Cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and preparation method thereof

A nano-ceramic powder and co-doping technology, which is applied in the field of cerium-calcium double-element co-doped lanthanum zirconate nano-ceramic powder and its preparation, can solve the problems of reducing thermal conductivity and achieve simple equipment and excellent anti-sintering performance , The effect that the preparation process is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

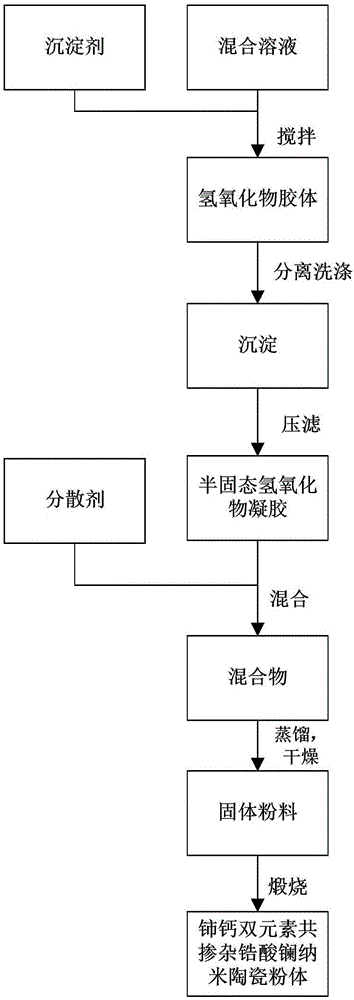

[0034] Please refer to figure 1 , an embodiment of the present invention provides a method for preparing a cerium-calcium double-element co-doped lanthanum zirconate nano-ceramic powder, comprising the following steps:

[0035] S1, mixing cerium salt, calcium salt, zirconium salt and lanthanum salt with a concentration of 0.1-1mol / L to prepare a mixed solution, adding the mixed solution to the precipitant by reverse titration, stirring and standing for aging, A hydroxide colloid is obtained.

[0036] In step S1, the cerium salt is ceric sulfate or cerium nitrate, the calcium salt is calcium nitrate, calcium chloride or calcium sulfate, the zirconium salt is zirconium oxychloride, and the lanthanum salt is lanthanum nitrate or lanthanum chloride. In the mixed solution, calcium ions, The molar ratio of cerium ion, zirconium ion and lanthanum ion is 1:7:14:18~2:5:7:6, the precipitation agent is ammonia water or ammonium oxalate, the volume concentration of ammonia water is 25%~1...

Embodiment 1

[0049] Mix cerium nitrate solution with a concentration of 0.2mol / L, zirconium oxychloride solution with a concentration of 0.356mol / L, calcium nitrate solution with a concentration of 0.5mol / L and lanthanum nitrate solution with a concentration of 0.5mol / L to prepare calcium The molar ratio of ions, cerium ions, zirconium ions and lanthanum ions is a mixed solution of 1:7:14:18, and the mixed solution is added to ammonia water with a volume concentration of 40% by reverse titration, and stirred into the ammonia water reaction system The pH value of the solution reaches 10, and it is left to age for 12 hours to obtain the hydroxide colloid; the hydroxide colloid is separated and washed by inorganic ceramic membrane separation technology to obtain a precipitate and a solution, and the pH value of the solution is measured. If the pH value of the solution is greater than 7 , then continue to separate until the pH value of the solution is 7 and the solution reacts with silver nitra...

Embodiment 2

[0052] Mix cerium nitrate solution with a concentration of 0.15mol / L, zirconium oxychloride solution with a concentration of 0.45mol / L, calcium nitrate solution with a concentration of 0.6mol / L and lanthanum nitrate solution with a concentration of 0.65mol / L to prepare calcium The molar ratio of ions, cerium ions, zirconium ions and lanthanum ions is a mixed solution of 1:4:7:8, and the mixed solution is added to ammonia water with a volume concentration of 30% by reverse titration, and stirred into the ammonia water reaction system The pH value of the solution reaches 11, and it is left to age for 11 hours to obtain the hydroxide colloid; the hydroxide colloid is separated and washed by inorganic ceramic membrane separation technology to obtain a precipitate and a solution, and the pH value of the solution is measured. If the pH value of the solution is greater than 7 , then continue to separate until the pH value of the solution is 7 and the solution does not react with silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com