Glass fiber impregnating compound and preparation method and application thereof

A technology for glass fiber and sizing agent, applied in the field of glass fiber sizing agent and its preparation, can solve problems such as performance degradation, achieve low stiffness, be beneficial to subsequent processing and mechanical strength, and reduce excessive looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

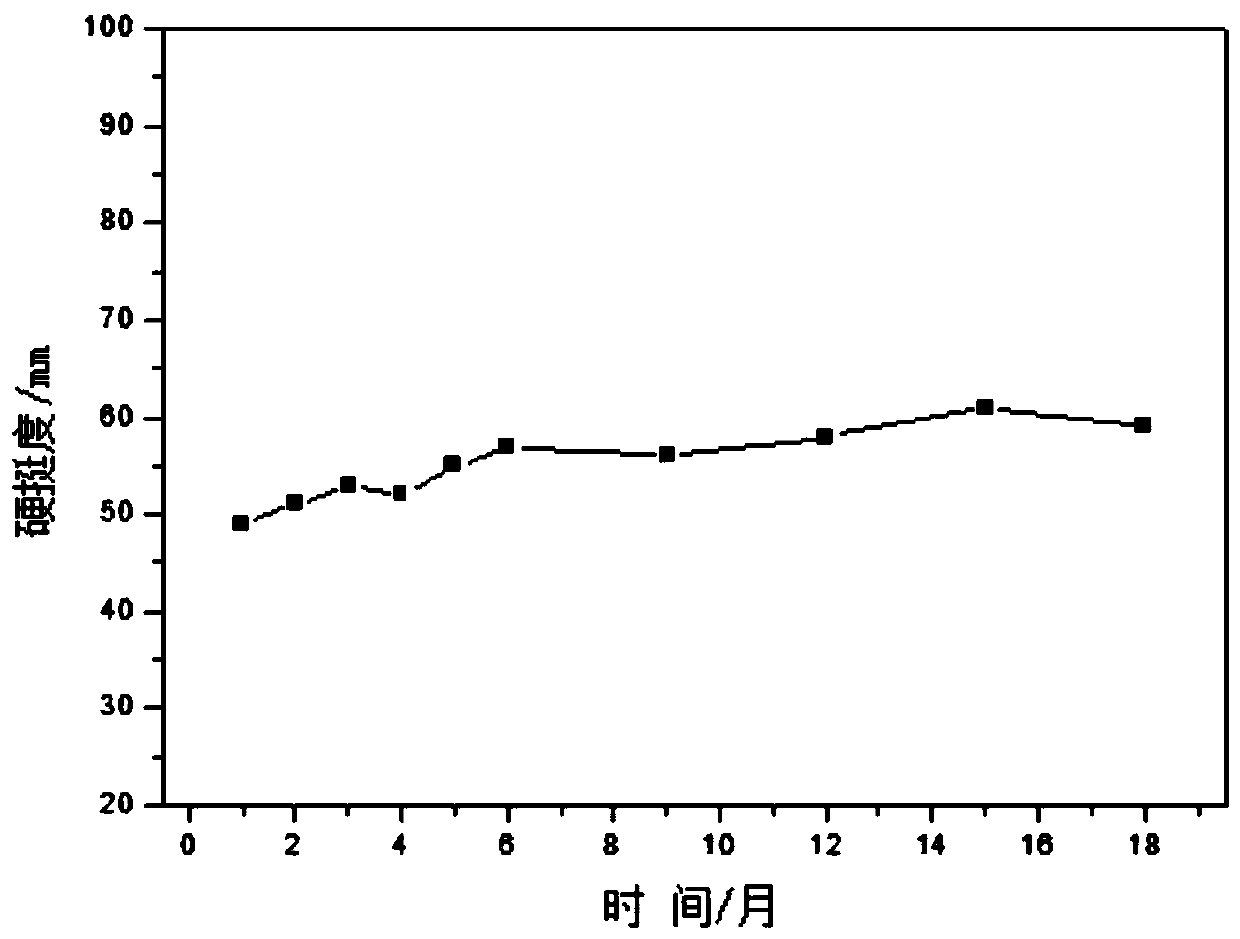

Image

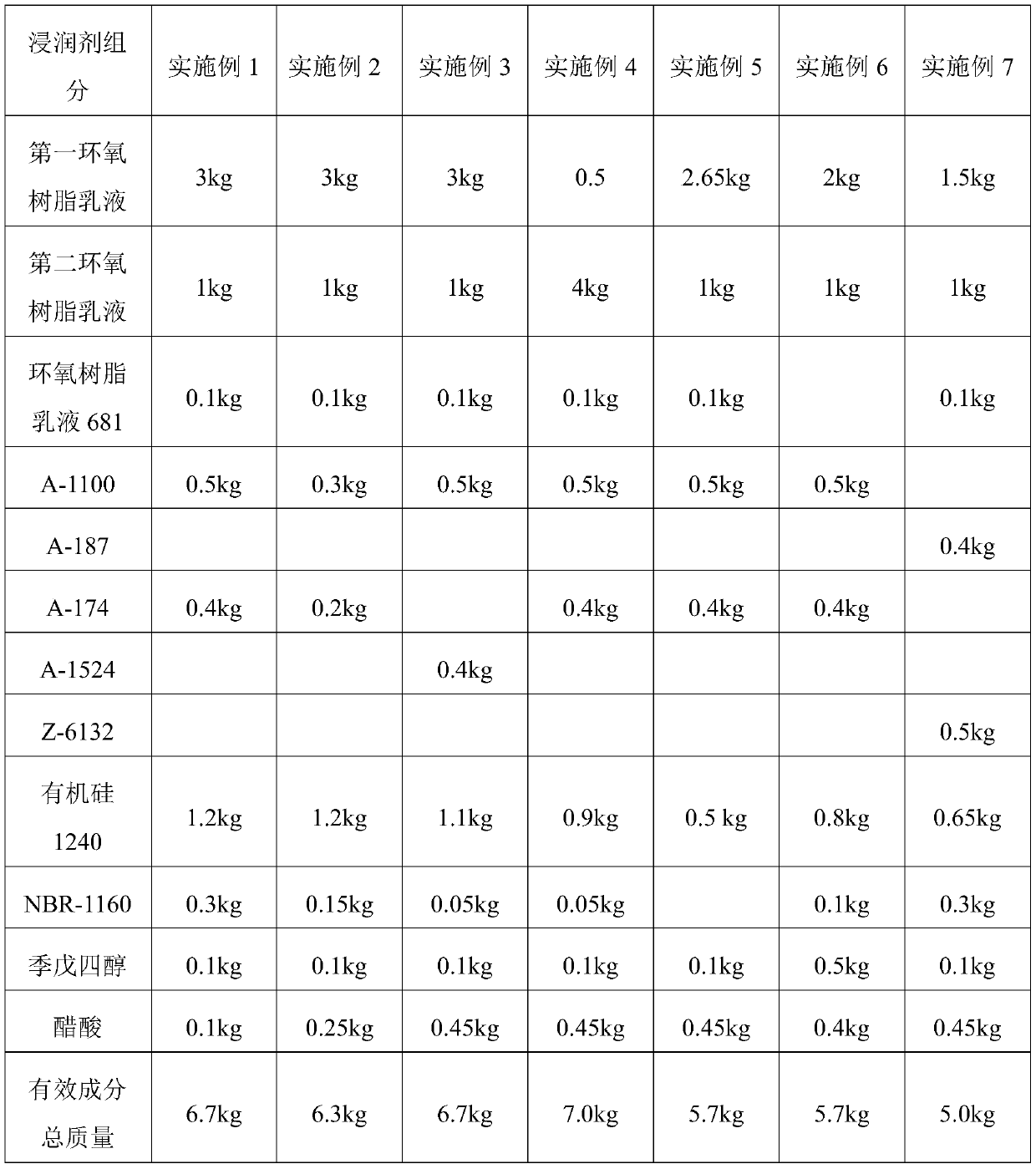

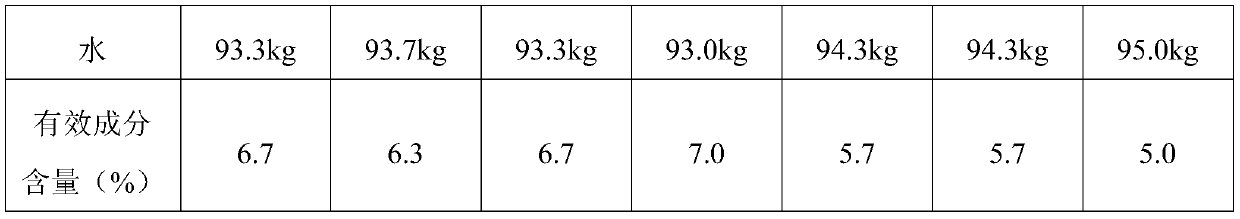

Examples

preparation example Construction

[0040] The preparation method specifically comprises the following steps:

[0041] (1) Add acetic acid to the first mixing container, add deionized water while stirring until the pH of the solution is 3.0 to 6.0, then add the silane coupling agent while stirring, and continue stirring until the surface of the solution is clear to obtain the silane coupling agent solution;

[0042] (2) Add the first epoxy resin emulsion in the second mixing container, add its 5 times of quality deionized water while stirring, then add the second epoxy resin emulsion, add its 5 times of its quality deionized water while stirring Ionized water to obtain diluted epoxy resin emulsion;

[0043] (3) Epoxy resin emulsion 681 is fully diluted with deionized water of 5 times its quality and then added to the second mixing container, and stirred evenly;

[0044] (4) Fully dilute silicone 1240, NBR-1160 and pentaerythritol with deionized water of 10 times the mass respectively, then add them to the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com