Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

909results about How to "Play a lubricating role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

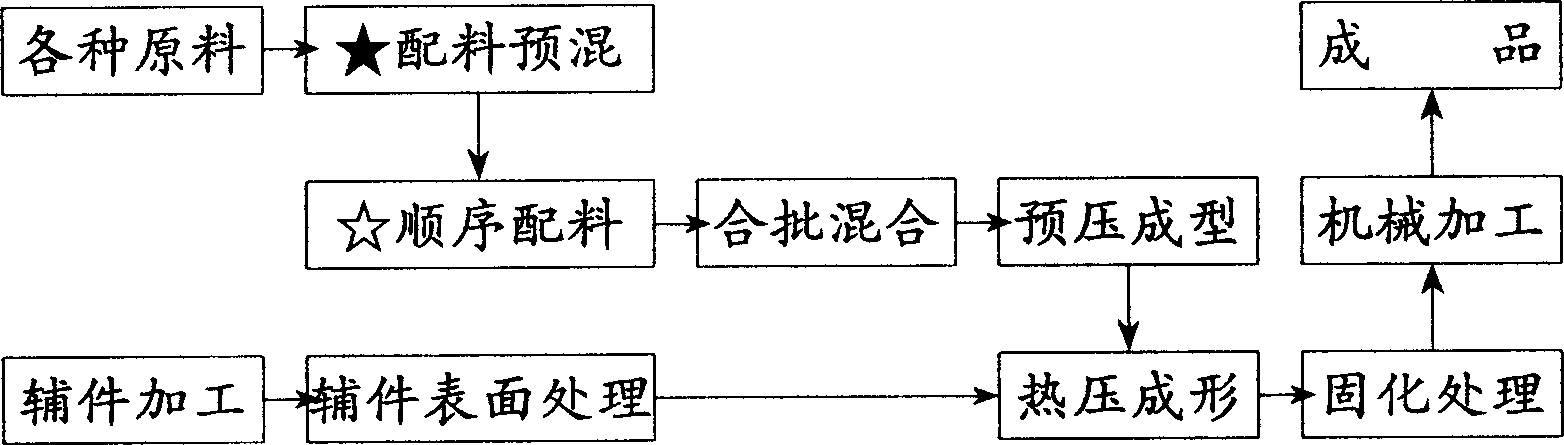

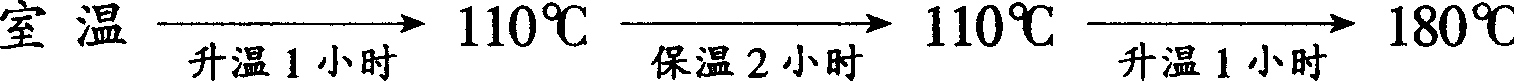

Environment-protection type high-performance automobile braking piece and making method

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

Heat-conductive silicone grease composition being high in heat conductivity and low in viscosity, and preparation method of the silicone grease composition

ActiveCN107603224ALiquidity is not affectedLiquidity impactHeat-exchange elementsNetwork structureSilicone grease

The invention discloses a heat-conductive silicone grease composition being high in heat conductivity and low in viscosity and freeness degree, and a preparation method of the silicone grease composition. The heat-conductive silicone grease composition includes organo-polysiloxane, heat conductive filler and other additives. By selecting the heat conductive fillers in multiple dimensions (one-dimension, two-dimension and three-dimension) and multiple scales (micron, submicron and nanometer) and in special ranges, synergistic effect among the multi-dimension and multi-scale fillers is achieved,thus achieving compact stack of the fillers in a local network structure. The heat-conductive silicone grease not only is improved in heat-conductivity but also has good flowability, low viscosity and low freeness degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

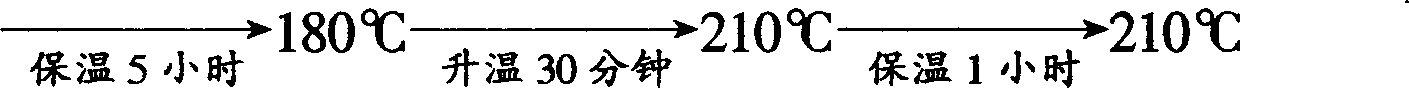

Cutting oil and preparation method thereof

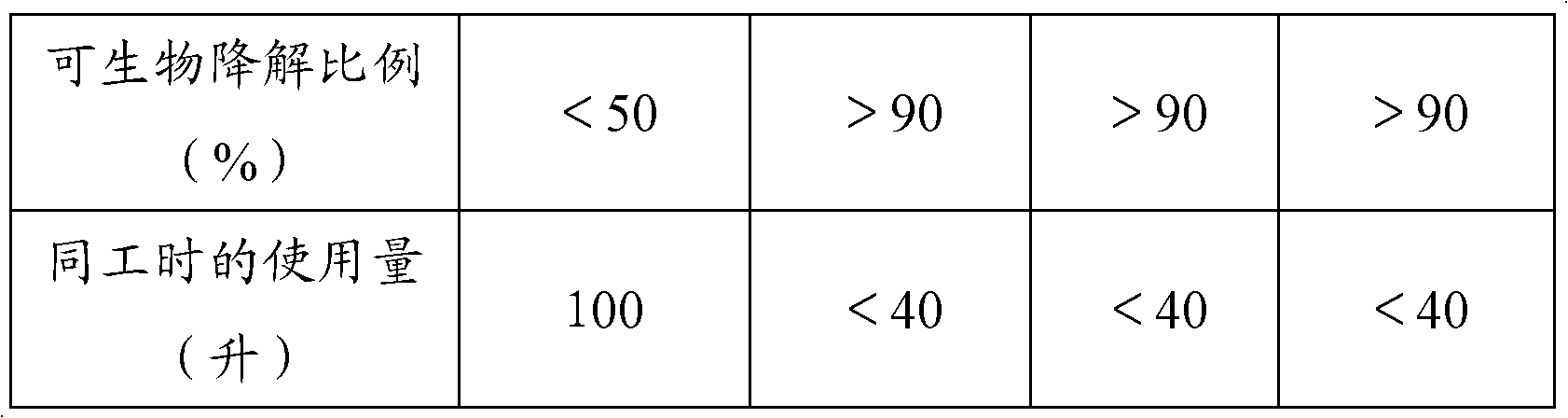

InactiveCN102031190AImprove low temperature performanceImprove filtering effectBase-materialsEcological environmentEnvironmental index

The invention provides environmentally-friendly efficient atomization cutting oil, which comprises the following components in percentage by weight: 20 to 40 percent of synthetic ester, 60 to 80 percent of vegetable oil, 0 to 3 percent of antioxidant, 0 to 2 percent of anti-rusting agent, 0 to 5 percent of extreme pressure abrasion-resistant agent and 0 to 1 percent of metal passivator. The synthetic ester and the vegetable oil are matched and used base oil, so the cutting oil has the advantages of good lubricating property and biodegradability, resource recycle, no toxicity and the like, has low toxin and low harm to the human body and the ecological environment, meets the requirements of related environmental indexes, has good low-temperature performance and oxidation stability and strong universality, is suitable for metal cutting and processing of most materials, is particularly special cutting oil for modern advanced semi-dry and trace lubrication processing and development, and is mainly used for oil mist lubrication; and the gas and liquid two-phase oil mist can play a role in lubricating, take away a large amount of heat, reduce the consumption of cutting fluid, lower the cost and reduce the discharge of waste solution, and is favorable for environmental protection.

Owner:东莞太平洋博高润滑油有限公司

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499AIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

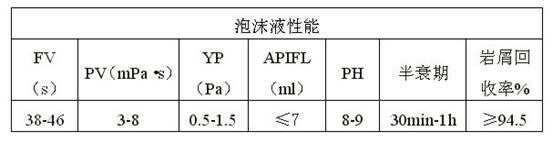

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life is moderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene)

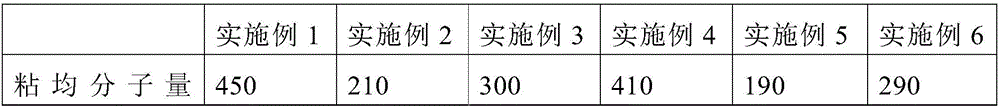

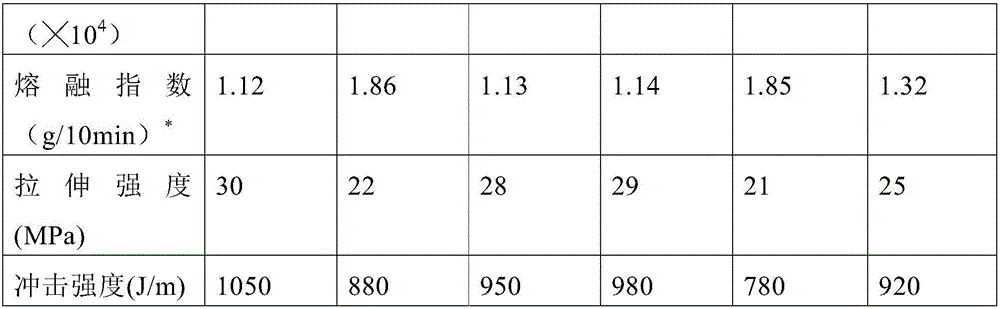

The invention relates to a preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene). The preparation method comprises the following steps: adding a certain amount of solvent oil in a dispersion medium, and polymerizing, thus obtaining UHMWPE containing the solvent oil; extruding through a screw extruder after mixing a flow modifier, a function additive processed by a coupling agent, an antioxidant and the UHMWPE containing the solvent oil at high speed, thus obtaining the injection molding grade UHMWPE. Compared with the prior art, the injection molding grade UHMWPE prepared by the method has good liquidity and good mechanical performance, can be machined and formed on a common injection molding and extrusion device, the machining efficiency is increased, and the injection molding grade UHMWPE can be widely applied to many fields of spaceflight, military industry, automobiles, high-speed rails, rail transit, spinner accessories and the like.

Owner:SHANGHAI RES INST OF CHEM IND

Long glassfiber reinforced nylon composite material and preparation method thereof

The invention belongs to the technical field of high-molecular composite materials, and relates to a long glassfiber reinforced nylon composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 100 parts of nylon, 2 to 10 parts of compatilizer, 0.1 to 0.5 part of antioxidant, 0.2 to 1.0 part of lubricant and 10 to 40 parts of glassfibers. Compared with the short glassfiber reinforcement mode, according to the composite material provided by the invention, abrasions among short glassfibers, a screw rod and a feed cylinder are decreased during a double-screw extruding process, namely, the minimum fiber retained in an injection-molding product is large in length, so that the glassfiber reinforced nylon composite material with excellent performance is prepared. Thus, the applications of the glassfiber reinforced nylon composite material in the fields of automobiles, electric appliances, machinery, military industry and the like are enlarged.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Fasteners such as bolts and nuts made of high-strength steel

The invention relates to a fastener with high performance and low cost, such as a screw bolt, a screw nut and the like made from high-strength steel. The raw material steel of the fastener contains the following ingredients in percentage by mass: 0.2-0.25% of C, 0.05-0.1% of Si, 0.3-0.4% of Mn, 0.08-0.1% of Al, 0.5-0.8% of Mo, 1.2-1.4% of Cr, less than 0.5% of Ni, 0.05-0.07% of Ti, 0.05-0.07% of Nb, 0.05-0.07% of V, 0.6-0.8% of Cu, 0.5-0.8% of W, 0.001-0.002% of B, less than 0.008% of P and less than 0.008% of S. An economical preparing process which has no need of carrying out annealing treatment before cold-processing is realized by using the unique processing steps, such as hot-rolling processing, drawing processing, cold-processing, quenching and tempering and the like and the excellent-malleability fastener with high tensile strength over 1300 MPa and over 4% percentage elongation.

Owner:NANTONG HAIOU LIFE SAVING & PROTECTION EQUIP

Perfluor high-temperature lubricating grease

The invention discloses perfluor high-temperature lubricating grease, which consists of base oil, thickening agent and additive, wherein the base oil is one or more of perfluor polyether oil, perfluor ester oil and perfluor hydrocarbon oil; the thickening agent is one or more of polytetrafluoroethylene, perfluor ethylene propylene copolymer, fluorocarbon wax, carbon black, silicon dioxide, titanium dioxide, molybdenum disulfide, rare earth fluoride, nano graphite, graphite fluoride and resin fluoride; and the additive is one or more of phosphorus cyanide, sodium dicaprate, sodium dicaprylate and antimony trioxide. The lubricating grease can be used for lubricating for a long term at the temperature of above 300 DEG C, and can also be used for lubricating in severe environments such as high pressure, high vacuum, high load, strong acid and base and strong corrosion.

Owner:上海相推环保科技有限公司

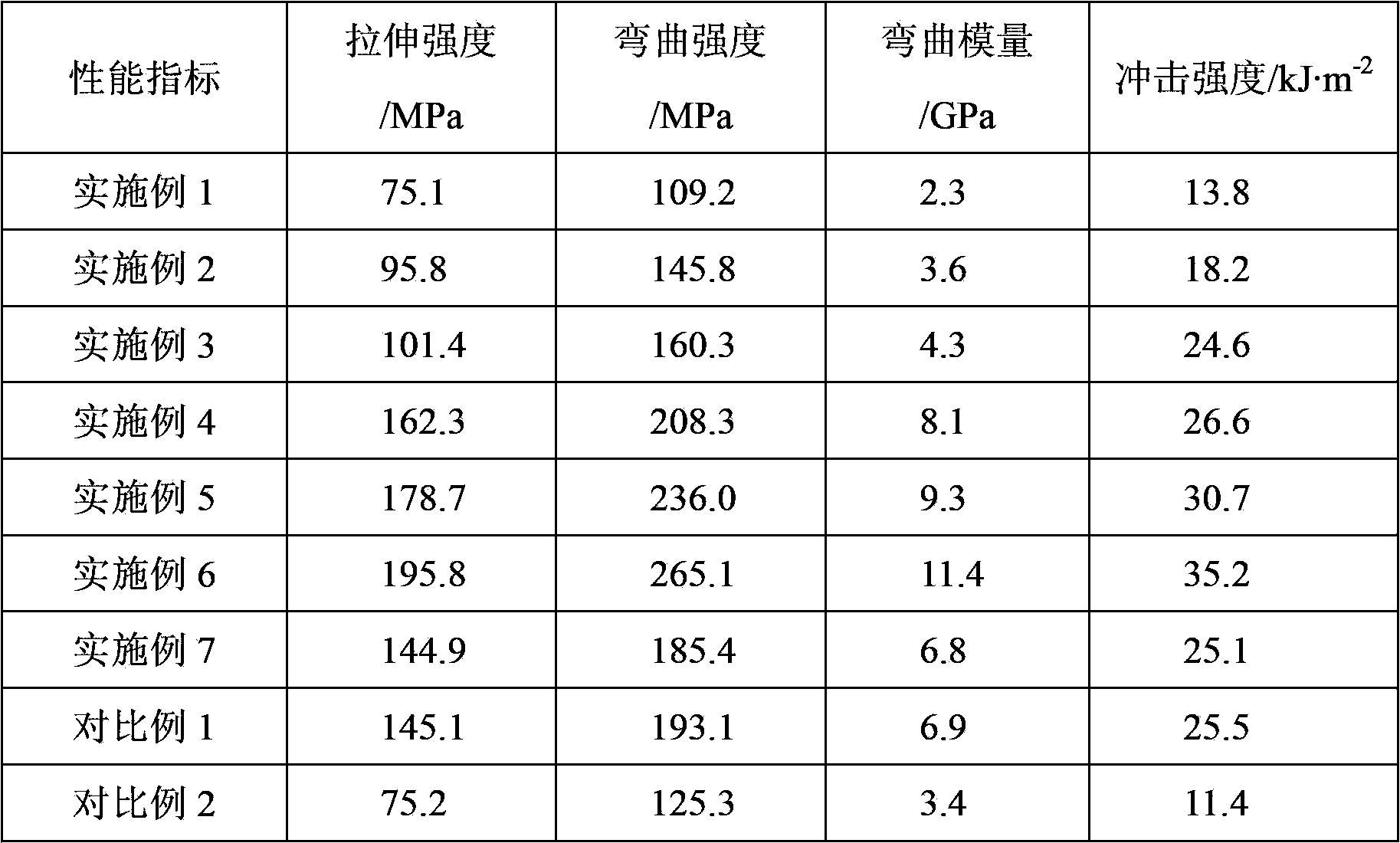

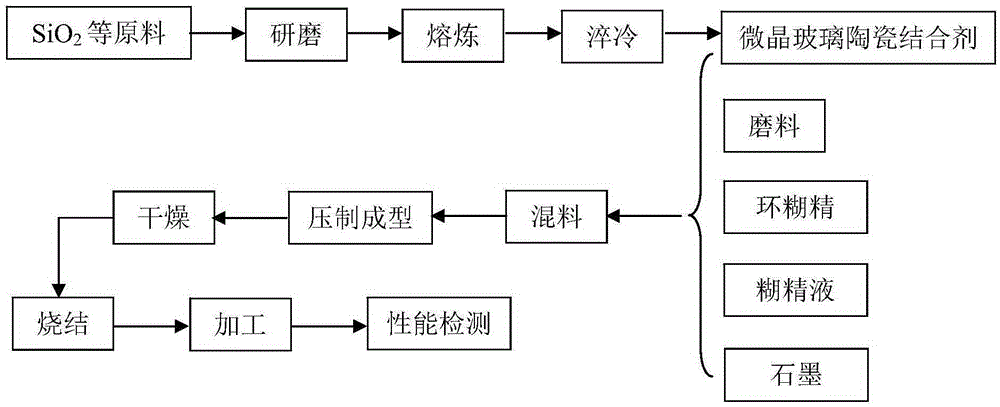

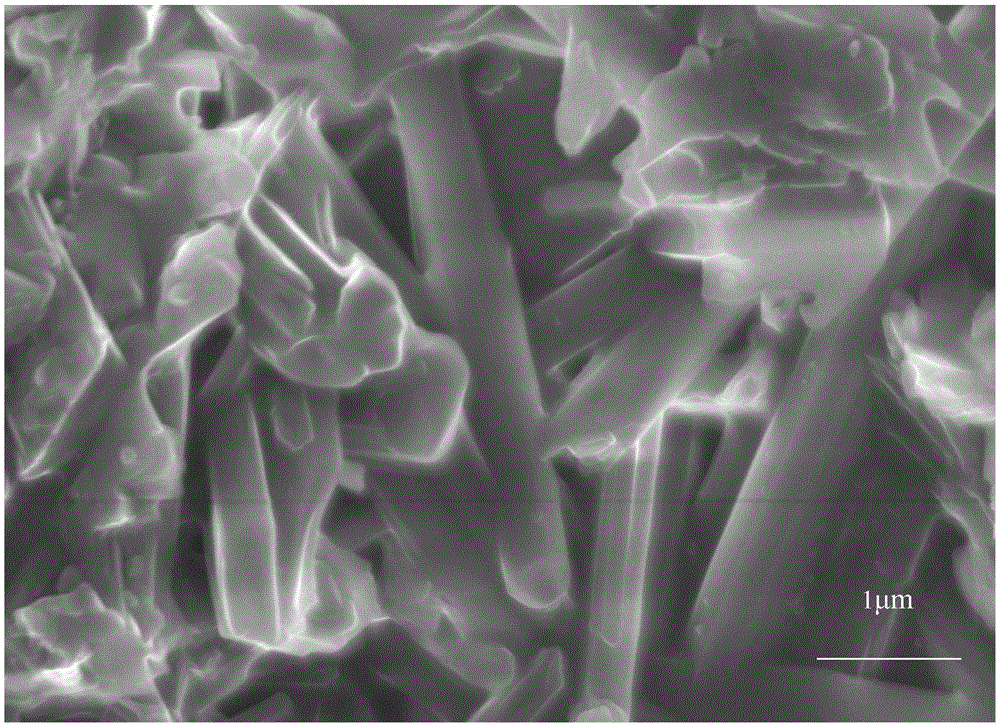

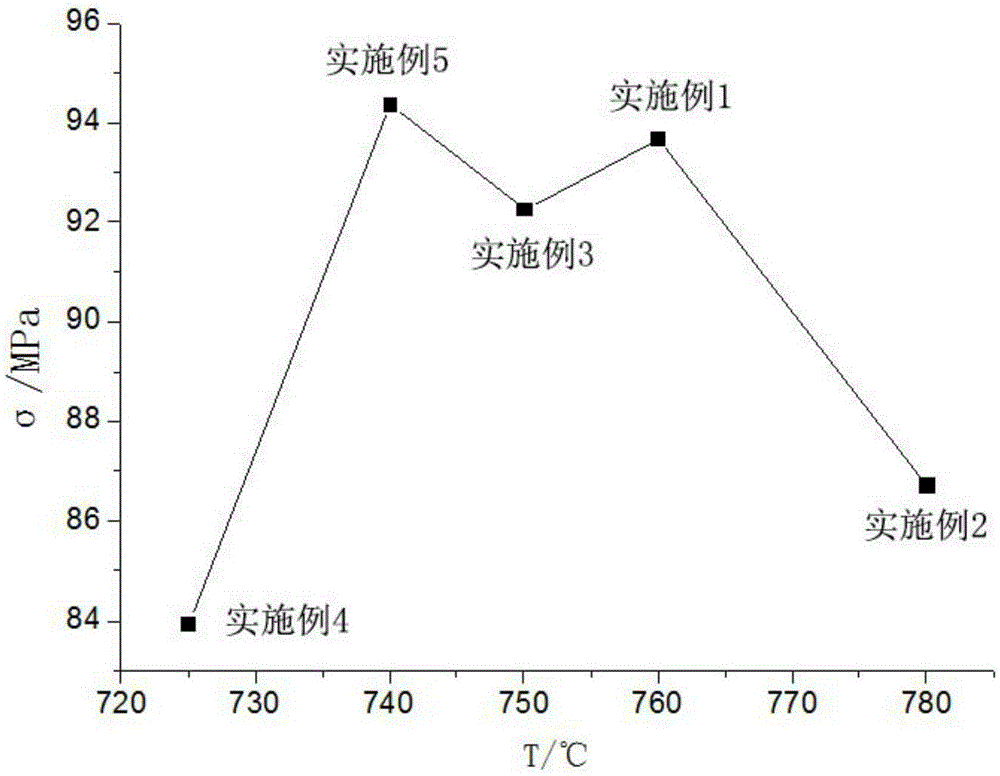

Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

ActiveCN105252435ASmall coefficient of thermal expansionLow crystallization temperatureAbrasion apparatusGrinding devicesTO-18Materials science

The invention discloses a microcrystalline glass ceramic binding agent, a preparing method thereof, an SG grinding wheel and a preparing method thereof. The binding agent is prepared from, by weight percentage, 40% to 65% of SiO2, 6% to 20% of Al2O3, 5% to 18% of Na2O, 0.5% to 5% of CaO, 3% to 10% of K2O, 8% to 35% of B2O3, 0.5% to 2% of MgO and 2% to 6% of TiO2. The microcrystalline glass ceramic binding agent is formed by reasonably selecting the raw materials, the scientific ratio is adopted, the binding agent has the beneficial effects of being low in thermal expansion coefficient and crystallization temperature and high in strength accordingly, the microcrystalline glass ceramic binding agent is suitable for being used as a binding agent of the SG grinding wheel, the firing temperature of the SG grinding wheel is greatly reduced, and the firing time of the SG grinding wheel is greatly shortened; and meanwhile the work efficiency and the machining accuracy of the SG grinding wheel are improved, grinding heat is reduced, and the service life of the grinding wheel is prolonged.

Owner:白鸽磨料磨具有限公司

Disassembling method of wind turbine generator system main bearing with shaft sleeve

The invention discloses a disassembling method of a wind turbine generator system main bearing with a shaft sleeve. The disassembling method is mainly used for disassembling the main bearing from a main shaft. The disassembling method comprises the following steps: A. cooling the main shaft; B. heating a bearing inner race of the main bearing, and C. dissembling the main bearing from the tail end of the main shaft using match of a bearing tensioner and the main bearing under the effect of external force. A certain temperature difference is formed between the main shaft and the bearing inner race of the main bearing by cooling the main shaft and heating the bearing inner race of the main bearing, magnitude of interference of assembling of the main shaft is offset using the expansion caused by heat and contraction caused by cold theory, and the main bearing can be disassembled from the main shaft safely and quickly using the bearing tensioner. Integrality of disassembling of the main bearing is guaranteed, damages to the main shaft by using the bearing tensioner to disassemble the main bearing directly can be avoided, and recycle of the main shaft saves large cost for an enterprise. The disassembling method of the wind turbine generator system main bearing with the shaft sleeve is simple in operation procedures at the same time, and an ideal disassembling method of the wind turbine generator system main bearing with the shaft sleeve is achieved.

Owner:GUODIAN UNITED POWER TECH CHIFENG

Glass bead with honeycomb holes and tile glue with glass bead

The invention provides a glass bead with honeycomb holes, which can be used as light-weight packing in dry mixed mortar. The glass bead is prepared by crushing a pure glass product recycled industrially or civilly into glass powder of below 400 meshes, uniformly mixing the glass powder, a foaming agent and an adhesive, and then fusing, swelling, cooling and screening the mixture under the condition of high temperature of 800-820 DEG C. The glass bead is a regular spherical particle with a rough appearance and has a honeycomb meshed structure internally; the particle size is 0.1-5mm; the stacking density is 310-460kg / m<3>; and the barrel pressure intensity is 2.6-2.8MPa. The glass bead with the honeycomb holes is regular in appearance, high in compression strength and low in water absorption rate, is used as the light-weight packing in the dry mixed mortar, has the characteristics of large volume yield and the like, is easy to construct and is an ideal material which replaces expanded perlite to be used as the light-weight packing in the dry mixed mortar. The invention also provides tile glue with the honeycomb-hole glass bead. The tile glue comprises the following raw materials in percentage by weight of: 45-50% of portland cement, 15-20% of glass bead with honeycomb holes, 10-15% of heavy calcium carbonate, 10-15% of fine sand and 6-9% of additive.

Owner:广东龙湖科技股份有限公司

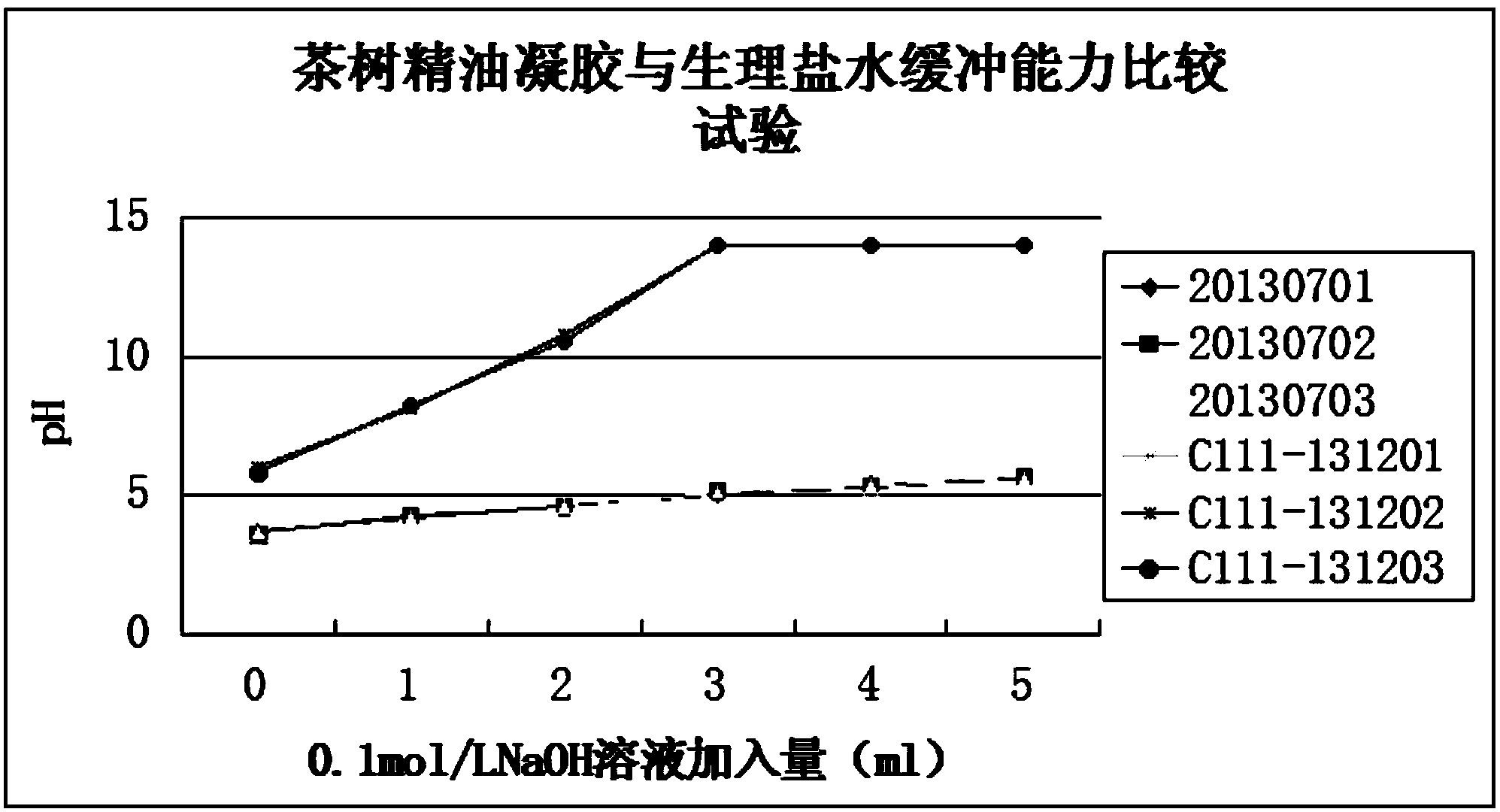

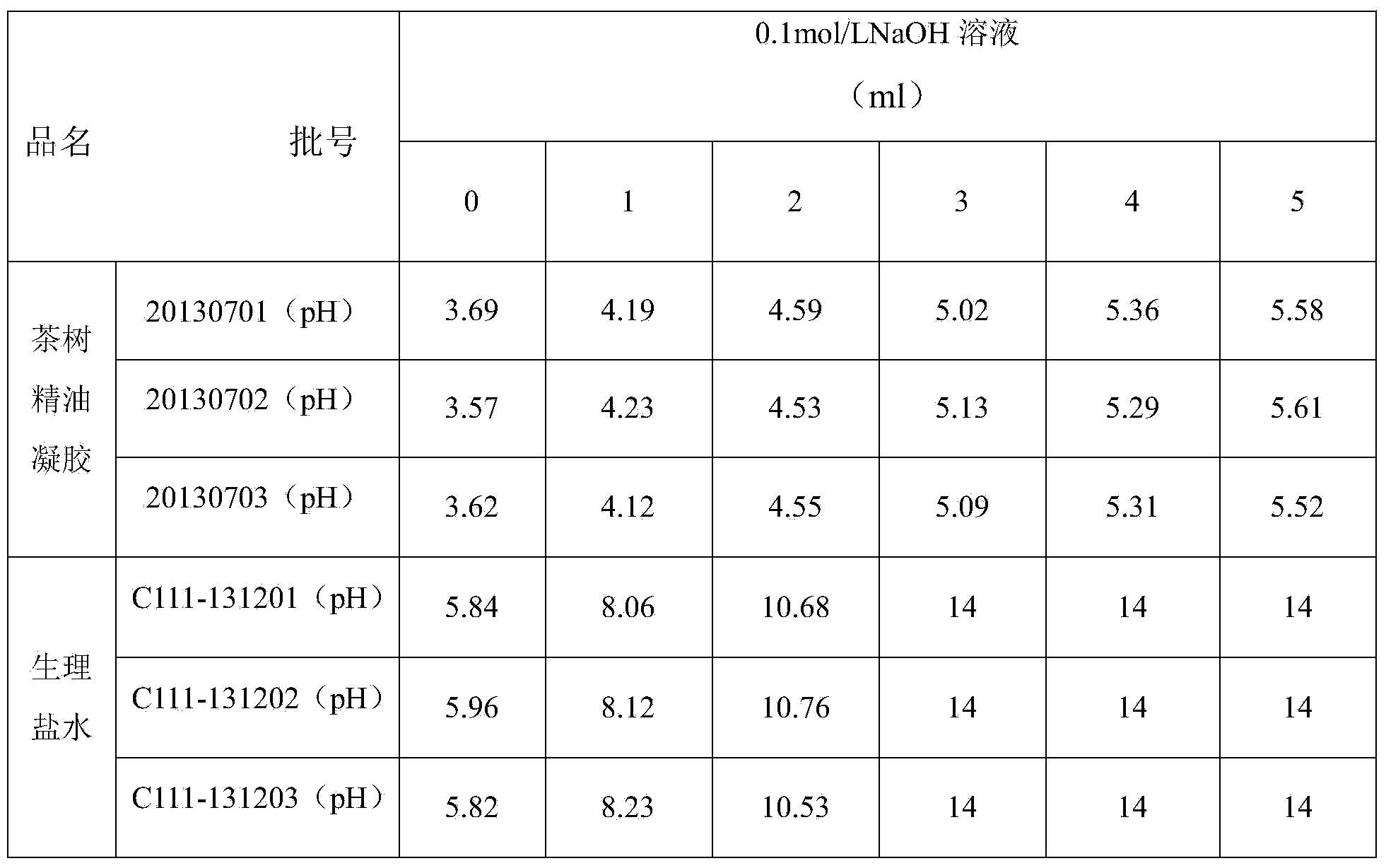

Tea tree essential oil antimicrobial gel for treating vaginal disease in gynecology

InactiveCN104224923AEnhanced inhibitory effectGood biocompatibilityAerosol deliveryAntisepticsEnterobacterDisease

The invention discloses a tea tree essential oil antimicrobial gel for treating a vaginal disease in gynecology. Every 1000 parts by weight of gel contains the following raw material components: 1 to 100 parts of tea tree essential oil, 0.5 to 20 parts of emulsifier, 1 to 50 parts of biological adhesive material and the balance of modified components and purified water. The tea tree essential oil is added into the high-molecular biological adhesive material to carry out solubilizer screening, so that the obtained tea tree essential oil gel has good biocompatibility, and is small in irritation and has no delayed type hypersensitivity in an actual application process. The clinical test proves that after the prepared tea tree essential oil gel is squeezed into the vagina of a female by virtue of a gel applicator, the tea tree essential oil contained in the prepared tea tree essential oil gel can be used for effectively inhibiting staphylococcus aureus, escherichia coli and candida albicans in the vagina and the cervix uteri, and rapidly relieving itching, removing peculiar smells and performing restoration and regeneration; and by virtue of a buffering ability of the tea tree essential oil gel, the weak acidity of normal physiology of the vagina can be maintained, and the moisture content of the vagina is supplemented at the same time so as to exert a lubricating function.

Owner:HAINAN HOTMED TIANYA PHARMA +1

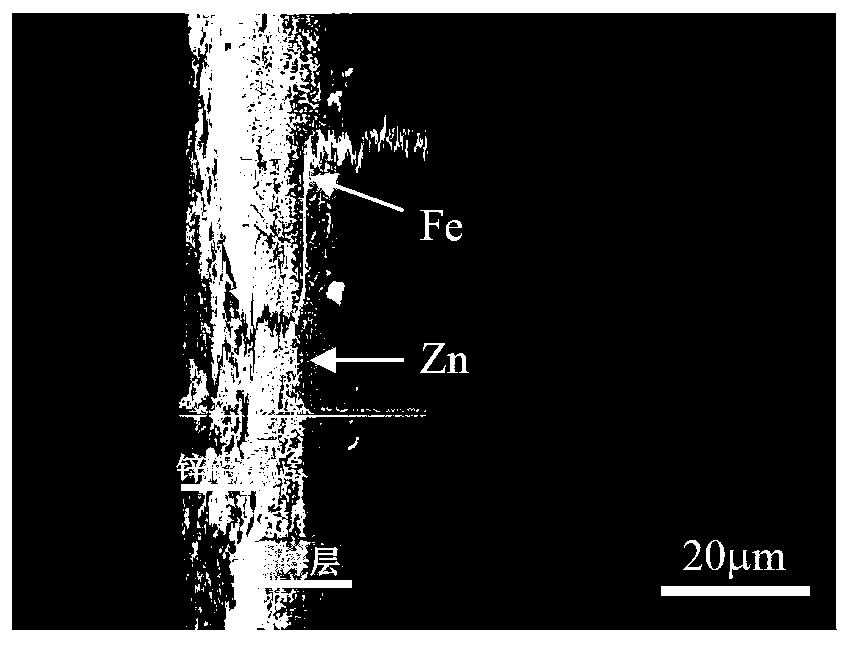

Production method for ship fastener complex coating

ActiveCN103316828AIncrease the effective thicknessSmall effective thicknessPretreated surfacesSpecial surfacesMetallic materialsDip-coating

The invention belongs to the technical field of metal material surface processing and relates to a production method for a ship fastener complex coating. A zinc impregnation coating, a zinc-aluminum coating and an epoxy coating are arranged on the fastener surface from internal to external and zinc impregnation, washing, zinc-aluminum coating liquid dip-coating, zinc-aluminum coating solidification, epoxy coating liquid dip-coating and epoxy coating solidification are performed on the faster after sequentially being performed on oil removing and rust removing to form into a protective layer. The production method for the ship fastener complex coating has the advantages of being simple in production technology and reasonable in principle. The complex coating has the advantages of being good in corrosion resistance, being capable of effectively solving the problem that the faster is corroded in the seawater environment and being environmentally friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

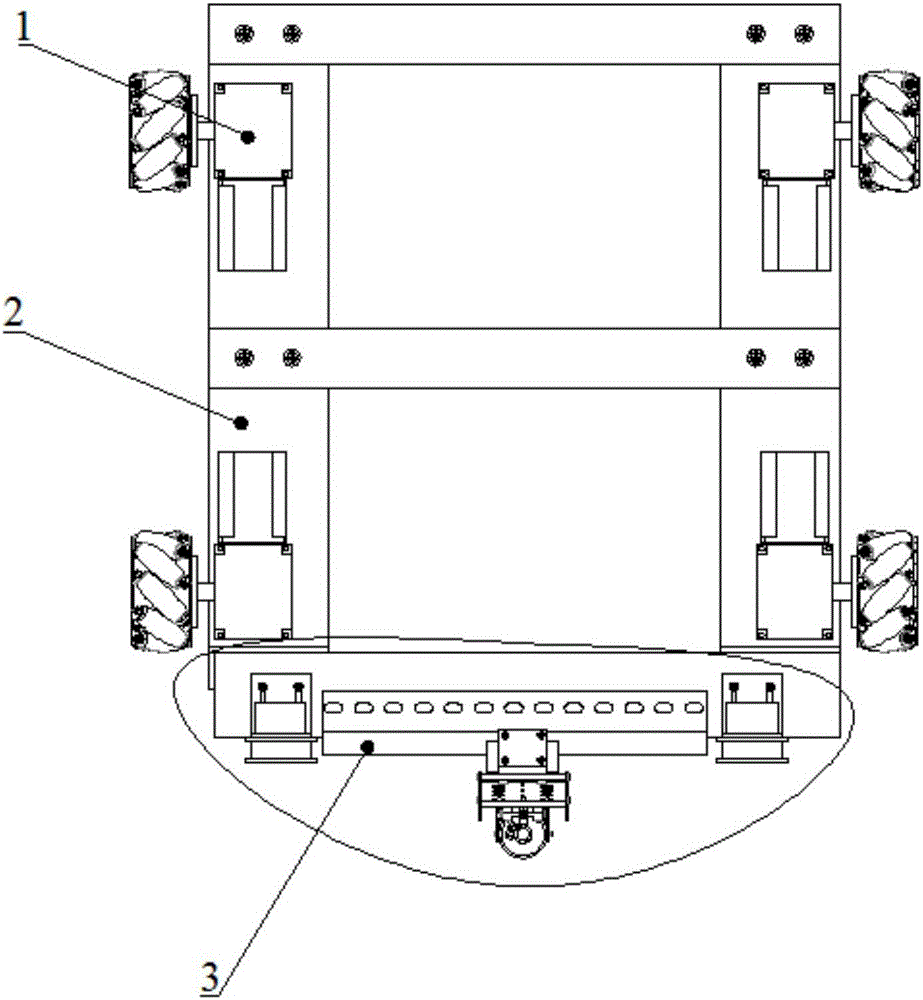

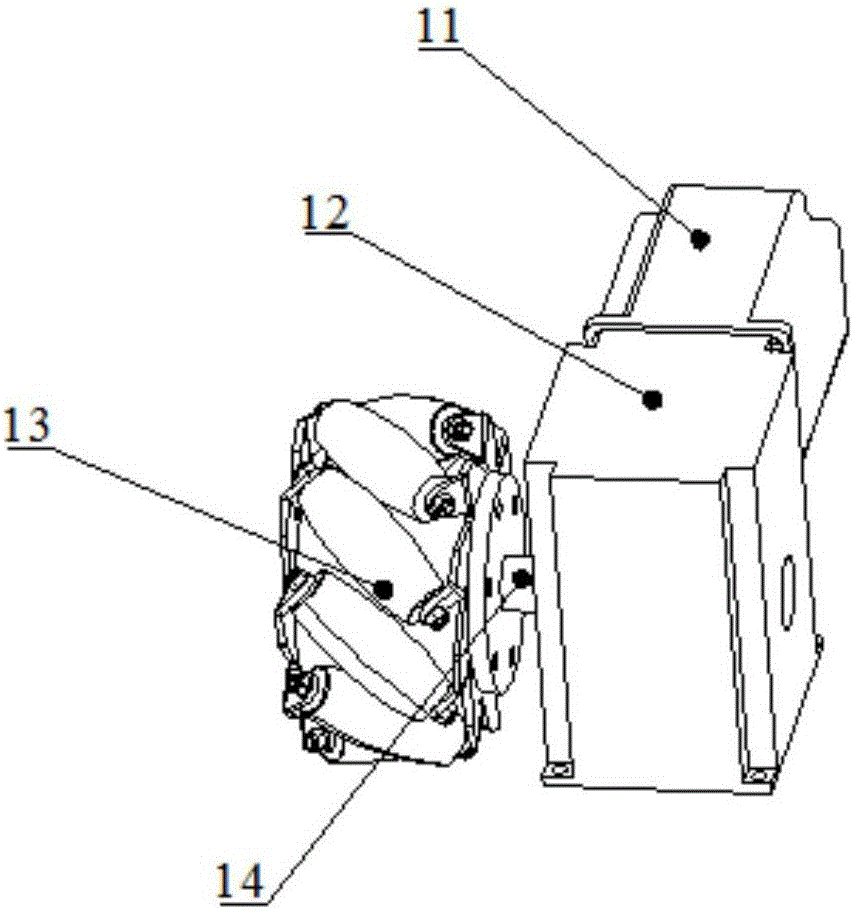

Robot for all-bearing defect detection of large-capacity flat-bottom container bottom plate and detection method

InactiveCN105973986AFacilitate all-round defect location detectionEasy to detect all-round defect position detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesIndependent motionLocation detection

The invention discloses a robot for all-bearing defect detection of a large-capacity flat-bottom container bottom plate and a detection method. The robot comprises a robot body, wherein a walking device and a detection device are arranged under the robot body, and the detection device is arranged at one end of the robot body; the walking device consists of four independent Mecanum wheel mechanisms which are arranged on the robot body; the detection device mainly consists of an ultrasonic probe and an ultrasonic probe adjusting mechanism, and the ultrasonic probe is connected with an ultrasonic generator; the ultrasonic probe adjusting mechanism comprises a first adjusting mechanism and a second adjusting mechanism; the first adjusting mechanism is used for driving the ultrasonic probe to move left and right along the horizontal direction; the second adjusting mechanism is used for adjusting the height of the ultrasonic probe, so that the ultrasonic probe is attached with the surface of the to-be-detected container bottom plate to be detected. The robot has the advantages that the all-bearing defect position detection can be performed on the detected container, the missed detection due to low feedback signal intensity caused by inverticality between ultrasonic direction and defect direction is avoided, and the detection accuracy is improved.

Owner:SICHUAN UNIV

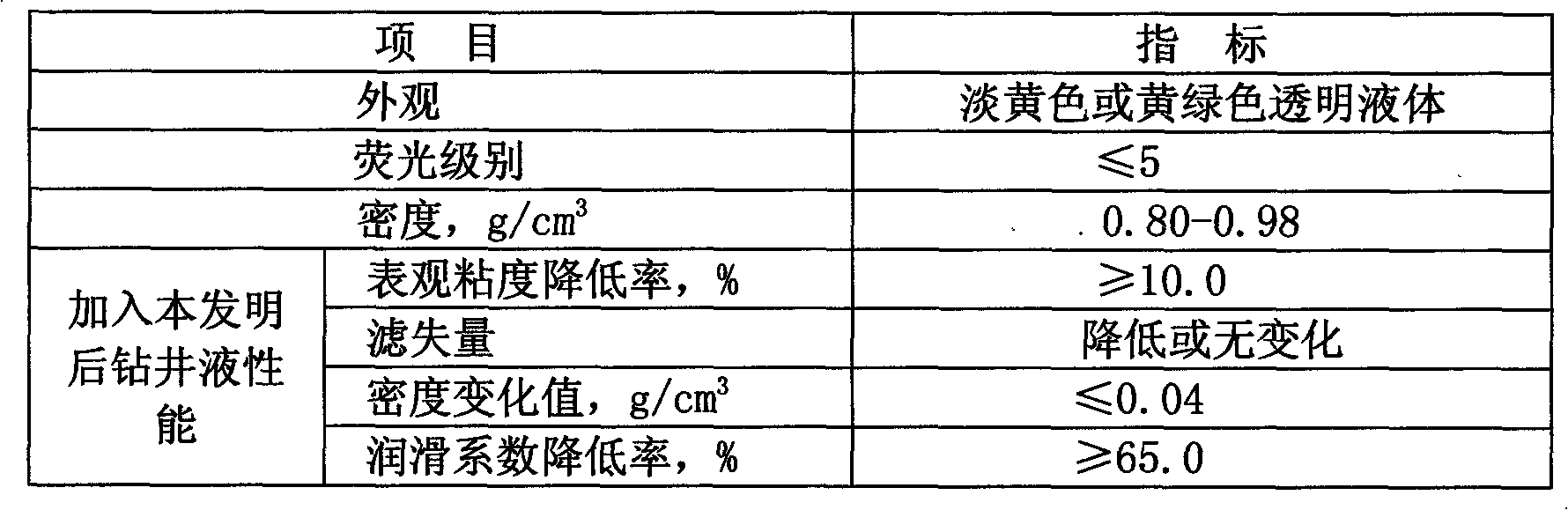

High-efficient antisticking lubricant for drilling fluid

ActiveCN102344783APlay a lubricating roleLow fluorescence levelDrilling compositionPolymer scienceFluorescence

A high-efficient antisticking lubricant for drilling fluid has a technical scheme that the lubricant is obtained by mixing five components of white oil which is used as a main raw material, oleic acid and methyl oleate which are used as auxiliary materials, a defoamer and an extreme pressure agent which are used as regulators, wherein the weight percent ranges of the components are 30%-70% of white oil, 18%-30% of oleic acid, 10%-20% of methyl oleate, 1%-10% of defoamer and 1%-10% of extreme pressure agents. The lubricant of the invention has the advantages of extreme pressure lubrication, sticking resistance, less fluorescence grade, and the like, does not cause index change of drilling fluid, has lubrication effect on hard surface to soft surface (drilling tool to mud cake) and hard surface to hard surface (drilling tool to rock), has good lubrication effect, and thus is a good lubricant for polymer drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

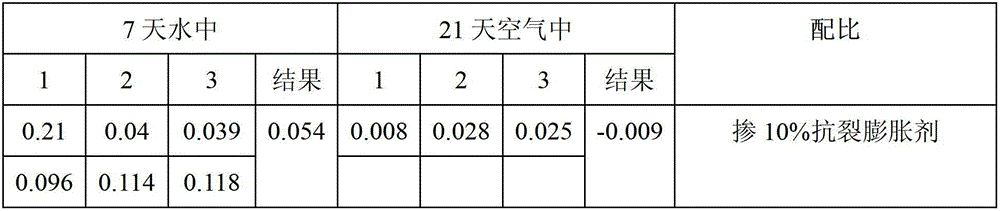

Anti-crack expanding agent and preparation method thereof

ActiveCN102745933AImprove densification performanceImprove waterproof performanceWollastoniteDickite

The invention discloses an anti-crack expanding agent which comprises the following ingredients by weight: 35%-40% of calcium oxide clinker, 15%-20% of gypsum, 30%-35% of dickite, 5%-10% of coal ash and 2%-5% of wollastonite powder, wherein the sum of the weight ratios is 100%. The invention further discloses a preparation method of the anti-crack expanding agent. Compared with the prior art, the anti-crack expanding agent disclosed by the invention has the advantages of being capable of effectively preventing concrete from cracking so as to improve compactness.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

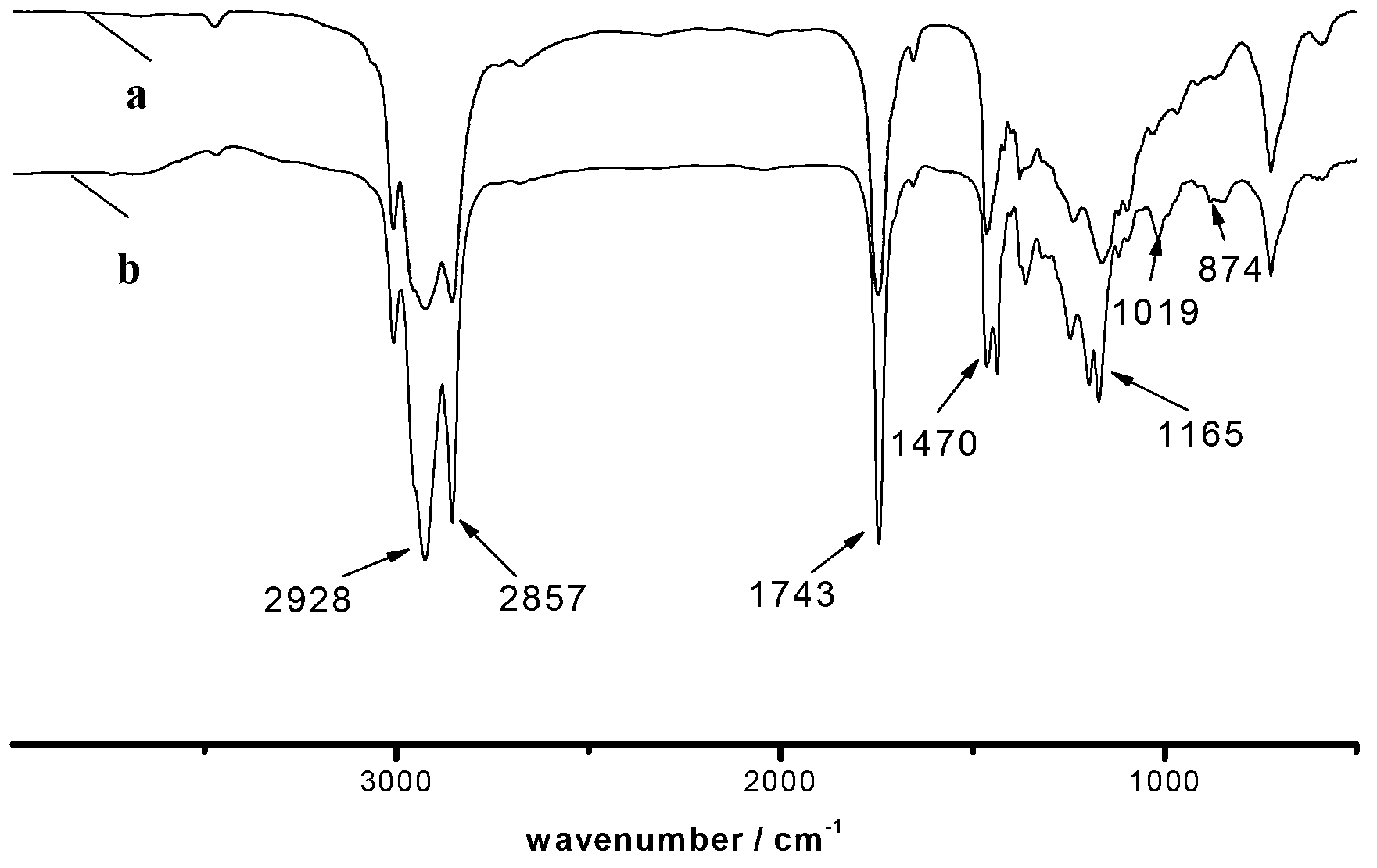

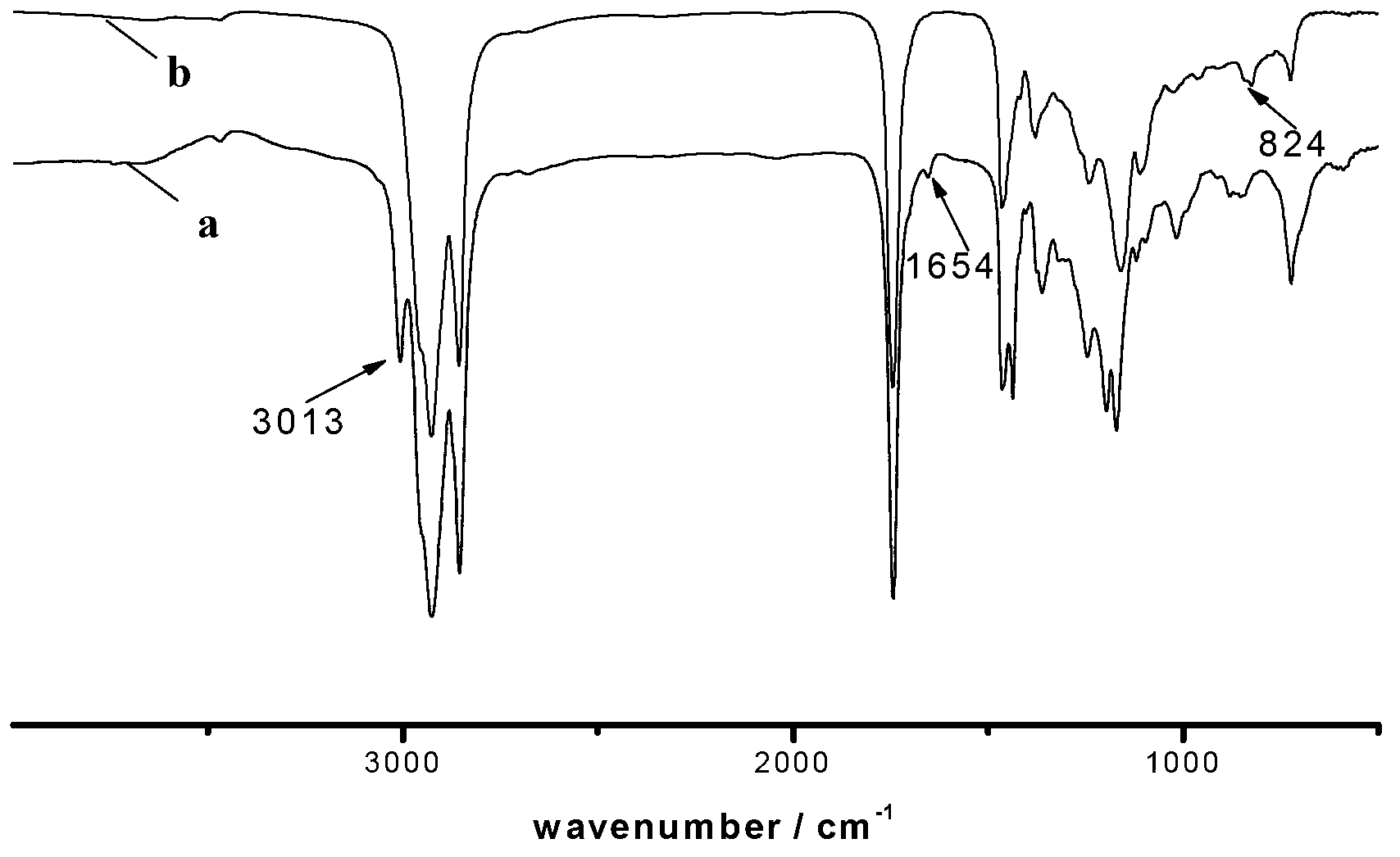

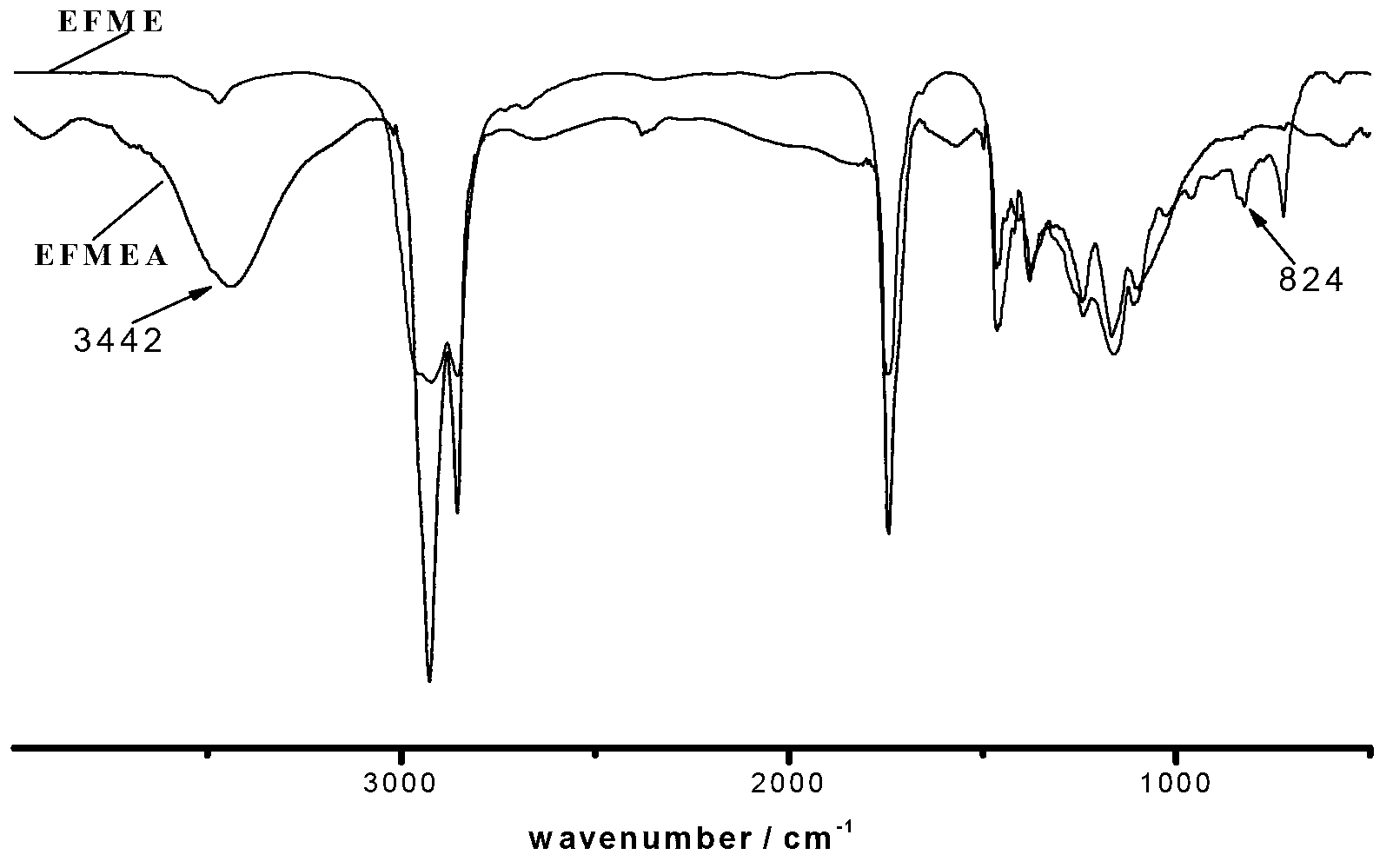

Method for preparing organic silicon modified plant oil

InactiveCN103266016AGood lubricityGood stabilityFatty acid chemical modificationBase-materialsOrganosiliconOxidation stability

The invention discloses a method for preparing organic silicon modified plant oil. The method comprises the following steps of: by taking colza oil as a raw material, preparing a colza oil alcohol orderly through methanol ester exchange, peracetic acid epoxidation and acetic acid ring opening; and then reacting organic silicon with the hydroxyl in the colza oil alcohol, thereby obtaining the organic silicon modified plant oil. The organic silicon modified plant oil produced by the method has good lubrication effect; and in addition, the oxidation stability of the organic silicon modified plant oil is also greatly improved.

Owner:HEFEI UNIV OF TECH

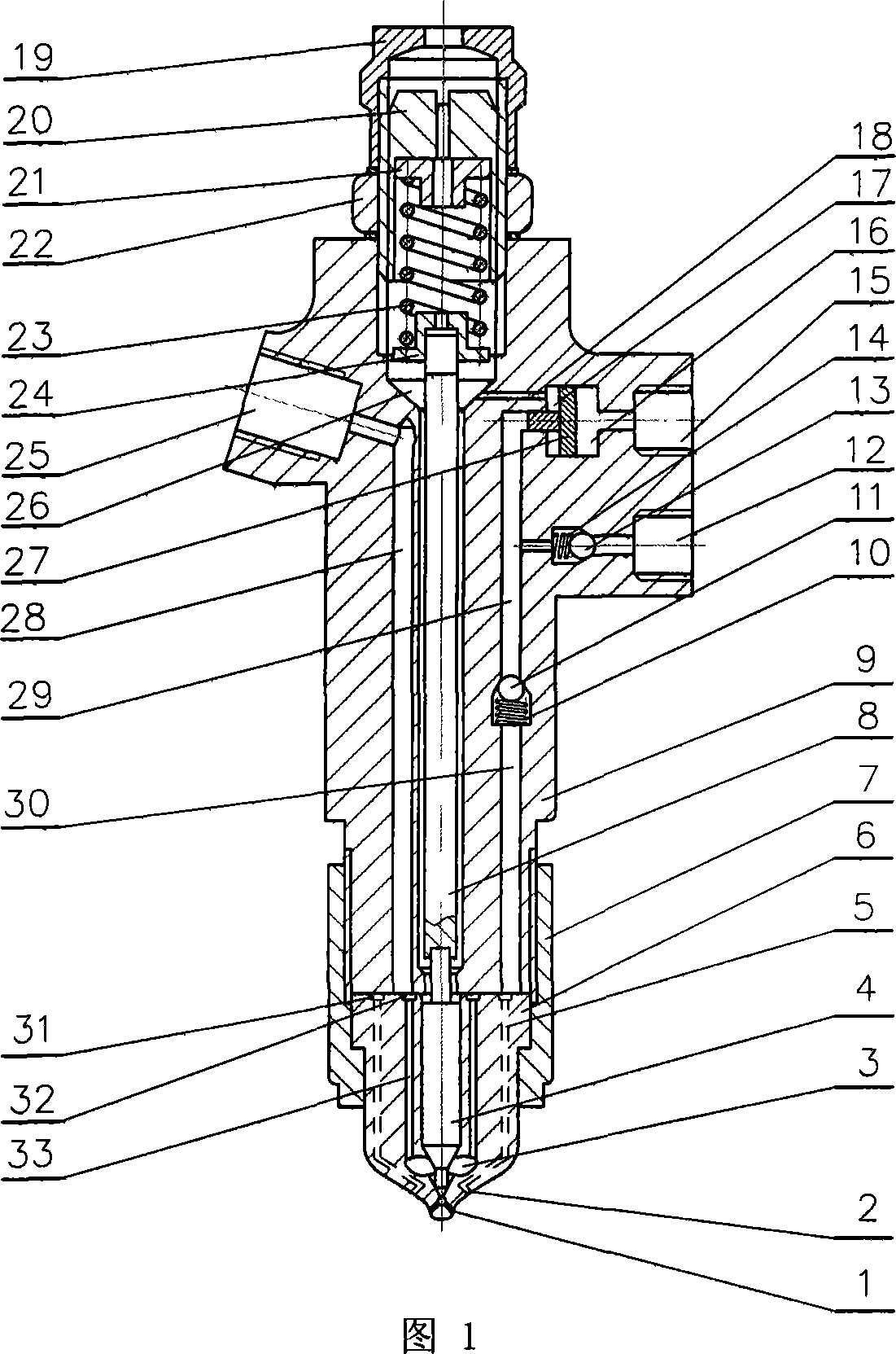

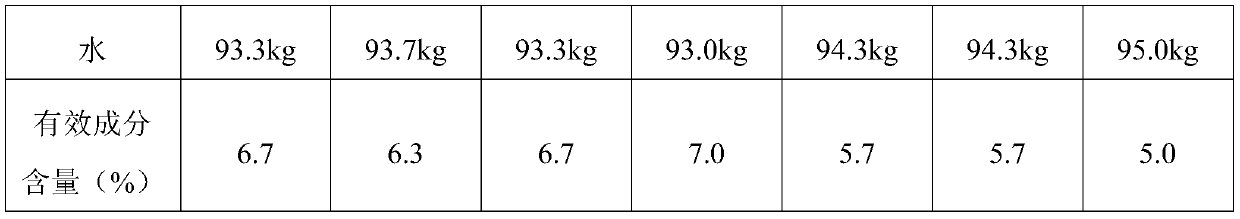

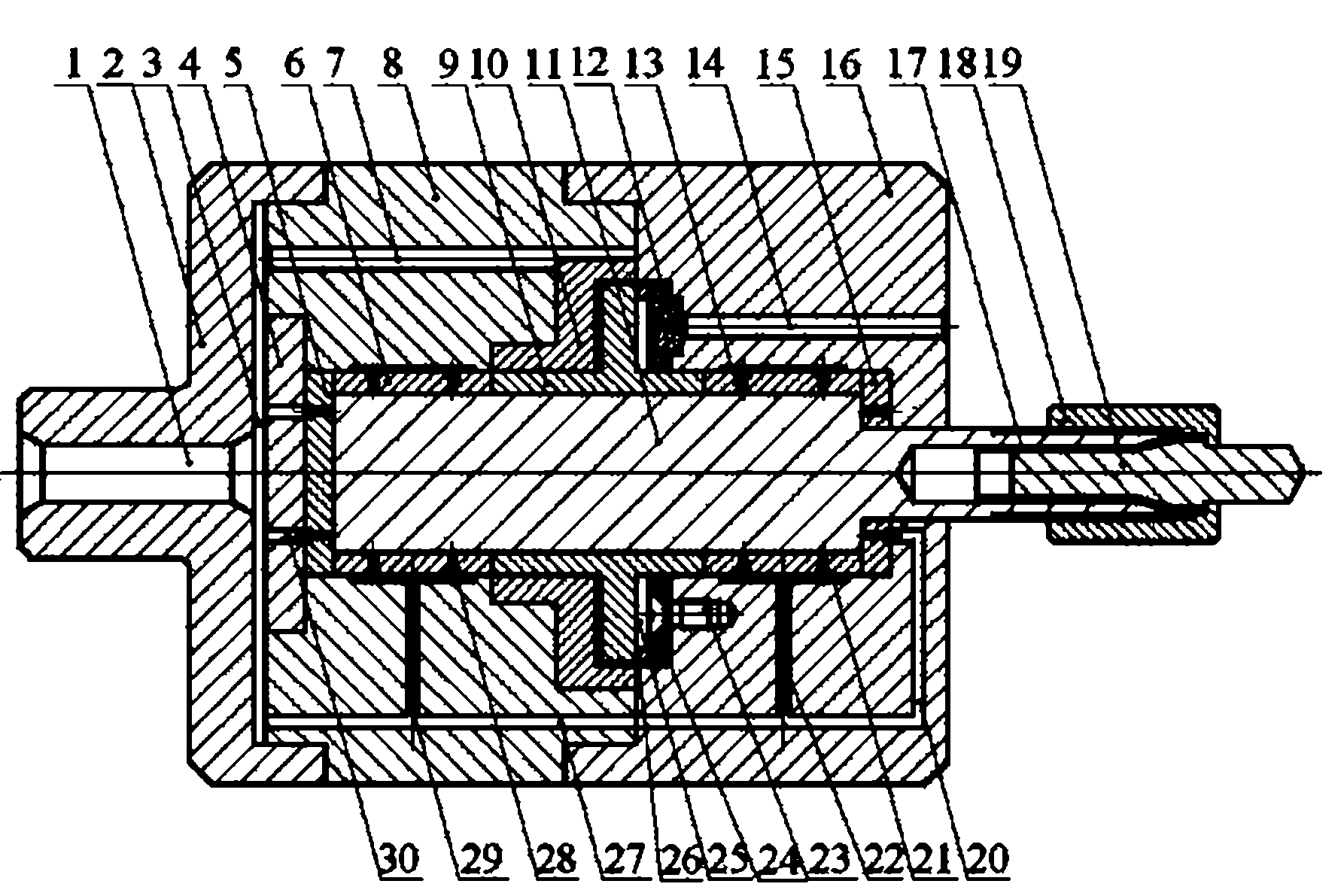

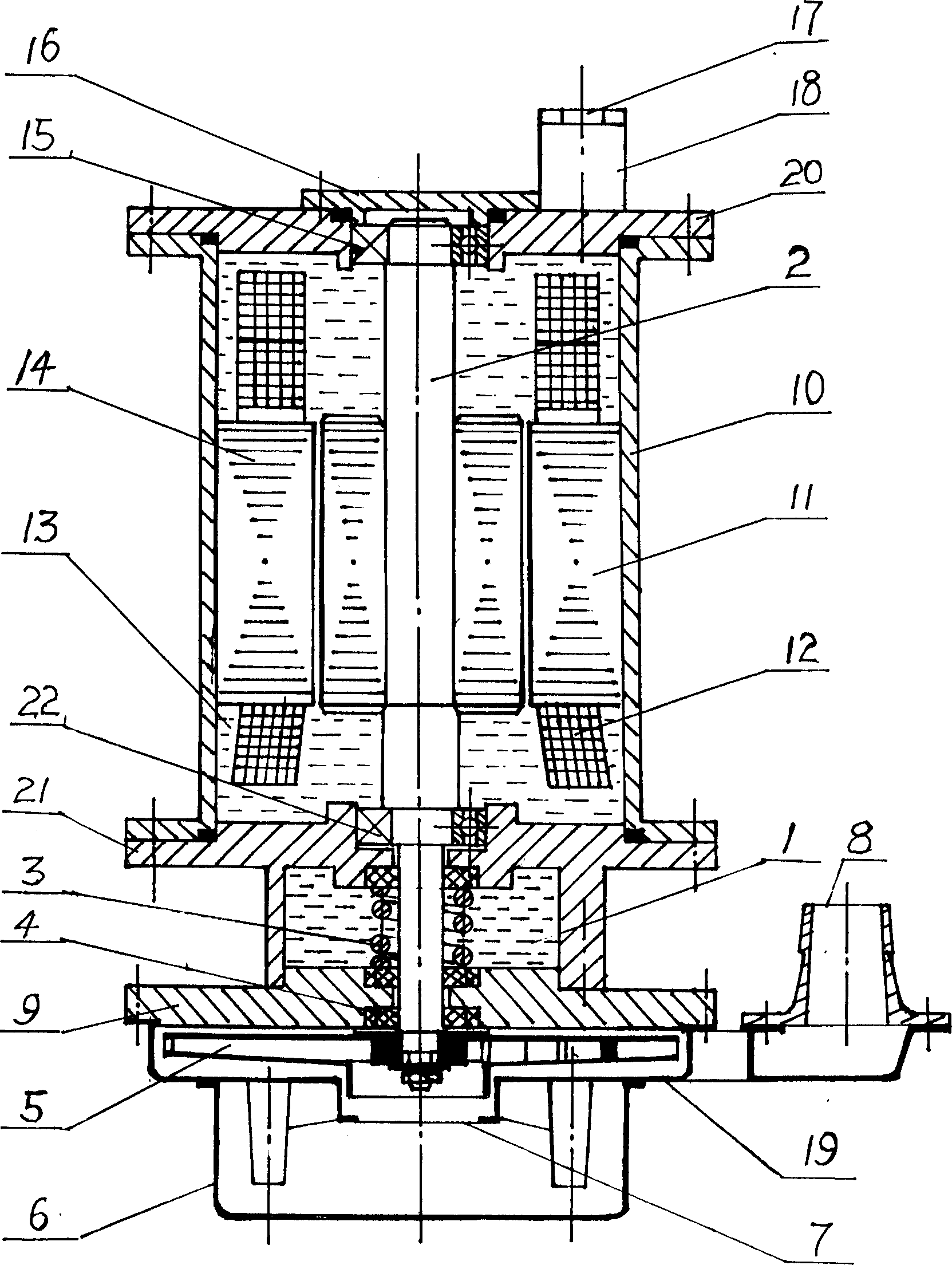

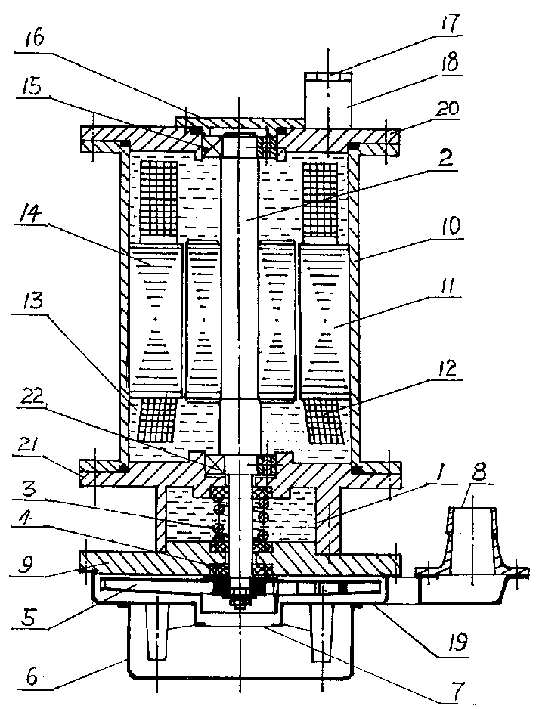

Double-layer injection fuel oil injector used for diesel oil and dimethyl ether

InactiveCN101117931AMinor changesPlay a lubricating roleFuel injection apparatusMachines/enginesFuel oilDiesel engine

A double-layer fuel injector used for diesel oil and DME mainly consists of a fuel injector needle valve, a fuel injector needle valve body, a fuel injector body, a DME oil outlet one-way valve, a DME oil inlet one-way valve and a pressure boosting piston, etc. The pressure boosting piston, the DME oil outlet one-way valve and the DME oil inlet one-way valve are arranged inside the fuel injector. The DME oil outlet one-way valve is communicated with a DME spray hole through a DME groove in the fuel injector needle valve body and a DME channel in the fuel injector needle valve body. A diesel oil inlet is communicated with the oil groove of a fuel injector through the diesel oil inlet of the fuel injector body, a rotating groove in the fuel injector needle valve body and the diesel oil channel in the fuel injector needle valve body. A diesel oil spray hole at the lower part of the fuel injector needle valve body is interleaved and arranged with the DME spray hole and the two have the same spray hole included angle. The present invention provides a double-layer fuel injector used for diesel oil and DME, wherein the original diesel engine fuel injection system can be used as a diesel fuel injection system and a DME drive system at the same time, and the two fuels are injected separately into the engine cylinders through the injector.

Owner:CHINA JILIANG UNIV

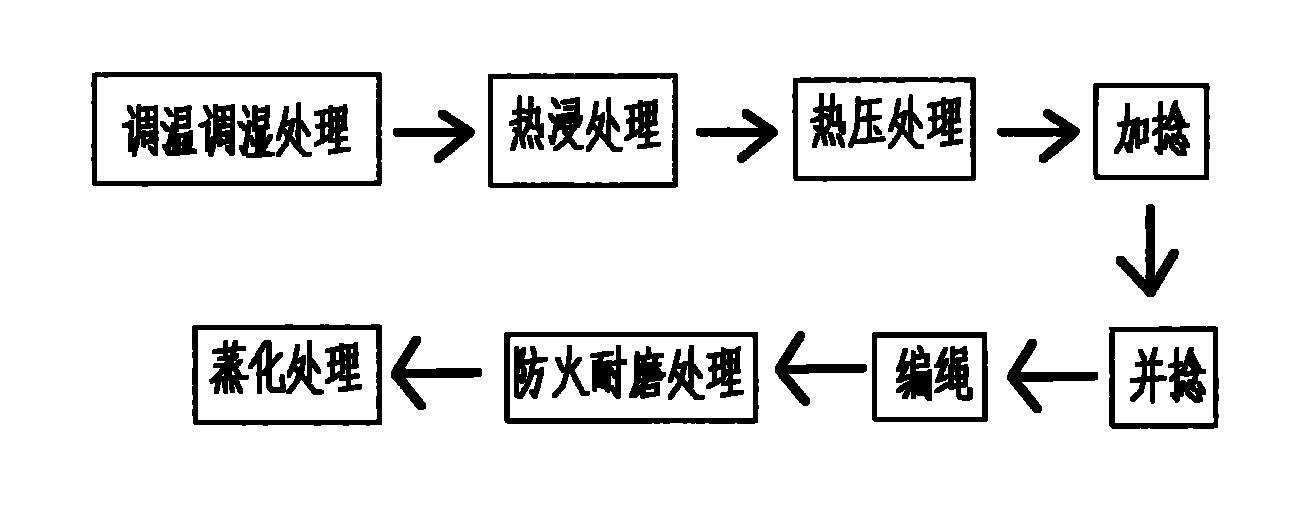

Method for producing basalt fiber rope net

ActiveCN101838885AImprove the finishHigh tensile strengthLiquid/gas/vapor removal by squeezing rollersBraidPolymer scienceActive agent

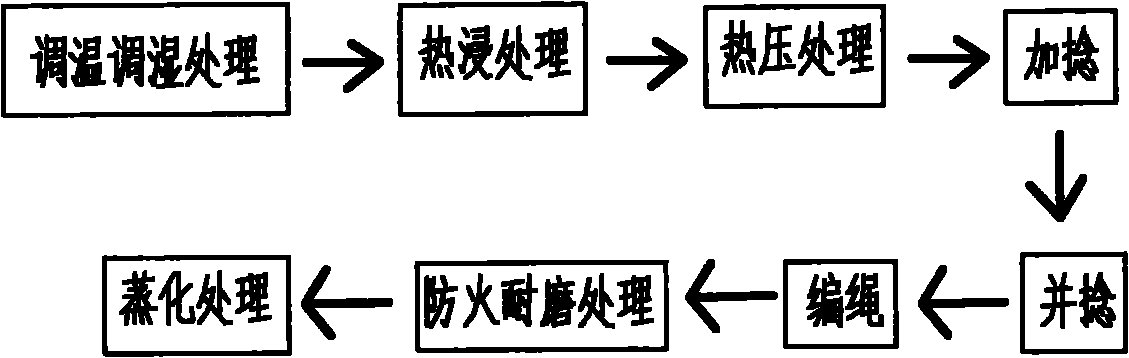

The invention discloses a method for producing basalt fiber rope nets, which comprises the following processes of: heat soaking treatment, hot-pressing treatment, weaving ropes, fireproof and wear-resistant treatment, steaming treatment, and the like. The heat soaking treatment solution contains an anionic surfactant, sodium alga acid and other aids; a tension regulation device is arranged on a high-speed braiding machine; and the fireproof and wear-resistant treatment solution contains PTFE, neutral salts, and other active agents. The method has reasonable process and advanced treatment technology and method, and the produced rope nets have the advantages of high temperature resistance, corrosion resistance, high intensity, high safety, and high cost performance.

Owner:TAIAN ROPE NET PLASTIC

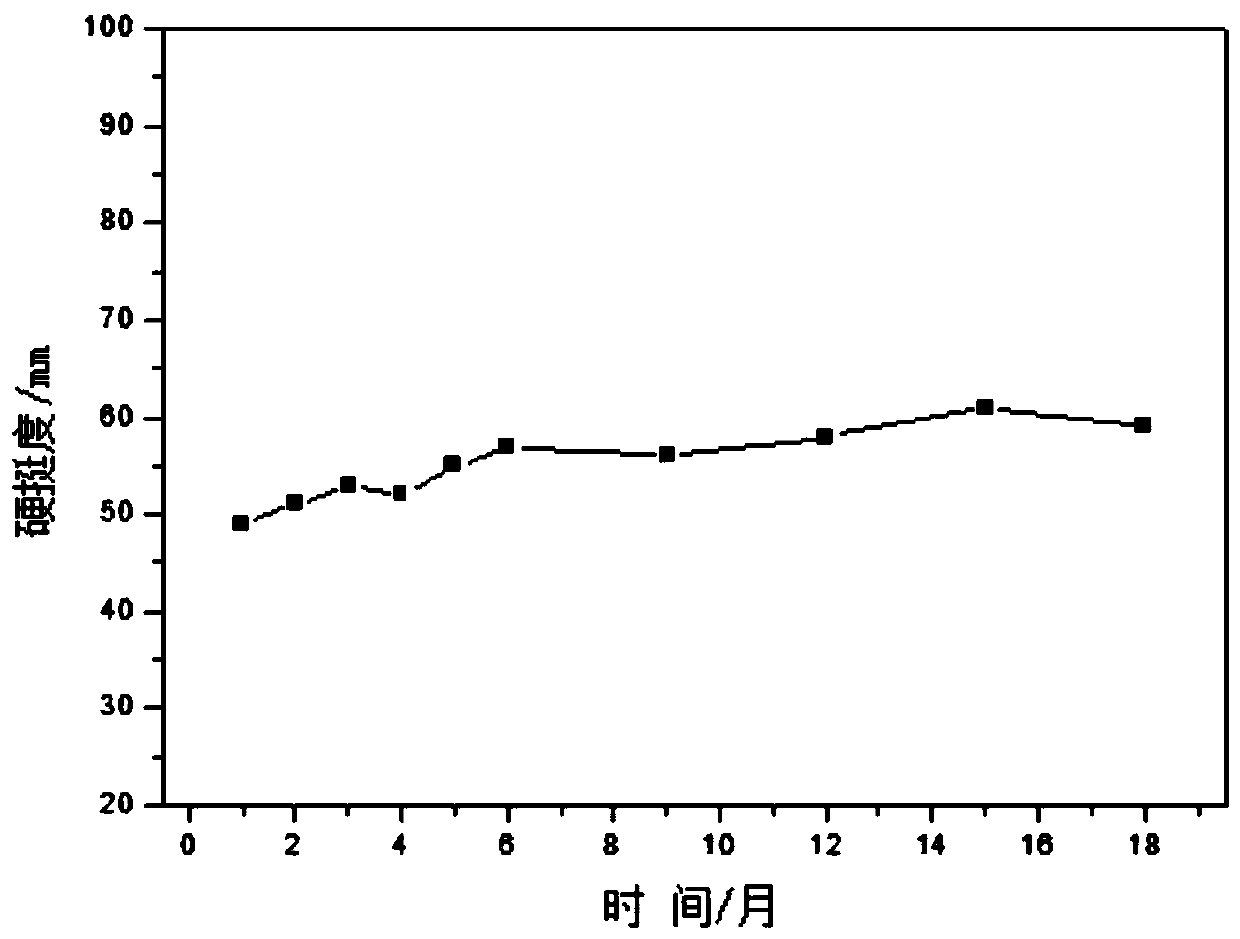

Copper-based oil bearing material and preparation method thereof

InactiveCN105689722APlay a lubricating roleHigh strengthTransportation and packagingMetal-working apparatusHeat conductingSolid solution strengthening

The invention discloses a graphene / copper oil bearing material and a preparation method thereof, and belongs to the field of graphene reinforced metal-matrix composites. Nickel powder, tin powder, copper powder and a dispersing agent are loaded on graphene according to a certain mass fraction for burdening, a planetary ball mill is used for mixing, and a graphene / copper-based oil bearing is obtained through pressing, sintering, oil immersing and die full shaping processes. The graphene is introduced by loading nickel particles on the graphene, and the purpose that graphene strengthening phases are evenly dispersed in a metal matrix to form strong interfacial chemical binding is achieved. On the other hand, copper and nickel form an infinite mutual-soluble solid solution, and the solid solution strengthening effect is achieved. The graphene / copper-based oil bearing manufactured through the method is even in structure and has good heat-conducting performance and high strength and abrasion resistance.

Owner:HEBEI UNIV OF ENG

Preparation method of Ti3SiC2/SiC functionally gradient material

ActiveCN105541331AUniform and dense structureModerate combinationOxidation resistantFunctionally gradient material

The invention discloses a preparation method of a Ti3SiC2 / SiC functionally gradient material, comprising the steps of mixing Ti3SiC2 powder and SiC powder in a die layer by layer in a gradient way, then preparing a blank, performing vacuum hot-pressing sintering on the blank to obtain a green body, and sequentially performing dipping densification and pyrolysis treatment on the green body; the SiC powder comprises micron beta-SiC powder and nanometer beta-SiC powder; the vacuum hot-pressing sintering temperature is 1600-1700 DEG C, and is kept for 3-5h, and the maximum pressure is 25MPa; the dipping densification comprises performing dipping densification on gradient layers containing 60-100 vol. percent of SiC in the green body subjected to the hot-pressing sintering in polycarbosilane liquid. The Ti3SiC2 / SiC functionally gradient material prepared by the method is high in compactness, contains multiple gradient layers along the thickness direction from Ti3SiC2 to SiC (designing can be performed as required), the structure is uniform and compact in each gradient layer, interfaces among the gradient layers are moderately combined, the mechanical strength is high, the breaking tenacity is good, under high temperature, the oxidation resistance and the thermal shock resistance are good, and the Ti3SiC2 / SiC functionally gradient material having 11 gradient layers and the thickness of 8-15mm can be prepared.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

High-performance concrete gel material for tunnel and application thereof

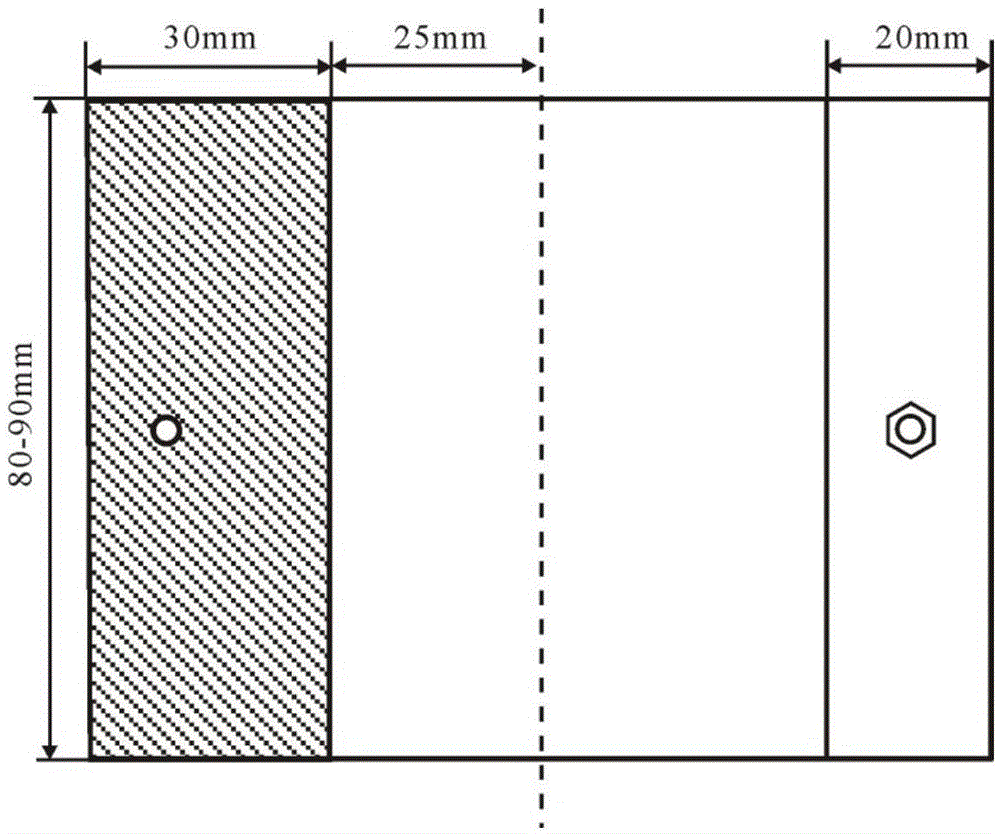

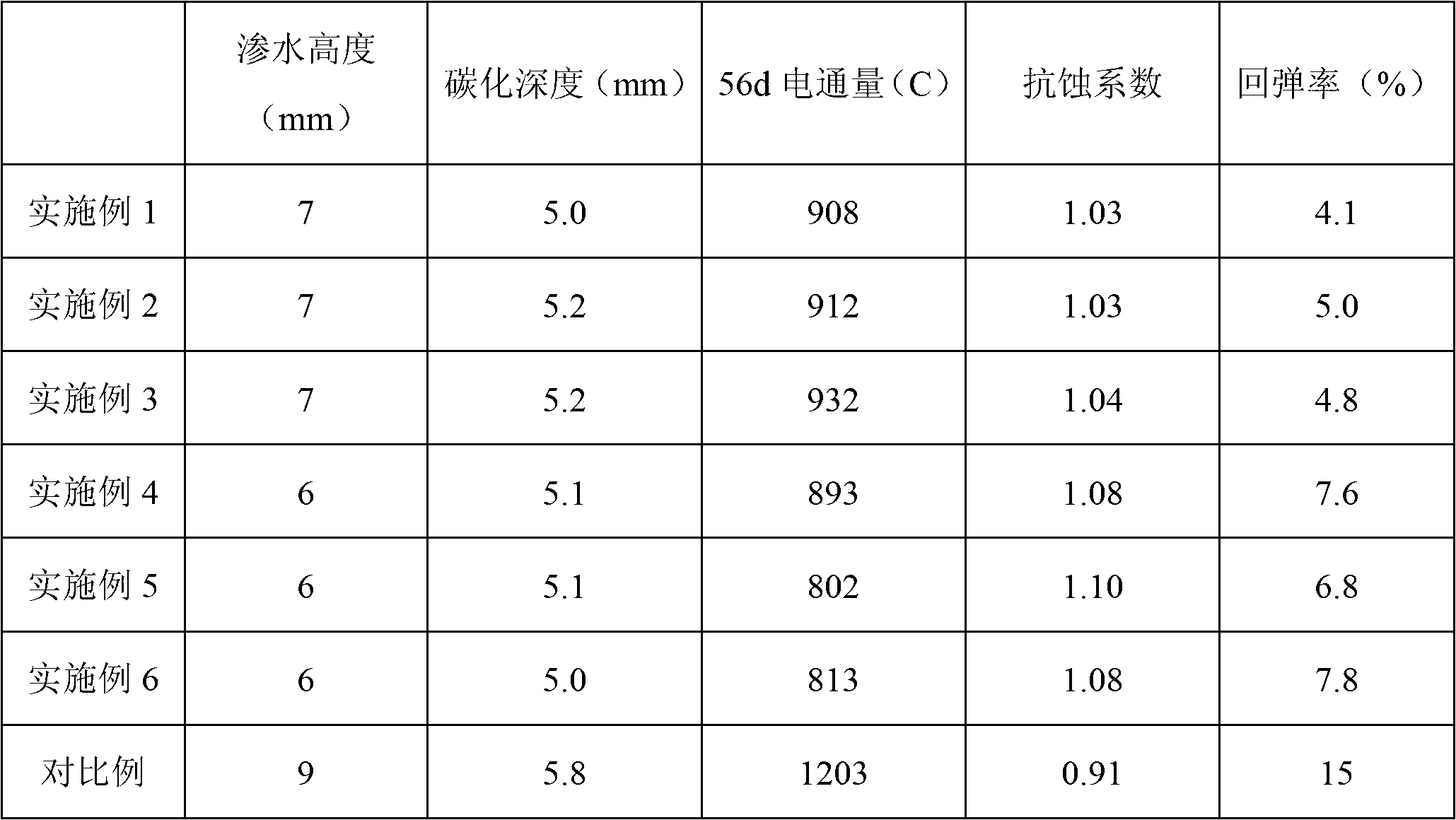

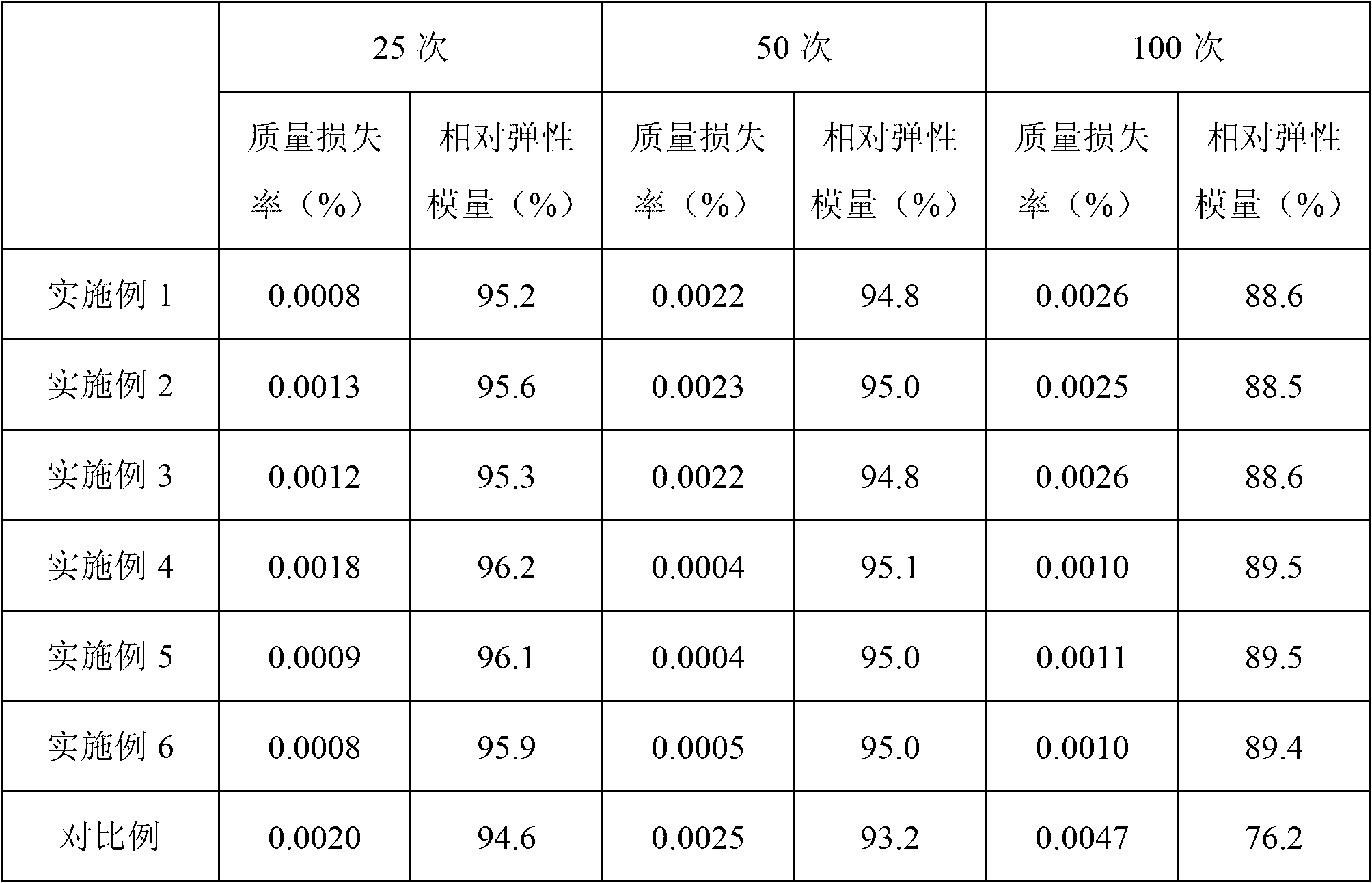

The invention discloses a concrete gel material which comprises cement and silica solution. The invention further discloses a high-performance concrete for tunnel prepared through the concrete gel material provided by the invention. The high-performance concrete is suitable to be applied to injecting concrete, moulding concrete and others. Through the adoption of the concrete gel material or the high-performance concrete for the tunnel provided by the invention for injecting the concrete, the rebound ratio can be effectively reduced and even reduced to 4.1% to the minimum; and the concrete gel material or the high-performance concrete is good in working performance; the obtained concrete finished product is high in early strength, and good in freezing resistance; the waterproof performance and the wearable performance are improved; the quantity of used cement can be reduced; the carbon emission can be reduced; and good economic benefit and environment-friendly benefit are brought.

Owner:中铁西南科学研究院有限公司

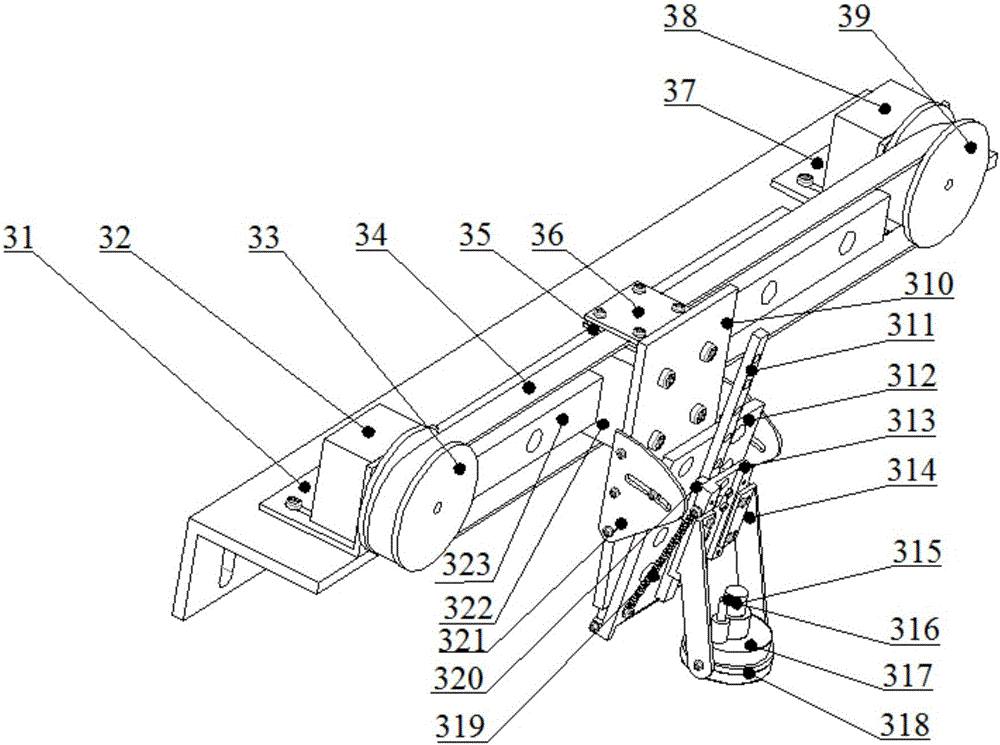

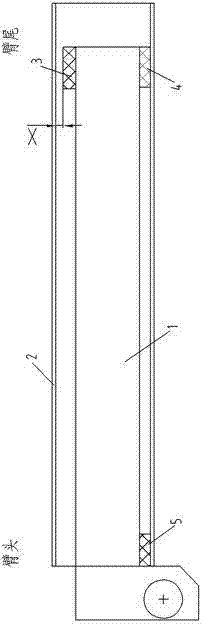

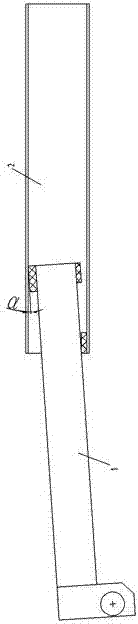

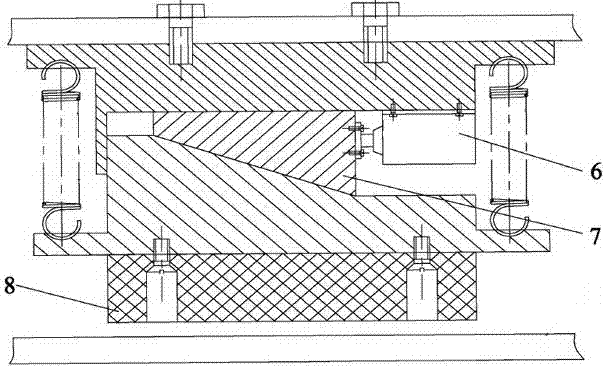

Retractable arm slide block assembly and retractable arm

ActiveCN103112785AReduce telescopic frictional resistanceImprove stretching smoothnessLifting devicesCranesClassical mechanicsStructural engineering

The invention discloses a retractable arm slide block assembly which has long service life and excellent performance. Slide block bodies are supported between two pin shaft seats by a transverse pin shaft in a swinging manner; the slide block bodies at the two sides of the vertical direction of the pin shaft are respectively provided with two sets of rolling friction assemblies; each set of the rolling friction assembly comprises a containing cavity which is located in the slide block body and is used for containing lubricating grease, and a guide hole for vertically penetrating through the slide block body; each guide hole contains a guide sleeve which is slidingly matched with the guide hole; each guide sleeve contains a slide block which is slidingly matched with an inner hole of the guide sleeve; and the slide blocks and the guide sleeves commonly contain a rolling ball body. The invention further discloses a retractable arm for mounting the slide block assembly. In a retraction route, the rolling friction of the rolling ball body realizes the relative retraction of an inner arm and an outer arm so that the retraction friction resistance is reduced and the retraction smoothness is enhanced. When a head stressing part of the inner arm is at a working state, the rolling friction assemblies are stressed to be retracted into the slide block bodies so that the slide block bodies are contacted with an outer wall face, the contact pressure is small and the slide block bodies and the inner and outer arms are protected.

Owner:山东鲁班机械科技有限公司

Microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and preparation method and application thereof

ActiveCN102585406AImproved creep propertiesGood flexibilityOther chemical processesOil and greaseTetrafluoroethylene

The invention discloses a microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and a preparation method and application thereof. The PTFE material consists of the following components in percentage by mass: 50 to 98 percent of PTFE resin, 1 to 30 percent of naphthalene and 1 to 20 percent of oil. The method comprises the following steps of: mixing the PTFE resin and the naphthalene, performing die pressing, and sintering to prepare a porous PTFE semi-finished product; and soaking the porous PTFE semi-finished product in the oil, putting into a vacuum box, and keeping in vacuum for at least 2 hours to obtain the microporous oil-containing self-lubricating PTFE material for sealing. The microporous oil-containing self-lubricating PTFE material for sealing has high self-sealing property, lubricating property and elasticity, a good self-lubricating effect can be achieved even if the oil is not changed for a long time when the material is used as a sealing material, and a long-acting sealing effect is achieved; and if an anti-rusting agent permeates pores, machine equipment can be protected, and the service life of a machine is prolonged.

Owner:GUANGZHOU MECHANICAL ENG RES INST

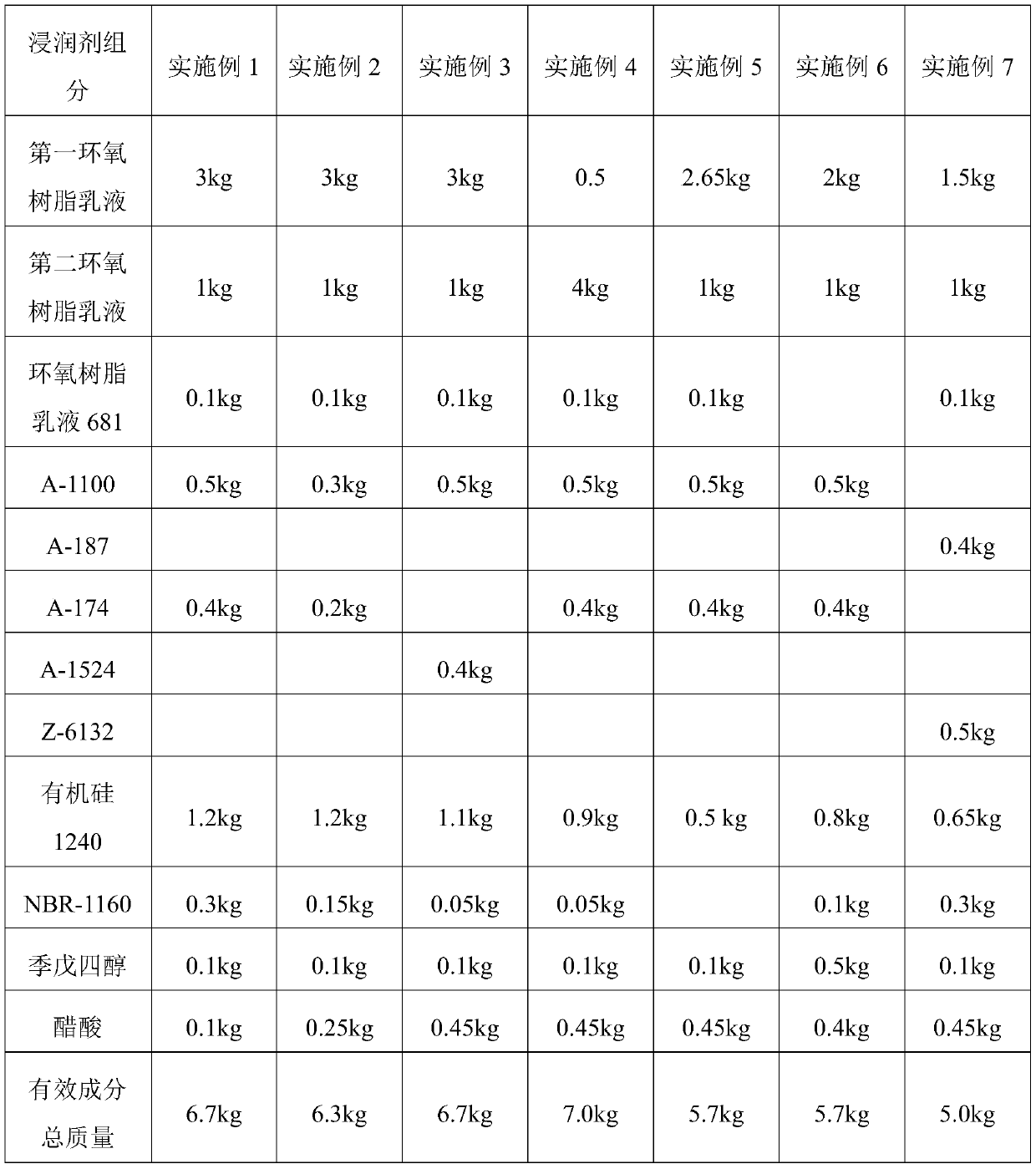

Glass fiber impregnating compound and preparation method and application thereof

The invention belongs to the technical field of impregnating compounds, and discloses a glass fiber impregnating compound and a preparation method and application thereof. The impregnating compound comprises a film-forming agent, a coupling agent, a lubricant, a wetting agent and a pH regulator, wherein the film-forming agent comprises two bisphenol A type epoxy resin emulsions with different epoxy equivalents. Compared with usage of an epoxy resin emulsion with a single epoxy equivalent as a film-forming agent, the film-forming agent disclosed by the invention has the advantages that the film-forming agent can ensure sufficient coating force of the epoxy resin emulsions on the surfaces of yarns and allow the yarns to have better softness; even if the yarns are stored for a long time, theyarns still have low stiffness, which is beneficial for subsequent processing and mechanical strength of a composite material; and meanwhile, the yarns have better damp-heat resistance and still havea good strength retention rate in a high-temperature and high-humidity environment due to matched use of the film-forming agent and the coupling agent.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

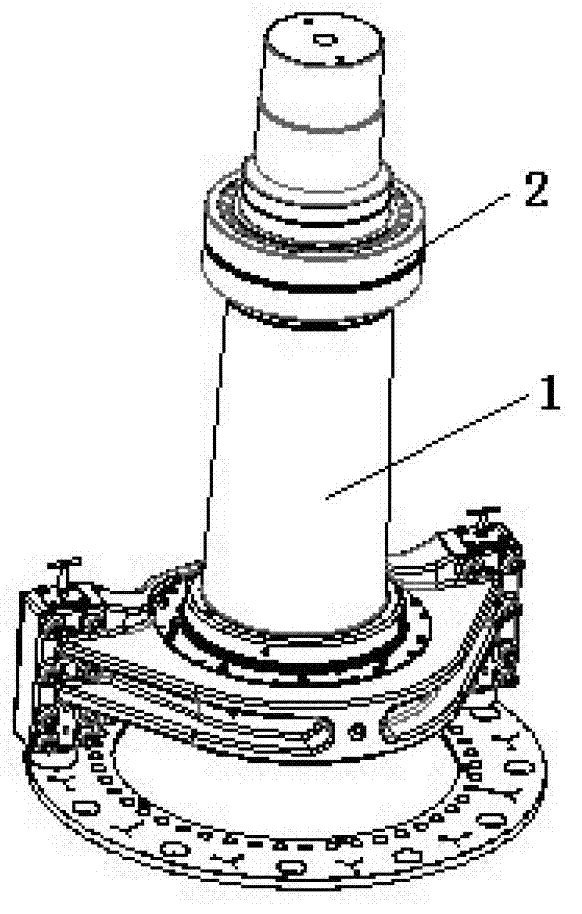

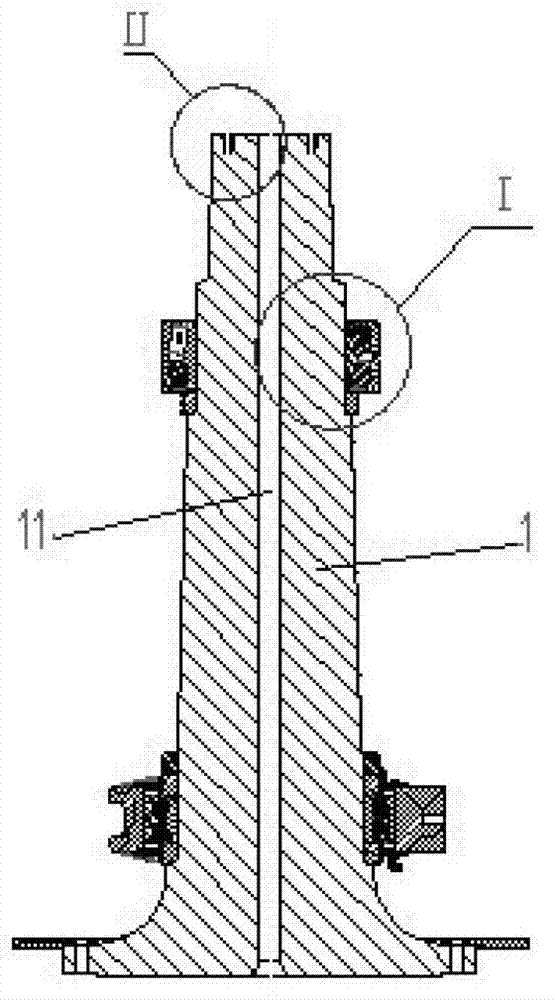

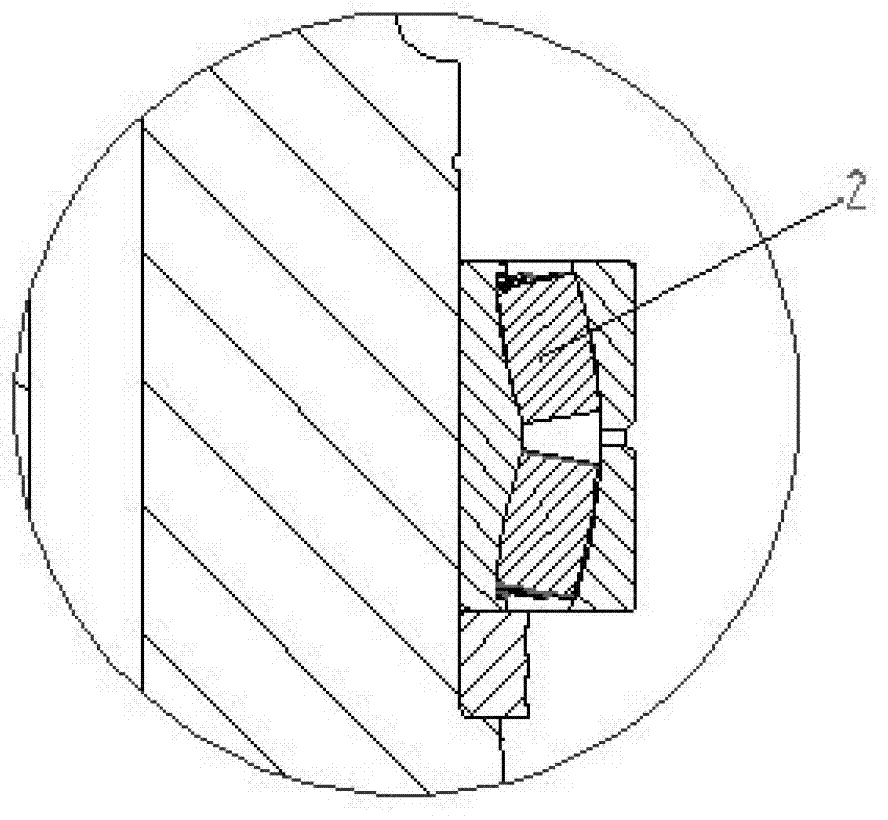

Turbine air-floatation main shaft

The invention discloses a turbine air-floatation main shaft. The turbine air-floatation main shaft comprises a shell and a shaft body penetrating through a first end part of the shell, wherein the shell comprises a ring-shaped turbine base, a first end cover and a second end cover; the first end cover is connected with a first end of the turbine base and is provided with an air inlet hole; the second end cover is connected with a second end of the turbine base and is provided with a plurality of exhaust holes; the first end part of the shell is formed by the second end cover; an air cavity is formed between the first end cover and the first end of the turbine; a pneumatic turbine machine is arranged in an inner cavity of the shell and at the middle part of the shaft body; air-floatation bearings are arranged at the other positions around the shaft body; a turbine stator and a turbine rotor of the pneumatic turbine machine are correspondingly and fixedly connected with the turbine base and the shaft body; the turbine base and the second end cover are internally provided with bearing air passages communicated with the air cavity; and the turbine base is also internally provided with a plurality of turbine air passages communicated with the air cavity. The turbine air-floatation main shaft disclosed by the invention has the advantages of simple and compact structure, high efficiency and rotating speed, smoothness in rotation, no wear, no need of adding lubricating oil inside and long working life.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for manufacturing dispersion strengthening copper-based oil bearing

The invention discloses a method for manufacturing a dispersion strengthening copper-based oil bearing, and belongs to the field of dispersion strengthening materials. According to the method, copper powder, aluminum powder, tin powder, graphite powder and nanometer yttrium oxide powder are mixed according to a certain proportion and placed into a frequency conversion high-energy vibration ball mill for high-energy ball milling after dispersing agents are added, then powder obtained through ball milling is pressed on a pressing machine to form a bearing base body blank, the formed blank is sintered and then immersed in oil, and finally the dispersion strengthening copper-based oil bearing can be obtained through full shaping of a die. By the adoption of the method, the abrasive resistance and lubricating performance of the manufactured dispersion strengthening copper-based oil bearing are better than those of a common copper-based oil bearing.

Owner:JIANGDU LEADER POWDER METALLURGY

Environment-friendly brake pad adopting copper-free microcrystalline friction materials

ActiveCN103821852ARich in microporesImprove frictional stabilityOther chemical processesBraking membersBrucitePetroleum coke

An environment-friendly brake pad adopting copper-free microcrystalline friction materials is made from components including acrylic pulp, mullite ceramic fibers, brucite fibers, nano tin powder, zinc sulfide, brown aluminum oxide, antimony sulfide, cellulosic fibers, iron black, calcium carbonate whiskers, calcium sulfate whiskers, potassium titanate, crystalline flake graphite, calcined petroleum coke, flake aluminum powder, nitrile rubber powder, phenolic resin, nanometer manganese hydroxide and molybdenum disulfide. Through reasonable collocation of the multiple components, advantages of the various components given full play to the friction materials can be guaranteed. By the reasonable collocation of the new fiber materials, the defect of respect performance can be made up, and high performance can be produced due to mutual influenced action. The environment-friendly brake pad is good in resistance to high-temperature recession, long in service life, good in wear-resisting performance, stable in friction coefficient and environment friendly.

Owner:摩擦一号制动科技(仙桃)有限公司

Oil-immersed water-proofing wire immersible motor for immersible pump and its making method

InactiveCN1395356AReduce temperature riseIncrease powerSupports/enclosures/casingsGreenhouseWater source

The invention discloses the submersible electric motor with oil immersed type water proof wire used for submersible pumps and its manufacturing method. The characters of the motor are as follows. The stator coil is the waterproof wire coil winding. The media for cooling the case shell chamber containing the stator and rotor is the insulating oil. The sealing system is composed of the airtight chamber, the mechanical seal and the rubber oil seal. Water is as the filler of the airtight chamber. The invention provides the following effects: lowering the temperature rise of the motor, increasing the power and service life of the motor, preventing water sources from pollution. The invented motor is especially suitable to rural areas for micro irrigation, sprinkling irrigation or used in greenhouse.

Owner:陈焯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com