Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185 results about "Lanthanum Ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum Cation (3) is the ionized form of lanthanum (trivalent ion) with phosphate binding property. Lanthanum ion binds dietary phosphate and inhibits the absorption of phosphate by forming highly insoluble lanthanum-phosphate complexes that reduce the concentrations of serum phosphate and calcium phosphate.

Lanthanum and magnesium doped high-nickel ternary lithium battery positive electrode material and preparation method

InactiveCN108550822AImprove electrochemical performanceStable structureCell electrodesSecondary cellsMaterial synthesisCobalt

The invention provides a lanthanum and magnesium doped high-nickel ternary lithium battery positive electrode material and a preparation method. A nickel source, a cobalt source and a manganese sourceare mixed with a lanthanum source and a magnesium source uniformly, then a precipitating agent and a chelating agent are added so as to prepare an NCM precursor paste, and the lanthanum doped high-nickel ternary cathode material Li<1.05-x>Mg<x>Ni<1-2y-z>Co<y>Mn<y>La<z>O<2> is synthesized through pre-sintering and sintering, wherein x is greater than 0 and is less than 0.05, y is greater than 0 and is less than or equal to 0.1, and z is greater than 0 and is less than or equal to 0.05. Through adoption of the high-nickel ternary lithium battery positive electrode material, the defect of low cycle stability of the traditional high-nickel ternary positive electrode material is overcome; lanthanum replaces cobalt and is doped in the lattice, and magnesium replaces lithium and is doped in thelattice, so that the doped lanthanum ions can effectively shorten the length of an axis c in the lattice and improve the ratio of an axis a to the axis c; the positive electrode material is synthesized and is guided to grow a better laminated structure, so that the material structure is more stable; and the doped magnesium impurity prevents cations from being arranged disorderly, so that the electrochemical performance of the positive electrode material is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

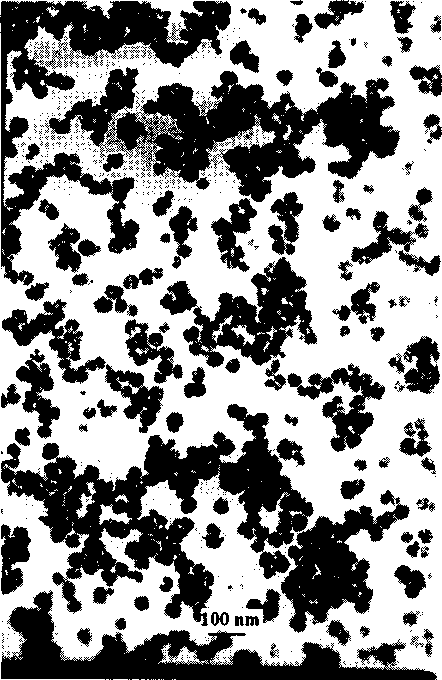

Nano-class conversion fluorescence material on fluoride matrix and its preparing process

InactiveCN1376759ASmall and uniform particle sizeThe particle size can be adjusted at willNanotechLuminescent compositionsYtterbium fluorideGadolinium oxide

A nano-class conversion fluorescent material used for biomolecular fluorescent marker is prepared through dissolving yttrium (or lanthanum or gadolinium) oxide in acid to obtain solution A, adding aminocarboxylic comple, adding it to the solution of fluoride, centrifugal treating, drying to obtain precursor, and high-temp calcining. Its advantages are 37-166 nm of granularity, low calcining temp and strong fluorescence.

Owner:CAPITALBIO CORP +1

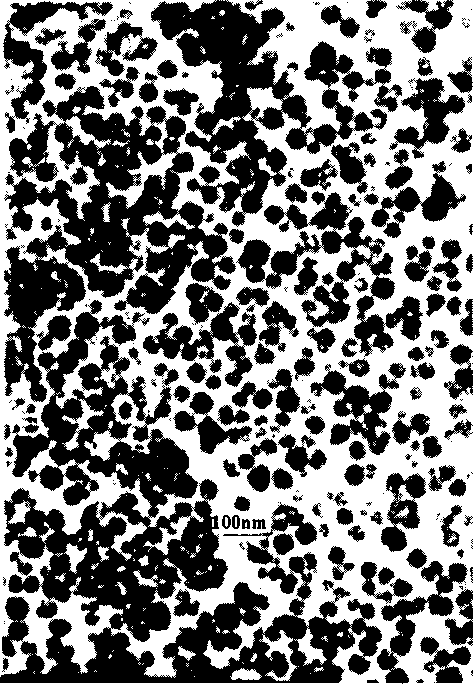

Ion thermal growth method of near infrared light upper conversion fluoride nano crystal

InactiveCN101476151ALow melting pointNon-volatilePolycrystalline material growthFrom normal temperature solutionsSolubilityLuminous intensity

The invention relates to an ion thermal growth method for converting fluoride nano crystal near infrared light which includes steps as follows: weighing some solid yttrium nitrate (lanthanum nitrate), ytterbium nitrate, erbium nitrate (thulium nitrate or holmium nitrate) pro rata. Mol ratio of the rare earth ion is that yttrium ion (lanthanum ion) : ytterbium ion : erbium ion (thulium ion, holmium ion) equal to 70-90 : 0 : 0.001-15; adding tetrafluoroborate type ion liquor into the mixing solid, selective adding some NaCl solid according with various basic, then placing the mixing solution into a high pressure reaction kettle with polyfluortetraethylene lining, placing into an oven for heating reacting, finally, washing, centrifugating, drying and obtaining the product. The prepared nano upper converting fluorescence material has small and uniform granule, strong lighting strength, better water-solubility and can satisfy need of biomolecule fluorescence mark material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for subjecting TiO2 photocatalyst to be supported on honeycomb ceramics surface

InactiveCN1962061ALarge specific surface areaGood light transmissionWater/sewage treatment by irradiationCatalyst activation/preparationOrthogonal methodHoneycomb

The invention relates to a method for preparing TiO2 catalyst on the surface carrier of three-dimension beehive ceramic network, wherein it uses orthogonal method to prepare the titanic acid gel and the titanic acid gel with silver, iron, or lanthanum ion; uses dichroite beehive cermai and beehive ceramic as carrier; using gel-sol method to carry the titanic acid gel on the carrier. The load amount of optical catalyst film on the ceramic carrier is 0.21mg / cm2; the TiO2 diameter is 15-20nm; the thickness of load film is 300-400nm; when using it to purify the formaldehyde, and the initial density is 0.42-0.49mg / m3, the formaldehyde density will be lower than 72.2-74% after seven hours; when using it to disinfect, and the initial virus density is 554-924cfu / m3, the virus number is reduced 67.0-75.9% after 14.5h.

Owner:JIANGSU GAOCHUN CERAMICS

Lanthanum-ferrite-doping formaldehyde gas sensitive material and preparation method thereof

InactiveCN101852754AHigh sensitivityGood choiceIron compoundsMaterial resistanceMicrowaveElectronegativity

The invention relates to a lanthanum-ferrite-doping formaldehyde gas sensitive material and a preparation method thereof, which belong to the formaldehyde gas sensitive material and the preparation method. The material of the invention comprises raw materials such as lanthanum nitrate, ferric nitrate, citric acid, dispersing agents, metal ions with the similar electronegativity and the ion diameter to iron ions or metal ions with the similar electronegativity and ion diameter to lanthanum ions and the like according to the mol ratio of 1 / 1 / (0.05 to 1.5) / (0.001 to 0.1) / (0.1 to 0.5). The preparation method comprises the steps of solution mixing, microwave reaction, gel drying, grinding and the like. Thereby, the formaldehyde gas sensitive material with the advantages of high sensitivity, good selectivity and high response-recovery time is obtained.

Owner:YUNNAN UNIV

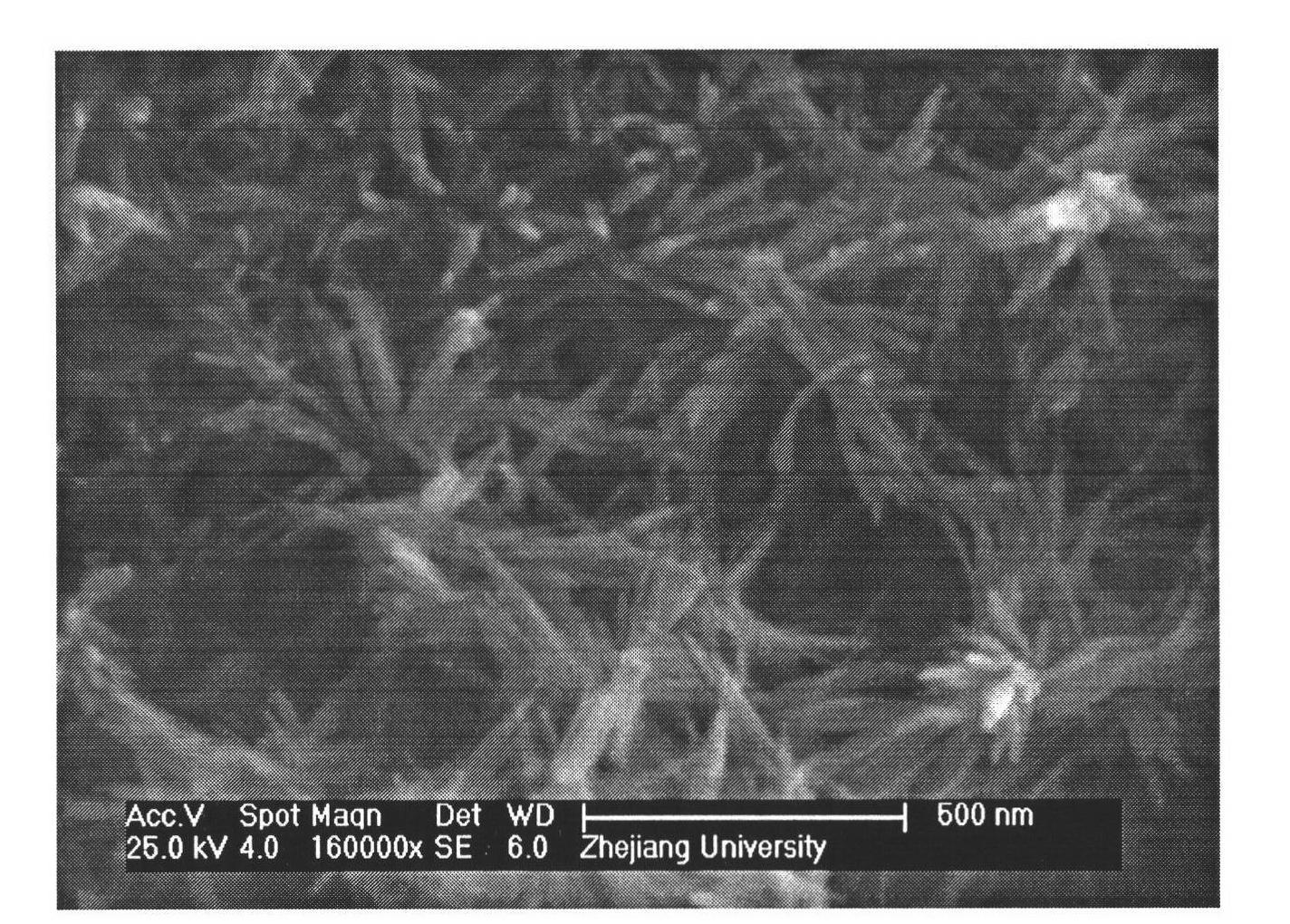

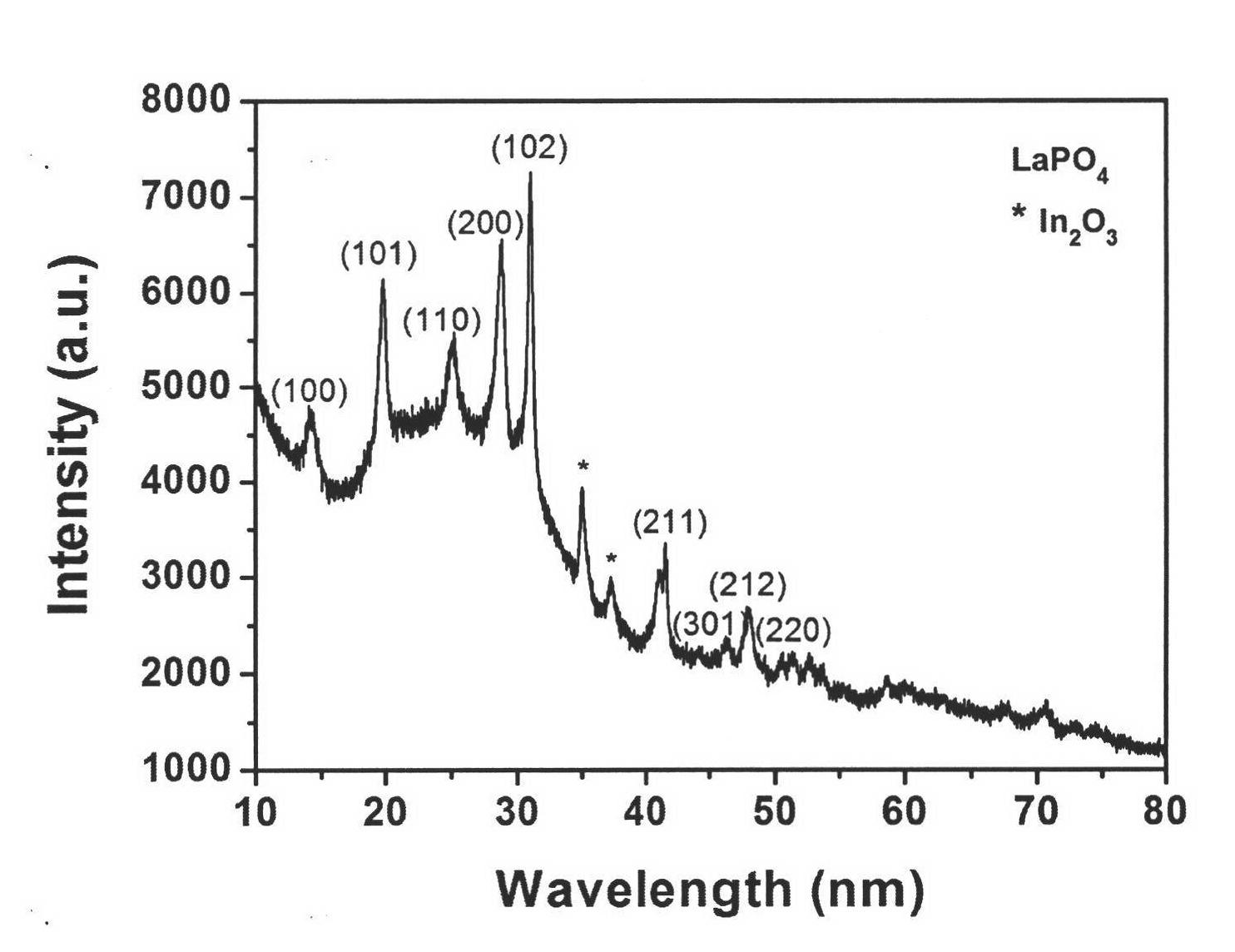

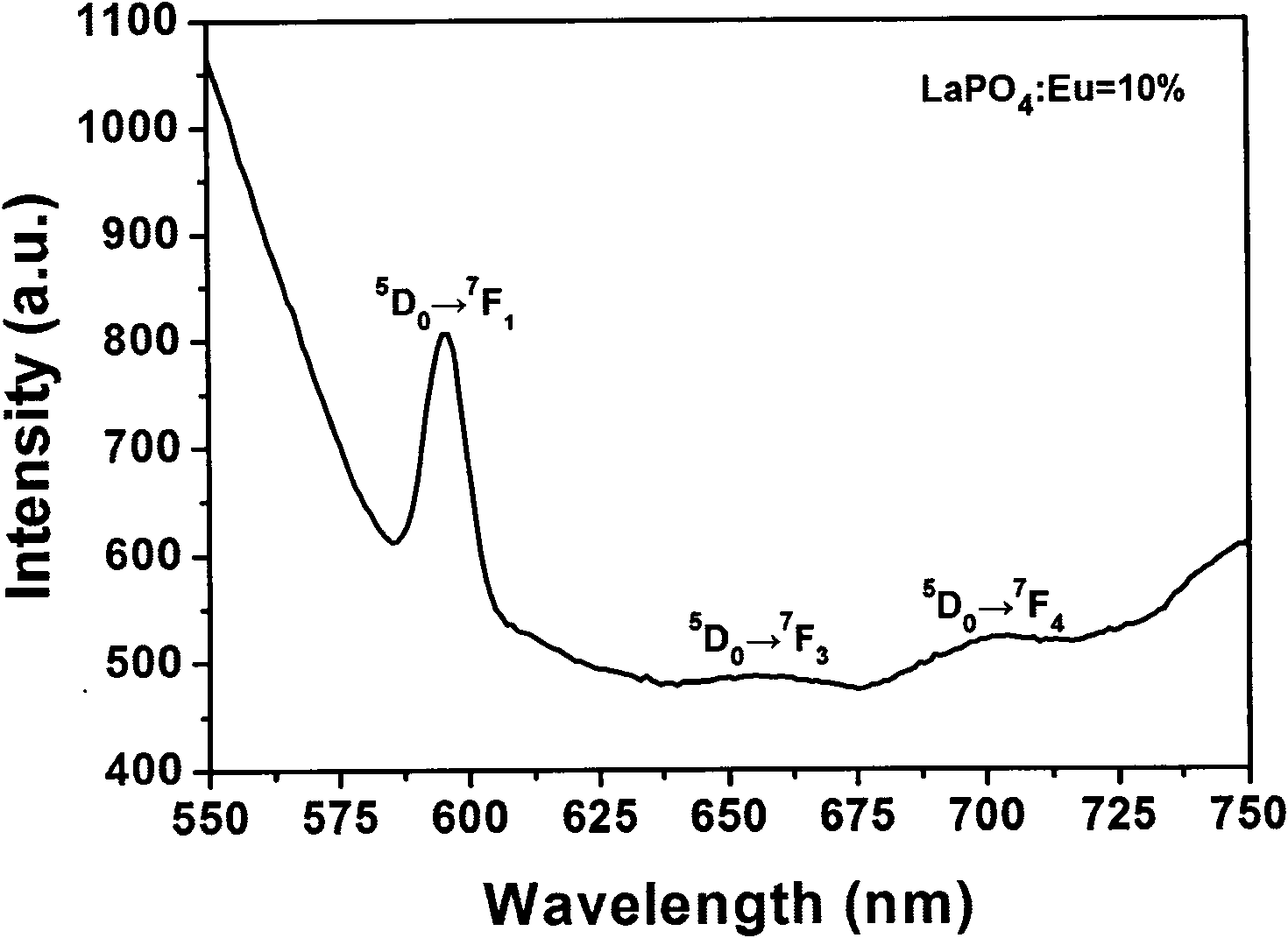

Electrochemical preparation method of lanthanum phosphate or rare earth doped lanthanum phosphate film

InactiveCN101962805ALow growth temperatureHigh crystallinityPolycrystalline material growthElectrolytic inorganic material coatingSodium phosphatesRare earth

The invention discloses a method for preparing a lanthanum phosphate or rare earth doped lanthanum phosphate film through electrodeposition, which comprises the following steps of: (1) cleaning ITO (Indium Tin Oxide) conducting glass 2-3 times with acetone, cleaning the ITO conducting glass with deionized water for 10-30 min in an ultrasonic cleaner, activating the ITO conducting glass in a 10 vol% saltpeter solution for 10-30 s, and cleaning with deionized water for later use; (2) adding a sodium phosphate solution into a 0.005-0.5 mol / L complex solution of ethylene diamine tetraacetic acid and lanthanide ions, and regulating the pH value to 4-6 to obtain an electrolyte for later use; and (3) placing the ITO conducting glass used as a working electrode, a platinum electrode used as a counter electrode and a calomel electrode used as a reference electrode in the electrolyte for electrodeposition to obtain the lanthanum phosphate film, wherein the positive deposition potential relative to the calomel electrode is 1.2-1.8 V. The invention has the advantages of simple equipment, low cost, normal pressure and low temperature. The method not only is applicable to scientific research, but also is hopeful for realizing large-scale industrial production.

Owner:ZHEJIANG UNIV

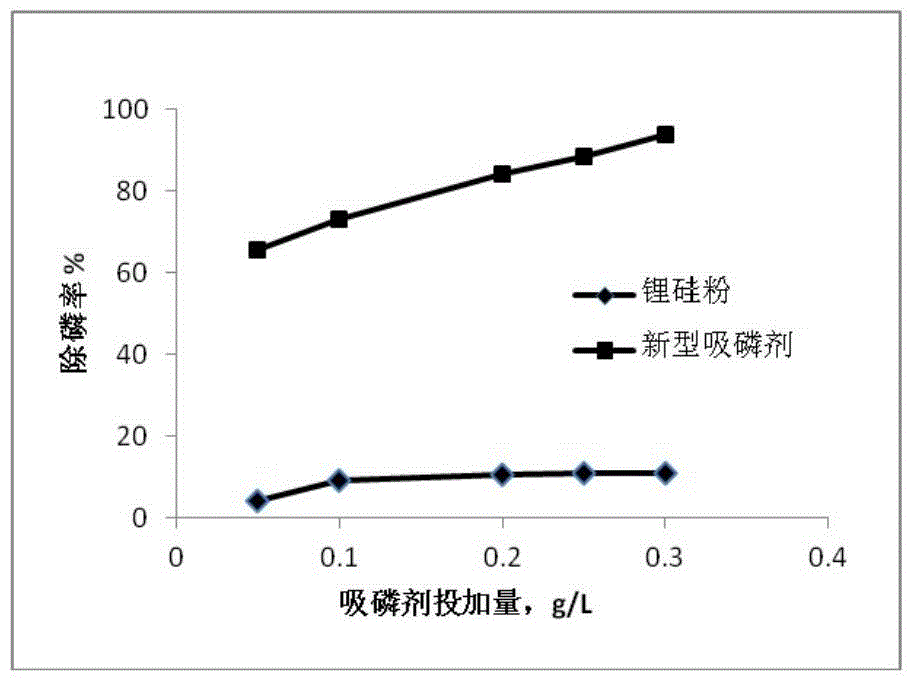

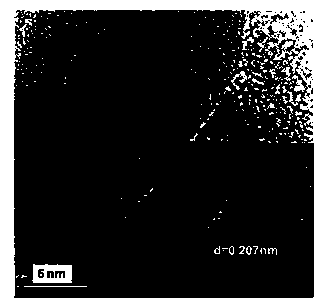

Absorbent used in sewage phosphorus removal, and preparation method thereof

InactiveCN104525090AWell-developed pore structureObvious pleatsOther chemical processesWater contaminantsAbsorption capacitySlag

The invention discloses an absorbent used in sewage phosphorus removal. A carrier of the absorbent is industrial lithium-silicon powder waste slag with a size no lower than 150 meshes. Lanthanum ions are loaded on the carrier. With the absorbent, the removal rate upon phosphorus in phosphorus-containing sewage and wastewater or natural water body with a total phosphorus concentration of 1mg / L and a pH value of 3-8 is always higher than 86%. The invention also discloses a preparation method of the absorbent. According to the invention, the carrier raw material lithium-silicon powder adopted by the absorbent is selected from industrial waste slag, such that the source is wide, and cost is low. With a developed pore structure, the carrier can provide sufficient active absorption points. Only trace of rare earth lanthanum used for modification is needed to be added. The obtained absorbent has excellent phosphorus absorption effects in natural water bodies, sewage and wastewater. With the absorbent, an absorption capacity is high, absorbent stability in water body is high, no water body secondary pollution is caused, and cost is low. The absorbent has a good application prospect.

Owner:SICHUAN UNIV

Nano-copper-cobalt bimetallic catalyst as well as preparation method and application thereof

ActiveCN103721721AEnhanced interactionGood dispersionOrganic compound preparationHydroxy compound preparationDispersityBULK ACTIVE INGREDIENT

The invention discloses a nano-copper-cobalt bimetallic catalyst as well as a preparation method and an application thereof. The catalyst takes SiO2, ZrO2, CeO2 or Al2O3 as a carrier and La2O3 as an aid, and is loaded with an active ingredient Cu[x]Co[1-x]. The preparation method comprises the following steps: soaking a mixed solution of lanthanum ions, copper ions, cobalt ions, citric acid and a chelating agent in the SiO2, ZrO2, CeO2 or Al2O3 carrier, drying and roasting to obtain a catalyst precursor; reducing the precursor through H2, CO or CH4 reducing gas or mixed gas containing the H2, CO or CH4 reducing gas and inert gas to obtain the loaded copper-cobalt bimetallic catalyst taking lanthanum oxide as the aid. The preparation method has the advantages that the interaction among Cu, Co and the lanthanum oxide is facilitated in the process of obtaining the catalyst through the precursor, and the components such as the Cu, the Co and the lanthanum oxide are high in dispersity and good in stability. The catalyst is used in reaction for preparing low-carbon alcohol from synthetic gas, and is relatively high in selectivity, activity and stability on alcohols each with 2-6 carbon atoms.

Owner:TIANJIN UNIV

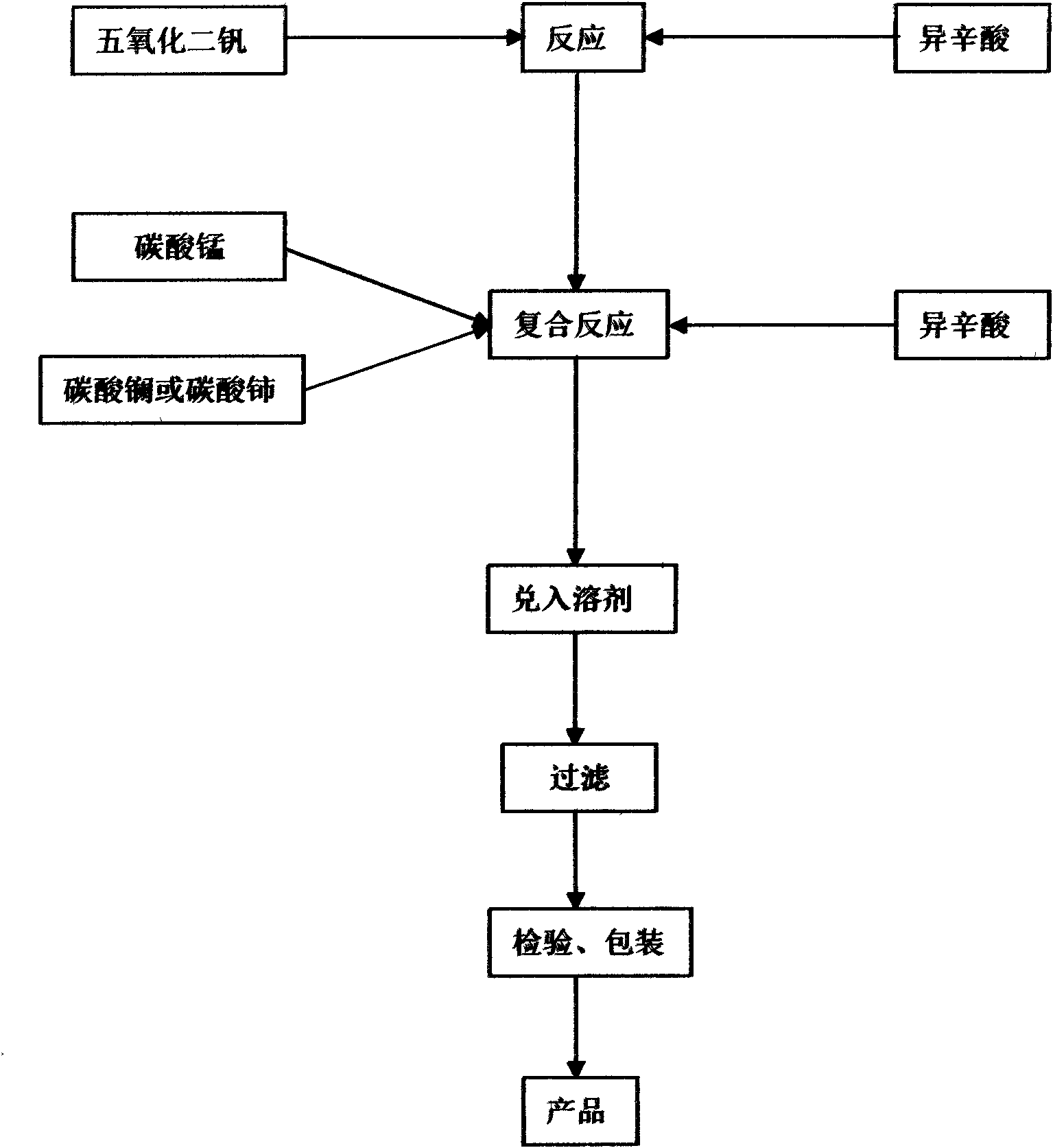

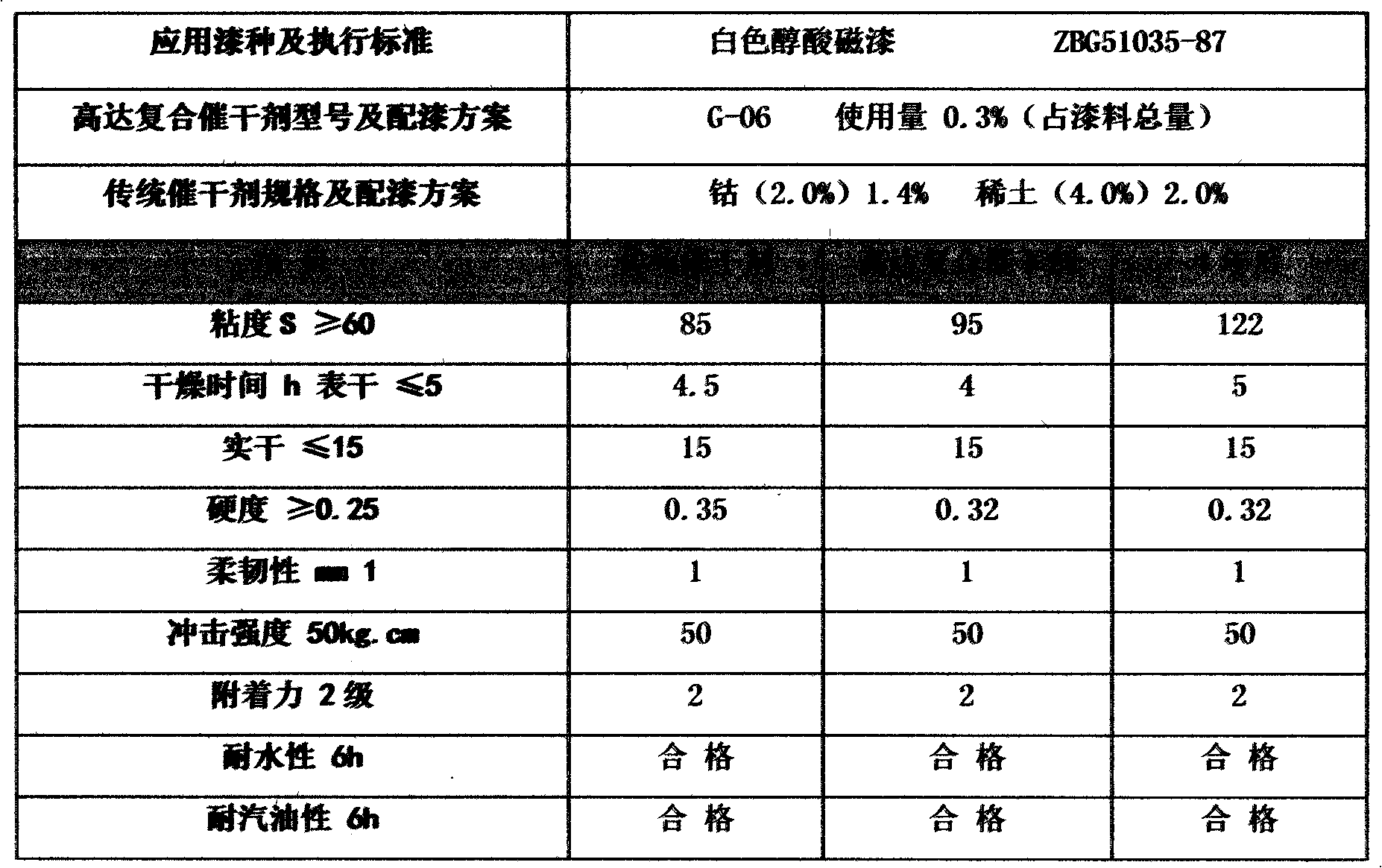

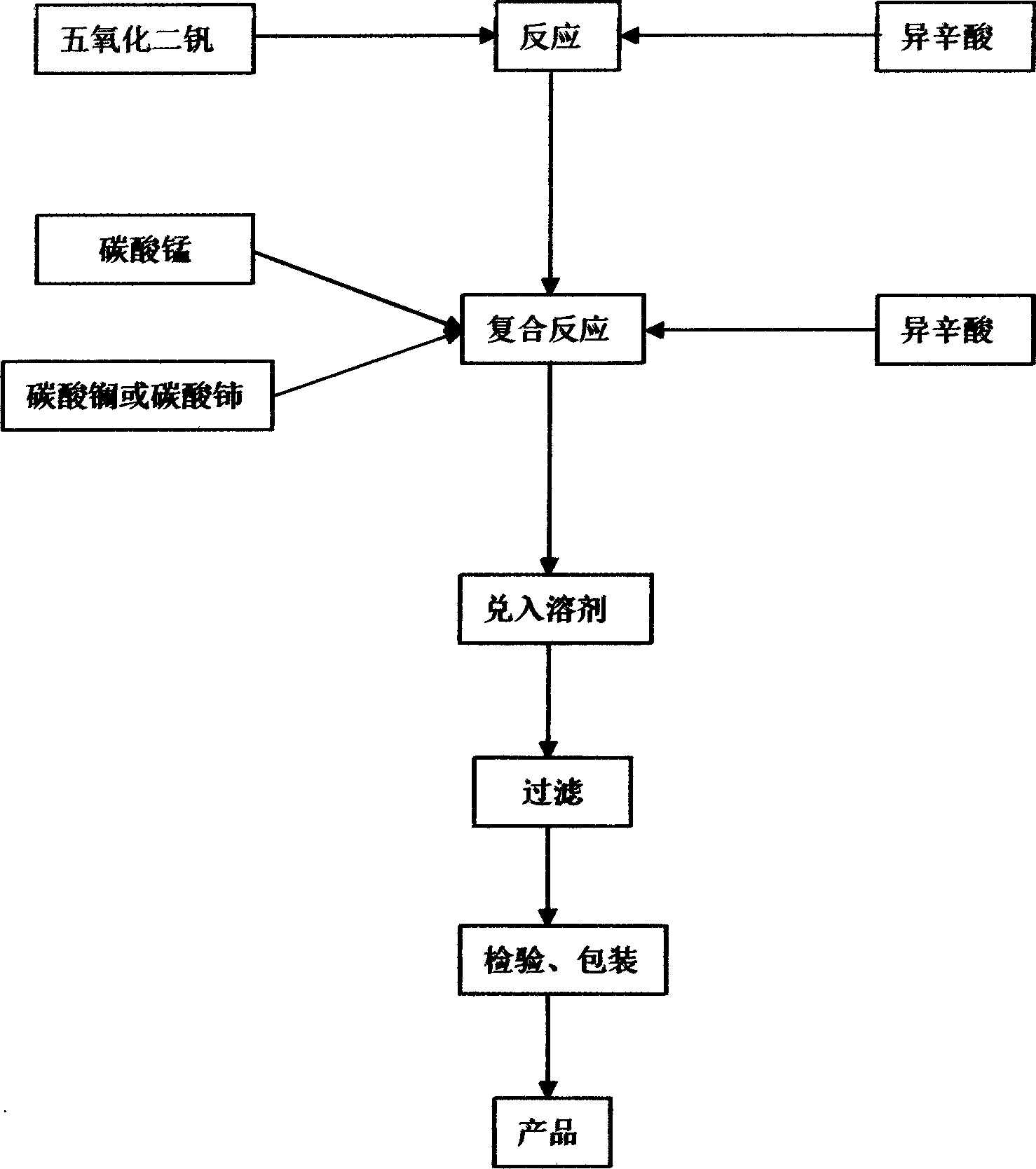

Composite dryer for paint and production method thereof

The invention discloses a production method of a composite dryer for paint. The production method comprises that a mixture of a light rare earth carbonate, manganese carbonate, vanadium pentoxide and isocaprylic acid undergo a composite reaction to produce the composite dryer for paint. The invention also provides the composite dryer for paint. The composite dryer for paint comprises active components of 1.5 to 2wt% of vanadium ions, 1.5 to 2.5wt% of manganese ions and 4 to 4.5wt% of cerium or lanthanum ions, wherein the total valence-alterable metal ion content is in a range of 7 to 9wt%. The composite dryer for paint can fully replace cobalt as a dryer, can eliminate the pollutants of cobalt and lead, and is nontoxic and environmentally friendly. The composite dryer for paint has integrated effects of a plurality of the existing driers. The production method saves a cost, simplifies a paint blending test, and is convenient for production. The composite dryer for paint has a low use amount and a low cost.

Owner:FUZHOU GAODA RARE EARTH MATERIALS

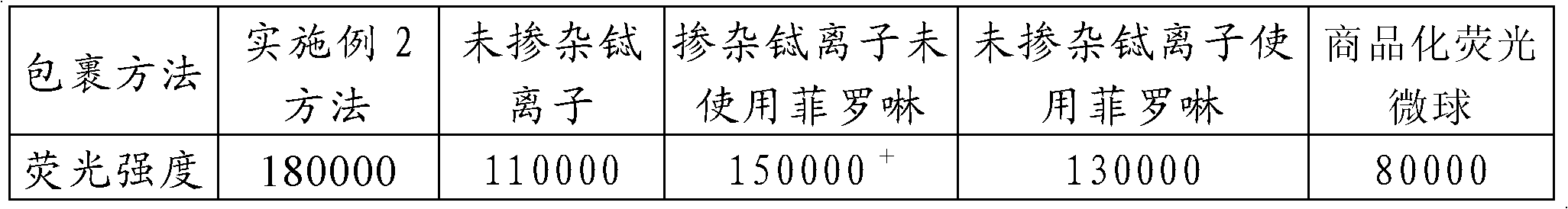

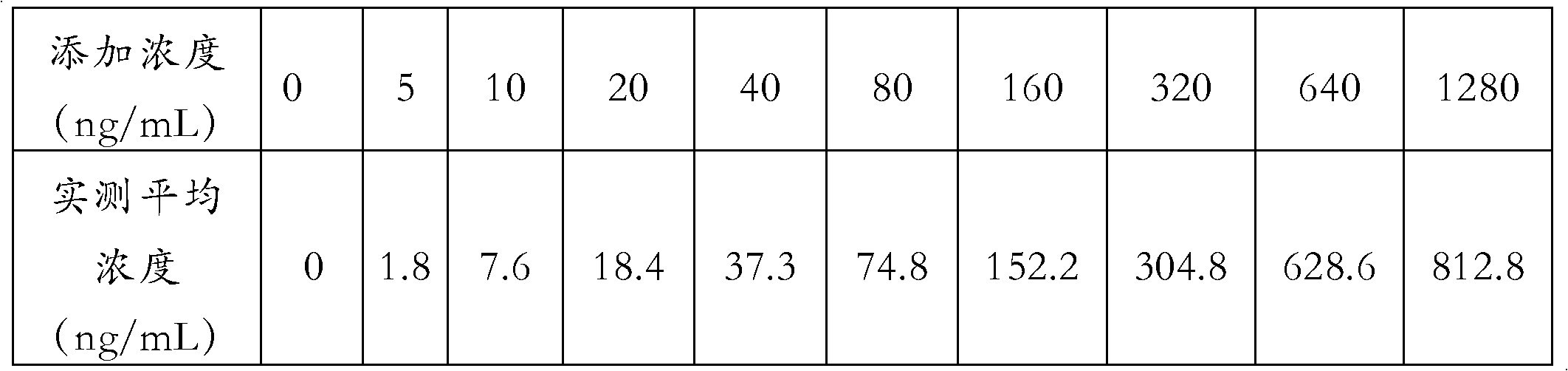

Nano-microsphere time resolution fluorescence probe as well as preparation method and use thereof

ActiveCN103013492AHigh fluorescence intensityImprove stabilityBiological testingFluorescence/phosphorescenceRare-earth elementFluorescence

The invention belongs to the technical field of detection, in particular relates to a nano-microsphere time resolution fluorescence probe as well as a preparation method and use for the nano-microsphere time resolution fluorescence probe, and discloses the nano-microsphere time resolution fluorescence probe. The nano-microsphere time resolution fluorescence probe is a nano-microsphere, which covers a rare earth element fluorescence coordination compound, with the high molecular material. The nano-microsphere time resolution fluorescence probe is characterized in that the rare earth element fluorescence coordination compound comprises the following substances of rare earth element ion, a beta-diketone body chelating agent and a fluorescence enhancement synergist according to a molar ratio of 1:4:5, wherein the rare earth element ion is a double-doping mixture which is formed by Eu<3+> and other lanthanum ions in the molar ratio of (100:1)- (1,000: 1).

Owner:上海溯源生物技术有限公司

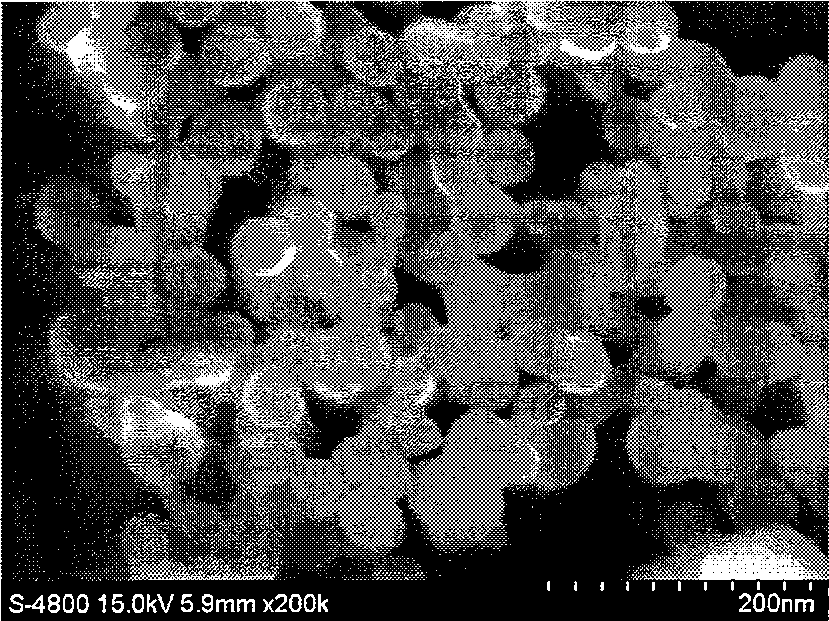

Method for preparing composite dephosphorus adsorbent by virtue of activated carbon fiber loaded with metal

InactiveCN102553533AReduce manufacturing costImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionActivated carbonIron salts

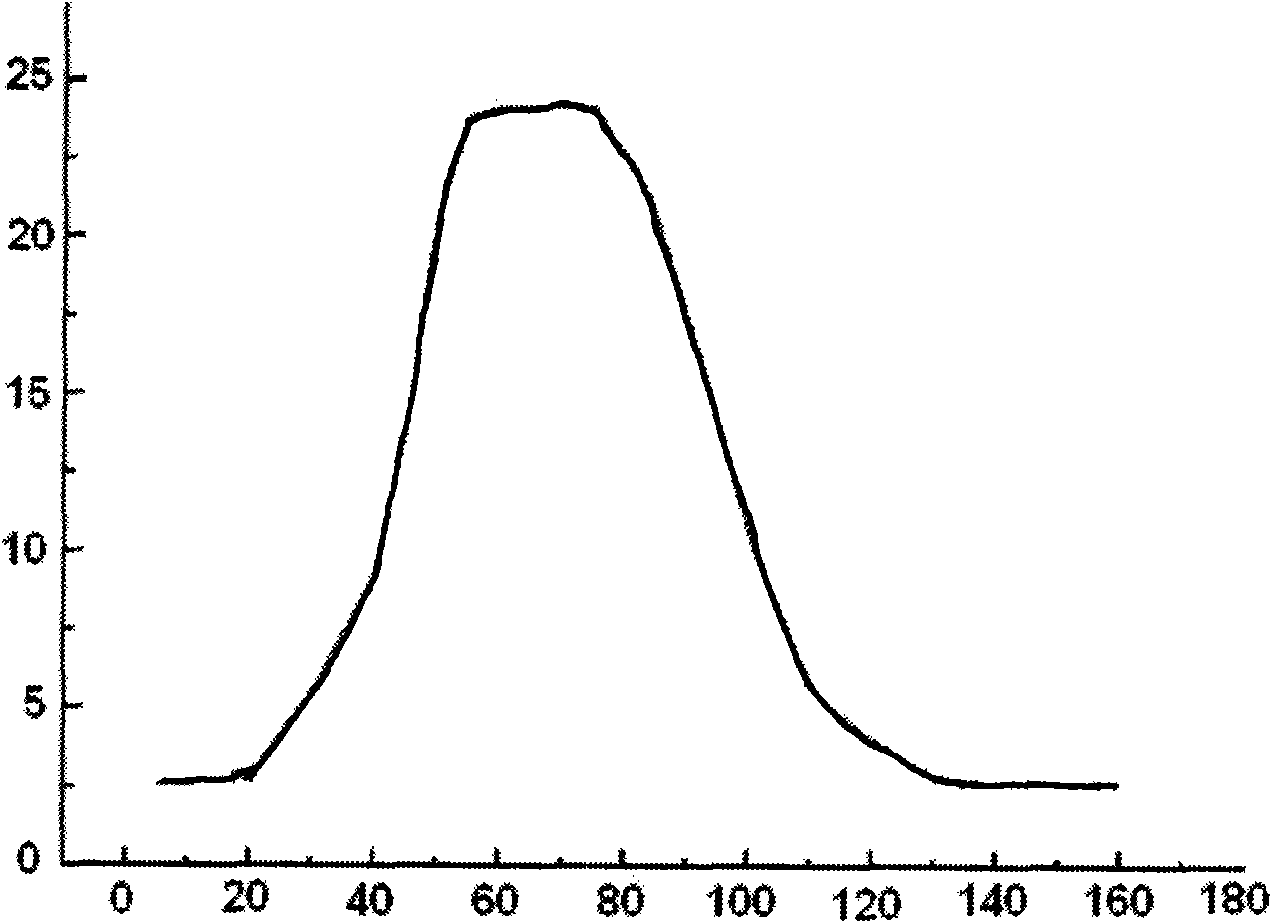

The invention discloses a method for preparing composite dephosphorus adsorbent by virtue of activated carbon fiber loaded with metal. Carbon fiber is used as a matrix which is loaded with a metallic compound. The method comprises the following steps of: a, mixing lanthanum ions into an iron salt for preparing a mixture solution of iron ions and lanthanum ions; b, putting the prepared solution under an ultrasound environment, additionally adding a radiation method, gradually adding a hydroxide solution into a metallic ion mixture solution until the pH reaches 9-10, and obtaining nano-particle suspension liquid of iron and lanthanum composite metal hydroxide; c, shearing activated carbon fiber into pieces, washing, dipping, filtering and drying; d, weighing the activated carbon fiber, adding the activated carbon fiber into the suspension liquid, processing by utilizing ultrasound waves, taking out solid matters, and washing for multiple times until the pH reaches 7; and e, drying the solid matters, obtaining an adsorbent material after cooling, and sealing the adsorbent material for storage. According to the invention, the iron and lanthanum composite metal hydroxide is in uniform particle size distribution on the carbon fiber matrix, has a high adsorption capacity and a low preparation cost and is suitable for industrial application.

Owner:SHANGHAI UNIV

Photocatalytic coating agent, preparation method and coating method thereof

InactiveCN106031887AImprove photocatalytic performanceTightly bondedCatalyst activation/preparationCeriumSilver ion

The present application discloses a photocatalytic coating agent and its preparation method and coating method. The photocatalytic coating agent comprises: composed of the following proportions in parts by mass, 0.1 to 20 parts of nano photocatalyst, binder 0.01 to 2 parts, 0.01 to 3 parts of water-soluble titanium compound and 100 parts of deionized water. The photocatalytic coating agent also comprises 0.001 to 0.2 parts by mass of metal ions; the metal ions are selected from gold ions, silver ions, platinum ions, palladium ions, rhodium ions, iridium ions, copper ions, iron ions , cobalt ions, nickel ions, manganese ions, vanadium ions, chromium ions, tantalum ions, lanthanum ions, cerium ions or a mixture of any proportion. The present application provides a photocatalytic coating agent, which is non-toxic and environmentally friendly, simple and easy to obtain, has high transparency, stable dispersion and suspension, high photocatalytic performance, and is easy to be tightly fixed on various substrate materials.

Owner:李建明

Neutral photocatalytic coating agent, preparation method and coating method thereof

InactiveCN106031886AImprove photocatalytic performanceTightly bondedOrganic-compounds/hydrides/coordination-complexes catalystsPretreated surfacesIridiumCerium

This application discloses a neutral photocatalytic coating agent, a preparation method and a coating method thereof. The neutral photocatalytic coating agent comprises, by mass, 0.1-20 parts of a nanometer photocatalytic material, 0.01-2 parts of a binder, 0.01-3 parts of a water-soluble titanium compound, a pH value adjusting agent, and 100 parts of deionized water, wherein the pH value of the neutral photocatalytic coating agent can achieve 6-8 with the pH value adjusting agent, the neutral photocatalytic coating agent further contains 0.001-0.2 part by mass of meta ions, and the metal ions are one or a mixture comprising a plurality of materials selected from gold ions, silver ion, platinum ion, palladium ion, rhodium ion, iridium ion, copper ions, iron ions, cobalt ions, nickel ions, manganese ions, vanadium ions, chromium ions, tantalum ions, lanthanum ions and cerium ions according to any ratios. The neutral photocatalytic coating agent of the present invention is neutral, non-corrosive and non-toxic, and has characteristics of environment protection, simpleness, easy obtaining, high transparency, stable dispersing and suspending property, and has high photocatalytic performance.

Owner:李建明

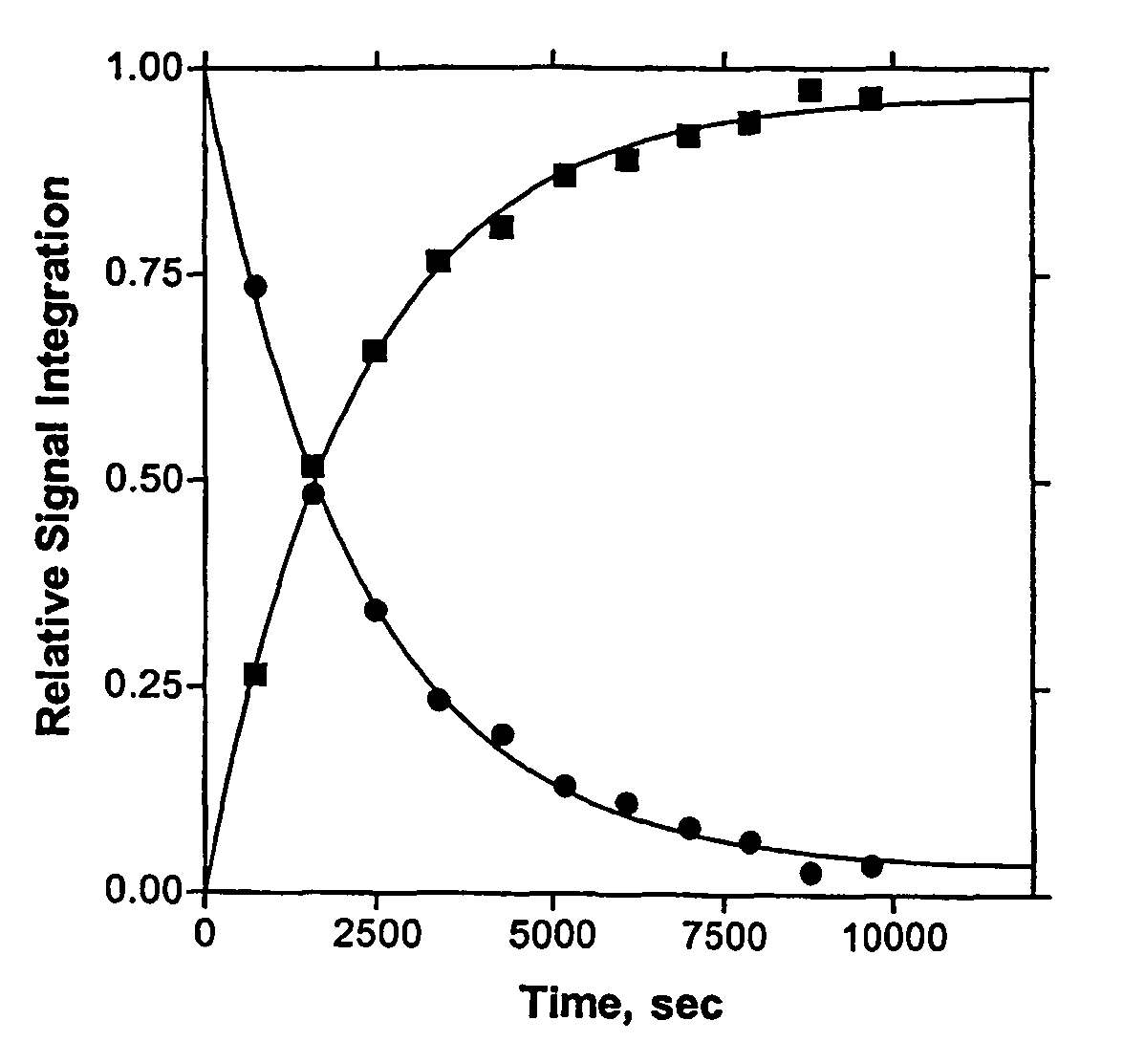

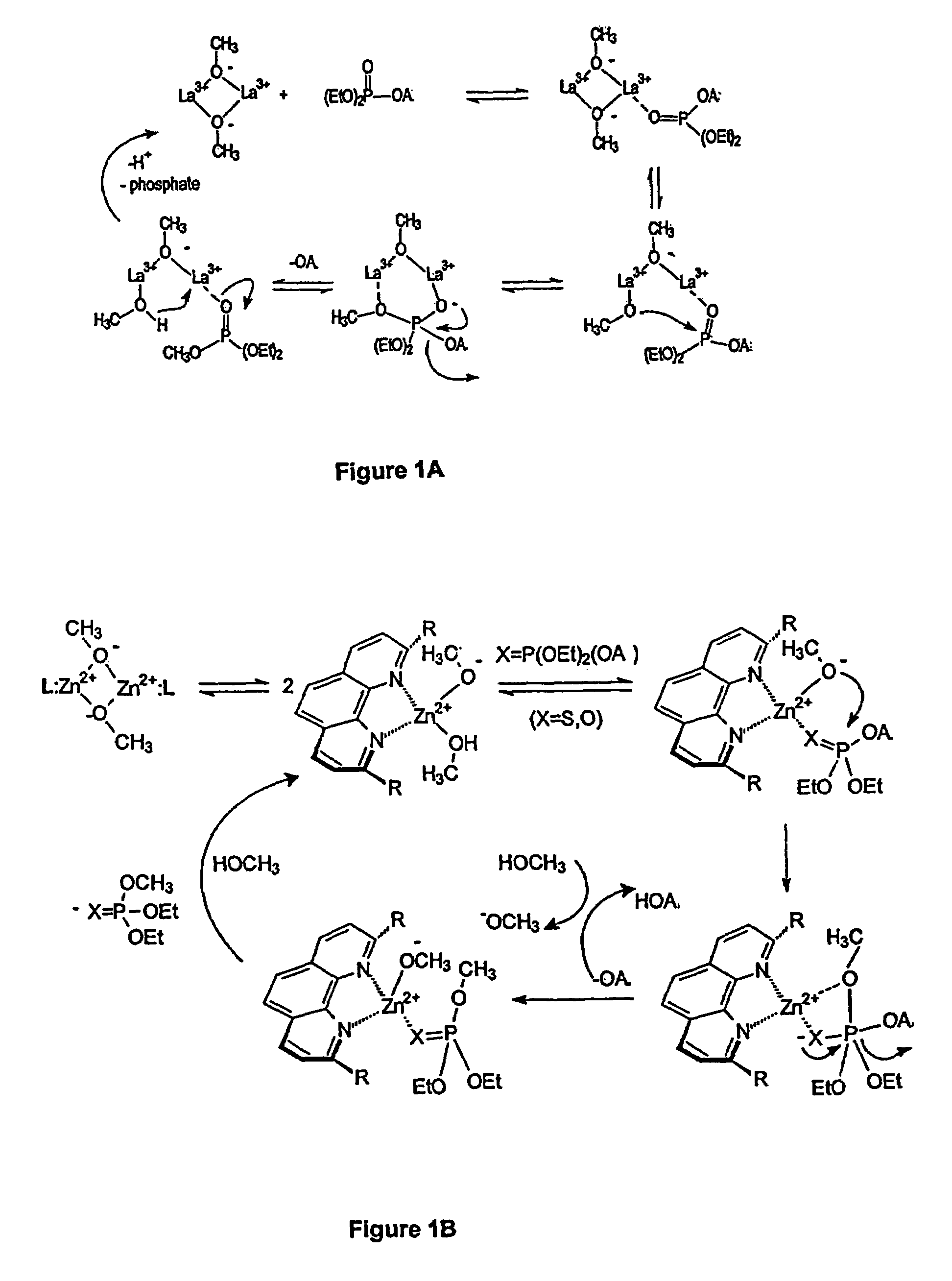

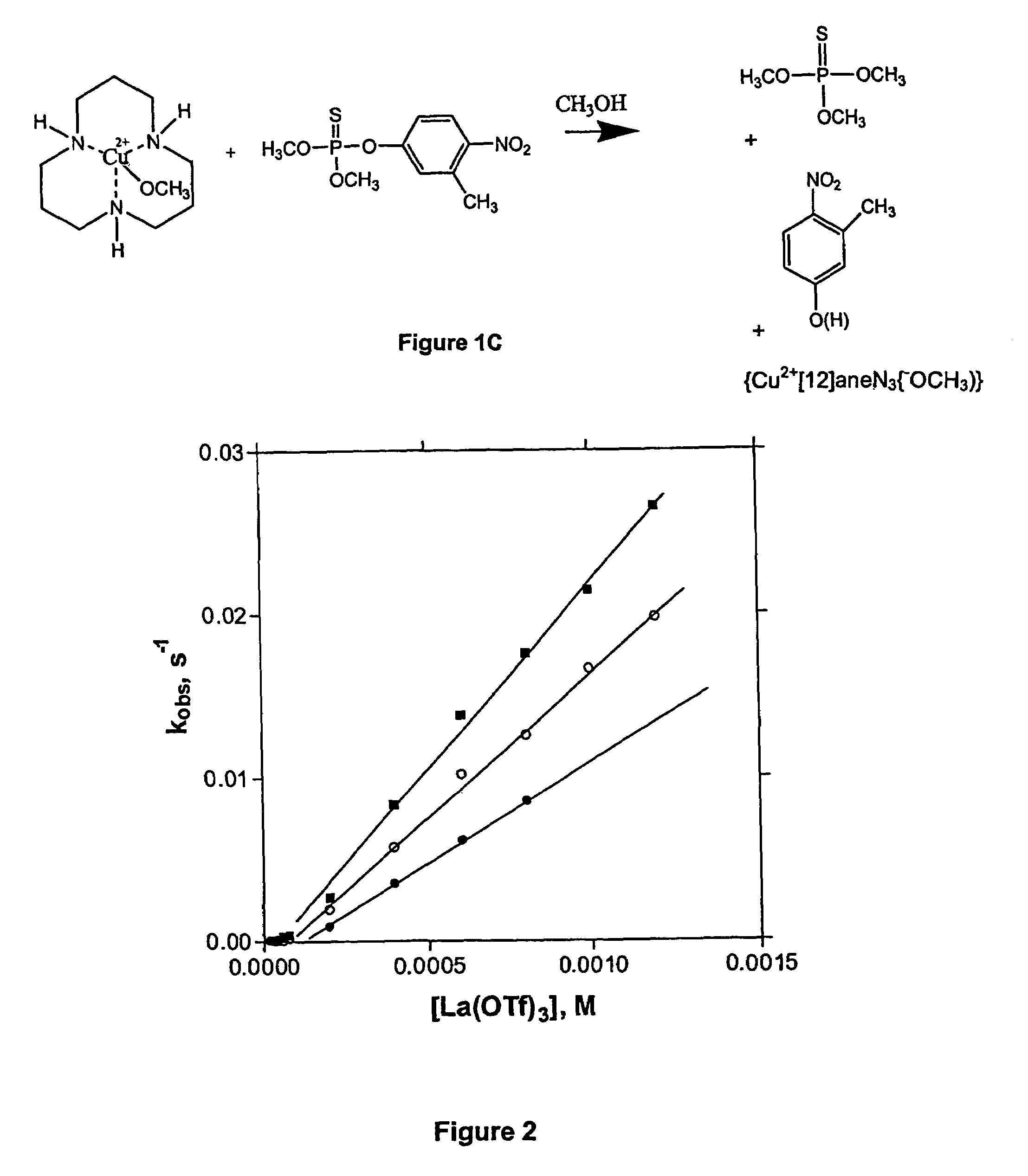

Method of decomposing organophosphorus compounds

ActiveUS7214836B2Easily and safely disposedCost efficientOrganic compound preparationPreparation by hydrolysisAlcoholLanthanum Ion

Methods and kits for decomposing organophosphorus compounds in non-aqueous media at ambient conditions are described. Insecticides, pesticides, and chemical warfare agents can be quickly decomposed to non-toxic products. The method comprises combining the organophosphorus compound with a non-aqueous solution, preferably an alcohol, comprising metal ions and at least a trace amount of alkoxide ions. In a first preferred embodiment, the metal ion is a lanthanum ion. In a second preferred embodiment, the metal ion is a transition metal.

Owner:QUEENS UNIV OF KINGSTON

Lanthanum-loaded di-amino modified meso-porous silicon material and preparation method thereof

InactiveCN106964317ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsPhosphate ionSewage

The invention discloses a lanthanum-loaded di-amino modified meso-porous silicon material and a preparation method thereof. The preparation method comprises the following steps: preparing MCM-41 meso-porous silicon material by using sodium hydroxide, cetyl trimethylammonium bromide, tetraethyl orthosilicate and water as raw materials; then carrying out di-amino modification on the MCM-41 meso-porous silicon material to obtain a di-amino modified meso-porous silicon material; and finally carrying out lanthanum loading with lanthanum nitrate isopropanol to obtain the lanthanum-loaded di-amino modified meso-porous silicon material. A large number of lanthanum ions are loaded on the surface of the material, by effects of the lanthanum ions and phosphate in water, the phosphate is fixed on the surface of an adsorption material, and therefore, phosphate ions in the water are removed. The lanthanum-loaded di-amino modified meso-porous silicon material can be used for an adsorption phosphorous removal process of sewage, the adsorption capacity can reach 38 mg / g or above, and therefore, the preparation method has good application prospect in the aspect of preparation of a phosphate adsorbent.

Owner:HEBEI NORMAL UNIV

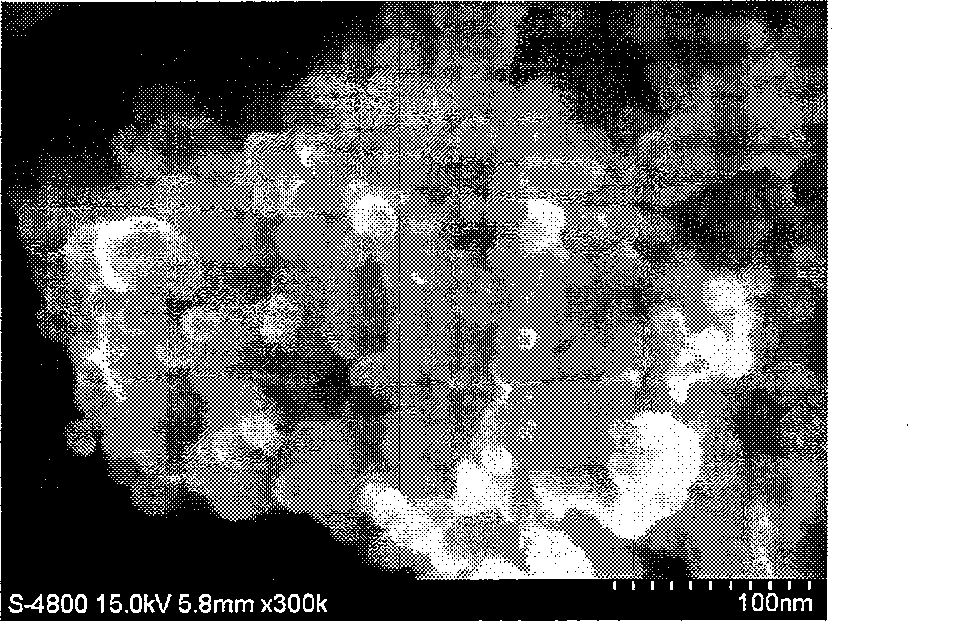

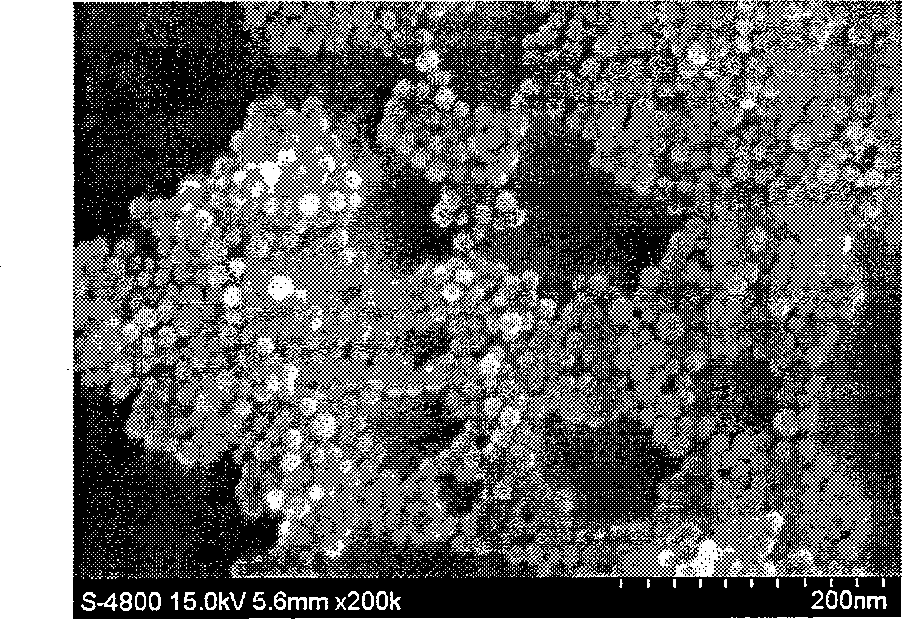

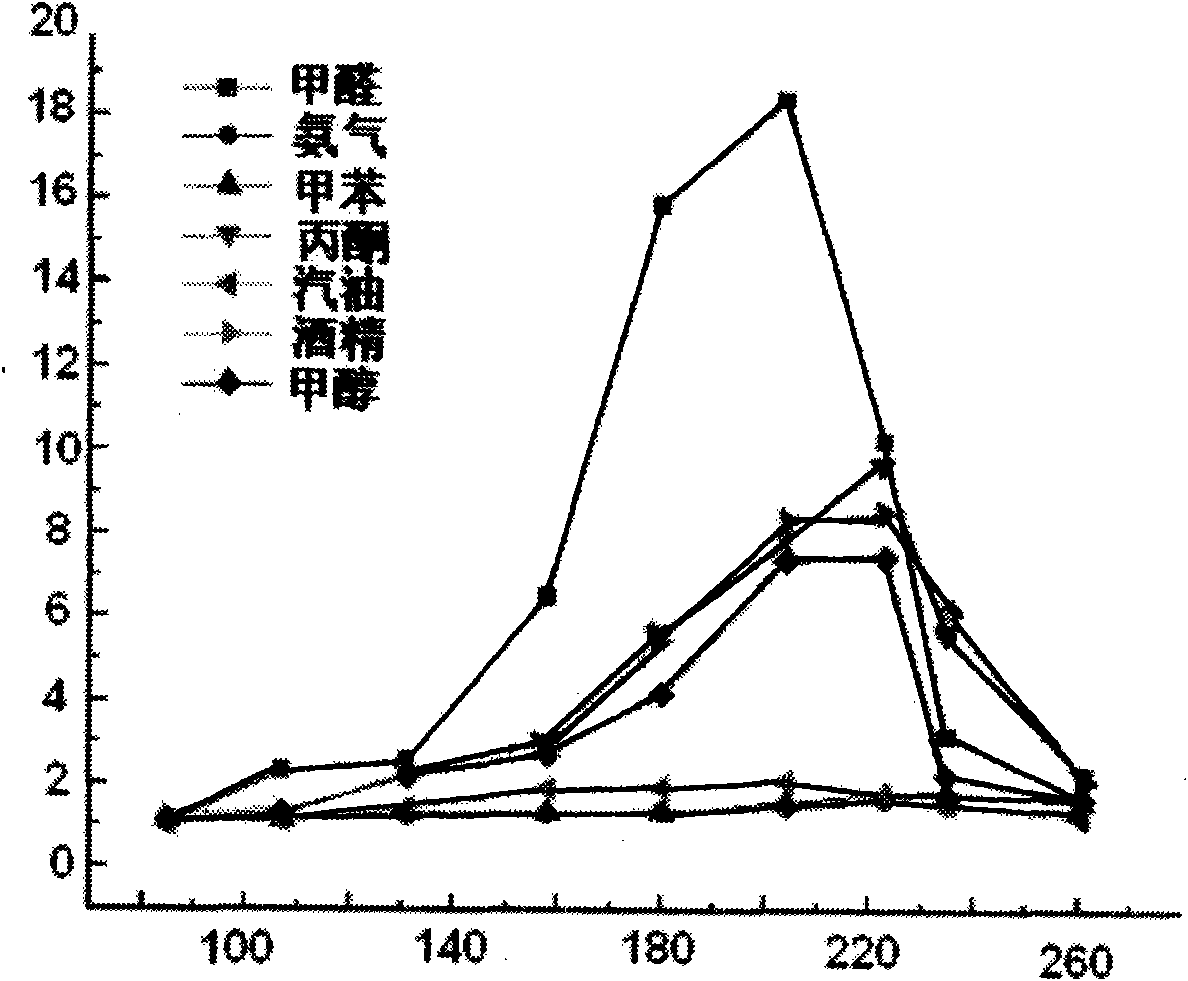

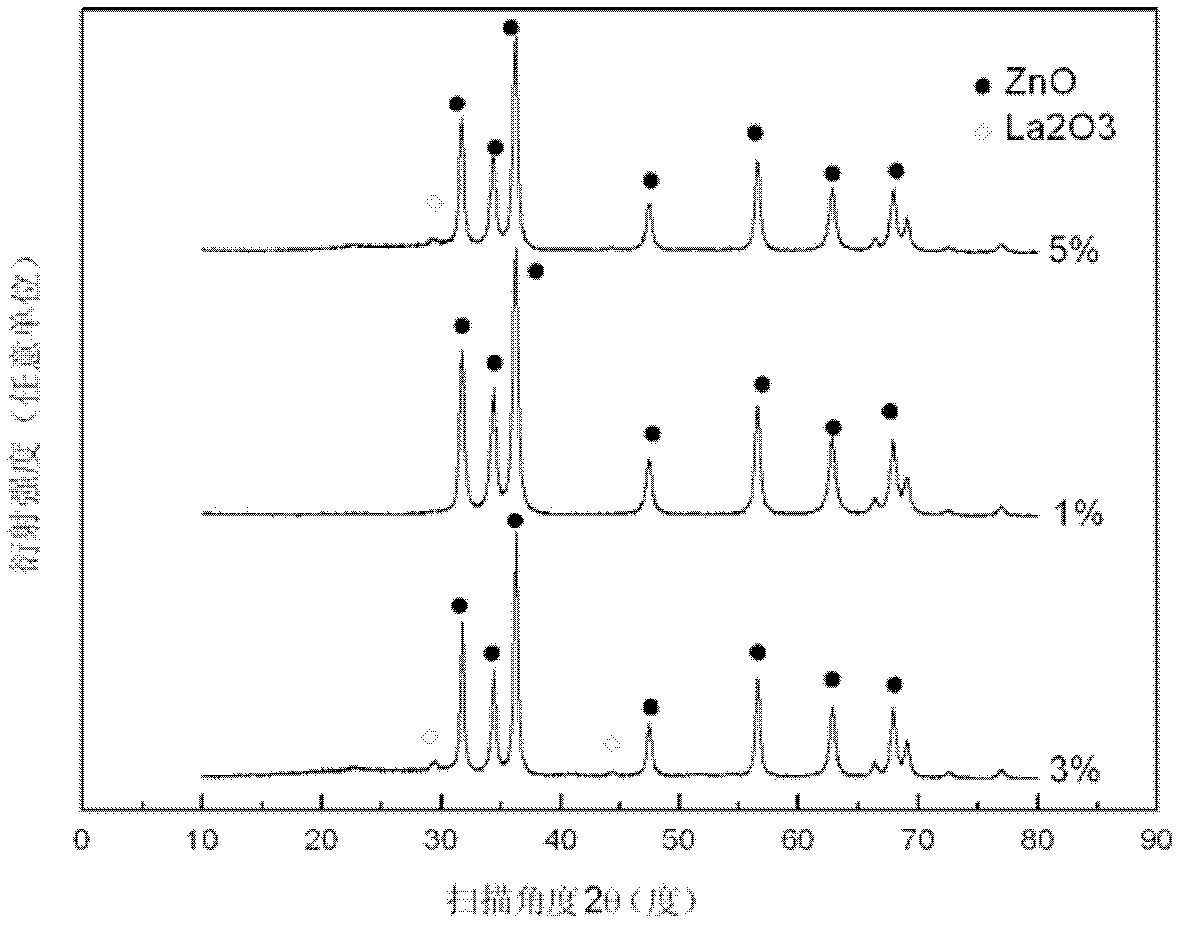

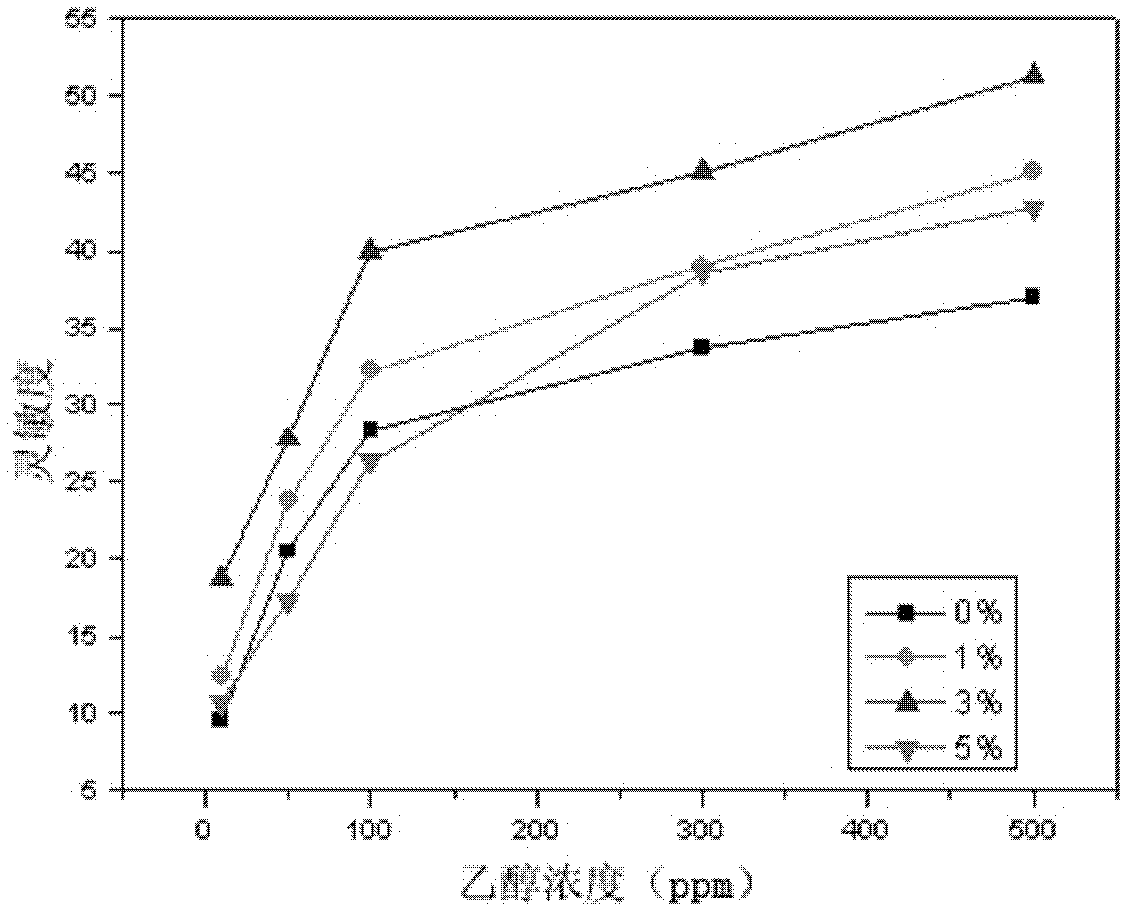

Preparation method and application of lanthanum ion-doped zinc oxide porous hollow sphere

InactiveCN102320648AIncrease the amount of adsorbed oxygenIncrease contact areaMaterial nanotechnologyZinc oxides/hydroxidesActive agentSlurry

A preparation method of lanthanum ion-doped zinc oxide porous hollow spheres uses lanthanum nitrate, hexamethylene tetramine and zinc nitrate as raw materials, uses sodium citrate as a surfactant, and performs a coprecipitation reaction in water for preparation; the lanthanum ion-doped zinc oxide porous hollow spheres are used to prepare side-heating gas-sensitive elements, and the method for preparing a side-heating gas-sensitive element comprises the following steps: mixing and uniformly blending lanthanum ion-doped zinc oxide powder and terpineol to prepare slurry, coating the slurry on a ceramic tube surface, performing high-temperature sintering and aging. The advantages and positive effects of the invention are that: 1) compared with other methods, the preparation method of liquid doped La3+ nanometer ZnO porous hollow spheres is simple in process, and low in cost; 2) the method can obtain uniformly-distributed ZnO nanometer porous hollow spheres with large specific surface area; 3) when the material is used to prepare side-heating gas-sensitive elements, the porous structure allows gas to contact fully, and the material is widely applicable to gas monitoring of ethanol, formaldehyde, ammonia, hydrogen.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

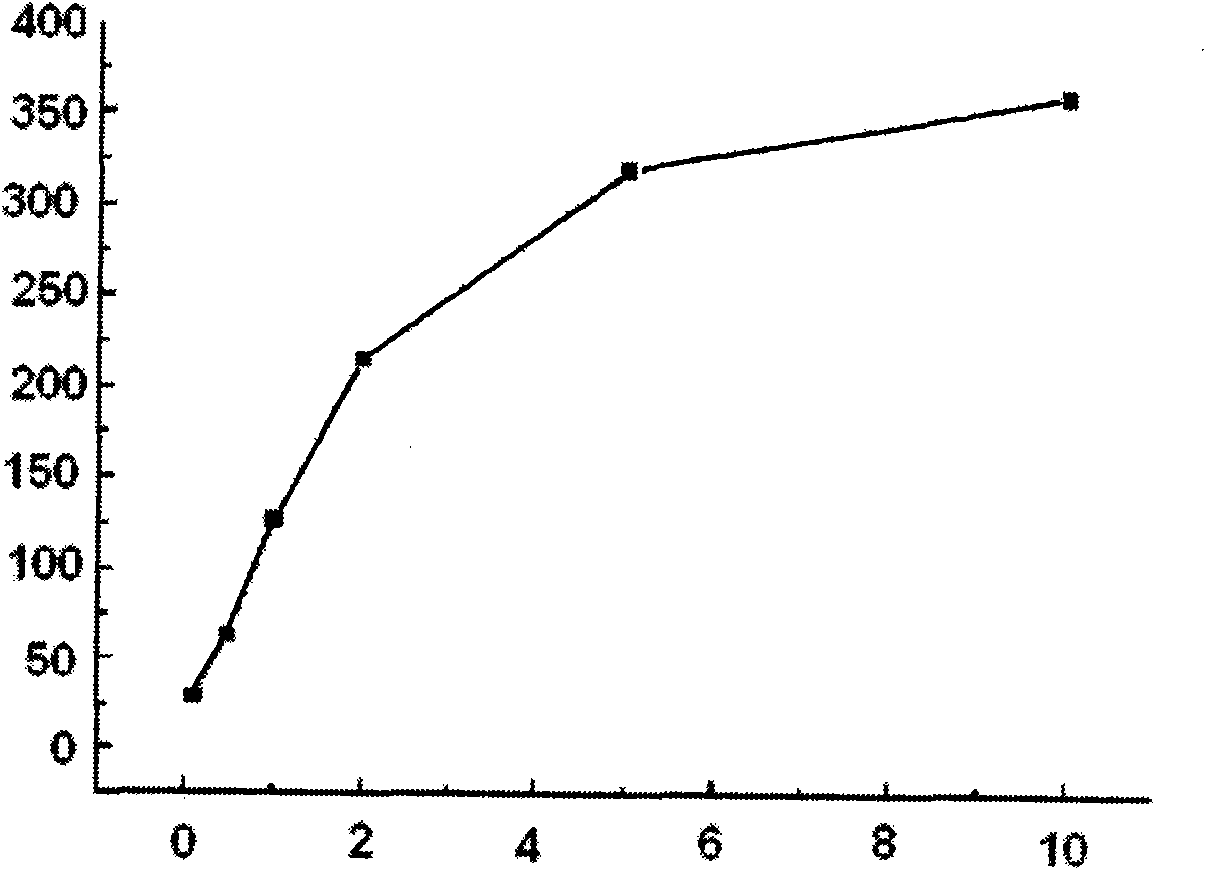

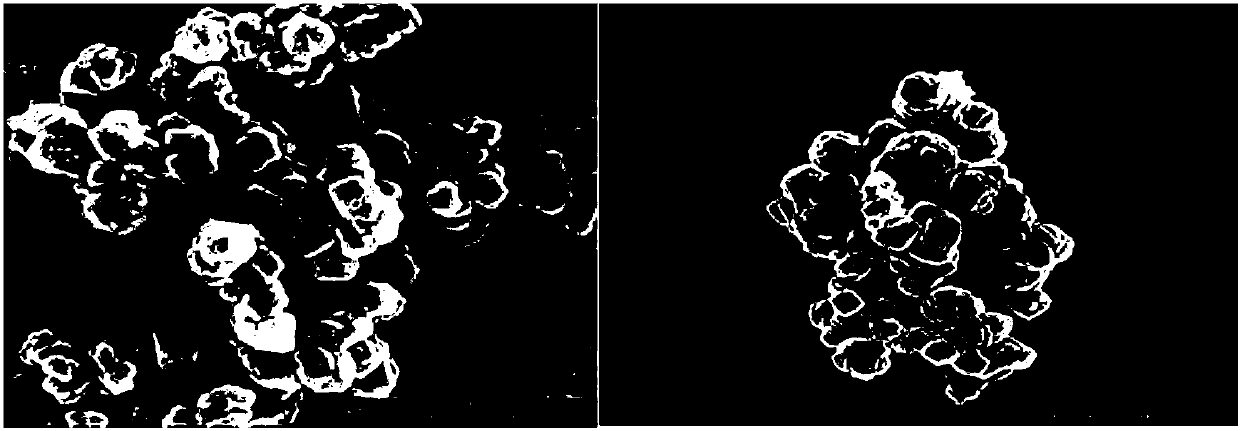

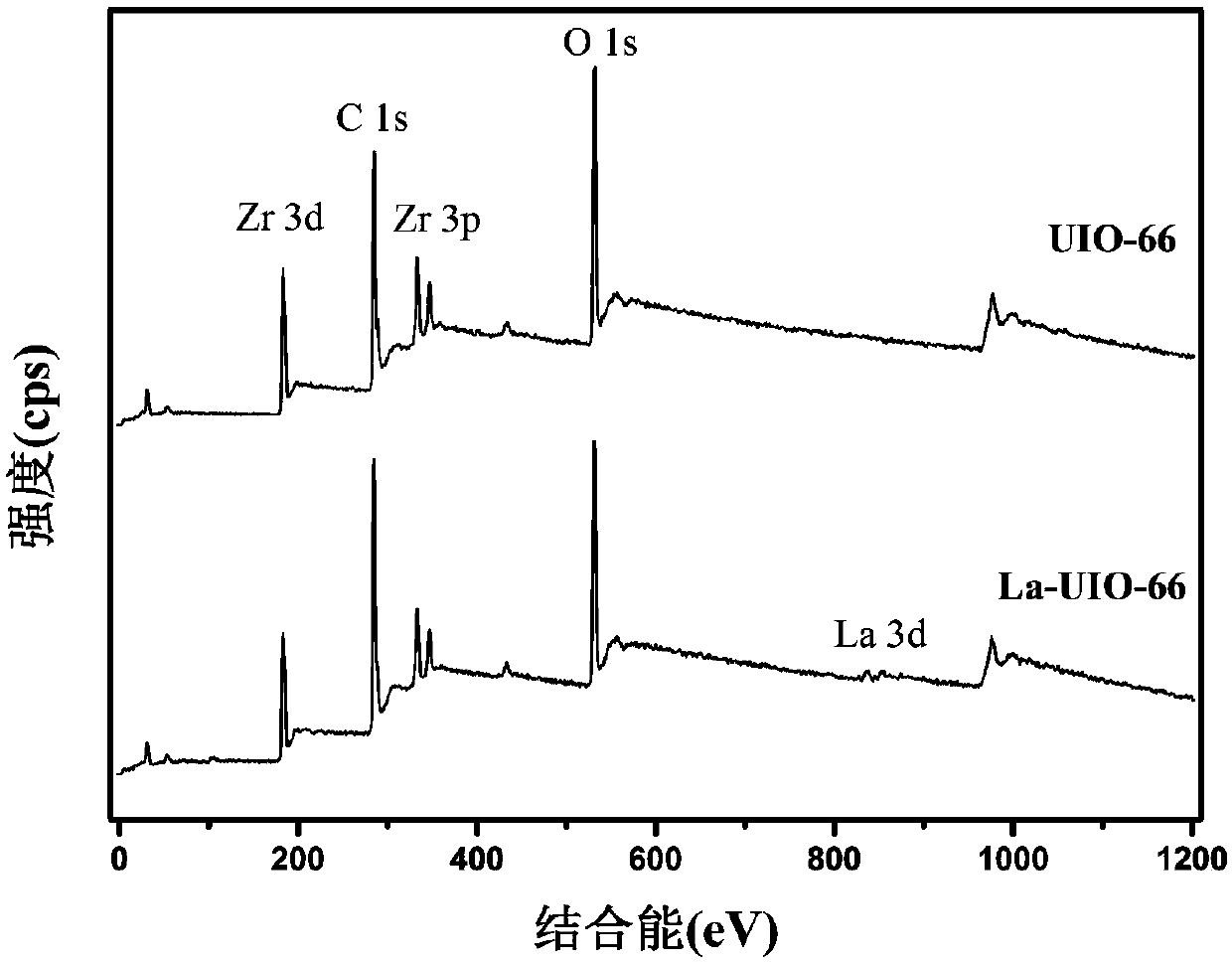

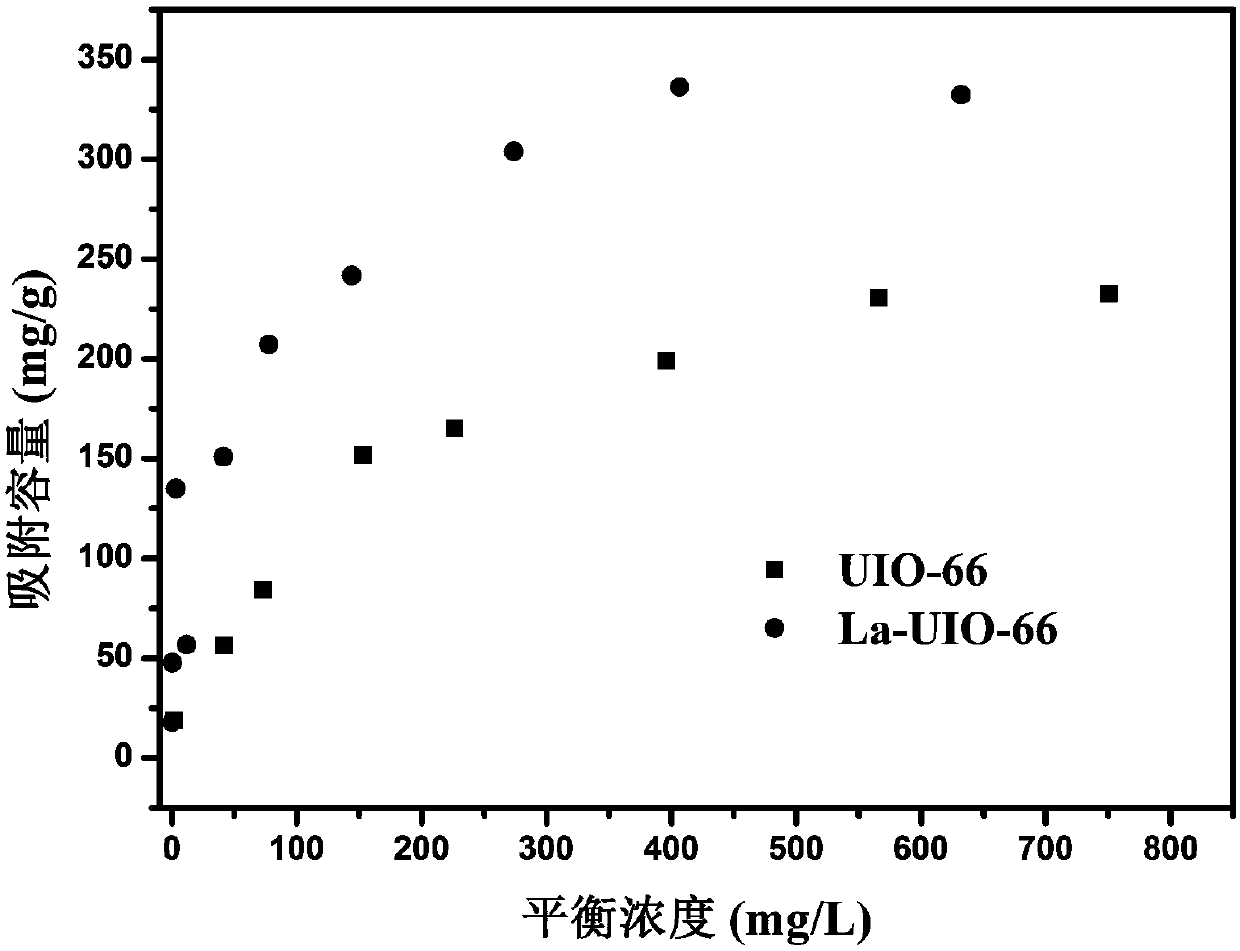

Lanthanum-doped metal organic framework material as well as preparation method and application thereof

ActiveCN107754765AFully generatedSimple and fast operationOther chemical processesWater contaminantsPhosphateMetal-organic framework

The invention provides a preparation method of a lanthanum-doped metal organic framework material. The preparation method comprises the following steps: firstly, fully reacting zirconium tetrachloridewith terephthalic acid to generate a base framework material; preferably reacting lanthanum chloride heptahydrate with the terephthalic acid while avoiding the reaction of the lanthanum chloride heptahydrate and the base framework material. The invention provides the lanthanum-doped metal organic framework material and application thereof in adsorption of phosphate radical. The lanthanum-doped metal organic framework material has two adsorption sites of zirconium ions and lanthanum ions which can be used for well adsorbing the phosphate radical. The results of the embodiment show that the maximal adsorption capacity of the lanthanum-doped metal organic framework material to the phosphate radical is 348.43mg / g; in the presence of more heteroions, the recognition of the phosphate radical can be maintained; after repeated use for five times, the adsorption capacity of La-UIO-66 to the phosphate radical is also kept at 100 percent; the lanthanum-doped metal organic framework material hasexcellent stability and recycling performance.

Owner:NANCHANG HANGKONG UNIVERSITY

Large mode field diameter negative refractive index mono-mode glass fiber

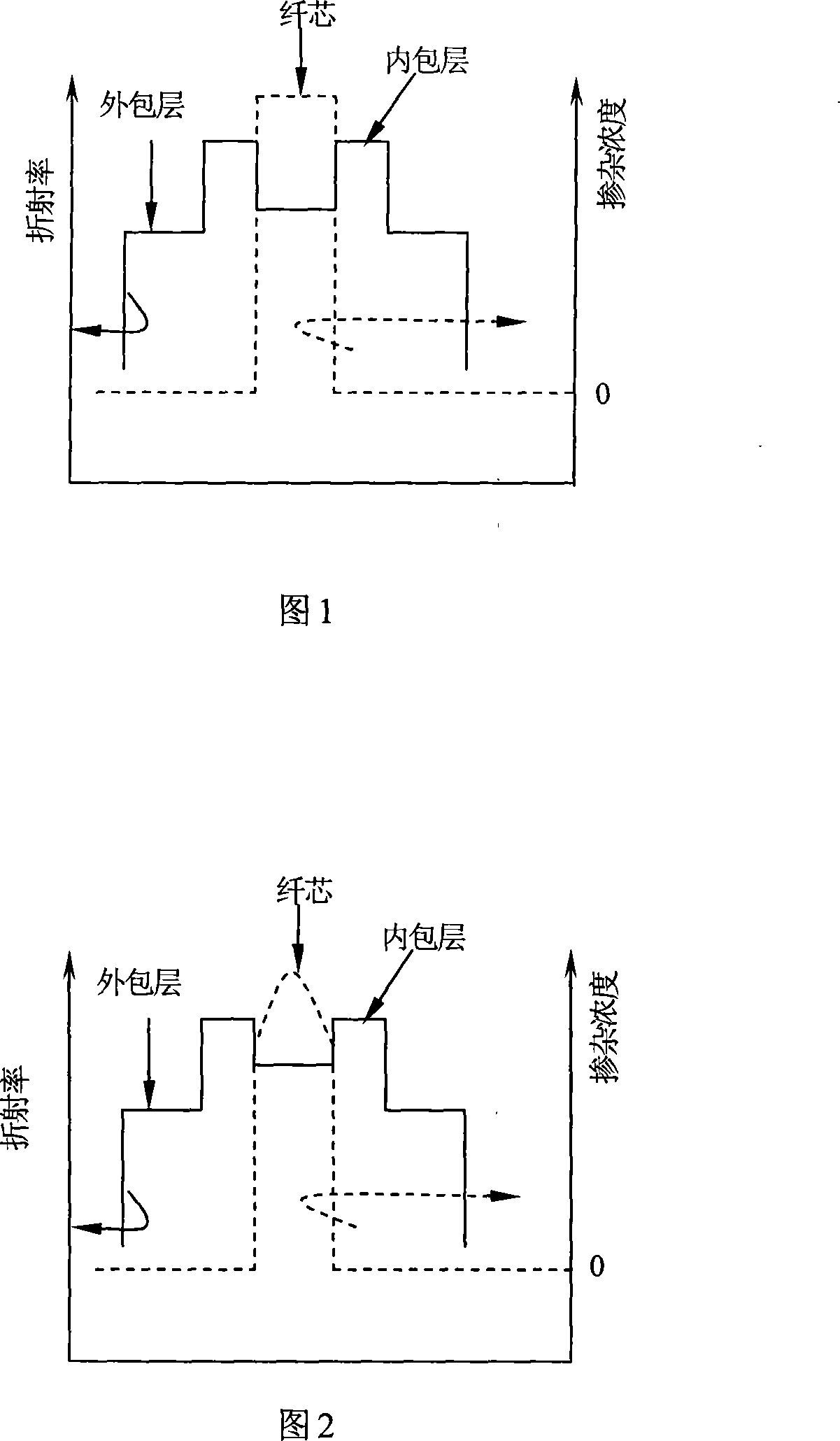

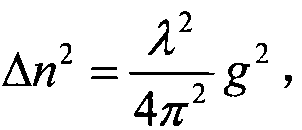

InactiveCN101201429ASuppression of higher order modesOptical fibre with graded refractive index core/claddingOptical waveguide light guideMode field diameterLanthanum Ion

The invention discloses a large mode field diameter and negative refractive index single mode glass fiber. The glass fiber comprises a fiber core, an inner cladding and an outer cladding; the refractive index of the fiber core is N1, the refractive indexes of the inner cladding and the outer cladding are respectively N2 and N3, which satisfy the relation: N2 is more than or equal to N1 and N2> N3; the lumination ion is mixed into the fiber core, which is the lanthanum ion or the combination of one or several transition metal ions; the mixing concentration is more than 1*1019 ions / cm3. The glass fiber of the invention forms the wave guiding structure between the fiber core and the inner cladding under the common function of the plus refractive index and the wave guiding refractive index; the laser oscillates stably in the fiber core. The invention realizes the large mode field diameter single mode laser output in the fiber.

Owner:SOUTH CHINA UNIV OF TECH

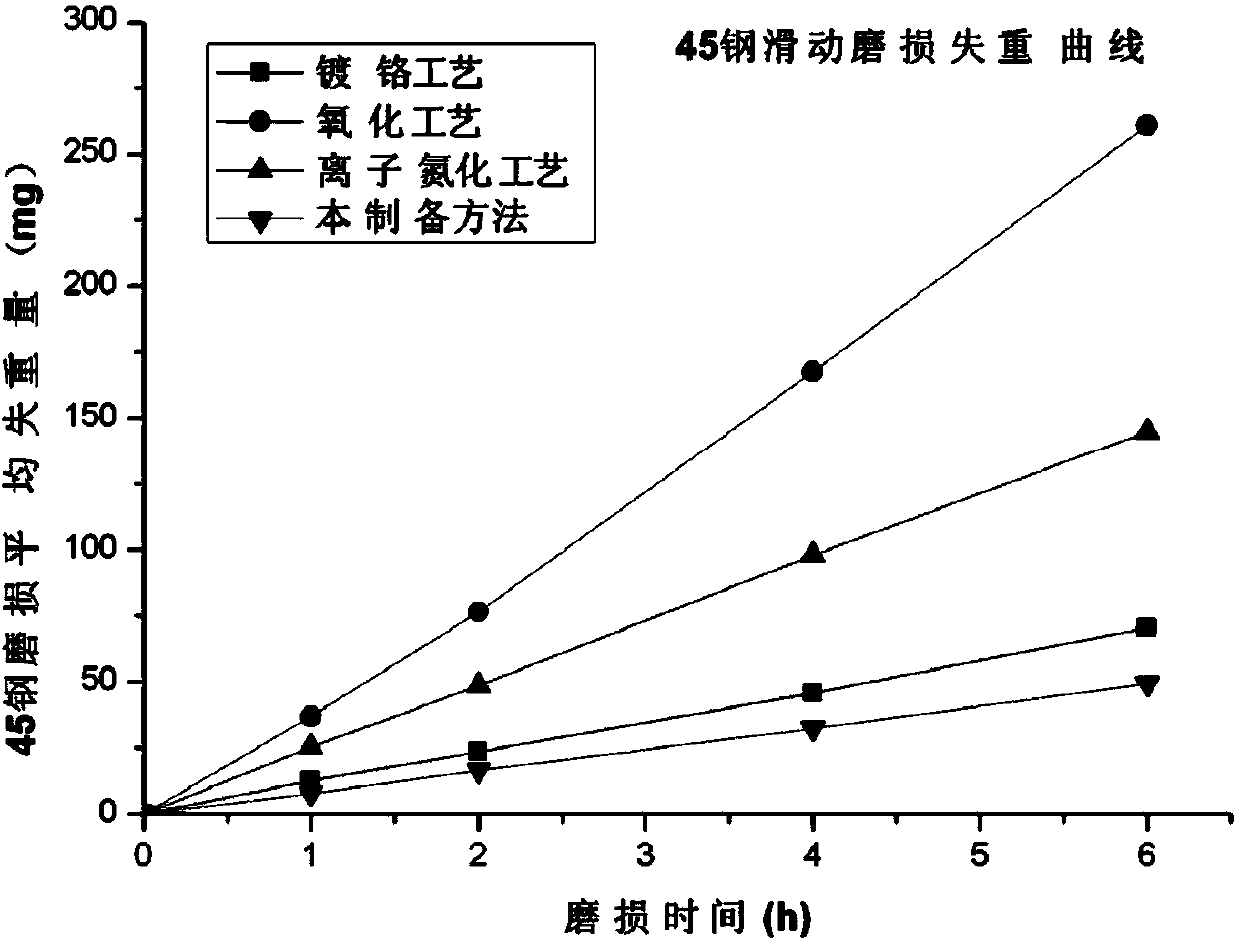

Method for improving corrosion resistance and wear resistance of optical shaft

ActiveCN104195506AImprove fatigue resistanceImprove corrosion resistanceSolid state diffusion coatingOptical axisPhysical chemistry

The invention belongs to the technical field of optical shaft processing, and particularly relates to a method for improving the corrosion resistance and wear resistance of an optical shaft. The method comprises the following steps: (1) placing the optical shaft into an air heating furnace, and preheating for 20-40min at 300-450DEG C; (2) placing the preheated optical shaft into a nitrogen-carbon-lanthanum ion infiltration furnace, and performing infiltration treatment for 90-150min at 550-630DEG C through a nitrogen-carbon-lanthanum ion infiltration agent; (3) placing the treated optical shaft into an ion activation furnace, and performing infiltration treatment for 30-90min at 450-550DEG C through an ionic activation infiltration agent; (4) placing the treated optical shaft in an oxygen ion infiltration furnace, and performing infiltration treatment for 15-30min at 370-430DEG C through an oxygen ion infiltration agent; (5) cleaning the infiltration agents on the surface of the optical shaft, and then drying; (6) placing the treated optical shaft into an ionic stabilization furnace containing an ion stabilizer, and performing ion stabilization treatment for 20-50min at 120-200DEG C; and (7) performing oil impregnated treatment to the treated optical shaft.

Owner:成都伍田机械技术有限责任公司

Modified attapulgite adsorbent and preparation method thereof

InactiveCN110193342ALarge specific surface areaIncrease the adsorption pointOther chemical processesWater contaminantsSorbentWastewater

The invention belongs to the technical field of adsorbent materials, and particularly relates to a modified attapulgite adsorbent and a preparation method thereof. The preparation method comprises: S1, pretreatment: breaking attapulgite, and grinding to obtain attapulgite powder; S2, acid modification: dispersing the attapulgite powder obtained in the step S1 in a hydrochloric acid solution for 2h at a constant temperature of 20 DEG C, washing with ultrapure water to achieve a neutral state, and carrying out vacuum drying at a temperature of 100-110 DEG C so as to be spare; S3, thermal modification: calcining the acid-modified attapulgite powder obtained in the step S2 for 2 h at a temperature of 550-850 DEG C, naturally cooling, and screening with a 200 mesh sieve so as to be spare; andS4, modification with lanthanum: adding the modified attapulgite powder obtained in the step S3 in a lanthanum nitrate solution at a constant temperature of 20 DEG C, impregnating for 2 h, dispersingfor 2 h, washing with ultrapure water to remove residual lanthanum ions, carrying out vacuum drying at a temperature of 100-110 DEG C, and screening with a 230 mesh sieve. According to the present invention, the modified attapulgite adsorbent can effectively remove phosphorus from wastewater.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

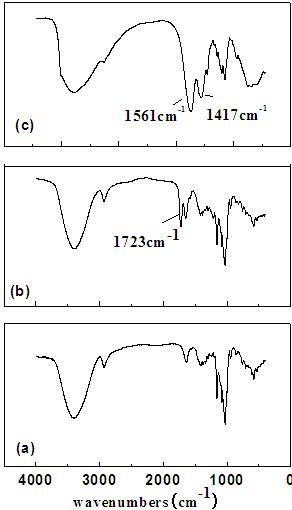

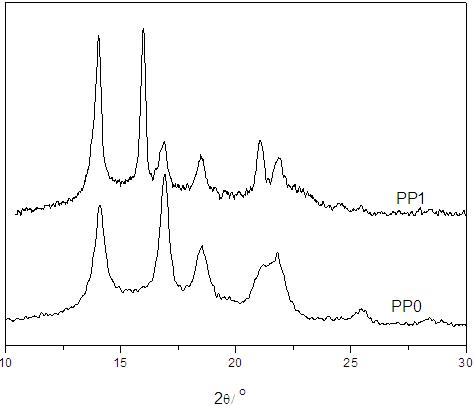

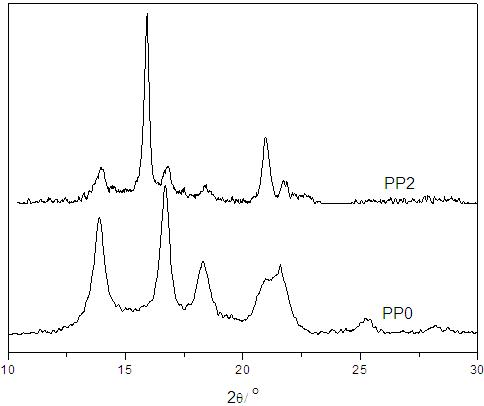

Beta-cyclodextrin derivative complex nucleating agent and application thereof in polypropylene

The invention provides a beta-cyclodextrin derivative complex nucleating agent and application thereof in polypropylene, which belong to the technical field of material high performance and solve the problems of poor modification performance, high cost and the like of a polypropylene beta nucleating agent in the prior art. The beta-cyclodextrin derivative complex nucleating agent is a complex of a beta-cyclodextrin derivative and lanthanum ions, is used for improving the beta-form content and the anti-impact capability of the polypropylene, has simple synthetic process and easy obtainment of raw materials, can induce the polypropylene to generate a higher content of beta-forms and can improve the anti-impact strength of the polypropylene.

Owner:FUZHOU UNIV

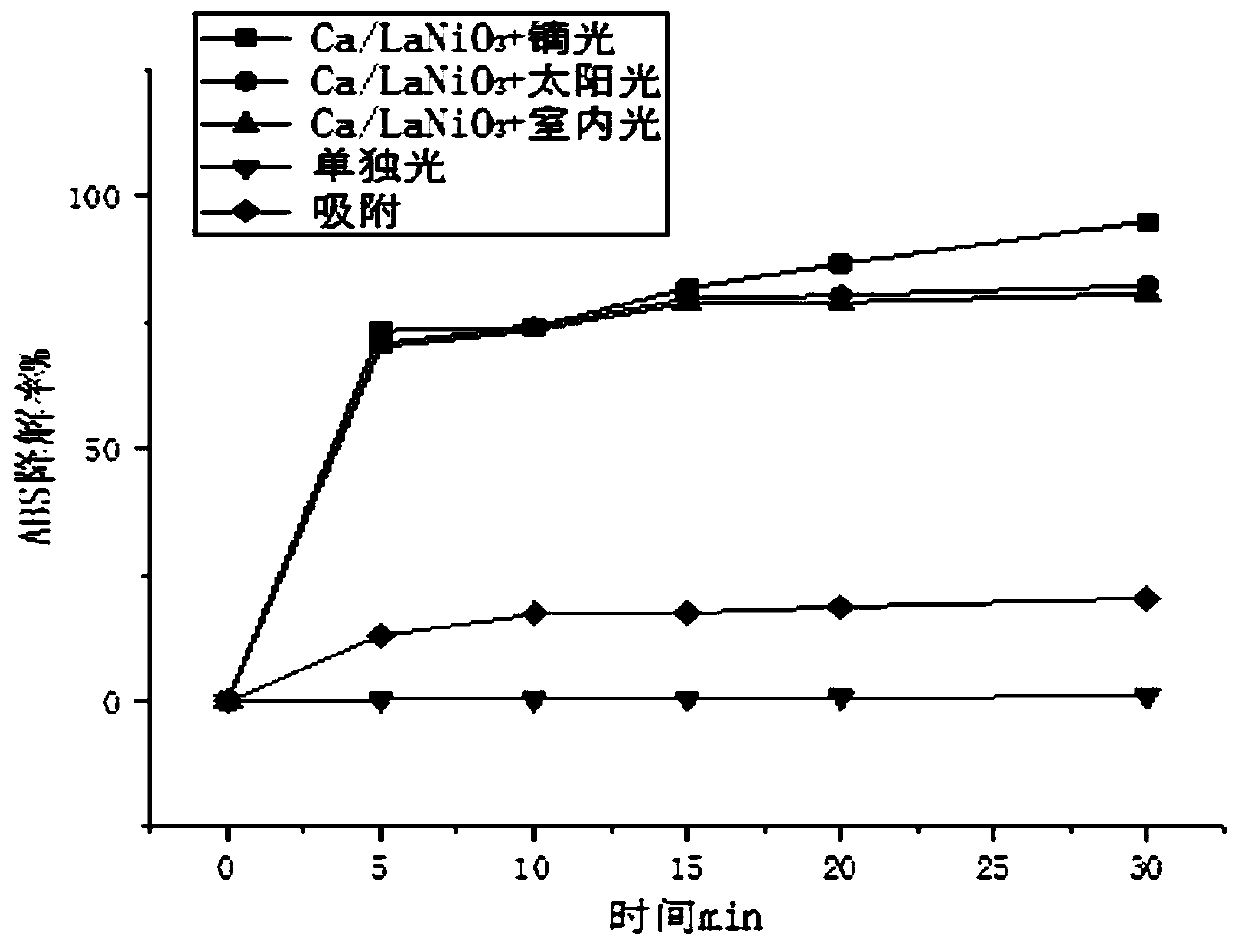

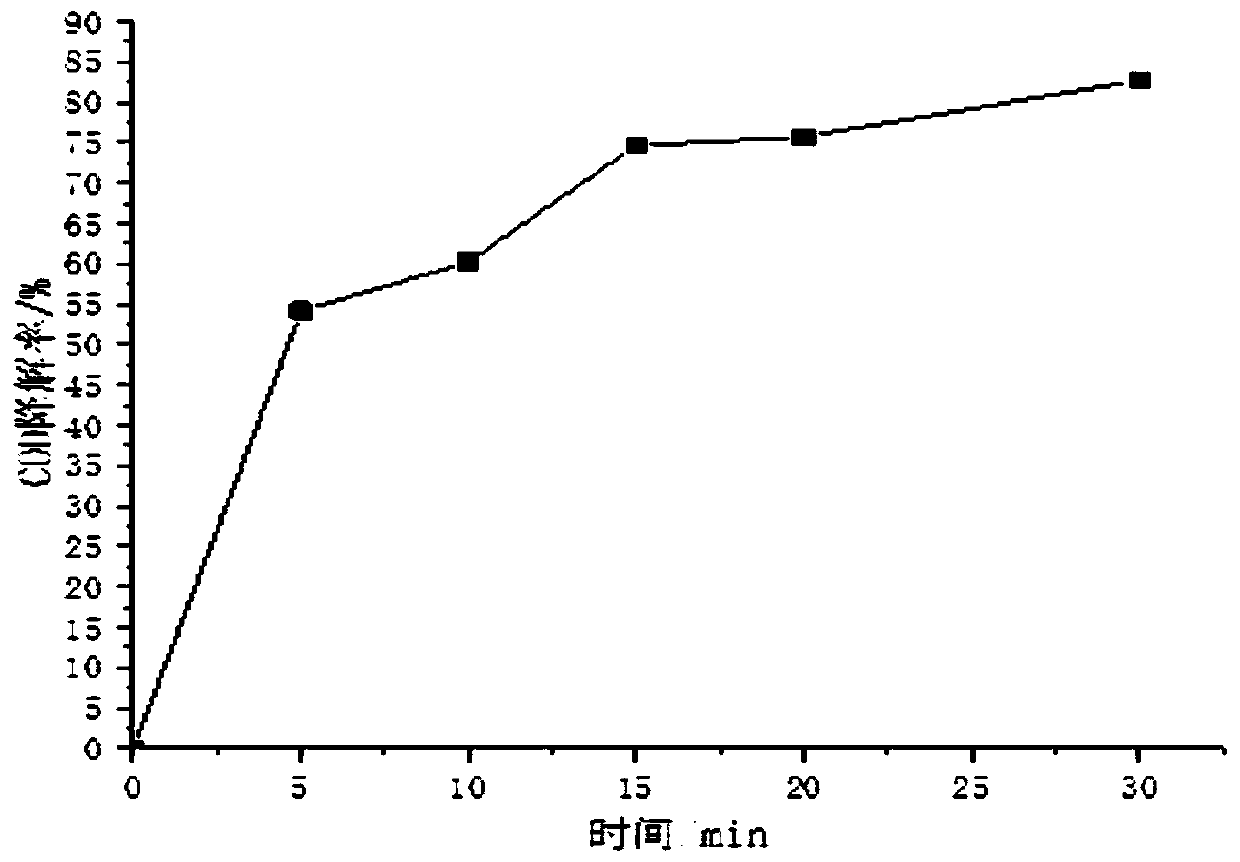

Preparation method and applications of calcium-doped LaNiO3 perovskite type photocatalyst

InactiveCN110465303ASynthesis conditions are simpleReduce secondary pollutionWater/sewage treatment by irradiationWater treatment compoundsNitrateDyeing wastewater

The invention relates to a perovskite type photocatalyst, and specifically discloses a preparation method and applications of a calcium-doped LaNiO3 perovskite type photocatalyst. The preparation method comprises: adding water to lanthanum nitrate and nickel nitrate, completely dissolving, adding fully dissolved nickel nitrate, adding an ammonia water solution in a dropwise manner under stirring conditions, adjusting the pH value of the solution to 9-12, generating a precipitate, filtering the product, washing, drying, and roasting, wherein a molar ratio of the calcium ions to the lanthanum ions is 0.1-0.5. The invention further discloses applications of the calcium-doped LaNiO3 perovskite type photocatalyst in degradation of methyl orange in printing and dyeing wastewater. According to the present invention, the preparation method has characteristics of simple synthesis conditions and low secondary pollution, and the obtained calcium-doped LaNiO3 perovskite type photocatalyst has goodcatalytic effect, wherein the degradation effect reaches 95.01%.

Owner:YULIN NORMAL UNIVERSITY

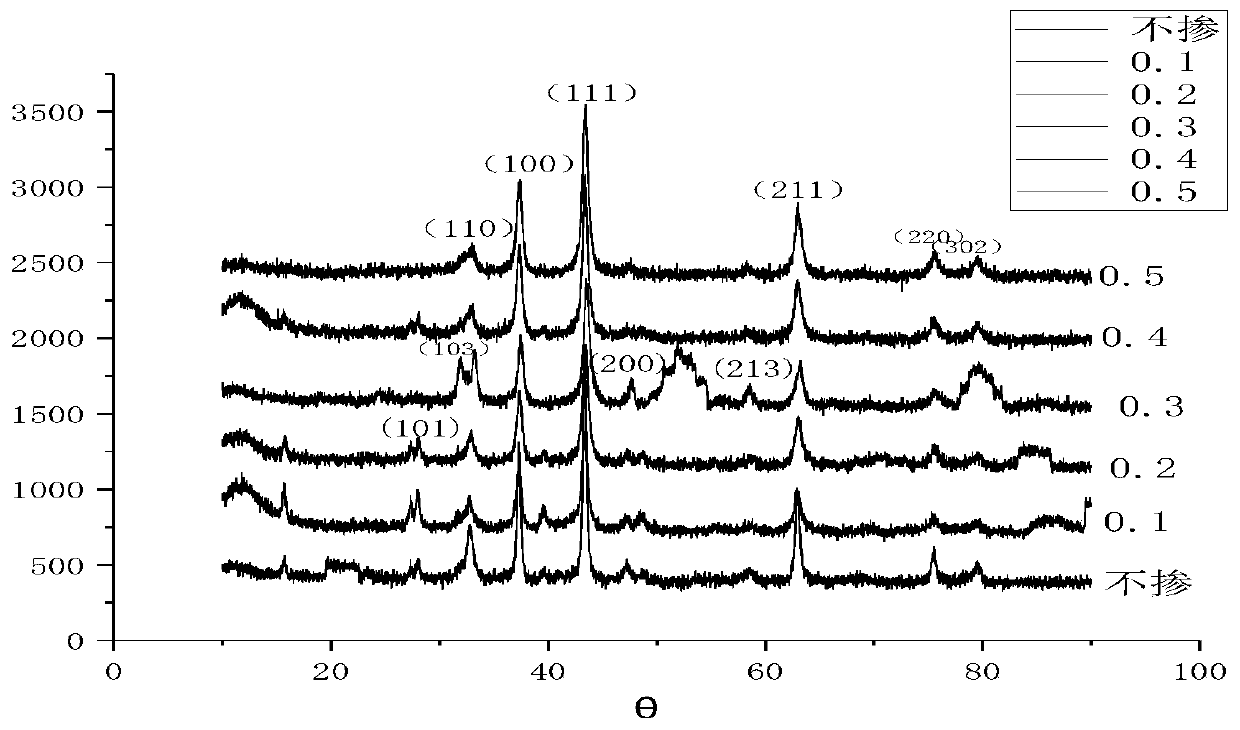

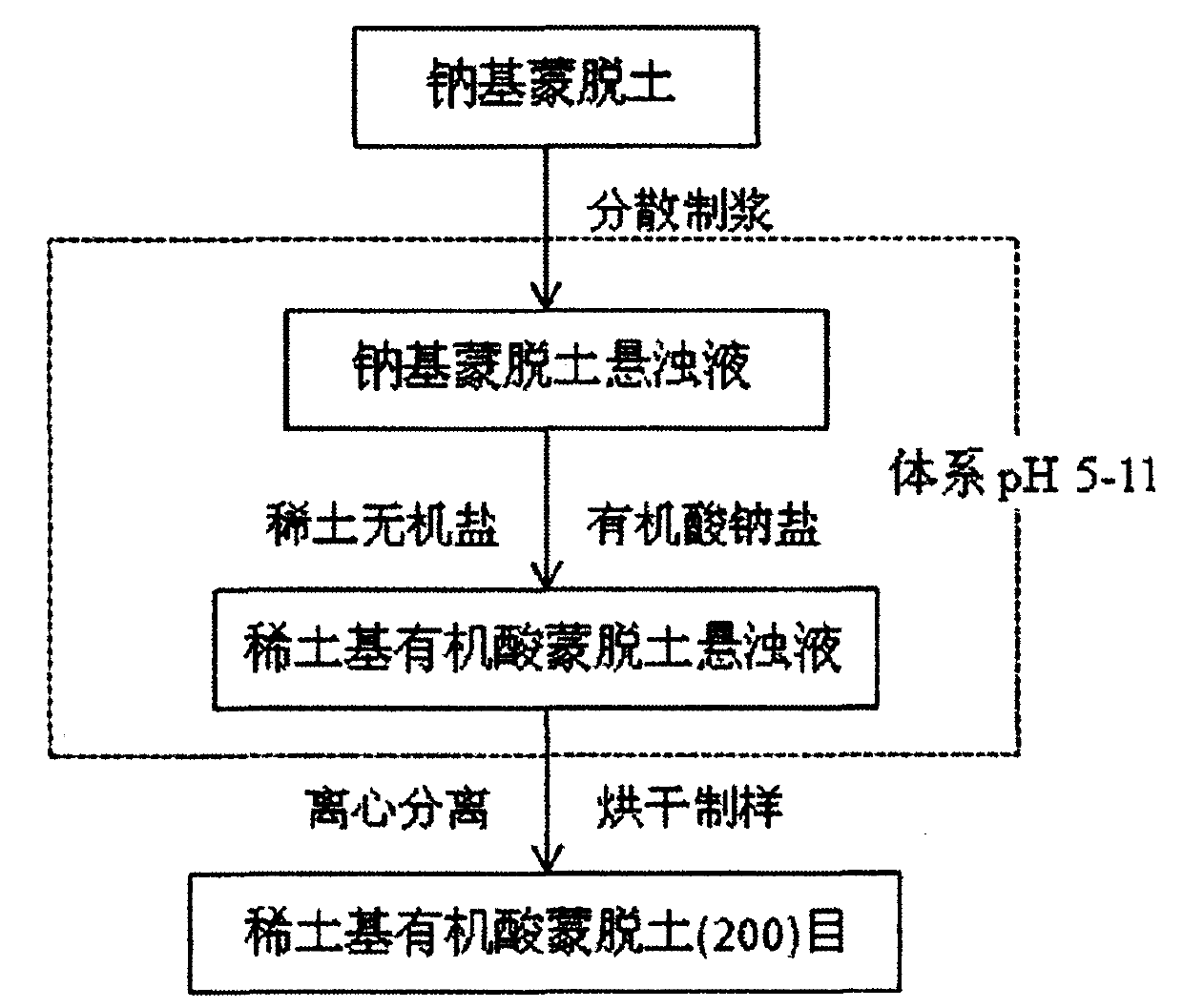

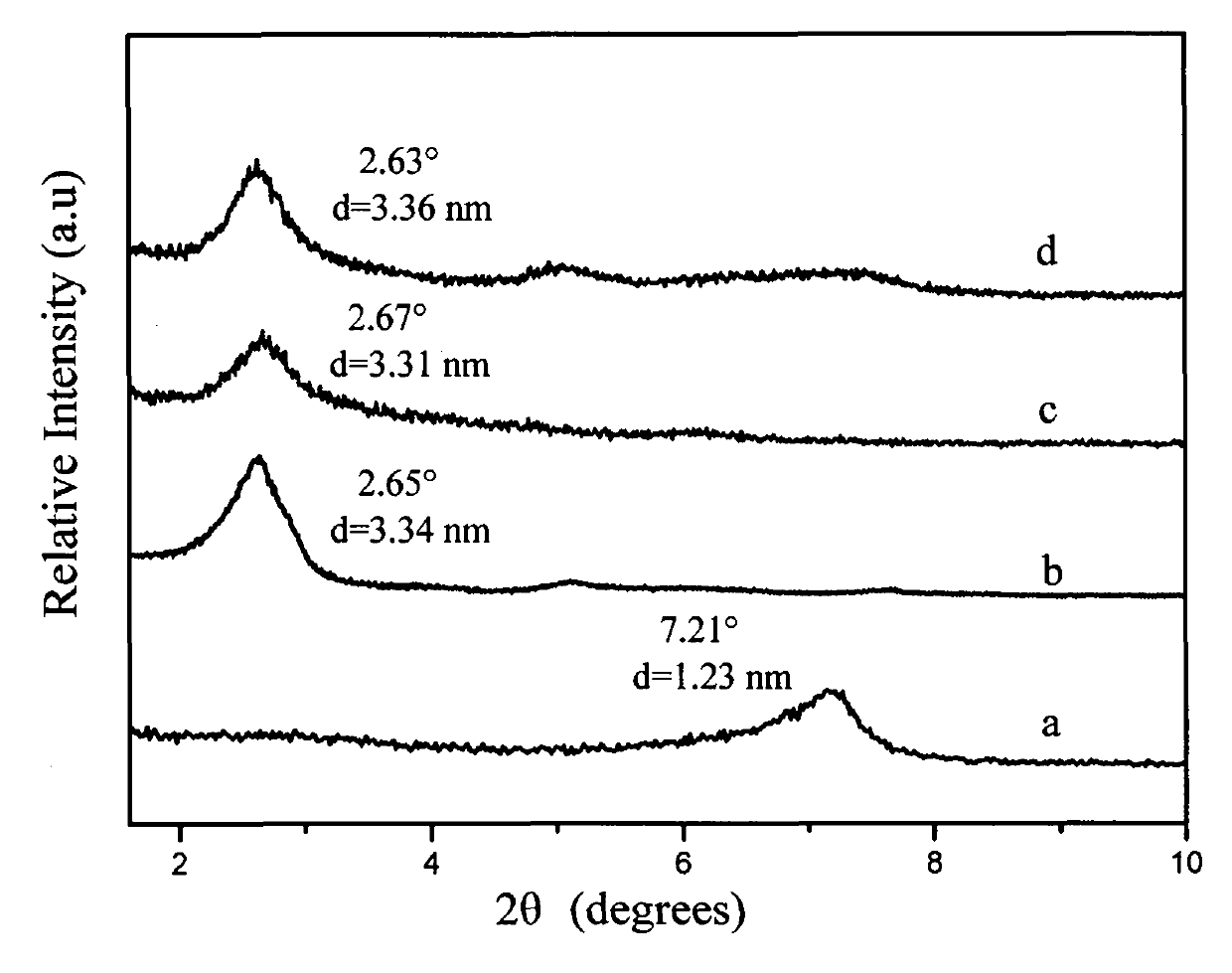

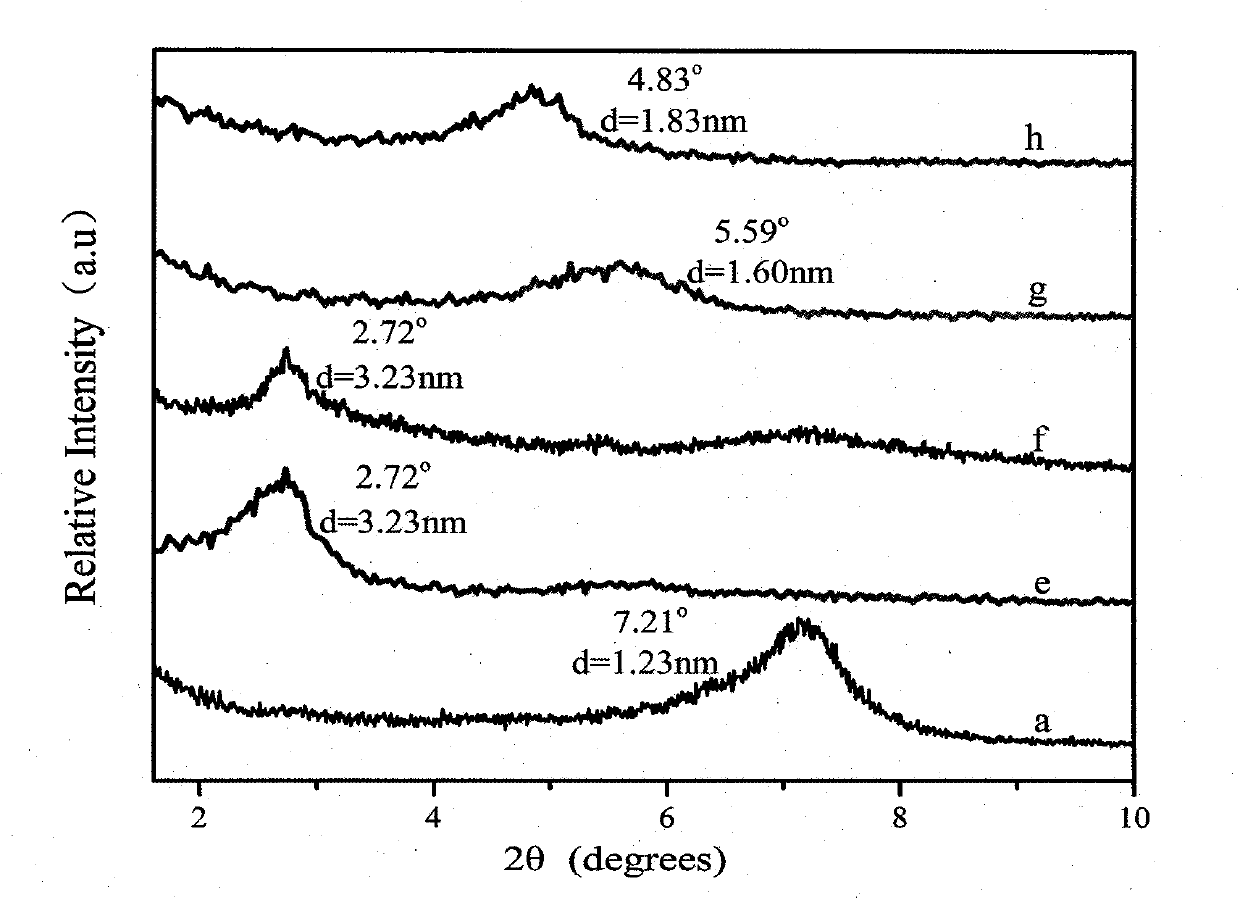

Lanthanum-based organic acid montmorillonite and water phase one-step preparation technology thereof

InactiveCN103467777AIncrease layer spacingSimple preparation processPigment treatment with non-polymer organic compoundsPolymer modifiedRare earth

The invention relates to lanthanum-based organic acid montmorillonite and a water phase one-step preparation technology thereof. The lanthanum-based organic acid montmorillonite is characterized in that: the crystal structure of the lanthanum-based organic acid montmorillonite is montmorillonite lamellar structure; part of the plurality of ionic bonds of rare earth lanthanum ions among the sheets of montmorillonite are combined with the montmorillonite sheets, and the rest of the ionic bonds are combined with acid groups of long-chain organic acids; and different organic acids are employed so as to obtain a plurality of kinds of lanthanum-based organic acid montmorillonite. According to the one-step preparation technology, Na-montmorillonite, rare earth lanthanum inorganic salts and the long-chain organic acids are taken as raw materials; Na-montmorillonite, the rare earth lanthanum inorganic salts and the long-chain organic acids are reacted in water phase so as to obtain the lanthanum-based organic acid montmorillonite. The water phase one-step preparation technology is simple for operation, is safe, and is friendly to the environment. Acting force between the organic acids and montmorillonite, and acting force between the rare earth lanthanum element and montmorillonite are strong; thermal performance is stable; form is uniform; organic content is more that 20%, and interlamellar spacing of montmorillonite is increased obviously. The lanthanum-based organic acid montmorillonite can be used in the fields such as preparation of polymer nanocomposites and polymer modification.

Owner:SHIHEZI UNIVERSITY

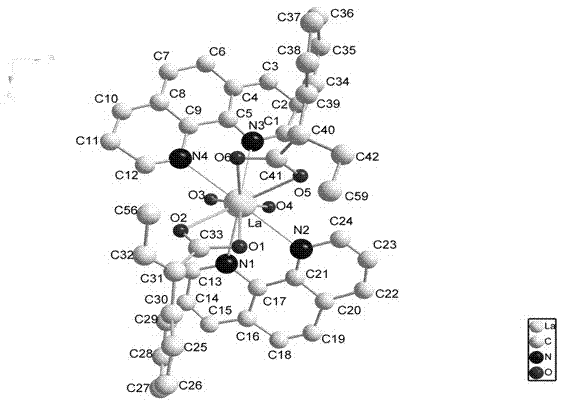

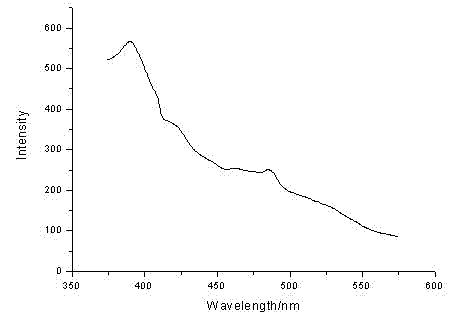

Rare-earth metal complex and preparation method thereof

InactiveCN102633823AClear compositionClear structureGroup 3/13 element organic compoundsLuminescent compositionsPhenylacetic acidRare earth

The invention provides a rare-earth metal complex, in particular to a rare-earth metal complex material which is valuable and potential in luminescence, wherein the lanthanum ions of the compound (La (C10H1102) (phen) 2 (NO3)) are connected with one another by organic complex, so that a three-dimensional space structure is formed. A preparation method of the rare-earth metal complex comprises the following steps of: allowing the molar ratio of raw materials such as lanthanum nitrate, 2-ethyl-phenylacetic acid and 1.10-phenanthroline to be 1:1:2; dropping hydrochloric acid to water / ethanol mixed solution as a solvent to adjust the PH value to be from 3 to 4, and carrying out a thermal reaction on the solvent and raising the temperature to 80 DEG C, wherein the cooling speed is 10 DEG C / h. The invention lays the foundation of the preparation method and the luminous function mechanism of the complex which is sequentially taken as the luminescent material; and the complex is the luminescent material which is valuable and potential.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Preparation method of lanthanum oxide-carrying zeolite for removing fluorine

InactiveCN101780397AWill not cause secondary pollutionSimple and fast operationOther chemical processesWater/sewage treatment by sorptionHigh concentrationWater quality

The invention discloses a preparation method of lanthanum oxide-carrying zeolite for removing fluorine, which comprises the following steps: adding a lanthanum chloride solution into raw material zeolite, and regulating the pH value of the solution with 28wt% of concentrated ammonia; after soaking and stirring, removing the filtered solution, drying and burning at high temperature; and after cooling, cleaning residual lanthanum ions, and drying to obtain the lanthanum oxide-carrying zeolite. The lanthanum oxide-carrying zeolite prepared by the method of the invention has strong fluorine adsorbing capacity and good fluorine removing effect, can not cause secondary pollution, can be used for removing fluorine in a static adsorption mode, can be filled into a packed column for removing fluorine in a dynamic adsorption mode, is suitable for water quality of different concentration and different hardness, is suitable for removing fluorine in drinking water, is suitable for deeply removing fluorine in high-concentration fluorine-containing waste water, can be recycled, and has simple and easy regeneration method and high regeneration efficiency.

Owner:GUANGDONG PHARMA UNIV

Lithium ion-type supercapacitor ternary composite negative electrode material and preparation method thereof

ActiveCN104733189AImprove conductivityGood chemical stabilityHybrid capacitor electrodesHybrid/EDL manufactureCarbon nanotubeManganate

The invention discloses a lithium ion-type supercapacitor ternary composite negative electrode material and a preparation method thereof. The composite material is formed by strontium-doped lanthanum manganate, lithium titanate and a carbon nano-tube, wherein the mass ratio of the strontium-doped lanthanum manganate to the lithium titanate to the carbon nano-tube is 10:80:10 to 5:90:5. The composite material preparation method comprises steps: a sol-gel method is firstly adopted to coat the surface of the carbon nano-tube with a layer of titanium dioxide, lithium salt is then introduced via a dipping method, and a lithium titanate / carbon nano-tube composite material is thus generated; and a sol containing lanthanum ions, strontium ions and manganese ions is used for dipping, a perovskite-type strontium-doped lanthanum manganate thin film is formed on the surface of the lithium titanate coating surface through high-temperature treatment, and thus a strontium-doped lanthanum manganate / lithium titanate / carbon nano-tube composite material is obtained. The prepared ternary composite material of the invention has high conductive performance and can be used to serve as the negative electrode material for the lithium ion-type supercapacitor, and the specific capacity can reach 153mAh / g at the rate of 10C.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

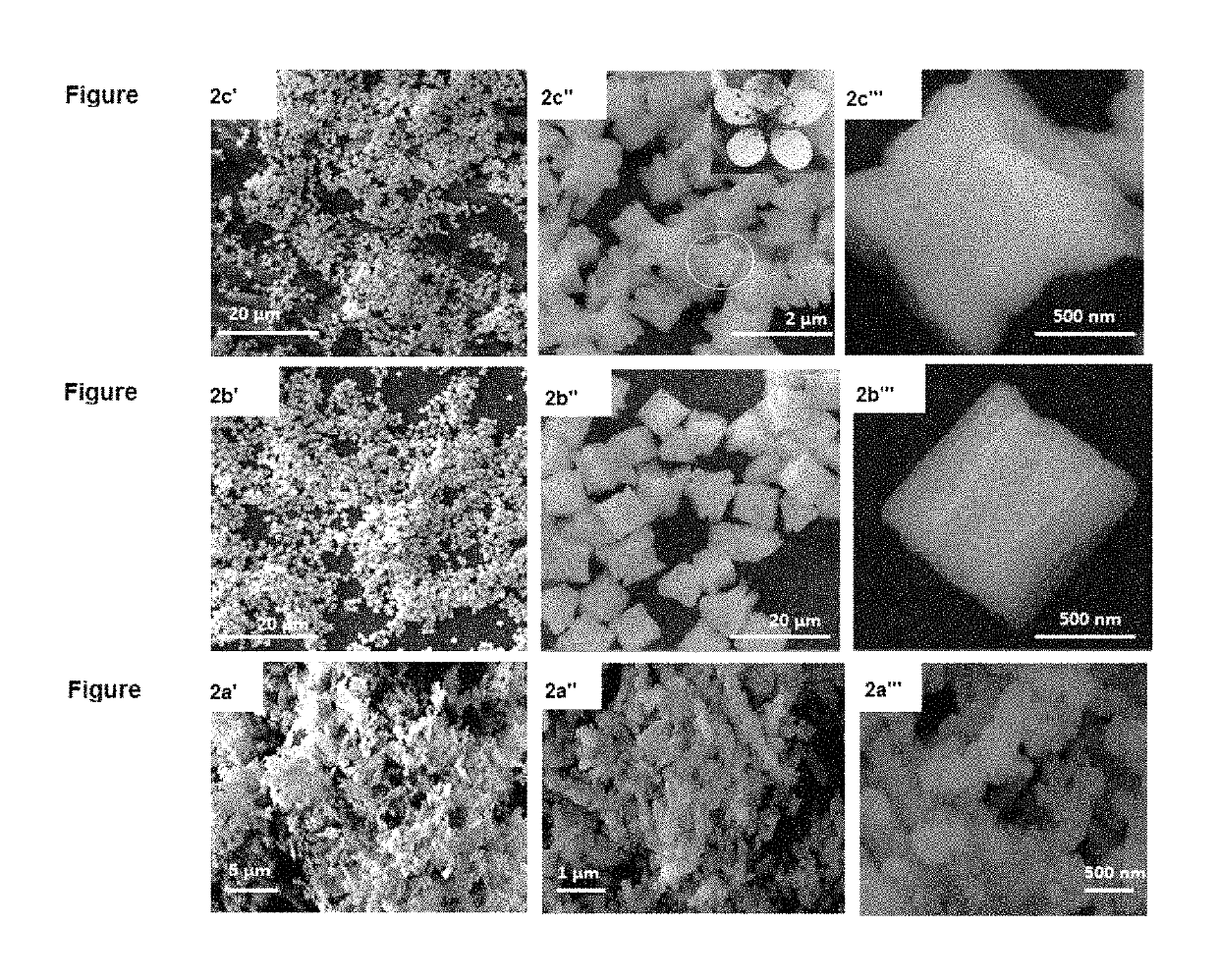

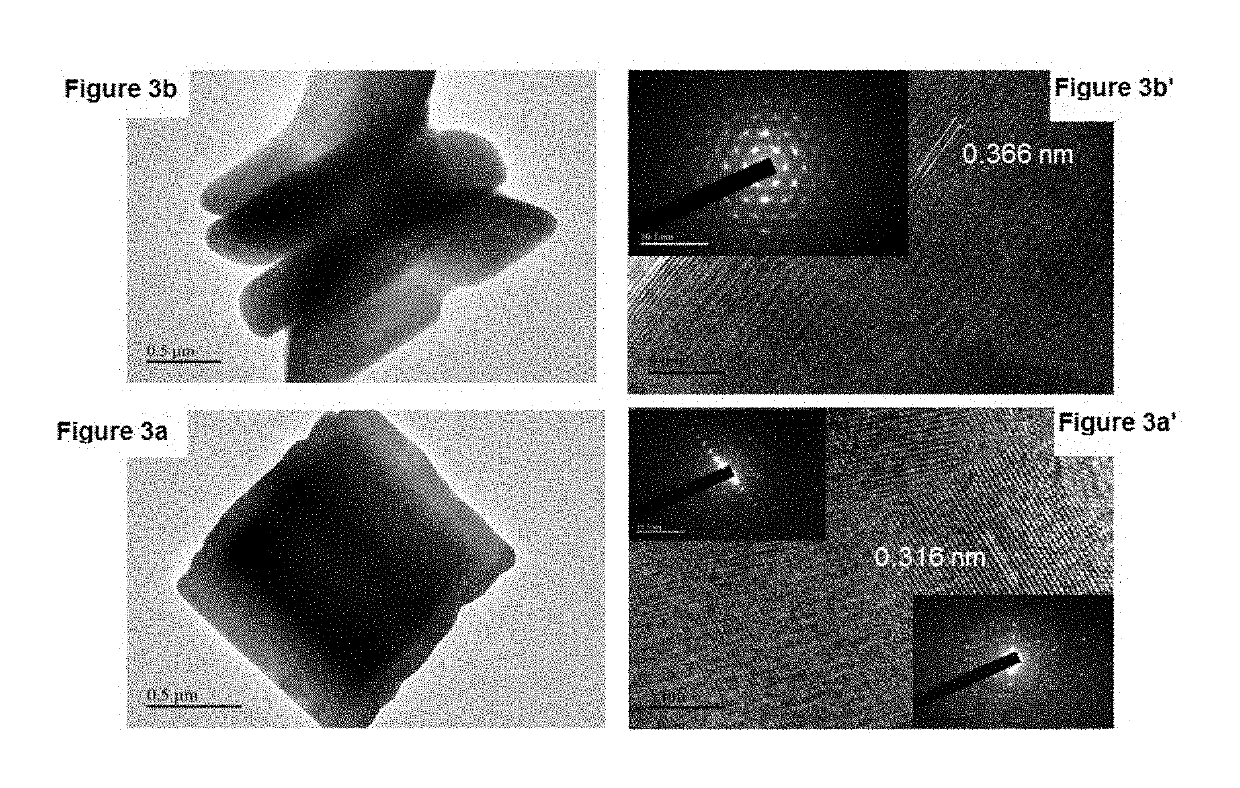

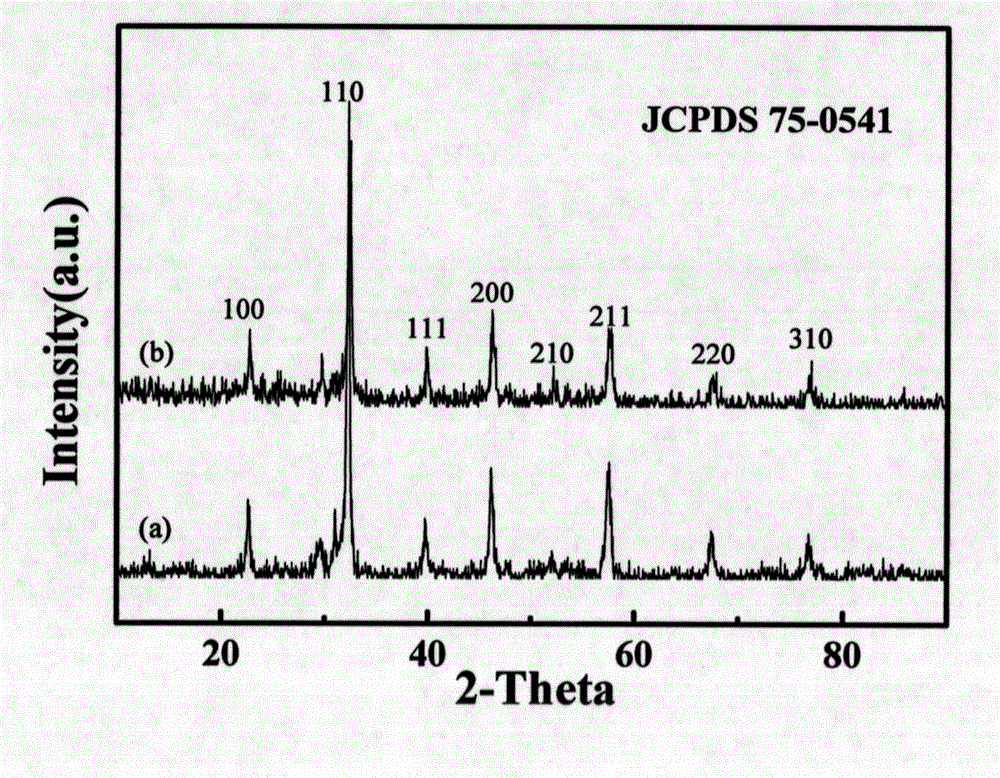

Low temperature hydrothermal method for the preparation of LaCO3OH nanoparticles

ActiveUS10322409B1Reducing the nitrogen monoxideReducing the nitrogen oxideExhaust apparatusDispersed particle separationNanoparticleNitrogen oxide

A hydrothermal method of preparing uniform, monodisperse ceramic lanthanum hydroxyl carbonate (LaCO3OH) having cherry-blossom-like nanogears and / or nanocubes is described. The method produced a hexagonal crystal with a crystal lattice in which at least on lanthanum ion is substituted with calcium ion. The ceramic nanoparticles produced by the method are good catalyst for the reduction of nitrogen oxides with a hydrocarbon. A method of reducing exhaust gases is described.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

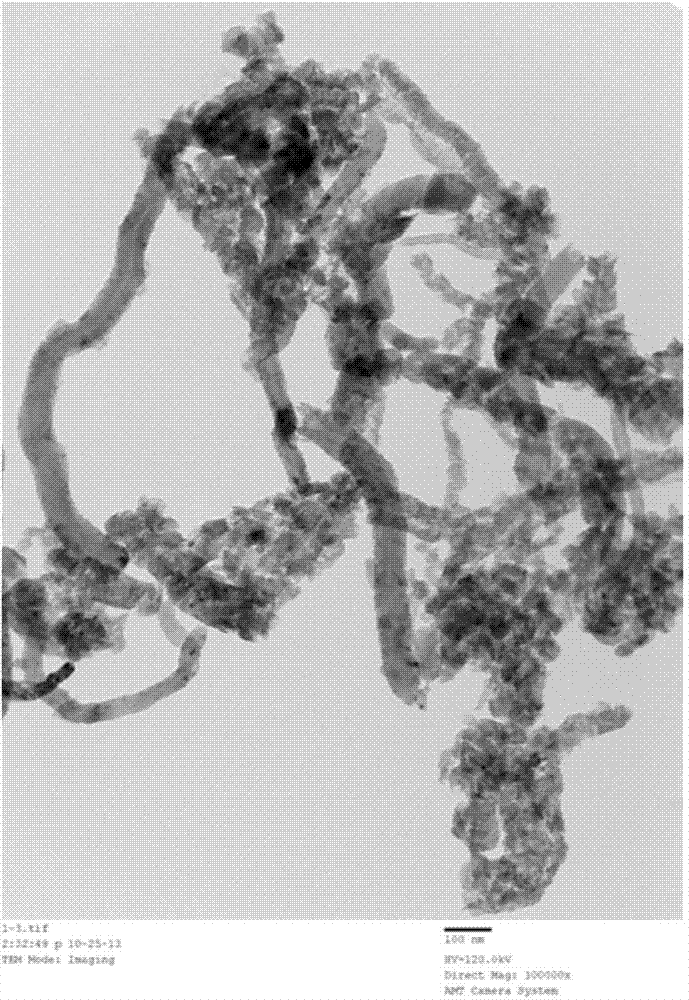

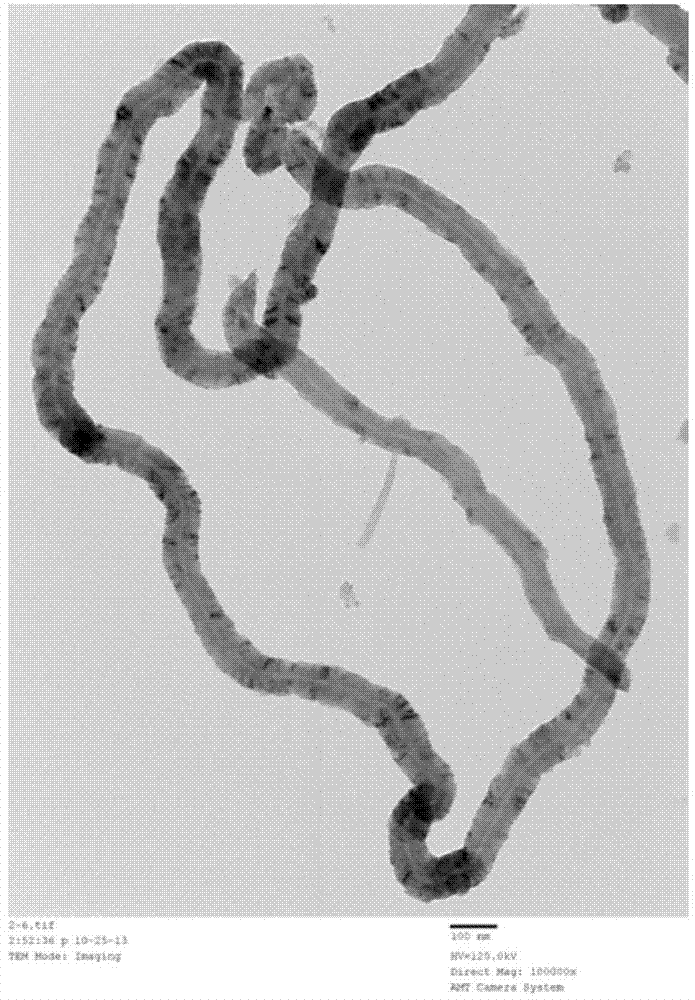

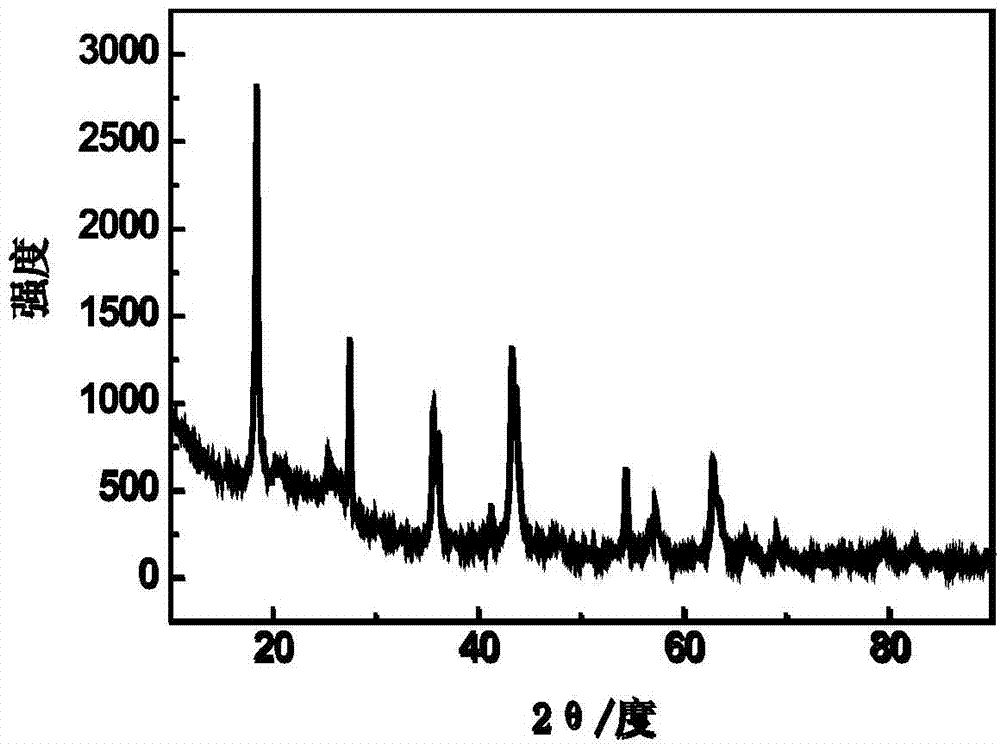

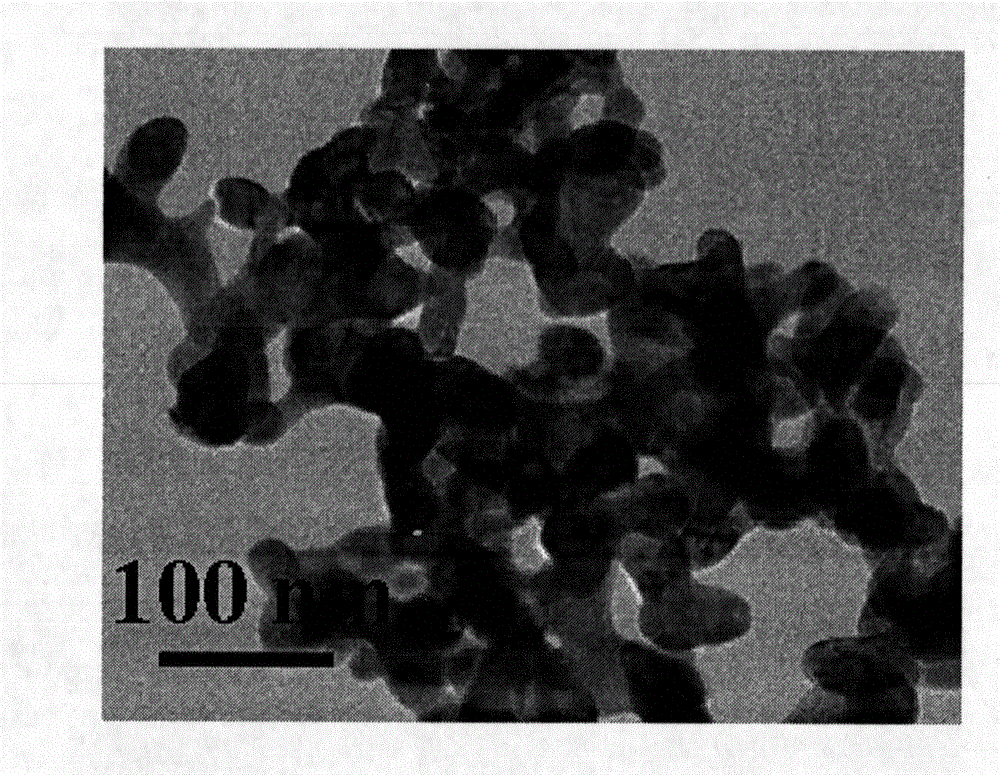

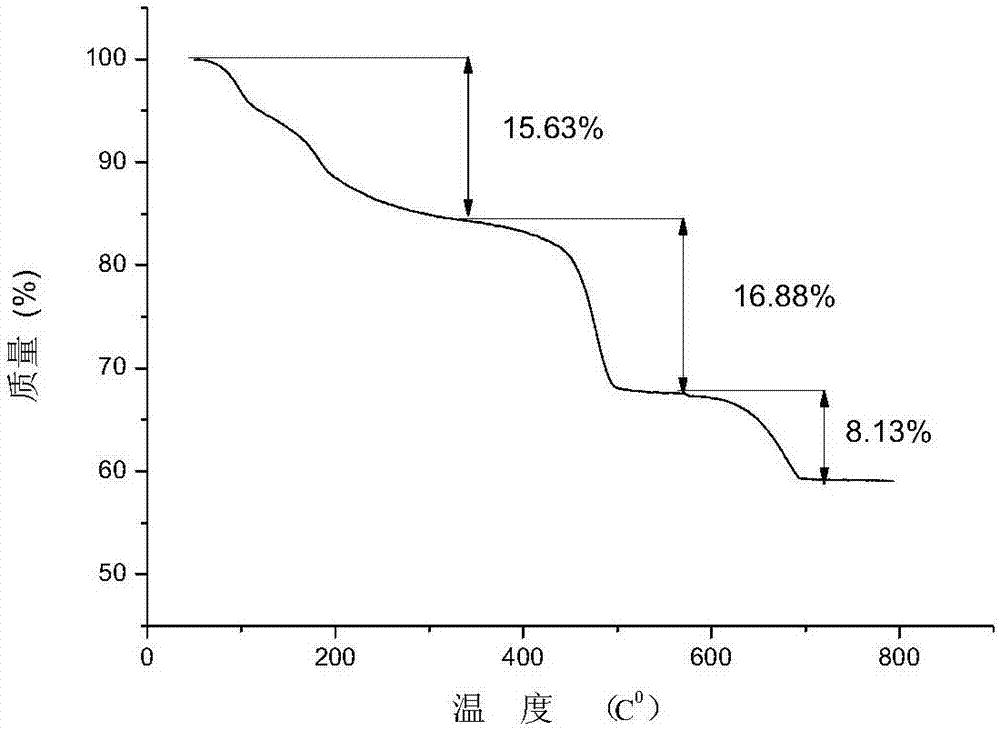

Core-shell type LaFeO3@C lithium battery anode material and preparation method thereof

ActiveCN104157856AChange thicknessSo as not to damageCell electrodesSecondary cellsCarbon layerNitrogen gas

The invention discloses a core-shell type LaFeO3@C lithium battery anode material and a preparation method thereof. The hydrothermal carbonization method is adopted for synthesizing a LaFeO3@C composite nanometer material with a core-shell structure for the first time. During the hydro-thermal synthesis process, carbonates and ammonia water are decomposed from urea, OH<-> is released from urea through hydrolysis, the solution is alkali, lanthanum ions and iron ions are precipitated, lanthanum and iron sediments are gathered for nucleation, a carbohydrate is subjected to the hydrothermal carbonization at 180 DEG C to form a shell carbon layer, so that the lanthanum and iron sediment cores can completely cover the inner part of the carbon layer to form the integral core-shell structure; the structure is further subjected to the high-temperature calcination under nitrogen, so that carbon-coated lanthanum ferrite, namely the LaFeO3@C is obtained for the first time. An electrochemical test proves that the lithium storage performance of the pure LaFeO3 nano-particles is quite small, the core-shell type LaFeO3@C nano-composite has excellent lithium storage performance and has great development potential and a scientific research value, and the application of the core-shell type LaFeO3@C nano-composite in the lithium battery anode material is a great discovery.

Owner:ANHUI UNIVERSITY

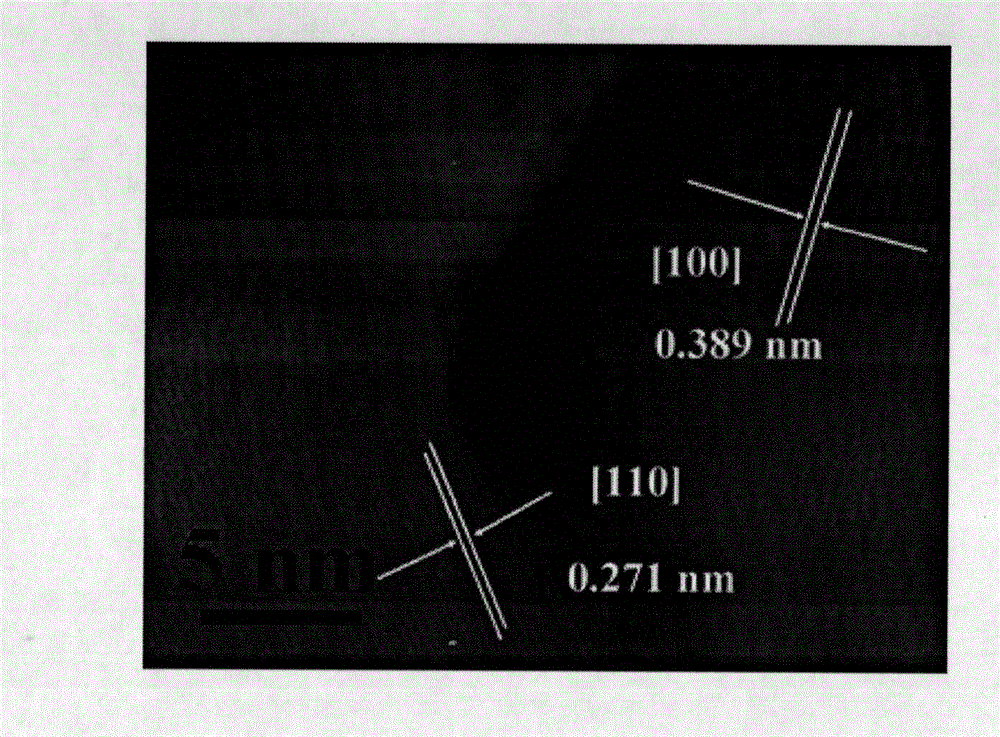

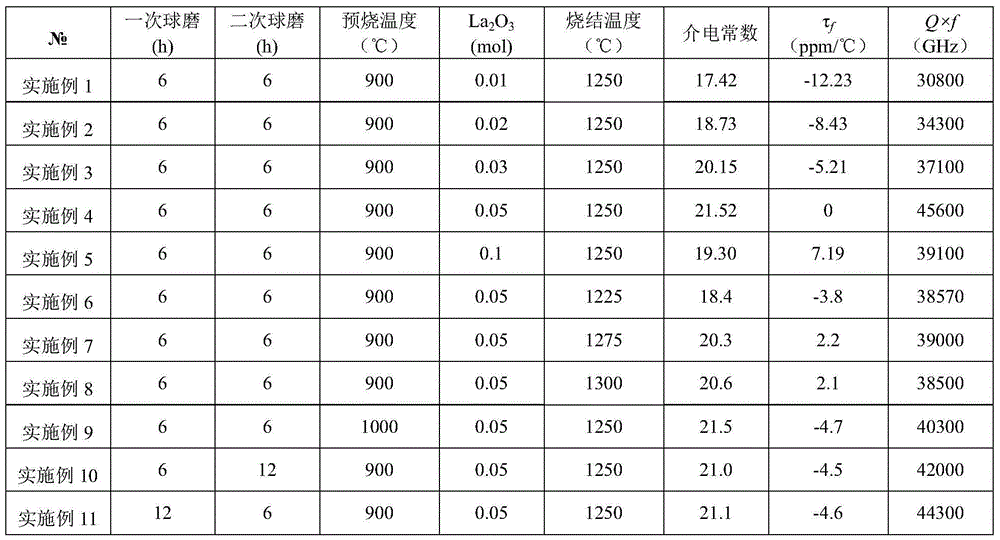

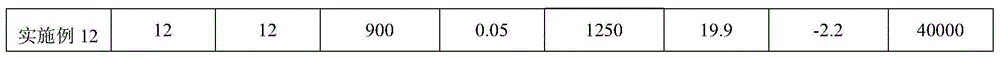

Neodymium niobate ceramic having improved microwave dielectric characteristic by substituting neodymium ions with lanthanum ions

The invention discloses neodymium niobate ceramic having improved microwave dielectric characteristic by substituting neodymium ions with lanthanum ions. The formula of the neodymium niobate ceramic is (Nd1-xLax)NbO4, in the formula, x is less than or equal to 0.1. The preparation method of the neodymium niobate ceramic comprises the following steps: firstly, preparing Nd2O3, La2O3 and Nb2O5 according to the chemical formula, ball-milling, drying, screening, and calcining for 4 hours at 900-1000 DEG C; pelleting, pressing to form a blank, and sintering at 1225-1300 DEG C, thereby obtaining the neodymium niobate ceramic. As lanthanum ions are adopted to substitute Nd on the A site in NdNbO4, the microwave dielectric property can be improved, the dielectric constant of the neodymium niobate ceramic is 21.52, the quality factor of the neodymium niobate ceramic is 45600GHz, and the resonance frequency temperature coefficient of the neodymium niobate ceramic is up to 0ppm / DEG C. The neodymium niobate ceramic is simple in preparation process, environment-friendly in process and is a microwave medium material with a good application prospect.

Owner:TIANJIN UNIV

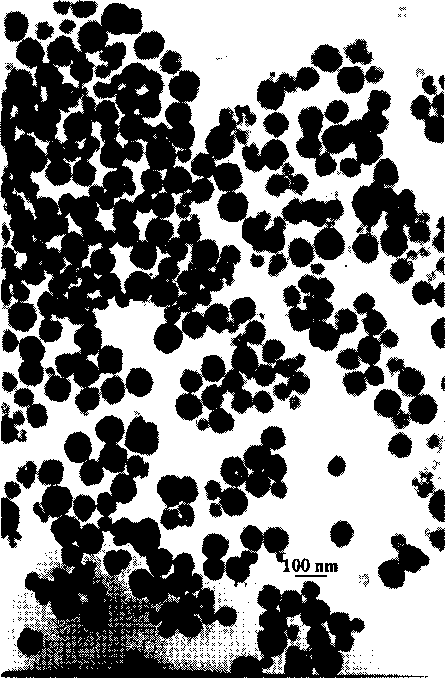

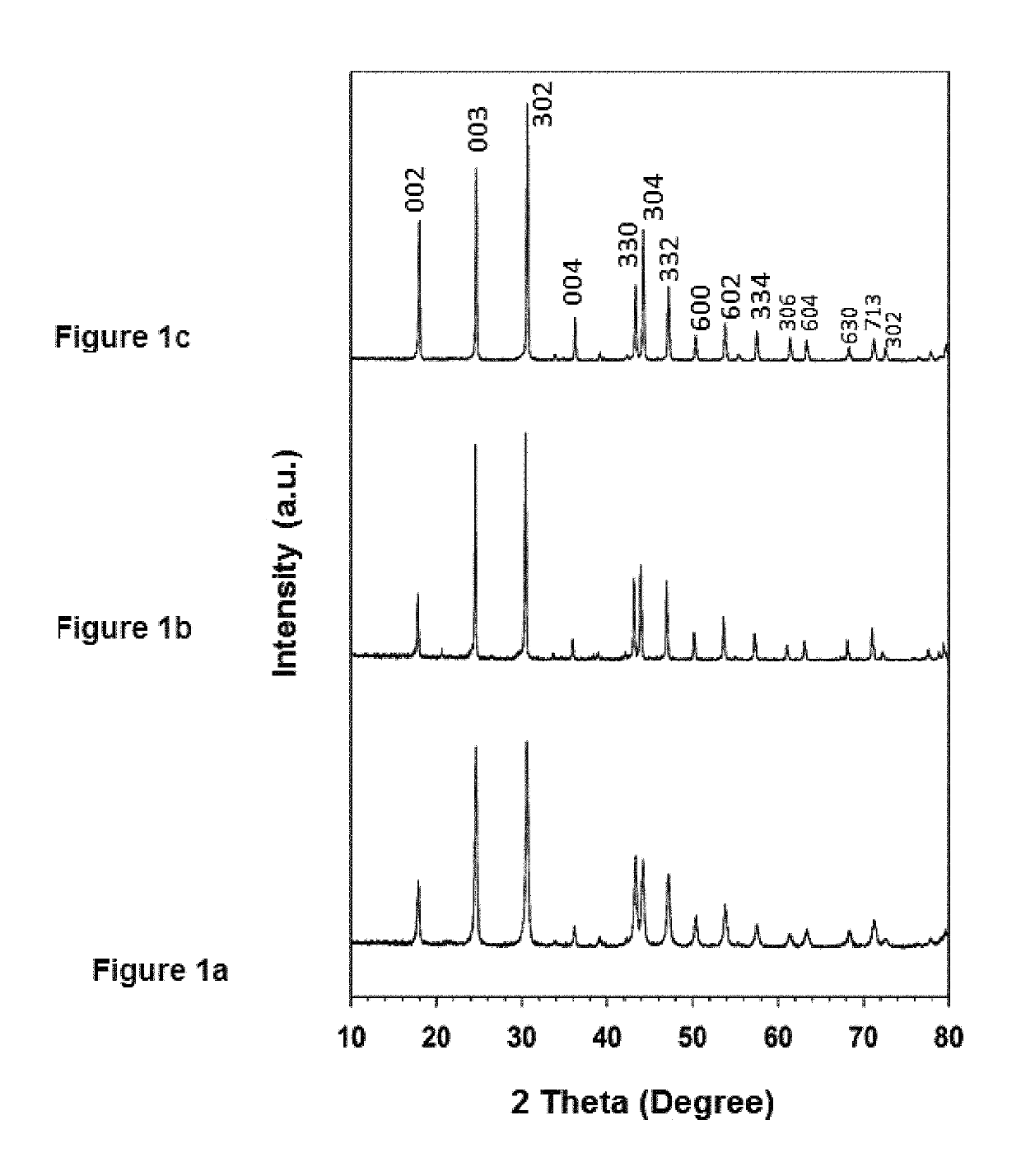

Nano-dephosphorizer, preparation method and application of same

InactiveCN107876000ALarge saturated adsorption capacitySignificant phosphorus fixation effectMaterial nanotechnologyOther chemical processesEmission standardNanoscopic scale

The invention provides a nano-dephosphorizer lanthanum carbonate hydrate, La2(CO3)3.nH2O, 1 <= n <= 8. The invention also provides a preparation method of the nano-dephosphorizer lanthanum carbonate hydrate. The method includes steps of: 1) adding an ionic liquid to a metal lanthanum ion solution with stirring to form a mixed solution; 2) adding a precipitant to the mixed solution to perform a precipitation reaction, and performing after-treatment to a reaction product to obtain the nano-dephosphorizer lanthanum carbonate hydrate, which is more than 100 mg / L in maximum saturation adsorption capacity and has strong removal capability on low-content phosphorus components in ecologic water domains, living or industrial wastewater, etc. After treatment, content of phosphates in the water sample can reach national first-level emission standard of phosphates. The nano-dephosphorizer has important significance for alleviating the gaining pressure of phosphorus environment pollution and a problem of daily production and domestic water.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com