Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Good thermal expansion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

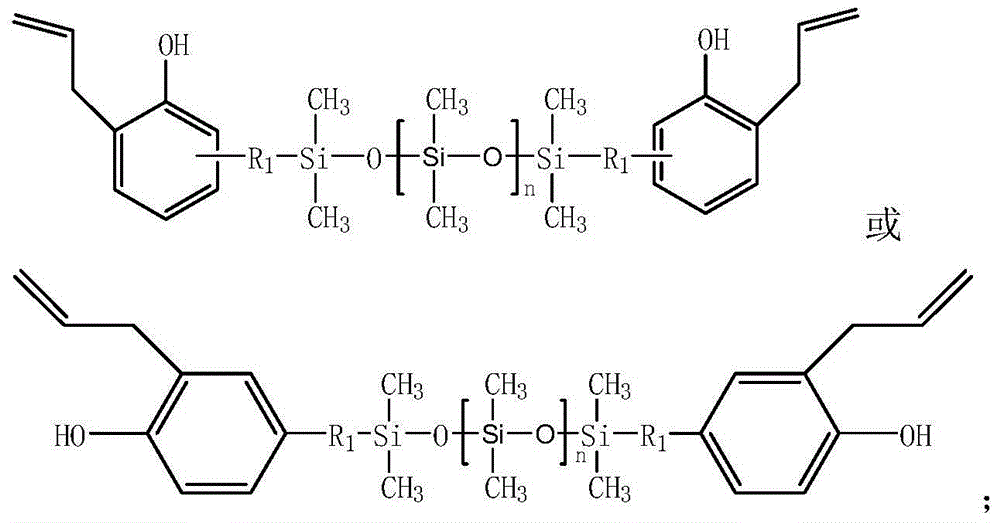

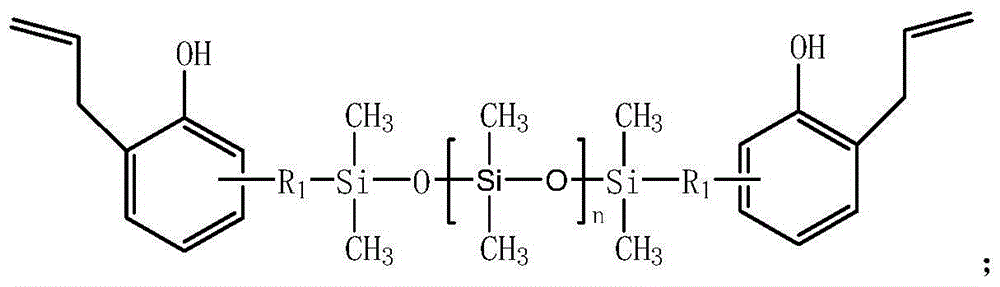

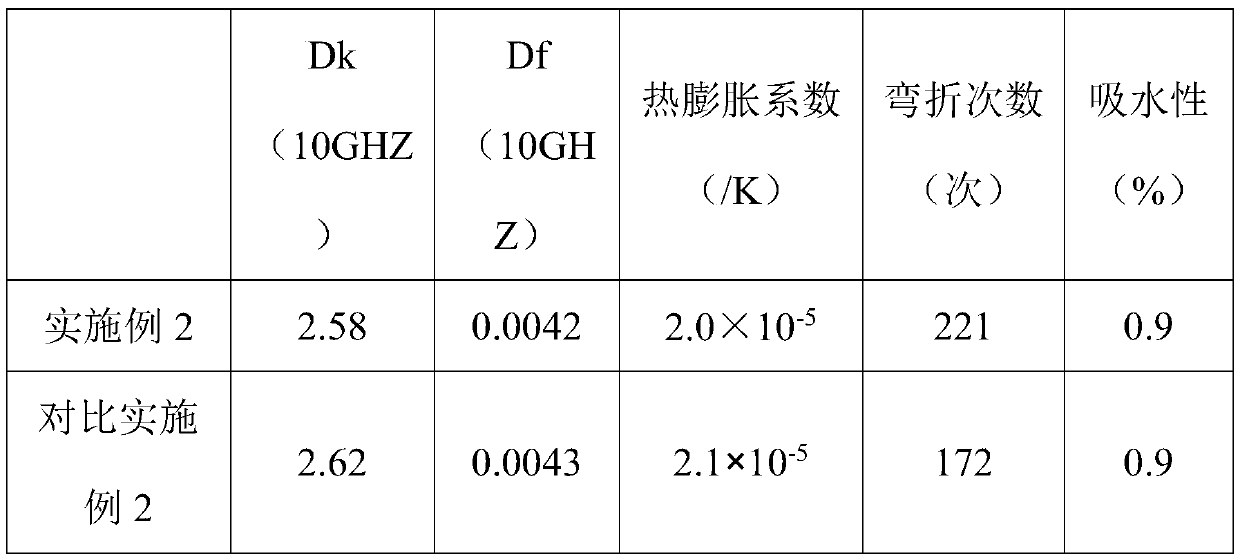

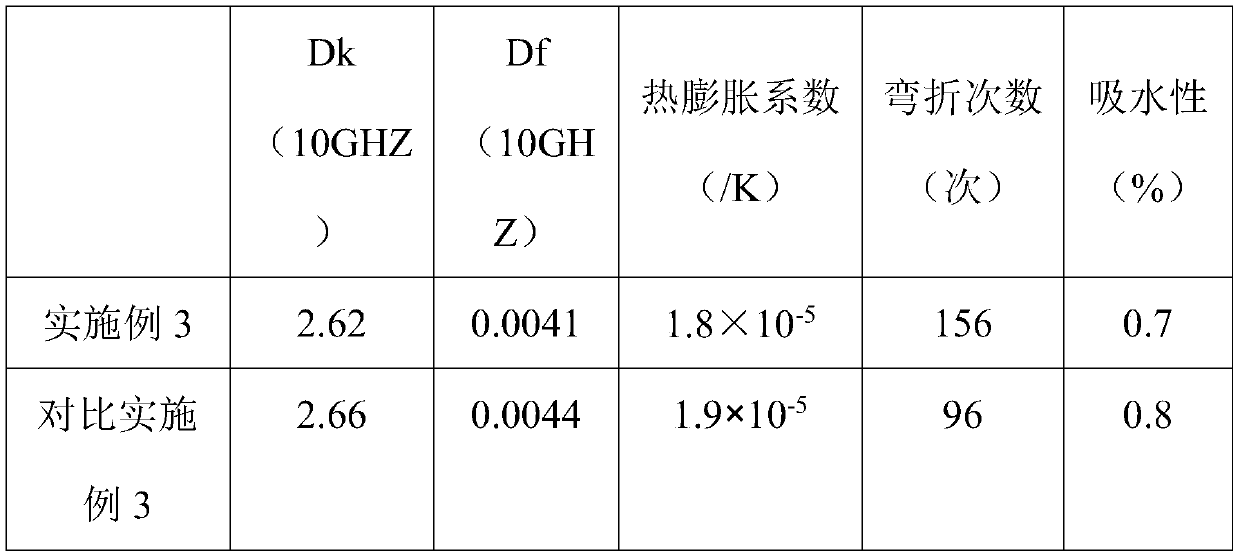

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

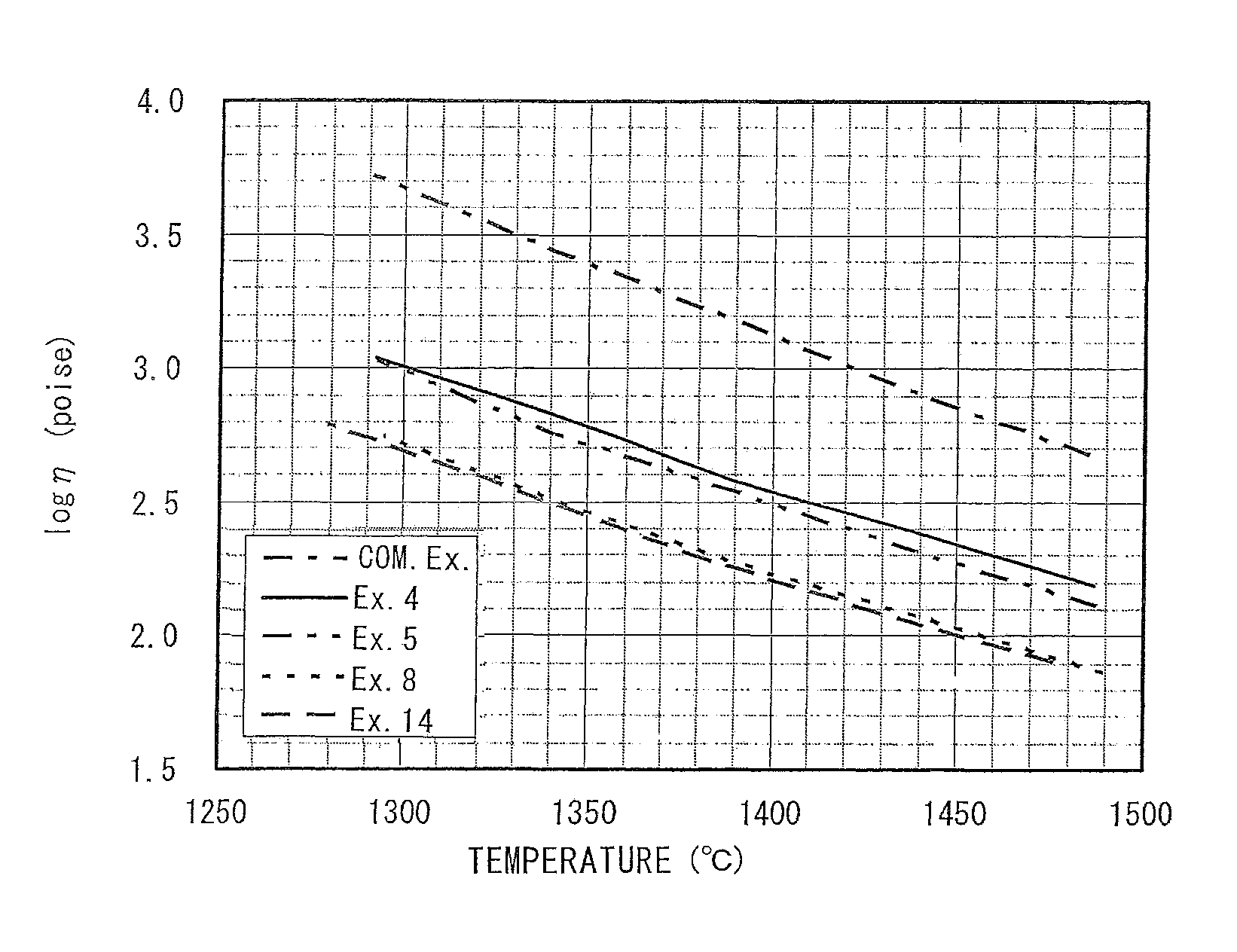

Glass-ceramics

InactiveUS8257831B2High strengthEasy to adaptMagnetic materials for record carriersRecord information storageSolid solutionGlass-ceramic

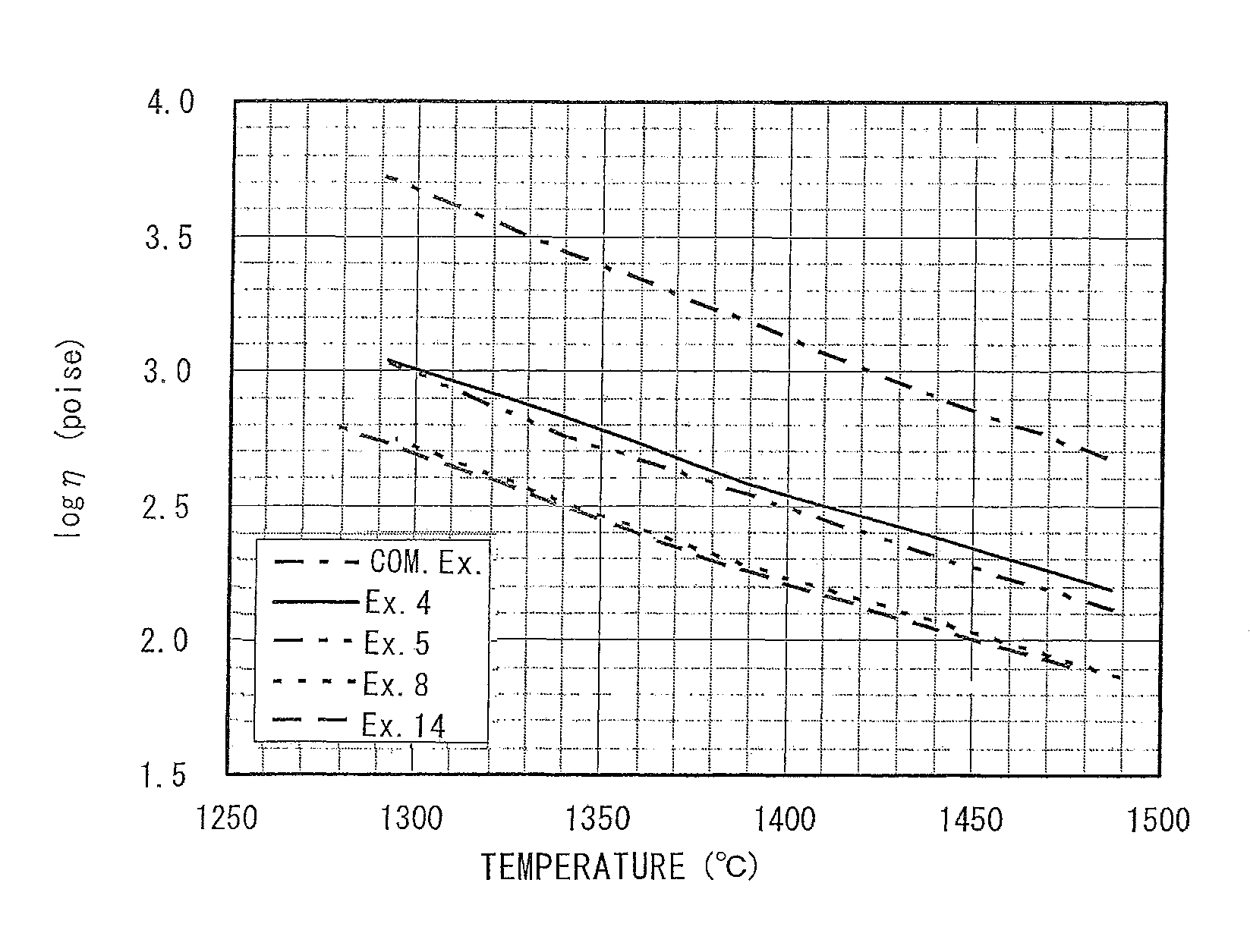

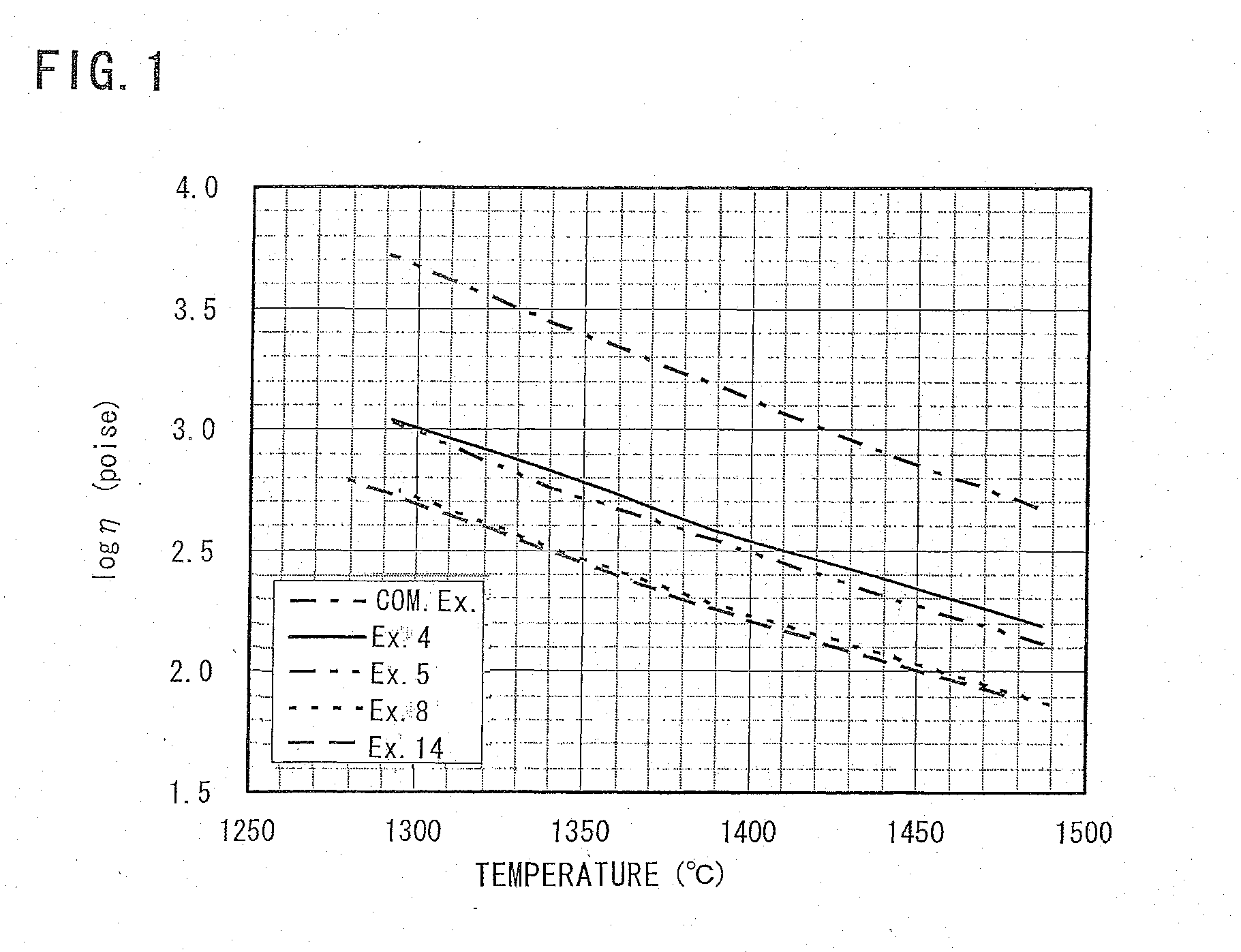

Glass-ceramics include SiO2, Al2O3 and Li2O on oxide basis. In the glass-ceramics, total amount in mass % of SiO2 and Al2O3 is less than 77% and Li2O / (SiO2+Al2O3) which is the ratio in mass % of the amount of Li2O to the total amount of SiO2 and Al2O3 is 0.064 or over. The glass-ceramics include at least one crystal phase selected from the group consisting of β-quartz, β-quartz solid solution, β-eucryptite, β-eucryptite solid solution, β-spodumene and β-spodumene solid solution.

Owner:OHARA

Vinyl chloride resin composition and molded article thereof

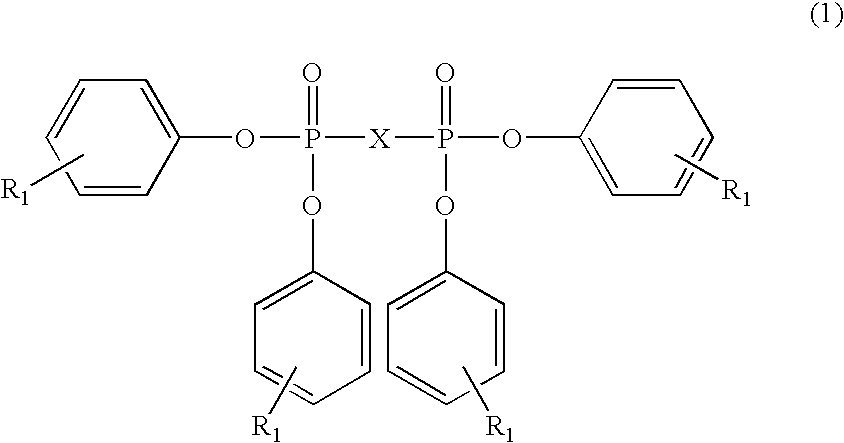

InactiveUS20070282027A1Good thermal expansion performanceHigh level of productivityPlastic/resin/waxes insulatorsDyeing processShell moldingGraphite

A thermally expandable vinyl chloride resin composition is provided. It includes (A) 100 parts by mass of a vinyl chloride resin, (B) 5 to 200 parts by mass of an inorganic filler, (C) 10 to 300 parts by mass of a thermally expandable graphite, (D) 0.1 to 10 parts by mass of a fluororesin, and (E) 10 to 300 parts by mass of a phosphorus compound. The composition exhibits favorable thermal expansion properties and favorable shape retention following thermal expansion upon exposure to high temperatures.

Owner:SHIN ETSU CHEM IND CO LTD

Glass-ceramics

InactiveUS20080268295A1High strengthEasy to adaptMagnetic materials for record carriersRecord information storageSolid solutionGlass-ceramic

Glass-ceramics include SiO2, Al2O3 and Li2O on oxide basis. In the glass-ceramics, total amount in mass % of SiO2 and Al2O3 is less than 77% and Li2O / (SiO2+Al2O3) which is the ratio in mass % of the amount of Li2O to the total amount of SiO2 and Al2O3 is 0.064 or over. The glass-ceramics include at least one crystal phase selected from the group consisting of β-quartz, β-quartz solid solution, β-eucryptite, β-eucryptite solid solution, β-spodumene and β-spodumene solid solution.

Owner:OHARA

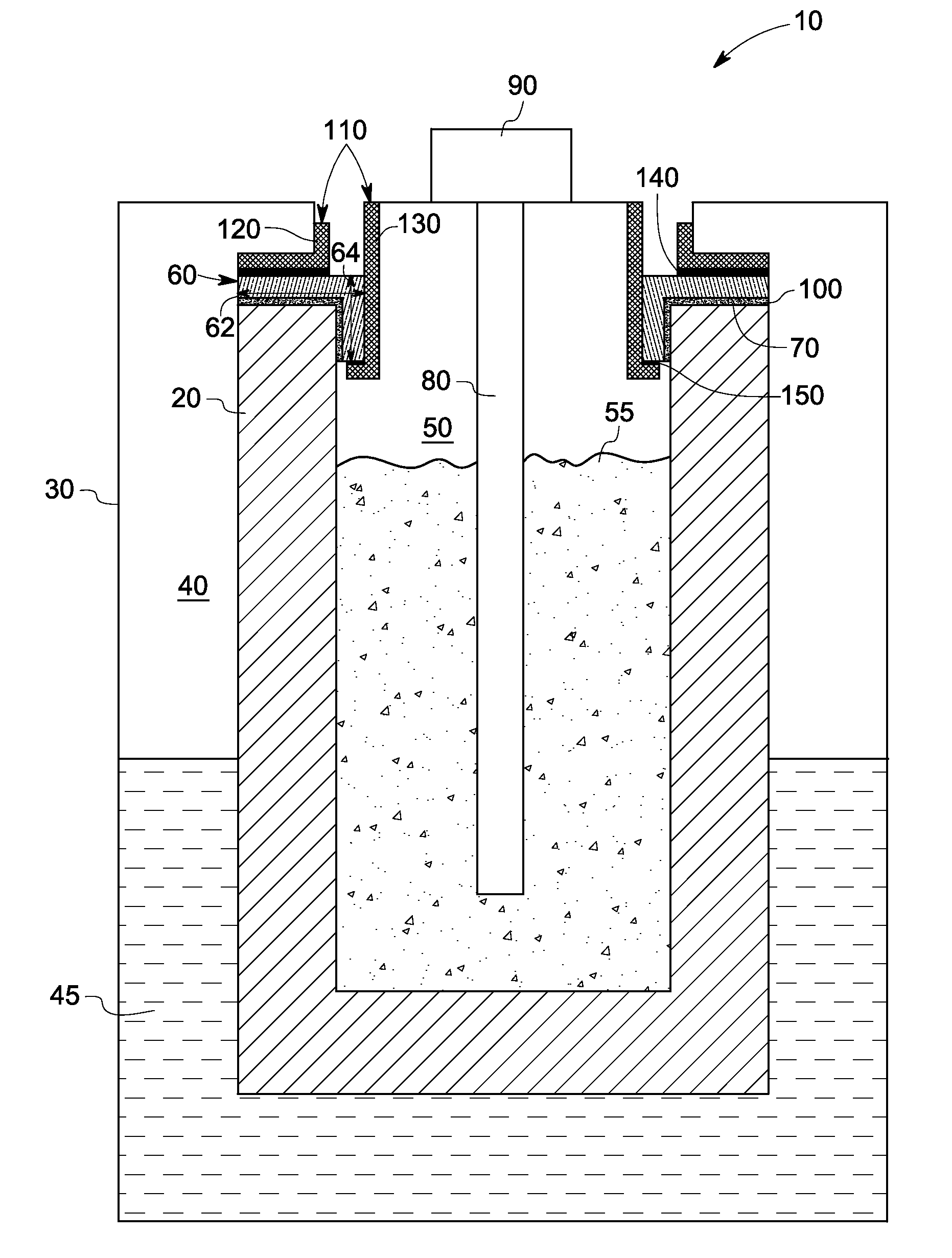

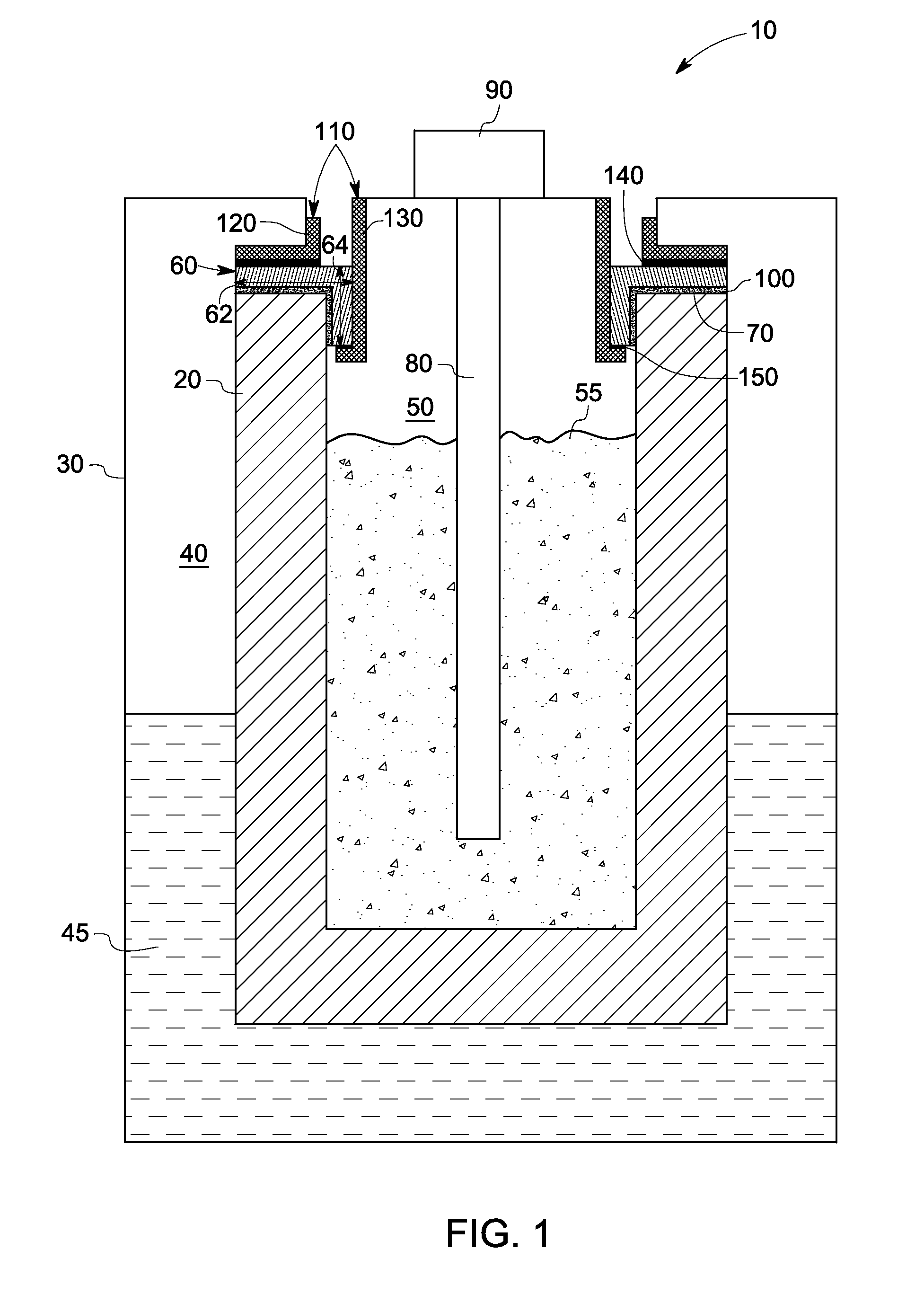

Braze compositions, and related articles and methods

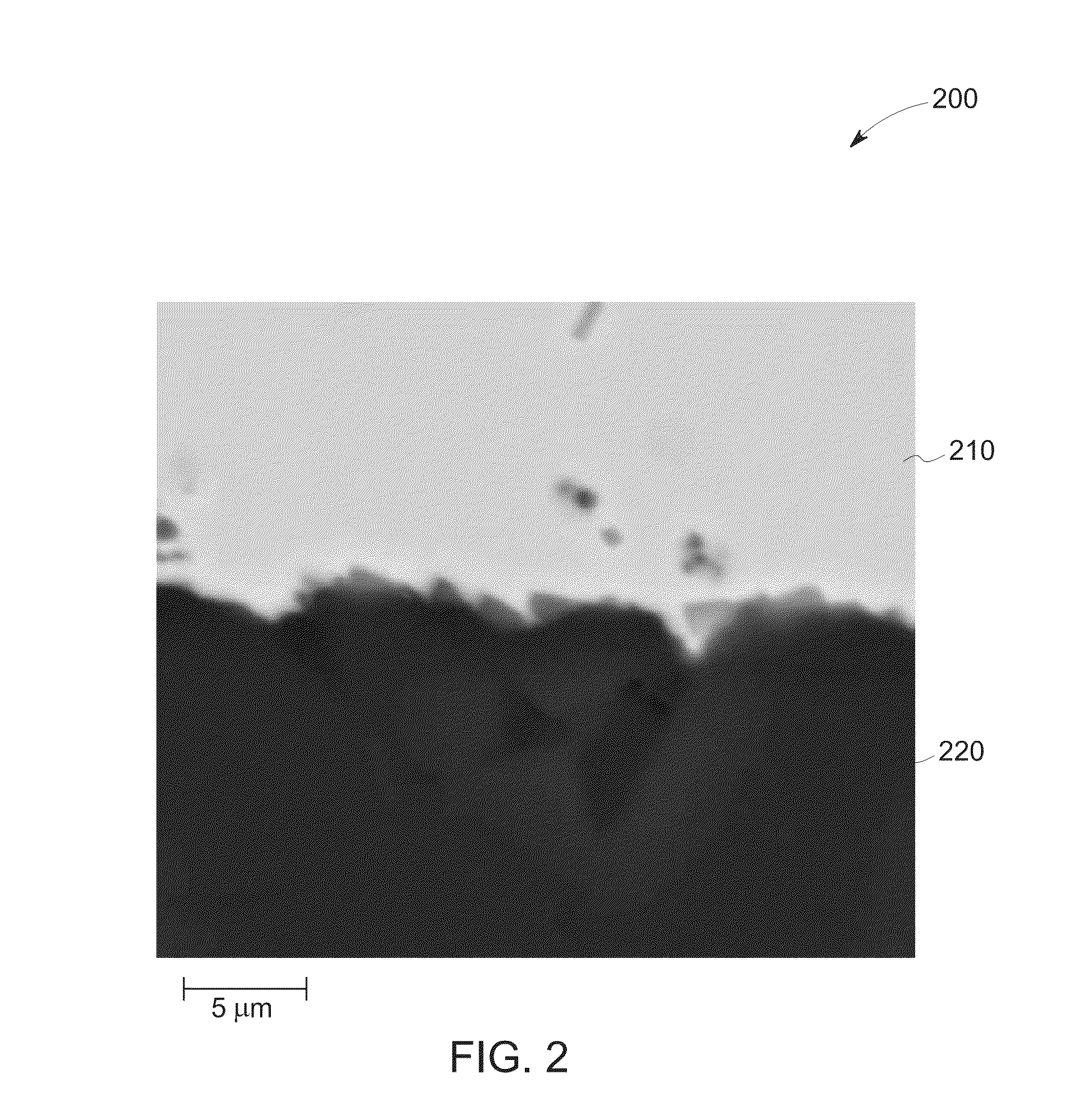

InactiveUS20130224561A1Increase temperatureGood thermal expansion performancePrimary cell to battery groupingFinal product manufactureAlloyElectrochemical cell

A braze alloy composition for sealing a ceramic component to a metal component in an electrochemical cell is presented. The braze alloy composition includes nickel, germanium, and an active metal element. The braze alloy includes germanium in an amount greater than about 5 weight percent, and the active metal element in an amount less than about 10 weight percent. A method for sealing a ceramic component to a metal component in an electrochemical cell and, an electrochemical cell sealed thereby, are also provided.

Owner:GENERAL ELECTRIC CO

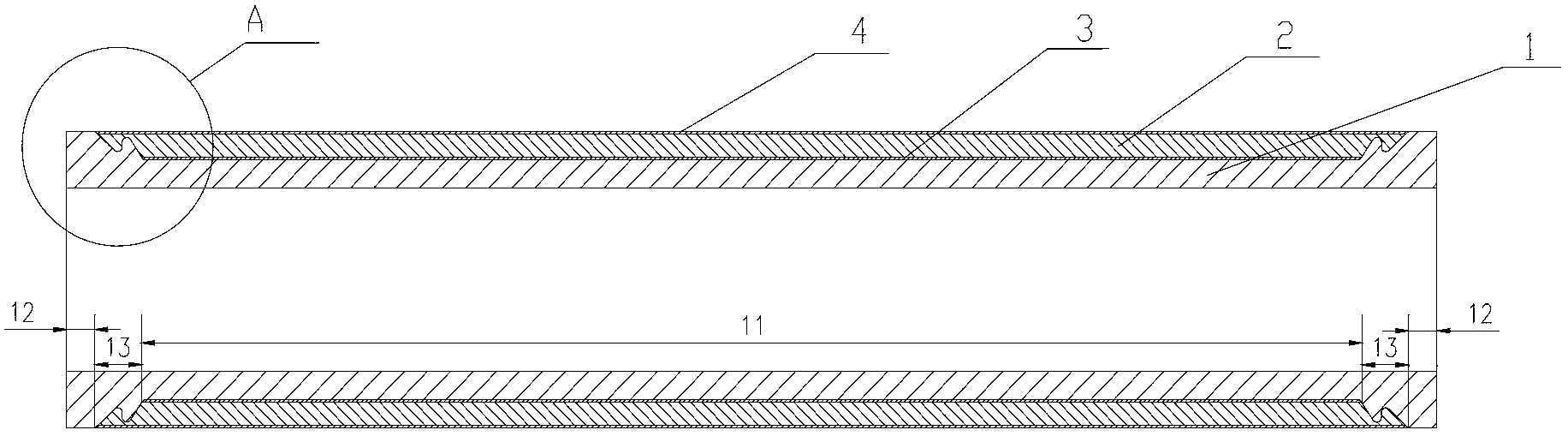

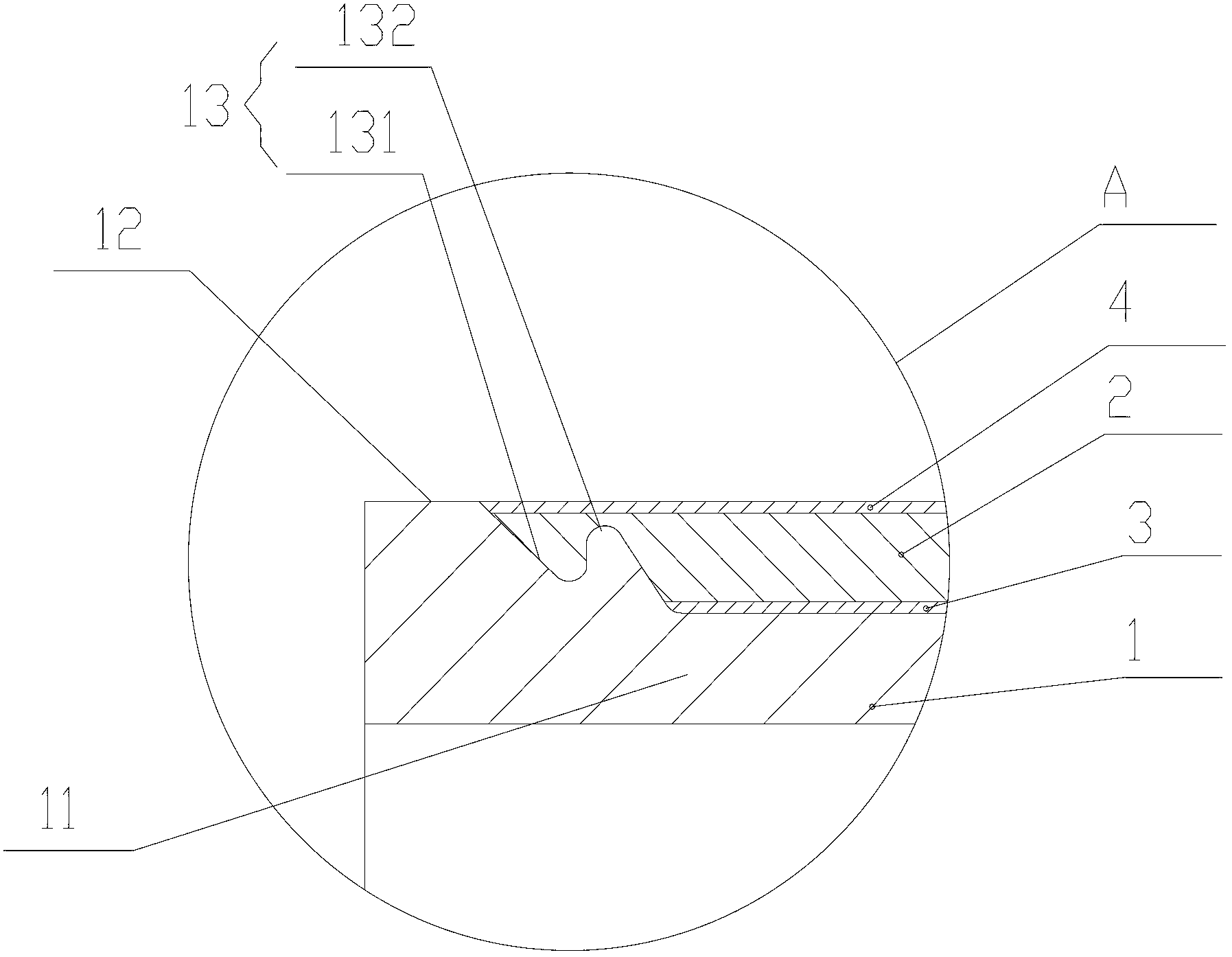

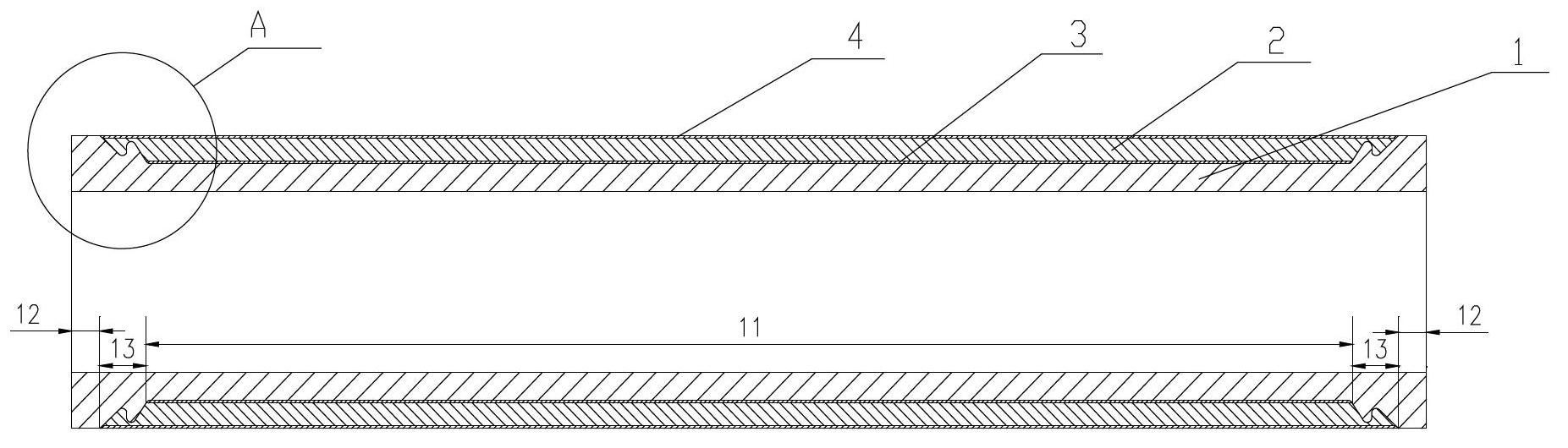

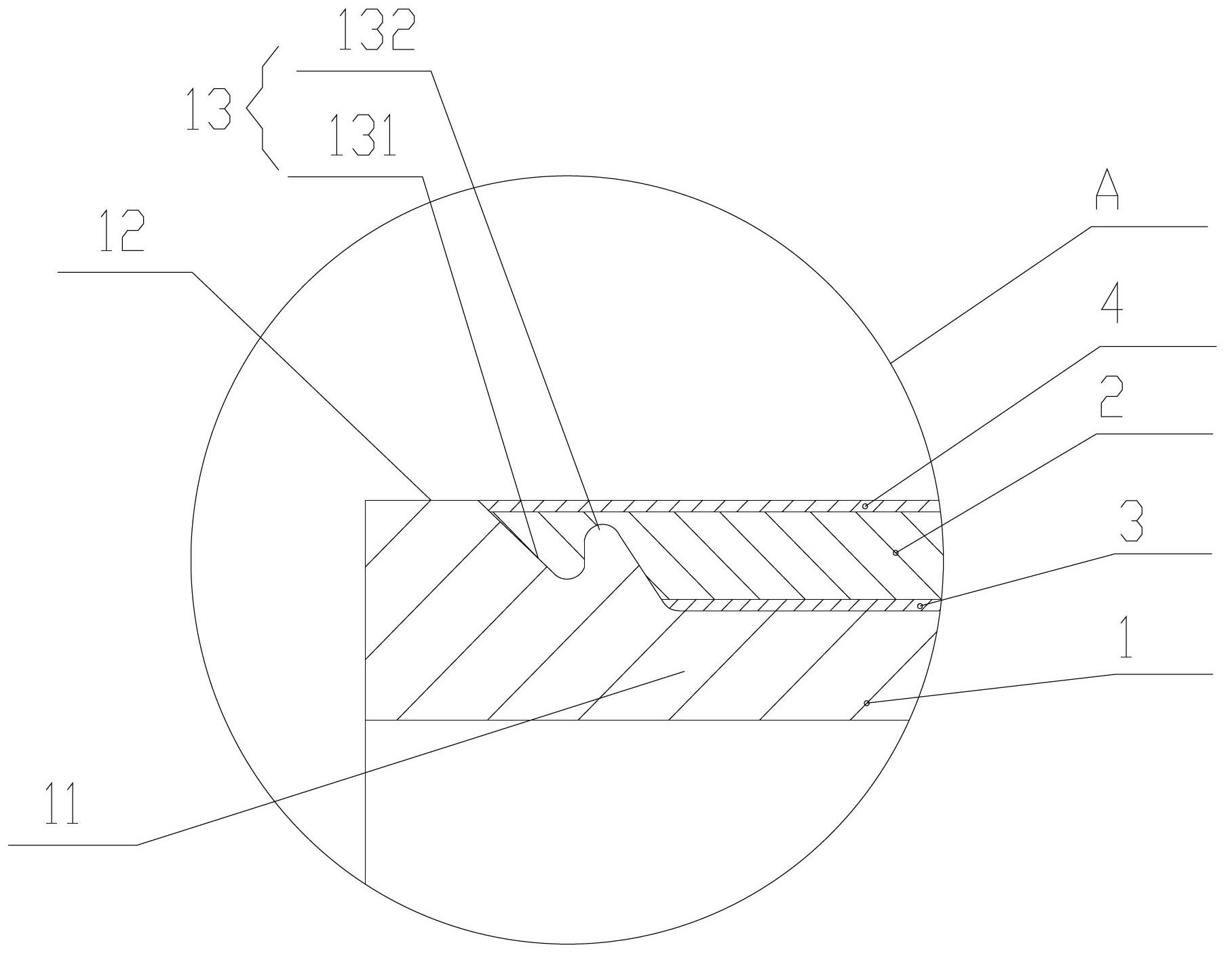

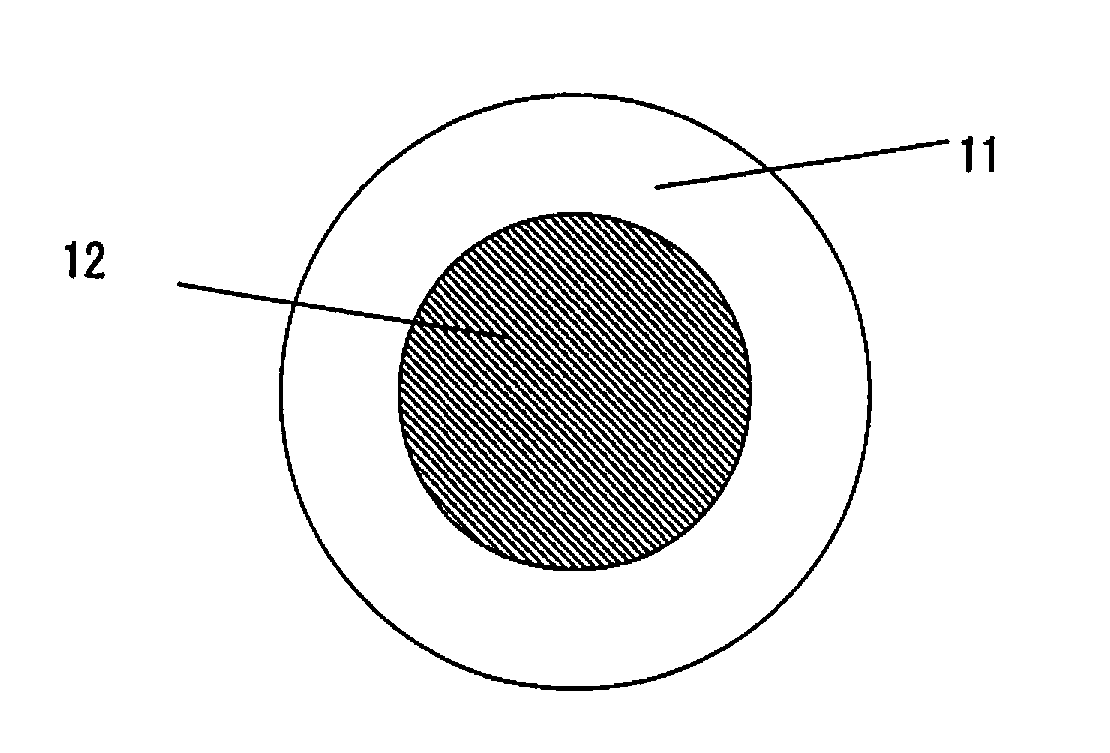

Cylinder body of actuating cylinder, manufacturing method thereof and concrete pumping equipment using the same

ActiveCN102705293AHigh strengthReduce weightFluid-pressure actuatorsPiston pumpsResin matrixFibrous composites

The invention discloses a cylinder body of an actuating cylinder, which comprises an inner lining (1) and a first fiber composite material layer (2) bonded outside the inner lining, wherein the first fiber composite material layer is laminated by a first fiber material and a resin matrix. The invention also discloses concrete pumping equipment comprising the cylinder body. Accordingly, the invention further discloses a manufacturing method of the cylinder body of the actuating cylinder, which comprises an inner lining forming step of forming the inner lining, and a bonding step of forming the first fiber composite material layer with the first fiber material and the resin matrix and bonding the first fiber composite material layer to the outer part of the inner lining. According to the technical scheme, the cylinder body of the actuating cylinder has higher strength and lighter weight, is better in fatigue resistance and corrosion resistance, and has low thermal expansibility. Besides, since the inner lining of the cylinder body can meet the requirements for tightness of the cylinder body inner wall and the wear resistance upon contact with a piston, the inner lining does not affect the service performance of the cylinder body.

Owner:ZOOMLION HEAVY IND CO LTD

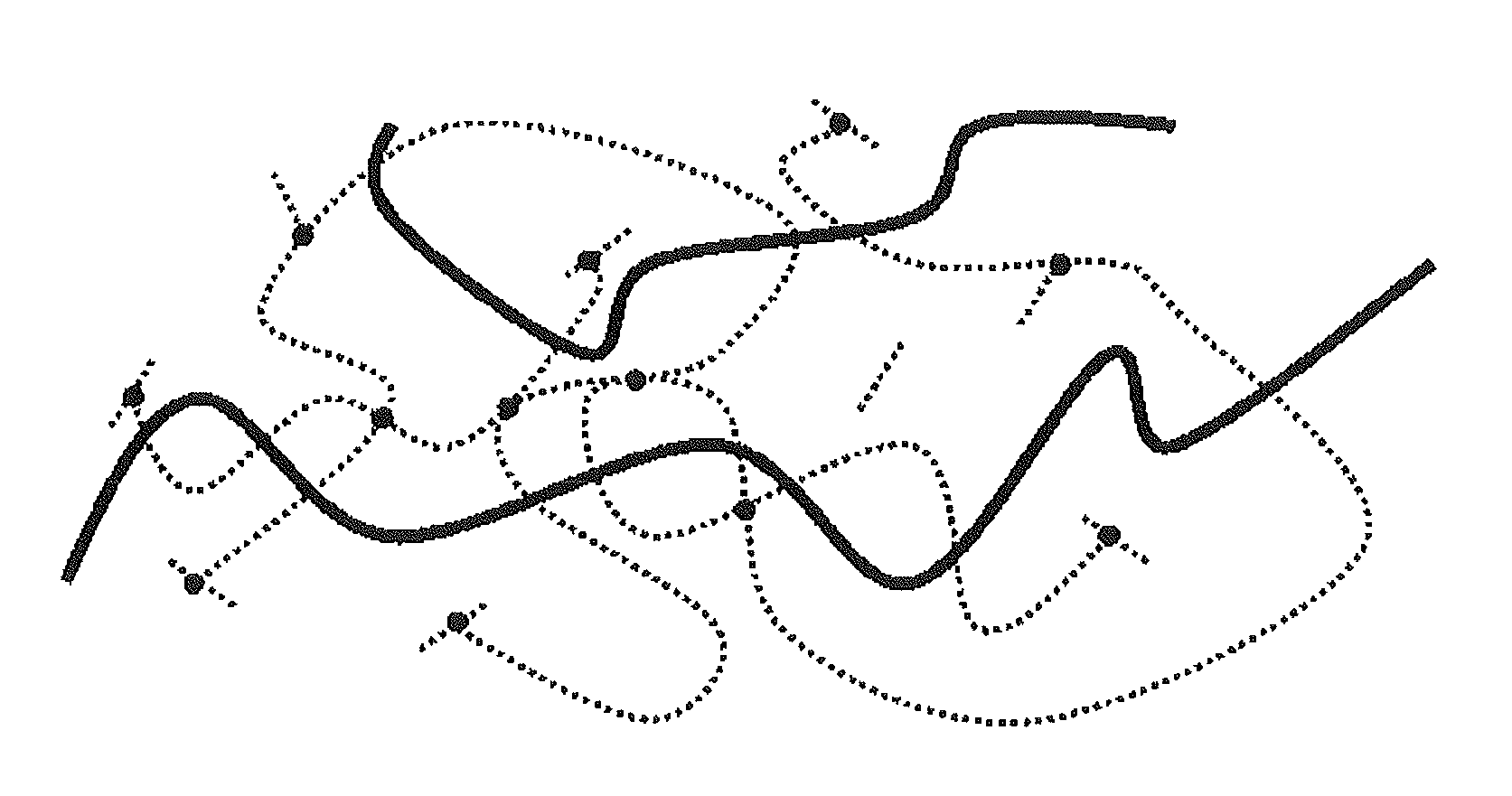

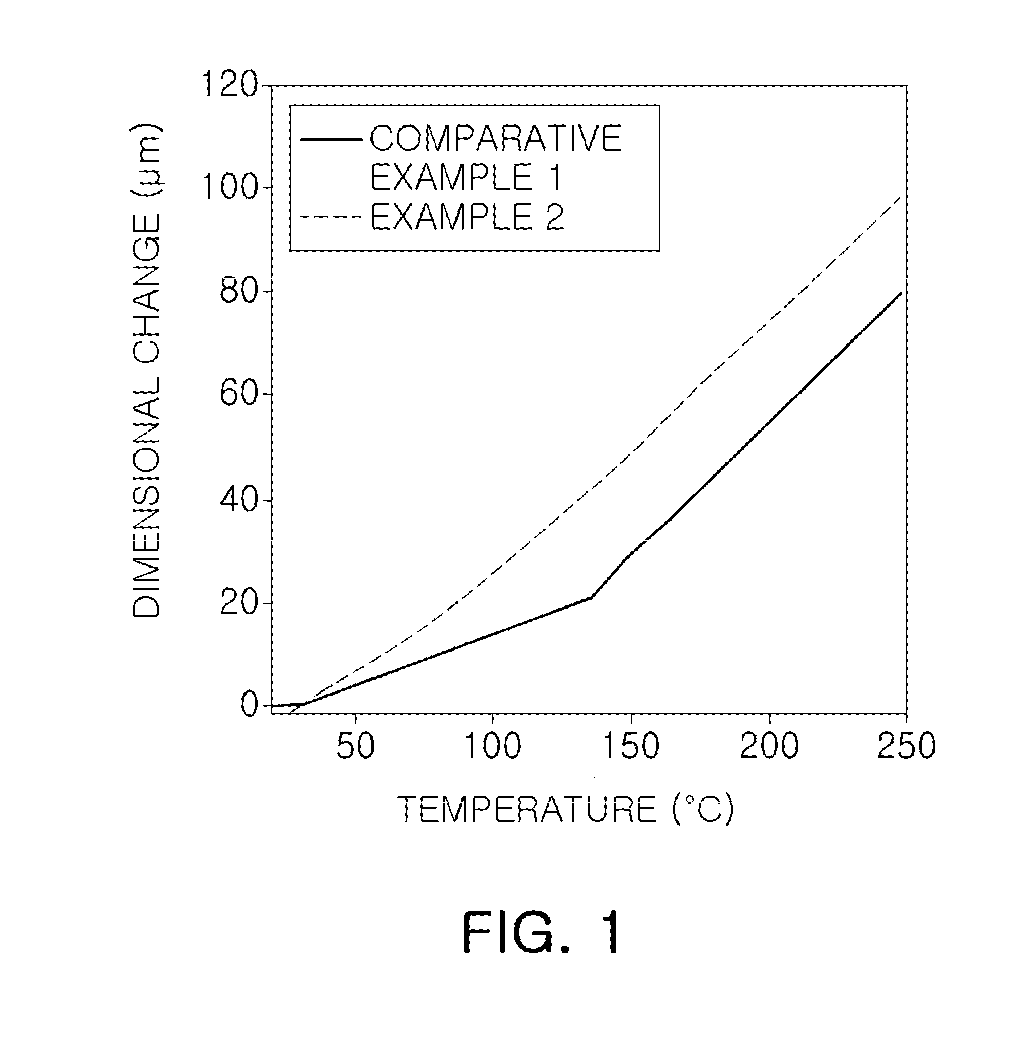

Process for producing resin varnish containing semi-ipn composite, thermosetting resin and, provided using the same, resin varnish for printed wiring board, prepreg and metal-clad laminate

InactiveUS20130040153A1Maintain good propertiesPromote absorptionOrganic dyesPrinted circuit manufactureEtherPrinted circuit board

A thermosetting resin varnish that includes a thermosetting resin composition of an uncured semi-IPN composite having compatibilized with one another (A) a polyphenylene ether, (B) a butadiene polymer which contains in the molecule thereof 40% or more of a 1,2-butadiene unit having a 1,2-vinyl group in the side chain thereof, and which is not chemically modified, and (C) a crosslinking agent; (D) an inorganic filler; and (E) a saturated thermoplastic elastomer. Also, a resin varnish for a printed circuit board, a prepreg, and a metal-clad laminate, using the thermosetting resin varnish.

Owner:FUJIMOTO DAISUKE +3

Braze compositions, and related devices

InactiveUS20130316226A1Less complicatedLess-expensive to processFinal product manufactureActive material electrodesAlloyBoron

A braze alloy composition for sealing a ceramic component to a metal component in an electrochemical cell is presented. The braze alloy composition includes nickel, silicon, boron, and an active metal element. The braze alloy includes nickel in an amount greater than about 50 weight percent, and the active metal element in an amount less than about 10 weight percent. An electrochemical cell using the braze alloy for sealing a ceramic component to a metal component in the cell is also provided.

Owner:GENERAL ELECTRIC CO

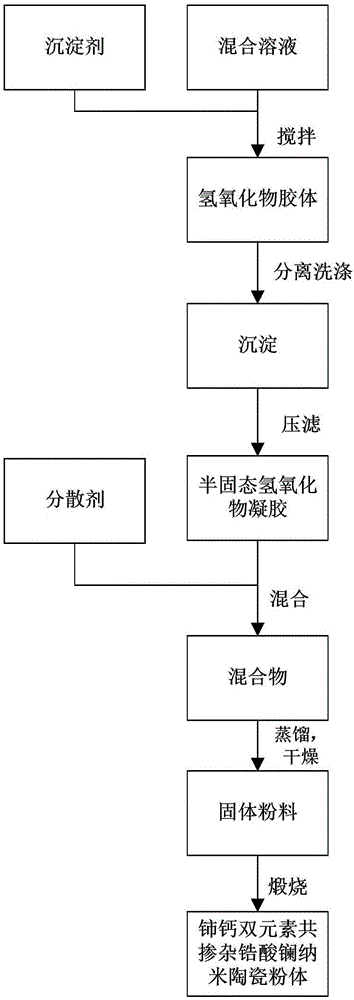

Cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and preparation method thereof

The invention provides cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and a preparation method thereof. The preparation method includes following steps: preparing a mixed solution, and mixing the same with a precipitant to obtain hydroxide colloid; separating and washing the hydroxide colloid to obtain precipitate; press-filtering the precipitate to obtain semi-solid-state hydroxide gel; well mixing the semi-solid-state hydroxide gel with a dispersant to obtain a mixture; distilling the mixture, and drying to obtain solid powder; calcining the solid powder to obtain the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder. The structural formula of the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder is (La1-2xCexCax)2(Zr0.7Ce0.3)2O7, wherein x is greater than or equal to 0.05 and smaller than or equal to 0.2. The preparation method is few in process and easy to control.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

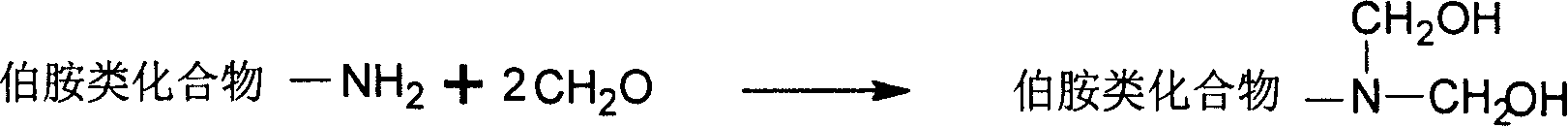

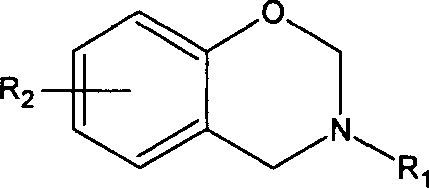

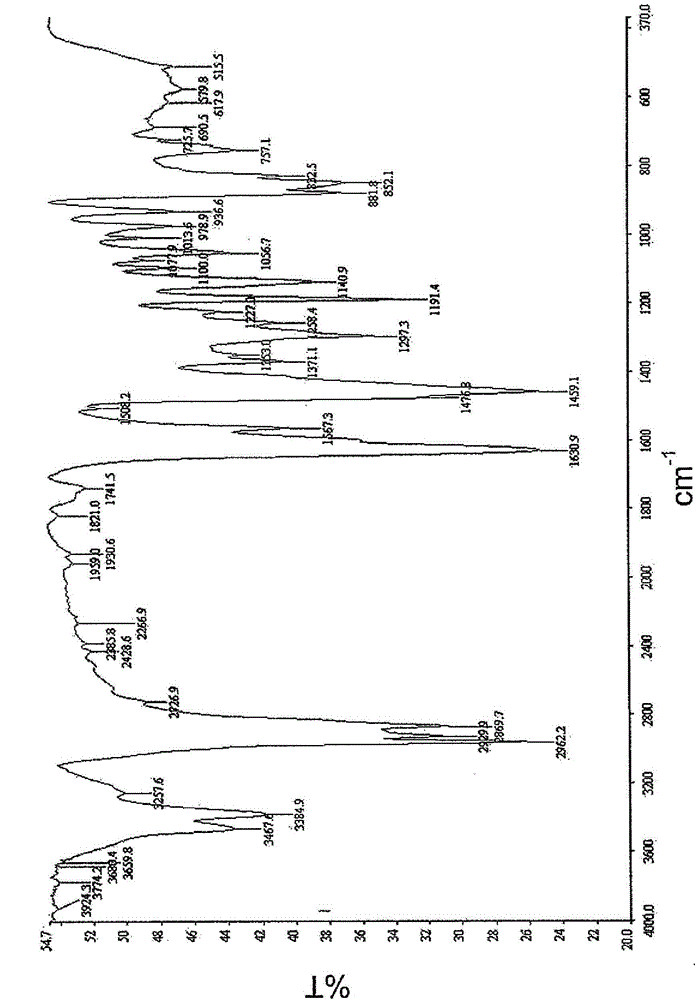

Benzo oxaxine intermediate containing aldehyde group and its preparation method

InactiveCN1865250AIncrease crosslink densityImprove thermal stabilityOrganic chemistryDistillationOrtho position

This invention relates to an aldehyde group-containing benzoxazine intermediate and and method for making same, characterizing: (1)add aminated compound 80-30wt and formaldehyde 20-110wt into the solvent 50-180wt at 4-20Deg C to react to produce N-dimethylol compound, adjust pH to 8-10 with base solution to stabilize the N-dimethylol compound in the solution; (2) add in aldehyde group-containing phenol derivatives 20-70wt to cause the N-dimethylol compound, phenolic hydroxyl group and the ortho-position of the benzene ring thereof for condensation reaction, and thus produce the aldehyde group-containing benzoxazine intermediate solution by dehydration and ring-closure, remove the solvent from the solution by press-decreasing distillation to produce the yellow aldehyde group-containing benzoxazine intermediate solid.

Owner:SICHUAN UNIV

Calendering system

The invention discloses a calendering system, which comprises a support, at least two feeding devices, at least one pressing device, a receiving device and a temperature regulating device. Wherein, at least two feeding devices are used to continuously output the substrate and the first film respectively; at least one pressing device is arranged on the support, and is used to press the first film from the feeding device on the substrate; the receiving device It is used to continuously collect the second film formed after pressing by the pressing device; the temperature regulating device is arranged between the feeding device and the pressing device, and is used to adjust the temperature of the first film from the feeding device. In the calendering system of this structure, a temperature adjustment device is installed between the feeding device and the closing device to adjust the physical properties of the first film before the pressing process, so that the thermal expansion, ductility, and flexibility of the first film are improved. The calendering quality of the film, the structure of the whole calendering system is simple and easy to operate.

Owner:YANCHENG ZENGCAI SCI & TECH

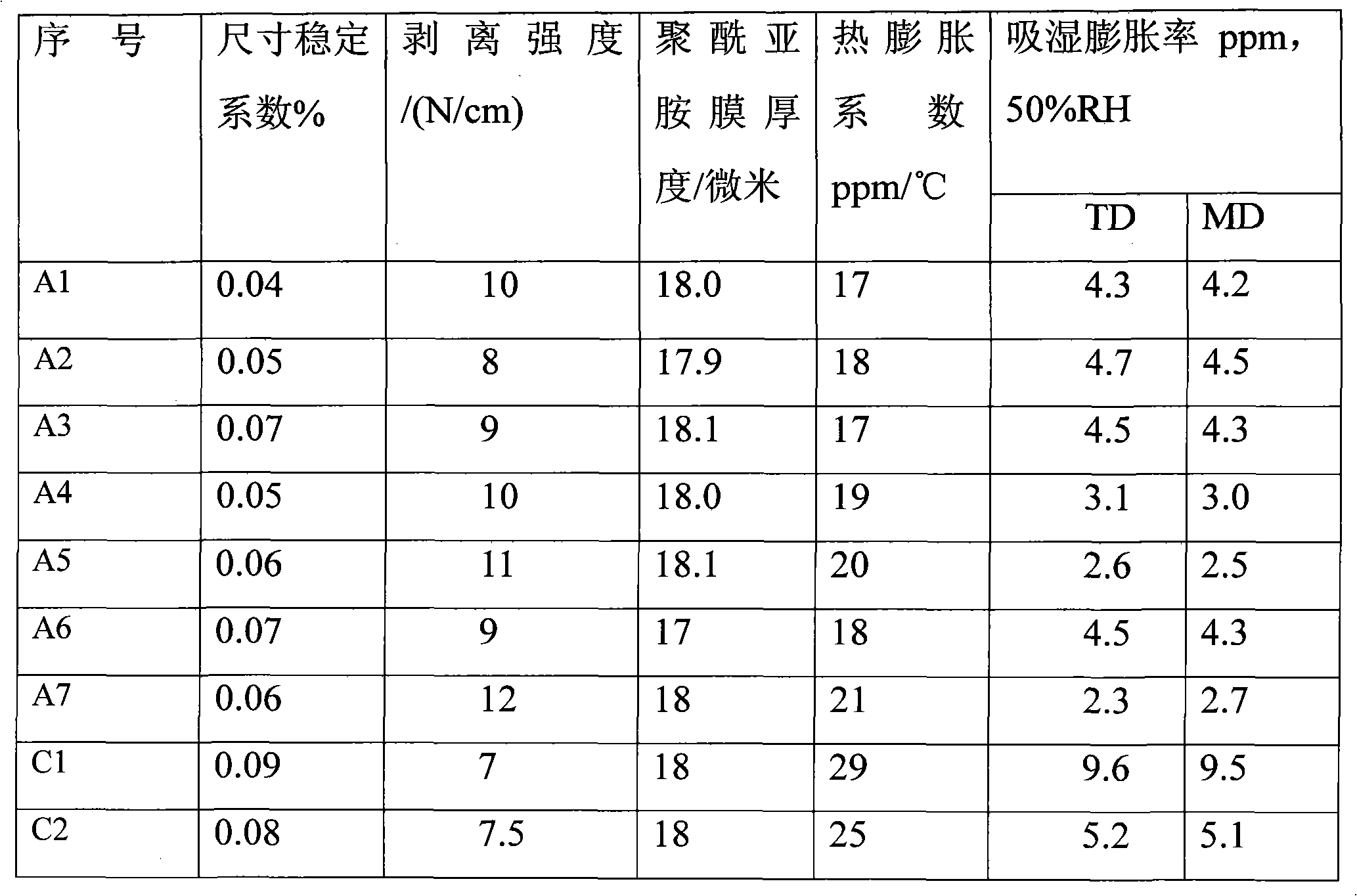

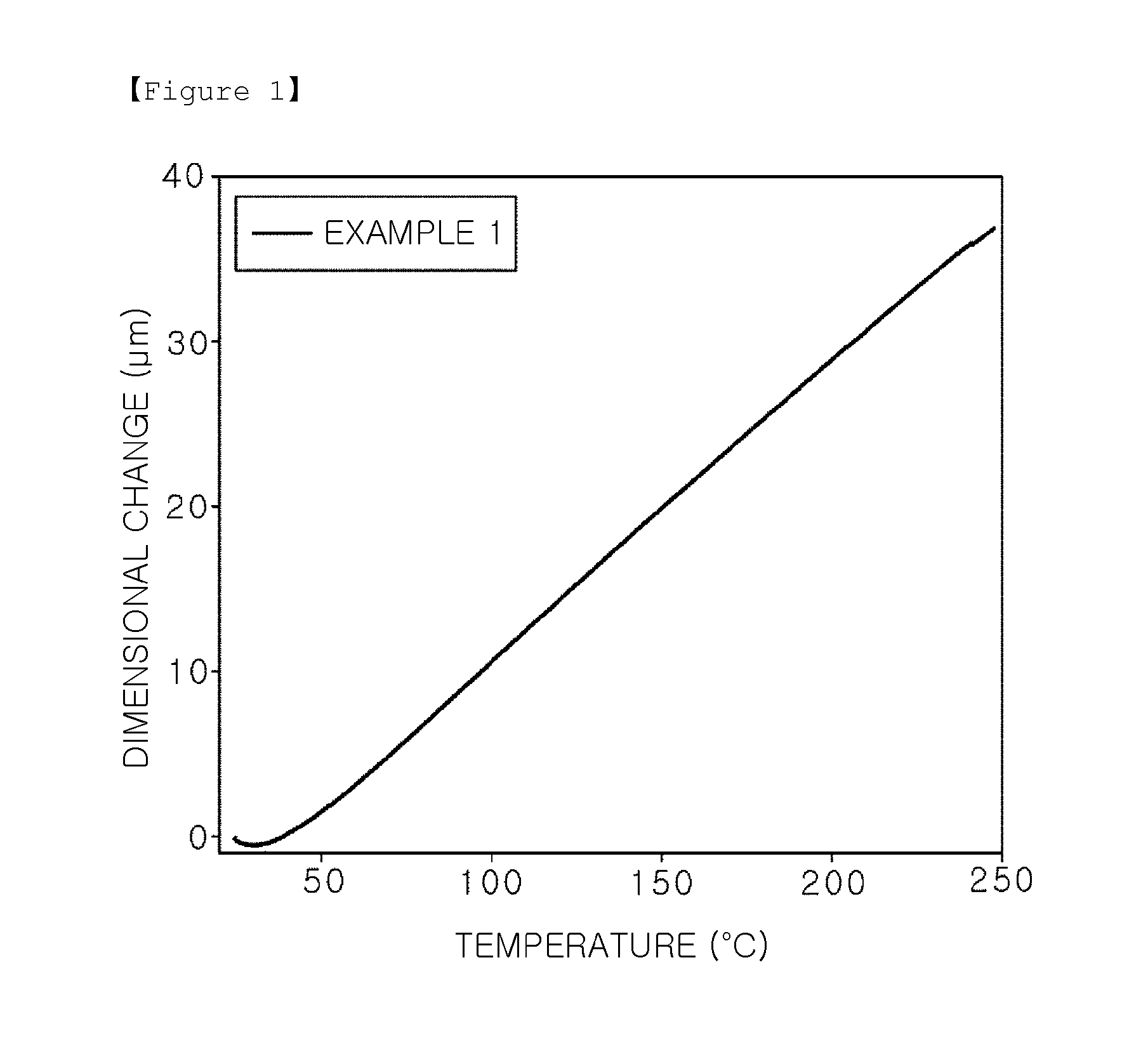

Metal laminated plate and preparation method thereof

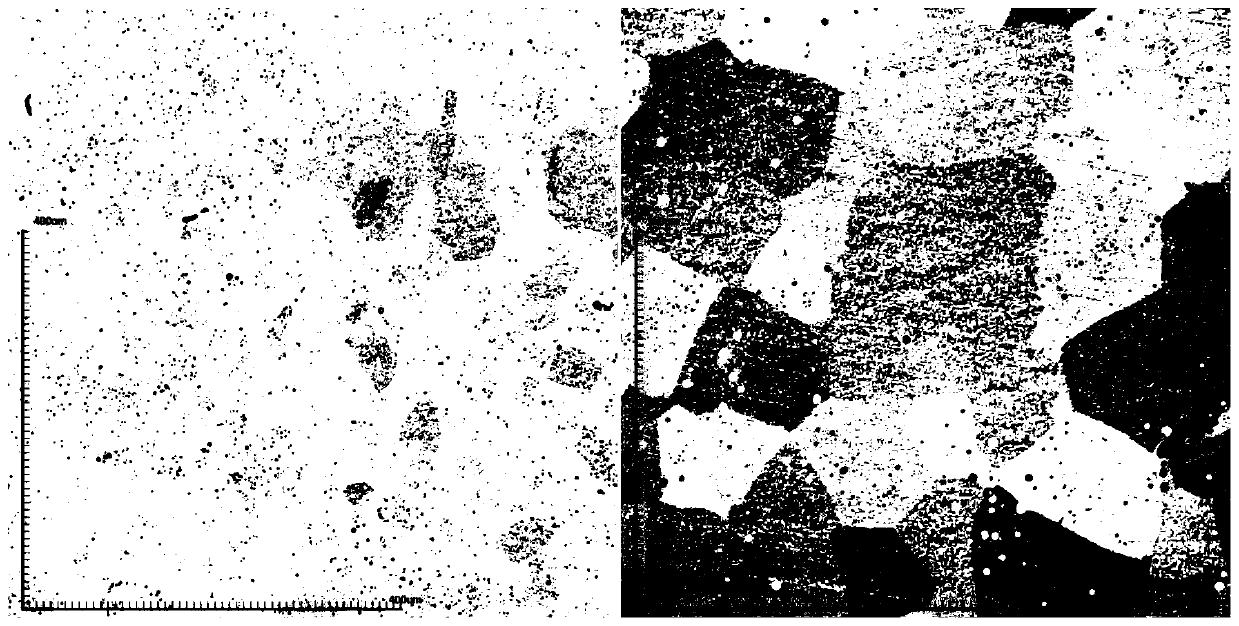

ActiveCN101648449AGood dimensional stabilityImprove thermal stabilityInsulating substrate metal adhesion improvementLaminationDiphenyl etherThermal expansion

The invention provides a metal laminated plate and a preparation thereof. The metal laminated plate consists of a polyimide resin layer and a metal layer, wherein the thermal expansion coefficient ofthe polyimide resin layer is 18 to 30 ppm / DEG C, and the hygroscopic expansion coefficient of the polyimide resin layer is 2 to 16 ppm; and the peeling strength between the polyimide resin layer and the metal layer is 10 to 20 N / mm. The method for preparing the metal laminated plate comprises the following steps: firstly, dissolving aromatic tetracarboxylic dianhydride and aromatic diamine in an polar aprotic solvent for reaction to form solution of polyamic acid, wherein the aromatic diamine may be benzidine, para-phenylene diamine, or 4,4'-diamino diphenyl ether; and secondly, coating the polyamic acid solution on the metal layer, and performing imidization to obtain the metal laminated layer. The metal laminated layer prepared by the method has the characteristics of high binding forcebetween the polyimide resin layer and the metal layer, high dimensional stability of the polyimide resin layer and small hygroscopic expansion coefficient.

Owner:BYD CO LTD

Epoxy compound having alkoxysilyl group, composition and hardened material comprising same, use for same, and production method for epoxy compound having alkoxysilyl group

ActiveUS20150051316A1Improve flame retardant performanceImprove heat resistanceTransistorSilicon organic compoundsEpoxyHeat resistance

The present invention relates to an alkoxysilylated epoxy compound, a composite exhibiting good heat resistance properties, low CTE and high glass transition temperature and not requiring a coupling agent, a composition including the same, a cured product formed of the composition, a use of the cured product, and a method of preparing the epoxy compound having alkoxysilyl group. An epoxy compound having an epoxy group and an alkoxysilyl group, a composition including the epoxy compound, a curing agent, a filler and / or a reaction catalyst, a cured product of the composition, and a use of the composition including an electronic part are provided. In a composite and / or cured product, the epoxy composition exhibits improved heat resistance properties, decreased CTE, and increased glass transition temperature or Tg-less. The cured product exhibits good flame retardant properties by the introduction of the alkoxysilyl group.

Owner:KOREA INST OF IND TECH

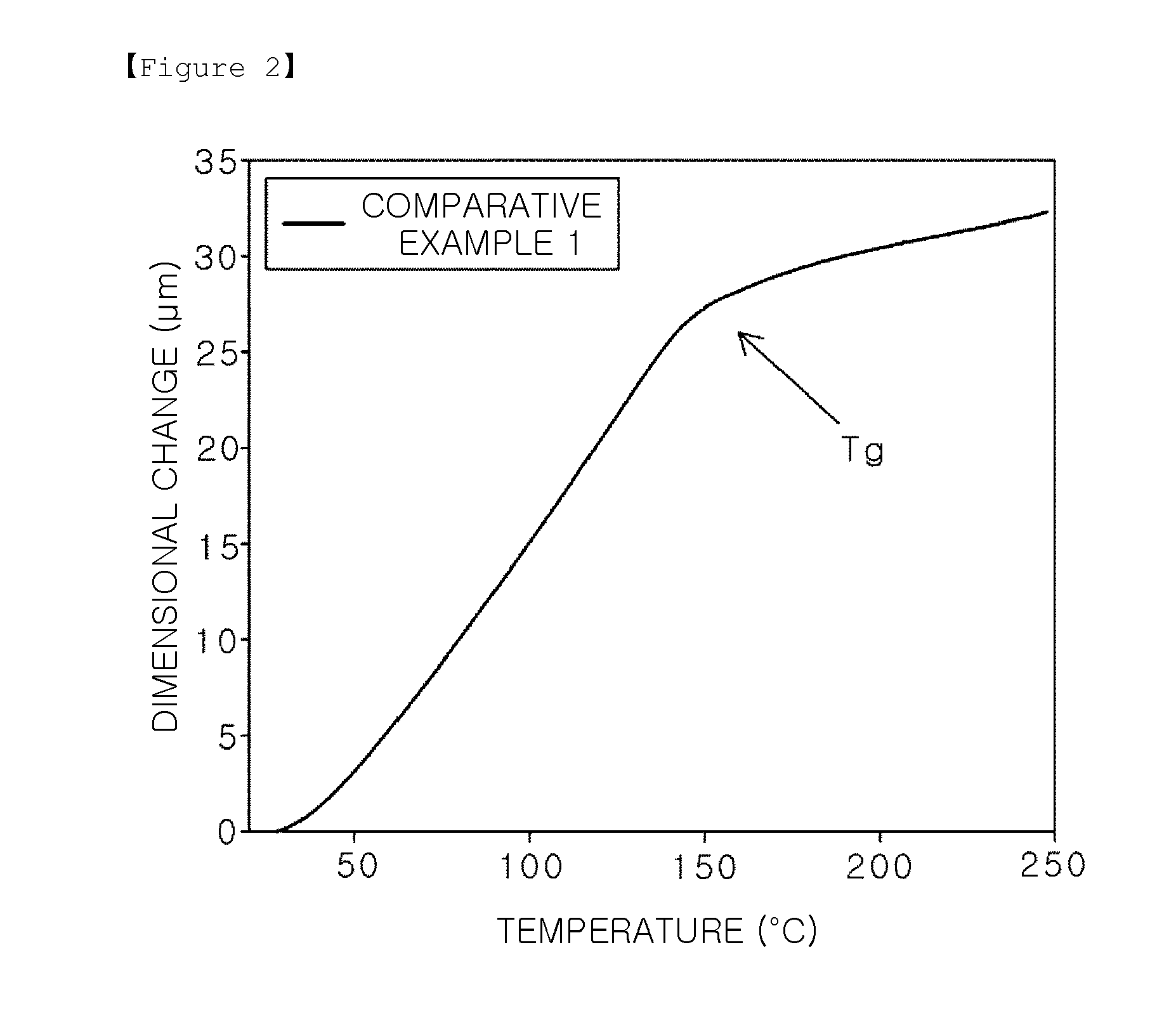

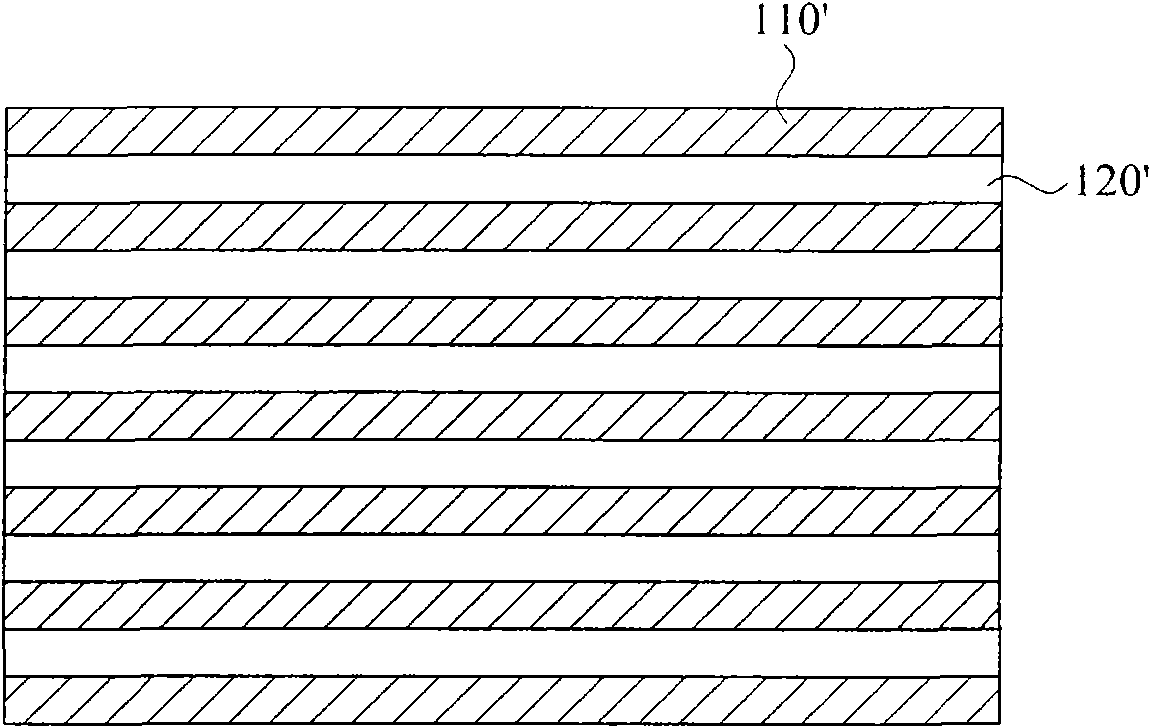

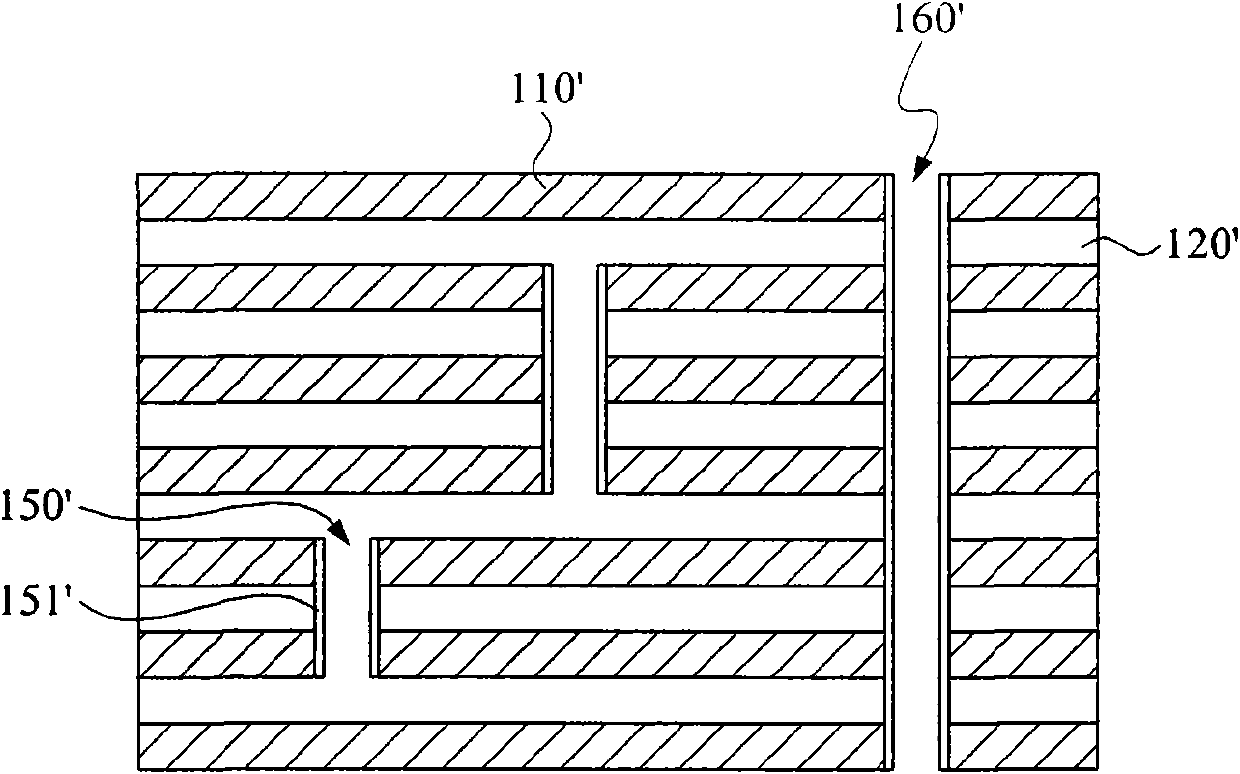

Multilayer laminated plate with spherical fillers, and circuit board thereof

InactiveCN102088817AImprove thermal conductivityImproved modulating thermal expansionCircuit susbtrate materialsPressboardHigh pressure

The present invention provides a multilayer laminated plate with spherical fillers and a circuit board thereof. The multilayer laminated plate is formed by alternate stacking and laminating of a plurality of conducting layers and insulating layers, one conducting layer and another adjacent conducting layer in the multilayer laminated plate are brought into conduction by a conductive pole in a buried hole structure in order to improve circuit designability, wherein the insulating layers of the multilayer laminated plate are provided with spherical fillers inside in order to increase heat conductivity of the insulating layers and modulate heat expansibility of the insulating layers. The insulating layers are formed by solidification of semi-solid films via a hot pressboard laminating program, during the hot pressboard laminating program with the proviso of high temperature and high pressure, the semi-solid films melt into resin solution and fill in the buried hole structure, then the resin solution further solidifies to form the insulating layers. The spherical fillers are uniformly distributed in the buried hole structure of the multilayer laminated plate, which can improve the overall heat conductivity and modulate the heat expansibility of the multilayer laminated plate. In addition, the multilayer laminated plate can effectively give off heat when used in circuit board downstream high temperature assembling technology, at the same time, heat resistance as well as process yield rate of the plate can be improved.

Owner:ELITE MATERIAL

Epoxy compound having alkoxysilyl group, method for preparing the same, composition including the same, cured product made from the composition, and use of the composition

ActiveUS9725590B2Improve flame retardant performanceImprove heat resistanceSilicon organic compoundsEpoxy resin adhesivesEpoxyPolymer science

Provided are an alkoxysilylated epoxy compound, a composite of which exhibits good heat resistance properties, particularly low CTE and increased glass transition temperature, and a cured product thereof exhibits good flame retardancy and composition of which does not require additional silane coupling agent, a method for preparing the same and a composition and a cured product including the same. An alkoxysilylated epoxy compound including at least one alkoxysilyl group and at least two epoxy groups, a method for preparing the same by epoxide ring-opening reaction of starting material and alkoxysilylation, an epoxy composition including the epoxy compound, and a cured product and a use of the composition are provided. Since chemical bonds may be formed between alkoxysilyl group and filler and between alkoxysilyl groups, chemical bonding efficiency of the composite may be improved. Thus, the composite exhibits good heat resistance properties and the cured product exhibits good flame retardancy.

Owner:KOREA INST OF IND TECH

Manufacturing method of cylinder of actuating cylinder

The invention discloses a manufacturing method of a cylinder of an actuating cylinder, which comprises a liner layer forming step to form the liner layer (1); and a combining step: a first fiber material preimpregnated with semisolid matrix resin is winded out of the liner layer (1) by a dry winding process so that a first fiber composite material layer (2) formed by the first fiber material and the matrix resin is combined out of the liner layer (1). The cylinder of the actuating cylinder manufactured by the manufacturing method comprises the liner layer and the first fiber composite material layer so that the cylinder is larger in strength, lighter in weight, fatigue resistant and good in anti-corrosion performance as well as smaller in thermal expansion. Furthermore, as the liner layer of the cylinder can meet the requirements of tightness of the inner wall of the cylinder and wear-resistance of the inner wall contacted with a piston, the usability of the cylinder is not affected. In addition, weight of the cylinder can be accurately controlled by using the first fiber composite material layer by the dry winding process, so that the production efficiency is higher.

Owner:ZOOMLION HEAVY IND CO LTD

Manufacturing process of car lamp reflector

InactiveCN105365148AQuality improvementHigh surface flatnessCoatingsForeign matterInjection molding machine

The invention discloses a manufacturing process of a car lamp reflector. The manufacturing process is characterized in that a bulk molding compound (BMC) is adopted as a material, and the reflector is manufactured in an injection molding machine through the BMC. The manufacturing process comprises the specific steps of 1, mold closing, wherein an upper mold block fast approaches a lower mold block, and after it is determined that no foreign matter exists, a system is converted into high pressure, and a mold plate is closed; 2, in-place forward movement of an injection table; 3, injection molding, wherein a screw is set at the three-section speed, pressure and stroke, and a melting material at the front end of a barrel is injected into a mold cavity; 4, heating and pressure maintaining, wherein the mold cavity is heated, meanwhile, the pressure of the barrel is kept, and finally the mold cavity is cooled and formed; 5, heating and glue melting; 6, retreating of the injection table, wherein the injection table retreats to the designated spot after glue melting is finished; and 7, ejection, wherein a product is ejected out by an ejector pin. The indexes of characteristics of the BMC and the forming condition in the injection molding machine are strictly controlled, so that the injection molding product is stable in stability, high in surface flatness and size precision and good in stability, and an excellent multi-curved-surface special-shaped reflector material is achieved.

Owner:刘平

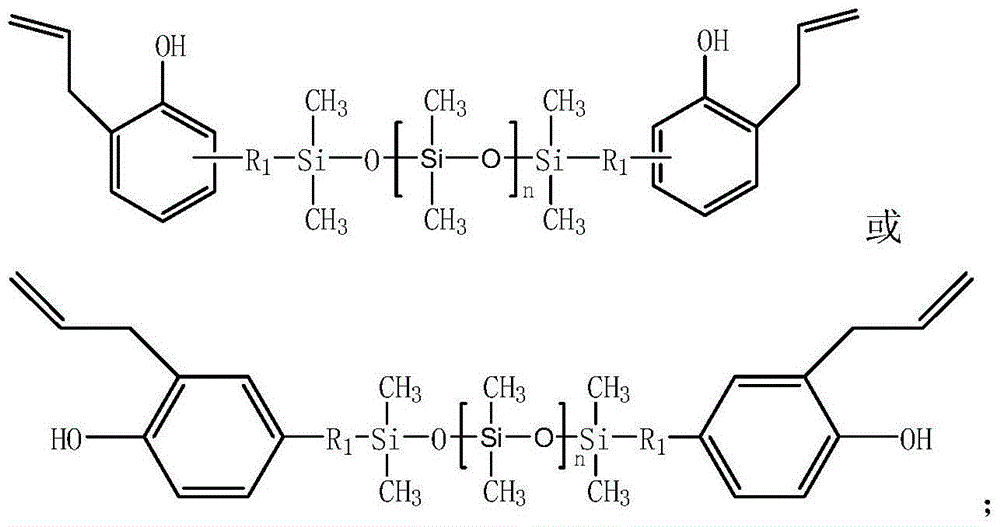

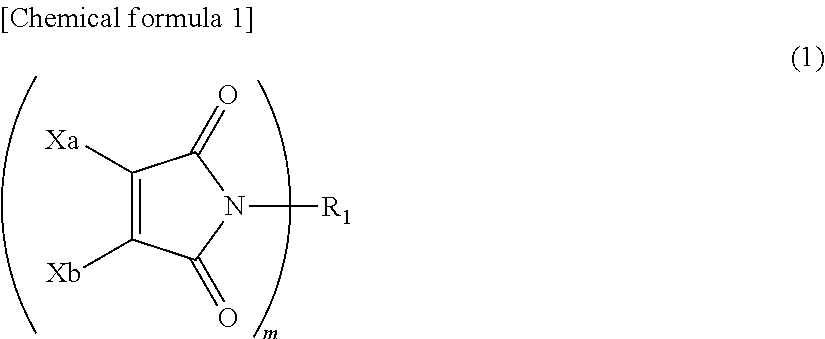

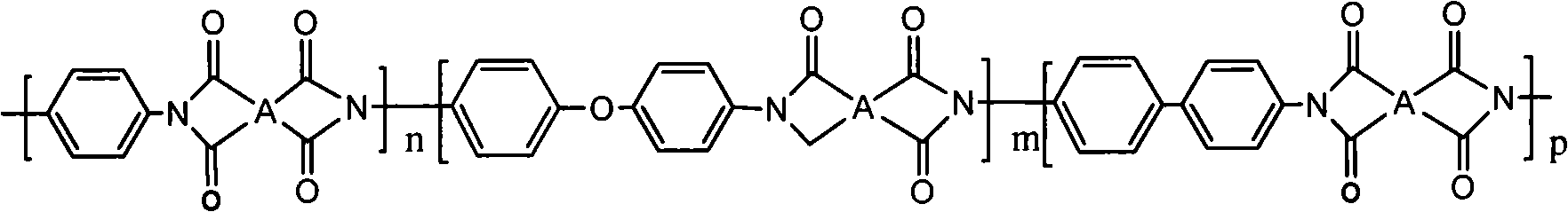

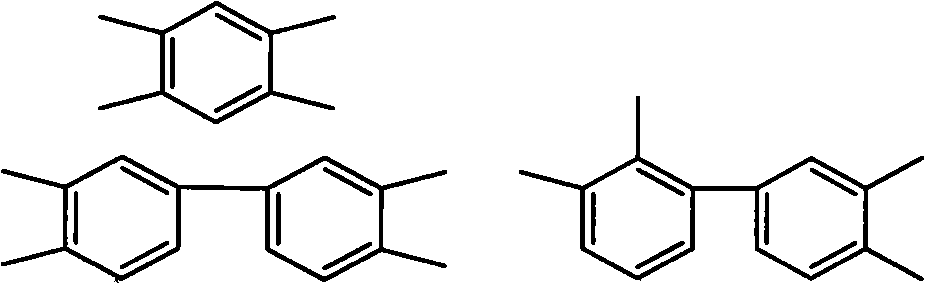

Polyimide material, preparation method thereof, metal laminate plate containing same and preparation method of metal laminate plate

InactiveCN101659746AGood hygroscopic expansionLow hygroscopic expansionSynthetic resin layered productsPretreated surfacesOrganic compoundStructural unit

The invention provides a polyimide material, a preparation method thereof, a metal laminate plate containing the same and a preparation method of the metal laminate plate. The polyimide material contains a polymer having the following repeated structural unit: in a figure (I), A is one or more of organic compounds of the following structure; m is an integer between 2 and 35; n is an integer between 2 and 35; p is an integer between 2 and 35; and n:m:p is 4-15:2-4:3-13. The metal laminate plate prepared by the method provided by the invention has the characteristics that: a binding force between a polyimide resin layer and a metallic layer is good, the size stability of the polyimide resin layer is high; and the wet swelling coefficient is small.

Owner:BYD CO LTD

Preparation method of enhanced UO2 nuclear fuel pellet

InactiveCN109903869ASimple methodDesign scienceNuclear energy generationReactors manufactureAtmosphereMaterials science

The invention discloses a preparation method of an enhanced UO2 nuclear fuel pellet to solve the problems of rapid degrease of the thermal conductivity at a high temperature and rapid weakening of thegaseous fission product retention capacity of UO2 fuel pellets in the prior art. The preparation method comprises the following steps: cold-pressing shaping of UO2-reinforcing phase compound particles having good sphericility to obtain a nuclear fuel pellet blank, and sintering of the nuclear fuel pellet then in an active atmosphere at a high temperature to obtain the enhanced UO2 nuclear fuel pellet. The UO2-reinforcing phase compound particles are prepared from UO2 powder, a reinforcing phase and a lubricant; and the use amount of the reinforcing phase is 0.05-5% of the weight of the UO2 powder. The method is simple, and is scientifically designed; and the thermal conductivity at a high temperature and the gaseous fission product retention capacity of the enhanced UO2 fuel pellet are greatly higher than those of the existing UO2 fuel pellets.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Braze compositions, and related devices

ActiveUS20130316222A1Less complicatedLess-expensive to processPrimary cell to battery groupingFinal product manufactureAlloyBraze alloy

A braze alloy composition for sealing a ceramic component to a metal component in an electrochemical cell is presented. The braze alloy composition includes copper, nickel, and an active metal element. The braze alloy includes nickel in an amount less than about 30 weight percent, and the active metal element in an amount less than about 10 weight percent. An electrochemical cell using the braze alloy for sealing a ceramic component to a metal component in the cell is also provided.

Owner:GENERAL ELECTRIC CO

Preparation method of calcium hexaluminate foamed ceramic with multilayer structure

The invention discloses a preparation method of a calcium hexaluminate foamed ceramic with a multilayer structure. The preparation method comprises the following steps: completely immersing a pretreated polyurethane sponge template in slurry I, extruding redundant slurry by rolling, then carrying out high-pressure blast or centrifugal slurry throwing, and drying at 100-120 DEG C for 16-24 hours; then putting the mixture into a muffle furnace at 700-900 DEG C, keeping the temperature for 2-4 hours, and naturally cooling; and completely immersing a calcium hexaluminate foamed ceramic preform in the slurry II, keeping for 3-7 minutes under a vacuum condition, carrying out high-pressure air blowing or centrifugal slurry throwing and natural drying to obtain a calcium hexaluminate foamed ceramic green body, drying for 16-24 hours at 100-120 DEG C, then putting the green body into a high-temperature furnace, carrying out heat preservation for 2-5 hours at 1500-1600 DEG C, and then cooling along with the furnace to obtain the calcium hexaluminate foamed ceramic with the multilayer structure. Through detection, the normal-temperature compressive strength of the prepared microporous multilayer structure calcium hexaluminate foamed ceramic is 3.0-8.0 MPa, the number of times of water cooling circulation is 12-20; and the anti-erosion and anti-scouring capability is excellent.

Owner:中冶武汉冶金建筑研究院有限公司

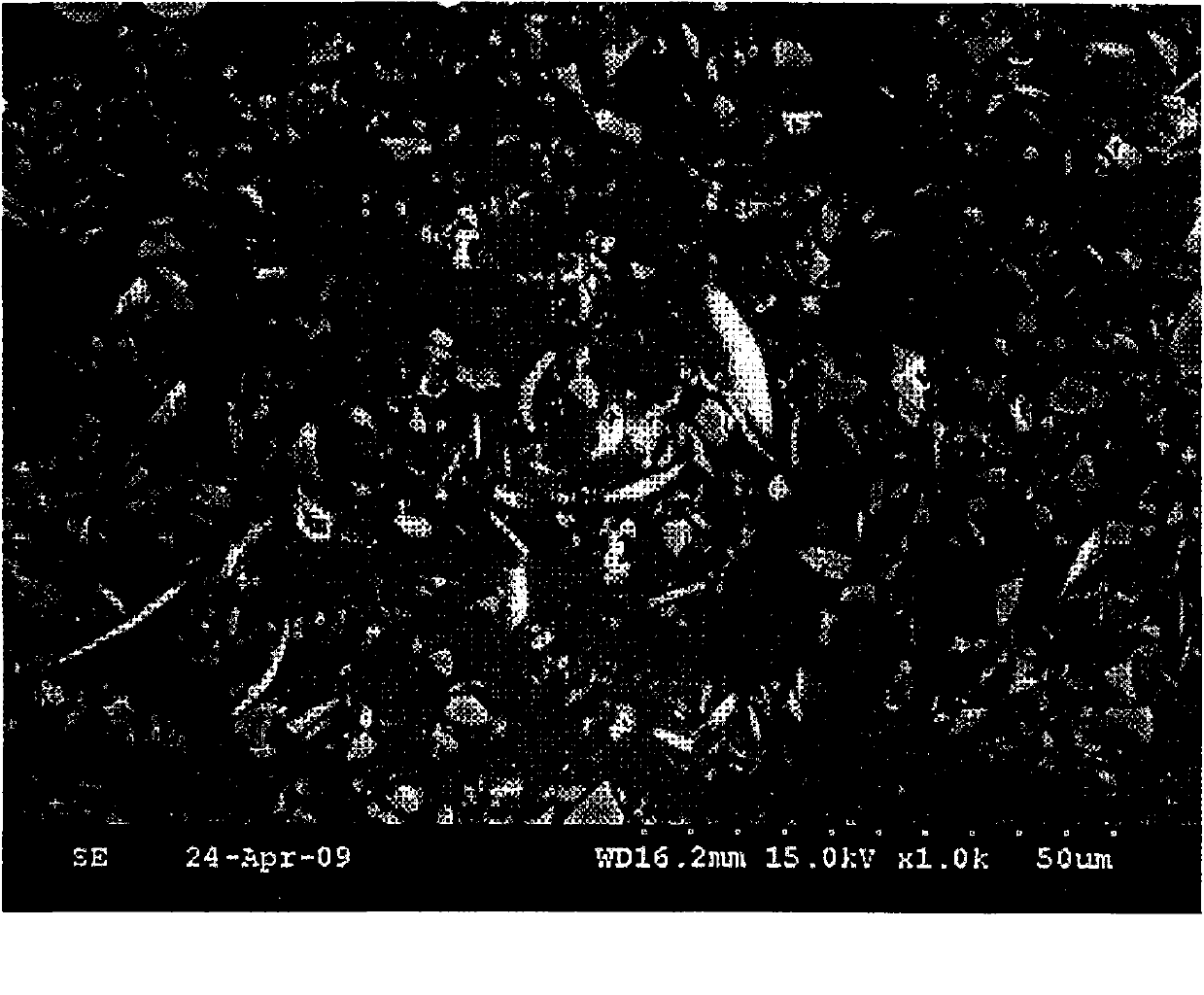

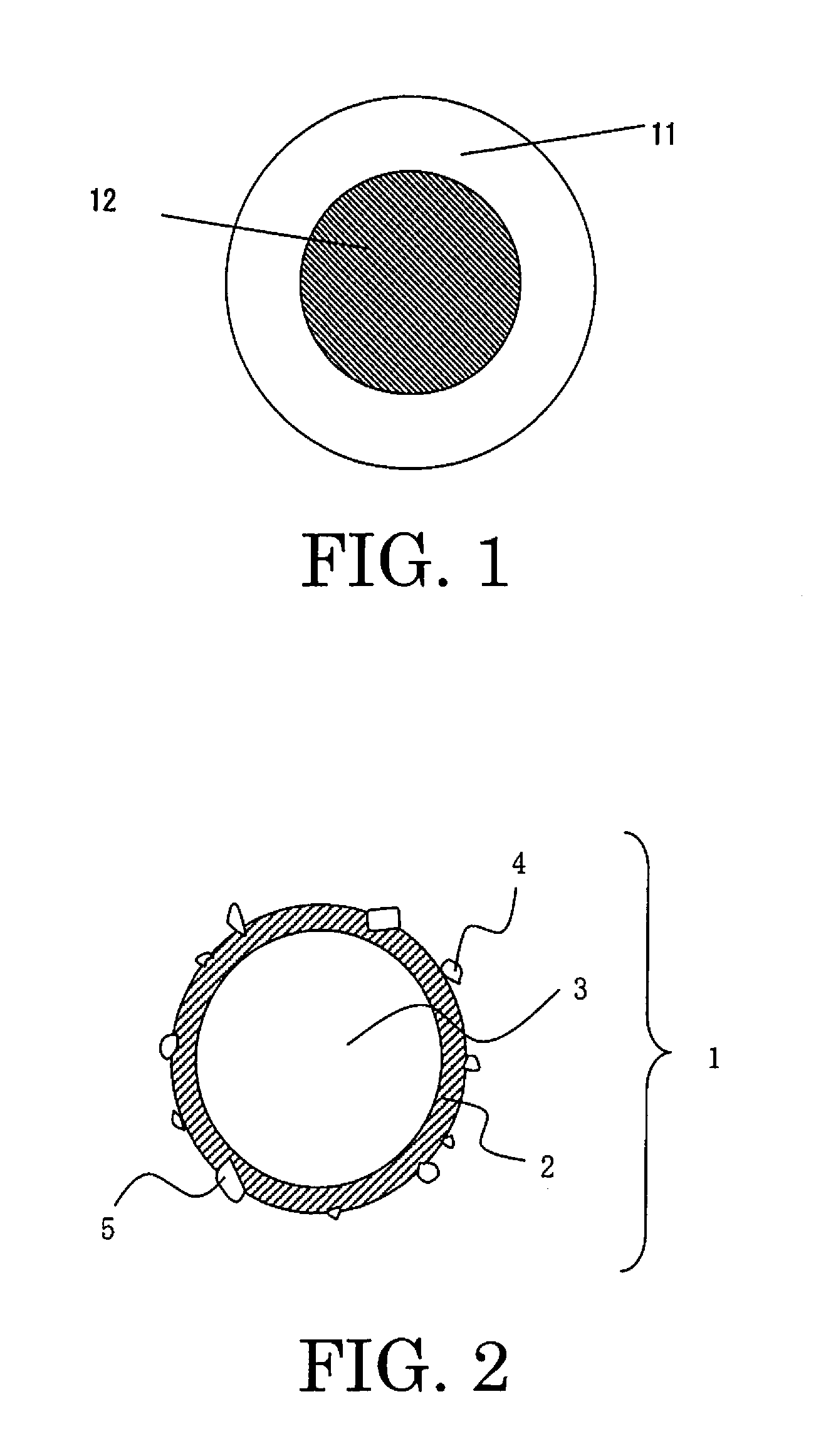

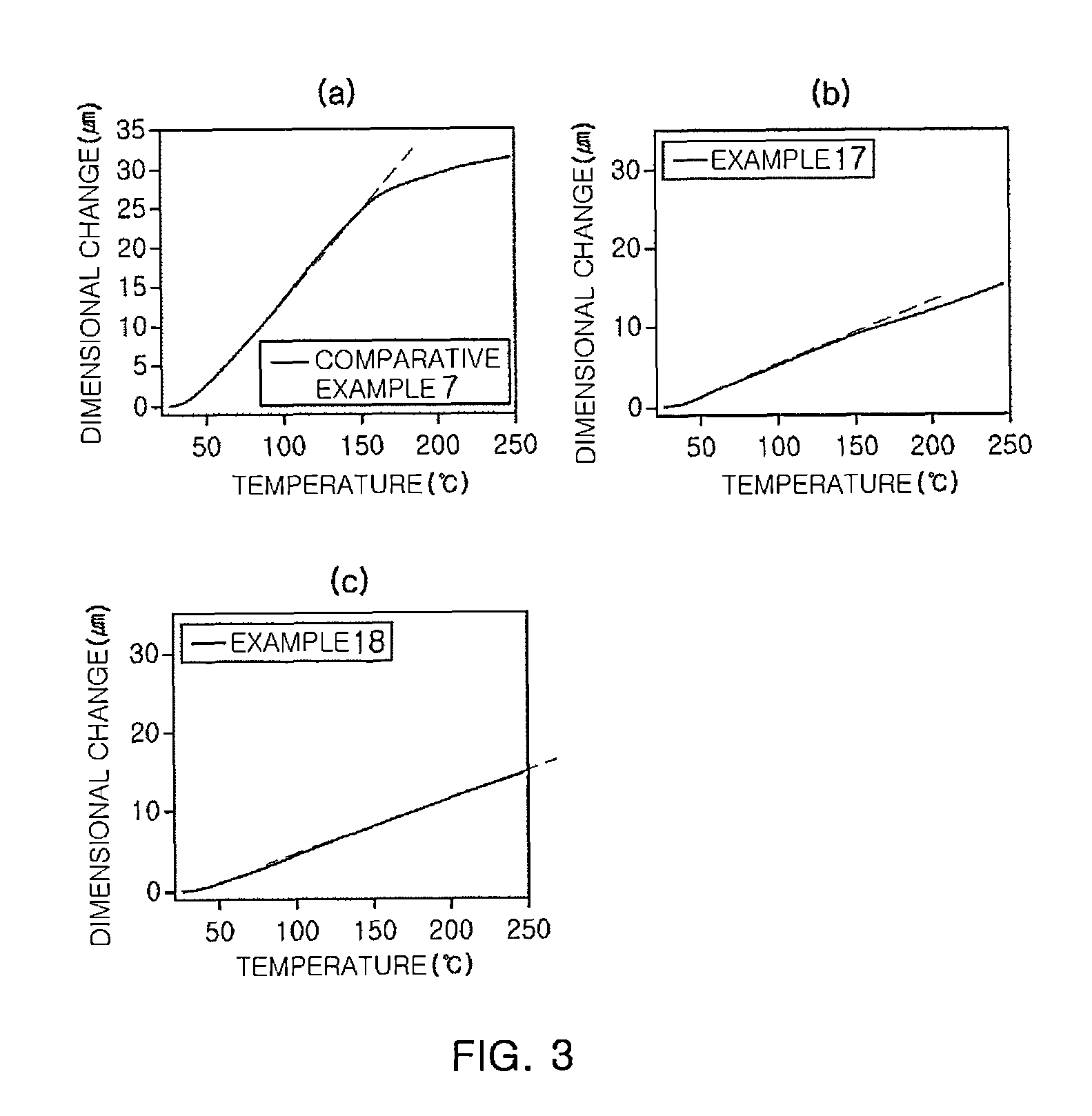

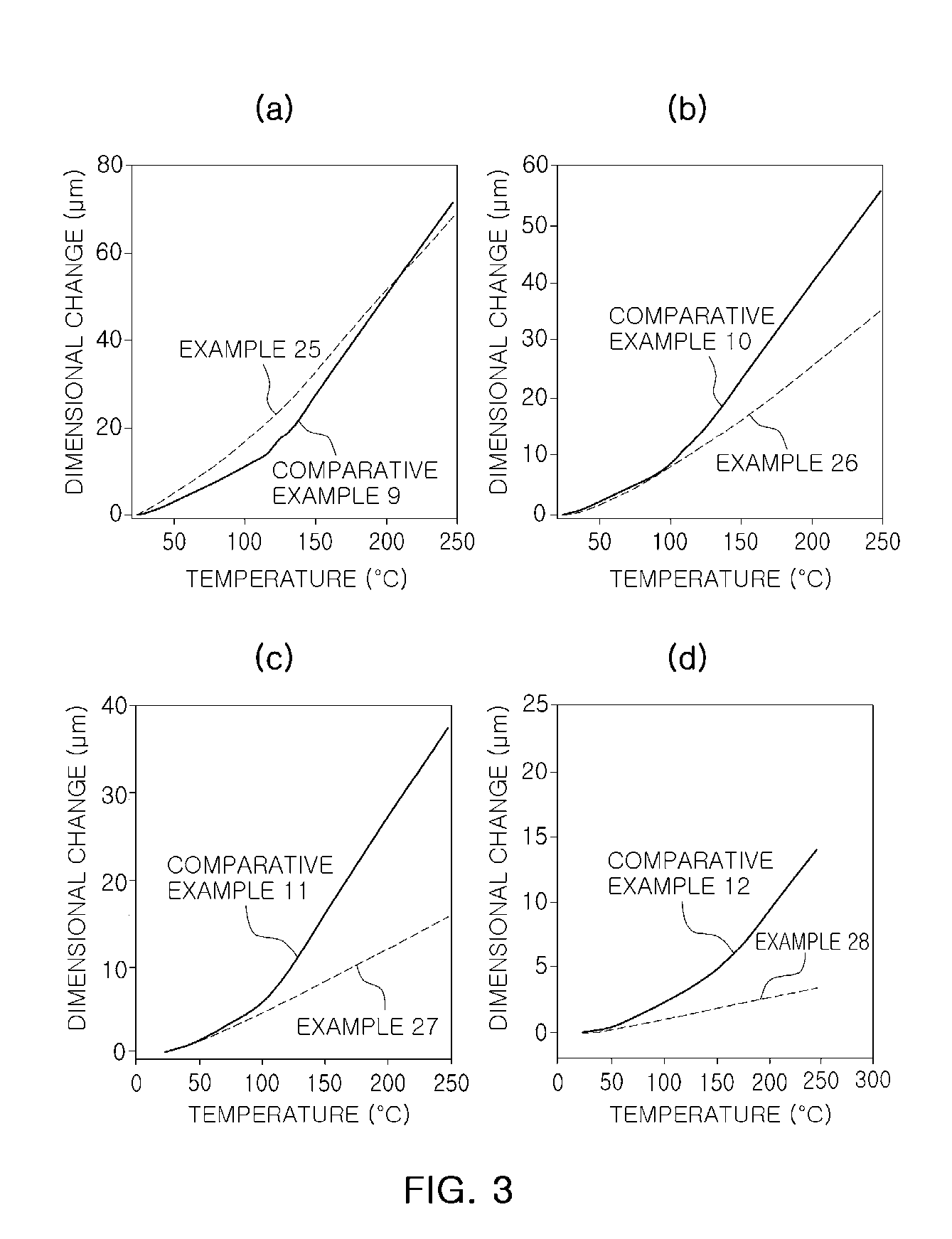

Heat-expandable microspheres, process for producing the same, and application thereof

ActiveUS20140364521A1High encapsulation efficiencyEasy to optimizeMacromolecular adhesive additivesAbsorbent padsMicrosphereBlowing agent

Heat-expandable microspheres with high encapsulation efficiency of a blowing agent and good heat-expansion performance, a process for reproducibly producing the heat-expandable microspheres and application thereof are provided. The heat-expandable microspheres comprise essentially a thermoplastic resin shell and a blowing agent encapsulated therein, and contain not more than 500 ppm of silicon, not more than 350 ppm of aluminum and not more than 600 ppm of the total of the silicon and aluminum. The heat-expandable microspheres retain at least 70% of the blowing agent encapsulated therein at the temperature which is the average of their expansion-initiation temperature and maximum expansion temperature.

Owner:MATSUMOTO YUSHI SEIYAKU

Epoxy compound having alkoxysilyl group, method of preparing the same, composition and cured product comprising the same, and uses thereof

ActiveUS9150686B2Improve flame retardant performanceImprove bindingGroup 4/14 element organic compoundsSynthetic resin layered productsEpoxyHeat resistance

Owner:KOREA INST OF IND TECH

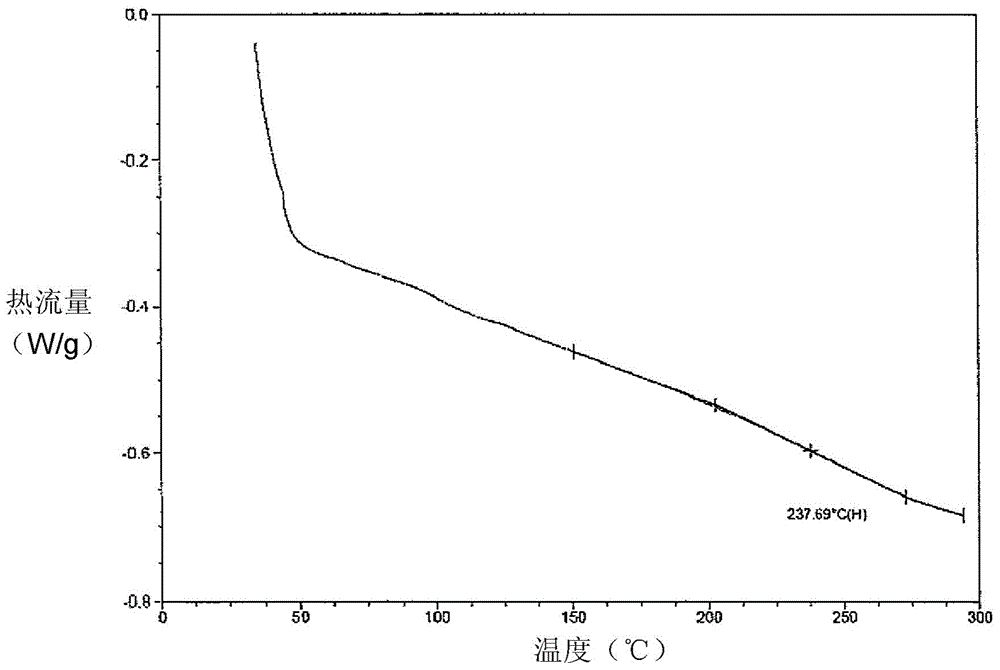

Temperature-sensing wax mixture for temperature-sensing component

The invention discloses a temperature-sensing wax mixture for a temperature-sensing component, comprising paraffin wax and heat-conducting carbon fibres having a heat conductivity coefficient of greater than 450 w / m.k. A preparation method for the temperature-sensing wax mixture comprises the following steps of: proportioning the paraffin wax and the heat-conducting carbon fibres in a certain proportioning ratio by weight, uniformly mixing, and then grinding for 50-120 hours by adopting a high-energy ball mill under the protection of an inert gas, thus coating a layer of paraffin wax protecting film around the heat-conducting carbon fibres, and then obtaining the temperature-sensing wax mixture. According to the temperature-sensing wax mixture, the heat-conducting carbon fibres are used for replacing copper powder, so that the cost is low, and the thermal expansion is good, and the selected heat-conducting carbon fibres have a heat conductivity coefficient of greater than 450 w / m.k, so that a response speed for temperature sense is greatly increased, and adaptability to application occasions with a high sensitivity requirement on the temperature-sensing component can be met; simultaneously, the heat-conducting carbon fibres and the paraffin wax are mixed and then ground by adopting the high-energy ball mill, thus coating a layer of paraffin wax protecting film around the heat-conducting carbon fibres, so that the heat sensitivity of the whole temperature-sensing wax mixture can be improved, and the process is simple and beneficial to industrialized production.

Owner:CIXI DONGNAN REINFORCED MATERIAL

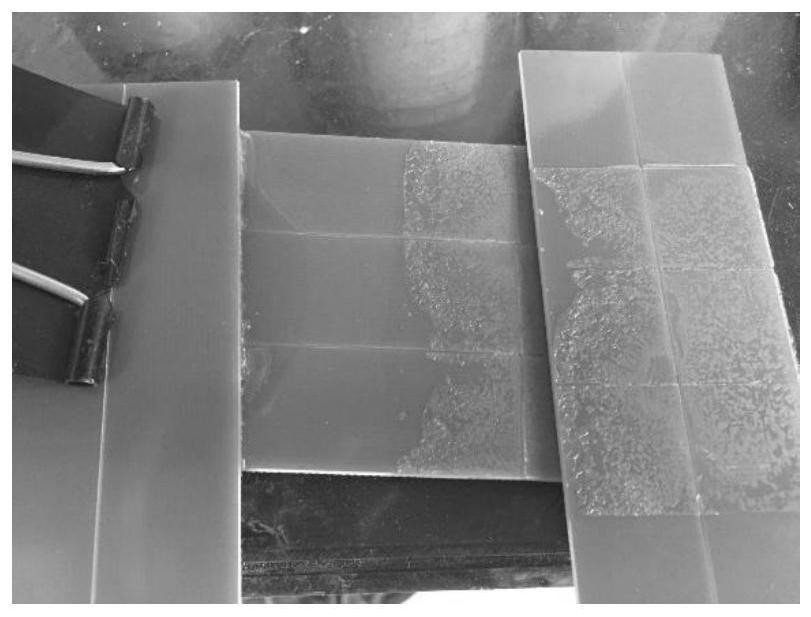

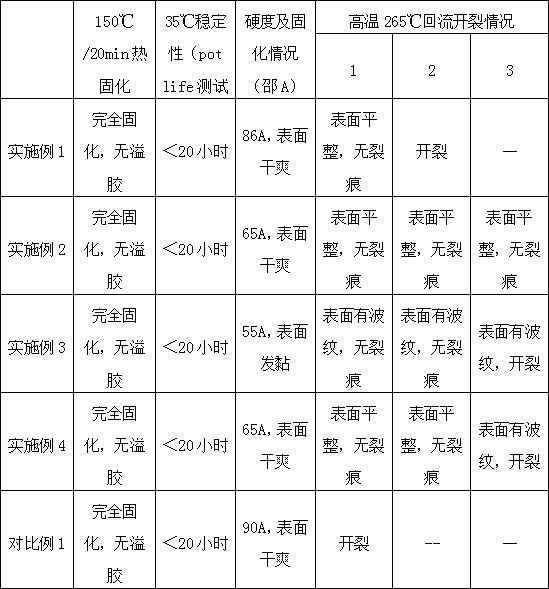

A kind of high temperature resistant flexible one-component epoxy sealing adhesive and preparation method thereof

ActiveCN111117542BGood flexibilityGel fastNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to the field of adhesives, in particular to a high-temperature-resistant flexible single-component epoxy sealing adhesive and a preparation method thereof. The high-temperature-resistant flexible single-component epoxy sealing adhesive is prepared from the following raw materials in parts by weight: 10-40 parts of epoxy resin, 10-30 parts of a mixed softening resin, 5-20 parts of an active diluent, 5-20 parts of a mixed curing agent, 0.01-1 part of a polymerization inhibitor, 0.1-5 parts of fumed silica, 0.01-1 part of an infiltration flow promoter and 5-30 parts of spherical silica powder, the mixed curing agent is a mixture of a modified amine latent heat curing agent and a modified imidazole latent heat curing agent, and the mixed softening resin is prepared from at least two of F100, F300, Capa3050, H2004, HEF750, HEF751, EP-4000L and EP-4000S. The adhesive disclosed by the invention can be widely applied to sealing processes of USB ports and high-temperature-resistant reflow soldering processes, has good bonding performance on PA46, stainless steel, PC and the like, and ensures excellent waterproof sealing performance and plugging resistance of the USB ports of electronic products.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

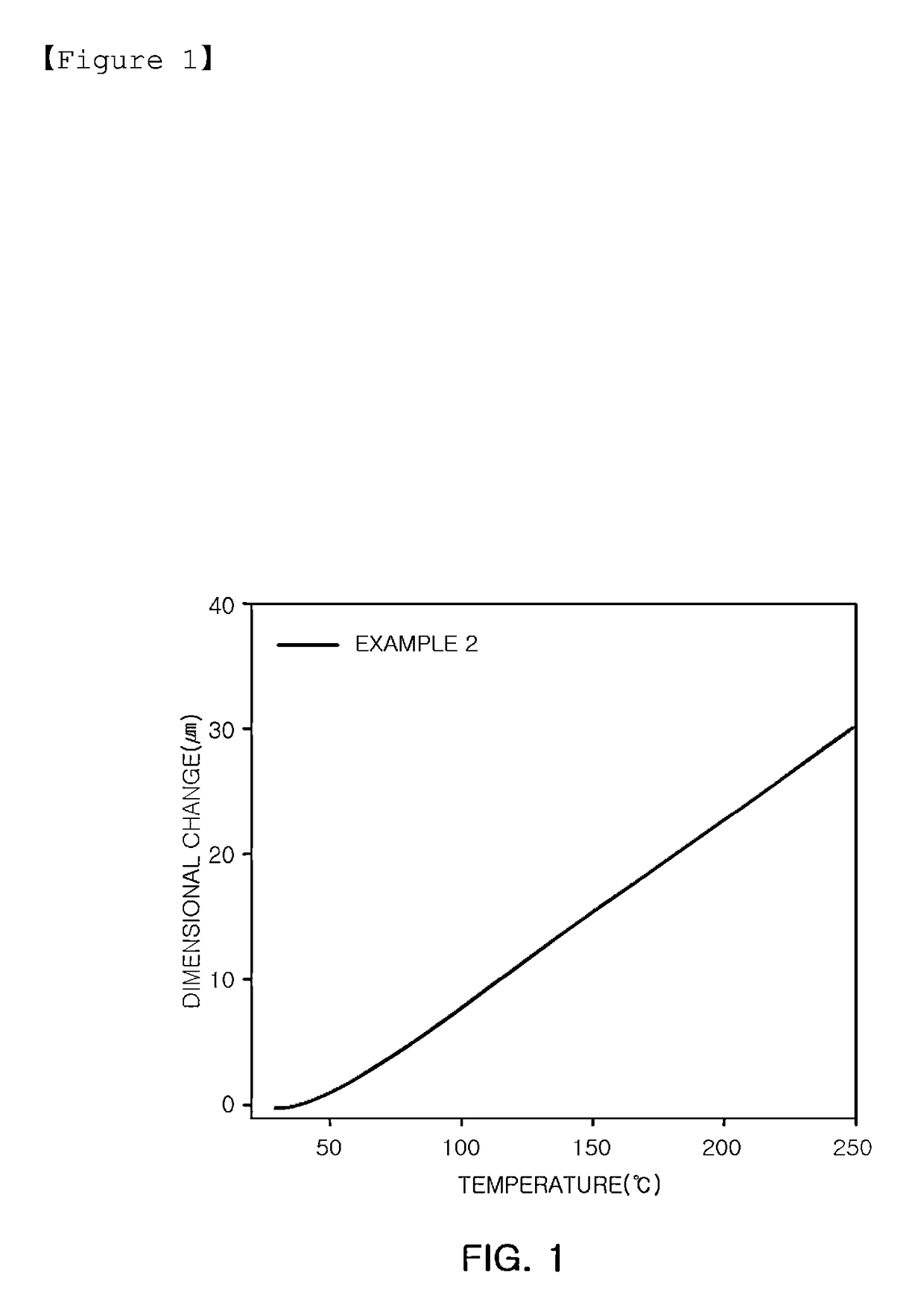

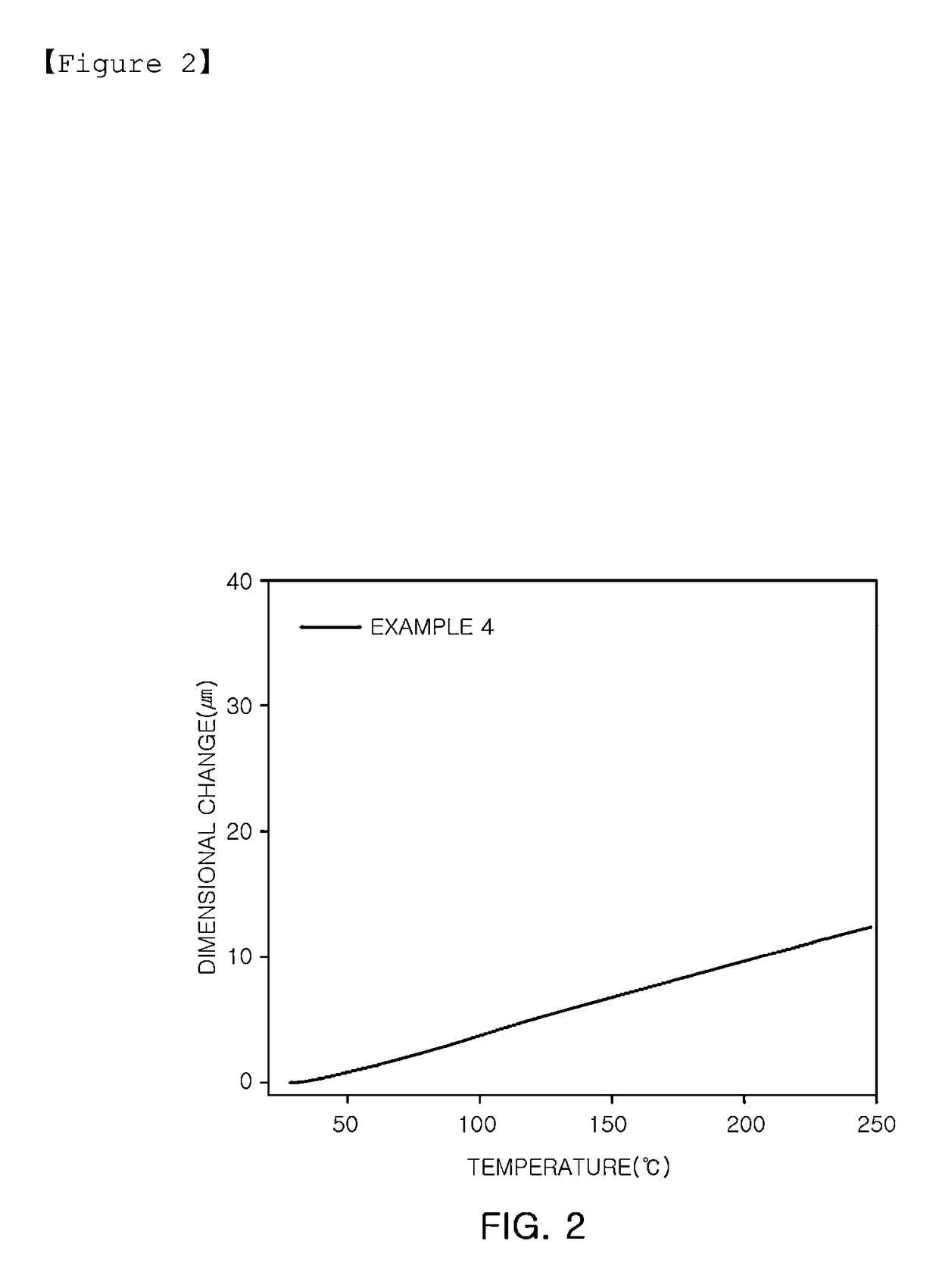

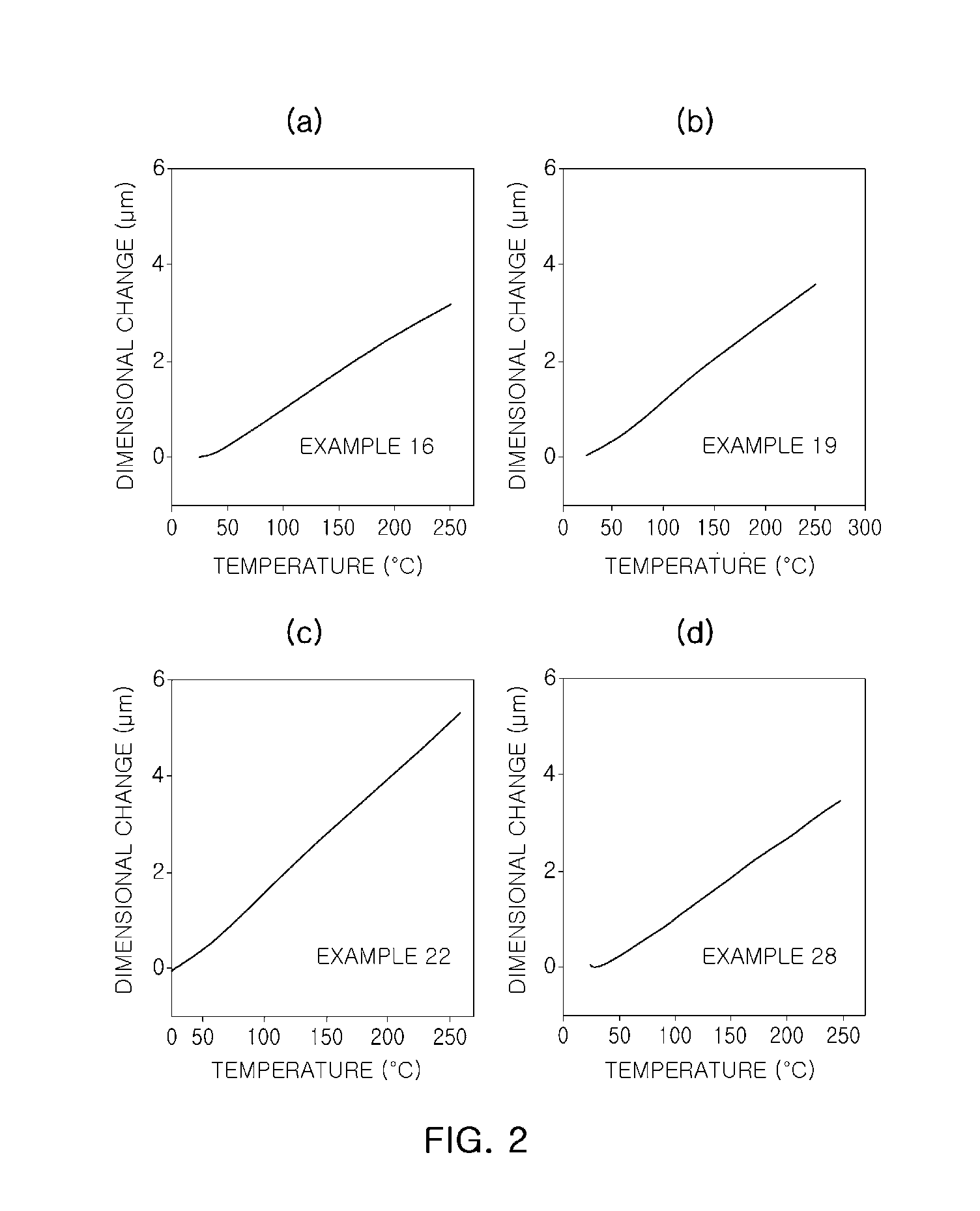

Preparation method of thin film used for flexible high-frequency copper clad laminate

ActiveCN110218316AGood thermal expansion performanceSmall water absorptionLaminationLamination apparatusComposite filmMicrosphere

The invention relates to a preparation method of a thermoplastic polyimide / modified silicon dioxide composite film which can be used for a flexible high-frequency copper clad laminate. The specific steps comprise preparing a nano-silica microsphere emulsion, preparing thermoplastic polyimide, using a silane coupling agent as a surfactant to combine polyimide and silicon dioxide, wherein the surface of nano-SiO2 is coated with the thermoplastic polyimide molecular layer, and the water absorbency of the composite is improved by adding SiO2, SiO2 is uniformly dispersed in the composite film, SiO2is used as a particle to restrict the expansion of the composite film in the thermal expansion process of the composite film, and the thermal expansion performance of the polyimide is effectively improved. After the preparation of silicon dioxide, silicon dioxide directly participates in the composite reaction with a polyimide precursor without drying, thereby avoiding the agglomeration of microspheres in the drying process during industrial production of nano-silicon dioxide, and enhancing the bending resistance of the prepared copper clad laminate.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Polytetrafluoroethylene high-frequency copper-clad plate with high thermal conductivity

ActiveCN111993720AImprove insulation performanceHigh thermal conductivitySynthetic resin layered productsLaminationThermal dilatationPolymer science

The invention discloses a polytetrafluoroethylene high-frequency copper-clad plate with high thermal conductivity, and relates to the technical field of high-frequency copper-clad plates. The invention discloses the polytetrafluoroethylene high-frequency copper-clad plate with high thermal conductivity, which comprises two copper layers, and characterized by comprising a high-thermal-conductivitypolytetrafluoroethylene substrate positioned between the two copper layers; the high-thermal-conductivity polytetrafluoroethylene substrate is prepared from the following raw materials in parts by weight: 70-80 parts of a PTFE / BN composite material, 0.8-1.5 parts of a titanate coupling agent, 5-10 parts of titanium powder, 5-8 parts of silicon oxide, 5-8 parts of yttrium oxide, 3-5 parts of aluminum oxide and a proper amount of ethanol. The invention further discloses the preparation method of the PTFE / BN composite material and a preparation method of the high-thermal-conductivity polytetrafluoroethylene substrate. The PTFE high-frequency copper-clad plate provided by the invention has the advantages of excellent heat-conducting property, higher dielectric constant, lower dielectric loss,high peel strength, high mechanical strength, low water absorption and low thermal expansion coefficient.

Owner:无锡睿龙新材料科技有限公司

Composition and cured article comprising inorganic particles and epoxy compound having alkoxysilyl group, use for same, and production method for epoxy compound having alkoxysilyl group

InactiveUS20150148452A1Improve heat resistance propertyDecrease CTESilicon organic compoundsOrganic compound preparationChemistryEpoxide Compound

There is provided a composition including an alkoxysilylated epoxy compound, a composition of which exhibits good heat resistance properties, low CTE and high glass transition temperature or Tg-less and not requiring a separate coupling agent, and inorganic particles, a cured product formed of the composition, and a use of the cured product. An epoxy composition including an alkoxysilylated epoxy compound and inorganic particles, an epoxy composition including an epoxy compound, inorganic particles and a curing agent, a cured product of the composition, and a use of the composition are provided. Since chemical bonds may be formed between the alkoxysilyl group and the inorganic particles and between the alkoxysilyl groups, a composition of the composition including the alkoxysilylated epoxy compound and the inorganic particles exhibits improved heat resistance properties, decreased CTE, and increased glass transition temperature or Tg less.

Owner:KOREA INST OF IND TECH

Modified benzoxazine resin and composition application thereof

InactiveCN106188538ALow dielectric lossImprove heat resistanceOrganic chemistryPrinted circuitsCombinatorial chemistry

Owner:ELITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com