Sheet polarizer and a fabricating method thereof

A polarizing plate and polarizing film technology, which is applied to polarizing elements, adhesive types, instruments, etc., can solve the problems of easy degradation of polarization performance, easy peeling of polarizing film and protective film, etc., and achieve high degree of polarization, excellent safety and sanitation, Excellent adhesive effect

Active Publication Date: 2010-08-25

SUMITOMO CHEM CO LTD +1

View PDF9 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in conventional polarizing plates in which a polarizing film and a protective film are laminated with an adhesive layer interposed therebetween, the polarizing performance tends to deteriorate, especially when exposed to a humid and hot environment for a long time, and the interface between the polarizing film and the protective film tends to peel off. such problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

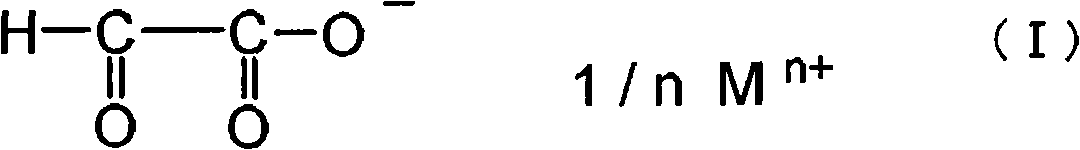

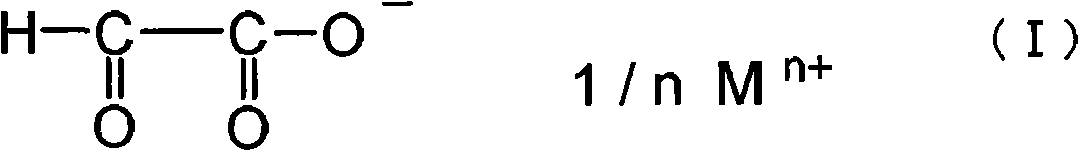

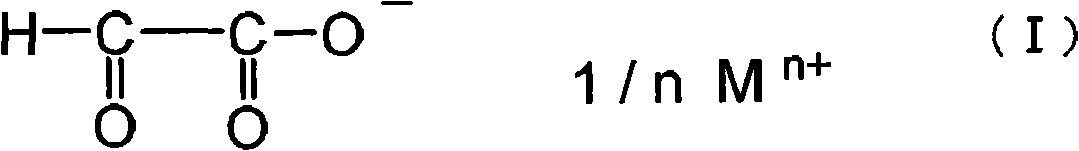

This invention provides a sheet polarizer,including polyvinyl alcohols polarizing film, sticking agent layer separated from polyvinyl alcohols polarizing film through at least on face and overlapped with protect film. Said sticking agent layer is comprised of sticking agent components containing followed water solution. Said water solution contains acetyl modified PVA resin and glyoxylate indicated by formula (I) and has a pH valve ranged in 4-10. where, the content of acetyl modified PVA resin is 1-8%( percentage by weight) compared to the 100% water(percentage by weight), the weight ratio of acetyl modified PVA resin with the solid glyoxylate is in the range of 1:0.03-0.25. in formula (I) , M represents alkali metals or alkaline-earth metals, n represents valence mumber correspond to M, indicating 1 or 2. According to said sheet polarizer, sticking property together with warm water resistance between the polarizing film and the protect film are improved.

Description

technical field The present invention relates to a polarizing plate in which a protective film is laminated on at least one surface of a polarizing film made of a polyvinyl alcohol-based resin via an adhesive layer, and a method for producing the same. Background technique A polarizing plate generally has a polarizing film formed of a polyvinyl alcohol-based resin adsorbed and aligned with a dichroic dye, and a protective film laminated on one or both sides of the polarizing film with an adhesive layer interposed therebetween. The polarizing plate is bonded to the liquid crystal cell with an adhesive through other optical films as needed, and becomes a component of the liquid crystal display device. As the use of liquid crystal display devices expands, it is required that they can be used in various environments. For this reason, components constituting liquid crystal display devices are required to have high environmental resistance. For example, liquid crystal display d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B5/30G02F1/1335C09J129/04

CPCC09J129/04G02B5/30

Inventor 竹厚流孙刚勇小野裕之田中晋一

Owner SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com