Preparation method of thin film used for flexible high-frequency copper clad laminate

A copper-clad laminate and high-frequency technology, which is applied in the field of preparation of thermoplastic polyimide/modified silica composite film, can solve the problem of failure to effectively reduce the thermal expansion coefficient of polyimide film, polyimide is easy to absorb water, etc. problems, to achieve the effect of reducing the probability of crack sources, avoiding environmental pollution, and avoiding microsphere agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a thin film that can be used for flexible high-frequency copper-clad laminates, characterized in that it comprises the following steps:

[0037] S1. preparing nano-silica microsphere emulsion;

[0038] S2. Preparation of thermoplastic polyimide / modified silica composite film:

[0039] S21. Mix and stir the diamine reagent, dodecyltrimethylammonium chloride and deionized water to obtain a uniform mixed solution;

[0040] S22. adding the silicon dioxide microsphere emulsion into the mixed solution, stirring evenly to obtain a uniform mixed emulsion;

[0041] S23. Add the dianhydride reagent and the silane coupling agent into the mixed emulsion, stir for 4-8 hours in a water bath at 4-15°C under the protection of an inert gas, and then stop stirring to obtain a polyamic acid copolymer and modified Composite emulsion of silicon dioxide; preferably, the inert gas is argon, and the gas intake rate of the argon is 0.1-1L / min; the solid content of the p...

Embodiment 1

[0061] S1. Preparation of nano-silica microspheres:

[0062] S11. Take 9g of tetraethyl orthosilicate and 100mL of ethanol (concentration is greater than 99.7wt%, the same below) in a beaker, and stir at a constant speed of 200RPM for 5min until the two are evenly mixed to obtain a mixed ethyl orthosilicate ethanol solution;

[0063] S12. Take 5mL of deionized water, 15mL of ammonia water (concentration: 25wt.%), and 80mL of ethanol in a beaker, and stir at a constant speed of 200RPM for 5min until the two are evenly mixed to obtain a mixed ammonia-ethanol solution;

[0064] S13. Under the condition of stirring at a constant speed of 500RPM, quickly add the prepared ammonia solution into the prepared tetraethyl orthosilicate solution, react for 10 hours under the condition of stirring at a constant speed of 500RPM, stop stirring, and place the mixed turbid solution in a centrifuge In the machine, centrifuge at 6000RPM to obtain silica microspheres with a particle size of 200-3...

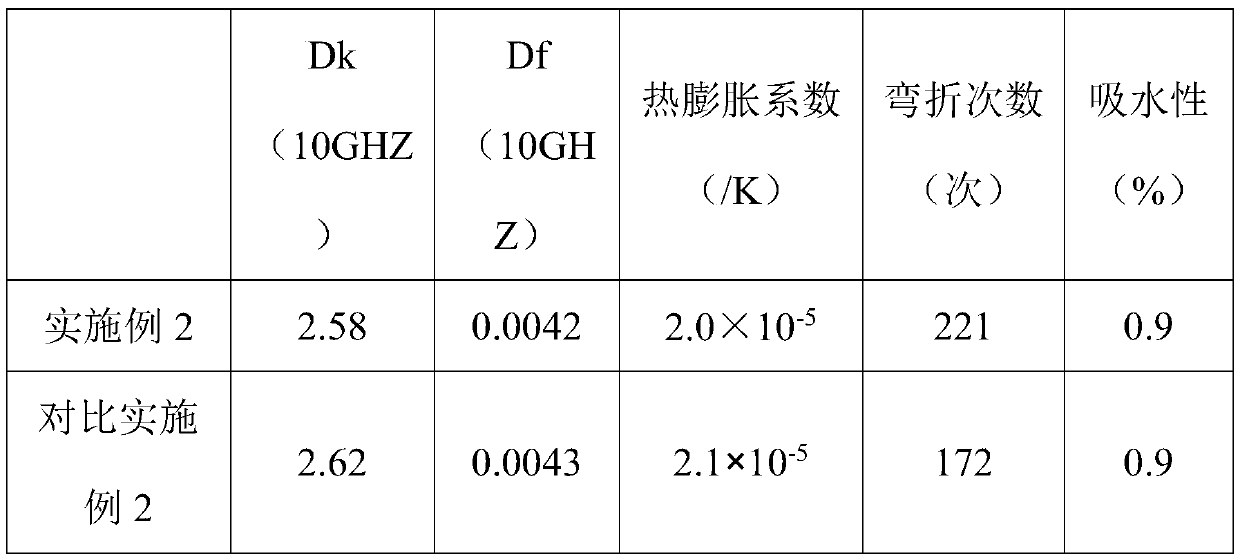

Embodiment 2

[0082] Others are the same as in Example 1, except that the volume of the silica emulsion added in the second step (2) is 2 mL, and the silane coupling agent added in the second step (3) is 0.03 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com