Multi-saw blade sawing and cooling system of woods and bamboos

A cooling system and multi-saw blade technology, applied in sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of large sawing force, thermal deformation of the saw blade, and affecting the quality of sawing, so as to reduce the deformation of the saw blade , Prolong tool life, good lubricating and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

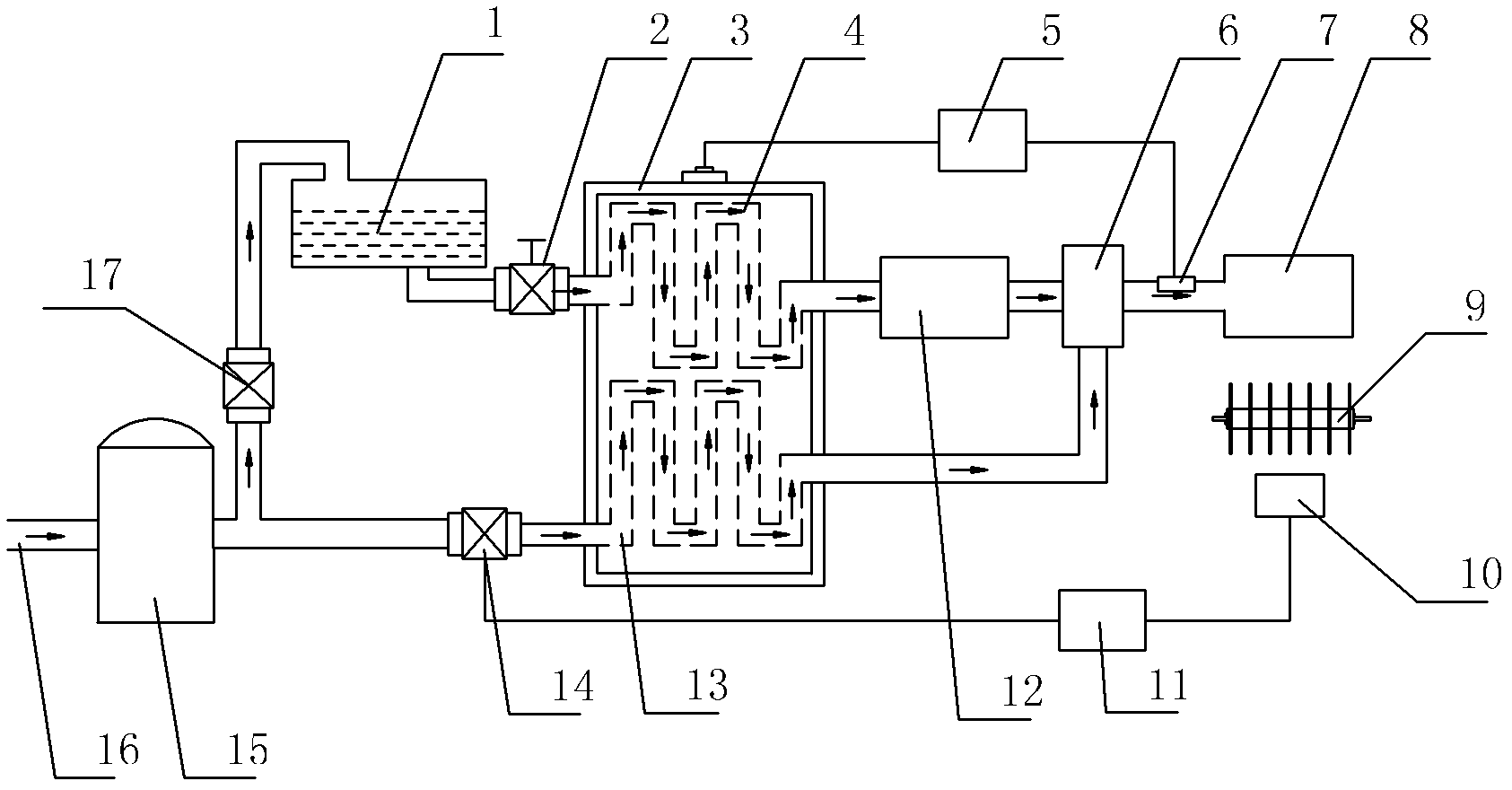

[0052] See figure 1 shown.

[0053] The invention includes: a liquid storage tank 1, a liquid flow regulating valve 2, a cooling device 3, a liquid pipeline 4, an atomized steam temperature controller 5, a mixing chamber 6, an atomized steam temperature detection sensor 7, a uniform supply nozzle 8, multiple Blade saw 9, non-contact temperature detector 10, cooling controller 11, ultrasonic atomization device 12, cold air pipeline 13, gas flow regulating valve 14, gas storage tank 15, gas source pipeline 16 and gas volume regulating valve 17, etc. composition.

[0054] The outside air first enters the air compressor to form compressed air. The compressed air enters the air storage tank 15 through the air source pipeline 16, a part of the gas passes through the air volume regulating valve 17 and enters the cold air pipeline in the cooling device through the gas pipeline, and the other part of the gas passes through the gas pipeline. The flow regulating valve 14 enters the liq...

Embodiment 2

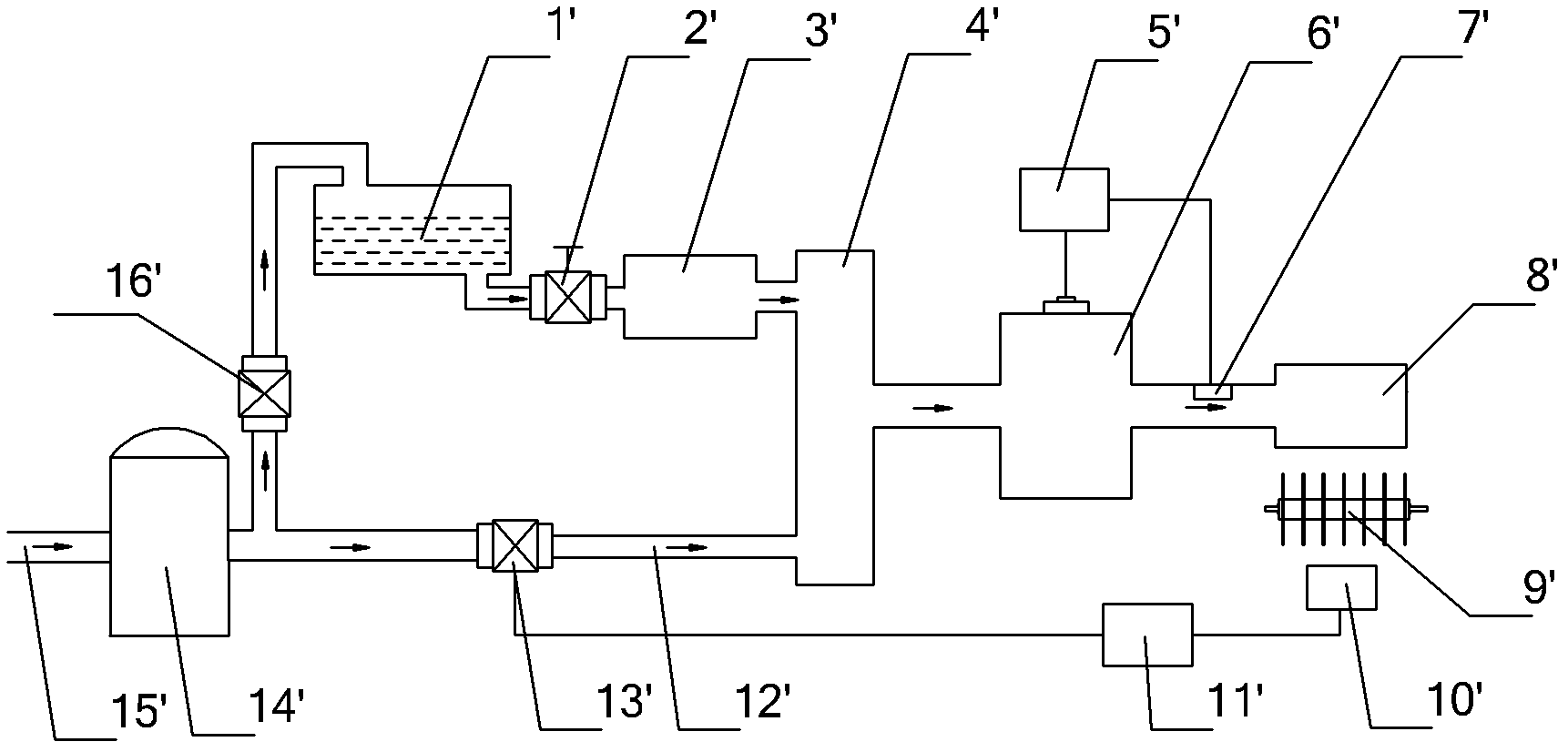

[0056] See figure 2 As shown, the present invention is a wood and bamboo sawing cooling system with multiple saw blades. 5', cooling device 6', atomized steam temperature detection sensor 7', uniform supply nozzle 8', multi-blade saw 9', non-contact temperature detector 10', cooling controller 11', gas pipeline 12', The gas flow regulating valve 13', the gas storage tank 14', the gas source pipeline 15' and the gas flow regulating valve 16' are composed of.

[0057] The outside air first enters the air compressor to form compressed air, the compressed air enters the air storage tank 14' through the air source pipeline 15', a part of the gas enters the mixing chamber 4' through the gas volume regulating valve 13' and the gas pipeline 12', and the other part of the gas Enter the liquid storage tank 1' through the gas flow regulating valve 16', enter the ultrasonic atomization device 3' through the liquid pipeline through the liquid flow regulating valve 2', and the ultrasonic ...

Embodiment 3

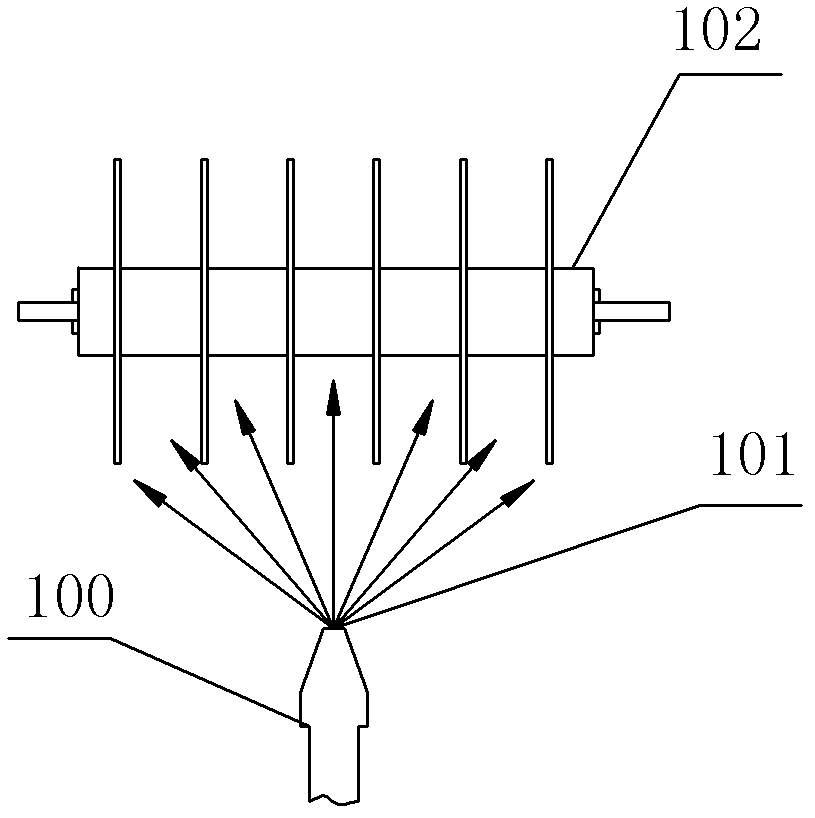

[0059] Traditional circular nozzles such as image 3 As shown, 100 is a nozzle seat, 101 is a nozzle hole, and 102 is a multi-saw blade group. When the circular nozzle hole 100 sprays atomized gas, the shape of the spray is mainly circular and fan-shaped. This type of nozzle produces When the spray is applied to the multi-saw blade group 102, the amount of atomized liquid droplets scattered on each saw blade is different, which will make the cooling effect between the saw blades inconsistent, and may also cause deformation of the saw blades.

[0060] A kind of narrow slit variable section nozzle of the present invention, such as Figure 4 As shown, 100' is a nozzle seat, 101' is a narrow slit variable-section nozzle, 102' is a multi-saw blade group, and the nozzle 101' is a long hole gradually narrowed from the middle to both ends in the length direction. Because the saw blades in the saw blade group 102' are not suitable for heat dissipation, the saw blades in the middle pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com