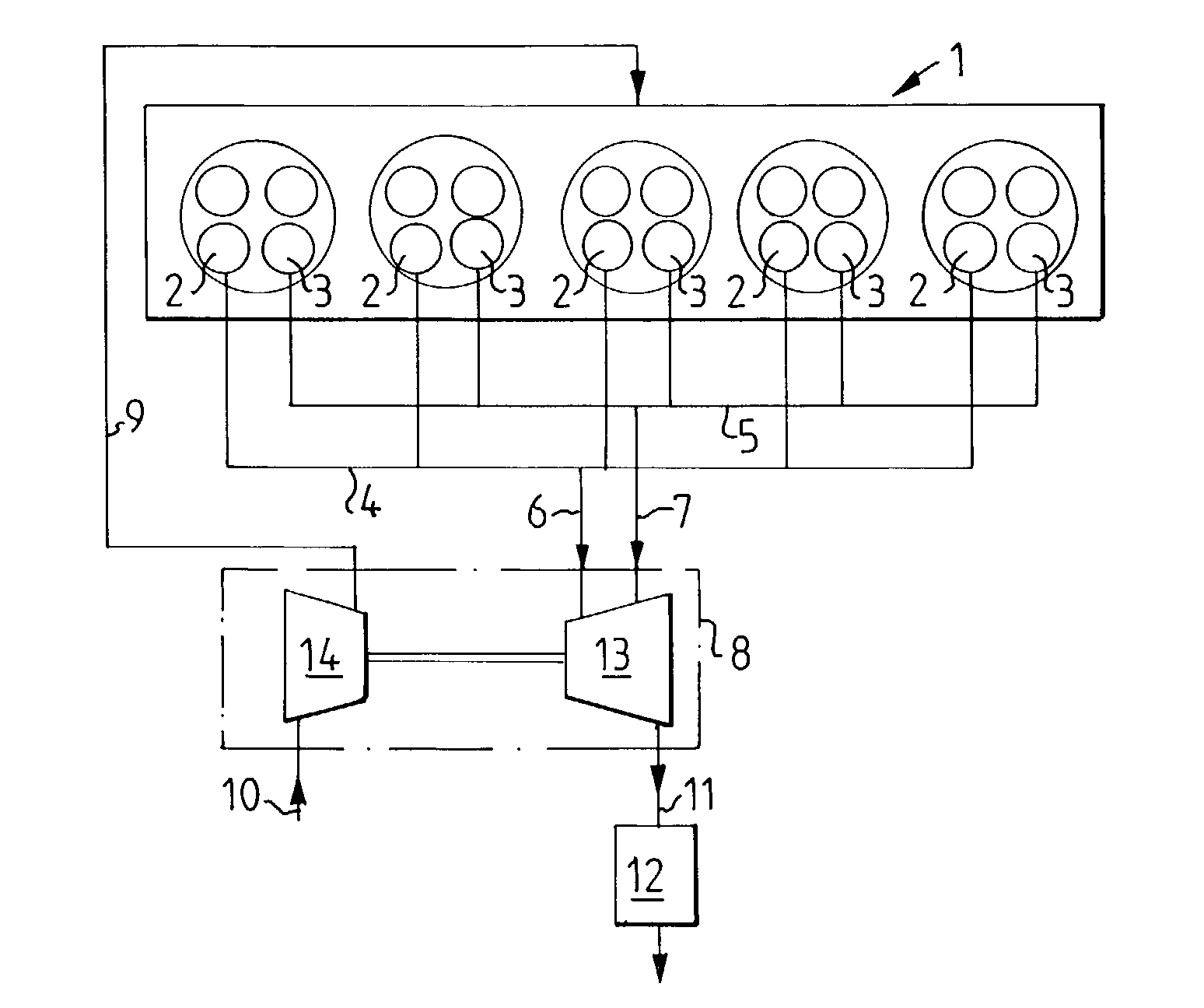

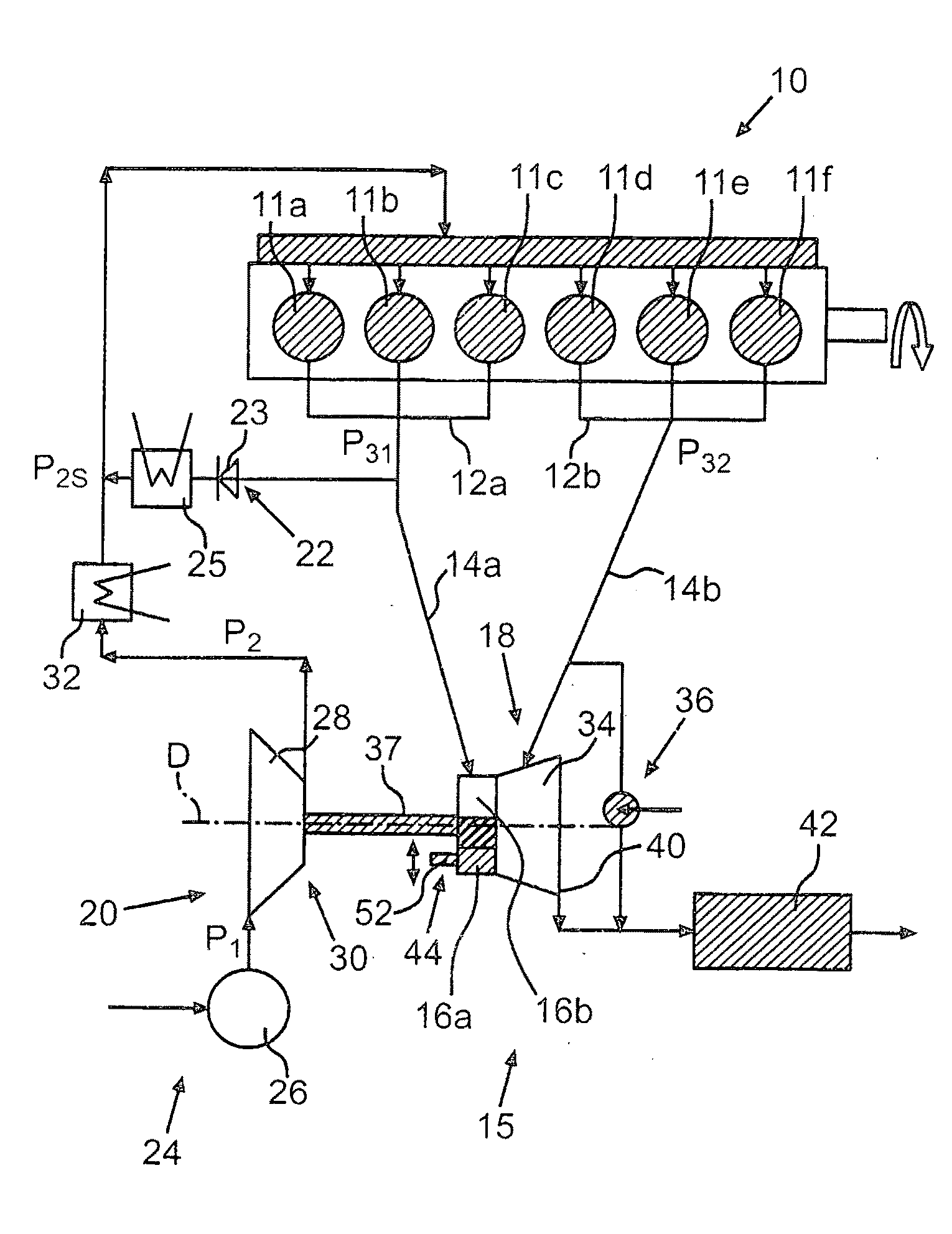

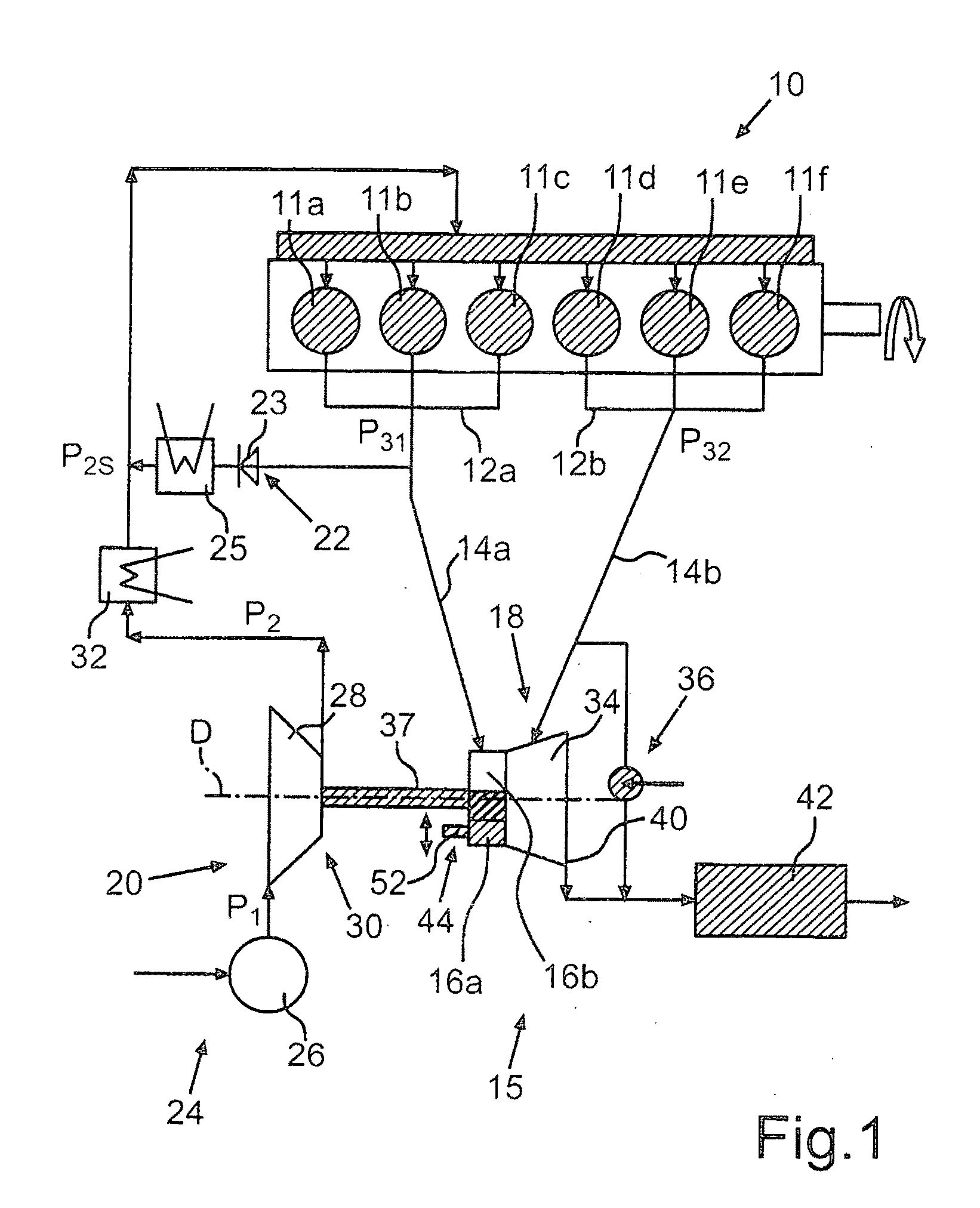

Method for driving an internal-combustion engine and an internal-combustion engine

InactiveUS20030000211A1Reduce deliveryEasy to solveElectrical controlInternal combustion piston enginesExhaust valveTurbine

In an internal-combustion engine having an exhaust-gas driven supercharger (8) and having at least two exhaust-gas valves (2, 3) per cylinder, a first exhaust-gas valve (2) in each cylinder is connected to a first exhaust manifold (4), whilst a second exhaust-gas valve (3) in each cylinder is connected to a second exhaust manifold (5). The two exhaust manifolds (4, 5) lead to at least one exhaust-gas turbine in at least one turbo compressor and the first exhaust-gas valves (2) are arranged to be opened at all engine speeds, whilst the second exhaust-gas valves (3) are arranged to be opened only at higher engine speeds. The first exhaust manifold (4) has a smaller flow area than the second exhaust manifold (5). By choosing which exhaust-gas valves are to be used, the size of the flow ducts between engine and exhaust-gas turbine can easily be suited to the size of the exhaust-gas flow which is available at the time.

Owner:SAAB AUTOMOBILE AB

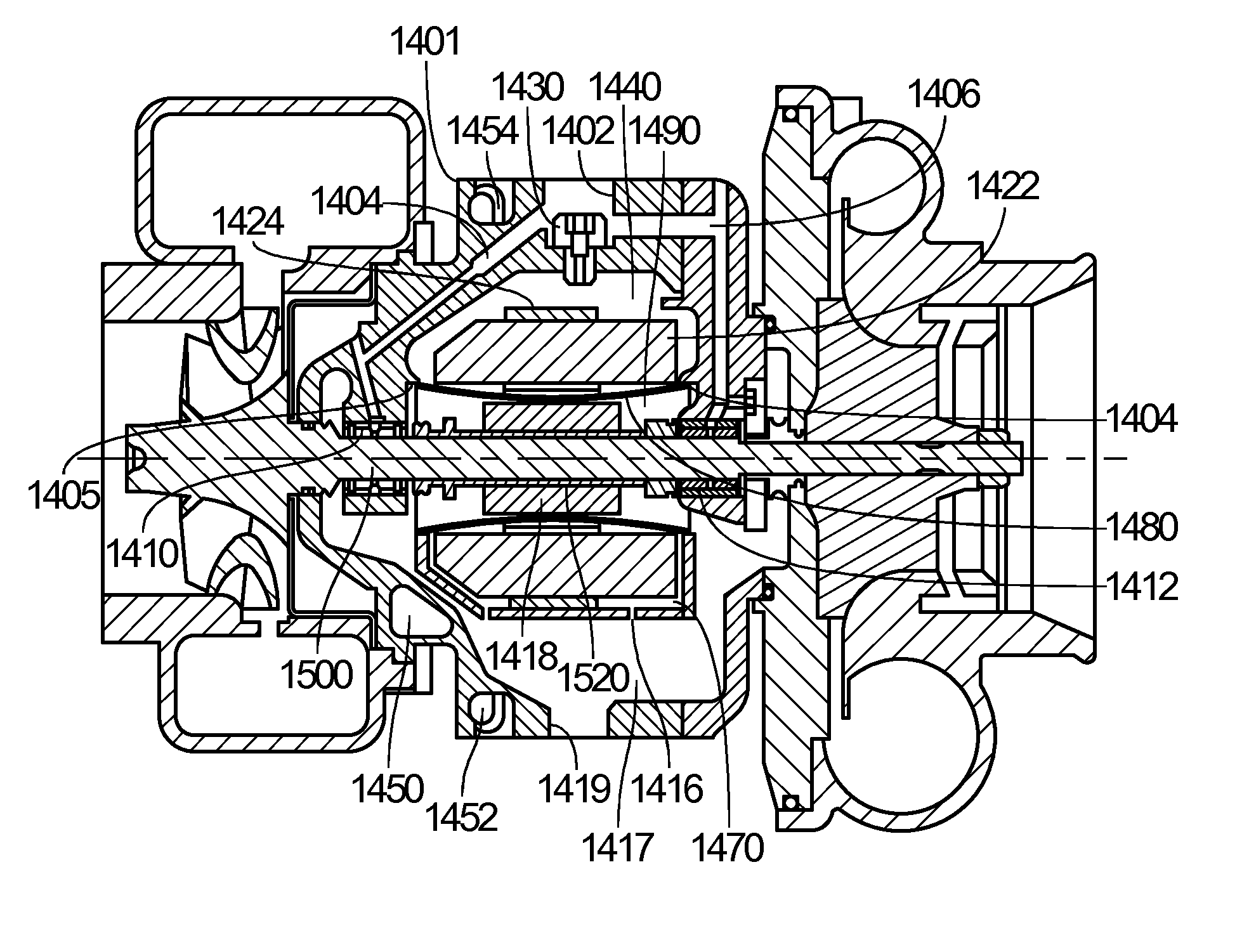

Cooling an electrically controlled turbocharger

An electrically controlled turbocharger has a motor mounted on a shaft in a motor housing between a turbine and compressor. Oil is sprayed onto the motor stator to cool the stator. An oil gallery is disposed above the stator to receive lubricating oil and contains apertures that perform as jets to allow oil to be sprayed directly on the motor stator. A coolant jacket is formed in the turbocharger housing between the turbine and the motor to allow liquid coolant to circulate therein and dissipate heat from the turbine end prior to reaching the motor components. Other embodiments provide for a stator component to be submerged in flowing cooling oil.

Owner:ECOMOTORS INT

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100139277A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

Owner:SUSTAINX

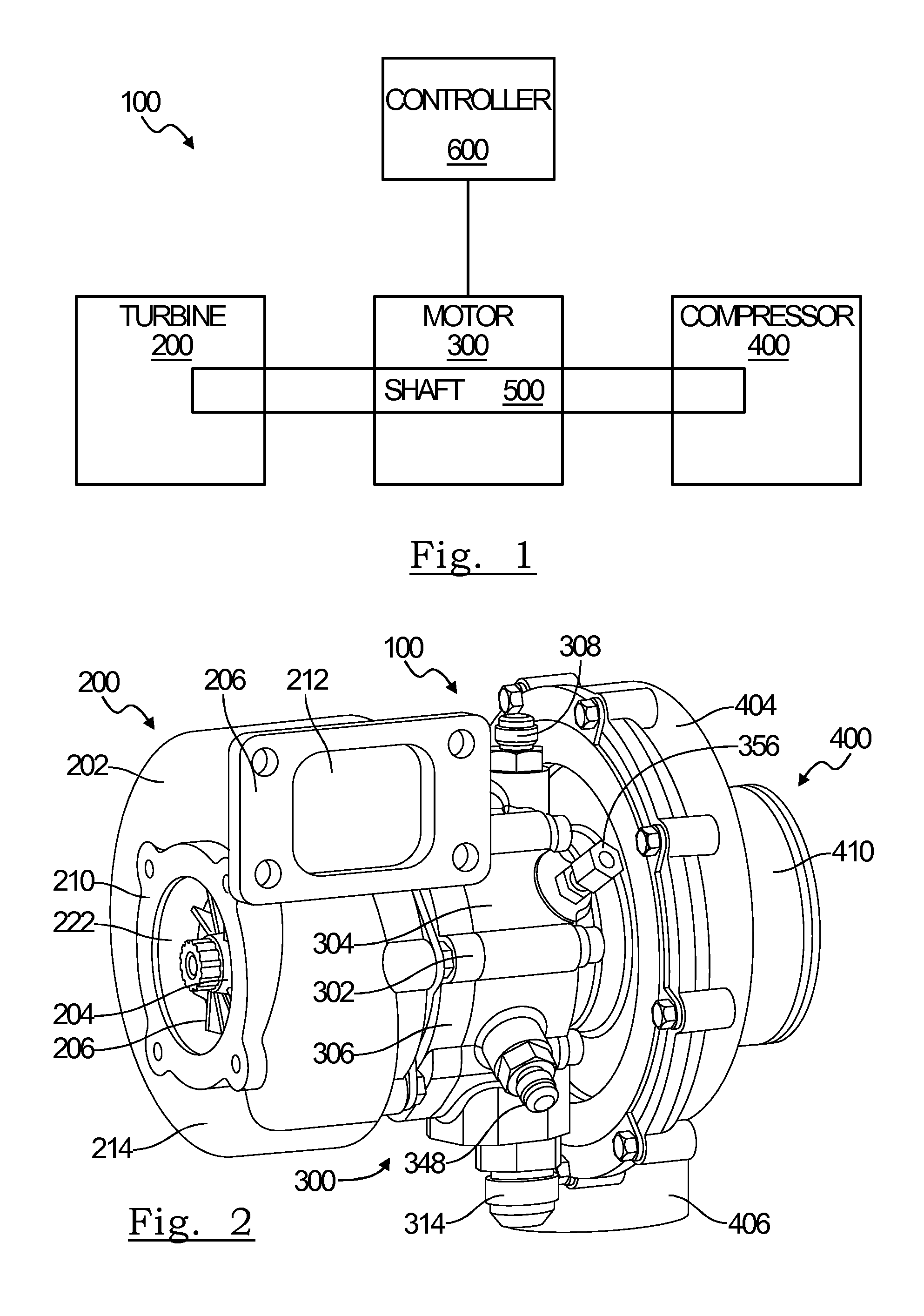

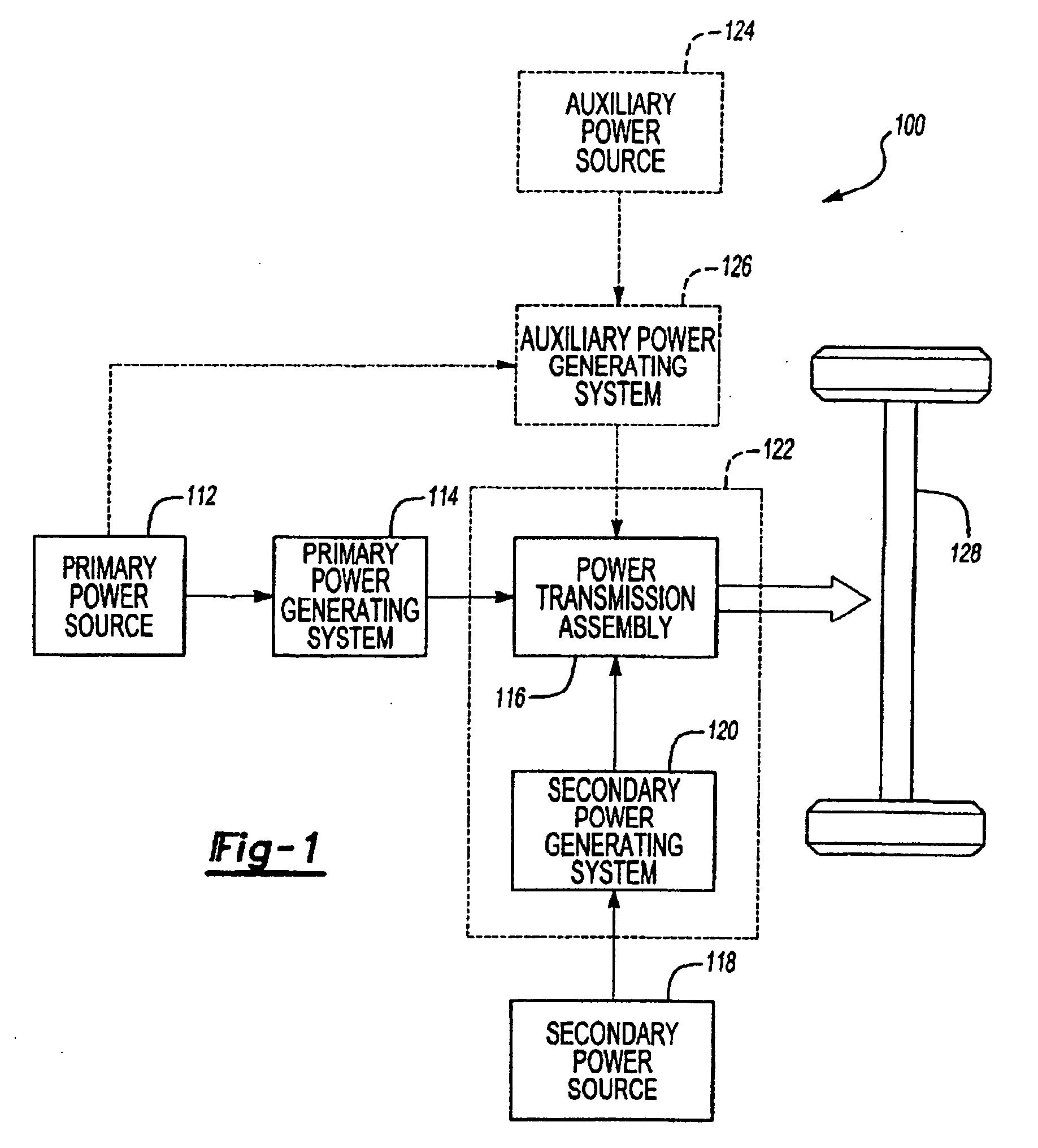

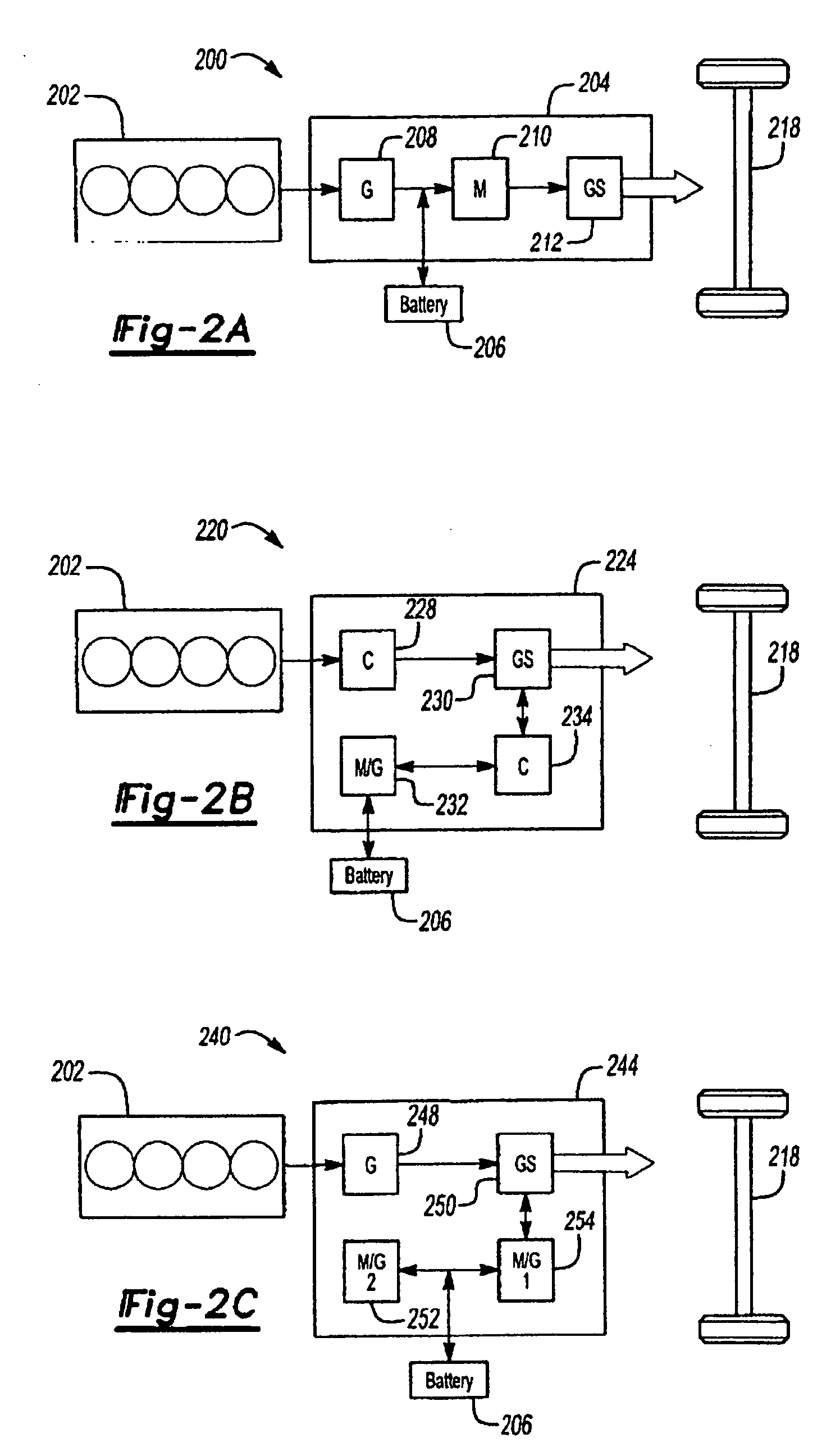

Supercharged hybrid input differential engine system

InactiveUS20100155157A1Increase pressure ratioImprove drivabilityElectric propulsion mountingCombustion enginesEngineeringHigh torque

A hybrid input differential engine system comprising a planetary gear set. Preferably, an ICE is connected to the planet gear carrier, the output shaft is connected to the ring gear, and the sun gear is connected to a supercharger / expander and an electric or hydraulic motor / generator. As engine torque increases, the supercharger speeds up, increasing torque still further, enabling a small displacement engine to have very high torque at low RPM. In cruise conditions, the sun gear direction is reversed by the motor / generator, causing the supercharger to act as an expander for efficiently throttling the engine. The motor / generator modulates the speed / torque relationships between the engine and the supercharger / expander. A second motor / generator may be used on the output shaft. The electric machines and electric storage may be downsized because less electrical power is needed for the operation of the system.

Owner:DELPHI TECH IP LTD

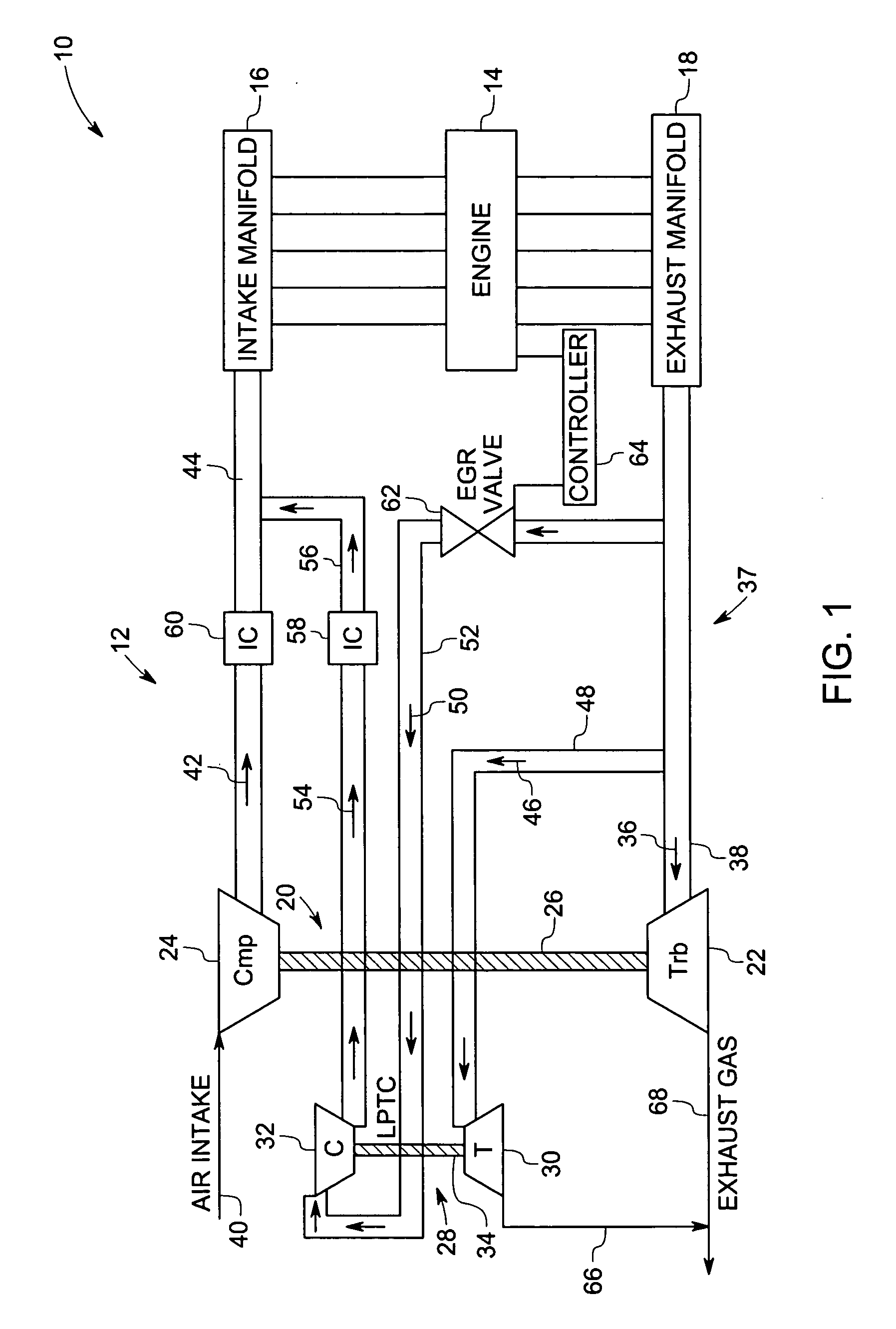

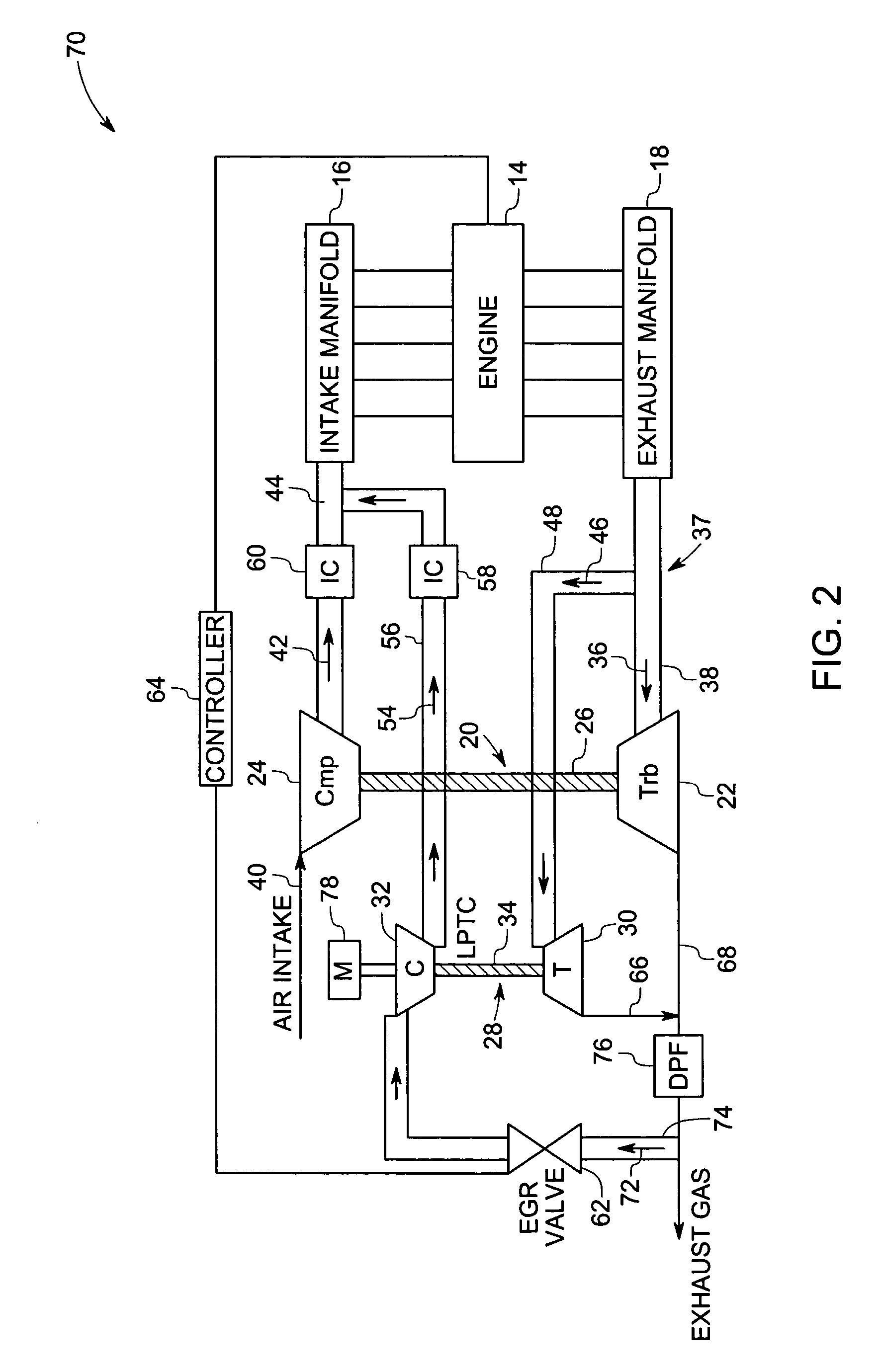

Turbocharged internal combustion engine with EGR flow

InactiveUS6981375B2Internal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExhaust gas recirculation

A turbocharged internal combustion engine is operated such that the intake manifold pressure generally exceeds the exhaust manifold pressure. A low pressure turbocharger and a high pressure turbocharger are provided in series. An exhaust gas recirculation (EGR) system passively routes a portion of the exhaust gases to the high pressure turbocharger compressor inlet.

Owner:DETROIT DIESEL CORP

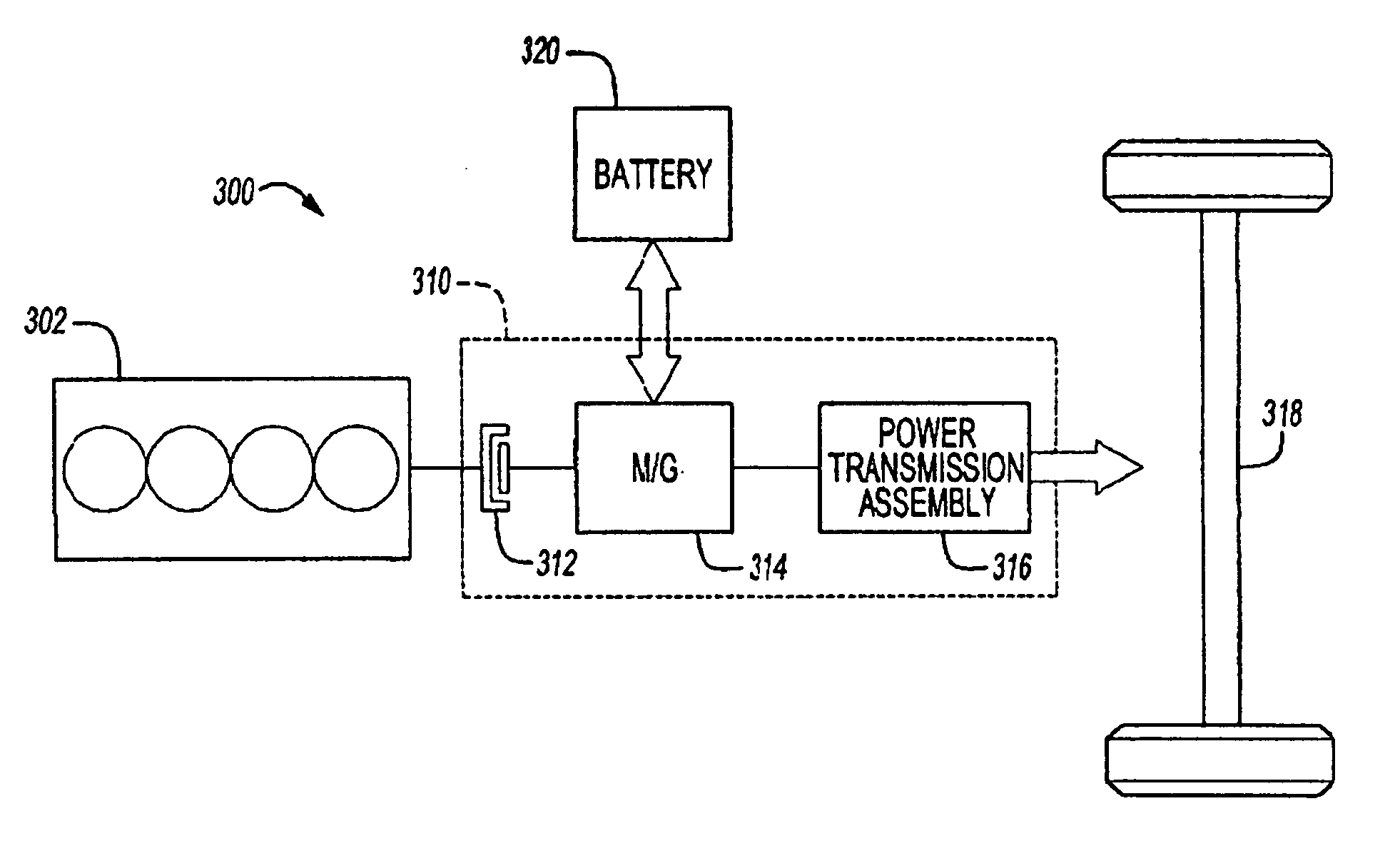

Hydrogen fuelled hybrid powertrain and vehicle

InactiveUS20060174624A1Increase output torqueImprove performanceReciprocating combination enginesElectrical controlDrivetrainEngineering

A hydrogen-powered hybrid powertrain system includes a hydrogen-fuelled internal combustion engine operating at a lean air / fuel mixture, and a supercharger for boosting a primary drive torque produced by the engine primarily over a high operating speed range. An electric motor / generator generates a secondary drive torque for the vehicle, such that the secondary drive torque complements the boosted primary drive torque over at least a low operating speed range of the powertrain. A disconnect clutch disposed between the engine and the motor / generator engages and disengages the engine from the motor / generator, and serves to transfer the boosted primary driver torque through the motor / generator and to a power transmission system. The input at the power transmission is thus a combination of the boosted primary drive torque and the secondary drive torque having an enhanced torque characteristic over at least the low operating speed range.

Owner:FORD GLOBAL TECH LLC

Supercharged internal combustion engine

InactiveUS7076952B1Short maintenance periodHigh strengthInternal combustion piston enginesJet pumpsCombustion chamberAir pump

Owner:VETROVEC JAN

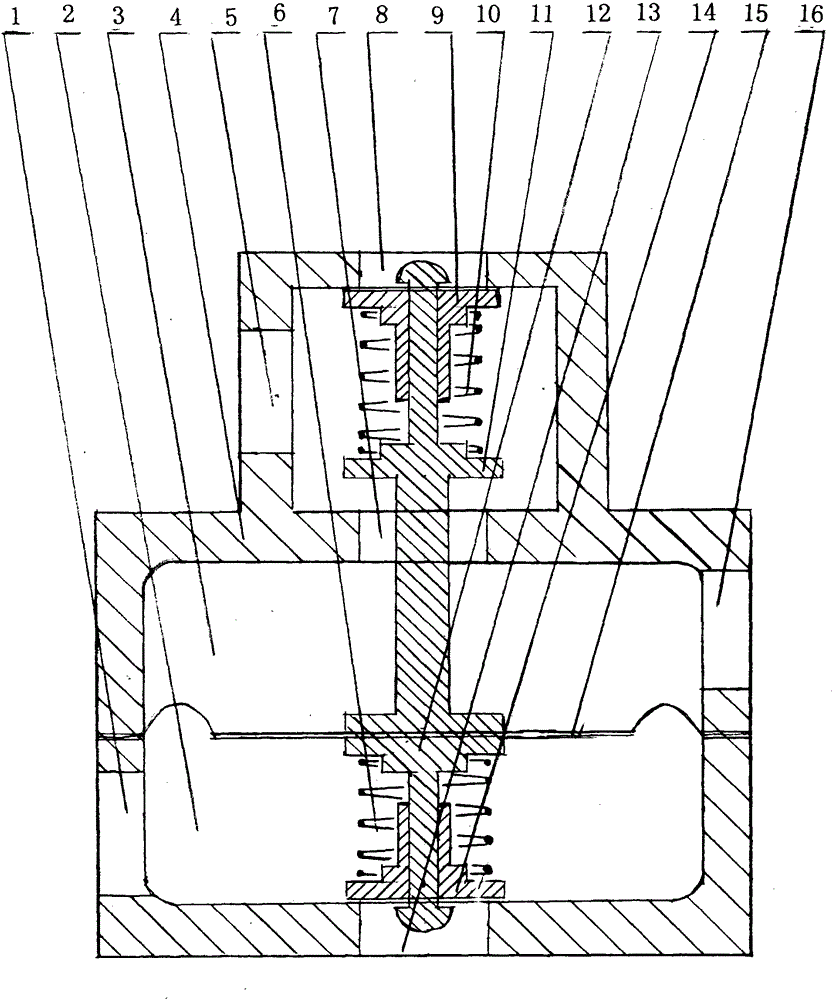

Intake pressure balancing adjuster for supercharged and intercooled gas engine

ActiveCN103603747ASimple structureIncrease the maximum output powerInternal combustion piston enginesFuel supply apparatusIntake pressureStreamflow

Disclosed is an intake control device for a supercharged and intercooled gas engine. By coaxial control bidirectional pressure relief means, the output pressure of two superchargers is simultaneously controlled by the aid of one device, the technical problem of unbalanced output pressure of the two superchargers is solved, a complicated structure respectively controlling the output pressure of the two superchargers is simplified, functional cost is reduced, reliability is improved, the influence of a balancer on maximum intake flow of the engine is thoroughly eliminated, and the maximum output power of the engine is improved. The device is applicable to the gas engine with air and gas respectively supercharged and intercooled.

Owner:陕西中唐电力能源科技有限公司

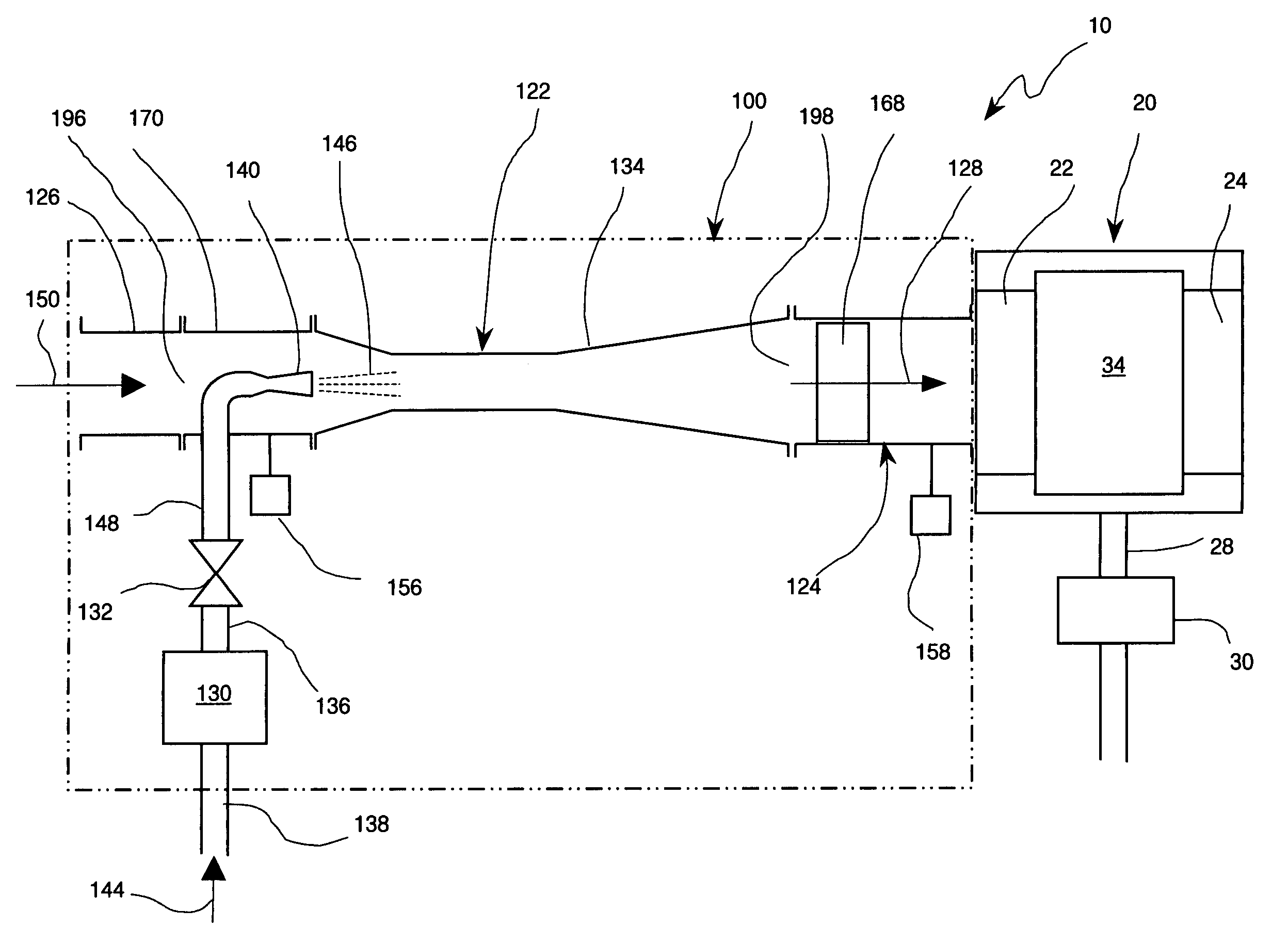

Turbocharged engine system and method of operation

ActiveUS20070119171A1Reduce pollutant emissionsNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

A system is provided. The system includes an internal combustion engine having an intake manifold and an exhaust manifold. The system also includes a high pressure turbocharger having a variable geometry high pressure turbine drivingly coupled to a high pressure compressor, wherein the variable geometry high pressure turbine is driven by a first portion of exhaust gases from the exhaust manifold, wherein the high pressure compressor is configured to compress an intake air and to provide the compressed intake air to the intake manifold. The system also includes a low pressure turbocharger having a variable geometry low pressure turbine drivingly coupled to a low pressure compressor, wherein the variable geometry low pressure turbine is driven by a second portion of the exhaust gases from the exhaust manifold, wherein the low pressure compressor is configured to compress a third portion of the exhaust gases from the exhaust manifold and to provide the compressed third portion to the intake manifold, wherein the first and second portions of the exhaust gases are different from one another.

Owner:GE GLOBAL SOURCING LLC

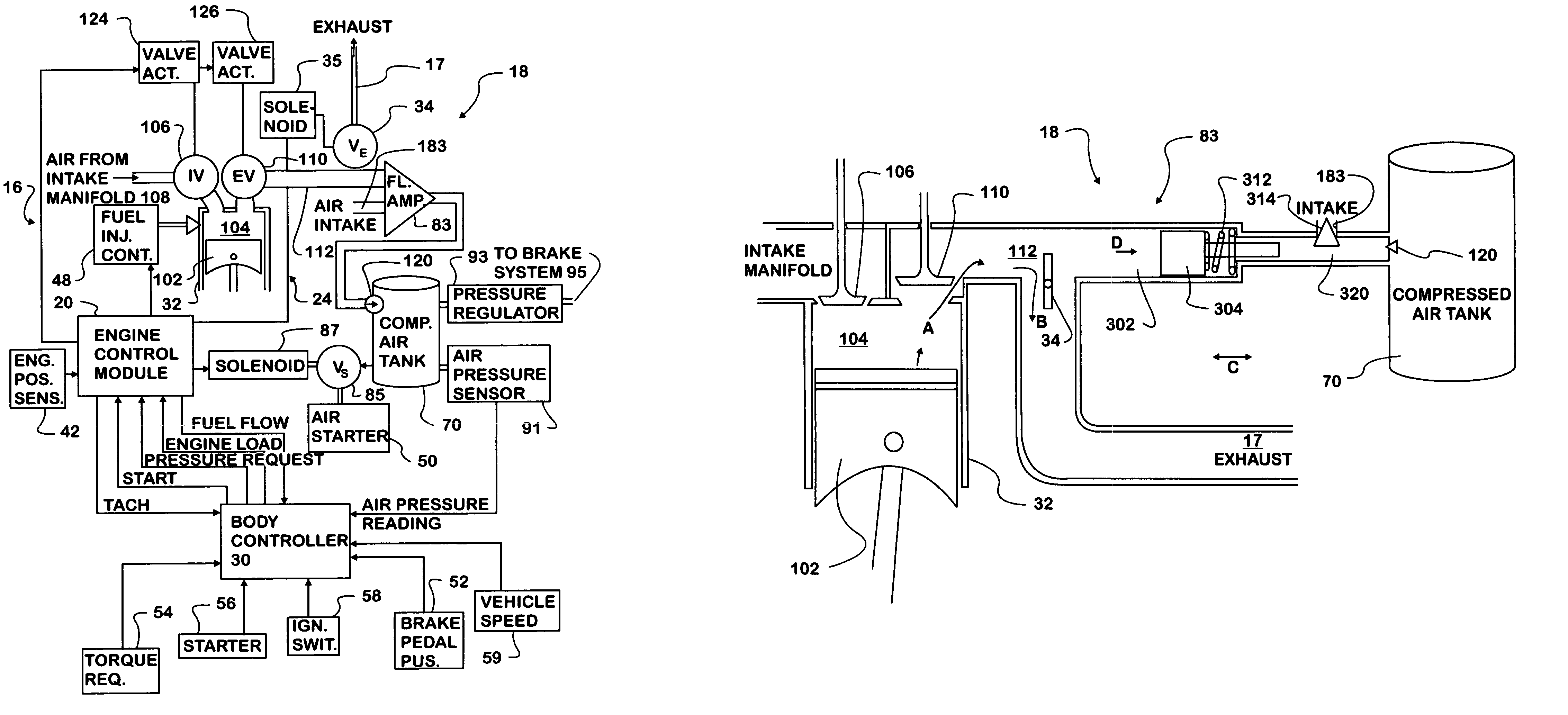

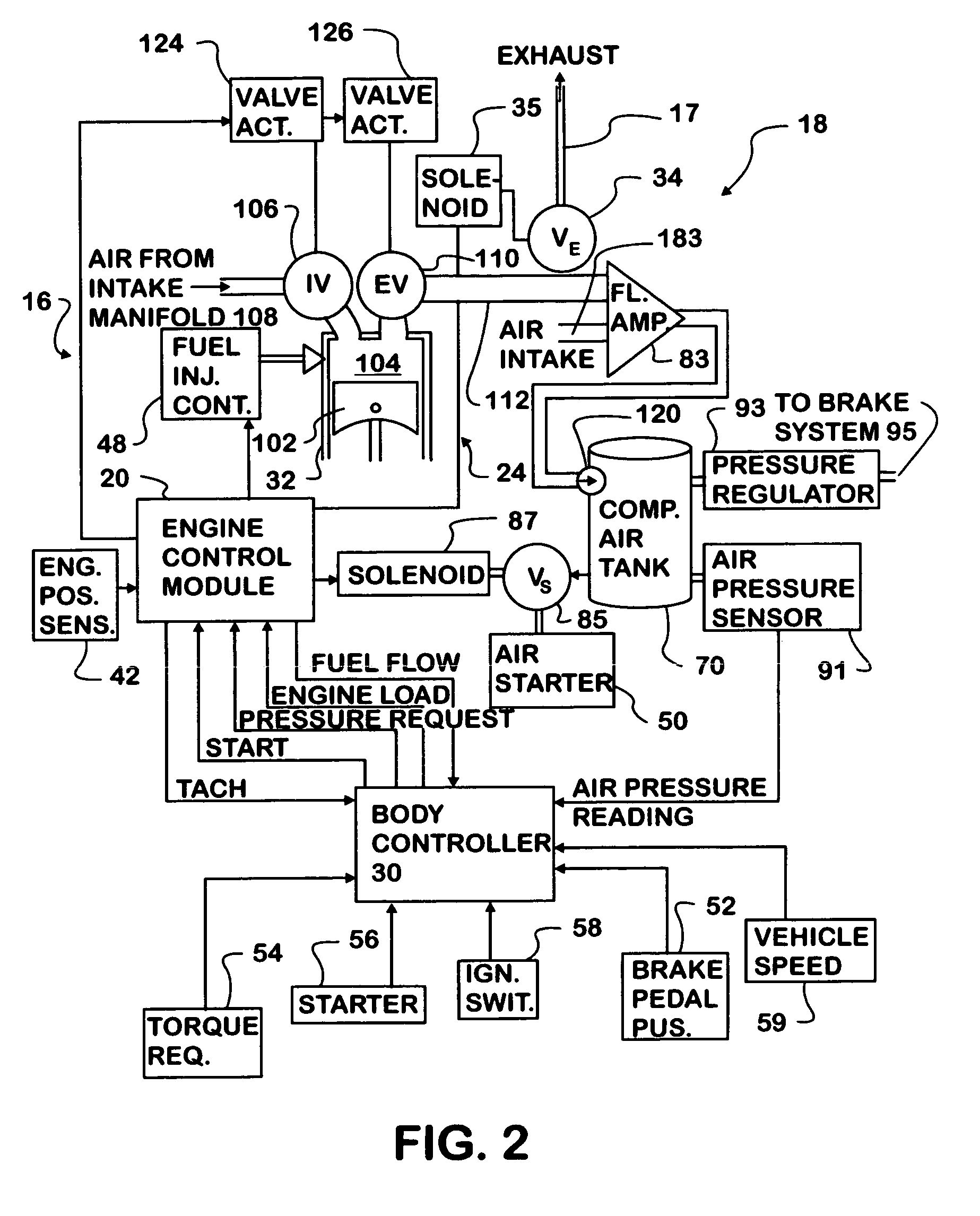

Engine based kinetic energy recovery system for vehicles

ActiveUS6922997B1Improve efficiencyEfficient use ofPower operated startersElectrical controlAir compressionHigh pressure

A motor vehicle kinetic energy recovery system uses one or more cylinders of an internal combustion engine as the first or primary stage in a multi-stage high pressure air compression system, a compressed air storage system, compressed air operated drive train boosters and vehicle management electronics to provide cooperation between the air compression, storage and booster systems. The multi-stage, high pressure air compressor system is operable through engine compression braking allowing kinetic energy of a vehicle to be recaptured during retardation of vehicle speed.

Owner:INT TRUCK INTPROP LLC

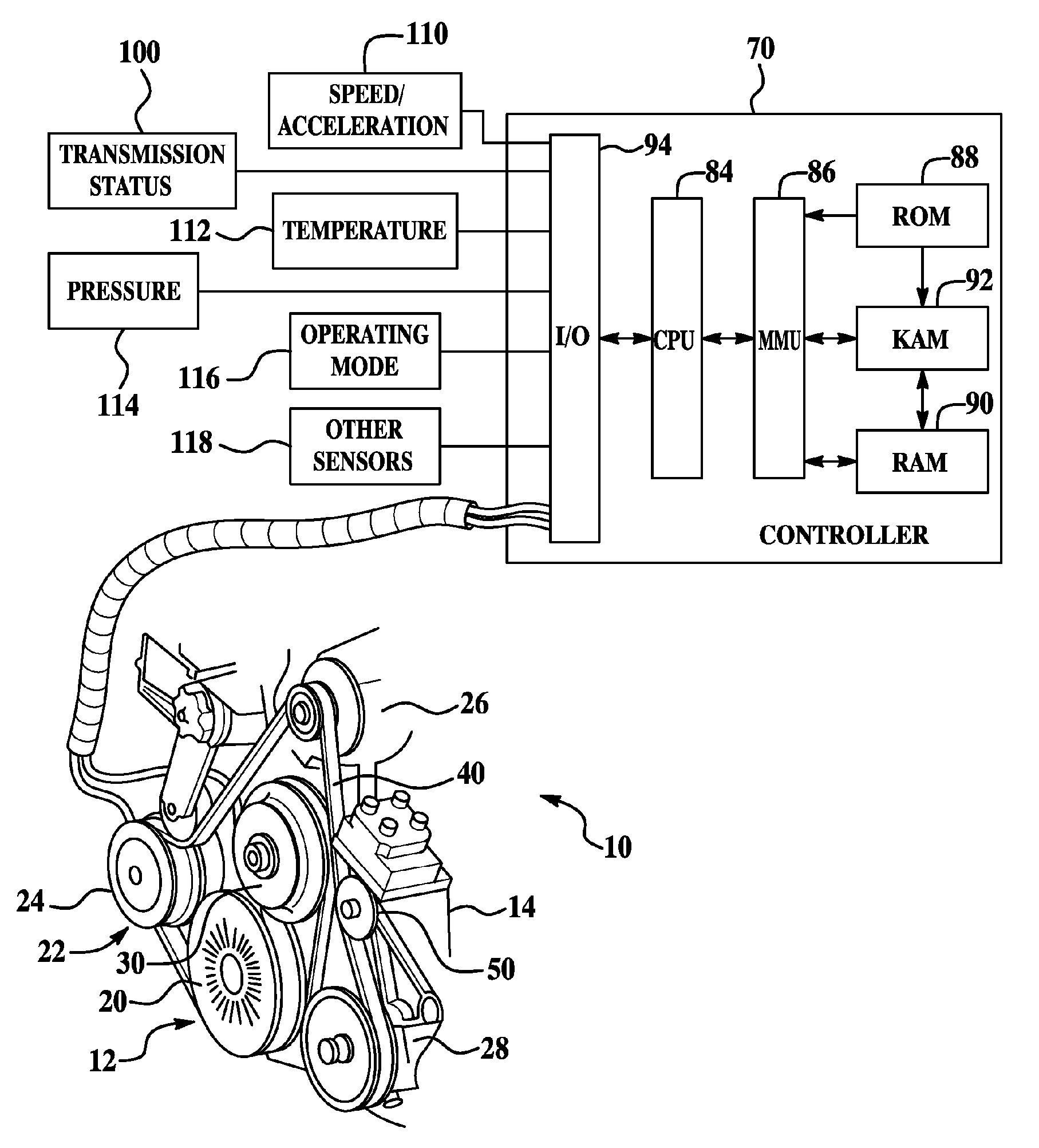

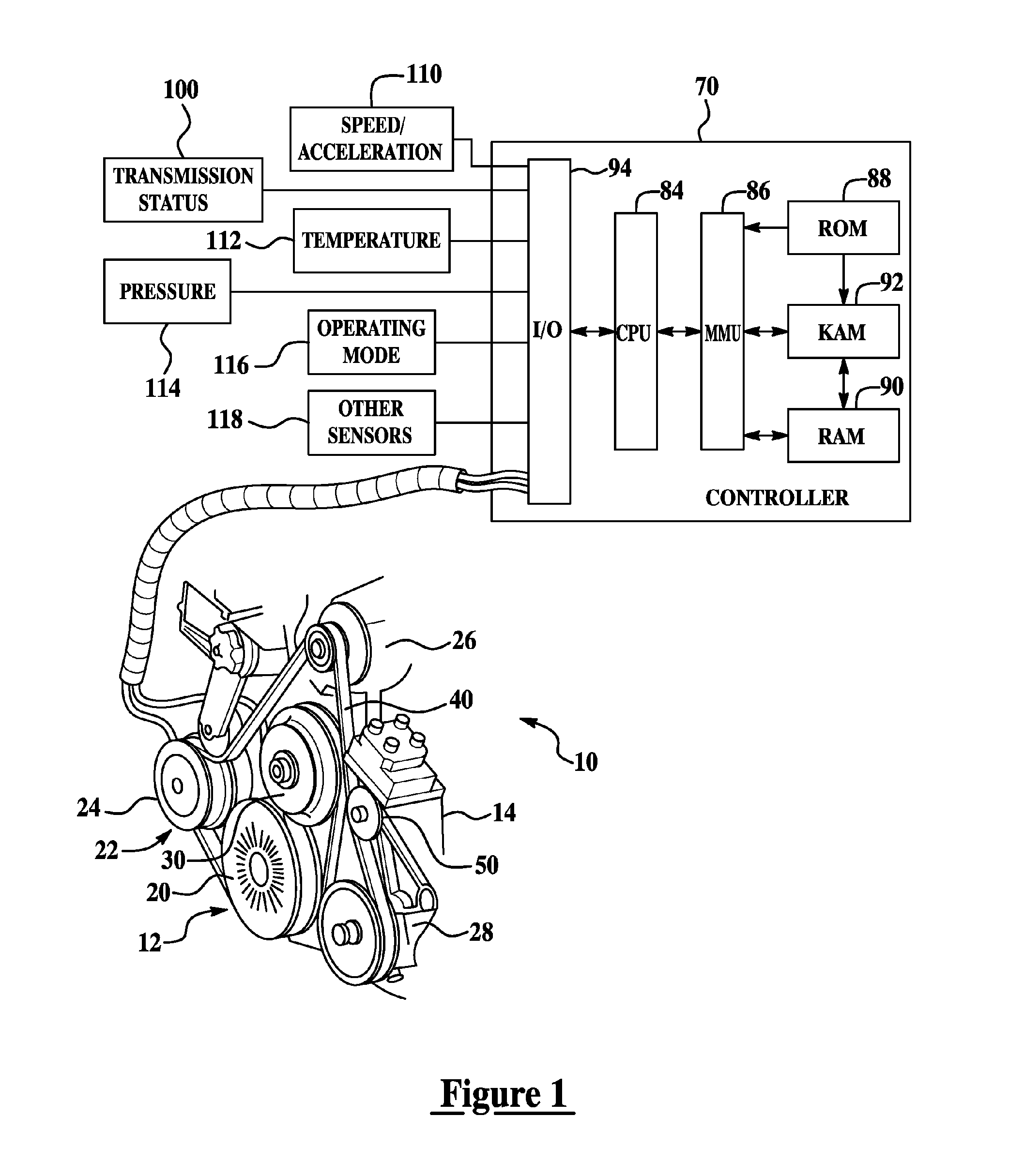

Electromagnetic coupling device for engine accessories

InactiveUS20070080037A1Reduce and eliminate powerEnhance engine/vehicle responseGearingMagnetically actuated clutchesElectromagnetic couplingAlternator

A system and method for controlling a plurality of accessories associated with a multiple cylinder internal combustion engine having the accessories coupled to an engine crankshaft by an electromagnetic coupling device with a flowable magnetic material disposed between a driving member and a driven member include selectively supplying power to the electromagnetic coupling device in response to at least one operating condition to simultaneously engage or disengage the plurality of engine accessories. Embodiments include a magnetic particle clutch or magnetorheological fluid clutch connected to an engine crankshaft and a plurality of engine accessories that may include an air conditioning compressor, water pump, power steering pump, alternator, and / or supercharger, for example.

Owner:FORD GLOBAL TECH LLC

System and method for diagnostic of low pressure exhaust gas recirculation system and adapting of measurement devices

InactiveUS7493762B2Electrical controlInternal combustion piston enginesMeasurement deviceTurbocharger

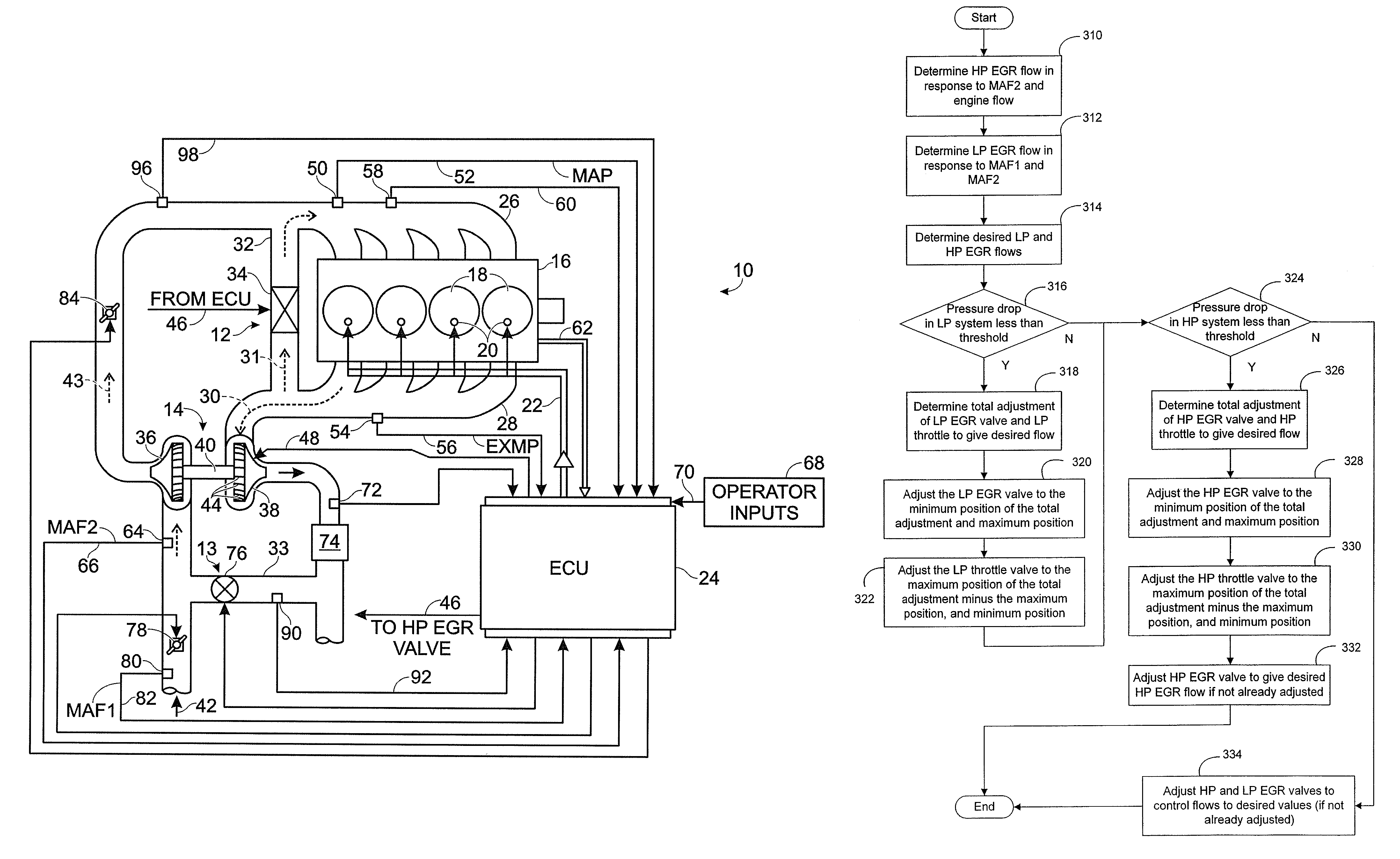

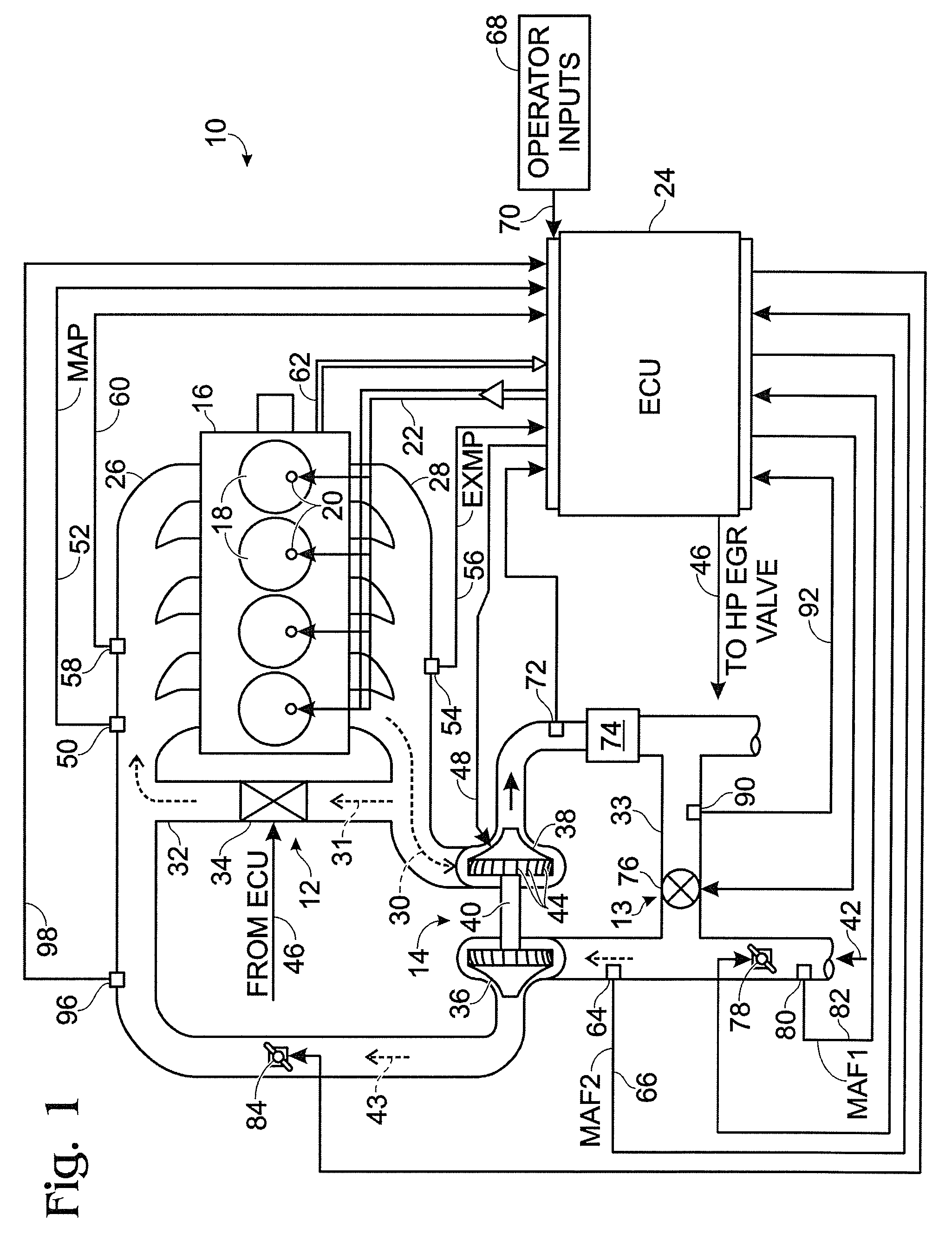

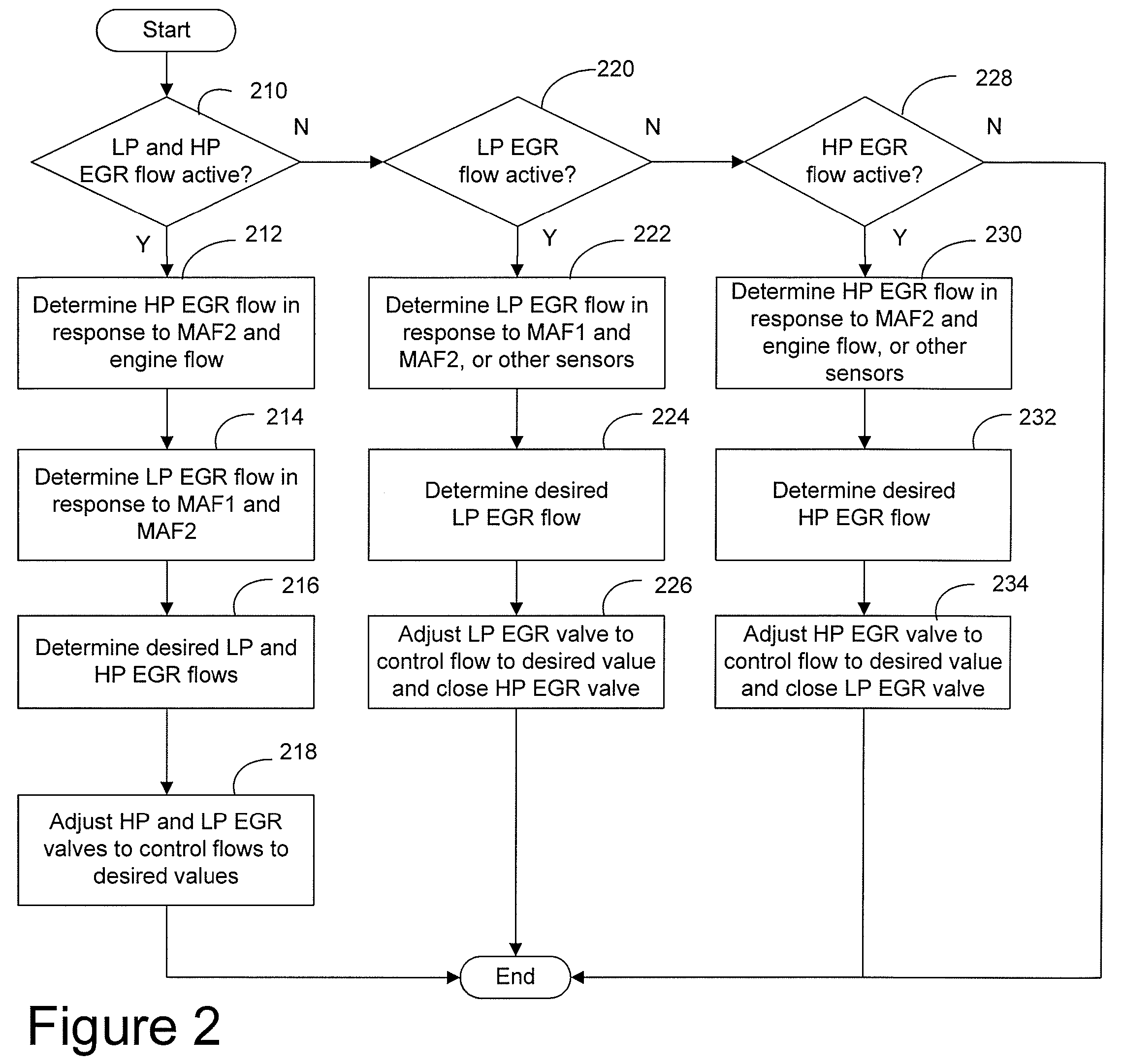

A system for a diesel engine having an intake manifold and an exhaust manifold comprises a turbocharger between the intake and exhaust manifolds of the engine, a low pressure exhaust gas recirculation system, and a high pressure exhaust gas recirculation system. Further, the system includes a controller for coordinating adjustment of exhaust gas recirculation valves and throttles in the system to compensate for interaction between the high and low pressure exhaust gas recirculation systems.

Owner:FORD GLOBAL TECH LLC

Twin-Charged Boosting System for Internal Combustion Engines

InactiveUS20100263375A1Shorten speedImprove cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

A boost system comprising a turbocharger, a supercharger operable as either a compressor or an expander. Air flows through the turbocharger, optionally through a first charge air cooler CAC1, then through the supercharger, a second charge air cooler CAC2, and into the engine. At low engine speeds, the supercharger may be used to compress air, which is tempered by CAC2. At high engine speeds, the turbocharger has excess capacity, resulting in a hot compressed air stream. The supercharger operates as an expander to cool the air stream and reduce the air pressure and temperature to a desired level. Temperature may be reduced to a level below that desired for combustion; CAC2 then rewarms the air, thereby storing cooling capacity. A useful embodiment incorporates a turbocharger with a hybrid gas / electric or diesel / electric engine arrangement wherein a supercharger and a starter / generator / motor are disposed on a disconnectable secondary drive powered by the engine.

Owner:DELPHI TECH INC

Adjustable high boost system with structure of series-parallel connection of turbochargers in different size

InactiveCN1737346AWide range of changesWide range of operating conditionsInternal combustion piston enginesSingle stageTurbocharger

This invention relates to a turbocharger multiple-series adjustable boost system, which belongs to combustion engine technique field. The system comprises diesel engine air inlet pipe, diesel engine, diesel engine discharge pipe, high-pressure turbine stage by-pass conduit and by-pass valve, high-pressure turbine stage by-pass conduit, high-pressure turbine stage, high and low pressure turbine connecting pipe flow change-over valve, high and low pressure turbine connecting pipe, low-pressure turbine stage by-pass conduit, low-pressure turbine, intercooler, high booster by-pass conduit and by-pass valve, high booster by-pass conduit, high blower, high and low pressure booster connecting pipe flow change-over valve, high and low pressure booster connecting pipe, low pressure booster by-pass conduit and low pressure booster, wherein the diesel engine is connected with diesel engine air inlet pipe and diesel engine discharge pipe separately, and the high pressure turbine outlet is connected with the low pressure turbine through the high and low pressure turbine conduit. By said invention, it can realize single-stage turbocharging, successive turbocharging and two-stage turbocharging.

Owner:SHANGHAI JIAO TONG UNIV

Internal combustion engine with an exhaust gas turbocharger

InactiveUS20110067397A1Improve efficiencyLarge operating regionInternal combustion piston enginesNon-fuel substance addition to fuelTurbine wheelInlet channel

In an internal combustion engine for a motor vehicle having an exhaust gas turbo-charger comprising a compressor arranged in an intake tract of the internal combustion engine and a turbine arranged in an exhaust gas tract of the internal combustion engine, with a turbine wheel disposed the turbine housing, an adjustment device is provided by means of which a spiral inlet cross section of a spiral turbine inlet channel and a nozzle cross section of the spiral inlet channel to the turbine wheel are jointly adjustable by a common adjustment device. The invention further relates to an exhaust gas turbocharger, a motor vehicle having an internal combustion engine and a method for operating an internal combustion engine having an exhaust gas turbocharger.

Owner:DAIMLER AG

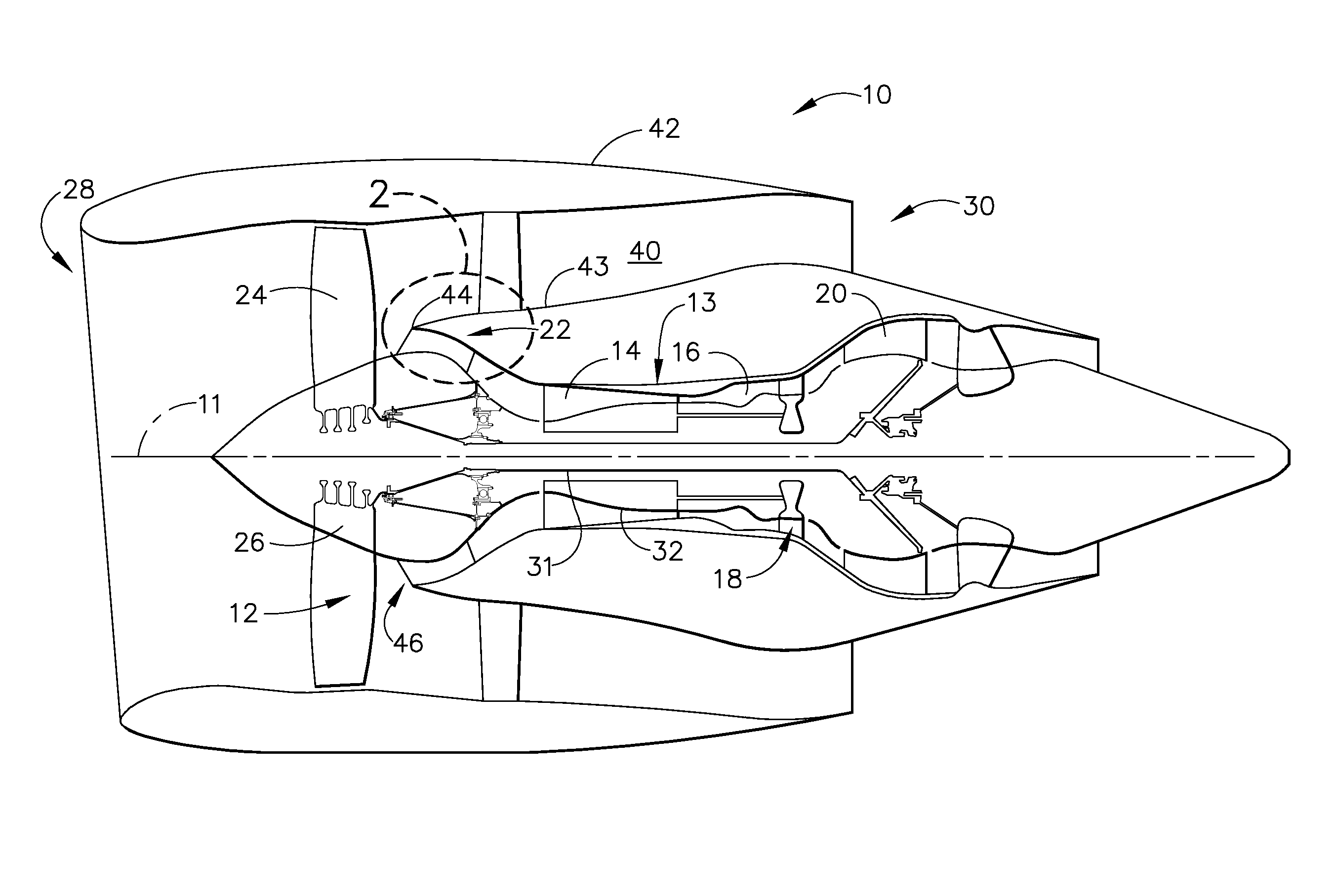

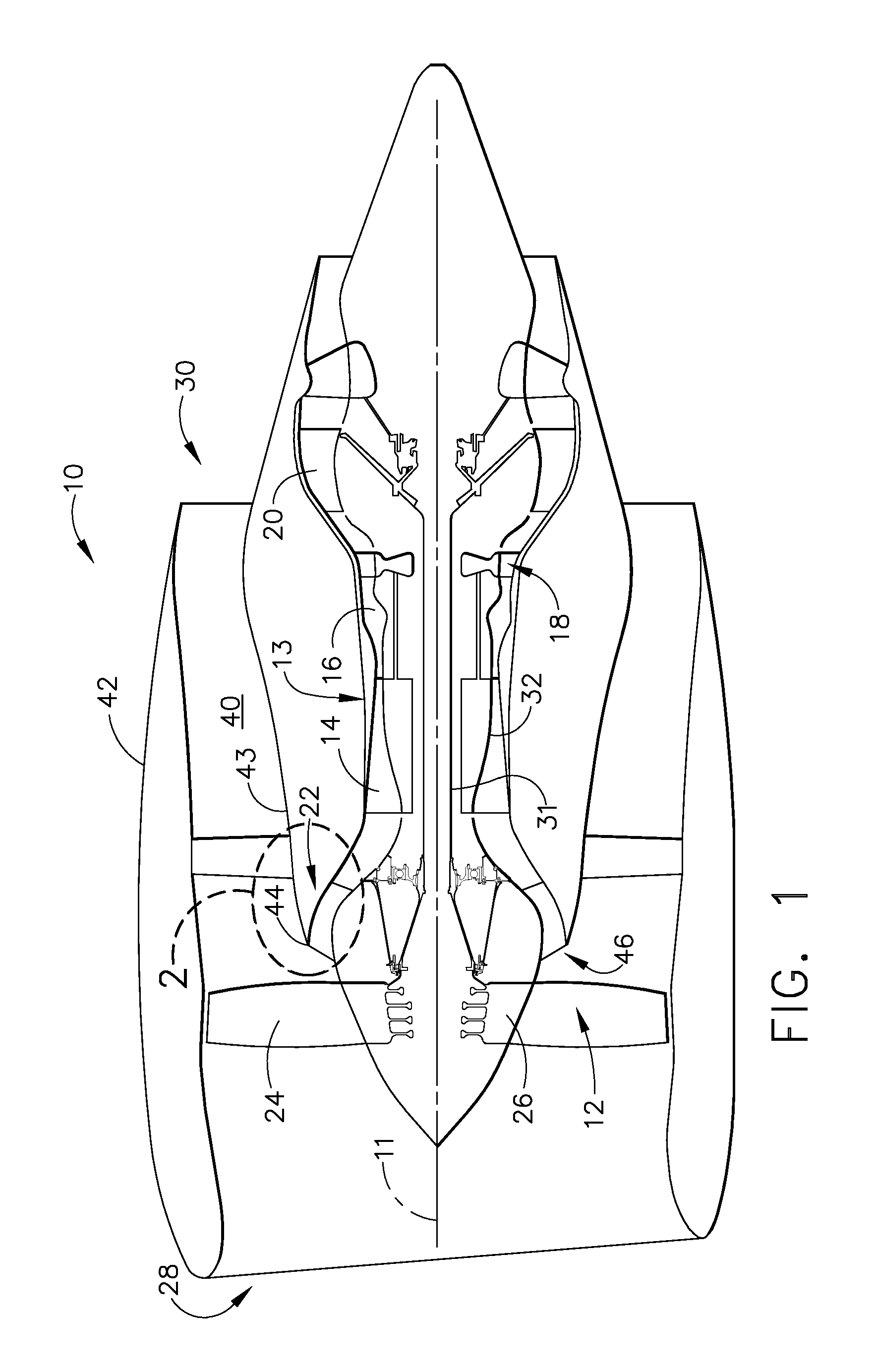

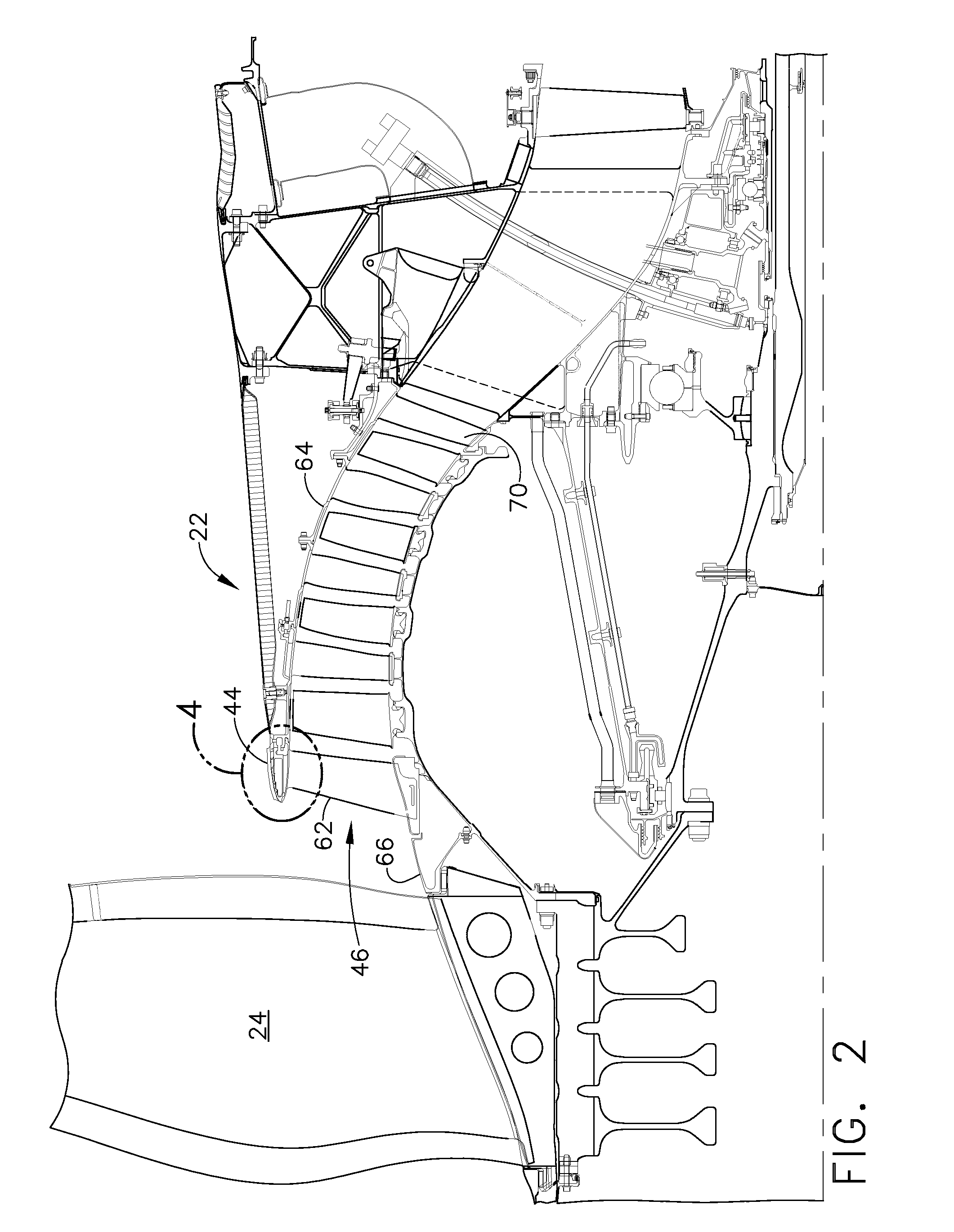

Method and apparatus for operating gas turbine engines

ActiveUS20100236213A1Outer walls isReduce the temperatureTurbine/propulsion engine coolingEfficient propulsion technologiesLeading edgeEngineering

A method for assembling a turbine engine to facilitate reducing an operating temperature of a lubrication fluid during engine operation, the gas turbine engine including a fan assembly, a booster downstream from the fan assembly, and a splitter circumscribing the booster. The method includes coupling a radially inner wall and a radially outer wall at a leading edge to form a splitter body, and coupling an inner support structure within the splitter body such that a cooling circuit is defined between at least a portion of the inner support structure and the inner and outer walls, said cooling circuit configured to circulate lubrication fluid therethrough such that as a temperature of the lubrication fluid is reduced and a temperature of at least a portion of the inner and outer walls is increased.

Owner:GENERAL ELECTRIC CO

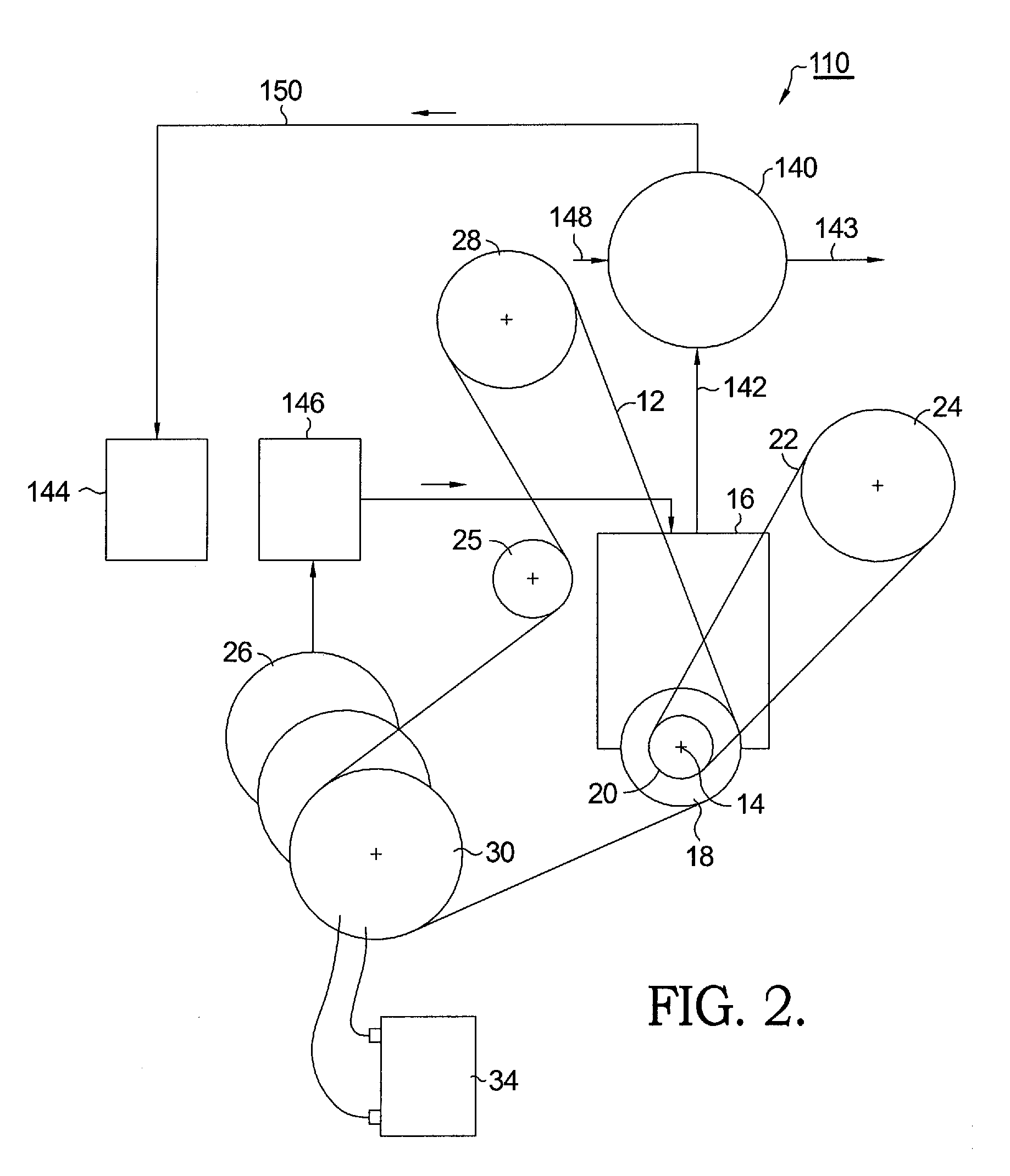

Air hybrid vehicle

InactiveUS20100314186A1Improve efficiencyLow techAuxillary drivesElectrical controlRegenerative brakeTurbocharger

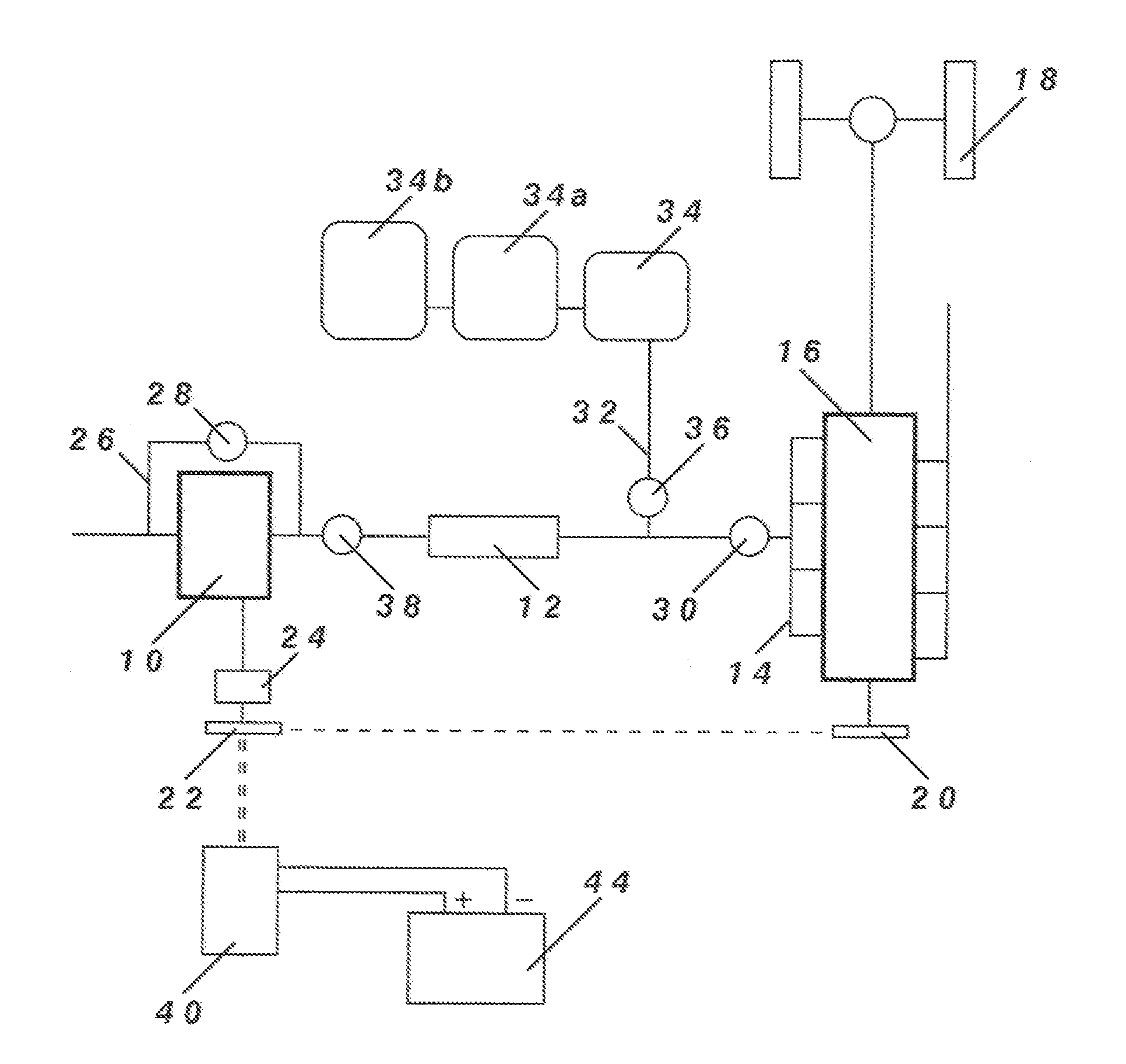

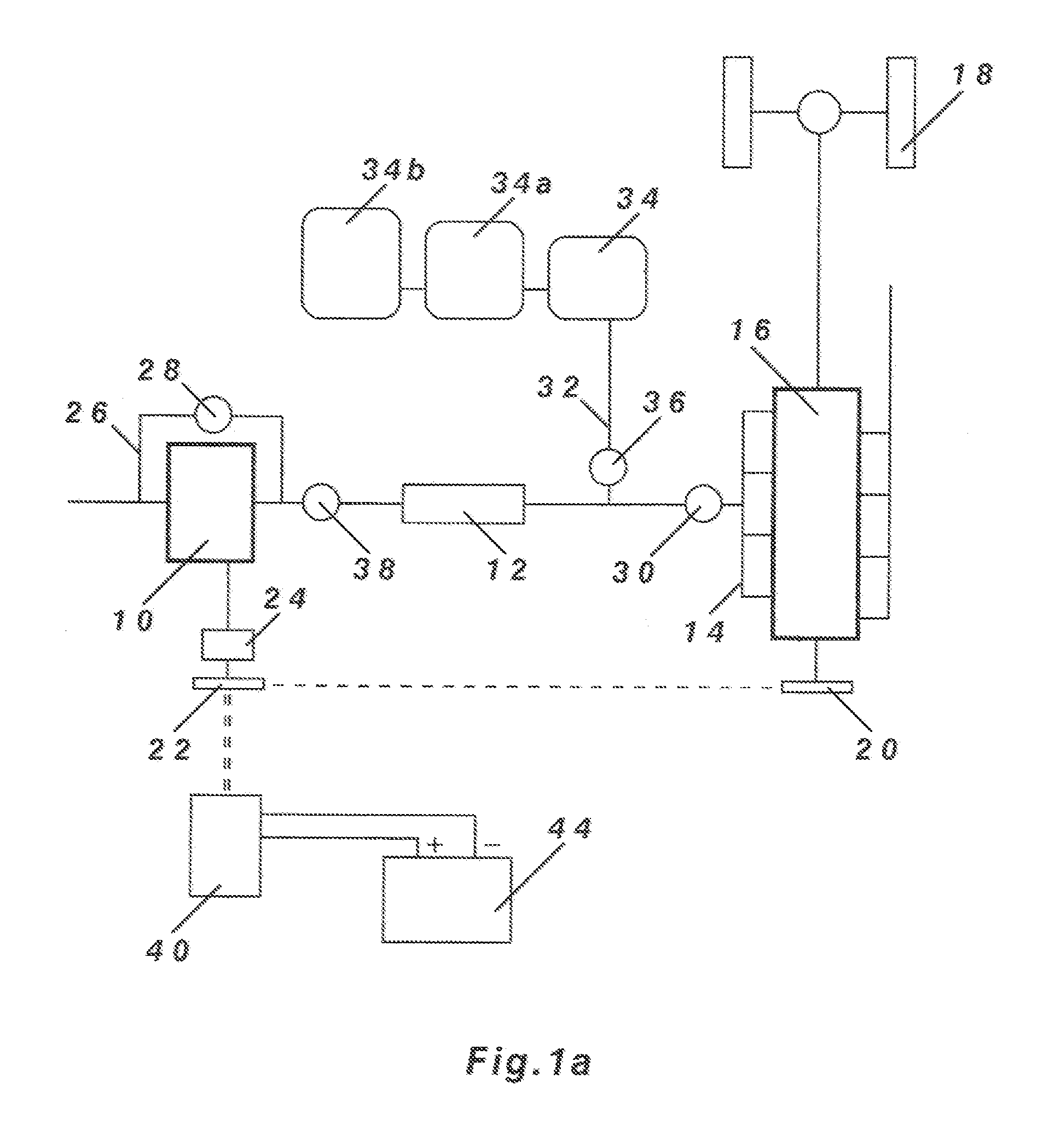

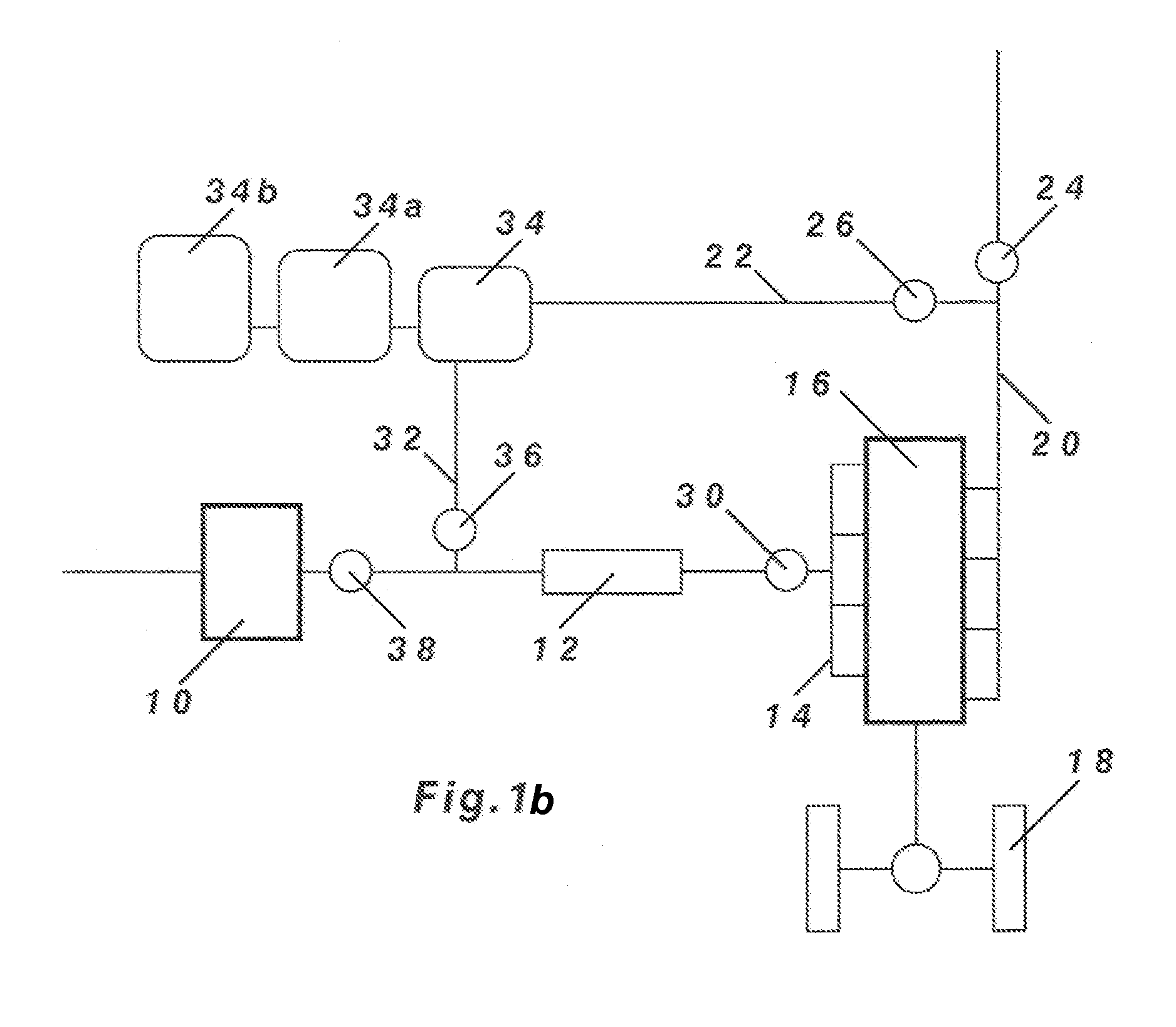

An air hybrid vehicle is described powered by an internal combustion engine (16) which may or may not be equipped with a supercharger or turbocharger (10) for boosting the engine (16). In the invention, power is taken from the vehicle to drive the engine (16) during deceleration or coasting of the vehicle. The engine (16) absorbs kinetic energy from the vehicle and uses that energy to produce boost air which is transferred and stored in a boost air storage tank (34) on board the vehicle at a storage pressure not exceeding 3 bar absolute pressure. The vehicle achieves fuel saving and high performance by boost substitution when this boost air is used to supply the engine (16) for short periods during acceleration or cruising of the vehicle without relying on any air charger, temporarily fulfilling the role of an air charger without actually driving an air charger by substituting the boost normally supplied by an air charger with an equivalent boost produced and stored during regenerative braking. To accommodate a large boost air storage tank (34), the body of the vehicle is adapted with air-tight volumes linked together to form one large storage volume.

Owner:MA INNOVATIONS 2T4LTD

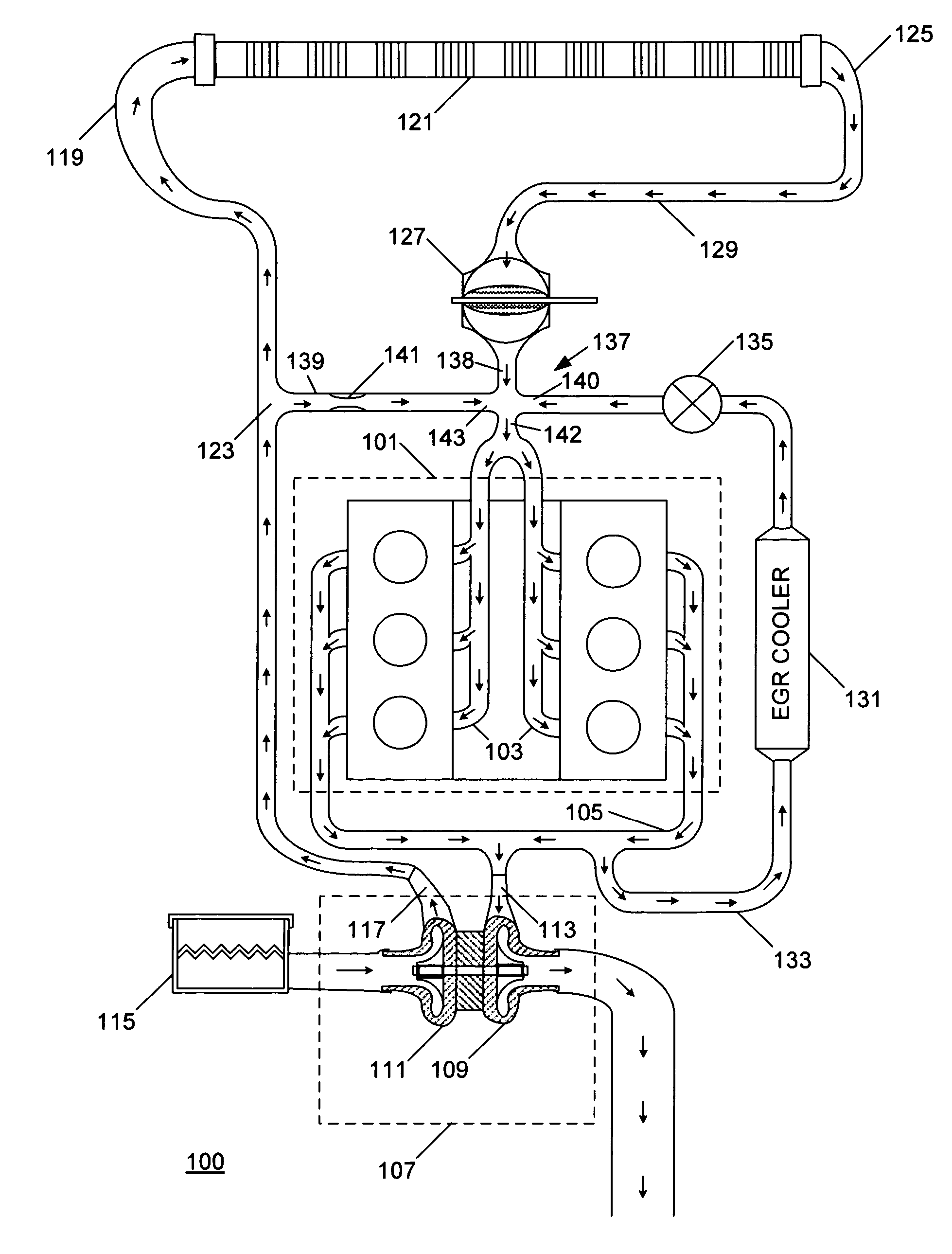

Diesel engine charge air cooler bypass passage and method

ActiveUS7257950B2Reduce condensationWell mixedNon-fuel substance addition to fuelInternal combustion piston enginesCold airTurbocharger

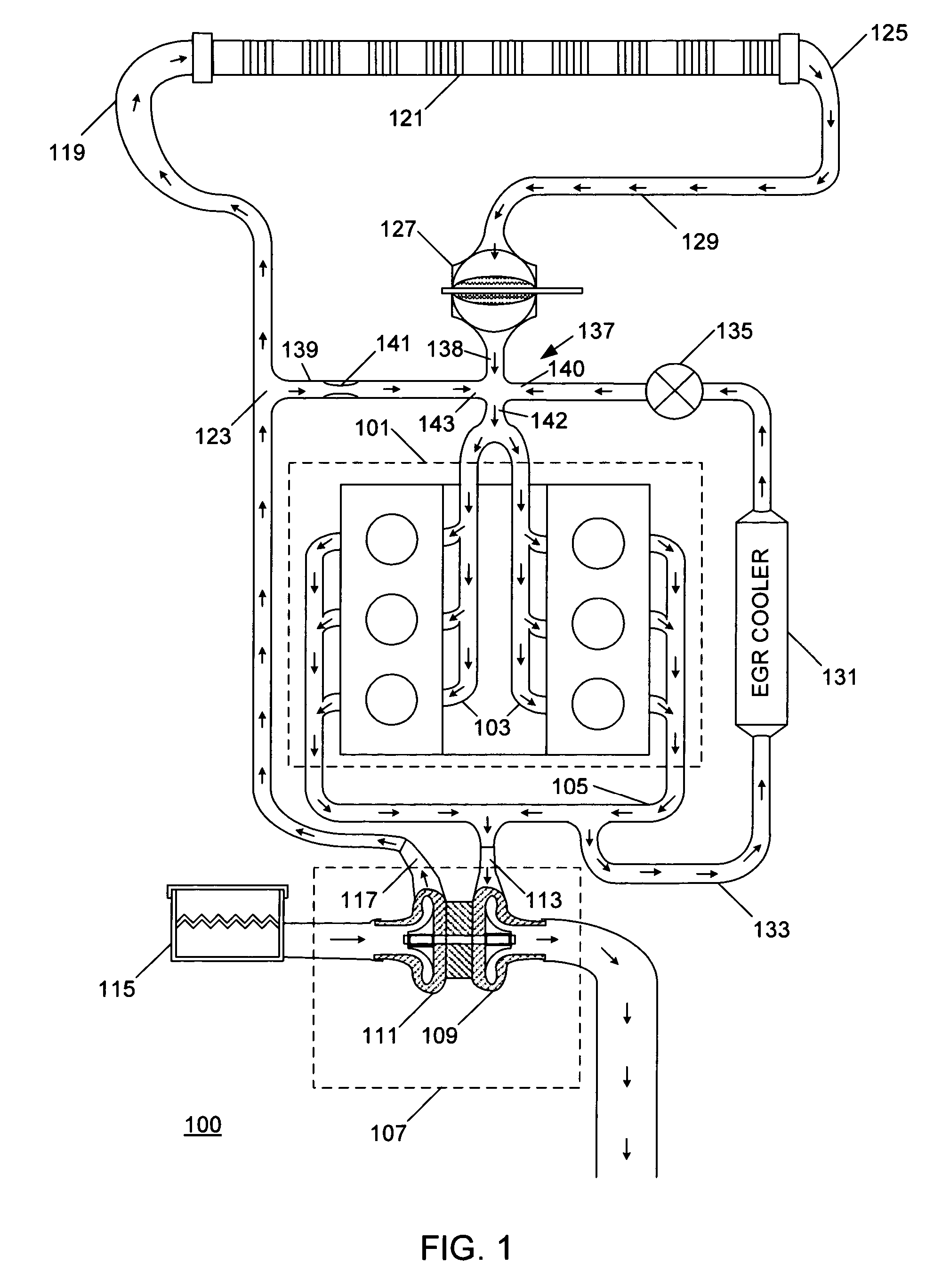

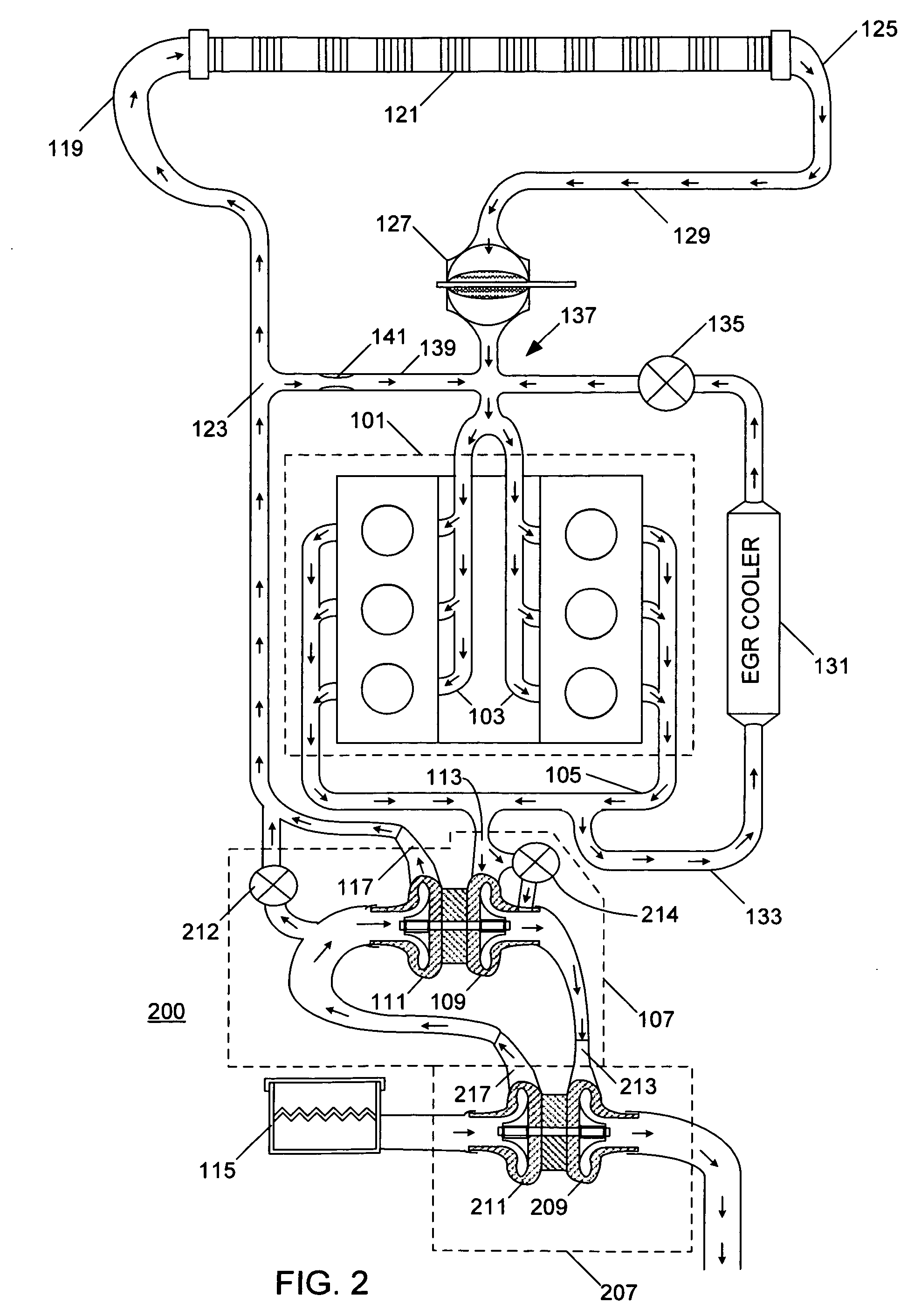

An internal combustion engine (100) includes a turbocharger (107) having a turbine (109) and a compressor (111). A charge-air cooler (121) is in fluid communication with an outlet (117) of the compressor (111) through a hot-air passage (123). An intake throttle (127) is in fluid communication with an outlet (125) of the charge-air cooler (121) through a cool-air passage (129). A junction (137) is located downstream of the intake throttle (127). An intake system (103) and an exhaust gas recirculation system (131, 133, 135) are in fluid communication with the junction (137). A bypass passage (139) containing an orifice (141) fluidly connects the hot-air passage (123) and the intake system (103).

Owner:INT ENGINE INTPROP CO LLC

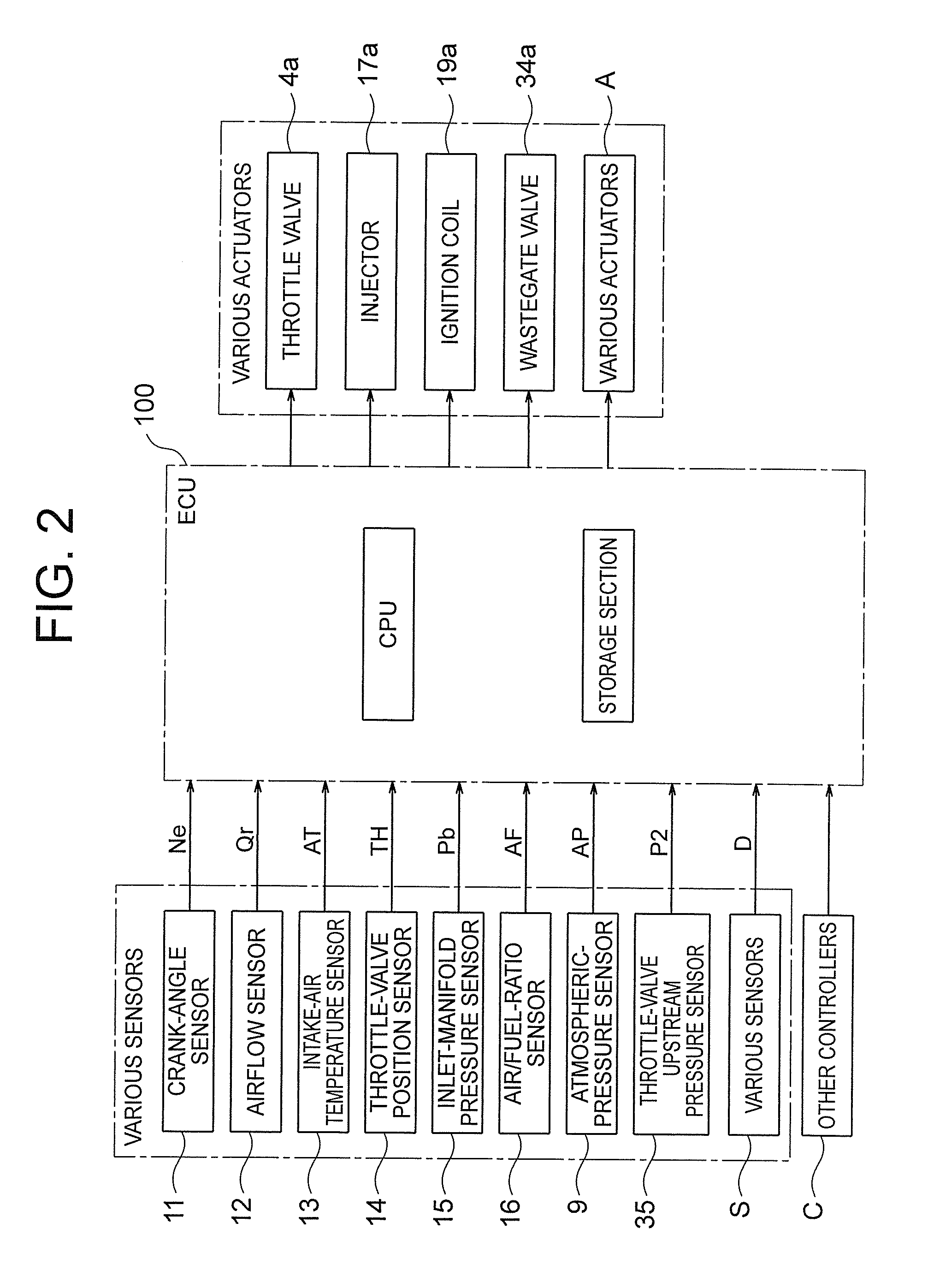

Control device for internal combustion engine and method for controlling internal combustion engine

ActiveUS20130282256A1Improve efficiencyAnalogue computers for vehiclesElectrical controlWastegateFuel efficiency

Provided is a control device for an internal combustion engine, capable of controlling acceleration-response characteristics, performing an operation at an optimal fuel-efficiency point, and learning variation factors in an internal combustion engine provided with a supercharger including a wastegate valve. A target throttle-valve upstream pressure is calculated based on a target charging efficiency and a rotation speed. An exhaust-gas flow rate is calculated based on an air / fuel ratio and an intake-airflow rate. A target compressor driving force is calculated based on a target intake-airflow rate and a target throttle-valve upstream pressure. A wastegate-valve control value is calculated from the exhaust-gas flow rate and the target compressor driving force by using the relationship in which the relation expression expressing the characteristics of the exhaust-gas flow rate and the target compressor driving force depends only on the wastegate-valve control value.

Owner:MITSUBISHI ELECTRIC CORP

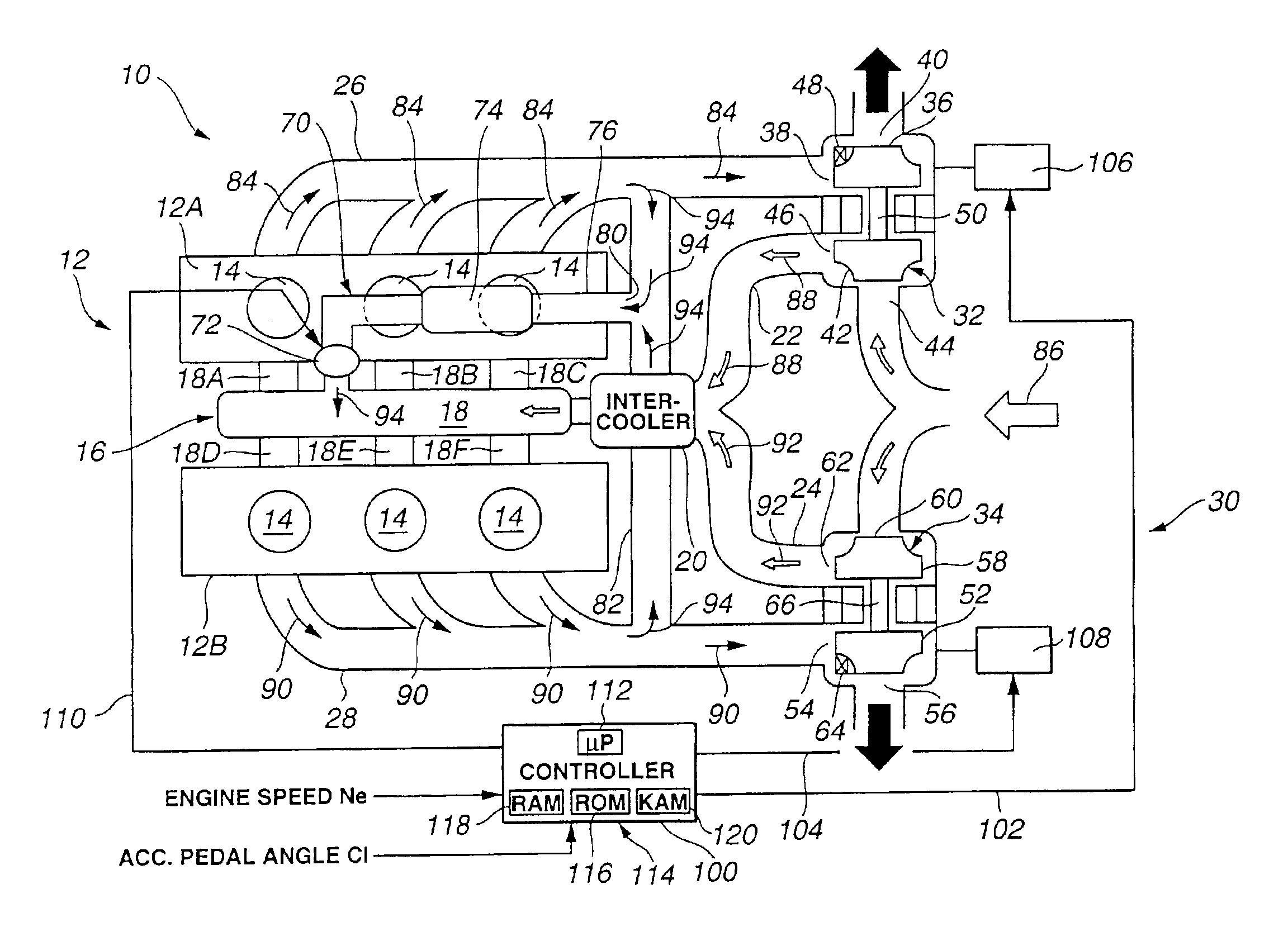

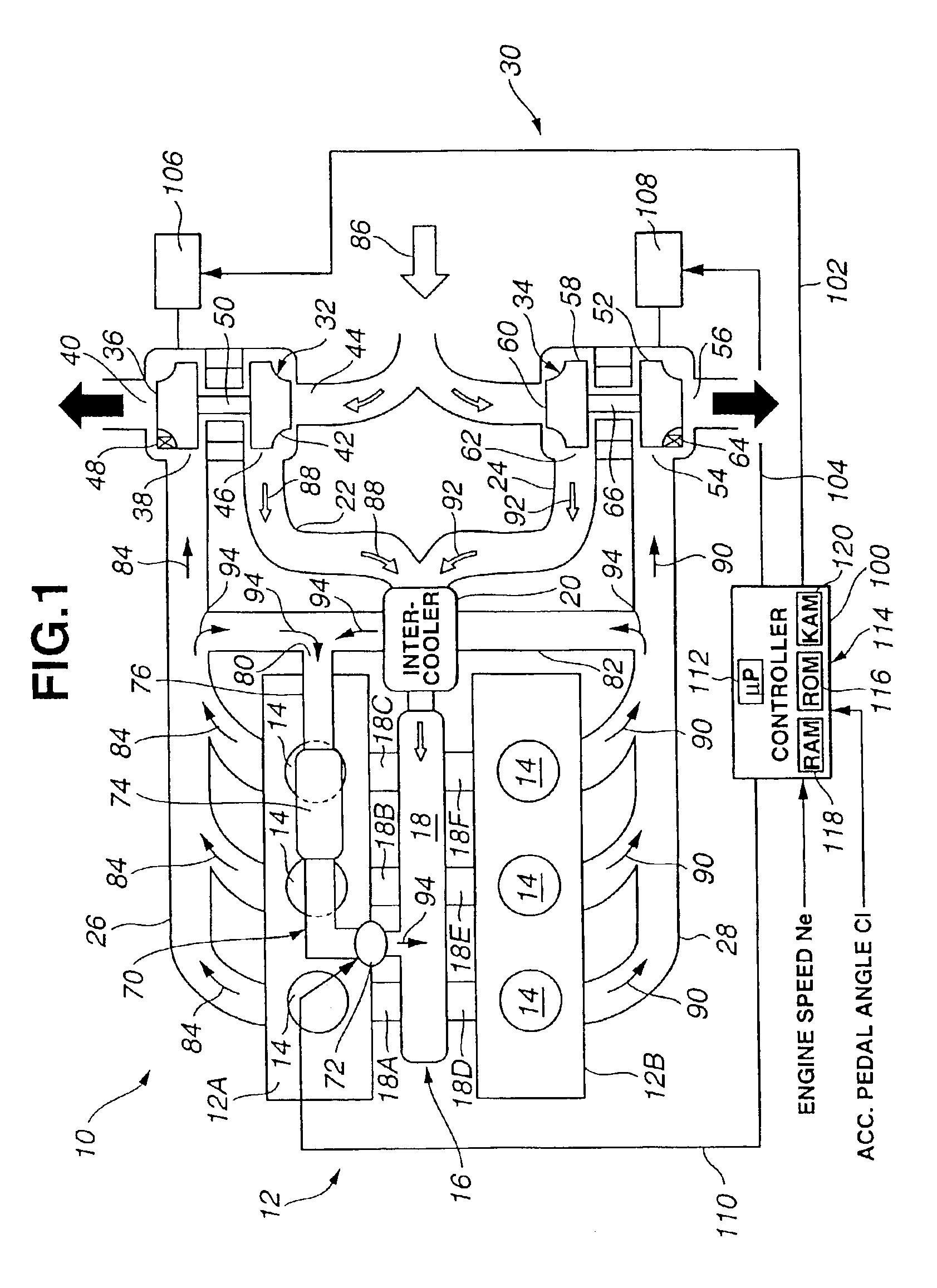

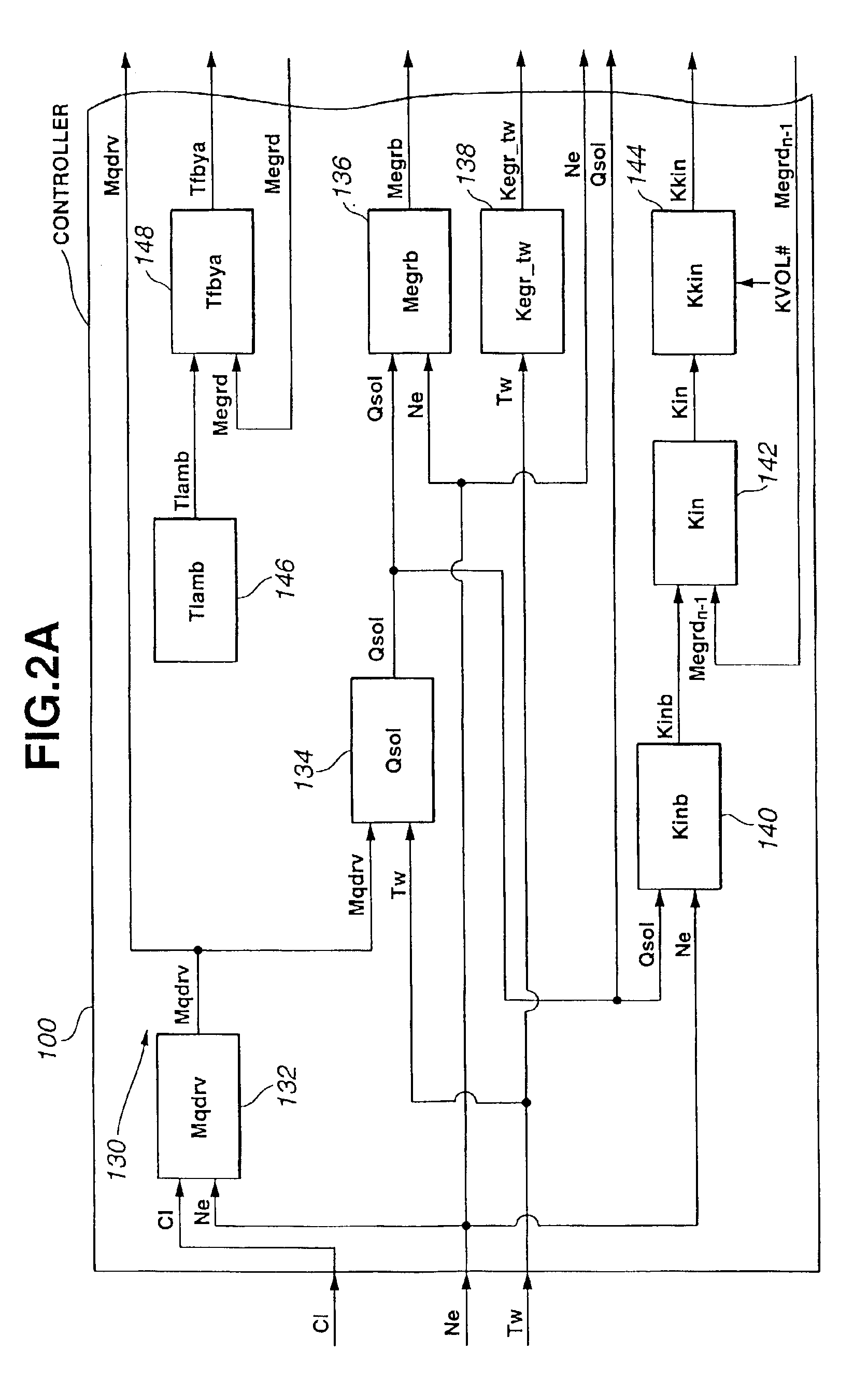

Control of multiple supercharged compression ignition engines having EGR

InactiveUS6917873B2Analogue computers for vehiclesElectrical controlExhaust gas recirculationSet point

A vehicle system controls a compression ignition internal combustion engine equipped with a supercharger system including a plurality of superchargers. The compression ignition internal combustion engine has an exhaust gas recirculation (EGR) system. The vehicle system determines a desired intake manifold supercharging state (tQac) and a desired EGR rate (Megr). The vehicle system includes control logics, each having a first input parameter and a second input parameter, for determining desired set points (Rvnt1 & Rvnt2) for the plurality of superchargers, respectively. The desired set points are used to control the plurality of superchargers, respectively. The vehicle system also includes control logic for determining the first input parameters in response to the desired intake manifold supercharging state. The vehicle system further includes control logic for determining the second input parameters in response to the desired EGR rate.

Owner:NISSAN MOTOR CO LTD

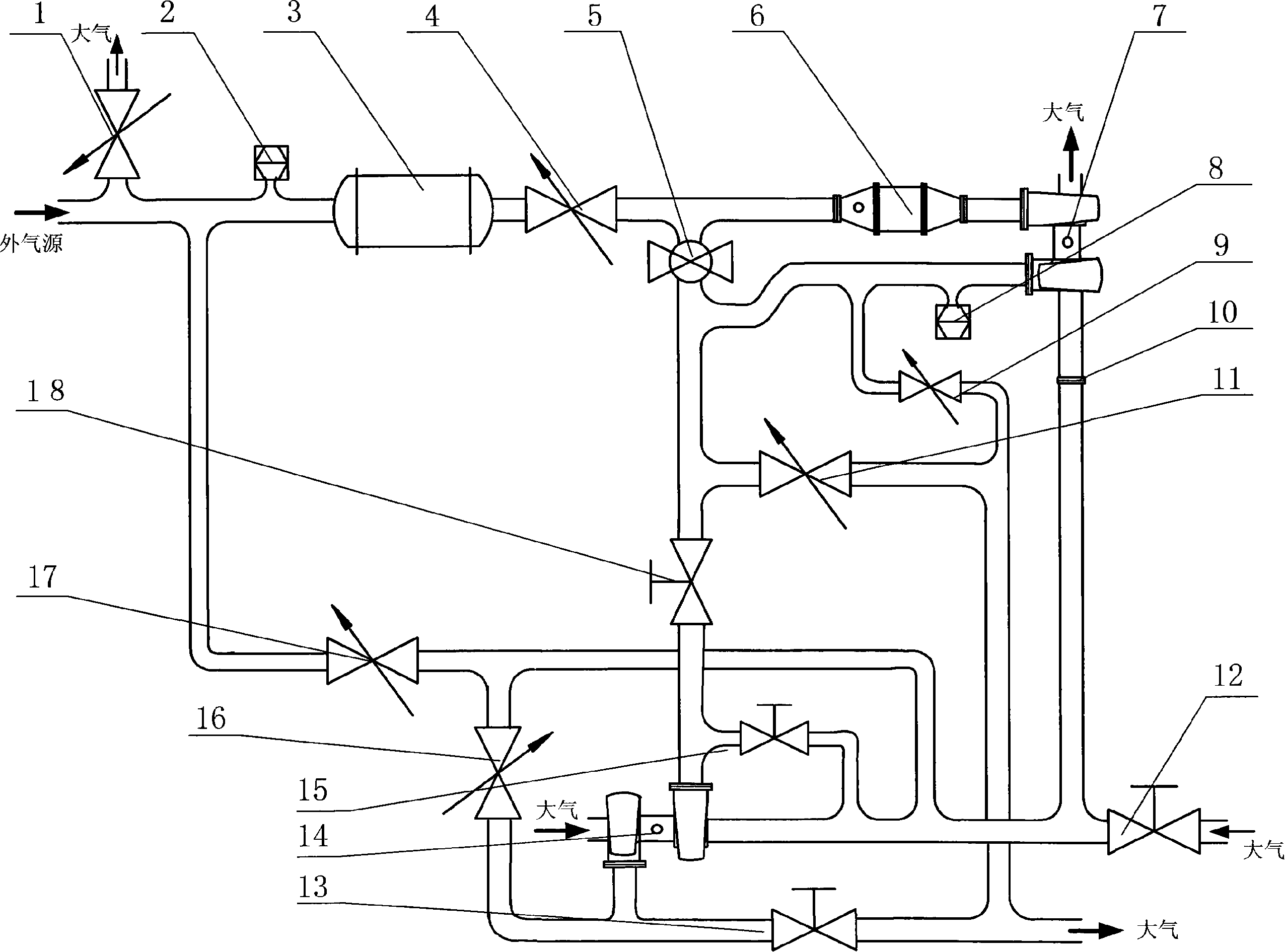

Turbine supercharger property test platform with assistant braking system

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com