Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1192 results about "Epoxide Compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

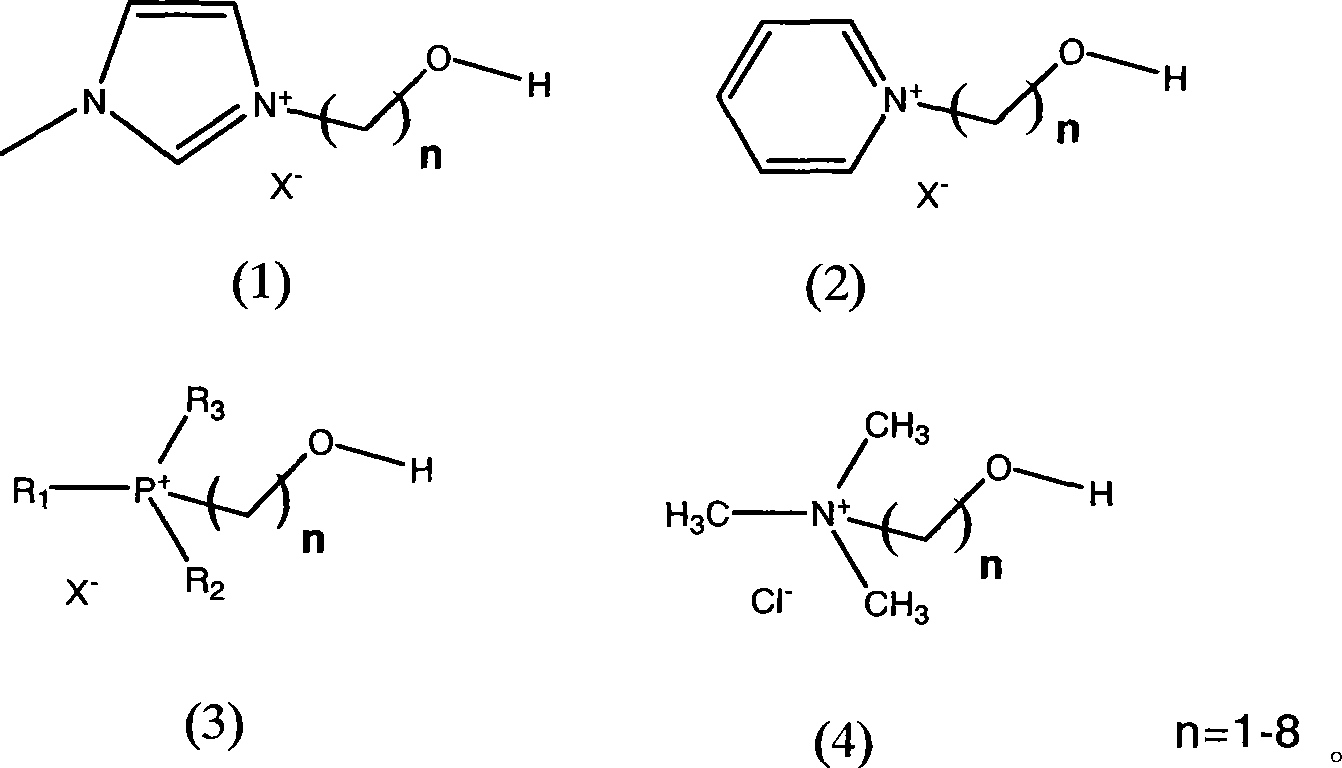

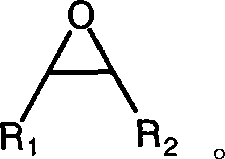

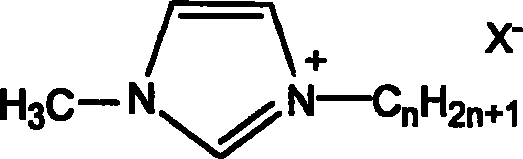

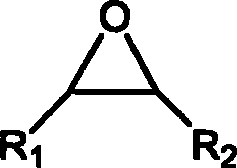

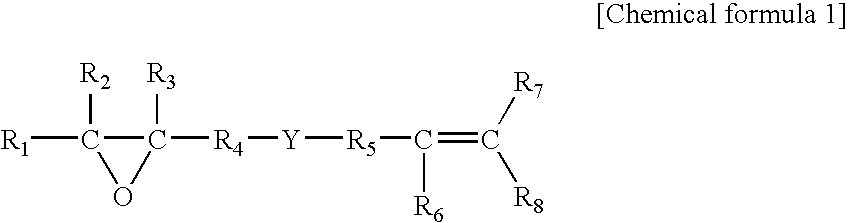

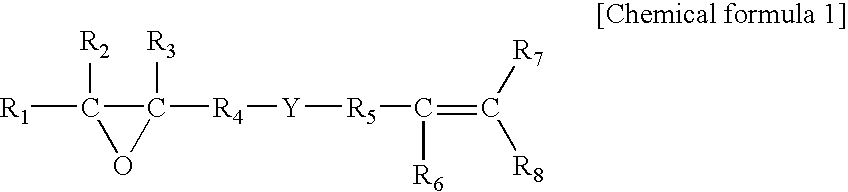

A cyclic ether compound with a three-atom ring containing oxygen linked to two carbons. These rings are highly stressed and more reactive than a typical acyclic ether.

Cationically polymerizable pigmented composition

InactiveUS6166100AGood dispersibilityMaintain good propertiesOrganic chemistryFilm/foil adhesivesEpoxyPolymer science

A cationically polymerizable pigmented composition comprising (A) a cationically polymerizable binder component containing at least one resin or compound selected from the group consisting of (A-1) a cationically polymerizable acrylic resin consisting of a copolymer of (a) a (meth) acrylic ester monomer having C6-31 aliphatic hydrocarbon group, (b) a polymerizable unsaturated monomer containing a polymerizable unsaturated group and at least one cationically polymerizable moiety selected from the group consisting of an epoxy group and an oxetane ring, and optionally (c) other polymerizable unsaturated monomer, and (A-2) a fatty acid-modified epoxy compound containing C6-32 aliphatic hydrocarbon group and epoxy group, (B) a cationic polymerization initiator initiating polymerization by irradiation or heating, and (C) a color pigment.

Owner:KANSAI PAINT CO LTD

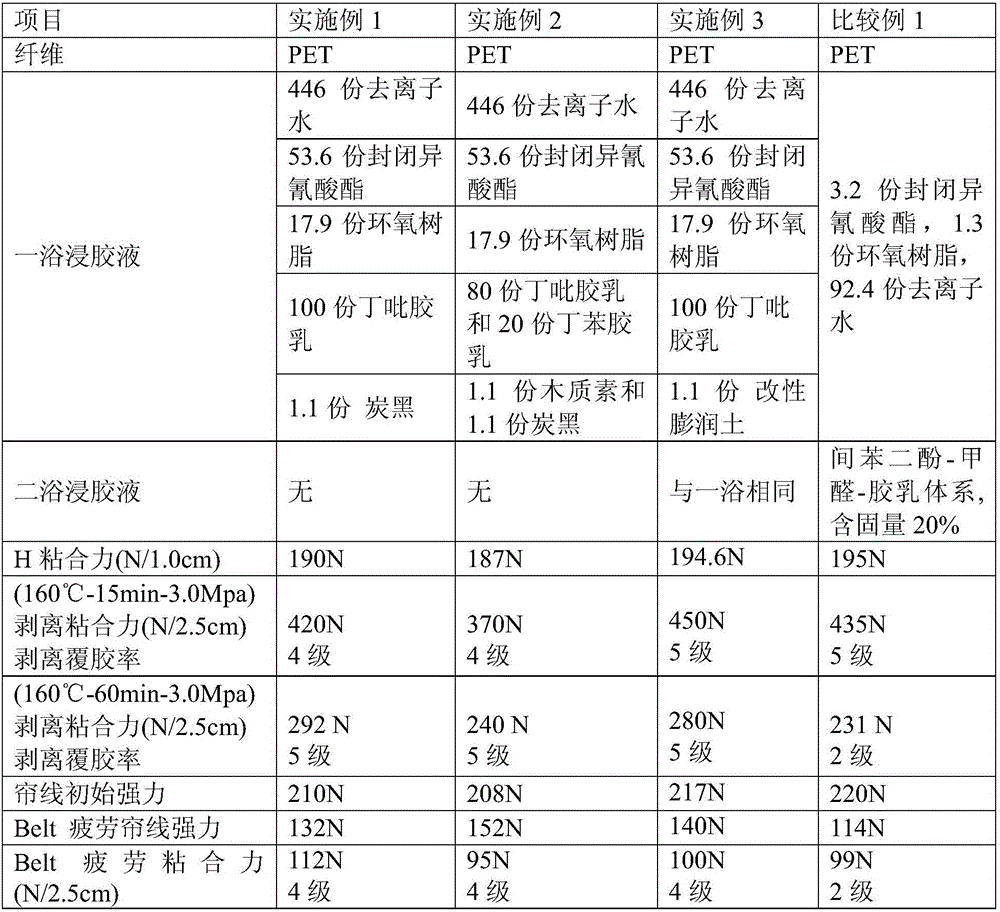

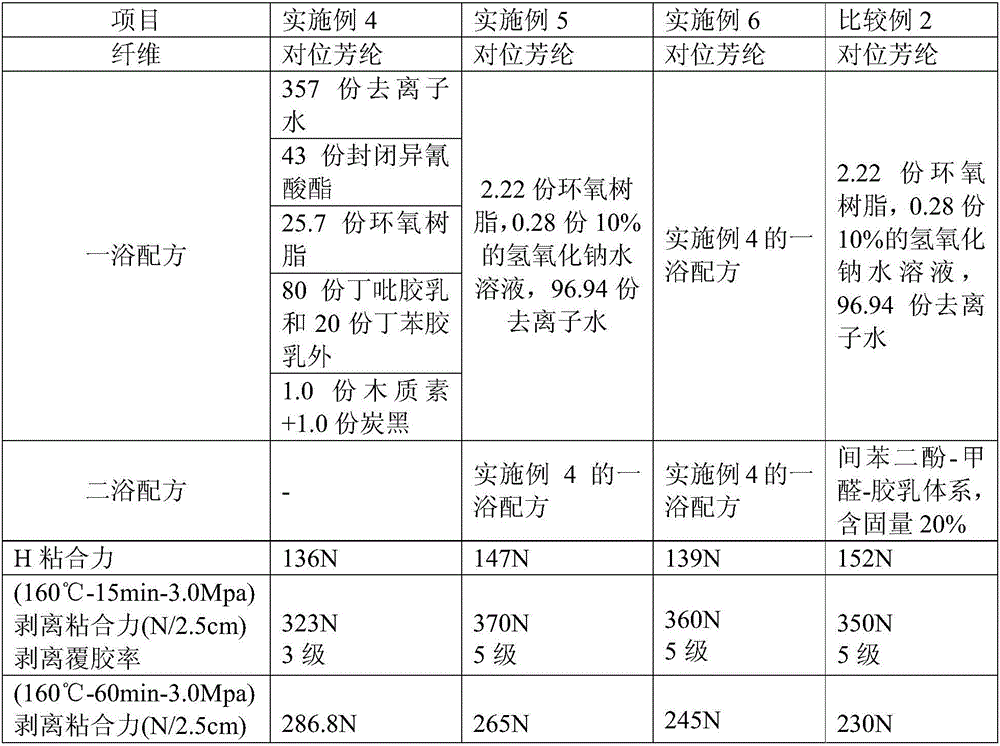

Environment-friendly fiber framework material dip solution and dipping process

The invention relates to an environment-friendly fiber framework material dip solution and a dipping process. The dip solution comprises, by weight parts, 3.3-190 parts of blocked isocyanate compound by dry weight, 6.6-140 parts of epoxy compound by dry weight, 80-100 parts of rubber latex by dry weight, 0.5-20 parts of rubber modifier by dry weight, and the balance water. The content of the dip solution is 5-25%, and a one-bath or double-bath dipping process is adopted to perform coating on a fiber framework material. The dip solution does not contain harmful substances such as resorcinol and formaldehyde and does not cause pollution to the environment, the dipping process is simple in steps and easy to operate, an organic fiber after dipping treatment is low in rigidity and facilitates postprocessing, and the dip solution has a good effect of being bonded to rubber and has a better dipping effect than conventional RFL.

Owner:JIANGSU TAIJI IND NEW MATERIALS CO LTD

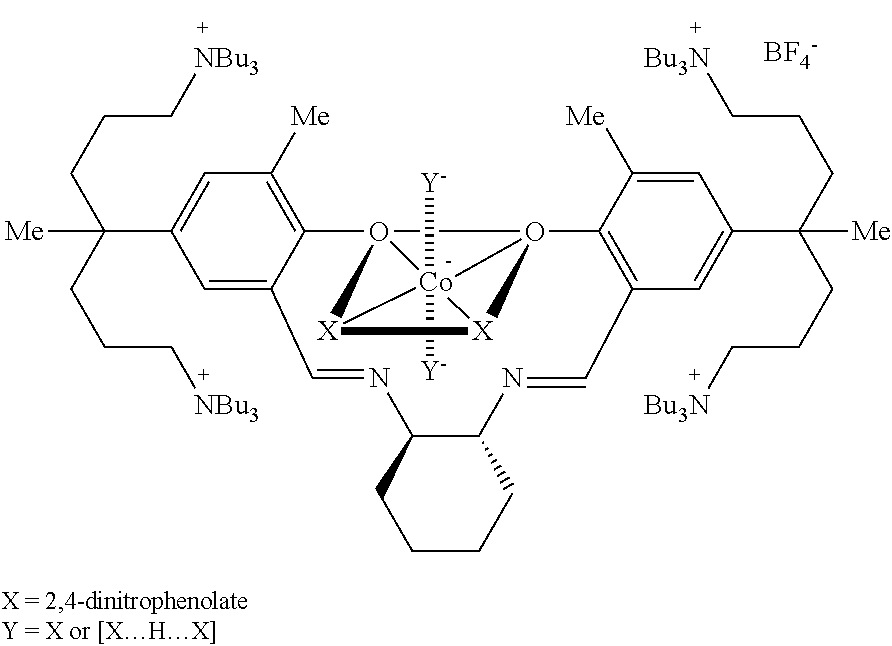

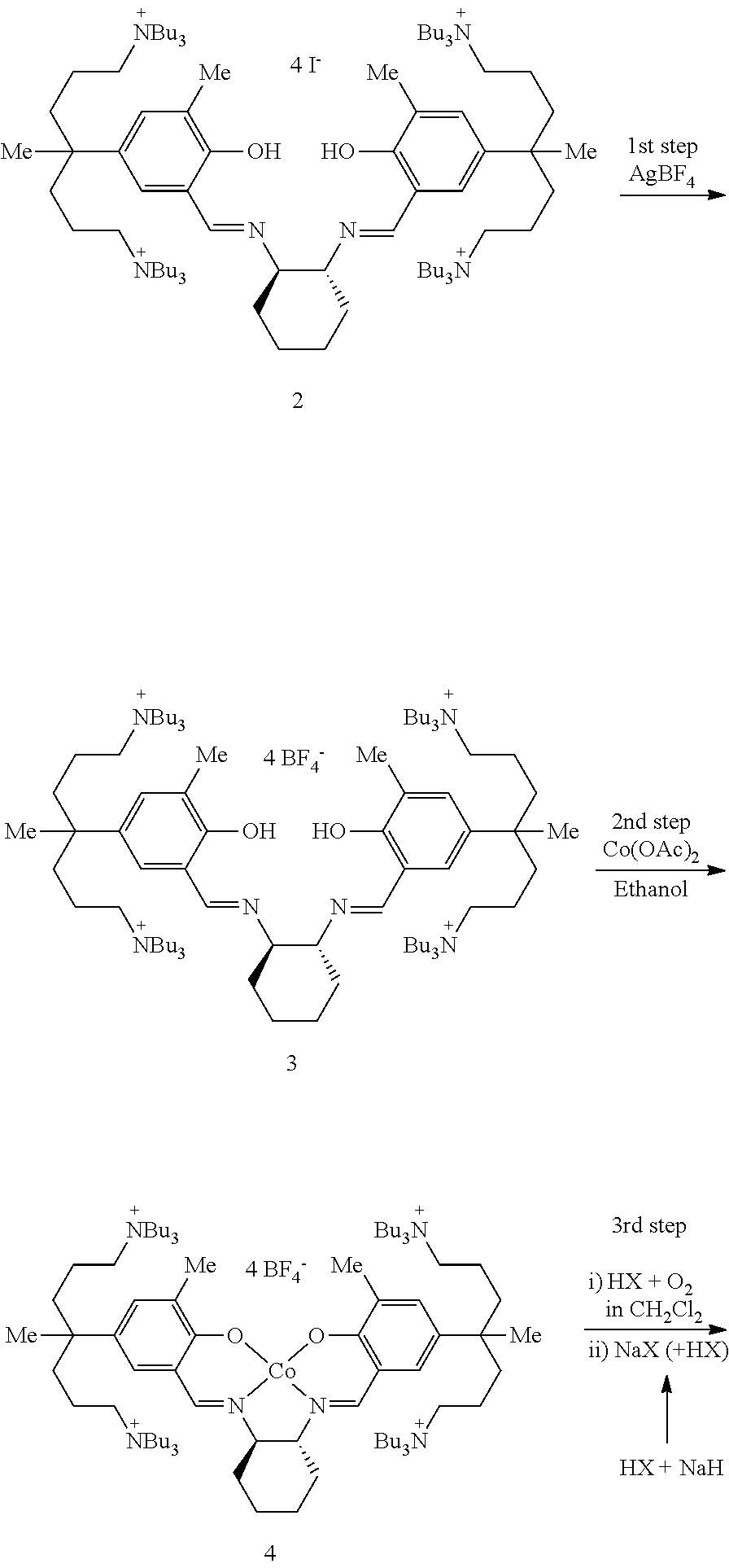

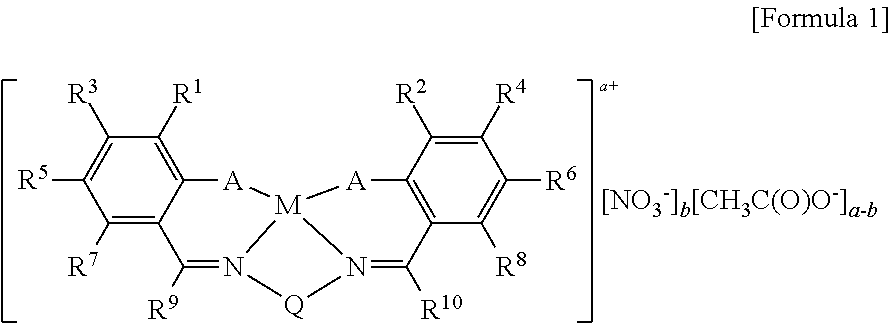

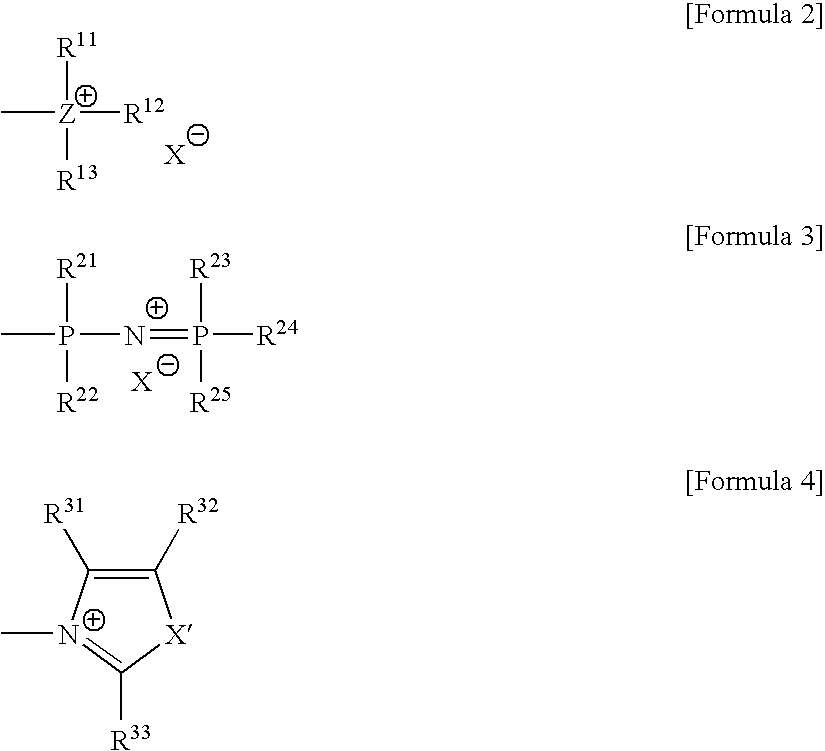

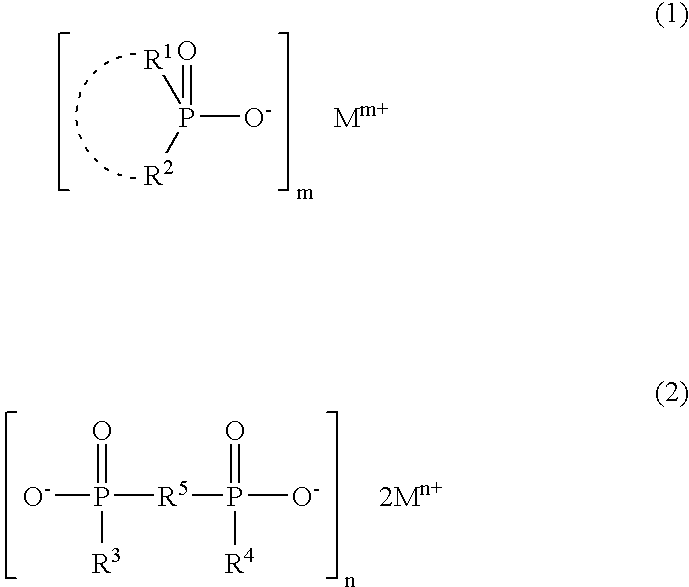

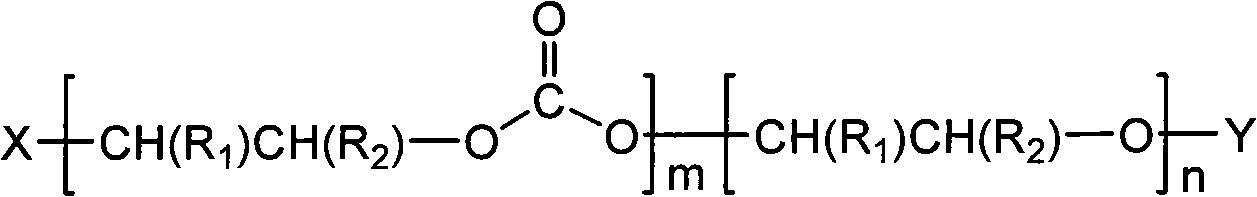

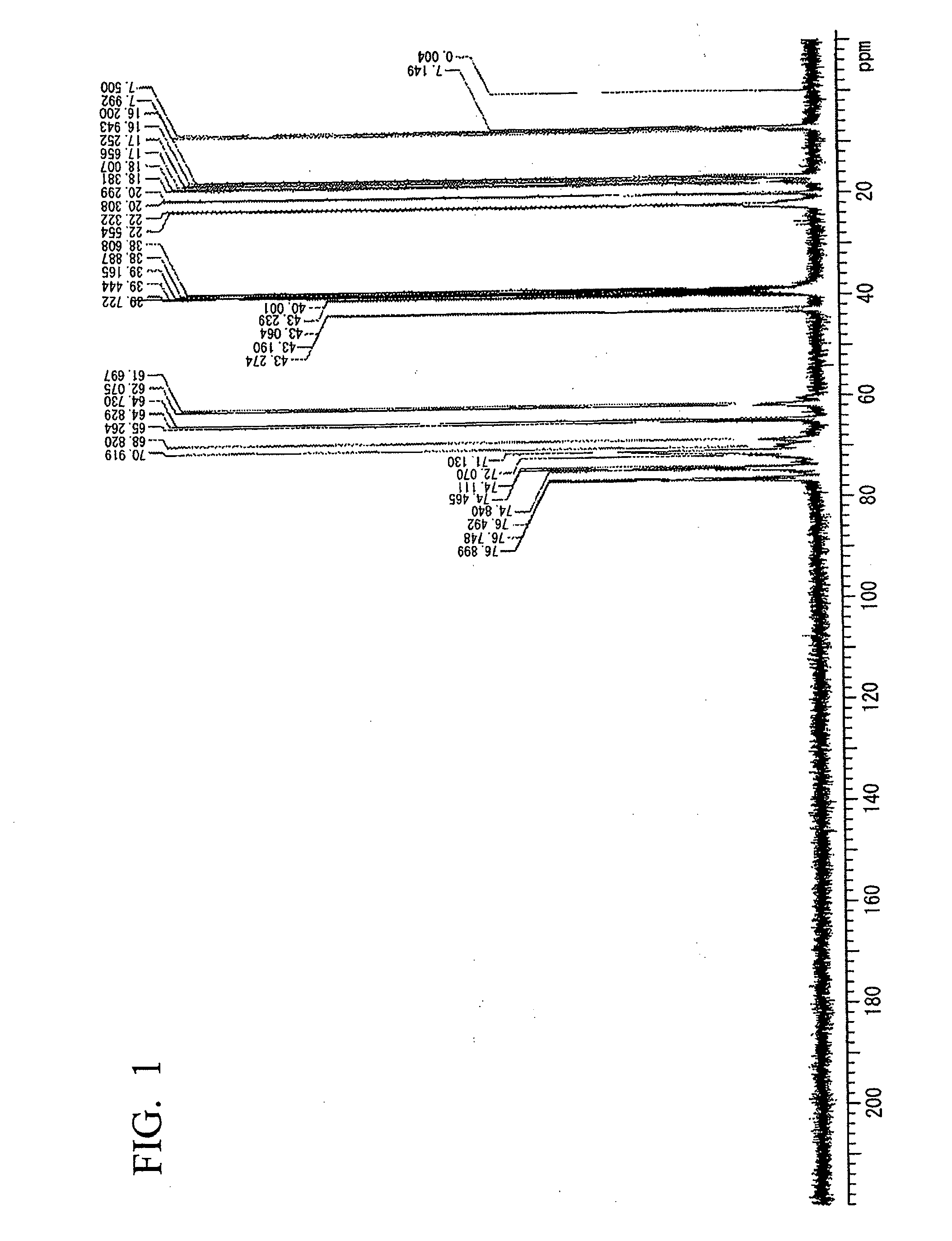

Catalytic system of nitrate anions for CO2/epoxide copolymerization

ActiveUS8598309B2Reduce manufacturing costEliminate needOrganic compound preparationGroup 8/9/10/18 element organic compoundsNitrate anionPolycarbonate

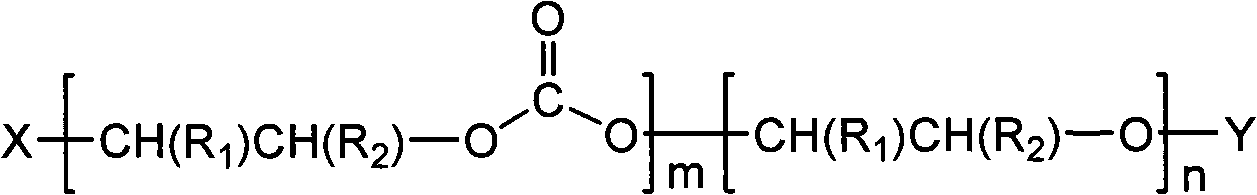

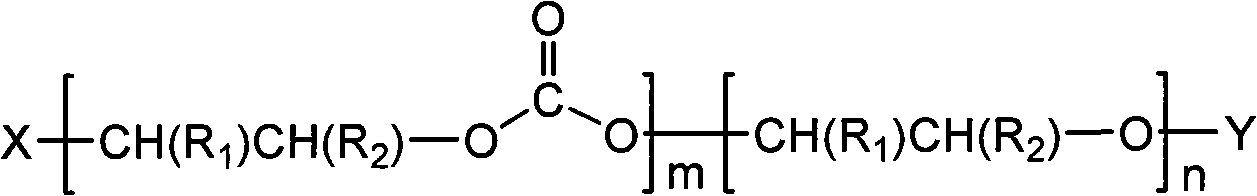

This invention relates to a Salen type ligand including three or more quaternary ammonium salts of nitrate anions, to a trivalent metal complex compound prepared from this ligand and a method of preparing the same, to a method of preparing polycarbonate by copolymerizing an epoxide compound and carbon dioxide using the complex compound as a catalyst, and to a method of separating and collecting the catalyst from the copolymer after copolymerization. This catalyst used to copolymerize an epoxide compound and carbon dioxide can be more simply prepared, and has lower catalyst preparation and recovery costs, and higher activity, compared to conventional catalysts.

Owner:SK INNOVATION CO LTD

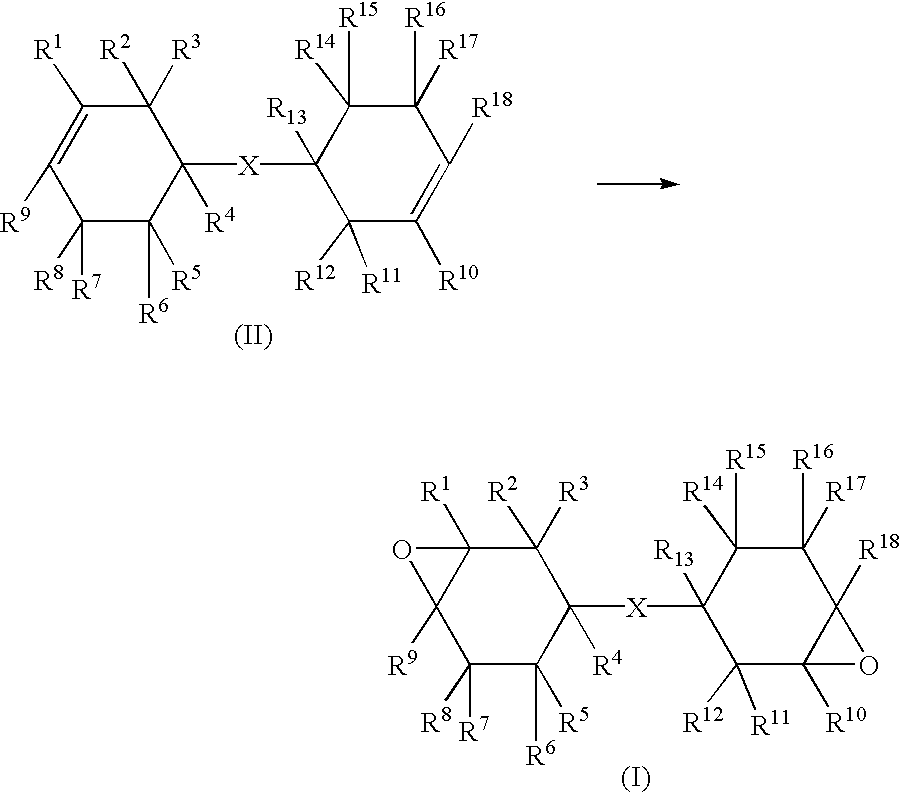

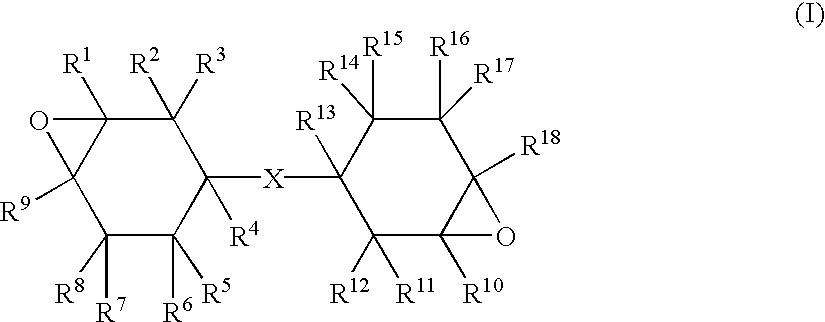

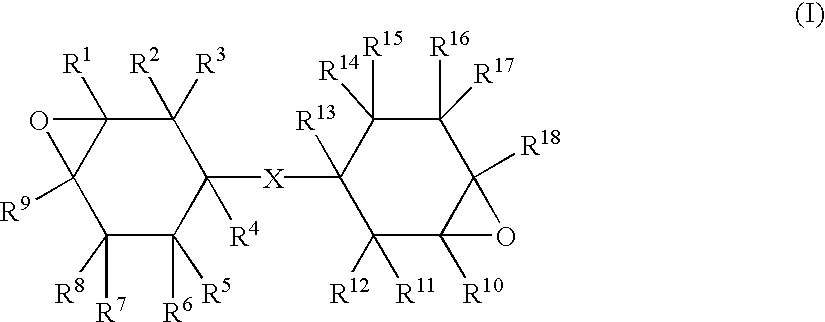

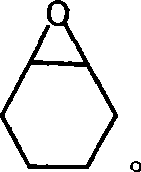

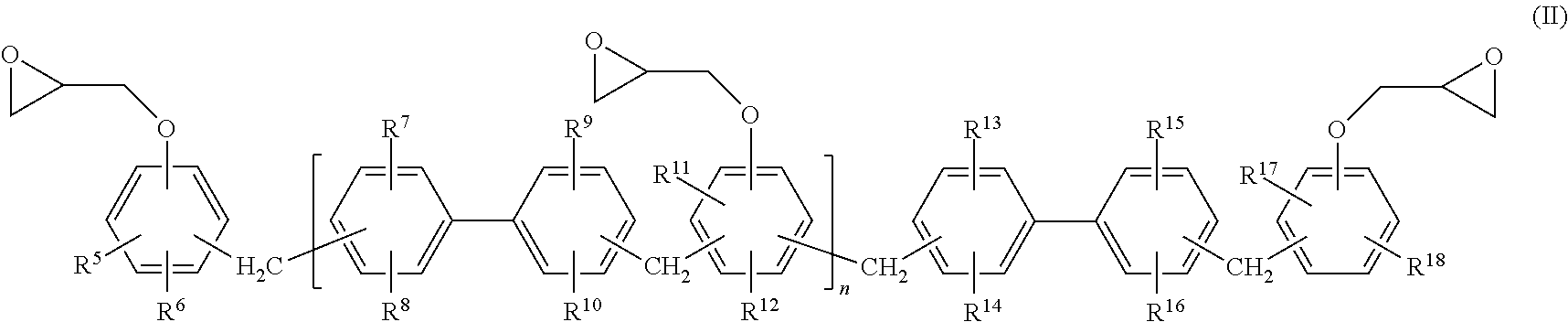

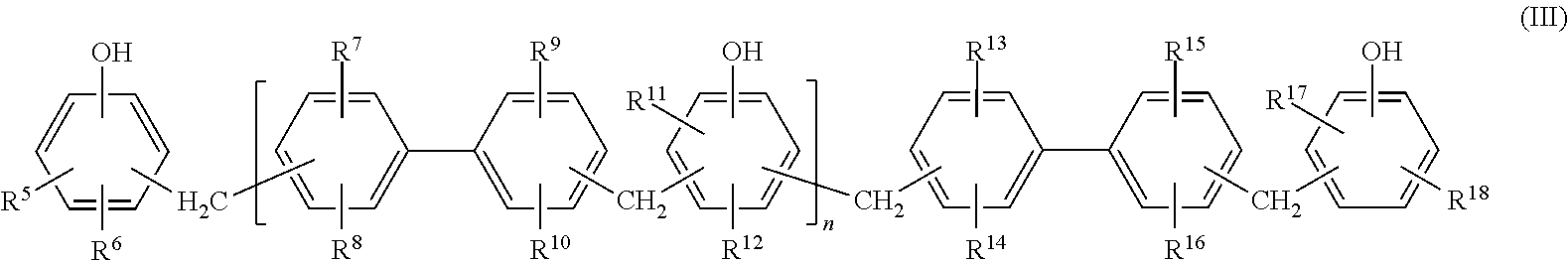

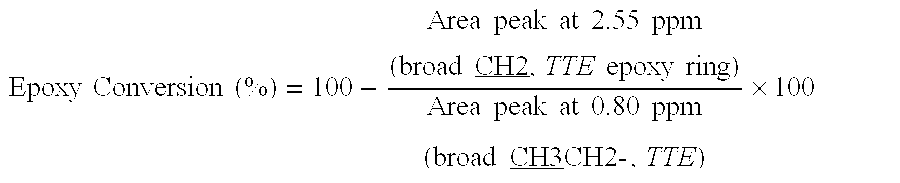

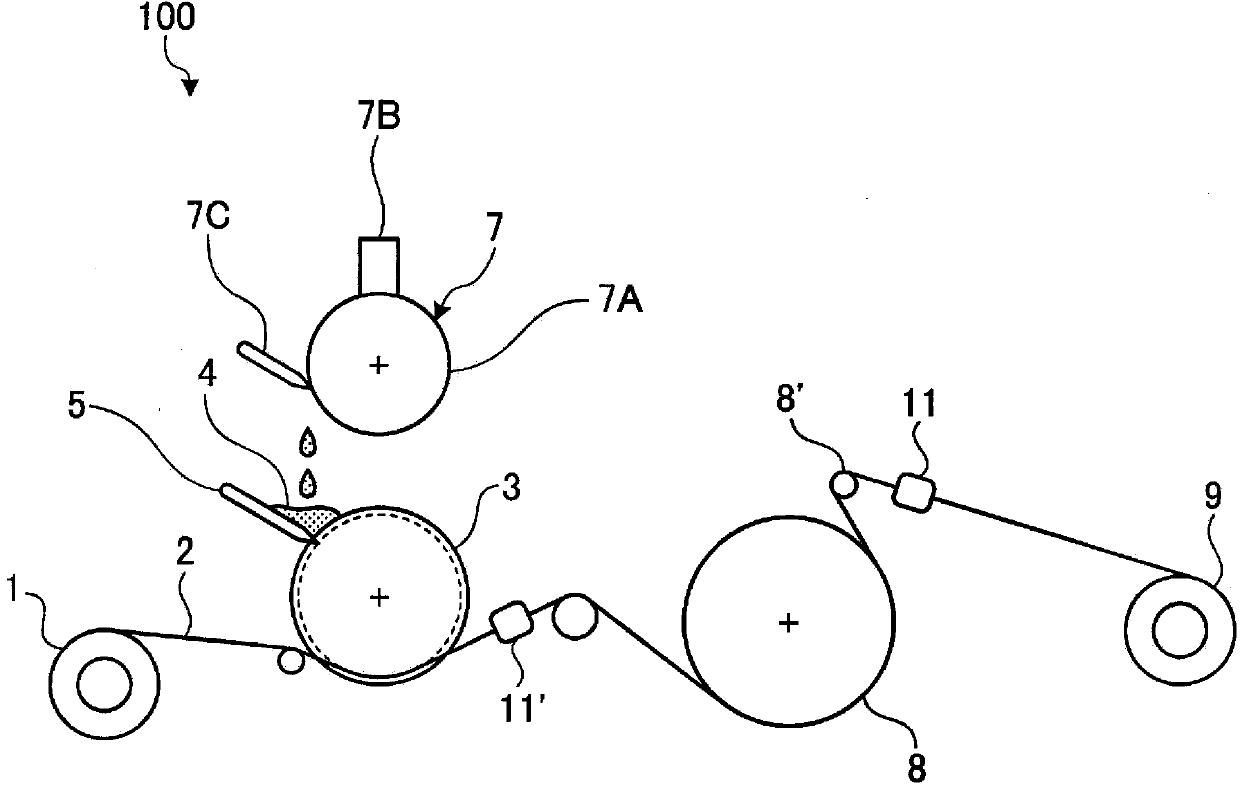

Method of producing epoxy compound, epoxy resin composition and its applications, ultraviolet rays-curable can-coating composition and method of producing coated metal can

The invention I provides a method of producing an alicyclic epoxy compound having a specific structure, which comprises epoxidizing an alicyclic olefin compound having a specific structure by using an aliphatic percarboxylic acid having low water content. The alicyclic epoxy compound is useful for use in coatings, inks, adhesives, sealants, encapsulants, stabilizers or the like. The invention II provides an epoxy resin composition containing the alicyclic epoxy compound as a main component, and a photosemiconductor device comprising a photosemiconductor element encapsulated with the epoxy resin composition. The epoxy resin composition can be cured by heating, thereby obtaining a cured product having excellent moisture and heat resistance and transparency. The invention III provides: an ultraviolet rays-curable can-coating composition containing the alicyclic epoxy compound as a main component, which can be cured by ultraviolet irradiation, and can form a coating film having excellent film performances such as processability, adhesion, hardness and scratch resistance, particularly film appearance and retort resistance; and a process of producing a coated metal can using the composition.

Owner:DAICEL CHEM IND LTD

Method for producing ring carbonic acid ester with hydroxyl ion liquid

ActiveCN101130537AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyThermal stability

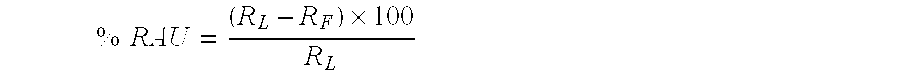

The invention discloses a making method of annular carbonate through hydroxy ion liquid, which comprises the following steps: adopting epoxy compound and carbon dioxide as reactant; using catalyst from one of hydroxy ion liquid; making the quantity of catalyst between 1X10-3 and 1. 5X10-2mol corresponding to epoxy compound; setting the reacting pressure at 0. 1-10. 0Mpa under 323. 15-483. 15K for 0. 3-5h; obtaining the product under mild reacting condition. The invention saves cost due to using mono-component catalyst with high selectivity, which displays good water and thermal stability to be used reciprocally.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing crosslinked aliphatic series polycarbonate

ActiveCN1775828AImprove mechanical properties and heat resistanceOvercome viscous flowSide chainDouble bond

The invention belongs to cross-linking type aliphatics polycarbonate preparation method. The method is used containing double bond epoxy compound, epoxy propane, and carbon dioxide ternary polymerization to make polycarbonate with side chain double bond and cross linking type polycarbonate by the cross linking of the side chain double bond. Compare with the non cross-linking polycarbonate, the heat resistance and mechanical property of the ternary polymerization carbonate is improved obviously after cross- linking. The copolymer not only will not be viscous flow at room temperature, but also can be long time use under 60 centigrade degree.

Owner:迁安市宏奥低碳科技有限公司

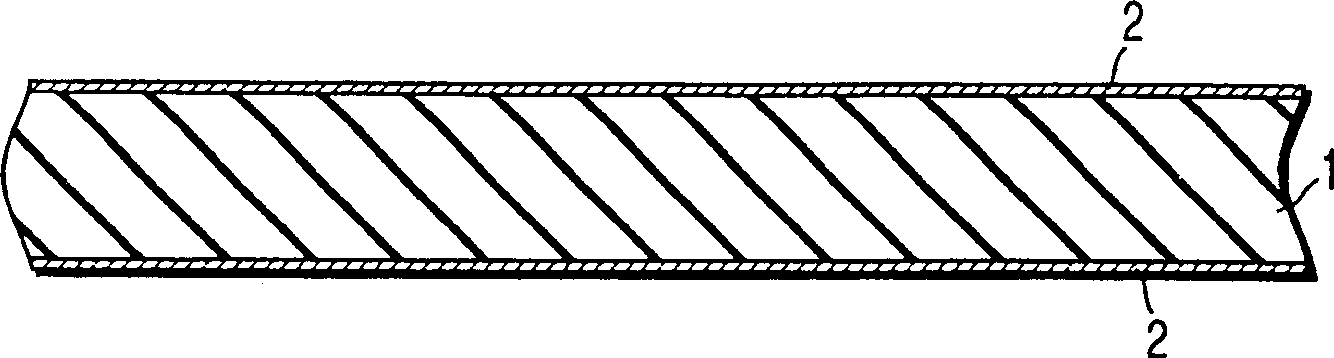

D1364 bt secondary coatings on optical fiber

The invention relates to a Radiation Curable Secondary Coating composition for use on an Optical Fiber. The Radiation Curable Secondary Coating composition is a urethane-free Alpha Oligomer prepared by reaction of the following: (a) an acrylate compound selected from an alcohol-containing acrylate or alcohol-containing methacrylate compound, (b) an anhydride compound, (c) an epoxy-containing compound, (d) optionally an extender compound, and (e) optionally a catalyst. The invention also relates to a coated wire and to a coated optical fiber.

Owner:DSM IP ASSETS BV

Cyanate resin, polyepoxide and metal complex curing agent

A curable mixture comprising at least one cyanate resin, at least one epoxide compound with more than one epoxy group per molecule, and a metal formula selected from the group consisting of MLxBy, M[SR]xBy, M[SR]x(N)y, M(PHal)m and M(PHal)m(N)n wherein M is a cation of a complexing metal, SR is an organic or inorganic acid residue, L is a chelating ligand, B is a Lewis base, PHal is an ion of a pseudohalide, N is a nitrogen base, x is an integer from 1 to 8, y is an integer from 1 to 5, z is an integer from 7 to 8, m is an integer from 2 to 3 and n is an integer from 1 to 2.

Owner:BAKELITE

Catalyst for olefin polymerization or copolymerization at high temperature

The catalyst for olefin polymerization or copolymerization at high temperature consists of three components, including component A, component B and component C. The component A is solid prepared through dissolving magnesium chloride in organic epoxy compound or organic phosphorus compound to form solution, mixing the solution with titanium tetrahalide and separating assistant to separate soli, and treating with electron donor and titanium tetrahalide. The component B is mixture of aluminoxane and alkyl aluminum compound. The component C is organic silane. At polymerization temperature higher than 90 deg.c, the catalyst has high stereo selectivity and high activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

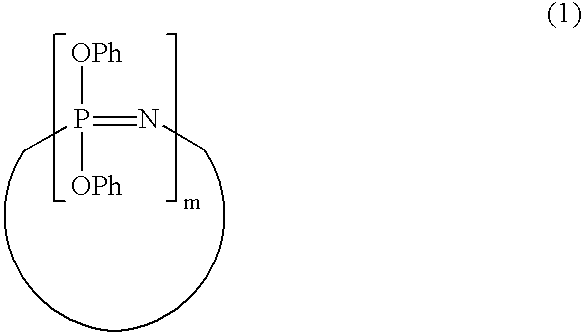

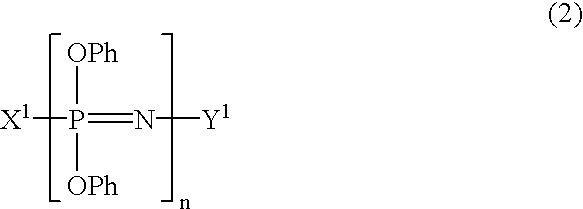

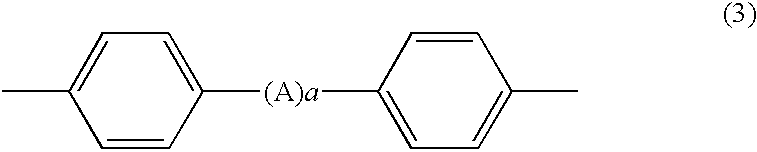

Process for producing phenoxyphosphazene compound, flame- retardant resin composition, and flame-retardant resin molding

InactiveUS20030040643A1Quality improvementIncrease resistanceGroup 5/15 element organic compoundsAlkanePolymer science

The phenoxyphosphazene compound of the present invention is prepared by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide or (c) both the adsorbent and reagent. Incorporation of the phenoxyphosphazene compound prepared by the process of the invention into a synthetic resin achives the following advantages: the synthetic resin can be prevented from discoloration; when the resultant resin composition is stored for a long time, the properties of the synthetic resin, such as heat resistance, weatherability, resistance to discoloration and chemical resistance are not deteriorated; and the resin composition gives a resin composition molded article excellent in properties such as flame retardancy, thermal stability, and moldability.

Owner:OTSUKA CHEM CO LTD

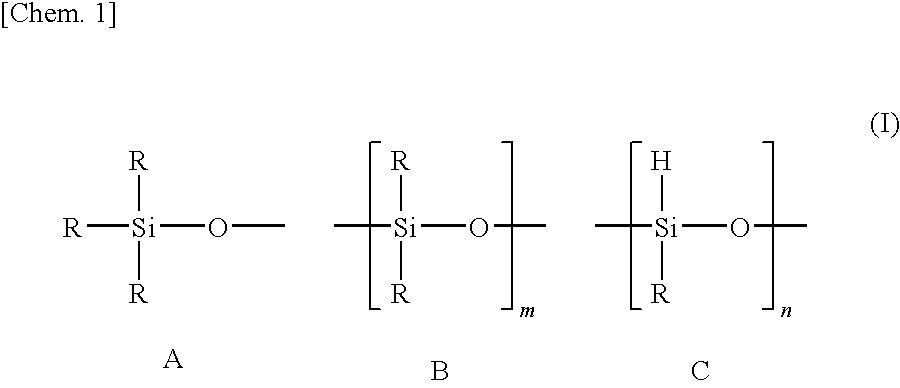

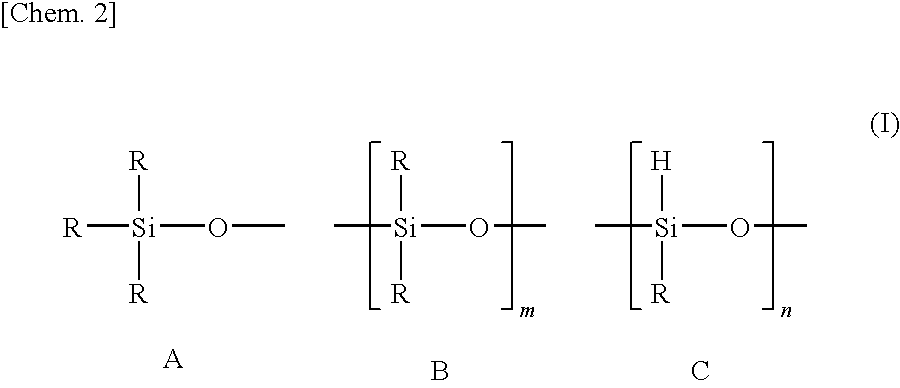

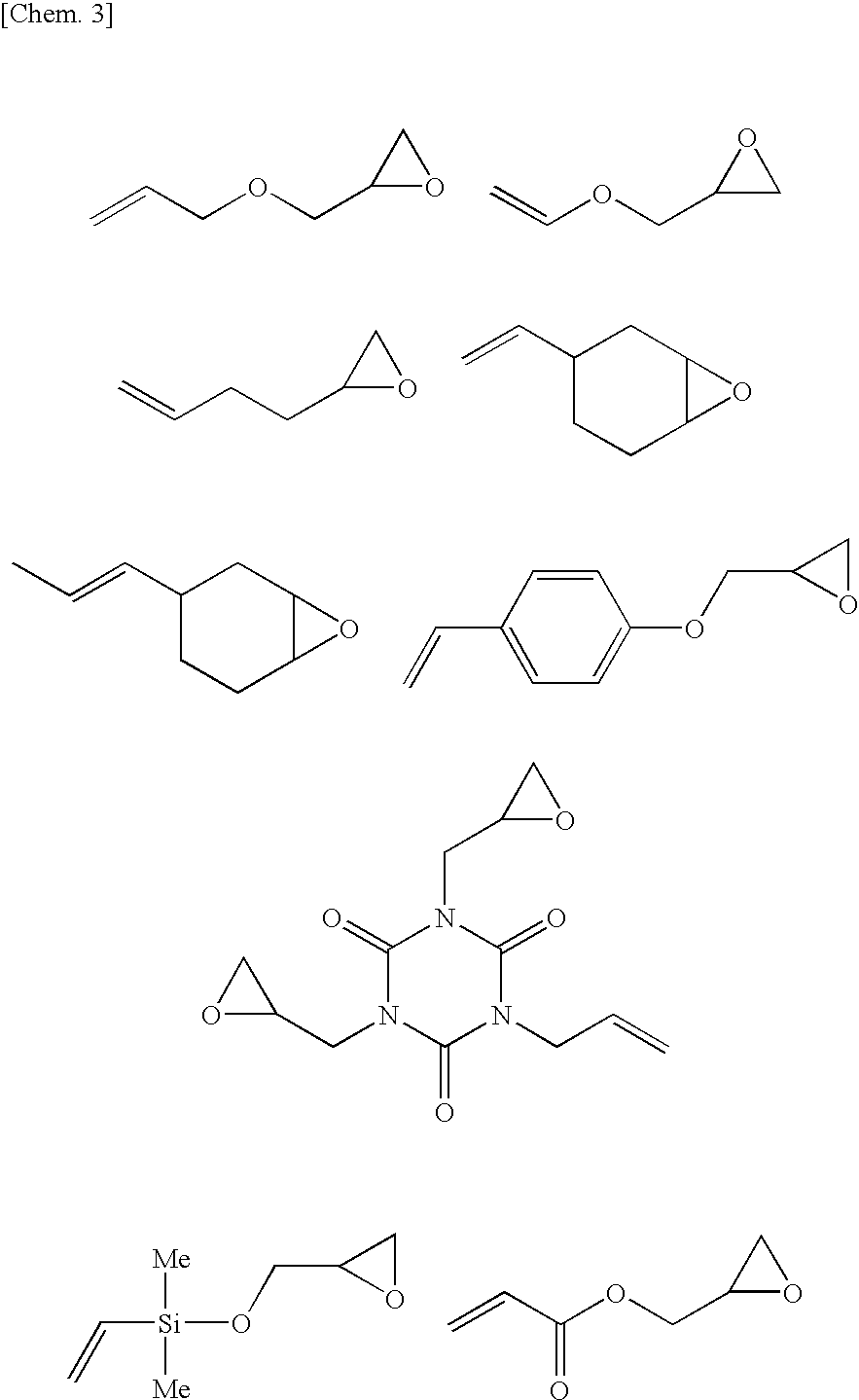

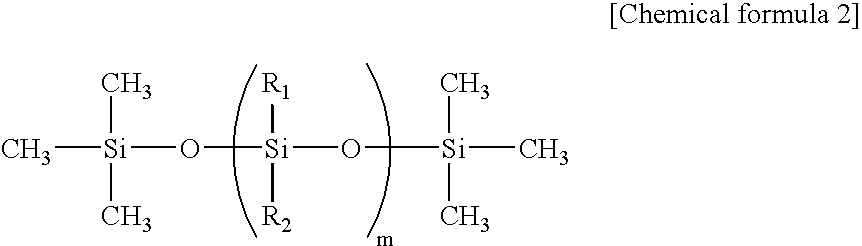

Composition for thermosetting silicone resin

InactiveUS20100225010A1Improve heat resistanceHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxyHydrosilylation

The present invention relates to a composition for a thermosetting silicone resin, the composition including: (A) an organohydrogenpolysiloxane; (B) an alkenyl group-containing epoxy compound; (C) an alkenyl group-containing cyclic siloxane; and (D) a hydrosilylation catalyst, a thermosetting silicone resin composition obtained by reacting the composition and a production method thereof, a photosemiconductor element-encapsulating material including the thermosetting silicone resin composition, and a photosemiconductor device including a photosemiconductor element encapsulated with the resin composition or the photosemiconductor element-encapsulating material.

Owner:NITTO DENKO CORP

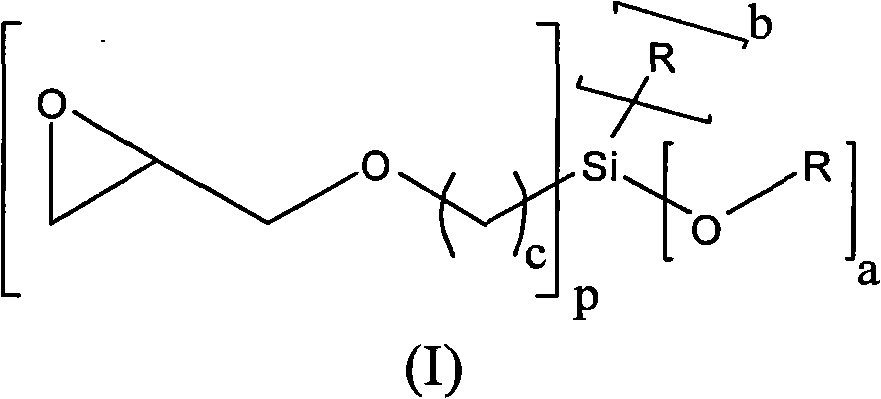

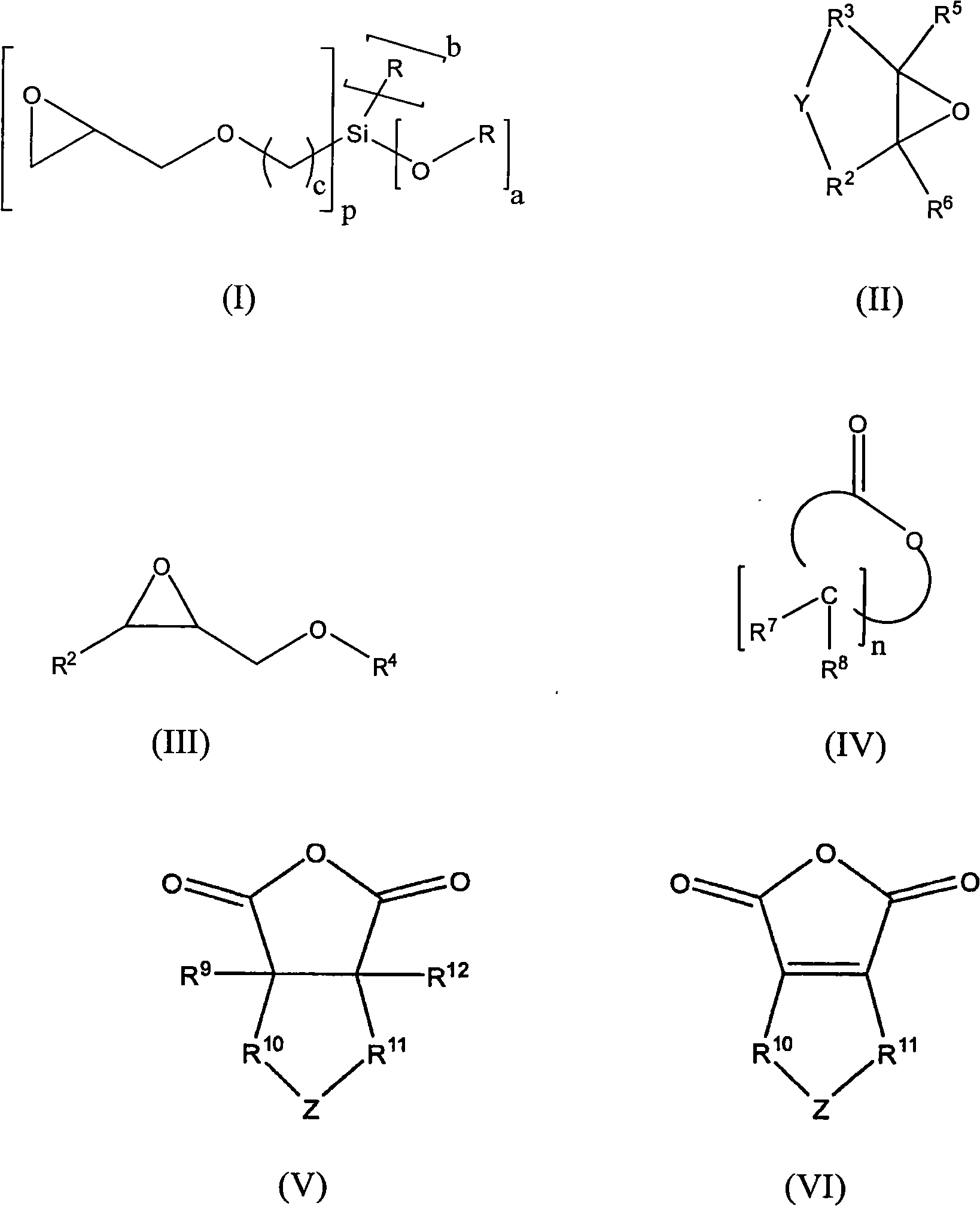

Copolymer of epoxy compounds and amino silanes

The present invention provides for a composition comprising the reaction product ofa. an oxirane or oxetane compound comprising at least two oxirane or oxetane groups; andb. an amino silane having the formula:N(H)(R1)R2Si(OR3)3-a-b-c(OR4)a(R5Si(OR6)d(R7)e)bR8c with R1 is chosen from the group consisting of H or a monovalent hydrocarbon radical containing one to 20 carbon atoms;R2 and R5 are independently selected from a group consisting of oxygen or a divalent linear or branched hydrocarbon radical consisting of 1-60 carbons;R4 is a hydrocarbon radical that contains 3 to 200 carbon atoms;R3, R6, R7, and R8 and are each independently selected from the group of monovalent linear or branched hydrocarbon radicals having from 1 to 200 carbon atoms;the subscript b is zero or a positive number and has a value ranging from 0 to 3;the subscripts a, and c are zero or positive and have a value ranging from 0 to 3 subject to the limitation that (a+b+c)≦3;the subscripts d and e are zero or positive and have a value ranging from 0 to 3 subject to the limitation that (d+e)≦3.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

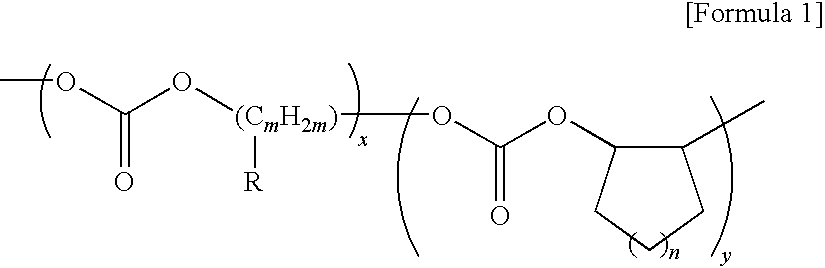

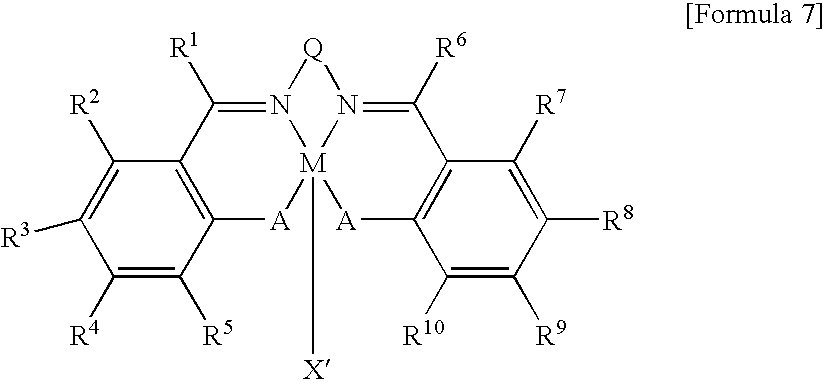

Bimetallic zinc complex and process of producing polycarbonate using the same as polymerization catalyst

ActiveUS7244805B2Reduce the amount requiredEconomically beneficialCosmetic preparationsMake-upPolycarbonatePolymerization catalysts

Provided are a bimetallic zinc complex and a method of producing polycarbonate, including polymerizing an epoxy compound and carbon dioxide using the bimetallic zinc complex. The bimetallic zinc complex according to the present invention has a distance between zinc-zinc atoms, which is maintained in a limited range regardless of its concentration in a reaction medium for the polymerization. Thus, the bimetallic zinc complex can have a polymerization activity even at a high ratio of monomer / catalyst, thereby reducing a catalyst amount to be used, which is economically advantageous. Further, the bimetallic zinc complex can produce a high molecular weight polycarbonate.

Owner:LG CHEM LTD

Polymeric Thermoplastic Compositions Having Excellent Resistance to Moisture and Oxygen Transmission and Sheet Which are Made of These Polymeric Thermoplastic Compositions

InactiveUS20100323201A1Improve moisture resistanceImprove stabilitySynthetic resin layered productsDomestic containersThermoplasticOxygen

Disclosed is a resin composition for blocking oxygen and moisture, and a sheet for blocking oxygen and moisture manufactured by using thereof, in which the resin composition includes polycarbonate terpolymer produced by reacting different two epoxides compounds with carbon dioxide.

Owner:SK INNOVATION CO LTD

Flame-retardant resin composition

ActiveUS20080167406A1Improve flame retardant performanceImprove machinabilityGroup 5/15 element organic compoundsPolytetramethylene terephthalateElastomer

A flame-retardant resin composition comprises 25 to 150 parts by weight of (B) a thermoplastic polyester elastomer, 5 to 40 parts by weight of (C) a phosphinic acid compound comprising a salt of at least one member selected from the group consisting of a phosphinic acid, a diphosphinic acid, and a polymerized product thereof, and 0.5 to 20 parts by weight of (D) an epoxy compound, relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin. Such a flame-retardant resin composition is useful for various molded products and for covering the surface of an electric wire, or the like. The present invention provides a halogen-free flame-retardant resin composition which has a high heat resistance and a high flame retardancy and is excellent in hydrolysis resistance, abrasion resistance, and moldability (e.g., extrusion properties).

Owner:WIN TECH POLYMER LTD

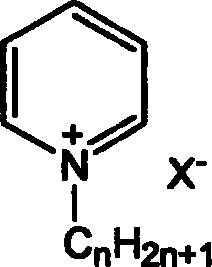

Process for preparing annular carbonate

ActiveCN1995032AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxySolvent

The invention discloses a making method of annular carbonate, which comprises the following steps: adopting epoxy compound and carbon dioxide as raw material; setting the weight rate of water and epoxy compound at 0.01-3 in the reacting course; selecting catalyst from one of quaternary ammonium salt, alkyl halide pyridine or halide 1, 3-imidazole dialkyl under 0.1-10.0Mpa at 313. 15-483. 15K for 0.5-6h.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Polyurethane microporous elastomer, preparation method and application thereof

ActiveCN101857670AGood physical propertiesImprove mechanical propertiesSolesElastomerPolymer science

The invention relates to the field of polyurethane, in particular to a polyurethane microporous elastomer, a preparation method and an application thereof. The polyurethane microporous elastomer is a reaction product of an isocyanate-terminated prepolymer obtained by reaction of isocyanate and first polyol, second polyol, a chain extender and a catalyst, and the first polyol and / or the second polyol at least comprise / comprises polycarbonate polyol obtained by reaction of carbon dioxide and an epoxy compound. The preparation method of the polyurethane microporous elastomer can not only reduce the demands on raw materials derived from the petrochemical industry, but also realize the environment-friendly utilization of greenhouse gas-carbon dioxide.

Owner:COVESTRO DEUTSCHLAND AG

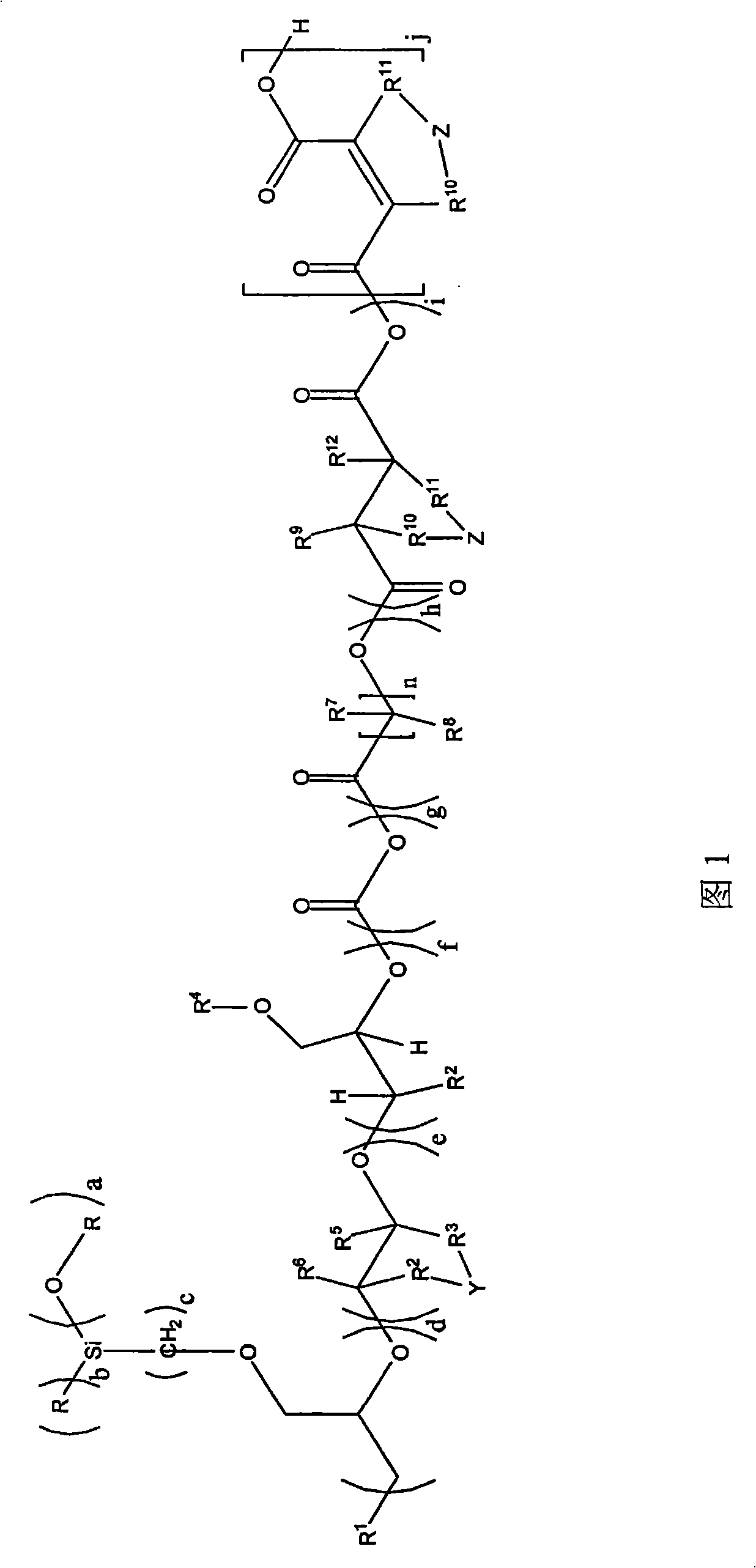

New polyether alcohols containing alkoxysilyl groups and method for production

ActiveCN101514243AIncrease reaction rateGroup 4/14 element organic compoundsPolymer scienceCarbon chain

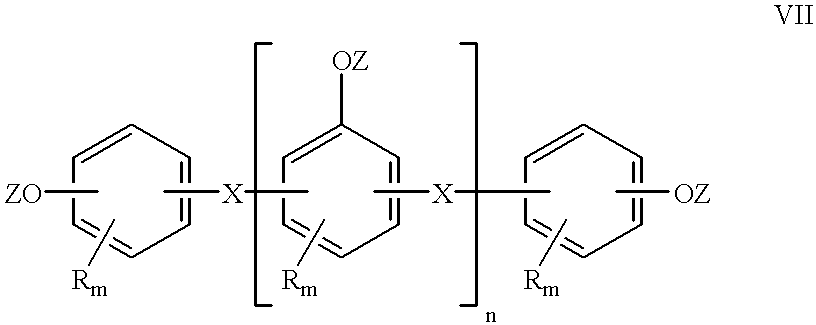

Polyether alcohols having alkoxysilyl groups, the use thereof and a process for their preparation by means of DMC catalysis, characterized in that one or more epoxy--functional alkoxysilanes are added individually or in a mixture with further epoxide compounds and optionally further comonomers, either in block form or in random distribution, onto a chain starter of the formula (VII) R1-H (VII) having at least one reactive hydroxyl group, where R1 is a saturated or unsaturated, optionally branched radical, or a polyether radical of the alkoxy-, arylalkoxy or alkylarylalkoxy group type, in which the carbon chain may be interrupted by oxygen atoms or corresponds to a polyetheralkoxy radical or to a singularly or multiply fused phenolic group.

Owner:EVONIK OPERATIONS GMBH

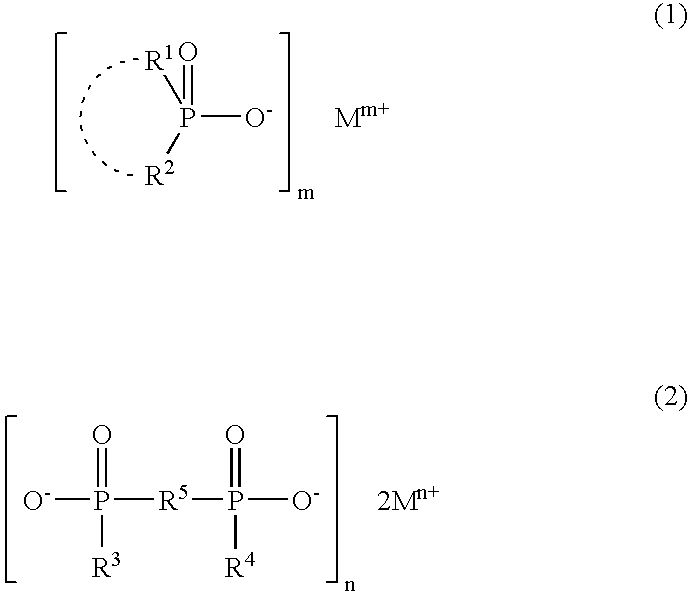

Photosensitive resin composition and application of the same

ActiveUS20130228727A1Improve stabilityGood stability of surface resistancePhotosensitive materialsPhotosensitive materials for photomechanical apparatusPolymer sciencePhotopigment

A photosensitive resin composition includes (A) an alkali-soluble resin, (B) a polysiloxane, (C) an ethylenically unsaturated compound, (D) a photo-initiator, (E) a first solvent, and (F) a black pigment dispersion. The alkali-soluble resin (A) includes an unsaturated-group-containing resin (A-1) obtained by subjecting a mixture containing (i) an epoxy compound having at least two epoxy groups and (ii) a compound having at least one carboxyl group and at least one ethylenically unsaturated group to polymerization. A weight ratio of the black pigment dispersion (F) to the polysiloxane (B) ranges from 5 to 35. Application of the photosensitive resin composition is also disclosed.

Owner:CHI MEI CORP

Photosensitive resin composition and application of the same

ActiveUS20130135763A1Good shading effectImprove surface smoothnessPhotosensitive materialsPhotomechanical apparatusChemical compoundSolvent

A photosensitive resin composition includes (A) an alkali-soluble resin, (B) a polysiloxane, (C) an ethylenically unsaturated compound, (D) a photo-initiator, (E) a black pigment, and (F) a solvent. The alkali-soluble resin includes an unsaturated-group-containing resin obtained by subjecting a mixture containing (i) an epoxy compound having at least two epoxy groups and (ii) a compound having at least one carboxyl group and at least one ethylenically unsaturated group to polymerization. A weight ratio of the unsaturated-group-containing resin to the polysiloxane ranges from 0.1 to 3.0. Application of the photosensitive resin composition is also disclosed.

Owner:CHI MEI CORP

Thermoplastic melt-mixed composition with epoxy-carboxylic acid compound heat stabilizer

Disclosed is a thermoplastic melt-mixed composition including: a) a semicrystalline polyamide resin; b) a polyepoxy compound including at least two or more epoxy groups; the polyepoxy compound having a number average molecular weight of less than 8000; one or more carboxylic acid compounds selected from the group consisting of polyacids, acid alcohols and combinations of these, the carboxylic acid compounds have a number average molecular weight of less than 2000; and optionally, d) reinforcing agent; e) polymeric toughener; and f) further additives.

Owner:EI DU PONT DE NEMOURS & CO

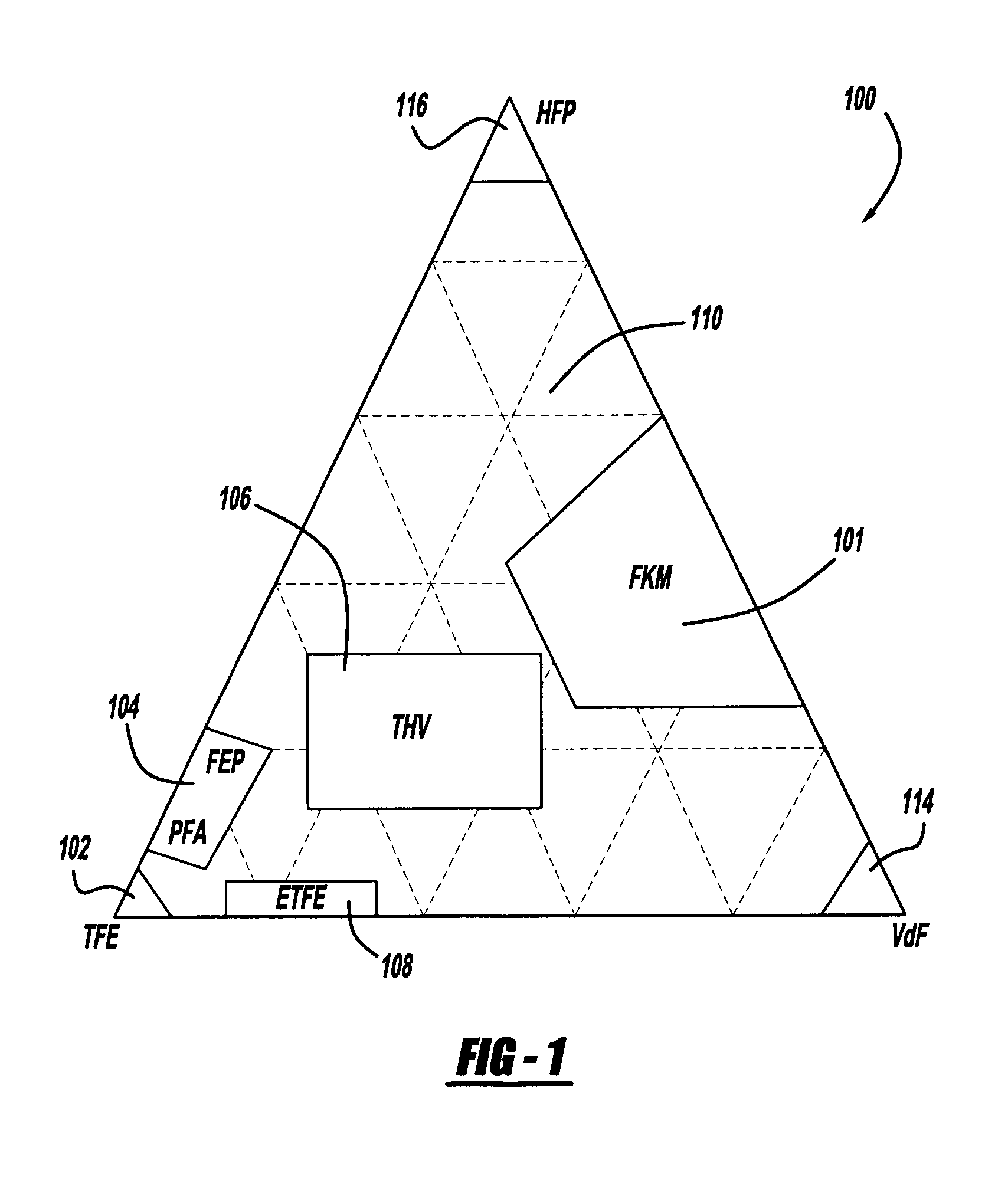

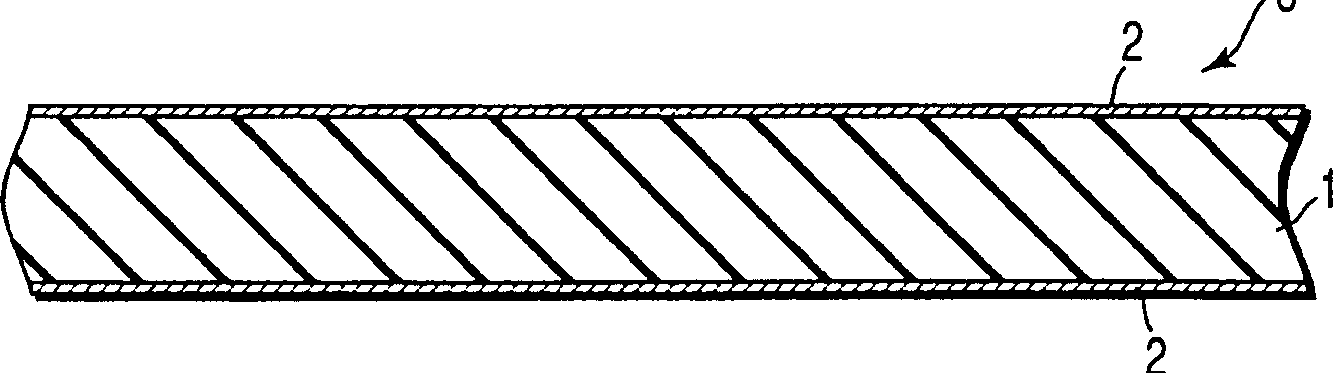

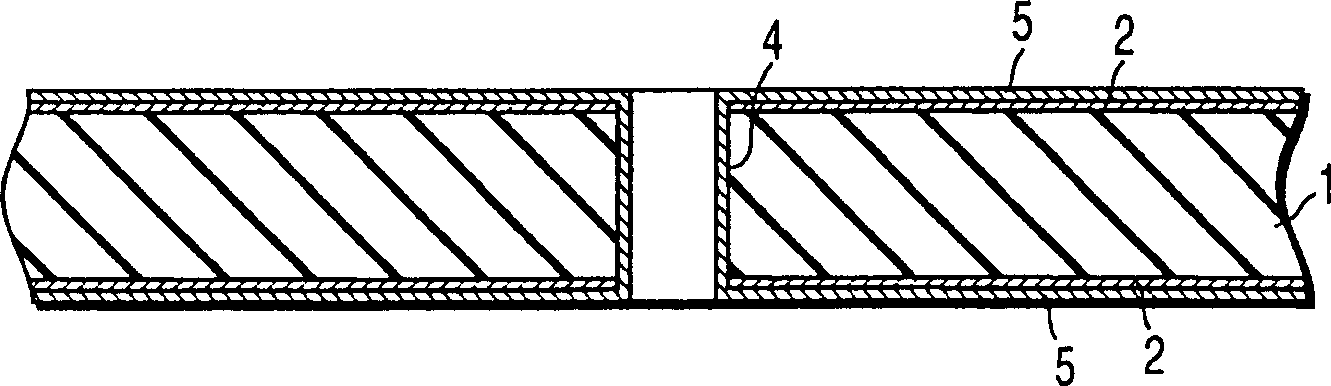

Melt-processable adhesives for bonding pervious fluoropolymeric layers in multilayer composites

A homogenous fluoropolymeric melt-bonded layer in a multilayer composite coheres to a pervious fluoropolymer layer of fluoroelastomeric thermoplastic and / or etched polytetrafluoroethylene. Before curing, the homogenous fluoropolymer has a stoichiometrically identical monomer unit with the pervious fluoropolymer, the homogenous fluoropolymer liquefaction range supra-point temperature is not greater than that of the pervious fluoropolymer, the homogenous fluoropolymer liquefaction range supra-point temperature is not less than the pervious fluoropolymer liquefaction range sub-point temperature, and the homogenous fluoropolymer liquefaction range supra-point viscosity is less than that of the pervious fluoropolymer. In some multilayer composites, the homogenous fluoropolymeric melt-bonded layer coheres to a third layer of plastic, metal, ceramic, rubber, wood, and / or leather. In such 3+ layer composites, the homogenous fluoropolymeric contains an epoxy compound, a phenoxy compound, silane, and / or a heat-polymerizable thermoplastic oligomer. Various composites according to the technology are adapted for use as gaskets, dynamic seals, compression seals, or o-rings.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Thermoplastic Resin Composition Having Improved Impact Resistance

ActiveUS20080160240A1Improve impact resistanceImprove flame retardant performanceOrganic chemistryLayered productsPolymer sciencePolyester resin

A thermoplastic resin composition with improved impact resistance can include (A) about 30 to about 99 parts by weight of an epoxy group-containing styrenic polymer comprising (A1) about 5 to about 100% by weight of an epoxy group-containing vinyl copolymer containing about 0.001 to about 5.0 mol % of an epoxy compound; and (A2) about 0 to about 95% by weight of a rubber modified styrenic copolymer resin; (B) about 1 to about 70 parts by weight of a polyester resin; (C) about 0.001 to about 10 parts by weight of a silicone oil, per 100 parts by weight of a base resin comprising (A) and (B); (D) about 3 to about 20 parts by weight of a bromine-containing flame retardant, per 100 parts by weight of a base resin comprising (A) and (B); and (E) about 0.1 to about 6 parts by weight of a flame retardant aid, per 100 parts by weight of a base resin comprising (A) and (B).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermoplastic polyester resin composition and molded article

InactiveCN1717452AImprove hydrolysis resistanceImprove heat resistancePolymer sciencePhenolic antioxidant

Owner:DAICEL CHEM IND LTD

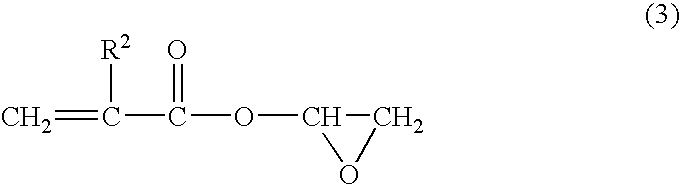

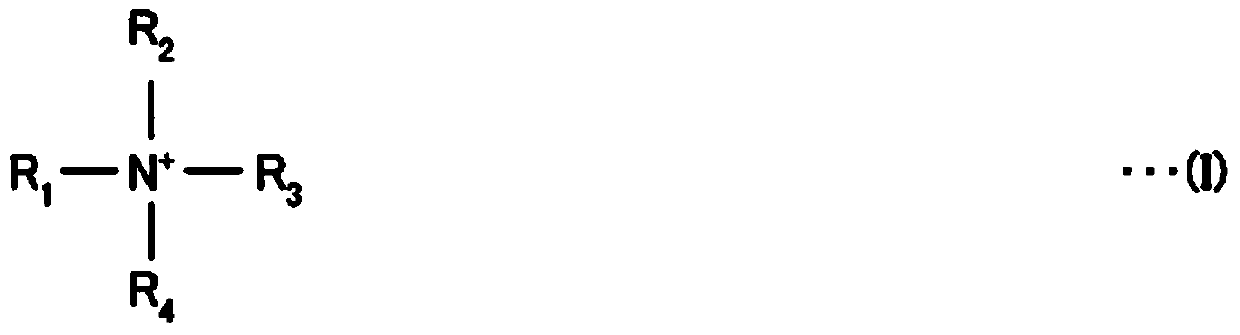

Carbon fiber molding material, molding material, and carbon fiber-strengthening composite material

InactiveCN103975003AGood adhesionCovalent bond formation promotionFibre typesWoven fabricsFiberPolymer science

A carbon fiber molding material is provided that exhibits excellent interfacial adhesion between the carbon fibers and a thermosetting resin, and that yields a molded product exhibiting excellent mechanical properties. The carbon fiber molding material is either (Z) a prepreg containing sizing agent-coated carbon fibers and a thermosetting resin, or (Y) a material for forming woven fabric or braided cords that employs sizing agent-coated carbon fibers. The sizing agent is characterized by containing the following components (A) and (B): component (A) is an epoxy compound having two or more epoxy groups, or two or more functional groups; component (B) is a compound containing one or more of the group consisting of a tertiary amine compound, a tertiary amine salt, a quaternary ammonium salt, a quaternary phosphonium salt, and a phosphine compound. The sizing agent is obtained by blending 0.1-25 parts by mass of the compound (B) with 100 parts by mass of the compound (A).

Owner:TORAY IND INC

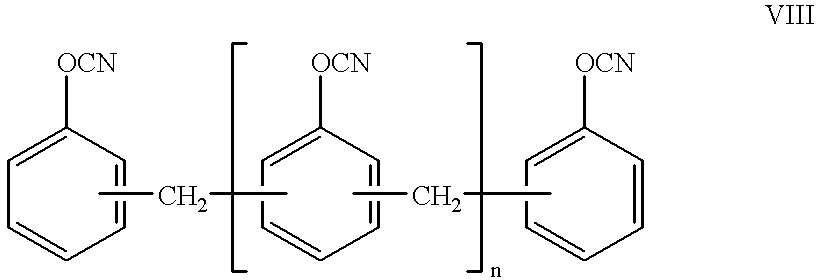

Halogen-free nonflammable epoxy resin composition, halogen-free nonfammable epoxy resin composition for build-up type multi-layer board

A halogen-free flame-retardant epoxy resin composition which comprises as the essential components (A) at least one crosslinked phenoxyphosphazene compound, (B) at least one polyepoxide compound such as bisphenol A type epoxy resin, (C) a curing agent for epoxy resins, e.g., bisphenol A type novolak resin, and (D) a curing accelerator for epoxy resins, and contains 0 to 50 wt.% of an inorganic filler.

Owner:OTSUKA CHEM CO LTD

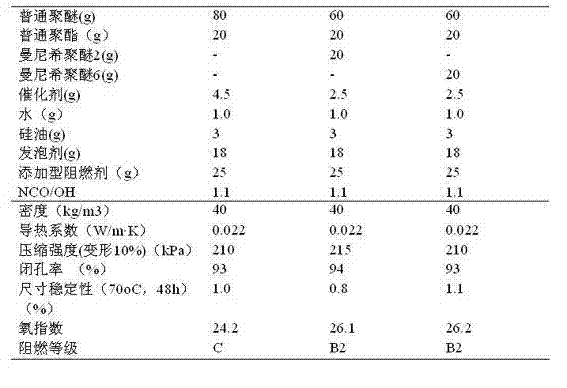

Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

The invention provides a preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect. The preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect comprises the following steps: reacting paraformaldehyde or formaldehyde solution with diethanol amine to obtain 3-ethoxyl-1,3-oxazolidine reaction liquid, and then carrying out reduced pressure distillation to obtain the product 3-ethoxyl-1,3-oxazolidine; reacting aromatic phenol compounds or / and melamine compounds with 3-ethoxyl-1,3-oxazolidine to obtain Mannich base as intermediate; and carrying out polymerization reaction between the intermediate Mannich base and epoxy compound to obtain crude product of reaction type Mannich polyether polyol with permanent flame retardant effect, then carrying out reduced pressure distillation to remove impurities with low boiling points, and thus obtaining finished product. The reaction type Mannich polyether polyol simultaneously has the high stability and thermal stability of rigid polyurethane foam and the flame resistance of phenolic foam, is applied to foaming rigid polyurethane foam, and has wide application prospect.

Owner:JIANGSU YOKE TECH

Hyperbranched Polyether Polyol and Urethane Resin Composition

InactiveUS20090286940A1Reduces viscosity of mixtureImprove workabilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHydroxyl valueOrganic chemistry

A hyperbranched polyether polyol obtained by a ring-opening reaction between a hydroxyalkyloxetane (a1) and a monofunctional epoxy compound (a2), wherein the polyether polyol includes a primary hydroxyl group (H1) and a secondary hydroxyl group (H2) in the molecular structure thereof, and has a number average molecular weight (Mn) of 1,000 to 4,000 and a hydroxyl value of 150 to 350 mg·KOH / g.

Owner:DAINIPPON INK & CHEM INC

Catalyst for producing epoxy compound and process for producing epoxy compounds with the same

InactiveUS20030171604A1High yieldImprove utilization efficiencyOrganic chemistryOther chemical processesIndiumHafnium

The present invention provides a catalyst capable of producing an epoxy compound in high yield and improving the utilization efficiency of the oxidizing agent as well as a method of producing an epoxy compound using that catalyst. A catalyst for producing an epoxy compound by oxidizing a compound having at least one ethylenic double bond with an oxidizing agent, comprising a polyatom-containing heteropolyoxometalate anion (A1) having two defective and / or three defective structure sites and containing silicon as the heteroatom, and an element (E1) being at least one element selected from the group consisting of vanadium, tantalum, niobium, antimony, bismuth, chromium, molybdenum, selenium, tellurium, rhenium, cobalt, nickel, ruthenium, rhodium, palladium, osmium, platinum, iridium, silver, gold, zinc, aluminum, gallium, indium, scandium, yttrium, titanium, zirconium, hafnium, germanium, tin and lanthanoids, and being different from the polyatom.

Owner:NIPPON SHOKUBAI CO LTD

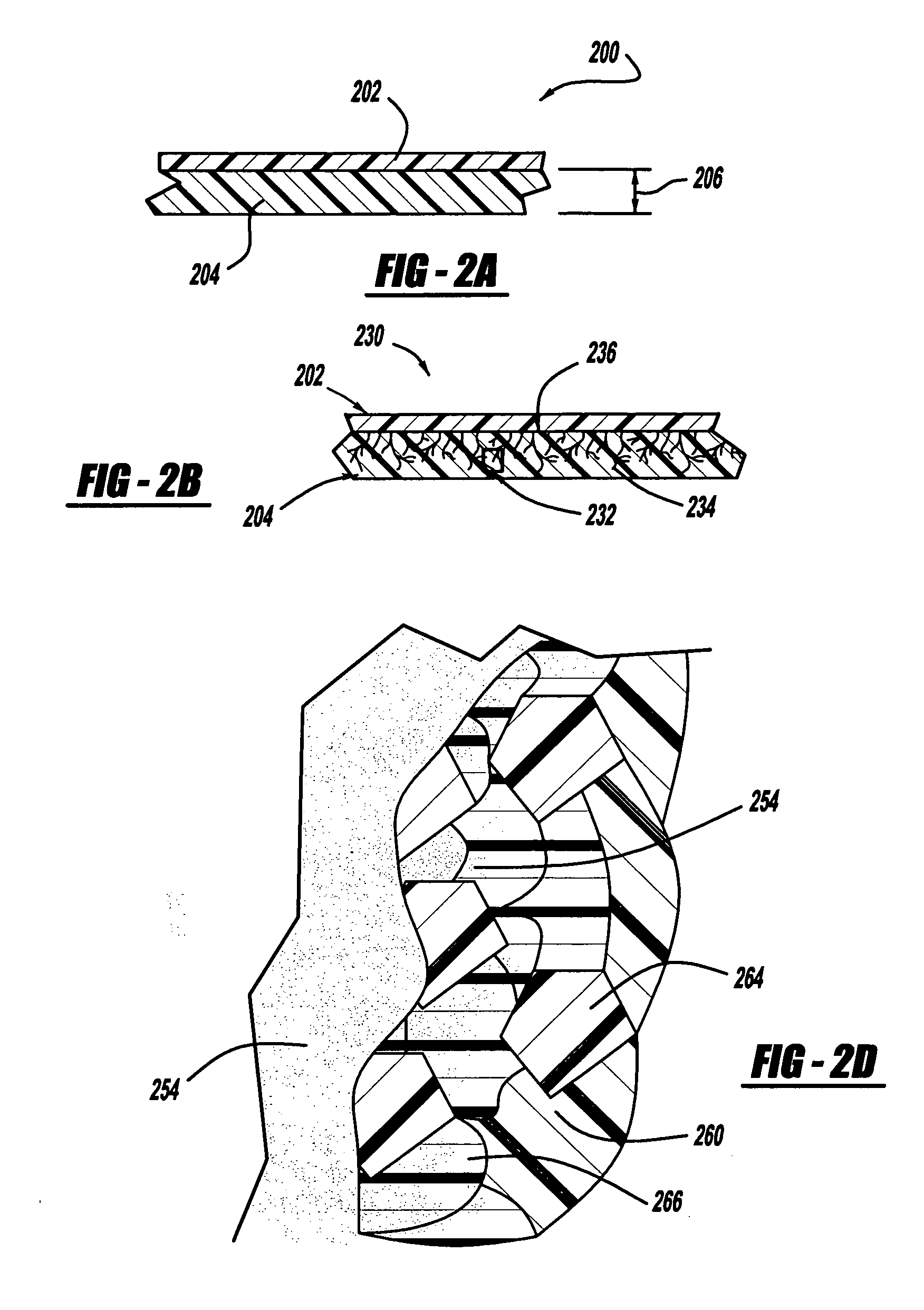

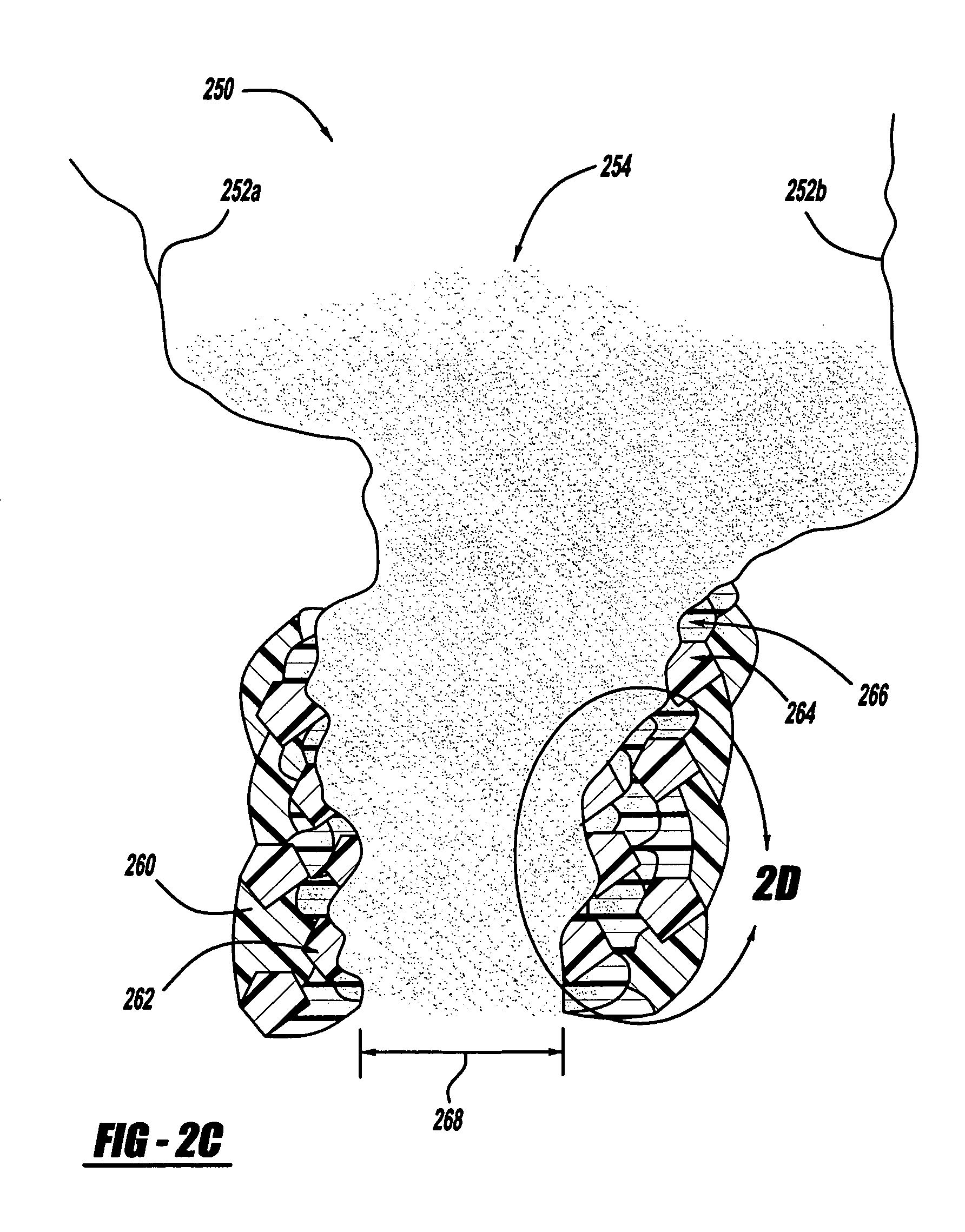

Multifilament aramid yarn with high fatigue resistance

A method for obtaining a cord with high fatigue resistance comprised of a multifilament aramid yarn includes the steps of: a) spinning a solution of an aromatic polyamide into a coagulation bath; b) optionally neutralizing and washing the resulting multifilament yarn; c) treating the yarn on-line with a curable epoxy compound, optionally together with or followed by treating the yarn with at least one alkaline curing agent; d) obtaining the yarn having a free epoxide content of not more than 10 mmoles / kg; e) converting the yarn to a cord; g) treating the cord with a coating which is adhesive to rubber and rubber-like materials and different from the curable epoxy compound, and subjecting the cord to a further process f) comprising the step of treating the cord with a curable epoxy compound between steps e) and g).

Owner:TEIJIN ARAMID BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com